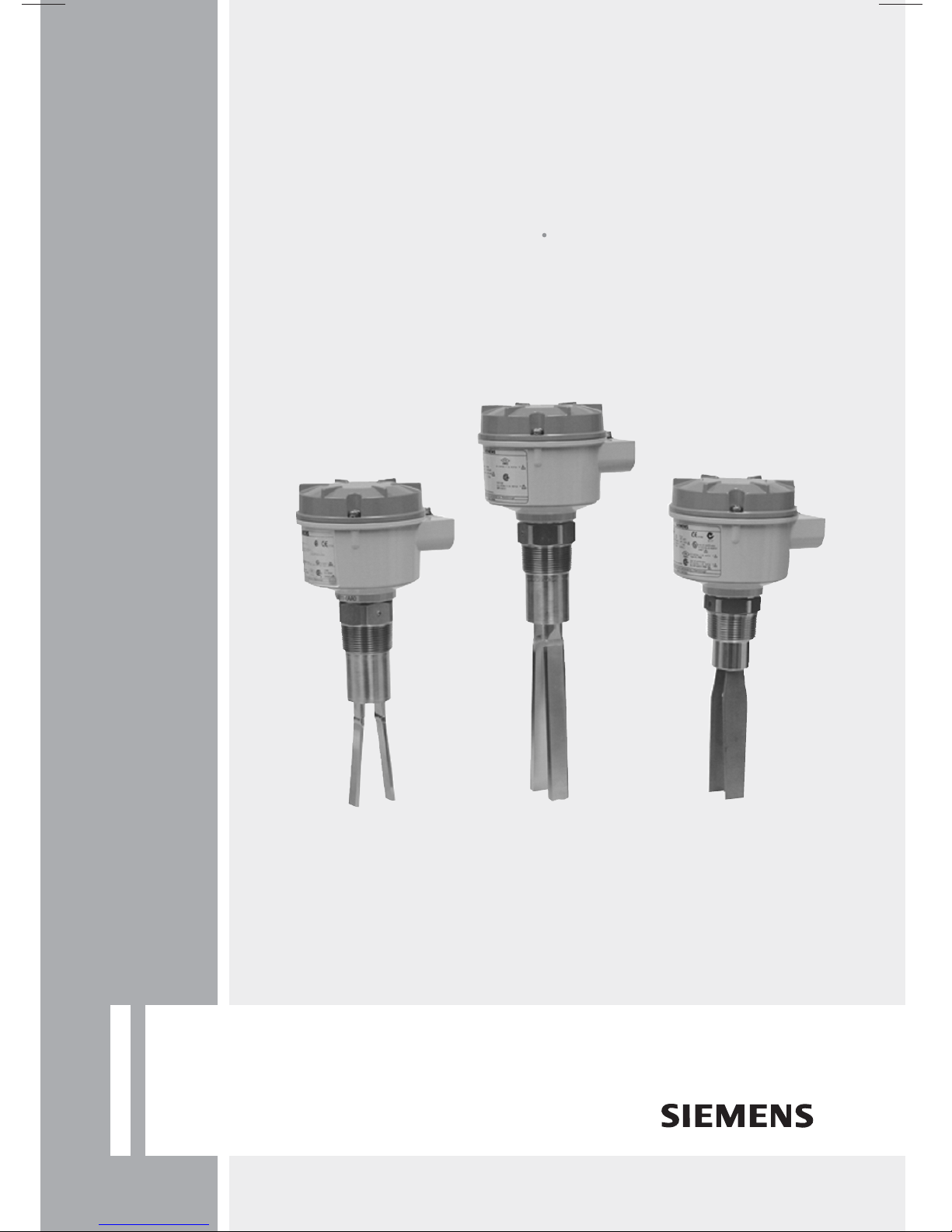

Siemens SITRANS LVS100, SITRANS LVS200 Operating Instructions Manual

Vibrating Switches

SITRANS LVS100/200

Operating Instructions 08/2012

SITRANS

Safety Notes

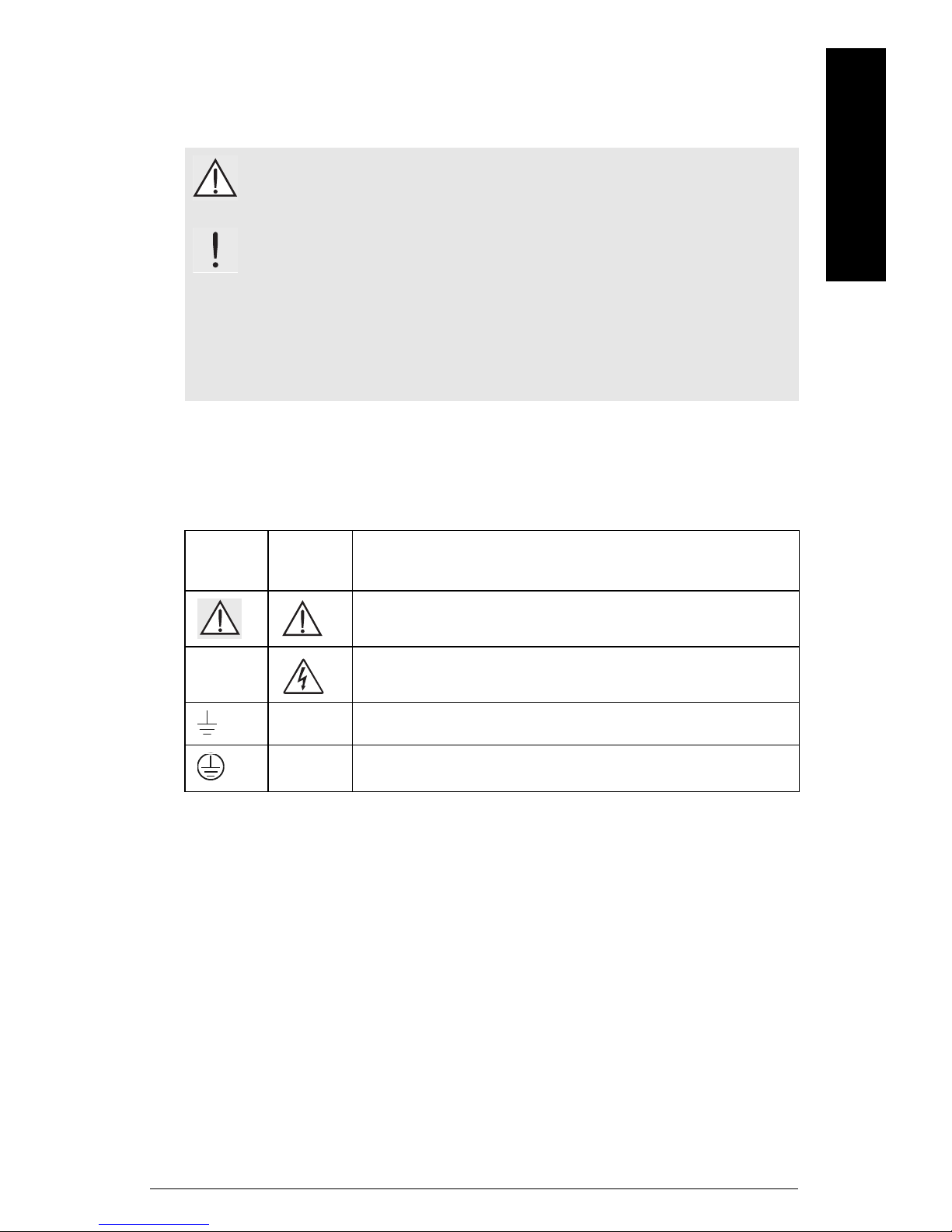

Special attention must be paid to warnings and notes highlighted from the rest of the text

by grey boxes.

WARNING: relates to a caution symbol on the product, and means

that failure to observe the necessary precautions can result in

death, serious injury, and/or considerable material damage.

WARNING

precautions can result in death, serious injury, and/or considerable

material damage.

CAUTION: means that failure to observe the necessary precautions can

result in considerable material damage.

Note:

manual.

1.

means important information about the product or that part of the operating

This symbol is used when there is no corresponding caution symbol on the

product.

Safety marking symbols

1

: means that failure to observe the necessary

English

mmmmm

In

Manual

On

Product

Description

(Label on product: yellow background.)

Caution: refer to accompanying documents (manual) for details.

(Caution symbol on product) Warning: Risk of electric shock

Earth (ground) Terminal

Protective Conductor Terminal

7ML19985FT63 SITRANS LVS100/200 – INSTRUCTION MANUAL Page EN-1

mmmmm

The Manual

Notes:

• Please follow the installation and operating procedures for a quick, trouble-free

English

• This manual applies to SITRANS LVS100 and SITRANS LVS200 only.

• Product details and instructions in this manual relate to both SITRANS LVS100 and

• This product is intended for use in industrial areas. Operation of this equipment in a

This manual will help you set up your SITRANS LVS100/200 for optimum performance. We

always welcome suggestions and comments about manual content, design, and

accessibility.

Please direct your comments to techpubs.smpi@siemens.com

Siemens Milltronics manuals, go to www.siemens.com/processautomation.

installation and to ensure the maximum accuracy and reliability of your

SITRANS LVS100/200

SITRANS LVS200 unless otherwise stated.

residential area may cause interference to several frequency based

communications.

. For the complete library of

Page EN-2 SITRANS LVS100/200 – INSTRUCTION MANUAL 7ML19985FT63

SITRANS LVS100 and LVS200

Introduction

Notes

• Installation, maintenance, and commissioning must be performed by qualified

technical personnel.

• SITRANS LVS100/200 must be used only in the manner outlined in this instruction

manual.

The SITRANS LVS100 and SITRANS LVS200 are available in a standard version, with the

SITRANS LVS200 offering two additional versions.

SITRANS LVS100, SITRANS LVS200 - Standard Version

• SITRANS LVS100/200 standard version is a vibrating level switch that detects high

or low levels of dry bulk solids in bins, silos, or hoppers. It has a compact design that

allows it to be top or side mounted and the vibrating fork ensures that the tines are

kept clean.

• SITRANS LVS100 is an entry level solids fork with a bulk density limit starting

at 60 g/l (3.8 lb/ft

4 000 mm (157").

• SITRANS LVS200 provides several output options for indication of point level

with products such as lime, styrofoam, flour, and plastic granules, starting at

20 g/l (1.2 lb/ft

measure bulk densities of less than 5g/l. In addition, the LVS200 has a wider

range of process configurations. SITRANS LVS200 standard length fork is

available with variable cable extension lengths to a maximum of 20 000 mm

(787") (cable extensions for top mount applications only). An optional longer

fork is available for increased sensitivity.

3

). The LVS100 is available with rigid extension options to

3

). It handles a broader range of applications and is able to

English

mmmmm

SITRANS LVS200 - Liquid/Solid Interface Version

• The SITRANS LVS200, liquid/solid interface version, is a vibrating level switch that

can also detect settled solids within liquids, or solids within confined spaces such

as feed pipes. This version is designed to ignore liquids in order to detect the

interface between a solid and a liquid. The design incorporates a short fork, and is

also available with variable cable extension lengths to a maximum of 7 000 mm

(275.59"), for top mount applications only.

SITRANS LVS200 - Pipe Extension Version

• The SITRANS LVS200, pipe extension version, is a vibrating level switch that

incorporates a customer supplied pipe extension [maximum length 3800 mm (150")]

with the standard or liquid/solid (short) LVS200 fork and electronics. This allows for

separation of the electronics and tuning fork for applications requiring a rigid

extension. Please see

information on assembly.

7ML19985FT63 SITRANS LVS100/200 – INSTRUCTION MANUAL Page EN-3

SITRANS LVS200 Pipe Extended Version on page 26

for

mmmmm

Product Features

• High resistance to mechanical forces

• Strong vibration resistance to high bulk material loads

• Rotatable enclosure

• LVS100: R 1½" (BSPT); 1¼" NPT (Taper) threaded connection

English

• LVS200: Stainless steel 1½” NPT or R 1½” (BSPT) threaded connection, or R 2"

(BSPT) or NPT sliding sleeve. DN 100 and 2, 3, 4" ASME flange and Triclamp 2"

options available.

• Suitable for high or low density material

LVS100 standard version: 30 g/l (1.9 lb/ft

LVS200 standard version: 20 g/l (1.2 lb/ft

LVS200 standard version with low density fork: 5 g/l (0.3 lb/ft3) min.

LVS200 liquid/solid interface version: 50 g/l (3.0 lb/ft

Product Applications

• Dry lime, styrofoam, flour, plastic granules

• High or low density, dry bulk materials

• Interface detection of a solid within a liquid (filter beds)

• Flow or no flow detection in pipe using liquid/solid LVS200 version

3

) min.

