Page 1

© Siemens AG 2011

SIMATIC PCS 7 TeleControl

Process control system with

integral telecontrol technology

Brochure · January 2011

SIMATIC PCS 7

Answers for industry.

Page 2

© Siemens AG 2011

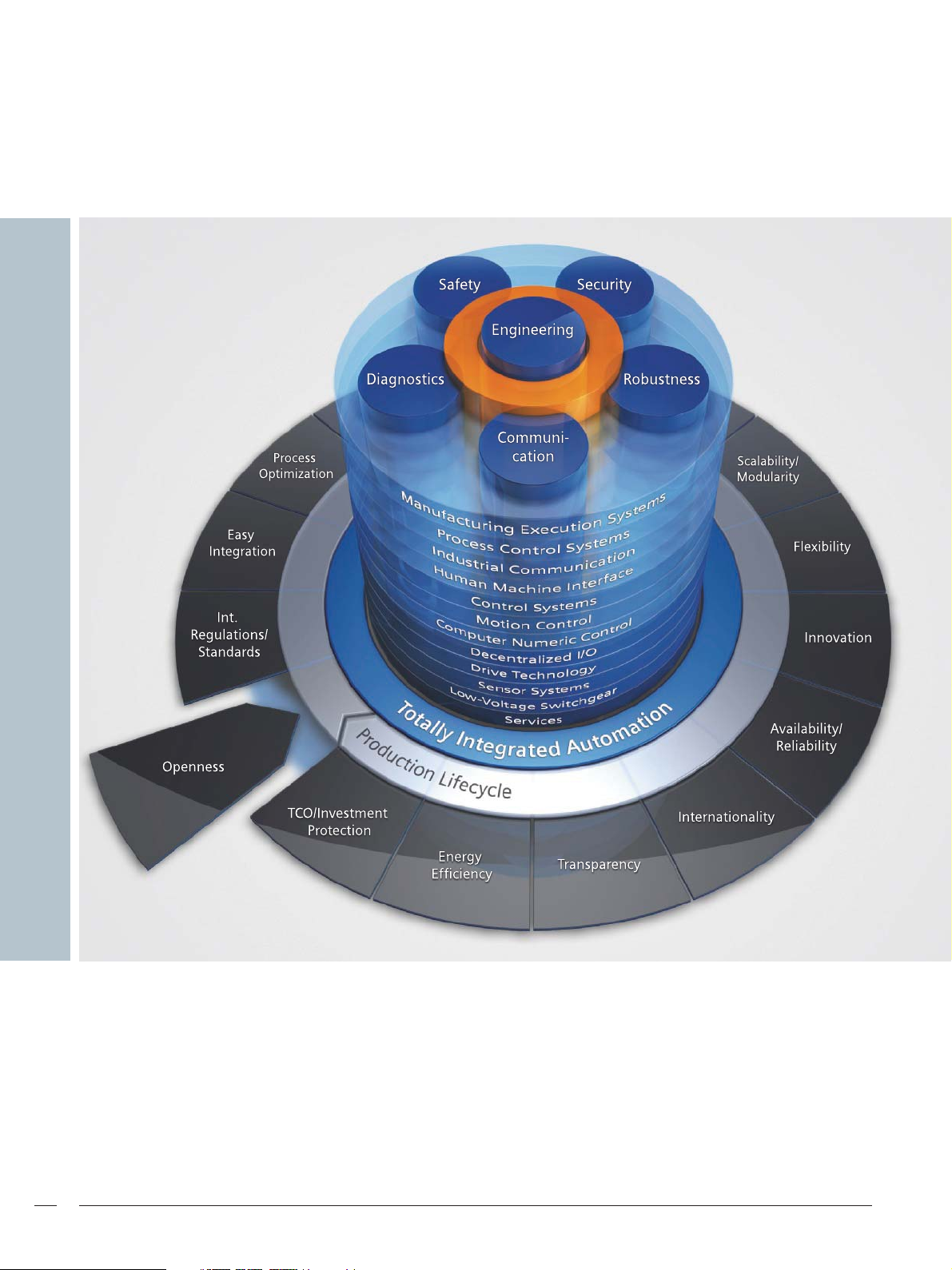

Totally Integrated Automation

Set new productivity standards

for constant competitive advantages

The optimization of processes improves quality, shortens the

time to market and reduces the total cost of ownership.

To survive in increasingly tougher international competition,

today it is more important than ever to consistently tap all

optimization potentials throughout the entire lifecycle of a

plant. At the same time, the perfect balance between quality,

time and costs is the decisive success factor.

Totally Integrated Automation2

With Totally Integrated Automation (TIA) from Siemens, a

seamless offering of perfectly matched products, systems,

and solutions for all hierarchy levels of industrial automation,

you are optimally equipped for this purpose.

Page 3

© Siemens AG 2011

Contents

Integration of the telecontrol technology in TIA has made it

possible to combine the automation of central plants and the

monitoring of distributed units in a single process control

system.

Homogenous operator control and monitoring using a common control station, uniform configuration with the same

engineering system, and consistent utilization of hardware

components from the TIA product portfolio result in significant savings with regard to investments, operation and

servicing.

text

SIMATIC PCS 7 TeleControl. . . . . . . . . . . . . . . . . . . . . 4

Process control system with integral

telecontrol center...................................................... 4

Typical application areas............................................ 5

SIMATIC PCS 7 TeleControl system architecture . . . 6

System overview....................................................... 6

Topologies ................................................................ 9

SIMATIC PCS 7 TeleControl system components . . 10

PCS 7 TeleControl Operator System.......................... 10

PCS 7 TeleControl engineering station ..................... 12

Remote terminal units............................................. 13

Telecontrol protocols . . . . . . . . . . . . . . . . . . . . . . . . 14

General/elementary telecontrol functions................ 14

SINAUT ST7 telecontrol protocol .............................. 15

DNP3 telecontrol protocol ....................................... 20

IEC 870-5-101/IEC 870-5-104 telecontrol protocol ... 23

Modbus telecontrol protocol.................................... 26

Redundancy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Increasing the plant availability ............................... 27

Migration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Migration of existing telecontrol systems................. 28

