Page 1

Operating Instructions 09/2007

SICLOCK TC 400

Plant Central Clock

SICLOCK

s

Page 2

Page 3

s

Preface, Table of contents

Safety Information

SICLOCK® TC 400

Plant Central Clock

Operating Instructions

Description

Hardware Description

Operation Planning

Installation

Connecting

Configuration Tool

Parameterization

Parameterization and Operation on the Device

Parameter Table

Service and Maintenance

Messages

Technical Data

Dimension Drawing

Circuit Diagrams

09/2007

A2B00073596-01

Spare Parts / Accessories

Appendix

ESD Guidelines

List of Symbols

Glossary, Index

Page 4

Safety notices

This manual contains information that must be observed to ensure your personal safety and to prevent

property damage. The notices referring to your personal safety are highlighted in the manual by a safety

alert symbol, notices referring to property damage only, have no safety alert symbol. Depending on the

hazard level, warnings are displayed in descending order as follows:

Danger

indicates that death or serious injury will result if proper precautions are not taken.

Warning

indicates that death or serious injury may result if proper precautions are not taken.

Caution

with a warning triangle indicates that minor personal injury can result if proper precautions are not taken.

Caution

without a warning triangle means that material damage can occur if the appropriate precautions are not

taken.

Notice

means an undesirable result or state can occur if the corresponding instruction is not followed.

In the event of a number of levels of danger prevailing simultaneously, the warning corresponding to the

highest level of danger is always used. A warning with a warning triangle indicating risk of physical injury

may also include a warning of the risk of damage to property.

Qualified personnel

The associated device/system may only be installed and used in conjunction with this documentation.

Only qualified personnel should be allowed to commission and operate the device/system. For the purpose of the safety information in this documentation, a “qualified person” is someone who is authorized to

energize, ground, and tag equipment, systems, and circuits in accordance with established safety procedures.

Intended use

Please note the following:

Warning

This equipment is only allowed to be used for the applications described in the catalog and in the technical

description, and only in conjunction with non-Siemens equipment and components recommended by Siemens. Correct transport, storage, installation and assembly, as well as careful operation and maintenance,

are required to ensure that the product operates safely and without faults.

Registered Trademarks

All designations with the trademark symbol ® are registered trademarks of Siemens AG. Other designations in this documentation may be trademarks whose use by third parties for their own purposes can violate the rights of the owner.

Disclaimer of liability

We have checked that the contents of this publication agree with the hardware and software described

here. Nevertheless, we cannot assume responsibility for any deviations that may arise. The information

given in this publication is reviewed at regular intervals and any corrections that might be necessary are

made in the subsequent editions.

Siemens AG

I&S EDM

Frauenauracher Strasse 98

D-91056 Erlangen

GERMANY

© Siemens AG 2007

Technical data subject to change

Page 5

Preface

This document is a compilation of the information required for the operation and

parameterization of the SICLOCK TC 400 plant central clock.

Scope

This manual is valid for the SICLOCK® TC 400 product with firmware version V1.0

and processor version V1.0 in conjunction with the SICLOCK TC 400 configuration tool as of Version 1.0.

Recycling and disposal

The SICLOCK TC 400 is environmentally friendly and is thus recyclable. To recycle and dispose of your old device in an environmentally friendly way, please contact a company certified to deal with electronic waste.

Hotline and Internet addresses

If you have any questions, please contact our hotline:

Phone:

Fax:

E-mail:

Internet:

The latest information on SICLOCK products, product support and FAQs can be

found on the Internet.

+49 (9131) 7-2 88 66

+49 (9131) 18-8 06 04

siclock@siemens.com

http://www.siemens.de/siclock (German)

http://www.siemens.com/siclock (international)

SICLOCK

®

TC 400 Operating Instructions

Preface-3© Siemens AG 2007 All Rights Reserved

Page 6

Preface

Preface-4

© Siemens AG 2007 All Rights Reserved

SICLOCK

®

TC 400 Operating Instructions

Page 7

Table of contents

Preface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Preface-3

Table of contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Contents-5

1 Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

2 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.1 Configuration of the SICLOCK TC 400 hardware . . . . . . . . . . . . . . . 2-12

2.2 External synchronization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

2.3 Time receivers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2.3.1 Plant synchronization via Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2.3.2 Plant synchronization via point-to-point connection . . . . . . . . . . . . . 2-15

2.4 Time management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2.5 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2.6 Redundancy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

3 Hardware Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

3.1 External design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

3.2 Connection elements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

3.3 Operator controls and displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

3.4 Scope of delivery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

4 Operation Planning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

4.1 Overview of operation planning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

4.2 Transport and storage conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

4.3 Unpacking and checking the delivery . . . . . . . . . . . . . . . . . . . . . . . . 4-28

4.4 Mounting position and fixing method. . . . . . . . . . . . . . . . . . . . . . . . . 4-29

4.4.1 Installation instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

4.4.2 Permitted mounting position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

4.4.3 Fixing method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

5Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-31

5.1 Installation overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-31

6 Connecting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-33

6.1 Connecting overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-33

6.2 Connecting the power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-34

SICLOCK

®

TC 400

Contents-5© Siemens AG 2007 All Rights Reserved

Page 8

Table of contents

6.3 Connecting the external synchronization . . . . . . . . . . . . . . . . . . . . . 6-35

6.3.1 SICLOCK GPS1000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-37

6.3.2 SICLOCK DCFRS industrial version . . . . . . . . . . . . . . . . . . . . . . . . . 6-38

6.3.3 SICLOCK GPSDEC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-39

6.3.4 Third-party systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-40

6.4 Connecting the time receivers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-41

6.4.1 Point-to-point connections via OUTPUT 1 to 3 . . . . . . . . . . . . . . . . . 6-41

6.4.2 Redundant point-to-point connections. . . . . . . . . . . . . . . . . . . . . . . . 6-43

6.5 Connecting an alarm output and a warning output . . . . . . . . . . . . . . 6-44

7 Configuration Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-45

7.1 Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-48

7.2 General functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-50

7.2.1 Establish/disconnect online connection. . . . . . . . . . . . . . . . . . . . . . . 7-51

7.2.2 Authorization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-52

7.3 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-53

7.3.1 Sorting the parameter table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-57

7.3.2 Showing/hiding parameter table entries . . . . . . . . . . . . . . . . . . . . . . 7-57

7.3.3 Editing parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-58

7.3.4 Reading parameters / writing parameters / resetting parameters to factory set-

tings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-59

7.4 Archive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-60

7.4.1 Sorting the archive table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-62

7.4.2 Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-63

7.5 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-64

8 Parameterization and Operation on the Device. . . . . . . . . . . . . . . . . . . . . . 8-67

8.1 Operating display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-68

8.2 Operation and parameterization . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-70

8.2.1 Authorization (enter password) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-71

8.2.2 Parameter list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-72

8.2.3 Editing dialog box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-73

9 Parameterization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-75

9.1 Linking the external synchronization . . . . . . . . . . . . . . . . . . . . . . . . . 9-76

9.1.1 Radio clocks via terminals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-76

9.1.2 Operation as NTP client . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-77

9.1.3 Redundancy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-77

9.2 Linking the time receivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-78

9.2.1 NTP server service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-78

9.2.2 SIMATIC method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-79

9.2.3 OUTPUT 1 to 3 via terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-80

9.2.4 OUTPUT 1 and 2 redundant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-81

9.2.5 Output telegram (for OUTPUT 1 to 3) . . . . . . . . . . . . . . . . . . . . . . . . 9-82

Contents-6

© Siemens AG 2007 All Rights Reserved

SICLOCK

®

TC 400

Page 9

Table of contents

9.3 General settings on the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-83

9.3.1 Time management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-83

9.3.2 Synchronization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-84

9.3.3 Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-85

9.3.4 System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-85

9.3.5 Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-86

9.3.6 Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-86

10 Parameter Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-87

11 Service and Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-99

11.1 Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-99

11.2 Restoring the factory settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-99

11.3 Software update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-100

12 Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-101

13 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-105

14 Dimension Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-109

15 Circuit Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-111

15.1 Terminal assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-111

16 Spare Parts / Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-113

A Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-115

A.1 Directives and declarations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-115

A.2 Certificates and approvals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-116

B ESD Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-117

B.1 Electrostatic sensitive devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-117

B.2 Electrostatic charging of persons . . . . . . . . . . . . . . . . . . . . . . . . . . . B-118

B.3 Basic measures to protect against the

discharge of static electricity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-119

C List of Symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-121

D Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-123

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Index-129

© Siemens AG 2007 All Rights Reserved

SICLOCK

®

TC 400

Contents-7

Page 10

Table of contents

Contents-8

© Siemens AG 2007 All Rights Reserved

SICLOCK

®

TC 400

Page 11

Safety Information 1

Caution

Please observe the safety instructions on the back of the cover sheet of this documentation. You should not make any expansions to your device unless you have

read the relevant safety instructions.

If you have questions about the validity of the installation in the planned environment, please contact your service representative.

Repairs

Only authorized personnel are permitted to repair the device.

Warning

Unauthorized opening and improper repairs can cause considerable damage to

property or danger for the user.

System expansions

Only install system expansions intended for this device. If you install other

upgrades, you may damage the system or violate the safety requirements and

regulations for radio frequency interference suppression.

Contact your technical support team or where you purchased your device to find

out which system expansion devices may safely be installed.

Caution

If you install or exchange system expansions and damage your device, the warranty becomes void.

SICLOCK

®

TC 400

1-9© Siemens AG 2007 All Rights Reserved

Page 12

Safety Information

Battery

This device is equipped with a Lithium battery. Batteries may only be replaced by

qualified personnel. See also Battery (Section 11.1).

Caution

There is the risk of an explosion if the battery is not replaced as directed. Replace

only with the same type or with an equivalent type recommended by the manufacturer. Dispose of used batteries in accordance with local regulations.

