Siemens SIMODRIVE 611A Installation And Planning Manual

SIEMENS

Installation and Planning Guide

Edition 04.99

6SN1197-IRWFD-0BP2

BP1952

SIMODRIVE 611A

Transistor PWM Inverters and

Motors for AC Feed Drives

Manufacturers’ Service Documentation

CONTENTS

SECTION 0

Preliminary Information 0-7

SECTION 1 – Analog Feed Drives

Supply Infeed (NE) Module

General Information 1-19

Function overview and settings 1-20

Service and diagnostics 1-23

Technical data 1-25

Interface Overview 1-35

Interface Overview – 5/10kW 1-42

Line Fuses, Commutating Reactors, and Transformers 1-44

Power Modules

General Information 1-61

Technical Data 1-62

Load Duty Cycle Definition 1-69

Control Components

Feed control with user-friendly interface 1-71

Function overview via parameter board 1-73

Main Spindle option board – functions 1-77

Feed control with standard interface 1-80

Start-up

Short Start-up, settings 1-83

Adaptation Tables 1-85

Speed controller optimization 1-96

Tachometer adjustments 1-97

Setting of proportional gain (Kp) without adaptation 1-97

Setting the integral action time (Tn) without adaptation 1-98

Integral action time with adaptation (if required) 1-99

Proportional gain with adaptation 1-100

Speed controller I-component limit 1-101

Drift component (offset) 1-102

Setting elements with standard interface 1-103

Setting elements with user-friendly interface 1-107

Setpoint interfaces 1-111

Start-up of Main Spindle Option Board

Powering On

Maintenance and Diagnostics

Test sockets and displays 1-124

User-friendly interface 1-124

Standard interface (two-axis) 1-126

Troubleshooting 1-127

1-113

1-121

iii

Electrical Block Diagram

Standard controller board 1-128

User-friendly controller board 1-129

Board Component Layout

Parameter board 1-130

Motor to Drive Connections

Feedback cable connection and Power lead connection 1-132

Important Circuit Information

Application Examples

EMC Measures

Mounting Dimensions

Drive modules 1-161

Reactors 1-163

Overall Interface and Start-up Procedures

Power and Grounding 1-165

Infeed Module – connection and start-up notes 1-168

Standard Version Feed Module – connection and Start-up notes 1-172

2-Axis, Standard Version Feed Module – connection and Start-up notes 1-175

User-Friendly Version Feed Module – connection and Start-up notes 1-178

Main Spindle Option Board – Connections and Notes 1-181

Monitoring and Pulsed Resistor Module – Connections and Notes 1-182

Cross-reference, Old complete unit order codes to new component order codes 1-183

Tightening torque specifications for drive screws and connections 1-184

Part numbers for Drive connectors 1-185

1-133

1-149

1-156

1-159

iv

Section - AL S

General Information on AC Servo Motors

Electrical Data

Definitions AL S/1-1

Rating plate data AL S/1-9

Mechanical Data

Definitions AL S/2-1

Mounted / integrated components AL S/2-10

Functions – options

Termination Technology

Power cable AL S/4-1

Signal cable AL S/4-2

Cable versions AL S/4-3

AL S/1-1

AL S/2-1

AL S/3-1

AL S/4-1

Section – 1FT5

General Information on AC Servo Motors

Motor Description

Characteristics and technical data 1FT5/1-1

Functions and options 1FT5/1-6

Interfaces 1FT5/1-18

Thermal motor protection 1FT5/1-19

Encoder 1FT5/1-19

1FT5/1-1

Order designations

Technical Data and Characteristics

Speed/Torque diagrams 1FT5/3-1

Standard motors 1FT5/3-1

Short motors 1FT5/3-30

Cantilever/axial force diagrams 1FT5/3-36

Standard motors 1FT5/3-37

Short motors 1FT5/3-44

1FT5/2-1

1FT5/3-1

Section – GE

Feedback and Encoders for 1FT5…

Thermistors

Tachometer

Built-in Encoder (ROD 320

Built-on Encoder (ROD 426)

GE/1-1

GE/1-2

GE/1-3

GE/1-5

v

SECTION 0

PRELIMINARY INFORMATION

0-7

Foreword

This document is part of the documentation developed for SIMODRIVE. All documents are available individually. The documentation list, which includes all

Advertising Brochures, Catalogs, Overviews, Short Descriptions, User Manuals

and Technical Descriptions can be obtained from your local Siemens Office

with Order No., location and price.

This Manual does not purport to cover all details or variations in equipment, nor

to provide for every possible contingency to be met in connection with installation, operation or maintenance.

Should further information be desired or should particular problems arise, which

are not covered sufficiently for the purchaser’s purposes, the matter should be

referred to the local Siemens sales office.

The contents of this Guide shall neither become part of nor modify any prior or

existing agreement, commitment or relationship. The sales contract contains the

entire obligation of Siemens. The warranty contained in the contract between

the parties is the sole warranty of Siemens. Any statements contained here do

not create new warranties nor modify the existing warranty.

Siemens AG 1998 All Rights reserved 6SN1197–0AA00 02.98 Edition

SIMODRIVE 611 (PJ)

0-9

Foreword

Definitions

02.98

Qualified personnel

For the purpose of this Guide and product labels, a ”qualified person” is

someone who is familiar with the installation, mounting, start–up and operation of the equipment and the hazards involved. He or she must have the

following qualifications:

– trained and authorized to energize, de–energize, clear, ground and tag

circuits and equipment in accordance with established safety procedures.

– trained in the proper care and use of protective equipment in accordance

with established safety procedures.

– trained in rendering first aid

Danger

!

This symbol in the document indicates that death, severe personal injury or

substantial property damage will result if proper precautions are not taken.

Warning

!

!

!

This symbol appears in the document if death, severe personal injury or property damage can result if proper precautions are not taken.

Caution

This symbol appears in the document indicating that minor personal injury or

material damage can result if proper precautions are not taken.

Important

This symbol appears in the documentation if a particular issue is significant.

Note

For the purposes of this Guide, ”Note” indicates information about the product

or the respective part of the Guide which is essential to highlight.

0-10

Siemens AG 1998 All Rights reserved 6SN1197–0AA00 02.98 Edition

SIMODRIVE 611 (PJ)

02.98

Foreword

Important

!

!

The listed filter modules/line filters generate a high discharge current through

the protective conductor. Due to the high discharge current of the filter, there

must be a good permanent connection between the protective conductor of the

filter module/line filter and the cabinet.

The measures according to pr EN 50178/94 Part 5.3.2.1 must be implemented,

e.g.

1.A copper protective conductor with a minimum cross–section of 10mm

should be connected or

2.a second conductor should be connected in parallel to the protective conductor through separate terminals.

This cable must fulfill by itself the requirements for protective conductors according to IEC 364–5–543.

Warning

Operational electrical equipment has parts and components which are at hazardous voltage levels.

Incorrect handling of these units, i. e., not observing the warning information

can therefore result in severe bodily injury or material damage.

Only appropriately qualified personnel may commission/start–up this equipment.

This personnel must have in–depth knowledge regarding all of the warning

information and service instructions according to this Guide.

Perfect and safe operation of this equipment assumes professional transport,

storage, mounting and installation as well as careful operator control and service.

Hazardous axis motion can occur when working with the equipment.

Further, all of the valid national, regional and plant/system–specific regulations

must be adhered to.

2

Note

When handling cables observe the following

they must not be damaged,

they must not be stressed and

they must not come into contact with rotating components.

Note

For IT– and TT supply networks, connected measuring equipment and programmers must be referred to the reference potential of the module group.

Siemens AG 1998 All Rights reserved 6SN1197–0AA00 02.98 Edition

SIMODRIVE 611 (PJ)

0-11

Foreword

02.98

Important

!

!

M600 and M500 are not PE potentials. Hazardous voltages between

300...400V can occur at these terminals with respect to PE. These potentials

may not be connected to PE.

Note

”Safe separation” must be provided between the temperature sensor and the

motor winding of third–party motors.

Warning

Start–up/commissioning is absolutely prohibited until it has been ensured that

the machine, in which the components described here are to be installed, fulfills

the regulations/specifications of the Directive 89/392/EEC.

Warning

!

The information and instructions in all of the documentation supplied and any

other instructions must always be observed to eliminate hazardous situations

and damage.

for special versions of the machines and equipment, the information in the

associated catalogs and quotation is valid.

further, all of the relevant national, local and plant/system–specific regula-

tions and specifications must be taken into account.

all work must be undertaken with the system in a no–voltage condition (po-

wered–down)!

Warning

!

Perfect and safe operation of this equipment assumes professional transport,

storage, mounting and installation as well as careful operator control and service.

Severe bodily injury or material damage could occur if the warning information

is not observed.

0-12

Warning

!

After all voltages have been disconnected, hazardous voltages are present for

at least 4 minutes.

In order to ensure that no hazardous voltages occur, a voltage measurement

should be made. (Generating principle for rotating motors)

Siemens AG 1998 All Rights reserved 6SN1197–0AA00 02.98 Edition

SIMODRIVE 611 (PJ)

02.98

Foreword

Warning

!

!

The rated current of the connected motor must match the rated drive converter

current, as otherwise motor feeder cable protection is not guaranteed. The

cross–section of the motor feeder cable must be dimensioned for the rated

drive converter current.

