Siemens SITRANS P DS III, SITRANS P410 Operating Instructions Manual

SITRANS P DS III/P410 with

PROFIBUS PA

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

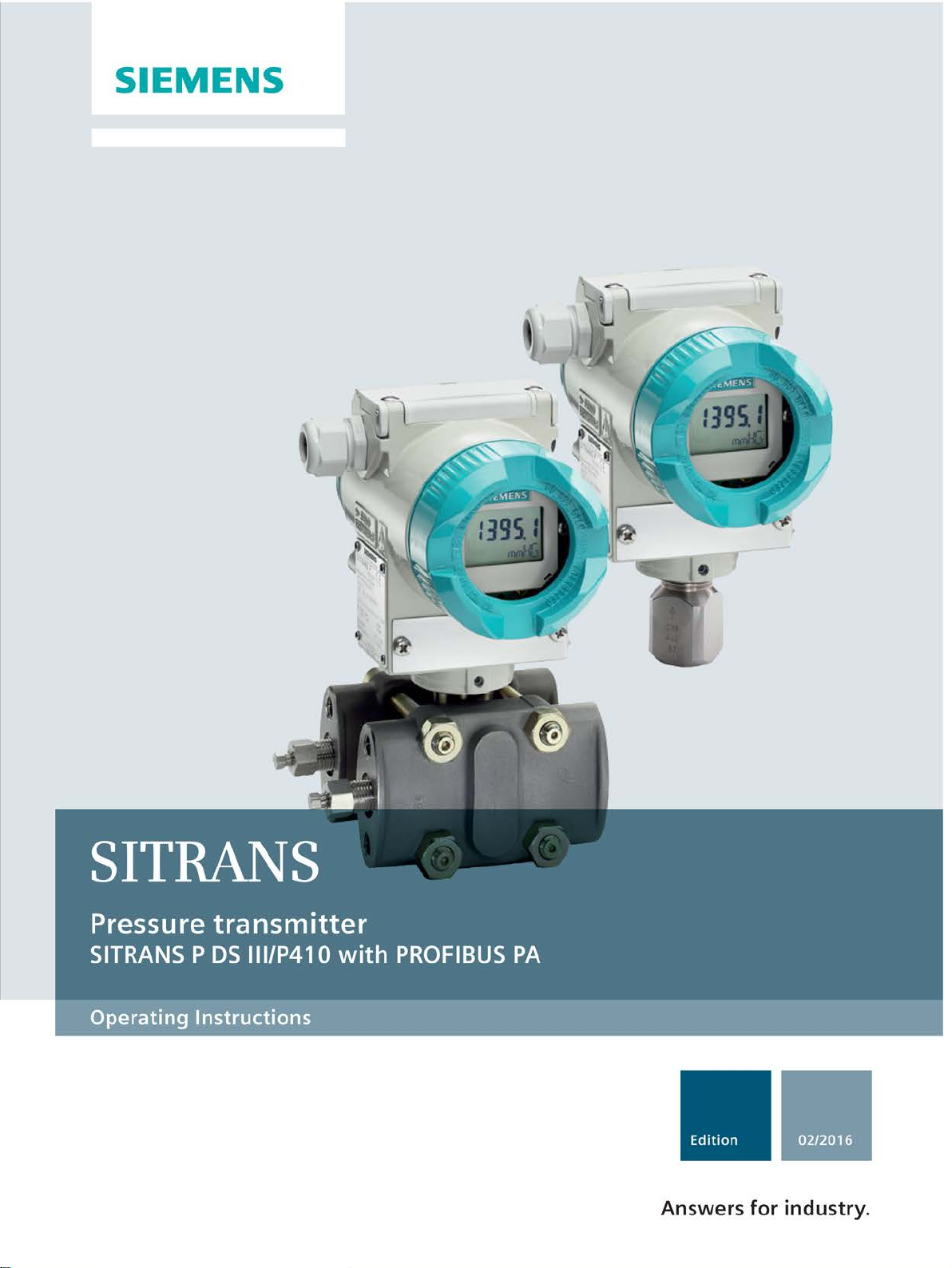

SITRANS

Pressure transmitter

SITRANS P DS III/P410 with

PROFIBUS PA

Operating Instructions

7MF4.34

02/2016

A5E00053276

Introduction

1

Safety information

2

Description

3

Installing / mounting

4

Connecting up

5

Operation

6

Operator control functions

via PROFIBUS

7

Functional safety

8

Configuration/project

engineering

9

Commissioning

10

Repair and maintenance

11

Interrupts, error and system

alarms

12

Technical data

13

Dimension drawings

14

Spare parts / accessories

15

Appendix

A

List of

abbreviations/acronyms

B

-08

Siemens AG

Division Process Industries and Drives

Postfach 48 48

90026 NÜRNBERG

GERMANY

Document order number: A5E00053276

Ⓟ

Copyright © Siemens AG 2016.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

re required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance a

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

for the specific

03/2016 Subject to change

Table of contents

1 Introduction ........................................................................................................................................... 11

2 Safety information ................................................................................................................................. 15

3 Description ............................................................................................................................................ 21

1.1 Purpose of this documentation ............................................................................................... 11

1.2 Product information ................................................................................................................. 11

1.3 History ..................................................................................................................................... 11

1.4 Scope of the instructions ........................................................................................................ 12

1.5 Checking the consignment ..................................................................................................... 12

1.6 Transportation and storage ..................................................................................................... 13

1.7 Notes on warranty ................................................................................................................... 13

2.1 Precondition for use ................................................................................................................ 15

2.1.1 Laws and directives ................................................................................................................ 15

2.1.2 Conformity with European directives ...................................................................................... 15

2.2 Improper device modifications ................................................................................................ 16

2.3 Requirements for special applications .................................................................................... 16

2.4 Use in hazardous areas .......................................................................................................... 17

2.4.1 Use of incorrect device parts in potentially explosive environments ...................................... 18

2.4.2 Electrostatic-sensitive devices ................................................................................................ 19

3.1 System configuration .............................................................................................................. 21

3.2 Application .............................................................................................................................. 22

3.3 SITRANS P DS III and SITRANS P410 .................................................................................. 24

3.4 Structure ................................................................................................................................. 24

3.5 Nameplate layout .................................................................................................................... 26

3.6 Measuring point label layout ................................................................................................... 27

3.7 Principle of operation .............................................................................................................. 27

3.7.1 Overview of mode of operation ............................................................................................... 27

3.7.2 Operation of the electronics .................................................................................................... 28

3.7.3 Principle of operation of the measuring cell ............................................................................ 29

3.7.3.1 Measuring cell for gauge pressure ......................................................................................... 30

3.7.3.2 Measuring cell for differential pressure and flow rate ............................................................. 31

3.7.3.3 Measuring cell for level ........................................................................................................... 32

3.7.3.4 Measuring cell for absolute pressure from the differential pressure series ............................ 33

3.7.3.5 Measuring cell for absolute pressure from the gauge pressure series ................................... 34

3.7.3.6 Measuring cell for gauge pressure, front-flush membrane ..................................................... 34

3.7.3.7 Measuring cell for absolute pressure, front-flush membrane ................................................. 35

3.8 Remote seal ............................................................................................................................ 36

SITRANS P DS III/P410 with PROFIBUS PA

Operating Instructions, 02/2016, A5E00053276-08

5

Table of contents

4 Installing / mounting .............................................................................................................................. 39

5 Connecting up....................................................................................................................................... 63

6 Operation .............................................................................................................................................. 71

3.9 SIMATIC PDM ........................................................................................................................ 36

3.10 PROFIBUS ............................................................................................................................. 37

3.10.1 Transmission technology ....................................................................................................... 37

3.10.2 Bus topology .......................................................................................................................... 37

3.10.3 Properties ............................................................................................................................... 38

4.1 Basic safety instructions ........................................................................................................ 39

4.1.1 Installation location requirements .......................................................................................... 43

4.1.2 Proper mounting..................................................................................................................... 43

4.2 Disassembly ........................................................................................................................... 44

4.2.1 Incorrect disassembly ............................................................................................................ 44

4.3 Installation (except level) ....................................................................................................... 45

4.3.1 Installation mounting (except for level) .................................................................................. 45

4.3.2 Installation (except level) ....................................................................................................... 46

4.3.3 Fastening ............................................................................................................................... 46

4.4 "Level" installation .................................................................................................................. 48

4.4.1 Instructions for level installation ............................................................................................. 48

4.4.2 Installation for level ................................................................................................................ 49

4.4.3 Connection of the negative pressure line .............................................................................. 50

4.5 "Remote seal" installation ...................................................................................................... 53

4.5.1 Remote seal installation ......................................................................................................... 53

4.5.2 Installation of the remote seal with the capillary line .............................................................. 54

4.6 Turing the measuring cell against housing ............................................................................ 60

4.7 Rotating the display ............................................................................................................... 61

5.1 Basic safety instructions ........................................................................................................ 63

5.1.1 Hazardous contact voltage in versions with 4-conductor extension ...................................... 63

5.1.2 Incorrect measured values with incorrect grounding ............................................................. 65

5.2 Connecting the device ........................................................................................................... 66

5.2.1 PROFIBUS assembly guidelines ........................................................................................... 66

5.3 Connecting the M12 connector .............................................................................................. 68

