Page 1

TPS3 09

Surge Protective Device

User Manual

Page 2

V

WARNING -

Hazardous Voltage & Shock Hazard

Failure to Follow These Instructions Could Result in Death or Serious Injury

• Only qualified licensed electricians should install or service SPDs

• Hazardous voltages exist within SPDs

• SPDs should never be installed or serviced when energized

• Use appropriate safety precautions including Personal Protection Equipment

• Failure to follow these instructions can result in death, serious injury, and/or equipment damage.

• This manual shall be read in entirety prior to installing

Bonding and Grounding Hazard

Verify that the neutral conductor in the service entrance equipment is bonded to ground in accordance with the National

Electrical Code (NEC®) and all applicable codes.

Verify that the neutral terminal (XO) on the secondary side of distribution transformers are grounded to the system ground

in accordance with the NEC® and all applicable codes.

During installation into an electrical system the SPD must not be energized until the electrical system is completely installed,

inspected and tested. All conductors must be connected and functional including the neutral (if required). The voltage

rating of the SPD and system must be veried before energizing the SPD.

Failure to follow these guidelines can lead to abnormally high voltages at the SPD. This may cause the SPD to fail. The

warranty is voided if the SPD is incorrectly installed and/or if the neutral conductor in the service entrance equipment or

downstream of separately derived systems is not bonded to ground in accordance with the NEC®.

Do Not Hi-Pot Test SPDs

Any factory or on-site testing of power distribution equipment that exceeds normal operating voltage such as

high-potential insulation testing, or any other tests where the suppression components will be subjected to higher voltage

than their rated Maximum Continuous Operating Voltage (MCOV) must be conducted with the SPD disconnected from the

power source. For 4-wire systems, the neutral connection at the SPD must also be disconnected prior to performing highpotential testing and then reconnected after test completion.

Failure to disconnect SPD and associated components during elevated voltage testing will damage the SPD and will void

the warranty.

Page 3

Introduction

Figure 1: SPD Types

Thank you for choosing the Siemens TPS3 09 Surge Protective Device

(SPD). TPS3 09 is a high quality, high energy surge suppressor designed

to protect sensitive equipment from damaging transient overvoltages.

The TPS3 09 is parallel connected such that circuit ampacity is

unlimited. Proper installation is important to maximize performance.

Please follow steps outlined herein. These instructions are not intended

to replace national or local codes. Follow all applicable electrical codes

to ensure compliance.

WARNING -

V

• Only qualified licensed electricians should install or service

SPDs

• SPDs should never be installed or serviced when energized

or during electrical storms

• Use appropriate safety precautions including Personal

Protection Equipment

• Failure to follow these instructions can result in death,

serious injury, and/or equipment damage

• When used in outdoor applications, customer must seal

the conduit nipple using watertight fittings (not included)

