Page 1

SITRANS P

© Siemens AG 2008

measuring instruments

for pressure

2/2 Product overview

2/4 Transmitters for gage, absolute and

differential pressure

2/4 Z series for gage pressure

2/6 Z series for gage and absolute pressure

2/12 SITRANS P250 for differential pressure

2/17 ZD series for gage and absolute pressure

2/21 Transmitters for food, pharma-

ceuticals and biotechnology

2/21 SITRANS P Compact for gage

and absolute pressure

2/28 SITRANS P300 for gage and absolute

essure

pr

2/47 Transmitters for gage pressure for pa-

per industry

SITRANS P300 and DS III series with

PMC connection

2/47 Technical description

Technical specifications, ordering data,

dimensional drawings

2/52 -

2/58 - SITRANS P300 with PMC connection

2/63 Transmitters for gage, absolute and

2/63 Technical description

2/70 -

2/79 - for gage and absolute pressure with

2/89 - f

2/98 -

2/107 - for differential pressure and flow

2/124 - for level

2/134 SITRANS P Accessories

2/134 Supplementary electronics for 4-wire con-

2/136 Accessories/spare parts for SITRANS P,

2/142 Factory-mounting of valve manifolds on

DS III series with PMC connection

differential pressure, flow and level

DS III, DS III PA and DS III FF series

Technical specifications, ordering data,

dimensional drawings

for gage pressure

front-flush diaphragm

or absolute pressure (from gage

pressure series)

for absolute pressure

(from differ

nection

P300 and DS III series

SITRANS P transmitters

ential pressure series)

2/150 Remote seals for transmitters and

pressure gages

2/150 Technical description

2/158 Diaphragm seals of sandwich design

2/161 Diaphragm seals of flange design

2/170 Quick-release diaphragm seals

2/173 Miniature diaphragm seal

2/174 Flushing rings

2/176 Clamp-on seals of flange design

2/179 Quick-release clamp-on seals

2/182 Remote seals - Measuring setups

2/187 Questionnaire

2/190 Fittings

2/190 Technical description

2/191 Selection aid

Shut-off valves for gage and absolute

pressure transmitters

2/193 Shut-off valves to DIN 16270, DIN 16271

and DIN 16272

2/195 Angle adapter

2/196 Double shut-off valves

2/197 Accessories for shut-off

valves/double shut-off valves

2/198 2-way valve manifolds DN 5

Shut-off valves for differ

transmitters

2/201 2-, 3- and 5-spindle valve manifolds DN 5

2/204 Multiway cocks PN 100

2/206 3-way and 5-way valve manifolds DN 5

2/209 3-way valve manifold DN 8

2/212 Valve manifold combination DN 5/DN 8

2/214 Valve manifold combination DN 8

2/216 2-, 3- and 5-spindle valve manifolds for

installing in protective boxes

2/220 3- and 5-spindle valve manifolds for

vertical angular diff. pr

2/223 Low-pressure multiway cock

Accessories

2/225 Oval flange

2/226 Adapters, connection glands

2/227 Connection parts G½

2/228 Water traps, Sealing rings to EN 837-1

2/229 Pressure surge reducers

2/230 Primary shut-off valves

2/232 Compensation vessels

2/233 Connection parts

ential pressure

essure lines

2/146 Transmitters for hydrostatic level

2/146 MPS series (submersible sensor)

You can download all instructions, catalogs and certificates for SITRANS P free

of charge at the following Internet address:

www.siemens.com/sitransp

Siemens FI 01 · 2009

Page 2

SITRANS P measuring instruments for pressure

2

© Siemens AG 2008

Product overview

■

Overview

SITRANS P – measuring instruments for pressure, absolute pressure, differential pressure, flow and level

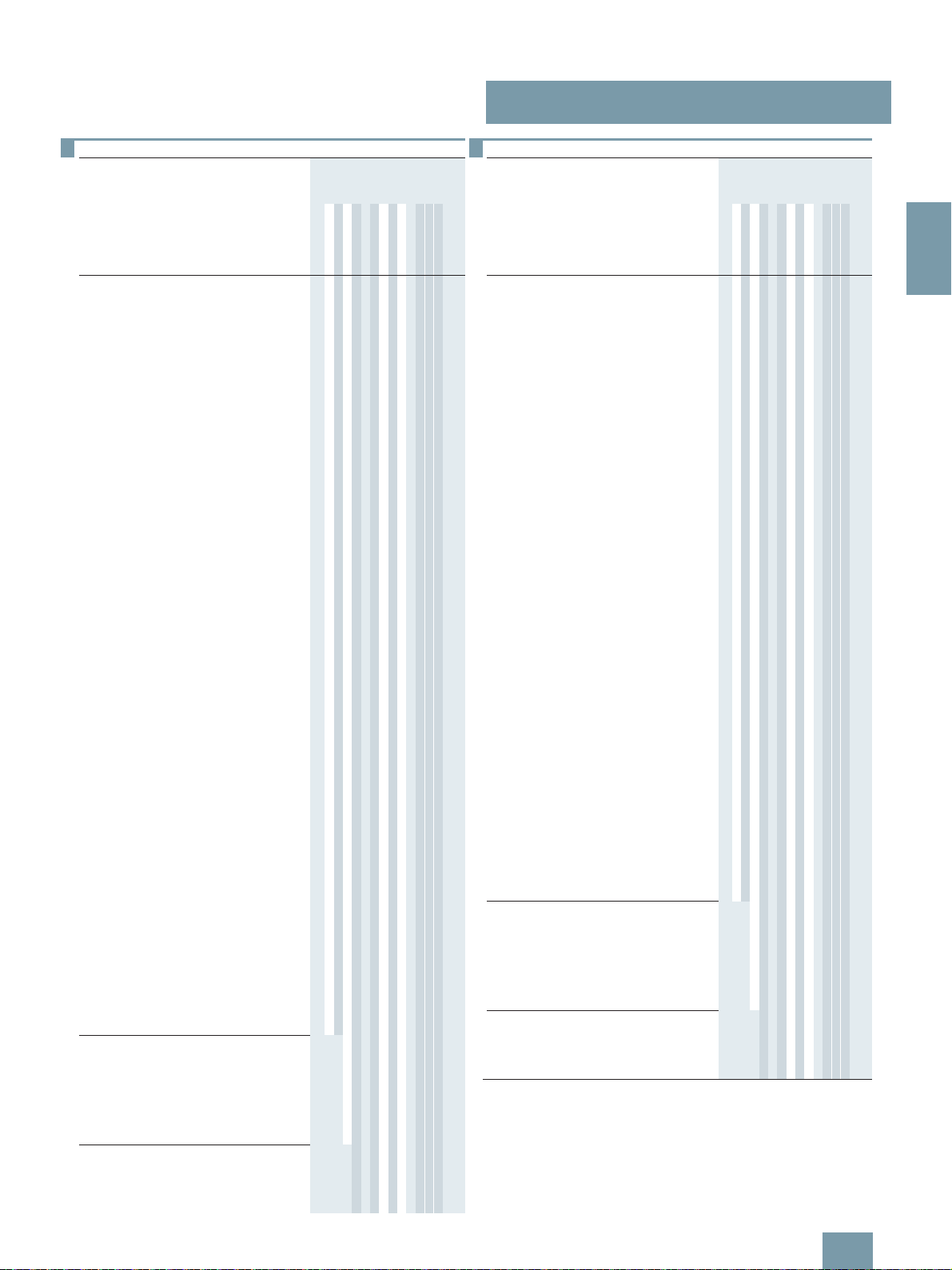

Application Description Page Software for

Two- or three-wire transmitters

for measuring gage and absolute pressure

SITRANS P, Z series

Compact single-range transmitters

Analog electronics

Available ex stock

Parameterization

2/4 –

Two- or three-wire transmitters

for measuring differential pressure

Two- or three-wire transmitters

for measuring gage and absolute pressure

Transmitters for gage and absolute pressure for food, pharmaceuticals and biotechnology

Two-wire transmitters for measuring gage and absolute pressure

Two-wire transmitters for measuring gage pressure

SITRANS P250

Compact single-range transmitters

Analog electronics

Available ex stock

SITRANS P, ZD series

Range adjustment: 5 : 1

Digital display

Available ex stock

SITRANS P Compact

Single-range transmitters in 2-wire system

Hygiene-based design with various aseptic connec-

tions according to EHEDG, FDA and GMP recommendations.

SITRANS P300

• Hygiene-based design according to EHEDG, FDA

and GMP

• Parameterization over 3 buttons or communication

over HART, PROFIBUS PA or FOUNDATION

Fieldbus

• Standard process connection G½, ½-NPT and

flush-mounted process connections available

• Measuring range adjustment 100 : 1

SITRANS P300 and DS III series with PMC connection for the paper industry

• Measuring range adjustment 100 : 1

• Process connections for the paper industry

• Parameter assignment over 3 buttons and HART,

PROFIBUS PA or FOUNDATION Fieldbus

2/12 –

2/17 –

2/21 –

2/28 SIMATIC PDM

2/47 SIMATIC PDM

2/2

Siemens FI 01 · 2009

Two-wire transmitters for measuring:

• Gage pressure,

• Absolute pressure

• Differential pressure and

• Flow or

• Level

Supplementary electronics for

adaptation of two-wire transmitters for four-wire connections

SITRANS P, DS III series

SITRANS P, DS III PA series

SITRANS P, DS III FF series

Range adjustment: 100 : 1

Parameterization using:

• 3 keys and HART for DS III series

• 3 keys and PROFIBUS-PA for DS III PA series

• 3 buttons and FOUNDATION Fieldbus for DS III FF

series

• Available ex stock

Output: 0 or 4 to 20 mA

Power supply: 24 V AC/DC, 230 V AC

2/63 SIMATIC PDM

SIMATIC PDM

2/134 –

Page 3

SITRANS P measuring instruments for pressure

© Siemens AG 2008

Product overview

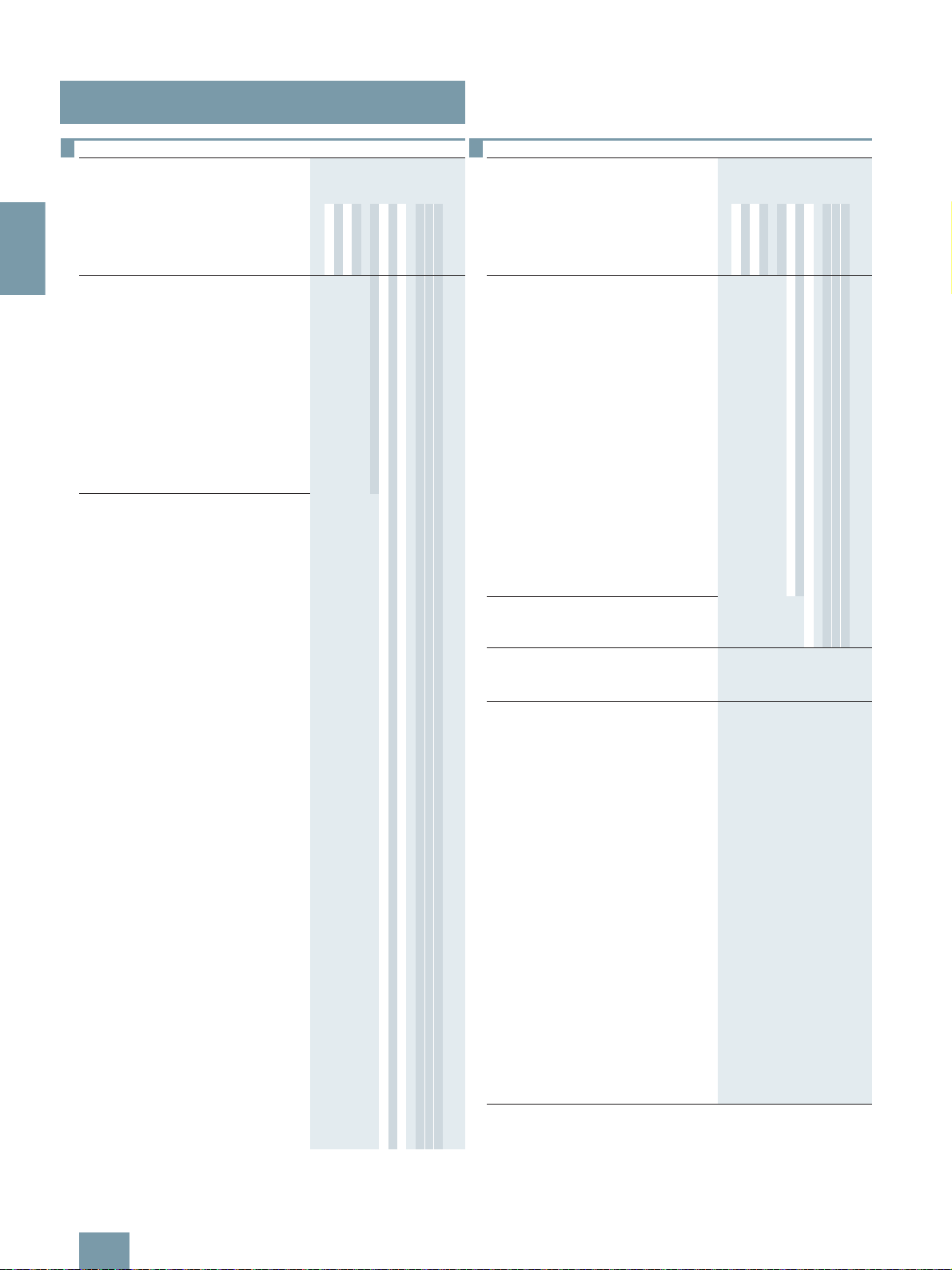

Application Description Page Software for

2-wire transmitter for measuing

hydrostatic levels

Remote seals for measuring

viscous, corrosive or fibrous

media (as well as media at

extreme temperatures)

Shutting off the lines for the

medium and differential pressure

Mounting of transmitter on valve

manifold or shut-off fitting

SITRANS P, MPS series (submersible sensor)

For measuring liquid levels in wells, tanks, channels,

dams etc.

Remote seals in sandwich and flange designs

Quick-release remote seals for the food industry

Wide range of diaphragm materials and filling liq-

uids available

Shut-off fittings and valve manifolds available in

steel, brass or stainless steel

Valve manifolds available for the various process

connections of the SITRANS P transmitters

2/146 –

2/150 –

2/190 –

Parameterization

2

Siemens FI 01 · 2009

2/3

Page 4

SITRANS P measuring instruments for pressure

2

p

I

0

, U

B

U

const.

U

I

© Siemens AG 2008

Transmitters for gage, absolute and differential pressure

Z series for gage pressure

■

Overview

SITRANS P pressure transmitters, Z series for gage pressure

(7MF1562-...)

The SITRANS P pressure transmitter, Z series (7MF1562-...),

measures the gage pressure of aggressive and non-aggressive

gases, liquids and vapors.

■

Design

The main components of the pressure transmitter are:

• Brass housing with silicon measuring cell and electronics

plate

• Process connection

• Electrical connection

The silicon measuring cell has a thin-film strain gage which is

mounted on a ceramic diaphragm. The ceramic diaphragm can

also be used for aggressive media.

The process connection to DIN EN 837-1 is made of brass and

has a male thread G½B or a female thread G

The electrical connection is made using a plug to DIN 43650

with a M16x1.5 cable inlet.

■

Function

The pressure transmitters of the Z series for gage pressure measure the pressure of aggressive and non-aggressive gases,

liquids and vapors.

The measuring cell is temperature-compensated.

Mode of operation

1

/8B.

■

Benefits

• High measuring accuracy

• Sturdy brass housing

• For aggressive and non-aggressive media

• For measuring the pressure of liquids, gases and vapor

• Temperature-compensated measuring cell

• Compact design

■

Application

The pressure transmitter of the Z series for gage pressure

(7MF1562-...) is used above all in the following industrial areas:

• Power engineering

• Mechanical engineering

• Shipbuilding

• Water supply etc.

A concrete application example is the measurement of com-

pressed air containing oil in compressors or compressor stations.

