Page 1

SIMATIC Sensors Image processing systems Vision Sensor SIMATIC VS120

DOCUMENTATION

Operating Instructions Edition 02/2006

Image Processing Systems

SIMATIC VS120

simatic sensors

DOCUMENTATION

Page 2

Page 3

SIMATIC Sensors

Image processing systems

Vision Sensor SIMATIC VS120

Operating Instructions

Introduction

Safety instructions

Description

Image processing

Network and system

integration

Installation

Connecting

1

2

3

4

5

6

7

Commissioning

Operation

Process interfacing over an

automation system (PLC,

PC)

Alarm, error and system

messages

Technical data

Dimension drawings

Scope of

delivery/Spares/Accessories

8

9

10

11

12

13

14

Edition 02/2006

A5E00757507-01

Service & Support

Directives and declarations

15

16

Page 4

Safety Guidelines

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

Danger

indicates that death or severe personal injury will result if proper precautions are not taken.

Warning

indicates that death or severe personal injury may result if proper precautions are not taken.

Caution

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

Caution

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

Notice

indicates that an unintended result or situation can occur if the corresponding information is not taken into

account.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The device/system may only be set up and used in conjunction with this documentation. Commissioning and

operation of a device/system may only be performed by qualified personnel. Within the context of the safety notes

in this documentation qualified persons are defined as persons who are authorized to commission, ground and

label devices, systems and circuits in accordance with established safety practices and standards.

Prescribed Usage

Note the following:

Warning

This device may only be used for the applications described in the catalog or the technical description and only in

connection with devices or components from other manufacturers which have been approved or recommended

by Siemens. Correct, reliable operation of the product requires proper transport, storage, positioning and

assembly as well as careful operation and maintenance.

Trademarks

All names identified by ® are registered trademarks of the Siemens AG. The remaining trademarks in this

publication may be trademarks whose use by third parties for their own purposes could violate the rights of the

owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Siemens AG

Automation and Drives

Postfach 48 48

90437 NÜRNBERG

GERMANY

Order No.: A5E00757507-01

Edition 02/2006

Copyright © Siemens AG 2006.

Technical data subject to change

Page 5

Table of contents

1 Introduction............................................................................................................................................. 1-1

2 Safety instructions .................................................................................................................................. 2-1

3 Description.............................................................................................................................................. 3-1

3.1 Product description .................................................................................................................... 3-1

3.2 Performance features ................................................................................................................ 3-2

3.3 Function ..................................................................................................................................... 3-3

3.4 System components .................................................................................................................. 3-4

3.5 System requirements................................................................................................................. 3-5

3.6 Design of the SIMATIC VS120 processing unit......................................................................... 3-6

3.7 Design of the sensor head with LED ring flash.......................................................................... 3-8

4 Image processing ................................................................................................................................... 4-1

4.1 General information ................................................................................................................... 4-1

4.2 Shutter Speed and Brightness................................................................................................... 4-2

4.2.1 Different exposures and brightnesses ....................................................................................... 4-2

4.2.2 Disturbing contours caused by shine......................................................................................... 4-3

4.3 Generating models and detecting orientation............................................................................ 4-5

4.3.1 Setting for the Precision parameter ........................................................................................... 4-5

4.3.2 Measures for optimizing object recognition ...............................................................................4-6

4.4 Quality of the measured values ................................................................................................. 4-7

4.5 Geometric distortion................................................................................................................... 4-8

4.6 Main ROI and sub-ROI .............................................................................................................. 4-8

4.6.1 Example: Main ROI and 3 sub-ROIs .........................................................................................4-9

4.6.2 Example of the influence of sub-ROIs on the quality value..................................................... 4-10

4.7 Job parameter.......................................................................................................................... 4-13

4.8 Search parameter .................................................................................................................... 4-16

4.9 Model type parameter .............................................................................................................. 4-17

4.10 Model sets................................................................................................................................ 4-19

5 Network and system integration...............................

...............................................................................

5-1

5.1 Overview .................................................................................................................................... 5-1

5.2 System configuration over digital I/O ......................................................................................... 5-2

5.3 PROFIBUS DP system configuration ........................................................................................ 5-3

5.4 PROFINET IO system configuration.......................................................................................... 5-4

5.5 System configuration with Ethernet or RS-232 over Com server.............................................. 5-5

Vision Sensor SIMATIC VS120

Operating Instructions, Edition 02/2006, A5E00757507-01

iii

Page 6

Table of contents

6 Installation .............................................................................................................................................. 6-1

6.1 Installing the SIMATIC VS120 processing unit .......................................................................... 6-1

6.2 Installing the sensor head with LED ring flash........................................................................... 6-1

7 Connecting ............................................................................................................................................. 7-1

7.1 Guidelines on installation and avoiding electrical interference .................................................. 7-1

7.2 Guidelines on installation when using PROFIBUS DP or PROFINET IO.................................. 7-1

7.3 Connecting components ............................................................................................................ 7-2

8 Commissioning ....................................................................................................................................... 8-1

8.1 Prerequisites .............................................................................................................................. 8-1

8.2 Overview of the steps in commissioning.................................................................................... 8-2

8.3 Turn on the VS120 processing unit............................................................................................ 8-3

8.4 Establish an Ethernet connection between the processing unit and PG / PC........................... 8-5

8.4.1 Select the connection variant..................................................................................................... 8-5

8.4.1.1 Connection variants ................................................................................................................... 8-5

8.4.1.2 Operating the VS120 processing unit as a DHCP server.......................................................... 8-6

8.4.1.3 Connecting the VS120 processing unit manually ...................................................................... 8-7

8.4.1.4 Integrating the VS120 processing unit as a DHCP client in a network...................................... 8-9

8.4.1.5 Integrating the VS120 processing unit as a device in a PROFINET IO network..................... 8-10

8.4.2 Check whether a proxy server is being used ........................................................................... 8-12

8.4.3 Change the proxy configuration of your Internet Explorer ....................................................... 8-13

8.4.4 Check the connection............................................................................................................... 8-14

8.5 Start setup support over the Internet Explorer......................................................................... 8-15

8.6 Adjust the sensor head using setup support............................................................................ 8-17

9 Operation................................................................................................................................................ 9-1

9.1 Overview .................................................................................................................................... 9-1

9.2 Working with the processing unit ............................................................................................... 9-1

9.2.1 Introduction ................................................................................................................................ 9-1

9.2.2 Adjust ......................................................................................................................................... 9-2

9.2.3 Connect......................................................................................................................................

9-2

9.2.4 RUN............................................................................................................................................ 9-9

9.2.5 Options..................................................................................................................................... 9-15

9.2.6 Maintain.................................................................................................................................... 9-18

9.3 Working with setup support...................................................................................................... 9-19

9.3.1 Introduction .............................................................................................................................. 9-19

9.3.2 Adjust Sensor........................................................................................................................... 9-24

9.3.3 Connections ............................................................................................................................. 9-25

9.3.4 Train ......................................................................................................................................... 9-27

9.3.5 Processing................................................................................................................................ 9-33

9.3.6 Options..................................................................................................................................... 9-37

9.3.7 Information ............................................................................................................................... 9-43

9.3.8 Maintain.................................................................................................................................... 9-49

9.3.9 Stop.......................................................................................................................................... 9-51

10 Process interfacing over an automation system (PLC, PC) .................................................................. 10-1

10.1 Integrating the PROFIBUS DP slave SIMATIC VS120 in HW Config ..................................... 10-1

10.2 Integrating the PROFINET IO device SIMATIC VS120 in HW Config..................................... 10-4

10.3 Control over the "DI/DO" I/O interface ..................................................................................... 10-7

Vision Sensor SIMATIC VS120

iv Operating Instructions, Edition 02/2006, A5E00757507-01

Page 7

Table of contents

10.4 Control over PROFIBUS DP and PROFINET IO................................................................... 10-10

10.4.1 Principle of data transfer over PROFIBUS DP and PROFINET IO ....................................... 10-10

10.4.2 Assignments for PROFIBUS DP / PROFINET IO-relevant interfaces for the

processing unit....................................................................................................................... 10-11

10.4.2.1 Control byte............................................................................................................................ 10-11

10.4.2.2 Status byte ............................................................................................................................. 10-12

10.4.2.3 User data interface "Send" VS120 processing unit >>> automation system......................... 10-12

10.4.2.4 User data interface "Receive" automation system >>> VS120 processing unit.................... 10-14

10.4.3 Programming data fragmentation .......................................................................................... 10-14

10.5 Function block FB1 ................................................................................................................ 10-16

10.5.1 Job ......................................................................................................................................... 10-16

10.5.2 Parameter .............................................................................................................................. 10-17

10.5.3 Operator control ..................................................................................................................... 10-19

10.5.4 Error information .................................................................................................................... 10-20

10.6 Sample programs................................................................................................................... 10-21

10.6.1 Example 1: Program for interfacing the SIMATIC VS120 processing unit with a

SIMATIC controller using FB1 ............................................................................................... 10-21

10.6.2 Example 2: Program for archiving diagnostic information on a PC/PG................................. 10-23

11 Alarm, error and system messages ...................................................................................................... 11-1

11.1 Overview .................................................................................................................................. 11-1

11.2 Error messages and error handling ......................................................................................... 11-1

11.3 Diagnostics based on the "BF" LED ...................................................................................... 11-10

11.4 Slave diagnostics or /O device diagnostics ........................................................................... 11-11

12 Technical data ...................................................................................................................................... 12-1

12.1 General technical specifications .............................................................................................. 12-1

12.2 Technical specifications of SIMATIC VS120 ........................................................................... 12-5

12.3 Port assignment of the processing unit.................................................................................... 12-8

13 Dimension drawings ............................................................................................................................. 13-1

13.1 SIMATIC VS120 processing unit ............................................................................................. 13-1

13.2 SIMATIC VS120 sensor head.................................................................................................. 13-2

13.3 SIMATIC VS120 lighting unit ...............................

....................................................................

13-3

14 Scope of delivery/Spares/Accessories.................................................................................................. 14-1

14.1 Components............................................................................................................................. 14-1

14.2 Full packages ........................................................................................................................... 14-2

14.3 Accessories.............................................................................................................................. 14-4

14.4 C-mount lens and inspection window size............................................................................... 14-5

15 Service & Support................................................................................................................................. 15-1

15.1 A&D Mall / Interactive Catalog (CA01) .................................................................................... 15-1

15.2 Service and support ................................................................................................................. 15-1

16 Directives and declarations................................................................................................................... 16-1

Glossary ..................................................................................................................................... Glossary-1

Index................................................................................................................................................ Index-1

Vision Sensor SIMATIC VS120

Operating Instructions, Edition 02/2006, A5E00757507-01

v

Page 8

Table of contents

Vision Sensor SIMATIC VS120

vi Operating Instructions, Edition 02/2006, A5E00757507-01

Page 9

Introduction

Purpose of the manual

This manual contains all the information you require to install, commission and work with the

SIMATIC VS120 Vision Sensor System.

It is intended both for persons configuring and installing automated plants with image

processing systems and for service and maintenance technicians.

Scope of this manual

The manual is valid for all supplied versions of the SIMATIC VS120 Vision Sensor system

and the processing unit with order number (MLFB) 6GF1 018-2AA10.

1

Vision Sensor SIMATIC VS120

Operating Instructions, Edition 02/2006, A5E00757507-01

1-1

Page 10

Introduction

Vision Sensor SIMATIC VS120

1-2 Operating Instructions, Edition 02/2006, A5E00757507-01

Page 11

Safety instructions

Caution

Please observe the safety instructions on the back of the cover sheet of this documentation.

You should not make any expansions to your device unless you have read the relevant

safety instructions.

This device meets the relevant safety requirements in compliance with IEC, VDE, and EN. If

you have questions about the validity of the installation in the planned environment, please

contact your service representative.

Repairs

Only authorized personnel are permitted to repair the device.

Warning

Unauthorized opening of and improper repairs to the device may result in substantial

damage to equipment or risk of personal injury to the user.

2

System expansion

Only install system expansions intended for this device. If you install other upgrades, you

may damage the system or violate the safety requirements and regulations for radio

frequency interference suppression. Contact your technical support team or where you

purchased your device to find out which system expansion devices may safely be installed.

