Page 1

© Siemens AG 2011

Products and functions for

efficient maintenance in the

process automation

Brochure · October 2011

Maintenance System

Answers for industry.

Page 2

Benefits of intelligent maintenance

Continuous plant monitoring

■ Reduces the risk of failures, and increases the

availability

■ Enables maintenance to be planned

Optimized use of maintenance resources

■ Increases maintenance quality

■ Achieves cost savings

The potential for savings arises

■ During maintenance itself and

■ by avoiding consequential costs

Corrective Preventive

Maintenance

Time-dependent

Load-dependent

Condition-based

G_ST80_XX_00410

© Siemens AG 2011

Introduction

Increase in productivity through intelligent maintenance

How can the productivity of a plant with a high level of automation be increased even further?

Plant operators in all sectors consider increased availability and shorter downtimes to be the most effective lever toward increasing productivity. Investigations have shown

that downtimes are frequently the result of insufficient

maintenance – despite the fact that maintenance is already a significant portion of the lifecycle costs.

Intelligent maintenance strategies can make a significant contribution toward increasing productivity:

• Failures can be prevented by monitoring the current plant

condition.

• Maintenance can then be planned. It does not wait until a

fault has occurred, but implements appropriate measures

in advance for avoiding faults. The timing of maintenance

can be planned such that the existing resources can be

used optimally.

• Innovative maintenance strategies pay for themselves

twice: planning security and the specific application of methods reduces the direct maintenance costs.

• Plant availability is increased at the same time. This means

that consequential costs resulting from failures, such as

quality deficiencies or loss of image, are reduced.

Totally Integrated Automation supports intelligent maintenance strategies. The SIMATIC Maintenance Station is of significant importance, and presents the information relevant to

maintenance from all automation components in a uniform

and clear manner, thus providing the maintenance engineer

with valuable support for making decisions.

Condition Monitoring, that is to say status monitoring, aims

to detect imminent faults at an early stage. It provides information on the remaining duration of use. In the case of condition-based maintenance, the maintenance measures are

only initiated when the period of use has expired.

It has been shown in practice that optimum results can be

achieved through intelligent combination of the different strategies.

Maintenance strategies

There are two maintenance strategies: response to failures or

taking preventive measures. In the case of failure-oriented

corrective maintenance, measures are only initiated when a

fault has occurred, i.e. failures are acceptable in this case and

may be minimized by a redundant plant design.

The objective of preventive strategies is to carry out mainte-

nance measures before faults even occur, in order to avoid

possible downtimes. This strategy can be satisfied using

time-dependent and load-dependent measures. Regular

maintenance work is an example of time-dependent measures. The load state is determined from the number of switching operations, operating hours or load peaks.

Introduction2

Maintenance strategies

Page 3

© Siemens AG 2011

Contents

Text

Introduction

Increase in productivity through

intelligent maintenance . . . . . . . . . . . . . . . . . . . . . . . 2

Plant-level asset management as a

maintenance task . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Intelligent maintenance

in process engineering . . . . . . . . . . . . . . . . . . . . . . . . 6

SIMATIC PCS 7 Maintenance Station

More productivity with

Totally Integrated Automation . . . . . . . . . . . . . . . . . . . 7

Visualization of information

for maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Maintenance Station –

User interface for maintenance . . . . . . . . . . . . . . . . . . 9

Add-ons as options for the SIMATIC PCS 7

Maintenance Station . . . . . . . . . . . . . . . . . . . . . . . . . 12

Monitoring and diagnostics

for industrial PCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

of networks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

for process instrumentation and analytics . . . . . . . . 16

for positioners and control valves . . . . . . . . . . . . . . . 21

of 24 V load feeders . . . . . . . . . . . . . . . . . . . . . . . . . . 22

of wear in the motor. . . . . . . . . . . . . . . . . . . . . . . . . . 22

of drive components. . . . . . . . . . . . . . . . . . . . . . . . . . 25

Plant-level asset management with

Totally Integrated Automation components . . . . . . . 27

Introduction 3

Page 4

© Siemens AG 2011

Plant Asset Management as a maintenance task

General information

Various tasks have to be handled during the operating phase

of a plant, for which different groups of persons are responsible.

The production personnel operate and monitor the plant, and

make sure that the desired products are produced with the appropriate quality, in the defined quantity, at a specified time,

and with minimum resources with respect to personnel, raw

materials, energy, costs, etc.

Maintenance staff must

• ensure a high availability of the plant,

• ensure this availability in the long term by implementing

optimization measures, and

• carry out maintenance measures with minimum use of personnel, material, energy, costs, etc.

As a result of their different tasks, these two groups of persons

have different information requirements.

Information on the measured process tags is available for the

plant operator. Apart from the measured value itself and its

status, this may, for example, be the information on whether

the measured value is still valid.

The focus of interest for the maintenance engineer is the status of the production equipment that is reflected in the states

of the devices and components used (i.e. particularly in the

states of the field devices). Typical states in this respect include "Component OK", "Maintenance required", "Failure" or

"Function check".

SIMATIC PCS 7 allows a clear classification of the information

for the user groups Plant Operators and Maintenance Engineers.

Different demand for information at the plant

Plant operator

Information on the process such as:

• Recipe parameters

• Temperature characteristic

• Pressure values

•Raw material stocks

•Output

Maintenance personnel

Information on the state of the production equipment such as:

• Components OK

•Maintenance required

•Failure

• Functional check

Introduction4

Page 5

© Siemens AG 2011

Asset management in production

The term asset management comes from the world of finance

and economics and refers to the manner in which a company

deals with its long-term and current assets. These include the

production equipment with its plant components such as apparatus, machines, pipelines etc. and the equipment and devices for their automation. All these are referred to as assets.

In association with production, asset management covers all

activities and measures which serve toward retaining or increasing the value of a plant. This is called Plant Asset Management.

Benefits of Plant Asset Management

Plant Asset Management allows the maintenance engineer

• to unambiguously identify and evaluate the assets, this means the production equipment and its components;

• to carry out the appropriate measures in the case of deviations from the desired or expected state.

As a result of monitoring, i.e. the recording and evaluation of

status variables, the condition of a component or device can

be determined.

It can be recognized, for example, that no signal is received

from the sensor, resulting in the diagnosis "Open circuit". This

result triggers a maintenance request, and maintenance must

then be carried out to eliminate the open circuit.

This measure – replacement of a faulty line in this example –

ensures that the component is returned to the desired condition and closes the maintenance cycle. This means that Plant

Asset Management is the basis for increased productivity.

Maintenance

measure

Maintenance

request

Monitoring

Diagnostics

Introduction 5

Page 6

© Siemens AG 2011

Intelligent maintenance in process engineering

Despite the different tasks of operators and maintenance

staff, it is meaningful and necessary to map the information of both staff groups within one process control system

and not to use different systems.

There are various reasons for this:

• Uniform visualization for all components and devices.

• No limitation to selection of field devices.

• The same information sources (field devices) are relevant

to both automation and maintenance.

• There is a close link between automation and asset management functions because, for example, the current

control strategy of the plant plays an important role for the

assessment of a component status.

• Engineering data for automation can also be used for maintenance.

• Simplified handling of the system, since users need only be

acquainted with the engineering, operator control and monitoring tools of a single system.

The process control special interest group of the pharmaceuticals industry (NAMUR) has formulated essential requirements

(NE 91) from the user's viewpoint. This attaches special significance to the integration of the Plant Asset Management into

the process control system.

• Plant Asset Management is a part of the process control

system

• Recording and assessing the status of the assets

• Inclusion of all assets (process control devices and plant

components)

• Separation of maintenance-relevant information and process data

• Uniform visualization for all assets

• No limitation to selection of field devices

In addition, there is a requirement (NE 107) that all field devices must provide standardized status messages about their

status as follows:

• Good

No known restriction of function

•Uncertain

Operation outside the specified range

• Device failure

Need for maintenance

•Maintenance required

Function check (process value manipulated)

• Function check, local operation

Failure (process value invalid)

Processing plants, whose open and closed loop control is performed with SIMATIC PCS 7 and components of Totally Integrated Automation, satisfy the user requirements formulated

by NAMUR.

