Siemens SITRANS LR250 Operating Instructions Manual

SITRANS LR250 (FOUNDATION

FIELDBUS)

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________

___________________

___________________

___________________

SITRANS

Radar Transmitters

SITRANS LR250 (FOUNDATION

FIELDBUS)

Operating Instructions

08/2014

Introduction

1

Safety information

2

Description

3

Installing/mounting

4

Connecting

5

Commissioning

6

Remote operation

7

Parameter reference

8

Service and maintenance

9

Diagnosing and

troubleshooting

10

Technical data

11

Dimension drawings

12

Appendix A: Technical

reference

A

Appendix B:

Communications via

Foundation Fieldbus

B

Appendix C: Certificates and

support

C

List of abbreviations

13

LCD menu structure

14

A5E32221411-AC

Legal information

Warning notice system

DANGER

will

WARNING

may

CAUTION

NOTICE

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

indicates that death or severe personal injury

indicates that death or severe personal injury

indicates that minor personal injury can result if proper precautions are not taken.

indicates that property damage can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will be

used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to property

damage.

The product/system described in this documentation may be operated only by

in accordance with the relevant documentation, in particular its warning notices and safety instructions. Qualified

personnel are those who, based on their training and experience, are capable of identifying risks and avoiding

potential hazards when working with these products/systems.

result if proper precautions are not taken.

result if proper precautions are not taken.

for the specific task

Note the following:

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication may

be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software described.

Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the information in this

publication is reviewed regularly and any necessary corrections are included in subsequent editions.

Siemens AG

Industry Sector

Postfach 48 48

90026 NÜRNBERG

GERMANY

Order number: A5E32221411

Ⓟ 05/2014 Subject to change

Copyright © Siemens AG 2014.

All rights reserved

Table of contents

1 Introduction ........................................................................................................................................... 11

2 Safety information ................................................................................................................................. 15

3 Description ............................................................................................................................................ 19

4 Installing/mounting ................................................................................................................................ 21

1.1 LR250 FF manual usage ............................................................................................................. 11

1.2 Purpose of this documentation .................................................................................................... 11

1.3 Document history ......................................................................................................................... 11

1.4 Firmware revision history ............................................................................................................. 12

1.5 Designated use ............................................................................................................................ 12

1.6 Checking the consignment ........................................................................................................... 13

1.7 Transportation and storage .......................................................................................................... 13

1.8 Notes on warranty ........................................................................................................................ 13

2.1 Preconditions for safe use ........................................................................................................... 15

2.1.1 Safety marking symbols ............................................................................................................... 15

2.1.2 Laws and directives ..................................................................................................................... 15

2.1.3 FCC Conformity ........................................................................................................................... 15

2.1.4 Conformity with European directives ........................................................................................... 16

2.1.5 CE Electromagnetic Compatibility (EMC) Conformity.................................................................. 17

2.2 Improper device modifications ..................................................................................................... 17

2.3 Requirements for special applications ......................................................................................... 18

2.4 Use in hazardous areas ............................................................................................................... 18

3.1 SITRANS LR250 overview ........................................................................................................... 19

3.2 Programming ................................................................................................................................ 20

3.3 Applications .................................................................................................................................. 20

3.4 Approvals and certificates ............................................................................................................ 20

4.1 Basic safety information ............................................................................................................... 21

4.1.1 Pressure applications ................................................................................................................... 22

4.1.1.1 Pressure Equipment Directive, PED, 97/23/EC ........................................................................... 23

4.2 Installation location requirements ................................................................................................ 24

4.3 Proper mounting........................................................................................................................... 26

4.3.1 Nozzle design ............................................................................................................................... 27

SITRANS LR250 (FOUNDATION FIELDBUS)

Operating Instructions, 08/2014, A5E32221411-AC

3

Table of contents

5 Connecting ............................................................................................................................................41

6 Commissioning ......................................................................................................................................55

7 Remote operation ..................................................................................................................................79

4.3.2 Nozzle location ............................................................................................................................ 28

4.3.3 Orientation in a vessel with obstructions ..................................................................................... 31

4.3.4 Mounting on a Stillpipe or Bypass Pipe ...................................................................................... 32

4.3.5 Device orientation ....................................................................................................................... 33

4.4 Installation instructions ................................................................................................................ 34

4.4.1 Threaded versions ...................................................................................................................... 36

4.4.2 Flanged versions ......................................................................................................................... 37

4.4.3 Hygienic versions ........................................................................................................................ 39

4.5 Disassembly ................................................................................................................................ 40

5.1 Basic safety information .............................................................................................................. 41

5.2 Connecting SITRANS LR250 ...................................................................................................... 42

5.3 Wiring setups for hazardous area installation ............................................................................. 46

5.3.1 Configuration with Foundation Fieldbus for hazardous areas .................................................... 46

5.3.2 Intrinsically safe wiring ................................................................................................................ 48

5.3.2.1 Intrinsically safe wiring (FM/CSA) ............................................................................................... 48

5.3.3 Non-sparking wiring .................................................................................................................... 51

5.3.4 Non-incendive wiring (US/Canada only) ..................................................................................... 51

5.4 Instructions specific to hazardous area installations ................................................................... 52

5.4.1 (Reference European ATEX Directive 94/9/EC, Annex II, 1/0/6) ............................................... 52

6.1 Basic safety information .............................................................................................................. 55

6.2 Operating via the handheld programmer .................................................................................... 55

6.2.1 Power up ..................................................................................................................................... 56

6.2.2 Handheld programmer functions ................................................................................................. 56

6.2.2.1 The LCD display .......................................................................................................................... 57

6.2.2.2 Handheld programmer (Part No. 7ML1930-1BK) ....................................................................... 59

6.2.3 Programming ............................................................................................................................... 60

6.2.3.1 Quick Start Wizard via the handheld programmer_note ............................................................. 65

6.2.3.2 Auto False Echo Suppression ..................................................................................................... 69

6.2.3.3 Requesting an Echo Profile ........................................................................................................ 70

6.2.3.4 Device Address ........................................................................................................................... 71

6.3 Application examples .................................................................................................................. 71

6.3.1 Liquid resin in storage vessel, level measurement ..................................................................... 72

6.3.2 Horizontal vessel with volume measurement.............................................................................. 74

6.3.3 Application with stillpipe .............................................................................................................. 76

7.1 Operating via AMS Device Manager ........................................................................................... 79

7.1.1 Functions in AMS Device Manager ............................................................................................. 79

7.1.2 Key features of AMS Device Manager Rev. 9.0 ......................................................................... 81

7.1.2.1 Pull-down menu access .............................................................................................................. 82

SITRANS LR250 (FOUNDATION FIELDBUS)

4 Operating Instructions, 08/2014, A5E32221411-AC

Table of contents

8 Parameter reference ........................................................................................................................... 143

7.1.3 Adding a new device .................................................................................................................... 82

7.1.3.1 Electronic Device Description (EDD) ........................................................................................... 82

7.1.4 Master Reset ................................................................................................................................ 84

7.1.5 Scan Device ................................................................................................................................. 84

7.1.6 Sensor calibration ........................................................................................................................ 85

7.1.7 Configuring a new device ............................................................................................................. 85

7.1.7.1 Quick Start Wizard via AMS Device Manager ............................................................................. 85

7.1.8 Changing parameter settings using AMS Device Manager ......................................................... 91

7.1.9 Configure/Setup (Level Transducer Block-LTB) .......................................................................... 92

7.1.9.1 Identification (LTB) ....................................................................................................................... 92

7.1.9.2 Operation (LTB) ........................................................................................................................... 93

7.1.9.3 Setup (LTB) .................................................................................................................................. 95

7.1.9.4 Linearization (LTB) ....................................................................................................................... 97

7.1.9.5 Signal processing ......................................................................................................................... 99

7.1.9.6 Maintenance & Diagnostics (LTB) ............................................................................................. 104

7.1.9.7 Communication (LTB) ................................................................................................................ 107

7.1.10 Configure/Setup (Liquid Crystal Display Block-LCD)................................................................. 107

7.1.10.1 Identification (LCD) .................................................................................................................... 107

7.1.10.2 Operation (LCD) ......................................................................................................................... 108

7.1.10.3 Setup (LCD) ............................................................................................................................... 109

7.1.10.4 Communication (LCD) ............................................................................................................... 109

7.1.11 Configure/Setup (Diagnostic Transducer Block-DIAG) ............................................................. 110

7.1.11.1 Identification (DIAG) ...................................................................................................................

7.1.