Caution

If you install or exchange system expansions and damage your device, the warranty

becomes void.

Vision Sensor SIMATIC VS120

Operating Instructions, Edition 02/2006, A5E00757507-01

2-1

Page 12

Safety instructions

Vision Sensor SIMATIC VS120

2-2 Operating Instructions, Edition 02/2006, A5E00757507-01

Page 13

Description

3.1 3.1 Product description

The SIMATIC VS120 Vision Sensor is used for the optical detection and testing of objects

with lighting from above. The SIMATIC VS120 Vision Sensor checks whether or not the

correct object is being tested, whether or not it is damaged and the position of the object.

The SIMATIC VS120 Vision Sensor returns the following recognition values during object

recognition:

• x coordinate

• y coordinate

• Angle

• Quality rating of the specimen, number of detected parts

This object recognition data is transferred to processing units in automation systems. The

data is processed in the processing units of the automation systems.

The SIMATIC VS120 Vision Sensor is suitable for:

• Recognition of parts in sorting tasks

• Determining the position for Pick & Place applications

3

• Checking the presence and position of objects in production

• Checking position in feed systems, for example with oscillating conveyors, workpiece

holder, conveyor belts, circulating systems, grasper units and robots.

• Quality control of specimens

Vision Sensor SIMATIC VS120

Operating Instructions, Edition 02/2006, A5E00757507-01

3-1

Page 14

Description

3.2 Performance features

3.2 3.2 Performance features

• Overhead lighting head with LED ring flash

• Object recognition with object search and object test

• Commissioning using adjustment support on the PG / PC with installed Internet Explorer

• Up to 20 objects tested per second

• Up to 64 specimens can be stored

• Two digital outputs are available for sorting the specimens: OK, N_OK

• Fully Web-based user interface

• Extensive operator control and monitoring functions even in the processing mode

• Wide-ranging diagnostics and logging functions: Error image memory and event logging

• Firmware update using operator interface of the Web browser

• Control via Digital I/O, PROFIBUS DP and PROFINET IO

• Result output via:

– PROFIBUS DP

– PROFINET IO

– RS-232 port of an RS-232 Ethernet converter

– TCP/IP connection of the PC / PG

Vision Sensor SIMATIC VS120

3-2 Operating Instructions, Edition 02/2006, A5E00757507-01

Page 15

Description

3.3 Function

3.3 3.3 Function

Testing correctness of individual characteristics of the specimen

64 models are available for the recognition of specimens. The SIMATIC VS120 checks

whether or not the individual characteristics of the specimens have the same shape as the in

the trained model.

When specifying the recognition and evaluation areas, avoid shiny surfaces on specimens.

Principle of edge recognition

To recognize image patterns, edges are used. These edges from the images are the

transitions from light to dark or vice versa. A model is created from the sum of the edges

extracted in the image and their arrangement.

Recognition and localization of parts

The SIMATIC VS120 scans specimens and determines the coordinates including the roll

angle and passes them to the control system such as S7, for example, via PROFIBUS DP.

Testing the completeness of a model

The SIMATIC VS120 also checks specimens for completeness. Deviations from the trained

model are detected and the quality values of the evaluation are displayed.

Sorting functions for models and model sets

Depending on the importance of the application, 15 model sets with 64 different models can

be assembled and saved for processing. The models are sorted according to the application

with a controller for processing with the SIMATIC VS120.

