Siemens Sitrans Probe LR Operating Instructions Manual

Radar Transmitters

SITRANS Probe LR

Operating Instructions 01/2011

SITRANS

Safety Guidelines: Warning notices must be observed to ensure personal safety as well as that of

others, and to protect the product and the connected equipment. These warning notices are

accompanied by a clarification of the level of caution to be observed.

Qualified Personnel: This device/system may only be set up and operated in conjunction with this

manual. Qualified personnel are only authorized to install and operate this equipment in accordance with

established safety practices and standards.

Unit Repair and Excluded Liability:

• The user is responsible for all changes and repairs made to the device by the user or the user’s

agent.

• All new components are to be provided by Siemens Milltronics Process Instruments.

• Restrict repair to faulty components only.

• Do not reuse faulty components.

Warning: Cardboard shipping package provides limited humidity and moisture protection. This product

can only function properly and safely if it is correctly transported, stored, installed, set up, operated, and

maintained.

This product is intended for use in industrial areas. Operation of this equipment in a residential area

may cause interference to several frequency based communications.

Note: Always use product in accordance with specifications.

Copyright Siemens AG 2011. All Rights

Disclaimer of Liability

Reserved

This document is available in bound version and in

electronic version. We encourage users to purchase

authorized bound manuals, or to view electronic

versions as designed and authored by Siemens

Milltronics Process Instruments. Siemens Milltronics

Process Instruments will not be responsible for the

contents of partial or whole reproductions of either

bound or electronic versions.

While we have verified the contents of this

manual for agreement with the

instrumentation described, variations remain

possible. Thus we cannot guarantee full

agreement. The contents of this manual are

regularly reviewed and corrections are

included in subsequent editions. We welcome

all suggestions for improvement.

Technical data subject to change.

MILLTRONICS®is a registered trademark of Siemens Milltronics Process Instruments.

Contact SMPI Technical Publications European Authorized Representative

at the following address:

Technical Publications Siemens AG

Siemens AG Industry Sector

Siemens Milltronics Process Instruments 76181 Karlsruhe

1954 Technology Drive, P.O. Box 4225 Deutschland

Peterborough, Ontario, Canada, K9J 7B1

Email: techpubs.smpi@siemens.com

• For a selection of Siemens Milltronics level measurement manuals, go to:

www. siemens.com/processautomation. Under Process Instrumentation, select

Measurement

• For a selection of Siemens Milltronics weighing manuals, go to:

www. siemens.com/processautomation. Under Weighing Technology, select

Weighing Systems

and then go to the manual archive listed under the product family.

and then go to the manual archive listed under the product family.

Level

Continuous

© Siemens AG 2011

Table of Contents

Safety Notes ...........................................................................................................................................1

Safety marking symbols ............................................................................................................1

The Manual ............................................................................................................................................1

Application Examples .................................................................................................................2

Support ..........................................................................................................................................2

Abbreviations and Identifications ...........................................................................................2

SITRANS Probe LR ............................................................................................................4

Applications ..................................................................................................................................4

SITRANS Probe LR System Implementation ........................................................................5

Programming ................................................................................................................................5

SITRANS Probe LR Approvals and Certificates ..................................................................5

Specifications ....................................................................................................................7

SITRANS Probe LR ............................................................................................................................... 7

Power............................................................................................................................................. 7

Performance................................................................................................................................. 7

Interface ........................................................................................................................................ 8

Programmer (infrared keypad)................................................................................................ 8

Mechanical................................................................................................................................... 9

Environmental.............................................................................................................................. 9

Process........................................................................................................................................ 10

Approvals (verify against device nameplate)..................................................................... 10

Installation ..................................................................................................................................................11

Mounting location ...............................................................................................................................12

Location on a nozzle, or on a manhole cover ....................................................................14

Mounting Instructions .......................................................................................................................14

SITRANS Probe LR: Dimensions ...........................................................................................15

Wiring ................................................................................................................................16

Power ...........................................................................................................................................16

Connecting SITRANS Probe LR .......................................................................................................16

Operating SITRANS Probe LR .......................................................................................18

RUN Mode ..................................................................................................................................18

Display ......................................................................................................................................... 18

PROGRAM Mode ......................................................................................................................19

Programming.............................................................................................................................. 19

Display ......................................................................................................................................... 19

Low temperature effects on RUN/PROGRAM modes ......................................................20

Security ........................................................................................................................................21

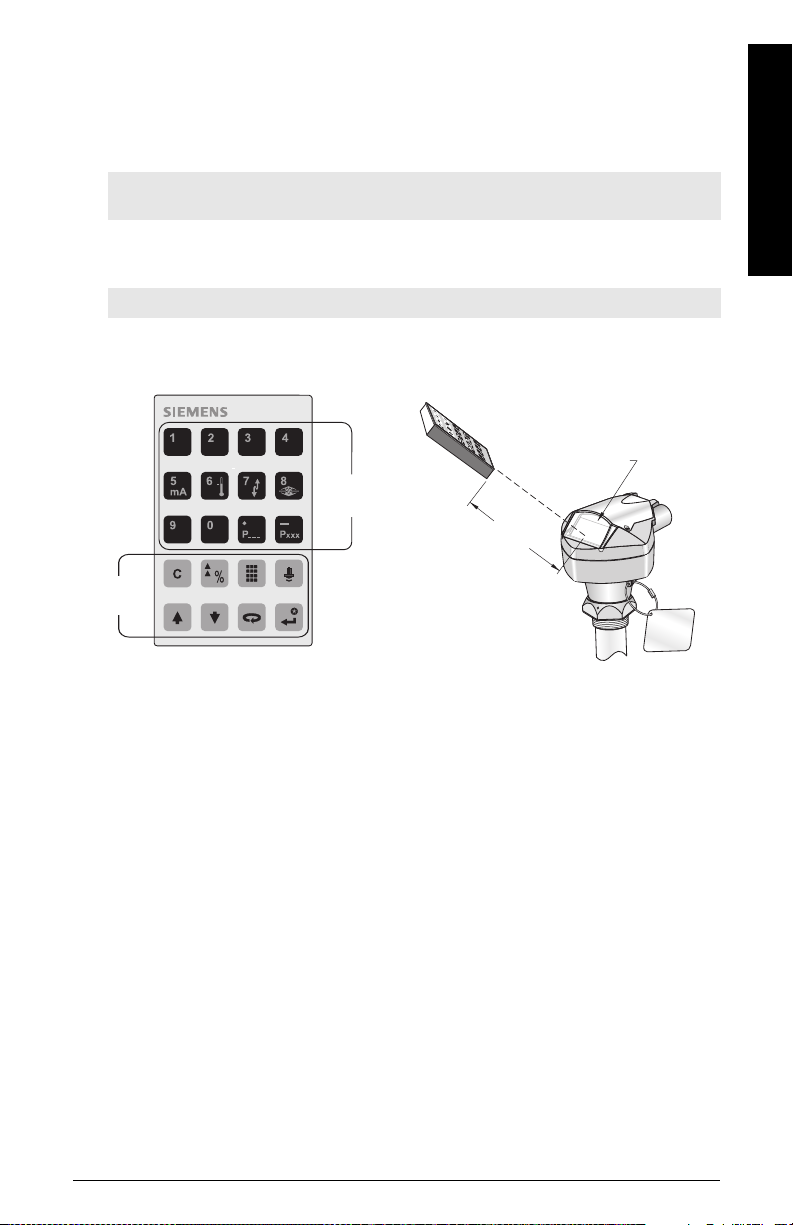

Handheld programmer .............................................................................................................21

Activating SITRANS Probe LR .........................................................................................................22

Accessing a parameter ...........................................................................................................22

Changing a Parameter Value .................................................................................................23

Using Units or Percent (%) ..................................................................................................... 24

Table of Contents

i

Quick Setup for local operation (outline) ......................................................................................24

Setup Instructions .....................................................................................................................24

Additional Settings .............................................................................................................................29

Application Examples ....................................................................................................30

Example 1: Liquid resin in storage vessel, level measurement .....................................30

Example 2: Horizontal vessel with volume measurement ...............................................32

Parameter Reference ....................................................................................................35

Table of C on t en ts

Helpful Hints ............................................................................................................................... 35

To access a parameter and change a value (primary index): ....................................... 35

To access a secondary index and change a value: ......................................................... 36

Quick Start (P001 to P010)................................................................................................................. 38

Volume (P050 to P055)........................................................................................................................ 42

Lock (P069)............................................................................................................................................ 47

Failsafe (P070 to P073)....................................................................................................................... 47

mA Output (P201 to P215).................................................................................................................. 48

Installation Records (P341 to P346) ................................................................................................ 52

Range Calibration (P652 to P655) .................................................................................................... 53

Rate (P700 and P701).......................................................................................................................... 55

Measurement Verification (P709 to P713) ................................................................................... 56

Communications (P799)..................................................................................................................... 59

Echo Processing (P800 to P807) .................................................................................................