11.2 Operation (DIAG) ....................................................................................................................... 110

110

7.1.11.3 Communication (DIAG) .............................................................................................................. 111

7.1.12 Configure/Setup (Resource Block - RESOURCE) ..................................................................... 111

7.1.12.1 Identification (RESOURCE) ....................................................................................................... 111

7.1.12.2 Wizards (RESOURCE) .............................................................................................................. 112

7.1.12.3 Operation (RESOURCE) ........................................................................................................... 113

7.1.12.4 Maintenance & Diagnostics (RESOURCE) ............................................................................... 116

7.1.12.5 Communication (RESOURCE) .................................................................................................. 118

7.1.12.6 Security (RESOURCE) .............................................................................................................. 119

7.1.13 Device Diagnostics (Level Transducer Block - LTB) ................................................................. 119

7.1.13.1 Alarms & Errors (LTB) ................................................................................................................ 120

7.1.13.2 Extended Diagnostics (LTB) ...................................................................................................... 123

7.1.14 Device Diagnostics (Liquid Crystal Display Block - LCD) .......................................................... 124

7.1.14.1 Alarms & Errors (LCD) ............................................................................................................... 124

7.1.15 Device Diagnostics (Diagnostic Transducer Block - DIAG) ....................................................... 124

7.1.15.1 Alarms & Errors (DIAG) ............................................................................................................. 124

7.1.16 Device Diagnostics (Resource Block - RESOURCE) ................................................................ 124

7.1.16.1 Alarms & Errors (RESOURCE) .................................................................................................. 124

7.1.16.2 Extended Diagnostics (RESOURCE) ........................................................................................ 127

7.1.17 Process Variables (Level Transducer Block - LTB) ................................................................... 128

7.1.18 Password Protection .................................................................................................................. 129

7.1.18.1 User Manager utility ................................................................................................................... 129

7.1.19 AMS menu structure ..................................................................................................................

130

SITRANS LR250 (FOUNDATION FIELDBUS)

Operating Instructions, 08/2014, A5E32221411-AC

5

Table of contents

9 Service and maintenance ..................................................................................................................... 197

10 Diagnosing and troubleshooting ........................................................................................................... 203

11 Technical data ..................................................................................................................................... 213

12 Dimension drawings ............................................................................................................................. 221

8.1 Alphabetical parameter list ........................................................................................................ 191

9.1 Basic safety information ............................................................................................................ 197

9.2 Cleaning .................................................................................................................................... 197

9.3 Maintenance and repair work .................................................................................................... 198

9.3.1 Unit repair and excluded liability ............................................................................................... 199

9.3.2 Part replacement ....................................................................................................................... 199

9.4 Disposal .................................................................................................................................... 201

10.1 Device status icons ................................................................................................................... 204

10.2 General fault codes ................................................................................................................... 205

10.3 Operation troubleshooting ......................................................................................................... 210

11.1 Power ........................................................................................................................................ 213

11.2 Performance .............................................................................................................................. 213

11.3 Interface .................................................................................................................................... 215

11.4 Mechanical ................................................................................................................................ 215

11.5 Environmental ........................................................................................................................... 218

11.6 Process ..................................................................................................................................... 218

11.7 Approvals .................................................................................................................................. 219

11.8 Programmer (infrared keypad) .................................................................................................. 220

12.1 Threaded horn antenna............................................................................................................. 221

12.2 Threaded horn antenna with extension ..................................................................................... 224

12.3 Flanged horn antenna ............................................................................................................... 226

12.4 Flanged horn antenna with extension ....................................................................................... 228

12.5 Flanged encapsulated antenna (2"/DN50/50A sizes only) ....................................................... 230

12.6 Flanged encapsulated antenna (3"/DN80/80A sizes and larger) .............................................. 232

12.7 Hygienic encapsulated antenna (2" ISO 2852 sanitary clamp) ................................................ 234

12.8 Hygienic encapsulated antenna (3" ISO 2852 sanitary clamp) ................................................ 235

12.9 Hygienic encapsulated antenna (4" ISO 2852 sanitary clamp) ................................................ 236

12.10 Hygienic encapsulated antenna (DN 50 nozzle/ slotted nut to DIN 11851) .............................. 237

12.11 Hygienic encapsulated antenna (DN 80 nozzle/ slotted nut to DIN 11851) .............................. 238

SITRANS LR250 (FOUNDATION FIELDBUS)

6 Operating Instructions, 08/2014, A5E32221411-AC

Table of contents

A Appendix A: Technical reference ......................................................................................................... 265

12.12 Hygienic encapsulated antenna (DN 100 nozzle/ slotted nut to DIN 11851) ............................ 239

12.13 Hygienic encapsulated antenna (DN 50 aseptic slotted nut to DIN 11864-1) ........................... 240

12.14 Hygienic encapsulated antenna (DN 80 aseptic slotted nut to DIN 11864-1) ........................... 241

12.15 Hygienic encapsulated antenna (DN 100 aseptic slotted nut to DIN 11864-1) ......................... 242

12.16 Hygienic encapsulated antenna (DN 50 aseptic flange to DIN 11864-2) .................................. 243

12.17 Hygienic encapsulated antenna (DN 80 aseptic flange to DIN 11864-2) .................................. 244

12.18 Hygienic encapsulated antenna (DN 100 aseptic flange to DIN 11864-2) ................................ 245

12.19 Hygienic encapsulated antenna (DN 50 aseptic clamp to DIN 11864-3) .................................. 246

12.20 Hygienic encapsulated antenna (DN 80 aseptic clamp to DIN 11864-3) .................................. 247

12.21 Hygienic encapsulated antenna (DN 100 aseptic clamp to DIN 11864-3) ................................ 248

12.22 Hygienic encapsulated antenna (Tuchenhagen Type N) .......................................................... 249

12.23 Hygienic encapsulated antenna (Tuchenhagen Type F) ........................................................... 250

12.24 Threaded PVDF antenna ........................................................................................................... 251

12.25 Threaded connection markings .................................................................................................. 252

12.26 Raised-Face flange per EN 1092-1 for flanged horn antenna ................................................... 253

12.27 Raised-Face flange per EN 1092-1 for flanged encapsulated antenna..................................... 255

12.28 Flat-Face flange ......................................................................................................................... 258

12.29 Aseptic/hygienic flange DN50, DN80, DN100 for DIN 11864-2 ................................................. 261

12.30 Process connection tag (pressure rated versions) .................................................................... 264

A.1 Principles of operation ............................................................................................................... 265

A.2 Echo processing......................................................................................................................... 266

A.2.1 Process Intelligence ................................................................................................................... 266

A.2.2 Echo Selection ........................................................................................................................... 266

A.2.3 CLEF Range .............................................................................................................................. 269

A.2.4 Measurement Response ............................................................................................................ 270

A.2.5 Echo Threshold .......................................................................................................................... 270

A.2.6 Echo Lock .................................................................................................................................. 271

A.2.7 Auto False Echo Suppression .................................................................................................... 271

A.2.8 Measurement Range ................................................................................................................. 273

A.2.9 Damping ..................................................................................................................................... 273

A.2.10 Loss of Echo (LOE) .................................................................................................................... 274

A.2.10.1 LOE Timer .................................................................................................................................. 274

A.3 Maximum Process Temperature Chart ...................................................................................... 274

A.4 Process Pressure/Temperature derating curves ....................................................................... 276

A.4.1 Pressure Equipment Directive, PED, 97/23/EC ......................................................................... 277

SITRANS LR250 (FOUNDATION FIELDBUS)

Operating Instructions, 08/2014, A5E32221411-AC

7

Table of contents

B Appendix B: Communications via Foundation Fieldbus ........................................................................ 291

C Appendix C: Certificates and support ................................................................................................... 293

13 List of abbreviations ............................................................................................................................. 295

14 LCD menu structure ............................................................................................................................. 296

Glossary .............................................................................................................................................. 301

Index ................................................................................................................................................... 307

A.4.2 Horn antenna ............................................................................................................................ 278

A.4.3 Flanged horn antenna ............................................................................................................... 279

A.4.4 Flanged encapsulated antenna ................................................................................................. 284

A.4.5 PVDF antenna ........................................................................................................................... 286

A.4.6 Hygienic encapsulated antenna ................................................................................................ 287

B.1 Field Communicator 375 (F375) ............................................................................................... 291

C.1 Certificates ................................................................................................................................ 293

C.2 Technical support ...................................................................................................................... 293

SITRANS LR250 (FOUNDATION FIELDBUS)

8 Operating Instructions, 08/2014, A5E32221411-AC

Table of contents

SITRANS LR250 (FOUNDATION FIELDBUS)

Operating Instructions, 08/2014, A5E32221411-AC

9

1

1.1

LR250 FF manual usage

Note

1.2

Purpose of this documentation

1.3

Document history

Edition

Remark

This manual applies to the SITRANS LR250 (FOUNDATION™ Fieldbus) only.