Vision Sensor SIMATIC VS120

Operating Instructions, Edition 02/2006, A5E00757507-01

3-3

Page 16

Description

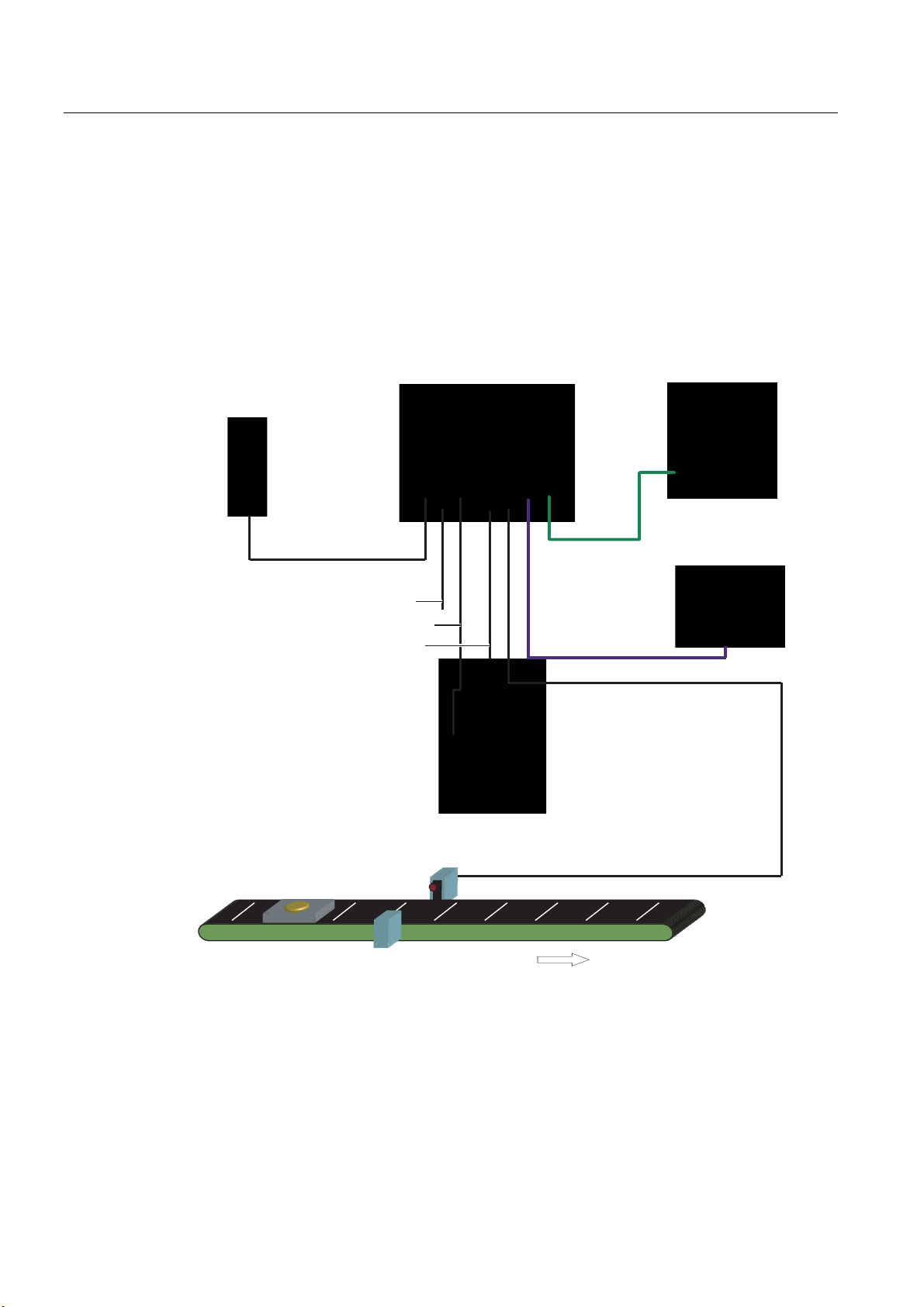

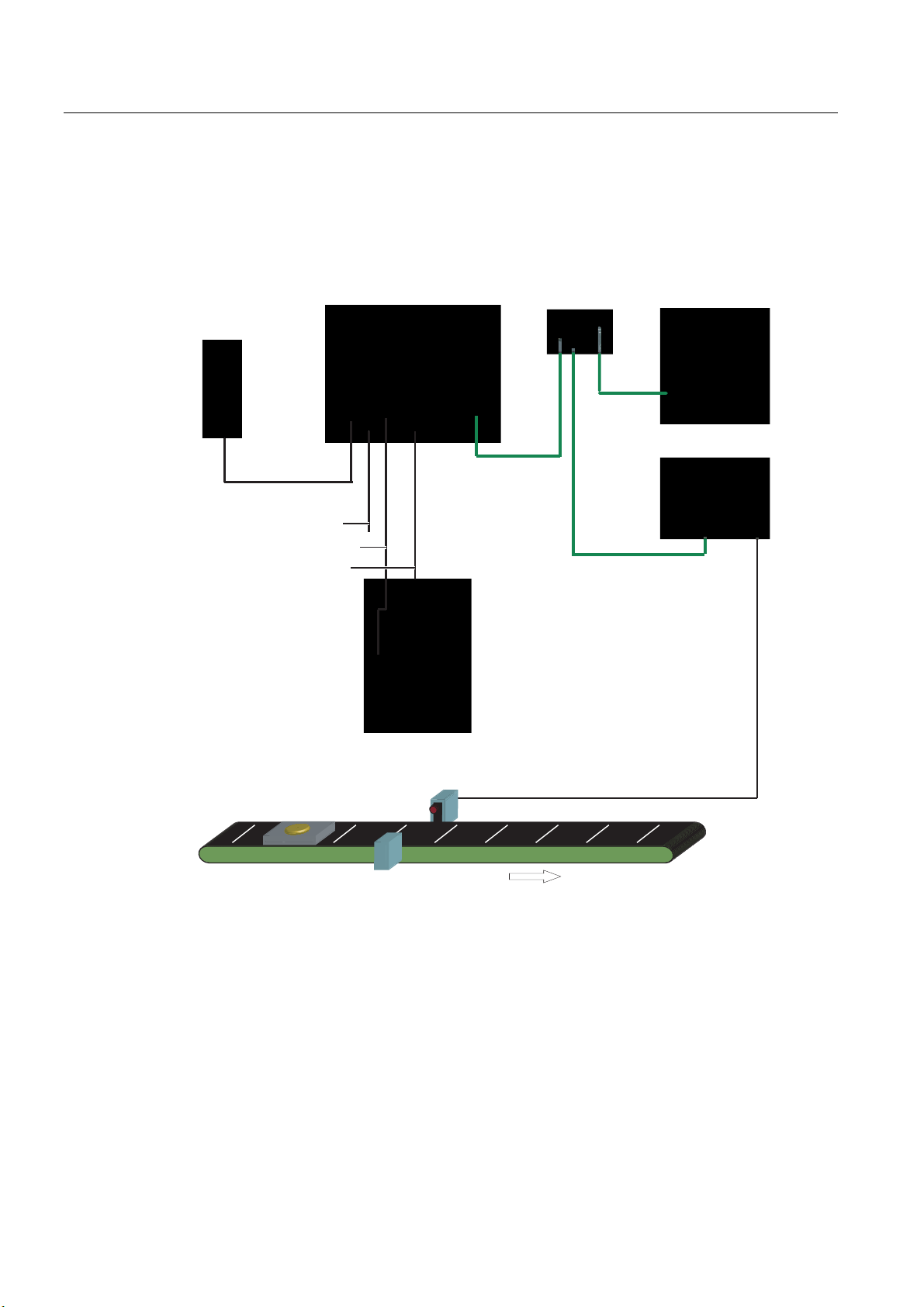

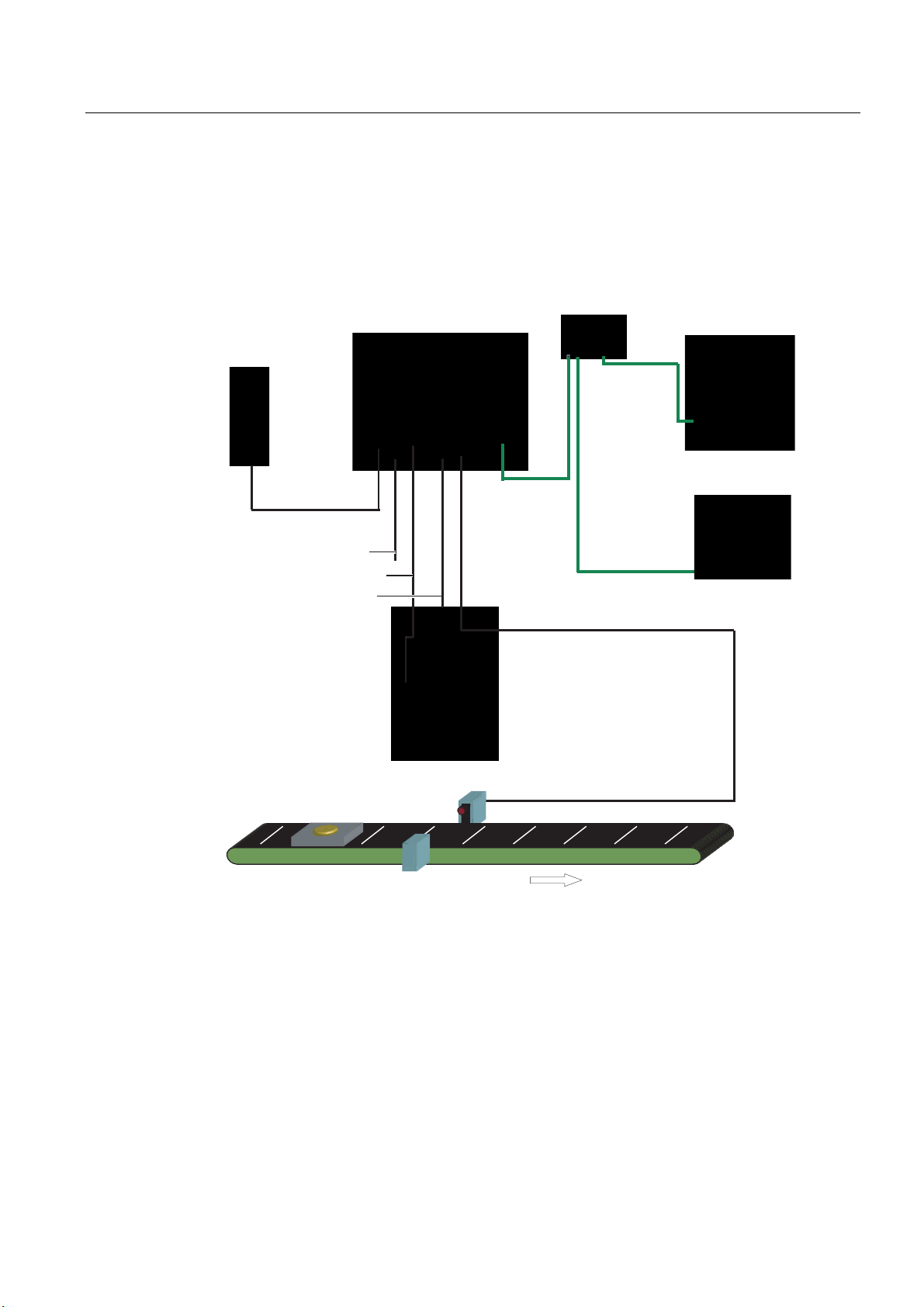

3.4 System components

3.4 3.4 System components

SIMATIC VS120 Vision Sensor full package comprising:

• Sensor

• Processing unit

• Lighting

• Cable

3RZHU

VXSSO\

3RZHUVXSSO\FDEOH

)XQFWLRQDOHDUWKLQJ

/LJKWLQJFDEOH

6HQVRUFDEOH

3URFHVVLQJXQLW

3*3&IRU

DGMXVWPHQWVXSSRUW

5- (WKHUQHW

FDEOH

$XWRPDWLRQV\VWHP

352),%86b'3

','2FDEOH

6HQVRUKHDG

/('ULQJIODVK

2EMHFW

3KRWRHOHFWULFEDUULHU

&RQYH\RUXQLW

&RQYH\RUXQLW

Figure 3-1 Example of a typical system configuration with conveyor system

Vision Sensor SIMATIC VS120

3-4 Operating Instructions, Edition 02/2006, A5E00757507-01

Page 17

Description

3.5 System requirements

3.5 3.5 System requirements

You require the following hardware and software components for the SIMATIC VS120 Vision

Sensor system:

Hardware

• SIMATIC VS120 processing unit

• Sensor head with CCD sensor chip for detection of the object

• LED ring flash for SIMATIC VS with degree of protection IP65 (not included in every full

package), for optimum illumination of the object

• Cables:

– Power supply cable

– Lighting cable

– Sensor cable

– DI / DO cable

• Documentation package

Software

– Operating Instructions (compact)

– Documentation CD

You also require the following:

• 24 V DC, 2 A power supply; (20.4...28.8 V DC, safety extra low voltage, SELV).

• PC / PG with the following configuration:

– At least 500 MHz clock frequency

– Graphics card with at least 65536 colors and a resolution of at least 1024 x 768 pixels

– Ethernet port with up to 100 Mbps (protocol: TCP/IP)

• Crossover RJ-45 Ethernet cable for connecting the processing unit and the PC / PG

• Microsoft Windows XP Professional SP1 operating system with Internet Explorer 6.0 as of

SP1

• Microsoft Java VM or Sun Java VM version J2SE 1.4.2_06 or J2SE 5.0 (you will find

more detailed information on the Internet at the following address

http//:www.java.sun.com/J2SE)

Vision Sensor SIMATIC VS120

Operating Instructions, Edition 02/2006, A5E00757507-01

3-5

Page 18

Description

3.6 Design of the SIMATIC VS120 processing unit

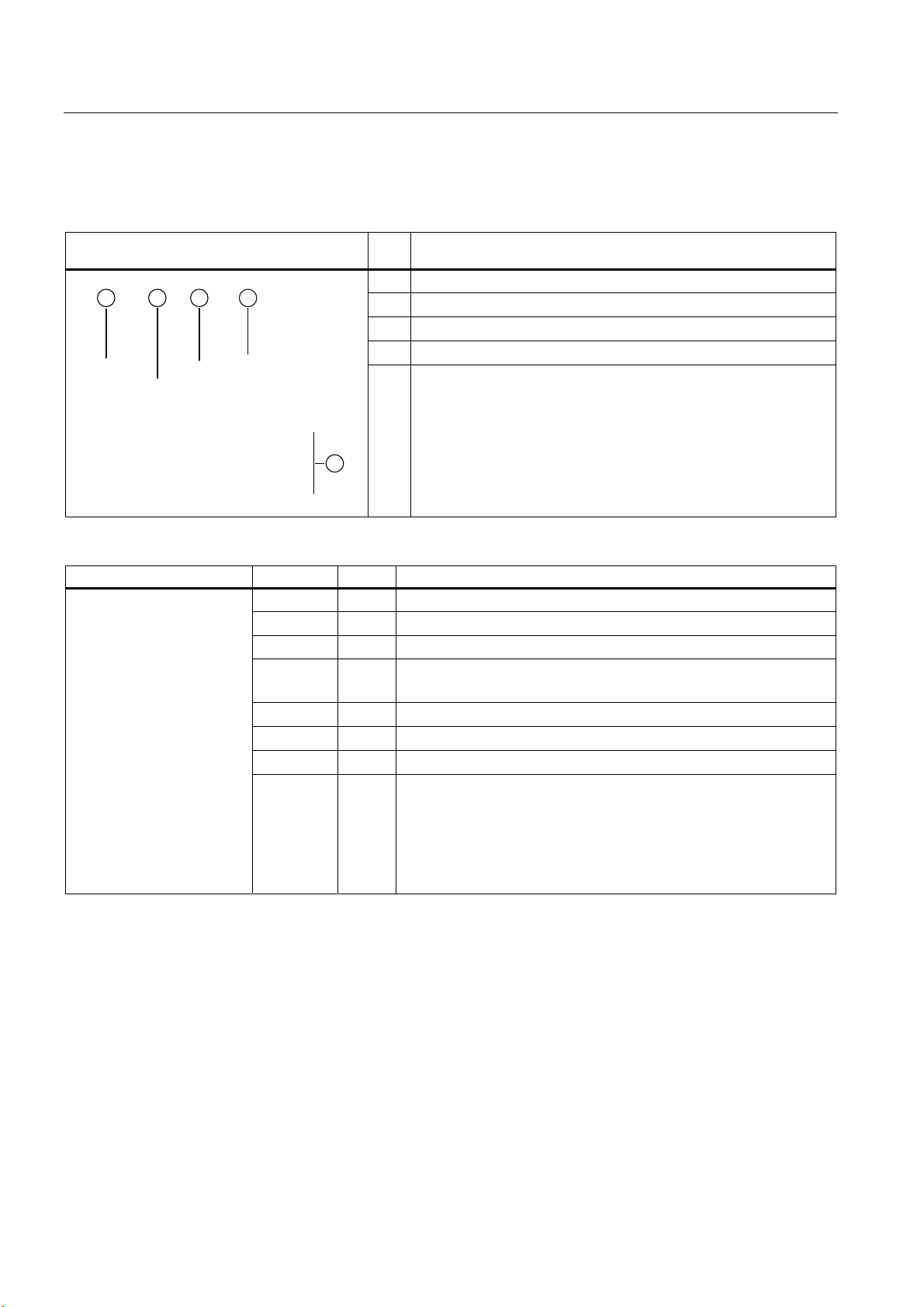

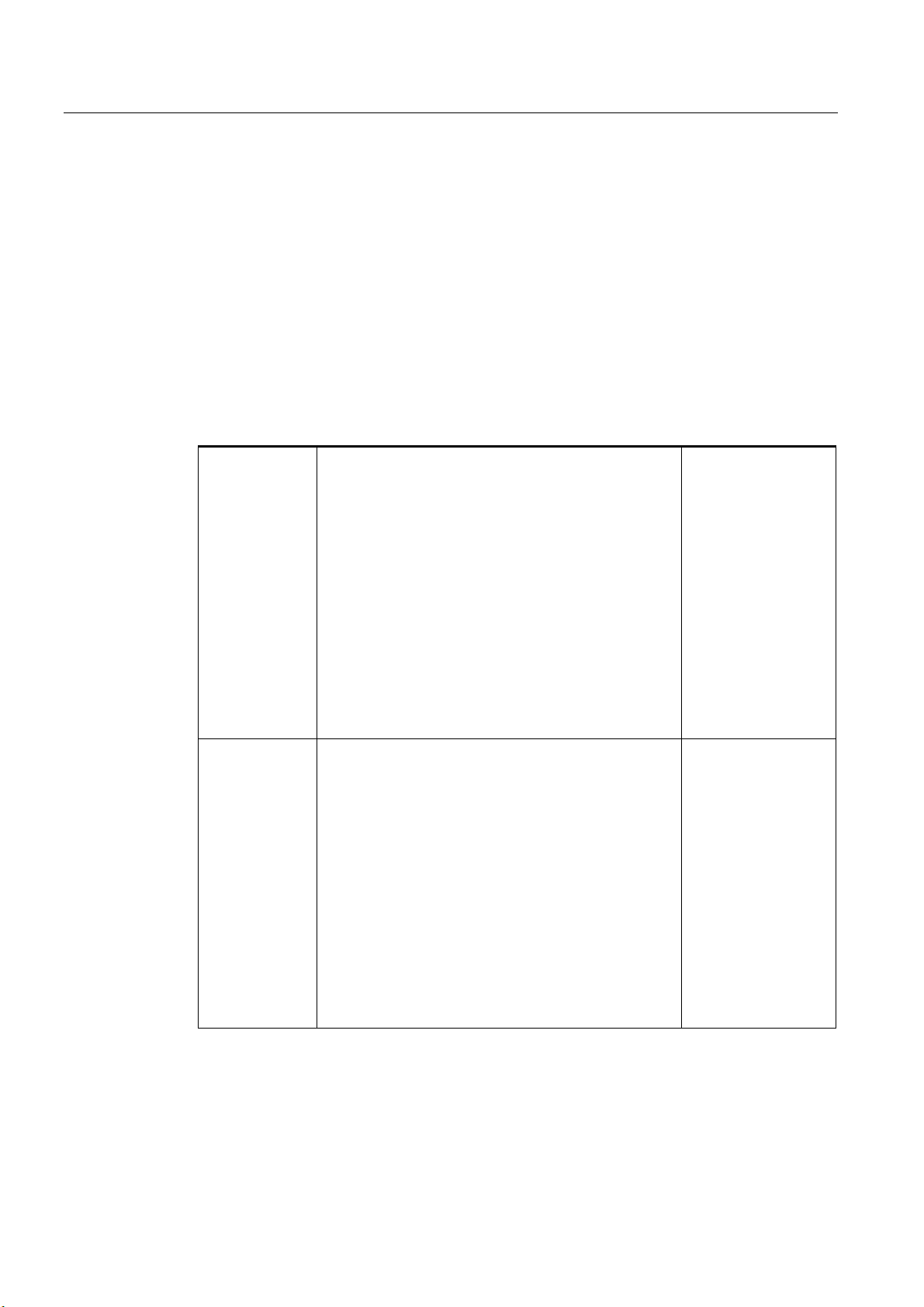

3.6 3.6 Design of the SIMATIC VS120 processing unit

VS120 processing unit (MLFB 6GF1 0182AA10)

Item

Meaning

No.

