Siemens SITRANS L Pointek ULS200 Operating Instructions Manual

Pointek ULS200

SITRANS L

Ultrasonic non-contacting switch

Pointek ULS200

Operating Instructions

7ML1510-.....(ULS200)

01/2019

A5E32268616-AB

Introduction

1

Safety notes

2

Description

3

Installing/mounting

4

Operating

5

Application examples

6

Connection

7

Service and maintenance

8

Troubleshooting

9

Technical data

10

Dimension drawings

11

Certificates and support

A

Siemens AG

Digital Industries

Postfach 48 48

90026 NÜRNBERG

GERMANY

Document order number: A5E32268616

Ⓟ 05/2019 Subject to change

Copyright © Siemens AG 2019.

All rights reserved

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Pointek ULS200

Operating Instructions, 01/2019, A5E32268616-AB 3

Table of contents

1 Introduction ................................................................................................................................................ 5

1.1 Operating instructions scope .................................................................................................... 5

1.2 Industrial usage ......................................................................................................................... 5

2 Safety notes ............................................................................................................................................... 6

3 Description ................................................................................................................................................. 7

3.1 Device overview ........................................................................................................................ 7

4 Installing/mounting ..................................................................................................................................... 8

4.1 Mounting location ...................................................................................................................... 8

4.2 Mounting instructions .............................................................................................................. 10

4.3 Instructions specific to hazardous area installations (Reference European ATEX

Directive 94/9/EC, Annex II, 1/0/6) ......................................................................................... 10

5 Operating ................................................................................................................................................. 12

5.1 Startup .................................................................................................................................... 12

5.2 Display/operation status ......................................................................................................... 12

5.3 Quick start ............................................................................................................................... 13

5.4 Operating adjustments ............................................................................................................ 15

5.4.1 Operating adjustments ............................................................................................................ 15

5.4.2 Output function ........................................................................................................................ 17

5.4.3 Setpoints ................................................................................................................................. 19

5.4.4 Relay delay ............................................................................................................................. 19

5.4.5 Relay deadband (reset) .......................................................................................................... 20

5.4.6 Blanking .................................................................................................................................. 21

5.4.7 Range limit .............................................................................................................................. 21

5.4.8 Speed of response .................................................................................................................. 23

5.4.9 Fail-safe mode ........................................................................................................................ 24

5.4.10 Fail-safe timer ......................................................................................................................... 24

5.4.11 Units ........................................................................................................................................ 24

6 Application examples ............................................................................................................................... 25

6.1 Applications ............................................................................................................................. 25

6.2 High level alarm switch ........................................................................................................... 27

6.3 High/low level alarm switch ..................................................................................................... 28

6.4 Low level alarm switch ............................................................................................................ 29

6.5 Dual pump control ................................................................................................................... 30

6.6 Pump control with level alarm ................................................................................................. 31

Table of contents

Pointek ULS200

4 Operating Instructions, 01/2019, A5E32268616-AB

7 Connection .............................................................................................................................................. 32

7.1 Interface ................................................................................................................................. 32

7.1.1 Relay output - DC contact voltage and current limits ............................................................. 34

7.2 Wiring ..................................................................................................................................... 35

7.2.1 Power ..................................................................................................................................... 36

7.2.2 Minimum supply voltage - DC relay version .......................................................................... 36

8 Service and maintenance ........................................................................................................................ 37

8.1 Maintenance ........................................................................................................................... 37

8.2 Unit Repair and Excluded Liability ......................................................................................... 37

9 Troubleshooting ....................................................................................................................................... 38

10 Technical data ......................................................................................................................................... 39

10.1 AC version .............................................................................................................................. 39

10.1.1 Power ..................................................................................................................................... 39

10.1.2 Fuse ....................................................................................................................................... 39

10.1.3 Output .................................................................................................................................... 39

10.2 DC version ............................................................................................................................. 39

10.2.1 Power ..................................................................................................................................... 39

10.2.2 Output .................................................................................................................................... 40

10.3 Operating conditions .............................................................................................................. 40

10.4 Process pressure ................................................................................................................... 40

10.5 Switching range ...................................................................................................................... 40

10.6 Memory .................................................................................................................................. 40

10.7 Programming .......................................................................................................................... 41