FOUNDATION™ Fieldbus is a trademark of Fieldbus Foundation.

Follow these operating instructions for quick, trouble-free installation, and maximum accuracy

and reliability of your device.

We always welcome suggestions and comments about manual content, design, and

accessibility. Please direct your comments to:

Technical publications (mailto:techpubs.smpi@siemens.com

These instructions contain all information required to commission and use the device. It is your

responsibility to read the instructions carefully prior to installation and commissioning. In order to

use the device correctly, first review its principle of operation.

The instructions are aimed at persons mechanically installing the device, connecting it

electronically, configuring the parameters and commissioning it, as well as service and

maintenance engineers.

The following table notes major changes in the documentation compared to the previous edition.

January 2014

August 2014

• Flanged encapsulated antenna version added.

• Hygienic encapsulated antenna version added.

)

SITRANS LR250 (FOUNDATION FIELDBUS)

Operating Instructions, 08/2014, A5E32221411-AC

11

Introduction

1.4

Firmware revision history

Firmware

rev.

PDM EDD

rev.

Date

Changes

1.5

Designated use

Note

Use in a domestic environment

1.4 Firmware revision history

This history establishes the correlation between the current documentation and the valid

firmware of the device.

The documentation of this edition is applicable for the following firmware:

1.01.00 1.01.00 25 Feb 2010

1.01.04 1.01.00 2 Aug 2011

1.01.05 1.01.00 31 Oct 2012

Use the device to measure process media in accordance with the information in the operating

instructions.

This is a Class A Group 1 equipment intended for use in industrial areas.

In a domestic environment this device may cause radio interference.

• Initial release.

• Threaded PVDF antenna supported.

• Antenna parameter removed.

• Quickstart on local display enhancements.

SITRANS LR250 (FOUNDATION FIELDBUS)

12 Operating Instructions, 08/2014, A5E32221411-AC

Introduction

1.6

Checking the consignment

WARNING

Using a damaged or incomplete device

1.7

Transportation and storage

CAUTION

Insufficient protection during storage

1.8

Notes on warranty

1.6 Checking the consignment

1. Check the packaging and the device for visible damage caused by inappropriate handling

during shipping.

2. Report any claims for damages immediately to the shipping company.

3. Retain damaged parts for clarification.

4. Check the scope of delivery by comparing your order to the shipping documents for

correctness and completeness.

Danger of explosion in hazardous areas.

• Do not use damaged or incomplete devices.

To guarantee sufficient protection during transport and storage, observe the following:

● Keep the original packaging for subsequent transportation.

● Devices/replacement parts should be returned in their original packaging.

● If the original packaging is no longer available, ensure that all shipments are properly

packaged to provide sufficient protection during transport. Siemens cannot assume liability

for any costs associated with transportation damages.

The packaging only provides limited protection against moisture and infiltration.

• Provide additional packaging as necessary.

The contents of this manual shall not become part of or modify any prior or existing agreement,

commitment or legal relationship. The sales contract contains all obligations on the part of

Siemens as well as the complete and solely applicable warranty conditions. Any statements

regarding device versions described in the manual do not create new warranties or modify the

existing warranty.

The content reflects the technical status at the time of publishing. Siemens reserves the right to

make technical changes in the course of further development.

SITRANS LR250 (FOUNDATION FIELDBUS)

