Siemens SITRANS LUT400 User Manual

Communications

For SITRANS LUT400 (HART)

Manual 02/2014

Safety Guidelines: Warning notices must be observed to ensure personal safety as well as that of

others, and to protect the product and the connected equipment. These warning notices are

accompanied by a clarification of the level of caution to be observed.

Qualified Personnel: This device/system may only be set up and operated in conjunction with this

manual. Qualified personnel are only authorized to install and operate this equipment in accordance with

established safety practices and standards.

Unit Repair and Excluded Liability:

The user is responsible for all changes and repairs made to the device by the user or the user’s

agent.

All new components are to be provided by Siemens Milltronics Process Instruments.

Restrict repair to faulty components only.

Do not reuse faulty components.

Warning: Cardboard shipping package provides limited humidity and moisture protection. This product

can only function properly and safely if it is correctly transported, stored, installed, set up, operated, and

maintained.

This product is intended for use in industrial areas. Operation of this equipment in a residential area

may cause interference to several frequency based communications.

Note: Always use product in accordance with specifications.

Copyright Siemens AG 2013. All Rights

Disclaimer of Liability

Reserved

This document is available in bound version and in

electronic version. We encourage users to purchase

authorized bound manuals, or to view electronic

versions as designed and authored by Siemens

Milltronics Process Instruments. Siemens Milltronics

Process Instruments will not be responsible for the

contents of partial or whole reproductions of either

bound or electronic versions.

While we have verified the contents of this

manual for agreement with the

instrumentation described, variations remain

possible. Thus we cannot guarantee full

agreement. The contents of this manual are

regularly reviewed and corrections are

included in subsequent editions. We welcome

all suggestions for improvement.

Technical data subject to change.

MILLTRONICS®is a registered trademark of Siemens Milltronics Process Instruments.

Contact SMPI Technical Publications European Authorized Representative

at the following address:

Technical Publications Siemens AG

Siemens AG Industry Sector

Siemens Milltronics Process Instruments 76181 Karlsruhe

1954 Technology Drive, P.O. Box 4225 Deutschland

Peterborough, Ontario, Canada, K9J 7B1

Email: techpubs.smpi@siemens.com

For a selection of Siemens Milltronics level measurement manuals, go to:

www. siemens.com/processautomation. Under Process Instrumentation, select

Measurement

For a selection of Siemens Milltronics weighing manuals, go to:

www. siemens.com/processautomation. Under Weighing Technology, select

Weighing Systems

and then go to the manual archive listed under the product family.

and then go to the manual archive listed under the product family.

Level

Continuous

© Siemens AG 2013

Table of Contents

Table of Contents ...............................................................................................................i

Introduction ........................................................................................................................1

Overview .................................................................................................................................................1

Safety Notes ...........................................................................................................................................1

The Manual ............................................................................................................................................1

Technical Support .................................................................................................................................2

Service & Support on the Internet ..........................................................................................2

Additional Support ......................................................................................................................2

Abbreviations and Identifications ...........................................................................................3

Operation via SIMATIC PDM 6 (HART) ..........................................................................5

Features .........................................................................................................................................5

Functions .......................................................................................................................................5

SIMATIC PDM version ...............................................................................................................6

Electronic Device Description (EDD) ......................................................................................6

Configuring a new device .........................................................................................................7

Quick Start Wizard via SIMATIC PDM ...................................................................................7

Quick Start (Level)............................................................................................................. 9

Quick Start (Volume)....................................................................................................... 12

Quick Start (Volume - Linearization)........................................................................... 15

Quick Start (Flow)............................................................................................................ 19

Pump Control Wizard ...............................................................................................................22

Changing parameter settings using SIMATIC PDM .........................................................24

Parameters accessed via pull-down menus ......................................................................25

Set Address ................................................................................................................................27

Echo Profile Utilities .................................................................................................................27

Maintenance ..............................................................................................................................32

Process Variables .....................................................................................................................36

Operation via Web Browser (USB) ..............................................................................41

Features .......................................................................................................................................41

Functions .....................................................................................................................................41

Installation ..................................................................................................................................41

Installing the USB driver................................................................................................ 41

Installing the web browser interface ......................................................................... 42

Accessing the device via the web browser .......................................................................43

Changing parameter settings using the browser .............................................................45

Configuring a new device .......................................................................................................45

Browser Menu Parameter Function Groups ......................................................................46

Operation via AMS Device Manager (HART) .............................................................49

Features .......................................................................................................................................49

Functions .....................................................................................................................................49

Electronic Device Description (EDD) ....................................................................................50

Configuring a new device .......................................................................................................50

Startup .........................................................................................................................................50

Master Reset.................................................................................................................... 52

Pull-down menu access................................................................................................ 52

Table of Contents

i

Scan Device...................................................................................................................... 52

Device configuration ................................................................................................................53

Quick Start Wizards via AMS Device Manager ................................................................54

Wizard - Quick Start (Level).......................................................................................... 55

Wizard - Quick Start (Volume)...................................................................................... 57

Wizard - Quick Start (Volume - Linearization).......................................................... 60

Wizard - Quick Start (Flow)........................................................................................... 63

Table o f C on t en t s

Changing parameter settings using AMS Device Manager ..........................................68

Device Diagnostics View ........................................................................................................75

Process Variables View ..........................................................................................................76

Password Protection ................................................................................................................76

User Manager Utility ................................................................................................................77

AMS Menu Structure ..............................................................................................................78

Operation via Field Communicator

375/475 (FC375/FC475) (HART) .......................................................................................97

Features .......................................................................................................................................97

Functions .....................................................................................................................................97

Configuring a new device .......................................................................................................97

HART FC375/FC475 Menu Structure .....................................................................................98

Operation via FDT (Field Device Tool) .......................................................................133

Features .....................................................................................................................................133

Functions ...................................................................................................................................133

Device Type Manager (DTM) ...............................................................................................133

SITRANS DTM version 3.1 ......................................................................................... 133

Electronic Device Description (EDD) ..................................................................................133

Configuring a new device .....................................................................................................133

ii

Introduction

Overview

The SITRANS LUT400 ultrasonic controller may be operated via remote communications,

using various PC software such as:

• SIMATIC PDM

• Web Browser Interface (used with Web Server Abyss - provided for your

convenience)

• AMS Device Manager

• Field Communicator 375/475 (FC375/FC475) (HART)

• A Field Device Tool (FDT), such as PACTware or Fieldcare

Please consult the appropriate manufacturer’s operating instructions for general details

on how to operate each software package.

Safety Notes

Special attention must be paid to warnings and notes highlighted from the rest of the text

by grey boxes.

Note: means important information about the product or that part of the operating

manual.

The Manual

This manual provides information on the use of SITRANS LUT400 with various remote

communications software packages noted above. The manual is designed to help you get

the most out of your ultrasonic device when used in conjunction with a remote

communications tool. It provides information for the various tools in the following areas:

COMMS LUT400

• Features and Functions

• Installation, Startup, and Configuration of the SITRANS LUT400

• Quick Start Wizards and Pump Control Wizards

• Changing parameters

• Parameter menus

This manual should be used in conjunction with the SITRANS LUT40 0 (HART) Operating

Instructions (7ML19985MV01)

for optimum performance. We always welcome suggestions and comments about

manual content, design, and accessibility. Please direct your comments to

techpubs.smpi@siemens.com

For other Siemens level measurement manuals, go to:

www.siemens.com/level

1.

See DVD shipped with device or download manual from product page of our

website: Go to www.siemens.com/sitransLUT400 > Technical Info > Manuals/

Operating instructions.

A5E33701270 COMMUNICATIONS FOR SITRANS LUT400 (HART) – MANUAL Page 1

1

to help you set up your device via remote communications

.

, and look under Level Measurement.

Technical Support

If you have any technical questions about the device described in these Operating

Instructions and do not find the answers, you can contact Customer Support:

• Via the Internet using the Support Request:

Support request (http://www.siemens.com/automation/support-request

• Via Phone:

• Europe: +49 (0) 911 895 7222

• America: +1 423 262 5710

• Asia-Pacific: +86 10 6475 7575

Further information about our technical support is available on the Internet at

Technical support (http://support.automation.siemens.com/WW/view/en/16604318

Service & Support on the Internet

In addition to our documentation, we offer a comprehensive knowledge base online on

COMMS LUT400

the Internet at:

Service & Support (http://www.siemens.com/automation/service&support

There you will find:

• The latest product information, FAQs, downloads, tips and tricks.

• Our newsletter, providing you with the latest information about our products.

• Our bulletin board, where users and specialists share their knowledge worldwide.

• Your local contact partner for Industry Automation and Drives Technologies in our

partner database.

• Information about field service, repairs, spare parts and lots more under "Services".

)

)

)

Additional Support

Please contact your local Siemens representative and offices if you have additional

questions about the device.

Find your contact partner at:

Local contact person (http://www.siemens.com/automation/partner

Page 2 COMMUNICATIONS FOR SITRANS LUT400 (HART) – MANUAL A5E33701270

)

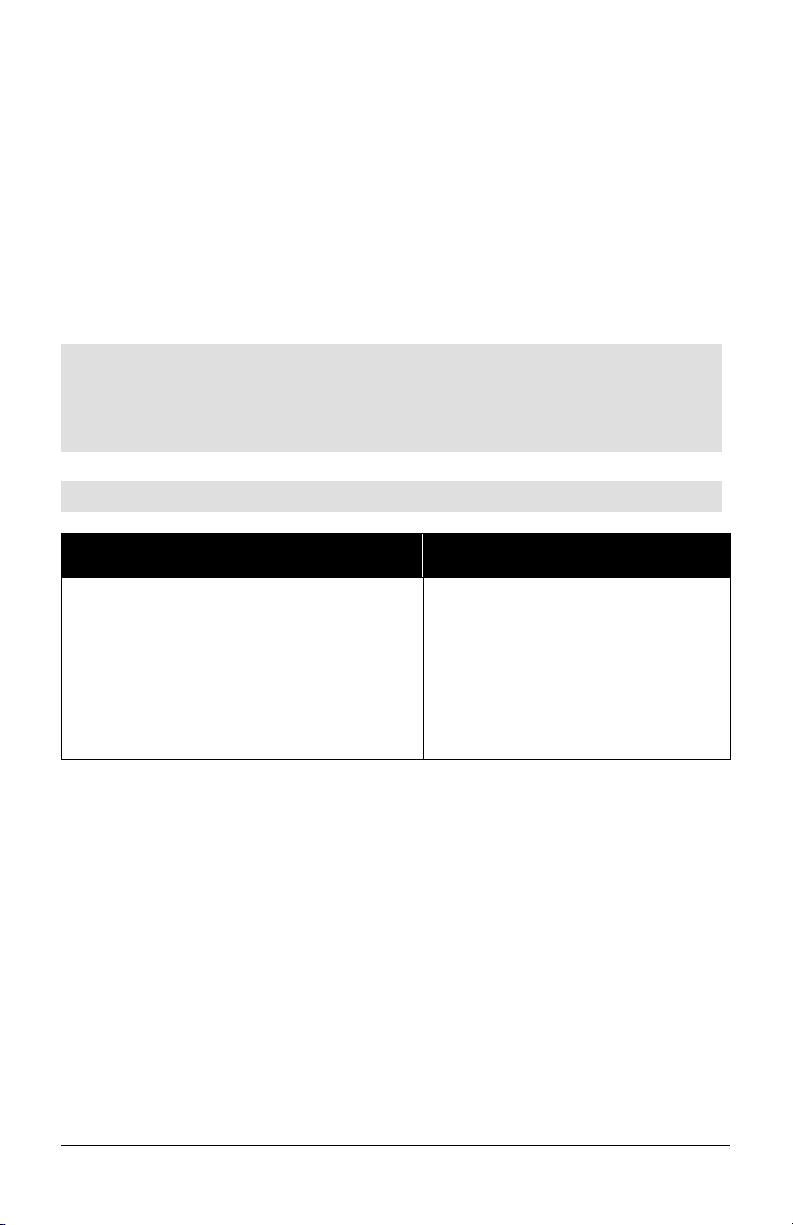

Abbreviations and Identifications

Short

form

AMS Emerson AMS Device Manager

DD See EDD

DTM Device Type Manager

EDD Electronic Device Description (also referred to as DD)

FC Field Communicator 375/475

FDT Field Device Tool

LCD Liquid Crystal Display

LUI Local User Interface

PDM SIMATIC Process Device Manger

PMD Primary Measuring Device

PV Primary Value measured value

USB Universal Serial Bus

Long Form Description

software package used to

commission and maintain

SITRANS LUT400

a type of software that ’plugs

into’ a Field Device Tool (FDT).

