Siemens SITRANS LPS200 Operating Instructions Manual

Rotating Paddle Switch

SITRANS LPS200

Operating Instructions 08/2012

SITRANS

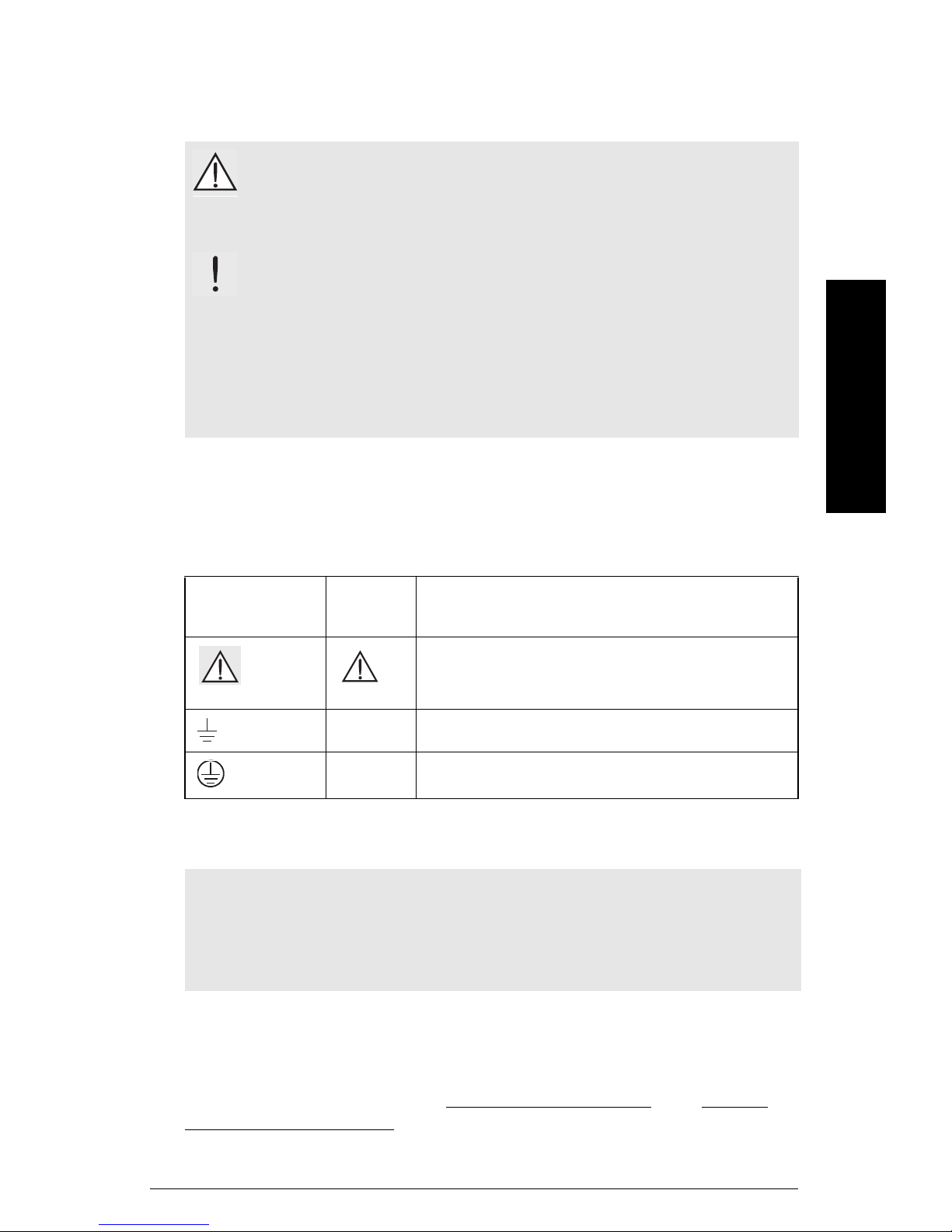

Safety Notes

Special attention must be paid to warnings and notes highlighted from the rest of the text

by grey boxes.

WARNING: relates to a caution symbol on the product, and means

that failure to observe the necessary precautions can result in

death, serious injury, and/or considerable material damage.

English

mmmmm

WARNING

1

: means that failure to observe the necessary

precautions can result in death, serious injury, and/or considerable

material damage.

CAUTION: means that failure to observe the necessary precautions can

result in considerable material damage.

Note:

manual.

1.

means important information about the product or that part of the operating

This symbol is used when there is no corresponding caution symbol on the

product.

Safety marking symbols

In

manual

On

Product

Description

(Label on product: yellow background.)

Caution: refer to accompanying documents (manual) for details.

Earth (ground) Terminal

Protective Conductor Terminal

The Manual

Notes:

• Please follow the installation and operating procedures for a quick, trouble-free

installation and to ensure the maximum accuracy and reliability of your SITRANS LPS200.

• This manual applies to SITRANS LPS200 only.

This manual will help you set up your SITRANS LPS200 for optimum performance. We

always welcome suggestions and comments about manual content, design, and

accessibility.

Please direct your comments to techpubs.smpi@siemens.com

Siemens Milltronics manuals, go to www.siemens.com/processautomation

. For the complete library of

.

7ML19985FS62 SITRANS LPS200 – OPERATING INSTRUCTIONS Page EN-1

mmmmm

SITRANS LPS200 Introduction

Notes

• Installation, maintenance, and commissioning must be performed by qualified

English

SITRANS LPS200 Features

technical personnel.

• SITRANS LPS200 must be used only in the manner outlined in this instruction

manual.

• This product is intended for use in industrial areas. Operation of this equipment in a

residential area may cause interference to several frequency based

communications.