Warning

Risk of explosion and release of harmful substances!

Therefore, do not throw Lithium batteries into an open fire, do not solder or open

the cell body, do not short-circuit or reverse polarity, do not heat up above 100°

C, dispose as regulated and protected against direct exposure to sunlight, humidity and condensation.

ESD guidelines

Modules containing electrostatic sensitive devices (ESDs) can be identified by the

following label:

Strictly follow the guidelines mentioned below when handling modules which are sensitive

to ESD:

• Always discharge your body's static electricity before handling modules which

are sensitive to ESD (for example,

by touching a grounded object).

• All devices and tools must be free of static charge.

• Always pull the mains connector and disconnect the battery before you install

or remove modules which are sensitive to ESD.

• Handle modules fitted with ESDs by their edges only.

• Do not touch any connector pins.

1-10

© Siemens AG 2007 All Rights Reserved

SICLOCK

®

TC 400

Page 13

Description 2

Modern automation systems consist of a variety of computers, controllers and

systems that exchange data with one another. For real-time operation of such

plants, it is essential that the times of all components are synchronous. This

applies especially for error tracing, when event messages receive a time stamp

and when cause and effect have to be identified through a reliable chronological

sequence.

As plant central clock, SICLOCK TC 400 supplies the various plant components

with the exact and reliable time, which is obtained from one or more external synchronizations with an official or legal time, usually GPS or DCF77 radio clocks.

The time is distributed via Ethernet, and also via point-to-point outputs.

Note

Use only one device as plant central clock to supply the time to all components

throughout the plant.

Exception: redundant operation of the plant central clock.

SICLOCK

®

TC 400

2-11© Siemens AG 2007 All Rights Reserved

Page 14

Description

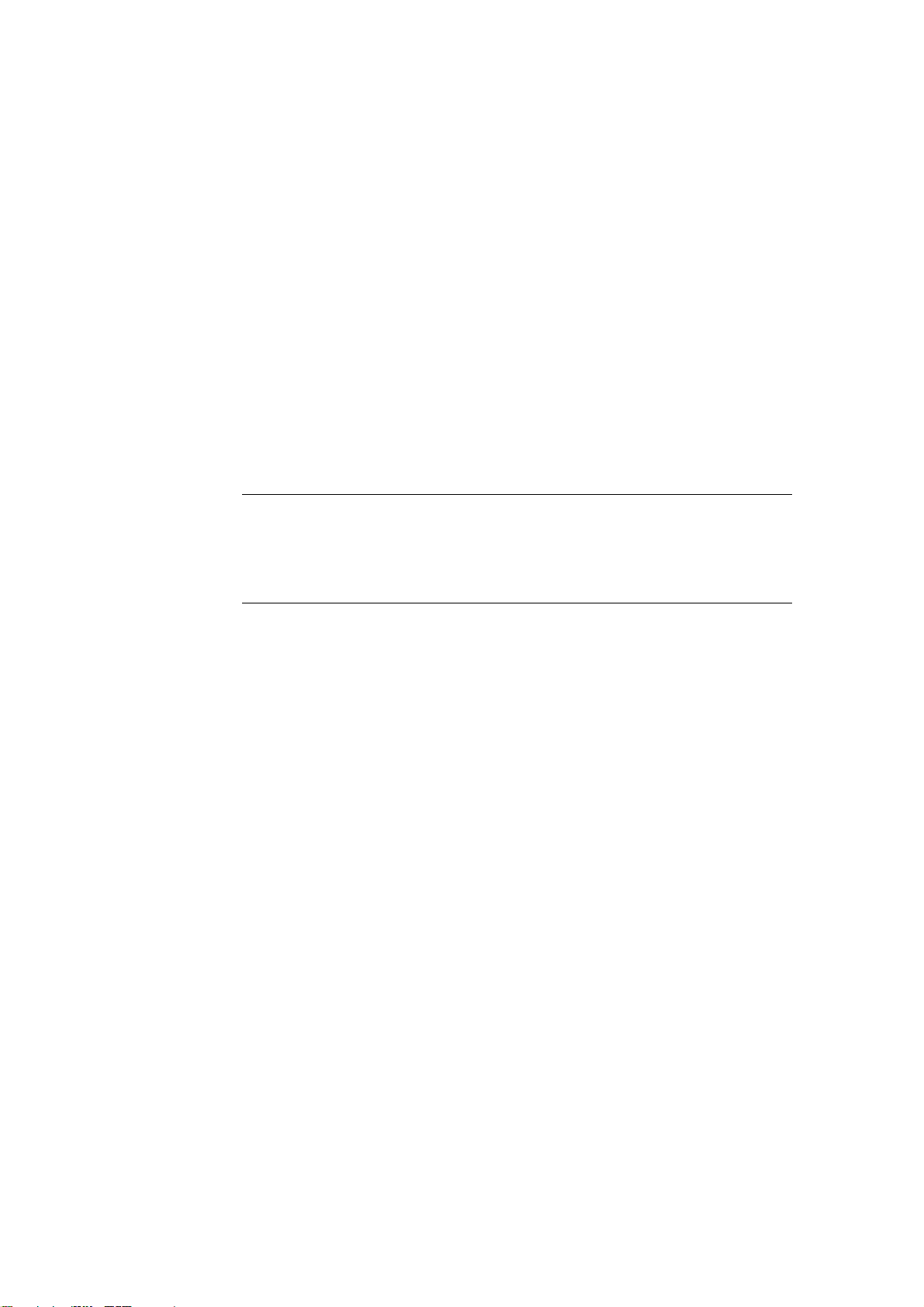

2.1 Configuration of the SICLOCK TC 400 hardware

The following figure shows a connection example of the SICLOCK TC 400 to a

SICLOCK GPS1000 as radio clock and an NTP server as an additional external

synchronization.

([WHUQDOV\QFKURQL]DWLRQV

6,&/2&.7&

;

287387

287387

287387

5$',2&/2&.

5$',2&/2&.

$/$50

:$51,1*

(WKHUQHW3RUWV

6,&/2&.3&21

3&21

HOHFWULFDORSWLFDOSXOVHFRQYHUWHURSWLRQDO

3&21

$ODUPZDUQLQJ

,QVWUXPHQWDWLRQ

DQGFRQWURO

,QVWUXPHQWDWLRQ

DQGFRQWURO

([WHUQDOV\QFKURQL]DWLRQ

([WHUQDOV\QFKURQL]DWLRQ

3&21

6

3&

Arbeitsstation

6,&/2&.*36

1736HUYHU

7LPHUHFHLYHUV

5HFHLYHUVYLD

FXUUHQWVLJQDO

YROWDJHVLJQDO

5HFHLYHUVYLD

3&21

6

3&

Arbeitsstation

3&

Arbeitsstation

2-12

Figure 2-1 Application example

© Siemens AG 2007 All Rights Reserved

SICLOCK

®

TC 400

Page 15

2.2 External synchronization

SICLOCK TC 400 can be matched to the local official time or GMT via external

synchronization in order to automate or restrict manual actions, such as daylight

saving time switchovers and leap seconds, to a minimum.

External synchronizations can be GPS or DCF77 radio clocks, servers (e.g. time

signal from an NTP server), further SICLOCK TC 400 devices or other signal

sources. They are connected to RADIO CLOCK 1 or RADIO CLOCK 2 or to one

of the four Ethernet ports on the device.

NTP servers are supported as external synchronization on the Ethernet ports.

Possible radio clocks to RADIO CLOCK 1 and RADIO CLOCK 2:

• SICLOCK GPS1000

• SICLOCK GPSDEC

• SICLOCK DCFRS

Third-party products can be connected via TTY (passive). The following protocols

are supported:

Description

• Demodulated DCF77

• Serial:

Further information

Linking the external synchronization (Section 9.1)

− Meinberg compatible (including time zones)

− Meinberg compatible (not including time zones)

− NMEA (0183/ZDA)

© Siemens AG 2007 All Rights Reserved

SICLOCK

®

TC 400

2-13

Page 16

Description

2.3 Time receivers

The time receivers of the plant can be connected via Ethernet or directly on the

device via point-to-point connections.

2.3.1 Plant synchronization via Ethernet

Physical access

There are four Ethernet interfaces available as physical access to the network

with the following specification:

• 100Base TX via RJ-45 socket

Protocols

The following protocols have been implemented:

• NTP server according to RFC2030

− Any/unicast mode

− Multicast mode

− Multicast mode with local time

• Time synchronization with the SIMATIC method

− PCS7-compatible mode

− S5-compatible mode

The time telegrams can be sent individually at each Ethernet port every second, every 10 seconds or every minute.

2-14

© Siemens AG 2007 All Rights Reserved

SICLOCK

®

TC 400

Page 17

2.3.2 Plant synchronization via point-to-point connection

Non-networked plant equipment is synchronized via OUTPUTs 1 to 3 (point-topoint connections). They can be parameterized independently.

OUTPUTs 1 and 2

• Current signal: 20 mA active, floating

or

• Voltage signal: 24 V, floating

OUTPUT 3

RS422, floating

Output signal

• DCF77 with local time, invertible

Description

• DCF77 with UTC, invertible

• Pulse per second, invertible

• Pulse per minute, invertible

• Serial telegram (parameterizable output telegram, see below)

Output telegram (setting applies to all three outputs)

• Meinberg compatible (including time zones)

• Meinberg compatible (not including time zones)

• NMEA (0183/ZDA)

© Siemens AG 2007 All Rights Reserved

SICLOCK

®

TC 400

2-15

Page 18

Description

2.4 Time management

Various functions are available in SICLOCK TC 400 in order to generate the time

valid for the plant from the external synchronization. This includes setting options

for time zones as well as the parameterizable daylight saving time.

Time assurance through protected synchronization

If a discontinuity of more than 5 s occurs in the external synchronization, the protected synchronization is activated and, for safety reasons, the synchronization

not performed.