Algorithm (P820) .................................................................................................................................. 62

TVT (Time Varying Threshold) Adjustment Parameters (P831 to P839) ............................... 63

Test (P900 to P924) ............................................................................................................................. 66

Measurement ...................................................................................................................................... 67

..... 59

ii

Appendix A: Alphabetical Parameter List .................................................................69

Appendix B: Programming Chart ..................................................................................72

Appendix C: HART ...........................................................................................................75

HART Communications for SITRANS Probe LR ...........................................................................75

HART Electronic Device Description (EDD) .................................................................................75

HART Communicator 275/375: ................................................................................................76

SIMATIC Process Device Manager (PDM) ..................................................................................79

Maintenance settings (accessible via PDM only) ............................................................79

HART Version .......................................................................................................................................80

Burst mode .................................................................................................................................80

Appendix D: Troubleshooting .......................................................................................81

Communication Troubleshooting ....................................................................................................81

Generally: ....................................................................................................................................81

Specifically: .................................................................................................................................81

General Fault Codes ...........................................................................................................................82

Fault Codes (Firmware Revision 3.02 or higher) ..........................................................................82

Fault Codes (Firmware Revision 1.05 or earlier) ..........................................................................85

Operation Troubleshooting ...............................................................................................................88

Maintenance ....................................................................................................................91

Unit Repair and Excluded Liability ..................................................................................................91

Appendix E: Technical Reference ................................................................................92

Principles of Operation ......................................................................................................................92

Transceiver ...........................................................................................................................................92

Typical Receiver Signal ........................................................................................................... 93

Near Blanking ............................................................................................................................93

Loss of Echo (LOE) ..............................................................................................................................93

Range Extension ........................................................................................................................94

False-Echo Suppression ...................................................................................................................94

TVT (Time Varying Threshold) curves ............................................................................................94

Auto False-Echo Suppression ................................................................................................94

RUN/PROGRAM ..................................................................................................................................96

Output ...........................................................................................................................................96

Failsafe ..................................................................................................................................................97

Chemical compatibility .......................................................................................................................97

Appendix F: Special Applications ................................................................................98

Application Example: Stilling-well .........................................................................................98

Appendix G: hazardous area installations ...............................................................100

Wiring Details ....................................................................................................................................100

Intrinsically Safe Model .........................................................................................................100

FM/CSA ......................................................................................................................................101

EU Equivalency ....................................................................................................................... 101

Loop Voltage versus Loop Resistance ...............................................................................102

IS Safety Barrier Selection ...................................................................................................102

How to select a passive barrier for SITRANS Probe LR .............................................. 102

PLC Input Modules................................................................................................................. 103

Passive Shunt Diode Barriers ............................................................................................ 103

Active barriers (repeating barriers)................................................................................... 103

Table of Contents

iii

Instructions specific to hazardous area installations ..............................................................104

(Reference European ATEX Directive 94/9/EC, ................................................................104

Annex II, 1/0/6) .........................................................................................................................104

Product Nameplate ..........................................................................................................................105

Intrinsically safe connection drawing (FM) ................................................................................106

Intrinsically safe connection drawing (CSA) ..............................................................................107

Non-incendive connection drawing (FM) ...................................................................................108

Appendix H: Firmware Revision History ...................................................................109

Table of C on t en ts

Glossary ..........................................................................................................................111

Index ................................................................................................................................115

iv

Safety Notes

Special attention must be paid to warnings and notes highlighted from the rest of the text

by grey boxes.

1

WARNING: relates to a caution symbol on the product, and means

that failure to observe the necessary precautions can result in death,

serious injury, and/or considerable material damage.

WARNING

1

: means that failure to observe the necessary

precautions can result in death, serious injury, and/or considerable

material damage.

Note:

means important information about the product or that part of the operating

manual.

Safety marking symbols

In manual: On product: Description

Earth (ground) Terminal

(Label on product: yellow background.) WARNING: refer

to accompanying documents (manual) for details.

The Manual

SITRANS Probe LR

Notes:

• Please follow the installation and operating procedures for a quick, trouble-free

installation and to ensure the maximum accuracy and reliability of your

SITRANS Probe LR.

• This manual applies to the SITRANS Probe LR only.

• This product is intended for use in industrial areas. Operation of this equipment in a

residential area may cause interference to several frequency based

communications.

This manual will help you set up your SITRANS Probe LR for optimum performance. We

always welcome suggestions and comments about manual content, design, and

accessibility.

Please direct your comments to techpubs.smpi@siemens.com

measurement manuals, go to www.siemens.com/level

Measurement.

1.

This symbol is used when there is no corresponding symbol on the product.

7ML19985HR02 SITRANS Probe LR – INSTRUCTION MANUAL Page 1

. For other Siemens level

, and look under Level

WARNING: Changes or modifications not expressly approved by

Siemens could void the user’s authority to operate the equipment.

Note:

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference,

in which case the user will be required to correct the interference at his own expense.

Application Examples

The application examples used in this manual illustrate typical installations using

SITRANS Probe LR. Because there is often a range of ways to approach an application,

other configurations may also apply.

SITRANS Probe LR

In all examples, substitute your own application details. If the examples do not apply to

your application, check the applicable parameter reference for the available options.

Standard applications are found in the main body of the manual: for more specialized

applications, please see

Support

If you have questions you can access our 24-hour hotline at:

www.siemens.com/automation/support-request

Appendix F: Special Applications

.

, page 98.

Phone: +49 180 50 50 222

Abbreviations and Identifications

Short

form

A/D Analog to digital

CE / FM /

CSA

C

i

D/A Digital to analog

DAC Digital Analog Converter

DCS Distributed Control System control room apparatus

Page 2 SITRANS Probe LR – INSTRUCTION MANUAL 7ML19985HR02

Long Form Description Units

Conformitè Europèene / Factory

Mutual / Canadian Standards

Association

Internal capacitance

safety approval

Short

form

Long Form Description Units

FV Full Vacuum

ESD Electrostatic Discharge

HART

I

i

I

o

Highway Addressable Remote

Trans duc er

Input current mA

Output current mA

IS Intrinsically Safe safety approval

L

i

Internal inductance mH

LRV Lower Range Value value for process empty level 4 mA

LSL Lower Sensor Limit

mH MilliHenry 10

μF MicroFarad 10

μs Microsecond 10

below which no PV is

anticipated

-3

-6

-6

Henry

Farad

Second

PBT Polybutylene terephthalate

PED Pressure Equipment Directive safety approval

PEI Polyether Imide

pF Pico Farads 10

-12

Farad

ppm Parts per Million

PV Primary Variable measured value

SELV Safety Extra Low Voltage

SV Secondary Variable equivalent value

TV Transmitter Variable

TVT Time Varying Threshold sensitivity threshold

U

i

U

o

Input voltage V

Output voltage V

URV Upper Range Value value for process full level 20 mA

USL Upper Sensor Limit

a.

100% is most commonly set to 20 mA, and 0% to 4 mA: however, the settings

above which no PV is

anticipated

can be reversed.

SITRANS Probe LR

a

a

7ML19985HR02 SITRANS Probe LR – INSTRUCTION MANUAL Page 3

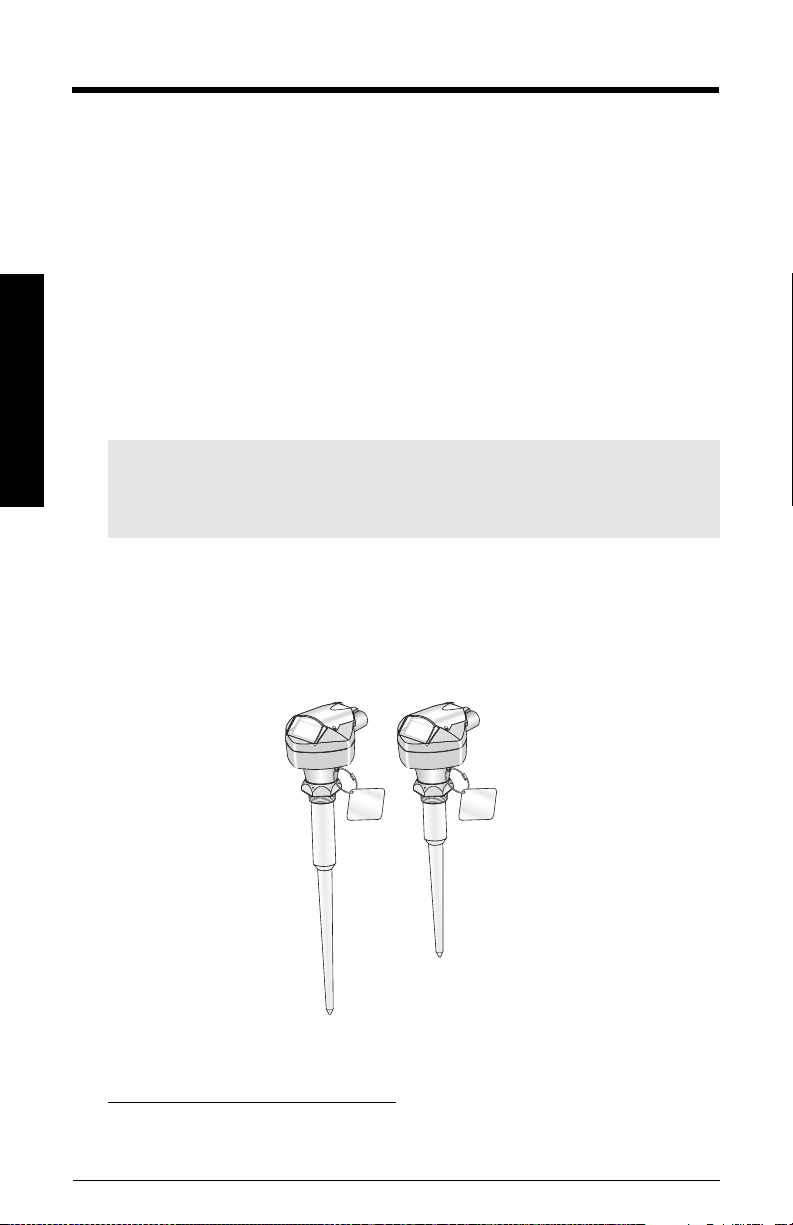

SITRANS Probe LR

shield length: 100 mm (4"):

use for nozzles of 100 mm (4") or less

in length

shield length 250 mm (10"):

use for long nozzles of 250 mm (10")

or less in length

SITRANS Probe LR is a 2-wire loop-powered, continuous level measuring instrument that

utilizes advanced pulse radar technology at 5.8 GHz (6.3 GHz in North America). The

instrument consists of an electronic component coupled to the antenna and process

connection. It is very easy to install and set up, using either the infrared handheld

programmer locally, or using SIMATIC

Communication is via HART

been field-proven in over 500,000 applications worldwide (ultrasonic and radar).