The resulting information is divided up to prevent the plant

operators and maintenance staff from being flooded with information. To achieve this, a Maintenance Station (MS) is introduced in addition to the operator station (OS). Maintenance-relevant information is kept away from the operator

station. This information is collected and presented on the

Maintenance Station. The same HMI tools are used for the

operator station and the Maintenance Station and the HMI

philosophy is identical.

Plant Asset Management with SIMATIC PCS 7

■ Process engineering plants with SIMATIC PCS 7 and com-

ponents of Totally Integrated Automation meet the requirements of NAMUR.

■ Automation and Plant Asset Management run on the

same system.

■ The information for plant operators maintenance staff is

divided between the operator station and the Maintenance Station.

■ Shared configuration and uniform user interfaces mini-

mize the expense of an effective Plant Asset Management.

Introduction6

Page 7

Central control room with plant-wide maintenance overview

Inbound process Productions process Outbound process

G_ST80_XX_00337

Maintenance Station

Server (WinCC)

Maintenance Station

Server SIMATIC PCS 7

,QWHUQHW

Maintenance Station

Server (WinCC)

Maintenance

Station Client

+ Web Server

Maintenance

Station Client

© Siemens AG 2011

SIMATIC PCS 7 Maintenance Station

More productivity with Totally Integrated Automation

Integrated plant and cross-system maintenance

Plant Asset Management is only truly productive if maintenance staff can view diagnostic information relating to the entire process chain. In practice, this means that the same maintenance team that is responsible for the actual process can

support inbound and outbound processes such as logistics,

bottling and packaging plants without having to build up a

great deal of additional expertise. If the process control system and the controllers of the upstream and downstream systems originate from different vendors, different alarm systems can cause considerable additional expense.

If a plant is automated with SIMATIC PCS 7, therefore it is worthwhile for the plant operators to select machines and systems that are automated with SIMATIC and visualized with

SIMATIC WinCC for their inbound and outbound processes, as

then they can exploit all the advantages of Totally Integrated

Automation.

If machines or systems for inbound/outbound processes are

operated and monitored by means of SIMATIC WinCC, then

the SIMATIC Maintenance Station presents itself as an option

to SIMATIC WinCC for maintenance-relevant information.

The integrated functionality of Totally Integrated Automation

also makes it possible, using the SIMATIC PCS 7 Maintenance

Station, to monitor the packaging or bottling line by means of

a client. Display, logic, and message management are identical. The uniform look and feel saves on overhead and generates a high degree of acceptance within the maintenance

team. The SIMATIC Maintenance Station for SIMATIC PCS 7

and SIMATIC WinCC makes a significant contribution to increasing maintenance productivity and thus to increasing the

availability of the overall plant.

Optimizing instead of repairing

The task of maintenance is not only to avoid unscheduled production downtimes, but also to optimize the running of the

plant. Optimization must be based on analysis of traceable

processes. The Maintenance Station offers the basic data set

for integrated analysis of all weak points. This is not unusual

in a process control system. However, in inbound and outbound processes diagnostics are often restricted to signaling

a fault and then forgetting about it as soon as it has been repaired. With Totally Integrated Automation, the Maintenance

Station becomes the basis for Total Productive Maintenance.

SIMATIC Maintenance Station: Collecting diagnostic information from the entire process chain centrally – even via the Web

Suitable protective measures (among others IT-Security, e.g. network segmentation) have to be taken up to ensure a safe operation of the plant.

You find further information about the topic of Industrial Security on the Internet under www.siemens.com/industrialsecurity.

SIMATIC PCS 7 Maintenance Station 7

Page 8

Overview

Automation

system (AS)

Detailed view

Component/

Device

Plant view

AS rack

1

Subnet

AS rack

2...n

G_ST70_XX_00413

Identification of device

Operate state display

Maintenance state display

Maintenance group display

G_ST80_XX_00421

© Siemens AG 2011

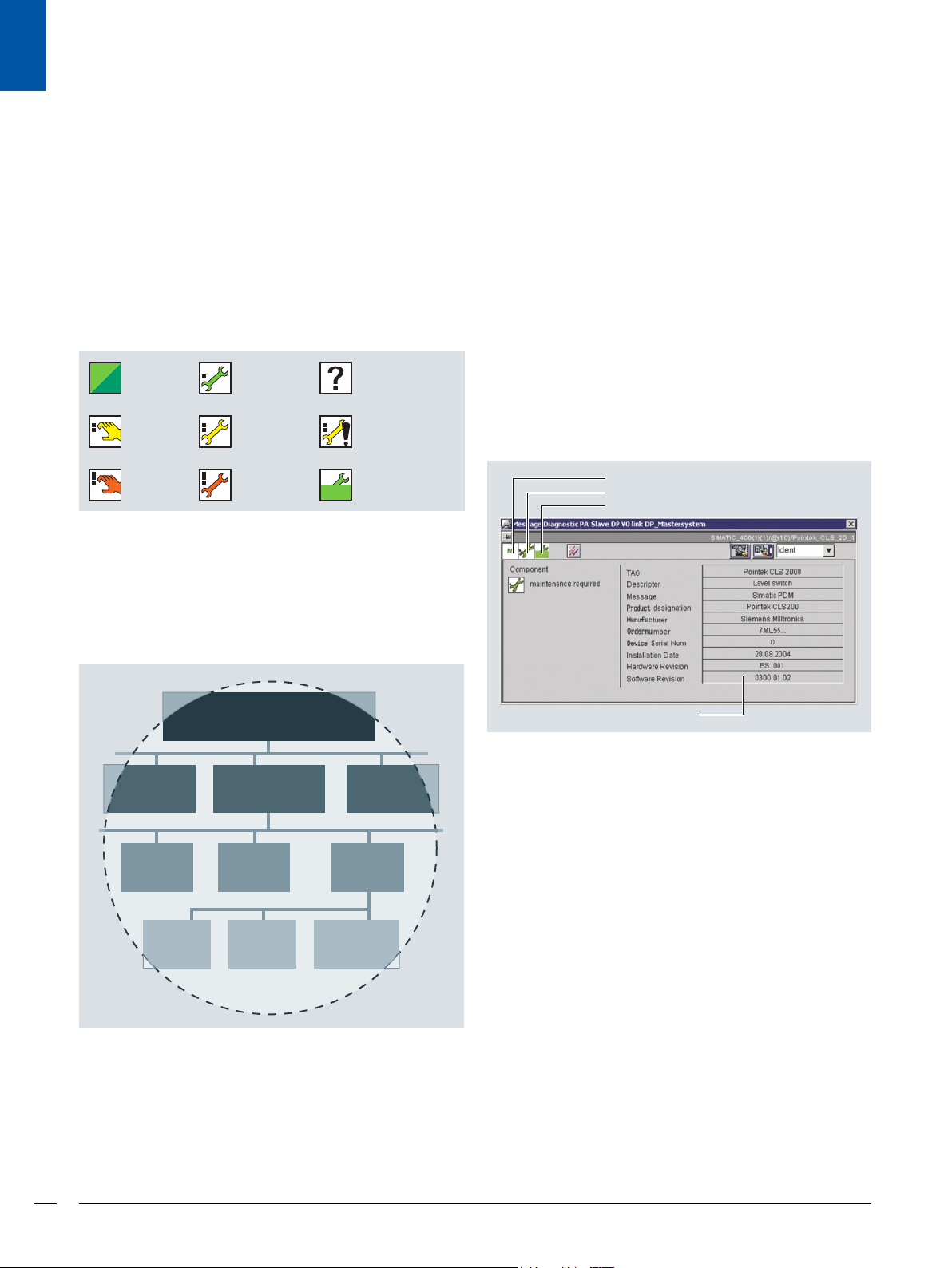

Visualization of information for maintenance

In order to recognize the conditions of individual devices

or components unequivocally, a uniform symbol representation has been implemented.

