Siemens SITRANS F US Protocol Manual

SITRANS F US

Clamp-on Ultrasonic Flowmeters

Communications Protocol Manual

11/2015Edition

Answers for industry.

SITRANS F US

Clamp-on Ultrasonic Flowmeters

F US Clamp-on Communications

Protocol Manual

Hardware Installation Manual

11/2015

A5E34981613

Introduction

1

Installing/Mounting

2

BACnet Communications

3

HART Communications

4

Consolidated Modbus

Registers

5

WEB Configuration Utility

6

Appendix A

A

-AC

Siemens

Division Process Industries and Drives

Postfach 48 48

90026 NÜRNBERG

GERMANY

Order number: A5E34981613

Ⓟ

Copyright © Siemens 2015.

All rights reserved

Legal information Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

for the specific

11/2015 Subject to change

Table of contents

1 Introduction ............................................................................................................................................. 7

2 Installing/Mounting .................................................................................................................................. 9

3 BACnet Communications ...................................................................................................................... 29

4 HART Communications ......................................................................................................................... 37

5 Consolidated Modbus Registers ............................................................................................................ 53

6 WEB Configuration Utility ...................................................................................................................... 61

A Appendix A ........................................................................................................................................... 67

1.1 History ....................................................................................................................................... 7

2.1 Items Supplied .......................................................................................................................... 9

2.2 F US Clamp-on Communications Module Installation .............................................................. 9

2.3 Flowmeter Setup ..................................................................................................................... 17

3.1 BACnet Communications ........................................................................................................ 29

3.2 BACnet Protocol Implementation Conformance Statement ................................................... 31

3.3 BACnet Alarms ....................................................................................................................... 34

4.1 Universal HART Commands ................................................................................................... 37

4.2 Common Practice HART Commands ..................................................................................... 43

4.3 Device Specific HART Commands ......................................................................................... 45

4.4 HART F US1010 Setup........................................................................................................... 46

4.5 Troubleshooting Diagnostics .................................................................................................. 52

5.1 Consolidated Modbus Registers ............................................................................................. 53

6.1 WEB Configuration Utility ....................................................................................................... 61

A.1 Modbus, EIP, HART & N2 Profile Mappings .......................................................................... 67

A.1.1 Introduction ............................................................................................................................. 67

A.1.2 Profile 1 ................................................................................................................................... 68

A.1.3 Profile 2 ................................................................................................................................... 69

A.1.4 Profile 3 ................................................................................................................................... 70

A.1.5 Profile 4 ................................................................................................................................... 71

A.1.6 Profile 5 ................................................................................................................................... 72

A.1.7 Profile 6 ................................................................................................................................... 74

A.1.8 Profile 7 ................................................................................................................................... 76

A.1.9 Profile 8 ................................................................................................................................... 78

A.1.10 Profile 9 ................................................................................................................................... 80

A.1.11 Profile 10 ................................................................................................................................. 81

A.1.12 Profile 11 ................................................................................................................................. 83

A.1.13 Profile 12 ................................................................................................................................. 85

A.1.14 Profile 13 ................................................................................................................................. 87

A.1.15 Profile 14 ................................................................................................................................. 90

A.1.16 Profile 15 .................................................................................................................................

A.1.17 Profile 16 ................................................................................................................................. 95

A.1.18 Profile 17 ................................................................................................................................. 97

92

F US Clamp-on Communications Protocol Manual

Hardware Installation Manual, 11/2015, A5E34981613-AC

3

Table of contents

Glossary .............................................................................................................................................. 183

Index ................................................................................................................................................... 189

Tables

A.1.19 Profile 18 .............................................................................................................................. 101

A.1.20 Profile 19 .............................................................................................................................. 104

A.1.21 Profile 20 .............................................................................................................................. 107

A.1.22 Profile 21 .............................................................................................................................. 111

A.1.23 Profile 22 .............................................................................................................................. 115

A.1.24 Profile 23 .............................................................................................................................. 119

A.1.25 Profile 24 .............................................................................................................................. 120

A.1.26 Profile 25 .............................................................................................................................. 122

A.1.27 Profile 26 .............................................................................................................................. 124

A.1.28 Profile 27 .............................................................................................................................. 128

A.1.29 Profile 28 .............................................................................................................................. 131

A.1.30 Profile 29 .............................................................................................................................. 133

A.1.31 Profile 30 .............................................................................................................................. 135

A.1.32 Profile 31 .............................................................................................................................. 138

A.1.33 Profile 32 .............................................................................................................................. 141

A.1.34 Profile 33 .............................................................................................................................. 145

A.1.35 Profile 34 ..............................................................................................................................

148

A.1.36 Profile 35 .............................................................................................................................. 150

A.1.37 Profile 36 .............................................................................................................................. 152

A.1.38 Profile 37 .............................................................................................................................. 155

A.1.39 Profile 38 .............................................................................................................................. 157

A.1.40 Profile 39 .............................................................................................................................. 159

A.1.41 Profile 40 .............................................................................................................................. 161

A.1.42 Profile 41 .............................................................................................................................. 164

A.1.43 Profile 42 .............................................................................................................................. 167

A.1.44 Profile 43 .............................................................................................................................. 171

A.1.45 Profile 44 .............................................................................................................................. 173

A.1.46 Profile 45 .............................................................................................................................. 175

A.1.47 Profile 46 .............................................................................................................................. 177

Table 2- 1 Mounting Kit ................................................................................................................................. 11

Table 2- 2 Profile Selection: 1 - 46 ................................................................................................................ 16

Table 4- 1 RS-485 Connector J1 ................................................................................................................... 38

Table 4- 2 Command 0 - Read Unique Identifier .......................................................................................... 38

Table 4- 3 Command 1 - Read Primary Variable .......................................................................................... 38

Table 4- 4 Command 2 - Read Loop Current and Percent of Range ........................................................... 39

Table 4- 5 Command 3 - Read Dynamic Variable and Loop Current ........................................................... 39

Table 4- 6 Command 6 - Writing Polling Address ......................................................................................... 39

Table 4- 7 Command 7 - Read Loop Configuration ...................................................................................... 39

Table 4- 8 Command 8 - Read Dynamic Variable Classifications ................................................................ 39

Table 4- 9 Command 9 - Read Device Variable with Status ......................................................................... 40

Table 4- 10 Command 11 - Read Unique identifier Associated with Tag ....................................................... 40

Table 4- 11 Command 12 - Read Message .................................................................................................... 41

Table 4- 12 Command 13 - Read Tag, Descriptor, Date ................................................................................ 41

F US Clamp-on Communications Protocol Manual

4 Hardware Installation Manual, 11/2015, A5E34981613-AC

Table of contents

Figures

Table 4- 13 Command 14 - Read Primary Variable Transducer Information ................................................. 41

Table 4- 14 Command 15 - Read Device Information .................................................................................... 41

Table 4- 15 Command 16 - Read Final Assembly Number ............................................................................ 41

Table 4- 16 Command 17 - Write Message .................................................................................................... 42

Table 4- 17 Command 18 - Write Tag, Descriptor, Date ................................................................................ 42

Table 4- 18 Command 19 - Write Final Assembly Number ............................................................................ 42

Table 4- 19 Command 20 - Read Log Tag ..................................................................................................... 42

Table 4- 20 Command 21 - Read Unique Identifier Associated with Long Tag .............................................. 42

Table 4- 21 Command 22 - Write Long Tag .................................................................................................... 43

Table 4- 22 Command 38 - Reset Configuration Changed Flag..................................................................... 43

Table 4- 23 Command 48 - Read Additional Device Status ........................................................................... 43

Table 4- 24 Command 35 - Write Primary Range Values ............................................................................... 43

Table 4- 25 Command 40 - Enter/Exit Fixed Current Mode ............................................................................ 43

Table 4- 26 Command 44 - Write Primary variable Units ............................................................................... 43

Table 4- 27 Command 45 - Trim Loop Current Zero ...................................................................................... 44

Table 4- 28 Command 46 - Trim Loop Current Gain ...................................................................................... 44

Table 4- 29 Command 50 - Read Dynamic Variable Assignments................................................................. 44

Table 4- 30 Command 51 - Write Dynamic Variable Assignments ................................................................. 44

Table 4- 31 Command 53 - Write Device Variable Units ................................................................................ 44

Table 4- 32 Request ........................................................................................................................................ 45

Table 4- 33 Response ..................................................................................................................................... 45

Table 4- 34 Request ........................................................................................................................................ 45

Table 4- 35 Response ..................................................................................................................................... 45

Table 4- 36 Request ........................................................................................................................................ 45

Table 4- 37 Response ..................................................................................................................................... 45

Table 4- 38 Request ........................................................................................................................................ 46

Table 4- 39 Response ..................................................................................................................................... 46

Table 4- 40 F_US1010 Clamp-on Communications Module - HART Device Variables ................................ 48

Figure 2-1 New Communications Module Installation ................................................................................... 11

Figure 2-2 SITRANS F US Clamp-on Communications Module A5E31949269 ........................................... 12

Figure 2-3 New Communications Module Installation ................................................................................... 13

Figure 2-4 DIP Switches SW1-A and SW2-B ................................................................................................ 14

Figure 2-5 Communications Cable Installation.............................................................................................. 19

Figure 2-6 FieldServer Toolbox Tour ............................................................................................................ 20

Figure 2-7 User Messages ............................................................................................................................ 27

F US Clamp-on Communications Protocol Manual

Hardware Installation Manual, 11/2015, A5E34981613-AC

5

Table of contents

Figure 3-1 Typical F US Clamp-on Flowmeter BACnet Application .............................................................. 29

Figure 4-1 HART Connections ...................................................................................................................... 37

Figure 4-2 Typical Connection of F US flowmeter with HART F_US1010 Option ........................................ 47

Figure 4-3 Process Variables View ............................................................................................................... 49

Figure 4-4 Dynamic Variables Changes View ............................................................................................... 50

Figure 4-5 Dynamic Variables View .............................................................................................................. 51

Figure 4-6 Device Information ....................................................................................................................... 52

Figure 6-1 Tool Box Utility ............................................................................................................................. 62

Figure 6-2 BACnet Parameters ..................................................................................................................... 63

Figure 6-3 Modbus Settings .......................................................................................................................... 64

Figure A-1 Profile Example ............................................................................................................................ 67

F US Clamp-on Communications Protocol Manual

6 Hardware Installation Manual, 11/2015, A5E34981613-AC

1

Note

It is the responsibility of the customer that the instructions and directions provided are read,

understood and followed by the relevant personnel before installing the device.

Note

For complete Safety Considerations and Ratings, refer

included with the flowmeter.

1.1

History

Edition

Remarks

12/2014

First edition of the SITRANS F US Communication Protocol Operating Instructions.

These SITRANS F US Clamp-on Communications Protocol installation instructions are for

Siemens SITRANS F US clamp-on ultrasonic flow meters equipped with the communication

option.

The instructions are aimed at persons that mechanically install the device, connect it

electronically, configure the parameters and commission it as well as service and

maintenance engineers.

to the Operating Instructions manual

The contents of these instructions are regularly reviewed and corrections are included in

subsequent editions. We welcome all suggestions for improvement.

The following table shows the most important changes in the documentation compared to

each previous edition.

5/2015 Second edition of the SITRANS F US Communication Protocol Operating Instructions.

The most important changes are as follows:

• Front and back manual cover updates to system designation text (i.e. From:

SITRANS F - To: SITRANS F US).

11/2015 Third edition of the SITRANS F US Communication Protocol Operating Instructions. This

document replaces all previous instructions for use. The most important changes are as

follows:

• Revised Flowmeter Setup and Communications Card Setup procedures.

• Revised Web Configuration Utility Setup procedure.

• Troubleshooting Diagnostic procedures have been added.

