Siemens SITRANS FS230 Operating Instructions Manual

Compact Operating Instructions

Answers for industry.

02/2017

Edition

Ultrasonic Flowmeters

SITRANS FS230

SITRANS F

English ······························································································ 1

Deutsch ·························································································· 28

Español ··························································································· 55

Français ·························································································· 81

Italiano ····························································································108

Nederlands ·····················································································134

© Siemens AG 2017. All rights reserved

A5E38755607-AA, 02/2017

1

SITRANS F

Ultrasonic Flowmeters

SITRANS FS230

Compact Operating Instructions

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent damage to property. The

notices referring to your personal safety are highlighted in the manual by a safety alert symbol, notices referring only to property damage

have no safety alert symbol. These notices shown below are graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will be used. A notice warning of

injury to persons with a safety alert symbol may also include a warning relating to property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by

personnel qualified

for the specific task in accordance with

the relevant documentation, in particular its warning notices and safety instructions. Qualified personnel are those who, based on their

training and experience, are capable of identifying risks and avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical documentation. If products

and components from other manufacturers are used, these must be recommended or approved by Siemens. Proper transport, storage,

installation, assembly, commissioning, operation and maintenance are required to ensure that the products operate safely and without any

problems. The permissible ambient conditions must be complied with. The information in the relevant documentation must be observed.

SITRANS FS230

2 A5E38755607-AA, 02/2017

1

Introduction

1.1

Purpose of the documentation

This document contains all essential health and safety information required for safe use of the device.

Before installation and commissioning of the device, the operating instructions on the electronic data medium must be read

carefully.

1.2

Revision history

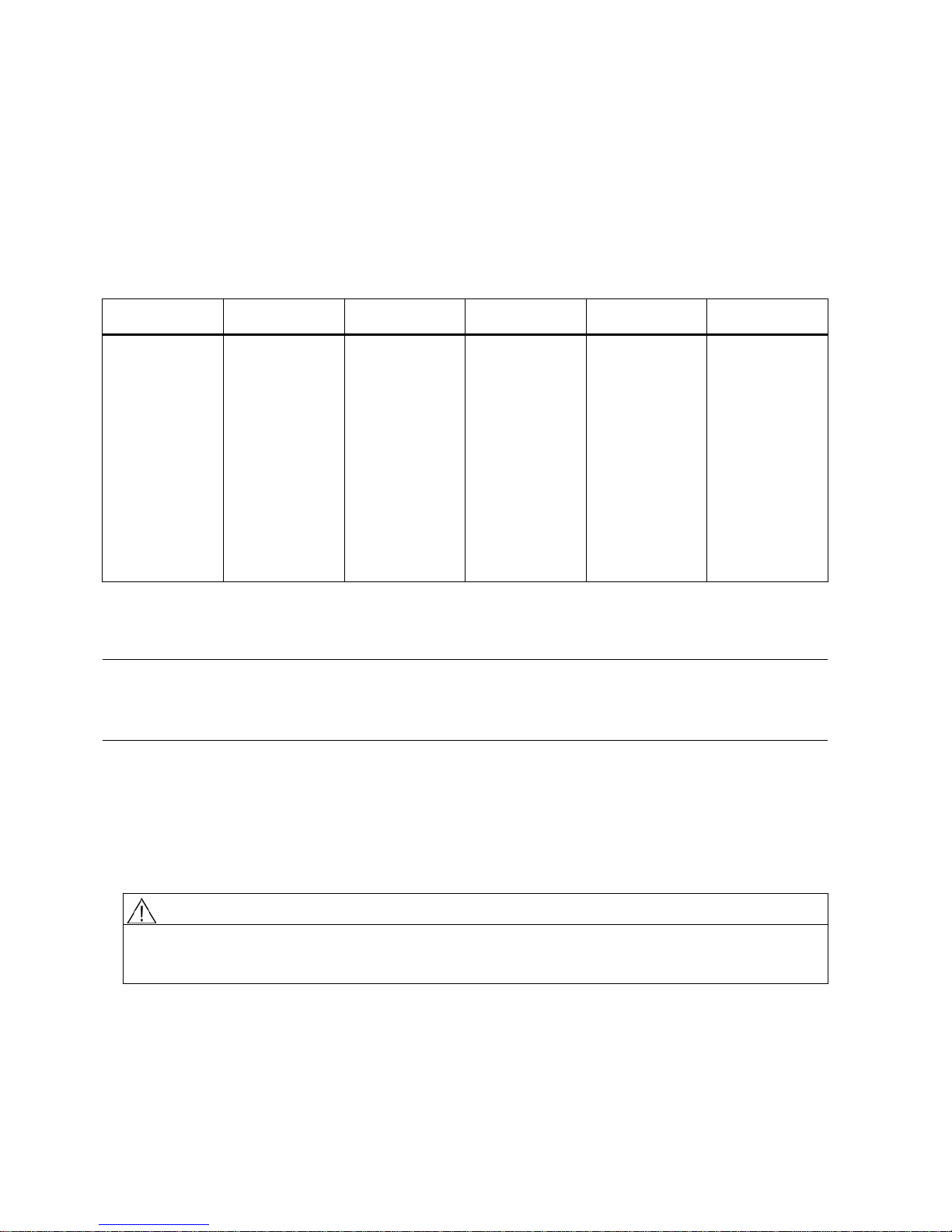

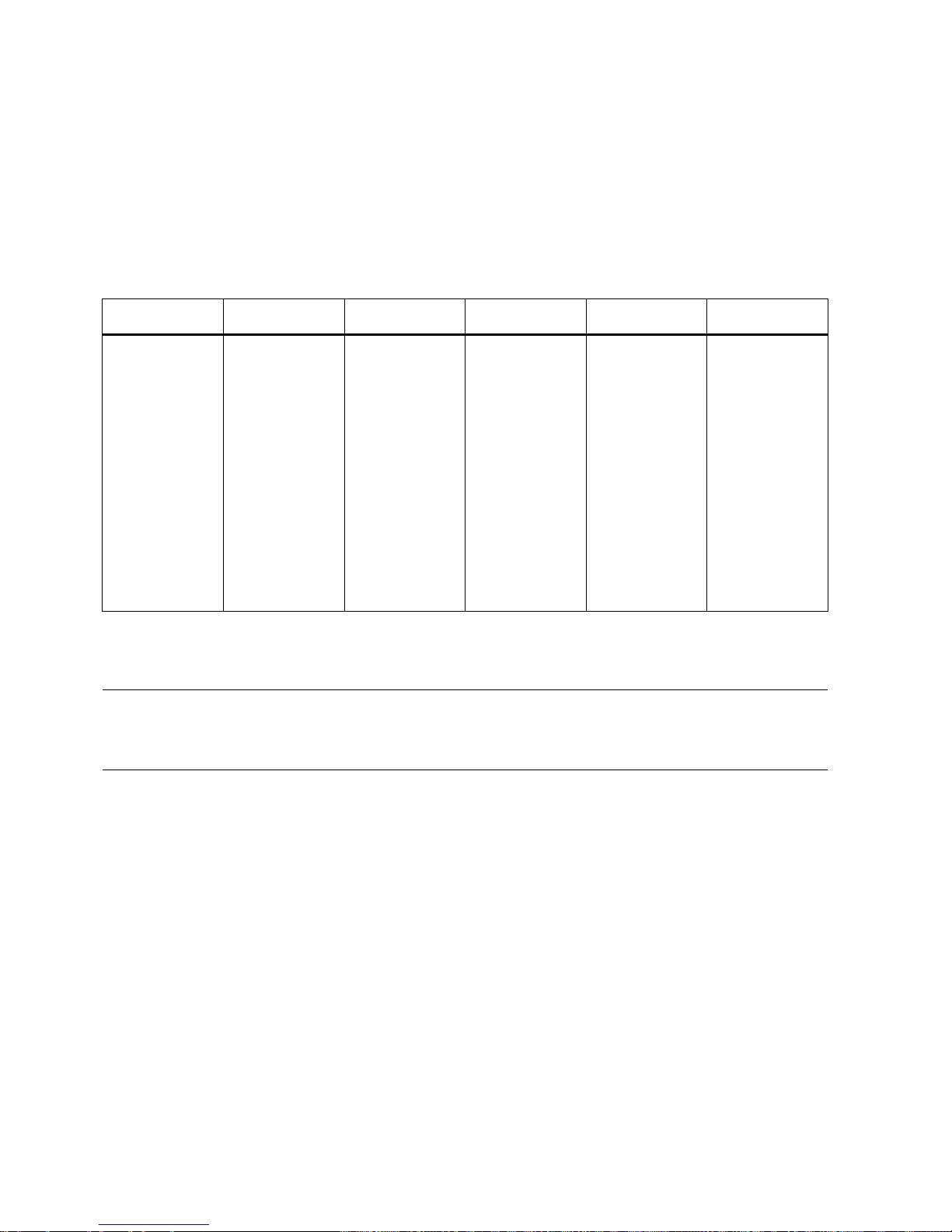

The following table shows major changes in the documentation compared to the previous edition.

Edition

Remarks

FW version

HW version

EDD version

HART device

revision

02/2017

• First edition

1.00.00 01

• SIMATIC PDM

driver for

HART 1.00.00

• SIMATIC PDM

driver for

Modbus

1.00.00

• AMS driver for

HART 1.00.00

• FC475 driver

for HART

1,00.00

• DTM/FDT

driver for

HART 1.00.00

1

1.3

Designated use

Use the device to measure process medium in accordance with the information in the operating instructions.

Note

Use in a domestic environment

This Class A Group 1 equipment is intended for use in industrial areas.

In a domestic environment this device may cause radio interference.

1.4

Checking the consignment

1. Check the packaging and the delivered items for visible damage.

2. Report any claims for damages immediately to the shipping company.

3. Retain damaged parts for clarification.

4. Check the scope of delivery by comparing your order to the shipping documents for correctness and completeness.

WARNING

Using a damaged or incomplete device

Risk of explosion in hazardous areas.

•

Do not use damaged or incomplete devices.

SITRANS FS230

A5E38755607-AA, 02/2017

3

1.5

Security information

Siemens provides products and solutions with industrial security functions that support the secure operation of plants,

systems, machines, and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is necessary to implement – and

continuously maintain – a holistic, state-of-the-art industrial security concept. Siemens’ products and solutions only form one

element of such a concept.