Application examples. . . . . . . . . . . . . . . . . . . . . . . . 30

Automation of a gas pipeline with slide valve and

measuring stations.................................................. 30

Automation of a sewage treatment plant with

pumping station and stormwater overflow tank....... 31

Totally Integrated Automation 3

Page 4

© Siemens AG 2011

SIMATIC PCS 7 TeleControl

Process control system with integral telecontrol center

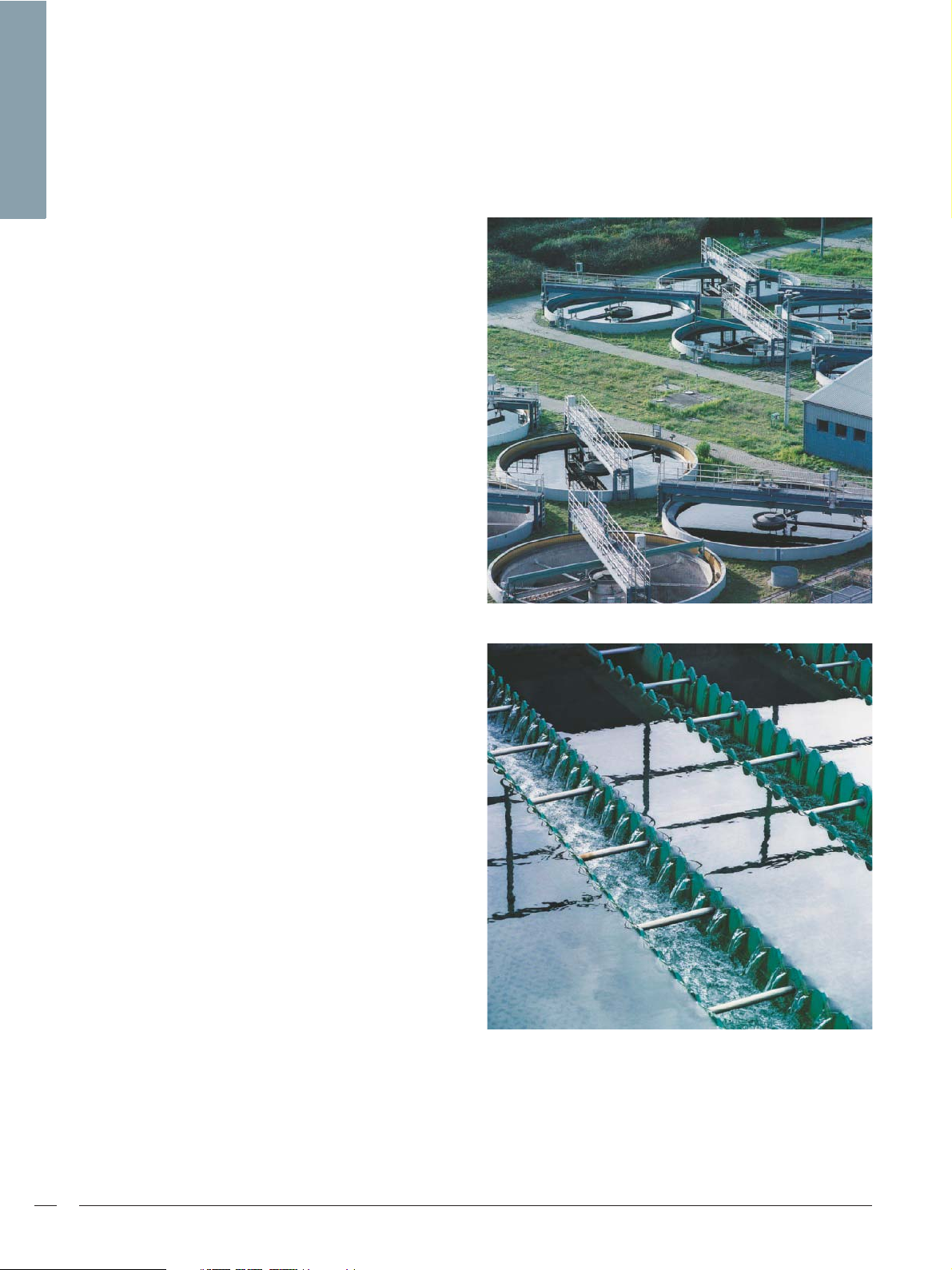

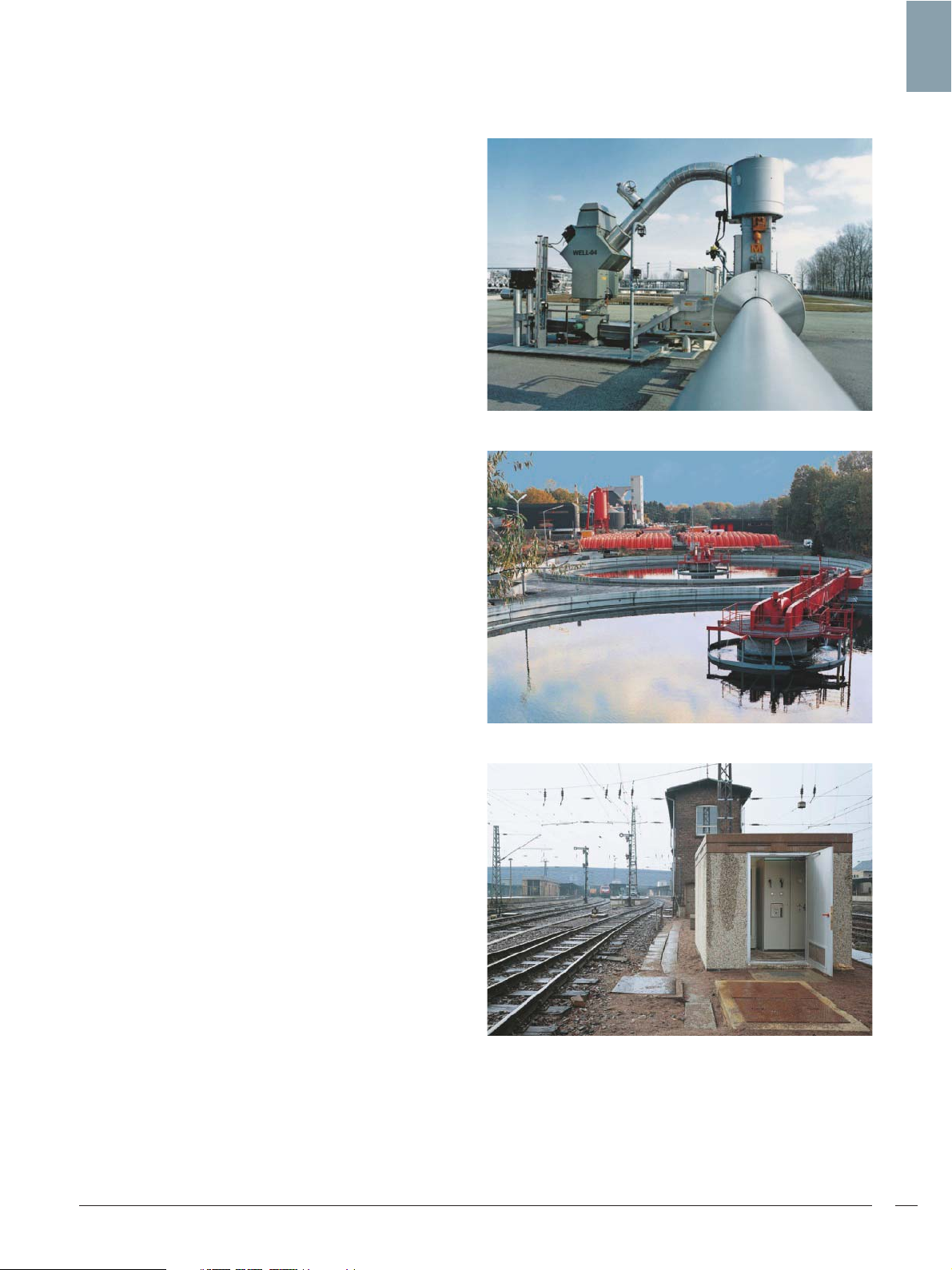

Automation of widely spread process plants

In a number of industries, especially the oil & gas,

water & wastewater, power and transportation sectors,

plants may sometimes be extremely widely spread. Individual

distributed units may even be more than a thousand kilometers away from a central unit with a significantly higher degree

of automation.

With a gas pipeline, for example, several slide valve and measuring stations are distributed between one of the compressor

stations at the beginning of the pipeline and the relief station

at the end.

A further example is the canal system of a widely branched

wastewater network connected to a central sewage treatment

plant via pumping stations and stormwater overflow tanks.

In both cases it is necessary to monitor regional units such

as stormwater overflow tanks, pumping stations, slide valve

stations or measuring stations from a far off control center, or

to control them in the context of the complete plant.

Telecontrol systems with which automation functions can be

executed from a remote control center over a telecommunication network (wide area network/WAN) are the ideal solution

for such tasks.

The automation of a process plant, as described above, is distributed in conventional implementation concepts between

heterogeneous system levels. Process control systems (PCS)

are normally used for units with a higher degree of automation, e.g. the central sewage treatment plant. On the other

hand, the local automation of small units with a low degree of

automation (pumping stations, stormwater overflow tanks) is

carried out using simple remote terminal units (RTUs) which

communicate with their control center by means of a telecontrol link. To enable global monitoring, all systems of the automation project (PCS and RTU) are integrated in a host network

control system.

However, it is far more effective if the telecontrol center for

the RTUs is directly integrated into the process control system

using SIMATIC PCS 7 TeleControl. In this case, the network

control system as a superimposed integration level can be

omitted. Uniform process control and totally integrated engineering for central and widely distributed units, together with

simple and convenient data management, result in high efficiency with regard to operation and engineering. Low training

and servicing costs are further positive aspects.

SIMATIC PCS 7 TeleControl4

Page 5

© Siemens AG 2011

Typical application areas

Remote control and monitoring of distributed stations, as well

as data recording and transmission, with the following focal

points:

Oil and gas industries

• Compressor, pressure reduction, transfer, block valve, and

metering stations in gas networks

• Pumping and block valve stations in oil pipelines

• Automation on the wellhead of gas and oil wells

• Stations for the injection of water or CO2 in gas or oil fields

Water industry

• Well, pumping and valve stations in water supply networks

and irrigation plants

• Stormwater overflow tanks and pumping equipment in

wastewater networks

• Storage units (elevated tanks)

Energy management, environmental protection,

and transportation

• Equipment for power generation and distribution

• District heat supply

• Traffic control systems

• Tunnels

• Railway stations

• Lighthouses

• Environmental monitoring equipment

• Weather stations

SIMATIC PCS 7 TeleControl 5

Page 6

,QGXVWU LDO(WKHU QHW

WAN

WAN WAN

G_PCS7_XX _00175

WAN

S7-400

+ CP 441

S7-300

+ CP 341

PCS 7 TeleControl

OS Server

Engineering Station

PCS 7 OS Clients

PCS 7 OS Single Station

(dedicated or

dual channel)

TIM 4R-IE (ST7)

or Converter

TCP/IP ↔ serial

(DNP3)

Widely distributed

TeleControl outstations

Widely distributed

TeleControl outstations

Widely distributed

TeleControl outstations

TIM 4R-IE (ST7)

or TCP/IP

WAN router

(DNP3)

TCP/IP

WAN router

Converter

TCP/IP ↔ serial

TCP/IP communication:

SINAUT ST7

Serial communication:

SINAUT ST7 or DNP3

TCP/IP communication:

Modbus or IEC 870-5-104

Serial communication:

Modbus or IEC 870-5-101

Third-party RTU

Third-party RTU

(DNP3 only)

Third-party RTU

(DNP3 only)

Third-party RTU

ET 200S with

integral PN CPU

ET 200S with integral

CPU + serial interface

S7-300

+ CP 343 or

PN interface

S7-400

+ CP 443 or

PN interface

S7-400

+ TIM 4R-IE or

TIM 4R-IE DNP3

S7-400

+ TIM 4R-IE or

TIM 4R-IE DNP3

S7-300

+ TIM 3V-IE or

TIM 3V-IE DNP3

S7-300

+ TIM 3V-IE or

TIM 3V-IE DNP3

© Siemens AG 2011

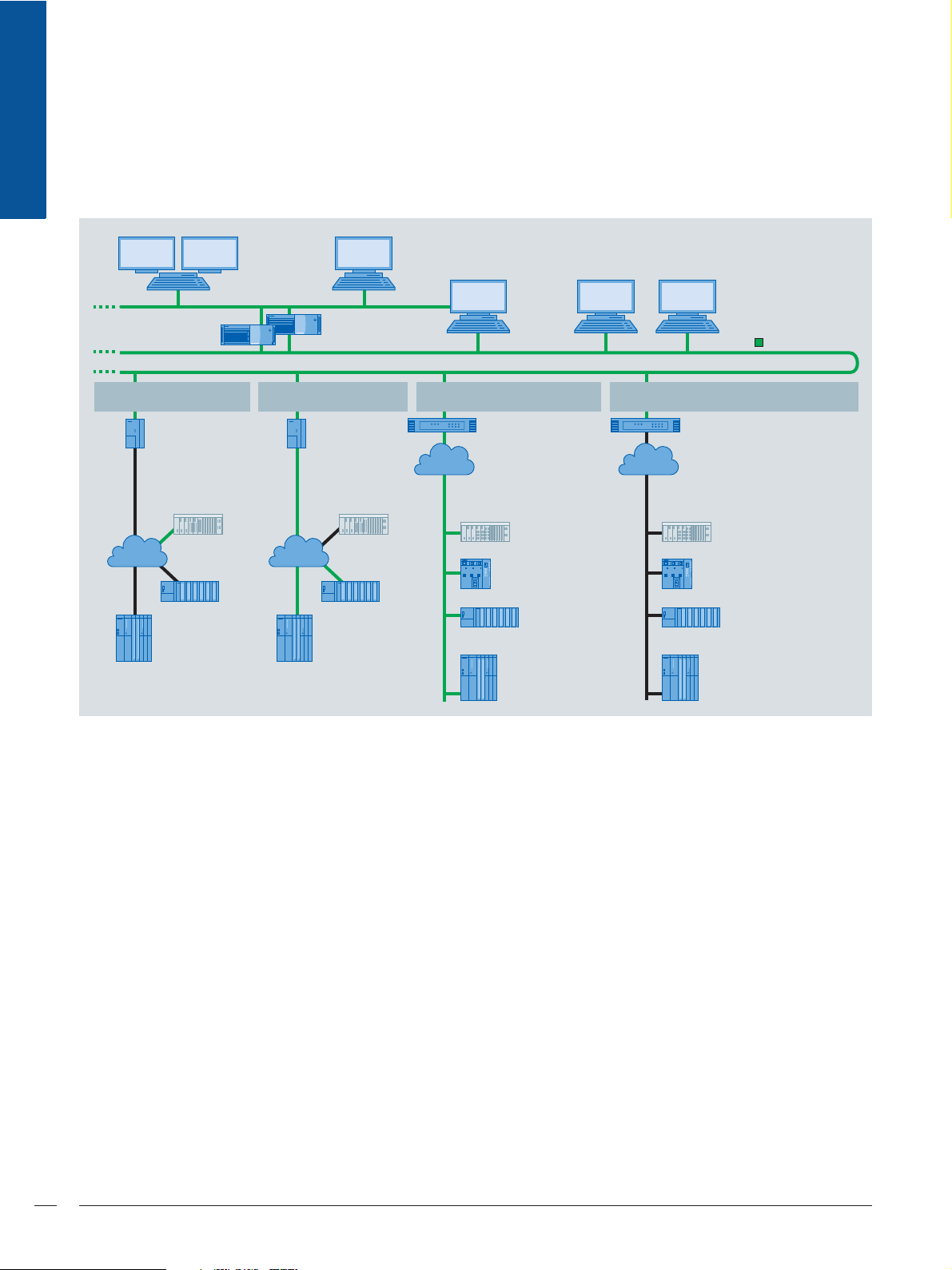

SIMATIC PCS 7 TeleControl system architecture

System overview

SIMATIC PCS 7 TeleControl system architecture

Integration in process control

The telecontrol center for the outstations (RTU) is integrated

into the process control of the SIMATIC PCS 7 process control

system in the form of an operator station in single station or

server design (also redundant as option). No additional automation system for conditioning telecontrol-specific data need

be planned in the SIMATIC PCS 7 system. With large quantity

frameworks, a PCS 7 TeleControl operator station (single station/server) is preferably responsible only for the telecontrol

mode (dedicated). With small quantity frameworks, a server

or a single station can also control SIMATIC PCS 7 automation

systems (AS) in central plant areas in addition to the telecontrol systems (dual-channel mode).