There are symbols for the device status itself and also for the

importance of a maintenance request. In addition, the status

of a maintenance measure is displayed. The conditions of all

devices and equipment of the automation technology and of

the plant components are indicated by these standardized

symbols.

*RRG

6LPXODWLRQ

/RFDORSHUDWRU

FRQWURO

Uniform symbols for the conditions of components and devices

0DLQWHQDQFH

UHTXLUHPHQW

ORZ

0DLQWHQDQFH

UHTXHVW

DYHUDJH

0DLQWHQDQFH

DODUP

KLJK

0DLQWHQDQFH

MREXQNQRZQ

QRWUHTXHVWHG

0DLQWHQDQFH

MRE

UHTXHVWHG

0DLQWHQDQFH

MRE

EHLQJSURFHVVHG

Besides the uniform display of symbols, a significant detail for

the overview is a hierarchical structuring of information in

which the maintenance engineer also has access to all required details of the components and devices, based on an overview display (plant view).

The overview display uses the standardized symbols to visualize the condition of a component itself and also provides collective information on the conditions of all devices in the subordinate hierarchies.

The collective condition message shows the OK condition or

the seriousness of a possible problem in red, yellow, or green,

as per a traffic light. A button can be used to access all subordinate hierarchy levels step-by-step down to the bottom device level.

Further views of the maintenance information are available in

addition so that the maintenance engineer has a complete

overview of all current information of the asset relevant to

maintenance. This permits assessment of the plant status at a

glance.

Extract from the hierarchical visualization of the maintenance

information

SIMATIC PCS 7 Maintenance Station8

Detailed view of a component

The information is consistently structured and hierarchically

organized. The quantity of information displayed on each individual screen always remains manageable for the maintenance engineer, who nevertheless has easy access at any time

to the complete information.

Page 9

© Siemens AG 2011

Maintenance Station – User interface for maintenance

The SIMATIC PCS 7 Maintenance Station software package

is available as an alternative to SIMATIC PCS 7 for implementing Plant Asset Management. You can use this software package to expand an Operator Station to a

Maintenance Station.

The maintenance engineer can process the diagnostics messages and maintenance requests of the assets on the Maintenance

Station. Via the Maintenance Station the engineer can access:

• Electronic components of the process control system: intelligent field devices and I/O modules, field bus, controller,

network components and plant bus as well as servers and

clients of the operator systems.

• Mechanical components that do not belong directly to the

process control system such as pumps, motors, centrifuges, heat exchangers or control loops (passive or indirect

assets). These are represented by proxy objects in which

the diagnostics rules are stored.

Monitoring and diagnostics of mechanical components

Exceeding the limits of the pump's rated operating range and

deviations from the anticipated characteristic curve are reported to the user as maintenance alarm via the PumpMon block.

The block outputs are simultaneously made available for

further processing. In this way, the user gets the opportunity

to intervene in a preventive way to prevent damage to the

pumps, which helps to reduce plant downtimes and increase

its availability. It also allows the pump layout to be optimized.

PumpMon block: Transport characteristic curve with current operating

point

For mechanical components without self-diagnostics (pumps,

heat exchangers, valves, compressors, etc.), inadmissible operating states can be determined from various measured values

that already exist in a process control system using special diagnostic blocks. Deviations from an established normal status

can be used for this, for example.

Pump monitoring with the block PumpMon

The diagnostic block PumpMon is used for

• Warning of pump damage when there is blocking, dry running, gas in the transported substance, cavitations, overload, or improper running;

• Early detection of initial pump damage, such as wear or decreasing pump efficiency;

• Long-term optimization the pump design by means of statistical analysis of the operating data, for example, recording the load spectrum.

Valve monitoring with the block ValveMon

Abrasion, cavitation, corrosion of the valve plug or seat as well

as caking (fouling, deposits) are the most common signs of

wear for valves. ValveMon monitors the valve status according

to specific process values and enables the detection of malfunctions and impending failures at an early stage.

Heat exchanger monitoring with the block HeatXchMon

The main problem with heat exchangers is fouling. Fouling results when residues of the process medium are deposited on

the transfer surfaces and thus impair efficiency. HeatXchMon

determines deviations of the current heat flow from the reference heat flow in the clean state. The current degree of fouling, the energy loss and daily costs can thus be precisely calculated and displayed.

The HeatXchMon block not only indicates the current performance capability of the heat exchanger, it also calculates the daily energy loss due to

the degree of fouling.

SIMATIC PCS 7 Maintenance Station 9

Page 10

Technological plant view

Maintenance

Station

Transfer of maintenancerelevant information to the

Maintenance Station

Operator

Station

G_ST70_XX_00414

© Siemens AG 2011

Performance monitoring of turbo compressors with the

block CompMon:

Depending on the type of medium, the aerodynamic performance of a turbo compressor can be impaired by fouling,

caking, or abrasion. The location of the operating point can

also be affected by variances in the state of the medium being

pumped in depending on temperature, pressure and composition or by changes to the flow resistance on the load side.

The block CompMon calculates performance characteristics

(e.g. conveyance or efficiency) and issues a warning if the corresponding values indicate damage to the compressor, caking

by pollutants on the runner or erosion of the blades from the

fluid.

Standard diagnostics functions

In order to obtain information on the diagnostics status of individual plant areas or components, maintenance engineers

can change from the overview display to the respective diagnostics display of the subordinate hardware level. If a fault is

signaled in the overview display, the "loop in alarm" function

permits rapid switching to the diagnostics faceplate of the associated component. The information is filtered according to

the area of responsibility of the user.

The following information can be offered:

Configuring a Maintenance Station

When setting up a Maintenance Station, the user only

has to assign the corresponding attribute once during the configuration. This automatically generates a technological hierarchy for diagnostics displays.

The diagnostics displays can be subsequently expanded by

project-specific contents.

• Display of diagnostics status determined by the system

• Information on the component, such as process tag name,

manufacturer or serial number

• Display of diagnostics messages of a component

• Visualization of type and current state of initiated maintenance measure

Design of a Maintenance Station

The SIMATIC PCS 7 Maintenance Station is of modular design.

In small plants it is possible to install the operator station and

the Maintenance Station on the same PC. Just like the operator system, the Maintenance Station can be expanded into a

client/server application with multi-client operation. The signals and messages from the components and devices which

are relevant to maintenance are collected and saved on the

server of a client/server application. They are displayed on the

client.

The SIMATIC PCS 7 Maintenance Station is based on standard

SIMATIC products:

• SIMATIC PCS 7 ES / OS

for configuration and HMI functions

• SIMATIC PDM

for connecting the field devices and

• SIMATIC SNMP OPC Server

for interfacing network components

When configuring PCS 7, the technological plant view automatically

becomes its own maintenance area

Visualization in the Maintenance Station

In the operating state, the Maintenance Station's client requests cyclic data from the associated server. The client can

additionally access hardware components and field devices directly by means of an online connection so that the maintenance engineer has the relevant information available at all

times. Various components with highly different diagnostics

capabilities are used for SIMATIC PCS 7. However, from the viewpoint of maintenance, all components are displayed in the

same manner. Therefore the maintenance and diagnostics

conditions of the components are represented by standardized symbols.

SIMATIC PCS 7 Maintenance Station10

Page 11

Block icon

Device faceplate

G_ST80_X_00422

Symbol display of a component

© Siemens AG 2011

Overview of components on a PROFIBUS segment with symbol displays

Symbol displays and component faceplates

The conditions of the components or also of subordinate components are visualized using

standardized symbol displays in

the diagnostics displays. The

symbol displays of the components contain:

• Bitmap of component

• Tag designation of component

• Maintenance state display

• Group display for maintenance messages from subordinate

components

Clicking an element in the symbol display either opens the

subordinate hierarchy level or a component faceplate. This

faceplate contains various views of the respective component

in which further device-specific information can be output.