HART device used to

commission and maintain

SITRANS LUT400

a standard used in software

packages designed to

commission and maintain field

devices such as SITRANS

LUT400

software package used to

commission and maintain

SITRANS LUT400

COMMS LUT400

A5E33701270 COMMUNICATIONS FOR SITRANS LUT400 (HART) – MANUAL Page 3

COMMS LUT400

Notes

Page 4 COMMUNICATIONS FOR SITRANS LUT400 (HART) – MANUAL A5E33701270

Operation via SIMATIC PDM 6 (HART)

(SITRANS LUT400 compatible with PDM version 6.1)

Features

SIMATIC PDM is a software package used to commission and maintain SITRANS LUT400 and

other process devices. Please consult the LUT400 online help for details on using SIMATIC

PDM. (More information can be found at www.siemens.com/simatic-pdm

SIMATIC PDM monitors the process values, alarms and status signals of the device. It allows

you to display, compare, adjust, verify, and simulate process device data; also to set schedules

for calibration and maintenance.

Functions

Notes:

• For a complete list of parameters, see

operating instructions1.

• While the device is in PROGRAM MODE, the output remains active and

continues to respond to changes in the device.

Parameters are identified by name and organized into function groups. The menu

structure for SIMATIC PDM is almost identical to that of the SITRANS LUT400 LCD. See

LCD Menu Structure

in chart format.

in LUT400 operating instructions1 for a complete list of parameters

Parameter reference (LUI)

.)

in LUT400

Operation - PDM

For a list of parameters that do not appear in the menu structure and are accessed via pulldown menus in SIMATIC PDM see page 26. See also

SIMATIC PDM

on page 24 for more details.

Changing parameter settings using

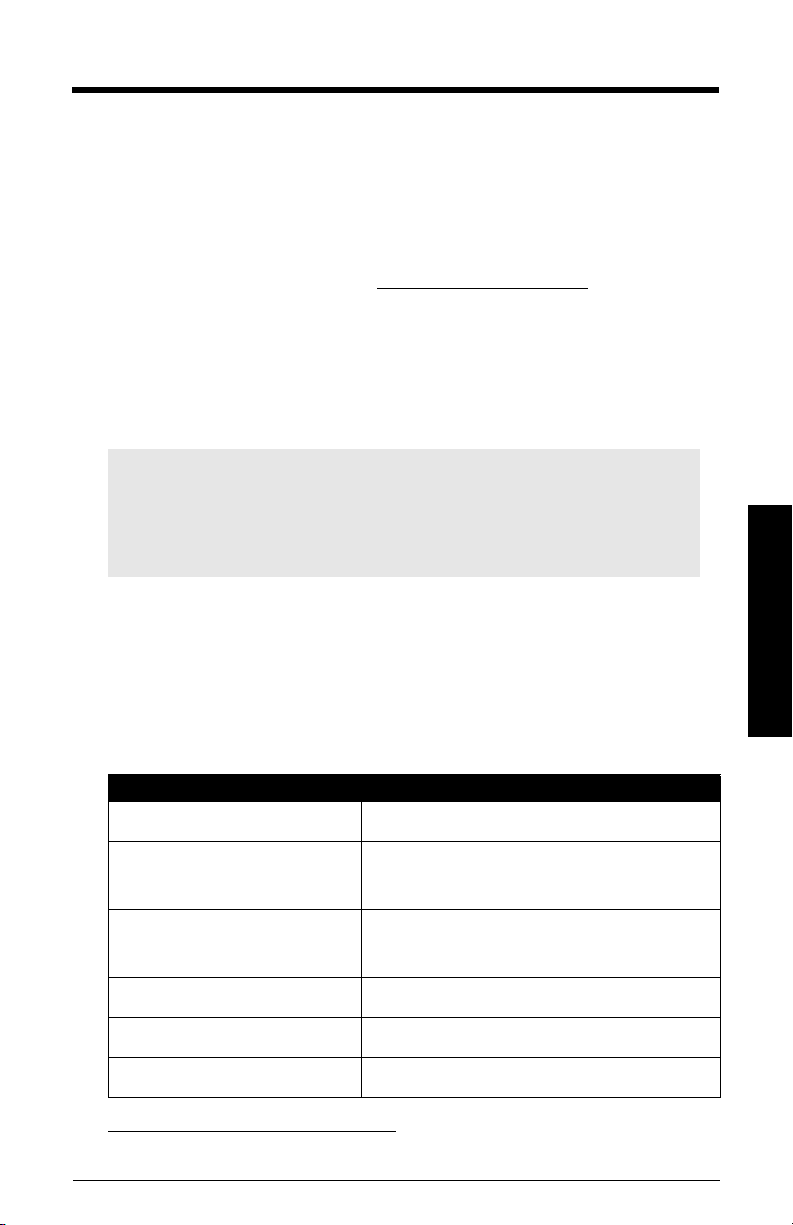

Feature page Function

Quick Start (Level) 9 Device configuration for simple level applications

Quick Start (Volume) 12

Quick Start (Volume - Linearization)

Quick Start (Flow) 19 Device configuration for simple flow applications

Pump Control Wizard 22 Pump control setup

Echo Profile Utilities 27 Echo profile viewing/comparison

1.

SITRANS LUT400 (HART) Operating Instructions (7ML19985MV01)

A5E33701270 COMMUNICATIONS FOR SITRANS LUT400 (HART) – MANUAL Page 5

Device configuration for simple volume

applications

Device configuration for volume applications

15

using complex vessel shapes

Feature (cont’d) page Function

matching

Firmware

and EDD

revisions

To check it in PDM, go to SITRANS LUT400 HART > Identification > Device.

TVT Shaper 29 Manual TVT adjustment

Auto False Echo Suppression 30 Screen out false echoes

Maintenance 32 Set schedules for device/sensor maintenance

Process Variables 36 Monitor process variables and level trend

SIMATIC PDM version

Check the support page of our website to make sure you have the latest version of SIMATIC

PDM, the most recent Service Pack (SP) and the most recent hot fix (HF). Go to:

http://support.automation.siemens.com/WW/

llisapi.dll?func=cslib.csinfo&lang=en&objiD=10806857&subtype=133100

Electronic Device Description (EDD)

You can locate the EDD in Device Catalog, under Sensors/Level/Echo/Siemens AG/

SITRANS LUT400. (The EDD is written for forward compatibility.)

As a guideline to locate the correct EDD, the major and minor numbers should match

between the EDD revision and the Firmware revision in the device (e.g. major and minor

numbers in bold text: 1.0 0 .00-04).

Operation - PDM

Installing a new version of SIMATIC PDM requires the most recent Service Pack (SP) and

the most recent hot fix (HF).

To install a new EDD

• Go to www.siemens.com/sitransLUT400 > Support > Software Downloads to

download the most up-to-date EDD from the product page of our website.

• Save the files to your computer and extract the zipped file to an easily accessed

Page 6 COMMUNICATIONS FOR SITRANS LUT400 (HART) – MANUAL A5E33701270

location.

• Launch SIMATIC PDM – Manage Device Catalog, browse to and select the folder

which contains the unzipped EDD file.

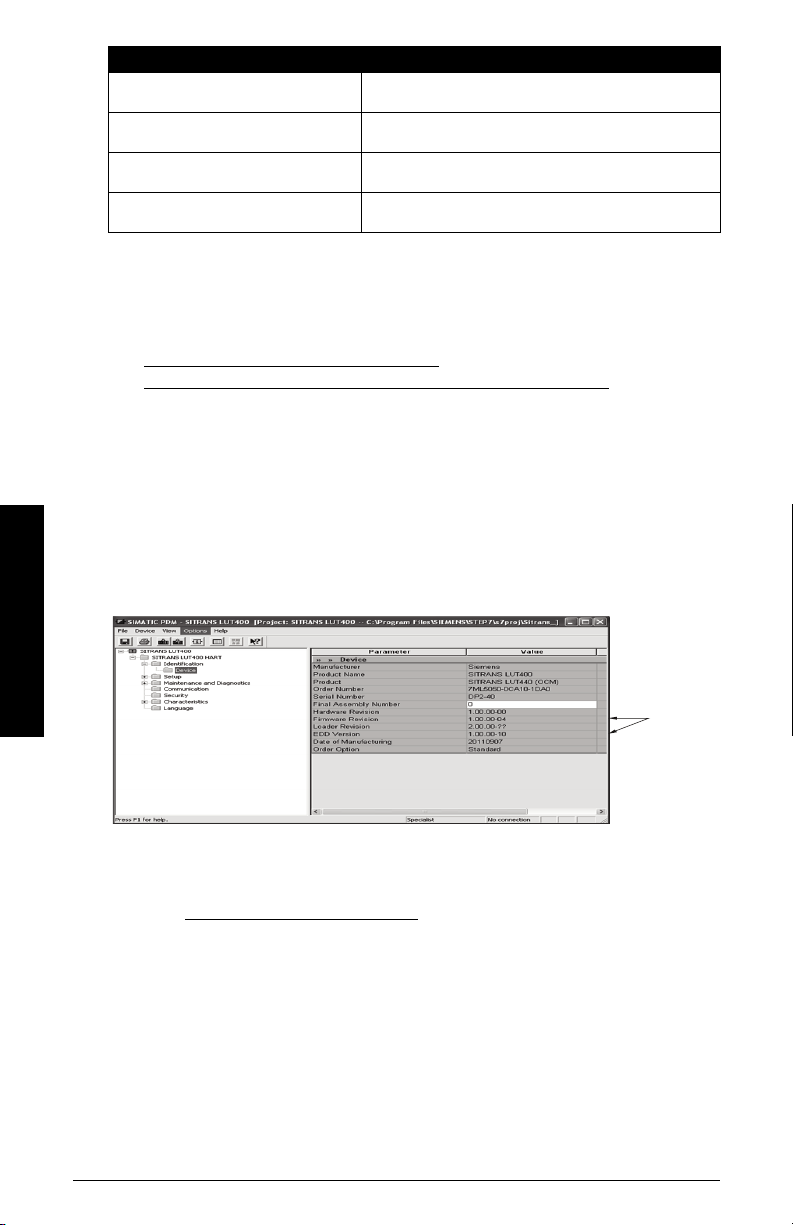

Configuring a new device

Notes:

• The first time the device is configured, you will be prompted to select a language

(English, German, French, Spanish, Chinese, Italian, Portuguese, or Russian). To

change the language again, use Language parameter [see

(LUI)

in LUT400 operating instructionsa].

• Clicking on Cancel during an upload from device to SIMATIC PDM will result in some

parameters being updated.

• Application Guides for setting up HART devices with SIMATIC PDM can be

downloaded from the product page of our website at:

www.siemens.com/sitransLUT400

a.

SITRANS LUT400 (HART) Operating Instructions (7ML19985MV01)

.

Parameter reference

1) Check that you have the most recent EDD, and if necessary update it (see

new EDD

2) Configure the device using the Quick Start Wizard. See

SIMATIC PDM

Before initiating a Quick Start Wizard to configure the device, you may wish to gather the

necessary parameter values. Parameter Configuration Charts listing all parameters and

available options for each application type are available on our website. Go to:

www.siemens.com/sitransLUT400

and select from options on the chart that apply to your application, then complete the

Quick Start Wizard via SIMATIC PDM

above).

Quick Start Wizard via

on page 7.

> Support > Application Guides. You can record data

on page 7.

Quick Start Wizard via SIMATIC PDM

Note: The layout of the dialog boxes shown may vary according to the resolution

setting for your computer monitor.

The graphic Quick Start Wizard provides an easy step-by-step guide to help you

configure the device for a simple application.

Please consult the operating instructions or online help for details on using SIMATIC

PDM. (Application Guides for setting up Siemens HART instruments with SIMATIC PDM

are available on our website: www.siemens.com/processautomation

1. If you have not already done so, check that you have the most up-to-date Electronic

Device Description (EDD) for your instrument. (See

page 7.)

2. Launch SIMATIC Manager and create a new project for LUT400. (Application Guides

for setting up HART devices with SIMATIC PDM can be downloaded from the

product page of our website at www.siemens.com/sitransLUT400

Configuring a new device

.)

.)

To install a

Operation - PDM

on

A5E33701270 COMMUNICATIONS FOR SITRANS LUT400 (HART) – MANUAL Page 7

3. After opening object in SIMATIC PDM, set the product capabilities when prompted.

Quick

Starts

If you do not know the model connected, click on Read Product Capabilities from

Device, and the model will be automatically selected.