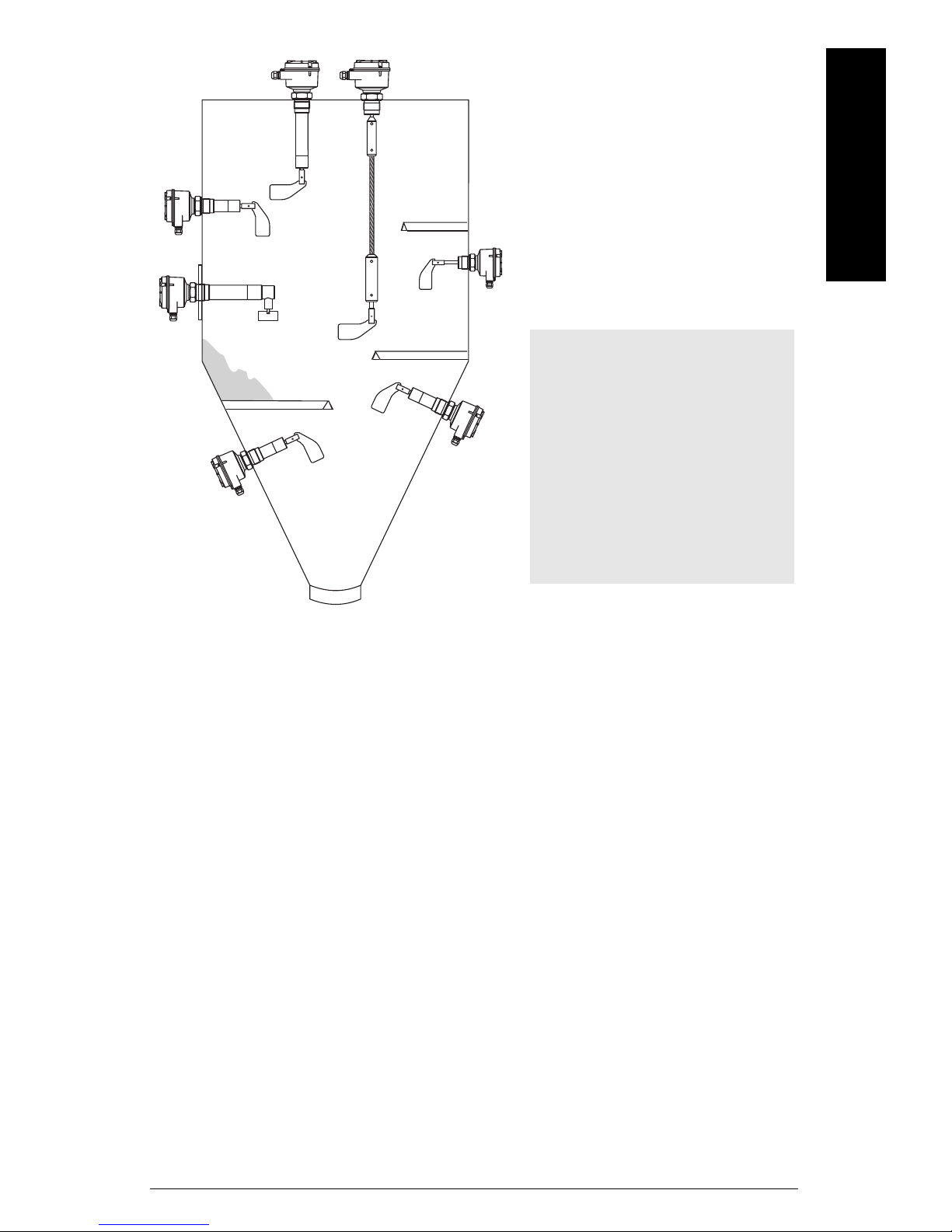

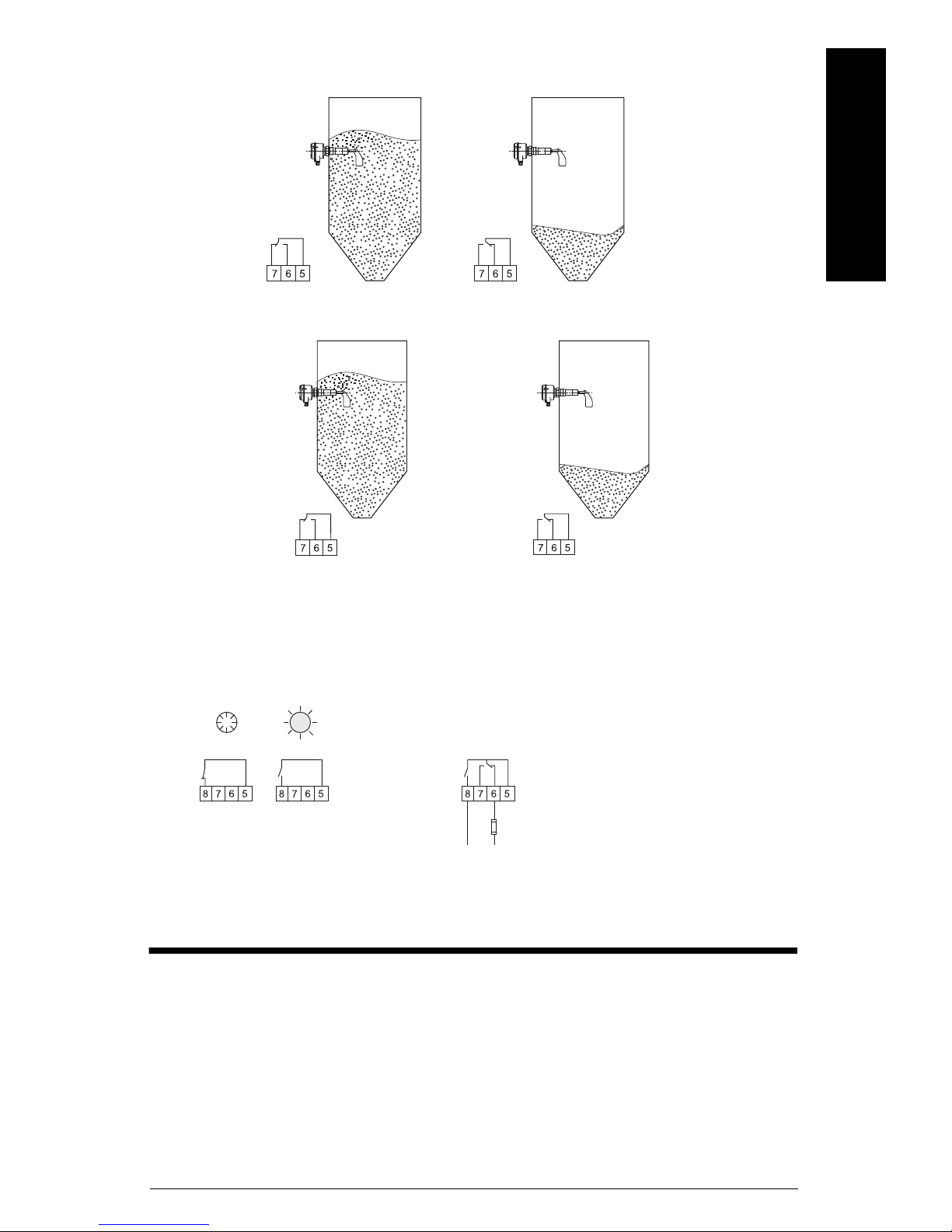

The SITRANS LPS200 rotating paddle switch is used for level monitoring of bulk

materials. It can be used to detect full, demand, or empty conditions in silos, hoppers, or

storage vessels of materials such as grain, feed, cement, plastic granulate, and wood

chips. The paddle switch measures bulk densities as low as 100 g/l (6.2 lb/ft

standard measuring vane, 35 g/l (2.2 lb/ft3) with the optional hinged vane, or 15 g/l

(0.9 lb/ft3) with the optional rectangular vane.

• High integrity mechanical seal

• AC, DC, or switch-selectable power supply

• Unique friction clutch mechanism. When the measuring vane encounters sudden

resistance, the friction clutch slips to prevent internal component damage.

• Optional fail-safe function alarms on fault conditions or component failure

• Rotatable enclosure

• Optional vanes for use with high and low bulk densities to 15 g/l (0.9 lb/ft

• Compact, rigid extension (top mounted only), angled rigid extension, and cable

extension configurations available

• High temperature and high pressure models available

• Optional extension kit available for the compact version

3

) with the

3

)

SITRANS LPS200 Applications

• Grain, feed, cement, plastic granulate, wood chips, rice, soybeans, etc.

