Page 1

SIEMENS SpecTRON 8

MANUAL

Doc No:

0075

Rev No:

8

Category:

Technical

Created By:

W.Barrett

PRODUCTS – OPERATIONS

3 Document is uncontrolled outside of document management system

Unrestricted

© Siemens plc. 2019 All Rights Reserved.

Page i of iii

Page 2

SIEMENS SpecTRON 8

MANUAL

Doc No:

0075

Rev No:

8

Category:

Technical

Created By:

W.Barrett

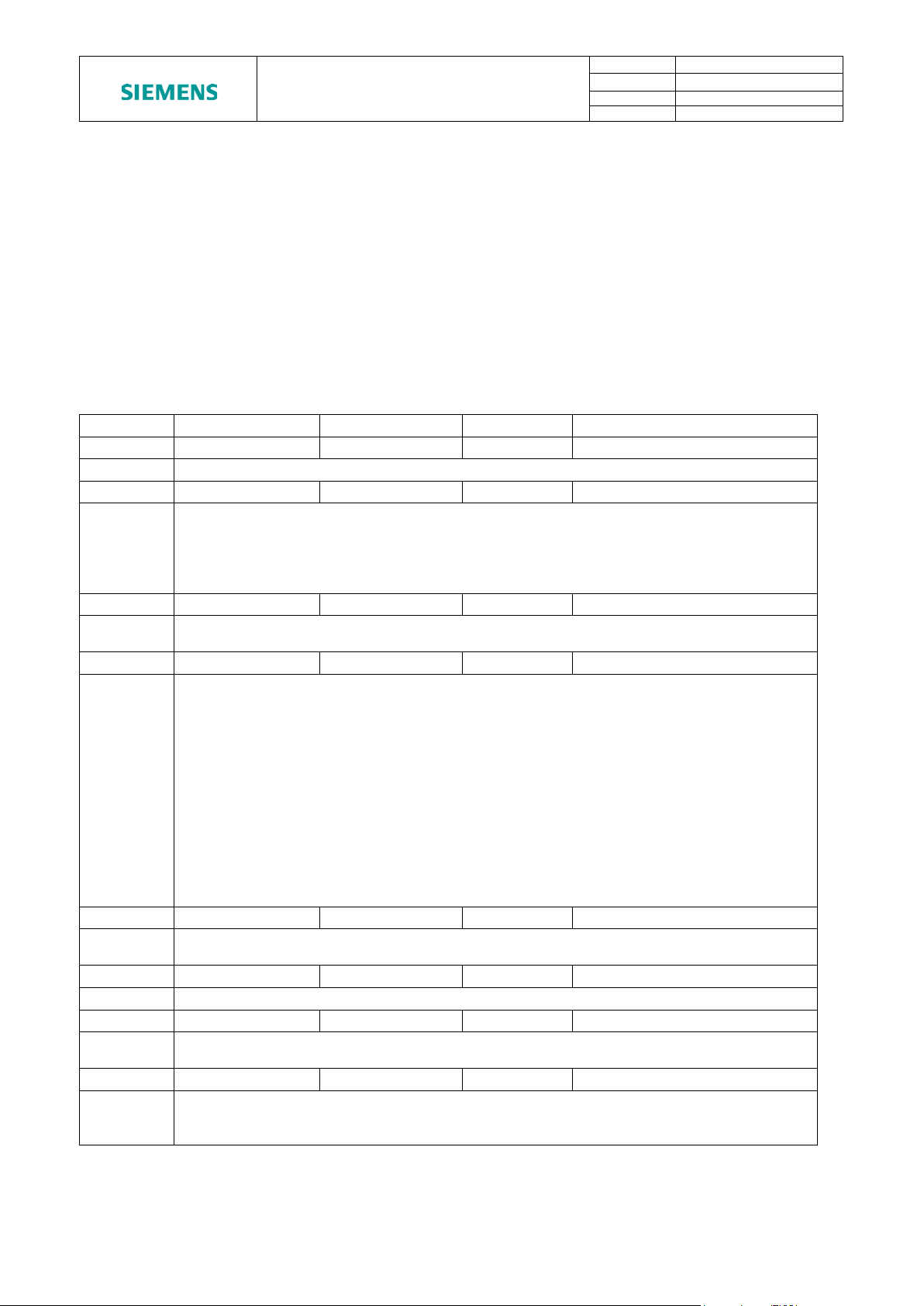

Revision

Author

Checker

Issue Date

1 W. Barrett

M. Simmonds

27/03/13

First Issue

2

S. Roberts

D. Church

22/07/2013

Section 2.3.1 - Outside Pressurised Diameter for AquaTRON 200 added to document.

Section 7.4 - Figure 14 updated to show up to date Receptacle Shroud.

3

W. Barrett

S. Spencer

23/08/2013

Section 7.1 – Amended 60 day exposure time to be only applicable from Jan 2013. 30 days

before this date.

4

A. Plinston

J. Ronald

28/02/2014

Section 4.1 - Slinging instruction added for ROV connectors with locking mechanism.

mate procedure added for ROV connectors with locking

Mate procedures added for connectors with locking

New Corporate cover added.

5

J. Ronald

W. Barrett

14/05/2014

Section 2 – Health and Safety notes added with contact email address.

Added Section 12 – Information & Notes / Health & Safety Feedback.

6

M. Gretton

B. Leach

04/06/2014

Section 2 – Health and Safety note added for Receptacle connectors.

7

S. Roberts

P. Edmondson

15/07/2014

Section 5 – Note added to ensure hose is protected from direct sunlight to avoid the

maximum temperature being exceeded.

8

T. Tioffo

K. Higgs

17/07/2017

Updated visual representations

Section 8.4 - Note added for flushing port adaptor.

PRODUCTS – OPERATIONS

SIEMENS SpecTRON 8 PRODUCTS -

PROTECTION, STORAGE, SHIPMENT, UNPACKING,

DEPLOYMENT & MAINTENANCE INSTRUCTIONS

General

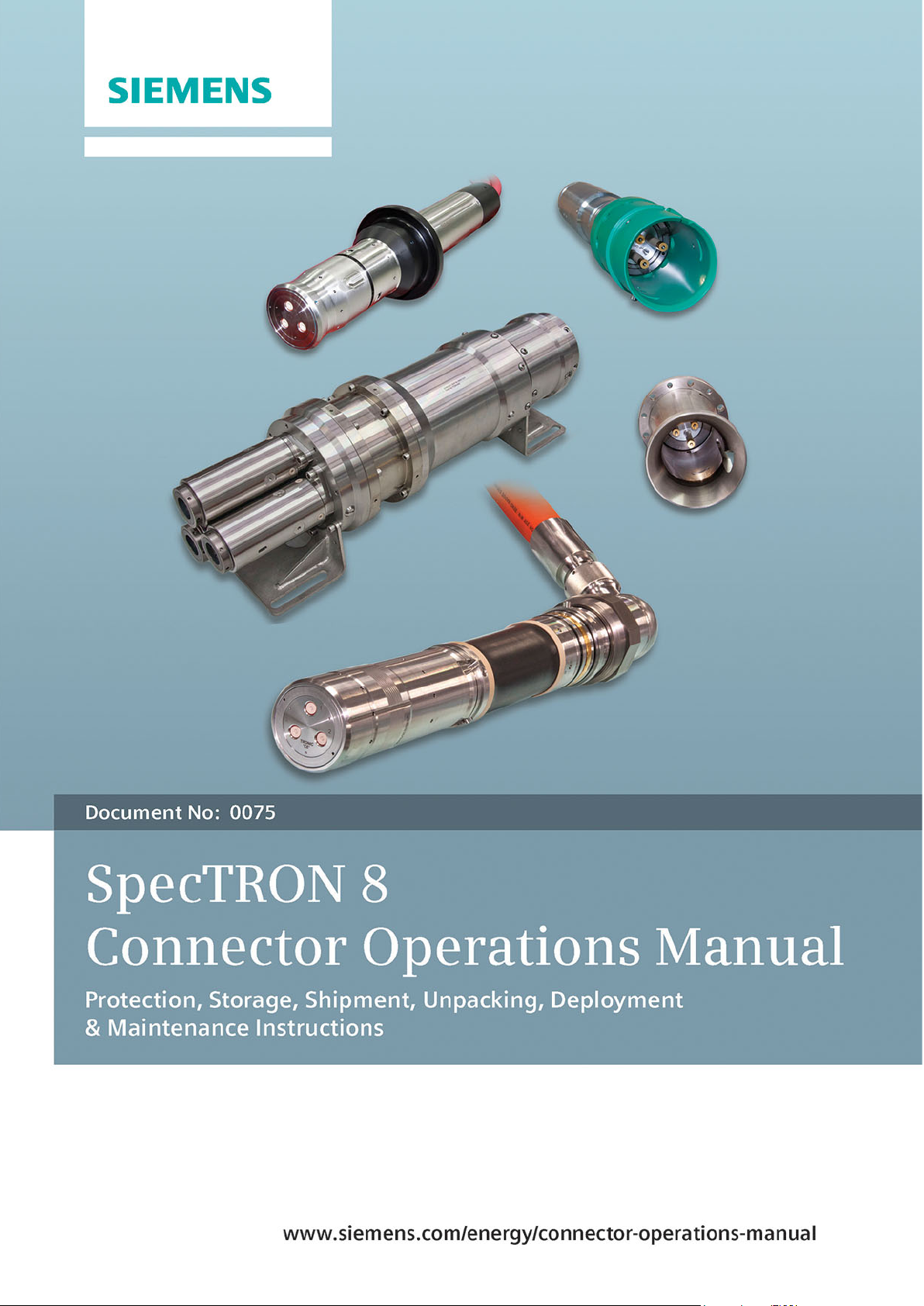

Thank you for purchasing a Siemens Subsea SpecTRON 8 product. The information that

follows is an overview of the protection, storage, shipment, unpacking, deployment and

maintenance instructions for Siemens Subsea SpecTRON products.

Siemens Subsea recommends the termination of all equipment must only be undertaken

by suitably trained and qualified personnel.

Revision Control:

Section 2.3.2 - Details of AquaTRON 50 added to Operations Manual.

Section 2.3.3 - Details of internal cables added

Section 4 - Minimum Bend Radius of AquaTRON 50 added to document.

Section 7.4 - Figure 14 updated to show connectors with locking mechanism.

Section 7.6 - Figure 17 updated to show connectors with locking mechanism.

Section 7.6 - Figures 18 & 19 added showing 3 finger jaw for fishtail ROV handle

Section 8.3 & 8.4 - Mate & De-mate procedures added for ROV connectors with locking

mechanism.

Section 8.7 – Emergency Demechanism.

Section 8 - Figures 23, 24, 25, 26 & 27 added

Section 9 - Manual Mate & Demechanism.

Section 9 - Figures 30 & 31 added

Section 5.1 - Note added for lifting precaution over coating components.

Unrestricted

3 Document is uncontrolled outside of document management system

© Siemens plc. 2019 All Rights Reserved.