F US Clamp-on Communications Protocol Manual

Hardware Installation Manual, 11/2015, A5E34981613-AC

7

Introduction

1.1 History

F US Clamp-on Communications Protocol Manual

8 Hardware Installation Manual, 11/2015, A5E34981613-AC

2

2.1

Items Supplied

2.2

F US Clamp-on Communications Module Installation

WARNING

Hazardous Voltage

NOTICE

Electrostatic Discharge, All Electronic Assemblies

Note

For proper installation, mounting, wiring, and menu configuration of the flowmeter please

refer to the Operating Instructions manual supplied with the flowmeter.

The following parts are provided when the Communications Module is purchased separately:

● SITRANS F US Clamp-on Communications Module A5E31949269

● Four captive screws

● Four captive standoffs

May cause death or serious personal injury.

Disconnect power before working on this product.

Take precautions against static discharge when handling circuit boards. Semiconductor

devices must be protected from electrostatic discharge. A properly grounded conductive

wrist strap must be worn whenever a circuit board assembly is handled or touched.

F US Clamp-on Communications Protocol Manual

Hardware Installation Manual, 11/2015, A5E34981613-AC

9

Installing/Mounting

New Communications Module Installation.

Note

Refer to page 10 for the New Communications Module Installation

Mounting Kit

Meter Type

Meter Configuration

installed

only installed

Field Upgrade with New Communications Module.

2.2 F US Clamp-on Communications Module Installation

These Communications Module installation instructions address the three types of

installation procedures for the flowmeter:

1. Flowmeters purchased with the correct MLFB number that includes the Communications

Module will be installed by the factory and no installation of the Communications Module

is required.

2.

Procedure requires installation of Communications Module with the necessary mounting

kit:

procedure.

1015N-5M-MK1 All meter types that include

1010N-5 Analog Input module

(i.e. FUS, FUE, FUG, FUH

1010 Systems).

1015N-5M-MK2 FUS1010N/DN without 1010N-

5 Analog Input module.

3.

1010N-2 I/O Module with

1010N-5 Analog Input Module

1010N-7 Expanded I/O Module

with 1010N-5 Analog Input

Module installed

1010N-2 I/O Module only installed

1010N-7 Expanded I/O Module

Required installation procedures include:

● Removal of the existing communications module

● Installation of Communications Module (no mounting kit necessary)

F US Clamp-on Communications Protocol Manual

10 Hardware Installation Manual, 11/2015, A5E34981613-AC

Installing/Mounting

New Communications Module Installation

Mounting Kit

Meter Type

Meter Configuration

1010N-2M Module installed

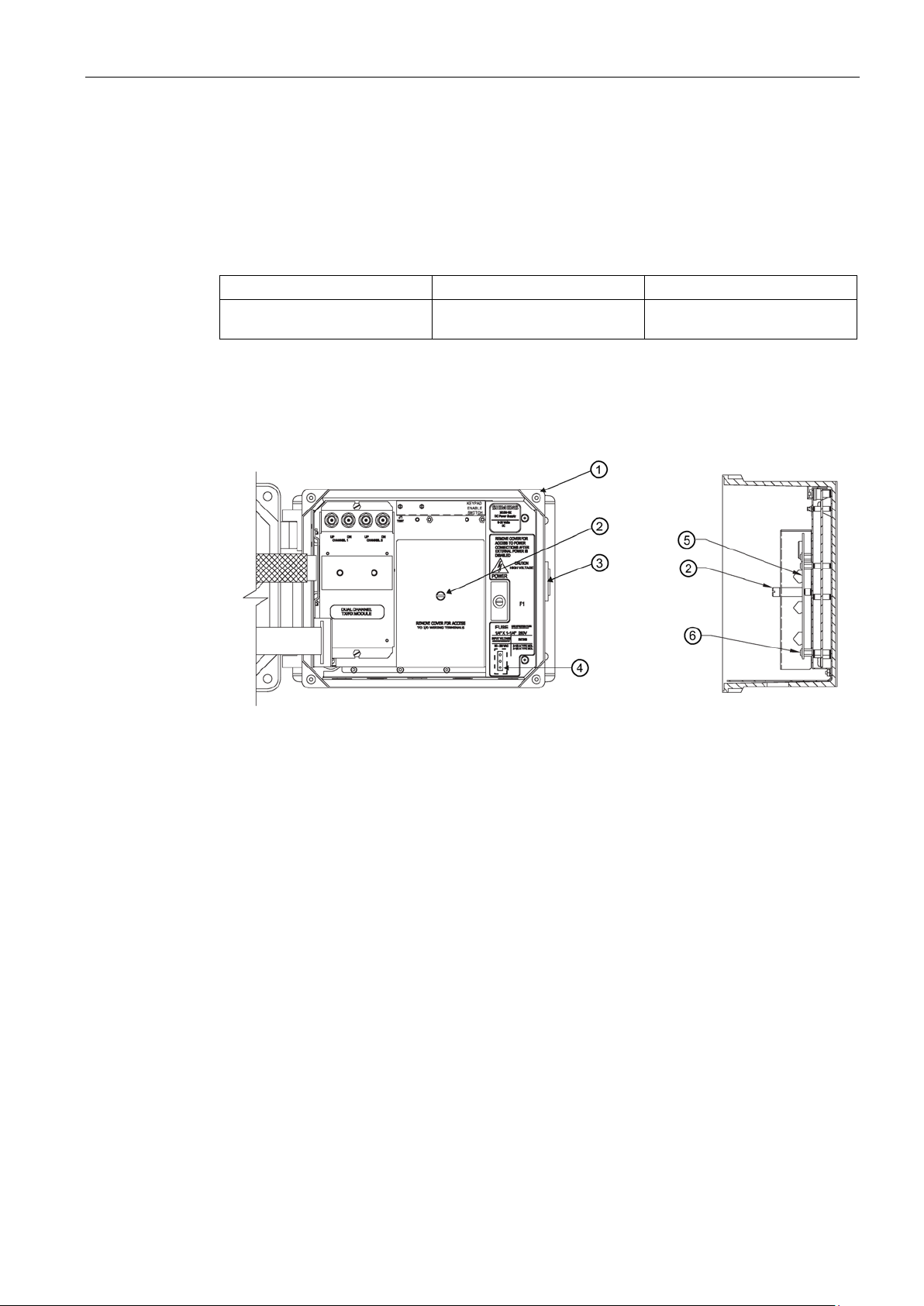

①

Flowmeter

④

Power Connector location

②

standoff

⑤

③

Flowmeter Cover Latch

⑥

I/O Module captive mounting screws

2.2 F US Clamp-on Communications Module Installation

This installation procedure is for flowmeters with an I/O Module installed but no Modbus

Communications Module previously installed. Mounting kits are also required for this

installation.

Table 2- 1 Mounting Kit

1015N-5M-MK3 1010MN 1010N-8M I/O Module with

1. Disconnect power to the unit.

2. Open the flowmeter cover by releasing the side cover latch

3. Loosen the I/O Module cover captive screw

standoff.

I/O Module cover, cover screw,

Figure 2-1 New Communications Module Installation

② and remove the cover, screw and

I/O Module

③.

4. Remove the four mounting screws and standoffs ⑥ that secure the I/O Module ⑤ and

5. Install the new standoffs supplied in the mounting kit in the vacant positions.

F US Clamp-on Communications Protocol Manual

Hardware Installation Manual, 11/2015, A5E34981613-AC

discard.

11

Installing/Mounting

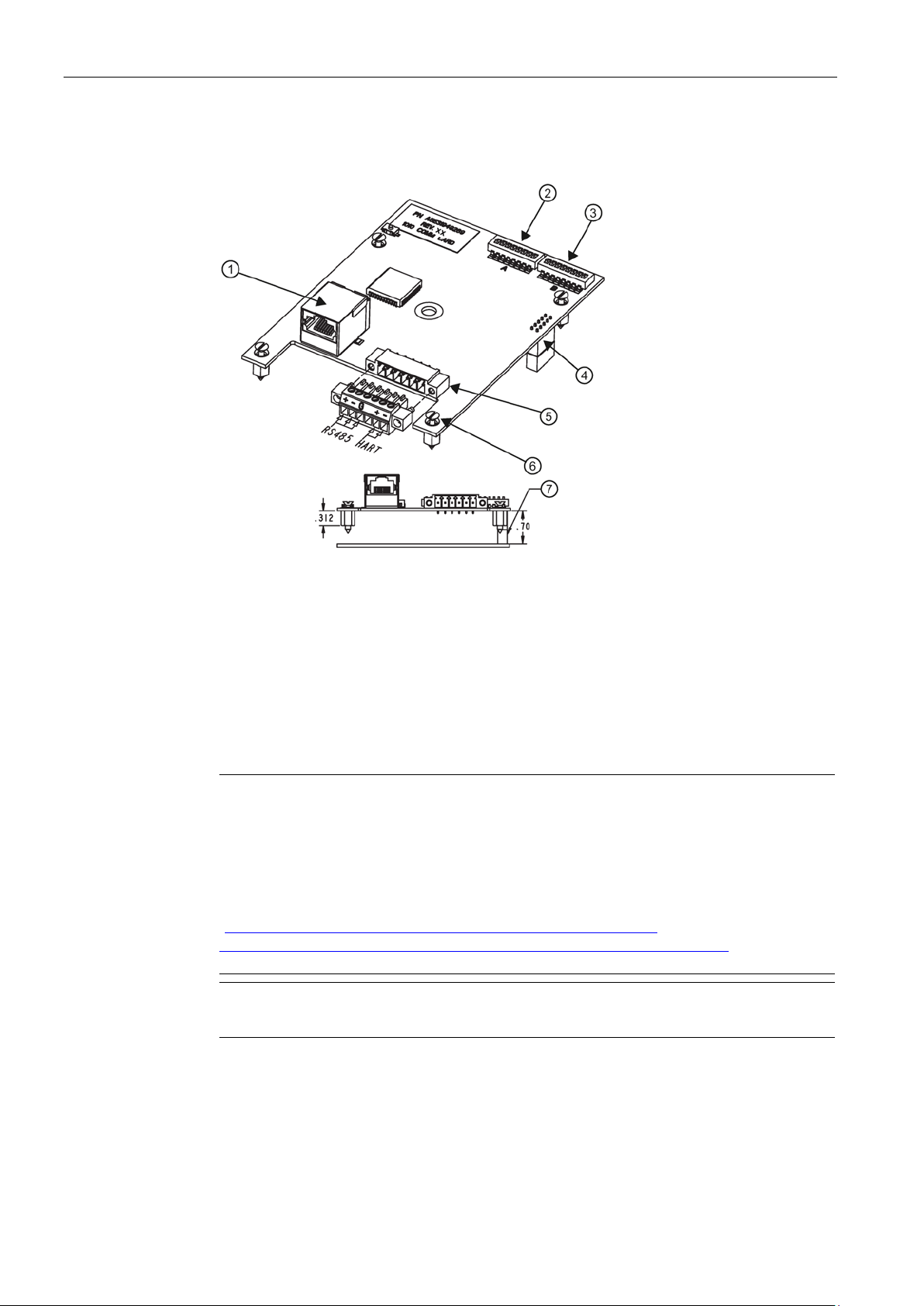

①

Ethernet Connector J5

⑤

RS-485 Connector J1

②

SW1

⑥

Captive Screw and Standoff

③

SW2

⑦

Standoff

④

J3

Note

Ethernet Web Utility Toolbox

This Web utility is used to change settings including IP addresses for multiple metes and

to locate

The web utility can be found at

http://www.fieldserver.com/techsupport/utility/downloads.php

(

XmlEditor.InternalXmlClipboard:6489c307

The default IP address is: 192.168.0.2

Note

RS-485 can be used for all communication protocols except HART.

