Siemens SIMOTICS A-1FV5, SIMOTICS A-1PV5 Operating Instructions Manual

SIMOTICS A-1FV5/1PV5

synchronous/induction motors

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

SIMOTICS A-1FV5/1PV5 synchronous/induction motors

Operating Instructions

03/2014

610.45002.40

Introduction

1

Safety notes

2

Description

3

Preparing for use

4

Mounting

5

Connection

6

Commissioning

7

Operation

8

Service and maintenance

9

Decommissioning and

disposal

10

Appendix

A

Siemens AG

Industry Sector

Postfach 48 48

90026 NÜRNBERG

GERMANY

Order number: 610.45002.40

Ⓟ

Copyright © Siemens AG 2014.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

for the specific

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

03/2014 Subject to change

Table of contents

1 Introduction ............................................................................................................................................. 7

2 Safety notes ............................................................................................................................................ 9

3 Description ............................................................................................................................................ 15

4 Preparing for use .................................................................................................................................. 23

5 Mounting ............................................................................................................................................... 29

2.1 General safety information ............................................................................................................. 9

2.2 Safety and operating instructions................................................................................................. 10

2.3 Observing the five safety rules ..................................................................................................... 11

2.4 Thermal hazard ............................................................................................................................ 11

2.5 Information about electromagnetic fields ..................................................................................... 12

2.6 Electrostatic sensitive devices (ESD) .......................................................................................... 13

3.1 Application .................................................................................................................................... 15

3.2 Rating plate (type plate) ............................................................................................................... 16

3.3 Technical features ........................................................................................................................ 17

3.4 Design .......................................................................................................................................... 18

3.4.1 Regulations .................................................................................................................................. 18

3.4.2 Types of construction ................................................................................................................... 18

3.4.3 Degree of protection .................................................................................................................... 18

3.4.4 Ambient conditions ....................................................................................................................... 19

3.4.5 Cooling ......................................................................................................................................... 19

3.4.6 Noise emission ............................................................................................................................. 22

4.1 Shipment and packaging ............................................................................................................. 23

4.2 Transport and storage .................................................................................................................. 23

4.2.1 Transport ...................................................................................................................................... 23

4.2.2 Storage ......................................................................................................................................... 26

5.1 Installation .................................................................................................................................... 29

5.2 Fixing ............................................................................................................................................ 30

5.3 Attaching the output elements ..................................................................................................... 31

5.4 Vibration load ............................................................................................................................... 33

SIMOTICS A-1FV5/1PV5 synchronous/induction motors

Operating Instructions, 03/2014, 610.45002.40

5

Table of contents

6 Connection ........................................................................................................................................... 35

7 Commissioning ..................................................................................................................................... 43

8 Operation .............................................................................................................................................. 49

9 Service and maintenance ...................................................................................................................... 53

10 Decommissioning and disposal ............................................................................................................. 57

A Appendix .............................................................................................................................................. 61

Index .................................................................................................................................................... 65

6.1 Mechanical connection of water cooling system ......................................................................... 35

6.2 Electrical connection ................................................................................................................... 36

6.2.1 Safety information ....................................................................................................................... 36

6.2.2 Cable entry and routing ............................................................................................................... 37

6.2.3 Circuit diagram ............................................................................................................................ 38

6.2.4 Terminal box ............................................................................................................................... 39

6.2.5 Data for electrical connection ...................................................................................................... 40

6.2.6 Signal connection ........................................................................................................................ 41

6.2.7 Connecting the temperature sensor ............................................................................................ 42

6.2.8 Connecting the ground conductor ............................................................................................... 42

6.2.9 Connecting-up a converter .......................................................................................................... 42

7.1 Measures prior to commissioning ............................................................................................... 43

7.2 Performing a trial run ................................................................................................................... 45

7.3 Checking the insulation resistance ............................................................................................. 45

7.4 Switching on the motor ................................................................................................................ 47

7.5 Liquid cooling .............................................................................................................................. 47

8.1 Safety instructions during operation ............................................................................................ 49

8.2 Stoppages ................................................................................................................................... 50

8.3 Shutdown .................................................................................................................................... 50

8.4 Faults ........................................................................................................................................... 50

9.1 Safety information ....................................................................................................................... 53

9.2 Maintenance intervals ................................................................................................................. 55

9.3 General inspection guidelines ..................................................................................................... 56

9.4 Bearing replacement intervals .................................................................................................... 56

10.1 Decommissioning ........................................................................................................................ 57

10.2 Disposal....................................................................................................................................... 57

A.1 List of abbreviations .................................................................................................................... 61

A.2 Siemens Service Center ............................................................................................................. 62

A.3 Declaration of conformity ............................................................................................................ 63

SIMOTICS A-1FV5/1PV5 synchronous/induction motors

6 Operating Instructions, 03/2014, 610.45002.40

1

Note

All data that are generally applicable for the motor also always apply to the generator.

Text format features

Note

A Note is an important item of information about the product, handling of the product

or the relevant section of the document. Notes provide you with help or further

suggestions/ideas.

These operating instructions describe the motor and explain how to handle the motor from

the delivery to the disposal stage.