Time assurance through microstepping mode

A time difference between the external synchronization and the device, which can

occur through a temporary radio failure or switchover to a substitute synchronization, is automatically cleared unnoticeably in microstepping mode for the plant

operation. There is no inconsistency in the time.

Further information and parameterization options for protected synchronization

and the microstepping mode are described in Section Synchronization

(Section 9.3.2).

Note

Only parameterize the plant time at one location within the synchronization hierarchy, ideally at the plant central clock.

2.5 Commissioning

The commissioning can be divided into the following steps:

1. Installation (Section 5)

2. Connecting (Section 6)

3. Assigning IP address on the device

Parameterization and Operation on the Device (Section 8)

4. Parameterization (Section 9)

With a few exceptions, the settings are made with the configuration tool, see

Configuration Tool (Section 7).

2-16

© Siemens AG 2007 All Rights Reserved

SICLOCK

®

TC 400

Page 19

2.6 Redundancy

Redundant external synchronization

Up to two radio clocks and up to four time servers can be operated on the

SICLOCK TC 400 for the external synchronization.

The priorities of the external synchronizations and therefore the redundancy

behavior can be set via parameters, see Redundancy (Section 9.1.3).

Redundant SICLOCK TC 400 plant central clock

A SICLOCK TC 400 can be operated via various ports on a redundant network

and several SICLOCK TC 400 can be operated as servers on one network.

For further information, refer to Chapters Configuration Tool (Section 7) and

Parameter Table (Section 10).

Redundant control of time receivers (output redundancy)

Description

At least two SICLOCK TC 400 are used for an output redundancy. With the appropriate parameterization, OUTPUTs 1 and 2 of the two devices can each be connected redundantly with the other.

For further information, refer to Sections Redundant point-to-point connec-

tions (Section 6.4.2) and OUTPUT 1 and 2 redundant (Section 9.2.4).

© Siemens AG 2007 All Rights Reserved

SICLOCK

®

TC 400

2-17

Page 20

Description

2-18

© Siemens AG 2007 All Rights Reserved

SICLOCK

®

TC 400

Page 21

Hardware Description 3

This chapter describes the hardware design with connections, the operator controls and displays.

3.1 External design

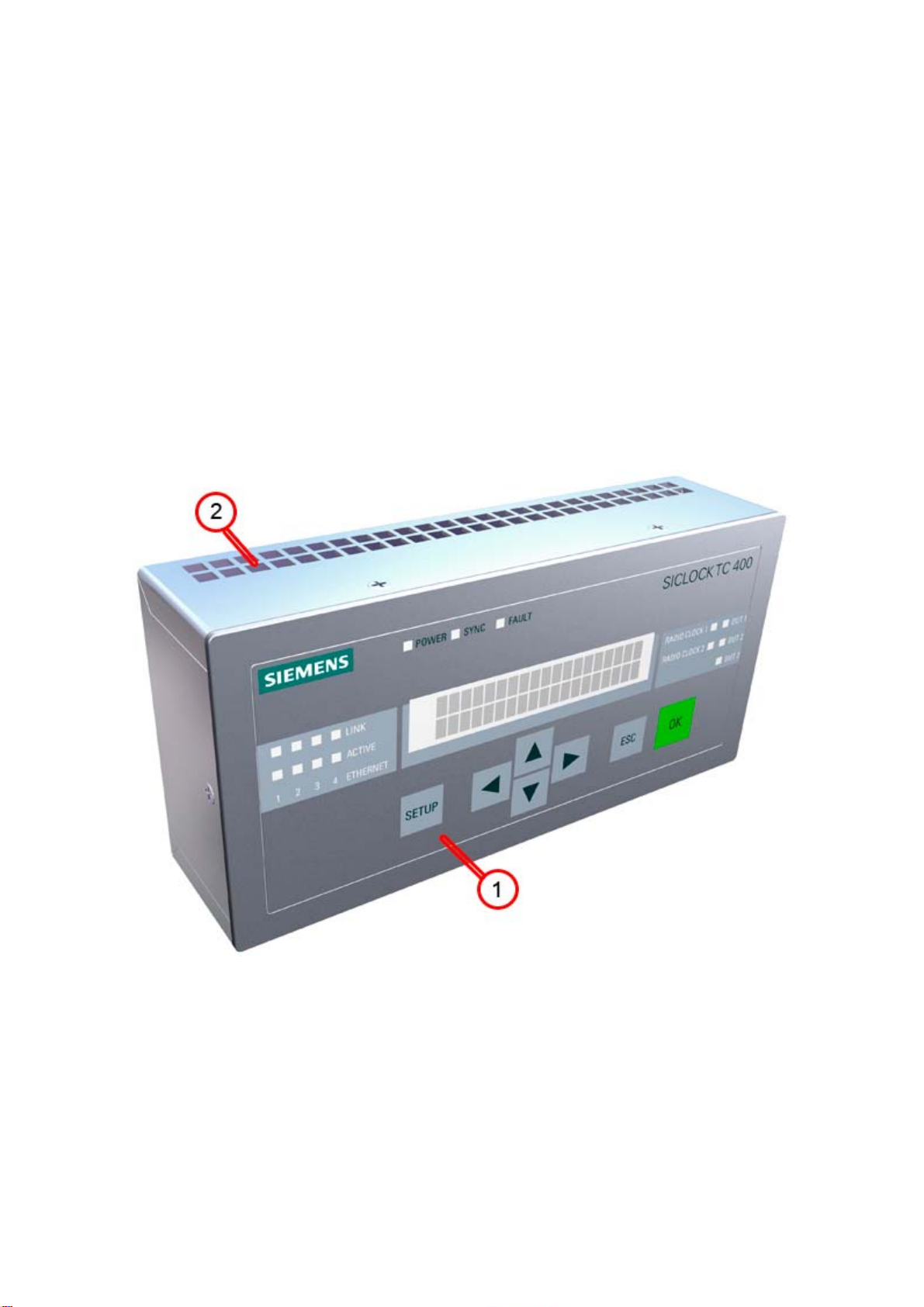

The following figures show the displays and operator controls as well as the connections of the SICLOCK TC 400.

Figure 3-1 SICLOCK TC 400 - perspective view with front panel and ventilation grille

(1) Panel with operator controls and displays

(2) Ventilation grille

SICLOCK

®

TC 400

3-19© Siemens AG 2007 All Rights Reserved

Page 22

Hardware Description

3.2 Connection elements

The following figure shows the connections of the SICLOCK TC 400.

Figure 3-2 SICLOCK TC 400 - arrangement of the connections

(1) Terminal X1 - 24 V power supply

(2) Terminal X2 - connecting terminal for radio clocks, outputs and alarm

See also Terminal assignment (Section 15.1).

(3) Four Ethernet ports

3-20

© Siemens AG 2007 All Rights Reserved

SICLOCK

®

TC 400

Page 23

3.3 Operator controls and displays

The front panel shows the current mode in the display and with LEDs. The device

can be operated directly via the keypad. A Web-based configuration tool is available for a wide range of configuration options, see Configuration Tool

(Section 7).

