Siemens Sitrans LR400 Instruction Manual

Instruction Manual May 2008

sitrans

LR400

Safety Guidelines: Warning notices must be observed to ensure personal safety as well as that of

others, and to protect the product and the connected equipment. These warning notices are

accompanied by a clarification of the level of caution to be observed.

Qualified Personnel: This device/system may only be set up and operated in conjunction with this

manual. Qualified personnel are only authorized to install and operate this equipment in accordance with

established safety practices and standards.

Unit Repair and Excluded Liability:

• The user is responsible for all changes and repairs made to the device by the user or the user’s

agent.

• All new components are to be provided by Siemens Milltronics Process Instruments Inc.

• Restrict repair to faulty components only.

• Do not reuse faulty components.

Warning: This product can only function properly and safely if it is correctly transported, stored,

installed, set up, operated, and maintained.

This product is intended for use in industrial areas. Operation of this equipment in a residential area

may cause interference to several frequency based communications.

Note: Always use product in accordance with specifications.

Copyright Siemens Milltronics Process

Disclaimer of Liability

Instruments Inc. 2008. All Rights Reserved

This document is available in bound version and in

electronic version. We encourage users to purchase

authorized bound manuals, or to view electronic versions

as designed and authored by Siemens Milltronics Process

Instruments Inc. Siemens Milltronics Process Instruments

Inc. will not be responsible for the contents of partial or

whole reproductions of either bound or electronic

versions.

While we have verified the contents of this

manual for agreement with the

instrumentation described, variations

remain possible. Thus we cannot

guarantee full agreement. The contents of

this manual are regularly reviewed and

corrections are included in subsequent

editions. We welcome all suggestions for

improvement.

Technical data subject to change.

MILLTRONICS®is a registered trademark of Siemens Milltronics Process Instruments Inc.

Contact SMPI Technical Publications European Authorized Representative

at the following address:

Technical Publications Siemens AG

Siemens Milltronics Process Instruments Inc. Industry Sector

1954 Technology Drive, P.O. Box 4225 76181 Karlsruhe

Peterborough, Ontario, Canada, K9J 7B1 Deutschland

Email: techpubs.smpi@siemens.com

• For a selection of Siemens Milltronics level measurement manuals, go to:

www. siemens.com/processautomation. Under Process Instrumentation, select

Measurement

• For a selection of Siemens Milltronics weighing manuals, go to:

www. siemens.com/processautomation. Under Weighing Technology, select

Weighing Systems

and then go to the manual archive listed under the product family.

and then go to the manual archive listed under the product family.

Level

Continuous

© Siemens Milltronics Process Instruments Inc. 2008

Table of Contents

Table of Conetns

General Information ........................................................................................................... 1

Safety Notes .............................................................................................................................................1

The Manual ...............................................................................................................................................1

Abbreviations and Identifications .......................................................................................................2

SITRANS LR400 .......................................................................................................................................3

Structure ....................................................................................................................................................3

System Implementation .........................................................................................................................4

Programming ............................................................................................................................................4

Specifications ...................................................................................................................... 5

SITRANS LR400 .............................................................................................................................5

Dimensions ...............................................................................................................................................9

Air Purging System (Optional) ........................................................................................ 13

Installation ......................................................................................................................... 15

Mounting Location ................................................................................................................................15

Beam Width ..................................................................................................................................16

Correct Installation in Mounting Nozzle ................................................................................16

Electrical Connection ...........................................................................................................................17

mmmmm

Start Up ............................................................................................................................... 19

Self-test ....................................................................................................................................................19

Multi-display ...........................................................................................................................................19

Local Programming ...............................................................................................................................19

Auto-Setup ..............................................................................................................................................19

Operation ............................................................................................................................20

General Information ..............................................................................................................................20

Operating SITRANS LR400 ..................................................................................................................20

Selecting a Parameter .........................................................................................................................21

Structure of Parameters ............................................................................................................21

Changing a Parameter Value ..............................................................................................................22

Disabling and Enabling Programming ..............................................................................................23

Parameter Operating Examples .........................................................................................................24

Parameters (HART) ...........................................................................................................26

Vessel Functional Dimensions ...........................................................................................................27

Required Parameters ............................................................................................................................27

Additional Parameters .........................................................................................................................29

Parameters (PROFIBUS PA) ............................................................................................ 68

Troubleshooting ................................................................................................................. 81

Classification of Faults .........................................................................................................................81

Self-test ....................................................................................................................................................81

7ML19985FH06 SITRANS LR400 (7ML5421) – INSTRUCTION MANUAL i

Symptoms, Causes and Their Remedy ............................................................................................81

Fault Messages .....................................................................................................................................82

Unit Repair and Excluded Liability ..........................................................................................84

Antenna Maintenance ..................................................................................................... 86

mmmmm

Cleaning the Antenna ..........................................................................................................................86

Hazardous Installation .....................................................................................................87

Table of Con tent s

Appendix I ..........................................................................................................................88

Ambient/Operating Temperature Specification .............................................................................88

Appendix II ......................................................................................................................... 89

Process Pressure/Temperature De-rating ......................................................................................89

Appendix III ........................................................................................................................91

Measuring Principle .............................................................................................................................91

Appendix IV ........................................................................................................................93

HART Communications for SITRANS LR400 ..................................................................................93

HART Device Description (DD) .................................................................................................93

SIMATIC Process Device Manager (PDM) ...........................................................................93

HART Communicator 275/375: ..................................................................................................94

Appendix V .........................................................................................................................97

PROFIBUS PA Communications for SITRANS LR400 ...................................................................97

Device Description ......................................................................................................................97

The GSD file ..................................................................................................................................97

Bus address (Device Address) .................................................................................................97

Bus Termination ...........................................................................................................................98

Power Demands ..........................................................................................................................98

Cyclic versus Acyclic Data ........................................................................................................98

Cyclic Data ....................................................................................................................................98

Status Word ............................................................................................................................... 100

Extended Diagnostics ..............................................................................................................101

Acyclic Data ................................................................................................................................101

Configuration Example: ............................................................................................................101

Appendix VI: Firmware Revision History ...................................................................102

Glossary ............................................................................................................................ 104

Index .................................................................................................................................. 107

ii SITRANS LR400 (7ML5421) – INSTRUCTION MANUAL 7ML19985FH06

General Information

Safety Notes

Special attention must be paid to warnings and notices highlighted from the rest of the

text by grey boxes.

WARNING: relates to a caution symbol on the product, and means

that failure to observe the necessary precautions can result in

death, serious injury, and/or considerable material damage.

WARNING: means that failure to observe the necessary

precautions can result in death, serious injury, and/or considerable

material damage.

CAUTION: means that failure to observe the necessary precautions can

result in considerable material damage.

General Information

mmmmm

Note:

manual.

• These instructions do not claim to cover all details or variations in equipment, or to

• For further information or to resolve issues not covered in the manual, consult your

means important information about the product or that part of the operating

provide for every possible contingency that may arise during installation, operation,

or maintenance.

Siemens Milltronics representative.

The Manual

IMPORTANT: All specifications are subject to change without notice.

Please ensure that any safety-related information is confirmed with a

qualified Siemens Milltronics representative.

WARNINGS:

• Changes or modifications not expressly approved by Siemens Milltronics

could void the user’s authority to operate the equipment.

• This equipment is intended to be used only in fully enclosed metal and

concrete containers.

Note: This equipment has been tested and found to comply with the limits for a Class

A digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his

own expense.

7ML19985FH06 SITRANS LR400 (7ML5421) – INSTRUCTION MANUAL Page 1

This manual will help you set up your SITRANS LR400 for optimal performance. This

manual applies to the HART and PROFIBUS SITRANS LR400. For HART parameters,

please see page 26. For PROFIBUS PA parameters, see page 68. We always welcome

suggestions and comments about manual content, design, and accessibility.

Please direct your comments to techpubs.smpi@siemens.com. For the complete library of

Siemens Milltronics manuals, go to www.siemens.com/processautomation.

WARNINGS:

• Installation shall only be performed by qualified personnel and in

accordance with local governing regulations.

• The SITRANS LR400 is to be used only in the manner outlined in this

manual, otherwise protection provided by equipment may be impaired.

Note: This product is intended for use in industrial areas. Operation of this equipment

in a residential area may cause interference to several frequency based

communications.

mmmmm

Qualified personnel

General Information

Qualified personnel are familiar with the installation, commissioning, and operation of

this equipment. In addition the person must be:

• trained and authorized to operate and service equipment/systems in accordance

with established safety procedures relating to electrical circuits, high pressures and

aggressive media.

• trained in the proper care and use of protective equipment in accordance with

established safety practices.

• trained in rendering first aid.

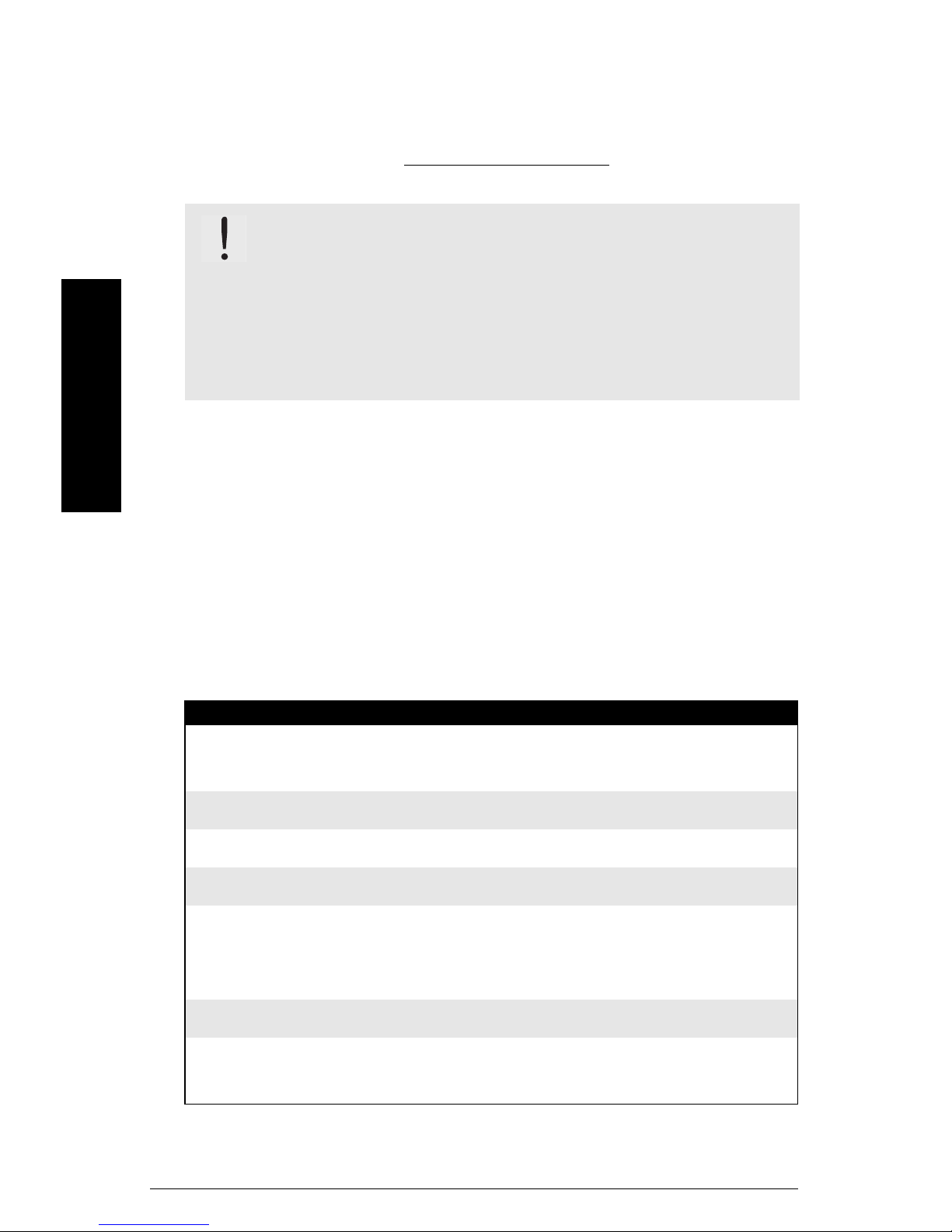

Abbreviations and Identifications

Short form Long form Description

CE / FM / CSA Conformitè Europèene / Factory Mutual /

Canadian Standards Association

ESD Electrostatic Discharge

HART® Highway Addressable Remote Transducer

IS Intrinsically Safe safety approval

safety approval

LRV Lower Range Value value for process

PED Pressure Equipment Directive safety approval

URV Upper Range Value value for process full

1.

100% is most commonly set to 20 mA and 0% to 4 mA.

HART is a registered trademark of the HART Communication Foundation.

Page 2 SITRANS LR400 (7ML5421) – INSTRUCTION MANUAL 7ML19985FH06

empty level

(symbol 4 mA)

level (symbol 20 mA)

1

1

SITRANS LR400

r

SITRANS LR400 is a long-range FMCW radar level transmitter. It is suitable for use in

liquids and solids, for low dielectric liquids, and high pressure applications or applications

with extreme dust. This version also incorporates a purging option for sticky solids

applications. The narrow antenna beam results in a sharp emission cone, which makes

SITRANS LR400 quite insensitive to vessel interferences.

Note: This manual applies to the 7ML5421 version only. Please see Instruction

Manual 7ML19985JC02 for information about the SITRANS LR400, 7ML5420

version.

