Page 1

SIMATIC NET

SPC3 Siemens PROFIBUS Controller

Hardware Description

Date 2003/04/09

Page 2

Page 3

SPC3

Hardware Description

SIMATIC - NET

(Siemens PROFIBUS Controller

according to IEC 61158)

Version: 1.3

Date: 2003/04

Page 4

PROFIBUS Interface Center

SPC3

Liability Exclusion

We have tested the contents of this document regarding agreement with the

hardware and software described. Nevertheless, there may be deviations, and

we don’t guarantee complete agreement. The data in the document is tested

periodically, however. Required corrections are included in subsequent

versions. We gratefully accept suggestions for improvement

Copyright

Copyright © Siemens AG 2003. All Rights Reserved.

Unless permission has been expressly granted, passing on this document or

copying it, or using and sharing its content are not allowed. Offenders will be

held liable. All rights reserved, in the event a patent is granted or a utility model

or design is registered.

Subject to technical changes.

Page 2 V1.3 SPC3 Hardware Description

2003/04 Copyright (C) Siemens AG 2003. All rights reserved.

Page 5

Included the specification of the different manufacturers in

Included the specification of the different manufacturers in

SPC3 PROFIBUS Interface Center

Versions

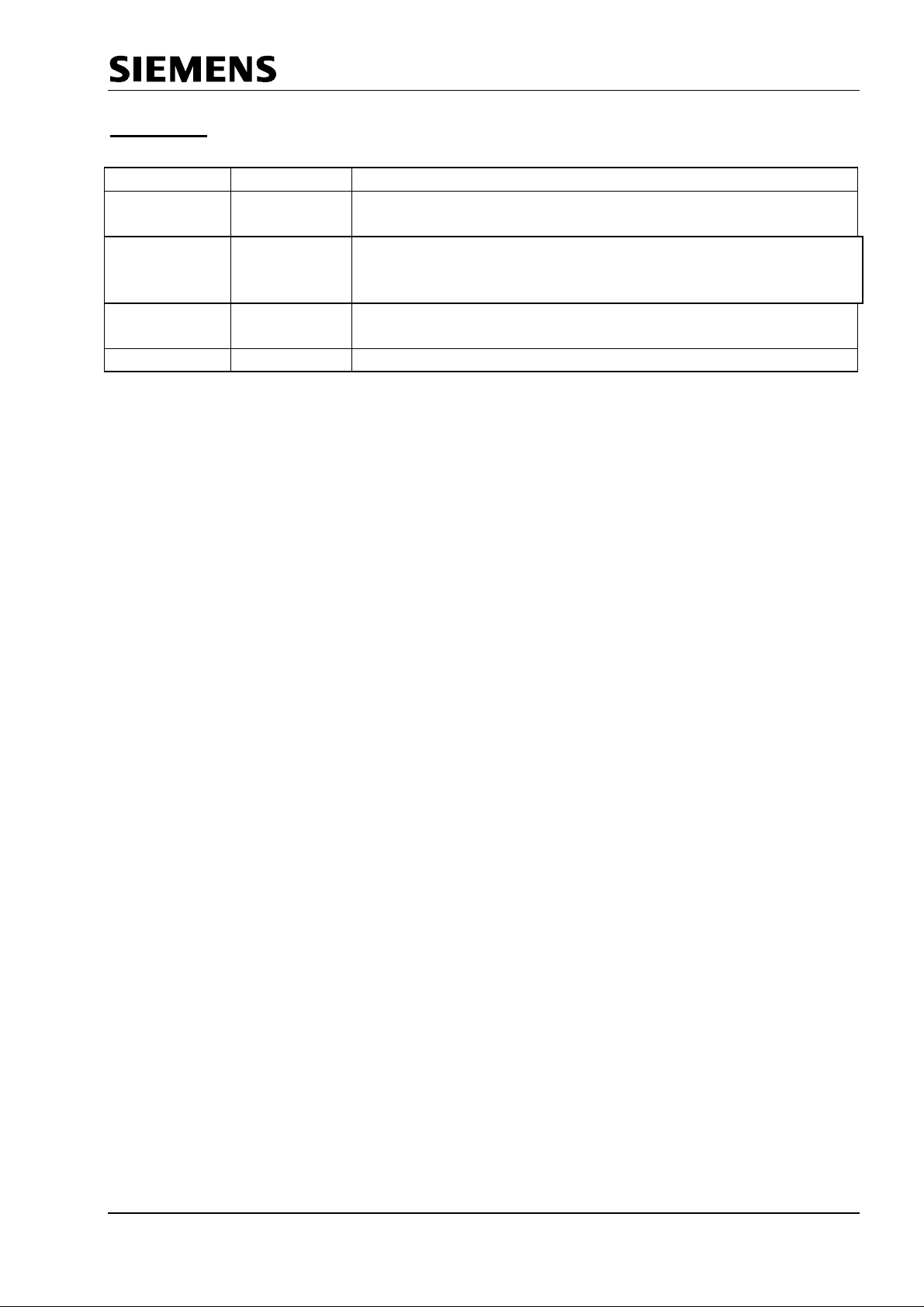

Release Date Changes

V 1.1 12/23/99 Chapter 8.2 Current consumption without bus accesses

Chapter 10.1 Contact persons

V 1.2 09/25/02

Chap. 8.1, 8.3, 8.5 and 10.3 Order numbers

chap 10.1 contact persons

V 1.3 2003/04

Chap. 8.1, 8.3, 8.5 and 10.3

SPC3 Hardware Description V1.3 Page 3

Copyright (C) Siemens AG 2003 All rights reserved. 2003/04

Page 6

PROFIBUS Interface Center

SPC3

Directory

1 INTRODUCTION 7

2 FUNCTION OVERVIEW 8

3 PIN DESCRIPTION 9

4 MEMORY ALLOCATION 11

4.1 Memory Area Distribution in the SPC3 11

4.2 Processor Parameters (Latches/Register) 13

4.3 Organizational Parameters (RAM) 15

5 ASIC INTERFACE 17

5.1 Mode Register 17

5.1.1 Mode Register 0 17

5.1.2 Mode Register 1 (Mode-REG1, writable): 19

5.2 Status Register 20

5.3 Interrupt Controller 22

5.4 Watchdog Timer 25

5.4.1 Automatic Baud Rate Identification 25

5.4.2 Baud Rate Monitoring 25

5.4.3 Response Time Monitoring 25

6 PROFIBUS-DP INTERFACE 26

6.1 DP_Buffer Structure 26

6.2 Description of the DP Services 29

6.2.1 Set_Slave_Address (SAP55) 29

6.2.2 Set_Param (SAP61) 30

6.2.3 Check_Config (SAP62) 31

6.2.4 Slave_Diagnosis (SAP60) 32

6.2.5 Write_Read_Data / Data_Exchange (Default_SAP) 33

6.2.6 Global_Control (SAP58) 35

6.2.7 Read_Inputs (SAP56) 36

6.2.8 Read_Outputs (SAP57) 36

6.2.9 Get_Config (SAP59) 36

7 HARDWARE INTERFACE 37

7.1 Universal Processor Bus Interface 37

7.1.1 General Description 37

7.1.2 Bus Interface Unit (BIU) 37

7.1.3 Switching Diagram Principles 39

7.1.4 Application with the 80 C 32 41

7.1.5 Application with th 80 C 165 42

Page 4 V1.3 SPC3 Hardware Description

2003/04 Copyright (C) Siemens AG 2003. All rights reserved.

Page 7

7.1.6 Interface Signals 43

SPC3 PROFIBUS Interface Center

7.2 UART 43

7.3 ASIC Test 43

8 TECHNICAL DATA 44

8.1 Maximum Limit Values 44

8.2 Permitted Operating Values 44

8.3 DC-Specifikation of the I/O- Drivers 44

8.4 AC-Specification for the Output Drivers 45

8.5 Timing Characteristics 46

8.5.1 SYS Bus Interface 46

8.5.2 Timing in the Synchronous C32-Mode: 47

8.5.3 Timing in the Asynchronous Intel Mode (X86 Mode) : 49

8.5.4 Timing in the Synchronous Motorola Mode (E_Clock-Mode, for example, 68HC11) : 50

8.5.5 Timing in the Asynchronous Motorola-Mode (for example, 68HC16) : 52

8.5.6 Serial Bus Interface 54

8.5.7 Housing 55

8.5.8 Processing Instructions 56

9 PROFIBUS INTERFACE 57

9.1 Pin Assignment 57

9.2 Example for the RS 485 Interface 58

10 APPENDIX 59

10.1 Addresses 59

10.2 General Definition of Terms 60

10.3 Ordering of ASICs 60

10.3.1 SPC3 (AMI) 60

10.3.2 SPC3 (ST) 60

11 APPENDIX A: DIAGNOSTICS PROCESSING IN PROFIBUS DP 61

11.1 Introduction 61

11.2 Diagnostics Bits and Expanded Diagnostics 61

11.2.1 STAT_DIAG 61

11.2.2 EXT_DIAG 61

11.2.3 EXT_DIAG_OVERFLOW 63

11.3 Diagnostics Processing from the System View 63

12 APPENDIX B: USEFUL INFORMATION 64

12.1 Data format in the Siemens PLC SIMATIC 64

SPC3 Hardware Description V1.3 Page 5

Copyright (C) Siemens AG 2003 All rights reserved. 2003/04

Page 8

PROFIBUS Interface Center

SPC3

Page 6 V1.3 SPC3 Hardware Description

2003/04 Copyright (C) Siemens AG 2003. All rights reserved.

Page 9

SPC3 PROFIBUS Interface Center

1 Introduction

For simple and fast digital exchange between programmable logic controllers, Siemens offers its users

several ASICs. These ASICs are based on and are completely handled on the principles of the EN 50170

Vol. 2, of data traffic between individual programmable logic controller stations.

The following ASICs are available to support intelligent slave solutions, that is, implementations with a

microprocessor.

The ASPC2 already has integrated many parts of Layer 2, but the ASPC2 also requires a processor’s

support. This ASIC supports baud rates up to 12 Mbaud. In its complexity, this ASIC is conceived primarily

for master applications.

Due to the integration of the complete PROFIBUS-DP protocol, the SPC3 decisively relieves the processor

of an intelligent PROFIBUS slave. The SPC3 can be operated on the bus with a baud rate of up to 12

MBaud.

However, there are also simple devices in the automation engineering area, such as switches and

thermoelements, that do not require a microprocessor to record their states.

There are two additional ASICs available with the designations SPM2 (Siemens Profibus Multiplexer,

Version 2 ) and LSPM2 (Lean Siemens PROFIBUS Multiplexer) for an economical adaptation of these

devices. These blocks work as a DP slave in the bus system (according to DIN E 19245 T3) and work with

baud rates up to 12 Mbaud. A master addresses these blocks by means of Layer 2 of the 7 layer model.

After these blocks have received an error-free telegram, they independently generate the required response

telegrams.

The LSPM2 has the same functions as the SPM2, but the LSPM2 has a decreased number of I/O ports and

diagnostics ports.

SPC3 Hardware Description V1.3 Page 7

Copyright (C) Siemens AG 2003 All rights reserved. 2003/04

Page 10

PROFIBUS Interface Center

SPC3

2 Function Overview

The SPC3 makes it possible to have a price-optimized configuration of intelligent PROFIBUS-DP slave

applications.

The processor interface supports the following processors:

Intel: 80C31, 80X86

Siemens: 80C166/165/167

Motorola: HC11-,HC16-,HC916 types

In SPC3, the transfer technology is integrated (Layer 1), except for analog functions (RS485 drivers), the

FDL transfer protocol (Fieldbus Data Link) for slave nodes (Layer 2a), a support of the interface utilities

(Layer 2b), some Layer 2 FMA utilities, and the complete DP slave protocol (USIF: User Interface, which

makes it possible for the user to have access to Layer 2). The remaining functions of Layer 2 (software

utilities and management) must be handled via software.

The integrated 1.5k Dual-Port-RAM serves as an interface between the SPC3 and the

software/application. The entire memory is subdivided into 192 segments, with 8 bytes each. Addressing

from the user takes place directly and from the internal microsequencer (MS) by means of the so-alled base

pointer. The base-pointer can be positioned at any segment in the memory. Therefore, all buffers must

always be located at the beginning of a segment.

If the SPC3 carries out a DP communication the SPC3 automatically sets up all DP-SAPs. The various

telegram information is made available to the user in separate data buffers (for example, parameter setting

data and configuration data). Three change buffers are provided for data communication, both for the

output data and for the input data. A change buffer is always available for communication. Therefore, no

resource problems can occur. For optimal diagnostics support, SPC3 has two diagnostics change buffers

into which the user inputs the updated diagnostics data. One diagnostics buffer is always assigned to SPC3

in this process.

The bus interface is a parameterizable synchronous/asynchronous 8-bit interface for various Intel and

Motorola microcontrollers/processors. The user can directly access the internal 1.5k RAM or the parameter

latches via the 11-bit address bus.

After the processor has been switched on, procedural-specific parameters (station address, control bits, etc.)

must be transferred to the Parameter Register File and to the mode registers.

The MAC status can be scanned at any time in the status register.

Various events (various indications, error events, etc.) are entered in the interrupt controller. These

events can be individually enabled via a mask register. Acknowledgement takes place by means of the

acknowledge register. The SPC3 has a common interrupt output.

The integrated Watchdog Timer is operated in three different states: ‘Baud_Search’, ‘Baud_Control,’ and

‘DP_Control’.

The Micro Sequencer (MS) controls the entire process.

Procedure-specific parameters (buffer pointer, buffer lengths, station address, etc.) and the data buffer are

contained in the integrated 1.5kByte RAM that a controller operates as Dual-Port-RAM.

In UART, the parallel data flow is converted into the serial data flow, or vice-versa. The SPC3 is capable of

automatically identifying the baud rates (9.6 kBd - 12 MBd).

The Idle Timer directly controls the bus times on the serial bus cable.

Page 8 V1.3 SPC3 Hardware Description

2003/04 Copyright (C) Siemens AG 2003. All rights reserved.