The OS clients of the client/server multi-user system are able

to display data from RTUs and SIMATIC PCS 7 AS - which they

receive from a server with dual-channel functionality or from

two separate servers - together in one process image. Display

is primarily on faceplates for process objects such as motors,

valves etc., but also by means of trend curves and messages.

Engineering

To enable engineering of the PCS 7 TeleControl operator station (single station/server), the functions of the engineering

station of the SIMATIC PCS 7 process control system are

expanded by DBA technology (Data Base Automation) and

the SIMATIC PCS 7 TeleControl block library.

Communication with the outstations

(remote terminal units)

For communication with the outstations, SIMATIC PCS 7

TeleControl uses the SINAUT ST7, DNP3 and Modbus protocols

(both via serial and TCP/IP communication connections) as

well as IEC 870-5-101 (serial) and IEC 870-5-104 (Ethernet

TCP/IP).

SIMATIC PCS 7 TeleControl system architecture6

Page 7

© Siemens AG 2011

The serial RTU link is possible at low cost via the following

components which can be connected directly to the PCS 7

TeleControl OS (single station or server):

• SINAUT TIM communication modules

(SINAUT ST7 telecontrol protocol)

• TCP/IP converters – serial

(DNP3, Modbus, IEC 870-5-101 telecontrol protocols)

Devices from MOXA or Lantronix can be used as serial

TCP/IP converters.

By means of Ethernet TCP/IP, the RTUs can be connected directly or via TCP/IP WAN routers to the SIMATIC PCS 7 system

bus (SINAUT ST7, DNP3, Modbus, IEC 870-5-104 telecontrol

protocols). When using the SINAUT ST7 telecontrol protocol,

the SINAUT TIM communication module can be used in addition to the TCP/IP WAN router or as an alternative.

Telecontrol communication over the wide area network is

largely determined by the communication infrastructure

which already exists. Various transmission media such as

dedicated line, analog or digital telephone networks, wireless

networks (GSM or private), DSL or GPRS can also be combined

with each other.

Outstations (remote terminal units)

Since the requirements of the widely distributed units with regard to scope and performance of the automation functions

are usually in the low to mid range, controllers with minimum

dimensioning are normally used as RTUs.

SIMATIC PCS 7 TeleControl particularly supports the following

types of RTU for distributed automation on site:

• Controllers integrated in SIMATIC ET 200S

(Modbus, IEC 870-5-101/104 telecontrol protocols)

• SIMATIC S7-300/S7-300F controllers

(SINAUT ST7, DNP3, Modbus, IEC 870-5-101/104 telecontrol protocols)

• SIMATIC S7-400/S7-400F controllers

(SINAUT ST7, DNP3, Modbus, IEC 870-5-101/104 telecontrol protocols)

• SIMATIC S7-400H/S7-400FH redundant controllers

(IEC 870-5-101/104 and DNP3 telecontrol protocols)

In addition to these, appropriate third-party RTUs can also be

connected to the telecontrol center in SIMATIC PCS 7 by

means of the DNP3, Modbus, IEC 870-5-101/104 telecontrol

protocols.

SIMATIC PCS 7 TeleControl cannot only integrate newly configured RTUs into SIMATIC PCS 7, it can also migrate units which

already exist outdoors by means of DNP3, IEC 870-5-101/104,

Modbus or EDC drivers. The Data Base Automation (DBA) software substantially facilitates project-specific adaptation of the

system and importing of existing configurations during migration. Extensions can be added during plant operation if necessary.

SIMATIC PCS 7 TeleControl system architecture 7

Page 8

© Siemens AG 2011

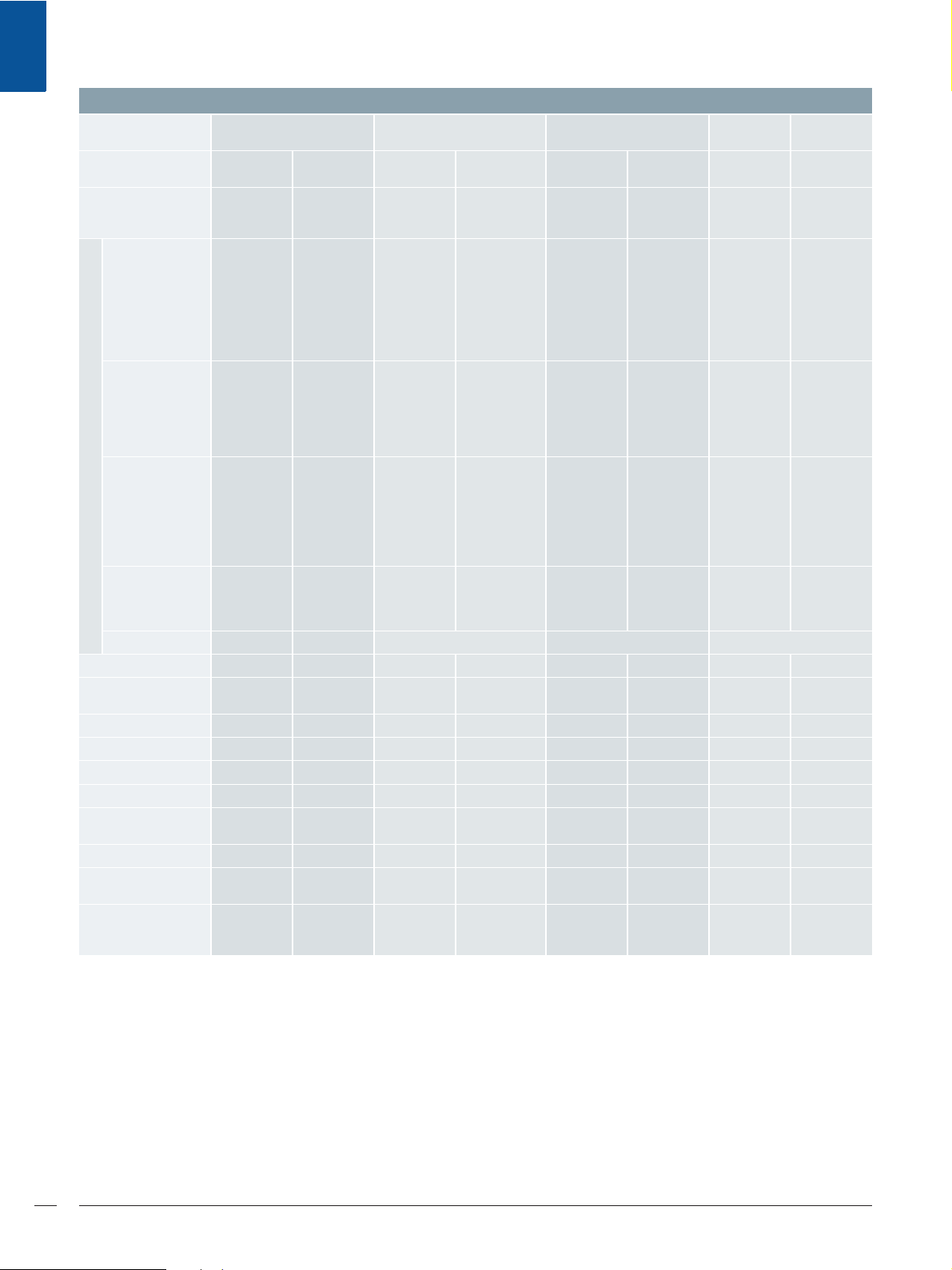

Spectrum of outstations and integration versions

Telecontrol protocol SINAUT ST 7 Modbus DNP3 IEC 870-5-

Type of communication

Interface on the

PCS 7 TeleControl OS

ET 200S with integral CPU (corresponds to S7-314)

RTU/interface

S7-300/

S7-300F

S7-400/

S7-400F

S7-400H/

S7-400FH

Third-party station – – Depends on type of station Depends on type of station Depends on type of station

Dialup lines 4 – – – 4 – – –

Dedicated line and

radio networks

Master-slave 4 4 4 4 4 4 4 4

Peer-to-peer 4 4 – – – – 4 4

Mesh networks 4 4 – – 4 4 4 4

Time tagging in RTU 4 4 – – 4 4 4 4

RTU time synchronization

Data buffering in RTU 4 4 – – 4 4 4 1) 4 1)

Routing with

SIMATIC PDM

International standard

1)

Data buffering is limited to two SIMATIC S7 data blocks. Depending on the

SIMATIC CPU, this corresponds to approx. 800 to 3 200 buffered frames.

Serial Ethernet

TCP/IP

TIM 4R-IE TCP/IP WAN

router or/and

TIM 4R-IE

– – IM 151-7 CPU

TIM 3V-IE TIM 3V-IE CP 341 CP 343 +

TIM 4R-IE TIM 4R-IE CP 441 CP 443 +

– – – – TIM 4R-IE

4 4 4 4 4 4 4 4

4 4

4 4 – – – – – 4

– –

Serial Ethernet

TCP/IP

converter

serial

or

IM 151-8

PN/DP CPU

as well as

1 SI module

Modbus

– –

4

(many ver-

sions)

–

TCP/IP

TCP/IP

WAN router

IM 151-8

PN/DP CPU

+ S7OpenModbus

software /

TCP PN-CPU

SW library

SW library

4

(many ver-

sions)

