Page 1

Operating Instructions 11/2012

SICLOCK TC100

Plant Central Clock

SICLOCK

s

Page 2

s

Preface, Table of Contents

Safety instructions

SICLOCK® TC100

Plant Central Clock

Operating Instructions

Description

Hardware description

Operation planning

Mounting

Connection

Configuration Tool

Parameter assignment

Parameter assignment and operation

of the device

Parameter table

Service and maintenance

Messages

Technical data

Dimension drawing

Circuit diagrams

Spare parts / accessories

Annex

ESD guidelines

List of icons

Glossary, Index

11/2012

A2B00094941-02

Page 3

Safety notices

This manual contains information that must be observed to ensure your personal safety and to prevent

property damage. The notices referring to your personal safety are highlighted in the manual by a safety

alert symbol, notices referring to property damage only, have no safety alert symbol. Depending on the

hazard level, warnings are displayed in descending order as follows:.

Danger

indicates that death or serious injury will result if proper precautions are not taken.

Warning

indicates that death or serious injury may result if proper precautions are not taken.

Caution

with a warning triangle indicates that minor personal injury can result if proper precautions are not taken.

Caution

without a warning triangle means that material damage can occur if the appropriate precautions are not

aken.

Notice

means an undesirable result or state can occur if the corresponding instruction is not followed.

In the event of a number of levels of danger prevailing simultaneously, the warning corresponding to the

highest level of danger is always used. A warning with a warning triangle indicating risk of physical injury

may also include a warning of the risk of damage to property.

Qualified personnel

The associated device/system may only be installed and used in conjunction with this documentation.

Only qualified personnel should be allowed to commission and operate the device/system. For the purpose of the safety information in this documentation, a “qualified person” is someone who is authorized to

energize, ground, and tag equipment, systems, and circuits in accordance with established safety

procedures.

Intended use

Please note the following:

Warning

This equipment is only allowed to be used for the applications described in the catalog and in the technical

description, and only in conjunction with non-Siemens equipment and components recommended by

Siemens. Correct transport, storage, installation and assembly, as well as careful operation and maintenance,

are required to ensure that the product operates sa

Registered Trademarks

All designations with the trademark symbol ® are registered trademarks of Siemens AG. Other designations in this documentation may be trademarks whose use by third parties for their own purposes can violate the rights of the owner.

Disclaimer of liability

We have checked that the contents of this publication agree with the hardware and software described

here. Nevertheless, we cannot assume responsibility for any deviations that may arise. The information

given in this publication is reviewed at regular intervals and any corrections that might be necessary are

made in the subsequent editions.

fely and without faults.

Siemens AG

I IA CE EDM

Frauenauracher Strasse 98

D-91056 Erlangen

Germany

© Siemens AG 2010

Technical data subject to change.

Page 4

Preface

This document contains the information required for operating and assigning

parameters to the SICLOCK TC100 central plant clock.

Area of application

This manual is valid for the SICLOCK

and processor version V1.0 in conjunction with the SICLOCK TC100

Configuration Tool version 1.0 or higher.

Recycling and disposal

Die The SICLOCK TC100 is low in contaminants and can therefore be recycled.

For ecologically compatible recycling and disposal of your old device, contact a

certificated disposal service for electronic scrap.

Technical Assistance

®

TC100 product with firmware version V1.0

If you have

Phone:

any technical questions, please contact Technical Assistance:

+49 (911) 895-59 00

Monday to Friday, 8 am – 5 pm CET

Fax:

E-Mail:

+49 (911) 895-59 07

siclock@siemens.com

The latest information on SICLOCK products, product support and FAQs can be

found on the Internet:

• http://www.siemens.de/siclock (German)

• http://www.siemens.com/siclock (international)

SICLOCK

®

TC100 Operating Instructions

Preface-3© Siemens AG 2010 All Rights Reserved

Page 5

Preface

Preface-4

© Siemens AG 2010 All Rights Reserved

SICLOCK

®

TC100 Operating Instructions

Page 6

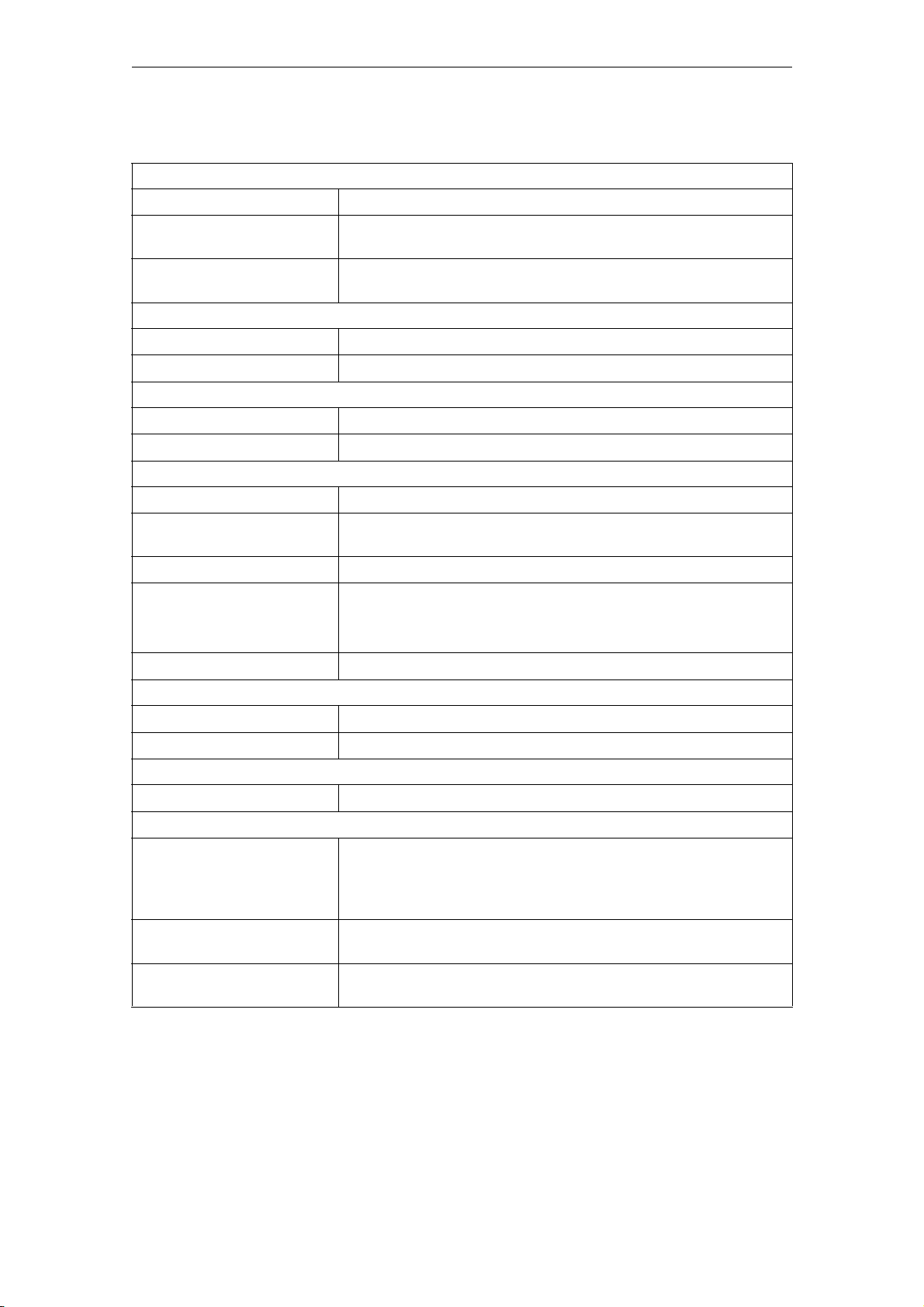

Table of Contents

Preface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Preface-3

1 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

2 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.1 Layout of the SICLOCK TC100 hardware . . . . . . . . . . . . . . . . . . . . 2-12

2.2 External synchronization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

2.3 Time receivers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2.3.1 Plant synchronization via Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2.4 Time management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

2.5 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

2.6 Redundancy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

3 Hardware description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

3.1 Exterior design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

3.2 Connection elements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

3.3 Operator controls and displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

3.4 Scope of supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

4 Operation planning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

4.1 Overview of operation planning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

4.2 Transport / storage conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

4.3 Unpacking and checking the delivery . . . . . . . . . . . . . . . . . . . . . . . . 4-26

4.4 Mounting position and fastening . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

4.4.1 Installation guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

4.4.2 Permissible mounting position. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

4.4.3 Type of fixation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

5 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-29

5.1 Overview of mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-29

6 Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-31

6.1 Overview of connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-31

6.2 Connecting the power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-32

SICLOCK

®

TC100 Operating Instructions

Contents-5© Siemens AG 2010 All Rights Reserved

Page 7

Table of Contents

6.3 Connecting external synchronization . . . . . . . . . . . . . . . . . . . . . . . . 6-33

6.3.1 SICLOCK GPS1000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-35

6.3.2 SICLOCK DCFRS Industrial version . . . . . . . . . . . . . . . . . . . . . . . . . 6-36

6.3.3 SICLOCK GPSDEC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-37

6.3.4 Third-party systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-38

6.4 Connecting alarm and warning outputs. . . . . . . . . . . . . . . . . . . . . . . 6-39

7 Configuration Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-41

7.1 Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-44

7.2 General functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-46

7.2.1 Connect / disconnect online connection . . . . . . . . . . . . . . . . . . . . . . 7-47

7.2.2 Authorization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-48

7.3 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-49

7.3.1 Sorting Parameter tables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-53

7.3.2 Hiding / showing Parameter table entries . . . . . . . . . . . . . . . . . . . . . 7-53

7.3.3 Editing parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-54

7.3.4 Reading / writing parameters, setting to factory defaults . . . . . . . . . 7-56

7.4 Archive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-57

7.4.1 Sorting the Archive table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-60

7.4.2 Filters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-61

7.5 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-62

8 Parameter assignment and operation of the device . . . . . . . . . . . . . . . . . 8-65

8.1 Status display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-66

8.2 Operation and parameter assignment. . . . . . . . . . . . . . . . . . . . . . . . 8-68

8.2.1 One-button operation with the MODE button . . . . . . . . . . . . . . . . . . 8-68

8.2.2 Network settings on the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-70

8.2.3 Readout versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-71

9 Parameter assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-73

9.1 Connecting external synchronization . . . . . . . . . . . . . . . . . . . . . . . . 9-74

9.1.1 Radio clocks via terminals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-74

9.1.2 Operation as NTP client . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-75

9.1.3 Redundancy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-75

9.2 Connecting time receivers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-76

9.2.1 NTP server service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-76

9.2.2 SIMATIC mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-77

9.3 General settings on the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-78

9.3.1 Time management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-78

9.3.2 Synchronization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-79

9.3.3 Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-80

9.3.4 System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-80

9.3.5 Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-81

9.3.6 Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-81

10 Parameter table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-83

Contents-6

© Siemens AG 2010 All Rights Reserved

SICLOCK

®

TC100 Operating Instructions

Page 8

Table of Contents

11 Service and maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-89

11.1 Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-89

11.2 Restoring factory defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-89

11.3 Software update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-90

12 Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-91

13 Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-95

14 Dimension drawing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-99

15 Circuit diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-101

15.1 Terminal assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-101

16 Spare parts / accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-103

AAnnex. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-105

A.1 Directives and declarations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-105

A.2 Certificates and approvals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-106

B ESD guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-107

B.1 Electrostatic sensitive devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-107

B.2 Electrostatic charging of persons . . . . . . . . . . . . . . . . . . . . . . . . . . . B-108

B.3 Fundamental measures to protect against static discharge . . . . . . . B-109

C List of icons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-111

D Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-113

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Index-119

© Siemens AG 2010 All Rights Reserved

SICLOCK

®

TC100 Operating Instructions

Contents-7

Page 9

Table of Contents

Contents-8

© Siemens AG 2010 All Rights Reserved

SICLOCK

®

TC100 Operating Instructions

Page 10

Safety instructions 1

Caution

Please observe the safety instructions on the back of the cover sheet of this documentation. You should not expand your device unless you have read the relevant

safety instructions.

