TPS3 Internal Manual

Surge Protective Device

User Manual - CANADA

V DANGER

Hazardous voltage.

Will cause death or serious injury.

Keep Out.

Qualied personnel only.

Disconnect and lock off all power before

working on this equipment.

• Only qualified licensed electricians should install or service SPDs

• Hazardous voltages exist within SPDs

• SPDs should never be installed or serviced when energized

• Use appropriate safety precautions including Personal Protection Equipment

• Failure to follow these instructions can result in death, serious injury, and/or equipment damage.

• This manual shall be read in entirety prior to installing

NOTICE

CONDUCTING DIELECTRIC AND/OR

HI-POTENTIAL TESTING WILL CAUSE

INTERNAL DAMAGE TO TPS3 UNIT.

Do not perform dielectric or high potential

tests with the TPS3 unit installed.

Bonding and Grounding Hazard

Verify that the neutral conductor in the service entrance equipment is bonded to ground in accordance with the National

Electrical Code (NEC®) and all applicable codes.

Verify that the neutral terminal (XO) on the secondary side of distribution transformers are grounded to the system ground

in accordance with the NEC® and all applicable codes.

During installation into an electrical system the SPD must not be energized until the electrical system is completely installed,

inspected and tested. All conductors must be connected and functional including the neutral (if required). The voltage

rating of the SPD and system must be verified before energizing the SPD.

Failure to follow these guidelines can lead to abnormally high voltages at the SPD. This may cause the SPD to fail. The

warranty is voided if the SPD is incorrectly installed and/or if the neutral conductor in the service entrance equipment or

downstream of separately derived systems is not bonded to ground in accordance with the NEC®.

Do Not Hi-Pot Test SPDs

Any factory or on-site testing of power distribution equipment that exceeds normal operating voltage such as

high-potential insulation testing, or any other tests where the suppression components will be subjected to higher voltage

than their rated Maximum Continuous Operating Voltage (MCOV) must be conducted with the SPD disconnected from the

power source. For 4-wire systems, the neutral connection at the SPD must also be disconnected prior to performing highpotential testing and then reconnected after test completion.

Failure to disconnect SPD and associated components during elevated voltage testing will damage the SPD and will void

the warranty.

Table of Contents

Introduction .......................................................................................................................... 1

Warning & Safety Information............................................................................................................................................1

Qualified Person ................................................................................................................................................................1

Danger..............................................................................................................................................................................1

Notice ...............................................................................................................................................................................1

Do Not Hi-Pot Test SPDs .....................................................................................................................................................1

Limited Warranty ...............................................................................................................................................................1

Unpacking & Preliminary Inspection...................................................................................................................................1

Storage .............................................................................................................................................................................1

Industry Standards Changes - 2009 ...................................................................................................................................2

Equipment Performance ....................................................................................................................................................2

Voltage Rating ..................................................................................................................................................................2

General Information ..............................................................................................................4

Precautionary Statement Regarding SPDs on Ungrounded Systems ....................................................................................4

Overcurrent Protection ......................................................................................................................................................4

System Grounding.............................................................................................................................................................4

Environment .....................................................................................................................................................................4

Audible Noise ....................................................................................................................................................................4

Dead Front Modification Instruction Changes for P1 SPD ....................................................................................................4

P1 Dead Front Knockout Plate Removal Instructions ...........................................................................................................4

TPS3 01 Installation Instructions for: Lighting Panelboards Original P1, P2, P3 ................... 5

Internal Phase Labeling Connections .................................................................................................................................5

TPS3 01 Installation Instructions for: 400/600 Amp S1/S2 & All SE Panels .............................. 6

Internal Phase Labeling Connections .................................................................................................................................6

TPS3 02 Installation Instructions for: Lighting Panelboards Revised P1 ............................... 7

Internal Phase Labeling Connections .................................................................................................................................7

TPS3 05 and TPS3 06 Module Replacement Instructions ..................................................... 9

TPS3 01 and TPS3 06 Module Installation Instructions: MCC ............................................. 10

UL 1283 Required Language Concerning the Installation of EMI Filters .............................................................................10

W Option Suffix: .............................................................................................................................................................10

Operation ............................................................................................................................11

TPS3 Control & Diagnostic Display Panel ..........................................................................................................................11

Display Panel with Surge Counter Option .........................................................................................................................11

Dry Contacts Feature .......................................................................................................................................................11

Maintenance ....................................................................................................................... 12

Troubleshooting & Service ...............................................................................................................................................12

Abnormal N-G Voltage Indicators .....................................................................................................................................12

Module Replacement & Service .......................................................................................................................................12

Display Replacement .......................................................................................................................................................12

Preventive Maintenance (Inspection &Testing) .................................................................................................................12

Corrective Maintenance (Repair) ......................................................................................................................................12

Technical Support ...........................................................................................................................................................12

Figures

Figure 1: SPD Types ..........................................................................................................................................................2

Figure 2: Dead Front Modification Instruction ...................................................................................................................4

Figure 3: 250 AmpMax P1 Panels ......................................................................................................................................5

Figure 4: 400/600 Amp S1/S2 and all SE Panels - TPS3 01 Unit with the NK Accessory Kit ..................................................6

Figure 5: 250 Amp Max Revised P1 Panels .........................................................................................................................7

Figure 6: SPD & Neutral Riser Connection Details for Revised P1 Panels .............................................................................8

Figure 7: P4, P5 and Front Connected Distribution Switchboards .......................................................................................9

Figure 8: Service Section Switchboards and Low Voltage Switchgear .................................................................................9

Figure 9: Installation in an MCC ......................................................................................................................................10

Figure 10: Basic Display - Horizontal ...............................................................................................................................11

Figure 11: Basic Display - Vertical ...................................................................................................................................11

Figure 12: Dry Contact Connection Configuration ...........................................................................................................11

Tables

Table 1: Type Designations ...............................................................................................................................................2

Table 2: Model Number Decoder .......................................................................................................................................3

Table 3: Contents for Installation in Lighting Panelboards Type P1, P2, P3 ..........................................................................5

Table 4: Contents for Installation in 400/600 Amp S1/S2 and all SE Panels .........................................................................6

Table 5: Content for Installation in Lighting Panelboards Revised P1 ..................................................................................7

Introduction

Thank you for choosing Siemens TPS3 Surge Protective Device (SPD).

This is a high quality, high energy surge suppressor designed to protect

sensitive equipment from damaging transient overvoltages.

Proper installation is important to maximize performance. Please follow

the steps outlined herein.

These instructions do not purport to cover all details or variations in

equipment, nor to provide for every possible contingency to be met in

connection with installation, operation or maintenance. Should further

information be desired or should particular problems arise which are

not covered sufficiently for the purchaser’s purposes, the matter should

be referred to the local Siemens sales office.