Page 11

SPC3 PROFIBUS Interface Center

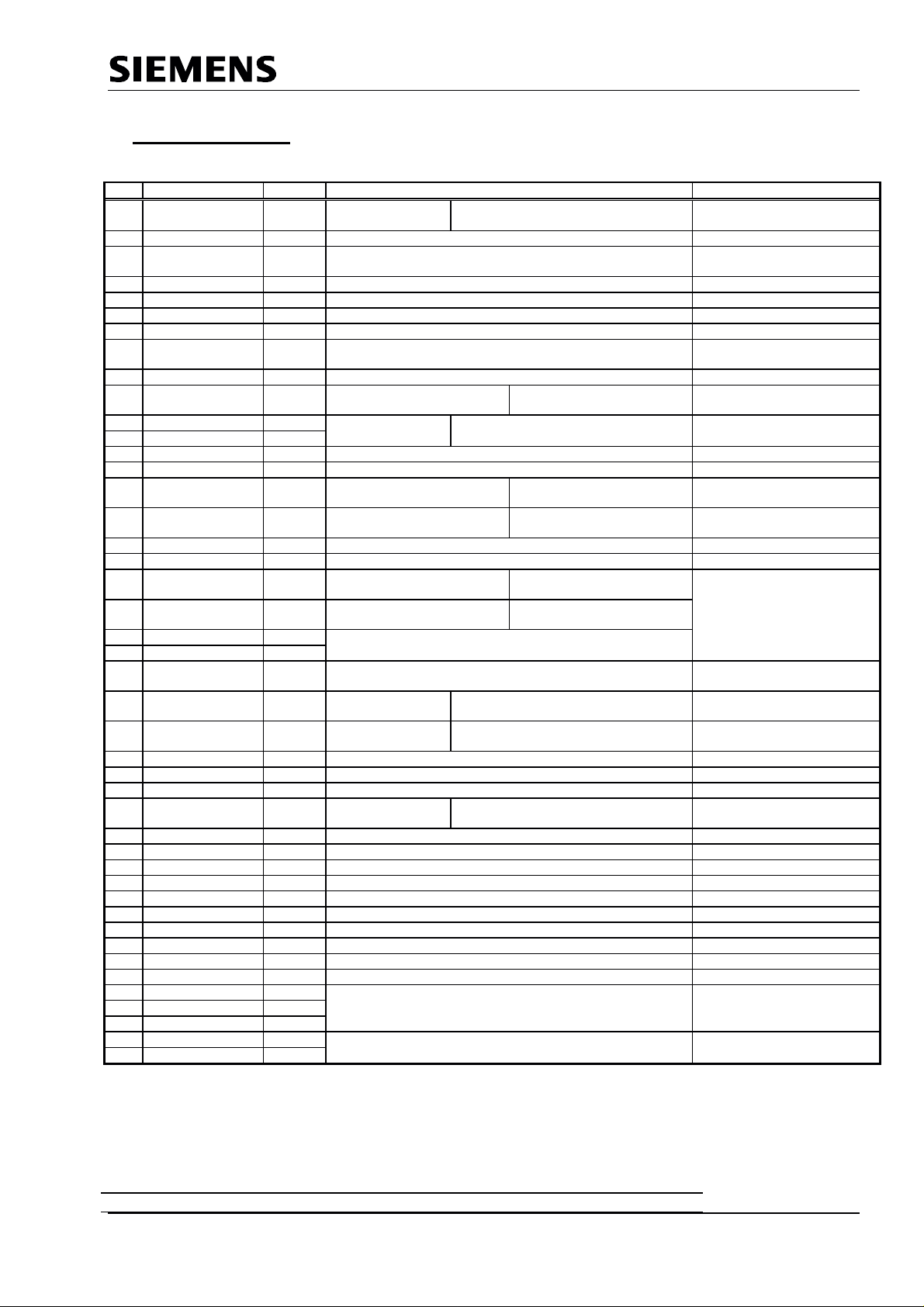

3 Pin Description

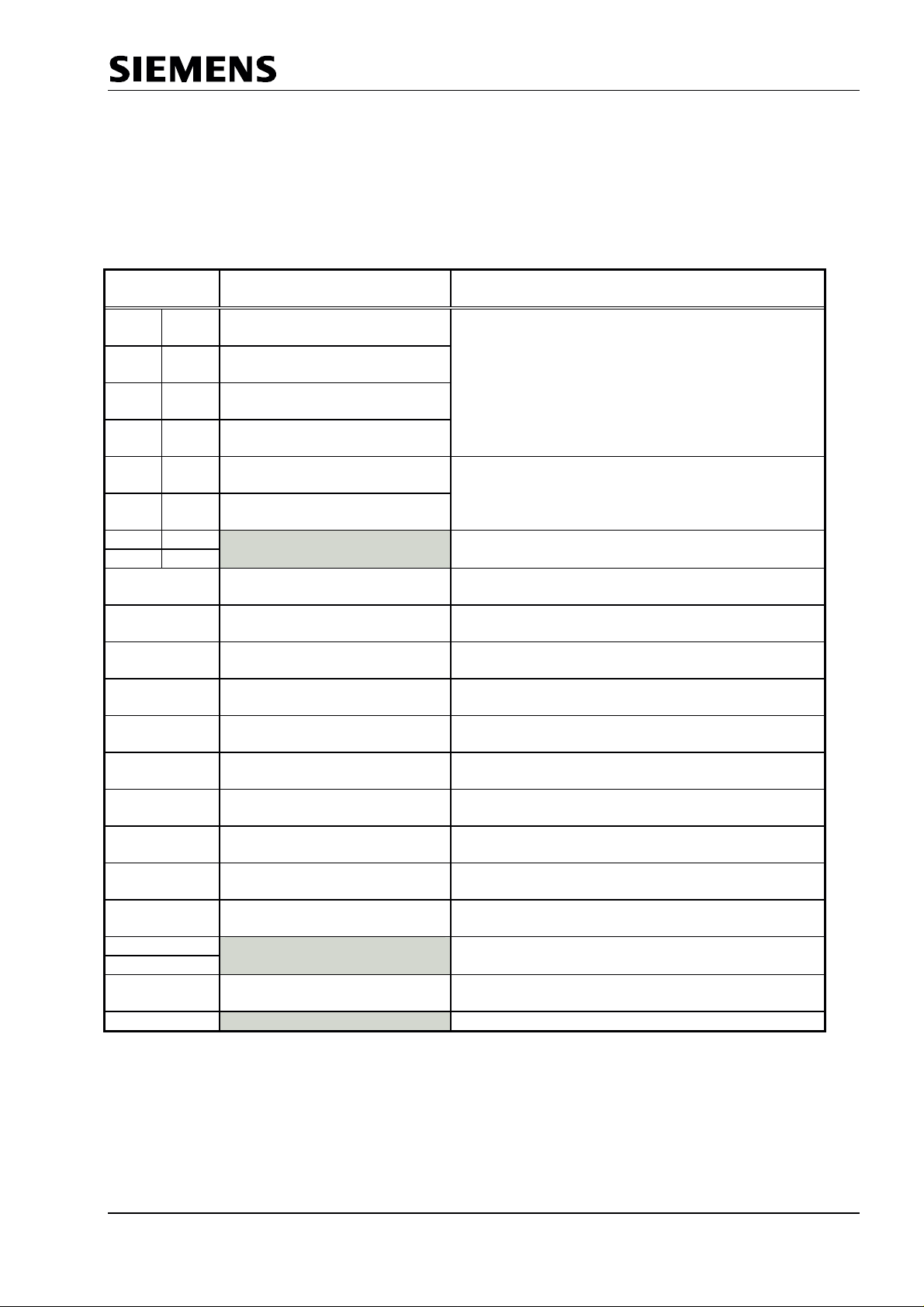

The SPC3 has a 44-pin PQFP housing with the following signals:

Pin Signal Name In/Out Description Source / Destination

1 XCS I© Chip-Select C32 Mode: place on VDD.

2 XWR/E_Clock I© Write signal /EI_Clock for Motorola CPU

3 DIVIDER I© Setting the scaler factor for CLK2OUT2/4.

4 XRD/R_W I© Read signal / Read_Write for Motorola CPU

5 CLK I(TS) Clock pulse input System

6 VSS

7 CLKOUT2/4 O Clock pulse divided by 2 or 4 System, CPU

8 XINT/MOT I© <log> 0 = Intel interface

9 X/INT O Interrupt CPU, Interrupt-Contr.

10 AB10 I(CPD) Address bus C32 mode: <log> 0

11 DB0 I©/O Data bus C32 Mode: Data/address bus multiplexed CPU, memory

12 DB1 I©/O C165 Mode: Data/address bus separated

13 XDATAEXCH O Data_Exchange state for PROFIBUS-DP LED

14 XREADY/XDTACK O Ready for external CPU System, CPU

15 DB2 I©/O Data bus C32 mode: data bus/address

16 DB3 I©/O C165 mode: data/address bus

17 VSS

18 VDD

19

DB4

20 DB5 I©/O C165 mode: data bus/address

21 DB6 I©/O

22 DB7 I©/O

23 MODE I <log> 0 = 80C166 Data bus/address bus separated; ready signal

24 ALE/AS I© Address latch enable C32 mode: ALE

25 AB9 I Address bus C32 mode: <log> 0

26 TXD O Serial send port RS 485 sender

27 RTS O Request to Send RS 485 sender

28 VSS

29 AB8 I© Address bus C32 Mode : <log> 0

30 RXD I© Serial receive port RS 485 receiver

31 AB7 I© Address bus System, CPU

32 AB6 I© Address bus System, CPU

33 XCTS I© Clear to send <log> 0 = send enable FSK modem

34 XTEST0 I© Pin must be placed fixed at VDD.

35 XTEST1 I© Pin must be placed fixed at VDD.

36 RESET I(CS) Connect reset input with CPU’s port pin.

37 AB4 I© Address bus System, CPU

38 VSS

39 VDD

40 AB3 I©

41 AB2 I© Address bus System, CPU

42 AB5 I©

43 AB1 I© Address bus System, CPU

44 AB0 I©

I©/O Data bus C32 mode: data bus/address

low potential means divided through 4

<log> 1 = Motorola interface

<log> 1 = 80C32 data bus/address bus multiplexed, fixed timing

C165 Mode: CS-Signal

C165 mode: address bus

bus multiplexed

separate

bus multiplexed

bus separate

C165 mode: <log> 0

C165 mode: address bus

C165 Mode: address bus

Figure 3.1: SPC3 Pin Assignment

Note: •••• All signals that begin with X.. are LOW active

• VDD = +5V, VSS = GND

Input levels: I ©: CMOS

I (CS): CMOS Schmitt trigger

CPU (80C165)

System

CPU, memory

CPU, memory

System

CPU (80C32)

CPU (C165), memory

SPC3 Hardware Description V1.3 Page 9

Copyright (C) Siemens AG 2003 All rights reserved. 2003/04

Page 12

PROFIBUS Interface Center

I (CPD): CMOS with pull down

I (TS): TTLt Schmitt trigger

SPC3

Page 10 V1.3 SPC3 Hardware Description

2003/04 Copyright (C) Siemens AG 2003. All rights reserved.