Hardware Description

Figure 3-3 SICLOCK TC 400 front view

© Siemens AG 2007 All Rights Reserved

SICLOCK

®

TC 400

3-21

Page 24

Hardware Description

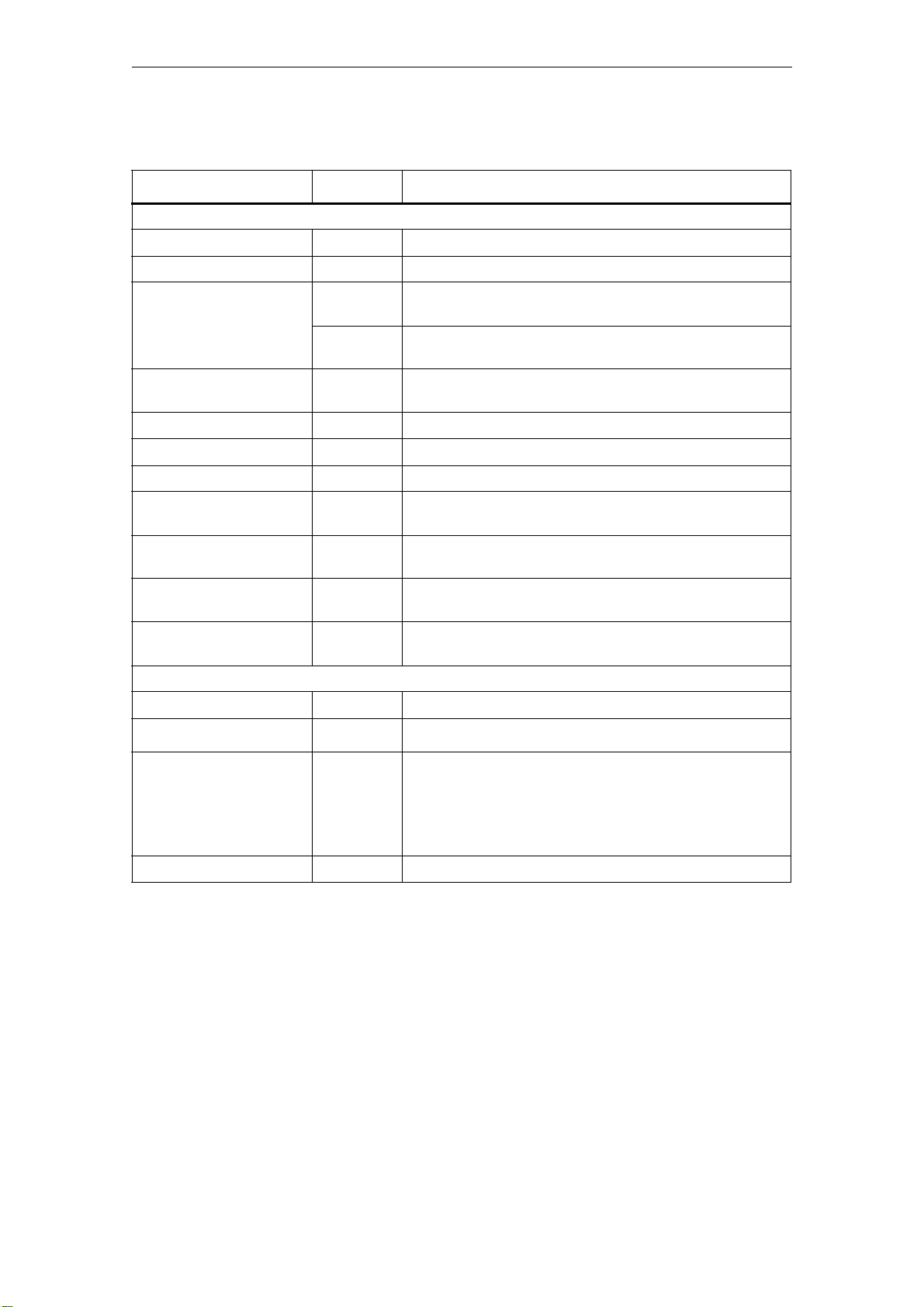

Table 3-1 Meaning of the displays and operator controls

Name Color (LED) Meaning

Displays

POWER Green Ready to run

SYNC Green SICLOCK TC 400 has been externally synchronized

FAULT Red Alarm

The associated message text is shown in the display.

Flashing red Warning

The associated message text is shown in the display.

LINK (Port 1-4) Yellow Physical connection has been established, possible to send

and receive

ACTIVE (Port 1-4) Green Display of the data traffic for the respective port

RADIO CLOCK 1 Yellow Receive signal of radio clock 1

RADIO CLOCK 2 Yellow Receive signal of radio clock 2

OUT 1 Green Output 1

Output signal at the terminal

OUT 2 Green Output 2

Output signal at the terminal

OUT 3 Green Output 3

Output signal at the terminal

Display Display of time, date and synchronization or message text

when an error occurs

Operator controls

SETUP Call of the password input or parameter list

↑ ↓ ← →

ESC • Cancellation of an entry and return to the call menu.

OK Accepting of entries and acknowledging of messages

Navigation in the menus

• Switchover from an information message or warning to the

mode display

• Change to operator control for a limited period when a per-

sistent message is pending.

For further information, see Parameterization and Operation on the Device

(Section 8)

.

3-22

© Siemens AG 2007 All Rights Reserved

SICLOCK

®

TC 400

Page 25

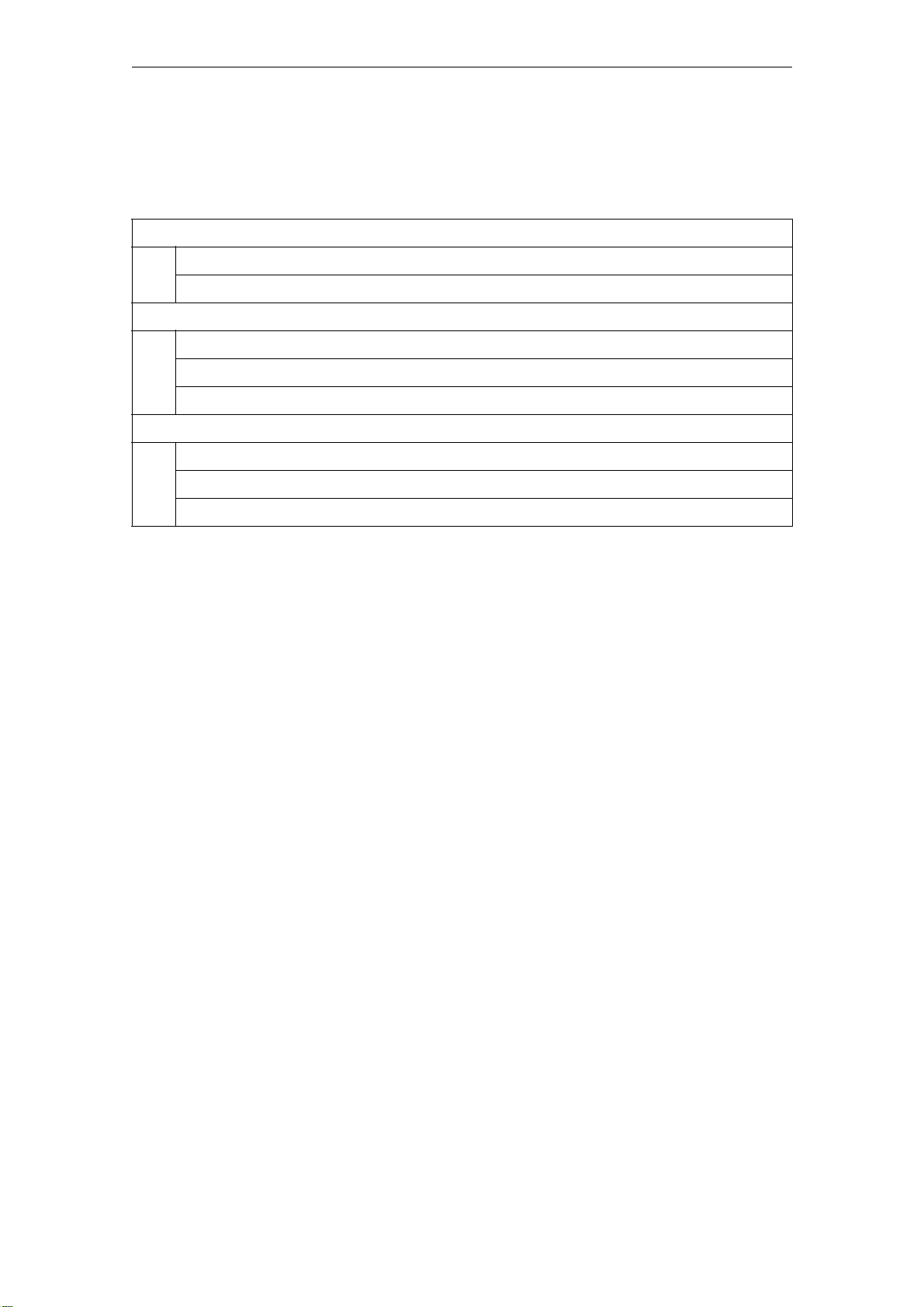

3.4 Scope of delivery

Table 3-2 Scope of delivery of the individual device versions

2XV9450-2AR01

SICLOCK TC 400 single device with terminal strips connected at X1 and X2

Operating instructions on CD

2XV9450-2AR10 (SICLOCK TC 400 standard package)

SICLOCK TC 400 single device with terminal strips connected at X1 and X2

Operating instructions on CD

SICLOCK GPS1000 radio clock complete with mounting frame and lightning protection

2XV9450-2AR20 (SICLOCK TC 400 DCF77 package)

SICLOCK TC 400 single device with terminal strips connected at X1 and X2

Operating instructions on CD

Hardware Description

SICLOCK DCFRS radio clock industrial version complete with mounting frame

© Siemens AG 2007 All Rights Reserved

SICLOCK

®

TC 400

3-23

Page 26

Hardware Description

3-24

© Siemens AG 2007 All Rights Reserved

SICLOCK

®

TC 400

Page 27

Operation Planning 4

4.1 Overview of operation planning

SICLOCK TC 400 has been designed for weather-protected, stationary operation

in an industrial environment.

The operating conditions surpass the requirements according to DIN IEC 607213-3:

• Class 3M3 (mechanical requirements)

• Class 3K3 (climatic requirements)

General information about operation

Caution

The device is approved for operation in closed rooms only. The guarantee is void

if this stipulation is ignored.

Condensation

When transporting the device at low temperatures, ensure that no moisture forms

on or in the device. This also applies if the device is subjected to extreme changes

in temperature.

Commissioning

Allow the device to slowly adjust to room temperature before commissioning. Do

not place the device near heat radiation. With large differences in temperature,

harmful condensation can be avoided by leaving the device in the transport packaging.

If condensation occurs, wait at least about 12 hours before you switch on the

device (for 20° C temperature difference). The waiting period is extended accordingly for greater temperature differences.

Avoid extreme ambient conditions. Protect your device against dust, moisture and

heat. For further information, see Chapter Technical Data (Section 13).

Do not place the device in direct sunlight.

SICLOCK

®

TC 400

4-25© Siemens AG 2007 All Rights Reserved

Page 28

Operation Planning

Use in residential areas and operation in the public network

If you operate the SICLOCK TC 400 in residential areas or in the public network,

you must ensure that it complies with the limit class B according to EN 55022 with

regard to the emission of radio interference.

Note

This is a a class A device. The device may cause RF interference in residential

areas or in the public network. In this case, the operator company may be held

liable for taking appropriate measures.

The following measures are recommended to ensure the interference complies

with limit class B:

• Installation of the SICLOCK TC 400 in grounded control cabinets / control

boxes

• Use of filters in electrical supply lines

Use with additional measures

Applications where the use of the SICLOCK TC 400 or similar device requires

additional measures:

• Locations with a high percentage of ionizing radiation

• Locations with extreme operating conditions, such as

− dust accumulation

− corrosive vapors or gases

− strong electric or magnetic fields

− damp and wet rooms

− strong oscillations, shocks, vibrations

− strong radiant heat

• In systems, which require special monitoring, such as

− elevators

− electrical plants in potentially hazardous areas

An additional measure, for example, would be to install the SICLOCK TC 400 in

a cabinet or housing.

4-26

© Siemens AG 2007 All Rights Reserved

SICLOCK

®

TC 400

Page 29

4.2 Transport and storage conditions

Although the device is of rugged design, its internal components are sensitive to

severe vibrations or shock. You must therefore protect the device against severe

mechanical loads.