Do Not Hi-Pot Test SPDs

This entire user manual should be read prior to beginning installation.

These instructions are not intended to replace national or local codes.

Follow all applicable electrical codes to ensure compliance. Installation

of this SPD should only be performed by qualified electrical personnel.

All Siemens SPDs are extensively tested in accordance with industry

standards such as ANSI/IEEE C62.41.1, C62.41.2, C62.45, C62.62,

C62.72, UL 1449, UL 1283, IEC 61643, etc.

Warning & Safety Information

This equipment contains hazardous voltages. Death, serious injury,

or property damage can result if safety instructions are not followed.

Only qualified personnel should work on or around this equipment

after becoming thoroughly familiar with all warnings, safety notices,

and maintenance procedures contained herein.

The successful and safe operation of this equipment is dependent upon

proper handling, installation, operation, and maintenance.

Qualified Person

For the purposes of this manual and product labels, a QUALIFIED

PERSON is one who is familiar with the installation, construction, and

operation of this equipment, and the hazards involved. In addition, he

or she has the following qualifications:

(a) Is trained and authorized to energize, deenergize, clear,

ground and tag circuits and equipment in accordance with

established safety practices.

(b) Is trained in the proper care and use of personal protective

equipment (PPE) such as rubber gloves, hard hat, safety

glasses or face shields, flash clothing, etc. in accordance with

established safety practices.

(c) Is trained in rendering first aid.

Any factory or on-site testing of power distribution equipment that

exceeds normal operating voltage such as high-potential insulation

testing, or any other tests where the suppression components

will be subjected to higher voltage than their rated Maximum

Continuous Operating Voltage (MCOV) must be conducted with

the SPD disconnected from the power source. For 4-wire systems,

the neutral connection at the SPD must also be disconnected prior

to performing high-potential testing and then reconnected after

test completion.

Failure to disconnect SPD and associated components during

elevated voltage testing will damage the SPD and will void the

warranty.

Limited Warranty

Siemens warrants its AC Panel protection products against defective

workmanship and materials for 10 years. Liability is limited to the repair

or replacement of the defective product at Siemens’ option. A Return

Material Authorization number (RA#) must be given by the company

prior to the return of any product. Returned products must be sent

to the factory with the transportation charges prepaid. In addition,

the company also warranties unlimited replacement of modular and

component parts within the warranty period previously described.

The company specifically disclaims all other warranties, expressed or

implied. Additionally, the company is not responsible for incidental or

consequential damages resulting from any defect in any product or

component thereof.

The sales contract contains the entire obligation of Siemens. This

instruction manual shall not become part of or modify any prior existing

agreement, commitment or relationship.

Unpacking & Preliminary Inspection

Danger

For the purposes of this manual and product labels, DANGER indicates

an imminently hazardous situation, which, if not avoided, will result

in death or serious injury.

Notice

For the purposes of this manual and product labels, NOTICE indicates

a potentially hazardous situation which, if not avoided, could result in

damage to the equipment but does not create a potential for personal

injury.

1

Inspect the entire shipping container for damage or signs of mishandling

before unpacking the unit. Remove the packing material and further

inspect the unit for any obvious shipping damages. If any damage was

found and is a result of shipping or handling, immediately file a claim

with the shipping company and forward a copy to your local Siemens

sales office.

Storage

The unit should be stored in a clean, dry environment. Storage

temperature is -55ºC (-67ºF) to +85ºC (+185ºF). Avoid exposing the

unit to areas of high condensation. All of the packaging materials

should be left intact until the unit is ready for installation. If the unit

has been stored for an extended period of time, it may be necessary

to clean the unit and make a complete inspection of the unit prior to

installing and placing into service.