2.2 F US Clamp-on Communications Module Installation

6. Place the Communications Module over the I/O Module and align connector J3 with P1 of

the I/O Module (figure 2-2).

Figure 2-2 SITRANS F US Clamp-on Communications Module A5E31949269

7. Gently press the Communications Module down to connect it to the I/O Module.

8. Tighten the captive screws to secure the Communications Module and I/O Module.

9. If using Ethernet IP, connect the Ethernet connector.

communications modules on the same network.

http://www.fieldserver.com/techsupport/utility/downloads.php. //

-3482-c2fd-cc08-262dd24d5093).

10.If using RS-485, connect RS-485 connector to J1.

11.Referring back to figure 2-1, after Communications Module installation is complete, place

the new Communications Module cover supplied in the mounting kit over the board and

tighten the captive screw

②.

12.Close the flowmeter cover and secure the side latch.

F US Clamp-on Communications Protocol Manual

12 Hardware Installation Manual, 11/2015, A5E34981613-AC

Installing/Mounting

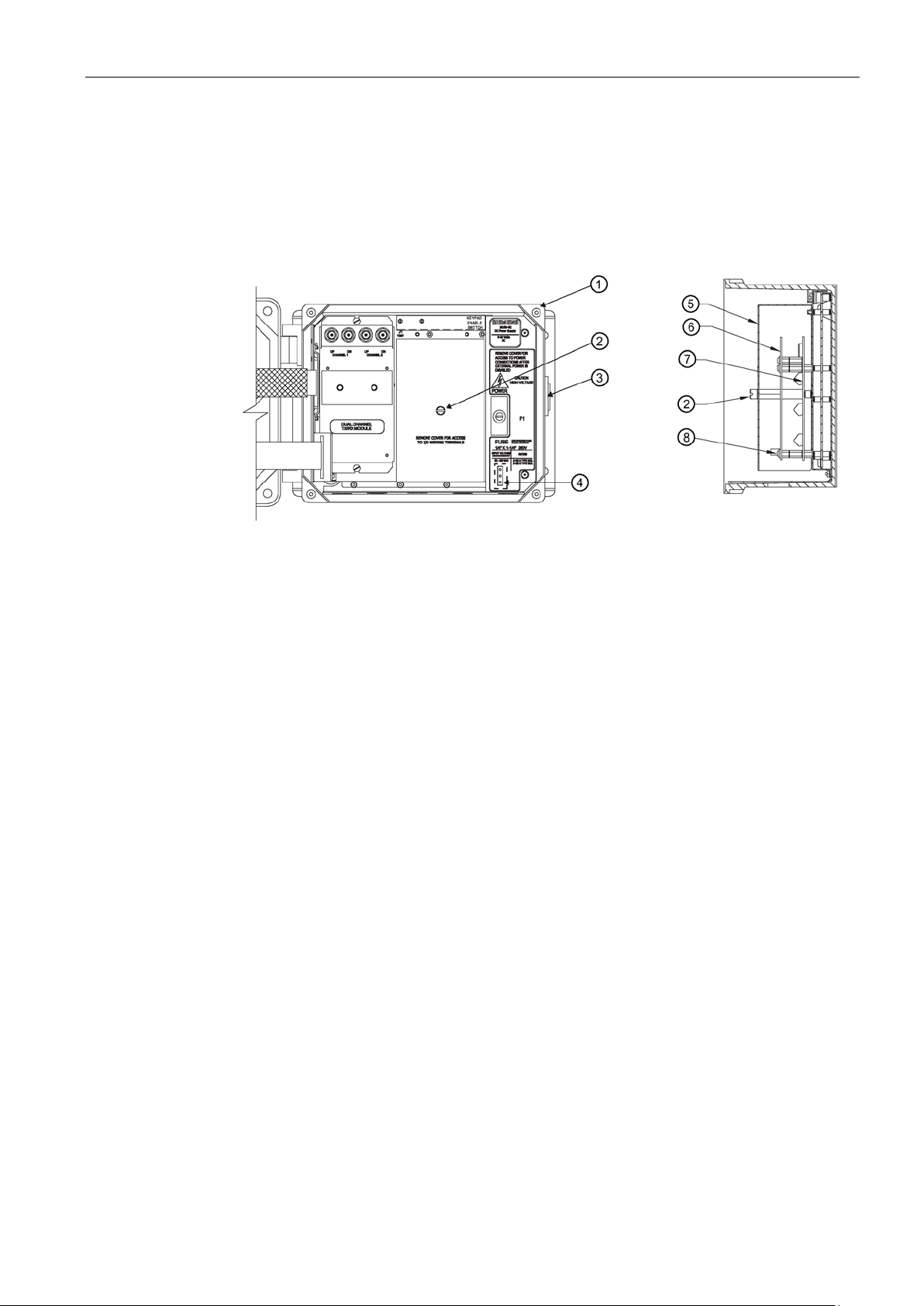

Fielded Upgrade with New Communications Module

①

Flowmeter

⑤

Modbus Communications Module cover

②

cover screw and standoff

⑥

③

Flowmeter Cover Latch

⑦

I/O Module

④

Power Connector location

⑧

captive screws

2.2 F US Clamp-on Communications Module Installation

This installation procedure is intended for flowmeters that are to be upgraded from the

1015N-5M Modbus Communications Module to the new Communications Module.

1. Disconnect power to the unit.

2. Open the flowmeter cover by releasing the side cover latch

Modbus Communications Module

Figure 2-3 New Communications Module Installation

3. Loosen the I/O Module cover captive screw ② and remove the cover ⑤.

Modbus Communications Module

③.

4. Loosen the four mounting screws and standoffs

Communications Module.

5. Remove the Modbus Communications Module

6. Install the new standoffs supplied in the mounting kit in the vacant positions.

7. Place the Communications Module over the I/O Module and align connector J3 with P1 of

the I/O Module (figure 2-2).

8. Gently press the Communications Module down to connect it to the I/O Module.

9. Tighten the captive screws to secure the Communications Module and the I/O Module.

10.If using Ethernet IP, connect the Ethernet connector.

11.If using RS485, connect RS-485 connector to J1 (refer to RS-485 Connector J1 table

below).

12.After Communications Module installation is complete, replace the Communications

Module cover and tighten the captive screw.

13.Close the flowmeter cover and secure the side latch.

⑧ that secure the Modbus

⑥.

F US Clamp-on Communications Protocol Manual

Hardware Installation Manual, 11/2015, A5E34981613-AC

13

Installing/Mounting

RS-485 Connector J1

Pin

Signal

Description

J1-1

RS-485+

Signal +

J1-2

RS-485-

Signal -

J1-3

RS-485 GND

Ground

J1-4

N/A

No Connection

J1-5

HART

No Connection

J1-6

HART

No Connection

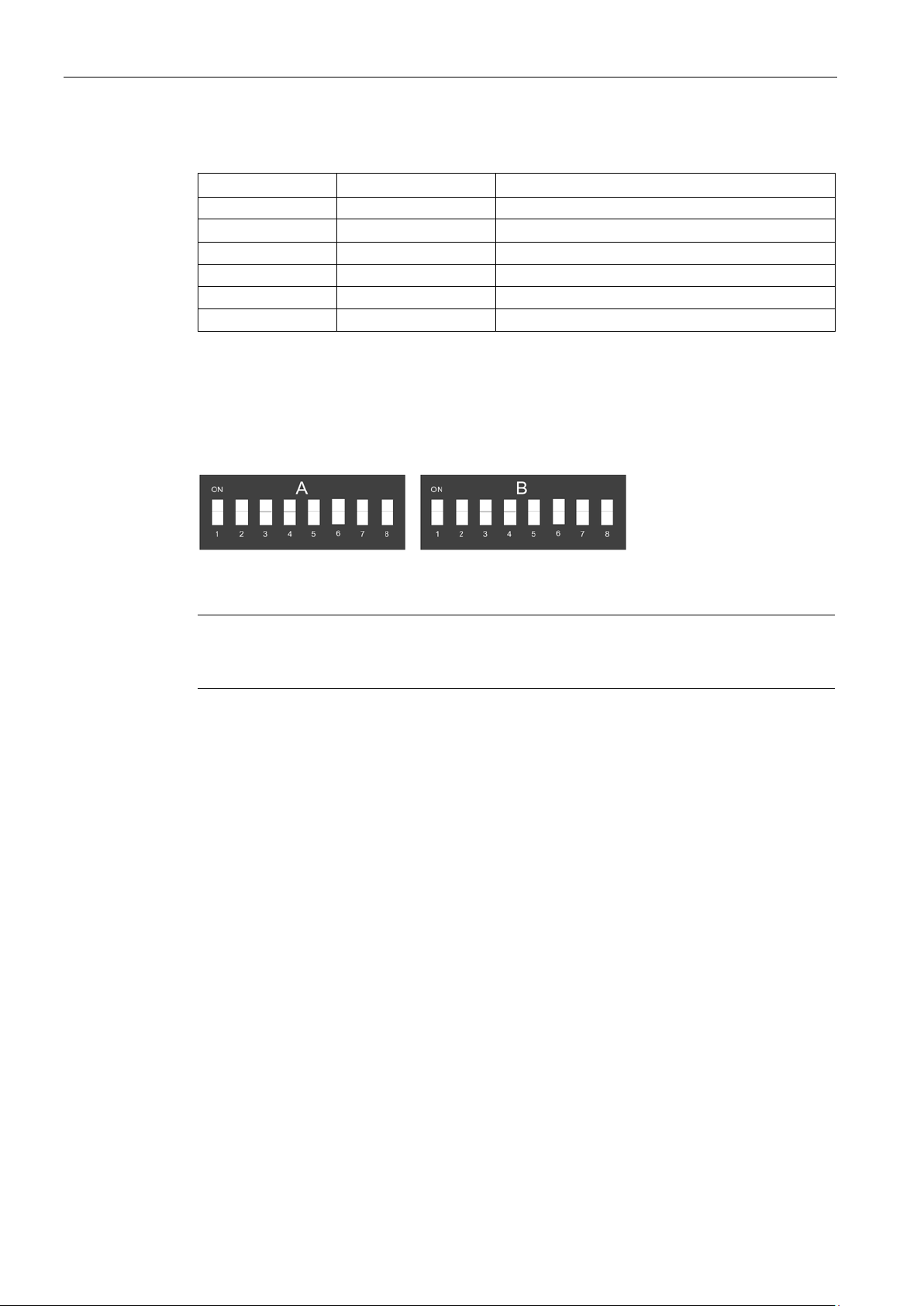

DIP Switch Settings - SW1-A and SW2-B

Note

Only SW2-B (1-6) are to be used for HART Communication. All other switch settings are set

to the OFF position.

Address Selection: SW1-A (1-6)

Switch Code: A1=1, A2=2, A3=4, A4=8, A5=16, A6=32

2.2 F US Clamp-on Communications Module Installation

There are two 8-position switches that are used to select protocols, baud rate, address and

profiles. These DIP switch settings refer to the communication module configuration file that

is used and the protocol and address that allow the required proper communications output.

Figure 2-4 DIP Switches SW1-A and SW2-B

These switches enable setting of the physical address on the RS485 network.

For example, to set address to equal 44 set switches to: A1 Off, A2 Off, A3 On, A4 On, A5

Off, A6 On

F US Clamp-on Communications Protocol Manual

14 Hardware Installation Manual, 11/2015, A5E34981613-AC

Installing/Mounting

Baud Rate Selection: SW1-A (7-8) - To Network

9600

A7 OFF

A8 OFF

19200

A7 ON

A8 OFF

38400

A7 OFF

A8 ON

76800

A7 ON

A8 ON

Profile Selection: SW2-B (1-6)

Protocol Selection: SW2-B (7-8)

Hart

Modbus RTU/Modbus TCP/IP

B7 OFF

B8 OFF

BACnet IP/BACnet MSTP

B7 ON

B8 OFF

Ethernet /IP

B7 OFF

B8 ON

N2 Metasys

B7

B8

Note

When using the WEB utility there are

position of the DIP switches:

•

•

•

•

Determine Flowmeter Firmware Version

2.2 F US Clamp-on Communications Module Installation

See selection table 2-1.

is active at all times. (SW-2 B7 and B8 are not required for HART communication.)

