Siemens SINAMICS G120P CU230P-2 Compact Operating Instructions

___________________

___________________

___________________

___________________

___________________

SINAMICS

SINAMICS G120P

CU230P-2 Control Units

Compact Operating Instructions

Edition 01/2017

01/2017

A5E38815802B AA

Fundamental safety

instructions

1

Scope of delivery

2

Installing

3

Commissioning

4

More information

5

Siemens AG

Division Digital Factory

Postfach 48 48

90026 NÜRNBERG

GERMANY

A5E38815802B AA

Ⓟ

01/2017 Subject to change

Copyright © Siemens AG 2015 - 2017.

All rights reserved

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by

personnel qualified

for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

CU230P-2 Control Units

Compact Operating Instructions, 01/2017, A5E38815802B AA

3

Table of contents

1 Fundamental safety instructions .............................................................................................................. 4

1.1 General safety instructions ....................................................................................................... 4

1.2 Industrial security ...................................................................................................................... 5

2 Scope of delivery .................................................................................................................................... 6

3 Installing ................................................................................................................................................. 7

3.1 Plugging the Control Unit onto the Power Module .................................................................... 7

3.2 Overview of the interfaces ...................................................................................................... 10

3.3 Terminal strips ........................................................................................................................ 12

3.4 Factory interface settings ........................................................................................................ 14

3.5 Default setting of the interfaces .............................................................................................. 16

4 Commissioning ..................................................................................................................................... 33

4.1 Tools to commission the converter ......................................................................................... 33

4.2 Commissioning with BOP-2 operator panel ............................................................................ 34

4.2.1 Start quick commissioning and select the application class ................................................... 34

4.2.2 Identifying the motor data and optimizing the closed-loop control ......................................... 38

4.3 Connecting the inverter to the fieldbus ................................................................................... 40

4.3.1 PROFINET and PROFIBUS ................................................................................................... 40

4.3.2 Modbus RTU ........................................................................................................................... 43

4.3.3 BACnet MS/TP ........................................................................................................................ 44

4.4 Frequently required parameters ............................................................................................. 46

5 More information ................................................................................................................................... 49

5.1 Overview of the manuals ........................................................................................................ 49

5.2 Technical support .................................................................................................................... 50

This manual describes how you install the CU230P-2 Control Unit of the SINAMICS G120P

inverter and commission it.

What is the meaning of the symbols in the manual?

Reference to further information in the manual

An operating instruction starts here.

This concludes the operating instruction.

Download from the Internet

DVD that can be ordered

CU230P-2 Control Units

4 Compact Operating Instructions, 01/2017, A5E38815802B AA

1

1.1

General safety instructions

WARNING

Danger to life if the safety instructions and residual risks are not observed

If the safety instructions and residual risks in the associated hardware documentation are

not observed, accidents involving severe injuries or death can occur.

• Observe the safety instructions given in the hardware documentation.

• Consider the residual risks for the risk evaluation.

WARNING

Danger to life or malfunctions of the machine as a result of incorrect or changed

parameterization

As a result of incorrect or changed parameterization, machines can malfunction, which in

turn can lead to injuries or death.

• Protect the parameterization (parameter assignments) against unauthorized access.

• Respond to possible malfunctions by applying suitable measures (e.g. EMERGENCY

STOP or EMERGENCY OFF).

Fundamental safety instructions

1.2 Industrial security

CU230P-2 Control Units

Compact Operating Instructions, 01/2017, A5E38815802B AA

5

1.2

Industrial security

Note

Industrial security

Siemens provides products and solutions wit

h industrial security functions that support the

secure operation of plants, systems, machines and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement

– and continuously maintain – a holistic, state-of-the-art industrial

security concept. Siemens products and solutions only represent one component of such a

concept.

The customer is responsible for preventing unauthorized access to its plants, systems,

machines and networks. Systems, machin

es and components should only be connected to

the enterprise network or the internet if and to the extent necessary and with appropriate

security measures (e.g. use of firewalls and network segmentation) in place.

Additionally, Siemens’ guidance on approp

riate security measures should be taken into

account. For more information about industrial security, please visit:

Industrial security (

http://www.siemens.com/industrialsecurity).

Siemens’ produ

cts and solutions undergo continuous development to make them more

secure. Siemens strongly recommends to apply product updates as soon as available and to

always use the latest product versions. Use of product versions that are no longer supported,

and fa

ilure to apply latest updates may increase customer’s exposure to cyber threats.

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS

Feed at:

Industrial security (

http://www.siemens.com/industrialsecurity).

WARNING

Danger to life as a result of unsafe operating states resulting from software manipulation

Software manipulations (e.g. viruses, trojans, malware or worms) can cause unsafe

operating states in your system that may lead to death, serious injury, and property

damage.

• Keep the software up to date.

• Incorporate the automation and drive components into a holistic, state-of-the-art

industrial security concept for the installation or machine.

• Make sure that you include all installed products into the holistic industrial security

concept.

• Protect files stored on exchangeable storage media from malicious software by with

suitable protection measures, e.g. virus scanners.

