Siemens SITRANS RD200 Operating Instructions Manual

Communications and Displays

SITRANS RD200

Operating Instructions 11/2012

SITRANS

Safety Guidelines: Warning notices must be observed to ensure personal safety as well as that of

others, and to protect the product and the connected equipment. These warning notices are

accompanied by a clarification of the level of caution to be observed.

Qualified Personnel: This device/system may only be set up and operated in conjunction with this

manual. Qualified personnel are only authorized to install and operate this equipment in accordance with

established safety practices and standards.

Unit Repair and Excluded Liability:

The user is responsible for all changes and repairs made to the device by the user or the user’s

agent.

All new components are to be provided by Siemens Milltronics Process Instruments.

Restrict repair to faulty components only.

Do not reuse faulty components.

Warning: Cardboard shipping package provides limited humidity and moisture protection. This product

can only function properly and safely if it is correctly transported, stored, installed, set up, operated, and

maintained.

This product is intended for use in industrial areas. Operation of this equipment in a residential area

may cause interference to several frequency based communications.

Note: Always use product in accordance with specifications.

Copyright Siemens AG 2012. All Rights

Disclaimer of Liability

Reserved

This document is available in bound version and in

electronic version. We encourage users to purchase

authorized bound manuals, or to view electronic

versions as designed and authored by Siemens

Milltronics Process Instruments. Siemens Milltronics

Process Instruments will not be responsible for the

contents of partial or whole reproductions of either

bound or electronic versions.

While we have verified the contents of this

manual for agreement with the

instrumentation described, variations remain

possible. Thus we cannot guarantee full

agreement. The contents of this manual are

regularly reviewed and corrections are

included in subsequent editions. We welcome

all suggestions for improvement.

Technical data subject to change.

MILLTRONICS®is a registered trademark of Siemens Milltronics Process Instruments.

Contact SMPI Technical Publications European Authorized Representative

at the following address:

Technical Publications Siemens AG

Siemens AG Industry Sector

Siemens Milltronics Process Instruments 76181 Karlsruhe

1954 Technology Drive, P.O. Box 4225 Deutschland

Peterborough, Ontario, Canada, K9J 7B1

Email: techpubs.smpi@siemens.com

For a selection of Siemens Milltronics level measurement manuals, go to:

www. siemens.com/processautomation. Under Process Instrumentation, select

Measurement

For a selection of Siemens Milltronics weighing manuals, go to:

www. siemens.com/processautomation. Under Weighing Technology, select

Weighing Systems

and then go to the manual archive listed under the product family.

and then go to the manual archive listed under the product family.

Level

Continuous

© Siemens AG 2012

Table of Contents

Table of Contents

SITRANS RD200 .................................................................................................................1

SITRANS RD200 ....................................................................................................................................1

Safety Notes ...........................................................................................................................................1

The Manual ............................................................................................................................................2

Specifications ....................................................................................................................3

Power............................................................................................................................................. 3

Mounting....................................................................................................................................... 3

Memory ......................................................................................................................................... 4

Programming................................................................................................................................ 4

Display ........................................................................................................................................... 4

Outputs........................................................................................................................................... 4

Serial Communications.............................................................................................................. 5

Inputs.............................................................................................................................................. 6

Enclosure ...................................................................................................................................... 6

Weight............................................................................................................................................ 6

Approvals...................................................................................................................................... 6

Dimensions .........................................................................................................................7

RD200 Meter Dimensions - Side View .............................................................................................7

RD200 Case Dimensions - Top View ................................................................................................7

Installation ..........................................................................................................................9

Unpacking ...............................................................................................................................................9

Panel Mounting Instructions ..............................................................................................................9

Connections .........................................................................................................................................11

Connector Labeling ...................................................................................................................11

Power Connections ..................................................................................................................11

Signal Connections ...................................................................................................................12

Serial Communication ..............................................................................................................15

Relays and 24 V Output Connections ...................................................................................15

4 to 20 mA Output and Input Signal Connections ..............................................................15

mmmmm

Setup ..................................................................................................................................17

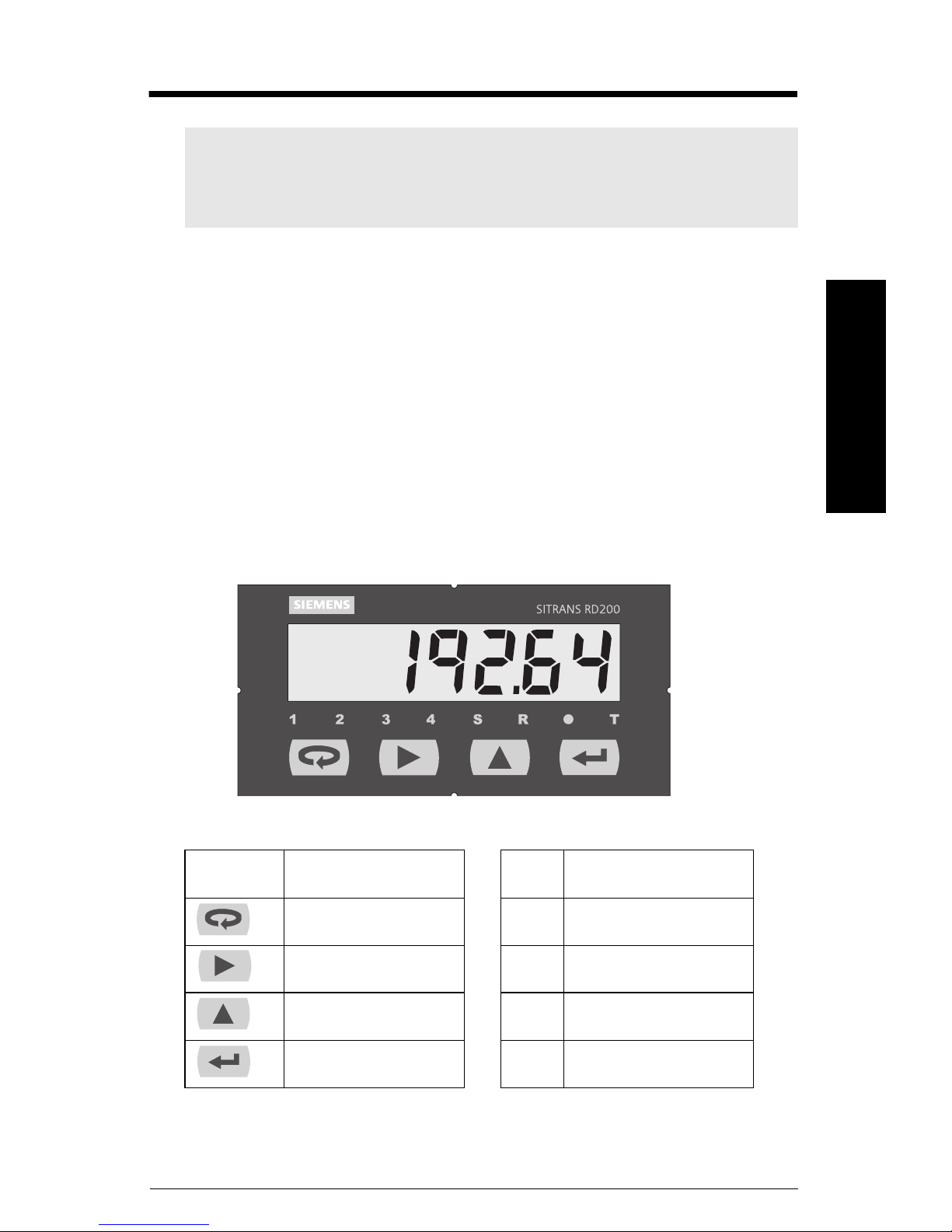

Front panel buttons and status LED indicators ............................................................................17

Display functions and messages ....................................................................................................18

Main menu ............................................................................................................................................20

Setting numeric values ......................................................................................................................20

Setting up the meter (SEtu) ..............................................................................................................20

Setting the input signal (inPt) .................................................................................................21

Setting the decimal point (dEc.P) ..........................................................................................23

Setting the temperature scale (F C) ......................................................................................23

Setting relay operation (rELY) ................................................................................................24

Relay and Alarm Operation ....................................................................................................27

Scaling the 4 to 20 mA analog output (Aout) ......................................................................33

Program sensor break output value (SEbr) ........................................................................34

Analog output when display is out of range .......................................................................34

Programming the meter (ProG) .......................................................................................................35

Scaling the 4 to 20 mA analog input (ScAL) ........................................................................35

i

mmmmm

Calibrating the SITRANS RD200 (CAL) .................................................................................36

Recalibrating temperature inputs (CAL) ..............................................................................37

Recalibrating process inputs (ICAL) .....................................................................................38

Security .................................................................................................................................................39

Locking the meter by setting a password (PASS) ............................................................39

Unlocking the meter (unLC) ....................................................................................................39

Advanced Features Menu ................................................................................................................41

Advanced features menu and display messages .............................................................41

Table o f Cont en ts

Offset adjustment (Adj) ............................................................................................................42

Noise filter (FLtr) ........................................................................................................................43

Noise filter bypass (bYPS) ......................................................................................................43

Serial communications (SErL) ................................................................................................44

Select menu (SELc) ...................................................................................................................45

SITRANS RD Software .............................................................................................................47

Meter copy function (CoPY) ...................................................................................................47

Internal calibration (ICAL) .......................................................................................................48

Troubleshooting .........................................................................................................................50

Operation ..........................................................................................................................53

Front panel buttons operation .........................................................................................................53

Maximum/Minimum readings ..........................................................................................................53

Appendix A - Factory Defaults ......................................................................................55

Appendix B - Troubleshooting Tips .............................................................................57

Appendix C - Quick User Interface Reference Guide ...............................................59

Appendix D - Serial Communication Protocol (PDC) ...............................................61

SITRANS RD200 PDC .........................................................................................................................61

Table of Commands ..................................................................................................................62

Command Packet Format ........................................................................................................63

Reply Packet Format ................................................................................................................64

Read Only Commands ..............................................................................................................64

No-Data Commands .................................................................................................................67

Read/Write Commands ...........................................................................................................69

Appendix E - Modbus Register Tables ........................................................................85

Register Overview ..............................................................................................................................85

Tables ....................................................................................................................................................95

Input configuration ....................................................................................................................95

Decimal Point for RD200 ..........................................................................................................96

Relay Configuration ..................................................................................................................96

4-20 mA Output Modes ...........................................................................................................97

Available Register Table .........................................................................................................97

ii

SITRANS RD200

SITRANS RD200

SITRANS RD200 is a universal input, panel mount remote digital display for process

instrumentation.

It accepts a single input of current, voltage, thermocouple, or RTD signals, and the four

front panel buttons make the setup and programming an easy task.

The isolated 24 V DC transmitter power (optional) can be used to power the input

transmitter, the 4 to 20 mA output, or other devices.

Two relays (optional) can be used for alarm indication or process control applications,

such as alternating pump control.

4-20 mA isolated output and Modbus® RTU serial communication options make

SITRANS RD200 an excellent addition to any system.

Safety Notes

Special attention must be paid to warnings and notes highlighted from the rest of the text

by grey boxes.

CAUTION: relates to the caution symbol on the product, and means

that failure to observe the necessary precautions can result in

electric shock.

WARNING: relates to a caution symbol on the product, and means

that failure to observe the necessary precautions can result in

death, serious injury, and/or considerable material damage.

SITRANS RD200

mmmmm

WARNING: means that failure to observe the necessary precautions

can result in death, serious injury, and/or considerable material

damage.

CAUTION: means that failure to observe the necessary precautions can

result in considerable material damage.

Note: means important information about the product or that part of the operating

manual.

7ML19985JS01 SITRANS RD200 – OPERATING INSTRUCTIONS Page 1

The Manual

This manual provides instructions for the SITRANS RD200 remote display. The manual is

designed to help you get the most out of your Remote Display, and it provides information

on the following:

• Product specifications

• Outline diagrams

• Installation requirements

• Wiring diagrams

• How to program the unit

• Principles of operation

• Troubleshooting tips

• Factory defaults

• Quick user reference

mmmmm

If you have any questions, comments, or suggestions about the manual contents, please

email us at techpubs.smpi@siemens.com

.

SITRANS RD200

For the complete library of Siemens Milltronics manuals, go to www.siemens.com/

processautomation.