Warning

Before commissioning the 611D, the encoder cable must be checked to ensure

that it has no ground faults. If there is a ground fault, uncontrolled movement

could occur for pulling loads.

No longer occurs from: 6SN1118–0DV2V–0AA0 Version C.

Note

If a system high voltage test is made, the overvoltage limiting module must be

removed in order to prevent the voltage limiting responding.

When configuring the system, the connection between the voltage limiting circuit and the central grounding point should be as short as possible and be low

ohmic.

Note

The terminal blocks of the SIMODRIVE 611 modules are exclusively used to

electrically connect that particular module; if they are used for any other purpose (e.g. as handle) this can cause damage to the module.

0-13

08.95

Warning

!

Operational electrical equipment has parts and components which are at hazardous voltage levels.

Incorrect handling of these units, i.e. not observing the warning information, can

therefore lead to death, severe bodily injury or significant material damage.

Only appropriately qualified personnel may commission/start–up this equipment.

This personnel must have in–depth knowledge regarding all of the warning

information and service measures according to this Manual.

Perfect, safe and reliable operation of this equipment assumes that it has been

professionally transported, stored, mounted and installed as well as careful

operator control and service.

Hazardous axis motion can occur when working with the equipment.

Note

When handling cables, observe the following

they must not be damaged,

they must not be strained and

they must not come into contact with rotating components.

Note

It is not permissible to connect SIMODRIVE equipment to a supply system with

ELCBs (this restriction is permitted acc. to DIN VDE 0160 / 05.88, Section 6.5).

When operational, protection against direct contact is provided in a form to allow the unit to be used in enclosed electrical equipment rooms (DIN VDE 0558

Part 1 / 07.87, Section 5.4.3.2.4).

In compliance with DIN VDE 0160 / 05.88, all SIMODRIVE units are subject to

a high–voltage test at the time of routing testing. If the electrical equipment of

industrial tools is subject to a high–voltage test, all connections must be disconnected so that sensitive electronic components in the SIMODRIVE converter

are not damaged

(permissible acc. to DIN VDE 0113 / 06.93, Part 1, Section 20.4).

Warning

!

Start–up/commissioning is absolutely prohibited until it has been ensured that

the machine in which the components described here are to be installed, fulfills

the regulations/specifications of the Directive 89/392/EWG.

0-14

Siemens AG 1997 All Rights reserved 6SN1197–0AA20

SIMODRIVE 611 (PJ)

08.95

Warning

!

The information and instructions in all of the documentation supplied and any

other instructions must always be observed to eliminate hazardous situations

and damage.

SFor special versions of the machines and equipment, the information in the

associated catalogs and quotations applies.

SFurther, all of the relevant national, local and plant/system–specific regula-

tions and specifications must be taken into account.

SAll work should be undertaken with the system in a no–voltage condition!

SFor the feed motors, when the rotor is rotating, a voltage is present at the

motor terminals (as a result of the integrated permanent magnets).

SThe motor must be connected according to the circuit diagram supplied.

SIt is not permissible to directly connect the motor to the three–phase supply

and this would destroy the motor.

SSurface temperatures of above 100

surface.No temperature–sensitive parts or components, e.g. cables or electronic components may be in contact with or connected to the motor.

d

C can occur at the motor enclosure

Warning

!

The holding brake is only designed for a limited number of emergency braking

operations. It is not permissible to use it as working brake.

Siemens AG 1997 All Rights reserved 6SN1197–0AA20

SIMODRIVE 611 (PJ)

0-15

Foreword

02.98

ESDS instructions

Components which can be destroyed by electrostatic discharge

Components which can be destroyed by electrostatic discharge are individual

components, integrated circuits, or boards, which when handled, tested or

transported, could be destroyed by electrostatic fields or electrostatic discharge. These components are designated as ESDS (ElectroStatic Discharge

Sensitive Devices).

Handling ESDS boards:

When handling components which can be destroyed by electrostatic di-

scharge, it should be ensured that personnel, the work station and packaging are well grounded.

Electronic boards should only be touched when absolutely necessary.

Components may only be touched, if

– you are continuously grounded through an ESDS bracelet,

– you are wearing ESDS shoes or ESDS shoe grounding strips in con-

junction with an ESDS floor surface.

Boards may only be placed on conductive surfaces (desk with ESDS sur-

face, conductive ESDS foam rubber, ESDS packing bag, ESDS transport

containers).

Boards may not be brought close to data terminals, monitors or television

sets (a minimum of 10 cm should be kept between the board and the

screen).

Boards may not be brought into contact with materials which can be char-

ged–up and which are highly insulating, e. g. plastic foils, insulating desktops, articles of clothing manufactured from man–made fibers.

Measuring work may only be carried out on the boards, if

– the measuring equipment is grounded (e. g. via the protective conduc-

tor) or

– for floating measuring equipment, the probe is briefly discharged before

making measurements (e. g. a bare control housing is touched).

0-16

Siemens AG 1998 All Rights reserved 6SN1197–0AA00 02.98 Edition

SIMODRIVE 611 (PJ)

Section 1

611A - Analog Feed Drives

1-17

1-18

Supply Infeed (NE)

The infeed/regenerative feedback module (I/R module) and the module for the

uncontrolled infeed (UE module), is used to feed the DC link. Beyond this, the

I/R–, UE–, and the monitoring module (monitoring module) also provide the

electronics power supply for the connected modules.

For the I/R module, when braking, the kinetic energy of the drives, fed back into

the DC link, is fed back into the line supply.

For the UE module, when braking, the drive kinetic energy, fed back into the DC

link, is converted into heat in the brake resistors which are either integrated or

mounted. This heat is then dissipated to the environment. When required, additional single or several pulsed resistor modules can be used within the configuring limits (pulsed resistor modules) (a pulsed resistor is not integrated in all of

the modules).

The I/R–, UE module is located as the first module to the left in the drive group.

The monitoring module is located in the drive group, to the left of the modules to

be supplied.

To fulfill the CE conformance for the radio interference voltage limit values, filter

modules, line filters and screen cables are available.

Siemens AG 1998 All Rights reserved 6SN1197–0AA00 02.98 Edition

SIMODRIVE 611 (PJ)

1-19

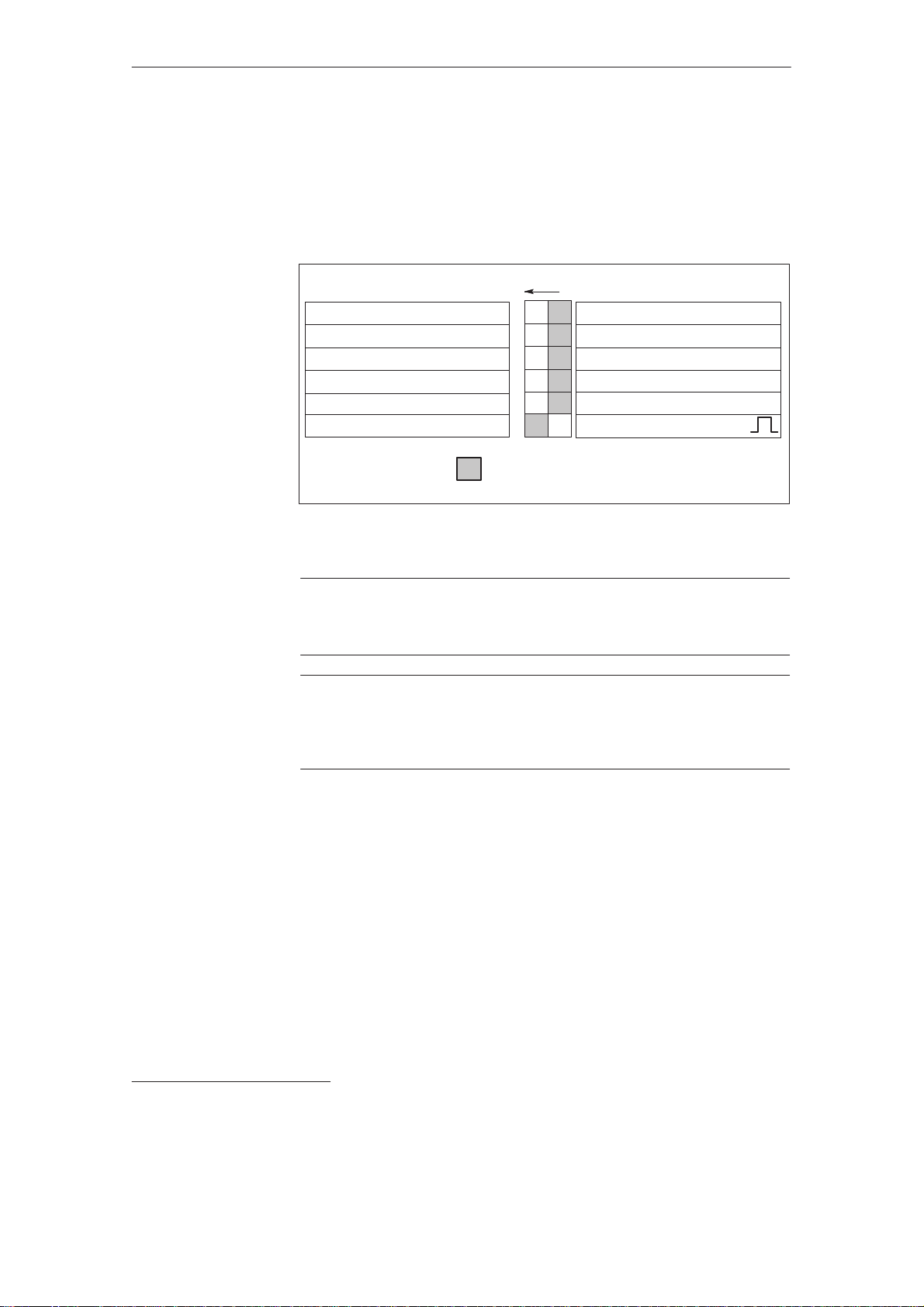

3.1 Function overview and settings

Function overview and settings

A switch S1 is provided on the upper side of the NE and monitoring module to

set the following functions (for UE5 KW on the front panel):

