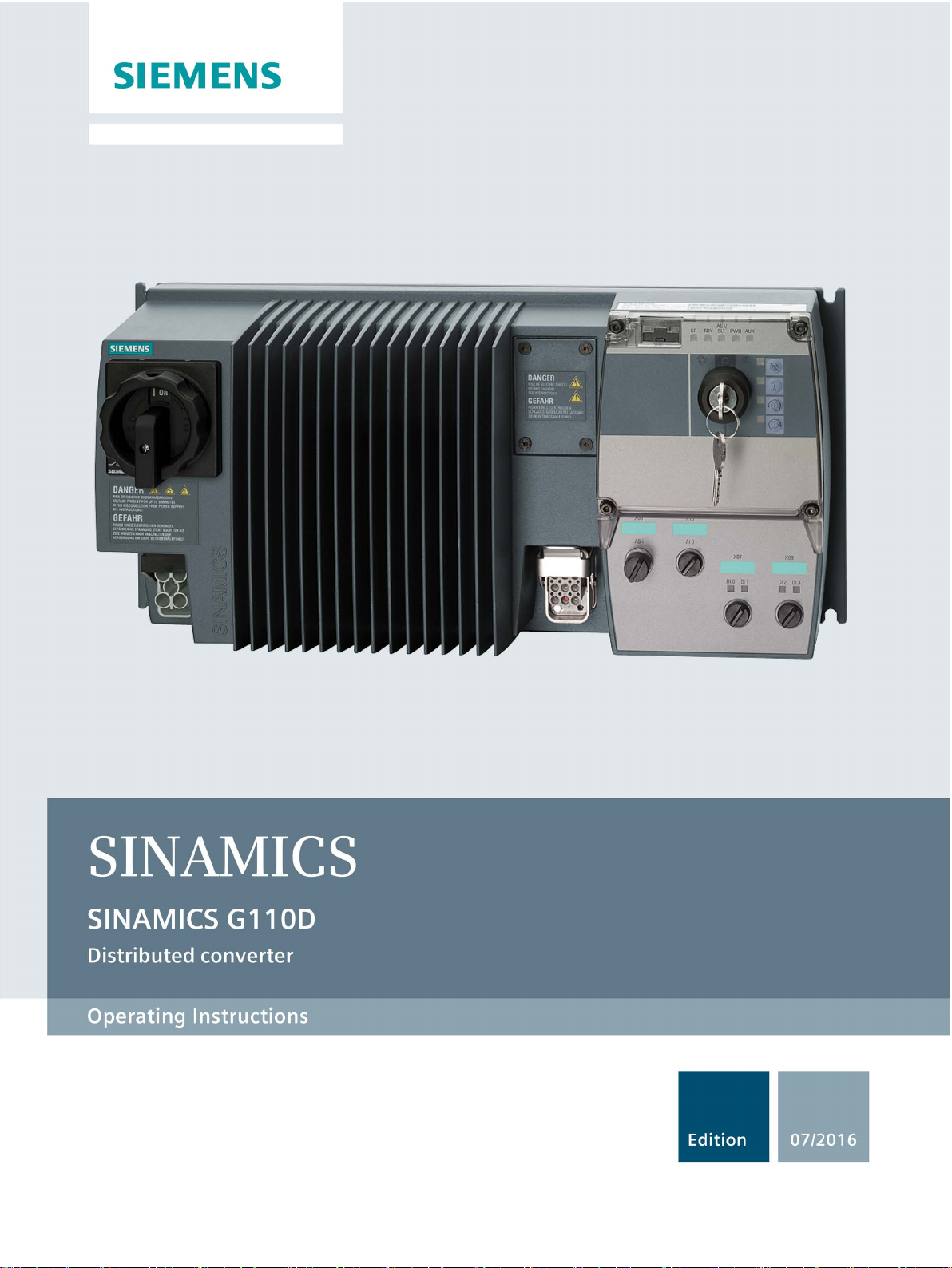

Siemens SINAMICS G110D Operating Instructions Manual

SINAMICS G110D

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

SINAMICS

SINAMICS G110D

Distributed Converter SINAMICS

G110D

Operating Instructions

Edition 07/2016, Firmware version 3.63

07/2016, FW V3.63

A5E36768472B AB

Fundamental safety

instructions

1

Introduction

2

Description

3

Connection

4

Commissioning

5

Functions

6

Service and maintenance

7

Messages and fault codes

8

Technical data

9

Appendix A

A

Siemens AG

Division Digital Factory

Postfach 48 48

90026 NÜRNBERG

GERMANY

Document order number: (null)

Ⓟ

Copyright © Siemens AG 2013 - 2016.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

for the specific

06/2016 Subject to change

Table of contents

1 Fundamental safety instructions .............................................................................................................. 9

2 Introduction ........................................................................................................................................... 17

3 Description ............................................................................................................................................ 29

4 Connection ........................................................................................................................................... 35

5 Commissioning ..................................................................................................................................... 61

1.1 General safety instructions ....................................................................................................... 9

1.2 Safety instructions for electromagnetic fields (EMF) .............................................................. 13

1.3 Handling electrostatic sensitive devices (ESD) ...................................................................... 13

1.4 Industrial security .................................................................................................................... 14

1.5 Residual risks of power drive systems .................................................................................... 15

2.1 About this manual ................................................................................................................... 17

2.2 Adapting the Inverter to the application .................................................................................. 19

2.2.1 General basics ........................................................................................................................ 19

2.2.2 Parameter ............................................................................................................................... 20

2.2.3 Parameters with follow-on parameterization .......................................................................... 21

2.2.4 Frequently required parameters ............................................................................................. 21

2.3 Extended adaptation of parameters ........................................................................................ 23

2.3.1 BICO technology: basic principles .......................................................................................... 23

2.3.2 BICO technology: example ..................................................................................................... 26

3.1 Overview of SINAMICS G110D Inverters ............................................................................... 29

3.2 Components of the Inverter system ........................................................................................ 30

4.1 Procedure for installing the Inverter ........................................................................................ 35

4.2 General layout of SINAMICS G110D ...................................................................................... 36

4.3 Removal of CU area cover and braking resistor connection hatch ........................................ 37

4.4 Drill pattern for the SINAMICS G110D ................................................................................... 38

4.5 Mounting orientation ............................................................................................................... 39

4.6 Ambient operating conditions ................................................................................................. 40

4.7 SINAMICS G110D Specifications ........................................................................................... 42

4.8 Cables and connections ......................................................................................................... 47

4.9 Configuring the AS-i slave ...................................................................................................... 53

4.10 Using the AS-i Programmer .................................................................................................... 58

5.1 Typical commissioning scenarios ........................................................................................... 61

5.2 Restoring the factory settings ................................................................................................. 63

SINAMICS G110D

Operating Instructions, 07/2016, FW V3.63, A5E36768472B AB

5

Table of contents

6 Functions .............................................................................................................................................. 91

5.3 Preparing for commissioning ................................................................................................. 64

5.4 Prerequisites of using the factory settings ............................................................................. 66

5.5 Factory settings for the Inverter ............................................................................................. 67

5.6 Commissioning with STARTER ............................................................................................. 69

5.7 Basic commissioning with IOP ............................................................................................... 80

5.8 Example application ............................................................................................................... 82

5.9 Backup data and storage ....................................................................................................... 86

5.9.1 Saving and transferring data using the IOP ........................................................................... 86

5.9.2 Saving and transferring data using the SD memory card ...................................................... 88

6.1 Overview of Inverter functions ............................................................................................... 91