Customer is responsible to prevent unauthorized access to its plants, systems, machines and networks. Systems, machines

and components should only be connected to the enterprise network or the internet if and to the extent necessary and with

appropriate security measures (e.g. use of firewalls and network segmentation) in place.

Additionally, Siemens’ guidance on appropriate security measures should be taken into account. You can find more

information about industrial security by visiting:

http://www.siemens.com/industrialsecurity

.

Siemens’ products and solutions undergo continuous development to make them more secure. Siemens strongly

recommends to apply product updates as soon as available and to always use the latest product versions. Use of product

versions that are no longer supported, and failure to apply latest updates may increase customer’s exposure to cyber

threats.

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS Feed under

http://www.siemens.com/industrialsecurity

.

1.6

Transportation and storage

To guarantee sufficient protection during transport and storage, observe the following:

● Keep the original packaging for subsequent transportation.

● Devices/replacement parts should be returned in their original packaging.

● If the original packaging is no longer available, ensure that all shipments are properly packaged to provide sufficient

protection during transport. Siemens cannot assume liability for any costs associated with transportation damages.

NOTICE

Insufficient protection during storage

The packaging only provides limited protection against moisture and infiltration.

• Provide additional packaging as necessary.

Special conditions for storage and transportation of the device are listed in Technical data (Page 21).

1.7

Notes on warranty

The contents of this manual shall not become part of or modify any prior or existing agreement, commitment or legal

relationship. The sales contract contains all obligations on the part of Siemens as well as the complete and solely applicable

warranty conditions. Any statements regarding device versions described in the manual do not create new warranties or

modify the existing warranty.

The content reflects the technical status at the time of publishing. Siemens reserves the right to make technical changes in

the course of further development.

SITRANS FS230

4 A5E38755607-AA, 02/2017

2

Safety notes

2.1

Preconditions for use

This device left the factory in good working condition. In order to maintain this status and to ensure safe operation of the

device, observe these instructions and all the specifications relevant to safety.

Observe the information and symbols on the device. Do not remove any information or symbols from the device. Always

keep the information and symbols in a completely legible state.

2.1.1

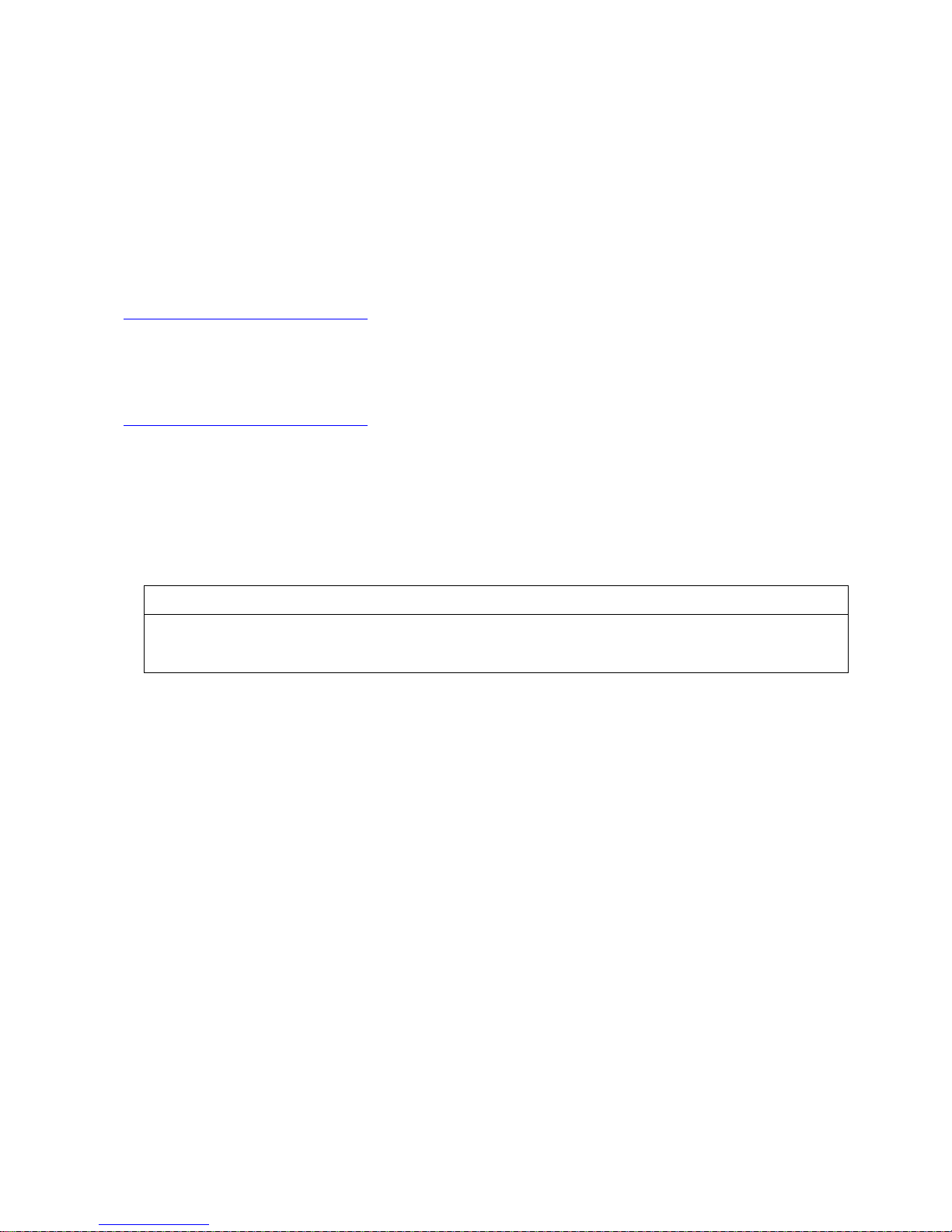

Warning symbols on the device

Symbol

Explanation

Consult operating instructions

2.1.2

SIL note

Note

Functional safety applications (SIL)

If the device is used in a functional safety application, ref

er to the functional safety manual.

2.1.3

Laws and directives

Observe the safety rules, provisions and laws applicable in your country during connection, assembly and operation. These

include, for example:

● National Electrical Code (NEC - NFPA 70) (USA)

● Canadian Electrical Code (CEC) (Canada)

Further provisions for hazardous area applications are for example:

● IEC 60079-14 (international)

● EN 60079-14 (EC)

The CE marking on the device symbolizes the conformity with the following European directives:

Electromagnetic compatibility EMC

2014/30/EU

Directive of the European Parliament and of the Council on the harmonisation of the

laws of the Member S

tates relating to electromagnetic compatibility

Low voltage directive LVD

2014/35/EU

Directive of the European Parliament and of the Council on the harmonisation of the

laws of the Member States relating to the making available on the market of electrical

equipment designed for use within certain voltage limits

Atmosphère explosible ATEX

2014/34/EU

Directive of the European Parliament and the Council on the harmonisation of the

laws of the Member States relating to equipment and protective systems inten

ded for

use in potentially explosive atmospheres

The applicable directives can be found in the EU declaration of conformity of the specific device.

WARNING

Improper device modifications

Risk to personnel, system and environment can result from modifications to the device, particularly in hazardous areas.

• Only carry out modifications that are described in the instructions for the device. Failure to observe this requirement

cancels the manufacturer's warranty and the product approvals.

SITRANS FS230

A5E38755607-AA, 02/2017

5

2.2

Requirements for special applications

Due to the large number of possible applications, each detail of the described device versions for each possible scenario

during commissioning, operation, maintenance or operation in systems cannot be considered in the instructions. If you need

additional information not covered by these instructions, contact your local Siemens office or company representative.

Note

Operation under special ambient conditions

We highly recommend that you contact your Siemens representative or our application department before you operate the

device u

nder special ambient conditions as can be encountered in nuclear power plants or when the device is used for

research and development purposes.

2.3

Use in hazardous areas

Qualified personnel for hazardous area applications

Persons who install, connect, commission, operate, and service the device in a hazardous area must have the following

specific qualifications:

● They are authorized, trained or instructed in operating and maintaining devices and systems according to the safety

regulations for electrical circuits, high pressures, aggressive, and hazardous media.

● They are authorized, trained, or instructed in carrying out work on electrical circuits for hazardous systems.

● They are trained or instructed in maintenance and use of appropriate safety equipment according to the pertinent safety

regulations.

WARNING

Use in hazardous areas

Risk of explosion.

• Only use equipment that is approved for use in the intended hazardous area and labelled accordingly.

WARNING

Loss of safety of device with type of protection "Intrinsic safety Ex i"

If the device has already been operated in non-intrinsically safe circuits or the electrical specifications have not been

observed, the safety of the device is no longer ensured for use in hazardous areas. There is a risk of explosion.

• Connect the device with type of protection "Intrinsic safety" solely to an intrinsically safe circuit.

•

Observe the specifications for the electrical data on the certificate and/or in Technical data (Page 21).

SITRANS FS230

6 A5E38755607-AA, 02/2017

3

Installing/mounting

3.1

Basic safety notes

CAUTION

Hot surfaces resulting from hot process media

Risk of burns resulting from surface temperatures above 70 °C (155 °F).

• Take appropriate protective measures, for example contact protection.

• Make sure that protective measures do not cause the maximum permissible ambient temperature to be exceeded.

Refer to the information in Technical data (Page 21).

WARNING

Exceeded maximum ambient or process media temperature

Danger of explosion in hazardous areas.

Device damage.

• Make sure that the maximum permissible ambient and process media temperatures of the device are not exceeded.

Refer to the information in Technical data (Page 21).

WARNING

Open cable inlet or incorrect cable gland

Danger of explosion in hazardous areas.

• Close the cable inlets for the electrical connections. Only use cable glands or plugs which are approved for the relevant

type of protection.

3.1.1

Installation location requirements

NOTICE

Strong vibrations

Damage to device.

• In plants with strong vibrations, mount the transmitter in a low vibration environment.

CAUTION

Aggressive atmospheres

Damage to device through penetration of aggressive vapors.

•

Ensure that the device is suitable for the application.

CAUTION

Direct sunlight

Device damage.

The device can overheat or materials become brittle due to UV exposure.

• Protect the device from direct sunlight.

• Make sure that the maximum permissible ambient temperature is not exceeded. Refer to the information in Technical

data (Page 21).

