Siemens SIMOTICS DP, SIMOTICS SD, SIMOTICS 1LP, SIMOTICS 1PC, SIMOTICS 1PF Compact Operating Instructions

...

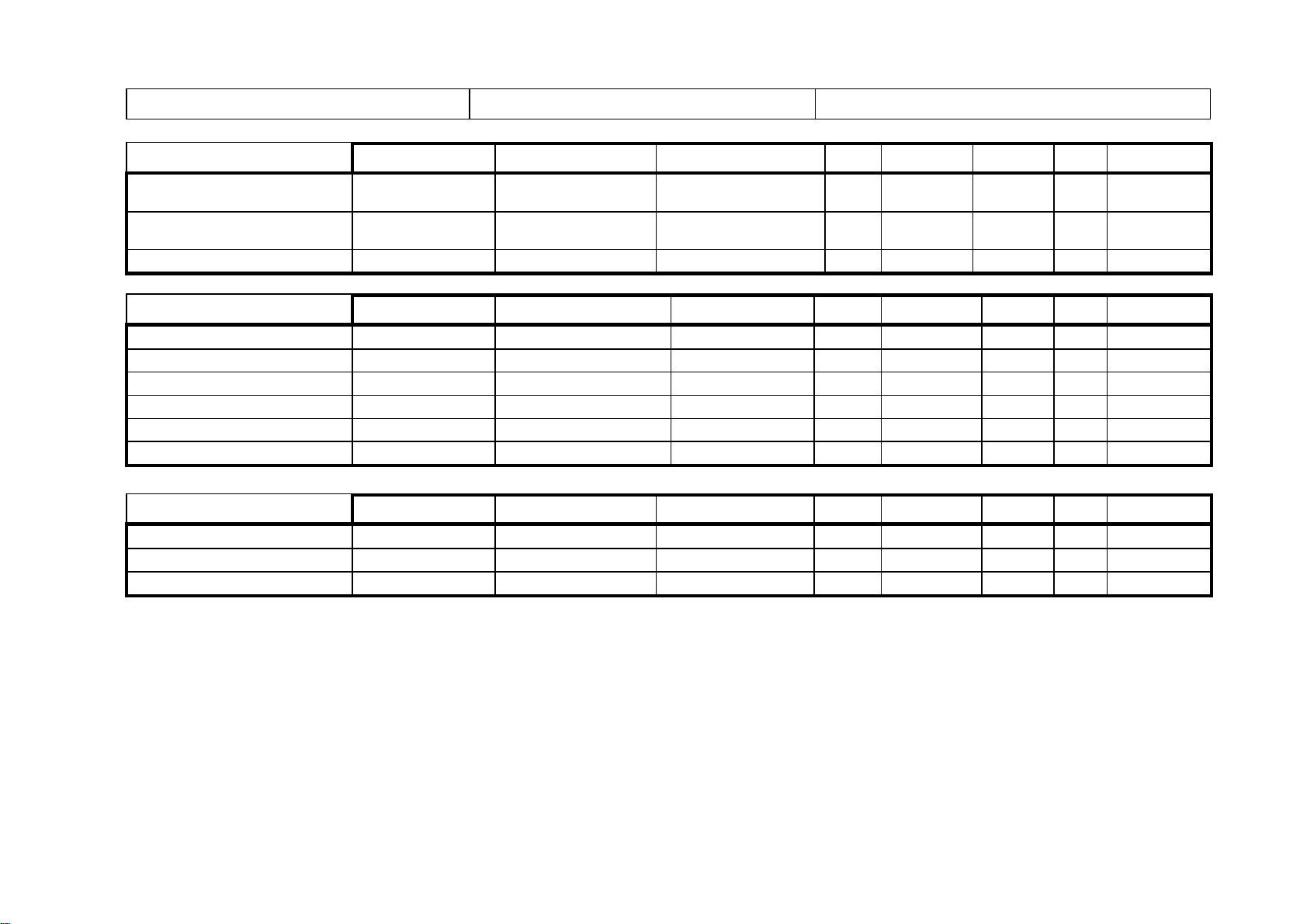

Contents Equipment manua ls K230F

No.

