Siemens SIMATIC TDC System Manual

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

SIMATIC TDC

SIMATIC TDC hardware

System Manual

08/2017

A5E01114865

Preface

Installation and EMC

guidelines

1

General technical

specifications

2

Rack

3

CPU modules

4

Signal modules

5

Communication modules

6

Interface module

7

Submodules

8

Service & Support

A

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

-AL

Siemens AG

Division Digital Factory

Postfach 48 48

90026 NÜRNBERG

GERMANY

Ⓟ

Copyright © Siemens AG 2017.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

for the specific

07/2017 Subject to change

Preface

Purpose of this manual

Basic knowledge required

Scope of the manual

Position in the information landscape

Title

Content

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

This manual describes the principles of using the functions of the hardware components,

while setting the focus on the corresponding Technology and Drive Control components

SIMATIC TDC.

This manual is intended for commissioning personnel. Comprehension of this manual

requires general knowledge of automation engineering.

This manual is valid for SIMATIC D7-SYS as of version 8.1.

This manual is part of the documentation package for the Technology and Drive Control

components FM 458, SIMATIC TDC and SIMATIC D7-SYS.

SIMATIC TDC hardware

System Manual, 08/2017, A5E01114865-AL

3

Preface

Title

Content

Just a few steps away from the first project

System software

n communicates basic knowledge of the structure of a CPU's operating system and

Configuring communication

configure links to communication partners.

Basic software

CFC

The CFC language (Continuous Function Chart) offers you the possibility of designing graphic

SFC

position the SFC elements of the chart according to defined rules.

Section 1

all target systems

Section 2

only

Section 3

only

Section 4

only

T400.

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

System and Communication Configuration D7-SYS

(http://support.automation.

siemens.com/WW/

view/de/8776461/0/en)

D7-SYS - STEP 7, configuring CFCs and SFCs

(http://support.automation.

siemens.com/WW/

view/de/8776786/0/en)

This section provides an extremely simple introduction into the methodology of the structure

and programming of the SIMATIC TDC control system. It is interesting especially for first-time

users.

This sectio

application programs. It should be used under the aspect of obtaining an overview of programming methodology and using this information as a basis for designing user programs.

This section communicates basic knowledge of the communication possibilities and how to

This section explains the principles of the usage and functions of the STEP 7 automation

software. Newcomers are provided an outline of the procedures to follow when configuring,

programming, and commissioning a station.

While working with the basic software, you can directly rely on the Online Help system that

offers support when it comes to detailed questions on using the software.

interconnections for blocks.

While working with the particular software, you can always consult the Online Help to get

answers to detailed questions regarding the use of the editors/compiler.

Configuring sequential controls using SIMATIC S7 SFCs (Sequential Function Chart).

You create the sequential chart in the SFC Editor based on various graphic resources and

Hardware These manuals form a reference for the entire hardware spectrum.

D7-SYS Selecting function

blocks

(http://support.automation.

siemens.com/WW/

view/de/14952400/0/en)

SIMATIC TDC hardware

4 System Manual, 08/2017, A5E01114865-AL

The Reference Manual provides you with an overview of all of the function blocks for the corresponding Technology and Drive Control components SIMATIC TDC, FM 458-1 DP as well

as the T400 and SIMADYN D systems which are being phased out.

This section describes the function blocks that can be configured in

SIMATIC D7-SYS.

This section describes the function blocks that can be configured

This section describes the function blocks that can be configured

application module.

This section describes the function blocks that can be configured

of

for SIMATIC TDC.

for the FM 458-1 DP

for SIMADYN D and

Preface

Signpost

Special notes

Recycling and disposal

Additional support

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

As first-time user, you should use the manual as follows:

● Read the initial sections before using the software so that you become familiar with the

terminology and procedural principles.

● You can then go ahead and use the respective sections of the manual, for example, if you

intend to run a specific task (e.g. loading programs).

If you have already gained some experience while running a small project, you can read

individual sections of the manual in order to obtain information on specific topics.

The objective of the user part of this manual is to provide information on basic procedures,

but does not contain any detailed instructions with individual step sequences. For more

information on the software dialogs and their handling, refer to the Online Help.

The products can be recycled due to their low-pollutant content. Contact a certified

electronic-waste disposal company to recycle and dispose of your old equipment in an

environment-friendly manner.

● You can find information on the technical support offer in the appendix (Page 221) to this

documentation.

● You can find the offer for technical documentation for the individual SIMATIC products

and systems on the Internet (http://www.siemens.com/simatic-tech-doku-portal).

● You can find the online catalog and online ordering system on the Internet

(http://mall.automation.siemens.com).

SIMATIC TDC hardware

System Manual, 08/2017, A5E01114865-AL

5

Preface

Security information

Open Source Software

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial

security concept. Siemens’ products and solutions only form one element of such a concept.

Customer is responsible to prevent unauthorized access to its plants, systems, machines

and networks. Systems, machines and components should only be connected to the

enterprise network or the internet if and to the extent necessary and with appropriate security

measures (e.g. use of firewalls and network segmentation) in place.

Additionally, Siemens’ guidance on appropriate security measures should be taken into

account. For more information about industrial security, please visit

(http://www.siemens.com/industrialsecurity).

Siemens’ products and solutions undergo continuous development to make them more

secure. Siemens strongly recommends to apply product updates as soon as available and to

always use the latest product versions. Use of product versions that are no longer supported,

and failure to apply latest updates may increase customer’s exposure to cyber threats.

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS

Feed under (http://www.siemens.com/industrialsecurity).

Open-source software is used in the firmware of the product described. Open Source

Software is provided free of charge. We are liable for the product described, including the

open-source software contained in it, pursuant to the conditions applicable to the product.

Siemens accepts no liability for the use of the open source software over and above the

intended program sequence, or for any faults caused by modifications to the software.

For legal reasons, we are obliged to publish the original text of the license conditions and

copyright notices.

You can find this information on the supplied CD/DVD.

SIMATIC TDC hardware

6 System Manual, 08/2017, A5E01114865-AL

Table of contents

Preface ................................................................................................................................................... 3

1 Installation and EMC guidelines ............................................................................................................ 13

2 General technical specifications ............................................................................................................ 37

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

1.1 Qualified personnel ................................................................................................................. 13

1.2 Danger and warning information ............................................................................................. 14

1.3 Introduction ............................................................................................................................. 15

1.4 CE label .................................................................................................................................. 16

1.5 EMC Directive ......................................................................................................................... 16

1.6 Low-voltage directive .............................................................................................................. 17

1.7 Machinery directive ................................................................................................................. 17

1.8 Installation ............................................................................................................................... 17

1.9 Fire protection ......................................................................................................................... 18

1.10 Control cabinet ........................................................................................................................ 20

1.11 Equipotential bonding ............................................................................................................. 22

1.12 Protective ground .................................................................................................................... 28

1.13 Power losses in the control cabinet ........................................................................................ 29

1.14 Power supply .......................................................................................................................... 30

1.15 Rack ........................................................................................................................................ 32

1.16 Cables ..................................................................................................................................... 32

1.17 ESD Directives ........................................................................................................................ 35

2.1 Climatic conditions .................................................................................................................. 37

2.2 Electrical protection and safety requirements ......................................................................... 37

2.3 External supply of the SIMATIC TDC modules (digital outputs) ............................................. 37

2.4 Mechanical requirements ........................................................................................................ 38

2.5 Electromagnetic requirements (industry) ................................................................................ 38

SIMATIC TDC hardware

System Manual, 08/2017, A5E01114865-AL

7

Table of contents

3 Rack ..................................................................................................................................................... 39

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

3.1 Rack UR6021 (6DD1682-0CH3) ............................................................................................ 39

3.1.1 Areas of application ............................................................................................................... 39

3.1.2 Mechanical layout .................................................................................................................. 40

3.1.3 Control and display elements ................................................................................................. 41

3.1.4 Status and fault displays ........................................................................................................ 42

3.1.5 Power supply .......................................................................................................................... 42

3.1.6 Wiring diagram ....................................................................................................................... 43

3.1.7 Voltage monitoring ................................................................................................................. 44

3.1.8 Battery backup ....................................................................................................................... 45

3.1.9 Modules .................................................................................................................................. 47

3.1.10 Power supply potentials ......................................................................................................... 47

3.1.11 Ventilation/cooling .................................................................................................................. 48

3.1.12 Technical specifications ......................................................................................................... 51

3.2 Rack UR5213 (6DD1682-0CH2) ............................................................................................ 54

3.2.1 Areas of application ............................................................................................................... 54

3.2.2 Mechanical layout .................................................................................................................. 54

3.2.3 Control and display elements ................................................................................................. 55

3.2.4 Status and fault displays ........................................................................................................ 56

3.2.5 Power supply .......................................................................................................................... 56

3.2.6 Wiring diagram ....................................................................................................................... 57

3.2.7 Voltage monitoring ................................................................................................................. 58

3.2.8 Battery backup ....................................................................................................................... 59

3.2.9 Modules .................................................................................................................................. 60

3.2.10 Power supply potentials ......................................................................................................... 60

3.2.11 Ventilation/cooling .................................................................................................................. 61

3.2.12 Technical specifications ......................................................................................................... 63

3.3 Rack UR5213 (6DD1682-0CH0) ............................................................................................ 66

3.3.1 Areas of application ............................................................................................................... 66

3.3.2 Mechanical layout .................................................................................................................. 66

3.3.3 Control and display elements ................................................................................................. 67

3.3.4 Status and fault displays ........................................................................................................ 68

3.3.5 Power supply .......................................................................................................................... 68

3.3.6 Voltage monitoring ................................................................................................................. 70

3.3.7 Battery backup ....................................................................................................................... 71

3.3.8 Ventilation/cooling .................................................................................................................. 72

3.3.9 Technical specifications .........................................................................................................