SITRANS FS230

A5E38755607-AA, 02/2017

7

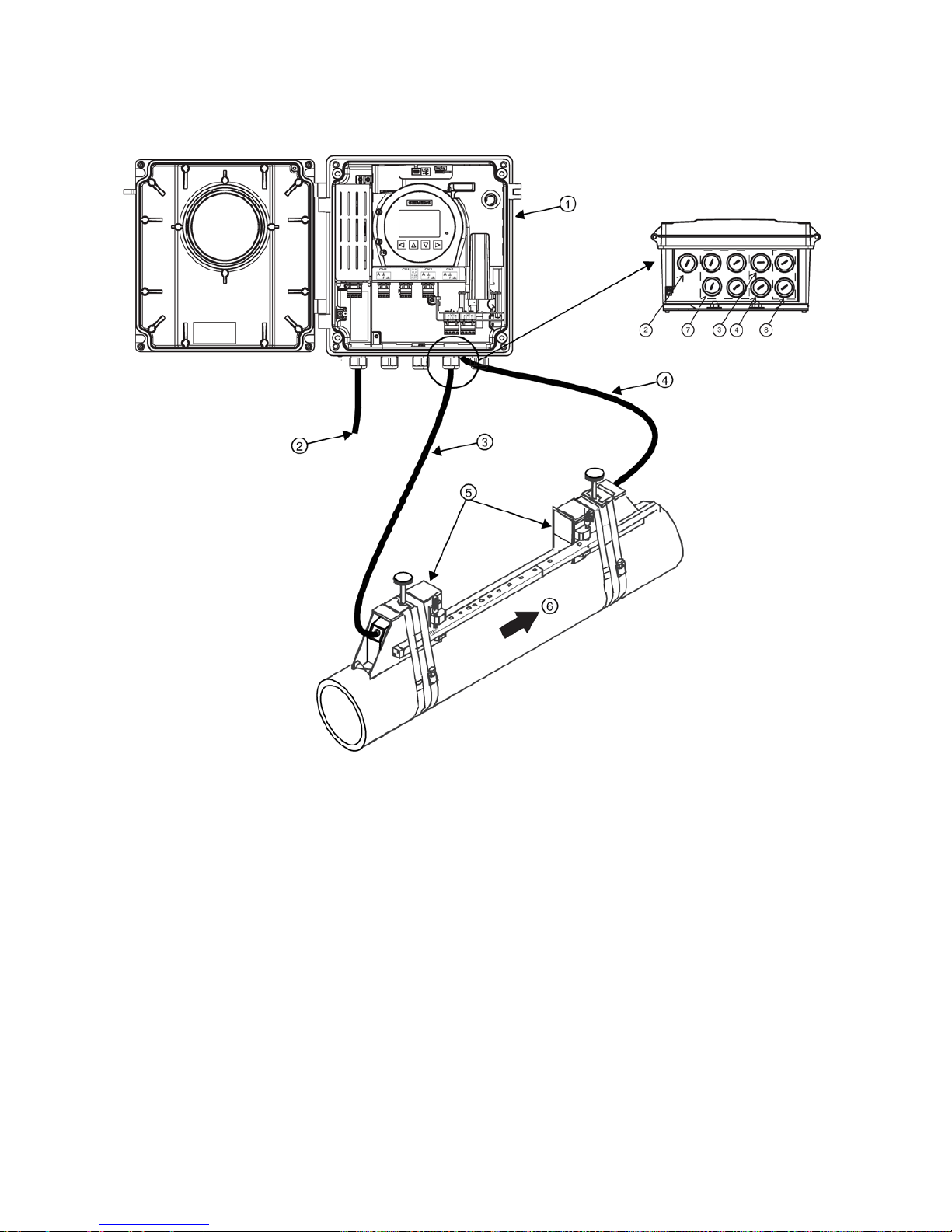

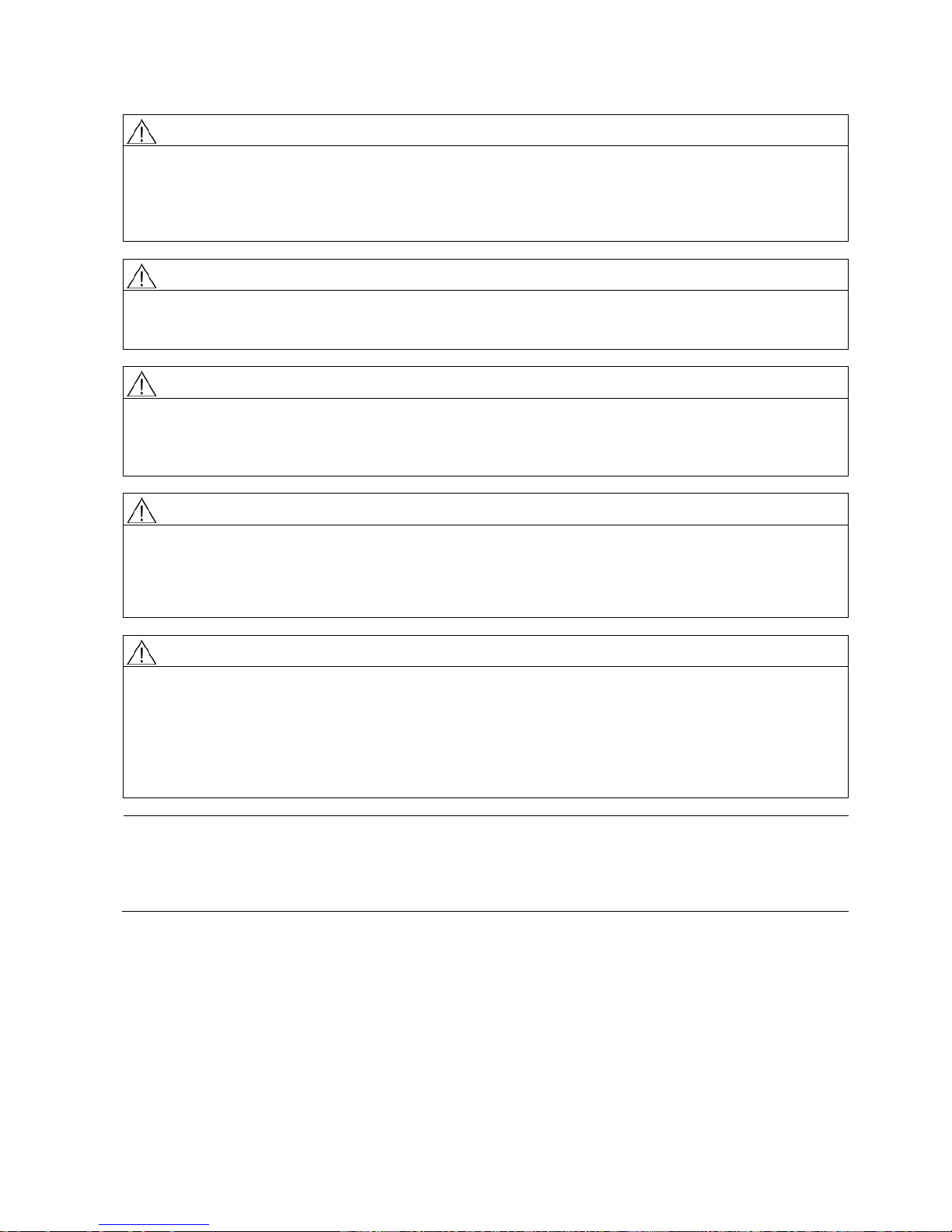

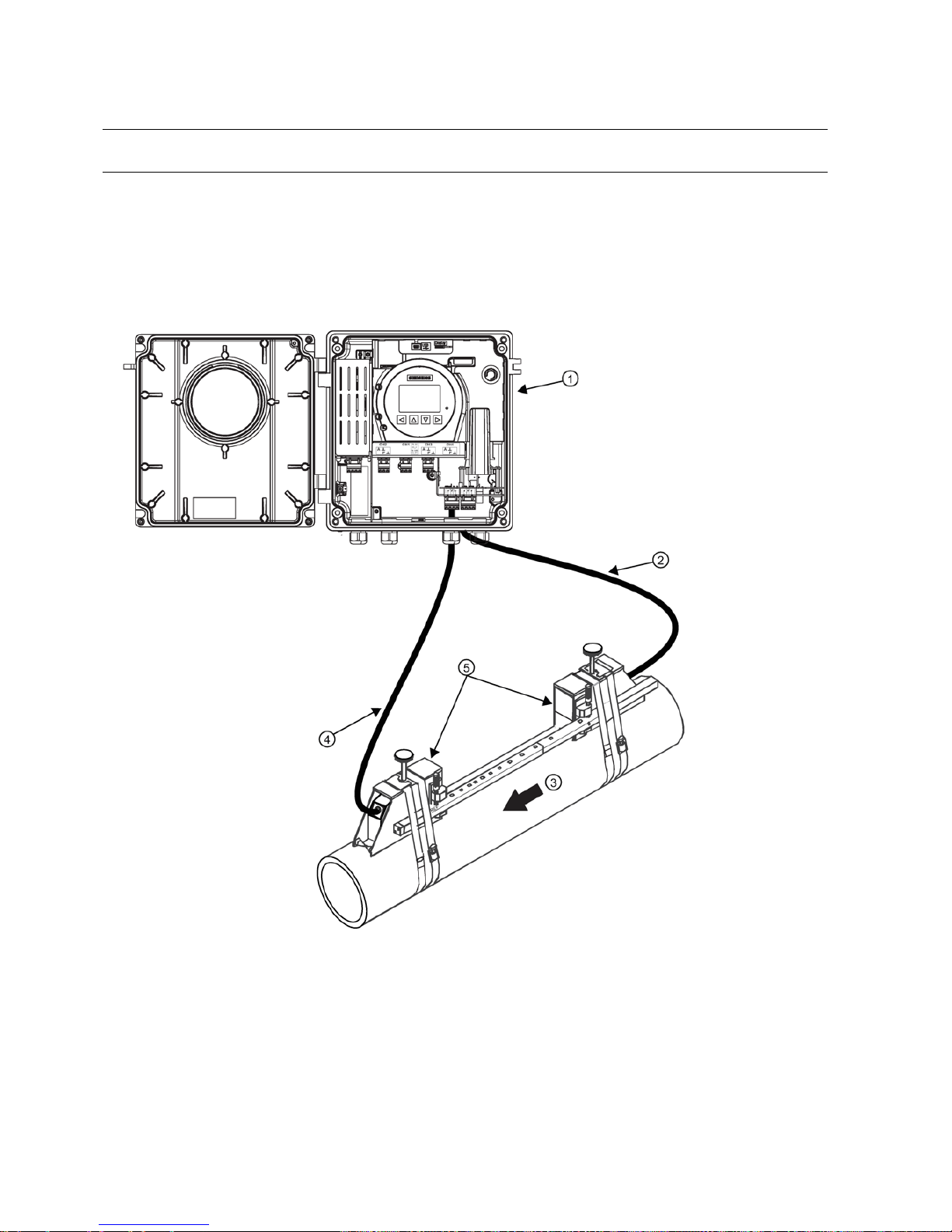

Typical system overview

The illustration below shows a typical transmitter and clamp-on sensor flowmeter configuration.

