Siemens SIMOCODE pro C, SIMOCODE pro V PB, SIMOCODE pro V MR, SIMOCODE pro S, SIMOCODE pro V EIP System Manual

Industrial Controls

Motor management and

control devices

SIMOCODE pro

System Manual

05/2019

A5E40507475002A/RS

Introduction

1

Advantages/benefits/configuration

with SIMOCODE pro

2

Areas of application

3

Features

4

Overview of functions

5

Check list for selecting a device

series

6

An overview of system components

7

Description of system components

8

Compartment identification

9

Accessories

10

3UF50 compatibility mode

11

Mounting, wiring, connecting, system

interfaces, configuration guidelines

12

Commissioning, service,

troubleshooting

13

Safety and commissioning

information for Ex areas

14

Technical data

15

CAx data, dimension drawings

16

List of abbreviations

A

SIMOCODE pro

-AD/004

Siemens AG

Smart Infrastructure

Control Products

Postfach 2355

90713 FUERTH

GERMANY

Copyright © Siemens AG 2017.

All rights reserved

Legal information

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Ⓟ 05/2019 Subject to change

Table of contents

1 Introduction ............................................................................................................................................. 9

1.1 Important notes ......................................................................................................................... 9

1.2 Siemens Industry Online Support ........................................................................................... 12

1.3 Siemens Industry Online Support app .................................................................................... 14

1.4 Support Request ..................................................................................................................... 15

1.5 Security information ................................................................................................................ 16

1.6 Current information about operational safety ......................................................................... 17

1.7 Information about third-party software .................................................................................... 18

1.8 Recycling and disposal ........................................................................................................... 22

1.9 What is SIMOCODE pro? ....................................................................................................... 23

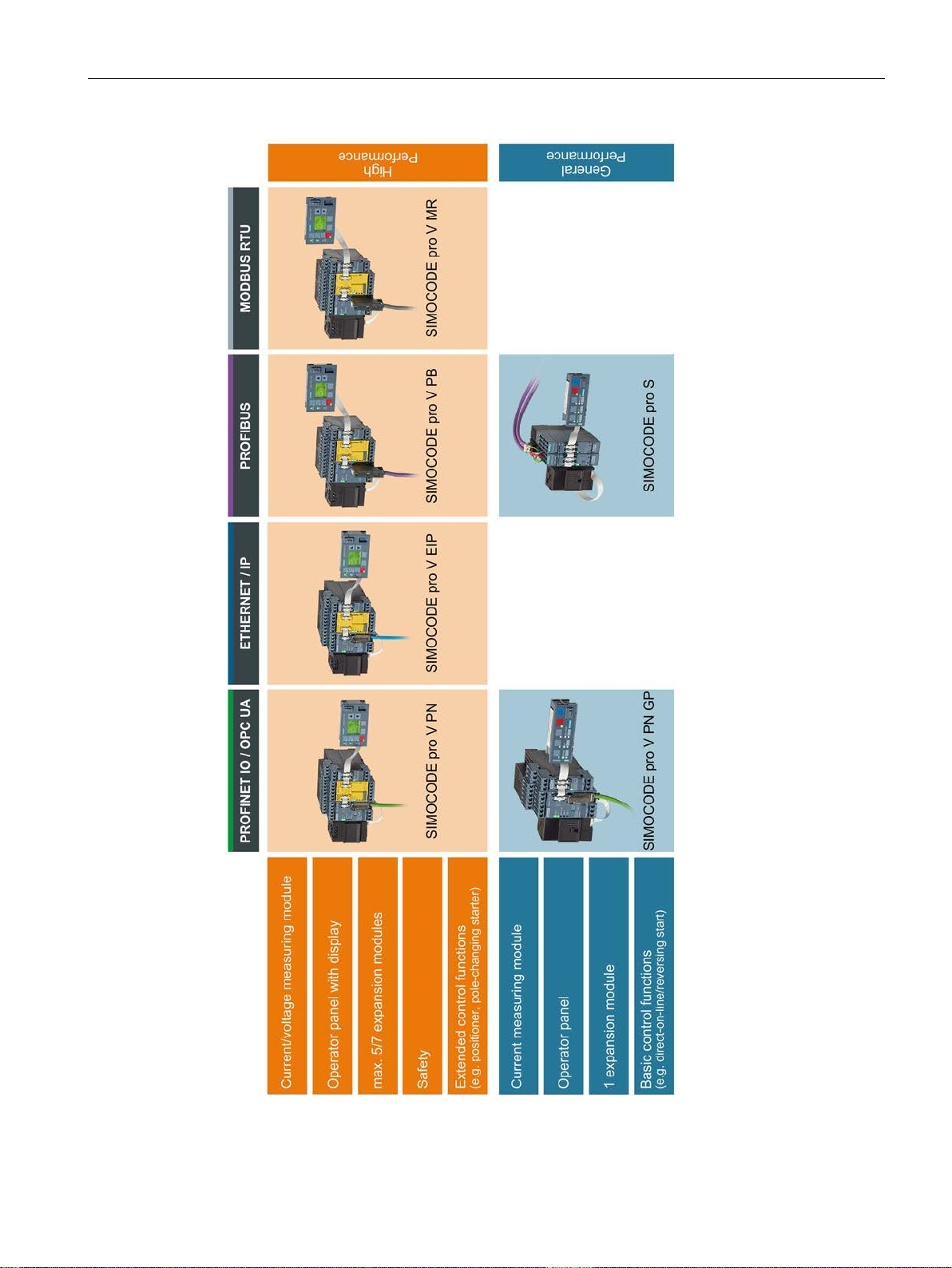

1.10 Device series .......................................................................................................................... 24

1.11 Modules, interfaces, configuration options ............................................................................. 26

2 Advantages/benefits/configuration with SIMOCODE pro ........................................................................ 29

2.1 Advantages/benefits ............................................................................................................... 29

2.2 Independent operation ............................................................................................................ 32

2.3 Simplifying configuration with SIMOCODE pro ...................................................................... 33

2.4 Typical configuration ............................................................................................................... 35

3 Areas of application .............................................................................................................................. 39

4 Features ............................................................................................................................................... 41

