Siemens SITRANS P200, 7MF1565 Series Operating Instructions Manual

Pressure transmitter

SITRANS P200 (7MF1565)

Operating Instructions

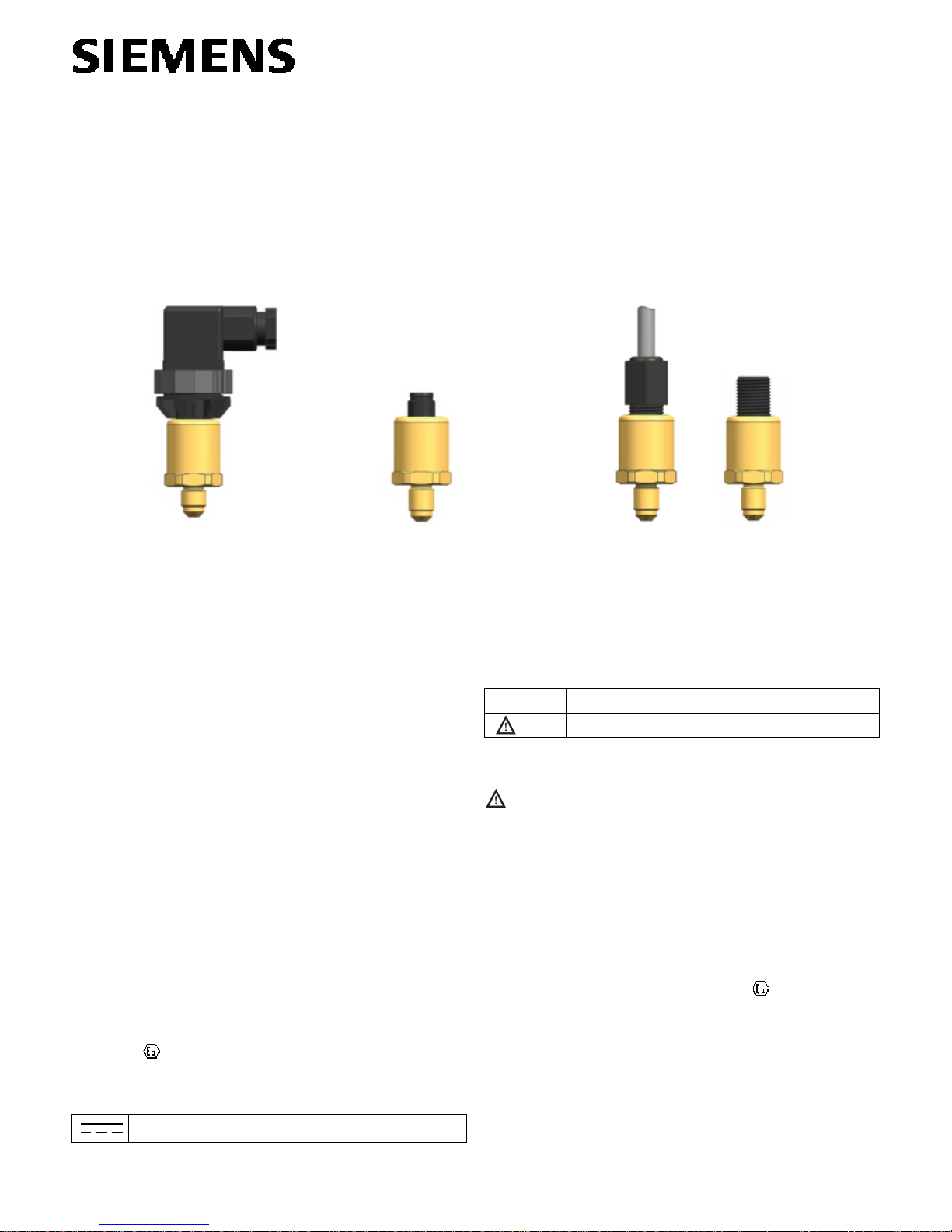

7MF1565 with plug complying with EN 175301-803-A

Type 7MF1565-*****-1**1

Type 7MF1565-*****-5**1

7MF1565 with plug M12x1

Type 7MF1565-*****-2**1

7MF1565 with cable (2 m)

Type 7MF1565-*****-3**1

7MF1565 with fast-fit cable gland

Type 7MF1565-*****-4**1

Range of application SITRANS P200, type 7MF1565

The pressure transmitter is used to measure relative pressure and

absolute pressure of gases and liquids in the following

industrial sectors:

Mechanical engineering Shipbuilding

Power engineering Chemicals

Water supply Pharmaceuticals

Device design without explosion protection

The pressure transmitter consists of a piezoresistive measuring cell with a

diaphragm, installed in a stainless steel housing. It can be electrically connected

using a plug complying with EN 175301-803-A (IP65), a round plug M12 (IP67),

a cable (IP67) or a fast-fit cable gland (IP67). The output signal is 4 to 20 mA or

0 to 10 V.