(1) Status LEDs

(2) LCD display

(3) Keypad

(4) Housing consisting of hood and base

(5) Interfaces

Status LEDs LEDs Color Meaning

SF Red General fault

POWER Green Power supply is turned on

TRAINED Green Selected model has been trained

READY Green

OK Green Result good: Model was recognized

- Green N_OK Yellow Result bad: Object was not recognized

BF Red Bus fault on PROFIBUS DP or PROFINET IO

• off = device startup or SIMATIC VS120 in Stop

• on = SIMATIC VS120 in Run

Vision Sensor SIMATIC VS120

3-6 Operating Instructions, Edition 02/2006, A5E00757507-01

Page 19

Description

3.6 Design of the SIMATIC VS120 processing unit

LCD display and keypad Item

Designation Meaning

No.

(1) LCD

display

(2)

Keypad

Displays menu commands (lines 1 to 3) and the keys

that are currently available (line 4)

Navigation from menu to menu and within the menus

Interfaces Item

Meaning

No.

(1) Supply voltage 24 V DC, circular M12 connector

(2) Functional ground with M5 screw-type connector

(3) Lighting unit, circular M12 connector

(4) Sensor head, HD D-sub connector, 26-pin

(5) I/O, D-sub connector, 15-pin

(6) PROFIBUS DP, D-sub connector, 9-pin

(7) Ethernet / PROFINET IO; RJ-45 plug

Vision Sensor SIMATIC VS120

Operating Instructions, Edition 02/2006, A5E00757507-01

3-7

Page 20

Description

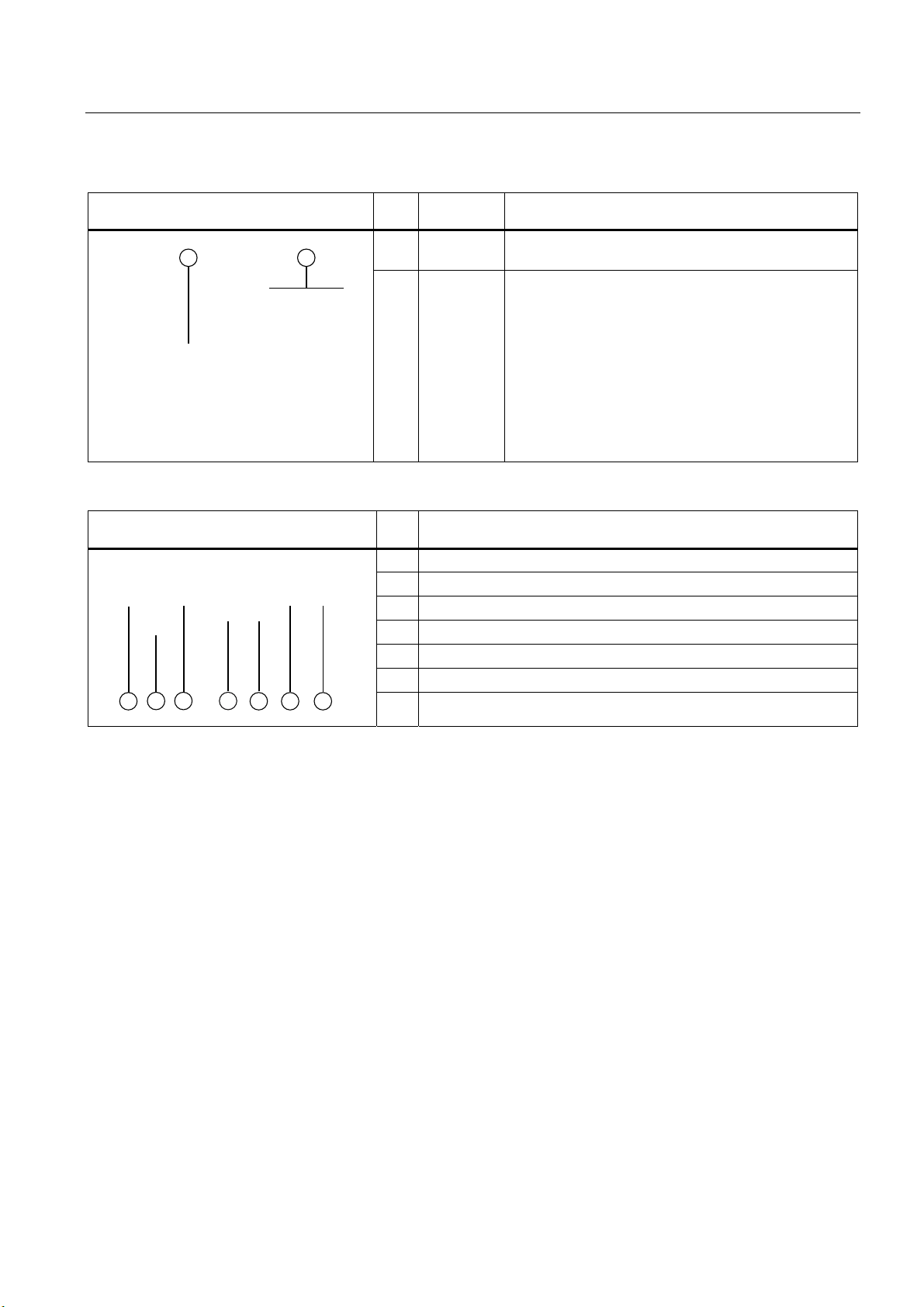

3.7 Design of the sensor head with LED ring flash

3.7 3.7 Design of the sensor head with LED ring flash

Sensor head with LED ring flash Item

No.

(1)

(2)

(3)

(4)

Meaning

Circular connector M12

Sensor head

LED ring flash (not supplied with all full packages)

Lens, permanently installed and non-adjustable (fixed focus version)

Vision Sensor SIMATIC VS120

3-8 Operating Instructions, Edition 02/2006, A5E00757507-01

Page 21

Image processing

4.1 4.1 General information

To form patterns that can be recognized, edges (transitions from light to dark or vice versa)

from the image are used. Although the algorithm extracts the edges automatically, the user

must make sure that the lighting is ideal for an image with good contrast; in other words, to

create models for recognition, it is essential to use the lighting correctly to achieve an image

with high contrast.

Note

The installation of suitable lighting often involves more time than all the other activities such

as securing the camera, connecting to the PLC, training, setting the correct triggers etc.

together. With metallic surfaces in particular, it is advisable to ask the advice of a lighting

expert due to the possible shine.

Part of object recognition is the recognition of the position of the object in the image.

The starting point is the midpoint of the image to which all coordinates relate. The top left

has the coordinates (-320; 240) and bottom right (320; -240).

4

If the object is not recognized, the position at the top left is output for x / y. The user should

always query whether or not this is an OK / N_OK evaluation and not rely on the x / y

positions!

Vision Sensor SIMATIC VS120

Operating Instructions, Edition 02/2006, A5E00757507-01

4-1

Page 22

Image processing

4.2 Shutter Speed and Brightness

4.2 4.2 Shutter Speed and Brightness

Correct exposure time (shutter speed) influences the quality of the extracted edges. To

control the exposure time / brightness, you can use the parameters Shutter speed and

Brightness.

The shutter speed / brightness must be set to obtain the optimum contrast. The automatic

exposure control can help to achieve the optimum shutter speed setting.

Below, you will find examples of different shutter speeds and disturbing contours:

4.2.1 Different exposures and brightnesses

Correct exposure

Shutter speed: 3800

Brightness: 357

Overexposure

Shutter speed: 6000

Brightness: 357

or

Shutter speed: 3800

Brightness: 500

Vision Sensor SIMATIC VS120

4-2 Operating Instructions, Edition 02/2006, A5E00757507-01

Page 23

Image processing

4.2 Shutter Speed and Brightness

Underexposure

4.2.2 Disturbing contours caused by shine

Shiny areas on the surfaces of the part cause disturbing edges that must be avoided for a

representative model. In the example shown below, you can see clearly that even the

automatic shutter control can cause bad edges in this case. These edges make recognition

of the parts unreliable since they are often not reproducible.

Shutter speed: 800

Brightness: 357

or

Shutter speed: 3800

Brightness: 93

Unwanted edge lines

In the trained model shown here, you can see

unwanted edge lines that reduce quality during

the search and recognition and therefore ought

to be avoided.

Vision Sensor SIMATIC VS120

Operating Instructions, Edition 02/2006, A5E00757507-01

4-3

Page 24

Image processing

4.2 Shutter Speed and Brightness

Remedy by manual overexposure

If this method cannot be used, the user can do the following:

• Use the erasure function on the edges of the model to enable optimally training for the

contour

This image was manually overexposed. The

contour is ideal and can be clearly recognized.

• Correct the problem by setting the shutter speed offset for automatic exposure control

Other interference affecting object recognition

In addition to the previously mentioned interference, other factors can also have a negative

influence on the search for a pattern.

• Shadows (particularly caused by the depth of the objects)

• Non-uniform lighting

• Geometric distortion by the lens, particularly when the camera is not perpendicular to the

pattern

• Blurring due to motion if the shutter speed is too slow for moving parts

There are functions and parameters in the SIMATIC VS120 Vision Sensor to reduce the

negative effects of such interference in recognizing parts. They help to create optimal edges

from the image to generate patterns.

Vision Sensor SIMATIC VS120

4-4 Operating Instructions, Edition 02/2006, A5E00757507-01

Page 25

Image processing

4.3 Generating models and detecting orientation

4.3 4.3 Generating models and detecting orientation

A model is created from the sum of the edges extracted in the image and their arrangement.

To ensure good processing quality, the contours of the model should lie within the ROI

(Region of Interest).

4.3.1 Setting for the Precision parameter

The precision setting is based on the size of the ROIs and recognizable changes in the

specimen. The search for a part in the image is "pyramidal". It starts with a coarse search at

low resolution and finishes with a fine search at high resolution. The Precision parameter

affects the coarse and fine search.

Coarse and fine search

The table shows the start and end values of the resolution during the search process with

the various levels of precision.