Page 13

SPC3 PROFIBUS Interface Center

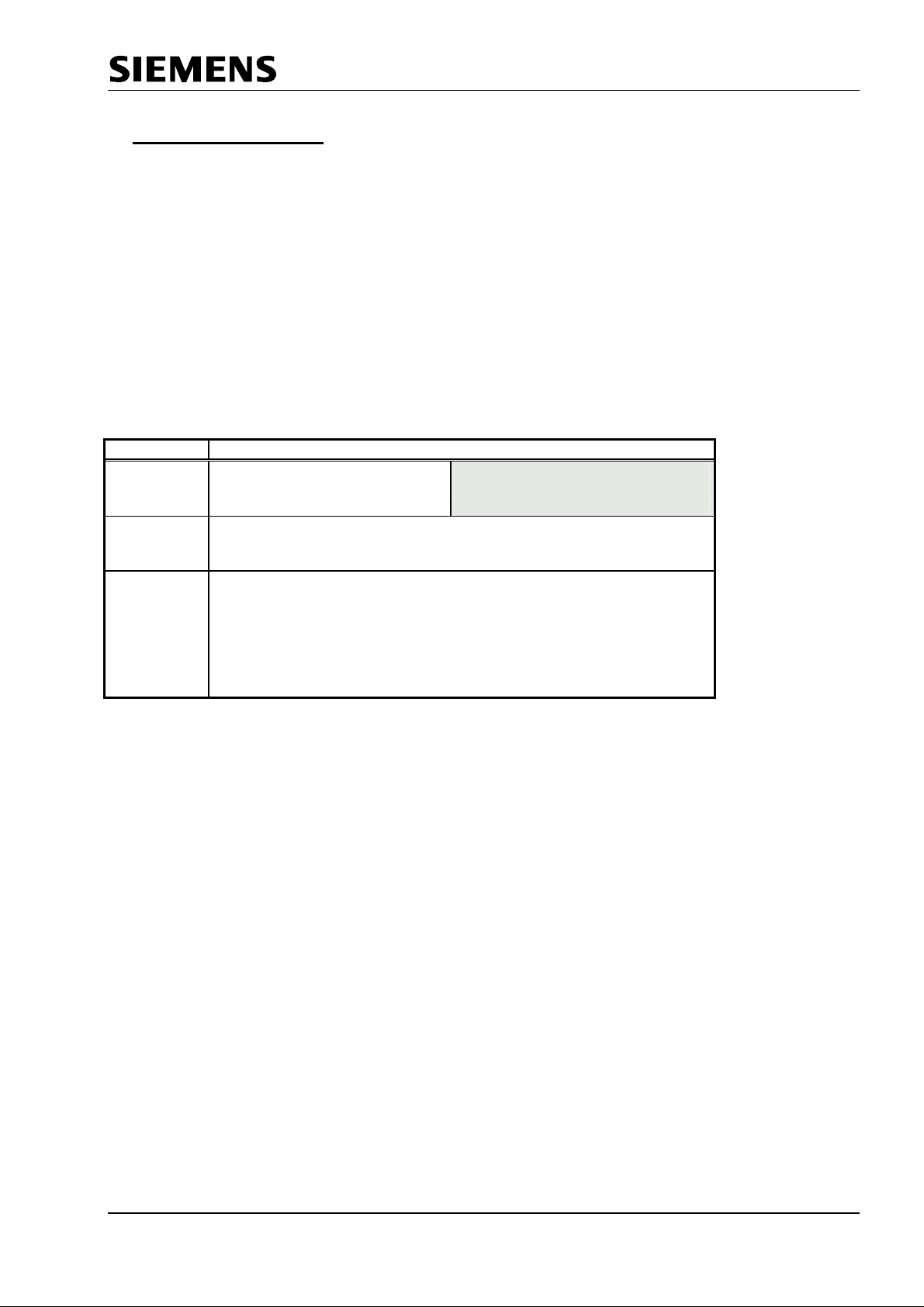

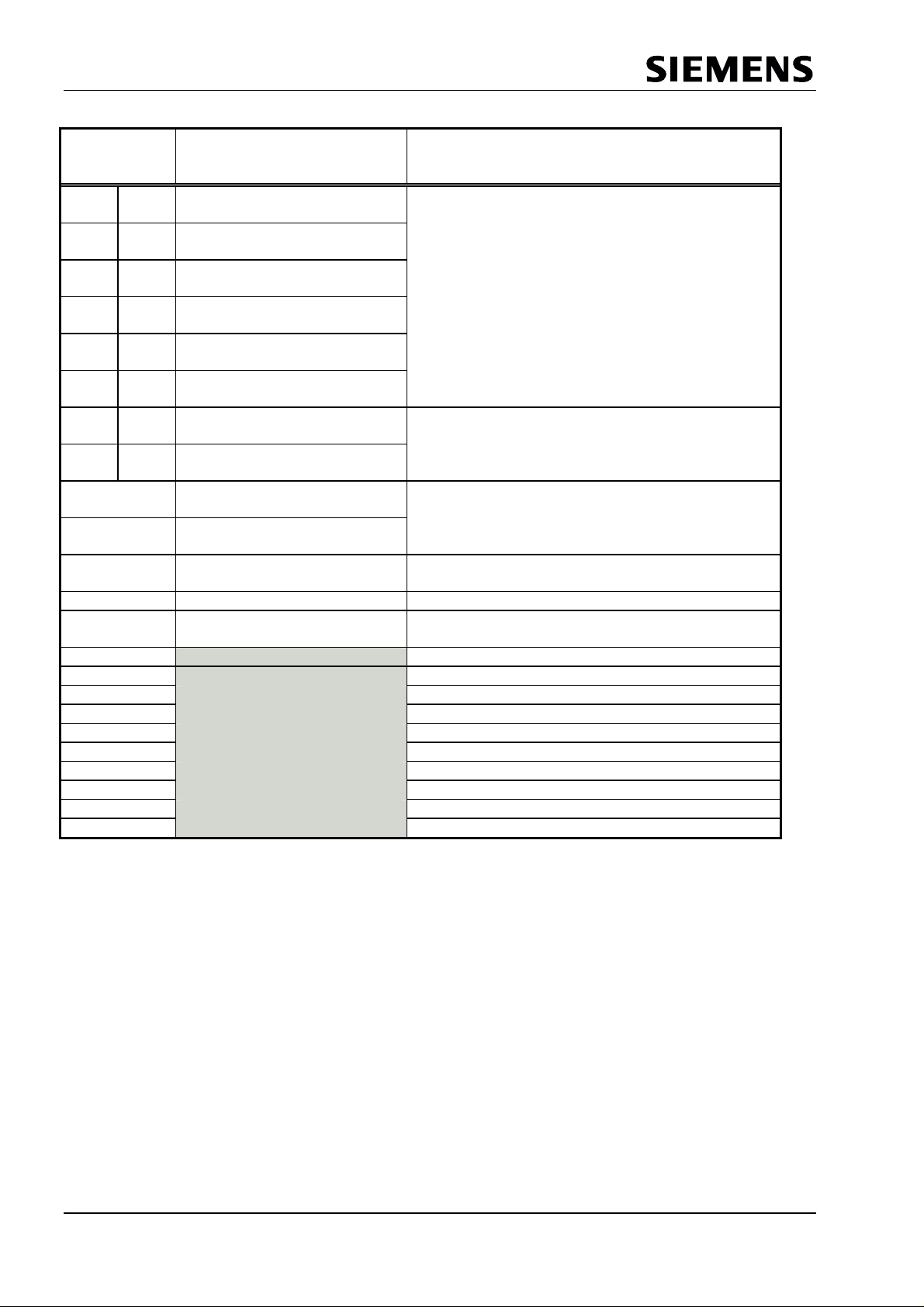

4 Memory Allocation

4.1 Memory Area Distribution in the SPC3

The figure displays the division of the SPC3 1.5k internal address area.

The internal latches/register are located in the first 21 addresses. The internal latches/register either come

from the controller or influence the controller. Certain cells can be only read or written. The internal work

cells to which the user has no access are located in RAM at the same addresses.

The organizational parameters are located in RAM beginning with address 16H. The entire buffer structure

(for the DP-SAPS) is written based on these parameters. In addition, general parameter setting data

(station address, Ident no., etc.) are transferred in these cells and the status displays are stored in these

cells (global control command, etc.).

Corresponding to the parameter setting of the organizational parameters, the user-generated buffers are

located beginning with address 40H. All buffers or lists must begin at segment addresses (48 bytes

segmentation).

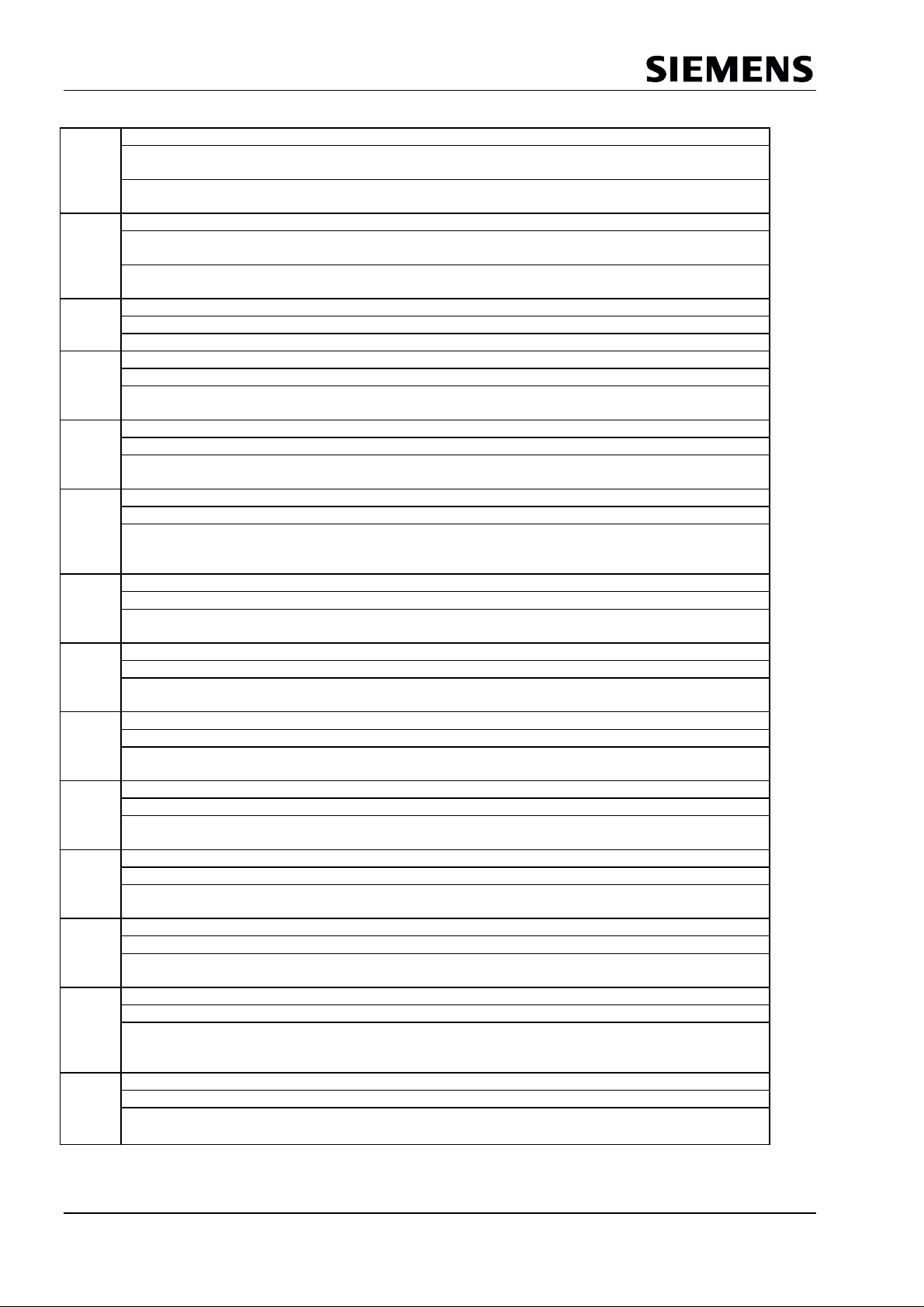

Address Function

000H Processor parameters internal work cells

Latches/register

(22 bytes)

016H Organizational

parameters

(42 bytes)

040H DP- buffer: Data In (3) *

Data Out (3) *

Diagnostics (2)

Parameter setting data (1)

5FFH Configuration data (2)

Figure 4.1: SPC3 Memory Area Distribution

Auxiliary buffer (2)

SSA-buffer(1)

Caution:

The HW prohibits overranging the address area. That is, if a user writes or reads past the memory

end, 400H is subtracted from this address and the user therefore accesses a new address. This

prohibits overwriting a process parameter. In this case, the SPC3 generates the RAM access

violation interrupt. If the MS overranges the memory end due to a faulty buffer initialization, the

same procedure is executed.

* Data In is the input data from PROFIBUS slave to master

Data out is the output data from PROFIBUS master to slave

SPC3 Hardware Description V1.3 Page 11

Copyright (C) Siemens AG 2003 All rights reserved. 2003/04

Page 14

PROFIBUS Interface Center

SPC3

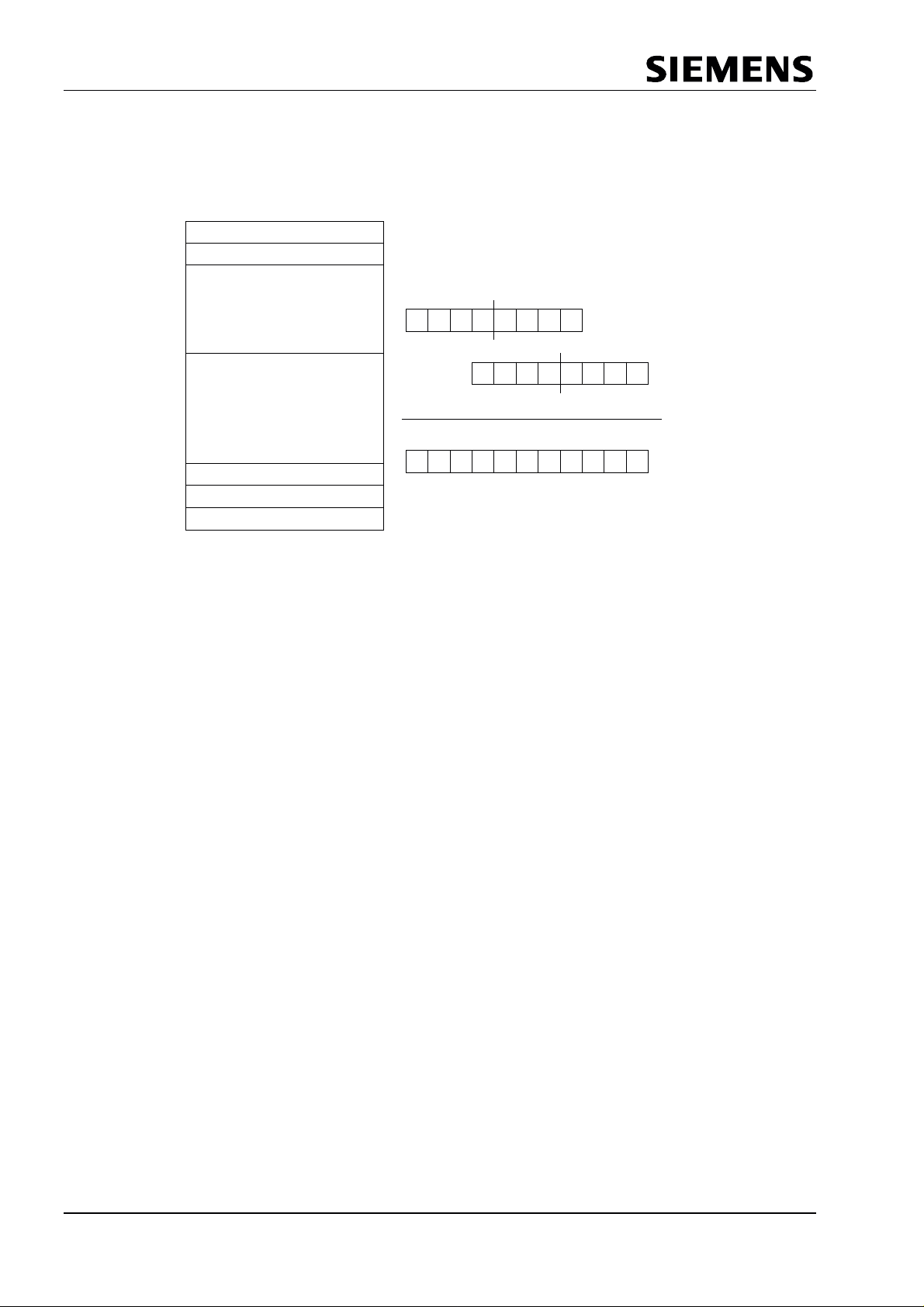

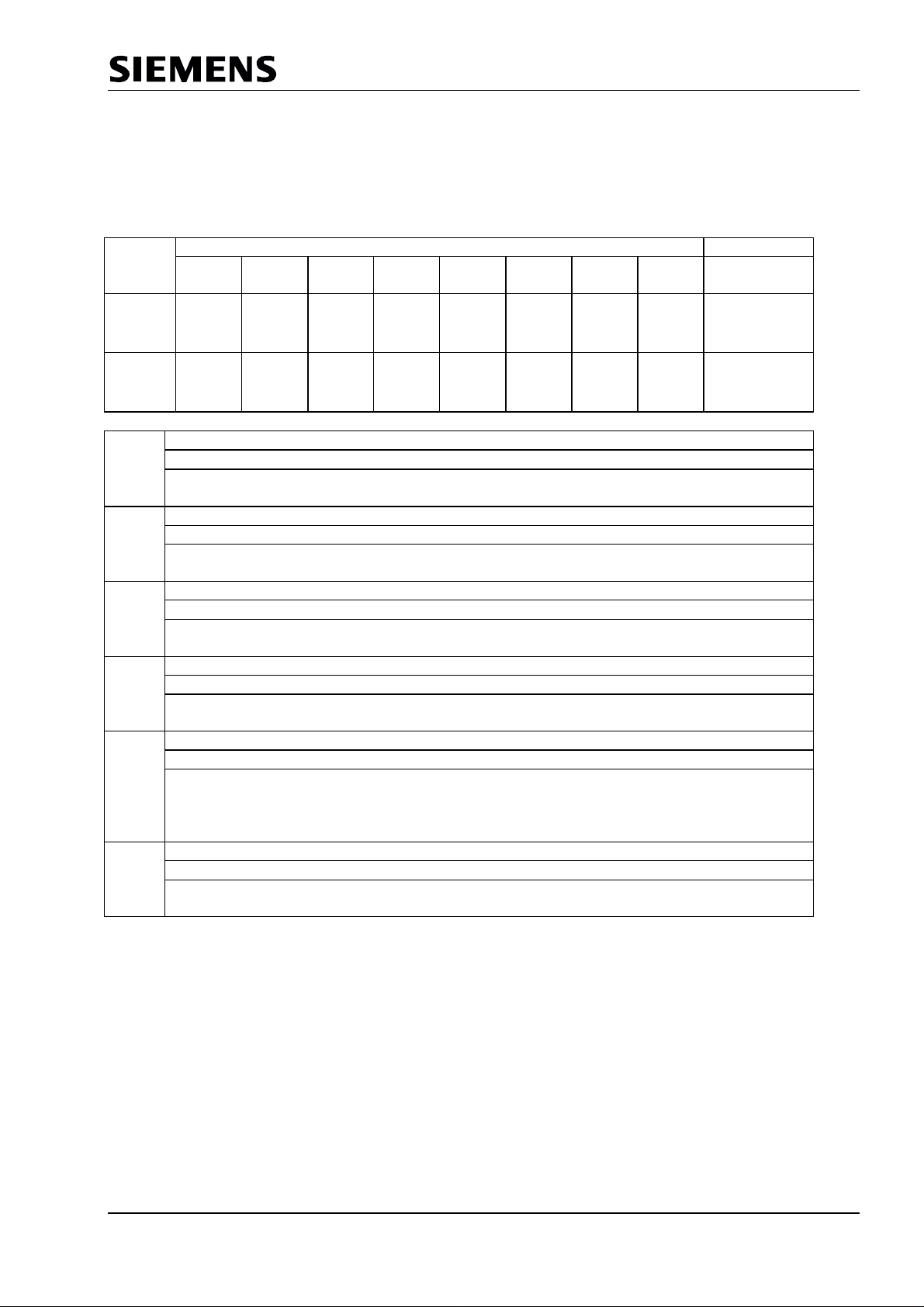

The complete internal RAM of the SPC 3 is divided logically into 192 segments. Each segment consists of 8

bytes. For more informations about the contents of the 3 memory areas see previous chapter.The physical

address is build by multiplikation with 8.

internal SPC 3 RAM (1.5 kByte)

Segment 0

Segment 1

Segment 2

8 Bit Segmentaddresses

(Pointer to the buffers

+

Segment 190

Segment 191

07

010

Page 12 V1.3 SPC3 Hardware Description

2003/04 Copyright (C) Siemens AG 2003. All rights reserved.