Device design with explosion protection

The pressure transmitter consists of a piezoresistive measuring cell with a diaphragm, installed in a stainless steel housing. It can be electrically connected with

a plug complying with EN 175301-803-A (IP65) or a round plug M12 (IP67). The

output signal is 4 to 20 mA.

Installation

The location of the device has no influence on the precision of the measure-

ment.

Before installation, compare the process data with the data of the name plate.

The medium being measured must be suitable for the parts of the pressure

transmitter in contact with the medium.

The overload limit must not be exceeded.

Connect the devices to a fixed cable installation.

Grounding for devices

The pressure transmitter must be connected to the equipotential bonding system

of the plant via the metal housing (process connection) and the ground conductor of the plug.

Direct current

Safety instructions

Symbol Explanation of the warning symbol on the device

Read the information in the operating instructions

In terms of a safety-instrumented system, this device left the factory in perfect

condition. To maintain this status and to ensure safe operation of the device,

observe the following notes:

The device may only be used for the purposes specified in these instructions.

When connecting up, installing and operating the device, the directives and

laws of your country apply.

Devices with the type of protection "intrinsic safety„ lose their approval, if they

are operated on electrical circuits that do not conform to the test certification

valid for your country.

Connect the device to a low voltage power supply with safe separation (SELV).

The device should only be supplied with limited energy according to UL 61010-1

Second Edition, Section 9.3 or LPS in conformance with UL 60950-1 or class 2 in

compliance with UL 1310 or UL 1585.

The device can be operated both at high pressure and with aggressive and

hazardous media. This means that if the device is not used properly, serious

bodily injury and/or considerable damage to property cannot be excluded. This

should be kept in mind particularly when the device was in use and is replaced.

The installation, mounting and commissioning of the devices should be

performed only by trained personnel and should comply with the standards

EN 60079-14 and EN 61241-14.

The overload limit should be monitored and kept to at all times.