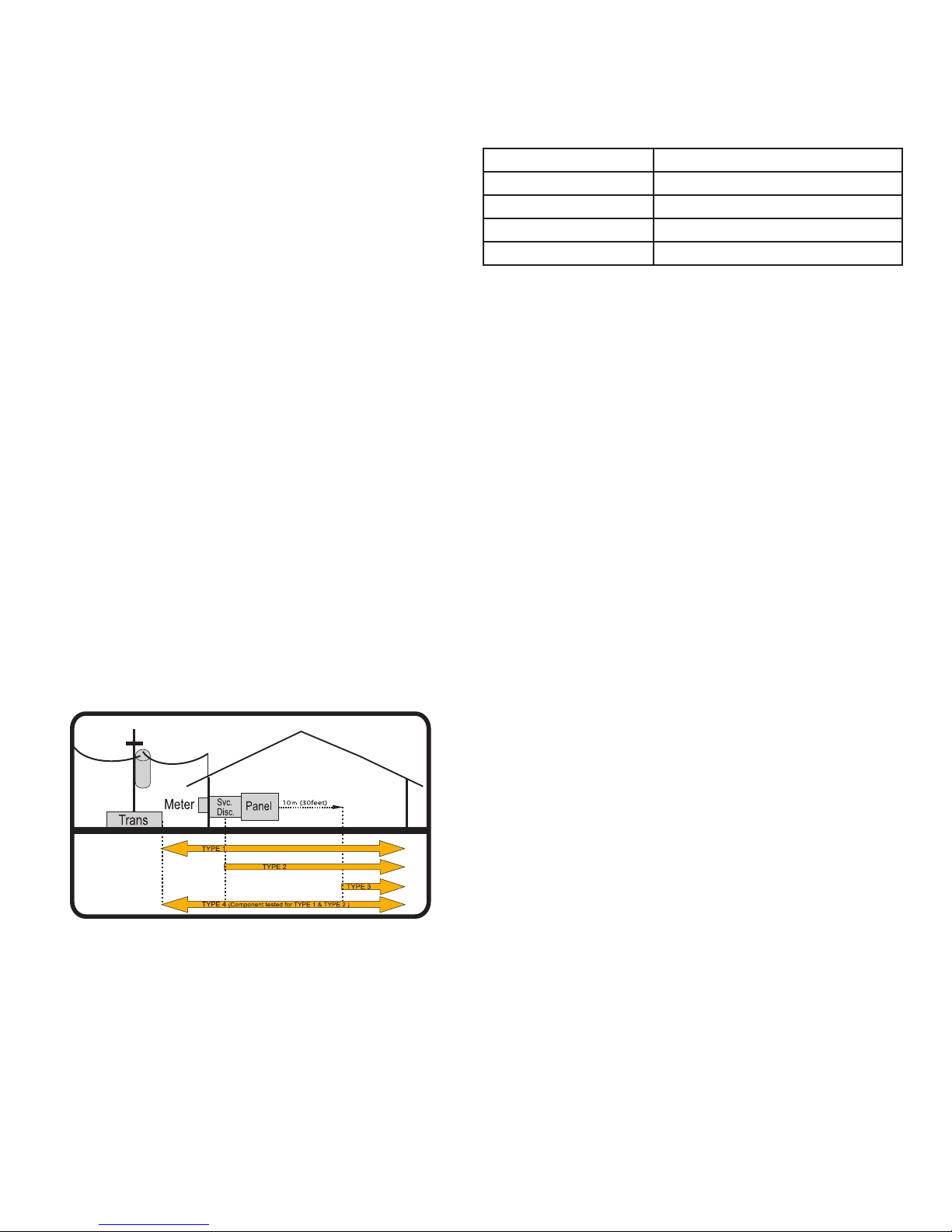

Industry Standards Changes - 2009

Siemens TPS3 SPDs have the following Type designations

UL 1449 Third Edition and 2008 NEC® Article 285 generated substantial

changes.

• The term TVSS changed to SPD

• Types 1, 2, 3 & 4 SPDs are created

• UL 1449 clamping voltage performance testing changed from

500A to 3,000A

• UL 1449 added new Nominal Discharge Current testing (I nominal,

or In), which consists of more rigorous duty-cycle testing

The SPD Type category is important to understand before installing

any SPD. Type 1 and 2 SPDs are fully UL Listed devices whereas Type

4 SPDs are UL Recognized devices.

Type 1 – Installed on line or load side of the Main Overcurrent Protection

(OCP), similar to obsolete products known as Secondary Surge Arrestors,

except now includes rigorous safety testing. Includes all OCP & safety

disconnectors inside the SPD.

Type 2 – Installed on load side of the Main OCP, similar to previous

products known as TVSS. May or may not require external OCP.

Type 3 – Point of Utilization, direct plug in type devices, surge strips,

etc. Theses devices are intended for installation 10 meters from the

panel (rationale based on IEEE Cat. A location).

Type 4 – Surge suppression components, could be a basic component

or a complete module. Type 4 components can be tested for Type 1,

Type 2 or Type 3 applications.

Figure 1: SPD Types

NEC® Art 285 & UL 1449-3

SPD Types: Types 1, 2, 3, & 4

Based on Location within electrical distribution system

(also coincides with ANSI / IEEE C62.41.2 - 2002 Categories C, B & A)

Table 1: Type Designations

SIEMENS TPS3 SERIES TYPE RATING

TPS3 01 & L1 Type 1 Component Assembly

TPS3 02 & L2 Type 1 Component Assembly

TPS3 05 & L5 Type 1

TPS3 06 & L6 Type 1 Component Assembly

For further information, please review latest editions of NEC® Art. 285,

UL 1449, contact your local Siemens sales office or contact Siemens

TPS Tech Support at (888) 333-3545.

Equipment Performance

As SPDs sense overvoltage, they create a momentary internal short

circuit, thereby redirecting harmful surge energy to earth ground.

SPDs are capable of repeating this function repeatedly. For optimum

protection, staged surge suppression should be implemented at the

service entrance and all other distribution or panelboard locations

feeding sensitive equipment.

Voltage Rating

Prior to installing the TPS3 SPD, verify that the unit has the correct

voltage rating for the equipment installed by checking the nameplates

of both the equipment and TPS3 module. The service type should

match the intended power source. See Table 2 on the following page

for voltage applications.

2

Table 2: Model Number Decoder

Phase A (BLK)

Phase A (BLK)

}

Catalog #

TPS3

Default

Voltage

Code

TPS Series

Description

Surge

Current

Option

Codes

Rating

- Example: TPS3C0120X0 = SPD for a 208/120V panelboard with a surge current

capacity of 200 kA per phase and a surge counter option

TPS SERIES DESCRIPTION

TPS3 01 SPD for “Original P1”, P2, P3 Lighting and Power Distribution Panelboards, MCC and Busway

TPS3 L1 10 Mode SPD for SPD for “Original P1”, P2, P3 Lighting and Power Distribution Panelboards, MCC and Busway

TPS3 02 SPD for “Revised P1” Lighting Panelboard

TPS3 L2 10 mode SPD for “Revised P1” lighting Panelboard

TPS3 05 SPD for P4 & P5 Panelboards and Distribution Switchboards

TPS3 L5 10 Mode SPD for P4 & P5 Panelboards and Distribution Switchboards

TPS3 06 SPD for SB1, SB2, SB3, Type RCS Switchboards, MCC and Busway

TPS3 L6 10 Mode SPD for SB1, SB2, SB3, Type RCS Switchboards, MCC and Busway

VOLTAGE CODES

A = 240/120V Split Phase 1Ø, 3W Plus Grnd (Fig 1)

B = 240/120V 3Ø, High Leg Delta (B High) (Fig 3)

C = 208Y/120V 3Ø, 4W Plus Grnd (Fig 2)

D = 240V 3Ø, 3W Plus Grnd (Fig4)

E = 480Y/277V 3Ø, 4W Plus Grnd (Fig 2)

F = 480V 3Ø, 3W Plus Grnd (Fig 4)

G = 600V 3Ø, 3W Plus Grnd (Fig 4)

K = 380Y/220V 3Ø, 4W Plus Grnd (Fig 2)

L = 600Y/347V 3Ø, 4W Plus Grnd (Fig 2)

S = 400Y/230V 3Ø, 4W Plus Grnd (Fig 2)

TPS3 01 TPS3 L1 TPS3 02 TPS3 L2 TPS3 05 TPS3 L5 TPS3 06 TPS3 L6

√ √ √ √ √ √ √ √

√ √ √ √ √ √ √ √

√ √ √ √ √ √ √ √

√ √ √ √

√ √ √ √ √ √ √ √

√ √ √ √

√ √ √ √

√ √ √ √ √ √ √ √

√ √ √ √

√ √ √ √ √ √ √ √

SURGE CURRENT RATING

10 = 100kA per phase

15 = 150kA per phase

20 = 200kA per phase

25 = 250kA per phase

30 = 300kA per phase

40 = 400kA per phase

45 = 450kA per phase

50 = 500kA per phase

OPTION CODE / DESCRIPTION

X = Surge Counter

W = Terminal Lugs (for circuit breaker connection)

- used with P1, P2, P3 panels only

B = Busway Application

M = MCC Application

Figure 1

Hot (BLK)

V

}

Neutral (WHT)

}

V

Hot (BLK)

Ground (GRN)