General Information

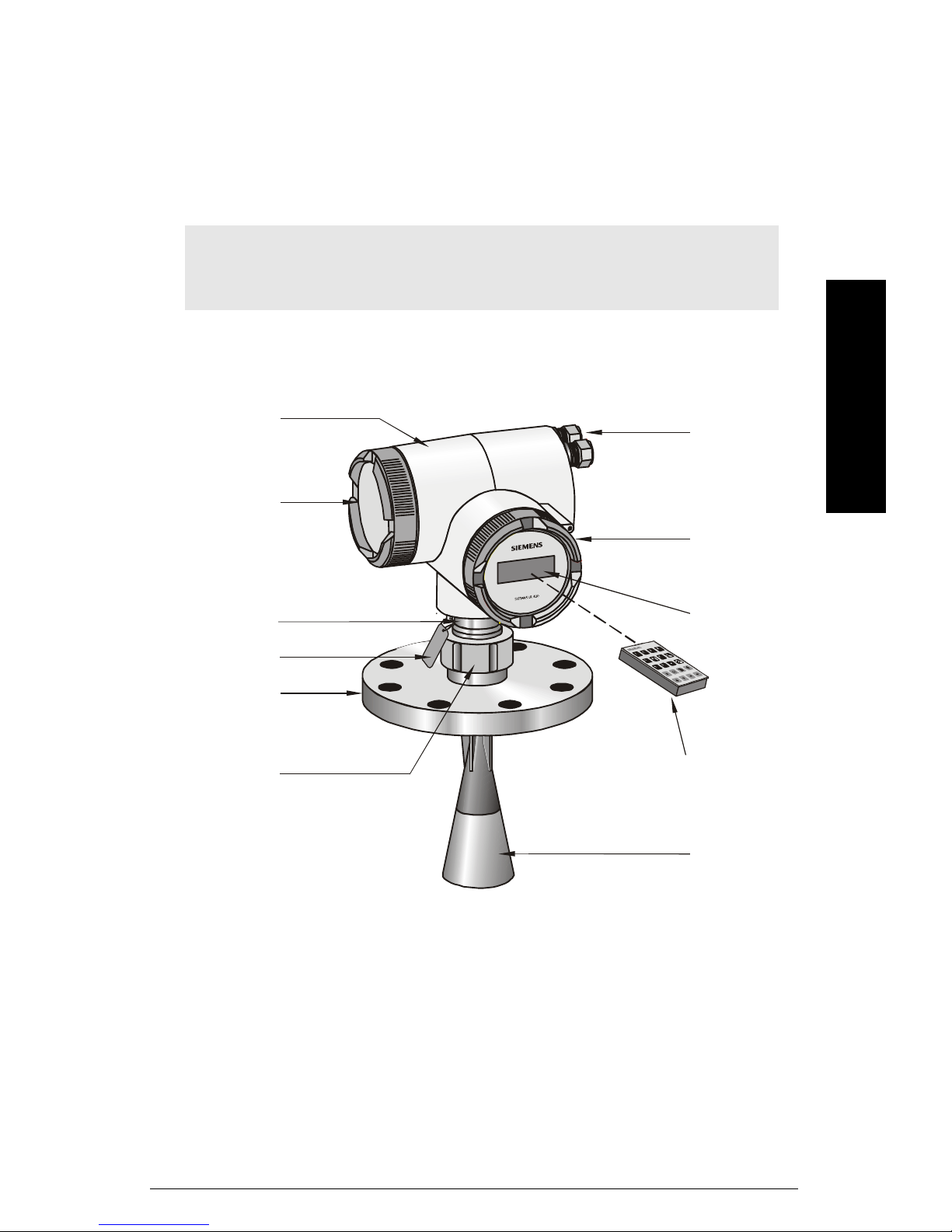

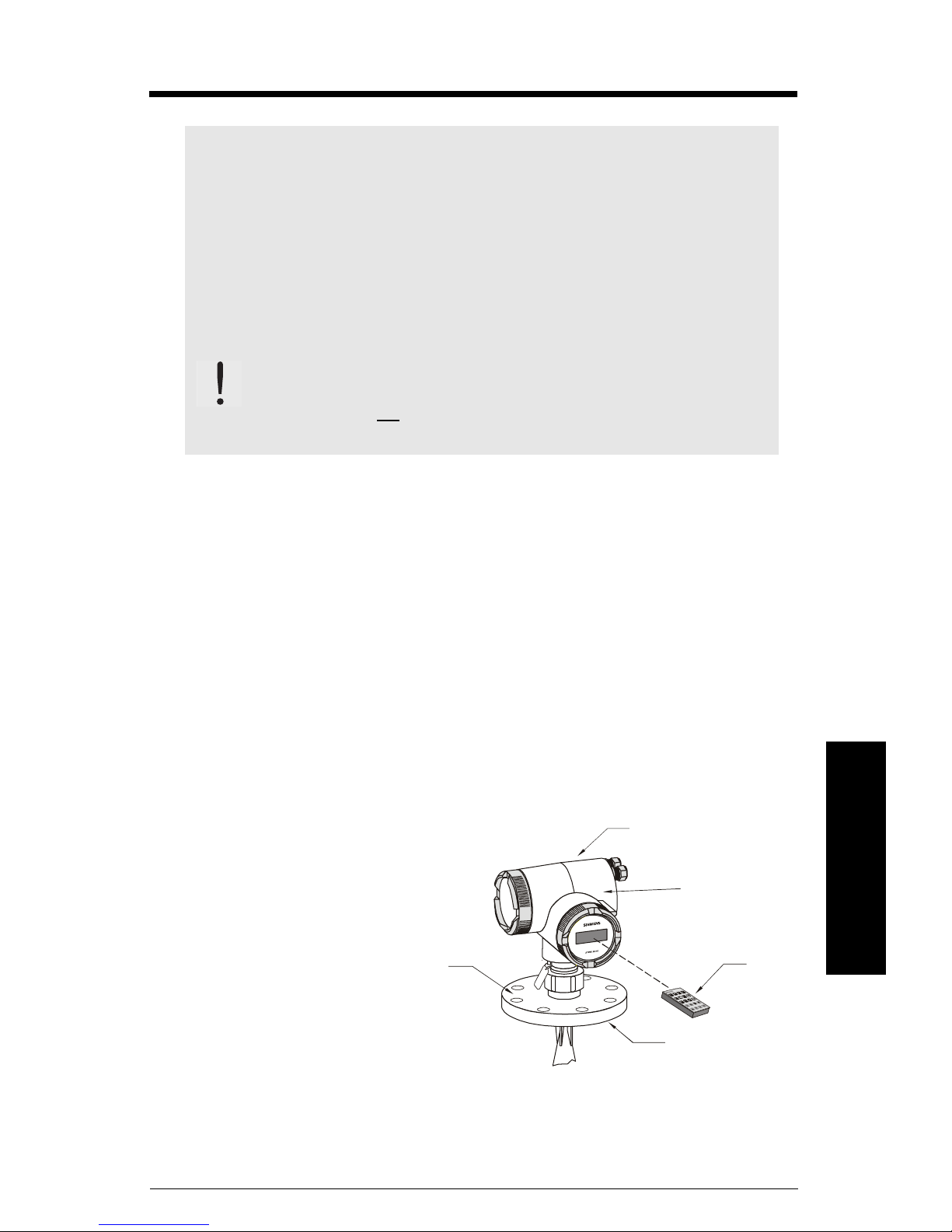

Structure

housing

connection

cover

intermediate

flange

device tag

process flange

threaded ring

mmmmm

cable gland

electronics cove

display module

infra-red hand

programmer

(ordered

separately)

The terminals for the power cable and the signal cable are behind the connection cover

on the left side of the housing. The signal cable must be fed in from the right through the

cable glands.

The end of the antenna must reach inside the vessel through the vessel nozzle (see

page 16).

If the device is rotated, return the orientation of the housing to its previous position with

reference to the enclosure, to ensure similar performance.

7ML19985FH06 SITRANS LR400 (7ML5421) – INSTRUCTION MANUAL Page 3

horn antenna

System Implementation

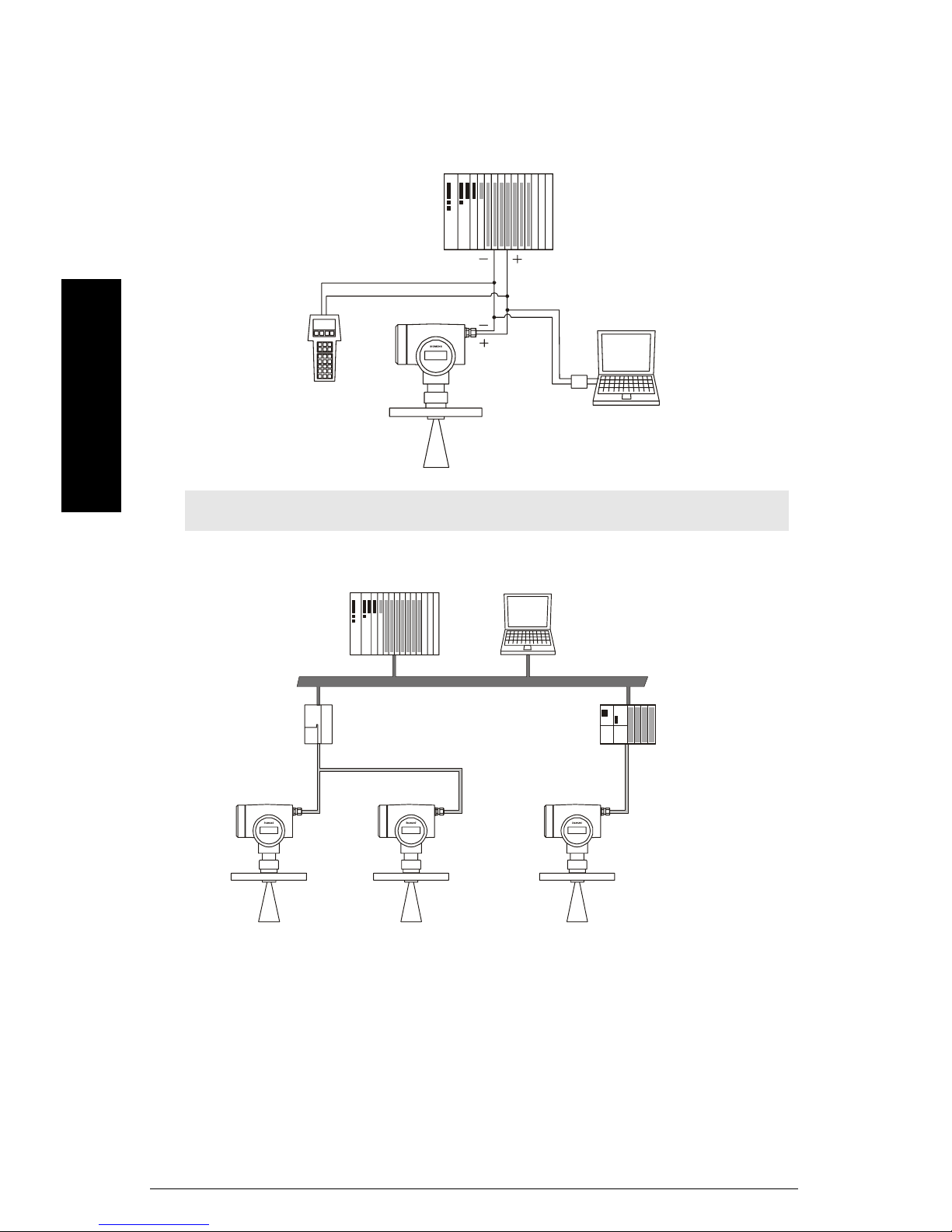

SITRANS LR400 supports HART communication protocol, and SIMATIC PDM software.

Typical PLC/mA configuration with HART

PLC with mA

input card

HART

HART Communicator 275

SITRANS LR 400

mmmmm

SITRANS LR400

General Information

Note: A 250 ohm loop resistor may be required, depending on PLC input resistance.

PC/laptop with HART

modem running PDM

Typical PLC/mA configuration with PROFIBUS PA

Class 1

Master

DP/PA

Coupler

SITRANS LR 400 SITRANS LR 400 SITRANS LR 400

PLC

PROFIBUS PA

SITRANS LR400

SITRANS LR400

PDM

SITRANS LR400

Programming

Class 2

Master

ET200

HART

SITRANS LR400 carries out its level measurement function according to the set of built-in

parameter tables. You can make parameter changes via the hand programmer, a PC

running SIMATIC PDM or a HART handheld communicator.

Page 4 SITRANS LR400 (7ML5421) – INSTRUCTION MANUAL 7ML19985FH06

Specifications

Note: Siemens Milltronics makes every attempt to ensure the accuracy of these

specifications, but reserves the right to change them at any time.

SITRANS LR400

Power

Power Supply

• 100 to 230 V AC, ±15%, 50/60 Hz, 6 W

• 24 V DC, +25/-20%, 6 W

• Fuse (AC) SI1 Fast acting ceramic, 4 x 20 mm, 1 A, 250 V AC

• Fuse (DC) SI1 Fast acting ceramic, 4 x 20 mm, 2 A, 250 V AC

Performance

SI2 Slow-Blow, 4 x 20 mm, 0.63 A, 250 V AC

SI2 Slow-Blow, 4 x 20 mm, 0.63 A, 250 V AC

• Frequency 25 GHz nominal

• Measuring range 0.35 to 50 m (1.15 to 164 ft)

Measured value error (under reference conditions)

• Measuring error ≤ ± 5 mm (0.2") at 1 to 10 m (3.3 to 32.8 ft.) distance

≤

± 15 mm (0.6") at 10 to 50 m (32.8 to 164 ft) distance

•Dead band

• Additional contribution of ≤ 0.1%

analog output

• Long-term stability ≤

• Repetitive accuracy ≤ ± 1 mm at 0 to 50 m, damping ≥ 1 s

1

0 to 350 mm from bottom edge of flange

± 1 mm/year

Interface

• Analog output (Not applicable to PROFIBUS PA option)

Signal range 4 to 20 mA

Fail signal 3.6 mA; 22.5 mA or last value

Load Max. 600 Ω; (330 Ω for [ia] versions, Area classification

options G, L, P, S)

2

, for HART3 communication min. 230 Ω

Specifications

mmmmm

1.

For solids applications, setting a dead band of 1 m is recommended because of

lower reflectivity and increased angles of repose.

2.

See Selection and Ordering Data sheet

3.

HART®is a registered trademark of HART Communication Foundation.

7ML19985FH06 SITRANS LR400 (7ML5421) – INSTRUCTION MANUAL Page 5

Relay Configurable as a device status or limit value

(level, volume, mass)

Either NCC or NOC function

max. 50 V DC, max. 200 mA, rating max. 5 W.

Self-resetting fuse, R

= 9 Ω

i

• Electrical isolation Outputs electrically isolated from the power supply and

from each other

• Display LCD, two lines of 16 characters each,

configurable for the following displays:

level, volume, mass, amplitude, digital output,

temperature, validity, signal-to-noise ratio

Programmer (infrared keypad)

Siemens Milltronics Infrared IS (Intrinsically Safe) hand programmer for hazardous and

all other locations (battery is non-replaceable)

• approval: ATEX II 1 G, EEx ia IIC T4, certificate SIRA 01ATEX2147

CSA and FM Class I, Div. 1, Gr. A, B, C, D T6 @ max. ambient

temperature of 40 °C (104 °F)

• ambient temperature: −20 to 40 °C (−5 to 104 °F)

• interface: proprietary infrared pulse signal

• power: 3 V lithium battery

• weight: 150 g (0.3 lb)

mmmmm

•color: black

Mechanical

Specifications

Flange

• Process Connection Flange DIN 2527, ANSI B16.5, or JIS B2238 equivalent bolt

pattern (See page 11 for flange dimensions.)

• Materials of the wetted Stainless steel 316/316L flange and 304 horn, PTFE

parts – in contact with emitter (or glass/PTFE, Zone 0 and Zone 20 devices)

the process

• Pressure (vessel) Varies with connection type. Refer to Appendix IV for

specifications.