Page ii of iii

Page 3

SIEMENS SpecTRON 8

MANUAL

Doc No:

0075

Rev No:

8

Category:

Technical

Created By:

W.Barrett

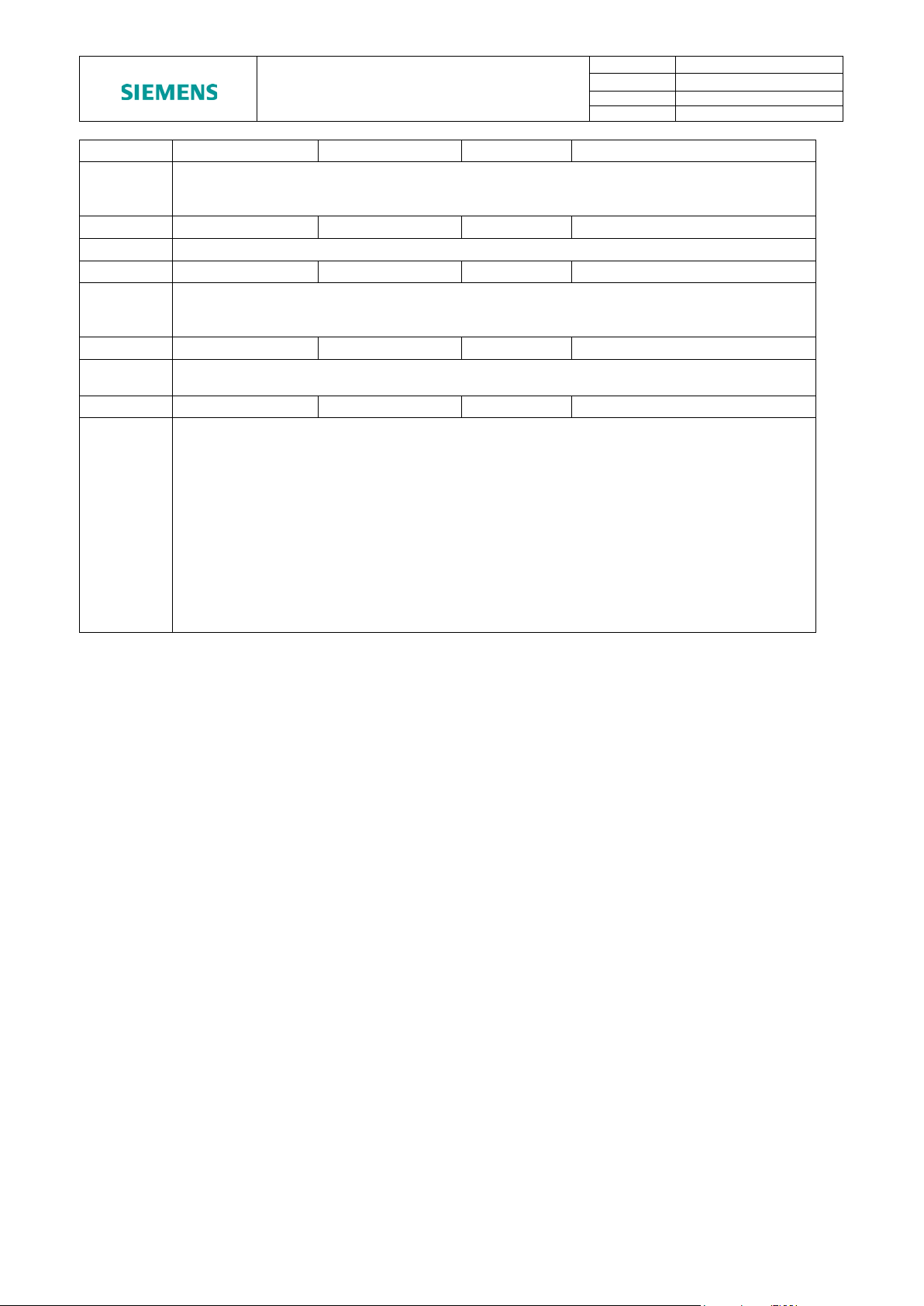

9

J. Keith

D. Church

18/10/2017

Document tracked changes removed.

10

T. Archer

D. Church

23/02/2018

Correcting Figure Numbers, Adding optional packaging section

11

D. Brown

S. Fitton

23/01/2019

Section 1 – Note added to include the Dual Penetrator as an included connector type.

Assembly.

12

S.Hargreaves

M.Earnshaw

04/07/2019

Section 3.3.1 - Updated Hose weight to match current calculated weight

Section 8.6 - Added in weight restrictions for EFLs

13

S.Hargreaves

M.Earnshaw

12/09/2019

Section 5.1 - Figure 8 updated to include central slinging position on the Dual Penetrator

Document header revision corrected.

Section 5.1 – Figure 8 added for the recommended lifting positions for the Dual Penetrator

Assembly and added note about inboard termination.

Updated whole document to latest Siemens template format.

Section 3.3.3 – Added cable OD, MBR, Weight in Air and Weight in Water for both 35mm

and 4mm

Created Section 3.3.4 to include test connector cable information.

Changed Rev 12 Sections 10.2, 10.3, 10.5 and 10.6 into sub sections of 10.1 and 10.2 as

10.1 and 10.2 didn’t have any content underneath their titles.

Created Section 11 to describe connection points etc. for test connectors.

Section 5.1 Figures 4, 5, 6 & 7 – Corrected positions of arrows.

Document Control Page – Removed Tronic reference and replaced with Siemens.

2

.

PRODUCTS – OPERATIONS

2

Unrestricted

3 Document is uncontrolled outside of document management system

© Siemens plc. 2019 All Rights Reserved.

Page iii of iii

Page 4

SIEMENS SpecTRON 8

MANUAL

Doc No:

0075

Rev No:

8

Category:

Technical

Created By:

W.Barrett

PRODUCTS – OPERATIONS

Contents

1. SCOPE ............................................................................................................................................. 2

2. HEALTH & SAFETY ........................................................................................................................ 2

3. SPECIFICATION .............................................................................................................................. 3

3.1 ELECTRICAL ............................................................................................................................... 3

3.2 ENVIRONMENTAL ...................................................................................................................... 3

3.3 HOSE & CABLE ........................................................................................................................... 3

4. MARKING ........................................................................................................................................ 5

5. PROTECTION, HANDLING AND SHIPMENT ................................................................................. 6

5.1 LIFTING OF JUMPERS & CONNECTORS ................................................................................. 7

6. UNPACKING .................................................................................................................................. 11

6.1 PROTECTIVE CAPS ................................................................................................................. 11

7. STORAGE ...................................................................................................................................... 15

8. DEPLOYMENT & MAINTENANCE ................................................................................................ 15

8.1 GENERAL .................................................................................................................................. 15

8.2 PROTECTION OF RECEPTACLE CONTACT PINS ................................................................. 16

8.3 OVER CURRENT CAPACITY.................................................................................................... 16

8.4 REMOVAL OF MARINE GROWTH AND CALCAREOUS DEPOSITS ...................................... 17

8.5 STAB PLATE CONNECTORS ................................................................................................... 19

8.6 ROV CONNECTORS ................................................................................................................. 20

9. ROV MATE / DE-MATE PROCEDUREs ....................................................................................... 23

9.1 ROV MATING PROCEDURE..................................................................................................... 23

9.2 ALIGNMENT AND MATING PROCEDURE – CONNECTORS WITHOUT LOCKING

MECHANISM ............................................................................................................................. 23

9.3 ALIGNMENT AND MATING PROCEDURE – CONNECTORS WITH LOCKING

MECHANISM ............................................................................................................................. 27

9.4 ROV DE-MATING PROCEDURE .............................................................................................. 29

9.5 DE-MATING PROCEDURE - CONNECTORS WITHOUT LOCKING MECHANISM ................. 29

9.6 DE-MATING PROCEDURE - CONNECTORS WITH LOCKING MECHANISM ........................ 29

9.7 EMERGENCY DE-MATE PROCEDURE – CONNECTORS WITH LOCKING

MECHANISM ONLY .................................................................................................................. 31

10. MANUAL MATE/ DE-MATE PROCEDUREs ............................................................................ 32

10.1 MANUAL MATING PROCEDURE ......................................................................................... 32

10.2 MANUAL DE-MATING PROCEDURE ................................................................................... 34

11. TOPSIDE TEST CONNECTORS ............................................................................................... 36

12. INSTALLATION ......................................................................................................................... 37

12.1 CONNECTOR & PENETRATOR INSTALLATION ................................................................ 37

12.2 HOSE ROUTING AND SUPPORT ........................................................................................ 37

13. INFORMATION & NOTES / HEALTH & SAFETY FEEDBACK ................................................ 38

Document is uncontrolled outside of document management system

Unrestricted

© Siemens plc. 2019 All Rights Reserved.

Page 1 of 38

Page 5

SIEMENS SpecTRON 8

MANUAL

Doc No:

0075

Rev No:

8

Category:

Technical

Created By:

W.Barrett

Note: All receptacle’s (male pins) must be mated to its correct mating half before it

is energised (this includes the correct Test, Dummy and Wet Mate Pair).

PRODUCTS – OPERATIONS

1. SCOPE

This procedure includes information on the following connector types:

• SpecTRON 8 ROV Plugs

• SpecTRON 8 ROV Receptacles

• SpecTRON 8 Penetrators

• SpecTRON 8 Dual Penetrator

• SpecTRON 8 Tree Cap Plug (TCP)

• SpecTRON 8 Tubing Hanger Receptacle (THR)

• SpecTRON 8 ROV Dummy Connectors (Plugs & Receptacles)

• SpecTRON 8 ROV Parking Receptacle

2. HEALTH & SAFETY

• Manual Handling, Lifting and Carrying are known to be the largest contributors to

occupational ill-health.

• Ensure that mechanical handling aids are used whenever possible to avoid manual

handling.

• Where manual handling is considered appropriate for the task safe lifting guidelines

must be followed, e.g. adopt correct posture, consider team lifting, employ safe

lifting technique, etc.

• Only competent persons are permitted to perform tasks without supervision, if in

doubt ask.

• Good Housekeeping avoids Slips Trips and Falls, keep your area clean and tidy.

• It is the operator’s responsibility to comply with current Company & regional health

and safety legislation.

• Caution shall be exercised during assembly to ensure that fittings and hydraulic /

pneumatic equipment are properly installed.

In the event of a safety incident or any safety improvement suggestions, please contact

the Health & Safety Department at prodsafe.gb@siemens.com and/or complete and return

the punch list in section 13.

Unrestricted

Document is uncontrolled outside of document management system

© Siemens plc. 2019 All Rights Reserved.

Page 2 of 38

Page 6

SIEMENS SpecTRON 8

MANUAL

Doc No:

0075

Rev No:

8

Category:

Technical

Created By:

W.Barrett

PRODUCTS – OPERATIONS

3. SPECIFICATION

The following is a basic specification for SpecTRON 8 connectors. Actual product may

vary. Please refer to product specific data sheet or Project specific Design Input Document

for more detailed information.

