Siemens SPC4000 Installation & Configuration Manual

Intrusion Control Panel

SPC4000

Installation&Configuration

Manual

Building Technologies

Fire Safety & Security Products

Data and design subject to change without notice. / Supply subject to availability.

© 2008 Copyright by

Siemens Building Technologies

We reserve all rights in this document and in the subject thereof. By acceptance of the document the recipient acknowledges these rights

and undertakes not to publish the document nor the subject thereof in full or in part, nor to make them available to any third party without our

prior express written authorization, nor to use it for any purpose other than for which it was delivered to him.

Contents

1 Security ....................................................................................................9

1.1 Target group..............................................................................................9

1.2 General safety instructions .......................................................................9

1.2.1 General information...................................................................................9

1.2.2 Transport.................................................................................................10

1.2.3 Setup.......................................................................................................10

1.2.4 Operation ................................................................................................10

1.2.5 Service and maintenance .......................................................................11

1.3 Meaning of the written warning notices ..................................................11

1.4 Meanings of the hazard symbols ............................................................12

2 Directives and Standards.....................................................................13

2.1 EU Directives ..........................................................................................13

3 Technical Data.......................................................................................14

3.1 SPC4000.................................................................................................14

3.2 Keypad ....................................................................................................14

3.3 8 Input / 2 Output Expander....................................................................16

3.4 8 Output Expander..................................................................................17

3.5 Wireless Expander..................................................................................17

4 Product description ..............................................................................18

4.1 SPC Features..........................................................................................19

5 Mounting System Equipment ..............................................................20

5.1 Mounting Controller Enclosures..............................................................20

5.1.1 Standard Enclosure ................................................................................20

5.2 Mounting a keypad..................................................................................21

5.3 Mounting an expander ............................................................................21

6 Controller Hardware .............................................................................22

7 Wiring the System.................................................................................24

7.1 Wiring the X-BUS Interface.....................................................................24

7.1.1 Spur (Chain) Configuration .....................................................................25

7.1.2 Star (Multi-drop) Configuration................................................................26

7.2 Wiring of Branch Expander .....................................................................28

7.3 Wiring the Relay Output..........................................................................29

7.4 Wiring the Zone Inputs............................................................................30

7.5 Wiring an External SAB Bell ...................................................................32

7.6 Wiring an Internal Sounder ..................................................................... 32

7.7 Installing Plug-in Modules .......................................................................33

7.8 Wireless Receiver Module ...................................................................... 33

7.8.1 Installing a Wireless Receiver Module....................................................33

7.8.2 Installing an External Antenna ................................................................34

7.8.3 Installing an External Antenna with Mounting Bracket............................34

8 Keypad User Interface ..........................................................................35

8.1 Keypad Display .......................................................................................37

8.2 Data entry on the SPC Keypad...............................................................38

8.2.1 Entering Numeric values.........................................................................38

8.2.2 Entering Text........................................................................................... 38

8.2.3 Selecting a Programming Option............................................................38

Siemens Building Technologies

Fire Safety & Security Products 09.2008

3

9

Starting the System ..............................................................................39

9.1 Engineer Modes ......................................................................................39

9.2 Programming Tools.................................................................................39

9.2.1 Fast Programmer ....................................................................................40

9.3 Configuring Start-up Settings..................................................................40

9.4 Creating System Users ...........................................................................41

9.5 Configuring and Using the Portable ACE Profile ....................................42

9.6 Configuring 868MHz Wireless Fob Devices ...........................................42

9.6.1 Clearing Alerts Using the Wireless FOB Device .....................................42

10 Engineer Programming Via the Keypad .............................................43

10.1 System Status .........................................................................................43

10.2 Configuring Communication Modules .....................................................43

10.2.1 Configuring a GSM or PSTN Modem......................................................44

10.3 Variables .................................................................................................46

10.3.1 Security Grade ........................................................................................48

10.3.2 Application...............................................................................................49

10.3.3 System Areas..........................................................................................49

10.3.4 Partset A / Partset B................................................................................49

10.3.5 Call ARC Mssg........................................................................................50

10.3.6 Keyfob Restore .......................................................................................50

10.3.7 User Duress ............................................................................................50

10.3.8 Retrigger..................................................................................................50

10.3.9 Bell on 1st................................................................................................51

10.3.10 Bell on Failed to Set (FTS)......................................................................51

10.3.11 Strobe on Failed to Set (FTS) .................................................................51

10.3.12 Code Digits..............................................................................................51

10.3.13 Open Zones.............................................................................................51

10.3.14 Show State..............................................................................................52

10.3.15 EOL Resistance ......................................................................................52

10.3.16 SMS Auth Mode ......................................................................................52

10.3.17 Pace and Pin...........................................................................................52

10.3.18 Restore on Unset ....................................................................................52

10.3.19 Offline Tamper ........................................................................................53

10.4 Timers .....................................................................................................54

10.4.1 Ext Bell Time ...........................................................................................56

10.4.2 Int Bell Time ............................................................................................56

10.4.3 Ext Bell Delay..........................................................................................56

10.4.4 Strobe Time.............................................................................................57

10.4.5 Chime Time.............................................................................................57

10.4.6 Dialler Delay............................................................................................57

10.4.7 Soak Days...............................................................................................57

10.4.8 Dknock Delay ..........................................................................................57

10.4.9 Mains Sig Delay ......................................................................................58

10.4.10 Keypad Timeout ......................................................................................58

10.4.11 Wireless Fail to Set (FTS)*......................................................................58

10.4.12 Wireless Lost* .........................................................................................58

10.4.13 Engineer Access .....................................................................................58

10.4.14 Entry Time...............................................................................................59

10.4.15 Exit Time .................................................................................................59

10.4.16 Fullset Bell...............................................................................................59

10.4.17 Fullset Strobe ..........................................................................................59

10.4.18 Final Exit..................................................................................................59

10.4.19 Tech Delay ..............................................................................................60

10.4.20 Fail to Set ................................................................................................60

4

Siemens Building Technologies

Fire Safety & Security Products 09.2008

10.5 Areas.......................................................................................................61

10.5.1 Add..........................................................................................................62

10.5.2 Delete......................................................................................................62

10.5.3 Edit ..........................................................................................................63

10.6 X-BUS .....................................................................................................64

10.6.1 X-BUS Programming ..............................................................................66

10.6.2 Reconfigure.............................................................................................66

10.6.3 Locate .....................................................................................................66

10.6.4 Monitor ....................................................................................................67

10.6.5 Edit ..........................................................................................................67

10.7 Wireless ..................................................................................................68

10.7.1 Add..........................................................................................................68

10.7.2 Remove...................................................................................................68

10.7.3 Ext Antenna.............................................................................................68

10.7.4 Supervision .............................................................................................68

10.7.5 Sensor Type............................................................................................68

10.8 Zone Types and Assignable Attributes ...................................................68

10.9 Programming Zones ...............................................................................69

10.10 Outputs....................................................................................................71

10.10.1 Outputs Types and Output Ports ............................................................71

10.10.2 Programming Outputs.............................................................................73

10.11 Communication .......................................................................................75

10.11.1 Modems ..................................................................................................75

10.11.2 Central Station ........................................................................................76

10.12 Test .........................................................................................................77

10.12.1 Bell Test ..................................................................................................78

10.12.2 Walk Test ................................................................................................ 78

10.12.3 Zone Monitor ...........................................................................................78

10.12.4 Output Test .............................................................................................79

10.12.5 Soak Test ................................................................................................80

10.12.6 Audible Options....................................................................................... 80

10.13 Utilities.....................................................................................................81

10.13.1 Sys Software ...........................................................................................81

10.13.2 Defaults ...................................................................................................82

10.13.3 Fast Programmer ....................................................................................82

10.13.4 SPC Pro ..................................................................................................82

10.14 Isolate......................................................................................................82

10.15 Event Log ................................................................................................ 83

10.16 Change Code ..........................................................................................83

10.17 Users.......................................................................................................83

10.17.1 Adding .....................................................................................................83

10.17.2 Editing .....................................................................................................84

10.17.3 Deleting ...................................................................................................84

10.18 Setup SMS .............................................................................................. 84

10.19 Installer Text............................................................................................85

11 User Access Via the Keypad................................................................86

11.1 Setting the System: FULLSET ................................................................ 86

11.2 Setting the system: PARTSET A ............................................................86

11.3 Setting the System: PARTSET B............................................................87

11.4 Failing to Set the System ........................................................................87

11.5 Force Setting the System........................................................................87

11.6 Unsetting the System..............................................................................88

11.7 Restoring an Alarm Activation (Alert)......................................................88

11.8 Coded Restore ........................................................................................89

Siemens Building Technologies

Fire Safety & Security Products 09.2008

5

12

User Menus Via the Keypad.................................................................90