This setting decides what parameters are visible from the PDM menus.

4. Open the menu Device – Master Reset and click on OK to perform a reset to Factory

Defaults.

5. After the reset is complete upload parameters to the PC/PG.

6. Configure the device via the Quick Start Wizard for your application.

Quick Start Wizard steps

Notes:

• The Quick Start wizard settings are inter-related and changes apply only after you

click on Apply and Transfer at the end of the final step.

• Initial Quick Start parameter values are not default values and do not necessarily

reflect the current device configuration.

Operation - PDM

• The format of date fields in PDM will reflect the user’s operating system

configuration.

• Click on BACK to return and revise setting or Cancel to exit the Quick Start.

Open the Device menu in SIMATIC PDM and select the Quick Start applicable to your

application:

Page 8 COMMUNICATIONS FOR SITRANS LUT400 (HART) – MANUAL A5E33701270

• Quick Start (Level) (see page 9)

• Quick Start (Volume) (see page 12)

• Quick Start (Volume - Linearization) (see page 15)

• Quick Start (Flow) (see page 19)

Follow steps within the wizard to configure your device.

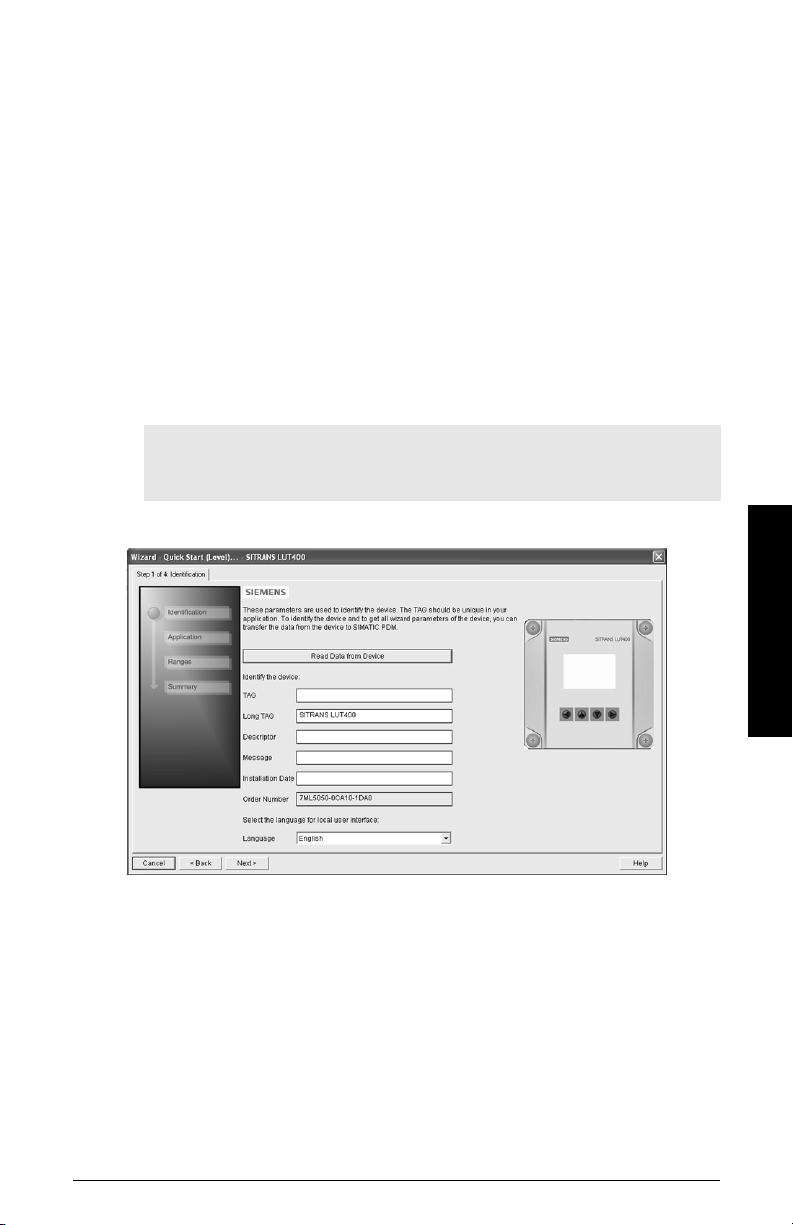

Quick Start (Level)

Step 1 – Identification

1. You can accept the default values without modification (TAG, Long TAG, Descriptor,

Message, and Installation Date fields can be left blank),

OR

1. Click on Read Data from Device (if this is not the first time running the Quick Start

Wizard).

2. The default Language is English. Select a different language value from the dropdown box if you wish to change the language displayed on the device.

Note: Italian, Portuguese and Russian are not supported in SIMATIC PDM for

SITRANS LUT400. If the device is set to one of these languages, it may be

necessary to switch the device to English, German, French, Spanish or Chinese.

Operation - PDM

3. After making all desired changes, click on Next.

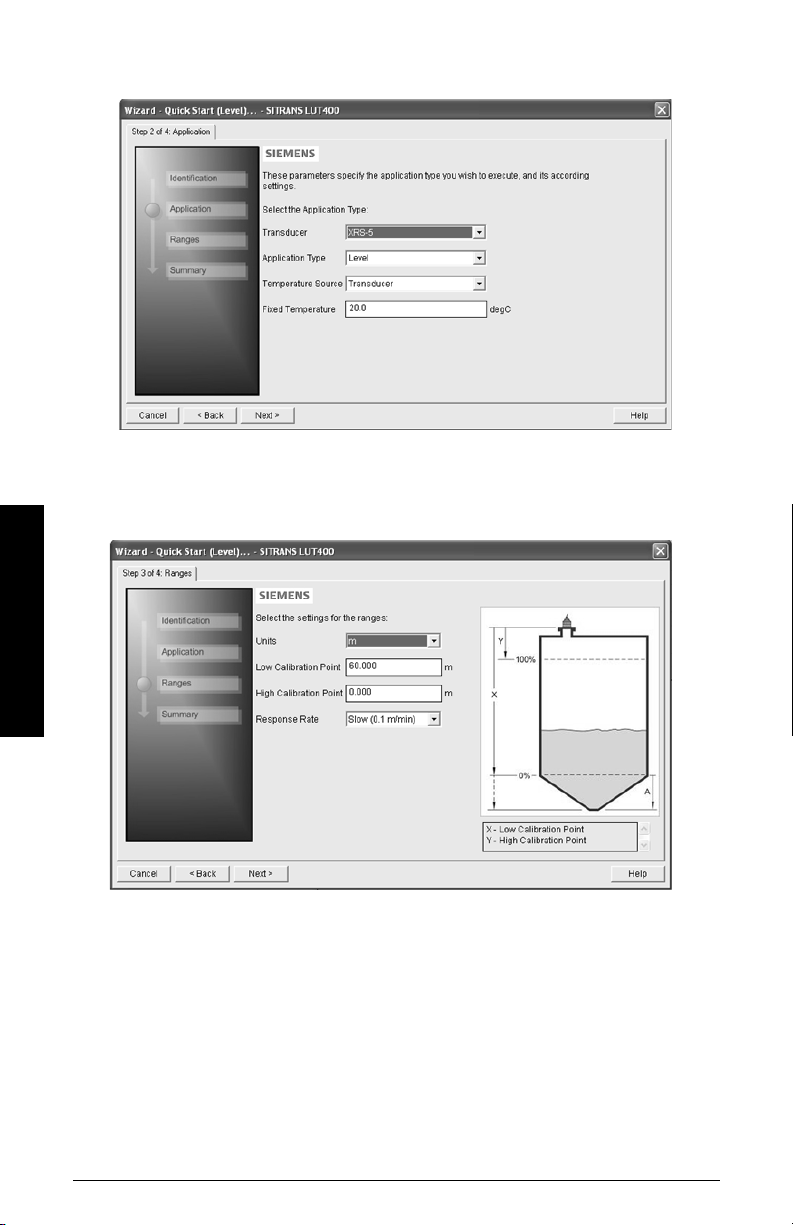

Step 2 – Application

1. Select the Transducer that will operate with the LUT400.

2. Select the Application Type (Level, Space, Distance).

A5E33701270 COMMUNICATIONS FOR SITRANS LUT400 (HART) – MANUAL Page 9

3. Select the Temperature Source (Transducer, Fixed Temperature, External TS-3,

Average of Transducer and TS-3), and if Fixed, enter the Fixed Temperature value.

4. Click on Next.

Step 3 - Ranges

1. Modify parameters as required.

Operation - PDM

2. Click on Next.

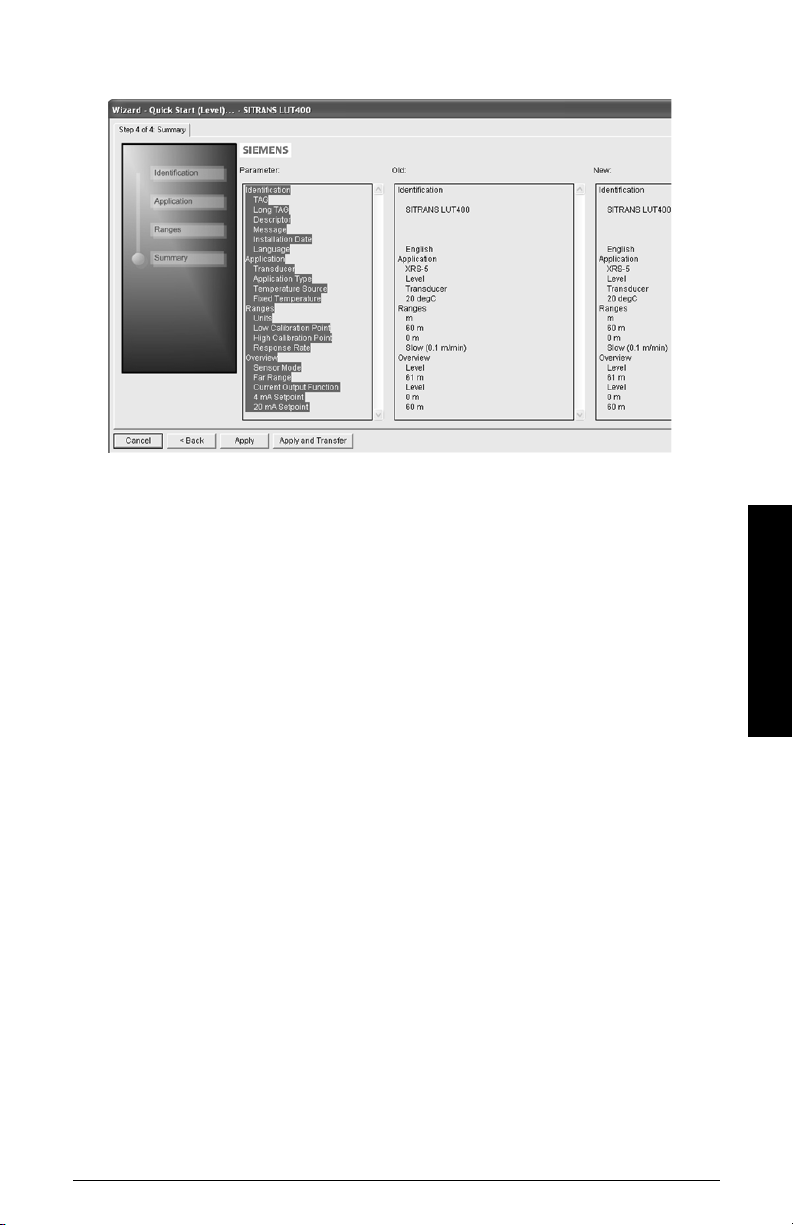

Step 4 – Summary

1. Check parameter settings, and click on Cancel to abort, or apply your changes.

Page 10 COMMUNICATIONS FOR SITRANS LUT400 (HART) – MANUAL A5E33701270

2. Click Apply to save your changes and return to the main menu, or click Apply and

Trans fer to save your changes and transfer settings to the device.

The message Quick Setup was successful will appear. Click on OK.

Configuration via the SIMATIC PDM Quick Start Wizard for a Level application is now

complete.

