673

7

Butterfly valves VKF10…

VKF11…

Butterfly valves designed in intermediate flange design, for mounting into gas

trains

Valve either metallically tight or swing thru

DN32...DN200

Effective rotation angle 5…85°

Suitable for gases in the I…III range, air and flue gas up to 180°C

Including coupling for D-shaft Ø 10 mm and ASK33.1 mounting plate

The option is available to install the butterfly valve in the next nominal size

up to ensure it is positioned more securely

Installation in ISO 7005 and ANSI flange connections

The VKF10/VKF11 and this data sheet are intended for original equipment

manufacturers (OEMs) using the VKF10/VKF11 in or on their products.

Use

CC1N7673en

25.03.2019

As a controlling device in combustion plants, for example:

As a gas control valve

As an air control valve

As a flue gas valve in the case of flue gas recirculation

For applications with a large control range

Suitable for slightly aggressive biogases and recycling gases

Building Technologies

Supplementary documentation

r

Product type

VKF1x

Warning notes

Mounting notes

Startup notes

Type of documentation

Mounting Instruction

Documentation numbe

74 319 0516 0 (M7673)

To avoid personal injury or damage to property or the environment, the following

warning notes must be observed.

Interventions and changes are strictly forbidden.

All activities (mounting, installation, service work, etc.) must be performed by

qualified staff

These valves must not be put back into operation following impact or shock; even if

they do not exhibit any visible damage, their safety functions may be impaired

Ensure that the relevant national safety regulations are complied with

Mounting between counter-flanges conforming to ISO 7005-2 and ANSI

Butterfly valve and actuator can be assembled directly on site with ease

No special tools or adjustment required

The butterfly valve can accommodate flow in either direction

Use flange gaskets that are suitable for the type of gas

The butterfly valve may only be put into operation if the actuator is correctly fitted

The direction of rotation when opening the damper should be clockwise (looking

towards the front face of the axle)

Ensure the actuators being combined rotate in the correct direction: Direction of

rotation ‘counterclockwise’ (12:00 09:00) looking towards the front face of the

actuator axles

Disk turns in clockwise direction Flow increases

Disk turns in counterclockwise direction Flow decreases

2/16

Building Technologies CC1N7673en

25.03.2019

Standards and certificates

Applicable regulations:

Gas Appliances Regulation 2016/426

Compliance with the regulations of the applied directives is verified by the adherence to

the following standards/regulations:

Safety and control devices for burners and appliances

DIN EN 13611

burning gaseous and/or liquid fuels – General requirements

Safety and control devices for gas burners and gas-burning

ISO 23550

appliances – General requirements

EAC Conformity (Eurasian Conformity)

ISO 9001:2015

ISO 14001:2015

OHSAS 18001:2007

China RoHS

Hazardous substances table:

http://www.siemens.com/download?A6V10883536

Service notes

The VKF10/VKF11 butterfly valve requires no maintenance

The butterfly valve may only be put back into operation if the actuator is correctly

fitted

The tightness must be checked when mounting or replacing it

Disposal notes

Prior to disposal, the butterfly valve must be dismantled and separated into its various

materials. Local and currently valid legislation must be complied with. The

VKF10/VKF11 does not contain any electronics.

Mechanical design

VKF10 butterfly valve

The valve disk and shaft are made of stainless steel.

The valve disk does not close against an end stop.

After mounting the actuator, the position indicator and valve disk are both at 5° so that

the effective setting range can be used.

VKF11 butterfly valve

The valve disk and shaft are made of stainless steel.

The valve disk closes against an end stop (approx. 5° position).

3/16

Building Technologies CC1N7673en

25.03.2019

Type summary

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

Article no. Type

KF10

S55592-G101-A100

S55592-G102-A100

S55592-G103-A100

S55592-G104-A100

S55592-G105-A100

S55592-G106-A100

S55592-G107-A100

S55592-G108-A100

S55592-G109-A100

VKF10.032 32 + 40 < 2%

VKF10.040 40 + 50 < 2%

VKF10.050 50 + 65 < 2%

KF10.065 65 + 80 < 2%

KF10.080 80 + 100 < 2%

KF10.100 100 + 125 < 2%

KF10.125 125 + 150 < 2%

KF10.150 150 + 200 < 2%

KF10.200 200 < 2%

Article no. Type

KF11

S55592-G110-A100

S55592-G111-A100

S55592-G112-A100

S55592-G113-A100

S55592-G114-A100

S55592-G115-A100

S55592-G116-A100

S55592-G117-A100

S55592-G118-A100

Key

DN Nominal diameter

Suitable actuators Required mounting plate *)Data sheet no

KF11.032 32 + 40 < 0.5%

KF11.040 40 + 50 < 0.5%

KF11.050 50 + 65 < 0.5%

KF11.065 65 + 80 < 0.5%

KF11.080 80 + 100 < 0.5%

KF11.100 100 + 125 < 0.5%

KF11.125 125 + 150 < 0.5%

KF11.150 150 + 200 < 0.5%

KF11.200 200 < 0.5%

DN

[mm]