to ensure a watertight connection

• Read this manual in entirety prior to installing

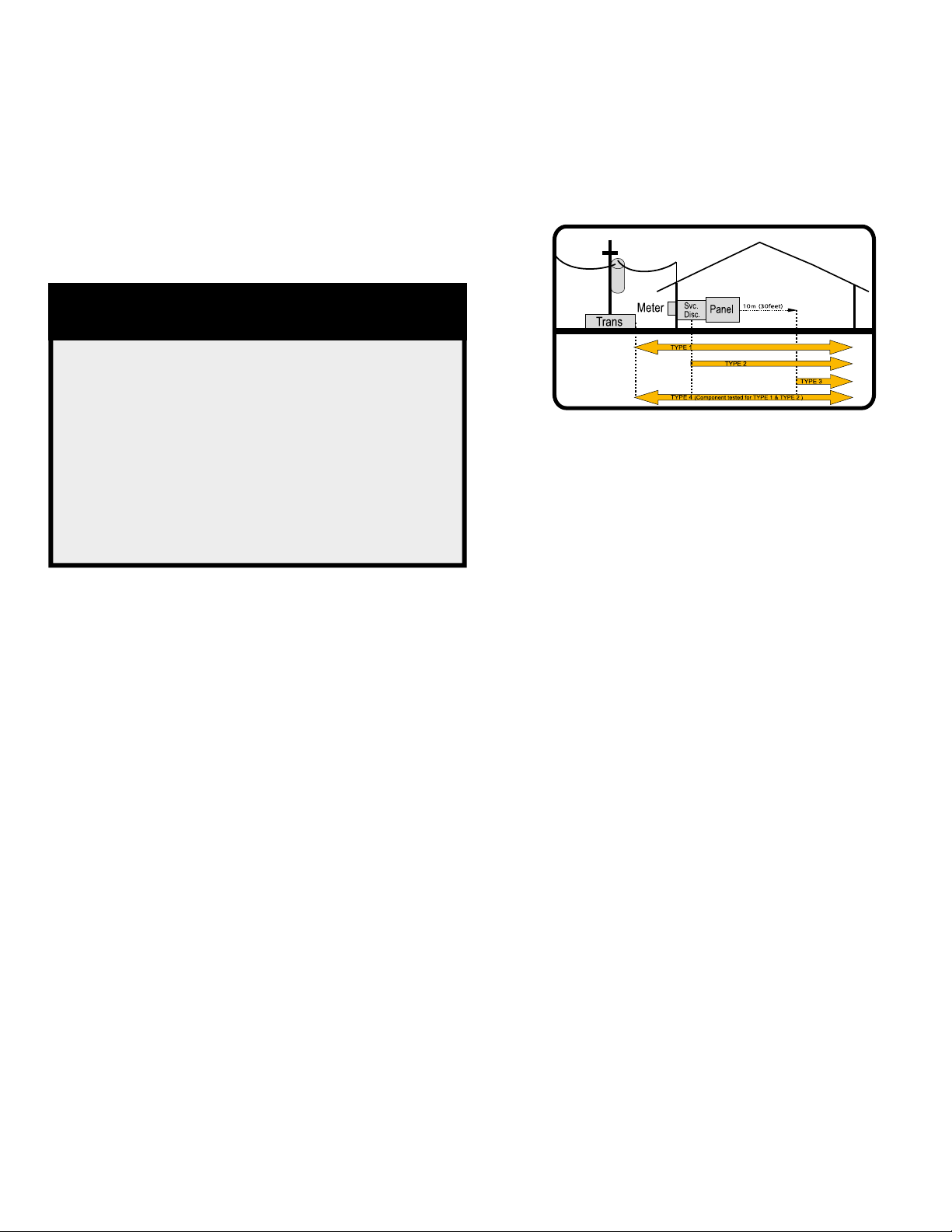

Industry Standards Changes - 2009

UL 1449 Third Edition and 2008 NEC® Article 285 generated substantial

changes.

• The term TVSS changed to SPD

• Types 1, 2, 3 & 4 SPDs are created

• UL 1449 clamping voltage performance testing changed from

500A to 3,000A

• UL 1449 added new I nominal testing (In), which consists of more

rigorous duty-cycle testing

The SPD Type category is important to understand before installing

any SPD. Type 1 and 2 SPDs are fully UL Listed devices whereas Type

4 SPDs are UL Recognized devices.

Type 1 – Installed on line or load side of the Main Overcurrent

Protection (OCP), similar to what you knew as SSA, except now includes

rigorous safety testing. Includes all OCP & safety disconnectors inside

the SPD

Type 2 – Installed on load side of the Main OCP, similar to what you

know as hardwired SPD, and it may require external OCP.

Type 3 – Point of Utilization, direct plug in type devices, similar to what

you know as surge strips. Theses devices are intended for installation

10 meters from the panel (rational based on IEEE Cat. A location).

Type 4 – Surge suppression components, could be a basic component

or a complete module. Type 4 components can be tested for Type 1,

Type 2 or Type 3 applications.

Hazardous Voltage & Shock Hazard

2008 NEC Art 285 & UL 1449-3

SPD Types: Types 1, 2, 3, & 4

Based on Location within electrical distribution system

(also coincides with ANSI/IEEE C62.41.2 - 2002 Categories C, B &A)

For further information, please review latest editions of NEC® Art. 285,

UL 1449, contact your local Siemens sales ofce or contact Siemens

TPS Tech Support at 1.888.333.3545.

The TPS3 09 is a Type 1 SPD. Type 1 SPDs are evaluated more rigorously

by UL 1449 for 2008 NEC® Article 285 compliance. Type 1 SPDs and

their connecting leads have been evaluated for line side applications

without need for supplemental overcurrent protection. Type 1 SPDs

include internal overcurrent protection. As a generalization, there are

practical maintenance reasons for installing on the load side of the main

overcurrent device (i.e. Type 2 installation). When connected on load

side of main disconnect, a 30A circuit breaker is recommended due to

10 AWG conductors. The circuit breaker serves as a disconnecting device

and provides NEC® imposed short circuit protection to the conductors

in Type 2 or 4 applications.

Simplified Explanation of Operation

SPDs sense overvoltage and create a momentary short circuit to redirect

harmful surge energy to earth ground. SPD’s are not a one time device.