10.8 Temperature compensation ................................................................................................... 41

10.9 Display ................................................................................................................................... 41

10.10 Construction ........................................................................................................................... 41

10.11 Approvals ............................................................................................................................... 42

11 Dimension drawings ................................................................................................................................ 43

11.1 Standard ................................................................................................................................. 43

11.2 Sanitary .................................................................................................................................. 45

11.3 Dimension notes .................................................................................................................... 46

A Certificates and support ........................................................................................................................... 47

A.1 Certificates ............................................................................................................................. 47

A.2 Technical support ................................................................................................................... 47

Pointek ULS200

Operating Instructions, 01/2019, A5E32268616-AB 5

1

1.1 Operating instructions scope

This manual outlines the essential features and functions of the device.

1.2 Industrial usage

Note

This product is intended for use in industrial areas. Operation of this equipment in a

residential area may cause interference to several frequency based communications.

Pointek ULS200

6 Operating Instructions, 01/2019, A5E32268616-AB

2

Warning notices must be observed to ensure personal safety as well as that of others, and to

protect the product and the connected equipment. These warning notices are accompanied

by a clarification of the level of caution to be observed.

Pointek ULS200

Operating Instructions, 01/2019, A5E32268616-AB 7

3

WARNING

Improper device modifications

Risk to personnel, system and environment can result from modifications to the device,

particularly in hazardous areas.

• Only carry out modifications that are described in the instructions for the device. Failure

to observe this requirement cancels the manufacturer's warranty and the product

approvals.

Note

The device is to be used only in the manner outlined in this manual, otherwise protection

provided by the equipment may be impaired.

3.1 Device overview

The device is an ultrasonic based process level switch providing high or low switch action on

liquids or solids. The sensor is ETFE or PVDF, allowing it to be used in a wide variety of

industries. The device is used to measure liquids, slurries, and fluid materials, as well as

chemicals and plugged chute detection.

The device contains an ultrasonic transducer and temperature sensing element. The

transducer emits a series of ultrasonic pulses. Each pulse is reflected as an echo from the

material and sensed by the transducer. The device processes the echo using Siemens’

proven Sonic Intelligence techniques. Filtering is applied to help discriminate between the

true echo from the material and the false echoes from acoustical and electrical noises and

agitator blades in motion. The time for the pulse to travel to the material and back is

temperature compensated and then converted into distance for display and relay actuation.

The device is an excellent primary detection device, but should not be used as a backup

device. For backup devices use a contacting technology such as the Pointek CLS200.

Pointek ULS200

8 Operating Instructions, 01/2019, A5E32268616-AB

4

WARNING

Materials of construction compatibility

Materials of construction are chosen based on their chemical compatibility (or inertness) for

general purposes. For exposure to specific environments, check with chemical compatibility

charts before installing.

WARNING

Explosion hazard

Substitution of components may impair suitability for Class I, Division 2 applications.

WARNING

Device functionality

This product can only function properly and safely if it is correctly transported, stored,

installed, set up, operated, and maintained.

WARNING

Selecting bolting and gasket material

The user is responsible for the selection of bolting and gasket materials which will fall within

the limits of the flange and its intended use, and which are suitable for the service

conditions.

4.1 Mounting location

Recommendations:

● Ambient temperature within -40 to +60 °C (-40 to +140 °F), -20 °C (-4 °F) if metal

mounting.

● Easy access for viewing the display and programming via two push buttons.

● An environment suitable to the housing rating and materials of construction.

● Keep the sound path perpendicular to the material surface.