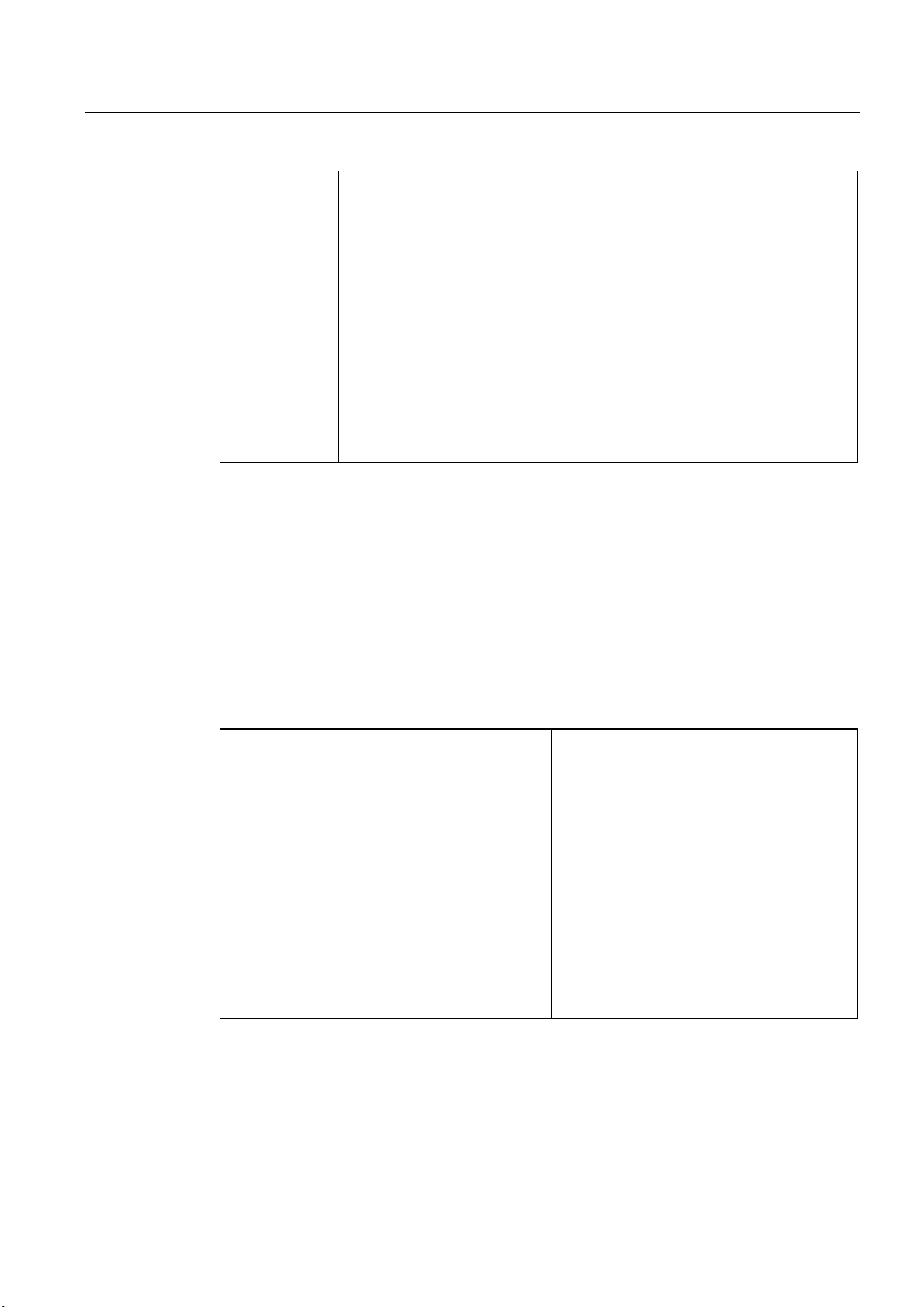

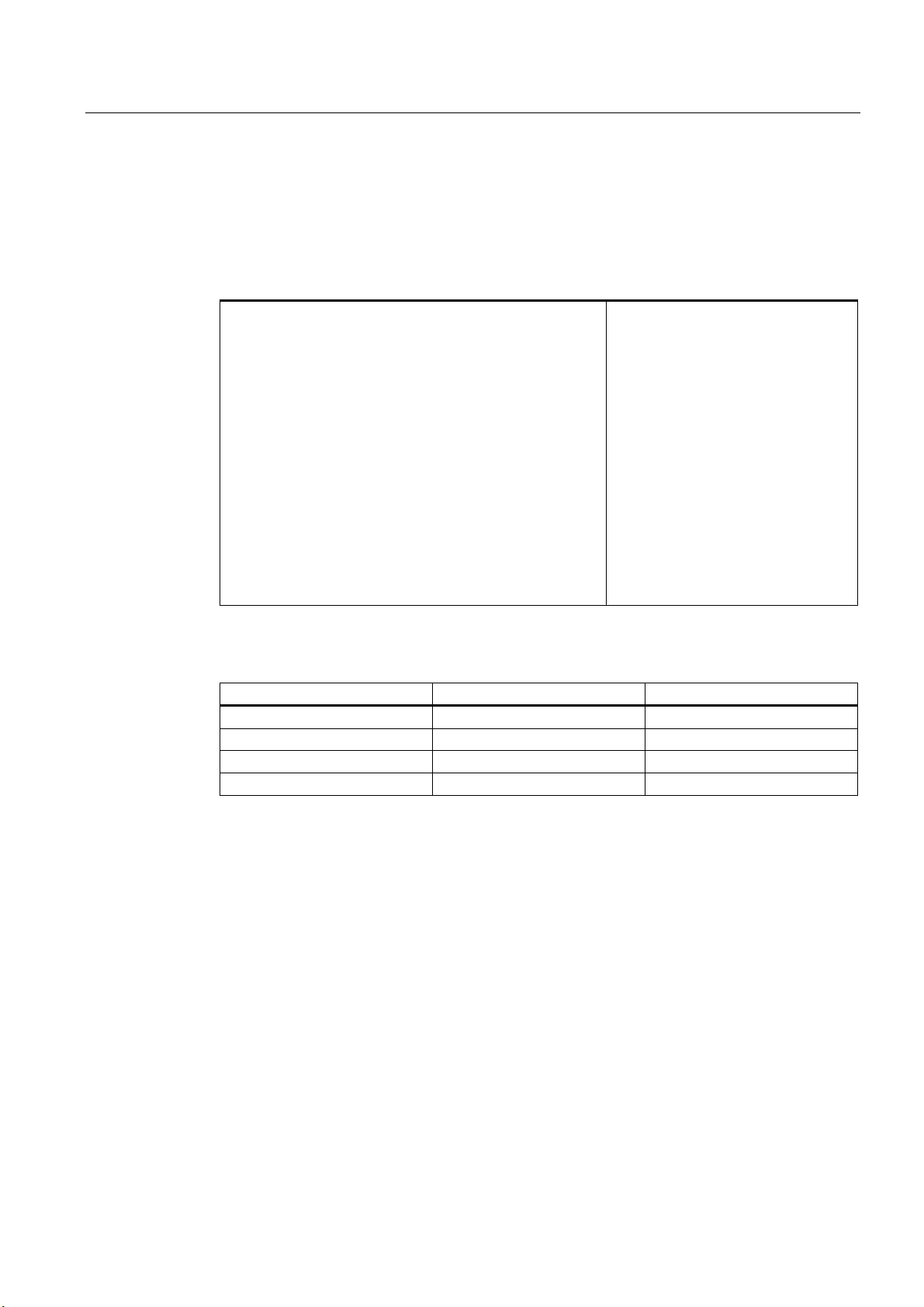

Precision level Start value for the resolution

Width x Height (in pixels)

Fine1 320 x 240 640 x480

Fine2 160 x 120 640 x480

Fine3 80 x 60 640 x480

Medium1 80x60 320 x 240

Medium2 40x30 320 x 240

Coarse1 40x30 160 x 120

Coarse2 20x15 160 x 120

End value for the resolution

Width x Height (in pixels)

The precision for determining the position should be set as follows:

• "Fine" for the sub-pixel range

• "Medium" for +/-1 pixel and +/-1°

• "Coarse" for +/- 2 pixels and +/-1°

– The precision for determining the position still depends on the pattern size and the

number of edges found in it and may therefore deviate from the values shown above.

– The angle precision can be increased to < 1° with the "Angle Precision" parameter in

"Options - Extras tab".

Note

If the setting is "Fine1" and the model is large, the processing times may be several

seconds.

Vision Sensor SIMATIC VS120

Operating Instructions, Edition 02/2006, A5E00757507-01

4-5

Page 26

Image processing

4.3 Generating models and detecting orientation

Note

If exposure is set to "Manual" and the user changes the precision in the adjustment

support (adjust sensor), the "shutter speed" exposure parameter is adjusted

automatically. Depending on the distance of the object to the camera, this can cause

inaccuracies.

Example for declaring the Precision parameter

A wall is hung full of A4 sheets on which various texts have been printed. An observer has

the task of finding a specific sheet among all the others.

Procedure:

• To accelerate the search, the observer stands at a considerable distance from the wall.

The distance from the wall selected by the observer depends on the criteria on which the

search is based, among other factors.

• The observer begins to presort all the sheets. If the observer is looking for a large rough

drawing, they will stand a long way away to be able to see all drawings at the same time.

In this case, the observer would select "Fine3".

• If the observer concentrates on details, such as text format or heading, he would move

closer. Since he is examining more details, the search takes correspondingly longer. In

this case, the observer would select Fine2 or Fine1.

• Once the observer has made a rough selection, he moves closer to the sheets and

investigates each sheet in detail. He now exactly compares individual words and image

details with a reference sheet. The observer no longer examines each sheet in detail

because he has already limited the selection.

The algorithm of the SIMATIC VS120 Vision Sensor works in much the same way as the

example described above.

4.3.2 Measures for optimizing object recognition

Problem: Object was not trained

If the object could not be trained, the reason may be that there were not enough contours in

the selected ROI.

Remedy

• Make sure that the ROI is selected correctly (position and size) and that the object is

within the ROI when training.

• If this problem still occurs, the object to be trained has too few contours. In this case, a

change in the setting of the precision towards greater precision might help, for example,

from Medium2 to Medium1 or to Fine1.

Vision Sensor SIMATIC VS120

4-6 Operating Instructions, Edition 02/2006, A5E00757507-01

Page 27

Image processing

4.4 Quality of the measured values

• If these measures still do not lead to success, try the following for example:

– Select other lighting

– Specify other more detailed object regions in the ROI

– Enlarge the ROI or similar

• Another remedy is to change the brightness with high contrast in order to clearly detect

the change in the image.

4.4 4.4 Quality of the measured values

All the displayed measured values for imaging geometry of a read model are subject to the

following inaccuracies.

Processing precision

• for the position (x and y coordinates): up to ± 0.1 pixels

• for the angle (angle precision): up to ± 0,2°

The processing precision is influenced by the following factors:

• Lighting effects such as reflection and shadow

• Perspective distortion, such when the camera is too close to or at too oblique an angle to

the object

• Differences in the object, for example, dirty objects

• Variation in the trained background structure

Fluctuations in size

Fluctuations in size in the image up to ± 10 % are tolerated, if the specimens are the same

position as the trained pattern. These fluctuations can be caused by the following:

• Different distances between specimens and the lens caused by a different position on the

conveyor belt or workpiece holder

• Different pattern sizes in the specimen

Perspective distortion

• Perspective distortion in the recorded image are tolerated if the specimens have the

same orientation as the trained pattern.

• If there is perspective distortion and the orientation is different, no general statement is

possible. In this case, the shape of the specimens and the angle between the camera

level and pattern level are the factors that determine whether or not the specimens can

be recognized.

Vision Sensor SIMATIC VS120

Operating Instructions, Edition 02/2006, A5E00757507-01

4-7

Page 28

Image processing

4.5 Geometric distortion

Relationship between resolution and pixel size

The following table shows which actual length corresponds to the side length of a pixel.

Remember that this value applies only for the specified image width. The sensor heads

6GF2 002-8DA (SIMATIC VS120 for large specimens) and 6GF2 002-8EA (SIMATIC VS120

for small specimens) were based on the maximum possible image widths.

Graphic

width

SIMATIC VS120

for large specimens

SIMATIC VS120

for small specimens

C/CS mount 12 mm 12/640 = 0.02 mm / pixel 12/320 = 0.04 mm / pixel

70 mm 70/640 = 0.11 mm / pixel 70/320 = 0,22 mm / pixel

40 mm 40/640 = 0,06 mm / pixel 40/320 = 0,13 mm / pixel

Resolution per pixel

at 640*480

Resolution per pixel

at 320*240

4.5 4.5 Geometric distortion

Geometric distortion caused by the lens is compensated. With sensor heads with fixed

lenses, the value of the distortion is set automatically and should no longer be changed. If

standard lenses with a C mount are used, the user can make the compensation manually by

changing the parameters.

4.6 4.6 Main ROI and sub-ROI

Processing with main ROIs is usually sufficient to evaluate the image. ROIs (Region of

Interest) are used to distinguish a part from the background better. The sub-ROI option

added to the main ROI allows certain details of patterns, which would otherwise be

indistinguishable in comparison to the total contour, to be weighted more heavily. Testing for

damage or completeness are examples of this.

This is, for example, the case if you have shiny areas or variable areas in the object. Using

sub-ROIs, you can concentrate the search and the evaluation on the important

characteristics and suppress irrelevant ones.

Procedure

1. Training of the main ROI concentrating on the invariable characteristics of the specimen

2. Select the "ROI: New" button the dialog "Training - ROI tab" of the adjustment support. A

rectangle or circle appears on the screen depending on the shape selected for the subROI.