Operating Instructions, 08/2014, A5E32221411-AC

13

2

2.1

Preconditions for safe use

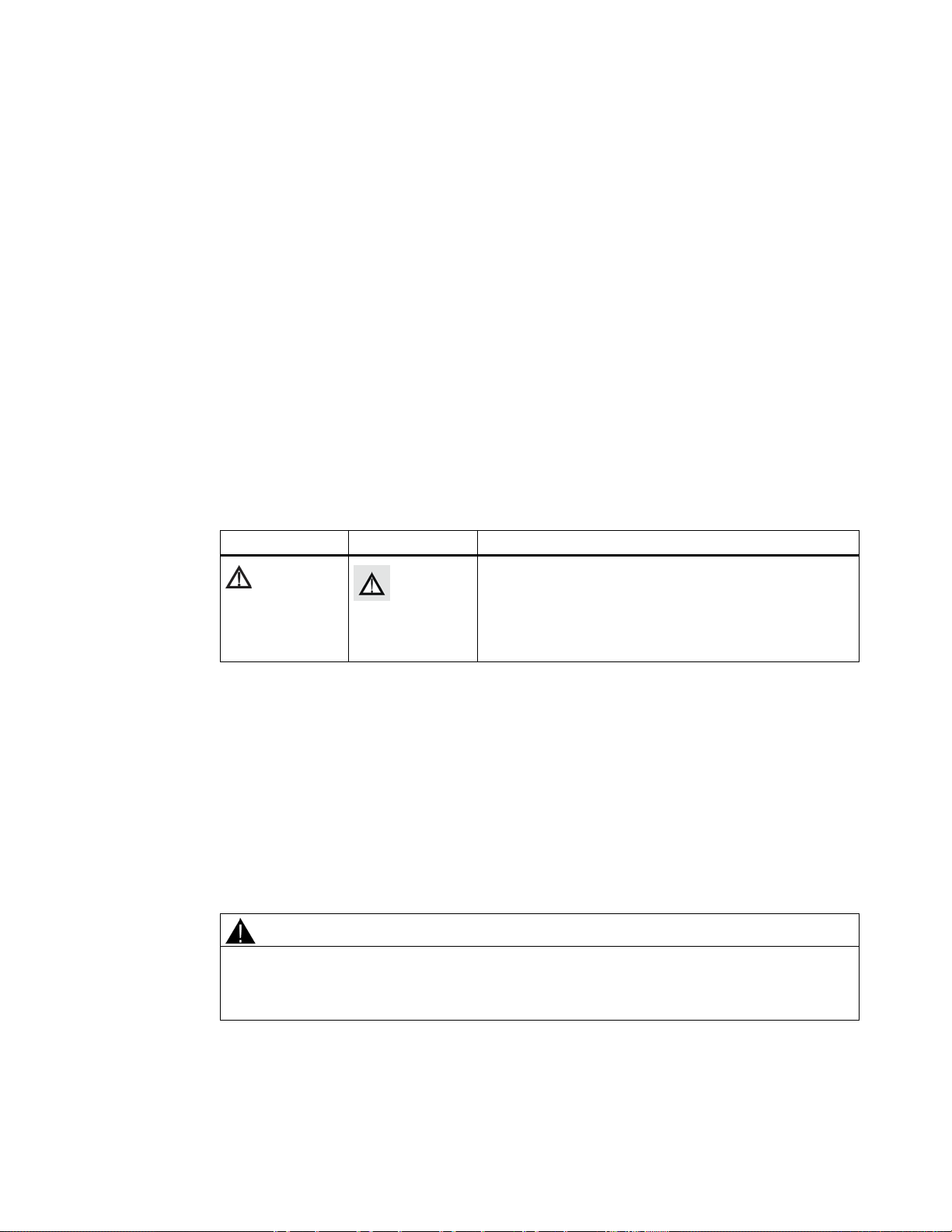

2.1.1

Safety marking symbols

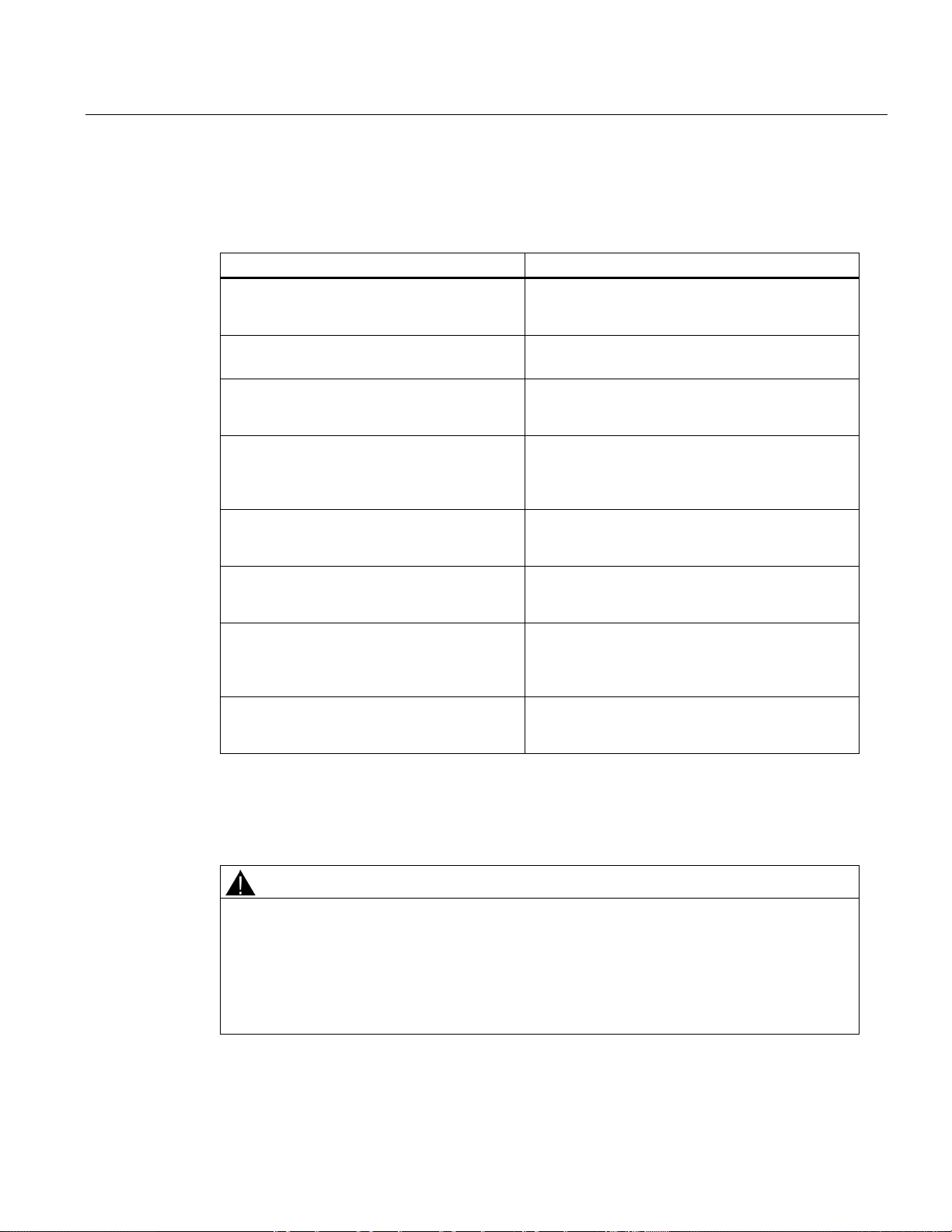

In manual

On product

Description

2.1.2

Laws and directives

2.1.3

FCC Conformity

US Installations only: Federal Communications Commission (FCC) rules

WARNING

This device left the factory in good working condition. In order to maintain this status and to

ensure safe operation of the device, observe these instructions and all the specifications

relevant to safety.

Observe the information and symbols on the device. Do not remove any information or symbols

from the device. Always keep the information and symbols in a completely legible state.

Observe the test certification, provisions and laws applicable in your country during connection,

assembly and operation.

Changes or modifications not expressly approved by Siemens Milltronics could void the

user’s authority to operate the equipment.

(Label on product:

yellow

background.)

WARNING: refer to accompanying documents (manual) for

details.

SITRANS LR250 (FOUNDATION FIELDBUS)

Operating Instructions, 08/2014, A5E32221411-AC

15

Safety information

Note

2.1.4

Conformity with European directives

potentially explosive atmospheres.

2.1 Preconditions for safe use

• This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment.

• This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is

likely to cause harmful interference to radio communications, in which case the user will

be required to correct the interference at his own expense.

The CE marking on the device symbolizes the conformity with the following European directives:

Electromagnetic

compatibility EMC

2004/108/EC

Low voltage directive LVD

2006/95/EC

Atmosphère explosible

ATEX

94/9/EC

Directive of the European Parliament and of the Council on the

approximation of the laws of the Member States relating to

electromagnetic compatibility and repealing Directive

89/336/EEC.

Directive of the European Parliament and of the Council on the

harmonisation of the laws of Member States relating to

electrical equipment designed for use within certain voltage

limits.

Directive of the European Parliament and the Council on the

approximation of the laws of the Member States concerning

equipment and protective systems intended for use in

Radio and

telecommunications terminal

equipment R&TTE

1999/5/EC

The applicable directives can be found in the EC conformity declaration of the specific device.

SITRANS LR250 (FOUNDATION FIELDBUS)

16 Operating Instructions, 08/2014, A5E32221411-AC

Directive of the European Parliament and of the Council on

radio equipment and telecommunications terminal equipment

and the mutual recognition of their conformity.

Safety information

2.1.5

CE Electromagnetic Compatibility (EMC) Conformity

EMC Standard

Title

2.2

Improper device modifications

WARNING

Improper device modifications

2.2 Improper device modifications

This equipment has been tested and found to comply with the following EMC Standards:

CISPR 11:2009 + A1:2010/EN

55011:2009 + A1:2010, CLASS A

EN 61326:2013

(IEC 61326:2012)

EN61000-4-2:2009 Electromagnetic Compatibility (EMC) Part 4-2:

EN61000-4-3:2006 + A1:2008 + A2:2010 Electromagnetic Compatibility (EMC) Part 4-3:

EN61000-4-4:2004 + A1:2010 Electromagnetic Compatibility (EMC) Part 4-4:

EN61000-4-5:2006 Electromagnetic Compatibility (EMC) Part 4-5:

EN61000-4-6:2010 Electromagnetic Compatibility (EMC) Part 4-6:

EN61000-4-8:2010 Electromagnetic Compatibility (EMC) Part 4-8:

Limits and methods of measurements of radio

disturbance characteristics of industrial, scientific,

and medical (ISM) radio-frequency equipment

Electrical Equipment for Measurement, Control and

Laboratory Use – Electromagnetic Compatibility.

Testing and measurement techniques –

Electrostatic discharge immunity test.

Testing and measurement techniques – Radiated,

radio-frequency, electromagnetic field immunity test

2006 + A1:2008 + A2:2010.

Testing and measurement techniques – Electrical

fast transient/burst immunity test.

Testing and measurement techniques – Surge

immunity test.

Testing and measurement techniques – Immunity to

conducted disturbances, induced by radiofrequency fields.

Testing and measurement techniques – Power

frequency magnetic field immunity test.

SITRANS LR250 (FOUNDATION FIELDBUS)

Operating Instructions, 08/2014, A5E32221411-AC

Danger to personnel, system and environment can result from modifications to the device,

particularly in hazardous areas.

• Only carry out modifications that are described in the instructions for the device. Failure

to observe this requirement cancels the manufacturer's warranty and the product

approvals.

17

Safety information

2.3

Requirements for special applications

Note

Operation under special ambient conditions

2.4

Use in hazardous areas

Qualified personnel for hazardous area applications

WARNING

Loss of safety of device with type of protection "Intrinsic safety Ex i"

2.3 Requirements for special applications

Due to the large number of possible applications, each detail of the described device versions

for each possible scenario during commissioning, operation, maintenance or operation in

systems cannot be considered in the instructions. If you need additional information not covered

by these instructions, contact your local Siemens office or company representative.

We highly recommend that you contact your Siemens representative or our application

department before you operate the device under special ambient conditions as can be

encountered in nuclear power plants or when the device is used for research and

development purposes.

Persons who install, connect, commission, operate, and service the device in a hazardous area

must have the following specific qualifications:

● They are authorized, trained or instructed in operating and maintaining devices and systems

according to the safety regulations for electrical circuits, high pressures, aggressive, and

hazardous media.

● They are authorized, trained, or instructed in carrying out work on electrical circuits for

hazardous systems.

● They are trained or instructed in maintenance and use of appropriate safety equipment

according to the pertinent safety regulations.

If the device has already been operated in non-intrinsically safe circuits or the electrical

specifications have not been observed, the safety of the device is no longer ensured for use

in hazardous areas. There is a danger of explosion.

• Connect the device with type of protection "Intrinsic safety" solely to an intrinsically safe

circuit.

• Observe the specifications for the electrical data on the certificate.