Before you start using the motor, you must read these operating instructions to ensure safe,

problem-free operation and to maximize the service life.

Siemens strives continually to improve the quality of information provided in these operating

instructions. If you find any mistakes or would like to offer suggestions about how this

document could be improved, please contact the Siemens Service Center.

Always follow the safety instructions and notices in these operating instructions. The warning

notice system is explained on the rear of the inside front.

In addition to the safety-related notices and instructions which you must read, you will find

the text in these operating instructions is formatted in the following way:

1. Handling instructions are always formatted as a numbered list. Always perform the steps

● Lists are formatted as bulletted lists.

in the order given.

– Lists on the second level are hyphenated.

SIMOTICS A-1FV5/1PV5 synchronous/induction motors

Operating Instructions, 03/2014, 610.45002.40

7

Introduction

SIMOTICS A-1FV5/1PV5 synchronous/induction motors

8 Operating Instructions, 03/2014, 610.45002.40

2

2.1

General safety information

Safety and commissioning information for converter-fed low-voltage three-phase motors

DANGER

qualified, responsible personnel

injury or material damage

national, local and plant/system-specific regulations and requirements

Special versions

construction variants

type

designation and serial number

(in accordance with the Low Voltage Directive 2006/95/EC)

All work associated with transporting, connecting, commissioning, and maintaining the

motors must be carried out by

note IEC 60364).

(DIN EN 50110-1;

Failure to follow proper procedures may result in

The valid

carefully observed.

aspects. If in doubt, you are strongly advised to contact the manufacturer specifying the

carried out by the SIEMENS Service Center.

Vehicles with converter-fed low-voltage three-phase motors must fulfill the protective

requirements of the EMC Directive 2004/108/EC.

The user is responsible for ensuring that installation is carried out properly. The signal and

power cables must be shielded.

The information provided by the converter manufacturer regarding EMC-compliant

installation must be observed.

and

may differ with respect to certain technical

(see rating plate) or arrange for any maintenance work to be

.

must be

SIMOTICS A-1FV5/1PV5 synchronous/induction motors

Operating Instructions, 03/2014, 610.45002.40

9

Safety notes

2.2

Safety and operating instructions

The safe use of electrical machines

WARNING

Rotating or live parts

Qualified personnel

Note

Siemens Service Center

We recommend engaging the support and services of your local Siemens Service Center

for all planning, installation, commissioning, and maintenance work.

2.2 Safety and operating instructions

Rotating or live parts are dangerous.

Fatal or severe injuries and substantial material damage can occur if the required covers

are removed or if the machines are not handled, operated, or maintained properly.

Covers must only be removed and the motor operated in accordance with the relevant

regulations. The motor must be maintained on a regular basis.

These operating instructions only contain the information necessary for ensuring that the

motor is operated by properly trained personnel in accordance with its intended purpose.

Those responsible for plant safety must ensure the following:

● The basic planning work for the system and all work relating to transportation, assembly,

installation, commissioning, maintenance and repairs is carried out by qualified personnel

and checked by responsible, suitably skilled personnel.

● The operating instructions and the motor documentation are available at all times.

● The technical data and specifications relating to installation, connection, ambient and

operating conditions are taken into account at all times.

● The system-specific installation and safety regulations are observed.

● Personal protective equipment is used.

● Unqualified persons must not work on or in the vicinity of these motors at any time.

SIMOTICS A-1FV5/1PV5 synchronous/induction motors

10 Operating Instructions, 03/2014, 610.45002.40

Safety notes

2.3

Observing the five safety rules

Five safety rules

2.4

Thermal hazard

CAUTION

Do not touch any hot surfaces!

Only operate the motors in conjunction with effective temperature control.

2.3 Observing the five safety rules

For your personal safety and to prevent material damage when working on the machine,

always observe the safety instructions and the following five safety rules. Apply the five

safety rules in the order stated before starting work at the machine.

1. Disconnect the system.

You must also make sure that the auxiliary circuits are also disconnected.

2. Protect against reconnection.

3. Make sure that the equipment is de-energized.

4. Ground and short-circuit.

5. Cover or enclose adjacent components that are still live.

When work has been completed, remove these measures in reverse order.

The surface temperature of the motors can exceed 65 °C.

Temperature-sensitive components (electric cables, electronic components) must not be

placed on hot surfaces. If the motors overheat, this can destroy the windings/bearings and

the permanent magnet may become demagnetized

SIMOTICS A-1FV5/1PV5 synchronous/induction motors

Operating Instructions, 03/2014, 610.45002.40

11

Safety notes

2.5

Information about electromagnetic fields

Note

Permanent magnets

The rotors of 1FV5 synchronous motors contain permanent magnets with high magnetic flux

densities and strong forces of attraction to ferromagnetic bodies.

Persons with cardiac pacemakers are endangered in the vicinity of a disassembled rotor.

Data stored o

WARNING

Electromagnetic fields

2.5 Information about electromagnetic fields

n electronic data carriers can be destroyed.

Electromagnetic fields are generated when electrical power engineering installations

(e.g. transformers, converters, or motors) are operated.