Page 2 SITRANS RD200 – OPERATING INSTRUCTIONS 7ML19985JS01

Specifications

Power

Input voltage option 1

• 85 to 265 V AC, 50/60 Hz; 90 to 265 V DC, 20 W max.

• UL Recognized, 5 A max, slow blow

• May share one 5 A fuse among up to 6 meters

Input voltage option 2

• 12 to 36 V DC, 12 to 24 V AC, 6 W max.

• UL Recognized, 5 A max, slow blow

• May share one 5 A fuse among up to 6 meters

Transmitter power supply

One or two isolated transmitter power supplies (optional)

• Single power supply: one 24 V DC ± 10% @ 200 mA maximum

• Dual power supplies: one 24 V DC ± 10% @ 200 mA maximum, and

one 24 V DC ± 10% @ 40 mA maximum

External loop power supply

• 35 V DC maximum

Specifications

mmmmm

Input impedance

• Voltage ranges: greater than 1 MΩ

• Current ranges: 50 - 100 Ω (depending on resettable fuse impedance)

Output loop resistance

• 24 V DC 10 to 700 Ω maximum

• 35 V DC (external) 100 to 1200 Ω maximum

Mounting

Location

• Indoor/outdoor

• Panel mount 1/8 DIN

• Two panel mounting bracket assemblies provided

Ambient temperature

• Operating temperature range: 0 to +65 °C (0 to +149 °F)

• Storage temperature range: -40 to +85 °C (-40 to +185 °F)

Relative humidity

• Relative humidity: 0 to 90% non-condensing

7ML19985JS01 SITRANS RD200 – OPERATING INSTRUCTIONS Page 3

Installation category

•II

Memory

• Non-volatile

• Stores settings for minimum of ten years if power is lost

Programming

Primary

• Front panel

Secondary

• Meter Copy

• PC with SITRANS RD Software

Display

• 14 mm (0.56") high, red LED

• Four digits (-1999 to 9999), automatic lead zero blanking

• Eight intensity levels

• 2x option: 30.5 mm (1.20") high, red LED

Update Rate

mmmmm

• Process/RTD: 3.7 to 5/second

• Thermocouple: 1.8 to 2.5/second

Specifications

Overange

• Display flashes 9999

Underange

• Display flashes -1999

Outputs

mA Analog

• 4 to 20 mA

• Isolated (optional)

Relays

1

• 2 SPDT Form C relays, 3A (optional)

• Auto initializing

• All relays rated 3A @ 30 V DC or 3A @ 250 V AC, non-inductive

1.

All relays are certified only for use with equipment that fails in a state at or

under the rated maximums of the relays.

Page 4 SITRANS RD200 – OPERATING INSTRUCTIONS 7ML19985JS01

Control Relays

• Pump alternation

• On and off time delay

• Fail-safe or non fail-safe

• Front panel ACK or PC

Alarm Relay

• High or low alarm

• 0 to 100% deadband, user selectable

• Auto and manual reset via front panel or PC

• Latch or non-latch

Accuracy

• ±0.1% FS ±0.004 mA

Serial Communications

Note: The RD200 does not support 8N1. It will be fixed to 8N2 when parity setting

"None" is selected.

Connections

•PDC standard

• RS-232 or RS-422/485 running Modbus®RTU and ASCII via RJ-11 connector

Setup

• Meter address

• PDC protocol: 0 to 99

• Modbus protocol: 1 to 247

•Baud rate

• 300 to 19200 bps

• Transmit time delay

• Programmable between 0 and 199 ms or transmitter always on for RS-422

communication

•Data

• 8 bit (1 start bit, 1 stop bit)

•Parity

• None, even, or odd (Modbus only; PDC protocol does not use parity)

• Byte-to-Byte timeout

• 0.01 to 2.54 sec (Modbus only)

• Turn around delay

• Less than 2 ms (fixed)

Refer to

Modbus Register Tables

Appendix D - Serial Communication Protocol (PDC)

on page 85 for details.

on page 61 and

Specifications

mmmmm

Appendix E -

Software

• SITRANS RD Software

7ML19985JS01 SITRANS RD200 – OPERATING INSTRUCTIONS Page 5

Inputs

Process (field selectable)

• ±20 mA DC (4 to 20 mA, 0 to 20 mA)

• ±10 V DC (1 to 5 V, 0 to 5 V, 0 to 10 V)

Temperature (field selectable)

Thermocouple temperature:

• Type J, K, E, T, Type T using 0.1 ° display resolution

RTD temperature:

•100 Ω RTD

Accuracy

•Process

• ±0.05% of span ±1 count, square root: 10 to 100% FS

• Thermocouple temperature

• Type J: ±1 °C in range -50 to +750 °C (±2 °F in range -58 to +1382 °F)

•Type K: ±1 °C in range -50 to +1260 °C (±2 °F in range -58 to +2300 °F)

• Type E: ±1 °C in range -50 to +870 °C (±2 °F in range -58 to +1578 °F)

•Type T: ±1 °C in range -180 to +371 °C (±2 °F in range -292 to +700 °F)

• Type T, 0.1 °Res: ±1 °C in range -180.0 to +371 °C (±1.8 °F in range -199.9 to

+700 °F)

• RTD temperature

•100 Ω RTD: ±1 °C in range -200 to +750 °C (±1 °F in range -328 to +1382 °F)

mmmmm

Specifications

Enclosure

• High impact plastic, UL 94V-0

• Color: gray

• Degree of protection: front panel Type 4X, NEMA 4X, IP65; panel gasket provided

• 62 mm x 119 mm x 106 mm (2.45" x 4.68" x 4.19") (H x W x D)

• Optional thermoplastic, stainless steel, steel, for 1-6 meters (all with UL Listing and

CSA Certification)

• Optional polycarbonate for 1 meter [available with optional zinc plated or stainless

steel 2" (5.08 cm) mounting kits]

Weight

• 269 g (9.5 oz) (including options)

Approvals

•CE

•UL

•

UL

C

Note: Testing was conducted on SITRANS RD200 meters installed through the covers

of grounded metal enclosures with cable shields grounded at the point of entry

representing installations designed to optimize EMC performance.

Page 6 SITRANS RD200 – OPERATING INSTRUCTIONS 7ML19985JS01

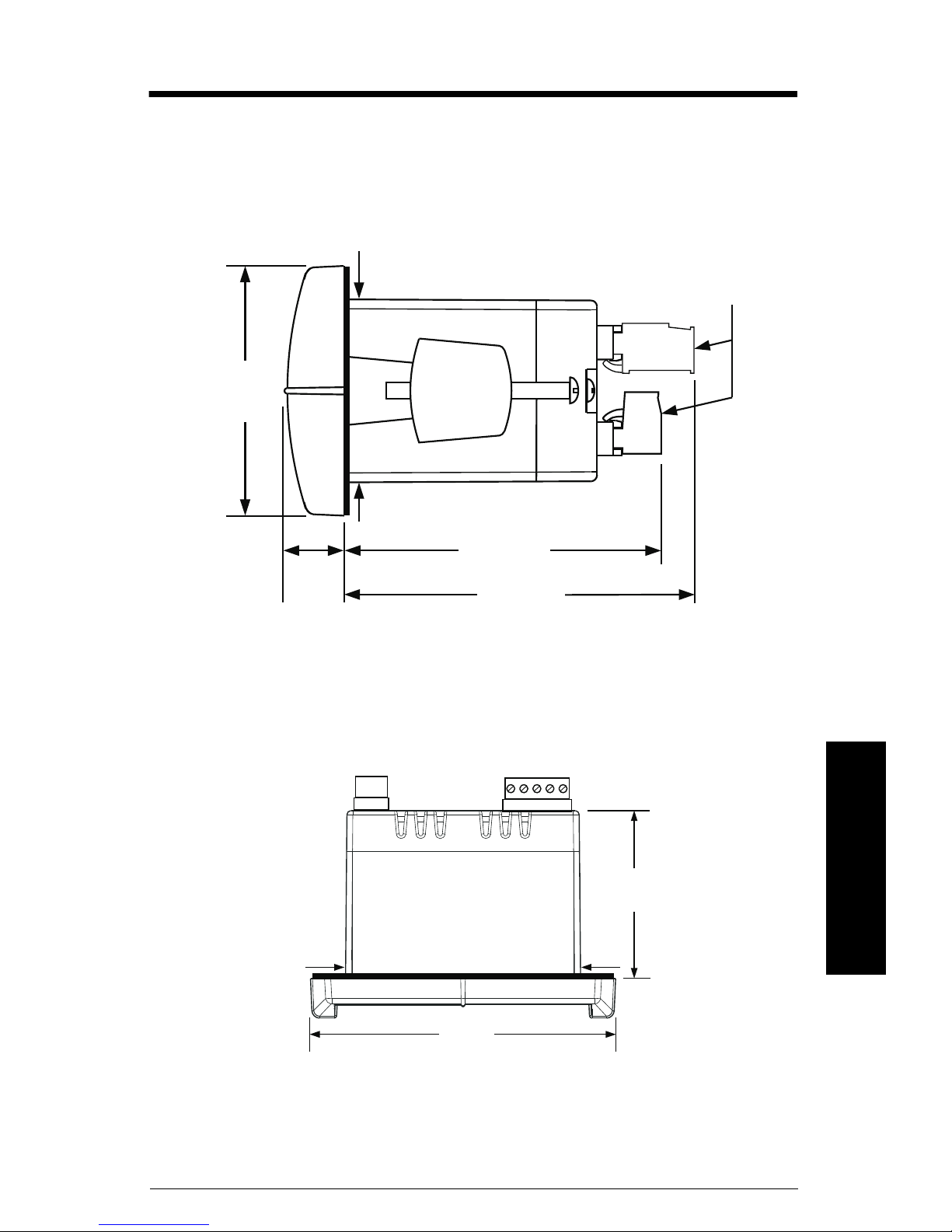

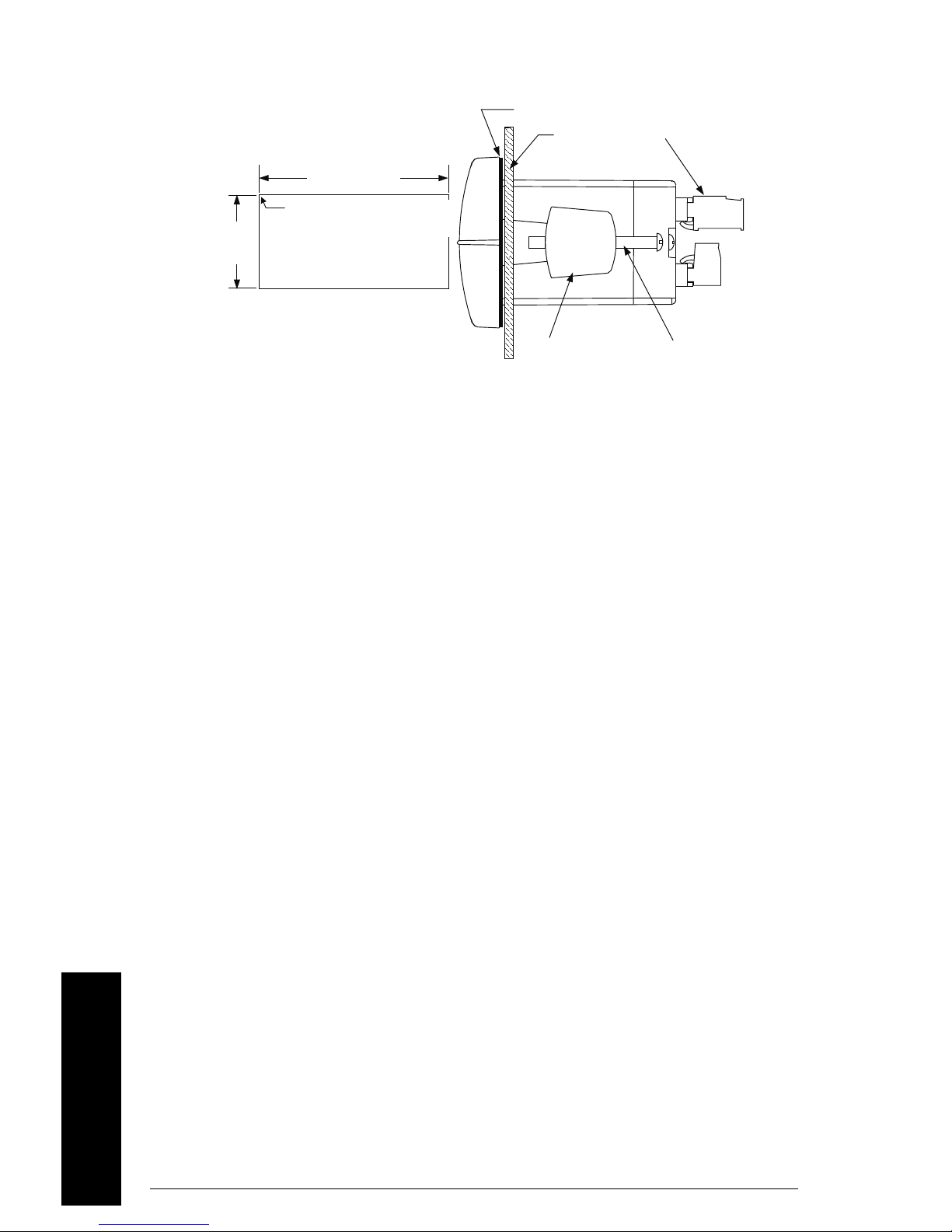

Dimensions

45 mm

(1.76")

