Page 1

®

Page 2

Preface

CE

This instrument conforms to the provisions of the EU Directive on In Vitro Diagnostic Medical Devices

(98/79/EC) of the European Parliament and the Council of 27 October 1998.

The contents of this manual with all figures, tables and graphics are intellectual property of ELITechGroup.

Unauthorized commercial or non-commercial excerption or copying of contents and use of this manual (in

total or in parts) are strictly forbidden unless the editor gives written permission for it.

This manual was written and produced with the utmost care. However, errors cannot be fully excluded.

ELITechGroup does not take any responsibilities and accepts no liabilities for incidents of any kind that may

occur because of errors in the manual.

All product names mentioned in this manual are registered trademarks.

®

The Viva-E

conformity. This declaration is supplied with each device in a separate file.

Please call Technical Support if you need advice or you have any questions.

has been conceptualized, manufactured and tested in accordance with the declaration of

®

Manufacturer:

ELITechGroup B.V.

also trading as ELITechGroup Clinical Systems

Van Rensselaerweg 4

6956 AV Spankeren

The Netherlands

Telephone: +31 313 430 500

Telefax: +31 313 427 807

e-mail: service.ecsnl@elitechgroup.com

Internet: www.elitechgroup.com

1

Until December 1, 2013 ELITechGroup B.V. was known as Vital Scientific B.V.

Any reference in this manual to Vital Scientific B.V. or Vital should be read as ELITechGroup B.V. or

ELITechGroup Clinical Systems.

1

,

Distributed by:

Siemens Healthcare Diagnostics Products GmbH

European Headquarters

Ludwig-Erhard Str. 12

65760 Eschborn,

Germany

www.siemens.com/diagnostics

In the US:

Siemens Healthcare Diagnostics Inc.

P.O. Box 6101

Glasgow Business Community

Newark, Delaware 19714-6101

USA

1-800-227-8994

www.siemens.com/diagnostics

Viva-E, Syva and EMIT are trademarks of Siemens Healthcare Diagnostics (formerly Dade Behring). All

other trademarks are trademarks or registered trademarks of their respective owners.

Article No.: 6002-380-410 V05

Page 3

®

Contents

1. SAFETY PRECAUTIONS AND POTENTIAL HAZARDS

1.1 General .......................................................................................................................................................1-2

1.1.1 Basic assumptions for risk analysis ...........................................................................................1-2

1.1.2 Operator qualification.................................................................................................................1-2

1.1.3 Service technician qualification ..................................................................................................1-3

1.2 Description of symbols ................................................................................................................................1-4

1.2.1 Symbols on the instrument.........................................................................................................1-4

1.2.2 Symbols in the manual...............................................................................................................1-4

1.3 Hazards.......................................................................................................................................................1-5

1.3.1 Electrical hazards.......................................................................................................................1-5

1.3.2 Mechanical hazards ...................................................................................................................1-5

1.3.3 Sample and reagent arms..........................................................................................................1-5

1.3.4 Lamp ..........................................................................................................................................1-5

1.3.5 Chemical hazards ......................................................................................................................1-5

1.3.6 Biohazard...................................................................................................................................1-6

1.3.7 Operational requirements...........................................................................................................1-6

1.3.8 Transport and storage requirement............................................................................................1-6

1.4 Installation ...................................................................................................................................................1-7

1.4.1 External connections..................................................................................................................1-7

1.4.2 Maintenance...............................................................................................................................1-7

1.4.3 Instrument unused for one month or longer ...............................................................................1-7

1.4.4 Coolant liquid .............................................................................................................................1-7

1.5 Use of materials with the analyzer ..............................................................................................................1-8

1.5.1 Specimens .................................................................................................................................1-8

1.5.2 Reagents and calibrators ...........................................................................................................1-8

1.5.3 Controls...................................................................................................................................... 1-8

1.5.4 Analytical results ........................................................................................................................1-8

2. INTRODUCTION

2.1 The system..................................................................................................................................................2-2

2.1.1 Intended use .............................................................................................................................2-2

2.1.2 System presentation ..................................................................................................................2-2

2.1.3 Computer control........................................................................................................................2-3

2.2 Modules.......................................................................................................................................................2-4

2.2.1 General ......................................................................................................................................2-4

2.2.2 Rotors.........................................................................................................................................2-5

2.2.3 Pipette system ..........................................................................................................................2-5

2.3 Cooling unit ................................................................................................................................................2-6

2.4 External barcode reader..............................................................................................................................2-7

2.5 Installation ...................................................................................................................................................2-8

2.5.1 Installation requirements ...........................................................................................................2-8

2.5.2 Move the analyzer .....................................................................................................................2-8

2.6 Performance and technical data ...............................................................................................................2-9

2.6.1 Performance ..............................................................................................................................2-9

2.6.2 Sample system ..........................................................................................................................2-9

2.6.3 Reagent system ......................................................................................................................2-10

2.6.4 Measurement station ..............................................................................................................2-10

2.6.5 Minimum PC requirements ......................................................................................................2-11

2.6.6 Cooling unit .............................................................................................................................2-11

2.6.7 External barcode reader ..........................................................................................................2-12

2.6.8 Accuracy and precision ..........................................................................................................2-12

2.7 Analyzer technical data (without washing unit or computer) ....................................................................2-13

2.7.1 Dimensions and weight ..........................................................................................................2-13

2.7.2 Power requirements ................................................................................................................2-13

2.7.3 Environmental requirements ................................................................................................... 2-13

2.7.4 Approvals ................................................................................................................................2-13

VITAL SCIENTIFIC B.V. i

Page 4

3. SYSTEM HANDLING BASICS

3.1 Work Preparation ........................................................................................................................................3-2

3.1.1 Use of the manual......................................................................................................................3-2

3.1.2 Parts of the screen.....................................................................................................................3-3

3.1.3 Navigation keys..........................................................................................................................3-4

3.1.4 Emergency halt ..........................................................................................................................3-4

3.1.5 Messages ..................................................................................................................................3-4

3.2 Start the analyzer for the first time ..............................................................................................................3-5

3.2.1 Prepare the analyzer..................................................................................................................3-5

3.2.2 Start the analyzer....................................................................................................................... 3-5

3.2.3 Install the cooling unit ................................................................................................................3-6

3.2.4 Set the reagent rotor type .........................................................................................................3-7

3.2.5 Passwords .................................................................................................................................3-8

3.2.6 System liquid..............................................................................................................................3-9

3.2.7 System parameters .................................................................................................................3-10

3.3 Checklist....................................................................................................................................................3-12

3.3.1 Checklist for routine operation ...............................................................................................3-12

4. BASIC ROUTINE

4.1 Preparing tests ............................................................................................................................................4-2

4.1.1 Methods to enter sample information and select tests...............................................................4-2

4.2 Enter sample data and test requests .......................................................................................................4-3

4.2.1 Request samples screen ...........................................................................................................4-3

4.2.2 Request samples parameters ...................................................................................................4-4

4.2.3 Request samples function keys .................................................................................................4-5

4.2.4 Request samples and assign tests with an external barcode reader ........................................ 4-6

4.2.5 Manually request samples and assign tests ............................................................................4-6

4.2.6 Request (multiple) samples efficiently .......................................................................................4-7

4.2.7 Requesting priority samples.......................................................................................................4-7

4.2.8 Request a test for a reagent blank.............................................................................................4-7

4.2.9 Request a control test ..............................................................................................................4-8

4.2.10 Request a test for calibration ...................................................................................................4-9

4.2.11 View, edit or delete sample requests ........................................................................................4-9

4.2.12 Print a worklist..........................................................................................................................4-10

4.3 Load the sample rotor and start the tests ...............................................................................................4-11

4.3.1 Preparation of samples, dead volume and over sampling ...................................................4-11

4.3.2 Loading pediatric sample cups.............................................................................................