Serial Ethernet

TCP/IP

converter

serial

– – IM 151-7 CPU

TIM 3V-IE

DNP3

TIM 4R-IE

DNP3

DNP3

4 4 4 4

4 4 4 4

–

TCP/IP

TCP/IP

WAN router

TIM 3V-IE

DNP3

TIM 4R-IE

DNP3

TIM 4R-IE

DNP3

101

Serial Ethernet

TCP/IP

converter

serial

or

IM 151-8

PN/DP CPU

as well as

1 SI module +

SIPLUS RIC

library

CP 341 +

SIPLUS RIC

library

CP 441 +

SIPLUS RIC

library

ET 200M +

2 x CP 341 +

SIPLUS RIC

library

–

IEC 870-5104

TCP/IP

TCP/IP

WAN router

IM 151-8

PN/DP CPU +

SIPLUS RIC

library

CP 343 +

IEC on S7

or integral

PN interface

+ SIPLUS RIC

library

CP 443 +

SIPLUS RIC

library

or integral

PN interface

+ SIPLUS RIC

library

CP 443 +

SIPLUS RIC

library

SIMATIC PCS 7 TeleControl system architecture8

Page 9

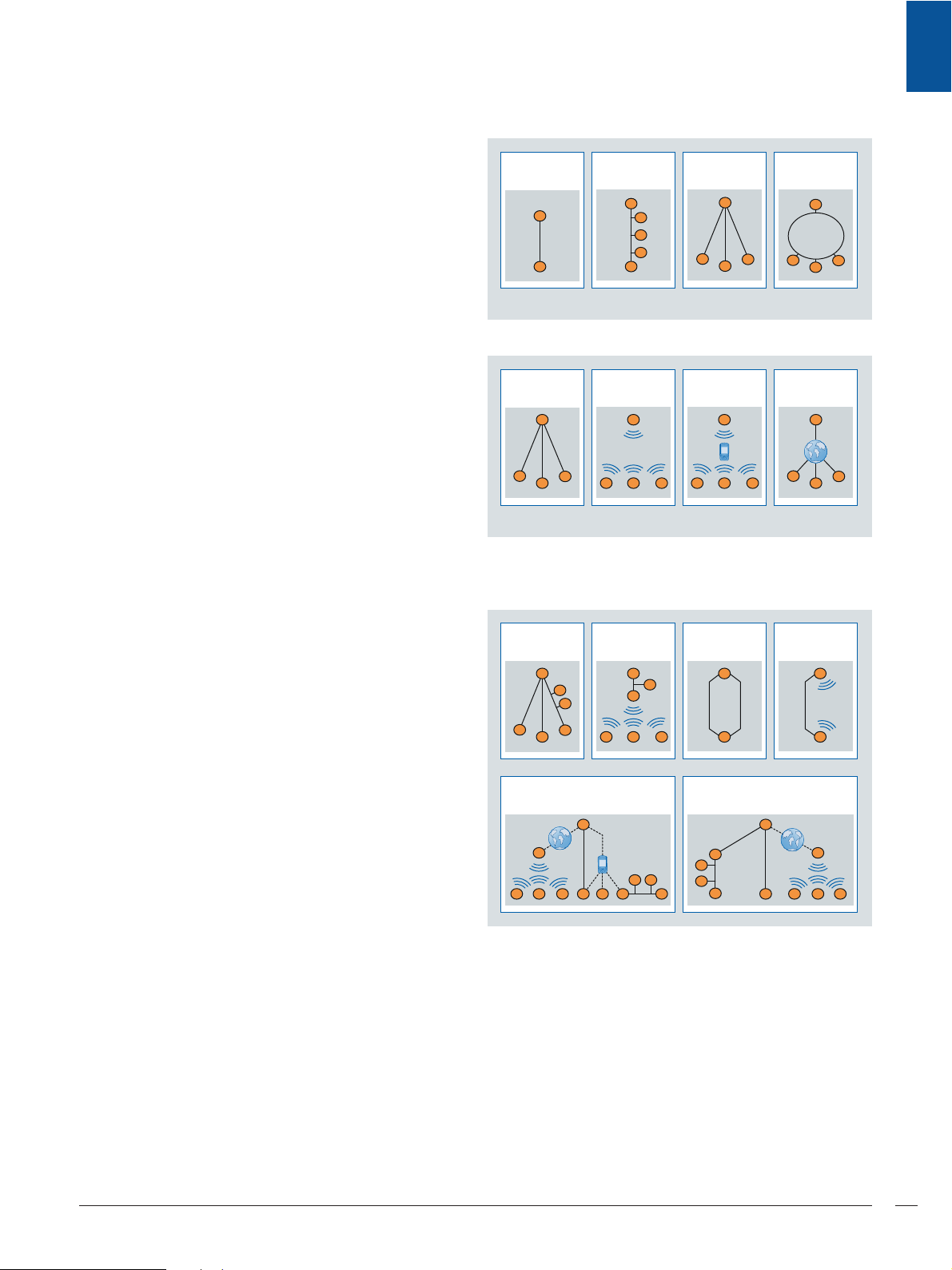

Topologies

© Siemens AG 2011

Basic topologies

Differently structured telecontrol networks can be implemented in the wide area network (WAN) based on the following

four basic topologies.

Media versions

Depending on the support provided by the selected telecontrol protocol, various transmission media are available for

these basic topologies, e.g. dedicated line, private wireless

networks, mobile radio networks, dial-up networks (wireless/landline), DSL over Internet.

Some of these media versions are shown in the example of the

star topology.

Point-to-

point

Star via

dedicated line

Multi-point Star Ring

Star via

wireless

Dial-up

network via

wireless

Star via

Internet

Combinations of basic topologies and media versions

Through a combination of several basic topologies of the

same or different media versions, it is additionally possible to

design more complex network topologies, even with redundant communication paths.

This allows adaptation to the respective local conditions and

to the existing infrastructure.

Star +

multi-point

Complex network structure,

example of SINAUT ST7/DNP3

communication

Nodes

Path

redundancy,

1 medium

Complex network structure,

example of I EC 870- 5-104

communication

redundancy,

2 media

Path

SIMATIC PCS 7 TeleControl system architecture 9

Page 10

© Siemens AG 2011

SIMATIC PCS 7 TeleControl system components

PCS 7 TeleControl Operator System

Single-user and multi-user systems

Depending on the magnitude of the automation project and

the required number of operator stations, the SIMATIC PCS 7

TeleControl Operator System can be configured either as a single-user system (PCS 7 TeleControl OS single station) or as a

multi-user system with client/server architecture:

• Single-user system

- Up to 5 000 process objects

- Up to approx. 3 000 measuring points

- Low number of operator stations

• Multi-user system (client/server)

- Up to 8 500 process objects per OS server

- Up to approx. 5 000 measuring points per OS server

- Up to 32 operator stations (OS clients)

In a single-user system architecture, all operation and monitoring functions for a complete project (plant/unit) are concentrated in one station.

A multi-user system has up to 32 operator stations (OS clients)

which are supplied with data from one or more servers

(OS server or PCS 7 TeleControl OS server) via the terminal

bus.

The multi-client architecture of the multi-user system allows

an OS client to call data from various servers, e.g. from two

separate servers for local units and for units connected by

means of PCS 7 TeleControl.

The PCS 7 TeleControl OS server of the multi-user system can

also have a redundant design. All internally generated information (e.g. alarm states or results of calculations) is matched

in the redundant pair of PCS 7 TeleControl OS servers.

The graduated scalability of the process objects of PCS 7

TeleControl OS single station and PCS 7 TeleControl OS server

permits fine and flexible matching of the SIMATIC PCS 7

TeleControl Operator System to the size of the respective

automation project.

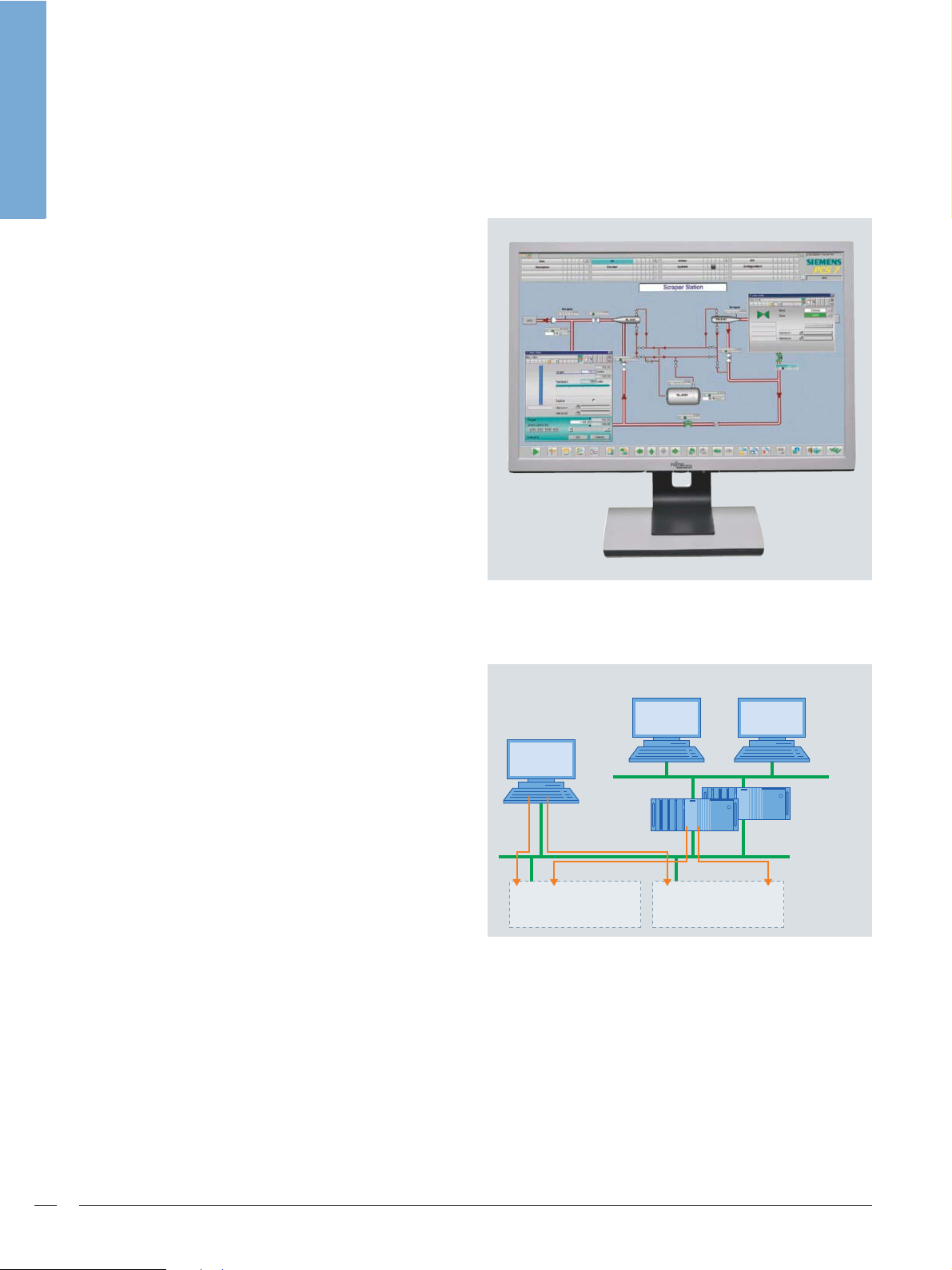

Uniform process control for central and remote units

Dual-channel operation

OS clients

OS single station

SIMATIC PCS 7

+ TeleControl

(dual ch ann el)

PCS 7

automation system

Dual-channel operation with single-user and multi-user systems

· · ·

OS server

(single or

redundant)

Tel eC on trol

RTUs

PCS 7 TeleControl OS single station and PCS 7 TeleControl OS

server are preferably used just for telecontrol functions (dedicated), but can also access central SIMATIC PCS 7 plant areas

via an additional second channel in the case of small quantity

frameworks (double-channel operation). In this way, data

from the RTUs of the telecontrol system can be displayed in

one process image together with data from SIMATIC PCS 7 AS.

G_PCS7_XX_00261

SIMATIC PCS 7 TeleControl system components10

Page 11

© Siemens AG 2011

PCS 7 TeleControl blocks for system-conformant operator

control and monitoring

The RTUs are integrated into the PCS 7 TeleControl Operator

System by means of the PCS 7 TeleControl blocks such that

there is no difference for the operator with regard to operating philosophy and alarm behavior for the central or remote

automation functions.