62 mm

(2.45")

15 mm

(0.59")

81 mm

(3.2")

91 mm

(3.6")

Screw terminal connector

[0.5 Nm (4.5 lb/in)

tightening torque]

64 mm

(2.5")

119 mm

(4.68")

92 mm

(3.61")

RD200 Meter Dimensions - Side View

RD200 Case Dimensions - Top View

7ML19985JS01 SITRANS RD200 – OPERATING INSTRUCTIONS Page 7

Dimensions

mmmmm

Notes

mmmmm

Dimensions

Page 8 SITRANS RD200 – OPERATING INSTRUCTIONS 7ML19985JS01

Installation

WARNING: Risk of electrical shock.

WARNING: Hazardous voltages exist within enclosure. Installation

and service should be performed only by trained service personnel.

CAUTION: Read complete instructions prior to installation and operation

of the meter.

Notes:

• There is no need to remove the meter from its case to complete the

installation, wiring, and setup of the meter.

• Installation must only be performed by qualified personnel, and in

accordance with local governing regulations.

Unpacking

Remove the meter from box. Inspect the packaging and contents for damage. Report

damages, if any, to the carrier.

If any part is missing or the meter malfunctions, please contact your local Siemens

representative for assistance.

Panel Mounting Instructions

1. Prepare a standard 1/8 DIN panel cutout – 92 mm x 45 mm (3.622 " x 1.772 ").

• Clearance: allow at least 102 mm (4 ") behind the panel for wiring

• Panel thickness: 1.0 mm to 6.4 mm (0.04 " to 0.25")

• Recommended minimum panel thickness to maintain Type 4X

rating: 1.5 mm (0.06 ") steel panel, 4.1 mm (0.16 ") plastic panel.

Refer to

2. Remove the two mounting brackets provided with the meter. Back off the two

3. Insert meter into the panel cutout.

4. Install mounting brackets and tighten the screws against the panel. To achieve a

Troubleshooting

screws so that there is 6.4 mm (¼ ") or less through the bracket. Slide the bracket

toward the front of the case and remove.

proper seal, tighten the mounting bracket screws evenly until meter is snug to the

panel along its short side. DO NOT OVER TIGHTEN, as the rear of the panel may be

damaged.

on page 50 for more details.

Installation

mmmmm

7ML19985JS01 SITRANS RD200 – OPERATING INSTRUCTIONS Page 9

Panel Cutout and Mounting

92 mm (3.622")

square corners to 1.5 mm

(0.060") max radius

A

45 mm

(1.772")

panel cutout

to DIN 43700

B

tolerances:

A: +0.8 mm (+0.032")

-0.0 mm (-0.000 ")

B: +0.6 mm (+0.024")

-0.0 mm (-0.000")

mounting

bracket

mounting

screw

removable

connectors

panel

gasket

mmmmm

Installation

Page 10 SITRANS RD200 – OPERATING INSTRUCTIONS 7ML19985JS01

Connections

!

AC or DC

power

required external fuse: 5

A max, slow blow

power

connector

Notes:

• Verify that all system components are installed in accordance with

instructions.

• All connections are made to removable screw terminal connectors located

at the rear of the meter.

WARNING:

• Use copper wire with +60 °C or +60/75 °C (+140 °F or +140/167 °F)

insulation for all line voltage connections.

• Observe all safety regulations.

• Electrical wiring should be performed in accordance with all

applicable national, state, and local codes to prevent damage to

the meter and ensure personnel safety.

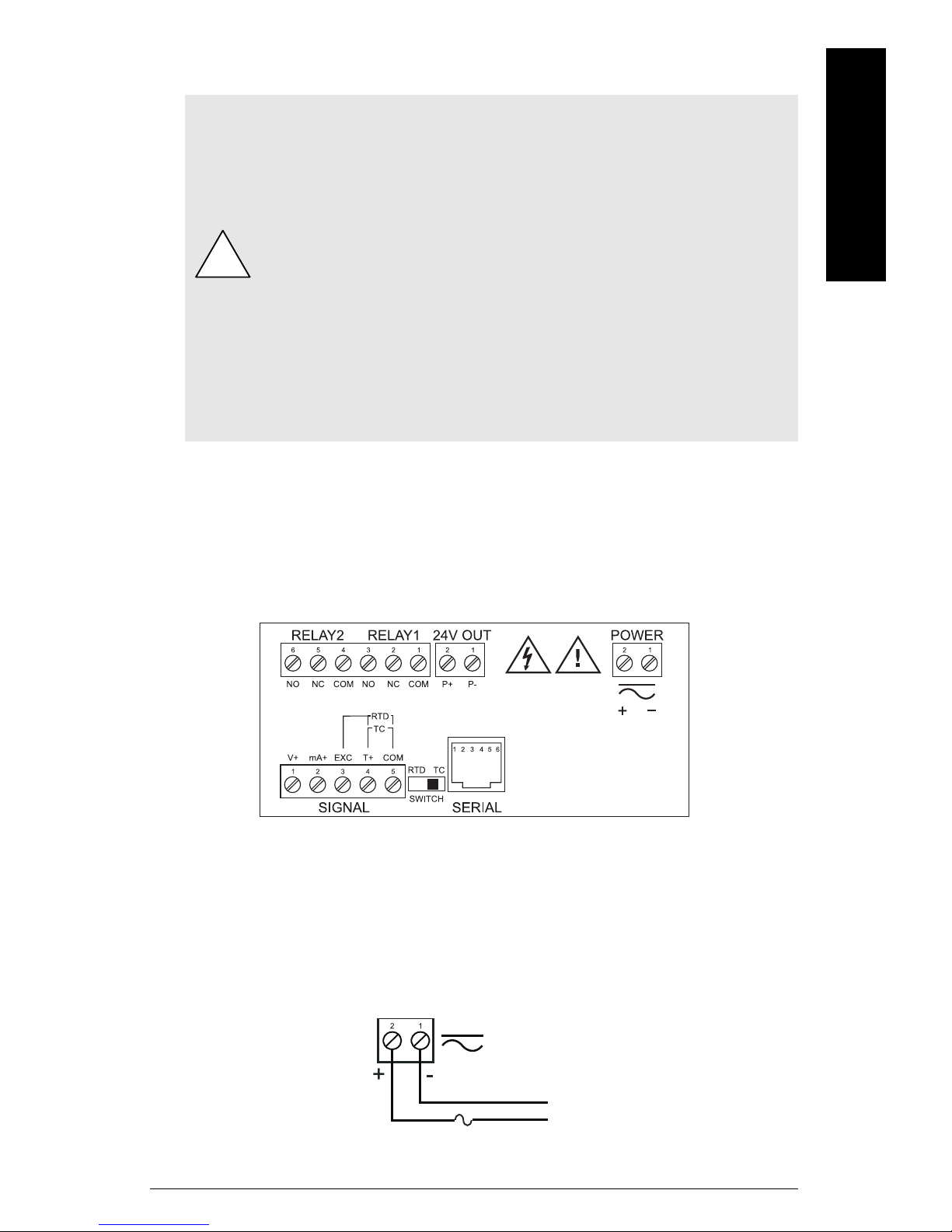

Connector Labeling

The connectors label, affixed to the meter, shows the location of all connectors available

with requested configuration. It also identifies the location of the RTD/TC selector switch.

Connections

mmmmm

Connector Labeling for Two Relays and 24 V Supply

Power Connections

Power connections are made to a two-terminal connector labeled POWER on diagram

Connector Labeling for Two Relays and 24 V Supply. The meter will operate regardless of

DC polarity connection. The + and - symbols are only a suggested wiring convention.