Pointek ULS200

Operating Instructions, 01/2019, A5E32268616-AB 9

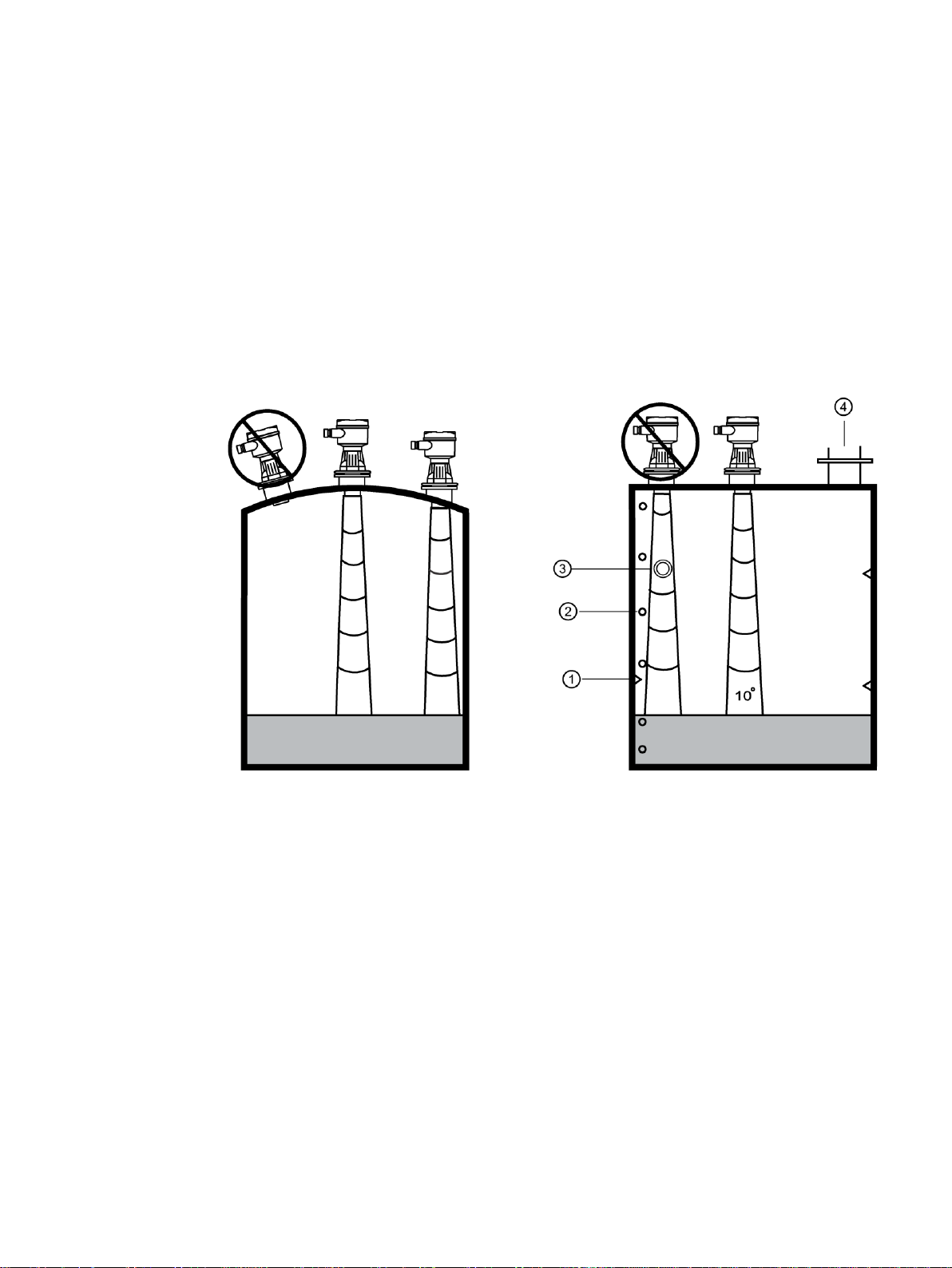

Precautions:

● Avoid proximity to high voltage or current wiring, high voltage or current contacts, and to

variable frequency motor speed controllers.

● Avoid interference to the sound path from obstructions or from the fill path.

The sound path should be:

● Perpendicular to the monitored surface

● Clear of rough walls, seams, rungs, or other obstructions

● Clear of the fill path

①

Seams

②

Rungs

③

Pipe

④

Fill

Pointek ULS200

10 Operating Instructions, 01/2019, A5E32268616-AB

4.2 Mounting instructions

Note

Ideally, mount the device so that the face of the transducer is at least 250 mm (9.84 inch)

above the highest anticipated level.

The device is available in three thread types: 2" NPT, 2" BSPT, or 2" G.

Before inserting the device into its mounting connection, ensure that the threads are of the

same type to avoid damaging them. Simply screw the device into the process connection,

and hand tighten.