SPLIT

2 Hots, 1 Neu, 1 Grnd

3

TPS3 01 TPS3 L1 TPS3 02 TPS3 L2 TPS3 05 TPS3 L5 TPS3 06 TPS3 L6

√ √ √ √

√ √ √ √ √ √ √ √

√ √ √ √

√ √ √ √

√ √ √ √ √ √ √ √

TPS3 01 TPS3 L1 TPS3 02 TPS3 L2 TPS3 05 TPS3 L5 TPS3 06 TPS3 L6

√ √ √ √ √ √ √ √

√ √ √ √

√ √ √ √

√ √ √ √

Figure 2

Phase B (BLK)

B

A

Neutral (WHT)

N

V

}

Phase C (BLK)

C

Ground (GRN)

WYE

3 Hots, 1 Neu, 1 Grnd

Figure 3

Phase B (ORNG)

V

}

Phase C (BLK)

Neutral (WHT)

Ground (GRN)

HI-LEG DELTA (B High)

3 Hots, (B HIGH),

1 Neu, 1 Grnd

Figure 4

Phase A (BLK)

V

Phase B (BLK)

Phase C (BLK)

Ground (GRN)

DELTA & HRG WYE

3 Hots, 1 Grnd

√

√ √

√

General Information

Audible Noise

This device features internal overcurrent and overtemperature

protection that will disconnect affected surge suppression components

at the end of their useful life, but will maintain power to the load – now

unprotected. If this situation is undesirable for the application, follow

these instructions for servicing or replacing the device.

Service of this unit consists of replacing the internal module and/or

display assembly.

There are no user-serviceable parts inside the replaceable module. Do

not attempt to disassemble the module as it stores charge.

Precautionary Statement Regarding SPDs on Ungrounded Systems

Caution – Ungrounded systems are inherently unstable and can

product excessively high line-to-ground voltages during certain fault

conditions. During these fault conditions, any electrical equipment

including an SPD, may be subjected to voltages which exceed their

designed ratings. This information is being provided to the user so

that an informed decision can be made before installing any electrical

equipment on an ungrounded power system.

Overcurrent Protection

The TPS3 SPD unit draws very little current under normal operation and

will only conduct current for a very brief duration upon encountering

a transient surge. The TPS3 unit contains overcurrent and thermal

protection to protect against abnormal overvoltage conditions.

The SPD’s background noise is negligible which permits installation

within the equipment in almost any room.

Dead Front Modification Instruction Changes for P1 SPD

The TPS3 unit requires a dead front opening to display its face

plate. Remove any installed cover from a dead front opening at the

TPS3 module location. If there is no dead front opening, follow the

instructions in Fig. 2 to create an opening by removing a knockout plate.

P1 Dead Front Knockout Plate Removal Instructions

Stand the removed dead front on the floor with the plate to be removed

in the upper position, as shown below. Grasping the upper edge of

the dead front, press the cover plate out of the cutout.

Figure 2: Dead Front Modification Instruction

System Grounding

An equipment grounding conductor must be used on all electrical

circuits connected to the SPD.

For the best performance, use a single point ground system where

the service entrance grounding electrode system is connected to and

bonded to building steel, metallic piping, driven rods, etc. (NEC® and

IEEE Std 142-2007 are appropriate standards).

For sensitive electronics and computer systems, ground impedance

should be as low as possible. When metallic raceway is used as an

additional grounding conductor, an insulated grounding conductor

should be run inside the raceway and sized per the NEC®. Adequate

electrical continuity must be maintained at all raceway connections.

Do not use isolating bushings to interrupt a metallic raceway run.

A separate isolated ground for the SPD is NOT recommended because

it may isolate the SPD from the rest of the electrical system, thus

decreasing performance. Proper equipment connections to grounding

system and ground grid continuity should be verified via inspections

and tested on a regular basis as part of a comprehensive electrical

maintenance program.

On 4-Wire Power Systems, neutral to ground bonding (Main Bonding

Jumper) must be installed per the NEC®. Failure to do so WILL damage

SPDs.

Environment

The unit is designed to operate inside the equipment in a room ambient

temperature range of: -40ºC (-40ºF) to +60ºC (+140º F) with relative

humidity of 0%-95% (non-condensing).

4

V DANGER

Hazardous voltage.

Will cause death or serious injury.

Keep Out.

Qualied personnel only.

Disconnect and lock off all power before

working on this equipment.

NOTICE

CONDUCTING DIELECTRIC AND/OR

HI-POTENTIAL TESTING WILL CAUSE

INTERNAL DAMAGE TO TPS3 UNIT.

Do not perform dielectric or high potential

tests with the TPS3 unit installed.

TPS3 01 Installation Instructions for: Lighting Panelboards Original P1, P2, P3

If model number includes W option suffix, additional instructions

follow:

The following instructions are for the installation of the Siemens TPS3

01 and L1 SPD modules in Siemens Original P1, P2 and P3 lighting

panelboards. Be aware of differences between the Revised P1 and

Original P1 panelboards. SPDs for Original P1 and Revised P1 are not

interchangeable. Original P1 panelboards use TPS3 01 or L1 SPDs,

whereas Revised P1 panelboards use TPS3 02 or L2 SPDs.

To determine if a customer has a Revised P1 panel – look at the part

number of the interior. If the part number ends with “N” or “T” then

it is a Revised P1. If it does not end in either “N” or “T” then it is an

Original P1 panel. For example: P1E42MC250A is an Original P1 panel

and P1E42MC250AT is a Revised P1 panel. If it is a Revised P1 panel

ending in “N” – then there is no Subfeed space and no place for an

SPD to be installed internally.

Figure 3: 250 Amp Max P1 Panels

3

1

SIEMENS

Sentron TPS

4

5

Deadfront

Support

2

Table 3: Content for Installation in Lighting Panelboards P1, P2, P3

Item Description Qty.

1 TPS3 (See Page 2, Table 1) 1

2 #10-32 x 1/4 Slotted Hex Thread Forming Screw 4

3 1/4-20 Hex Head SEMS Assembly 3

4 #10-24 Slotted Hex Thread Forming Screw 2

5 #10-32 x 5/8 Slotted Hex Thread Forming Screw 4

Determine the mounting location of the TPS3 in the distribution

equipment. If it is to be mounted in the top of the distribution

equipment or relocated after installation, internal phase labeling

connections must be changed to ensure proper diagnostic board

indication. These modifications should be made prior to installation.

If the TPS3 module is field installed in the bottom, or if it is mounted in

a factory assembled panelboard, the internal phase label connections

are correct as shipped.

Internal Phase Labeling Connections

A single 14 wire ribbon cable is attached to the display pcb. When the

ABC phase sequence changes to CBA, the single connector is removed

from the normal “ABC” jack and installed in the jack labeled “CBA”.