12.1 Inhibiting a Zone......................................................................................90

12.2 Viewing Inhibited Zones ..........................................................................90

12.3 Inhibiting a Zone or Fault ........................................................................91

12.4 Isolating a Zone or Fault .........................................................................91

12.5 Setting the Time and Date ......................................................................92

12.6 Performing Tests on the System.............................................................92

12.7 Performing a Walk Test...........................................................................93

12.8 Viewing the Event Log ............................................................................93

12.9 Enabling the Chime Function..................................................................94

12.10 Adding, Editing, and Deleting Users .......................................................94

12.10.1 Adding .....................................................................................................94

12.10.2 Editing .....................................................................................................95

12.10.3 Deleting ...................................................................................................95

12.11 Changing a User Code............................................................................96

12.12 Using SMS ..............................................................................................96

12.12.1 SMS Events.............................................................................................97

12.12.2 SMS Control............................................................................................98

12.12.3 SMS Commands .....................................................................................99

12.13 Allowing Engineer Access.......................................................................99

12.14 Language ................................................................................................99

12.15 Status Summary......................................................................................99

12.15.1 Zones ....................................................................................................100

12.15.2 System Alerts ........................................................................................100

12.15.3 Expanders .............................................................................................100

12.15.4 Keypads ................................................................................................100

12.16 Log ........................................................................................................101

12.17 Utilities...................................................................................................101

12.17.1 Allowing Engineer/Manufacturer Access ..............................................101

12.17.2 Changing Access Code.........................................................................101

12.17.3 Setting the Time and Date ....................................................................101

12.18 SMS.......................................................................................................101

12.18.1 SMS Events...........................................................................................102

12.18.2 SMS Control..........................................................................................102

12.19 X-10 Outputs .........................................................................................102

13 Using the Fast Programmer...............................................................103

13.1 Connecting the Fast Programmer to a PC............................................103

13.2 Connecting the Fast Programmer to the SPC Controller......................104

13.3 Configuring with the Fast Programmer .................................................105

13.4 Firmware Upgrade using the keypad ....................................................105

14 Intruder Alarm Functionality ..............................................................106

14.1 Commercial Mode Operation ................................................................106

14.2 Domestic Mode Operation ....................................................................106

14.3 Full and Local Alarms on the SPC ........................................................107

15 System Examples and Scenarios......................................................108

15.1 When to Use a Common Area ..............................................................108

6

Siemens Building Technologies

Fire Safety & Security Products 09.2008

16 Appendix..............................................................................................110

16.1 Appendix A: Keypad User Menu...........................................................110

16.2 Appendix B: Keypad Engineer Menu....................................................111

16.3 Appendix C: Keypad Full Engineer Menu.............................................112

16.4 Appendix E: SPC Controller Status LEDs ............................................113

16.5 Appendix F: Powering Expanders from the Auxiliary Power Terminals114

16.6 Appendix G: Calculating the Battery Power Requirements ..................116

16.7 Appendix H: Domestic and Commercial Mode Default Settings ..........117

16.8 Appendix I: Wiring of X10 Interface to the SPC Controller ...................118

16.9 Appendix J: SIA Codes .........................................................................118

16.10 Appendix k: System Variables ..............................................................121

16.11 Appendix L: Zone Types .......................................................................122

16.12 Appendix M: Zone Attributes.................................................................123

16.13 Appendix N: Zone Types and Assignable Attributes ............................124

16.14 Appendix O: Wiring of Mains Cable to the SPC Controller...................126

17 Keyword index.....................................................................................127

Siemens Building Technologies

Fire Safety & Security Products 09.2008

7

8

Siemens Building Technologies

Fire Safety & Security Products 09.2008

1 Security

1.1 Target group

Security

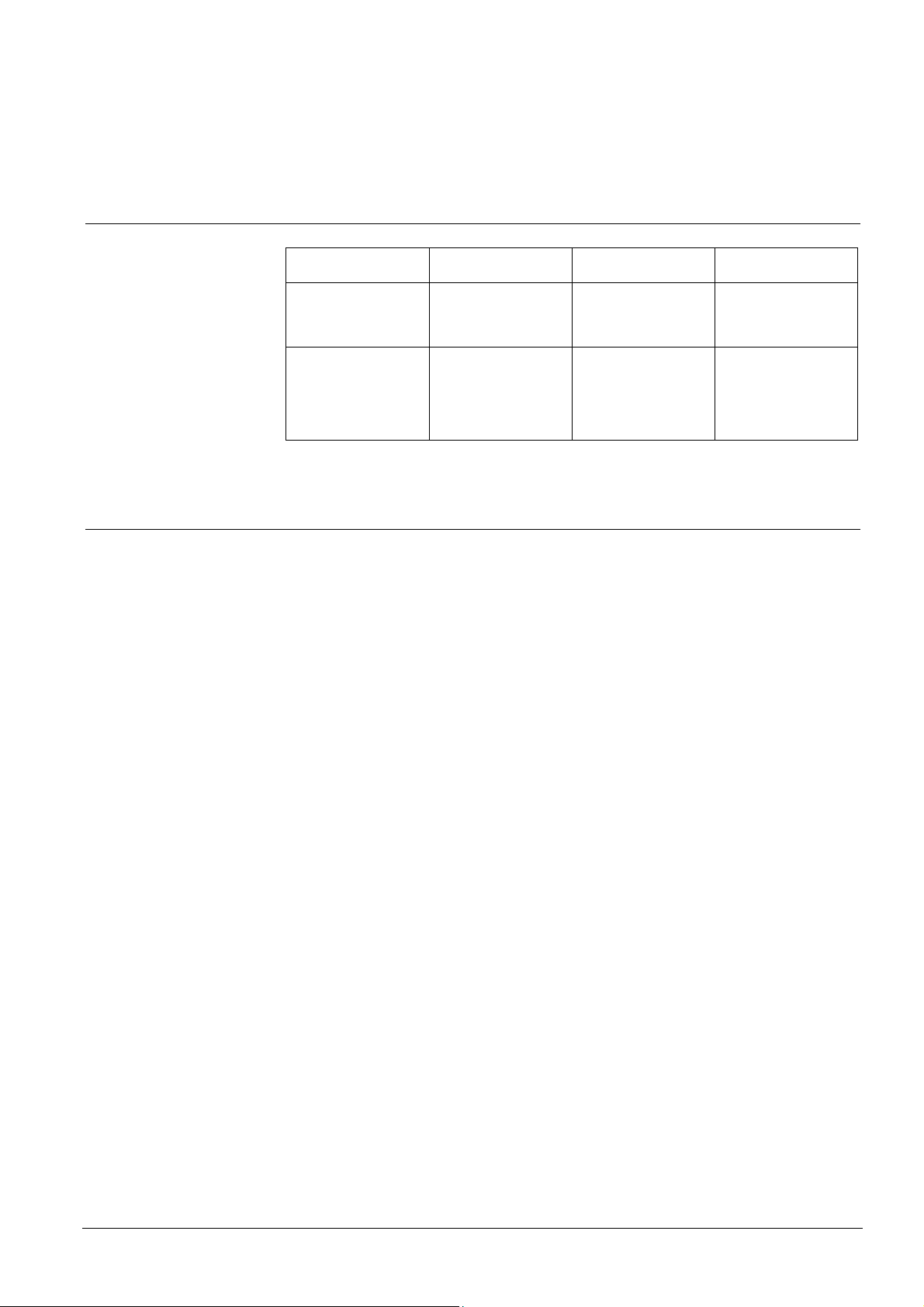

Target readers Qualification Activity Condition of the

Installation personnel Technical training for

Operational startup

personnel

building or electrical

installations.

Has appropriate

technical training with

regard to the tasks and

the products, devices or

systems to be put in

service.

1.2 General safety instructions

1.2.1 General information

– Read the general safety precautions before operating the unit.

– Keep this document for later reference.

– Always pass this document on together with the product.

– Please also take into account any additional country-specific, local safety

standards or regulations concerning project planning, operation and disposal of

the product.

Assembles and installs

the hardware

components on site.

Puts the device or

system which is readily

assembled and installed

on site into service.

equipment

Individual components

that need to be

assembled and

installed.

New, readily assembled

and installed device or

modified device.

Liability claim

– Do not connect the device to the 230 V supply network if it is damaged or any

parts are missing.

– Do not make any changes or modifications to the device unless they are

expressly mentioned in this manual and have been approved by the

manufacturer.

– Use only spare parts and accessories that have been approved by the

manufacturer.

Siemens Building Technologies

Fire Safety & Security Products 09.2008

9

Security

1.2.2 Transport

1.2.3 Setup

Unit damage during transport

– Keep the packaging material for future transportation.

– Do not expose the device to mechanical vibrations or shocks.

Radio interference with other devices in the environment

– When handling modules that are susceptible to electrostatic discharge, please

observe the ESD guidelines.

Damage due to unsuitable mounting location

– The environmental conditions recommended by the manufacturer must be

observed. See Section

– Do not operate the device close to sources of powerful electromagnetic

3 Technical Data.

radiation.

1.2.4 Operation

Danger of electrical shock due to incorrect connection

– Connect the device only to power sources with the specified voltage. Voltage

supply requirements can be found on the rating label of the device.

– Make sure the device is permanently connected to the electricity supply; a

readily accessible disconnect device must be provided.

– Make sure the circuit the device is connected to is protected with a 16 A (max.)

fuse. Do not connect any devices from other systems to this fuse.

– This device is designed to work with TN power systems. Do not connect the

device to any other power systems.

– Electrical grounding must meet the customary local safety standards and

regulations.

– Primary supply cables and secondary cables should be routed such that they do

not run in parallel or cross over or touch one anther inside the housing.

– Telephone cables should be fed into the unit separately from other cables.

Risk of cable damage due to stress

– Make sure that all outgoing cables and wires are sufficiently strain-relieved.

Dangerous situation due to false alarm

– Make sure to notify all relevant parties and authorities providing assistance

before testing the system.

– To avoid panic, always inform all those present before testing any alarm

devices.

10

Siemens Building Technologies

Fire Safety & Security Products 09.2008

Danger of explosion or burn hazard if the battery is improperly installed

– When inserting new batteries make sure the battery poles are correctly

positioned.

– Use only batteries that have been approved by the manufacturer (type: sealed

cell valve-regulated).

– Do not shorten the battery pins.

– Do not expose the battery to fire or high temperatures.

– Do not disassemble the battery.

– Discard used batteries according to local regulations.

– Make sure to insert the battery correctly and to fasten the battery strap or clip

provided for this purpose.

1.2.5 Service and maintenance

Danger of electrical shock during maintenance

– Maintenance work must only be carried out by trained specialists.

Security

– Always disconnect the power cable and other cables from the main power

supply before performing maintenance.

Danger of electrical shock while cleaning the device

– Do not use liquid cleaners or sprays that contain alcohol, spirit or ammonia.

1.3 Meaning of the written warning notices

Signal Word Type of Risk

DANGER Danger of death or severe bodily harm.

WARNING Possible danger of death or severe bodily harm.

CAUTION Danger of minor bodily injury or property damage

IMPORTANT Danger of malfunctions

11

Siemens Building Technologies

Fire Safety & Security Products 09.2008

Security

1.4 Meanings of the hazard symbols

WARNING Warning of a hazard area

WARNING Warning of dangerous electrical voltage

12

Siemens Building Technologies

Fire Safety & Security Products 09.2008

2 Directives and Standards

2.1 EU Directives

This product complies with the requirements of the European Directives

2004/108/EC “Directive of Electromagnetic Compatibility” and 2006/95/EC “Low

Voltage Directive”. The EU declaration of conformity is available to the responsible

agencies at:

Siemens Building Technologies

Fire & Security Products GmbH & Co. oHG

76181 Karlsruhe

European Directive 2004/108/EC „Electromagnetic Compatibility”

Compliance with the European Directive 2004/108/EC has been proven by testing

according to the following standards:

emc emission EN 55022 Class B

emc immunity EN 50130-4

Directives and Standards

European Directive 2006/95/EC „Low-Voltage Directive”

Compliance with the European Directive 2006/95/EC has been proven by testing

according to the following standard:

Safety: EN 60950-1

13

Siemens Building Technologies

Fire Safety & Security Products 09.2008

Technical Data

3 Technical Data

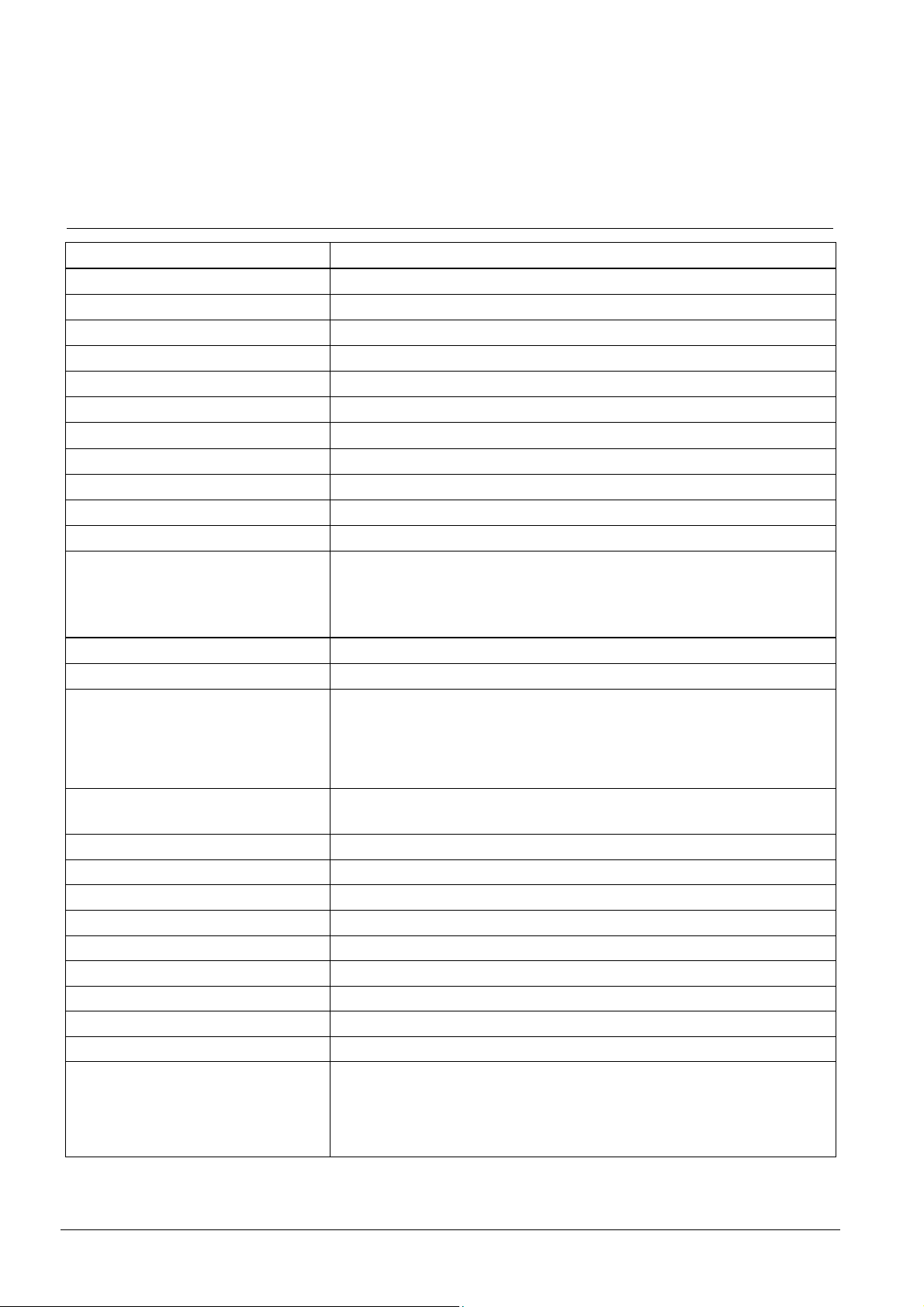

3.1 SPC4000

Mains voltage 230 VAC, +10 to -15 %, 50 Hz

Fuse 250 mA T

Power consumption 100 mA @ 230 V AC

Auxiliary power (nominal) 1) Max. 750 mA @ 12 VDC

Battery Optional

Battery type Sealed cell valve-regulated

Battery capacity Max. 7 AH / 12 V

Battery charger Max. 24h for 80 % of battery capacity

Operating voltage n.a.