• Horn types Short horn, 74 mm (2.9") diameter

Long horn, 93 mm (3.7") diameter

Page 6 SITRANS LR400 (7ML5421) – INSTRUCTION MANUAL 7ML19985FH06

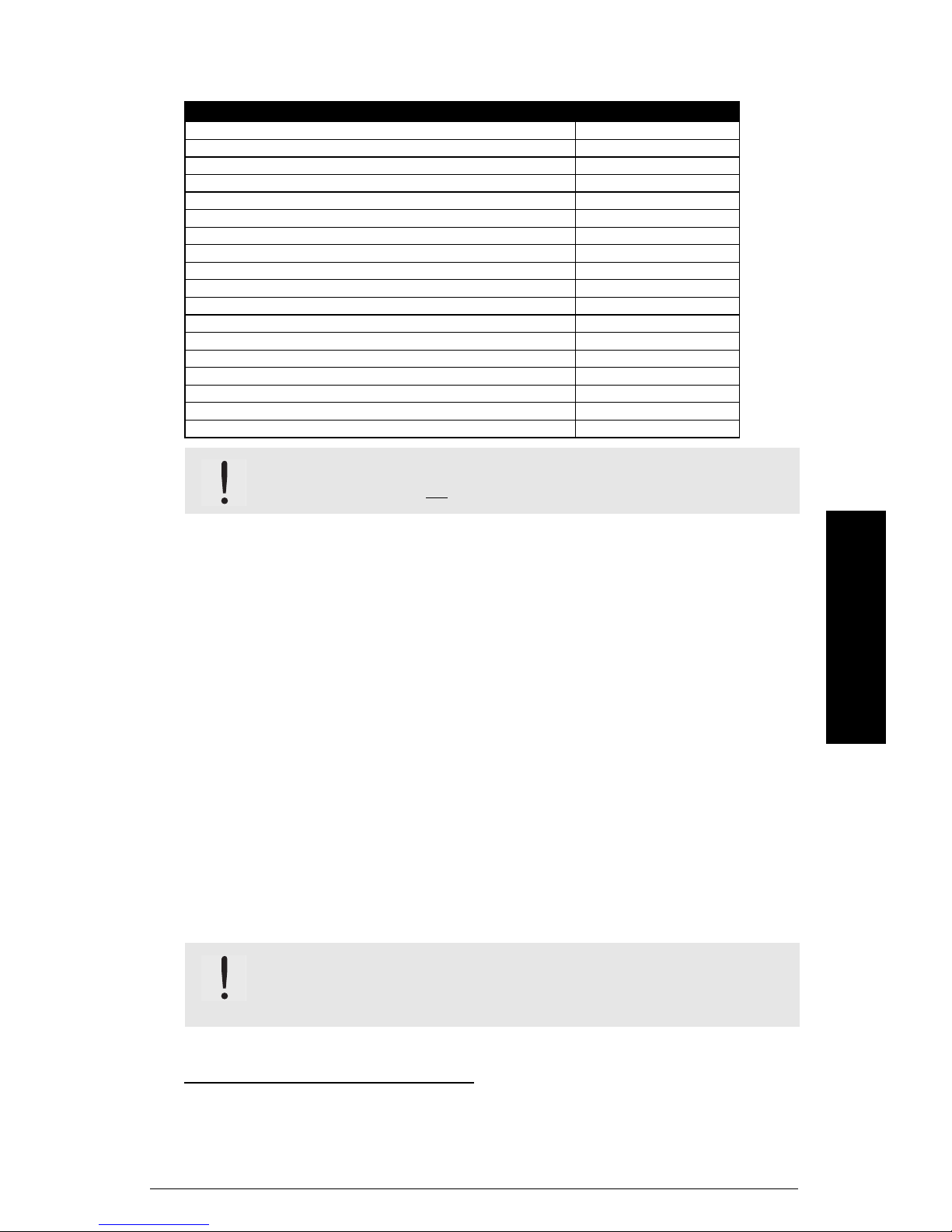

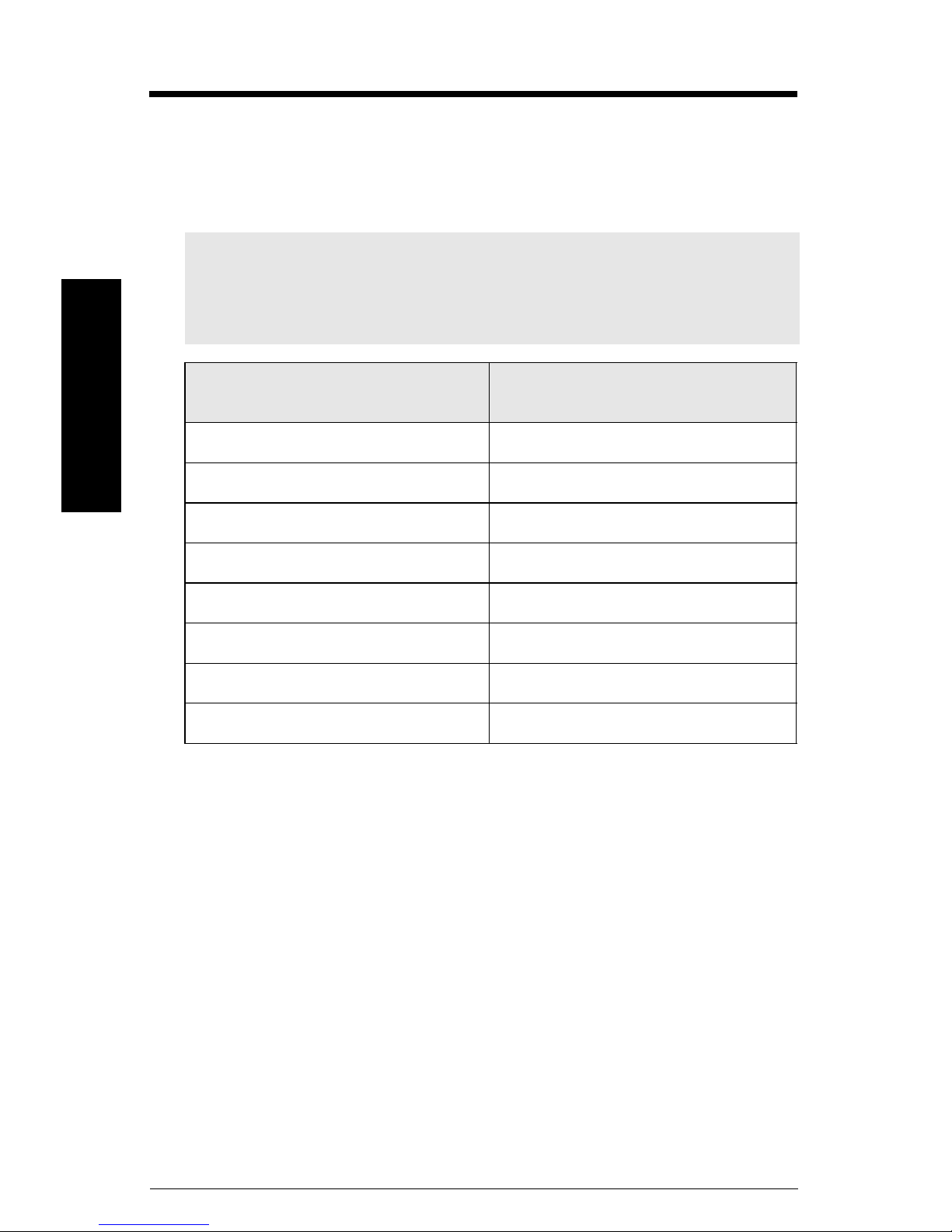

Weight

• Weight of instrument and flange

Process Connection Weight

DN80 PN16, flat faced 11.9 kg (26.1 lbs)

DN80 PN40, flat faced 12.9 kg (28.4 lbs)

DN100 PN16, flat faced 13.2 kg (28.9 lbs)

DN100 PN40, flat faced 15.5 kg (34.1 lbs)

DN150 PN16, flat faced 19.2 kg (42.1 lbs)

DN150 PN40, flat faced 24.1 kg (43.1 lbs)

3", 150 lb class, raised faced 12.2 kg (26.8 lbs)

3", 300 lb class, raised faced 14.3 kg (31.5 lbs)

4", 150 lb class, raised faced 14.8 kg (32.5 lbs)

4", 300 lb class, raised faced 20.2 kg (44.4 lbs)

6", 150 lb class, raised faced 20.1 kg (44.2 lbs)

6", 300 lb class, raised faced 31.8 kg (69.9 lbs)

JIS DN80 10K, flat faced 11.9 kg (26.1 lbs)

JIS DN100 10K, flat faced 13.2 kg (28.9 lbs)

JIS DN150 10K, flat faced 19.2 kg (42.1 lbs)

Universal, 3" / 80 mm, flat faced, 0.5 bar maximum (purge option) 10.9 kg (24 lbs)

Universal, 4" / 100 mm, flat faced, 0.5 bar maximum (purge option) 12.7 kg (28 lbs)

Universal, 6" / 150 mm, flat faced, 0.5 bar maximum (purge option) 15.0 kg (33 lbs)

WARNING: This product is designated as a Pressure Accessory per

Directive 97/23/EC and is not intended for use as a safety device.

Enclosure

• construction Die-cast aluminum, painted (polyester powder-coated)

• conduit 2 x M20

or 2 x ½” NPT (option)

• ingress protection Type 4X/NEMA 4X, Type 6/NEMA 6, IP67

Environmental

2

1

• location indoor/outdoor

• altitude 2000 m (6562 ft) max

• ambient temperature

3

-40 to 65 °C (-40 to 149 °F)

• relative humidity suitable for outdoor (Type / NEMA 4X, 6/ IP67)

• installation category II

• pollution degree 4

• Perm. ambient -40 to 65 °C (-40 to 149 °F) (non-hazardous version)

temperature LCD: -10 to 55 °C (14 to 131 °F)

Observe the temperature classes in hazardous areas!

WARNING: Materials of construction are chosen based on their chemical

compatibility (or inertness) for general purposes. For exposure to specific

environments, check with chemical compatibility charts before installing.

Specifications

mmmmm

1.

Use only approved, suitable sized hubs for watertight applications.

2.

See Process/Ambient de-rating curves in Appendix III.

3.

-20 °C (-4 °F) temperature rating available on SITRANS LR400 with ATEX rating.

7ML19985FH06 SITRANS LR400 (7ML5421) – INSTRUCTION MANUAL Page 7

Process

• Process Temperature -40 to 200 °C (-40 to 392 °F)

Optional (7ML5421 version) -40 to 250 °C (-40 to 482 °F)

• Pressure (vessel) Varies with connection type. Refer to Appendix IV for

specifications.

Communication

• Communication: HART

Load 230 to 600 Ω, 230 to 500 Ω when connecting a coupling

module

Line two-wire shielded: ≤ 3000 m

multi-wire shielded: ≤ 1500 m

Protocol HART, Version 5.1

• Communication: PROFIBUS PA

Protocol Layer 1 and 2 PROFIBUS PA,

technology: IEC 61158-2, slave-functionality

Device Class A

Device Profile 3.0

• Software for PC/Laptop Windows 95/98/2000/XP or NT 4.0

SIMATIC® PDM

Approvals (verify against device nameplate)

• Explosion Protection Certificate No. PTB 00 ATEX 1024

mmmmm

Specifications

*Refer to device II 1/2G EEx d IIC T6II 2G EEx d IIC T6

nameplate II 1/2G EEx dem IIC T6II 2G EEx dem IIC T6

II 1/2G EEx dem [ib] IIC T6II 2G EEx dem [ib] IIC T6

II 1/2G EEx dem [ia] IIC T6II 2G EEx dem [ia] IIC T6

FM/CSA Class I, Div. 1, Groups B, C, D; Class II/III, Div. 1,

Groups E, F, G

• General CSAus/c, FM, CE

• Radio FCC, Industry Canada, European Radio(R&TTE)

• Shipping - Lloyd’s Register of Shipping, Categories ENV1, ENV2,

ENV3, and ENV5

- ABS

WARNING: This product is designated as a Pressure Accessory per

directive 97/23/EC and is not

Page 8 SITRANS LR400 (7ML5421) – INSTRUCTION MANUAL 7ML19985FH06

intended for use as a safety device.

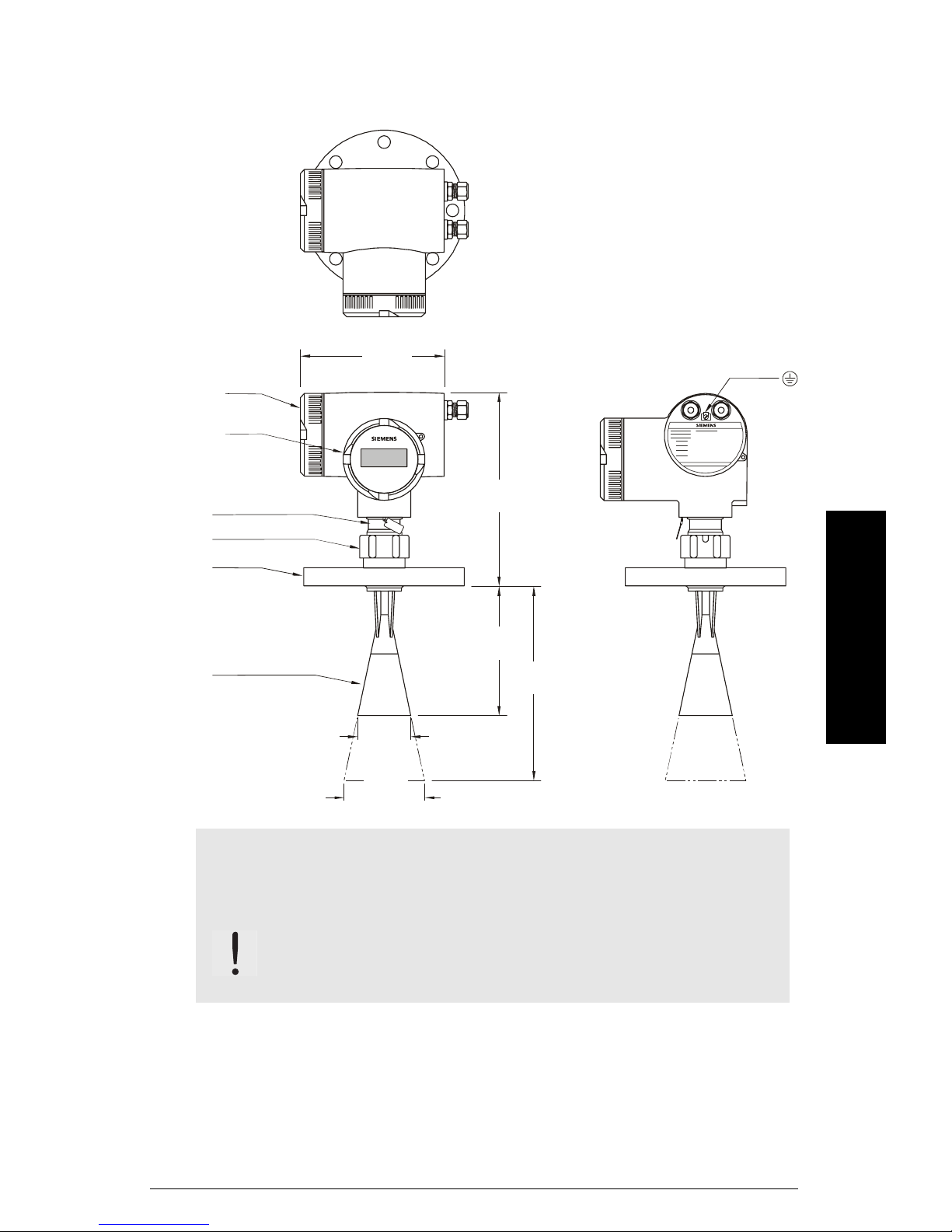

Dimensions

SITRANS LR400 (7ML5421 version) (without Temperature Extension)

connection

cover

electronics

cover

intermediate

flange

threaded

ring

process

flange*

horn

204 mm

(8.0")

SITRANS LR 400

74 mm

(2.9")

93 mm

(3.7")

earth

terminal

257 mm

(10.1")**

Specifications

mmmmm

191 mm

(7.5")

238 mm

(9.4")

Note: Process temperature and pressure capabilities are dependent upon

information on the process device tag. See Appendix IV (Process Pressure/

Temperature de-Rating). Reference drawing listed on the tag is available upon

request.