4.3 Instructions specific to hazardous area installations (Reference

European ATEX Directive 94/9/EC, Annex II, 1/0/6)

The following instructions apply to equipment covered by certificate number SIRA

00ATEX1205:

1. The equipment may be used with flammable gases and vapours with apparatus group IIC

and temperature class T5.

2. The equipment is certified for use in an ambient temperature range of -20 to +60 °C

(-4 to +140 °F).

3. The equipment has not been assessed as a safety related device (as referred to by

Directive 94/9/EC Annex II, clause 1.5).

4. Installation and inspection of this equipment shall be carried out by suitably trained

personnel in accordance with the applicable code of practice (EN 60079-14 and

EN 60079-17 in Europe).

5. Repair of this equipment shall be carried out by suitably trained personnel in accordance

with the applicable code of practice (e.g. EN 60079-19 within Europe).

6. Components to be incorporated into or used as replacements in the equipment shall be

fitted by suitably trained personnel in accordance with the manufacturer’s documentation.

Pointek ULS200

Operating Instructions, 01/2019, A5E32268616-AB 11

7. The certification of this equipment relies upon the following materials used in its

construction:

Aluminum alloy T356 T6 (main enclosure) and A356 T6 (lid)

GE Lexan 943A polycarbonate

Two-part epoxy encapsulant

Silicon based coating

Santoprene 111-55 gasket

Master Bond Polysulphide EP21LPT or Dow Corning 3-4207 encapsulant

(transducer)

ETFE (transducer)

Epoxy syntactic foam (transducer)

If the equipment is likely to come in contact with aggressive substances, then it is the

responsibility of the user to take suitable precautions that prevent it from being adversely

affected, thus ensuring that the type of protection is not compromised.

Aggressive substances:

e.g. acidic liquids or gases that may attack

metals, or solvents that may affect polymeric

materials

Suitable precautions:

e.g. regular checks as part of routine inspec-

tions or establishing from the material’s data

sheet that it is resistant to specific chemicals.

8. Equipment Marking:

The equipment marking contains at least the information on the product nameplate,

shown on the inside front cover of this manual.

9. Special Condition for Safe Use: The apparatus must only be supplied from a circuit

containing a suitable rate fuse having a breaking capacity of at least 4 000 A.

Pointek ULS200

12 Operating Instructions, 01/2019, A5E32268616-AB

5

5.1 Startup

With the device correctly installed (or aimed at a wall 0.25 to 5 m away), apply power and

view the startup sequence. It will light all possible LED values, show product revision

number, product model number, and will enter run mode. Then, the display shows the

measurement of the distance from the transducer face to the material level in the units

indicated.