SITRANS LR250 (FOUNDATION FIELDBUS)

18 Operating Instructions, 08/2014, A5E32221411-AC

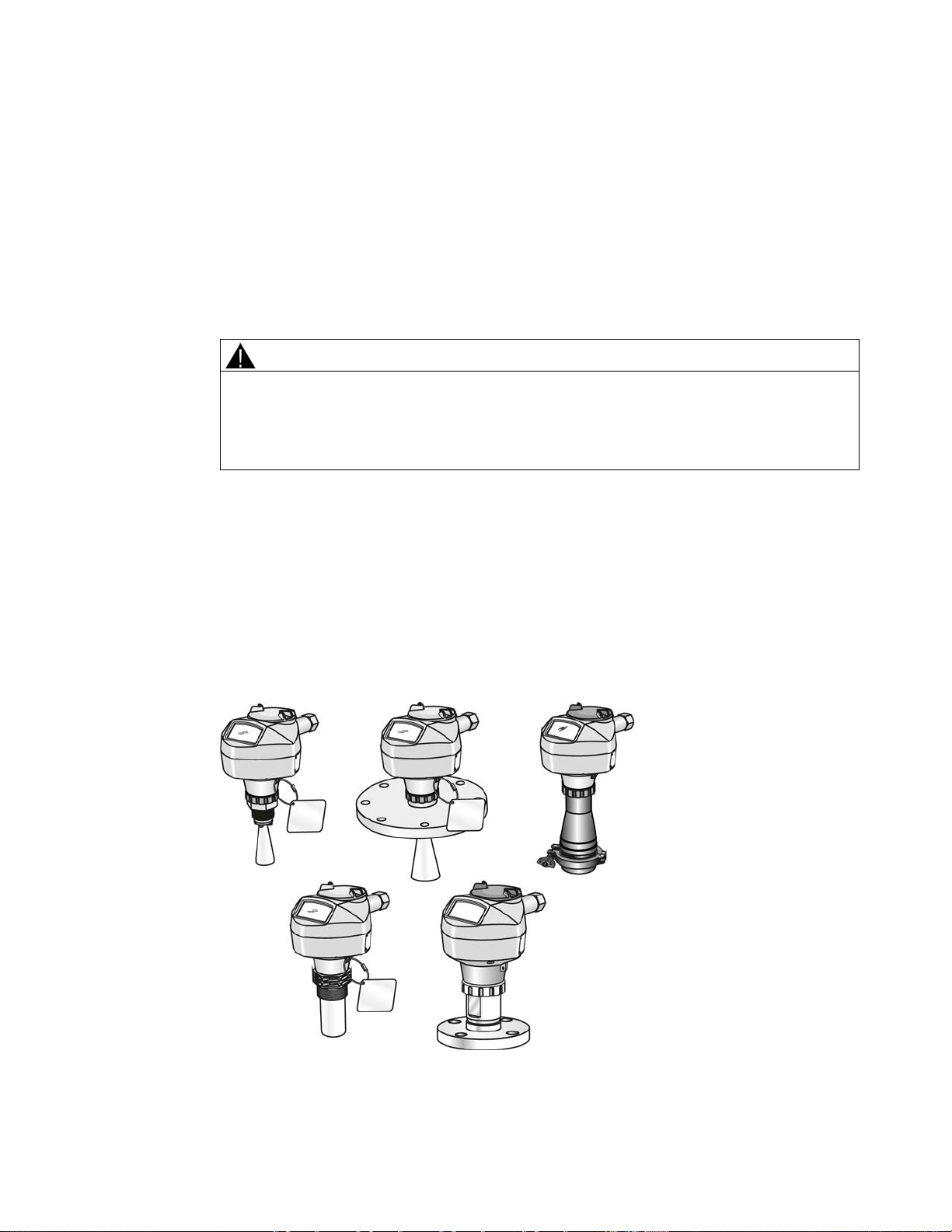

3

3.1

SITRANS LR250 overview

WARNING

Loss of protection

Danger to personnel, system and environment can result from improper use of the device.

• SITRANS LR250 is to be used only in the manner outlined in this manual, otherwise

protection provided by the device may be impaired.

SITRANS LR250 is a 2-wire 25 GHz pulse radar level transmitter for continuous monitoring of

liquids and slurries in storage vessels including high pressure and high temperature, to a range

of 20 meters (66 feet). It is ideal for small vessels, material such as chemicals, food, beverages,

solvents (including those of corrosive or aggressive nature), and low dielectric media.

The device consists of an electronic circuit coupled to an antenna and either a threaded or

flange type process connection.

This device supports Foundation Fieldbus (FF) communication protocol. Signals are processed

using Process Intelligence which has been field proven in over 1,000,000 applications worldwide

(ultrasonic and radar). This device can be configured as an FF (H1) Link Master.

SITRANS LR250 (FOUNDATION FIELDBUS)

Operating Instructions, 08/2014, A5E32221411-AC

19

Description

3.2

Programming

3.3

Applications

3.4

Approvals and certificates

Note

Process Connections

3.2 Programming

This device is very easy to install and configure via a graphical local user interface (LUI). You

can modify the built in parameters either locally via the Siemens infrared handheld programmer,

or from a remote location using one of the following options:

● FF host system

● AMS Device Manager

● liquids and slurries

● bulk storage vessels

● simple process vessels

● corrosive and aggressive

● hygienic/sanitary

For further details see Approvals (Page 219).

SITRANS LR250 is available with approvals for General purpose, sanitary or hygienic and for

hazardous areas. In all cases, check the nameplate on your device, and confirm the approval

rating.

A wide range of process connections and antenna options are available to suit virtually any

vessel configuration.

SITRANS LR250 (FOUNDATION FIELDBUS)

20 Operating Instructions, 08/2014, A5E32221411-AC

4

4.1

Basic safety information

Note

Material compatibility

WARNING

Unsuitable connecting parts

WARNING

Exceeded maximum ambient or process media temperature

WARNING

Open cable inlet or incorrect cable gland

Siemens can provide you with support concerning selection of sensor components wetted by

process media. However, you are responsible for the selection of components. Siemens

accepts no liability for faults or failures resulting from incompatible materials.

Danger of injury or poisoning.

In case of improper mounting hot, toxic and corrosive process media could be released at

the connections.

• Ensure that connecting parts (such as flange gaskets and bolts) are suitable for

connection and process media.

Danger of explosion in hazardous areas.

Device damage.

• Make sure that the maximum permissible ambient and process media temperatures of

the device are not exceeded.

Danger of explosion in hazardous areas.

• Close the cable inlets for the electrical connections. Only use cable glands or plugs

which are approved for the relevant type of protection.

SITRANS LR250 (FOUNDATION FIELDBUS)

Operating Instructions, 08/2014, A5E32221411-AC

21

Installing/mounting

WARNING

Incorrect conduit system

4.1.1

Pressure applications

DANGER

Pressure applications

WARNING

Pressure applications

WARNING

Exceeded maximum permissible operating pressure

4.1 Basic safety information

Danger of explosion in hazardous areas as result of open cable inlet or incorrect conduit

system.

• In the case of a conduit system, mount a spark barrier at a defined distance from the

device input. Observe national regulations and the requirements stated in the relevant

approvals.

Danger to personnel, system and environment will result from improper disassembly.

• Never attempt to loosen, remove, or disassemble process connection while vessel

contents are under pressure.

Danger to personnel, system and environment can result from improper installation.

• Improper installation may result in loss of process pressure.

Danger of injury or poisoning.

The maximum permissible operating pressure depends on the device version. The device

can be damaged if the operating pressure is exceeded. Hot, toxic and corrosive process

media could be released.

• Make sure that the device is suitable for the maximum permissible operating pressure of

your system.

SITRANS LR250 (FOUNDATION FIELDBUS)

22 Operating Instructions, 08/2014, A5E32221411-AC

Installing/mounting

Note

Note

4.1.1.1

Pressure Equipment Directive, PED, 97/23/EC

4.1 Basic safety information

• The process connection tag shall remain with the process pressure boundary assembly.

(The process pressure boundary assembly comprises the components that act as a

barrier against pressure loss from the process vessel: that is, the combination of process

connection body and emitter, but normally excluding the electrical enclosure). In the

event the device package is replaced, the process connection tag shall be transferred to

the replacement unit.

• SITRANS LR250 units are hydrostatically tested, meeting or exceeding the requirement

of the ASME Boiler and Pressure Vessel Code and the European Pressure Equipment

Directive.

• The serial numbers stamped in each process connection body, (flange, threaded, or

sanitary), provide a unique identification number indicating date of manufacture.

Example: MMDDYY – XXX (where MM = month, DD = day, YY = year, and XXX=

sequential unit produced)

• Further markings (space permitting) indicate flange configuration, size, pressure class,

material, and material heat code.

Siemens Level Transmitters with flanged, threaded, or sanitary clamp type process mounts have

no pressure-bearing housing of their own and, therefore, do not come under the Pressure

Equipment Directive as pressure or safety accessories (see EU Commission Guideline 1/8 and

1/20).