6.2 Inverter Control ...................................................................................................................... 94

6.2.1 Frequency inverter control using digital inputs (two/three-wire control) ................................ 94

6.2.2 Two-wire control, method 1 .................................................................................................... 97

6.2.3 Two-wire control, method 2 .................................................................................................... 98

6.2.4 Two-wire control, method 3 .................................................................................................... 99

6.2.5 Three-wire control, method 1 ............................................................................................... 100

6.2.6 Three-wire control, method 2 ............................................................................................... 101

6.3 Command sources ............................................................................................................... 102

6.3.1 Selecting command sources ................................................................................................ 102

6.3.2 Assigning functions to digital inputs ..................................................................................... 103

6.3.3 Controlling the motor using the fieldbus .............................................................................. 104

6.4 Setpoint sources .................................................................................................................. 105

6.4.1 Selecting the setpoint source [P1000] ................................................................................. 105

6.4.2 Frequency setpoint using analog input [P1000=2] .............................................................. 106

6.4.3 Using a motorized potentiometer as a setpoint source........................................................ 107

6.4.4 Using fixed frequencies as a setpoint source ...................................................................... 108

6.4.5 Running the motor in jog mode (JOG function) ................................................................... 109

6.4.6 Specifying the motor speed via the fieldbus ........................................................................ 110

6.5 Changing over the command data sets (manual, automatic) .............................................. 111

6.6 Setpoint preparation ............................................................................................................. 114

6.6.1 Overview of setpoint preparation ......................................................................................... 114

6.6.2 Minimum frequency and maximum frequency ..................................................................... 115

6.6.3 Parameterizing the ramp-function generator ....................................................................... 116

6.7 Motor control ........................................................................................................................ 118

6.7.1 V/f control with linear characteristics.................................................................................... 118

6.7.2 V/f control with parabolic characteristic ............................................................................... 120

6.7.3 Typical applications for V/f control ....................................................................................... 120

6.7.4 Additional characteristics of the V/f control .......................................................................... 121

6.8 Protection functions ............................................................................................................. 122

6.8.1 Protective functions of the frequency inverter ...................................................................... 122

6.8.2 Overtemperature protection for the Inverter ........................................................................ 123

6.8.3 Overcurrent protection ......................................................................................................... 126

6.8.4 Limiting the maximum DC link voltage ................................................................................. 127

6.8.5 Load torque monitoring (system protection) ........................................................................ 128

SINAMICS G110D

6 Operating Instructions, 07/2016, FW V3.63, A5E36768472B AB

Table of contents

7 Service and maintenance .................................................................................................................... 197

8 Messages and fault codes ................................................................................................................... 205

9 Technical data .................................................................................................................................... 209

A Appendix A ......................................................................................................................................... 213

Index................................................................................................................................................... 219

6.9 Technological functions ........................................................................................................ 130

6.9.1 Technological functions ........................................................................................................ 130

6.9.2 Braking functions .................................................................................................................. 130

6.9.2.1 Braking functions of the Inverter ........................................................................................... 130

6.9.2.2 DC braking ............................................................................................................................ 132

6.9.2.3 Dynamic braking ................................................................................................................... 135

6.9.2.4 Parameterizing a motor holding brake .................................................................................. 137

6.9.3 Automatic restart and flying restart ....................................................................................... 141

6.9.3.1 Automatic restart ................................................................................................................... 141

6.9.3.2 Flying restart ......................................................................................................................... 146

6.9.4 PID technology controller ...................................................................................................... 149

6.9.5 Logical functions using function blocks ................................................................................. 150

6.9.6 Changing over drive data sets .............................................................................................. 151

6.10 Quick Stop function ............................................................................................................... 154

6.11 Operation in fieldbus systems ............................................................................................... 157

6.11.1 Communication via AS-i Network ......................................................................................... 157

6.11.1.1 Overview ............................................................................................................................... 157

6.11.1.2 Connecting the Inverter to AS-i network ............................................................................... 159

6.11.1.3 Example: configuring the Inverter on the AS-i network ........................................................ 160

6.11.1.4 AS-i Profile ............................................................................................................................ 168

6.11.1.5 Step 7 example conveyor program ....................................................................................... 186

6.11.1.6 Example application .............................................................................................................. 193

7.1 Behaviour of the Inverter when replacing components ........................................................ 197

7.2 Replacing the Inverter ........................................................................................................... 199

7.3 Local/remote switch cover .................................................................................................... 200

7.4 Repair switch ........................................................................................................................ 203

8.1 Fault codes ........................................................................................................................... 205

8.2 LED States ............................................................................................................................ 206

9.1 Technical data of the SINAMICS G110D.............................................................................. 209

9.2 Pulse frequency and current reduction ................................................................................. 211

A.1 Electromagnetic compatibility ............................................................................................... 213

A.1.1 Electromagnetic compatibility ............................................................................................... 213

A.1.2 Classification of EMC categories .......................................................................................... 214

A.1.3 EMC performance ................................................................................................................. 216

A.2 Standards .............................................................................................................................. 218

SINAMICS G110D

Operating Instructions, 07/2016, FW V3.63, A5E36768472B AB

7

Table of contents

SINAMICS G110D

8 Operating Instructions, 07/2016, FW V3.63, A5E36768472B AB

1

1.1

General safety instructions

DANGER

Danger to life due to live parts and other energy sources

WARNING

Danger to life through a hazardous voltage when connecting an unsuitable power supply

Death or serious injury can result when live parts are touched.

• Only work on electrical devices when you are qualified for this job.

• Always observe the country-specific safety rules.

Generally, six steps apply when establishing safety:

1. Prepare for shutdown and notify all those who will be affected by the procedure.

2. Disconnect the machine from the supply.

– Switch off the machine.

– Wait until the discharge time specified on the warning labels has elapsed.

– Check that it really is in a no-voltage condition, from phase conductor to phase

conductor and phase conductor to protective conductor.

– Check whether the existing auxiliary supply circuits are de-energized.

– Ensure that the motors cannot move.

3. Identify all other dangerous energy sources, e.g. compressed air, hydraulic systems, or

water.

4. Isolate or neutralize all hazardous energy sources by closing switches, grounding or

short-circuiting or closing valves, for example.

5. Secure the energy sources against switching on again.

6. Ensure that the correct machine is completely interlocked.

After you have completed the work, restore the operational readiness in the inverse

sequence.

Touching live components can result in death or severe injury.

• Only use power supplies that provide SELV (Safety Extra Low Voltage) or PELV-

(Protective Extra Low Voltage) output voltages for all connections and terminals of the

electronics modules.

SINAMICS G110D

Operating Instructions, 07/2016, FW V3.63, A5E36768472B AB

9

Fundamental safety instructions

WARNING

Danger to life when live parts are touched on damaged devices

WARNING

Danger to life through electric shock due to unconnected cable shields

WARNING

Danger to life due to electric shock when not grounded

WARNING

Danger to life due to electric shock when opening plug connections in operation

NOTICE

Material damage due to loose power connections

1.1 General safety instructions

Improper handling of devices can cause damage.

For damaged devices, hazardous voltages can be present at the enclosure or at exposed

components; if touched, this can result in death or severe injury.

• Ensure compliance with the limit values specified in the technical data during transport,

storage and operation.

• Do not use any damaged devices.

Hazardous touch voltages can occur through capacitive cross-coupling due to unconnected

cable shields.