①

FST030 wall mounted transmitter

⑤

Sensors

②

Power cable

⑥

Flow direction

③

Upstream sensor cable (1A) Path 1

⑦

Ports for I/O, Communications, RTDs

④

Downstream sensor cable (1B) Path 1

⑧

Path 2 - Upstream (2A), Downstream (2B). (Ports for

Path 2 sensor cables, if applicable.)

Figure 3-1 Wall mount transmitter overview (Reflect mount)

SITRANS FS230

8 A5E38755607-AA, 02/2017

3.2

Installing sensors in Reflect mount

Reflect mount - Sensor installation using mounting frames and spacer bar

1. Use the Wizard setup procedure to program the meter for application parameters such as pipe size, liquid type, and

sensor size. Once entered the transmitter will return a spacing index number appropriate for the application.

2. Using the supplied space bar, set the distance between the sensors according to the spacing index number provided by

transmitter. The spacing index provides the correct distance apart for the sensors based on the pipe size given.

Before continuing refer to the Reflect mount installation diagram example below.

①

Sensor clamping screw

⑥

Spacer bar pin and reference hole

②

Customer pipe

⑦

Mounting strap

③

7ME39600*** Mounting Frame

⑧

Larger pipes may need additional mounting straps

④

Spring Clip (not present on some mounting frame models) ⑨ Orientation for Single path sensor at the 9 o'clock

position

⑤

Spacer bar

⑩

Orientation for Dual path sensor at the 10 and 2

o'clock positions

Figure 3-2 Reflect mount

3.3

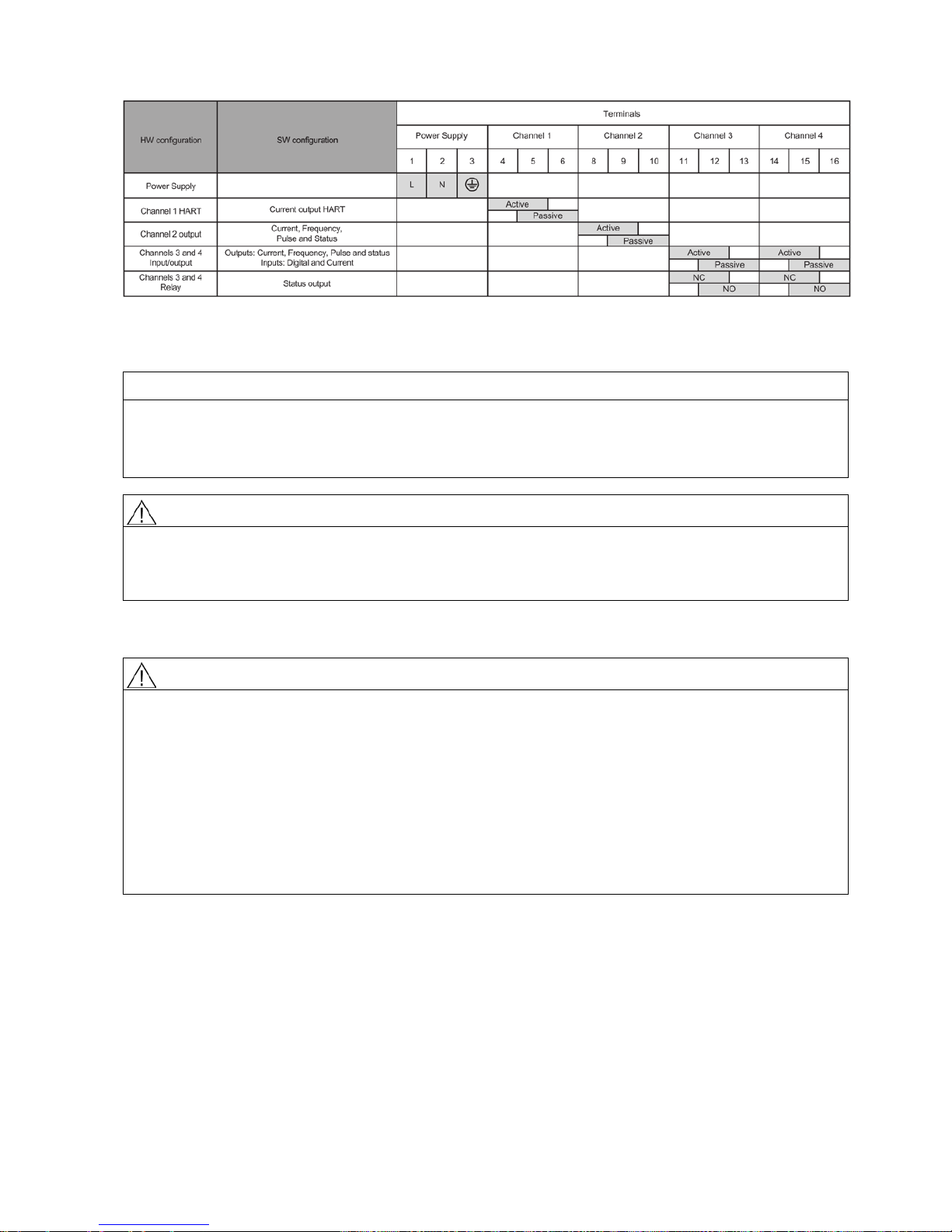

Terminal Layout

Figure 3-3 Terminal layout - wall mount housing

SITRANS FS230

A5E38755607-AA, 02/2017

9

Figure 3-4 Termination/configuration overview (HART)

3.4

Incorrect mounting

NOTICE

Incorrect mounting

The device can be damaged, destroyed, or its functionality impaired through improper mounting.

• Before installing ensure there is no visible damage to the device.

•

Mount the device using suitable tools. See operating instructions.

CAUTION

Loss of type of protection

Damage to device if the enclosure is open or not properly closed. The type of protection specified on the nameplate or in

Technical data (Page 21) is no longer guaranteed.

•

Make sure that the device is securely closed.

3.5

Disassembly

WARNING

Incorrect disassembly

The following risks may result through incorrect disassembly:

- Injury through electric shock

- Risk through emerging media when connected to the process

- Risk of explosion in hazardous area

In order to disassemble correctly, observe the following:

• Before starting work, make sure that you have switched off all physical variables such as pressure, temperature,

electricity etc. or that they have a harmless value.

• If the device contains hazardous media, it must be emptied prior to disassembly. Make sure that no environmentally

hazardous media are released.

•

Secure the remaining connections so that no damage can result if the process is started unintentionally.

SITRANS FS230

10 A5E38755607-AA, 02/2017

4

Connecting

4.1

Basic safety notes

WARNING

Unsuitable cables, cable glands and/or plugs

Risk of explosion in hazardous areas.

• Use only cable glands/plugs that comply with the requirements for the relevant type of protection.

• Tighten the cable glands in accordance with the torques specified in Transmitter (Page 12).

• Close unused cable inlets for the electrical connections.

• When replacing cable glands use only cable glands of the same type.

• After installation check that the cables are seated firmly.

WARNING

Hazardous contact voltage

Risk of electric shock in case of incorrect connection.

• For the electrical connection specifications, refer to the information in Technical data (Page 21).

• At the mounting location of the device observe the applicable directives and laws for installation of electrical power

installations with rated voltages below 1000 V.

NOTICE

Condensation in the device

Damage to device through formation of condensation if the temperature difference between transportation or storage and

the mounting location exceeds 20 °C (36 °F).

•

Before taking the device into operation let the device adapt for several hours in the new environment.

WARNING

Missing PE/ground connection

Risk of electric shock.

Depending on the device version, connect the power supply as follows:

•

Power plug

: Ensure that the used socket has a PE/ground conductor connection. Check that the PE/ground conductor

connection of the socket and power plug match each other.

•

Connecting terminals

: Connect the terminals according to the terminal connection diagram. First connect

the PE/ground

conductor.

NOTICE

Ambient temperature too high

Damage to cable sheath.

• At an ambient temperature ≥ 60 °C (140 °F), use heat-resistant cables suitable for an ambient temperature at least

20 °C (36 °F) higher.

WARNING

Improper power supply

Risk of explosion in hazardous areas as result of incorrect power supply, e.g. using direct current instead of alternating

current.

• Connect the device in accordance with the specified power supply and signal circuits. The relevant specifications can

be found in the certificates, in Technical data (Page 21) or on the nameplate.

SITRANS FS230

A5E38755607-AA, 02/2017

11

WARNING

Lack of equipotential bonding

Risk of explosion through compensating currents or ignition currents through lack of equipotential bonding.

• Ensure that the device is potentially equalized.

Exception

: It may be permissible to omit connection of the equipotential bonding for devices with type of protection

"Intrinsic safety Ex i".

WARNING

Unprotected cable ends

Risk of explosion through unprotected cable ends in hazardous areas.

•

Protect unused cable ends in accordance with IEC/EN 60079-14.

WARNING

Improper laying of shielded cables

Risk of explosion through compensating currents between hazardous area and the non-hazardous area.

• Shielded cables that cross into hazardous areas should be grounded only at one end.

•

If grounding is required at both ends, use an equipotential bonding conductor.

WARNING

Insufficient isolation of intrinsically safe and non-intrinsically safe circuits

Risk of explosion in hazardous areas.

• When connecting intrinsically safe and non-intrinsically safe circuits ensure that isolation is carried out properly in

accordance with local regulations for example IEC 60079-14.

•

Ensure that you observe the device approvals applicable in your country.

WARNING

Connecting device in energized state

Risk of explosion in hazardous areas.

• Connect devices in hazardous areas only in a de-energized state.

Exceptions

:

• Devices having the type of protection "Intrinsic safety Ex i" may also be connected in energized state in hazardous

areas.

•

Exceptions for type of protection "Non-sparking nA" (Zone 2) are regulated in the relevant certificate.

Note

Electromagnetic compatibility (EMC)

You can use this device in industrial environments, households and small busine

sses.