7ML19985JS01 SITRANS RD200 – OPERATING INSTRUCTIONS Page 11

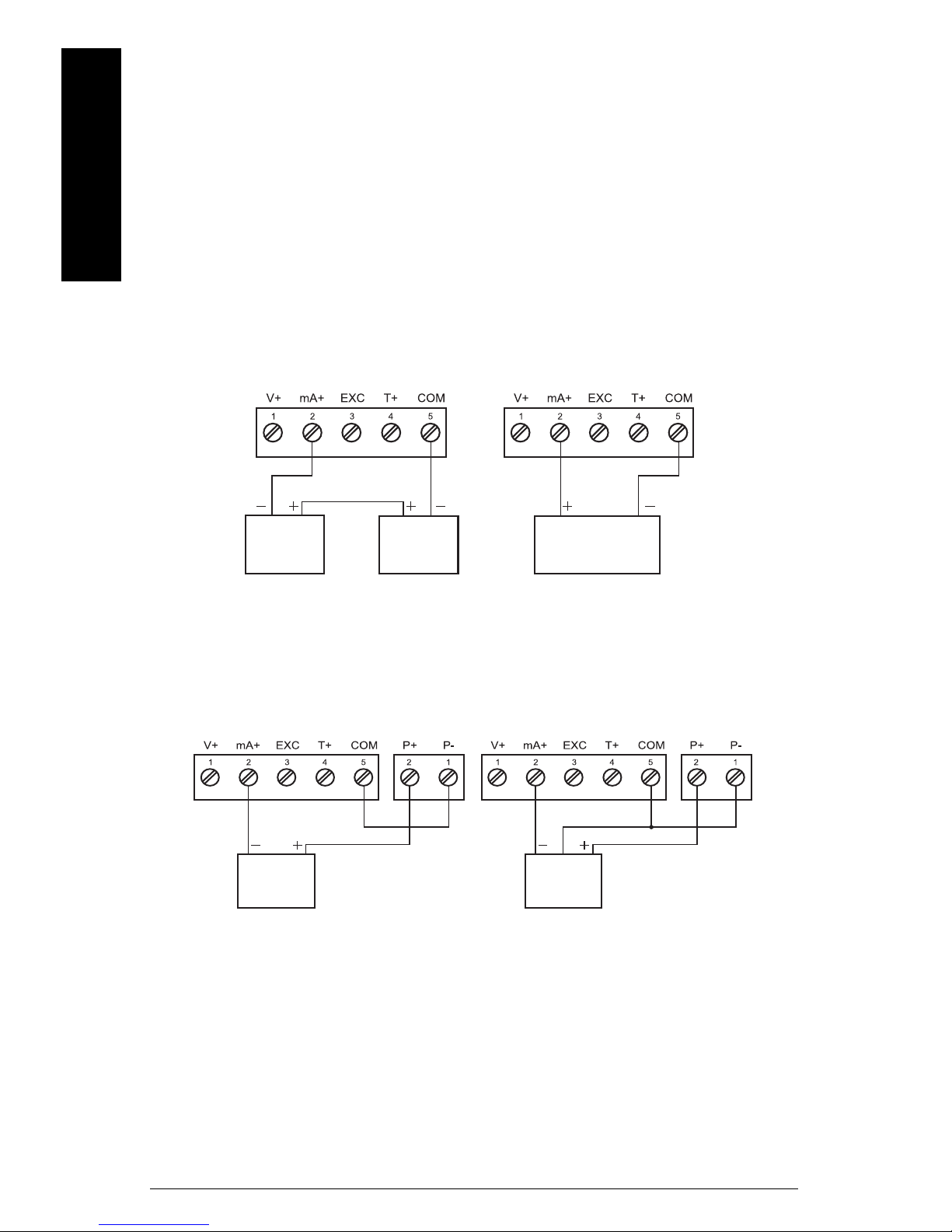

mmmmm

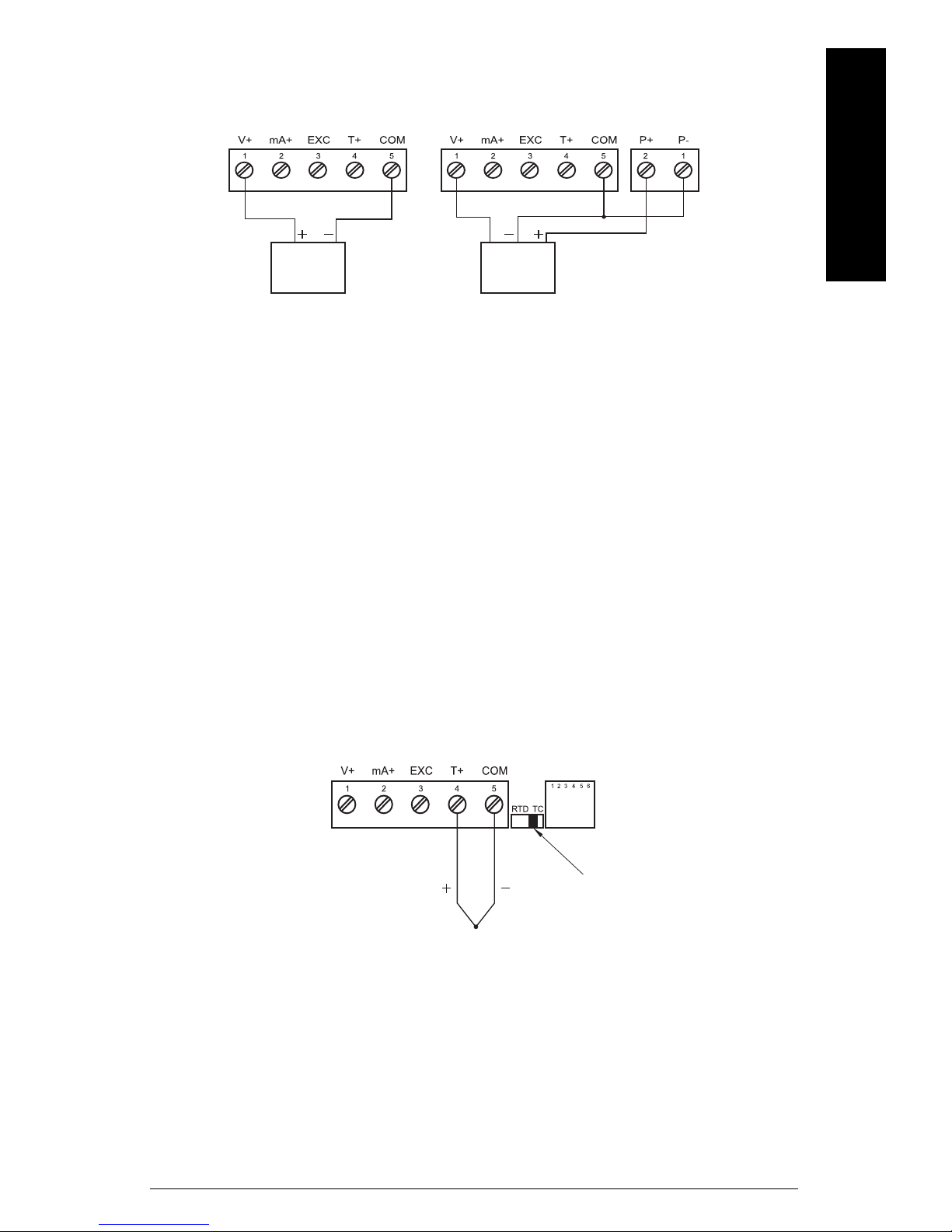

Transmitter powered by ext. supply or self-powered

signal connector

signal connector

2-wire

4 to 20 mA

transmitter

external

power

supply

2-wire 4 to 20 mA

self-powered

transmitter

2-wire

4 to 20 mA

transmitter

3-wire

4 to 20 mA

transmitter

signal connector

signal connector

24 V out

24 V out

signal

Transmitter powered by internal supply (optional)

Signal Connections

Signal connections are made to a five-terminal connector labeled

SIGNAL on diagram Connector Labeling for Two Relays and 24 V Supply. The COM

(common) terminal is the return for all types of input signals.

Current and Voltage Connections

Connections

The following figures show examples for current and voltage connections.

There are no switches or jumpers to set up for current and voltage inputs. Setup and

programming is performed through the front panel buttons.

The current input is protected against current overload by a fuse capable of being reset.

The display may or may not show a fault condition depending on the nature of the

overload.

The fuse limits the current to a safe level when it detects a fault condition, and

automatically resets itself when the fault condition is removed.

Page 12 SITRANS RD200 – OPERATING INSTRUCTIONS 7ML19985JS01

voltage

signal

3-wire

voltage

transducer

signal connector

signal connector

signal

24 V out

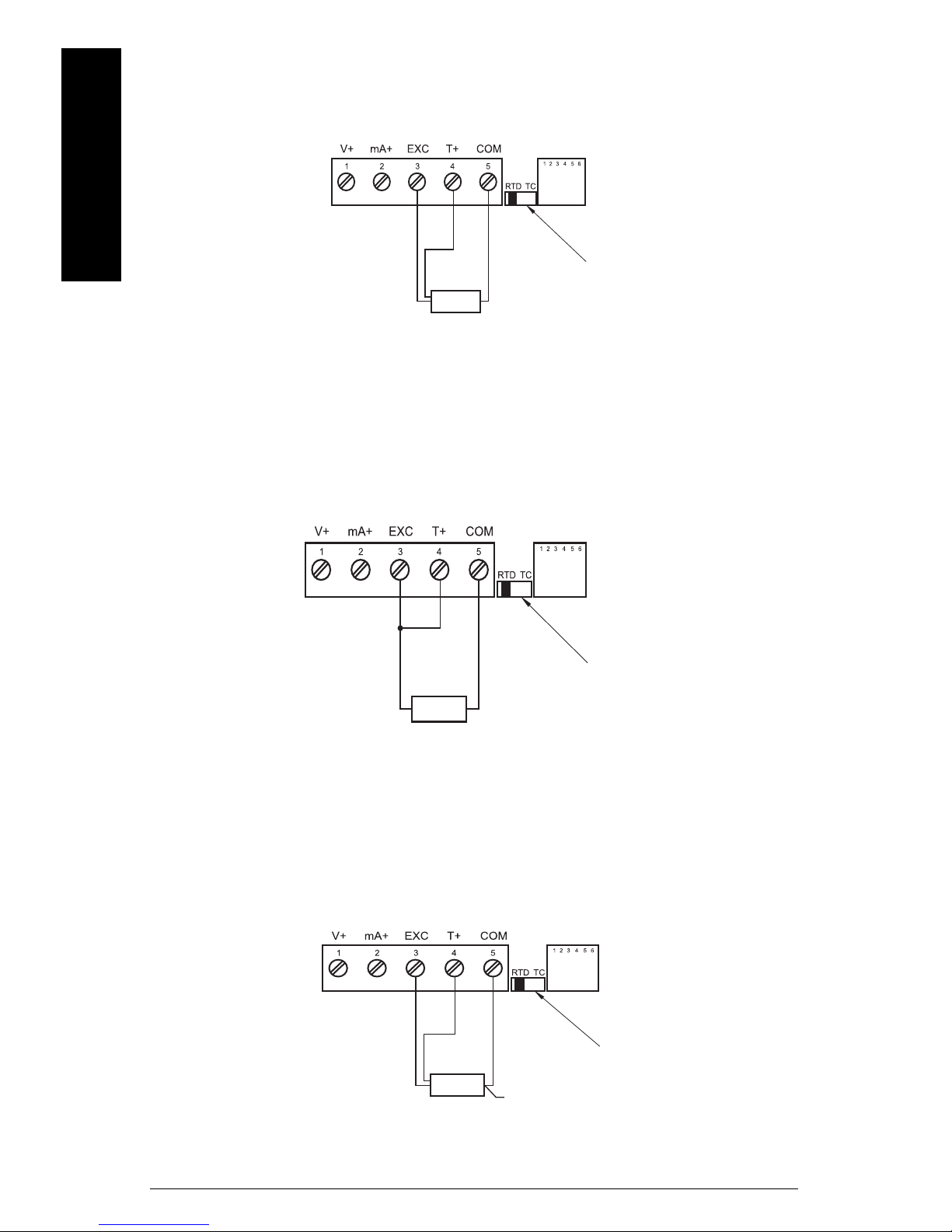

Thermocouple input connections

signal connector

TC

switch position

Voltage input connections

The meter is capable of accepting any voltage from -10 V DC to +10 V DC.

Thermocouple and RTD connections

The following figures show examples for thermocouple and RTD connections.

Connections

mmmmm

The RTD/TC selector switch must be set to the proper position for the meter to accept the

selected temperature input.

The input type is selected using the Setup (

Selected thermocouple input must correspond to thermocouple sensor and wire type

used.

SEtu

) menu.

7ML19985JS01 SITRANS RD200 – OPERATING INSTRUCTIONS Page 13

mmmmm

Three-wire RTD input connections

switch position

signal connector

RTD

sensor

Two-wire RTD input connections

signal connector

switch position

RTD

sensor

Four-wire RTD input connections

signal connector

switch position

RTD

sensor

NC

Connections

The meter accepts two, three, or four-wire RTDs. The three-wire RTD connection has

built-in lead wire compensation.

Lead wire compensation for two-wire RTDs can be applied using the Adjust (

Offset adjustment (Adj)

See

Page 14 SITRANS RD200 – OPERATING INSTRUCTIONS 7ML19985JS01

on page 42.

Adj

) menu.

The four-wire RTD connection is similar to the three-wire. One of the leads of a four-wire

RTD is not connected, and may be clipped off.

Connections

The three-wire connection provides sufficient lead wire compensation to provide

accurate readings even with long leads.

Serial Communication

Serial communication connection is made to an RJ11 connector labeled SERIAL on

Connector Labeling for Two Relays and 24 V Supply

Device to use For interfacing

RS232 serial adapter RS232

RS422/485 serial adapter RS422/485

SITRANS RD200 meter copy cable Meter-to-meter (for cloning purposes -

copying programmed settings from one

meter to other meters)

on page 11.