6.1 Overview of operation ............................................................................................................ 71

6.2 Basic safety instructions ........................................................................................................ 72

6.3 Information on operation ........................................................................................................ 72

6.4 Display ................................................................................................................................... 73

6.4.1 Display elements .................................................................................................................... 73

6.4.2 Units display ........................................................................................................................... 74

6.4.3 Error display ........................................................................................................................... 74

6.4.4 Mode display .......................................................................................................................... 75

6.4.5 Status display ......................................................................................................................... 76

6.5 Local operation....................................................................................................................... 76

6.5.1 Control elements for local operation ...................................................................................... 76

SITRANS P DS III/P410 with PROFIBUS PA

6 Operating Instructions, 02/2016, A5E00053276-08

Table of contents

7 Operator control functions via PROFIBUS ............................................................................................. 95

6.5.2 Operation using buttons .......................................................................................................... 79

6.5.3 Setting/adjusting electrical damping ....................................................................................... 79

6.5.4 Calibrate zero point ................................................................................................................. 80

6.5.5 Locking of buttons and functions ............................................................................................ 81

6.5.6 Measured value display .......................................................................................................... 82

6.5.7 Unit .......................................................................................................................................... 84

6.5.8 Bus address ............................................................................................................................ 88

6.5.9 Device operation type ............................................................................................................. 88

6.5.10 Position of the decimal point ................................................................................................... 90

6.5.11 Display of the zero-point adjustment ...................................................................................... 90

6.5.12 LO calibration .......................................................................................................................... 91

6.5.13 HI calibration ........................................................................................................................... 92

7.1 Communications structure for PROFIBUS PA ....................................................................... 95

7.1.1 Overview ................................................................................................................................. 95

7.1.2 Block model for collection and processing of measured values ............................................. 95

7.1.3 Pressure transducer block ...................................................................................................... 98

7.1.3.1 Pressure transducer block (transducer block 1) ..................................................................... 98

7.1.3.2 Linearization type function group .......................................................................................... 100

7.1.3.3 Units of the pressure transducer block ................................................................................. 102

7.1.4 Electronics temperature transducer block ............................................................................ 103

7.1.5 Analog input function block ................................................................................................... 104

7.1.6 Totalizer function block ......................................................................................................... 105

7.2 Overview of operating functions ........................................................................................... 106

7.3 Measurement ........................................................................................................................ 106

7.4 Settings ................................................................................................................................. 107

7.4.1 Overview of settings .............................................................................................................. 107

7.4.2 Settings ................................................................................................................................. 107

7.4.3 Pressure measurement......................................................................................................... 107

7.4.4 Level measurement .............................................................................................................. 108

7.4.5 Flow measurement ............................................................................................................... 111

7.4.6 Adjusting to a desired process value .................................................................................... 114

7.5 Electrical damping (filter time constant) ................................................................................ 116

7.6 Key lock and write protection ................................................................................................ 116

7.7 Warning and alarm limits ...................................................................................................... 117

7.8 Failure behavior .................................................................................................................... 119

7.8.1 Overview of failure behavior ................................................................................................. 119

7.8.2 Output ................................................................................................................................... 119

7.8.3 Totalizer output ..................................................................................................................... 119

7.9 Diagnostics functions ............................................................................................................ 120

7.9.1 Operating hours counter ....................................................................................................... 120

7.9.2 Calibration interval and service interval ................................................................................ 120

7.9.3 Clearing warning ................................................................................................................... 121

7.9.4 Clearing the alarm ................................................................................................................. 121

7.9.5 Min/max indicator .................................................................................................................. 122

7.10 Simulation ............................................................................................................................. 122

7.10.1 Overview of simulation .......................................................................................................... 122

SITRANS P DS III/P410 with PROFIBUS PA

Operating Instructions, 02/2016, A5E00053276-08

7

Table of contents

8 Functional safety .................................................................................................................................. 129

7.10.2 Simulating output ................................................................................................................. 123

7.10.3 Simulating input.................................................................................................................... 123

7.10.4 Simulating the pressure sensor ........................................................................................... 124

7.10.5 Simulating sensor and electronics temperature ................................................................... 125

7.11 Calibrating the sensor .......................................................................................................... 125

7.12 Correcting for positional error .............................................................................................. 126

7.13 Reset .................................................................................................................................... 127

7.13.1 Resetting to delivery state .................................................................................................... 127

7.13.2 Warm start/restart ................................................................................................................ 128

7.13.3 Resetting the PROFIBUS address....................................................................................... 128

8.1 Safety function ..................................................................................................................... 129

8.2 Safety Integrity Level (SIL) ................................................................................................... 130

8.3 Settings ................................................................................................................................ 132

8.4 Safety-related characteristics ............................................................................................... 132

8.5 Maintenance/check .............................................................................................................. 133

8.5.1 Overview .............................................................................................................................. 133

8.5.2 Checking safety function/proof test ...................................................................................... 134

8.5.2.1 Checking temperature sensors ............................................................................................ 135

8.5.2.2 Check response time of pressure transmitter. ..................................................................... 135

8.5.2.3 Two-point measurement ≥ 10% of the maximum measuring range .................................... 135

8.5.2.4 Two-point measurement ≥ 50% of the maximum measuring range .................................... 138

8.5.2.5 Checking pressure transmitter for external damage ............................................................ 140

8.6 Add-on parts ......................................................................................................................... 140

8.6.1 Checking a device with add-on pneumatic block ................................................................. 140

8.6.2 Checking a device with add-on remote seal ........................................................................ 141

8.7 PROFIsafe ........................................................................................................................... 141

8.7.1 Introduction .......................................................................................................................... 141

8.7.2 Technical advantages of PROFIsafe ................................................................................... 141

8.7.3 Further information ............................................................................................................... 143

8.7.4 Preconditions ....................................................................................................................... 144

8.7.5 PROFIsafe Configuration ..................................................................................................... 144

8.7.5.1 Import EDD with SIMATIC PDM .......................................................................................... 145

8.7.5.2 Configure CPU with HW Config ........................................................................................... 145

8.7.5.3 Configure device with HW Config ........................................................................................ 145

8.7.5.4 Configure CFC ..................................................................................................................... 148

8.7.6 Write protection .................................................................................................................... 150

8.7.6.1 Overview .............................................................................................................................. 150

8.7.6.2 Activate write protection using PIN in SIMATIC PDM .......................................................... 151

8.7.7 PROFIsafe Commissioning .................................................................................................. 151

8.7.7.1 Activate and parameterize PROFIsafe with SIMATIC PDM ................................................ 152

8.7.7.2 Commission PROFIsafe with SIMATIC PDM ...................................................................... 153

8.7.7.3 Check write protection with SIMATIC PDM ......................................................................... 158

8.7.7.4 Speeding up the commissioning process ............................................................................ 159

8.7.7.5 Resetting the device ............................................................................................................ 159

8.7.8 Quit PROFIsafe commissioning ........................................................................................... 160

8.7.8.1 Preparations for maintenance and service .......................................................................... 160

SITRANS P DS III/P410 with PROFIBUS PA

8 Operating Instructions, 02/2016, A5E00053276-08

Table of contents

9 Configuration/project engineering ........................................................................................................ 165

10 Commissioning ................................................................................................................................... 171

11 Repair and maintenance ..................................................................................................................... 181

12 Interrupts, error and system alarms ..................................................................................................... 189

13 Technical data .................................................................................................................................... 193

8.7.8.2 Deactivating PROFIsafe commissioning in SIMATIC PDM .................................................. 160

8.7.8.3 Disable write protection using PIN in SIMATIC PDM ........................................................... 160

8.7.9 Replacing a device ................................................................................................................ 161

8.7.9.1 Making settings locally .......................................................................................................... 161

8.7.9.2 Configuration with host system ............................................................................................. 162

9.1 Cyclical data transfer ............................................................................................................ 165

9.2 Configuring ............................................................................................................................ 165

9.2.1 Overview of configuration ..................................................................................................... 165

9.2.2 Configuration of user data .................................................................................................... 165

9.2.3 Transmission of user data over PROFIBUS ......................................................................... 167

9.2.4 Status .................................................................................................................................... 167

9.2.5 Diagnosis .............................................................................................................................. 168

9.3 Acyclic data transfer .............................................................................................................. 170

10.1 Basic safety instructions ....................................................................................................... 171

10.2 Introduction to commissioning .............................................................................................. 171

10.3 Gauge pressure, absolute pressure from differential pressure series, and absolute

pressure from gauge pressure series ................................................................................... 172

10.3.1 Commissioning for gases ..................................................................................................... 172

10.3.2 Commissioning with steam or liquid ..................................................................................... 174

10.4 Differential pressure and flow rate ........................................................................................ 175

10.4.1 Safety notes for commissioning with differential pressure and flow rate .............................. 175

10.4.2 Commissioning in gaseous environments ............................................................................ 176

10.4.3 Commissioning for liquids ..................................................................................................... 177

10.4.4 Commissioning with vapor .................................................................................................... 179

11.1 Basic safety instructions ....................................................................................................... 181

11.2 Maintenance and repair work ............................................................................................... 184

11.2.1 Defining the maintenance interval ........................................................................................ 184

11.2.2 Checking the gaskets............................................................................................................ 185