You should always use the original packaging for shipping and transporting the

device.

Unpack the device at its final destination.

Do not transport the device when it is mounted.

Observe the notes about temporary storage in Chapter Service and Mainte-

nance under Battery (Section 11.1).

The following information applies to modules transported and stored in the original packaging.

The climatic environmental conditions correspond to IEC 60721-3-2, Class 2K4

for transport

The mechanical environmental conditions correspond to IEC 60721-3-2, Class

2M2 for transport

Operation Planning

Caution

Risk of damage to the device!

If you are transporting the device in cold weather with large fluctuations in temperature, care must be taken to ensure that no moisture forms on or in the device

(condensation).

If condensation has developed, wait at least 12 hours before you switch on the

device.

Caution

Observe these conditions each time the device is transported, otherwise the guarantee is void.

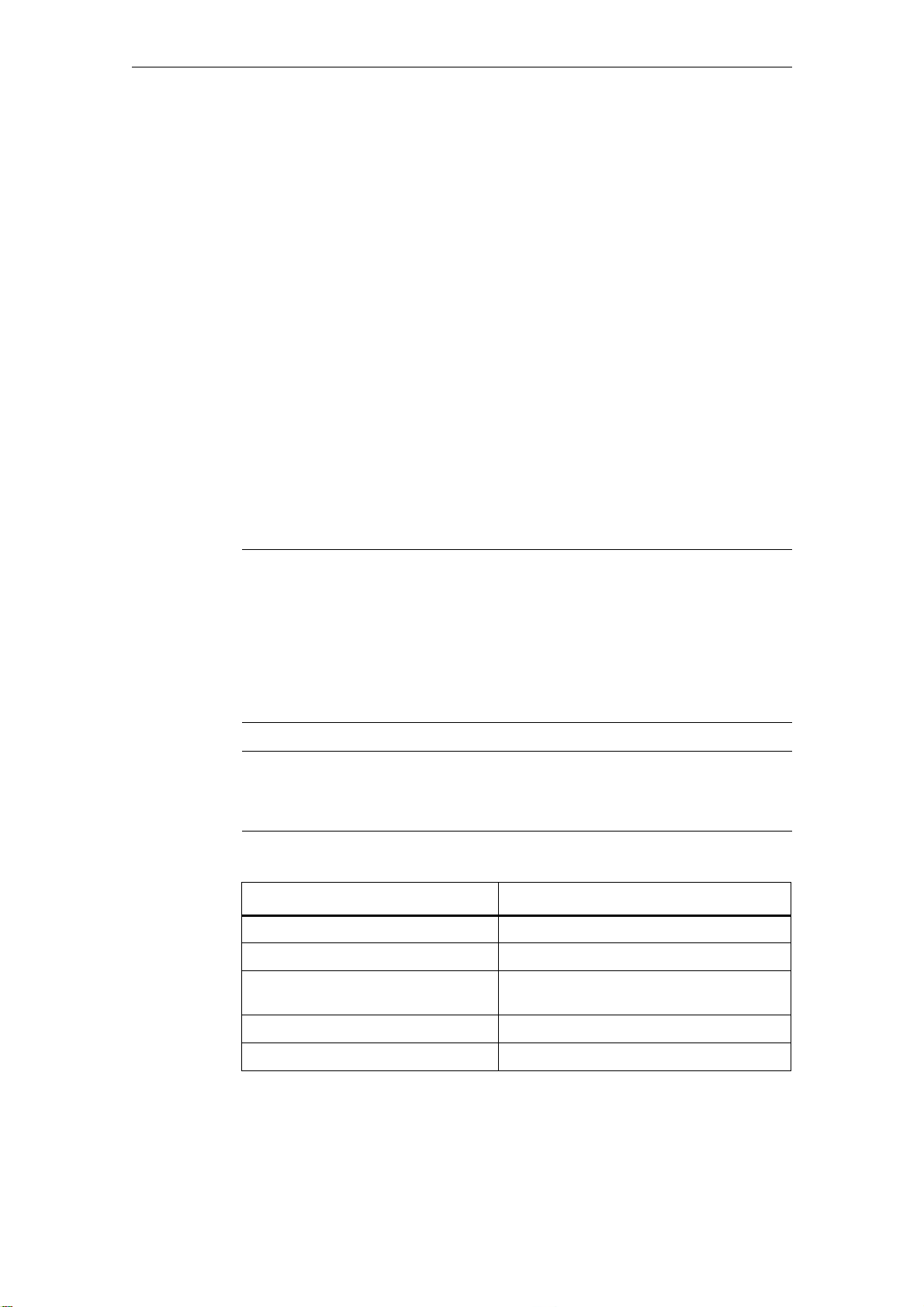

Table 4-1 Transport and storage conditions

Type of condition Permissible range

Free fall (in transport packaging)

Temperature

Atmospheric pressure

Maximum temperature change

<= 1 m

-40° C to +70° C

1080 to 660 hPa (corresponds to an altitude

of -1000 to 3500 m)

20° C/h

Relative humidity

© Siemens AG 2007 All Rights Reserved

SICLOCK

®

TC 400

10 to 95% (at 25° C without condensation)

4-27

Page 30

Operation Planning

4.3 Unpacking and checking the delivery

The device has been completely assembled, tested and packed in the factory and

has no internal transport locks.

If there are large temperature differences between the transport medium and the

location where the device is unpacked, it is recommended that the device be left

in the transport packaging in order to avoid harmful condensation.

Procedure

• Please check the packaging material for transport damage upon delivery.

• If any transport damage is present at the time of delivery, lodge a complaint at

the shipping company in charge. Have the shipper confirm the transport damage immediately.

• Unpack the device.

• Keep the packaging material in case you have to transport the device again.

Caution

The packaging protects the device during transport and storage. Transport the

device only in the original packaging!

• Please keep the enclosed documentation in a safe place. You will need the

documentation when you commission the device for the first time.

• Check the package contents for completeness and any visible transport dam-

age. Check for completeness using the enclosed "Contents of Delivery" list.

• Notify the delivery service in charge immediately if the package contents are

incomplete or damaged.

Warning

Make sure that a damaged device is not installed and commissioned unintentionally.

4-28

© Siemens AG 2007 All Rights Reserved

SICLOCK

®

TC 400

Page 31

4.4 Mounting position and fixing method

4.4.1 Installation instructions

Before installing the device, read the following general installation instructions.

Warning

Hazardous voltage

Isolate the power supply to the control cabinet before opening it. Ensure that the

power to the control cabinet cannot be turned on accidentally.

• Position the device/display in an ergonomic position favorable to the user.

Choose a suitable installation height.

• Position the device/display so that it is not subject to direct sunlight or other

strong sources of light.

Operation Planning

• Provide adequate volume in the control cabinet for air circulation and heat

transport. Maintain a clearance of 100 mm above and below. This clearance

is increased accordingly with connection cables.

• Position the device so that the air vents of the housing are not covered up fol-

lowing installation.

• Also provide enough free space for device expansions.

• Note the reinforcement in the control cabinet for stabilizing the installation cut-

out. Install reinforcement if required.

• Install the device in such a way that there is no danger, for example, of it falling

out.

• During assembly, please comply with the permissible mounting positions.

See also Dimension Drawing (Section 14).

© Siemens AG 2007 All Rights Reserved

SICLOCK

®

TC 400

4-29

Page 32

Operation Planning

4.4.2 Permitted mounting position

The only permissible mounting position is horizontal, i.e. the display is read horizontally. Adequate ventilation cannot be guaranteed in other mounting positions

Figure 4-1 Horizontal mounting position

4.4.3 Fixing method

The housing can be snapped onto DIN rails or fixed to SIMATIC S5 standard

mounting rails.

See also Installation overview (Section 5.1).

4-30

© Siemens AG 2007 All Rights Reserved

SICLOCK

®

TC 400

Page 33

Installation 5

5.1 Installation overview

Figure 5-1 SICLOCK TC 400 - installation view

The SICLOCK TC 400 should be installed in the control cabinet at an easily

accessible position.

The housing can be snapped onto DIN rails (EN 50022-35) or fixed to SIMATIC

S5 standard mounting rails (6ES5 710-8maxx).

There must be a space of 100 mm above the device for snapping the device on

and off the DIN rail and for unobstructed heat dissipation.

There must be a space of at least 100 mm below the device for the process signal

connectors.

It is recommended that a suitable cable duct be installed below this space.

Note

Ensure that the snap fasteners are correctly locked.

See also Dimension Drawing (Section 14).

SICLOCK

®

TC 400

5-31© Siemens AG 2007 All Rights Reserved

Page 34

Installation

5-32

© Siemens AG 2007 All Rights Reserved

SICLOCK

®

TC 400

Page 35

Connecting 6

6.1 Connecting overview

Caution

Only connect I/O devices that are suitable for industrial use.

Caution

Strictly adhere to the specifications for I/O devices.

Note the following requirements for the setup:

• The device may only be connected to 24 VDC power supplies that meet the

requirements of a functional extra-low-voltage with safe isolation (PELV). The

cable cross-section must be chosen to ensure that no damage can result from

a cable overheating in the event of a short-circuit in the SICLOCK TC 400. For

cable cross-section, see Connecting the power supply (Section 6.2).

• Avoid extreme environmental conditions as far as possible.

• Protect the device against dust, moisture, heat and severe vibration.

• Do not place the device in direct sunlight.

• Install the device in such a way that it does not present a hazard (e.g. by falling

out).

• Do not cover the vent slots.

• Permitted mounting position (Section 4.4.2).

SICLOCK

®

TC 400

6-33© Siemens AG 2007 All Rights Reserved

Page 36

Connecting

6.2 Connecting the power supply

The power supply is connected to the X1 terminal strip and must always be via a

time-lag 1 A fuse. The device does not have a separate power switch.