• Low or high bulk density materials

Principle of Operation

A low revolution gearing motor drives a rotating measuring vane. When material reaches

the rotating vane, rotation stops, actuating a microswitch contact closure. When the

vane is no longer covered, rotation resumes and the microswitch reverts to its normal

condition.

The synchronous induction motor is freely suspended within the housing. When the

rotation is slowed by the material, the reaction torque is used to operate a micro-switch

that gives an electrical signal to stop the motor. When the material level moves away

from the rotating vane, a spring draws the motor back into operating position, the

microswitch returns to operating position, and the motor is switched back on.

Two motor speeds are available: 1 rpm, for storage silos

Page EN-2 SITRANS LPS200 – OPERATING INSTRUCTIONS 7ML19985FS62

5 rpm, for faster process requirements

Specifications

Note: Siemens Milltronics makes every attempt to ensure the accuracy of these

specifications but reserves the right to change them at any time.

Power

• 115 V AC, 50 to 60 Hz, 4 VA

• 230 V AC, 50 Hz, 6 VA

• 24 or 48 V AC

• 24 V DC, 2.5 W

All voltages ± 15 % (including ± 10 % according to IEC 61010-1)

Performance

Alarm delay

• 1 rpm model (storage applications) approx. 1.3 s

• 5 rpm model (process applications) approx. 0.26 s

Sensitivity

• adjustable spring tension position

• optional measuring vanes available, depending on customer sensitivity

requirements

English

mmmmm

Approximate minimum material density

Standard measuring vane

• 100 g/l (6.2 lb/ft

• 200 g/l (12.5 lb/ft

Hinged measuring vane

• 35 g/l (2.2 lb/ft

• 70 g/l (4.4 lb/ft

Rectangular measuring vane (98 x 250 mm)

• 15 g/l (0.9 lb/ft

• 20 g/l (1.2 lb/ft

• See “Measuring Vanes” on page 10 for more information.

3

) when vane is covered by 10 cm (4") of material

3

) when vane is covered by more than 10 cm (4") of material

3

) when vane is covered by 10 cm (4") of material

3

) when vane is covered by more than 10 cm (4") of material

3

) when vane is covered by 10 cm (4") of material

3

) when vane is covered by more than 10 cm (4") of material

Alarm Output

• microswitch SPDT or DPDT contact 5 A at 250 VAC, non-inductive

microswitch SPDT or DPDT contact 4 A at 30 V DC, non-inductive

7ML19985FS62 SITRANS LPS200 – OPERATING INSTRUCTIONS Page EN-3

mmmmm

Mechanical

English

Process Connections

• threaded connection 1", 1¼”, 1½" NPT or 1", 1¼”, 1½" BSP

• material: stainless steel 303 (1.4305) or 316L

(1.4404), optional aluminum

• flanged connection DN 32 PN 6, DN 100 PN 6, DN 100 PN 16,

2", 3", 4" ASME, 150 lb, B 16.5 (1.4541/321)

• Tri-clamp 2" DN50 ISO 2852

Enclosure

• construction epoxy coated aluminum

• conduit entry 2 x M20 x 1.5, or

2 x ½” NPT

• ingress protection Type 4X/NEMA 4X/IP66

• vane and shaft construction stainless steel 304 and 303 (1.4301 and 1.4305)

or 316L (1.4404)

Weight

Standard temperature:

• compact 1.8 kg (4.0 lb)

• extended 2.2 kg (4.9 lb)

• angled extended 4.0 kg (8.8 lb)

• cable 3.2 kg (7.1 lb)

High temperature:

• compact 2.6 kg (5.7 lb)

• extended 3.0 kg (6.6 lb)

• angled extended 5.2 kg (11.4 lb)

• cable 4.0 kg (8.8 lb)

Environmental

• location indoor/outdoor

• altitude max. 2000 m (6562 ft)

• ambient temperature –25 to +60 °C (–13 to +140 °F)

• relative humidity 0 to 100 %, suitable for outdoor (ingress

• Installation category III

• Pollution degree 2

protection: Type 4X/NEMA 4X/IP66)

Note: With the heated enclosure option, the ambient temperature rating improves to

–40 to +60 °C (–40 to +140 °F).

Page EN-4 SITRANS LPS200 – OPERATING INSTRUCTIONS 7ML19985FS62

Process

Temperature

Standard model:

• –25 to +80 °C (–13 to +176 °F)

• CSA temperature code: T5

• maximum surface temperature +120 ºC (+248 ºF) [ATEX relevant]

High temperature option:

• CE and General Purpose –25 to +600 °C (–13 to +1112 °F)

• FM/ATEX Hazardous –25 to +250 °C (–13 to +482 °F)

• CSA Class II Group E, F –25 to +195 °C (–13 to +383 °F), CSA

temperature code: T2D

• CSA Class II Group G –25 to +160 °C (–13 to +320 °F), CSA

temperature code: T3B

• maximum surface temperature +220 ºC (+428 ºF) [ATEX relevant]

Pressure

• standard model max. 0.8 bar, gauge (11.6 psi, gauge)

• high pressure options max. 5 bar, gauge (72.5 psi, gauge)

max. 10 bar, gauge (145 psi, gauge)

Note: The device construction allows over-pressure between –0.2 and 0.1 bar in

hazardous areas.

English

mmmmm

WARNINGS:

• This product is designated as a Pressure Accessory per Directive

97 / 23 / EC, and is not

intended for use as a safety device.

• Materials of construction are chosen based on their chemical

compatibility (or inertness) for general purposes. For exposure to

specific environments, check with chemical compatibility charts

before installing.

Approvals

• FM/CSA Class II, Div. 1, Group E, F, G, Class III

• ATEX II 1/2 D (dust explosion)

• IECEx t IIIC Da/Db

•CE

•C-TICK

•FM/

CSA

C

(see product nameplate for approval details)

General Purpose

USA

7ML19985FS62 SITRANS LPS200 – OPERATING INSTRUCTIONS Page EN-5

mmmmm

Installation

Mounting

English

Notes:

• Installation shall be performed by qualified personnel and in accordance with local

governing regulations.

• For heavy material, only top mounting of paddle switch is recommended.

• Compact SITRANS LPS200 is recommended for side mounting on bins for low or

intermediate levels.

• For SITRANS LPS200 Cable extension, the maximum pull force of the rope must not

exceed 4 kN (28 kN with reinforced option).

• When installing LPS200 with rigid extension kit, ensure product is top mounted and

never side or angle mounted.

WARNINGS:

• This product is designated as a Pressure Accessory per

Directive 97/23/EC, and is not

• Improper installation may result in loss of process pressure.

intended for use as a safety device.

SITRANS LPS200 is normally mounted into the vessel top (full detector) or through the

tank wall at the detection level (full, demand or empty detector). SITRANS LPS200 can be

installed through a standard 1¼" NPT or 1½" BSPT pipe coupling, depending on the

chosen process thread.