3.1 ELECTRICAL

Rated Voltage: 5/8.7(10) kV

Rated Frequency: 1-200Hz

Rated Current: 335 A (@25°C, 50Hz)

220 A (@110°C, 50Hz THR only)

220 A (@90°C, 50Hz TCP only)

3.2 ENVIRONMENTAL

Storage Temperature: -30°C to + 60°C

Handling Temperature: -25°C to +70°C

Operating temperature: +4°C to + 40°C ROV

+4°C to + 110°C THR

+4°C to + 90°C TCP

Max Deployment Rate: 20bar / min

Max Water Depth: 3000 m

3.3 HOSE & CABLE

3.3.1 AQUATRON 200 (2” BORE)

Outside Diameter: 64.4 mm Nom

Outside Pressurised Diameter: 66 mm Nom

Minimum Bend Radius: 375 mm

Weight in Air (Inc cable and oil): 4.8 kg/m

Weight in Water (Inc cable and oil): 1.45 kg/m

3.3.2 AQUATRON 50 (1/2” BORE)

Outside Diameter: 25.2 ± 0.6 mm

Minimum Bend Radius: 125 mm

Weight in Air (Inc cable and oil): 0.66 kg/m

Weight in Water (Inc cable and oil): 0.14 kg/m

Document is uncontrolled outside of document management system

Unrestricted

© Siemens plc. 2019 All Rights Reserved.

Page 3 of 38

Page 7

SIEMENS SpecTRON 8

MANUAL

Doc No:

0075

Rev No:

8

Category:

Technical

Created By:

W.Barrett

Note: When performing terminations (e.g. inboard) involving exposed unscreened

cable (i.e. no hose), consideration should be given to proximity to “sharp/point”

earths.

PRODUCTS – OPERATIONS

3.3.3 CABLE SPECIFICATION (EXCLUDING THR + UMBILICAL RECEPTACLES)

Cable for Phase: 35mm2 Flexible Cable (Unscreened)

Outside Diameter: 18.10 ± 0.40 mm

Minimum Bend Radius: 110 mm

Weight in Air: 0.55 kg/m

Weight in Water: 0.29 kg/m

Cable for Signal Return: 4mm2 Flexible Cable (Unscreened)

Outside Diameter: 8.95 ± 0.20 mm

Minimum Bend Radius: 55 mm

Weight in Air: 0.11 kg/m

Weight in Water: 0.04 kg/m

3.3.4 TEST CONNECTOR CABLE SPECIFICATION

Cable for Phase: 35mm2 Flexible Cable (Screened)

Outside Diameter: 24.5 mm

Minimum Bend Radius: 125 mm

Weight in Air: 1.04 kg/m

Weight in Water: 0.56 kg/m

Unrestricted

Document is uncontrolled outside of document management system

© Siemens plc. 2019 All Rights Reserved.

Page 4 of 38

Page 8

SIEMENS SpecTRON 8

MANUAL

Doc No:

0075

Rev No:

8

Category:

Technical

Created By:

W.Barrett

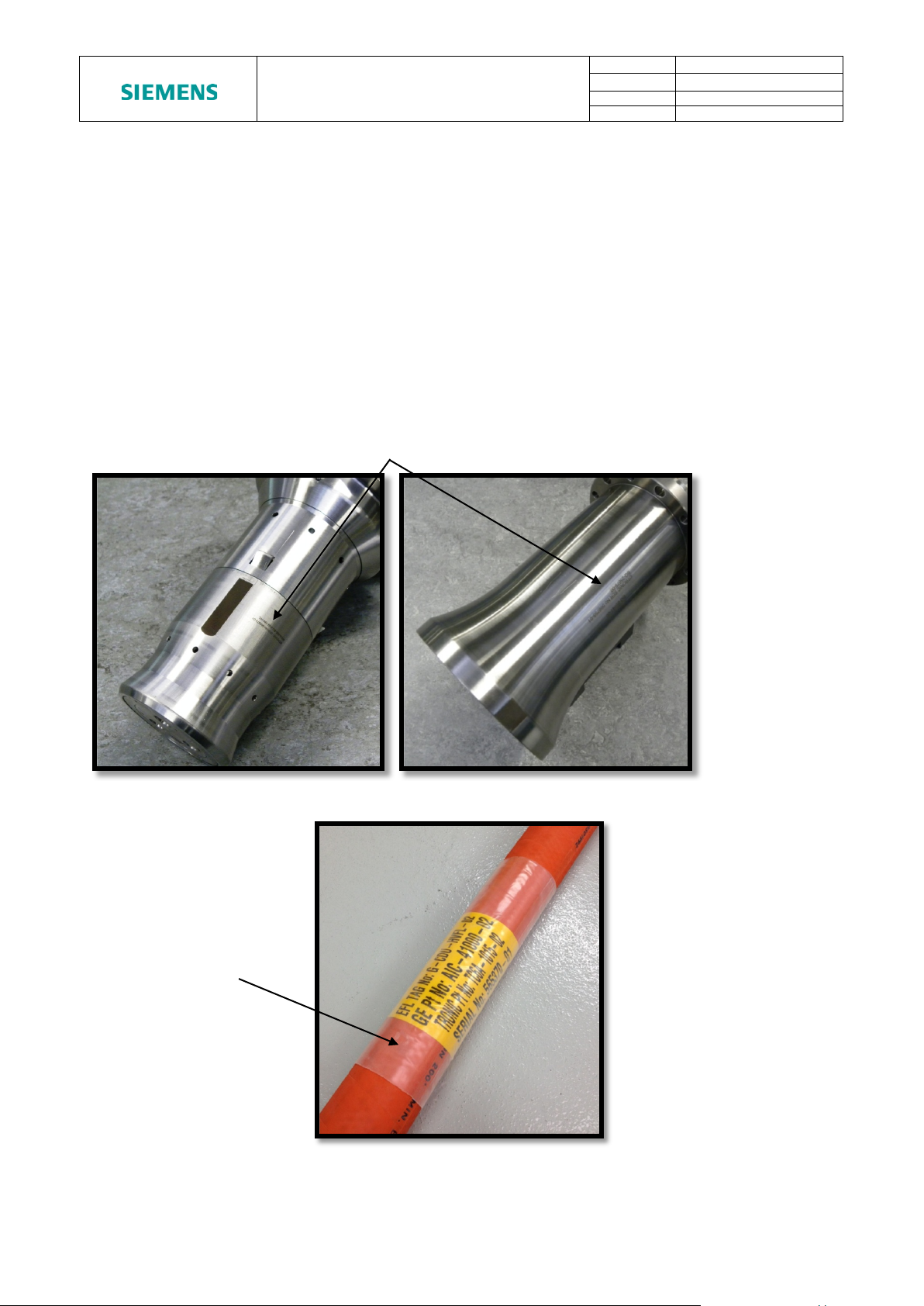

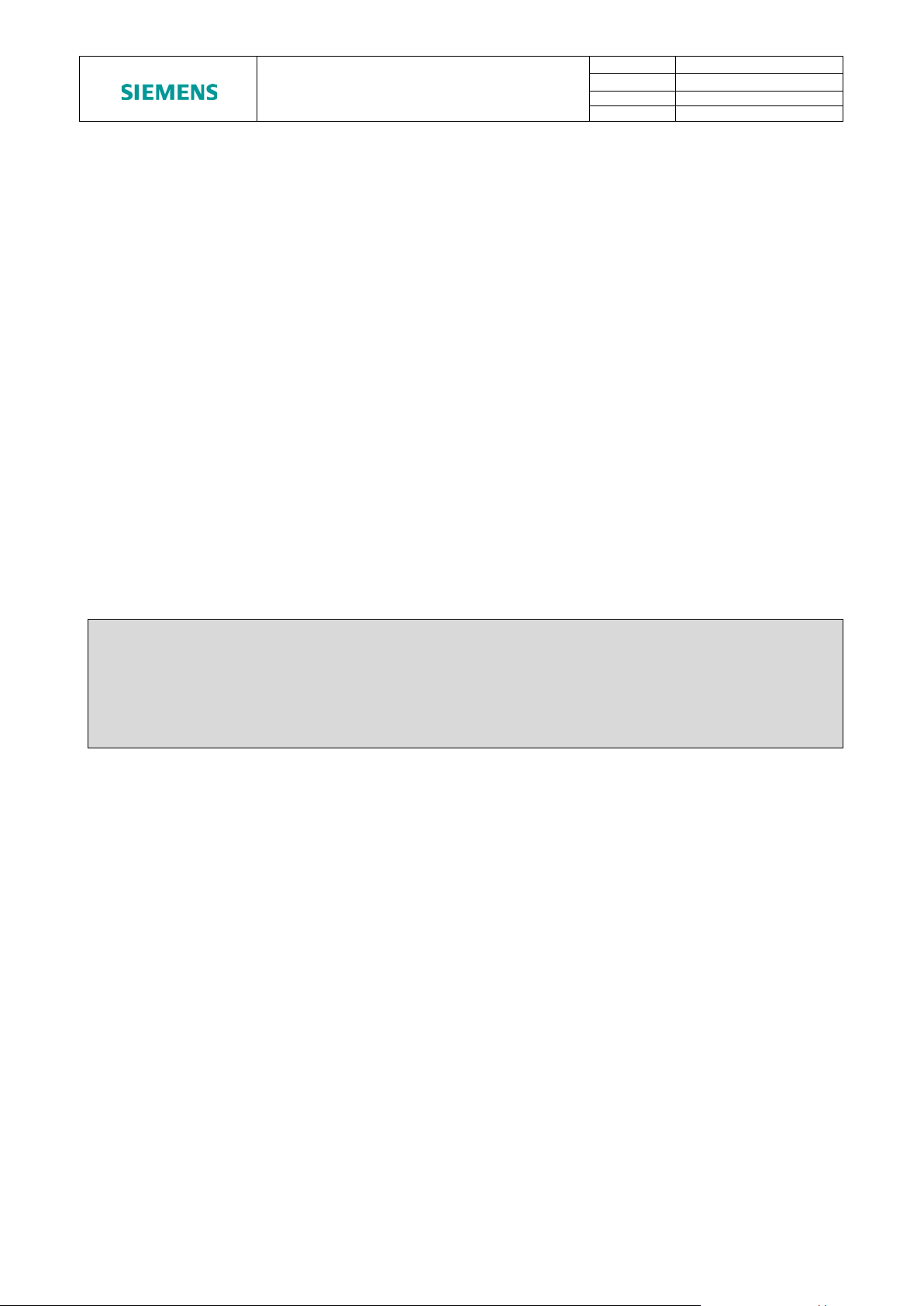

Marking of Siemens Subsea Part

No and Serial No for individual

Marking of Siemens

PRODUCTS – OPERATIONS

4. MARKING

Siemens Subsea Connectors and Penetrators are marked with the Siemens Subsea part

number and unique serial number. Marking locations are typically on the Plug Nose and

Receptacle Shroud for Wet Mate Connectors and on the Flange of Penetrators. Figure 1

shows the typical marking locations for a Plug and Receptacle. Marking is typically by

laser etching.

Harnesses are also marked with the Siemens Subsea part number and unique serial

number for the harness as shown in Figure 2. Client and project specific information is also

usually added to these labels. Labels are typically black text on a yellow background

underneath clear heat shrink. Typically, labels are located at each end of the harness and

also centrally.