Figure 6-1 Connecting the power supply

Note before connecting

Warning

Only connect the device to 24 VDC power supplies that meet the requirements of

a functional extra-low voltage with safe isolation (PELV); in addition, a protective

conductor must also be connected. The cable cross-section must be matched to

the short-circuit current of the 24 VDC power supply, so that with a short-circuit,

damage is not caused by the cable. Only connect cables with a cross-section of

minimum 0.25 mm

Notice

The 24 VDC power supply must be adapted to the input data of the device, see

Technical Data (Section 13).

Caution

Ensure that the functional ground is connected correctly.

Make sure the polarity is correct for DC voltage.

Functional check

After switching on, the POWER LED must show a green light.

2

(AWG23) to maximum 2.50 mm2 (AWG13).

6-34

© Siemens AG 2007 All Rights Reserved

SICLOCK

®

TC 400

Page 37

6.3 Connecting the external synchronization

The signal of the connected radio clock is detected automatically and displayed

in the /Inputs/Input 1/Status (0.20.02)

(0.21.02) parameter).

X2-7

X2-8

48 V

48 V

X2-9

X2-10

X2-11

X2-7

passi ve

Radio Cloc k 1

passi ve

Radio Cloc k 2

parameter (or /Inputs/Input 2/Status

Connecting

48 V

48 V

X2-8

X2-9

X2-10

X2-11

activ e

Radio Cloc k 1

activ e

Radio Clock 2

Figure 6-2 Circuit diagram for a passive and an active radio clock

Table 6-1 Terminal assignment of the radio clock inputs

Terminal Designation

X2-7 RADIO CLOCK GND

X2-8 RADIO CLOCK 1A

X2-9 RADIO CLOCK 1B

X2-10 RADIO CLOCK 2A

X2-11 RADIO CLOCK 2B

Note

If you are operating two radio clocks, connect the preferred model to RADIO

CLOCK 1.

© Siemens AG 2007 All Rights Reserved

SICLOCK

®

TC 400

6-35

Page 38

Connecting

Functional check

The receive signal of the radio clocks is displayed on the front panel with the

"RADIO CLOCK 1" and "RADIO CLOCK 2" LEDs.

The status of the radio clock is displayed in the /Inputs/Input 1/Status (0.20.02)

/Inputs/Input 2/Status (0.21.02)

) parameter.

(or

Possible states:

• GPS (SICLOCK GPS1000 and SICLOCK GPSDEC)

• GPS (faulty)

The signal reception is temporarily faulty.

• DCF77 (SICLOCK DCFRS and SICLOCK GPSDEC)

• DCF77 (faulty)

The signal reception is temporarily faulty.

• Serial

− Meinberg

Receiving Meinberg format

− NMEA

Receiving NMEA format

− Telegram (faulty)

Fault detected in telegram or telegram failure

• No signal

The connection of individual sources to the external synchronization is described

in the following.

6-36

© Siemens AG 2007 All Rights Reserved

SICLOCK

®

TC 400

Page 39

6.3.1 SICLOCK GPS1000

The GPS1000 receiver is connected as shown in Fig. 6-3.

;

5$',2&/2&.*1'

5$',2&/2&.$

5$',2&/2&.%

5$',2&/2&.$

5$',2&/2&.%

Connecting

6

7

8

9

10

11

PD[P

/LJKWQLQJSURWHFWLRQ

Figure 6-3 SICLOCK GPS1000 radio clock connection to RADIO CLOCK 1

We recommend a 2-wire, shielded cable, e.g. LiYCY 2x1 mm², as radio clock

cable. The cable shield should be connected one-sided to a suitable place at the

installation location.

An additional parameterization of the GPS1000 is not required.

Warning

Use lightning protection for the outdoor GPS antenna.

Functional check

When the GPS1000 is receiving correctly, the "RADIO CLOCK 1" or "RADIO

CLOCK 2" LED on the front panel should flash at approx. 1 Hz.

After receiving for approximately three minutes the /Inputs/Input 1/Status

(0.20.02) or /Inputs/Input 2/Status (0.21.02) parameter must change to "GPS".

© Siemens AG 2007 All Rights Reserved

SICLOCK

®

TC 400

6-37

Page 40

Connecting

6.3.2 SICLOCK DCFRS industrial version

The industrial version of the SICLOCK DCFRS radio clock contained in the

DCF77 package is connected as shown in Fig. 6-4. The polarity is not important

here.

max. 1000 m

;

6

5$',2&/2&.*1'

5$',2&/2&.$

5$',2&/2&.%

5$',2&/2&.$

5$',2&/2&.%

7

8

9

10

11

Figure 6-4 SICLOCK DCFRS industrial version radio clock connection to

Warning

Lightning protection must also be installed when used outdoors.

Note

The radio clock cable shield should be connected one-sided to a suitable place at

the installation location.

Functional check

When the SICLOCK DCFRS is receiving correctly, the "RADIO CLOCK 1" or

"RADIO CLOCK 2" LED on the front panel should flash at approx. 1 Hz.

After receiving for approximately three minutes the /Inputs/Input 1/Status

(0.20.02) or /Inputs/Input 2/Status (0.21.02) parameter must change to "DCF77".

Note

When selecting the location for the antenna, it is especially important that there is

as little electromagnetic interference on the DCF77 carrier frequency as possible.

Do not mount the antenna close to drives, neon lamps, monitors and other emitters of interference.

RADIO CLOCK 1

6-38

© Siemens AG 2007 All Rights Reserved

SICLOCK

®

TC 400

Page 41

6.3.3 SICLOCK GPSDEC

A SICLOCK GPSDEC decoder is connected as shown in Fig. 6-5.

;

5$',2&/2&.*1'

5$',2&/2&.$

5$',2&/2&.%

5$',2&/2&.$

5$',2&/2&.%

Figure 6-5 SICLOCK GPSDEC radio clock connection to RADIO CLOCK 1

Connecting

'&)77<

6

7

8

9

10

11

PD[P

Caution

The SICLOCK GPSDEC may only be operated as active radio clock.

Operation as passive radio clock results in the destruction of the SICLOCK GPSDEC.

Table 6-2 Recommended parameterization of the GPSDEC decoder for the

Functional check

When the GPSDEC is receiving correctly, the "RADIO CLOCK 1" or "RADIO

CLOCK 2" LED on the front panel should flash at approx. 1 Hz.

After receiving for approximately three minutes the /Inputs/Input 1/Status

(0.20.02) or /Inputs/Input 2/Status (0.21.02) parameter must change to "GPS" or

"DCF77".

SICLOCK TC 400 synchronization

Parameter Setting

Time difference compared to GMT 00:00

Switchover to daylight saving time "None"

X1.5-8 (DCF77TTY) "DCF without ZZB"

© Siemens AG 2007 All Rights Reserved

SICLOCK

®

TC 400

6-39

Page 42

Connecting

6.3.4 Third-party systems

Third-party systems that fulfill the following requirements can be sued for the

external synchronization of the SICLOCK TC 400.

Requirements

• Active radio clock signal with 20 mA rated current

• Supported signals:

− Demodulated DCF77

− Serial:

Meinberg compatible (including time zones)

Meinberg compatible (not including time zones)

NMEA (0183/ZDA)

Functional check

After receiving for approximately three minutes the /Inputs/Input 1/Status

(0.20.02) or /Inputs/Input 2/Status (0.21.02) parameter must change to "Meinberg", "NMEA" or "DCF77".

6-40

© Siemens AG 2007 All Rights Reserved

SICLOCK

®

TC 400

Page 43

6.4 Connecting the time receivers

Time receivers can be connected via point-to-point connections (OUTPUT 1 to 3)

or via Ethernet.

Four Ethernet ports are available for the Ethernet connection and can be parameterized accordingly.

A redundant point-to-point connection can be implemented via OUTPUTs 1 and

2 when two SICLOCK TC 400s are used.

6.4.1 Point-to-point connections via OUTPUT 1 to 3

Current signal – low-resistance receiver (e.g. optocoupler)

Point-to-point connections via an active current interface can be connected to

OUTPUTs 1 and 2 as shown in Fig. 6-6.

77<DFWLYH

Connecting

1

2

24 V / 20 mA

3

4

Figure 6-6 OUTPUTs 1 and 2 as current interface

Table 6-3 Terminals of OUTPUTs 1 and 2

Terminal Designation

1OUTPUT 1 GND

2OUTPUT 1

3OUTPUT 2

4OUTPUT 2 GND

© Siemens AG 2007 All Rights Reserved

SICLOCK

®

TC 400

6-41

Page 44

Connecting

24 V voltage signal – high-resistance receiver (greater than 1.2 kOhm)

A high-resistance receiver can also be connected directly. The output then functions as a 24 V voltage output.

Connection as in Fig. 6-6.

RS422

An RS422 interface is available at OUTPUT 3 for a high-precision point-to-point

connection. The connection is made as shown in Fig. 6-7.

RS422

5

6

A

B

Figure 6-7 OUTPUT 3 RS422

Table 6-4 OUTPUT 3 terminals

Terminal Designation

5OUTPUT 3A

6OUTPUT 3B

6-42

© Siemens AG 2007 All Rights Reserved

SICLOCK

®

TC 400

Page 45

6.4.2 Redundant point-to-point connections

OUTPUT 1 and OUTPUT 2 of the devices are decoupled internally so that one

output of each device can be connected in parallel to the same time receiver.

Connecting

7LPHUHFHLYH U

UHGXQGDQWWLPHIURPE RWK

6,&/2&.DQG

UHVSHFWLYHO\

Figure 6-8 Example with redundant time reception at OUTPUT 1

Further information

Redundancy (Section 2.6)

OUTPUT 1 and 2 redundant (Section 9.2.4)

6,&/2&.