3

) min.

3

) min.

Principle of Operation

A signal from the electronic circuit excites a crystal in the probe, causing the fork to

vibrate. If the fork is covered by material, the change in vibration is detected by electronic

circuitry which causes the relay to change state after a one second delay. When the

material no longer reaches the tines, full vibration resumes and the relay reverts to its

normal state.

WARNINGS:

• This product is designed as a Pressure Accessory per Directive 97 / 23 / EC

and is not

• Materials of construction are chosen based on their chemical

compatibility (or inertness) for general purposes. For exposure to

specific environments, check with chemical compatibility charts

before installing.

intended for use as a safety device.

Page EN-4 SITRANS LVS100/200 – INSTRUCTION MANUAL 7ML19985FT63

Specifications

Note: Siemens Milltronics makes every attempt to ensure the accuracy of these

specifications but reserves the right to change them at any time.

Power

LVS10 0

• 19 to 230 V AC,

LVS20 0

• 19 to 230 V AC, +10 %, 50 to 60 Hz, 1.8 VA / 19 to 55 V DC, +10 %, 1.5 W

• 18 to 50 V DC 3-wire PNP

• 7 to 9 V DC (requires NAMUR switch amplifier) NAMUR IEC 60947-506, 2-wire

• 8/16 mA or 4 to 20 mA; 12.5 to 35 V DC, 2-wire

10 %, 50 to 60 Hz, 22 VA / 19 to 40 V DC, 10 %, 2 W

Performance

Measuring frequency

LVS10 0

• standard approx. 200 Hz

LVS20 0

English

mmmmm

• standard approx. 125 Hz

• liquid/solid interface version approx. 350 Hz

• enhanced sensitivity option approx. 90 Hz

Signal delay

• probe uncovered to covered approx. 1 second

• probe covered to uncovered approx. 1 to 2 seconds

Relay delay (DPDT version) (LVS200)

• adjustable up to 30 seconds

Sensitivity

• high or low, switch selectable

Minimum material density

LVS10 0

• standard version approx. 30 g/l (1.9 lb/ft

LVS20 0

• standard version approx. 20 g/l (1.2 lb/ft³)

• standard version with low density fork approx. 5 g/l (0.3 lb/ft³)

• liquid/solid interface version approx. 50 g/l (3 lb/ft³)

3

)

7ML19985FT63 SITRANS LVS100/200 – INSTRUCTION MANUAL Page EN-5

mmmmm

Alarm Output

English

Maximum particle size

• LVS100 8 mm (0.32")

• LVS200 10 mm (0.39")

LVS10 0

• version with 2 relays DPDT relay

relay fail-safe: high or low,

switch selectable

relay 8 A at 250 V AC,

non-inductive / relay 5 A at 30 V DC,

non-inductive

LVS20 0

• version with 1 relay SPDT relay

relay fail-safe: high or low,

switch selectable

relay 8 A at 250 V AC,

non-inductive / relay 5 A at 30 V DC,

non-inductive

• version with 2 relays DPDT relay

relay fail-safe: high or low,

switch selectable

relay 8 A at 250 V AC,

non-inductive / relay 5 A at 30 V DC,

non-inductive

• 3-wire PNP open collector: permanent load

maximum 0.4 A, short circuit and

overload protected;

turn-on voltage: max. 50 V (reverse

protection)

• mA output (build-up detection) 8/16 mA or 4 to 20 mA;

resolution 4 to 20 mA, ±0.1 mA

Page EN-6 SITRANS LVS100/200 – INSTRUCTION MANUAL 7ML19985FT63

Mechanical

Process Connection

LVS10 0

• thread R 1½" (BSPT); 1¼" NPT (Taper)

ANSI B 1.20.1

• thread material stainless steel 316 Ti (1.4581) or

304 (1.4301) for specific configurations

LVS20 0

• thread 1½” NPT (Taper), R 1½” (BSPT)

• thread material stainless steel 304 (1.4301) or

optional stainless steel 316 Ti (1.4571)/

316L (1.4404)

• flanges DN 100 PN6, DN 100 PN16,

2", 3", 4" ASME 150 lb flanges

• optional sliding bushing with R 2" (BSPT) or NPT (Taper) thread

• Tri-clamp 2" (DN50) ISO 2852

Tines

• tine material stainless steel 316Ti (1.4571)/ 316L (1.4581)

1

(PTFE

coated tines are available upon special request. Contact your local Siemens

representative for ordering information.)

English

mmmmm

Enclosure

• construction epoxy-coated aluminum

• conduit entry 2 x M20x1.5, or 2 x ½” NPT

• ingress protection Type 4X/NEMA 4X/IP66

Weight

• standard version, no extensions 2.0 kg (4.4 lb)

• solids/liquids, no extensions 1.9 kg (4.2 lb)

Environmental

• location indoor/outdoor

• altitude max. 2000 m (6562 ft)

• ambient temperature –40 to +60 °C (–40 to +140 °F)

• relative humidity 0 to 100% (suitable for outdoor: ingress

• overvoltage category II

• pollution degree 2

protection: Type 4X/NEMA 4X/IP66)

1.

Polytetrafluoroethylene

7ML19985FT63 SITRANS LVS100/200 – INSTRUCTION MANUAL Page EN-7

mmmmm

Process

English

Temperature

• All approvals except CSA Class II,

Group G: –40 to +150 °C (–40 to +302 °F)

• CSA Class II, Group G: –40 to +140 °C (–40 to +284 °F), CSA

temperature code T3B

• For applications with process temperature greater than +80 °C (+176 °F), the

maximum threaded bushing surface temperature must not exceed +80 °C (+176 °F)

• Maximum enclosure surface temperature (Category 2D): +120 °C (+248 °F) (ATEX

relevant)

• Maximum extension surface temperature (Category 1D): +150 °C (+302 °F) (ATEX

relevant)

Note: SITRANS LVS200 can be installed with an optional temperature isolator

extension. The isolator increases the distance of the electronics from the process

surface, thus allowing for a higher ambient temperature. See “Temperature Isolator

Option (LVS100/200)” on page 11. for more information.

Pressure

• max 10 bar, gauge (145 psi, gauge)

Note: Pressure information for hazardous areas

The device construction allows over-pressure up to 10 bar. This pressure is allowed for

test purposes. The ATEX approval applies to over-pressure between –0.2 and 0.1 bar in

hazardous areas. For higher or lower pressures, the approval is not valid.

Approvals

LVS10 0

•CE

• ATEX II 1/2D

• IECEx t IIIC Da/Db

• CSA/FM Class II, III, Div. 1, Groups E, F, G

•C-TICK

LVS20 0

•FM/

•CE

• CSA/FM Dust Ignition Proof

• ATEX II 1/2D

• IECEx t IIIC Da/Db

• CSA/FM IS Class I, II, III, Div. 1, Groups A to G,

• FM Class I, AEx ia IIC, CSA Class 1, Ex ia IIC, available only with 7 to 9 V DC power

• ATEX II 1G and 1/2G EEx ia IIC; ATEX II 1D and 1/2D, available only with 7 to 9 V DC

•C-TICK

CSAUS General Purpose

C

supply with NAMUR switch amplifier

power supply with NAMUR switch amplifier

Page EN-8 SITRANS LVS100/200 – INSTRUCTION MANUAL 7ML19985FT63

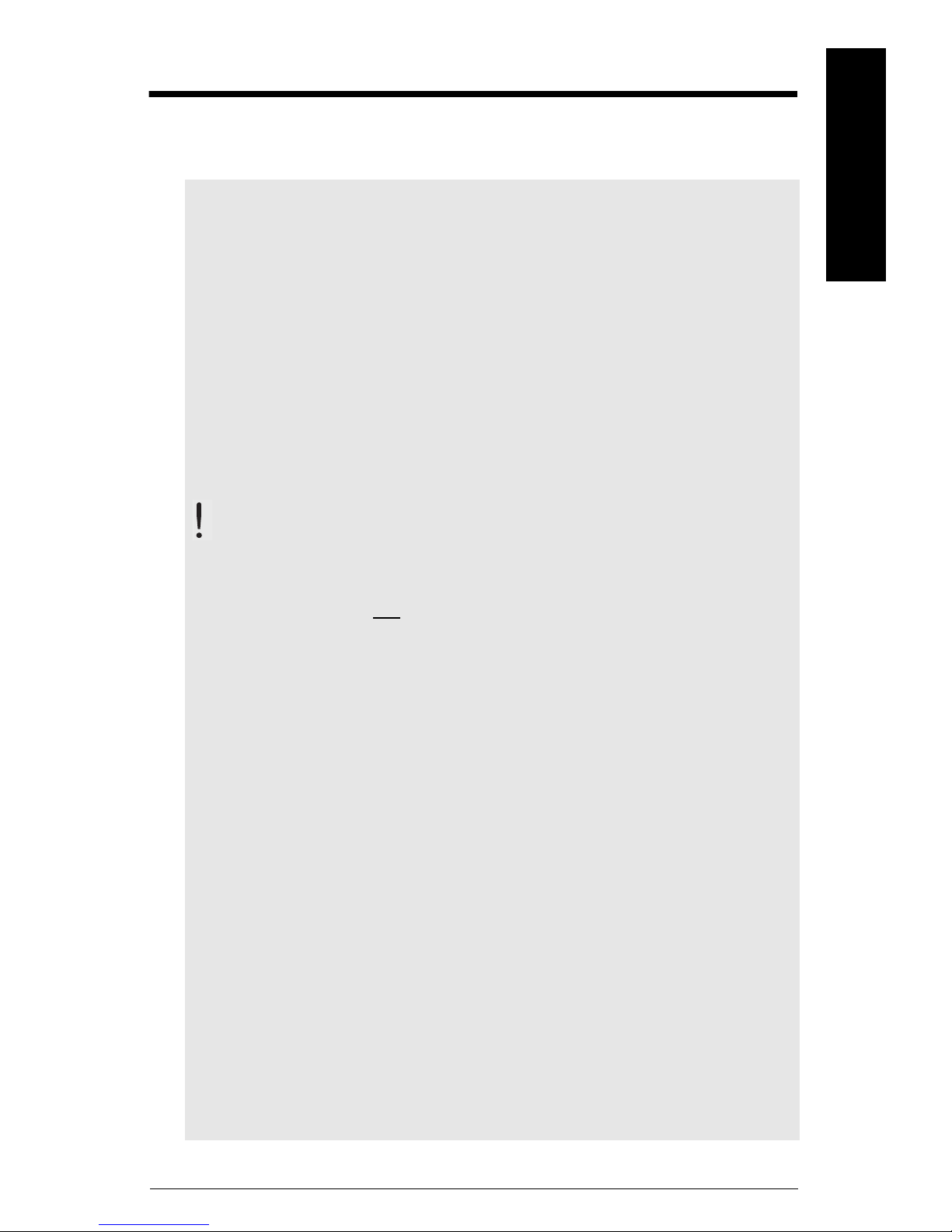

Installation

Mounting

Notes:

• Installation shall be performed by qualified personnel and in accordance with local

governing regulations.

• Do not bend, shorten or extend the tines.

• Position the tines using a 50 mm open-end wrench when installing the process

connection (do not turn the housing). When side mounting SITRANS LVS100/200,

position the tines vertically, with the tine orientation marking facing up or down.

• In pressure applications, use PTFE tape or other appropriate sealant to seal

tapered threaded connections.

• After mounting, ensure the cable entries point downward to prevent water entering

the housing.

• For the SITRANS LVS100/200 extended model, the torque due to material loading at

the mounting point may not exceed 250 Nm.

• Mounting torque for the 1½" thread connection may not exceed 80 Nm.

English

mmmmm

WARNINGS:

LVS100 and LVS200:

• This product is designated as a Pressure Accessory per Directive

97 / 23 / EC and is not

intended for use as a safety device.

• Improper installation may result in loss of process pressure.

• To install devices in hazardous locations, observe all valid installation

regulations.

• For Dust Ex installations: Before opening the device lid, ensure there

are no deposits present.

• Do not remove lid while circuits are live.

• Install the SITRANS LVS100/200 so mechanical friction or impact does

not cause sparks between the aluminium enclosure and steel vessel.

LVS200:

• Installation in Zone 0 (electronics: NAMUR): The intrinsic safe supply

circuit must have galvanic isolation to a non- intrinsically safe area.

Otherwise, provide protection for the device against lightning strikes

(see EN 60079-14).

• Power supply (electronics: NAMUR): Intrinsically safe protection is

only valid when connected to a certified intrinsically safe power

supply.

