Siemens sitrans LVS200 Instruction Manual

Instruction Manual November 2006

sitrans

sitrans

LVS200

English

Deutsch

Español

Français

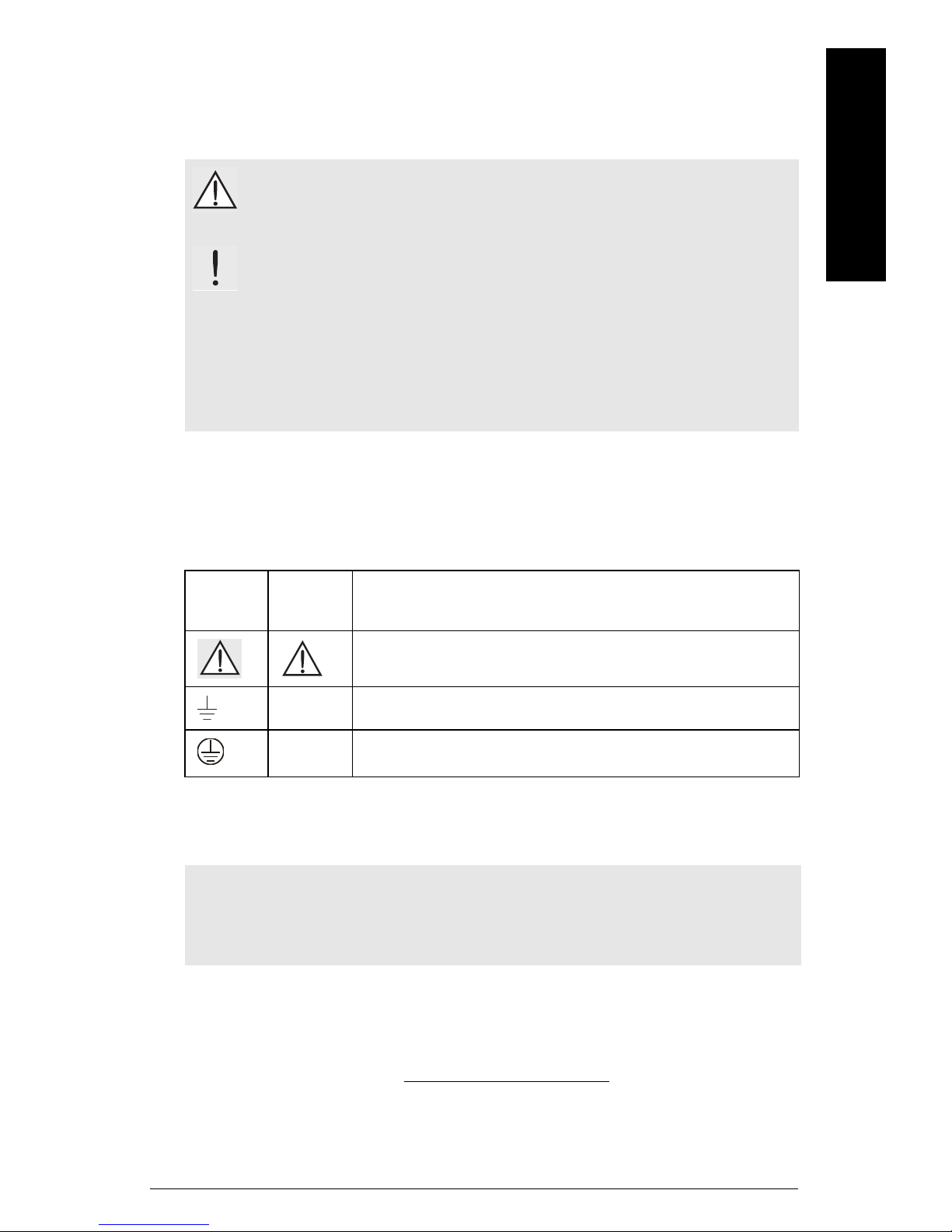

Safety Notes

Special attention must be paid to warnings and notes highlighted from the rest of the text

by grey boxes.

WARNING: relates to a caution symbol on the product, and means

that failure to observe the necessary precautions can result in

death, serious injury, and/or considerable material damage.

English

mmmmm

WARNING

1

: means that failure to observe the necessary

precautions can result in death, serious injury, and/or considerable

material damage.

CAUTION: means that failure to observe the necessary precautions can

result in considerable material damage.

Note:

manual.

1.

means important information about the product or that part of the operating

This symbol is used when there is no corresponding caution symbol on the

product.

Safety marking symbols

In

Manual

On

Product

Description

(Label on product: yellow background.)

Caution: refer to accompanying documents (manual) for details.

Earth (ground) Terminal

Protective Conductor Terminal

The Manual

Notes:

• Please follow the installation and operating procedures for a quick, trouble-free

installation and to ensure the maximum accuracy and reliability of your SITRANS LVS200

• This manual applies to SITRANS LVS200 only.

This manual will help you set up your SITRANS LVS200 for optimum performance. We

always welcome suggestions and comments about manual content, design, and

accessibility.

Please direct your comments to techpubs.smpi@siemens.com

Siemens Milltronics manuals, go to www.siemens.com/processautomation.

. For the complete library of

7ML19985FT62 SITRANS LVS200 – INSTRUCTION MANUAL Page EN-1

mmmmm

SITRANS LVS200 Introduction

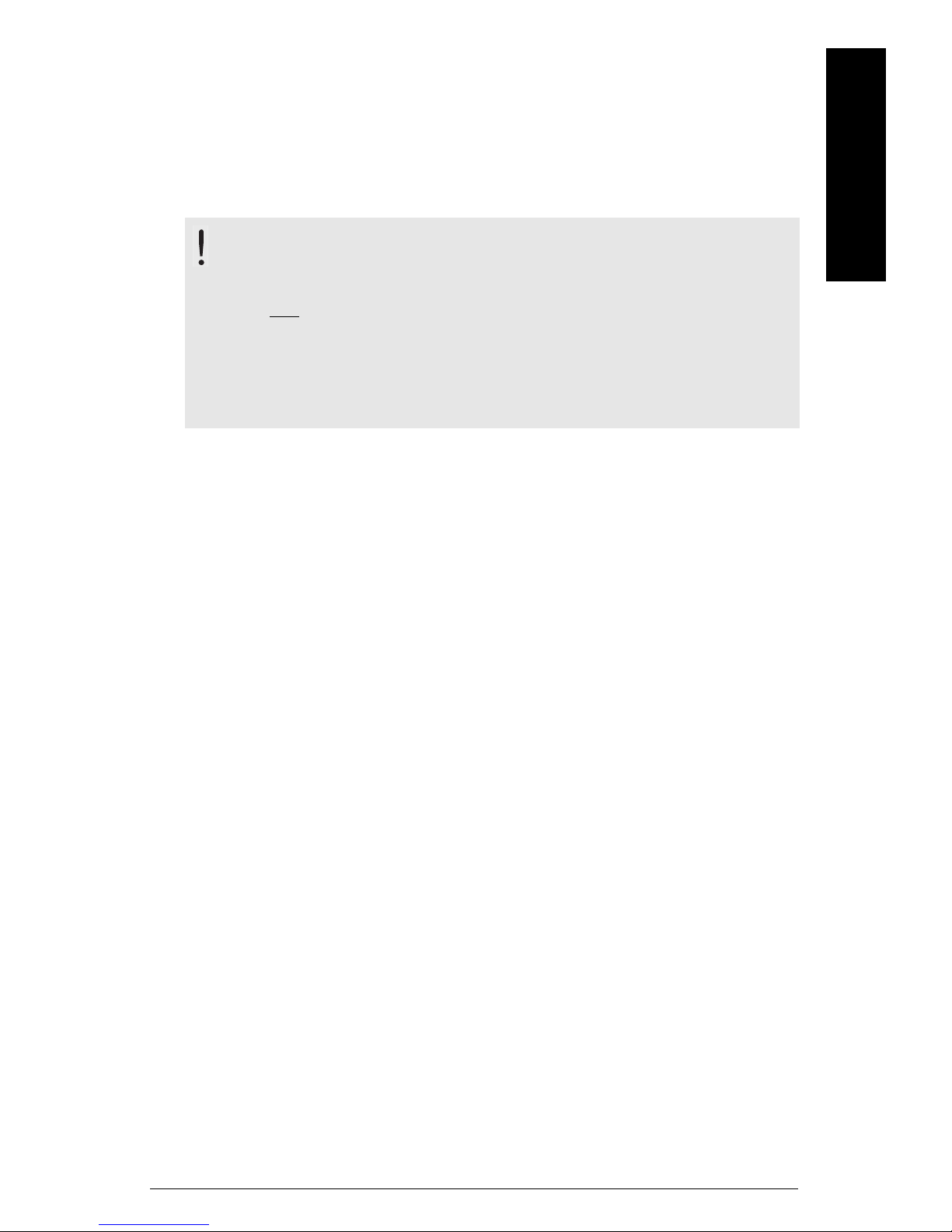

Notes

• Installation, maintenance, and commissioning must be performed by qualified

English

technical personnel.

• SITRANS LVS200 must be used only in the manner outlined in this instruction

manual.

SITRANS LVS200 is available in three versions:

• The SITRANS LVS200, standard version, is a vibrating level switch that detects high

or low levels of dry bulk solids in bins, silos, or hoppers. SITRANS LVS200 provides a

contact output for levels of products such as lime, styrofoam, flour, and plastic

granules. The compact design allows SITRANS LVS200 to be top or side mounted.

The standard length LVS200 fork is also available with variable cable extension

lengths to a maximum of 20 000 mm (787"). An optional longer fork is available for

increased sensitivity. SITRANS LVS200 cable extension is for top mount applications

only. The vibrating fork design ensures that the tines are kept clean.

• The SITRANS LVS200, liquid/solid interface version, is a vibrating level switch that

can also detect settled solids within liquids, or solids within confined spaces such

as feed pipes. This version is designed to ignore liquids in order to detect the

interface between a solid and a liquid. The design incorporates a short fork, and is

also available with variable cable extension lengths to a maximum of 20 000 mm

(787"), for top mount applications only.