Equipment

Manufacturer

Document

No. of pages

1

Technical Data List

1

Installation,

maintenance

Installation,

maintenance

Installation,

maintenance

See Hoist

motor

Installation,

maintenance

See Hoist

gear

Installation,

maintenance

See Hoist

motor

Installation,

maintenance

8

Slewing brake

Krøll K-Brake

Adjustment

2

Stromag Serie

51 / 51 DZ

2 Hoist motor Siemens

3 Hoist gear Bonfigioli

6 Trolley motor Siemens

7 Trolley gear Bonfigioli

- Slewing motor Siemens

Slewing gear Bonfigioli

9 Limit switches

32

54

46

Installation, adjusting 31

TECHNICAL DATA LIST

K230F 11596 + 11597

KRØLL CRANES A/S

HOIST

MANUFAC

TYPE

SERIAL NO.

kW

RPM

RATIO

QTY

P/N

E1509/5428379_02 001

E1509/5428379_02 002

4197677 01

4196220 01

SLEWING

MANUFAC

TYPE

SERIAL NO.

kW

RPM

RATIO

QTY

P/N

MOTOR without encoder

Siemens

1LA7113-4AA11-Z

11.5

2850

- 1 15.00050889

MOTOR with encoder

Siemens

1LA7113-4AA11-Z

11.5

2850

- 1 15.00050890

BRAKE

Krøll Cranes A/S

K-Brake 180V

- - - - 2

16.00045720

GEAR

Bonfiglioli

309L4HZ

SK 1500863X

- - 1:465

2

17.00057190

SLEWING RING

Rothe Erde

061.50.1390.203.49.1502

- - - 1

37.00037277

TROLLEY

MANUFAC

TYPE

SERIAL NO.

kW

RPM

RATIO

QTY

P/N

MOTOR WITH BRAKE

Siemens

1LP7113

6 - 1 15.00050891

GEAR

Bonfiglioli

A55

4194676 0X

-

1:40.303

1

17.00063214

12

MOTOR WITH BRAKE

GEAR

Siemens 1LP9207

Bonfiglioli A90

42.5 1750 - 1 15.00050916

- - 1:55.03 1 17.00063202

L:\Tor\Projekter\K230F\11596 11597\Manual\08 Equipment manuals\01 QA 37_1 Technical data list.doc Page 1of 1 FORM QA 37

SIMOTICS Low-voltage motors

GP, SD, DP

1LA , 1LE, 1LF, 1LG, 1LP, 1PC, 1PF, 1PK, 1PP, 1PQ, 2KG

Compact Operating Instructions

02/2013Ausgabe

5 610 00000 02 001

© Siemens AG 2013

Answers for industry.

SIMOTICS GP, SD, DP

Low-voltage motors

Compact Operating Instructions

1 Introduction

1.1 Information for the reader

Explanation of the icons

Note for 1LE1, 1MB1, 1PC1, 1PC3 machines

Note for 1LE1, 1PC1 and 1PC3 machines, frame sizes 80 and 90 with central

terminal box locking

2 Safety notes

2.1 Information for those responsible for the plant or system

This electric machine has been designed and built in accordance with the

specifications contained in Directive 2006/95/EC ("Low-Voltage Directive") and is

intended for use in industrial plants. Please observe the country-specific regulations

when using the electric machine outside the European Community.

Follow the local and industry-specific safety and setup regulations.

The persons responsible for the plant must ensure the following:

● Planning and configuration work and all work carried out on and with the machine

is only to be done by qualified personnel.

● The operating instructions must always be available for all work.