SITRANS Probe LR is available in two versions

• General Purpose (non-hazardous)

• Intrinsically Safe (with suitable barrier)

2

. Signals are processed using Sonic Intelligence® which has

Applications

1

PDM from a remote location.

SITRANS Probe LR

Notes:

• Please refer to product label for approval information.

• SITRANS Probe LR is to be used only in the manner outlined in this manual,

otherwise protection provided by the equipment may be impaired.

SITRANS Probe LR is designed to measure liquid levels in a variety of applications:

• liquid bulk storage vessels

• simple process vessels with gentle agitation

• liquids

• slurries

1.

SIMATIC®is a registered trademark of Siemens AG.

2.

HART® is a registered trademark of the HART Communication Foundation.

Page 4 SITRANS Probe LR – INSTRUCTION MANUAL 7ML19985HR02

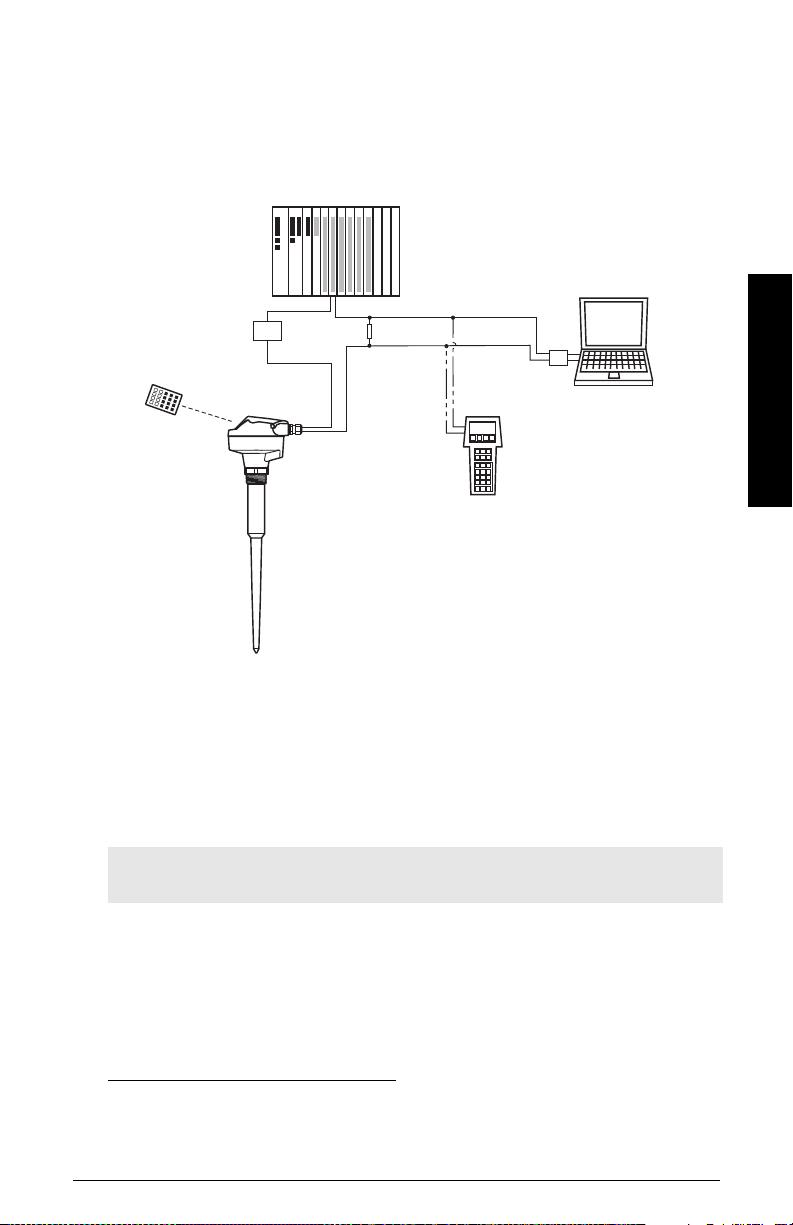

SITRANS Probe LR System Implementation

active PLC

HART modem

SITRANS

Probe LR

power supply

1

Typical PLC/mA configuration with HART

R2= 250 Ω

HART

communicator

SITRANS Probe LR1supports HART2communication protocol and SIMATIC PDM

software.

SITRANS Probe LR

Programming

SITRANS Probe LR carries out its level measurement function according to the set of

built-in parameters. You can make parameter changes via the handheld programmer, via

a PC using SIMATIC PDM, or via a HART Handheld Communicator.

SITRANS Probe LR Approvals and Certificates

Note: Please see

approvals listing.

1.

Depending on the system design, the power supply may be separate from the

PLC, or integral to it.

2.

A 250 Ohm resistor may be required if the loop resistance is less than 250 Ohms.

7ML19985HR02 SITRANS Probe LR – INSTRUCTION MANUAL Page 5

Approvals (verify against device nameplate)

on page 10 for an

SITRANS Probe LR

Notes

Page 6 SITRANS Probe LR – INSTRUCTION MANUAL 7ML19985HR02

Specifications

Notes:

• Siemens makes every attempt to ensure the accuracy of these specifications but

reserves the right to change them at any time.

• Please check the ambient and operating temperatures under

and

Approvals (verify against device nameplate)

(verify against device nameplate)

about to use or install.

on page 10, for the specific configuration you are

SITRANS Probe LR

Power

on page 10; also check

Enclosure

on page 9,

Approvals

Nominal 24 V DC at

max. 550 Ohm.

• Maximum 30 V DC

• 4 to 20 mA

For other configurations, see the chart

versus Loop Resistance

on page 102.

Performance

Reference operating conditions according to IEC 60770-1

• ambient temperature +15 to +25 oC (+59 to +77 oF)

• humidity 45% to 75% relative humidity

• ambient pressure 860 to 1060 mbar g (86000 to 106000 N/m

Measurement Accuracy (measured in accordance with IEC 60770-1)

• non-linearity (accuracy) the greater of: 10 mm (0.4"), or 0.10% of Span

(including hysteresis and non-repeatability)

• non-repeatability 5 mm (included in non-linearity specification)

• deadband (resolution) 5 mm (included in non-linearity specification)

Analog Output Accuracy (measured in accordance with IEC 60770-1)

• non-linearity (accuracy) 0.125% of Span (including hysteresis and nonrepeatability)

• non-repeatability 0.025% of Span (included in non-linearity

specification)

• deadband (resolution) 0.0375% of Span (included in non-linearity

specification)

Loop Voltage

2

g)

Specifications

7ML19985HR02 SITRANS Probe LR – INSTRUCTION MANUAL Page 7

Frequency 5.8 GHz (6.3 GHz in N. America): refer to product

Max. measurement range

Update time mA output and loop display is updated once per

Minimum detectable distance

Influence of ambient temperature 0.003% / K

Dielectric constant εr > 3 (for < 3 use waveguide antenna or stillpipe)

Memory:

• non-volatile EEPROM

• no battery required.

Interface

•HART

• configuration: Siemens SIMATIC PDM (PC), or

HART handheld communicator, or

Siemens infrared handheld programmer

• analog output: 4 to 20 mA, ± 0.02 mA accuracy

• display (local): multi-segment alphanumeric liquid crystal with bar graph

Programmer (infrared keypad)

Specifications

Siemens Milltronics Infrared IS (Intrinsically Safe) Handheld Programmer for hazardous

and all other locations (battery is non-replaceable)

nameplate for confirmation

1)

20 m (65 ft)

second

1)2)

0.3 m (1 ft), plus the shield length (if any)

(representing level)

• approval: ATEX II 1 G, EEx ia IIC T4, certificate SIRA 01ATEX2147

FM/CSA Class 1, Div. 1, Groups A, B, C, D

• ambient temperature: −20 to +40 °C (−5 to +104 °F)

• interface: proprietary infrared pulse signal

• power: 3 V lithium battery

• weight: 150 g (0.3 lb)

•color: black

1.

Referenced from the sensor reference point.

2.

See 'Near Blanking' on page 93 for more details.

Page 8 SITRANS Probe LR – INSTRUCTION MANUAL 7ML19985HR02

Mechanical

Process Connections:

• threaded connection 1.5” NPT, BSP, or G (BS EN ISO 228-1)

Antenna:

• polypropylene rod hermetically sealed construction

standard 100 mm (4") shield for maximum 100 mm (4") nozzle,

or optional 250 mm (10") long shield

Notes:

• Please check the ambient and operating temperatures under

Approvals (verify against device nameplate)

and

(verify against device nameplate)

about to use or install.

• The use of approved watertight conduit hubs/glands is required for Type 4X /

NEMA 4X, Type 6 / NEMA 6, IP67, IP68 (outdoor applications).

Enclosure

• body construction PBT (polybutylene terephthalate)

• lid construction hard-coated PEI (polyether imide)

• conduit entry 2 x M20x1.5 (plastic strain relief) or 2 x 1/2" NPT thread

• ingress protection Type 4X / NEMA 4X, Type 6 / NEMA 6, IP67, IP68 (see note

on page 10, for the specific configuration you are

below)

on page 10; also check

Enclosure

on this page,

Approvals

Specifications

Weight:

• standard model

1

1.97 kg (4.35 lb.)

Environmental

• location: indoor/ outdoor

• altitude: 5000 m (16,404 ft) max.

• ambient temperature: −40 to +80 °C (−40 to +176 °F)

• relative humidity: suitable for outdoor

Type 4X / NEMA 4X, Type 6 / NEMA 6, IP67, IP68 enclosure

(see note below)

• installation category: I

• pollution degree: 4

1.

Unit with 100 mm (4") rod and adaptors

7ML19985HR02 SITRANS Probe LR – INSTRUCTION MANUAL Page 9

Process

•temperature: −40 to +80 °C (−40 to +176 °F).

