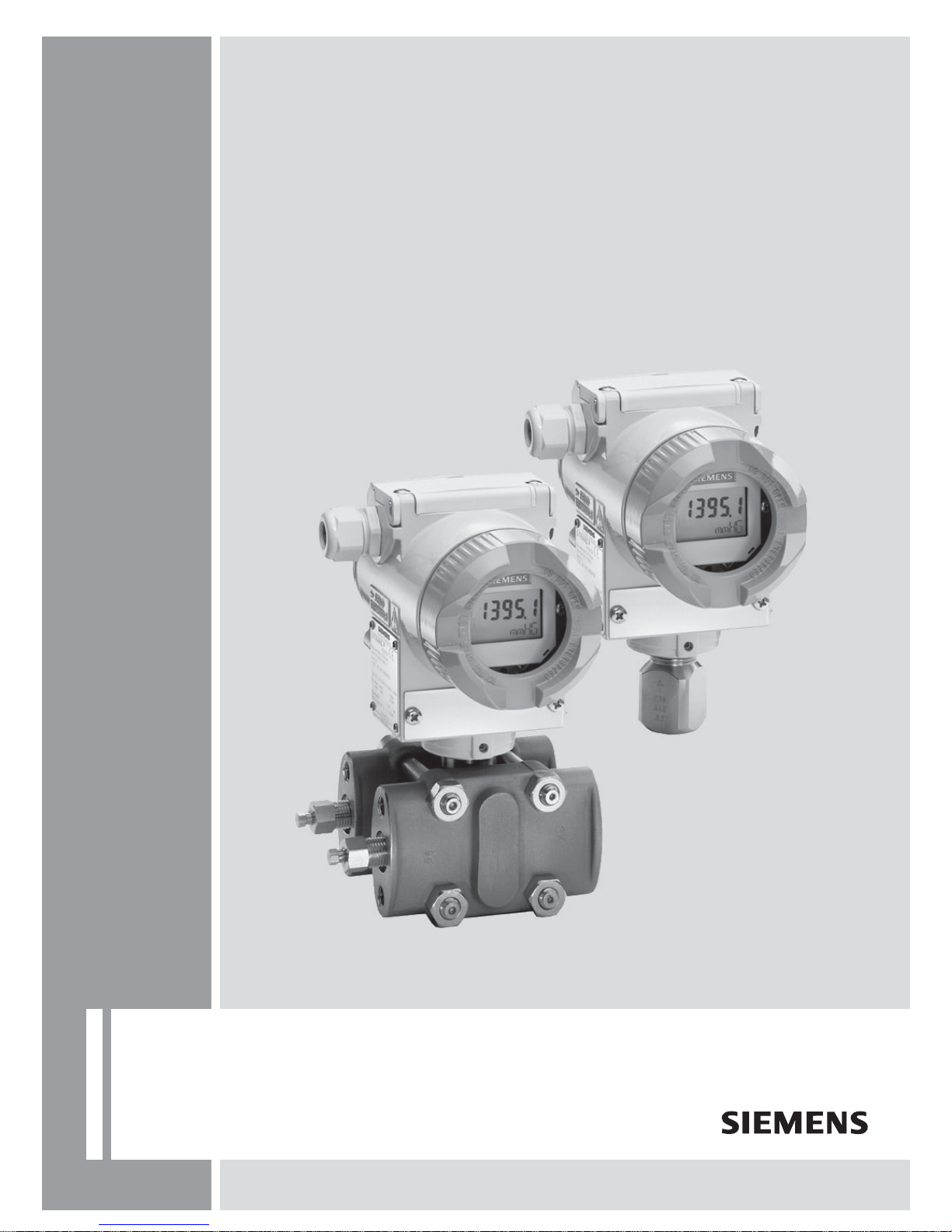

Siemens SITRANS P Series,SITRANS P DS III Series Operating Instructions Manual

Pressure transmitter

SITRANS P, DS III series

Compact Operating Instructions

•

08/2011

SITRANS

English..................................................................................................................................................................4

Български ..........................................................................................................................................................50

Češt

ina ...............................................................................................................................................................99

S

uomi ...............................................................................................................................................................145

S

lovenčina........................................................................................................................................................190

S

lovenščina ......................................................................................................................................................237

© Siemens Ⓟ2011

A5E03434645-01, 08/2011

3

SITRANS

Pressure transmitter

SITRANS P, DS III series (7MF4.33.. 7MF4.34.. 7MF4.35..)

Compact Operating Instructions

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent damage to property. The

notices referring to your personal safety are highlighted in the manual by a safety alert symbol, notices referring only to property damage

have no safety alert symbol. These notices shown below are graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

CAUTION

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

NOTICE

indicates that an unintended result or situation can occur if the relevant information is not taken into account.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will be used. A notice warning of

injury to persons with a safety alert symbol may also include a warning relating to property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific task in accordance with

the relevant documentation, in particular its warning notices and safety instructions. Qualified personnel are those who, based on their

training and experience, are capable of identifying risks and avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical documentation. If products

and components from other manufacturers are used, these must be recommended or approved by Siemens. Proper transport, storage,

installation, assembly, commissioning, operation and maintenance are required to ensure that the products operate safely and without any

problems. The permissible ambient conditions must be complied with. The information in the relevant documentation must be observed.

© Siemens Ⓟ2011

4 A5E03434645-01, 08/2011

Introduction

Purpose of this documentation

These instructions are a brief summary of important features, functions and safety information, and contain all information

required for safe use of the device. It is your responsibility to read the instructions carefully prior to installation and

commissioning. In order to use the device correctly, first review its principle of operation.

The instructions are aimed at persons who mechanically assemble the device, connect it electrically, and start it up.

To achieve optimum usage of the device, read the detailed version of the manual on the electronic data medium.

See also

Instructions and Manuals (http://www.siemens.com/processinstrume

ntation/documentation)

History

This history establishes the correlation between the current documentation and the valid firmware of the device.

The documentation of this edition is applicable for the following firmware:

Edition Firmware identifier nameplate System integration Installation path for PDM

08/2011 HART:

FW: 11.03.03, FW: 11.03.04,

FW: 11.03.05, FW: 11.03.06

PA/FF: FW: 0300.01.08

PDM 6.01); Dev. Rev.3

DD Rev.2

SITRANS P DSIII.2

1)

up to SP05 Hotfix 5

Purpose

Overview

Depending on the version, a transmitter measures corrosive, non-corrosive and hazardous gases, vapors and liquids.

You can use the transmitter for the following types of measurement:

● Gauge pressure

● Absolute pressure

● Differential pressure

With appropriate parameter settings and the necessary add-on parts (e.g. flow orifices and remote seals), the pressure

transmitter can also be used for the following measurements:

● Level

● Volume

● Mass

● Volume of flow

● Mass flow rate

The output signal is always a load-independent direct current between 4 and 20 mA.

You can install the "intrinsically-safe" or "explosion-proof" version of the transmitter in hazardous areas. The devices have an

EC type examination certificate and comply with the appropriate harmonized European CENELEC directives.

Transmitters with remote seals of different shapes can be delivered for special applications. For example, measuring high-

viscosity substances is a special application.

Operate the device in accordance with the specifications in Section Technical specifications (Page 35).

F

or additional information, please refer to the operating instructions for the device.

SITRANS P, DS III series (7MF4.33.. 7MF4.34.. 7MF4.35..)

A5E03434645-01, 08/2011

5

Checking the consignment

1. Check the packaging and the device for visible damage caused by inappropriate handling during shipping.

2. Report any claims for damages immediately to the shipping company.

3. Retain damaged parts for clarification.

4. Check the scope of delivery by comparing the shipping documents with your order for correctness and completeness.

WARNING

Using a damaged or incomplete device

Danger of explosion in hazardous areas.

● Do not use any damaged or incomplete devices.