• For the LVS Pipe extended and cable extended models with Namur

electronics for gas hazardous approvals: When mounting the units on a

vessel lid that separates Zone 0 (Cat. 1G) from Zone 1 (Cat 2G), the units

have no safe separation between Zone 0 and Zone 1. Gas can pass

from Zone 0 through the unit to Zone 1.

7ML19985FT63 SITRANS LVS100/200 – INSTRUCTION MANUAL Page EN-9

mmmmm

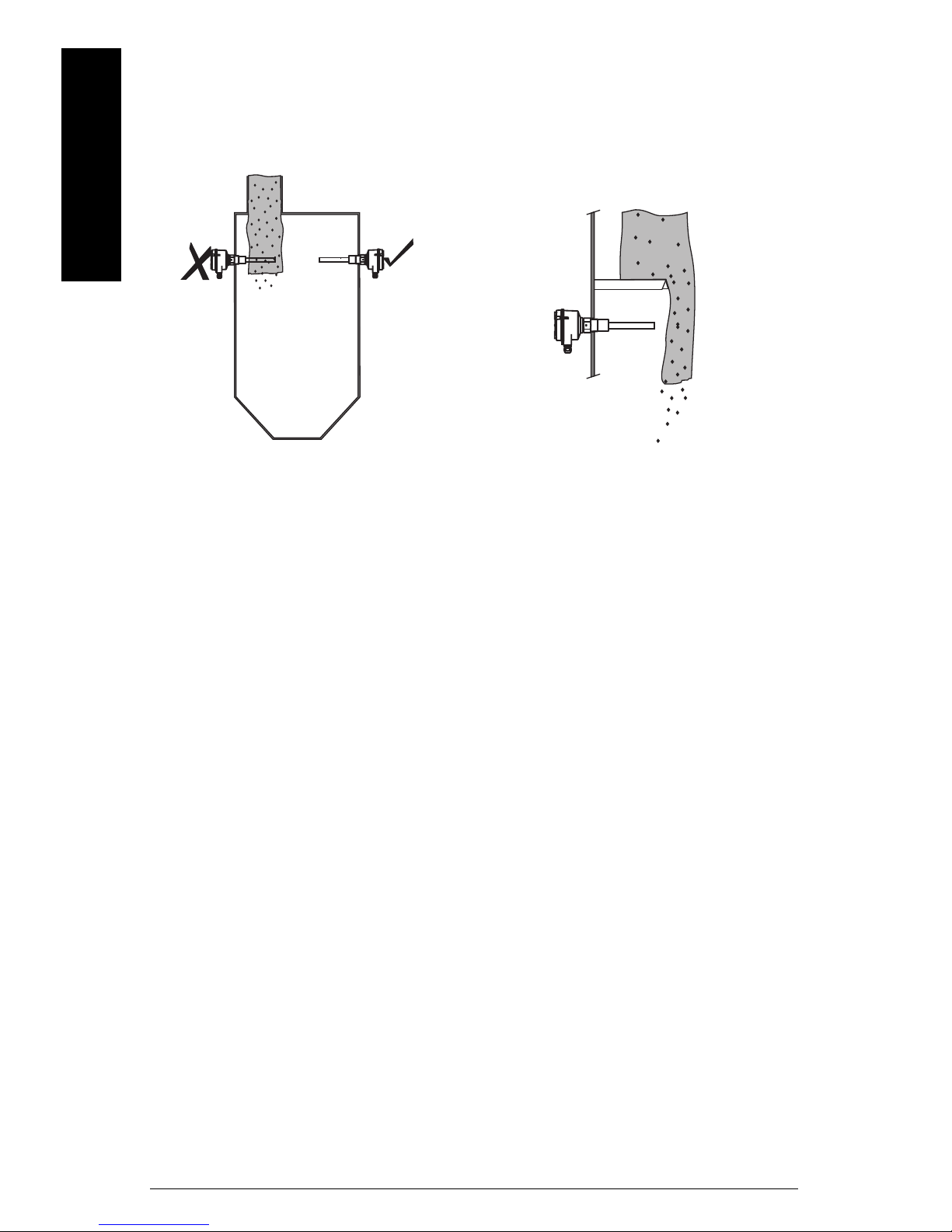

Cable gland faces

downward to avoid

water penetration.

Protection in case of

high material loading.

Use angle mounting for flowing

material only.

If angle mounting is required

with high material loading,

customer-supplied protection

from falling material must be in

place.

*

max. deviation

from vertical

max. length L

5º 4 m

45º 1.2 m

>45º 0.6 m

*

L

Tine orientation

marking facing

sideways.

Position tines vertically

to avoid product buildup: use a 50 mm openend wrench to turn the

process connection

until the tine

orientation marking

faces up or down.

Rigid extension with

sliding sleeve

Cable

extension

version

SITRANS LVS100/200 is normally mounted into the vessel top for full detection, or

through the tank wall at the detection level, for full, demand, or empty detection.

English

Page EN-10 SITRANS LVS100/200 – INSTRUCTION MANUAL 7ML19985FT63

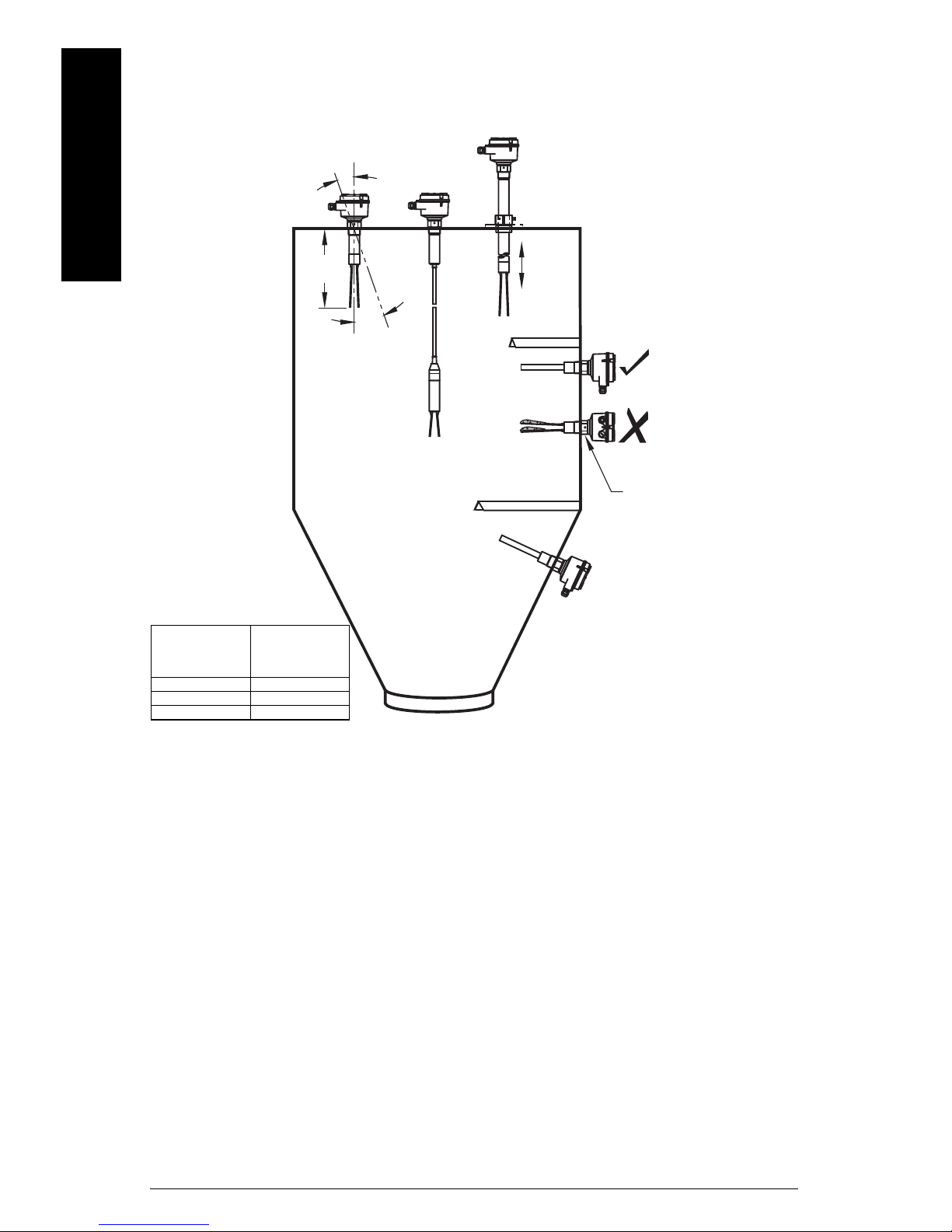

Temperature Isolator Option (LVS100/200)

$ installed without temperature

isolator, process connection at surface

% installed without temperature

isolator, process connection above

surface

& installed with temperature isolator

option

Installing SITRANS LVS100/200 with

the temperature extension allows the

device to be operated at higher

ambient temperatures, &, than would

be possible otherwise, $.

Process Temperature (LVS200)

Process Temperature (LVS100)

When installed with the temperature isolator option, SITRANS LVS100/200 can operate in

higher ambient temperatures.

English

mmmmm

7ML19985FT63 SITRANS LVS100/200 – INSTRUCTION MANUAL Page EN-11

mmmmm

Caution:

• Locate SITRANS LVS100/200

out of path of falling material

• Protect shaft and tines from falling

material

OR

Process Cautions

English

Page EN-12 SITRANS LVS100/200 – INSTRUCTION MANUAL 7ML19985FT63

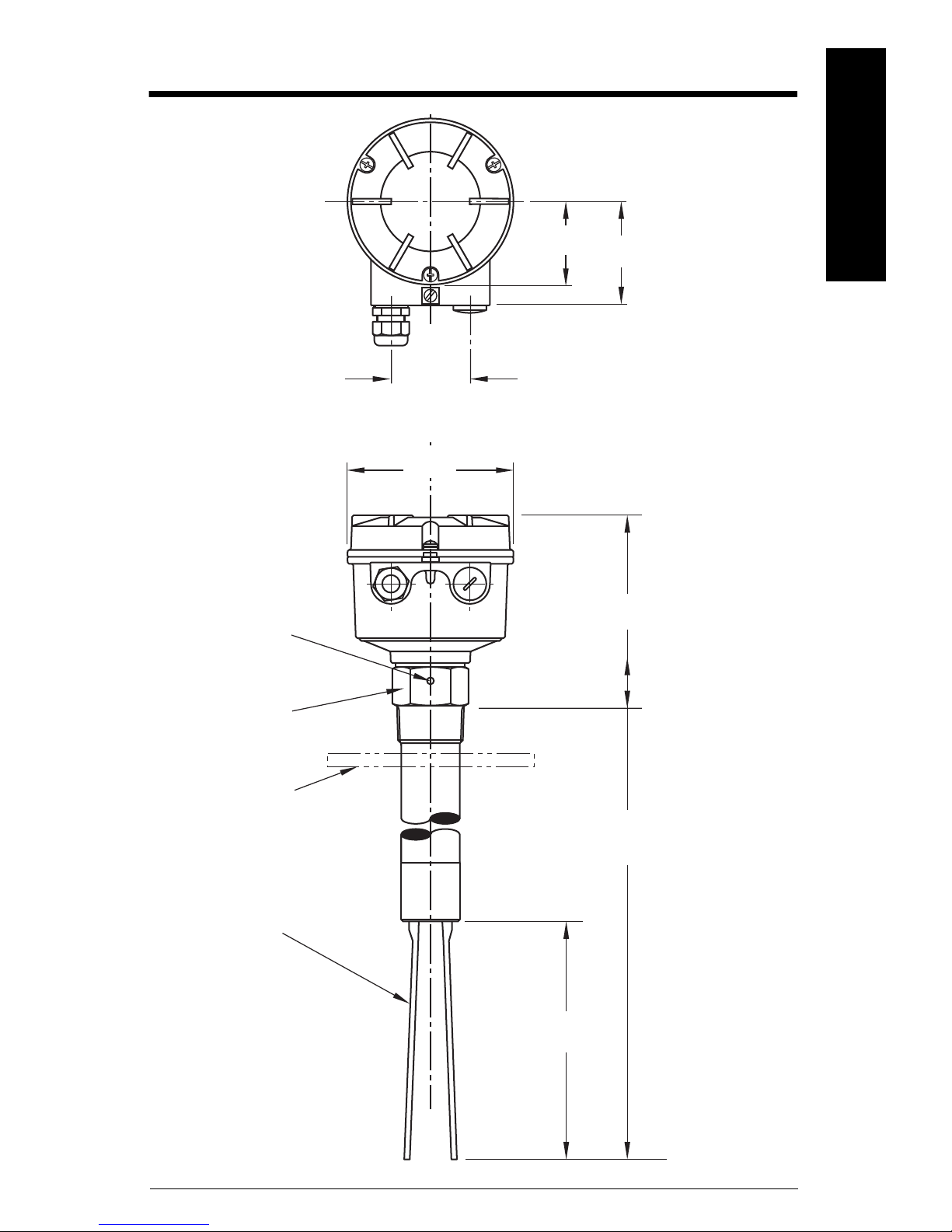

Dimensions - SITRANS LVS100

120 mm

(4.72")