They reset automatically and wait for the next surge. SPDs are capable

of repeating this function thousands of times.

Parts List and Inspection

Items included in the package consist of the following:

• 1 TPS3 09 SPD including 3’ (1~m) conductors

• 1 User’s Manual (this document)

If the Flush Mount Kit was ordered , additional parts are supplied as

follows:

• 1 Flush Mount Plate

• 4 Mounting Screws

Page 4

Carefully inspect each item in the package for signs of damage. If

damage is found, please contact Siemens TPS Technical Support:

1.888.333.3545. For more information about this product or other

Siemens products, visit www.usa.siemens.com.

Figure 2: Dimensions and Weight

3.00

1.50

1.08

CAUTION

Phase Indicators

On-Full Protection

HAZARDOUS VOLTAGE

Disconnect all power supplying this equipment before replacing.

Failure to do so will result in death or serious injury.

Off-No Proection

DANGER

TPS3 03’s have demonstrated 200kA Short Circuit Current Ratings

(SCCR) including leads (120/240V Split phase models have 100kA

SCCRs). See UL Label markings on SPD or see Data Sheet for specs for

verification. Supplemental overcurrent protection is not required to

protect this SPD. However, NEC® convention requires that connecting

conductors have overcurrent protection in Type 2 or 4 applications.

Follow applicable codes.

This device features internal overcurrent and overtemperature

protection that will disconnect effected surge suppression components

at the end of their useful life, but will maintain power to the load – now

unprotected. If this situation is undesirable for the application, follow

these instructions for replacing the device. TPS3 09 is ultrasonically

welded closed and contains no user serviceable parts.

Table 2: Specifications

Specifications

Temperature Operating -40oC (-40oF) to 60oC (+140oF)

o

Temperature Storage -55

Wire Size & Installation Torque 10 AWG; 18 inch-pounds

Appropriate Circuit Breaker

based on conductor size

NEMA 250 Enclosure Rating

C (-67oF) to 65oC (+149oF)

30A (SPD includes internal OCP)

Type 4X with appropriate

sealing & sealing condulets

Voltage Rating & Application

Before installing SPD, verify the nameplate voltage has the same

voltage rating as the power distribution system. If unsure, call

Siemens TPS Tech Support at 1.888.333.3545 before proceeding. The

SPDs specifier or user should be familiar with the configuration and

arrangement of the power distribution system. The system is defined

by how the secondary windings of the transformer supplying the

service entrance main or load are conFigured. This includes whether or

not the transformer windings are referenced to earth via a grounding

conductor. The system configuration is not based on how any specific

load or equipment is connected to a particular power distribution

system. SPDs should be installed per the distribution system, not per

a load or motor’s wiring connection.

For example, suppose a 480V three phase motor appears to be

connected as a 480V Delta. In actuality, the serving distribution

system might be a 480Y/277V grounded Wye, with or without a

neutral pulled to the motor or MCC. The system is still a 480Y/277V

Wye, even though the load is connected as a Delta. A grounded Wye

has a defined reference to ground (i.e., neutral is bonded to ground).

In contrast, some Delta systems are ungrounded, which have no

reference to ground.

Table 2: Model Number Decoder

Model

Voltage

Code

Service Voltage

TPS3A09 A 240/120V 1Ø, 3W Plus Ground,

TPS3B09 B 240/120V 3Ø, 4W Plus Ground High Leg Delta

TPS3C09 C 208Y/120V 3Ø, 4W Plus Ground

TPS3D09 D 240V 3Ø, 3W Plus Ground

TPS3E09 E 480Y/277V 3Ø, 4W Plus Ground

TPS3F09 F 480V 3Ø, 3W Plus Ground

TPS3G09 G 600V 3Ø, 3W Plus Ground

TPS3K09 K 380Y/220V 3Ø, 4W Plus Ground

TPS3L09 L 600Y/347V 3Ø, 4W Plus Ground

TPS3S09 S 400Y/230V 3Ø, 4W Plus Ground

SPDs on Ungrounded Systems

Caution – Ungrounded systems are inherently unstable and can

produce excessively high line-to-ground voltages during certain fault

conditions. During these fault conditions, any electrical equipment

including an SPD, may be subjected to voltages which exceed their

designed ratings. This information is being provided to the user so

that an informed decision can be made before installing any electrical

equipment on an ungrounded power system.

Page 5

V

CAUTION

CONDUCTING DIELECTRIC AND/OR

HI-POTENTIAL TESTING WILL CAUSE

INTERNAL DAMAGE TO TPS3 UNIT.

