Ultrasonic flowmeters

SITRANS FUP1010 IP67 7ME3510 Portable Flowmeter

Operating Instructions - March 2012

SITRANS F

Answers for industry.

SIEMENS

SIEMENS

SITRANS F

Ultrasonic Flowmeters FUP1010 IP67 Portable

Operating Instructions

| Introduction | 1 |

|---|---|

| Safety notes | 2 |

| Description | 3 |

| Installing/mounting | 4 |

| Connecting | 5 |

| Commissioning | 6 |

| Functions | 7 |

| Alarm, error, and system messages | 8 |

| Maintenance and service | 9 |

| Troubleshooting | 10 |

| Technical data | 11 |

| Appendix | Α |

| Appendix | В |

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are graded according to the degree of danger.

indicates that death or severe personal injury will result if proper precautions are not taken.

indicates that death or severe personal injury may result if proper precautions are not taken.

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

CAUTION

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

NOTICE

indicates that an unintended result or situation can occur if the relevant information is not taken into account

If more than one degree of danger is present, the warning notice representing the highest degree of danger will be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific task in accordance with the relevant documentation, in particular its warning notices and safety instructions. Qualified personnel are those who, based on their training and experience, are capable of identifying risks and avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

Siemens products may only be used for the applications described in the catalog and in the relevant technical documentation. If products and components from other manufacturers are used, these must be recommended or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and maintenance are required to ensure that the products operate safely and without any problems. The permissible ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the information in this publication is reviewed regularly and any necessary corrections are included in subsequent editions.

Siemens AG Industry Sector Postfach 48 48 90026 NÜRNBERG GERMANY

Order number: A5E02951522 © 03/2012 Technical data subject to change

Copyright © Siemens AG 2012. All rights reserved

Table of contents

| 1 | Introdu | uction | 9 |

|---|---|---|---|

| 1.1 | Preface | 9 | |

| 1.2 | Items supplied | 9 | |

| 1.3 | History | 9 | |

| 1.4 | Further Information | 10 | |

| 2 | Safety | notes | 11 |

| 2.1 | Laws and directives | 11 | |

| 2.2 | Lithium batteries | 12 | |

| 2.3 | Certificates | 12 | |

| 3 | Descri | ption | 13 |

| 3.1 | FUP1010 features | 13 | |

| 3.2 | Applications | 14 | |

| 3.3 | Theory of Operation | 15 | |

| 4 | Installi | ing/mounting | |

| 4.1 | Installation safety precautions | 21 | |

| 4.2 | Use according to specifications | 21 | |

| 4.3 | Application Guidelines | ||

| 4.4 | AC Battery Charger | ||

| 5 | Conne | ecting | |

|

5.1

5.1.1 5.1.2 |

Transmitter Wiring

Forming the Internal Battery Connecting AC Power Adapter/Charger |

||

|

5.2

5.2.1 5.2.2 5.2.3 5.2.4 5.2.5 5.2.6 5.2.7 |

Sensor Wiring

Preliminary Installation Procedures Sensor Identification and Selection Navigating the Menu Setting the Parameters Reflect Mount Direct Mount 1012T Mounting Tracks |

||

| 5.3 | Zero Flow Adjust Menu | 61 | |

| 6 | Comm | lissioning | |

| 6.1 | General requirements | ||

| 6.2 | Commissioning | 67 |

| 6.3 | Empty Pipe Set | ||||

|---|---|---|---|---|---|

| 6.4 | Installation Menus | 72 | |||

| 7 | Functio | ons | 77 | ||

| 7.1 | Selecting Flow Units | ||||

| 7.2 | Span Data | ||||

| 7.3 | Logger Control | ||||

| 7.4 | Operation Adjust Menu Settings | ||||

| 7.5 | Setting Relays | ||||

| 7.6 | Memory Control | ||||

| 7.7 | Analog Out Setup | ||||

| 7.8 | Analog Input Setup | ||||

| 7.9 | Analog Output Trim | ||||

| 7.10 | RTD Calibration | ||||

| 7.11 | Reflexor | ||||

| 8 | Alarm, | error, and system messages | 115 | ||

| 8.1 | Alarm Letter Codes | 115 | |||

| 9 | Maintenance and service | ||||

| 9.1 | Maintenance | 117 | |||

| 9.2 | Technical support | 117 | |||

| 9.3 | Replacing the battery | ||||

| 9.4 | Battery disposal | 121 | |||

| 9.5 | Disposal | ||||

| 9.6 | Return procedures | ||||

| 10 | Trouble | eshooting | |||

| 10.1 | Troubleshooting | ||||

| 10.2 | F4 Reset Procedure | ||||

| 10.3 | Test Facilities Graph Screen | ||||

| 10.4 | Site Setup Data | ||||

| 11 | Techni | ical data | |||

| 11.1 | Technical Data | ||||

| Α | Appen | dix | |||

| A.1 | Ordering | 143 | |||

| A.2 | I/O Connections and Wiring | 143 | |||

| A.3 | Site Setup For SITRANS F | 145 | |||

| A.4 | Flowrate Calibration and Calibration Tables | ||||

| В | Appendix | ٢ | 155 |

|---|---|---|---|

| B.1 | Installation/Outline Drawings | 155 | |

| Glossary | 157 | ||

| Index | 163 |

Tables

| Table 4- 1 | Power Cord Codes | 24 |

|---|---|---|

| Table 5- 1 | Keypad Function Chart | 35 |

| Table 5- 2 | Pipe Configuration Option List Definitions | |

| Table 7- 1 | Totalizer Modes | 78 |

| Table 7- 2 |

Totalizer Controls (the "n" in

|

80 |

| Table 7- 3 | Logger Control Menu Option List | 83 |

| Table 7-4 | Relay Option List | 89 |

| Table 7- 5 | Memory Control Menu | 91 |

| Table 7- 6 | Analog Outputs | 92 |

| Table 7- 7 | Analog Out Setup Data Categories | 92 |

| Table 7-8 | Analog Out Trim Menu Structure | 97 |

| Table 7- 9 | RTD Calibrate Menu Structure | 101 |

| Table 7- 10 | Inline Metal and Plastic Pipe Cable Connections | 105 |

| Table 7- 11 | Cursor Definitions | 110 |

| Table 7- 12 | Diagnostic Data | 112 |

| Table 8- 1 | Alarm Codes and Descriptions | 115 |

| Table 10- 1 | Troubleshooting Tips | 123 |

| Table 10- 2 | Description of Graph Screen Text Display Parameters | 134 |

| Table 10- 3 | Hot Key Summary | 135 |

| Table 10- 4 | Site Setup Menu Items | 136 |

| Table 11- 1 | Performance Specifications | 141 |

| Table A- 1 | Part Numbers and Connection Data | 143 |

| Table A- 2 | 2 Channel/2 Path Input/Output Terminal Block Wiring | 144 |

Figures

| Figure 3-1 | Weatherproof Case-shown open | 13 |

|---|---|---|

| Figure 4-1 | Power Adapter/Battery Charger | 23 |

| Figure 5-1 | Power Adapter/AC-Charger for Dual Channel Flow Meter | 27 |

| Figure 5-2 | Reflect Mount (Pipe shown from above in 12 o'clock position) | 28 |

|---|---|---|

| Figure 5-3 | Direct Mount (Pipe shown from above in 12 o'clock position) | 29 |

| Figure 5-4 | Sensor Alignment (Horizontal Plane) | 30 |

| Figure 5-5 | Pipe Surface Preparation | 31 |

| Figure 5-6 | Universal Sensor Label | 32 |

| Figure 5-7 | Hi Precision Sensor Label | 33 |

| Figure 5-8 | KeyPad | 34 |

| Figure 5-9 | Typical Installation Menu Screen | 35 |

| Figure 5-10 | Reflect Mount with EZ-Clamp and Spacer Bar | 41 |

| Figure 5-11 | Sensor Mounting with E-Z Clamp and Spacer Bar | 43 |

| Figure 5-12 | E-Z Clamp S-Hook | 43 |

| Figure 5-13 | Sensor | 43 |

| Figure 5-14 | Connecting Sensors to Flow Meter | 44 |

| Figure 5-15 | Mylar Spacing Guide | 45 |

| Figure 5-16 | EZ Clamping Sensor to Pipe | 46 |

| Figure 5-17 | E-Z Clamp S-Hook | 46 |

| Figure 5-18 | Sensor | 46 |

| Figure 5-19 | Wrapping the Mylar Spacing Guide around the pipe (End View) | 48 |

| Figure 5-20 | Finding the Halfway Distance | 49 |

| Figure 5-21 | Aligning the Sensors for Direct Mode (End View) | 49 |

| Figure 5-22 | Connecting Sensors to Flow Meter | 50 |

| Figure 5-23 | Reflect Mount with Model 1012TP Mounting Track (Side View) | 52 |

| Figure 5-24 | Reflect Mode Chain Loop (Front View) | 53 |

| Figure 5-25 | Direct Mount 180° opposed with Mounting Tracks | 55 |

| Figure 5-26 | Direct Mount Roller Chain | 57 |

| Figure 5-27 | Wrapping the Mylar Spacing Guide around pipe (End View) | 58 |

| Figure 5-28 | Finding the Halfway Distance | 58 |

| Figure 5-29 | Track Rail Alignment | 59 |

| Figure 5-30 | REF and Number Index Pin Locations | 60 |

| Figure 7-1 | Sensor Mounting Examples | 104 |

| Figure 7-2 | Adjacent Sensor Mounting | 105 |

| Figure 7-3 | In-Line Sensor Mounting | 106 |

| Figure 7-4 | Spectra Graph Display Screen | 109 |

| Figure 9-1 | Faceplate Removal | 119 |

| Figure 9-2 | Battery Cover Removal | 120 |

| Figure 9-3 | Battery Removal/Replacement | 121 |

| Figure 10-1 | Test Facilities Graph Screen | .127 |

|---|---|---|

| Figure 10-2 | Setting Digital Damping Factor | .130 |

| Figure 10-3 | Setting the MinDamp Factor | .131 |

| Figure 10-4 | Envelope Threshold Adjustment | .133 |

Table of contents

Introduction

1.1

Preface

These instructions contain all the information you need for using the device.

The instructions are aimed at persons mechanically installing the device, connecting it electronically, configuring the parameters and commissioning it as well as service and maintenance engineers.

Note

It is the responsibility of the customer that the instructions and directions provided in the manual are read, understood and followed by the relevant personnel before installing the device.

1.2 Items supplied

- SITRANS F Transmitter

- SITRANS F literature CD

- For additional items refer to your packing slip.

Inspection

- 1. Check for mechanical damage due to possible improper handling during shipment. All claims for damage are to be made promptly to the shipper.

- 2. Make sure the scope of delivery, and the information on the type plate corresponds to the ordering information.

1.3 History

The contents of these instructions are regularly reviewed and corrections are included in subsequent editions. We welcome all suggestions for improvement.

The following table shows the most important changes in the documentation compared to each previous edition.

FUP1010 IP67 Portable

1.4 Further Information

| Edition | Remarks |

|---|---|

| 2/2010 | First Edition |

|

3/2012 Second Edition of Operating Instructions for the SITRANS FUP1010 IP67 portable f

meter. This document replaces all previous instructions for use. The most important changes are as follows: |

|

| The most important changes are as follows: | |

| Updated "Forming the Internal Battery" procedure | |

| Removed all references to External Battery Pack and Charger | |

| Added Reflexor operating mode chapter | |

| Updated Sensor label and sensor selection procedures | |

| Added 2mA drop fault indication note | |

| Added DIN pipe size table 2448 reference note | |

| Added Empty Pipe Set procedure | |

| Updated Troubleshooting Table | |

1.4 Further Information

The contents of these Operating Instructions shall not become part of or modify any prior or existing agreement, commitment or legal relationship. All obligations on the part of Siemens AG are contained in the respective sales contract which also contains the complete and solely applicable warranty conditions. Any statements contained herein do not create new warranties or modify the existing warranty.

Product information on the Internet

The Operating Instructions are available on the CD-ROM shipped with the device, and on the Internet on the Siemens homepage, where further information on the range of SITRANS F flowmeters may also be found:

Product information on the internet (http://www.siemens.com/flow)

Worldwide contact person

If you need more information or have particular problems not covered sufficiently by the operating instructions, please get in touch with your contact person. You can find contact information for your local contact person on the Internet:

Local contact person (http://www.automation.siemens.com/partner)

Safety notes

Correct, reliable operation of the product requires proper transport, storage, positioning and assembly as well as careful operation and maintenance. Only qualified personnel should install or operate this instrument.

Note

Alterations to the product, including opening or improper repairs of the product, are not permitted.

If this requirement is not observed, the CE mark and the manufacturer's warranty will expire.

2.1 Laws and directives

General requirements

Installation of the equipment must comply with national regulations. For example, the National Electrical Codes.

Instrument safety standards

The device has been tested at the factory, based on the safety requirements. In order to maintain this condition over the expected life of the device the requirements described in these Operating Instructions must be observed.

CAUTION

Aaterial compatibilit

Siemens can provide assistance with the selection of sensor parts. However, the full responsibility for the selection rests with the customer and Siemens can take no responsibility for any failure due to material incompatibility.

2.2 Lithium batteries

CE marked equipment

The CE-mark symbolizes the compliance of the device with the following Directives:

- EMC-Directive 2004/108/EC

- Low voltage Directive 2006/95/EC

- ATEX Directive 94/9/EC

2.2 Lithium batteries

Lithium batteries are primary power sources with high energy content designed to represent the highest possible degree of safety.

Potential hazard

Lithium batteries may present a potential hazard if they are abused electrically or mechanically. This is in most circumstances associated with the generation of excessive heat where internal pressure may cause the cell to rupture.

Thus the following basic precautions should be observed when handling and using lithium batteries:

- Do not short-circuit, recharge or connect with false polarity.

- Do not expose to temperature beyond the specified temperature range or incinerate the battery.

- Do not crush, puncture or open cells or disassemble battery packs.

- Do not weld or solder to the battery's body.

- Do not expose contents to water.

2.3 Certificates

Certificates are posted on the Internet and on the documentation CD-ROM shipped with the device.