4.3.3 Sample Handling screen ......................................................................................................... 4-12

4.3.4 Sample rotor positions and color codes ...................................................................................4-12

4.3.5 Worklist and color codes ..........................................................................................................4-14

4.3.6 Sample Handling function keys................................................................................................4-15

4.3.7 Load barcoded samples (with external barcode reader)..........................................................4-16

4.3.8 Load samples (without barcodes) ............................................................................................4-16

4.3.9 Load samples with mouse........................................................................................................4-17

4.3.10 Load samples during a sample run ..........................................................................................4-17

4.3.11 Load a reagent blank ...............................................................................................................4-17

4.3.12 Load a control ..........................................................................................................................4-18

4.3.13 Load a calibrator ......................................................................................................................4-18

4.4 Reagent info screen ..................................................................................................................................4-19

4.4.1 Reagent info parameters..........................................................................................................4-19

4.4.2 Reagent info function keys.......................................................................................................4-20

4.4.3 Check and refill reagents .........................................................................................................4-21

4.5 Start and stop the sample run ...................................................................................................................4-22

4.5.1 Start the analysis run ...............................................................................................................4-22

4.5.2 Unload samples .......................................................................................................................4-22

4.5.3 Error and warning messages ...................................................................................................4-23

4.6 Check and validate the results .................................................................................................................4-25

4.6.1 Evaluate results screen...................................................................................................

4.6.2 Sample list................................................................................................................................4-25

®

....4-11

.........4-25

ii VITAL SCIENTIFIC B.V.

Page 5

®

4.6.3 Sample details..........................................................................................................................4-26

4.6.4 Test results...............................................................................................................................4-26

4.6.5 Evaluate results function keys..................................................................................................4-27

4.6.6 Validation of a result.................................................................................................................4-28

4.6.7 Evaluate historic results ........................................................................................................... 4-28

4.6.8 Result details ...........................................................................................................................4-29

4.6.9 Result details function keys......................................................................................................4-31

4.6.10 Information screen for blank/calibration ...................................................................................4-32

4.6.11 Result details for a two reagent kinetic test..............................................................................4-33

4.6.12 Result details for an endpoint test with a reagent blank...........................................................4-35

4.6.13 Result details for a two point test .............................................................................................4-36

4.6.14 Result details for a measurement with a prozone check..........................................................4-38

4.6.15 Automatic results printout......................................................................................................... 4-39

5. EXTENDED ROUTINE

5.1 Program controls ......................................................................................................................................5-2

5.1.1 Introduction ................................................................................................................................5-2

5.1.2 Program control screen..............................................................................................................5-2

5.1.3 Program control parameters .....................................................................................................5-2

5.1.4 Program control function keys ...................................................................................................5-3

5.1.5 Enter a new control ....................................................................................................................5-3

5.1.6 Change a control (e.g. when the batch/lot number has changed) .............................................5-4

5.1.7 Program a control.......................................................................................................................5-5

5.1.8 Westgard rules .......................................................................................................................... 5-7

5.2 Calibrator programming ...........................................................................................................................5-8

5.2.1 Calibrators..................................................................................................................................5-8

5.2.2 Program a calibrator...................................................................................................................5-8

5.2.3 Program calibrator parameters ...............................................................................................5-10

5.2.4 Program calibrator function keys .............................................................................................5-10

5.3 Test programming ..................................................................................................................................5-11

5.3.1 Introduction ..............................................................................................................................5-11

5.3.2 Load the test parameters .........................................................................................................5-11

5.3.3 Program a new test or modify an existing test ........................................................................5-12

5.3.4 Test programming - Test parameters 1 .................................................................................5-14

5.3.5 Test programming - Test parameters 2 ...............................................................................5-18

5.3.6 Program test calibrator parameters ........................................................................................5-25

5.3.7 Program calibrator function keys .............................................................................................5-28

5.3.8 Calibration curves algorithms...................................................................................................5-29

5.3.9 Accept calibration curve parameters........................................................................................5-31

5.3.10 Absorbance check for calibrated tests .....................................................................................5-31

5.4 Quality control ..........................................................................................................................................5-32

5.4.1 Introduction ..............................................................................................................................5-32

5.4.2 Quality control screen ..............................................................................................................5-32

5.4.3 Quality control parameters .....................................................................................................5-32

5.4.4 Quality control function keys ....................................................................................................5-32

5.4.5 Graphic representation of quality control .................................................................................5-33

5.4.6 Fields visible in graphic and table modes (left hand side)........................................................5-33

5.4.7 Description of the graphic display ............................................................................................5-34

5.4.8 Description of the table mode ..................................................................................................5-35

5.5 Cuvette incompatibility ..............................................................................................................................5-36

5.5.1 Introduction ..............................................................................................................................5-36

5.5.2 Start needle and cuvette incompatibility...................................................................................5-36

5.5.3 Incompatibility parameters .......................................................................................................5-36

5.5.4 Incompatibility screen...............................................................................................................5-37

5.5.5 Define incompatible tests.........................................................................................................5-38

5.5.6 Define compatible tests............................................................................................................5-39

5.6 Profiles ...................................................................................................................................................... 5-40

5.6.1 Introduction ..............................................................................................................................5-40

5.6.2 Program profiles ......................................................................................................................5-40

VITAL SCIENTIFIC B.V. iii

Page 6

5.6.3 Program profile function keys...................................................................................................5-41

5.7 Reagent position .......................................................................................................................................5-42

5.7.1 Introduction to reagent position................................................................................................5-42

5.7.2 Program a reagent position......................................................................................................5-42

5.7.3 Reagent position function keys ................................................................................................5-43

5.8 Calculated results ....................................................................................................................................5-45

5.8.1 Introduction to calculated results..............................................................................................5-45

5.8.2 Calculated result programming screen ....................................................................................5-46

5.8.3 Calculated result programming parameters .............................................................................5-46

5.8.4 Calculated result programming function keys ..........................................................................5-48

5.9 Test messages and flags ..........................................................................................................................5-49

5.9.1 Introduction ..............................................................................................................................5-49

5.9.2 Test messages function keys...................................................................................................5-49

5.9.3 Test flags .................................................................................................................................5-50

5.9.4 Custom automatic evaluation and rerun ..................................................................................5-53

5.10 Set up a report ..........................................................................................................................................5-54

5.10.1 Introduction ..............................................................................................................................5-54

5.10.2 Report setup segments............................................................................................................ 5-54

5.10.3 Define a report set-up .............................................................................................................. 5-55

5.10.4 Report setup tabs and data fields ............................................................................................5-56

5.10.5 Report setup function keys.......................................................................................................5-59

®

6. MAINTENANCE

6.1 Maintenance procedures.............................................................................................................................6-2

6.1.1 User maintenance......................................................................................................................6-2

6.1.2 Replace cuvette rotor.................................................................................................................6-3

