Siemens SITRANS L Series, SITRANS LPS200 Operating Instructions Manual

SITRANS L

Rotating Paddle Switch

SITRANS LPS200

Operating Instructions

7ML5725-.....-...., 7ML5726-.....-...., 7ML5727-.....-....,

7ML5728

04/2019

A5E34210883

Introduction

1

Safety notes

2

Description

3

Applications

4

Installing/mounting

5

Connection

6

Service and maintenance

7

Technical data

8

Dimension drawings

9

Technical reference

A

Certificates and support

B

SITRANS LPS200

-.....-...., 7ML5730-.....-....

-AB

Siemens AG

Division Process Industries and Drives

Postfach 48 48

90026 NÜRNBERG

GERMANY

Document order number: A5E34210883

Ⓟ

Copyright © Siemens AG 2019.

All rights reserved

indicates that death or severe personal injury will result if proper precautions are not taken.

indicates that death or severe personal injury may result if proper precautions are not taken.

indicates that minor personal injury can result if proper precautions are not taken.

indicates that property damage can result if proper precautions are not taken.

Siemens products may only be used for the applications described in the catalog and in the relevant technical

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

WARNING

CAUTION

NOTICE

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

07/2019 Subject to change

Table of contents

1 Introduction ............................................................................................................................................. 5

1.1 Operating instructions scope .................................................................................................... 5

2 Safety notes ............................................................................................................................................ 6

2.1 Safety marking symbols ............................................................................................................ 6

3 Description .............................................................................................................................................. 7

3.1 SITRANS LPS200 Overview .................................................................................................... 7

3.2 Features .................................................................................................................................... 7

4 Applications ............................................................................................................................................ 8

5 Installing/mounting .................................................................................................................................. 9

5.1 Food grade material ................................................................................................................ 10

5.2 Ambient temperature (housing)/process temperature ............................................................ 11

5.3 Process cautions ..................................................................................................................... 12

5.4 Sensitivity ................................................................................................................................ 13

6 Connection ........................................................................................................................................... 14

6.1 Universal voltage, DPDT, fail-safe .......................................................................................... 15

6.2 AC or DC version, SPDT ........................................................................................................ 16

6.3 Switching logic (universal voltage, DPDT) .............................................................................. 17

6.4 Signal output: delay (universal voltage, DPDT) ...................................................................... 18

6.5 Alarm output - fail-safe option (universal voltage, DPDT) ...................................................... 19

6.6 Switching logic (AC or DC version, SPDT) ............................................................................. 20

SITRANS LPS200

Operating Instructions, 04/2019, A5E34210883-AB

3

Table of contents

7 Service and maintenance ...................................................................................................................... 21

7.1 Maintenance ........................................................................................................................... 21

7.2 Unit repair and excluded liability ............................................................................................ 21

8 Technical data ...................................................................................................................................... 22

8.1 Power ..................................................................................................................................... 22

8.2 Performance ........................................................................................................................... 23

8.3 Alarm output ........................................................................................................................... 23

8.4 Mechanical ............................................................................................................................. 24

8.5 Environmental ........................................................................................................................ 25

8.6 Process .................................................................................................................................. 26

8.7 Approvals ............................................................................................................................... 27

9 Dimension drawings .............................................................................................................................. 28

9.1 Dimensions and temperature ranges ..................................................................................... 28

9.2 Extensions .............................................................................................................................. 30

9.3 Measuring vanes .................................................................................................................... 31

A Technical reference .............................................................................................................................. 32

A.1 Principle of operation ............................................................................................................. 32

B Certificates and support ........................................................................................................................ 33

B.1 Technical support ................................................................................................................... 33

B.2 Certificates ............................................................................................................................. 33

SITRANS LPS200

4 Operating Instructions, 04/2019, A5E34210883-AB

1

Note

•

•

Please follow the installation and operating procedures for a quick, trouble-free

installation and to ensure the maximum accuracy and reliability of your device.