The blocks required for data conditioning and display are

saved in a library. These blocks support SIMATIC PCS 7 compliant operator control by means of symbols and faceplates, as

well as the hierarchy of SIMATIC PCS 7 fault messages.

In addition to blocks for processing of process data, the

library also contains blocks for diagnostics and for control

of communication. If necessary, the supplied basic library can

be extended by new script-based block types specific to the

project by using the DBA Type Editor.

Long-term archiving and

logging

The PCS 7 TeleControl Operator System includes a high-performance cyclic archive based on Microsoft SQL Server for timelimited saving of process values and messages/events. Data

from this cyclic archive can be exported time-controlled or

event-controlled to a long-term archive (StoragePlus/central

archive server).

The logging system of the PCS 7 TeleControl Operator System

supports the display and evaluation of data recorded during

operation by means of various predefined types of protocol

which can also be matched individually:

• Message sequence report

• Message and archive log

• Measured value log

• Operator input log

• System message log

•User log

The logs saved in EMF format can be previewed on the screen,

and can be printed manually or time- or event-controlled.

In order to comply with statutory directives and standards it

may be necessary to provide special proof, e.g. proof of conformity with the ATV M260 standard for sewage treatment

plants. The SIMATIC PCS 7 add-on product ACRON equipped

with additional functionalities for long-term archiving and

logging provides excellent support for this purpose.

SIMATIC PCS 7 TeleControl system components 11

Page 12

© Siemens AG 2011

PCS 7 TeleControl engineering station

Engineering station of the SIMATIC PCS 7 process control system

To enable engineering of the PCS 7 TeleControl operator station (single station/server), the functions of the engineering

station of the SIMATIC PCS 7 process control system are expanded by DBA technology (Data Base Automation) and the

SIMATIC PCS 7 TeleControl block library.

Data Base Automation (DBA)

Engineering can be automated efficiently and in conformance

with SIMATIC PCS 7 using the DBA technology. DBA supports

plant expansion during ongoing operation, and facilitates

project-specific adaptation of the system as well as importing

of existing configurations in the course of migration.

The DBA executed in the engineering station automatically

generates the OS runtime database with the display hierarchy,

required variables, alarms, alarm messages and alarm priorities, as well as the specific faceplates and block symbols.

The display hierarchy is the basis for navigation between the

process displays, for alarm management, and for implementation of safety measures. DBA positions the type-specific block

symbols, e.g. measured value, counter value, motor or gate

valve, in the process images. These symbols are linked to the

corresponding function blocks and faceplates through the database. Manual configuration is mainly limited to the design

and positioning of the static graphic elements, e.g. pipes or

tanks.

SIMATIC PCS 7 TeleControl block library

In addition to the SIMATIC PCS 7 TeleControl basic library,

new user blocks can also be defined using the DBA type editor.

During database generation, the user blocks are treated like

the blocks from the basic library.

Using the DBA type editor it is possible to assign the frequently

unstructured variables of an RTU once to a block type and to

display the variable structured on the operator station via the

block's faceplate.

SIMATIC PCS 7 TeleControl blocks

The PCS 7 TeleControl OS symbols, faceplates and diagnostics

displays created in conformance with SIMATIC PCS 7 take into

account the specific features of telecontrol applications. This

is demonstrated, for example, by the example of the counter

block which offers versatile conditioning options for information on transported or processed quantities. At least one

OS faceplate and one OS symbol are available for each type

of block.

In addition to arrangement of information in a variable structure, the user blocks generated with the DBA type editor can

also calculate derived values using Visual Basic scripts in the

server. This results in numerous possibilities for extending the

functionality and for adapting the system to individual customer requirements.

Type-specific OS faceplates and OS symbols for the user blocks

can be created using the standard tools for SIMATIC PCS 7

OS engineering (Graphics Designer and Faceplate Designer).

SIMATIC PCS 7 TeleControl system components12

Page 13

Remote terminal units

Classification of the remote terminal units

© Siemens AG 2011

RTU Applications

RTU Small: controller integrated in SIMATIC ET 200S

RTU with up to approx. 30 I/Os

For small, cost-sensitive applications

RTU Medium: SIMATIC S7-300/S7-300F controller

RTU with up to approx. 100 I/Os

For medium-sized applications;

extremely flexible configuration

S7-300F for safety-related applications

RTU Large: SIMATIC S7-400/S7-400F controller

Possible telecontrol protocols

• Modbus No buffering

• IEC 870-5-101

• IEC 870-5-104

•SINAUT ST7

•DNP3

• Modbus No buffering

• IEC 870-5-101

• IEC 870-5-104

Information points/

buffer size

Up to approx. 200 information

points

Buffer size:

800 information points

TIM buffering

(up to 16 000 frames or up to

32 000 frames with TIM 3V-IE

Advanced)

Up to approx. 2 000 information points

Buffer size: 800 to 3 200 information points

RTU with up to approx. 500 I/Os

For larger applications requiring

increased performance

S7-400F for safety-related applications

RTU Large: SIMATIC S7-400H/S7-400FH controller

Like S7-400/S7-400F •DNP3 TIM buffering

The remote control units supported by SIMATIC PCS 7

TeleControl have a performance classified as Small, Medium

or Large.

Controllers of SIPLUS extreme design are also available in all

performance classes, and can be operated under extreme conditions, e.g. ambient temperatures from -25 °C to +70 °C, condensation or exposure to media.

•SINAUT ST7

•DNP3

• Modbus No buffering

• IEC 870-5-101

• IEC 870-5-104

• IEC 870-5-101

• IEC 870-5-104

In addition, the SIMATIC S7-300F and S7-400F controllers can

be used to implement safety-related applications on site and

automatically set the plant to a safe status in the event of a

dangerous fault.

TIM buffering

(up to 56 000 frames)

Up to approx. 5 000 information points

Buffer size: 3 200 information

points

(up to 56 000 frames)

Up to approx. 5 000 information points

Buffer size: 3 200 information

points

SIMATIC PCS 7 TeleControl system components 13

Page 14

© Siemens AG 2011

Telecontrol protocols

General/elementary telecontrol functions

Telecontrol systems use special protocols to implement data

transmission between the control center and the outstations

(RTUs) at the process level for the automation functions on

site. These telecontrol protocols manage the secure and errorfree data transmission over the WAN even with a low bandwidth and poor transmission quality.

In addition to short transmission times for the information,

this task requires effective protection of the frames against:

• Undetected bit errors

• Undetected frame errors resulting from synchronization

errors

• Undetected loss of information

• Frame falsification

• Segregation or fault in related information

This particularly applies to event-controlled frames over transmission channels with a limited bandwidth and uncertain

noise response.

Since irregular bit sequences are compiled for data transmission, no limitation in codes must exist.

Time tagging

When linking RTUs by means of SINAUT ST7, DNP3,

IEC 870-5-101 or IEC 870-5-104 telecontrol protocol, the raw

data in the outstations is provided with a time tag and transmitted to the PCS 7 TeleControl OS (server/single station)

acting as control center. Adaptation, further processing, and

archiving are carried out here. This procedure is appropriate

for the event-based principle of operation of the telecontrol

protocol as well as the subsequent chronological processing

of data previously buffered in the outstation.

Clock synchronization

The PCS 7 TeleControl OS is the clock master for the RTUs

connected by means of SINAUT ST7, DNP3, IEC 870-5-101 or

IEC 870-5-104, and regularly synchronizes their date and time

via the telecontrol connection. Switching over between summertime and wintertime is also considered during the synchronization.

Data buffering

The SINAUT ST7, DNP3, IEC 870-5-101 and IEC 870-5-104

telecontrol protocols support reliable on-site intermediate

buffering of the data including time tag, e.g. if a communication path is faulty or a station has failed. In addition, intermediate buffering of data can also be an effective means

for reducing connection costs in the dial-up network.

A data update for all participating communication partners

is performed automatically following debugging or restarting

of the failed station. Important events are not lost, and the

integrity of the control center archive is assured.

General/elementary telecontrol functions14

Page 15

SINAUT ST7 telecontrol protocol

© Siemens AG 2011

6,0$7,&3&6ZLW K6,0$7,&3&67HOH&RQWURO

Industrial Ethernet

TIM 4R-IE

IP-based

WAN

S7-300

with TIM 3V-IE

SINAUT ST7 stations

Overview of SIMATIC PCS 7 TeleControl with SINAUT ST 7 telecontrol

protocol

S7-400

and

TIM 4R-IE

Classic

WAN

The telecontrol system based on the SINAUT ST7 telecontrol

protocol is used for fully-automatic monitoring and control of

widely distributed outstations (RTUs) which exchange data

with each other and with one or more control centers over a

wide variety of WAN (Wide Area Network) media.

SIMATIC S7-300/S7-300F and SIMATIC S7-400/S7-400F controllers are used for the outstations and node stations, and

SIMATIC PCS 7 with SIMATIC PCS 7 TeleControl for the control

center. Further hardware and software components round off

the range of products:

• TIM communication modules

• MD modem modules

•GSM/GPRS components

• TCP/IP routers and switches

• SCALANCE S612 and S613 security modules

• Dedicated-line accessories

•Cables

G_PCS7_XX_00262

• SINAUT ST7 engineering software, comprising:

- SINAUT TD7 library with blocks for the data point objects

of the SIMATIC S7 CPU or the TIM module

- SINAUT ST7 engineering package for configuration of

stations, networks and connections as well as for diagnostics

In order to implement complete hierarchical telecontrol networks, the basic topologies of point-to-point, multi-point, star

and ring can be configured using classic or also TCP/IP-based

media, and combined flexibly independent of the infrastructural conditions. SINAUT ST7 is thus distinguished by a wide

range of possible selections and combinations.