• As a minimum, connect cable shields and the conductors of power cables that are not

used (e.g. brake cores) at one end at the grounded housing potential.

For missing or incorrectly implemented protective conductor connection for devices with

protection class I, high voltages can be present at open, exposed parts, which when

touched, can result in death or severe injury.

• Ground the device in compliance with the applicable regulations.

When opening plug connections in operation, arcs can result in severe injury or death.

• Only open plug connections when the equipment is in a no-voltage state, unless it has

been explicitly stated that they can be opened in operation.

Insufficient tightening torques or vibrations can result in loose electrical connections. This

can result in damage due to fire, device defects or malfunctions.

• Tighten all power connections with the specified tightening torques, e.g. line supply

connection, motor connection, DC link connections.

• Check all power connections at regular intervals. This applies in particular after

transport.

SINAMICS G110D

10 Operating Instructions, 07/2016, FW V3.63, A5E36768472B AB

Fundamental safety instructions

WARNING

Danger to life due to fire spreading if housing is inadequate

WARNING

Danger to life through unexpected movement of machines when using mobile wireless

devices or mobile phones

WARNING

Danger to life due to the motor catching fire in the event of insulation overload

WARNING

Danger to life due to fire if overheating occurs because of insufficient ventilation clearances

1.1 General safety instructions

Fire and smoke development can cause severe personal injury or material damage.

• Install devices without a protective housing in a metal control cabinet (or protect the

device by another equivalent measure) in such a way that contact with fire is prevented.

• Ensure that smoke can only escape via controlled and monitored paths.

Using mobile wireless devices or mobile phones with a transmit power > 1 W closer than

approx. 2 m to the components may cause the devices to malfunction, influence the

functional safety of machines therefore putting people at risk or causing material damage.

• Switch the wireless devices or mobile phones off in the immediate vicinity of the

components.

There is higher stress on the motor insulation through a ground fault in an IT system. If the

insulation fails, it is possible that death or severe injury can occur as a result of smoke and

fire.

• Use a monitoring device that signals an insulation fault.

• Correct the fault as quickly as possible so the motor insulation is not overloaded.

Inadequate ventilation clearances can cause overheating of components with subsequent

fire and smoke. This can cause severe injury or even death. This can also result in

increased downtime and reduced service lives for devices/systems.

• Ensure compliance with the specified minimum clearance as ventilation clearance for

the respective component.

SINAMICS G110D

Operating Instructions, 07/2016, FW V3.63, A5E36768472B AB

11

Fundamental safety instructions

WARNING

Danger of an accident occurring due to missing or illegible warning labels

NOTICE

Device damage caused by incorrect voltage/insulation tests

WARNING

Danger to life when safety functions are inactive

Note

Important safety notices for Safety Integrated functions

If you want to use Safety Integrated functions, y

Safety Integrated manuals.

1.1 General safety instructions

Missing or illegible warning labels can result in accidents involving death or serious injury.

• Check that the warning labels are complete based on the documentation.

• Attach any missing warning labels to the components, in the national language if

necessary.

• Replace illegible warning labels.

Incorrect voltage/insulation tests can damage the device.

• Before carrying out a voltage/insulation check of the system/machine, disconnect the

devices as all converters and motors have been subject to a high voltage test by the

manufacturer, and therefore it is not necessary to perform an additional test within the

system/machine.

Safety functions that are inactive or that have not been adjusted accordingly can cause

operational faults on machines that could lead to serious injury or death.

• Observe the information in the appropriate product documentation before

commissioning.

• Carry out a safety inspection for functions relevant to safety on the entire system,

including all safety-related components.

• Ensure that the safety functions used in your drives and automation tasks are adjusted

and activated through appropriate parameterizing.

• Perform a function test.

• Only put your plant into live operation once you have guaranteed that the functions

relevant to safety are running correctly.

ou must observe the safety notices in the

SINAMICS G110D

12 Operating Instructions, 07/2016, FW V3.63, A5E36768472B AB

Fundamental safety instructions

1.2

Safety instructions for electromagnetic fields (EMF)

WARNING

Danger to life from electromagnetic fields

1.3

Handling electrostatic sensitive devices (ESD)

NOTICE

Damage through electric fields or electrostatic discharge

1.2 Safety instructions for electromagnetic fields (EMF)

Electromagnetic fields (EMF) are generated by the operation of electrical power equipment

such as transformers, converters or motors.

People with pacemakers or implants are at a special risk in the immediate vicinity of these

devices/systems.

• Ensure that the persons involved are the necessary distance away (minimum 2 m).

Electrostatic sensitive devices (ESD) are individual components, integrated circuits, modules

or devices that may be damaged by either electric fields or electrostatic discharge.

Electric fields or electrostatic discharge can cause malfunctions through damaged

individual components, integrated circuits, modules or devices.

• Only pack, store, transport and send electronic components, modules or devices in their

original packaging or in other suitable materials, e.g conductive foam rubber of

aluminum foil.

• Only touch components, modules and devices when you are grounded by one of the

following methods:

– Wearing an ESD wrist strap

– Wearing ESD shoes or ESD grounding straps in ESD areas with conductive flooring

• Only place electronic components, modules or devices on conductive surfaces (table

with ESD surface, conductive ESD foam, ESD packaging, ESD transport container).

SINAMICS G110D

Operating Instructions, 07/2016, FW V3.63, A5E36768472B AB

13

Fundamental safety instructions

1.4

Industrial security

Note

Industrial security

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, solutions, machines, equipment and/or networks. They are

important components in a holistic industrial security concept. With

products and solutions undergo continuous development. Siemens recommends strongly

that you regularly check for product updates.

For the secure operation of Siemens products and solutions, it is necessary to take suitable

preventive

state

also be considered. For more information about industrial security, visit this

(

To stay informed about product updates as they occur, sign up for a product

newsletter. For more information, visit this address (

).

WARNING

Danger as a result of unsafe operating states resulting from software manipulation

WARNING

Danger to life due to software manipulation when using exchangeable storage media

1.4 Industrial security

this in mind, Siemens’

action (e.g. cell protection concept) and integrate each component into a holistic,

-of-the-art industrial security concept. Third-party products that may be in use should

address

http://www.siemens.com/industrialsecurity).

-specific

http://support.automation.siemens.com

Software manipulation (e.g. by viruses, Trojan horses, malware, worms) can cause unsafe

operating states to develop in your installation which can result in death, severe injuries

and/or material damage.

• Keep the software up to date.

You will find relevant information and newsletters at this address

(http://support.automation.siemens.com).

• Incorporate the automation and drive components into a holistic, state-of-the-art

industrial security concept for the installation or machine.

You will find further information at this address

(http://www.siemens.com/industrialsecurity).

• Make sure that you include all installed products into the holistic industrial security

concept.

Storing files onto exchangeable storage media amounts to an increased risk of infection,

e.g. with viruses and malware. As a result of incorrect parameterization, machines can

malfunction, which in turn can lead to injuries or death.

• Protect files stored on exchangeable storage media from malicious software by taking

suitable protection measures, e.g. virus scanners.