There are three standard views.

This is recorded, and signaled in the symbols. A work instruction number and a comment can still be entered for each work

request. The instruction number has no effect within the

Maintenance Station and is only included in the report. This

can be used for transfer to maintenance planning.

Faceplate for maintenance view

Process Device Management

There are additional views depending on the diagnostics capability of a device. For example, in the component operating

display for intelligent field devices (DP, PA, HART), additional

information is output that the Process Device Management

(PDM) makes available. Changes in the parameterization are

managed in a change logbook and can be called up from the

Maintenance Station. In this case, the time and name of the

responsible operator are output.

Configuration changes can also be output. The diagnostic information of intelligent field devices is determined with the

PDM on the basis of the EDD of a field device. In the EDD, the

device manufacturer also specifies, for example, the supplementary information to be provided in the event of faults. This

can also display the cause, a trend statement and instructions

for clearing the fault. In addition, PDM can be called directly

from the faceplate. This call makes all vendor-specific information and documents incorporated by the vendor available for

intelligent field devices.

Identification

Depending on the component, the identification view displays

all information available from the hardware configuration or

via SIMATIC PDM in the device description, of the Electronic

Device Description (EDD). In addition, the maintenance status

is displayed and, if available, the status of a redundant component.

Messages

The Messages view displays diagnostics error messages, operator inputs, and maintenance requests.

Maintenance

The Maintenance view is used for the response of the operator

to a maintenance request of a component. Maintenance work

can be requested. The status of the work can also be specified.

Faceplate, detail view of a component

SIMATIC PCS 7 Maintenance Station 11

Page 12

© Siemens AG 2011

Add-ons as options for the SIMATIC PCS 7 Maintenance Station

Alarm Control Center alarm management system

The WinCC Alarm Control Center (ACC) alarm management

system transmits alarms from visualization and control systems to mobile receivers such as cellphones or pagers.

The messages are automatically sent to the responsible person or group of people. If no response is received within a programmable period of time from a notified person (such as a

text message), other people are notified. In conjunction with

the escalation system, alarm scenarios can be implemented

for a wide range of requirements.

Anticipatory planning with the help of performance and calendar

information

Even the basic package incorporates a shift management facility, enabling personnel to be assigned depending on the time

and the day of the week.

Text messages are sent via ISDN, analog modem or GSM modem. For additional requirements, transmission channels are

available for systems including VOIP, voice and PABX systems.

Configuration and user control is web-based, via LAN or Wireless LAN.

Further options allows the Alarm Control Center to be adapted

to individual requirements. The Replication option enables

high-availability, redundant systems to be configured. The

dialog module permits active contacting of participants, e.g.

to log off a station by remote configuration or to query process values. Advanced call archive analysis enables detailed

logs to be generated, and supports other quality assurance

measures.

Further information:

www.siemens.com/alarmcc

PM-MAINT intelligent maintenance management

The PM-MAINT add-on supplements the SIMATIC Maintenance

Station with the following functions:

Maintenance planning

PM-MAINT can be used for planning, based on performance

data or calendar intervals, so as to define clearly when which

maintenance tasks are to be carried out. Damage reports and

repair jobs from the SIMATIC Maintenance Station also enable

unforeseen maintenance work to be scheduled.

Management of supplementary information

Data essential to effective maintenance can be entered relating to the maintained plant and machinery. In addition to

component, manufacturer and sourcing data, electronic documents can also be linked to the items and related maintenance jobs. This provides maintenance staff with direct access

to aids such as repair instructions, circuit diagrams, photos,

manuals and the like.

PM-MAINT status window

Archiving of maintenance data

All maintenance activities are logged in an archive. Analysis of

the archive enables maintenance operations to be assessed in

detail, providing for continuous improvement.

Further information:

www.siemens.com/pm-maint

SIMATIC PCS 7 Maintenance Station12

Page 13

© Siemens AG 2011

Monitoring and diagnostics

for industrial PCs

SIMATIC IPCs are rugged industrial PCs for professional automation solutions in 24-h operation. Because of their

high system availability, in PCS 7 systems they are often

used, for example, as operator or Maintenance Station or

also as engineering station or OPC server.

The SIMATIC IPC DiagMonitor monitoring and signaling software recognizes possible hardware and software faults at an

early point in time, and provides corresponding messages for

the Maintenance Station. In connection with several SIMATIC

IPCs, client/server network architectures can be set up via LAN

and can centrally monitor all SIMATIC IPCs in plant facilities

using DiagMonitor. The integrated webserver lets you view

and manage data via an internet browser. Efficient service

structures can be established by integrating automated communication paths, e.g. by means of Ethernet, e-mail, or text

messages (phone).

DiagMonitor supplements the operating data of the monitored PCs with text messages, transmits them via the SNMP OPC

server and outputs them in the associated asset management

view.

• The "Monitoring 1" view indicates the number of operating

hours of the SIMATIC IPC and the interior unit temperature

at different measurement points in the device, e.g. at the

processor and at the motherboard.

• In two additional views the speeds of the fans are output or

diagnostic data and information on the status of the drives

is displayed. It is then possible, for example, for the user to

replace hard disks as a preventive measure before a loss of

data occurs (preventive maintenance).

(www.siemens.com/diagmonitor)

Operating hours and device internal temperatures in Monitoring 1 view

In addition, the user is warned in good time of fan or hard disk

failures (preventive maintenance). In the event of an alarm, the

DiagMonitor can also start autonomous programs such as special PC tools or user-specific applications for individual response

to alarms.

Prevention of potential failures

• Diagnostics and signaling functions for PC temperature,

fan, drives, system status (watchdog)

• Operating hours counter for preventive maintenance;

• Recording and evaluation of operating data

• Integral log function, comprehensive text messages and

online help in German and English.

Possibilities for minimizing PC downtimes:

• Product Equipment Data is an online service tool for simple

and quick information about the equipment configuration

in the delivery condition. The information also supports the

procurement of spare parts (www.siemens.com/ped).

• The after-sales information system for SIMATIC IPC/PG offers product and contact information on the Internet in one

central location (www.siemens.com/asis).

Monitoring Signaling Alerting Visaulization

• PC hardware functions

• Interior unit temperature

•Device fan

•Drive state

•System states

• Runtime meter

The SIMATIC IPC DiagMonitor supports fast detection and efficient avoidance of potential system failures

•Overshoot/undershoot

of permissible operating

temperature

• Fan failure/fault

• Drive problems

• Program interruption

following a watchdog

timeout

• Maintenance intervals

(freely selectable)

•LAN

• Text message to mobile

phone

• E-mail to alert designated person

• OPC and/or SNMP to

user software

• Diagnostic LEDs on each

unit

• Local on own monitor

• Via LAN on the central

server

• Graphic display of measured data

• Web server

• SIMATIC Maintenance

Station

Operating and

recording

• Activates reset

(watchdog)

•Runs programs

automatically

(batch/executable files)

• Records events (log file)

Monitoring and diagnostics 13

Page 14

© Siemens AG 2011

Monitoring and diagnostics of networks

SIMATIC PCS 7 communicates with the subordinate components of Totally Integrated Automation via Industrial

Ethernet and PROFIBUS and uses the network components

and communications processors (CPs) of SIMATIC NET. In

addition to reliable communications, these also offer the

facility for network diagnostics during runtime.

Monitoring of PROFINET/Industrial Ethernet

Network components

Network components are SCALANCE X (Industrial Ethernet

switches), SCALANCE W (Industrial WLAN), and SCALANCE S

(Industrial Security).

SCALANCE X-200 managed

Universally applicable, from machine-level applications to

networked plant sections. Configuration and remote diagnostics are integrated in the STEP 7 engineering tool. This increases plant availability. Devices with a high degree of protection permit a cabinet-free construction. Appropriate switches

(SCALANCE X-200IRT) are also available for use in plant section networks with hard real-time demands and maximum

availability.