150 mm

(5.91")

customer

supplied

process

flange

170 to 4000 mm (6.69 to 157"):

customer-specified rigid

extension

125 mm (4.92"):

standard fork

60 mm

(2.36")

60 mm

(2.36")

75 mm

(2.95")

tine

orientation

marking

Zone 21

ATEX Category 2D

IECEx EPL Db

Zone 20

ATEX Category 1D

IECEx EPL Da

threaded

bushing [max.

temp. +80°C

(+176°F)]

tine

English

mmmmm

7ML19985FT63 SITRANS LVS100/200 – INSTRUCTION MANUAL Page EN-13

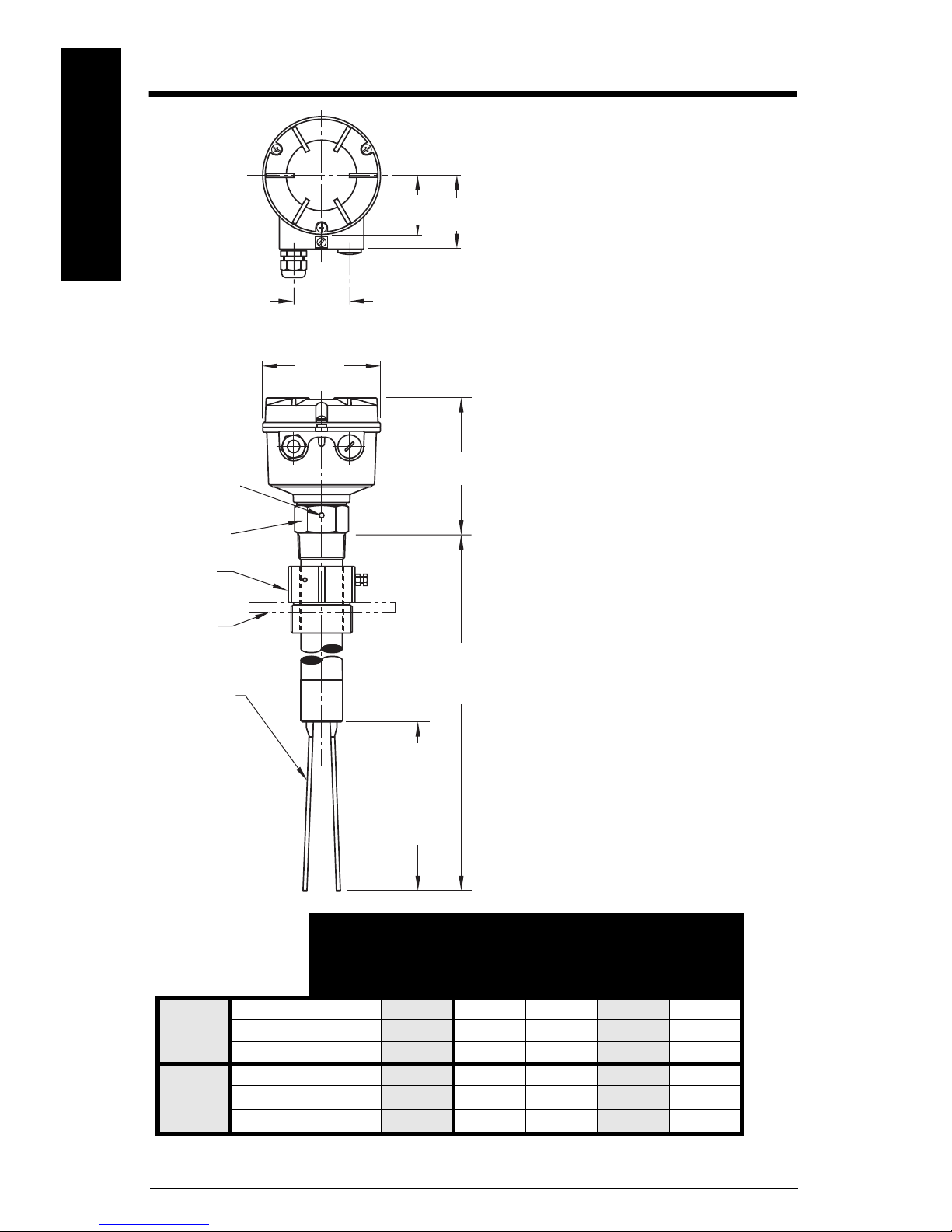

mmmmm

120 mm

(4.72")

150 mm

(5.91")

customer

supplied

process

flange

165 mm (6.5"): compact solids/liquids interface model

230 mm (9.0"):compact standard version

300 to 40 00 mm (11.81 to 157"): customer-specified rigid

extension

170 mm (6.69"):

standard fork

195 mm (7.68"):

low density fork

100 mm (3.94"):

liquid/solid

(short) fork

60 mm

(2.36")

60 mm

(2.36")

75 mm

(2.95")

tine

orientation

marking

**A

**B

threaded

bushing [max.

temp. +80°C

(+176°F)]

optional

sliding

bushing*

*Note: The clamping screws of the sliding bushing must

be tightened to 10 Nm.

tine

Universal voltage Relay SPDT

Universal Voltage Relay DPDT

3-wire PNP

2 wire without contact

8/16 mA or 4-20 mA

(non-intrisically safe)

NAMUR IEC 60945-5-6 (Intrinsically Safe)

8/16 mA or 4-20 mA (intrinsically safe)

**A

EPL (IECEx) Da Db Da Db Ga Gb

Category (ATEX) 1D

2D 1D 2D 1G 2G

Zone 20

21 20 21 01

**B

EPL (IECEx) Da Da Da Da Ga Ga

Category (ATEX)

1D 1D 1D 1D 1G 1G

Zone

20 20 20 20 00

Dimensions - SITRANS LVS200

English

Page EN-14 SITRANS LVS100/200 – INSTRUCTION MANUAL 7ML19985FT63

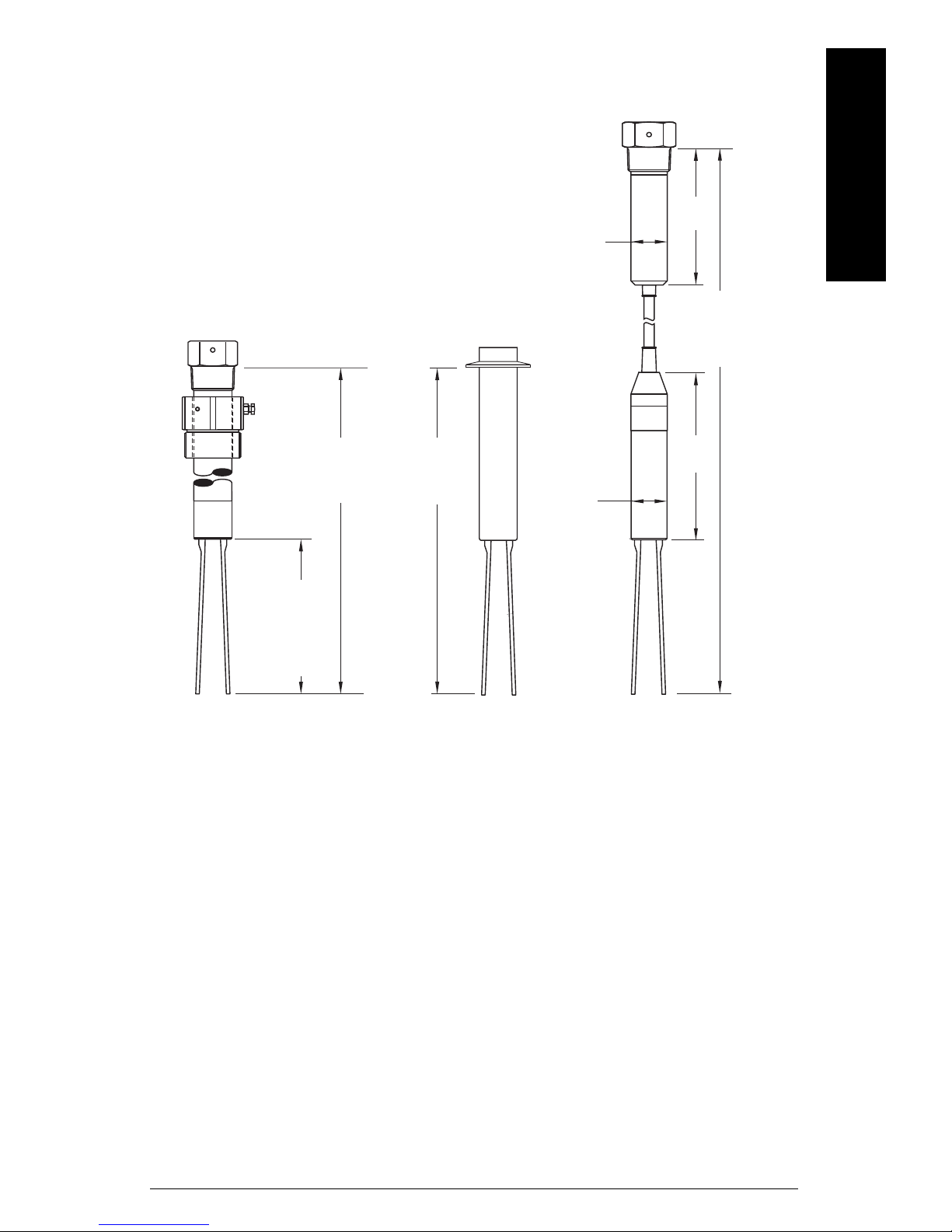

Dimensions (LVS200 Forks)

165 mm (6.5"): compact solids/liquids

interface model

230 mm (9.0"):compact standard version

300 to 4000 mm (11.81 to 157"): customerspecified rigid extension

170 mm (6.69"):

standard fork

195 mm (7.68"):

low density fork

100 mm (3.94"):

liquid/solid

(short) fork

195 mm

(7.68")

700 to

20 000 mm*

(27.56 to 787")

155 mm

(6.1")

ø 42 mm

(1.67")

ø 42 mm

(1.67")

Cable version

TriClamp version

Standard version

*Note: Cable version with Liquids/solids interface

model option length to 7000 mm (275.59")

Cable version with NAMUR electronics length to

10 000 mm (393.7")

English

mmmmm

7ML19985FT63 SITRANS LVS100/200 – INSTRUCTION MANUAL Page EN-15

Wiring

mmmmm

English

WARNINGS:

• Open SITRANS LVS100/200 only when supply voltage is switched off.

• All field wiring must have insulation suitable for at least 250 V AC.

• A disconnect switch must be in close proximity to the equipment and

within easy reach of the operator.

• Unused cable conduit fittings must be locked with a closing element or

plug.

• Observe all pertinent rules and regulations in the country of

installation.

Notes:

European requirements

• Cable gland/closing element: The screwed cable gland and closing element must have

the following specifications: Ingress protection IP66, temperature range from -40 to

70 °C (-40 to 158 °F), UL or VDE certified (depending on the country where the unit is

installated), pull relief.

Make sure the screwed cable gland safely seals the cable and that it is tight (danger of

water intrusion). Cable glands that are not used have to be locked with a closing

element.

•Conduit system: In case of using a conduit system (with NPT thread) instead of a cable

gland, the regulations of the coutnry where the unit is installed must be observed. The

conduit must have a tapered thread either ½" NPT or ¾" NPT in accordance with the unit

and ANSI B 1.20.1. Not used inlets must be closed tight with a metal closing element.

• Cable glands and conduit system for ATEX/IECEx (Dust and Gas Hazardous Locations):

Installation according to the regulations of the country where the unit is installed.

Not used entries have to be closed with blanking elements certified for this purpose.

Where available, the factory provided parts must be used.

A strain relief must be provided for the field wiring cables, when the device is installed

with the facotry provided cable glands.

The diameter of the field wiring cable must match to the clamping range of the cable

clamp.

If other than the factory provided parts are used, the following must be ensured:

• The parts must have an approval adequate to the approval of the level sensor

(certificate and type of protection).

• The approved temperature range must be from the min. ambient temperature of

the level sensor to the max. ambient temperature of the level sensor increased

by 10K.

• The parts must be mounted according to the instructions of the supplier.