5 Overview of functions ............................................................................................................................ 47

5.1 Protection functions ................................................................................................................ 47

5.2 Monitoring functions ................................................................................................................ 49

5.3 Safety-oriented tripping ........................................................................................................... 52

5.4 Control functions ..................................................................................................................... 53

5.5 Communication ....................................................................................................................... 54

5.6 Standard functions .................................................................................................................. 57

5.7 Freely-programmable logic modules ...................................................................................... 58

5.8 Operating, service and diagnostics data................................................................................. 59

6 Check list for selecting a device series .................................................................................................. 61

7 An overview of system components ...................................................................................................... 65

SIMOCODE pro

System Manual, 05/2019, A5E40507475002A/RS-AD/004

3

Table of contents

8 Description of system components ........................................................................................................ 81

8.1 Basic units (BU) ..................................................................................................................... 81

8.2 Operator panel (OP) .............................................................................................................. 85

8.3 Operator panel with display ................................................................................................... 88

8.3.1 Description of the operator panel with display ....................................................................... 88

8.3.2 Operator controls and display elements of the operator panel with display .......................... 92

8.3.3 Menu of the operator panel with display ................................................................................ 94

8.3.3.1 Timing charts .......................................................................................................................... 94

8.3.3.2 Displays of the operator panel with display ......................................................................... 109

8.3.3.3 Read and adapt main display .............................................................................................. 112

8.3.3.4 Display of measured values in the measured values display .............................................. 115

8.3.3.5 Motor protection and motor control status ........................................................................... 117

8.3.3.6 Display of statistical and maintenance-relevant information on the

statistics/maintenance display ............................................................................................. 119

8.3.3.7 Status display for fieldbus communication ........................................................................... 120

8.3.3.8 Displays the current status of all device I/Os ....................................................................... 122

8.3.3.9 Parameters ........................................................................................................................... 124

8.3.3.10 Adapt display settings .......................................................................................................... 126

8.3.3.11 Resetting, testing and parameterizing via commands ......................................................... 129

8.3.3.12 Displaying all pending messages ......................................................................................... 130

8.3.3.13 Displaying all pending warnings........................................................................................... 130

8.3.3.14 Displaying all pending faults ................................................................................................ 130

8.3.3.15 Reading the device's internal error buffer ............................................................................ 130

8.3.3.16 Reading the device's internal event memory ....................................................................... 131

8.3.3.17 Identification of the motor feeder and the SIMOCODE pro components............................. 132

8.4 Current measuring modules (IM) for the SIMOCODE pro C, SIMOCODE pro S, and

SIMOCODE pro V device series .......................................................................................... 133

8.5 Current / voltage measuring modules (UM, UM+) for the SIMOCODE pro V

High Performance device series ..........................................................................................

6 Decoupling module (DCM) for 1st generation current/voltage measuring modules

8.

135

(e.g. 3UF711.1AA000) ......................................................................................................... 142

8.7 Spectrum of the expansion modules ................................................................................... 146

8.8 Digital module (DM) ............................................................................................................. 147

8.9 Fail-safe digital module (DM-F) ............................................................................................ 148

8.10 Analog module (AM) ............................................................................................................ 151

8.11 Ground-fault module (EM) ................................................................................................... 152

8.12 Temperature module (TM) ................................................................................................... 153

8.13 Multifunction module ............................................................................................................ 154

8.14 Configuration information for SIMOCODE pro V when using an older basic unit ............... 155

8.15 Configuration notes for use of a SIMOCODE pro V MR and SIMOCODE pro V EIP

basic unit .............................................................................................................................. 158

SIMOCODE pro

4 System Manual, 05/2019, A5E40507475002A/RS-AD/004

Table of contents

9 Compartment identification .................................................................................................................. 159

9.1 Applications and advantages of compartment identification ................................................ 159

9.2 Hardware and software requirements for compartment identification .................................. 162

9.3 Operating compartment identification ................................................................................... 163

9.4 Mounting, wiring, interfaces, compartment identification ...................................................... 167

9.5 Commissioning and service compartment identification ....................................................... 170

9.6 Alarm, fault, and system events for compartment identification ........................................... 171

9.7 Compartment identification dimension drawings .................................................................. 172

9.8 Technical data compartment identification ........................................................................... 173

10 Accessories ........................................................................................................................................ 175

11 3UF50 compatibility mode ................................................................................................................... 179

11.1 Application, Win-SIMOCODE-DP converter ......................................................................... 179

11.2 Diagram of send and receive data ........................................................................................ 180

11.3 Diagram of diagnostics data ................................................................................................. 181

12 Mounting, wiring, connecting, system interfaces, configuration guidelines............................................ 185

12.1 Mounting ............................................................................................................................... 185

12.1.1 Mounting basic units, expansion modules, and the decoupling module .............................. 185

12.1.2 Mounting the bus terminal .................................................................................................... 188

12.1.3 Mounting of digital modules DM-F Local and DM-F PROFIsafe .......................................... 189

12.1.4 Mounting of current measuring modules .............................................................................. 189

12.1.5 Mounting the current / voltage measuring modules .............................................................. 191

12.1.6 Mounting of the operator panel and operator panel with display .......................................... 193

12.2 Wiring, connecting ................................................................................................................ 195

12.2.1 Wiring basic units, expansion modules and the decoupling module .................................... 195

12.2.2 Wiring digital modules DM-F Local and DM-F PROFIsafe ................................................... 221

12.2.3 Wiring of current measuring modules ................................................................................... 226

12.2.4 Wiring of current / voltage measuring modules .................................................................... 228

12.2.5 Measuring current with an external current transformer (interposing transformer) .............. 233

12.3 System interfaces ................................................................................................................. 236

12.3.1 Information about the system interfaces ............................................................................... 236

12.3.2 System interfaces on basic units, expansion modules, decoupling module, current

measuring modules and current / voltage measuring modules ............................................ 237

12.3.3 System interfaces on the digital modules DM-F Local and DM-F PROFIsafe ..................... 242

12.3.4 System interfaces on the operator panel and the operator panel with display ..................... 243

12.3.5 Closing the system interfaces with the system interface cover ............................................ 247

12.3.6 PROFIBUS DP to a 9-pole SUB-D socket ............................................................................ 248

12.3.7 Ethernet cable to RJ45 socket (PROFINET and EtherNet/IP) ............................................. 249

12.3.8 Modbus RTU connection to the SIMOCODE pro device ...................................................... 250

12.4 Configuration guidelines ....................................................................................................... 252

12.4.1 Configuration guidelines on PROFIBUS DP .........................................................................

4.2 Configuration guidelines on PROFINET ............................................................................... 254

12.