Lock off all power supplying this equipment before working on it.

Remove the trim and dead front.

Remove the two (2) dead front supports.

Position the TPS3 unit on the panel base rail so that the TPS3 neutral

connector is in front of the panel neutral and the phase tabs are behind

the interior bus. Slide the unit toward the interior until the four mounting

holes line up with the four holes in the base rail.

Note: If a neutral lug is mounted in the position where the TPS3 neutral

connection is made, it must be moved to one of the three remaining

neutral lug positions prior to TPS3 installation.

Attach the TPS3 unit (item 1) to the base rail using four (4) of the #1032 slotted hex washer head thread forming screws (item 2) provided

as shown in Figure 3.

Fasten unit to the main bus using the 1/4-20 hex head (with captive

washer) assembly machine screws (item 3) provided. Do not tighten

at this time.

Fasten TPS3 neutral to panel neutral using two (2) #10-24 slotted hex

washer head thread forming screws (item 4).

If the four (4) interior leveling screws are not already installed four

(4) additional screws (item 5) are provided for installation to ensure

proper ground path for TPS3 module.

Torque all connections to the values as specified on the installation

and maintenance instruction label affixed to the rear of the dead front.

Replace dead front supports by installing screws, finger tight. Then

tighten with tool. Replace trim.

5

V DANGER

Hazardous voltage.

Will cause death or serious injury.

Keep Out.

Qualied personnel only.

Disconnect and lock off all power before

working on this equipment.

NOTICE

CONDUCTING DIELECTRIC AND/OR

HI-POTENTIAL TESTING WILL CAUSE

INTERNAL DAMAGE TO TPS3 UNIT.

Do not perform dielectric or high potential

tests with the TPS3 unit installed.

TPS3 01 Installation Instructions for: 400/600 amp S1/S2 and All SE Panels

If model number includes W option suffix, additional instructions

follow:

Note that this installation is very similar to TPS3 used in S3 Panels

except that the neutral connector is wired rather than pigtailed

and the neutral connector is at line end of the panel.

The following instructions are for the installation of Siemens TPS3 01

and L1 SPD modules in Siemens 400/600 amp S1/S2 and all SE Panels.

All hardware is supplied for complete installation of the TPS3 module.

Figure 4: 400/600 Amp S1/S2 and all SE Panels TPS3 01 Unit with the NK Accessory Kit

These modifications should be made prior to installation. If the TPS3

module is field installed in the bottom, or if it is mounted in a factory

assembled panelboard, the internal phase label connections are correct

as shipped.

Internal Phase Labeling Connections

A single 14 wire ribbon cable is attached to the display pcb. When the

ABC phase sequence changes to CBA, the single connector is removed

from the normal “ABC” jack and installed in the jack labeled “CBA”.

Lock off all power supplying this equipment before working on it.

Remove the trim and dead front.

Install the mounting bracket (Item 5) to the base rail as shown

in Figure 3 using two (2) of the #10 thread forming screws

(item 3).

Position the TPS3 unit on the panel base rail so that the phase tabs are

on top of the interior bus and the four mounting holes line up with the

two holes in the base rail and the two holes in the mounting bracket.

Attach the TPS3 unit (item 1) to the base rail using four (4) of the #10

slotted hex washer head thread forming screws (item 3) provided as

shown in Figure 4.

Fasten unit to the main bus using the phase connectors (item 6). The

connectors will be attached to the unit with three (3) 1/4" hex head

SEMS assemblies (item 2) provided. Then they will be connected to

the interior with three (3) 1/4" carriage bolts and three (3) belleville

washer nuts (items 7 & 8). Do not tighten at this time.

Table 4: Contents for Installation in 400/600 Amp S1/S2

and all SE Panels

Item Description Qty.

1 TPS3 (See Page 2, Table 1) 1

2 1/4-20 Hex Head SEMS Assembly 3

3 10-24 Head Thread Forming Screw 6

4 TPS3 Neutral Connection Point -

5 TPS3 Mounting Bracket 1

6 Phase Connectors 3

7 1/4" Carriage Bolt 3

8 1/4" Belleville Washer Nut 3

Determine the mounting location of the TPS3 in the distribution

equipment. If it is to be mounted in the top of the distribution equipment

or relocated after installation, internal phase labeling connections

must be changed to ensure proper diagnostic board indication.

Fasten TPS3 neutral to panel neutral at the neutral connection point

(item 4).

Torque all connections to the values as specified on the installation

and maintenance instruction label affixed to the rear of the dead front.

Replace dead front and trim.

6

Internal Phase Labeling Connections

V DANGER

Hazardous voltage.

Will cause death or serious injury.

Keep Out.

Qualied personnel only.

Disconnect and lock off all power before

working on this equipment.

TPS3 02 Installation Instructions for:

Lighting Panelboards Revised P1

If model number includes W option suffix, additional instructions follow:

The following instructions are for the installation of the Siemens TPS3

02 and L2 SPD modules in Siemens Revised P1 lighting panelboards. Be

aware of differences between the Revised P1 and Original P1 panelboards.

SPDs for Original P1 and Revised P1 are not interchangeable. Original P1

panelboards use TPS3 01 or L1 SPDs, whereas Revised P1 panelboards

use TPS3 02 or L2 SPDs.

To determine if a customer has a Revised P1 panel – look at the part

number of the interior. If the part number ends with “N” or “T” then

it is a Revised P1. If it does not end in either “N” or “T” then it is an

Original P1 panel. For example: P1E42MC250A is an Original P1 panel

and P1E42MC250AT is a Revised P1 panel. If it is a Revised P1 panel

ending in “N” – then there is no Subfeed space and no place for an SPD

to be installed internally.

All hardware is supplied for complete installation of the TPS3 module.

See page 3, Table 2 for Catalog numbers.

Figure 5: 250 Amp Max Revised P1 Panels

2

13

2

2

13

1

4

A single 14 wire ribbon cable is internally attached to the display pcb.

Display board must be removed with 4 black phillips screws. When the

ABC phase sequence changes to CBA, the single connector is removed

from the normal “ABC” jack and installed in the jack labeled “CBA”.

Lock off all power supplying this equipment before working on it.

Remove the trim and dead front. If SPD is hard-buss connected to busses:

(If connected through breaker, see W option instructions on page 10)

Attach Connectors (items 5, 6 & 7) to outboard and center Phase buss

bars using ¼”-20 x ½” slotted machine screws (item 3). Each Connector

is Phase specific. Refer to Figures 5 & 6 (top right) for orientation. For

400A use inner holes on outer phases and center hole on center phase.

Machine screws thread into the Connector mounted below the buss

bar. Do not tighten at this time.