287387

287387

287387*1'

287387*1'

ಹ

ಹ

7LPHUHFHLYHU

6,&/2&.

287387

287387

287387*1'

287387*1'

ಹ

ಹ

7LPHUHFHLYHU

© Siemens AG 2007 All Rights Reserved

SICLOCK

®

TC 400

6-43

Page 46

Connecting

6.5 Connecting an alarm output and a warning output

The SICLOCK TC 400 automatically performs various functional tests during

operation. When an error occurs, the appropriate messages are generated on the

display. A distinction is made between alarms and warnings.

An alarm output and a warning output are available on terminal X2 for the external

monitoring.

;

;

;

Figure 6-9 Alarm output X2-13 and warning output X2-14

Table 6-5 Parameters that influence the alarm response

/Synchronization/Advanced/Monitoring/monitor status of synchronization (0.09.14)

/Network Settings/Ethernet 1/Advanced Settings Adapter 1/monitor link state (0.05.09)

/Network Settings/Ethernet 2/Advanced Settings Adapter 2/monitor link state (0.05.10)

/Network Settings/Ethernet 3/Advanced Settings Adapter 3/monitor link state (0.05.11)

/Network Settings/Ethernet 4/Advanced Settings Adapter 1/monitor link state (0.05.12)

/NTP Client/Monitoring/monitor server (0.18.04)

/Inputs/Input 1/Monitoring/monitor input (0.20.01)

/Inputs/Input 2/Monitoring/monitor input (0.21.01)

/Environment/Advanced/Temperature/monitoring (0.24.01)

Example:

The alarm output is to be set when no external synchronization is available.

With the configuration tool, set the parameter entry /Synchronization/Advanced/Monitoring/monitor status of synchronization (0.09.14) = "Alarm"

to activate the monitoring / alarm output when an error occurs.

6-44

Note

The contacts are designed as fail-safe NC contacts. The appropriate contact is

opened when an alarm or a warning is pending.

© Siemens AG 2007 All Rights Reserved

SICLOCK

®

TC 400

Page 47

Configuration Tool 7

The SICLOCK TC 400 configuration tool is available for the easy parameterization and configuration of the SICLOCK TC 400. The tool can be called as up Web

interface via an Internet browser.

With the configuration tool, you can view and change parameters online and

offline, view archives and perform searches in them with filter criteria and load,

save and change the parameterization of the SICLOCK TC 400 device.

Figure 7-1 SICLOCK TC 400 configuration tool

(1) Toolbar of the configuration tool

(2) Working area of the configuration tool

You can make settings and assign parameters in the Parameters tag

You can check states and search for events in the Archives tag

SICLOCK

®

TC 400

7-45© Siemens AG 2007 All Rights Reserved

Page 48

Configuration Tool

Requirements

PC

• Screen resolution of at least 1280x1024 pixels

• Java Runtime, at least V1.4.0 or higher

• Web browser, e.g. Microsoft Internet Explorer

• Connection via one of the four Ethernet ports of the device

SICLOCK TC 400

• Assignment of an IP address on the device

A valid IP address must be assigned for the Ethernet port of the device that is

to be used for the configuration.

Default addresses as delivered each with subnet mask 255.255.255.0:

− Port 1: 192.168.1.10

− Port 2: 192.168.2.20

− Port 3: 192.168.3.30

− Port 4: 192.168.4.40

PC must be in the same subnet.

Parameters, entries and lists

A parameter is considered as a group of associated values. Each value is designated as an entry of its parameter.

Parameters of the same kind can form a list. Such lists are displayed as [ ].

Notice

Entries can be edited individually, but not read or written individually. The parameter is always read or written with all its entries. If a list is being considered, the

entire list is read or written.

Parameters are identified by their unique parameter number. The parameter

number is always in three parts, e.g. 0.05.12.

7-46

© Siemens AG 2007 All Rights Reserved

SICLOCK

®

TC 400

Page 49

Example of the /Display/View (0.10.01) parameter with the entries "Language"

and "Time":

Figure 7-2 Parameter view

Working with the configuration tool

Configuration Tool

To start the configuration tool:

1. Open the Web browser.

2. Enter the address of the device port, e.g. 192.168.1.10

3. If necessary, confirm the installation and execution of the applet with "Yes" or

"Always".

−> The configuration tool is started and displayed in the browser.

Note

Note the information in your browser about restrictions because of strict safety

settings.

To parameterize the SICLOCK TC 400 with the configuration tool:

1. Connect the configuration tool to the SICLOCK TC 400 with the button.

2. For a new parameterization of the device, load the parameters to the configuration tool with the button or open an existing parameter file (*.u600) with

the button.

3. Parameterize the SICLOCK TC 400 according to your hardware configuration

and your requirements.

In online mode, changes take effect immediately on the device.

4. Save the configuration as parameter file (*.u600) on your PC with the

button.

Note

In order to be able to access the last version of the SICLOCK TC 400 parameterization, we recommend that you save the current parameterization of SICLOCK

TC 400 as *.u600 file before you make any changes.

© Siemens AG 2007 All Rights Reserved

SICLOCK

®

TC 400

7-47

Page 50

Configuration Tool

7.1 Menus

Table 7-1 Menus in the configuration tool

Menu/Function Meaning/Note

File

Open Load a parameterization/archive from the local file system

See also General functions (Section 7.2).

Save Save of a parameterization/archive to the local file system

See also General functions (Section 7.2).

Exit Exit the application

Connection See also Establish/disconnect online connection (Section 7.2.1).

Connect Connect to a device

Disconnect Disconnect from a device

Data transfer

(online connection required)

See also Establish/disconnect online connection (Section 7.2.1).

Download parameters

from device

Refresh parameters

from device

Upload parameters to

device

Download archive Download the entire archive from the connected device to the PC

Refresh archive Re-request/refresh the archive of a connected device

View

Parameters Change to the Parameters view

Archive/Events Change to the Archive/Events view

Language Selection of the languages available for the user interface

Download all parameters from a connected device to the PC

See also Parameters (Section 7.3).

Refresh all parameters previously loaded to the PC with the values of

the connected device

See also Parameters (Section 7.3).

Write all parameters from the PC to the connected device

See also Parameters (Section 7.3).

See also Archive (Section 7.4).

See also Archive (Section 7.4).

See also Parameters (Section 7.3).

See also Archive (Section 7.4).

Depending on the version, several languages may be offered for selection

• English (standard language)

• German

The language/naming of the parameters and archives is supplied by the

device. If the language set in the configuration tool is known to the

device, then the parameter/archive is displayed in this language. If the

language is not known to the device, the display is in the standard language.

7-48

© Siemens AG 2007 All Rights Reserved

SICLOCK

®

TC 400

Page 51

Table 7-1 Menus in the configuration tool

Menu/Function Meaning/Note

?

Help... Call the help system

Version… Display the version information of the configuration tool

Configuration Tool

© Siemens AG 2007 All Rights Reserved

SICLOCK

®

TC 400

7-49

Page 52

Configuration Tool

7.2 General functions

The toolbar of the configuration tool provides general functions for the parameters

and the archive. You can also acknowledge events and authorize yourself on the

configuration tool.

Table 7-2 Operator options and displays in the toolbar of the configuration tool

Field/Button Meaning/Instruction

Load a parameterization/archive from the local file system

The file must be present in U600 format (*.u600). When opening, the

Open

Save

IP address

Connect to device

Disconnect from device

Authorization - password

parameterization and the archive are loaded from the file.

Notice

The currently loaded data (parameterization and archive) is overwritten.

Save of a parameterization/archive to the local file system

The data (parameterization and archive) is saved in U600 format (*.u600).

IP address of the SICLOCK TC 400

You enter the IP address of the device here.

Connect to a device

The connection is established to the device with the specified IP address.

Disconnect from device

The established connection is disconnected.

See also Establish/disconnect online connection (Section 7.2.1).

Password input to activate a higher access level

Password of the device as delivered: "2222"

See also Authorization (Section 7.2.2).

Perform the authorization with the entered password

Authorize

Event

(online connection

required)

Acknowledge event

(online connection

required)

7-50

Events currently pending in the device

Events pending on the device (e.g. warnings, alarms, …) are displayed in

online mode

No information is displayed in offline mode.

Acknowledge pending event

In online mode, an acknowledgement for the pending event is sent to the

device. If acknowledgeable, the device clears the event from the display.

Events that cannot be acknowledged (persistent messages) remain in the

display.

© Siemens AG 2007 All Rights Reserved

SICLOCK

®

TC 400

Page 53

Table 7-2 Operator options and displays in the toolbar of the configuration tool

Field/Button Meaning/Instruction

Acknowledge all pending events

In online mode, an acknowledgement for all pending events is sent to the

Acknowledge all events

Ignore event

device. There is an acknowledgement even when the cause of the event is

still present. In this way it is possible, for example, to clear persistent

alarms.

Discard the pending event

The event display is cleared without interaction with the device.

7.2.1 Establish/disconnect online connection

To establish an online connection to the SICLOCK TC 400:

1. Enter the IP address of the device in the toolbar.

Configuration Tool

2. Start the connection build-up by clicking the icon next to the IP address

field.

−> The configuration tool changes to online mode:

To disconnect the online connection to the SICLOCK TC 400:

1. Click the icon next to the IP address field.

−> The configuration tool changes to offline mode:

Note

The device is disconnected if there have not been any operator actions for approx.

two hours

© Siemens AG 2007 All Rights Reserved

SICLOCK

®

TC 400

7-51

Page 54

Configuration Tool

7.2.2 Authorization

There are authorization levels for each parameter, which permit or prohibit read

and write access to the parameter. The user interface starts with the lowest authorization level, which usually only permits read access to parameters.

More rights can be obtained by entering the appropriate password.

The password can be changed by the user:

• /System/Authorization For Standard Protection (2.06.02)

As delivered, the password on the device is "2222"

The current authorization level is indicated by the color of the password field.