Do not perform dielectric or high potential

tests with the TPS3 unit installed.

TPS3 09 Installation Instructions

Pre-Plan your installation. You need to accomplish the following:

• Meet all National and Local codes (NEC® Article 285 and UL

1449 address SPDs)

• Confirm System voltage to SPD voltage (120V SPD will fail

instantly on 240V, 277V, etc.)

• Mount SPD as close to panel or equipment as possible to keep

leads short (long leads hurt performance substantially)

• Ensure leads are as short and straight as possible, including

neutral and ground. If using a breaker, use a breaker position

that is close to the SPD and the panel’s neutral & ground

• If using a breaker, recommended breaker size is 30A due to

10 AWG conductor

• Make sure system is grounded per NEC

before energizing SPD (inadvertent system problem may fail

SPD).

• Never Hi-Pot test Any SPD (will prematurely fail SPD)

• Do not install the TPS3 09 through the bottom of a NEMA

3R pan el. Drippi ng water will prem ature ly fail the SPD.

1. Use voltmeter to check voltages and ensure correct SPD. See Data

Sheet for specs & wire-outs

2. Determine Mounting location – weather resistant equipment

may be required

3. If SPD has optional Dry Contact and Flush Mount Kit, pre-plan

their installation. See Figures 4&6. (If flush mounting, be careful

to not drop SPD into wall)

4. Remove power from panel/source. Confirm panel/source is

deenergized.

5. Identify breaker location and SPD location. Position SPD such that

LEDs are best visible.

6. Mount SPD – weather resistant applications require additional

sealing, o-rings, etc. (not included)

- Remove an appropriately sized knockout from panel.

- Connect conductors as appropriate – short and straight as possible

(Hi-Legs are Phase B)

- Note that the metallic connection hub is not grounded within the SPD

and proper grounding requires connection of the green conductor

ground.

7. Label or mark conductors as appropriate (neutral: white, ground:

green, energized: black, hi-leg: orange)

8. Make sure system is bonded per NEC

faults before energizing (N-G bonding not per NEC

#1 cause of SPD failures)

9. Energize and confirm proper operation of green LED indicators

and/or options.

®

and clear of faults

®

and is clear of hazards or

®

will fail SPDs:

V DANGER

Hazardous voltage.

Will cause death or serious injury.

Keep Out.

Qualied personnel only.

Disconnect and lock off all power before

working on this equipment.

• Use closest breaker to SPD

B C

A

BREAKER

GN

Figure 4: Typical Flush Mount Installation

Mounting Surface

Mounting Screws

(4 places, through mountingplate into mounting

surface, screws not provided)

Removed Material

Flush Mount Plate

Flush Mount Kit Screws

(8-32 x 5/8” Thread Cutting, 4 places, through

plate into SPD)

Figure 5: Lead Lengths

Leads: Short & Straight

Cut Excess; Do Not Coil or Loop

• Locate SPD close to intended

breaker

• Keep Leads Short as Possible

• Avoid Sharp Bends

X

Not

Good

p

Good

SPD

Phase, Ground,

and Neutral Wires

• CUT OFF EXCESS

LENGTH

• DO NOT LOOP OR

COIL

• SHORT &

STRAIGHT

Page 6

Connecting Optional Form C Dry Contact & Audible Alarm

(“D” suffix near end of model number)

CONNECTING TO OPTIONAL REMOTE INDICATOR IF EQUIPPED

(“E” SUFFIX NEAR END OF MODEL NUMBER)

Three (3) 3’ (~1m) 18 AWG wires are included through the nipple with

this option. (These are smaller than the 10 AWG SPD conductors.)

Gray is Common, Red is Normally Open and Blue is Normally Closed.

(We generally recommend the Normally Closed configuration because

it detects disconnected or failed wiring whereas normally open does

not.)

If the dry contacts are not utilized, insulate lead ends, coil and secure.

Audible alarm will still function correctly.

The contact is rated 250V, 5A. Higher energy applications require

supplemental relaying. This option monitors suppression element

condition and is not intended for use as phase loss or phase detection

monitoring.

Normal Operation

Green LED Indicators

Each phase’s LED Indicator illuminates when the SPD is energized

and operating correctly. Every suppression element is monitored and

connected by logic to the LED. Should any suppression element fail,

the green LED will extinguish.

Form C Dry Contact and Audible Alarm Option

Similar to the Green LEDs above, the dry contact will change state and

the audible alarm will sound upon suppression element failure. The

audible alarm may be silenced by removing power to the SPD.