Current consumption 1) Max. 100 mA @ 12 V DC

Number of on-board zones 8

EOL resistor Dual 4K7 (default), other resistor combinations configurable

1 internal bell (max. 400 mA resistive),

Number of on-board open collector

outputs.

Number of on-board relays 1 strobe, 30 V / 1 A (resistive switching current)

Field bus 2) X-BUS on RS-485 (307 kb/s)

Interfaces

Tamper contact

Operating temperature 5 - 40 °C

Relative humidity Max. 90 % (no condensation)

Housing protection IP30

Colour RAL 9003

Housing protection class Class II Indoor General

Mounting Surface, wall mounted

Housing material Steel, > 1.2 mm

Housing Metal enclosure

Housing can contain up to 1 additional Expander (size 150 mm x 82 mm)

Standards

1)

For EN compliance the supplied current needs to be supported by the battery for required stand by time

2)

Max. 400m between devices with cable types IYSTY 2 x 2 x Ø 0,6 mm (min.), UTP cat5 (solid core) or Belden 9829

1 external bell (max. 400 mA resistive),

3 general outputs (each max. 400 mA resistive,

supplied via auxiliary output)

1 x X-BUS (1 spur),

1 x RS232 (RJ45 ports, for X-10 or external communications),

1 x USB (PC connection for terminal program access),

1 x SPC Fast Programmer

On-board front cabinet spring tamper

+ 2 auxiliary tamper inputs

Designed to meet

EN50131-1:2006 (Grade 2)

TS50131-3:2003 (Grade 2)

EN50131-6:2008 (Grade 2)

14

Siemens Building Technologies

Fire Safety & Security Products 09.2008

3.2 Keypad

LC-display 2 x 16 characters

Special function keys Multi dimensional navigation key and 2 soft keys

Status LEDs 3

Card reader SPCK421: 125 kHz, EM 4102 or compatible (e.g. SiPASS)

Card read distance SPCK421: 10 mm

Operating voltage 9.5 – 14 V DC

Current consumption 2)

Field bus 3) X-BUS on RS-485 (307 kb/s)

Tamper contact Front/rear spring tamper

Operating temperature 5 - 40 °C

Relative humidity Max. 90 % (no condensation)

SPCK420: Min: 60 mA at 12 V DC, Max. 70 mA at 12 V DC

SPCK421: Min. 90 mA at 12 V DC, Max. 110 mA at 12 V DC

Technical Data

Housing protection IP30

Housing protection class Class II Indoor General

Housing material ABS

Colour RAL 9003

Mounting Surface, wall-mounted, height of 1.30 - 1-50 m

Designed to meet

Standards

1)

For EN compliance the supplied current needs to be supported by the battery for required stand by time

2)

Max. 400m between devices with cable types IYSTY 2 x 2 x Ø 0,6 mm (min.), UTP cat5 (solid core) or Belden 9829

EN50131-1:2006 (Grade 3),

TS50131-3:2003 (Grade 3)

15

Siemens Building Technologies

Fire Safety & Security Products 09.2008

Technical Data

3.3 8 Input / 2 Output Expander

Operating voltage 9.5 – 14 V DC

Current consumption 1) Min. 45 mA at 12 V DC

Max. 80 mA at 12 V DC

Number of on-board zones 8

EOL resistor Dual 4K7 (default), other resistor combinations config.

Number of on-board relays 2 single-pole changeover, 30 V DC / 1 A

(resistive switching current)

Field bus 2) X-BUS on RS485 (307 kb/s)

Interfaces X-BUS (In, Out, Branch)

Tamper contact On-board front cabinet spring tamper

Operating temperature 5 - 40 °C

Relative humidity Max. 90 % (no condensation)

Housing protection IP30

Colour RAL 9003

Housing protection class Class II Indoor General

Mounting Surface, wall-mounted

Housing material ABS

Housing Plastic enclosure

Standards Designed to meet

EN50131-1:2006 (Grade 3),

1)

For EN compliance the supplied current needs to be supported by the battery for required stand by time

2)

Max. 400m between devices with cable types IYSTY 2 x 2 x Ø 0,6 mm (min.), UTP cat5 (solid core) or Belden 9829

TS50131-3:2003 (Grade 3)

16

Siemens Building Technologies

Fire Safety & Security Products 09.2008

3.4 8 Output Expander

Operating voltage 9.5 – 14 V DC

Current consumption 1)

Number of on-board relays

Field bus 2) X-BUS on RS485 (307 kb/s)

Interfaces X-BUS (In, Out, Branch)

Tamper contact On-board front cabinet spring tamper

Operating temperature 5 - 40 °C

Relative humidity Max. 90 % (no condensation)

Housing protection IP30

Colour RAL 9003

Housing protection class Class II Indoor General

Mounting Surface, wall-mounted

Min. 55 mA at 12 V DC

Max. 180 mA at 12 V DC

8 single-pole changeover, 30 V DC / 1 A

(resistive switching current)

Technical Data

Housing material ABS

Housing Plastic enclosure

Designed to meet

Standards

1)

For EN compliance the supplied current needs to be supported by the battery for required stand by time

2)

Max. 400m between devices with cable types IYSTY 2 x 2 x Ø 0,6 mm (min.), UTP cat5 (solid core) or Belden 9829

EN50131-1:2006 (Grade 3),

TS50131-3:2003 (Grade 3)

3.5 Wireless Expander

Wireless features and devices will be available with a later market package.

17

Siemens Building Technologies

Fire Safety & Security Products 09.2008

Product description

4 Product description

The SPC Series Controller is a true hybrid Controller with eight on-board wired

zones that communicate with intruder devices.

The flexible design of the Controller allows the functional components

(PSTN/GSM/RF) to be mixed and matched, improving the capability of the system.

Using this approach, an installer can ensure that an efficient installation with

minimal wiring is achieved.

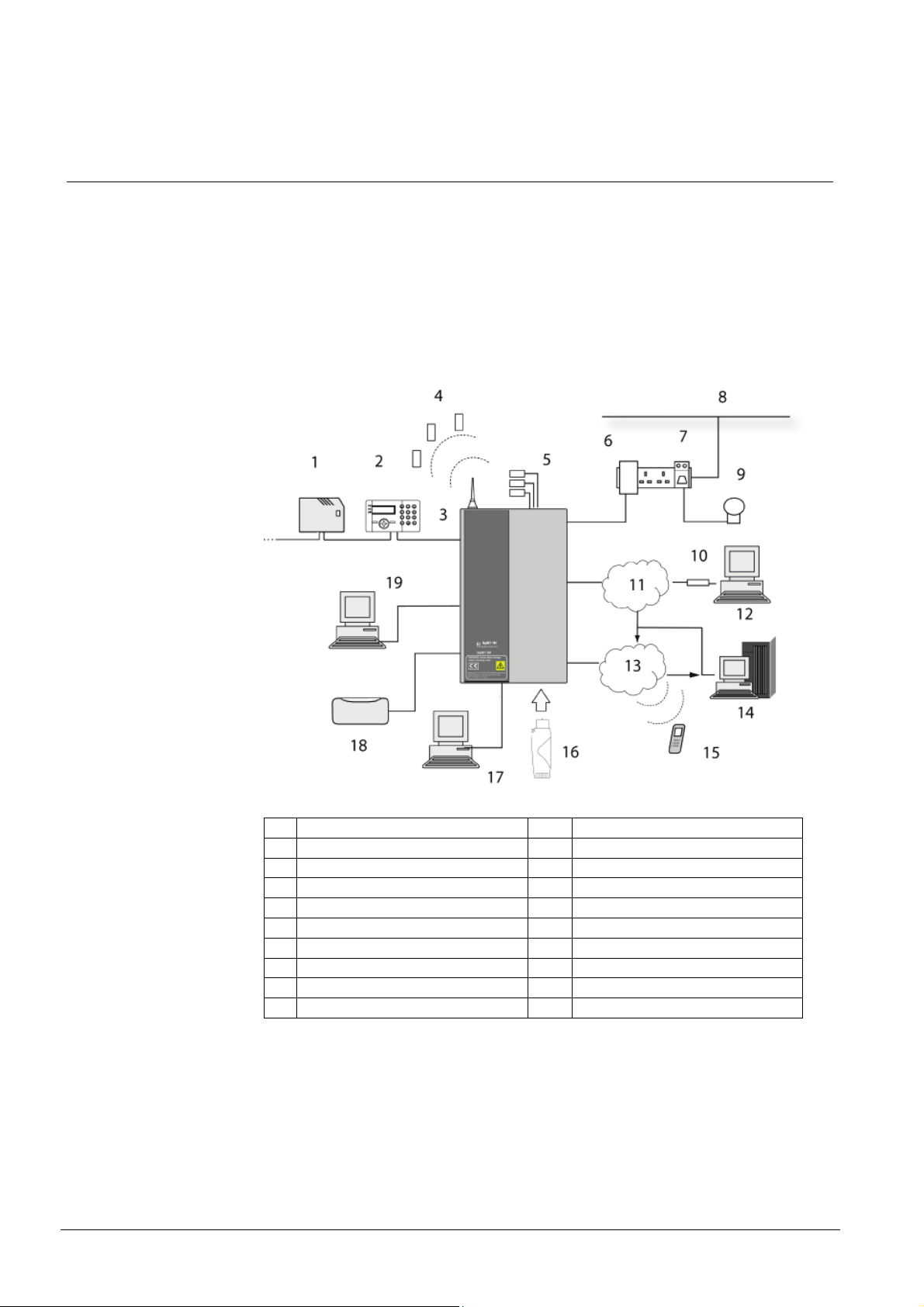

1 Expander 11 PSTN

2 Keypad 12 Remote PC

3 X-Bus 13 GMS

4 Wireless sensors 14 Central station receiver

5 Wired sensors 15 Text messages to mobile phone

6 X10 controller 16 Fast programmer

7 X10 output controller module 17 SPC Pro

8 Power line 18 Bell/strobe

9 Appliance 19 SPC Pro via USB

10 Modem

*Wireless features and devices will be available with a later market package.