The device is maintenance-free

© Siemens 2011

A5E03304326-01, 03/2011

© Siemens AG 2011

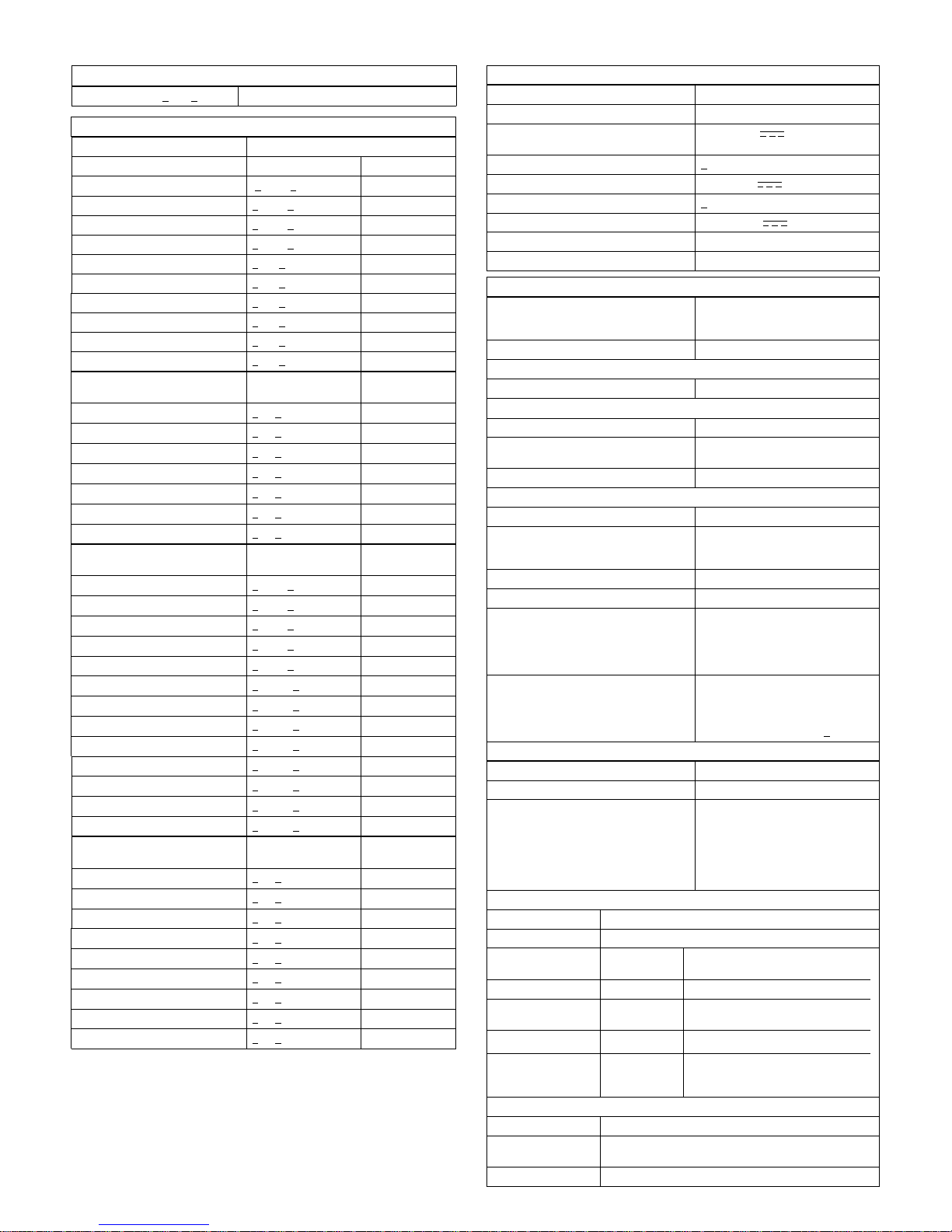

Technical data

SITRANS P200 (7MF1565)

A5E03304326-01, 03/2011

Mode of operation

Measuring range > 1 ... < 60 bar Piezoresistive with ceramic diaphragm

Input

Measured variable input

Measuring range for gauge pressure Overload limit Burst pressure

0 ... 1 bar g

> -0.4 / < 2.5 bar g > 2.5 bar

0 ... 1.6 bar g

> -0.4 / < 4 bar g > 4 bar

0 ... 2.5 bar g

> -0.8 / < 6.25 bar g > 6.25 bar

0 ... 4 bar g

> -0.8 / < 10 bar g > 10 bar

0 ... 6 bar g

> -1 / < 15 bar g > 15 bar

0 ... 10 bar g

> -1 / < 25 bar g > 25 bar

0 ... 16 bar g

> -1 / < 40 bar g > 40 bar

0 ... 25 bar g

> -1 / < 62.5 bar g > 62.5 bar

0 ... 40 bar g

> -1 / < 100 bar g > 100 bar

0 ... 60 bar g

> -1 / < 150 bar g > 150 bar

Measuring range for absolute

pressure

Overload limit Burst pressure

0 ... 1 bar a

> 0 / < 2.5 bar a > 2.5 bar

0 ... 1.6 bar a

> 0 / < 4 bar a > 4 bar

0 ... 2.5 bar a

> 0 / < 6.25 bar a > 6.25 bar

0 ... 4 bar a

> 0 / < 10 bar a > 10 bar

0 ... 6 bar a

> 0 / < 15 bar a > 15 bar

0 ... 10 bar a

> 0 / < 25 bar a > 25 bar

0 ... 16 bar a

> 0 / < 40 bar a > 40 bar

Measuring range for gauge

pressure (for US market only)

Overload limit Burst pressure

0 ... 10 psi g

> -5.8 / < 35 psi g > 35 psi

0 ... 15 psi g

> -5.8 / < 35 psi g > 35 psi

3 ... 15 psi g

> -5.8 / < 35 psi g > 35 psi

0 ... 20 psi g

> -5.8 / < 50 psi g > 50 psi

0 ... 30 psi g

> -5.8 / < 80 psi g > 80 psi

0 ... 60 psi g

> -11.5 / < 140 psi g > 140 psi

0 ... 100 psi g

> -14.5 / < 200 psi g > 200 psi

0 ... 150 psi g

> -14.5 / < 350 psi g > 350 psi

0 ... 200 psi g

> -14.5 / < 550 psi g > 550 psi

0 ... 300 psi g

> -14.5 / < 800 psi g > 800 psi

0 ... 500 psi g

> -14.5 / < 1 400 psi g > 1 400 psi

0 ... 750 psi g

> -14.5 / < 2 000 psi g > 2 000 psi

0 ... 1 000 psi g

> -14.5 / < 2 000 psi g > 2 000 psi

Measuring range for absolute

pressure

(for US market only)