WARNING: The user is responsible for the selection of bolting and

gasket materials which will fall within the limits of the flange and its

intended use and which are suitable for the service conditions.

*Flange according to DIN 2527 / ANSI B 16.5 / JIS B2238 bolt hole pattern

**An optional purging system can be installed between the flange and the horn antenna.

See page 13 for Air Purging information.

7ML19985FH06 SITRANS LR400 (7ML5421) – INSTRUCTION MANUAL Page 9

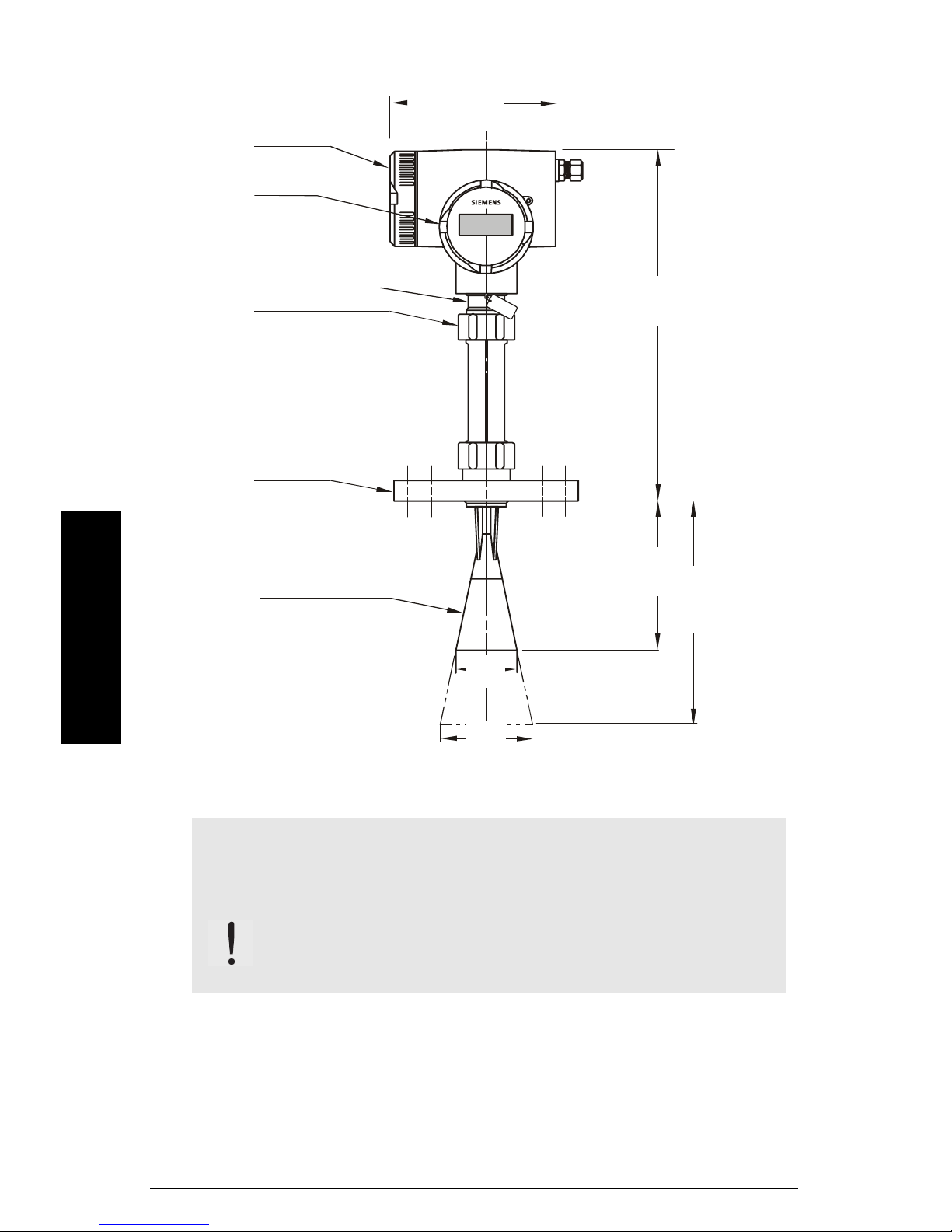

SITRANS LR400 (7ML5421 version) with optional Temperature Extension

204 mm

(8.0")

connection

cover

electronics

cover

SITRANS LR 400

intermediate

flange

threaded

ring

process

flange*

384 mm

(15.1")

191 mm

(7.5")

horn

mmmmm

74 mm

Specifications

(2.9")

93 mm

(3.7")

238 mm

(9.4")

*Flange according to DIN 2527 / ANSI B 16.5 / JIS B2238 bolt hole pattern

Note: Process temperature and pressure capabilities are dependent upon

information on the process device tag. See Appendix IV (Process Pressure/

Temperature de-Rating). Reference drawing listed on the tag is available upon

request.

WARNING: The user is responsible for the selection of bolting and

gasket materials which will fall within the limits of the flange and its

intended use and which are suitable for the service conditions.

Page 10 SITRANS LR400 (7ML5421) – INSTRUCTION MANUAL 7ML19985FH06

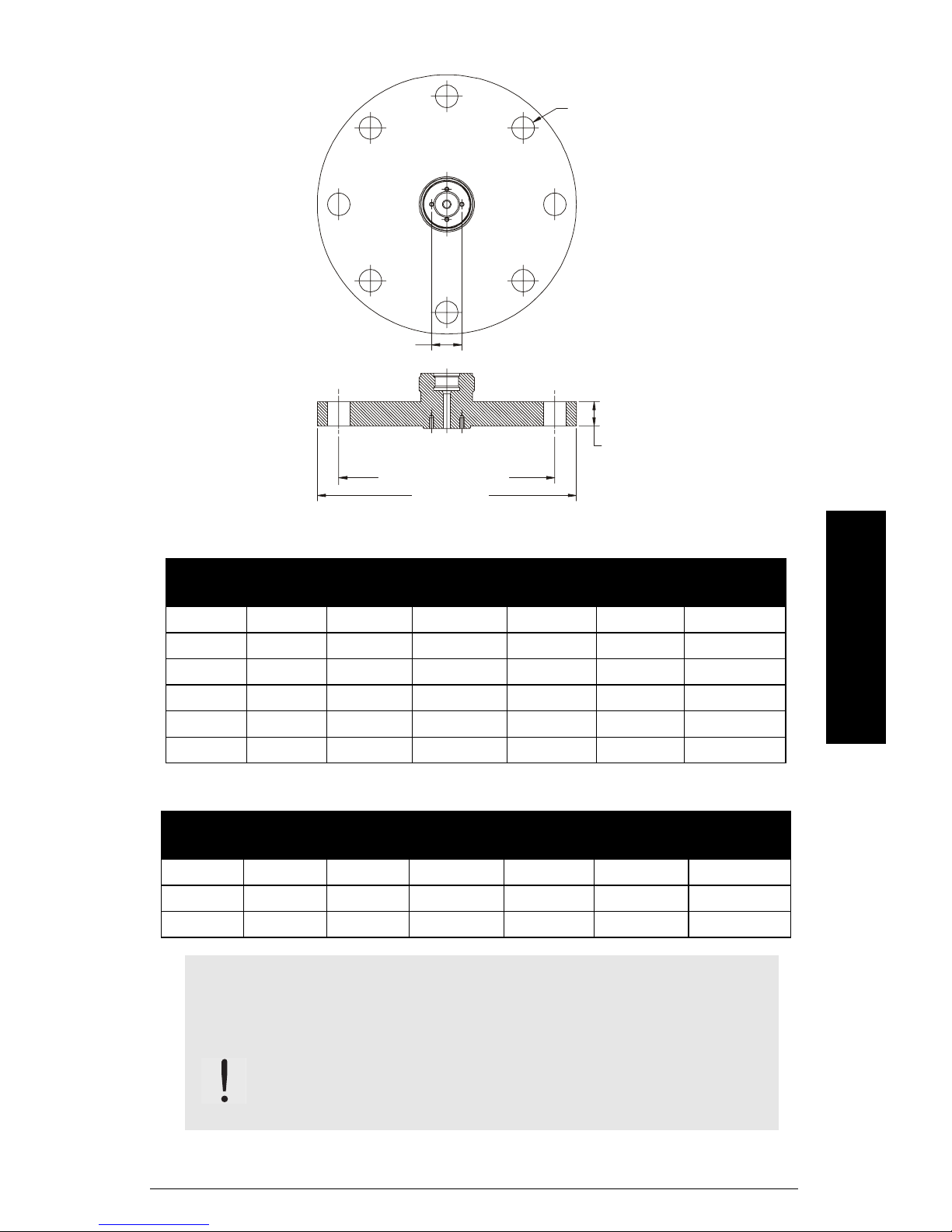

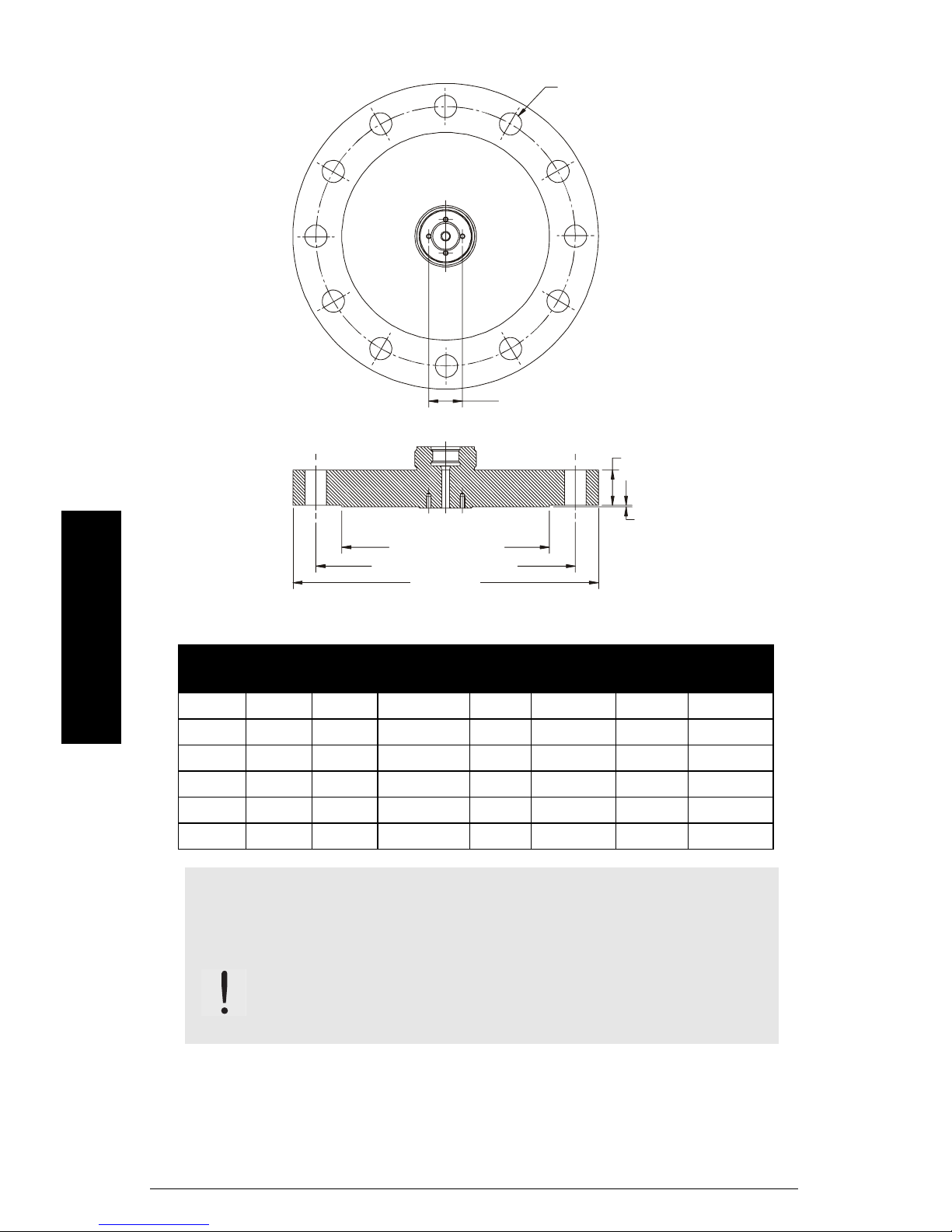

DIN / JIS Flat Face Flange Diagram (7ML5421 version only)

bolt hole Ø

horn mounting holes

thickness (s)

bolt hole circle Ø

flange O.D.

Flange according to DIN 2527 (see Flange Diagram above)

Pipe Size

Flange

Size

Flange

O.D.