DN

[mm]

Leakage rate where

p = 0.5 kPa air

Leakage rate where

p = 0.5 kPa air

SQM33 ASK33.1 N7813

SQM40.xx5xxx ASK33.1 N7817

SQM45.295A9 ASK33.1 N7814

SQM50 with AGA58.5 ASK33.3 N7815

SQN7x.xxxxx1 ASK33.5

*) ASK33.1 included in scope of delivery

N7804

N7802

Caution!

Only counterclockwise actuators may be used for the VKF10/VKF11.

4/16

Building Technologies CC1N7673en

25.03.2019

Ordering

Butterfly valve and actuator must be ordered as individual items.

Please specify the quantity, names, and type references when ordering.

Example:

1 VKF11.040 butterfly valve

1 SQM40.245A11 actuator

Delivery

Butterfly valve and actuator are packed as individual items.

Accessories

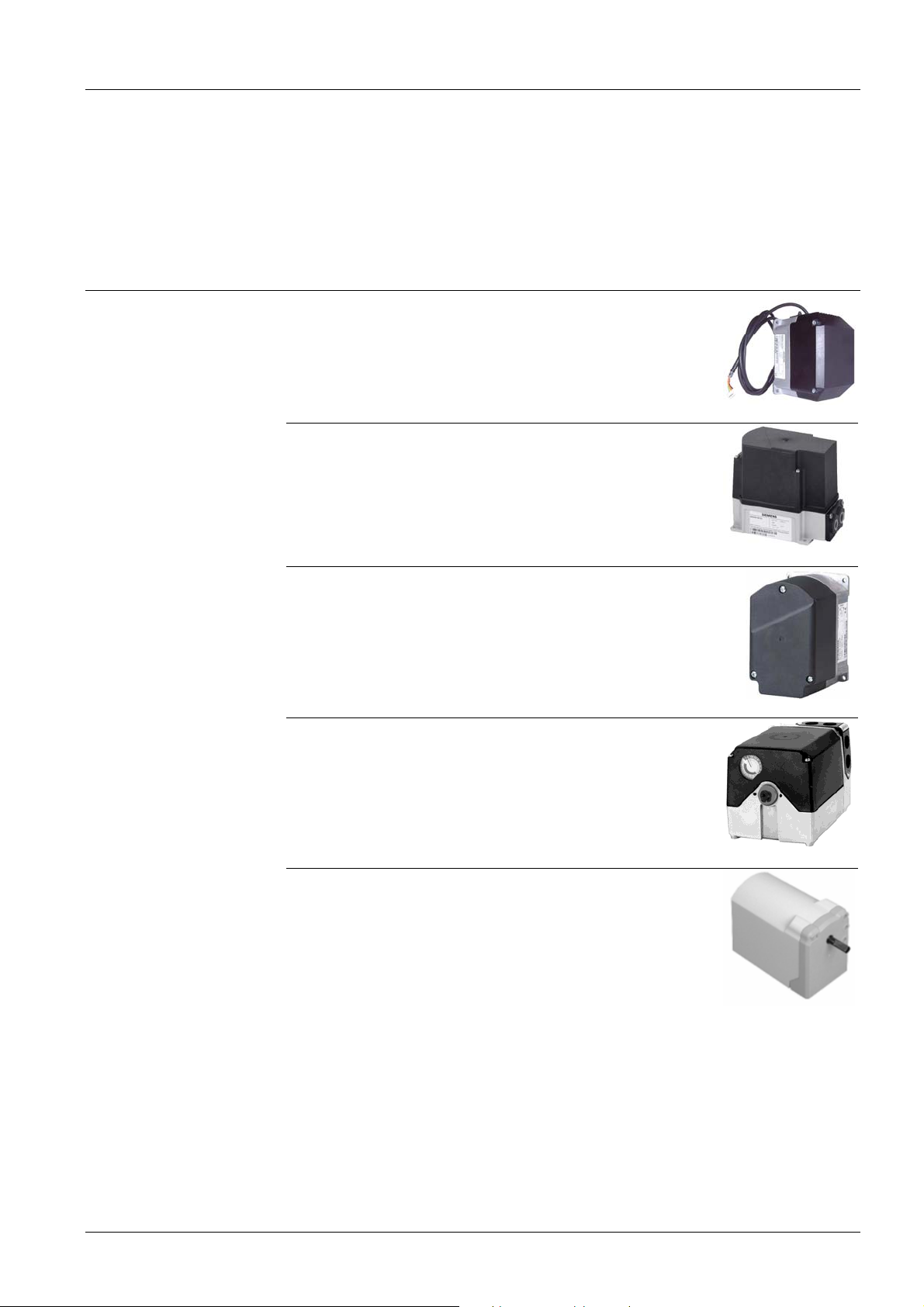

Actuator

SQM33 actuator

(to be ordered separately)

Refer to data sheet N7813

SQM40 actuator

(to be ordered separately)

Refer to data sheet N7817

SQM45 actuator

(to be ordered separately)

Refer to data sheet N7814

SQM50 actuator

(to be ordered separately)

Mounting sets must be ordered separately, see

Accessories – Mounting plate.

Refer to data sheet N7815

SQN7x.xxxxx1 actuator

(to be ordered separately)

Mounting sets must be ordered separately, see

Accessories – Mounting plate.

Refer to data sheet N7802/N7804

5/16

Building Technologies CC1N7673en

25.03.2019

Accessories (continued)

Mounting plate

ASK33.1 mounting plate

Article no: BPZ:ASK33.1

(included in scope of delivery)

Mounting plate for mounting actuators SQM33, SQM40

and SQM45

Note!

The required screws (3x M5 countersunk screws and 4x M5 screws) are included in

the packaging for the ASK33.1.

ASK33.3 mounting plate

Article no: BPZ:ASK33.3

(to be ordered separately)

Larger mounting plate required to replace existing