Fig. 1 SPC Overview

18

Siemens Building Technologies

Fire Safety & Security Products 09.2008

4.1 SPC Features

The following features are incorporated into the SPC4000 Controller design:

z 8 Inputs with configurable wiring - No End Of Line (NEOL), Single End Of Line

(SEOL), Dual End Of Line (DEOL) and Anti-masking PIR supervision (MPIR)

z 6 Outputs – 3 x open collector, 1 x single pole Relay, 1x External Bell and 1 x

Internal Bell

z Wireless transceiver module (868 Mhz) supporting multiple wireless zones

(Optional)*

z PSTN Modem module (Optional)

z GSM module – Future Release (Optional)

z 1 x X10 Port

z 1 x RS232 Serial port terminal connector Interfaces

z 1 x USB Interface port

z X-BUS Communications Interface – 1 comms channel (1A, 1B)

z Front Tamper spring with tamper by-pass jumper

z PSU interface – AC power in via transformer

z Fast Programmer support – for fast local download of firmware

z SPC Pro programming application

*These features and devices will be available with a later market package.

Product description

19

Siemens Building Technologies

Fire Safety & Security Products 09.2008

Mounting System Equipment

5 Mounting System Equipment

5.1 Mounting Controller Enclosures

The Controller is supplied in two enclosure variations (standard and hinged). Each

enclosure offers easy access and installation within a robust design.

5.1.1 Standard Enclosure

The SPC standard enclosure is supplied with metallic cover. The cover is attached

to the base of the enclosure by two securing screws located on the top and bottom

of the front cover.

To open the enclosure, remove both screws with the appropriate screwdriver and

lift the cover directly from the base.

The standard enclosure contains the SPC Controller Printed Circuit Board (PCB)

mounted on four support pillars. An optional Input/Output module can be mounted

directly beneath the Controller PCB. A battery with capacity of 7AH (max) can be

accommodated below the SPC Controller.

An optional external antenna must be fitted to enclosures with metallic lid if the

wireless functionality* is required. If an antenna is fitted to the unit, it must be

enabled in the firmware.

The SPC standard enclosure provides three screw holes for wall mounting the unit.

To wall mount the enclosure, remove the cover and locate the initial fixing screw

hole at the top of the cabinet. Mark the position of this screw hole on the desired

location on the wall and drill the initial screw hole. Screw the unit to the wall and

mark the position of the bottom two screw hole positions with the unit vertically

aligned.

* Wireless features and devices will be available with a later market package.

20

Siemens Building Technologies

Fire Safety & Security Products 09.2008

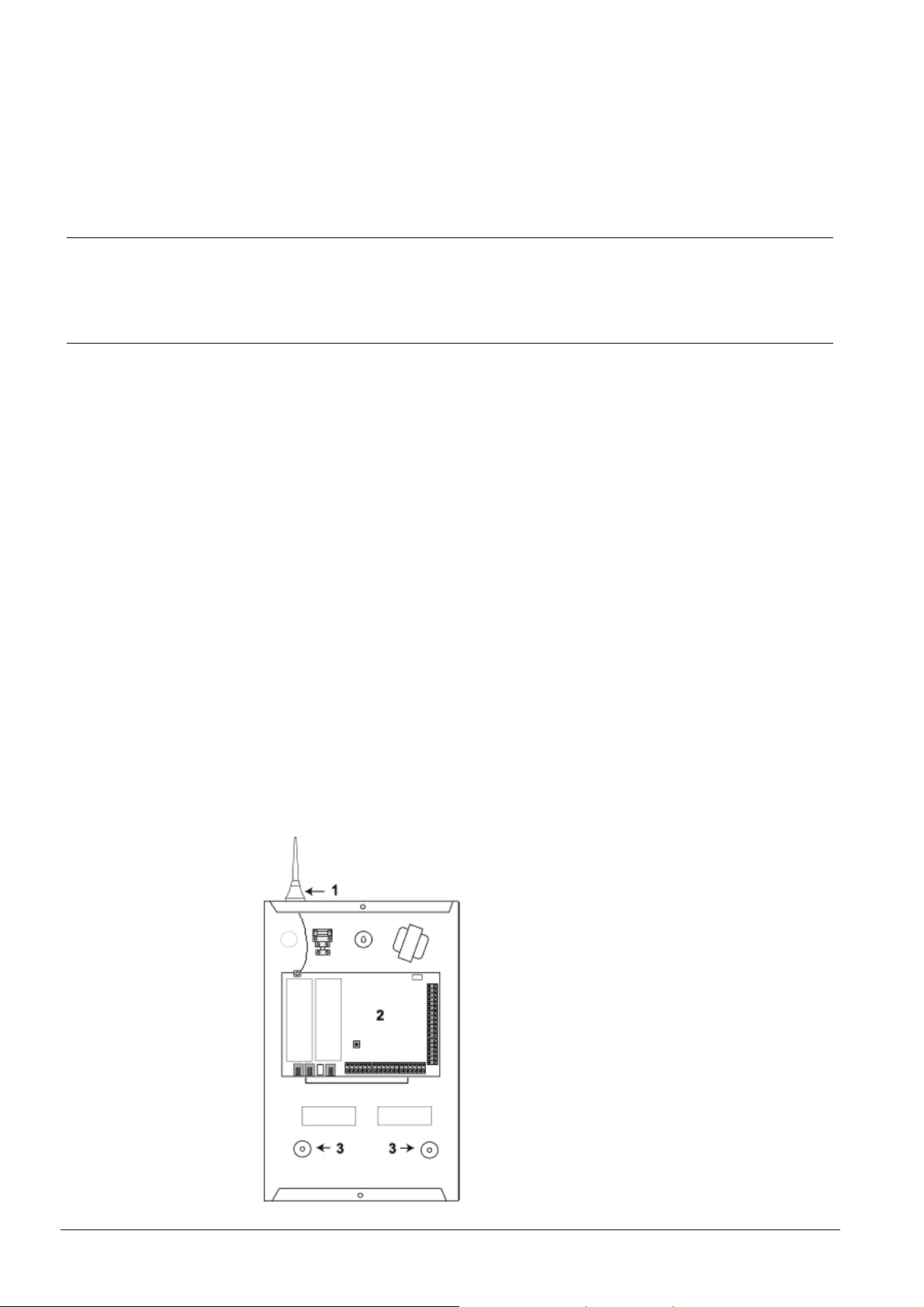

1 Wireless Antenna

NOTE: Wireless features and devices will

be available with a later market package.

2 SPC Controller

3 Wall Mounting Screw Holes

Fig. 2 Standard Enclosure

5.2 Mounting a keypad

For mounting please refer to the corresponding Installation Instruction.

5.3 Mounting an expander

For mounting please refer to the corresponding Installation Instruction.

Mounting System Equipment

21

Siemens Building Technologies

Fire Safety & Security Products 09.2008

Controller Hardware

6 Controller Hardware

The SPC Controller provides eight on-board wired zones and 24 on-board wireless

zones that communicate with intruder devices using the new European standard

wireless frequency 868 MHz*, providing greater security from interference and

jamming. For larger applications the SPC system components can be mixed and

matched to expand both the wired and wireless zones, providing flexibility in cost

effective design and efficient installation with minimal wiring.

*NOTE: Wireless features and devices will be available with a later market package.