02.98

3

ON: OFF:

U

=415V10% V

supply

Fault message

Regenerative feedback off

=480V+6%–10%

U

supply

Controlled infeed off

Sinusoidal current operation

Standard setting

Figure 3-1DIL switch S1

DC link

=625 V

S1

1)

1

2

3

4

5

6

U

=400V10% V

supply

Ready signal

Regenerative feedback on

Standard, refer to switch S1.1

Controlled infeed

Square–wave current operation

DC link

600 V

1)

Important

!

For I/R modules, Order No. 6SN114–10–01 the basic setting is for

sinusoidal current operation.

Important

!

Terminal 63 (pulse enable) and/or terminal 48 (starting terminal, contactor control) must be de–energized or disconnected before the drive is powered–up or

down using the main circuit–breaker or line contactor!

Switch S 1.1 :

OFF:I/R module, V

UE module V

=400V10%; V

supply

=400V10%; V

supply

Monitoring thresholds: (I/R, UE, monitoring modules)

Pulsed resistor on=644V; Pulsed resistor off=618V

>>=695V

V

ON: I/R module V

DC link

UE module V

=415V10%; V

supply

=415V10%; V

supply

Monitoring thresholds: (I/R, UE, monitoring modules)

Pulsed resistor on=670V; Pulsed resistor off=640V

>>=710V

V

DC link

PW=pulsed resistor

1)

only possible for the I/R module, monitoring thresholds are increased for all NE modules.

Siemens AG 1998 All Rights reserved 6SN1197–0AA00 02.98 Edition

1-20

=600V

DC link

DC link=Vsupply

=625V

DC link

DC link=Vsupply

SIMODRIVE 611 (PJ)

1.35

1.35

02.98

3.1 Function overview and settings

Switch S 1.2 :

OFF:Ready signal (X111 ready relay)

For S1.2=OFF, the relay switches, if the following conditions are fulfilled:

– Internal main contactor CLOSED (terminals NS1 - NS2 connected, ter-

minal 48 enabled)

– Terminal 63, 64=ON (energized)

– No fault present (also not for FD 611 A Standard and resolver and 611 D

drives).

– FD with Standard interface or resolver is enabled in the ”ready” setting

(terminals 663, 65)

– NCU for 840D must have run–up

– MCU must have run–up

ON: Fault message (X111 ready relay)

For S1.2=ON, the relay switches, if the following conditions are fulfilled:

– Internal main contactor CLOSED (terminals NS1 - NS2 connected, termi-

nal 48 enabled)

– No fault present (also not on FD 611 A Standard and resolver or 611 D

drives).

– Feed drive with standard interface or resolver is enabled for the ”Ready”

setting (terminals 663, 65)

– NCU for 840D must have run–up

– MCU must have run–up

Switch S 1.3 :

Switch S 1.4 :

OFF:Standard setting, regenerative feedback active

I/R modules are capable of regenerative feedback.

UE module: The pulsed resistor in the module is effective.

ON: Regenerative feedback disabled

I/R modules: Regenerative feedback is inhibited.

UE module: The pulsed resistor in the

module is not effective.

Comment:

This function is only effective for 10kW from

Order No. 6SN1146–1AC00–0AA1, and for UE 5kW, not for

UE 28kW.

OFF:Standard setting for all NE modules, refer to S 1.1

ON: V

=480V+6% / –10%; V

supply

=700...750V in regenerative feedback operation

V

DC link

DC link=Vsupply

1.35 for infeed operation

Monitoring thresholds: (I/R–, UE–, monitoring modules)

Pulsed resistor on=744V; Pulsed resistor off=718V

>>=795V

V

DC link

S1.4 overwrites the setting of S1.1

Comment: Uncontrolled operation in the infeed direction.

Note

Only in conjunction with modules Order No. 6SN114–10–01.

For motors with shaft height t100: Utilized up to max. 60 k values.

Please observe the Planning Guide, Motors.

S1.4 ON overwrites the functions of S1.5 and S1.1.

Siemens AG 1998 All Rights reserved 6SN1197–0AA00 02.98 Edition

SIMODRIVE 611 (PJ)

1-21

3.1 Function overview and settings

02.98

3

Switch S 1.5 :

Switch S 1.6 :

This function is only available in conjunction with I/R modules

Order No.: 6SN114V–1VV0V–0VV1

OFF:Standard setting, controlled infeed active

ON: Uncontrolled operation in the infeed direction V

DC link=Vsupply

1.35

OFF:Square–wave current operation (the line supply is loaded with a

square–wave current)

ON: This function is only available in conjunction with I/R modules

Order No.: 6SN114V–1VV0V–0VV1

Sinusoidal current operation (the line supply is loaded with sinusoidal

current)

Sinusoidal current is only permissible if the following

components are available:

I/R

16 kW

6SN114V–

1B

V01–0BA1

HF reactor

16 kW

6SN1111–

0AA00–0BA

Line filter for

sinusoidal

current

6SN1111–

0AA01–2BA

1)

16 kW

V

V

I/R

36 kW

6SN114V–

1B

V02–0CA1

HF reactor

36 kW

6SN1111–

0AA00–0CA

Line filter for

sinusoidal

0AA01–2CA

current

36 kW

6SN1111–

1)

V

V

I/R

55 kW

6SN114V–

1B

V0V–0DA1

HF reactor

55 kW

6SN1111–

0AA00–0DA

Line filter for

sinusoidal

1)

filter

55 kW

6SN1111–

0AA01–2DA

V

V

I/R

80 kW

6SN114V–

1BB00–0EA1

HF reactor

80kW

6SN1111–

0AA00–1EA

Line filter for

sinusoidal

0AA01–2EA

current

80 kW

6SN1111–

1)

V

Line filter for

V

6SN114V–

1BB01–0FA1

HF reactor

6SN1111–

0AA00–1FA

sinusoidal

6SN1111–

0AA01–2FA

I/R

120 kW

120kW

current

120 kW

V

1)

V

Important

!

For all of the combinations which are not listed here, only

square–wave current operation setting is permissible.