• The SITRANS LVS200, pipe extension version, is a vibrating level switch that

incorporates a customer supplied pipe extension [maximum length 3800 mm (150")]

with the standard or liquid/solid (short) LVS200 fork and electronics. This allows for

separation of the electronics and tuning fork for specialized applications. Please

SITRANS LVS200 Pipe Extended Version

see

assembly.

on page 18 for information on

Product Features

• High resistance to mechanical forces

• Strong vibration resistance to high bulk material loads

• Rotatable enclosure

• Stainless steel 1½” NPT or 1½” BSPT threaded connection, or 2" BSP or NPT sliding

sleeve. DN 100 and 2, 3, 4" ASME flange options available.

• Suitable for low density material

standard version: 20 g/l (1.2 lb/ft

standard version with low density fork: 5 g/l (0.3 lb/ft

liquid/solid interface version: 50 g/l (3 lb/ft

Product Applications

• Dry lime, styrofoam, flour, plastic granules

• High or low density, dry bulk materials

• Interface detection of a solid within a liquid (filter beds)

• Flow or no flow detection in pipe using liquid/solid LVS200 version

Page EN-2 SITRANS LVS200 – INSTRUCTION MANUAL 7ML19985FT62

3

)

3

)

3

)

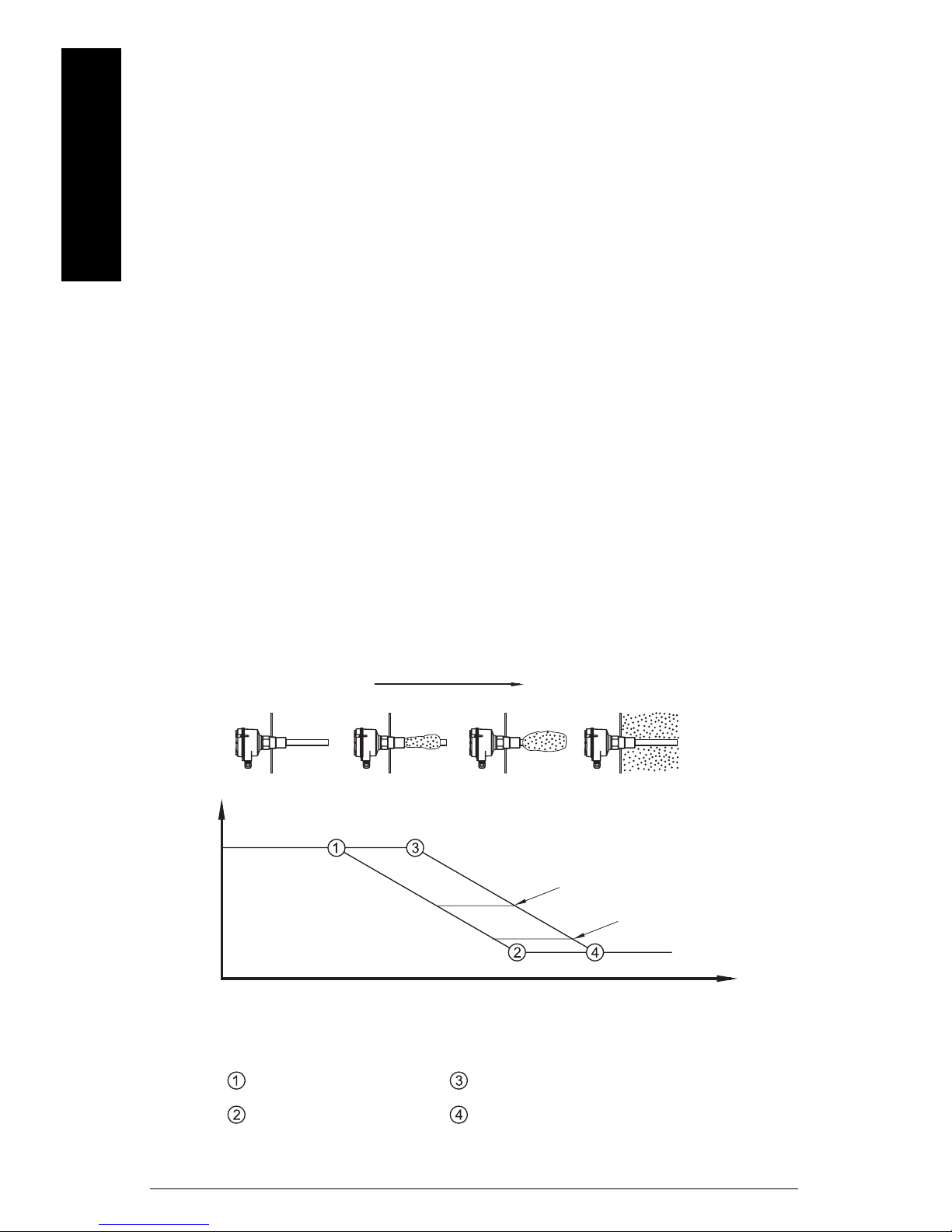

Principle of Operation

A signal from the electronic circuit excites a crystal in the probe, causing the fork to

vibrate. If the fork is covered by material, the change in vibration is detected by electronic

circuitry which causes the relay to change state after a one second delay. When the

material no longer reaches the tines, full vibration resumes and the relay reverts to its

normal state.

WARNINGS:

• This product is designed as a Pressure Accessory per Directive 97 / 23 / EC

and is not

• Materials of construction are chosen based on their chemical

compatibility (or inertness) for general purposes. For exposure to

specific environments, check with chemical compatibility charts

before installing.

intended for use as a safety device.

English

mmmmm

7ML19985FT62 SITRANS LVS200 – INSTRUCTION MANUAL Page EN-3

mmmmm

Specifications

Note: Siemens Milltronics makes every attempt to ensure the accuracy of these

specifications but reserves the right to change them at any time.

English

Power

• 19 to 230 V AC, +10 %, 50 to 60 Hz, 8 VA

• 19 to 55 V DC, +10 %, 1.5 W

• 18 to 50 V DC 3-wire PNP

• 7 to 9 V DC (requires NAMUR switch amplifier) NAMUR IEC 60947-506, 2-wire

• 8/16 mA or 4 to 20 mA; 12.5 to 35 V DC, 2-wire

Performance

Measuring frequency

• standard approx. 125 Hz

• liquid/solid interface version approx. 350 Hz

• enhanced sensitivity option approx. 90 Hz

Signal delay

• probe uncovered to covered approx. 1 second

• probe covered to uncovered approx. 1 to 2 seconds

Relay delay (DPDT version)

• adjustable up to 30 seconds

Sensitivity

• high or low, switch selectable

Minimum material density

• standard version approx. 20 g/l (1.2 lb/ft³)

• standard version with low density fork approx. 5 g/l (0.3 lb/ft³)

• liquid/solid interface version approx. 50 g/l (3 lb/ft³)

Maximum particle size

• 10 mm (0.39")

Alarm Output

• Version with 1 relay SPDT relay

• Version with 2 relays DPDT relay

• relay fail-safe high or low, switch selectable

• relay 8 A at 250 V AC, non-inductive; relay 5 A at 30 V DC, non-inductive

• 3-wire PNP open collector: permanent load

maximum 0.4 A, short circuit and

overload protected;

turn-on voltage: max. 50 V (reverse protection)

Page EN-4 SITRANS LVS200 – INSTRUCTION MANUAL 7ML19985FT62

• mA output (build-up detection) 8/16 mA or 4 to 20 mA;

resolution 4 to 20 mA, ±0.1 mA

Mechanical

Process Connection

• thread 1½” NPT, 1½” BSPT

• flanges DN 100 PN6, DN 100 PN16,

• optional sliding bushing with 2" NPT or BSP thread

• thread material stainless steel 303 (1.4301) or

Tines

• tine material stainless steel 316Ti (1.4571)

(PTFE

Milltronics representative for ordering information.)

Enclosure

• construction epoxy-coated aluminum

• conduit entry 2 x M20x1.5, or 2 x ½” NPT

• ingress protection Type 4X/NEMA 4X/IP66

Weight

2", 3", 4" ASME 150 lb flanges

optional stainless steel 316 Ti (1.4571)

1

coated tines are available upon special request. Contact your local Siemens

English

mmmmm

• standard version, no extensions 2.0 kg (4.4 lb)

• solids/liquids, no extensions 1.9 kg (4.2 lb)

Environmental

• location indoor/outdoor

• altitude max. 2000 m (6562 ft)

• ambient temperature –40 to 60 °C (–40 to 140 °F)

• relative humidity 0 to 100% (suitable for outdoor: ingress

• installation category III

• pollution degree 2

Process

Temperature

• All approvals except CSA Class II, Group G: –40 to 150 °C (–40 to 302 °F)

• CSA Class II, Group G: –40 to 140 °C (–40 to 284 °F), CSA

• For applications with process temperature greater than 80 °C (176 °F), the

maximum threaded bushing surface temperature must not exceed 80 °C (176 °F)

protection: Type 4X/NEMA 4X/IP66)

temperature code T3B

1.

Polytetrafluoroethylene

7ML19985FT62 SITRANS LVS200 – INSTRUCTION MANUAL Page EN-5

• Maximum enclosure surface temperature (Category 2D): 90 °C (194 °F) (ATEX

relevant)

• Maximum extension surface temperature (Category 1D): 150 °C (302 °F) (ATEX

relevant)

mmmmm

English

Approvals

Pressure

• max 10 bar, gauge (145 psi, gauge)

Note: Pressure information for hazardous areas

The device construction allows over-pressure up to 10 bar. This pressure is allowed for

test purposes. The ATEX approval applies to over-pressure between –0.2 and 0.1 bar in

hazardous areas. For higher or lower pressures, the approval is not valid.