SIMOCODE pro

System Manual, 05/2019, A5E40507475002A/RS-AD/004

252

5

Table of contents

13 Commissioning, service, troubleshooting.............................................................................................. 255

13.1 General information about commissioning and service ....................................................... 255

13.2 Commissioning..................................................................................................................... 257

13.2.1 Commissioning with PROFIBUS .......................................................................................... 257

13.2.1.1 PROFIBUS commissioning steps ........................................................................................ 257

13.2.1.2 Setting the PROFIBUS DP address..................................................................................... 258

13.2.1.3 Diagnostics via LED display on the basic unit and on the operator panel (PROFIBUS) ..... 259

13.2.1.4 Diagnostics via LED display on the modules DM-F Local or DM-F PROFIsafe .................. 259

13.2.2 Commissioning with PROFINET .......................................................................................... 260

13.2.2.1 PROFINET commissioning steps ........................................................................................ 260

13.2.2.2 Setting IP parameters and PROFINET device name .......................................................... 261

13.2.2.3 Setting the time manually after switch-on or recovery of the supply voltage ....................... 263

13.2.2.4 Diagnostics via LED display on the basic unit and on the operator panel (PROFINET) ..... 264

13.2.3 Commissioning with Modbus ............................................................................................... 265

13.2.3.1 Commissioning with Modbus RTU ....................................................................................... 265

13.2.4 Commissioning with EtherNet/IP ......................................................................................... 270

13.2.4.1 EtherNet/IP commissioning steps ........................................................................................ 270

13.2.4.2 Setting IP parameters and EIP device name ....................................................................... 271

13.2.4.3 Set the time manually after switch-on or recovery of the supply voltage ............................. 273

13.2.4.4 Diagnostics via LED display on the basic unit and on the operator panel with

EtherNet/IP ........................................................................................................................... 274

13.3 Service ................................................................................................................................. 275

13.3.1 Preventive maintenance ...................................................................................................... 275

13.3.2 Backing up and saving parameters...................................................................................... 277

13.3.3 Replacing SIMOCODE pro components ............................................................................. 279

13.3.4 Exchanging a 3UF52 operator panel for a 3UF720 operator panel .....................................

13.

3.5 Restoring factory settings .................................................................................................... 285

283

13.3.6 Firmware update of device components .............................................................................. 286

13.3.7 Support Request .................................................................................................................. 287

13.4 Troubleshooting ................................................................................................................... 288

13.4.1 Error buffer ........................................................................................................................... 288

13.4.2 Event memory ...................................................................................................................... 290

13.4.3 Alarms, faults, and system events - error handling .............................................................. 291

14 Safety and commissioning information for Ex areas ............................................................................. 303

14.1 Motor protection functions (overload protection, thermistor protection) .............................. 303

14.1.1 Module integration ............................................................................................................... 303

14.1.2 Information and standards ................................................................................................... 304

14.1.3 Installation and commissioning – motor protection functions (overload protection,

thermistor protection) ........................................................................................................... 305

14.1.3.1 Operating Instructions .......................................................................................................... 305

14.1.3.2 Setting the rated motor current ............................................................................................ 305

14.1.3.3 SIMOCODE pro with thermistor input .................................................................................. 307

14.1.3.4 Sensor circuit wiring ............................................................................................................. 308

14.1.3.5 Short-circuit protection for type of coordination 2 according to IEC 60947-4-1 ................... 309

14.1.3.6 Cable protection ................................................................................................................... 309

14.1.3.7 Test ...................................................................................................................................... 309

14.1.3.8 Further safety guidelines ...................................................................................................... 311

14.1.3.9 Ambient conditions ............................................................................................................... 311

14.1.3.10 Safety values ........................................................................................................................ 312

SIMOCODE pro

6 System Manual, 05/2019, A5E40507475002A/RS-AD/004

Table of contents

14.1.4 Maintenance and repairs ...................................................................................................... 312

14.1.5 Warranty ............................................................................................................................... 312

14.1.6 Further information ................................................................................................................ 313

14.2 Dry-running protection for centrifugal pumps by active power monitoring ........................... 314

14.2.1 Module integration ................................................................................................................ 314

14.2.2 Information and standards .................................................................................................... 314

14.2.3 Installation and commissioning – dry-running protection for centrifugal pumps by

means of active power monitoring ........................................................................................ 318

14.2.3.1 Operating Instructions ........................................................................................................... 318

14.2.3.2 General information on installation and commissioning ....................................................... 318

14.2.3.3 Special conditions for commissioning and operation ............................................................ 319

14.2.3.4 Setting the parameters.......................................................................................................... 320

14.2.3.5 Line protection ...................................................................................................................... 322

14.2.3.6 Test ....................................................................................................................................... 322

14.2.3.7 Further safety information ..................................................................................................... 325

14.2.3.8 Environmental conditions ...................................................................................................... 325

14.2.3.9 Safety values ........................................................................................................................ 326

14.2.4 Periodic tests ........................................................................................................................ 326

14.2.5 Maintenance and repair ........................................................................................................ 326

14.2.6 Warranty ............................................................................................................................... 327

14.2.7 More information ................................................................................................................... 327

15 Technical data .................................................................................................................................... 329

15.1 Common technical data ........................................................................................................ 329

15.2 Technical specifications of the SIMOCODE pro C / pro S / pro V PB /

pro V MR basic units ............................................................................................................. 332

15.3 Technical specifications of the SIMOCODE pro V PN / pro V PN GP /

pro V EIP basic units............................................................................................................. 337

15.4 Technical data of the current measuring modules and the current / voltage measuring

modules ................................................................................................................................ 340

15.5 Technical data of the decoupling module ............................................................................. 345