ON

ON

parameters under View/Data Arrays/ that identify the

DA-DIP: All 16 positions of switches A & B are identified in decimal form

DA-DIP_A: All 8 positions of switch are identified in decimal form

DA-DIP_B: Positions 1-4 of switch B are identified in decimal form

DA-DIP_S: Positions 5-8 of switch B are identified in decimal form

To determine the firmware version of your flowmeter refer to the table below. The firmware

version is listed in the Meter Facilities menu of the flowmeter and can be located using the

following procedure:

1. At the meter, press the <MENU> key.

2. Press the <Down Arrow> and scroll to [Meter Facilities].

3. Press the <Right Arrow>.

4. Press the <Down Arrow> and scroll to [System Info].

5. Press the <Right Arrow> to read your flowmeter version.

F US Clamp-on Communications Protocol Manual

Hardware Installation Manual, 11/2015, A5E34981613-AC

15

Installing/Mounting

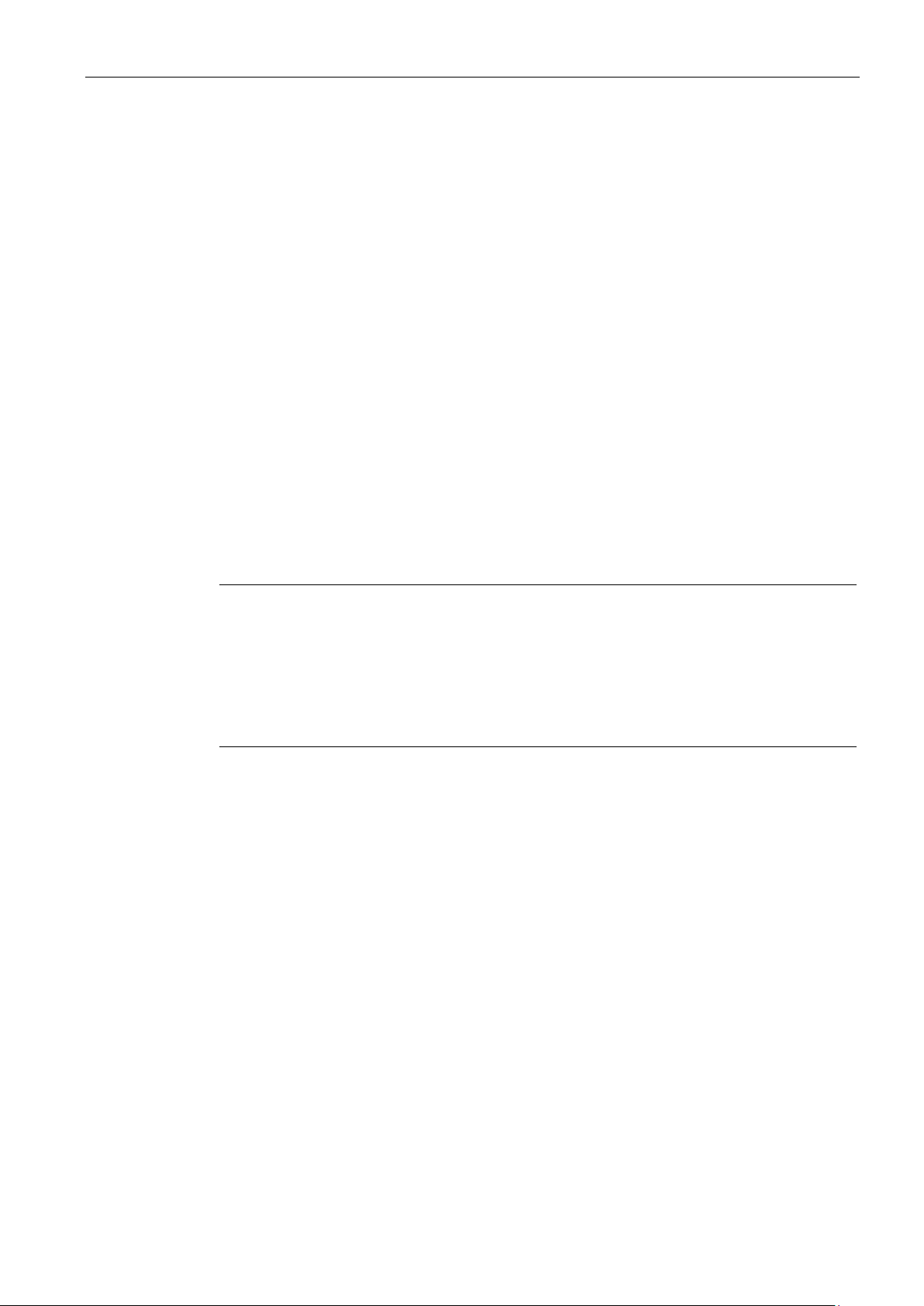

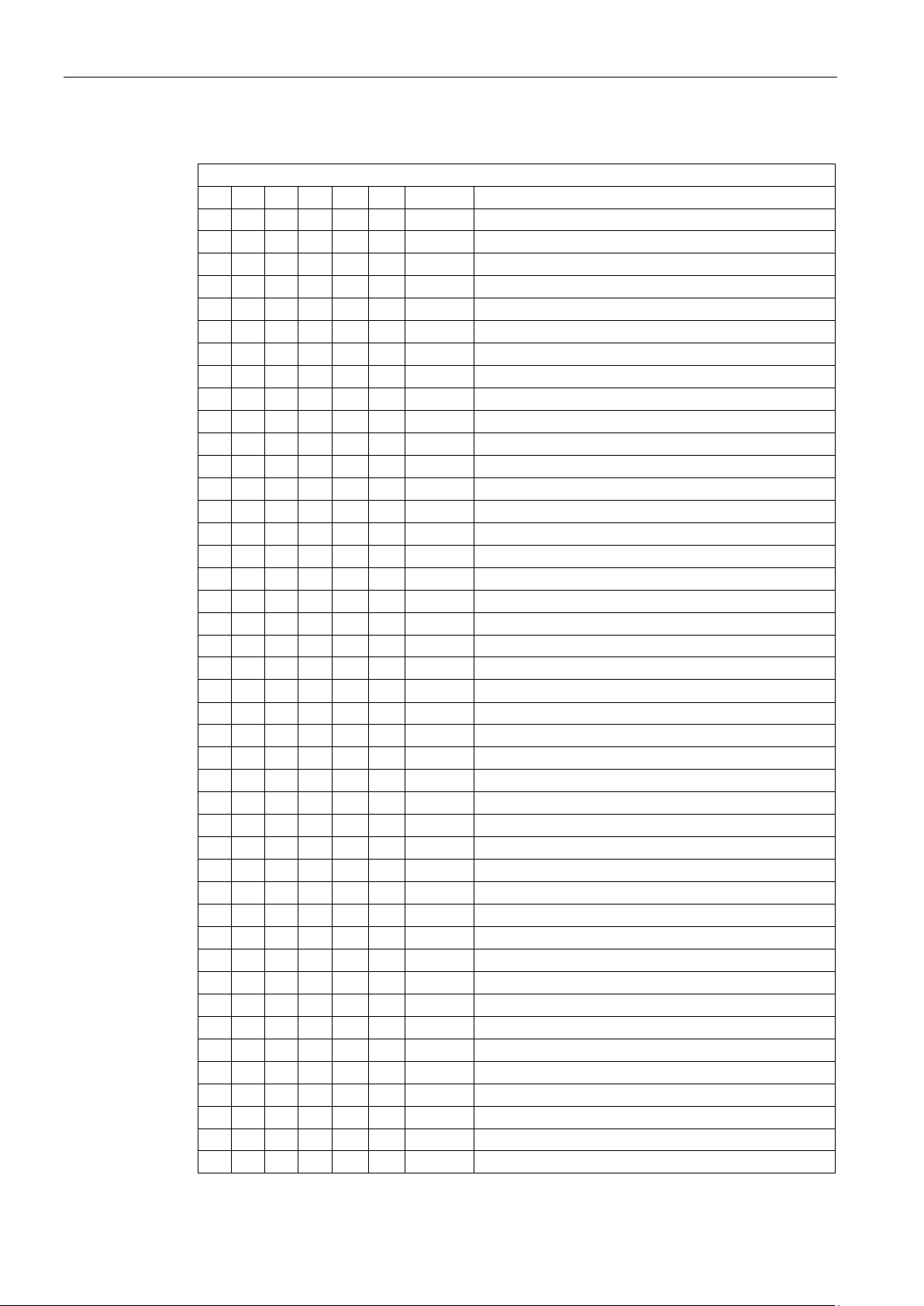

Profile Selection

B1

B2

B3

B4

B5

B6

Profile

Flowmeter Firmware Version & Configuration

Off

Off

Off

Off

Off

Off

profile 1

5N01-5.04.05 CH1: Clamp-On

On

Off

Off

Off

Off

Off

profile 2

5N01-5.04.05 CH1: Reflexor

Off

On

Off

Off

Off

Off

profile 3

5N02-5.04.05 CH1: Clamp-On

On

On

Off

Off

Off

Off

profile 4

5N02-5.04.05 CH1: Reflexor

Off

Off

On

Off

Off

Off

profile 5

5N03-5.04.05 CH1: Clamp-On CH2: Clamp-On

On

Off

On

Off

Off

Off

profile 6

5N03-5.04.05 CH1: Reflexor CH2: Reflexor

Off

On

On

Off

Off

Off

profile 7

5N03-5.04.05 CH1: Clamp-on CH2: Reflexor

On

On

On

Off

Off

Off

profile 8

5N03-5.04.05 Dual Path: Clamp-On

Off

Off

Off

On

Off

Off

profile 9

5N03-5.04.05 CH1+2: Clamp-On

On

Off

Off

On

Off

Off

profile 10

5N03-5.04.05 CH1-2: Clamp-On

Off

On

Off

On

Off

Off

profile 11

5N04-5.04.05 CH1: Clamp-On CH2: Clamp-On

Off

Off

On

On

Off

Off

profile 13

5N04-5.04.05 CH1: Clamp-On CH2: Reflexor

Off

On

On

On

Off

Off

profile 15

5N04-5.04.05 CH1+2: Clamp-On

On

On

On

On

Off

Off

profile 16

5N04-5.04.05 CH1-2: Clamp-On

Off

Off

Off

Off

On

Off

profile 17

5MN01-5.04.05 4 Channel Flow: Clamp-On

On

Off

Off

Off

On

Off

profile 18

5MN01-5.04.05 CH5: Clamp-On

Off

On

Off

Off

On

Off

profile 19

5MN01-5.04.05 Quad Path: Clamp-On

On

On

Off

Off

On

Off

profile 20

5MN02-5.04.05 4 Channel Flow: Clamp-On

Off

Off

On

Off

On

Off

profile 21

5MN02-5.04.05 CH5: Clamp-On

On

Off

On

Off

On

Off

profile 22

5MN02-5.04.05 Quad Path: Clamp-On

Off

On

On

Off

On

Off

profile 23

5EN02-5.04.05 Ch1: Clamp-On

On

On

On

Off

On

Off

profile 24

5EN02-5.04.05 Ch1: Reflexor

Off

Off

Off

On

On

Off

profile 25

5EN03-5.04.05 Ch1: Clamp-On Ch2: Clamp-On

On

Off

Off

On

On

Off

profile 26

5EN03-5.04.05 Ch1:Reflexor Ch2: Reflexor

Off

On

Off

On

On

Off

profile 27

5EN03-5.04.05 Ch1: Clamp-On Ch2: Reflexor

On

On

Off

On

On

Off

profile 28

5EN03-5.04.05 Dual Path: Clamp-On

Off

Off

On

On

On

Off

profile 29

5EN03-5.04.05 Ch1+2: Clamp-On

On

Off

On

On

On

Off

profile 30

5EN04-5.04.05 Ch1: Clamp-On Ch2: Clamp-On

Off

On

On

On

On

Off

profile 31

5EN04-5.04.05 Ch1: Reflexor Ch2: Reflexor

On

On

On

On

On

Off

profile 32

5EN04-5.04.05 Ch1: Clamp On Ch2: Reflexor

On

Off

Off

Off

Off

On

profile 34

5EN04-5.04.05 Dual Path: Clamp-On

On

On

Off

Off

Off

On

profile 36

5PVN02-5.04.05 Dual Path: Clamp-On

Off

Off

On

Off

Off

On

profile 37

5PVN03-5.04.05 Dual Path: Clamp-On

On

Off

On

Off

Off

On

profile 38

5BN01-5.04.05 CH1: Clamp-On

Off

On

On

Off

Off

On

profile 39

5BN02-5.04.05 CH1: Clamp-On CH2: Clamp-On

On

On

On

Off

Off

On

profile 40

5DVN02-5.04.05 Dual Path: Clamp-On

Off

Off

Off

On

Off

On

profile 41

5DVN03-5.04.05 Dual Path: Clamp-On

On

Off

Off

On

Off

On

profile 42

5DVN04-5.04.05 Quad Path: Clamp-On

Off

On

Off

On

Off

On

profile 43

5GN03-5.04.05 CH1: Clamp-On

2.2 F US Clamp-on Communications Module Installation

Table 2- 2 Profile Selection: 1 - 46

On On Off On Off Off profile 12 5N04-5.04.05 CH1: Reflexor CH2: Reflexor

On Off On On Off On profile 14 5N04-5.04.05 Dual Path: Clamp-On

Off Off Off Off Off On profile 33 5EN04-5.04.05 Ch1+2: Clamp-On

Off On Off Off Off On profile 35 5PVN01-5.04.05 CH1: Clamp-On

F US Clamp-on Communications Protocol Manual

16 Hardware Installation Manual, 11/2015, A5E34981613-AC

Installing/Mounting

On

On

Off

On

Off

On

profile 44

5GN04-5.04.05 Dual Path: Clamp-On

Off

Off

On

On

Off

On

profile 45

5GN05-5.04.05 Dual Path: Clamp-On

On

Off

On

On

Off

On

profile 46

5GN07-5.04.05 Quad Path: Clamp-On

2.3

Flowmeter Setup

Note

The Flowmeter Setup procedure must be done to every channel of the meter.

Configure RS-232 Setup

Configure Logger Setup

Note

This Logger Setup procedure must be done for both channels if it is configured as a dual

channel unit, or all channels, if a multi

manual for the FUS1010 flowmeter for menu details, if required.

2.3 Flowmeter Setup

In order for the Communications Module (P/N A5E31949269) to work properly, all of the

possible Logger configuration choices in the site setup must be correct.

In the [Meter Facilities] menu:

1. On the flowmeter keypad, press the <MENU> key.

2. Press <Left> arrow key until [Meter Type] appears then press <Down> arrow key to

[Meter Facilities].

3. Scroll to [RS-232 Setup] then press <Right> arrow key.

4. Set Baud: 9600

5. Set Parity: Odd

6. Set Data Bits: 7

7. Line Feed: NO

8. Network ID: 0

1. On the flowmeter keypad, press the <MENU> key.

-channel unit. Refer to the Operation Instructions

2. Press <Left> arrow key until [Meter Type] appears then press <Down> arrow key to

[Meter Facilities].

3. With [Meter Type] shown press <Right> arrow key until [Chan/Path Setup] appears.

4. Select [Channel 1] and the appropriate sensor type; we are setting up within the context

of the site setup that was created for this installation.

5. Use the <UP/DN> arrow keys and scroll to [Logger Setup]. Use the <Right> arrow key to

access the submenu.

6. Five menu choices will be shown. Since we have to check each one, the order in which

you change these is not important. Use the <UP/DN> arrow keys to select the main

F US Clamp-on Communications Protocol Manual

Hardware Installation Manual, 11/2015, A5E34981613-AC

17

Installing/Mounting

DO NOT select

[Sonilocator]

Channel Setup

Note

If ALL channels are not [Enabled], the Modbus card will NOT provide valid data.

Note

For all 1010 flowmeters the site names must be

Card itself.

Please view the "Web Configuration Utility" at the end of this procedure and refer and follow

the instructions concerning "site_idx

2.3 Flowmeter Setup

choices. Use the <Right> arrow key to access the choices. Using the <UP/DN> arrow

keys, select the item desired as defined below. Pressing the <ENTER> key will select that

choice.

● Logger Mode: Set to RS-232 Output

● Logger Data ON: Select All Items (Note: If any FUH1010 system,

in the Logger Data drop down menu.)

● Log Interval Set: Set to 5 secs

● Logger Events: Set to NONE

Press the <Right> arrow to access. Highlight each Logger item using the <UP/DN> arrow

keys, and then press the <ENTER> key to set EVERY choice on. Each item will have [+]

sign to left of item when selected.

Use the <Left> arrow key to back out of the nested menu to return to the top menu. Use of

the <Left> arrow key intermediately saves the configuration information permanently. You

also must then Re-Save the site.

For each channel set the Logger to [On Demand.]

1. Set all Data elements: ON (denoted by +)

2. Set [Events]: Off

3. Set [display/Memory Datalogger: Off

4. Enable all Channels

duplicated on the Communications Module

"