Page EN-6 SITRANS LPS200 – OPERATING INSTRUCTIONS 7ML19985FS62

English

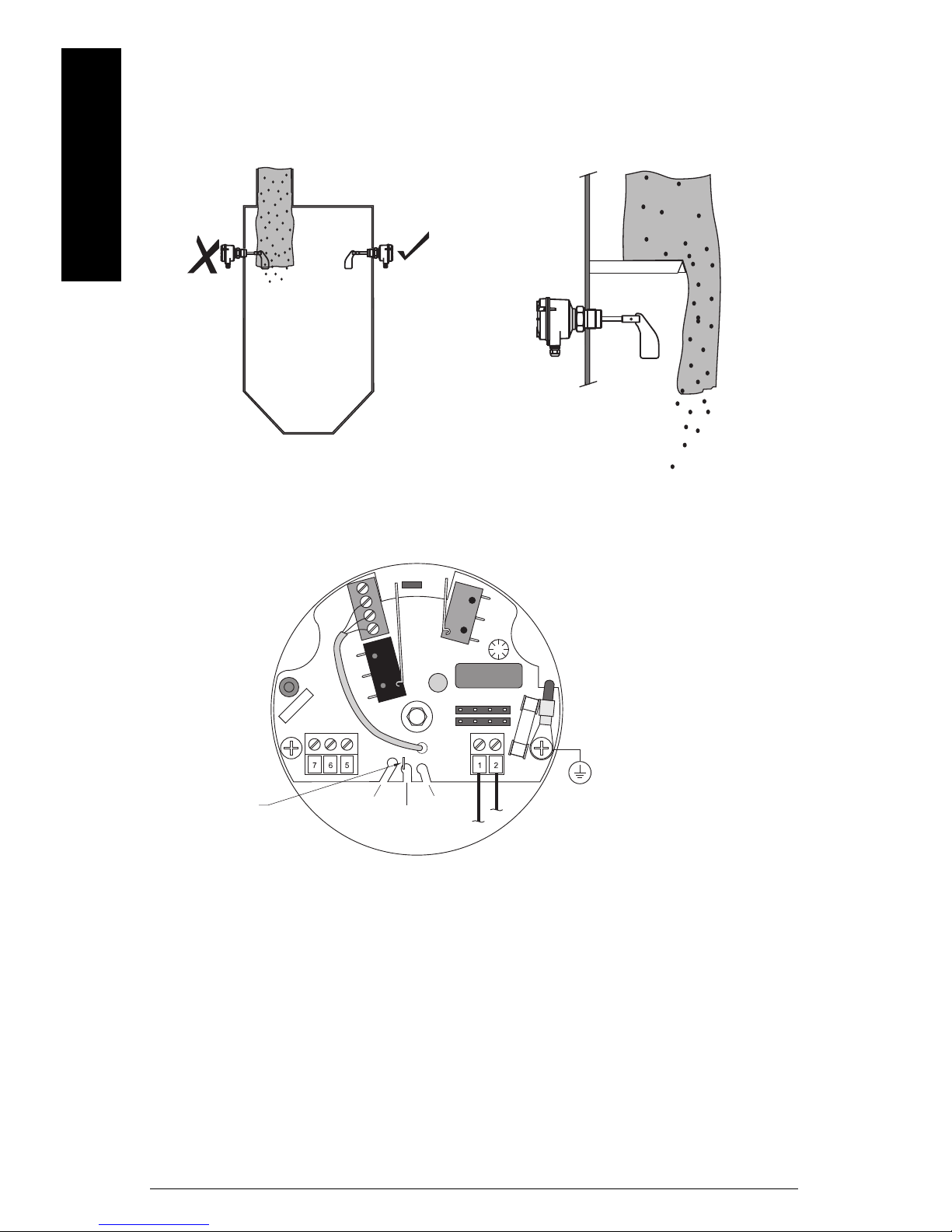

After mounting and as a precaution

against water ingress into the

housing, turn the housing clockwise

until the cable entries point

downward.

Notes:

• Ensure measuring vane is out of

any region that is susceptible to

build-up.

• For heavy material loads and

protection against falling

material, provide angled

protection.

• Ensure cable gland faces

downward to avoid water

intrusion.

mmmmm

7ML19985FS62 SITRANS LPS200 – OPERATING INSTRUCTIONS Page EN-7

mmmmm

Caution: Keep SITRANS LPS200

out of path of falling material.

Caution: Protect shaft and

measuring vane from falling

material.

sensitivity

spring

low

medium

high

AC (SPDT relay) version shown

Process Cautions

English

Sensitivity

To adjust the sensitivity of SITRANS LPS200, use pliers to move the sensitivity spring to

the appropriate position (factory setting is medium). The optional measuring vanes can

also improve sensitivity.