SINAUT ST7 telecontrol protocol 15

Page 16

TIM 4R-IE

TIM 3V-IE

MD 720-3

G_PCS7_XX_00264

MD720-3

MD720-3

MD720-3

MD720-3

MD720-3

TIM 4R-IE

Ethernet

RTU S7-400

TIM 4R-IE

RTU S7-400

RTU S7-300

TIM 3V-IE

RTU S7-300

Control center

SIMATIC PCS 7 TeleControl

Option:

redundant

network access

in the master

station

Mobile

wireless

network

Dial-up

networ k via

wireless

© Siemens AG 2011

Control center

SIMATIC PCS 7 TeleControl

Ethernet

RTU S7-400

MD2

TIM 4R-IE

RS 485

MD2 MD2

· · ·

TIM 4R-IE MD2

RTU S7-400

RTU S7-300 RTU S7-300

RTU S7-300

TIM 3V-IE MD2

· · ·

TIM 3V-IE MD2TIM 4R-IE MD2

SINAUT ST7 - example of classic dedicated network (star + multi-point topologies)

TIM 3V-IE

MD2

Range without repeaters (example)

with conductor cross-section 0.8 mm

- 1 200 bit/s max. 33 km

- 2 400 bit/s max. 27 km

- 19 200 bit/s max. 11 km

Dedicated network

with star topology

Star +

multi-point

G_PCS7_XX_00263

SINAUT ST7 - example of classic mobile radio network (GSM) with CSD data service (star topology)

Classic WAN media

• Dedicated copper line, private or rented

• Private radio network (optionally with time slot procedure)

• Analog telephone network

• Digital ISDN network

• Mobile radio network GSM

SINAUT ST7 telecontrol protocol16

Page 17

MD741-1

Ethernet

TIM 3V-IE

Advanced

RTU S7-300

TIM 4R-IE MD2

MD2

TIM 4R-IE MD2

RTU S7-400

Ethernet

TIM 4R-IE MD2

G_PCS7_XX_00266

SCALANCE

S612/613

Control center

SIMATIC PCS 7 TeleControl

Radio

network

GPRS

network

Dedicated

line

Redundant transmission path:

classic WAN + classic WAN

Control center

SIMATIC PCS 7 TeleControl

Internet

Dedicated

line

Redundant transmission path:

classic WAN + TCP/IP-based WAN

Path

redundancy,

2 media

DSL router

© Siemens AG 2011

TIM 3V-IETIM 4R-IE

Control center

931WXQQHO

· · ·

TIM 4R-IE

RTU

S7-300

TIM 3V-IE

SCALANCE

S612/613

RTU S7-400

SIMATIC PCS 7 TeleControl

Ethernet

DSL

router

Firewall

RTU

S7-300

SINAUT ST7 - example of secure TCP/IP-based connection over Internet via DSL (star topology)

DSL router

Firewall

Internet

Firewall

DSL router

SCALANCE

S612/613

Star via

Internet

G_PCS7_XX_00265

SINAUT ST7 - example of redundant telecontrol connections (point-to-point topology)

TCP/IP-based WAN media

• Special radio network optimized for Ethernet, e.g. with

SCALANCE W industrial wireless LAN components

• SCALANCE X switches with optical ports and fiber-optic

cables for distances up to 120 km

• Public network and Internet via DSL or GPRS

• Broadband system such as OTN, PCM30, etc.

To achieve redundant data transmission, it is also possible to

connect an outstation via two transmission paths to the control center in the SIMATIC PCS7 process control system or to a

node station. It is irrelevant whether the two paths are of the

same type or different, e.g. dedicated line with telephone network/ISDN and GPRS.

SINAUT ST7 telecontrol protocol 17

Page 18

© Siemens AG 2011

Special characteristics

of SINAUT ST7 communication

Up to 10 000 stations can be addressed with SINAUT ST7.

Information on the source and target addresses is included

in the message frames. The functionality of SINAUT ST7

communication is particularly characterized by the following features:

Change-driven data transmission

• Change-driven transmission of process data between

RTUs as well as between an RTU and the control center

• Signaling of failures in connections, RTUs or the control

center

• Automatic data updating for all communication partners involved following troubleshooting and following

the startup of an RTU or control center

Chronological processing of process data

• Time tagging of all data frames at the place of origin allows process data to be archived by the process control

system in the correct chronological order

• The time of the SINAUT ST7 stations in the WAN can

be synchronized via SIMATIC PCS 7 (including summertime/wintertime switchover)

Local data storage

• Depending on the version, the TIM communication

module can temporarily store (for several hours or even

days) up to 56 000 message frames should the connection or the communication partner fail

• Intermediate storage of message frames of lower priority in the case of priority-controlled data transmission

(with dial-up networks or quantity-dependent data

transmission costs)

Remote programming and remote diagnostics

• Remote diagnostics and remote programming over the

WAN using the "PG routing" function

• PG routing shares the available bandwidth with the process data transmission, but has a higher priority

• Uploads, downloads, remote diagnostics, firmware upgrades or changes in automation functions on the stations can be carried out online from the control center

in SIMATIC PCS 7

Alarm output per text message

• The RTUs can send text messages depending on events

in order to alarm personnel on call

• Receipt of messages can be acknowledged from a

mobile phone

• Depending on the services offered by the mobile radio

provider, the text message can also be output as an

e-mail, fax or voice mail

SIMATIC water library: block symbol and faceplate for a valve

Technological configuration with the

SIMATIC water library

The SIMATIC water library from Siemens supports effective

configuration of the SIMATIC PCS 7 process control system

with technological function blocks for implementing applications for water supply and disposal.

These technological function blocks can now also be used on

the basis of the SINAUT ST7 telecontrol protocol. The telecontrol functions are integrated using additive blocks in the CFC,

i.e. without modifying the existing technological function

blocks or the associated block symbols and faceplates. The

philosophy of SIMATIC PCS 7 TeleControl with regard to uniform process control of central and remote units using an

operator system is thus extended in the direction of uniform

engineering. Standardization and reuse of the ready-made

functions significantly reduces the requirements for engineering, testing and training, as well as maintenance and

updating.

SINAUT ST7 telecontrol protocol18

Page 19

Operating modes

© Siemens AG 2011

The communication mode between the control center and

outstation (RTU) depends on the support provided by the telecontrol protocol, the configuration of the telecontrol communication, and the type of WAN.

The SINAUT ST 7 telecontrol protocol supports the following

operating modes:

•Polling

- Control of data exchange by the TIM module of the control center

- The TIM of the control center calls the outstations and

node stations one after the other

- Stations with modified data (since the last transmission)

send this when called

- Stations without modified data only acknowledge the

call

- Transmission of control center data for the stations in

between the calls

- Data exchange using internode communication between

the stations is possible via the polling TIM of the control

center

• Polling with time slot procedure

- Operating mode for a radio network with division of the

radio frequency between several providers

- Typically 6 s/min (time slot) for each provider for data

exchange

- Data exchange during the time slot is carried out as

described under "Polling"

- Following the data exchange, the frequency swaps to the

next provider

- Data exchange using internode communication between

the stations is possible via the polling TIM of the control

center

- Control of the polling TIM by DCF77 or GPS radio-controlled clock for exact observation of the time slot

• Spontaneous mode in dial-up networks

- Data from outstations and node stations can be assigned

priorities for transmission in the dial-up network: normal,

high, alarm

- Immediate establishment of a dial-up connection for

data with alarm priority or high priority; priority transmission of alarm frames

- Intermediate storage of data with normal priority; transmission during the next dial-up connection with the partner in the original chronological order (FIFO principle)

- Transmitted data from the control center always has high

priority

- Data exchange possible between the stations with direct

internode communication

• Spontaneous mode in the TCP/IP-based WAN

- Establishment of a permanent S7 connection between

two TIMs or between TIM and control center

- Exchange of SINAUT ST7-specific data packets via this

S7 connection using S7 communication functions with

application of the TCP/IP transport protocol

- If the data transmission costs are related to the data

quantity, processing is carried out with priority as with

spontaneous mode for dial-up networks: immediate

transmission of data with high priority and alarm priority

(latter with priority); collection of data with normal priority and transmission in larger blocks

- If the data quantity is not cost-relevant, all data is transmitted immediately to the respective partner, i.e. without intermediate storage. Message frames with alarm

priority then have priority.

• Multi-master polling with time slot procedure

- Operating mode for communication between outstations and more than one control center via dedicated line

or radio network

- Each control center is assigned one or more time slots

per minute for polling

- Separate data buffer for each control center in the stations (including node stations)

- Data exchange using internode communication between

the stations is possible via the polling TIM of the active

control center

- Redundant internode communication is possible; upon

failure of the preferred control center, internode communication is carried out via the TIM of the alternative control center

- Each TIM of the control centers involved must be controlled by means of a DCF77 or GPS radio-controlled

clock for exact observation of the time slot

SINAUT ST7 telecontrol protocol 19

Page 20

DNP3 telecontrol protocol

© Siemens AG 2011

Widely distributed outstations (RTUs) can be controlled and

monitored with the DNP3 telecontrol protocol via serial or

Ethernet TCP/IP communication links by means of the telecontrol center in SIMATIC PCS 7. The control center integrated

with SIMATIC PCS 7 TeleControl into the operator system of

the process control system is the master during telecontrol

communication.

The slaves are represented by the outstations. SIMATIC

S7-300/S7-300F and S7-400/S7-400F/S7-400H/S7-400FH

controllers as well as third-party RTUs can be used as outstations.

Control center

SIMATIC PCS 7 TeleControl

DNP3 master

Ethernet

RS 485

MD2

MD2 MD2

· · ·

Further hardware and software components round off the

range of products:

• TIM communication modules

•TCP/IP converters – serial and MD modem modules

•GSM/GPRS components

• TCP/IP routers and switches

• SCALANCE S612 and S613 security modules

• Dedicated-line accessories

•Cables

• Engineering package for configuration of DNP3 data

objects, stations, networks and connections as well as

for diagnostics

In order to implement the telecontrol networks, the basic

topologies of point-to-point, multi-point, star and ring can be

configured using classic or also TCP/IP-based media, and combined flexibly independent of the infrastructural conditions.

Range without repeaters (example)

with conductor cross-section 0.8 mm

- 1 200 bit/s max. 33 km

- 2 400 bit/s max. 27 km

TCP/IP to serial

converter

- 19 200 bit/s max. 11 km

Dedicated network

with star topology

RTU S7-400H RTU S7-400

TIM 4R-IE

DNP3 (slave)

DNP3 - example of classic dedicated network (star + multi-point topologies)

MD2

TIM 4R-IE

DNP3 (slave)

MD2

· · ·

Classic WAN media

• Dedicated line via modem, e.g. SINAUT MD2

• Private wireless networks

• Analog telephone network

• Digital ISDN network

• Mobile radio network GSM

RTU S7-300

TIM 3V-IE

DNP3 (slave)

RTU S7-300

TIM 3V-IE

DNP3 (slave)

MD2

MD2

Star +

multi-point

G_PCS7_XX_00267

DNP3 telecontrol protocol20

Page 21

MD741-1

G_PCS7_XX_00269

Ethernet

RTU S7-300

TIM 4R-IE DNP3 (Slave) MD2

MD2

MD2

RTU S7-400

Ethernet

MD2

SCALANCE

S612/613

Control center SIMATIC PCS 7

TeleControl DNP3 master

Control center SIMATIC PCS 7

TeleControl DNP3 master

Dedicated

line

Redundant transmission path:

classic WAN + classic WAN

Dedicated

line

Redundant transmission path:

classic WAN + TCP/IP-based WAN

Path

redundancy,

2 media

TCP/IP to serial

converter

TCP/IP to serial

converter

TIM 3V-IE Advanced

DNP3 (slave)

Radio

network

GPRS network

Internet

DSL router

© Siemens AG 2011

Control center

DNP3 master

931WXQQHO

RTU S7-300

SCALANCE

S612/613

RTU S7-400H

SIMATIC PCS 7 TeleControl

Ethernet

DSL

Firewall

router

RTU S7-400

· · ·

TIM 4R-IE DNP3 (Slave)

DNP3 - example of secure TCP/IP-based connection over Internet via DSL (star topology)

TIM 4R-IE DNP3 (Slave)

TIM 3V-IE DNP3 (Slave)

SCALANCE

S612/613

DSL router

Firewall

Internet

Firewall

DSL router

SCALANCE

S612/613

Star via

Internet

G_PCS7_XX_00268

DNP3 - example of redundant telecontrol connections (point-to-point topology)

TCP/IP-based WAN media

• Ethernet networks, e.g. SCALANCE X with fiber-optic

cables

• Industrial Wireless LAN with SCALANCE W

• Public networks and the Internet using DSL and/or GPRS

To permit redundant data transmission, outstations can be

connected to the SIMATIC PCS 7 TeleControl center over two

paths.