11.2.3 Display in case of a fault ....................................................................................................... 185

11.2.4 Changing the measuring cell and application electronics..................................................... 186

11.3 Cleaning ................................................................................................................................ 186

11.3.1 Servicing the remote seal measuring system ....................................................................... 187

11.4 Return procedure .................................................................................................................. 187

11.5 Disposal ................................................................................................................................ 188

12.1 Overview of status codes ...................................................................................................... 189

12.2 Errors .................................................................................................................................... 192

13.1 Overview of technical data .................................................................................................... 193

SITRANS P DS III/P410 with PROFIBUS PA

Operating Instructions, 02/2016, A5E00053276-08

9

Table of contents

14 Dimension drawings ............................................................................................................................. 229

15 Spare parts / accessories ..................................................................................................................... 245

A Appendix ............................................................................................................................................. 249

B List of abbreviations/acronyms ............................................................................................................. 255

Glossary .............................................................................................................................................. 259

Index ................................................................................................................................................... 263

13.2 SITRANS P DS III input ....................................................................................................... 194

13.3 SITRANS P410 input ........................................................................................................... 200

13.4 Output .................................................................................................................................. 202

13.5 Measuring accuracy of SITRANS P DS III ........................................................................... 203

13.6 Measuring accuracy of SITRANS P410 ............................................................................... 211

13.7 Operating conditions ............................................................................................................ 214

13.8 Construction ......................................................................................................................... 218

13.9 Display, keyboard and auxiliary power ................................................................................ 224

13.10 Certificates and approvals ................................................................................................... 225

13.11 PROFIBUS communication ................................................................................................. 227

14.1 SITRANS P, DS III/P410 for gauge pressure and absolute pressure from the gauge

pressure series..................................................................................................................... 229

14.2 SITRANS P DS III/P410 for differential pressure, flow rate and absolute pressure from

the differential pressure series ............................................................................................. 231

14.3 SITRANS P DS III/P410 for level ......................................................................................... 234

14.4 SITRANS P DS III (flush-mounted) ...................................................................................... 235

14.4.1 Note 3A and EHDG .............................................................................................................. 236

14.4.2 Connections as per EN and ASME ...................................................................................... 237

14.4.3 F&B and pharma flange ....................................................................................................... 238

14.4.4 PMC Style ............................................................................................................................ 242

14.4.5 Special connections ............................................................................................................. 243

15.1 Order data ............................................................................................................................ 245

15.2 Spare parts/accessories for SITRANS P DS III ................................................................... 245

15.3 Order data for SIMATIC PDM .............................................................................................. 247

15.4 Ordering data for PROFIBUS accessories .......................................................................... 248

A.1 Certificate ............................................................................................................................. 249

A.2 Certificates (China) .............................................................................................................. 249

A.3 Literature and standards ...................................................................................................... 253

A.4 Technical support ................................................................................................................. 254

B.1 Pressure transmitter ............................................................................................................. 255

B.2 Functional safety .................................................................................................................. 257

SITRANS P DS III/P410 with PROFIBUS PA

10 Operating Instructions, 02/2016, A5E00053276-08

1

1.1

Purpose of this documentation

1.2

Product information

See also

1.3

History

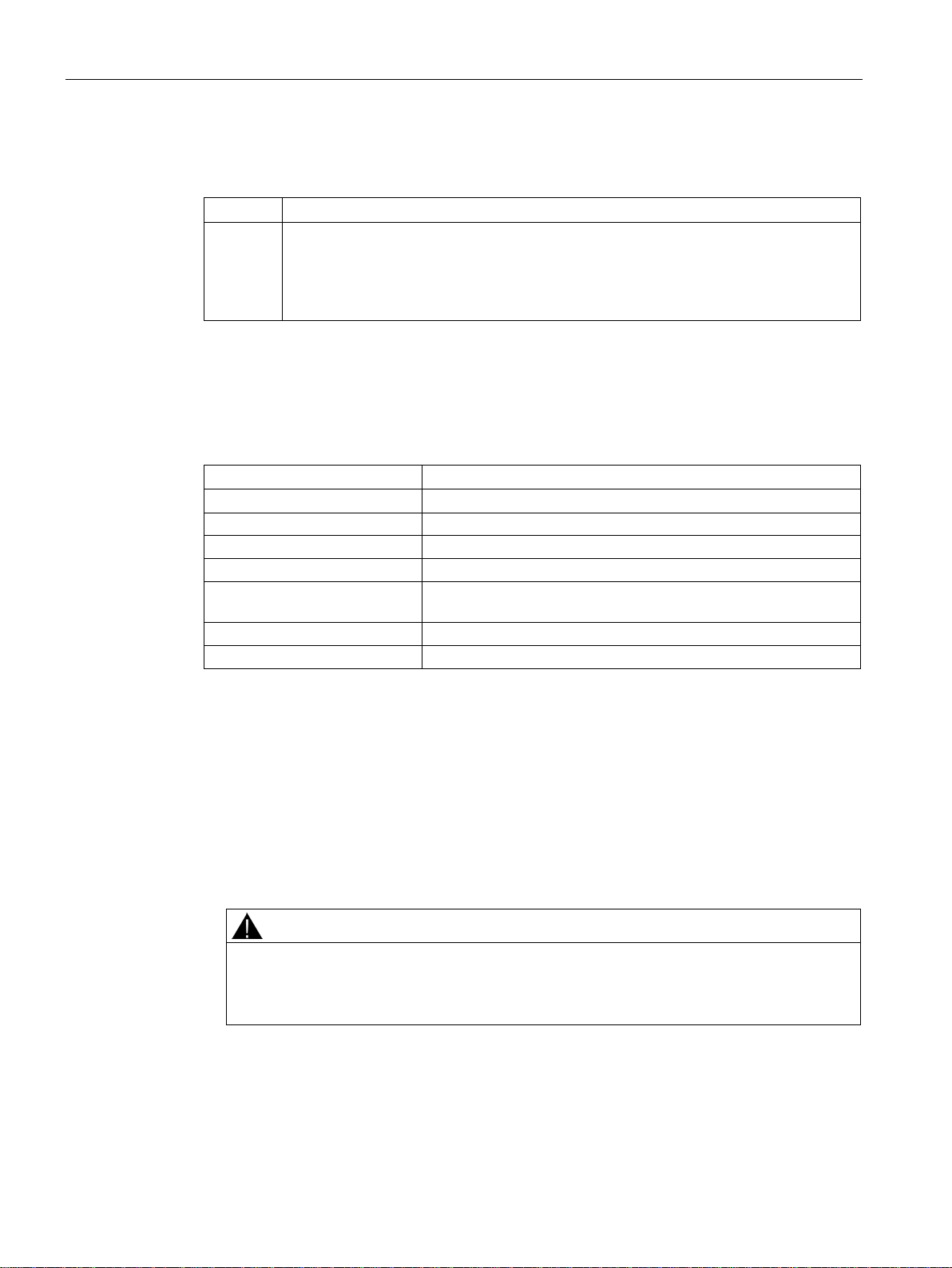

Edition

Firmware identifier nameplate

System integration

These instructions contain all information required to commission and use the device. Read

the instructions carefully prior to installation and commissioning. In order to use the device

correctly, first review its principle of operation.

The instructions are aimed at persons mechanically installing the device, connecting it

electronically, configuring the parameters and commissioning it, as well as service and

maintenance engineers.

The programming manual is an integral part of the CD, which is either supplied or can be

ordered. The programming manual is also available on the Siemens homepage.

On the CD, you will also find the catalog extract with the ordering data, the Software Device

Install for SIMATIC PDM for additional installation, and the required software.

Process instrumentation catalog (http://www.siemens.com/processinstrumentation/catalogs)

Product information on SITRANS P in the Internet (http://www.siemens.com/sitransp)

This history establishes the correlation between the current documentation and the valid

firmware of the device.

The documentation of this edition applies to the following firmware:

12/2015 FW:300.01.08

FW:301.01.10

PROFIsafe

FW:301.02.03

FW:301.02.04

SIMATIC PDM V8.x

SITRANS P DS III/P410 with PROFIBUS PA

Operating Instructions, 02/2016, A5E00053276-08

11

Introduction

Edition

Remark

1.4

Scope of the instructions

Order number

SITRANS P DS III/P410 for

7MF4134..

Gauge pressure, flush mounted diaphragm

7MF4334..

Absolute pressure from the differential pressure series

464/2320 psi)

7MF4534..

Differential pressure and flow rate, PN 420 (MAWP 6092 psi)

7MF4634..

Level

1.5

Checking the consignment

WARNING

Using a damaged or incomplete device

See also

1.4 Scope of the instructions

The most important changes in the documentation when compared with the respective

previous edition are given in the following table.

12/2015 All safety information has been revised.

The following chapters have also been changed:

• "Functional safety" chapter

• "Technical data" chapter

Table 1- 1 "7MF4.34.." stands for:

7MF4034.. Gauge pressure

7MF4234.. Absolute pressure from the gauge pressure series

7MF4434.. Differential pressure and flow rate, PN 32/160 (MAWP

1. Check the packaging and the delivered items for visible damage.

2. Report any claims for damages immediately to the shipping company.

3. Retain damaged parts for clarification.

4. Check the scope of delivery by comparing your order to the shipping documents for

correctness and completeness.