Page 15

SPC3 PROFIBUS Interface Center

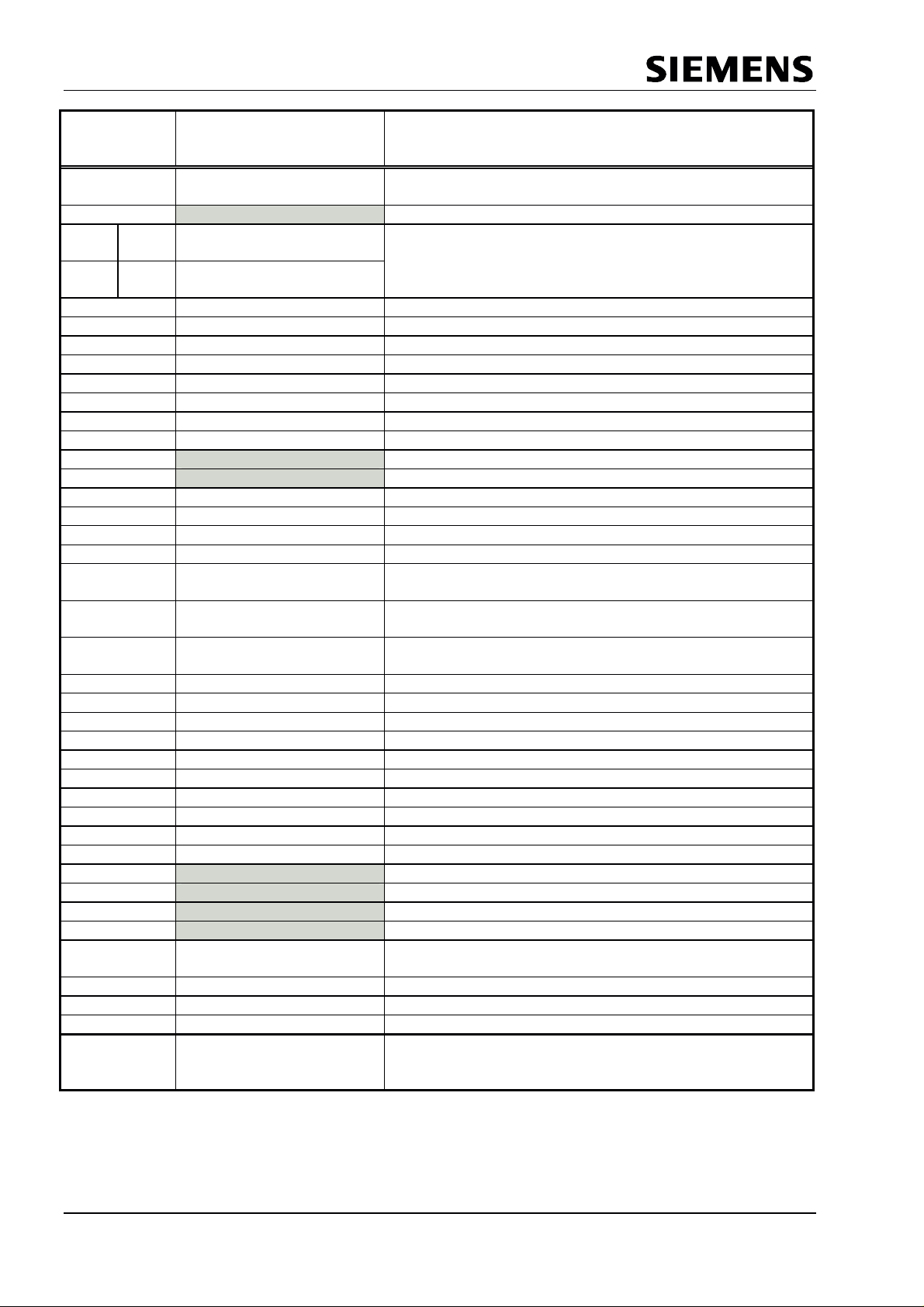

4.2 Processor Parameters (Latches/Register)

These cells can be either read only or written only. SPC3 carries out “address swapping” for an access to

the address area 00H - 07H (word register) in the Motorola mode. That is, the SPC3 exchanges

address bit 0 (generated from an even address, one uneven, and vice-versa). The following sections more

clearly explain the significance of the individual registers.

Address

Intel / Motorla

00H 01H Int-Req-Reg

01H 00H Int-Req-Reg

02H 03H Int—Reg

03H 02H Int—Reg

04H 05H Status-Reg

05H 04H Status-Reg

06H 07H Reserved

07H 06H

08H DIN_Buffer_SM

09H New_DIN_Buffer_Cmd

0AH DOUT_Buffer_SM

0BH Next_DOUT_Buffer_Cmd

0CH DIAG_Buffer_SM

0DH New_DIAG_Puffer_Cmd

0EH User_Prm_Data_OK

0FH UserPrmDataNOK

10H User_Cfg_Data_OK

11H User_Cfg_Data_NOK 1..0 The user negatively acknowledges the configuration

12H Reserved

13H

14H SSA_Bufferfreecmd The user has fetched the data from the SSA buffer

15H Reserved

Name Bit

No.

7..0

15..8

7..0

15..8

7..0

15..8

7..0

1..0

7..0

1..0

3..0

1..0

1..0

1..0

1..0

Significance (Read Access!)

Interrupt Controller Register

Status Register

Buffer assignment of the

DP_Din_Buffer_State_Machine

The user makes a new DP Din buffer available in

the N state.

Buffer assignment of the

DP_Dout_Puffer_State_Machine

The user fetches the last DP Dout-Buffer from the N

state.

Buffer assignment for the

DP_Diag_Puffer_State_Machine

The user makes a new DP Diag Buffer available to

the SPC3.

The user positively acknowledges the user

parameter setting data of a Set_Param-Telegram.

The user negatively acknowledges the user

parameter setting data of a Set_Param-Telegram.

The user positively acknowledges the configuration

data of a Check_Config-Telegram.

data of a Check_Config-Telegram.

and enables the buffer again.

Figure 4.2: Assignment of the Internal Parameter Latches for READ

SPC3 Hardware Description V1.3 Page 13

Copyright (C) Siemens AG 2003 All rights reserved. 2003/04

Page 16

PROFIBUS Interface Center

Val

Address

Intel

/Motorola

00H 01H Int-Req-Reg

01H 00H Int-Req_Reg

02H 03H Int-Ack-Reg

03H 02H Int-Ack-Reg

04H 05H Int—Mask-Reg

05H 04H Int—Mask-Reg

06H 07H Mode-Reg0

07H 06H Mode-Reg0-S

08H Mode-Reg1-S

09H Mode-Reg1-R

0AH WD Baud Ctrl -

0BH MinTsdr_Val

OCH

0DH Reserved

0EH

0FH

10H

11H

12H

13H

14H

15H

Figure 4.3: Assignment of the Internal Parameter Latches for WRITE

Name Bit

No.

7..0

15..8

7..0

15..8

7..0

15..8

7..0

15..8

7..0

7..0

7..0

7..0

SPC3

Significance (Write Access !)

Interrupt- Controller - Register

Setting parameters for individual bits

Root value for baud rate monitoring

MinTsdr time

Page 14 V1.3 SPC3 Hardware Description

2003/04 Copyright (C) Siemens AG 2003. All rights reserved.

Page 17

SPC3 PROFIBUS Interface Center

4.3 Organizational Parameters (RAM)

The user stores the organizational parameters in RAM under the specified addresses. These parameters

can be written and read.

SPC3 Hardware Description V1.3 Page 15

Copyright (C) Siemens AG 2003 All rights reserved. 2003/04

Page 18

PROFIBUS Interface Center

bit wachdog timer, the user is

If parameters are set for the Spec_Prm_Buffer_Mode (see

mode register 0), this cell defines the length of the param

Address

Intel

/Motorola

16H R_TS_Adr

17H reserved Pointer to a RAM address which is presetted with 0FFH

18H 19H R_User_Wd_Value

19H 18H R_User_Wd_Value 15

1AH R_Len_Dout_Puf Length of the 3 Dout buffers

1BH R_Dout_buf_Ptr1 Segment base address of Dout buffer 1

1CH R_Dout_buf_Ptr2 Segment base address of Dout buffer 2

1DH R_Dout_buf_Ptr3 Segment base address of Dout buffer 3

1EH R_Len_Din_buf Length of the 3 Din buffers

1FH R_Din_buf_Ptr1 Segment base address of Din buffer 1

20H R_Din_buf_Ptr2 Segment base address of Din buffer 2

21H R_Din_buf_Ptr3 Segment base address of Din buffer 3

22H reserved Preset with 00H.

23H reserved Preset with 00H.

24H R Len Diag buf1 Length of Diag buffer 1

25H R Len Diag buf2 Length of Diag buffer 2

26H R_Diag_Puf_Ptr1 Segment base address of Diag buffer 1

27H R_Diag_Puf_Ptr2 Segment base address of Diag buffer 2

28H R Len Cntrl Pbuf1 Length of Aux buffer 1 and the control buffer belonging to it,

29H R Len Cntrl Puf2 Length of Aux-Buffer 2 and the control buffer belonging to

2AH R Aux Puf Sel Bit array, in which the assignments of the Aux-buffers ½ are

2BH R_Aux_buf_Ptr1 Segment base address of auxiliary buffer 1

2CH R_Aux_buf_Ptr2 Segment base address of auxiliary buffer 2

2DH R_Len_SSA_Data Length of the input data in the Set_Slave_Address-buffer

2EH R SSA buf Ptr Segment base address of the Set_Slave_Address-buffer

2FH R_Len_Prm_Data Length of the input data in the Set_Param-buffer

30H R_Prm_buf_Ptr Segment base address of the Set_Param-buffer

31H R_Len_Cfg_Data Length of the input data in the Check_Config-buffer

32H R Cfg Buf Ptr Segment base address of the Check_Config-buffer

33H R_Len_Read_Cfg_Data Length of the input data in the Get_Config-buffer

34H R_Read_Cfg_buf_Ptr Segment base address of the Get_Config-buffer

35H reserved Preset with 00H.

36H reserved Preset with 00H

37H reserved Preset with 00H.

38H reserved Preset with 00H.

39H R_Real_No_Add_Change This parameter specifies whether the DP slave address may

3AH R_Ident_Low The user sets the parameters for the Ident_Low value.

3BH R_Ident_High The user sets the parameters for the Ident_High value.

3CH R_GC_Command The Global_Control_Command last received

3DH R_Len_Spec_Prm_buf

Name Bit No. Significance

7..0

7..0

..8

Set up station address of the relevant SPC3

Based on an internal 16monitored in the DP_Mode.

for example, SSA-Buf, Prm-Buf, Cfg-Buf, Read-Cfg-Buf

it, for example, SSA-Buf, Prm-Buf, Cfg-Buf, Read-Cfg-Buf

defined to the control buffers, SSA-Buf, Prm-Buf, Cfg-Buf

again be changed at a later time point.

SPC3

buffer.

Figure 4.4: Assignment of the Organizational Parameters

Page 16 V1.3 SPC3 Hardware Description

2003/04 Copyright (C) Siemens AG 2003. All rights reserved.