Page EN-8 SITRANS LPS200 – OPERATING INSTRUCTIONS 7ML19985FS62

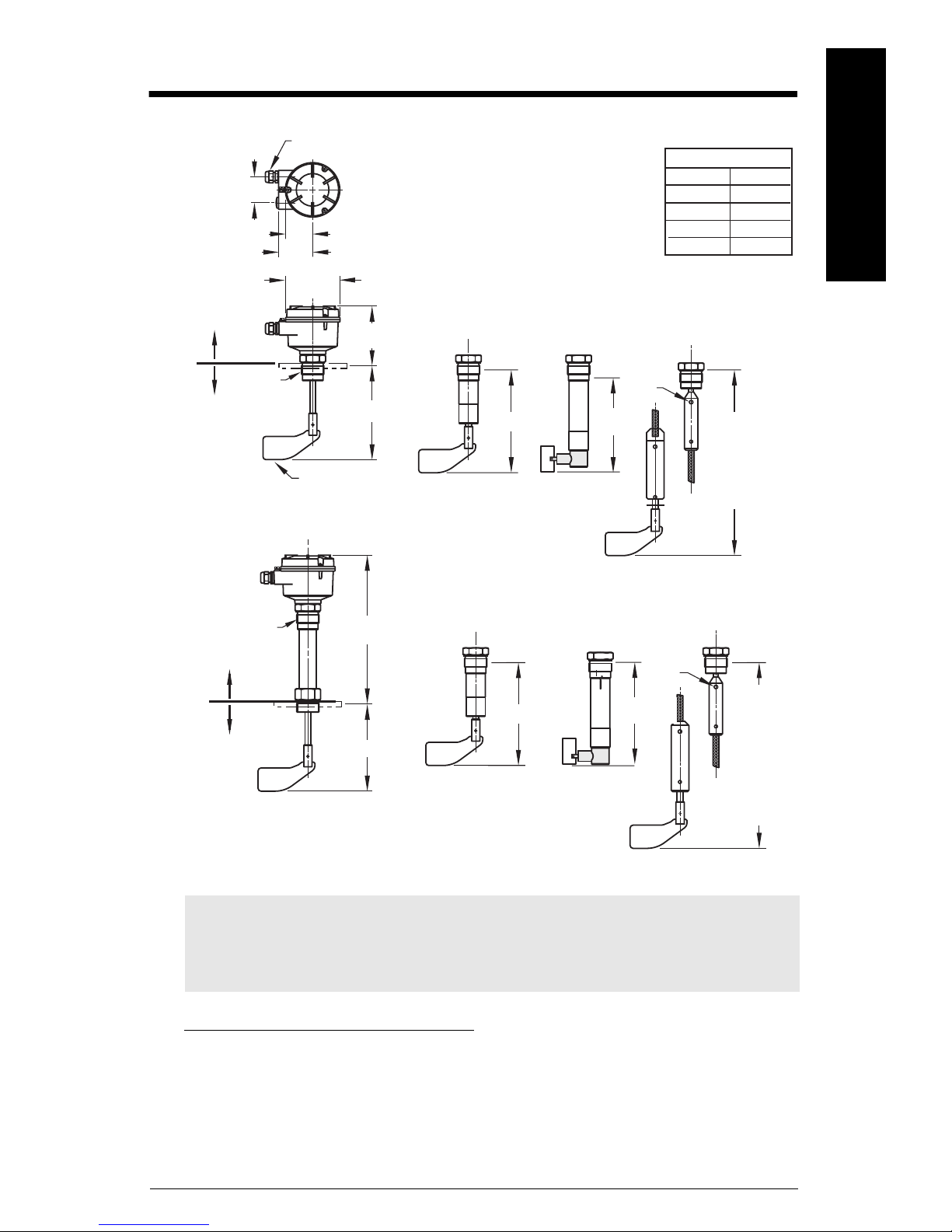

Dimensions and Temperature Ranges

L = Length

150 mm

5.91"

200 mm

250 mm

300 mm

7.87"

9.84"

11.81"

100 mm

3.94"

60 mm (2.36")

75 mm (2.95")

60 mm (2.36")

BSP: 20.5 mm (0.81")

NPT: 24 mm (0.94")

measuring vane

rope

fixing

conduit connection M20 or ½” NPT

123 mm (4.84")

120 mm

(4.72")

A

2)

rope

fixing

Zone 21 (ATEX

Category 2D

IECEx EPL Db)

Zone 20 (ATEX

Category 1D

IECEx EPL Db)

High Temperature Model: compact version

2000 mm

(78.74")

standard,

can be

shortened

by the

customer,

total length

available

10000 mm

(393.7")

2000 mm

(78.74")

standard: can

be shortened

by the

customer

process

temperature

–25 to +80 oC

(–13 to +176 oF)

ambient

temperature:

–25 to +60 oC

(–13 to +140 oF)

process

temperature

3)

–25 to +250 °C

(–13 to +482 °F)

extended angle extension rope option

ambient

temperature:

–25 to +60 oC

(–13 to +140 oF)

125 to 300 mm

(4.92 to 8.46")

125 to 300 mm

(4.92 to 8.46")

thread length:

L

1)

L

1)

L

1)

L

1)

optional

process

range

thread length:

BSP: 20.5 mm (0.81")

NPT: 24 mm (0.94")

extended angle extension rope option

Zone 21 (ATEX

Category 2D

IECEx EPL Db)

Zone 20 (ATEX

Category 1D

IECEx EPL Db)

Standard Model: compact version

1) 2) 3)

English

mmmmm

Notes:

• For heavy material, only top mounting of paddle switch is recommended.

• Compact LPS200 is recommended for side mounting on bins for low or intermediate

material levels.

1)

For 35 x 106 mm boot-shaped, and 65 x 210 mm hinged measuring vanes, add 16 mm (0.63")

to extension length.

2)

A = 200 mm (7.87") for 250 ºC (482 ºF);

= 400 mm (15.74") for 600 ºC (1112 ºF);

3)

For use with all approval options except CSA Class II. See “Temperature” on page 5 for

more details.

7ML19985FS62 SITRANS LPS200 – OPERATING INSTRUCTIONS Page EN-9

mmmmm

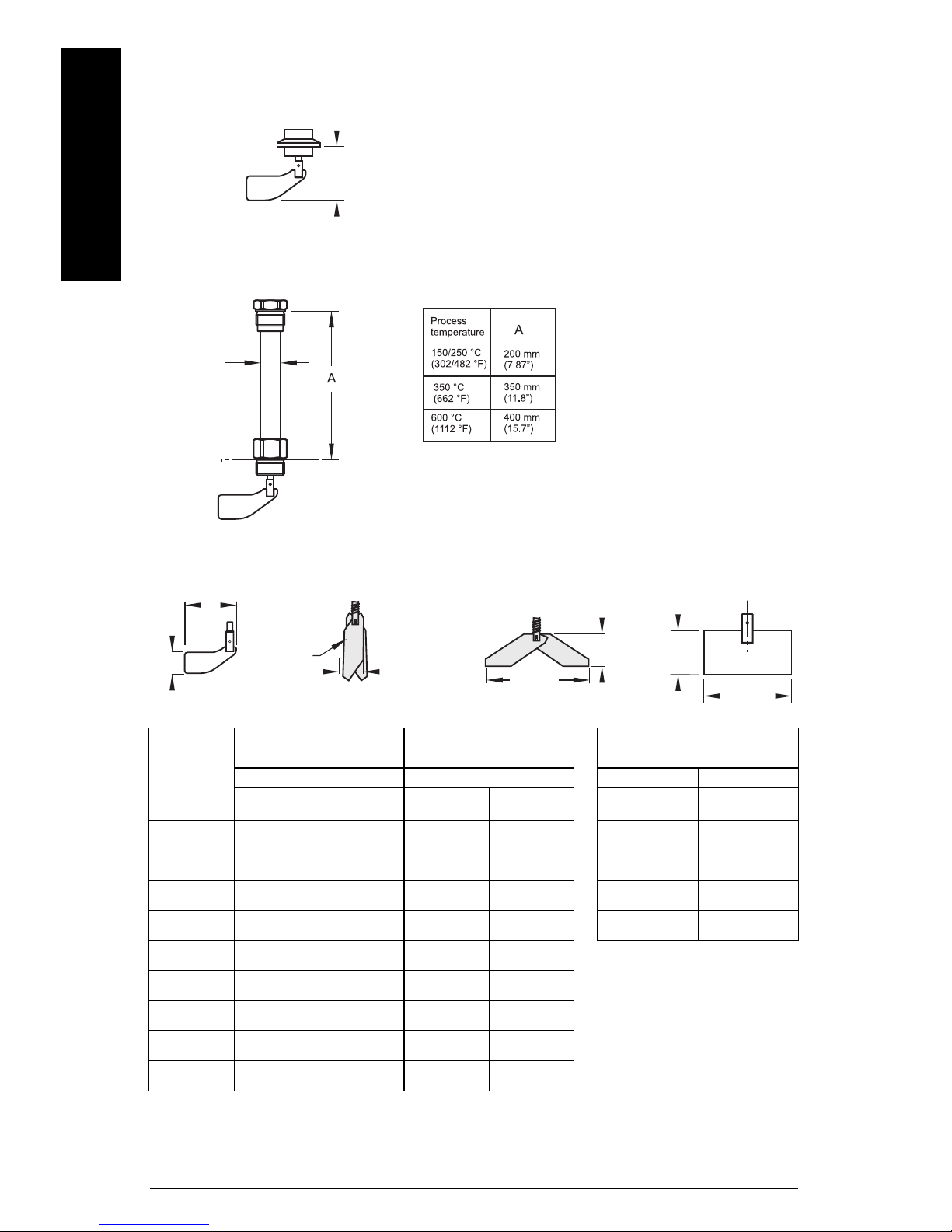

Standard Model: Triclamp

70 to 1500 mm

(2.76 to 59")