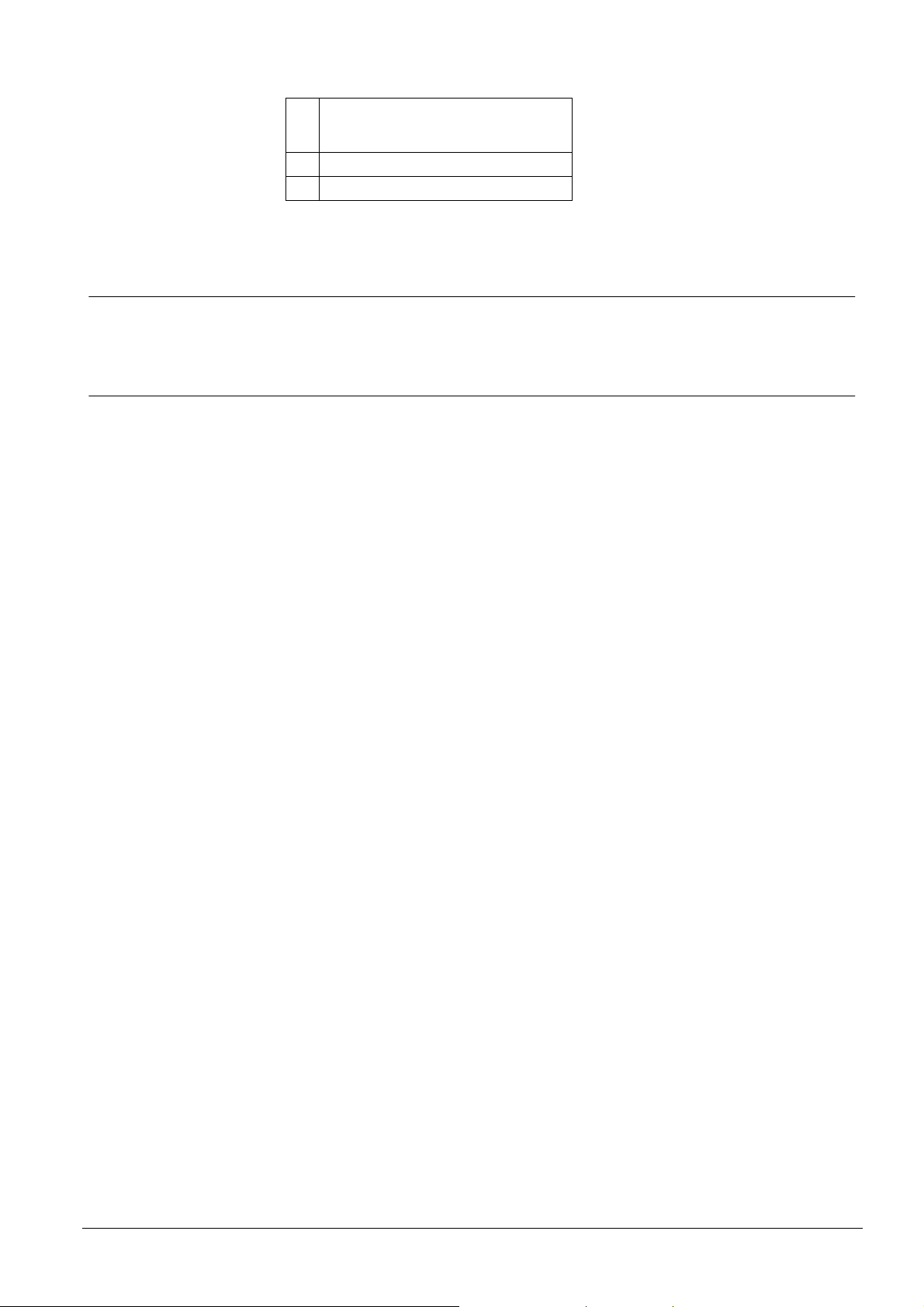

Fig. 3 SPC4000 Controller

22

Siemens Building Technologies

Fire Safety & Security Products 09.2008

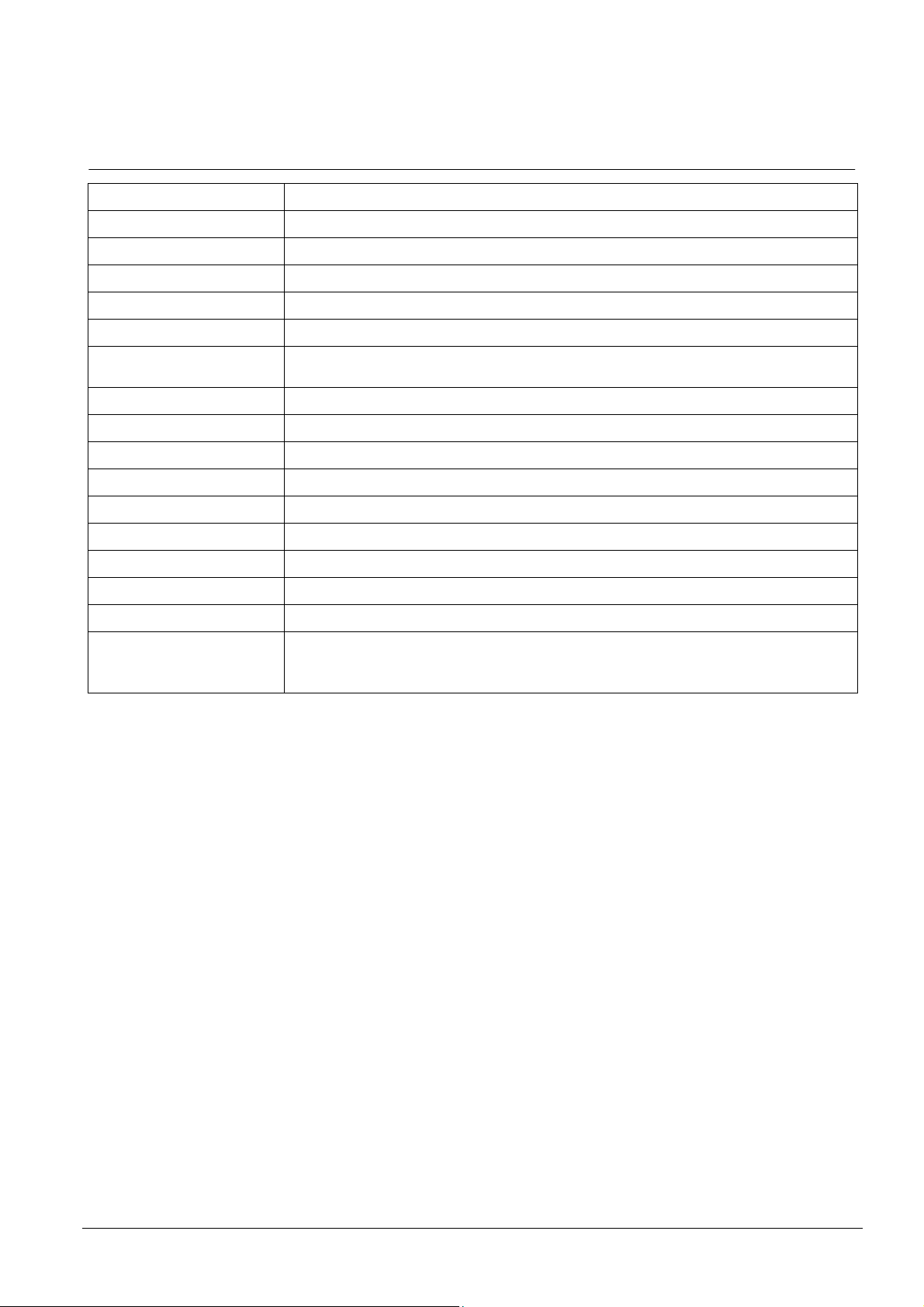

Controller Hardware

1 Optional Wireless Module

2 SPC Status LEDs These 6 LEDs display the status of various system parameters as described in Section

3 AC Power Input The mains AC input voltage is applied to this 2-pin connection via a transformer contained

4 Reset Switch Press this switch once to reset the SPC Controller. To reset the programming settings to

5 Earth Connection Terminal This terminal provides an earth connection point providing a common ground for the

6 Auxiliary 12 V Output The SPC Controller provides an auxiliary 12 V DC output that can be used to supply power

7 X-BUS Interface This is the SPC communications bus used to network Expanders together on the system.

8 On-board Outputs Outputs OP4, OP5, and OP6 are 12 V open collector resistive outputs that share a 400 mA

9 Relay Output The SPC Controller provides a 1 A, single-pole, changeover relay that can be used to drive

10 Internal Bell / External Bell Internal and external bell outputs (INT+, INT-, EXT+, EXT-) are resistive outputs with a 400

11 Zone Inputs The Controller provides eight on-board zone inputs that can be monitored using a variety of

12 Front Tamper This on-board front tamper (switch & switch) provides the cabinet tamper protection.

13 Tamper Terminals The Controller provides two additional tamper input terminals that can be connected to

14 Tamper Bypass [LK1] The jumper setting determines the operation of the tamper. The tamper operation can be

15 USB Interface The USB interface is used to access terminal programs.

16 Fast Programmer Port for connecting to the Fast Programmer.

17 Serial Port 1 This RS232 serial port may be used to interface to an X10 protocol device.

18 X10/Serial Port 2 This port may be enabled for connecting to the X-10 port or it may be enabled as a

19 Optional Plug-in Modules A primary (left slot) and back-up (right slot) module can be connected to the SPC

NOTE: Wireless features and devices will be available with a later market package.

16.4 Appendix E: SPC Controller Status LEDs.

in the SPC Enclosure. The earth lead from the mains supply is wired to a connection point

on the metal cabinet.

default and reboot the Controller, hold down the button for 10 seconds and release.

Note: Configuration will be lost.

Controller PCB with ancillary devices.

to Expanders and devices such as latches, bells, etc. See Section

Powering Expanders from the Auxiliary Power Terminals. The maximum deliverable

current is 750 mA.

See Section

channel (1A 1B) for manually addressed Expanders only.

current rating with the auxiliary 12 V Output.

the strobe output on the external bell.

mA current rating. The BHO (Bell Hold Off), TR (Tamper Return), and EXT outputs are

used to connect an external bell to the Controller. The INT+ and INT- terminals are used to

connect to internal devices such as an internal sounder. See Section

Sounder.

supervision configurations. These configurations can be programmed from system

programming. The default configuration is Dual End of Line (DEOL) using resistor values of

4K7. See Section

auxiliary tamper devices to provide increased tamper protection. These terminals should

be shorted when not in use.

overridden by fitting LK1. The engineer must ensure that LK1 is removed before leaving

site for the system to comply with standards.

communications channel with the back-up modem module. If a back-up modem is

installed, ensure no devices are connected to this serial port.

Controller. These modules can be GSM or PSTN modules offering increased

communication functionality. The back-up module should not be connected if serial port 2

interface is connected to an external modem or other device.