(at process connection)

• pressure (vessel): maximum 3 bar, gauge (43.5 psi, gauge)

Notes:

• Please check the ambient and operating temperatures under

and

Approvals (verify against device nameplate)

(verify against device nameplate)

on page 10, for the specific configuration you are

on page 10; also check

about to use or install.

• The use of approved watertight conduit hubs/glands is required for Type 4X /

NEMA 4X, Type 6 / NEMA 6, IP67, IP68 (outdoor applications).

Enclosure

Approvals (verify against device nameplate)

•General CSA

• Radio Europe (R&TTE), FCC, Industry Canada

• Hazardous Intrinsically Safe: (Europe) ATEX II 1 G, EEx ia IIC T4

(US/Canada) FM/CSA: (barrier required)

Class I, Div. 1, Groups A, B, C, D

Class II, Div. 1, Groups E, F, G

Class III T4

, FM, CE, C-TICK

US/C

on this page,

Approvals

1

(Australia) ANZEx Ex ia IIC T4

o

C) IP67, IP68

Specifications

(Tamb = –40 to +80

(International) IECEx TSA 04.0020X Ex ia IIC T4

(Brazil) INMETRO: BR-Ex ia IIC T4

2

Non-incendive: (US) FM

:

Class I, Div. 2, Groups A, B, C, D T5

• Marine Lloyd’s Register of Shipping

ABS Type Approval

Note: EN 6100 0-4-3 (CE EMC) testing was conducted on the SITRANS Probe LR while

mounted in a metallic vessel.

1.

See 'Intrinsically safe connection drawing (FM)' on page 106 for drawing number 23651611, or

'Intrinsically safe connection drawing (CSA)' on page 107 for drawing number 23651621.

2.

See 'Non-incendive connection drawing (FM)' on page 108 for drawing number 23650537.

Page 10 SITRANS Probe LR – INSTRUCTION MANUAL 7ML19985HR02

Installation

1

WARNINGS:

• Installation shall only be performed by qualified personnel and in

accordance with local governing regulations.

• SITRANS Probe LR ‘is to be used only in the manner outlined in this

manual, otherwise protection provided by the device may be impaired.

• Never attempt to loosen, remove, or disassemble process connection

or instrument housing while vessel contents are under pressure.

• This product is designated as a Pressure Accessory per Directive 97/ 23

/ EC and is not

• Materials of construction are chosen based on their chemical

compatibility (or inertness) for general purposes. For exposure to

specific environments, check with chemical compatibility charts

before installing.

• The user is responsible for the selection of bolting and gasket materials

which will fall within the limits of the flange and its intended use and

which are suitable for the service conditions.

• Improper installation may result in loss of process pressure.

Notes:

• Refer to the device nameplate for approval information.

• The Process Device Tag shall remain with the process pressure boundary

assembly1. In the event the instrument package is replaced, the Process Device Tag

shall be transferred to the replacement unit.

• SITRANS Probe LR units are hydrostatically tested, meeting or exceeding the

requirements of the ASME Boiler and Pressure Vessel Code and the European

Pressure Equipment Directive.

• The serial numbers stamped in each process connection body provide a unique

identification number indicating date of manufacture.

Example: MMDDYY – XXX (where MM = month, DD = day, YY = year, and

Further markings (space permitting) indicate flange configuration, size, pressure

class, material, and material heat code.

intended for use as a safety device.

XXX= sequential unit produced

Installation

1.

The process pressure boundary assembly comprises the components that act as a barrier

against pressure loss from the process vessel: that is, the combination of process connection

body and emitter, but normally excluding the electrical enclosure.

7ML19985HR02 SITRANS Probe LR – INSTRUCTION MANUAL Page 11

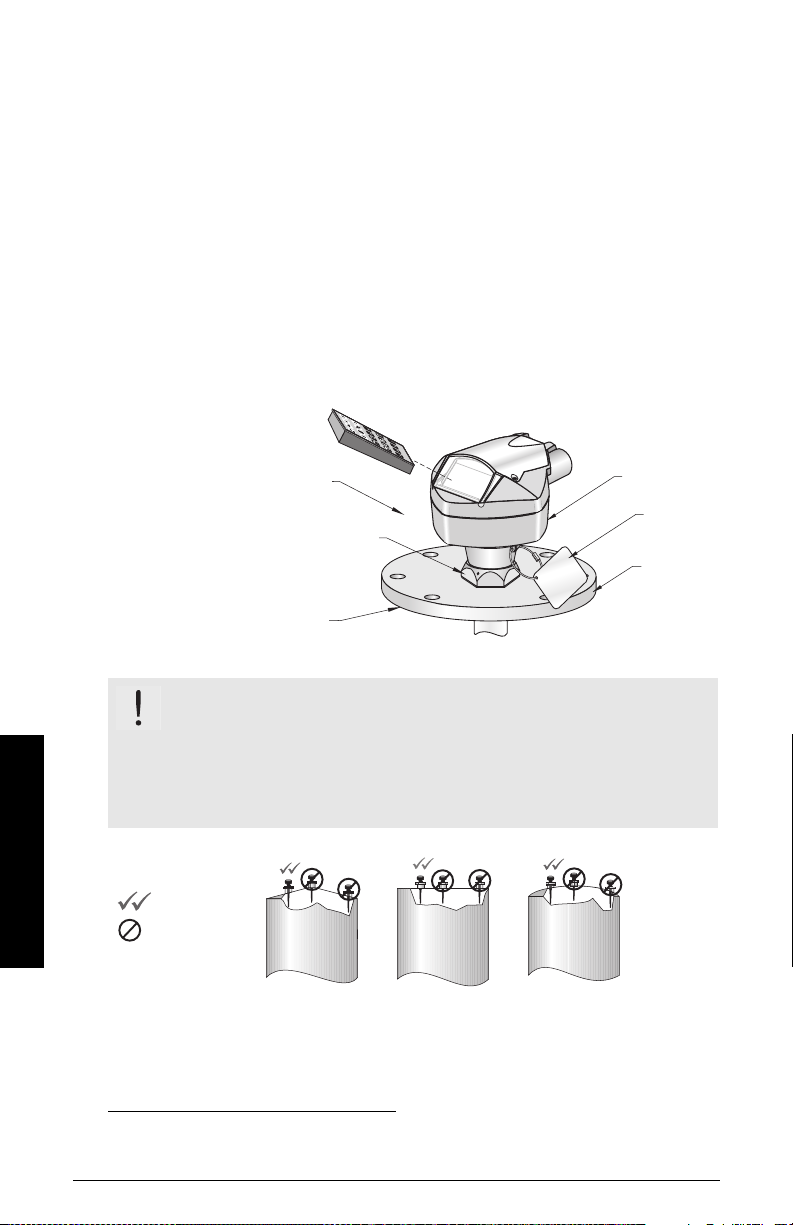

Mounting location

process temperature:

–40 to 80

o

C (–40 to 176 oF)

ambient temperature

(surrounding enclosure volume)

–40 to 80

o

C (–40 to 176 oF)

handheld programmer

nameplate

location

process

device tag

customersupplied

flange

locking collar

1

over threaded connection;

secured by three 2 mm Allen set-screws

Coni

Fl at

Flat Parabolic Conical

preferred

undesirable

Recommendations:

• Ensure ambient temperature is within –40 to 80 oC (–40 to 176 oF).

• Provide easy access for viewing the display and programming via the handheld

programmer.

• Ensure the environment is suitable to the housing rating and materials of

construction.

Precautions:

• Avoid proximity to high voltage or current wiring, high voltage or current contacts,

and to variable frequency motor speed controllers.

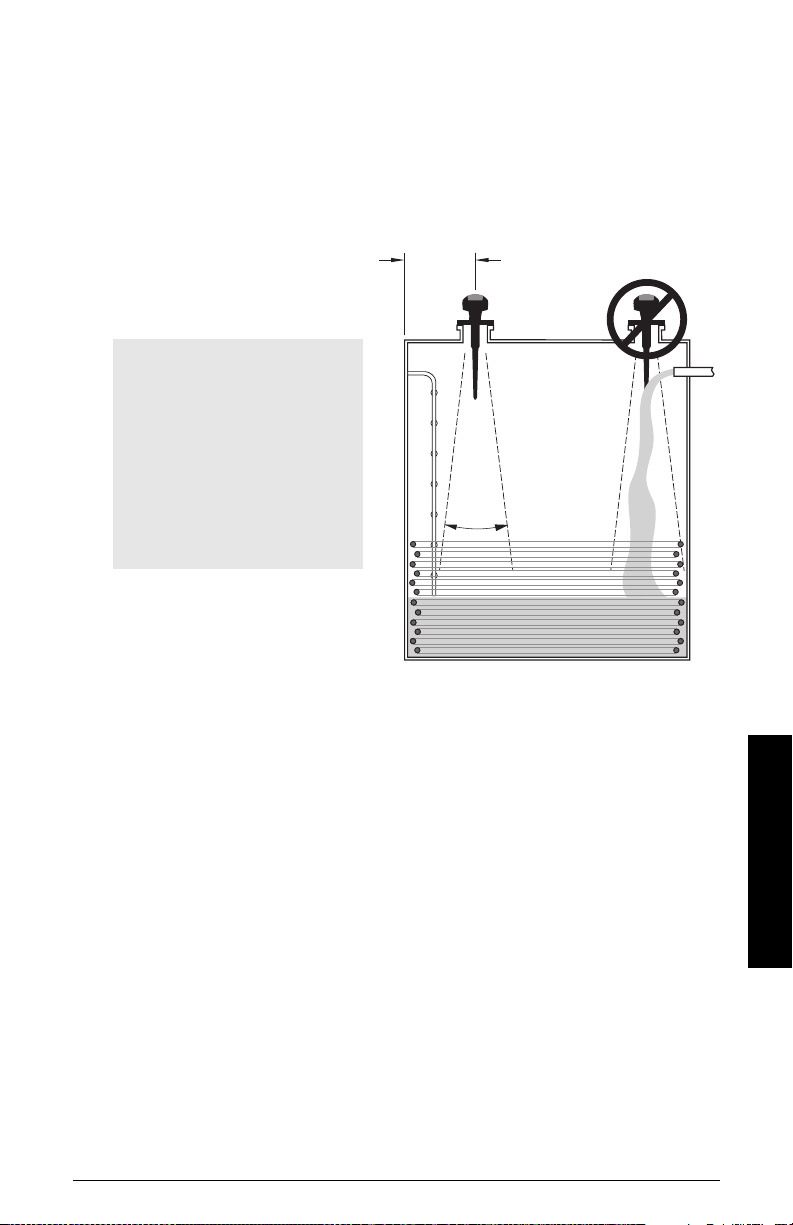

• Avoid interference to the emission cone from obstructions or from the fill path.