Danger of explosion in hazardous areas.

• Do not use damaged or incomplete devices.

Return procedure (Page 187)

SITRANS P DS III/P410 with PROFIBUS PA

12 Operating Instructions, 02/2016, A5E00053276-08

Introduction

1.6

Transportation and storage

CAUTION

Insufficient protection during storage

1.7

Notes on warranty

1.6 Transportation and storage

To guarantee sufficient protection during transport and storage, observe the following:

● Keep the original packaging for subsequent transportation.

● Devices/replacement parts should be returned in their original packaging.

● If the original packaging is no longer available, ensure that all shipments are properly

packaged to provide sufficient protection during transport. Siemens cannot assume

liability for any costs associated with transportation damages.

The packaging only provides limited protection against moisture and infiltration.

• Provide additional packaging as necessary.

Special conditions for storage and transportation of the device are listed in "Technical data"

(Page 193).

The contents of this manual shall not become part of or modify any prior or existing

agreement, commitment or legal relationship. The sales contract contains all obligations on

the part of Siemens as well as the complete and solely applicable warranty conditions. Any

statements regarding device versions described in the manual do not create new warranties

or modify the existing warranty.

The content reflects the technical status at the time of publishing. Siemens reserves the right

to make technical changes in the course of further development.

SITRANS P DS III/P410 with PROFIBUS PA

Operating Instructions, 02/2016, A5E00053276-08

13

Introduction

1.7 Notes on warranty

SITRANS P DS III/P410 with PROFIBUS PA

14 Operating Instructions, 02/2016, A5E00053276-08

2

2.1

Precondition for use

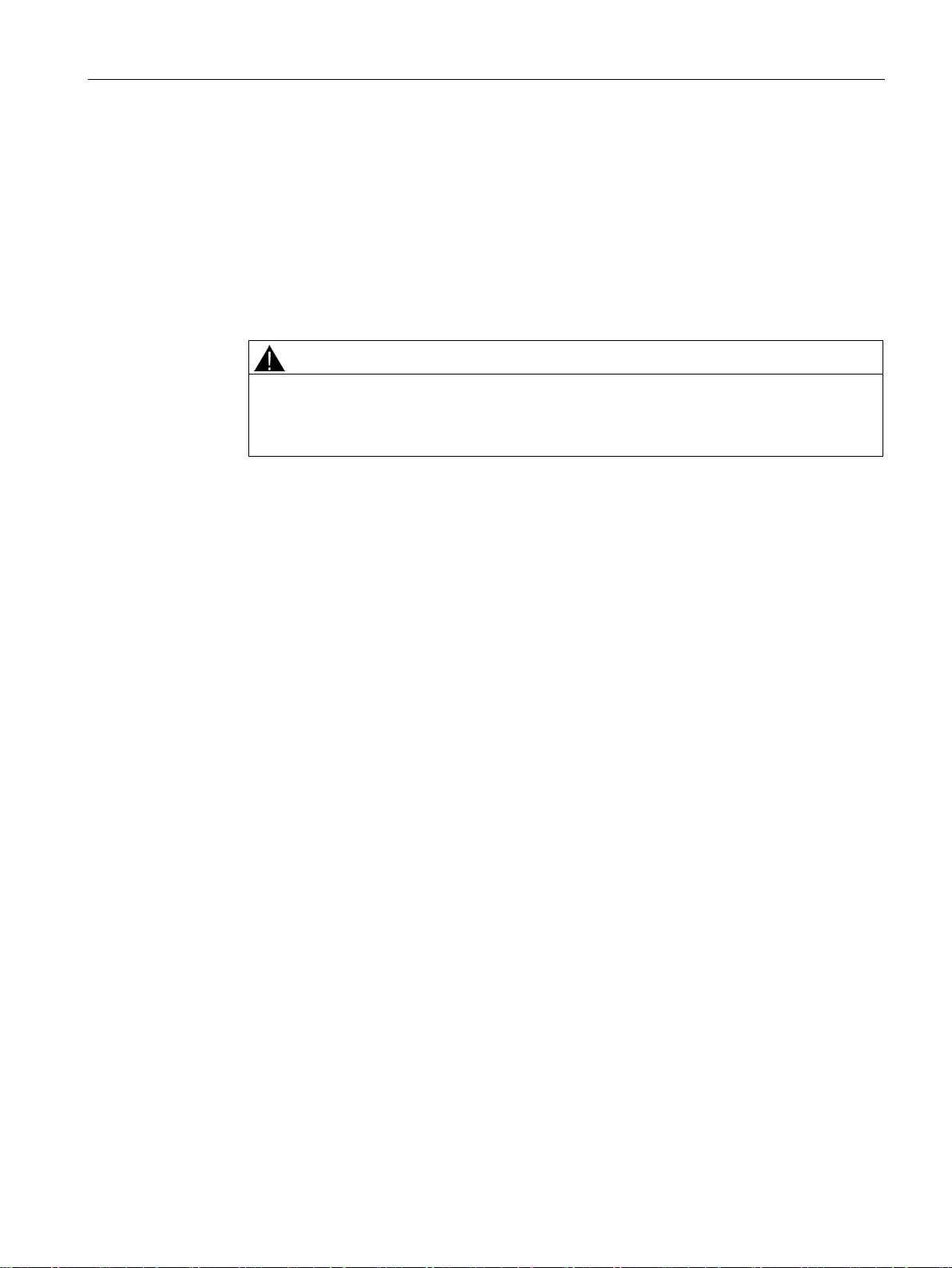

Symbol

Explanation

2.1.1

Laws and directives

2.1.2

Conformity with European directives

Electromagnetic Compat

i

2004/108/EC

Directive of the European Parliament and of the Council on the

approximation of the laws of the Member States relating to electromagnetic compatibility and repealing Directive 89/336/EEC.

Atmosphère explosible

ATEX

94/9/EC

Directive of the European Parliament and the Council on the

approximation of the laws of the Member States concerning

equipment and protective systems intended for use

ly explosive atmospheres.

Pressure Equipment D

rect

97/23/EC

Directive of the European Parliament and of the Council on the

approximation of the laws of the Member States concerning

pressure equipment.

This device left the factory in good working condition. In order to maintain this status and to

ensure safe operation of the device, observe these instructions and all the specifications

relevant to safety.

Observe the information and symbols on the device. Do not remove any information or

symbols from the device. Always keep the information and symbols in a completely legible

state.

Consult operating instructions

Observe the test certification, provisions and laws applicable in your country during

connection, assembly and operation. These include, for example:

● National Electrical Code (NEC - NFPA 70) (USA)

● Canadian Electrical Code (CEC) (Canada)

Further provisions for hazardous area applications are for example:

● IEC 60079-14 (international)

● EN 60079-14 (EC)

The CE mark on the device is a sign of conformity with the following European directives:

ibil-

ty EMC

in potential-

i-

ive PED

SITRANS P DS III/P410 with PROFIBUS PA

Operating Instructions, 02/2016, A5E00053276-08

15

Safety information

2.2

Improper device modifications

WARNING

Improper device modifications

2.3

Requirements for special applications

Note

Operation under special ambient conditions

We highly recommend that you contact your Siemens representative or our application

department before you operate the device under special ambie

encountered in nuclear power plants or when the device is used for research and

development purposes.

2.2 Improper device modifications

The standards applied can be found in the EC declaration of conformity for the device.

Danger to personnel, system and environment can result from modifications to the device,

particularly in hazardous areas.

• Only carry out modifications that are described in the instructions for the device. Failure

to observe this requirement cancels the manufacturer's warranty and the product

approvals.

Due to the large number of possible applications, each detail of the described device

versions for each possible scenario during commissioning, operation, maintenance or

operation in systems cannot be considered in the instructions. If you need additional

information not covered by these instructions, contact your local Siemens office or company

representative.

nt conditions as can be

SITRANS P DS III/P410 with PROFIBUS PA

16 Operating Instructions, 02/2016, A5E00053276-08

Safety information

2.4

Use in hazardous areas

Qualified personnel for hazardous area applications

WARNING

Unsuitable device for the hazardous area

See also

WARNING

Loss of safety of device with type of protection "Intrinsic safety Ex i"

2.4 Use in hazardous areas

Persons who install, connect, commission, operate, and service the device in a hazardous

area must have the following specific qualifications:

● They are authorized, trained or instructed in operating and maintaining devices and

systems according to the safety regulations for electrical circuits, high pressures,

aggressive, and hazardous media.

● They are authorized, trained, or instructed in carrying out work on electrical circuits for

hazardous systems.

● They are trained or instructed in maintenance and use of appropriate safety equipment

according to the pertinent safety regulations.

Danger of explosion.

• Only use equipment that is approved for use in the intended hazardous area and

labelled accordingly.

Technical data (Page 193)

If the device has already been operated in non-intrinsically safe circuits or the electrical

specifications have not been observed, the safety of the device is no longer ensured for use

in hazardous areas. There is a danger of explosion.

• Connect the device with type of protection "Intrinsic safety" solely to an intrinsically safe

circuit.

• Observe the specifications for the electrical data on the certificate and/or in Chapter

"Technical data (Page 193)".