15.6 Technical data of the expansion modules ............................................................................ 346

15.6.1 Technical data of the digital modules ................................................................................... 346

15.6.2 Technical data, digital modules DM-F Local and DM-F PROFIsafe ..................................... 347

15.6.3 Technical data of the DM-F Local digital module ................................................................. 349

15.6.4 Technical data of the DM-F-PROFIsafe digital module ........................................................ 351

15.6.5 Safety-related technical data of the digital modules DM-F Local and DM-F PROFIsafe ..... 352

15.6.6 Technical data of the analog module .................................................................................... 352

15.6.7 Technical data of the ground-fault module 3UF7500-1AA00-0 ............................................ 354

15.6.8 Technical data of the ground-fault module 3UF7510-1AA00-0 ............................................ 355

15.6.9 Technical data of the temperature module ........................................................................... 356

15.7 Technical data of the multifunction module .......................................................................... 357

15.8 Technical data of the operator panels .................................................................................. 360

15.8.1 Technical data of the operator panel .................................................................................... 360

15.8.2 Technical data of the operator panel with display ................................................................ 361

15.9 Technical data of the compartment identification ................................................................. 363

SIMOCODE pro

System Manual, 05/2019, A5E40507475002A/RS-AD/004

7

Table of contents

15.10 Short-circuit protection with fuses for motor feeders for short-circuit currents up to

100 kA and 690 V for 1st generation current / voltage measuring module ......................... 364

15.11 Typical reaction times .......................................................................................................... 365

15.11.1 Typical reaction times of the SIMOCODE pro C/V device series ........................................ 365

15.11.2 Typical response times of SIMOCODE pro S device series ................................................ 366

15.11.3 Typical reaction times of the Modbus RTU device series .................................................... 367

15.12 Technical data in Siemens Industry Online Support ............................................................ 368

16 CAx data, dimension drawings ............................................................................................................. 369

16.1 CAx data .............................................................................................................................. 369

A List of abbreviations ............................................................................................................................. 371

A.1 List of abbreviations ............................................................................................................. 371

Glossary .............................................................................................................................................. 375

Index ................................................................................................................................................... 399

SIMOCODE pro

8 System Manual, 05/2019, A5E40507475002A/RS-AD/004

1

1.1 Important notes

Purpose of this manual

The SIMOCODE pro System Manual describes in detail the motor management system and

its functions. It contains information about configuring, commissioning, service and

maintenance.

In addition to help on how to identify and rectify faults in the event of a malfunction, the

manual also contains specific information for servicing and maintenance.

Required basic knowledge

To understand this manual you will require basic knowledge of low-voltage controls and

distribution, digital circuit engineering and automation technology.

Scope of the manual

This manual is applicable to the listed SIMOCODE pro system components. It contains a

description of the components applicable at the time of printing the manual. SIEMENS

reserves the right to include updated information about launched new components or new

versions of components in a Product Information.

Manual Collection

A Manual Collection (https://support.industry.siemens.com/cs/document/109743951), a

collection of the following five SIMOCODE pro manuals, is available in Industry Online

Support:

● SIMOCODE pro - 1 Getting Started

● SIMOCODE pro - 2 System Manual

● SIMOCODE pro - 3 Parameterization

● SIMOCODE pro - 4 Applications

● SIMOCODE pro - 5 Communication.

SIMOCODE pro

System Manual, 05/2019, A5E40507475002A/RS-AD/004

9

Introduction

Response

Function 1

Function 2

Function 3

Tripping — X (d)

X

Signaling X X

—

Deactivated X X

X (d)

Delay

0 to 25.5 s (default: 0)

—

—

1.1 Important notes

Device series

When reference is made to "SIMOCODE pro", the reference also includes the following

device series:

SIMOCODE pro C (see Device series (Page 24))

SIMOCODE pro S (see Device series (Page 24))

SIMOCODE pro V PB (PROFIBUS) (see Device series (Page 24))

SIMOCODE pro V PN (PROFINET) (see Device series (Page 24))

SIMOCODE pro V PN GP (PROFINET) (see Device series (Page 24))

SIMOCODE pro V MR (Modbus RTU) (see Device series (Page 24))

SIMOCODE pro V EIP (EtherNet/IP) (see Device series (Page 24))

When reference is made to "SIMOCODE pro V", the reference also includes all pro V

devices, independently of communication.

SIMOCODE pro response tables

Specific responses (deactivated, signaling, warning, tripping) can be parameterized for

various SIMOCODE pro functions, such as overload. These are always displayed in tabular

form:

● "X" = Applicable

● "—" = not applicable

● Default values are marked "d" for "default" in parentheses.

Warning X (d) X —

Short description of the responses:

● Tripping: The contactor controls QE* are tripped. A fault message is generated which is

available as diagnostics via the communication bus. The fault message and the

device-internal signal remain on until the appropriate length of time has elapsed or the

cause of the fault has been eliminated and acknowledged.

SIMOCODE pro

10 System Manual, 05/2019, A5E40507475002A/RS-AD/004

● Warning: In addition to the device-internal signal, a warning signal is generated that is

available as diagnostics via the communication bus.

● Signaling: Only a device-internal signal is generated, which can be further processed as

required.

● Deactivated: The appropriate function is switched off, no signals are generated.

A delay time can also be set for specific responses.

Introduction

1.1 Important notes

Operating instructions and other manuals

● Please read the operating instructions of the respective components (Operating

instructions (https://support.industry.siemens.com/cs/ww/en/ps/16027/man

● In addition to the "SIMOCODE pro" manual collection, the following manuals are available

to you:

– The manual "SIMOCODE pro Safety fail-safe digital modules"

(https://support.automation.siemens.com/WW/view/en/50564852

– The appropriate manual for the DP master

– The system manual "SIMATIC PROFINET System Description"

(https://support.automation.siemens.com/WW/view/en/19292127

– The manual "Fault-tolerant S7-400H systems"

(https://support.automation.siemens.com/WW/view/en/1186523

– Programming manual "PROFINET IO - from PROFIBUS DP to PROFINET IO"

(https://support.automation.siemens.com/WW/view/en/19289930

– The application description "Saving Energy with SIMATIC S7 and ET200 S"

(https://support.automation.siemens.com/WW/view/en/41986454

)

))

)

)

)

)

More information

You will find further information on the Internet:

● SIMOCODE pro (https://www.siemens.com/simocode

● Information and Download Center (https://www.siemens.com/sirius/infomaterial)

● Siemens Industry Online Support (SIOS)

● Certificates (https://support.industry.siemens.com/cs/ww/en/ps/16027/cert).