CU230P-2 Control Units

6 Compact Operating Instructions, 01/2017, A5E38815802B AA

2

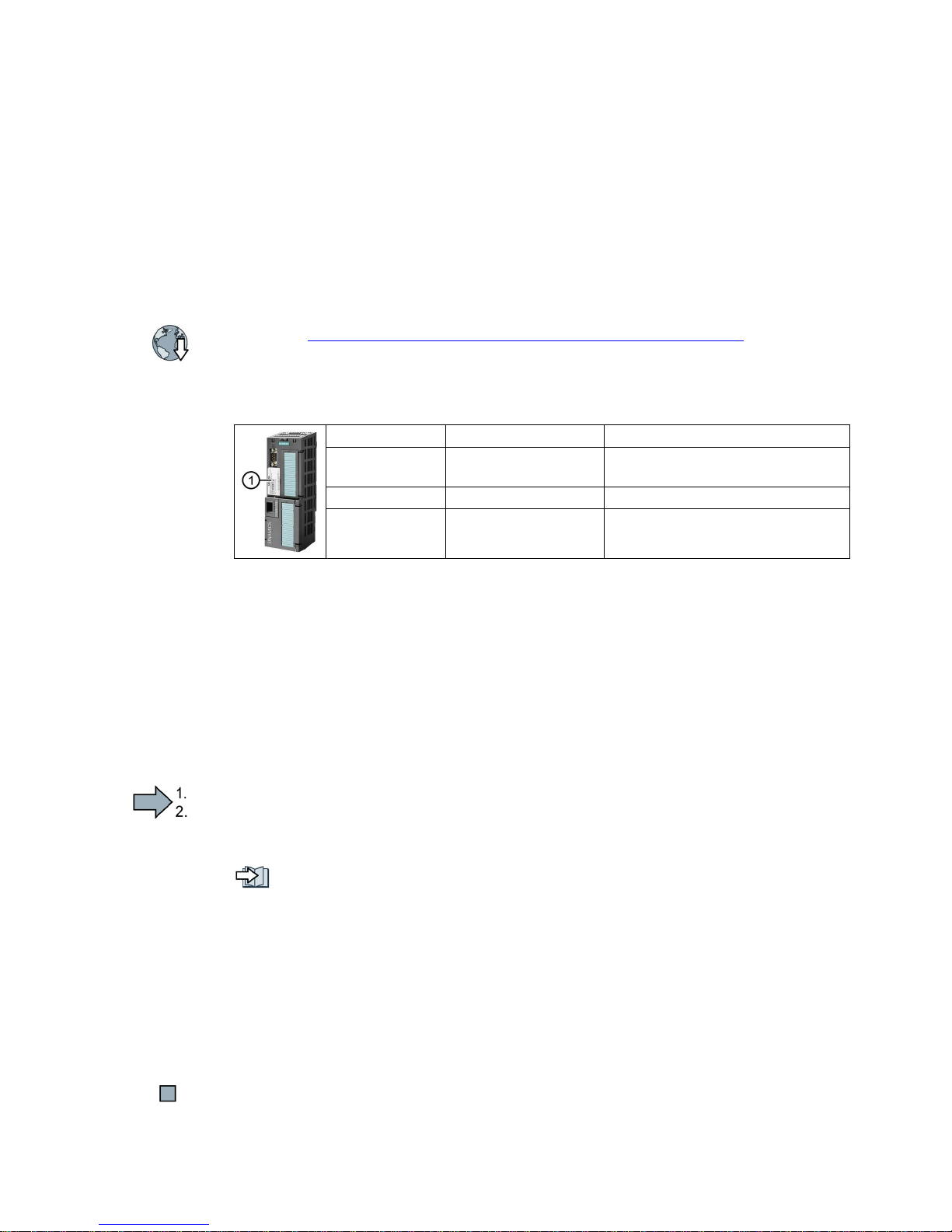

The delivery comprises at least the following components:

● A CU230P-2 Control Unit ready for operation with installed firmware. Options for

upgrading and downgrading the firmware can be found on the Internet:

Firmware (http://support.automation.siemens.com/WW/news/en/67364620).

The fieldbus interface of the Control Unit depends on the Article No. You can find the

designation, the article number, the hardware version (e.g. 02) and the firmware version

(e.g. 4.6) on the Control Unit rating plate

①.

Designation

Article number

Fieldbus

CU230P-2 HVAC 6SL3243-0BB30-1HA3 USS, Modbus RTU, BACnet MS/TP,

P1

CU230P-2 DP

6SL3243-0BB30-1PA3

PROFIBUS DP

CU230P-2 PN 6SL3243-0BB30-1FA0 PROFINET IO, EtherNet/IP

● Compact Operating Instructions in German and English

● The inverter contains open-source software (OSS). OSS comprises open source text and

satisfies special license terms.

The OSS license terms are saved in the inverter. You can transfer the OSS license terms

to a PC using a memory card where you can read them.

Transferring OSS license terms to a PC

Procedure

To transfer OSS license terms to a PC, proceed as follows:

1. Switch off the inverter power supply.

2. Insert an empty memory card into the card slot of the inverter.

Overview of the interfaces (Page 10)

3. Switch on the inverter power supply.

4. The inverter writes file "Read_OSS.ZIP" to the memory card within approximately

30 seconds.

5. Switch off the inverter power supply.

6. Withdraw the memory card from the inverter.

7. Insert the memory card into the card reader of a PC.

8. Please read the license terms.

You have transferred the OSS license terms to a PC.

CU230P-2 Control Units

Compact Operating Instructions, 01/2017, A5E38815802B AA

7

3

3.1

Plugging the Control Unit onto the Power Module

Permissible Power Modules

You may operate the Control Unit with the following Power Modules:

•

PM230

•

PM240P-2

•

PM240-2

•

PM250

•

PM330

Installing the Control Unit - General

Each Power Module has an appropriate holder for the Control Unit and a release

mechanism.