If you have questions about the validity of the installation in the planned environment, please contact your service representative.

Repairs

Only authorized personnel are permitted to repair the device.

Warning

Unauthorized opening and improper repairs can cause considerable damage to

property or danger for the user.

System expansions

Only install system expansion devices designed for this device. The installation

of other expansions can damage the system and violate the radio-interference

suppression regulations.

Contact your technical support team or where you purchased your PC to find out

which system expansion devices may safely be installed.

Caution

If you install or exchange system expansions and damage your device, the warranty becomes void.

SICLOCK

®

TC100 Operating Instructions

1-9© Siemens AG 2010 All Rights Reserved

Page 11

Sicherheitshinweise

Safety information

Siemens offers IT security mechanisms for its automation and drive product po

folio in order to support the safe operation of the plant/machine. Our products are

also continuously developed further with regard to IT security. We therefore

recommend that you keep yourself informed about updates and upgrades for our

products and always use the latest version of each product. For information on

this topic, refer to: Industry Online Support (http://www.siemens.com/automation/csi_de_WW). You can register for a product-specific newsletter here.

For the safe operation of a plant/machine, however, it is also necessary to integrate the automation components into an overall IT security concept for the entire

plant/machine which corresponds to state-of-the-art IT technology. You can find

information on this at: Industrial Security (http://www.siemens.com/industrialsecurity).

Products used from other manufacturers should also be taken into account here.

Network security

In order to protect the entire plant from attack

ding measures must be taken.

Caution

Failures or damage to your overall system

Unauthorized persons can gain entry into your network via the Ethernet ports and

make changes to the SICLOCK TC100 parameterization. This can result in the

time being adjusted. Individual or even all clients to be synchronized can be removed from the synchronization cycle. This has the potential to cause failures or

damage throughout the plant.

s on network security, corres

rt-

pon-

Please adhere to the following safety measures:

− Ensure that your network is protected against unauthorized access by instal-

ling a firewall at all Ethernet ports.

− Change the default password immediately after commissioning.

− Limit the number of people to whom this password is known to the absolute

minimum.

− Change the password regularly.

1-10

© Siemens AG 2010 All Rights Reserved

SICLOCK

®

TC100 Operating Instructions

Page 12

Battery

Safety Information

This device is fitted with a Lithium battery. Batteries may only be replaced by

qualified personnel. See Battery (Chapter 11.1).

Caution

There is the risk of an explosion if the battery is not replaced as directed. Replace

only with the same type or with an equivalent type recommended by the manufacturer. Dispose of used batteries in accordance with local regulations.

Warning

Risk of explosion and release of harmful substances!

For this reason, do not throw lithium batteries into open fires, do not solder on the

cell body, do not open, do not short circuit, do not reverse polarity, do not heat

above 100°C, dispose of correctly, and protect against direct sunlight, dampness

and dew.

EGB directives

Modules containing electrostatic sensitive devices (ESDs) can be identified by the

following label:

Strictly follow the guidelines mentioned below when handling modules which are sensitive

to ESD:

• Before working with modules with ESDs, you must discharge all your personal static

(e.g. by touching a grounded object).

• All devices and tools must be free of static charge.

• Always pull the mains connector before you install or remove modules which

are sensitive to ESD.

• Handle modules fitted with ESDs by their edges only.

• Do not touch any pins.

© Siemens AG 2010 All Rights Reserved

SICLOCK

®

TC100

1-11

Page 13

Safety Information

1-12

© Siemens AG 2010 All Rights Reserved

SICLOCK

®

TC100 Operating Instructions

Page 14

Description 2

Modern automation systems are made up of a multitude of computers, controllers

and systems, that exchange data with one another. In order to operate such systems in real time, it is absolutely essential to synchronize the clock times of all the

components involved. This particularly applies to error tracing if event messages

are time stamped, and cause and effect have to be identified by a reliable chronological order.

As a central plant clock, SICLOCK TC100 supplies the various plant components

with a precise, reliable clock time, which is usually obtained from one or more

external synchronizations with official or statutory times of day, usually GPS or

DCF77 radio clocks.

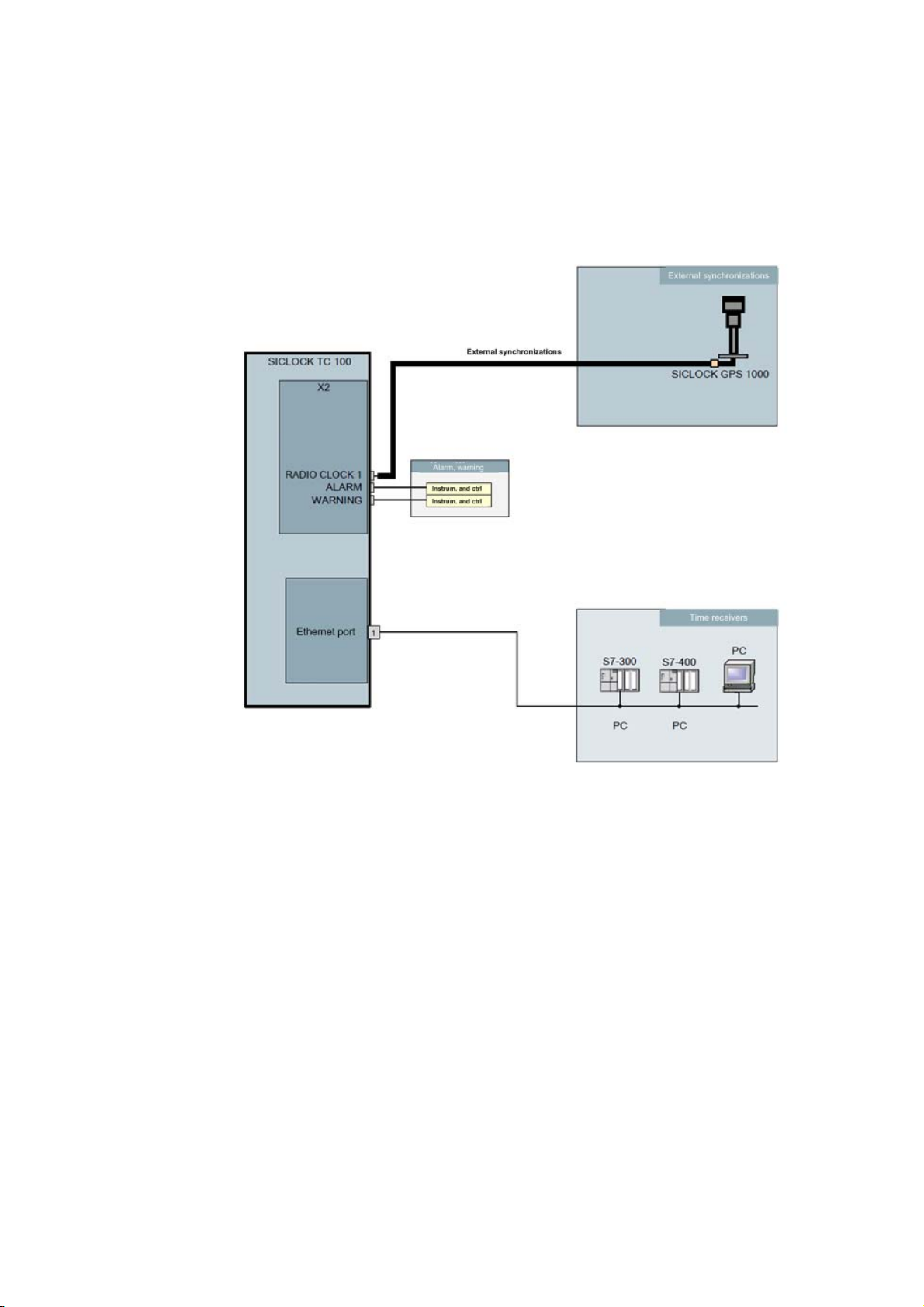

SICLOCK TC100 distributes the time solely via Ethernet.

Note

Use one single device as the central clock for the whole plant, which supplies the

clock time to all the other devices.