Disclaimer of liability

The products described here have been developed to perform safety-related functions as

part of a complete plant or machine. In general, a complete safety system consists of

sensors, evaluation units, signaling devices and methods for safe tripping. The manufacturer

is responsible for ensuring safe functioning of the complete plant or machine. Siemens AG,

its subsidiaries, and associated companies (hereinafter referred to as "Siemens") are not in a

position to guarantee every characteristic of a complete plant or machine not designed by

Siemens.

Siemens also denies all responsibility for any recommendations that are made or implied in

the following description. No new guarantee, warranty, or liability claims above those

standard to Siemens can be derived from the following description.

(https://support.industry.siemens.com/cs/ww/en/ps

)

)

Recycling and disposal

For environmentally friendly recycling and disposal of your old device, please contact a

company certified for the disposal of electronic waste and dispose of the device in

accordance with the regulations in your country.

SIMOCODE pro

System Manual, 05/2019, A5E40507475002A/RS-AD/004

11

Introduction

1.2 Siemens Industry Online Support

1.2 Siemens Industry Online Support

Information and service

At Siemens Industry Online Support you can obtain up-to-date information from our global

support database quickly and simply. To accompany our products and systems, we offer a

wealth of information and services that provide support in every phase of the lifecycle of your

machine or plant – from planning and implementation and commissioning, right through to

maintenance and modernization:

● Product support

● Application examples

● Services

● Forum

● mySupport

Link: Siemens Industry Online Support (https://support.industry.siemens.com/cs/de/en)

Product support

Here you will find all the information and comprehensive know-how for your product:

● FAQs

Our replies to frequently asked questions.

● Manuals/operating instructions

Read online or download, available as PDF or individually configurable.

● Certificates

Clearly sorted according to approving authority, type and country.

● Characteristics

For support in planning and configuring your system.

● Product announcements

The latest information and news concerning our products.

● Downloads

Here you will find updates, service packs, HSPs and much more for your product.

● Application examples

Function blocks, background and system descriptions, performance statements,

demonstration systems, and application examples, clearly explained and represented.

● Technical data

Technical product data for support in planning and implementing your project.

Link: Product support (https://support.industry.siemens.com/cs/ww/en/ps)

SIMOCODE pro

12 System Manual, 05/2019, A5E40507475002A/RS-AD/004

Introduction

1.2 Siemens Industry Online Support

mySupport

With "mySupport", your personal work area, you get the very best out of your Industry Online

Support experience. Everything enables you to find the right information - every time.

The following functions are now available:

● Personal Messages

Your personal mailbox for exchanging information and managing your contacts

● Requests

Use our online form for specific solution suggestions, or send your technical inquiry

directly to a specialist in Technical Support

● Notifications

Make sure you always have the latest information - individually tailored to your needs

● Filter

Simple management and re-use of your filter settings from Product Support and the

Technical Forum

● Favorites / Tagging

Create your own knowledge database by assigning "Favorites" and "Tags" to

documents – simply and efficiently

● Entries last viewed

Clear presentation of your last viewed entries

● Documentation

Configure your individual documentation from different manuals – quickly and without

complications

● Personal data

Change personal data and contact information here

● CAx data

Simple access to thousands of items of CAx data such as 3D models, 2D dimension

drawings, EPLAN macros, and much more

SIMOCODE pro

System Manual, 05/2019, A5E40507475002A/RS-AD/004

13

Introduction

Link for Android

Link for iOS

Link for Windows Phone

1.3 Siemens Industry Online Support app

1.3 Siemens Industry Online Support app

Siemens Industry Online Support app

You can use the Siemens Industry Online Support app to access all the device-specific

information available on the Siemens Industry Online Support portal for a particular article

number, including operating instructions, manuals, datasheets, FAQs etc.

The Siemens Industry Online Support app is available for iOS, Android or Windows Phone

devices. You can download the app from the following links:

SIMOCODE pro

14 System Manual, 05/2019, A5E40507475002A/RS-AD/004

Introduction

Support Request:

Internet (https://support.industry.siemens.com/My/ww/en/requests)

1.4 Support Request

1.4 Support Request

Using the Support Request form in Online Support you can send your query directly to our

Technical Assistance. After describing your query in a few guided steps, you will immediately

be provided with possible suggestions for solving the problem.

SIMOCODE pro

System Manual, 05/2019, A5E40507475002A/RS-AD/004

15

Introduction

1.5 Security information

1.5 Security information

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial

security concept. Siemens’ products and solutions constitute one element of such a concept.

Customers are responsible for preventing unauthorized access to their plants, systems,

machines and networks. Such systems, machines and components should only be

connected to an enterprise network or the internet if and to the extent such a connection is

necessary and only when appropriate security measures (e.g. firewalls and/or network

segmentation) are in place.

For additional information on industrial security measures that may be implemented,

please visit

https://www.siemens.com/industrialsecurity

Siemens’ products and solutions undergo continuous development to make them more

secure. Siemens strongly recommends that product updates are applied as soon as they are

available and that the latest product versions are used. Use of product versions that are no

longer supported, and failure to apply the latest updates may increase customer’s exposure

to cyber threats.

To stay informed about product updates, subscribe to the

Siemens Industrial Security RSS Feed under

https://www.siemens.com/industrialsecurity

SIMOCODE pro

16 System Manual, 05/2019, A5E40507475002A/RS-AD/004

Introduction

DANGER

Hazardous Voltage

Can Cause Death, Serious Injury or Risk of Property Damage

Please take note of our latest information!