Electromagnetic fields can interfere with electronic devices, which could cause them to

malfunction. Heart pacemakers can be affected, for example, which could potentially

damage a person's health or even result in death. Steps must be taken, therefore, to

ensure that persons with heart pacemakers cannot enter these areas.

The plant operator is responsible for taking appropriate measures (labels and hazard

warnings) to adequately protect operating personnel and others against any possible risk.

● Observe the relevant nationally applicable health and safety regulations. In Germany,

"electromagnetic fields" are subject to regulations BGV B11 and BGR B11 stipulated by

the German statutory industrial accident insurance institution.

● Display adequate hazard warning notices.

● Place barriers around hazardous areas.

● Take appropriate measures (e.g. shields) to reduce electromagnetic fields at their source.

SIMOTICS A-1FV5/1PV5 synchronous/induction motors

12 Operating Instructions, 03/2014, 610.45002.40

Safety notes

2.6

Electrostatic sensitive devices (ESD)

ESD guidelines

NOTICE

Electrostatic discharge

NOTICE

Use conductive packaging material

2.6 Electrostatic sensitive devices (ESD)

Electronic modules contain components that can be destroyed by electrostatic discharge.

These modules can be easily destroyed by improper handling.

To protect your equipment against damage, follow the instructions given below.

● Never touch electronic modules unless absolutely necessary in the course of

maintenance and repair procedures.

● If the modules have to be touched, the body of the person concerned must be

electrostatically discharged immediately beforehand and be grounded.

● Electronic modules should not come into contact with electrically insulating materials

(e.g. plastic foil, plastic parts, insulating table supports, or clothing made of synthetic

fibers).

● Always place the modules on conductive bases.

● Always store and transport electronic modules or components in conductive packaging

(e.g. metallized plastic or metal containers).

Electronic modules must be stored, transported, and dispatched in conductive

packaging.

Electronic modules that are not correctly stored, transported, or dispatched can be

damaged.

Pack electronic modules in appropriate conductive packaging (e.g. foam rubber or

aluminum foil).

SIMOTICS A-1FV5/1PV5 synchronous/induction motors

Operating Instructions, 03/2014, 610.45002.40

13

Safety notes

(1)

Sitting

(2)

Standing

(3)

Standing/sitting

ESD protective measures

a

= conductive floor

b

= ESD table

c

= ESD footwear

d

= ESD coat

s

= ESD wrist strap

f

= cubicle ground connection

2.6 Electrostatic sensitive devices (ESD)

The necessary ESD protective measures for electrostatically sensitive devices are illustrated

once again in the following drawings:

Figure 2-1 ESD protective measures

SIMOTICS A-1FV5/1PV5 synchronous/induction motors

14 Operating Instructions, 03/2014, 610.45002.40

3

3.1

Application

Proper usage

Mode of operation and design

The motors are designed for installation in electrically driven vehicles. and are characterized

by their high power density, ruggedness, long lifetime, and overall reliability. The three-phase

motors are either closed-loop speed or torque controlled using a converter. The direct

connection to the three-phase line supply is not permissible. It is forbidden to install them in

hazardous areas unless they are explicitly designed for this.

The 1PV5 motors are liquid-cooled squirrel-cage induction motors.

The 1FV5 generators are liquid-cooled synchronous motors with permanent magnet rotors.

Both active parts are equipped with two temperature sensors integrated in the stator winding,

where the second can be used as a reserve.

An encoder system for sensing the speed and direction of rotation is optionally installed in

the NDE bearing shield of the motors.