F US Clamp-on Communications Protocol Manual

18 Hardware Installation Manual, 11/2015, A5E34981613-AC

Installing/Mounting

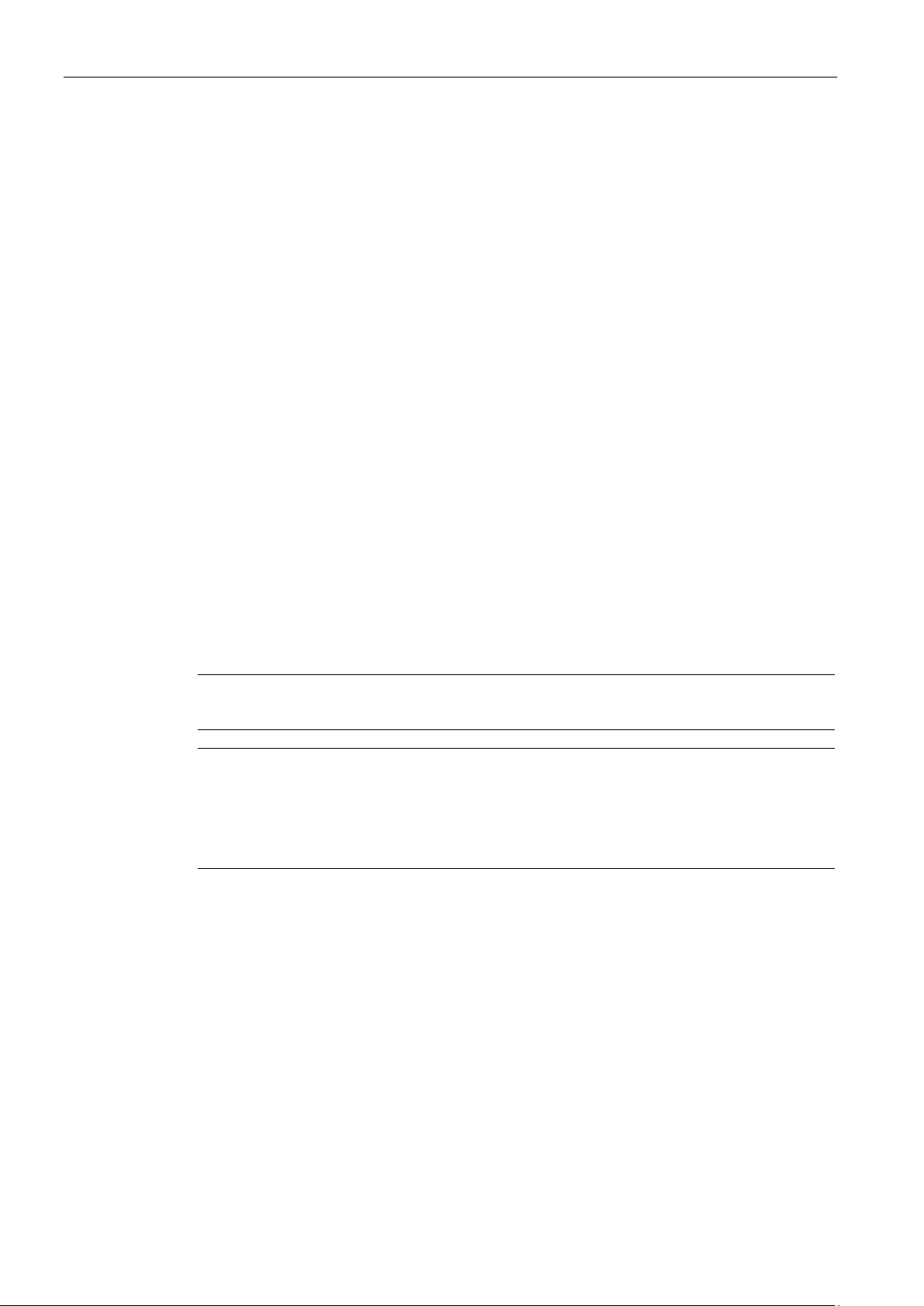

Communications Cable Installation

FieldServer Toolbox

2.3 Flowmeter Setup

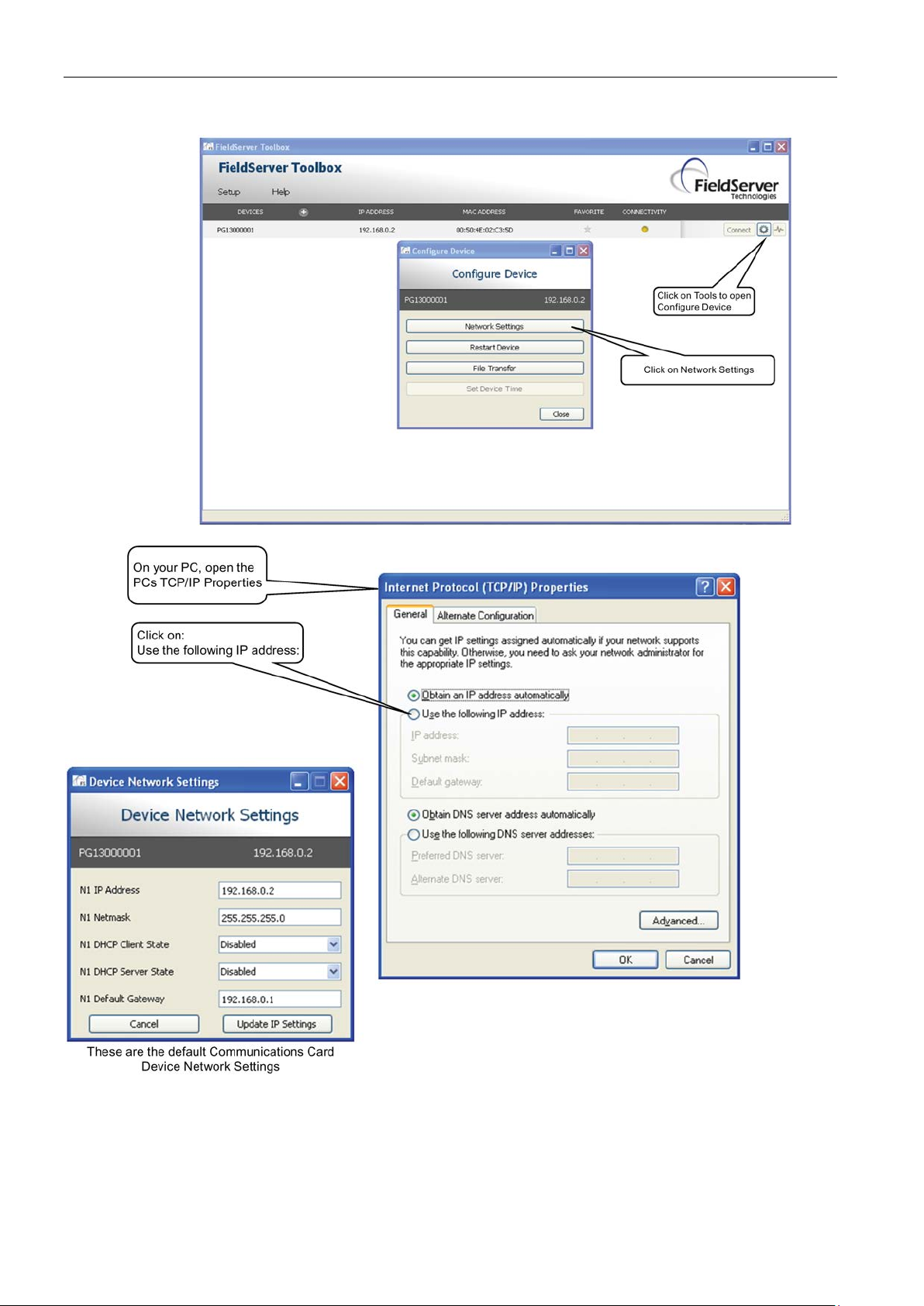

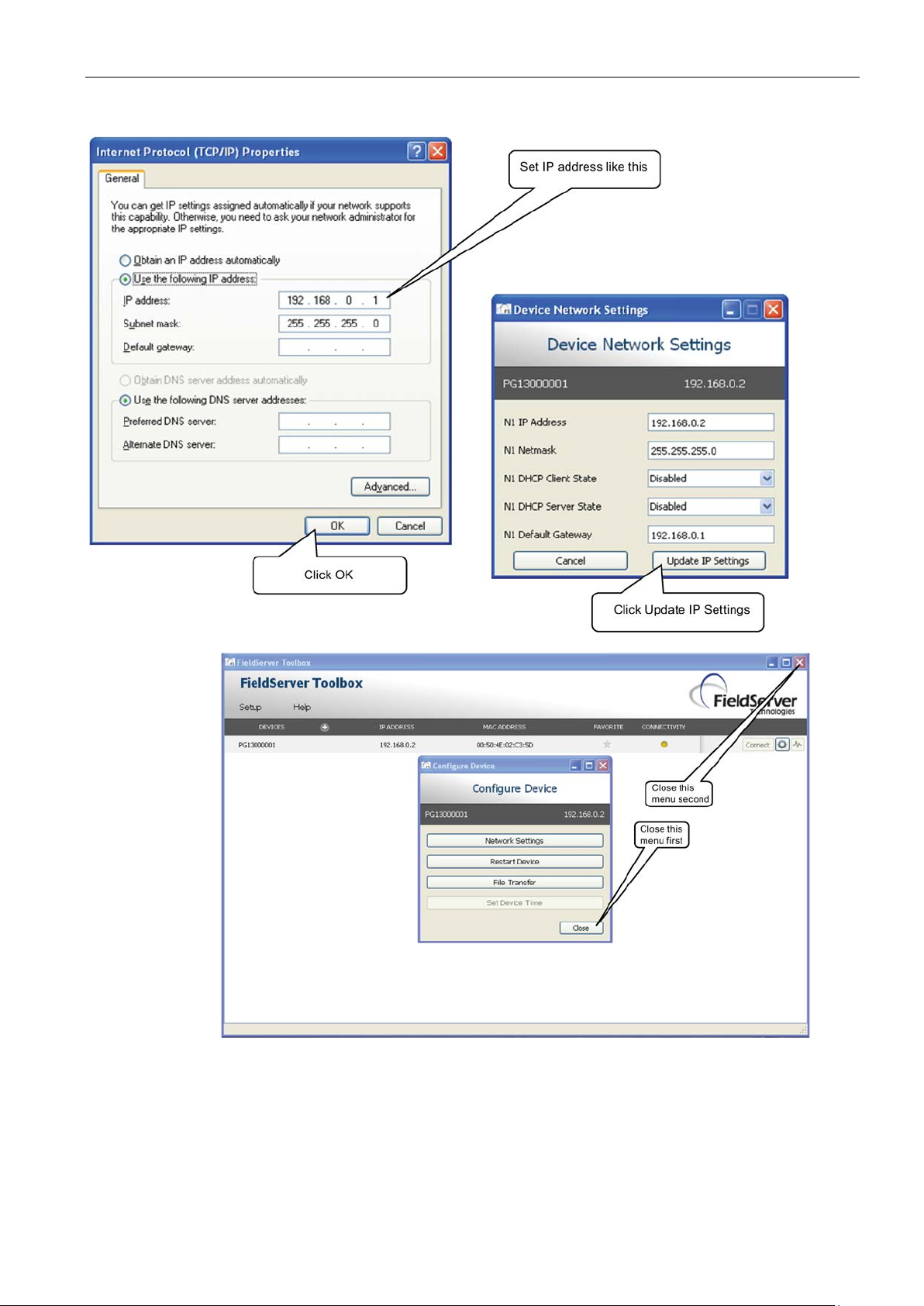

Connect Communication cable (Cat5 type) from J1 to the Ethernet port of your PC.