Position the TPS3 unit (item 1) on the panel base rail so that the TPS3

neutral connector is in front of the panel neutral and the phase tabs

are above the Connectors. Slide the TPS3 unit toward the interior until

the four mounting holes line up with the four holes in the base rail.

Attach the TPS3 unit to the base rail using four (4) of the #10-24 x 9/16”

slotted hex washer head thread forming screws (item 2) provided as

shown in Figures 5 and 6 (top right).

Fasten TPS3 unit’s Phase tabs to the Connectors using three (3) of

the #10-24 x 9/16” slotted hex washer head thread forming screws

(item 2). Do not tighten at this time.

Table 5: Content for Installation in Lighting Panelboards Revised P1

Item Description Qty. Torque Value

1 TPS3 (See Page 3, Table 2) (SPD) 1

#10-24 x 9/16” Slotted Hex Thread

2

Forming Screw (Bus rail mounting Screws)

1/4-20 x 1/2” Slotted Hex Head

3

Machined Screw (busbar connection)

1/4-20 x 5/8 Hex Head Machined

4

Screw (busbar connection)

5 Connector Outboard Phase 1

7 30 lb-in

3 72 lb-in

1* 72 lb-in

2

10

11

12

Determine the mounting location of the TPS3 in the distribution

equipment. If the TPS3 module is field installed in the bottom, or if

it is mounted in a factory assembled panelboard, the internal phase

label connections are correct as shipped. If mounted in the top of

the distribution equipment or relocated after installation, internal

phase labeling connections must be changed to ensure proper

diagnostic board indication. These modifications should be made

prior to installation.

7

8

6 Connector Center Phase 1

7 Connector Outboard Phase 1

8 Neutral Jumper 1*

9 Nut ¼-20 SEMS 1*

10 Neutral Riser Support 1*

#10-16 x ½” Type BT Slotted

11

Hex Thread Forming Screw

12 Neutral Riser 1*

5/16”-18 x ½” Slotted Hex Thread

13

Forming Screw

1* 15 lb-in

2*

CU - 72 lb-in

AL - 108 lb-in

Parts with asterisk (*) not included in Delta units having no neutral.

If panel is equipped with a neutral conductor:

• (250A only, not required for 400A) Install Neutral Riser Support

(item 10) per Figure 5 using #10-16 x ½” Type BT Slotted Hex

Thread Forming Screw (item 11). Do not tighten at this time.

• (250A only, not required for 400A) Install Neutral Riser (item 12)

per Figure 5. Use two (2) 5/16”-18 Slotted Hex Thread Forming

Screws (item 13) to connect one end of Neutral Riser to existing

Neutral Bussing provided with panel and other end of Neutral

Riser to Neutral Riser Support.

• Attach Neutral Jumper (item 8) to top side of TPS3 (item 1) neutral

tab with ¼-20 x 5/8” machine screw (item 4) and ¼”-20 SEMS nut

(item 9). Do not tighten at this time. (400A panels only: rotate

neutral jumper so single-hole end lands on SPD neutral to ensure

proper height and fitment. Use (1) 5/16” - 18 slotted hex thread

forming screw (item 13) to connect other end of neutral jumper

to existing neutral bussing.)

Figure 6: SPD & Neutral Riser Connection Details for Revised P1 Panels

Buss Connector Detail

5

6

7

3

250 Amp 18 Circuit

3

Torque all connections to the values as specified on the installation

and maintenance instruction label affixed to the rear of the dead front.

Replace trim and deadfront.

400 Amp Panels

1

2

4

13

2

8

NOTE ORIENTATION

OF NEUTRAL CONNECTOR

250 Amp 42 Circuit

250 Amp 54 Circuit 250 Amp 66 Circuit

* Note bolt

location

differences of

neutral riser

depending

on number of

circuits.

8

V DANGER

Hazardous voltage.

Will cause death or serious injury.

Keep Out.

Qualied personnel only.

Disconnect and lock off all power before

working on this equipment.

NOTICE

CONDUCTING DIELECTRIC AND/OR

HI-POTENTIAL TESTING WILL CAUSE

INTERNAL DAMAGE TO TPS3 UNIT.

Do not perform dielectric or high potential

tests with the TPS3 unit installed.

TPS3 05 and TPS3 06 Module Replacement Instructions

The following instructions are for the replacement of Siemens TPS3

SPD module in Siemens TPS3 05 unit.

Figure 6: P4, P5 & Front Connected Distribution Switchboards

NOTE: TPS3 05 unit may be replaced only if supplied with an internal

disconnect.

Lock off all power supplying this equipment before working on it.

The following instructions are for the replacement of Siemens TPS3

SPD module in Siemens TPS3 06 unit.

Figure 7: Service Section Switchboards & Low Voltage Switchgear

NOTE: TPS3 06 unit may be replaced only if supplied with an internal

disconnect.

Lock off all power supplying this equipment before working on it.

Open unit door and turn the internal disconnect to the off position.

Remove the neutral lug wire from the disconnect switch.

Remove the phase lug wires from the TPS3 05 unit.

Remove the TPS3 05 unit and discard properly.

Replace unit with the new TPS3 05 unit.

Attach the phase lug wires to the correct phase on the TPS3 unit.

Attach the neutral wire back to the disconnect switch.

Torque all connections to the values as specified on the installation

and maintenance instruction label affixed to the rear of the dead front.

Do not over torque disconnect switch connections as they will fail.

Turn the internal disconnect back to the on position.

Close unit doors before reenergizing.

9

Open unit door and turn the internal disconnect to the off position.

Remove the neutral lug wire from the disconnect switch.

Remove the phase wires from the TPS3 06 unit lugs.

Remove the TPS3 06 unit with the panel and diagnostics display and

discard properly.

Replace units with the new TPS3 06 units.

Attach the phase lug wires to the correct phase on the TPS3 06 unit.

Attach the neutral wire back to the disconnect switch.

Torque all connections to the values as specified on the installation

and maintenance instruction label affixed to the rear of the dead front.

Do not over torque disconnect switch connections as they will fail.

Turn the internal disconnect back to the on position.

Close unit doors before reenergizing.

V DANGER

Hazardous voltage.

Will cause death or serious injury.

Keep Out.

Qualied personnel only.

Disconnect and lock off all power before

working on this equipment.

NOTICE

CONDUCTING DIELECTRIC AND/OR

HI-POTENTIAL TESTING WILL CAUSE

INTERNAL DAMAGE TO TPS3 UNIT.

Do not perform dielectric or high potential

tests with the TPS3 unit installed.