SIMOTICS A-1FV5/1PV5 synchronous/induction motors

Operating Instructions, 03/2014, 610.45002.40

15

Description

3.2

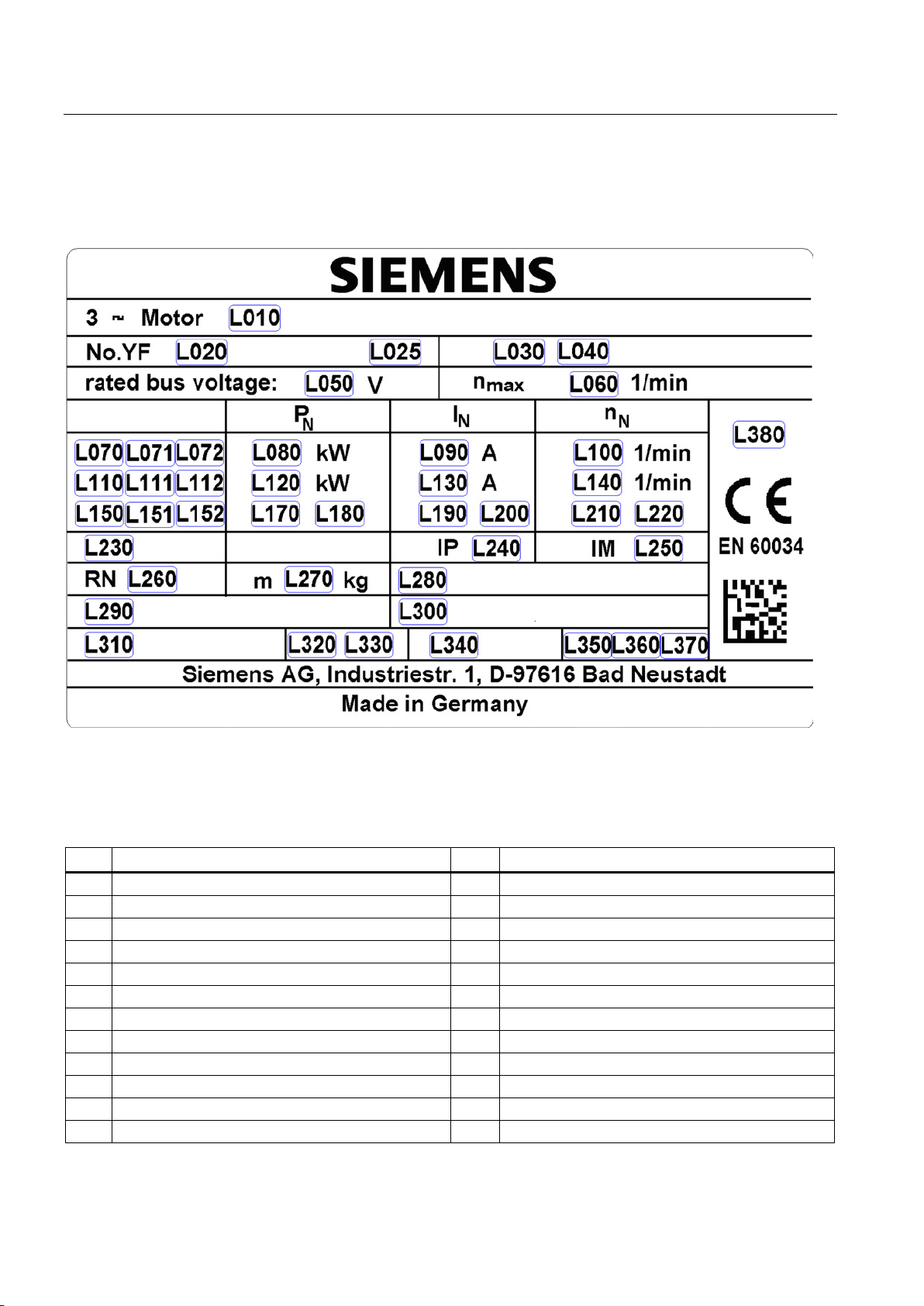

Rating plate (type plate)