This manual applies to SITRANS LPS200 only.

1.1 Operating instructions scope

This manual will help you set up your device for optimum performance.

SITRANS LPS200

Operating Instructions, 04/2019, A5E34210883-AB

5

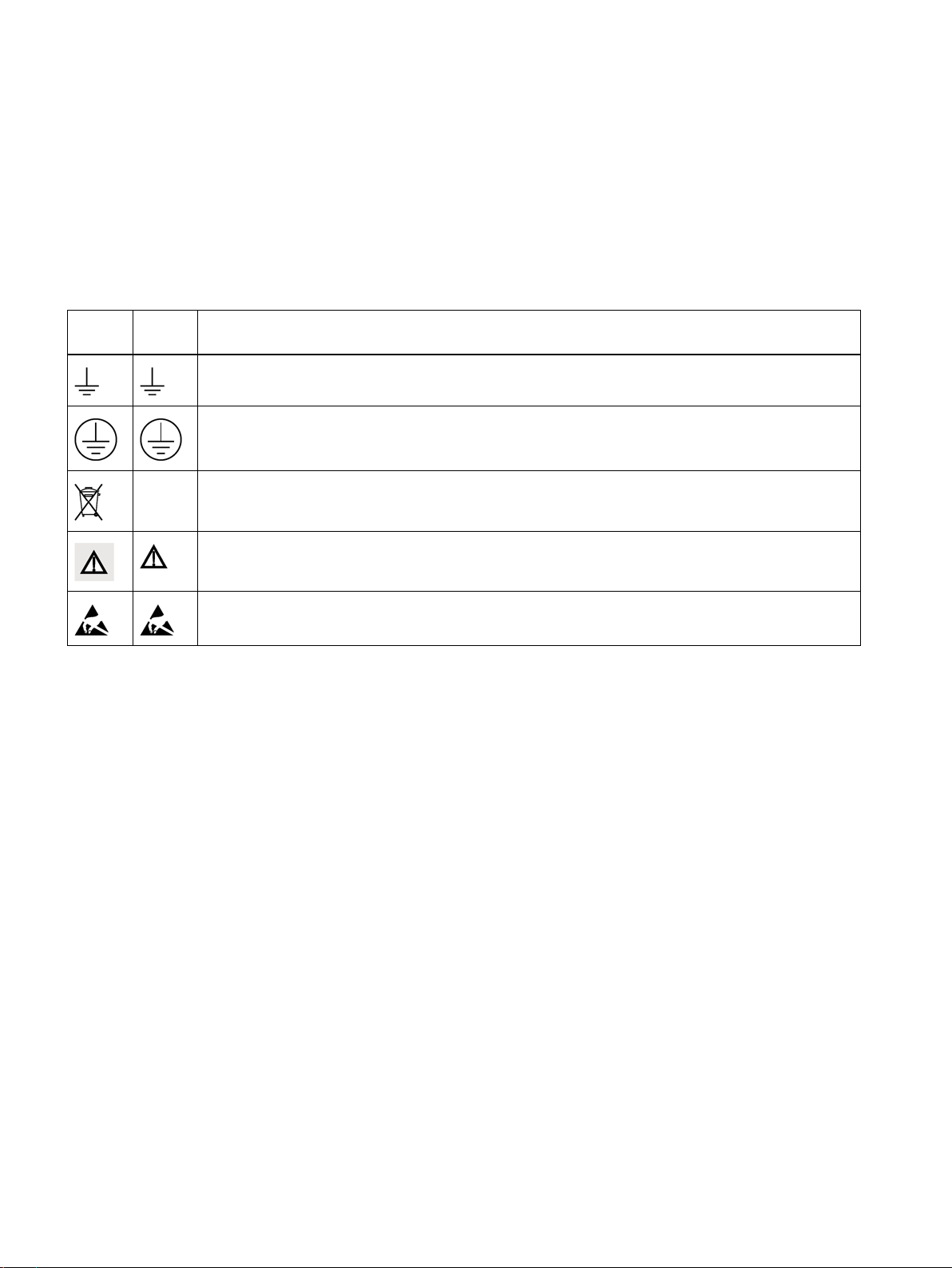

2

In manual

On

product

Description

CAUTION: Observe electrostatic discharge precautions prior to handling electronic components within

2.1 Safety marking symbols

earth (ground) terminal (shield)

protective conductor terminal

Dispose of in an environmentally safe manner, and according to local regulations.