mmmmm

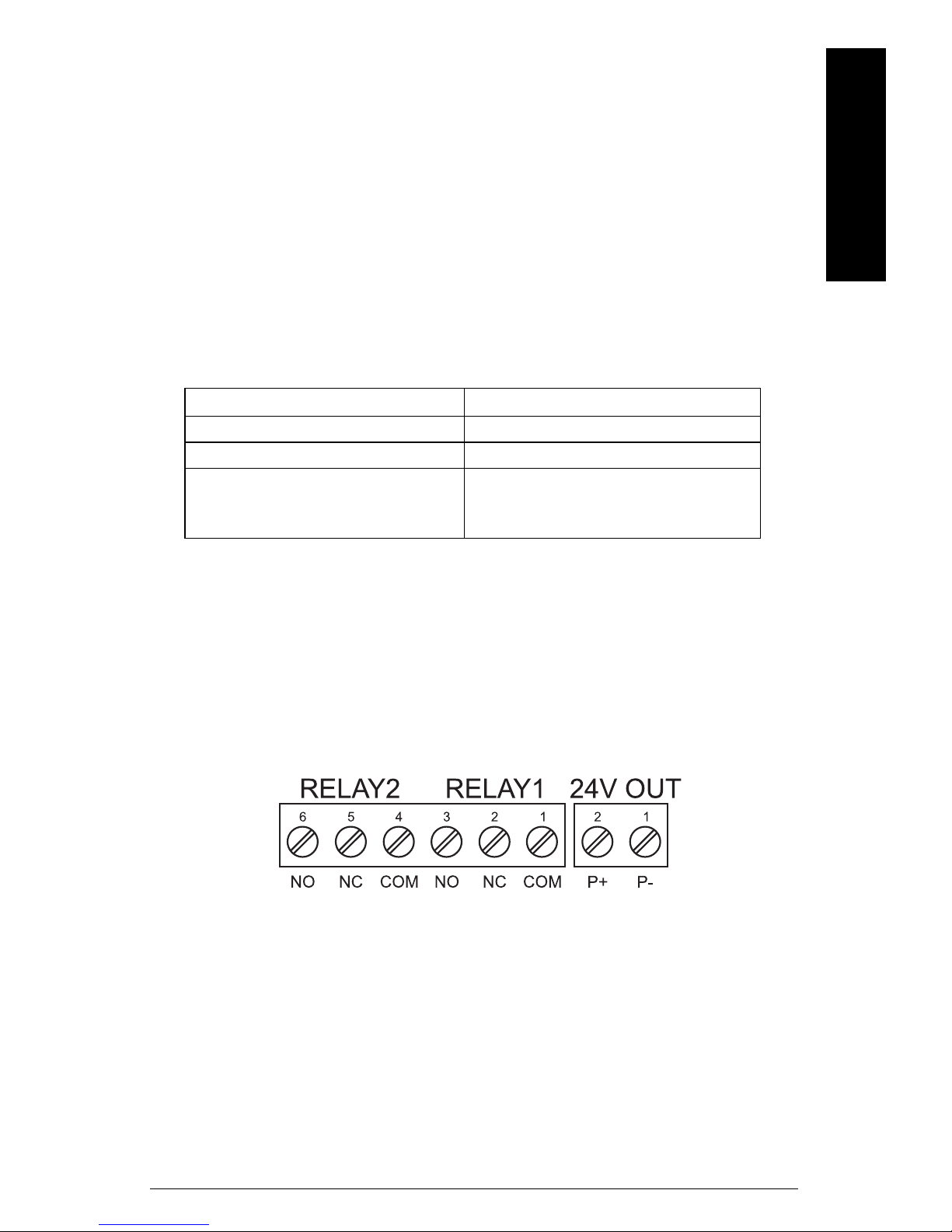

Relays and 24 V Output Connections

Relay connections are made to a six-terminal connector labeled

RELAY1, RELAY2 on

COM (common) terminals of the relays should not be confused with the COM (common)

terminal of the SIGNAL connector. The 24 V DC output is available at the connector

labeled 24V OUT, next to the relay connector.

Connector Labeling for Two Relays and 24 V Supply

on page 11. The

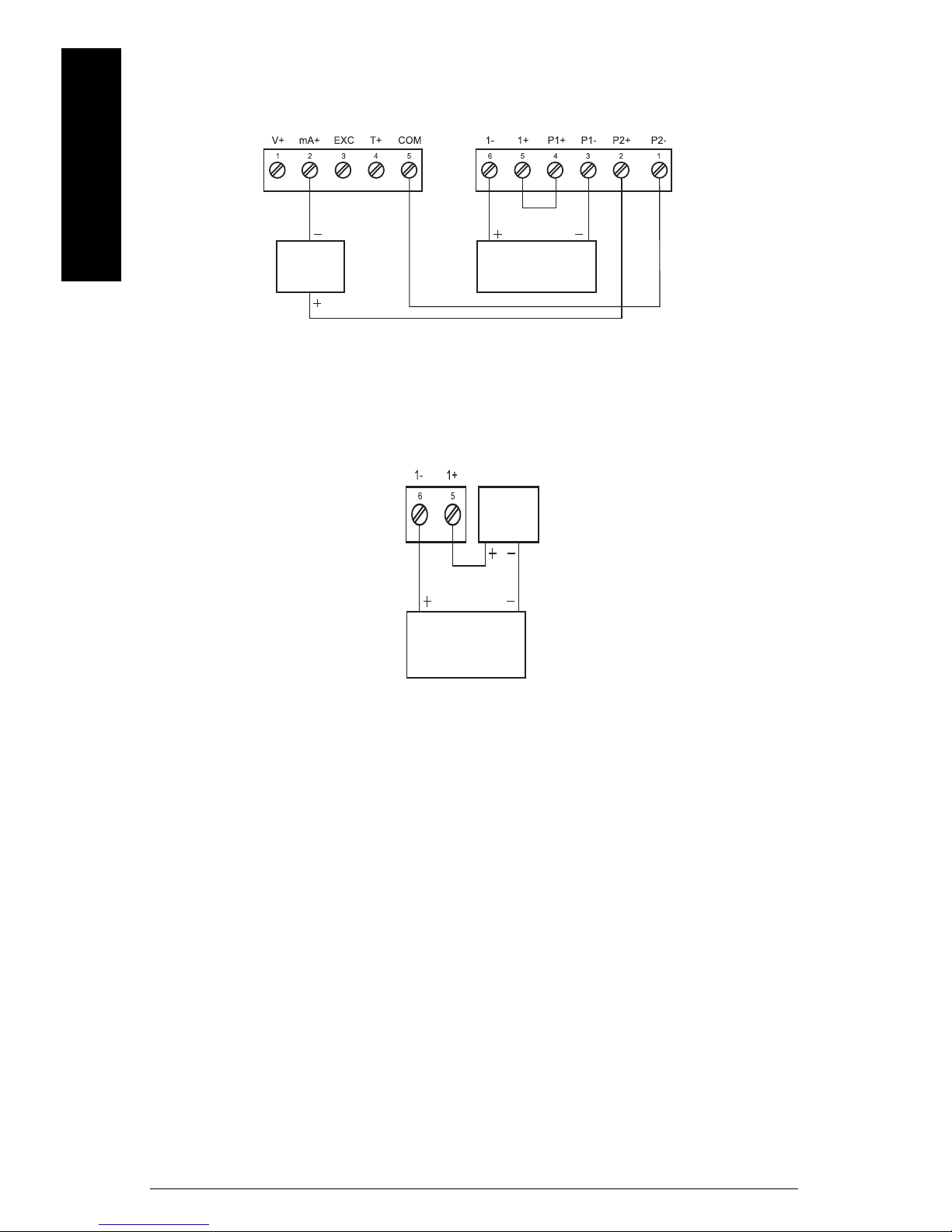

4 to 20 mA Output and Input Signal Connections

Connections for the 4 to 20 mA transmitter output are made to the connector terminals

labeled mA OUT, I-, I+. The 4 to 20 mA output may be powered from an internal power

supply (optional) or from an external power supply.

7ML19985JS01 SITRANS RD200 – OPERATING INSTRUCTIONS Page 15

mmmmm

4 to 20 mA Output and Input Signal Powered by Meter

signal connector

2-wire

4 to 20 mA

transmitter

remote display,

chart recorder

mA out

24 V out

4 to 20 mA Output Powered Externally

remote display,

chart recorder

mA out

external

power

supply

Connections

Page 16 SITRANS RD200 – OPERATING INSTRUCTIONS 7ML19985JS01

Setup

Notes:

• The meter is factory calibrated prior to shipment, for all input types, in

milliamps, volts, and degrees respectively.

• The calibration equipment is certified to NIST standards.

There are no jumpers involved in the setup of the meter. The RTD/TC selector switch,

located between the SIGNAL and SERIAL connectors, must be set accordingly for the

meter to accept RTD or thermocouple inputs. See Connector Labeling diagram on

page 11.

Setup and program the device using the front panel buttons.

After power and signal connections have been completed and verified, apply power to

the meter.

See

Appendix C - Quick User Interface Reference Guide

on page 59 for more

details.

Front panel buttons and status LED indicators

Setup

mmmmm

Button

Symbol

Menu 1 Alarm 1

Right arrow/Reset 2 Alarm 2

Up arrow/Max S Set point indicator

Enter/Ack R Reset point indicator

7ML19985JS01 SITRANS RD200 – OPERATING INSTRUCTIONS Page 17

Description LED Status

Press Menu to enter or exit Program Mode at any time.

Press Right arrow to move to the next digit during programming.

Press Up arrow to scroll through the menus, decimal point, or to increment the

value of a digit.

Press Enter/Ack to access a menu or to accept a setting.

Press and hold Right arrow and Menu for three seconds to access

Advanced Features menu of the meter.