Operation - PDM

A5E33701270 COMMUNICATIONS FOR SITRANS LUT400 (HART) – MANUAL Page 11

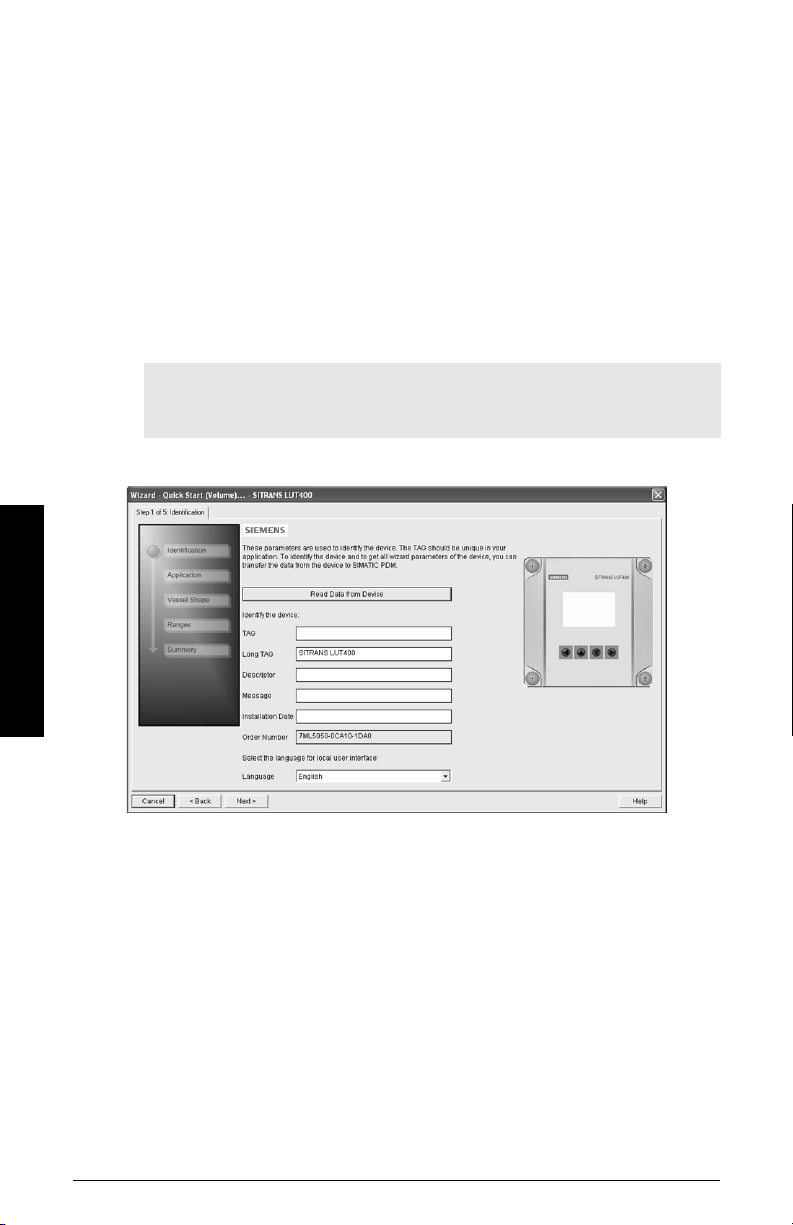

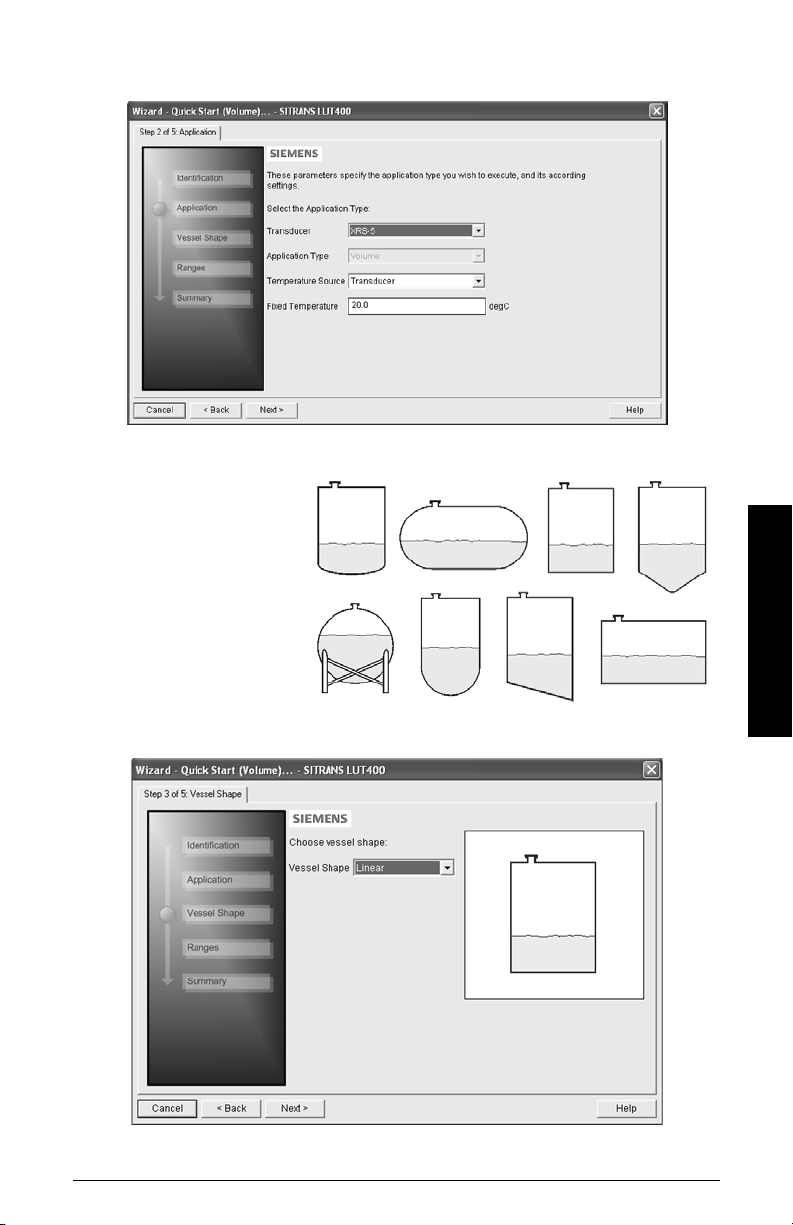

Quick Start (Volume)

Use this wizard to configure volume applications employing standard vessel shapes.

Open the menu Device – Wizard - Quick Start (Volume):

Step 1 – Identification

1. You can accept the default values without modification (TAG, Long TAG, Descriptor,

Message, and Installation Date fields can be left blank),

OR

1. Click on Read Data from Device (if this is not the first time running the Quick Start

Wizard).

2. The default Language is English. Select a different language value from the dropdown box if you wish to change the language displayed on the device.

Note: Italian, Portuguese and Russian are not supported in SIMATIC PDM for

SITRANS LUT400. If the device is set to one of these languages, it may be

necessary to switch the device to English, German, French, Spanish or Chinese.

Operation - PDM

3. After making all desired changes, click on Next.

Step 2 – Application

1. Select the Transducer that will operate with the LUT400.

The Application Type defaults to Volume.

Page 12 COMMUNICATIONS FOR SITRANS LUT400 (HART) – MANUAL A5E33701270

2. Select the Temperature Source (Transducer, Fixed Temperature, External TS-3,

Average of Transducer and TS-3), and if Fixed, enter the Fixed Temperature value.

3. Click on Next.

Step 3 - Vessel Shape

The vessel shapes shown

are predefined.

To describe a more

complex shape see

Quick

Start (Volume Linearization)

on page 15.

Operation - PDM

1. Select a Vessel

Shape for your Volume application.

2. Click on Next.

A5E33701270 COMMUNICATIONS FOR SITRANS LUT400 (HART) – MANUAL Page 13

Step 4 - Ranges

1. Modify parameters as required. (Vessel Dimension A and L are required for certain

Vessel Shapes selected in previous step.)

2. Click on Next.

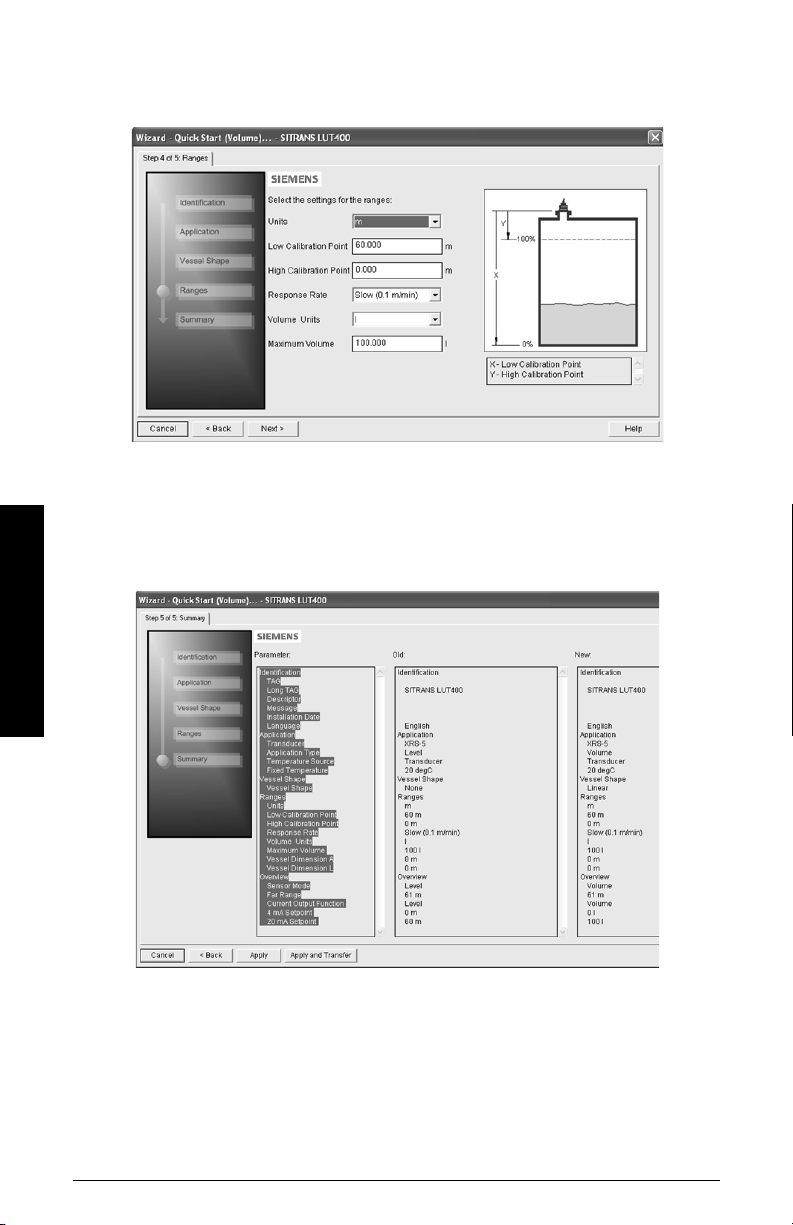

Step 5 – Summary

1. Check parameter settings, and click on Cancel to abort, or apply your changes.

2. Click Apply to save your changes and return to the main menu, or click Apply and

Trans fer to save your changes and transfer settings to the device.

Operation - PDM

The message Quick Setup was successful will appear. Click on OK.

Configuration via SIMATIC PDM Quick Start Wizard for a simple Volume application is

now complete.