See also

Technical data (Page 141)

Certificates on the Internet (http://www.siemens.com/processinstrumentation/certificates)

Description

3.1 FUP1010 features

Description

The Siemens SITRANS FUP1010 Weatherproof IP67 Portable flow meters achieve highly accurate flow measurements using ultrasonic transit-time technology. The sensors are mounted on the outside of the pipe, preventing contact with the medium. This means no cavities or clogging by high paraffin liquids found in many hydrocarbon applications.

The sensors offer superior performance in terms of volumetric flow accuracy, density accuracy, and turn-down ratio. The sensor construction makes installation and commissioning of even the largest sizes very straight forward and easy.

The sensors deliver true multi parameter measurements i.e.: volume flow and temperature.

The flow meter has a degree of protection of IP67.

Note

This operating Instructions manual applies to the following FUP1010 IP67 (weather proof) operating systems: Version 3.02.00K and later and version 4.03.00 and later.

Portable Configurations

The FUP1010 weatherproof single and dual channel flow meters use a compact and rugged submersible, weatherproof case. The following portable models are available:

- FUP1010 Weatherproof Single Channel Multi-Function Portable

- FUP1010 Weatherproof Dual Channel/Dual Path Multi-Function Portable

Figure 3-1 Weatherproof Case-shown open

FUP1010 IP67 Portable Operating Instructions, 03/2012, A5E02951522-02

3.2 Applications

Channel Functions

The system software allows simultaneous operation of one channel in the Transit-Time mode and the other in Reflexor mode.

Transit-Time Mode

All SITRANS F 1010 models use transit-time flow measurement technology varying only in functionality and environmental housing.

Reflexor Mode

The SITRANS F 1010 transit-time flow meter is highly resistant to the effects of liquid nonhomogeneity caused by the inclusion of air or solid particulate. However, sonic beam scattering may occur when mineral-based solids or gaseous content is a high percentage of the volume. This can cause difficulty in operation due to signal attenuation. Liquid conditions that may be unsuitable for transit-time operation can be measured using the Reflexor mode. Dual channel portable systems allow operation with one transit-time channel and one Reflexor channel measuring flow on the same pipe.

3.2 Applications

Measurement of Liquids

SITRANS F flow meters are designed for measurement of a variety of liquids and gases. The transmitters are multi-parameter devices offering accurate measurement of mass flow, volume flow, density, and temperature.

Typical Applications

The typical applications of the flowmeter are:

- Fuel Flow Measurement

- Hydraulic Oil Leak Detection

- Measurement of Additives

- Oil & Gas: Filling of gas bottles, furnace control, CNG-dispensers, test separators

- Crude Oil

- Finished Hydrocarbon Products

- Fuel Oil

- Bunker Fuel

Description

3.3 Theory of Operation

Typical Industries Serviced

- HVAC (Hotels, Airports, Government)

- Power Generation (Nuclear, Fossil, and Hydro)

- Chemical Processing

- Food and Pharmaceutical

- Aircraft Avionics and Ground Support

- Water and Wastewater

- Aerospace

- Automobile Manufacturing

- Hydrocarbon Industries

3.3 Theory of Operation

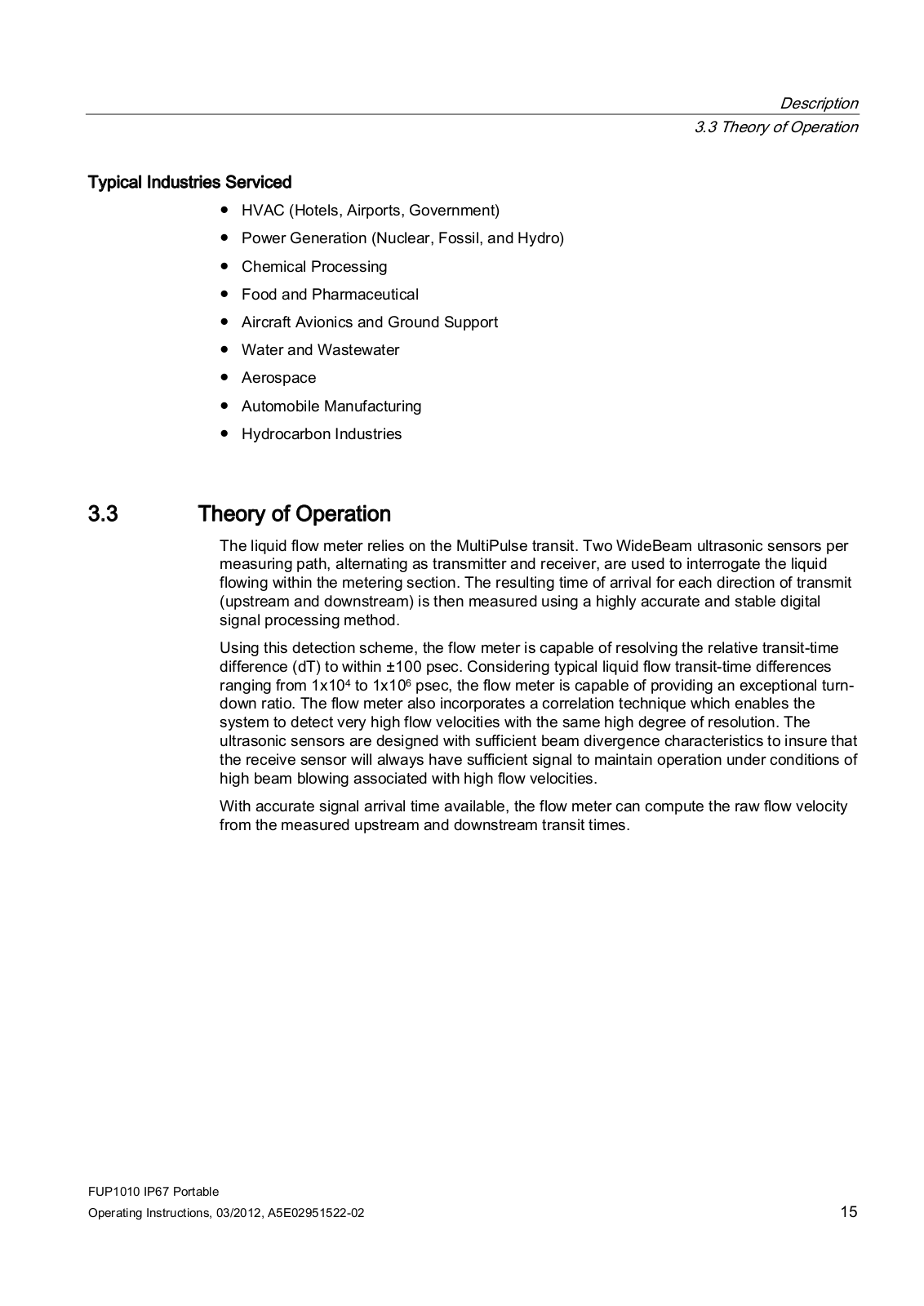

The liquid flow meter relies on the MultiPulse transit. Two WideBeam ultrasonic sensors per measuring path, alternating as transmitter and receiver, are used to interrogate the liquid flowing within the metering section. The resulting time of arrival for each direction of transmit (upstream and downstream) is then measured using a highly accurate and stable digital signal processing method.

Using this detection scheme, the flow meter is capable of resolving the relative transit-time difference (dT) to within ±100 psec. Considering typical liquid flow transit-time differences ranging from 1x104 to 1x106 psec, the flow meter is capable of providing an exceptional turn-down ratio. The flow meter also incorporates a correlation technique which enables the system to detect very high flow velocities with the same high degree of resolution. The ultrasonic sensors are designed with sufficient beam divergence characteristics to insure that the receive sensor will always have sufficient signal to maintain operation under conditions of high beam blowing associated with high flow velocities.

With accurate signal arrival time available, the flow meter can compute the raw flow velocity from the measured upstream and downstream transit times.

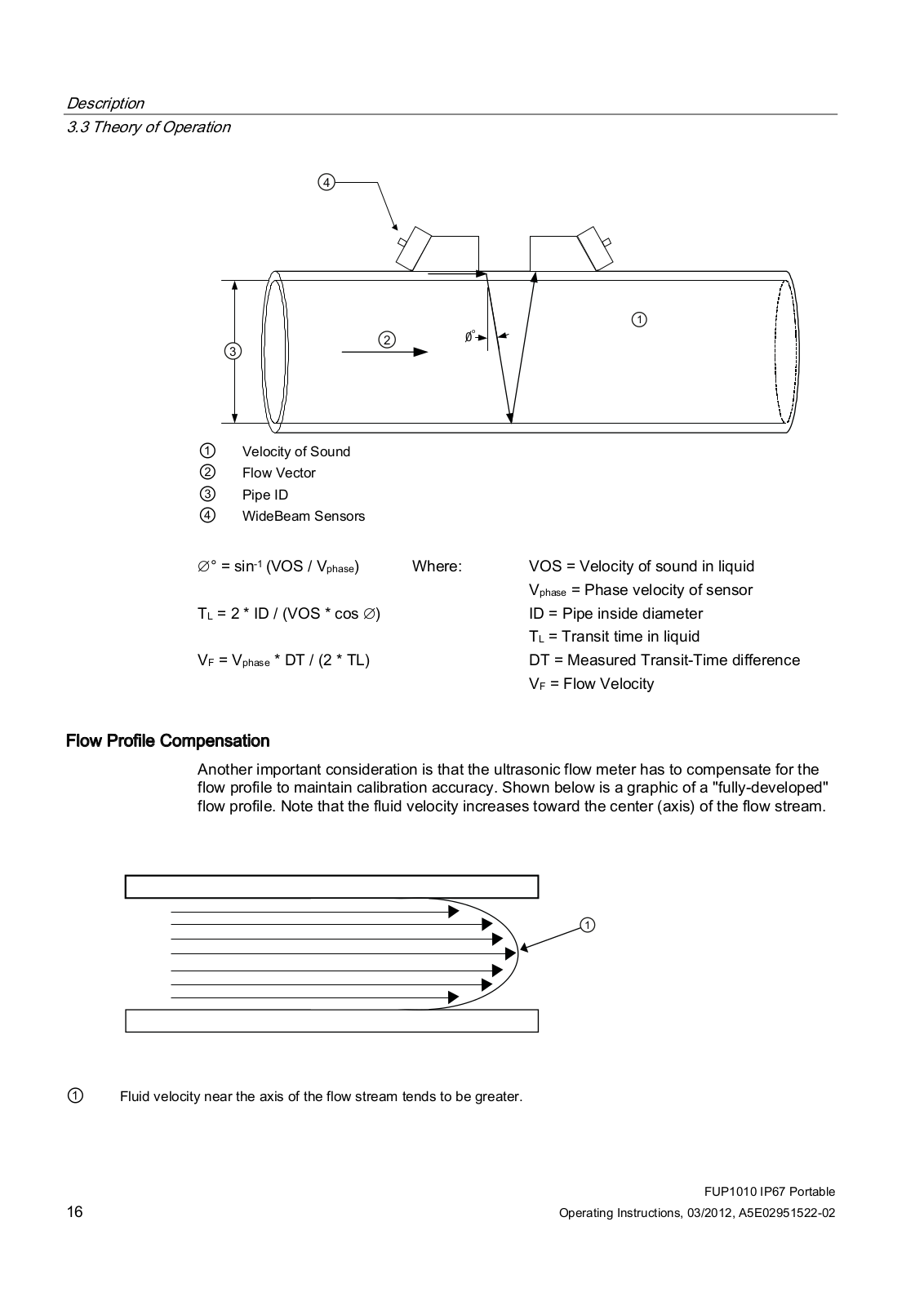

Flow Profile Compensation

Another important consideration is that the ultrasonic flow meter has to compensate for the flow profile to maintain calibration accuracy. Shown below is a graphic of a "fully-developed" flow profile. Note that the fluid velocity increases toward the center (axis) of the flow stream.

(1) Fluid velocity near the axis of the flow stream tends to be greater.

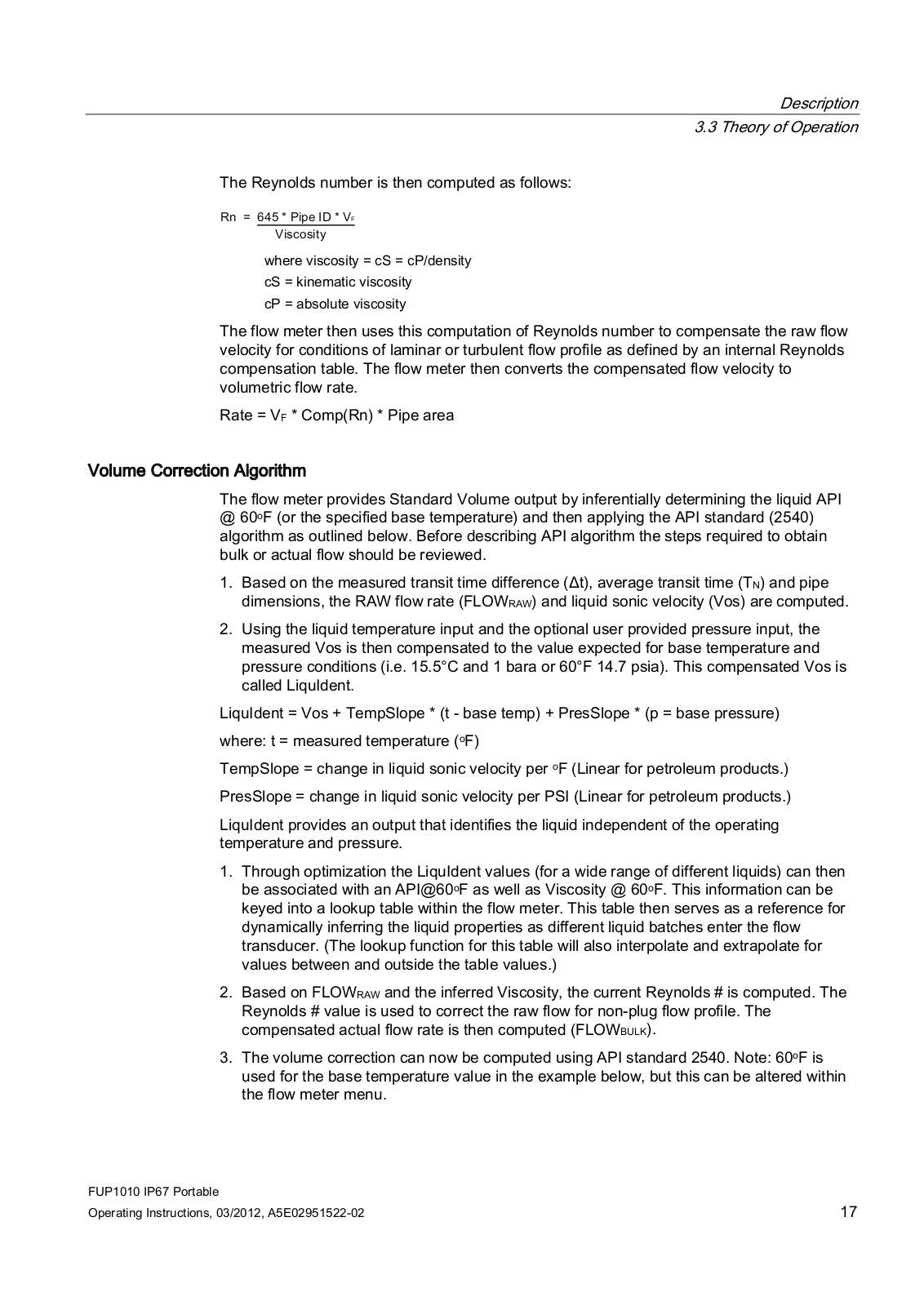

The Reynolds number is then computed as follows:

Rn = 645 * Pipe ID * VF Viscosity where viscosity = cS = cP/density cS = kinematic viscosity cP = absolute viscosity

The flow meter then uses this computation of Reynolds number to compensate the raw flow velocity for conditions of laminar or turbulent flow profile as defined by an internal Reynolds compensation table. The flow meter then converts the compensated flow velocity to volumetric flow rate.