7.1 Wiring the X-BUS Interface. SPC4000 supports one communication

7.4 Wiring the Zone Inputs.

16.5 Appendix F:

7.6 Wiring an Internal

23

Siemens Building Technologies

Fire Safety & Security Products 09.2008

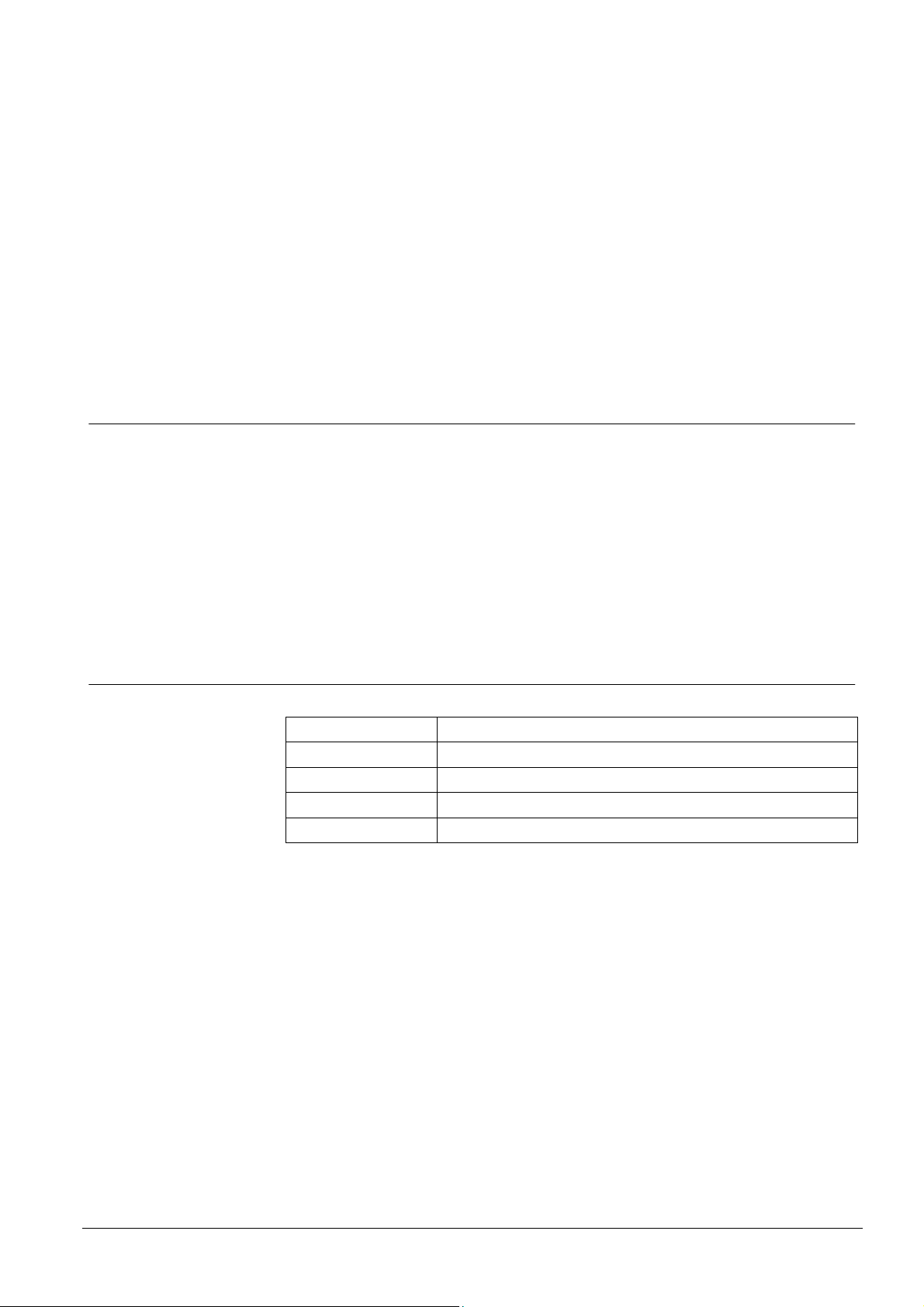

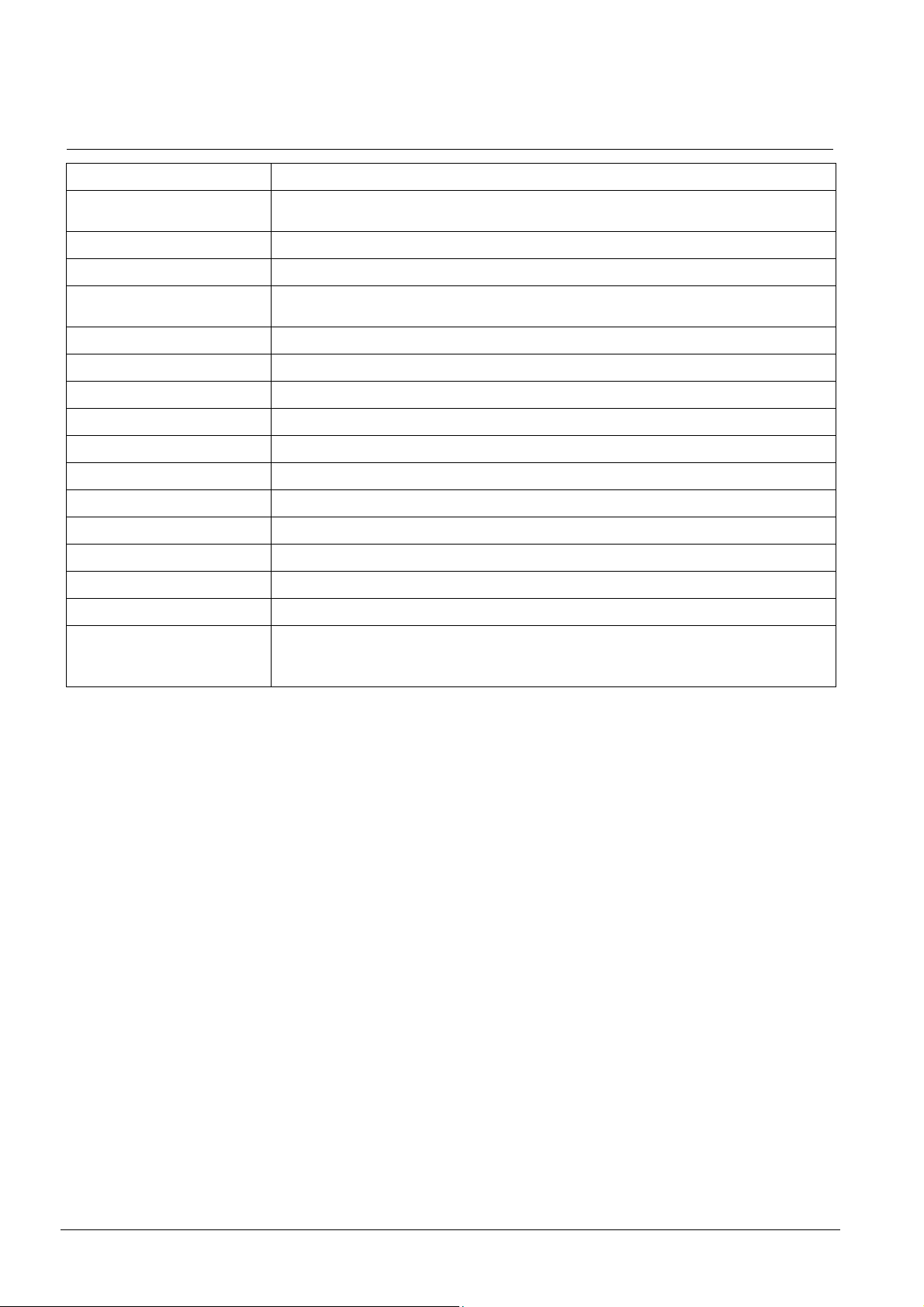

Wiring the System

7 Wiring the System

7.1 Wiring the X-BUS Interface

The X-BUS interface provides for the connection of Expanders to the SPC

Controller. The X-BUS can be wired in a number of different confirmations

depending on the installation requirements. The X-BUS interface baud rate is

307kb.

Expander / Expander for all cable types.

Tab. 1 shows the maximum distances between Controller / Expander or

Cable Type Distance

CQR standard alarm cable 200 m

UTP Category: 5 (solid core) 400 m

Belden 9829 400 m

IYSTY 2 x 2 x 0.6 (min) 400 m

Tab. 1 Cable Type and Distance

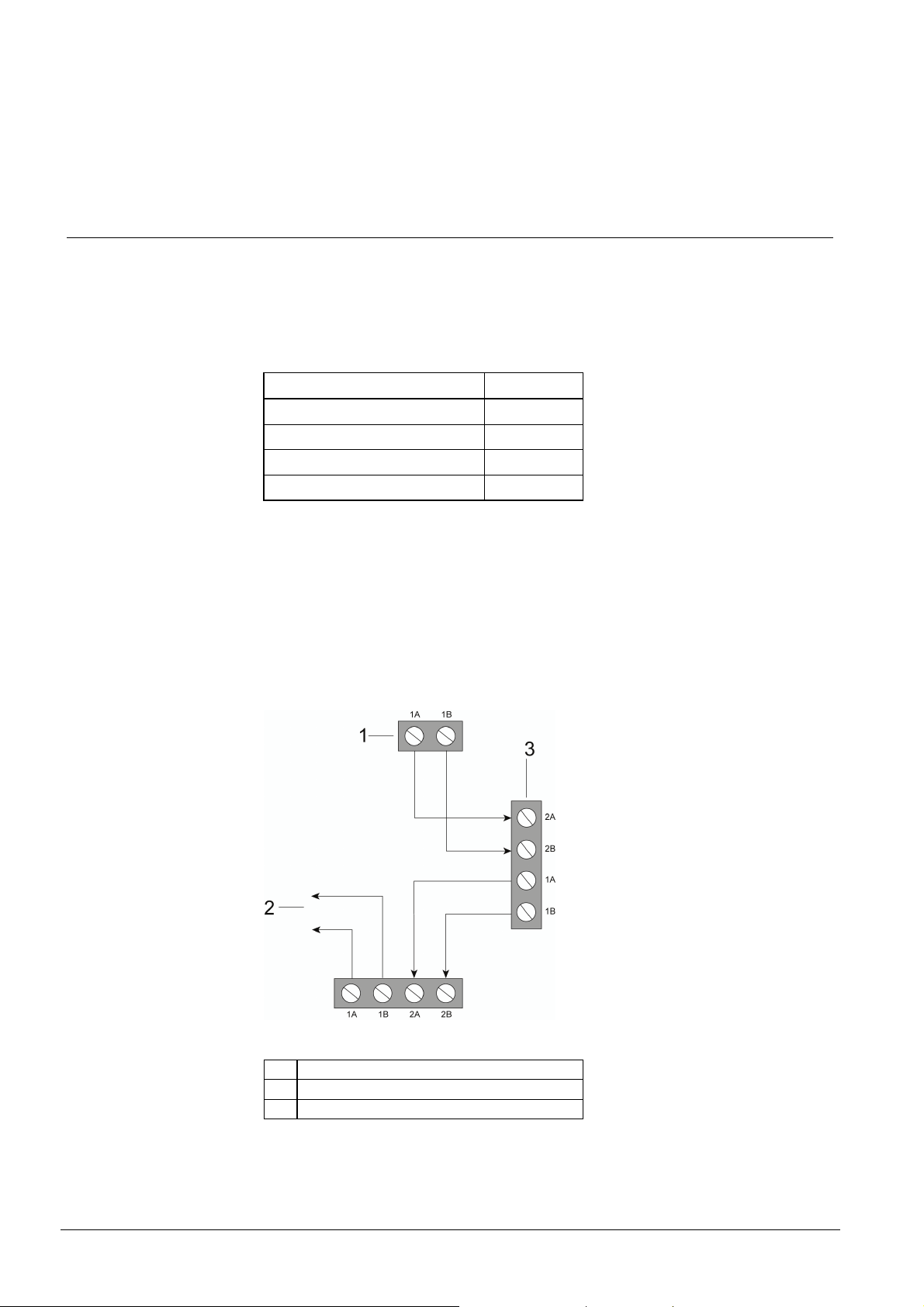

Each device has 2 terminals, 1A and 1B, for connection to Expanders via the XBUS cable. The SPC Controller initiates a detection procedure on power up to

determine the number of Expanders connected on the system and the topology in

which they are connected.

The following modules have Branch Expander wiring capability: 8 Input / 2 Output

Expander, 8 Output Expander. See Section

7.2 Wiring of Branch Expander for

instructions on branch expander wiring.