For metal housings there is an increased electromagnetic compatibility compared to high

-frequency radiation. This

protection can be increased by grounding the housing, see

Technical data (Page 21).

SITRANS FS230

12 A5E38755607-AA, 02/2017

Note

Improvement of interference immunity

•

Lay signal cables separate from cables with voltages > 60 V.

•

Use cables with twisted wires.

•

Keep device and cables in distance to strong electromagnetic fields.

•

Use shielded cables to guarantee the full specification according to HART.

•

Connect a load resistor of at least 230 Ω in series in the signal circuit in order to guarantee fault-free HART

communication. When power supply isolators are used for SITRANS HART transmitters, a load resistor is already

installed in the device.

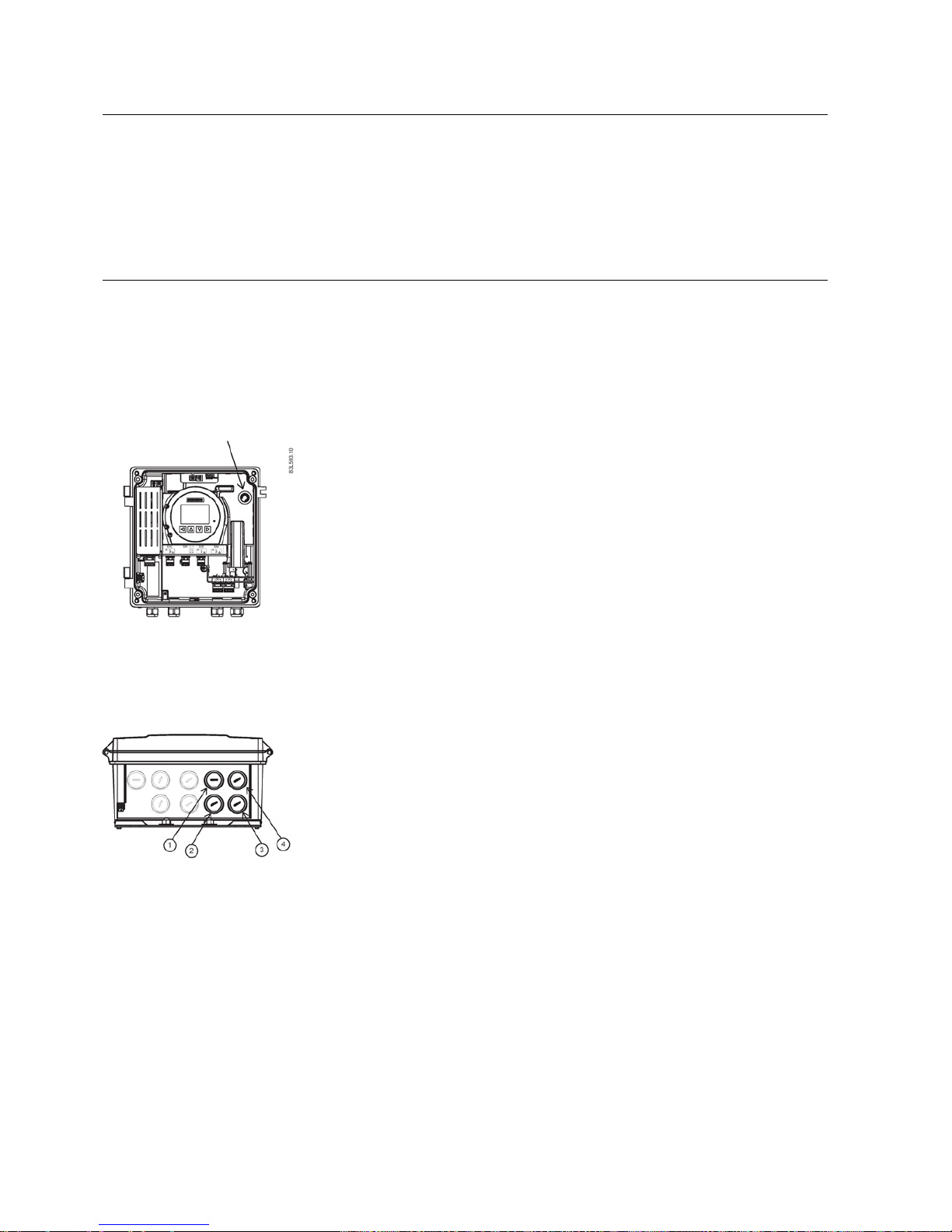

4.2

Transmitter

Preparing for the connection

1. Loosen the four lid screws.

2. Open the lid.

3. Remove F-connector tool from wall mount housing.

Figure 4-1 F-connector tool location

Connecting the flow sensor cables

When connecting the sensors it is required for the system to function that the sensor cables are connected correctly. Both

sensor cables for each path must be connected to the same port numbers (1A and 1B or 2A and 2B) on the transmitter.

The sensor cables are delivered with a premounted F-connector at transmitter end.

1. Remove blind plug from wall mount housing.

2. Slide the cable gland back onto the cable and allow access for ther F-connector tool.

3. Place F-connector tool around cable and slide up to engage F-connector nut.

4. Push cable through gland opening. Ensure that center lead is aligned with connector port in transmitter.

5. Tighten F-connector using tool until you meet mechanical stop.

SITRANS FS230

A5E38755607-AA, 02/2017

13

6. Remove F-connector tool.

7. Mount and tighten cable gland.

Repeat these steps for each sensor cable.

SITRANS FS230

14 A5E38755607-AA, 02/2017

4.3

Wall mount

Note

The following example is shown in the Reflect mount sensor configuration.

Connect sensor cables to the wall mounted transmitter as follows:

1. Fill connector end with Super Lube prior to connecting.

2. Apply Super Lube to the internal threads at the large end of the thread connector.

3. Observing the upstream and downstream orientation ③, connect upstream sensor cable ② to the transmitter port (1A)

and make connection snug.

4. Connect the downstream sensor cable

④ to the transmitter port (1B) and make connection snug.

①

Wall mounted transmitter

④

Downstream sensor cable (1B) Path 1

②

Upstream sensor cable (1A) Path 1

⑤

Sensors

③

Flow direction

Figure 4-2 Wall mount housing with transmitter-to- sensor cable connections

5. Tighten all cable glands to obtain optimum sealing.

6. Refer to transmitter FST030 Operating Instructions to program transmitter.

SITRANS FS230

A5E38755607-AA, 02/2017

15

4.4

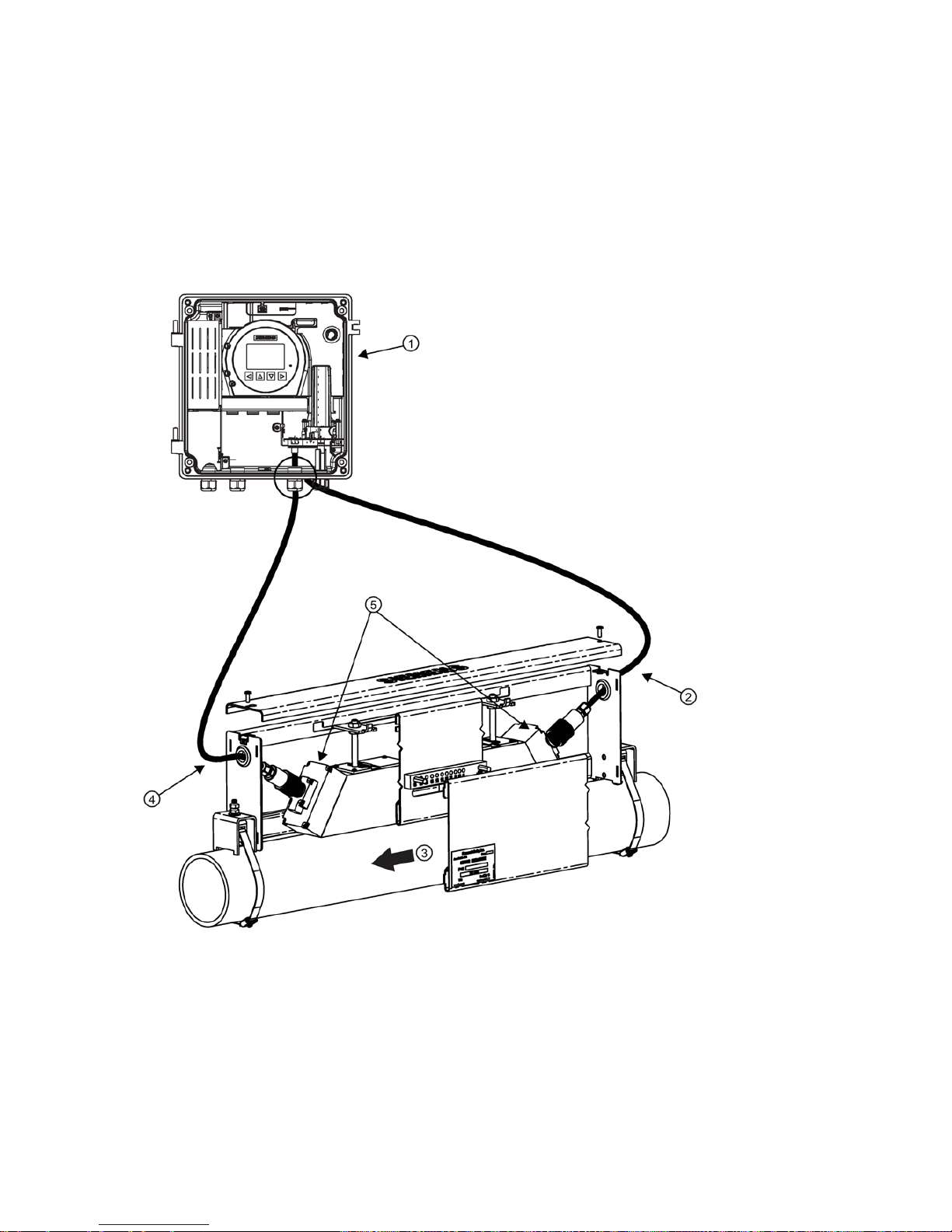

HI Precision mount

Single enclosure Reflect mount wiring

Connect sensor cables to the transmitter as follows:

1. Fill connector end with Super Lube prior to connecting.

2. Apply Super Lube to the internal threads at the large end of the thread connector.

3. Observing the upstream and downstream orientation ③, connect upstream sensor cable ② to transmitter port (1A) and

make connection snug.