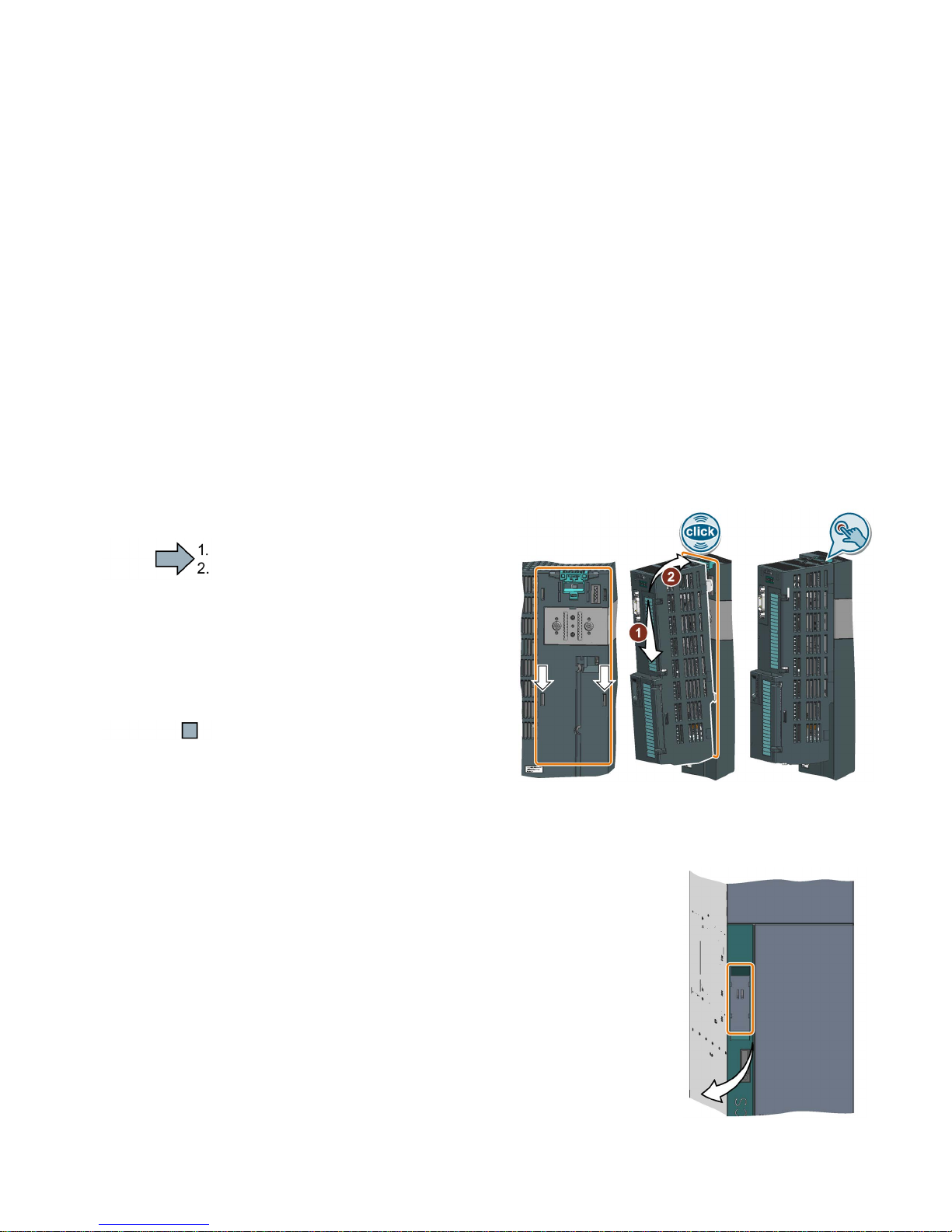

Inserting the Control Unit

Proceed as follows to plug the Control

Unit onto a Power Module:

1.

Place the two catches of the

Control Unit in the matching

grooves of the Power Module.

2.

Press the Control Unit onto the

Power Module until you hear that it

latches.

You have now plugged the Control

Unit onto the Power Module.

Removing the Control Unit

Remove the Control Unit from the Power Module by pressing the release mechanism.

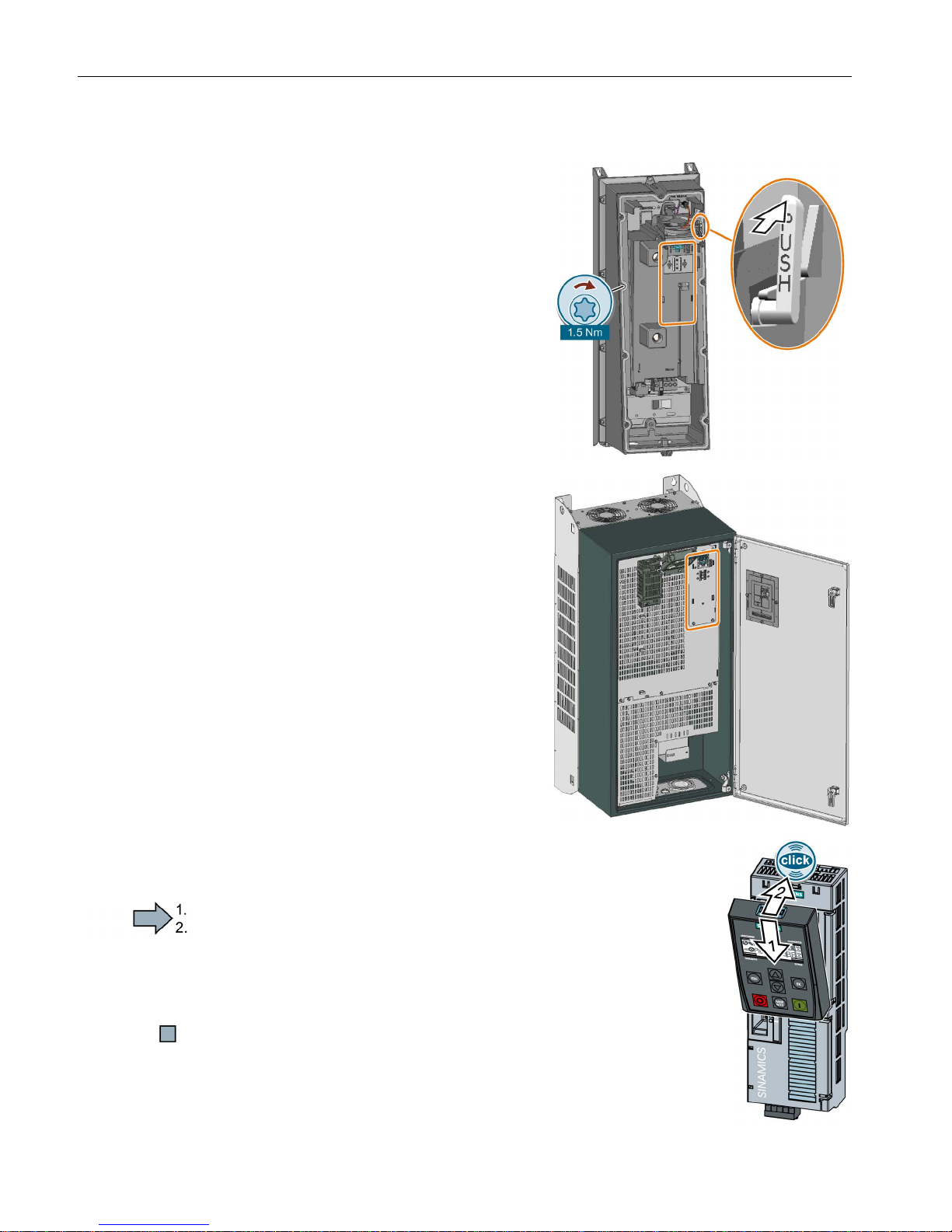

Special features for the PM330 Power Module

To insert or detach the Control Unit, you must open the left

-

hand cov

er of the Power Module.

Close the cover before you commission the inverter.

Installing

3.1 Plugging the Control Unit onto the Power Module

CU230P-2 Control Units

8 Compact Operating Instructions, 01/2017, A5E38815802B AA

Special features for the PM230 Power Module IP55, FSA … FSC

To insert or detach the

Control Unit, you must

release eight or ten fixing screws of the cover

and then remove the cover.

The Power Module release mechanism is

shown in the diagram.

Attach the cover again before you commission

the inverter. Do not damage the seal of the

cover when attaching it.

Installing the Control Unit, PM230 IP55 - FSD … FSF

To insert or detach the Control Unit, you must

open the front door of the Power Module.

Clos

e the door before you commission the in-

verter. Check to ensure that the seals are not

damaged.

Plugging on an operator panel

Procedure

To plug an Operator Panel on the Control Unit, proceed as follows:

1.

Locate the lower edge of the Operator Panel into the matching recess

of the Control Unit.

2.

Plug the Operator Panel onto the inverter until the latch audibly

engages.

You have plugged an operator panel onto the Control Unit.

The operator panel is ready for operation when you connect the inverter to the power supply.