Subsea Part No, Serial

No and client

information on

Document is uncontrolled outside of document management system

Figure 1 – Marking of Connectors

Figure 2 – Marking of Hoses

Unrestricted

© Siemens plc. 2019 All Rights Reserved.

Page 5 of 38

Page 9

SIEMENS SpecTRON 8

MANUAL

Doc No:

0075

Rev No:

8

Category:

Technical

Created By:

W.Barrett

Note: Maximum storage temperature takes into account solar gain. Skin

with similar properties must be used to ensure maximum storage temperature is

not exceeded.

PRODUCTS – OPERATIONS

5. PROTECTION, HANDLING AND SHIPMENT

Siemens Subsea electrical connectors are manufactured primarily from materials such as

316L stainless steel (UNS S31603), and Super Duplex stainless steel (UNS S32550).

Stainless steel 316L (UNS S31603) connectors and penetrators must be connected to a

CP (Cathodic Protection) system at all times in order to withstand harsh saliferous

environments. Super Duplex stainless steel (UNS S32550 / UNS S32760) ROV

connectors may be isolated from the CP system to reduce the possibility of hydrogen

embrittlement and calcareous deposits. ROV Connectors are designed with isolation

bushes and discs in order to isolate them from the structure as standard. Tree Cap Plugs,

Tubing Hanger Receptacles and Penetrators cannot be isolated from the structure and

thus may be connected to the CP system.

The connector insert and exposed parts are susceptible to mechanical damage if not

adequately protected. Dust caps or Protective caps are fitted to all Siemens Subsea

connectors before transport. Caps are recommended to remain in place until connectors

are deployed subsea.

The connectors can be shipped singularly or in multiples. Care should be taken to protect

the connector with bubble wrap or similar wrapping materials to avoid surface damage

during transit. If large numbers are shipped in one consignment a suitably reinforced box

will be necessary to withstand the weight. Protection caps must be fitted at all times

during transport.

temperature must not exceed 700C. Suitable protection i.e. a tarpaulin or material

If storage is carried out in saline conditions, e.g. on a ship’s deck or hold, then full dummy

connectors should be used.

Bulkhead type connectors with exposed tailing wires should be packed and shipped in a

suitably sized box to allow adequate space for the tailing wires without bending or kinking.

If the connectors are assembled onto hoses these must be suitably coiled and secured

with tape to prevent uncoiling during transit. The following bend radii are recommended for

storage/transport of hose.

• AquaTRON 2” NB (AquaTRON 200) - Minimum bend radii - 375mm

• AquaTRON 0.5” NB (AquaTRON 50) - Minimum bend radii - 125mm

Connectors are designed to withstand vibration that occurs during transportation and to

withstand being dropped from a height of 1m whilst in packaging.

Figure 3A shows how a SpecTRON 8 harness is packaged. The connectors on either end

of the harness have a transportation cap fitted and are surrounded in bubble wrap. The

base of the shipping crate is lined with protective packaging and the harness is positioned

so that the hose can be coiled without kinking. Any loose items are placed in a box inside

the crate. Protective packaging is then placed on top of the harness and secured in place

with a wooden baton, before the lid of the crate is screwed down.

Document is uncontrolled outside of document management system

© Siemens plc. 2019 All Rights Reserved.

Unrestricted

Page 6 of 38

Page 10

SIEMENS SpecTRON 8

MANUAL

Doc No:

0075

Rev No:

8

Category:

Technical

Created By:

W.Barrett

Note: Ensure that all coated components are handled with care during lifting to

avoid damaging the coating.

PRODUCTS – OPERATIONS

Figure 3A – Standard Packaging.

Figure 3B shows a different type of optionally purchased packaging the harness could be

supplied in. This crate is manufactured from polyethylene plastic and is dust, oil, chemical

and water resistant. The connectors on either end will have a transportation cap and will sit

within a foam insert which will be sized to the connector. Any loose items will be placed in

a box inside the crate.

Figure 3B – Optional Packaging

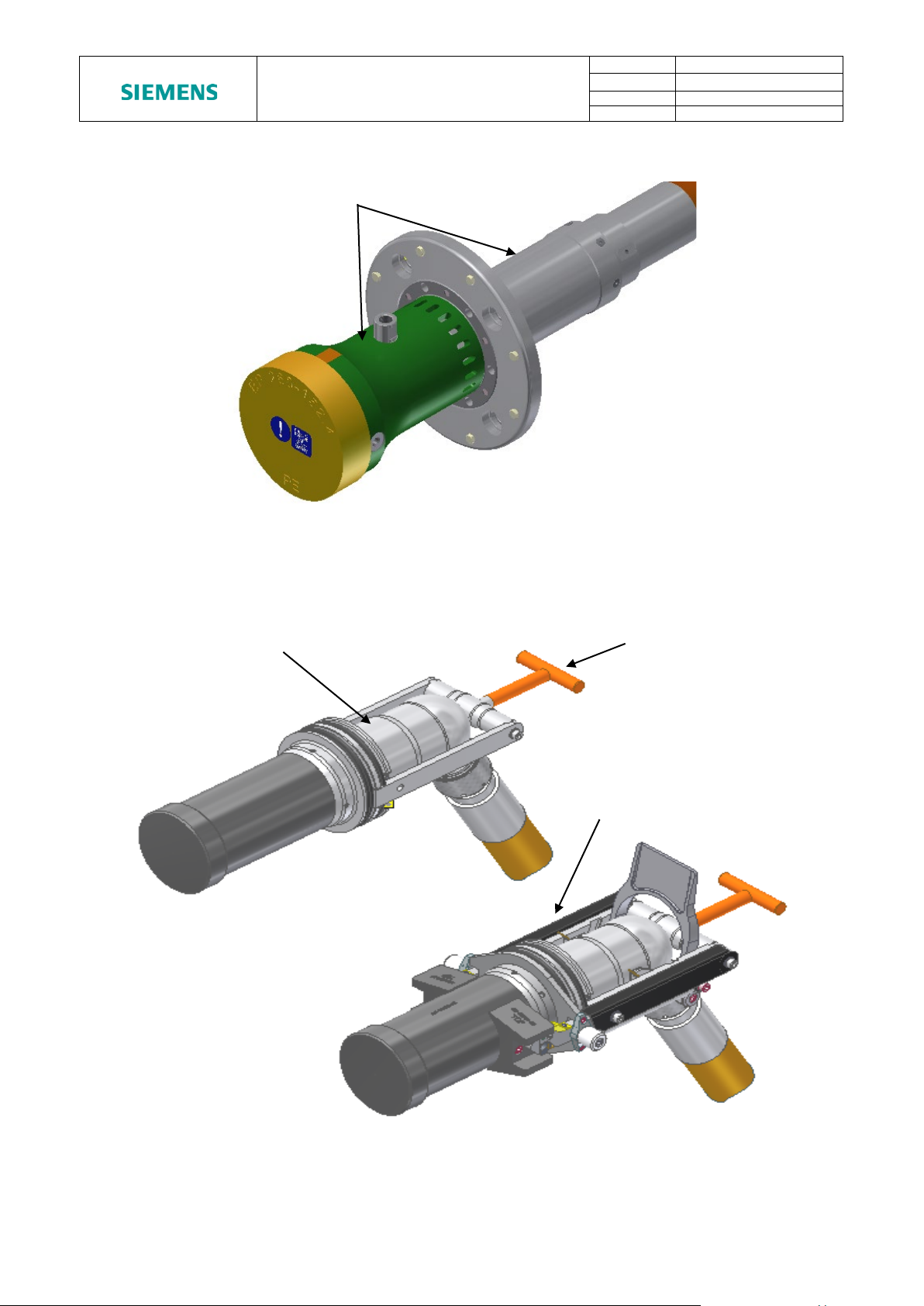

5.1 LIFTING OF JUMPERS & CONNECTORS

SpecTRON 8 harnesses typically weigh in excess of 30 kg and hence should not be

manually handled. Refer to the specific harness drawing for weight and length details. The

connectors can be safely slung around the locations shown in, Figure 4 , Figure 5, Figure

6 and Figure 7. The centre of gravity for the Connector or Penetrator is usually marked on

the outline drawing (supplied in documentation pack) but must be verified at low level

before commencing any lift.

Unrestricted

Document is uncontrolled outside of document management system

© Siemens plc. 2019 All Rights Reserved.

Page 7 of 38

Page 11

SIEMENS SpecTRON 8

MANUAL

Doc No:

0075

Rev No:

8

Category:

Technical

Created By:

W.Barrett

Sling around each side of

the Receptacle Flange

Do not sling around

release protective cap

Sling around Plug

Do not sling around

locking mechanism

PRODUCTS – OPERATIONS

ROV Receptacle

Rear Shell between

handlebars

Figure 4 - Recommended lift position - ROV Receptacle

handle as this may

the outside of the

connector handle as

this may damage the

ROV Plug (With / Without locking mechanism)

Figure 5 - Recommended lift positions - ROV Plug

Unrestricted

Document is uncontrolled outside of document management system

© Siemens plc. 2019 All Rights Reserved.

Page 8 of 38

Page 12

SIEMENS SpecTRON 8

MANUAL

Doc No:

0075

Rev No:

8

Category:

Technical

Created By:

W.Barrett

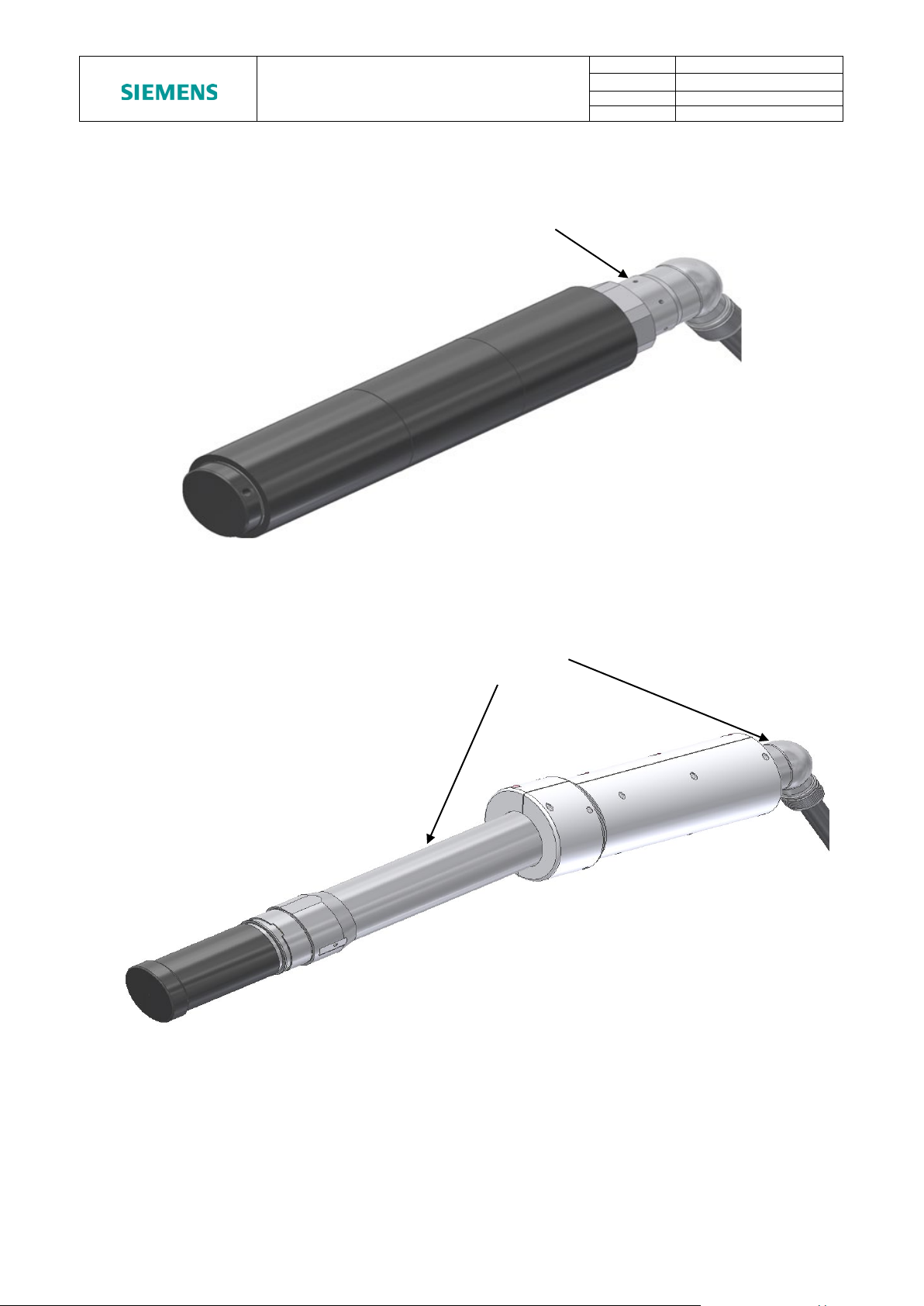

Sling around

Penetrator Rear Shell

Sling each

Protective Cap

PRODUCTS – OPERATIONS

Dummy, or parking connectors weigh less than 20 kg and can be lifted by hand, however correct

lifting practice should be observed at all times.

Figure 6 - Tree Cap Penetrator / Plug

Side of

Figure 7 - Tree Cap Penetrator / Plug

Unrestricted

Document is uncontrolled outside of document management system

© Siemens plc. 2019 All Rights Reserved.

Page 9 of 38

Page 13

SIEMENS SpecTRON 8

MANUAL

Doc No:

0075

Rev No:

8

Category:

Technical

Created By:

W.Barrett

Important Note: Connectors / Penetrators should NEVER be lifted by the hose or

in loss of continuity.

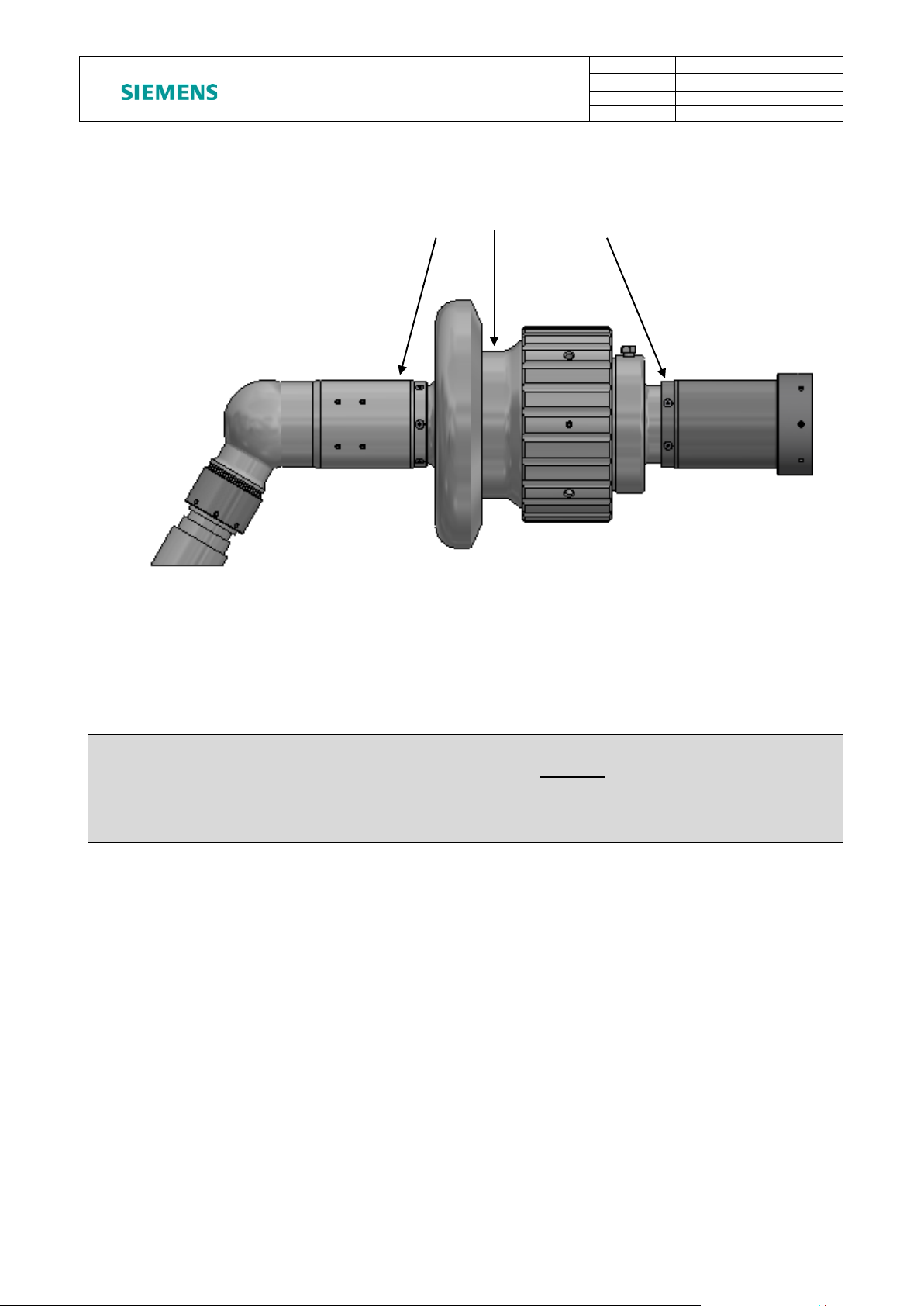

Sling around Dual Penetrator

the Dual Penetrator body as

PRODUCTS – OPERATIONS

body, or each side as close to

Figure 8 - Recommended Lift Positions - Dual Penetrator

For dual penetrator inboard termination details refer to project documentation.

cable, as this places unnecessary strain on the connector internals and may result

Connector / Penetrator. The maximum recommended length of hose which can be

unsupported during a lifting operation is 5 meters.

Protective caps should remain on wherever possible during lifting operations to minimise

the risk of damage to connector sealing or electrical components.

Unrestricted

Document is uncontrolled outside of document management system

© Siemens plc. 2019 All Rights Reserved.

Page 10 of 38

Page 14

SIEMENS SpecTRON 8

MANUAL

Doc No:

0075

Rev No:

8

Category:

Technical

Created By:

W.Barrett

Pull on ROV

Grip cap by

PRODUCTS – OPERATIONS

6. UNPACKING

Remove wrapping material taking care to inspect for any surface damage or items that

may have become separated from the connector, such as ‘O' seals. Do not use a knife to

cut the wrapping material, as this may cause damage to any elastomeric parts of the

connector. Do not remove protection caps until connectors are ready for installation. On

removal do not allow the hoses to drag over the edges of the packing crate.

6.1 PROTECTIVE CAPS

All SpecTRON 8 Connectors/Penetrators come supplied with a protective cap. These can

either be dust caps or protective caps. Dust caps (typically yellow in colour) can be simply

removed by twisting or pulling them off. Protective caps (typically black in colour) can be

removed as detailed below.

6.1.1 ROV PLUG CAP

The ROV Plug cap is latched onto the Plug connector via the connector latching

mechanism. In order to remove the cap, it is recommended that the operator stand the

Plug vertically on the cap, stand on the flange of the cap and pull on the ROV handle of

the Plug connector. This will disengage the latching mechanism of the Plug. Do not try to

pull the cap directly off the plug as this may damage the latching mechanism of the Plug.

Use the same method when engaging and disengaging the ROV plug cap on the Plug

connectors with the locking mechanism.

Handle

Refitting the Plug cap can be done by simply pushing the cap back onto the nose of the

plug until the latching mechanism of the plug engages.

standing on

flange

Figure 9 - ROV Plug Cap

Unrestricted

Document is uncontrolled outside of document management system

© Siemens plc. 2019 All Rights Reserved.

Page 11 of 38

Page 15

SIEMENS SpecTRON 8

MANUAL

Doc No:

0075

Rev No:

8

Category:

Technical

Created By:

W.Barrett

Remove the

Cap End

Pull the keyed

Pull on

remove

PRODUCTS – OPERATIONS

6.1.2 ROV RECEPTACLE CAP

The ROV Receptacle Cap can be removed by pulling on the cap. Refitting the Receptacle

cap can be done by simply pushing the cap back onto the Receptacle shroud.

Cap to

Figure 10 - ROV Receptacle Cap

6.1.3 TREE CAP PENETRATOR CAP – VERSION 1

Penetrator caps would usually be removed by Siemens Subsea site engineers during the

termination of the Penetrator to the module. It is recommended that only trained personnel

remove Penetrator caps though details are provided here for information only. The Tree

Cap Penetrator version 1 consists of modular parts to protect the entire length of the

connector. Carefully position the Plug & Penetrator on a suitable bench and remove the

protective cap taking care not to bend the compliant gland between plug and penetrator.

Cap End with a

dowel pin.

Figure 11 - Tree Cap Penetrator / Plug Removal of Keyed Cap

Unrestricted

Document is uncontrolled outside of document management system

© Siemens plc. 2019 All Rights Reserved.

Page 12 of 38

Page 16

SIEMENS SpecTRON 8

MANUAL

Doc No:

0075

Rev No:

8

Category:

Technical

Created By:

W.Barrett

Pull the

Unscrew this end

8kV Penetrator.

Remove

Sleeve

Remove

Sleeve

PRODUCTS – OPERATIONS

section attached to

whole cap

to remove

Figure 12 - Tree Cap Penetrator / Plug Protective Cap Removal

Protective Split

Protective Split

Figure 13 - Tree Cap Penetrator / Plug Split Sleeve Removal

Refitting the Penetrator cap is a reversal of the removal procedure.

Unrestricted

Document is uncontrolled outside of document management system

© Siemens plc. 2019 All Rights Reserved.