Rate = VF * Comp(Rn) * Pipe area

Volume Correction Algorithm

The flow meter provides Standard Volume output by inferentially determining the liquid API @ 60°F (or the specified base temperature) and then applying the API standard (2540) algorithm as outlined below. Before describing API algorithm the steps required to obtain bulk or actual flow should be reviewed.

- 1. Based on the measured transit time difference (Δt), average transit time (TN) and pipe dimensions, the RAW flow rate (FLOWRAW) and liquid sonic velocity (Vos) are computed.

- 2. Using the liquid temperature input and the optional user provided pressure input, the measured Vos is then compensated to the value expected for base temperature and pressure conditions (i.e. 15.5°C and 1 bara or 60°F 14.7 psia). This compensated Vos is called Liguldent.

Liguldent = Vos + TempSlope * (t - base temp) + PresSlope * (p = base pressure)

where: t = measured temperature (°F)

TempSlope = change in liquid sonic velocity per °F (Linear for petroleum products.)

PresSlope = change in liquid sonic velocity per PSI (Linear for petroleum products.)

Liquident provides an output that identifies the liquid independent of the operating temperature and pressure.

- Through optimization the LiquIdent values (for a wide range of different liquids) can then be associated with an API@60°F as well as Viscosity @ 60°F. This information can be keyed into a lookup table within the flow meter. This table then serves as a reference for dynamically inferring the liquid properties as different liquid batches enter the flow transducer. (The lookup function for this table will also interpolate and extrapolate for values between and outside the table values.)

- 2. Based on FLOWRAW and the inferred Viscosity, the current Reynolds # is computed. The Reynolds # value is used to correct the raw flow for non-plug flow profile. The compensated actual flow rate is then computed (FLOWBULK).

- 3. The volume correction can now be computed using API standard 2540. Note: 60°F is used for the base temperature value in the example below, but this can be altered within the flow meter menu.

a) ρ60 = (141.5 *999.012) / (131.5 + API60)

- where:p60 = density at 60°F (Kg/m3)

- b) α60 = K0 / ρ602 + K1 / ρ60

- where K0 and K1 are coefficients of thermal expansion.

- c) ρt =ρ60 * EXP (- α60 Δt (1 + 0.8 α60 Δt))

- where \Delta t = (t 60)°F and t = measured temperature

- d) Therefore the volume correction factor (VCF) = pt / p60

The final volume compensated flow rate is then: Std Flow = FLOWBULK * VCF

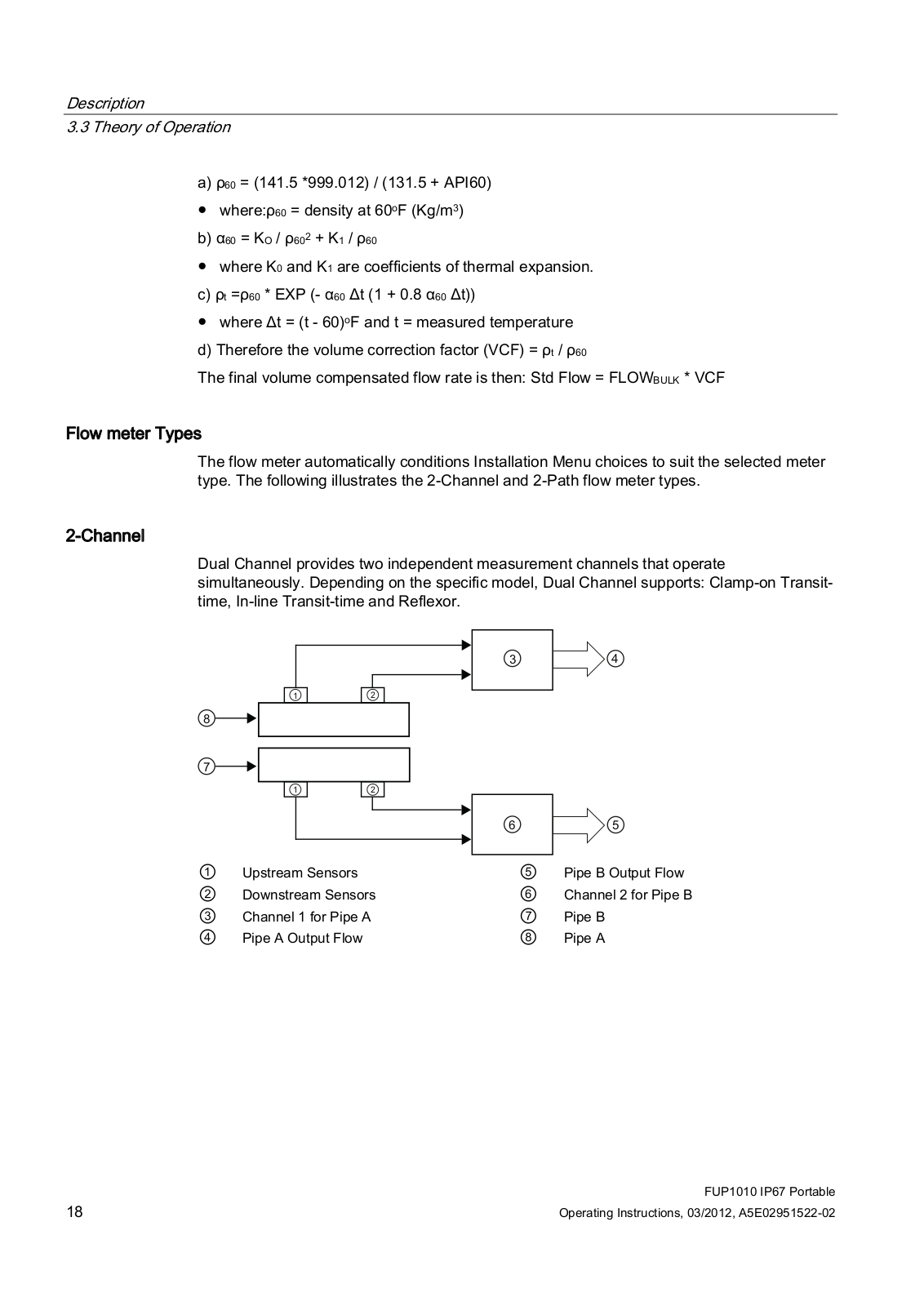

Flow meter Types

The flow meter automatically conditions Installation Menu choices to suit the selected meter type. The following illustrates the 2-Channel and 2-Path flow meter types.

2-Channel

Dual Channel provides two independent measurement channels that operate simultaneously. Depending on the specific model, Dual Channel supports: Clamp-on Transit-time, In-line Transit-time and Reflexor.

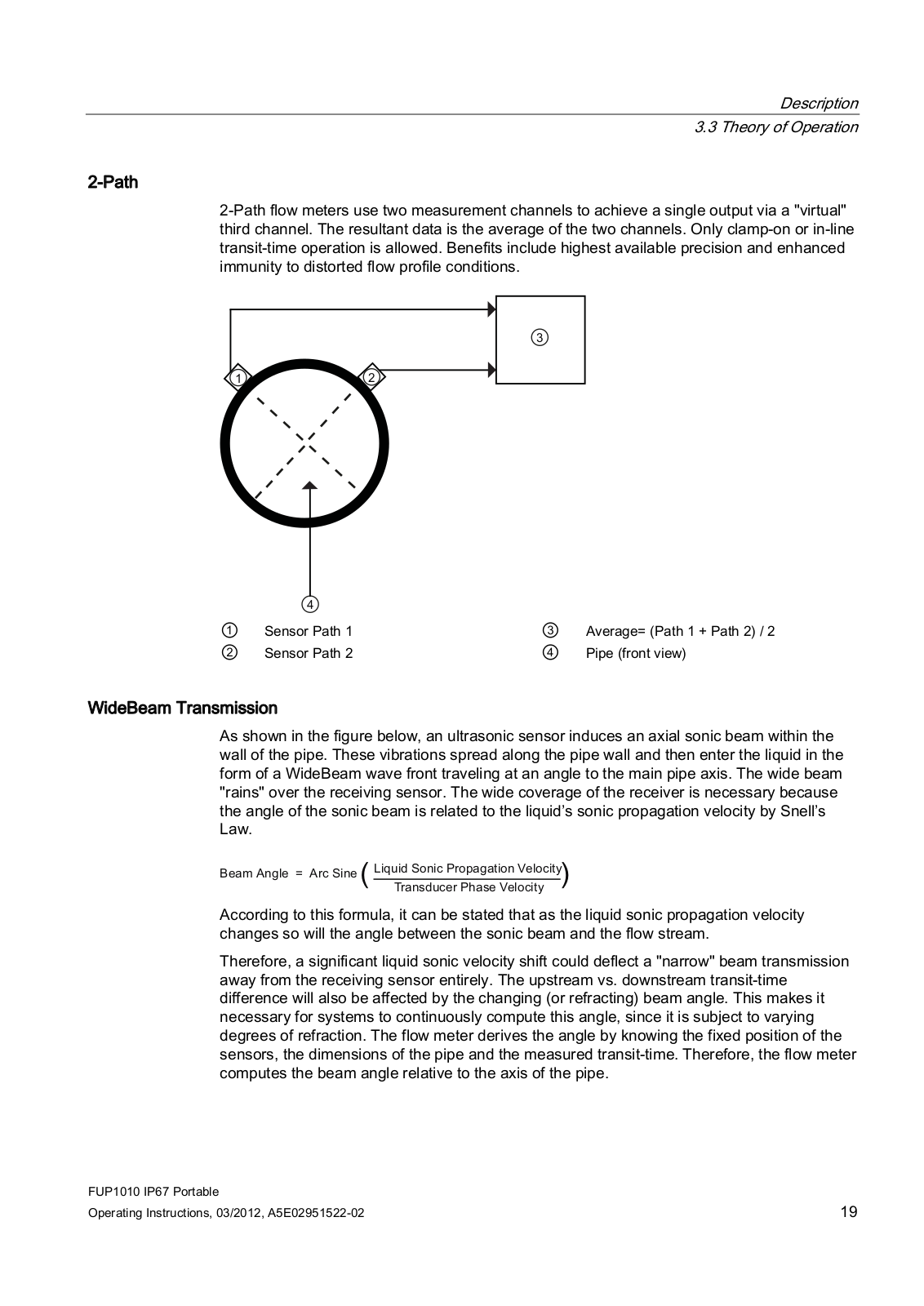

2-Path

2-Path flow meters use two measurement channels to achieve a single output via a "virtual" third channel. The resultant data is the average of the two channels. Only clamp-on or in-line transit-time operation is allowed. Benefits include highest available precision and enhanced immunity to distorted flow profile conditions.

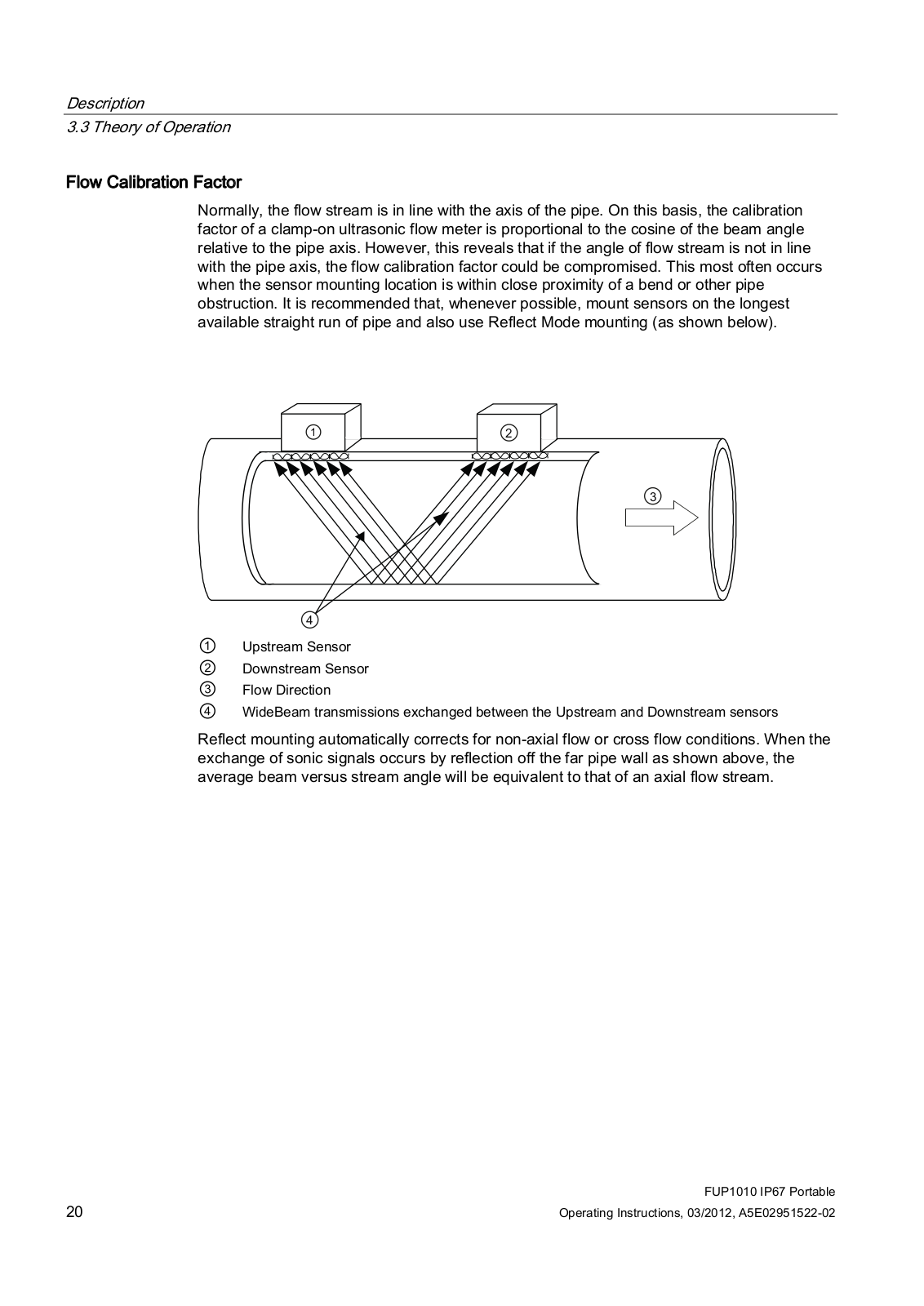

WideBeam Transmission

As shown in the figure below, an ultrasonic sensor induces an axial sonic beam within the wall of the pipe. These vibrations spread along the pipe wall and then enter the liquid in the form of a WideBeam wave front traveling at an angle to the main pipe axis. The wide beam "rains" over the receiving sensor. The wide coverage of the receiver is necessary because the angle of the sonic beam is related to the liquid's sonic propagation velocity by Snell's Law.