SINAMICS G110D

14 Operating Instructions, 07/2016, FW V3.63, A5E36768472B AB

Fundamental safety instructions

1.5

Residual risks of power drive systems

1.5 Residual risks of power drive systems

When assessing the machine- or system-related risk in accordance with the respective local

regulations (e.g., EC Machinery Directive), the machine manufacturer or system installer

must take into account the following residual risks emanating from the control and drive

components of a drive system:

1. Unintentional movements of driven machine or system components during

commissioning, operation, maintenance, and repairs caused by, for example,

– Hardware and/or software errors in the sensors, control system, actuators, and cables

and connections

– Response times of the control system and of the drive

– Operation and/or environmental conditions outside the specification

– Condensation/conductive contamination

– Parameterization, programming, cabling, and installation errors

– Use of wireless devices/mobile phones in the immediate vicinity of electronic

components

– External influences/damage

– X-ray, ionizing radiation and cosmic radiation

2. Unusually high temperatures, including open flames, as well as emissions of light, noise,

particles, gases, etc., can occur inside and outside the components under fault conditions

caused by, for example:

– Component failure

– Software errors

– Operation and/or environmental conditions outside the specification

– External influences/damage

3. Hazardous shock voltages caused by, for example:

– Component failure

– Influence during electrostatic charging

– Induction of voltages in moving motors

– Operation and/or environmental conditions outside the specification

– Condensation/conductive contamination

– External influences/damage

4. Electrical, magnetic and electromagnetic fields generated in operation that can pose a

risk to people with a pacemaker, implants or metal replacement joints, etc., if they are too

close

5. Release of environmental pollutants or emissions as a result of improper operation of the

system and/or failure to dispose of components safely and correctly

For more information about the residual risks of the drive system components, see the

relevant sections in the technical user documentation.

SINAMICS G110D

Operating Instructions, 07/2016, FW V3.63, A5E36768472B AB

15

Fundamental safety instructions

1.5 Residual risks of power drive systems

SINAMICS G110D

16 Operating Instructions, 07/2016, FW V3.63, A5E36768472B AB

2

2.1

About this manual

Who requires the operating instructions and why?

What is described in the operating instructions?

Additional information on SINAMICS G110D

As download:

As download

On DVD

These operating instructions primarily address fitters, commissioning engineers and machine

operators. The operating instructions describe the devices and device components and

enable the target groups being addressed to install, connect-up, parameterize, and

commission the inverters safely and in the correct manner.

These operating instructions provide a summary of all of the information required to operate

the inverter under normal, safe conditions.

The information provided in the operating instructions has been compiled in such a way that

it is sufficient for all standard applications and enables drives to be commissioned as

efficiently as possible. Where it appears useful, additional information for entry level

personnel has been added.

The operating instructions also contain information about special applications. Since it is

assumed that readers already have a sound technical knowledge of how to configure and

parameterize these applications, the relevant information is summarized accordingly. This

relates, e.g. to operation with fieldbus systems and safety-related applications.

●

Among other things, the List manual includes

– A detailed description of

– Function diagrams of all of the inverter functions

– A list of the fault messages and alarms

●

http://support.automation.siemens.com/WW/view/de/22339653/133300

●

low-voltage inverters, 5 languages.

– MLFB: 6SL3298-0CA00-0MG0 (supplied once)

– MLFB: 6SL3298-0CA10-0MG0 (update service for 1 year; supplied 4 times)

● As download: Catalog D 11.1: SINAMICS G110 / G120 Inverter Chassis Units SINAMICS

G120D and SINAMICS G110D Distributed Inverters.

List Manual SINAMICS G110D

all

of the parameters

: All of the operating instructions, manuals on SINAMICS G110D

: SD Manual Collection - all manuals on low-voltage motors, geared motors and

SINAMICS G110D

Operating Instructions, 07/2016, FW V3.63, A5E36768472B AB

17

Introduction

2.1 About this manual

http://sd.nes.siemens.de/sales_2003/support/info/catalogues/html_00/index.html#Catalogs_I

nverters

● The catalog includes ordering data as well as engineering and selection data.

SINAMICS G110D

18 Operating Instructions, 07/2016, FW V3.63, A5E36768472B AB

Introduction

2.2

Adapting the Inverter to the application

2.2.1

General basics

Parameterizable inverters transform standard motors into variable-speed drives

Many standard applications can function with the default parameters

Use the factory settings (where possible)

Use quick commissioning (for simple, standard applications)

2.2 Adapting the Inverter to the application

Inverters are parameterized to adapt them to the motor being driven so that this can be

optimally operated and protected. This is realized using one of the following operator units:

● Intelligent Operator Panel (IOP) hand-held kit.

● Software (STARTER commissioning tool) that allows the inverter to be parameterized

and controlled from a PC.

Inverters are used to improve and expand the starting and speed response of motors.

Although inverters can be parameterized for very specific applications, many standard

applications can be configured by means of just a few parameters.

For basic applications, commissioning can be carried out using just the factory settings.

In the majority of standard applications, commissioning can be carried out by entering or

changing just a few parameters during quick commissioning.

SINAMICS G110D

Operating Instructions, 07/2016, FW V3.63, A5E36768472B AB

19

Introduction

2.2.2

Parameter

Parameter types

Adjustable parameters

Example:

Display parameters

Example:

Change protection for setting parameters

2.2 Adapting the Inverter to the application

There are two types of parameters, adjustable and display parameters.

Adjustable parameters are represented with four digits preceded by the letter "P". You can

change the value of these parameters within a defined range.

P0305 is the parameter for the rated motor current in Amps. This parameter is set during

commissioning. You can enter values between 0.01 and 10000.

Display parameters are represented with four digits preceded by the letter "r". You cannot

change the value of these parameters.

r0027 is the parameter for the inverter output current. The inverter measures the current and

writes the current value to the parameter. You can display the parameter value, e.g. using an

analog output of the inverter.

The process of changing parameter values is subject to certain conditions. If an attempt to

change a parameter is rejected by the inverter, this can have a number of causes:

1. The inverter operating state does not allow you to change parameters.

For example, certain parameters can only be changed when the inverter is in

commissioning mode.

2. In some cases, you may not be able to change certain parameters due to automatic

follow-on parameterization.

Example: When P0701 = 1, the ON/OFF1 command is connected to digital input 0. As

follow-on parameterization, P0840 (source of the ON/OFF1 command) is assigned value

722.0 (status of digital input 0). which means that P0840 can no longer be changed.

3. Parameter protection via P0927 has been activated.

Example: P0927 = 1101 prevents parameters from being changed from the BOP.

For each parameter, the List Manual specifies whether and which conditions apply for

changing the values.

SINAMICS G110D

20 Operating Instructions, 07/2016, FW V3.63, A5E36768472B AB

Introduction

2.2.3

Parameters with follow-on parameterization

Example: Parameter P0700 (command source)

2.2.4

Frequently required parameters

Parameters that in many cases help

This is how you filter the parameter list to keep the number of displayed parameters to a minimum

Parameter

Description

User access level

3: Expert: To be used by experts

Parameter filter

3: Motor - data of the motor and output filter are displayed

How to switch to commissioning mode or restore the factory setting

Parameter

Description

Commissioning parameters

30: Factory setting - initiate restore factory settings

How to determine the firmware version of the Control Unit

Parameter

Description

r0018

The firmware version is displayed:

2.2 Adapting the Inverter to the application

When you change certain parameters, the system may automatically change other

parameters accordingly. This makes it much easier to parameterize complex functions.

Parameter P0700 can be used to switch the command source from the fieldbus to digital

inputs. When the value of P0700 is changed from 6 (command source "fieldbus") to 2

(command source "digital inputs"), other parameter values are changed automatically:

● New functions are assigned to the digital inputs (P0701 ... P0704)

● Inverter control is interconnected with the signals from the digital inputs (P0800, P0801,

P0840, etc.)