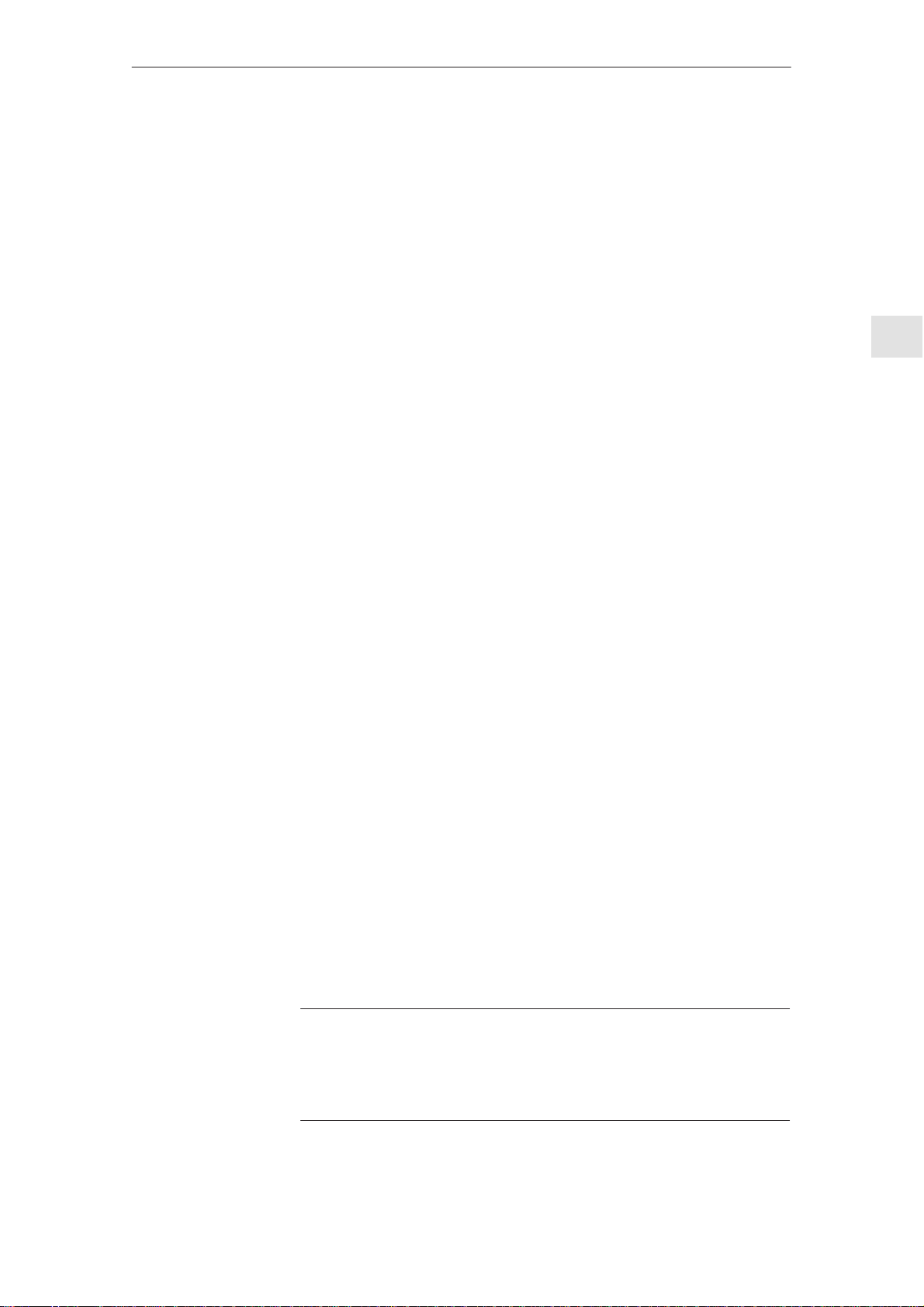

Table 3-1 Power factor

I/R

I/R

Sinusoidal current operation cos ϕ 0.98 cos λ = 0.97

Square–wave current opera-

cos ϕ 0.98 cos λ = 0.89

tion

UE

cos ϕ 0.87 cos λ = 0.67

cos ϕ: The power factor only includes the basic fundamental

cos λ: Power factor includes the basic fundamental and harmonic components

1)

In the line filters for sinusoidal operation, contrary to the filter modules 6SN1111–0AA01–0VAV for square–wave

current, commutating reactors are not included.

The HF commutating reactor must be mounted externally (refer to p. 1-45).

The line filter is required in order to achieve the CE Conformance for the radio interference voltage.

1-22

Siemens AG 1998 All Rights reserved 6SN1197–0AA00 02.98 Edition

SIMODRIVE 611 (PJ)

04.97

07.94

Service and diagnostics

Display elements of the monitoring– and NE modules

12

34

56

2 Service and dia

Supply infeed (NE)

gnostics

1 LED, red –

2 LED, red – 5 V voltage level faulted

3 LED green – external enable signals not available

4 LED yellow – DC link charged

5 LED, red – line supply fault (single– or multi–phase supply failure at the

6 LED red – DC link overvoltage

Effects:

1 red LED bright:Pulses for the complete drive group are canceled

2 red LED bright: Pulses for the complete drive group are canceled

4 yellow LED dark: xxxx

5 red LED bright: 1) Only the I/R module pulses are canceled (regenerative feedback

6 red LED bright:Pulses for the complete drive group are canceled

1) Line supply fault identification time approx. 30ms

Line supply fault is identified for a three–phase voltage < 280V.

For 1–phase supply failure, the drive axes pulses are canceled after approx. 1 min.

(latched signal) valid for Order No. 6SN1114

15 V electronics power supply faulted

(terminal 63 and/or terminal 64 missing)

terminals U1, V1, W1)

– commutating reactor either not available or incorrectly selected,

– fault level of the line supply or transformer too low

possible causes: Regenerative feedback off, setting–up operation,

line supply fault, for UE pulsed–resistor not operational, line supply

voltage too high, dynamic overload condition

no longer possible. Axes first continue to run. Ready relay drops–out

V–1VV0V–0VV1

1)

Siemens AG 1997 All Rights reserved

SIMODRIVE 611A Installation and Start–Up Guide/IAA/–04.97 Edition

1-23

1-24

02.98

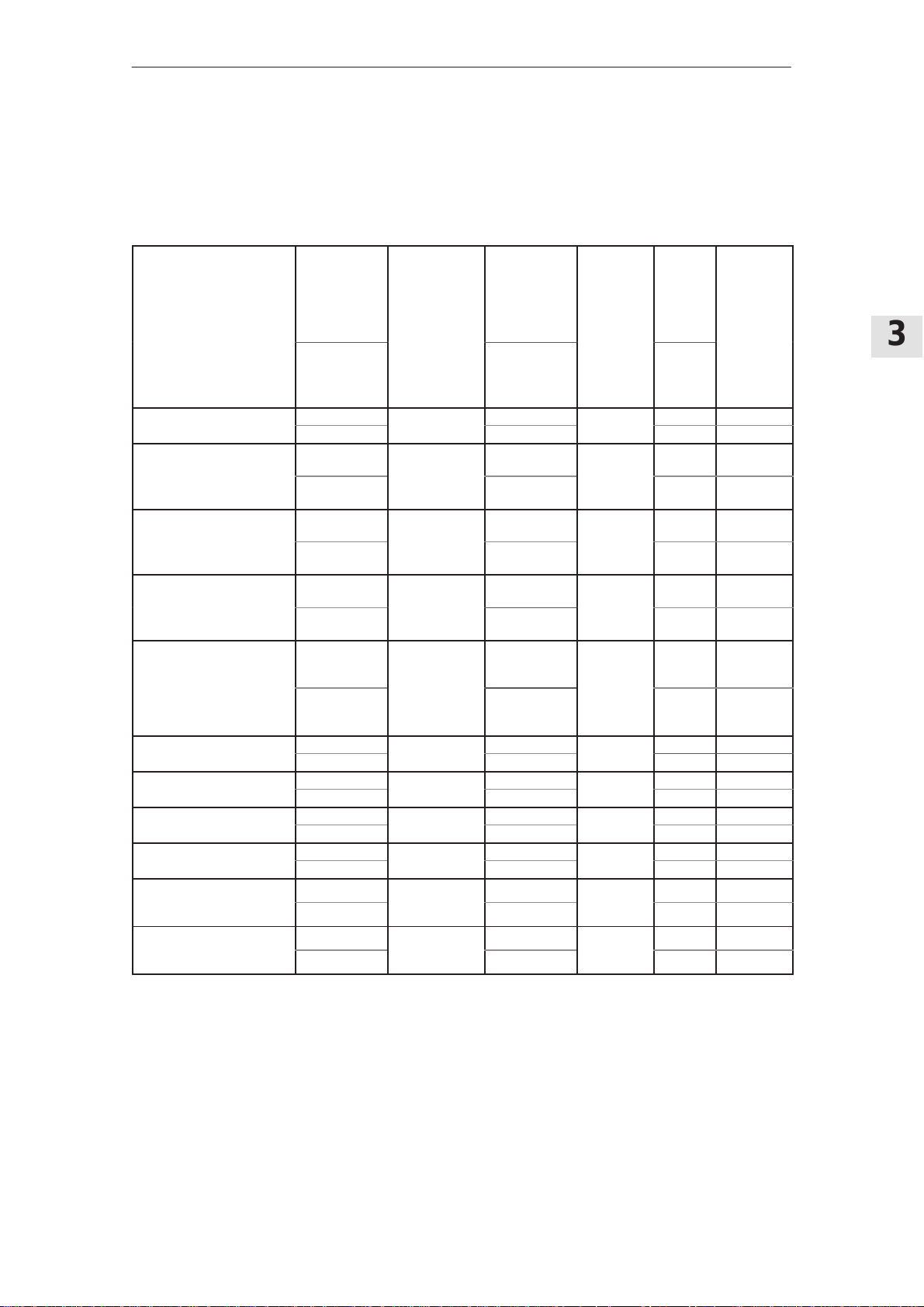

3.2.1 Technical data, supply infeed modules

Technical data

Technical data, supply infeed modules

Table 3-2 Technical data, supply infeed modules, internal cooling

Des.

Monitoringmodule

Monitoring module

Pulsedresistor

Pulsed resistor

UE module, 5/10 kW

UEmodule5/10kW

UEmodule10/25kW

UE module, 10/25 kW

UEmodule28/50kW

UE module, 28/50 kW

I/Rmodule16/21kW

I/R module, 16/21 kW

I/Rmodule36/47kW

I/R module, 36/47 kW

I/Rmodule55/71kW

I/R module, 55/71 kW

I/R module, 55/71 kW pipe

connection

I/R module, 80/104 kW

ipeconnectionorradial

ie connection or radial

p

fan

I/R module, 120/156 kW

ipeconnectionor

ie connection or

p

radial fan

1)

2)

3)

4)

5)

1)

If pipe cooling is not used, only Pv

If the internal pulsed resistor is shutdown, for internal cooling, the only power loss is Pv

The motor braking energy is converted into heat in the integrted pulsed resistor; a heat barrier may be

required, refer to p. 1-34

The 1st number is for cable lugs, the 2nd number is valid for finely–stranded conductors

without connector sleeve.

It can be used: a) 0.3/25 kW b) 2 x 0.3/25 kW c) 1.5/25 kW d) 2 x 1.5/25 kW

Pn/Ps6/P

for supply in-

max

feed [kW]

Pn/Ps6/P

for regenera-

max

tive feedback.