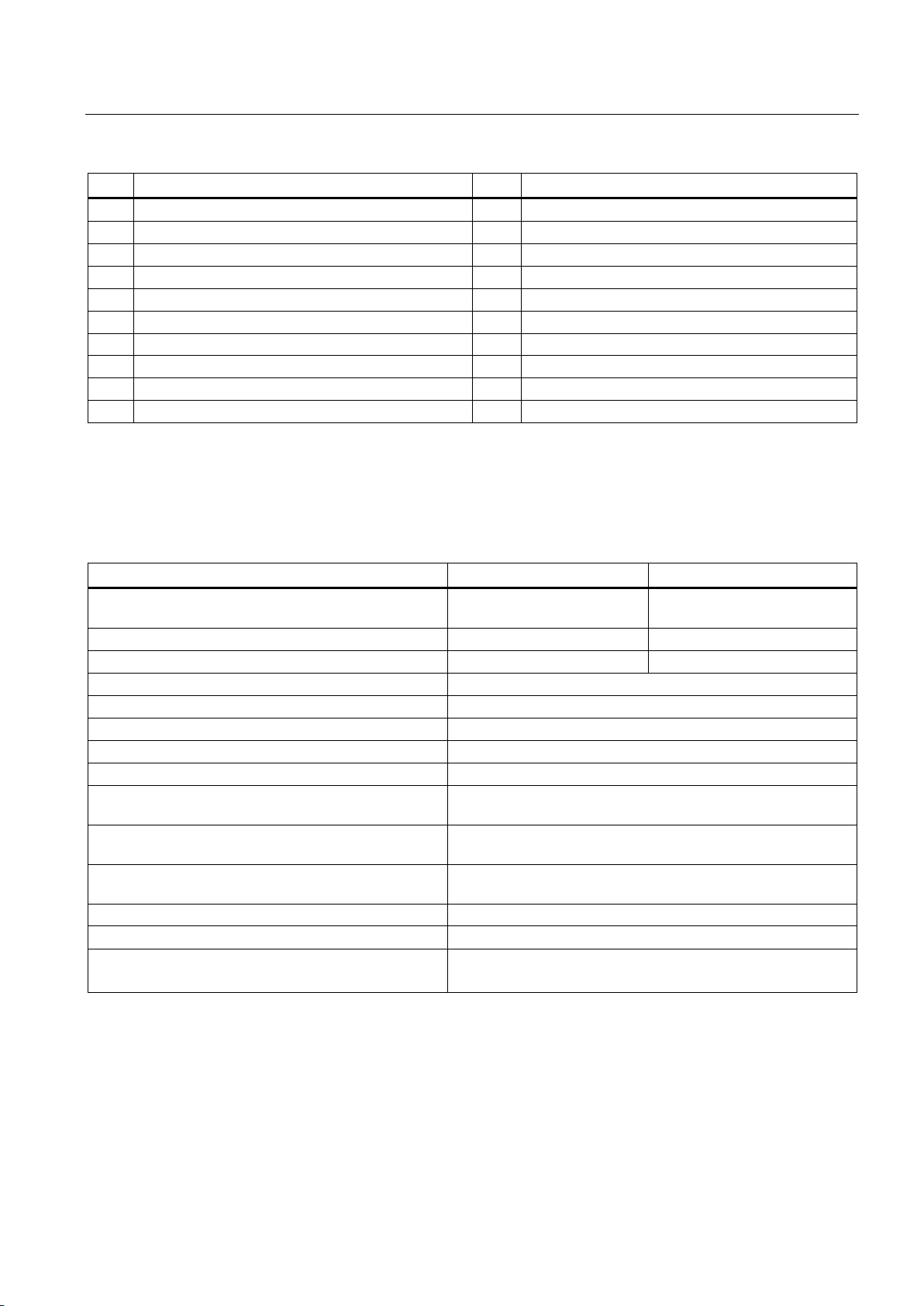

No.

Description

No.

Description

L010

MLFB

L170

Rated power PN (3)

L020

Factory serial number

L180

Unit rated power (3)

L025

Consecutive number

L190

Rated current IN (3)

L040

Options

L210

Rated speed nN (3)

L060

Maximum speed n

L230

Temperature class

L070

Operating mode (1)

L240

Degree of protection

L071

Rated time (1)

L250

Type of construction

L072

Unit rated time (1)

L260

Revision number

L080

Rated power PN (1)

L270

Weight

L090

Rated current IN (1)

L280

Temperature sensor

3.2 Rating plate (type plate)

The rating plate (type plate) shows the technical specifications for the supplied motor.

Figure 3-1 Schematic layout of rating plate

Table 3- 1 Elements on the rating plate

L030 Z: (For options) L200 Unit rated current IN (3)

L050 Rated voltage L220 Rated speed nN (3)

max

SIMOTICS A-1FV5/1PV5 synchronous/induction motors

16 Operating Instructions, 03/2014, 610.45002.40

Description

No.

Description

No.

Description

L100

Rated speed nN (1)

L290

Encoder (encoder)

L110

Operating mode (2)

L300

Optional customer information

L111

Rated time (2)

L310

Cooling method

L112

Unit rated time (2)

L320

Coolant flow

L120

Rated power PN (2)

L330

Unit coolant flow

L130

Rated current IN (2)

L340

Cooling pressure

L140

Rated speed nN(2)

L350

Maximum value

L150

Operating mode (3)

L360

Maximum coolant temperature

L151

Rated time (3)

L370

Unit maximum coolant temperature

L152

Unit rated time (3)