Installing

3.1 Plugging the Control Unit onto the Power Module

CU230P-2 Control Units

Compact Operating Instructions, 01/2017, A5E38815802B AA

9

Mounting the operator panel or dummy cover on the IP55 Power Module

Either an operator panel or the dummy cover must be plugged on for the inverter to achieve

degree of protection IP55.

①

Attaching the operator panel or dummy cover:

Press the operator panel or dummy cover onto the

inverter as shown until you hear it click into place.

②

Removing the operator panel or dummy cover:

Use a suitable screwdriver to pres

s the interlock

downwards.

Tools to commission the converter (Page 33)

The following accessory is included in the Power Module scope of supply to connect the

Control Unit with the operator panel:

● An adapter, required for PM230 IP55 Power Modules, FSA … FSC

● A connecting cable and a bar to fix the connector, required for PM230 IP55 Power

Modules, FSD … FSF

Adapter

Connecting cable

Installing

3.2 Overview of the interfaces

CU230P-2 Control Units

10 Compact Operating Instructions, 01/2017, A5E38815802B AA

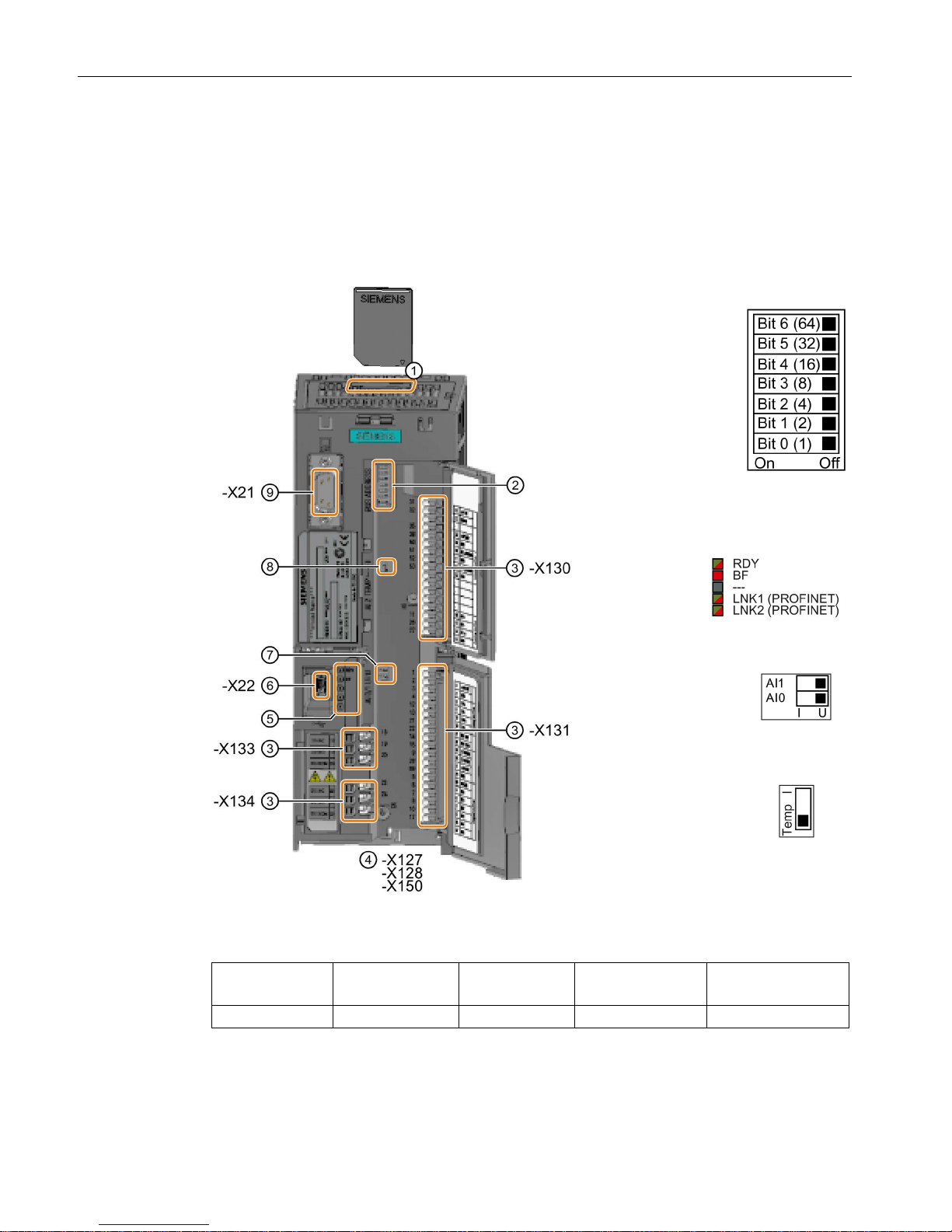

3.2

Overview of the interfaces

Interfaces at the front of the Control Unit

To access the interfaces at the front of the Control Unit, you must lift the Operator Panel (if

one is being used) and open the front doors.

①

Memory card slot

②

Selecting the

fieldbus address:

•

CU230P-2 DP

•

CU230P-2

HVAC

•

CU230P-2 BT

③

Terminal strips

④

Fieldbus interfaces at the lower

side

⑤

Status LED

⑥

USB interface for connection to a

PC

⑦

Switch for AI

0 and

AI

1 (U/I)