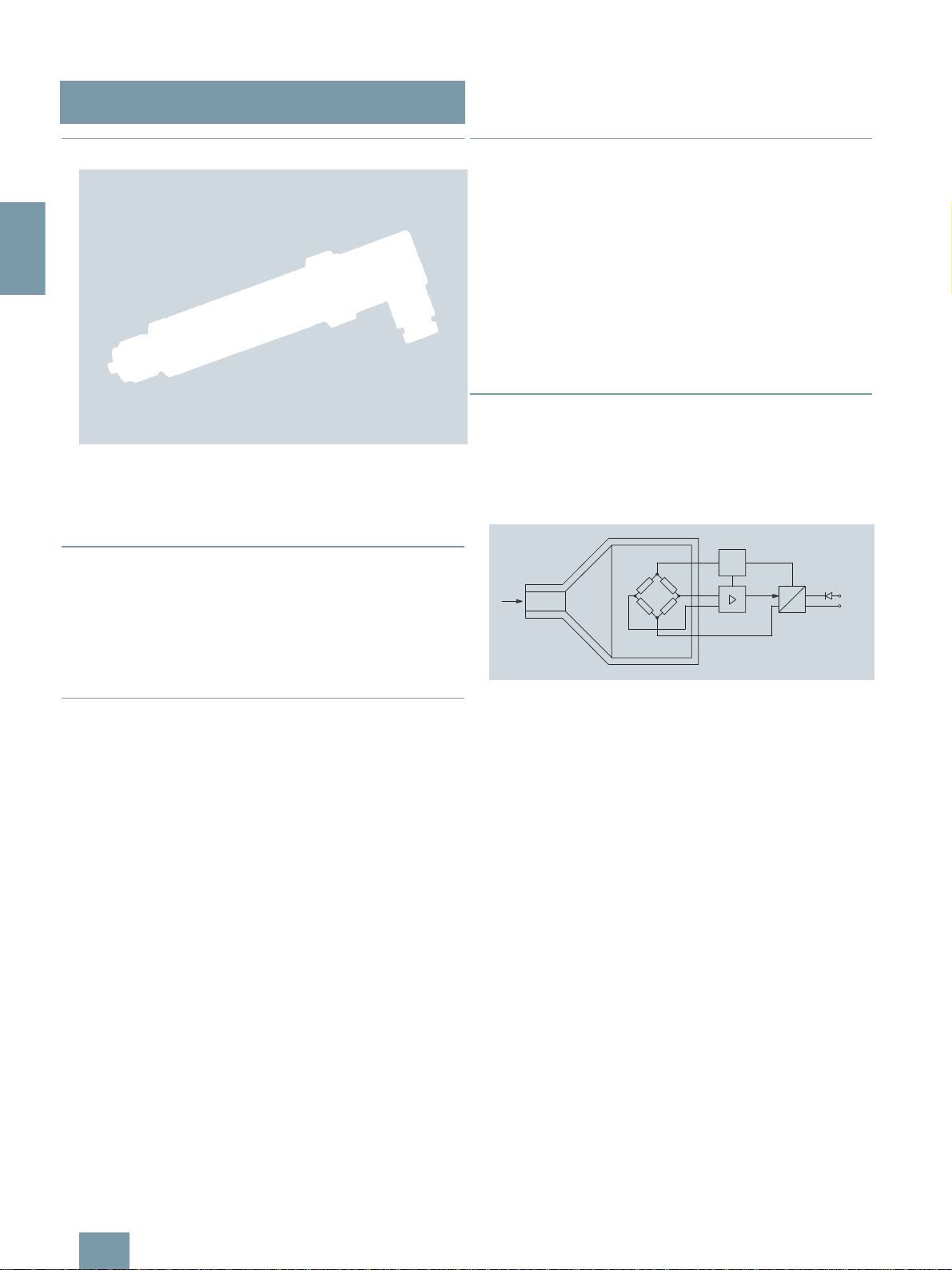

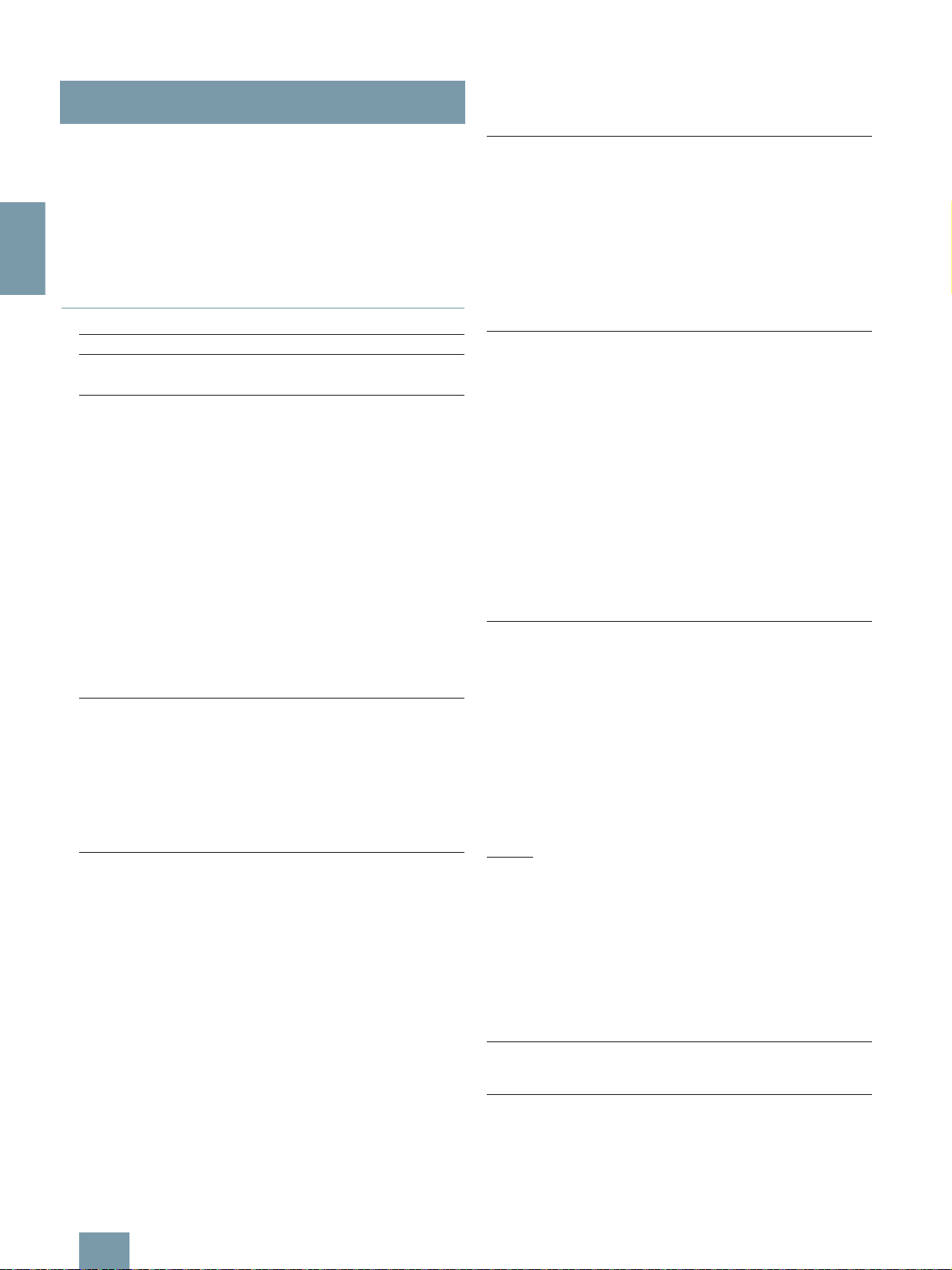

SITRANS P pressure transmitters, Z series (7MF1562-...), functional diagram

The thin-film measuring cell has a thin-film resistance bridge at

which the operating pressure p is transmitted through a ceramic

diaphragm.

The measuring cell output voltage is fed to an amplifier and converted into an output current of 4 to 20 mA. The output current

is linearly proportional to the input pressure.

2/4

Siemens FI 01 · 2009

Page 5

SITRANS P measuring instruments for pressure

1+

2-

+

Signal

R

L

U

B

I

0

I0 Output current

U

B

Power supply

R

L

Load

Connections:

1 (+U

B

)

2 (-U

B

)

© Siemens AG 2008

Transmitters for gage, absolute and differential pressure

Z series for gage pressure

■

Technical specifications

SITRANS P pressure transmitter, Z series for gage pressure

Mode of operation

Measuring principle Thin-film strain gage

Input

Measured variable Realtive pressure

Measured range 0 to 16 bar g (0 to 232 psi g) or

0 to 25 bar g (0 to 363 psi g)

Output

Current output signal 4 ... 20 mA

Measuring accuracy To EN 60770-1

Error in measurement (at 25 °C

(77 °F), including conformity error,

hysteresis and repeatability)

Response time T

Long-term drift

• Start of scale 0.3% of full-scale value/year - typ-

• Measured span 0.3% of full-scale value/year - typ-

Influence of ambient temperature

• Start of scale 0.3%/10 K (0.3%/10 K) of full-

• Measured span 0.3%/10 K (0.3%/10 K) of full-

Rated conditions

Medium conditions

• Process temperature -30 ... +120 °C (-22 ... +248 °F)

Degree of protection to EN 60529 IP65

Ambient conditions

• Ambient temperature -25 ... 85 °C (-13 ... +185 °F)

• Storage temperature -50 ... 100 °C (-58 ... +212 °F)

99

0.5% of full-scale value-typical

< 0.1 s

ical

ical

scale value - typical

scale value - typical

Design

Weight ≈ 0.2 kg (≈ 0.44 lb)

Wetted parts materials

• Measuring cell Al

• Process connection Brass, mat. No. 2.0402

• Gasket Viton

Process connection Male thread G½B

Power supply

Terminal voltage on pressure transmitter

• For current output 10 to 36 V DC

Certificate and approvals

Classification according to pressure

equipment directive

(DRGL 97/23/EC)

■

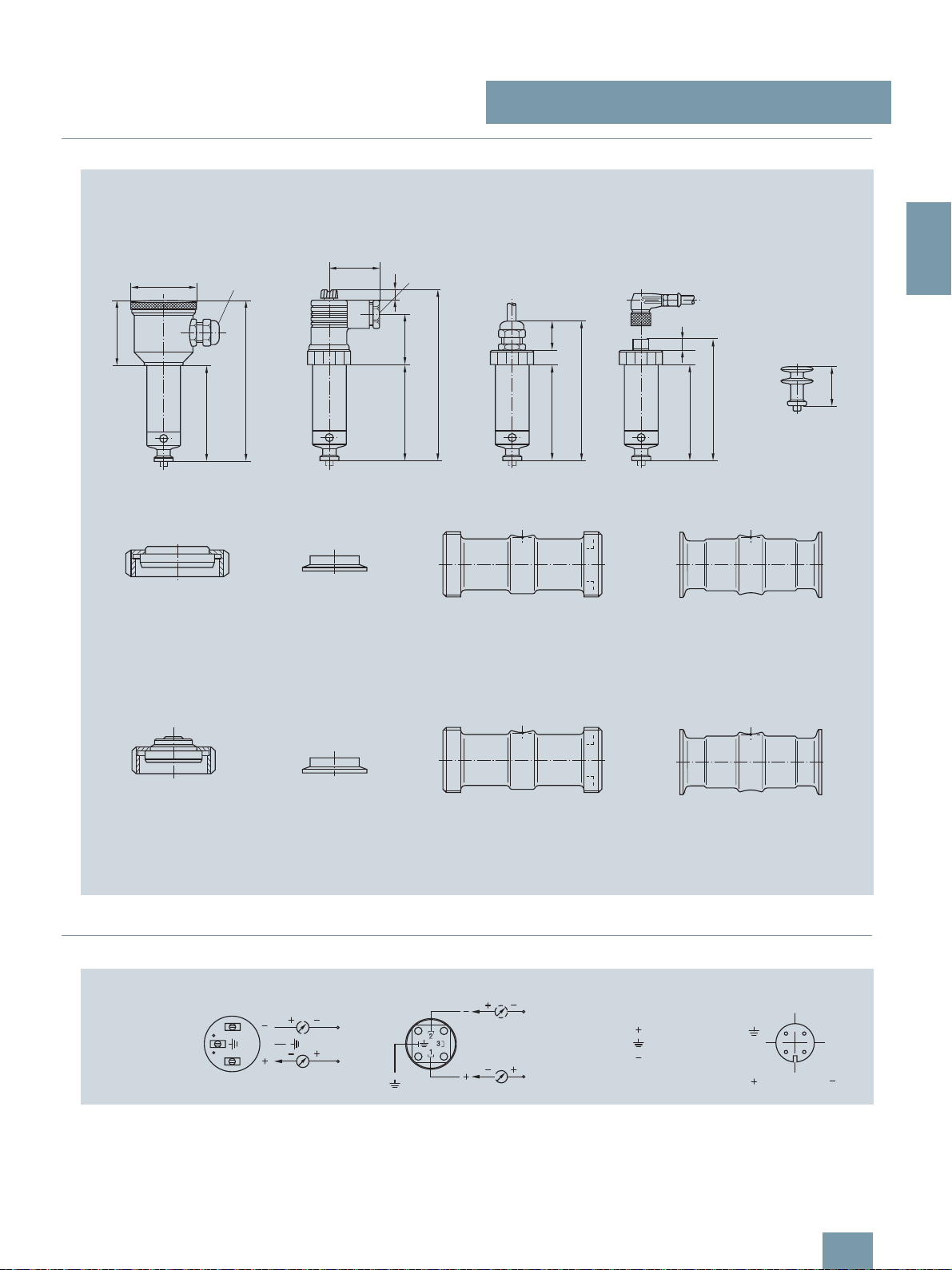

Dimensional drawings

B

8

/

G

*%

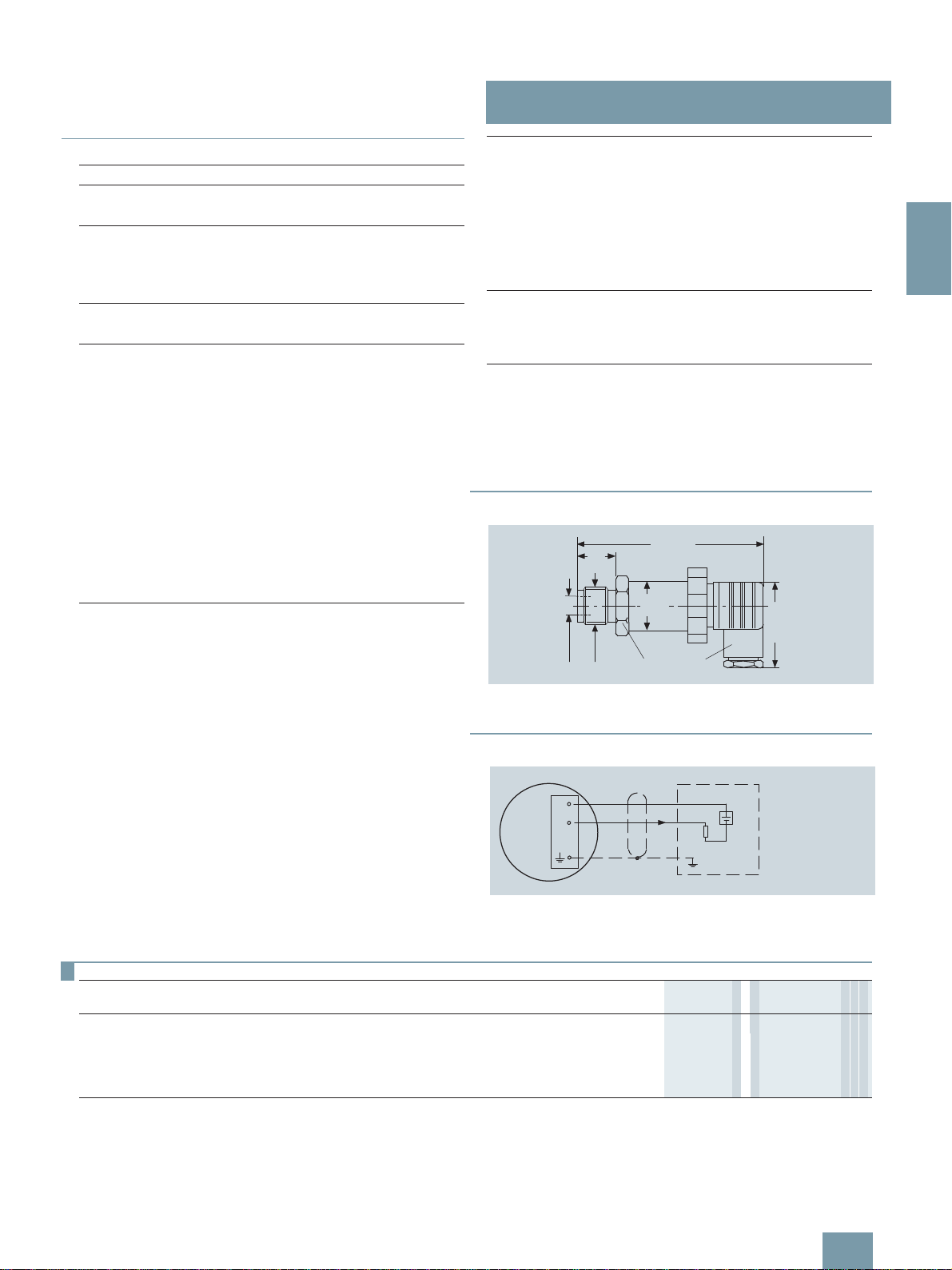

SITRANS P pressure transmitters, Z series (7MF1562-...), dimensions in

mm (inch)

■

Schematics

ෘ

6:

GLDP

- 96%

2O3

1

/8B

female thread G

For gases of fluid group 1 and

liquids of fluid 1; complies with

requirements of article 3, paragraph 3 (sound engineering practice)

0[

2

Selection and Ordering data Order No. Order code

■

SITRANS P pressure transmitters, Z series for pressure

2-wire system, characteristic rising

Measured range Max. working pressure

0 ... 16 bar g (0 ... 232 psi g) 32 bar g (464 psi g) 3CB

0 ... 25 bar g (0 ... 363 psi g) 64 bar g (928 psi g) 3CD

Other version for measuring range ≥ 1 bar g (≥ 14.5 psi g), add Order code and plain text:

Measuring range: ... to ... bar g (psi g)

D) Subject to export regulations AL: N, ECCN: EAR99H.

SITRANS P pressure transmitters, Z series (7MF1562-...), connection diagram

D)

7MF1562 -

777

0 0

9AA H 1 Y

Siemens FI 01 · 2009

7 7 7

2/5

Page 6

SITRANS P measuring instruments for pressure

2

p

I

0

, U

B

U

const.

U

I

© Siemens AG 2008

Transmitters for gage, absolute and differential pressure

Z series for gage and absolute pressure

■

Overview

SITRANS P pressure transmitters, Z series for pressure and absolute

pressure (7MF1564-...)

SITRANS P pressure transmitters, Z series (7MF1564-...), measure the gage and absolute pressure as well as the level of liquids and gases.

■

Benefits

• High measuring accuracy

• Sturdy stainless steel housing

• For aggressive and non-aggressive media

• For measuring the pressure of liquids, gases and vapor

• Temperature-compensated measuring cell

• Compact design

■

Application

The pressure transmitter of the Z series for gage pressure and

absolute pressure (7MF1564-...) is used above all in the following industrial areas:

• Chemical industry

• Pharmaceutical industry

• Food industry

• Mechanical engineering

• Shipbuilding

• Water supply

■

Design

The design of the pressure transmitter is dependent on the measuring range.

Measuring range <1 bar (<14.5 psi)

Main components:

• Stainless steel housing with piezo-resistive silicon measuring

cell (with stainless steel diaphragm, temperature-compensated) and electronics module

• Process connection made of stainless steel in diverse designs

(see Selection and Ordering data)

• Electrical connection made using a plug to DIN 43650 with the

cable inlet M16 x 1.5, ½-14 NPT or round plug connector M12.

The pressure transmitters with a nominal range < 1 bar g

(< 14.5 psi g) are optionally available with or without explosion

protection.

Measuring range

Main components:

• Stainless steel housing with ceramic measuring cell and electronics module. The temperature-compensated ceramic measuring cell has a thin-film strain gage which is mounted on a

ceramic diaphragm. The ceramic diaphragm can also be

used for aggressive media.

• Process connection made of stainless steel in diverse designs

(see Selection and Ordering data)

• Electrical connection made using a plug to DIN 43650 with the

cable inlet M16 x 1.5, ½-14 NPT or round plug connector M12.

The pressure transmitters with a nominal range ≥ 1barg

(≥ 14.5 psi g) are optionally available with or without explosion

protection.

■

Function

The pressure transmitter measures the gage and absolute pressure as well as the level of liquids and gases.