• CSA/FM General Purpose

•CE

• CSA/FM Dust Ignition Proof

• ATEX II 1/2 D

• CSA/FM IS Class I, II, III, Div. 1, Groups A to G, FM Class I, Aex ia IIC, CSA Class 1,

Ex ia IIC, available only with 7 to 9 V DC power supply with NAMUR switch

amplifier

• ATEX II 1 G and 1/2 G Eex ia IIC; ATEX II 1 D and 1/2 D, available only with 7 to 9 V DC

power supply with NAMUR switch amplifier

Page EN-6 SITRANS LVS200 – INSTRUCTION MANUAL 7ML19985FT62

Installation

Mounting

Notes:

• Installation shall be performed by qualified personnel and in accordance with local

governing regulations.

• Do not bend, shorten or extend the tines.

• Position the tines using a 50 mm open-end wrench when installing the process

connection (do not turn the housing). When side mounting SITRANS LVS200,

position the tines vertically, with the tine orientation marking facing up or down.

• In pressure applications, use PTFE tape or other appropriate sealant to seal

tapered threaded connections.

• After mounting, ensure the cable entries point downward to prevent water entering

the housing.

• For the SITRANS LVS200 extended model, the torque due to material loading at the

mounting point may not exceed 250 Nm.

• Mounting torque for the 1½" thread connection may not exceed 80 Nm.

WARNINGS:

• This product is designated as a Pressure Accessory per Directive

97 / 23 / EC and is not

• Improper installation may result in loss of process pressure.

• To install devices in hazardous locations, observe all valid installation

regulations.

• For ATEX installations, observe the requirements of EN 50281-1-2

regarding dust deposits and temperatures. Before opening the device

lid, ensure there are no deposits present.

• Do not remove lid while circuits are live.

• Install the SITRANS LVS200 so mechanical friction or impact does not

cause sparks between the aluminium enclosure and steel vessel.

• Installation in Zone 0 (electronics: NAMUR): The intrinsic safe supply

circuit must have galvanic isolation to a non- intrinsically safe area.

Otherwise, provide protection for the device against lightning strikes

(see EN 60079-14).

• Power supply (electronics: NAMUR): Intrinsically safe protection is

only valid when connected to a certified intrinsically safe power

supply.

• For the LVS Pipe extended and cable extended models with Namur

electronics for gas hazardous approvals: When mounting the units on a

vessel lid that separates Zone 0 (Cat. 1G) from Zone 1 (Cat 2G), the units

have no safe separation between Zone 0 and Zone 1. Gas can pass

from Zone 0 through the unit to Zone 1.

intended for use as a safety device.

English

mmmmm

7ML19985FT62 SITRANS LVS200 – INSTRUCTION MANUAL Page EN-7

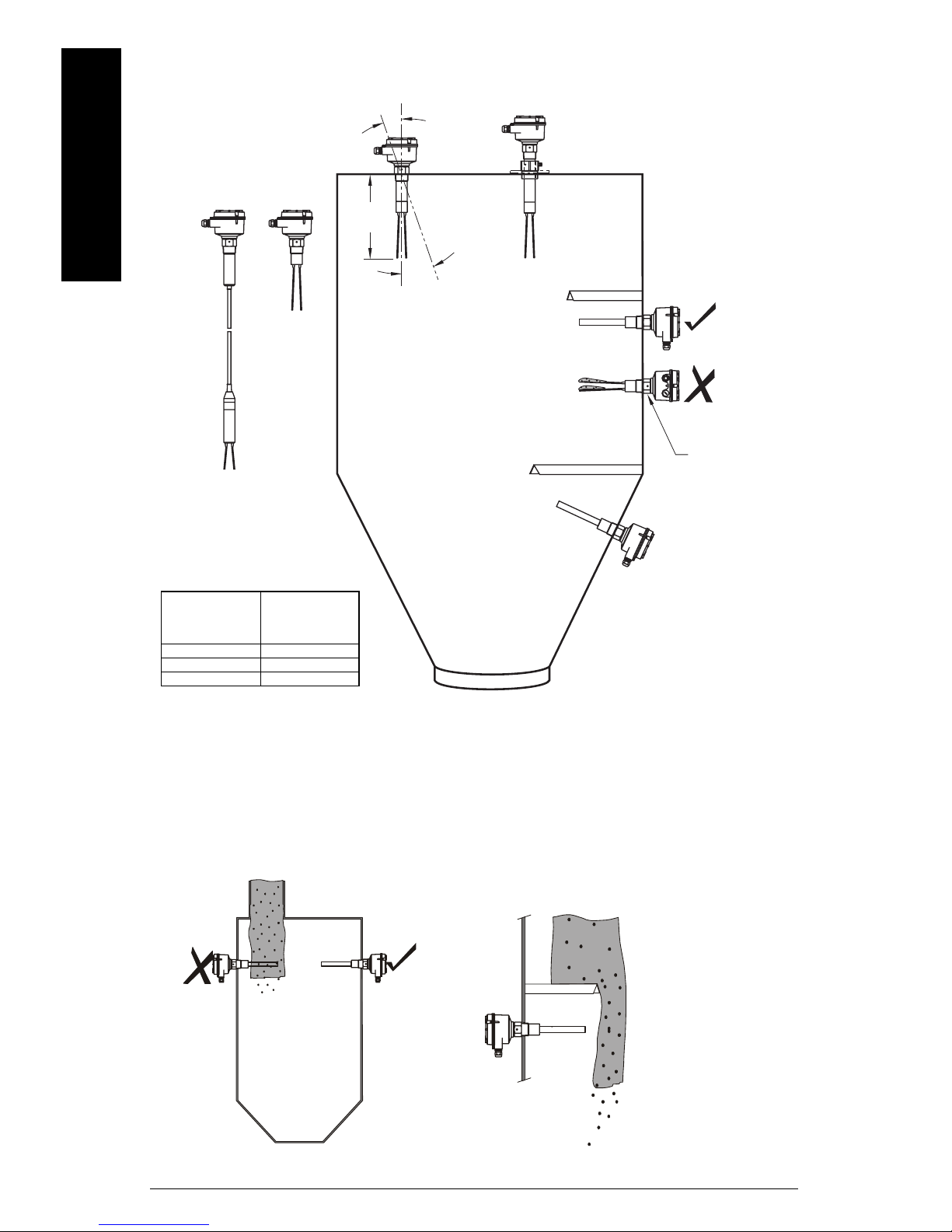

SITRANS LVS200 is normally mounted into the vessel top for full detection, or through the

tank wall at the detection level, for full, demand, or empty detection.

mmmmm

English

Cable

extension

version

Standard

version

*

L

α

Cable gland faces

downward to avoid

water penetration.

Sliding

bushing

version

Position tines vertically

to avoid product buildup: use a 50 mm openend wrench to turn the

process connection

until the tine

orientation marking

faces up or down.

Protection in case of

high material loading.

Tine orientation

marking facing

sideways.

*

max. deviation

from vertical

max. length L

α

5º 4 m

45º 1.2 m

>45º 0.6 m

Process Cautions

Caution:

• Locate SITRANS LVS200 out of path of falling material.

or:

• Protect shaft and tines from falling material.

Use angle mounting for flowing

material only.

If angle mounting is required

with high material loading,

customer-supplied protection

from falling material must be in

place.