Page 14 COMMUNICATIONS FOR SITRANS LUT400 (HART) – MANUAL A5E33701270

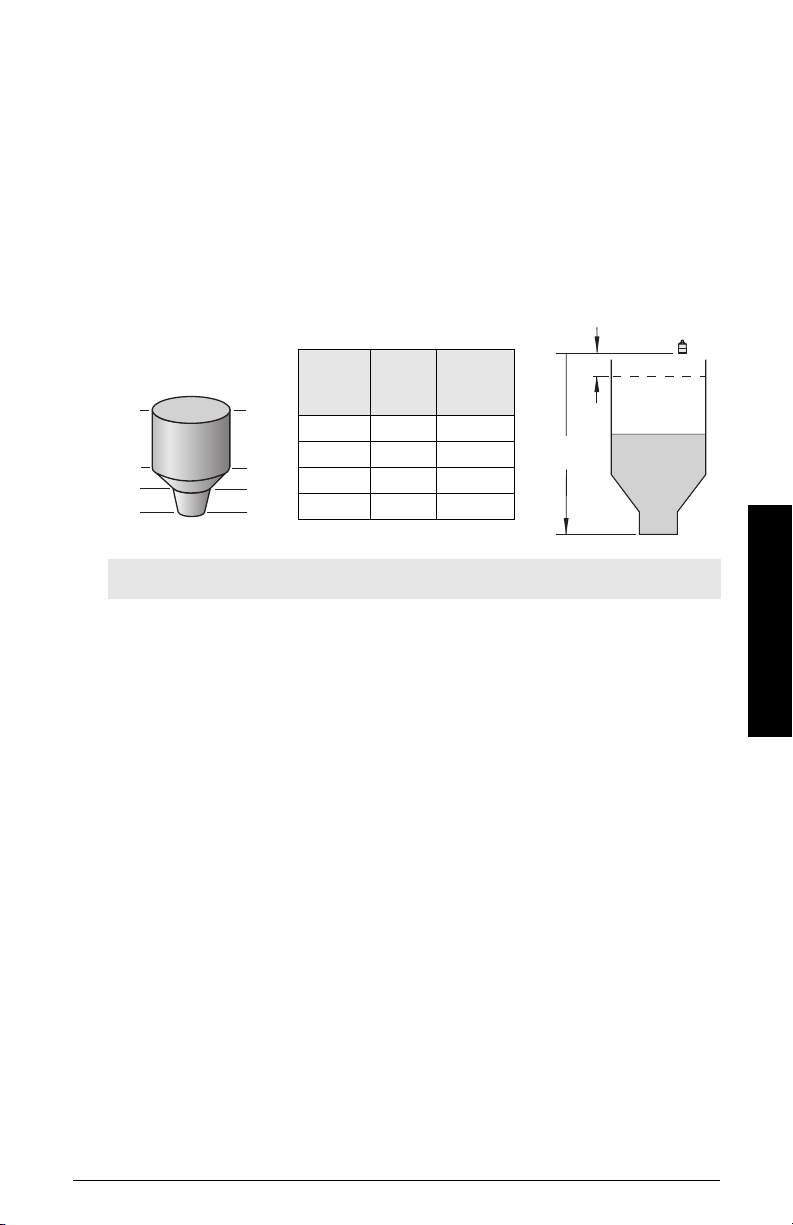

Quick Start (Volume - Linearization)

4

Breakpoint

number

3

2

1

Breakpoint no.

Level

value

(m)

Vol ume

value

(l)

1 (0%) 0 0

25500

3 9 3000

4 (100%) 19.5 8000

Level

value

9

5

0

20 m

0.5 m

19.5

Use this wizard to configure volume applications employing more complex vessel shapes.

Using Linearization via the Quick Start wizard

You can use the linearization feature to define a more complex vessel shape and enter up

to 32 level breakpoints where the corresponding volume is known. The values

corresponding to 0% and 100% levels must be entered. Breakpoints can be ordered from

top to bottom or the reverse, but should be entered in the wizard from the bottom to the

top of the vessel so that the characterization chart accurately reflects values as they are

entered.

Example:

Note: values are for example purposes only.

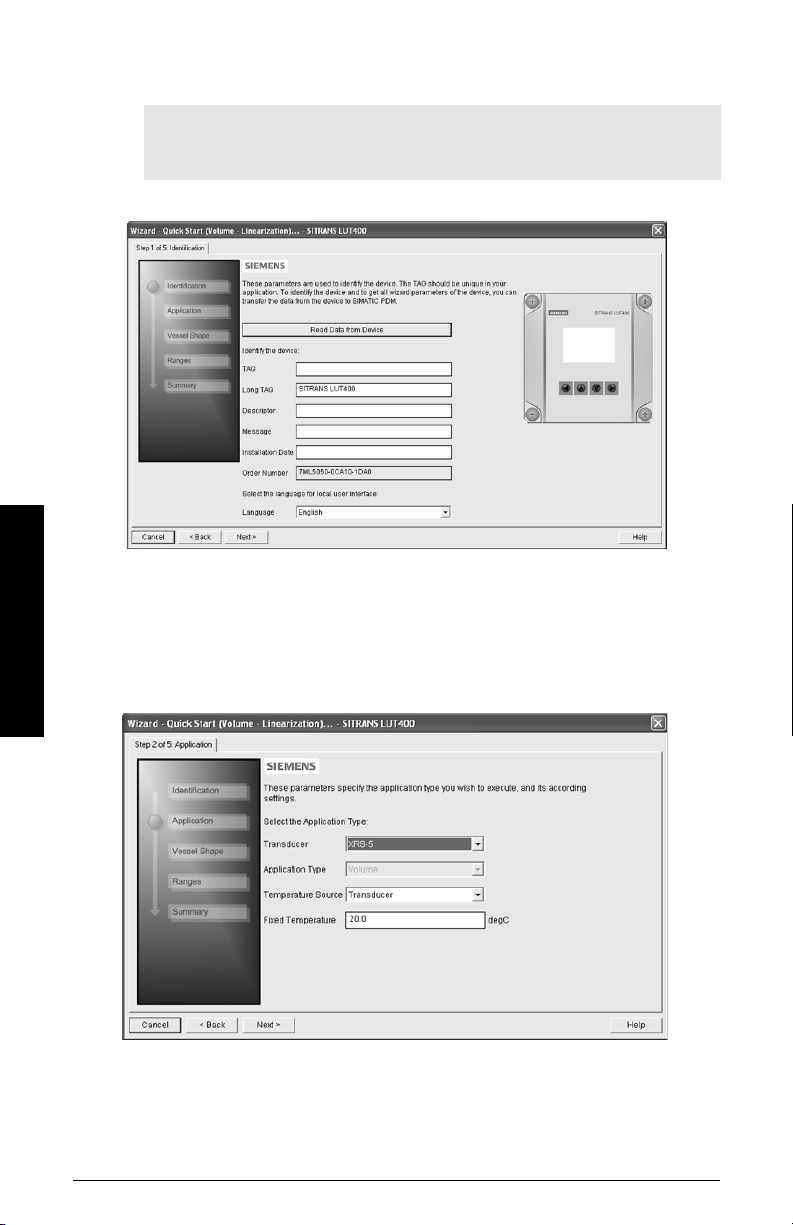

Open the menu Device – Wizard - Quick Start (Volume - Linearization):

Operation - PDM

Step 1 – Identification

1. You can accept the default values without modification (TAG, Long TAG, Descriptor,

Message, and Installation Date fields can be left blank),

OR

1. Click on Read Data from Device (if this is not the first time running the Quick Start

Wizard).

A5E33701270 COMMUNICATIONS FOR SITRANS LUT400 (HART) – MANUAL Page 15

2. The default Language is English. Select a different language value from the drop-

3. After making all desired changes, click on Next.

Step 2 – Application

1. Select the Transducer that will operate with the LUT400.

Operation - PDM

2. Select the Temperature Source (Transducer, Fixed Temperature, External TS-3,

down box if you wish to change the language displayed on the device.

Note: Italian, Portuguese and Russian are not supported in SIMATIC PDM for

SITRANS LUT400. If the device is set to one of these languages, it may be

necessary to switch the device to English, German, French, Spanish or Chinese.

The Application Type defaults to Volume.

Average of Transducer and TS-3), and if Fixed, enter the Fixed Temperature value.

3. Click on Next.

Page 16 COMMUNICATIONS FOR SITRANS LUT400 (HART) – MANUAL A5E33701270

Step 3 – Vessel Shape

1. In this step, there are two options: Linearization Table and Curve Table. Breakpoints

will be entered in the same manner regardless of the table type selected, however a

different algorithm is used for Curve Table, to smooth the lines between breakpoints.

For example, use Curve Table when vessel sides are more rounded rather than

straight angles. Make a selection and click on NEXT.

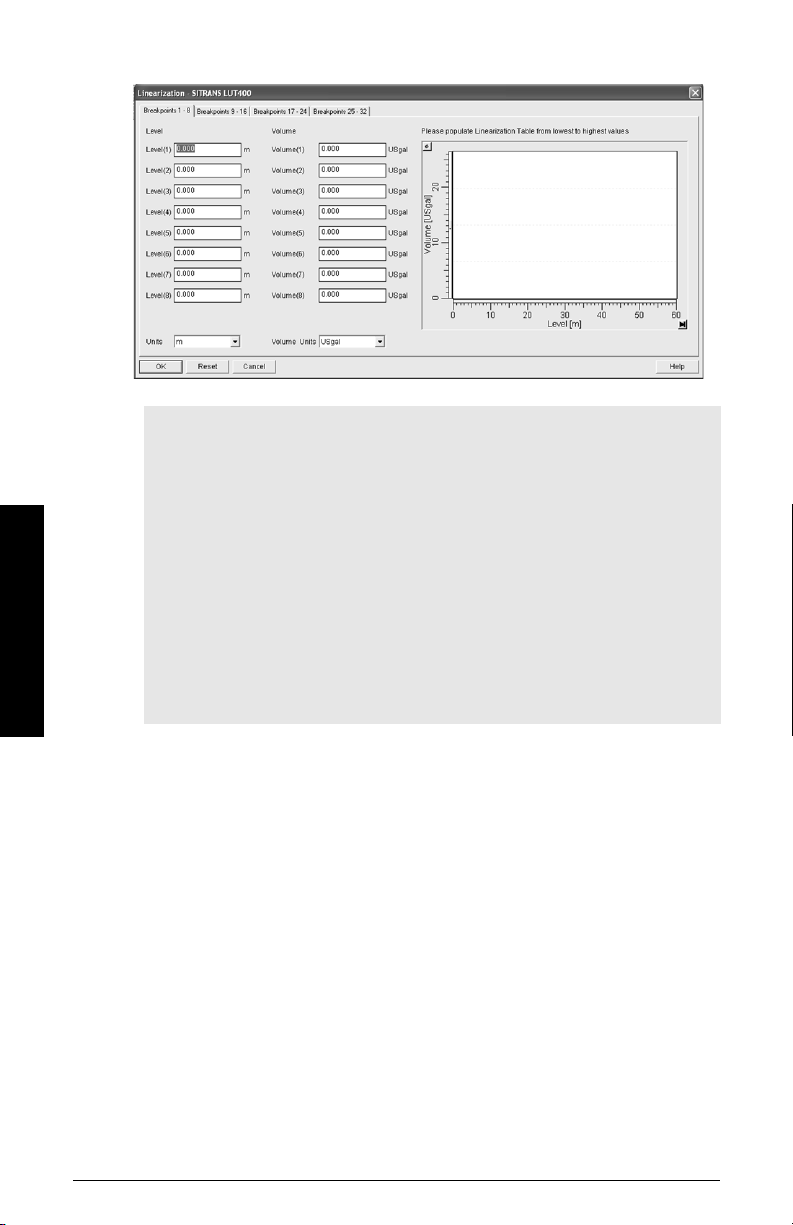

Step 4 - Ranges

1. Modify parameters as required.

Operation - PDM

2. Click on Linearization to set breakpoints.

3. In the Linearization window click on the appropriate Breakpoint tab to open the

dialog window.

A5E33701270 COMMUNICATIONS FOR SITRANS LUT400 (HART) – MANUAL Page 17

Operation - PDM

a. Enter the desired Level and Volume values, and click on OK.

Notes:

• The Reset button resets values to the values in the offline table.

• When entering breakpoints via the wizard, values should be entered from the

bottom to the top of the vessel so that the characterization chart accurately

reflects values as they are entered.

• To add points for Level and Volume equal to 0, enter these points first.

• When using a linear table, add at least two points.

• When using a curve table, add at least four points.

• If entering or modifying breakpoints via the parameter menu (after initial wizard

is complete), ensure

level/volume values being transferred, otherwise two uploads must be

performed:

a) one to read Linearization Table as enabled,

b) and one to transfer breakpoint values.

2.6.1.Vessel Shape

is set to Linearization Table prior to

c. Back in the Step 4 of 5: Ranges window, click on NEXT.

Step 5 - Summary

1. Check parameter settings, and click on Cancel to abort, or apply your changes.

2. Click Apply to save your changes and return to the main menu, or click Apply and

Trans fer to save your changes and transfer settings to the device.

The message Quick Setup was successful will appear. Click on OK.

Configuration via SIMATIC PDM Quick Start Wizard for a Volume application with a

complex vessel shape is now complete.