3.4 S

lot covers ............................................................................................................................. 74

73

SIMATIC TDC hardware

8 System Manual, 08/2017, A5E01114865-AL

Table of contents

4 CPU modules ........................................................................................................................................ 75

5 Signal modules ................................................................................................................................... 103

6 Communication modules ..................................................................................................................... 121

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

4.1 CPU module CPU555 ............................................................................................................. 75

4.1.1 Areas of application ................................................................................................................ 75

4.1.2 Control and display elements ................................................................................................. 76

4.1.3 Status and fault displays ......................................................................................................... 78

4.1.4 Application notes and immunity to interference ...................................................................... 81

4.1.5 Connection options ................................................................................................................. 82

4.1.6 Additional components............................................................................................................ 82

4.1.7 Pin assignments ...................................................................................................................... 83

4.1.8 Note on firmware update ........................................................................................................ 83

4.1.9 Technical specifications/performance features ...................................................................... 84

4.2 CPU module CPU550/CPU551 .............................................................................................. 88

4.2.1 Areas of application ................................................................................................................ 88

4.2.2 Using the CPU551 - 6DD1600-0BA3 ...................................................................................... 88

4.2.3 Control and display elements ................................................................................................. 90

4.2.4 Status and fault displays ......................................................................................................... 91

4.2.5 Application notes and immunity to interference ...................................................................... 94

4.2.6 Connection options ................................................................................................................. 94

4.2.7 Additional components............................................................................................................ 95

4.2.8 Pin assignments ...................................................................................................................... 95

4.2.9 Technical specifications/performance features ...................................................................... 97

5.1 SM500 signal module ........................................................................................................... 103

5.1.1 Areas of application .............................................................................................................. 103

5.1.2 Control and display elements ............................................................................................... 103

5.1.3 Status and fault displays ....................................................................................................... 105

5.1.4 Application notes and immunity to interference .................................................................... 105

5.1.5 Connection options ............................................................................................................... 106

5.1.6 Additional components.......................................................................................................... 107

5.1.7 Incremental encoder input settings ....................................................................................... 108

5.1.8 Pin assignments .................................................................................................................... 110

5.1.9 Technical specifications/performance features .................................................................... 116

6.1 CP50M1 communication module .......................................................................................... 121

6.1.1 Areas of application .............................................................................................................. 121

6.1.2 Control and display elements ............................................................................................... 123

6.1.3 Status and fault displays ....................................................................................................... 124

6.1.4 Application notes and immunity to interference .................................................................... 125

6.1.5 Connection options ............................................................................................................... 125

6.1.6 Additional components.......................................................................................................... 126

6.1.7 Pin assignments .................................................................................................................... 127

6.1.8 Technical specifications/performance features .................................................................... 128

SIMATIC TDC hardware

System Manual, 08/2017, A5E01114865-AL

9

Table of contents

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

6.2 CP51M1 communication module ......................................................................................... 130

6.2.1 Areas of application ............................................................................................................. 130

6.2.2 Control and display elements ............................................................................................... 131

6.2.3 Status and fault displays ...................................................................................................... 132

6.2.4 Application notes and immunity to interference ................................................................... 133

6.2.5 Connection options .............................................................................................................. 133

6.2.6 Additional components ......................................................................................................... 134

6.2.7 Pin assignments ................................................................................................................... 134

6.2.8 Technical specifications/performance features .................................................................... 135

6.3 GDM memory module CP52M0 ........................................................................................... 137

6.3.1 Areas of application ............................................................................................................. 137

6.3.2 Control and display elements ............................................................................................... 138

6.3.3 Status and fault displays ...................................................................................................... 139

6.3.4 Application notes and immunity to interference ................................................................... 141

6.3.5 Connection options .............................................................................................................. 144

6.3.6 Additional components ......................................................................................................... 144

6.3.7 Pin assignments ................................................................................................................... 145

6.3.8 Technical specifications/performance features .................................................................... 147

6.4 CP52IO GDM interface module ........................................................................................... 149

6.4.1 Areas of application ............................................................................................................. 149

6.4.2 Control and display elements ............................................................................................... 150

6.4.3 Status and fault displays ...................................................................................................... 152

6.4.4 Application notes and immunity to interference ................................................................... 152

6.4.5 Connection options .............................................................................................................. 153

6.4.6 Additional components ......................................................................................................... 154

6.4.7 Pin assignments ................................................................................................................... 154

6.4.8 Technical specifications/performance features .................................................................... 155

6.5 CP52A0 GDM access module ............................................................................................. 156

6.5.1 Areas of application ............................................................................................................. 156

6.5.2 Using the CP52A0 - 6DD1660-0BH1 ................................................................................... 157

6.5.3 Control and display elements ............................................................................................... 157

6.5.4 Status and fault displays ...................................................................................................... 159

6.5.5 Application notes and immunity to interference ................................................................... 160

6.5.6 Connection options .............................................................................................................. 161

6.5.7 Additional components ......................................................................................................... 161

6.5.8 Pin assignments ...................................................................................................................

9 Technical specifications/performance features .................................................................... 162

6.5.

6.6 CP53M0 coupling module .................................................................................................... 163

6.6.1 Areas of application ............................................................................................................. 163

6.6.1.1 CP53M0 as slave ................................................................................................................. 163

6.6.1.2 CP53M0 as master .............................................................................................................. 165

6.6.2 Control and display elements ............................................................................................... 167

6.6.3 Status and fault displays ...................................................................................................... 169

6.6.4 Application notes and immunity to interference ................................................................... 171

6.6.5 Connection options .............................................................................................................. 172

6.6.6 Additional components ......................................................................................................... 172

6.6.7 Pin assignments ................................................................................................................... 173

6.6.8 Technical specifications/performance features .................................................................... 173

162

SIMATIC TDC hardware

10 System Manual, 08/2017, A5E01114865-AL

Table of contents

7 Interface module ................................................................................................................................. 175

8 Submodules ........................................................................................................................................ 217

A Service & Support ............................................................................................................................... 221

Index................................................................................................................................................... 225

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

7.1 Interface module SB10 ......................................................................................................... 175

7.1.1 Signals .................................................................................................................................. 177

7.1.2 Application notes ................................................................................................................... 178

7.1.3 Technical specifications ........................................................................................................ 179

7.1.4 Pin assignment ..................................................................................................................... 180

7.1.5 Block diagram ....................................................................................................................... 181

7.2 Interface module SB60 ......................................................................................................... 182

7.2.1 Signals .................................................................................................................................. 184

7.2.2 Application notes ................................................................................................................... 184

7.2.3 Technical specifications ........................................................................................................ 185

7.2.4 Pin assignment ..................................................................................................................... 186

7.2.5 Block diagram ....................................................................................................................... 187

7.3 Interface module SB61 ......................................................................................................... 188

7.3.1 Signals .................................................................................................................................. 190

7.3.2 Application notes ................................................................................................................... 191

7.3.3 Technical specifications ........................................................................................................ 194

7.3.4 Pin assignment ..................................................................................................................... 195

7.3.5 Block diagram ....................................................................................................................... 196

7.4 Interface module SB70 ......................................................................................................... 197

7.4.1 Signals .................................................................................................................................. 199

7.4.2 Application notes ................................................................................................................... 200

7.4.3 Technical specifications ........................................................................................................ 201

7.4.4 Pin assignment ..................................................................................................................... 202

7.4.5 Block diagram ....................................................................................................................... 203

7.5 Interface module SB71 ......................................................................................................... 204

7.5.1 Signals .................................................................................................................................. 206

7.5.2 Application notes ................................................................................................................... 206

7.5.3 Technical specifications ........................................................................................................ 208

7.5.4 Pin assignment ..................................................................................................................... 209

7.5.5 Block diagram ....................................................................................................................... 210

7.6 Interface modules SU12 und SU13 ...................................................................................... 211

7.6.1 Function description .............................................................................................................. 212

7.6.2 Additional components.......................................................................................................... 213

7.6.3 Application notes ................................................................................................................... 213

7.6.4 Pin/terminal assignment X1/X2 ............................................................................................. 214

7.6.5 Technical specifications ........................................................................................................ 216

8.1 Program memory modules CPU555 ..................................................................................... 217

8.2 Program memory modules CPU550/551 .............................................................................. 219

A.1 Service & Support ................................................................................................................. 221

SIMATIC TDC hardware

System Manual, 08/2017, A5E01114865-AL

11

Table of contents

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

SIMATIC TDC hardware

12 System Manual, 08/2017, A5E01114865-AL

1

Note

These Operating Instructions do not purport to cover

nor to provide for every possible contingency to be met in connection with installation,

operation or maintenance.