Page EN-8 SITRANS LVS200 – INSTRUCTION MANUAL 7ML19985FT62

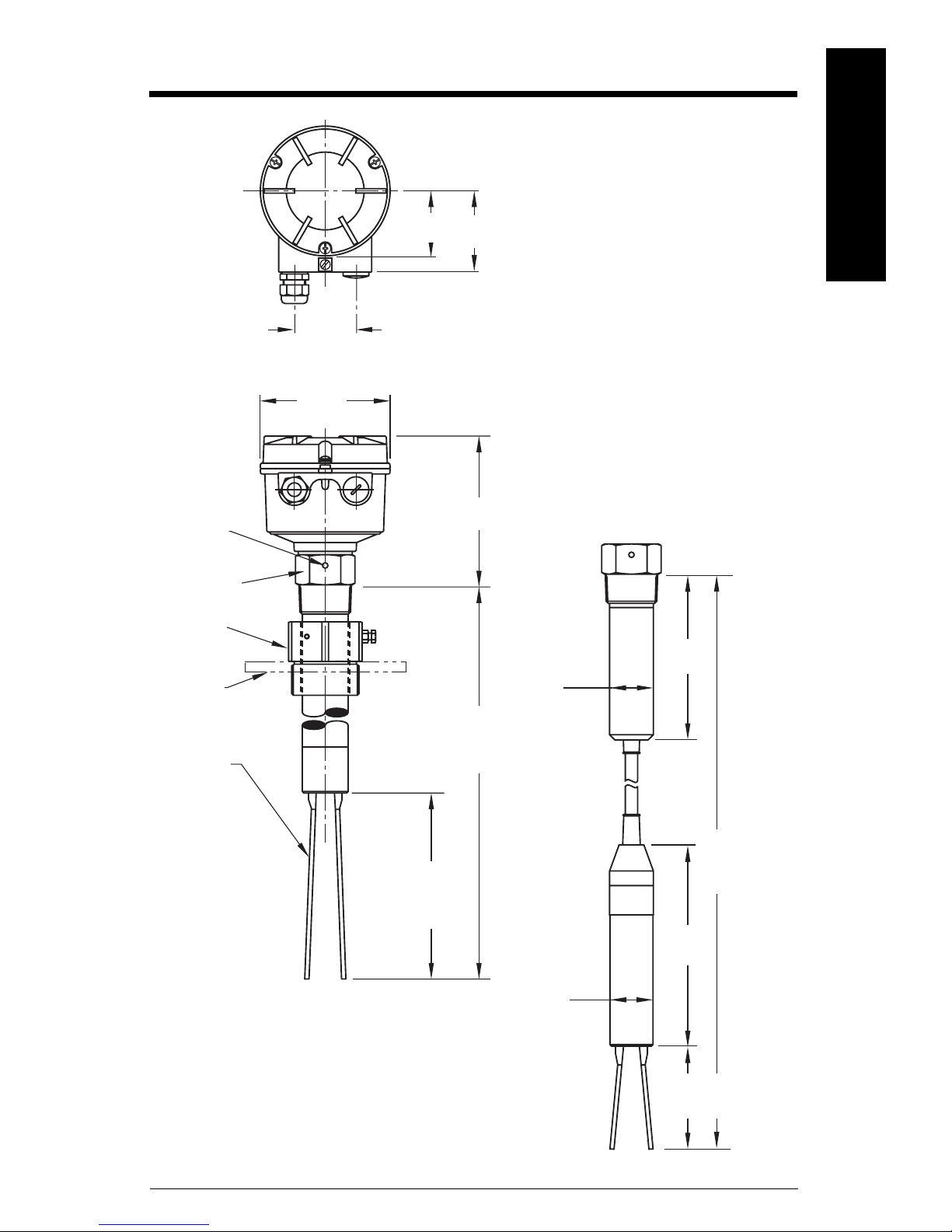

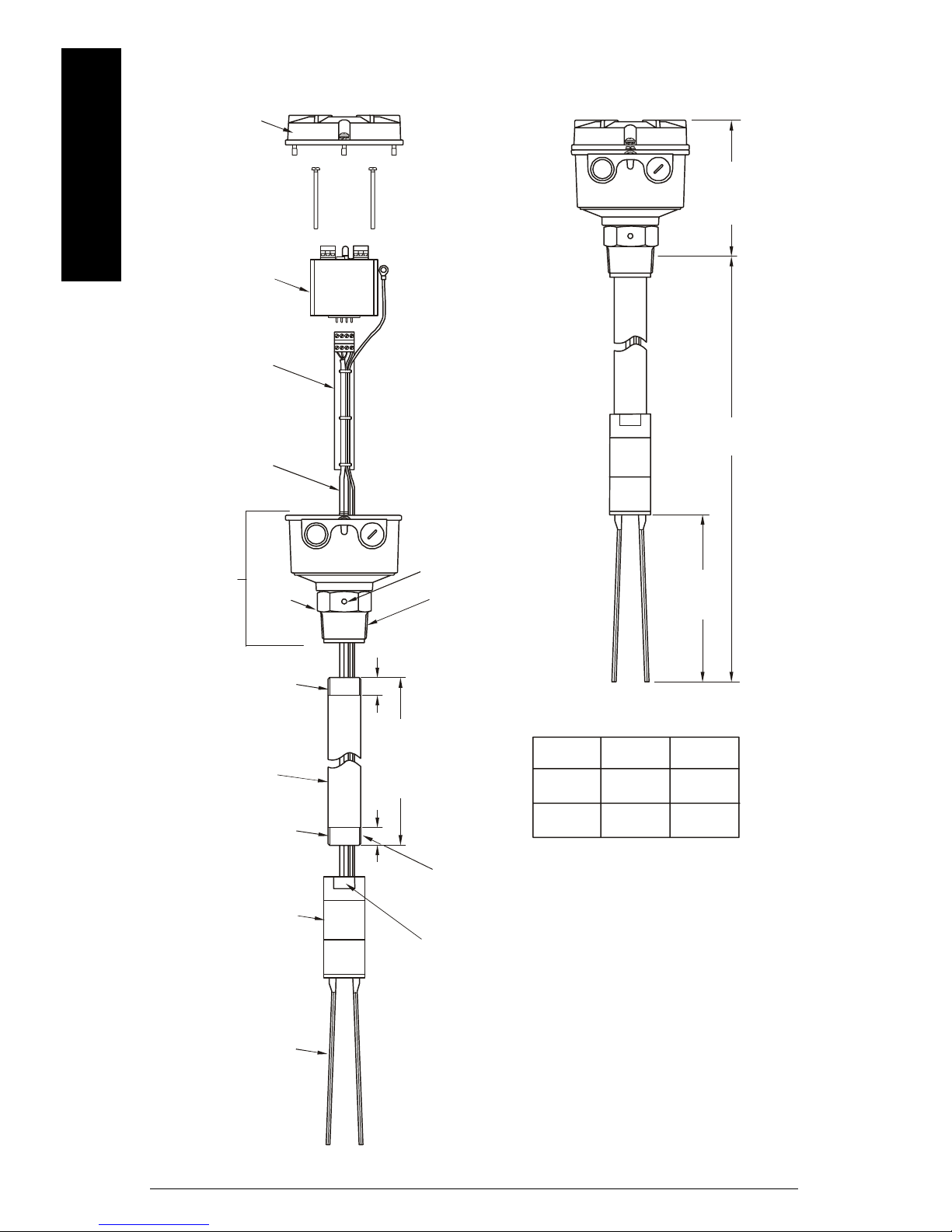

Dimensions

English

mmmmm

tine

orientation

marking

threaded

bushing

[max. temp.

80°C (176°F)]

optional

sliding

bushing*

customer

supplied

process

flange

tine

60 mm

(2.36")

120 mm

(4.72")

60 mm

(2.36")

Zone 21

(Cat. 2)

Zone 20

(Cat. 1)

165 mm (6.5"): compact solids/liquids interface model

230 mm (9.0"):compact standard version

300 to 40 00 mm (11.81 to 157"): customer-specified rigid

extension

75 mm

(2.95")

150 mm

(5.91")

Cable version

ø 42 mm

(1.67")

155 mm

(6.1")

*Note: The clamping screws of the sliding bushing

must be tightened to 10 Nm.

** Cable version with Liquids/solids interface

model option length to 7000 mm (275.59")

Cable version with NAMUR electronics length to

10 000 mm (393.7")

7ML19985FT62 SITRANS LVS200 – INSTRUCTION MANUAL Page EN-9

170 mm (6.69"):

standard fork

195 mm (7.68")

low density fork

700 to

20 000 mm**

(27.56 to 787")

195 mm

(7.68")

ø 42 mm

(1.67")

100 mm (3.94"):

solids/liquids

interface model

Wiring

mmmmm

English

WARNINGS:

• Open SITRANS LVS200 only when supply voltage is switched off.

• All field wiring must have insulation suitable for at least 250 V AC.

• A disconnect switch must be in close proximity to the equipment and

within easy reach of the operator.

• Use appropriate conduit or cable glands in hazardous locations.

Unused cable conduit fittings must be locked with a closing element or

plug.

• Observe all pertinent rules and regulations in the country of

installation.

Notes:

European requirements

• When mounting SITRANS LVS200 in hazardous areas, make sure the customer

supplied cable glands and/or plugs are certified ATEX 100a flameproof. The

certified temperature range must be at least -40 to 70 °C (-40 to 158 °F). The

minimum ingress protection requirement of IP6x according to European Standard

EN 60529 must be satisfied. Observe special conditions for safe use of the cable

gland described in the gland’s approval documentation.

• The requirements of European Standard EN 50281-1-2 regarding dust deposits and

temperature must be followed.

Connection recommendations

• Use a fuse for the signal output (max. 10 A).

• Provide protection for relay contacts to protect the device against spikes if inductive

loads are connected.

Precautions

• Before opening the lid, ensure there are no dust deposits around SITRANS LVS200,

and that the atmosphere around the instrument is settled.

• Make sure the main voltage does not exceed the maximum voltage listed on the

product label.

• Ensure that no more than 8 mm of each wire is stripped (to avoid danger of contact

with live parts).

• Ensure the boots for protecting cable terminations are no longer than 8 mm (to avoid

danger of contact with live parts).