Mode of operation

SITRANS P pressure transmitters, Z series (7MF1564-...), functional diagram

The mode of operation of the pressure transmitter is dependent

on the measuring range.

Measuring range <1 bar (<14.5 psi)

The silicon measuring cell of the pressure transmitter has a

piezo-resistive bridge to which the operating pressure is transmitted through silicone oil and a stainless steel diaphragm.

The measuring cell output voltage is fed to an amplifier and converted into an output current 4 ... 20 mA. The output current is

linearly proportional to the input pressure

Measuring range

The thin-film measuring cell has a thin-film resistance bridge to

which the operating pressure p is transmitted through a ceramic

diaphragm.

The voltage output from the measuring cell is converted by an

amplifier into an output current 4 ... 20 mA or an output voltage

of 0 ... 10 V DC.

The output current and voltage are linearly proportional to the input pressure

≥1 bar (≥14.5 psi)

≥1 bar (≥14.5 psi)

2/6

Siemens FI 01 · 2009

Page 7

SITRANS P measuring instruments for pressure

122 (4.8) without Ex protection

1)

131 (5.15) with Ex protection

(diam. 1.1)

M16x1,5

or

½-14 NPT

1) Length on version for voltage

output 0 ... 10 V: 96 (3.8)

2) Inner diameter 3 (0.12)

Ø

27

50

G¼B

2)

16

(1.97)

SW27

(0.63)

© Siemens AG 2008

Transmitters for gage, absolute and differential pressure

Z series for gage and absolute pressure

■

Technical specifications

SITRANS P pressure transmitters, Z series for gage pressure, absolute pressure and level

Mode of operation

• Measuring range <1 bar

Piezo-resistive

(<14.5 psi)

• Measuring range ≥1bar

Thin-film strain gage

(≥14.5 psi)

Input

Measured variable Gage and absolute pressure

Measured range

• Pressure

- Metric 0 ... 400 bar g (0 ... 5802 psi g)

- US measuring range 0 ... 6000 psi g

• Absolute pressure

- Metric 0 ... 16 bar a (0 ... 232 psi a)

- US measuring range 0 ... 300 psi a

Output

Output signal

• Current output signal 4 ... 20 mA

• Voltage output signal (only mea-

0...10VDC

suring range ≥ 1 bar (14.5 psi))

Accuracy To EN 60770-1

Error in measurement (at 25 °C

0.25% of full-scale value – typical

(77 °F), including conformity error,

hysteresis and repeatability)

Response time T

99

< 0.1 s

Long-term drift

• Start of scale 0.25% of full scale value/year

• Full-scale value 0.25% of full scale value/year

Influence of ambient temperature

• Start of scale 0.25%/10 K (0.25%/10 K) of full-

scale value

• Full-scale value 0.25%/10 K (0.25%/10 K) of full-

scale value

Rated operating conditions

Process temperature -30 ... +120 °C

(-22 … +248 °F)

Ambient temperature -25 ... +85 °C (-13 … +185 °F)

Storage temperature -50 ... +100 °C

(-58 … +212 °F)

Degree of protection to EN 60529 IP65

Design

Weight ≈ 0.25 kg (≈ 0.55 lb)

Wetted parts materials

• Measuring cell

- Measuring range <1 bar

Stainless steel, 1.4571/316Ti

(<14.5 psi)

- Measuring range ≥1 bar

(≥14.5 psi)

• Process connection Stainless steel, mat. No.

• Gasket Viton

Process connection See Selection and Ordering data

Al

– 96%

2O3

1.4571/316Ti

Power supply U

H

Terminal voltage on pressure transmitter

• For current output 10 ... 36 V DC

• For voltage output signal (only

15 ... 36 V DC

measuring range ≥ 1 bar

(14.5 psi))

Certificate and approvals

Classification according to pressure

equipment directive

(DRGL 97/23/EC)

For gases of fluid group 1 and liquids of fluid 1; complies with

requirements of article 3, paragraph 3 (sound engineering practice)

Explosion protection

• Intrinsic safety "i" (only with current

output)

TÜV 02 ATEX 1953X

- Identification Ex II 1/2G EEx ia IIC T4

• Intrinsic safety "T.I.I.S." (only with

applied

current output)

Lloyds Register of Shipping Certificate No. 03/30003

■

Dimensional drawings

1)

5

20

(0.2)

(0.8)

2)

B

½

G

1) Length on version for voltage

output 0 ... 10 V: 106 (4.2)

2) Inner diameter 3 (0.12)

132 (5.2) without Ex protection

141 (5.6) with Ex protection

27

Ø

(diam. 1.1)

SW27

M16x1,5

or

½-14 NPT

Pressure transmitter 7MF1564-... with process connection G½" male,

dimensions in mm (inch)

Pressure transmitter 7MF1564-... with process connection G¼" male,

dimensions in mm (inch)

50

2

(1.97)

Siemens FI 01 · 2009

2/7

Page 8

SITRANS P measuring instruments for pressure

2

ZLWKRXW([SURWHFWLRQ

81)

GLDP

6:

0[

RU

137

ZLWK([SURWHFWLRQ

/HQJWKRQYHUVLRQIRUYROWDJH

RXWSXW9

ZLWKRXW([SURWHFWLRQ

137

ZLWK([SURWHFWLRQ

GLDP

6:

0[

RU

137

/HQJWKRQYHUVLRQIRUYROWDJH

RXWSXW9

Ø27

(diam. 1.1)

1) Length on version for voltage

output 0 ... 10 V: 98 (3.9)

124 (4.88) without Ex protection

1)

133 (5.23) with Ex protection

M16x1.5

or

½-14 NPT

50

28

(1.97)

SW27

(1.1)

¼-18 NPT

129 (5.2) without Ex protection

1)

138 (5.6) with Ex protection

(diam. 1.1)

M16x1,5

or

½-14 NPT

1) Length on version for voltage

output 0 ... 10 V: 103 (4.1)

21

50

Ø

27

G1

(1.97)

SW39

(0.8)

ZLWKRXW([SURWHFWLRQ

137

ZLWK([SURWHFWLRQ

GLDP

6:

0[

RU

137

/HQJWKRQYHUVLRQIRUYROWDJH

RXWSXW9

ZLWKRXW([SURWHFWLRQ

137

ZLWK([SURWHFWLRQ

GLDP

6:

0[

RU

137

/HQJWKRQYHUVLRQIRUYROWDJH

RXWSXW9

1+

2-

+

Signal

R

L

U

B

I

0

I0 Output current

U

B

Power supply

R

L

Load

Connections:

1 (+U

B

)

2 (-U

B

)

1+

3+

+

Signal

2-

R

L

U

B

U

0

U0 Output voltage

U

B

Power supply

R

L

Load

Connections:

1 (+U

B

)

2 (-U

B

)

3 (U

0

)

© Siemens AG 2008

Transmitters for gage, absolute and differential pressure

Z series for gage and absolute pressure

Pressure transmitter 7MF1564-... with process connection 7/16-20 UNF

male, dimensions in mm (inch)

Pressure transmitter 7MF1564-... with process connection ¼"-18 NPT

male, dimensions in mm (inch)

Pressure transmitter 7MF1564-... with process connection ½"-14 NPT

male, dimensions in mm (inch)

Pressure transmitter 7MF1564-... with process connection ½"-14 NPT

female, dimensions in mm (inch)

■

Schematics

Pressure transmitter 7MF1564-... with process connection ¼"-18 NPT

female, dimensions in mm (inch)

Pressure transmitter 7MF1564-... with process connection G1“ male,

dimensions in mm (inch)

2/8

Siemens FI 01 · 2009

SITRANS P pressure transmitters, Z series (7MF1564-...), connection

diagram, with current output (top) and voltage output (bottom)

Page 9

SITRANS P measuring instruments for pressure

© Siemens AG 2008

Transmitters for gage, absolute and differential pressure

Z series for gage and absolute pressure

Selection and Ordering data Order No. Order code

■

SITRANS P pressure transmitters for pressure, series Z for gage and absolute pressure

2 or 3-wire system, rising characteristic curve

Measuring range perm. working pressure Burst pressure

Min. Max.

For gage pressure

with metal measuring cell

0 ... 100 mbar g (0 ... 1.45 psi g) -0,6 bar g (-8.7 psi g) 0,6 bar g (8.7 psi g) 1 bar g (14.5 psi g)

0 ... 160 mbar g (0 ... 2.32 psi g) -0,6 bar g (-8.7 psi g) 0,6 bar g (8.7 psi g) 1 bar g (14.5 psi g)

0 ... 250 mbar g (0 ... 3.63 psi g) -1 bar g (-14.5 psi g) 1bar g (14.5 psi g) 1.7 bar g (25 psi g)

0 ... 400 mbar g (0 ... 5.80 psi g) -1 bar g (-14.5 psi g) 1bar g (14.5 psi g) 1.7 bar g (25 psi g)

0 ... 600 mbar g (0 ... 8.70 psi g) -1 bar g (-14.5 psi g) 3bar g (43.5 psi g) 5 bar g (72 psi g)

Other version for measuring range < 1 bar (< 14.5 psi g), add Order code and plain text:

measuring range: ... up to ... mbar g (psi g)

with ceramic measuring cell

0 ... 1 bar g (0 ... 14.5 psi g) -0,4 bar g (-5.8 psi g) 2bar g (30 psi g) 5 bar g (72 psi g)

0 ... 1.6 bar g (0 ... 23.2 psi g) -0,4 bar g (-5.8 psi g) 3,2 bar g (45 psi g) 5 bar g (72 psi g)

0 ... 2.5 bar g (0 ... 36.3 psi g) -0,8 bar g (-11.6 psi g) 5bar g (72 psi g) 12 bar g (175 psi g)

0 ... 4 bar g (0 ... 58.0 psi g) -0,8 bar g (-11.6 psi g) 8bar g (115 psi g) 12 bar g (175 psi g)

0 ... 6 bar g (0 ... 87.0 psi g) -1 bar g (-14.5 psi g) 12 bar g (175 psi g) 25 bar g (360 psi g)

0 ... 10 bar g (0 ... 145 psi g) -1 bar g (-14.5 psi g) 20 bar g (290 psi g) 50 bar g (725 psi g)

0 ... 16 bar g (0 ... 232 psi g) -1 bar g (-14.5 psi g) 32 bar g (460 psi g) 50 bar g (725 psi g)

0 ... 25 bar g (0 ... 363 psi g) -1 bar g (-14.5 psi g) 50 bar g (725 psi g) 120 bar g (1750 psi g)

0 ... 40 bar g (0 ... 580 psi g) -1 bar g (-14.5 psi g) 80 bar g (1150 psi g) 120 bar g (1750 psi g)

0 ... 60 bar g (0 ... 870 psi g) -1 bar g (-14.5 psi g) 120 bar g (1750 psi g) 250 bar g (3600 psi g)

0 ... 100 bar g (0 ... 1450 psi g) -1 bar g (-14.5 psi g) 200 bar g (2900 psi g) 450 bar g (6525 psi g)

0 ... 160 bar g (0 ... 2320 psi g) -1 bar g (-14.5 psi g) 320 bar g (4640 psi g) 450 bar g (6525 psi g)

0 ... 250 bar g (0 ... 3626 psi g) -1 bar g (-14.5 psi g) 500 bar g (7250 psi g) 650 bar g (9425 psi g)

0 ... 400 bar g (0 ... 5802 psi g) -1 bar g (-14.5 psi g) 600 bar g (8700 psi g) 650 bar g (9425 psi g)

Other version for measuring range ≥ 1 bar g (≥ 14.5 psi g), add Order code and plain text:

measuring range: ... up to... bar (psi g)

For absolute pressure

0 ... 600 mbar a (0 ... 8.7 psi a) 0 bar a (0 psi a) 3bar a (43.5 psi a) 5bar a (72 psi a)}J)

0 ... 1 bar a (0 ... 14.5 psi a) 0 bar a (0 psi a) 2bar a (30 psi a) 5bar a (72 psi a)}J)

0 ... 1.6 bar a (0 ... 23.2 psi a) 0 bar a (0 psi a) 3,2 bar a (45 psi a) 5bar a (72 psi a)}J)

0 ... 2.5 bar a (0 ... 36.3 psi a) 0 bar a (0 psi a) 5bar a (72 psi a) 12 bar a (175 psi a)}J)

0 ... 4 bar a (0 ... 58.0 psi a) 0 bar a (0 psi a) 8bar a (115 psi a) 12 bar a (175 psi a)}J)

0 ... 6 bar a (0 ... 87.0 psi a) 0 bar a (0 psi a) 12 bar a (175 psi a) 25 bar a (360 psi a)}J)

0 ... 10 bar a (0 ... 145 psi) 0 bar a (0 psi a) 20 bar a (290 psi a) 50 bar a (725 psi a)}J)

0 ... 16 bar a (0 ... 232 psi) 0 bar a (0 psi a) 32 bar a (460 psi a) 50 bar a (725 psi a)}J)

Other version for measuring range < 1 bar (< 14.5 psi a), add Order code and plain text:

measuring range: ... up to ... mbar a (psi a)

} Available ex stock D) Subject to export regulations AL: N, ECCN: EAR99H.

J) Subject to export regulations AL: 9I999, ECCN: EAR99.

1)

The transmitters can also be ordered with special measuring ranges, e.g. the transmitter with the 1 bar measuring cell (14.5 psi measuring cell):

-0.2 ... +0.8 bar g (-2.9 ... +11.6 psi g) or

-0.4 ... +0.6 bar g (-5.8 ... +8.7 psi g) or ..., however start-of-scale value not under -0.4 bar g (-5.8 psi g), also see column "min. perm. operating pressure"

Please note:

• It is not possible to have a smaller span than the smallest span of the device of the entire device range.

• The value must not fall below the minimum permissible operating pressure of the special measuring range of the selected

measuring cell.

• The required span of the device must lie between the smallest and the largest possible span of the entire device range.

1)

1)

D)

7 M F 1 5 6 4 -

} 3AA 0

} 3AB 0

} 3AC 0

} 3AD 0

} 3AG 0

} 3BA

} 3BB

} 3BD

} 3BE

} 3BG

} 3CA

} 3CB

} 3CD

} 3CE

} 3CG

} 3DA

} 3DB

} 3DD

} 3DE

J)

777 7 7-77717 77

9AC 0 H 1 Y

9AA H 1 Y

5AG 0

5BA

5BB

5BD

5BE

5BG

5CA

5CB

9AB 0 H 1 Y

2

Siemens FI 01 · 2009

2/9

Page 10

SITRANS P measuring instruments for pressure

2

© Siemens AG 2008

Transmitters for gage, absolute and differential pressure

Z series for gage and absolute pressure

Selection and Ordering data Order No. Order code

■

SITRANS P pressure transmitters for pressure, series Z for pressure and absolute pressure

2 or 3-wire system, rising characteristic curve

Measuring range Perm. working pressure Burst pressure

min. max.

Measuring ranges for gage pressure (only for US market)

(0 ... 10 psi g) (-3 psi g) (20 psi g) (60 psi g)

(0 ... 15 psi g) (-6 psi g) (30 psi g) (72 psi g)

(3 ... 15 psi g) (-6 psi g) (30 psi g) (72 psi g)

(0 ... 20 psi g) (-6 psi g) (40 psi g) (72 psi g)

(0 ... 30 psi g) (-6 psi g) (60 psi g) (72 psi g)

(0 ... 60 psi g) (-11.5 psi g) (120 psi g) (175 psi g)

(0 ... 100 psi g) (-14.5 psi g) (200 psi g) (360 psi g)

(0 ... 150 psi g) (-14.5 psi g) (300 psi g) (725 psi g)

(0 ... 200 psi g) (-14.5 psi g) (400 psi g) (725 psi g)

(0 ... 300 psi g) (-14.5 psi g) (600 psi g) (1750 psi g)

(0 ... 500 psi g) (-14.5 psi g) (1000 psi g) (1750 psi g)

(0 ... 750 psi g) (-14.5 psi g) (1500 psi g) (3600 psi g)

(0 ... 1000 psi g) (-14.5 psi g) (2000 psi g) (3600 psi g)

(0 ... 1500 psi g) (-14.5 psi g) (3000 psi g) (6525 psi g)

(0 ... 2000 psi g) (-14.5 psi g) (4000 psi g) (6525 psi g)

(0 ... 3000 psi g) (-14.5 psi g) (6000 psi g) (9425 psi g)

(0 ... 5000 psi g) (-14.5 psi g) (8700 psi g) (9425 psi g)

(0 ... 6000 psi g) (-14.5 psi g) (8700 psi g) (9425 psi g)

Other version, add Order code and plain text: Measuring range: ... up to ... psi g 9BA H 1 Y

Measuring ranges for absolute pressure (only for US market)

(0 ... 10 psi a) (0 psi a) (20 psi a) (60 psi a) J)

(0 ... 15 psi a) (0 psi a) (30 psi a) (72 psi a) J)

(0 ... 20 psi a) (0 psi a) (40 psi a) (72 psi a) J)

(0 ... 30 psi a) (0 psi a) (60 psi a) (72 psi a) J)

(0 ... 60 psi a) (0 psi a) (120 psi a) (175 psi a) J)

(0 ... 100 psi a) (0 psi a) (200 psi a) (360 psi a) J)

(0 ... 150 psi a) (0 psi a) (300 psi a) (725 psi a) J)

(0 ... 200 psi a) (0 psi a) (400 psi a) (725 psi a) J)

(0 ... 300 psi a) (0 psi a) (600 psi a) (1725 psi a) J)

Other version, add Order code and plain text: Measuring range: ... up to ... psi a

Output signal

4 ... 20 mA;C 2-wire system; power supply 10 ... 36 V DC } 0

0 ... 10 V; 3-wire system; power supply 15 ... 36 V DC 1 0

Explosion protection

Without } 0

With explosion protection Ex II 1/2 G EEx ia IIC T4 (only for version 4 ... 20 mA; 2-wire system;

power supply 10 ... 30 V DC)

With explosion protection "Intrinsic safety T.I.I.S." (available soon) 2

Electrical connection

Plug to DIN 43650, Form A, cable inlet M16 x 1.5 } 1

Round connector M12, IP67 2

Plug to DIN 43650, cable inlet ½-14 NPT 3

Plug to DIN 43650, cable inlet Pg11 4

Cable gland Pg11 with 2 m PE cable, IP68 6

Special version (specify Order code and plain text) 9 N 1 Y

} Available ex stock D) Subject to export regulations AL: N, ECCN: EAR99H.

J) Subject to export regulations AL: 9I999, ECCN: EAR99.