According to this formula, it can be stated that as the liquid sonic propagation velocity changes so will the angle between the sonic beam and the flow stream.

Therefore, a significant liquid sonic velocity shift could deflect a "narrow" beam transmission away from the receiving sensor entirely. The upstream vs. downstream transit-time difference will also be affected by the changing (or refracting) beam angle. This makes it necessary for systems to continuously compute this angle, since it is subject to varying degrees of refraction. The flow meter derives the angle by knowing the fixed position of the sensors, the dimensions of the pipe and the measured transit-time. Therefore, the flow meter computes the beam angle relative to the axis of the pipe.

low Calibration Factor

Normally, the flow stream is in line with the axis of the pipe. On this basis, the calibration factor of a clamp-on ultrasonic flow meter is proportional to the cosine of the beam angle relative to the pipe axis. However, this reveals that if the angle of flow stream is not in line with the pipe axis, the flow calibration factor could be compromised. This most often occurs when the sensor mounting location is within close proximity of a bend or other pipe obstruction. It is recommended that, whenever possible, mount sensors on the longest available straight run of pipe and also use Reflect Mode mounting (as shown below).

- Flow Direction

- WideBeam transmissions exchanged between the Upstream and Downstream sensors

Reflect mounting automatically corrects for non-axial flow or cross flow conditions. When the exchange of sonic signals occurs by reflection off the far pipe wall as shown above, the average beam versus stream angle will be equivalent to that of an axial flow stream

Installing/mounting

4.1 Installation safety precautions

ligh pressure hazard

In applications with working pressures/media that can be dangerous to people, surroundings, equipment or others in case of pipe fracture, we recommend that special precautions such as special placement, shielding or installation of a pressure guard or a safety valve are taken when the sensor is mounted.

4.2 Use according to specifications

"Use according to specifications" covers:

- Use within technical limits.

- Consideration of liquid specifications and references.

- Consideration of specifications as to installation, commissioning and maintenance.

- Operating pressure and temperature must be within the limits indicated on the product label.

- Flow and density must be within the specified limits

Do NOT:

- Use the flow meter as elastic equalization in pipe systems to compensate for e.g. pipe displacement, pipe vibration, expansion, etc.

- Use the flow meter as footboard for installation purposes.

- Use the flow meter as support of external loads like pipes, etc.

- Change the flow meter in any way. For e.g. decomposition of material in connection with processing, welding and use of accessories and spare parts not approved by Siemens.

Note

If the flow meter is not used according to the specifications, the manufacturer cannot be held responsible for any resulting damage.

4.3 Application Guidelines

4.3 Application Guidelines

Basic Requirements

- Determine pipe material and dimensions.

- Avoid vertical pipes flowing in a downward direction.

- Avoid installation of sensors on the top and bottom of horizontal pipes, if possible.

- Select a location with the longest straight run of pipe.

- Identify upstream piping configuration (elbow, reducer, etc.).

- Pipe surface should be smooth and, if necessary, free of paint.

- Avoid pressure reduction components upstream.

- Avoid mounting on or near weld seams.

- Pipe must be full to achieve proper operation.

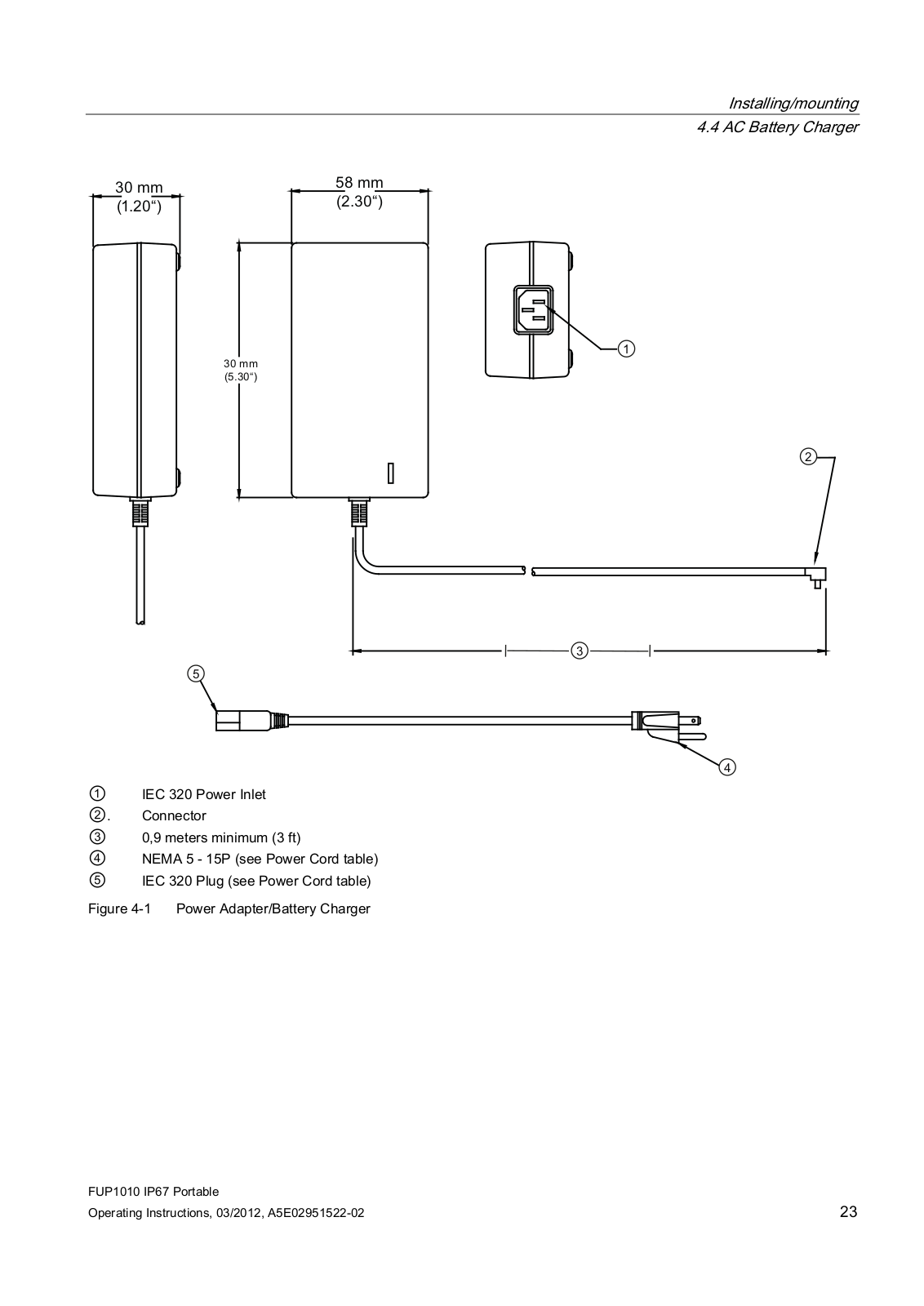

4.4 AC Battery Charger

The flow meter has an optional battery charger that operates from a 100, 110 or 220 VAC (50 Hz or 60 Hz) power source. It has a universal power input that requires no user switching. Optional cords can be provided for connection to AC outlets in most countries.

The 1015BCK-1 Power Adapter/Battery charger is NOT waterproof or water resistant. Do not allow it to become wet, or attempt to use it when wet. Exposure to a wet or submerged environment will result in damage to the unit that cannot be repaired and could expose the user to the risk of electric shock.

Installing/mounting

4.4 AC Battery Charger

- 2. Connector

- 0,9 meters minimum (3 ft)

- A NEMA 5 15P (see Power Cord table)

- 5 IEC 320 Plug (see Power Cord table)