Page EN-10 SITRANS LVS200 – INSTRUCTION MANUAL 7ML19985FT62

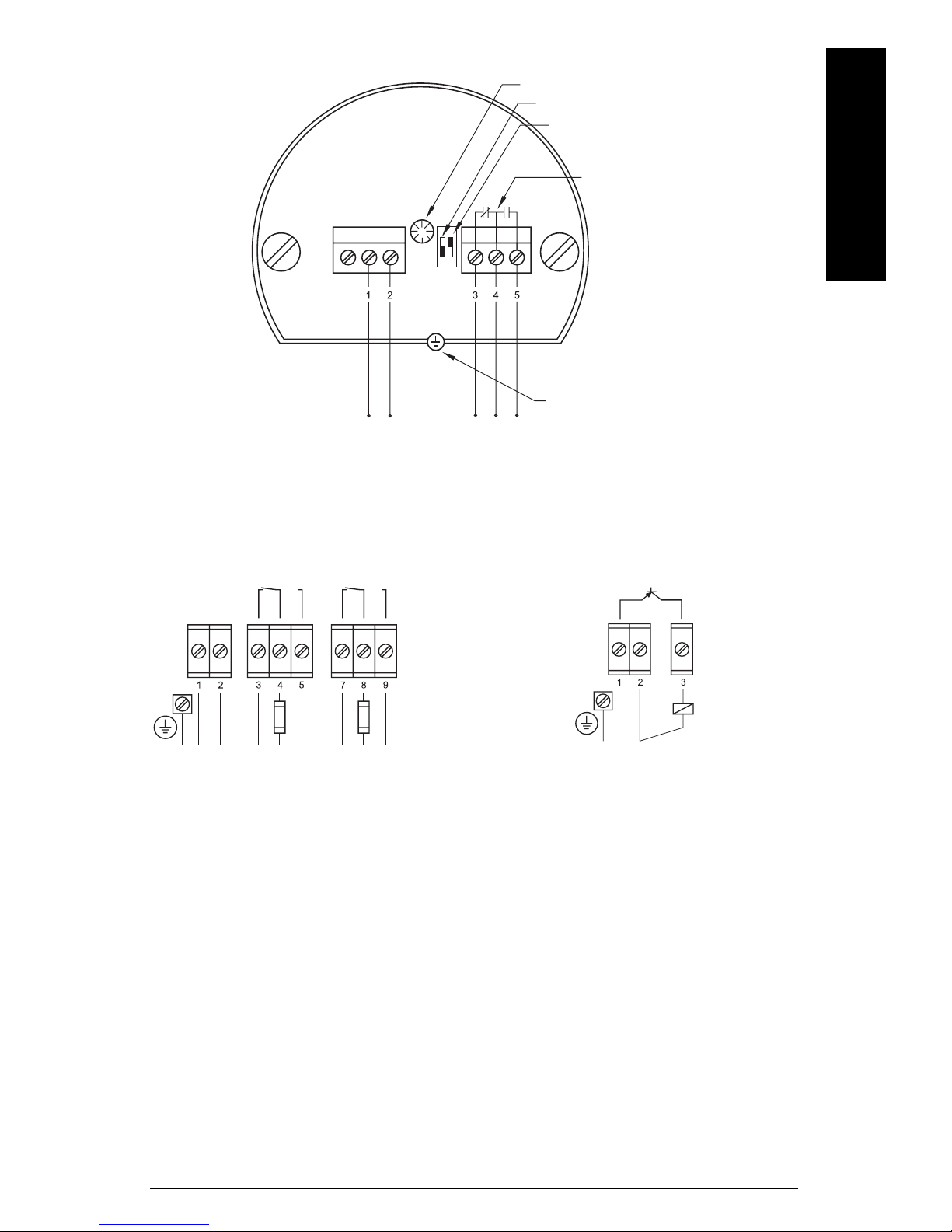

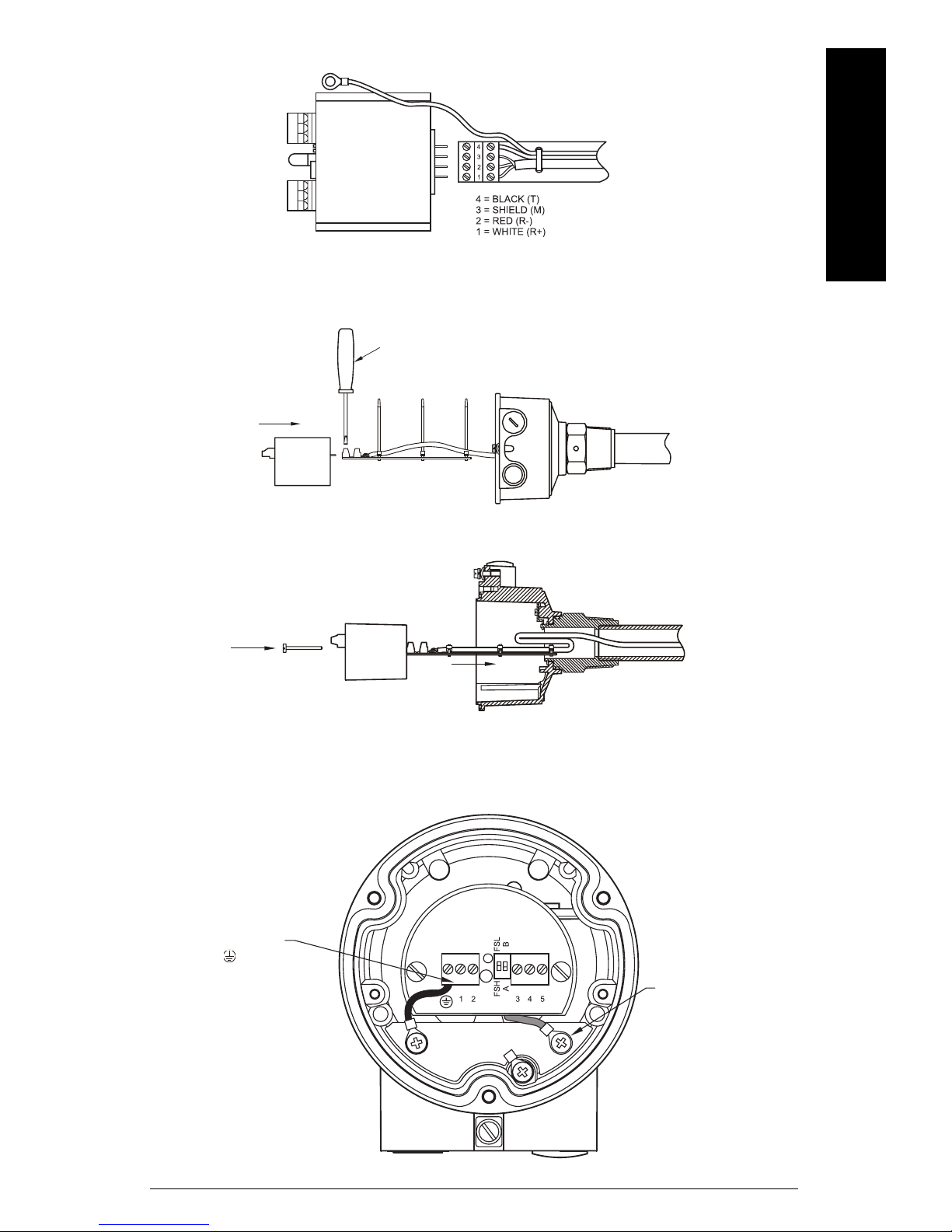

Universal voltage (SPDT relay)

AC: terminal 1: L

terminal 2: N

19 to 230 V AC, + 10 %, 50 to 60 Hz, 8 VA

DC: terminal 1: +

terminal 2: 19 to 55 V DC, + 10 %, 1.5 W

LED

FSH/FSL adjustment

sensitivity adjustment

B = factory setting,

A = decreased sensitivity

English

mmmmm

alarm output relay

FSL

B

A

FSH

protective earth terminal

Universal voltage (DPDT relay) 3-wire PNP

-

+

PE

N

L

signal output

-

+

AC: terminal 1: L

terminal 2: N

19 to 230 V AC, + 10 %, 50 to 60 Hz, 18 VA

DC: terminal 1: +

terminal 2: 19 to 55 V DC, + 10 %, 2 W

DC: terminal 1: +

terminal 2: 18 to 50 V DC, + 10 %, 1.5 W

PE

load

7ML19985FT62 SITRANS LVS200 – INSTRUCTION MANUAL Page EN-11

mmmmm

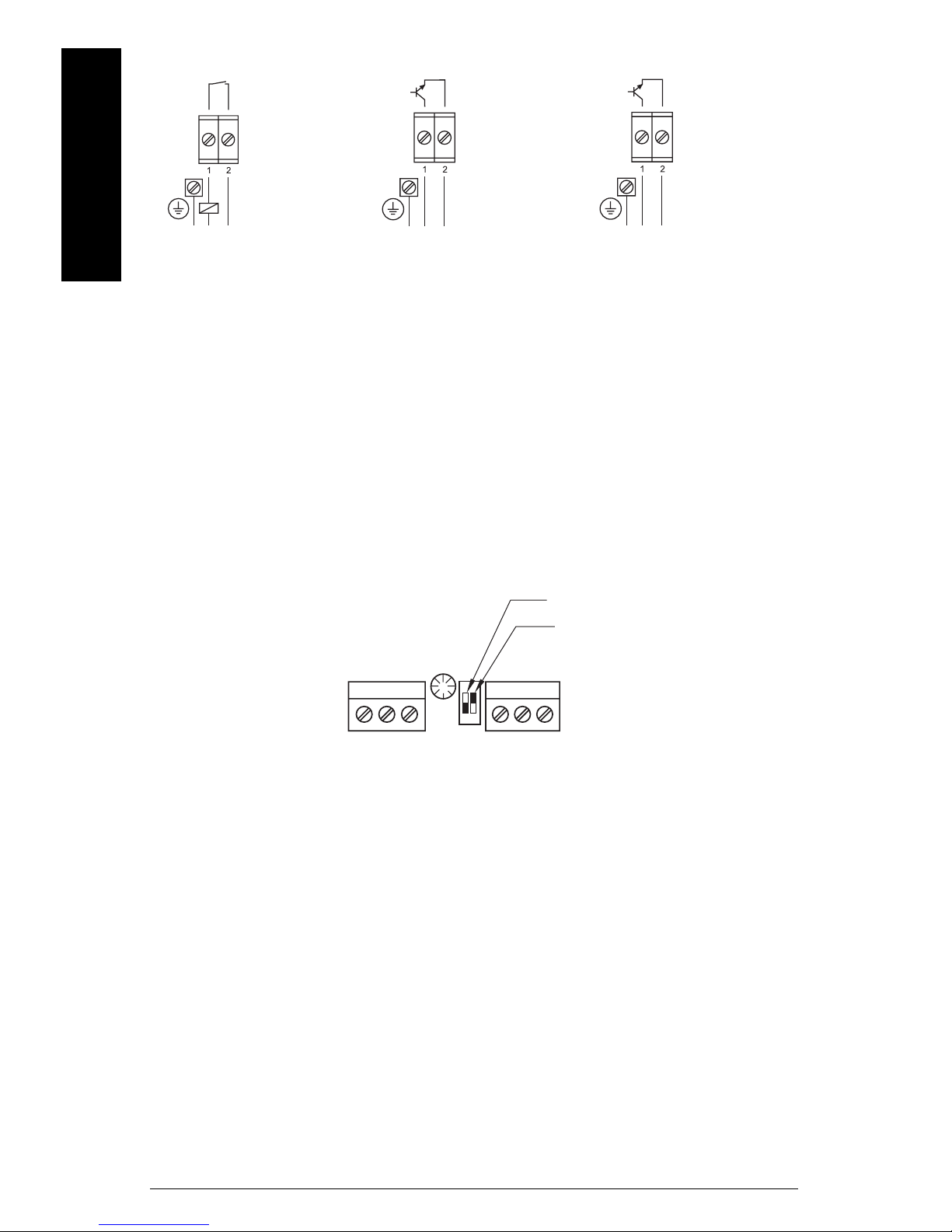

2-wire NAMUR IEC 60947-5-6 8/16 mA or 4 to 20 mA

English

-

+

PE

N

L

AC: terminal 1: L

terminal 2: N

19 to 230 V AC, + 10 %,

50 to 60 Hz, 1.5 VA

DC: terminal 1: +

terminal 2: 19 to 230 V DC, + 10 %, 1 W

-

+

PE

ca. 7 to 9 V DC,

intrinsically safe

(IEC 60947-5-6)

PE

DC: terminal 1: +

terminal 2: -

12.5 to 36 V DC, + 0 %

-

+

Sensitivity

If the measured material tends to cake or build up, the sensitivity adjustment switch can

be set to position A to decrease the sensitivity of the probe (factory setting is position B).

The sensitivity for interface applications should be set to position B, while the setting for

high-flow applications should be position A.