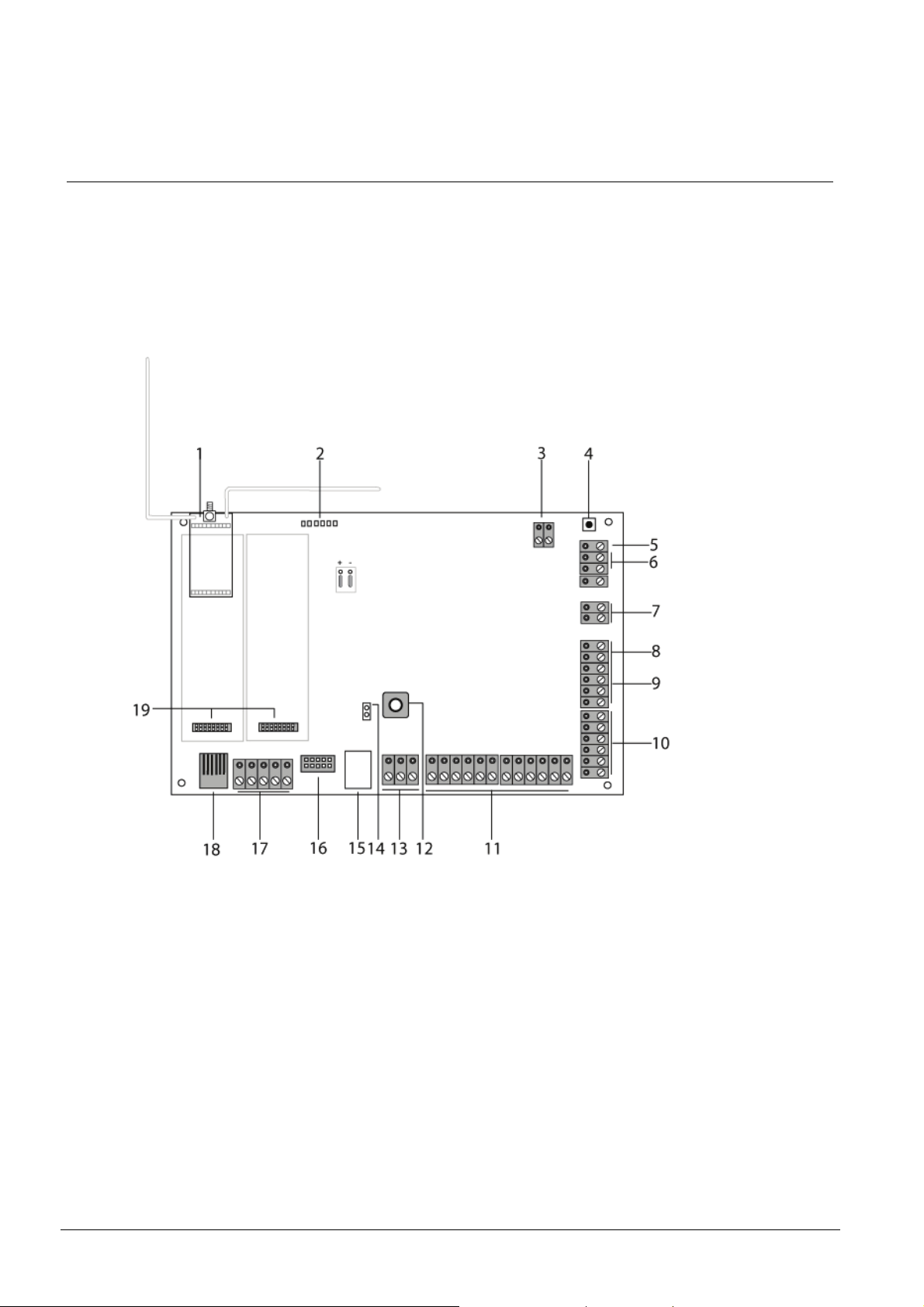

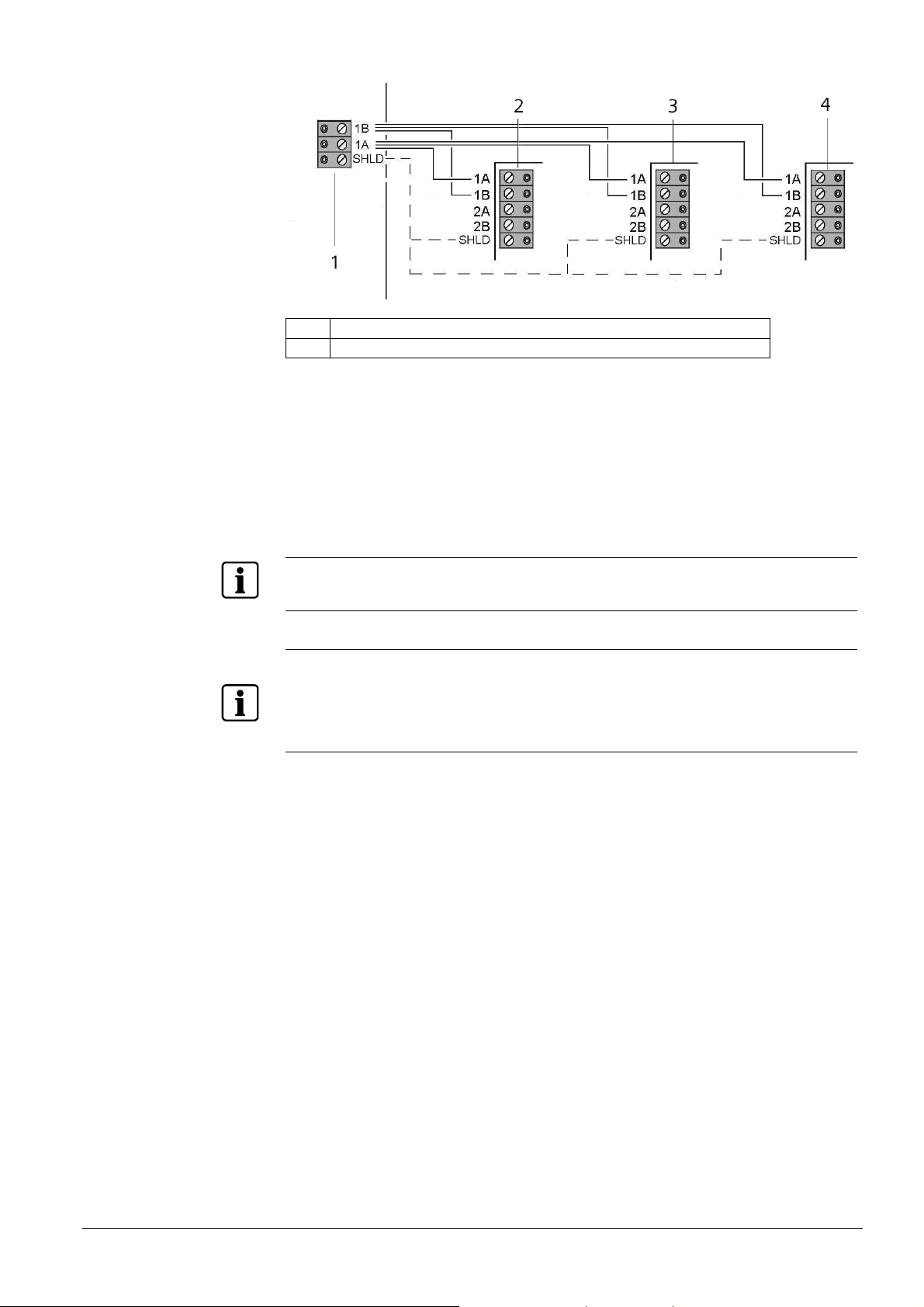

1 From Previous Expander

2 To Next Expander

3 SPC Controller

Fig. 4 Wiring of Expanders

24

Siemens Building Technologies

Fire Safety & Security Products 09.2008

7.1.1 Spur (Chain) Configuration

The Spur, or open loop, cabling method offers a high level of fault tolerance and

may be more convenient on certain installations. In the case of a cable fault or

break, all Expanders and detectors up to the fault continues to be supervised.

On the SPC, only a single port supports a group of Expanders. The last Expander

in an open loop configuration is not wired back to the controller and can be

identified by the fast LED flashing light (one flash every 0.2 seconds approx) when

in Full Engineer programming.

Numbering for the Expanders commences at the Expander nearest to the

Controller and ends with the Expander connected farthest from the SPC Controller.

Eg. if six Expanders are connected in an open loop configuration, then the nearest

Expander on the X-BUS connection is Expander 1, the second nearest Expander is

2, etc. ending with the Expander wired farthest from the SPC Controller, which is

Expander 6.

Within the open loop wiring configuration all Expanders/Keypads are fitted with a

jumper, as default, allowing termination on the device.

Wiring the System

1 Controller

2 Expander Three

3 Expander Two

4 Expander One

Fig. 5 Spur (Chain) Configuration

25

Siemens Building Technologies

Fire Safety & Security Products 09.2008

Wiring the System

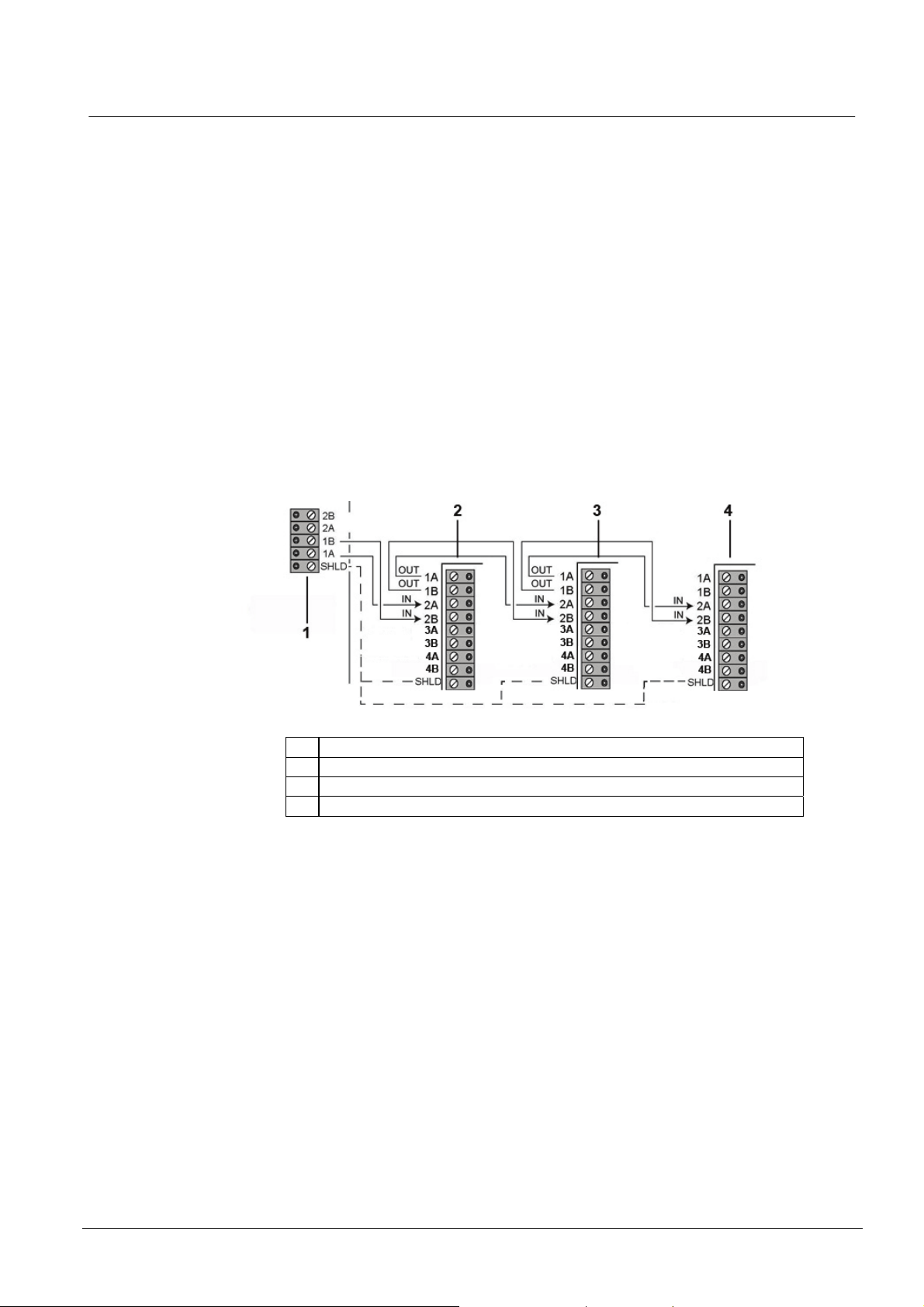

1 SPC Controller X-BUS Terminal Block

2 Expander Three

3 Expander Two

4 Expander One

Fig. 6 Open Loop (Spur) Configuration

7.1.2 Star (Multi-drop) Configuration

The star cabling method is most effective with homes that are prewired with fourcore cable. These configurations allow for a maximum cable length of 200 metres.

A star configuration is established when multiple Expanders are wired back to the

same input channel of the X-BUS on the SPC Controller. See wiring configuration

in

Fig. 7.

1 SPC Controller

2 - 4 Expanders

Fig. 7 Star Configuration

26

Siemens Building Technologies

Fire Safety & Security Products 09.2008

1 SPC Controller

2 - 4 Expanders

Fig. 8 Multi-Drop Configuration

The multi-drop configuration varies in that each Expander uses the same

communication channel as it wires onto the next Expander, with all Expanders

using the same input channel. See multi-drop configuration in

A cable break in the X-BUS connection results in disconnection with the single

Expander on that cable. All other Expanders are unaffected as there are separate

communication paths. A short in the cable renders all Expanders disabled.

NOTE

On a Star wiring or Multi-Drop configuration, all Expanders should not have a jumper fitted (no

termination).

NOTE

Cable Shielding

The shielding terminals (SH) should only be used for cables types with shielding (e.g. Belden 9829). If

shielding is required (i.e. sites with high electric field interference) connect the cable shield to the SH

terminals on the SPC Controller and all networked Expanders. Earth the SH terminal on the Controller

ONLY. Do NOT earth the SH terminal on any of the Expanders.

Wiring the System

Fig. 8.