4. Connect downstream sensor cable

④ to the transmitter port (1B) and make connection snug.

①

Wall mounted transmitter

③

Flow direction

②

Upstream sensor cable to internal DSL port

(1A) Path 1

④

Downstream sensor cable to transmitter port (1B) Path 1

⑤

Hi Precision mounted sensors

Figure 4-3 Hi Precision Reflect mount single enclosure wiring

5. Tighten all cable glands to obtain optimum sealing.

SITRANS FS230

16 A5E38755607-AA, 02/2017

Dual enclosure Reflect mount wiring

Referring to the Hi Precision single enclosure reflect mount figure above, connect the Hi Precision mount reflect Dual

enclosure sensor cables to the transmitter ports as follows:

1. Observing the upstream and downstream orientation

③, connect sensor cables to transmitter ports.

2. Tighten all cable glands to obtain optimum sealing.

3. Refer to transmitter FST030 Operating Instructions to program transmitter.

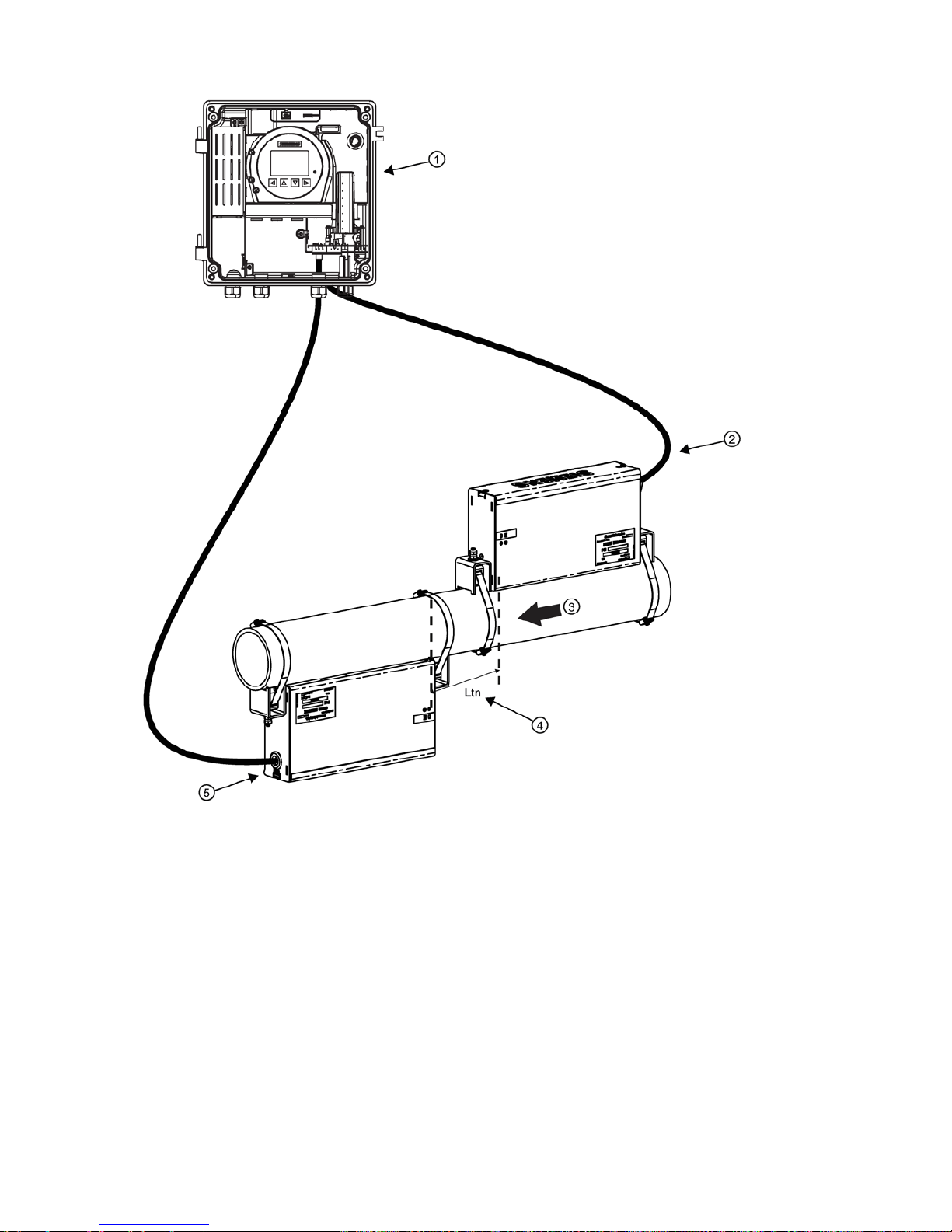

Dual enclosure direct mount wiring

Connect sensor cables to the DSL and transmitter as follows:

1. Fill connector end with Super Lube prior to connecting.

2. Apply Super Lube to the internal threads at the large end of the thread connector.

3. Observing the upstream and downstream orientation ③, connect upstream sensor cable ② to transmitter port (1A) and

make connection snug.

4. Connect downstream sensor cable

⑤ to transmitter port (1B) and make connection snug.

SITRANS FS230

A5E38755607-AA, 02/2017

17

①

Wall mounted transmitter

③

Flow direction

②

Upstream sensor cable to transmitter port

(1A) Path 1

④

Ltn (spacing distance between sensors)

⑤

Downstream sensor cable to transmitter port (1B) Path 1

Figure 4-4 HI Precision Direct mount Dual enclosure sensor wiring

5. Tighten all cable glands to obtain optimum sealing.

6. Refer to transmitter FST030 Operating Instructions to program transmitter.

SITRANS FS230

18 A5E38755607-AA, 02/2017

5

Commissioning

5.1

Basic Safety Notes

5.1.1

Toxic gases and liquids

DANGER

Toxic gases and liquids

Danger of poisoning when venting the device: if toxic process media are measured, toxic gases and liquids can be

released.

• Before venting ensure that there are no toxic gases or liquids in the device, or take the appropriate safety measures.

WARNING

Commissioning and operation with pending error

If an error message appears, correct operation in the process is no longer guaranteed.

• Check the gravity of the error.

• Correct the error.

• If the error still exists:

– Take the device out of operation.

– Prevent renewed commissioning.

5.1.2

Improper commissioning in hazardous areas

WARNING

Improper commissioning in hazardous areas

Device failure or risk of explosion in hazardous areas.

• Do not commission the device until it has been mounted completely and connected in accordance with the information

in Technical data (Page 21).

•

Before commissioning take the effect on other devices in the system into account.

5.1.3

Opening device in energized state

WARNING

Opening device in energized state

Risk of explosion in hazardous areas

• Only open the device in a de-energized state.

• Check prior to commissioning that the cover, cover locks, and cable inlets are assembled in accordance with the

directives.

Exception

: Devices having the type of protection "Intrinsic safety Ex i" may also be opened in energized state in hazardous

areas.

CAUTION

Loss of type of protection

Damage to device if the enclosure is open or not properly closed. The type of protection specified on the nameplate or in

Technical data (Page 21) is no longer guaranteed.

•

Make sure that the device is securely closed.

SITRANS FS230

A5E38755607-AA, 02/2017

19

WARNING

Hazardous contact voltage

Risk of injury through hazardous contact voltage when the device is open or not completely closed.

The degree of protection specified on the nameplate or in Technical data (Page 21) is no longer guaranteed if the device is

open or not properly closed.

•

Make sure that the device is securely closed.

5.1.4

Risk of explosion when medium above 100 °C flows through the process flange

WARNING

Risk of explosion when medium above 100 °C flows through the process flange

Explosion protection is no longer guaranteed and the approval is nullified.

It is prohibited for medium above 100 °C to continually flow through the process

flange.

WARNING

Loss of explosion protection

Risk of explosion in hazardous areas if the device is open or not properly closed.

•

Close the device as described in Connecting (Page 10).

5.1.5

Hot surfaces

WARNING

Hot surfaces

Risk of burns resulting from hot surfaces.

•

Take corresponding protective measures, for example by wearing protective gloves.

5.2

Local display

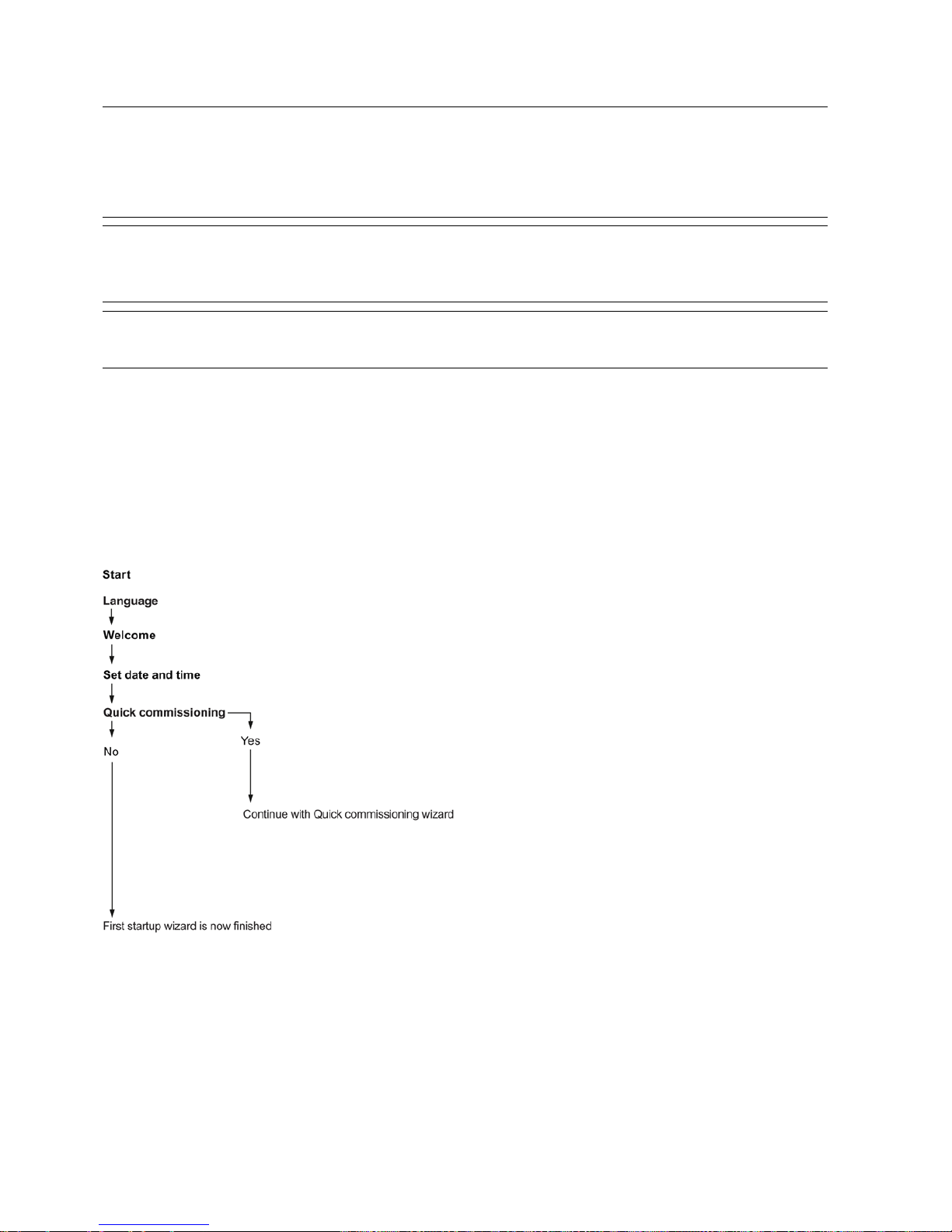

The device is commissioned/operated with the touch keypad on the local display.

