Siemens SKP Series, SKP70.110U17, SKP70.111U17, SKP70.192U17, SKP70.191U17 Technical Instructions

...

SKP Series

SKP70…U.. Air/Gas Ratio Controlling Actuators

With Safety Shutoff Function—

For Use With Gas Valves VG…

Te

Tecccchhhhnnnniiiiccccaaaal I

TeTe

l Innnnssssttttrrrruuuuccccttttiiiion

l Il I

onssss

onon

Document No. 155-516P25

SKP70…U..

Rev. 2, December, 1998

DDDDes

esccccrrrriiiippppttttiiiioooonnnn

eses

SKP70… pressure regulating electro-hydraulic actuators are used in combination with

VG… series gas valves to provide slow opening fast closing shutoff and air/gas ratio

control for industrial and commercial burner applications.

The SKP70… controls the burner manifold gas pressure as a function of the

combustion air pressure without the need for an additional constant gas pressure

regulator.

Since three functions, safety shutoff, constant pressure regulation and air/gas ratio

control can be performed by a single valve, fewer components and fittings are required

to assemble a gas train reducing both the size and the weight of the gas train

significantly. The total pressure drop across the gas train arrangement is reduced,

allowing for the use of smaller diameter gas trains in most applications.

The modular design allows the SKP70… to be used in combination with all VG… series

gas valves from ½-inch to 5-inch in size. The actuator is easily mounted on the square

flange of any VG… valve by means of four bolts contained in the terminal box of the

actuator. No gaskets or seals are required when mounting the actuator. The valve

position is shown by a visible position indicator displaying the entire stroke range of the

actuator.

Siemens Building Technologies, Inc.

Landis Division

Technical Instructions

Document No. 155-516P25

Rev. 2, December, 1998

FFFFeeeeaaaattttur

ures

es

urur

eses

AAAApp

ppli

liccccaaaattttiiiioooonnnn

pppp

lili

UL listed, FM approved, CGA and AGA certified, IRI approvable, ISO 9001 certified;

x

European, Australian and Japanese approved versions available.

Safety shutoff function, pressure regulating function and air/gas ratio control in one

x

compact unit.

Simplifies commissioning and reduces startup time.

x

Maintains air/gas ratio when the air flow is disrupted.

x

Automatic compensation for combustion chamber back pressure fluctuations.

x

No mechanical wear or play that causes drifting.

x

Compensation for air temperature fluctuations.

x

Visual stroke position indicator.

x

Can be mounted in any location.

x

Optional auxiliary switches available.

x

Excellent tracking characteristics

x

SKP70… series actuators can be combined with ½-inch to 5-inch VG… series gas valve

bodies. VG… series gas valves are ordered as separate items (

Instruction No. 155-512P25).

VG…U.. Technical

See

PPPPrrrroooodu

ducccct

dudu

t NNNNuuuummmmbbbbeeeerrrrssss

t t

If the combustion air pressure exceeds the permissible value of 12” or 20” w.c. (

Specifications), the pressure must be reduced by means of a pressure reducing Tfitting (

A motorized pressure reducing control (SQN37… ) can also be installed in the air

impulse line to continuously optimize combustion when used in conjunction with an

oxygen trim system.

Figure 4, AGA78).