If you need further information or encounter special problems that are not adequately treated

in the

Siemens office.

Furthermore, the contents of these Operating Instructions shall not become a part of or

modify any prior or existing agreement, commitment, or legal relationsh

the part of Siemens AG are contained in the respective sales contract which also contains

the complete and solely applicable warranty conditions. These contractual guarantee

provisions are neither broadened nor restricted by the text

1.1

Qualified personnel

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

all details or variations in equipment,

operating instructions, you can obtain the necessary information from your local

ip. All obligations on

in these operating instructions.

in the context of the operating manual or of warning notices on the product itself are persons

familiar with installation, assembly, commissioning and operation of the product and holding

qualifications appropriate to their activity, such as:

1. Trained and authorized to power up, shut down, ground and tag electrical circuits and

equipment in accordance with safety standards.

2. Trained in the proper care and use of protective equipment in accordance with safety

standards.

SIMATIC TDC hardware

System Manual, 08/2017, A5E01114865-AL

13

Installation and EMC guidelines

1.2

Danger and warning information

WARNING

Danger, high voltage

NOTICE

Electrostatic sensitive devices

NOTICE

Lifting and carrying heavy loads

NOTICE

Cleaning the devices

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

1.2 Danger and warning information

During operation of electrical devices, certain parts of these devices are necessarily under

dangerous voltage.

Ignorance of the safety instructions may result in severe injury or property damage.

Particularly the warning notes in the corresponding Operating Instructions must be strictly

observed.

The modules contain components that are sensitive to electrostatic charge. Always

discharge your body before you touch an electronic module. This can be done quite simply

by touching a conductive, grounded object immediately before you handle the component

(e.g. bright metal parts of the control cabinet, grounding contact of socket outlet.)

Note the regulations/notes on lifting and carrying heavy loads.

Use only a vacuum cleaner and dry cloths to clean the devices.

SIMATIC TDC hardware

14 System Manual, 08/2017, A5E01114865-AL

Installation and EMC guidelines

1.3

Introduction

What is EMC ?

Intrinsic immunity to interference:

Immunity to external interference:

Degree of interference emission

Operational reliability and immunity to interference

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

1.3 Introduction

Electromagnetic compatibility (EMC) is the ability of an electrical device to function, fault-free

in a specified electromagnetic environment without influencing the environment in an

inadmissible fashion.

This design and EMC Directive supplements the documentation on the individual

components.

The SIMATIC TDC control system consists of individual components (e.g. racks, modules,

interface modules, operator control panels, position transmitters). The components can be

installed in the widest range of system configurations to suit individual requirements. In an

environment that contains distributed components it is imperative not to neglect interference

and to conform with special installation and EMC requirements of the plant.

EMC therefore represents a quality feature for

●

variables

●

electromagnetic disturbance variables

●

radiation

The manufacturer of the control system and users (including end customers) must take

specific measures in order to achieve the maximum possible operational reliability and safety

and interference immunity for a complete system (control and drive system).

Proper functioning of SIMATIC TDC can only be ensured if all of these measures have been

observed in compliance with legal provisions (2004/108/EC).

Resistance against internal electrical disturbance

Resistance of the system against external

: Environmental effects caused by electromagnetic

SIMATIC TDC hardware

System Manual, 08/2017, A5E01114865-AL

15

Installation and EMC guidelines

1.4

CE label

1.5

EMC Directive

Industrial aera of applicaion

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

1.4 CE label

Our products meet the requirements and protection objectives of the EC Directives listed

below and comply with Harmonized European Standards (EN) for programmable controllers

that were published in the Official Journals of the European Community:

● 2006/95/EC "Electrical equipment for use within specific voltage limits" (Low-voltage

directive)

● 2004/108/EC "Electromagnetic Compatibility" (EMC Directive)

The EC Declarations of Conformity are available to relevant authorities at the following

address:

Siemens AG

Digital Factory

Factory Automation

DF FA AS DH AMB

PO box 1963

92209 Amberg / Germany

SIMATIC products are designed for use in industrial environments.