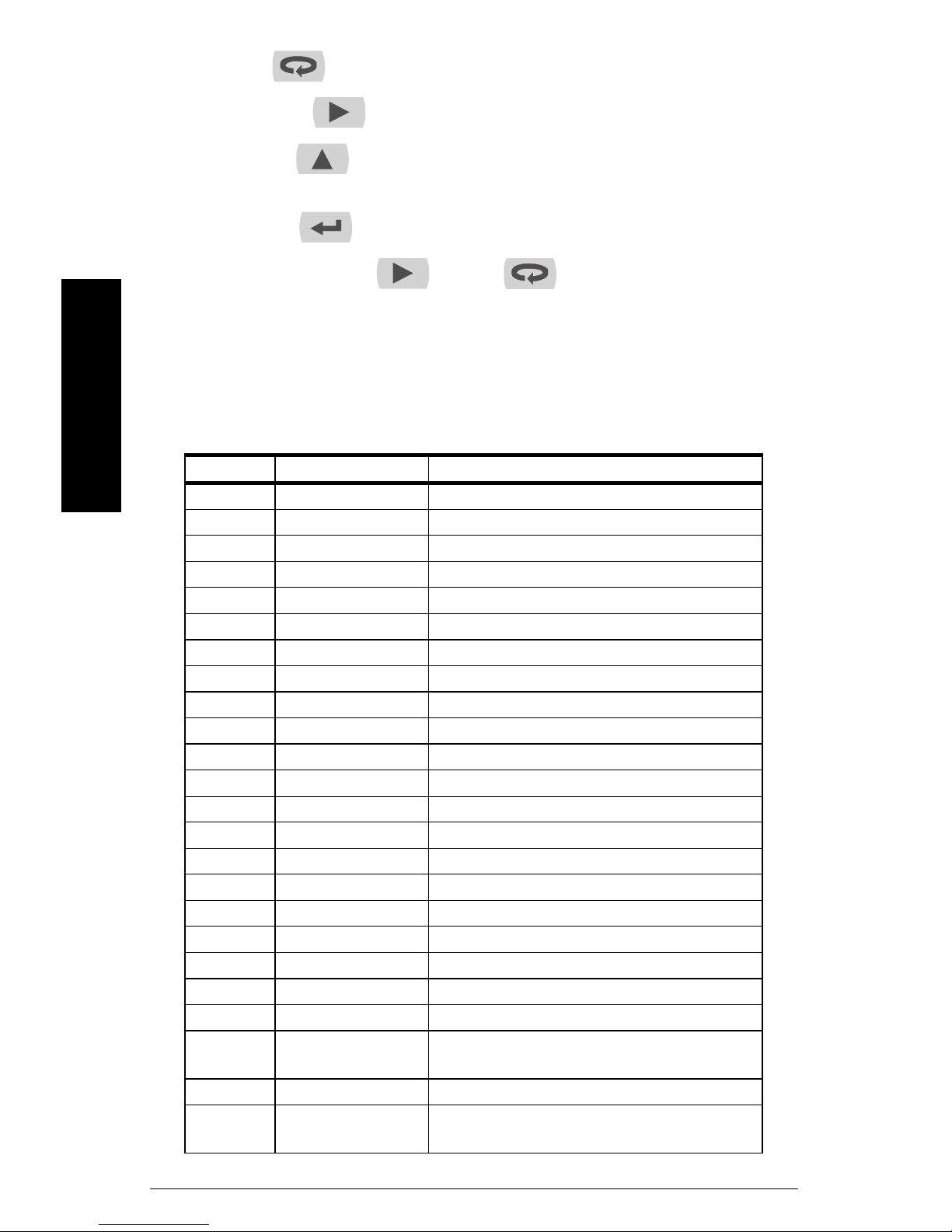

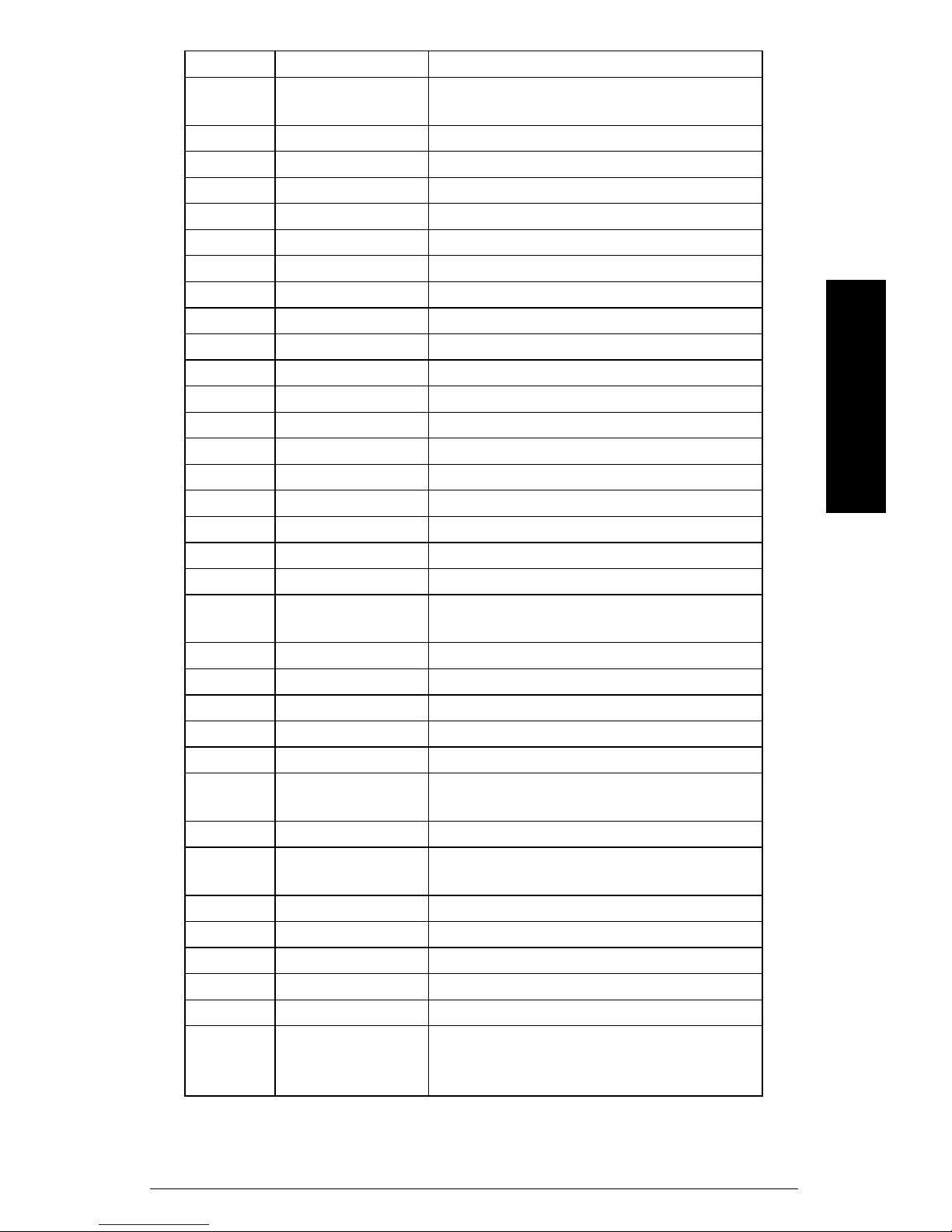

Display functions and messages

mmmmm

Setup

The following table shows the displayed functions and messages with their action/setting

description.

Display Parameter Action/Setting

SEtu Setup Enter Setup menu

inPt Input Enter Input menu

4-20 4-20 mA Set meter for 4 to 20 mA input

0-10 0-10 VDC Set meter for ±10 VDC input

rtd RTD Set meter for RTD input

A385 Alpha 385 Set α = 0.00385 European curve 100Ω RTD

A392 Alpha 392 Set α = 0.00392 American curve 100Ω RTD

tC TC Set meter for TC input

0 J 0 J Type J

1 k 1 K Type K

2 T 2 T Type T

3 t.0 3 T.0 Type T, 0.1° resolution

4 E 4 E Type E

F C °F or °C Set temperature scale

°F °F Set meter to Fahrenheit

°C °C Set meter to Celsius

dEc.P Decimal point Set decimal point for process inputs

rELy Relay Enter the Relay menu

rLY1 Relay1 Relay 1 setup

Act1 Action1 Set relay 1 action (automatic, latching, etc.)

Auto Automatic Set relay for automatic reset

A-m Auto-manual Set relay for automatic + manual reset any

time

LtCH Latching Set relay for latching operation

L-CL Latching-cleared Set relay for latching operation with manual

reset only after alarm condition has cleared

Page 18 SITRANS RD200 – OPERATING INSTRUCTIONS 7ML19985JS01

Altr Alternate Set relays for pump alternation control

oFF Off Disable relay and front panel status LEDs

Disable relay’s fail-safe operation

SEt1 Set1 Program set point 1

rSt1 Reset1 Program reset point 1

rLY2 Relay2 Setup relay 2

Act2 Action2 Set relay 2 action (automatic, latching, etc.)

SEt2 Set2 Program set point 2

rSt2 Reset2 Program reset point 2

FLSF Fail-safe Enter Fail-safe

menu

FLS1 Fail-safe1 Set relay 1 fail-safe operation

On On Enable fail-safe operation

FLS2 Fail-safe2 Set relay 2 fail-safe operation

dLAy Delay Enter Time delay

menu

dLy1 Delay1 Enter relay 1 time delay setup

On1 On1 Set relay 1 on time delay

OFF1 Off1 Set relay 1 off time delay

dLy2 Delay2 Enter relay 2 time delay setup

On2 On2 Set relay 2 on time delay

OFF2 Off2 Set relay 2 off time delay

Aout Analog Output Enter the Analog Output menu

SEbr Sensor break Program TC or RTD sensor break value for

analog out

out1 Output 1 Program output 1 value (e.g. 4 mA)

out2 Output 2 Program output 2 value (e.g. 20 mA)

ProG Program Enter the Program menu

ScAL Scale Enter the Scale menu

CAL Calibrate Enter the Calibrate menu

inP1 Input 1 Calibrate input 1 signal or program input 1

value

diS1 Display 1 Program display 1 value

inP2 Input 2 Calibrate input 2 signal or program input 2

value

diS2 Display 2 Program display 2 value

err Error Error, calibration not successful, check signal

PASS Password Enter the Password menu

unLC Unlocked Program password to lock meter

LoCd Locked Enter password to unlock meter

9999

-1999

open

Flashing display Overrange condition

Underrange condition

Open TC or RTD sensor

Setup

mmmmm

7ML19985JS01 SITRANS RD200 – OPERATING INSTRUCTIONS Page 19

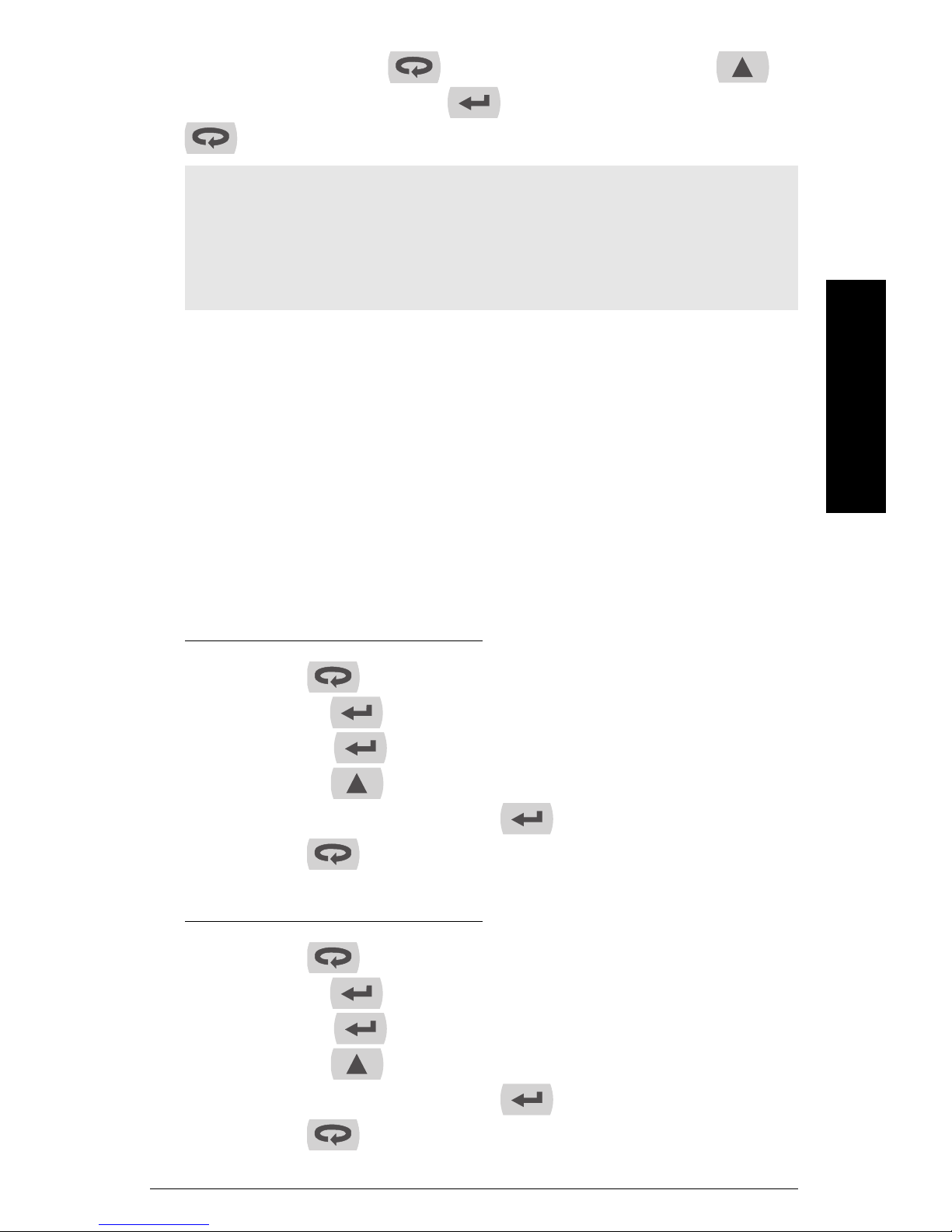

Main menu

The main menu includes the most common functions: Setup, Program, and Password.

Press Menu to enter Program Mode then press Up arrow to scroll

through the main menu options; Setup (

Press Menu at any time to exit and return to Run Mode. Changes made to

settings prior to pressing Enter/Ack are not saved.

Changes to the settings are saved only after pressing Enter/Ack .

The display moves to the next menu every time a setting is accepted by

pressing Enter/Ack .

mmmmm

Setup

SEtu

), Program (

ProG

), and Password (

PAS S

).

Setting numeric values

The numeric values are set using the Right and Up arrow buttons.

When in programming mode and setting a numeric value, press Right arrow to

select next digit and Up arrow to increment digit value.

The digit being changed is displayed brighter than the rest.

Press Enter/Ack at any time to accept a setting or Menu to exit without

saving changes.

Setting up the meter (SEtu)

The Setup menu is used to select:

• Input signal the meter will accept

• Decimal point position for process inputs

•Units (°F or °C) for temperature inputs

• Relay operation

• 4 to 20 mA analog output setup

Page 20 SITRANS RD200 – OPERATING INSTRUCTIONS 7ML19985JS01

From Run mode, press Menu to access any menu or press Up arrow to

scroll through choices. Use Enter/Ack to accept any entry and press Menu

to exit at any time.

Notes:

• The relay menu is always available even if the relay option is not installed.

• Visual alarm indication is available through front panel LEDs and the

SITRANS RD Software.

• The Analog Output menu is available if selected in the Advanced Features

menu. 4 to 20 mA output option board is installed and setup at the factory.

Setting the input signal (inPt)

Setup

mmmmm

Enter the Input menu to set up the meter to display current (

thermocouple (

The voltage input is capable of accepting any signal from -10 to +10 V DC. Select voltage

input to accept 0-5, 1-5, 0-10, or ±10 V DC signals.

The current input is capable of accepting any signal from -20 to 20 mA. Select current

input to accept 0 to 20 or 4 to 20 mA signals.