Figure 4-1 Power Adapter/Battery Charger

4.4 AC Battery Charger

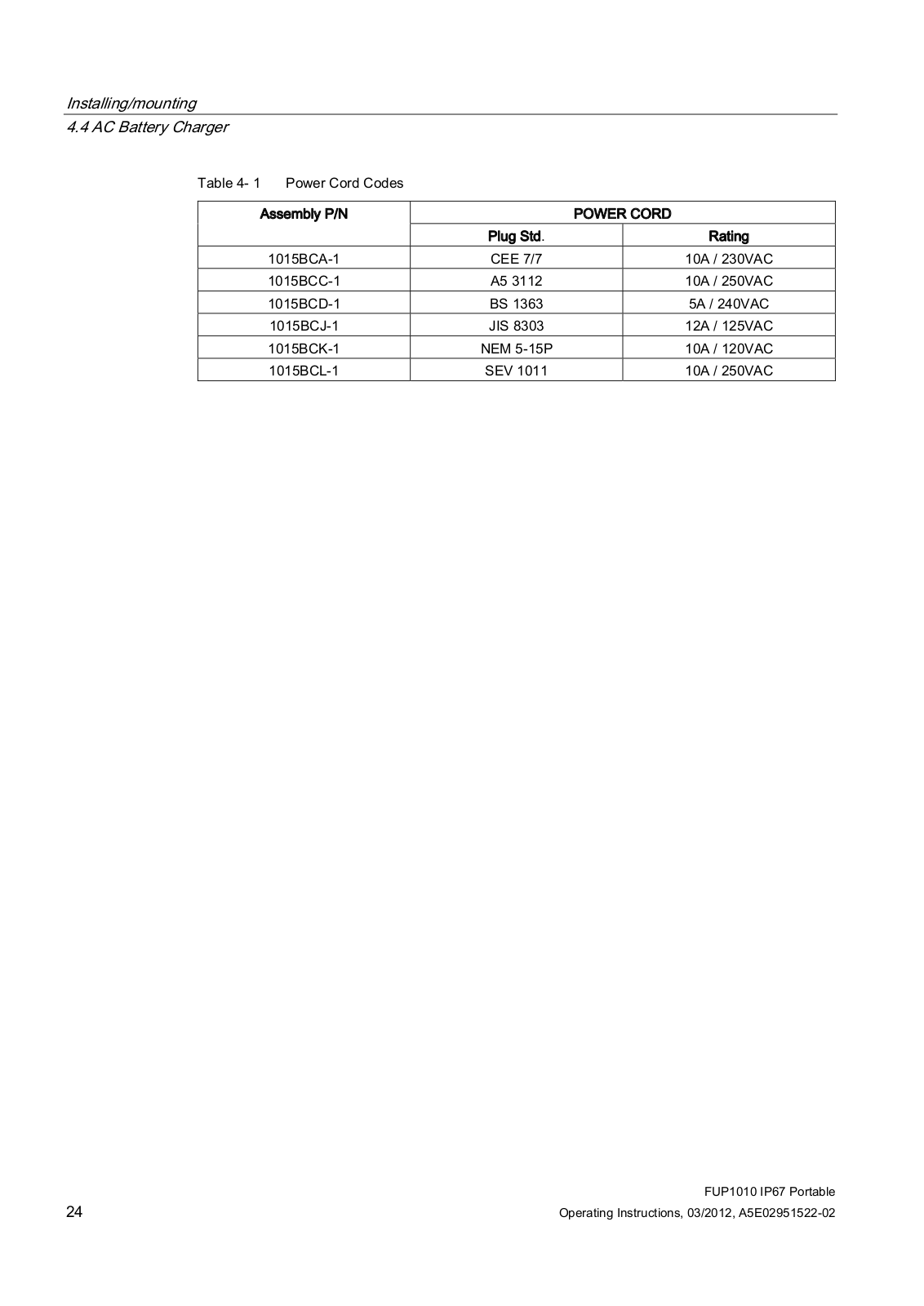

| Table 4-1 F | ower Cord | Codes |

|---|

| Assembly P/N | POWER CORD | ||

|---|---|---|---|

| Plug Std. | Rating | ||

| 1015BCA-1 | CEE 7/7 | 10A / 230VAC | |

| 1015BCC-1 | A5 3112 | 10A / 250VAC | |

| 1015BCD-1 | BS 1363 | 5A / 240VAC | |

| 1015BCJ-1 | JIS 8303 | 12A / 125VAC | |

| 1015BCK-1 | NEM 5-15P | 10A / 120VAC | |

| 1015BCL-1 | SEV 1011 | 10A / 250VAC | |

Connecting

5.1 Transmitter Wiring

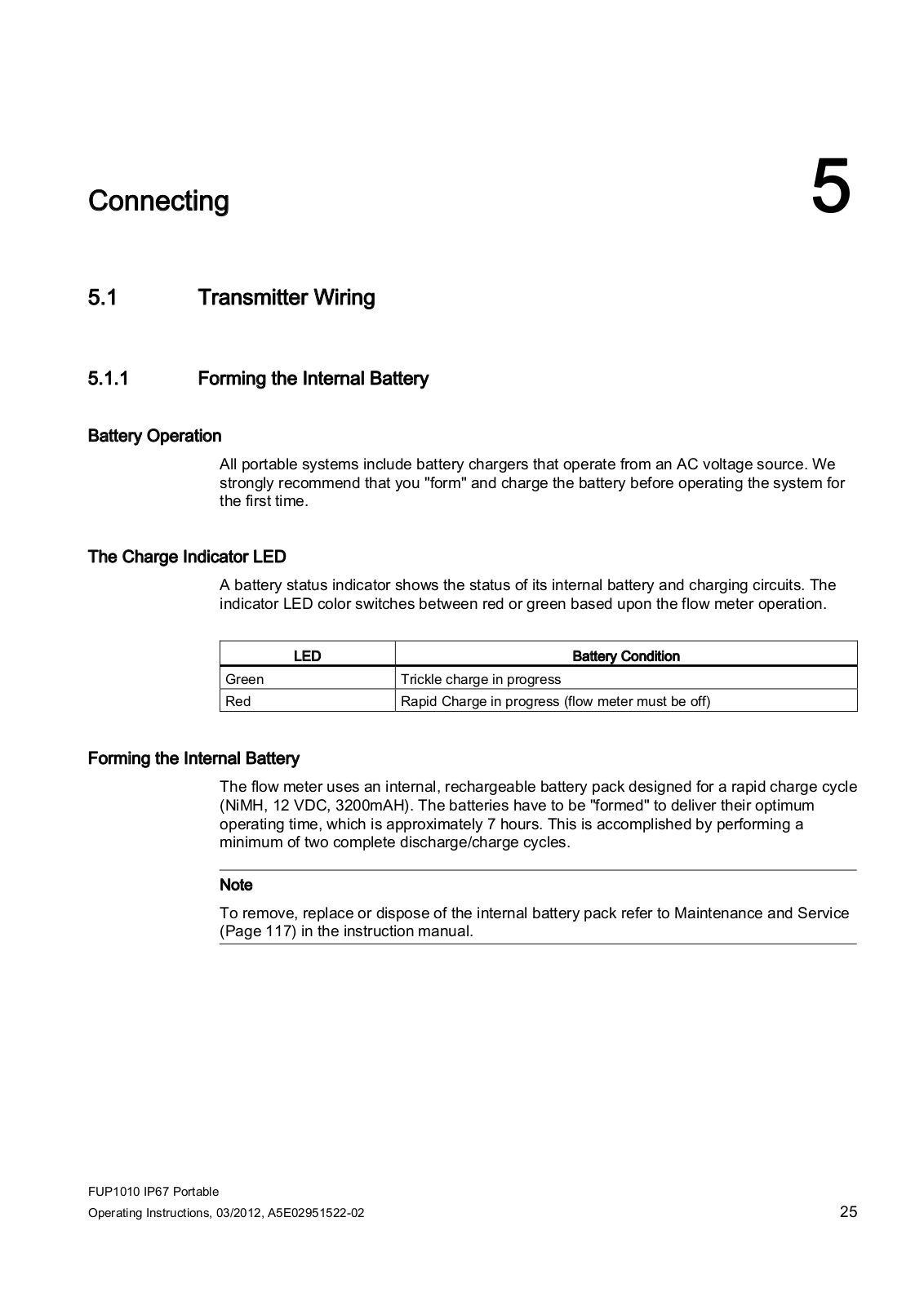

5.1.1 Forming the Internal Battery

Battery Operation

All portable systems include battery chargers that operate from an AC voltage source. We strongly recommend that you "form" and charge the battery before operating the system for the first time.

The Charge Indicator LED

A battery status indicator shows the status of its internal battery and charging circuits. The indicator LED color switches between red or green based upon the flow meter operation.

| LED Battery Condition | |

|---|---|

| Green | Trickle charge in progress |

| Red | Rapid Charge in progress (flow meter must be off) |

Forming the Internal Battery

The flow meter uses an internal, rechargeable battery pack designed for a rapid charge cycle (NiMH, 12 VDC, 3200mAH). The batteries have to be "formed" to deliver their optimum operating time, which is approximately 7 hours. This is accomplished by performing a minimum of two complete discharge/charge cycles.

Note

To remove, replace or dispose of the internal battery pack refer to Maintenance and Service (Page 117) in the instruction manual.

5.1 Transmitter Wiring

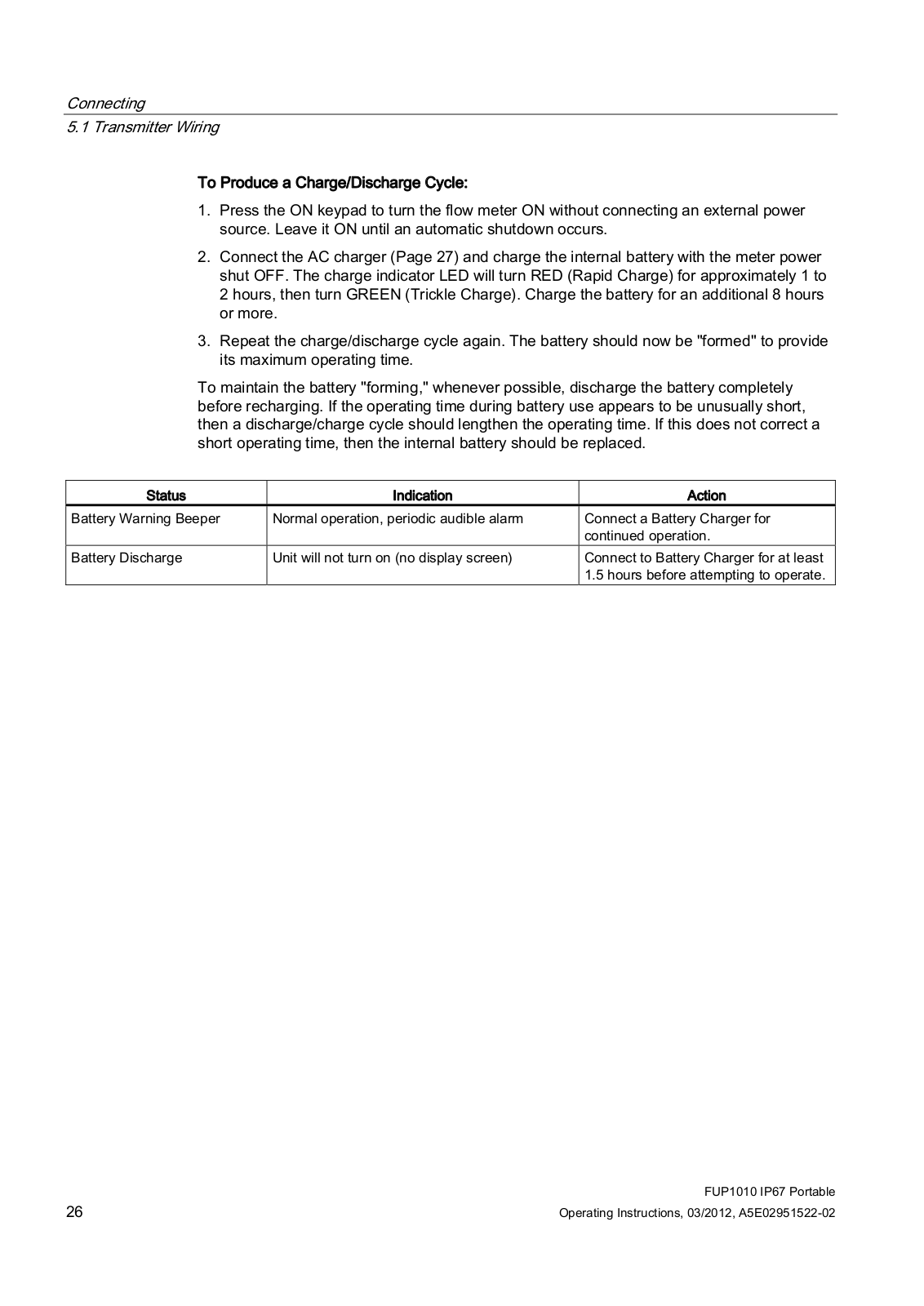

To Produce a Charge/Discharge Cycle:

- 1. Press the ON keypad to turn the flow meter ON without connecting an external power source. Leave it ON until an automatic shutdown occurs.

- Connect the AC charger (Page 27) and charge the internal battery with the meter power shut OFF. The charge indicator LED will turn RED (Rapid Charge) for approximately 1 to 2 hours, then turn GREEN (Trickle Charge). Charge the battery for an additional 8 hours or more.

- 3. Repeat the charge/discharge cycle again. The battery should now be "formed" to provide its maximum operating time.

To maintain the battery "forming," whenever possible, discharge the battery completely before recharging. If the operating time during battery use appears to be unusually short, then a discharge/charge cycle should lengthen the operating time. If this does not correct a short operating time, then the internal battery should be replaced.

| Status | Indication | Action |

|---|---|---|

| Battery Warning Beeper | Normal operation, periodic audible alarm |

Connect a Battery Charger for

continued operation. |

| Battery Discharge | Unit will not turn on (no display screen) | Connect to Battery Charger for at least 1.5 hours before attempting to operate. |

5.1 Transmitter Wiring

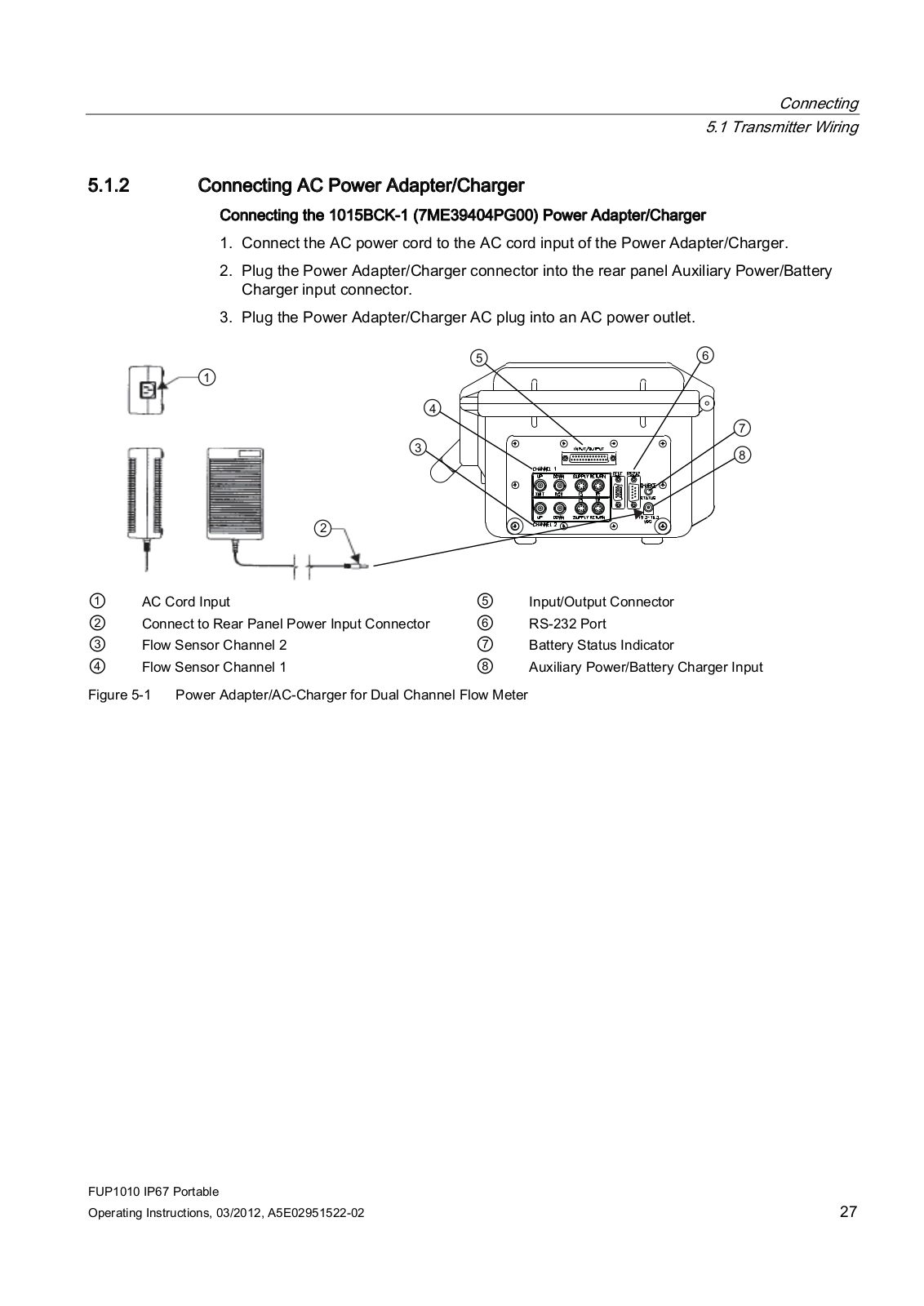

5.1.2 Connecting AC Power Adapter/Charger

Connecting the 1015BCK-1 (7ME39404PG00) Power Adapter/Charger

- 1. Connect the AC power cord to the AC cord input of the Power Adapter/Charger.

- 2. Plug the Power Adapter/Charger connector into the rear panel Auxiliary Power/Battery Charger input connector.

- 3. Plug the Power Adapter/Charger AC plug into an AC power outlet.