SITRANS LR250 (FOUNDATION FIELDBUS)

Operating Instructions, 08/2014, A5E32221411-AC

23

Installing/mounting

4.2

Installation location requirements

WARNING

Aggressive atmospheres

CAUTION

Direct sunlight

4.2 Installation location requirements

Danger to personnel, system and environment can result from unsuitable environment.

• Provide an environment suitable to the housing rating and materials of construction.

Device damage.

The device can overheat or materials become brittle due to UV exposure.

• Protect the device from direct sunlight.

• Make sure that the maximum permissible ambient temperature is not exceeded. Refer

to the information in Chapter "Technical data".

SITRANS LR250 (FOUNDATION FIELDBUS)

24 Operating Instructions, 08/2014, A5E32221411-AC

Installing/mounting

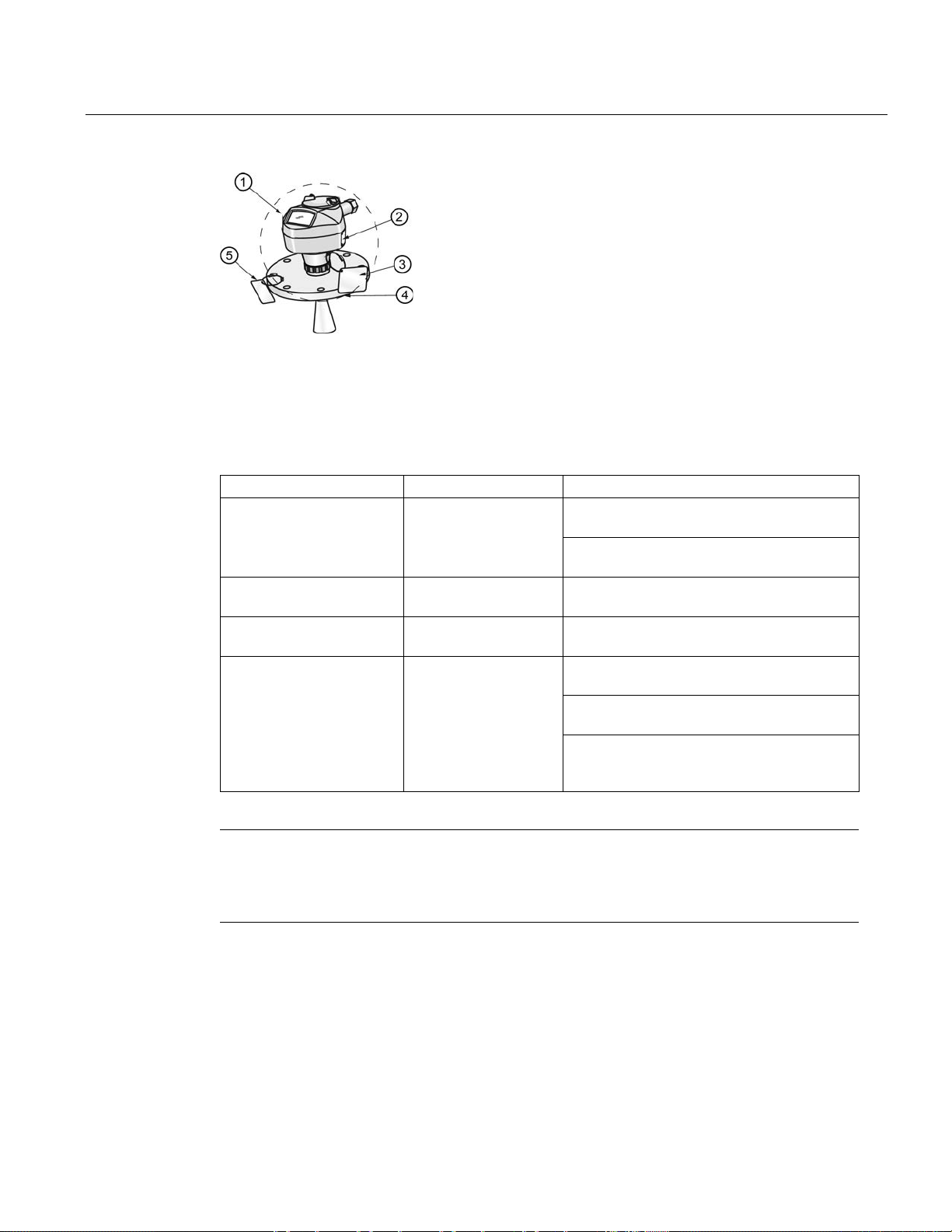

①

②

③

④

⑤

Antenna

①

③

Note

4.2 Installation location requirements

Ambient temperature

Device nameplate

Device tag

Process temperature (at process connection)

Process connection tag (contains process connection related information)

Horn -40 to +80 °C

(-40 to +176 °F)

PVDF -40 to +80 °C

(-40 to +176 °F)

Flanged encapsulated -40 to +80 °C

(-40 to +176 °F)

Hygienic encapsulated -40 to +80 °C

(-40 to +176 °F)

with FKM O-ring:-40 to +200 °C (-40 to

392 °F)

with FFKM O-ring:-20 to +200 °C (-4 to

+392 °F)

-40 to +80 °C

(-40 to +176 °F)

-40 to +170 °C

(-40 to +338 °F)

-40 to +170 °C

(-40 to +338 °F)

with FKM seals used on process connection:

-20 to +170 °C (-4 to +338 °F)

with EPDM seals used on process

connection:

-40 to +120 °C (-40 to +248 °F)

Details about the process connection, process temperature and materials are laser etched

into the body of the flanged and hygienic versions. All other SITRANS LR250 versions have

details listed on a tag.

SITRANS LR250 (FOUNDATION FIELDBUS)

Operating Instructions, 08/2014, A5E32221411-AC

25

Installing/mounting

4.3

Proper mounting

Note

NOTICE

Incorrect mounting

Note

4.3 Proper mounting

• Correct location is key to a successful application.

• Avoid reflective interference from vessel walls and obstructions by following guidelines in

this chapter.

The device can be damaged, destroyed, or its functionality impaired through improper

mounting.

• Before installing ensure there is no visible damage to the device.

• Make sure that process connectors are clean, and suitable gaskets and glands are

used.

• Mount the device using suitable tools. Refer to the information in Installation instructions

(Page 34) for installation torque requirements.

• On devices with a removable head, there is no limit to the number of times a device can

be rotated without damage.

• When mounting, orient the front or back of the device towards the closest vessel wall or

obstruction.

• Do not rotate the enclosure after programming and vessel calibration, otherwise an error

may occur, caused by a polarity shift of the transmit pulse.

SITRANS LR250 (FOUNDATION FIELDBUS)