FSH/FSL adjustment or

High/Low Alarm setting (NAMUR)

sensitivity adjustment:

B = factory setting

FSL

B

A

FSH

A = decreased sensitivity

Page EN-12 SITRANS LVS200 – INSTRUCTION MANUAL 7ML19985FT62

Switching Logic

Probe uncovered

Signal Output

Model Failsafe low Failsafe high

English

mmmmm

SPDT relay

4

5

3

5

4

3

DPDT relay

3-wire PNP

2-wire

8/16 mA I = 16 mA I = 8 mA

Signal Output LED

Low alarm setting High alarm setting

NAMUR IEC 60947-5-6 I < 1 mA I > 2.2 mA

Signal Output LED

Probe covered

Signal Output

Model Failsafe low Failsafe high

SPDT relay

5

4

3

DPDT relay

3-wire PNP

2-wire

8/16 mA I = 8 mA I = 16 mA

Signal Output LED

Low alarm setting High alarm setting

NAMUR IEC 60947-5-6 I >2.2 mA I < 1 mA

4

5

3

Signal Output LED

7ML19985FT62 SITRANS LVS200 – INSTRUCTION MANUAL Page EN-13

mmmmm

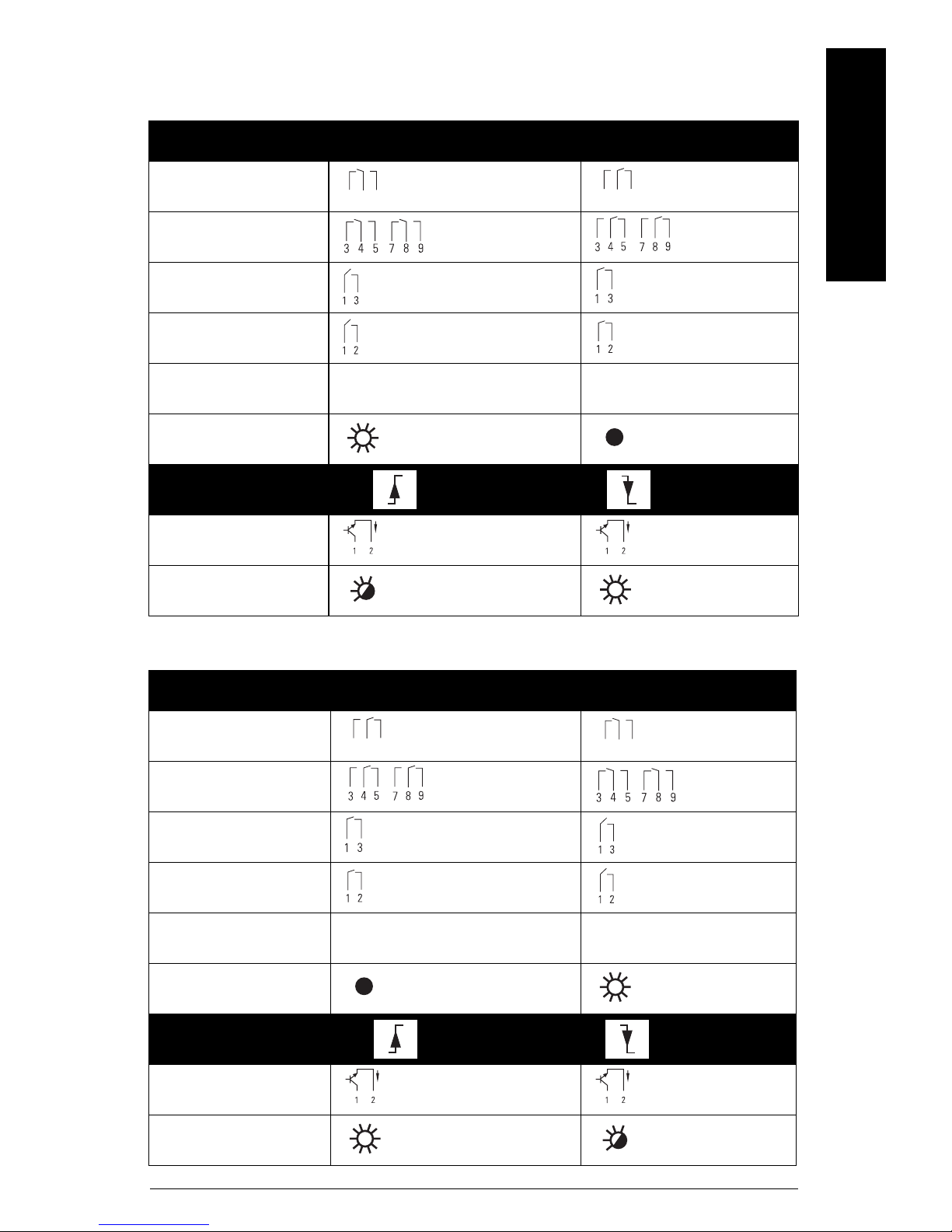

Signal output and test options

Note: The signal output and test options listed below apply only to specific power

supply options.

English

Signal Output Delay

Universal voltage (DPDT) model

The signal output can be delayed and is adjustable from 0 to 30 seconds. Turn the

potentiometer clockwise to increase the delay time.

Potentiometer T1: Delay when output switches from fork covered to uncovered.

Potentiometer T2: Delay when output switches from fork uncovered to covered.

Test function

NAMUR model (IEC 60947-5-6) and 8/16 mA or 4 to 20 mA model

If the fork is uncovered, pressing this button will stop the vibration and the signal output

will switch to indicate a covered fork. You can test the vibration and the electronics

without removing the LVS200 from the vessel. If the fork is covered, pressing the button

has no effect.

NAMUR model

Test button

Electronic module

diagnostic LED

sensitivity adjustment:

B = factory setting

B

A

A = decreased sensitivity

Page EN-14 SITRANS LVS200 – INSTRUCTION MANUAL 7ML19985FT62

8/16 or 4 to 20 mA model

y

Test bu tton

diagnostic LED

sensitivity adjustment:

B = factory setting

B

A

Sensor switches at high level

Fail-safe function will default to full signal

Sensor switches at low level

Fail-safe function will default to empty signal

A = decreased sensitivit

filling or emptying

output setting

signal output LED

Vibration amplitude diagnosis

NAMUR module (IEC 60947-5-6) and and 8/16 mA or 4 to 20 mA model

Measurement quality is related to the vibration amplitude of the fork. The diagnostic LED

indicates the quality of the vibration being sent to the LVS200 electronics.

English

mmmmm

• Diagnostic LED off: measurement quality is good. The vibration amplitude is strong.

• Diagnostic LED blinking: measurement quality is poor and vibration amplitude is

decreasing as fork becomes encrusted. When this happens, set the sensitivity

switch to decreased sensitivity.

• Diagnostic LED on: vibration has stopped and fork is fully encrusted with material.

Current output setting

8/16 mA

The chart below illustrates the output current when:

•Fork is clean

• Fork is encrusted: weak vibration amplitude is shown

• Fork is fully encrusted and vibration has stopped.

Diagnosis

Setting

Signal

output LED

Diagnosis

LED

D Off

D On I = 20 mA I = 6 mA

I = 16 mA I = 8 mA

I = 16 mA I = 8 mA

I = 8 mA I = 16 mA

7ML19985FT62 SITRANS LVS200 – INSTRUCTION MANUAL Page EN-15

mmmmm

The output current can indicate weak vibration amplitude with the diagnosis setting D

ON. If the diagnosis is set to D OFF, the output will be either 8 mA or 16 mA depending on

high or low level settings.

If the diagnosis is set to D ON, the output will change from 16 to 20 mA and from 8 to 6 mA

if the vibration is weak. This output can be passed to an external 4 to 20 mA output. There

English

is an internal delay of 10 seconds before the change happens, so that the external output

does not indicate a weak vibration when the vibration is stopped and started during

normal measurement operation.

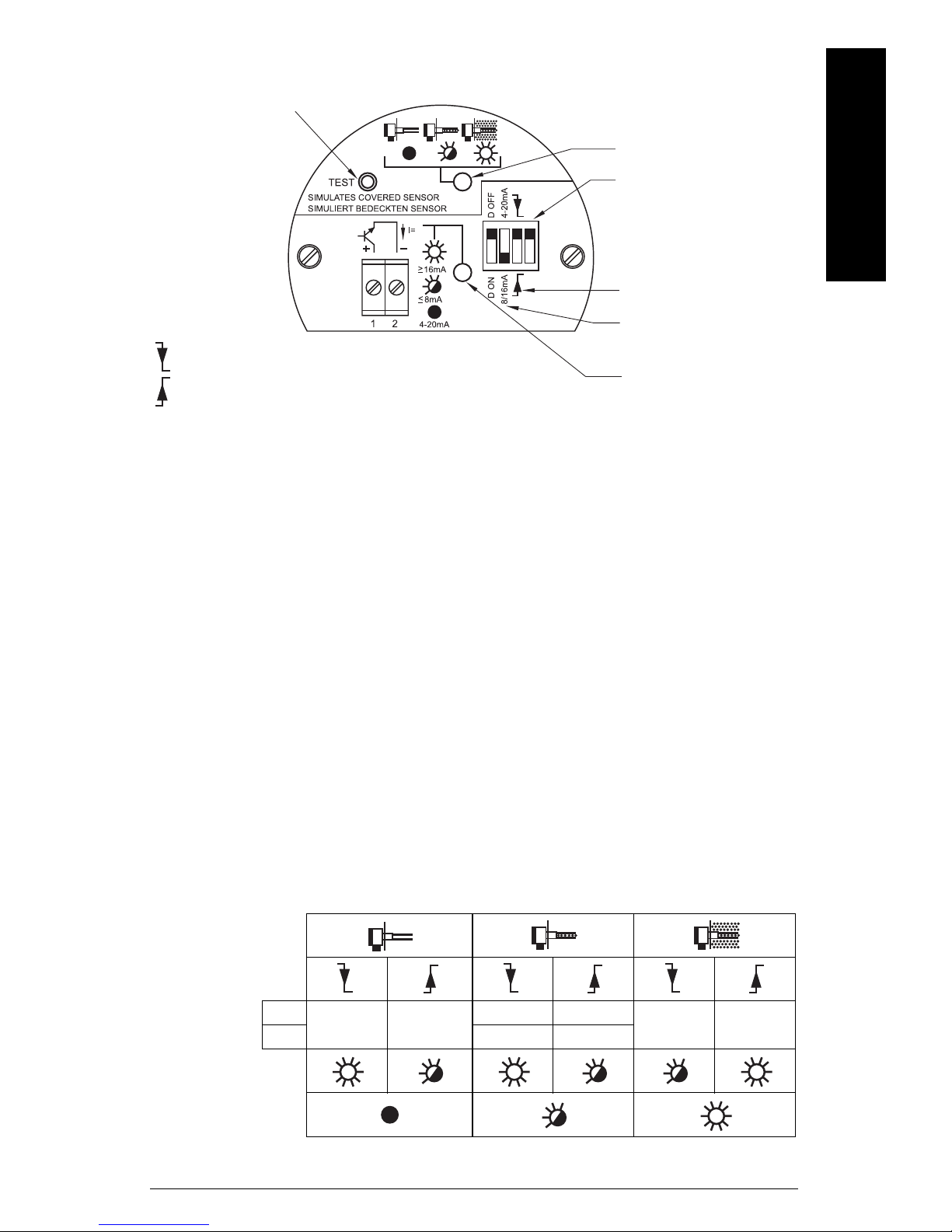

Buildup Detection (8/16 mA or 4 to 20 mA version)