For UE with

internal pulsed resistor

[kW]

Power los-

ses[W]

Pv

/Pv

tot.

int

ext

1)

/Pv-

[kW]

– –

70/–/70 –

–

/310

310/–/10

5/6.5/10

/270

270/–/70

10/13/25

/450

450/–/150

2)

2)

2)

0.3/–/25

(450 V DC)

0.2/–/10

(450 V DC)

0.3/–/25

(450 V DC)

3)

3)

3)

28/36/50

0.3/–/25

5)

(450 V DC)

250/–/250

16/21/35

320/–/320

36/47/70

585/–/585

55/71/91

745/–/745

55/71/91

–/630/115

80/104/131

1280/1090/190

120/156/175

1950/1660/290

16/21/35

16/21/35

36/47/70

36/47/70

55/71/91

55/71/91

55/71/91

55/71/91

80/104/131

80/104/131

120/156/175

120/156/175

has to be taken into account.

tot

Input current

[A]

for 3–ph.

400 V AC,

600 V DC

Pn/Ps6/P

max

Output cur-

rent [A]

–

–

11.3/14.7/22.6

9.3/12/18.6

(540 V DC)

21.8/28.5/54.5

18.5/24/46.5

(540 V DC)

58.5/75/104.5

52/67/93

(540 V DC)

27/35.5/59

26.5/35/58

60.5/79/117.5

60/78/116

92.5/119/153

91/118/151

92.5/119/153

91/118/151

134/175/220

133/173/218

202/262/294

200/260/291

Max.

cross–sec-

4)

tion

[mm2]

16/10

16/10

6/4

6/4

6/4

6/4

16/10

16/10

50

50

16/10

16/10

50

50

95 or

2 x 35

95 or

2 x 35

95 or

2 x 35

150 or

2 x 50

Module

width

[mm]

Weight

[kg]

50 –

5 –

50

5

50

6.5 –

100

9.5 –

200

13.5

100 –

10.5 –

200 –

15.5 –

300 –

26 –

300 –

26 –

300 –

26 –

300 –

28 –

.

int

Energy of

the pulsed

resistor

for 1 x bra-

king ope-

ration

int.: E

max

7.5 kWs

ext.: E

max

180 kWs

int.: E

13.5 kWs

int.: E

7.5 kWs

max

max

=

=

External 1:

=

E

max

7.5 kWs

External 2:

=

E

max

180 kWs

3

=

=

Siemens AG 1998 All Rights reserved 6SN1197–0AA00 02.98 Edition

SIMODRIVE 611 (PJ)

1-25

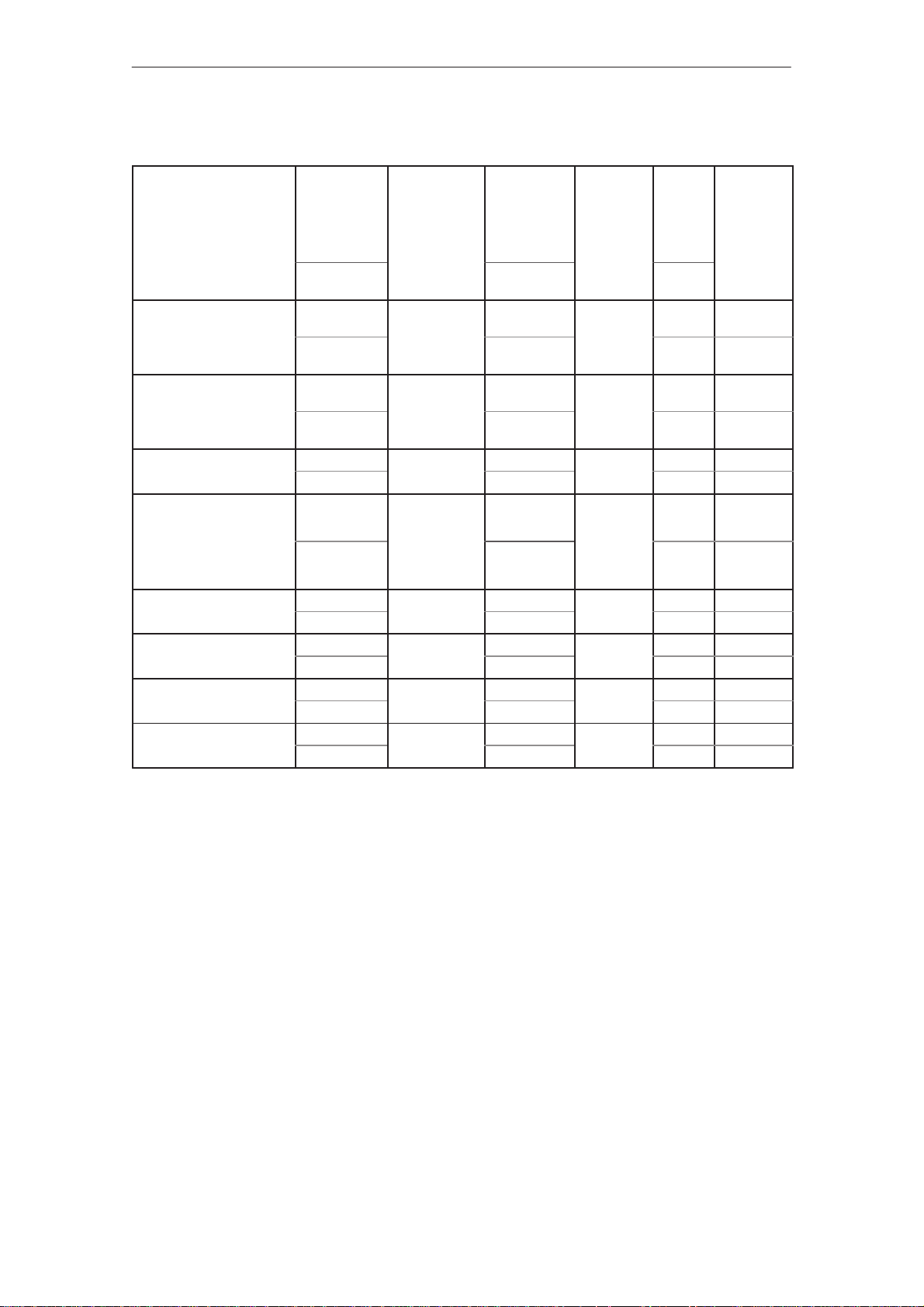

3.2.1 Technical data, supply infeed modules

Table 3-3 Technical data, supply infeed modules, external cooling

02.98

3

Des.

UEmodule5/10kW

UE module, 5/10 kW

UEmodule10/25kW

UE module, 10/25 kW

I/Rmodule16/21kW

I/R module, 16/21 kW

UEmodule28/50kW

UE module, 28/50 kW

I/Rmodule36/47kW

I/R module, 36/47 kW

I/Rmodule55/71kW

I/R module, 55/71 kW

I/Rmodule80/104kW

I/R module, 80/104 kW

I/Rmodule120/156kW

I/R module, 120/156 kW

Pn/Ps6/P

for supply in-

max

feed [kW]

Losses [W]

Pv

/Pv

ext

int

5/6.5/10

/270

2)

–/–/70

10/13/25

331/119

2)

/

31

16/21/35

270/50

28/36/50

160/90

36/47/70

535/50

55/71/91

630/115

80/104/131

1090/190

120/156/175

1660/290

Pn/Ps6/P

for regenera-

max

tive feedback.

For UE with

internal pulsed resistor

[kW]

[kW]

0.2/–/10

3)

(450 V DC)

3)

03/–/25

0.3/–/25

16/21/35

16/21/35

0.3/–/25

3)

5)

(450 V DC)

36/47/70

36/47/70

55/71/91

55/71/91

80/104/131

80/104/131

120/156/175

120/156/175

Input current

[A]

for 3–ph.

400 V AC,

600 V DC

Pn/Ps6/P

max

Output cur-

rent [A]

11.3/14.7/22.6

9.3/12/18.6

(540 V DC)

21.8/28.5/54.5

18.5/24/46.5

(540 V DC)

27/35.5/59

26.5/35/58

58.5/75/104.5

52/67/93

(540 V DC)

60.5/79/117.5

60/78/116

92.5/119/153

91/118/151

134/174/220

133/173/218

202/262/294

200/260/291

Max.

cross–sec-

4)

tion

[mm2]

6/4

6/4

16/10

16/10

16/10

16/10

50

50

50

50

95 or

2 x 35

95 or

2 x 35

150 or

2 x 50

Module

width

[mm]

Weight

[kg]

50

6.5 –

100

9.5 –

100 –

10.5 –

200

13.5

200 –

15.5 –

300 –

26 –

300 –

26 –

300 –

28 –

Energy of

the pulsed

resistor for

1 x braking

operation

int.: E

13.5 kWs

int.: E

7.5 kWs

max

max

=

=

External 1:

=

E

max

7.5 kWs

External 2:

=

E

max

180 kWs

1)

2)

3)

4)

5)

1-26

If pipe cooling is not used, only Pv

f the internal pulsed resistor is shutdown, for internal coolingthe only power loss is Pv

The braking energy of the motors is converted into heat in the integrated/mounted pulsed resistor,

has to be taken into account.

tot

.

int

if required, a heat barrier may be required, refer to p. 1-34

The 1st number is for cable lugs, the 2nd number is valid for finely–stranded conductors

without connector sleeve.