For more information about follow-on parameterization for P0700, see the List Manual.

Table 2- 1

P0003 =

1: Standard: Allows access to the most frequently used parameters (factory setting)

2: Extended: Extended access, e.g. to inverter I/O functions

P0004 =

Table 2- 2

P0010 =

Table 2- 3

0: All the parameters are displayed (factory setting).

2: Inverter

0: Ready (factory setting)

1: Perform quick commissioning

SINAMICS G110D

Operating Instructions, 07/2016, FW V3.63, A5E36768472B AB

21

Introduction

This is how you reset the parameters to the factory setting

Parameter

Description

P0010 = 30

30: Factory setting - initiate restore factory settings

This is how you select the command source of the control signals (ON/OFF, reversing) of the inverter

Parameter

Description

6: Fieldbus ; default setting

This is how you select the setpoint source for the frequency

Parameters

Description

6: Fieldbus

This is how you parameterize the up and down ramps

Parameters

Description

Minimum frequency

0.00 [Hz] factory setting

Maximum frequency

50.00 [Hz] factory setting

Ramp-up time

10.00 [s]

Ramp-down time

10.00 [s]

This is how you optimize the starting behavior of the V/f control for a high break loose torque and overload

Parameters

Description

P0003 = 2

Extended access

Voltage boost to compensate resistive losses

V_ConBoost, 100 = sqrt(3) * P0305 * P0350 * (P1310/100)

Voltage when accelerating

V_AccBoost,100 = sqrt(3) * P0305 * P0350 * (P1311/100)

2.2 Adapting the Inverter to the application

Table 2- 4

P0970 = 1 1: Resetting - restoring all parameters to the factory setting

Table 2- 5

P0700 = 0: Factory default setting

Table 2- 6

P1000 = 0: No main setpoint

2: Digital inputs

4: USS on RS 232

1: MOP setpoint

3: Fixed frequency (factory default setting)

4: USS at RS 232

Table 2- 7

P1080 = …

P1082 = …

P1120 = …

P1121 = …

Table 2- 8

P1310 = …

P1311 = …

The voltage boost is effective from standstill up to the rated speed.

The voltage boost continually decreases with increasing speed.

The maximum voltage boost is effective at speed zero and is in V:

The voltage boost is effective from standstill up to the rated speed.

The voltage boost is independent of the speed.

The voltage boost in V is:

SINAMICS G110D

22 Operating Instructions, 07/2016, FW V3.63, A5E36768472B AB

Introduction

2.3

Extended adaptation of parameters

2.3.1

BICO technology: basic principles

Functional principle of BICO technology and inverter open-loop control functions

Binectors and connectors

Definition of BICO technology

Bi

BICO

2.3 Extended adaptation of parameters

The inverter software offers a range of open-loop control functions, communication functions,

as well as various diagnostics and operating functions. These functions are interconnected

via internal signal paths and represent the default control structure.