mounting plate

Required for mounting the actuators SQM5 with AGA58.5.

Note!

The required screws (4x M6x15) are included in the packaging for the ASK33.3.

Drive shafts

ASK33.5 mounting plate

Article no: S55857-Z101-A100

(to be ordered separately)

Mounting plate for mounting the actuator SQN7x.xxxA21

Reducing sleeve included in scope of delivery

Note!

The required screws are included in the standard scope of delivery.

AGA58.5 drive shaft

Article no: BPZ:AGA58.5

For installation in the SQM50 and mounting on the VKF1x

D shaft Ø 10 mm

6/16

Building Technologies CC1N7673en

25.03.2019

Technical data

General unit data

Environmental

conditions

Gas types 1% H2S, 1% NH3 maximum Gas families I…III, air and flue gas

Operating pressure

Up to and including DN100 Max. 150 kPa (1.5 bar)

From DN125 Max. 100 kPa (1 bar)

Mounting positions

7632z01/0103

Leakage rate at VKF11 (internal) Refer to Type summary

Effective rotation angle 85° butterfly valve

Materials

Valve body GGG40.3

Cast iron with nodular graphite

according to DIN EN 1563

Shaft and valve disk Stainless steel

Shaft seal 2 O-rings

No non-ferrous metals

Weight Refer to Dimensions

Storage DIN EN 60721-3-1

Climatic conditions Class 1K3

Mechanical conditions Class 1M2

Temperature range -20…+60°C

Humidity < 95% r.h.

Transport DIN EN 60721-3-2

Climatic conditions Class 2K2

Mechanical conditions Class 2M2

Temperature range -20…+60°C

Humidity < 95% r.h.

Operation DIN EN 60721-3-3

Climatic conditions Class 3K5

Mechanical conditions Class 3M2

Temperature range

VKF10/VK11 -15…+180°C (air and flue gas)

-15…60°C (gas)

Humidity < 95% r.h.

Caution!

Condensation, formation of ice, and ingress of water are not permitted.