SITRANS P DS III/P410 with PROFIBUS PA

Operating Instructions, 02/2016, A5E00053276-08

17

Safety information

2.4.1

Use of incorrect device parts in potentially explosive environments

WARNING

Use of incorrect device parts in potentially explosive environments

WARNING

Risk of explosion due to electrostatic charge

2.4 Use in hazardous areas

Devices and their associated device parts are either approved for different types of

protection or they do not have explosion protection. There is a danger of explosion if device

parts (such as covers) are used for devices with explosion protection that are not expressly

suited for this type of protection. If you do not adhere to these guidelines, the test

certificates and the manufacturer warranty will become null and void.

• Use only device parts that have been approved for the respective type of protection in

the potentially explosive environment. Covers that are not suited for the "explosionproof" type of protection are identified as such by a notice label attached to the inside of

the cover with "Not Ex d Not SIL".

• Do not swap device parts unless the manufacturer specifically ensures compatibility of

these parts.

To prevent the build-up of an electrostatic charge in a hazardous area, the key cover must

be closed during operation and the screws tightened.

The key cover may be opened temporarily at any time for the purposes of operating the

pressure transmitter, even during plant operation; the screws should then be tightened

again.

SITRANS P DS III/P410 with PROFIBUS PA

18 Operating Instructions, 02/2016, A5E00053276-08

Safety information

2.4.2

Electrostatic-sensitive devices

NOTICE

Electrostatic-sensitive devices

2.4 Use in hazardous areas

The device contains electrostatic-sensitive devices (ESD). ESD can be destroyed by

voltages far too low to be detected by humans. These voltages can occur if you simply

touch a component part or the electrical connections of a module without being

electrostatically discharged. The damage to a module caused by overvoltage cannot

normally be detected immediately; it only becomes apparent after a longer period of

operating time has elapsed.

Protective measures against the discharge of static electricity:

• Make sure that no power is applied.

• Before working with modules, make sure that you discharge static from your body, for

example by touching a grounded object.

• Devices and tools used must be free of static charge.

• Hold modules only by their edges.

• Do not touch connector pins or conductor tracks on a module with the ESD notice.

SITRANS P DS III/P410 with PROFIBUS PA

Operating Instructions, 02/2016, A5E00053276-08

19

Safety information

2.4 Use in hazardous areas

SITRANS P DS III/P410 with PROFIBUS PA

20 Operating Instructions, 02/2016, A5E00053276-08

3

3.1

System configuration

Overview

System communication

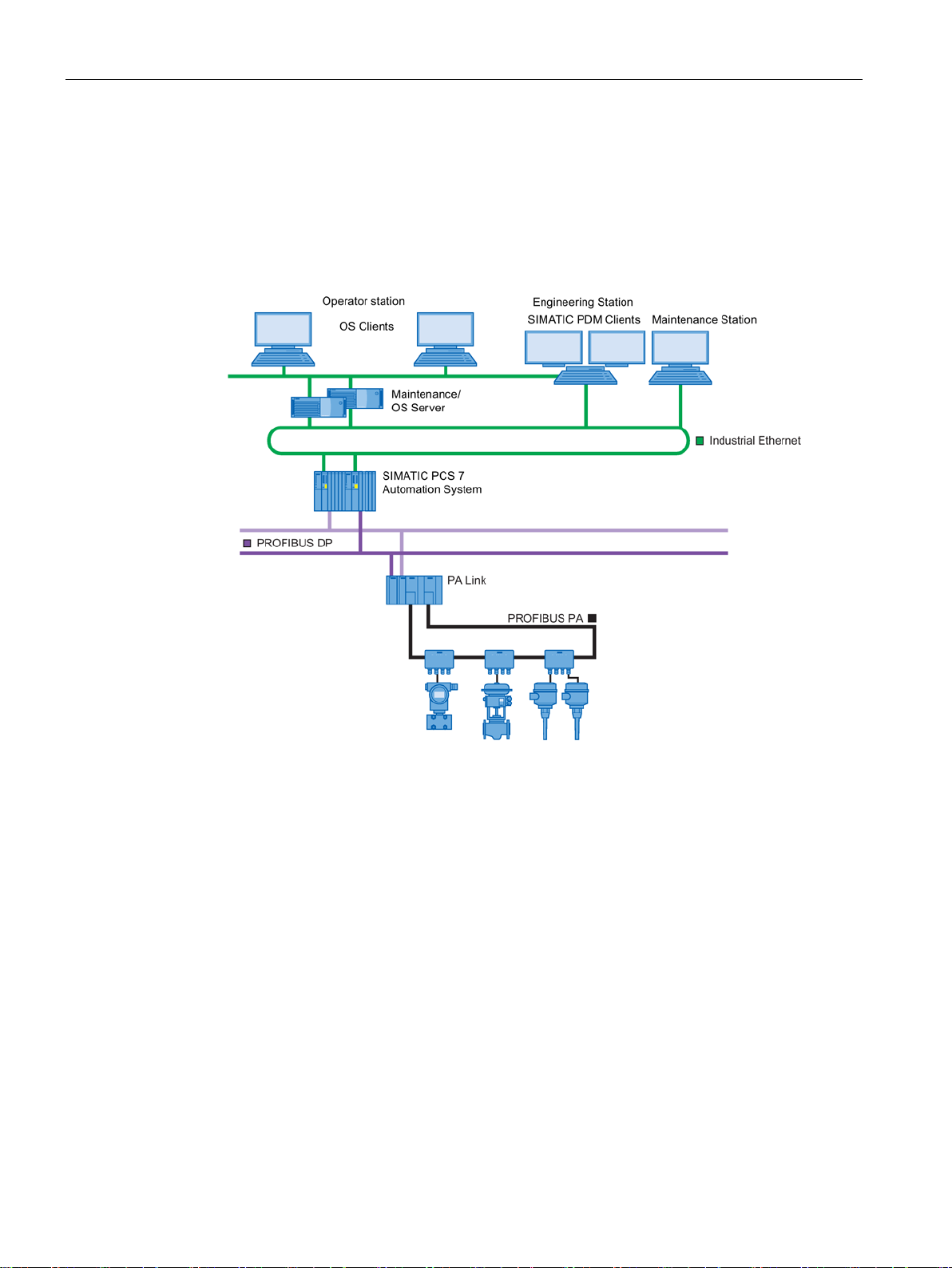

The pressure transmitter can be used in a number of system configurations.

Use with the SIMATIC PCS 7 Automation System is described below.

The operator station of the SIMATIC PCS 7 process control system allows easy and safe

control of the process by the operating personnel via OS clients.

The maintenance station assists the maintenance engineer in guaranteeing high plant

availability, securing this long-term using optimization measures, and implementing the

maintenance measures using a minimum of personnel, materials, energy, expenses, etc.

SITRANS P DS III/P410 with PROFIBUS PA

Operating Instructions, 02/2016, A5E00053276-08

21

Description

3.2

Application

Overview

3.2 Application

The field devices are integrated over PROFIBUS PA with:

● PA Link to the gateway between PROFIBUS PA and PROFIBUS DP

● Control system, e.g. SIMATIC PCS 7 Automation System, which communicates over

PROFIBUS

● Engineering station, SIMATIC PDM (Process Device Manager) which communicates over

Industrial Ethernet

Image 3-1 Possible system configuration

Depending on the variant, the pressure transmitter measures corrosive, non-corrosive and

hazardous gases, vapors and liquids.

Depending on the device version, you can use the pressure transmitter for the following

types of measurement:

● Gauge pressure

● Absolute pressure

● Differential pressure

SITRANS P DS III/P410 with PROFIBUS PA

22 Operating Instructions, 02/2016, A5E00053276-08

Description

Gauge pressure

Absolute pressure

Differential pressure and flow rate

3.2 Application

With appropriate parameter settings and the necessary add-on parts (e.g. flow limiters and

remote seals), the pressure transmitter can also be used for the following measurements:

● Level

● Volume

● Mass

● Volume flow

● Mass flow

The output signal is a process-based, digital PROFIBUS PA/FOUNDATION™ Fieldbus FF

signal.

You can install the "intrinsically-safe" or "flameproof enclosure" version of the pressure

transmitter in hazardous areas. The devices have an EC-Type Examination Certificate, and

comply with the corresponding harmonized European directives of the CENELEC.

The pressure transmitter is available with various designs of the remote seal for special

applications. A special application, for example, is the measurement of highly viscous

materials.

This version measures the gauge pressure of corrosive, non-corrosive and toxic gases,

vapors and liquids.

The smallest nominal measuring range is 0.01 bar g/1kPa g/14.5 psi g, the largest is

700 bar g/70 MPa g/10153 psi g.

This version measures the absolute pressure of corrosive, non-corrosive and toxic gases,

vapors and liquids.

There are two series: A "Differential pressure" series and a "Gauge pressure" series. The

"Differential pressure" series features a high overload capacity.

The smallest nominal measuring range of the "Differential pressure" series is

8.3 mbar a/0.83kPa/3.63 psi a, the largest is 100 bar a/10 MPa a/1450 psi a.

The smallest nominal measuring range of the "Gauge pressure" series is

8.3 mbar a/0.83kPa/3.63 psi a, the largest is 30 bar a/3 MPa/435 psi a.