It can be used: a) 0.3/25 kW b) 2 x 0.3/25 kW c) 1.5/25 kW d) 2 x 1.5/25 kW

Siemens AG 1998 All Rights reserved 6SN1197–0AA00 02.98 Edition

SIMODRIVE 611 (PJ)

02.98

3.2.1 Technical data, supply infeed modules

Definition of

powers

Pn, Ps6, P

modules.

P

n

P

s6

P

max

max

Refer to the following load duty diagrams for the duty cycle diagrams.

Pv

total

Pv

pipe

Pv

ext

Pv

int

Supply

voltage and

frequency

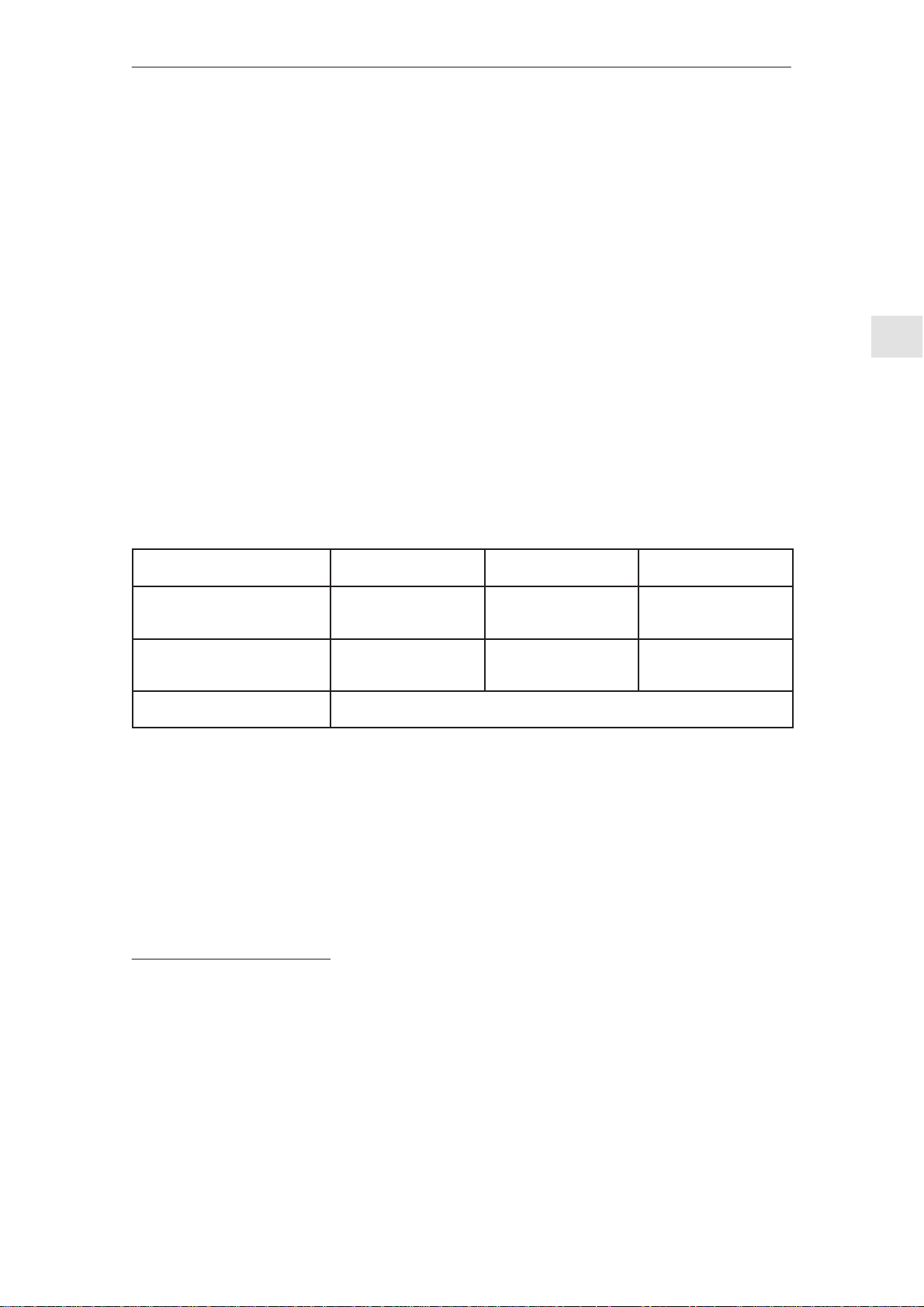

Table 3-4 Supply voltage and frequency

S1, S4 = OFF

Vn = 3–ph. 400V AC

3–ph. 360...440V AC

NE modules up to Pn v55kW

I/R modules Pn = 80/120kW

power connection: U1, V1, W1

Coil connection: L1, L2

3–ph. 300...360V AC

3–ph. 360...440V AC

3–ph. 300...360V AC

Data is valid for the total, permitted voltage range of the I/R

Continuous output of the NE module.

Output for max. 4 min for an S6 duty cycle.

Peak output.

Total module power loss;

Power loss dissipated with pipe cooling;

Power loss dissipated with external cooling;

Power loss which cannot be dissipated through pipe– or ex-

ternal cooling.

This power loss remains in the cabinet.

45...65Hz

45...65Hz

S1 = ON

Vn = 3–ph. 415V AC

3–ph. 373...457V AC

1)

3–ph. 312...373V AC

45...65Hz

3–ph. 373...457V AC

1)

3–ph. 312...373V AC

45...65Hz

3–ph. 360...457V AC / 45...53Hz

3–ph. 400...510V AC / 57...65Hz

1)

1)

S4 = ON

Vn = 3–ph. 480V AC

3–ph. 432...509V AC

3–ph. 408...432V AC

55...65Hz

3–ph. 432...509V AC

3–ph. 408...432V AC

55...65Hz

1)

1)

Cooling type

All I/R modules and the UE 28 kW are force ventilated.

The UE modules 5kW, 10kW, the monitoring module as well as the pulsed resi-

stor module, are self–ventilated.

No ground–fault

Before powering–up for the first time, the cabinet wiring, motor/encoder feeder

cables and the DC link connections must be checked to ensure that they do not

have a ground fault.

1)

The drive power supply can be operated in the range from 3–ph. 323 to 3–ph. 509 V AC. However, for I/R modules,

operation of the power supply up to 3–ph. 280 V AC is only valid as long as the I/R module actively controls the

DC link voltage 600 V or 625 V and there is a three–conductor connection (as set in the factory).

De–rating to 0.7P

A

2)

In the infeed direction, the DC link voltage is uncontrolled, therefore a 600 V DC link voltage

will not be achieved. Observe the restrictions regarding the acceleration time and stall torque of the motors.

Siemens AG 1998 All Rights reserved 6SN1197–0AA00 02.98 Edition

SIMODRIVE 611 (PJ)

P

+E

P

. Power supply rating must, under the conditions, also be reduced to 70%.

n

0.7 x (17+8) or for UE 5 kW 0.7 x (7+3.5)