WARNING: refer to accompanying documents (manual) for details.

the wiring compartment.

SITRANS LPS200

6 Operating Instructions, 04/2019, A5E34210883-AB

3

Note

•

•

•

Installation, maintenance, and commissioning must be performed by qualified technical

personnel.

The device must be used only in the manner outlined in this instruction manual.

This product is intended for use in industrial areas. Operation of this equipment in a

residential area may cause interference to several frequency-based communications.

3.1 SITRANS LPS200 Overview

The device rotating paddle switch is used for level monitoring of bulk materials. It can be

used to detect full, demand, or empty conditions in silos, hoppers, or storage vessels of

materials such as grain, feed, cement, plastic granulate, and wood chips. The paddle switch

measures bulk densities as low as 100 g/l (6.2 lb/ft

35 g/l (2.2 lb/ft

rectangular vane.

3

) with the optional hinged vane, or 15 g/l (0.9 lb/ft3) with the optional

3

) with the standard measuring vane,

3.2 Features

● High integrity mechanical seal.

● AC, DC, or universal power supply.

● Unique friction clutch mechanism. When the measuring vane encounters sudden

resistance, the friction clutch slips to prevent internal component damage.

● Optional fail-safe function alarms on fault conditions or component failure.

● Rotatable enclosure.

● Optional vanes for use with high and low bulk densities to 15 g/l (0.9 lb/ft

● Compact, rigid extension (top mounted only), angled rigid extension, and cable extension

configurations available.

● High temperature and high pressure models available.

● Optional extension kit available for the compact version.

SITRANS LPS200

Operating Instructions, 04/2019, A5E34210883-AB

3

).

7

4

● Grain, feed, cement, plastic granulate, wood chips, rice, soybeans, etc.

● Low or high bulk density materials.