26 Operating Instructions, 08/2014, A5E32221411-AC

Installing/mounting

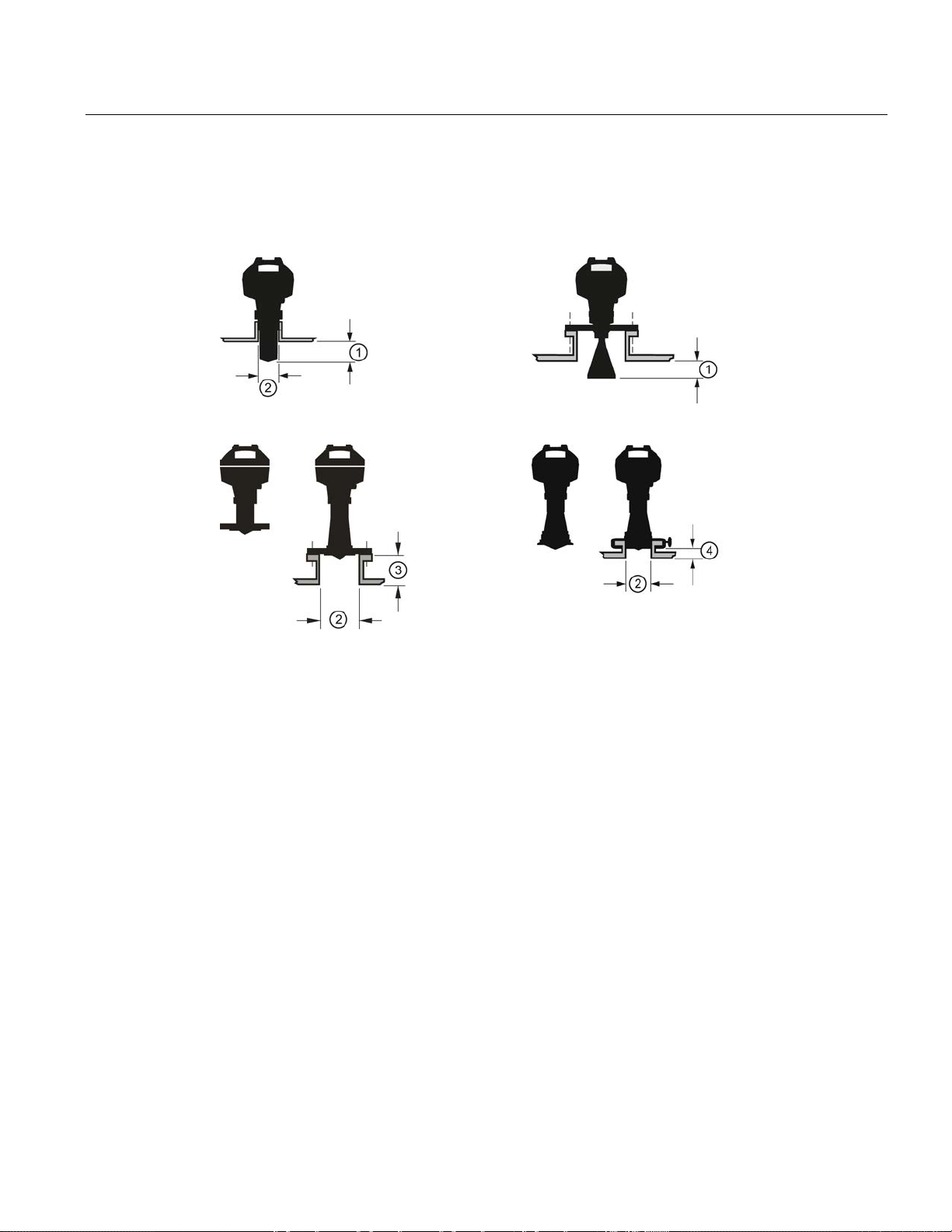

4.3.1

Nozzle design

Threaded PVDF antenna

Stainless steel horn antenna

Flanged encapsulated antenna (FEA)

Hygienic encapsulated antenna (HEA)

4.3 Proper mounting

Minimum clearance: 10 mm (0.4")

①

Minimum diameter: 50 mm (2")

②

Maximum nozzle length

③

Maximum length/diameter ratio 1:1

④

● The end of the antenna must protrude a minimum of 10 mm (0.4") to avoid false echoes

being reflected from the nozzle

● Minimum recommended nozzle diameter for the threaded PVDF antenna is 50 mm (2").

● An antenna extension (100 mm/3.93") is available for the horn antenna only.

1)

.

● The maximum nozzle length for the FEA is 500 mm (19.68") when the nozzle diameter is

DN150 (6"). Only shorter lengths are recommended for smaller diameters.

● When installing the SITRANS LR250 with hygienic process connection, it is good hygienic

practice to install the antenna in a nozzle that has a maximum length/diameter ratio of 1:1.

For example, 2" (DN50) diameter nozzle should be no longer than 2" (50 mm).

● When removing any sanitary/hygienic clamp version of the HEA to clean the lens, ensure it is

re-installed in the exact position it was removed from, to avoid re-commissioning the device.

1)

Not applicable for FEA or HEA

SITRANS LR250 (FOUNDATION FIELDBUS)