1.6 Current information about operational safety

1.6 Current information about operational safety

Important note for maintaining operational safety of your system

Systems with safety-related characteristics are subject to special operational safety

requirements on the part of the operator. The supplier is also obliged to comply with special

product monitoring measures. For this reason, we publish a special newsletter containing

information on product developments and features that are (or could be) relevant to

operation of safety-related systems. By subscribing to the appropriate newsletter in the

Industry newsletter system (https://www.industry.siemens.com/newsletter

that you are always up-to-date and able to make changes to your system, when necessary.

Sign on to the following newsletter under "Products & Solutions":

• Control Components and System Engineering News

• Safety Integrated Newsletter.

), you will ensure

SIMOCODE pro

System Manual, 05/2019, A5E40507475002A/RS-AD/004

17

Introduction

Support Request:

Internet (https://support.industry.siemens.com/My/ww/en/requests)

1.7 Information about third-party software

1.7 Information about third-party software

Third-party software components

This product, this solution or this service ("product") contains the third-party software

components listed below. These consist either of open source software that is licensed

under a license recognized by Open Source Initiative (http://www.opensource.org

license defined by Siemens as being comparable ("OSS") and/or commercial software or

freeware. With regard to the OSS components, the relevant OSS terms and conditions take

priority over all other terms and conditions applicable to this product.

SIEMENS is providing you with the OSS portions of this product at no additional cost. Insofar

as SIEMENS has combined or linked, according to the definition of the applicable license,

specific components of the product with OSS components that are licensed under

GNU LGPL Version 2 or a later version, and insofar as the applicable object file may not be

used without restrictions ("LGPL-licensed module", whereby the LGPL-licensed module and

the components with which the LGPL-licensed module is combined are hereinafter referred

to as "combined product") and the applicable LGPL license criteria are fulfilled, you may

additionally (i) edit the combined product for your own purposes and may in particular

acquire the right to edit the combined product to link it with a modified version of the LGPLlicensed module and (ii) reverse engineer the combined product, but solely for the purpose

of error correction of your edits. The right to edit shall not include the right to distribute. You

must treat as confidential all information you acquire from reverse engineering of the

combined product.

) or a

Certain OSS licenses require SIEMENS to publish the source code, e.g. the

GNU General Public License, the GNU Lesser General Public License and the

Mozilla Public License. Insofar as these licenses apply and the product has not already been

delivered with the necessary source code, anyone may request a copy of the source code

from Support Request during the period of time specified in the applicable OSS license:

Use the Support Request online form to send your query directly to our Technical Support.

After describing your query in a few guided steps, you will immediately be provided with

possible suggestions for solving the problem.

Subject: open source inquiry (specify the product name and version, where applicable)

SIEMENS can charge a processing fee of up to 5 euros to respond to the inquiry.

SIMOCODE pro

18 System Manual, 05/2019, A5E40507475002A/RS-AD/004

Introduction

NOTICE

Open source software and/or third-party software included in this product

Component

Open Source

Software [Yes/No]

Acknowledgements/

Comments

License conditions and copyright notices

COMPONENT TIVA PRODUCTS - 2.1.0 (see below)

1.7 Information about third-party software

Warranty regarding use of open source software

The warranty obligations of SIEMENS are laid down in the applicable contract with

SIEMENS. Insofar as you modify the product or the OSS components or use them in a

manner other than specified by SIEMENS, warranty shall be ruled out and no technical

support shall be provided. The following license terms and conditions may contain liability

limitations that apply between you and the relevant licensor. To clarify matters, your attention

is drawn to the fact that SIEMENS shall not cede any warranty obligations on behalf of or as

an obligation for a third-party licensor.

Please note the following license terms and conditions and copyright notices applicable to

the open source software and/or other components (or parts thereof):

tiva ware - 2.1.0 NO LICENSE AND COPYRIGHT INFORMATION FOR

SIMOCODE pro

System Manual, 05/2019, A5E40507475002A/RS-AD/004

19

Introduction

1.7 Information about third-party software

LICENSE CONDITIONS AND COPYRIGHT NOTICES

Commercial Software: tiva ware - 2.1.0

Enclosed you'll find license conditions and copyright notices applicable for Commercial

Software tiva ware - 2.1.0.

License conditions:

//

// Redistribution and use in source and binary forms, with or without

// modification, are permitted provided that the following conditions

// are met:

//

// Redistributions of source code must retain the above copyright

// notice, this list of conditions and the following disclaimer.

//

// Redistributions in binary form must reproduce the above copyright

// notice, this list of conditions and the following disclaimer in the

// documentation and/or other materials provided with the

// distribution.

//

// Neither the name of Texas Instruments Incorporated nor the names of

// its contributors may be used to endorse or promote products derived

// from this software without specific prior written permission.

//

// THIS SOFTWARE IS PROVIDED BY THE COPYRIGHT HOLDERS AND

CONTRIBUTORS

// "AS IS" AND ANY EXPRESS OR IMPLIED WARRANTIES, INCLUDING, BUT NOT

// LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR

// A PARTICULAR PURPOSE ARE DISCLAIMED. IN NO EVENT SHALL THE COPYRIGHT

// OWNER OR CONTRIBUTORS BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL,

// SPECIAL, EXEMPLARY, OR CONSEQUENTIAL DAMAGES (INCLUDING, BUT NOT

// LIMITED TO, PROCUREMENT OF SUBSTITUTE GOODS OR SERVICES; LOSS OF

USE,

// DATA, OR PROFITS; OR BUSINESS INTERRUPTION) HOWEVER CAUSED AND ON

ANY

// THEORY OF LIABILITY, WHETHER IN CONTRACT, STRICT LIABILITY, OR TORT

// (INCLUDING NEGLIGENCE OR OTHERWISE) ARISING IN ANY WAY OUT OF THE

USE

// OF THIS SOFTWARE, EVEN IF ADVISED OF THE POSSIBILITY OF SUCH DAMAGE.