High Temperature Model: Temperature Extended Shaft

ø33 mm

(ø1.3")

fold together

to lead into

mounting hole

min. 37 mm

(1.46")

210 mm

(8.27")

65 mm

(2.56")

35 mm

(1.38")

106 mm

(4.17")

Hinged

Rectangular

A

B

Standard

Extensions

English

Measuring Vanes

Vane completely covered

with bulk material

Van e

boot shaped

35 x 106 mm

boot shaped

28 x 98 mm

rectangular

50 x 98 mm

rectangular

50 x 150 mm

rectangular

50 x 250 mm

rectangular

98 x 150 mm

rectangular

98 x 250 mm

hinged

65x 210 mm

hinged

60 x 200 mm

Spring Adjustment Spring Adjustment A B

Light Central

(factory setting)

200 g/l

(12.5 lb/ft³)

300 g/l

(18.7 lb/ft³)

300 g/l

(18.7 lb/ft³)

80 g/l

(5.0 lb/ft³)

30 g/l

(1.9 lb/ft³)

30 g/l

(1.9 lb/ft³)

20 g/l

(1.2 lb/ft³)

70 g/l

(4.4 lb/ft³)

70 g/l

(4.4 lb/ft³)

300 g/l

(18.7 lb/ft³)

500 g/l

(31.2 lb/ft³)

500 g/l

(31.2 lb/ft³)

120 g/l

(7.5 lb/ft³)

50 g/l

(3.1 lb/ft³)

50 g/l

(3.1 lb/ft³)

30 g/l

(1.9 lb/ft³)

100 g/l

(6.2 lb/ft³)

100 g/l

(6.2 lb/ft³)

Bulk material covers the

vane up to 10 cm (3.93")

(6.2 lb/ft³)

(9.4 lb/ft³)

(9.4 lb/ft³)

(2.5 lb/ft³)

(0.9 lb/ft³)

(0.9 lb/ft³)

(0.9 lb/ft³)

(2.2 lb/ft³)

(2.2 lb/ft³)

Light Central

(factory setting)

100 g/l

150 g/l

150 g/l

40 g/l

15 g/l

15 g/l

15 g/l

35 g/l

35 g/l

150 g/l

(9.4 lb/ft³)

150 g/l

(9.4 lb/ft³)

250 g/l

(15.6 lb/ft³)

60 g/l

(3.7 lb/ft³)

25 g/l

(1.6 lb/ft³)

25 g/l

(1.6 lb/ft³)

15 g/l

(0.9 lb/ft³)

50 g/l

(3.1 lb/ft³)

50 g/l

(3.1 lb/ft³)

Rectangular vane options

50 mm (1.97") 98 mm (3.86")

50 mm (1.97") 150 mm (5.90")

50 mm (1.97") 250 mm (9.84")

98 mm (3.86") 150 mm (5.90")

98 mm (3.86") 250 mm (9.84")