Page 13 of 38

Page 17

SIEMENS SpecTRON 8

MANUAL

Doc No:

0075

Rev No:

8

Category:

Technical

Created By:

W.Barrett

Pull cap to

remove

Unscrew fasteners

Cap

PRODUCTS – OPERATIONS

6.1.4 TREE CAP PENETRATOR CAP – VERSION 2

Penetrator caps would usually be removed by Siemens Subsea site engineers during the

termination of the Penetrator to the module. It is recommended that only trained personnel

remove Penetrator caps though details are provided here for information only. The Tree

Cap Penetrator version 2 consists of split halves to protect the compliant gland. Carefully

position the Plug & Penetrator on a suitable bench and remove the protective cap taking

care not to bend the compliant gland between plug and penetrator.

and Remove Split

Figure 14 - ROV Receptacle - Penetrator - Tree Cap Plug Jumper

Unrestricted

Document is uncontrolled outside of document management system

© Siemens plc. 2019 All Rights Reserved.

Page 14 of 38

Page 18

SIEMENS SpecTRON 8

MANUAL

Doc No:

0075

Rev No:

8

Category:

Technical

Created By:

W.Barrett

Note: It is important to isolate and earth prior to disconnect in order to remove

pins once the plug is removed.

PRODUCTS – OPERATIONS

7. STORAGE

The connectors must be stored in a clean dry area and be protected by bubble wrap or

similar. Suitable protection caps must be fitted and the storage temperature should be

between -30°C and 60°C (Project Specific Connectors storage Temperature may vary).

Humidity of the store room should be below 75%. Very moist or very dry conditions should

be avoided. The Plug connector and hoses should be protected from strong sunlight and

strong artificial light with a high ultra violet content. The connectors should not be allowed

to come into contact with solvents, oil, greases or any other semi-solid materials. If

glanded connectors are to be stored bolted into their interfaces prior to cable termination,

then ensure the cable entry point into the gland is covered to prevent water ingress.

8. DEPLOYMENT & MAINTENANCE

The following section details deployment and maintenance instructions for SpecTRON 8

connectors & hose.

All information contained within this section is generic. Where customer or project-specific

information is required, please refer to the relevant project specification or scope of supply.

any stray charges in the system. If left, this can induce corrosion on the exposed

8.1 GENERAL

The SpecTRON 8 range of Power connectors has been developed for long term reliable

high power system applications associated with offshore installations. The underwater

mateable capacity of these connectors is achieved using pressure compensated electrical

inserts employing the CE principle.

Connectors are usually supplied with protective caps. The protective caps must be

removed prior to mating the connectors. Refer to section 6.1 for instructions for removal of

protective caps.

All mild steel sealing interfaces shall be inlayed with Inconel 625, or similar, where no

additional protection (e.g. CP, Paint etc.) can be provided. This is to prevent localised

pitting of the interface.

If the connectors are to be left unmated, in seawater, for any length of time dummy

connectors must be used to protect the pin contacts in the receptacle connectors. Over

exposure will increase the risk of corrosion damage or marine growth on the contact

surfaces of the receptacle contact pins. This could lead to damage to the seals and

insulation within the socket contacts.

Unrestricted

Document is uncontrolled outside of document management system

© Siemens plc. 2019 All Rights Reserved.

Page 15 of 38

Page 19

SIEMENS SpecTRON 8

MANUAL

Doc No:

0075

Rev No:

8

Category:

Technical

Created By:

W.Barrett

Important Note: 60 days* is the maximum cumulative allowable exposure of

the connector. This only applies with power off.

Important Note: Under NO circumstances must connectors be demated whilst live.

Neither should connectors be partially mated with power applied.

Important Note: NO part of the connectors should be dismantled prior to or during

deployment, apart from the removal of protective caps, since there are no user

serviceable parts inside.

PRODUCTS – OPERATIONS

Plug connectors may be left unmated, in seawater, for an indefinite period of time.

However it is recommended that the Plug connectors are mated into a Parking Receptacle

during this time in order to protect the socket contacts and latching mechanism.

It is good practice to always fit the protective cap when a connector is unmated topside

prior to deployment to provide mechanical protection.

unprotected contact pins (receptacle connectors only) to seawater over the life of

*60 days applicable to Receptacle connectors supplied from January 2013. Connectors supplied before this

date may be limited to 30 days. Contact Siemens Subsea for further information on specific connector serial

numbers.

The appropriate test connector must always be used to make electrical contact during

testing. UNDER NO CIRCUMSTANCES should a foreign object (such as a screwdriver,

test probe, or crocodile clip) be used as a test connection as this could damage the seals

and insulation. Such actions will invalidate the warranty of the connector.

Guide pins must never be removed from test connectors as this can lead to damage and

will invalidate the connector warranty.

Refer to project specific data sheets and scope of supply drawings for performance

specifications and detailed deployment instructions.

8.2 PROTECTION OF RECEPTACLE CONTACT PINS

Under no circumstances must the contact pins in the receptacle connector be exposed to

seawater with power on. If this situation does occur the contact surfaces of the pins will

very rapidly degrade by electrolytic action. If these damaged pins are subsequently mated

into a socket insert there is a very high risk of damage to the insulation and seals within

the plug connector.

8.3 OVER CURRENT CAPACITY

Over current capacity varies for each product. Please refer to the product datasheet.

Unrestricted

Document is uncontrolled outside of document management system

© Siemens plc. 2019 All Rights Reserved.

Page 16 of 38

Page 20

SIEMENS SpecTRON 8

MANUAL

Doc No:

0075

Rev No:

8

Category:

Technical

Created By:

W.Barrett

PRODUCTS – OPERATIONS

8.4 REMOVAL OF MARINE GROWTH AND CALCAREOUS DEPOSITS

To remove calcite growth from Siemens Subsea connectors, a solution of 50% Citric Acid

is recommended. All Seawater exposed elastomeric materials in Siemens Subsea

connectors have been fully tested against 50% Citric Acid and are compatible for duration

of 1 hour. In addition, the thermoplastic materials have good resistance to Citric Acid.

It is recommended the solution is introduced through the flushing port adaptor (as per

Figure 15) to provide maximum saturation within the Plug/Receptacle annulus. Others

cavities on the receptacle shroud can be utilised to introduce the solution dependant on

access capability.

Other acid cleaners, such as 50% Acetic Acid, should not be used as they may cause

deterioration of the elastomeric materials.

Chiselling and abrasive methods are not recommended. Wiping with a soft, clean cloth is

acceptable providing care is taken inside the Receptacle shroud to avoid imparting a

bending load on the power pin/s. Use of water jetting for the removal of sand/silt is

acceptable given the following limitations:

• All forms of water jet cleaning of connectors in air must be avoided. The likelihood

of damage to connectors is great, given the high localised impact velocities of the

water jet.

• Submerged water jet cleaning of connectors is acceptable, providing the critical

areas identified in Figure 14 & Figure 15 are avoided. Particularly, the jet should

not be directed at the Plug front face / shuttle pins as this could result in a risk of

water being forced through the primary seals and/or front seal. Remaining areas

indicated below are suitable for submerged water jet cleaning.

Document is uncontrolled outside of document management system

Unrestricted

© Siemens plc. 2019 All Rights Reserved.

Page 17 of 38

Page 21

SIEMENS SpecTRON 8

MANUAL

Doc No:

0075

Rev No:

8

Category:

Technical

Created By:

W.Barrett

Flushing Port

PRODUCTS – OPERATIONS

Adaptor

Figure 15 - Connector Power Washing Precautions

Figure 16 - Connector Power Washing Precautions

Unrestricted

Document is uncontrolled outside of document management system

© Siemens plc. 2019 All Rights Reserved.

Page 18 of 38

Page 22

SIEMENS SpecTRON 8

MANUAL

Doc No:

0075

Rev No:

8

Category:

Technical

Created By:

W.Barrett

PRODUCTS – OPERATIONS

8.5 STAB PLATE CONNECTORS

Compliance

One half of a stab mate connector pair must be allowed to float so that misalignment

tolerances can be accommodated.

Mate/De-Mate Speed

The connectors have been designed to operate across a wide range of mate / de-mate

speeds with POWER OFF. There is no practical limit to the speed at which the connectors

maybe mated or de-mated, however as a guide:

Mating speed should not exceed 1 m/s.

De-mating speed should not exceed 5 m/s

Pre-Mating Checks

Before mating, the receptacle connector should be checked for debris. The connectors

have been designed to accommodate sand and silt contamination; however large pieces

of debris should be removed using a water jet.

Partial Disconnection

Partial disconnection with the contact pin remaining between the primary and secondary

diaphragms is not recommended. In this condition the level of insulation between the

contact pin and socket contact is reduced and the connector is relying on the primary seals

within the plug. There is also an increased risk of insulation break down at increased

voltages.

Interrupted Connection

Interrupted connection (i.e. Partial mate to full de-mate) can be carried out without any

adverse affect to connectors, as long as the power is off.

Cathodic Protection:

Stainless steel 316L (UNS S31603) connectors must be connected to the CP (Cathodic

Protection) system at all times. Super Duplex stainless steel (UNS S32550 / UNS S32760)

connectors may be isolated from the CP system through the design of the structure to

which they are connected to reduce the possibility of hydrogen embrittlement and

calcareous deposits. However, it should be noted that Tree Cap Plugs, Tubing Hanger

Receptacles and Penetrators cannot be isolated from the structure as they do not utilise

isolation discs and bushes due to their mechanical and pressure retaining requirements.

Document is uncontrolled outside of document management system

Unrestricted

© Siemens plc. 2019 All Rights Reserved.

Page 19 of 38

Page 23

SIEMENS SpecTRON 8

MANUAL

Doc No:

0075

Rev No:

8

Category:

Technical

Created By:

W.Barrett

PRODUCTS – OPERATIONS

8.6 ROV CONNECTORS

ROV Manipulator

SpecTRON 8 connectors are fitted with either an ISO 13628 T-bar handle or an ISO 13628

Fish Tail Handle.

ROV EFLs under or equal to 30m require no buoyancy aids for subsea deployment.

ROV EFLs over 30m require buoyancy aids which must be placed at reasonable positions

along the harness and are suitable to support 1.45kg (See 3.3.1) per metre length in

excess of 30m e.g. a 50m EFL requires buoyancy aids to cover 20*1.45 = 29kg worth of

additional hose weight in water.

T Bar Handle

T-bar handle connectors must be manipulated using a Parallel Jaw ROV manipulator

similar to that shown in Figure 17.

Figure 17 - Recommended ROV Manipulator Jaw for T Bar Handle

The T bar should be held by the crossbar of the T as shown in Figure 18 and not by the

shaft. If the T bar is held incorrectly there is a risk that the latch mechanism of the

connector will not engage correctly.

Unrestricted

Document is uncontrolled outside of document management system

© Siemens plc. 2019 All Rights Reserved.

Page 20 of 38

Page 24

SIEMENS SpecTRON 8

MANUAL

Doc No:

0075

Rev No:

8

Category:

Technical

Created By:

W.Barrett

PRODUCTS – OPERATIONS

Document is uncontrolled outside of document management system

Figure 18 - ROV Connector Handling

Unrestricted

© Siemens plc. 2019 All Rights Reserved.