6.1.3 Manual cuvette rotor blank measurement..................................................................................6-3

6.1.4 Exclude a stained cuvette ..........................................................................................................6-4

6.1.5 Blank rotor function keys............................................................................................................6-5

6.1.6 Replace the photometer lamp....................................................................................................6-5

6.1.7 Replace syringes........................................................................................................................6-8

6.1.8 Washing/filling cuvette rotor .......................................................................................................6-9

6.1.9 Needle rinse.............................................................................................................................6-10

6.1.10 Replace the water filter ............................................................................................................6-10

6.1.11 Replace the drying block..........................................................................................................6-11

6.2 Troubleshooting ........................................................................................................................................6-12

6.2.1 Introduction ..............................................................................................................................6-12

6.2.2 Defective mixer belt..................................................................................................................6-12

6.2.3 Sample needle clogged............................................................................................................6-13

6.2.4 Removal of the rotor tray..........................................................................................................6-13

6.2.5 Error history..............................................................................................................................6-13

6.2.6 Error messages........................................................................................................................6-15

6.2.7 Hardware-error messages .......................................................................................................6-16

7. INSTALLATION

7.1 Hardware installation...................................................................................................................................7-2

7.2 Software installation....................................................................................................................................7-3

7.2.1 General ......................................................................................................................................7-3

7.2.2 Prepare PC ................................................................................................................................7-3

7.2.3 Install software ...........................................................................................................................7-6

7.2.4 Files............................................................................................................................................7-7

7.3 Configure software ......................................................................................................................................7-8

7.3.1 Introduction ................................................................................................................................7-8

7.3.2 Start communication selection ...................................................................................................7-9

7.3.3 Printer parameters ...................................................................................................................7-10

7.3.4 Host communication parameters .............................................................................................7-10

7.3.5 Communication function keys ..................................................................................................7-10

7.3.6 Configure analyzer communication handler.............................................................................7-11

7.3.7 Configure host port settings .....................................................................................................7-12

iv VITAL SCIENTIFIC B.V.

Page 7

7.3.8 Host - PC communication ........................................................................................................7-12

7.4 System backup procedure ........................................................................................................................7-13

7.4.1 Backup files..............................................................................................................................7-13

7.4.2 Start Restore point ...................................................................................................................7-13

7.4.3 Restore point parameters.........................................................................................................7-13

7.4.4 Restore point function keys......................................................................................................7-14

7.5 Data backup procedure.............................................................................................................................7-15

7.5.1 Setup........................................................................................................................................ 7-15

7.5.2 Data backup.............................................................................................................................7-15

7.6 Importing and exporting data ....................................................................................................................7-16

7.6.1 Exporting data..........................................................................................................................7-16

7.6.2 Importing data ..........................................................................................................................7-17

8. RESULTS EXPORT FILE

8.1 General .......................................................................................................................................................8-2

8.1.1 Introduction ................................................................................................................................8-2

8.1.2 Summary of new features ..........................................................................................................8-2

8.2 View or change system parameters (additions) ..........................................................................................8-3

8.3 Export results .............................................................................................................................................. 8-5

8.3.1 Select information and create export files..................................................................................8-5

8.3.2 Automatically create archive and export files.............................................................................8-7

8.4 Archive and search results ..........................................................................................................................8-8

8.4.1 Archive results............................................................................................................................8-8

8.4.2 Search results ............................................................................................................................8-8

8.5 Copy export files or archived results files to a USB drive ...........................................................................8-9

8.6 Networking ................................................................................................................................................8-10

VITAL SCIENTIFIC B.V. v

Page 8

®

vi VITAL SCIENTIFIC B.V.

Page 9

®

1SAFETY PRECAUTIONS AND POTENTIAL HAZARDS

Safety Precautions and Potential Hazards

Safety Precautions and Potential Hazards

VITAL SCIENTIFIC B.V. 1-1

Page 10

®

Safety Precautions and Potential Hazards

1.1 General

Before you start installing and working with the analyzer, you should read the safety precautions and

regulations shown in this chapter. Safety comes first!

The analyzer was designed and manufactured according to modern standards and with regard to

international safety regulations. All possible risks that were known at the time of manufacturing were

taken into account and either eliminated or reduced. Nevertheless, some sources of danger cannot

be eliminated. Please note the following guidelines.

When operating the analyzer all national or international guidelines and regulations must be

observed, as in the normal lab routine. Power supply accessories (cables/plugs) must be installed in

such a way that sources of danger (overheating of cables, short circuit due to incorrect fuse ratings,

loose cables etc.) are eliminated. The user should be aware, that if the analyzer is used in a manner

not specified by the manufacturer, the protection provided by the equipment may be impaired. The

analyzer is supplied without anti-virus software. If you connect the analyzer to a network, make sure

that the network has the necessary protection.

1.1.1 Basic assumptions for risk analysis

Following assumptions are the basis for the risk analysis. It is assumed that:

• The Samples were adequately derived, prepared, handled, and labeled before being loaded

into the device.

• Reagents and calibrators were adequately stored, prepared, handled, and labeled before being

loaded into the device.

• Adequate quality control procedures are observed by laboratory personnel to check the

performance of the analyzing system by adequate use of control material.

• Laboratory personnel involved in operation and handling of the device are adequately trained.

• Laboratory personnel involved in operation and handling of the device are aware of the risks

involved in handling material of human origin (biological hazards) and that correct procedures

are followed to prevent infection.

• Service personnel involved in preventive and corrective maintenance of the device are

adequately trained.

• Service personnel who maintain the device know the risks of biological hazards and follow the

correct precautions.

• Preventive maintenance is performed in accordance with the instructions provided by the User

Manual and the Service Manual.

• Original replacement parts are used in maintenance of the device.

• Original disposables are used in operation of the device.

• Reagents and methods are validated before actual samples are measured.

• Service personnel must follow the instructions to install and check the device.

• Limit checks are correctly implemented and used in the test parameter settings. (absorbance,

reagent blank absorbance, control, calibrator, etc.).

• A rotor blank run is performed once every day before measurements are performed.

• Test results obtained from the instrument are carefully examined by an expert before any further

measures are taken based on the analytical results.

1.1.2 Operator qualification

The analyzer should only be used by qualified and trained personnel, who have taken part in a

special operator training course on the instrument.

For clinical tests, the instrument should be used under the management of a doctor or clinical

inspector.

1-2 VITAL SCIENTIFIC B.V.

Page 11

®

1.1.3 Service technician qualification

To install, maintain and repair the instrument, a service technician has to be trained on the

instrument by the manufacturer or their representative. A service technician is also expected to be

familiar with the normal operation of the instrument as described in the operator manual and the

special operations as described in the Service manual.

Safety Precautions and Potential Hazards

VITAL SCIENTIFIC B.V. 1-3

Page 12

®

Safety Precautions and Potential Hazards

1.2 Description of symbols

1.2.1 Symbols on the instrument

WARNING

Attention, consult instructions for use. This symbol appears on several parts of the analyzer. The

specific meaning that applies for those parts is described in 1.3 Hazards.

WARNING

Hot surface. This label is attached on or close to parts of the instrument that get hot when the

instrument is switched on. Make sure to keep fingers and other body parts clear of the hot surface.

WARNING

Pinch point. Fingers and other body parts can be pinched where this label shows. Make sure to

keep fingers and other body parts clear of the pinch point.