See

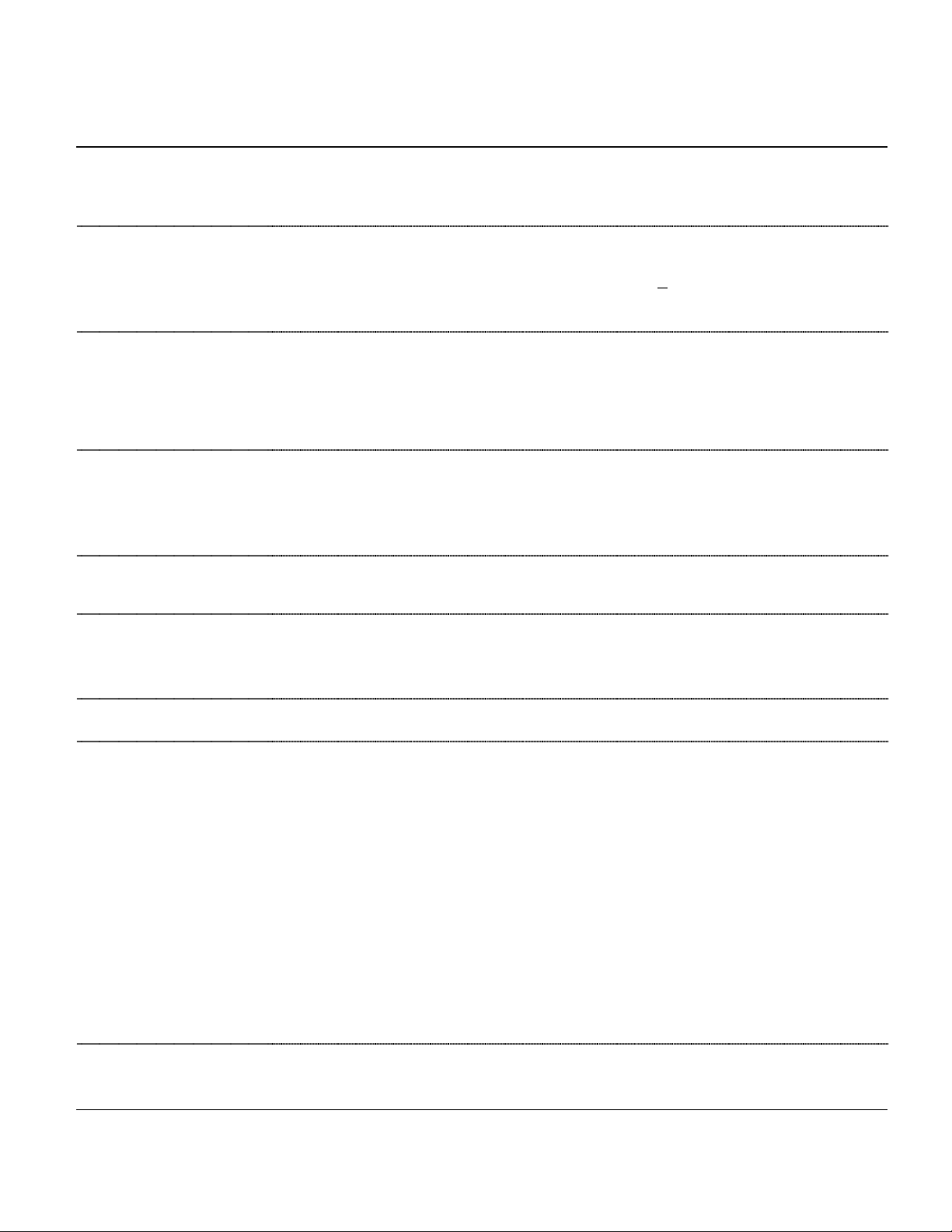

TTTTaaaabbbblllle

e 1111.

. PPPPrrrroooodddduuuucccct

e e

. .

OOOOrrrrddddeeeer

r NNNNuuuummmmbbbbeeeerrrrO

r r

SKP70.110U17 110-120 Vac No —

SKP70.111U17 110-120 Vac Auxiliary SPDT

SKP70.191U17 110-120 Vac Proof of Closure SPST

SKP70.192U17 110-120 Vac

SKP70.110U27 220-240 Vac No —

SKP70.111U27 220-240 Vac Auxiliary SPDT

SKP70.192U27 220-240 Vac

AGA78

OOOppppeeeerrrraaaattttiii

ing

ng

ngng

VVVVoooollllttttaaaage

ge

gege

Air pressure reducing T-fitting

t NNNNuuuummmmbbbbeeeerrrrssss

t t

PPPPrrrroo

oof

f oooof

f CCCClllloooossssuuuurrrreeee

oooo

f f

f f

&

& AAAAuuuuxxxxiiiilllliiiiaaaarrrry

& &

Proof of Closure

Proof of Closure

y SSSSwwwwiiiittttcccchhhh

y y

& Auxiliary

& Auxiliary

TTTTyyyyppppe o

SSSSwwwwiiiittttcccchhhh

SPST

SPST

SPST

SPST

e offff

e oe o

See

IIIInnnnssssttttaaaall

PPPPaaaage

ge 2222 oooof

ge ge

llaaaattttiiiioooon

n CCCCoooonnnnvvvveeeennnnttttiiiioooonnnn

llll

n n

WARNING:

f 9999 Siemens Building Technologies, Inc.

f f

Personal injury/loss of life may occur if a

procedure is not performed as specified.

Landis Division

SKP70…U.. Air/Gas Ratio Controlling Actuators Technical Instructions

155-516P25

Rev. 2, December, 1998

SSSSppppeeeecccciiiiffffiiiiccccaaaattttiiiioooonnnnssss

Agency approvals

Power supply

Operating environment

Physical characteristics

Connections

Operating characteristics

Control signal

Operation/installation

Auxiliary features

As safety shut-off valve UL/429, FM/7400, CGA/3.9,

AGA/Z 21.21 in combination with

VG…U.. series gas valves

UL recognized when used with other valves.

Operating voltage 110 to 120 Vac + 10%-15%

220 to 240 Vac + 10%-15%

Operating frequency 50 to 60 Hz + 6%

Power consumption 20 VA

Duty cycle 100%

o

Ambient operating temperature 15

to 140oF (-10o to 60o C)

Mounting position Optional, with diaphragms in vertical

position but not upside down

Maximum temperature of air and flue

gas at the control connections 140

o

F (60oC)

Maximum inlet gas pressure Same as VG… valve

Weight 5.5 lb (2.5 kg)

Enclosure NEMA 1, 2, 5 and 12 for indoor use

Dimensions

Specification for valves

Figure 6

See

gas valve Technical Instruction

See

No. 155-512P25

Conduit connection ½-inch NPSM adapter

Gas/air/combustion chamber pressure

connections ¼” NPT

Output force 100 lb (450 N)

Maximum stroke 0.7” (18 mm)

Opening time for maximum stroke 12 s

Closing time < 0.8 s

Reference input signal Combustion air pressure

Control characteristic integral action

Setting range of gas to air pressure ratio 0.4:1 to 9:1

Permissible pressures

during operation for accurate control Min. air presssure: 0.2” w.c.

Max. air pressure: with Pg/Pa <2; 20” w.c.

Max. air pressure: with Pg/Pa >2; 12” w.c.

with higher air pressures use AGA78

Min. downstream gas pressure: 0.4” w.c.

Max. downstream gas pressure: 40” w.c.

Minimum time required for high to low

fire load changes Approx. 5 s

Permissible leakage test pressure 20 psi

Permissible leakage test vacuum 3 psi

Minimum diameter of impulse pipes ¼” inside diameter (

Installation)

See

Minimum distance between gas

impulse pipe connection and gas

valve outlet 5 x pipe diameter

Capacity of auxiliary switch 6 (3) A, 250 Vac

Setting range of auxiliary switch Full stroke

Siemens Building Technologies, Inc PPPPaaaage

Landis Division

ge 3333 oooof

ge ge

f 9999

f f

Loading...

Loading...