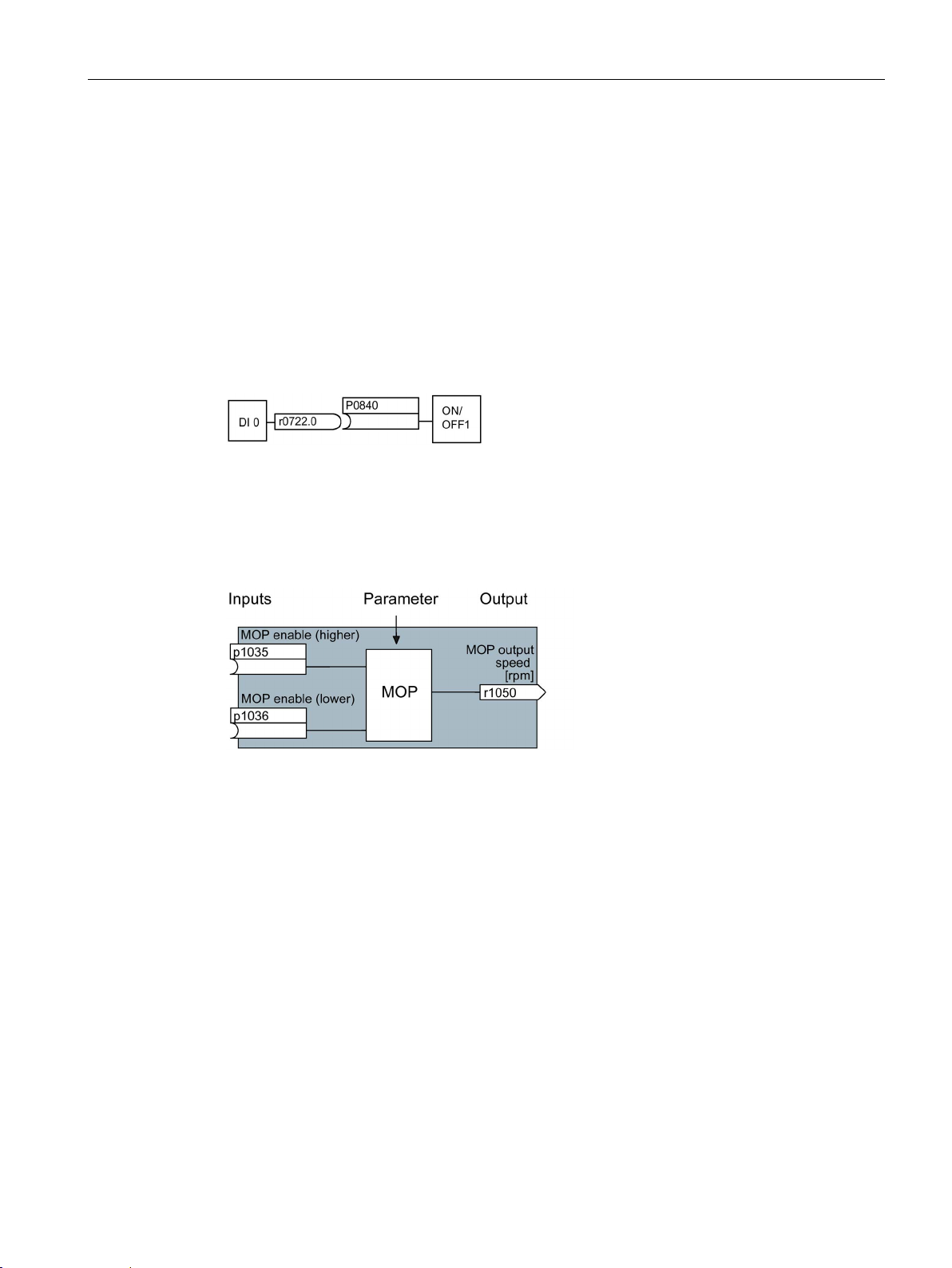

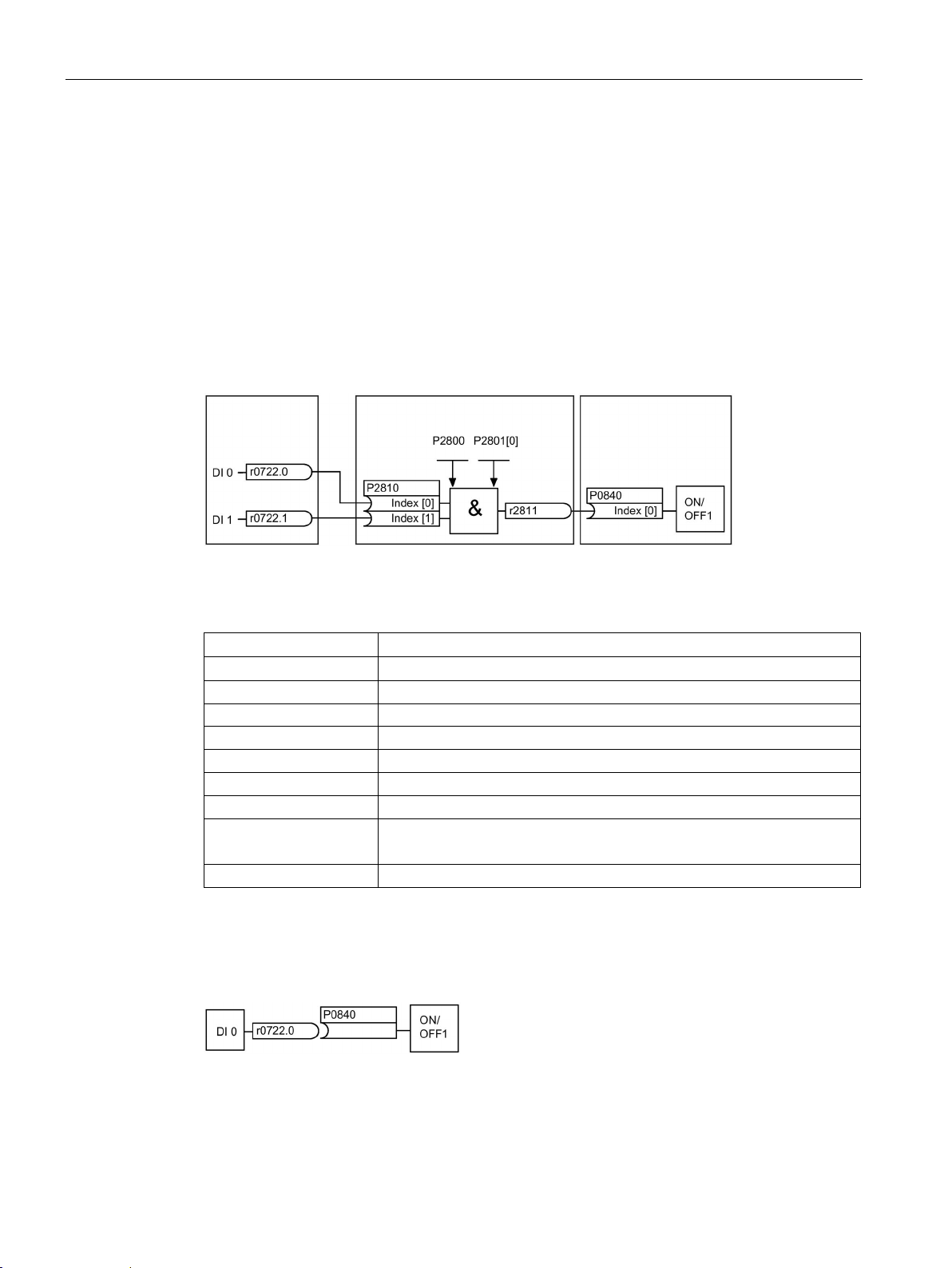

Image 2-1 Example: Pre-assigned signal interconnection for digital input 0 of a non-bus-capable

Control Unit

The functions can be parameterized and interconnected as required. The signal

interconnection of the functions is realized, contrary to electric circuitry, not using cables, but

in the software. The various functions use a range of inputs, outputs, and parameters.

Image 2-2 Example: MOP function (motorized potentiometer)

Connectors and binectors are elements used to exchange signals between the individual

functions. Connectors and binectors can be seen as "storage compartments":

● Connectors are used to store "analog" signals (e.g. speed setpoint)

● Binectors are used to store "digital" signals (e.g. 'MOP raise' command)

BICO technology describes the type of parameterization that can be used to disconnect all

the internal signal interconnections between the functions or establish new connections. This

is realized using

Connector Technology)

SINAMICS G110D

Operating Instructions, 07/2016, FW V3.63, A5E36768472B AB

nectors and Connectors. Hence the name

technology. ( Binector

23

Introduction

BICO parameters

BICO symbols, representation, and description

Abbreviation and symbol

Description

Function

Abbreviation and symbol

Description

Function

2.3 Extended adaptation of parameters

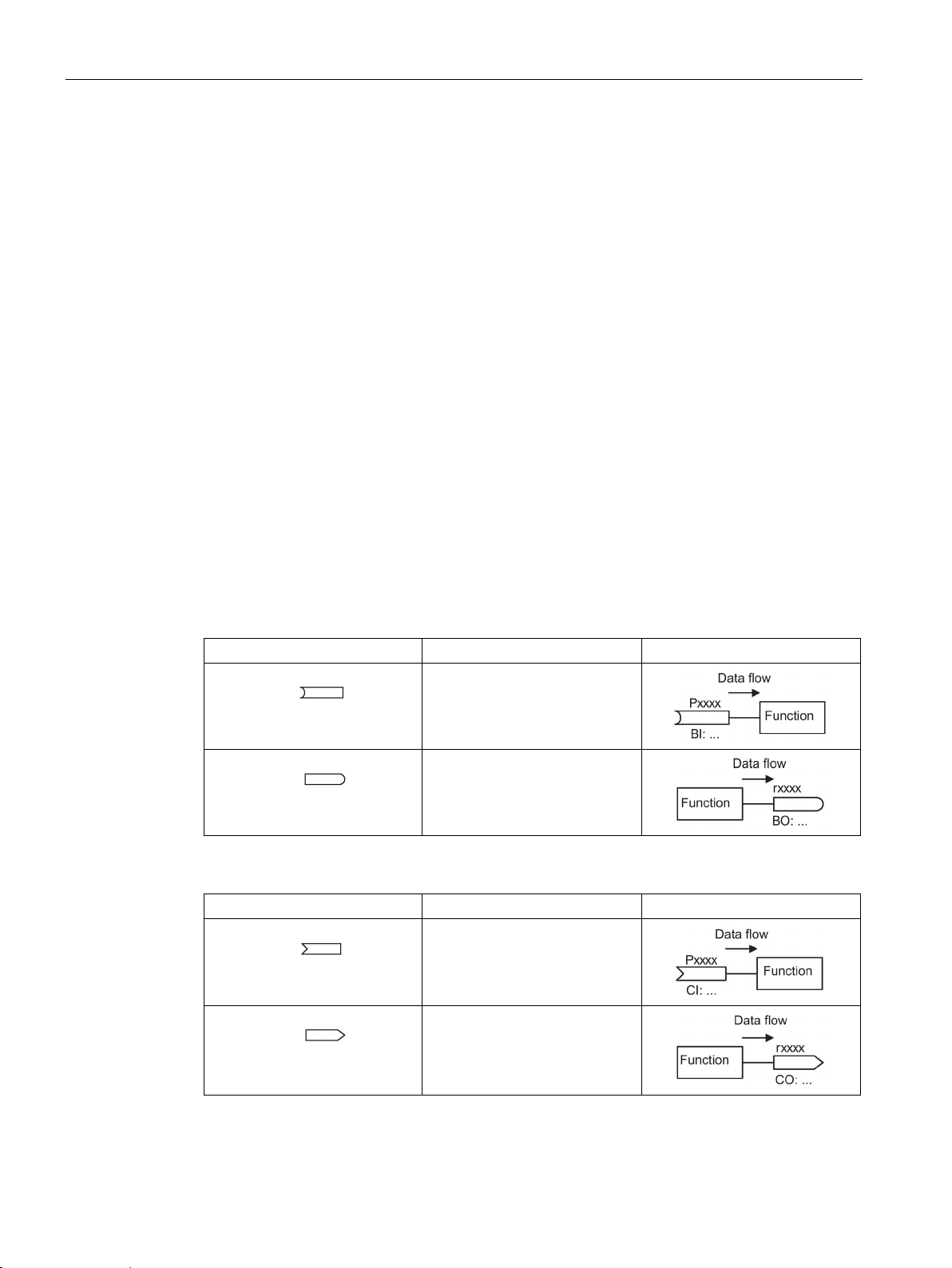

You can use the BICO parameters to define the sources of the input signals of a function.