BIOHAZARD

The contents of the container marked with this symbol are a biological hazard and are potentially

infectious. This symbol is shown on waste bottles.

ATTENTION

This symbol means that at the end of life, the analyzer must be separately collected in accordance

to the European Directive 2002/96/EC.

1.2.2 Symbols in the manual

WARNING

Failure to follow information contained in warning messages could lead to serious personal injury

and/or damage to the analyzer.

ATTENTION

Failure to follow information contained in the attention messages could lead to damage to the

analyzer.

Note

Notes contain additional information corresponding to the text.

1-4 VITAL SCIENTIFIC B.V.

Page 13

®

1.3 Hazards

1.3.1 Electrical hazards

WARNING

To prevent the risk of electrical shock and/or damage to the instrument, operators should not open

the covers of live parts (electrical) of the instrument. Only authorized personnel, e.g. service

technicians, may open the instrument to perform maintenance or repairs.

Touching the live parts when the power is on may cause severe injury or death.

1.3.2 Mechanical hazards

WARNING

DO NOT wear loose garments or jewelry that could catch in mechanisms.

DO NOT put your fingers/hands into the pathway of any part while the analyzer is in operation.

DO NOT attempt mechanical repair unless the instrument is not in operation or OFF.

1.3.3 Sample and reagent arms

WARNING

Do not touch movable parts of the system (rotors, arms, etc.) while they are in motion.

Particular attention and caution must be paid to sample and reagent needles. Although the greatest

possible safety precautions were taken, these parts still are potentially hazardous. However, the

system automatically interrupts the procedure if the needles are touched. Always keep rotors

covered with the supplied caps, except when loading or unloading. Covering protects sample

material and reagents from contamination.

Safety Precautions and Potential Hazards

1.3.4 Lamp

WARNING

During operation, the photometric lamp becomes extremely hot. DO NOT look directly into the light

path of the lamp when it is on.

DO NOT touch the lamp when it is on!

If the lamp needs to be changed, wait until the lamp has cooled down.

1.3.5 Chemical hazards

The operator is responsible for taking all necessary precautions against hazards associated with the

use of clinical laboratory chemicals. Specific recommendations for each reagent used with the

analyzer are normally found on the manufacturer's package inserts or on product information sheets

for each chemical. Wipe up any reagent spillage on the instrument immediately.

Additional precautions:

Consult the reagent manufacturer for information on the concentrations of heavy metals and other

toxic constituents in each reagent.

Avoid direct body-contact with reagents and cleaning solutions. Direct body-contact may result in

irritation or damage to your skin. Refer to the manufacturer's reagent kit box and package inserts, or

product information sheets for specific instructions.

VITAL SCIENTIFIC B.V. 1-5

Page 14

®

Safety Precautions and Potential Hazards

1.3.6 Biohazard

BIOHAZARD

Patient samples, controls, calibrators and liquid waste are potentially infectious. The handling of

patient samples, control sera and liquid waste must be performed according to national and

international laboratory safety regulations.

Patient samples, controls, calibrators and liquid waste should be considered potentially infectious

and capable of transmitting human immunodeficiency virus (HIV), hepatitis B virus (HBV) and other

blood borne pathogens. The handling of these substances must be performed in accordance with

established laboratory safety regulations in order to minimize risk to laboratory staff. This includes

wearing of gloves, splash protection, etc. Contact of skin and mucous membranes must be avoided.

This also applies to all components of the instrument that are exposed to these substances. If any

specimen is spilled on the instrument, wipe it up immediately and clean the contaminated surface

with a disinfectant.

In various countries there are regulations on the disposal of waste. Refer to local sources for

additional information on correct waste disposal.

1.3.7 Operational requirements

WARNING

Do not place the analyzer against a wall. There must be access at all times to the rear panels of the

analyzer. Make sure the power switch can be reached and there is free circulation of ventilation air.

ATTENTION

The cooling unit must be filled with liquid. The level should be visible and between a minimum and

a maximum level. Check liquid level every 3 months. For details on the liquid to be used, see

2.3 Cooling unit.

1.3.8 Transport and storage requirement

ATTENTION

Always store the analyzer in an environment with temperatures between -10 °C and +45 °C.

1-6 VITAL SCIENTIFIC B.V.

Page 15

1.4 Installation

The analyzer, cooling unit and other devices, parts and accessories are shipped in transport boxes

and have to be unpacked and installed by a qualified service technician from the manufacturer or his

designated representative. If these instructions are not observed, The manufacturer does not

assume responsibility for occurring damage or improper operation of the analyzer. The customer is

responsible for providing the necessary facilities as described in detail in 2.6 Performance and

technical data.

1.4.1 External connections

ATTENTION

Only instruments that meet the relevant safety requirements may be connected to the analyzer.

Only use UL-listed power supply cable and power distribution blocks.

1.4.2 Maintenance

ATTENTION

For continued protection against risk of fire only use fuses of the specified type and current ratings.

Safety Precautions and Potential Hazards

For maintenance and repair procedures (e.g. replacement of cuvette rotor, photometer lamp) follow

the instructions given by service personnel or specified in the manual.

Do not use unsuitable tools for repairs (e.g. screwdrivers which are not insulated for work performed

at electrical components).

During operation and maintenance of the instrument, proceed according to the instructions and do

not touch any parts of the instrument other than those specified.

Avoid touching any mechanical parts while the instrument is operating. This may cause operation to

stop or damage the instrument.

Only original spare parts should be used in the maintenance of this analyzer.

Only original disposables and accessories should be used in the operation of this analyzer.

Make sure the front covers are closed while the instrument is in operation.

1.4.3 Instrument unused for one month or longer

If the instrument is not to be used for one month or longer, contact Siemens Healthcare Diagnostics

Technical Support for further information before you switch off the analyzer.

1.4.4 Coolant liquid

The cooling unit of the analyzer is filled with ethylene glycol. Any spills during maintenance should

be disposed of according to local regulations.

VITAL SCIENTIFIC B.V. 1-7

Page 16

®

Safety Precautions and Potential Hazards

1.5 Use of materials with the analyzer

1.5.1 Specimens

This analyzer is designed for measurements of analytes in samples of serum, plasma and urine or

extract solutions from the Siemens immunosuppressant assays. Patient samples should be

prepared and handled in accordance with the instructions from the reagent manufacturer. Refer to

the reagent kit insert for detailed instructions.

ATTENTION

Make sure that the sample/reagent mixture does not contain any blood clots, dust or other insoluble

contaminants. If insoluble contaminants are contained in the sample, correct measuring values may

not be obtained.

1.5.2 Reagents and calibrators

The manufacturer recommends the use of Syva®/Siemens reagents and calibrators in combination

with this analyzer.

ATTENTION

Treat all reagents according the manufacturer's recommendations. Refer to the reagent kit box and

package inserts, and product information sheets for specific instructions.

WARNING

Vital Scientific B.V. assumes no responsibility for erroneous test results caused by reagent kits,

calibrators and test parameters that are not provided by Vital Scientific B.V.

WARNING

Siemens assumes no responsibility for erroneous test results caused by reagent kits, calibrators

and test parameters that are not provided by Siemens.