The elements are actuated by touching the glass panel on the appropriate key. Pressing harder will not activate the key, but

using a thumb instead of a finger tip will help. The text display above the operating elements gives a menu-guided operation

of the individual device function/parameters. Successful operation of the key is confirmed by a small green LED at the right

of the display.

①

Full graphical display

②

LED (for indication of key operation)

③

Touch keypad

Figure 5-1 Local display

SITRANS FS230

20 A5E38755607-AA, 02/2017

Note

(Re-)calibration of the keypad

When the lid is closed, all keys are (re

-)calibrated (< 5 seconds). During (re-)calibration the LED is on and the keys cannot

be operated.

If one of the keys is pressed for more than 10 seconds, the (re

-)calibration of this key begins which has a duration of less

than 10 seconds. Release the key for further operation.

Note

HMI timeout

If no key is pressed for 1

0 minutes, the display switches to show operation view. If Backlight is set to Automatic, display

backlight goes off automatically 30 seconds after the last keypress.

Note

Operation does not require opening of the device. This means that the high degree

of protection of IP67 and safety in

hazardous areas are guaranteed at all times.

5.3

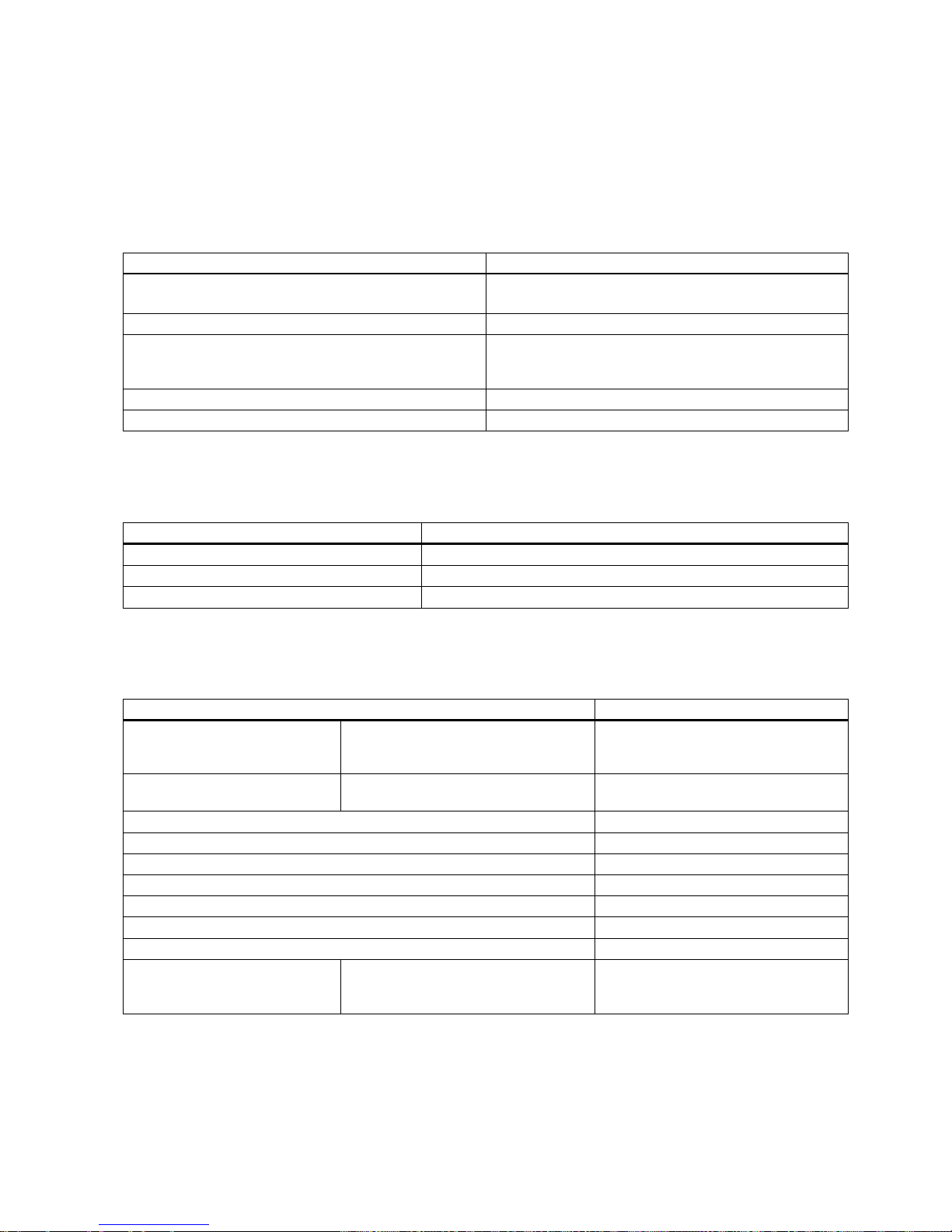

Initial startup

The first time the device is powered up, you will be prompted to set the language. The device always starts up showing

Language in English. When the language has been set, you will be prompted to set the date and time.

Before using the flow meter for the first time, essential parameters should be considered. After confirming/changing date and

time you can choose to accept the default values or start the Quick commissioning wizard.

You will be asked if you want to start the Quick commissioning wizard. If you choose Yes (recommended), the Quick

commissioning wizard will start. If you choose No, you accept the default values of the device, and the next HMI view will be

the operation view 1.

Text

Options/description

Language

Set the language: English, Deutsch, Français, Italiano, Español, 汉语

Welcome

Information about the Quick commissioning wizard

Set date and time

The set date and time (real time clock) is used for all time stamps of logged information

Quick commissioning The Quick commissioning wizard comprises the most important parameters/menus for

quick configuration of the flowmeter

SITRANS FS230

A5E38755607-AA, 02/2017

21

6

Technical data

6.1

Power

Table 6-1 Power supply

Description

Specification

Supply voltage

• 100 to 240 V AC +10/-10%, 47 to 63 Hz

•

20 to 27 V DC +10/-10%

Power consumption

15 VA/7.5 W

Fluctuation

•

Transient overvoltages up to the levels of overvoltage

category II

•

Temporary overvoltages occurring on mains supply only

Reverse polarity protection (y / n)

Y

Galvanic isolation

3000 V AC

6.2

HART interface

Table 6-2 HART communication

Description

Specification

HART revision

7.5

Supported Device Managers

SIMATIC PDM V8.2 SP1 or newer

Supported Device Description (EDD)

V1.00.00

6.3

Operating conditions

Table 6-3 Basic conditions

Description

Specification

Ambient temperature

(Humidity max. 90 %)

Operation:

Transmitter without display

Display

-40 to +60 °C (-40 to +140 °F)

-20 to +60 °C (-4 to +140 °F)

Ambient temperature

(Humidity max. 90 %)

Storage: -40 to +70 °C (-40 to +158 °F)

Climate class DIN 60721-3-4

Altitude

Up to 2000 m (6560 ft)

Relative humidity 95 %

Bump resistance

On request

Shock resistance

On request

Thermal shock

On request

Vibration resistance

On request

EMC performance

•

Emission

• Immunity

•

EN 55011 / CISPR-11

• EN/IEC 61326-1 (Industry)

NAMUR NE 21

SITRANS FS230

22 A5E38755607-AA, 02/2017

Table 6-4 Process medium conditions

Description

Specification

Process medium temperature (Ts) (min to max)

-50 to +200 °C (-58 to 492 °F)

Process medium density (min to max)

1 to 5000 kg/m3 (0.06 to 312 lb/ft3)

Process medium gauge pressure (min to max)

0 to 160 bar (0 to 2321 psi)

Process medium absolute pressure (min to max) Stainless steel: 1 to 101 bar (14.5 to

1465 psi)

Hastelloy: 1 to 161 bar (14.5 to 2335 psi)

Process medium viscosity

Gases and non-compressible liquids

SITRANS FS230

A5E38755607-AA, 02/2017

23

7

Service and maintenance

7.1

Basic safety notes

Note

The device is maintenance

-free.

7.1.1

Maintenance

The device is maintenance-free. However, a periodic inspection according to pertinent directives and regulations must be

carried out.

An inspection can include check of:

● Ambient conditions

● Seal integrity of the process connections, cable entries, and cover screws

● Reliability of power supply, lightning protection, and grounds

NOTICE

Repair and service must be carried out by Siemens authorized personnel only.

Note

Siemens defines flow sensors as non

-repairable products.

WARNING

Impermissible repair and maintenance of the device

•

Repair and maintenance must be carried out by Siemens authorized personnel only.

WARNING

Impermissible repair of explosion protected devices

Risk of explosion in hazardous areas

•

Repair must be carried out by Siemens authorized personnel only.

WARNING

Dust layers above 5 mm

Risk of explosion in hazardous areas.

Device may overheat due to dust build up.

•

Remove dust layers in excess of 5 mm.

NOTICE

Penetration of moisture into the device

Device damage.

•

Make sure when carrying out cleaning and maintenance work that no moisture penetrates the inside of the device.

CAUTION

Releasing button lock

Improper modification of parameters could influence process safety.

•

Make sure that only authorized personnel may cancel the button locking of devices for safety-related applications.