D)

7 M F 1 5 6 4 -

J)

777 7 7-77717 77

4BA

4BB

4BC

4BD

4BE

4BF

4BG

4CA

4CB

4CD

4CE

4CF

4CG

4DA

4DB

4DD

4DE

4DF

6AG

6BA

6BB

6BD

6BE

6BG

6CA

6CB

6CC

9BB H 1 Y

1

2/10

Siemens FI 01 · 2009

Page 11

SITRANS P measuring instruments for pressure

© Siemens AG 2008

Transmitters for gage, absolute and differential pressure

Z series for gage and absolute pressure

Selection and Ordering data Order No. Order code

■

SITRANS P pressure transmitters for pressure, series Z for pressure and absolute pressure

2 or 3-wire system, rising characteristic curve

Process connection

G½" male to EN 837-1 (½" BSP male) (standard for metric pressure ranges mbar, bar) } A

G½" male thread and G1/8" female thread B

G¼“ male to EN837-1 (¼“ BSP male) C

7/16"-20 UNF male D

¼"-18 NPT male (standard for pressure ranges psi) E

¼"-18 NPT female F

½"-14 NPT male G

½"-14 NPT female H

RC ½" male to JIS B 7505 K

G1" male (only for measuring ranges ≥ 1 bar g (14.5 psi g)) and max. permissible working pressure

100 bar g (1450 psi g)

Special version (specify Order code and plain text) Z P 1 Y

Sealing material between sensor and housing

Viton (standard) } A

Neoprene B

Perbunan C

Special version (specify Order code and plain text) Z Q 1 Y

Further designs Order code / Order No.

Quality inspection certificate (Factory calibration) to IEC 60770-2,

add "-Z" to Order No. and Order code.

Oxygen version, oil and grease-free cleaning (only if the sealing material between sensor and housing is

Viton and only for measuring ranges ≥ 1 bar g (≥ 14.5 psi g)

and ≥ 1 bar a (≥ 14.5 psi a)

Accessories Order No.

Quality inspection certificate (Factory calibration) to IEC 60770-2 supplied later,

specify factory no. of transmitter.

} Available ex stock D) Subject to export regulations AL: N, ECCN: EAR99H.

D)

7 M F 1 5 6 4 -

C11

E10

D)

7MF1564-8CC11

777 7 7-77717 77

M

2

Siemens FI 01 · 2009

2/11

Page 12

SITRANS P measuring instruments for pressure

2

© Siemens AG 2008

Transmitters for gage, absolute and differential pressure

SITRANS P250 for differential pressure

■

Overview

SITRANS P250 transmitter for differential pressure

The SITRANS P250 transmitter measures the differential pres-

sure of liquids and gases.

■

Benefits

• High measuring accuracy

• Sturdy stainless steel enclosure

• For aggressive and non-aggressive media

• For the measurement of the differential pressure of liquids and

gases

• Temperature-compensated measuring cell

• Compact design

■

Application

The SITRANS P250 transmitter for differential pressure is primarily used in the following industries:

• Chemical industry

• Pharmaceutical industry

• Food industry

• Mechanical engineering

• Shipbuilding

• Water supply

■

Design

Main components:

• Stainless steel enclosure with piezo-resistive ceramic measur-

ing cell and (temperature-compensated) electronics module.

• Process connection made of stainless steel in diverse designs

(see Selection and ordering data)

• Electrical connection through connectors acc. to EN 175301-

803-A and round connectors M12, as well as with permanently

fixed cable

■

Function

The pressure transmitter measures the differential pressure of

liquids and gases.

Mode of operation

p1p

2

U

const.

U

I

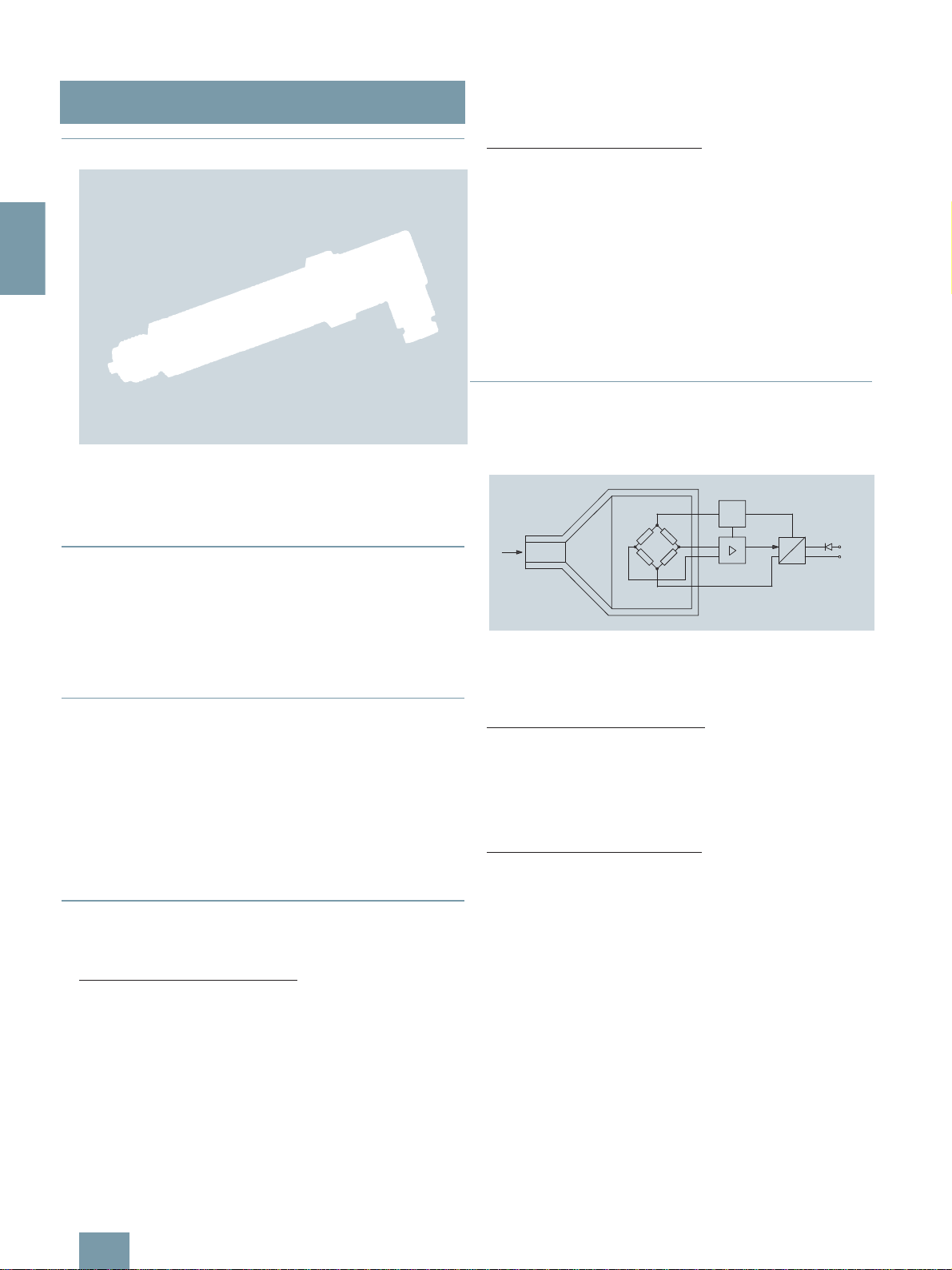

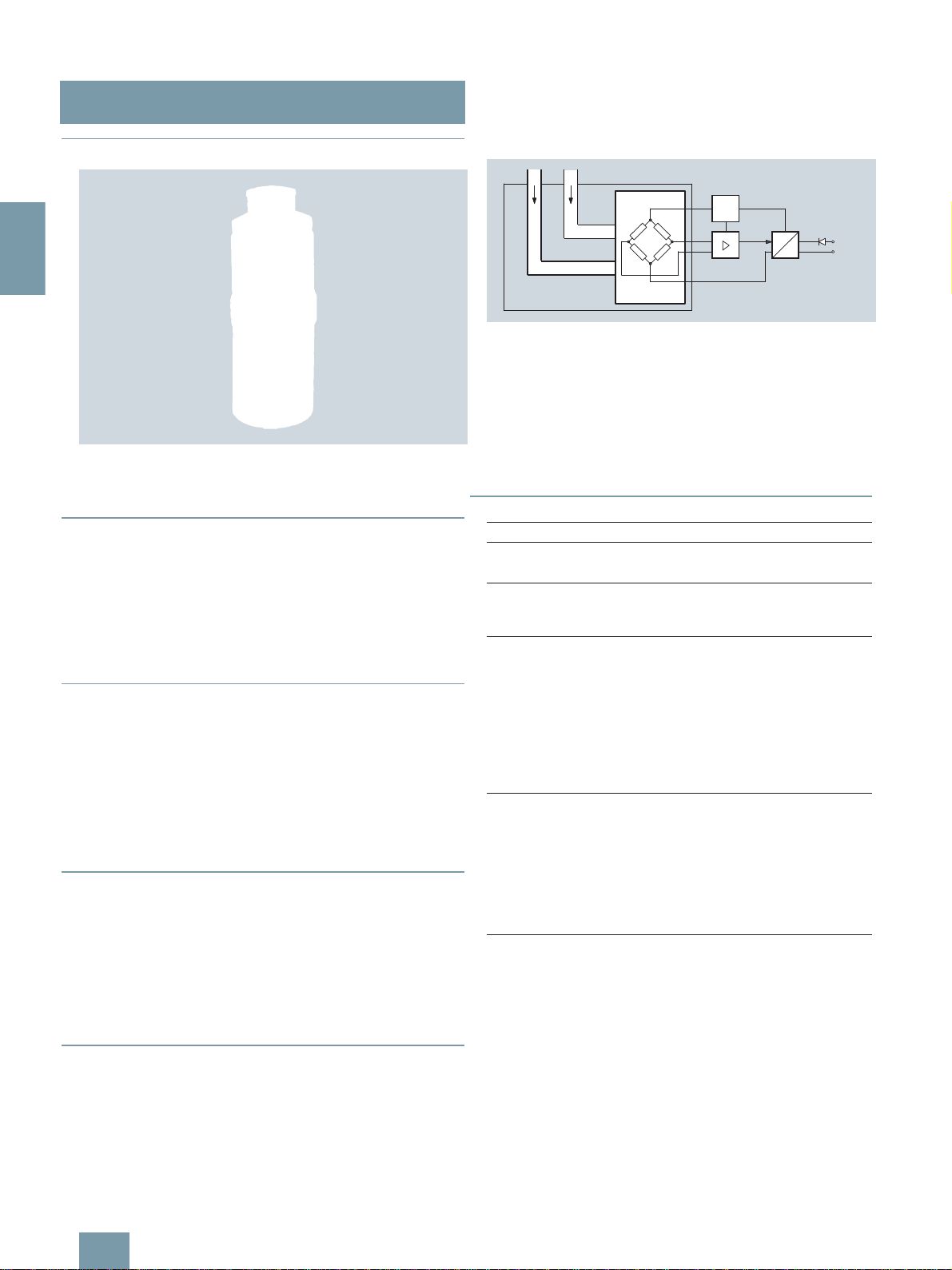

SITRANS P250 pressure transmitter, function diagram

The piezo-resistive ceramic measuring cell (membrane) has a

Wheatstone bridge circuit, on which the operating pressure P1

and P2 of the media acts at both ends.

The voltage output from the measuring cell is converted by an

amplifier into an output current of 4 to 20 mA or an output voltage

of 0 to 5 or 10 V DC.

The output current and voltage are linearly proportional to the input pressure.

■

Technische Daten

SITRANS P250 differential pressure transmitter

Application

Differential pressure transmitter Liquids and neutral gases

Mode of operation

Measuring principle Piezo-resistive measuring cell

Input

Measured variable Differential pressure

Measuring range 0 ... 0.1 to 0 ... 25 bar

Operating pressure ≤ 25 bar (363 psi) at a differential

Burst pressure 1.5 x operating pressure

Output

Output signal

• Current output signal 4 ... 20 mA

• Voltage output signal 0 ... 5 V and 0 ... 10 V DC

Load

3-wire > 10 kΩ

2-wire ≤ (U

Measuring accuracy

Dynamic behavior (at 25°C (77°F),

including conformity error, hysteresis and repeatability)

Long-term drift acc. to IEC 60770 ≤ 0.5 % of full-scale value/year

Influence of ambient temperature

• Start of scale ≤ 0.6 %/10 K of full-scale value

• Full-scale value ≤ 0.22 %/10 K of full-scale value

Dynamic behavior Suitable for static and dynamic

Response time T

Load variation < 50 Hz

99

(ceramic diaphragm)

(0 ... 1.45 to 0 ... 363 psi)

pressure range < 6 bar (87 psi)

≤ 50 bar (725 psi) at a differential

pressure range > 10 bar (145 psi)

- 11 V) / 0.02 A

H

≤ 1 % of typical full-scale value,

see "Measuring range" table

(≤ 1.2 %/10 K for measuring cell

0 ... 0.1 bar (1.45 psi))

(≤ 0.37 %/10 K for measuring cell

0 ... 0.1 bar (1.45 psi))

measurements

< 5 ms

I

, U

0

B

2/12

Siemens FI 01 · 2009

Page 13

SITRANS P measuring instruments for pressure

© Siemens AG 2008

Transmitters for gage, absolute and differential pressure

SITRANS P250 for differential pressure

Conditions of use

Ambient conditions

• Temperature of medium -15 ... +85 °C (5 ... 185 °F)

• Ambient temperature -15 ... +85 °C (5 ... 185 °F)

• Storage temperature -40 ... +85 °C (-40 ... +185 °F)

Degree of protection acc. to

IP65

EN 60529

Mounting position Any

Mounting Mounting bracket, included in

delivery

Design

Weight Approx. 430 g (approx. 0.95 lb)

Enclosure material Stainless steel 1.4305/AISI 303

Electrical connection • Plug EN 175301-803-A

• Circular plug EN 60130-9

• Cable 1.5 m

Process connection • Hose sleeve Ø 4 mm/6 mm

• Pipe union Ø 6 mm/8 mm

• Male thread 7/16-20 UNF, G1/8

• Female thread 1/8-27 NPT

• (Standard), G1/8

Wetted parts materials Stainless steel 1.4305/AISI 303,

CuZn nickel-plated

• Process connection Approx. 430 g (approx. 0.95 lb)

• Diaphragm Ceramic Al

2O3

(96 %)

• Sealing material FPM (standard), EPDM, NBR,

MVQ, CR

Power supply U

H

Terminal voltage on pressure transmitter

• 2-wire, 4 ... 20 mA 11 ... 33 V DC

• 3-wire, 0 ... 5 V DC 11 ... 33 V DC/

24 V AC ±15 %

• 3-wire, 0 ... 10 V DC 18 ... 33 V DC/

24 V AC ±15 %

Current consumption at nominal

pressure

• 2-wire < 20 mA

•3-wire < 5mA

Protection against polarity reversal Protected against short-circuit

and polarity reversal. Each connection against the other with

max. supply voltage.

Certificates and approvals

Approval CE conformity

Measuring range Max. per-

missible

operating

pressure

(on either

side)

Burst

pressure

Max. permissible

operating

pressure

(on one

side)

Accuracy

[bar] [psi]

0 ... 0.1 0 ... 1.45 25 bar

0 ... 0.2 0 ... 2.9 25 bar

0 ... 0.25 0 ... 3.63 25 bar

0 ... 0.3 0 ... 4.35 25 bar

0 ... 0.4 0 ... 5.8 25 bar

0 ... 0.5 0 ... 7.25 25 bar

0 ... 0.6 0 ... 8.7 25 bar

0 ... 1.0 0 ... 14.5 25 bar

0 ... 1.6 0 ... 23.2 25 bar

0 ... 2.5 0 ... 36.3 25 bar

0 ... 4 0 ... 58 25 bar

0 ... 6 0 ... 87 25 bar

0 ... 10

0 ... 145 50 bar

0 ... 16 0 ... 232

0 ... 25 0 ... 363 50 bar

■

Schematics

1

2

1+

2-

(363 psi)

(363 psi)

(363 psi)

(363 psi)

(363 psi)

(363 psi)

(363 psi)

(363 psi)

(363 psi)

(363 psi)

(363 psi)

(363 psi)

(725 psi)

50 bar

(725 psi)

(725 psi)

I

O

37,5 bar

(544 psi)

37,5 bar

(544 psi)

37,5 bar

(544 psi)

37,5 bar

(544 psi)

37,5 bar

(544 psi)

37,5 bar

(544 psi)

37,5 bar

(544 psi)

37,5 bar

(544 psi)

37,5 bar

(544 psi)

37,5 bar

(544 psi)

37,5 bar

(544 psi)

37,5 bar

(544 psi)

75 bar

(1088 psi)

75 bar

(1088 psi)

75 bar

(1088 psi)

+

U

B

R

L

0.6 bar

(8.7 psi)

0.6 bar

(8.7 psi)

0.6 bar

(8.7 psi)

0.6 bar

(8.7 psi)

1.2 bar

(17.4 psi)

1.2 bar

(17.4 psi)

1.2 bar

(17.4 psi)

2 bar

(29 psi)

3.2 bar

(46.4 psi)

5 bar

(72.5 psi)

8 bar

(116 psi)

12 bar

(174 psi)

20 bar

(290 psi)

32 bar

(464 psi)

50 bar

(725 psi)

Connection: 1 (+),

2 (-)