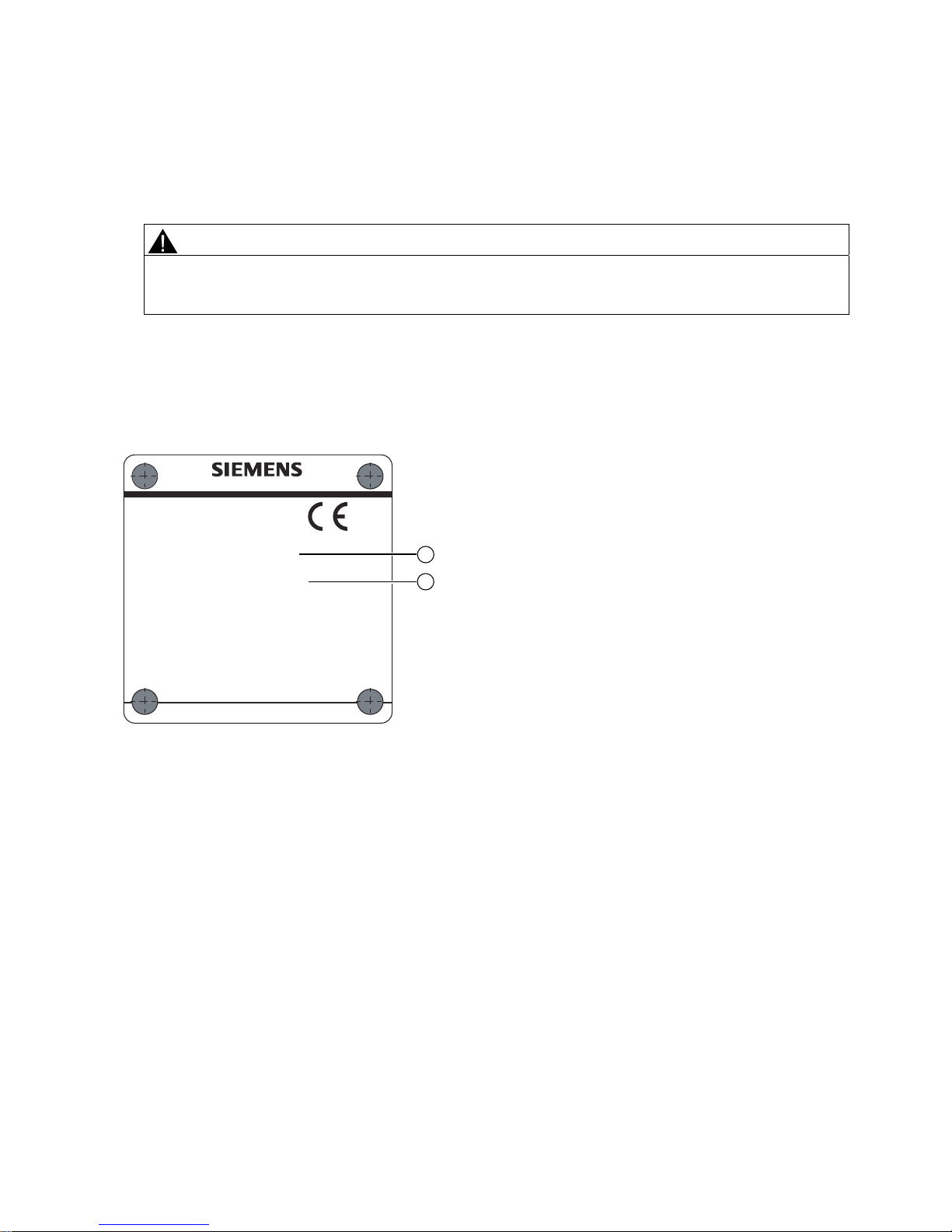

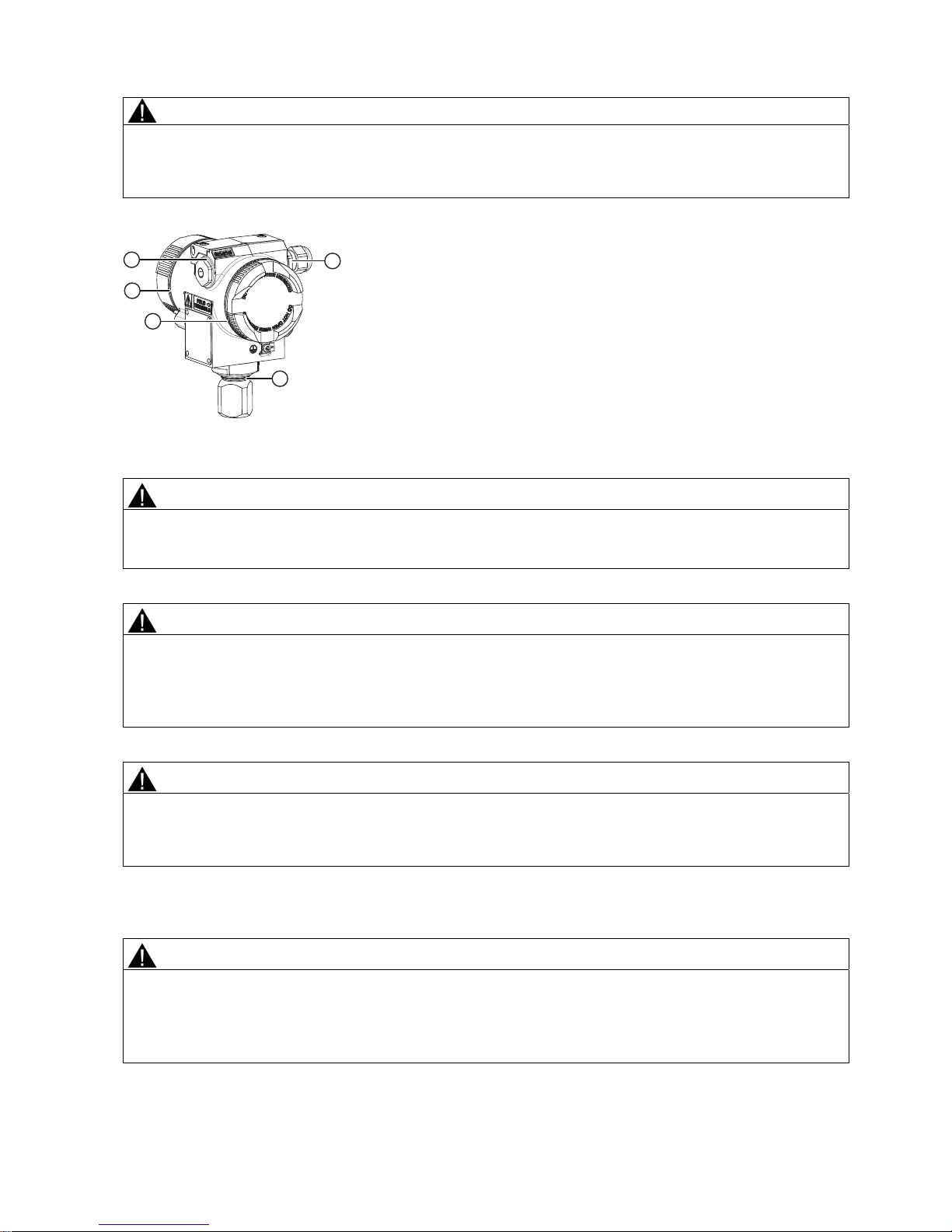

Nameplate layout

Nameplate with general information

The nameplate bearing the Order No. and other important information, such as design details and technical data, is on the

side of the enclosure.

Filling

Silikonöl

Mat.: Connec. Diaphr.

V :DC1 0.5-45 V (not intr.s ave ) outp.:4-20 mA

H

Measuring span

Ove rrange limits

Type of protection IP 65

Fab. Nr. N1LN1 1-0047 11

Tr ansmit ter for pressur e

1.4404 2.481 9

7MF4033-1EB1 0-1DA1

: 0.6 3 - 63 bar

:-1-100 bar

Made in Fr ance

0032

PED:SEP

SITRANS P

D-76181 Karlsr uhe

① Order number (machine-readable product code) ② Serial number

Figure 1 Example of a nameplate

SITRANS P, DS III series (7MF4.33.. 7MF4.34.. 7MF4.35..)

6 A5E03434645-01, 08/2011

Nameplate with approval information

On the opposite side is the nameplate with approval information. This nameplate shows e.g. the hardware and firmware

versions. Certificate information is also listed if the transmitter is an ex-version.

V :DC 10. 5 - 4 5 V outp.: 4 - 20mA

H

II 1/2 G Ex d IIC T4/T6

PTB 99 ATEX 116 0

FW : 1 3.0 1.02 HW : 01.02.03

T = -40 ... 85/60 °C

a

Observ e EC-Type Examination Certicate !

SITRANS P

D-76181 Karlsr uhe

,,*([G,,&77

):[[\\]] +:[[\\]]

&RPSDWLELOLW\PDUN

3URGXFWYHUVLRQFRQQHFWLRQERDUG

6HULDOQXPEHU

):YHUVLRQ

'RFXPHQW5HYLVLRQ

'HYLFHW\SH

① Characteristics for hazardous area ④ Group (gas, dust)

② Category for operating area ⑤ Maximum surface temperature (temperature class)

③ Type of protection

Figure 2 Example of a nameplate

Transportation and storage

To guarantee sufficient protection during transport and storage, observe the following:

● Keep the original packaging for subsequent transportation.

● Devices/replacement parts should be returned in their original packaging.

● If the original packaging is no longer available, ensure that all shipments are properly packaged to provide sufficient

protection during transport. Siemens cannot assume liability for any costs associated with transportation damages.

CAUTION

Insufficient protection during storage

The packaging only provides limited protection against moisture and infiltration.

● Provide additional packaging as necessary.

Special conditions for storage and transportation of the device are listed in "Technical data" (Page 35).

Notes on warranty

The contents of this manual shall not become part of or modify any prior or existing agreement, commitment or legal

relationship. The sales contract contains all obligations on the part of Siemens as well as the complete and solely applicable

warranty conditions. Any statements regarding device versions described in the manual do not create new warranties or

modify the existing warranty.

The content reflects the technical status at the time of publishing. Siemens reserves the right to make technical changes in

the course of further development.

SITRANS P, DS III series (7MF4.33.. 7MF4.34.. 7MF4.35..)

A5E03434645-01, 08/2011

7

Safety instructions

Precondition for use

This device left the factory in good working condition. In order to maintain this status and to ensure safe operation of the

device, observe these instructions and all the specifications relevant to safety.

Observe the information and symbols on the device. Do not remove any information or symbols from the device. Always

keep the information and symbols in a completely legible state.

Warning symbols on the device

Symbol Explanation

Consult operating instructions

Laws and directives

Observe the test certification, provisions and laws applicable in your country during connection, assembly and operation.

These include, for example:

● National Electrical Code (NEC - NFPA 70) (USA)

● Canadian Electrical Code (CEC) (Canada)

Further provisions for hazardous area applications are for example:

● IEC 60079-14 (international)

● EN 60079-14 (EC)

Conformity with European directives

The CE mark on the device is a sign of conformity with the following European directives:

Electromagnetic Compatibility

EMC

2004/108/EC

Directive of the European Parliament and of the Council on the

approximation of the laws of the Member States relating to electromagnetic

compatibility and repealing Directive 89/336/EEC.

Atmosphère explosible ATEX

94/9/EC

Directive of the European Parliament and the Council on the approximation

of the laws of the Member States concerning equipment and protective

systems intended for use in potentially explosive atmospheres.

Pressure Equipment Directive

PED

97/23/EC

Directive of the European Parliament and of the Council on the

approximation of the laws of the Member States concerning pressure

equipment.

The standards applied can be found in the EC declaration of conformity for the device.

Improper device modifications

WARNING

Improper device modifications

Danger to personnel, system and environment can result from modifications to the device, particularly in hazardous areas.

● Only carry out modifications that are described in the instructions for the device. Failure to observe this requirement

cancels the manufacturer's warranty and the product approvals.

SITRANS P, DS III series (7MF4.33.. 7MF4.34.. 7MF4.35..)

8 A5E03434645-01, 08/2011

Requirements for special applications

Due to the large number of possible applications, each detail of the described device versions for each possible scenario

during commissioning, operation, maintenance or operation in systems cannot be considered in the instructions. If you need

additional information not covered by these instructions, contact your local Siemens office or company representative.

Note

Operation under special ambient conditions

We highly recommend that you contact your Siemens representative or our application department before you operate the

device under special ambient conditions as can be encountered in nuclear power plants or when the device is used for

research and development purposes.

Use in hazardous areas

Qualified personnel for hazardous area applications

Persons who install, assemble, commission, operate and service the device in a hazardous area must have the following

specific qualifications:

● They are authorized, trained or instructed in operating and maintaining devices and systems according to the safety

regulations for electrical circuits, high pressures and aggressive as well as hazardous media.

● They are authorized, trained, or instructed in carrying out work on electrical circuits for hazardous systems.

● They are trained or instructed in maintenance and use of appropriate safety equipment according to the pertinent safety

regulations.

WARNING

Unsuitable device for the hazardous area

Danger of explosion.

● Only use equipment that is approved for use in the intended hazardous area and labelled accordingly.

See also

Technical specifications (Page 35)

WARNING

Loss of safety of device with type of protection "Intrinsic safety Ex i"

If the device has already been operated in non-intrinsically safe circuits or the electrical specifications have not been

observed, the safety of the device is no longer ensured for use in hazardous areas. There is a danger of explosion.

● Connect the device with type of protection "Intrinsic safety" solely to an intrinsically safe circuit.

● Observe the specifications for the electrical data in the certificate and in Technical data (Page 35).

WARNING

Use of incorrect device parts in potentially explosive environments

Devices and their associated device parts are either approved for different types of protection or they do not have

explosion protection. There is a danger of explosion if device parts (such as covers) are used for devices with explosion

protection that are not expressly suited for this type of protection. If you do not adhere to these guidelines, the test

certificates and the manufacturer warranty will become null and void.

● Use only device parts that have been approved for the respective type of protection in the potentially explosive

environment. Covers that are not suited for the "explosion-proof" type of protection are identified as such by a notice

label attached to the inside of the cover with "Not Ex d Not SIL".

● Do not swap device parts unless the manufacturer specifically ensures compatibility of these parts.

SITRANS P, DS III series (7MF4.33.. 7MF4.34.. 7MF4.35..)

A5E03434645-01, 08/2011

9

WARNING

Risk of explosion due to electrostatic charge

To prevent the build-up of an electrostatic charge in a hazardous area, the key cover must be closed during operation and

the screws tightened.

The key cover may be opened temporarily at any time for the purposes of operating the transmitter, even during plant

operation; the screws should then be tightened again.

Installing/mounting

Basic safety instructions

WARNING

Wetted parts unsuitable for the process media

Danger of injury or damage to device.

Hot, toxic and corrosive media could be released if the process medium is unsuitable for the wetted parts.

● Ensure that the material of the device parts wetted by the process medium is suitable for the medium. Refer to the

information in "Technical data" (Page 35).

WARNING

Incorrect material for the diaphragm in Zone 0

Danger of explosion in the hazardous area. In the case of operation with intrinsically safe supply units of category "ib" or

devices of the flameproof enclosure version "Ex d" and simultaneous use in Zone 0, transmitter explosion protection

depends on the tightness of the diaphragm.

● Ensure that the material used for the diaphragm is suitable for the process medium. Refer to the information in the

section "Technical specifications (Page 35)".

WARNING

Unsuitable connecting parts

Danger of injury or poisoning.

In case of improper mounting hot, toxic and corrosive process media could be released at the connections.

● Ensure that connecting parts (such as flange gaskets and bolts) are suitable for connection and process media.

Note

Material compatibility

Siemens can provide you with support concerning selection of sensor components wetted by process media. However, you

are responsible for the selection of components. Siemens accepts no liability for faults or failures resulting from incompatible

materials.

SITRANS P, DS III series (7MF4.33.. 7MF4.34.. 7MF4.35..)

10 A5E03434645-01, 08/2011

WARNING

Exceeded maximum permissible operating pressure

Danger of injury or poisoning.

The maximum permissible operating pressure depends on the device version. The device can be damaged if the operating

pressure is exceeded. Hot, toxic and corrosive process media could be released.

● Make sure that the device is suitable for the maximum permissible operating pressure of your system. Refer to the

information on the nameplate and/or in "Rated operating conditions" (Page 35).

WARNING

Exceeded maximum ambient or process media temperature

Danger of explosion in areas subject to explosion hazard.

Device damage.

● Make sure that the maximum permissible ambient and process media temperatures of the device are not exceeded.

Refer to the information in Chapter Technical specifications (Page 35).

WARNING

Open cable inlet or incorrect cable gland

Danger of explosion in hazardous areas.

● Close the cable inlets for the electrical connections. Only use cable glands or plugs which are approved for the relevant

type of protection.

WARNING

Incorrect conduit system

Danger of explosion in hazardous areas as result of open cable inlet or incorrect conduit system.

● In the case of a conduit system, mount a spark barrier at a defined distance from the device input. Observe national

regulations and the requirements stated in the relevant approvals.

See also

Technical specifications (Page 35)

WARNING

Incorrect mounting at Zone 0

Danger of explosion in areas subject to explosion hazard.

● Ensure sufficient tightness at the process connection.

● Observe the standard IEC/EN 60079-26.

SITRANS P, DS III series (7MF4.33.. 7MF4.34.. 7MF4.35..)