7/16

Building Technologies CC1N7673en

25.03.2019

Flow chart

)

00

5

3000

Illustration of the VKF10.032 to VKF10.080, characteristic curve for the effective positioning range (5°…85°)

5

450

400

350

300

250

kv values

200

150

100

50

0

5 1525354555657585

Opening angle in degrees (°

Illustration of the VKF10.100 to VKF10.200, characteristic curve for the effective positioning range (5°…85°)

7673d03en/1018

VKF10.080

VKF10.065

VKF10.050

VKF10.040

VKF10.032

2500

2000

1500

kv values

1000

500

0

5 1525354555657585

Opening angle in degrees (°)

7673d04en/1018

VKF10.200

VKF10.150

VKF10.12

VKF10.100

8/16

Building Technologies CC1N7673en

25.03.2019

Flow chart (continued)

Illustration of the comparison between the VKF10.040 and VKF11.040, lower opening range (5°…25°)

10

kv values

VKF10.040

VKF11.040

9

8

7

6

5

4

3

2

1

0

510152025

Opening angle in degrees (°)

7673d05en/1018

Type Opening angle

5° *) 15° *) 25° *) 35° 45° 55° 65° 75° 85°

VKF10.032 0.6 1.6 2.8 5.6 9.5 15.3 23.7 30.9 33.7

VKF10.040 0.8 2.2 5.1 9.7 16.5 26.4 40.1 60.2 84.1

VKF10.050 0.8 3.0 7.6 15.7 29.0 47.5 74.3 120.3 150.1

VKF10.065 1.5 4.9 12.7 29.4 54.0 83.4 131.0 208.2 249.8

VKF10.080 2.7 9.4 25.4 53.6 87.4 140.9 220.0 325.6 382.9

VKF10.100 3.7 12.0 34.0 65.3 118.9 193.1 308.3 532.4 785.5

VKF10.125 5.9 23.5 69.3 135.8 229.3 350.2 545.6 921.6 1120.1

VKF10.150 6.2 26.0 90.2 182.2 322.9 499.3 767.2 1287.4 1702.4

VKF10.200 9.8 46.9 177.3 320.5 517.7 809.9 1186.8 1813.4 2337.8

VKF11.032 0.2 1.0 2.8 5.6 9.5 15.3 23.7 30.9 33.7

VKF11.040 0.2 1.9 5.1 9.7 16.5 26.4 40.1 60.2 84.1

VKF11.050 0.2 2.6 7.6 15.7 29.0 47.5 74.3 120.3 150.1

VKF11.065 0.3 4.3 12.7 29.4 54.0 83.4 131.0 208.2 249.8

VKF11.080 0.3 9.0 25.4 53.6 87.4 140.9 220.0 325.6 382.9

VKF11.100 0.3 11.4 34.0 65.3 118.9 193.1 308.3 532.4 785.5

VKF11.125 0.3 19.5 69.3 135.8 229.3 350.2 545.6 921.6 1120.1

VKF11.150 0.4 21.3 90.2 182.2 322.9 499.3 767.2 1287.4 1702.4

VKF11.200 0.6 39.2 177.3 320.5 517.7 809.9 1186.8 1813.4 2337.8

*) The characteristic curves follow the same course above 25°

9/16

Building Technologies CC1N7673en

25.03.2019

Flow chart (continued)

Caution!

In the case of burners operating with small low-fire volumes, select a tightly sized valve

If the gas pressure exceeds the maximum permissible operating pressure, reduce the gas pressure with a pressure

controller

The pressure drop (maximum flow characteristic) is based on a fully open valve

Conversion of air flow rate to a corresponding gas flow rate (natural gas)

Basis for scale

Conversion to air (m³/h) from other types of gases:

Abscissa Medium

Volumetric flow “QG” in m³/h

1 Air 1 1

2 Natural gas 0.61 1.28

3 Propane 1.562 0.8

4 City gas 0.46 1.47

QL=

QG

QL = air volume in m³/h that produces the same pressure drop as “QG”.