•

I 0/4 mA … 20 mA

•

U -10/0 V … 10 V

⑧

Switch for AI

2

Current or te

m-

per

ature input

⑨

Connection to the operator panel

Table 3- 1 Number of inputs and outputs

Digital inputs DI

Digital outputs DO

Analog inputs AI

Analog outputs AO

Input for motor tem-

perature sensor

6 3 4 2 1

Installing

3.2 Overview of the interfaces

CU230P-2 Control Units

Compact Operating Instructions, 01/2017, A5E38815802B AA

11

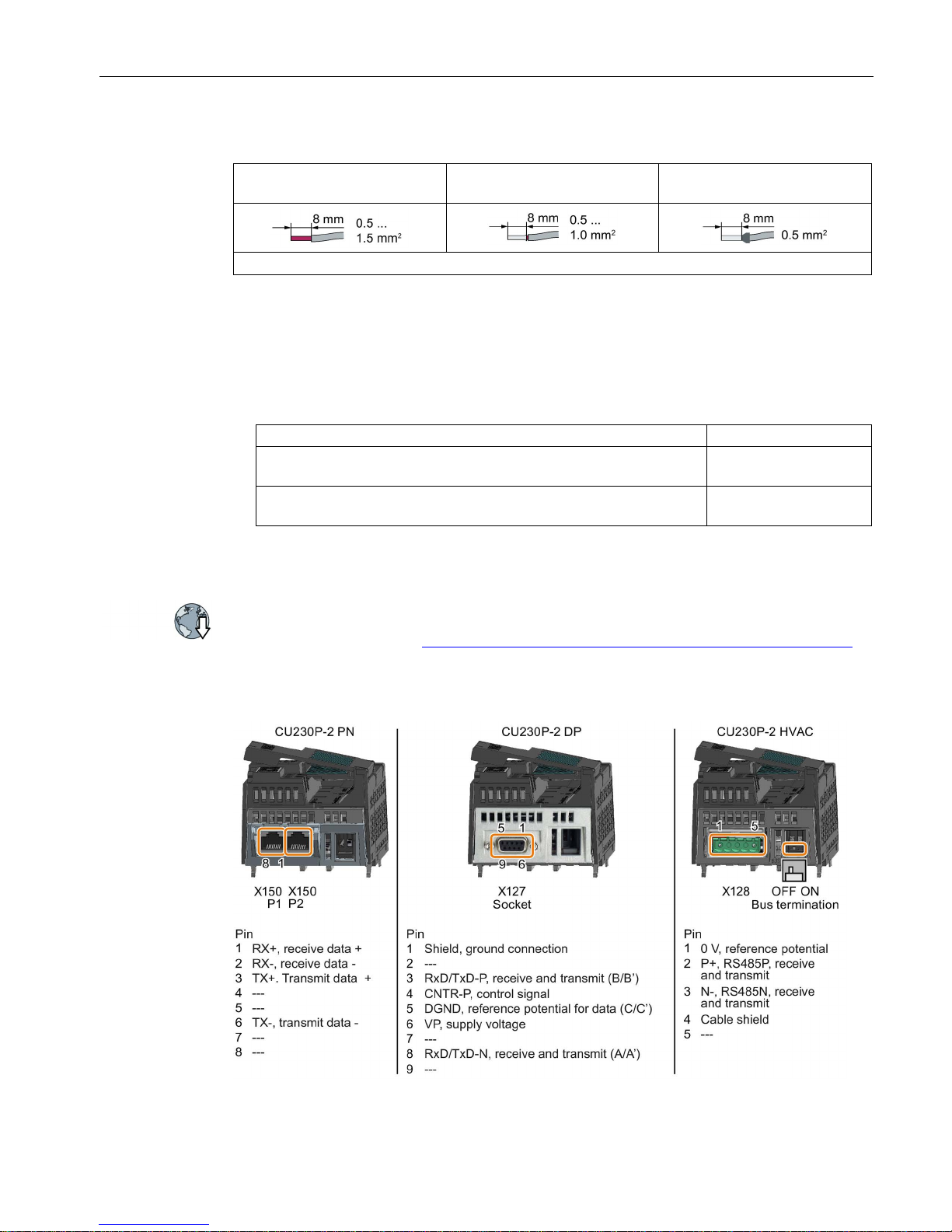

Table 3- 2 Permissible cables and wiring options

Solid or flexible conductors Finely stranded conductor with

non-insulated end sleeve

Finely stranded conductor with

partially insulated end sleeve

Cables with twin end sleeves are not permissible.

EMC-compliant wiring

Measures to ensure EMC-compliant wiring of the Control Unit:

● Use the shield connection kit of the Control Unit to connect the shield and provide strain

relief for cables/conductors.

Shield connection kit

Article number

Shield connection kit 1 for the CU230P-2 Control Units with all fieldbus

interfaces except for PROFINET.

6SL3264-1EA00-0FA0

Shield connection kit 3 for the CU230P-2 and CU240E-2 Control Units

with PROFINET interface.

6SL3264-1EA00-0HB0

● If you use shielded cables, then you must connect the shield to the mounting plate of the

control cabinet or with the shield support of the inverter through a good electrical

connection and a large surface area.

Additional information about EMC-compliant wiring is available on the Internet:

EMC installation guideline (http://support.automation.siemens.com/WW/view/en/60612658)