This version measures corrosive, non-corrosive and toxic gases, vapors and liquids. You can

use it for the following types of measurement:

● Differential pressure

● Gauge pressure, suitable for small positive or negative pressure value

● In combination with a primary element: flow rate q ~

SITRANS P DS III/P410 with PROFIBUS PA

Operating Instructions, 02/2016, A5E00053276-08

23

Description

Level

3.3

SITRANS P DS III and SITRANS P410

SITRANS P DS III and SITRANS P410

3.4

Structure

3.3 SITRANS P DS III and SITRANS P410

The smallest nominal measuring range is 20 mbar (8.03 in H2O), the largest is

30 bar (435 psi).

This version with mounting flange measures the level of non-corrosive, corrosive and toxic

liquids in open and closed containers. The smallest nominal measuring range is

250 mbar (3.63 psi), the largest is 5 bar (72.5 psi). The nominal diameter of the mounting

flange is DN 80 or DN 100, or 3" or 4".

For the level measurement on open containers, the low-pressure side of the measuring cell

remains open. This measurement is referred to as "Measurement against atmospheric

pressure". For the measurement on closed containers, the low-pressure side is usually

connected to the container. This balances out the static pressure.

The parts wetted by the medium are made of various materials according to the corrosion

resistance required.

These instructions describe the pressure transmitters SITRANS P DS III and

SITRANS P410. The main difference of the SITRANS P410 is the higher measuring

precision compared to the SITRANS P DS III. Refer to the information in the section

Technical data (Page 193).

You order SITRANS P410 using the order option C41 for specific device versions.

Depending on a customer-specific order, the device comprises different parts.

SITRANS P DS III/P410 with PROFIBUS PA

24 Operating Instructions, 02/2016, A5E00053276-08

Description

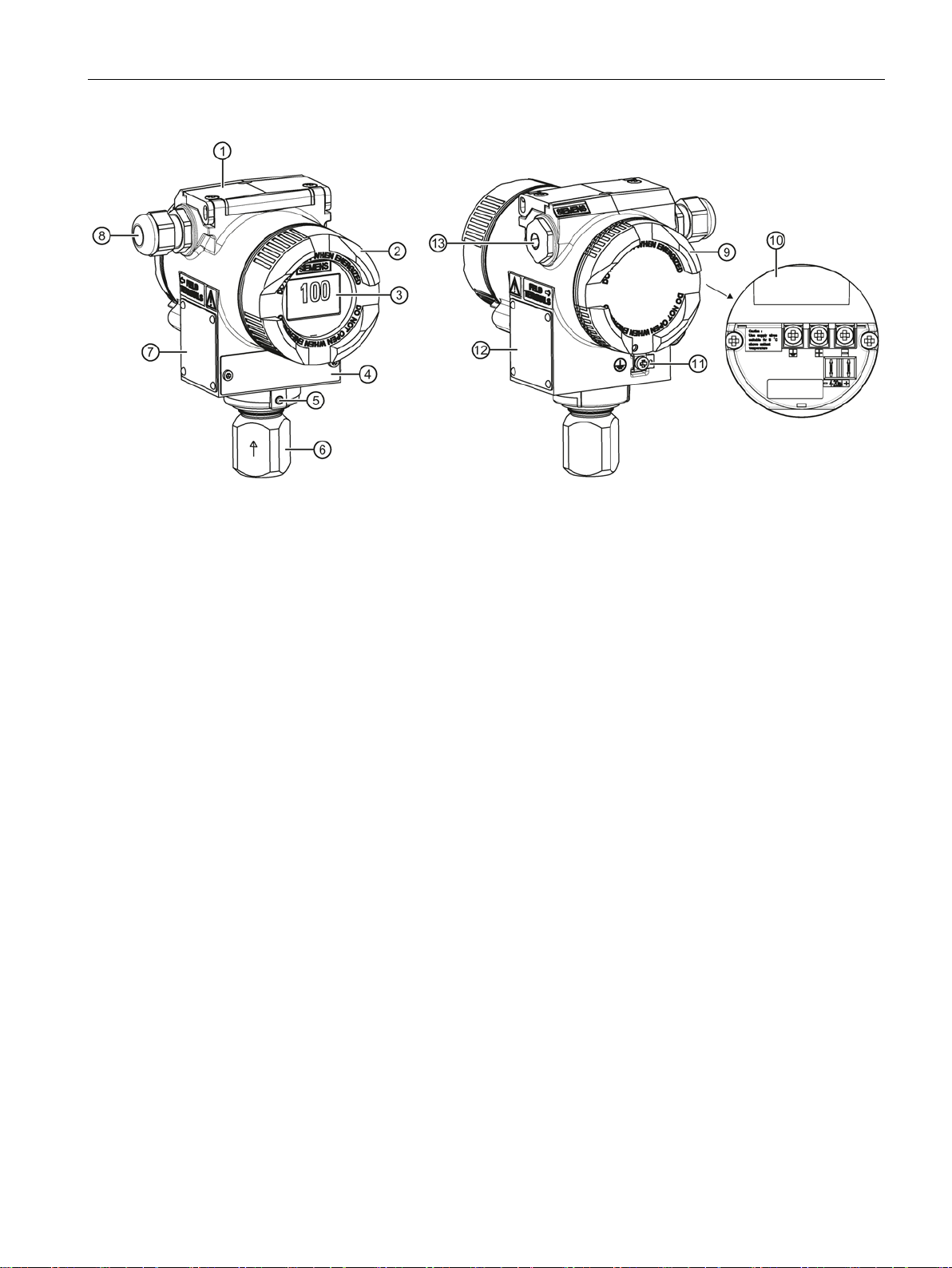

①

Key cover

⑧

Cable inlet, optionally with cable gland

②

Cover (front), optionally with inspection window

⑨

Cover (rear) for electrical terminal compartment

③

Display (optional)

⑩

Electrical terminal compartment

④

⑪

ing terminal

⑤

Retaining screw; twist proofing of the measuring cell

in relation to the electronics enclosure

⑫

⑥

Process connection

⑬

Blanking plug

⑦

Nameplate (general information)

3.4 Structure

Measuring point label

Image 3-2 View of the pressure transmitter: Left: Front right: Rear view

● The electronics enclosure is made of die cast aluminum or precision cast stainless steel.

● The housing has a removable circular cover at the front and the back.

● Depending on the device version, the front cover

window. You can read the measured values straight off the digital display through this

inspection window.

● The cable inlet

right-hand one can be used. The unused opening is closed with a blanking plug

● The protective conductor terminal/equipotential bonding terminal

of the enclosure.

● The electrical terminal compartment

when you remove the back cover

● The measuring cell with a process connection

enclosure. This measuring cell is secured against twisting by a retaining screw

Thanks to the modular design of the pressure transmitter, the measuring cell and

application electronics or connection board can be replaced if required.

⑧ to the electrical terminal compartment is at the side; either the left or

Protective conductor connector/equipotential bond-

Nameplate (approval information)

⑩ for the auxiliary power and shield is accessible

⑨.

② may be designed as an inspection

⑬.

⑪ is located at the back

⑥ is located in the lower section of the

⑤.

● On the upper face of the enclosure you can see crosshead screws which secure the key

①, under which there are 3 keys for local operation.