Page 19

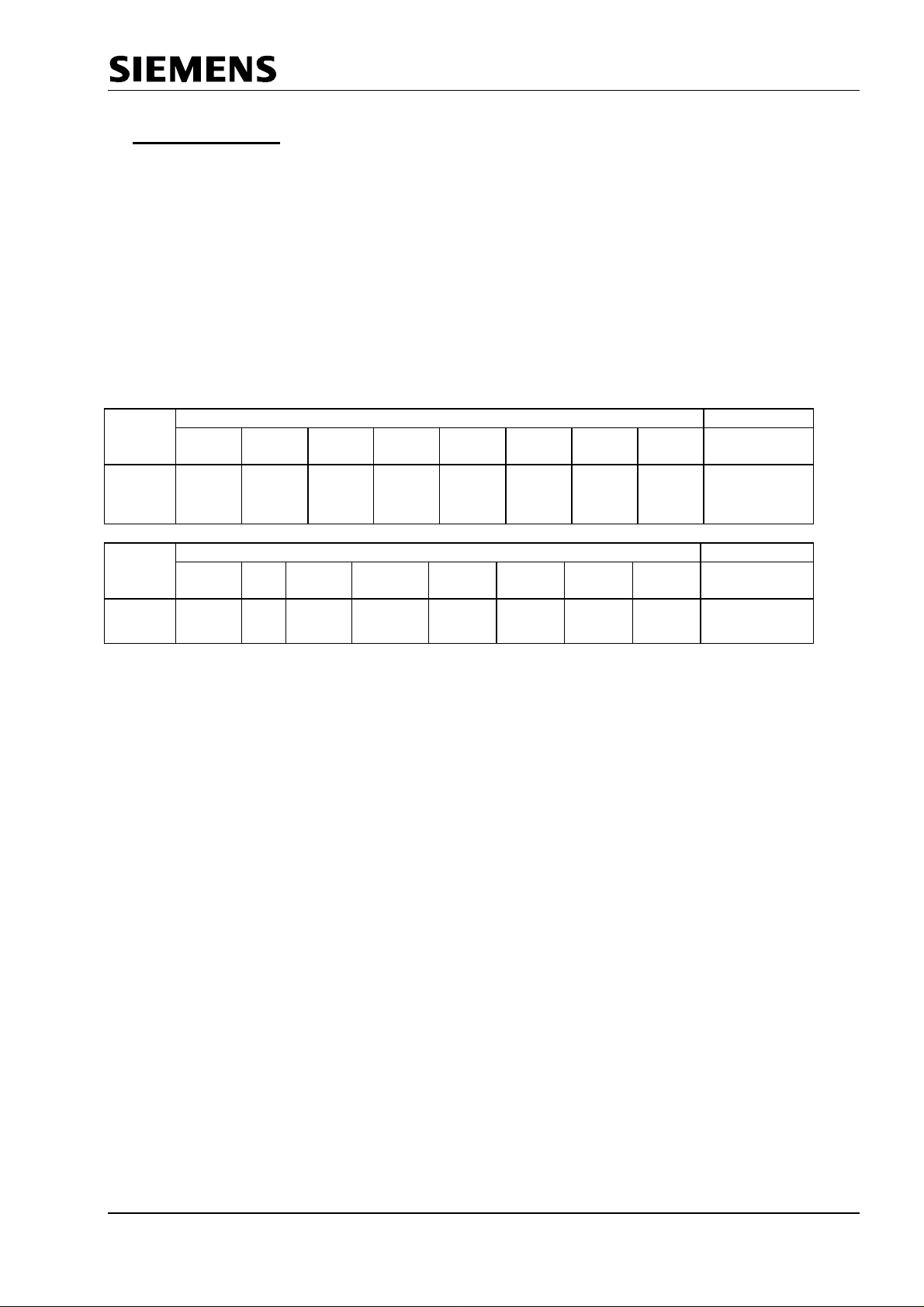

SPC3 PROFIBUS Interface Center

5 ASIC Interface

The registers that determine both the hardware function of the ASIC as well as telegram processing are

described in the following.

5.1 Mode Register

Parameter bits that access the controller directly or which the controller directly sets are combined in two

mode registers (0 and 1) in the SPC3.

5.1.1 Mode Register 0

Setting parameters for Mode Register 0 takes place in the offline state only (for example, after

switching on). The SPC3 may not exit offline until Mode Register 0, all processor parameters, and

organizational parameters are loaded (START_SPC3 = 1, Mode-Register 1).

Address Bit Position Designation

Control

Register

06H

(Intel)

Address Bit Position Designation

Control

Register

07H

(Intel)

*) When Spec_Clear_Mode (Fail Safe Mode ) = 1 the SPC3 will accept data telegramm with a data unit=0 in

the state Data Exchange. The reaction to the outputs can be parameterized f.e. in the parameterization

telegram ( only available from version Step C).

**) When using a big number of parameters to be transmitted from the PROFIBUS-Master to the slave the

Auxiliary buffer ½ has to have the same size like the Parameterization buffer. Sometimes this could reach

the limit of the available memory space in the SPC3. When Spec_Prm_Puf_Mode = 1 the parameterization

data are processed directly in this special buffer and the Auxiliary buffers can be held compact.

7 6 5 4 3 2 1 0

Freeze_

Support-

ed

Sync_

Support-

ed

EARLY_

RDY

INT_

POL MinTSDR

DIS_

STOP_

CON

TROL

DIS_

START_

CON

TROL

15 14 13 12 11 10 9 8

Spec_Cle

ar_Mode

*)

Spec_Prm_

Puf_Mode

**)

WD

Test

User

Time

base

EOI

Time

base

DP

Mode

Mode Reg0

7..0

Mode-Reg0

13 .. 8

SPC3 Hardware Description V1.3 Page 17

Copyright (C) Siemens AG 2003 All rights reserved. 2003/04

Page 20

PROFIBUS Interface Center

ram telegram overwrites this memory cell in the DP mode.

SPC3

Bit 0 DIS_START_CONTROL

Monitoring the following start bit in UART. Set-Param Telegram overwrites this memory cell in

the DP mode. (Refer to the user-specific data.)

0 = Monitoring the following start bit is enabled.

1 = Monitoring the following start bit is switched off.

Bit 1 DIS_STOP_CONTROL

Stop bit monitoring in UART. Set-Pa

(Refer to the user-specific data.)

0 = Stop bit monitoring is enabled.

1 = Stop bit monitoring is switched off.

Bit 2 EN_FDL_DDB

Reserved

0 = The FDL_DDB receive is disabled.

Bit 3 MinTSDR

Default setting for the MinTSDR after reset for DP operation or combi operation

0 = Pure DP operation (default configuration!)

1 = Combi operation

Bit 4 INT_POL

Polarity of the interrupt output

0 = The interrupt output is low-active.

1 = The interrupt output is high-active.

Bit 5 EARLY_RDY

Moved up ready signal

0 = Ready is generated when the data are valid (read) or when the data are accepted

(write).

1 = Ready is moved up by one clock pulse.

Bit 6 Sync_Supported

Sync_Mode support

0 = Sync_Mode is not supported.

1 = Sync_Mode is supported.

Bit 7 Freeze_Supported

Freeze_Mode support

0 = Freeze_Mode is not supported.

1 = Freeze_Mode is supported.

Bit 8 DP_MODE

DP_Mode enable

0 = DP_Mode is disabled.

1 = DP_Mode is enabled. SPC3 sets up all DP_SAPs.

Bit 9 EOI_Time base

Time base for the end of interrupt pulse

0 = The interrupt inactive time is at least 1 usec long.

1 = The interrupt inactive time is at least 1 ms long.

Bit 10 User_Time base

Time base for the cyclical User_Time_Clock-Interrupt

0 = The User_Time_Clock-Interrupt occurs every 1 ms.

1 = The User_Time_Clock-Interrupt occurs every 10 ms.

Bit 11 WD_Test

Test mode for the Watchdog-Timer, no function mode

0 = The WD runs in the function mode.

1 = Not permitted

Bit 12 Spec_Prm_Puf_Mode

Special parameter buffer

0 = No special parameter buffer.

1 = Special parameter buffer mode .Parameterization data will be stored directly in the

special parameter buffer.

Bit 13 Spec_Clear_Mode

Special Clear Mode (Fail Safe Mode)

0 = No special clear mode.

1 = Special clear mode. SPC3 will accept datea telegramms with data unit = 0.

Figure 5.1: Mode-Register 0 Bit 12 .. 0.(can be written to, can be changed in offline only)

Page 18 V1.3 SPC3 Hardware Description

2003/04 Copyright (C) Siemens AG 2003. All rights reserved.

Page 21

SPC3 PROFIBUS Interface Center

5.1.2 Mode Register 1 (Mode-REG1, writable):

Some control bits must be changed during operation. These control bits are combined in Mode-Register 1

and can be set independently of each other (Mode_Reg_S) or can be deleted independently of each other

(Mode_Reg_R). Various addresses are used for setting and deleting. Log ‘1’ must be written to the bit

position to be set or deleted.

Address Bit Position Designation

Control

7 6 5 4 3 2 1 0

Register

08H

09H

Res_

User_WD

Res_

User_WD

EN_

Change_

Cfg_

Puffer

EN_

Change_

Cfg_

Puffer

User_

Leave_

Master

User_

Leave_

Master

Go_

Offline

Go_

Offline

EOI START_

SPC3

EOI START_

SPC3

Mode-Reg_S

7..0

Mode-Reg_R

7..0

Bit 0 START_SPC3

Exiting the Offline state

1 = SPC3 exits offline and goes to passive-idle. In addition, the idle timer and

Wd timer are started and ‘Go_Offline = 0’ is set.

Bit 1 EOI

End of Interrupt

1 = End of Interrupt: SPC3 switches the interrupt outputs to inactive and again

sets EOI to log.’0.’

Bit 2 Go_Offline

Going into the offline state

1 = After the current requests ends, SPC3 goes to the offline state and again

sets Go_Offline to log.’0.’

Bit 3 User_Leave_Master

Request to the DP_SM to go to ‘Wait_Prm.’

1 = The user causes the DP_SM to go to ‘Wait_Prm.’ After this action, SPC3

sets User_Leave_Master to log.’0.’

Bit 4 En_Change_Cfg_Puffer

Enabling buffer exchange (Cfg buffer for Read_Cfg buffer)

0 = With ‘User_Cfg_Data_Okay_Cmd,’ the Cfg buffer may not be exchanged for

the Read_Cfg buffer.

1 = With ‘User_Cfg_Data_Okay_Cmd,’ the Cfg buffer must be exchanged for

the Read_Cfg buffer.

Bit 5 Res_User_Wd

Resetting the User_WD_Timers

1 = SPC3 again sets the User_Wd_Timer to the parameterized value

‘User_Wd_Value

15..0.

’ After this action, SPC3 sets Res_User_Wd to log.’0.’

Figure 5..2: Mode Register1 S and Mode Register1 R Bit7..0.(writable)

SPC3 Hardware Description V1.3 Page 19

Copyright (C) Siemens AG 2003 All rights reserved. 2003/04

Page 22

PROFIBUS Interface Center

SPC3

5.2 Status Register

The status register mirrors the current SPC3 status and can be read only.

Address Bit Position Designation

Control

Register

04H

(Intel)

1 0 1 0

Address Bit Position Designation

Control

Register

05H

(Intel)

3 2 1 0 3 2 1 0

7 6 5 4 3 2 1 0

WD_State DP_State

RAM

access

violation

Diag_

Flag

FDL_

IND_ST

Offline/

Passive-

Idle

15 14 13 12 11 10 9 8

SPC3 Release Baud Rate Status-Reg

Status-Reg

7..0

15 .. 8

Page 20 V1.3 SPC3 Hardware Description

2003/04 Copyright (C) Siemens AG 2003. All rights reserved.

Page 23

SPC3 PROFIBUS Interface Center

Bit 0 Offline/Passive-Idle

Offline-/Passive-Idle state

0 = SPC3 is in offline.

1 = SPC3 is in passive idle.

Bit 1 FDL_IND_ST

FDL indication is temporarily buffered.

0 = No FDL indication is temporarily buffered.

1 = No FDL indication is temporarily buffered.

Bit 2 Diag_Flag

Status diagnostics buffer

0 = The DP master fetches the diagnostics buffer.

1 = The DP master has not yet fetched the diagnostics buffer.

Bit 3 RAM Access Violation

Memory access > 1.5kByte

0 = No address violation

1 = For addresses > 1536 bytes, 1024 is subtracted from the current address,

and there is access to this new address.

Bits

DP-State

1..0

4,5

DP-State Machine state

00 = ’Wait_Prm’ state

01= ’Wait_Cfg’ state

10 = ’DATA_EX’ state

11= Not possible

Bits

WD-State

1..0

6,7

Watchdog-State-Machine state

00 = ’Baud_Search’ state

01= ’Baud_Control’ state

10 = ’DP_Control’ state

11= Not possible

Bits

Baud rate

3..0

:

8,9

10,11 The baud rates SPC3 found

0000 = 12 MBaud

0001 = 6 MBaud

0010 = 3 MBaud

0011 = 1.5 MBaud

0100 = 500 kBaud

0101 = 187.5 kBaud

0110 = 93.75 kBaud

0111 = 45.45 kBaud

1000 = 19.2 kBaud

1001 = 9.6 kBaud

Rest = Not possible

Bit 12 SPC3-Release

3..0

:

13,14, Release no. for SPC3

15 0000 = Release 0

Rest = Not possible

Figure 5.3: Status Register Bit15 .. 0.(readable)

SPC3 Hardware Description V1.3 Page 21

Copyright (C) Siemens AG 2003 All rights reserved. 2003/04

Page 24

PROFIBUS Interface Center

uP

SPC3

5.3 Interrupt Controller

The processor is informed about indication messages and various error events via the interrupt controller.

Up to a total of 16 events are stored in the interrupt controller. The events are carried out on an interrupt

output. The controller does not have a prioritization level and does not provide an interrupt vector (not

8259A compatible!).

The controller consists of an Interrupt Request Register (IRR), an Interrupt Mask Register (IMR), an Interrupt

Register (IR), and an Interrupt Acknowledge Register (IAR).

uP uP uP

SEP_INT

IR

SPC3

uP

S

IRR IMR

R

S

R

X/INT

FF

INT_Pol

IAR

Each event is stored in the IRR. Individual events can be suppressed via the IMR. The input in the IRR is

independent of the interrupt masks. Event signals not masked out in the IMR generate the X/INT interrupt

via a sum network. The user can set each event in the IRR for debugging.

Each interrupt event the processor processed must be deleted via the IAR (except for New_Prm_Data,

New_DDB_Prm_Data, and New_Cfg_Data). Log ‘1’ must be written on the relevant bit position. If a new

event and an acknowledge from the previous event are present at the IRR at the same time, the event

remains stored. If the processor subsequently enables a mask, it must be ensured that no prior input is

present in the IRR. For safety purposes, the position in the IRR must be deleted prior to the mask enable.

uP

Prior to exiting the interrupt routine, the processor must set the “end of interrupt signal (E01) = 1” in the

mode register. The interrupt cable is switched to inactive with this edge change. If another event must be

stored, the interrupt output is not activated again until after an interrupt inactive time of at least 1 usec or 12 ms. This interrupt inactive time can be set via ‘EOI_Timebase.’ This makes it possible to again come into

the interrupt routine when an edge-triggered interrupt input is used.

The polarity for the interrupt output is parameterized via the INT_Pol mode bit. After the hardware reset,

the output is low-active.

Address Bit Position Designation

Control

7 6 5 4 3 2 1 0

Register

00H

(Intel)

Res Res Res User_

Timer_

Clock

WD_DP_

Mode_

Timeout

Baud_

rate_

Detect

Go/Leave

Data_

EX

MAC_

Reset

Int-Req-Reg

7..0

Address Bit Position Designation

Control

15 14 13 12 11 10 9 8

Register

01H

(Intel)

Res Res DX_OUT Diag_

Puffer_

Changed

New_

Prm_

Data

New_

Cfg_

Data

New_

SSA_

Data

New_GC

Com

mand

Int-Req-Reg 7

15..8

Page 22 V1.3 SPC3 Hardware Description

2003/04 Copyright (C) Siemens AG 2003. All rights reserved.

Page 25

Bit 0 MAC_Reset

After it processes the current request, the SPC3 has arrived at the offline state (through

setting the ‘Go_Offline bit’ or through a RAM access violation).