L380

UL mark

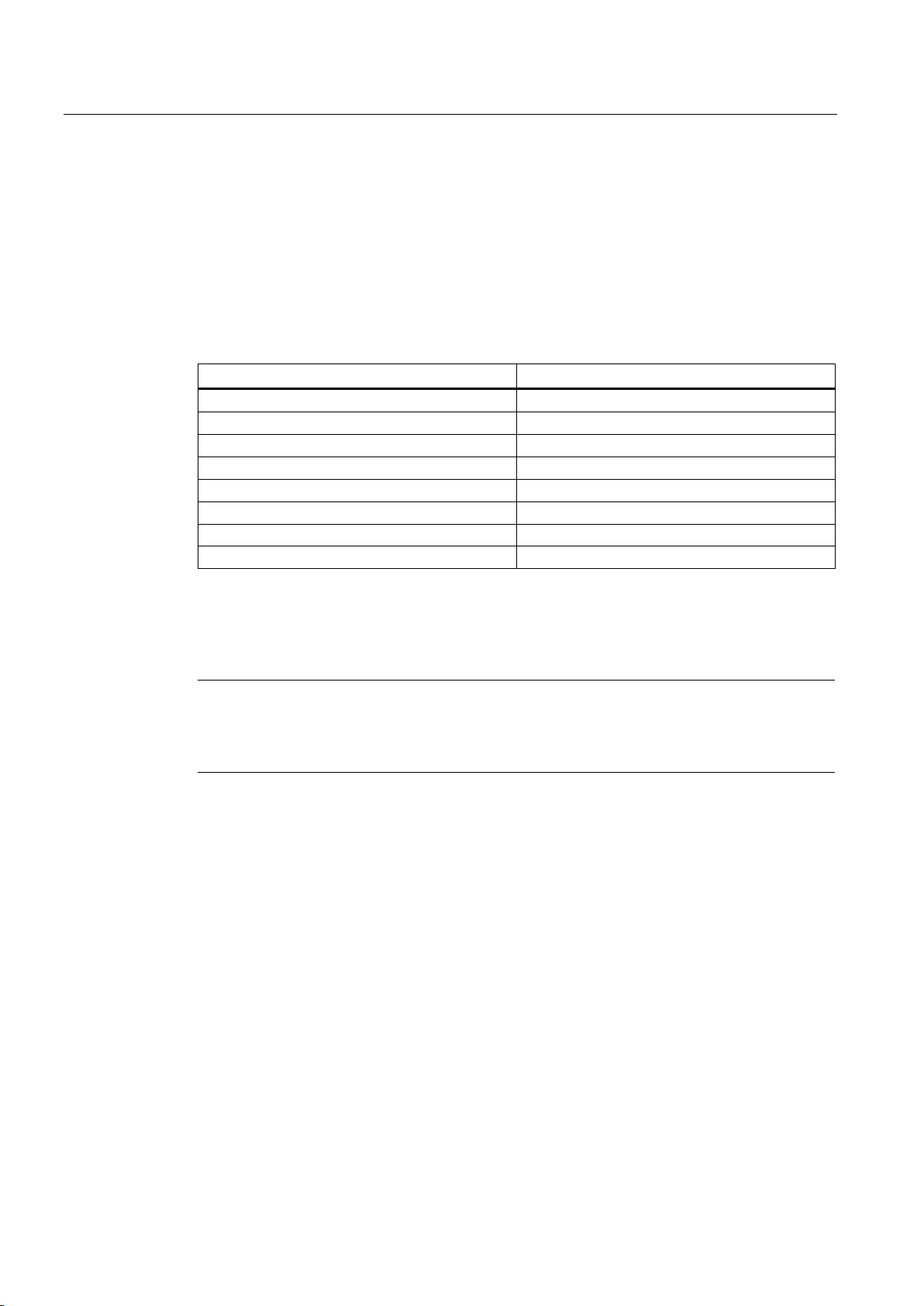

3.3

Technical features

1FV5

1PV5

synchronous motor

Magnet material

Rare-earth magnetic material

---

Speed encoder (optional)

Rotor position encoder (RPE)

Toothed-wheel encoder (64 pin)

Insulation of stator winding according to EN 60034–1

Thermal class 180 (H)

Cooling

Liquid cooling

Installation altitude according to EN 60034-1

≤ 2500 m above sea level, otherwise power derating

Degree of protection to EN60034-5

IP65/IP69K (without DE shaft output)

EN 60034-11

(half-key balancing)

in accordance with DIN 42955

Vibration severity grade according to EN 60034-14

Grade A is maintained up to rated speed

Sound pressure level according to DIN EN ISO 1680

75 dB (A) + 3 dB (A) tolerance

12-pin signal connector

3.3 Technical features

Table 3- 2 Technical features

Type of motor Permanent-magnet

Type of construction acc. to EN 60034–7 IM B5

Temperature monitoring in accordance with

DE shaft extension accordance with DIN 748-3 Plain or geared shaft, optional shaft with fitted key and keyway

Radial eccentricity, concentricity and axial eccentricity

Connection Terminal board in the terminal box for power

2 x KTY 84-130 temperature sensor in the stator winding

Tolerance N (normal)

Induction motor

SIMOTICS A-1FV5/1PV5 synchronous/induction motors

Operating Instructions, 03/2014, 610.45002.40

17

Description

3.4

Design

3.4.1

Regulations

Feature

Standard

Rated and operation characteristics

IEC/EN 60034-1

Degree of protection

IEC/EN 60034-5

Cooling

IEC/EN 60034-6

Type of construction

IEC/EN 60034-7

Terminal markings

IEC/EN 60034-8

Noise emission

IEC/EN 60034-9

Temperature monitoring

IEC/EN 60034-11

Vibration severity grades

IEC/EN 60034-14

(1)

The degree of protection and type of construction of the motor are stamped on its rating plate.

Note

Make sure that your end product is in compliance with all of the applicable legislation!

You

and requirements.

3.4.2

Types of construction

3.4.3

Degree of protection

3.4 Design

The motors comply with the following regulations according to IEC 60034-x/EN 60034-x:

Table 3- 3 Regulations that have been applied

(1)

(1)

The three-phase motors comply with the relevant sections of EN 60034 and EN 60204-1.

Three-phase motors comply with Low-Voltage Directive 2006/95/EC. Standard motors

comply with the UL regulations. "UR" is stamped on the rating plate of these motors.

must take into account the applicable national, local, and system-specific regulations

The motor has type construction IM B5.

The motors have degree of protection IP65/IP69K. In order to guarantee the degree of

protection, the drive end flange must be suitably implemented.