Page 18 COMMUNICATIONS FOR SITRANS LUT400 (HART) – MANUAL A5E33701270

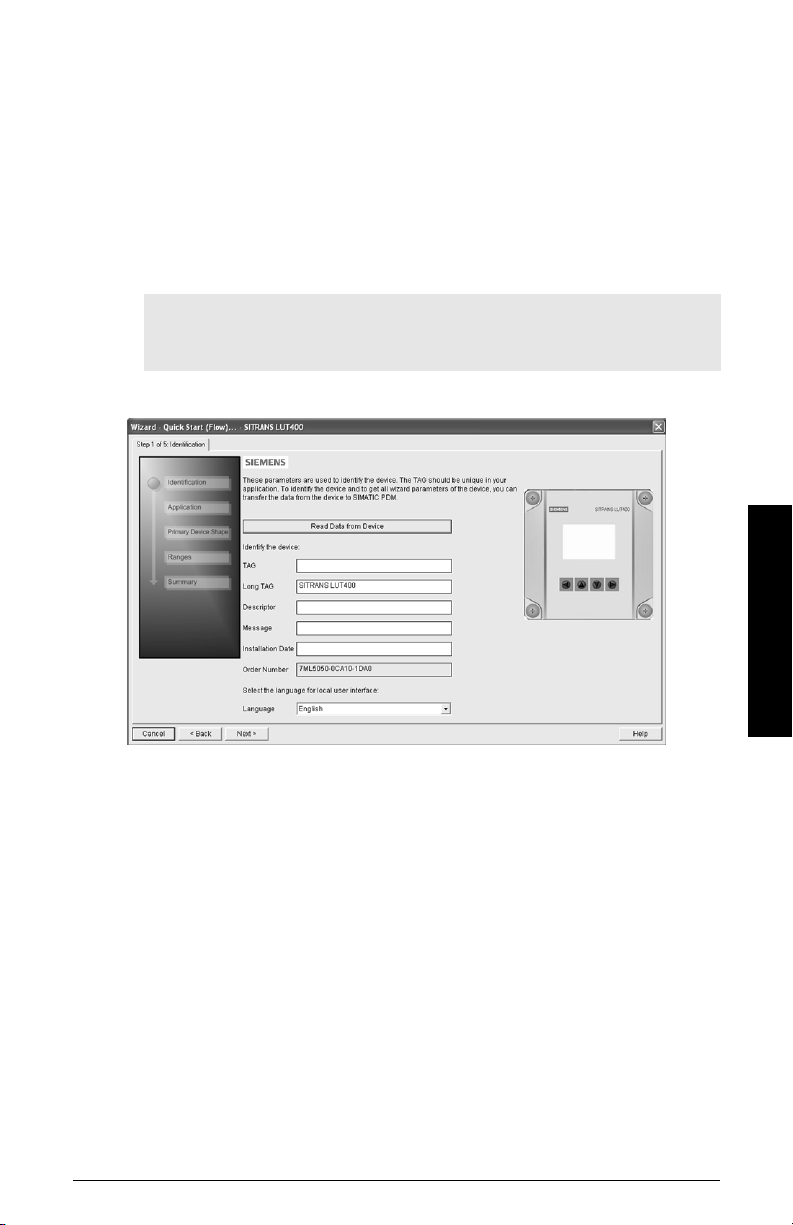

Quick Start (Flow)

Step 1 – Identification

1) You can accept the default values without modification (TAG, Long TAG, Descriptor,

Message, and Installation Date fields can be left blank),

OR

1) Click on Read Data from Device (if this is not the first time running the Quick Start

Wizard).

2. The default Language is English. Select a different language value from the dropdown box if you wish to change the language displayed on the device.

Note: Italian, Portuguese and Russian are not supported in SIMATIC PDM for

SITRANS LUT400. If the device is set to one of these languages, it may be

necessary to switch the device to English, German, French, Spanish or Chinese.

Operation - PDM

3) After making all desired changes, click on Next.

A5E33701270 COMMUNICATIONS FOR SITRANS LUT400 (HART) – MANUAL Page 19

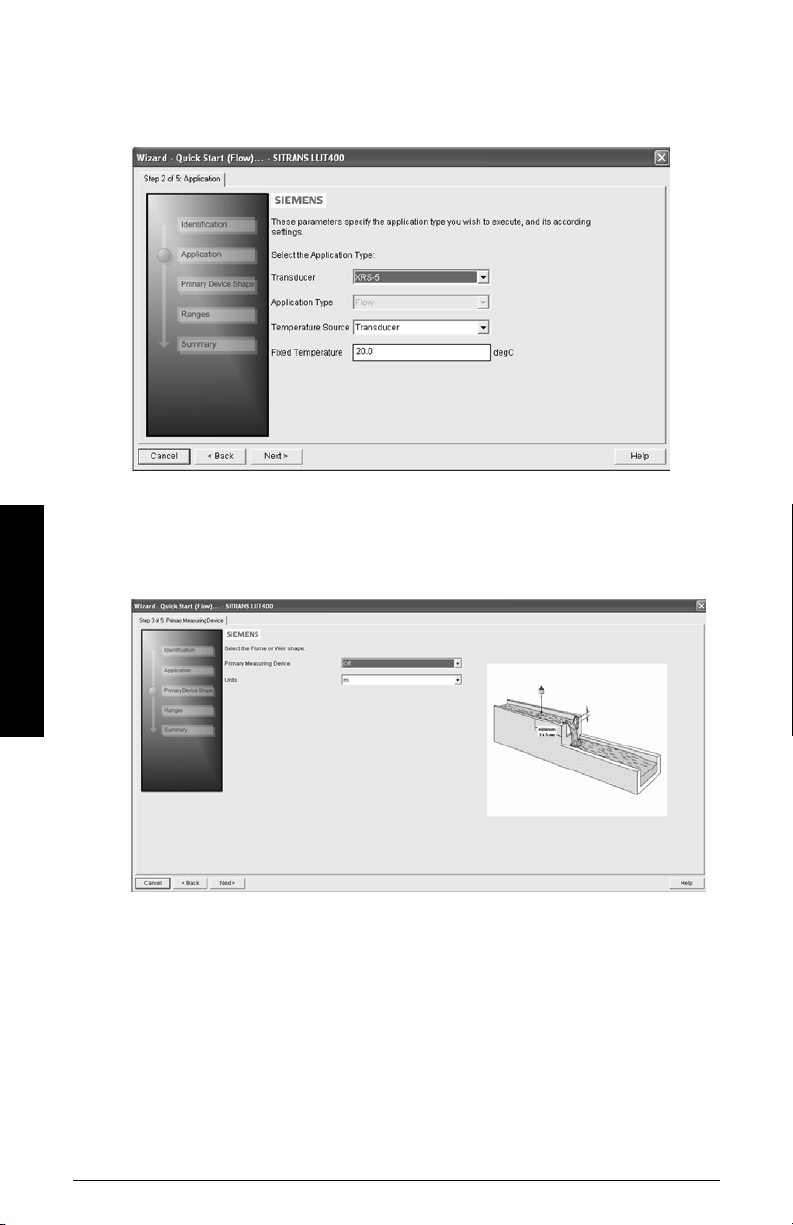

Step 2 – Application

1) Select the Transducer that will operate with the LUT400.

2) Select the Temperature Source (Transducer, Fixed Temperature, External TS-3,

Average of Transducer and TS-3), and if Fixed, enter the Fixed Temperature value.

3) Click on Next.

Step 3 – Primary Device Shape

1) Select a Primary Measuring Device for your Flow application and change Units if

desired.

Operation - PDM

2. Additional parameter default values appear depending on the Primary Measuring

Device selected. Modify as required.

3. Click on Next.

Page 20 COMMUNICATIONS FOR SITRANS LUT400 (HART) – MANUAL A5E33701270

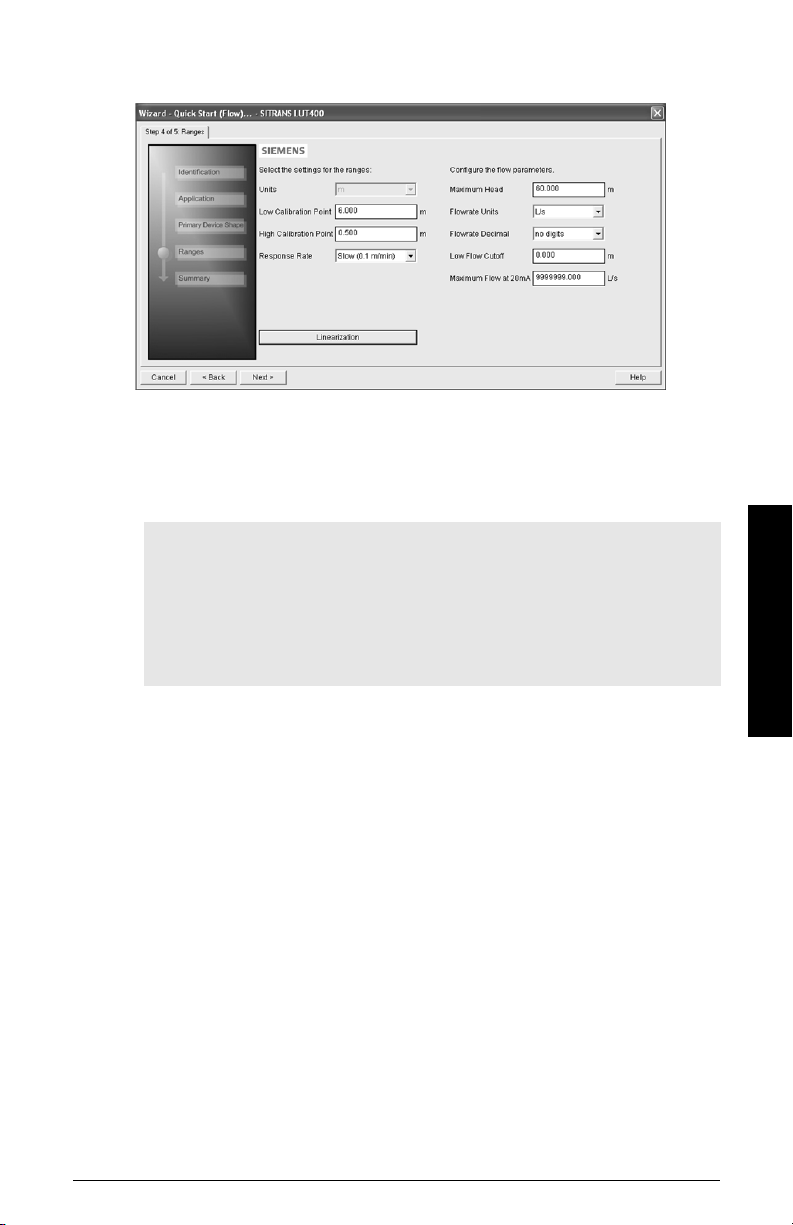

Step 4 - Ranges

1) Modify parameters as required.

2. If PMD selected in Step 3 was Universal Head Flow, the Linearization button will

appear in Step 4. Click on Linearization to set Head and Flow Breakpoints, then click

OK to return to the Step 4.

3. Click on Next.

Notes:

• If entering or modifying breakpoints via the parameter menu (after initial wizard

is complete), ensure

Head Flow prior to head/flow values being transferred, otherwise two uploads

must be performed:

a) one to read Universal Head Flow as enabled,

b) and one to transfer breakpoint values.

2.15.1.Primary Measuring Device (PMD)

is set to Universal

Step 5 – Summary

1. Check parameter settings, and click on Cancel to abort, or apply your changes.

2. Click Apply to save your changes and return to the main menu, or click Apply and

Trans fer to save your changes and transfer settings to the device.

The message Quick Setup was successful will appear. Click on OK.

Configuration via SIMATIC PDM Quick Start Wizard for a Flow application is now

complete.