Figure 2-5 Communications Cable Installation

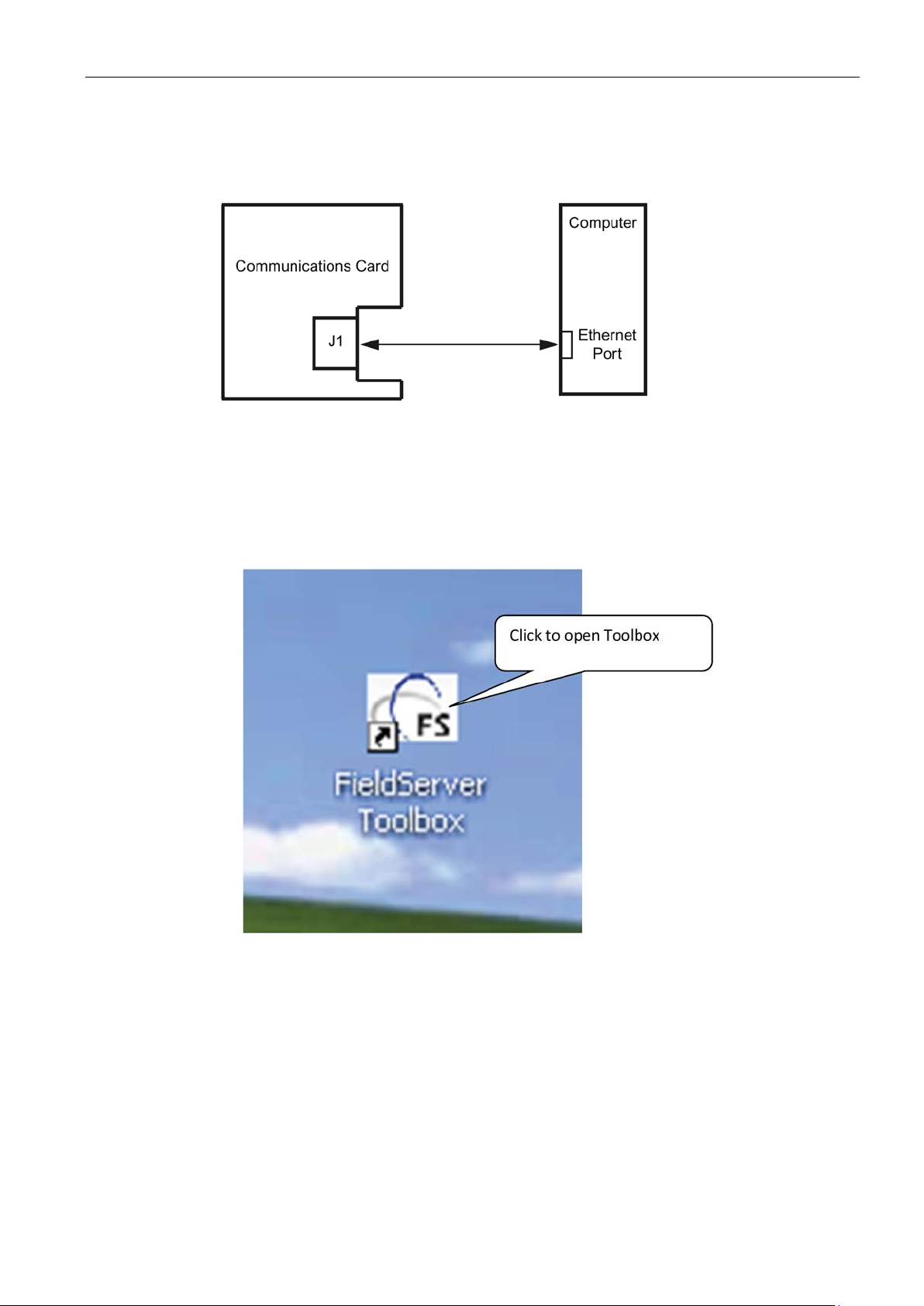

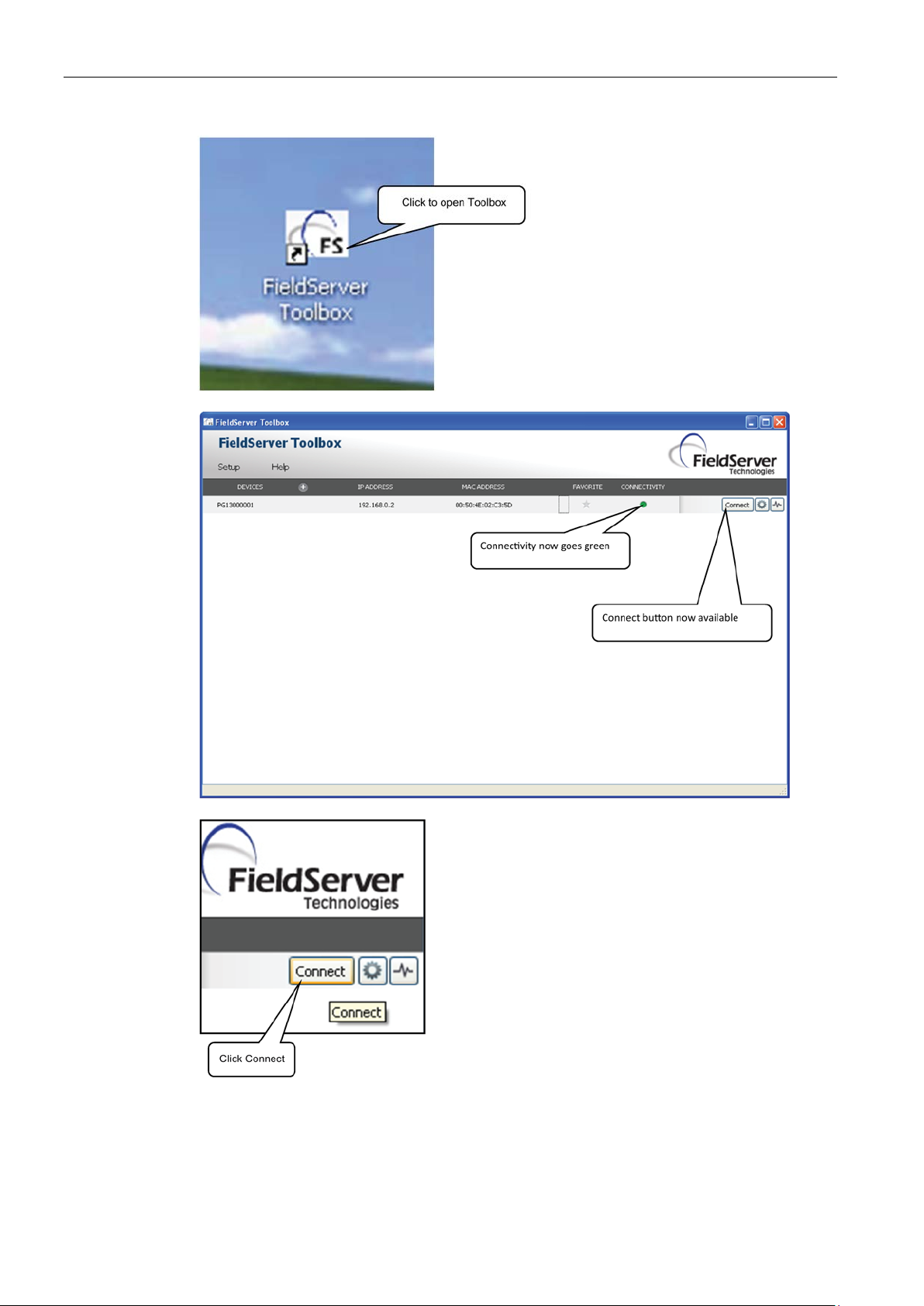

1. Download FieldServer Toolbox from here if you do not have it installed:

http://bit.ly/FStoolbox

2. After FieldServer Toolbox installs, click on the desktop icon.

F US Clamp-on Communications Protocol Manual

Hardware Installation Manual, 11/2015, A5E34981613-AC

19

Installing/Mounting

2.3 Flowmeter Setup

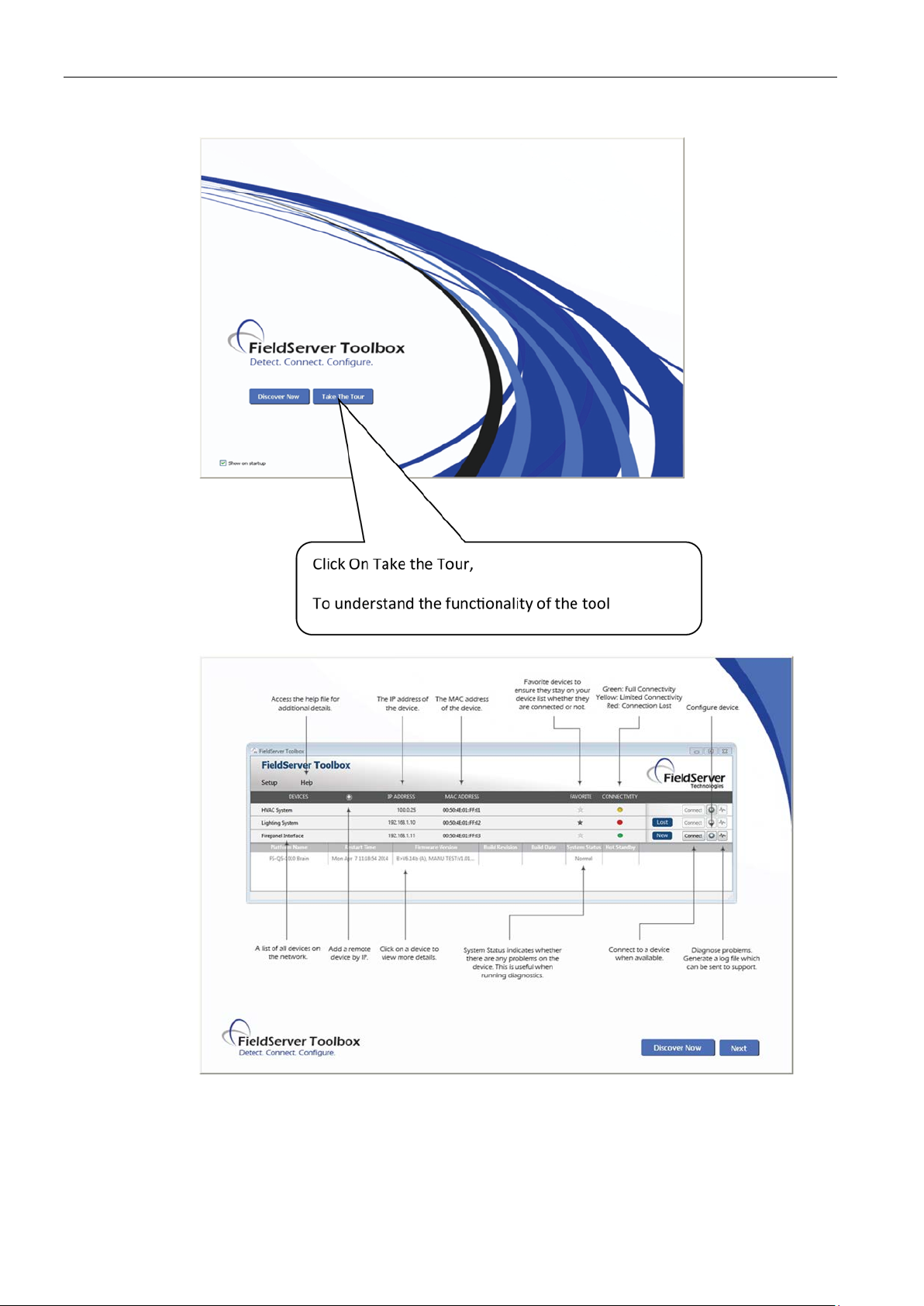

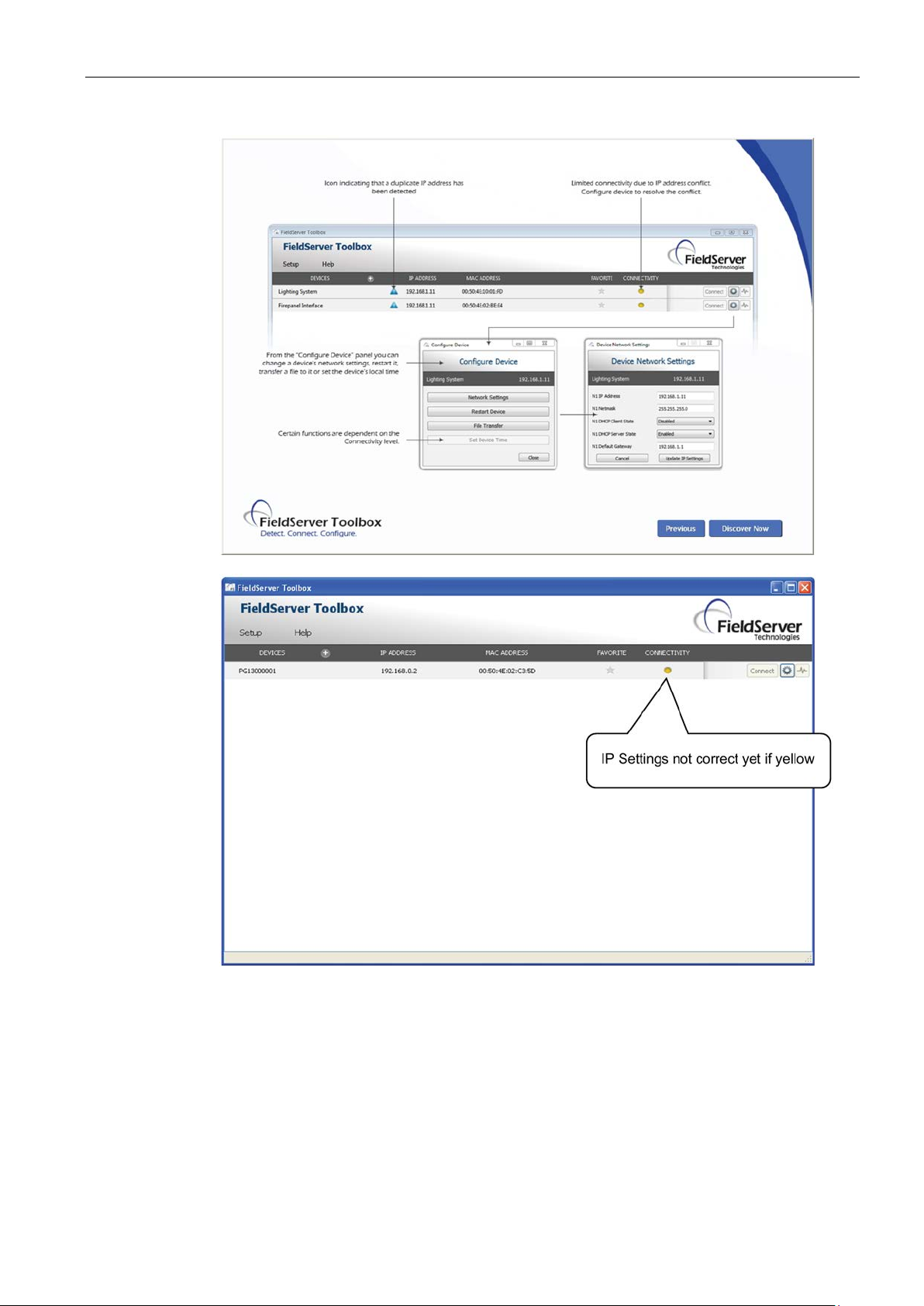

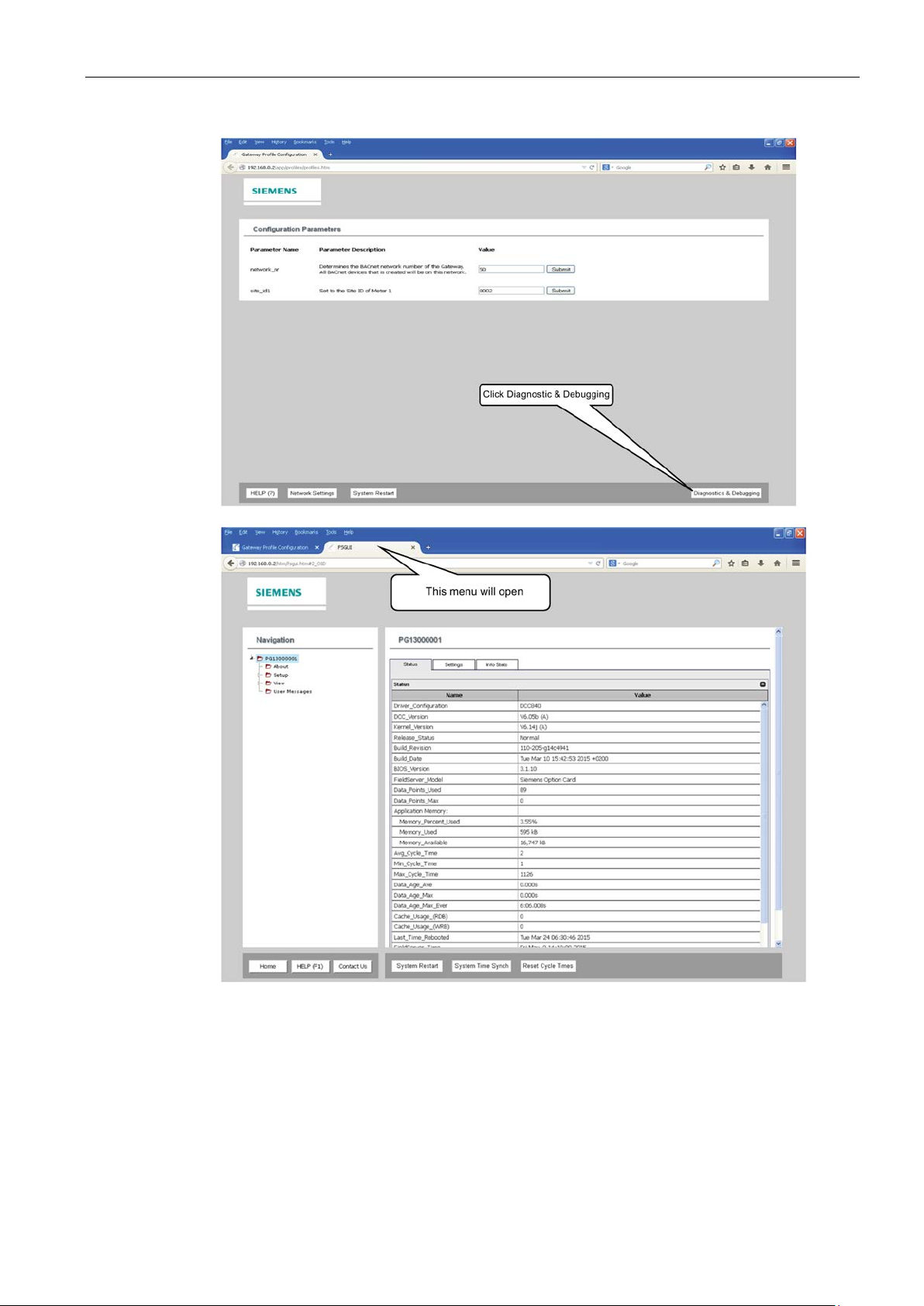

Figure 2-6 FieldServer Toolbox Tour

F US Clamp-on Communications Protocol Manual

20 Hardware Installation Manual, 11/2015, A5E34981613-AC

Installing/Mounting

2.3 Flowmeter Setup

F US Clamp-on Communications Protocol Manual

Hardware Installation Manual, 11/2015, A5E34981613-AC

21

Installing/Mounting

2.3 Flowmeter Setup