3. Changing the size and position of the sub-ROI in the same way you define the main ROI

Vision Sensor SIMATIC VS120

4-8 Operating Instructions, Edition 02/2006, A5E00757507-01

Page 29

Image processing

4.6 Main ROI and sub-ROI

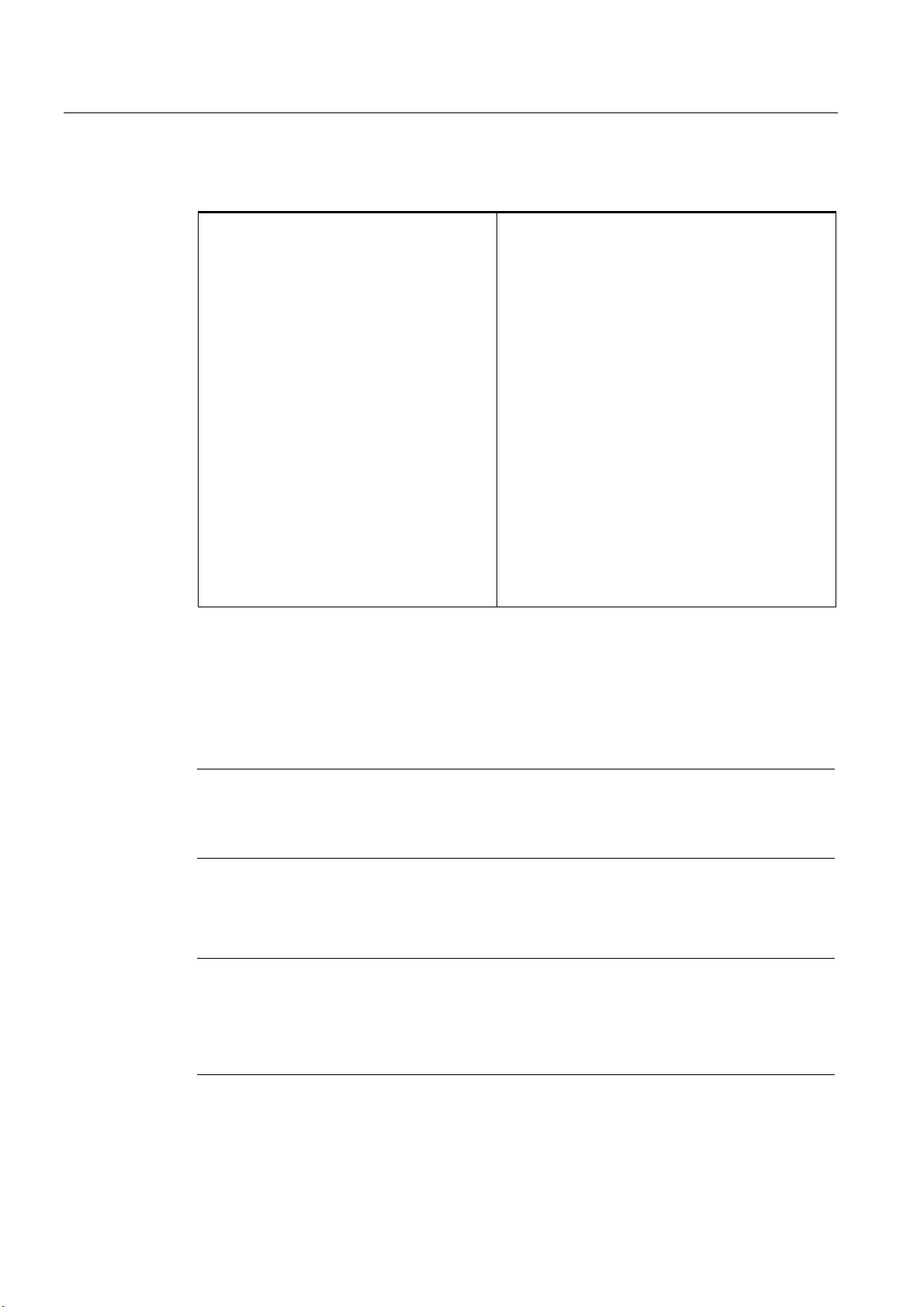

4.6.1 Example: Main ROI and 3 sub-ROIs

Example: Main ROI and 3 sub-ROIs

Task description: The task is to check whether the Siemens logo was printed completely.

In the image on the left, you can see

the edges marked for sub-ROI3. The

main ROI is the large window, while

sub-ROI1 encompasses "SIE" and

sub-ROI2 encompasses "ME".

Parameter assignment

Parameter name Main ROI Sub-ROI 1, 2 and 3

Task Find (default) Find (default)

scaling Fixed Fixed (default)

Precision Fine3 Fine1

Model. type Edges (default) Edges (default)

• The sub-ROIs can be set with the precision Fine1 since the pattern windows are small.

This ensures that no details are lost.

• Fine3 should, however, be selected for the main ROI otherwise the processing time will

take too long. In this case, the selection of the precision (Fine1, Fine2 or Fine3) has no

effect on the quality value of the result.

Vision Sensor SIMATIC VS120

Operating Instructions, Edition 02/2006, A5E00757507-01

4-9

Page 30

Image processing

4.6 Main ROI and sub-ROI

Example of recognition of a bad object

In this example, the "S“ and the "N“ are missing. If

only one ROI had been trained, the quality would

have been 87.2% (=quality of the main ROI).

Sub-ROI1: 60.6%

Sub-ROI2: 98.7%

Sub-ROI3: 42.0%

70% is selected as the quality limit for all ROIs and

an object is then evaluated as N_OK if a sub-ROI

falls below the quality limit.

4.6.2 Example of the influence of sub-ROIs on the quality value

Based on the example below, we will illustrate the effects on the quality value of a specimen

of using sub-ROIs.

The example model appears as follows:

Note

If features are allowed in the area enclosed by the ROI or sub-ROIs that you do not want to

be evaluated, select "Find" as the job in the "Options - Training tab" of the adjustment

support. Otherwise, select the value "Identify".

Note

If only one main ROI is used, the cumulative quality corresponds to the quality of the main

ROI.

If sub-ROI and main ROI are used, the cumulative quality is calculated from the average of

the sub-ROI qualities.

Vision Sensor SIMATIC VS120

4-10 Operating Instructions, Edition 02/2006, A5E00757507-01

Page 31

Image processing

4.6 Main ROI and sub-ROI

Without sub-ROIs, green rectangle means

main ROI.

With sub-ROIs, red rectangle means sub-ROIs

The following specimens must be evaluated:

Specimen 1: Job: Without sub-ROIs With sub-ROIs

Note

is the cumulative quality of the main-ROI

• Q

C

• Q

is the average value of the quality of the sub-ROIs

A

Identify QC = 100 % QA = 100 %

Find Q

= 100 % QA = 100 %

C

Specimen 2: Job: Without sub-ROIs With sub-ROIs

Vision Sensor SIMATIC VS120

Operating Instructions, Edition 02/2006, A5E00757507-01

Identify QC < 100 % QA < 100 %

Find Q

= 100 % QA = 100 %

C

4-11

Page 32

Image processing

4.6 Main ROI and sub-ROI

Specimen 3: Job: Without sub-ROIs With sub-ROIs

Identify QC < 100 % QA = 100 %

Find Q

= 100 % QA = 100 %

C

Specimen 4: Job: Without sub-ROIs With sub-ROIs

Identify QC < 100 % QA = 100 %

Find Q

< 100 % QA = 100 %

C

Specimen 5: Job: Without sub-ROIs With sub-ROIs

Identify QC < 100 % QA < 100 %

Find Q

= 100 % QA = 100 %

C

Vision Sensor SIMATIC VS120

4-12 Operating Instructions, Edition 02/2006, A5E00757507-01

Page 33

Image processing

4.7 Job parameter

4.7 4.7 Job parameter

The Job parameter has the options "Find" and "Identify"

Find

If the "Find“ option is selected, additional edges of the specimen are not taken into

consideration.

Identify

If the "Identify" option is selected, additional edges of the detected specimen are taken into

consideration and compared with the edges of the reference model.

Example

Metal plate with three holes. If "Find" is set, the quality 100% will be output for a metal plate

with an additional hole. If "Identify" is set, the quality value will be lower because the

additional edges of the fourth hole do not have corresponding edges in the reference image.

Vision Sensor SIMATIC VS120

Operating Instructions, Edition 02/2006, A5E00757507-01

4-13

Page 34

Image processing

4.7 Job parameter

Example 1

Trained sub-ROI

"Find" job. Result:

Quality 99.3%

"Identify" job.

Result: Quality 69%

The additional edges of the object

pattern that are not included in the

reference pattern can be clearly seen.

Vision Sensor SIMATIC VS120

4-14 Operating Instructions, Edition 02/2006, A5E00757507-01

Page 35

Image processing

4.7 Job parameter

Example 2

An additional sub-ROI is trained:

"Find" job

If the "Job" parameter is set to the value

"Find", the following quality values are

obtained:

• Main ROI: 98.7%

• Additional sub-ROI: 90.5%

Even a value of 90.5% is too unreliable

to be able to set the quality limit here.

Vision Sensor SIMATIC VS120

Operating Instructions, Edition 02/2006, A5E00757507-01

"Identify" job.

The "Job" parameter is now set to

"Identify" for the additional sub-ROI. The

following result is then achieved:

Quality value of the additional sub-ROI:

69.3%

Changes can now no longer be reliably

detected with an increased quality limit.

4-15

Page 36

Image processing

4.8 Search parameter

4.8 4.8 Search parameter

Two areas can be specified for image recognition.

• Limited: The ROIs around the specimen cannot extend beyond the edge of the image.

Limited is the default value.

• Open: The ROIs around the specimens can go beyond the edge of the image by a

maximum value specified by d

You must specify the maximum value d by the following when an open area is used:

dmax = 30%

RI

22

EK

+

1B2.2.

E

K

Figure 4-1 Search parameter

w = width

h = height

d = maximum value for the position beyond the edge of the image

OK = position for processing OK

N_OK = position for processing not OK

1) = center point of the pattern

2) = image area

Vision Sensor SIMATIC VS120

4-16 Operating Instructions, Edition 02/2006, A5E00757507-01

Page 37

Image processing

4.9 Model type parameter

4.9 4.9 Model type parameter

The human eye instinctively classifies edges with a strong contrast as being more important

than those with a weak contrast. In the "Model type" parameter, this phenomenon is taken

into consideration in the processing with two settings:

• Edges if prominent edges of the specimen are important for processing. Edges is the

default value

• Area if all the edges in the specimen are weighted the same for processing.

Vision Sensor SIMATIC VS120

Operating Instructions, Edition 02/2006, A5E00757507-01

4-17

Page 38

Image processing

4.9 Model type parameter

Example

The cross in the middle is a contour with

significantly greater contrast than other

contours. If an application requires this

region to be weighted as being more

important than the rest for the search,

"Edge" should be set as the model type.

"Edge“ model type parameter

Result: Quality value 53%

"Area“ model type parameter

If you want all areas to be weighted the

same, select "Area".

Result: Quality value 76.5%

Vision Sensor SIMATIC VS120

4-18 Operating Instructions, Edition 02/2006, A5E00757507-01

Page 39

Image processing

4.10 Model sets

4.10 4.10 Model sets

Features

• The model sets functions enables the SIMATIC VS120 Vision Sensor to classify (sort)

parts.

• Classification involves individual examination of the models in the model set.

Classification is considered successful if at least one of these models is evaluated as OK.

A model with the highest cumulative quality is determined from all the models evaluated

as OK. This evaluation result is generated as "Best".

• The number of models allowed in a model set depends on the complexity of the mode

and is limited by the storage capacity of the VS120 processing unit.

• Increasing the number of models in the model set, increases beyond proportion the

processing time by several seconds.

• Up to 40 trained models can be added to each model set.

• The option of integrating several models in a single model set can be enabled in Options

> Extras > Use Multimodel.

Note

Exposure Control Model Set

The settings for the model with the lowest model number always apply for setting the

exposure of a model set.

Note

Error messages

The following error messages can occur in processing mode for the model sets:

• One of the models in the model set has not yet been trained.

• A model set contains models with different precision (important in this respect: only

the precision value of the parameter counts, in other words, all models must be either

"Fine" or "Coarse").

• The model set contains too many models that are too large so that there is not enough

storage space.