5.2 Display/operation status

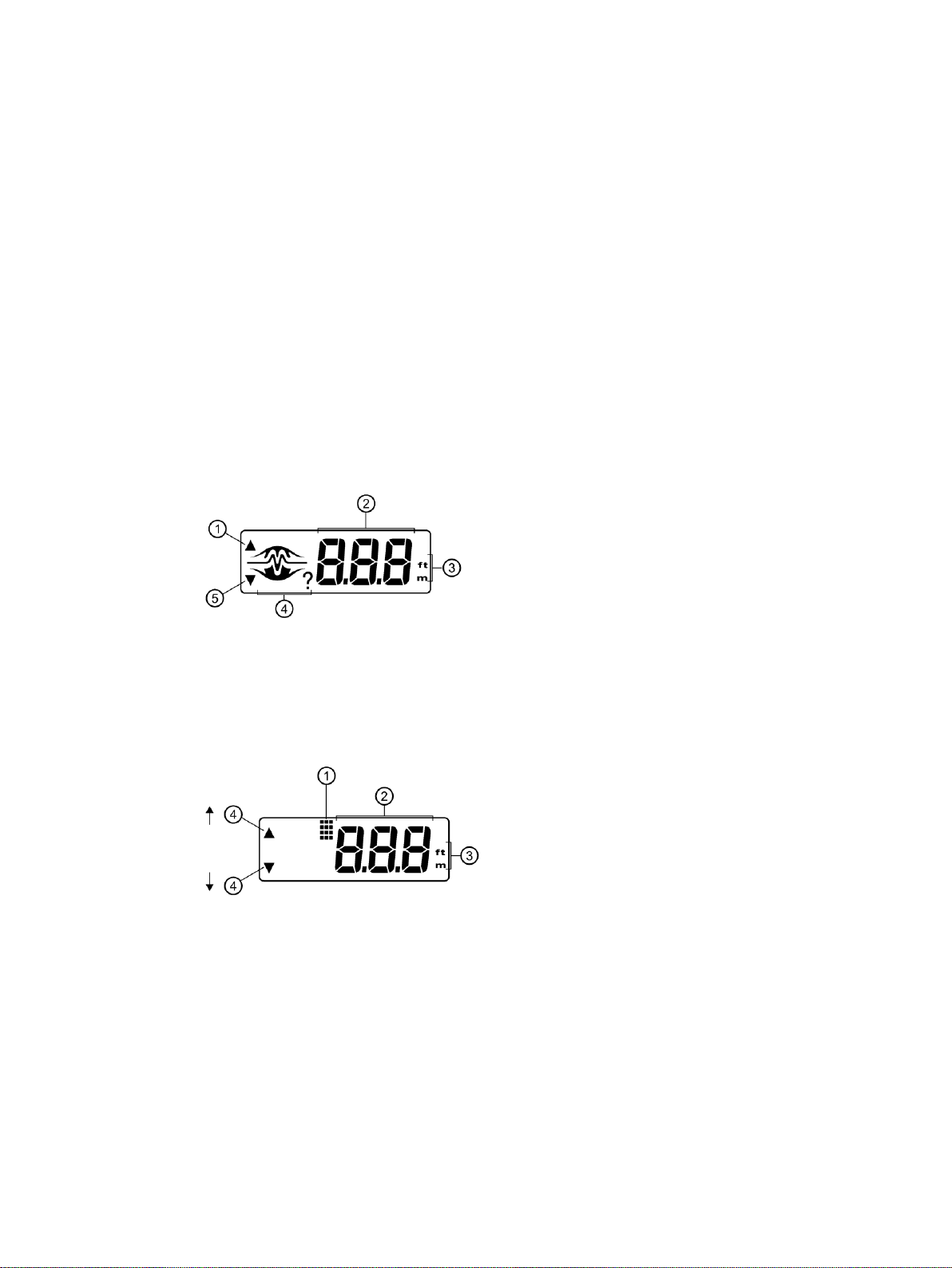

①

Output 1

②

Reading

③

Units

④

Operation status

⑤

Output 2

①

Program mode

②

Adjustment value

③

Units

④

Key

Pointek ULS200

Operating Instructions, 01/2019, A5E32268616-AB 13

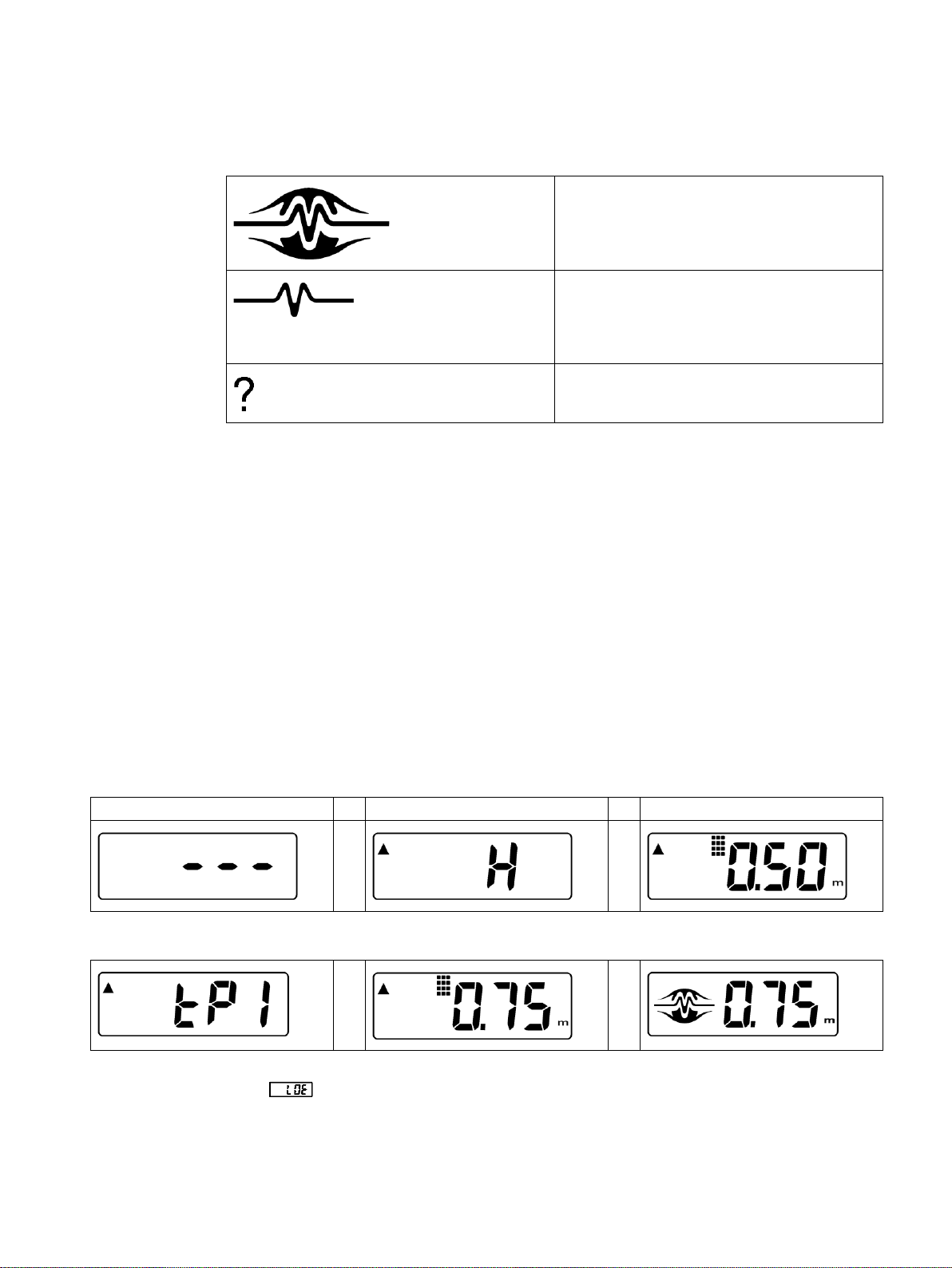

Operation status - run mode

Echoes are valid and within range.

Echoes are lost due to poor conditions or out of

range. This may be typical in applications where

there are deep vessels and the material level is

normally out of range. Refer to Troubleshooting

(Page 38).

Extended loss of echo period. Operation has

gone into fail-safe. Refer to Troubleshooting

(Page 38).

5.3 Quick start

To set a basic high/low application where you can easily adjust the measured distance, use

the method below. The device relays are preset as: relay 1 = alarm 1, high alarm at 0.25 m;

relay 2 = alarm 2, low alarm at 5.00 m.

To change the setpoints by reference method, set the material or target to the distance as

displayed. Press the 1/↑ or 2/↓ key. The display shows the current setpoint function and

value. Press the alarm key a second time so the device changes the setpoint to the value

currently being measured. After viewing or changing the setpoint, the device reverts to the

run mode.

Relay 1

1. Position the unit so that it reads 0.75 m.

2. Press 1/↑

Function display: high alarm

Current setpoint, 0.5 m

⇒ ⇒

3. Press 1/↑

⇒ ⇒

4. Once installed, the unit will register a high alarm at 0.75 m from the sensor face. If Loss of

Echo appears, complete steps 1 to 3 again.