• Conduit systems for FM and CSA (Dust and Gas Hazardous Locations):

General requirements: In addition the regulations of the country must be observed. The

used flameproof seals and blanking elements must have an adequate type approval and

a temperature range of at least -40 to 80 °C (-40 to 176 °F). In addition, they shall be

suitable for the conditions and correctly installed. Where available, the provided original

parts of the manfacturer must be used.

Page EN-16 SITRANS LVS100/200 – INSTRUCTION MANUAL 7ML19985FT63

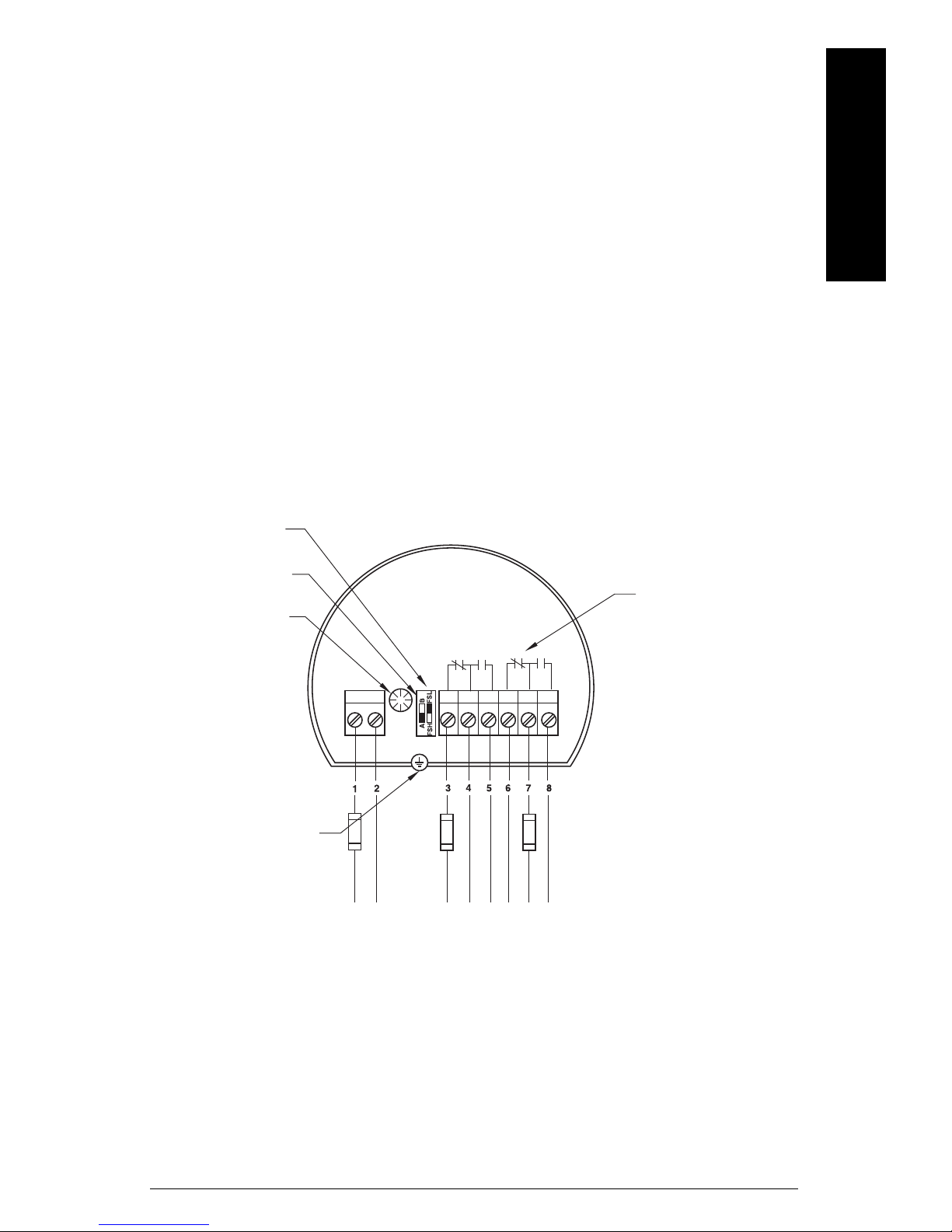

Connection recommendations

alarm output relays

FSH/FSL adjustment

sensitivity adjustment

B = factory setting,

A = decreased sensitivity

AC: terminal 1: L

terminal 2: N

19 to 230 V AC, ± 10 %,

50 to 60 Hz, 22 VA

DC: terminal 1: +

terminal 2: 19 to 40 V DC, ± 10 %, 2 W

LED

protective

earth

terminal

fuses: max. 10 A, fast or slow,

HBC, 250 V

• Use a fuse for the signal output (max. 10 A).

• Provide protection for relay contacts to protect the device against spikes if inductive

loads are connected.

Precautions

• Before opening the lid, ensure there are no dust deposits around

SITRANS LVS100/200, and that the atmosphere around the instrument is settled.

• Make sure the main voltage does not exceed the maximum voltage listed on the

product label.

• Ensure that no more than 8 mm of each wire is stripped (to avoid danger of contact

with live parts).

• Ensure the boots for protecting cable terminations are no longer than 8 mm (to avoid

danger of contact with live parts).

• For installation of the 3-wire PNP electronics (Protection Class III), the insulation of

the connected power supply and output load must meet the relevant standards.

Universal voltage (DPDT relay)

(LVS100)

English

mmmmm

7ML19985FT63 SITRANS LVS100/200 – INSTRUCTION MANUAL Page EN-17

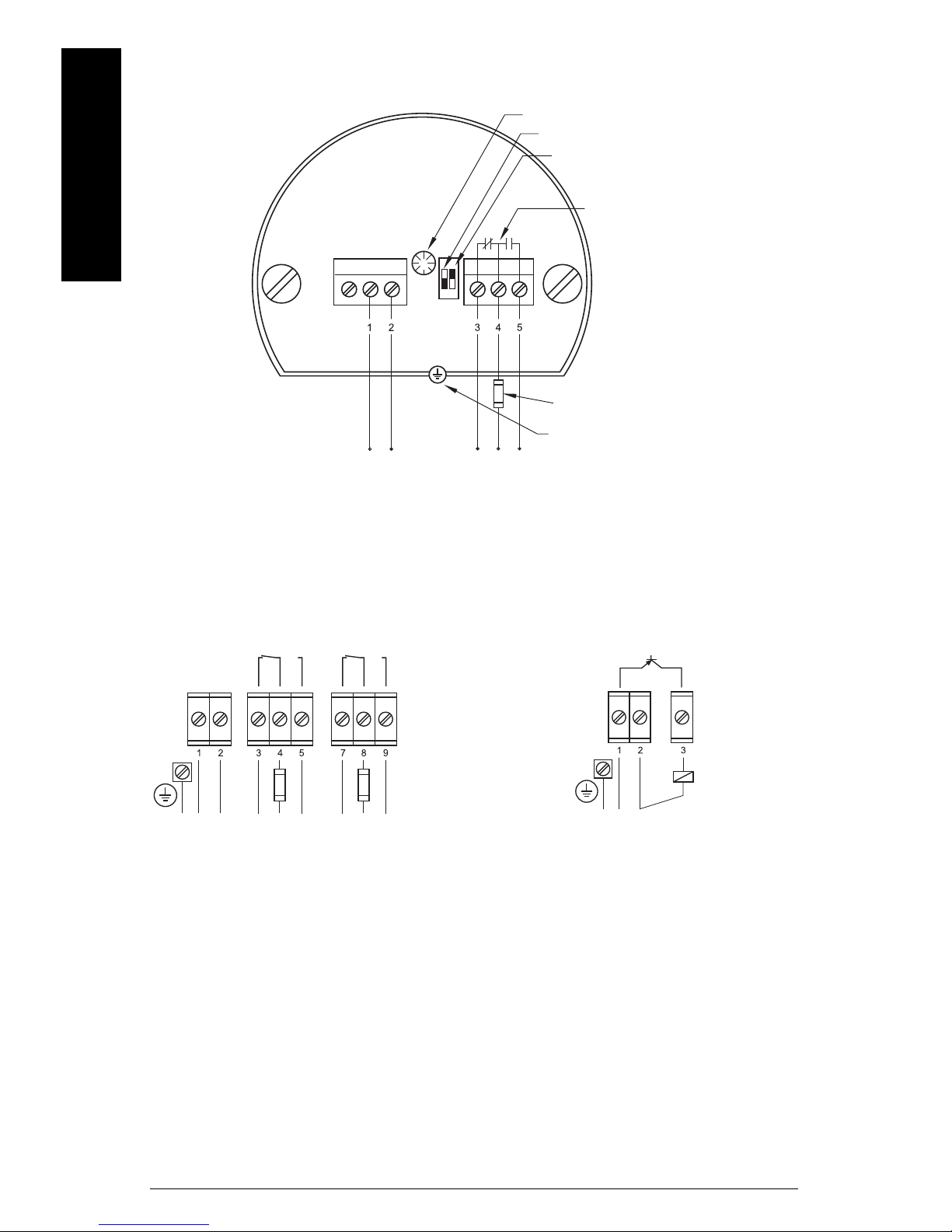

mmmmm

alarm output relay

FSH/FSL adjustment

sensitivity adjustment

B = factory setting,

A = decreased sensitivity

AC: terminal 1: L

terminal 2: N

19 to 230 V AC, + 10 %, 50 to 60 Hz, 18 VA

DC: terminal 1: +

terminal 2: -

19 to 55 V DC, + 10 %, 1.5 W

protective earth terminal

A

B

FSH

FSL

LED

fuses: max. 10 A, fast or slow,

HBC, 250 V

PE

+

L

N

alarm output relays

PE

+

-

load

AC: terminal 1: L

terminal 2: N

19 to 230 V AC, + 10 %, 50 to 60 Hz, 18 VA

DC: terminal 1: +

terminal 2: 19 to 55 V DC, + 10 %, 2 W

DC: terminal 1: +

terminal 2: 18 to 50 V DC, + 10 %, 1.5 W

fuses: max. 10 A, fast

or slow, HBC, 250 V

Universal voltage (SPDT relay)

(LVS200)

English

Universal voltage (DPDT relay) 3-wire PNP

(LVS200) (LVS200)

Page EN-18 SITRANS LVS100/200 – INSTRUCTION MANUAL 7ML19985FT63

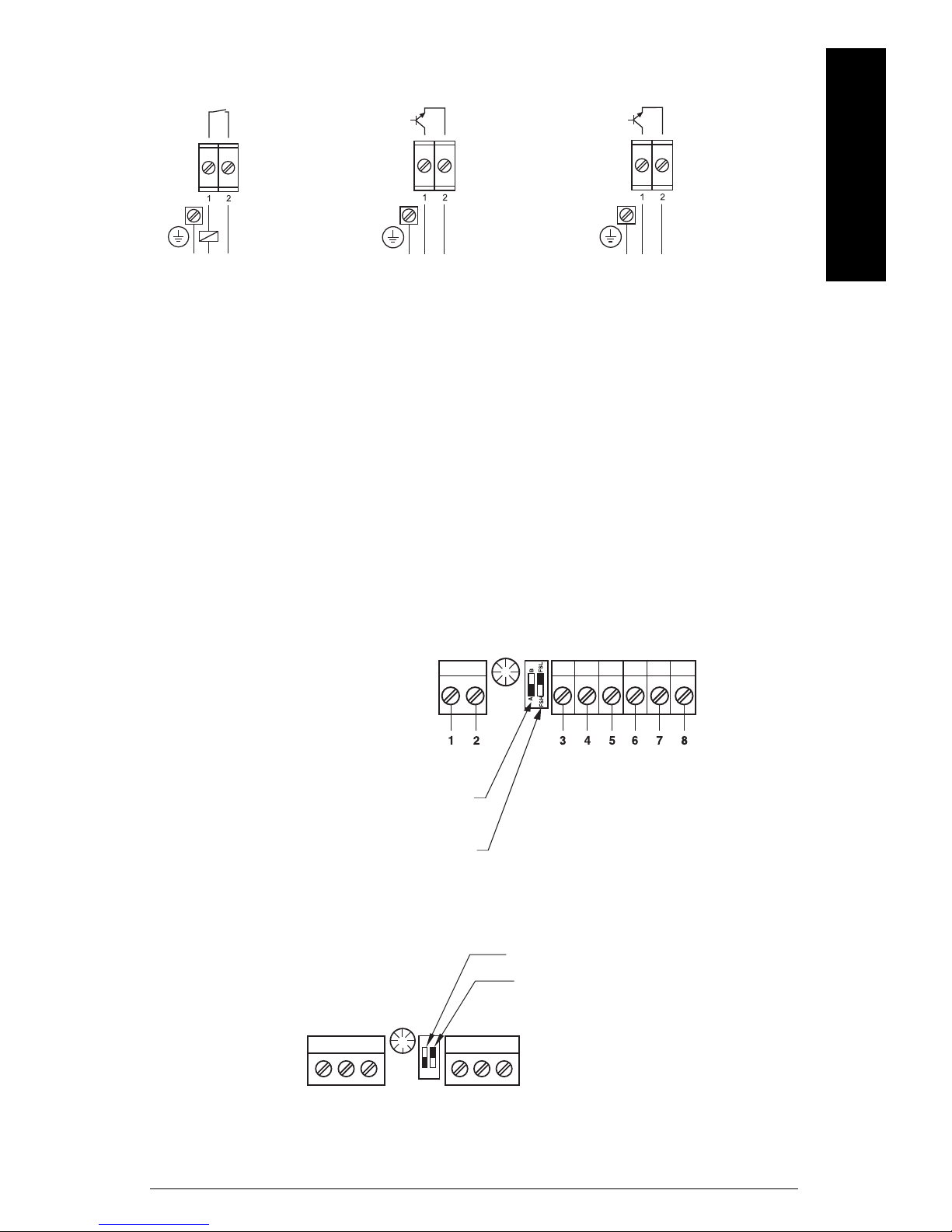

2-wire NAMUR IEC 60947-5-6 8/16 mA or 4 to 20 mA

PE

+

L

N

PE

+

-

PE

+

-

AC: terminal 1: L

terminal 2: N

19 to 230 V AC, + 10 %,

50 to 60 Hz, 1.5 VA

DC: terminal 1: +

terminal 2: 19 to 230 V DC, + 10 %, 1 W

ca. 7 to 9 V DC,

intrinsically safe

(IEC 60947-5-6)