1-27

3.2.1 Technical data, supply infeed modules

Rated load duty

cycles for NE modules

02.98

3

P

max

P

s6

P

n

0.4 P

P

max

P

n

P

n

P

condition

4 min

0.2 s

10 min

10 s

P

P

max

P

s6

P

n

0.4 P

t

10 s

n

t

60 s

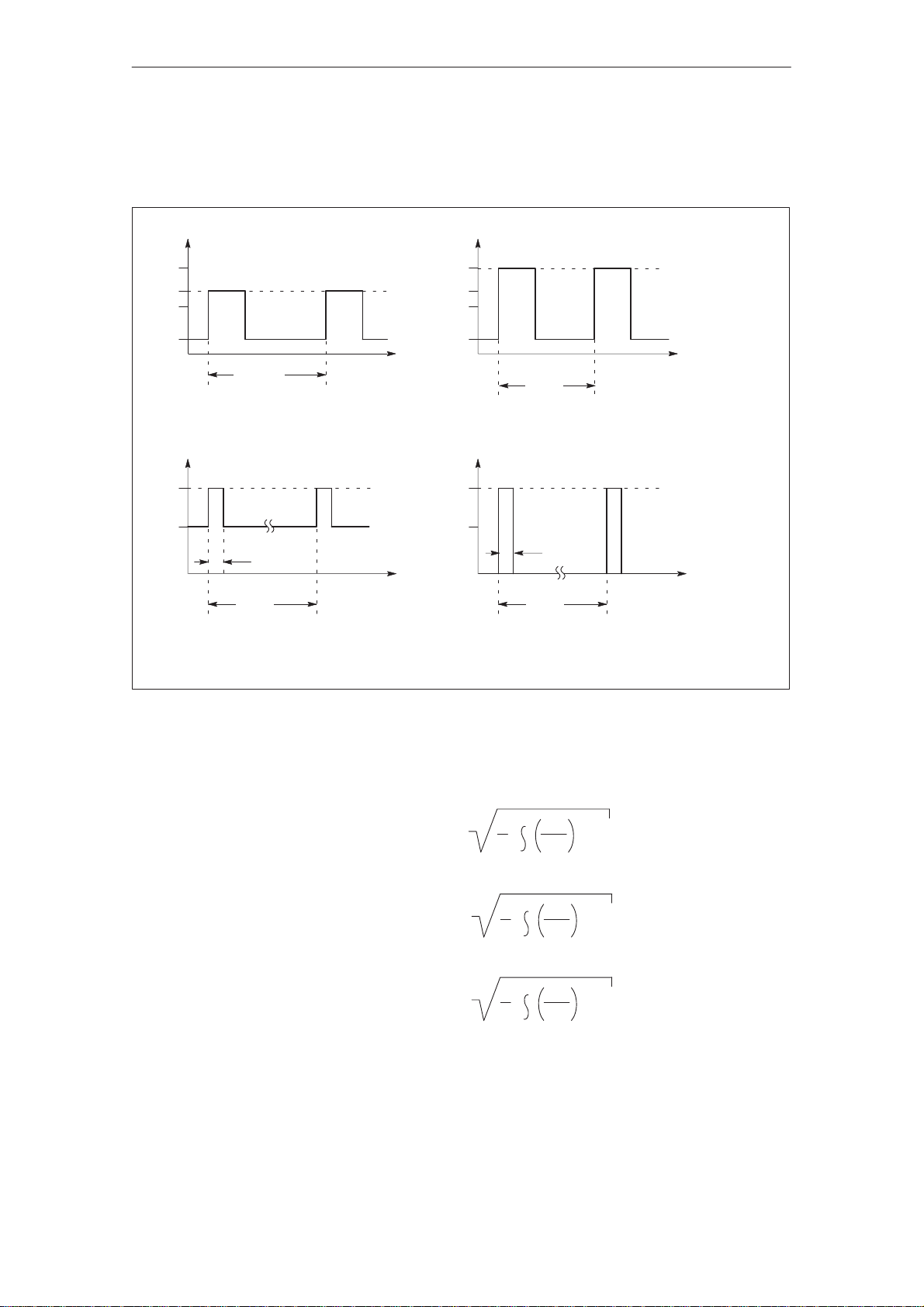

Peak output duty cycle with pre–loading conditionS6 duty cycle with pre–loading condition

P

FP

n

P

n

4 s

t

t

10 s

Peak output duty cycle without pre–loading conditionPeak output duty cycle with pre–loading

F:For all NE modules up to Pn 80 kW, F=1.6

For Pn=120 kW, F=1.4

Figure 3-2

The following rule of thumb is valid:

For load duty cycles with a period T10 s:

For load duty cycles with a period 10 s < T 1 min:

T

1

T

0

T

1

T

0

T

1

T

0

P

2

P

(t)

dt < 1.03;

P

n

2

P

(t)

dt < 0.90;

P

n

2

P

(t)

dt < 0.89;For load duty cycles with a period 1 min < T 10 min:

P

n

= the instantaneous power demand

(t)

Pn < P

(t)

tŮ[0, T ]

Pn < P

(t)

tŮ[0, T ]

< P

P

n

(t)

tŮ[0, T ]

P

P

P

max

max

max

;

;

;

1-28

Siemens AG 1998 All Rights reserved 6SN1197–0AA00 02.98 Edition

SIMODRIVE 611 (PJ)

02.98

3.2.1 Technical data, supply infeed modules

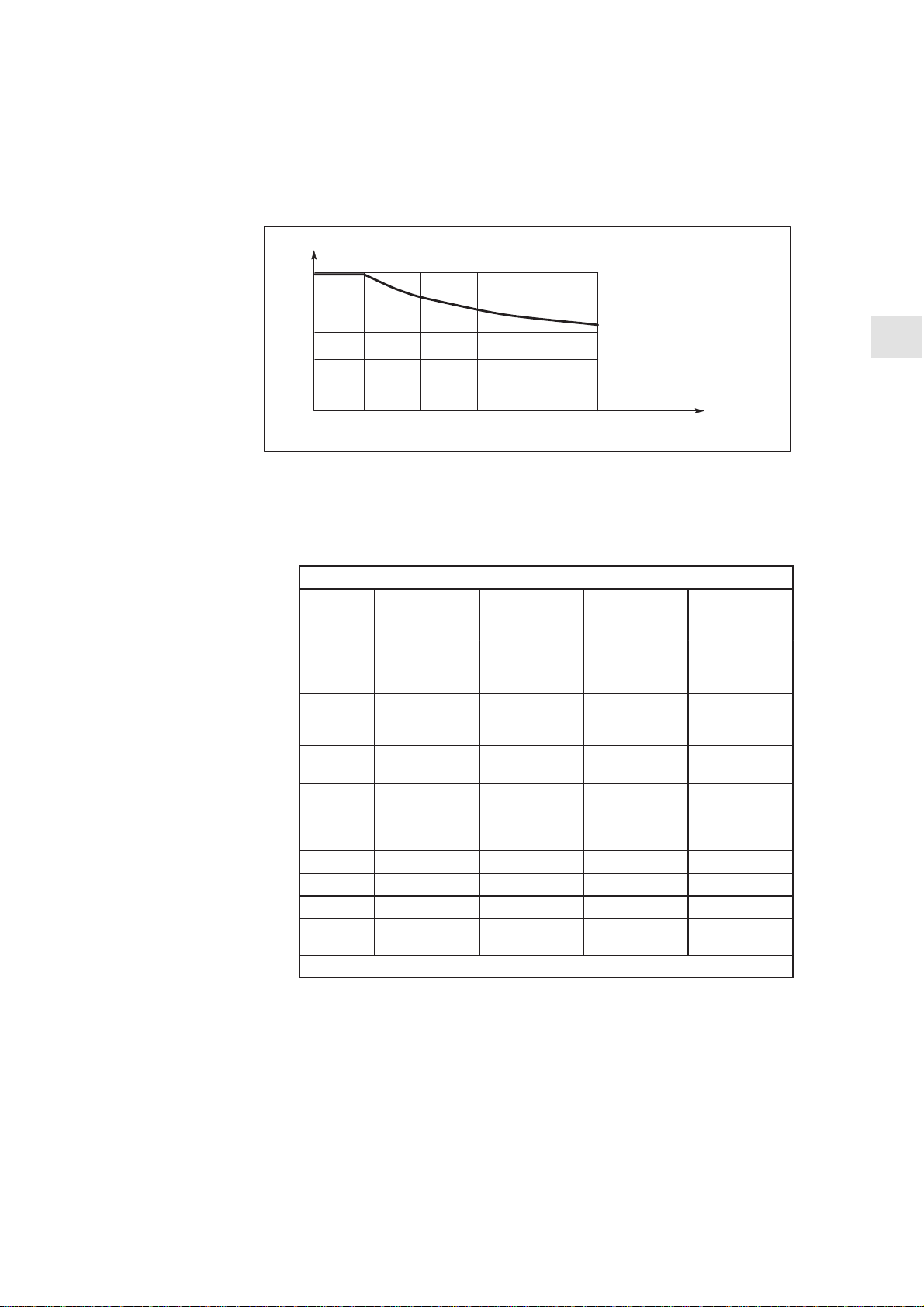

De–rating as a

function of the installation altitude

All of the specified outputs are valid up to an installation altitude of 1000 m. For

an installation altitude > 1000 m, the specified outputs should be reduced according to the diagrams below. For installation altitudes > 2000 m

1)

transformer must be used (refer to Section 2.4).