I

Output current

O

R

Load

L

UB Power supply

≤ 1,0 %

≤ 1,0 %

≤ 0,5 %

≤ 0,5 %

≤ 0,8 %

≤ 0,5 %

≤ 0,5 %

≤ 0,5 %

≤ 0,5 %

≤ 0,5 %

≤ 0,5 %

≤ 0,5 %

≤ 0,5 %

≤ 0,5 %

≤ 0,5 %

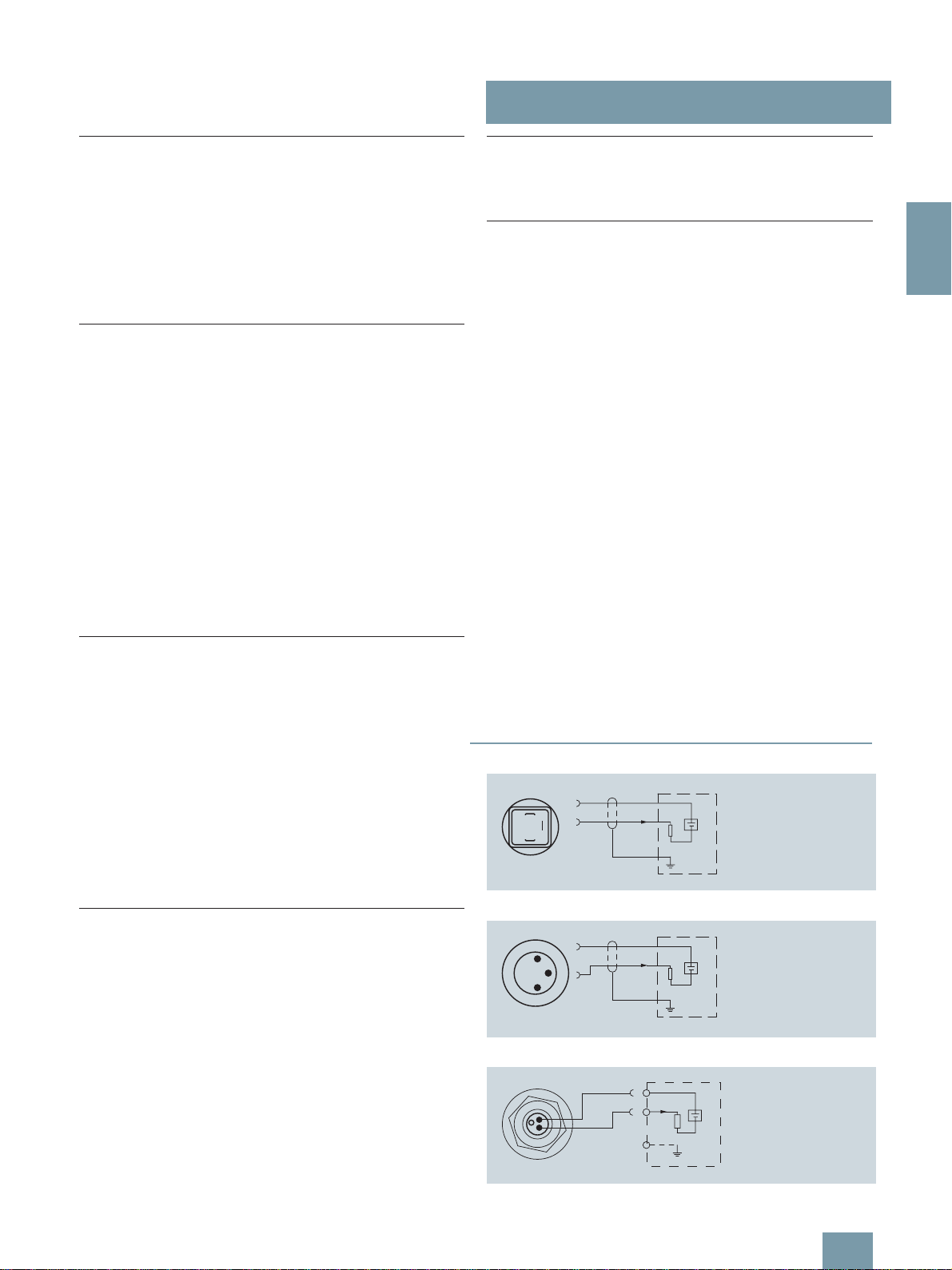

Connection with current output 4 ... 20 mA and plug to EN 175301-803-A

3

1

1+

2

3-

I

O

R

L

+

U

B

Connection: 1 (+),

3 (-)

Output current

I

O

Load

R

L

Power supply

U

B

2

Connection with current output 4 ... 20 mA and round connector

1+

I

O

2-

R

L

Connection: 1 (+, brown),

2 (-, green)

+

U

Output current

I

B

O

Power supply

U

B

Load

R

L

Connection with current output 4 ... 20 mA and permanently fixed cable

Siemens FI 01 · 2009

2/13

Page 14

SITRANS P measuring instruments for pressure

2

Cable

~95 (3.7)

~138 (5.4)

© Siemens AG 2008

Transmitters for gage, absolute and differential pressure

SITRANS P250 for differential pressure

1

3

2

Connection with voltage output 0 ... 5 V DC (0 ... 10 V DC) and plug to EN

175301-803-A

3

1

1+

2+

U

O

3-

1

U

3

O

2

2

R

L

R

L

Connection: 1 (+UB),

2 (-),

+

U

3 (+U

B

U

Output voltage

O

Load

R

L

Power supply

U

B

Connection: 1 (+UB, brown),

2 (+U

+

3 (-, white)

U

B

Output voltage

U

O

Power supply

U

B

Load

R

L

)

0

, green),

0

Connection with voltage output 0 ... 5 V DC (0 ... 10 V DC) and round connector

1+

U

O

3+

R

2-

L

Connection: 1 (+UB),

+

2 (-),

U

B

3 (+U

U

U

R

Output voltage

o

Power supply

B

Load

L

)

0

Connection with voltage output 0 ... 5 V DC (0 ... 10 V DC) and permanently fixed cable

Round connector

EN 60130-9

(mounted)

~158 (6.2)

~108(4.3)

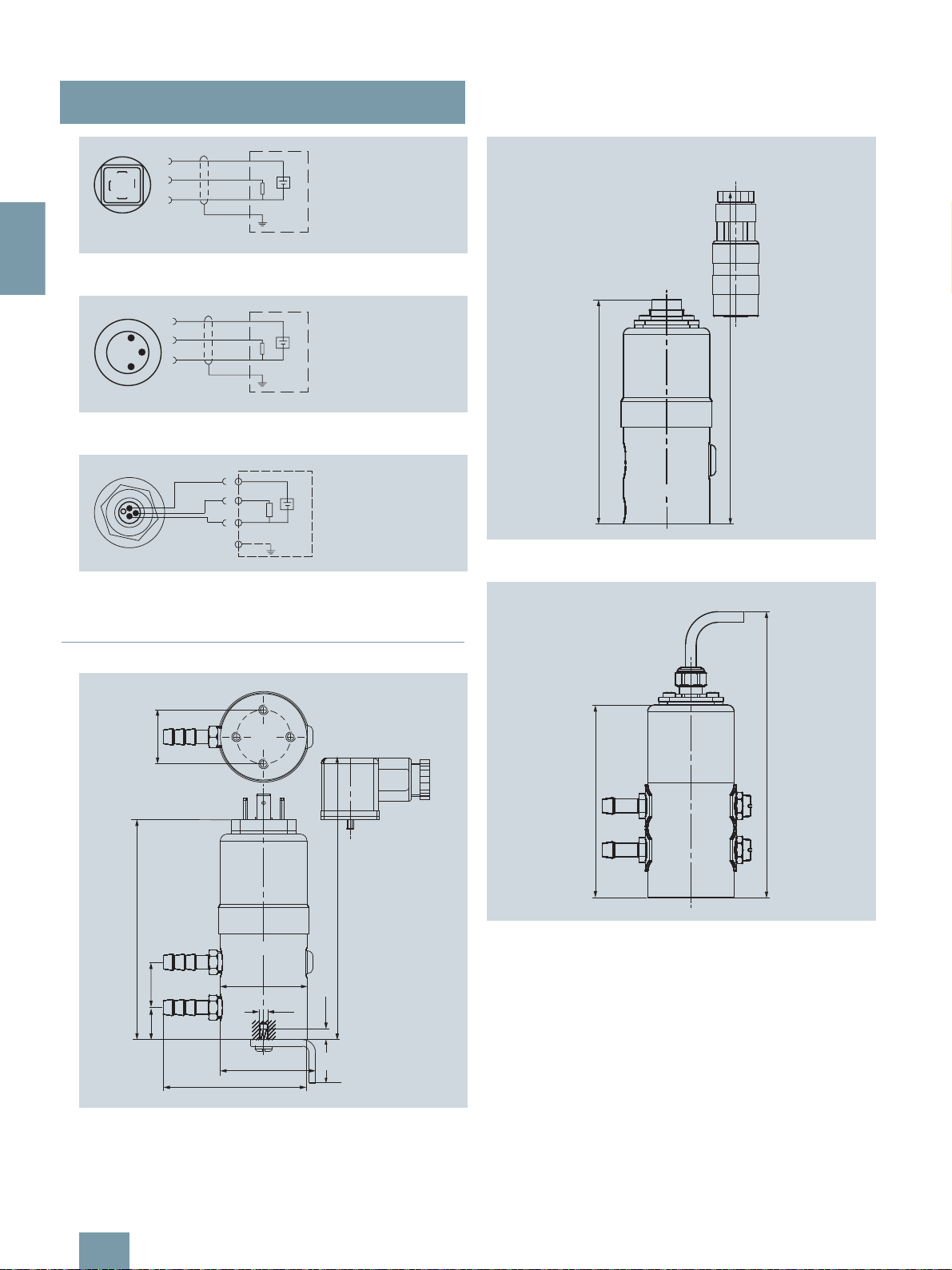

SITRANS P250 differential pressure transmitter with round connector to

EN 60130-9, dimensions in mm (inch)

■

Dimensional drawings

Ø 25

(0.98)

Stainless

102 (4.02)

P2

P1

15 ± 0,5 21 ± 0,8

44 (1.7)

X

M 4

Socket outlet

EN 175301-803-A

(mounted)

~ 136 (5.4)

5 (0.2)

20 (0.79)

SITRANS P250 differential pressure transmitter with cable, dimensions in

mm (inch)

SITRANS P250 differential pressure transmitter with socket outlet to

EN 175301-803-A, dimensions in mm (inch)

2/14

Siemens FI 01 · 2009

Page 15

SITRANS P measuring instruments for pressure

a

L

1/8-27 NPT

7/16-20 UNF

© Siemens AG 2008

Transmitters for gage, absolute and differential pressure

SITRANS P250 for differential pressure

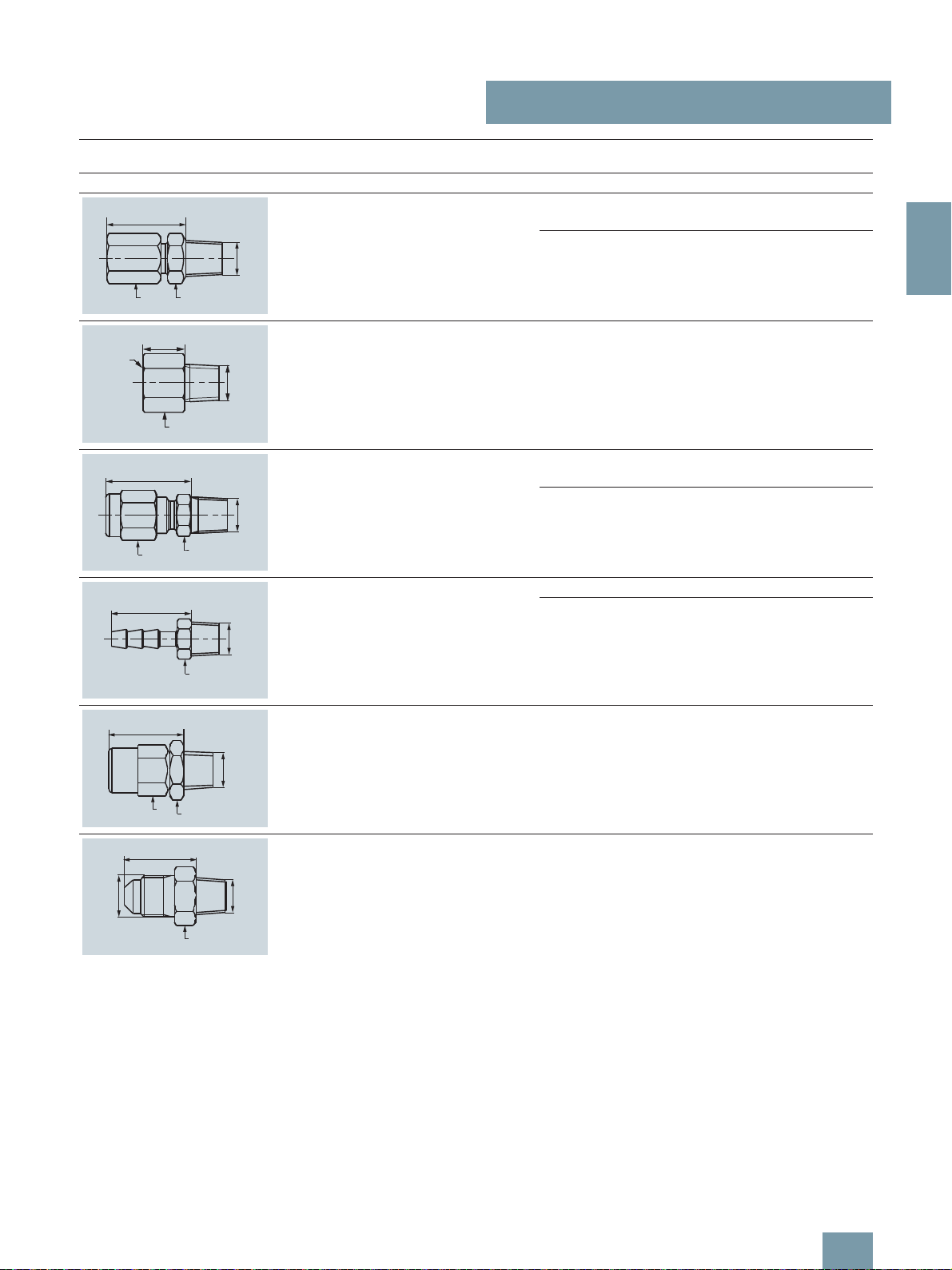

Process connections Ø Width across

[mm] [inch] [mm] [inch] [mm] [inch]

L

ab

Pipe union with screw-in nipple for outer pipe

(stainless steel 1.4305/AISI 303)

1/8-27 NPT

6a = 10

8a = 12

flats

b = 12

b = 14

LX

24 65

26 67

2

G1/8

L

a

L

a

L

b

L

a

Female thread G1/8

(stainless steel 1.4305/AISI 303)

1/8-27 NPT

Pipe union with screw-in nipple for outer pipe

(CuZn nickel-plated)

1/8-27 NPT

Hose connection for hose (CuZn nickel-plated,

stainless steel 1.4571/AISI 316TI)

1/8-27 NPT

Male thread G1/8

(CuZn nickel-plated)

- a = 14 12 53

6a = 10

b = 12

8a = 12

b = 14

4 a = 10 20 61

6 a = 10 25 66

-a = 10

b = 12

24 65

25 66

20 61

a

b

1/8-27 NPT

Male thread G1/8

7/16-20 UNF (CuZn nickel-plated)

- a = 14 18 59

Siemens FI 01 · 2009

2/15

Page 16

SITRANS P measuring instruments for pressure

2

© Siemens AG 2008

Transmitters for gage, absolute and differential pressure

SITRANS P250 for differential pressure

Selection and ordering data Order No. Order code

■

SITRANS P 250 pressure transmitter for differential pressure

Accuracy ≤ 1 %, wetted parts ceramic/stainless steel 1.4301,

scope of delivery: transmitter, mounting bracket and instruction manual, without explosion protection

Measuring range

0 ... 0.1 bar (0 ... 1.45 psi)

0 ... 0.2 bar (0 ... 2.90 psi)

0 ... 0.25 bar (0 ... 3.63 psi)

0 ... 0.3 bar (0 ... 5.35 ps)

0 ... 0.4 bar (0 ... 5.80 psi)

0 ... 0.5 bar (0 ... 7.25 psi)

0 ... 0.6 bar (0 ... 8.70 psi)

0 ... 1.0 bar (0 ... 14.5 psi)

0 ... 1.6 bar (0 ... 23.2 psi)

0 ... 2.5 bar (0 ... 36.3 psi)

0 ... 4.0 bar (0 ... 58.0psi)

0 ... 6.0 bar (0 ... 87.0 psi)

0 ... 10.0 bar (0 ... 145 psi)

0 ... 16.0 bar (0 ... 232 psi)

0 ... 25.0 bar (0 ... 363 psi)

Output signal

4 ... 20 mA

0 ... 5 V DC

0 ... 10 V DC

Electrical connection

• Plug acc. to EN 175 301-803-A (suitable coupling included in scope of delivery) } 1

• Round connector acc. to EN 60139-9 2

• Cable 1.5 m with cable gland 3

Process connection

• Without connections, female thread 1/8-27 NPT } A

• Hose connection

- CuZn nickel-plated, for hose ∅ 4 mm B

- CuZn nickel-plated, for hose ∅ 6 mm C

- PVDF, for hose ∅ 6 mm D

• Pipe union

- CuZn nickel-plated, for pipe ∅ 6 mm E

- Stainless steel 1.4304, for pipe ∅ 6 mm F

- CuZn nickel-plated, for pipe ∅ 8 mm G

- Stainless steel 1.4304, for pipe ∅ 8 mm H

• Male thread, 7/16-20 UNF (CuZn nickel-plated) L

• Adapter

- Inner, G1/8 (stainless steel), for pipe ∅ 6 mm M

- Outer, with union nut, for pipe ∅ 6 mm N

sealing material

• Fluoro rubber (Viton/FPM) } A

• Ethylene propylene diene monomer rubber (EPDM) B

• Nitrile butadiene rubber (NBR) C

• Silicone rubber (MVQ) D

• Neoprene (CR) E

Weitere Ausführungen Kurzangabe

Please add "-Z" to Order No. and specify Order code(s).