1.5.3 Controls

The manufacturer recommends the use of quality control solutions with known values for each test

in accordance with international regulations and guidelines. Results obtained should fall within the

limits defined by the day to day variability of the system as determined in the user laboratory. If the

results fall outside the laboratory’s established limits, refer to the troubleshooting information in this

manual or contact your agent.

1.5.4 Analytical results

The analytical results do not only depend upon correct operation of the analyzer but also on a

variety of external influences beyond the control of the manufacturer. Therefore the test results

obtained with this instrument must be carefully examined by a clinical inspector or doctor, before any

diagnostic or therapeutic measures are taken based on the analytical results.

WARNING

An incorrectly measured result may lead to an error in diagnosis, thereby posing a danger to the

patient.

1-8 VITAL SCIENTIFIC B.V.

Page 17

®

2INTRODUCTION

Introduction

Introduction

VITAL SCIENTIFIC B.V. 2-1

Page 18

®

Introduction

2.1 The system

2.1.1 Intended use

The analyzer is an automatic chemistry analyzer, used in combination with certain reagents for in

vitro diagnostic measurement of analytes in samples of serum, plasma, urine and aqueous standard

solutions. Most clinical chemistry tests that require a photometric measurement can be adapted for

the system. The analyzer is intended for use in laboratories. The analyzer has to be operated by

trained operators.

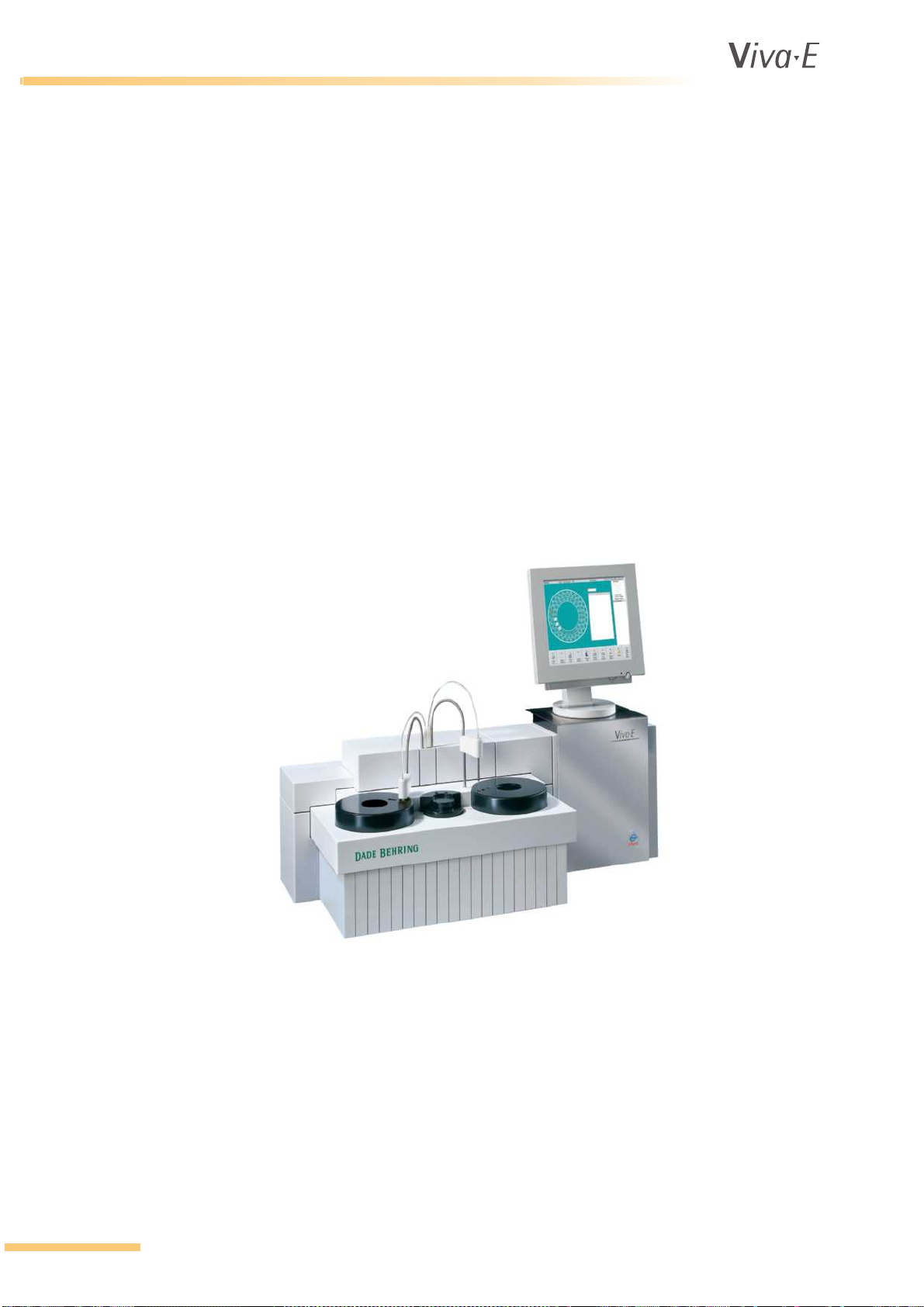

2.1.2 System presentation

The analyzer is a universal system. The price-performance-relation is optimized for small and

medium workload; up to 180 tests per hour. It is easy to adapt the analyzer in any kind of laboratory.

In the main unit of the system, the actual analyzer, all liquid handling and measurements take place.

A separate computer controls the analyzer unit, collects the raw data and provides the user

interface. A cooling unit enables the system to ensure the precision of all ´on-board´ reagents.

Environmental compatibility and economic efficiency are guaranteed. Easy operation (menu and

message control by display), short training time as well as recording of sample and test data with

barcode scanner reduce personnel assignment and save a maximum of time.

2-2 VITAL SCIENTIFIC B.V.

Page 19

®

2.1.3 Computer control

ATTENTION

Only run the software in order to operate the analyzer. The use of other software might cause

failure in the communication between the analyzer and the computer.

An external computer and a monitor provide the user interface for the analyzer. The operating

system is Microsoft

test results are saved on the computer. The software provides a standard way of output on a printer,

but the operator can change the format of the result report. Test parameters, control results and

calibration results are also saved on the computer and are ready for access.

It is possible to connect the analyzer to a lab data processing system (central processor/host

computer). If this is the case, it is possible to enter test requests directly from the host computer.

Also, the test results can be transferred to the host computer.

®

Introduction

Windows®. A keyboard or a barcode reader is necessary to enter data. The

VITAL SCIENTIFIC B.V. 2-3

Page 20

®

Introduction

2.2 Modules

2.2.1 General

Note

In the screen texts system liquid is replaced by water.

The analyzer is microprocessor controlled. All mechanical functions are directed and monitored by

dedicated processors. The operator has a constant view on the hardware status and performance of

the chemistries. When errors or flagged results occur for open channel assays, the analyzer offers

an automatic re-run facility. The re-run facility includes automatic pre-dilution by sample reduction

for high results. The results are printed as the analysis sequence is completed. The print is held

when a test is in evaluation or re-run. This prevents mixing-up the analysis sequence. The operator

can change the format of the result report. Prints of calibration curves, reaction curves, LeveyJennings plots, test methods, etc. are possible.