A5E03434645-01, 08/2011

11

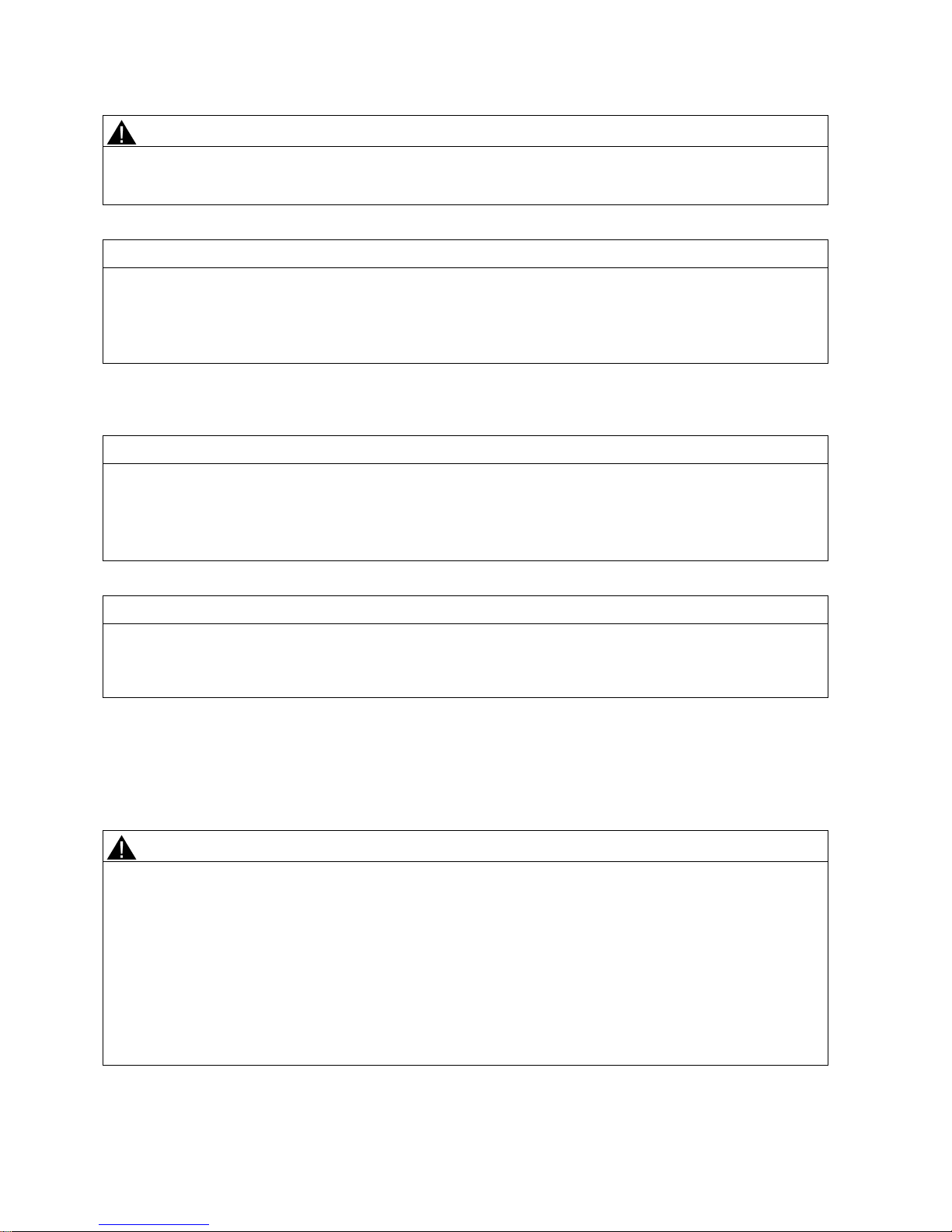

WARNING

Danger with "flameproof enclosure" protection

Danger of explosion in hazardous areas. An explosion may be caused by hot gas escaping from the flameproof enclosure

if there is too little space between it and the fixed parts.

● Ensure that there is a space of at least 40 mm between the flameproof joint and the fixed parts.

① Flameproof joint

WARNING

Loss of explosion protection

Danger of explosion in hazardous areas if the device is open or not properly closed.

● Close the device as described in Chapter "Connecting the device (Page 21)".

CAUTION

Hot surfaces resulting from hot process media

Danger of burns resulting from surface temperatures above 70 °C (155 °F).

● Take appropriate protective measures, for example contact protection.

● Make sure that protective measures do not cause the maximum permissible ambient temperature to be exceeded.

Refer to the information in Chapter Technical specifications (Page 35).

CAUTION

External stresses and loads

Damage to device by severe external stresses and loads (e.g. thermal expansion or pipe tension). Process media can be

released.

● Prevent severe external stresses and loads from acting on the device.

Installation location requirements

WARNING

Insufficient air supply

The device may overheat if there is an insufficient supply of air.

● Install the device so that there is sufficient air supply in the room.

● Observe the maximum permissible ambient temperature. Refer to the information in the section "Technical

specifications (Page 35)".

SITRANS P, DS III series (7MF4.33.. 7MF4.34.. 7MF4.35..)

12 A5E03434645-01, 08/2011

CAUTION

Aggressive atmospheres

Damage to device through penetration of aggressive vapors.

● Ensure that the device is suitable for the application.

CAUTION

Direct sunlight

Increased measuring errors.

● Protect the device from direct sunlight.

Make sure that the maximum ambient temperature is not exceeded. Refer to the information in the section Technical

specifications (Page 35).

Proper mounting

CAUTION

Incorrect assembly

The device can be damaged or destroyed or its functionality impaired through incorrect assembly.

● Make sure before installing the device that there is no visible damage.

● Check that the process connections are clean and the right seals and cable glands have been used.

● Assemble the device using suitable tools, observing the torques specified in the technical specifications.

NOTICE

Loss of degree of protection

Damage to device if the enclosure is open or not properly closed. The degree of protection specified on the nameplate or in

"Technical data" (Page 35) is no longer guaranteed.

● Make sure that the device is securely closed.

See also

Connecting the device (Page 21)

Disassembly

WARNING

Incorrect disassembly

The following dangers may result through incorrect disassembly:

- Injury through electric shock

- Danger through emerging media when connected to the process

- Danger of explosion in hazardous area

In order to disassemble correctly, observe the following:

● Before starting work, make sure that you have switched off all physical variables such as pressure, temperature,

electricity etc. or that they have a harmless value.

● If the device contains dangerous media, it must be emptied prior to disassembly. Make sure that no environmentally

hazardous media are released.

● Secure the remaining connections so that no damage can result if the process is started unintentionally.

SITRANS P, DS III series (7MF4.33.. 7MF4.34.. 7MF4.35..)

A5E03434645-01, 08/2011

13

Installation (except level)

Instructions for installation (except level)

Conditions

NOTICE

Compare the desired operating data with the data on the nameplate.

Please also refer to the information on the remote seal if this is fitted.

Note

Protect the transmitter against:

● Direct heat radiation

● Rapid temperature fluctuations

● Heavy contamination

● Mechanical damage

● Direct sunlight

The installation location is to be as follows:

● Easily accessible

● As close as possible to the measuring point

● Vibration-free

● Within the permitted ambient temperature values

Installation configuration

The transmitter may in principle be configured above or below the pressure tapping point. The recommended configuration

depends on the aggregate state of the medium.

Installation configuration for gases

Install the transmitter above the pressure tapping point.

Lay the pressure tubing with a constant gradient to the pressure tapping point, so that any condensation produced can drain

in the main line and thereby avoid corruption of the measured values.

Installation configuration for vapor and liquid

Install the transmitter below the pressure tapping point.

Lay the pressure tubing with a constant gradient to the pressure tapping point so that any gas pockets can escape in the

main line.

Installation (except level)

NOTICE

Damage to measuring cell

When installing the process connection of the pressure transmitter, do not rotate the housing. Rotating the housing may

damage the measuring cell.

To avoid damage to the device, tighten the threaded nuts of the measuring cell using a wrench.

Procedure

Attach the transmitter to the process connection with an appropriate tool.

SITRANS P, DS III series (7MF4.33.. 7MF4.34.. 7MF4.35..)

14 A5E03434645-01, 08/2011

See also

Introduction to commissioning (Page 24)

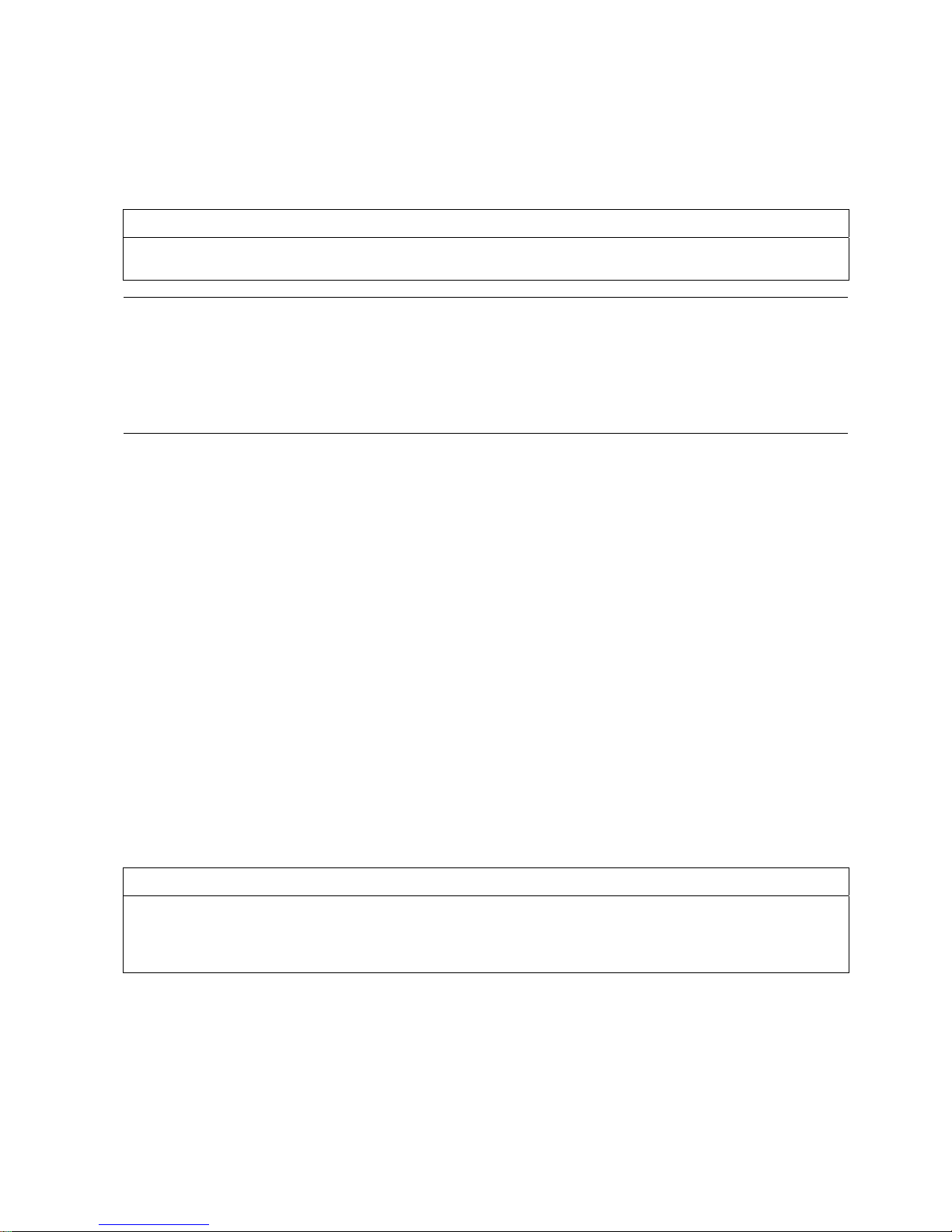

Fastening

Fastening without the mounting bracket

You can fasten the transmitter directly on the process connection.

Fastening with the mounting bracket

You can fasten the mounting bracket as follows:

● On a wall or a mounting frame using two screws

● On a vertical or horizontal mounting tube (Ø 50 to 60 mm) using a tube bracket

Fasten the transmitter mounting bracket using the two screws provided.