Page 21 of 38

Page 25

SIEMENS SpecTRON 8

MANUAL

Doc No:

0075

Rev No:

8

Category:

Technical

Created By:

W.Barrett

PRODUCTS – OPERATIONS

Fish Tail Handle

Fish Tail Handle connectors must be manipulated using a 3-finger ROV manipulator jaw

similar to that shown in Figure 19. The handle should be held in the ROV jaw as shown in

Figure 20.

Figure 19 - Recommended ROV Manipulator Jaw for Fishtail Handle

Document is uncontrolled outside of document management system

Figure 20 - ROV Connector Handling

Unrestricted

© Siemens plc. 2019 All Rights Reserved.

Page 22 of 38

Page 26

SIEMENS SpecTRON 8

MANUAL

Doc No:

0075

Rev No:

8

Category:

Technical

Created By:

W.Barrett

Alignment Indicators

Physical Key / Keyway

PRODUCTS – OPERATIONS

9. ROV MATE / DE-MATE PROCEDURES

9.1 ROV MATING PROCEDURE Pre Mating Checks

Before mating, the receptacle shroud should be checked for debris. The connectors have

been designed to accommodate sand and silt contamination. However, large pieces of

debris should be removed.

9.2 ALIGNMENT AND MATING PROCEDURE – CONNECTORS WITHOUT LOCKING MECHANISM

• The connectors have been designed to self align during mating, however they must be

roughly aligned using the alignment marks on the top of the Connector body &

Alignment flange / Receptacle shroud prior to mating. (Figure 21A & Figure 21B).

• Note the location of the alignment key/keyway on the underside of the Connectors.

(Figure 21A & Figure 21B).

• Compliance is built into the connector handle, and the receptacle mount. This flexibility

accommodates misalignment and allows fine adjustments during the final approach

prior to connector engagement.

• The mating stroke should be as close as possible to one smooth movement, i.e. avoid

‘pumping’. Using the ROV manipulator jaw, the pilot should grip the ROV handle as

shown in Figure 18 or Figure 20.

• The internal latch mechanism is activated by pushing the connectors together until the

flanges of the plug and receptacle are fully home (Figure 23).

• To ensure correct engagement, the ROV pilot should open the jaw and operate a final

push operation before withdrawing from the T bar with a fully open jaw (Figure 22).

This ensures that the internal latch mechanism is not accidentally disengaged as the

ROV pulls away from the connector.

• As dictated by Industry best practice, all ROV operations are to be recorded on video.

The video is to be retained and made available to Siemens Subsea as and when

required.

Figure 21A - Alignment Indicators Coated (Connectors without Locking Mechanism)

Unrestricted

Document is uncontrolled outside of document management system

© Siemens plc. 2019 All Rights Reserved.

Page 23 of 38

Page 27

SIEMENS SpecTRON 8

MANUAL

Doc No:

0075

Rev No:

8

Category:

Technical

Created By:

W.Barrett

Important Note: Siemens Subsea reserves the right to reject any investigation

operations and no video can be

provided.

WARNING NOTE: DO NOT pull on the ROV handle to check the connector is

the connector.

PRODUCTS – OPERATIONS

Figure 21B – Alignment Indicators Uncoated (Connectors without Locking Mechanism)

where there are suspected unsuccessful ROV

correctly mated as this will disengage the internal latch mechanism and de-mate

Figure 22 - Final Push with Open Jaw

Unrestricted

Document is uncontrolled outside of document management system

© Siemens plc. 2019 All Rights Reserved.

Page 24 of 38

Page 28

SIEMENS SpecTRON 8

MANUAL

Doc No:

0075

Rev No:

8

Category:

Technical

Created By:

W.Barrett

Note: When relaxed there may be a small gap between the two (due to the springs

in the Plug pushing against the Receptacle pins).

Important Note: A pull-check on the handle should NEVER be made as this will

release the internal latching mechanism causing the connectors to separate.

PRODUCTS – OPERATIONS

Post-Mating checks:

• Correct mating of the connector must be determined by visual inspection only (Figure

23).

• The shoulder on the Plug should butt up against the shroud of the Receptacle.

Mechanical Forces & Misalignment during Mating / De-Mating:

If mate / de-mate forces, maximum misalignment or over stroking forces have been

defined, these will be specified in the product datasheet or design input document.

Figure 23 - Mating Check - Fully Mated. Note Small Gap between Flanges.

Unrestricted

Document is uncontrolled outside of document management system

© Siemens plc. 2019 All Rights Reserved.

Page 25 of 38

Page 29

SIEMENS SpecTRON 8

MANUAL

Doc No:

0075

Rev No:

8

Category:

Technical

Created By:

W.Barrett

PRODUCTS – OPERATIONS

Figure 24 - Mating Check - Locking Mechanism Engaged.

Document is uncontrolled outside of document management system

Unrestricted

© Siemens plc. 2019 All Rights Reserved.

Page 26 of 38

Page 30

SIEMENS SpecTRON 8

MANUAL

Doc No:

0075

Rev No:

8

Category:

Technical

Created By:

W.Barrett

Pins

Locks

Alignment Indicators

Physical Key / Keyway

PRODUCTS – OPERATIONS

9.3 ALIGNMENT AND MATING PROCEDURE – CONNECTORS WITH LOCKING MECHANISM

• The procedure for mating a connector with Locking Mechanism is identical to the

standard ROV connector without Locking Mechanism (refer to Section 9.2).

• The locking mechanism engages automatically during mating and requires no

additional action from the ROV pilot.

Figure 25A - Alignment Indicators Coated (Connectors with Locking Mechanism)

Figure 25B – Alignment Indicators Uncoated (Connectors with Locking Mechanism)

Unrestricted

Document is uncontrolled outside of document management system

© Siemens plc. 2019 All Rights Reserved.

Page 27 of 38

Page 31

SIEMENS SpecTRON 8

MANUAL

Doc No:

0075

Rev No:

8

Category:

Technical

Created By:

W.Barrett

Important Note: Siemens Subsea reserve the right to reject any investigation

where there are suspected unsuccessful ROV operations and no video can be

provided.

WARNING NOTE: DO NOT pull on the ROV handle to check the connector is

this may result in damage to the locking mechanism.

Note: When relaxed there may be a small gap between the two (due to the springs

in the Plug pushing against the Receptacle pins).(Figure 23)

Important Note: A pull-check on the handle should NEVER be made as this could

shear the emergency release shear pins and release the internal latching

mechanism causing the connectors to separate.

PRODUCTS – OPERATIONS

correctly mated as this may result in damage to the locking mechanism.

NEVER pull on the ROV handle without first disengaging the locking mechanism as

Figure 26 - Final Push with Open Jaw

Post-Mating checks:

• Correct engagement of the locking mechanism must be confirmed by visual inspection

(Figure 24).

• The shoulder on the Plug should also butt up against the shroud of the Receptacle.

• Use Figure 23 as guidance for correct engagement of the locking mechanism. If the

post mating checks show the locking mechanism is not correctly engaged then the

plug must be de-mated (following the procedure in section 9.6) then re-mated.

Mechanical Forces & Misalignment during Mating / De-Mating

If the mate / de-mate forces, maximum misalignment or over stroking forces are defined,

these will be specified in the product datasheet or design input document.

Document is uncontrolled outside of document management system

© Siemens plc. 2019 All Rights Reserved.

Unrestricted

Page 28 of 38

Page 32

SIEMENS SpecTRON 8

MANUAL

Doc No:

0075

Rev No:

8

Category:

Technical

Created By:

W.Barrett

Note: If the ROV handle is held incorrectly there is a risk that the internal latch

mechanism of the connector will not disengage properly.

Note: If the ROV handle is held incorrectly there is a risk that the internal latch

mechanism of the connector will not disengage properly.

PRODUCTS – OPERATIONS

9.4 ROV DE-MATING PROCEDURE

9.5 DE-MATING PROCEDURE - CONNECTORS WITHOUT LOCKING MECHANISM

• To De-mate the connector, Grip the ROV handle (T-handle or fishtail) correctly with

the ROV jaw (Figure 18 or Figure 20)

• De-mating is achieved by a straight pull on the ROV handle sufficient to release the

internal latching mechanism. Do not pull on the gland or hose.

9.6 DE-MATING PROCEDURE - CONNECTORS WITH LOCKING MECHANISM

• Before De-mating the connector the ROV pilot must first release the locking

mechanism.

• The locking mechanism is released by pushing forward the release paddle using the

nose of the ROV manipulator jaw. (Figure 27)

• The locks will disengage from the receptacle pins when the paddle is pushed fully

forward. (Figure 27)

• When this action has been performed correctly the release paddle will remain in the

forward position after the ROV jaw is retracted.

• Figure 26 Detail view shows the locks in the disengaged position.

• To De-mate the connector, Grip the ROV handle (T-handle or fishtail) correctly with

the ROV jaw (Figure 18 or Figure 20).

• De-mating is achieved by a pull on the ROV handle sufficient to release the internal

latching mechanism. Do not pull on the gland or hose.

• As the connector is de-mated the release paddle will automatically return to the default

position. No ROV pilot action is required.

• On de-mating, the locking mechanism re-sets automatically and can be immediately

re-mated if required. No ROV pilot action is required prior to re-mating.

Manual Mating / De-Mating of ROV connectors

Refer to Section 10 for manual Mating / De-mating procedure.

Cathodic Protection

The ROV connectors are designed to operate when isolated from the CP [Cathodic

Protection] system. The ROV connectors will not suffer damage by being connected to the

CP system; however there may be a tendency for increased calcareous deposits on metal

surfaces, and the possibility of hydrogen embrittlement.

Unrestricted

Document is uncontrolled outside of document management system

© Siemens plc. 2019 All Rights Reserved.

Page 29 of 38

Page 33

SIEMENS SpecTRON 8

MANUAL

Doc No:

0075

Rev No:

8

Category:

Technical

Created By:

W.Barrett

Release

Paddle

ROV

Handle

PRODUCTS – OPERATIONS

Document is uncontrolled outside of document management system

Figure 27 - Locking Mechanism Disengaged

Unrestricted

© Siemens plc. 2019 All Rights Reserved.

Page 30 of 38

Page 34

SIEMENS SpecTRON 8

MANUAL

Doc No:

0075

Rev No:

8

Category:

Technical

Created By:

W.Barrett

Note: Following an emergency de-mate the connector is still functional and can be

Continued operation is possible due to the internal

latches which remain fully functional.

PRODUCTS – OPERATIONS

9.7 EMERGENCY DE-MATE PROCEDURE – CONNECTORS WITH LOCKING MECHANISM ONLY

The emergency De-mate procedure is to be used in the event of a malfunction or failure of

the locking mechanism which is preventing normal operation.

• To De-mate the connector Grip the T-handle or fishtail handle correctly with the ROV

jaw (Figure 18 or Figure 20).

• De-mating is achieved by pulling on the ROV handle (Do not pull on the gland or

hose). A pull force of 3 to 4kN is required to break the internal shear pins and release

the mechanism allowing the connector to de-mate.

safely re-mated if required.