TPS3 01 and TPS3 06 Module Installation

Instructions: MCC

Figure 8: Installation

in an MCC

The following instructions are for the replacement of Siemens TPS3

SPD module in a TIASTAR MCC.

This unit is intended for custom factory installation during MCC

manufacture. Unit must be removed from the MCC or withdrawn

to the TEST position. Familiarize with the TPS and MCC mounting

hardware-mount in gear such that the leads are as short and straight

as possible without distorting the stab assembly. Failure to do so will

result in decreased performance.

Diagnostic Display Connected via Ribbon Cable – to be mounted in a

suitable location such that the display is visible to user and/or protected

via an access door.

A successful installation includes:

• Meets all national and local codes.

• Mount TPS as close as possible to electrical connection.

• Ensure leads are as short and straight as possible.

• Gently twist or tie-wrap conductors together wherever possible.

• Ensure that N-G bonding hazard warning label is attached to TPS

as reminder to installing contractor.

• Ensure all power is off and unit is deenergized.

• Verify that TPS and intended voltage are correct.

• Install #6 conductor leads to phase, neutral and ground connections.

• Mount Diagnostic Display at appropriate location.

• Connect ribbon cables from Diagnostic Display to circuit board on

Main TPS Backplane Assembly.

• Connect to the Dry Contact terminal block if appropriate.

Before bench testing

• Ensure test voltage is appropriate and grounded Wye system

– Failure to ensure reference to ground will fail unit.

• Ensure unit is touch safe and that all appropriate enclosures are secure.

• Do not Hi-Pot test SPDs.

• Do not bench test using ungrounded system – must be grounded

Wye system.

UL 1283 required language concerning the installation of EMI Filters

a) An insulated grounding conductor that is identical in size and

insulation material and thickness to the grounded and ungrounded

circuit supply conductors, except that it is green with or without

one or more yellow stripes, is to be installed as part of the circuit

that supplies the filter. Reference should be made to Table 250-122

of the National Electrical Code regarding the appropriate size of the

grounding conductor.

b) The grounding conductor mentioned in item a is to be grounded

to earth at the service equipment or other acceptable building earth

ground such as the building frame in the case of a high-rise steelframe structure.

c) Any attachment-plug receptacles in the vicinity of the filter are to

be of a grounding type, and the grounding conductors serving these

receptacles are to be connected to earth ground at the service equipment

or other acceptable building earth ground such as the building frame

in the case of a high-rise steel-frame structure.

d) Pressure terminal or pressure splicing connectors and soldering lugs

used in the installation of the filter shall be identified as being suitable

for the material of the conductors. Conductors of dissimilar metals shall

not be intermixed in a terminal or splicing connector where physical

contact occurs between dissimilar conductors unless the device is

identified for the purpose and conditions of use.

Additional instructions for TPS3 01 & L1, 02 & L2 SPDs including:

W Option Suffix:

The W option includes repositioned phase connection tabs that allow

for wire connections to a circuit breaker within the panelboard. This

differs from non-W models, which bolts directly to bus bars.

The circuit breaker serves as a disconnector device and overcurrent

protection to the connecting conductors. The TPS3 SPD includes internal

overcurrent and overtemperature protective equipment. The breaker

does not provide overcurrent protection to the SPD.

Recommended breaker and conductor size is 60A with a 6 AWG

conductors. Other combinations are possible. Terminal lugs will accept

2-14 AWG. Breaker size should be at least 20A. All applicable codes

must be followed.

Circuit breaker MUST be located immediately adjacent to SPD to minimize

lead lengths. Move or adjust breaker positions as appropriate. Every

effort must be taken to reduce lead lengths. Failure to install short

leads will degrade SPD performance.

Install appropriate circuit breaker in panelboard.

Confirm that all LEDs are green and that touchpads on display operate

correctly.

10

Prior to installing SPD, install, rotate and tighten box lug terminals to the

top of the SPD phase connection tabs, pointing toward breaker location.

Mount the SPD using supplied hardware, per previous instructions.

Connect the neutral connection by wire or bracket as appropriate.

Install conductors: Identify each panelboard buss as Phase A, B and C.

When the SPD is installed, the SPD’s Phase Tabs will have near proximity

above energized panelboard busses. The SPD’s phase connections must

correspond to buss phases. Connect conductors from the SPD’s Phase

Tabs to corresponding circuit breaker connections. For example, when

energized, the SPD Phase Tab for Phase A must be located above the

panelboard buss for Phase A. The SPD Phase Tab for Phase B must be

located above the panelboard buss for Phase B. The SPD Phase Tab

for Phase C must be located above the panelboard buss for Phase C.

Conductors must be as short and straight as possible. Use gentle radius

on any bends. Do not kink wires. Prevent wires from encroaching

breaker locations.

Torque all connections to the values specified on the installation and

maintenance instruction label affixed to the rear of the dead front.

Replace dead front supports and trim.

Energize breaker and confirm proper SPD operation.

Test: Tests red Service LED and Audible Alarm, and changes state of

Dry Contacts.

Alarm Silence: Turns Audible Alarm off. (Alarm is deactivated when

the Silence LED is illuminated.)

Surge Counter Count: (if equipped) Increments optional surge counter

by one (+1).

Surge Counter Reset: (if equipped) Resets optional surge counter to

zero (0).

Figure 9: Display - Horizontal

(Shown with Surge Counter)

Figure 10: Display - Vertical

(Shown with Surge Counter)

Operation

TPS3 surge protective devices require minimal attention after installation.

TPS3’s contain diagnostic circuits which monitor the suppressor's status

continuously and automatically. All phase indicators and controls are

located on the display panel of the unit. Display panels are formatted

either for horizontal or for vertical mounting orientation as required

for each application.

TPS3 Control & Diagnostic Display Panel

TPS3’s are equipped with a status indicating LED for each phase on

the panel. When all LED's are green, the suppressor is on-line and

functioning properly. If a fault condition occurs, the audible alarm will

sound, the Red Service LED will illuminate and the LED representing the

affected phase will extinguish, indicating that the unit needs service.

The audible alarm can be silenced by pressing ALARM SILENCE on

the touchpad. The audible alarm and Dry Contact can be tested by

depressing TEST. If a fault alarm occurs, see Corrective Maintenance

(Testing and Repair) for further information.

Display Panel with Surge Counter Option

The surge counter option provides a means to display the total number

of transient voltage surge events since the counter was last reset. The

counter includes Eprom memory, which retains counter memory in

the event of a power loss. The RESET touchpad will reset the counter

to zero. The COUNT touchpad increments the counter by one (1) and

tests the circuitry for proper operation. If a fault alarm does occur, see

Corrective Maintenance (Testing and Repair) for further information.