DC: terminal 1: +

terminal 2: -

12.5 to 36 V DC, + 0 %

sensitivity adjustment:

B = factory setting

A = decreased sensitivity

FSH/FSL adjustment or

High/Low Alarm setting

FSH/FSL adjustment or

High/Low Alarm setting (NAMUR)

sensitivity adjustment:

B = factory setting

A = decreased sensitivity

FSH

FSL

A

B

(LVS200) (LVS200) (LVS200)

Sensitivity

English

mmmmm

If the measured material tends to cake or build up, the sensitivity adjustment switch can

be set to position A to decrease the sensitivity of the probe (factory setting is position B).

The sensitivity for interface applications should be set to position B, while the setting for

high-flow applications should be position A.

LVS100

LVS200

7ML19985FT63 SITRANS LVS100/200 – INSTRUCTION MANUAL Page EN-19

mmmmm

7

6

5

4

3

8

8

7

6

5

4

3

3

4

5

3

4

5

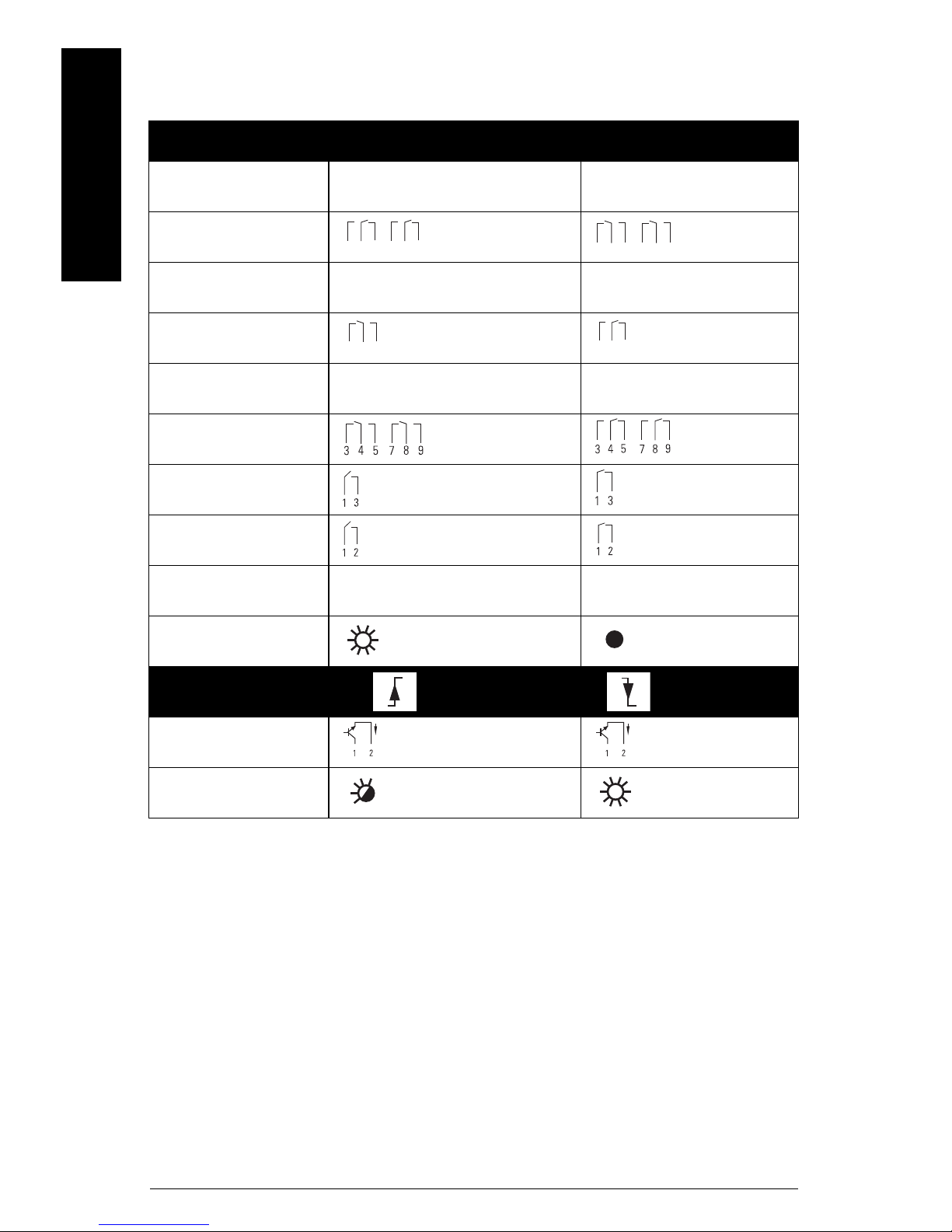

Switching Logic

Probe uncovered

Model Failsafe low Failsafe high

English

LVS10 0

DPDT relay

LVS20 0

SPDT relay

LVS20 0

DPDT relay

3-wire PNP

Signal Output

2-wire

8/16 mA I = 16 mA I = 8 mA

Signal Output LED

Low alarm setting High alarm setting

NAMUR IEC

60947-5-6

I < 1 mA I > 2.2 mA

Signal Output LED

Page EN-20 SITRANS LVS100/200 – INSTRUCTION MANUAL 7ML19985FT63

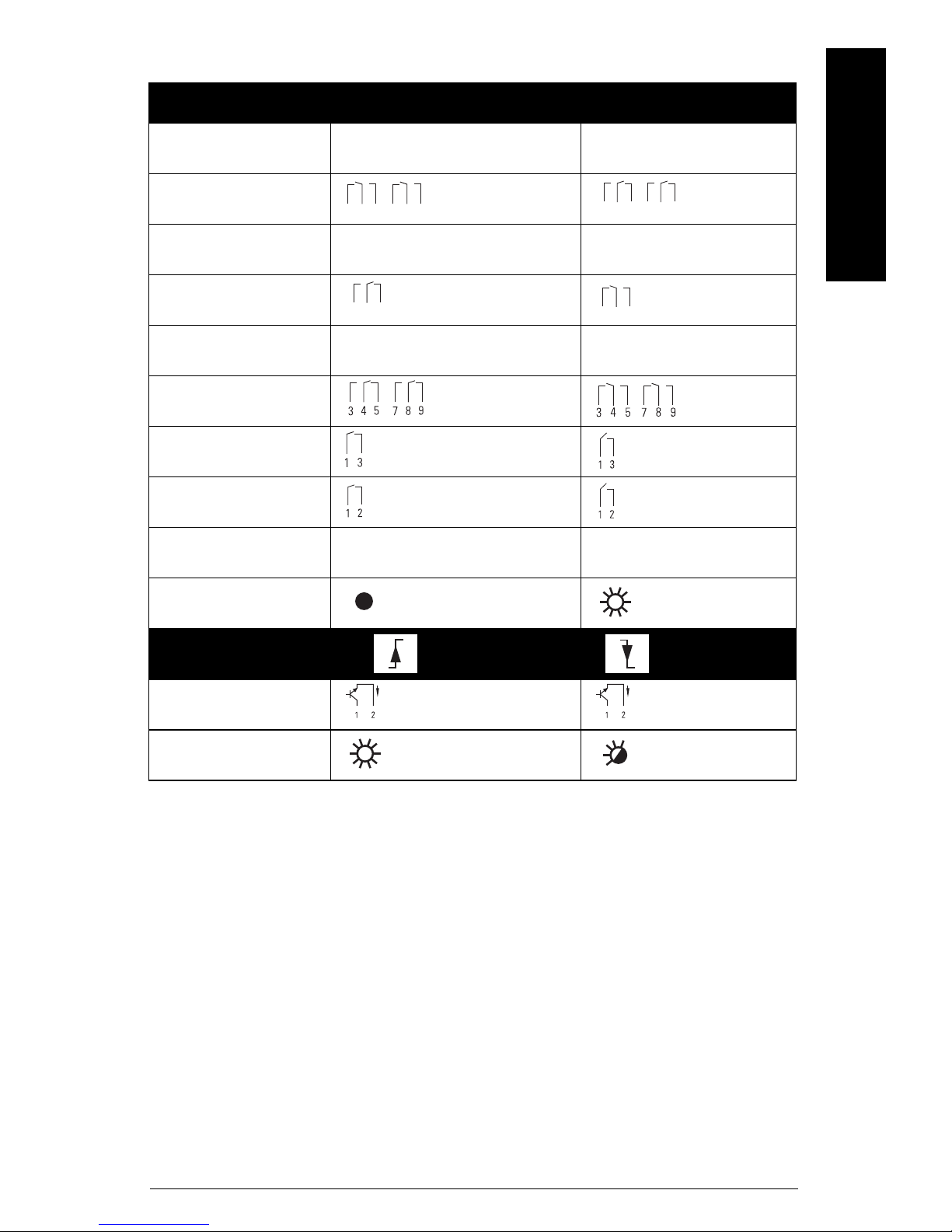

Probe covered

8

7

6

5

4

3

7

6

5

4

3

8

3

4

5

3

4

5

Signal Output

Model Failsafe low Failsafe high

LVS10 0

DPDT relay

LVS20 0

SPDT relay

LVS20 0

DPDT relay

3-wire PNP

2-wire

English

mmmmm

8/16 mA I = 8 mA I = 16 mA

Signal Output LED

Low alarm setting High alarm setting

NAMUR IEC

60947-5-6

I >2.2 mA I < 1 mA

Signal Output LED

7ML19985FT63 SITRANS LVS100/200 – INSTRUCTION MANUAL Page EN-21

mmmmm

Test button

Electronic module

diagnostic LED

NAMUR model

sensitivity adjustment:

B = factory setting

A = decreased sensitivity

A

B

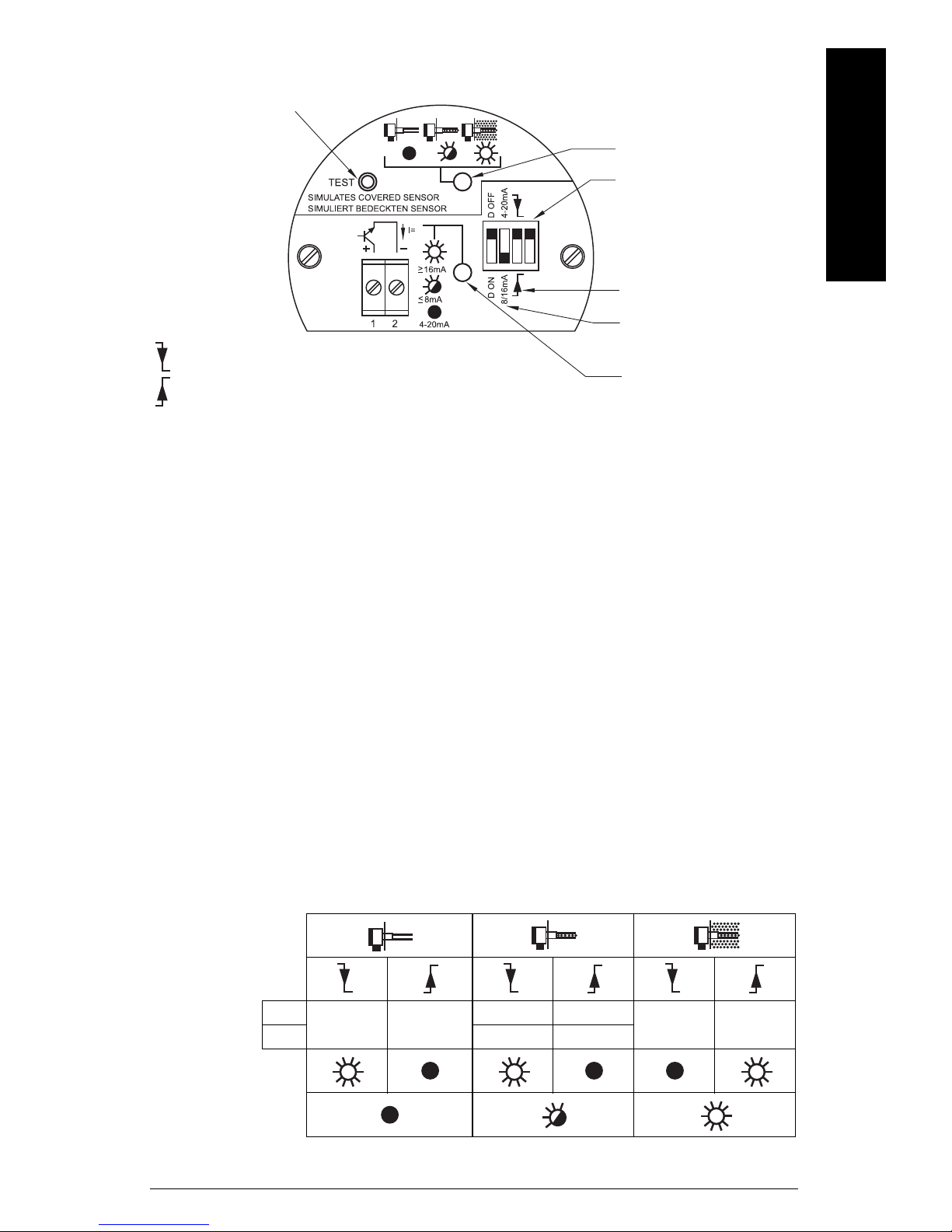

Signal output and test options (LVS200)

Note: The signal output and test options listed below apply only to specific power

supply options.

English

Signal Output Delay

Universal voltage (DPDT) model

The signal output can be delayed and is adjustable from 0 to 30 seconds. Turn the

potentiometer clockwise to increase the delay time.

Potentiometer T1: Delay when output switches from fork covered to uncovered.

Potentiometer T2: Delay when output switches from fork uncovered to covered.

Test function

NAMUR model (IEC 60947-5-6) and 8/16 mA or 4 to 20 mA model

If the fork is uncovered, pressing this button will stop the vibration and the signal output

will switch to indicate a covered fork. You can test the vibration and the electronics

without removing the LVS200 from the vessel. If the fork is covered, pressing the button

has no effect.

Page EN-22 SITRANS LVS100/200 – INSTRUCTION MANUAL 7ML19985FT63

Vibration amplitude diagnosis

8/16 or 4 to 20 mA model

Test butt on

diagnostic LED

sensitivity adjustment:

B = factory setting

A = decreased sensitivity

B

A

filling or emptying

output setting

signal output LED

Sensor switches at high level

Fail-safe function will default to full signal

Sensor switches at low level

Fail-safe function will default to empty signal

NAMUR module (IEC 60947-5-6) and and 8/16 mA or 4 to 20 mA model

Measurement quality is related to the vibration amplitude of the fork. The diagnostic LED

indicates the quality of the vibration being sent to the LVS200 electronics.

English

mmmmm

• Diagnostic LED off: measurement quality is good. The vibration amplitude is strong.

• Diagnostic LED blinking: measurement quality is poor and vibration amplitude is

decreasing as fork becomes encrusted. When this happens, set the sensitivity

switch to decreased sensitivity.

• Diagnostic LED on: vibration has stopped and fork is fully encrusted with material.

Current output setting

8/16 mA

The chart below illustrates the output current when:

•Fork is clean

• Fork is encrusted: weak vibration amplitude is shown

• Fork is fully encrusted and vibration has stopped.

Diagnosis

Setting

Signal

output LED

Diagnosis

LED

D Off

D On I = 20 mA I = 6 mA

7ML19985FT63 SITRANS LVS100/200 – INSTRUCTION MANUAL Page EN-23

I = 16 mA I = 8 mA

I = 16 mA I = 8 mA

I = 8 mA I = 16 mA

mmmmm

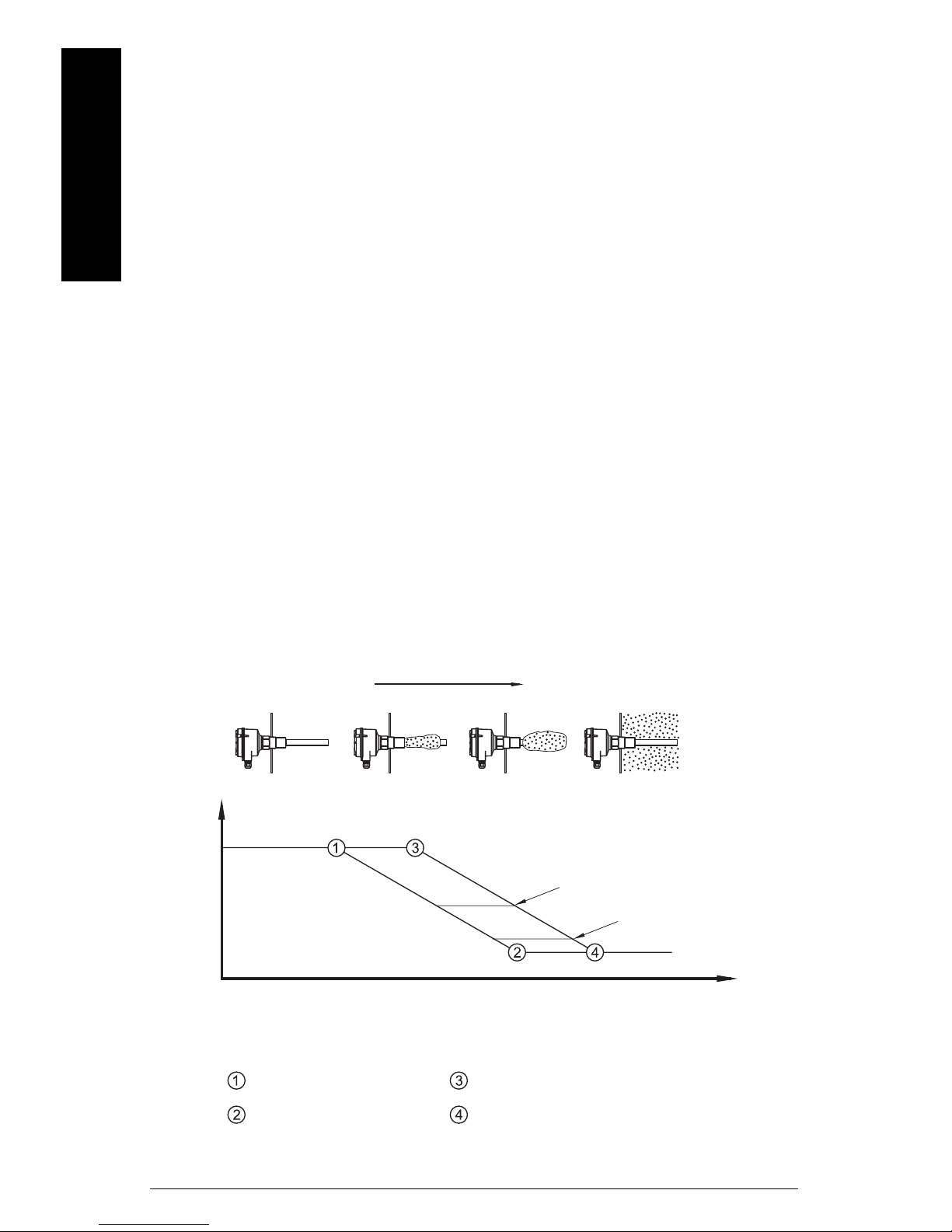

increasing material buildup

Amplitude is 100%

Amplitude is 0%

Amplitude is 100%

Amplitude is 0%

With standard sensitivity setting

With decreased sensitivity setting

6 mA

7/8 mA

12/12.5 mA

20 mA

output current

s

t

a

n

d

a

r

d

s

e

n

s

i

t

i

v

i

t

y

d

e

c

r

e

a

s

e

d

s

e

n

s

i

t

i

v

i

t

y

Vibration damping by material

The output current can indicate weak vibration amplitude with the diagnosis setting D

ON. If the diagnosis is set to D OFF, the output will be either 8 mA or 16 mA depending on

high or low level settings.

If the diagnosis is set to D ON, the output will change from 16 to 20 mA and from 8 to 6 mA

if the vibration is weak. This output can be passed to an external 4 to 20 mA output. There

English

is an internal delay of 10 seconds before the change happens, so that the external output

does not indicate a weak vibration when the vibration is stopped and started during

normal measurement operation.

Buildup Detection (8/16 mA or 4 to 20 mA version)

With the 4 to 20 mA setting, you can recognize material buildup on the fork using a PLC or

data logger.

In this mode, the Diagnostic setting has no influence. The LED showing signal output is

off.

20 mA: The fork is clean.

<20 mA and >12/12.5 mA: The vibration amplitude is decreased by the material buildup.

<12/12.5 mA and >7/8 mA: This range indicates a weak vibration. The internal LED

showing diagnosis begins blinking to indicate a weak signal. If you are using a PLC to

evaluate the echo, delay the response time to this indicator for approximately 10 seconds.

A hysteresis of 0.5 mA (between 12 and 12.5 mA) is recommended.

7/8 mA: This point indicates that the fork is mostly encrusted.

6 mA: This point indicates that the fork is fully encrusted.

Page EN-24 SITRANS LVS100/200 – INSTRUCTION MANUAL 7ML19985FT63

Maintenance

SITRANS LVS100/200 require no maintenance or cleaning under normal operating

conditions. Under severe operating conditions, the tines may require periodic cleaning.

Brush off any accumulated deposits, taking care not to bend the tines.

Unit Repair and Excluded Liability

All changes and repairs must be done by qualified personnel, and applicable safety

regulations must be followed. Please note the following:

• The user is responsible for all changes and repairs made to the device.

• All new components must be provided by Siemens Milltronics Process Instruments Inc.

• Restrict repair to faulty components only.

• Do not re-use faulty components.