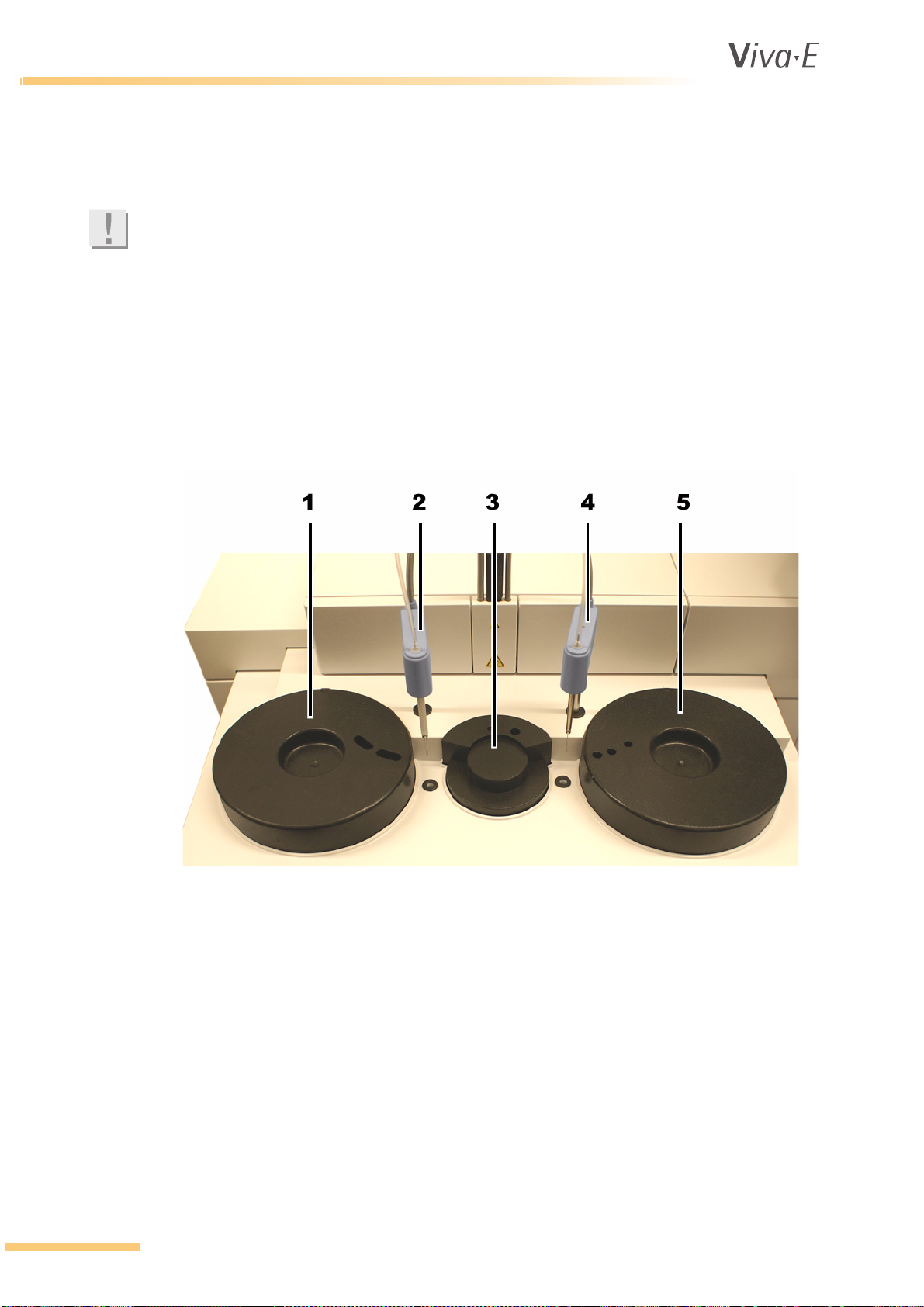

1 Reagent rotor

2 Reagent pipette

3 Cuvette rotor

4 Sample pipette

5 Sample rotor

2-4 VITAL SCIENTIFIC B.V.

Page 21

®

2.2.2 Rotors

Sample rotor

The sample rotor is designed to accept a variety of sample tubes and cups. The sample rotor is

covered. Emergency (STAT) samples and samples in pediatric cups can be tested without

interference of the routine workload.

Reagent rotor

The reagent rotor compartment is cooled to a maximum of 12°C below ambient temperature. The

rotor is covered to protect light sensitive reagents and to isolate from ambient temperature.

Cuvette rotor

Note

Replace the cuvette rotor when one of the eight wavelengths shows the message SD.ERR after the

rotor blank measurement. The quality and reliability is not guaranteed when the cuvette rotor is not

replaced.

The multi-use cuvette rotor contains 48 cuvettes and is incubated at 37°C. The cuvette rotor, made

for the manufacturer, is covered by a heated cover.

The maximum incubation time after sample addition is 11.5 minutes with a single reagent and 11.25

minutes with two or more reagents. After the last measurement, the rotor is washed and dried. To

avoid drying-in of the rotor, the reagent pipette automatically fills the rotor with water.

Introduction

Washing unit

The washing unit aspirates the reaction mixture after analysis and washes the cuvettes with 4 x 500

µl water. The waste is disposed in a waste container. The washing unit is equipped with liquid

sensors to avoid the flooding of the system with water.

2.2.3 Pipette system

Pipettes

Two syringes, a 1000 µl and a 100 µl, are used in combination with a valve block to pipette reagents

and samples. The pipette mechanisms are water-filled. Pipetting takes place by means of positive

water displacement with air bubble separation.

Sample pipette mechanism

The sample probe is equipped with a level detector and can aspirate volumes between 2µl and 30 µl

(in steps of 0.1 µl). The level detector in the sample probe detects if sufficient sample is present. The

probe dispenses the sample into the cuvette rotor and also mixes the reaction mixture. When a

sample is needed, the probe senses the liquid to take up an air bubble first before taking up the

sample. The probe is washed internally and externally afterwards.

Reagent pipette mechanism

The reagent probe is equipped with a level detector and can aspirate volumes between 10 µl and

399 µl (in steps of 1.0 µl). The level detector in the reagent probe detects if sufficient reagent is

present. A heating element in the probe pre-heats the cooled reagents. Reagents must be prepared

outside the analyzer. After the probe transfers the aspirated volume of reagent into the cuvette rotor,

the probe is washed internally and externally. After a 2nd or 3rd reagent is dispensed, the reagent

probe mixes the reaction mixture before it goes to the wash.

VITAL SCIENTIFIC B.V. 2-5

Page 22

®

Introduction

2.3 Cooling unit

WARNING

The cooling unit with the analyzer is filled with ethylene glycol. Any spills during maintenance

should be disposed of according to local regulations.

The analyzer is equipped with an external cooling unit that guarantees cooling for loaded reagents.

The cooling unit operates as a sealed unit and needs little maintenance. The cooling unit is placed

behind the liquid waste and water bottles and provides a constant temperature for the reagents

located on the rotor, as required by the application protocol. When an acoustic signal sounds, the

cooling liquid must be refilled.

Note

Use a mixture of 1 part EUROL

The control display shows the temperature of the cooling liquid. The actual temperature of the

reagents will be slightly higher. The user cannot change the temperature setting of the cooling unit.

The unit and coolant are free from chlorofluorocarbons.

The installation is made by the service engineer and is not described in this manual.

®

to 1 part water.

2-6 VITAL SCIENTIFIC B.V.