Overload limit Burst pressure

0 ... 10 psi a

> 0 / < 35 psi a > 35 psi

0 ... 15 psi a

> 0 / < 35 psi a > 35 psi

0 ... 20 psi a

> 0 / < 50 psi a > 50 psi

0 ... 30 psi a

> 0 / < 80 psi a > 80 psi

0 ... 60 psi a

> 0 / < 140 psi a > 140 psi

0 ... 100 psi a

> 0 / < 200 psi a > 200 psi

0 ... 150 psi a

> 0 / < 350 psi a > 350 psi

0 ... 200 psi a

> 0 / < 550 psi a > 550 psi

0 ... 300 psi a

> 0 / < 800 psi a > 800 psi

Output

Current signal 4 ... 20 mA

Burden (U

B

- 10 V) / 0.02 A

Auxiliary power U

B

DC 7 ... 33 V (10 to 30 V for

hazardous areas)

Current consumption I

B

< 20 mA

Voltage signal 0 ... 10 VDC

Burden > 10 kΩ

Auxiliary power U

B

12 ... 33 VDC

Current consumption < 7 mA at 10 kΩ

Characteristic Linear rising

Measuring accuracy

Measurement deviation at 25 ÀC (77 ÀF),

Characteristic deviation, hysteresis and

repeatability included

typically: 0.25 % of full scale value

maximum: 0.5 % of full scale value

Setting T99 < 0.1 s

Long-term drift

Start-of-scale value and measuring span 0.25 % of full scale value/year

Ambient temperature influence

Start-of-scale value and measuring span

0.25 %/10 K of full-scale value

Vibration influence (complying with IEC

60068-2-6)

0.005 %/g to 500 Hz in all

directions

Auxiliary power influence 0.005 %/V

Conditions during operation

Ambient air temperature -25 ⁄ +85 ÀC (-13 to +185 ÀF)

Altitude max. 2 000 m ASL

Use an appropriate power supply for

altitudes higher than 2000 m ASL.

Relative humidity 0 ... 100 %

Storage temperature -50 ⁄ +100 ÀC (-58 to +212 ÀF)

Degree of protection (complying with

EN 60529)

IP65 with plug complying with

EN 175301-803-A

IP67 with M12 plug

IP67 with cable

IP67 with cable fast-fit gland

Electromagnetic compatibility

complying with EN 61326-1

complying with EN 61326-2-3

complying with NAMUR NE21, only

for ATEX device and max. measured value deviation of < 1 %

Construction

Weight approx. 0.090 kg (0.198 lb)

Process connections Dimension drawings

Electrical connections

Plug complying with EN 175301-

803-A Form A with cable inlet

M16x1.5 or -14NPT or Pg 11

M12 plug

2- or 3-wire (0.5 mm

2

)

Cable (± 5.4 mm)

Fast-fit cable gland

Material of the parts in contact with measured material

Measuring cell AI

2O3

- 96 %

Process connection stainless steel, material no. 1.4404 (SST 316 L)

Material of parts not in contact with the medium

Housing stainless steel, material no. 1.4404 (SST 316 L)

Pin and socket plastic

connector housing CuZn, nickel-plated (plug M12)

Cable PVC spec.

Sealing material

Position 15 of

order number

Media temperature

Viton (FPM) A -15 ... +125 ÀC (+5 ⁄ +257ÀF)

Neoprene (CR) B -35 ... +100 ÀC < 100 bar

(-31 ⁄ +212 ÀF; < 1 450 psi)

Perbunan (NBR) C -20 ... +100 ÀC (-4 ⁄ +212 ÀF)

EPDM D -40 ... +145 ÀC < 100 bar

(-40 ⁄ +293 ÀF; < 1 450 psi),

can be used for drinking water

© Siemens AG 2011

Loading...

Loading...