English

mmmmm

7ML19985FT63 SITRANS LVS100/200 – INSTRUCTION MANUAL Page EN-25

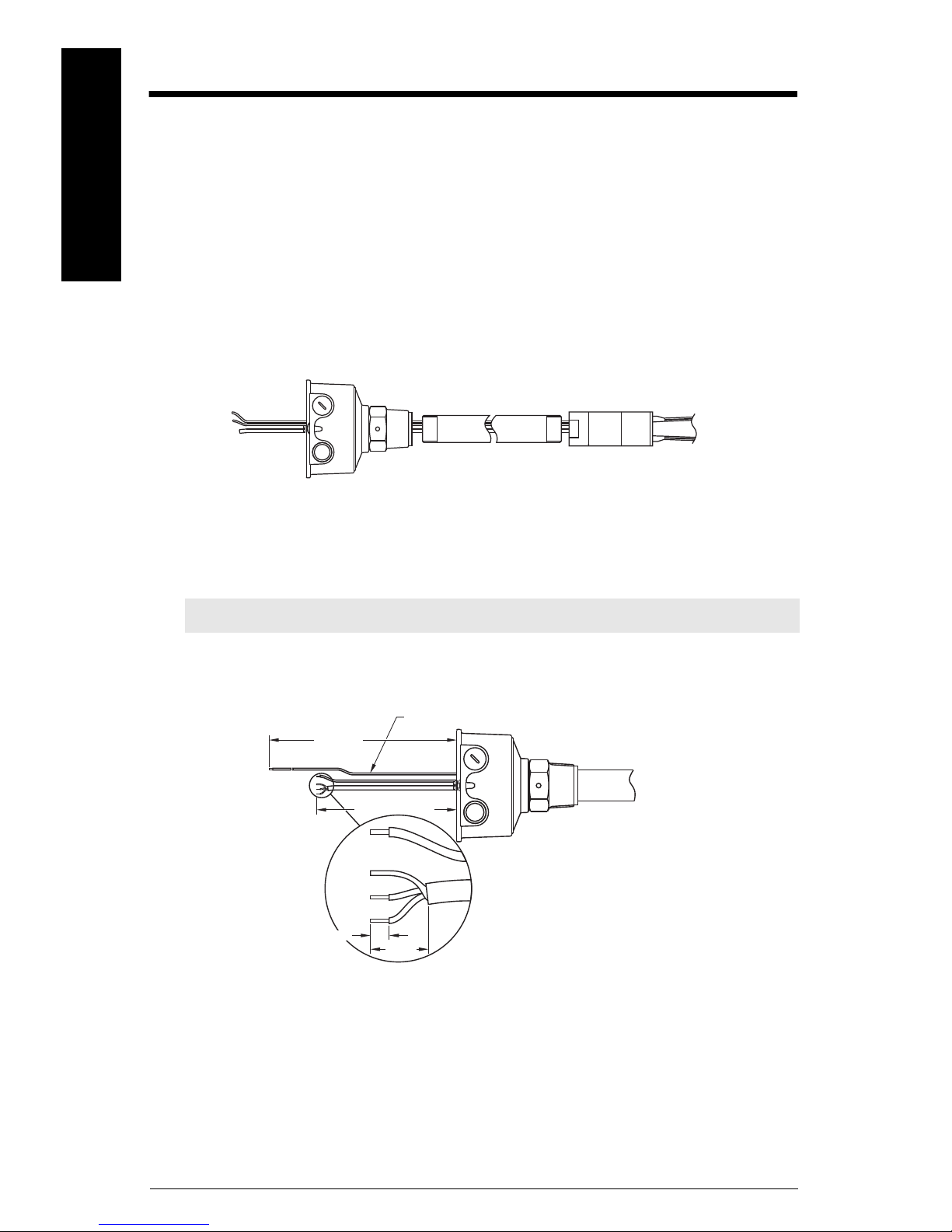

SITRANS LVS200 Pipe Extended Version

enclosure

customer supplied

pipe extension

fork assembly

earth cable (green/yellow)

220 mm

(8.7")

150 mm (5.9")

8 mm max.

18 mm

mmmmm

Assembly

English

Suggested tools:

• medium Phillips or 6 to 8 mm (¼”) flat screwdriver • terminal crimper

• 3 mm (1/8”) flat screwdriver • 36 mm open end wrench

• wire cutters • pipe wrench

•wire strippers

1. Open the enclosure lid; remove electronics module.

2. Lead the sensor cable through the customer supplied 1" tube and enclosure.

3. Assemble the fork assembly, the pipe extension, and the enclosure using the 36 mm

open end wrench. Seal the pipe threads with an appropriate sealant.

Note: Do not turn fork assembly. Do not bend the fork during assembly.

4. Line up the fork and the tine orientation marking as shown in dimension drawing on

page 16. (The tine orientation marking on the process connection is to identify the

vertical orientation of the fork.)

5. Shorten sensor cable to a free length of 150 mm (5.9").

6. Shorten earth cable to a free length of 220 mm (8.7").

7. Prepare sensor cable as shown above, stripping a maximum of 8 mm from each

wire.

Page EN-26 SITRANS LVS100/200 – INSTRUCTION MANUAL 7ML19985FT63

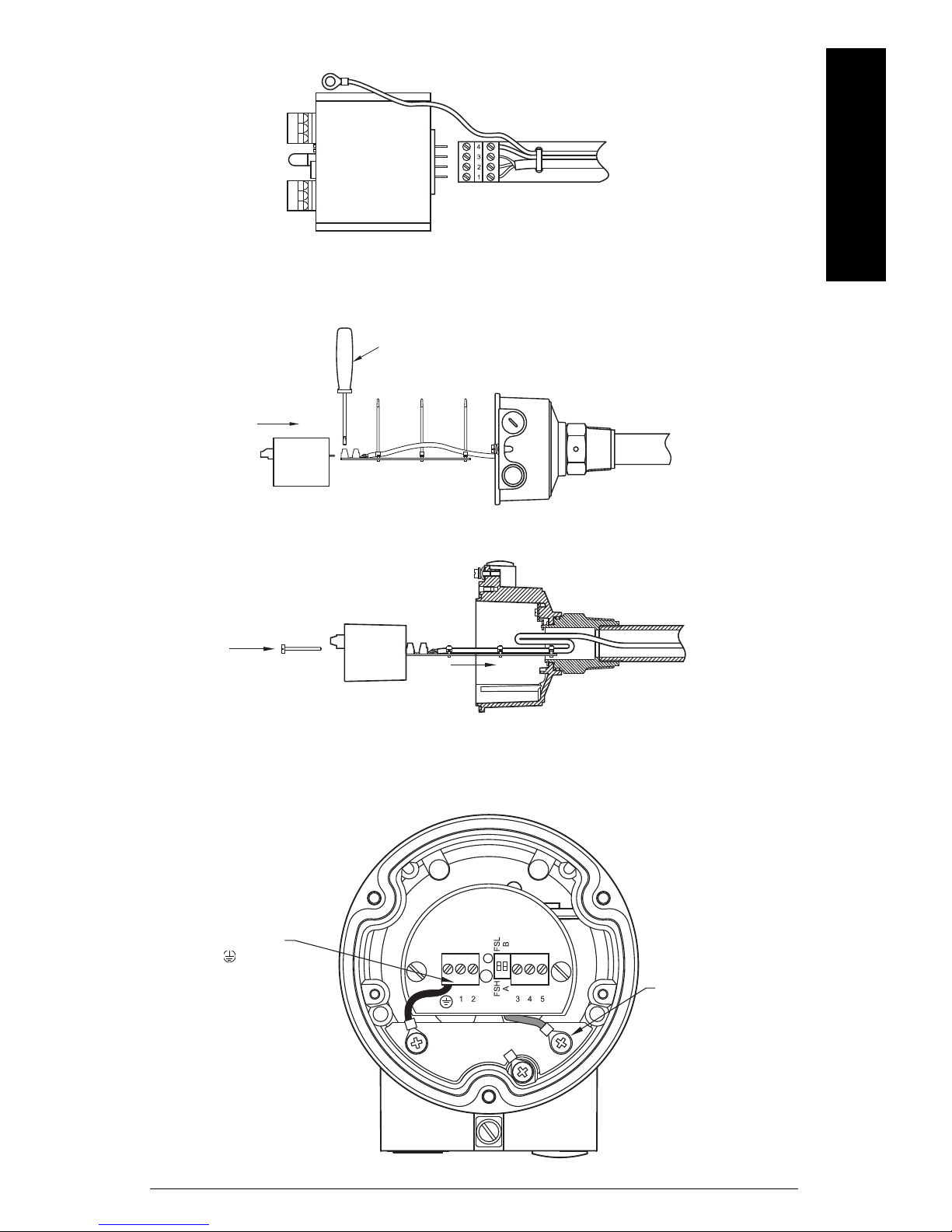

8. Connect the sensor cable to the terminal connection board shown above.

electronics

module, flat

side up

4 = BLACK (T)

3 = SHIELD (M)

2 = RED (R-)

1 = WHITE (R+)

3 mm (1/8”) screw driver

cable ties

Connect protection earth

of the enclosure to

terminal of the

electronics module.

Connect earth cable

of the fork to the

electronics earth

terminal.

9. Secure the sensor cable with cable ties.

10. Crimp the ring terminal 4 mm (0.19") to sensor earth cable.

11. Connect electronics module and terminal connection board. Be sure that all

terminals are tight.

English

mmmmm

12. Insert the electronics module into the housing. The terminal connection board is

used to guide the cable into the extension tube.

13. Fold cable as shown in diagram above.

14. Secure the electronics module as shown in diagram below.

7ML19985FT63 SITRANS LVS100/200 – INSTRUCTION MANUAL Page EN-27

mmmmm

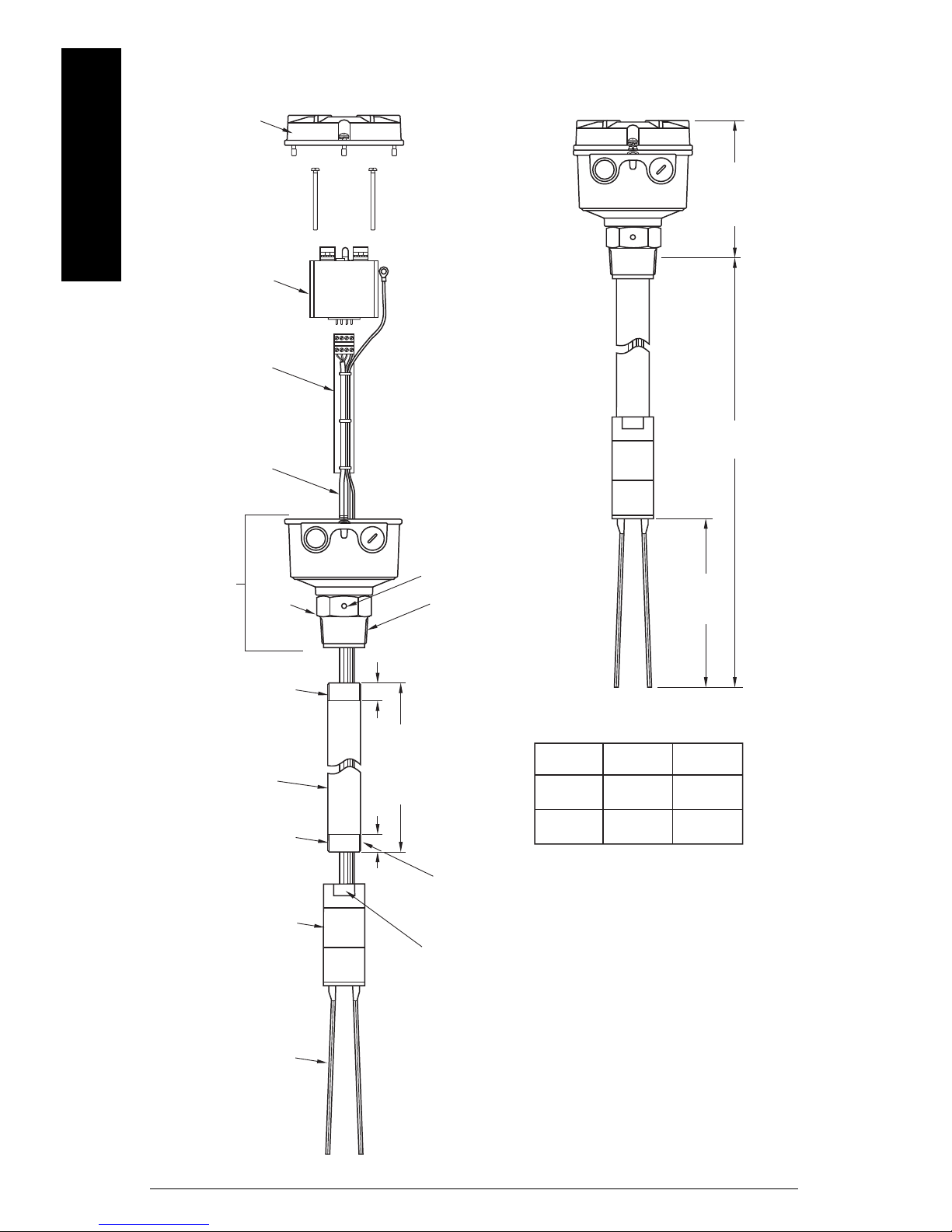

½” NPT

M20x1.5

1½”NPT

1 ½" BSPT

1" NPT

G1"

lid

electronics module

terminal connection

board

sensor cable

enclosure

assembly

process

connection

tine orientation marking

process thread 1 ½” NPT

(taper) or

R 1 ½” (BSPT)

thread G1” or 1" NPT

(use appropriate

thread sealant)

fork

fork assembly

thread G1” or 1" NPT

(use appropriate

thread sealant)

1" schedule 40 pipe

(internal min.

dia. 25.4 mm (customer

supplied and mounted)

X = L - 255 mm

(10")

min.

18 mm

(0.75")

min.

18 mm

(0.75")

SW 36

Note: Threaded

engagement to be a

min. of 7 mm (0.27")

approx.

138 mm

(5.4")

L = 300 to 3800 mm

(11.8 to 149.6")

170 mm

(6.7")

process

thread

cable

entries

1" pipe

thread

Assembly Overview Drawing

English

Page EN-28 SITRANS LVS100/200 – INSTRUCTION MANUAL 7ML19985FT63

Loading...

Loading...