Page 23

®

2.4 External barcode reader

ATTENTION

Switch off the computer before you install the external barcode reader.

You can shorten the operator time with an optional external barcode reader. This hand held barcode

reader can be connected to the keyboard of the PC. When requesting tests, you can enter sample

ID numbers from barcodes on the sample tubes. You can then assign tests with the use of the

barcode request menu card.

Most of the available barcodes can be read. The Codabar barcode is used for test requisitions. The

Codabar start character is used to differentiate between tests and profiles.

Introduction

The barcode reader can also be used to identify the samples when loading them or when viewing

the test results.

Note

The external barcode reader has a separate instruction manual. Please read the barcode reader

manual for information and user instruction.

Note

The manufacturer recommends that a fault safe barcode reader is used. Barcode readers that do

not use a checksum can give improper or false readings.

VITAL SCIENTIFIC B.V. 2-7

Page 24

®

Introduction

2.5 Installation

2.5.1 Installation requirements

Only a qualified service technician may unpack the analyzer, cooling unit and other devices. The

manufacturer does not take responsibility for damage or improper operation of the analyzer, when

these instructions are not observed. The analyzer is inspected and ready for use when it is handed

over to the user.

Use the analyzer in closed rooms. It must be placed on a flat, horizontal surface that is not subject to

vibrations. Avoid exposure to direct sunlight.

The electrical connection has to be grounded according to common regulations to ensure proper

operation of the analyzer.

The analyzer is compliant with the requirements of the applicable EMC standards. Electronic

equipment that exceed the radiation limits defined in the EMC standards, like GSM and other

handheld mobile equipment, may affect proper operation of the equipment.

Note

This is a class A product. This product may cause interference in a domestic environment. In this

case the user may be required to take adequate arrangements.

2.5.2 Move the analyzer

Please follow the instructions below when the instrument needs to be moved.

1. Switch off the analyzer, the computer and the cooling unit.

2. Disconnect all cables and tubes.

3. Pull up the arm and place the arm protection tube over the shaft. This prevents the arm from

moving down.

4. Move the analyzer with at least 2 persons. Hold the instrument only by the metal frame on the

bottom.

ATTENTION

Do not lift the instrument by the door that covers the syringes. The door might come off the hinges,

causing the instrument to drop.

5. Connect all cables and tubes again when the analyzer is in place.

2-8 VITAL SCIENTIFIC B.V.

Page 25

®

2.6 Performance and technical data

2.6.1 Performance

Maximum throughput One reagent: 180 tests per hour

Two reagents: 133 tests per hour

Three reagents: 65 tests per hour

Accuracy Refer to 2.6.8 Accuracy and precision

Precision Refer to 2.6.8 Accuracy and precision

Programmable tests 5 per programmed reagent disc

Preprogrammed tests Up to 115

Quality control 1-3 per parameter, 120 controls programmable per reagent rotor

Sample processing Prioritized: STAT, Pediatric, Normal, in that order

Introduction

2.6.2 Sample system

Sample positions 51 patient samples

Emergency samples 3 positions

Calibrators 9 positions plus maximum 51 patient positions

Pediatric samples 6 positions, overflow goes to sample positions 1 - 51

Blank position 1

Controls 4 positions plus maximum 51 patient positions

Rinsing position 1

Sample tubes Primary/secondary tubes

Sample needle With level detector and integrated mixer

Pipetting capacity 2-30 µl (steps of 0.1 µl)

Syringe 100 µl

Diameter: 13 mm

Height: max. 78 mm

Adapter 6 (pediatric, sample rotor)

VITAL SCIENTIFIC B.V. 2-9

Page 26

®

Introduction

2.6.3 Reagent system

Reagent rotor (Emit) 26 positions: 13 x 14 ml, 13 x 28 ml bottles

Volume/test Reagent 1: 110 – 399 µl, reagent 2: 0 – 180 µl,

Cooling Up to 12 °C below ambient temperature

Needle Pre-heated, with level detector

Pipetting capacity 400 µl (steps of 1 µl)

Syringe 1000 µl

Adaptors (Emit) 10 in total: 5 for 6 ml bottle, 5 for 3 ml bottle

2.6.4 Measurement station

Cuvette rotor Multi use disposable rotor with 48 cuvettes

reagent 3: 0 – 180 µl

Path length 6.8 mm

Minimum volume 220 µl

Maximum volume 400 µl

Wash station Fully automatic with overflow-level detector

Cuvette rinsing 4 × 500 µl system liquid

Light source Halogen lamp 12V 20W

Wavelength 340, 415, 505, 546, 570, 600, 660, and 700 nm

Wavelength uncertainty +/- 2 nm

Spectral half-width value 10 +/- 2 nm

Measuring range -0.1 to 3.0 Abs.

Temperature 37 °C ± 0.2 °C

Cycle time 27 sec. (DUAL MODE)

2-10 VITAL SCIENTIFIC B.V.

Page 27

®

2.6.5 Minimum PC requirements

CPU Intel® Pentium® 800 MHz

RAM 128 MB

Monitor VGA monitor 1024 x 768 pixels

Hard Disk 2 GB

Additional drive CD-ROM drive

Operating system Windows

Serial ports 1 required for analyzer, 1 optional for host connection (a LAN

LAN connection Optional for host connection (a serial port can be used instead)

USB Ports One optional for printer

Parallel Ports Optional for printer

®

2000 or Windows® XP

connection can be used instead)

Introduction

2.6.6 Cooling unit

Weight (empty) 19.6 kg

Weight (filled) approx. 23 kg

Required space 84 cm²

Dimensions (cm) 24W × 37H × 35L

Coolant 3.5 liter, glycol-based

System Closed circulation

Connection Mains electrical connector

Power consumption 340 VA max.

At operating voltage 110 or 230 VAC (device-dependent)

Line frequency 50/60 Hz

VITAL SCIENTIFIC B.V. 2-11

Page 28

®

Introduction

2.6.7 External barcode reader

Version Hand device

Technology CCD

Barcodes (standard) Codabar

Barcodes (optional) UPC-A +2, +5

UPC-E +2, +5

EAN-13 +2, +5

EAN-8 +2, +5

Code 39

Code 93

Code 128

Code 2 out of 5

2.6.8 Accuracy and precision

The chemical performance of clinical chemistry analyzers, in terms of accuracy and precision,

depend on the following: the characteristics of the instrument; the measurement techniques and the

materials used. Therefore, the chemical performance characteristics of a clinical chemistry analyzer

can only be established and postulated in terms of: the analyte; the specific reagent kit and

calibrator(s) used; the type and constitution of the specimens involved; etc.

The analyzers are designed as open systems. ´Open´ implies that most clinical chemistry tests and

techniques that require photometric measurement, can be adapted on the system. Only the test

parameters for a specific test need to be adjusted. The user needs to establish the required test

parameter settings to achieve satisfactory results, utilizing appropriate methods. The methods are

preferably based on international guidance documents, for example ECCLS or CLSI guidelines.

The manufacturer does not suggest or propose any particular reagents, calibrators and/or controls

on their analyzers from a specific manufacturer. Obtain information on the performance

characteristics from the selected reagent distributor and/or manufacturer. Various reagent

manufacturers have performed performance studies on these series of analyzers in combination

with their reagent kits. Therefore, they have application sheets available for various analytes. The

required information usually can be obtained from the reagent package inserts. Please contact your

local representative and/or reagent manufacturer for further information on the chemical

performance of their reagents on these analyzers.