DNP3 telecontrol protocol 21

Page 22

© Siemens AG 2011

Special characteristics

of DNP3 communication

Change-driven data transmission

• Change-driven transmission of process data between

RTU and control center

• Signaling of RTU, control center or connection failure

• Automatic data updating for all communication partners involved following troubleshooting and following

the startup of the RTU or control center

Chronological processing of process data

• Time tagging of all data frames at the place of origin allows process data to be archived by the process control

system in the correct chronological order

• The time of the DNP3 stations in the WAN can be synchronized via SIMATIC PCS 7 (including summertime/

wintertime switchover)

Local data storage

• The TIM communication module can temporarily store

(for several hours or even days) message frames should

the connection or the communication partner fail

• Intermediate storage of message frames of lower

priority in the case of priority-controlled data transmission (with dial-up networks or quantity-dependent

data transmission costs)

Operating modes

The DNP3 telecontrol protocol supports the following

operating modes (functional principle similar to that

described in the section for the SINAUT ST7 telecontrol

protocol):

•Polling

• Polling with time slot procedure

• Multi-master polling with time slot procedure

• Spontaneous mode in dial-up networks

• Spontaneous mode in the TCP/IP-based WAN

DNP3 telecontrol protocol22

Page 23

© Siemens AG 2011

IEC 870-5-101/IEC 870-5-104 telecontrol protocol

SINAUT

MD741-1

IEC 60870-5 -104

SIPLUS RIC Bundle

with SIMATIC S7-400

DSL router

SCALANCE S612,

security module

Control center

IEC 60870-5 -101

SINAUT

MD2

Radio

network

SIPLUS RIC Bundle

with SIMATIC S7-300

SIPROTEC

7SJ63

SINAUT

MD741-1

SIPLUS RIC Bundle

with SIMATIC S7-300

IEC 60870-5 -103

SINAUT

MD741-1

SIPLUS RIC Bundle

with SIMATIC ET 200S

SIPLUS RIC Bundle

with SIMATIC ET 200S

SINAUT

MD2

Flexible communication options in the WAN with IEC 870-5-101/IEC 870-5-104 telecommunication protocols

A telecontrol center which is seamlessly integrated into the

SIMATIC PCS 7 process control system by means of SIMATIC

PCS 7 TeleControl can control and monitor geographically dis-

The performance of the telecontrol stations can be scaled

with SIPLUS RIC bundles configured as slaves for the tele-

control link as shown below:

persed outstations via serial (IEC 870-5-101 telecontrol protocol) or Ethernet TCP/IP (IEC 870-5-104 telecontrol protocol)

communication links.

SIMATIC S7 controllers (SIMATIC ET 200S with integral CPU,

SIMATIC S7-300/S7-300F, and SIMATIC S7-400/S7-400F/

S7-400H/S7-400FH) as well as third-party RTUs can be used as

Performance

SIPLUS RIC Bundle

with SIMATIC S7-400

outstations in this context. The control center is the master

during communication with the outstations.

SIPLUS RIC Bundle

with SIMATIC S7-300

The IEC 870-5-101 and IEC 870-5-104 telecontrol protocols

are anchored in the telecommunication product range

SIPLUS RIC. Based on specific libraries for telecontrol protocols, SIPLUS RIC comprises low-cost bundles for outstations

SIPLUS RIC Bundle with

SIMATIC ET 200S

which are based on SIMATIC ET 200S with integral CPU,

SIMATIC S7-300 or SIMATIC S7-400.

Parameterization of SIMATIC STEP 7

Scalable performance of SIPLUS RIC bundles

IEC 60870-5 -101

SINAUT

MD2

SIPLUS RIC Bundle

with SIMATIC S7-300

Data volume

G_PCS7_XX_00217

IEC 870-5-101/IEC 870-5-104 telecontrol protocol 23

Page 24

© Siemens AG 2011

The SIPLUS RIC bundles usually comprise:

•CPU

• Interface/communication module (if necessary)

•Memory card

• CD with library and registration code.

SIPLUS RIC products require additional material to establish

telecommunication links, e.g. TCP/IP converters – serial,

dedicated line modems, media converters, TCP/IP routers,

SCALANCE S612 and S613 security modules, switches, cables

etc.

In order to implement telecontrol networks, basic topologies

including point-to-point, multi-point, star and ring can be configured using classic or TCP/IP-based media. These can be

combined flexibly independent from existing infrastructure.

Control center

SIMATIC PCS 7 TeleControl

IEC 870-5-104

RTU S7-400

MD741

Ethernet

Internet

Classic WAN media

(IEC 870-5-101 telecontrol protocol)

• Dedicated line via modem, e.g. SINAUT MD2

• Dedicated line over fiber-optic cables

• Private wireless networks

TCP/IP-based WAN media

(IEC 870-5-104 telecontrol protocol)

• Ethernet networks, e.g. SCALANCE X with fiber-optic

cables

• Industrial Wireless LAN with SCALANCE W

• Public networks and the Internet using DSL and/or GPRS

• Satellite communication, e.g. with Inmarsat

SCALANCE

S613

DSL router

CP 443

Third-Party RTU

IEC 870-5-104 - example of TCP/IP-based WAN with GPRS radio network (star topology)

IEC 870-5-104

IEC 870-5-104

GPRS

radio network

RTU S7-300

with CP 343

MD741 MD741

IEC 870-5-104

RTU ET 200S

with IM 151-8

PN/DP CPU

Star via

wireless

IEC 870-5-104

G_PCS7_XX_00270

IEC 870-5-101/IEC 870-5-104 telecontrol protocol24

Page 25

© Siemens AG 2011

Control center

SIMATIC PCS 7 TeleControl

SCALANCE

S613

DSL router

MD741

RTU S7-300

with CP 343

RTU ET 200S

with IM 151-8

PN/DP CPU

RTU S7-300 with

CP 343

RTU S7-400 with

CP 443

Ethernet

Internet

Third-Party RTU

IEC 870-5-104

IEC 870-5-104

GPRS radio

network

IEC 870-5-104 - example of complex TCP/IP-based WAN with cable and GPRS networks

It is also possible to connect an outstation via two transmission paths to the control center in the SIMATIC PCS7 process

control system to achieve redundant data transmission.

Redundant transmission paths can be based on the same

or different communication protocols.

IEC 870-5-104

MD741

IEC 870-5-104

RTU ET 200S

with IM 151-8

PN/DP CPU

Complex network structure,

combination of different

topolo gies and m edia

G_PCS7_XX_00271

Control center

SIMATIC PCS 7 client

Terminal bus (Ethernet)

PCS 7 TeleControl

OS server,

redundant

Redundant system bus

TCP/IP to serial

converter

RTU S7-300

with 2 x CP 343

RTU S7-400 with

2 x CP 443

IEC 870-5-104

RTU S7-400 with CP 443

(left) and CP 441

IEC 870-5-101IEC 870-5-104

RTU ET 200S

with IM 151-8 PN/DP CPU

and 1 SI interface module

RTU S7-300

with CP 343 (left)

and CP 341

IEC 870-5-101/104 - example of redundant telecommunication links (IEC 870-5-101 representation without modems)

Path

redundancy,

1 medium

G_PCS7_XX_00272

IEC 870-5-101/IEC 870-5-104 telecontrol protocol 25

Page 26

Modbus telecontrol protocol

© Siemens AG 2011

The Modbus telecommunication protocol is suitable for the

integration of existing units with a Modbus infrastructure into

the SIMATIC PCS 7 process control system.

Telecontrol communication for control and monitoring of

widely distributed outstations (RTUs) from a control center in

SIMATIC PCS 7 is possible with this protocol via both serial and

TCP/IP communication links.

The control center, represented by the SIMATIC PCS 7 Operator

System with SIMATIC PCS 7 TeleControl, is the Modbus master.

SIMATIC S7 controllers (SIMATIC ET 200S with integral CPU,

SIMATIC S7-300/S7-300F, and SIMATIC S7-400/S7-400F) as

well as third-party RTUs with a suitable Modbus interface can

be used as outstations (Modbus slaves).

The SIPLUS RIC range includes low-cost bundles for outstations with Modbus telecontrol protocol (serial or TCP/IP),

based on SIMATIC ET 200S with integral CPU and SIMATIC

S7-300. These usually comprise:

•CPU

• Interface/communication module (if necessary)

•Memory card

• CD with library and registration code.

In addition, further material is required to establish

the telecommunication links, e.g. TCP/IP converters – serial,

dedicated line modems, media converters, TCP/IP routers,

switches, cables etc.

The Modbus telecontrol protocol can be used to implement

telecontrol networks based on point-to-point and multi-point

topologies, both serial and TCP/IP. The following media can be

used for this:

Classic WAN media

• Dedicated line via modem, e.g. SINAUT MD2

• Dedicated line over fiber-optic cables

• Private wireless networks

TCP/IP-based WAN media

• Ethernet networks, e.g. SCALANCE X with fiber-optic

cables

• Industrial Wireless LAN with SCALANCE W

• Public networks and the Internet using DSL and/or GPRS

To permit redundant data transmission, outstations can be

connected to the control center in the SIMATIC PCS 7 process

control system over two paths. Two operating modes are

available:

TCP/IP WAN router

SCALANCE

X101-1LD

Fiber-optic cable

SCALANCE

X101-1LD

SIMATIC S7-400 with

CP 443 and software library

(Modbus slave)

Control center

Modbus master

TCP/IP to serial converter

SINAUT

MD2

SINAUT

MD2

SIPLUS RIC bundle

with SIMATIC ET 200S

(Modbus slave)

• Load sharing: parallel utilization of both paths

• Master/standby: only one path is active, the other is passive

SINAUT

MD2

SIPLUS RIC bundle

with SIMATIC S7-300

(Modbus slave)

Point-to-

point

Multi-point

G_PCS7_XX_00273

Modbus - example of serial and TCP/IP telecontrol connections (multi-point/point-to-point topologies)

Modbus telecontrol protocol26

Page 27

© Siemens AG 2011

Redundancy

Increasing the plant availability

For the individual telecontrol protocols, reference was already

made as to how the availability of telecontrol communication

can be increased using redundant transmission paths. However, as a result of seamless integration of the telecontrol

technology into the SIMATIC PCS 7 process control system, the

redundant design of the telecontrol communication is embedded in the redundancy concept of the complete system and

must therefore be considered globally.

SIMATIC PCS 7

OS clients

Terminal bus

Control center

SIMATIC PCS 7

TeleControl OS

with redundant

servers

The example of a SIMATIC PCS 7 process control system

with integral telecontrol linking of RTUs on the basis of

the IEC 870-5-101/IEC 870-5-104 protocols demonstrates the

various possibilities for increasing plant availability:

• Redundant SIMATIC PCS 7 TeleControl OS servers for process control of central and widely distributed units and for

archiving

• Redundant system bus for system communication

• Redundant telecontrol communication between control

center and RTUs over two separate transmission paths

• Redundant RTUs on the basis of S7-400H/ S7-400FH controllers for local automation of remote units

• Redundant PROFIBUS for communication between controller and process I/O (I/O modules, process instruments and

devices in the field)

• Redundant process I/O

It is also possible to implement safety-related functions in

the RTU (up to SIL 3) based on the S7-400FH controller and

F modules in the ET 200M remote I/O station.