Exception: Redundant operation of the central plant clock

SICLOCK

®

TC100 Operating Instructions

2-1© Siemens AG 2010 All Rights Reserved

Page 15

Description

2.1 Layout of the SICLOCK TC100 hardware

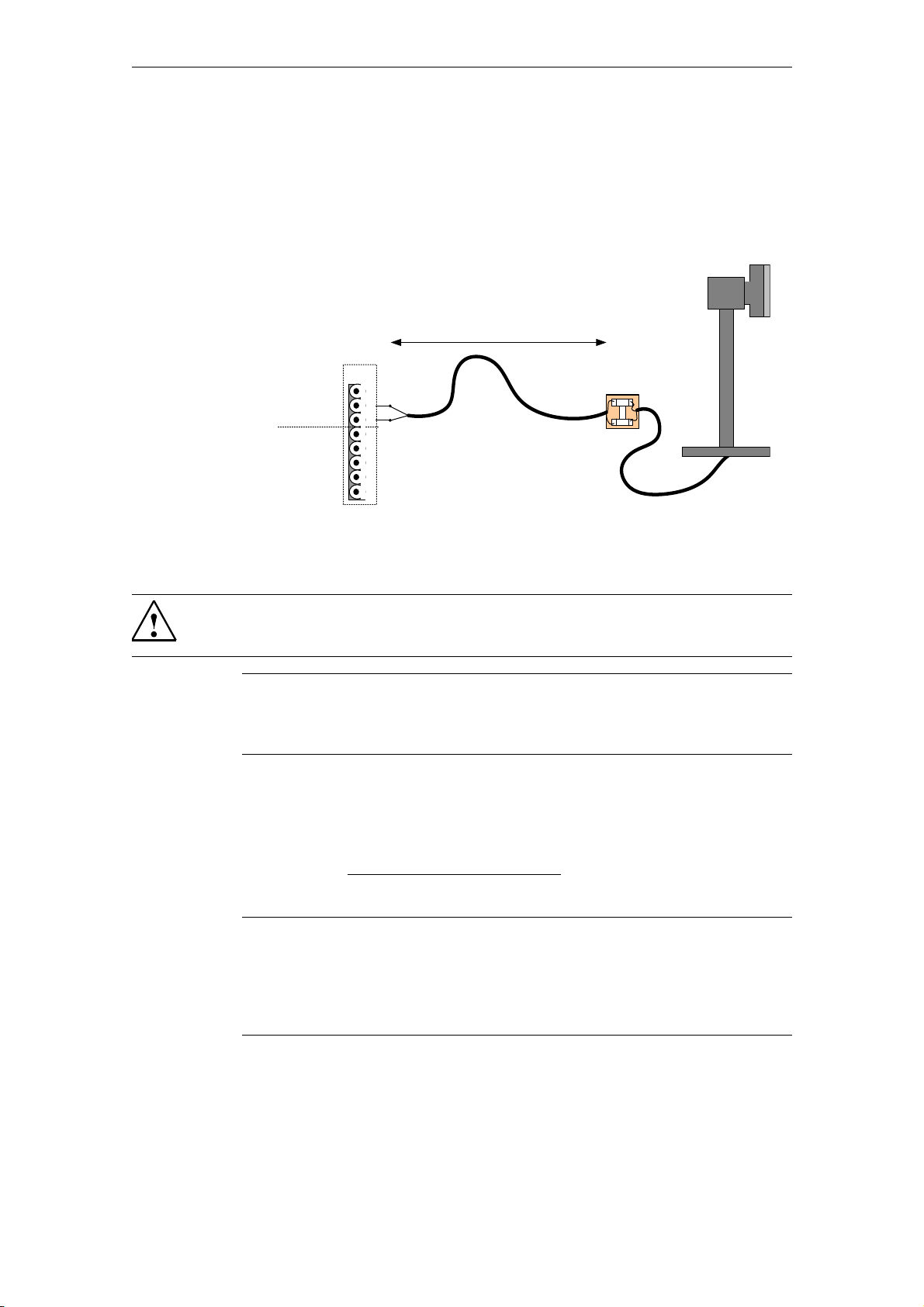

The following diagram shows an application example of a SICLOCK TC100, with

a SICLOCK GPS1000 as the radio clock and an NTP server as an additional

external synchronization.

Figure 2-1 Application Example

2-1

© Siemens AG 2010 All Rights Reserved

SICLOCK

®

TC100 Operating Instructions

Page 16

2.2 External synchronization

SICLOCK TC100 can be externally synchronized to the applicable, statutory national time or GMT in order to automate or minimize manual interventions, such as

daylight saving time changes and leap seconds.

External synchronizations can be GPS or DCF77 radio clocks, servers (e.g. the

time signal from an NTP server), SICLOCK TC400 devices, SICLOCK TC100

devices or other signal sources. They are connected to the RADIO CLOCK of the

device.

The Ethernet port supports NTP servers as external synchronizations.

Possible RADIO CLOCKS are:

• SICLOCK GPS1000

• SICLOCK GPSDEC

(SICLOCK GPSDEC has been discontinued, please use SICLOCK GPS1000)

LOCK DCFRS

SIC

ವ

Third-party products can be connected passively via TTY. The following protocols

are supported:

Description

• Demodulated DCF77

• Serial:

− Meinberg format (time-zone dependent)

− Meinberg format (time-zone independent)

− NMEA (0183/ZDA)

Get more information

Connecting external synchronization (Chapter 9.1)

© Siemens AG 2010 All Rights Reserved

SICLOCK

®

TC100 Operating Instructions

2-1

Page 17

Description

2.3 Time receivers

The time receivers in the plant are connected solely via Ethernet.

2.3.1 Plant synchronization via Ethernet

Physical access

An Ethernet port with the following specification is provided to enable physical

access to the network:

• 100Base-TX via RJ-45 socket

Protocols

The following protocols are implemented:

• NTP server according to RFC2030

− Any/unicast mode

− Any/unicast mode with local time

− Multicast mode

− Multicast mode with local time

• Time synchronization in the SIMATIC procedure

− PCS7-compatible mode

− S5-compatible mode

Thetime message frames can be transmitted to each Ethernet port individually either every second or every 10 seconds.

2-1

© Siemens AG 2010 All Rights Reserved

SICLOCK

®

TC100 Operating Instructions

Page 18

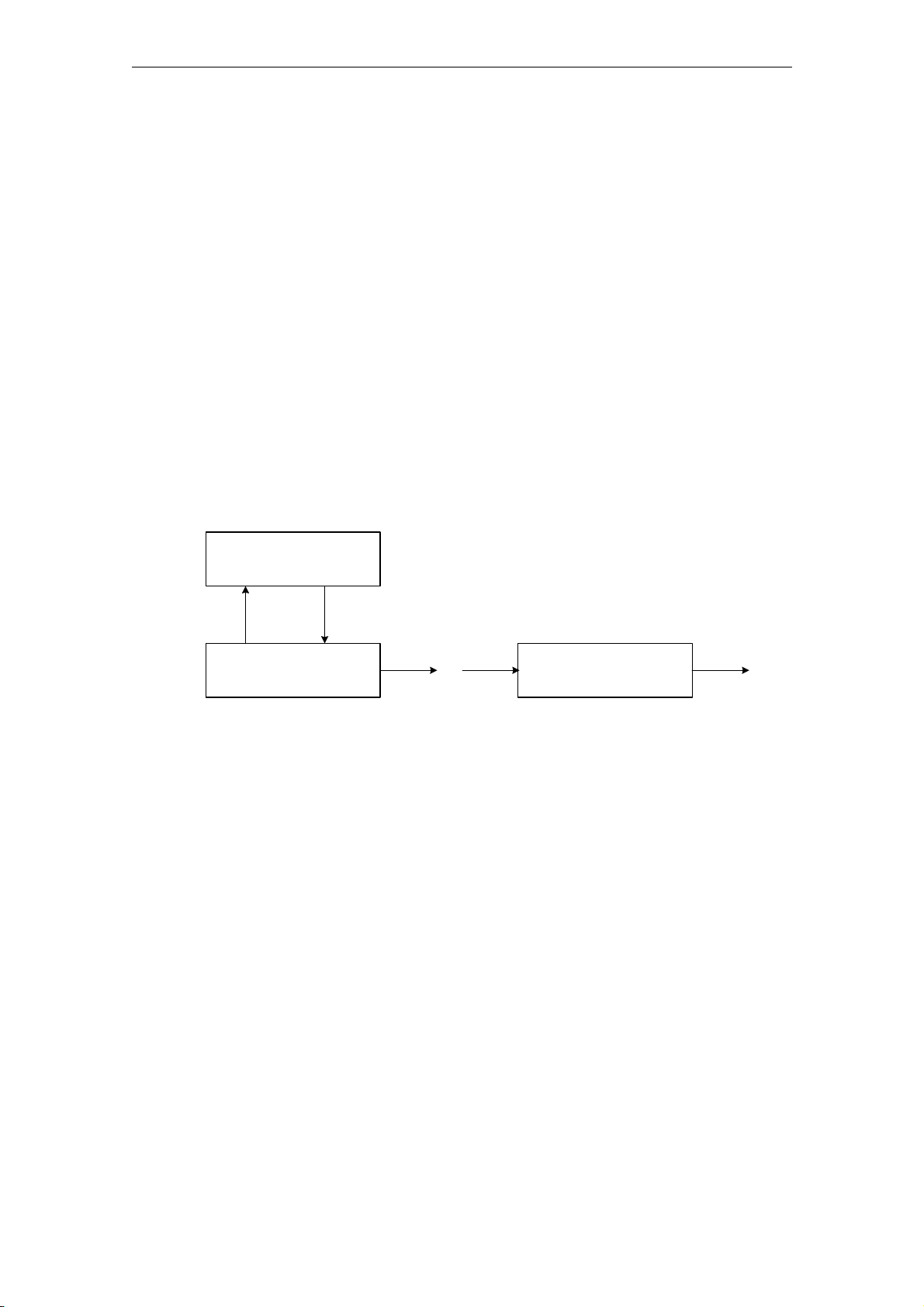

2.4 Time management

The SICLOCK TC100 has a range of functions for generating the valid plant time

from the external synchronization. This includes the option of setting times zones

and the parameterizable generation of daylight saving.

Time security through protected synchronization

If a discontinuity of longer than five seconds occurs in the external synchronization, the protected synchronization is activated, and the synchronization is not

executed for safety reasons.

Time security through microstep mode

A time difference between the external synchronization and the device, such as

can occur as the result of a brief loss of loss of radio contact or switching to a substitute synchronization, is run down automatically in microstep mode that is imperceptible to the operation of the plant. No time jump occurs.

Description

More detailed information and the options for parameter assignment for protected

synchronization and microstep mode are described in the chapter

Synchronization (Chapter 9.3.2).

Note

Parameterize the plant time at one single point within the synchronization hierarchy, ideally on the central plant clock.

2.5 Commissioning

Commissioning can be subdivided into the following steps:

1. Mounting (Chapter 5)

2. Connection (Chapter 6)

3. Assignment of an IP address to the device

Parameter assignment and operation of the device (Chapter 8)

4. Parameter assignment (Chapter 9)

With few exceptions, the settings are made with the Configuration Tool, see

Configuration Tool (Chapter 7).

© Siemens AG 2010 All Rights Reserved

SICLOCK

®

TC100 Operating Instructions

2-1

Page 19

Description

2.6 Redundancy

Redundant external synchronization

Up to four time servers can be run on the SICLOCK TC100 for external synchronization via NTP. However, they must all be in the same IP network.

Radio clocks cannot be connected redundantly to a SICLOCK TC100.

The order of priority among the external synchronizations (radio clock or NTP server), and thus the redundancy behavior, can be set with parameters, see

Redundancy (Chapter 9.1.3).

Redundant SICLOCK TC100 central plant clocks

A number of SICLOCK TC100s can be run as redundant time servers in a single

network.

You will find more detailed information in the chapters Configuration Tool

(Chapter 7) and Parameter table (Chapter 10).

You can find more information on redundancy in

„Application Note 01

08“ on http://www.siemens.com/siclock under "FAQ".

2-1

© Siemens AG 2010 All Rights Reserved

SICLOCK

®

TC100 Operating Instructions

Page 20

Hardware description 3

The layout of the hardware, together with the connectors, operator controls and

displays are described in this chapter.

3.1 Exterior design

The display and operator controls together with the connectors on the

SICLOCK TC100 are shown in the following figures.