This means that using BICO parameters you can define from which connectors and

binectors a function reads-in its input signals, thereby enabling you to "interconnect" the

functions stored in the devices in accordance with your requirements. Five different BICO

parameter types are available:

● Binector inputs: BI

● Connector inputs: CI

● Binector outputs: BO

● Connector outputs: CO

● Binector/connector outputs: CO/BO

Binector/connector outputs (CO/BO) are parameters that combine more than one binector

output in a single word (e.g. r0052 CO/BO: status word 1). Each bit in the word represents a

digital (binary) signal. This feature reduces the number of parameters and makes it easier to

set parameters by means of the serial interface (data transfer).

BICO parameters of type CO, BO, or CO/BO can be used more than once.

Table 2- 9 Binector symbols

BI

BO

Table 2- 10 Connector symbols

CI

CO

Binector input

Binector output

Connector input

Connector output

SINAMICS G110D

24 Operating Instructions, 07/2016, FW V3.63, A5E36768472B AB

Introduction

Abbreviation and symbol

Description

Function

When do you need to use BICO technology?

What precautions should you take when using BICO technology?

What sources of information do you need to help you set parameters using BICO

technology?

2.3 Extended adaptation of parameters

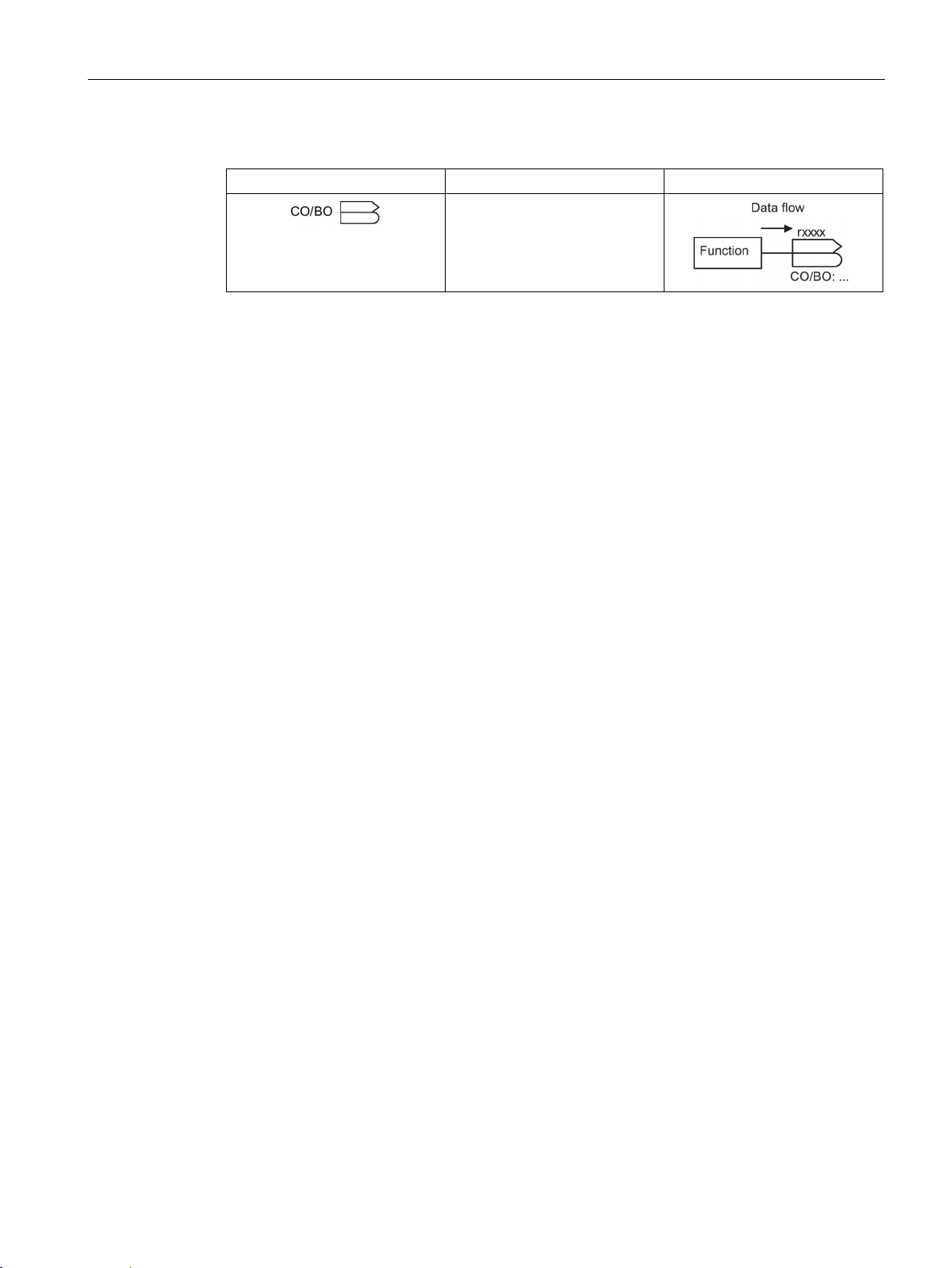

Table 2- 11 Connector and binector output symbols

Binector/connector output

BICO technology allows you to adapt the inverter to a wide range of different requirements.

This does not necessarily have to involve highly complex functions.

Example 1: Assign a different function to a digital input.

Example 2: Switch over the speed setpoint from the fixed frequency to the analog input.

Always apply caution when handling internal interconnections. Note which changes you

make as you go along since the process of analyzing them later can be quite difficult.

The STARTER commissioning tool offers various screens that make it much easier for you

to use BICO technology. The signals that you can interconnect are displayed in plain text,

which means that you do not need any prior knowledge of BICO technology.

● This manual is sufficient for simple signal interconnections, e.g. assigning a different

significance to the to digital inputs.

● The parameter list in the List Manual is sufficient for signal interconnections that go

beyond just simple ones.

● You can also refer to the function diagrams in the List Manual for complex signal

interconnections.

SINAMICS G110D

Operating Instructions, 07/2016, FW V3.63, A5E36768472B AB

25

Introduction

2.3.2

BICO technology: example

Example: Shifting a basic PLC functionality into the inverter

Parameter

Description

P0003 = 3

Enable expert access to parameters

P0700 = 2

Select the command source: Digital inputs

P0701 (e.g.) = 99

Enable/"open" digital input 0 (DI0) for BICO parameterization

P0702 (e.g.) = 99

Enable/"open" digital input 1 (DI1) for BICO parameterization

P2801 [In000] = 1

Individual enable of the AND function block

P2810 [In000] = 722.0

Connect the status of DI0 to the 2nd AND

r0722.1 = Parameter that displays the status of digital input 1.