27

Siemens Building Technologies

Fire Safety & Security Products 09.2008

Wiring the System

7.2 Wiring of Branch Expander

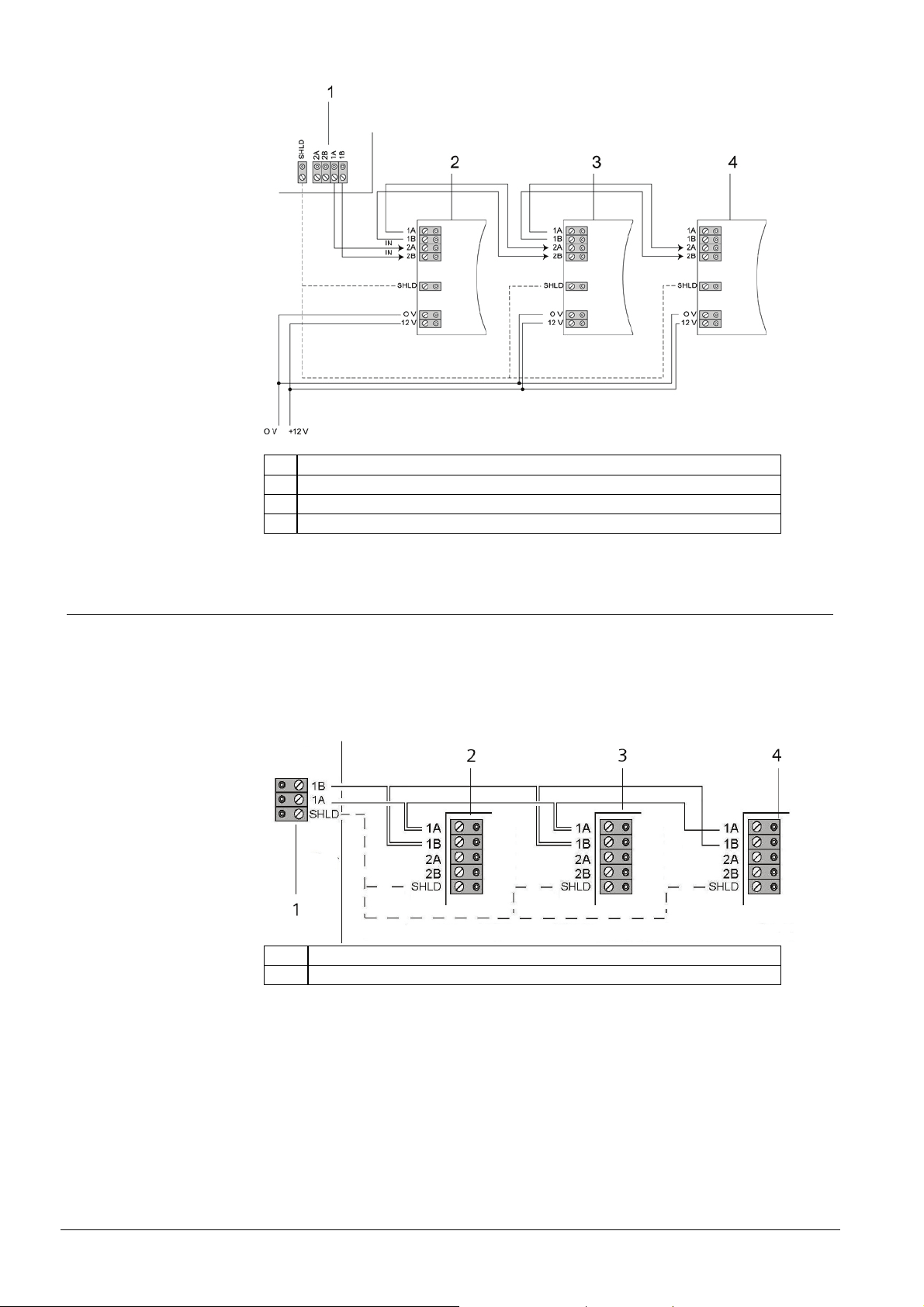

The wiring of the X-BUS interface with eight terminals 1A/1B to 4A/4B provides for

the connection of an additional branch Expander.

If the branch is not used then the terminals 1A/1B are used to connect to the next

Expander/Keypad. Terminals 3A/3B 4A/4B are then not used. Branches are on all

Expanders except Keypads.

1 Previous Expander

2 Wireless Gateway Expander (NOTE: Wireless

features and devices will be available with a later

market package.)

3 Next Expander

4 Branch

Fig. 9 Wiring of a Branch Expander

28

Siemens Building Technologies

Fire Safety & Security Products 09.2008

7.3 Wiring the Relay Output

The SPC Controller has one on-board 1-Amp single pole changeover relay that

can be assigned to any of the SPC system outputs. This relay output can switch a

rated voltage of 30 V DC (non-inductive load).

When the relay is activated the Common terminal connection (COM) is switched

from the Normally Closed terminal (NC) to the Normally Open terminal (NO).

Wiring the System

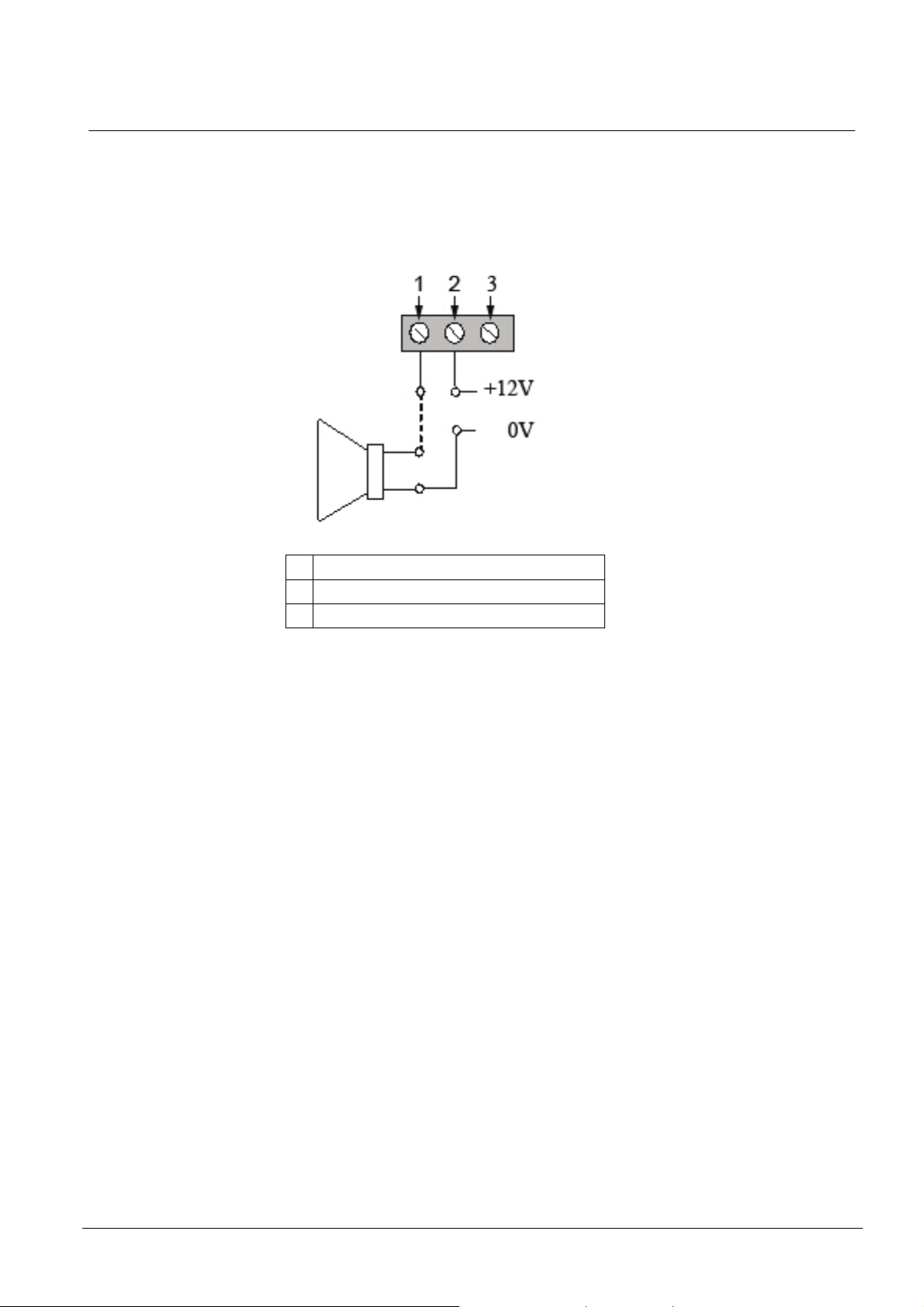

1 Normally Open terminal (NO)

2 Common terminal connection (COM)

3 Normally Closed terminal (NC)

Fig. 10 Standard Wiring

29

Siemens Building Technologies

Fire Safety & Security Products 09.2008

Wiring the System

7.4 Wiring the Zone Inputs

The SPC Controller has eight on-board zone inputs. By default these inputs are

monitored using End of Line supervision. The installer can choose from:

z NEOL

z SEOL

z DEOL

z Anti-masking PIR

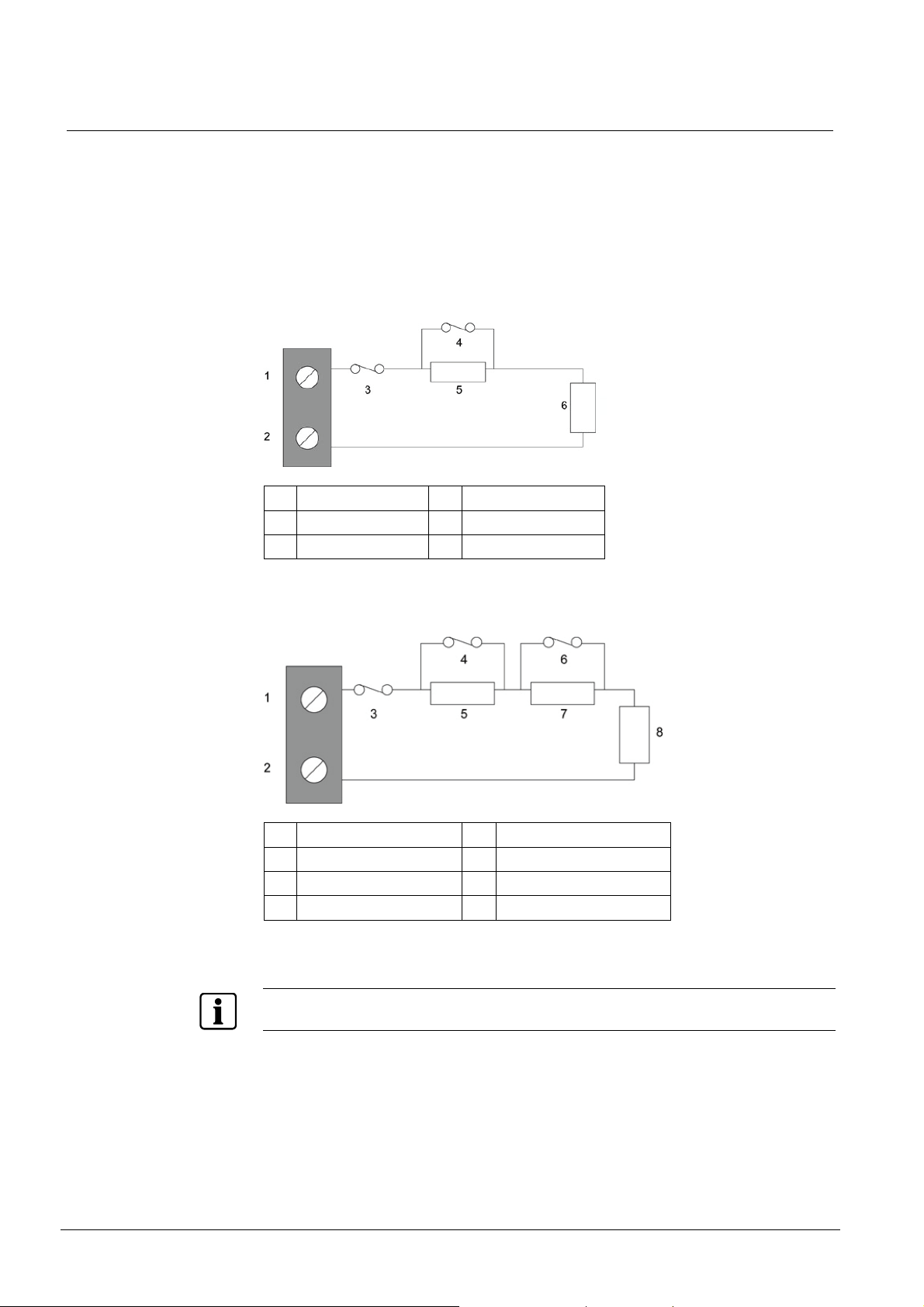

1 Input 1 4 Alarm

2 COM 5 Resistor

3 Tamper 6 4K7 EOL

Fig. 11 Default Configuration (DEOL 4K7)

1 Input 2 5 Alarm

2 COM 6 Anti-masking

3 Tamper 7 2K2

4 1K 8 EOL IK

Fig. 12 Anti-Masking PIR Configuration

Anti-Masking is only reported as "Alarm" type to ARC and if area or system is set.

30

Siemens Building Technologies

Fire Safety & Security Products 09.2008

Loading...

Loading...