Operation - PDM

A5E33701270 COMMUNICATIONS FOR SITRANS LUT400 (HART) – MANUAL Page 21

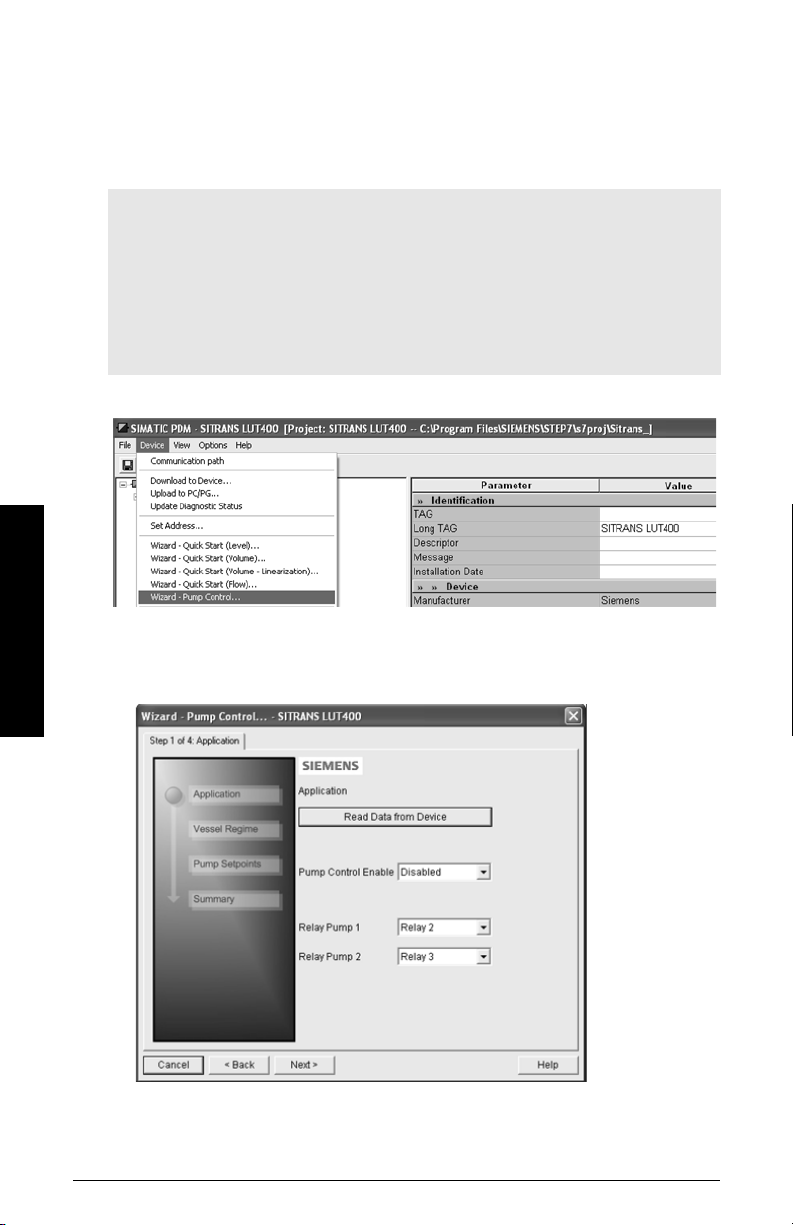

Pump Control Wizard

The Pump Control Setup Wizard provides an easy step-by-step guide to help you

configure the pumps and relays for a simple application.

Pump Control Wizard steps

Notes:

• Complete the appropriate Quick Start Wizard (Level, Volume, or Volume

Linearization) prior to programming pump control.

• The Pump Control Setup Wizard settings are inter-related and changes apply only

after you click on Apply and Transfer at the end of the final step.

• Initial Pump Control Wizard parameter values are not default values and do not

necessarily reflect the current device configuration.

• Click on BACK to return and revise setting or Cancel to exit the Pump Control Wizard.

Launch SIMATIC PDM, open the menu Device – Wizard - Pump Control, and follow steps.

Step 1 – Application

Operation - PDM

1) Enable pump control, and select which relay is wired to Pump 1. (The relay for Pump

2 will be set automatically based on your selection for Pump 1.)

2. Click on Next.

Page 22 COMMUNICATIONS FOR SITRANS LUT400 (HART) – MANUAL A5E33701270

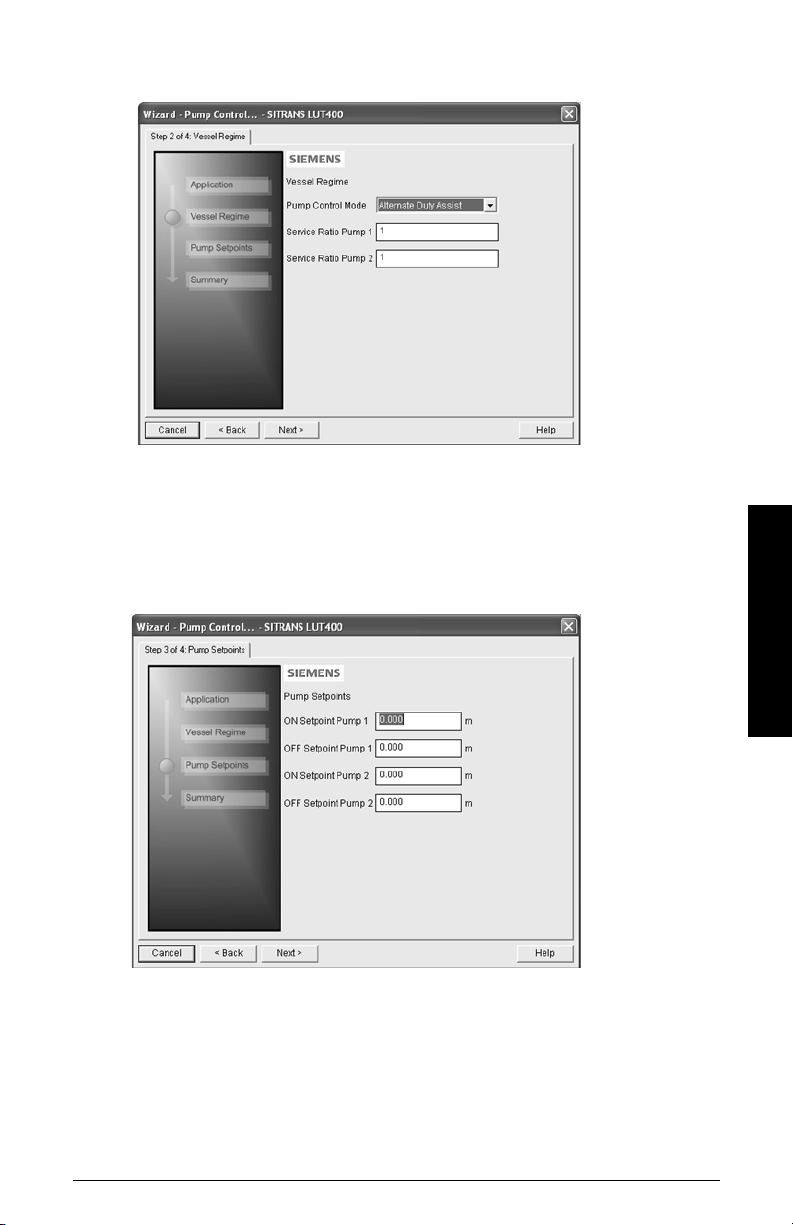

Step 2 – Vessel Regime

1) Select the Pump Control Mode.

2. If Service Ratio Duty Assist, or Service Ratio Duty Backup selected enter the Service

Ratio for each pump.

3. Click on Next.

Step 3 – Pump Setpoints

1) Enter the start level (ON Setpoint), and stop level (OFF Setpoint) for each pump, then

click on Next.

Operation - PDM

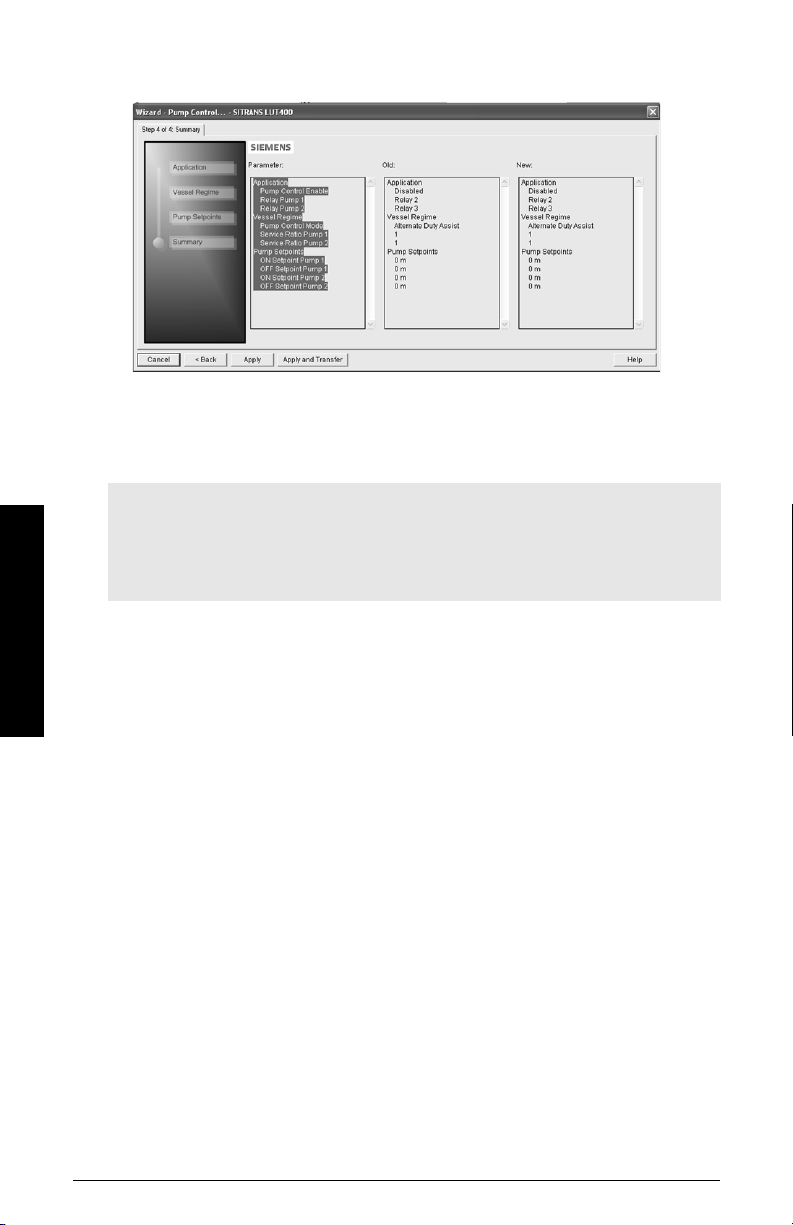

Step 4 – Summary

1. Check parameter settings, and click on Cancel to abort, or apply your changes.

A5E33701270 COMMUNICATIONS FOR SITRANS LUT400 (HART) – MANUAL Page 23

2. Click Apply to save your changes and return to the main menu, or click Apply and

Trans fer to save your changes and transfer settings to the device.

Pump configuration via PDM Pump Control Wizard is now complete.

Changing parameter settings using SIMATIC PDM

Notes:

• For a complete list of parameters, see

instructionsa.

• Clicking on Cancel during an upload from device to SIMATIC PDM will result in some

parameters being updated.

a.

SITRANS LUT400 (HART) Operating Instructions (7ML19985MV01)

Parameter reference (LUI)

in LUT400 operating

Operation - PDM

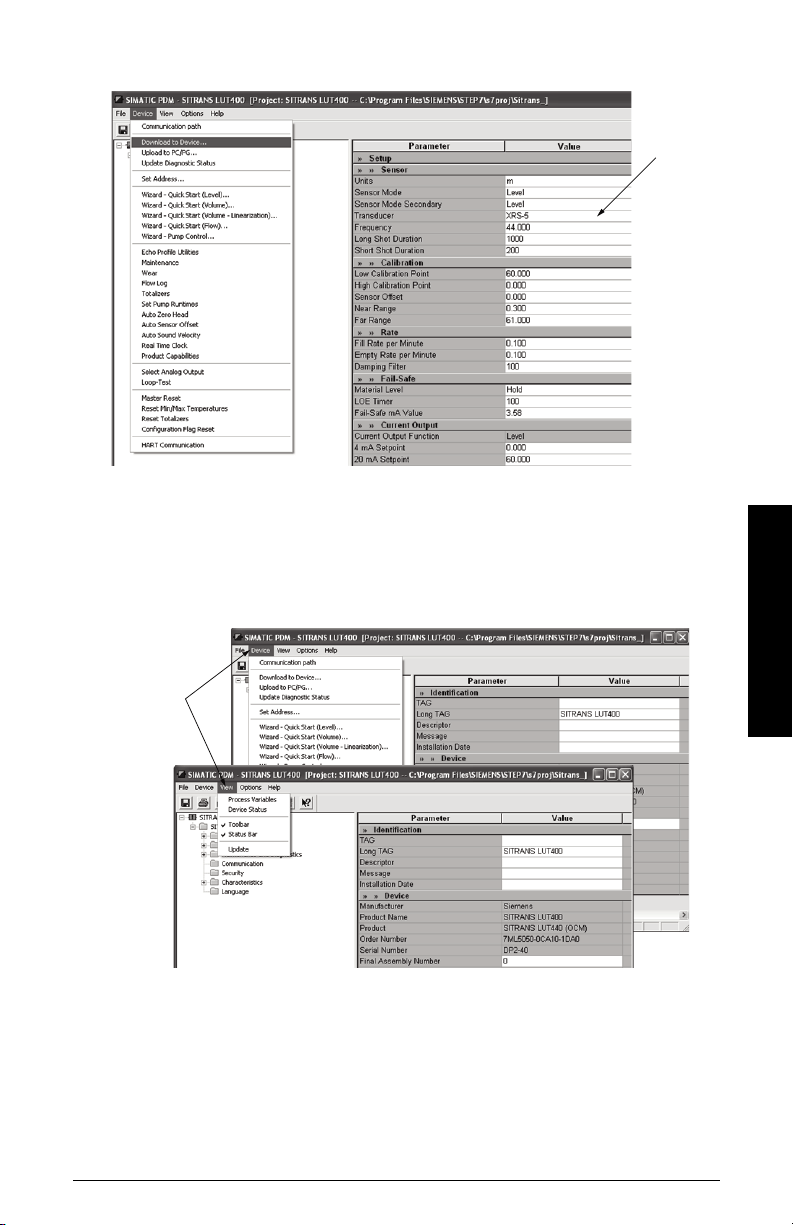

Many parameters are accessed via the 5-level menu in PDM. See

pull-down menus

1) Launch SIMATIC PDM, connect to SITRANS LUT400, and upload data from the

device.