● Interference emission requirements to EN 61000-6-4: 2007 + A1:2011

● Immunity to interference requirements to EN 61000-6-2: 2005

SIMATIC TDC hardware

16 System Manual, 08/2017, A5E01114865-AL

Installation and EMC guidelines

1.6

Low-voltage directive

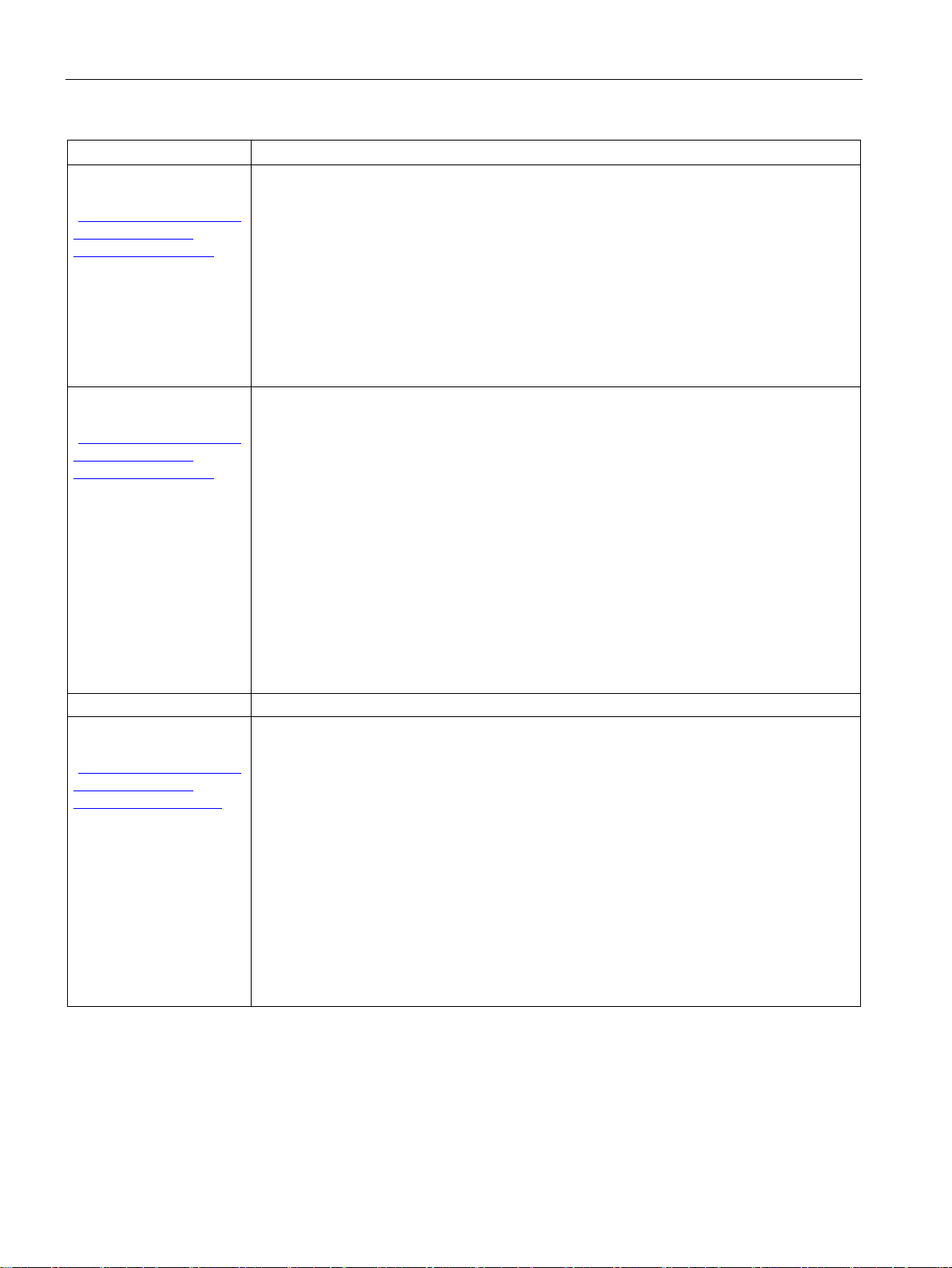

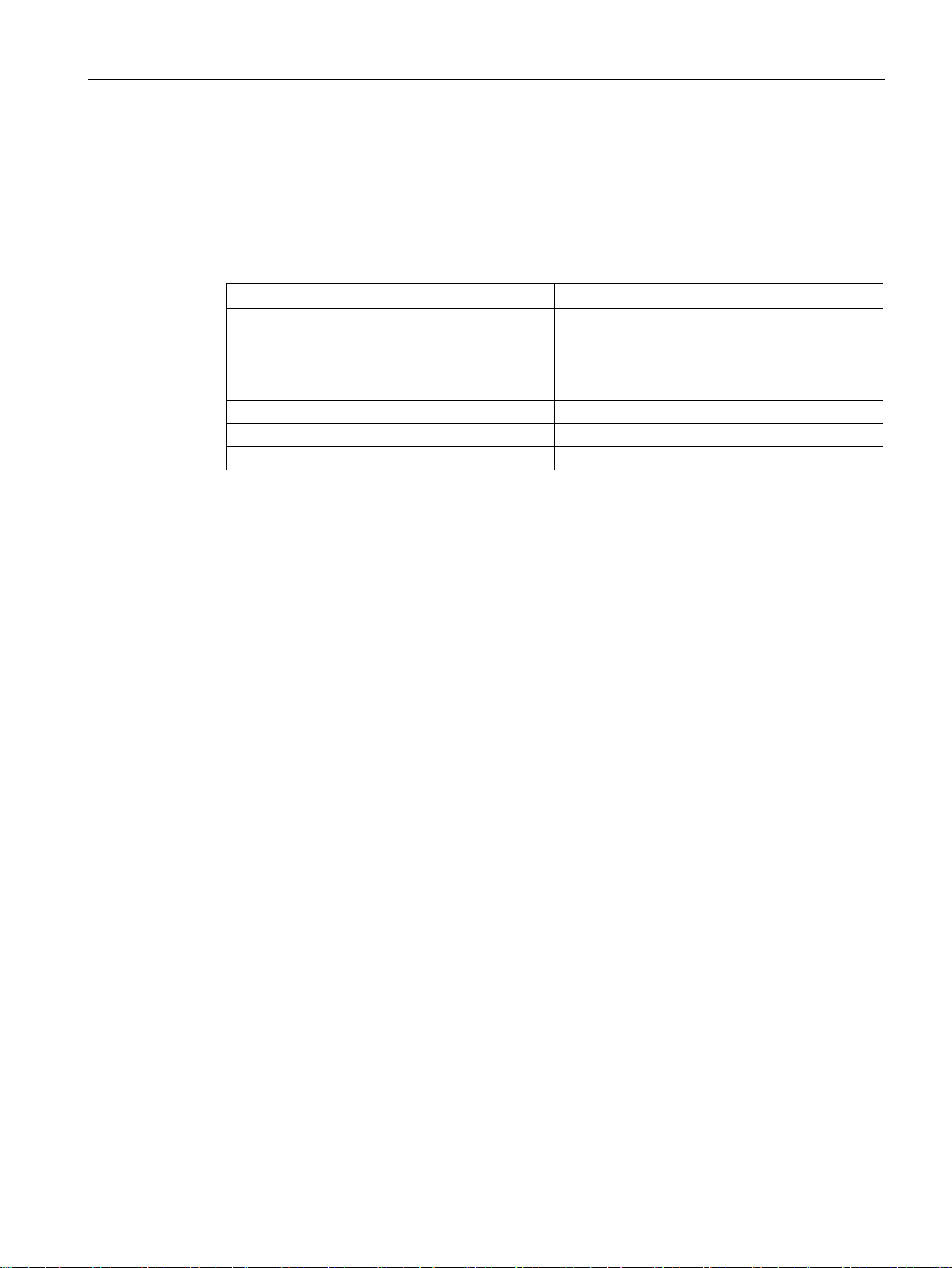

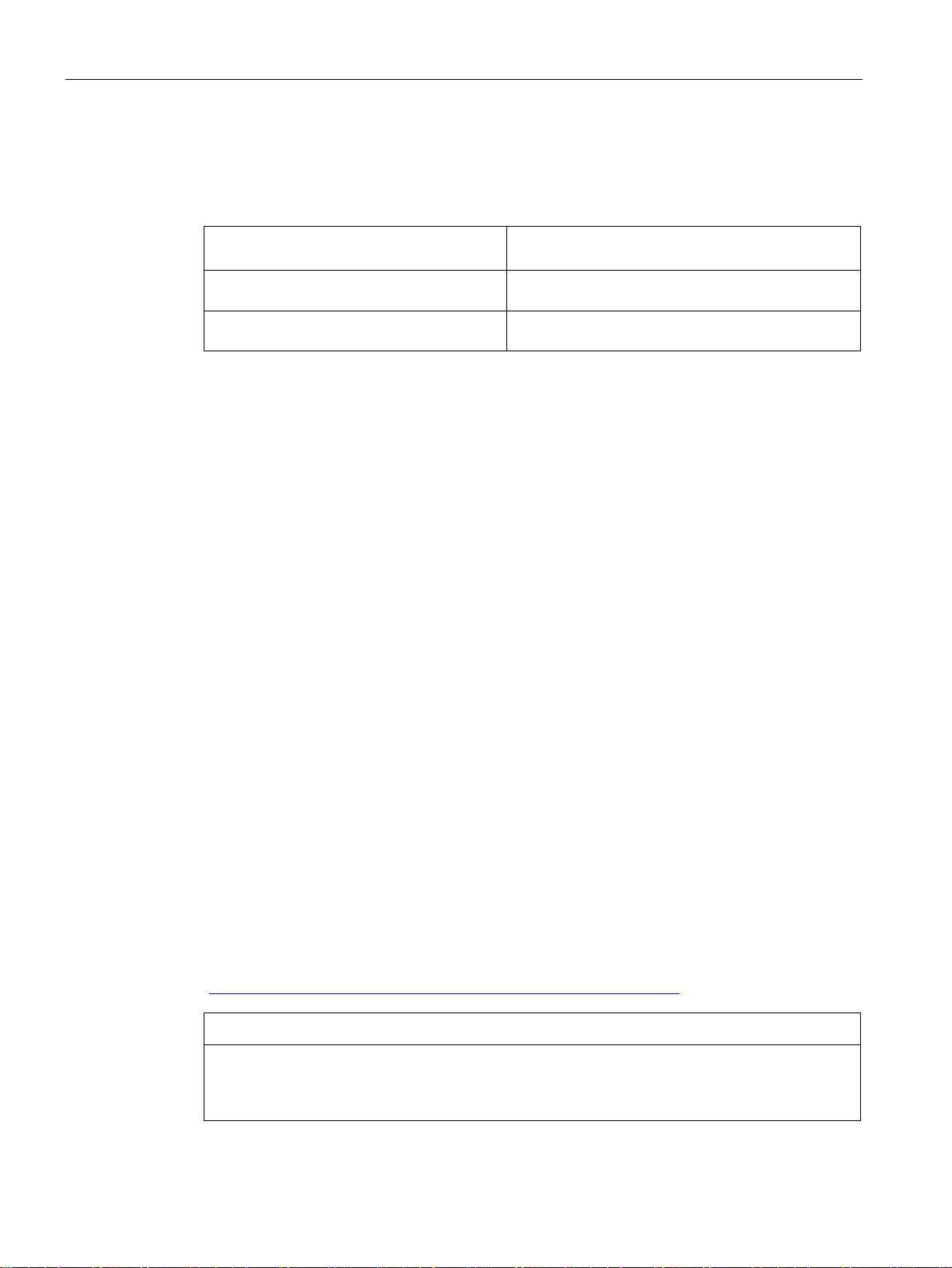

Name

Article number

UR5213

6DD 1682-0CH0

UR5213

6DD 1682-0CH2

SB 60

6DD 1681-0AF4

SB 70

6DD 1681-0AG2

Fan tray

6DD1683-0CH3

1.7

Machinery directive

Expert personnel

Input of external voltages

1.8

Installation

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

1.6 Low-voltage directive

The products listed in the table below fulfill the requirements of EU directive 2006/95/EC,

"Low-voltage Directive". Compliance with this EC directive was tested in accordance with

DIN 61131-2 (corresponds to IEC 61131-2).

The following components are also affected in SIMATIC TDC:

PS5213 6DD 1683-0CH0

UR6021 6DD 1682-0CH3

These components are compliant with requirements of the Low-voltage Directive.

In accordance with the Machinery Directive 2006/42/EC, it must be ensured that a failure or

malfunction of SIMATIC TDC will not trigger a hazardous state of the machine/plant. This

must always be taken into account when configuring the machine/system.