Figure 5-1 Power Adapter/AC-Charger for Dual Channel Flow Meter

5.2 Sensor Wiring

5.2 Sensor Wiring

5.2.1 Preliminary Installation Procedures

Reflect and Direct Sensor Mounting

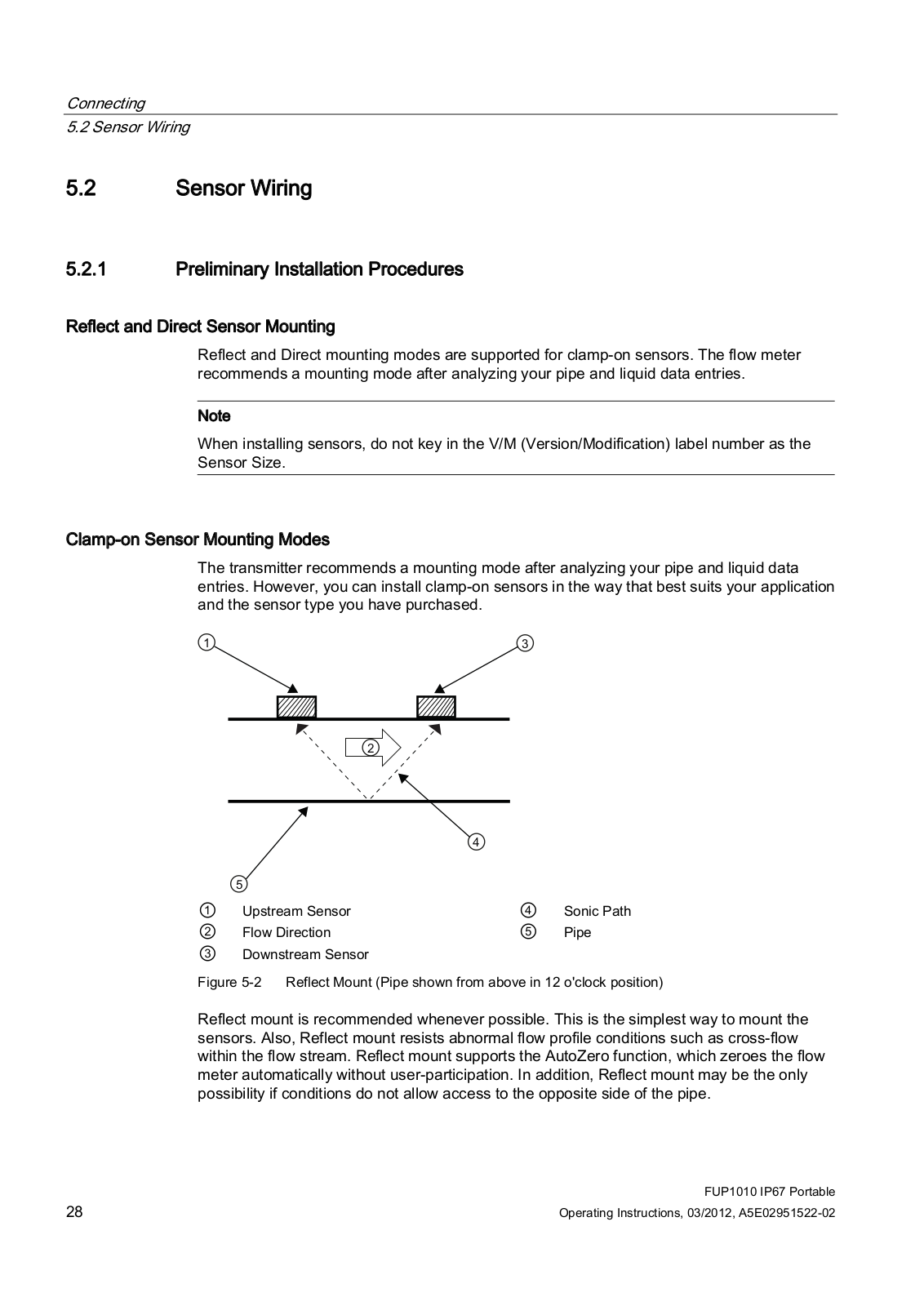

Reflect and Direct mounting modes are supported for clamp-on sensors. The flow meter recommends a mounting mode after analyzing your pipe and liquid data entries.

Note

When installing sensors, do not key in the V/M (Version/Modification) label number as the Sensor Size.

Clamp-on Sensor Mounting Modes

The transmitter recommends a mounting mode after analyzing your pipe and liquid data entries. However, you can install clamp-on sensors in the way that best suits your application and the sensor type you have purchased.

Figure 5-2 Reflect Mount (Pipe shown from above in 12 o'clock position)

Reflect mount is recommended whenever possible. This is the simplest way to mount the sensors. Also, Reflect mount resists abnormal flow profile conditions such as cross-flow within the flow stream. Reflect mount supports the AutoZero function, which zeroes the flow meter automatically without user-participation. In addition, Reflect mount may be the only possibility if conditions do not allow access to the opposite side of the pipe.

Direct mount provides a shorter sonic beam path. This usually improves performance with sonically attenuative liquids or pipe materials. We recommend using Direct mount for plastic pipes. Compared to Direct mounting, Reflect mount requires almost double the amount of mounting length. Therefore, Direct mount may be the only option if the availability of mounting space is limited.

Figure 5-3 Direct Mount (Pipe shown from above in 12 o'clock position)

Mounting Supplies

The following items will be needed to mount the sensors (most are supplied):

- Mounting Frames or Mounting tracks

- Tape, chalk and a ruler or measuring tape

- Spacer Bar

- Mounting Guide (for Direct Mount)

- Ultrasonic coupling compound and/or coupling pads

- Sensors (matched set)

Selecting a location for the sensors

- 1. Locate the sensors downstream from the center of the longest available straight run. A location ten pipe diameters or greater downstream from the nearest bend will provide the best flow profile conditions.

- 2. Do not, if possible, install the sensors downstream from a throttling valve, a mixing tank, the discharge of a positive displacement pump or any other equipment that could possibly aerate the liquid. The best location will be as free as possible from flow disturbances, vibration, sources of heat, noise, or radiated energy.

- 3. Avoid mounting the sensors on a section of pipe with any external scale. Remove all scale, rust, loose paint, etc., from the location.

- 4. Do not mount the sensors on a surface aberration (pipe seam, etc.)

- 5. Do not mount sensors from different ultrasonic flow meters on the same pipe. Also, do not run the sensor cables in common bundles with cables from communication equipment, other Siemens systems, or any type of ultrasonic equipment. You can run these cables through a common conduit ONLY if they originate at the same flow meter.

- 6. Never mount sensors under water, unless you order submersible units and you install them in accordance with factory instructions.

- 7. Never mount sensors on the top or bottom of a horizontal pipe. The best placement on a horizontal pipe is either the ten o'clock and two o'clock position for Reflect Mode, or one sensor at nine o'clock and one sensor at three o'clock for Direct Mode. Mounting on a vertical pipe is recommended only if flow is in the upward direction. When mounting on a vertical pipe flowing in a downward direction make sure there is sufficient back pressure in the system to maintain a full pipe.

eparing the Pipe

- 1. Pick a mounting location with the longest straight run. You must have easy access to at least one side of your pipe. The pipe at the mounting location must remain full, even at zero flow.

- 2. Decide on your mounting mode (Direct or Reflect). Always use Reflect Mode whenever possible. You may only need to use Direct Mode if your pipe is plastic.

- 3. After receiving the spacing dimensions from the Installation Menu, prepare the pipe surface. De-grease the surface, if necessary, and remove any grit, corrosion, rust, loose paint, etc. Use abrasive material provided to provide a clean contact surface for the sensors.

5.2 Sensor Wiring

Note

Please note that the instructions show vertical mounting for clarity purposes only. Do not install sensors on the top of a pipe.

- 4. Clean an area 13 mm (1/2-inch) on either side of the sensors.

- 5. Clean an additional 13 mm (1/2-inch) along the length of the sensors.

5.2.2 Sensor Identification and Selection

Sensor identification

The sensor part number located on the front face provides a detailed identification. For example, the Part Number: 1011HNFS-D1H-UT1-S2 means:

5.2 Sensor Wiring

1011 Universal series sensors and mounting frames have the following color codes for easy identification:

- Gold size 'A'

- Blue size 'B'

- Red size 'C'

- Green size 'D'

- Black size 'E'

Note

Check to make sure that the sensors are a matched set with the same serial numbers and marked with an "A" and "B" (e.g., 19256A and 19256B).

Note

Sensor Model names for Version 3 op systems are as follows: 1011H Hi Precision, 1011 Universal and 991 Universal.

Typical Sensor Labels

(2) Sensor size

Figure 5-6 Universal Sensor Label

Connecting

5.2 Sensor Wiring

Sensor Selection

Note

The transmitter must be powered up before you can select a sensor model. Refer to Transmitter Wiring (Page 25).

Before selecting sensors proceed to Setting the Parameters (Page 36) and perform the preliminary programming procedures.

5.2 Sensor Wiring

5.2.3 Navigating the Menu

Installation Menu Navigation

| L | • | |||||||

|---|---|---|---|---|---|---|---|---|

| 4 | 5 | 6 | * | HELP | ||||

| 1 | 2 | 3 | — | */- | CTRL | ALT |

DATA

LOG |

|

| 0 | ٠ | ÷ | F1 | F2 | F3 | F4 |

Figure 5-8 Keypad

Note

Use <Left Arrow> key to return to previous menus.

Connecting

5.2 Sensor Wiring

Table 5-1 Keypad Function Chart

| Keys | Description |

|---|---|

| MENU | Press to activate the Installation Menu. |

| ENTER | Store numeric data, select from option lists, etc. |

| Left / Right Arrows | Menu navigation keys move cursor. |

| Up / Down Arrows |

Same as

|

| CLR | Erases data or selects list options. |

| Numbers 0 - 9 | Use to type numeric data. |

| Decimal Point | Use for decimal points in numeric data. |

| Math Operators | 4-function math operations in numeric entry cells. |

| "F" Keys 1, 2, and 3 | Used to start/stop/reset Totalizer. |

| F4 | Caution: used during power up for system reset. |

| CTRL and ALT | Used as shift keys for alternative key functions. |

| DATALOG | Triggers immediate Datalogger report. |

| Plus and Minus [+ / -] | Changes the sign of numeric data. |

5.2 Sensor Wiring

5.2.4 Setting the Parameters

Select Language and Units

Note

Before creating a site select a language and then English or Metric units from the Meter Facilities menu.

To select English or metric units:

- 1. In Meter Type Menu, scroll to [Meter Facilities] menu. Press <Right Arrow> and select preferred units.

- 2. Press <ENTER> to select. Press <Left Arrow> and <Up Arrow> to return to main menu.

Select a Meter Type

- 1. Press the <MENU> key and select the Meter Type.

- 2. Press the <Right Arrow> and scroll to [Dual Path Flow].

- 3. Press <ENTER> to select. The [Dual Path Flow] menu will appear.

| Siemens | Dual Path [1] | Path 1 | |||

|---|---|---|---|---|---|

| Select Meter Type | |||||

| Meter Type | >Dual Path Flow | ||||

| Language | |||||

4. Press <ENTER> to select. Press <Right Arrow> to select meter function. Press <ENTER>.

Create a Site

1. Before proceeding make sure that English or Metric units have been selected.

- 2. At the [Channel Setup] menu press <Right Arrow> and then <Down Arrow> to highlight [Create/Name Site]. Press <Right Arrow> to enter a Site name.

- 3. Press <ENTER> to create Site name (e.g., ABC).

Connecting

5.2 Sensor Wiring

| Siemens | Dual Path [1] | 7 |

|---|---|---|

| Right Arrow & | Enter Creates a new Site | |

|

Recall Site

Channel Enat |

No sites

ble No |

1 |

|

Create/Name

Site Security |

Site ?

Off |

Í |

|

Delete Site

Save/Rename |

||

| Chan/Path Se | tup | |

| ① Insert de | sired name (8 characters max.) | - |

Note

To select letters: Press <Right Arrow> to cursor and then press <Up/Down Arrows> to select letters. Press <ENTER> when done.

Note

To select English or metric units: In Meter Type Menu, scroll to [Meter Facilities] menu. Press <Right Arrow> and select preferred units. Press <ENTER> to select. Press <Left Arrow> and <Up Arrow> to return to main menu.

- 4. Scroll to [Save/Rename Site]. Press <Right Arrow> then press <ENTER> to save site.

- 5. Press <Left Arrow> and return to the main menu.

Select Pipe Class

- 1. Press the <Down Arrow> and then <Right Arrow> to highlight [Pipe Data].

- 2. Press the <Right Arrow> to select [Pipe Class]. Press <Right Arrow> again and scroll to desired Pipe Class.

- 3. Press <ENTER> to select.

| Siemens | Dual Path | [1] | ABC |

|---|---|---|---|

| Pick Pipe Class | |||

| Path | 1 | ||

| Pick Pipe Class | ASA | A Carb | . Steel |

| Select Pipe Size | 803 | 540 | |

|

Pipe OD

|

8.62 | 25 | |

| Pipe Material | Ste | el | |

| Wall Thickness | 0.32 | 22 | |

| Liner Material | Nor | ne | |

| Liner Thickness | 0.000 | C | |

| Dino Doto | |||

| Pipe Data |

4. Pre-programmed Pipe Size and relevant pipe parameters will appear in menu cells. Press <Right Arrow> and scroll to desired pipe size. Press <ENTER>. Enter dimensions manually if pre-programmed dimensions do not match application.

Note

The DN sizes listed in the [Select Pipe Size] menu option list are referenced to DIN Table 2448. After selecting pipe size, check pipe OD and wall thickness for correct dimensions.

5. Press the <Left Arrow> and return to the main menu.

Select a Liquid Class

- 1. Press the <Down Arrow> and scroll to [Application Data].

- 2. Press the <Right Arrow> to select [Liquid Class].

- 3. Press the <Right Arrow> again and scroll to desired liquid.

- 4. Press <ENTER> to save selection.

① Select from list.

Select Pipe Configuration

- 1. Scroll down to [Pipe Config] and press the <Right Arrow>.

- 2. Select a configuration that approximates the conditions upstream of your sensor mounting location. (Refer to the definitions below.)

- 3. Press <ENTER> to save selection.

Connecting

5.2 Sensor Wiring

- ① Use this menu cell to enter the number of pipe diameters between the upstream configuration and the sensor installation.

- ② Use this menu cell to select the pipe configuration that most accurately represents the upstream pipe condition.

- 4. Press the <Left Arrow> and return to the main menu.