F US Clamp-on Communications Protocol Manual

22 Hardware Installation Manual, 11/2015, A5E34981613-AC

Installing/Mounting

2.3 Flowmeter Setup

F US Clamp-on Communications Protocol Manual

Hardware Installation Manual, 11/2015, A5E34981613-AC

23

Installing/Mounting

2.3 Flowmeter Setup

F US Clamp-on Communications Protocol Manual

24 Hardware Installation Manual, 11/2015, A5E34981613-AC

Installing/Mounting

2.3 Flowmeter Setup

F US Clamp-on Communications Protocol Manual

Hardware Installation Manual, 11/2015, A5E34981613-AC

25

Installing/Mounting

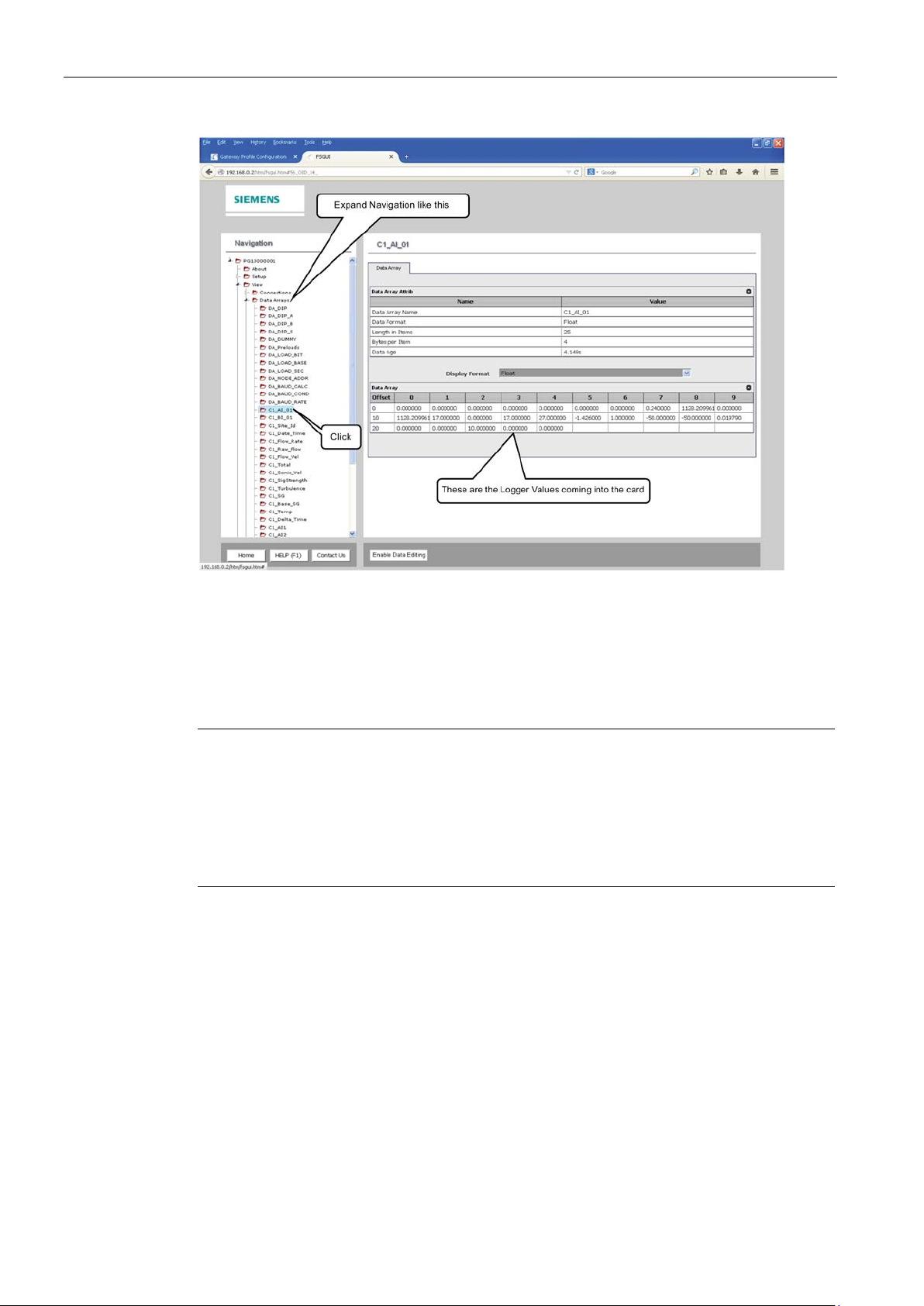

View - Data Arrays

Note

When using the WEB utility there are parameters under View - Data Arrays that identify the

position of the DIP switches in decimal form:

•

•

•

•

2.3 Flowmeter Setup

Here you can view the data coming from the meter as it is stored before being mapped to the