The system may not be commissioned until it has been proven that the final product is in

compliance with the directive.

Only expert personnel may configure, commission, service and operate SIMATIC TDC.

An external voltage source (e.g. pulse encoder) that is connected to SIMATIC TDC module

inputs must be shut down simultaneously with the shutdown or failure of the SIMATIC TDC

power supply.

SIMATIC TDC components are considered open equipment that must be installed in metallic

enclosures containing shielding and equipotential busbars in compliance with the

requirements of IEC 61131-2 (11.1.2; mechanical strength, flame resistance, stability and

shock protection are significant here).

SIMATIC TDC hardware

System Manual, 08/2017, A5E01114865-AL

17

Installation and EMC guidelines

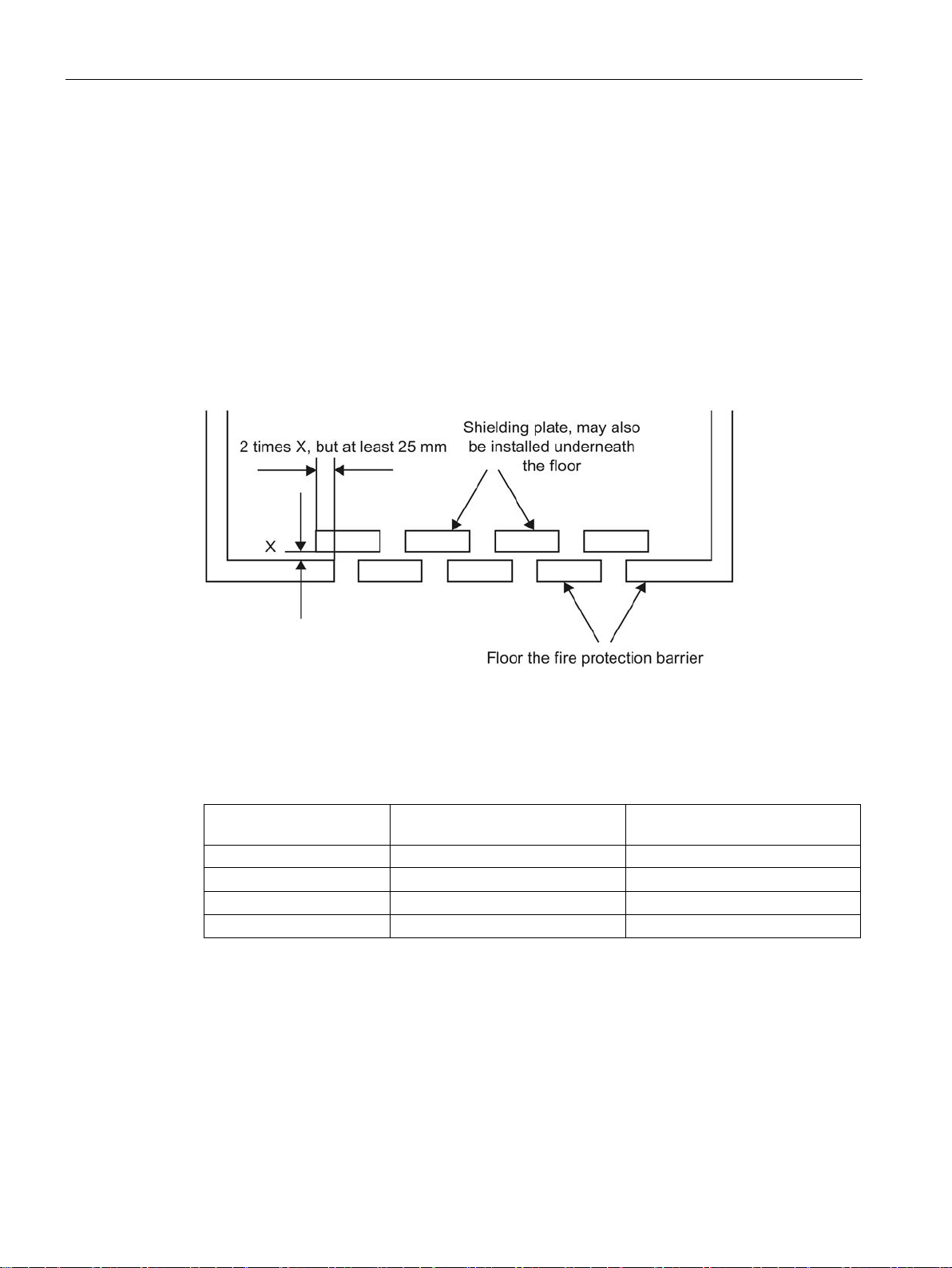

1.9

Fire protection

Example 1

Partition below the rack

Example 2

Metal panel

[mm]

[mm]

0.76

1.1

1.7 (35 holes/100 mm2)

0.76

1.2

2.4

0.89

1.9

3.2 (10 holes/100 mm2)

0.99

1.6

2.7

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

1.9 Fire protection

As output power exceeds the limit of circuitry with power limiting to IEC 61010-1 /

IEC 61131-2, malfunction of a SIMATIC TDC component may pose the risk of fire according

to IEC 61010-1 / IEC 61131-2. In order to prevent spreading of fire, suitable measures must

be taken to prevent ignition of adjacent parts or components as a result of burning parts that

possibly drop out of a component.

Two examples of a fire protection barrier to IEC 61010-1

Accepted perforation of a metal panel

Minimum thickness [mm] Maximum diameter of the holes

Minimum hole pitch, center-center

SIMATIC TDC hardware

18 System Manual, 08/2017, A5E01114865-AL

Installation and EMC guidelines

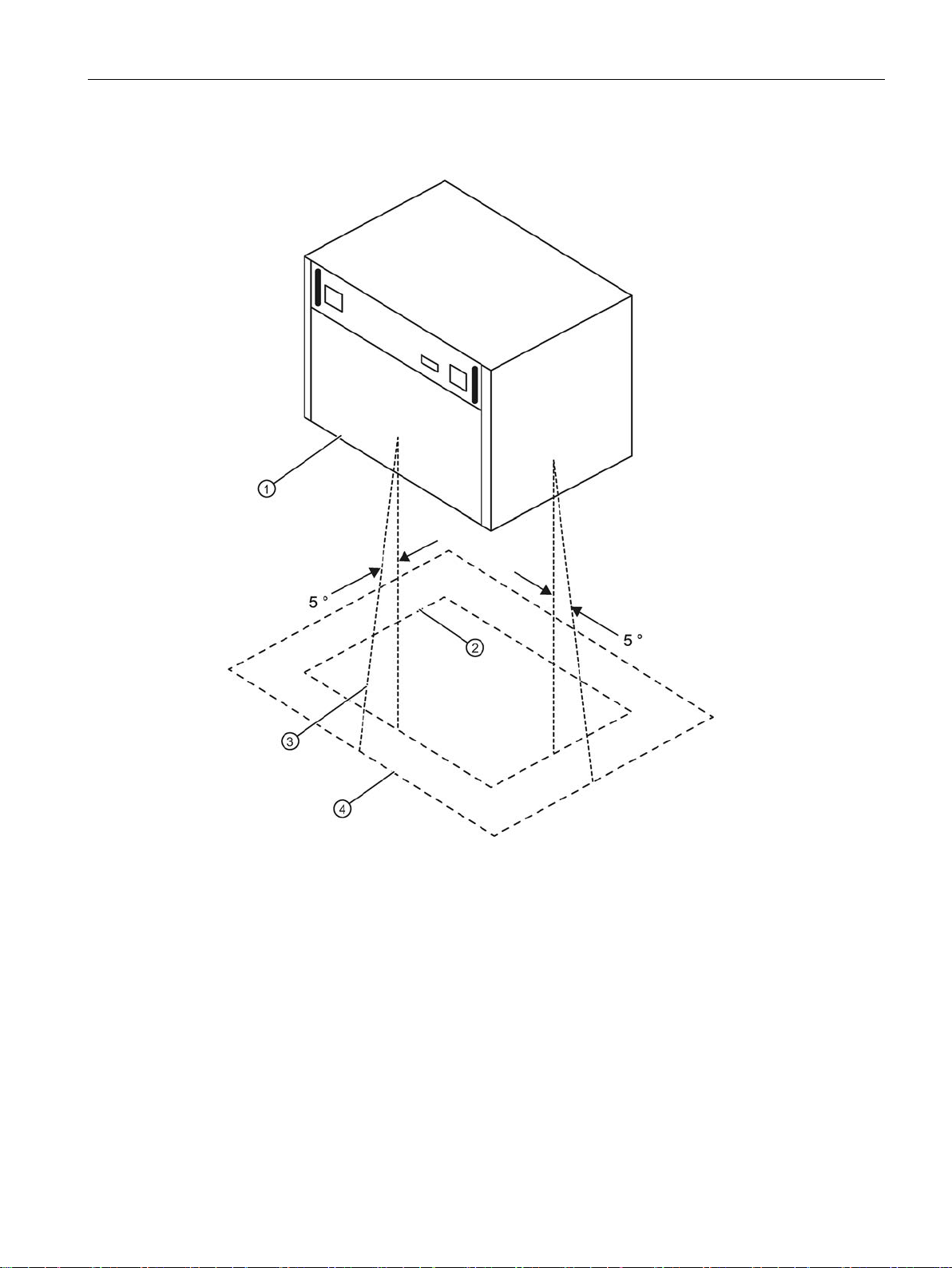

Minimum size of the fire protection barrier

①

Rack

②

Vertical projection of the rack

③

+50 from the vertical projection profile

④

Minimum size of the barrier

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

1.9 Fire protection

SIMATIC TDC hardware

System Manual, 08/2017, A5E01114865-AL

19

Installation and EMC guidelines

1.10

Control cabinet

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

1.10 Control cabinet

● All control cabinets must be equipped with a grounding/equipotential busbar that must be

connected directly to the cabinet frame at both ends.