SCALANCE X-300 managed

Networking of subsystems/plant sections, as well as for connecting to the enterprise network. The SCALANCE X-300 managed product line combines the firmware functionality of

SCALANCE X-400 with the compact design of SCALANCE X-

200. The SCALANCE X-300 switches thus offer expanded management features and firmware functionality in comparison

with the SCALANCE X-200 switches. Moreover, electrical and

optical Gigabit Ethernet ports are available, as well the XR-300

Rack Switches as versions in 19-inch design.

SCALANCE X-400 managed (Layer 3)

For use in high-performance plant networks (e.g. with highspeed redundancy). Due to the modular design, the switches

can be adapted to the task at hand. Due to the support of IT

standards (e.g. VLAN, IGMP, RSTP), the seamless integration

of automation networks into existing office networks is possible. Routing functions on Layer 3 support communication between different IP subnets.

SCALANCE W

Thanks to wireless communication, an even higher level of

plant flexibility can be achieved, maintenance work is simplified, and service times and downtimes are reduced. The

IWLAN solution from Siemens Industry makes these advantages available through a coordinated portfolio of WLAN equipment for industrial use, even for fail-safe communication in

the context of operator and machine safety. This

IWLAN access points and client modules (SCALANCE W),

includes

Selection of network components with diagnostics capability

wireless connections for PROFIBUS and distributed I/Os, mobile operator panels, planning software, and extensive accessories.

SCALANCE S

The SCALANCE S security modules enable logging of access

data in one log file (syslog protocol). These data show how,

when, and by whom the network has been accessed.

attempts can be detected early

measures taken.

Network management

The integrated network management with the standard SNMP

(Simple Network Management Protocol) in SCALANCE X and

W provides information for device diagnostics.

The network management products SINEMA E (SIMATIC Network Manager Engineering), SINEMA Server (Management),

and the SNMP OPC server provide support in the planning and

simulation or monitoring and diagnosis of wireless and wired

networks in the industrial environment.

SINEMA Server is specifically used in larger networks and for

extensive network management. The SNMP OPC server is

used exclusively for the processing of SNMP message frames

and their transfer to be represented in other systems.

SINEMA Server network management

The SINEMA Server (Simatic Network Manager) network management software diagnoses and visualizes Ethernet networks. It continuously logs network activities using various

protocols such as SNMP, DCP, and LLDP and makes them

available to users and other systems on the network, e.g. HMI

software such as WinCC, for evaluation and further processing. Devices, their properties and their topology are recognized, and network statistics are compiled by means of autodiscovery.

and appropriate preventive

Attack

Monitoring and diagnostics14

Page 15

© Siemens AG 2011

These can be displayed graphically and if desired also supplemented using individual diagnostics screens. In addition, at

runtime cyclical data from Ethernet participants is queried and

network alarms are reported. Websites are used to present

and pass on the information. Furthermore, the software offers

an e-mail client function and OPC server in order to forward

network data and alarms to other systems. SINEMA Server can

be easily integrated in HMI (Human Machine Interface) and visualization systems such as SIMATIC WinCC. Changes in the

network are also accordingly logged and archived in a database. For the analysis of past network failures or as evidence of

network availability, the database information can be prepared and documented as reports for any configurable period of

time. The SINEMA user interface and its available features are

accessible via the browser from any computers on the network.

Monitoring of PROFIBUS

Online diagnostics with diagnostic repeater

Particularly in the case of exceptional stress, e.g. trailing

cables or strong vibrations, frequent inspection of the cables

is recommended to reduce failures to a minimum. The diagnostic repeater is available for this purpose. It is integrated as

an RS 485 repeater in the PROFIBUS network and also has powerful features for the diagnosis of cable faults.

The diagnostics repeater determines the bus system topology.

If there is a fault, a standard diagnostic message is automatically transmitted to the master.

This means that even sporadic cable faults can be detected

and signaled. Even maintenance engineers without PROFIBUS

expertise can also quickly and reliably locate and fix bus cable

faults.

Diagnosis of optical PROFIBUS links with OLM

To set up optical PROFIBUS connections, optical link modules

(OLMs) are used. They offer the following diagnostic options:

• Function monitoring by means of signaling contact

• Signaling of the fiber-optic cable quality with LEDs for

channel monitoring

• Analog value signaling of the fiber optic line quality; evaluation with voltmeter via measurement terminal or reading

to the PLC via analog module

The following components can be diagnosed:

• SCALANCE X, W and S network components

• SIMATIC NET Industrial Ethernet CPs

• SIMATIC S7 with integrated PROFINET interface

• PROFINET IO devices, e.g. ET 200

• Other Ethernet devices

SNMP OPC server

The SNMP OPC Server enables diagnostic and configuration

data to be read from any Ethernet devices and displayed on

the Maintenance Station. Alongside standard maintenance

data, simple plant network problems such as failure of a line

can be quickly and easily detected by means of this software.

Device configuration is integrated into STEP 7. Ethernet devices can be read from a STEP 7 project or, using the autodiscovery function, directly from the live network. The user can

easily add all devices detected there to the device list for monitoring on the OPC Server. Then this configuration data is exported into the Maintenance Station, where tags, alarms and

faceplates are automatically created for the devices concerned.

Benefits of network monitoring and diagnostics

• High network availability through targeted and rapid localization of faults

• Documentation of network activities for analysis and verification of network availability

• Monitoring and improvement of the network capacity utilization

• Automatic recognition of new or faulty participants

• Integration of diagnostics data in automation and visualization systems

• Detailed and clear graphical network representation

Monitoring and diagnostics 15

Page 16

© Siemens AG 2011

Monitoring and diagnostics for process instrumentation and process analytics

Standardized and meaningful diagnostics alarms are a

part of the electrical device description (EDD). SIMATIC

PCS 7 utilizes the EDD and forwards the relevant message

automatically to the Maintenance Station. The user receives information not only about which problem is involved

but also on how to resolve it.

The PROFIBUS profile specification 3.01 supplies an upgrade

of the status byte, now designated "Condensed Status". The

purpose of the "Condensed Status" is to reduce the number of

alarms and make them more user-friendly. In addition, users

have the opportunity of changing the priority level for each diagnostic alarm and thus define what is relevant to their own

process.

Numerous EDDs are currently being upgraded to Enhanced

EDDs. They have the following advantages:

• New standardized "look & feel" for all Siemens devices

• Quick start wizards for faster commissioning

• Improved representation of graphics for advanced diagnostic functions

All of these functions help to reduce the maintenance costs by

accelerating the diagnostic process.

When using PROFIBUS, Asset Management functions can be

used to greatest effect if the devices used conform to the

PROFIBUS "Identification and Maintenance" specification as

well as profile specification Version 3.01. Siemens devices

conform to these standards and the following information is

made available:

•Manufacturer

• Order numbers

•Description

• Installation date

• Serial number

• Hardware and software modifications

Temperature measurement

SITRANS T are the temperature measuring instruments for

process engineering plants. They support commissioning and

maintenance in an optimum manner and can be used in different designs, such as complete measuring point, head-mounted transmitter, DIN rail mounted or distributed device.For

preventive maintenance, for example, the following functions

are available:

• Universal connection of resistance thermometers, thermoelements, resistance-type transmitters and DC voltage signals

• Monitoring of the measuring point for short circuit and

open circuit

• Min/max pointer for monitoring the electronics and sensor

temperature

The following devices are available as head-mounted transmitters or integrated into a complete measuring point:

SITRANS TH300 – the HART device

The operating hours counter evaluates the temperature values of the sensor and electronics, edits them and displays them

in eight temperature classes. The measured values can be archived. The sensor temperature can indicate aging processes

and can be used for anticipatory maintenance. The output

current is monitored cyclically, simulated as a fixed value or

ramp function:

• Memory function of RAM, ROM, EPROM according to

checksum method

• Program sequence due to targeted approach to checkpoints (watchdog)

SITRANS TH400 for PROFIBUS PA

Possibility of connecting two sensors in redundant mode. The

profile 3.0 device ensures easy interchangeability. With FISCO

certification, use in potentially explosive areas is uncomplicated.