various protocol parameters. This may be useful to determine that the data is being received

by the Communications Module. Values being set to 0 may indicate a problem with the

configuration setup in the flowmeter.

DA-DIP: All 16 positions of switches A & B

DA-DIP_A: All 8 positions of switch A

DA-DIP_B: Positions 1-4 of switch B

DA-DIP_S: Positions 5-8 of switch B

F US Clamp-on Communications Protocol Manual

26 Hardware Installation Manual, 11/2015, A5E34981613-AC

Installing/Mounting

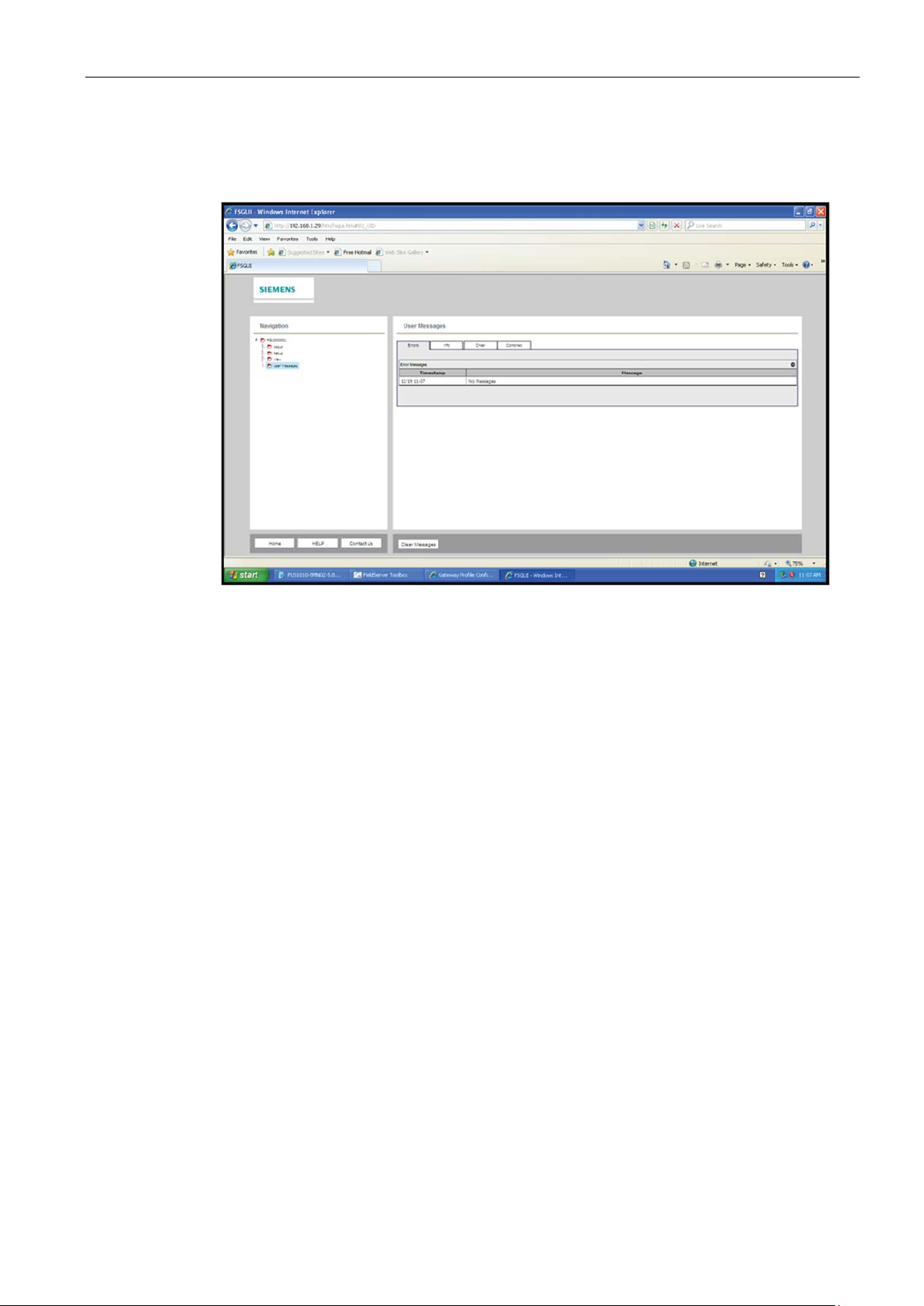

User Messages

2.3 Flowmeter Setup

Here you can view any messages that may indicate an error.

Figure 2-7 User Messages

F US Clamp-on Communications Protocol Manual

Hardware Installation Manual, 11/2015, A5E34981613-AC

27

Installing/Mounting

2.3 Flowmeter Setup

F US Clamp-on Communications Protocol Manual

28 Hardware Installation Manual, 11/2015, A5E34981613-AC

Loading...

Loading...