SITRANS LPS200

8 Operating Instructions, 04/2019, A5E34210883-AB

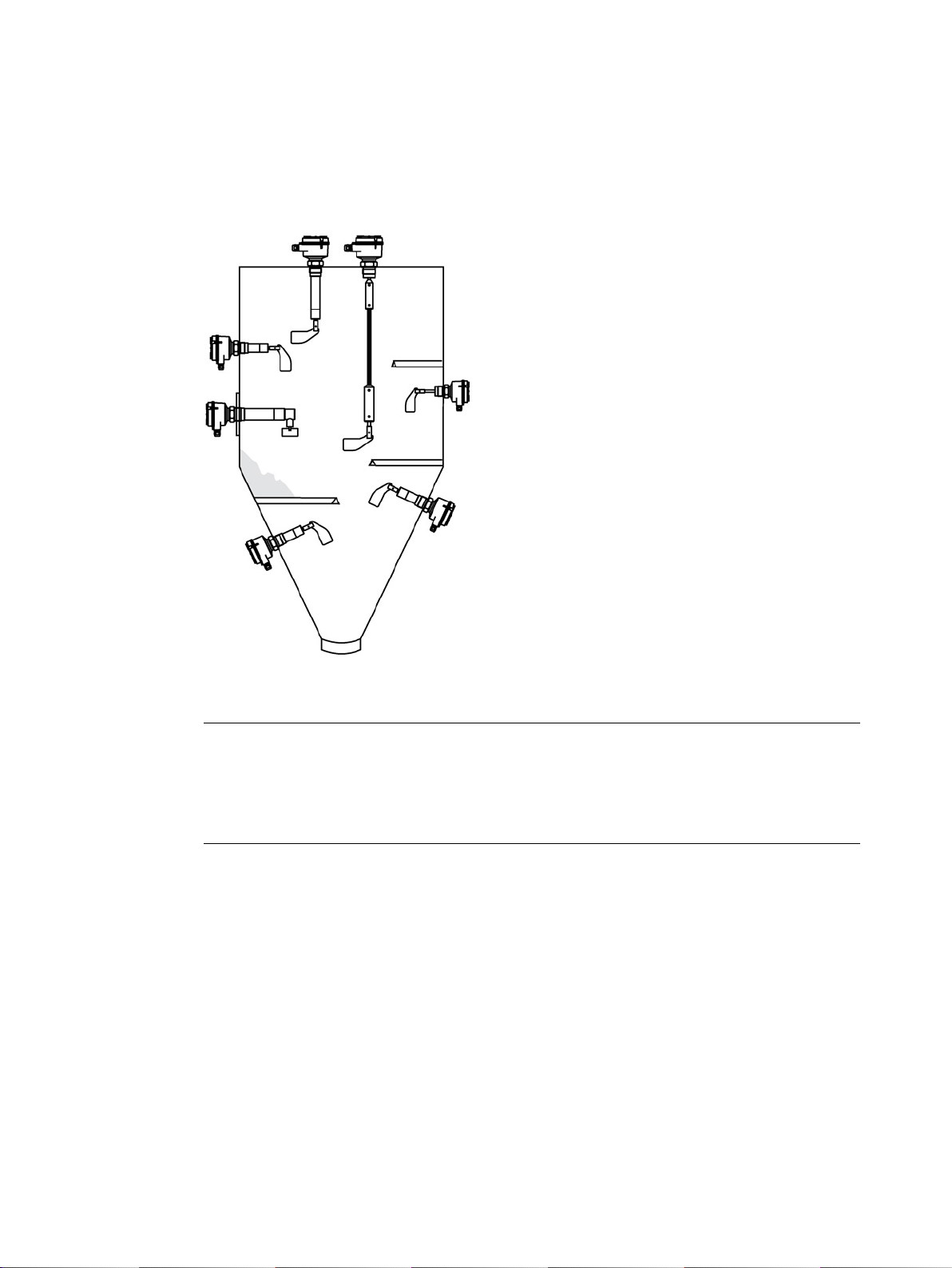

5

N

•

•

•

•

•

Installing/mounting

ote

Installation shall be performed by qualified personnel and in accordance with local

governing regulations.

For heavy material, only top mounting of paddle switch is recommended.

Compact SITRANS LPS200 is recommended for side mounting on bins for low or

intermediate levels.

For SITRANS LPS200 Cable extension, the maximum pull force of the rope must not

exceed 4 kN (28 kN with reinforced option).

When installing LPS200 with rigid extension kit, ensure product is top mounted and never

side or angle mounted.

WARNING

This product is designated as a Pressure Accessory per Directive 97/23/EC and is not

ntended for use as a safety device.

i

WARNING

Improper installation may result in loss of process pressure.

The device is normally mounted into the vessel top (full detector) or through the tank wall at

the detection level (full, demand or empty detector). The device can be installed through a

standard 1¼" NPT or 1½" BSPT pipe coupling, depending on the chosen process thread.

SITRANS LPS200

Operating Instructions, 04/2019, A5E34210883-AB

9

Note

•

•

•

5.1 Food grade material

The materials are available for use under normal and predictable applications (according to

directive 1935/2004 Art. 3). Other conditions can influence safety.

After mounting and as a precaution against water ingress into the housing, turn the housing

clockwise until the cable entries point downward.

Ensure measuring vane is out of any region that is susceptible to build-up.

For heavy material loads and protection against falling material, provide angled

protection.

Ensure cable gland faces downward to avoid water intrusion.

SITRANS LPS200

10 Operating Instructions, 04/2019, A5E34210883-AB

Loading...

Loading...