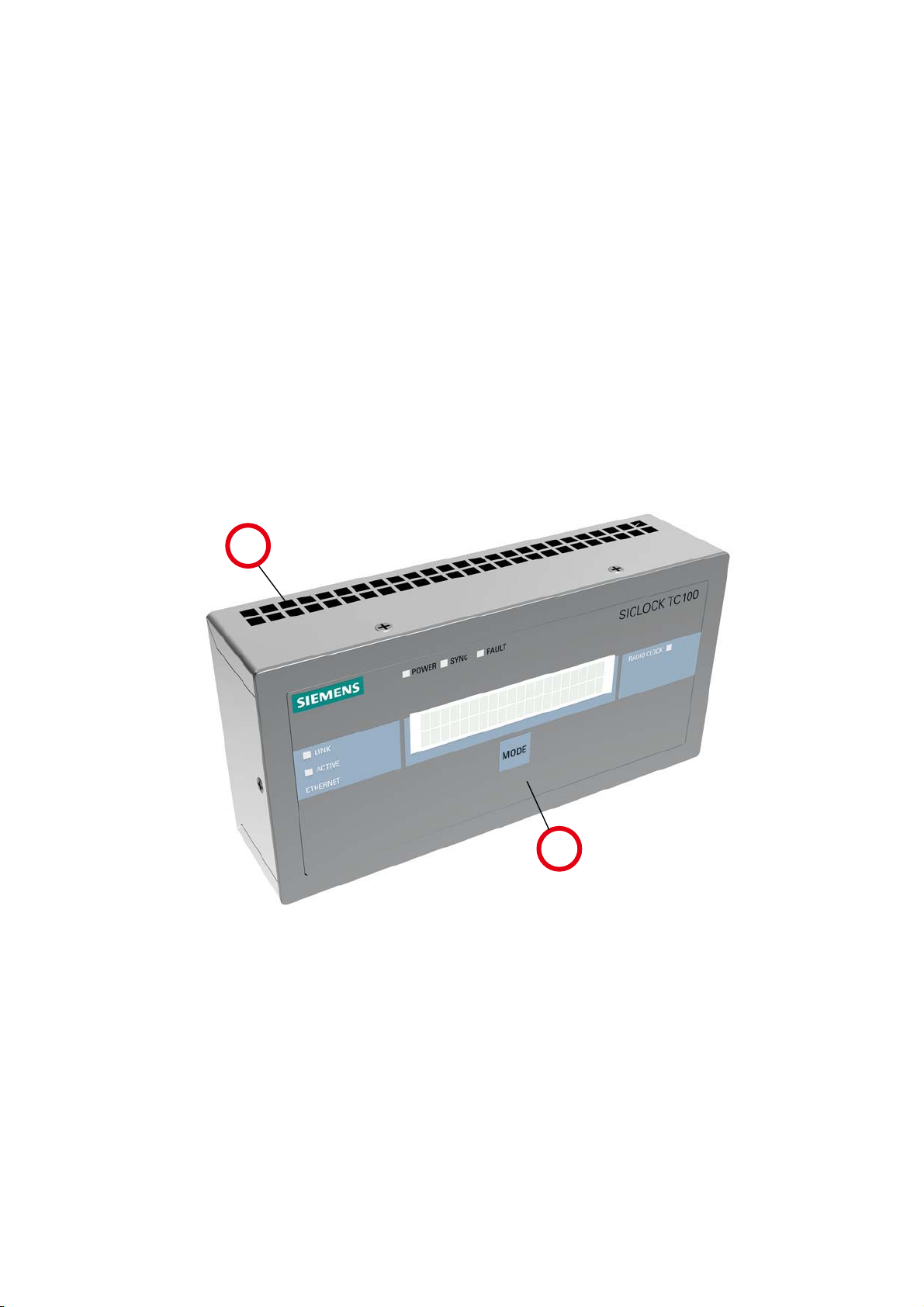

Figure 3-1 Perspective view of the SICLOCK TC100 showing the front panel and ventilation grille

(1) Panel with operator and display controls

(2) Ventilation grille

SICLOCK

®

TC100 Operating Instructions

3-1© Siemens AG 2010 All Rights Reserved

Page 21

Hardware description

3.2 Connection elements

The following figure shows the connectors on the SICLOCK TC100.

Figure 3-2 SICLOCK TC100 - layout of connectors

(1) Terminal X1 - 24V supply voltage

(2) Terminal X2 - connecting terminal for radio clocks, outputs and alarm

See also Terminal assignment (Chapter 15.1).

(3) Ethernet port

3-

© Siemens AG 2010 All Rights Reserved

SICLOCK

®

TC100 Operating Instructions

Page 22

3.3 Operator controls and displays

The display and LEDs on the front panel show the current operating state. The

keypad can be used for the basic operation of the device. A Web-based Configuration Tool is available for more extensive configuration options, see

Configuration Tool (Chapter 7).

Hardware description

Figure 3-3 SICLOCK TC100 front view

© Siemens AG 2010 All Rights Reserved

SICLOCK

®

TC100 Operating Instructions

3-

Page 23

Hardware description

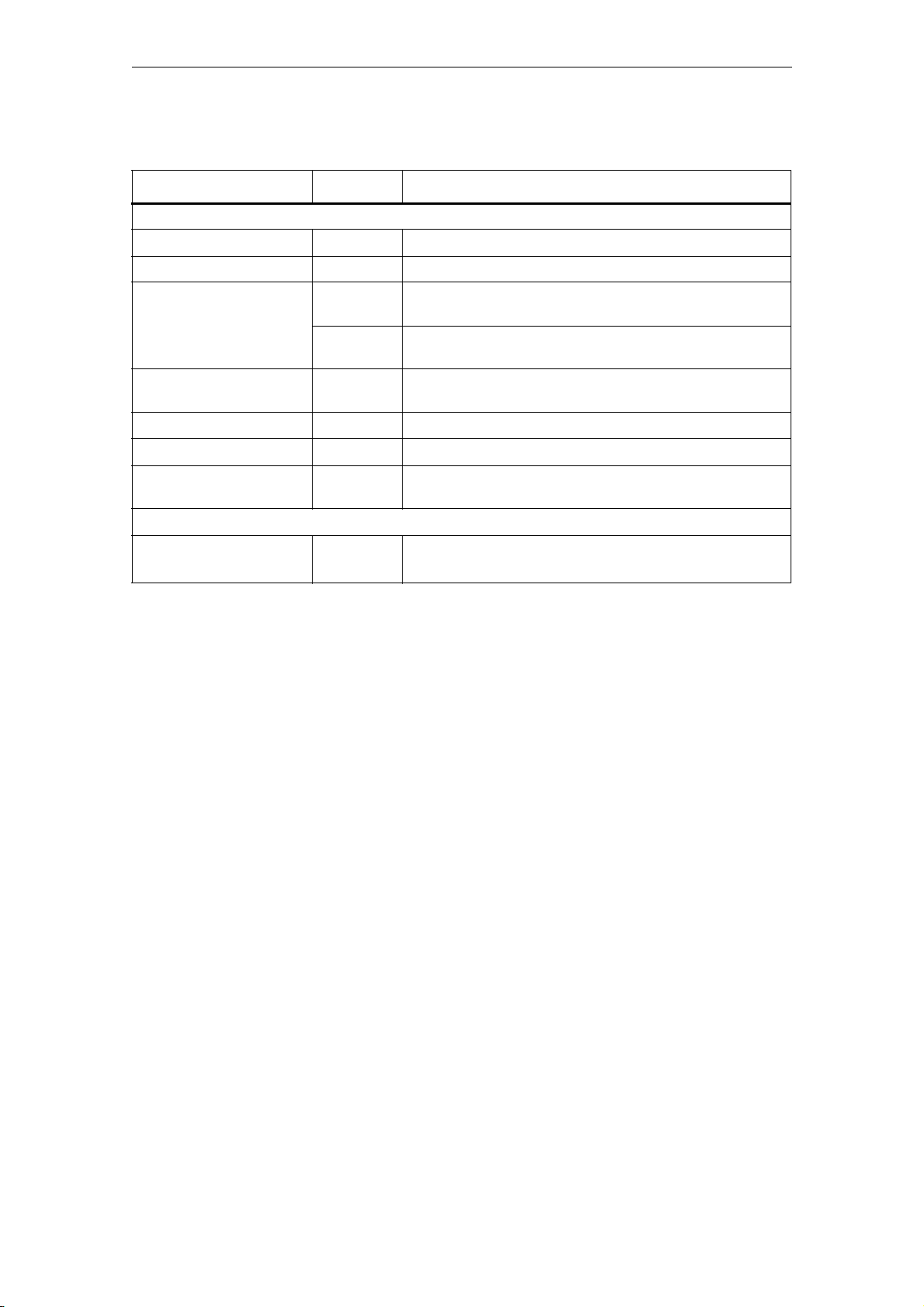

Table 3-1 Meanings of the displays and operator controls

Name Color (LED) Meaning

Displays

POWER Green Operational readiness

SYNC Green SICLOCK TC100 is externally synchronized.

FAULT Red Alarm

The associated message text is shown in the display.

Flashing red Warning

The associated message text is shown in the display.

LINK Green The physical connection has been made, transmission and

reception are possible.

ACTIVE Green Display of the data traffic for the particular port

RADIO CLOCK Yellow Incoming signal from the radio clock

Display Display of the time, date and synchronization, or message

text in the case of an error

Operator controls

MODE Call and edit the basic parameter list

Acknowledge messages

For more detailed information see Parameter assignment and operation of the device

(Chapter 8)

.