SIMOTICS A-1FV5/1PV5 synchronous/induction motors

18 Operating Instructions, 03/2014, 610.45002.40

Description

3.4.4

Ambient conditions

3.4.5

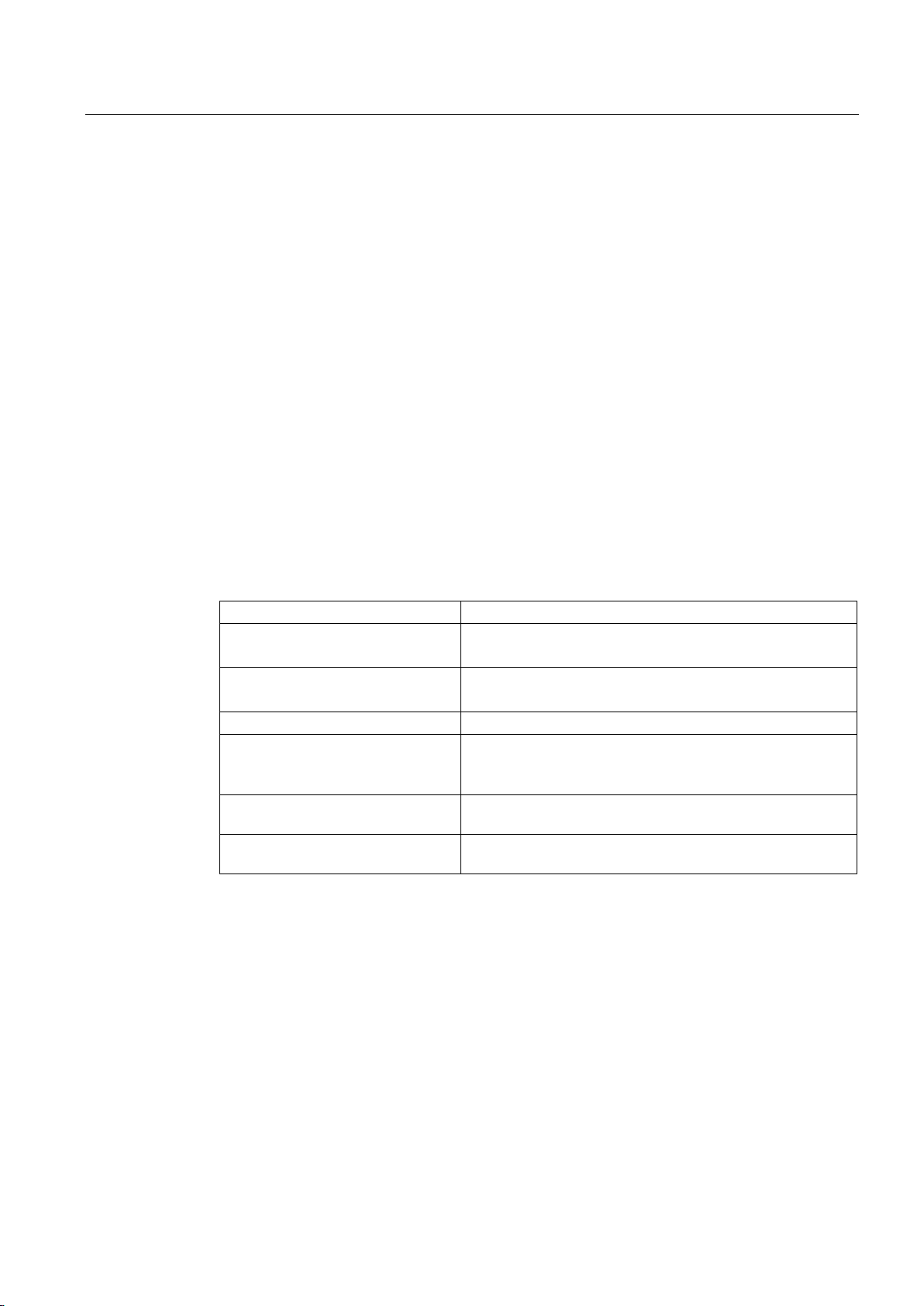

Cooling

Water cooling

Coolant

Water/anti-freeze mixture, 50/50 %

Female thread in the bearing shield Pg 13.5 /8 deep

Lower values will result in a derating

Max. pressure at inlet

max. 2.5 bar

< 0.4 bar for minimum cooling water flow with 1FV516

at T

<60 °C; T

> -40 °C

temperature, without derating

higher values will result in derating

3.4 Design

The motors are designed for ambient temperatures from -40 °C to +70 °C and installation

altitudes up to 2500 m above sea level. In the case of different ambient conditions, contact

the manufacturer.

The motor can only be operated in a closed coolant circuit with a cooling unit. The motor is

connected to the cooling circuit using two hose connections with an outer diameter of 18 mm

at the NDE bearing shield of the motor. On motors with angled hose connections, after

loosening the locknuts they can be adjusted in both directions (preferred direction clockwise;

max. 1 revolution). After adjusting the position, the coolant connections must be fixed by

tightening the union nuts.

The inlet and outlet connections can be selected as required.

Table 3- 4 Technical data of the water cooling

Cooling water connection Hose connection with an outer diameter of 18

Cooling water flow 16 l/min

Pressure loss between inlet and

outlet

Min. cooling water inlet temperature T

Maximum cooling water inlet

< 0.2 bar for minimum cooling water flow with

1PV513/1FV513

> T

cool

ambient

≤ 55 °C,

ambient

– 5 K

coolmin

As coolant, only a water/anti-freeze mixture in a ratio of 50 % / 50 % is permissible. Glycol is

recommended as antifreeze. When you select a different anti-freeze, a minimum steadystate temperature of -40 °C must be observed. Different anti-freeze agents should not be

mixed.

A filter (100 µm) must be installed in the inlet pipe to protect the motor against pollution.

Additional protection for the motor must be provided by means of a pressure relief valve

installed downstream from the filter.

If a throttle is needed to restrict the flow, it is best to install it downstream of the motor. It is

not permissible to install the throttle directly in front of the inlet because the effects of

cavitation may damage the motor.