SIMOCODE pro

20 System Manual, 05/2019, A5E40507475002A/RS-AD/004

Introduction

1.7 Information about third-party software

Copyrights:

Copyright © 2013-2014 Texas Instruments Incorporated

Copyright © 2012-2014 Texas Instruments Incorporated

Copyright © 2011-2014 Texas Instruments Incorporated

Copyright © 2010-2014 Texas Instruments Incorporated

Copyright © 2008-2014 Texas Instruments Incorporated

Copyright © 2007-2014 Texas Instruments Incorporated

Copyright © 2006-2014 Texas Instruments Incorporated

Copyright © 2005-2014 Texas Instruments Incorporated

SIMOCODE pro

System Manual, 05/2019, A5E40507475002A/RS-AD/004

21

Introduction

1.8 Recycling and disposal

1.8 Recycling and disposal

For environmentally friendly recycling and disposal of your old device, please contact a

company certified for the disposal of old electrical and/or electronic devices and dispose of

the device in accordance with the regulations in your country.

SIMOCODE pro

22 System Manual, 05/2019, A5E40507475002A/RS-AD/004

Introduction

1.9 What is SIMOCODE pro?

1.9 What is SIMOCODE pro?

SIMOCODE pro (SIRIUS Motor Management and Control Device) is a flexible and modular

motor management system for motors with constant speeds in low-voltage applications. It

optimizes the link between the control system and the motor feeder, increases plant

availability and allows significant savings to be made during installation, commissioning,

operation and maintenance. SIMOCODE pro is installed in the low-voltage switchgear

system and links the higher-level automation system and the motor feeder intelligently. It

comprises the following functions:

● Multifunctional and electronic full motor protection, independently of the

automation system

● Integrated control functions for motor control (instead of hardware)

● Detailed operating, service and diagnostics data

● Fail-safe shutdown up to SIL3 using fail-safe expansion modules

(High Performance units only)

● Open communication through PROFIBUS DP, PROFINET, Modbus RTU and EtherNet/IP

● Parameterization with the SIMOCODE ES (TIA Portal) software package

Only the switching and short-circuit protection mechanisms of the main circuit

(contactors, circuit breakers, fuses) are additionally needed.

SIMOCODE pro

System Manual, 05/2019, A5E40507475002A/RS-AD/004

23

Introduction

1.10 Device series

1.10 Device series

The following functionally graduated device series are available for SIMOCODE pro:

● Basic units:

SIMOCODE pro C - the compact system for PROFIBUS DP communication with a

direct-on-line and reversing starter function and/or for controlling a circuit breaker

(MCCB).

● General Performance units:

– SIMOCODE pro S - the smart system for PROFIBUS DP with direct-on-line, reversing,

and star-delta starter function or for controlling a circuit breaker or soft starter. Its

expandability with a multifunction module ensures there are always plenty of inputs

and outputs. It enables precise ground-fault monitoring via the 3UL23 residual current

transformer and temperature measurement.

– SIMOCODE pro V PN GP - the smart system for PROFINET with direct-on-line,

reversing, and star-delta starter function or for controlling a circuit breaker or soft

starter. Its expandability with an expansion module ensures there are always plenty of

inputs and outputs, precise ground-fault monitoring via the 3UL23 residual current

transformer and temperature measurement.

● High Performance units:

SIMOCODE pro V – the variable system that offers numerous functions, such as voltage

measurement and fail-safe shutdown, in addition to all the SIMOCODE pro C/pro S

functions. Devices are available for the following communication protocols:

– PROFIBUS DP

– Modbus RTU

– PROFINET

– EtherNet/IP.

See Check list for selecting a device series (Page 61).

SIMOCODE pro

24 System Manual, 05/2019, A5E40507475002A/RS-AD/004

Introduction

1.10 Device series

Figure 1-1 SIMOCODE pro device series

SIMOCODE pro

System Manual, 05/2019, A5E40507475002A/RS-AD/004

25

Introduction

NOTICE

Maximum length of the connecting cable

NOTICE

The maximum distance between modules

1.11 Modules, interfaces, configuration options

1.11 Modules, interfaces, configuration options

For each feeder, every system comprises a basic unit and a separate current measuring

module. Both modules are connected to each other electronically via the system interface,

by means of a connecting cable, and can be installed together as a unit (behind one another)

or separately (side-by-side). An operator panel can also be connected optionally via the

second system interface on the basic unit, and installed in the switchgear cabinet door. The

current measuring module and the operator panel are connected to the basic unit via

connecting cables, which also supply the power. More inputs, outputs and functions can be

added to the SIMOCODE pro S, pro V PB, pro V MR, pro V EtherNet/IP and

pro V PN /pro V PN GP basic units by means of optional expansion modules, thus

supplementing the inputs and outputs already existing on the basic unit. All modules are

connected by connecting cables. The connecting cables are available with different lengths

(ribbon cable 0.025 m, 0.1 m, 0.15 m, 0.3 m, 0.5 m; round cable 0.5 m, 1.0 m, 2.5 m).

The total length of all cables must not exceed 3 m on either of the system interfaces of the

basic unit!

The maximum distance between the modules (e. g. between the basic unit and the current

measuring module) must not exceed 2.5 m.

SIMOCODE pro

26 System Manual, 05/2019, A5E40507475002A/RS-AD/004

Introduction

1.11 Modules, interfaces, configuration options

Additional control programs (star-delta starters, Dahlander starters, pole-changing starters,

soft starters, each program also possible in combination with reversing starter, solenoid

valve and positioner) are integrated in SIMOCODE pro V High Performance units. The

SIMOCODE pro V device type is also particularly versatile. Its functionality can be expanded,

if required, for example:

● The number and type of binary inputs and outputs can be increased in stages and

adapted.

● A current/voltage measuring module can be used for additional voltage measurement and

for monitoring power-related measured values (power management).

● A temperature module enables the evaluation of several analog temperature sensors.

● A ground-fault detection system can be integrated together with a summation current

transformer.

● An analog module extends the system by additional analog inputs and outputs, for

example, for fill-level or flow-rate monitoring.

● An operator panel with display (OPD) is available as an alternative to the standard

operator panel (OP)

(restriction in the case of the SIMOCODE pro V PB: from version *E03*).

A special current/voltage measuring module for dry-running protection of centrifugal pumps

in hazardous areas by active power monitoring can be used in combination with the following

high performance devices with PTB 18 ATEX 5003:

● SIMOCODE pro V PB from version *E16*

● SIMOCODE pro V PN from version *E13*

● SIMOCODE pro V EIP from version *E04*

SIMOCODE pro C and SIMOCODE pro S are upwardly-compatible with SIMOCODE pro V.