● It is not allowed to operate contactors without protective circuit in a control cabinet

containing SIMATIC TDC components.

● If contactors without protective circuit are operated in a control cabinet next to the

SIMATIC TDC cabinet, the cabinets must be partitioned by means of a sheet steel panel.

● All control cabinets in which SIMATIC TDC components are operated must be equipped

with a shielding busbar that must be connected directly at both ends to the cabinet frame.

● It is not allowed to use gas discharge lamps in the cabinet.

● The cabinet must be designed to enable unobstructed air convection.

SIMATIC TDC hardware

20 System Manual, 08/2017, A5E01114865-AL

Installation and EMC guidelines

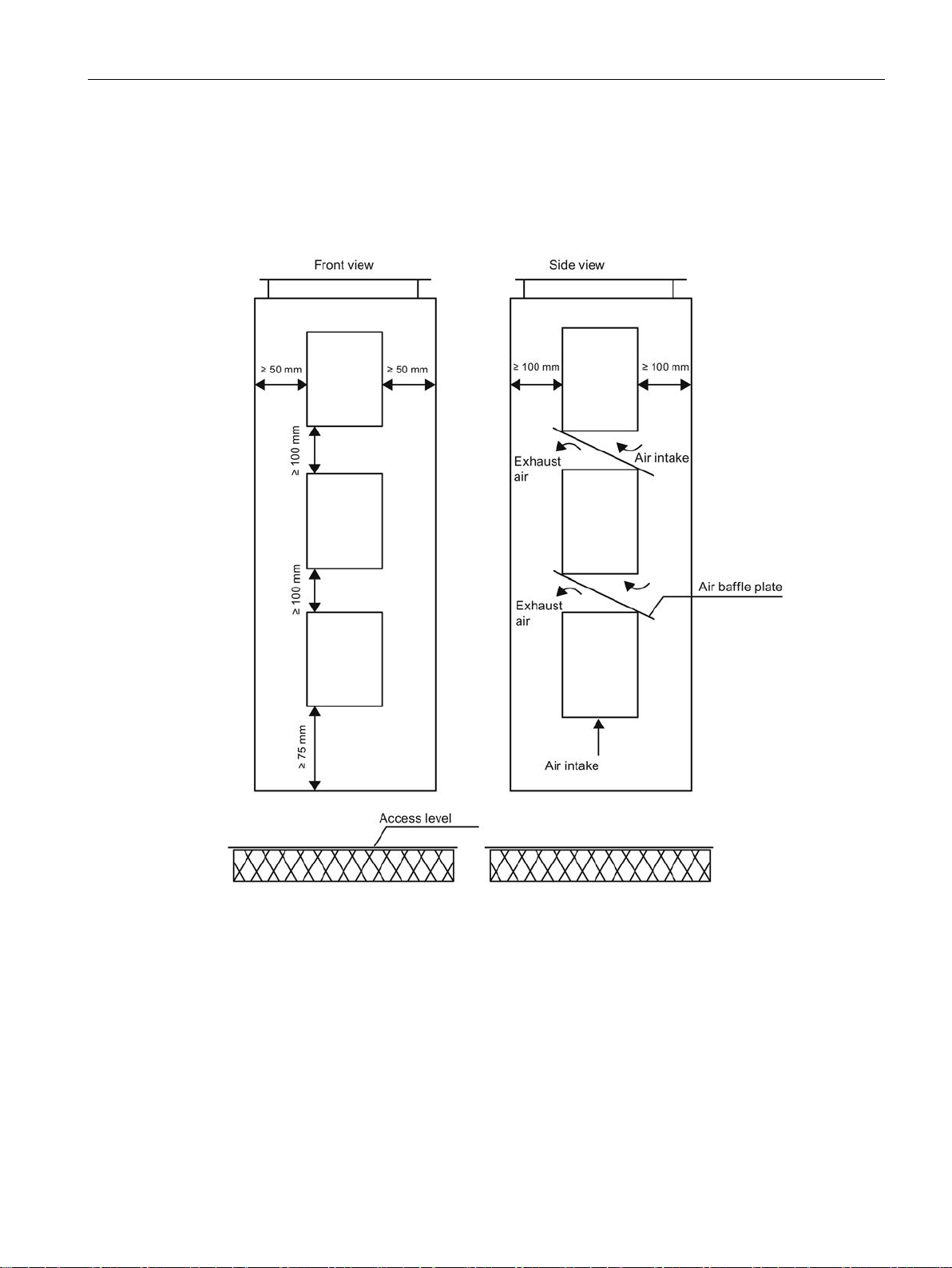

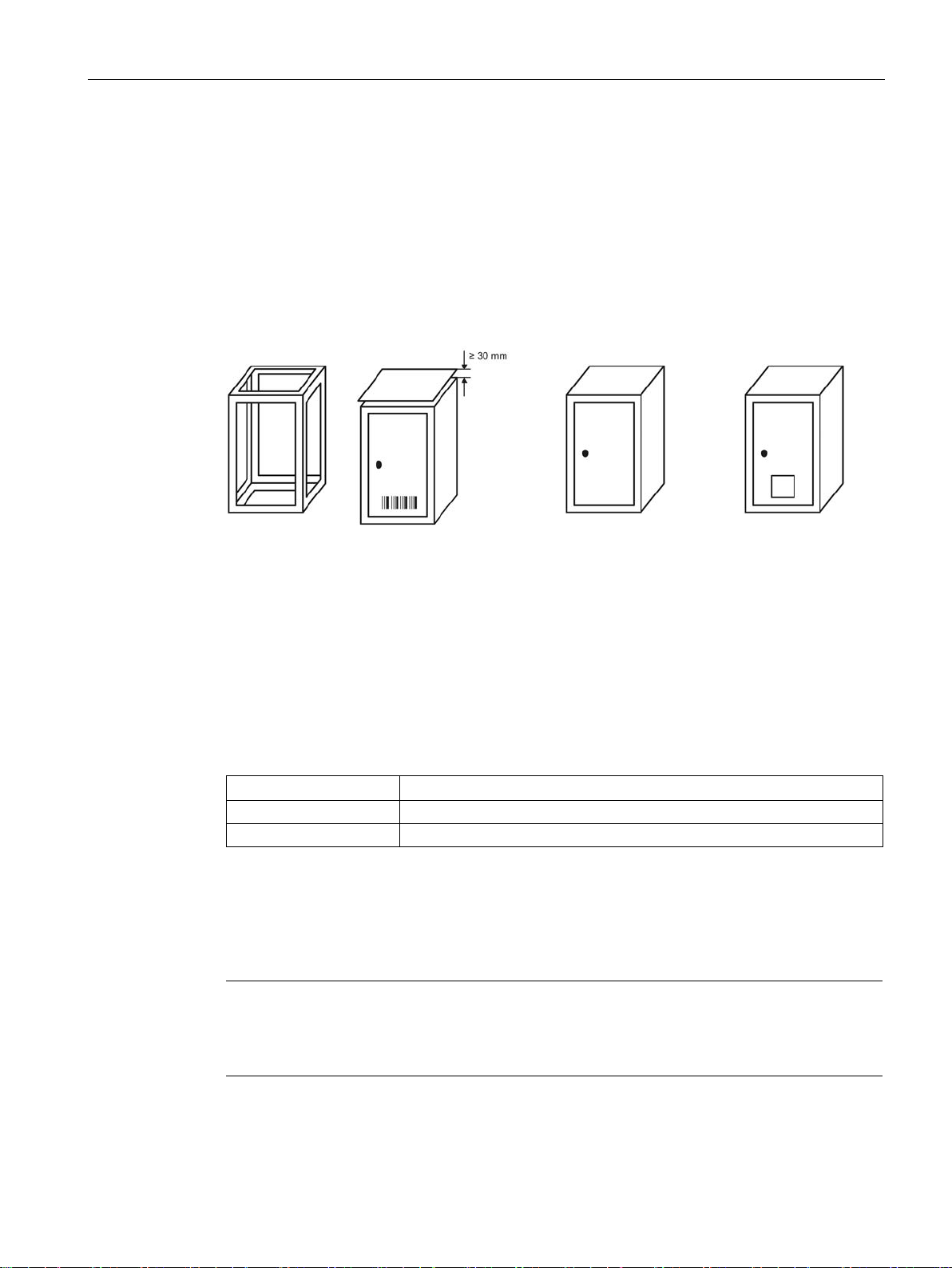

Arrangement and clearances

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

1.10 Control cabinet

The following minimum dimensions must be maintained for stacked installations of

SIMATIC TDC racks:

e.g. control cabinet 2200 x 600 x 600 mm

SIMATIC TDC hardware

System Manual, 08/2017, A5E01114865-AL

21

Installation and EMC guidelines

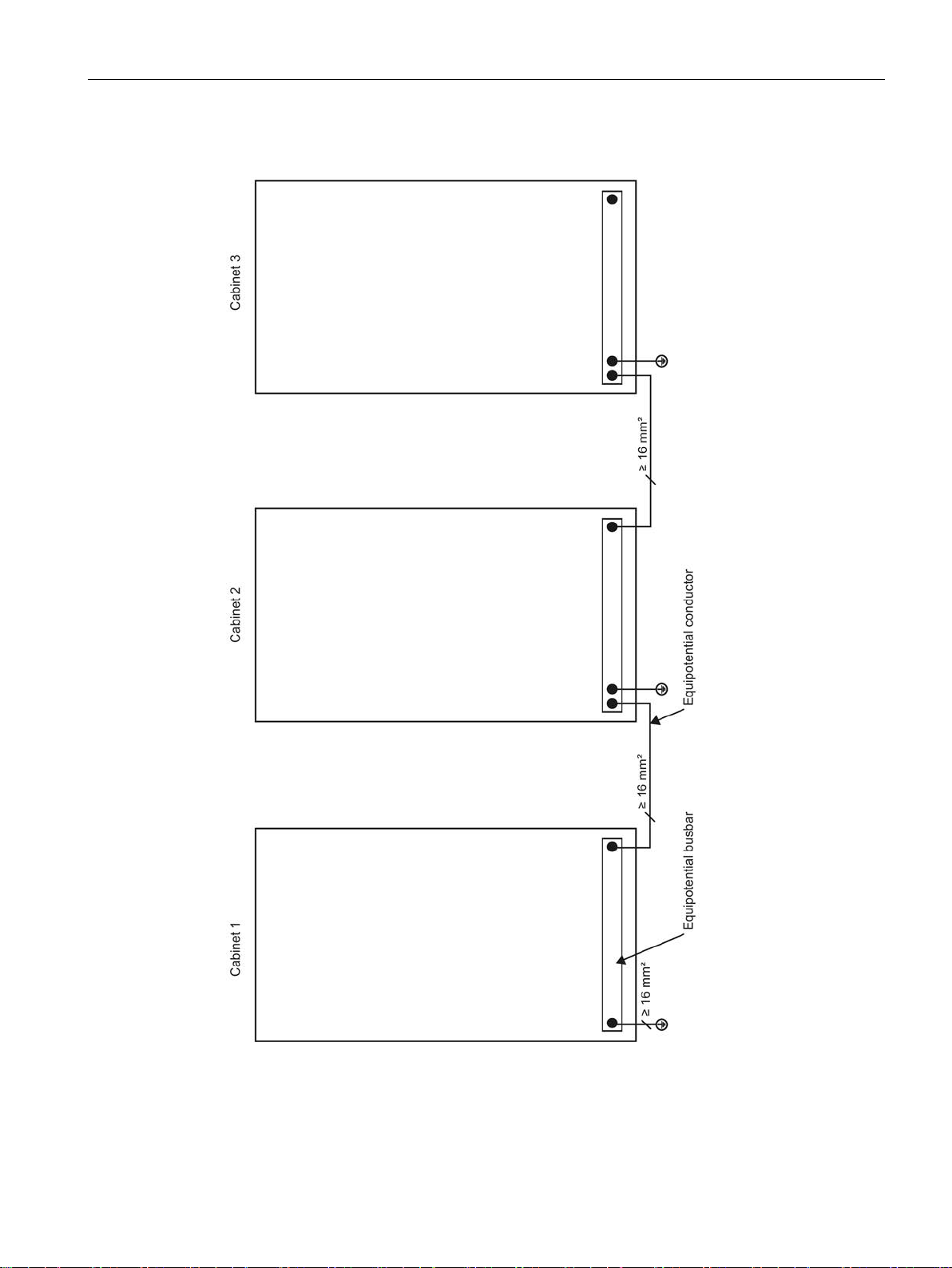

1.11

Equipotential bonding

Principle of the connection

Equipotential busbar

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

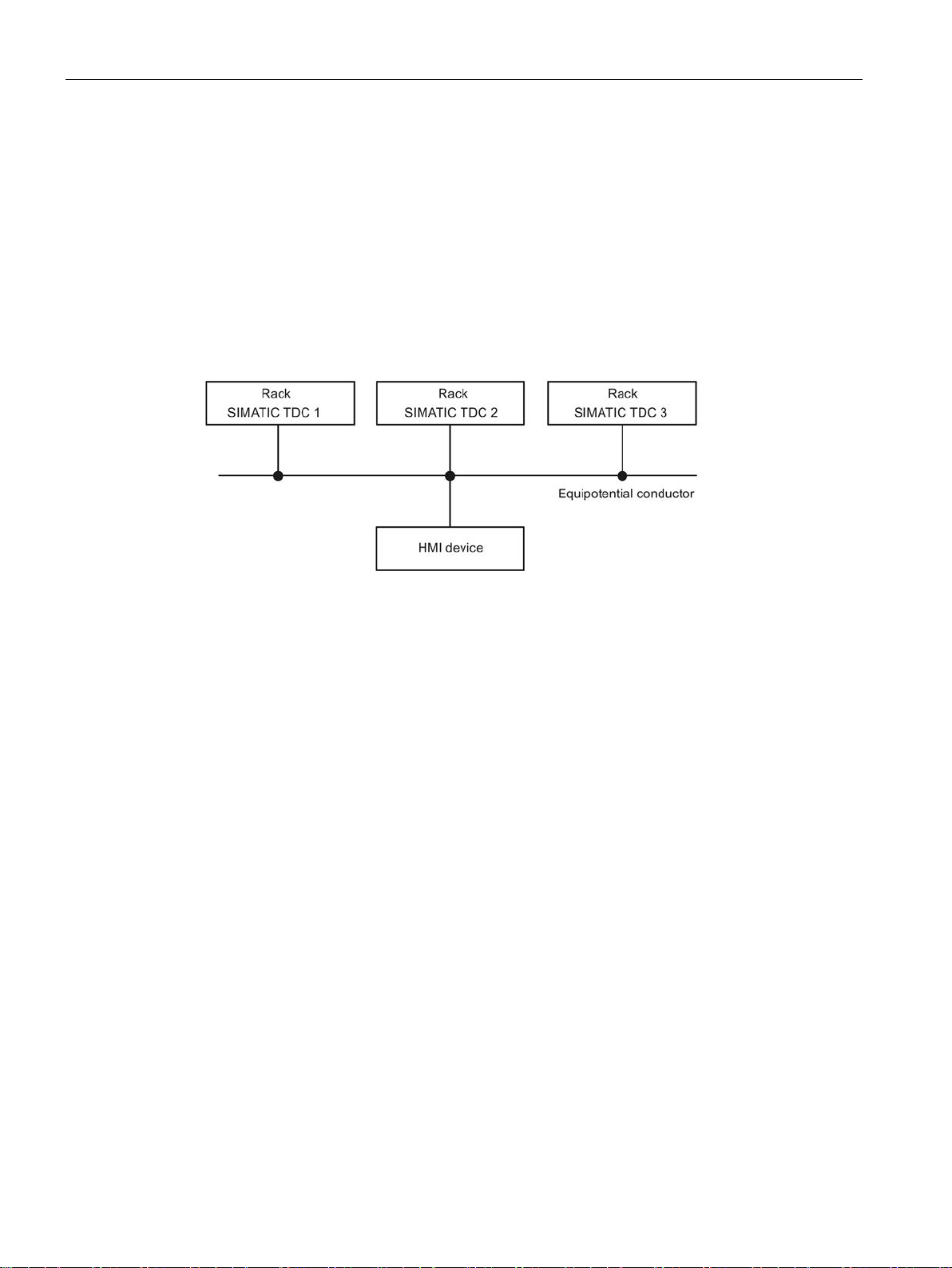

1.11 Equipotential bonding

In order to ensure disturbance-free operation, the networked components may not develop

different potentials. For this reason, all components must be interconnected by means of

equipotential bonding with a minimum cross-section of 16 mm

All components (racks, power supplies, etc.) that are connected by signal cables must also

be interconnected by means of equipotential bonding (exception: components with fiber-optic

connections).