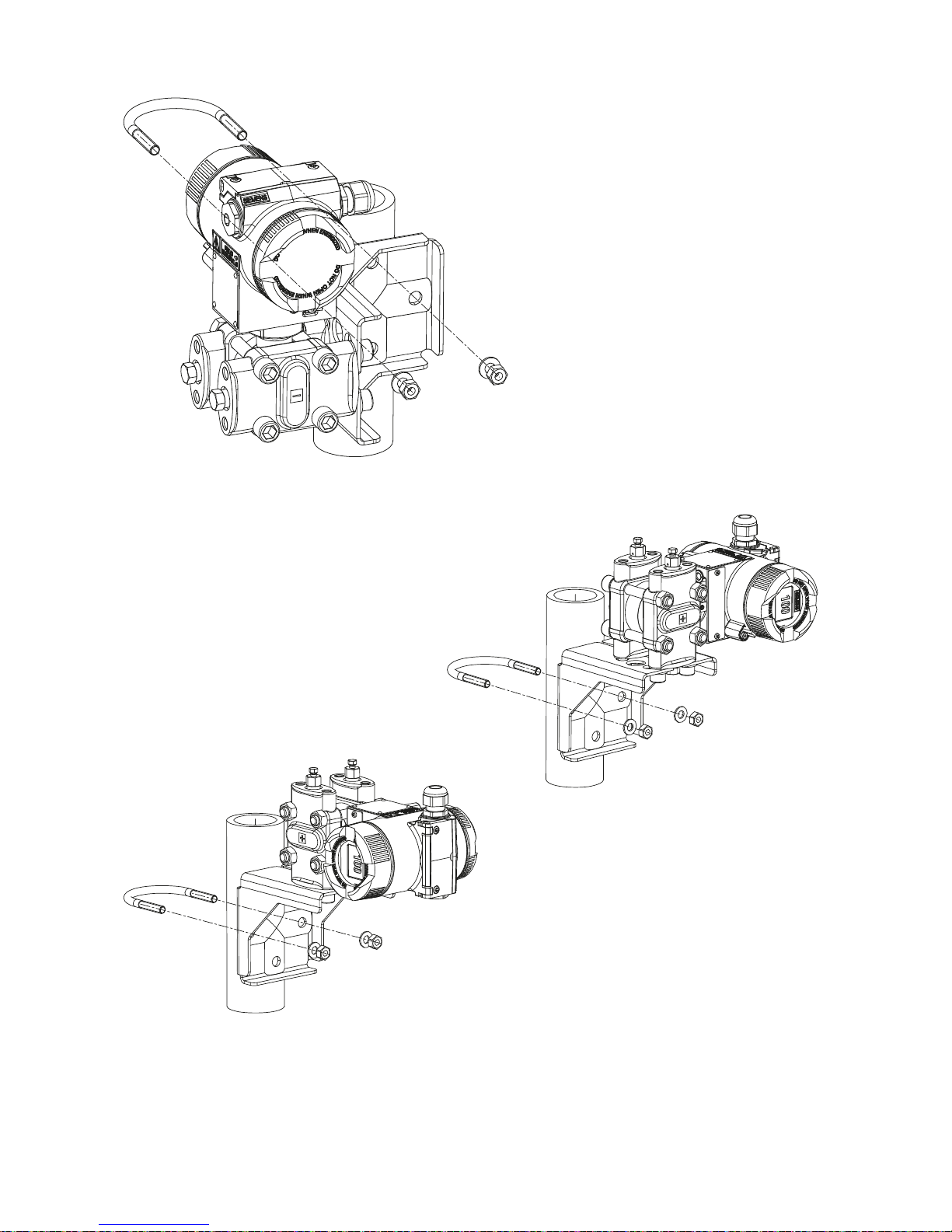

Figure 3 Fastening the transmitter on the mounting bracket

SITRANS P, DS III series (7MF4.33.. 7MF4.34.. 7MF4.35..)

A5E03434645-01, 08/2011

15

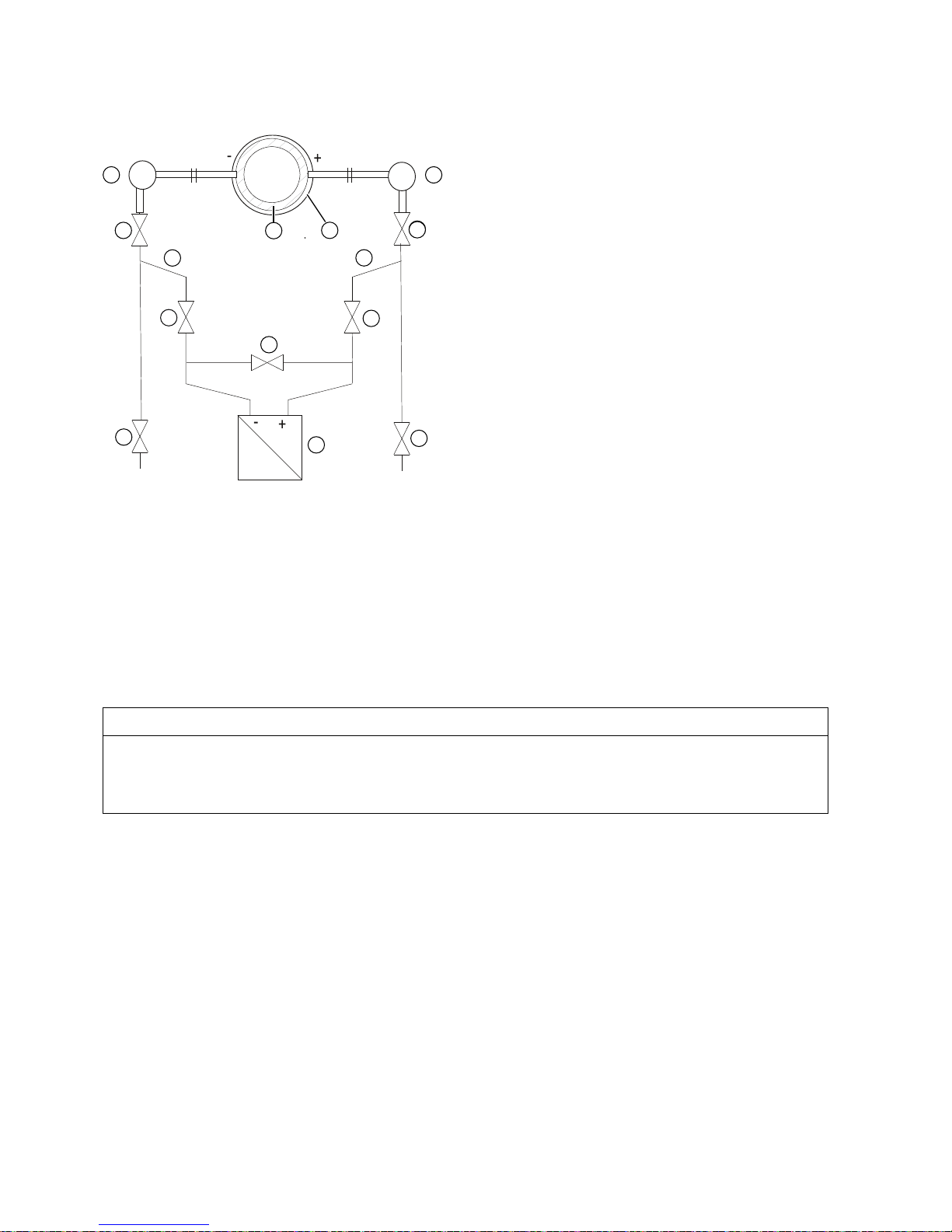

Figure 4 An example of fastening the transmitter on the mounting bracket in the case of differential pressure and

horizontal differential pressure lines

Figure 5 An example of fastening on the mounting bracket in the case of differential pressure and vertical differential

pressure lines

SITRANS P, DS III series (7MF4.33.. 7MF4.34.. 7MF4.35..)

16 A5E03434645-01, 08/2011

"Level" installation

Instructions for level installation

Requirements

NOTICE

Compare the desired operating data with the data on the nameplate.

Please also refer to the information on the remote seal if this is fitted.

Note

Protect the transmitter from:

● Direct heat

● Rapid temperature changes

● Severe soiling

● Mechanical damage

● Direct sunlight

Note

Select the height of the mounting flange such that the pressure transmitter is always mounted below the lowest fill height to

be measured.

The installation location is to be as follows:

● Easily accessible

● The measuring point must be as close as possible

● Vibration-free

● Within the permitted ambient temperature values

Installation for level

Note

Seals are required for the installation. The seals must be compatible with the medium to be measured.

Seals are not included in the delivery.

Procedure

To install the transmitter for level, proceed as follows:

1. Attach the seal to the container's mating flange.

Ensure that the seal is centrically positioned and that it does not restrict the movement of the flange's seal diaphragm in

any way as otherwise the tightness of the process connection is not guaranteed.

2. Screw on the transmitter's flange.

3. Observe the installation position.

SITRANS P, DS III series (7MF4.33.. 7MF4.34.. 7MF4.35..)

A5E03434645-01, 08/2011

17

Connection of the negative pressure line

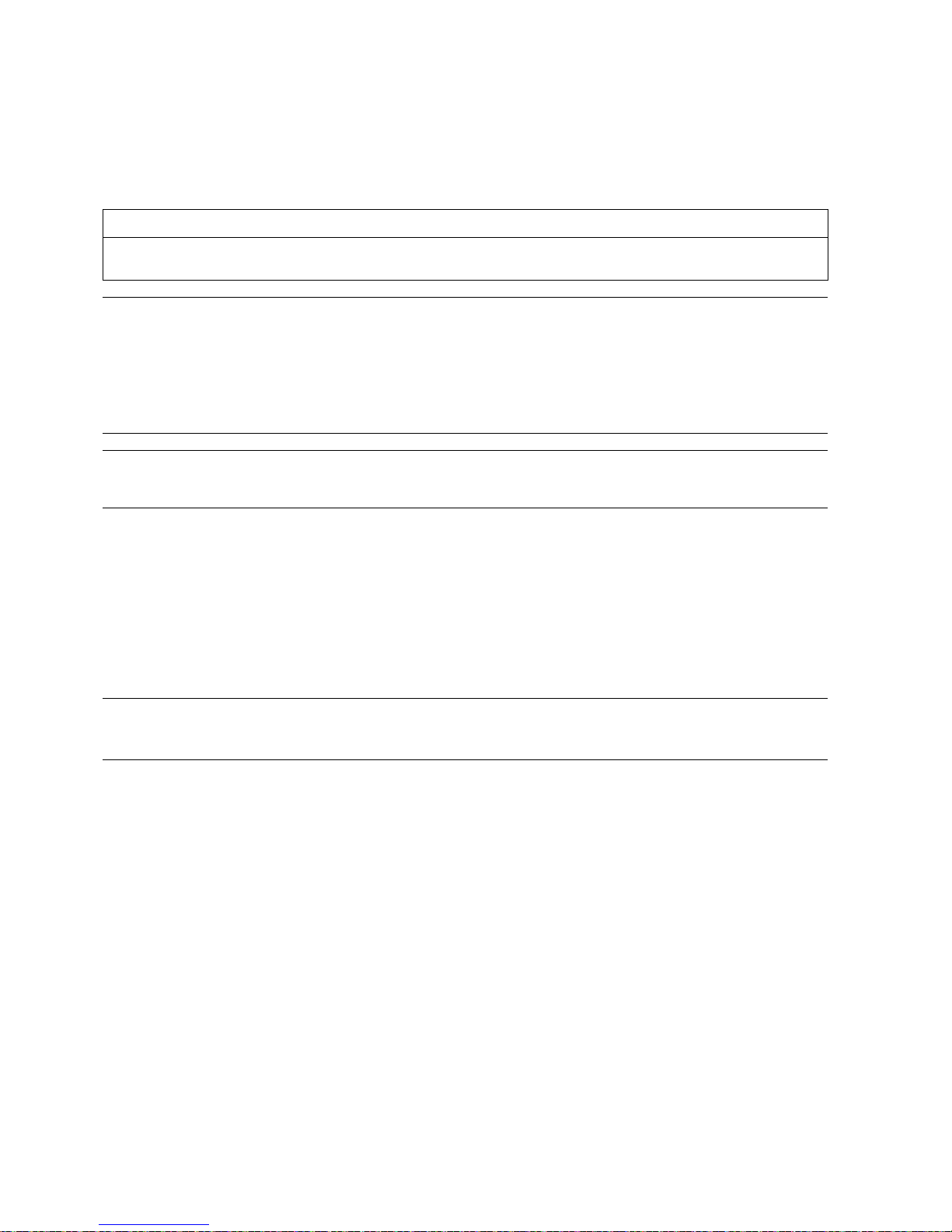

Measurement in an open container

A line is not required when taking measurements in an open container since the negative chamber is connected with the

atmosphere.

Ensure that no dirt enters the open connection ports, for example by using connection screws with a 7MF4997-1CP bleed

valve.

+

)XOOVFDOHYDOXH

6WDUWRIVFDOHYDOXH

K

2

K

8

Measurement assembly on an open container

Formula:

Start of scale value: p

MA

= ρ · g · hU

Full scale value: p

ME

= ρ · g · hO

hU Lower filling height ΔpMA Start of scale value

h

O

Upper filling height ΔpME Full scale value

p Pressure ρ Density of the measured medium in the

container

g Acceleration due to gravity

SITRANS P, DS III series (7MF4.33.. 7MF4.34.. 7MF4.35..)