cover

SITRANS P DS III/P410 with PROFIBUS PA

Operating Instructions, 02/2016, A5E00053276-08

25

Description

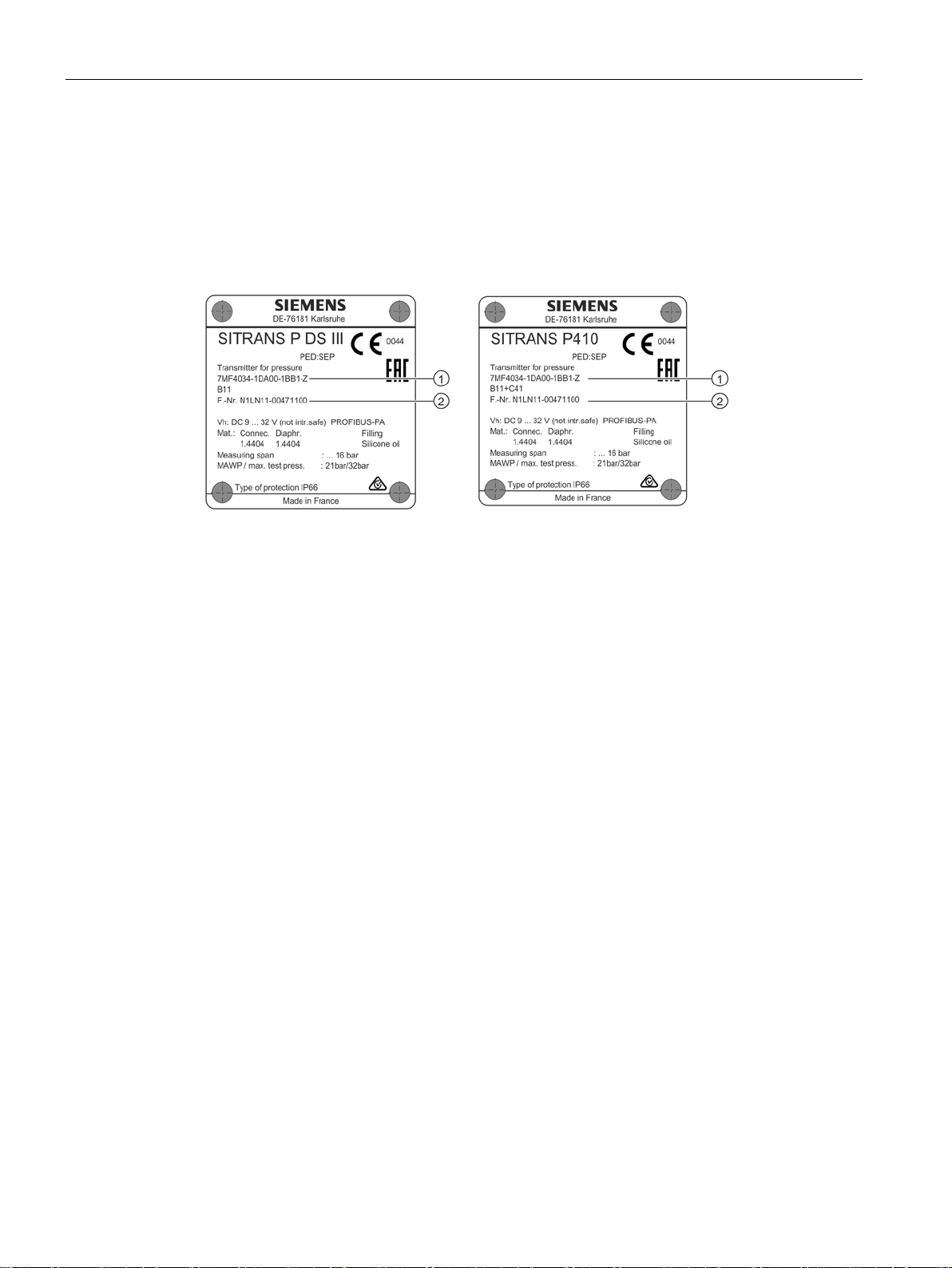

3.5

Nameplate layout

Nameplate with general information

①

code)

②

Nameplate with approval information

3.5 Nameplate layout

The label which bears the Order No. and other important information such as design details

or technical data is present on the side of the housing.

Order number (machine-readable product

Serial number

On the opposite side is the nameplate with approval information. This nameplate shows the

firmware and hardware versions, for example. You must also observe the information in the

relevant certificate for a pressure transmitter version for use in hazardous areas.

SITRANS P DS III/P410 with PROFIBUS PA

26 Operating Instructions, 02/2016, A5E00053276-08

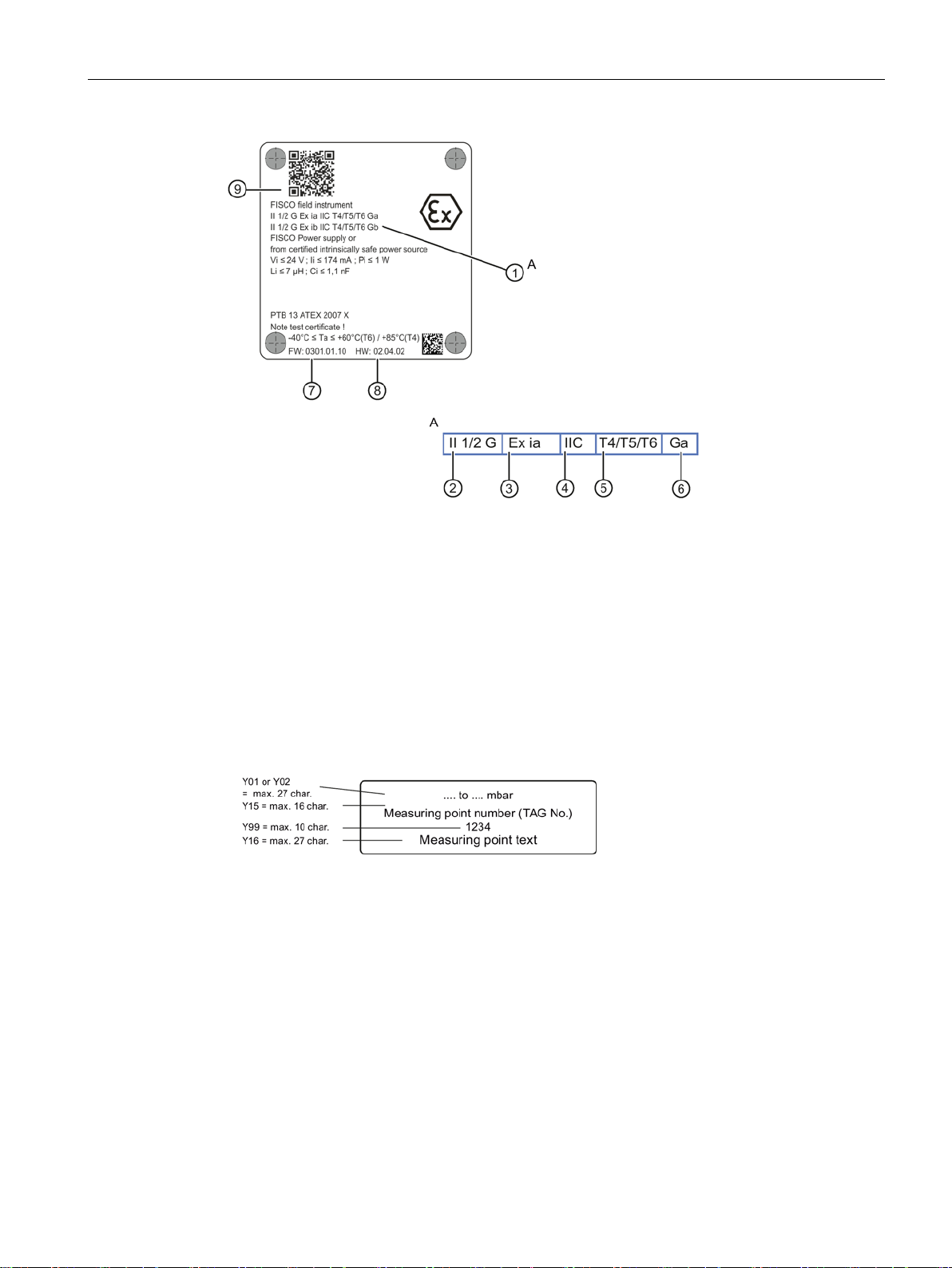

Description

①

⑤

ture class)

②

Category of the operating range

⑥

Device protection level

③

Type of protection

⑦

Firmware identifier

④

Group (gas, dust)

⑧

Hardware identifier

⑨

vice-specific information on the product

teristics ①

3.6

Measuring point label layout

3.7

Principle of operation

3.7.1

Overview of mode of operation

3.6 Measuring point label layout

Characteristics of the hazardous area

Maximum surface temperature (tempera-

QR code to the mobile website with de-

Image 3-3 Example of measuring point label

A More detailed information on the charac-

This chapter describes how the pressure transmitter works.

First the electronics are described, and then the physical principle of the sensors which are

used with the various device versions for the individual measurement types.