Interfaces at the lower side of the CU230P-2 Control Unit

Installing

3.3 Terminal strips

CU230P-2 Control Units

12 Compact Operating Instructions, 01/2017, A5E38815802B AA

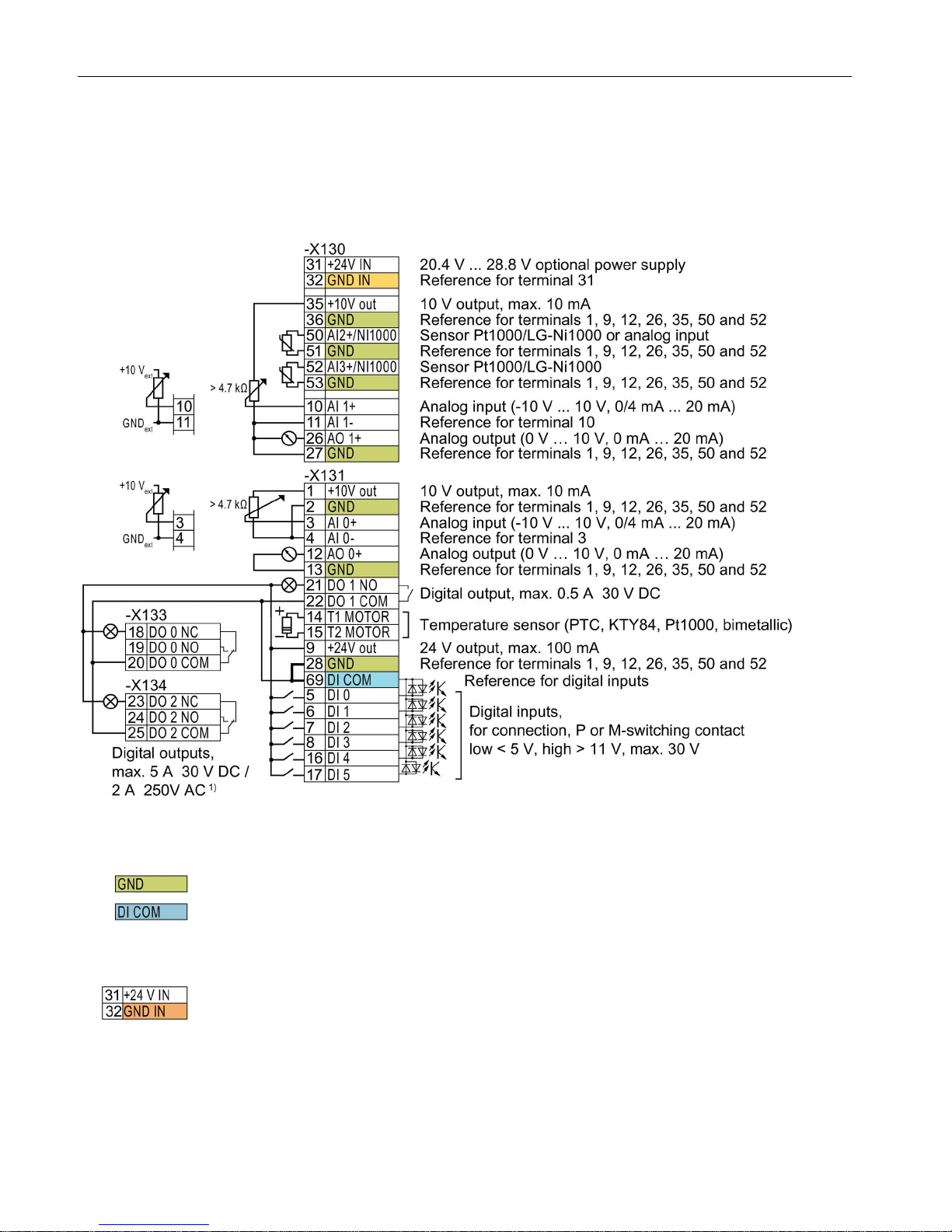

3.3

Terminal strips

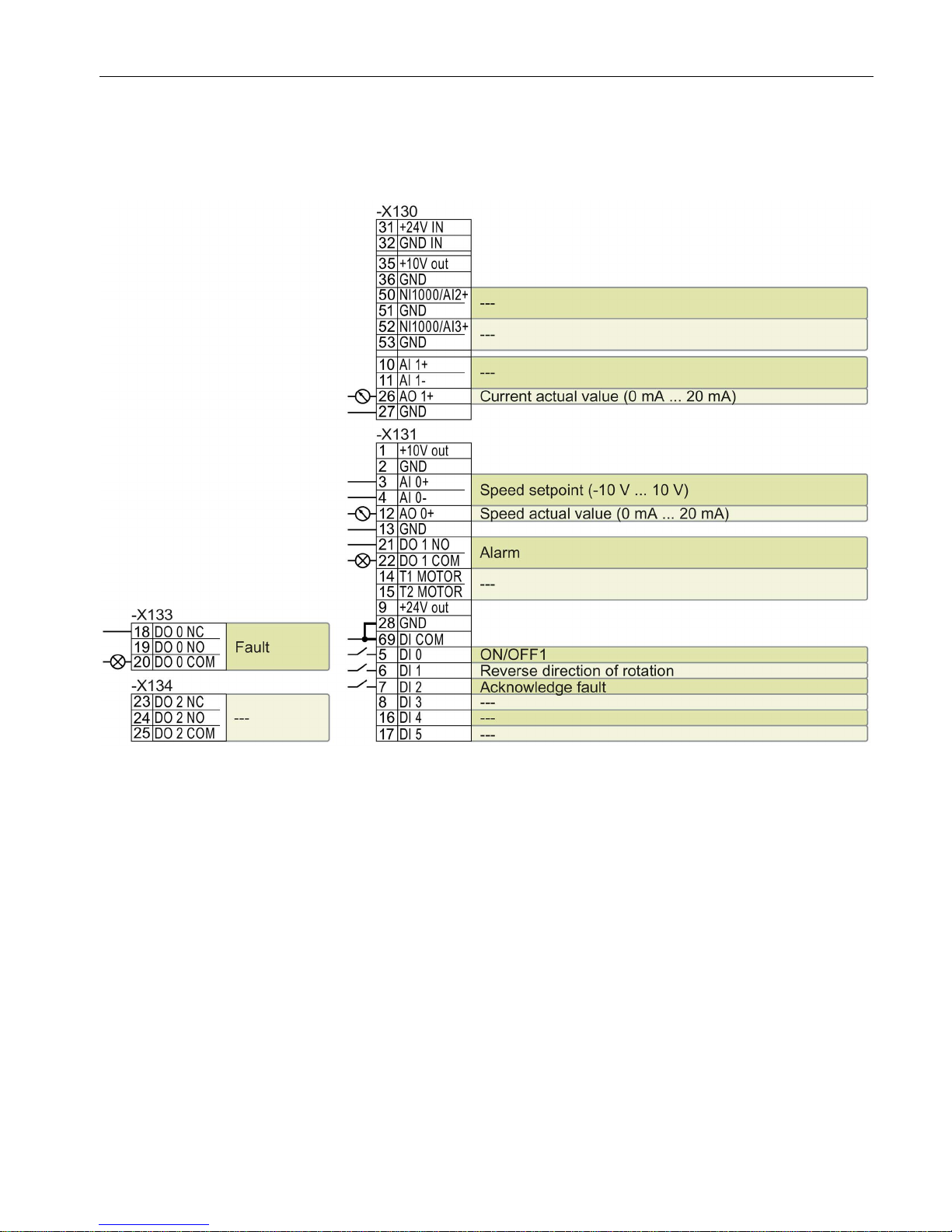

Terminal strips with wiring example

1)

The following applies to systems compliant with UL: Maximum current, 3 A 30 VDC or 2 A 250 VAC

Figure 3-1 Wiring the digital inputs with p-switching contacts and an internal 24 V power supply (terminal 9)

All terminals labelled with reference potential "GND" are connected internally in the inverter.

Reference potential "DI COM" is electrically isolated from "GND". The Control Unit is

delivered with a jumper between terminals 28 and 69.

→ If, as shown above, you wish to use the 24-V supply from terminal 9 as supply for the

digital inputs, then it is mandatory that this jumper is used.

When an optional 24 V power supply is connected at terminals 31, 32, even when the Power

Module is disconnected from the line supply, the Control Unit remains in operation. The

Control Unit thus maintains fieldbus communication, for example.

→ At terminals 31, 32, only connect a power supply that is in accordance with SELV (Safety

Extra Low Voltage) or PELV (Protective Extra Low Voltage).

Installing

3.3 Terminal strips

CU230P-2 Control Units

Compact Operating Instructions, 01/2017, A5E38815802B AA

13

→ if you also wish to use the power supply at terminals 31, 32 for the digital inputs, then you

must connect "DI COM" and "GND IN" with one another at the terminals.

You may use the internal 10 V power supply or an external power supply for the analog

inputs.

→ When you use the internal 10 V power supply, you must connect AI 0 or AI 1 with "GND".