Pointek ULS200

14 Operating Instructions, 01/2019, A5E32268616-AB

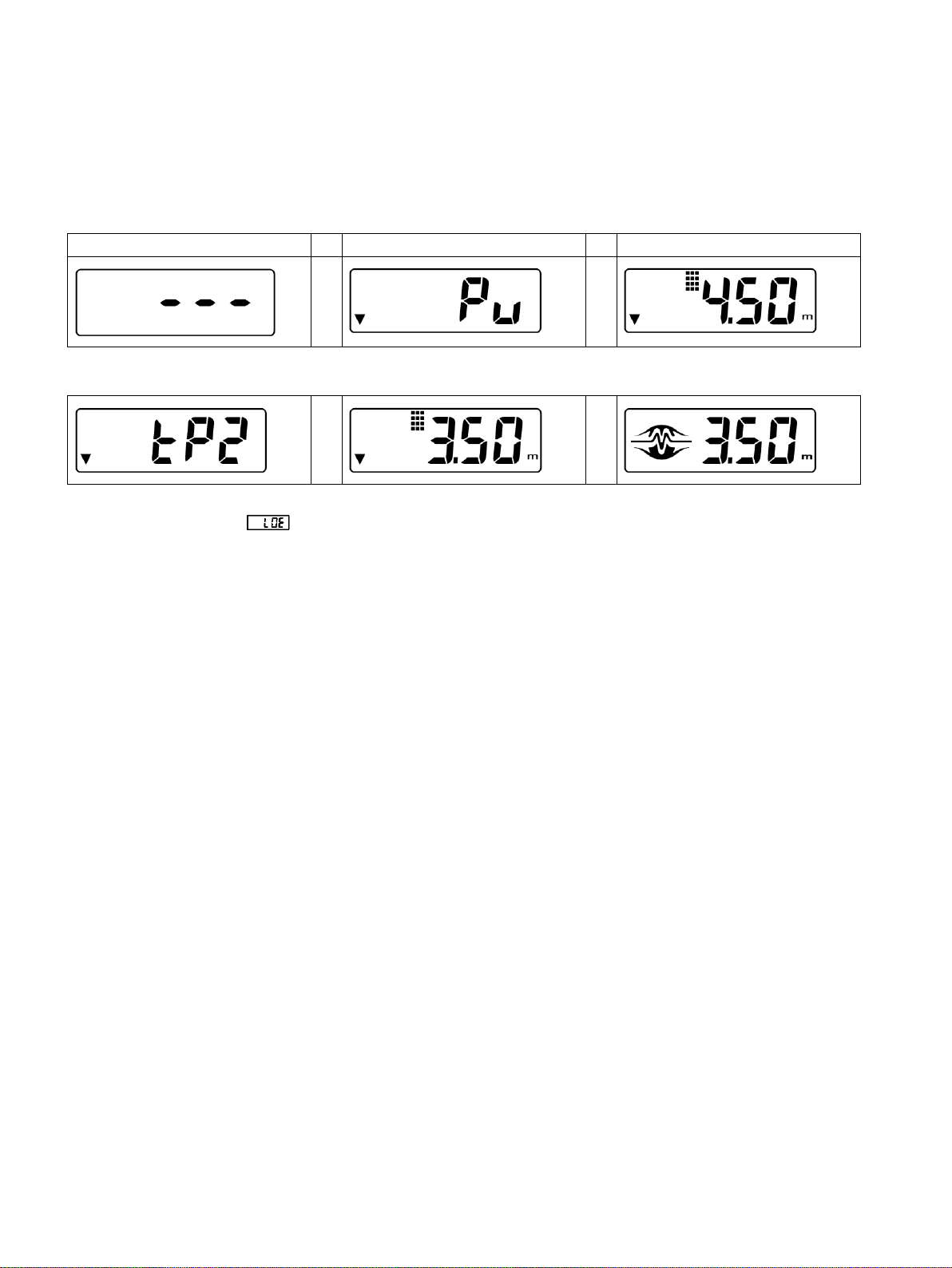

Relay 2

1. Position the unit do that it reads 3.50 m.

2. Press 2/↓.

Function display: pump up control

⇒ ⇒

3. Press 2/↓.

⇒ ⇒

4. Once installed, the unit will register a low alarm at 3.50 m from the sensor face. If Loss of

Echo appears, complete steps 1 to 3 again.