Thickness

(s)

Bolt Hole

Circle Ø

Bolt Hole ØNumber of

80 mm PN 16 200 mm 20.0 mm 160 mm 18.0 mm 8

100 mm PN16 220 mm 20.0 mm 180 mm 18.0 mm 8

150 mm PN 16 285 mm 22.0 mm 240 mm 22.0 mm 8

80 mm PN 40 200 mm 24.0 mm 160 mm 18.0 mm 8

100 mm PN 40 235 mm 24.0 mm 190 mm 22.0 mm 8

150 mm PN 40 300 mm 28.0 mm 250 mm 26.0 mm 8

Flange according to JIS B 2238

Pipe Size

Flange

Size

Flange

O.D.

Thickness

(s)

Bolt Hole

Circle Ø

Bolt Hole Ø

80 mm 10 K 185 mm 20.0 mm 150 mm 19.0 mm 8

100 mm 10 K 210 mm 22.0 mm 175 mm 19.0 mm 8

150 mm 10 k 280 mm 24.0 mm 240 mm 23.0 mm 8

Note: Process temperature and pressure capabilities are dependent upon

information on the process device tag. See Appendix IV (Process Pressure/

Temperature de-Rating). Reference drawing listed on the tag is available upon

request.

WARNING: The user is responsible for the selection of bolting and

gasket materials which will fall within the limits of the flange and its

intended use and which are suitable for the service conditions.

Specifications

Bolts

mmmmm

Number of

Bolts

7ML19985FH06 SITRANS LR400 (7ML5421) – INSTRUCTION MANUAL Page 11

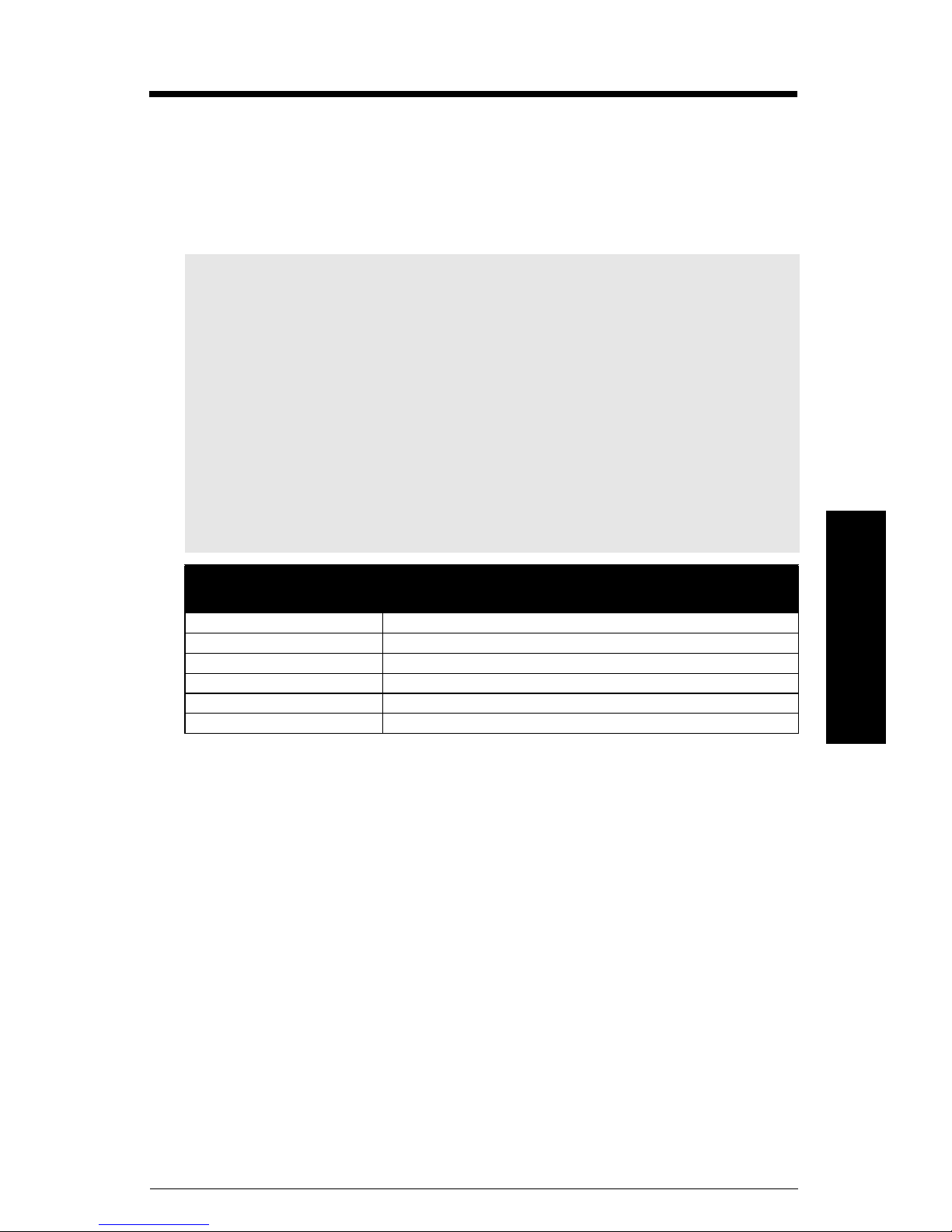

ANSI Raised Face Flange Diagram (7ML5421 version only)

bolt hole Ø

horn mounting holes

thickness (s)

raised face thickness

face O.D.

bolt hole circle Ø

flange O.D.

mmmmm

Flange according to ANSI B 16.5 (see Flange Diagram above)

Specifications

Pipe

Size

Flange

Size

Flange

O.D.

Thickness

(s)

Face

O.D.

Bolt Hole

Circle Ø

0.063" (mm)

Bolt

Hole Ø

Number

of Bolts

3" 150 # 7.50" 0.941" 5.0" 6.00" 0.75" 4

4" 150 # 9.00" 0.941" 6.19" 7.50" 075" 8

6" 150 # 11.00" 1.00" 8.5" 9.50" 0.88" 8

3" 300 # 8.25" 1.12" 5.0" 6.62 0.88" 8

4" 300 # 10.00" 1.25" 6.19" 7.88" 0.88" 8

6" 300 # 12.51" 1.44" 8.5" 10.62" 0.88" 12

Note: Process temperature and pressure capabilities are dependent upon

information on the process device tag. See Appendix IV (Process Pressure/

Temperature de-Rating). Reference drawing listed on the tag is available upon

request.

WARNING: The user is responsible for the selection of bolting and

gasket materials which will fall within the limits of the flange and its

intended use and which are suitable for the service conditions.

Page 12 SITRANS LR400 (7ML5421) – INSTRUCTION MANUAL 7ML19985FH06

Air Purging System (Optional)

For more frequent cleaning, a purging system can be installed between the flange and the

horn antenna. The system provides an 1/8" inlet (female thread) on the flange where

cooling air or cleaning fluid passes through the flange and exits the inside of the horn to

clean it. The customer will supply the purging medium by manual or automatic valve

system. This option is only available with universal flange for purging shown on page 14.

Notes:

• The Air Purge feature should not be activated with a dust cap in place.

• Purge duration, pressure, and interval, will vary with each application. It is the user’s

responsibility to determine the requirements depending on the application and

cleaning required.

• Short duration bursts of high pressure provide more effective cleaning than

continuous low pressure air.

• Some dust particles are highly abrasive and can be drawn into the inside of the horn

during purge cleaning, damaging the internal PTFE emitter of the antenna. A

replacement kit is available from your local Siemens Milltronics representative.

• It is the customer’s responsibility to ensure that any vacuum or pressure in the

measured vessel is maintained, considering the hole that passes through the

process connection and SITRANS LR400 antenna system.

Air Consumption

(Flowrate versus applied pressure)

Air Pressure Approximate inlet volume flow rate (standard cubic feet/minute)

20 5 SCFM

40 6 SCFM

60 8 SCFM

80 9 SCFM

90 10 SCFM

Specifications

mmmmm

7ML19985FH06 SITRANS LR400 (7ML5421) – INSTRUCTION MANUAL Page 13

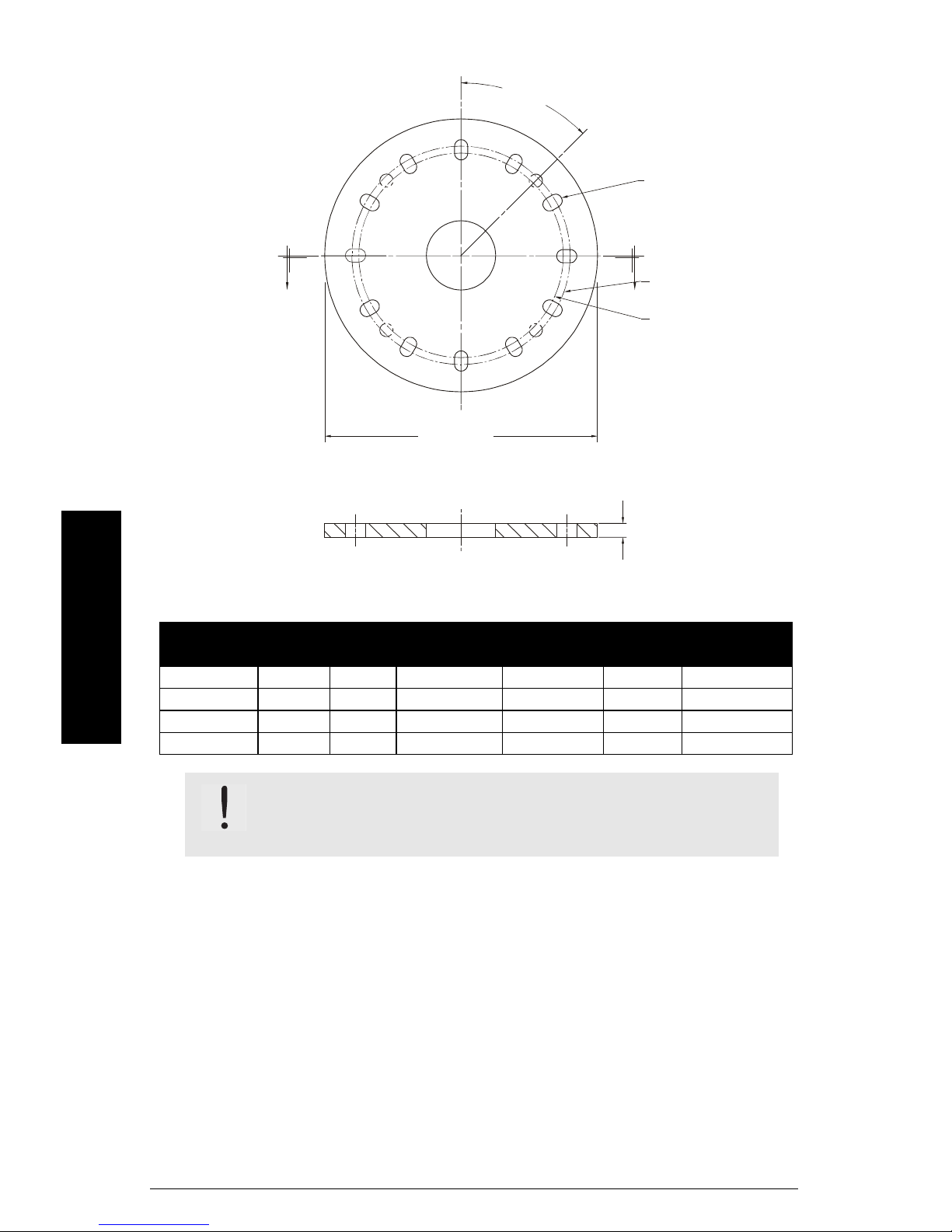

Universal Slotted Flange Diagram (for use with Air Purging Option only)

45°

number of

slotted bolt

holes

A

flange O.D.

section A-A

A

bolt hole

circle max Ø

bolt hole

circle min Ø

thickness

Flange according to Universal Slotted Flange (see Flange Diagram above)

mmmmm

Pipe

Size

Specifications

3" or 80 mm 7.87" 0.40" 6.30" 5.90" 0.38" 8

Flange

O.D.

Thick-

ness (s)

Bolt Hole

Circle Max Ø

Bolt Hole

Circle Min Ø

Bolt Hole

radius

Number of

Slotted Holes

4" or 100 mm 9.00" 0.40" 7.50" 6.89" 0.38" 8

6" or 150 mm 11.22" 0.40" 9.50" 9.44" 0.45" 8

8" or 200 mm 13.5" 0.40" 11.75" 11.4" 0.45" 12

WARNING: The user is responsible for the selection of bolting and

gasket materials which will fall within the limits of the flange and its

intended use and which are suitable for the service conditions.

Page 14 SITRANS LR400 (7ML5421) – INSTRUCTION MANUAL 7ML19985FH06

Installation

Notes:

• SITRANS LR400 is rated for Type 4X/NEMA 4X, Type 6/NEMA 6, IP67.

Follow all installation and operating instructions to meet the

requirements of this type of protection. Use only approved, suitable

sized hubs for watertight applications.

• Observe all maximum permissible ambient and process temperatures.

Refer to Appendix III (Ambient/Operating Temperature Specification).

Provide a warning sign and/or touch guard if the surface of the

measuring instrument can become hotter than 70 °C (158 °F) in use.

WARNINGS:

• This product is designated as a Pressure Accessory per directive

97/23/EC and is not

• Improper installation may result in loss of process pressure.

Mounting Location

intended for use as a safety device.

Recommendations

• Position device with easy access for viewing display and programming via handheld

programmer.

• Mount device in an environment suitable to the housing rating and the materials of

construction.