X

H

100 %

80 %

60 %

40 %

20 %

0 %

0

1000

Figure 3-3

Caution: Pn, Ps6 and P

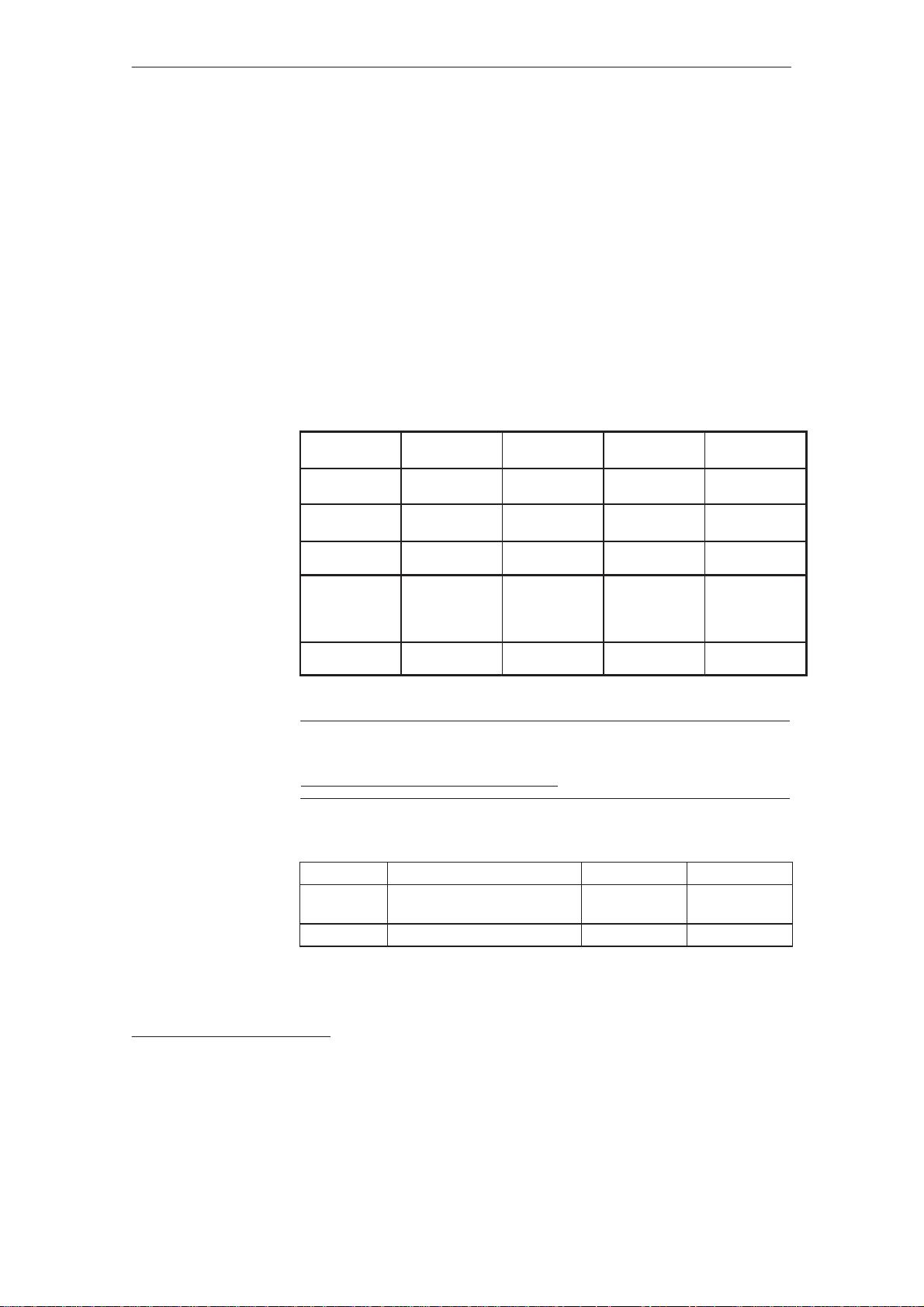

Table 3-5 UE modules with pulsed resistors

Order No.,

pulsed resistor

Integrated

in

Can be

used for

Can be

used for

Pn 0.3 kW 1.5 kW 0.3 kW 0.2 kW

P

max

E

max

Degree of

protection

Dimension drawings, refer to p. 1-161

2000

External pulsed

resistor 0.3/25

kW

6SN1113–

1AA00–0DA0

UE module 28kWUE module 28

25 kW 25 kW 25 kW 10 kW

7.5 kWs 180 kWs 7.5 kWs 13.5 kWs

IP 54 IP20 refer to module refer to module

3000 4000 5000

must be de–rated in the same way.

max

Pulsed resistors, technical data

External pulsed

resistor 1.5/25

kW

6SN1113–

1AA00–0CA0

– – UE 10 kW,

kW

–

Pulsed resistor

module

6SN1113–

1AB0–0BA

P

n altitude=xHPn1000m

P

n altitude=xHPs61000m

P

max. altitude=xHPmax.

/100%

1000m

Installation altitude (m)

Internal pulsed

resistor 0.3/25

kW

– –

pulsed resistor

module

– –

– –

Internal pulsed

resistor 0.2/10

kW

UE 5 kW

an isolating

/100%

/100%

1)

The rated insulation voltage depends on the installation altitude.

Siemens AG 1998 All Rights reserved 6SN1197–0AA00 02.98 Edition

SIMODRIVE 611 (PJ)

1-29

3.2.1 Technical data, supply infeed modules

02.98

3

Engineering information is valid for

UE 5 kW, 10 kW,

28 kW and pulsed

resistor module

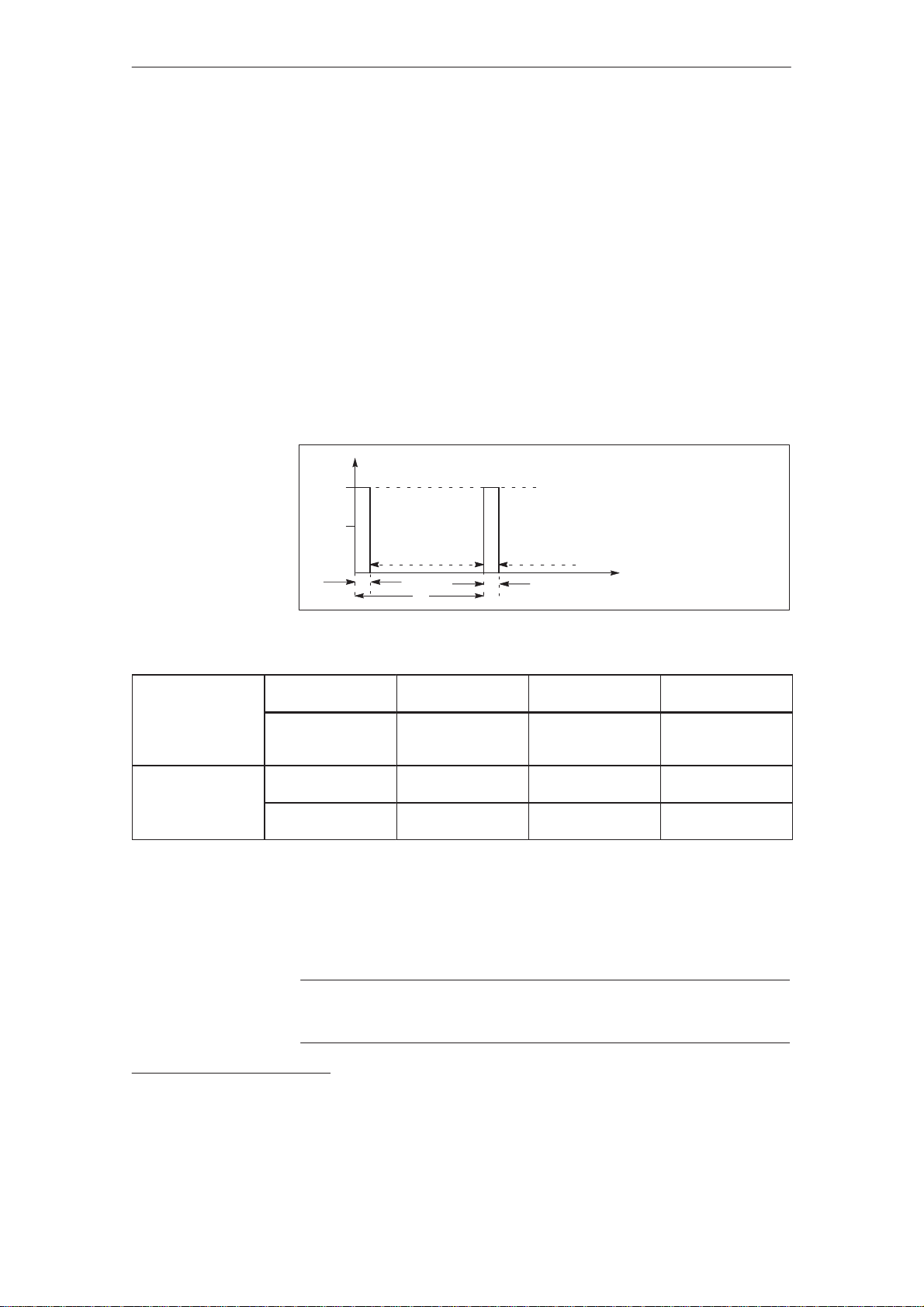

Load duty cycles

for braking operations

Dimensioning the load duty cycles with pulsed resistors

Des.Units Explanation

E Ws Regenerative feedback energy when braking a motor from n

to n

1

T s Period of the braking load duty cycle

A s Load duration

2

J kgm

Total moment of inertia (including J motor)

M Nm Braking torque

n RPM Speed

Pn W Continuous rating of the pulsed resistor

W Peak rating of the pulsed resistor

P

max

Ws Energy of the pulsed resistor for a single braking operation

E

max

P (kW)

P

max

P

n

0 kW 0 kW

A

T

A

t (s)

2

Table 3-6 Examples

Example A=

Figure 3-4Load duty cycle for internal and external pulsed resistors

E

Pn

P

T=

A=

T=

max

max

Pulsed resistor

0.2/10 kW

13500 Ws

10000 W

1)

200 W

0.2 s

10 s

1.35 s

67.5 s

Pulsed resistor

0.3/25 kW

7500 Ws

300 W

25000W

0.12 s

10 s

0.3 s

25 s

Pulsed resistor

1.5/25 kW

180000Ws

All of the following conditions must be fulfilled:

1.P

2.Emax E; E=J[(2πn

3.P

M2πn/60

max

E/T

n

/60)2–(2πn1/60)2]/2

2

Note

For UE 5 kW and UE 10 kW, it is not possible to connect an external resistor.

1500 W

25000W

0.6 s

10 s

7.2 s

120 s

1)

As a result of the mechanical dimensions, the resistor can accept a relatively high level of energy.

Siemens AG 1998 All Rights reserved 6SN1197–0AA00 02.98 Edition

1-30

SIMODRIVE 611 (PJ)

Loading...

Loading...