Code 2 of 5 interleaved

MSI/Plessey

2-12 VITAL SCIENTIFIC B.V.

Page 29

®

Introduction

2.7 Analyzer technical data (without washing unit or computer)

2.7.1 Dimensions and weight

Width 115 cm

Height 49 cm

Depth 56 cm

Weight approx. 85 kg

2.7.2 Power requirements

Line Voltage 110/240 V nominal, tolerance 10%

Line Frequency 50/60 Hz

Power Consumption 1000VA

Installation category II (in accordance with IEC 664)

2.7.3 Environmental requirements

Ambient temperature 15 to 32 °C

Max. relative humidity 85% @ 32 °C

Pollution degree 2 (in accordance with IEC 664)

2.7.4 Approvals

CE

CB

UL

Note

The approvals listed here refer only to the instrument and operator console, not to additional

devices (cooling). For the approvals for these devices please refer to the corresponding manuals.

VITAL SCIENTIFIC B.V. 2-13

Page 30

®

Introduction

2-14 VITAL SCIENTIFIC B.V.

Page 31

®

3SYSTEM HANDLING BASICS

System Handling Basics

System Handling Basics

VITAL SCIENTIFIC B.V. 3-1

Page 32

®

System Handling Basics

3.1 Work Preparation

WARNING

Read this chapter carefully before you start to work with the analyzer. Always observe the safety

instructions in order to prevent accidents.

Note

In this manual, the dilution ratios are given as parts of the sample to parts of the resultant solution.

Thus, a dilution ratio of 1:5 means 1 part of the sample diluted with 4 parts of diluent that results in

5 parts of solution.

3.1.1 Use of the manual

The Introduction chapter describes the analyzer and its functional modules. The Basic Routine

chapter describes the daily work procedures. The Extended Routine chapter describes less often

used screens, with the parameters and their possible values. Step-by-step procedures are given for

all basic and extended routine operations. Names and values that appear on the screen are shown

in specific fonts and styles to indicate MENU NAMES, FUNCTION KEYS and PARAMETER NAMES.

Example: manually enter sample data and request tests

1. Select F8 REQUEST SAMPLES from the MAIN MENU.

2. Enter the SAMPLE ID:.

3. Enter the other parameters as required or press TAB to go to the tests selection.

4. Select the required tests, profiles and/or calculated results from the TESTS: list.

5. Select F8 NEW SAMPLE to save the sample in the worklist and start the definition of a new

sample.

6. If no more samples are needed, you can proceed to loading samples by pressing F9 SAMPLE

HANDLING.

3-2 VITAL SCIENTIFIC B.V.

Page 33

®

3.1.2 Parts of the screen

System Handling Basics

1. Status line

2. Main screen area

3. Menu Tree

4. Function keys F1 to F10

Status line

The status line shows following information:

• Status of the analyzer, e.g. STAND-BY.

• Request Buffer: information about the number of samples that is requested but not yet loaded.

• Tray Buffer: information about the current number of sample tubes loaded into the analyzer.

• Reagent disc: name of the selected reagent disc.

• Time and Date.

• The state of the external interface (if connected), e.g. HOST.

Main screen area

This area is specific for the menus that can be selected via the menu tree or function keys. The

screens are explained in subsequent chapters.

Function keys

Information of the specific function of the function keys is on constant display on the monitor. All

displays have a common structure with the Function Keys at the bottom of the monitor. You can

press the function keys on the keyboard, or you can click on the button with the mouse.

VITAL SCIENTIFIC B.V. 3-3

Page 34

®

System Handling Basics

3.1.3 Navigation keys

Arrow Keys Go to another field

TAB Switch between left and right fields

PAGE UP/DOWN, HOME, END Scroll through a list

ENTER Select the next field

F1 - F10, SHIFT, CTRL, ALT Go to the associated screen or execute the associated

Spacebar Select or deselect a checkbox and go from left to right

3.1.4 Emergency halt

To halt the analyzer

1. To immediately halt the analyzer, press ALT+F10.

2. The analyzer goes to the inactive state and all in-process measurements are lost.

3. You can repeat these measurements once the analyzer is reset.

function. Function keys can be combined with the Shift,

Ctrl and/or Alt keys to associate more functions to the

same function key.

side tab fields.

To reset the analyzer

1. Select F5 SPECIAL FUNCTIONS from the MAIN MENU.

2. Select F1 ROTOR/SYSTEM.

3. Select F1 RESET SYSTEM to reset the analyzer.

3.1.5 Messages

If an error occurs in the analyzer or the operation routine, the analyzer displays an error message on

the monitor. The message gives information about the error condition and, if possible, instructions

on how to solve the problem. The message is accompanied by an acoustic signal. To turn off the

acoustic signal press the spacebar.

Example:

This message shows when the analyzer liquid is low. You must fill the water container. See the list of

error messages in 6.2 Troubleshooting.

3-4 VITAL SCIENTIFIC B.V.

Page 35

®

3.2 Start the analyzer for the first time

WARNING

Do not install the analyzer yourself. The analyzer must be installed by qualified service technician.

After installation and before you can use the analyzer in normal routine operation, several system

adjustments must be made.

3.2.1 Prepare the analyzer

Do following operations in this sequence:

1. Connect the cooling unit. See 3.2.3 Install the cooling unit.

2. Switch the analyzer on. See 3.2.2 Start the analyzer.

3. Install the password. See 3.2.5 Passwords.

4. Fill the system with system liquid. See 3.2.6 System liquid.

5. Set up the system parameters. See 3.2.7 System parameters.

6. Program the calibrators. See 5.2 Calibrator programming.

7. Load or program the test parameters. See 5.3 Test programming.

8. Program the controls. See 5.1 Program controls.

9. Define the incompatible tests. See 5.5 Cuvette incompatibility.

10. Program the profiles. See 5.6 Profiles.

11. Position the reagents. See 5.7 Reagent position.

System Handling Basics

3.2.2 Start the analyzer

1. Set the main switch to ON. It is located on the rear panel of the analyzer.

2. Set the PC to ON.

3. Start the analyzer software. The MAIN MENU appears on the monitor. When the analyzer

remains on, but is not active carrying out processes, the analyzer goes to STAND-BY mode.

The analyzer starts with a system reset. The analyzer is now ready for operation.

The manufacturer recommends that the analyzer and the user software are switched on at all times.

This makes sure that a cuvette blank is done daily. If the analyzer is switched off, a manual cuvette

blank measurement must be done when you switch on the analyzer again. See 3.2.7 System

parameters.

VITAL SCIENTIFIC B.V. 3-5

Page 36

®

System Handling Basics

3.2.3 Install the cooling unit

The additional external cooling unit of the analyzer guarantees necessary cooling for loaded

reagents. The cooling unit operates with a sealed cycle technology. The cooling unit requires

virtually no maintenance. Unit and coolant are free from CFC.

Fill the unit with coolant and demineralized or distilled water before you put the analyzer in

operation. Only refill the coolant in large intervals, since the coolant circulates in a closed liquid

cycle. Refill the liquid if the LED flashes and/or an acoustic signal is heard.

Note

Use a mixture of 1 part EUROL

ATTENTION

Check the cooling unit for the correct voltage before you connect the cooling unit.