Quality inspection certificate (Factory calibration) to IEC 60770-2 supplied C11

} Available ex stock

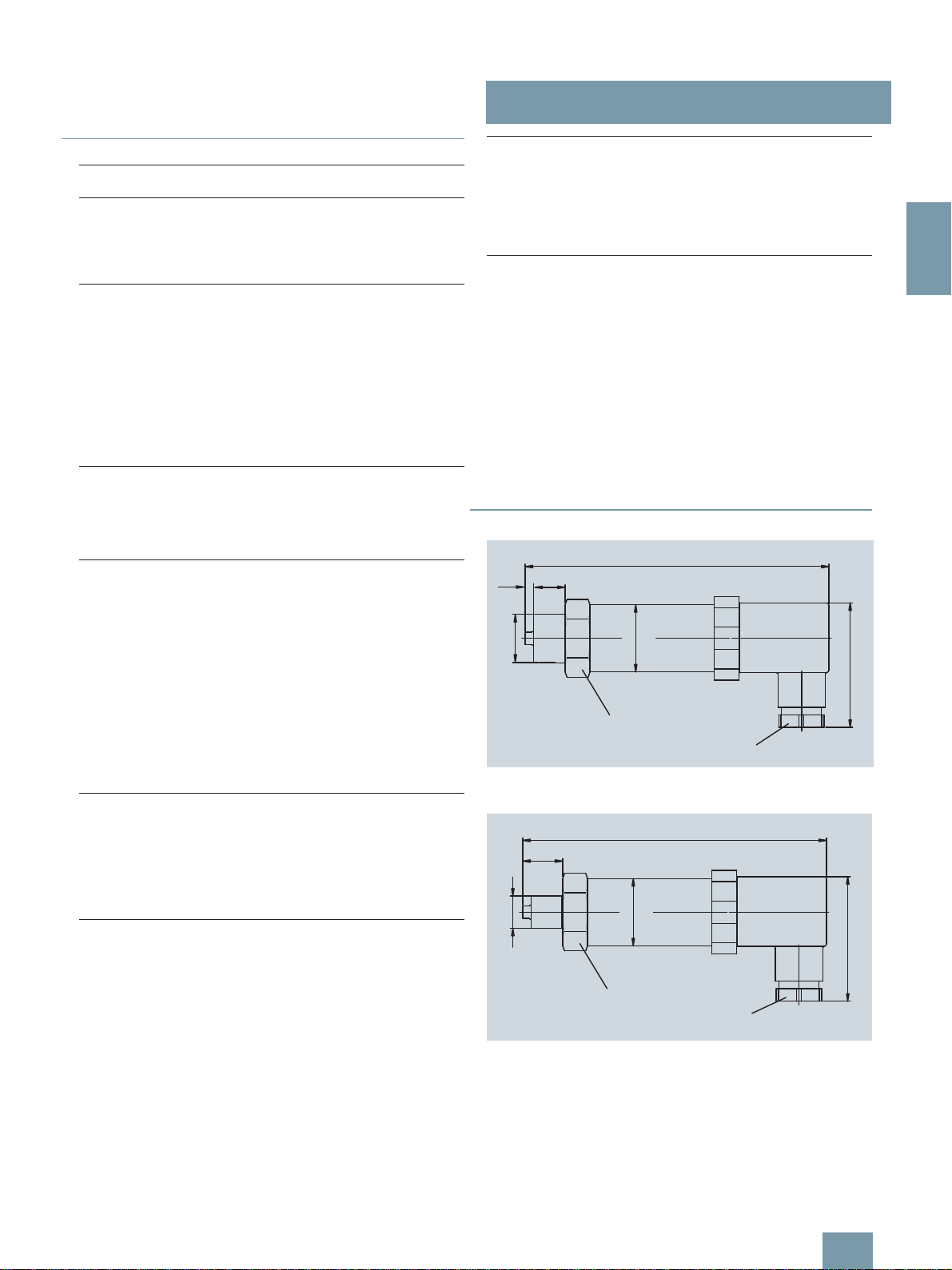

7 M F 1 6 4 1 -

} 3AA

} 3AC

} 3AD

} 3AE

} 3AF

} 3AG

} 3AH

} 3BA

} 3BB

} 3BD

} 3BE

} 3BG

} 3CA

} 3CB

} 3CD

} 0

777 7

77707 77

0 -

1

2

2/16

Siemens FI 01 · 2009

Page 17

SITRANS P measuring instruments for pressure

600.00

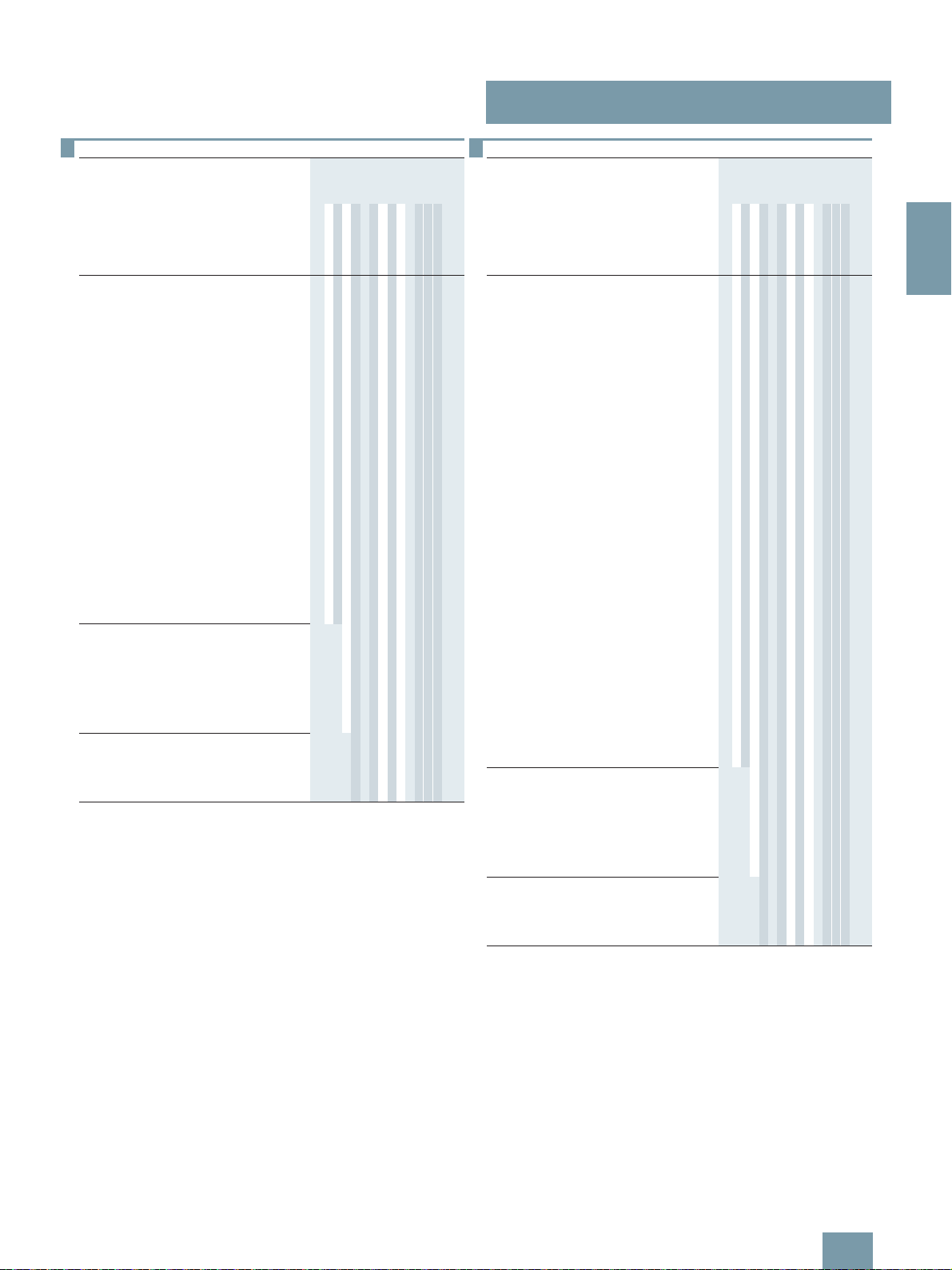

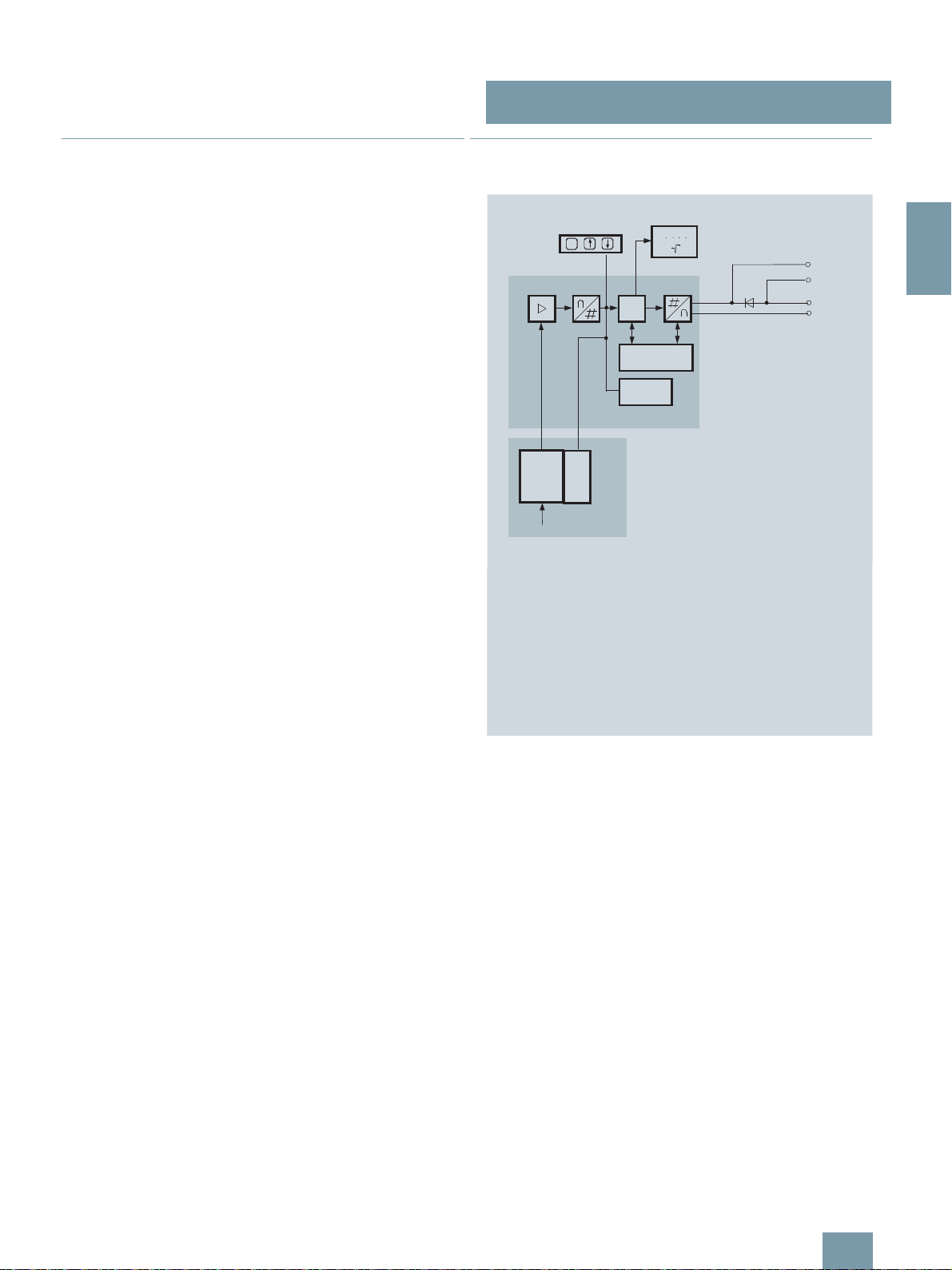

U

ref

P

A/D

D/A

EEPROM

+

-

LCD

Red LEDGreen LED

µC

U

K

U

A

U

I

EMC

4 ... 20 mA

UH, I

A

mbar

3 keys Configuring of parameters

A/D Analog-to-digital converter

D/A Digital-to-analog converter

EEPROM Memory for all parameters

EMC Output stage with protective components

I

A

Output current

U

ref

Reference voltage

LCD Display of measured values with dimensions

Green LED Display of normal mode

Red LED Display of error messages or limit violation

P Ceramic measuring cell

U

H

Power supply

µC Microcontroller for computing functions and monitoring

3 keys

© Siemens AG 2008

Transmitters for gage, absolute and differential pressure

ZD series for gage and absolute pressure

■

Overview

SITRANS P pressure transmitters, ZD series, are for measuring

the gage pressure, absolute pressure and level of liquids and

gases.

They are used to indicate and monitor the pressure measured at

the point of installation. ZD pressure transmitters are available in

an axial and a radial version.

At the rear of the housing is the electrical connection for the voltage supply using a current loop 4 ... 20 mA. The connection is

made with a plug connector.

At the front of the housing is the 5-digit display behind a glass

cover. Underneath the display are the 3 keys for parameterizing

the pressure transmitter. Above the display are a green and a red

LED for indicating the operating status.

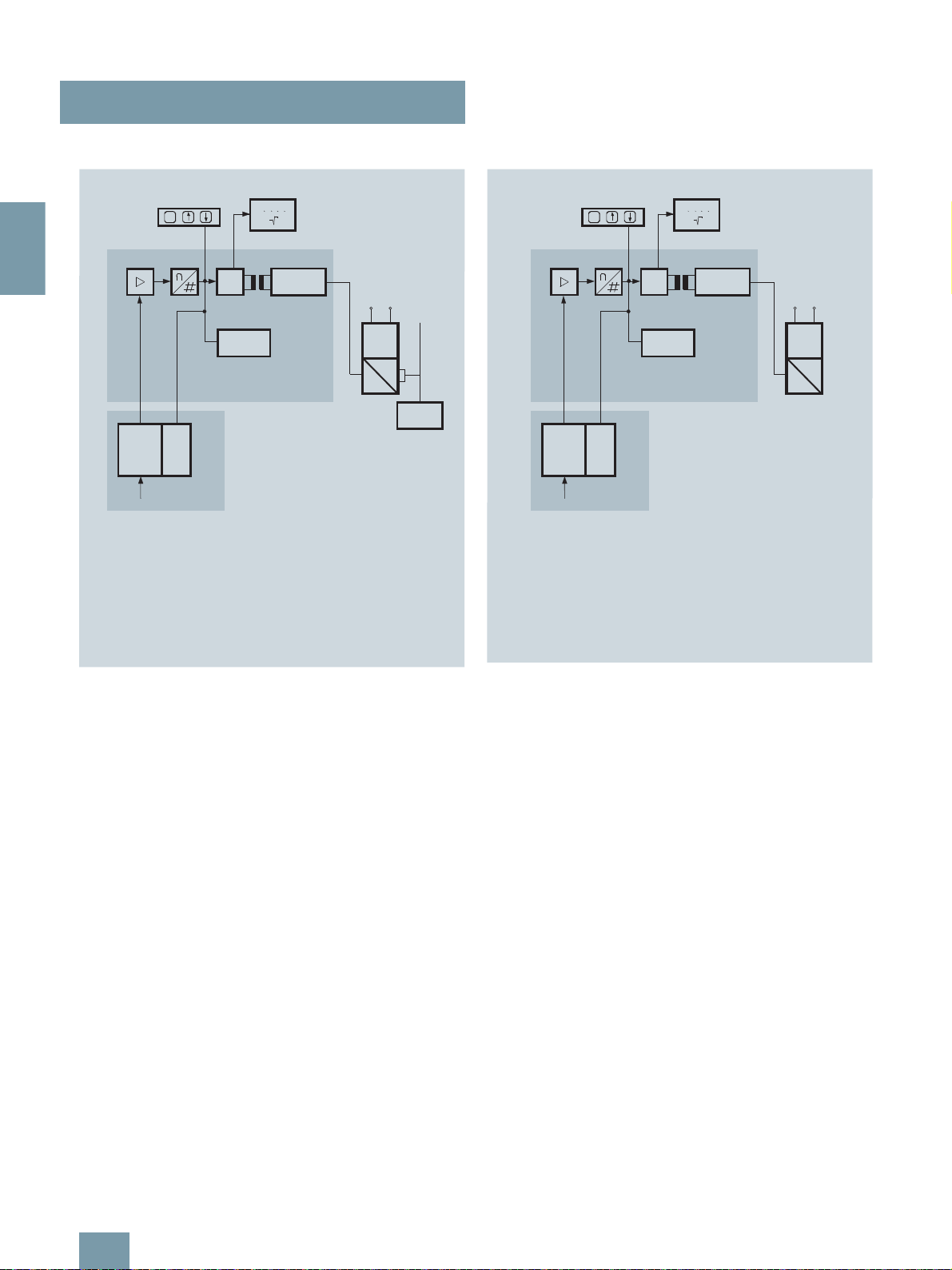

The ZD pressure transmitter is available in two versions (see "Dimension drawing"):

In the radial version (type A) the display is fitted in parallel with

the process connection. The display can be rotated by up to

±120° relative to the process connection.

In the axial version (type B) the display is at right angles to the

process connection. The display can be rotated by 360° relative

to the process connection.

■

Function

2

■

Benefits

• Robust stainless steel housing with 2 connection versions

• Integrated display with status messages

• Thin-film measuring cell with ceramic diaphragm

• 2-wire system, 4 ... 20 mA

• Parameterizable using keys underneath the housing cover

• Range adjustment 1:5 (max. 1:10)

• Measuring accuracy < 0.25% (typical)

■

Application

The ZD is a configurable pressure transmitter for measuring the

gage and absolute pressure of gases, liquids and vapor.

It is equipped with a display for indicating the pressure value at

the point of installation.

SITRANS P pressure transmitters, ZD series, are used in the fol-

lowing industrial areas for example:

• Chemical industry

• Mechanical engineering

• Food industry

• Pharmaceutical industry

• Shipbuilding

• Water supply

■

Design

The pressure transmitter is comprised of a thin-film measuring

cell with a ceramic diaphragm, an electronics board and a digi-

tal indicator.

All parts are accommodated in a stainless steel field housing

(∅ 80 mm) with a glass cover and stainless steel process con-

nection.

SITRANS P pressure transmitters, ZD series, mode of operation

Mode of operation

The ZD pressure transmitter has a thin-film strain gage which is

mounted on a ceramic diaphragm.

The measuring cell is temperature-compensated.

Functions

The ZD pressur

e transmitter has a 5-digit display behind a glass

cover. The following data are shown on the display:

•

Measured pressure

• Technical pressure dimension (default setting: bar)

• Limit violation in upward or downward direction, indicated by

LED and arrow symbols in the display

The pressure transmitter is set using the 3 input keys behind the

glass cover underneath the display.

The key "M" is used to select the operating mode. Following

modes of operation are available:

• Measured value

• Password

• Dimension

• Start and end of scale

• Upper and lower limit value

• Zero adjustment

Siemens FI 01 · 2009

2/17

Page 18

SITRANS P measuring instruments for pressure

2

© Siemens AG 2008

Transmitters for gage, absolute and differential pressure

ZD series for gage and absolute pressure

• Upper and lower current saturation limit

• Electrical damping

The other two keys are used to set the values in the individual op-

erating modes.

Two LED indicators are fitted above the display to monitor the set

range and the status.

The green LED signals that the measured pressure lies within the

set limits. The red LED lights up when the measured pressure

lies outside the set limits and when there is an error.