This information is read directly from the measuring instrument and stored in the SIMATIC PDM. Here, the data can easily

be recalled.

Monitoring and diagnostics16

SITRANS TW for rail mounting

For installation on mounting rail with integrated power supply, SITRANS TW is a universal 4-wire temperature transmitter

for mounting in control cabinets:

• Monitoring of limit values and output via HART or signaling

relay

• Runtime meter for electronics

SITRANS TH400 SITRANS TW

Page 17

© Siemens AG 2011

Pressure, absolute pressure, differential pressure, flow

and hydrostatic level measurement

SITRANS P is a family of pressure measuring instruments. The

SITRANS P DS III and P300 digital transmitters are suitable as

universal transmitters for measuring gauge pressure, absolute

pressure, and differential pressure, and also for flow and hydrostatic level measurement.

They have a series of integrated diagnostic and simulation

functions that allow the user to assess the specific state of the

device or of the whole measurement point during commissioning, servicing and maintenance operations.

SITRANS P300, digital display

Flow measurement

The preventive maintenance is supported by functions such

as:

• Operating hours counter for measuring cell and electronics,

• Event counter for upper and lower limit violation,

• Min/max pointer for pressure, sensor temperature and

electronics temperature, and

• Two freely parameterizable timers that can set off a warning or an alarm on reaching a preset threshold.

As part of the corrective maintenance the device diagnostics

effectively support the clearance of faults. For this, the following are cyclically monitored:

• Memory integrity of RAM, ROM and EEPROM by means of

checksum method

• Correct program sequence in microcontroller due to targeted approach to checkpoints (watchdog)

• Sensors for breakage and function of the linearization calculation

In addition, simulation functions are available for checking the

configuration of the transmitter and of the connected control

system input. These also contribute to fast and definitive troubleshooting and thus to greater efficiency in the maintenance

operations.

From the combination of the stated functions, measures can

be derived that contribute to the prognostic maintenance

and thus increase plant availability even further and help to

raise productivity.

For flow measurement, Siemens offers various contactless

measurement procedures:

• SITRANS F M MAGFLO magnetic-inductive flow meters

• SITRANS F C MASSFLO Coriolis mass flow meters

The devices are flexible in their application and can be positioned at any point in the installation.

MAGFLO and MASSFLO flow meters provide excellent, correct

and predictable information about the HART or PROFIBUS Profil interfaces. The latest MASSFLO version "SIMATIC SIFLOW

FC070 Coriolis transmitter" can be directly integrated into the

SIMATIC system via the backplane of the SIMATIC module.

SIMATIC SIFLOW FC070 has a SIMATIC S7-300 environment.

The SIMATIC SIFLOW FC070 permits seamless integration into

the automation system.

MAGFLO flow meters are used for applications with conductive liquids and MASSFLO flow meters, for example, for nonconductive liquids, high precision requirements or in processes in which the process parameters are subject to severe fluctuations.

MAGFLO flow meters are not sensitive to fluctuations in temperature, pressure, viscosity or electrical conductivity (min.

5 µS/cm guaranteed).

The device is equipped with a host of diagnostic functions that

are displayed in plain text and stored in a logbook. In this way,

sporadically occurring faults can also be located. These faults

are automatically sent to the system in accordance with the

standards of the diagnosed requirements of NAMUR NE 107.

SITRANS P DS III

The measuring transducer, including outputs, is monitored.

The pickups are continuously checked and empty pipe detection is performed. In addition, MAGFLO flow meters offer the

option of checking the entire measurement system with an

external verifier.

Monitoring and diagnostics 17

Page 18

© Siemens AG 2011

SITRANS F M MAGFLO SITRANS FC MASSFLO

MASSFLO flow meters are not sensitive to fluctuations in pressure, temperature, density, electrical conductivity or viscosity.

An ASIC guarantees improved reaction to discontinuities. The

devices are practically unaffected by external noise – an essential requirement for raising the dynamic range.

MASS 6000 monitors both application-dependent faults and

those device settings selected by the user:

• Excessive air in the measuring tube

• Empty tube detection

• Unstable flow signal

• Zero point error

• Density of fluid and temperature limits

• Measuring range limits

The user-specific settings are compared with the actual values

to determine an optimal setting. Faults, caused by mechanical

vibrations, cavitation or pump noises can affect the measurements.

Extended diagnostic functions in the MASS 6000 transmitter

by means of intrinsic sensor resonance frequency, pick-up amplitudes and signal-phase can identify these influences.

As NAMUR NE 107 is supported, extensive diagnostic functions are available in the Maintenance Station. This enables

the maintenance personnel to adopt the necessary measures.

From this standardized information (type and frequency of

the alarms), the user can draw conclusions that indicate imminent failure or predictive maintenance. This enables step to be

performed to improve the measurement quality or prevent a

loss of production.

Level measurement

Four different technologies are available for level measurement: Radar, capacitance, ultrasonic and Guided Wave Radar

technology.

Level measurement with contactless radar technology:

• SITRANS LR400/LR460/LR560 with FMCW radar

(Frequency Modulated Continuous Wave)

• SITRANS LR200/LR250/LR260, pulse radar

• SITRANS Probe LR, pulse radar

(radar measuring instruments are available with PROFIBUS

PA and with HART protocol)

Level measurement with contactless ultrasonic technology:

• SITRANS Probe LU is available either with PROFIBUS PA or

HART

Level measurement with contacting capacitance measuring

technology:

• POINTEK CLS 200/300

• SITRANS LC 300/500

POINTEK CLS 200/300 is available with PROFIBUS PA

SITRANS LC 500 is available with HART

Level measurement with contacting Guided Wave Radar

technology:

•SITRANS LG 200

SITRANS LG 200 is available with HART

Most Siemens level measuring instruments offer:

• Meaningful error messages to speed up troubleshooting

• Maintenance timers built into the measuring instrument

for easy changes

• Internal electronics temperature sensor for advance warning before an electronics failure occurs

• Recording of minimum and maximum values of internal

temperature and process variables for easier troubleshooting

• PROFIBUS PA Condensed Status:

- Easy filtering of alarms sent to the operator or mainte-

nance engineer (the right alarm to the right person)

- Full control of all alarms in the measuring instrument.

This lets the user turn off all alarms that do not concern

his respective application

• Enhanced EDDs (electronic device descriptions):

- Harmonized look and feel of different Siemens level

measuring instruments and even of different Siemens

measuring instruments

- Quick-start wizard for easy configuration and fewer

setup errors

- Echo profiles can be stored for faster troubleshooting

Monitoring and diagnostics18

Page 19

© Siemens AG 2011

SITRANS LG200: Guided Wave Radar level measuring instruments

SITRANS LR and LU: Radar and ultrasonic level measuring instruments

Gas analyzers

Siemens offers a wide range of gas analyzers:

• CALOMAT 6/62

Thermal conductivity gas analyzers for determining the

quantity of hydrogen or helium in binary gas mixtures

• FIDAMAT 6

Cumulative measurement of hydrocarbons according to

the flame ionization principle

• OXYMAT 6/61

Gas analyzers for measuring oxygen according to the paramagnetic principle

• OXYMAT 64

Gas analyzers for measuring trace oxygen by means of

ZrO2 sensors

• ULTRAMAT 6

One- and two-channel gas analyzers for highly selective

measurement of infrared-active components

•ULTRAMAT/OXYMAT 6

Combination of OXYMAT 6 and ULTRAMAT 6 in one device

• ULTRAMAT 23

Gas analyzers for measurement of up to three infrared-active components and oxygen

•LDS6

In-situ gas analyzer for the measurement of O2 (+temperature), NH3, HCI, HF, H2O, CO, CO2 and special applications

in flue gas before and after purification. Further applications are possible in the chemical and petrochemical industries, steel production, and cement and paper mills.