Dry Contacts Feature

TPS3 01, 05, and 06 units are equipped with dry contacts. This feature

provides Normally Open (N.O.) and Normally Closed (N.C.) circuits,

which can be used for remote indication of a failed transient voltage

surge suppressor. There is only one dry contact output consisting of

two electrically isolated sets of NC-C-NO contacts. This dry contact

output changes from "normal" to "alarm" if any problem occurs inside

the SPD (i.e.: loss of power to any phase, any thermal protector inside

the SPD opens, or any fuse inside the SPD opens). The dry contact

terminal block is located on the back of the module, opposite side of

bus tabs. This connector is designed for low voltage or control signals

only. Maximum voltage should not exceed 240 volts and maximum

current should not exceed 5 amperes. These contacts may be used to

provide a signal to an emergency management system or computer

interface board. The relay contact pin arrangement is outlined in the

table below.

The Normally Closed (N.C.) configuration is recommended because

it will detect a wiring defect, such as a cut wire(s), where Normally

Open (N.O.) will not.

Figure 11: Dry Contact Connection Configuration

DRY CONTACTS

NO

NC NC C NOC

Phase A, B & C: Green LED indicators—one per phase. Green is good.

Extinguished green LED indicates loss of protection. Every suppression

element in this SPD is monitored. N-G suppression element monitoring

is logic-connected to Phase A.

Service LED (red): LED illuminates in the event of problems. This

indicator is logic-connected to the Phase LEDs. Should a Phase LED go

out, the Service LED will illuminate and the Audible Alarm will sound.

11

Maintenance

Module Replacement & Service

SPDs require minimal maintenance. Periodic inspection of diagnostic

LED indicators ensures proper operation. Clean SPD as appropriate.

Troubleshooting & Service

Please contact TPS Technical Support at 1.888.333.3545 for service

related issues.

Quality SPDs are designed and tested to withstand severe duty. However,

there are various electrical anomalies against which SPDs cannot protect.

These are generally Sustained Overvoltages also known as Temporary

Overvoltages (TOVs). In this context, Sustained Overvoltages may be

only a few cycles. Failed SPDs tend to be symptoms, not root causes.

There may be larger issues at play. Regardless of cause, SPDs attempt

to protect their load until failure.

Bonding or reference to ground problems are the root cause of many

SPD problems. If the SPD shows problems on startup, there is reasonable

chance of bonding/grounding/misapplication issue. Such problems

permanently damage the SPD. If not corrected, SPD problems will

reoccur.

Tip: Visually confirm N-G bonding. Be aware that a voltmeter

measuring N-G can be misleading. For example, N-G voltage

could read 0V because neutral and ground are at the same

potential purely by happenstance, not because they are

bonded. Visually confirm bonding.

The module is field replaceable. Service should only be performed

by qualified persons. Deenergize SPD, confirm with appropriate

measurement equipment and discharge internal capacitance to ground.

Mark locations and carefully disconnect diagnostic cables, contacts,

connecting conductors, etc. Unbolt module from backplane. Reinstall

in reverse.

There are no user serviceable parts inside the module. Disassembly

is not permitted.

Modules may be returned to the factory for factory service, qualification

and return. Please contact factory at 1.888.333.3545 for assistance.

Display Replacement

The display is field replaceable. Service should only be performed

by qualified persons. Deenergize SPD, confirm with appropriate

measurement equipment and discharge internal capacitance to ground.

Mark locations and carefully disconnect diagnostic cables, contacts,

connecting conductors, etc. Unbolt display and replace. Reinstall in

reverse.

Note that a sealing gasket between the display and the enclosure is

a key component ensuring weather resistance. Replace the gasket

whenever the display is removed.

Preventive Maintenance (Inspection & Testing)

Tip: Experience indicates that regulation-challenged

generators can cause Sustained Overvoltages, as well as

ungrounded generators, and/or usual load transfer systems.

Abnormal N-G Voltage Indicators

This SPD include N-G voltage indicators. If the SPD detects excessive

N-G voltage, the Red Service LED will blink and the Audible Alarm will

cycle. This condition requires immediate attention as the SPD will fail.

Incorrectly bonded distribution systems damage SPDs. If the XO or N-G

bonding jumper is not installed, the electrical system has no reference to

ground. It becomes an ungrounded system. Please see previous section

regarding SPDs on ungrounded systems. Such systems are known to

eventually produce abnormally high L-G voltages. SPDs will attempt

to chase this system-level overvoltage abnormality until the SPD fails.

This effect is accelerated on Wye systems where SPDs are designed

for grounded systems. (SPDs for ungrounded systems generally have

higher MCOV to allow for L-G voltage fluctuations.) Failures of this

nature are not defects in the SPDs workmanship or material. This is

an installation error and is not covered by warranty.

A differential voltage circuit monitors neutral to ground voltage. When

N-G voltage becomes excessive, an amplifier energizes a resistor.

Eventually, that resistor will overheat and cause thermally sensitive

shrink wrap to shrink around the resistor. This does not occur on transient

or instantaneous N-G overvoltages. When the SPD is deenergized, the

shrink wrap covered resistor can be accessed by qualified personnel

under the display plate cover.

Inspection of the TPS3 SPD unit should be performed periodically,

to maintain reliable system performance and continued transient

voltage surge protection. The large variations in operating conditions

encountered by units in the field make it difficult to set a fixed

maintenance interval, but inspections utilizing the built-in diagnostics

should be performed at least on a weekly or monthly basis.

Corrective Maintenance (Repair)

The Siemens TPS3 unit is designed for years of reliable, trouble-free

operation. Unfortunately, in an extreme case, you may experience an

alarm condition. In this event, no attempt should be made to repair the

TPS3 itself. There are no serviceable parts within the unit. Any SPD that

requires service should be appropriately removed from the electrical

distribution equipment, and replaced by a new SPD of the same model.

Technical Support

1.888.333.3545

Prior to calling Siemens TPS3 Technical Support for assistance or ordering

parts, please have the following information available:

TPS3 model number: ________________________________

Manufacture date: _________________________________

Date of Purchase: ___________________________________

Your order number: _______________________________

Return Shipment Address:

Siemens - Attn: RA #___________

14550 58th Street North

Clearwater, FL 33760

12

Siemens Canada Limited

1577 North Service Road East

Oakville, ON L6H 0H6

SPD Hotline: 888.333.3545

info@purgethesurge.ca

European Authorized Representative

Obelis s.a.

Boulevard Général Wahis 53

1030 Brussels, BELGIUM

Tel: +(32) 2. 732.59.54

Fax: +(32) 2. 732.60.03

E-Mail: mail@obelis.net

2.16.15.lh #8225

Loading...

Loading...