Page EN-10 SITRANS LPS200 – OPERATING INSTRUCTIONS 7ML19985FS62

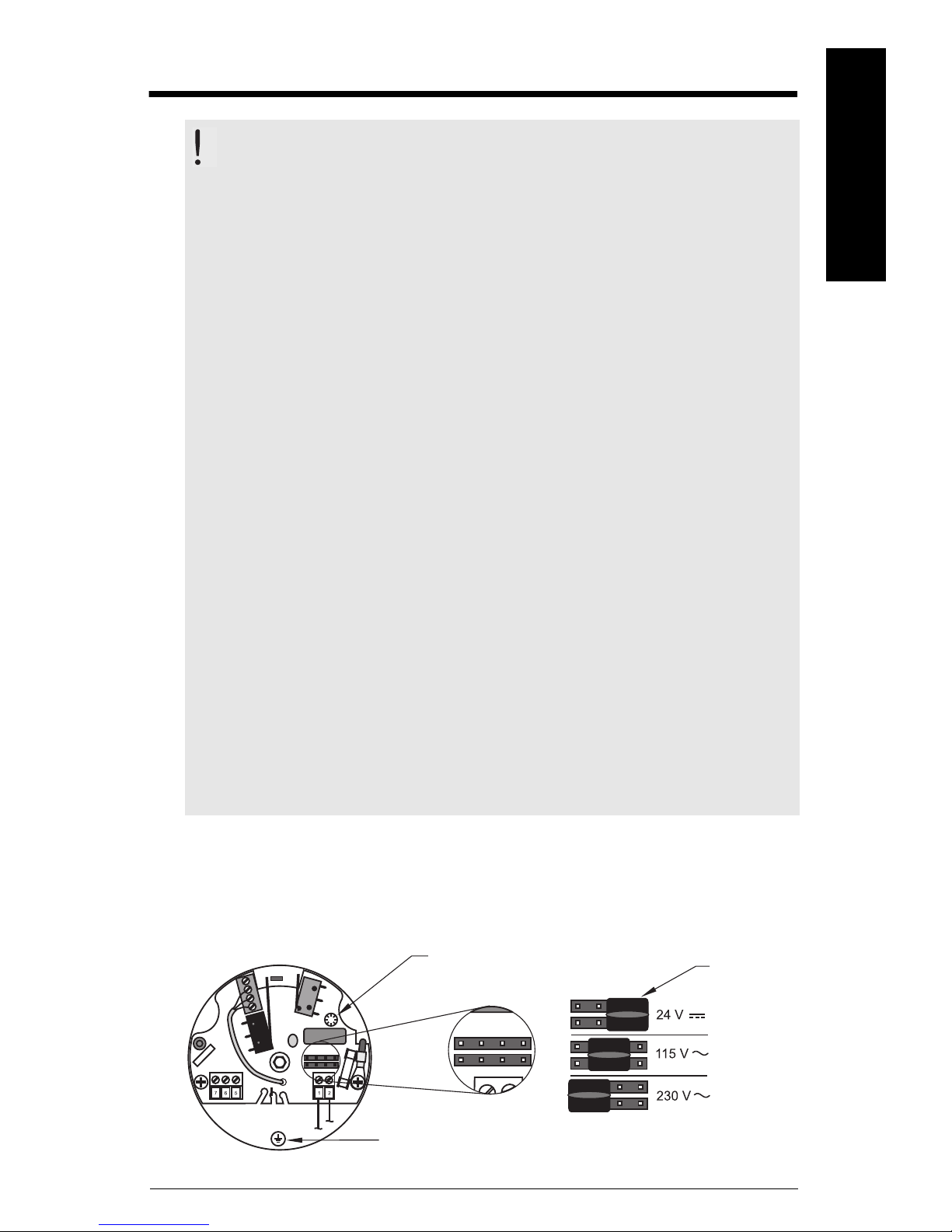

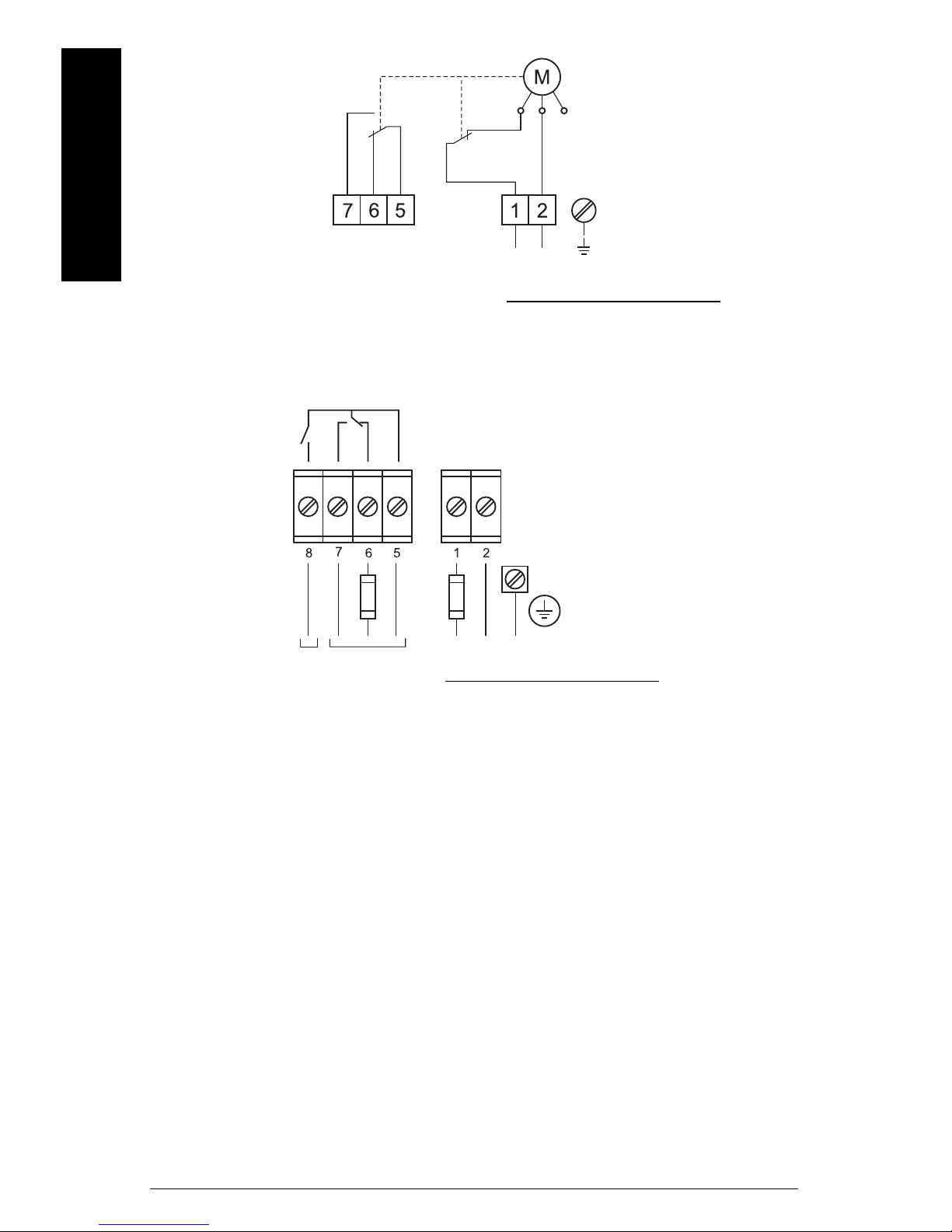

Wiring

voltage

jumper

lamp

protective earth

terminal

WARNINGS:

• Open SITRANS LPS200 only when supply voltage is switched off.

• For switch-selectable voltage version, select correct voltage using

manual voltage jumper before switching on the power supply.

Notes:

• All field wiring must have insulation suitable for at least 250 V AC.

• A disconnect switch shall be in close proximity to the equipment and within easy

reach of the operator.

• Unused cable conduit fittings must be locked with a closing element or plug.

• Commissioning must be done only with a closed device.

• Observe all pertinent rules and regulations of the country of installation.

European Standards

• Cable glands and conduit system for ATEX IECEx (Dust and Gas Hazardous Locations):

Installation according to the regulations of the country where the unit is installed.

Not used entries have to be closed with blanking elements certified for this purpose.

Where available, factory provided parts must be used.

A strain relief must be provided for the field wiring cables, when the device is installed with

the factory provided cable glands.

The diameter of the field wiring cable must match to the clamping range of the cable clamp.

If parts other than the factory provided parts are used, the following must be ensured:

The parts must have an approval adequate to the approval of the level sensor (certificate and

type of protection).

The approved temperature range must be from the minimum ambient temprature of the level

sensor to the maximum ambient temperature of the level sensor increased by 10K.

The parts must be mounted according to the instructions of the supplier.

• Conduit system for FM and CSA (Dust and Gas Hazardous Locations):

General requirements: In addition, the regulations of the country must be observed. The used

flameproof seals and blanking elements must have an adequate type approval and a

temperature range of at least -40 to 80 °C (-40 to 176 °F). In addition, they shall be suitable for

the conditions and correctly installed. Where available, the provided original parts of the

manufacturer must be used.

English

mmmmm

Connections

Switch-selectable voltage, SPDT relay

Select the voltage by placing the voltage jumper over the pins as illustrated below.

7ML19985FS62 SITRANS LPS200 – OPERATING INSTRUCTIONS Page EN-11

mmmmm

24 V DC, 2.5 W

All voltages ± 15 %

alarm output

relay

L

N

+

–

115 V AC, 50 to 60 Hz, 4 VA

230 V AC, 50 Hz, 6 VA

or:

24 V DC, 2.5 W

All voltages ± 15 %

alarm

output

L

N

+

–

24 V or 48 V or 115 V or 230 V AC,

50/60 Hz, 5 VA

or:

signal

output

PE

PE

Switching and timing behaviour:

If the vane is not covered, the

rotating vane shaft will send

pulses at 20 second intervals. In

case of fault, the pulses are

missed. After 30 seconds, the

alarm relay will open.

English

AC or DC version, SPDT relay, fail-safe

Connection Notes

• Before opening the lid, ensure there are no dust deposits around the SITRANS LPS200.

Ensure that the atmosphere around SITRANS LPS200 is settled.

• Use a fuse for the signal output (max. 6 A).

• Make sure the main voltage does not exceed the maximum voltage listed on the

product label and the setting of the voltage selector.

• In case of inexpert handling or handling malpractice, the electric safety of the

device cannot be guaranteed.

• Provide protection for relay contacts to protect the device against spikes if inductive

loads are connected.

Page EN-12 SITRANS LPS200 – OPERATING INSTRUCTIONS 7ML19985FS62

Switching Logic (switch-selectable voltage)

LED

red

LED

green

No

Fault

LED 2

off

Fault

LED 2

red

signal

output

Connection example

Full detector with fail-safe option.