•SITRANS SL

New diode laser in-situ gas analyzer for fast, contact-free

measurements; designed for operating in adverse ambient

conditions; consisting of a transceiver unit (sensors) for

each measuring point; comprehensive, integrated monitoring, control and communication functions.

SITRANS LC: capacitive level measuring instruments

Gas analyzers

Monitoring and diagnostics 19

Page 20

© Siemens AG 2011

The gas analyzers have extensive functions for device diagnostics and thus for corrective maintenance. In addition, they

are capable of detecting functional irregularities. These appear as a maintenance requirement or as a failure alarm in the

display of the Maintenance Station, at the signal output, or

they are signaled via PROFIBUS PA/DP to higher-level systems.

The messages are recorded in a logbook.

Possible causes for maintenance requests include:

• Calibration tolerance exceeded due to pollution of measurement chamber, drift or change of the calibration gas

• Use of incorrect test or comparison gas

• Detector defective or comparison gas failed

• Monitoring of external interfering signals, e.g. for sample

preparation for the OXYMAT 6:

- Maximum sample chamber or measuring head tempera-

ture exceeded

- Heating is defective

- Zero or comparison gas contains too much oxygen

- Monitoring of the magnetic field

•For FiIDAMAT 6:

- Combustion gas failure or flame extinguished

• For ULTRAMAT 6 and ULTRAMAT 23:

- Flow monitoring

- Monitoring of the chopper motor

•For LDS6:

- Monitoring of the transmission of the transceiver unit

Process gas chromatography

MAXUM edition II

A universal usable gas chromatograph, which provides numerous analytical options thanks to its modular structure. This

means that widely varying measuring tasks can be implemented using only one device platform. "Parallel chromatography", in which a complex analytical task is divided into several

simple simultaneous measurements, is possible.

MicroSAM

A compact, space-saving gas chromatograph to the fast, discontinuous analysis of gaseous samples. The use of standardized application modules permits the easy replacement of

modules, instead of repair on site.

SITRANS CV

A gas chromatograph specially developed for precisely determining calorific values. Based on the proven microsystem

technology of the MicroSAM and suited for custody transfer.

Process gas chromatography

Analyzer System Management

ASM is a SIMATIC WinCC-based software system that was developed to monitor, validate and conduct performance checks

on various types of analyzers, facilitate maintenance work,

and to record trends.

The complete range of functions of an ASM system encompasses an independent analyzer network and programmable controllers to integrate third-party devices as well as engineering

that allows the customer-specific plant requirements to be displayed in the ASM system. ASM can be integrated on a SIMATIC PCS 7 platform or it can be implemented on its own workstation as an independent solution.

Remote service

The remote service combines process analytics with state-ofthe-art information technology. Thus, various services which

previously required on-site intervention can now be offered

via a data line.

Siemens provides a remote service center, from which the

analyzers can be directly accessed for preventive and corrective measures.

Currently, this service is offered for the MAXUM, MicroSAM

and SITRANS CV gas chromatographs and for the LDS6 diode

laser gas analyzer. For optimal data security, proven mechanisms such as encryption, VPN, or call-back functions are

used.

Comprehensive maintenance and diagnostics information is

made available to the Maintenance Station via an OPC server

or via Modbus.

Monitoring and diagnostics20

Advantages: Significantly improved system availability and efficiency of the analytics with reduced downtimes.

Page 21

© Siemens AG 2011

Monitoring and diagnostics for positioners and valves

SITRANS VP300 and SIPART PS2 are intelligent electropneumatic positioners for control valves and two-position

valves in the process industry. Both devices can be used

very flexibly in various processes.

In addition to the standard function of each positioner, i.e.

controlling process valves, both devices also have comprehensive diagnostic functions, which can indicate critical statuses

of the drive or valve at any time during operation of the plant.

The following functions are available in both devices:

• Slow movement of a valve

• Clogging of a pipeline

• Tear-off of the valve plug

• Wear of the valve seat or valve plug

• Adhesion of the stuffing box

• Partial stroke test for two-position valves

In addition, both devices offer other individual functions for

detecting critical statuses of the control valve:

SITRANS VP300

For detecting positions, the device uses a permanent magnet

on the spindle of the drive and sensors in the interior of the

positioner. If the magnet is physically moved or missing, this

is detected and signaled by the positioner. In addition, the Partial Stroke Test is optionally SIL-certified.

The most important status parameters can be visualized using

a suitable HMI tool (e.g. SIMATIC PDM) both in trend view and

in histogram view.

The benefits of predictive maintenance are based on the fact

that the corresponding components can be used for their entire service life without the risk of failure or damage. The diagnostic functions in SITRANS VP300 and in SIPART PS2 also

help with the early detection of impending damage to the

drive or valve, which can lead to a plant stoppage in the worst

case scenario. Thus, information can be gained from the load

factor, which can be used to optimize the way in which the

plant is operated or for advance maintenance. In total, this

leads to an increase in the availability of the entire plant.

SIPART PS2

In addition to detecting pneumatic leaks, the device is also capable of performing a solenoid valve test. If a suitable solenoid valve is used, it is thus possible to make a reliable statement

about the correct functioning of the connected solenoid valve.

These faults are reported based on their severity and, consequently, the urgency of maintenance they require using the 3stage evaluation scale of the SIMATIC PCS 7 Maintenance Station. The faults are also displayed and analyzed on the on-site

display. Thus, faults can be detected early, long before failures

or even plant stoppages occur.

With regard to preventive maintenance measures, the following values are also monitored and a 3-stage message can

sometimes be output, as described above:

• Operating hours (also differentiated by temperature ranges and adjusting ranges)

• Operating temperature, current and min./max.

• Stroke counter (stroke integral)

• Number of changes in direction

SIPART PS2 and SITRANS VP300 POSITIONERS

SITRANS VP300 and SIPART PS2 offer a standard Partial Stroke Test in order

to extend the maintenance interval of two-position valves

Monitoring and diagnostics 21

Page 22

© Siemens AG 2011

Monitoring and diagnostics of 24 V load feeders

In the process industry, automation components are generally

powered with 24 V DC. With the SITOP PSE 200U selectivity

module, any 24 V load is reliably monitored for overload and

short circuit and in the event of faults it is switched off.

A selectivity module monitors up to 4 load feeders which can

also be connected in sequence following defined periods in

order to offload the power supply. Monitoring currents are adjustable between 0.5 to 3 A and 3 to 10 A. The electronic system allow short current spikes such as making current switching spikes, but longer-lasting overloads or short circuits are

switched off.

If one of the four outputs is switched off, a sum signaling contact is activated and can be evaluated by the higher-level automation system. The service technician recognizes on site

which 24-V feeder is concerned, since each output has a multi-color LED to indicate the current operating status. Besides

fast error detection and localization, this leads to a reduction

of downtimes.

Monitoring and diagnostics of wear in the motor and its vicinity

In the vicinity of motors, there are a number of wear fields: the

power distribution, the motor feeder or converter, the motor

itself, the supply lines, and the machine that the motor drives.

For the user it is of great benefit if routine (visual) inspections

by the servicing personnel, e.g. in order to determine the condition of the main contacts of contactors, can be omitted and

the device can diagnose its own condition.

Condition monitoring records the wear with the aid of measured values which can be used to determine the condition of

the affected components. Thus, depending on this condition,

it is possible to determine the optimal time for maintenance.

Continuous system monitoring allows for intelligent maintenance with the optimized use of maintenance resources. For

the motor environment, Siemens offers a series of condition

monitoring-capable protective devices and switching devices.

Intelligent maintenance with protection and switching

devices

Siemens protection and switching devices are

• Powerful products for industrial controls with comprehensive basic functions and

• Information for condition monitoring.