SITRANS FS230

24 A5E38755607-AA, 02/2017

7.2

Cleaning

Cleaning the enclosure

● Clean the outside of the enclosure with the inscriptions and the display window using a cloth moistened with water or a

mild detergent.

● Do not use any aggressive cleansing agents or solvents, e.g. acetone. Plastic parts or the painted surface could be

damaged. The inscriptions could become unreadable.

WARNING

Electrostatic charge

Risk of explosion in hazardous areas if electrostatic charges develop, for example, when cleaning plastic surfaces with a

dry cloth.

•

Prevent electrostatic charging in hazardous areas.

7.3

Maintenance and repair work

WARNING

Maintenance during continued operation in a hazardous area

There is a risk of explosion when carrying out repairs and maintenance on the device in a hazardous area.

• Isolate the device from power.

- or -

•

Ensure that the atmosphere is explosion-free (hot work permit).

WARNING

Impermissible accessories and spare parts

Risk of explosion in areas subject to explosion hazard.

• Only use original accessories or original spare parts.

• Observe all relevant installation and safety instructions described in the instructions for the device or enclosed with the

accessory or spare part.

WARNING

Humid environment

Risk of electric shock.

• Avoid working on the device when it is energized.

• If working on an energized device is necessary, ensure that the environment is dry.

•

Make sure when carrying out cleaning and maintenance work that no moisture penetrates the inside of the device.

CAUTION

Hot surfaces

Risk of burns during maintenance work on parts having surface temperatures exceeding 70 °C (158 °F).

• Take corresponding protective measures, for example by wearing protective gloves.

• After carrying out maintenance, remount touch protection measures.

SITRANS FS230

A5E38755607-AA, 02/2017

25

WARNING

Enclosure open

Risk of explosion in hazardous areas as a result of hot components and/or charged capacitors inside the device.

To open the device in a hazardous area:

1. Isolate the device from power.

2. Observe the wait time specified in Technical data (Page 21) or on the warning sign before opening the device.

3. Visually inspect sensor inlet and outlet.

Exception:

Devices exclusively having the type of protection "Intrinsic safety Ex i" may be opened in an energized state in

hazardous areas.

WARNING

Improper connection after maintenance

Risk of explosion in areas subject to explosion hazard.

• Connect the device correctly after maintenance.

• Close the device after maintenance work.

Refer to Connecting (Page 10).

7.4

Return procedure

Enclose the bill of lading, return document and decontamination certificate in a clear plastic pouch and attach it firmly to the

outside of the packaging.

Required forms

● Delivery note

● Return goods delivery note (http://www.siemens.com/processinstrumentation/returngoodsnote)

with the following information:

– Product (item description)

– Number of returned devices/replacement parts

– Reason for returning the item(s)

● Decontamination declaration (http://www.siemens.com/sc/declarationofdecontamination)

With this declaration you warrant "that the device/replacement part has been carefully cleaned and is free of residues.

The device/replacement part does not pose a hazard for humans and the environment."

If the returned device/replacement part has come into contact with poisonous, corrosive, flammable or water-

contaminating substances, you must thoroughly clean and decontaminate the device/replacement part before returning it

in order to ensure that all hollow areas are free from hazardous substances. Check the item after it has been cleaned.

Any devices/replacement parts returned without a decontamination declaration will be cleaned at your expense before

further processing.

7.5

Disposal

Devices described in this manual should be recycled. They may not be disposed of in the municipal

waste disposal services according to the Directive 2012/19/EC on waste electronic and electrical

equipment (WEEE).

Devices can be returned t

o the supplier within the EC, or to a locally approved disposal service for

eco

-friendly recycling. Observe the specific regulations valid in your country.

Further information about devices containing batteries can be found at: Information about battery /

product return (WEEE) (

https://support.industry.siemens.com/cs/document/109479891/)

SITRANS FS230

26 A5E38755607-AA, 02/2017

A

Appendix A

Technical Support

If this documentation does not provide complete answers to any technical questions you may have, contact Technical

Support at:

● Support request (http://www.siemens.com/automation/support-request

)

● More information about our Technical Support is available at

Technical Support (http://www.siemens.com/automation/csi/service

)

Internet Service & Support

In addition to our documentation, Siemens provides a comprehensive support solution at:

● Services & Support (http://www.siemens.com/automation/service&support)

Personal contact

If you have additional questions about the device, please contact your Siemens personal contact at:

● Partner (http://www.automation.siemens.com/partner)

In order to find the contact for your product, select under 'All Products and Branches' the path 'Automation Technology >

Sensor Systems'.

Documentation

You can find documentation on various products and systems at:

● Instructions and manuals Instructions and manuals (http://www.siemens.com/processinstrumentation/documentation)

A.1 Certificates

You can find certificates on the Internet at Certificates (http://www.siemens.com/processinstrumentation/certificates) or on

an included DVD.

SITRANS FS230

A5E38755607

, 02/2017

Trademarks

All names identified by ® are registered trademarks of

Siemens AG

. The remaining trademarks in this publication may be trademarks whose

use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication t

o ensure consistency with the hardware and software described. Since variance cannot

be precluded entirely, we cannot guarantee full consistency. However, the information in this publication is reviewed regular

ly and any

necessary corrections are included

in subsequent editions.

Siemens AG

Division Process Industries and Drives

Postfach 48 48

90026 NÜRNBERG

GERMANY

© Siemens AG 2017. Alle Rechte vorbehalten

A5E38755607-AA, 02/2017

27

SITRANS F

Ultraschall-Durchflussmessgeräte

SITRANS FS230

Kompaktbetriebsanleitung

Rechtliche Hinweise

Warnhinweiskonzept

Dieses Handbuch enthält Hinweise, die Sie zu Ihrer persönlichen Sicherheit sowie zur Vermeidung von Sachschäden beachten müssen.

Die Hinweise zu Ihrer persönlichen Sicherheit sind durch ein Warndreieck hervorgehoben, Hinweise zu alleinigen Sachschäden stehen

ohne Warndreieck. Je nach Gefährdungsstufe werden die Warnhinweise in abnehmender Reihenfolge wie folgt dargestellt.

GEFAHR

bedeutet, dass Tod oder schwere Körperverletzung eintreten

wird

, wenn die entsprechenden Vorsichtsmaßnahmen nicht getroffen

werden.

WARNUNG

bedeutet, dass Tod oder schwere Körperverletzung eintreten

kann

, wenn die entsprechenden Vorsichtsmaßnahmen nicht getroffen

werden.

VORSICHT

bedeutet, dass eine leichte Körperverletzung eintreten kann, wenn die entsprechenden Vorsichtsmaßnahmen nicht getroffen werden.

ACHTUNG

bedeutet, dass Sachschaden eintreten kann, wenn die entsprechenden Vorsichtsmaßnahmen nicht getroffen werden.

Beim Auftreten mehrerer Gefährdungsstufen wird immer der Warnhinweis zur jeweils höchsten Stufe verwendet. Wenn in einem

Warnhinweis mit dem Warndreieck vor Personenschäden gewarnt wird, dann kann im selben Warnhinweis zusätzlich eine Warnung vor

Sachschäden angefügt sein.

Qualifiziertes Personal

Das zu dieser Dokumentation zugehörige Produkt/System darf nur von für die jeweilige Aufgabenstellung

qualifiziertem Personal

gehandhabt werden unter Beachtung der für die jeweilige Aufgabenstellung zugehörigen Dokumentation, insbesondere der darin

enthaltenen Sicherheits- und Warnhinweise. Qualifiziertes Personal ist auf Grund seiner Ausbildung und Erfahrung befähigt, im Umgang mit

diesen Produkten/Systemen Risiken zu erkennen und mögliche Gefährdungen zu vermeiden.

Bestimmungsgemäßer Gebrauch von Siemens-Produkten

Beachten Sie Folgendes:

WARNUNG

Siemens-Produkte dürfen nur für die im Katalog und in der zugehörigen technischen Dokumentation vorgesehenen Einsatzfälle verwendet

werden. Falls Fremdprodukte und -komponenten zum Einsatz kommen, müssen diese von Siemens empfohlen bzw. zugelassen sein. Der

einwandfreie und sichere Betrieb der Produkte setzt sachgemäßen Transport, sachgemäße Lagerung, Aufstellung, Montage, Installation,

Inbetriebnahme, Bedienung und Instandhaltung voraus. Die zulässigen Umgebungsbedingungen müssen eingehalten werden. Hinweise

in den zugehörigen Dokumentationen müssen beachtet werden.

SITRANS FS230

28 A5E38755607-AA, 02/2017

1

Einleitung

1.1

Zweck dieser Dokumentation

Dieses Dokument enthält alle wesentlichen Gesundheits- und Sicherheitsinformationen, die für den sicheren Betrieb des

Gerätes benötigt werden.

Lesen Sie vor Einbau und Inbetriebnahme des Gerätes sorgfältig die Betriebsanleitung auf dem elektronischen Datenträger.

1.2

Revisionsüberblick

Die folgende Übersicht zeigt die wichtigsten Änderungen in der Dokumentation gegenüber der früheren Ausgabe.

Ausgabe

Bemerkungen

FW-Version

HW-Version

EDD-Version

HARTGeräterevision

02/2017

• Erstausgabe

1.00.00 01

• SIMATIC

PDM-Treiber

für HART

1.00.00

• SIMATIC

PDM-Treiber

für Modbus

1.00.00

• AMS-Treiber

für HART

1.00.00

• FC475-Treiber

für HART

1.00.00

• DTM/FDT-

Treiber für

HART 1.00.00

1

1.3

Bestimmungsgemäßer Gebrauch

Dieses Gerät ist zur Messung von Messstoffen gemäß den Informationen in der Betriebsanleitung bestimmt.

Hinweis

Nutzung in häuslicher Umgebung

Diese Einrichtung der Klasse A Gruppe 1 ist für den Einsatz im industriellen Bereich vorgesehen.

In häuslicher Umgebung kann das Gerät Funkstörungen verursachen.

1.4

Überprüfung der Lieferung

1. Prüfen Sie die Verpackung und die gelieferten Artikel auf sichtbare Schäden.

2. Melden Sie alle Schadenersatzansprüche unverzüglich dem Spediteur.

3. Bewahren Sie beschädigte Teile bis zur Klärung auf.

4. Prüfen Sie den Lieferumfang durch Vergleichen Ihrer Bestellung mit den Lieferpapieren auf Richtigkeit und

Vollständigkeit.

Loading...

Loading...