This means you can combine different series in your plant according to functional

requirements.

Depending on functional requirements, the systems can be used simultaneously in a

low-voltage switchboard without any problems and without any additional effort.

Parameterization of SIMOCODE pro C or SIMOCODE pro S can be transferred without a

problem.

SIMOCODE pro

System Manual, 05/2019, A5E40507475002A/RS-AD/004

27

Introduction

1.11 Modules, interfaces, configuration options

SIMOCODE pro

28 System Manual, 05/2019, A5E40507475002A/RS-AD/004

Advantages/benefits/configuration with

2

SIMOCODE pro

2.1 Advantages/benefits

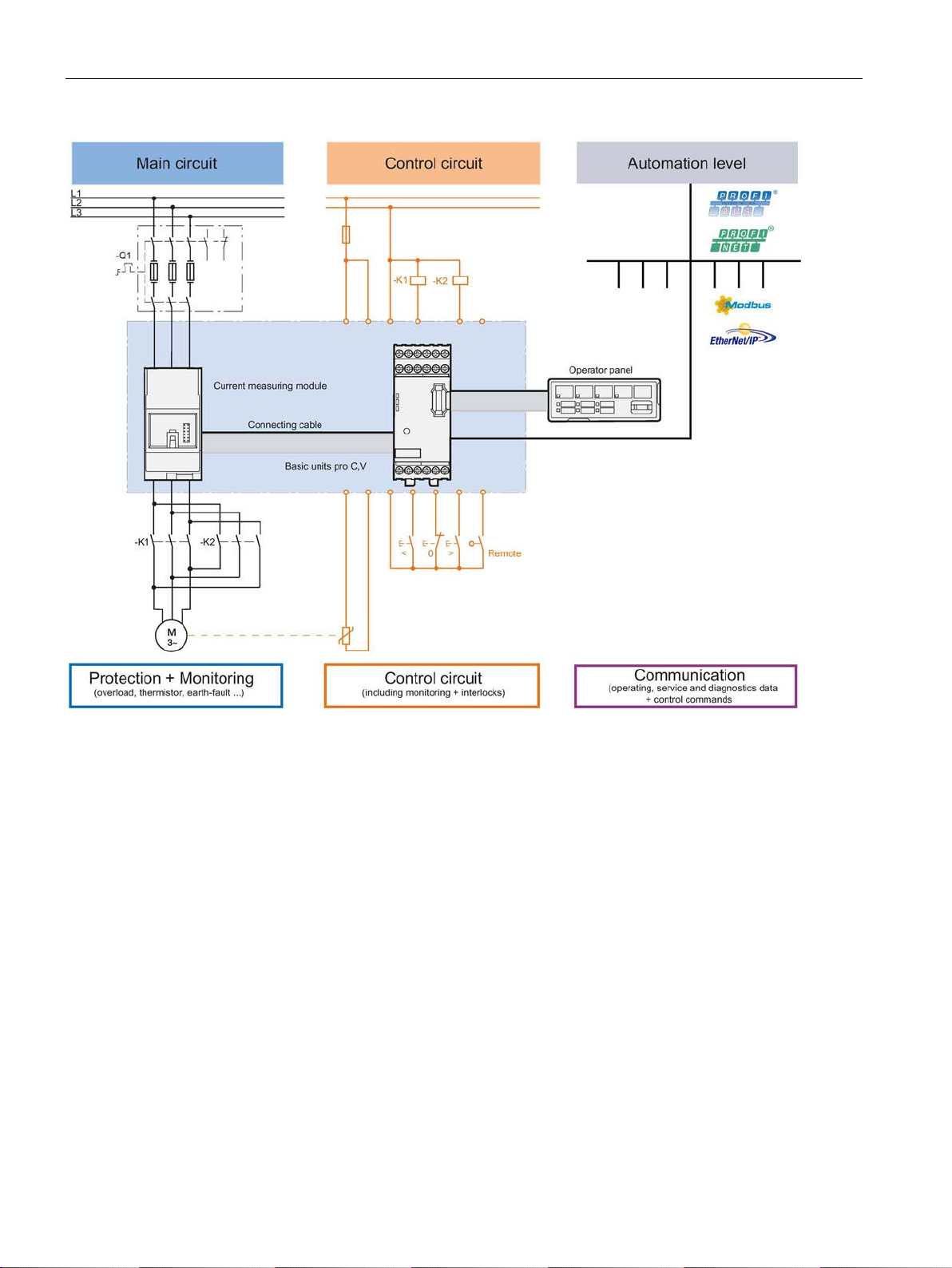

● The quantity of cabling required between the motor feeder and the PLC is reduced

significantly by connecting the entire motor feeder to the process control system via the

fieldbus (see Figures "SIMOCODE pro, integrated in the main circuit, control circuit and at

automation level (PLC)")

● Automated processes are decentralized by means of configurable control and monitoring

functions in the feeder. This saves automation system resources and ensures that the

feeder is fully functional and protected even if the control system or bus system fails.

● By recording and monitoring operating, service and diagnostics data in the feeder and

process control system, plant availability is increased, and the feeder is easier to service

and maintain.

● The user can implement plant-specific requirements for every motor feeder thanks to the

high degree of modularity.

● SIMOCODE pro provides compact solutions and different levels of functions for every

customer application.

● By replacing the control circuit hardware with an integrated control function, the quantity

of required hardware components with wiring is reduced. This drives down storage costs

and limits potential wiring errors.

● Using electronic full motor protection allows the motors to be used more efficiently and

ensures that the tripping characteristic remains stable and the tripping response stays the

same, even after many years.

SIMOCODE pro

System Manual, 05/2019, A5E40507475002A/RS-AD/004

29

Advantages/benefits/configuration with SIMOCODE pro

2.1 Advantages/benefits

Figure 2-1 SIMOCODE pro C, pro V, integrated in the main circuit, control circuit and at automation level (PLC)

SIMOCODE pro

30 System Manual, 05/2019, A5E40507475002A/RS-AD/004

Loading...

Loading...