18 A5E03434645-01, 08/2011

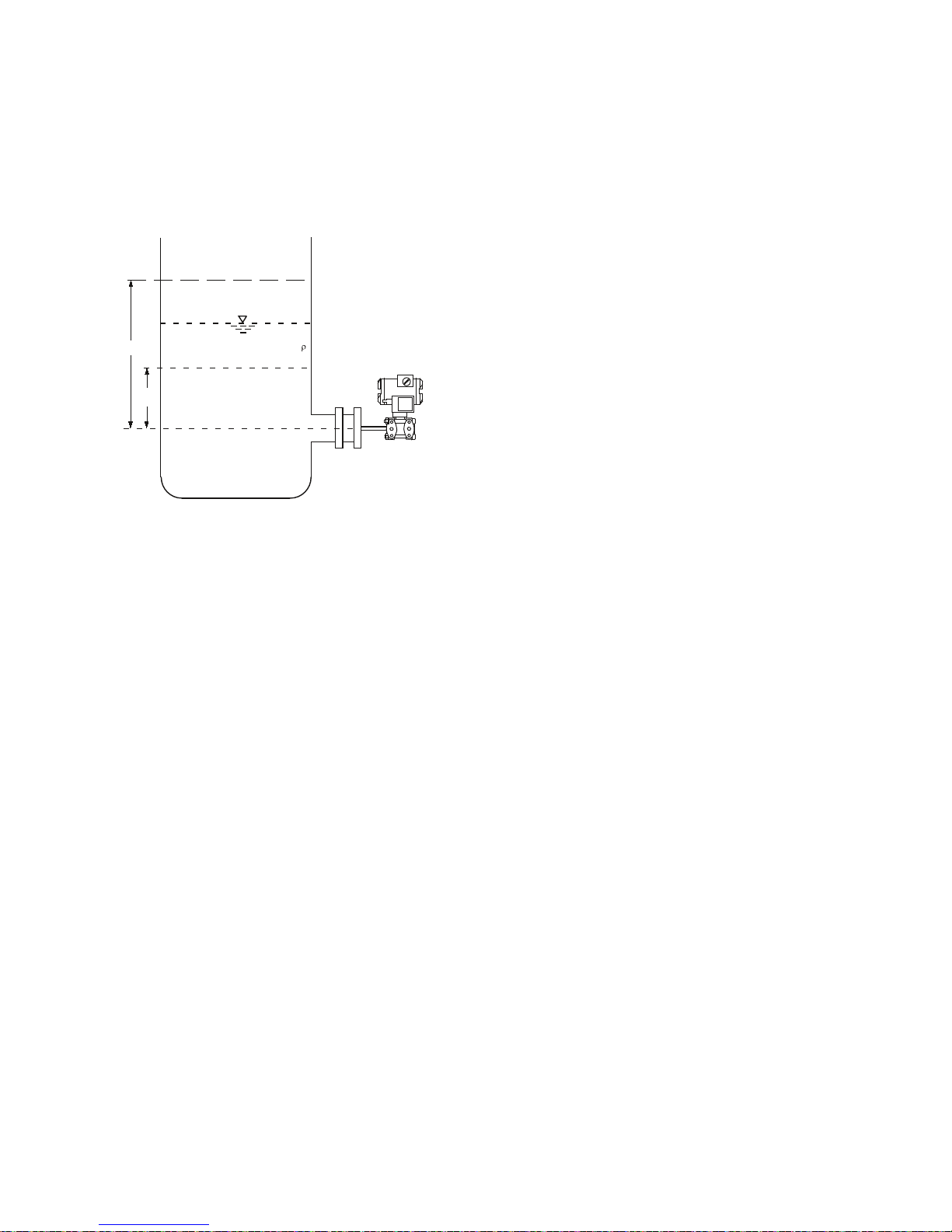

Measurement in a closed container

When taking measurements in a closed container without or with little condensate formation, the negative pressure line is

not filled. Lay the line in such a way that pockets of condensate do not form. Install a condensation container if required.

)XOOVFDOHYDOXH

6WDUWRIVFDOHYDOXH

0D[LPXPOHYHO

6WDWLF

SUHVVXUH

K

2

K

8

*DVILOOHGORZ

SUHVVXUHOLQH

7UDQVPLWWHU

UHIHUHQFHOLQH

Measurement assembly on a closed container (no or little

condensate separation)

Formula:

Start-of-scale value: Δp

MA

= ρ · g · hU

Full scale value: Δp

ME

= ρ · g · hO

hU Lower filling height ΔpMA Start of scale value

h

O

Upper filling height ΔpME Full scale value

p Pressure ρ Density of the measured medium in the

container

g Acceleration due to gravity

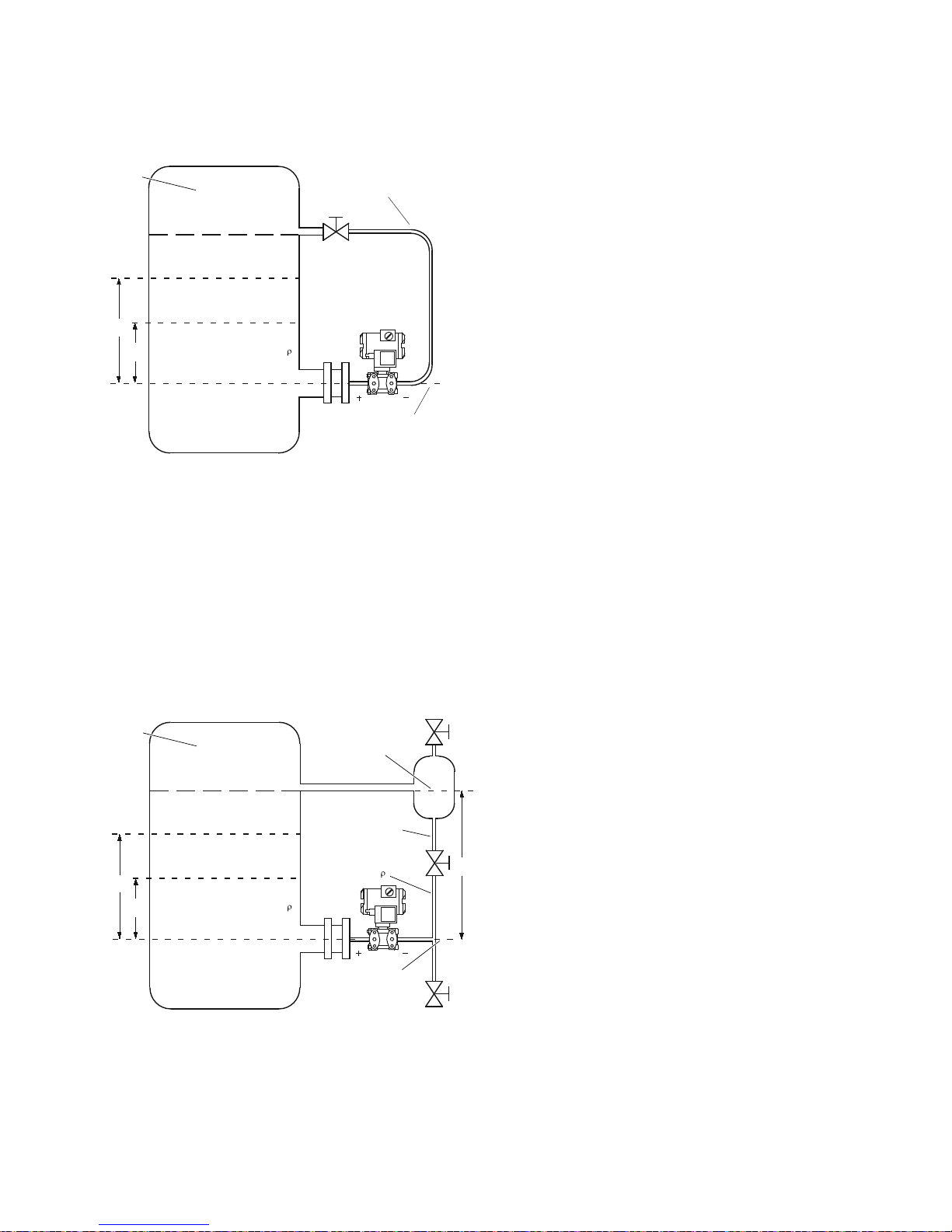

When taking measurements in a closed container with strong condensate formation, you must fill the negative pressure line

(mostly with the condensate of the measured medium) and install a condensate pot. You can cut off the device using the

dual pneumatic block 7MF9001-2.

'

-

K

2

K

8

)XOOVFDOHYDOXH

6WDUWRIVFDOHYDOXH

0D[LPXPOHYHO

6WDWLF

SUHVVXUH

&RQVWDQW

FRPSDULVRQ

OHYHO

/LTXLGILOOHG

ORZSUHVVXUHOLQH

7UDQVPLWWHU

UHIHUHQFHOLQH

K

Y

Measurement assembly on a closed container (strong condensate

formation)

Formula:

Start-of-scale value:

Δp

MA

= g · (hU · ρ- hV · ρ')

Full scale value:

Δp

MA

= g · (hO · ρ- hV · ρ')

SITRANS P, DS III series (7MF4.33.. 7MF4.34.. 7MF4.35..)

A5E03434645-01, 08/2011

19

hU Lower filling height ΔpMA Start of scale value

h

O

Upper filling height ΔpME Full scale value

h

V

Gland distance ρ Density of the measured medium in the

container

p Pressure ρ ' Density of fluid in the negative pressure line

corresponds to the prevailing temperature

there

g Acceleration due to gravity

The process connection on the negative side is a female thread 1/4-18 NPT or an oval flange.

Lay the line for the negative pressure using a seamless steel tube 12 mm x 1.5 mm.

Connecting

Basic safety instructions

WARNING

Unsuitable cables and/or cable glands

Danger of explosion in hazardous areas if you connect cables and/or cable glands which do not match one another or do

not comply with the technical requirements.

● Only use cables and cable glands complying with the requirements specified in the section Technical specifications

(Page 35).

● Tighten the cable glands in accordance with the specified torques.

● When replacing cable glands use only cable glands of the same type.

● After installation check that the cables are seated firmly.

WARNING

Hazardous contact voltage in versions with 4-conductor extension

Danger of electrocution in case of incorrect connection.

● For the electrical connection, please refer to the information in the section "Technical specifications (Page 35)".

WARNING

Improper power supply

Danger of explosion in hazardous areas as result of incorrect power supply, e.g. using direct current instead of alternating

current.

● Connect the device in accordance with the specified power supply and signal circuits. The relevant specifications can

be found in the certificates, in Chapter "Technical specifications (Page 35)" or on the nameplate.

WARNING

Unsafe extra-low voltage

Danger of explosion in hazardous areas due to voltage flashover.

● Connect the device to an extra-low voltage with safe isolation (SELV).

SITRANS P, DS III series (7MF4.33.. 7MF4.34.. 7MF4.35..)

20 A5E03434645-01, 08/2011

WARNING

Lack of equipotential bonding

Danger of explosion through compensating currents or ignition currents through lack of equipotential bonding.

● Ensure that the device is potentially equalized.

Exception: It may be permissible to omit connection of the equipotential bonding for devices with type of protection

"Intrinsic safety Ex i".

WARNING

Unprotected cable ends

Danger of explosion through unprotected cable ends in hazardous areas.

● Protect unused cable ends in accordance with IEC/EN 60079-14.

WARNING

Improper laying of shielded cables

Danger of explosion through compensating currents between hazardous area and the non-hazardous area.

● Only ground shielded cables that run into the hazardous area at one end.

● If grounding is required at both ends, use an equipotential bonding conductor

WARNING

Connecting device in energized state

Danger of explosion in hazardous areas.

● Connect devices in hazardous areas only in a de-energized state.

Exceptions:

● Circuits of limited energy may also be connected in the energized state in hazardous areas.

● Exceptions for type of protection "Non-sparking nA" (Zone 2) are regulated in the relevant certificate

WARNING

Incorrect selection of type of protection

Danger of explosion in areas subject to explosion hazard.

This device is approved for several types of protection.

1. Decide in favor of one type of protection.

2. Connect the device in accordance with the selected type of protection.

3. In order to avoid incorrect use at a later point, make the types of protection that are not used permanently

unrecognizable on the nameplate.

CAUTION

Ambient temperature too high

Damage to cable sheath.

● At an ambient temperature ≥ 60 °C (140 °F), use heat-resistant cables suitable for an ambient temperature at least 20

°C (68 °F) higher.

SITRANS P, DS III series (7MF4.33.. 7MF4.34.. 7MF4.35..)

A5E03434645-01, 08/2011

21

CAUTION

Incorrect measured values with incorrect grounding

The device must not be grounded via the "+" connection. It may otherwise malfunction and be permanently damaged.

● If necessary, ground the device using the "-" connection.

Note

Electromagnetic compatibility (EMC)

You can use this device in industrial environments, households and small businesses.

For metal housings there is an increased electromagnetic compatibility compared to high-frequency radiation. This

protection can be increased by grounding the housing, see section "Connecting the device (Page 21)".

Note

Improvement of interference immunity

● Lay signal cables separate from cables with voltages > 60 V.

● Use cables with twisted wires.

● Keep device and cables in distance to strong electromagnetic fields.

● Use shielded cables to guarantee the full specification according to HART.

● Connect a load resistor of at least 230 Ω in series in the signal circuit in order to guarantee fault-free HART

communication. When power supply isolators are used for HART transmitters, e.g. SITRANS I, a load resistor is already

installed in the device.