© Siemens AG 2010 - 2013. All rights reserved

34 56100000002001, 02/2013

11BSafety notes

● The technical data as well as the specifications relating to the permissible

installation, connection, ambient and operating conditions are taken into account

at all times.

● The specific setup and safety regulations as well as regulations on the use of

personal protective equipment are observed.

Note

Use the services and support provided by the appropriate Service Center for

planning, installation, commissioning, and servicing work.

In the individual chapters of this document, you will find safety instructions that must

be obeyed absolutely, for your own safety, to protect other people and to avoid

damage to property.

Observe the following safety instructions for all activities on and with the machine.

2.2 The five safety rules:

For your personal safety and to prevent material damage when carrying out any

work, always observe the safety instructions and the following five safety rules,

according to EN 50110-1 "Working in a voltage-free state". Apply the five safety rules

in the sequence stated before starting work.

Five safety rules

1. Disconnect the system.

Disconnect the auxiliary circuits, for example anti-condensation heating

2. Prevent reconnection.

3. Make sure that the equipment is at zero voltage

4. Ground and short-circuit

5. Cover or isolate nearby components that are still live.

To energize the system, apply the measures in reverse order.

2.3 Qualified personnel

All work at the machine must be carried out by qualified personnel only. For the

purpose of this documentation, qualified personnel is taken to mean people who fulfill

the following requirements:

● Through appropriate training and experience, they are able to recognize and

avoid risks and potential dangers in their particular field of activity.

● They have been instructed to carry out work on the machine by the appropriate

person responsible.

Standard motors

56100000002001, 02/2013

35

11BSafety notes

2.4 The safe use of electrical machines

WARNING

Live parts

Electrical machines contain live parts.

Fatal or severe injuries and substantial material damage can occur if the

required covers are removed or if the machines are not handled,

operated, or maintained properly.

● Only remove covers in compliance with the applicable regulations.

● Operate the machines properly.

Rotating parts

Electrical machines contain dangerous rotating parts.

Fatal or severe injuries and substantial material damage can occur if the required

covers are removed or if the machines are not handled, operated, or maintained

properly.

● Only remove covers in compliance with the applicable regulations.

● Operate the machines properly.

● Perform regular maintenance on the machine.

● Secure free-standing shaft extensions.

● Perform regular maintenance on the machine.

WARNING

WARNING

Hot surfaces

Electrical machines have hot surfaces.

Fatal or severe injuries and substantial material damage can occur if the

required covers are removed or if the machines are not handled,

operated, or maintained properly.

● Allow the machine to cool down before starting any work on it.

● Only remove covers in compliance with the applicable regulations.

● Operate the machines properly.

Standard motors

36 56100000002001, 02/2013

3 Description

3.1 Language versions on the Internet

Language versions can be found on the Internet

Internet page: http://www.siemens.com/motors

If you require additional language versions, please contact the Siemens Service

Center.

Intended use of the machines

These machines are intended for industrial installations. They comply with the

harmonized standards of the series EN / IEC 60034 (VDE 0530). Their use in

hazardous areas is forbidden unless the marking on the rating plate expressly

permits this operation. If other/more wide-ranging demands (e.g. protection so that

they cannot be touched by children) are made in special cases – i.e. use in nonindustrial installations – these conditions must have been complied with in the plant

or system itself when the motors are installed.

Note

Machine directive

Low-voltage motors are components designed for installation in machines in

accordance with the current Machinery Directive. The system may not be

commissioned until confirmation has been given that the final product is in

conformance with this directive (observe EN 60204-1 !).

Forced ventilation (optional): Cooling IC 416 in accordance with EN / IEC 60034-6

WARNING

Hot surfaces

Operating the machine without external fan results in overheating. This

may result in personal injury and material damage.

Never commission the machine without an external fan.

Cooling that does not depend on the speed is achieved by means of a separately

driven fan wheel (forced ventilation). Forced ventilation does not depend on the

operating state of the machine.