3-2

© Siemens AG 2010 All Rights Reserved

SICLOCK

®

TC100 Operating Instructions

Page 24

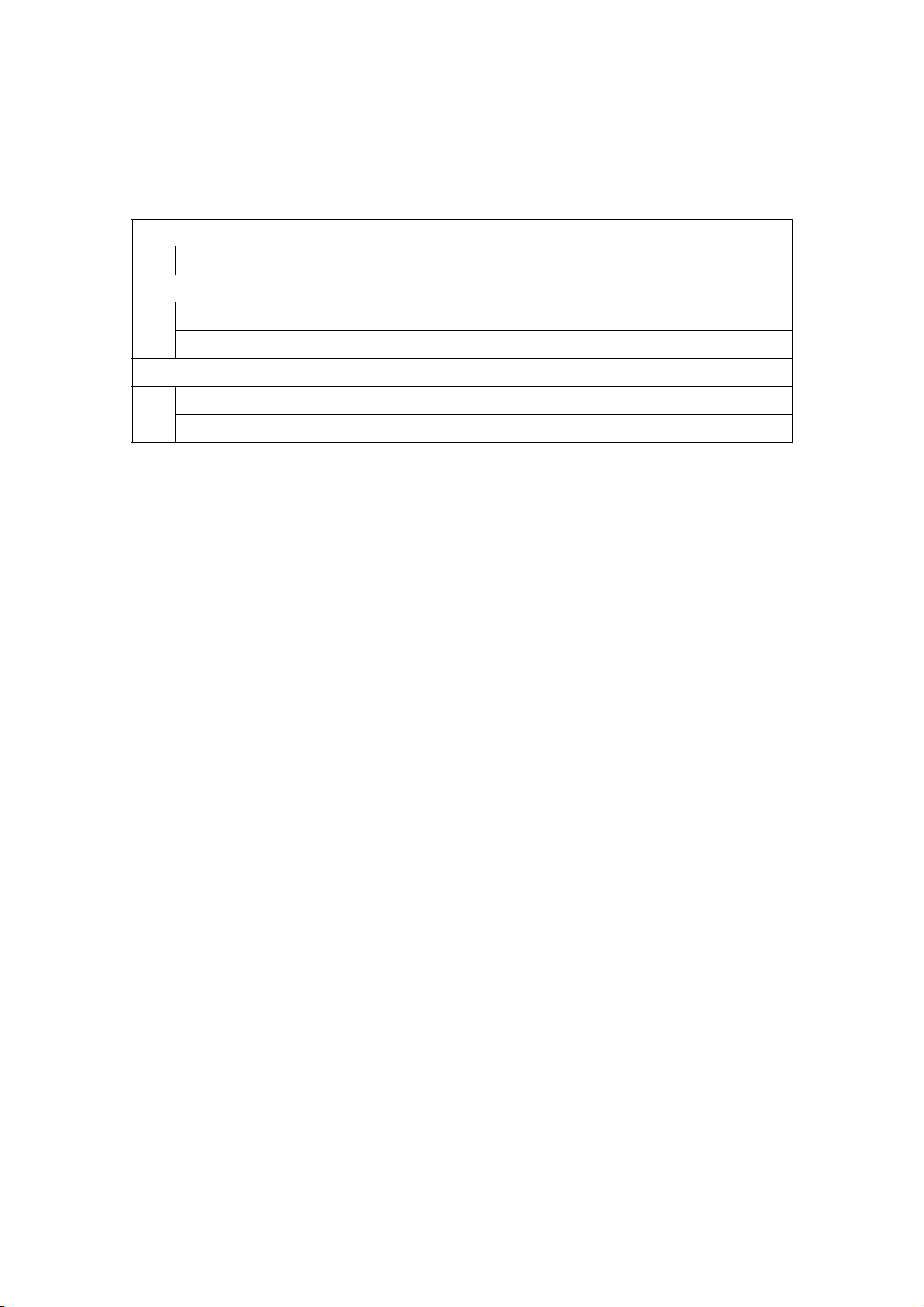

3.4 Scope of supply

Table 3-2 Scope of supply of the individual versions of the device

2XV9450-2AR22

Hardware description

SICLOCK TC100 single device with terminal strips connecte

d to X1 and X2

2XV9450-2AR50 (SICLOCK TC100 GPS1000 package)

SICLOCK TC100 single devi

ce with terminal strips connected to X1 and X2

SICLOCK GPS1000 radio clock with mounting frame and lightning protection

2XV9450-2AR26 (SICLOCK TC100 DCF77 package)

SICLOCK TC100 single device with terminal strips connected to X1 and X2

SICLOCK DCFRS industrial version of the radio clock, complete with mounting frame

© Siemens AG 2010 All Rights Reserved

SICLOCK

®

TC100 Operating Instructions

3-2

Page 25

Hardware description

3-2

© Siemens AG 2010 All Rights Reserved

SICLOCK

®

TC100 Operating Instructions

Page 26

Operation planning 4

4.1 Overview of operation planning

SICLOCK TC100 is designed for stationary use in weather-proof locations in an

industrial environment.

The operating conditions surpass the requirements of DIN IEC 60721-3-3.

• Class 3M3 (mechanical requirements)

• Class 3K3 (climatic requirements)

General notes on operation

Caution

The device is approved for operation in closed rooms only. The guarantee is void

if this stipulation is ignored.

Condensation

When transporting the device at low temperatures, ensure that no moisture gets

on or into the device. This also applies if the device is subjected to extreme changes in temperature.

Commissioning

Allow the device to slowly adjust to room temperature before commissioning the

device. However, do not expose the device to direct heat radiation. In the event

of greater temperature differences, harmful condensation can be avoided by leaving the device in its transport packaging.

If condensation develops, wait 12 hours before you switch on the device (for a

temperature difference of 20°C). For greater temperature differences, the waiting

time is correspondingly longer.

Avoid extreme ambient conditions. Protect your device against dust, moisture and

heat. Refer to Technical data (Chapter 13).

Do not place the device in direct sunlight.

SICLOCK

®

TC100 Operating Instructions

4-2© Siemens AG 2010 All Rights Reserved

Page 27

Operation planning

Use in residential areas, and operation in the public network

If you use the SICLOCK TC100 in residential areas or in the public network, you

must ensure that it complies with the limit value class B according to EN 55022

with regard to the emission of radio interference.

Note

This is a Class A system. The equipment may cause RF interference in residential

areas or the public network. In this case, the operating company may be required

to take appropriate measures.

The following measures are recommended to ensure the interference complies

with limit value class B:

• Install the SICLOCK TC100 in grounded control cabinets / control boxes

• Use filters in the supply lines

Usage with additional measures

SICLOCK TC100 must not be used in the following exemplary cases without

additional measures:

• At locations with a high level of ionizing radiation

• In aggressive environments caused, for example, by

− The development of dust

− Corrosive vapors or gases

− Strong electric or magnetic fields

− Damp and wet rooms

− Severe oscillations, shocks, vibrations

− High levels of radiant heat

• In systems that require special monitoring, such as.

− Elevators

− Electrical plants in potentially hazardous areas

One additional measure could be to install the SICLOCK TC100 in a cabinet or

housing.

4-2

© Siemens AG 2010 All Rights Reserved

SICLOCK

®

TC100 Operating Instructions

Page 28

4.2 Transport / storage conditions

Despite the device's rugged design, its internal components are sensitive to

severe vibrations and shock. You must therefore protect the device from severe

mechanical stresses.

You should always use the original packaging for shipping and transporting the

device.

Unpack the device at its installation location.

Do not transport the device when it is mounted.

Follow the instructions for temporary storage under Battery (Chapter 11.1) in

Service and maintenance.

The following information applies to modules transported or stored in their original

packaging.

The ambient conditions for transport comply with IEC 60721-3-2, class 2K4.

The mechanical environmental conditions for transport comply with

IEC 60721-3-2, class 2M2.

Operation planning

Caution

Risk of damage to the device!

If the device is transported in extreme weather conditions with large fluctuations

in temperature, care must be taken to ensure that no moisture forms on or in the

device (condensation).

If you notice any condensation, wait around 12 hours before switching on the

device.

Notice

Adhere to these stipulations each time the device is transported, otherwise the

guarantee is void.

Table 4-1 Shipping and storage conditions

Type of condition Permissible range

Free fall (in transport packaging)

Temperature

Atmospheric pressure

Maximum rate of temperature

<= 1 m

-40 °C to +70 °C

From 1080 to 660 hPa (corresponds to an

altitude from -1000 to 3500m)

20 °C/h

change

Relative humidity

© Siemens AG 2010 All Rights Reserved

SICLOCK

®

TC100 Operating Instructions

10 to 95 % (at 25°C without condensation)

4-2

Page 29

Operation planning

4.3 Unpacking and checking the delivery

The device is completely assembled, tested and packed in the factory, and has

no internal transport locks.

If there are large temperature differences between the means of transport and the

unpacking site, we recommend leaving the device in its transport packaging to

avoid harmful condensation.

Procedure

• Please check the packaging material for transport damage upon delivery.

• If any transport damage is present at the time of delivery, lodge a complaint

with the responsible shipping company. Have the shipper confirm the transport damage immediately.

• Unpack the device.

• Keep the packaging material in case you have to transport the device again.

Notice

The packaging protects the device during transport and storage. Transport the

device only in its original packaging!

• Please keep the accompanying documentation in a safe place. You will need

the documentation when you start up the device for the first time.

• Check the package contents for completeness and any visible transport

damage. Check for completeness using the enclosed "Contents of Delivery"

list.

• Notify the responsible delivery service immediately if the packages contents

are incomplete or damaged.

Warning

Ensure that a damaged device is neither inadvertently installed nor brought into

operation.

4-2

© Siemens AG 2010 All Rights Reserved

SICLOCK

®

TC100 Operating Instructions

Page 30

4.4 Mounting position and fastening

4.4.1 Installation guidelines

Before installing the device, read the following general notes relating to

installation.

Warning

Danger, high voltage!

Disconnect the power supply from the control cabinet before opening it. Ensure

that the power to the control cabinet cannot be switched on accidentally.

• Locate the device / display in an ergonomically advantageous position for the

user. Choose a suitable installation height.

Operation planning

• Position the device / display so that it is not exposed to direct sunlight or other

strong sources of light.

• Ensure that there is adequate free space in the control cabinet for air circula-

tion and heat transport. Maintain a clearance of 100mm above and below the

device. Connection cables increase these clearances correspondingly.

• Install the device in a position that does not block the air vents in the housing.

• Also provide enough free space to be able to remove the device.

• Fit struts in the control cabinet to stabilize the mounting cut-out. Install struts

where necessary.

• Install the device in such a way that it cannot pose any danger by, for example,

falling out.

• During assembly, please comply with the approved installation positions.

See Dimension drawing (Chapter 14).

© Siemens AG 2010 All Rights Reserved

SICLOCK

®

TC100 Operating Instructions

4-2

Page 31

Operation planning

4.4.2 Permissible mounting position

Only a horizontal mounting position is permitted, that is the display is read from a

horizontal viewing direction. The ventilation is inadequate in all other mounting

positions.

Figure 4-1 Horizontal mounting position

4.4.3 Type of fixation

The housing can be fixated by snap-on mounting to a standard mounting rail or

to a SIMATIC S5 DIN rail.

See Overview of mounting (Chapter 5.1).

4-

© Siemens AG 2010 All Rights Reserved

SICLOCK

®

TC100 Operating Instructions

Page 32

Mounting 5

5.1 Overview of mounting

Figure 5-1 SICLOCK TC100 - view of mounting

SICLOCK TC100 must be mounted in an easily accessible position in the control

cabinet.

The housing can be fixated by snap-on mounting to a standard mounting rail

(EN 50022-35) or to a SIMATIC S5 DIN rail (6ES5 710-8maxx).

A clearance of 100mm must be maintained above the device so that it can be

hooked in and out, and to facilitate unimpeded heat dissipation.

A clearance of at least 100mm must be maintained under the device for the process signal plug.

We recommend mounting a suitable cable channel below this clearance.

Note

Ensure that the snap-on mounting is locked correctly.

See also Dimension drawing (Chapter 14).

SICLOCK

®

TC100 Operating Instructions

5-© Siemens AG 2010 All Rights Reserved

Page 33

Mounting

5-3

© Siemens AG 2010 All Rights Reserved

SICLOCK

®

TC100 Operating Instructions

Page 34

Connection 6

6.1 Overview of connection

Notice

Only connect peripheral devices suitable for an industrial environment.

Caution

Strictly adhere

Ensure that the installation complies with the following conditions:

• The device may only be connected to 24 VDC power supply systems which

meet the requirements of a safe extra-low voltage with protective separation

according to SELV. The conductor cross-section selected must be large

enough so that if there is a short circuit in the SICLOCK TC100 no damage

can be caused by an overheated cable. For the conductor cross-section, see

Connecting the power supply (Chapter 6.2).

• Avoid extreme ambient conditions as far as possible.

• Protect the device against dust, moisture, heat and severe vibrations.