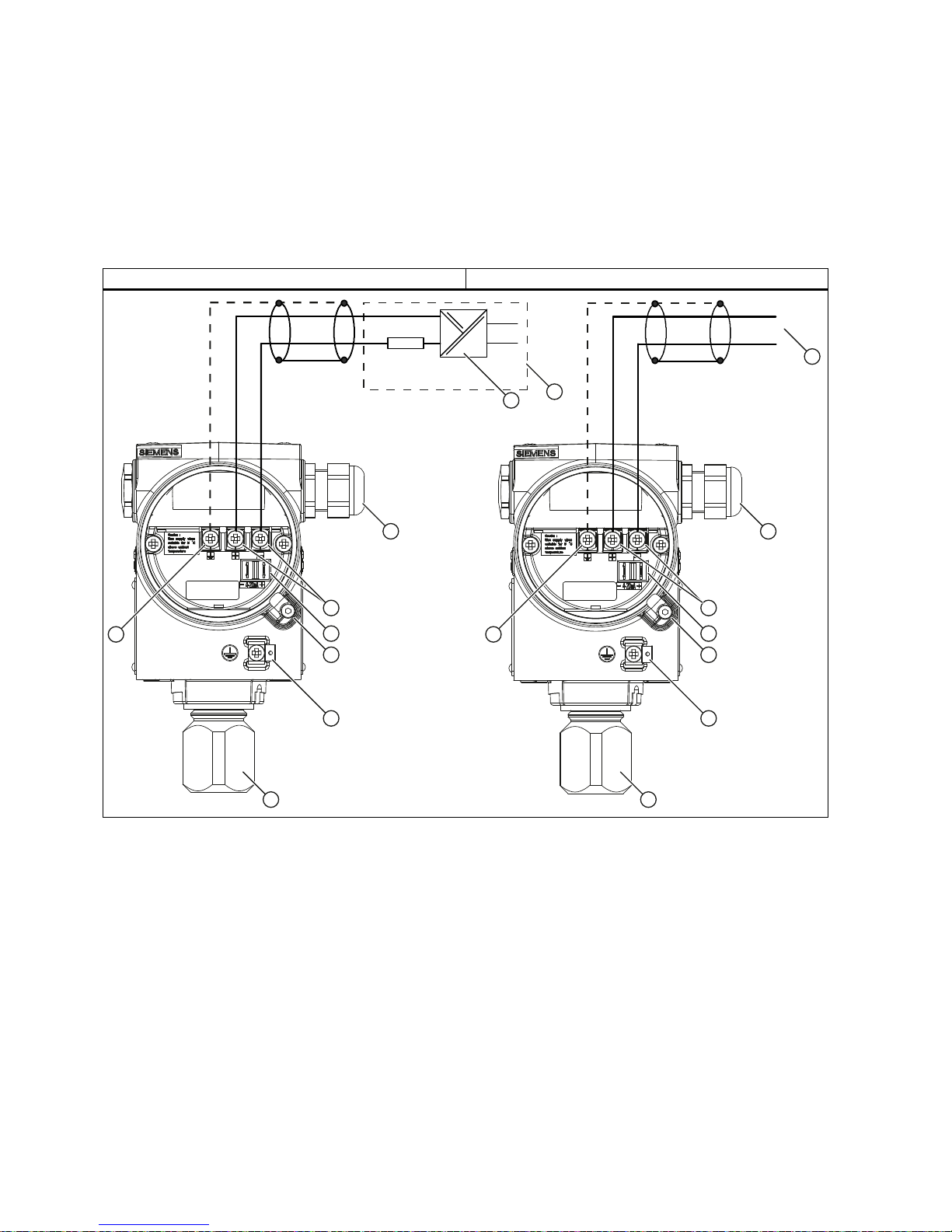

Connecting the device

Opening the device

1. Unscrew the cover of the electrical cable compartment. An identification text "FIELD TERMINAL" is provided at the side

of the housing.

SITRANS P, DS III series (7MF4.33.. 7MF4.34.. 7MF4.35..)

22 A5E03434645-01, 08/2011

Connecting the device

1. Lead the connecting cable through the cable gland ③.

2. Connect the device to the plant with the protective conductor connection

⑦.

3. Connect the wires to the connecting terminals

④ "+" and "-".

Ensure the correct polarity! If necessary, ground the device using the "-" connection by connecting the "-" connection to

the ground terminal ⑨.

4. If necessary, connect the shield to the screw of the ground terminal

⑨. This is electrically connected with the external

protective conductor connection.

HART PROFIBUS PA / Foundation™ Fieldbus FF

˖

①

Feed separator with integrated load

⑥

Safety catch

②

Auxiliary power

⑦

Protective conductor connection/

equipotential bonding terminal

③

Cable entry for auxiliary power/analog output

⑧

Process connection

④

Connecting terminals

⑨

Ground terminal

⑤

Test connector for direct current measuring

device or connection for external display

⑩

PROFIBUS PA / Foundation™ Fieldbus FF

Electrical connection, power supply

SITRANS P, DS III series (7MF4.33.. 7MF4.34.. 7MF4.35..)

A5E03434645-01, 08/2011

23

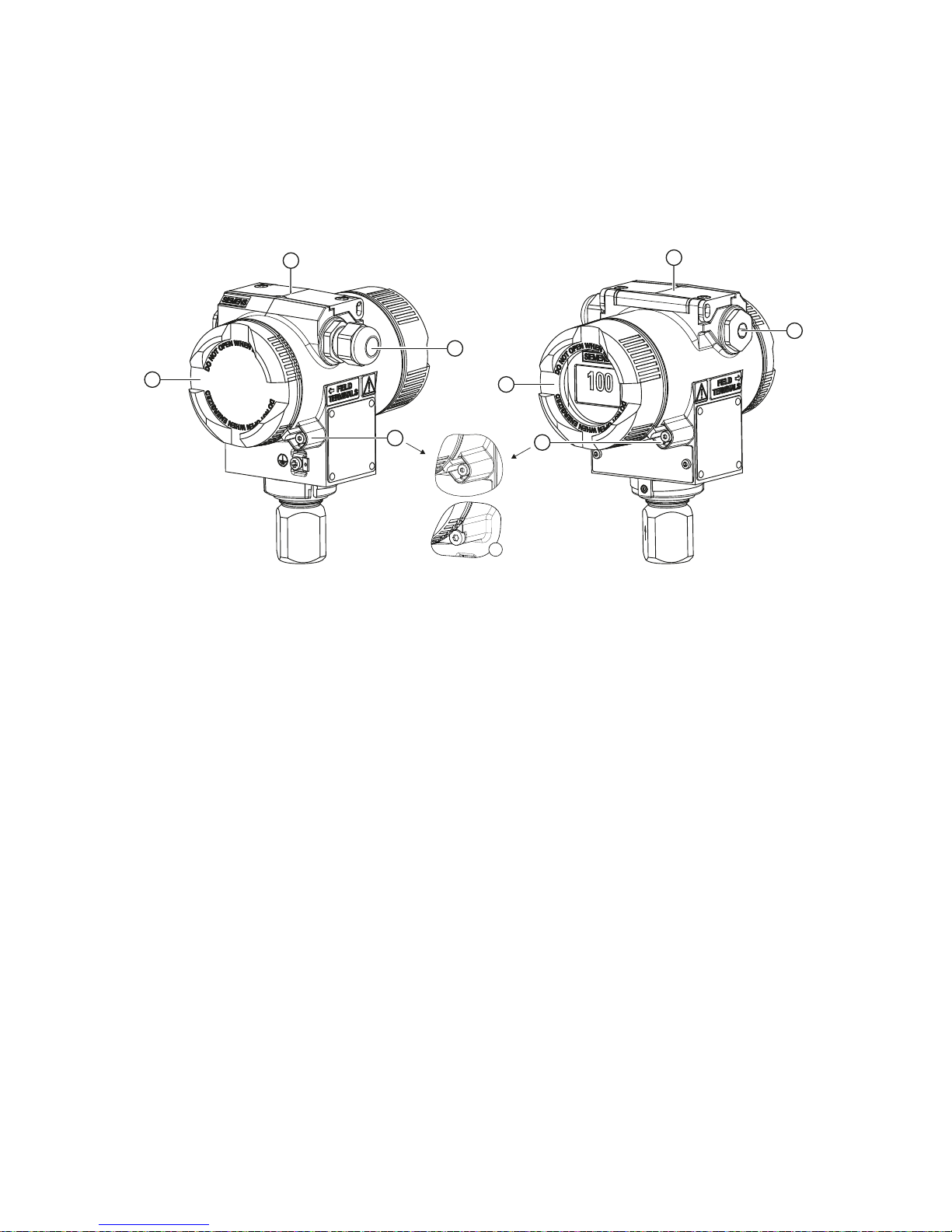

Closing the device

1. Screw the covers ④⑦ back on as far as they will go.

2. Secure each cover with the cover catch

③⑥.

3. Close the key cover

①.

4. Tighten the screws in the key cover.

5. Check the tightness of the blanking plugs

⑤ and cable gland ② in accordance with the degree of protection.

8

① Key cover ⑤ Blanking plug

② Cable gland ⑥ Safety catch (front)

③ Safety catch (back) ⑦ Cover (front), optionally with inspection window

④ Cover (rear) for electrical terminal compartment ⑧ Safety catch for stainless steel enclosure

Figure 6 View of the transmitter: Left: Back right: Front view

SITRANS P, DS III series (7MF4.33.. 7MF4.34.. 7MF4.35..)

24 A5E03434645-01, 08/2011

Commissioning

Basic safety instructions

DANGER

Toxic gases and liquids

Danger of poisoning when the device is vented.

If toxic process media are measured, toxic gases and liquids can be released when the device is vented.

● Before venting ensure that there are no toxic gases and liquids in the device. Take the appropriate safety measures.

WARNING

Improper commissioning in hazardous areas

Device failure or danger of explosion in hazardous areas.

● Do not commission the device until it has been mounted completely and connected in accordance with the information

in Chapter "Technical specifications (Page 35)".

● Before commissioning take the effect on other devices in the system into account.

WARNING

Opening device in energized state

Danger of explosion in areas subject to explosion hazard.

● Only open the device in a de-energized state.

● Check prior to commissioning that the cover, cover locks, and cable inlets are assembled in accordance with the

directives.

Exception: Devices having the type of protection "Intrinsic safety Ex i" may also be opened in energized state in hazardous

areas.

NOTICE

Hot surfaces

Hot process medium and high ambient temperatures lead to hot surfaces which can cause burns.

● Take corresponding protective measures, for example wear protective gloves.

Introduction to commissioning

Following commissioning, the transmitter is immediately ready for use.

To obtain stable measured values, the transmitter needs to be allowed to warm up for five minutes or so after the power

supply is switched on.

The operating data must correspond to the values specified on the nameplate. If you switch on the auxiliary power, the

transmitter will operate.

The following commissioning cases are typical examples. Configurations different from those listed here may be meaningful

depending on the system configuration.

SITRANS P, DS III series (7MF4.33.. 7MF4.34.. 7MF4.35..)