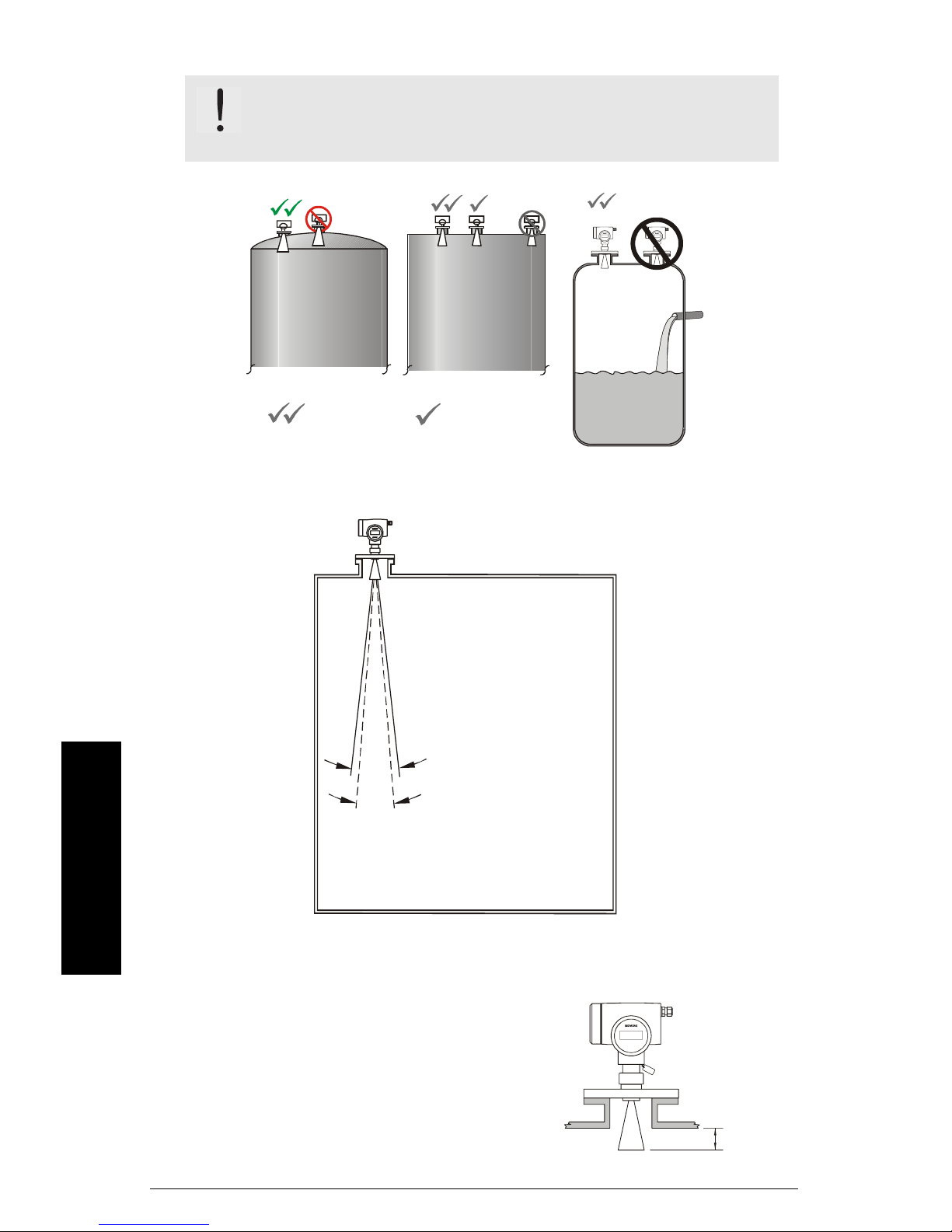

• Mount the unit more than 1 m away from the vessel walls, pipes and other

assemblies as well as the filling stream, because all these influences will become

noticeable as reflective interference. Align the antenna so that the radar cone

intersects the surface of the measuring medium as vertically as possible.

Precautions

• Do not mount in direct sunlight without the use of a sun shield.

ambient temperature

65 °C (149 °F) max.

Warning: Internal temperature

internal enclosure

temperature

must not exceed 85 °C (185 °F)!

flange

temperature

hand

programmer

Installation

mmmmm

• Avoid proximity to high voltage or current wiring, high voltage or current contacts,

and to variable frequency motor speed controllers.

• Avoid interference to emission cone from obstructions or from fill path.

• Avoid central locations on vesse

7ML19985FH06 SITRANS LR400 (7ML5421) – INSTRUCTION MANUAL Page 15

process temperature

WARNING: For vessels with conical or parabolic tops, avoid

mounting the unit at the center.

echoes into the centre, giving false readings.

The concavity of the top can focus

Parabolic or Conical

Beam Width

P a ra b o lic

is preferred

location

Flat

Flat

is acceptable

location

Keep the emission cone

(9° or 13° depending on

configuration), free of

obstructions.

SITRANS LR 400 SITRANS LR 400

mmmmm

Installation

Correct Installation in Mounting Nozzle

The bottom edge of the antenna must project

into the vessel to avoid reflective interference

at the wall of the nozzle. Above flange size

DN 150/6", the antenna need not project beyond

the nozzle unless the radiation cone (the

extension of the antenna’s angle) touches the

nozzle wall.

Page 16 SITRANS LR400 (7ML5421) – INSTRUCTION MANUAL 7ML19985FH06

13°

short horn antenna

long horn antenna

9°

SITRANS LR 400

10 mm

Electrical Connection

Notes:

• The equipment must be protected by a 15A fuse or circuit breaker in the

building installation.

• A circuit breaker or switch in the building installation, marked as the

disconnect switch, shall be in close proximity to the equipment and within

easy reach of the operator.

WARNING:

All field wiring must have insulation suitable for at least 250 V.

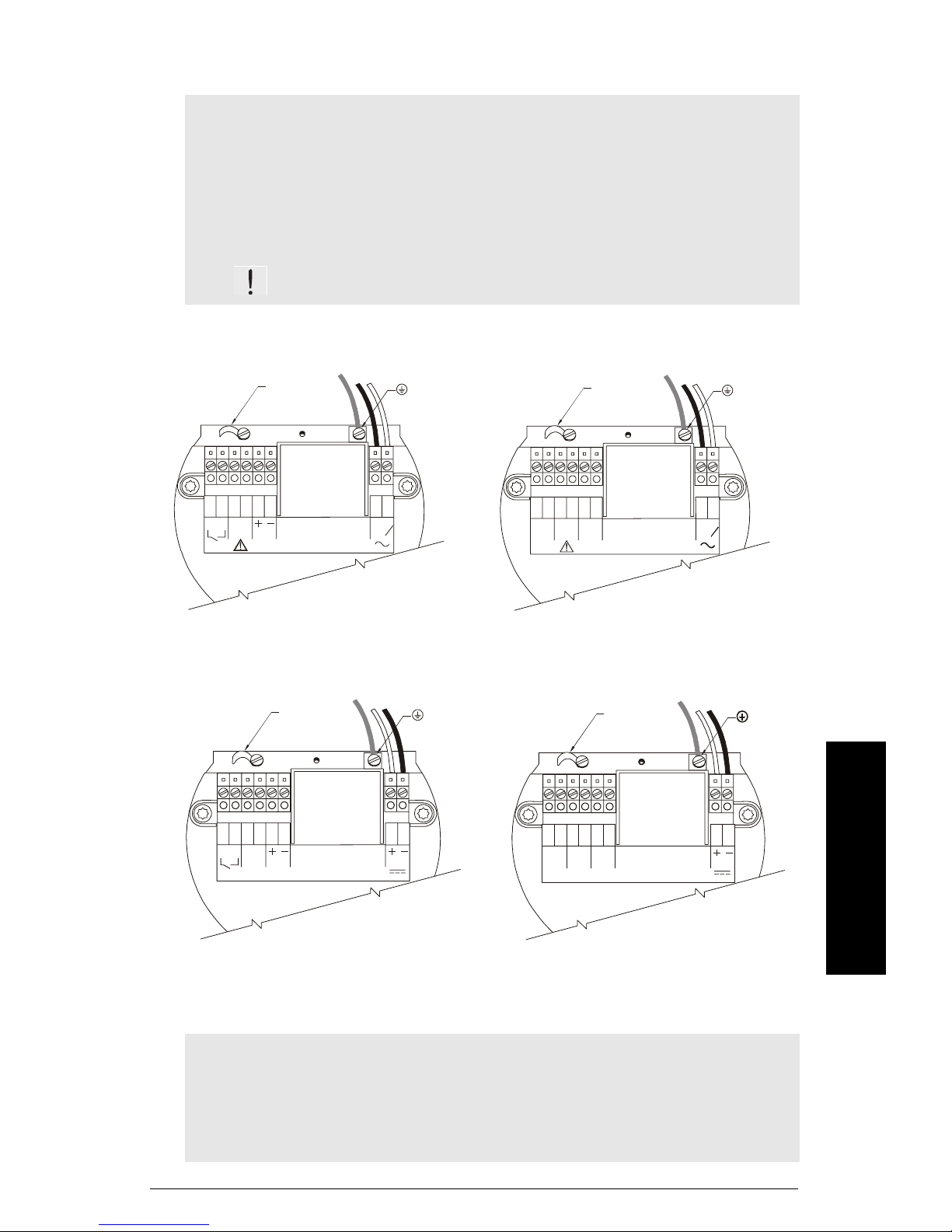

AC version:

HART wiring

cable clamp

earth

terminal

PROFIBUS wiring

cable clamp

earth

terminal

mA

DC version:

HART wiring

Rated temperature of

connection cables must

exceed maximum ambient

temperature by at least 15 K

12645378

L

1L2

N

645378

PROFIBUS PA

Rated temperature of

connection cables must

exceed maximum ambient

temperature by at least 15 K

PROFIBUS wiring

12645378

19- 30 V

earth

terminal

PROFIBUS PA

cable clamp cable clamp

Rated temperature of

connection cables must

mA

exceed maximum ambient

temperature by at least 15 K

Rated temperat ure of

connection cables must

exceed maximum ambient

temperature by at least 15 K

1

L1L

2

2

N

12645378

19-30 V

earth

terminal

Installation

mmmmm

• The DC input terminals shall be supplied from a source providing electrical isolation

between the input and output, in order to meet the applicable safety requirements of

IEC 61010-1

Notes (AC and DC versions):

• 4-20 mA, PROFIBUS PA, DC input circuits, 14 - 20 AWG, shielded copper

wire

• AC input circuit, min 14 AWG copper wire

• Recommended torque on terminal clamping screws, 0.5 - 0.6 Nm.

7ML19985FH06 SITRANS LR400 (7ML5421) – INSTRUCTION MANUAL Page 17

Connecting the SITRANS LR400:

1. Release the cover lock on the connection box with a 3 mm Allen key.

2. Unscrew the cover from the connection box.

3. Push the power cable and signal cable through the cable gland on the right of the

unit, up to the terminal strip. Lay the cable in a bend before the cable gland so that

moisture cannot enter the connection box.

4. Connect the earth conductor of the power supply to the earth terminal in the

connection box. Adjust the cable length so that the earth conductor would be last to

disconnect last if cable is pulled.

5. In devices with ignition protection types II 1/2G EEx dem [ia] IIC T6 and II 1/2G EEx

dem [ib] IIC T6 or II 2G EEx dem [ia] IIC T6 and II 2G EEx dem [ib] IIC T6 (7ML5421

version), mount the cover for the power supply terminals.

6. Tighten the cable screw gland and check the strain relief (pull and turn).

7. In devices with ignition protection type II 1/2G EEx D IIC T6 or II 2G EEx d IIC T6

(7ML5421 version), replace unused screw-type cable glands with a certified dummy

plug.

8. Screw the cover onto the housing and tighten it without using a tool. The sealing

ring must be clean and undamaged.

9. Mount the cover lock of the connection box cover.

10. Connect the earth terminal located between the screw-type cable glands to a

ground connection at your vessel by using a cable of a cross-section at least

2.5 mm

For error-free communication via the HART protocol, a load of at least 230 Ω must be

available in the signal circuit.

2

.

WARNINGS:

• To avoid short-circuits, do not connect a load resistance with bare wires in

the connection box.

• The housing cover may not be unscrewed in a hazardous area when the

device is under voltage (power supply, digital outputs on external supply).

• In devices with ignition protection types II 1/2G EEx dem [ia] IIC T6 and II 1/

2G EEx dem [ib] IIC T6 II 2G EEx dem [ia] IIC T6 and II 2G EEx dem [ib]

IIC T6 (7ML5421 version), only the cover of the connection box may be

unscrewed for test purposes. The cover on the power supply terminals may

not be removed!

mmmmm

Installation

Page 18 SITRANS LR400 (7ML5421) – INSTRUCTION MANUAL 7ML19985FH06

Start Up

Self-test

When power is supplied, the device performs a self-test. Then, when the multi-display

appears, the device is ready for programming.

Note: Frequent switching off and on of the device causes aging of the electronics

(monitored using Parameter 3.1).

Multi-display

The multi-display shows on the LCD after a successful self-test with the first line showing

level output and the second line showing signal-to-noise ratio (factory setting):

+1 2 300 m

.

bd03+

Local Programming

When the multi-display appears on the LCD, begin local

programming using the hand programmer. To access the

parameter settings, press LEFT once. Main Menu is visible

as the first LCD line. Then program the unit beginning with the

Auto-Setup parameters.

Auto-Setup

After switching on the SITRANS LR400, and after a successful self test, press LEFT to

access the parameters. Set the Auto-Setup parameters to make the system operational:

(see page 27)

• The language of the local user interface

• The unit of length of the measured level

• The nozzle height in the selected unit of length

•The vessel height in the selected unit of length

• The LRV (lower range value) as a distance from the bottom of the vessel

• The URV (upper range value) as a distance from the bottom of the vessel

• The damping of the measured level in seconds

• The application type

• The bus address by PROFIBUS PA communication (on PROFIBUS models)

Enter the necessary values as described in Parameters on page 26.

Note: It is strongly recommended that a Customer Code (Parameter 5.2) be entered

after all programming is completed to secure the programmed values from changes.

If the multi-display does not appear or displays incorrect measured values after AutoSetup, proceed as described in Troubleshooting on page 81.

Refer to the

7ML19985FH06 SITRANS LR400 (7ML5421) – INSTRUCTION MANUAL Page 19

Parameter

Start Up

mmmmm

section that begins on page 26 for a list of available parameters.

Operation

General Information

mmmmm

You can operate SITRANS LR400 with:

Operation

• Handheld infrared programmer

• Handheld HART Communicator

• PC/Laptop and SIMATIC PDM software via HART or PROFIBUS PA

Notes:

• SITRANS LR400 can be operated and programmed easily with SIMATIC

PDM software. This software gives you the added possibility of saving and

archiving your application-specific parameters and copying them back into

the device if necessary.

• It is best to perform the operations described in the following sections

directly on the device to familiarize yourself with the operation.