■

Technical specifications

SITRANS P pressure transmitters, ZD series

Mode of operation

Measuring principle Thin-film strain gage

Input

Measured variable Gage and absolute pressure

Measured range Resolution

0 ... 2 bar (0 ... 29 psi) 0.6 mbar (0.008 psi)

0 ... 10 bar (0 ... 145 psi) 3 mbar (0.044 psi)

0 ... 50 bar (0 ... 725 psi) 15 mbar (0.218 psi)

0 ... 200 bar (0 ... 2900 psi) 60 mbar (0.9 psi)

0 ... 400 bar (0 ... 5800 psi) 120 mbar (1.8 psi)

Measured range Overload limit

0 ... 2 bar (0 ... 29 psi) 5 bar (72.5 psi)

0 ... 10 bar (0 ... 145 psi) 25 bar (363 psi)

0 ... 50 bar (0 ... 725 psi) 120 bar (1740 psi)

0 ... 200 bar (0 ... 2900 psi) 500 bar (7250 psi)

0 ... 400 bar (0 ... 5800 psi) 600 bar (8700 psi)

Range adjustment (turndown) 5:1

Output

Output signal 4 ... 20 mA

Lower current limit min. 3.6 mA

Upper current limit max. 23 mA

Output protected against Reversed polarity, overvoltage

Max. load R

Voltage measurement Linear rising

Measuring accuracy To EN 60770-1

Error in measurement (including

non-linearity, hysteresis and repeatability, at 25 °C (77 °F))

Adjustment time < 100 ms

Long-term drift 0.25% of full scale value/year

Influence of ambient temperature < ±0.25%/10 K (< ±0.25%/10 K)

Vibration influence 0.05%/g to 500 Hz in all directions

Power supply effect < ±0.01%/V of full-scale value

and short-circuiting

= (UH- 12 V) / 0.023 A

B

< 0.25% of full-scale value (typical), max. 0.5%

of full-scale value

(to IEC 68-2-64)

Rated conditions

Ambient conditions

• Ambient temperature -25 ... +85 °C (-13 ... +185 °F)

• Storage temperature -40 ... +85 °C (-40 ... +185 °F)

Medium conditions

• Process temperature -30 ... +100 °C (-22 ... +212 °F)

Degree of protection IP65 to EN 60529

Electromagnetic compatibility

• Emitted interference and interfer-

ence immunity

Displays and controls

Display LCD, max. 5 digits, digit height

Decimal point Freely parameterizable

Limit values Freely parameterizable

Limit violation display Red LED and message on LCD

Parameterization With 3 keys

Units mA or % or physical variable

Damping

Design

Weight ≈0.6 kg (≈1.32 lb)

Electrical connection Using 2-pole plug connector with

Process connection • Male thread G½B and female

Version of housing/process connection

Material

Non-wetted parts materials

• Field housing Ø 80 mm (3.15 inch), stainless

• Cover Stainless steel, mat. No. 1.4016

Wetted parts materials

• Measuring cell Al

• Gasket Viton

• Process connection Stainless steel, mat. No.

Power supply

Terminal voltage on pressure transmitter (U

Certificate and approvals

Classification according to pressure

equipment directive 97/23/EC

)

H

To EN 61326/A1 appendix A

(1998)

9mm

(↑ symbol /↓ symbol in case of

limit violation in upward / downward direction)

(default setting: bar)

Other dimensions: mbar, kPa,

MPa, mmH

mmHg, kg/cm², torr, atm

Between 0.1 and 100 s

(increment: 0.1 s) freely parameterizable

M16x1.5-Cable inlet to

EN 175301-803A, plastic

thread G

• G½B to EN 837-1

• Female thread: ½-14 NPT

• Radial (type A), can be swiveled

by max. ±120° (α)

• Axial (type B), can be swiveled

by max. ±360°

steel mat. No. 1.4016

with glass

2O3

1.4571/316Ti

12 ... 30 V DC

For gases of fluid group 1 and liquids of fluid 1; complies with

requirements of article 3, paragraph 3 (sound engineering practice)

0, mH20, psi, inH20,

2

1

/8B

2/18

Siemens FI 01 · 2009

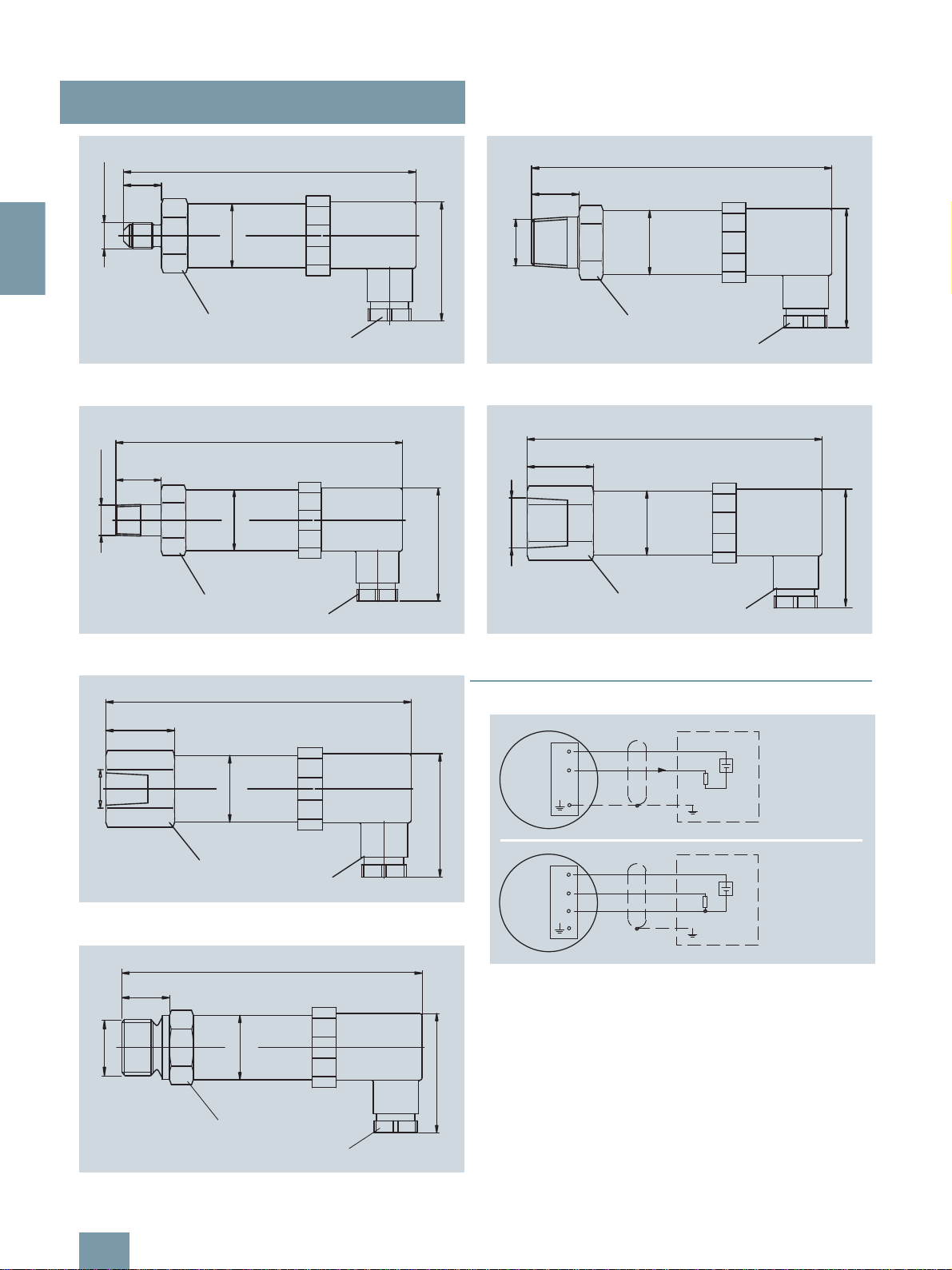

Page 19

SITRANS P measuring instruments for pressure

s

a

Ø 82 (3.23)

G½B

SW 27

48,5 (1.91)

M

45 (1.77)

152 (5.98)

Ø 82 (3.23)

48,5 (1.91)

45 (1.77)

½-14 NPT

G½B

M16x1,5

or

½-NPT

G

1

/8B

Ø 82 (3.23)

EN 837-1

Type A Type B

M16x1,5

or

½-NPT

1

2

1 (+)

2 (-)

I

0

R

L

U

B

+

UBPower supply

R

L

Load

I

0

Output current

© Siemens AG 2008

Transmitters for gage, absolute and differential pressure

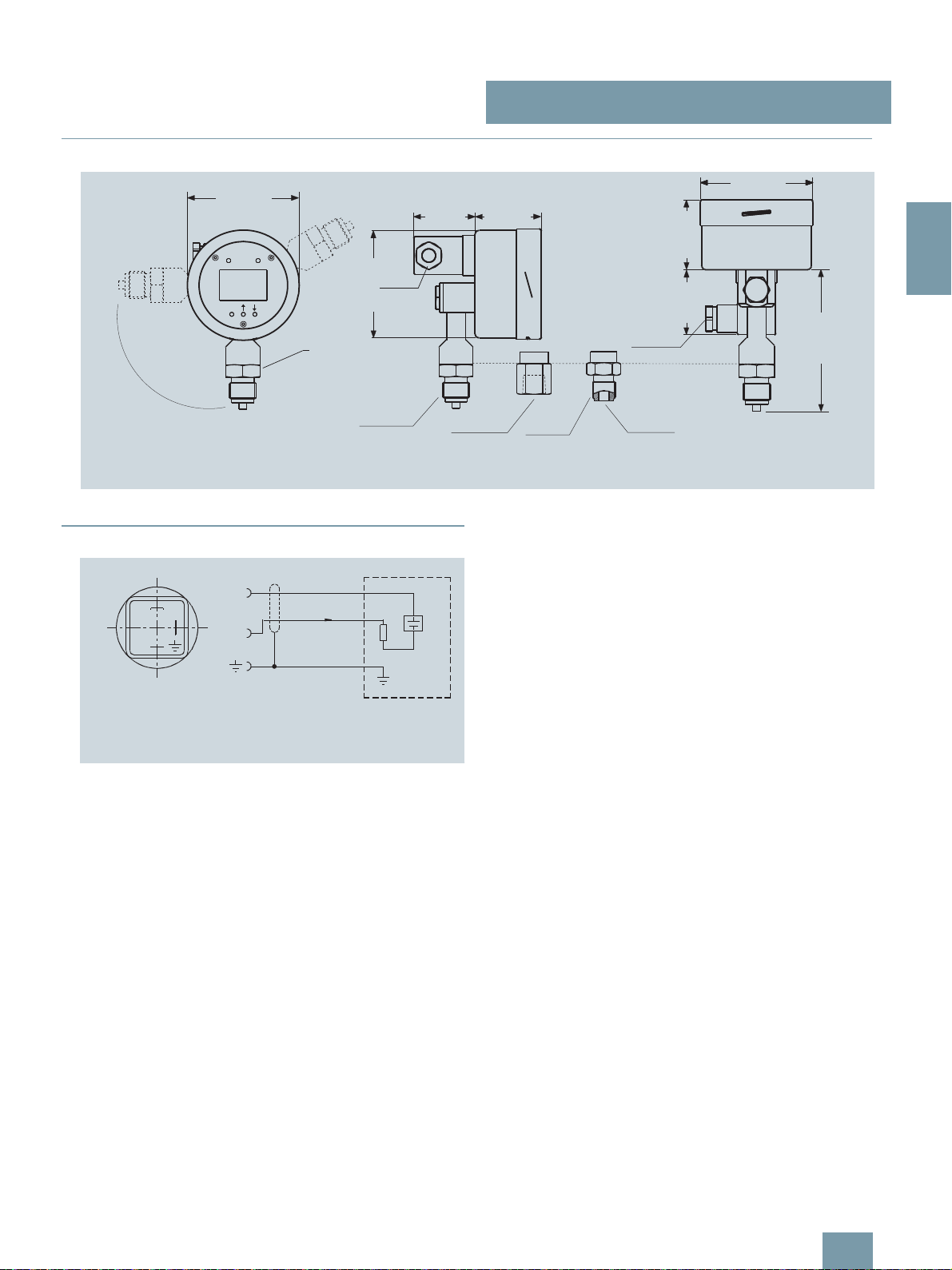

■

Dimensional drawings

SITRANS P pressure transmitters, ZD series, dimensional drawing, dimensions in mm (inch)

ZD series for gage and absolute pressure

2

■

Schematics

SITRANS P pressure transmitters, ZD series, connection diagram

Siemens FI 01 · 2009

2/19

Page 20

SITRANS P measuring instruments for pressure

2

© Siemens AG 2008

Transmitters for gage, absolute and differential pressure

ZD series for gage and absolute pressure

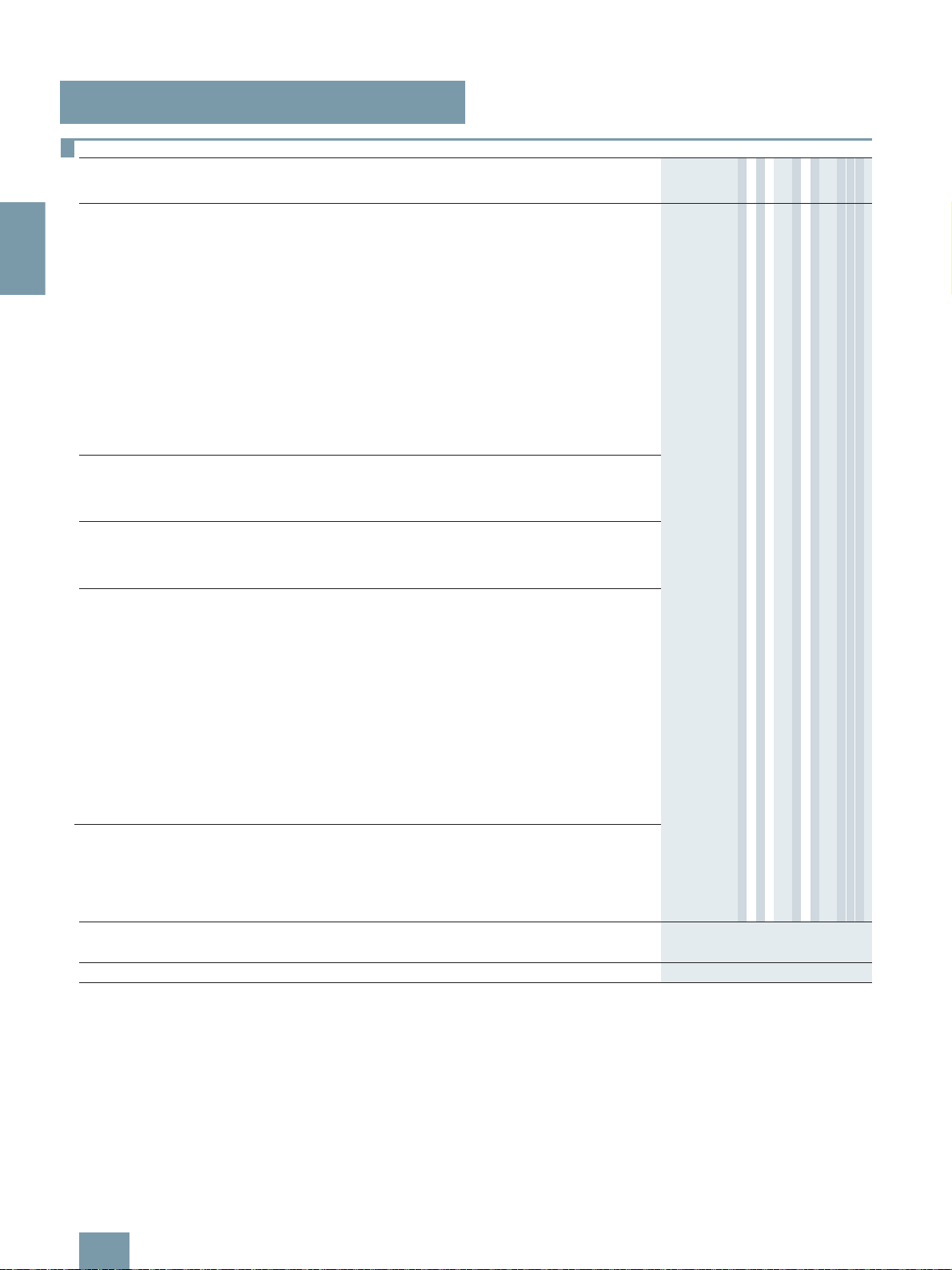

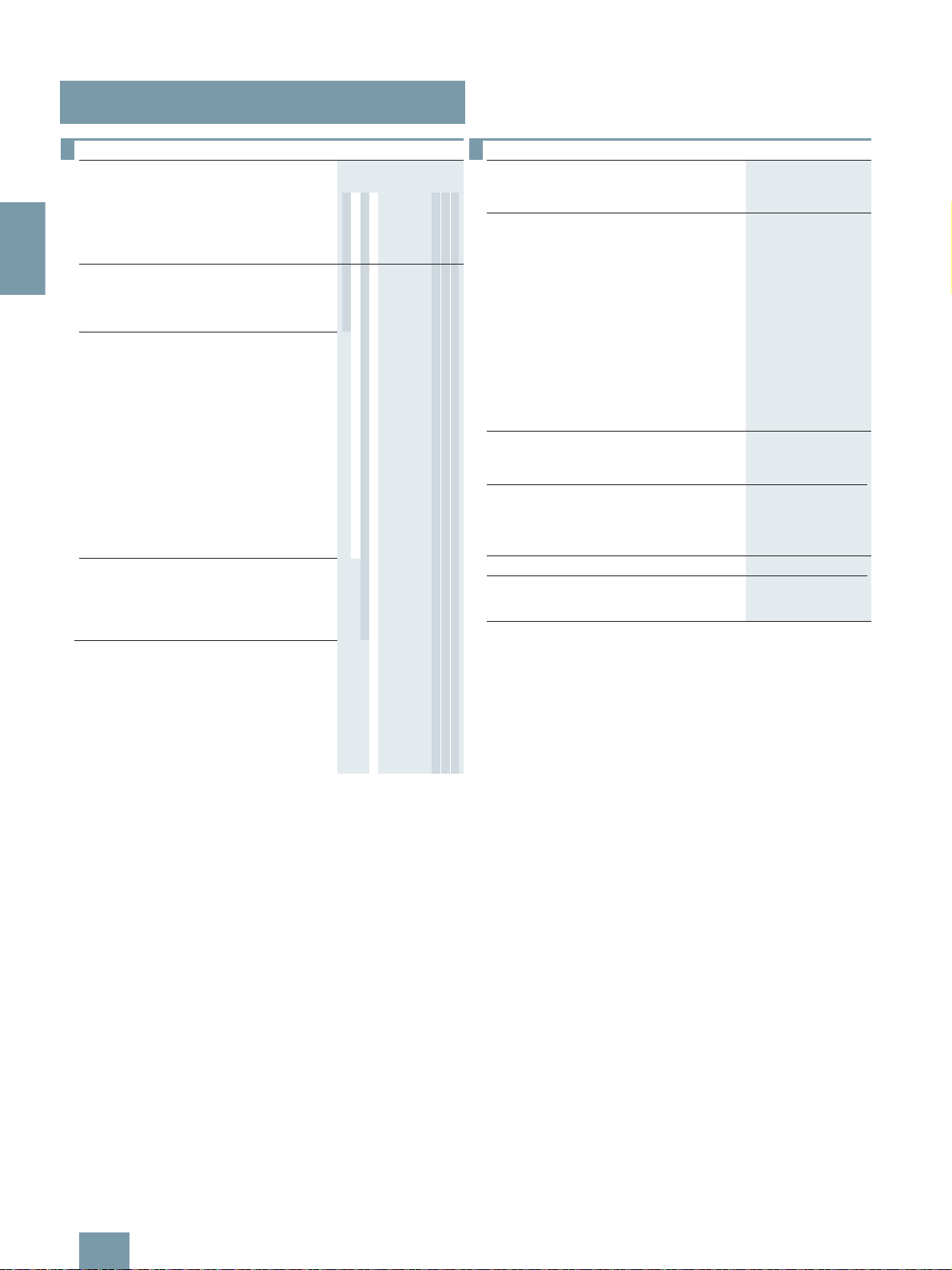

Selection and Ordering data Order No. Ord. Code

SITRANS P pressure transmitters, ZD

series for gage and absolute pressure

Conformity error 0.25%, range adjustment

1 : 5 (max. 1 : 10), housing and process

connection made of stainless steel,

membrane made of ceramic, 2-wire system,

output 4 ... 20 mA

Input variable

Gage pressure } 1

Absolute pressure }F)2

Measured range Span

0 ... 2 bar

(0 ... 29 psi)

0 ... 10 bar

(0 ... 145 psi)

0 ... 50 bar

(0 ... 725 psi)

0 ... 200 bar

(0 ... 2900 psi)

0 ... 400 bar

(0 ... 5800 psi)

Other version (on request)

add Order Code and plain text:

Process connection: ............