Redundant system bus

TCP/IP to serial

converter

IEC 870-5-101

redundant

RTU S7-400H

ET 200M redundant

with 2 x CP 341

Redundant telecontrol configuration based on the

IEC 870-5-101/IEC 870-5-104 protocols

TCP/IP

WAN router

IEC 870-5-104

redundant

RTU

S7-400H

with CP 443

ET 200M

redundant

G_PCS7_XX_00274

Redundancy 27

Page 28

Industrial Ethernet

TIM

4R-IE

S7-300

G_PCS7_XX_00180

S7-400 S5-115 S5-135/155

S5-100

IP-based

WAN

Classic

WAN

SINAUT ST7 stations SINAUT ST1 stations

6,0$7,&3&6ZLWK6,0$7,&3&67HOH&RQWURO

© Siemens AG 2011

Migration

Migration of existing telecontrol systems

Units with Modbus communication

The Modbus is widely used in automation plants due to its

straightforwardness and openness. The Modbus telecontrol

protocol can be used to implement both serial and TCP/IP communication links between a control center in SIMATIC PCS 7

and RTUs with a corresponding Modbus interface.

In this manner, existing units with a Modbus infrastructure

can be integrated at low cost into the SIMATIC PCS 7 process

control system. The RTUs of these units can be SIMATIC S7

controllers (SIMATIC ET 200S with integral CPU, SIMATIC

S7-300/S7-300F and SIMATIC S7-400/S7-400F) as well as

third-party RTUs. Whereas RTUs with Modbus TCP/IP interface

can be integrated directly, serial third-party RTUs require specific interface converters for telecontrol communication.

Engineering data of third-party RTUs can be imported in CSV

format into the PCS 7 TeleControl engineering (DBA). The status of the RTUs and the transmission paths is evaluated by the

"Diagnostics Modbus RTU" block and displayed in the control

center.

SINAUT ST1 stations based on SIMATIC S5

During the migration of existing systems, it is possible to integrate outstations based on SIMATIC S5 into the SIMATIC PCS 7

process control system using SIMATIC PCS 7 TeleControl. In

the process, the ST1 telecontrol protocol is converted into the

ST7 protocol in the central TIM communication module.

Third-party stations

In addition to the Modbus telecontrol protocol, the DNP3

(serial and TCP/IP), IEC 870-5-101 (serial) and IEC 870-5-104

(TCP/IP) telecontrol protocols basically also support the control center linking of third-party RTUs when migrating existing

systems. The implementation depends on whether the thirdparty RTU masters the corresponding protocol and whether

the interface converters are available if necessary.

Integration of SINAUT ST1 stations into telecontrol communication

Migration28

Page 29

HMI

LAN

SINAUT LSX

server (ST7)

© Siemens AG 2011

clients

SIMATIC PCS 7 TeleControlSINAUT LSX

PCS 7 clientsSINAUT LSX

PCS 7

Engineering

System

(DBA)

PCS 7

TeleControl

OS server

FEP

Front End

AS

WAN

RTU

Integration of existing SINAUT LSX systems per PCS 7 TeleControl S7 EDC driver

Processor

S7-300

S7-400

S5 / ST1

(KOMSYS)

Node

station

TIM

S5-115

S7

(EDC)

S5-135

ST1 RTUs ST7 RTUs

Integration of third-party stations with OPC

Along with additive engineering performance on the basis of

DBA technology, SIMATIC PCS 7 TeleControl also allows integration of third-party RTUs for which an OPC server exists into

the process control with the SIMATIC PCS 7 Operator System.

SIMATIC PCS 7 TeleControl then supports data exchange

between the operator system (OPC client) and the RTU

(OPC server) per OPC DA.

DSL router

SCALANCE

S612

Master

TIM (ST7)

Control center

IEC 60870-5-104

SIMATIC

PCS 7

S7-400

S7-300

S7-400

G_PCS7_XX_00275

SINAUT LSX systems

Existing SINAUT LSX systems can also be migrated with

SIMATIC PCS 7 TeleControl. The SIMATIC S7 controllers with

EDC communication protocol (Event Driven Communication)

installed in the SINAUT LSX systems are then integrated into

SIMATIC PCS 7 TeleControl per PCS 7 TeleControl S7 EDC

driver. Because the SINAUT LSX system can coexist at all levels

next to the new system architecture as long as necessary,

modernization is possible step-by-step and without shortlived intermediate solutions.

Linking of SIPROTEC or third-party protection equipment

The protocol expansion IEC 870-5-103 Master for SIPLUS RIC

bundles also allows interfacing of SIPROTEC or third-party protective equipment via SIMATIC PCS 7 TeleControl. The RTU

(ET 200S with CPU, S7-300 or S7-400 controller) then serves

as a converter between the IEC 870-5-103 protection data

protocol and the IEC 870-5-101 or IEC 870-5-104 protocol.

SINAUT

MD741-1

SIPLUS RIC bundle

with SIMATIC S7-300

Example of interfacing of SIPROTEC protective equipment

SIPROTEC

7SJ63

IEC 60870-5-103

Compared to PROFIBUS DP interfacing of the protective equipment, this configuration provides the following advantages:

• Greater distances are possible.

• The highly exact time stamps are transferred from the protective equipment to the control system.

Migration 29

G_PCS7_XX_00276

Page 30

© Siemens AG 2011

Application examples

Automation of a gas pipeline with block valve and metering stations

Uniform automation of all stations in the gas network

■ SIMATIC PCS 7 process control system for compressor

and pressure reducing stations

■ SIMATIC PCS 7 TeleControl with SINAUT telecontrol tech-

nology on the basis of S7-300/S7-400 controllers for

block valve and metering stations

■ Combination of process control at one operator station

(SIMATIC PCS 7 OS client)

■ Compliant process control with uniform faceplates,

alarms, trends etc.

High system availability resulting from redundancy

■ Redundant pair of SIMATIC PCS 7 OS servers

■ Redundant pair of SIMATIC PCS 7 TeleControl OS servers

■ Ring topology with redundant media Integral safety technology for emergency shutdown (ESD)

SIMATIC PCS 7

Engineering

Station

Industrial Ethernet

PROFIBUS

SIMATIC PCS 7 clients

SIMATIC PCS 7

FH controller

approx. 800 I/Os

Safety ESD

Compressor station

PCS 7 TeleControl

OS server

(redundant)

ESD is integrated homogenously into the automation plant

(compressor and relief stations):

• Redundant safety-related controllers

• Redundant PROFIBUS with PROFIsafe

• ET 200M with F modules

Pipeline

Metering stations

S7-400

controller

approx.

100 I/Os

SINAUT TIM

Local station

RTU S7-300 incl.

SINAUT TIM

approx. 30 I/Os

Block valve stations

Pipeline

Pressure reducing station

SIMATIC PCS 7

client

SIMATIC

PCS 7 server

(redundant)

SIMATIC PCS 7

FH controller

approx.

300 I/Os

Safety

ESD

G_PCS7_XX_00277

System architecture of gas pipeline automation with SIMATIC PCS 7 TeleControl

Application examples30

Page 31

© Siemens AG 2011

Automation of a sewage treatment plant with pumping station and stormwater overflow tank

Municipal sewerage

system

Industry

Private

Pumping

households

station

Aeration

Preliminary sedimentation

Prethickening

Delivery of

fecal matter

Stormwater

overflow tank

Digestion tank Dosing of flocculent

Gasometer

Lifting

equipment

Dosing of precipitant

Combined heat

and power plant

Screen

Final clarification

Sludge

dewatering

Preliminary sedimentation

Sand and

grease trap

Sludge treatment

Mechanical

purification

Digestion tank

Biological

purification

Drainage

Sludge output

Symbolic technical representation of a sewage treatment plant

Uniform control of the complete wastewater network

• SIMATIC PCS 7 process control system in the sewage treatment plant

• SIMATIC PCS 7 TeleControl with SIPLUS RIC telecontrol technology on the basis of the IEC 870-5-104 protocol

• Combination of process control at one operator station

(PCS 7 OS client)

• Compliant process control with uniform faceplates, alarms,

trends etc.

Secure communications

• Protection of telecontrol network by SCALANCE S613

industrial security module

• Application of GPRS technology

Reporting and archiving in compliance with

AT V-D VWK M 26 0

With application of the SIMATIC PCS 7 add-on product ACRON

Cost-effective RTUs exactly matched to the respective unit

• S7-300 controller for pumping station

• ET 200S with integral CPU for stormwater overflow tank

Sewage plant

SIMATIC PCS 7 OS clients

Industrial Ethernet

PCS 7 TeleControl OS

server (redundant)

Industrial Ethernet

SIMATIC PCS 7

controller

PROFIBUS I/O

approx. 500 I/Os

Aeration blowing

station

PROFIBUS

SIMATIC PCS 7

controller

PROFIBUS I/O

approx. 500 I/Os

Inflow

pre-treatment

System architecture of sewage treatment plant automation with SIMATIC PCS 7 TeleControl

SIMATIC PCS 7

controller

PROFIBUS I/O

approx. 500 I/Os

Sludge

treatment

DSL router

SCALANCE

S613

Internet

MD741

IEC 870-5-104

S7-300

approx. 150 I/Os

Pumping station

IEC 870-5-104

GPRS

MD741

IEC 870-5-104

ET 200S

with IM 151-8 CPU

approx. 25 I/Os

Stormwater overflow tank

Local

station

Local

station

G_PCS7_XX_00278

Application examples 31

Page 32

© Siemens AG 2011

Additional information

SIMATIC controllers:

www.siemens.com/simatic-controller

SIMATIC automation systems:

www.siemens.com/simatic

Totally Integrated Automation:

www.siemens.com/totally-integrated-automation

SIPLUS extreme – ruggedness and refinement:

www.siemens.com/siplus-extreme

Service and Support:

www.siemens.com/automation/service&support

SIMATIC contacts:

www.siemens.com/automation/partner

Information material to download:

www.siemens.com/simatic/printmaterial

SIMATIC Guide Manuals:

www.siemens.com/simatic-docu

Ordering on the Internet with the Industry Mall:

www.siemens.com/industrymall

Siemens AG

Industry Sector

Industrial Automation Systems

P.O. Box 4848

90026 NUREMBERG

GERMANY

Subject to change without prior notice

Order No.: E86060-A4678-A281-A1-7600

3P.8315.58.04 / Dispo 09508

BR 0111 3. ERD 32 En

Printed in Germany

© Siemens AG 2010

www.siemens.com/automation

The information provided in this brochure contains descriptions

or characteristics of performance which in case of actual use do

not always apply as described or which may change as a result of

further development of the products. The desired features are

only binding if explicitly agreed in the contract. Availability and

technical specifications are subject to change without notice.

Any product names mentioned may be trademarks or product

designations of Siemens AG or their suppliers, whose use by third

parties for their own purposes may infringe the rights of the

trademark owners.

Loading...

Loading...