A5E03434645-01, 08/2011

25

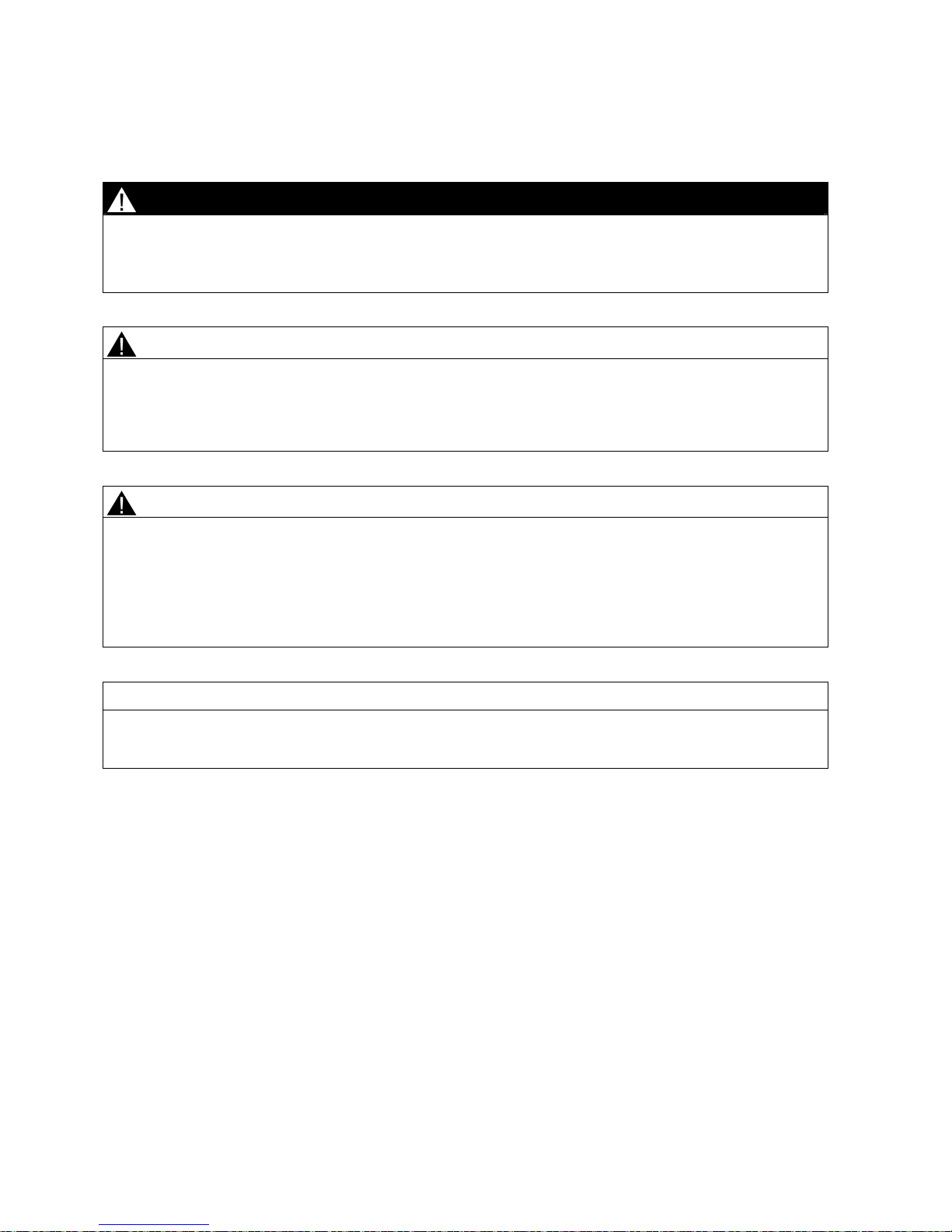

gauge pressure, absolute pressure from the differential pressure series and

absolute pressure from the gauge pressure series

Commissioning for gases

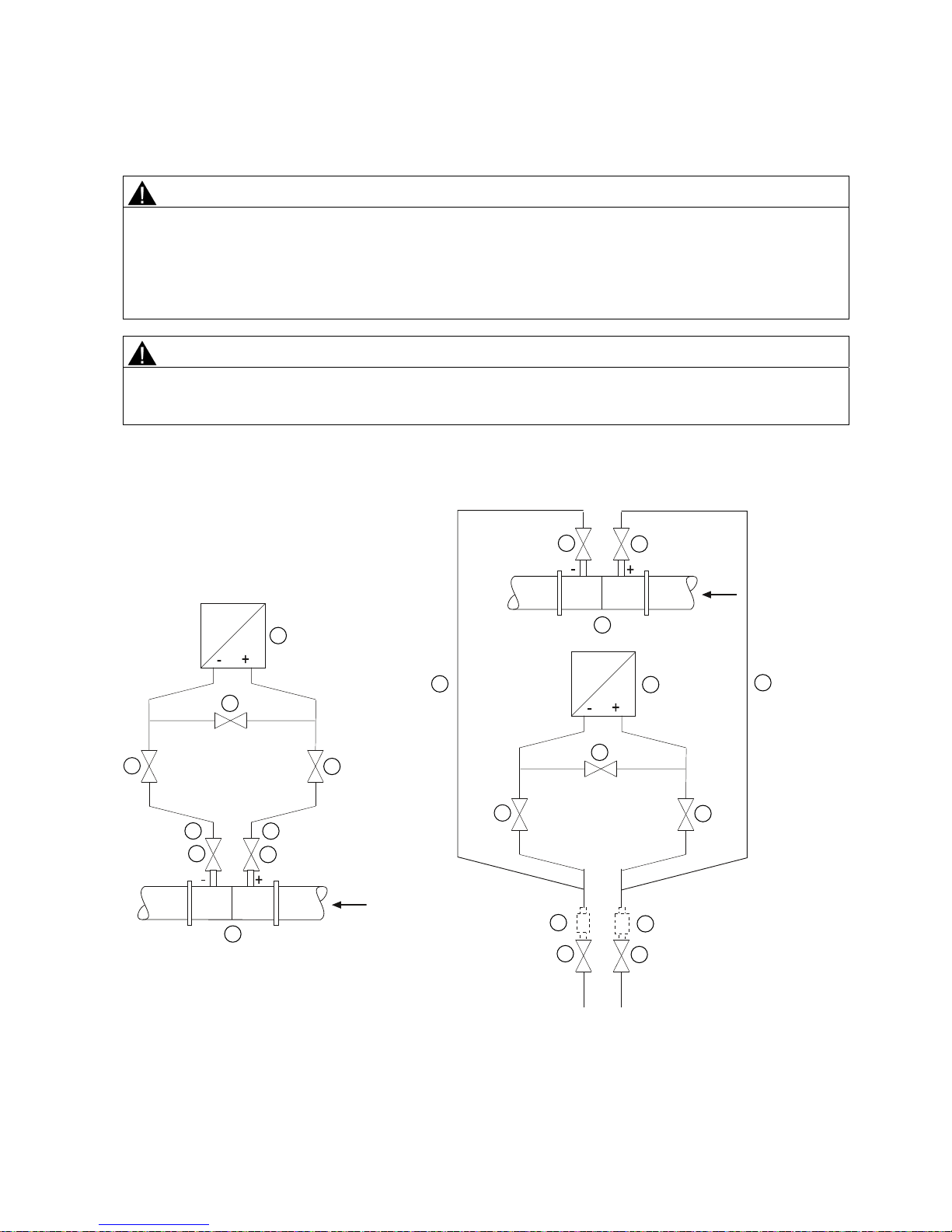

Usual arrangement Special arrangement

Measuring gases above the pressure tapping point Measuring gases below the pressure tapping point

①

Pressure transmitter

⑤

Pressure line

②

Shut-off module

⑥

Shut-off valve

③

Shut-off valve to process

⑦

Shut-off valve (optional)

⑧

Condensate vessel (optional)

④

Shut-off valve for test connection or for bleed

screw

⑨

Drain valve

Condition

All valves are closed.

Procedure

To commission the transmitter for gases, proceed as follows:

1. Open the shut-off valve for the test connection

④.

2. Via the test connection of the shut-off fitting

②, apply the pressure corresponding to the start of scale value to the

pressure transmitter

①.

3. Check the start of scale value.

SITRANS P, DS III series (7MF4.33.. 7MF4.34.. 7MF4.35..)

26 A5E03434645-01, 08/2011

4. If the start of scale value differs from the value desired, correct it.

5. Close the shut-off valve for the test connection ④.

6. Open the shut-off valve

⑥ at the pressure tapping point.

7. Open the shut-off valve for the process

③.

Commissioning with steam or liquid

① Pressure transmitter

② Shut-off fitting

③ Shut-off valve to process

④ Shut-off valve for test connection or for bleed screw

⑤ Pressure line

⑥ Shut-off valve

⑦ Blow-out valve

⑧ Compensation vessel (steam only)

Figure 7 Measuring steam

Requirement

All valves are closed.

Procedure

To commission the transmitter for steam or liquid, proceed as follows:

1. Open the shut-off valve for the test connection ④.

2. Via the test connection of the shut-off module

②, apply the pressure corresponding to the start of scale value to the

pressure transmitter

①.

3. Check the start of scale value.

4. If the start of scale value differs from the value desired, correct it.

5. Close the shut-off valve for the test connection

④.

6. Open the shut-off valve

⑥ at the pressure tapping point.

7. Open the shut-off valve for the process

③.

SITRANS P, DS III series (7MF4.33.. 7MF4.34.. 7MF4.35..)

A5E03434645-01, 08/2011

27

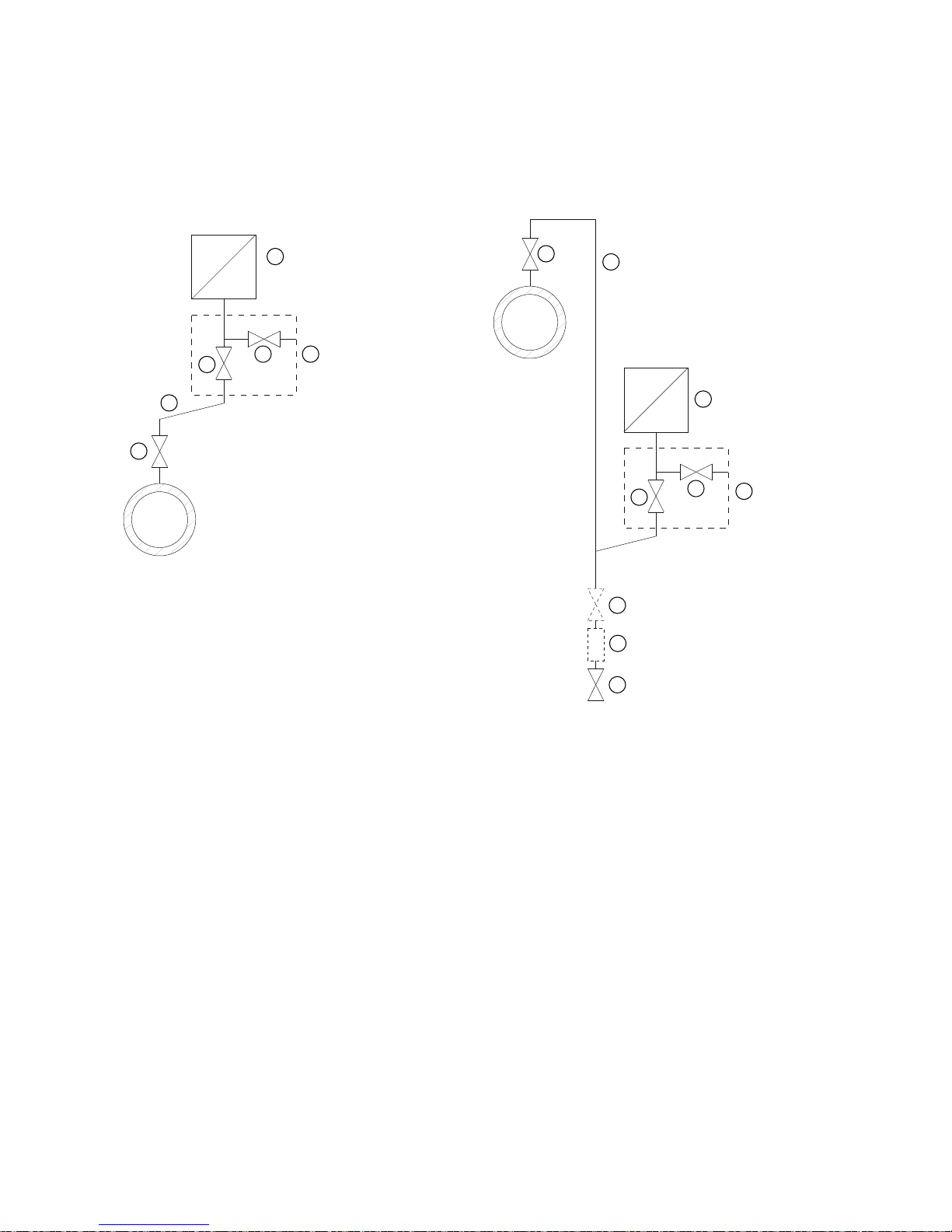

Differential pressure and flow rate

Safety notes for commissioning with differential pressure and flow rate

WARNING

Incorrect or improper operation

If the lock screws are missing or are not sufficiently tight, and/or if the valves are operated incorrectly or improperly, it could

lead to serious physical injuries or considerable damage to property.

Measure

● Take care that the locking screw and/or the vent valve are screwed in and tightened.

● Ensure that the valves are operated correctly and properly.

WARNING

Hot mediums

In the case of hot mediums, the individual operational steps should be carried out one after the other. Otherwise, it could

lead to excessive heating, thus causing damage to the valves and the transmitter.

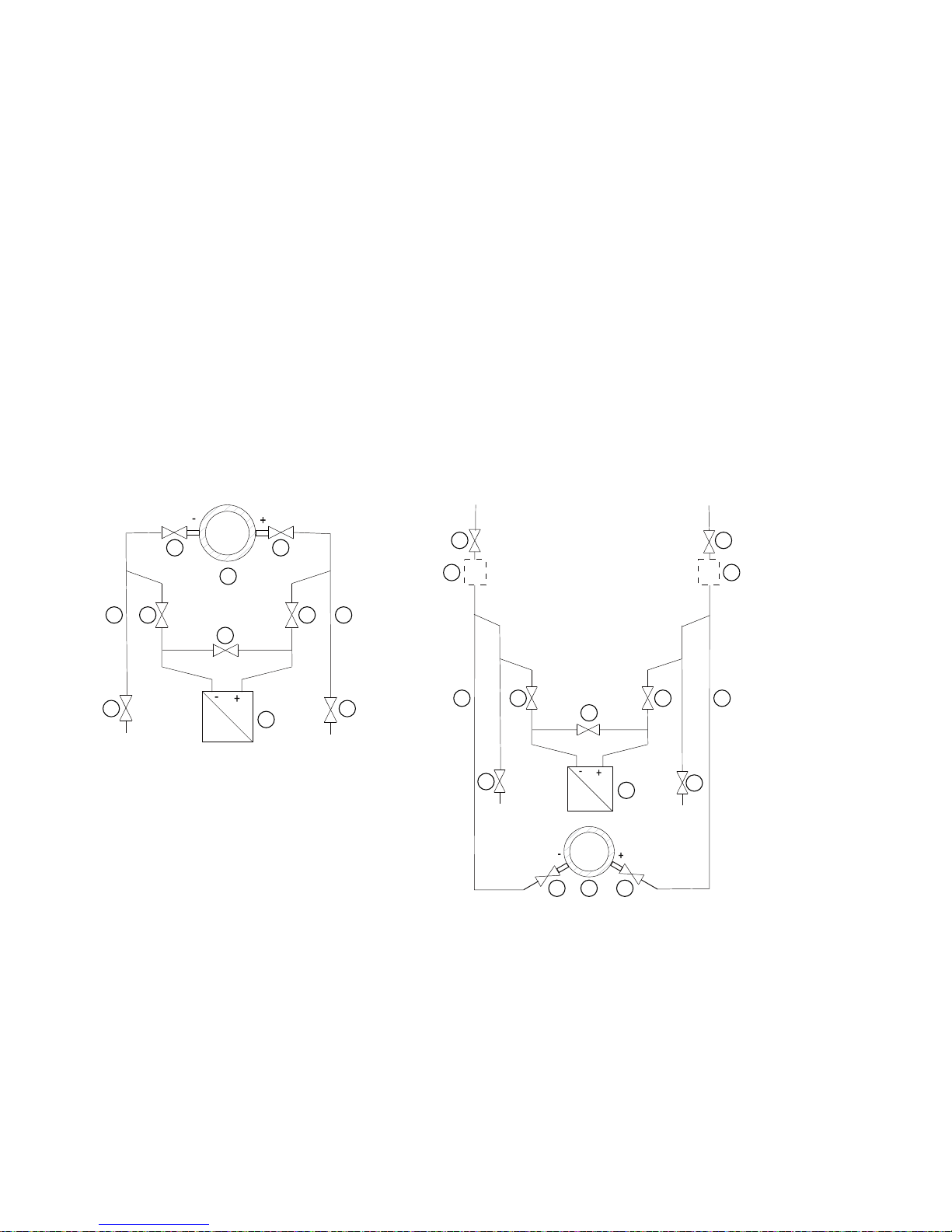

Commissioning in gaseous environments

Usual arrangement Special arrangement

①

Pressure transmitter

⑥

Shut-off valves

②

Stabilizing valve

⑦

Drain valves

③, ④

Differential pressure valves

⑧

Condensate vessels (optional)

SITRANS P, DS III series (7MF4.33.. 7MF4.34.. 7MF4.35..)