- Table 5- 2 Pipe Configuration Option List Definitions

| Options | Definitions |

|---|---|

| Fully Developed | Fully developed flow, as would be expected for very long straight pipe runs or installation downstream of a flow condition. |

| 1 Elbow | Single 90 degree Elbow upstream of sensor installation. |

| Dble Elbow+ | Double out-of-plane Elbows upstream of sensor installation. |

| Dble Elbow- | Double in-plane Elbows upstream of sensor installation. |

| Valve | Not available at this time. |

| Expander | Pipe expansion upstream of sensor installation. |

| Reducer | Pipe reduction upstream of sensor installation. |

| Norm Entry | Not available at this time. |

| Header Inlet | Header or pipe manifold upstream of sensor installation. |

| Intrusions | Not available at this time. |

Sensor Selection

The following is a typical sensor installation procedure.

- 1. Press <Left Arrow> to return to Main Menu. At the [Meter Type], press the <Right Arrow> and then <ENTER>.

- 2. The [Channel Setup] menu will appear.

- 3. Press the <Down Arrow> to select [Install Sensor].

FUP1010 IP67 Portable

- 4. Press the <Right Arrow> to [Sensor Model]. Press <Right Arrow> and scroll to select the sensor model number on the sensor label.

-

5. The drop down menu lists the following sensor selections:

- 1011 Universal

- 1011HP-T1 Usable -40 to 120°C, recommended for Ø Temperature <40°C; Standard.

- 1011HP-T2 Usable -40 to 120°C, recommended for Ø Temperature >40°C <80°C; Named as high temperature.

- 1011HP-T3 Usable -40 to 120°C, recommended for Ø Temperature >80°C <120°C; special request.

- 991 Universal

Note

The meter will automatically recommend a sensor depending on the application data that has been entered.

6. For this example, select the sensor model that appears on the sensor label then press <ENTER>.

- Select based on type

- 2 Select based on size

- ③ After sensor is mounted select [Install].

- 7. To select Sensor Size, press <Right Arrow>. Scroll to select the sensor size that matches the size indicated on the sensor label. Press <ENTER>.

- 8. At [Sensor Mount Mode], press the <Right Arrow>. Scroll to select [Reflect] or [Direct] mount and then press <ENTER>.

- 9. IMPORTANT: Record Spacing Method and Number Index. This data will be used to mount the sensors.

- 10.Sensors can now be mounted. Refer to mounting procedures and select the mounting mode desired.

- 11. After sensors are mounted scroll to [Install Complete] and select [Install].

5.2.5 Reflect Mount

Reflect Mount using E-Z Clamp and Spacer Bar

The EZ Clamp is a quick and easy way to securely mount sensors on any pipe. The spacer bar eliminates manual spacing measurements and provides rigidity for mounting the sensors while maintaining axial alignment.

Before beginning refer to the E-Z Clamp sensor installation diagram example below.

Figure 5-10 Reflect Mount with EZ-Clamp and Spacer Bar

Ltn Menu Cell

This view only menu cell shows the distance in inches or millimeters between the front faces of the sensors along the axis of the pipe. If you are mounting the sensors without a track or spacer bar, you have to space them according to this value. Note that Ltn may be a negative number for direct mount on very small pipes where the sensor spacing overlaps.

5.2 Sensor Wiring

Installation Procedure

- 1. After receiving the Number Index from the Installation Menu, prepare the pipe surface area where the sensors will be mounted. Check to ensure that you have a matched set of sensors. They both should have the same S/N number but marked with either an "A" or "B" (e.g., 100A and 100B).

- 2. Degrease the surface and remove any grit, corrosion, rust, loose paint, etc.

- 3. Assemble the sensors to the spacer bar, with the cable connectors facing away from each other as shown above. The spacer bar is attached to a sensor using a sensor index screw.

- 4. One sensor is attached using the "REF" hole on the spacer bar. The second sensor is attached to the spacer bar at the index hole specified by the Number Index recorded in Step 1.

Note

In some cases, the sensors may have two sets of securing holes. When using the EZ Clamp assembly, use the lower set of holes when attaching the spacer bar.

- Temporarily position the assembly (in the 10 o'clock position) at the location where it will be mounted. Ensure that this is a smooth area of the pipe without any raised spots (seams, etc.).

- 6. With a pencil or chalk mark a generous area around each sensor where they contact the pipe. Remove the assembly.

- 7. Prepare the two areas you marked by degreasing the pipe surface. Remove any grit, corrosion, rust, loose paint or surface irregularities with the abrasive pipe conditioning material provided.

- 8. Remove the sensor from the spacer bar that was attached through the REF hole. Attach the EZ clamp to the sensor under the spring clip. The adjusting nut knob should be pointing up and on the side opposite the spacer bar. Unscrew the knob until it's at the stop.

Connecting

5.2 Sensor Wiring

Note

To surround larger pipes, link multiple lengths of chain together by mating the Bit Snap and "S" hook.

9. Take sensor and apply a continuous lengthwise 3 mm (1/8-inch) bead of coupling compound across the center of the sensor emitting surface.

- 10.Place sensor in the middle of one of the areas you have cleaned. Ensure that the cable connector is facing away from where the other sensor will be placed.

- 11. While holding this sensor in-place, bring the chain around the pipe and attach the closest link onto the hook of the EZ clamp.

FUP1010 IP67 Portable

- 12. Tighten the adjusting nut until the chain is just snug around the pipe. Ensure that the chain is straight around the pipe and the sensor contacts the pipe at the white dot just under the front label. Ensure that there is equal space on either side of the dot between the edges of the sensor and pipe.

- 13.Repeat Steps 7, 8 and 9 for the second sensor leaving it attached to the spacer bar. At the same time that you place it in the middle of the second prepared pipe area, secure the spacing bar to the previously mounted sensor by inserting the sensor index screw through the REF hole on the bar and into lowest hole on sensor (i.e. for those sensors that have two holes).

- 14. Sight along spacer bar to ensure axial alignment to the pipe. Adjust if necessary. Tighten both chains and ensure that sensors did not move while tightening. Do not over tighten.

- 15.Observing the upstream and downstream orientation, attach the UP (upstream) and DN (downstream) cables to the sensors and make snug. Attach the other ends to the UP and DN terminals of the flow meter (see figure below).

16.Proceed to Commissioning (Page 67).

5.2.6 Direct Mount

Direct Mount - Installation with EZ Clamp and Spacing Guide

The combination of EZ Clamp and spacer guide is the recommended way to mount Direct Mode sensors. This method ensures that sensors will align exactly 180° from each other and remain spaced the proper distance apart.

For Direct Mode mounting, a spacer bar is used to establish the distance between sensors and a spacing guide is used to locate the sensors at the nine o'clock and three o'clock positions. Should the distance between sensors be beyond the span of a spacer bar, a measuring tape can be used. The Mylar spacing guide comes in various lengths and widths to accommodate most pipe sizes.

| Spacing Guide Sizes | ||||

|---|---|---|---|---|

| 5.08cm x 66.04cm) (2" x 26") | ||||

| 5.08cm x 114.3cm (2" x 45") | ||||

| 10.16 cm x 205.7cm (4" x 81") | ||||

| 10.16cm x 393.7cm (4" x 155") | ||||

| 15.2cm x 497.8cm (6" x 196") | ||||

Figure 5-15 Mylar Spacing Guide

Installation Procedure

- 1. Make a note of the Number Index displayed in the [Install Sensor] menu. Check to ensure that you have a matched set of sensors. They both should have the same S/N number but marked with either an "A" or "B" (e.g., 100A and 100B).

- 2. Temporarily position one of the sensors on the pipe where you will be mounting it. Ensure that this is a smooth area without any raised areas (seams, etc.) With a pencil or chalk, mark a generous area around all sides of the sensor. Remove the sensor.

- 3. Prepare the area you marked by degreasing the surface and removing any grit, corrosion, rust, loose paint or surface irregularities with the abrasive pipe conditioning material provided.

5.2 Sensor Wiring

4. Attach the EZ Clamp to the sensor under the spring clip. The adjusting nut knob should be pointing up and on the side opposite of the spacer bar. Unscrew the knob until it's at the stop.

Note

To surround larger pipes, link multiple lengths of chain together by mating the Bit Snap and "S" hook.

① Mate Bit Snap and "S" Hook to extend chain

Figure 5-17 E-Z Clamp S-Hook

5. Take sensor and apply a continuous lengthwise 3 mm (1/8-inch) bead of coupling compound across the center of the sensor emitting surface.

- 6. Place sensor at the center of the pipe in the middle of one of the areas you have cleaned. Ensure that the cable connector is facing away from where the other sensor will be placed.

- 7. While holding this sensor in place, bring the chain around the pipe and attach the closest cross-link onto the "S" hook of the EZ clamp.

- 8. Tighten the adjusting nut until the chain is just snug around the pipe. Ensure that the chain is straight around the pipe and the sensor contacts the pipe at the white dot just under the front label. Ensure that there is equal space on either side of the dot between the edges of the sensor and pipe. Adjust if necessary.

- 9. Tighten chain and ensure that the sensor does not move while tightening. Do not over tighten.

- 10.Attach the second sensor to the spacer bar at the index hole.

Note

In some cases the sensors may have two sets of holes for securing the spacer bar. When using the EZ Clamp assembly use the lower set of holes when attaching the spacer bar.

- 11.Do not apply any couplant to the second sensor. First attach the spacer bar assembly, with the second sensor attached to it, to the mounted sensor by inserting an index screw through the REF hole and into the lowest hole on the sensor. Tighten the screw.

- 12. Visually check that the spacer bar is axially aligned with the pipe.

- 13.Hold spacer bar assembly in this position and draw a pencil or chalk line along the back edge of the sensor and a dot below the sensor label white dot. See "A" below.

- 14.Disassemble the spacer bar and second sensor from the mounted sensor. Remove the second sensor from the spacer bar.

- 15.Use the spacer bar as a straight edge, align the mounted sensor's white dot and the pencil dot and draw a line across the dots (see "B" below). Set spacer bar aside.

5.2 Sensor Wiring

16.Wrap the Mylar spacing guide around the pipe so that the left edge is against the sensor edge mark (see "C" above). Arrange so that one end overlaps the other by at least 8 cm (3 inches). Trim to fit if necessary, but in order to keep the end square, be sure not to trim at the overlapping end.

Figure 5-19 Wrapping the Mylar Spacing Guide around the pipe (End View)

- 17.Realign left edge of the guide with the sensor edge mark. Line up both vertical edges of the guide and, ensuring that it is snug around the pipe, mark along the overlapping edge.

- 18.Remove Mylar spacing guide and lay it out on a flat surface. Either measure the exact distance half-way between the overlap edge and the mark at the overlap, or fold the guide from the overlap edge to the overlap mark and draw a line at the fold (halfway point).

- 19. Reinstall the spacing guide; its left edge abutting the sensor's edge mark on the pipe and the overlapping edge in line with the dot (now a line) on the pipe (see "C above). Tape it in this position on the pipe. Take the second frame and place it against the edge of the guide with its tapered roller centered on the center mark on the guide.

- 20. Temporarily position the sensor (in the 3 o'clock position opposite the mounted sensor see below) where it will be mounted. Ensure that this is a smooth area without any raised spots (seams, etc.). With a pencil or chalk, mark a generous area around all sides of the mounting frames. Remove the frame and the Mylar guide.

Figure 5-21 Aligning the Sensors for Direct Mode (End View)

- 21.Prepare the area you marked by de-greasing the surface, if needed, and removing any grit, corrosion, rust, loose paint or surface irregularities with the abrasive pipe conditioning material provided. Clean the pipe of any debris and abrasive particles.

- 22.Replace the Mylar spacer guide back in the same position it was in and retape it to the pipe.

- 23.Attached the EZ Clamp to the sensor under the spring clip. Unscrew the knob until it's at the stop.

- 24. Apply a continuous lengthwise 3mm (1/8-inch) bead of coupling compound across the center of the sensor emitting surface.

- 25.Hold the sensor in place and bring chain around pipe and attach to the closest link on the EZ Clamp "S" hook.

- 26. Tighten the adjusting nut until the chain is just snug around the pipe. Ensure that the chain is straight around the pipe and the sensor contacts the pipe at the white dot just under the front label. Ensure that there is equal space on either side of the dot between the edges of the sensor and pipe. Adjust if necessary.

- 27. Tighten chain and ensure that the sensor does not move while tightening. Do not over tighten.

- 28.Observing the upstream and downstream orientation, attach the UP (upstream ) and DN (downstream) cables to the sensors and make snug. Attach the other ends to the UP and DN terminals of the flow meter (see figure below).

29. Proceed to Commissioning (Page 67).

5.2.7 1012T Mounting Tracks

Using 1012T Sensor Mounting Tracks

The 1012TP and 1012THP Mounting Tracks provide a rigid mounting platform for Series 1011 Universal or high precision size A or B sensors. The mounting tracks service pipe sizes up to a maximum of 140 mm (5.00") outer diameter. The 1012TP mounting tracks support both Direct and Reflect mounting modes. The transmitter recommends the appropriate sensors, mounting track and mounting mode, based on the pipe data entries.

Installing a 1012T Mounting Track in Reflect Mode

The Sensor Installation procedures show how the automatic selection of sensors, mounting mode and spacing method are established. Examine the figure below, which illustrates a typical [Install Sensor] menu screen. Note the automatic assignment of mounting track part numbers, plus the designation of the Number Index.

| Siemens | Dual Path [1] SITE1 | ] |

|---|---|---|

| Install Complete? | ||

| Install Path | 1 | |

| Sensor Model | 1011HP-T1 4 | |

| Sensor Size | B3 | F ° |

| Sensor Mount Mo | de Reflect | |

| Spacing Offset | Minimum | |

| Number Index | 6 | 2 |

| Spacing Method | Track 1012TPH | |

| Ltn Value (in) | 0.581 | |

| Install Complete | No | |

| Empty Pipe Set | Channel Not Setup | |

| Zero Flow Adjust | Channel Not Setup | |

| Install Sensor |

Sensor type, size and mounting mode selection.

② Automatic selection of mounting track part number and Number Index.

- 1. Perform all required menu steps up until the point where you respond to the [Install Complete?] prompt.

- 2. Make a note of the Number Index. Check to ensure that you have a matched set of sensors. They both should have the same S/N number but marked with either an "A" or "B" (e.g., 100A and 100B).

Note

Index pins are used as stops against each sensor inserted at the reference hole for one sensor and the Number Index hole for the other sensor (see (9) in figure below).

Figure 5-23 Reflect Mount with Model 1012TP Mounting Track (Side View)

3. Place the track rail assembly on the top surface of the pipe at the location where you have determined it will be mounted. Ensure that it is a smooth area without any raised spots or seams.