• Avoid central locations on vessels.

1

WARNING: For vessels with conical or parabolic tops, avoid

mounting the instrument at the centre. (The concavity of the top can

focus echoes into the centre, giving false readings.)

Note:

Under certain circumstances, it may be acceptable to mount SITRANS Probe LR

at the centre of a flat-topped tank: please discuss this with your Siemens Milltronics

representative.

Installation

1.

PPage 12 SITRANS Probe LR – INSTRUCTION MANUAL 7ML19985HR02

When the locking collar is secured, it prevents the enclosure rotating on the threaded

connection.

Keep the emission cone free of interference:

minimum of 300 mm (1ft) for

every 3 m (10 ft) of vessel height.

beam

angle

28

o

Notes:

• Beam angle is defined at the

-3dB boundary, or 1/2 signal

level. Obstructions outside of

the beam may still be detected,

depending on the size, shape,

or distance from the antenna.

• For more detail on false

echoes, see

False-Echo

Suppression

on page 94.

• Make allowance for the emission cone spreading: allow a minimum of 300 mm (1 ft)

for every 3 m (10 ft) of vessel height.

• Locate the antenna away from the side wall, to avoid interference from indirect

echoes.

• Avoid interference from objects such as ladders or pipes, which can cause false

echoes.

• Make sure the beam angle does not intersect the fill path.

7ML19985HR02 SITRANS Probe LR – INSTRUCTION MANUAL Page 13

Installation

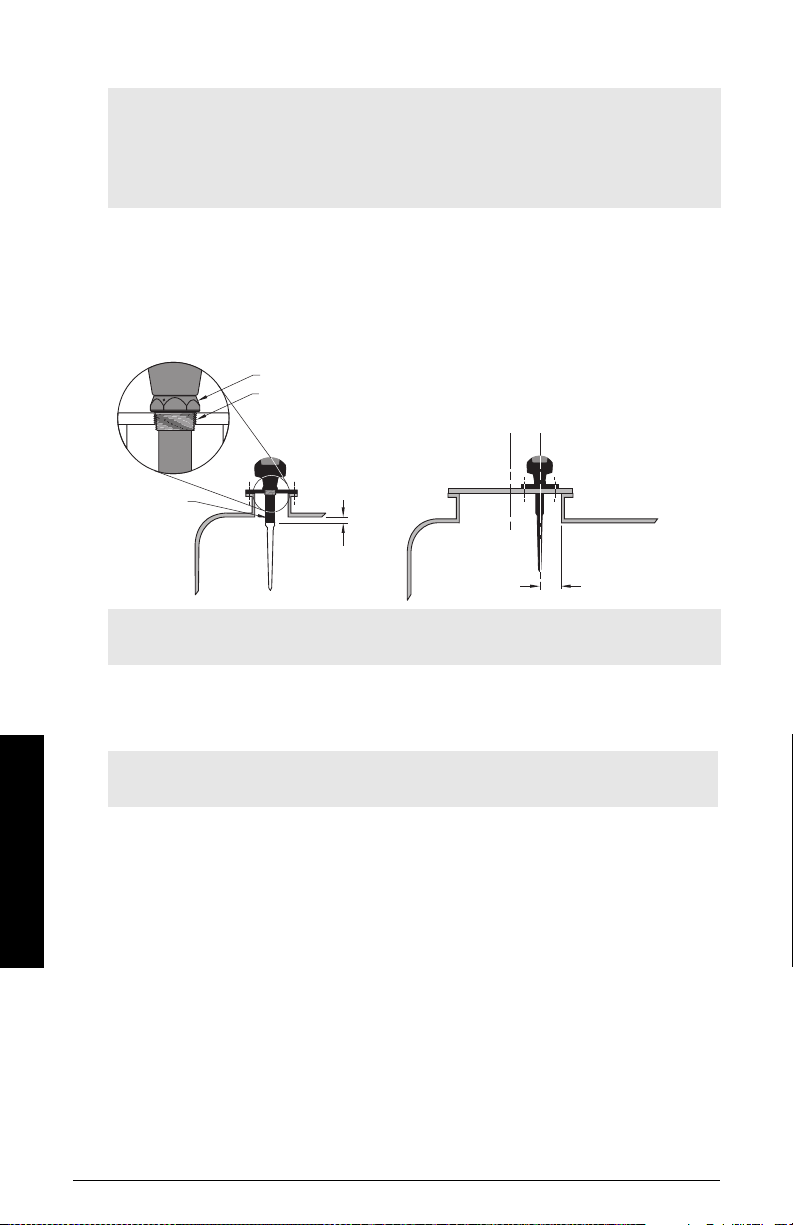

Location on a nozzle, or on a manhole cover

100 mm (4")

10 mm

(0.4")

locking collar secured by three 2 mm Allen set-screws

threaded connection

shield

Notes:

• Use the 100 mm (4") shield on nozzles that are 100 mm (4") in length, or shorter.

• Use the 250 mm (10") shield on nozzles that are 250 mm (10") in length, or shorter.

• If your nozzle is longer than 250 mm (10"), contact your local representative. You will

need to exchange the device for a different model with a longer shield length.

On a nozzle, the end of the shield section should protrude a minimum of 10 mm (0.4”) to

avoid interference.

A manhole cover is typically a covered nozzle with a diameter of 610 mm (24”) or greater.

To provide optimum signal conditions on a manhole cover, locate the antenna off-center,

typically 100 mm (4") from the side.

Note: For details on other applications, see

page 98.

Appendix F: Special Applications

Mounting Instructions

Note: Do not rotate the enclosure after programming and vessel calibration, otherwise

an error may occur, caused by a polarity shift of the transmit pulse.

1. Before inserting SITRANS Probe LR into its mounting connection, check to ensure

the threads are matching, to avoid damaging them.

Installation

2. Simply screw SITRANS Probe LR into the process connection, and hand tighten. For

pressure applications, it will be necessary to use PTFE tape (or other appropriate

thread sealing compound) and tighten the process connection beyond hand tight.

The maximum torque is 40 N-m (30 ft.lbs.).

3. If you want to rotate the enclosure, use a 2 mm Allen key to loosen the three setscrews that secure the locking collar.

4. Once the enclosure is in a suitable position, tighten the set-screws.

PPage 14 SITRANS Probe LR – INSTRUCTION MANUAL 7ML19985HR02

on

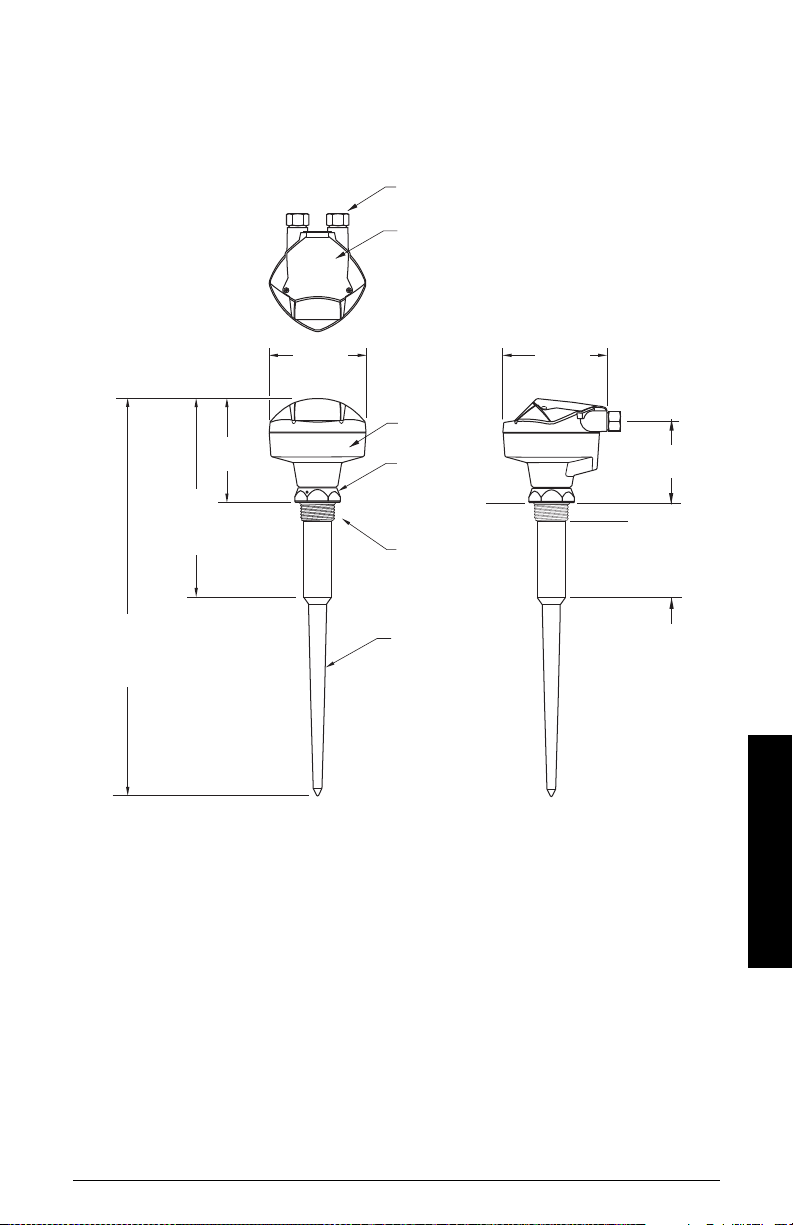

SITRANS Probe LR: Dimensions

reference

point

hinged lid

enclosure/

electronics

polypropylene

rod antenna

(internal) shield length

standard: 100 mm (4")

[optional: 250 mm (10")]

std. 273 mm (10.8") min.

option 423 mm (16.7") max.