SIMOTICS A-1FV5/1PV5 synchronous/induction motors

Operating Instructions, 03/2014, 610.45002.40

19

Description

Contents and chemical composition

Value

pH value

6 … 8

Sulfate ions

< 50 ppm

Dissolved solids

< 340 ppm

Total hardness

< 170 ppm

Electrical conductivity

< 500 μS/cm

Size of any particles in the coolant

< 100 µm

Note

Storing or transporting the motor

The cooling circuit must be emptied when storing the motor, for longer periods when the

motor is out of service and when the motor is being transported.

3.4 Design

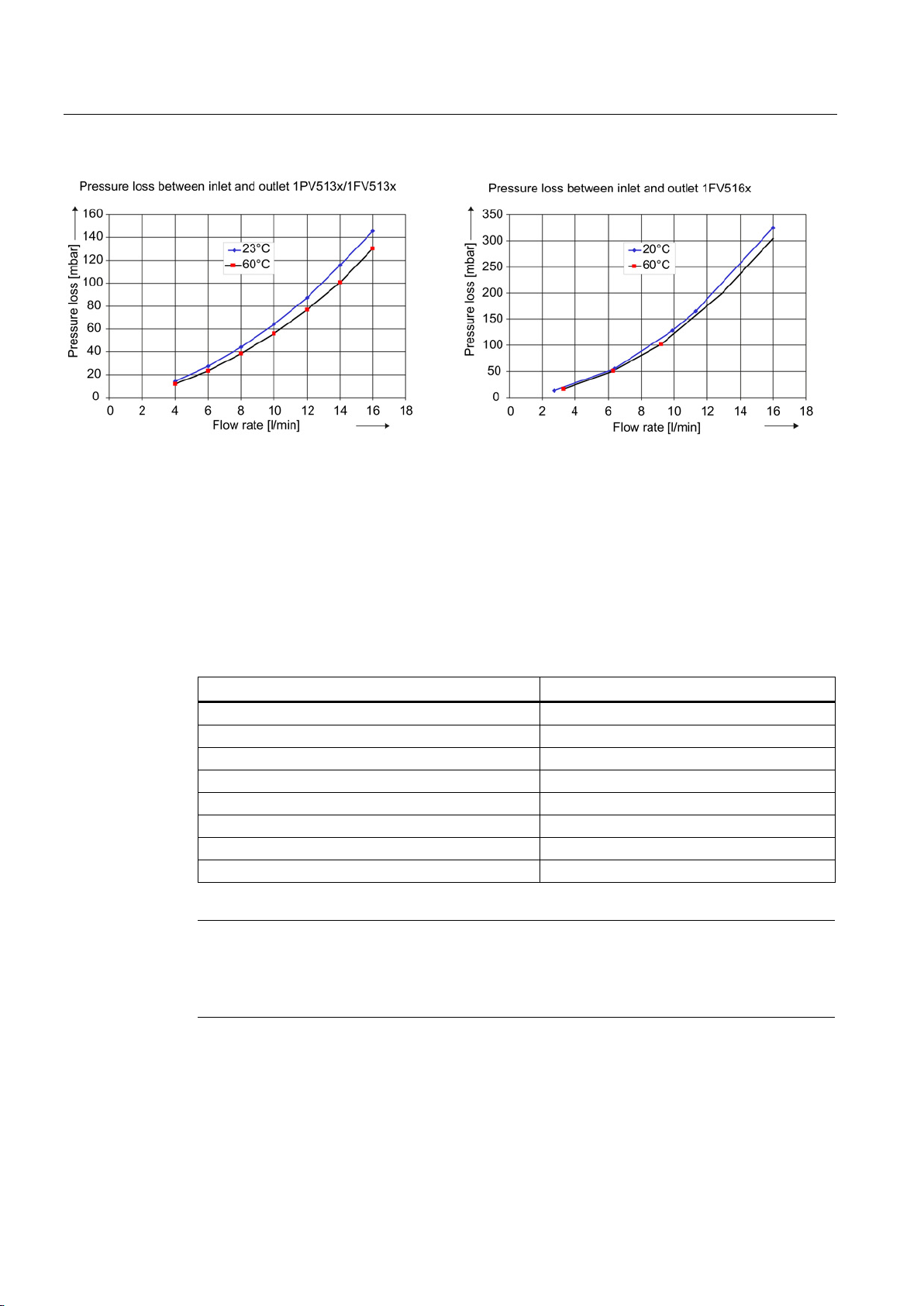

Figure 3-2 Pressure losses as a result of volumetric flow

Coolant temperatures below the ambient temperature lead to increased condensation of

water. The difference between the coolant inlet temperature and ambient temperature should

therefore not exceed maximum 5 Kelvin. If the motor is out of operation for a prolonged

period of time, coolant inflow must additionally be interrupted.

The values specified for the cooling water (refer to the following table) correspond to the

requirements of closed cooling circuits. Not all of the specified concentrations will occur in

the cooling water at the same time.

Table 3- 5 Water specifications for the coolant

Chloride ions < 40 ppm

Nitrate ions < 50 ppm

SIMOTICS A-1FV5/1PV5 synchronous/induction motors

20 Operating Instructions, 03/2014, 610.45002.40

Loading...

Loading...