f

Density ratio “dv” to air Conversion factor

1

f

v

d

10/16

Building Technologies CC1N7673en

25.03.2019

A

A

A

A

Dimensions

Dimensions in mm

DN32...DN50 DN65 DN80 DN100...DN125 DN150 DN200

7673m05/0318

Type DN A BØ CØ E

VKF1x.032 DN32 30 120 72 100 88.9 110 98.4 4xM16 4x1/2 4xM16 4x1/2 158 2.3

VKF1x.040 DN40 30 130 81.5 110 98.4 125 120.7 4xM16 4x1/2 4xM16 4x5/8 162 2.5

VKF1x.050 DN50 30 155 101 125 120.7 145 139.7 4xM16 4x5/8 4xM16 4x5/8 167 2.9

VKF1x.065 DN65 30 165 120 145 139.7 160 152.4 4xM16 4x5/8 8xM16 4x5/8 174.5 3.4

VKF1x.080 DN80 30 195 132.5 160 152.4 180 190.5 8xM16 4x5/8 8xM16 8x5/8 182 3.6

VKF1x.100 DN100 30 220 160 180 190.5 210 215.9 8xM16 8x5/8 8xM16 8x3/4 192 4.3

VKF1x.125 DN125 40 250 190 210 215.9 240 241.3 8xM16 8x3/4 8xM20 8x3/4 229.5 7.6

VKF1x.150 DN150 40 300 216 240 241.3 295 298.5 8xM20 8x3/4 12xM20 8x3/4 242 9.6

VKF1x.200 DN200 40 340 271 295 298.5 - - 12xM20 8x3/4 - - 267 12.8

ISO

E

SME

ER

ISO

*) ER

SME

*) F

ISO

F

SME

Screws

*) Reference circle for installation in one flange size higher

ISO

Screws

G Weight [kg]

SME

Building Technologies CC1N7673en

25.03.2019

11/16

Dimensions (continued)

Dimensions in mm

Installation examples for VKF1x with actuator

VKF10/VKF11 with SQM45 VKF10/VKF11 with SQM50 and ASK33.3/AGA58.5

132

133

119

7673z03/0318

90

140

193

G

Type DN G

VKF1x.032

VKF1x.040

VKF1x.050

VKF1x.065

VKF1x.080

VKF1x.100

VKF1x.125

VKF1x.150

VKF1x.200

DN32 158

DN40 162

DN50 167

DN65 174.5

DN80 182

DN100 192

DN125 229.5

DN150 242

DN200 267

12/16

Building Technologies CC1N7673en

25.03.2019

Dimensions (continued)

90

A

136

A

SK33.1

Dimensions in mm

76 0.15+

)

x

4

(

7

R

Sectional view B-B

22.3 0.1+

122 0.15+

A

14.8 0.1+

50 0.1+

7673m06en/1018

Sectional view A–A

L

Ø

6.5

+

8

6

O

R

K

Ø

50 0.1+

43

14.8 0.1+

4.6 0.1 (2x)+

Ø

22.3 0.1+

5

1

.

0

B

33 0.1+

90° (2x)

7 (2x)

B

90° (4x)

3

13 (2x)

Ø

Ø

Ø

M5 EP nuts (4x)

5.2 (4x)

13/16

Building Technologies CC1N7673en

25.03.2019

Dimensions (continued)

120

1

1

A

SK33.3

Dimensions in mm

105

22.3 ±0.1

7.5

M6.5 (4x)

44.5

5

100 ±0.15

55.5

7.5

50 ±0.1

5

14.8 ±0.1

A

50 ±0.1

LKR Ø68 ±0.1

Ø5.2 (3x)

3

14.8 ±0.1

B

B

x)

4

(

R3

Ø4.8 +0.1 (2x)

Sectional view

A

22.3 ±0.1

Ø7 (2x)

7673m07en/1018

4

5

°

B-B

90°

Ø13 (2x)

Sectional view

Building Technologies CC1N7673en

25.03.2019

A-A

90°

Ø43

Ø14

Ø18

14/16

Dimensions (continued)

A

SK33.5

Dimensions in mm

42

67

14.8 ±0.1

25

Ø68 ±0.15

22.3 ±0.1

Ø4.6 +0.1 (2x)

14.8 ±0.1

R

7

1

(2x

°

0

)

23.3 ±0.1

A

32 ±0.15

Reducing sleeve

A

Ø36

R

9 (2

x)

48 ±0.15

72 ±0.15

Sectional view A-A

M5 EP nuts (4x)

7673m09en/1018

Ø5.2 (x3)

90° (3x)

7.5 -0.1

15 -0.1

Ø16 -0.2

3

25 -0.1

20.5

12 +0.3

Ø8 H8

Ø10 h8

Fase 1x15°

7673m08en/1018

15/16

Building Technologies CC1N7673en

25.03.2019

Dimensions (continued)

A

GA58.5

Dimensions in mm

AGA58.5

25

19.5

17

14

10

8.5

7673m04en/1018

2019 Siemens AG Building Technologies, Berliner Ring 23, 76437 Rastatt, Germany

Subject to change!

16/16

Building Technologies CC1N7673en

25.03.2019

Loading...

Loading...