Bit 1 Go/Leave_DATA_EX

The DP_SM has entered or exited the ‘DATA_EX’ state.

Bit 2 Baudrate_Detect

The SPC3 has exited the ‘Baud_Search state’ and found a baud rate.

Bit 3 WD_DP_Control_Timeout

The watchdog timer has run out in the ‘DP_Control’ WD state.

Bit 4 User_Timer_Clock

The time base for the User_Timer_Clocks has run out (1/10ms).

Bit 5 Res

For additional functions

Bit 6 Res

For additional functions

Bit 7 Res

For additional functions

Bit 8 New_GC_Command

The SPC3 has received a ‘Global_Control telegram’ with a changed ‘GC_Command-

Byte,’ and this byte is stored in the ‘R_GC_Command’ RAM cell.

Bit 9 New_SSA_Data

The SPC3 has received a ‘Set_Slave_Address telegram’ and made the data available

in the SSA buffer.

Bit 10 New_Cfg_Data

The SPC3 has received a ‘Check_Cfg telegram’ and made the data available in the Cfg

buffer.

Bit 11 New_Prm_Data

The SPC3 has received a ‘Set_Param telegram’ and made the data available in the

Prm buffer.

Bit 12 Diag_Puffer_Changed

Due to the request made by ‘New_Diag_Cmd,’ SPC3 exchanged the diagnostics buffer

and again made the old buffer available to the user.

Bit 13 DX_OUT

The SPC3 has received a ‘Write_Read_Data telegram’ and made the new output data

available in the N buffer. For a ‘Power_On’ or for a ‘Leave_Master,’ the SPC3 deletes

the N buffer and also generates this interrupt.

Bit 14 Res

For additional functions

Bit 15 Res

For additional functions

Figure 5.4: Interrupt Request Register, IRR Bit 15..0 (writable and readable)

SPC3 PROFIBUS Interface Center

SPC3 Hardware Description V1.3 Page 23

Copyright (C) Siemens AG 2003 All rights reserved. 2003/04

Page 26

PROFIBUS Interface Center

The other interrupt controller registers are assigned in the bit positions, like the IRR.

Address Register Reset State Assignment

02H /

03H

04H /

05H

02H /

03H

Figure 5.5: Additional Interrupt Registers

The ‘New_Prm_Data’, ‘New_Cfg_Data’ inputs may not be deleted via the Interrupt Acknowledge Register.

The relevant state machines delete these inputs through the user acknowledgements (for example,

‘User_Prm_Data_Okay’ etc.).

Interrupt Register

(IR)

Interrupt Mask

Register

(IMR)

Interrupt

Acknowledge

Register

(IAR)

Readable

only

Writable, can

be changed

during

operation

Writable, can

be changed

during

operation

All bits deleted

All bits set Bit =

All bits deleted Bit =

SPC3

1

Bit =

0

1

Bit =

0

Mask is set and the interrupt

is disabled.

Mask is deleted and the

interrupt is enabled.

The IRR bit is deleted.

The IRR bit remains

unchanged.

Page 24 V1.3 SPC3 Hardware Description

2003/04 Copyright (C) Siemens AG 2003. All rights reserved.

Page 27

SPC3 PROFIBUS Interface Center

5.4 Watchdog Timer

5.4.1 Automatic Baud Rate Identification

The SPC3 is able to identify the baud rate automatically. The „baud search“ state is located after each

RESET and also after the watchdog (WD) timer has run out in the ‘Baud_Control_state.’

As a rule, SPC3 begins the search for the set rate with the highest baud rate. If no SD1 telegram, SD2

telegram, or SD3 telegram was received completely and without errors during the monitoring time, the

search continues with the next lowest baud rate.

After identifying the correct baud rate, SPC3 switches to the “Baud_Control” state and monitors the baud

rate. The monitoring time can be parameterized (WD_Baud_Control_Val). The watchdog works with a

clock of 100 Hz (10 msec). The watchdog resets each telegram received with no errors to its own station

address. If the timer runs out, SPC3 again switches to the baud search state.

5.4.2 Baud Rate Monitoring

The located baud rate is constantly monitored in ‘Baud_Control.’ The watchdog is reset for each error-free

telegram to its own station address. The monitoring time results from multiplying both

‘WD_Baud_Control_Val’ (user sets the parameters) by the time base (10 ms). If the monitoring time runs

out, WD_SM again goes to ‘Baud_Search’. If the user carries out the DP protocol (DP_Mode = 1, see Mode

register 0) with SPC3, the watchdog is used for the “DP_Control’ state, after a ‘Set_Param telegram’ was

received with an enabled response time monitoring ‘WD_On = 1.’ The watchdog timer remains in the baud

rate monitoring state when there is a switched off ‘WD_On = 0’ master monitoring. The PROFIBUS DP

state machine is also not reset when the timer runs out. That is, the slave remains in the DATA_EXchange

state, for example.

5.4.3 Response Time Monitoring

The ‘DP_Control’ state serves response time monitoring of the DP master (Master_Add). The set

monitoring times results from multiplying both watchdog factors and multiplying the result with the

momentarily valid time base (1 ms or 10 ms):

TWD = (1 ms or 10 ms) * WD_Fact_1 * WD_Fact_2 (See byte 7 of the parameter setting telegram.)

The user can load the two watchdog factors (WD_Fact_1, and WD_Fact_2) and the time base that

represents a measurement for the monitoring time via the ‘Set_Param telegram’ with any value between 1

and 255.

EXCEPTION: The WD_Fact_1=WD_Fact_2=1 setting is not permissible. The circuit does not check

this setting.

Monitoring times between 2 ms and 650 s - independent of the baud rate - can be implemented with the

permisible watchdog factors.

If the monitoring time runs out, the SPC3 goes again to ‘Baud_Control,’ and the SPC3 generates the

‘WD_DP_Control_Timeout-Interrupt’. In addition, the DP_State machine is reset, that is, generates the

reset states of the buffer management.

If another master accepts SPC3, then there is either a switch to ‘Baud_Control” (WD_On = 0), or there is a

delay in ‘DP_Control’ (WD_On = 1), depending on the enabled response time monitoring (WD_On = 0).

SPC3 Hardware Description V1.3 Page 25

Copyright (C) Siemens AG 2003 All rights reserved. 2003/04

Page 28

PROFIBUS Interface Center

SPC3

6 PROFIBUS-DP Interface

6.1 DP_Buffer Structure

The DP mode is enabled in the SPC3 with ‘DP_Mode = 1’ (see mode Register0). In this process, the

following SAPS are fixed reserved for the DP mode:

`

Default SAP: Data exchange (Write_Read_Data)

`

SAP53: reserved

`

SAP55: Changing the station address (Set_Slave_Address)

`

SAP56: Reading the inputs (Read_Inputs)

`

SAP57: Reading the outputs (Read_Outputs)

`

SAP58: Control commands to the DP-Slave (Global_Control)

`

SAP59: Reading configuration data (Get_Config)

`

SAP60: Reading diagnostics information (Slave_Diagnosis)

`

SAP61: Sending parameter setting data (Set_Param)

`

SAP62: Checking configuration data (Check_Config)

The DP Slave protocol is completely integrated in the SPC3 and is handled independently. The user must

correspondingly parameterize the ASIC and process and acknowledge transferred messages. Except for

the default SAP, SAP56, SAP57, and SAP58, all SAPS are always enabled. The remaining SAPS are not

enabled until the the DP Slave Machine (DP_SM) goes into the ‘DATA_EX’ state. The user has the

possibility of disabling SAP55. The relevant buffer pointer R_SSA_Puf_Ptr must be set to ‘00H’ for this

purpose. The DDB utility is disabled by the already described initialization of the RAM cells.

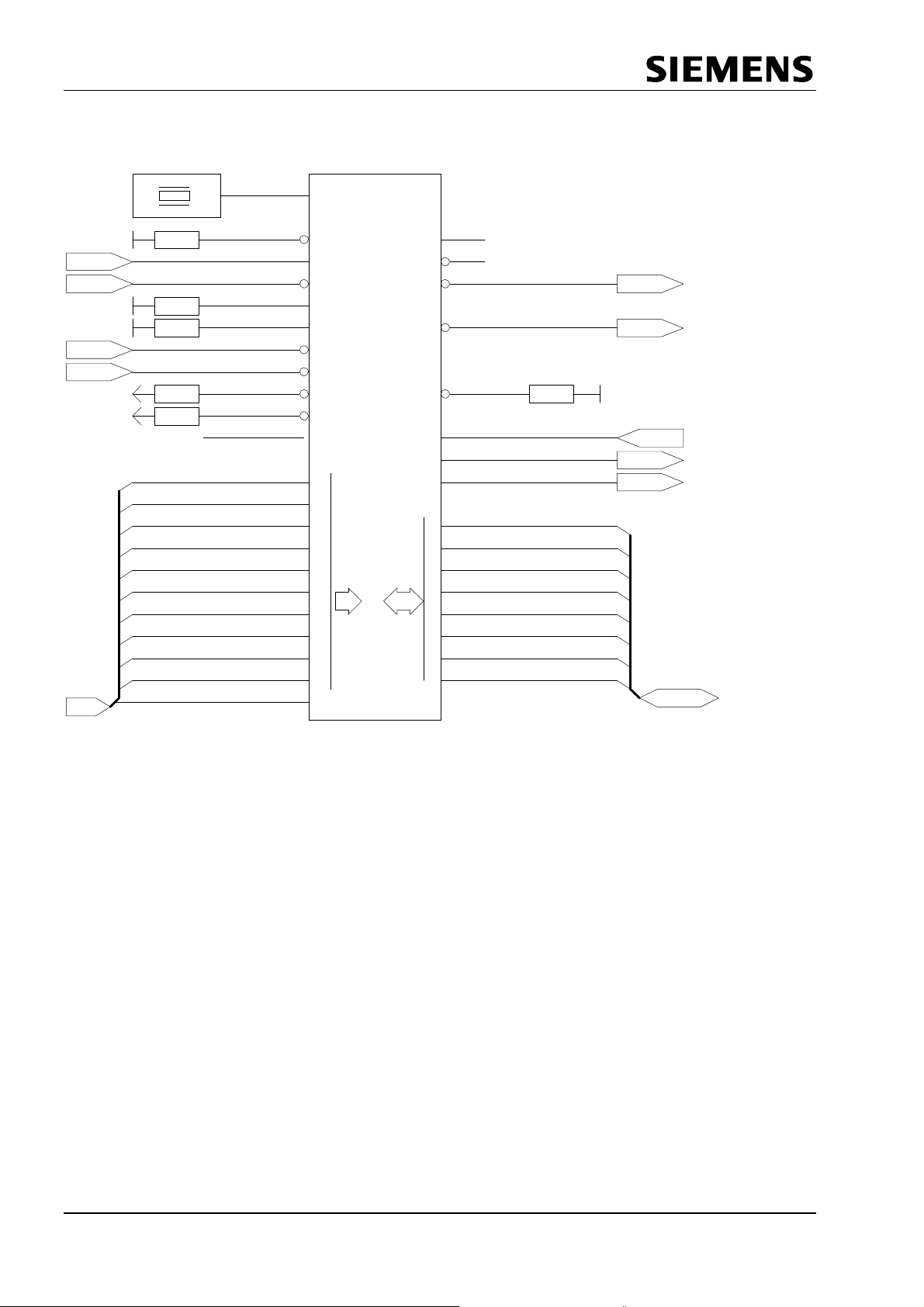

The DP_SAP buffer structure is displayed in Figure 6.1. The user configures all buffers (length and buffer

beginning) in the ‘offline state.’ During operation, the buffer configuration must not be changed, except for

the length of the Dout-/Din buffers.

The user may still adapt these buffers in the ‘Wait_Cfg’ state after the configuration telegram

(Check_Config). Only the same configuration may be accepted in the ‘DATA_EX’ state.

The buffer structure is divided into the data buffer, diagnostics buffer, and the control buffer.

Both the output data and the input data have three buffers each available with the same length. These

buffers function as change buffers. One buffer is assigned to the ‘D’ data transfer, and one buffer is

assigned to the ‘U’ user. The third buffer is either in a Next ‘N’ state or Free ‘F’ state, whereby one of the

two states is always unoccupied.

Two diagnostics buffers that can have varying lengths are available for diagnostics. One diagnostics buffer

is always the ‘D’ assigned to SPC3 for sending. The other diagnostics buffer belongs to the user for

preparing new diagnostics data, ‘U.’

The SPC3 first reads the different parameter setting telegrams (Set_Slave_Address, and Set_Param) and

the configuring telegram (Check_Config) into Aux-Puffer1 or Aux-Puffer 2.....

Page 26 V1.3 SPC3 Hardware Description

2003/04 Copyright (C) Siemens AG 2003. All rights reserved.

Page 29

SPC3 PROFIBUS Interface Center

N- U is changed by the userD-Nis changed by SPC 3

UART

D N

D N

Aux1/2-buffer

U

Dout-buffer

U

Din-buffer

D U

Diagnosticsbuffer

ReadConfigbuffer

User

Configbuffer

SSA-buffer

Aux1/2-buffer

Parambuffer

Figure 6.1: DP_SAP Buffer Structure

Data exchanged with the corresponding target buffer (SSA buffer, Prm buffer, and Cfg buffer). Each of the

buffers to be exchanged must have the same length. The user defines which Aux_buffers are to be used

for the above-named telegrams in the ‘R_Aux_Puf_Sel’ parameter cell. The Aux- buffer1 must always be

available. The Aux-buffer2 is optional. If the data profiles of these DP telegrams are very different, such as

the data amount in the Set_Param telegram is significantly larger than for the other telegrams, it is

suggested to make an Aux-Buffer2 available (Aux_Sel_Set_Param = 1) for this telegram. The other

telegrams are then read via Aux-Buffer 1 (Aux_Sel_..=0). If the buffers are too small, SPC3 responds with

“no resources”!

SPC3 Hardware Description V1.3 Page 27

Copyright (C) Siemens AG 2003 All rights reserved. 2003/04

Page 30

PROFIBUS Interface Center

SPC3

Address Bit Position Designation

RAM

7 6 5 4 3 2 0

Register

2AH 0 0 0 0 0

Set_

Slave_

Adr

Cfg

Set_

R_Aux_Puf_Sel

Prm

Check_

X1 X1 X1 See below for coding.

X1 Coding

0 Aux_Buffer1

1 Aux_Buffer2

Figure 6.2: Aux-Buffer Management

The user makes the configuration data (Get_Config) available in the Read_Cfg buffer for reading. The

Read_Cfg buffer must have the same length as the Cfg_buffer.

The Read_Input_Data telegram is operated from the Din buffer in the ‘D state’, and the Read_Output_Data

telegram is operated from the Dout buffer in the ‘U state.’