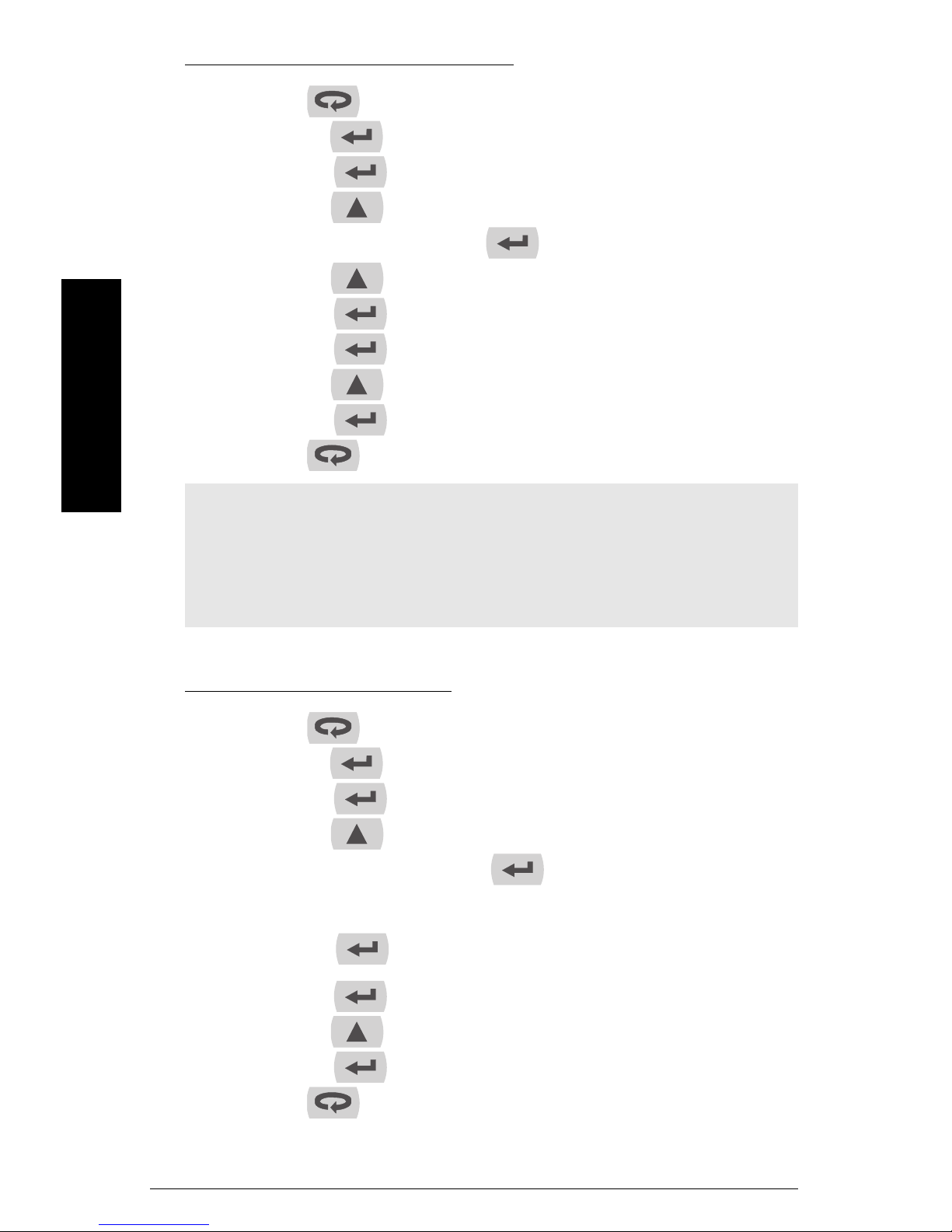

Setup meter to display current (

1. Press Menu to enter Programming Mode.

2. Press Enter/Ack to access Setup menu.

3. Press Enter/Ack to access Input menu.

4. Press Up arrow to scroll through choices;

5. When

6. Press Menu to return to Run Mode.

tC

), or RTD (

rtd

) inputs.

4-20

) input:

inPt

4-20

is displayed, press Enter/Ack to accept this choice.

4-20

), voltage (

SEtu

is displayed.

is displayed.

4-20, 0-10, tC, rtd

0-10

),

.

Setup meter to display voltage (

1. Press Menu to enter Program Mode.

2. Press Enter/Ack to access Setup menu.

3. Press Enter/Ack to access Input menu.

4. Press Up arrow to scroll through choices;

0-10

5. When

6. Press Menu to return to Run Mode.

7ML19985JS01 SITRANS RD200 – OPERATING INSTRUCTIONS Page 21

is displayed, press Enter/Ack to accept this choice.

0-10

) input:

4-20, 0-10, tC, rtd

.

Setup meter to display thermocouple (

tC

) input:

1. Press Menu to enter Program Mode.

2. Press Enter/Ack to access Setup menu.

3. Press Enter/Ack to access Input menu.

4. Press Up arrow to scroll through choices;

5. When tC is displayed, press Enter/Ack .

6. Press Up arrow until

7. P r e ss Enter/Ack to accept choice.

8. Press Enter/Ack to set Fahrenheit or Celsius input.

9. Press Up arrow to scroll through choices.

mmmmm

Setup

10. Press Enter/Ack to accept a choice.

11. Press Menu to return to Run Mode.

1 H

is displayed.

SEtu

is displayed.

inPt i

4-20, 0-10, tC, rtd

F C

is displayed.

s displayed.

.

Notes:

•If tC is selected, the input signal must be connected to the appropriate input

terminals and the RTD/TC selector switch must be set accordingly, see

Thermocouple input connections

• For thermocouple inputs, allow at least 30 minutes warm-up time for meter

to reach specified accuracy.

on page 13.

rtd

Setup meter to display RTD (

1. Press Menu to enter Program Mode.

2. Press Enter/Ack to access Setup menu.

3. Press Enter/Ack to access Input menu.

4. Press Up arrow to scroll through choices;

5. When

6. The display shows A385 or A392. Select the coefficient to match the RTD sensor,

7. P r e ss Enter/Ack to set Fahrenheit or Celsius input.

8. Press Up arrow to scroll through choices.

9. Press Enter/Ack to accept a choice.

10. Press Menu to return to Run Mode.

rtd

is displayed, press Enter/Ack .

either 0.00385 (European curve) or 0.00392 (American curve).

Press Enter/Ack to accept your selection.

) input:

SEtu

is displayed.

inPt i

s displayed.

4-20, 0-10, tC, rtd

F C

is displayed.

.

Page 22 SITRANS RD200 – OPERATING INSTRUCTIONS 7ML19985JS01

.

Notes:

•If

• For thermocouple inputs, allow at least 30 minutes warm-up time for meter

rtd

is selected, the input signal must be connected to the appropriate input

terminals and the RTD/TC selector switch must be set accordingly, see

Thermocouple input connections

to reach specified accuracy.

on page 13.

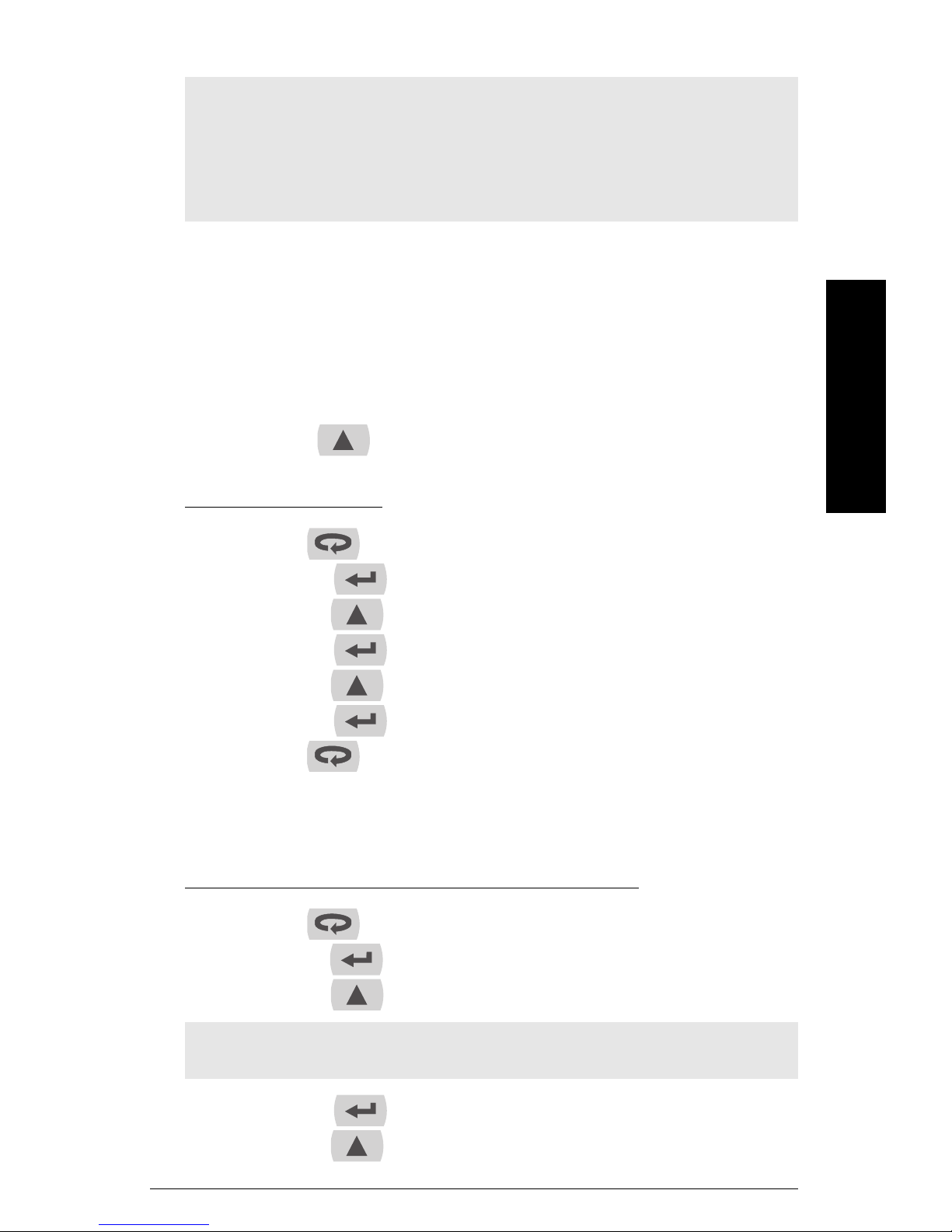

Setting the decimal point (dEc.P)

Decimal point for temperature inputs is fixed.

Decimal point for process inputs may be set with up to three decimal places or with no

decimal point at all.

Pressing Up arrow moves the decimal point one place to the right until no

decimal point is displayed, then it moves to the leftmost position.

To change the decimal point:

1. Press Menu to enter Program Mode.

2. Press Enter/Ack to access the Setup menu.

3. Press Up arrow to select decimal point modification.

4. Press Enter/Ack to display decimal point setting.

5. Press Up arrow to move the decimal point from left to right.

6. Press Enter/Ack to accept the displayed setting.

7. P r e ss Menu to return to Run Mode.

SEtu

is displayed.

inPt i

s displayed.

dEc.P

is displayed.

Setup

mmmmm

Setting the temperature scale (F C)

Set meter to display temperature in degrees Fahrenheit or Celsius:

1. Press Menu to enter Program Mode.

2. Press Enter/Ack to access Setup menu.

3. Press Up arrow until temperature selection menu is displayed (

Note: The temperature selection menu will only be available if the meter has been

setup for TC or RTD input. See

4. Press Enter/Ack to access the temperature selection menu.

5. Press Up arrow to scroll through choices;

7ML19985JS01 SITRANS RD200 – OPERATING INSTRUCTIONS Page 23

SEtu

is displayed.

Setting the input signal (inPt)

F

or C.

on page 21.

F C

).