134 mm

(5.3")

129 mm

(5.1")

139 mm

(5.5")

mounting thread

1/2" NPT thread

(or M20 plastic strain relief)

locking collar

103.5 mm

(4")

std. 552 mm (21.7") min.

option 702 mm (27.6") max.

23 mm (0.9")

std. 139 mm (5.47")

[optional 289 mm (11.38")]

7ML19985HR02 SITRANS Probe LR – INSTRUCTION MANUAL Page 15

Installation

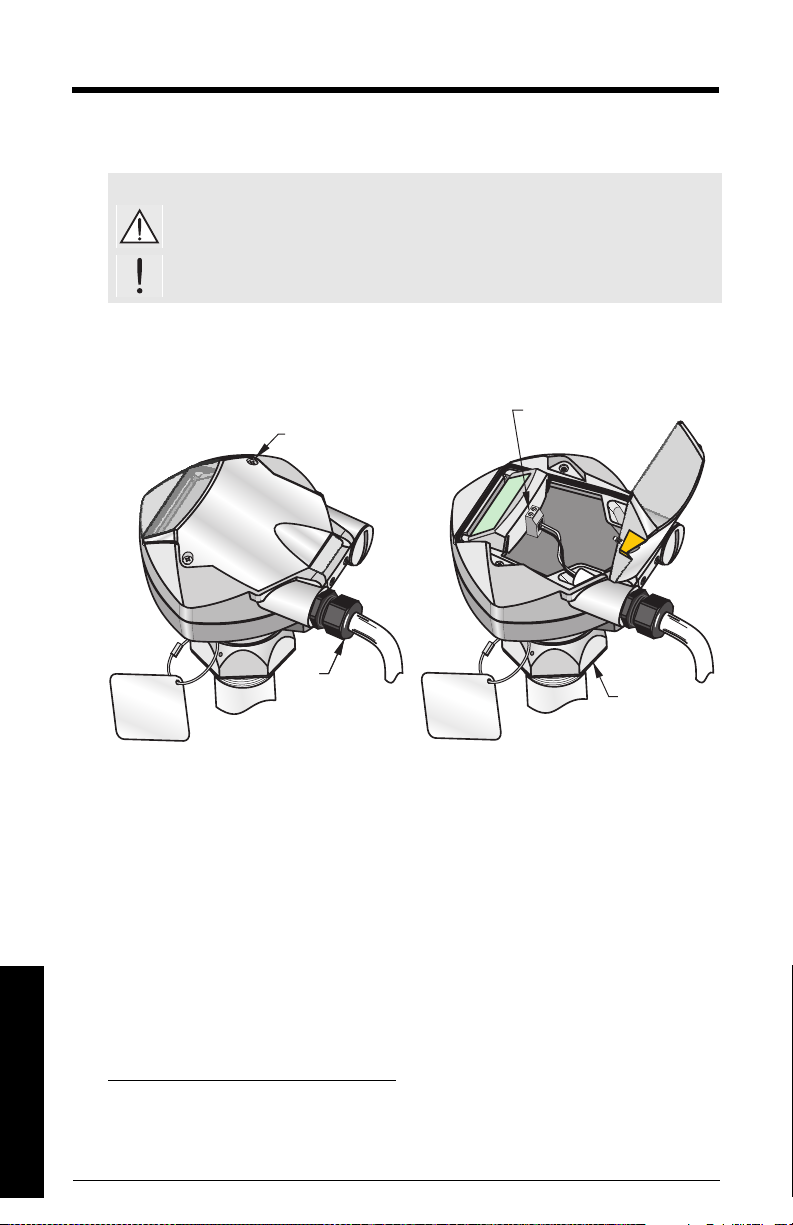

Wiring

locking collar

terminal block

lid screw (1 of 2)

Unscrew the two lid screws to access the

terminal block.

strain

relief

2

(or NPT cable entry)

Power

WARNINGS:

dc terminals shall be supplied from an SELV

with IEC-1010-1 Annex H.

All field wiring must have insulation suitable for rated voltages.

Connecting SITRANS Probe LR

1

source in accordance

1,2

,

Wiring

,

1.

Safety Extra Low Voltage

2.

If cable is routed through conduit, use only approved suitable-size hubs for

waterproof applications.

Page 16 SITRANS Probe LR – INSTRUCTION MANUAL 7ML19985HR02

Notes:

• Use shielded, twisted pair cable (wire gauge AWG 14 to 22).

• Separate cables and conduits may be required to conform to standard

instrumentation wiring practices or electrical codes.

• The non-metallic enclosure does not provide a continuous ground path between

conduit connections: use grounding type bushings and jumpers.

• For detailed information on Intrinsic Safety setups, see

Wiring Details

1. If you want to rotate the enclosure, use a 2 mm Allen key to loosen the 3 Allen setscrews securing the locking collar. Position the unit and retighten the screws.

2. Strip the cable jacket for approximately 70 mm from the end of the cable, and thread

the wires through the strain relief

1

.

3. Connect the wires to the terminals: the polarity

is identified on the terminal block.

4. Tighten the strain relief to form a good seal.

5. Close the lid and tighten screws: please do not

overtighten screws. (Recommended torque is

1.1 to 1.7 N-m (10 to 15 in-lb) of torque.)

on page 100.

1.

If cable is routed through conduit, use only approved suitable-size hubs for

waterproof applications.