Operating Instructions, 08/2014, A5E32221411-AC

27

Installing/mounting

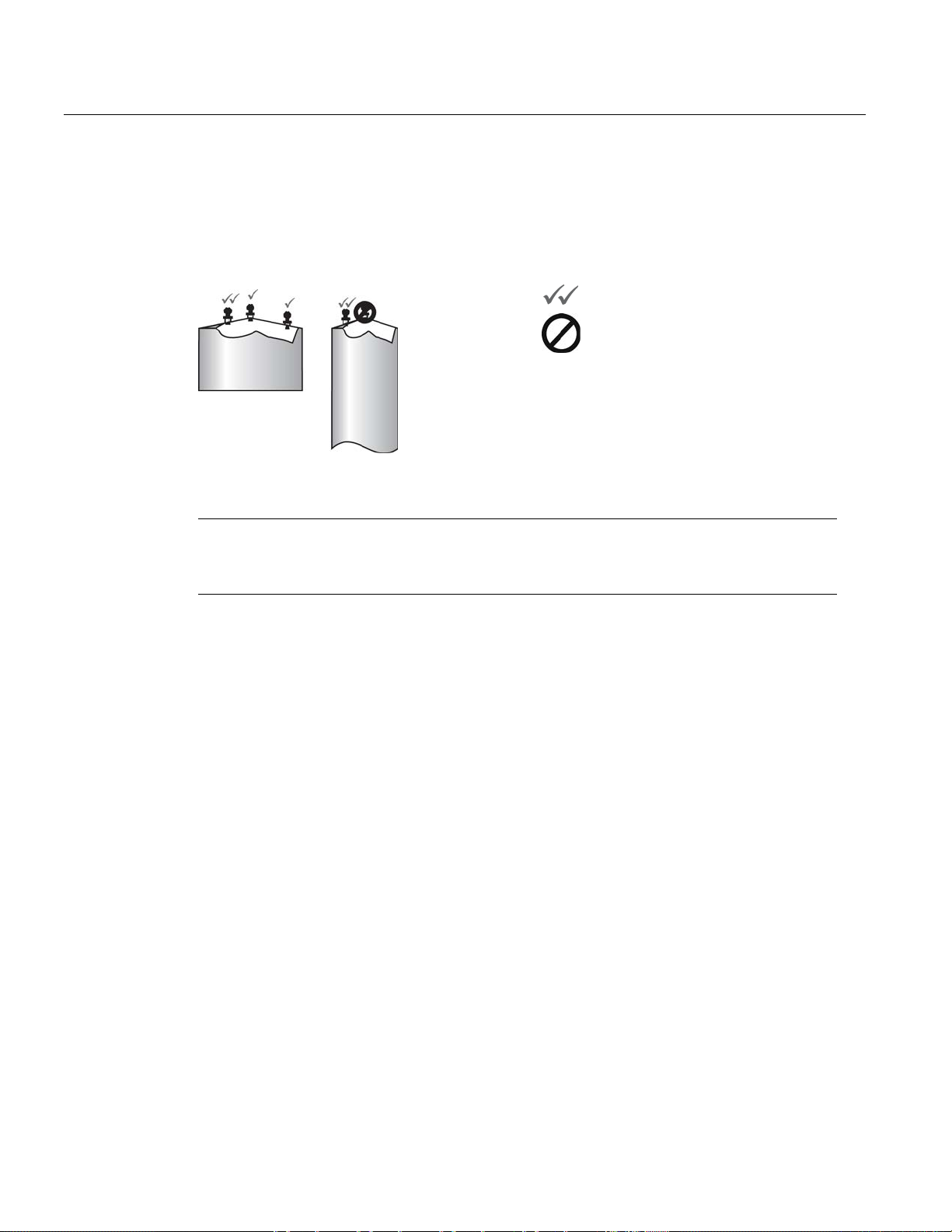

4.3.2

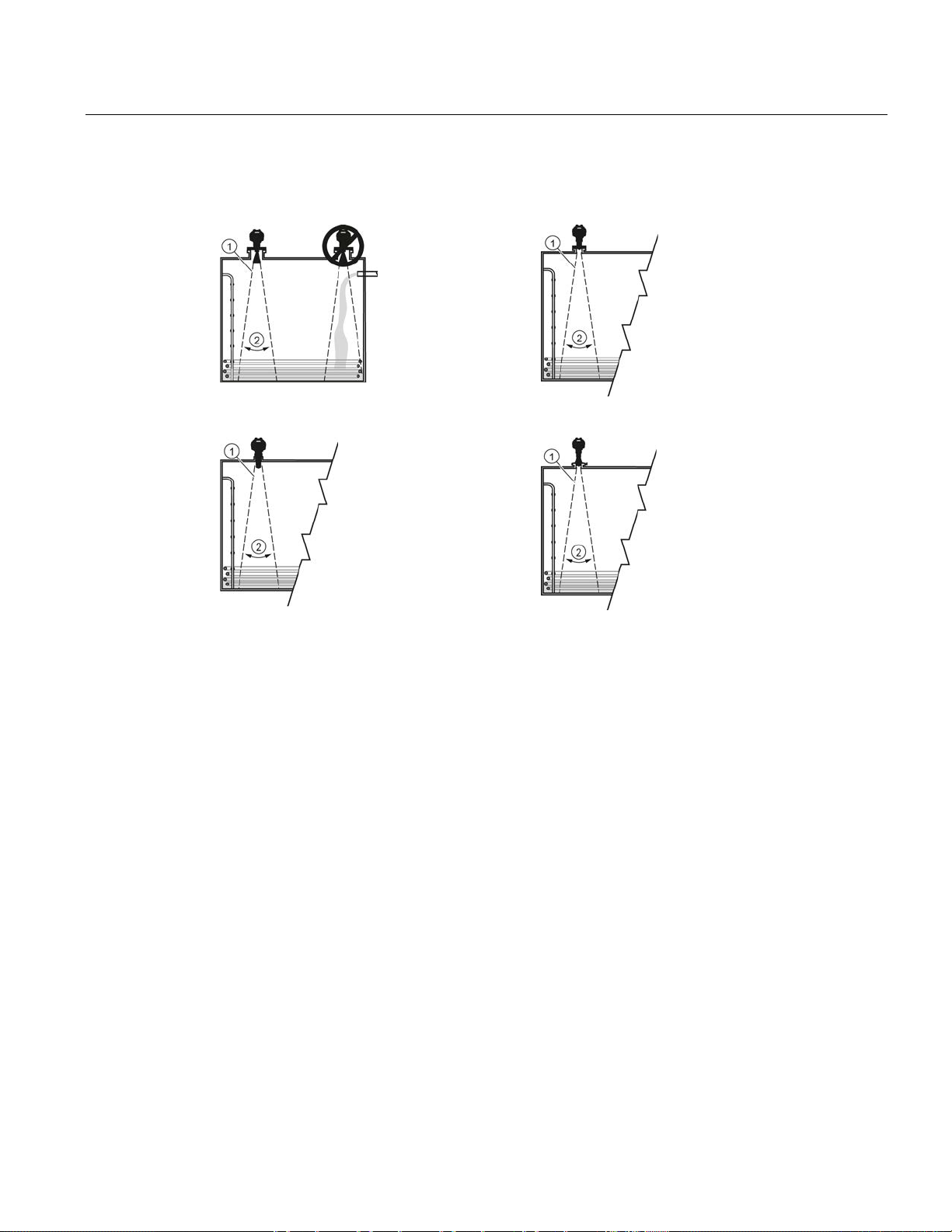

Nozzle location

Beam angle

Note

4.3 Proper mounting

● Avoid central locations on tall, narrow vessels

● Nozzle must be vertical and clear of imperfections

Preferred

Undesirable

• Beam width depends on antenna size and is approximate: see below.

• For details on avoiding false echoes, see Auto False Echo Suppression (Page 271).

● Beam angle is the width of the cone where the energy density is half of the peak energy

density.

● The peak energy density is directly in front of and in line with the antenna.

● There is a signal transmitted outside the beam angle, therefore false targets may be

detected.

SITRANS LR250 (FOUNDATION FIELDBUS)

28 Operating Instructions, 08/2014, A5E32221411-AC

Installing/mounting

Horn antenna

Flanged encapsulated antenna

Threaded PVDF antenna

Hygienic encapsulated antenna

4.3 Proper mounting

①

②

Emission cone

Beam angle

SITRANS LR250 (FOUNDATION FIELDBUS)

Operating Instructions, 08/2014, A5E32221411-AC

29

Installing/mounting

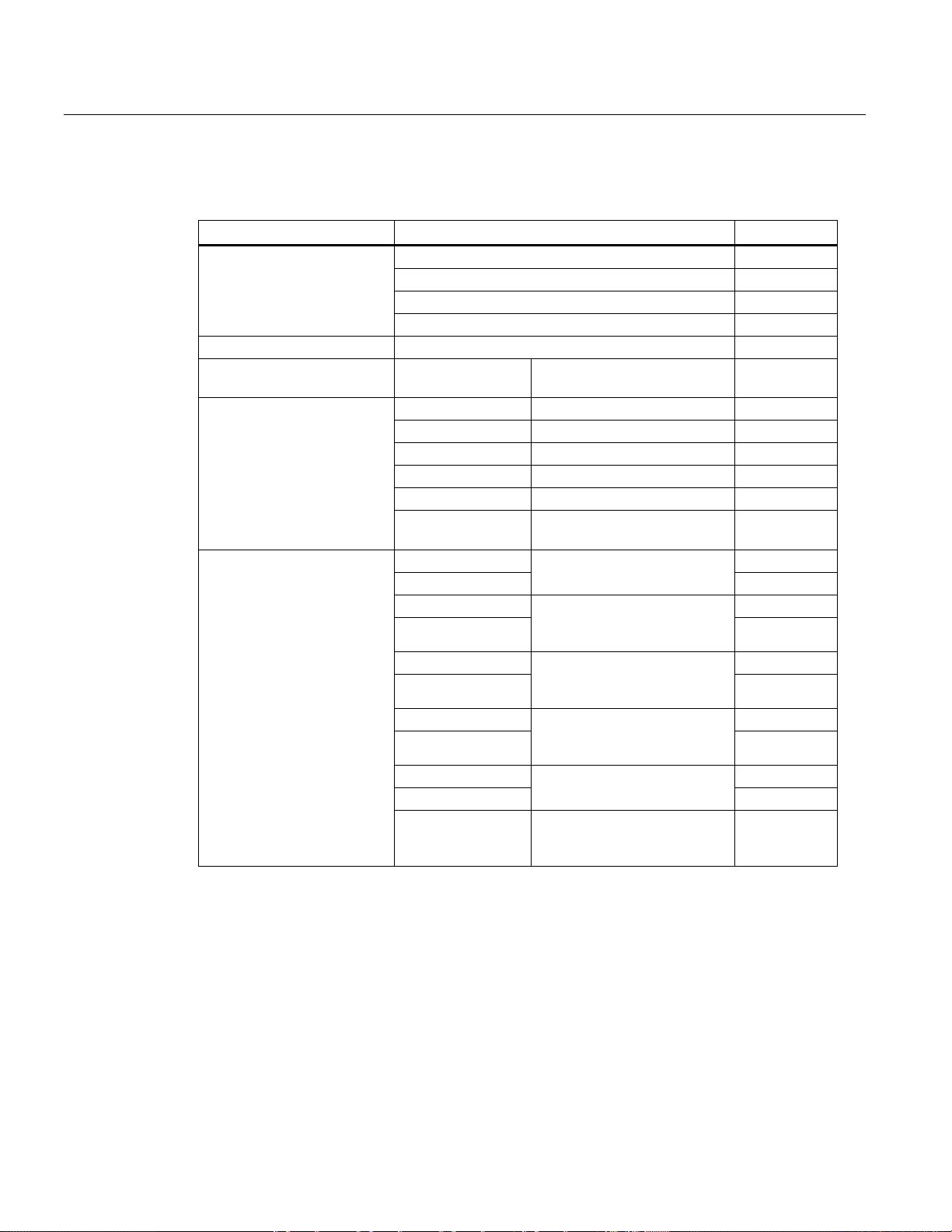

Emission cone type and beam angle

Antenna type

Antenna size

Beam angle

Process connection

size

Process connection type

Emission cone

Access for programming

4.3 Proper mounting

Horn 1.5" 19°

2" 15°

3" 10°

4" 8°

Threaded PVDF 19°

Flanged encapsulated 2" Class 150 ASME B16.5 12.8°

3, 4, 6" Class 150 ASME B16.5 9.6°

50A 10K JIS B 2220 12.8°

80A/100A/150A 10K JIS B 2220 9.6°

DN50 PN10/16 EN1092-1 12.8°

DN80/DN100/DN150 PN10/16 EN1092-1 9.6°

Hygienic encapsulated 2" Sanitary Clamp according to

3, 4" 9.6°

DN50 Aseptic/Hygienic nozzle/slotted

DN80/DN100 9.6°

DN50 Aseptic/Hygienic flanged

DN80/DN100 9.6°

DN50 Aseptic/Hygienic Clamp

DN80/DN100 9.6°

DN50 Hygienic nozzle/slotted nut

DN80/DN100 9.6°

Type F (50 mm)

and Type N

(68 mm)

ISO 2852

nut according to DIN 11864-1

[Form A]

according to DIN 11864-2

[Form A]

according to DIN 118643 [Form A]

according to DIN 11851

Tuchenhagen Varivent 12.8°

12.8°

12.8°

12.8°

12.8°

12.8°

● Keep emission cone free of interference from obstructions such as ladders, pipes, I-beams,

or filling streams.

● Provide easy access for viewing the display and programming via the handheld programmer.

SITRANS LR250 (FOUNDATION FIELDBUS)

30 Operating Instructions, 08/2014, A5E32221411-AC

Loading...

Loading...