Vision Sensor SIMATIC VS120

Operating Instructions, Edition 02/2006, A5E00757507-01

4-19

Page 40

Image processing

4.10 Model sets

Example

The model set consists of two models. You need to decide if the image to be processed

contains the "SIEMENS" model or the "COMPANY" model.

"SIEMENS" model "COMPANY" model

• The user selects this model set instead of the model in processing mode. Each captured

image is evaluated in comparison to the individual models in the model set.

• The first captured image contains the "SIEMENS" specimen. The contours of the

specimen match those in the "SIEMENS“ model, but deviate strongly from the contours of

the "COMPANY“ model. The VS120 processing unit delivers the result, OK, and the

number of the "SIEMENS“ model.

Vision Sensor SIMATIC VS120

4-20 Operating Instructions, Edition 02/2006, A5E00757507-01

Page 41

Image processing

4.10 Model sets

• The next captured image contains the "COMPANY" specimen. The contours of the

specimen match those in the "COMPANY“ model, but deviate strongly from the contours

of the "SIEMENS“ model. The VS120 processing unit delivers the result, OK, and the

number of the "COMPANY“ model.

Vision Sensor SIMATIC VS120

Operating Instructions, Edition 02/2006, A5E00757507-01

4-21

Page 42

Image processing

4.10 Model sets

Vision Sensor SIMATIC VS120

4-22 Operating Instructions, Edition 02/2006, A5E00757507-01

Page 43

Network and system integration

5.1 5.1 Overview

The SIMATIC VS120 system can be configured as follows for the acquisition and processing

of recognition values:

• System configuration with digital I/O

• PROFIBUS DP environment

• PROFINET IO environment

• System configuration Ethernet (TCP / IP) or RS-232, for example, via Com server

Note

Other combinations of modes are permitted, for example, control via PROFIBUS DP and

result output via RS-232.

5

Vision Sensor SIMATIC VS120

Operating Instructions, Edition 02/2006, A5E00757507-01

5-1

Page 44

Network and system integration

5.2 System configuration over digital I/O

5.2 5.2 System configuration over digital I/O

Acquisition and output of recognition values via digital I/O

3RZHU

VXSSO\

3RZHUVXSSO\FDEOH

)XQFWLRQDOHDUWKLQJFDEOH

3URFHVVLQJXQLW

3*3&IRU

DGMXVWPHQWVXSSRUW

5- (WKHUQHW

FDEOH

$XWRPDWLRQV\VWHP

/LJKWLQJFDEOH

6HQVRUFDEOH

','2FDEOH

6HQVRUKHDG

/('ULQJIODVK

2EMHFW

3KRWRHOHFWULFEDUULHU

&RQYH\RUXQLW

&RQYH\RUXQLW

Figure 5-1 System configuration via digital I/O

System features:

• A PC/PG dedicated to adjustment is connected via the Ethernet port.

• The connection to an automation system is established via digital I/Os.

• The SIMATIC VS120 is controlled by the automation system via digital I/Os.

• The OK or N_OK results of the specimen are passed to the automation system via

digital I/Os.

Vision Sensor SIMATIC VS120

5-2 Operating Instructions, Edition 02/2006, A5E00757507-01

Page 45

Network and system integration

5.3 PROFIBUS DP system configuration

5.3 5.3 PROFIBUS DP system configuration

Acquisition and output of recognition values in a PROFIBUS DP environment

3RZHU

VXSSO\

3RZHUVXSSO\FDEOH

)XQFWLRQDOHDUWKLQJFDEOH

/LJKWLQJFDEOH

6HQVRUFDEOH

3URFHVVLQJXQLW

3*3&IRU

VHWXSVXSSRUW

5- (WKHUQHW

FDEOH

$XWRPDWLRQV\VWHP

352),%86b'3

6HQVRUKHDG

','2FDEOH

/('ULQJIODVK

2EMHFW

Figure 5-2 System configuration with PROFIBUS DP

System features:

• A PC/PG dedicated to adjustment is connected via the Ethernet port.

• The connection to an automation system is established via PROFIBUS DP.

• The SIMATIC VS120 is controlled by the automation system via PROFIBUS DP.

• The results from the specimen are output to the automation system via PROFIBUS DP.

Vision Sensor SIMATIC VS120

Operating Instructions, Edition 02/2006, A5E00757507-01

3KRWRHOHFWULFEDUULHU

&RQYH\RUXQLW

&RQYH\RUXQLW

5-3

Page 46

Network and system integration

5.4 PROFINET IO system configuration

5.4 5.4 PROFINET IO system configuration

Acquisition and output of recognition values in a PROFINET IO environment

3RZHU

VXSSO\

3RZHUVXSSO\FDEOH

)XQFWLRQDOHDUWKLQJFDEOH

/LJKWLQJFDEOH

6HQVRUFDEOH

3URFHVVLQJXQLW

6HQVRUKHDG

/('ULQJIODVK

6ZLWFK

3*3&IRU

DGMXVWPHQWVXSSRUW

$XWRPDWLRQV\VWHP

352),1(7,2

','2FDEOH

2EMHFW

&RQYH\RUXQLW

3KRWRHOHFWULFEDUULHU

&RQYH\RUXQLW

Figure 5-3 System configuration with PROFINET IO

System features:

• A PC / PG dedicated to adjustment is connected via the Ethernet (TCP/IP) and a switch.

• There is also a connection to a PROFINET IO compliant automation system via Ethernet

and a switch.

• The SIMATIC VS120 is controlled by the automation system.

• The results from the specimen are output to the automation system via PROFINET IO.

Vision Sensor SIMATIC VS120

5-4 Operating Instructions, Edition 02/2006, A5E00757507-01

Page 47

Network and system integration

5.5 System configuration with Ethernet or RS-232 over Com server

5.5 5.5 System configuration with Ethernet or RS-232 over Com server

Acquisition and output of recognition values with Ethernet (TCP / IP)

3RZHU

VXSSO\

3RZHUVXSSO\FDEOH

)XQFWLRQDOHDUWKLQJFDEOH

/LJKWLQJFDEOH

6HQVRUFDEOH

3URFHVVLQJXQLW

6HQVRUKHDG

/('ULQJIODVK

6ZLWFK

3*3&IRU

DGMXVWPHQWVXSSRUW

5-

(WKHUQHW

FDEOH

+0,

','2FDEOH

2EMHFW

Figure 5-4 System configuration with Ethernet (TCP/IP)

System features:

• The PC / PG for adjustment support is connected to the processing unit via a network.

• The SIMATIC VS120 is controlled by the HMI.

• The results from the specimen are output to the HMI.

Vision Sensor SIMATIC VS120

Operating Instructions, Edition 02/2006, A5E00757507-01

3KRWRHOHFWULFEDUULHU

&RQYH\RUXQLW

&RQYH\RUXQLW

5-5

Page 48

Network and system integration

5.5 System configuration with Ethernet or RS-232 over Com server

3RZHU

VXSSO\

3RZHUVXSSO\FDEOH

)XQFWLRQDOHDUWKLQJFDEOH

/LJKWLQJFDEOH

6HQVRUFDEOH

3URFHVVLQJXQLW

6HQVRUKHDG

/('ULQJIODVK

6ZLWFK

&RPVHUYHU

HJ:7

','2FDEOH

3*3&IRU

DGMXVWPHQWVXSSRUW

5-

(WKHUQHW

FDEOH

+0,

56

2EMHFW

&RQYH\RUXQLW

3KRWRHOHFWULFEDUULHU

&RQYH\RUXQLW

Figure 5-5 System configuration with RS-232 via Com server

System features:

• The PC / PG for adjustment support is connected to the processing unit via a network.

• The results are output to the HMI via the RS-232 port of the Com server, for example

W&T.

Vision Sensor SIMATIC VS120

5-6 Operating Instructions, Edition 02/2006, A5E00757507-01

Page 49

Installation

6.1 6.1 Installing the SIMATIC VS120 processing unit

1. For the location of the fixing holes, refer to the

VS120 Processing Unit

2. Mount the processing unit so that it is easily accessible for the operator

6.2 6.2 Installing the sensor head with LED ring flash

Notice

Aligning the optical axis

Align the optical axis of the sensor head vertical to the direction in which the object is

conveyed. Otherwise the image of the object will be distorted. The evaluation will be

inaccurate.

If the objects always pass the sensor head in the same position, the angle of the mid axis of

the objects to the vertical can be up to 45°.

Dimensional Drawing of the SIMATIC

6

Notice

Distance D between sensor and object

The ideal distance D between sensor and object depends on the type of sensor head. With

sensor heads with the order numbers (MLFB) below, the recommended distance D is as

follows:

• 6GF2 002-8DA01: 100 mm

• 6GF2 002-8EA01: 90 mm

Vision Sensor SIMATIC VS120

Operating Instructions, Edition 02/2006, A5E00757507-01

6-1

Page 50

Installation

6.2 Installing the sensor head with LED ring flash

There are two possible ways to install the LED ring flash:

• LED ring flash on the sensor head, parallel to the optical axis of the sensor head

6HQVRUKHDG

'

2EMHFW

&RQYH\RUXQLW

Figure 6-1 Components

How to mount the LED ring flash on the sensor head

The LED ring flash is supplied with two mounting brackets to allow it to be mounted on the

sensor head.

/('ULQJIODVK

1. Screw the mounting bracket onto the LED ring sensor

2. Push the sensor head through the LED ring sensor

3. Guide the mounting brackets into the grooves of the sensor head

4. Secure the mounting bracket with screws.

Vision Sensor SIMATIC VS120

6-2 Operating Instructions, Edition 02/2006, A5E00757507-01

Page 51

Installation

6.2 Installing the sensor head with LED ring flash

How to mount the sensor head

A mounting plate is supplied with the sensor head.

1. Insert the mounting plate in one of the grooves of the sensor head

2. Secure the sensor to your holder with a mounting plate

How to mount the LED ring flash beside the sensor head

No ring light flash is supplied to secure the LED ring flash beside the sensor head For

ordering information on a suitable ring flash holder, refer to the section

Accessories

in the

operating instructions.

1. Mount the sensor head on your holder

2. Secure the LED ring flash to the ring flash holder

3. Secure the ring light holder to your holder

• LED ring flash beside the sensor head, at an angle to the optical axis of the sensor head

Notice

LED ring flash beside the sensor head

If the object causes interfering reflections when the LED ring flash is mounted on the

sensor head, mount the LED ring flash beside the sensor head.

/('ULQJIODVK

Figure 6-2 Components with ring light

2EMHFW

&RQYH\LQJXQLW

6HQVRUKHDG

Vision Sensor SIMATIC VS120

Operating Instructions, Edition 02/2006, A5E00757507-01

6-3

Page 52

Installation

6.2 Installing the sensor head with LED ring flash

Vision Sensor SIMATIC VS120

6-4 Operating Instructions, Edition 02/2006, A5E00757507-01

Page 53

Connecting

7.1 7.1 Guidelines on installation and avoiding electrical interference

To avoid interference, you must shield your system. Low-frequency (LF) and high-frequency

(HF) interference signals can result in an incorrect response if the system is badly grounded

or not shielded.

Interference signals can be caused, for example, by

• Switching relays or contactors (large, fast changes in current or voltage and HF

interference signals);

• Different ground potentials between two parts of the system (LF interference signals)

Using / installing interference-proof cable

• Always use the supplied cable to connect the sensor head.

• All plug-in connections must be secured by screws or a locking mechanism.

• Signal lines must not run parallel to power cables. A separate cable channel must be

used with a minimum clearance of 50 cm from power cables.

7

Note

For more detailed information, refer to the installation manual SIMATIC S7-300

Programmable Controller, Hardware and Installation in the section on "Wiring".

7.2 7.2 Guidelines on installation when using PROFIBUS DP or PROFINET IO

If you are using PROFIBUS DP or PROFINET I/O to control the device and/or to transfer the

results the installation and configuration guidelines must be kept to.

Vision Sensor SIMATIC VS120

Operating Instructions, Edition 02/2006, A5E00757507-01

7-1

Page 54

Connecting

7.3 Connecting components

7.3 7.3 Connecting components

Connect the processing unit with the other components using the connectors on the front

panel.

The pinning of the connectors is described in the section: "Technical specifications" and with

the description of the supplied cable in section: "Scope of delivery/Spares/Accessories".