7ML19985HR02 SITRANS Probe LR – INSTRUCTION MANUAL Page 17

Wiring

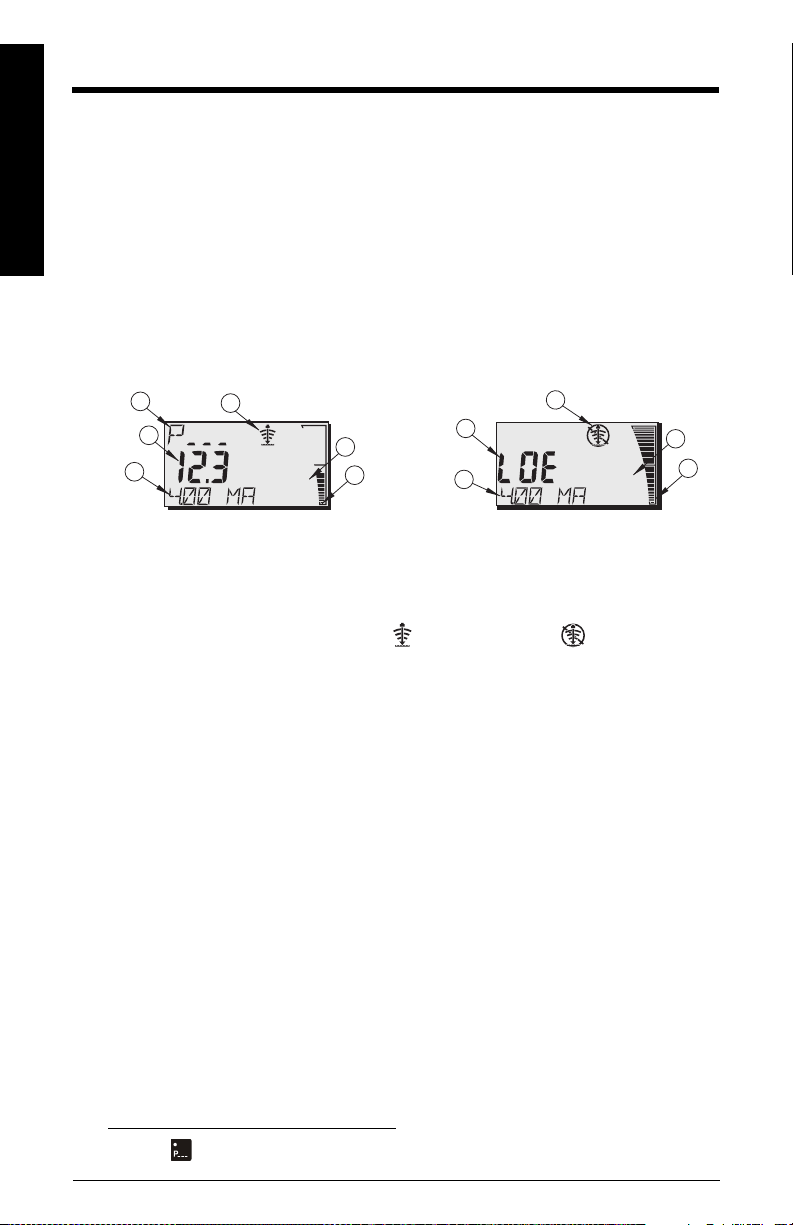

Operating SITRANS Probe LR

m

m

Normal operation Failsafe operation

1

3

4

5

1

3

4

5

2

6

6

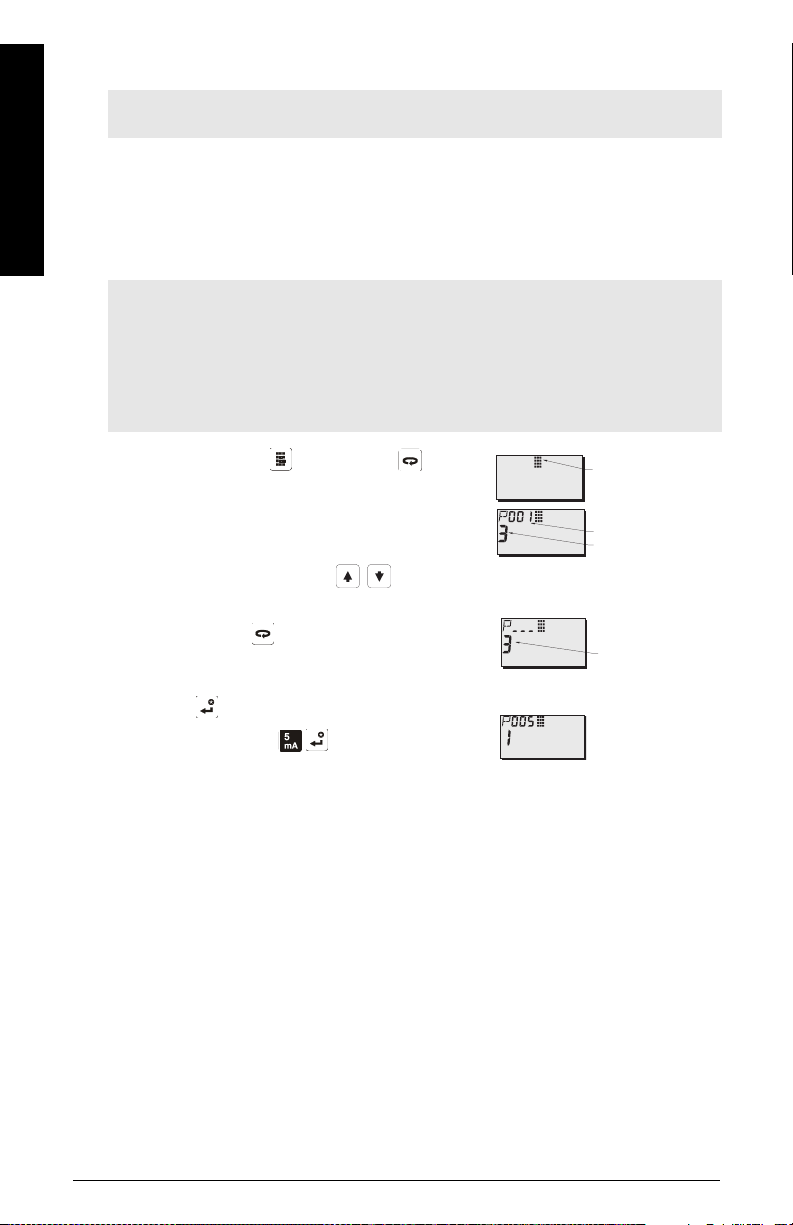

SITRANS Probe LR has two modes of operation: RUN and PROGRAM.

RUN Mode

Operation

SITRANS Probe LR automatically starts in RUN mode when power is applied, and detects

the material level. The primary reading displays the material level (in meters) referenced

from Empty (process empty level). This is the default start-up display mode.

System status is displayed on the LCD, or on a remote communications terminal.

Display

1 – Primary Reading (displays level, distance, or volume, in either units or percent)

2 – Secondary Reading (displays Parameter number for Auxiliary Reading1)

3 – Echo status indicator: Reliable Echo or Unreliable Echo

4 – Units or Percent

5 – Active bar graph represents material level

6 – Auxiliary Reading (depending on the parameter selected, it displays milliAmp value,

distance or confidence, with units where applicable)

If the echo confidence drops below the echo confidence threshold, the failsafe timer

starts running. When the timer expires, the letters LOE (Loss of Echo) alternate with the

reading every two seconds, and the Reliable Echo indicator is replaced by the Unreliable

Echo indicator. When a valid reading is received, the level reading display returns to

normal operation.

1.

Press to display the auxiliary reading field when in RUN mode.

Page 18 SITRANS Probe LR – INSTRUCTION MANUAL 7ML19985HR02

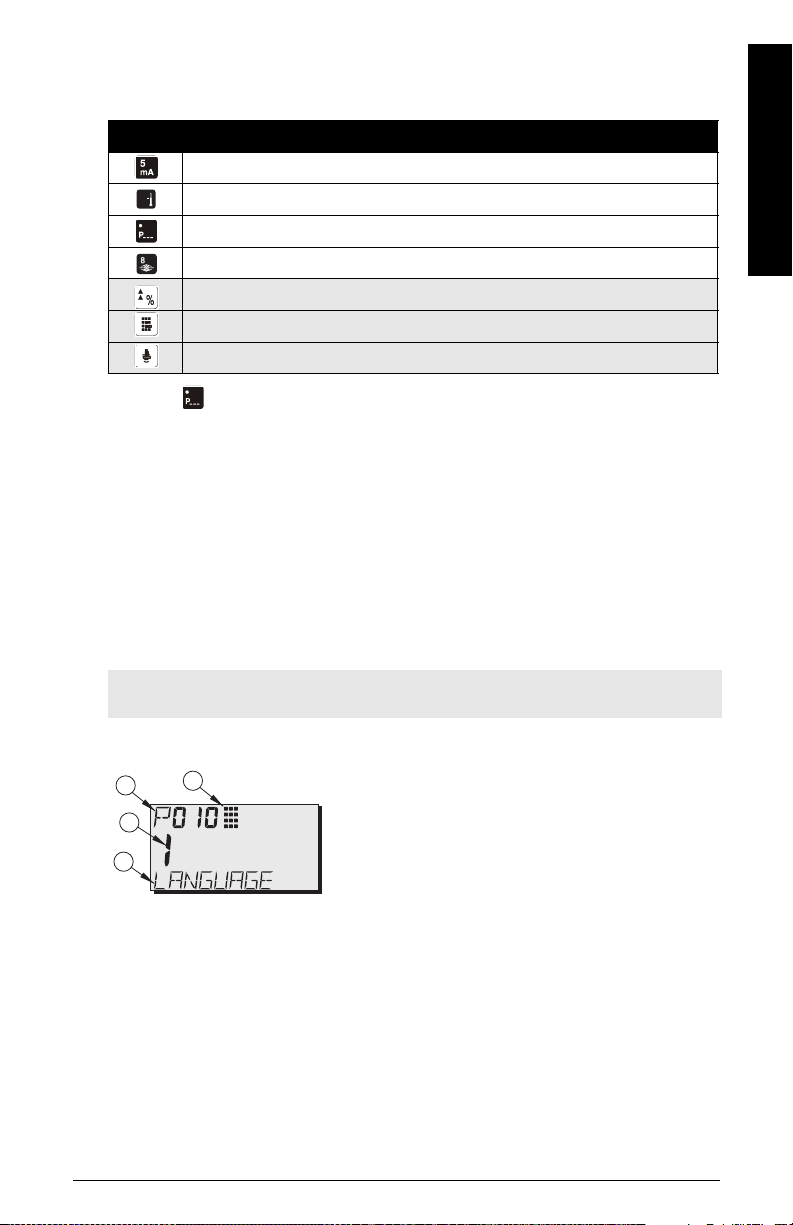

Handheld Programmer: function keys in RUN mode

6

1 – Primary Reading (displays parameter value)

2 – Secondary Reading (displays parameter number)

3 – Programming indicator

4 – Auxiliary Reading (displays parameter names for

the Quick Start parameters, if a language is

selected. It displays the index value for indexed

parameters, such as P054.)

1

2

3

4

Certain functions can be accessed directly from RUN mode by using specific keys.

Key Run Mode

mA output value displayed in auxiliary reading field.

Internal enclosure temperature displayed in auxiliary reading field.

a

Parameter for auxiliary readings

Displays the value representing Echo Confidence (P805).

Toggle between Units and % on reading display.

Initiate and complete PROGRAM mode access.

Distance displayed in auxiliary reading field.

a.

Press plus three-digit parameter number to set parameter to show in the auxiliary display.

.

PROGRAM Mode

Programming

• Set parameters to suit your specific application.

•Activate PROGRAM mode at any time, to change parameter values and set

operating conditions.

• For local programming, use the Siemens handheld programmer.

• For programming from a distance, use either a PC running SIMATIC PDM, or a HART

handheld communicator.

Operation

Note: Do not use the handheld programmer at the same time as SIMATIC PDM, or

erratic operation may result.

Display

7ML19985HR02 SITRANS Probe LR – INSTRUCTION MANUAL Page 19

Handheld Programmer: function keys in PROGRAM mode

Key Programming Mode

to

Val ues

Decimal point

Operation

Negative value

CLEAR value

TOGGLE between Units and % on parameter value

End PROGRAM session and enable RUN mode

Update echo quality parameters

Parameter scroll-up

Parameter scroll-down

DISPLAY opens parameter fields

ENTER the displayed value

Low temperature effects on RUN/PROGRAM modes

If the internal temperature falls to –30 oC (–22 oF) or below, it will affect both RUN and

PROGRAM modes.

RUN mode will operate normally, with the following exceptions:

• handheld programmer operation is disabled

• the LCD displays only limited information: the bar graph and the reliable/

unreliable echo indicator

PROGRAM mode:

• handheld programmer operation is disabled

Page 20 SITRANS Probe LR – INSTRUCTION MANUAL 7ML19985HR02

Security

display

handheld programmer

Numeric and

Auxiliary keys

Function

Keys

max. 600 mm

(2 ft)

The Lock parameter, P000, secures SITRANS Probe LR against changes via the handheld

programmer. To enable programming, set P00 0 to the Unlocked Value stored in P069.

To disable programming, enter a different value.

Note:

• A remote master can still change configuration, if P799 is set to allow this.

Handheld programmer

Note: For detailed instructions on using the handheld programmer, see the next page.

For direct access to SITRANS Probe LR, point the handheld programmer at the display

from a maximum distance of 600 mm (2 ft), and press the keys.