The fan wheel for the external flow of cooling air is powered by an independent

module and is enclosed by the fan cover.

Standard motors

56100000002001, 02/2013

37

12BDescription

3.2 Degree of protection

The degree of protection the machines feature is stated on the rating plate. They can

be installed in dusty or humid environments.

WARNING

Dangerous voltage

Condensation drain holes (optional)

Inserting objects into the condensation drain holes can damage the

winding and can result in death, serious injury and damage to property!

Note the following to maintain the degree of protection:

● Switch off the machine so that it is in a no-voltage condition, before

you open the condensation drain holes.

● Close the condensation drain holes (e.g. using T-plugs) before

Note

Storage

If the machines are used or stored outdoors, we recommend keeping them under a

shelter or an additional cover.

● Avoid exposing them to direct, intense solar radiation, rain, snow, ice, or dust for

extended periods.

● If necessary, please consult us or seek advice regarding technical issues.

commissioning the machine.

Environmental requirements

The machines are suitable for operation in tropical climates.

Guide value for the standard version 60 % relative humidity at an ambient

temperature of (T

) 40 °C.

amb

Ambient temperature: -20 °C to +40 °C

Installation altitude: ≤ 1000 m

Air with normal oxygen content, usually 21 % (V/V)

If the environmental requirements are different from the details listed here, then the

values on the rating plate will apply.

Standard motors

38 56100000002001, 02/2013

4 Preparing for use

WARNING

Use lifting eyes

The machine must only be transported and lifted using the lifting eyes, in a position

that is appropriate for its type of construction. Otherwise, it could fall over or slip in

the lifting tackle.

This can result in death, serious injury, or material damage.

● Use all the lifting eyes on the machine.

● Any eyes that are screwed in must be tightly fastened.

● Eyebolts must be screwed in right up to their supporting surface.

● If necessary, use suitable, sufficiently-sized transport equipment such as lifting

straps (EN1492-1) and lashing straps (EN12195-2).

WARNING

Suspended transport

If several items of transport material are used for fastening, two straps must be able

to carry the whole load.

● Use additional, suitable means of support for transport and during installation.

● Secure the support equipment to prevent it from slipping.

Storage time

Turn the shafts 1x every year to avoid bearing brinelling. Prolonged storage periods

reduce the useful life of the bearing grease (aging).

Open bearings

● For open bearings e.g. 1Z, check the state of the bearing grease over 12 months.

● Replace the grease if it can be identified that the grease has lost oil content or

has become dirty (ingress of condensation leads to consistency changes of the

grease).

Closed bearings

● For closed bearings, replace the DE and NDE bearings after a storage time of 48

months

Standard motors

56100000002001, 02/2013

39

5 Mounting, installation

5.1 Safety instructions

WARNING

Hot surfaces

Electrical machines have hot surfaces.

Fatal or severe injuries and substantial material damage can occur if the

required covers are removed or if the machines are not handled,

operated, or maintained properly.

● Allow the machine to cool down before starting any work on it.

● Only remove covers in compliance with the applicable regulations.

● Operate the machines properly.

It must be ensured that parts (cables etc.) do not come into contact with

the machine enclosure.

NOTICE

Before start-up, please check that

● the customer has set the correct direction of rotation of the machine - e.g. by

decoupling from the driven machine - by taking appropriate measures!

● there are no temperature-sensitive parts (cables etc.), which are in contact with

the machine enclosure.

● condensation drain holes are always located at the lowest point of the motor!

Note

Please note the technical data on the rating plates on the machine enclosure.

5.2 Electromagnetic compatibility

Note

If the torque levels are very unequal (e.g. when a reciprocating compressor is being

driven), a non-sinusoidal machine current will be induced whose harmonics can have

an impermissible effect on the supply system and cause impermissible interference

emissions as a result.

Standard motors

40 56100000002001, 02/2013

Loading...

Loading...