SITRANS P DS III/P410 with PROFIBUS PA

Operating Instructions, 02/2016, A5E00053276-08

27

Description

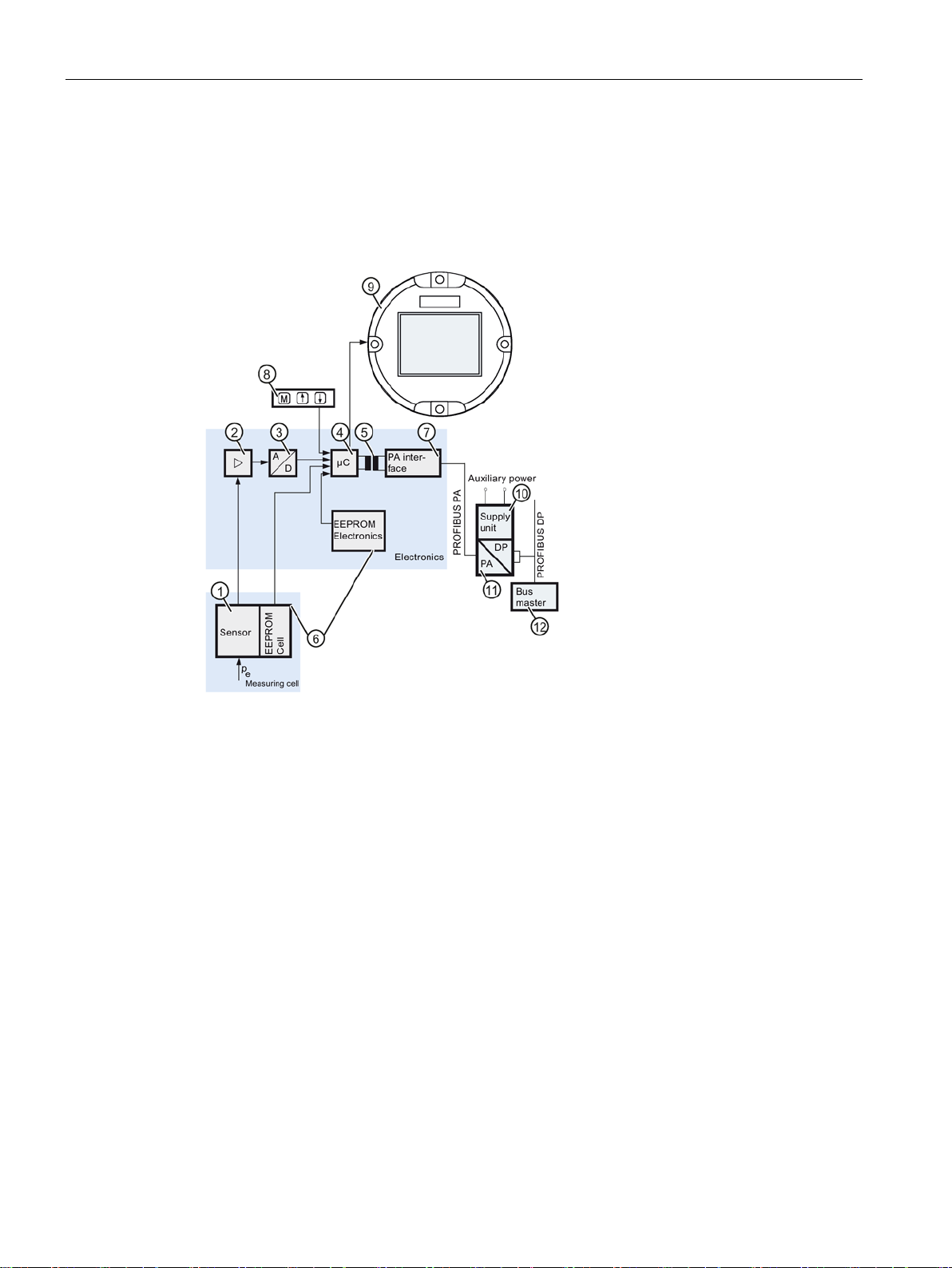

3.7.2

Operation of the electronics

Description

①

Measuring cell sensor

⑧

Buttons (local operation)

②

Measuring amplifier

⑨

Display

③

Analog-to-digital converter

⑩

Power supply

④

Microcontroller

⑪

DP/PA coupler or DP/PA link

⑤

Electrical isolation

⑫

Bus master

⑥

and in the electronics

⑦

PROFIBUS PA interface

Function

3.7 Principle of operation

Each with an EEPROM in the measuring cell

Image 3-4 Principle of operation of the electronics with PA communication

● The inlet pressure is converted into an electrical signal by the sensor

● This signal is amplified by the measuring amplifier

● The digital signal is analyzed in a microcontroller

● The signal is available at an electrically isolated PA interface

converter

and thermal characteristics.

③.

pe Input variable

② and digitized in an analog-to-digital

④ and corrected with regard to linearity

⑦ on the PROFIBUS PA.

①.

SITRANS P DS III/P410 with PROFIBUS PA

28 Operating Instructions, 02/2016, A5E00053276-08

Description

Operation

3.7.3

Principle of operation of the measuring cell

WARNING

Destruction of the seal diaphragm

Overview

3.7 Principle of operation

● The data specific to the measuring cell, the electronics data, and the parameterization

data are stored in two EEPROMs

the second with the electronics.

● The results with the status values and diagnostics data are transmitted cyclically over the

PROFIBUS PA. Parameterization data and error messages are transmitted acyclically by

SIMATIC PDM.

⑥. The first memory is linked with the measuring cell,

● The buttons

● If you have a display

Danger of injury or damage to device

If the seal membrane is destroyed, the sensor may also be destroyed. If the seal

membrane is destroyed, no reliable measured values can be output.

Hot, toxic and corrosive process media can be released.

• Ensure that the material of the device parts wetted by the process medium is suitable for

• Make sure that the device is suitable for the maximum operating pressure of your

• Define maintenance intervals for regular inspections in line with device use and

⑧ can be used to call up individual functions, so-called modes.

⑨, you can track the mode settings and other messages on it.

the medium. Refer to the information in Technical data (Page 193).

system. Refer to the information on the nameplate and/or in Technical data (Page 193).

empirical values. The maintenance intervals will vary from site to site depending on

corrosion resistance.

In the following sections, the process variable to be measured is called general inlet

pressure.

The following modes of operation are described:

● Gauge pressure

● Absolute pressure

SITRANS P DS III/P410 with PROFIBUS PA

Operating Instructions, 02/2016, A5E00053276-08

● Differential pressure and flow rate

● Level

The following process connections are available, for example:

● G1/2 B, 1/2-14 NPT

● Male thread: M20

29

Description

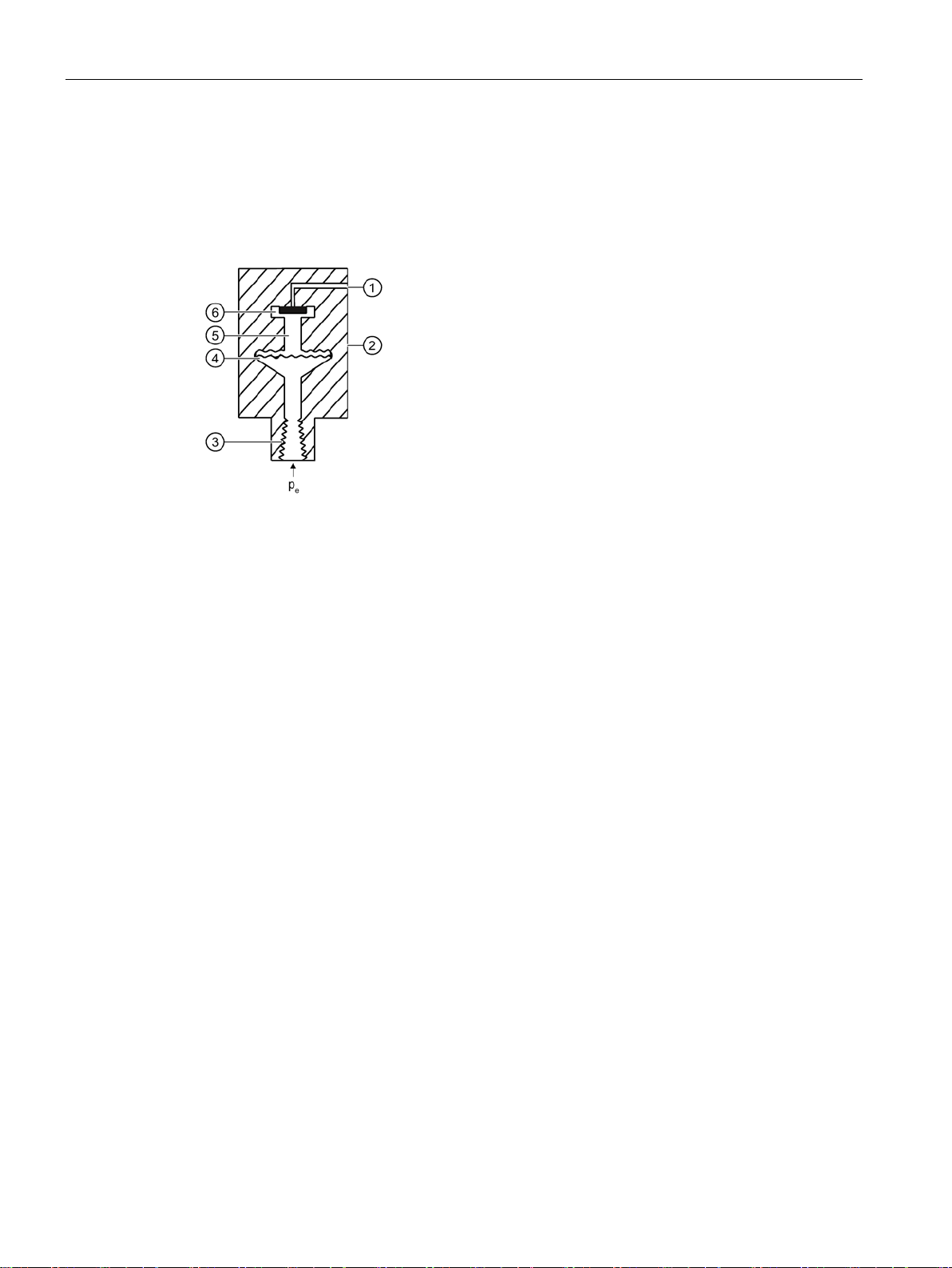

3.7.3.1

Measuring cell for gauge pressure

①

Reference pressure opening

⑤

Filling liquid

②

Measuring cell

⑥

Gauge pressure sensor

③

Process connection

pe

Inlet pressure

④

Seal diaphragm

3.7 Principle of operation

● Flange connection in accordance with EN 61518

● Flush-mounted process connections

Image 3-5 Function chart of measuring cell for gauge pressure

The inlet pressure (pe) is transferred to the gauge pressure sensor ⑥ via the seal diaphragm

④ and the fill fluid ⑤, displacing its measuring diaphragm. The displacement changes the

resistance of the four piezoresistors (bridge circuit) of the gauge pressure sensor. The

change in the resistance causes a bridge output voltage proportional to the inlet pressure.

Pressure transmitters with spans ≤ 6.3 MPa measure the inlet pressure against atmosphere,

those with spans ≥ 16 MPa the inlet pressure against vacuum.

SITRANS P DS III/P410 with PROFIBUS PA

30 Operating Instructions, 02/2016, A5E00053276-08

Loading...

Loading...