28 A5E03434645-01, 08/2011

⑤

Differential pressure lines

⑨

Differential pressure transducer

Transmitter above the differential pressure

transducer

Transmitter below the

differential pressure transducer

Condition

All shut-off valves are closed.

Procedure

To commission the transmitter for gases, proceed as follows:

1. Open both the shut-off valves

⑥ at the pressure tapping point.

2. Open the stabilizing valve

②.

3. Open the differential pressure valve (

③ or ④).

4. Check and if required correct the zero point when the start of scale value is 0 mbar (4 mA).

5. Close the stabilizing valve

②.

6. Open the other differential pressure valve (

③ or ④).

Commissioning for liquids

Usual arrangement Special arrangement

①

Pressure transmitter

⑦

Drain valves

②

Stabilizing valve

⑧

Gas collector vessels (optional)

③, ④

Differential pressure valves

⑨

Differential pressure transducer

⑤

Differential pressure lines

⑩

Vent valves

⑥

Shut-off valves

Transmitter below the differential pressure

transducer

Transmitter above the

differential pressure transducer

SITRANS P, DS III series (7MF4.33.. 7MF4.34.. 7MF4.35..)

A5E03434645-01, 08/2011

29

Condition

All valves are closed.

Procedure

WARNING

The transmitter should not be depressurized if toxic substances are being used.

To commission the transmitter with liquids, proceed as follows:

1. Open both the shut-off valves

⑥ at the pressure tapping point.

2. Open the stabilizing valve

②.

3. With transmitters below the differential pressure transducer, open both the drain valves one after the other

⑦ until the

air-free liquid emerges.

In the case of a transmitter above the differential pressure transducer, open both the vent valves one after the other

⑩

until the liquid emerges.

4. Close both drain valves

⑦ or vent valves ⑩.

5. Open the differential pressure valve

③ and the vent valve on the positive side of the transmitter ① slightly, until fluid

escapes without bubbles.

6. Close the vent valve.

7. Open the vent valve on the negative side of the transmitter

① slightly, until fluid escapes without bubbles.

8. Close the differential pressure valve

③.

9. Open the differential pressure valve

④ until the liquid emerges and then close it.

10. Close the vent valve on the negative side of the transmitter

①.

11. Open the differential pressure valve

③ by rotating it in half a turn.

12. Check and if required adjust the zero point (4 mA) if the start-of-scale value is 0 bar.

13. Close the stabilizing valve

②.

14. Open the differential pressure valves (

③ and ④) completely.

SITRANS P, DS III series (7MF4.33.. 7MF4.34.. 7MF4.35..)

30 A5E03434645-01, 08/2011

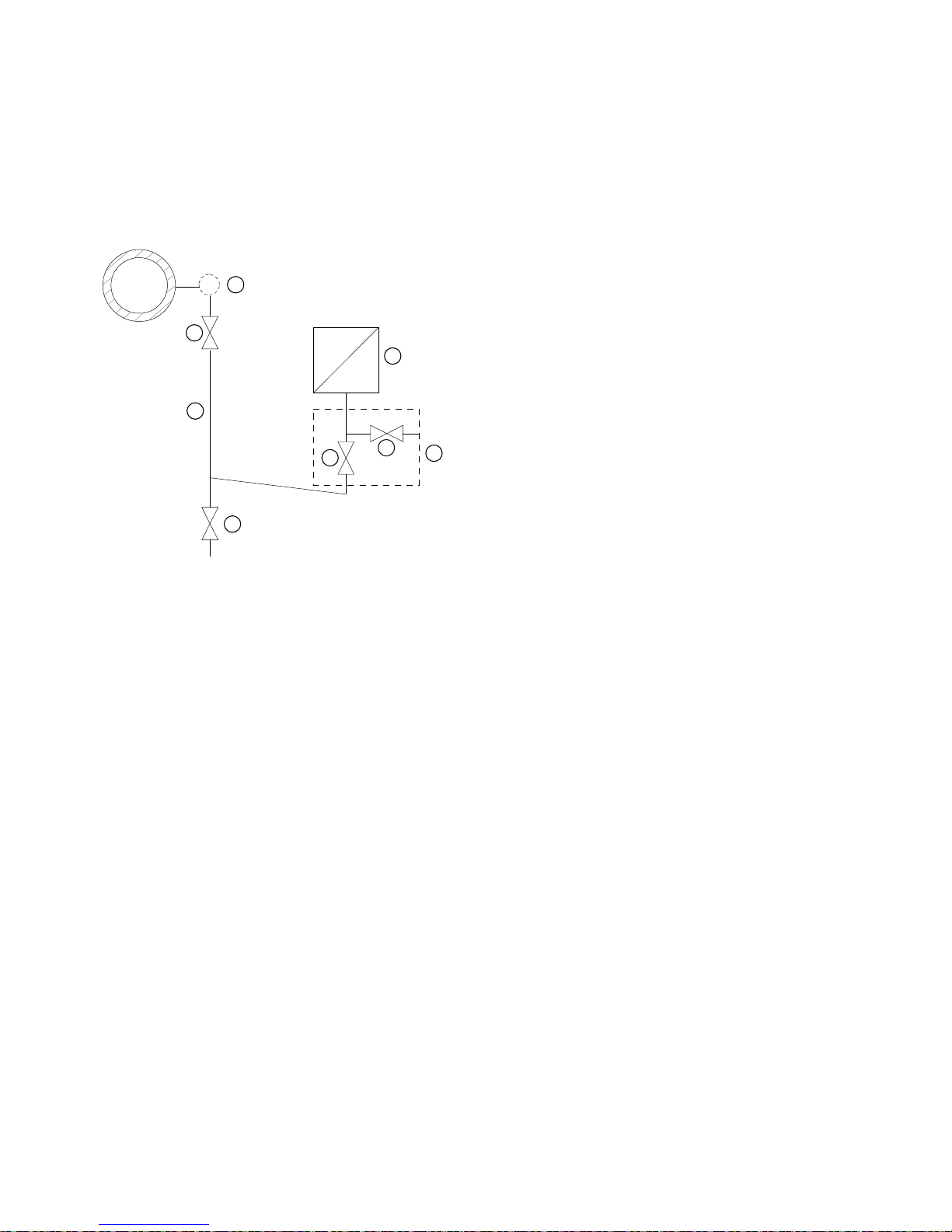

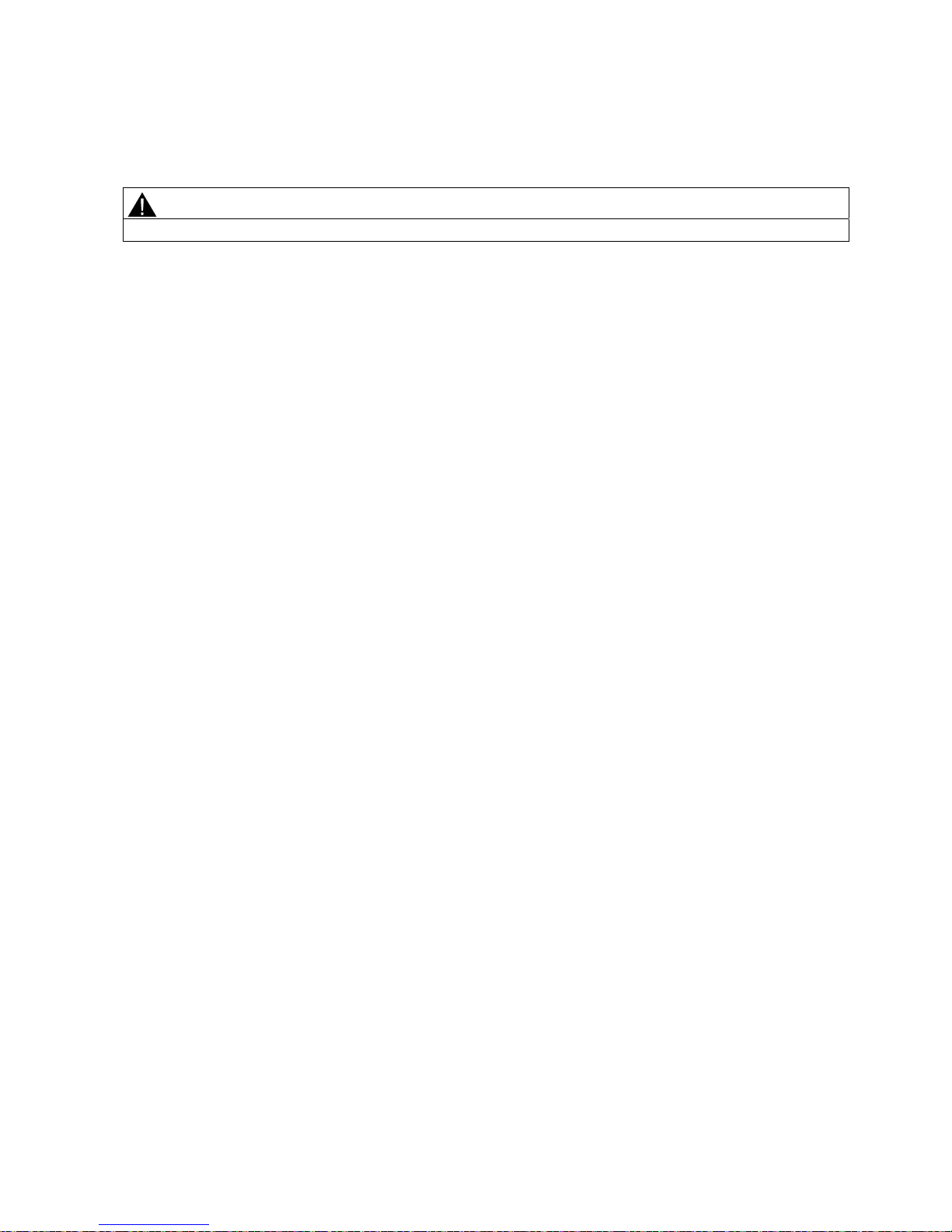

Commissioning with vapor

① Pressure transmitter ⑦ Drain valves

② Stabilizing valve ⑧ Condensate pots

③, ④ Differential pressure valves ⑨ Differential pressure transducer/Orifice plate

⑤ Differential pressure lines ⑩ Insulation

⑥ Shut-off valves

Figure 8 Measuring steam

Condition

All valves are closed.

Procedure

CAUTION

The measuring result is error-free only if the differential pressure lines ⑤ have equally high condensate columns with the

same temperature. The zero calibration must be repeated if required if these conditions are fulfilled. If the shut-off valves

⑥ and the differential pressure valves ③ are open at the same time and the stabilizing valve ② is opened, there is a

possibility of the transmitter

① being damaged due to the streaming vapor.

To commission the transmitter for vapor, proceed as follows:

1. Open both the shut-off valves

⑥ at the pressure tapping point.

2. Open the stabilizing valve

②.

3. Wait until the steam in the differential pressure lines

⑤ and in the equalizing vessels ⑧ has condensed.

4. Open the differential pressure valve

③ and the vent valve on the positive side of the transmitter ① slightly, until

condensate escapes without bubbles.

5. Close the vent valve.

6. Open the vent valve on the negative side of the transmitter

① slightly, until condensate escapes without bubbles.

7. Close the differential pressure valve

③.

8. Open the differential pressure valve

④ slightly, until condensate escapes without bubbles, then close it.

Loading...

Loading...