With the 4 to 20 mA setting, you can recognize material buildup on the fork using a PLC or

data logger.

In this mode, the Diagnostic setting has no influence. The LED showing signal output is

off.

20 mA: The fork is clean.

<20 mA and >12/12.5 mA: The vibration amplitude is decreased by the material buildup.

<12/12.5 mA and >7/8 mA: This range indicates a weak vibration. The internal LED

showing diagnosis begins blinking to indicate a weak signal. If you are using a PLC to

evaluate the echo, delay the response time to this indicator for approximately 10 seconds.

A hysteresis of 0.5 mA (between 12 and 12.5 mA) is recommended.

7/8 mA: This point indicates that the fork is mostly encrusted.

6 mA: This point indicates that the fork is fully encrusted.

increasing material buildup

20 mA

s

t

a

output current

With standard sensitivity setting

d

e

c

r

e

a

s

e

d

s

e

n

n

d

a

r

d

s

e

n

s

i

t

i

v

i

Vibration damping by material

s

i

t

i

v

i

t

y

t

y

With decreased sensitivity setting

12/12.5 mA

7/8 mA

6 mA

Amplitude is 100%

Amplitude is 0%

Page EN-16 SITRANS LVS200 – INSTRUCTION MANUAL 7ML19985FT62

Amplitude is 100%

Amplitude is 0%

Maintenance

SITRANS LVS200 requires no maintenance or cleaning under normal operating

conditions. Under severe operating conditions, the tines may require periodic cleaning.

Brush off any accumulated deposits, taking care not to bend the tines.

Unit Repair and Excluded Liability

All changes and repairs must be done by qualified personnel, and applicable safety

regulations must be followed. Please note the following:

• The user is responsible for all changes and repairs made to the device.

• All new components must be provided by Siemens Milltronics Process Instruments Inc.

• Restrict repair to faulty components only.

• Do not re-use faulty components.

English

mmmmm

7ML19985FT62 SITRANS LVS200 – INSTRUCTION MANUAL Page EN-17

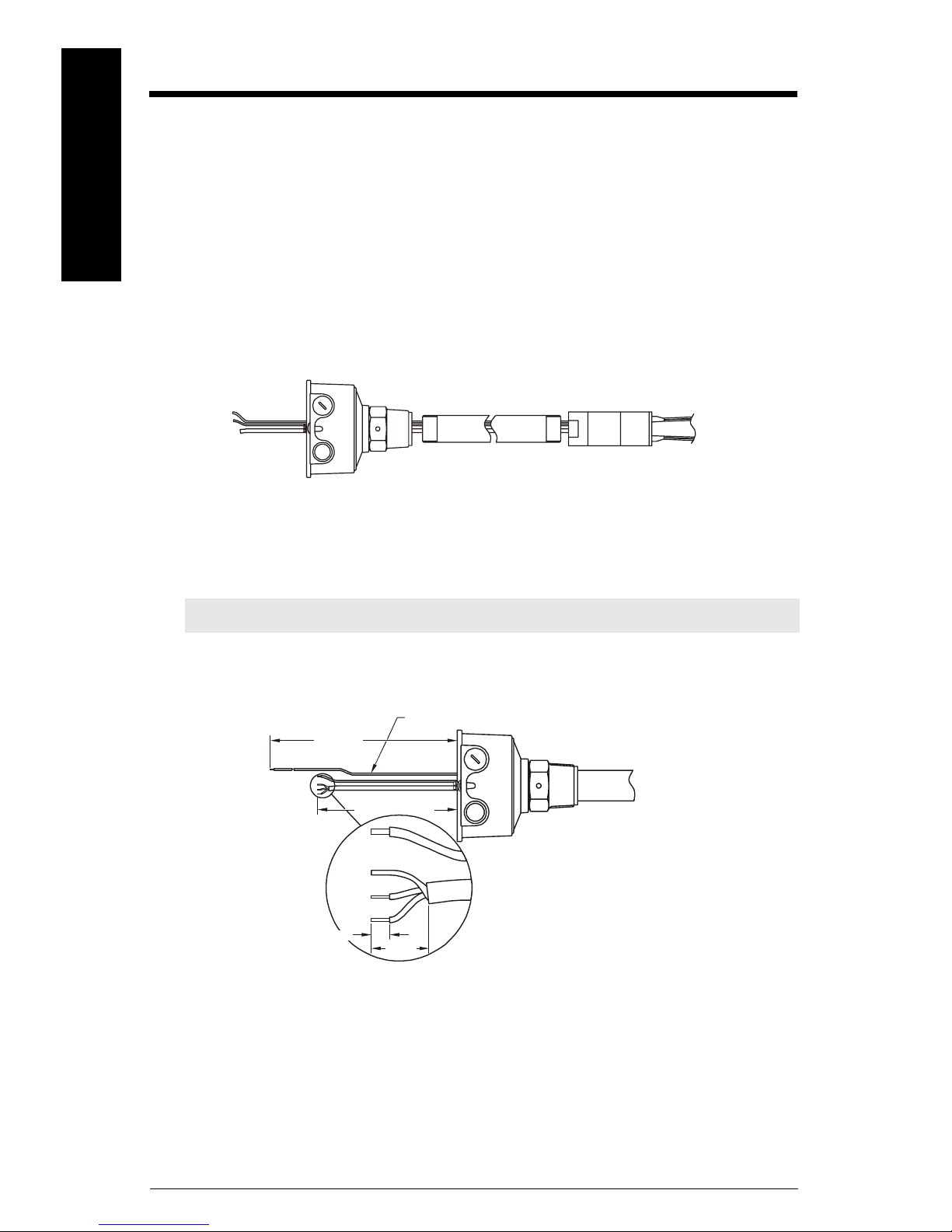

SITRANS LVS200 Pipe Extended Version

)

mmmmm

Assembly

English

Suggested tools:

• medium Phillips or 6 to 8 mm (¼”) flat screwdriver • terminal crimper

• 3 mm (1/8”) flat screwdriver • 36 mm open end wrench

• wire cutters • pipe wrench

•wire strippers

enclosure

customer supplied

pipe extension

fork assembly

1. Open the enclosure lid; remove electronics module.

2. Lead the sensor cable through the customer supplied 1" tube and enclosure.

3. Assemble the fork assembly, the pipe extension, and the enclosure using the 36 mm

open end wrench. Seal the pipe threads with an appropriate sealant.

Note: Do not turn fork assembly. Do not bend the fork during assembly.

4. Line up the fork and the tine orientation marking as shown in dimension drawing on

page 9. (The tine orientation marking on the process connection is to identify the

vertical orientation of the fork.)

220 mm

(8.7")

150 mm (5.9")

8 mm max.

5. Shorten sensor cable to a free length of 150 mm (5.9").

earth cable (green/yellow

18 mm

6. Shorten earth cable to a free length of 220 mm (8.7").

7. Prepare sensor cable as shown above, stripping a maximum of 8 mm from each

wire.

Page EN-18 SITRANS LVS200 – INSTRUCTION MANUAL 7ML19985FT62

electronics

module, flat

side up

8. Connect the sensor cable to the terminal connection board shown above.

9. Secure the sensor cable with cable ties.

10. Crimp the ring terminal 4 mm (0.19") to sensor earth cable.

3 mm (1/8”) screw driver

cable ties

11. Connect electronics module and terminal connection board. Be sure that all

terminals are tight.

English

mmmmm

12. Insert the electronics module into the housing. The terminal connection board is

used to guide the cable into the extension tube.

13. Fold cable as shown in diagram above.

14. Secure the electronics module as shown in diagram below.

Connect protection earth

of the enclosure to

terminal of the

electronics module.

Connect earth cable

of the fork to the

electronics earth

terminal.

7ML19985FT62 SITRANS LVS200 – INSTRUCTION MANUAL Page EN-19

Assembly Overview Drawing

lid

mmmmm

English

electronics module

terminal connection

board

sensor cable

enclosure

assembly

process

connection

thread G1” or 1" NPT

(use appropriate

thread sealant)

tine orientation marking

process thread 1 ½” NPT or

1 ½” BSP

min.

18 mm

(0.75")

approx.

138 mm

(5.4")

L = 300 to 3800 mm

(11.8 to 149.6")

170 mm

(6.7")

1" schedule 40 pipe

(internal min.

dia. 25.4 mm (customer

supplied and mounted)

thread G1” or 1" NPT

(use appropriate

thread sealant)

fork assembly

fork

X = L - 255 mm

(10")

min.