Caution

Do not connect or disconnect cables when the power supply is on.

Warning

Grounding the SIMATIC VS120 cancels the ungrounded configuration of the power unit.

Note

The DC load power supply must meet the following requirements:

Only a safe, isolated extra-low voltage of 24 V DC may be used as the load current supply.

Safe isolation can be implemented according to the requirements of:

- VDE 0100-410 / HD 384-4-41 S2 / IEC 60364-4-41 as protective extra low voltage with

safe isolation (PELV) or

- VDE 0805 / EN 60950 / IEC 60950 as safety extra-low voltage (SELV) or VDE 0106

Part 101.

The power supply chassis of the I/O and CPU must be connected to the power supply

chassis of the processing unit.

Vision Sensor SIMATIC VS120

7-2 Operating Instructions, Edition 02/2006, A5E00757507-01

Page 55

Connecting

7.3 Connecting components

Figure 7-1 Locations of the connection element

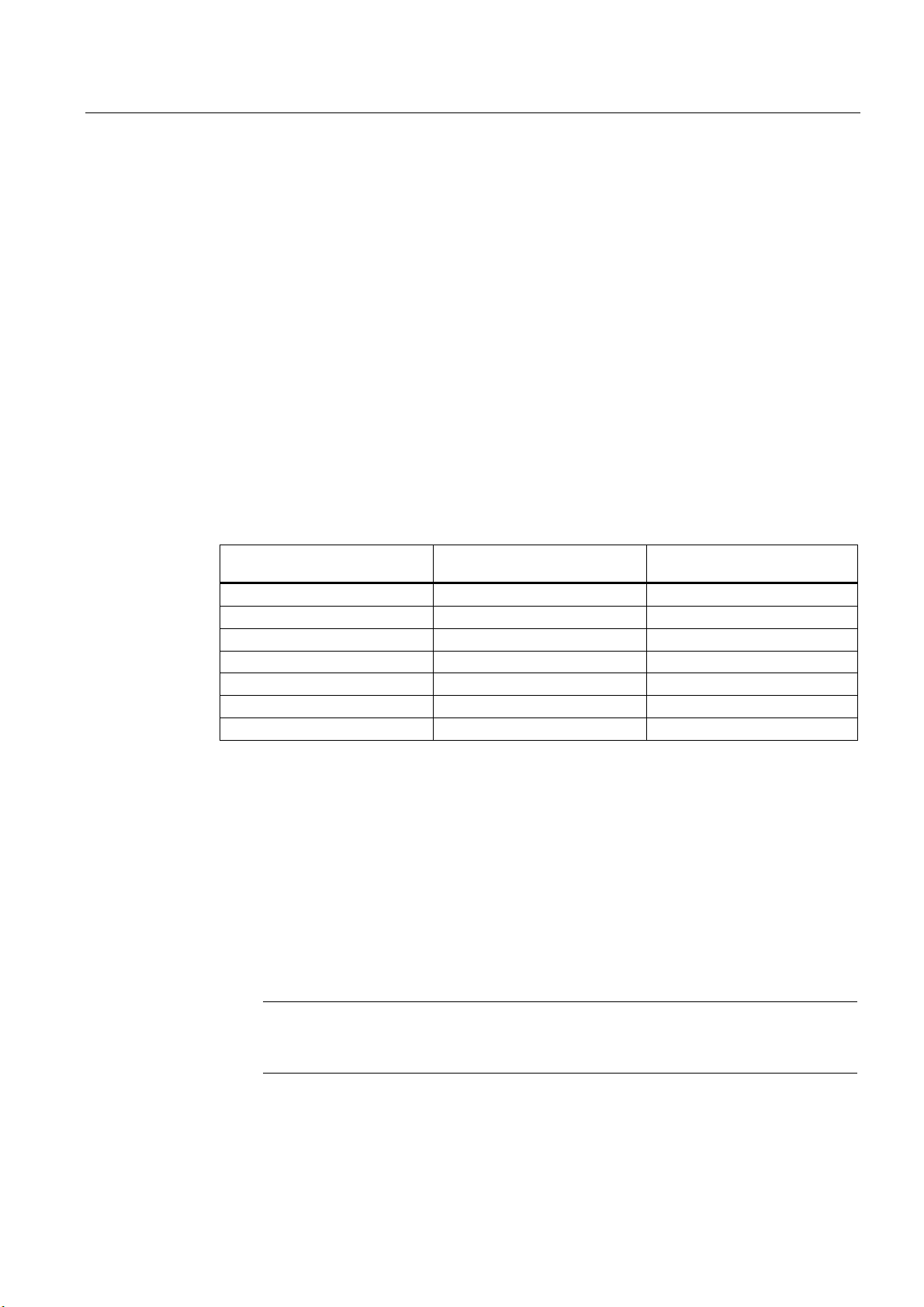

Wiring Connector label Type Number

of pins

Functional earth

Power supply IN 24 V DC Circular M12

Lighting unit LAMP Circular M12

Sensor head

(shielded cable)

I/O DI/DO D-sub 15 0.14 mm2 Socket

PROFIBUS DP DP D-sub 9 - Socket

Ethernet ETHERNET RJ45 8 - Socket

SENSOR HD D-sub 26 0.09 mm2 Socket

Screw-type

terminal

connector

connector

1 1.5 mm

4 0.56 mm2 Pin

4 0.23 mm2 Socket

Cable cross

section

2

Stranded

Type

conductor

Cable connection

• Read the guidelines on preventing electrical interference.

• Connect the processing unit to the sensor head and the lighting unit with the cables.

• Connect functional ground of the processing unit with chassis with a ring ∅ M5 and a

cable cross section of at least 1.5 mm

• Connect the processing unit to the 24 V DC load power supply with I = 2 A.

• Connect the PC/PG to the processing unit using an Ethernet cable.

• Arrange the cabling according to your configuration.

Vision Sensor SIMATIC VS120

Operating Instructions, Edition 02/2006, A5E00757507-01

2

.

7-3

Page 56

Connecting

7.3 Connecting components

Vision Sensor SIMATIC VS120

7-4 Operating Instructions, Edition 02/2006, A5E00757507-01

Page 57

Commissioning

8.1 8.1 Prerequisites

Notice

All activities are described based on the classic Windows Start menu.

If your Windows Start menu is not displayed in the classic style, change it as follows:

1. Right-click on the taskbar and select "Properties".

2. Change to the "Start Menu" tab and select the "Classic Start Menu" radio button.

3. Click "OK" to close the dialog box.

Requirements for commissioning:

• Administrator privileges

• Enabled JAVA JIT Compiler

8

Checking for administrator privileges

1. Click Start > Settings > Control Panel > Administrative Tools > Computer Management

2. Click on System > Local Users and Groups > Groups > Administrators

If you are included in the group of administrators, you have administrator privileges.

Otherwise contact your network administrator.

Vision Sensor SIMATIC VS120

Operating Instructions, Edition 02/2006, A5E00757507-01

8-1

Page 58

Commissioning

8.2 Overview of the steps in commissioning

Enabling the JAVA JIT compiler

1. Select Tools > Internet Options in the Internet Explorer and make the settings as shown

in the figure below:

Figure 8-1 Settings for the Java JIT compiler

8.2 8.2 Overview of the steps in commissioning

Step Activity

1 Turn on the VS120 processing unit

2

3 Establish and check the connections

4 Start adjustment support over the Internet Explorer

5 Adjust the sensor head using adjustment support

Establish an Ethernet connection between the VS120 processing unit and PG / PC:

2.1 Select the connection variant

2.2 Check if a proxy server is being used

2.3 If a proxy server is being used:

Change the proxy configuration of your Internet Explorer

Vision Sensor SIMATIC VS120

8-2 Operating Instructions, Edition 02/2006, A5E00757507-01

Page 59

Commissioning

8.3 Turn on the VS120 processing unit

8.3 8.3 Turn on the VS120 processing unit

Initial commissioning:

Turn on the power supply of the VS120 processing unit for its initial commissioning. The

VS120 processing unit then performs a self-test:

• Test of the Ethernet connection

• Function test of the sensor head

Note

During the initial commissioning, "Factory Settings Used" appears on the LCD display.

Confirm this with "OK.“

Once the self-test is completed, "Adjust" appears on the LCD display.

Normal mode:

Each time the SIMATIC VS120 starts up, the VS120 processing unit runs the following selftest:

• Test of the stored settings and model data

• Test of the Ethernet connection

• If appropriate, test of the connection to PROFINET IO

• If appropriate, test of the Ethernet RS-232 converter or TCP server and connection to the

PC / PG

• If appropriate, test of whether data can be exchanged with PROFIBUS DP

• Function test of the sensor head

• If appropriate, test of the connection for archiving model data

If the self-test completes without any errors, the main menu, the "Adjust" display or the RUN

menu is displayed on the LCD display depending on the status when the device was last

turned off.

• "Main" menu:

Vision Sensor SIMATIC VS120

Operating Instructions, Edition 02/2006, A5E00757507-01

8-3

Page 60

Commissioning

8.3 Turn on the VS120 processing unit

• "Adjust" displayed on the LCD display:

• "RUN" menu:

Note

Apart from controlling from the VS120 processing unit, you can also control

SIMATIC VS120 with the adjustment support.

Next step

Perform the activities described in the section

VS120 processing unit and PC / PG

.

Establish an Ethernet connection between the

Vision Sensor SIMATIC VS120

8-4 Operating Instructions, Edition 02/2006, A5E00757507-01

Page 61

Commissioning

8.4 Establish an Ethernet connection between the processing unit and PG / PC

8.4 8.4 Establish an Ethernet connection between the processing unit and

PG / PC

8.4.1 Select the connection variant

8.4.1.1 Connection variants

You can connect the VS120 processing unit via a direct connection or via a network with a

PC / PG. In all cases, the TCP/IP Ethernet protocol is used for communication.

Direct connection

• Operating the VS120 processing unit as a DHCP server

• Connecting the VS120 processing unit manually

Connection over a network

• Integrating the VS120 processing unit as a DHCP client in a network

• Integrating the VS120 processing unit as a device in a PROFINET IO network

Next step

Notice

Operating the VS120 processing unit in a network can interfere with the communication

in your network if you make certain settings in the Connect > Ports > Ethernet > IP Mode

menu. You should therefore only connect the VS120 processing unit to the network after

you have completed configuration and checked your settings carefully.

Select one of the connection variants from the next sections.

Vision Sensor SIMATIC VS120

Operating Instructions, Edition 02/2006, A5E00757507-01

8-5

Page 62

Commissioning

8.4 Establish an Ethernet connection between the processing unit and PG / PC

8.4.1.2 Operating the VS120 processing unit as a DHCP server

You want to do the following with the VS120 processing unit:

• Connect directly to the PC / PG

• Operate the VS120 processing unit as a DHCP server to assign the following addresses

of the processing unit automatically:

– IP address

– DNS server address

Notice

Under no circumstances connect the VS120 processing unit in this mode to an

existing DHCP server in the house network over a switch as you may disrupt the

operation of the house network. You can only implement an additional connection

from the PC to your previous network over a second network adapter in this PC.

Note

In this mode, you can connect up to four PCs to the VS120 processing unit via a

switch since a maximum of four IP addresses can be assigned automatically.

Procedure

1. Configure the VS120 processing unit as a DHCP server.

2. Configure your PC / PG as a DHCP client

3. Establish an Ethernet connection

Step 1: Configuring the VS120 processing unit as a DHCP server

1. After turning on the VS120 processing unit and after the self-test is completed, go to the

"Connect" menu and confirm with "OK".

2. Confirm the selected "Ports" menu command with "OK".

3. Change to the "Ethernet" menu and confirm with "OK"

4. Confirm the selected "IP Mode" menu command with "OK".

5. Select "DHCPSERV" and confirm with "OK"

Vision Sensor SIMATIC VS120

8-6 Operating Instructions, Edition 02/2006, A5E00757507-01

Page 63

Commissioning

8.4 Establish an Ethernet connection between the processing unit and PG / PC

Step 2: Configure your PC / PG as a DHCP client

1. Click Start > Settings > Network and Dial-up Connections

2. In the "Network and Dial-up Connections" dialog, select your active local area connection

to the network