SITOP PSE200U selectivity module

In these devices, the data or acquisition variables needed for

the basic functions are also used for condition monitoring or

condition monitoring statements can be derived from this data. The devices also have additional analog inputs, to which

special sensors for condition monitoring analyses can be connected (example: SIMOCODE).

Only when a large number of measured values must be recorded or they reach a very high degree of complexity, special devices purely for the purpose of condition monitoring are needed for monitoring bearings or pumps, for example.

Communication capability and integration in the

Maintenance Station

In addition to the condition monitoring capability of the devices, they also have corresponding communication functions

so that they can be optimally integrated into systems and

plants. In addition, they are integrated in the Maintenance

Station as follows:

• Via device ID IM0

• Via driver output for the control of the device condition status

• Via detailed diagnostics of the device condition (devicespecific)

• For devices with an AS-Interface connection, the integration into the Maintenance Station takes place via suitable

SIMATIC S7 communication processors (CPs) or AS-i links

Monitoring and diagnostics22

Page 23

0RWRUIHHGHU

© Siemens AG 2011

Number of overload tripping operations

Overload tripping operations can have different causes. They

can give information about the condition of the machine or

plant, or they can signal an incorrect setting or motor selection. If necessary, the motor size should be changed.

0RWRU

0DFKLQH

HJ

SXPS

G_ST80_XX_00427

Wear fields in the motor environment

Acquisition variables for wear fields

Contact erosion

The contact condition and thus the remaining life time of a

contactor can be determined directly based on the degree of

contact erosion. You can simultaneously use this to make a determination about the condition of the power distribution, the

motor feeder, or the converter.

Number of starts, breaking current

The number of starts or the level of the breaking current indirectly gives you information about the erosion of the switching contacts (empirical values, manufacturer's information). Using empirical values, it is also possible to make statements about the load of the driven machine.

Number of operating hours (with/without limit value)

The runtime effects the wear of the motor and the machine.

The need for maintenance can be determined based on empirical values, user knowledge or manufacturer's information.

Current limit/overload

Gradual changes in the overall application environment such

as pollution or bearing damage can cause increased current

consumption. Preventive maintenance can be planned and

carried out so that faults such as those caused by an overload

can be prevented.

Tem perat ur e

Corresponding sensors in the switchgear environment can

give information about the condition of the contacts. Warming of the ambient air can indicate that the switchgear is too

heavily utilized. One remedy is to avoid simultaneous activations, if applicable. The temperature of the motor or machine

can also indicate wear.

Ground fault or insulation detection

In isolated IT networks, faults can be detected in the motor or

supply line.

Underload/performance measurement

Performance measurements on machines can indicate broken

couplings, torn belts, slippage in the coupling bay, dry running of pumps, or fan filter contamination.

In addition, there is a series of special acquisition variables for

specific components such as pumps and general sensors whose measured values are recorded via analog inputs. In many

cases, the analysis of the described acquisition variables depends on the user's estimation.

Acquisition variables Devices for condition monitoring

SIRIUS comMotor contactor with RLT

Contact erosion; end of service life

Current detection

Performance recording/power factor

Number of starts/breaking current

Number of operating hours

Number of overload tripping operations

Current limit/overload

Tem per atur e

Ground fault detection (int./ext.)

Underload/performance measurement

Maintenance timer

General sensor technology via analog inputs

Acquisition variables which can be provided by Siemens protective devices and control cabinet devices

*

RLT stands for remaining life time monitoring

**

a power contactor is needed to activate the motor

● ●

pact starter

*

3RA6

SIRIUS motor

starter M200D

● ● ●

● ● ●

● ● ●

● ● ●

● ● ●

● ●

3RW44 soft

starter

● ●

SIMOCODE pro

**

3UF7

●

●

●

●

Monitoring and diagnostics 23

Page 24

Overview device functions

Motor contactor with RLT

SIRIUS compact starter and

infeed system for 3RA6

SIRIUS motor starter M200D

– innovative solution for distributed drive technology

3RW44 soft starter

SIMOCODE pro 3UF7

© Siemens AG 2011

■

Tried and tested SIRIUS technology

■

3 sizes S6, S10, S12 (55 to 250 kW at 400 V)

■

Can be used up to 60 °C without derating

■

Long electrical service life

■

Replaceable main current contacts

■

LED display of the remaining life time of the main current

contacts (60%, 40%, 20%)

■

With 20% or less remaining life time, a message is sent via

AS-Interface

■

Connection via AS-Interface

■

Compact starter up to 32 A as direct and reversing starter,

45/90 mm wide

■

Only one weld-free clearance, instead of circuit breaker,

contactor, and overload relay

■

Electronic trigger with wide setting range 1:4 (5 versions)

■

Integrated overload function with differentiated fault message

■

Infeed system up to 70 mm² and 100 A

■

Connection via AS-Interface

■

Degree of protection IP65 allows application-oriented setup

without a control cabinet

■

Protects, switches, and monitors the motor and application

■

Parameterization via STEP 7 HW Config

■

Connection to AS-i, PROFIBUS, and PROFINET

■

Little variance for all motor starter versions

■

Manual operation and main switch are integrated

■

Electronically controlled start-up and coasting of asynchronous motors

■

Integrated jumper contact system

■

Integrated motor overload intrinsic device protection

■

Adjustable current limiting

■

Integrated status and fault monitoring

■

Torque control

■

Integrated braking function (superimposed DC braking)

■

Compact design

■

5 sizes for the power range from 15 to 710 kW

■

Recording the active power

■

Connection via PROFIBUS

■

Intelligent connection of distributed drives to the control level

■

Autonomous function without PLC or bus

■

Comprehensive monitoring functionality

■

Graphical parameterization

■

Analog inputs/outputs for application monitoring

■

Integrated inputs/outputs for motor and application monitoring

■

Can be used for all motor applications

■

Flexible motor management system with integrated protection, control and monitoring functions

■

Intelligent pre-processing is possible

■

Modularly expandable system

■

Outputs for activating motor contactors

■

Connection via PROFIBUS

■

can also be used for safety functions (locally or via PROFIsafe)

Monitoring and diagnostics24

Page 25

© Siemens AG 2011

Monitoring and diagnostics of drive components

Diagnostics of drives

Hardly any other group of products influences plant availability as much as drive engineering. Production comes to a standstill when these products fail. Such unscheduled plant downtimes cause expensive production outages, unplanned repairs, and frequently consequential damage.

This is the reason why all drive systems and frequency converters of the SINAMICS, MASTERDRIVES and MICROMASTER ranges with their associated motors are integrated into the

SIMATIC PCS 7 Maintenance Station. This results in the common, uniform presentation of maintenance-relevant information which permits preventive and prognostic maintenance

strategies.

The components report autonomously that maintenance is required One example are the medium-voltage converters such

as SINAMICS GM150. For instance, by means of a differential

pressure procedure the degree of contamination of the dust

filters is determined.

In the water-cooled version, the analog conductivity measurement continuously monitors operation of the ion exchanger

and outputs an early-warning message when the exchange

capacity decreases. The operating fans for air cooling and the

pumps for water cooling are equipped with operating hour

counters that recommend checking of components on reaching a certain number of operating hours.

Status assessment of high-voltage machines

An established procedure for assessing the condition of

high-voltage machines is partial-discharge diagnostics (PD)

which is carried out as an offline or online measurement

depending on the application. This is an important measure within reliability-based maintenance strategies for large

drives.

In order to measure the PD signals, as an option the patented "SIEMENS Insulator Integrated Coupling Units" can be

installed in high-voltage motors at the factory.

The post insulators in the terminal box are simply replaced

by the Insulator Integrated Coupling Units. This results in

decisive benefits:

■ Simple, low-cost installation

■ No change in terminal box necessary

■ Rugged mechanical design

■ Highest and tested safety of the insulation distances

■ Direct interface to condition diagnostics

The CM 240NE chemistry module can be used in connection

with the SINAMICS G120 Control Unit CU 240S DP-F. The chemistry module includes a terminal strip that meets the

NAMUR specifications and thus the essential requirements of