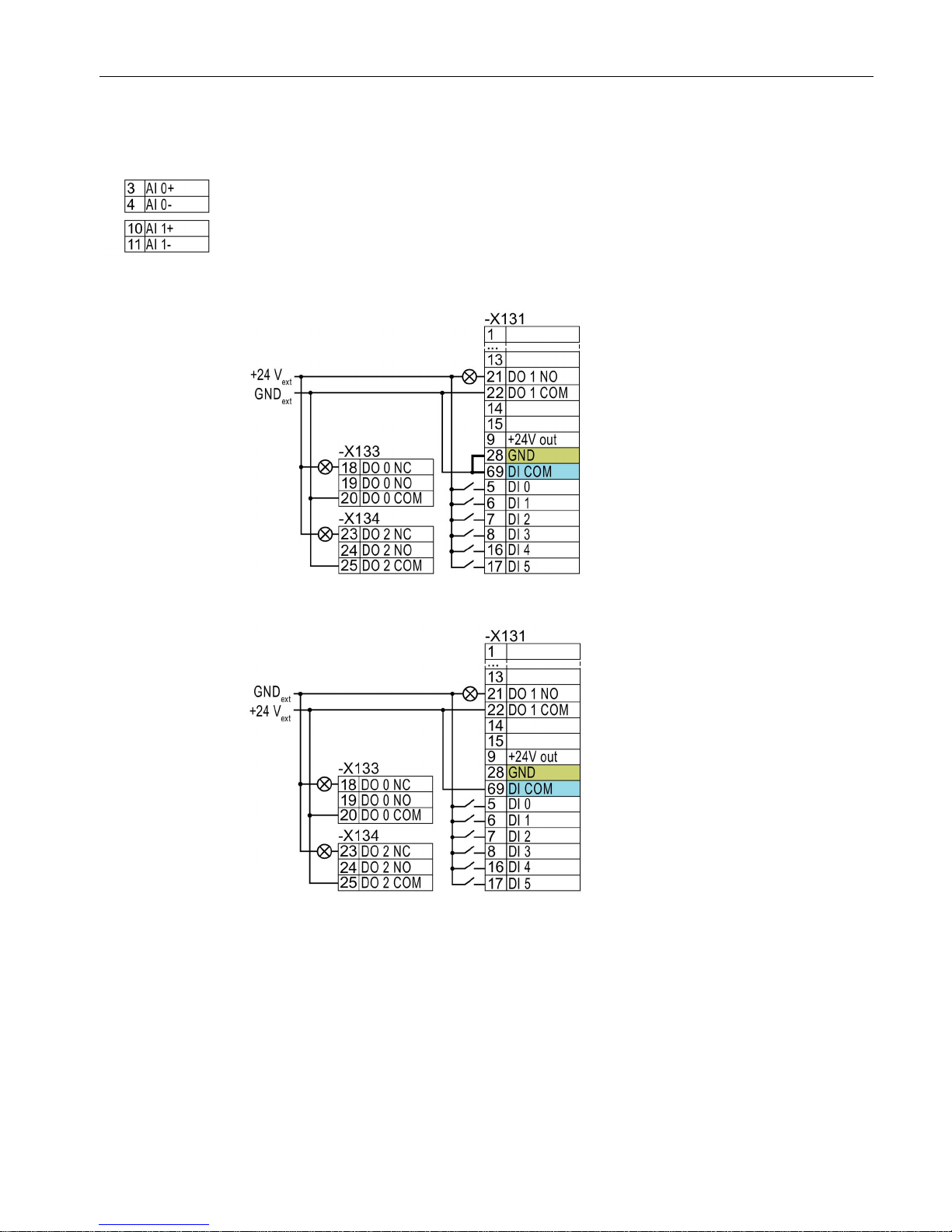

Additional options for wiring the digital inputs

Connecting P-switching contacts with an external

power supply

You must remove the jumper between

terminals 28 and 69 if it is necessary to

have electrical isolation between the

external power supply and the internal

inverter power supply.

Connecting M-switching contacts with an external

power supply

Remove the jumper between terminals

28 and 69.

Installing

3.4 Factory interface settings

CU230P-2 Control Units

14 Compact Operating Instructions, 01/2017, A5E38815802B AA

3.4

Factory interface settings

The factory setting of the interfaces depends on the Control Unit.