• Do not place the device in direct sunlight.

• Install the device in such a way that it cannot pose any danger, for example by

falling down.

• Do not cover the ventilation slots

• Permissible mounting position (Chapter 4.4.2).

to the specifications for peripheral equipment.

SICLOCK

®

TC100 Operating Instructions

6-3© Siemens AG 2010 All Rights Reserved

Page 35

Connection

6.2 Connecting the power supply

The power supply is connected to terminal strip X1, and muss pass through a

slow-blow 1A fuse. The device does not have a power switch.

Figure 6-1 Connecting the power supply

Note before connecting the device

Warning

The device may only be connected to 24 VDC power supply systems which meet

the requirements of a safe extra-low voltage with protective separation (SELV); a

protective conductor must also be connected. The conductors must be able to

withstand the short-circuit current of the 24 VDC power supply, so that a short circuit will not damage the cable. Only cables with a cross-section between a minimum of 0.25 mm

2

connected.

Notice

The 24 VDC power supply must match the input specification of the device

Technical data (Chapter 13).

Caution

Ensure that the functional grounding is connected correctly.

It is essential to ensure the correct polarity with direct current.

Functional check

(AWG23) and a maximum of 2.50 mm2(AWG13) may be

6-3

After switching on, the POWER LED must light up green.

© Siemens AG 2010 All Rights Reserved

SICLOCK

®

TC100 Operating Instructions

Page 36

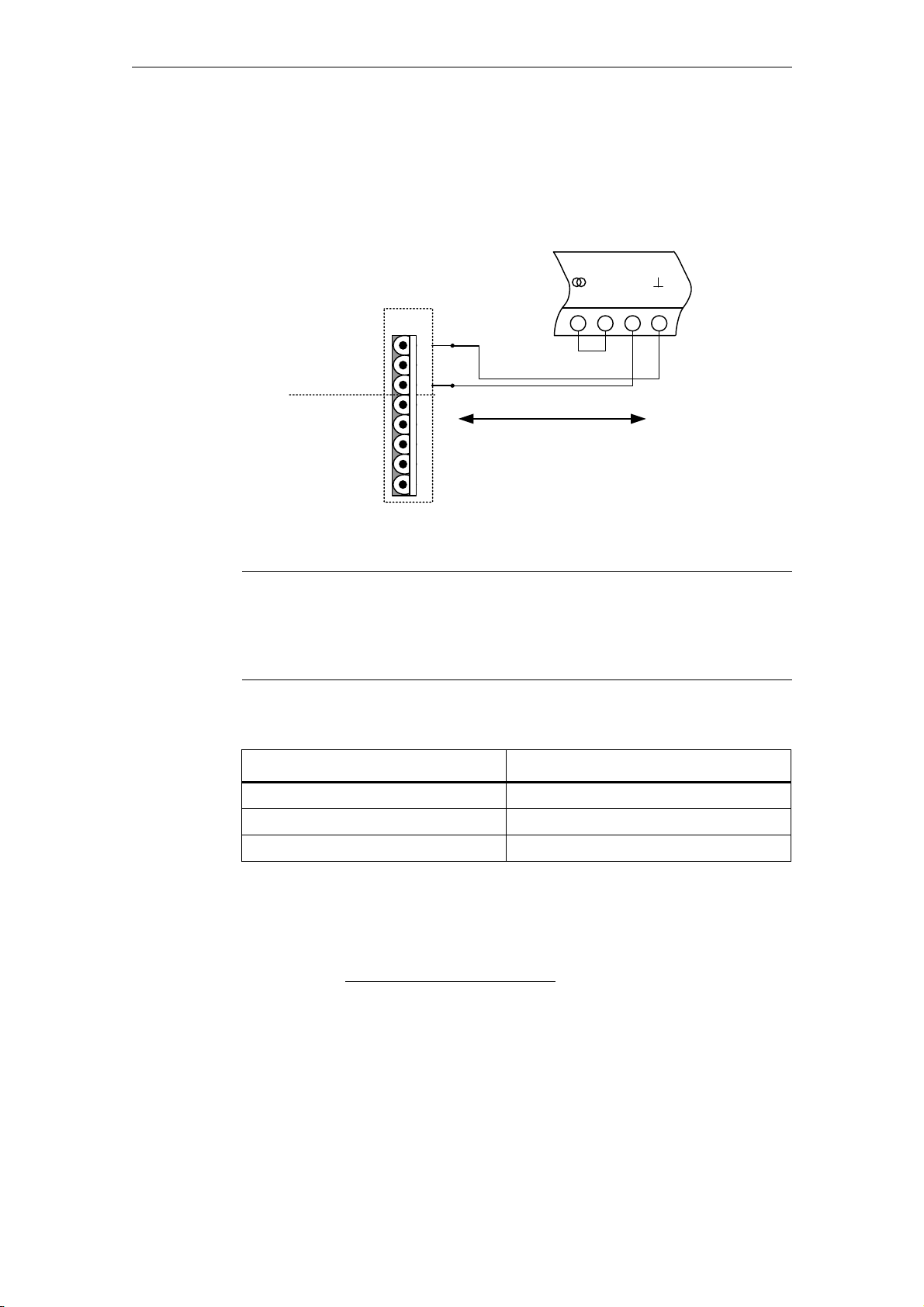

6.3 Connecting external synchronization

The signal from the connected radio clock is automatically detected, and displayed in the parameter /Inputs/Input 1/Status (0.20.02)

Connection

.

Figure 6-2 Circuit diagrams for a passive and an active radio clock

Table 6-1 Terminal assignment of radio clock inputs

Terminal Description

X2-1 RADIO CLOCK GND

X2-2 RADIO CLOCK 1A

X2-3 RADIO CLOCK 1B

© Siemens AG 2010 All Rights Reserved

SICLOCK

®

TC100 Operating Instructions

6-3

Page 37

Connection

Functional check

The incoming signal of the radio clock is indicated on the front panel by the

"RADIO CLOCK" LED.

The status of the radio clock is displayed in the parameter

/Inputs/Input 1/Status (0.20.02)

Possible states:

• GPS (SICLOCK GPS1000 and SICLOCK GPSDEC)

• GPS (disturbed)

• DCF77 (SICLOCK DCFRS and SICLOCK GPSDEC)

• DCF77 (disturbed)

• Serial

.

The signal reception is temporarily disturbed.

The signal reception is temporarily disturbed.

− Meinberg

Meinberg format being received

− NMEA

NMEA format being received

− Telegram (disturbed)

Error detected in telegram or loss of telegram

• No signal

The connection of individual sources of external synchronization is described in

the following.

6-3

© Siemens AG 2010 All Rights Reserved

SICLOCK

®

TC100 Operating Instructions

Page 38

6.3.1 SICLOCK GPS1000

The GPS receiver GPS1000 is connected according to Figure 6-3.

;

5$',2&/2&.*1'

5$',2&/2&.$

5$',2&/2&.%

Connection

/LJKWQLQJSURWHFWLRQ

PD[P

Figure 6-3 Connection of the radio clock SICLOCK GPS1000 to RADIO CLOCK 1

We recommend using a two-wire, shielded cable, e.g. LiYCY 2x1 mm² as the

radio clock cable. One end of the cable shielding must be connected to a suitable

point at the place of installation.

No further assignment of parameters to the GPS1000 is required.

Warning

Provide lightning protection for the GPS aerial in outdoor areas.

Functional check

The "RADIO CLOCK" LED on the front panel must flash at about 1Hz when the

GPS1000 is received correctly.

The parameter /Inputs/Input 1/Status (0.20.02)

three minutes reception.

must change to "GPS" after about

© Siemens AG 2010 All Rights Reserved

SICLOCK

®

TC100 Operating Instructions

6-3

Page 39

Connection

6.3.2 SICLOCK DCFRS Industrial version

The industrial version of the SICLOCK DCFRS radio clock included in the DCF77

package is connected as shown in Figure 6-4. In this case the polarity is irrelevant.

PD[P

;

5$',2&/2&.*1'

5$',2&/2&.$

5$',2&/2&.%

Figure 6-4 Connection of the radio clock SICLOCK DCFRS industrial version to

Warning

When used outdoors, a lightning conductor must also be installed.

Note

One end of the shielding of the radio clock cable must be connected to a suitable

point at the place of installation.

Functional check

The "RADIO CLOCK" LED on the front panel must flash at about 1Hz when the

SICLOCK DCFRS is received correctly.

The parameter /Inputs/Input 1/Status (0.20.02)

about three minutes reception.

Note

If possible select a location for the aerial where there is no electromagnetic interference on the DCF77 carrier frequency, because this is crucial for the quality of

reception. Do not mount the aerial anywhere near electric drives, neon tubes,

monitors or other emitters of interference.

RADIO CLOCK 1

must change to "DCF77" after

6-3

© Siemens AG 2010 All Rights Reserved

SICLOCK

®

TC100 Operating Instructions

Page 40

6.3.3 SICLOCK GPSDEC

(SICLOCK GPSDEC has been discontinued, please use SICLOCK GPS1000)

A SICLOCK GPSDEC decoder is connected as shown in Figure 6-5.

;

5$',2&/2&.*1'

5$',2&/2&.$

5$',2&/2&.%

Connection

'&)77<

PD[P

Figure 6-5 Connection of the radio clock SICLOCK GPSDEC to RADIO CLOCK 1

Caution

A SICLOCK GPSDEC may only be operated as an active radio clock.

Operation as a passive radio clock leads to the destruction of the

SICLOCK GPSDEC.

Table 6-2 Recommended assignment of parameters to the GPSDEC decoder for

Functional check

The "RADIO CLOCK" LED on the front panel must flash at about 1Hz when the

GPSDEC is received correctly.

The parameter /Inputs/Input 1/Status (0.20.02)

after about three minutes reception.

synchronizing a SICLOCK TC100

Parameter Setting

Time difference from GMT 00:00

Daylight saving time change „none“

X1.5-8 (DCF77TTY) „DCF without ZZB“

must change to "GPS" or "DCF77"

© Siemens AG 2010 All Rights Reserved

SICLOCK

®

TC100 Operating Instructions

6-3

Page 41

Connection

6.3.4 Third-party systems

Third-party systems can also be used for external synchronization of the

SICLOCK TC100 if the following conditions are fulfilled.

Prerequisites

• Active radio clock signal with 20mA rated current

• Supported signals:

− Demodulated DCF77

− Serial:

Meinberg format (time-zone dependent),

Meinberg format (time-zone independent),

NMEA (0183/ZDA)

Functional check

The parameter /Inputs/Input 1/Status (0.20.02)

must change to "Meinberg",

"NMEA" or "DCF77" after about three minutes reception.

6-

© Siemens AG 2010 All Rights Reserved

SICLOCK

®

TC100 Operating Instructions

Page 42

6.4 Connecting alarm and warning outputs

During operation, the SICLOCK TC100 automatically carries out a range of function tests. If an error occurs, the device generates corresponding messages on

the display. A distinction is made between alarms and warnings.

There is an alarm output and a warning output for external monitoring on terminal

X2.