2) Adjust parameter values in the parameter value field and then press Enter. The

status fields read Changed.

Page 24 COMMUNICATIONS FOR SITRANS LUT400 (HART) – MANUAL A5E33701270

below for the others.

Parameters accessed via

3) Open the Device menu, click on Download to device, then use File – Save, to save

value

fields

pull-down

menus

parameter settings. The status fields are cleared.

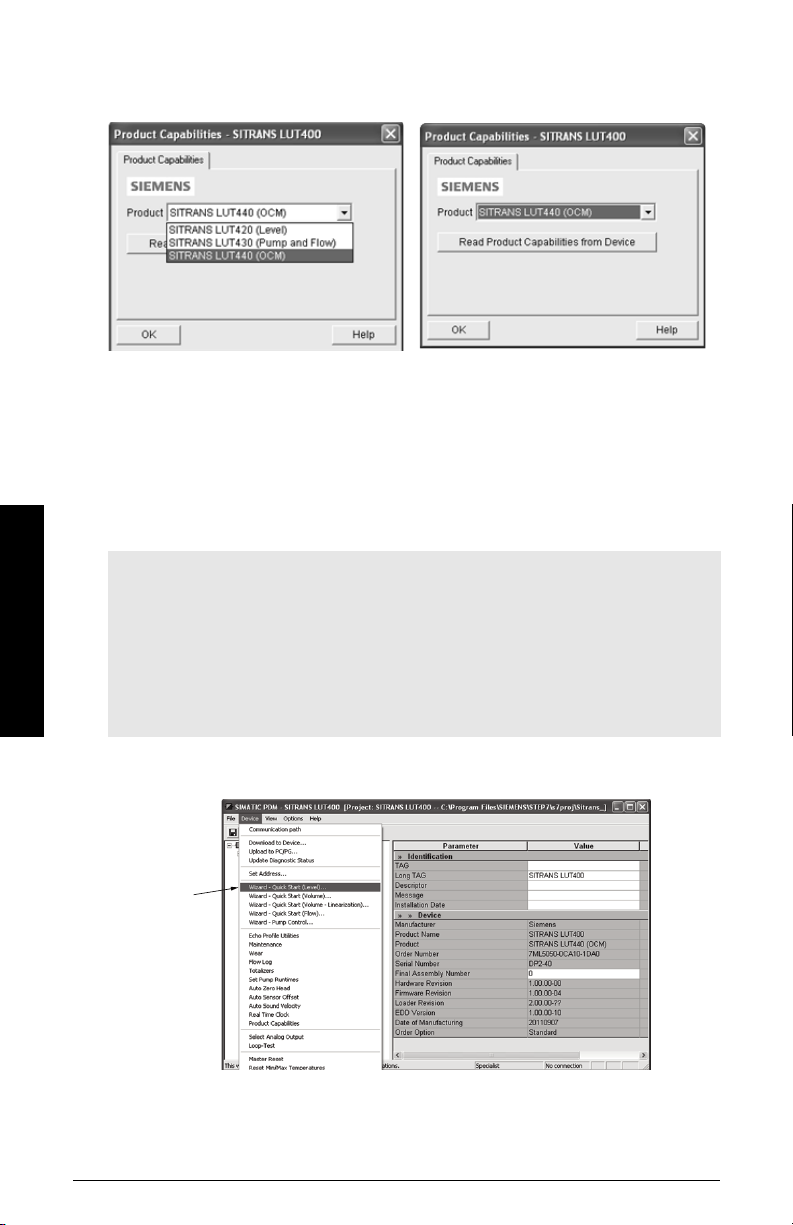

Parameters accessed via pull-down menus

You have access to a number of functions via pull-down menus from the menu bar under

Device or View.

For a complete list, see pull-down menus below.

Operation - PDM

A5E33701270 COMMUNICATIONS FOR SITRANS LUT400 (HART) – MANUAL Page 25

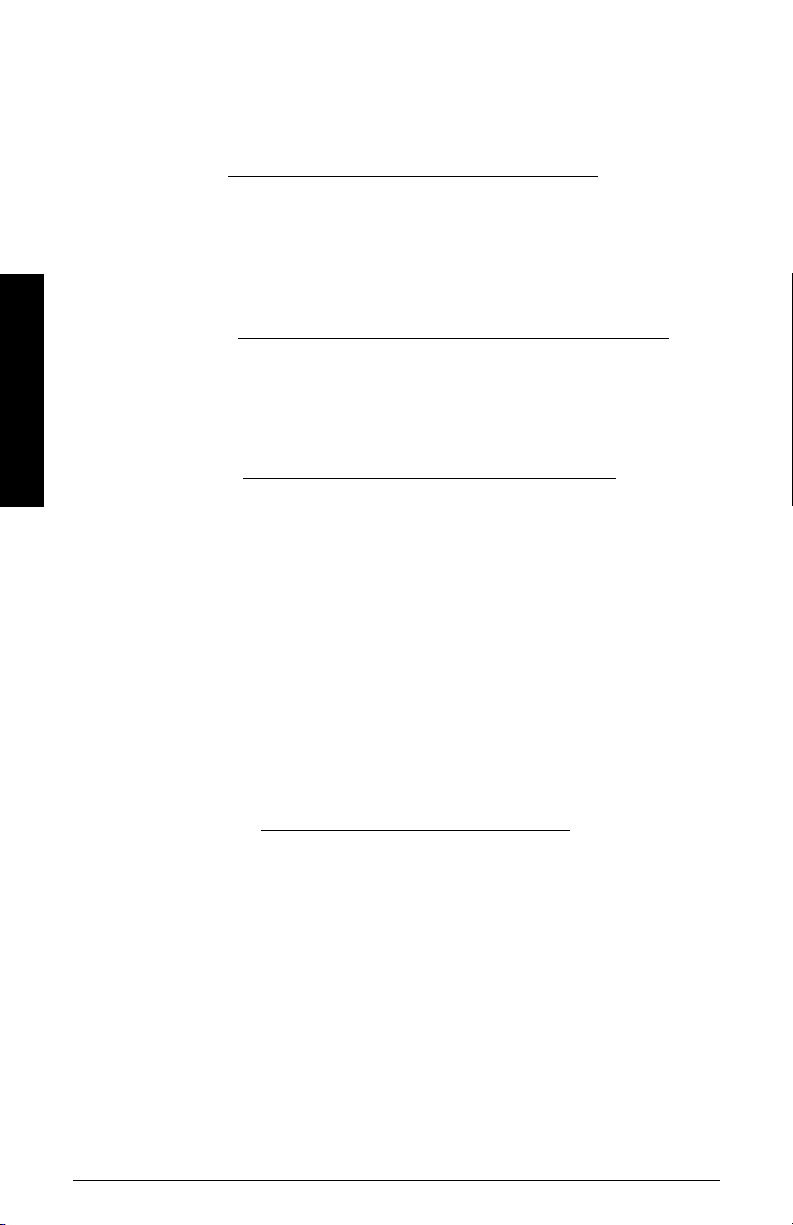

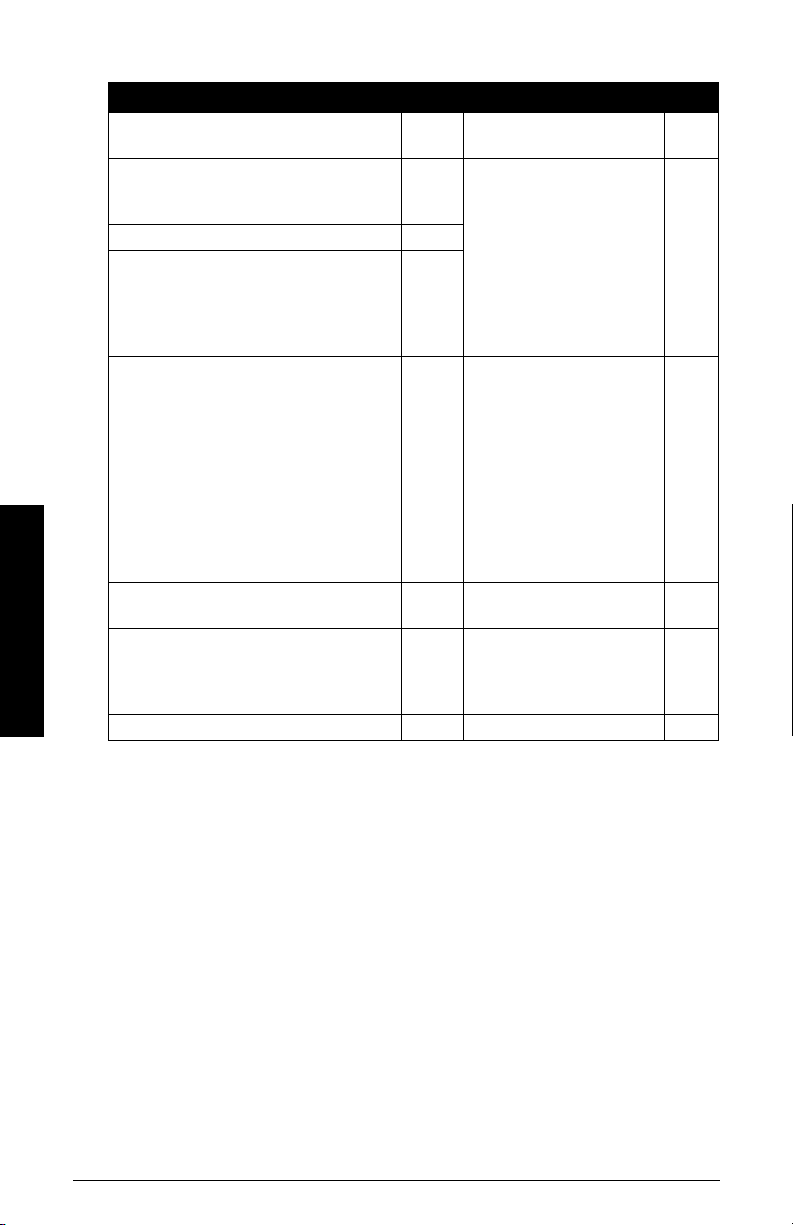

Pull-down menus

Operation - PDM

Device menus page View menus page

Communication path -

Download to Device

Upload to PC/PG

Update Diagnostic Status

Set Address 27

Wizard - Quick Start (Level)

Wizard - Quick Start (Volume)

Wizard - Quick Start (Volume - Linearization)

Wizard - Quick Start (Flow) *

Wizard - Pump Control

Echo Profile Utilities

Maintenance

Wear

Flow Log *

Tot a l i z ers *

Set Pumps Runtimes *

Auto Zero Head *

Auto Sensor Offset

Auto Sound Velocity

Real Time Clock

Product Capabilities

Select Analog Output

Loop-Test

Master Reset

Reset Min/Max Temperatures

Reset Totalizers *

Configuration Flag Reset

HART Communication 36

Process Variables

Device Status

-

-

-

9

12

15

19

22

27

32

33

33

33

33

34

34

34

34

34

35

35

35

36

36

36

To ol b a r

Status Bar

Update -

36

39

-

-

* Selected menus visible only if Product Capabilities set to Pump and Flow or OCM.

Page 26 COMMUNICATIONS FOR SITRANS LUT400 (HART) – MANUAL A5E33701270

Loading...

Loading...