Pointek ULS200

Operating Instructions, 01/2019, A5E32268616-AB 15

5.4 Operating adjustments

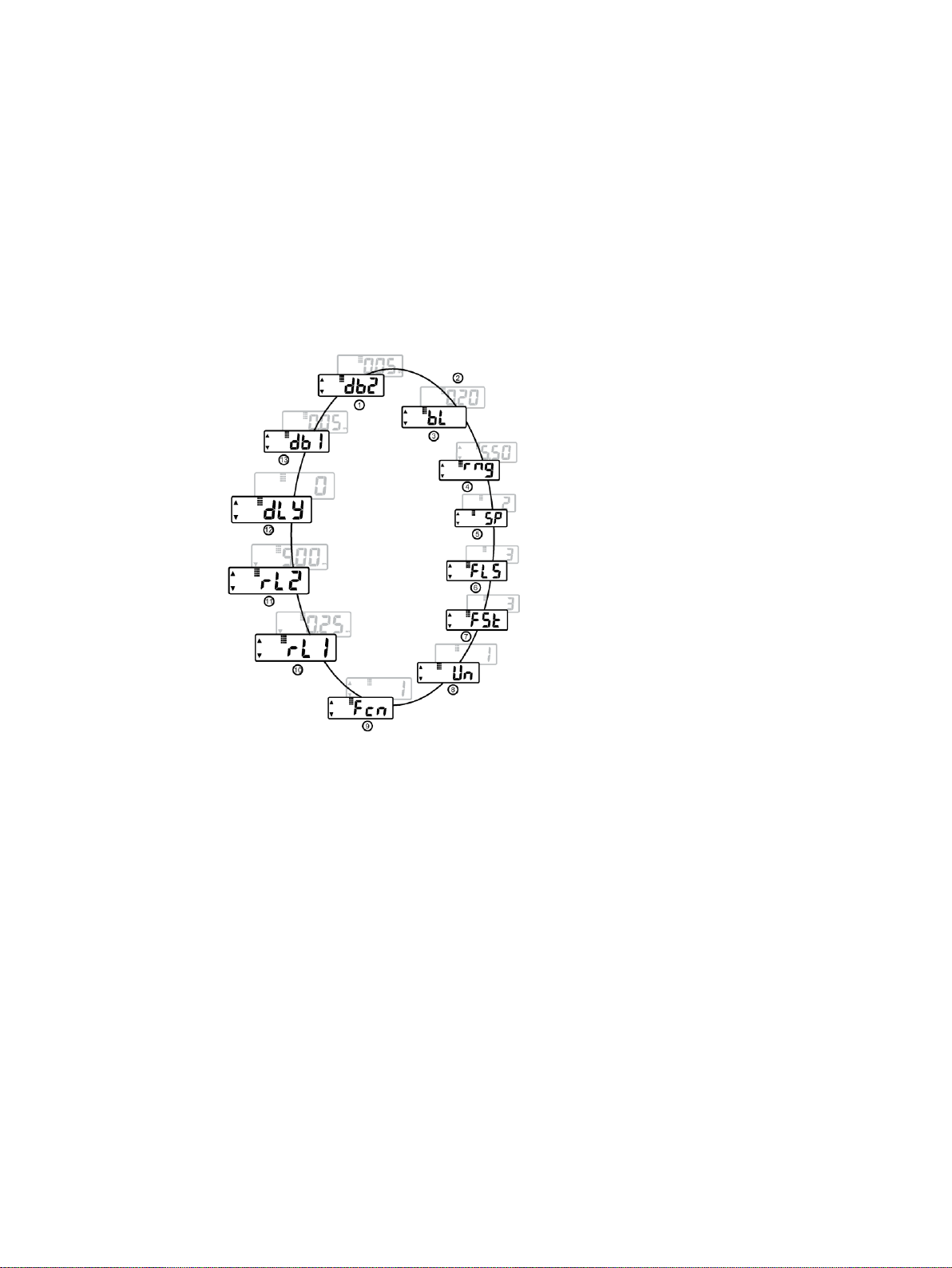

5.4.1 Operating adjustments

To access the operating adjustments, simultaneously press both keys repeatedly until the

desired adjustment is obtained. A viewing period of the adjustment value is initiated. During

this time the value can be changed by pressing either the 'up' or 'down' key. After viewing or

changing, operation automatically reverts to the run mode.

①

Deadband 2

②

On setpoint

③

Blanking

④

Range limit

⑤

Speed of Response

⑥

Fail-safe

⑦

Fail-safe timer

⑧

Units

⑨

Relay function

⑩

Relay 1

⑪

Relay 2

⑫

Delay

⑬

Deadband 1

Loading...

Loading...