;

;

;

Figure 6-6 Alarm output X2-7 and warning output X2-8

Table 6-3 Parameters affecting the alarm behavior

/Synchronization/Extended/Monitoring/Monitor Synchronization Status (0.09.14)

Connection

/Network Settings/Ethernet 1/Extended Settings Adapter 1/Monitor Link Status (0.05.09)

/NTP Client/Monitoring/Monitor Server (0.18.04)

/Environment/Extended/Temperature/Monitoring (0.24.01)

Example:

Set the alarm output if there is no external synchronization.

Use the Configuration Tool to set the parameter entry /Synchronisation/Exended/Monitoring/Monitor Synchronization Status (0.09.14) = "Alarm" to activate

monitoring / alarm output in case of error.

Note

The contacts are designed as wire-break-proof, normally closed contacts. If there

is an alarm or warning, the corresponding contact opens.

© Siemens AG 2010 All Rights Reserved

SICLOCK

®

TC100 Operating Instructions

6-

Page 43

Connection

6-4

© Siemens AG 2010 All Rights Reserved

SICLOCK

®

TC100 Operating Instructions

Page 44

Configuration Tool 7

The SICLOCK TC100 Configuration Tool is available to make it easier to assign

parameters and configure the SICLOCK TC100. The tool can be called from an

Internet browser as a Web interface.

With the Configuration Tool you can, among other things, view and change parameters online and offline, view archives, search them with specific filter criteria,

and load, backup and change the parameter assignments of the

SICLOCK TC100 device.

Figure 7-1 SICLOCK TC100 Configuration Tool

(1) Toolbar of the Configuration Tool

(2) Working area of the Configuration Tool

You can make settings and assign parameters in the Parameter tab, and check

and search for events in the Archive tab.

SICLOCK

®

TC100 Operating Instructions

7-4©Siemens AG 2010 All Rights Reserved

Page 45

Configuration Tool

Preconditions

PC

• Minimum screen resolution of 1280x1024

• Java Runtime of at least V1.4.0 or higher

• Web browser, e.g. Microsoft Internet Explorer

• Connection with the Ethernet port on the device

SICLOCK TC100

• Assignment of an IP address to the device

A valid IP address must be assigned to the Ethernet port of the device. The

device is supplied with the address 192.168.1.10 and subnet mask

255.255.255.0. See also Network settings on the device (Chapter 8.2.2).

The PC and device must be in the same subnetwork.

Parameters, entries and lists

A parameter is defined as a group of related values. Each of these values is termed an entry in its parameter.

Similar parameters can form a list. Such lists are indicated by [ ].

Notice

Entries can be individually edited, but not individually read or written. A parameter

is always read or written with all its entries. If it is a list, the complete list is read or

written.

Parameters are identified by their unique parameter number. The parameter

number always has three parts, e.g. 0.05.12.

Example: parameter /Display/Display (0.10.01)

with the entries "Language" and

"Time":

7-4

Figure 7-2 Parameter display

© Siemens AG 2010 All Rights Reserved

SICLOCK

®

TC100 Operating Instructions

Page 46

Working with the Configuration Tool

How to start the Configuration Tool:

1. Open the Web browser

2. Enter the address of the device port, e.g. 192.168.1.10

3. If necessary, confirm the installation and execution of the applet with "Yes"

and/or "Always".

−> The Configuration Tool is started and displayed in the browser.

Note

Take note of the information in your browser concerning restrictions as a result of

high security settings.

How to assign parameters to the SICLOCK TC100 with the Configuration

Tool:

1. Connect the Configuration Tool to the SICLOCK TC100 with the button

Configuration Tool

2. In the case of a new assignment of parameters to the device, load the parameters into the Configuration Tool with the button, or open an existing

parameter file (*.u600) with the button .

3. Assign parameters to the SICLOCK TC100 according to your hardware configuration and requirements.

In online mode, changes become immediately effective in the device.

4. Back up the configuration as a parameter file (*.u600) on your PC with the

button.

Note

In order to be able to fall back on the last version of the SICLOCK TC100 parameter assignment, we recommend backing up the current parameter assignment

of SICLOCK TC100 as a *.u600 file before you make any changes.

© Siemens AG 2010 All Rights Reserved

SICLOCK

®

TC100 Operating Instructions

7-4

Page 47

Configuration Tool

7.1 Menus

Table 7-1 Menus in the Configuration Tool

Menu / function Meaning / note

File

Open Loads a parameter assignment/an archive from the local file system

See also General functions (Chapter 7.2).

Save Saves a parameter assignment/an archive to a local file system

See also General functions General functions (Chapter 7.2).

End Exits application

Link See also Connect / disconnect online connection (Chapter 7.2.1).

Connect Connects to a device

Disconnect Disconnects from a device

Data transfer

(online connection required)

See also Connect / disconnect online connection (Chapter 7.2.1).

Download parameters

from device

Update the parameters

from the device

Upload parameters to

the device

Download archive Loads the complete archive from the connected device onto the PC

Update archive Requests/updates the archive of a connected device

View

Parameters Changes to parameter view

Archive/events Changes to the archive/events view

Language Selects one of the languages available for the user interface

Loads all parameters from a connected device onto the PC

See also Parameters (Chapter 7.3).

Updates all the parameters so far loaded on the PC with the values

from the connected device

See also Parameters (Chapter 7.3).

Writes all parameter from the PC into the connected device

See also Parameters (Chapter 7.3).

See also Archive (Chapter 7.4).

See also Archive (Chapter 7.4).

See also Parameters (Chapter 7.3).

See also Archive (Chapter 7.4).

Depending on the version, more languages could be offered for

selection:

• English (standard language)

• German

The language/naming of parameters and archives are supplied by the

device. Provided that the device recognizes the language set in the

Configuration Tool, the parameters and archives will be displayed in this

language. If the device does not recognize the language, the display will

be in the standard language.

7-4

© Siemens AG 2010 All Rights Reserved

SICLOCK

®

TC100 Operating Instructions

Page 48

Table 7-1 Menus in the Configuration Tool

Menu / function Meaning / note

?

Help… Calls Help system

Version… Displays version information for the Configuration Tool

Configuration Tool

© Siemens AG 2010 All Rights Reserved

SICLOCK

®

TC100 Operating Instructions

7-4

Page 49

Configuration Tool

7.2 General functions

The toolbar of the Configuration Tool provides general functions for the parameters and the archive. You can also acknowledge events, and authorize yourself in

the Configuration Tool.

Table 7-2 Possible operations and displays in the toolbar of the Configuration Tool

Field / button Meaning / instruction

Loads a parameter assignment/an archive from the local file system

The file must be in the U600 format (*.u600). The parameter assignment

Open

Save

IP address

Connect to device

Disconnect from device

and the archive are loaded from the file when it is opened.

Notice

The currently loaded data (parameter assignment and archive) are

overwritten.

Saves a parameter assignment/an archive to a local file system

The data (parameter assignment and archive) are saved in U600 format

(*.u600).

IP address of the SICLOCK TC100

Enter the IP address of the device here.

Connects to a device

The connection is established to the device with the given IP address.

Disconnects from device

The connection is terminated.

Die aufgebaute Verbindung wird getrennt.

See also Connect / disconnect online connection (Chapter 7.2.1).

Authorization - password

Authorize

Event

(online connection

required)

Confirm event

(online connection

required)

Enter a password to enable a higher access level

Password supplied with device: "2222"

See also Authorization (Chapter 7.2.2).

Executes authorization with the password entered

Events currently pending in the device

In online mode, the events pending in the device are shown (e.g.

warnings, alarms, etc.)

In offline mode, the display contains no information.

Acknowledges pending event

In online mode, an acknowledgment for the pending event is sent to the

device. Provided that it is acknowledgeable, the device deletes the event

from the display. Non-acknowledgeable events (persistent indications)

remain in the display.

7-4

© Siemens AG 2010 All Rights Reserved

SICLOCK

®

TC100 Operating Instructions

Page 50

Table 7-2 Possible operations and displays in the toolbar of the Configuration Tool

Field / button Meaning / instruction

Acknowledges all pending events

In online mode, an acknowledgment for all pending events is sent to the

Confirm all events

Ignore event

device. An acknowledgment is made, even if the cause of the event is still

pending. This enables, e.g., persistent alarms to be deactivated.

Rejects the pending event

The event display is deleted without interaction with the device.

7.2.1 Connect / disconnect online connection

How to establish an online connection to the SICLOCK TC100:

1. Enter the IP address of the device in the toolbar.:

Configuration Tool

2. Start establishing the connection by clicking the icon next to the IP

address field.

−> The Configuration Tool changes into online mode:

How to terminate the online connection to the SICLOCK TC100:

1. Click next to the IP address field.

−> The Configuration Tool changes into offline mode:

Note

The connection to the device is terminated after about two hours without operator

input.

© Siemens AG 2010 All Rights Reserved

SICLOCK

®

TC100 Operating Instructions

7-4

Page 51

Configuration Tool

7.2.2 Authorization

There are authorization levels for each parameter, which allow or forbid read and

write accesses to the parameter. The operator interface initially starts with the

lowest authorization level, which mostly only allows read access to parameters.

You obtain more rights by inputting the corresponding password.

The user can change the password.

• Parameter /System/Authorization For Standard Protection (2.06.02)

Note

The combination "0000" is not permitted as a password. Setting the password to

"0000" disables access with this authorization level. Access is then only possible

using the service password. The service password can be requested from Technical Assistance by an authorized person.

The device is supplied with the password: "2222"

The current authorization level is indicated by the color of the password field.

Write protection - red entry field

In this authorization level, the user typically has only read access to standard

parameters.

Standard protection - green entry field

In this authorization level, the user typically also has read access to extended

parameters and write access to standard parameters.

Online mode

Authorization is executed directly on the device, i.e. the device assigns an appropriate authorization level.

Offline mode

You can authorize yourself for a higher authorization level with a password, provided that it is included in the loaded offline authorization parameters.

7-

Note

In offline mode, it is not possible to authorize oneself with a password that is present in the device but is not included in the offline authorization parameters.

© Siemens AG 2010 All Rights Reserved

SICLOCK

®

TC100 Operating Instructions

Page 52

7.3 Parameters

You can set and transfer parameters to the SICLOCK TC100 in the Parameter

tab of the Configuration Tool in both offline and online modes.

Configuration Tool

Figure 7-3 SICLOCK TC100 Configuration Tool - Parameters

(1) Toolbar of the parameter tab

(2) Parameter tree

(3) Parameter table

(4) Parameter info

©Siemens AG 2010 All Rights Reserved

SICLOCK

®

TC100 Operating Instructions

7-

Page 53

Configuration Tool

Table 7-3 Possible operations and displays in the Parameter tab

Field / button Meaning / instruction

Outputs parameter assignment in a text file.

The currently displayed parameter assignment is output in a text file. The

Print table in text file

Download parameters

(online connection

required)

data can be further processed, e.g., with Excel.

Notice

Parameter assignments cannot be restored from these text files. In order to

restore a parameter assignment, it must have previously been saved in U600

format.

See open/save in General functions (Chapter 7.2).