4. Holding the track assembly in place, loop one of the roller chains under the pipe, pull it around and maintain tension while slipping a link over the tension screw hook. Tighten the tension screw enough to hold the assembly on the pipe, but still allow rotation. Repeat for the other roller chain.

2 Chain tension screw

Figure 5-24 Reflect Mode Chain Loop (Front View)

- 5. Rotate the track rail assembly to the intended mounting position on the pipe, then tighten both tension screws just enough to prevent rotation. Do not over tighten.

- 6. With pencil or chalk, mark a generous area around the perimeter of the track assembly. Loosen and move the track assembly away from the marked area.

- 7. Prepare the area you marked by degreasing the surface, if needed, and removing any grit, corrosion, rust, loose paint or surface irregularities with the abrasive pipe conditioning material provided. Clean the pipe of all debris and abrasive particles.

- 8. Rotate the track into the position that was just cleaned. Insert the index pin into the REF hole.

- 9. Select a sensor and apply a thin band of couplant compound to the sensor's emitting surface.

- 10.Place the sensor between the track rails, slightly behind the pin and under the clamping screw assembly. Slide it forward until it butts up firmly against the reference pin.

- 11. Once the sensor is in place secure it with the sensor clamping screw. Do not over tighten.

- 12.Repeat procedure for Number Index sensor making sure to insert an index pin into the correct Number Index hole. Refer to the Model 1012TP Mounting Track (side view) figure above.

- 13.Observing the upstream and downstream orientation, attach the UP (upstream) and DN (downstream) cables to the sensors and make snug. Attach the other ends to the UP and DN terminals of the flow meter.

Installing a 1012T Mounting Track in Direct Mode

The Sensor Installation procedures show how the automatic selection of sensors, mounting mode and spacing method are established. Examine the figure below, which illustrates a typical [Install Sensor] menu screen. Note the automatic assignment of model numbers for the sensor and mounting track, plus the designation of the Number Index.

| Siemens | Dual Path [1] | SITE1 |

|---|---|---|

| Install Complete? | ||

|

Install Path

Sensor Model Sensor Size Sensor Mount Mo Spacing Offset Number Index Spacing Method |

1

1011HF B3 Direct Minimu 4 ◀ Track 1 |

P-T1

m 012TPH◀ |

|

Install Complete

Empty Pipe Set Zero Flow Adjust Install Sensor |

No

Channe Channe |

el Not Setup

el Not Setup |

① Automatic selection of mounting track part number , mount mode and Number Index

The combination of two Model 1012TP Mounting Tracks and a spacer guide is the recommended way to mount sensors in the Direct Mode. This method ensures that sensors will align exactly 180° from each other and remain spaced the proper distance apart.

The Direct Mount configuration uses a set of two track rail assemblies; one for each sensor, installed 180° apart on the pipe. The set includes:

• Direct Mode Track Assembly - This track rail has number index holes for inserting an index pin to position the other sensor.

5.2 Sensor Wiring

Note

Index pins are used as stops against each sensor inserted at the reference hole for one sensor and the Number Index hole for the other sensor (see (1)) in figure below).

FUP1010 IP67 Portable Operating Instructions, 03/2012, A5E02951522-02

5.2 Sensor Wiring

Track Assembly Installation

- 1. Perform all required menu programming steps up until the point where you respond to the [Install Complete?] prompt.

- 2. Make a note of the Number Index displayed in the [Install Sensor] menu. Check to ensure that you have a matched set of sensors. They both should have the same S/N number but marked with either an "A" or "B" (e.g., 100A and 100B).

Note

Some sensors require a right-angle adapter. This adapter should be installed before placing the sensors in the tracks.

- 3. Prepare pipe for the track mounts by degreasing the surface, if needed, and removing any grit, corrosion, rust, loose paint or surface irregularities with the abrasive pipe conditioning material provided.

- 4. If this is a horizontal pipe, place the track rail assembly against the pipe. While holding track, place second track on pipe directly underneath (180°) and hold together in place.

- 5. Wrap the chain around the pipe; first onto the centering pin on the bottom track and then onto the hook on the top track.

Connecting

5.2 Sensor Wiring

Note

For a vertical pipe installation, use a tie, tape or bungee cord to hold the two tracks in place while chaining.

6. Finger-tighten the chain Tension Screw to secure the chain and tracks to the pipe.

5.2 Sensor Wiring

Positioning Track Assemblies

1. Wrap a length of the Mylar spacing guide around the pipe and against the end of the track assemblies. Ensure that the spacer guide edges on both sides align. Arrange so that one end overlaps the other by at least 8 cm (3 inches). Trim to fit if necessary, but in order to keep the end square, be sure not to trim at the overlapping end.

Figure 5-27 Wrapping the Mylar Spacing Guide around pipe (End View)

2. Remove the spacer guide. Measure or fold spacer guide to find its halfway distance. Mark a center line and then tape spacer guide to pipe.

5.2 Sensor Wiring

3. Use the edge of the Spacer Guide as a stop for both tracks to keep them parallel. Adjust tracks as necessary.

4. Loosen the chains enough to allow you to rotate the track assembly until the center of one track aligns with the center line on the Spacer Guide and the center of the other track aligns at the point where the Spacer Guide ends meet. The tracks should now be 180° apart. Tighten both chains but not too tight.

Sensor Installation

- 1. Insert an index pin into the REF hole of the track marked "Reflect Mode Spacing."

- 2. Take one of the sensors and insert it between the track rails and to the left of the index pin with the cable connector pointing away from the pin. Move the sensor until the pin stops it. Hold sensor in place. Move sensor clamping screw over the sensor and tighten.

③ Number Index hole

Figure 5-30 REF and Number Index Pin Locations

- 3. Insert the other index pin into the correct Number Index hole on the other track marked "Direct Mode Spacing."

- 4. Insert the second sensor into the track rail with its cable connector pointing away from the pin. Move the sensor until it's stopped by the pin. Move sensor clamping screw over the sensor and tighten.

Note

Remember to install the sensors with the cable connectors facing away from each other.

- 5. Using a pencil or chalk, mark a generous area around where the sensors contact the pipe.

- 6. Release the tension on the sensors and remove them.

- 7. Loosen the chains and rotate the track assembly on the pipe so you can gain access to the areas marked.

- 8. Prepare the areas you marked by degreasing the surface, if needed, and removing any grit, corrosion, rust, loose paint or surface irregularities with the abrasive pipe conditioning material provided.

- 9. Rotate the track assemblies into their original position on the pipe. Use the edge of the Mylar guide as a stop for both tracks and keep them parallel. Align each track with the "center line" you previously marked on the Spacing Guide. Tighten tracks securely.

- 10. This time, before installing each sensor, apply a 3mm (1/8-inch) continuous bead of couplant compound along the center (the long way) of the contact surface of the sensor. Also, keep the sensors lifted slightly from the pipe when installing until the sensor is against the pin; then push down against the pipe.

- 11.Once the sensors are in place, secure with its clamping screws. Do not over tighten.

- 12.Observing the upstream and downstream orientation, attach the UP (upstream) and DN (downstream) cables to the sensors and make snug. Attach the other ends to the UP and DN terminals of the transmitter.

- 13.Proceed to Commissioning (Page 67).

5.3 Zero Flow Adjust Menu

Zero Flow Compensation Methods

Unlike turbine flow meters ultrasonic transit-time flow meters provide active flow measurement right down to zero flow, however, the measurement of the transit-time delta is dependent on the similarity or "match" of the electronics, cables and ultrasonic sensors. Consequently some flow offset (or zero offset) may be present in any installation. To eliminate this residual zero offset Siemens has developed several different methods to insure proper zero flow compensation. The following paragraphs describe each method and when they should be used.

AutoZero

When the 1011HP sensors are mounted in the Reflect Mode configuration the AutoZero routine is automatically invoked at the end of the Initial Makeup. Flow does not have to be stopped to perform AutoZero since only the pipe wall signal is used in determining the zero offset and not the liquid component. The AutoZero routine performs a one-time analysis of the pipe wall component of the ultrasound signal to quantify any residual mismatch in the hardware. Once the AutoZero routine is complete, the system memorizes this measured zero offset and subtracts this value from the flow reading.

5.3 Zero Flow Adjust Menu

Actual Zero

The Actual Zero function simply averages the indicated "zero flow" readings (over a user defined time period) then stores this average value in memory. Under normal operation the indicated flow reading is zero compensated by simply subtracting this memorized value from the uncompensated flow reading. Actual Zero is the most positive method for zeroing the system; however, flow must be stopped with the line blocked (if possible) before invoking this function. If stopping flow is not possible then an alternate zeroing method should be selected.

ReversaMatic

This routine involves swapping the Up and Down sensors on the pipe (while keeping the cables attached) such that the difference in the transit-time change represents the zero offset. The fixed zero offset value is stored in memory in the same manner as described in Actual Zero. This routine would generally be used whenever flow cannot be stopped and the sensors cannot be mounted in the Reflect Mode configuration. Flow must be stable during the entire process.

ZeroMatic

When ZeroMatic is invoked the flow meter first performs the same analysis as described above in the AutoZero routine. However, after this analysis is complete the flow meter continues to interrogate the pipe wall signal and update the zero offset value under normal operation, such that the flow meter dynamically compensates for changing conditions which would normally result in zero drift. ZeroMatic will only operate with the sensors mounted in the Reflect Mode configuration and is recommended for applications which experience large temperature extremes.

Note

Invoking ZeroMatic will clear any existing "fixed" or memorized zero offset. If any zero offset remains after flow is stopped, an Actual Zero can be performed without interrupting ZeroMatic operation. To disable ZeroMatic, invoke it again, but then press <Left Arrow> to abort the installation.

Note

The ZeroClr command only resets the memorized zero offset registers not those set when the AutoZero routine is invoked.

Using Actual Zero

Note

Flow must be stopped with the line blocked (if possible) before invoking this function.

To invoke Actual Zero:

- 1. Access the [Zero Flow Adjust] option list by pressing <Right Arrow>.

- 2. Press <ENTER>. A pop-up window prompts you to set the current flow rate (in selected rate units) to equal zero (0.000).

Note

If a flow offset is desired (i.e., to test analog outputs) then press <Right Arrow> to enable numeric entry.

3. Press <ENTER> to start the Actual Zero process.

When you send the command, the flow meter analyzes the current flow rate for up to sixty seconds, integrating (averaging) the data for the best zero correlation. During this time, the menu prompt at the top of the display screen shows a timer that counts from zero to sixty. You can allow zero averaging for the entire period, or cancel the process at any time by pressing the <ENTER> key. This controls the amount of data the flow meter averages to obtain a zero level.

Using ReversaMatic

If site conditions do not permit stopping the flow rate at the mounting location, and you do not know the current flow rate, then you can use the ReversaMatic routine to establish the zero flow level. You should perform the ReversaMatic procedure as quickly as possible to ensure that the flow rate remains constant throughout the procedure.

To invoke ReversaMatic:

- 1. To access the [Zero Flow Adjust] option list press <Right Arrow>.

- 2. Move the cursor to [ReversaMatic]. Press <ENTER> to invoke the routine.

- 3. The flow meter begins to measure the positive flow rate. "Positive" flow refers to flow moving from upstream sensor location to the downstream sensor location. Note top prompt line shows: Reversamatic Action

- 4. Upon completion, the flow meter beeps and the display screen shows: Reverse Sensors / Press <ENTER>

- 5. Now remove then remount the upstream and downstream sensors in their reversed positions. Mount the Up sensor (without removing its cable) in the Down sensor/cable location. Mount Down sensor with its cable in the Up sensor/cable location. When remounting the sensors, couple them to the pipe properly. Press <ENTER> (after re-installing the sensors).

- 6. The flow meter measures the negative flow rate briefly, then beeps and repeats the prompt:

- 7. Now remount the sensors for normal operation (in their original orientation). When remounting sensors, couple them to the pipe properly. Press <ENTER> (after re-installing the sensors).

5.3 Zero Flow Adjust Menu

This completes the ReversaMatic procedure. The system's zero accuracy will be very close to that obtainable using the Actual Zero method, providing flow remained constant during this procedure.

A caution on the use of upper and lower flow limits (used to prevent flow mis-registration) prior to using the Reversal Zero technique (ReversaMatic): If the negative flow rate that the flow meter reads in the step during which the sensors are reversed is more negative than the lower flow limit, the meter will re-register positive and the Reversal Zero cycle will thus be corrupted.

Therefore, postpone the installation of upper and lower flow limits until the reversal zero procedure is executed successfully. For pipes that combine large diameters with very high flow velocities, it may be necessary to move the upper and lower flow limits out of the way until the reversal zero is completed. Moreover, pipes of this size frequently have excellent intrinsic zero performance and may not even need zeroing.

ZeroMatic (optional function)

Note

ZeroMatic is used in the Reflect Mode only. Invoking ZeroMatic clears any existing fixed zero offset.

Use this menu cell to select the ZeroMatic option. If conditions permit the use of the Auto Zero function then the ZeroMatic option can be used as well.

To select and enable the ZeroMatic option:

- 1. In the [Install Sensor] menu, press <Up Arrow> to scroll to the [Zero Flow Adjust] menu cell.

- 2. To access the [Zero Flow Adjust] option list press <Right Arrow>.

Note

If ZeroMatic is not running, the [Actual Zero] menu item will be displayed next to the [Zero Flow Adjust] menu cell.

3. Select the [ZeroMatic] menu cell by pressing <Up/Down Arrow> then press <ENTER>.

When the Initial Makeup of ZeroMatic is complete the screen will return to the [Install Sensor] menu and automatically highlight [Operation Adjust], which is the next menu cell.

5.3 Zero Flow Adjust Menu

To disable the ZeroMatic function:

- 1. Select the [Install Sensor] menu cell from the [Dual Path Flow] menu.

- 2. Scroll down to the [Zero Flow Adjust] menu cell by pressing <Up/Down Arrow>.

Note

The highlighted [ZeroMatic] menu item is the only indication that ZeroMatic is functioning.

- 3. Invoke the ZeroMatic initial makeup procedure as previously described above.

- 4. While ZeroMatic initial makeup is running, press <Left Arrow> to abort the process thereby disabling the function.

- 5. The screen will return to the [Dual Path Flow] menu and highlight the [Operation Adjust] menu cell.

Connecting