All buffer pointers are 8-bit segment addresses, because the SPC3 internally has only 8-bit address

registers. For a RAM access, SPC3 adds an 8-bit offset address to the segment address shifted by 3 bits

(result: 11-bit physical address). As regards the buffer start addresses, this results in an 8-byte graunularity

from this specification.

Page 28 V1.3 SPC3 Hardware Description

2003/04 Copyright (C) Siemens AG 2003. All rights reserved.

Page 31

SPC3 PROFIBUS Interface Center

6.2 Description of the DP Services

6.2.1 Set_Slave_Address (SAP55)

6.2.1.1 Sequence for the Set_Slave_Address Utility

The user can disable this utility by setting the ‘R_SSA_Puf_Ptr = 00H’ buffer pointer. The slave address

must then be determined, for example, by reading a switch, and written in the R_TS_Adr. RAM register.

The user must make a retentive memory possibility available (for example, EEPROM) to support this utility.

It must be possible to store the ‘station address’ and the ‘Real_No_Add_Change’ (‘True’ = FFH) parameter

in this external EEPROM. After each restart caused by a power failure, the user must again make these

values available to SPC3 in the R_TS_Adr und R_Real_No_Add_Change RAM register.

If SAP55 is enabled and the Set_Slave_Address telegram is correctly accepted, SPC3 enters all net data in

the Aux-Puffer1/2, exchanges the Aux buffer1/2 for the SSA buffer, stores the entered data length in

‘R_Len_SSA_Data’, generates the ‘New_SSA_Data’ interrupt and internally stores the new ‘station address’

and the new ‘Real_No_Add_Change’ parameter. The user does not need to transfer this changed

parameter to SPC3 again. After the user has read the buffer, the user generates the

‘SSA_Puffer_Free_Cmd’ (read operation on address 14H). This makes SPC3 again ready to receive an

additional Set Slave Address telegram (such as from another master).

SPC3 reacts independently when there are errors.

Address Bit Position Designation

Control

Register

14H 0 0 0 0 0 0 0 0 SSA_Puffer_Free_Cmd

don´t care

Figure 6.3: Coding SSA_Buffer_Free_Cmd

6.2.1.2 Structure of the Set_Slave_Address Telegram

The net data are stored as follows in the SSA buffer:

Byte Bit Position Designation

7 6 5 4 3 2 1 0

0 New_Slave_Address

1 Ident_Number_High

2 Ident_Number_Low

3 No_Add_Chg

4-243 Rem_Slave_Data additional application-

Figure 6.4: Data Format for the Set_Slave_Address Telegram

7 6 5 4 3 2 1 0

specific data

SPC3 Hardware Description V1.3 Page 29

Copyright (C) Siemens AG 2003 All rights reserved. 2003/04

Page 32

PROFIBUS Interface Center

SPC3

6.2.2 Set_Param (SAP61)

6.2.2.1 Parameter Data Structure

SPC3 evaluates the first seven data bytes (without user prm data), or the first eight data bytes (with user

prm data). The first seven bytes are specified according to the standard. The eighth byte is used for SPC3specific characteristics. The additional bytes are available to the application.

Byte Bit Position Designation

7 6 5 4 3 2 1 0

Lock

Unlo.

Sync

Free

WD

0

1

2

3

4

5

6

7

8-243

Req

Req

Req

Req

0 0 0 0 0 WD_

Res Res Res

on

Base

Dis

Stop

Station status

WD_Fact_1

WD_Fact_2

MinTSDR

Ident_Number_High

Ident_Number_Low

Group_Ident

Dis

Spec_User_Prm_Byte

Start

User_Prm_Data

Byte 7 Spec_User_Prm_Byte

Bit Name Significance Default State

0 Dis_Startbit The start bit monitoring in the

receiver is switched off with this bit.

Dis_Startbit= 1 ,

that is, start bit monitoring is

switched off.

1 Dis_Stopbit Stop bit monitoring in the receiver is

switched off with this bit.

Dis_Stopbit= 0,

that is, stop bit monitoring is not

switched off.

2 WD_Base This bit specifies the time base used

to clock the watchdog.

WD_Base= 0,

that is, the time base is 10 ms

WD_Base = 0: time base 10 ms

WD_Base = 1: time base 1 ms

3-7 res to be parameterized with 0 0

Figure 6.5: Data Format for the Set_Param_Telegram

6.2.2.2 Parameter Data Processing Sequence

In the case of a positive validatation for more than seven data bytes, SPC3 carries out the following

reaction, among others:

SPC3 exchanges Aux-Puffer1/2 (all data bytes are input here) for the Prm buffer, stores the input data

length in ‘R_Len_Prm_Data’, and triggers the ‘New_Prm_Data Interrupt’. The user must then check the

‘User_Prm_Data’ and either reply with the ‘User_Prm_Data_Okay_Cmd’ or with

‘User_Prm_Data_Not_Okay_Cmd.’ The entire telegram is input in the buffer, that is, application-specific

parameter data are stored beginning with data byte 8 only.

The user response (User_Prm_Data_Okay_Cmd or User_Prm_Data_Not_Okay_Cmd) again takes

back the ‘New_Prm_Data’ interrupt. The user may not acknowledge the ‘New_Prm_Data’ interrupt in

the IAR register.

The relevant diagnostics bits are set with the ‘User_Prm_Data_Not_Okay_Cmd’ message and are branched

to ‘Wait_Prm.’

The ‘User_Prm_Data_Okay’ and ‘User_Prm_Data_Not_Okay’ acknowledgements are reading accesses to

defined registers with the relevant signals:

• ‘User_Prm_Finished’: No additional parameter telegram is present.

• ‘Prm_Conflict’ : An additional parameter telegram is present, processing again

• ‘Not_Allowed’, Access not permitted in the current bus state

Page 30 V1.3 SPC3 Hardware Description

2003/04 Copyright (C) Siemens AG 2003. All rights reserved.

Page 33

Address Bit Position Designation

Control

Register

0EH 0 0 0 0 0 0

0 0 User_Prm_Finished

0 1 PRM_Conflict

1 1 Not_Allowed

Address Bit Position Designation

Control

Register

0FH 0 0 0 0 0 0

0 0 User_Prm_Finished

0 1 PRM_Conflict

1 1 Not_Allowed

Figure 6.6: Coding User_Prm_Data_Not/_Okay_Cmd

If an additional Set-Param telegram is supposed to be received in the meantime, the signal ‘Prm_Conflict’ is

is returned for the acknowledgement of the first Set_Param telegram, whether positive or negative. Then

the user must repeat the validation because the SPC3 has made a new Prm buffer available.

7 6 5 4 3 2 1 0

7 6 5 4 3 2 1 0

SPC3 PROFIBUS Interface Center

User_Prm_Data_Okay

User_Prm_Data_Not_Okay

6.2.3 Check_Config (SAP62)

The user takes on the evaluation of the configuration data. After SPC3 has received a validated

Check_Config-Telegram, SPC3 exchanges the Aux-Puffer1/2 (all data bytes are entered here) for the Cfg

buffer, stores the input data length in ‘R_Len_Cfg-Data,’ and generates ‘New_Cfg_Data-Interrupt’.

The user must then check the ‘User_Config_Data’ and either respond with ‘User_Cfg_Data_Okay_Cmd’ or

with ‘User_Cfg_Data_Not_Okay_Cmd’ (acknowledgement to the Cfg_SM). The net data is input in the

buffer in the format regulation of the standard.

The user response (User_Cfg_Data_Okay_Cmd or the User_Cfg_Data_Not_Okay_Cmd response)

again takes back the ‘New_Cfg_Data’ interrupt and may not be acknowledged in the IAR.

If an incorrect configuration is signalled back, various diagnostics bits are changed, and there is branching

to ‘Wait_Prm.“

For a correct configuration, the transition to ‘DATA_EX’ takes place immediately, if no Din_buffer is present

(R_Len_Din_Puf = 00H) and trigger counters for the parameter setting telegrams and configuration

telegrams are at 0. Otherwise, the transition does not take place until the first ‘New_DIN_Puffer_Cmd’ with

which the user makes the first valid ‘N buffer” available. When entering into ‘DATA_EX,’ SPC3 also

generates the ‘Go/Leave_Data_Exchange-Interrupt.

If the received configuration data from the Cfg buffer are supposed to result in a change of the Read-Cfgbuffer ( the change contains the data for the Get_Config telegram), the user must make the new Read_Cfg

data available in the Read-Cfg buffer before the ‘User_Cfg_Data_Okay_Cmd” acknowledgement. After

receiving the acknowledgement, SPC3 exchanges the Cfg buffer with the Read-Cfg buffer, if

‘EN_Change_Cfg_buffer = 1’ is set in mode register1.

During the acknowledgement, the user receives information about whether there is a conflict or not. If an

additional Check_Config telegram was supposed to be received in the meantime, the user receives the

‘Cfg_Conflict” signal during the acknowledgement of the first Check_Config telegram, whether positive or

negative. Then the user must repeat the validation, because SPC3 has made a new Cfg buffer available.

The ‘User_Cfg_Data_Okay_Cmd’ and ‘User_Cfg_Data_Not_Okay_Cmd’ acknowledgements are read

accesses to defined memory cells (see Section 2.2.1) with the relevant ‘Not_Allowed’, ‘User_Cfg_Finished,’

or ‘Cfg_Conflict’ signals (see Figure 3.7). If the ‘New_Prm_Data’and ‘New_Cfg_Data’ are supposed to

be present simultaneously during power up, the user must maintain the Set_Param and then the

Check_Config. acknowledgement sequence.

SPC3 Hardware Description V1.3 Page 31

Copyright (C) Siemens AG 2003 All rights reserved. 2003/04

Page 34

PROFIBUS Interface Center

SPC3

Address Bit Position Designation

Control

7 6 5 4 3 2 1 0

Register

10H 0 0 0 0 0 0

User_Cfg_Data_Okay

0 0 User_Cfg_Finished

0 1 Cfg_Conflict

1 1 Not_Allowed

Address Bit Position Designation

Control

7 6 5 4 3 2 1 0

Register

11H 0 0 0 0 0 0

User_Cfg_Data_Not_Okay

0 0 User_Cfg_Finished

0 1 Cfg_Conflict

1 1 Not_Allowed

Figure 6.7: Coding of the User_Cfg_Data_Not/_Okay_Cmd

6.2.4 Slave_Diagnosis (SAP60)

6.2.4.1 Diagnostics Processing Sequence

Two buffers are available for diagnostics. The two buffers can have varying lengths. SPC3 always has one

diagnostics buffer assigned to it, which is sent for a diagnostics call-up. The user can pre-process new

diagnostics data in parallel in the other buffer. If the new diagnostics data are to be sent now, the user uses

the ‘New_Diag_Cmd’ to make the request to exchange the diagnostics buffers. The user receives

confirmation of the exchange of the buffers with the ‘Diag_Puffer_Changed Interrupt.’

When the buffers are exchanged, the internal ‘Diag_Flag’ is also set. For an activated ‘Diag_Flag,’ SPC3

responds during the next Write_Read_Data with high-priority response data that signal the relevant master

that new diagnostics data are present at the slave. Then this master fetches the new diagnostics data with a

Slave_Diagnosis telegram. Then the ‘Diag_Flag” is reset again. If the user signals ‘Diag.Stat_Diag = 1,’

however (static diagnosis, see the structure of the diagnostics buffer), then ‘Diag_Flag’ still remains

activated after the relevant master has fetched the diagnosis. The user can poll the ‘Diag_Flag’ in the

status register to find out whether the master has already fetched the diagnostics data before the old data is

exchanged for the new data.

Status coding for the diagnostics buffers is stored in the‘Diag_bufferSM’ processor parameter. The user can

read this cell with the possible codings for both buffers: ‘User,’ ‘SPC3,’ or ‘SPC3_Send_Mode.’

Address Bit Position Designation

Control

7 6 5 4 3 2 0

Register

0CH 0 0 0 0 D_Puf2 D_Puf1 Diag_Puffer_SM

X1 X2 X1 X2 See below for coding.

X1 X2 Coding

0 0 Each for the D_Buf2 or D_Buf1

0 1 User

1 0 SPC3

1 1 SPC3_Send_Mode

Figure 6.8: Diag_Buffer Assignment

The ‘New_Diag_Cmd’ is also a read access to a defined processor parameter with the signal as to which

diagnostics buffer belongs to the user after the exchange, or whether both buffers are currently assigned to

SPC3 (‘no Puffer’, ‘Diag_Puf1’, ‘Diag_Puf2’).

Page 32 V1.3 SPC3 Hardware Description

2003/04 Copyright (C) Siemens AG 2003. All rights reserved.

Page 35

SPC3 PROFIBUS Interface Center

Address Bit Position Designation

Control

7 6 5 4 3 2 1 0

Register

0DH 0 0 0 0 0 0

New_Diag_Cmd

0 0 no Puffer

0 1 Diag_Puf1

1 0 Diag_Puf2

Figure 6.9: Coding Diag_Puffer_SM, New_Diag_Cmd

6.2.4.2 Structure of the Diagnostics Buffer:

The user transfers the diagnostics buffer displayed in the figure below to SPC3. The first 6 bytes are space

holders, except for the three least significant bit positions in the first byte. The user stores the diagnostics

bits, ‘Diag.Ext_Diag’ ‘Diag.Stat_Diag,” and Diag.Ext.Diag_Overflow’ in these three bit positions. The

remaining bits can be assigned in any order. When sending, SPC3 pre-processes the first six bytes

corresponding to the standard.

Byte Bit Position Designation

7 6 5 4 3 2 1 0

0

1

2

3

4

5

6-n

Ext_

The user must input

Diag

Overf

Stat

Diag

Ext_

Spaceholder

Diag

Spaceholder

Spaceholder

Spaceholder

Spaceholder

Spaceholder

Ext_Diag_Data (n = max 243)

Figure 6.10: Structure of the Diagnostics Buffer for Transfer to the SPC3

The ‘Ext-Diag_Data’ the user must enter into the buffers follow after the SPC3-internal diagnostics data.

The three different formats are possible here (device-related, ID-related, and port-related). In addition to the

‘Ext_Diag_Data,’ the buffer length also includes the SPC3 diagnostics bytes (R_Len_Diag_Puf1,

R_Len_Diag_Puf2).

6.2.5 Write_Read_Data / Data_Exchange (Default_SAP)

6.2.5.1 Writing Outputs

SPC3 reads the received output data in the D buffer. After error-free receipt, SPC3 shifts the newly filled

buffer from ‘D’ to ‘N.’ In addition, the ‘DX_Out_Interrupt’ is generated. The user now fetches the current

output data from ‘N.’ The buffer changes from ‘N’ to ‘U’ with the ‘Next_Dout_Buffer_Cmd,’ so that the

current data of the application can be sent back for the master’s Read_Outputs.