P0840 = r2811

Connect the AND output to the control command ON/OFF1

Explanations of the example

Open the default signal interconnection for BICO parameterization

2.3 Extended adaptation of parameters

A conveyor system is to be configured in such a way that it can only start when two signals

are present simultaneously. These could be the following signals, for example:

● The light barrier has been activated

● The protective door is closed

The task is realized by inserting free blocks between the digital input 0 and the internal ON

command for the motor and interconnecting them.

Image 2-3 Example: Signal interconnection for interlock

Table 2- 12 Parameterizing an interlock

P2800 = 1 Group enable all freely-programmable function blocks (FFB)

P2810 [In001] = r0722.1 Connect the status of DI1 to the 2nd AND input

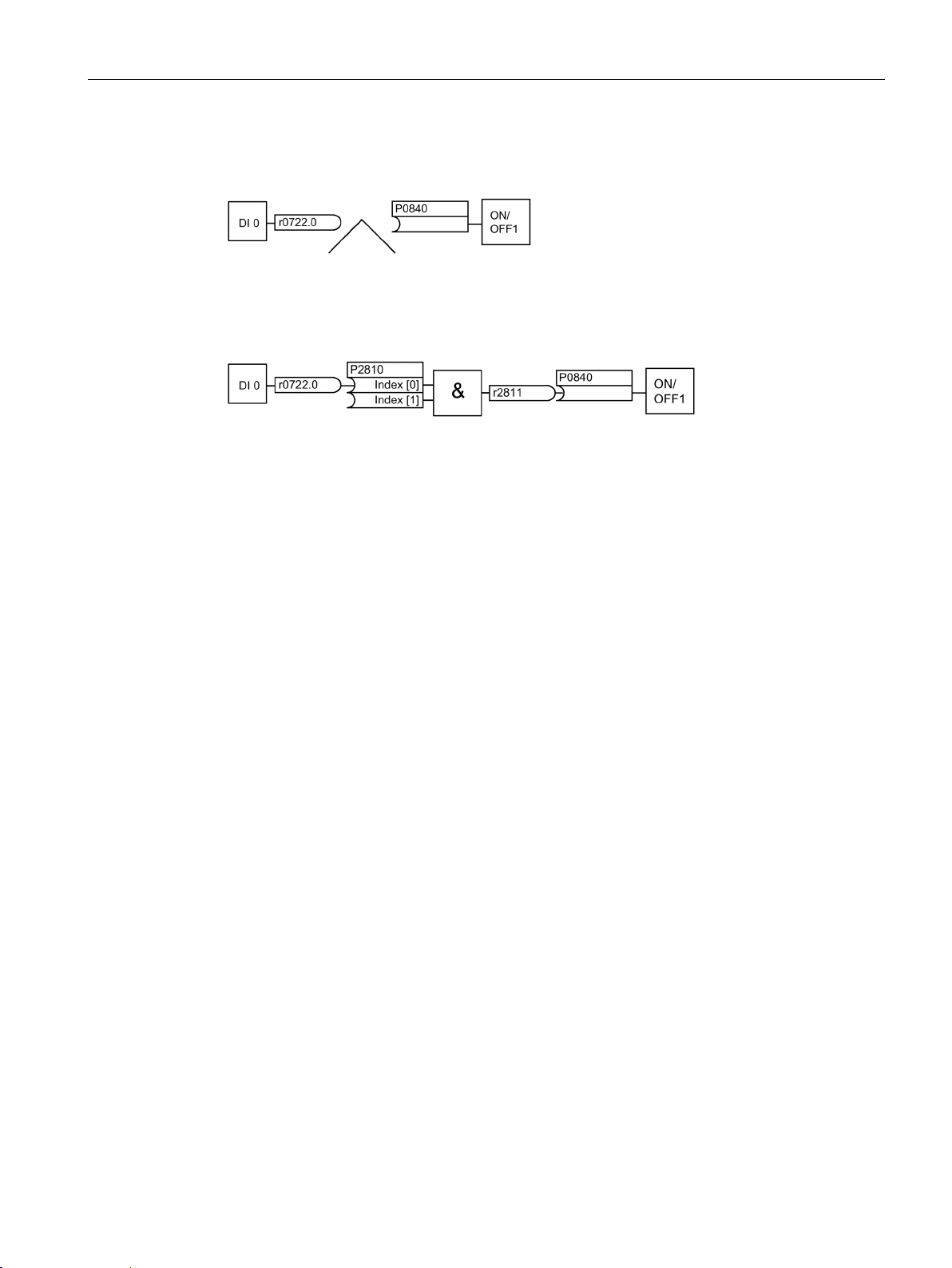

The default setting P0701 = 1 indicates the following internal signal interconnection:

Image 2-4 Default parameterization

SINAMICS G110D

26 Operating Instructions, 07/2016, FW V3.63, A5E36768472B AB

Introduction

Principle of connecting functions by means of BICO technology

2.3 Extended adaptation of parameters

The setting P0701 = 99 means that a pre-assigned signal interconnection is disconnected

and therefore the connection opened for BICO parameterization.

Image 2-5 BICO parameterization

When P0701 = 99, the binector input of the ON/OFF1 function (P0840) is available for

activation by a signal source other than r0722.0 (in this case r2811).

Image 2-6 Interconnection after insertion of two functions

A connection between two functions comprises a connector/binector and a BICO parameter.

Connections are always established with respect to the input of a particular function, which

means that the output of an upstream function must always be assigned to the input of a

downstream function. The assignment is always made by entering the number of the

connector/binector from which the required input signals are read in a BICO parameter.

SINAMICS G110D

Operating Instructions, 07/2016, FW V3.63, A5E36768472B AB

27

Introduction

2.3 Extended adaptation of parameters

SINAMICS G110D

28 Operating Instructions, 07/2016, FW V3.63, A5E36768472B AB

3

3.1

Overview of SINAMICS G110D Inverters

SINAMICS G110D Inverters

The SINAMICS G110D has been designed to provide an adaptable solution to conveyor

technology applications.

Each SINAMICS G110D Inverter is a complete Power Module and Control Unit in one

unique housing which is IP65 rated. The power output range extends from 0.75 kW to 7.5

kW.

The optional STARTER software allows commissioning of the Inverter using a PC with the

optional optical cables.

A range of additional, application-specific components are also available, for example,

braking resistors.

SINAMICS G110D

Operating Instructions, 07/2016, FW V3.63, A5E36768472B AB

29

Description

3.2

Components of the Inverter system

The Inverter system

Frame size A (FSA)

Frame size B (FSB)

3.2 Components of the Inverter system

The Inverter is available in three frame sizes:

6SL3511-0PE17-5AM0 - 0.75 kW

6SL3511-1PE17-5AM0 - 0.75 kW with repair switch

6SL3511-0PE21-5AM0 - 1.5 kW

6SL3511-1PE21-5AM0 - 1.5 kW with repair switch

6SL3511-0PE23-0AM0 - 3.0 kW

6SL3511-1PE23-0AM0 - 3.0 kW with repair switch

Image 3-1 SINAMICS G110D FSA

6SL3511-0PE24-0AM0 - 4.0 kW

6SL3511-1PE24-0AM0 - 4.0 kW with repair switch

Image 3-2 SINAMICS G110D FSB

SINAMICS G110D

30 Operating Instructions, 07/2016, FW V3.63, A5E36768472B AB

Loading...

Loading...