18 mm

(0.75")

SW 36

Note: Threaded

engagement to be a

min. of 7 mm (0.27")

process

thread

1 1/2" NPT

1 1/2" BSP

cable

entries

1/2" NPT

M20x1.5

1" pipe

thread

1" NPT

G 1"

Page EN-20 SITRANS LVS200 – INSTRUCTION MANUAL 7ML19985FT62

Sicherheitshinweise

Warn- und Hinweistexte müssen besonders beachtet werden. Diese sind grau hinterlegt

vom übrigen Text abgesetzt.

WARNUNG: bezieht sich auf ein Warnsymbol auf dem Produkt und

bedeutet, dass bei Nicht-Einhalt der entsprechenden Vorsichtsmaßnahmen Tod, schwere Körperverletzung und/oder erheblicher Sachschaden eintreten können.

WARNUNG

1

: bedeutet, dass bei Nicht-Einhalt der entsprechenden

Vorsichtsmaßnahmen Tod, schwere Körperverletzung und/oder

erheblicher Sachschaden eintreten können.

VORSICHT: bedeutet, dass bei Nicht-Einhalt der entsprechenden Vorsichtsmaßnahmen erheblicher Sachschaden eintreten kann.

Hinweis:

Betriebsanleitung, auf den besonders aufmerksam gemacht werden soll.

1.

Dieses Symbol wird verwendet, wenn sich kein entsprechendes

Vorsichtssymbol auf dem Produkt befindet.

steht für eine wichtige Information über das Produkt selbst oder den Teil der

Sicherheitssymbole

In der Betriebsanleitung

Auf dem

Produkt

Beschreibung

(Etikett auf dem Produkt: gelber Hintergrund.)

Vorsicht: Details sind in zugehörigen Dokumenten

(Betriebsanleitung) aufgeführt.

Deutsch

mmmmm

Erde (Masseklemme)

Schutzleiterklemme

Die Betriebsanleitung

Hinweise:

• Bitte beachten Sie die Vorschriften für Installation und Betrieb, um eine schnelle,

problemlose Installation, sowie maximale Genauigkeit und Zuverlässigkeit Ihres

SITRANS LVS200 zu gewährleisten.

• Diese Betriebsanleitung bezieht sich ausschließlich auf den SITRANS LVS200.

Mit Hilfe der vorliegenden Anleitung können Sie Ihren SITRANS LVS200 optimal einstellen. Für Vorschläge und Bemerkungen zu Inhalt, Aufbau und Verfügbarkeit der

Betriebsanleitung sind wir jederzeit offen.

Bitte richten Sie Ihre Kommentare an techpubs.smpi@siemens.com

www.siemens.com/processautomation finden Sie ein vollständiges Archiv aller Siemens

Milltronics Betriebsanleitungen.

. Unter

7ML19985FT62 SITRANS LVS200 – BETRIEBSANLEITUNG Seite DE-1

SITRANS LVS200: Einleitung

Hinweise:

• Installation, Wartung und Inbetriebnahme müssen durch qualifiziertes, technisches

Personal vorgenommen werden.

• Der SITRANS LVS200 darf nur gemäß den Anweisungen in dieser Betriebsanleitung verwendet werden.

Drei Ausführungen des SITRANS LVS200 stehen zur Verfügung:

• Der SITRANS LVS200, Standardausführung, ist ein Vibrations-Grenzstandschalter,

der die An- oder Abwesenheit rieselfähiger Schüttgüter in Behältern, Silos oder

Trichtern erfasst. SITRANS LVS200 liefert einen Signalausgang zur Anzeige eines

Min. oder Max. Alarms. Unterschiedliche Produkte können gemessen werden, wie

mmmmm

Deutsch

z. B. Kalk, Styropor, Mehl und Kunststoffgranulat. SITRANS LVS200 hat ein kompaktes Design und kann senkrecht oder waagrecht eingebaut werden. Die StandardSchwinggabelsonde des LVS200 ist auch mit verschiedenen Seilverlängerungen bis

maximal 20 000 mm (787") verfügbar. Für erhöhte Empfindlichkeit steht optional eine

längere Schwinggabelsonde zur Verfügung. Die Seilverlängerung des SITRANS

LVS200 ist nur für den Einbau von oben geeignet. Die vibrierende Schwinggabel

bewirkt eine gewisse Selbstreinigung des Gerätes vom Messstoff.

• Die Ausführung Trennschichtmessung Flüssigkeiten/Schüttgüter des SITRANS

LVS200 ist ein Vibrations-Grenzstandschalter, der auch abgesetzte Feststoffe in

Flüssigkeiten oder Feststoffe in beengten Anlagen, wie z. B. Speiserohren, erfassen

kann. Diese Ausführung ist so konzipiert, dass Flüssigkeiten ignoriert werden, um

die Trennschicht zwischen einem Feststoff und einer Flüssigkeit zu erfassen. Die mit

diesem Design verbundene kurze Schwinggabelsonde ist auch mit verschiedenen

Seilverlängerungen bis maximal 20 000 mm (787"), nur für den Einbau von oben verfügbar.

• Die Ausführung Rohrverlängerung des SITRANS LVS200 ist ein Vibrations-Grenzstandschalter, bei dem ein kundenseitiges Verlängerungsrohr [max. Länge 3800 mm

(150")] mit der Standard- oder Flüssigkeit/Feststoff-Ausführung (kurz) von LVS200

Schwinggabel und Elektronik verbunden wird. Dadurch kann die Elektronik für Sonderapplikationen von der Schwinggabel abgesetzt werden. Angaben zum Aufbau

finden Sie unter

SITRANS LVS200 Ausführung mit Rohrverlängerung

auf Seite 18.

Wesentliche Merkmale

• Hohe mechanische Beständigkeit

• Starke Schwingung, auch für hohe Belastungen geeignet

• Verdrehbares Gehäuse

• 1½” NPT oder 1½” BSPT Edelstahl-Gewindeanschluss, oder BSP oder NPT Schiebemuffe. DN 100 und 2, 3, 4" ASME Flanschoptionen verfügbar.

• Für leichtes Material geeignet

Standardausführung: 20 g/l (1,2 lb/ft

Standardausführung mit

Schwinggabel niedriges Schüttgewicht: 5 g/l (0,3 lb/ft

Ausführung Trennschichtmessung: 50 g/l (3 lb/ft

Seite DE-2 SITRANS LVS200 – BETRIEBSANLEITUNG 7ML19985FT62

3

)

3

)

3

)

Anwendungsbereiche

• Trockenkalk, Styropor, Mehl, Kunststoffgranulat

• Trockenes Schüttgut mit hoher oder geringer Dichte

• Trennschichterfassung von Feststoffen in einer Flüssigkeit (Filterbett)

• Flüssigkeit/Feststoff-Ausführung des LVS200 unterscheidet die Zustände Durchfluss/kein Durchfluss in Rohren

Arbeitsprinzip

Ein Signal vom elektrischen Schaltkreis bewirkt eine piezoelektrische Anregung der

Sonde, die zum Schwingen gebracht wird. Wird die Sonde durch das Füllgut bedeckt, so

wird die dadurch entstehende Dämpfung elektronisch registriert und ein entsprechender

Schaltausgang nach einer Sekunde Ansprechverzögerung betätigt. Sobald die Schwingsonde frei vom Materialdruck ist, nimmt die Schwingung wieder auf und das Relais kehrt

in seinen normalen Zustand zurück.

WARNUNGEN:

• Dieses Produkt wird als druckhaltendes Ausrüstungsteil im Sinne der

Richtlinie 97 / 23 / EG bezeichnet und ist nicht

heitsvorrichtung bestimmt.

für den Einsatz als Sicher-

Deutsch

mmmmm

• Die Werkstoffe werden entsprechend ihrer chemischen Beständigkeit

(oder Trägheit) für allgemeine Zwecke gewählt. Bei Einsatz in besonderen Umgebungen prüfen Sie vor Installation die chemische Beständigkeit anhand einschlägiger Tabellen.

7ML19985FT62 SITRANS LVS200 – BETRIEBSANLEITUNG Seite DE-3

Technische Daten

Hinweis: Siemens Milltronics ist bestrebt, die Genauigkeit der technischen Daten zu

gewährleisten, behält sich jedoch jederzeit das Recht auf Änderung vor.

Versorgungsspannung

• AC 19 ... 230 V, +10 %, 50 ... 60 Hz, 8 VA

• DC 19 ... 55 V, +10 %, 1,5 W

• DC 18 ... 50 V 3-Leiter PNP

• DC 7 ... 9 V (NAMUR Trennverstärker erforderlich) NAMUR IEC 60947-506, 2-Leiter

• 8/16 mA oder 4 ... 20 mA; DC 12,5 ... 35 V, 2-Leiter

mmmmm

Funktion

Deutsch

Messfrequenz

• Standard ca. 125 Hz

• Ausführung Trennschichtmessung ca. 350 Hz

• Option erhöhte Empfindlichkeit ca. 90 Hz

Signalverzögerung

• Sonde frei / bedeckt ca. 1 Sekunde

• Sonde bedeckt / frei ca. 1 bis 2 Sekunden

Relais Ansprechverzögerung (DPDT Ausführung)

• Einstellbar bis 30 Sekunden

Empfindlichkeit

• Max. oder Min., über Schalter wählbar

Min. Schüttgewicht

• Standardausführung ca. 20 g/l (1,2 lb/ft³)

• Standardausführung mit Schwinggabel

niedriges Schüttgewicht 5 g/l (0,3 lb/ft³)

• Ausführung Trennschichtmessung ca. 50 g/l (3 lb/ft³)

Maximale Korngröße

• 10 mm (0.39")

Alarmausgang

• Ausführung mit 1 Relais SPDT Relais

• Ausführung mit 2 Relais DPDT Relais

• Relais Failsafe Max oder Min, über Schalter wählbar

• Relais 8 A bei AC 250 V, ohmsche Last; Relais 5 A bei DC 30 V, ohmsche Last

• 3-Leiter PNP Open Collector: Dauerlast

Seite DE-4 SITRANS LVS200 – BETRIEBSANLEITUNG 7ML19985FT62

maximal 0,4 A, kurzschluss- und

überlastfest;

Schaltspannung: max. 50 V (Verpolungsschutz)

Loading...

Loading...