Process connection

G½B male thread and G1/8B female thread } A

G½B to EN 837-1

Female thread ½-14 NPT

G 1“ male thread

Design

Process connection vertically downwards,

thread in connector M16x1.5

Process connection horizontally to rear,

thread in connector M16x1.5

Process connection vertically downwards,

thread in connector ½"-14 NPT

Process connection horizontally to rear,

thread in connector ½"-14 NPT

0 ... 0.4 / 2 bar

(0 ... 5.8 / 29 psi)

0 ... 2 / 10 bar

(0 ... 5.8 / 145 psi)

0 ... 10 / 50 bar

(0 ... 145 / 725 psi)

0 ... 40 / 200 bar

(0 ... 580 / 2900 psi)

0 ... 80 / 400 bar

(0 ... 1160 / 5800 psi)

7M F 1 5 8 0 -

7 7 7 7

0

} D

} E

} F

} G

} H

Z J 1 Y

F)

B

F)

C

F)

M

} 1

2

} 3

4

7 7 7

Selection and Ordering data Order Code

Further designs

Please add "Z" to Order No. and specify Order

code(s) and plain text.

Quality inspection certificate (Factory calibration) to IEC 60770-2 supplied

Factory certificate

to EN 10204-2.2 supplied

Oxygen application, oil and grease-free

cleaned

(only in conjunction with the sealing material

Viton between sensor and enclosure and only

in conjunction with measuring ranges >= 1

bar g and 1 bar abs)

Sealing material FEP between sensor and

housing, instead of Viton

max. operating pressure 15 bar (218 psi),

max. measuring temperature -10 ... +50 °C

Additional data

Please add "Z" to Order No. and specify Order

code(s) and plain text.

Measuring range to be set,

specify in plain text:

Y01: ... up to ... mbar, bar, kPa, MPa, psi

TAG number made of stainless steel Y1 5

Accessories Order No.

Quality inspection certificate (Factory

calibration) to IEC 60770-2

specify factory of transmitter.

supplied later,

C1 1

C1 4

E1 0

E2 0

Y0 1

7MF1564-8CC11

} Available ex stock

F) Subject to export regulations AL: 9I999, ECCN: N.

2/20

Siemens FI 01 · 2009

Page 21

SITRANS P measuring instruments for pressure

© Siemens AG 2008

Transmitters for food, pharmaceuticals and biotechnology

■

Overview

The SITRANS P Compact pressure transmitter is designed for

the special requirements of the food, pharmaceutical and biotechnology industries.

The use of high-grade materials guarantees compliance with hygiene regulations.

Particular value has been placed on a high surface quality. It is

therefore possible, for example, to guarantee roughness values

down to R

(welded seam area R

can be electropolished in addition.

A further important feature is the hygiene-based design of the

process connection by means of various aseptic connections.

The completely welded stainless steel housing can be designed

up to degree of protection IP67.

Using appropriate thermal decouplers, the SITRANS P Compact

pressure transmitter can be used for process temperatures up to

200 °C (392 °F).

■

Benefits

• Measuring ranges from 0 to 160 mbar (0 to 2.32 psi) to 0 to

40 bar (0 to 580 psi)

• Linearity error including hysteresis < +0.2% of full-scale value

• Piezo-resistive measurement system, vacuum-proof and overload-proof

• Hygiene-based design according to EHEDG, FDA and GMP

recommendations

• Material and surface quality according to hygiene requirements

• Wetted parts made of stainless steel; completely welded

• Signal output 4 to 20 mA (0 to 20 mA as option)

• Stainless steel housing with degree of protection IP65 (IP67 as

option)

• Process temperature up to 200 °C (392 °F)

• Explosion protection II 2G EEx [ib] IIC T6 to ATEX

• Easy and safe to clean

=0.4μm (1.57 ⋅ 10-5inch) in the wetted area

a

<0.8μm (3.15 ⋅ 10-5inch)). The system

a

SITRANS P Compact

for gage and absolute pressure

■

Application

The SITRANS P Compact pressure transmitter is designed for

the special requirements of the food, pharmaceutical and biotechnology industries.

The use of high-grade materials guarantees compliance with hygiene regulations.

The SITRANS P Compact pressure transmitter is available in

many versions. Exact adaptation of the pressure transmitter to

conditions at the place of use is thus possible

■

Design

The electronics is potted to protect it against moisture, corrosive

atmospheres and vibration.

Notes on operating the pressure transmitter

Compensation of internal atmospheric pressure

Compensation of the internal atmospheric pressure of the

SITRANS P Compact pressure transmitters is performed as follows:

• in the plug versions by means of the screwed gland (IP65)

• in the field housings by means of an integral sintered filter

(IP65) or a vented cable (IP67)

• in versions with cable outlet by means of a vented cable (IP67)

In the absolute pressure range there is no need for compensation with respect to atmospheric pressure.

Note: These degrees of protection are only achieved under the

following conditions:

• if the pressure transmitter is installed correctly

• if the screwed glands are securely tightened

• if the cable diameters agree with the nominal diameters of the

gaskets in the housing

Note: The integral EMC measures are only effective if the earth

connection is made correctly.

CE marking

The CE marking of the pressure transmitter certifies compliance

with the guidelines of the European Council (9/336/EC), the EMC

law (13.11.1992), as well as the applicable generic standards.

Interference-free operation in systems and plants is achieved

only if the specifications for shielding, earthing, cable routing

and electrical isolation are observed during installation and assembly.

Hazardous areas

Note: Electrical equipment in hazardous areas must only be in-

stalled and operated by trained personnel.

Modifications to units and connections result in cancellation of

the explosion protection and guarantee.

With intrinsically-safe circuits, make sure that equipotential

bonding exists throughout the complete cabling inside and outside of the hazardous area. The limits specified in the ATEX approval must be observed.

2

Siemens FI 01 · 2009

2/21

Page 22

SITRANS P measuring instruments for pressure

2

© Siemens AG 2008

Transmitters for food, pharmaceuticals and biotechnology

SITRANS P Compact

for gage and absolute pressure

■

Function

The process pressure acts on a piezo-resistive semiconductor

measuring bridge through a remote seal and a transmission liquid. The pressure transmitter converts the pressure values into a

load-independent current.

A compensation network makes the output signal largely independent of the ambient temperature. As a result of a specially

adapted remote seal connection with minimized volume, the influence of the process temperature on the output signal is

greatly reduced compared to a conventional screw connection.

The pressure transmitters can be powered with a non-regulated

DC voltage of 10 to 30 V. Output signals common to measuring

technology are available.

■

Technical specifications

Pressure transmitters for food, pharmaceuticals and biotechnology

Mode of operation

Measuring principle Piezo-resistive

Input

Measured variable Gage or absolute pressure

Measured range 0 ... 160 mbar (0 ... 2.32 psi)

Output

Output signal

• Two-wire system 4 ... 20 mA

• Three-wire system 0 ... 20 mA

Measuring accuracy To EN 60770-1

Linearity error including hysteresis

(reference point adjustment)

Adjustment accuracy ≤± 0.2% of full-scale value

Adjustment time < 20 ms

Influence of ambient temperature

On th enclosure

• Zero < 0.2%/10 K of full-scale value

• Measured span < 0.2%/10 K of full-scale value

On the process connection (remote

seal)

• Flange remote seal

- DN 25 / 1" 4.8 mbar/10 K (0.070 psi/10 K)

- DN 32 / 1¼” 2.3 mbar/10 K (0.033 psi/10 K)

- DN 40 / 1½” 1.6 mbar/10 K (0.023 psi/10 K)

- DN 50 / 2" 0.6 mbar/10 K (0.009 psi/10 K)

• Clamp-on seal

- DN 25 / 1" 9.5 mbar/10 K (0.138 psi/10 K)

- DN 32 / 1¼” 4.1 mbar/10 K (0.060 psi/10 K)

- DN 40 / 1½” 3.9 mbar/10 K (0.057 psi/10 K)

- DN 50 / 2" 3.9 mbar/10 K (0.057 psi/10 K)

The zero error specified for the process connection should be considered as a guideline for a standard design. We will produce a detailed

system calculation on request. Systems with reduced remote seal errors

are available on request.

...

0 ... 40 bar (0 ... 580 psi)

≤ 0.2% of full-scale value

Zero error (depends on design)

Rated conditions

Installation conditions

• Mounting position Any, vertical as standard

Ambient conditions

• Ambient temperature -10 ... +70 °C (14 ... 158 °F)

• Storage temperature -10 ... +90 °C (14 ... 194 °F)

• Process temperature Max. 200 °C (392 °F), depends

• Degree of protection (to EN 60529) IP65, optional IP67

• Electromagnetic compatibility

- Emitted interference To EN 50081 Part 1, issue 1993

- Interference immunity to EN 50082 Part 2, issue March

Design

Weight (without remote seal)

• Field housing ≈ 460 g (≈ 1.01 lb)

• Housing with plug ≈ 200 g (≈ 0.44 lb)

Housing

• Designs • Field housing IP65 or IP67, with

• Material Stainless steel, mat.

Material of union nut Polyamide (with electrical con-

Process connection

• Versions See Ordering data

• Material of coupling Stainless steel, mat.

Power supply

Terminal voltage on transmitter 10 ... 30 V DC

Rated voltage 24 V DC

Certificate and approvals

Classification according to pressure

equipment directive

(DRGL 97/23/EC)

Explosion protection

• Intrinsic safety "i" TÜV 03 ATEX 2099 X

- Identification Ex II 2G EEx ib IIC T6

on design

(residential and industrial areas).

The unit has no own emissions.

1995 (industrial areas)

screwed gland

• Angled plug DIN 43650, IP65

• Cable connection, IP67

• Round plug connector M12,

IP65

No. 1.4404/1.4305

nection using plug or cable)

Electronics unit potted with sili-

cone

Internal ventilation for measuring

ranges < 16 bar (< 232 psi),

through housing thread or connection cable depending on

design

No. 1.4404/316L

For gases of fluid group 1 and liquids of fluid group 1; complies

with the requirements of article 3,

paragraph 1 (appendix 1);

assigned to category III, conformity evaluation module H by the

TÜV Nord

2/22

Siemens FI 01 · 2009

Page 23

SITRANS P measuring instruments for pressure

© Siemens AG 2008

Transmitters for food, pharmaceuticals and biotechnology

SITRANS P Compact

for gage and absolute pressure

Selection and Ordering data Order No. Ord. code

SITRANS P Compact pressure trans-

mitters for pressure and absolute

pressure with diaphragm flush at front

2-wire system

Process temperature up to 140 °C

(284 °F)

Accuracy: 0.2% of full-scale value

Output 4 ... 20 mA

Diaphragm seal

with quick-release clamp

Milk pipe union to DIN 11851 with

slotted union nut

•DN25 A D

•DN32 A E

•DN40 A F

•DN50 A G

•DN65 A H

Milk pipe union to DIN 11851 with

threaded socket

•DN25 B D

•DN32 B E

•DN40 B F

•DN50 B G

•DN65 B H

Clamp connection to DIN 32676

•DN25 C D

•DN40 C F

•DN50 C G

Clamp connection to ISO 2852

• 1 inch D M

•1½inch D N

• 2 inch D P

•2½inch D Q

IDF standard with slotted union nut

• 1 inch E M

•1½inch E N

• 2 inch E P

IDF standard with threaded socket

• 1 inch F M

•1½inch F N

• 2 inch F P

SMS standard with slotted union nut

• 1 inch GM

•1½inch GN

• 2 inch G P

SMS standard with threaded socket

• 1 inch H M

•1½inch H N

• 2 inch H P

DRD flange, without welding-type flange

• DN 50, PN 40 J H

Varivent connection (Tuchenhagen)

• D = 50, for Varivent housing DN 25 and

1 inch

• D = 68, for Varivent housing

DN 40 ... DN 125 and 1½ ... 6 inch

Special version

(add Order code and plain text)

Filling liquid

Vegetable oil 1

medicinal white oil 2

Food oil, FDA-listed 3

Special version

(add Order code and plain text)

Output signal

4 ... 20 mA 1

Special version

(add Order code and plain text)

7 M F 8 0 1 0 -

7 7 7 7-7777 7 7 7

1

K F

K L

Z A J 1 Y

9 L 1 Y

9 M 1 Y

Selection and Ordering data Order No. Ord. code

SITRANS P Compact pressure trans-

mitters for pressure and absolute

pressure with diaphragm flush at front

2-wire system

Process temperature up to 140 °C

(284 °F)

Accuracy: 0.2% of full-scale value

Output 4 ... 20 mA

Diaphragm seal

with aseptic connection

Aseptic screwed gland to DIN 11864-1,

form A,

with slotted union nut

• 1 inch PM

• 1½ inch P N

• 2 inch P P

• 2½ inch P Q

Aseptic screwed gland to

DIN 11864-1, form A

with threaded socket

• 1 inch QM

• 1½ inch QN

• 2 inch QP

• 2½ inch QQ

Aseptic screwed NEUMO

with slotted union nut

•DN25 RD

•DN32 RE

•DN40 R F

•DN50 RG

Aseptic screwed NEUMO

with threaded socket

•DN25 S D

•DN32 S E

•DN40 S F

•DN50 SG

Aseptic screwed NEUMO

with clamp connection, form R

•DN25 T D

•DN32 T E

•DN40 T F

•DN50 T G

Aseptic screwed NEUMO

with clamp connection, form V

•DN25 UD

•DN32 UE

•DN40 U F

•DN50 UG

Special version

(add Order code and plain text)

Filling liquid

Vegetable oil 1

medicinal white oil 2

Food oil, FDA-listed 3

Special version

(add Order code and plain text)

Output signal

4 ... 20 mA 1

Special version

(add Order code and plain text)

1)

Please specify as well:

Connections for pipes: R01, R02 or R03,

see table "Further designs" on next page

1)

1)

1)

1)

7 MF 8 0 1 0 -

7 7 7 7-7777 7 7 7

1

Z A J 1 Y

9 L 1 Y

9 M 1 Y

2

Siemens FI 01 · 2009

2/23

Page 24

SITRANS P measuring instruments for pressure

2

© Siemens AG 2008

Transmitters for food, pharmaceuticals and biotechnology

SITRANS P Compact

for gage and absolute pressure

Selection and Ordering data Order No. Ord. code

SITRANS P Compact pressure trans-

mitters for pressure and absolute

pressure with diaphragm flush at front

2-wire system

Process temperature up to 140 °C

(284 °F)

Accuracy: 0.2% of full-scale value

Output 4 ... 20 mA

Housing design (stainless steel mat.

No. 1.4404/316L) / electr. connection

Housing with angled plug to DIN 43650,

IP65

Housing with round plug M12, IP65,

union nut made of polyamide

Housing with round plug M12, IP65,

union nut made of stainless steel

Stainless steel field housing (small) with

cable gland, IP65

Stainless steel field housing (small) with

cable gland, IP67

Internal ventilation for measuring ranges

< 10 bar (< 145 psi)

Measured range Overload pressure

0 ... 160 mbar g

(0 ... 2.32 psi g)

0 ... 250 mbar g

(0 ... 3.63 psi g)

0 ... 400 mbar g

(0 ... 5.8 psi g)

0 ... 600 mbar g

(0 ... 8.7 psi g)

0 ... 1 bar g

(0 ... 14.5 psi g)

0 ... 1.6 bar g

(0 ... 23.2 psi g)

0 ... 2.5 bar g

(0 ... 36.3 psi g)

0 ... 4 bar g

(0 ... 58 psi g)

0 ... 6 bar g

(0 ... 87 psi g)

0 ... 10 bar g

(0 ... 145 psi g)

0 ... 16 bar g

(0 ... 232 psi g)

0 ... 25 bar g

(0 ... 363 psi g)

0 ... 40 bar g

(0 ... 580 psi g)

-160 ... 0 mbar g

(-2.32 ... 0 psi g)

-250 ... 0 bar g

(-3.73 ... 0 psi g)

-400 ... 0 bar g

(-5.8 ... 0 psi g)

-600 ... 0 bar g