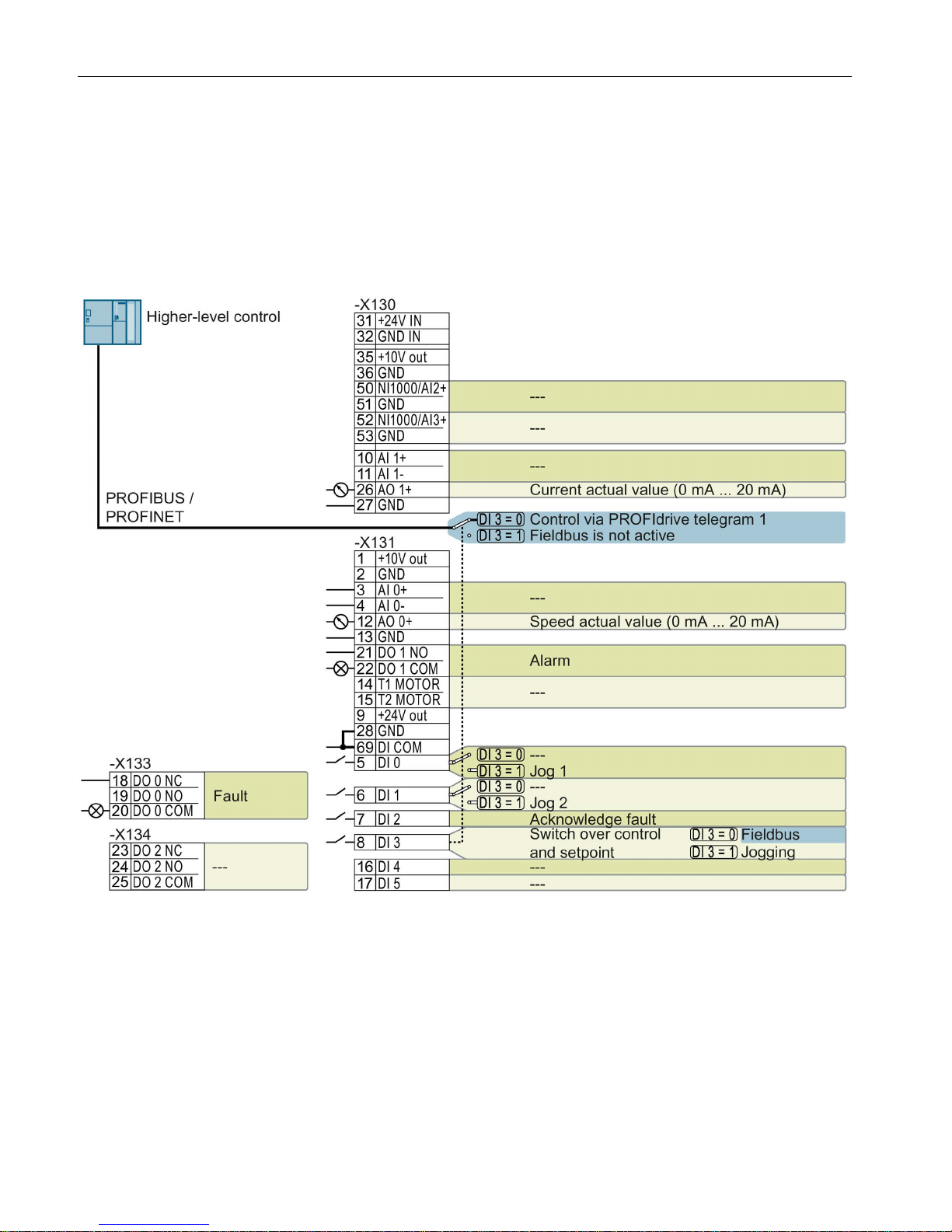

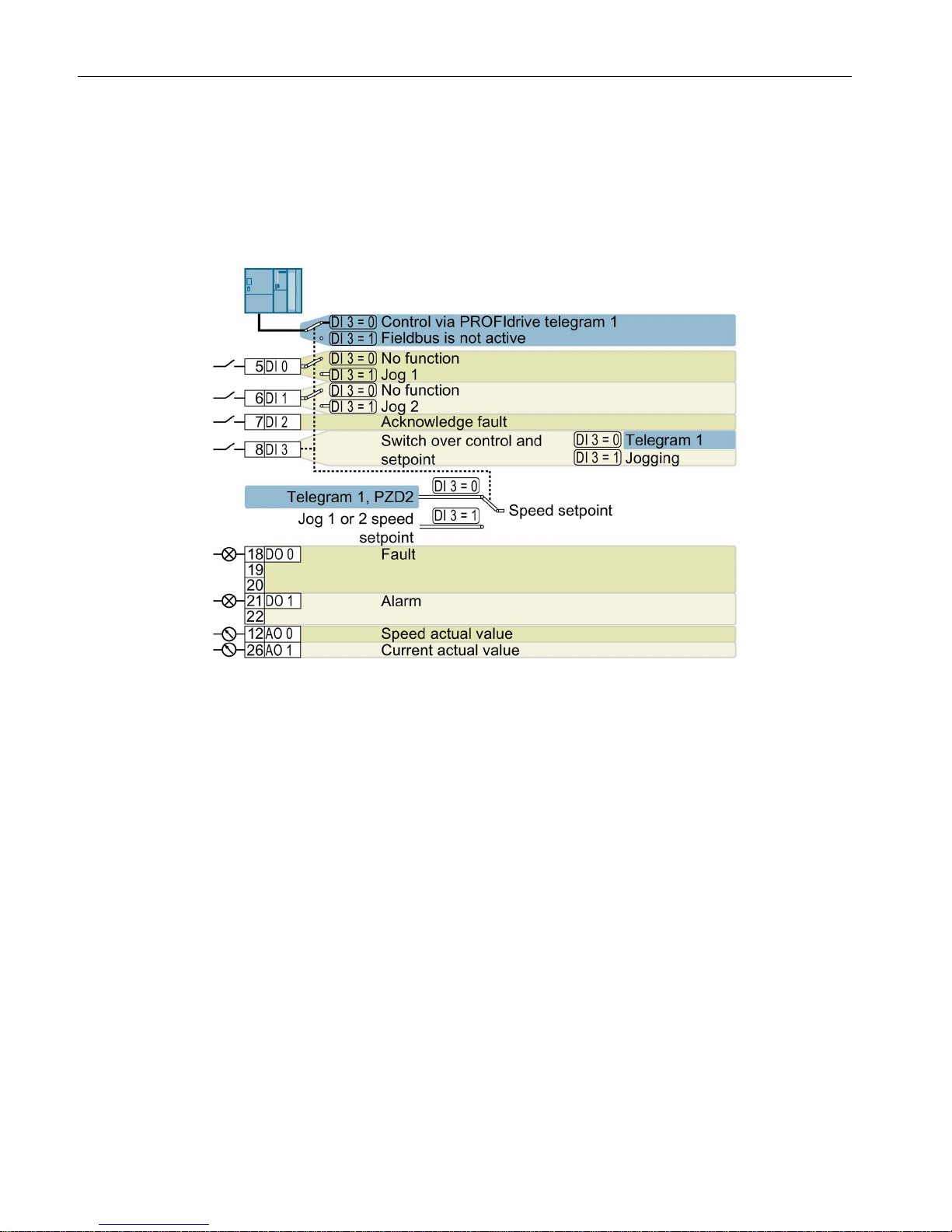

Control Units with PROFIBUS or PROFINET interface

The function of the fieldbus interface and digital inputs DI 0, DI 1 depends on DI 3.

--- No function.

DO x: p073x

AO 0: p0771[0]

DI x: r0722.x

Speed setpoint (main setpoint): p1070[0] = 2050[1]

Figure 3-2 Factory setting of the CU230P-2 DP and CU230P-2 PN Control Units

Installing

3.4 Factory interface settings

CU230P-2 Control Units

Compact Operating Instructions, 01/2017, A5E38815802B AA

15

Control Units with USS interface

The fieldbus interface is not active.

--- No function.

DO x: p073x

AO 0: p0771[0]

DI x: r0722.x

AI 0: r0755[0]

Speed setpoint (main setpoint): p1070[0] = 755[0]

Figure 3-3 Factory setting of CU230P-2 HVAC Control Units

Changing the function of the terminals

The function of the terminals and fieldbus interface can be adjusted.

In order that you do not have to successively change terminal for terminal, several terminals

can be jointly set using default settings ("p0015 Macro drive unit").

The terminal settings made in the factory described above correspond to the following

default settings:

● Default setting 12 (p0015 = 12): "Standard I/O with analog setpoint"

● Default setting 7 (p0015 = 7): "Fieldbus with data set switchover"

Installing

3.5 Default setting of the interfaces

CU230P-2 Control Units

16 Compact Operating Instructions, 01/2017, A5E38815802B AA

3.5

Default setting of the interfaces

Default setting 7: "Fieldbus with data set switchover"

Factory setting for inverters with PROFIBUS or PROFINET interface

DO 0: p0730, DO 1: p0731

AO 0: p0771[0], AO 1: p0771[1]

DI 0: r0722.0, …, DI 3: r0722.3

Speed setpoint (main setpoint): p1070[0] = 2050[1]

Jog 1 speed setpoint: p1058, factory setting: 150 rpm

Jog 2 speed setpoint: p1059, factory setting: -150 rpm

Designation in the BOP-2: FB cdS

Loading...

Loading...