Operating SITRANS LR400

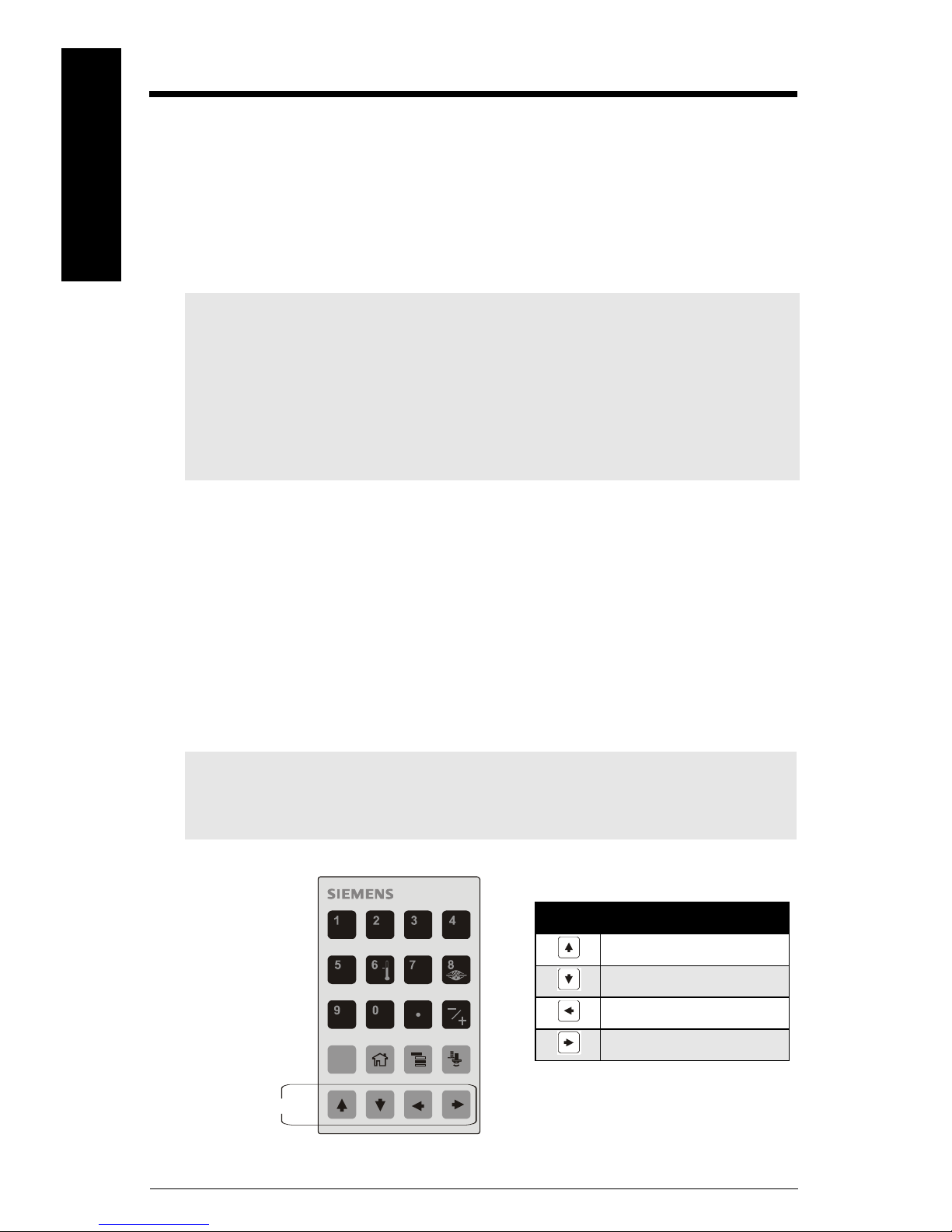

Use the arrow keys at the bottom of the hand programmer to program SITRANS LR400.

The two-line LCD displays the parameters. You can alter the setting or change to other

parameters using the arrows on the hand programmer (see page 22 for information on

navigating the menus using the arrow keys).

Hand Programmer

Note: The ARROW buttons shown below are required for programming

this product. The additional buttons on the hand programmer do not

apply to SITRANS LR400.

SITRANS LR400

buttons

Key Programming Mode

Paramet er scroll UP

Paramet er scroll DOWN

LEFT Arrow (or CANCEL)

RIGHT Arrow (or ENTER)

C

Page 20 SITRANS LR400 (7ML5421) – INSTRUCTION MANUAL 7ML19985FH06

Selecting a Parameter

After a successful self-test, SITRANS LR400 displays the two-line multi-display.

Press LEFT ARROW to access the parameter menus. The first line of the display

shows the current parameter menu level. The second line shows one of the parameters

you can access in the current parameter group.

Scroll through the parameters in the group by pressing UP and DOWN . RIGHT

accesses the parameter displayed on the second line. LEFT closes this parameter

and moves up one level until you return to the multi-display.

When you select a parameter, its current value is displayed in the second line. When the

cursor flashes, programming is enabled, (see Disabling and Enabling Programming on

page 23) and you can change the current setting. If the parameter is display only or if

programming is disabled, the cursor will not flash.

Note: The background illumination of the LCD switches on when the hand

programmer is used for programming. It goes out about three minutes after last

button press.

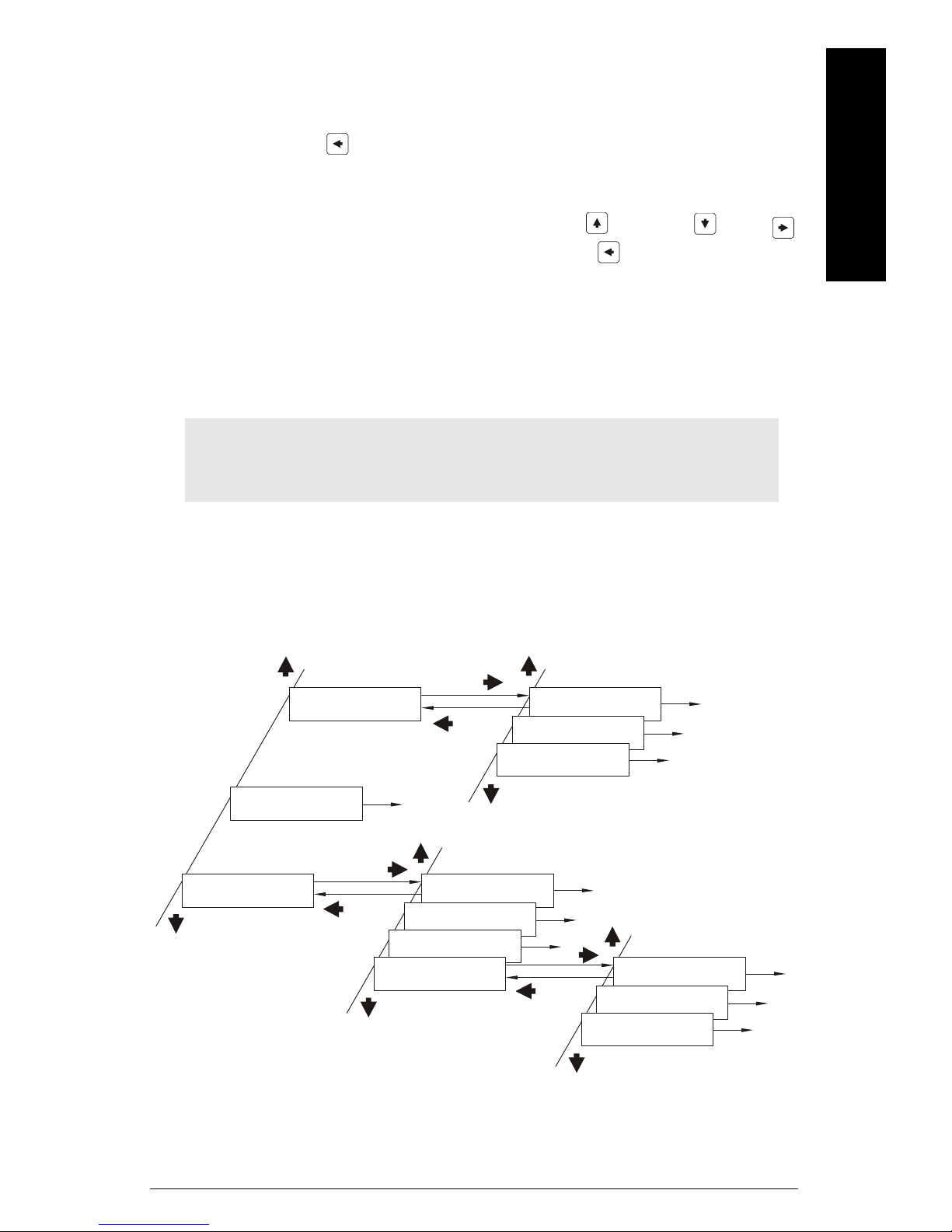

Structure of Parameters

Operation

mmmmm

Operation is hierarchically structured: the parameters are arranged in groups and

assigned a numerical menu identification (see example below from a HART device).

2. Display

1 Multi-display

2. Display

2 Level

2. Display

3 Volume

O

e

l

g

n

i

t

a

r

e

p

4.4 Digital outpu

1 Function DO

4.4 Digital outpu

3

l

e

2 Error level

v

4.4 Digital outpu

3 Signal type DO

1

l

e

v

e

l

g

n

i

t

Function group

a

r

e

3 Diagnostics

p

O

Function group

4 Device data

Function group

2 Display

g

n

i

t

a

r

e

p

O

4. Device data

2

l

2 Operat. param.

e

v

4. Device data

e

l

3 Analog output

4. Device data

4 Digital output

4. Device data

1 Units

7ML19985FH06 SITRANS LR400 (7ML5421) – INSTRUCTION MANUAL Page 21

mmmmm

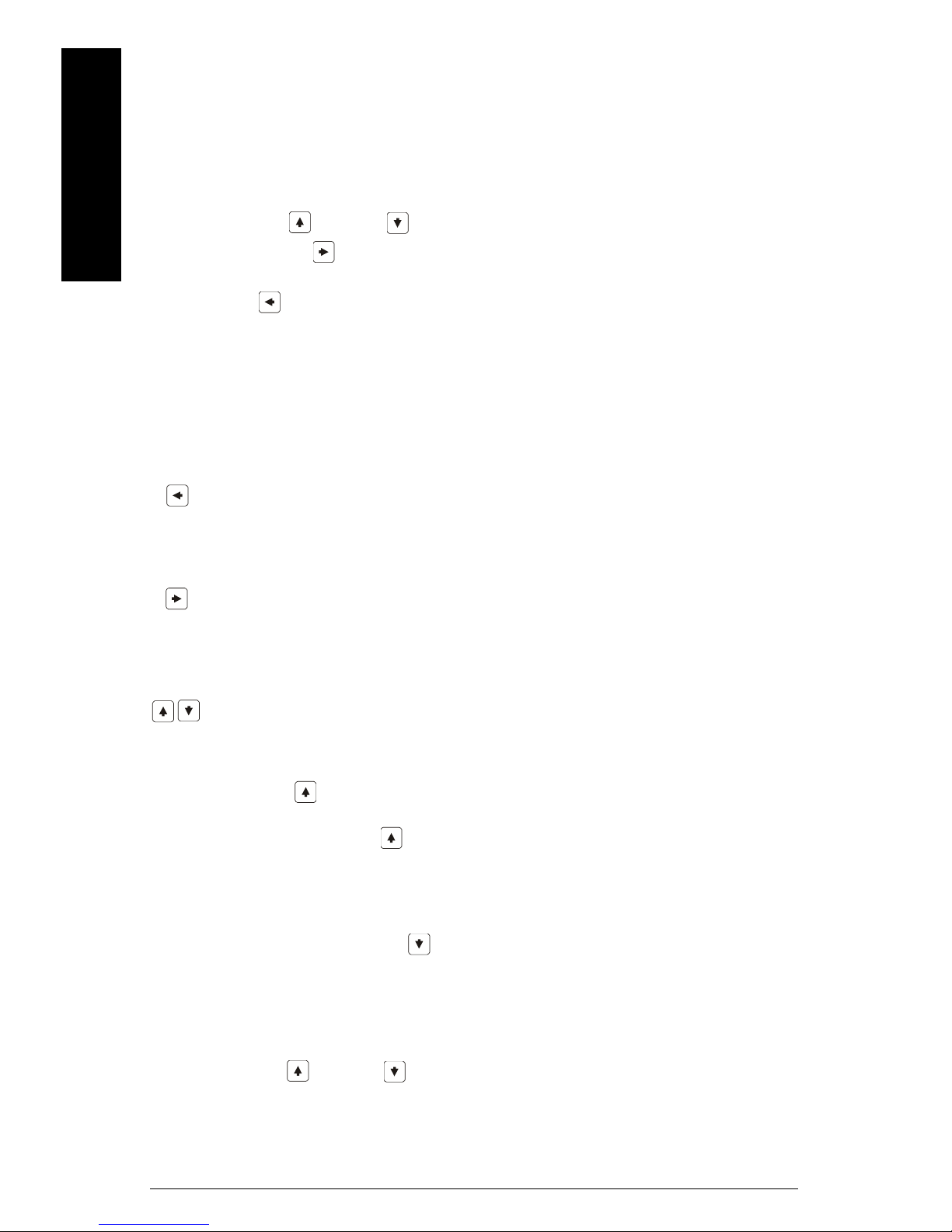

Changing a Parameter Value

Selecting a Parameter Value from a List

In many cases, you can assign a parameter a value from a list of options.

Operation

You will see a single entry of the possible choices in the second display line.

• Press UP or DOWN to cycle through the list and choose the desired entry.

Press RIGHT to assign the current entry to the parameter. The device accepts

the new setting, closes the input and returns to the next parameter level up.

• LEFT operates like a CANCEL key: When pressed, the device closes the

parameter input but keeps the originally displayed value. It does not save a changed

setting!

For an example of assigning a value from a selection list, see

Examples

on page 24.

Functions of Hand Programmer Keys

• Changes display from RUN mode to PROGRAM mode

• Operates as a CANCEL key when programming input position is at the far left

• Moves input position to the left during PROGRAM mode

Parameter Operating

• Operates as an ENTER key when input position is at the far right. If the input

value is not within the permissible input range. Then an error message is

displayed.

• Moves input position to the right during PROGRAM mode

• Changes input variable up or down

Top or bottom of representable range

If you press UP when the value is at the top of the representable range,

SITRANS LR400 automatically places the value at the next highest position. If 0.9 is

displayed and you press UP , the value becomes 1.0. So, 9 becomes 10, 90 or 99

become 100 (depending on whether you have set the input position to the second or first

9), etc.

This input system also works in the opposite direction: For example, when 100 is

displayed and you press DOWN on the first or second 0, the numeric value changes

to 90 or 99 and the device cancels the places in front of the decimal point.

Decimal point

You can also set the cursor to the decimal point (unless an integer value is currently

displayed). UP or DOWN will then multiply or divide the displayed value by 10. The

necessary additional places in front of the decimal point appear. You cannot change the

number of displayed decimal places.

Page 22 SITRANS LR400 (7ML5421) – INSTRUCTION MANUAL 7ML19985FH06

Display scrolling

Displayed text may be longer than the field of the display. An arrow pointing outward on

the right or left hand side of the display line indicates that the text continues outside the

multi-display. You can read the additional text using RIGHT and LEFT to move the

pointer past the end of the line.

See

Parameter Operating Examples

on page 24 for an example of manual input.

Disabling and Enabling Programming

To prevent unauthorized personnel causing programming errors using the display

module, set a customer code – a personal, number code up to 9 digits. A device protected

by a customer code still displays all functions and values but it requests input of the code

before resetting a parameter.

Note: The customer code is activated 10 minutes after you have programmed

Parameter 5.2 Customer Code.

Programming is enabled when you:

Operation

mmmmm

• enter the requested customer code for the current parameter

or

• release the programming lock using Parameter 5.1 Code Input on page 56.