Write protection - red entry field

At this authorization level, the user typically only has read access to standard

parameters.

Standard protection - green entry field

At this authorization level, the user typically also has read access to advanced

parameters and write access to standard parameters.

Online mode

Authorization is performed directly on the device, i.e. the device assigns an

appropriate authorization level.

parameter

Offline mode

You can authorize yourself for a higher authorization level with a password, when

this is contained in the loaded offline authorization parameters.

Note

It is not possible to authorize yourself in offline mode with a password that is available on the device, but is not contained in the offline authorization parameters.

7-52

© Siemens AG 2007 All Rights Reserved

SICLOCK

®

TC 400

Page 55

7.3 Parameters

You can set and transfer parameters of the SICLOCK TC 400 in offline and online

mode in the Parameters tab of the configuration tool.

Configuration Tool

Figure 7-3 SICLOCK TC 400 configuration tool - parameters

(1) Toolbar of the Parameters tab

(2) Parameter tree

(3) Parameter table

(4) Parameter information

© Siemens AG 2007 All Rights Reserved

SICLOCK

®

TC 400

7-53

Page 56

Configuration Tool

Table 7-3 Operator options and displays in the Parameters tab

Field/Button Meaning/Instruction

Output of the parameterization to a text file

The currently displayed parameterization is output to a text file. The data can,

Print table to text file

Download parameters

(online connection

required)

Refresh parameters

(online connection

required)

for example, be further edited with Excel.

Notice

Parameterizations cannot be restored from these text files. To restore a

parameterization, it must first have been saved in U600 format.

See Open/Save in General functions (Section 7.2).

Download parameters of the connected device

The parameters of the connected device including the description data (e.g.

texts in all languages) are downloaded. This can take several minutes. Implicitly the parameterization is downloaded again from the device.

Notice

The displayed parameterization data is overwritten. The archive data is not

taken over from the device, i.e. the displayed archive data is retained.

See also Establish/disconnect online connection (Section 7.2.1).

Download parameters of the connected device without parameter description

The parameters of a connected device are downloaded without the descrip-

tion data. This can take several minutes.

Notice

The displayed parameterization data is overwritten. The archive data is not

taken over from the device, i.e. the displayed archive data is retained.

See also Establish/disconnect online connection (Section 7.2.1).

Upload parameters

(online connection

required)

Monitor actual values

(online connection

required)

Transfer writeable values of the loaded parameters to the connected device

The following values/parameters are not transferred to the device:

• Value of write-protected parameters

• Critical operating parameters

• Display parameters

• Command parameters

An online connection must be established for the transfer of the parameters

and the configuration tool must have the appropriate authorization. See also

Establish/disconnect online connection (Section 7.2.1) and Authorization (Section 7.2.2).

Monitor current value/status of actual values

After the monitoring is activated, the current values or states are cyclically

read from the device and the display in the parameter tree and parameter

table is refreshed.

See also Establish/disconnect online connection (Section 7.2.1).

7-54

© Siemens AG 2007 All Rights Reserved

SICLOCK

®

TC 400

Page 57

Table 7-3 Operator options and displays in the Parameters tab

Field/Button Meaning/Instruction

Parameter tree Tree display of the parameters

The parameters are divided between the individual menus and submenus in

the tree.

Online mode:

In online mode, you can open a context menu by right-clicking the parameter/entry. The following functions are available:

• Read parameter individually

• Write parameter individually

• Reset parameter to factory setting

See Reading parameters / writing parameters / resetting parameters to

factory settings (Section 7.3.4).

Symbols:

• Write protection – the parameter cannot be edited

The current authorization level does not permit write access to this parameter.

• Unrestricted access

The current authorization level permits reading, editing and writing of the

parameter

• Unrestricted access without upload – critical operating parameter

The current authorization level permits reading, editing and writing of the

parameter

To protect such parameters in the device, the parameter must be explicitly

selected and written individually.

See Reading parameters / writing parameters / resetting parameters

to factory settings (Section 7.3.4)

• Display parameters

Display parameters can only be read and are typically actual values.

To refresh the actual value display, activate the automatic update .

• Entry – this is a parameter entry

Parameter table Tabular display of the parameters

You can edit the parameter values in this view, see Editing parameters

(Section 7.3.3).

Online mode:

In online mode, you can open a context menu by right-clicking the parameter/entry. The following functions are available:

• Read parameter individually

• Write parameter individually

• Reset parameter to factory setting

See Reading parameters / writing parameters / resetting parameters to

factory settings (Section 7.3.4).

Configuration Tool

© Siemens AG 2007 All Rights Reserved

SICLOCK

®

TC 400

7-55

Page 58

Configuration Tool

Table 7-3 Operator options and displays in the Parameters tab

Field/Button Meaning/Instruction

Number Unique, three-part parameter number, e.g. 000.005.00012

Parameter Associated values are grouped under a parameter.

Parameter lists are shown with square brackets after the parameter name,

e.g. "Leap second[20]".

Entry The individual values of a parameter are each called an entry of a parameter.

Note

Entries can be edited individually, but not read or written individually. The

entire parameter is always read or written with all its entries. If a list is being

considered, the entire list is read or written.

Value Numeric value or setting of the parameter entry

• Write protection – the parameter cannot be edited

The current authorization level does not permit write access to this parame-

ter.

• Unrestricted access

The current authorization level permits reading, editing and writing of the

parameter

• Unrestricted access without upload – critical operating parameter

The current authorization level permits reading, editing and writing of the

parameter

To protect such parameters in the device, the parameter must be explicitly

selected and written individually. See Reading parameters / writing

parameters / resetting parameters to factory settings (Section 7.3.4).

• Display parameters

Display parameters can only be read and are typically actual values.

To refresh the actual value display, activate the automatic update .

Parameter info Information about the selected parameter

Information about the selected parameter/entry is displayed here.

Note

If the configuration tool is not authorized or operated with a low authorization level,

not all parameters are displayed. This restriction affects, for example, settings

under "System".

The access rights also change with the authorization level.

7-56

© Siemens AG 2007 All Rights Reserved

SICLOCK

®

TC 400

Page 59

7.3.1 Sorting the parameter table

To sort the parameter table according to number or parameter:

1. Click the "Number" or "Parameter" column.

−> The table is sorted in alphabetical order according to the clicked column.

2. Click the "Number" or "Parameter" column again to reverse the alphabetical

order.

−> Depending on the current sorting, the alphabetical order is reversed to

either ascending or descending alphabetical order.

The current sorting order is indicated by an arrow next to the column title:

7.3.2 Showing/hiding parameter table entries

Configuration Tool

To show or hide parameter entries:

1. Click the symbol at the left side of the table next to the parameter.

−> The parameter entries are shown.

2. Click the symbol at the left side of the table next to the parameter.

−> The parameter entries are hidden.

Figure 7-4 Parameter table with shown and hidden entry

© Siemens AG 2007 All Rights Reserved

SICLOCK

®

TC 400

7-57

Page 60

Configuration Tool

7.3.3 Editing parameters

Requirement for the editing of a parameter entry

• It must be a writeable entry ( ).

To change the value of a parameter entry:

1. Show the values of the desired parameter in the parameter table, see Showing/hiding parameter table entries (Section 7.3.2).

2. Click the "Value" column of the parameter entry.

−> The dialog box to edit the entry is opened.

The input can be aborted with ESC.

Figure 7-5 Example of edit dialog box drop-down list

For parameters with units, you can also enter the new value without unit. Any

units that are entered are ignored, only the numeric value is accepted.

Figure 7-6 Example of edit dialog box numeric entry

Note

In online mode, the value is sent to the device when the input is completed.

To check whether the value has been accepted by the device:

1. In online mode, select the entry of the changed parameter, as described

above.

−> The current value in the device is displayed.

7-58

Note

Depending on the parameter/entry and operation status, the device checks

whether the value change has been accepted. If the device rejects the new value,

the old value is reset.

© Siemens AG 2007 All Rights Reserved

SICLOCK

®

TC 400

Page 61

Configuration Tool

7.3.4 Reading parameters / writing parameters / resetting parameters to factory settings

In online mode, you can individually read, write and reset parameters to their fac-

tory settings.

To initiate the "Read parameter", "Write parameter" or "Reset parameter to

factory setting" function:

1. Make sure that the configuration tool is connected to the device. See Estab-

lish/disconnect online connection (Section 7.2.1).

2. Select the desired parameter/entry in the parameter tree or parameter table.

3. Right-click the parameter or entry.

−> The context menu opens.

Left-click the desired function.

Figure 7-7 Context menu to read, write or reset parameter

© Siemens AG 2007 All Rights Reserved

SICLOCK

®

TC 400

7-59

Page 62

Configuration Tool

7.4 Archive

You can load archive data from the device and save it as a file as well as evaluate

and search the data with filter functions in the Archive tab of the configuration tool.

Figure 7-8 SICLOCK TC 400 configuration tool - archives

(1) Toolbar of the Archive tab

(2) Archive table

(3) Include filter (show events)

(4) Exclude filter (hide events)

7-60

© Siemens AG 2007 All Rights Reserved

SICLOCK

®

TC 400

Page 63

Table 7-4 Operator options and displays in the Archive tab

Field/Button Meaning/Instruction

Output of the archive to a text file

The currently displayed archive table is output to a text file. Events hidden via

Print table to text file

Download archive

(online connection

required)

Refresh archive

(online connection

required)

the filter are not output. The data can, for example, be further edited with

Excel.

Notice

Archives cannot be restored from these text files. To restore an archive, it

must first have been saved in U600 format.

See Open/Save in General functions (Section 7.2).

Download archive of the connected device

The archive of the connected device including the description data (e.g. texts

in all languages) is downloaded. This can take several minutes. Implicitly the

parameterization is downloaded again from the device.

Notice