Output signal signals a fault if level reaches

high level switching point, the main voltage

fails, there is a faulty connection, or if the

unit is faulty.

Switching Logic (non-switch selectable)

English

mmmmm

Alarm output - Fail-safe option

Maintenance

SITRANS LPS200 requires no maintenance or cleaning under normal operating

conditions. Under severe operating conditions, the measuring vane may require periodic

cleaning. Brush off any accumulated deposits, taking care not to bend the vane.

7ML19985FS62 SITRANS LPS200 – OPERATING INSTRUCTIONS Page EN-13

Unit Repair and Excluded Liability

All changes and repairs must be done by qualified personnel, and applicable safety

regulations must be followed. Please note the following:

mmmmm

English

• The user is responsible for all changes and repairs made to the device.

• All new components must be provided by Siemens Milltronics Process Instruments Inc.

• Restrict repair to faulty components only.

• Do not re-use faulty components.

Page EN-14 SITRANS LPS200 – OPERATING INSTRUCTIONS 7ML19985FS62

Sicherheitshinweise

Warn- und Hinweistexte müssen besonders beachtet werden. Diese sind grau hinterlegt

vom übrigen Text abgesetzt.

WARNUNG: bezieht sich auf ein Warnsymbol auf dem Produkt und

bedeutet, dass bei Nicht-Einhalt der entsprechenden Vorsichtsmaßnahmen Tod, schwere Körperverletzung und/oder erheblicher Sachschaden eintreten können.

WARNUNG

1

: bedeutet, dass bei Nicht-Einhalt der entsprechenden

Vorsichtsmaßnahmen Tod, schwere Körperverletzung und/oder

erheblicher Sachschaden eintreten können.

VORSICHT: bedeutet, dass bei Nicht-Einhalt der entsprechenden Vorsichtsmaßnahmen erheblicher Sachschaden eintreten kann.

Hinweis:

Betriebsanleitung, auf den besonders aufmerksam gemacht werden soll.

1.

Dieses Symbol wird verwendet, wenn sich kein entsprechendes Vorsichtssymbol auf dem Produkt befindet.

steht für eine wichtige Information über das Produkt selbst oder den Teil der

Sicherheitssymbole

In der Betriebsanleitung:

Auf dem

Produkt

Beschreibung

(Etikett auf dem Produkt: gelber Hintergrund.)

Vorsicht: Details sind in zugehörigen Dokumenten

(Betriebsanleitung) aufgeführt.

Deutsch

mmmmm

Erde (Masseklemme)

Schutzleiterklemme

Das Gerätehandbuch

Hinweise:

• Bitte beachten Sie die Vorschriften für Installation und Betrieb, um eine schnelle,

problemlose Inbetriebnahme, sowie maximale Genauigkeit und Zuverlässigkeit Ihres

SITRANS LPS200 zu gewährleisten.

• Dieses Gerätehandbuch bezieht sich ausschließlich auf den SITRANS LPS200.

Mit Hilfe des vorliegenden Gerätehandbuchs können Sie Ihren SITRANS LPS200 optimal

einstellen. Für Vorschläge und Bemerkungen zu Inhalt, Aufbau und Verfügbarkeit des

Gerätehandbuchs sind wir jederzeit offen.

Bitte richten Sie Ihre Kommentare an techpubs.smpi@siemens.com

mens.com/processautomation finden Sie ein vollständiges Archiv aller Siemens Milltronics Gerätehandbücher.

. Unter www.sie-

7ML19985FS62 SITRANS LPS200 – BETRIEBSANLEITUNG Seite DE-1

SITRANS LPS200, Einleitung

Hinweise:

• Installation, Wartung und Inbetriebnahme müssen durch qualifiziertes, technisches

Personal vorgenommen werden.

• Der SITRANS LPS200 darf nur gemäß den Anweisungen in dieser Betriebsanleitung verwendet werden.

• Dieses Produkt ist für den Einsatz im Industriebereich vorgesehen. Bei Verwendung

in Wohngebieten kann es zu Störungen von verschiedenen Funkanwendungen

kommen.

Der Drehflügelmelder Pointek LPS200 überwacht den Füllstand von Schüttgütern. Das

Drehflügelprinzip eignet sich für die Voll-, Bedarfs- oder Leermeldung bei Materialien wie

Getreide, Futterstoffe, Zement, Kunststoffgranulat und Holzspäne in Silos, Trichtern oder

mmmmm

Deutsch

Lagerbehältern. Mit dem Standardmessflügel misst der Drehflügelmelder bei niedrigen

Schüttdichten von 100 g/l (6.2 lb/ft

und mit dem optionalen Rechteckflügel sogar bis 15 g/l (0.9 lb/ft

3

), mit dem optionalen Klappflügel bis 35 g/l (2.2 lb/ft3)

3

).

SITRANS LPS200, Funktionen

• Mechanische Dichtung

• AC-, DC- oder per Schalter wählbare Spannungsversorgung

• Einzigartige Rutschkupplung. Stößt der Messflügel auf plötzlichen Widerstand, so

verhindert die Rutschkupplung eine Beschädigung interner Bauteile.

• Optionale Laufüberwachung für Alarm bei Fehlerbedingungen oder Ausfall eines

Bauteils

• Verdrehbares Gehäuse

• Optionale Messflügel für den Einsatz bei hoher oder niedriger Schüttdichte bis 15 g/l

• Kurze Ausführung, Ausführung mit Verlängerungsrohr senkrecht (nur Einbau von

oben), Winkelausführung und Seilverlängerungen verfügbar

• Ausführungen für hohe Temperaturen und für hohen Druck verfügbar

• Optionales Verlängerungsset für die kompakte Ausführung verfügbar

SITRANS LPS200, Anwendungsbereiche

• Getreide, Futter, Zement, Plastikgranulat, Holzspäne, Reis, Sojabohnen, usw.

• Materialien mit hoher oder geringer Dichte

Funktionsprinzip

Ein drehgelagerter Messflügel wird von einem Synchrongetriebemotor angetrieben.

Erreicht das Füllgut den Messflügel, so wird dieser angehalten. Es kommt zu einem Kontaktschluss des Relais. Wenn der Messflügel nicht mehr bedeckt ist, dreht er sich erneut

und das Relais kehrt in seinen normalen Zustand zurück.

Der synchronisierte Induktionsmotor ist frei im Gehäuse aufgehängt. Wenn die Drehbewegung durch das Material gebremst wird, entsteht ein Reaktionsdrehmoment, das ein

elektrisches Signal zum Stoppen des Motors ausgibt. Sobald sich der Materialfüllstand

vom Drehflügel entfernt, bringt eine Feder den Motor in seine Betriebsstellung zurück.

Zwei Motorgeschwindigkeiten sind verfügbar: 1 U/min, für Lagertanks

Seite DE-2 SITRANS LPS200 – BETRIEBSANLEITUNG 7ML19985FS62

5 U/min, für höhere Geschwindigkeitsanforderungen des Prozesses

Loading...

Loading...