The locking mechanism will be inoperable following the emergency release and the

connector must be recovered to the surface in order to repair the mechanism.

Figure 28 shows the appearance of a lock following an emergency release

Figure 28 - Lock after Emergency Release

Unrestricted

Document is uncontrolled outside of document management system

© Siemens plc. 2019 All Rights Reserved.

Page 31 of 38

Page 35

SIEMENS SpecTRON 8

MANUAL

Doc No:

0075

Rev No:

8

Category:

Technical

Created By:

W.Barrett

Note: This operation MUST NOT be performed in air.

WARNING NOTE: DO NOT pull on the ROV handle to check the connector is

the connector.

PRODUCTS – OPERATIONS

10. MANUAL MATE/ DE-MATE PROCEDURES

This section summarises the procedure to be followed for a diver or topside operator to

mate/de-mate the ROV connectors manually (as opposed to mating/de-mating using an

ROV).

10.1 MANUAL MATING PROCEDURE

10.1.1 ALIGNMENT AND MATING PROCEDURE – CONNECTORS WITHOUT LOCKING MECHANISM

Prior to commencing the mating of the connector pair it is assumed that the Receptacle

connector is mounted to its associated mounting plate, and that the Plug connector is in

the near vicinity. Grab bars or other interfaces should be present on the Receptacle

mounting structure. These should provide the diver with purchase and allow him to

address the connector square-on with the connector at chest height.

• Remove protective cap from Plug connector, or if Plug connector is mated to a

Parking/Dummy Receptacle remove as detailed in the manual de-mating procedure

below.

• If a Dummy Plug connector is mated to the Receptacle, remove using the manual demating procedure detailed below.

• Inspect the Receptacle pins and shroud, and ensure they are clean and free from

debris, etc. If any debris is present remove using a water jet.

• Insert the Plug Connector nose into the shroud of the Receptacle, and initially locate

the key on the Plug nose into the slot of the Receptacle shroud using the alignment

indicators, as shown in Figure 21A and Figure 21B. It should be noted that the

physical key/keyway are located on the underside of the connectors.

• The operator should now get into a comfortable position, square on, ready to fully

mate the connectors. The connector should be at chest height, with the grab bars or

other provided interfaces on the mounting structure being within easy reach. Using

the grab bars or other means to brace himself (i.e. tied to structure), the operator

should mate the connector by holding the ROV handle (Figure 29) and using one

smooth single stroke to push the Plug connector until it butts up against the

Receptacle. A maximum force of 76.5kgf (750N) will be required to mate the

connectors. Ensure the mating stroke is level, and the operator is able to complete the

stroke in one smooth consistent movement. Confirm that no bounce-back and failure

to latch home has occurred.

correctly mated as this will disengage the internal latch mechanism and de-mate

Unrestricted

Document is uncontrolled outside of document management system

© Siemens plc. 2019 All Rights Reserved.

Page 32 of 38

Page 36

SIEMENS SpecTRON 8

MANUAL

Doc No:

0075

Rev No:

8

Category:

Technical

Created By:

W.Barrett

PRODUCTS – OPERATIONS

• When the plug connector end stops abut to the receptacle this activates the internal

spring loaded internal latch mechanism, which prevents the connectors de-mating.

Pulling on the ROV Handle will de-activate this latch and hence will de-mate the

connector.

Figure 29 - Mate using ROV Handle

• To confirm that connectors are fully mated and the Plug is correctly latched home,

gently pull the Plug connector by holding the angled downward section of the Plug

gland near to the hose termination, as shown in Figure 20. If the connectors are

correctly latched and mated no axial movement in the Plug connector should be

present. As a visual inspection, the shoulder on the Plug should butt up against the

shroud of the Receptacle. However, when relaxed there may be a small gap between

the receptacle and connector (due to the springs in the Plug pushing against the

Receptacle pins), as shown in Figure 23.

Figure 30 - Check Connectors are Mated

Document is uncontrolled outside of document management system

Unrestricted

© Siemens plc. 2019 All Rights Reserved.

Page 33 of 38

Page 37

SIEMENS SpecTRON 8

MANUAL

Doc No:

0075

Rev No:

8

Category:

Technical

Created By:

W.Barrett

Note: When relaxed there may be a small gap between the two (due to the springs

in the Plug pushing against the Receptacle pins). (Figure 23)

PRODUCTS – OPERATIONS

10.1.2 ALIGNMENT AND MATING PROCEDURE – CONNECTORS WITH LOCKING MECHANISM

• The procedure for mating a connector with Locking Mechanism is identical to the

standard ROV connector without Locking Mechanism (refer to Section 10.1.1).

• The locking mechanism engages automatically during mating and requires no

additional action from the operator.

Post-Mating checks:

• Correct engagement of the locking mechanism must be determined by visual

inspection (Figure 24).

• If the post mating checks show the locking mechanism is not correctly engaged

(Figure 24) the plug must be de-mated following the procedure in section 10.2.2

and then re-mated following the procedure in section 10.1.2

• The shoulder on the Plug should butt up against the shroud of the Receptacle.

• As an additional confirmation that connectors are fully mated and the Plug is

correctly latched home, gently pull the Plug connector by holding the angled

downward section of the Plug gland near to the hose termination, as shown in

Figure 30. If the connectors are correctly latched and mated no axial movement in

the Plug connector should be present.

10.2 MANUAL DE-MATING PROCEDURE

10.2.1 DE-MATING PROCEDURE – CONNECTORS WITHOUT LOCKING MECHANISM

Prior to commencing the de-mating of the connector pair it is assumed that the Receptacle

connector is mounted in its associated structure, and a Plug connector is mated to it.

• The operator should brace himself using the grab bars or other provided interfaces,

and ensure the connector is at chest height. By gripping the ROV handle (as shown in

Figure 8), the connector can be de-mated from the Receptacle using one smooth

pulling movement along the axis of the connectors. Pulling the ROV handle

automatically releases the internal latching mechanism. A force of 40kgf (392N) is

required to de-mate the connectors.

• Once the Plug connector is fully separated from the receptacle connector, if

appropriate it can then be mated to the parking Receptacle, using the steps described

in the mating procedure in section 10.1.1. A dummy plug should also be mated to the

remaining Receptacle, again using the mating procedure in section 10.1.1

Unrestricted

Document is uncontrolled outside of document management system

© Siemens plc. 2019 All Rights Reserved.

Page 34 of 38

Page 38

SIEMENS SpecTRON 8

MANUAL

Doc No:

0075

Rev No:

8

Category:

Technical

Created By:

W.Barrett

Note: Once the connector is de-mated the locking mechanism will re-set

mated. The release paddle will

inspection

PRODUCTS – OPERATIONS

10.2.2 DE-MATING PROCEDURE – CONNECTORS WITH LOCKING MECHANISM

• Before De-mating the connector the operator must first release the locking

mechanism.

• The locking mechanism is released by pushing the release paddle fully forward.

• The locks will disengage from the receptacle pins when the paddle is pushed fully

forward. (Figure 27)

• When this action has been performed correctly the release paddle will remain in the

forward position after the operators hand is removed.

• The operator should brace himself using the grab bars or other provided interfaces,

and ensure the connector is at chest height. By gripping the ROV handle (as shown in

Figure 29), the connector can be de-mated from the Receptacle using one smooth

pulling movement along the axis of the connectors. Pulling the ROV handle

automatically releases the internal latching mechanism. A force of 40kgf (392N) is

required to de-mate the connectors.

automatically and can immediately be reautomatically return to the default position. This can be confirmed by a quick visual

• Once the connector is fully separated from the receptacle connector, if appropriate it

can then be mated to a parking receptacle, using the steps described in the mating

procedure in section 10.1.2. A dummy plug should also be mated into the remaining

Receptacle, again using the mating procedure in section 10.1.2

Document is uncontrolled outside of document management system

© Siemens plc. 2019 All Rights Reserved.

Unrestricted

Page 35 of 38

Page 39

SIEMENS SpecTRON 8

MANUAL

Doc No:

0075

Rev No:

8

Category:

Technical

Created By:

W.Barrett

Alignment Indicators

Physical Key / Keyway

ROV Based

Manually

Handle

PRODUCTS – OPERATIONS

11. TOPSIDE TEST CONNECTORS

SpecTRON 8 connectors can be electrically tested with the use of SpecTRON 8 plug and

receptacle topside test connector tailed harnesses as shown below in Figure 31.

These connector harnesses are terminated with 3-off M10 lugs for connection to a HV

supply and 3-off M4 lugs for connection to an earth source. Cable management must be

considered to ensure that the HV and earth connections are kept separated by the largest

reasonable distance possible to ensure no electrical shortages.

The design of these connectors is based on the ROV mating mechanism as described in

previous sections, therefore no additional mating / retaining equipment required.

Cleaning should be performed with “safe wipes” only. “Safe wipes” are available on the

internet and are lint-free, non-static, IPA based wipes for electronics. Consideration should

also be given to guidance in Section 8.4 on marine growth and calcareous deposit

removal.

Figure 31 - Tailed Test Harness Connection Points

Operated

Figure 32 - Alignment Indicators Coated (Topside Test Connectors)

Latch Features

Unrestricted

Document is uncontrolled outside of document management system

© Siemens plc. 2019 All Rights Reserved.

Page 36 of 38

Page 40

SIEMENS SpecTRON 8

MANUAL

Doc No:

0075

Rev No:

8

Category:

Technical

Created By:

W.Barrett

Compliantly mounted

Stauff clamp

PRODUCTS – OPERATIONS

12. INSTALLATION

12.1 CONNECTOR & PENETRATOR INSTALLATION

It is recommended that the installation of all SpecTRON Penetrators and Mounted

Connectors is undertaken by Siemens Subsea site engineers or trained personnel.

12.2 HOSE ROUTING AND SUPPORT

Hose should be routed in a manner to avoid bending beyond the MBR (375mm) or kinking

of the hose. Siemens Subsea recommend that rubber inlayed plastic clamps are used to

secure the hose (such as a Stauff pipe clamp with the correct inside diameter, refer to

section 3.3 for hose diameters) and manage the routing of the jumpers.

Careful consideration should be given to the placement of the first clamp on a compliant

mount connector so as not to restrict the compliancy of the connector or impart stresses

into the hose and cable. Where clamping is required on compliantly mounted connectors,

It is recommended that an ‘S’ type arrangement or similar as shown in Figure 33 is utilised

to take up the potential movement of the connector.

connector

Figure 33 - Potential Clamping of Hose on Compliant Connector

or similar

Unrestricted

Document is uncontrolled outside of document management system

© Siemens plc. 2019 All Rights Reserved.

Page 37 of 38

Page 41

SIEMENS SpecTRON 8

MANUAL

Doc No:

0075

Rev No:

8

Category:

Technical

Created By:

W.Barrett

DATE

DESCRIPTION

PRODUCTS – OPERATIONS

13. INFORMATION & NOTES / HEALTH & SAFETY FEEDBACK

Unrestricted

Document is uncontrolled outside of document management system

© Siemens plc. 2019 All Rights Reserved.

Page 38 of 38

Loading...

Loading...