Operation

7ML19985HR02 SITRANS Probe LR – INSTRUCTION MANUAL Page 21

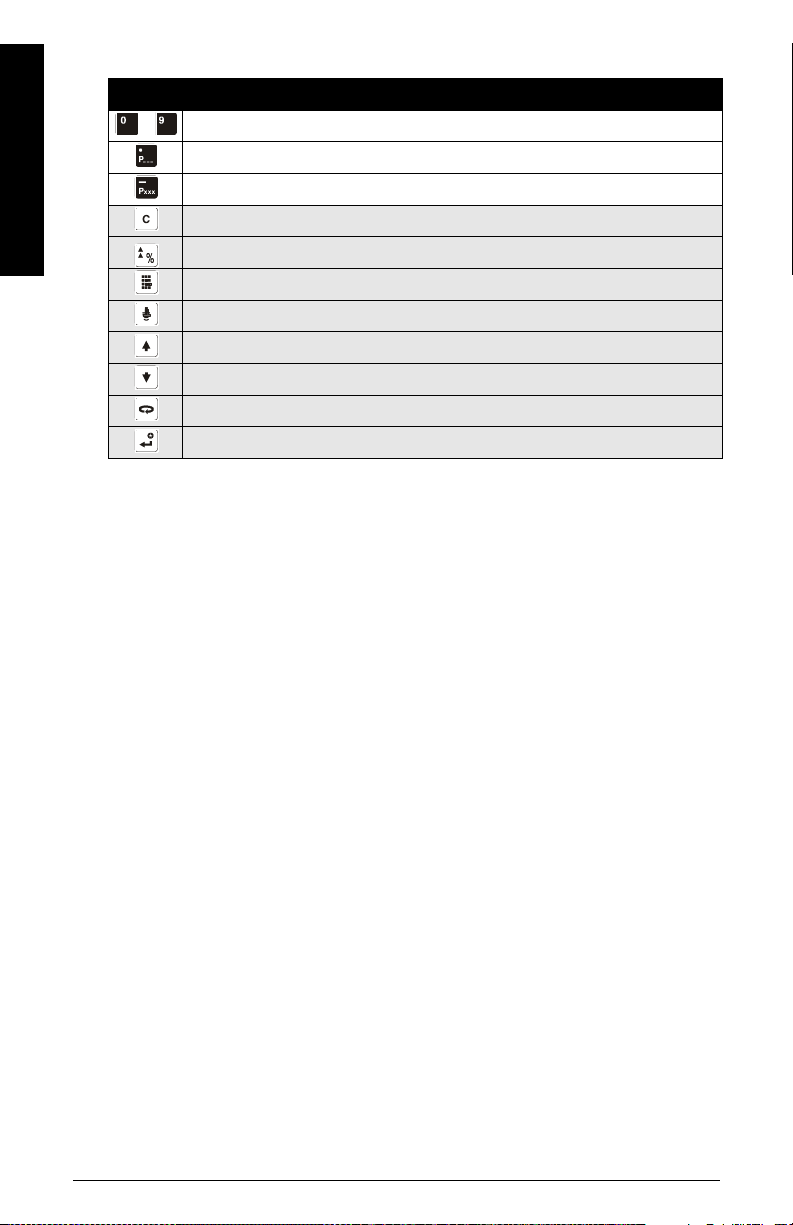

Activating SITRANS Probe LR

Param ete r Value

Parameter Number

PROGRAM Icon

current value

Note: Keep infrared devices such as laptops, cell phones, and PDAs, away from

SITRANS Probe LR to prevent inadvertent operation.

Power up the instrument. SITRANS Probe LR starts in RUN mode, and detects the

Operation

material level. It displays the material level (in meters) referenced from Empty (process

empty level). This is the default start-up mode.

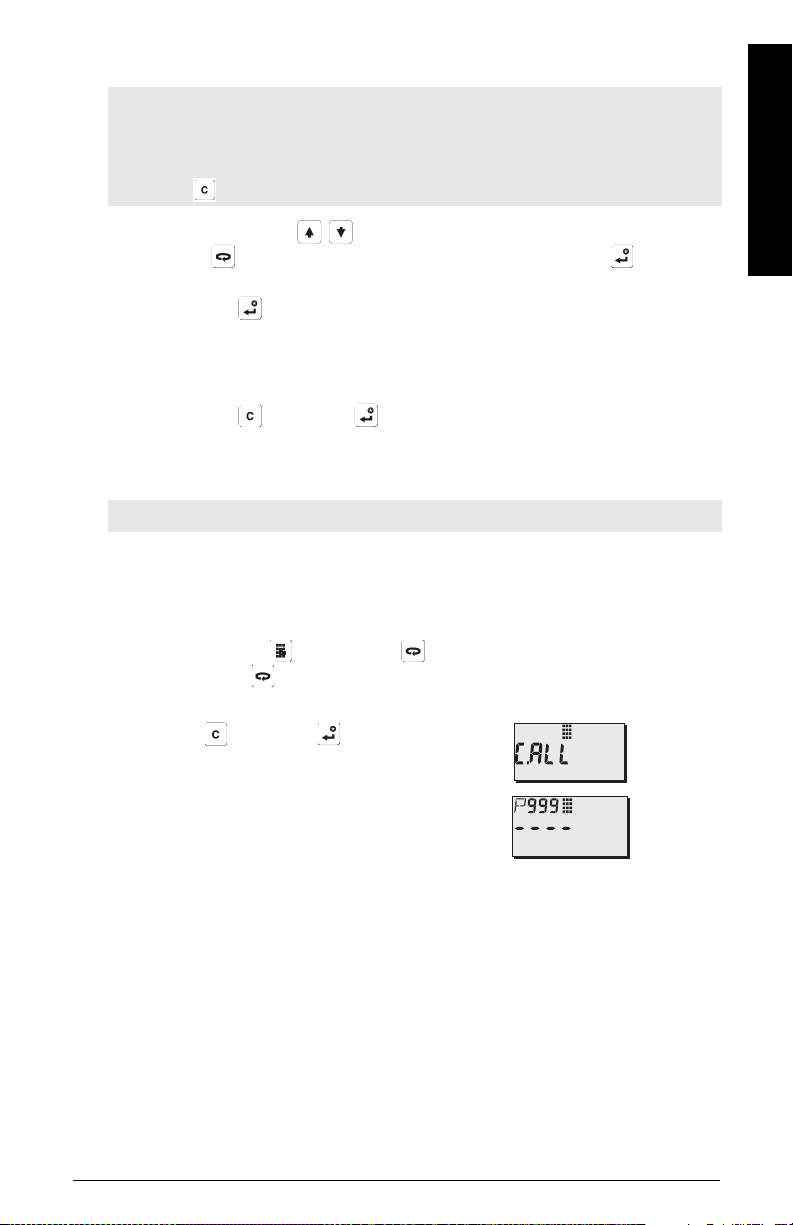

Accessing a parameter

Notes:

• The following instructions apply when using the Handheld Programmer.

• Do not use the Handheld Programmer at the same time as SIMATIC PDM, or erratic

operation may result.

• You do not need to key in initial zeros when entering a parameter number: for

example, for P005, key in 5.

1. Press PROGRAM then DISPLAY , to

activate PROGRAM mode.

2. Either use the ARROW keys to scroll to a

different parameter, or:

3. Press DISPLAY

Number field.

4. Key in the desired parameter number followed by

ENTER .

For example: press

The LCD displays the new parameter number and

value.

to open the Parameter

.

Page 22 SITRANS Probe LR – INSTRUCTION MANUAL 7ML19985HR02

Changing a Parameter Value

Notes:

• Security must be disabled to enable programming: set P000 to the Unlocked Value

stored in P069.

• Invalid entries will be rejected or limited.

• CLEAR can be used to clear the field.

1. Use the ARROW keys to scroll to the parameter number, or press

DISPLAY

2. Key in the new value.

3. Press ENTER to set the value.

and key in the parameter number followed by ENTER .

Parameter Reset to Factory Default

1. Scroll to the parameter or enter its address.

2. Press CLEAR then ENTER . The value returns to the default setting.

P999 Master Reset

Note: Following a Master Reset, complete reprogramming is required.

Resets all parameters to their factory settings, with the following exceptions:

• P0 00 and P069 are not reset.

• P838 is not reset (the learned TVT curve is not lost).

1. Press PROGRAM , then DISPLAY to activate PROGRAM mode.

2. Press DISPLAY to open parameter fields.

3. Key in 999.

Press CLEAR then ENTER , to Clear All and

initiate reset. The LCD displays C.ALL.

Operation

4. Reset complete. (Reset takes several seconds

to complete.)

7ML19985HR02 SITRANS Probe LR – INSTRUCTION MANUAL Page 23

Using Units or Percent (%)

Many parameters can be viewed either as a percentage, or in measurement units (P005).

View the parameter, then press MODE to toggle between units and percentage.

Quick Setup for local operation (outline)

Operation

Set the Quick Start parameters between P001 and P010 (the main settings that apply to all

applications and make the system operational). Then set P837 and P838 to ignore false

echoes, and return to RUN mode.

1. Select a language option, or numeric, for the auxiliary reading (P010).

2. Select the measurement mode: level, space, or distance (P001).

3. Set the response time to level changes (P003).

4. Select units of measurement: m, cm, mm, ft, or in. (P005).

5. Set process empty level (Empty: P006).

6. Set the range to be measured (Span: P007).

7. To ignore false echoes before the material echo, set Auto False-Echo Suppression

Distance (P838).

8. Enable Auto False-Echo Suppression (P837).

9. Return to RUN mode.

Setup Instructions

Notes:

•In PROGRAM mode, you can use the ARROW keys to scroll to a

parameter number.

• The default parameter values are indicated by an asterisk (*) in the tables.

Using the handheld programmer, set each parameter value to suit your application. (For

detailed instructions on accessing a parameter and changing the value, see page 22.)

Page 24 SITRANS Probe LR – INSTRUCTION MANUAL 7ML19985HR02

Loading...

Loading...