If the user’s evaluation cycle time is shorter than the bus cycle time, the user does not find any new buffers

with the next ‘Next_Dout_Buffer_Cmd’ in ‘N.’ Therefore, the buffer exchange is omitted, At a 12 Mbd baud

rate, it is more likely, however, that the user’s evaluation cycle time is larger than the bus cycle time. This

makes new output data available in ‘N’ several times before the user fetches the next buffer. It is

guaranteed, however, that the user receives the data last received.

For ‘Power_On’, ‘Leave_Master’ and the Global_Control-Telegram ‘Clear,’ SPC3 deletes the D buffer and

then shifts it to ‘N.’ This also takes place during the power up (entering into ‘Wait_Prm’). If the user fetches

this buffer, he receives the ‘U_buffer cleared’ display during the ‘Next_Dout_Buffer_Cmd.’ If the user is still

supposed to enlarge the output data buffer after the Check_Config telegram, the user must delete this delta

in the N buffer himself (possible only during the power-up phase in the ‘Wait_Cfg’ state).

If ‘Diag.Sync_Mode = 1’, the D buffer is filled but not exchanged with the Write_Read_Data-Telegram, but

rather exchanged at the next Sync or Unsync.

SPC3 Hardware Description V1.3 Page 33

Copyright (C) Siemens AG 2003 All rights reserved. 2003/04

Page 36

PROFIBUS Interface Center

SPC3

The user can read the buffer management state with the following codes for the four states: ‘Nil’,

‘Dout_Puf_Ptr1-3’. The pointer for the current data is in the “N” state.

Address Bit Position Designation

Control

7 6 5 4 3 2 0

Register

0AH F U N D Dout_Puffer_SM

X1 X2 X1 X2 X1 X2 X1 X2 See below for coding.

X1 X2 Coding

0 0 Nil

0 1 Dout_Puf_Ptr1

1 0 Dout_Puf_Ptr2

1 1 Dout_Puf_Ptr3

Figure 6.11: Dout_Buffer Management

When reading the ‘Next_Dout_Buffer_Cmd’ the user gets the information which buffer (U-buffer) belongs to

the user after the change, or whether a change has taken place at all.

Address Bit Position Designation

Control

7 6 5 4 3 2 1 0

Register

0BH 0 0 0 0

U_

Buffer

Cleared

State_

U_

Buffer

Ind_U_

Buffer

Next_Dout_Buf_Cmd

0 1 Dout_Buf_Ptr1

1 0 Dout_Buf_Ptr2

1 1 Dout_Buf_Ptr3

0 No new U buffer

1 New U buffer

0 U buffer contains data

1 U buffer was deleted

Figure 6.12: Next_Dout_Puffer_Cmd

The user must delete the U buffer during initialization so that defined (deleted) data can be sent for a

Read_Output Telegram before the first data cycle.

6.2.5.2 Reading Inputs

SPC3 sends the input data from the D buffer. Prior to sending, SPC3 fetches the Din buffer from ‘N’ to ‘D.’

If no new buffer is present in ‘N,’ there is no change.

The user makes the new data available in ‘U’. With the ‘New_Din_buffer_Cmd,’ the buffer changes from ‘U’

to ‘N’. If the user’s preparation cycle time is shorter than the bus cycle time, not all new input data are sent,

but just the most current. At a 12 Mbd baud rate, it is more probable, however, that the user’s preparation

cycle time is larger than the bus cycle time. Then SPC3 sends the same data several times in succession.

During start-up, SPC3 first goes to ‘DATA_EX’ after all parameter telegrams and configuration telegrams

are acknowledged, and the user then makes the first valid Din buffer available in ‘N’ with the

‘New_Din_Buffer_Cmd.

If ‘Diag.Freeze_Mode = 1’, there is no buffer change prior to sending.

The user can read the status of the state machine cell with the following codings for the four states: ‘Nil’,

‘Dout_Puf_Ptr1-3.’ (See Figure 3.13.) The pointer for the current data is in the “N” state.

Page 34 V1.3 SPC3 Hardware Description

2003/04 Copyright (C) Siemens AG 2003. All rights reserved.

Page 37

SPC3 PROFIBUS Interface Center

Address Bit Position Designation

Control

7 6 5 4 3 2 0

Register

08H F U N D Din_Buffer_SM

X1 X2 X1 X2 X1 X2 X1 X2 See below for coding.

X1 X2 Coding

0 0 Nil

0 1 Din_Buf_Ptr1

1 0 Din_Buf_Ptr2

1 1 Din_Buf_Ptr3

Figure 6.13: Din_Buffer Management

When reading the ‘New_Din_Buffer_Cmd’ the user gets the information which buffer (U-buffer) belongs to

the user after the change (Din_Buf_Ptr 1-3).

Address Bit Position Designation

Control

7 6 5 4 3 2 1 0

Register

09H 0 0 0 0 0 0

New_Din_Buf_Cmd

0 1 Din_Buf_Ptr1

1 0 Din_Buf_Ptr2

1 1 Din_Buf_Ptr3

Figure 6.14: Next_Din_Buffer_Cmd

6.2.5.3 User_Watchdog_Timer

After power-up (‘DATA_EX’ state), it is possible that SPC3 continually answers Write_Read_Data-telegrams

without the user fetching the received Din buffers or making new Dout buffers available. If the user

processor ‘hangs up,’ the master would not receive this information. Therefore, a ‘User_Watchdog_Timer’

is implemented in SPC3.

This User_Wd_Timer is an internal 16-bit RAM cell that is started from a ‘R_User_Wd_Value

15..0

’ value the

user parameterizes and is decremented with each received Write_Read_Data telegram from SPC3. If the

timer attains the ‘0000hex’ value, SPC3 transitions to the ‘Wait_Prm’ state, and the DP_SM carries out a

‘Leave_Master.’ The user must cyclically set this timer to its start value. Therefore, ‘Res_User_Wd = 1’

must be set in mode register 1. Upon receipt of the next Write_Read_Data telegram, SPC3 again loads the

User_Wd_Timer to the parameterized value ‘R_User_Wd_Value

15..0

’ and sets ‘Res_User_Wd = 0’ (Mode

Register 1). During power-up, the user must also set ‘Res_User_Wd = 1’, so that the User_Wd_Timer is

even set at its parameterized value.

6.2.6 Global_Control (SAP58)

SPC3 itself processes the Global_Control-Telegrams in the manner already described. In addition, this

information is available to the user.

The first byte of a valid Global_Control command is stored in the R_GC_Comand RAM cell. The second

telegram byte (Group_Select) is processed internally.

Address Bit Position Designation

RAM

7 6 5 4 3 2 1 0

Cell

3CH

Res Res Sync Un

sync

Freeze Un

freeze

Clear_

Data

Res

R_GC_Command

SPC3 Hardware Description V1.3 Page 35

Copyright (C) Siemens AG 2003 All rights reserved. 2003/04

Page 38

PROFIBUS Interface Center

Bit Designation Significance

0 Reserved

1 Clear_Data With this command, the output data is deleted in ‘D’ and is changed

to ‘N.’

2 Unfreeze With „Unfreeze,“ freezing input data is cancelled.

3 Freeze The input data is fetched from ‘N’ to ‘D’ and „frozen“. New input data

is not fetched again until the master sends the next ‘Freeze’

command.

4 Unsync The „Unsync“ command cancels the „Sync“ command.

5 Sync The output data transferred with a WRITE_READ_DATA telegram is

changed from ‘D’ to ‘N.’ The following transferred output data is kept

in ‘D’ until the next ‘Sync’ command is given.

6,7 Reserved The „Reserved“ designation specifies that these bits are reserved for

future function expansions.

Figure 6.15: Data Format for the Global_Control Telegram

If the Control_Comand byte changed at the last received Global_Control telegram, SPC3 additionally

generates the ‘New_GC_Command’ interrupt. During initialization, SPC3 presets the ‘R_GC_Command’

RAM cell with 00H. The user can read and evaluate this cell.

So that Sync and Freeze can be carried out, these functions must be enabled in the mode register.

SPC3

6.2.7 Read_Inputs (SAP56)

SPC3 fetches the input data like it does for the Write_Read_Data Telegram. Prior to sending, ‘N’ is shifted

to ‘D,’ if new input data are available in ‘N.’ For ‘Diag.Freeze_Mode = 1,’ there is no buffer change.

6.2.8 Read_Outputs (SAP57)

SPC3 fetches the output data from the Dout buffer in ‘U’. The user must preset the output data with ‘0’

during start-up so that no invalid data can be sent here. If there is a buffer change from ‘N’ to ‘U’ (through

the Next_Dout_Buffer_Cmd) between the first call-up and the repetition, the new output data is sent during

the repetition.

6.2.9 Get_Config (SAP59)

The user makes the configuration data available in the Read_Cfg buffer. For a change in the configuration

after the Check_Config telegram, the user writes the changed data in the Cfg buffer, sets

‘EN_Change_Cfg_buffer = 1’ (see Mode-Register1), and SPC3 then exchanges the Cfg buffer for the

Read_Cfg buffer. (See Section 3.2.3.) If there is a change in the configuration data (for example, for the

modular DP systems) during operation, the user must return with ‘Go Offline’ (see Mode Register1) to

‘Wait_Prm’ to SPC3.

Page 36 V1.3 SPC3 Hardware Description

2003/04 Copyright (C) Siemens AG 2003. All rights reserved.

Page 39

SPC3 PROFIBUS Interface Center

7 Hardware Interface

7.1 Universal Processor Bus Interface

7.1.1 General Description

SPC3 has a parallel 8-bit interface with an 11-bit address bus. SPC3 supports all 8-bit processors and

microcontrollers based on the 80C51/52 (80C32) from Intel, the Motorola HC11 family, as well as 8-/16-bit

processors or microcontrollers from the Siemens 80C166 family, X86 from Intel, and the HC16 and HC916

family from Motorola. Because the data formats from Intel and Motorola are not compatible, SPC3

automatically carries out ‘byte swapping’ for accesses to the following 16-bit registers (interrupt register,

status register, and mode register0) and the 16-bit RAM cell (R-User_Wd_Value). This makes it possible for

a Motorola processor to read the 16-bit value correctly. Reading or writing takes place, as usual, through

two accesses (8-bit data bus).

Due to the 11-bit address bus, SPC3 is no longer fully compatible to SPC2 (10-bit address bus). However,

AB(10) is located on the XINTCI output of the SPC2 that was not used until now. For SPC3, the AB(10)

input is provided with an internal pull-down resistor. If SPC3 is to be connected into existing SPC2

hardware, the user can use only 1 kByte of the internal RAM. Otherwise, the AB(10) cable on the modules

must be moved to the same place.

The Bus Interface Unit (BIU) and the Dual Port RAM Controller (DPC) that controls accesses to the internal

RAM belong to the processor interface of the SPC3.

In addition, a clock rate divider is integrated that the clock pulse of an external clock pulse generator divided

by 2 (Pin: DIVIDER = High-Potential) or 4 (Pin: DIVIDER = Low-Potential) makes available on the pin

CLKOUT2/4 as the system clock pulse so that a slower controller can be connected without additional

expenditures in a low-cost application. SPC3 is supplied with a clock pulse rate of 48MHz.

7.1.2 Bus Interface Unit (BIU)

The BIU forms the interface to the connected processor/microcontroller. This is a synchronous or

asynchronous 8-bit interface with an 11-bit address bus. The interface is configurable via 2 pins

(XINT/MOT, MODE). The connected processor family (bus control signals such as XWR, XRD, or R_W,

and the data format) is specified with the XINT/MOT pin. Synchronous (rigid) or asynchronous bus timing is

specified with the MODE pin.

Various Intel system configurations are displayed in the figures in Section 7.1.3. The internal address latch

and the integrated decoder must be used in the C32 mode. One figure displays the minimum configuration

of a system with SPC3, whereby the block is connected to an EPROM version of the controller. Only a

pulse generator is necessary as an additional block in this configuration. If a controller is to be used without

an integrated program memory, the addresses must once again be latched off for the external memory.

The connection schematic in the next figure is applicable for all Intel/Siemens processors that offer

asynchronous bus timing and evaluate the ready signal.

Notes:

If the SPC3 is connected to an 80286 processor, or others, it must be taken into consideration that the

processor carries out word accesses. That is, either a “swapper” is necessary that switches the characters

out of the SPC3 at the relevant byte position of the 16-bit data bus during reading, or the least significant

address bit is not connected, and the 80286 must read word accesses and evaluate only the lower byte, as

displayed in the figure.

SPC3 Hardware Description V1.3 Page 37

Copyright (C) Siemens AG 2003 All rights reserved. 2003/04

Page 40

PROFIBUS Interface Center

dresses AB7..0 externally

For microcontrollers with chip select logic (K, F1, HC16, and HC916), the chip select

address range, the priority, the polarity, and

For microcontrollers without chip select logic (N and M), and others, an external chip

The SPC3 output clock (CLKOUT2/4) must be four times larger than the E_CLOCK.

The SPC3 input clock (CLK) must be at least 10 times larger than the desired system

r 4), and it results in an

All other HC11 types with a multiplexed bus must externally select addresses AB7..0

Intel microcontroller CPU basis is 80C51/52/32, microcontrollers from various

The address decoder is switched on in SPC3. The CS signal is generated for SPC3

d with the ALE signal in an internal address

latch. The internal CS decoder is activated in SPC3 that generates its own CS signal

XINT/MO MODE The SPC3 interface supports the following processors/microcontrollers.

1 1 Motorola microcontroller with the following characteristics:

synchron-ous

Motorola

The following can be connected:

The address decoder is switched off in the SPC3. The CS signal is fed to SPC3.

Condition:

1 0 Motorola microcontroller with the following characteristics:

asynchron-ous

Motorola

The following can be connected:

The address decoder is switched off in SPC3. The CS signal is fed into SPC3.

0 1

synchron-ous

Intel

The following can be connected:

• Synchronous (rigid) bus timing without evaluation of the XREADY signal

• 8-bit non-multiplexed bus: DB7..0, AB10..0

• HC11 types: K, N, M, F1

• HC16- und HC916 types with programmable E clock timing

• All other HC11 types with a multiplexed bus must select ad

from DB7..0 data.

•

signals are programmable as regards the

the window width in the write cycle or read cycle.

•

select logic is required. This means additional hardware and a fixed assignment.

•

clock (E_Clock). The divider pin must be placed at „low“ (divide

E_CLOCK of 3 MHz

• Asychronous bus timing with evaluation of the XREADY signal

• 8-bit non-multiplexed bus: DB7..0, AB10..0

• HC16 and HC916 types

•

from data DB7..0.

• Chip select logic is available and programmable in all microcontrollers.

manufacturers:

• Sychronous (rigid) bus timing without evaluation of the XREADY signal

• 8-bit multiplexed bus: ADB7..0

• Microcontroller families from Intel, Siemens, and Philips, for example

internally.

• The lower address bits AB7..0 are store