Loads the parameters of the connected device

The parameters of the connected device, including its description data (e.g.

texts in all languages), are loaded. This can take several minutes. The

parameter assignment is also implicitly reloaded from the device.

Notice

The displayed parameter assignment data are overwritten. The archived data

are not accepted from the device, i.e. the displayed archived data are

retained.

See also Connect / disconnect online connection (Chapter 7.2.1).

Update parameters

(online connection

required)

Upload parameters

(online connection

required)

Observe actual values

(online connection

required)

Loads the parameters of the connected device without parameter description

The parameters of a connected device are loaded without the description

data. This can take several minutes.

Notice

The displayed parameter assignment data are overwritten. The archived data

are not accepted from the device, i.e. the displayed archived data are

retained.

See also Connect / disconnect online connection (Chapter 7.2.1).

Transfers the writable values of the loaded parameters to the connected

device

The following values/parameters are not transferred into the device:

• Values of write-protected parameters

• Operationally critical parameters

• Display parameters

• Command parameters

To transfer the parameter, an online connection must be established to the

device and the Confiiguration Tool correspondingly authorized. See also

Connect / disconnect online connection (Chapter 7.2.1) and

Authorization (Chapter 7.2.2).

Current values / states of actual values observed

After observation has been activated, the current values and/or states are

readout from the device cyclically, and the displays in the Parameter tree and

the Parameter table are updated.

See also Connect / disconnect online connection (Chapter 7.2.1).

7-5

© Siemens AG 2010 All Rights Reserved

SICLOCK

®

TC100 Operating Instructions

Page 54

Table 7-3 Possible operations and displays in the Parameter tab

Field / button Meaning / instruction

Parameter tree Tree display of parameters

The parameters are subordinated in the trees of the individual menus and

submenus.

Online mode:

In online mode, you can open a context menu with a right mouse click on the

parameter / entry. The following functions are available:

• Read individual parameters

• Write individual parameters

• Set parameters to factory settings

See Reading / writing parameters, setting to factory defaults

(Chapter 7.3.4).

Icons:

• Write protection – the parameter cannot be edited

The current authorization level does not allow write access to this

parameter.

• Master level

The current authorization level allows reading, editing and writing of the

parameter.

• Master level without upload– operationally critical parameter

The current authorization level allows reading, editing and writing of the

parameter.

In order to change such parameters in the device, you have to select the

parameter explicitly and write it individually.

See Reading / writing parameters, setting to factory defaults

(Chapter 7.3.4)

• Display parameters

Display parameters can only be read, and are typically actual values.

In order to update the display of actual values, activate automatic update

.

• Entry – this is a parameter entry

Parameter Table Tabular display of the parameters

You can edit the parameter values in this display, see Editing parameters

(Chapter 7.3.3).

Online mode:

In online mode, you can open a context menu with a right mouse click on the

parameter/entry. The following functions are available:

• Read individual parameters

• Write individual parameters

• Set parameters to factory settings

See Reading / writing parameters, setting to factory defaults

(Chapter 7.3.4).

Configuration Tool

© Siemens AG 2010 All Rights Reserved

SICLOCK

®

TC100 Operating Instructions

7-5

Page 55

Configuration Tool

Table 7-3 Possible operations and displays in the Parameter tab

Field / button Meaning / instruction

Number Unique, three-part parameter number, e.g. 000.005.00012

Parameter Related values are grouped in a parameter.

Parameter lists are displayed with square brackets after the parameter name,

e.g. "Leap second[20]".

Entry The individual values of a parameter are each defined as an entry in a

parameter.

Note

Entries can be individually edited but not individually read or written. The

complete parameter is always read or written with all its entries. If it is in a list,

the complete list is read or written.

Value Numerical value or setting of the parameter entry

• Write protection – the parameter cannot be edited

The current authorization level does not allow write access to this

parameter.

• Master level

The current authorization level allows reading, editing and writing of the

parameter.

Master level without upload – operationally critical parameter

The current authorization level allows reading, editing and writing of the

parameter.

In order to change such parameters in the device, you have to select the

parameter explicitly and write it individually. See Reading / writing

parameters, setting to factory defaults (Chapter 7.3.4).

Display parameters

Display parameters can only be read, and are typically actual values.

In order to update the display of actual values, activate automatic update

.

Parameter info Information about the selected parameter

Information on the selected parameter / entry is displayed here.

Note

If the Configuration Tool is not authorized or is used with lower authorization

rights, not all the parameters will be displayed. This restriction concerns, e.g., settings under "System“.

Furthermore, the access rights change with the authorization level.

7-5

© Siemens AG 2010 All Rights Reserved

SICLOCK

®

TC100 Operating Instructions

Page 56

7.3.1 Sorting Parameter tables

How to sort a Parameter table by number or parameter:

1. Click the "Number" or "Parameter" column with the mouse.

−> The table is sorted into alphabetical order according to the clicked column.

2. Click the "Number" or "Parameter" column again with the mouse to reverse the

alphabetical order.

−> The alphabetical order of the column is reversed in comparison to the current sorting in ascending or descending alphabetical order.

The current sorting order is shown by an arrow alongside the column header:

7.3.2 Hiding / showing Parameter table entries

Configuration Tool

How to hide and show parameter entries:

1. 1.Click with the mouse on the icon on the left-hand side of the table next to

the parameter.

−> The entries of the parameter are displayed.

2. 2.Click with the mouse on the .icon on the left-hand side of the table next to

the parameter.

−> The entries of the parameter are hidden.

Figure 7-4 Parameter table with shown and hidden entries

© Siemens AG 2010 All Rights Reserved

SICLOCK

®

TC100 Operating Instructions

7-5

Page 57

Configuration Tool

7.3.3 Editing parameters

Precondition for editing a parameter entry

• It must be a writable entry ( ).

How to change the values of a parameter entry:

1. Show the entries of the desired parameters in the Parameter table, see

Hiding / showing Parameter table entries (Chapter 7.3.2).

2. Click the "Value" column of the parameter entry with the mouse.

−> The dialog for editing the entry opens.

An entry can be canceled with ESC.

Figure 7-5 of an editing dialog drop down list box

You can enter new values for parameters with units without entering the unit. Any

units entered are ignored, only the numerical value is accepted.

Figure 7-6 Example of an editing dialog with a numerical entry

Note

In online mode, the value is sent to the device when the entry has been

completed.

7-5

© Siemens AG 2010 All Rights Reserved

SICLOCK

®

TC100 Operating Instructions

Page 58

Configuration Tool

How you check whether the value has been accepted by the device:

1. In online mode, select the entry of the changed parameter as described above.

−> The current value is displayed in the device.

Note

Depending on the parameter/entry and operating state, the device checks whether it can accept the changed value. If the device rejects the new value, it is reset

to the old value.

© Siemens AG 2010 All Rights Reserved

SICLOCK

®

TC100 Operating Instructions

7-5

Page 59

Configuration Tool

7.3.4 Reading / writing parameters, setting to factory defaults

In online mode, you can read or write an individual parameter, or reset it to the

factory setting.

How to activate the functions "Read parameter", "Write parameter" and

"Reset parameter to factory settings":

1. Ensure that the Configuration Tool is connected to the device.

See Connect / disconnect online connection (Chapter 7.2.1).

2. Select the desired parameter / entry from the Parameter tree or Parameter

table.

3. Right-click the parameter or entry.

−> The context menu opens.

Select the desired function with a left mouse click.

Figure 7-7 Context menu for reading, writing and resetting parameters

7-5

© Siemens AG 2010 All Rights Reserved

SICLOCK

®

TC100 Operating Instructions

Page 60

7.4 Archive

In the Archive tab of the Configuration Tool, you can load archived data from the

device, and save the data in a file, as well as evaluate and search the data with

filter functions.

Configuration Tool

Figure 7-8 SICLOCK TC100 Configuration Tool - Archives

(1) Toolbar of the Archive tab

(2) Archive table

(3) Include filter (shows events)

(4) Exclude filter (hides events)

© Siemens AG 2010 All Rights Reserved

SICLOCK

®

TC100 Operating Instructions

7-5

Page 61

Configuration Tool

Table 7-4 Possible operations and displays in the Archive tab

Field / button Meaning / instruction

Outputs the archive in a text file.

The currently displayed Archive table is output in a text file. Events hidden by

Print table in text file

Download archive

(online connection

required)

Update archive

(online connection

required)

the filter are not output. The data can be further processed, e.g., with Excel.

Notice

Archives cannot be restored from these text files. In order to restore an

archive, it must have previously been saved in U600 format.

See open/save in General functions (Chapter 7.2).

Loads the archive of the connected device

The archive of the connected device, including its description data (e.g. texts

in all languages), is loaded. This can take several minutes. The parameter

assignment is also implicitly reloaded from the device.

Notice

The currently loaded data (parameter assignment and archive) are

overwritten.

See also Connect / disconnect online connection (Chapter 7.2.1).

Loads the archive of the connected device without the parameter description

The archive of a connected device is loaded without the description data. The

loading process without the description data is quicker than "Download

archive". The parameter assignment is also implicitly reloaded from the

device.

Notice

The currently loaded data (parameter assignment and archive) are

overwritten.

See also Connect / disconnect online connection (Chapter 7.2.1).

View reduced to

incoming / outgoing

Switch Exclude-Include

view

Clear Include filter

Clear Exclude filter

Displays only incoming and outgoing events

Only persistent indications (typically alarms) are displayed in the Archive

table. This gives you a compact overview of important operational

malfunctions. The hidden events are displayed in the Exclude window of the

filter.

In order to display all events again, delete the Include filter.

See Filters (Chapter 7.4.2).

Switches an event from the Include to the Exclude filter, and vice versa

The events selected in the Include and Exclude filters are in each case

moved into the other filter.

See Filters (Chapter 7.4.2).

Removes all events from the Include filter

The events are moved into the Exclude filter.

See Filters (Chapter 7.4.2).

Removes all events from the Exclude filter

The events are moved into the Include filter.

See Filters (Chapter 7.4.2).

7-

© Siemens AG 2010 All Rights Reserved

SICLOCK

®

TC100 Operating Instructions

Page 62

Table 7-4 Possible operations and displays in the Archive tab

Field / button Meaning / instruction

Archive table Events are shown in tabular form.

Persistent indications trigger an incoming and an outgoing event, and are

highlighted in color:

• red = incoming

• green = outgoing

Typically, alarms are implemented in the device as persistent indications.

Type Event type:

• System

• Application

• Information

• Alarm

Note:

Each type of event is managed in its own buffer in the device. If a buffer is full,

the next message of this type overwrites the oldest message in the buffer.

See also Messages (Chapter 12).

Time Tripping event in the device, time base UTC

Configuration Tool

Event Message triggered by device.

The sum of all events forms the archive of the device.

Information Optional information accompanying the event.

+/- • ++ (incoming)

Event marked as incoming (persistent indication, e.g. alarm)

• -- (outgoing)

Event marked as outgoing (persistent indication, e.g. alarm)

Include filter Events shown in the Archive table.

See Filters (Chapter 7.4.2).