6. Press Enter/Ack to set Fahrenheit or Celsius input.

7. P r e ss Menu to return to Run Mode.

Setting relay operation (rELY)

This menu allows you to set up the operation of the relays:

• Relay action

• Automatic reset only (non-latching)

• Automatic + manual reset at any time (non-latching)

• Latching (manual reset only)

• Latching with Clear (manual reset only after alarm condition has cleared)

• Pump alternation control (automatic reset only)

mmmmm

Setup

• Off (relay and status LED disabled)

•Set point

• Reset point

• Fail-safe operation

• On (enabled)

• Off (disabled)

• Time delay

• On delay (0-199 seconds)

• Off delay (0-199 seconds)

Set Up Relays (rLY1, rLY2), Set points (SEt1, SEt2), and Reset points (rSt1, rSt2):

1. Press Menu to enter Program Mode.

2.

SEtu

is displayed. Press Enter/Ack to access the Setup menu.

rELy

3. Press Up arrow until

4. Press Enter/Ack to enter Relay menu.

5.

rLy1

is displayed. Press Enter/Ack to set up relay 1.

6.

Act1

is displayed. The relay Action menu allows the user to set up the action of the

relays.

Press Enter/Ack to set up action for relay 1.

7. P r e ss Up arrow to scroll through choices;

Auto

(Automatic reset only, non-latching),

A -m

(Automatic + manual reset at any time, non-latching),

LtCH

(Latching, manual reset only),

is displayed.

L -CL

(Latching with Clear, manual reset only after alarm condition has cleared),

ALtr

(Pump alternation control, automatic reset only),

oFF

(Off, relay and status LED disabled).

Page 24 SITRANS RD200 – OPERATING INSTRUCTIONS 7ML19985JS01

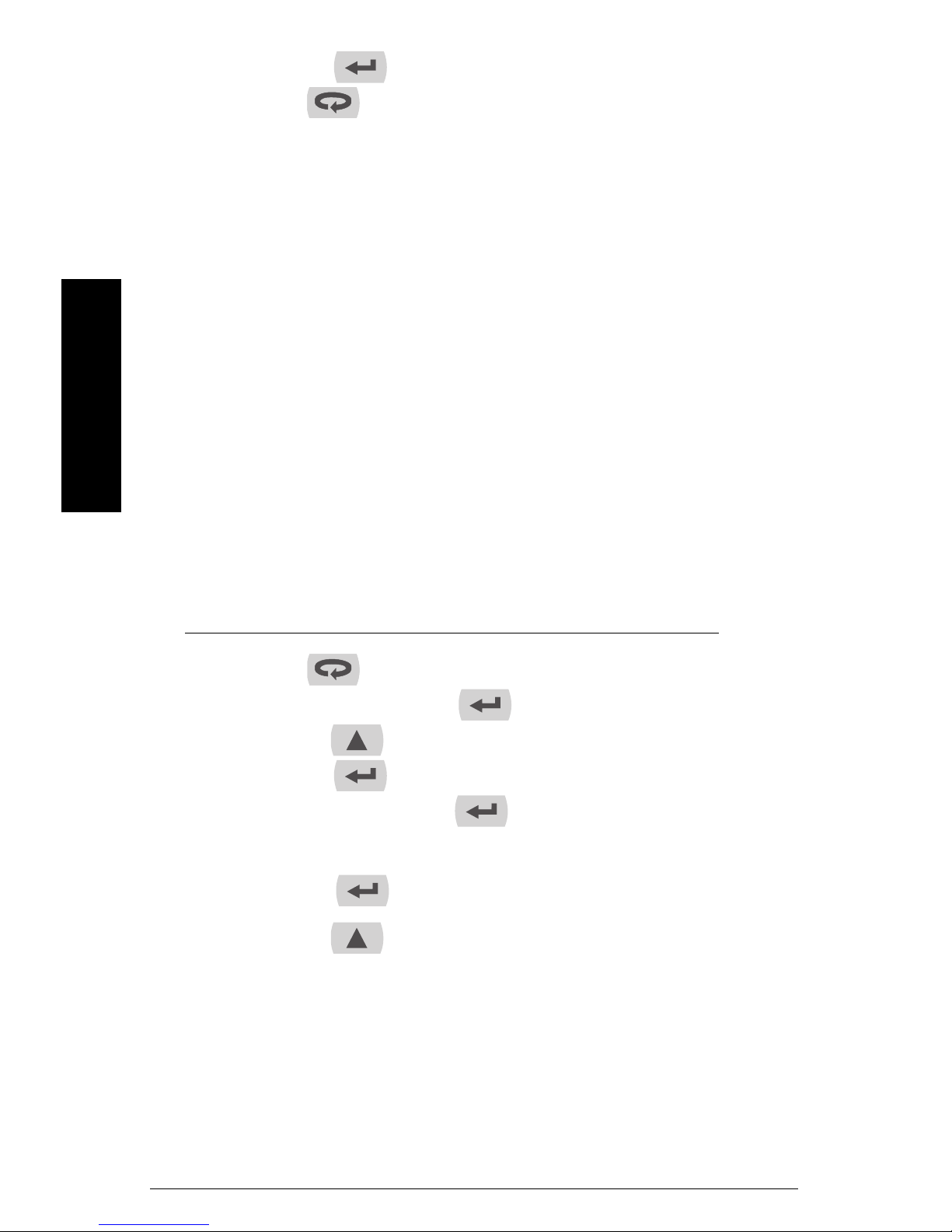

When your choice is displayed, press Enter/Ack to set relay 1 action (

SEt1

8.

9. Press Right arrow to change active digit and the Up arrow to

10. Press Enter/Ack to save displayed value.

11.

is displayed. The set point can be set to High Alarm Indication by programming

the set point above the reset point.

The set point can be set to Low Alarm Indication by programming the set point

below the reset point.

Press Enter/Ack to enter set point 1 programming.

increment active digit.

rSt1

is displayed. Press Enter/Ack to enter reset point 1 programming and

follow steps 8 and 9 above to program reset point 1 value.

Note: The deadband is determined by the difference between set and reset points.

Minimum deadband is one display count. If set and reset points are programmed the

same, relay will reset one count below set point.

12.

rLY2

is displayed. Press Enter/Ack to set up relay 2 or press Menu to

exit and return to Run Mode.

Act1

).

Setup

mmmmm

Setting fail-safe operation (FLSF: FLS1, FLS2)

The fail-safe operation is set independently for each relay. Select on to enable or select

off

to disable fail-safe operation.

Set up relays for fail-safe operation:

1. Press Menu to enter Program Mode.

2. Press Enter/Ack to access the Setup menu.

rELy

3. Press Up arrow until

4. Press Enter/Ack to enter Relay menu.

5. Press Up arrow until

6. Press Enter/Ack to access Fail-Safe Menu.

7. P r e ss Enter/Ack to set up fail-safe feature for relay 1.

8. Press the Up arrow to switch on or off.

is displayed.

FLSF

is displayed.

FLS1

is displayed.

9. Press Enter/Ack to accept settings.

10. Press Enter/Ack to set up fail-safe feature for relay 2 as in steps 7-9, or press

Menu to exit and return to Run Mode.

7ML19985JS01 SITRANS RD200 – OPERATING INSTRUCTIONS Page 25

FLS2

is displayed.

Once the Fail-Safe operation has been enabled, under normal conditions, the relays are

on, and under alarm conditions, the relays are off. (Notice that the functionality of the

relays is reversed when the Fail-Safe operation is disabled.)

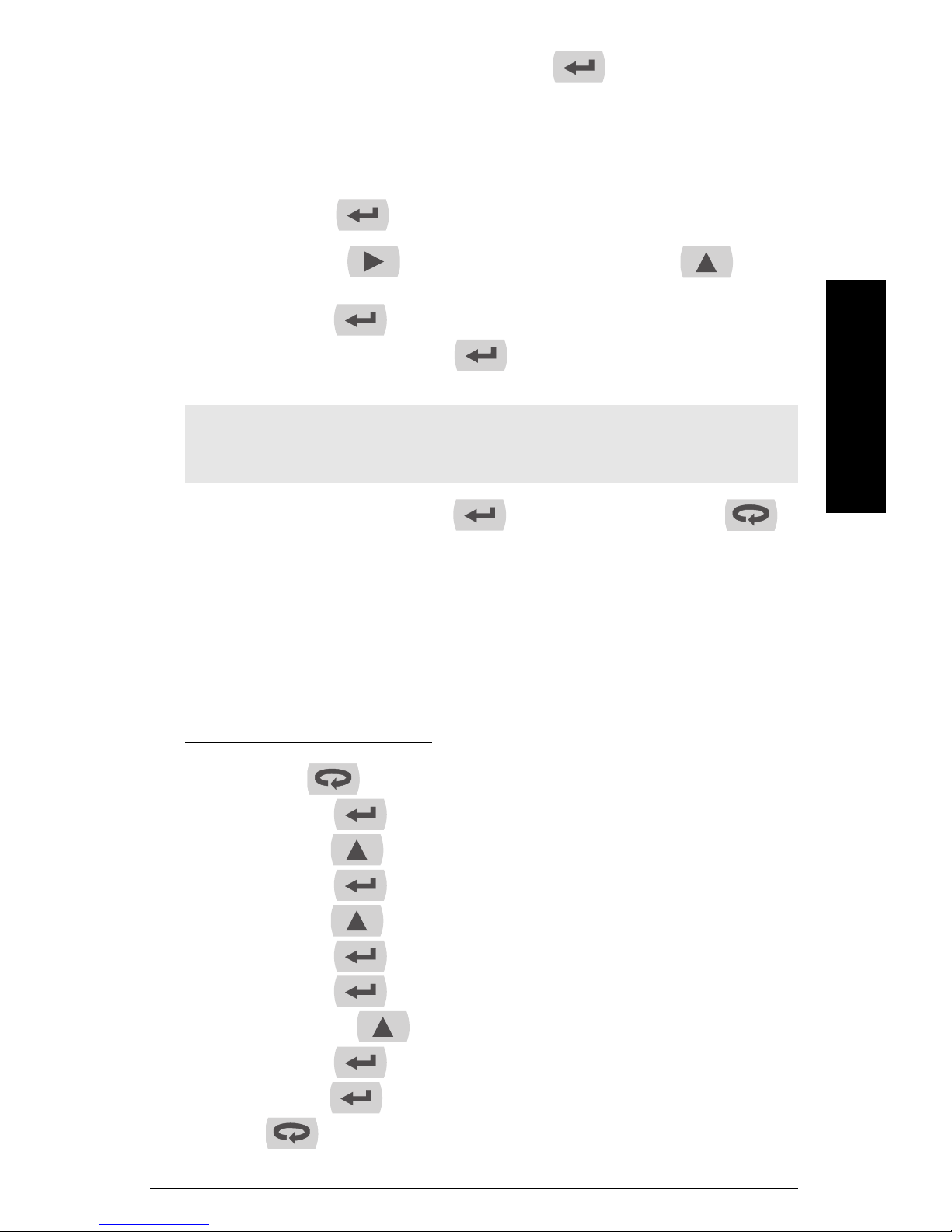

Programming time delay (dLA: dLy1, dLy2)

The On and

seconds. The relays will transfer only after the condition has been maintained for the

corresponding time delay.

The

On

OFF

The

mmmmm

Setup

Set up relay on and off time delays:

1. Press Menu to enter Program Mode.

2. Press Enter/Ack to access the Setup menu.

3. Press Up arrow until

4. Press Enter/Ack to enter Relay menu.

5. Press Up arrow until

6. Press Enter/Ack to enter Time Delay Menu.

7. P r e ss Enter/Ack to set time delay for relay 1.

OFF

time delays may be programmed for each relay between 0 and 199

time delay is associated with the set point.

time delay is associated with the reset point.

rELy

is displayed.

dLAy

is displayed.

dLy1

is displayed.

On1

is displayed.

8. Press Enter/Ack to proceed.

9. Press Up arrow to change digit and Right arrow to change active

digit.

10. Press Enter/Ack to accept setting.

11. Repeat steps 6-7 for

12. Press Enter/Ack to set up time delay for relay 2 as in steps 8-10, or press

Menu to exit and return to Run Mode.

On

The

on after the time delay has elapsed. The

point is reached and the relay will turn off after the time delay has elapsed.

time delay will count down when the set point is reached and the relay will turn

OFF1. dLy2

is displayed.

OFF

time delay will count down when the reset

Page 26 SITRANS RD200 – OPERATING INSTRUCTIONS 7ML19985JS01

Loading...

Loading...