Figure 6: Dry Contact

This option includes a supplemental diagnostic LED that can be

mounted in a conspicuous location. For example, assume that the

SPD is mounted such that it is not readily visible. A Remote Indicator

can provide visual indication of correct operation.

Operation is straightforward: Green LED On = SPD is OK. If the LED is

out, the SPD has failed; power is not present, or one or more phases

are not energized.

The Green LED assembly includes two pre-attached wires and two

butt-splice connectors. The SPD includes two yellow 18 AWG wired,

pre-wired through the SPD’s nipple mounting connection.

Pre-Plan the installation per normal Installation Instructions. Note that

the LED assembly and butt-splice connectors are not weather resistant

and should be protected accordingly.

Mount the LED assembly in an appropriate conspicuous location. Drill

a 1/4” diameter hole at the mounting location. Remove the hex nut

from the back side of the LED assembly and feed the LED indicator

wires through the hole. Install the hex nut.

Butt-splice the wires (polarity does not matter) from the LED wiring

assembly to the yellow SPD wires by inserting one end of each LED

wiring assembly lead into the butt-splice (supplied). Squeeze the metal

contact of the butt-splice downward. Ensure the wires cannot be pulled

out of the butt-splice. Fold the cover of the butt-splice over the metal

contact until the cover of the butt-splice latches to the bottom portion

of the butt-splice.

• Normally Closed (suggested):

Use Gray and Blue

• Normally Open:

Use Gray and Red

Power Leads

Blue Normally Closed

Gray Common

Red Normally Opened

Blue

Dry Contact Leads

Grey

Red

The enclosed label should be placed under the LED for reference. Plan

your installation for adequate label space.

After installation, test the Green LED by energizing, then deenergizing

the SPD, and verifying that the LED turns on and off appropriately. An

alternate test is to deenergize just one phase.

6

Page 7

V

CONDUCTING DIELECTRIC AND/OR

HI-POTENTIAL TESTING WILL CAUSE

INTERNAL DAMAGE TO TPS3 UNIT.

Do not perform dielectric or high potential

CAUTION

tests with the TPS3 unit installed.

V DANGER

Hazardous voltage.

Will cause death or serious injury.

Keep Out.

Qualied personnel only.

Disconnect and lock off all power before

working on this equipment.

Maintenance

SPDs require minimal maintenance. Periodic inspection of diagnostic

indicators is recommended to ensure proper operation.

Troubleshooting & Service

Please contact us for any service related issues.

Quality SPDs withstand severe duty and attempt to protect the

load until failure. There are electrical anomalies that SPDs cannot

protect against. These are generally Sustained Overvoltages also

known as Temporary Overvoltages (TOVs). In this context, Sustained

Overvoltages may be only a few cycles. Failed SPDs tend to be

symptoms, not root causes. A failed SPD is usually a sign of other

problems within the electrical distribution system. As a generalization,

the single largest cause of SPD failures is reference to ground issues.

If the SPD shows problems on startup, there is reasonable chance of

bonding/grounding/misapplication issue. This permanently damages

the unit. If not corrected, it will happen again.

Warranty and Customer Service

Limited Warranty

Siemens warrants its AC Panel protection products against defective

workmanship and materials for 10 years. Liability is limited to the repair

or replacement of the defective product at Siemens’ option. A Return

Material Authorization number (RA#) must be given by the company

prior to the return of any product. Returned products must be sent

to the factory with the transportation charges prepaid. In addition,

the company also warranties unlimited replacement of modular and

component parts within the warranty period previously described.

The company specically disclaims all other warranties, expressed or

implied. Additionally, the company is not be responsible for incidental

or consequential damages resulting from any defect in any product or

component thereof.

The sales contract contains the entire obligation of Siemens. This

instruction manual shall not become part of or modify any prior existing

agreement, commitment or relationship.

Technical Support

1.888.333.3545

Prior to calling Siemens TPS3 Technical Support for assistance or ordering

parts, please have the following information available:

TPS3 model number: ________________________________

Manufacture date: _________________________________

Date of Purchase: ___________________________________

Your order number: _______________________________

Return Shipment Address:

Siemens - Attn: RA #___________

14550 58th Street North

Clearwater, FL 33760

Clearwater, FL 33760

7

Page 8

Siemens Industry, Inc.

Building Technologies Division

5400 Triangle Parkway

Norcross, GA 30092

1-800-964-4114

info.us@siemens.com

12.09.09 #8173

Loading...

Loading...