The programming lock will be released for approximately 10 minutes. Any other code

number locks and disables programming.

When you return to the multi-display or enter a number in the Code Input parameter

which is different from the customer code, or do not operate the device for 10 minutes,

the programming lock is enabled.

Note: If Customer Code (Parameter 5.2) is 0, programming of parameters is always

enabled. We strongly recommend that a customer code be entered after all

programming is completed to secure the programmed values from change.

7ML19985FH06 SITRANS LR400 (7ML5421) – INSTRUCTION MANUAL Page 23

mmmmm

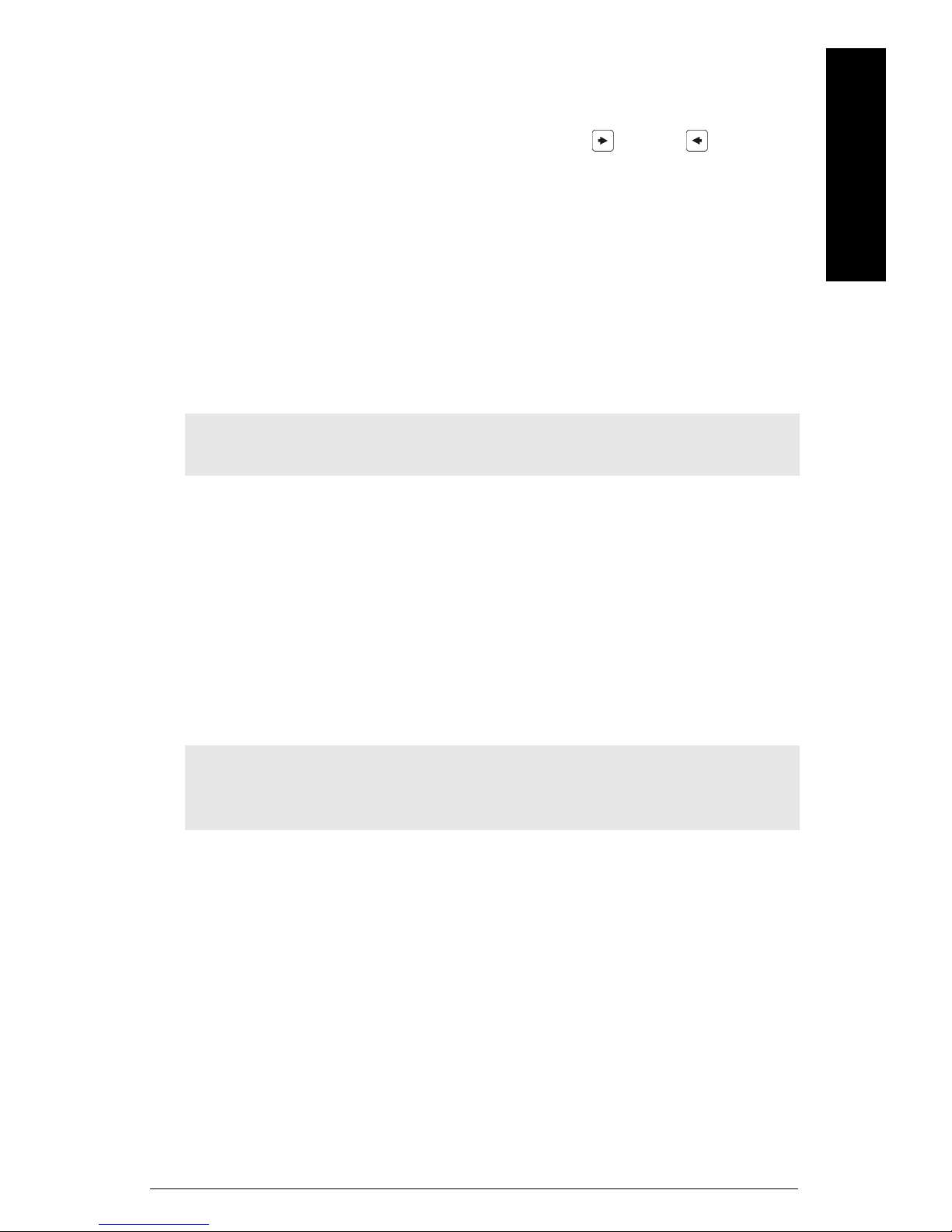

Parameter Operating Examples

Example (HART): Change the length unit from m to mm.

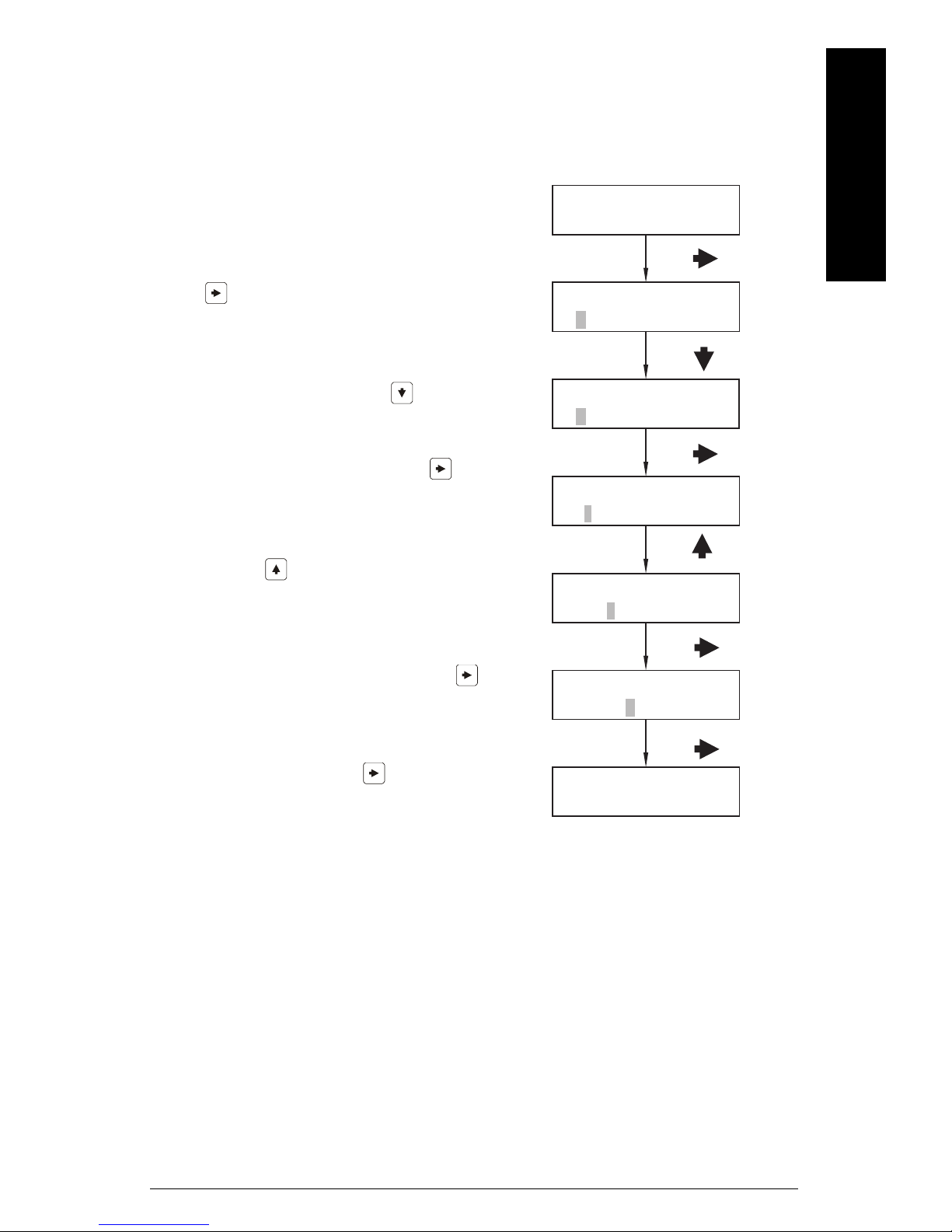

The example begins at the multi-display (1). Follow the bold arrowed path to complete the

task. Use the arrow buttons shown next to the numbered operation steps.

Operation

Function group

1 Auto-Setup

Function group

2 Display

Function group

3 Diagnostics

Function group

4 Device data

+12,300 m

+30 dB

4. Device data

1 Units

4. Device data

2. Operat. param.

4. Device data

3 Analog output

4.1 Units

1 Length Unit

4.3 Analog output

1 Error level

4.3 Analog output

2 AO select

4.1.1 Length unit

m

4.1.1 Length unit

cm

4.3.1 Error level

D: Error signal

4.3.2 AO select

1 Level

Page 24 SITRANS LR400 (7ML5421) – INSTRUCTION MANUAL 7ML19985FH06

Example 2: Change the filling speed from 2.0 cm/min to 100 cm/min.

Access the Fill speed parameter from the multi-display according to instructions on

page 22.

Operation

mmmmm

The default setting appears in the display.

Enable the programming by pressing RIGHT

. The second segment of the second

display line flashes.

Set the digit to 1 with DOWN .

Select the decimal point with RIGHT .

Press UP twice so that two other places

appear in front of the decimal point.

4.2.2.5.

+

2.00

4.2.2.5.

+

2.00

4.2.2.5.

+

1.00

4.2.2.5.

+

1.00

4.2.2.5.

+

100.00

Filling

cm/min

1x

Filling

cm/min

1x

Filling

cm/min

1x

Filling

cm/min

2x

Filling

cm/min

spe

spe

spe

spe

spe

Select the last decimal place with RIGHT .

End the input with RIGHT (ENTER).

4.2.2.5.

+

100.00

4.2.2.

Filling speed

5

Filling

Measur. cond

2x

spe

cm/min

1x

7ML19985FH06 SITRANS LR400 (7ML5421) – INSTRUCTION MANUAL Page 25

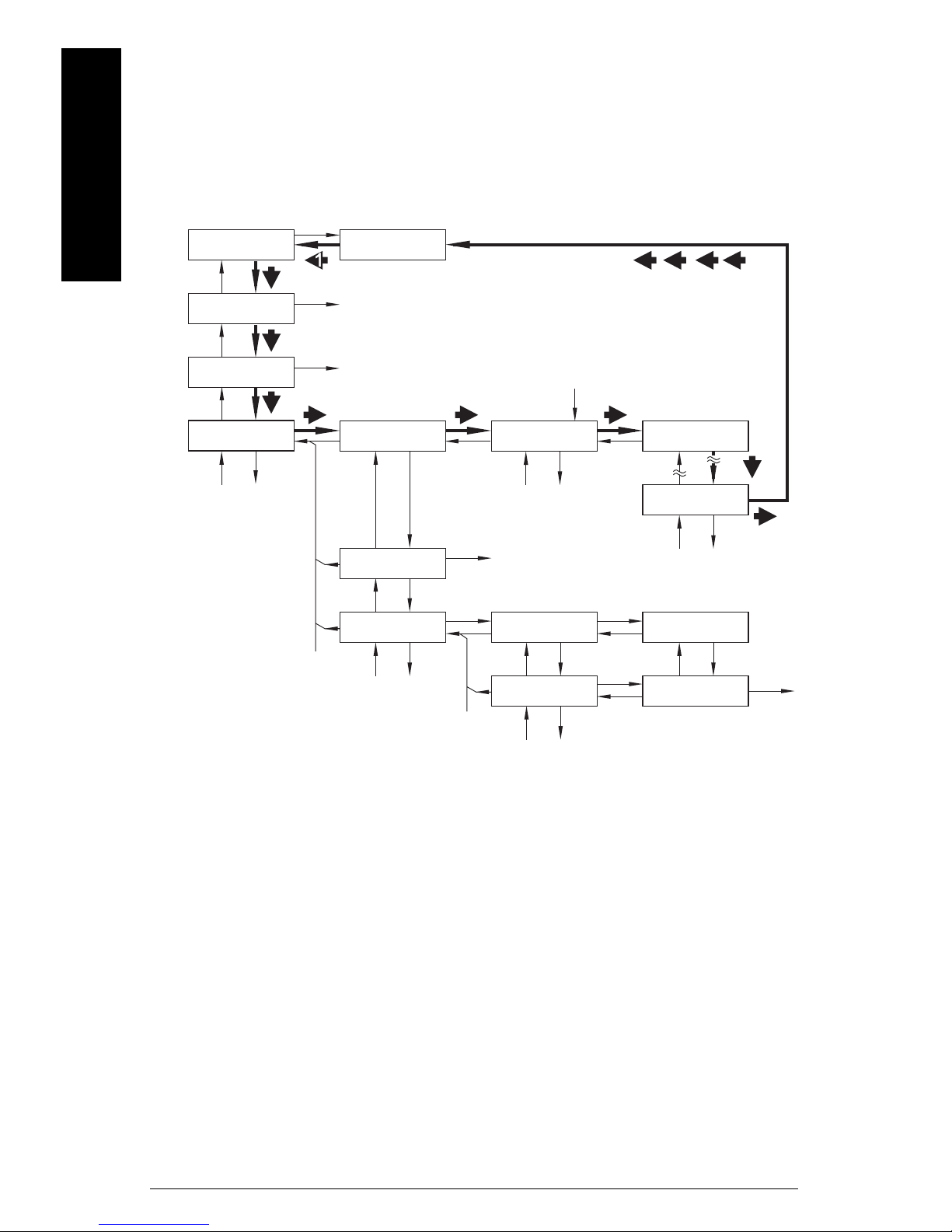

Parameters (HART)

The parameter groups are followed by the parameters within each group. The parameter

tables show the values you need to enter and are followed by additional information

when necessary. Factory settings are displayed after the parameter name, where

applicable.

Note: Parameter menus are dependent on selections made by the user.

In some cases, parameter menus are renumbered according to the

selection made at the previous menu level. See table below for an

example.

mmmmm

Parameters (HART)

When User chooses Parameter 4.2.2.1:

Application Type = Liquids (Process)

2: Surface

4.2.2.

4.2.2.3: Dead band 4.2.2.2: Dead band

4: Correction Factor 4.2.2.3: Correction Factor

4.2.2.

4.2.2.5: Filling Speed

6: Reflectivity

4.2.2.

4.2.2.7: Failsafe Level 4.2.2.4: Failsafe Level

4.2.2.8: Failsafe Timer 4.2.2.5: Failsafe Timer

9: Range Extension 4.2.2.6: Range Extension

4.2.2.

Default values are indicated as "F=" following the parameter number and name.

When User chooses Parameter 4.2.2.1:

Application Type = User tank1

(not available when 4.2.2.1 = User tank1)

(not available when 4.2.2.1 = User tank1)

(not available when 4.2.2.1 = User tank1)

Page 26 SITRANS LR400 (7ML5421) – INSTRUCTION MANUAL 7ML19985FH06

Loading...

Loading...