2

.

An equipotential busbar should be provided in each control cabinet to facilitate wiring.

All internal and external components must be interconnected with this equipotential busbar.

SIMATIC TDC hardware

22 System Manual, 08/2017, A5E01114865-AL

Installation and EMC guidelines

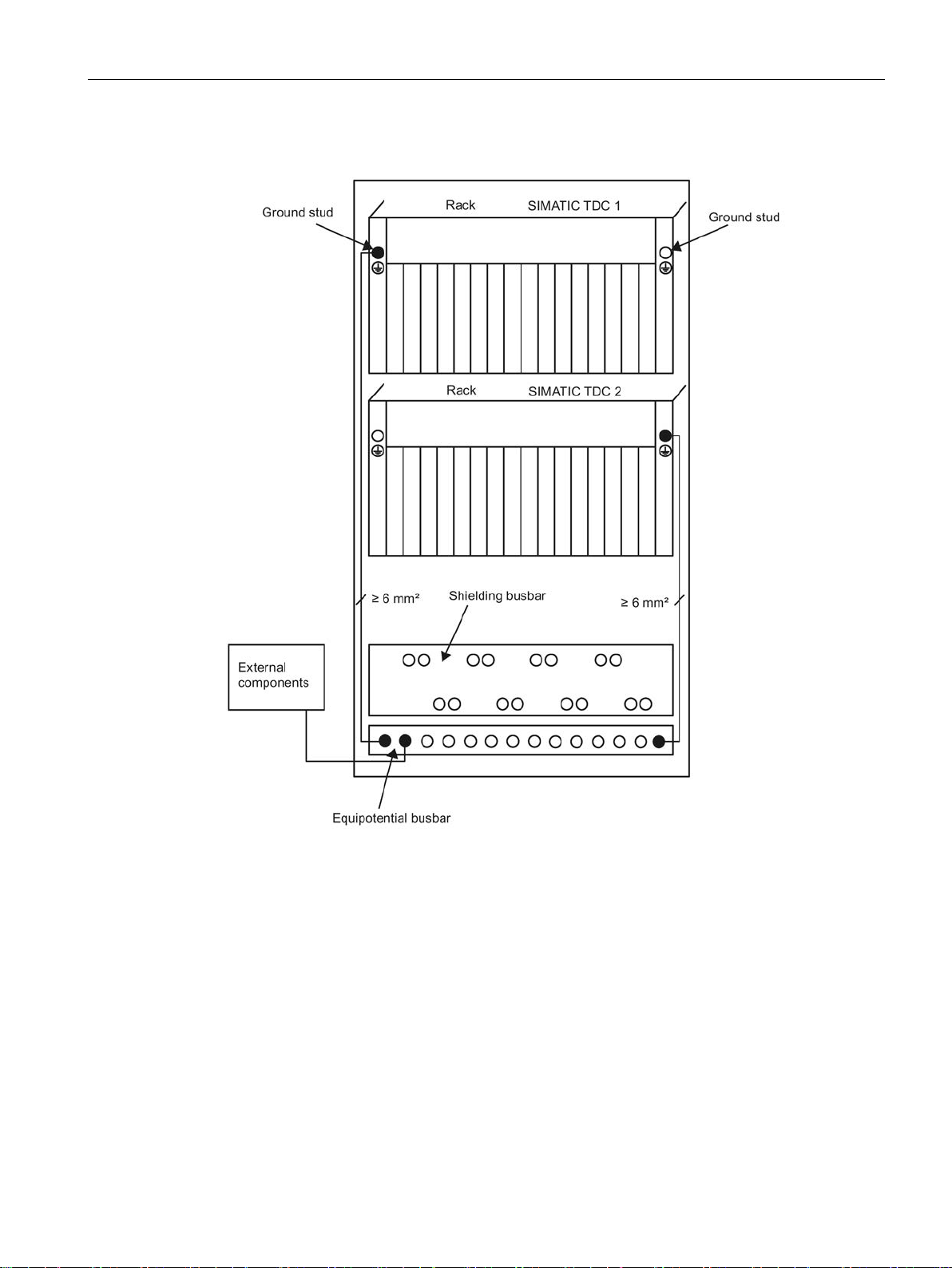

Schematic circuit diagram

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

1.11 Equipotential bonding

SIMATIC TDC hardware

System Manual, 08/2017, A5E01114865-AL

23

Installation and EMC guidelines

Practical application examples

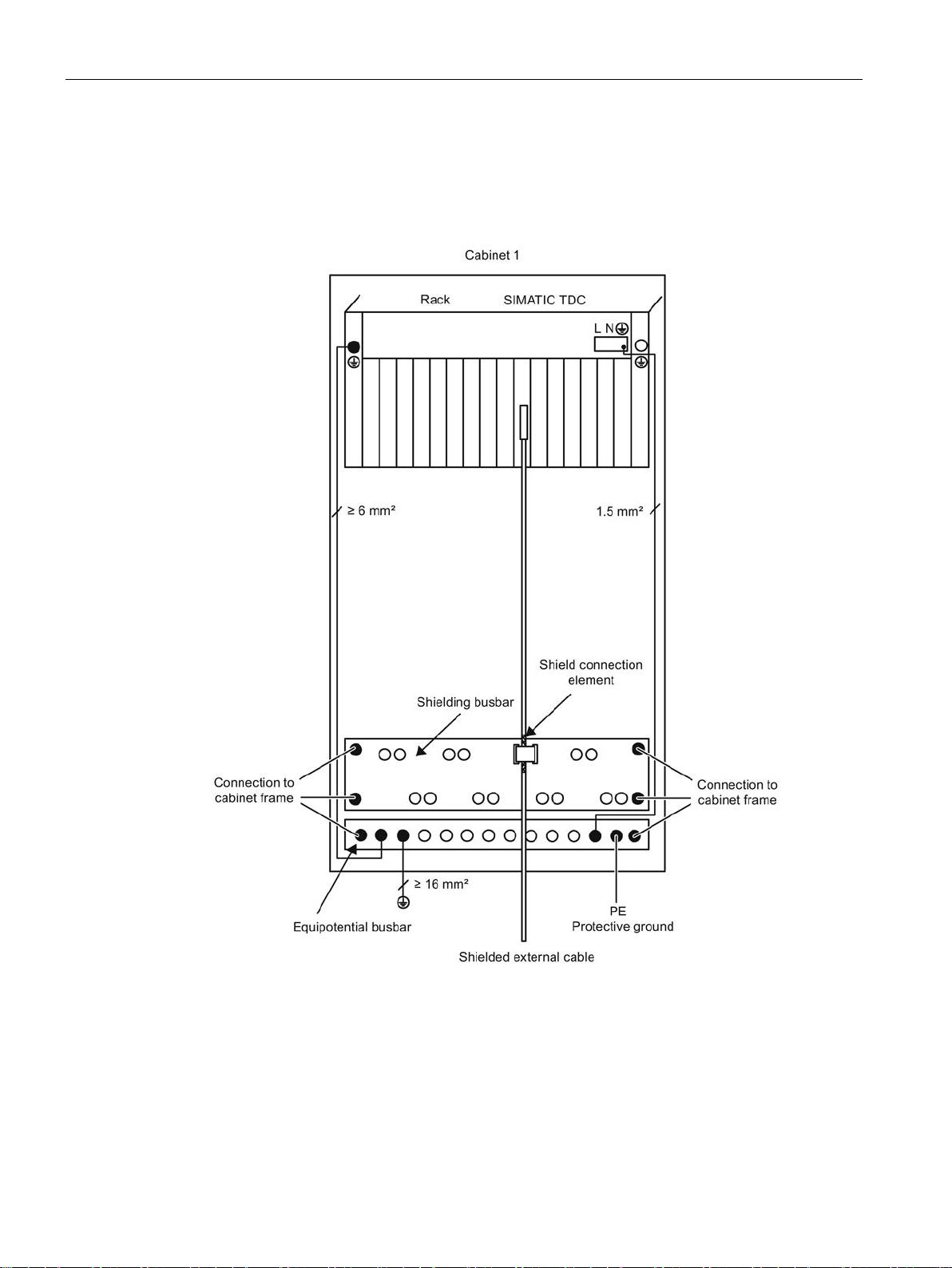

Termination of an external shielded cable

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

1.11 Equipotential bonding

The shield must be connected to the shielding bus.

SIMATIC TDC hardware

24 System Manual, 08/2017, A5E01114865-AL

Installation and EMC guidelines

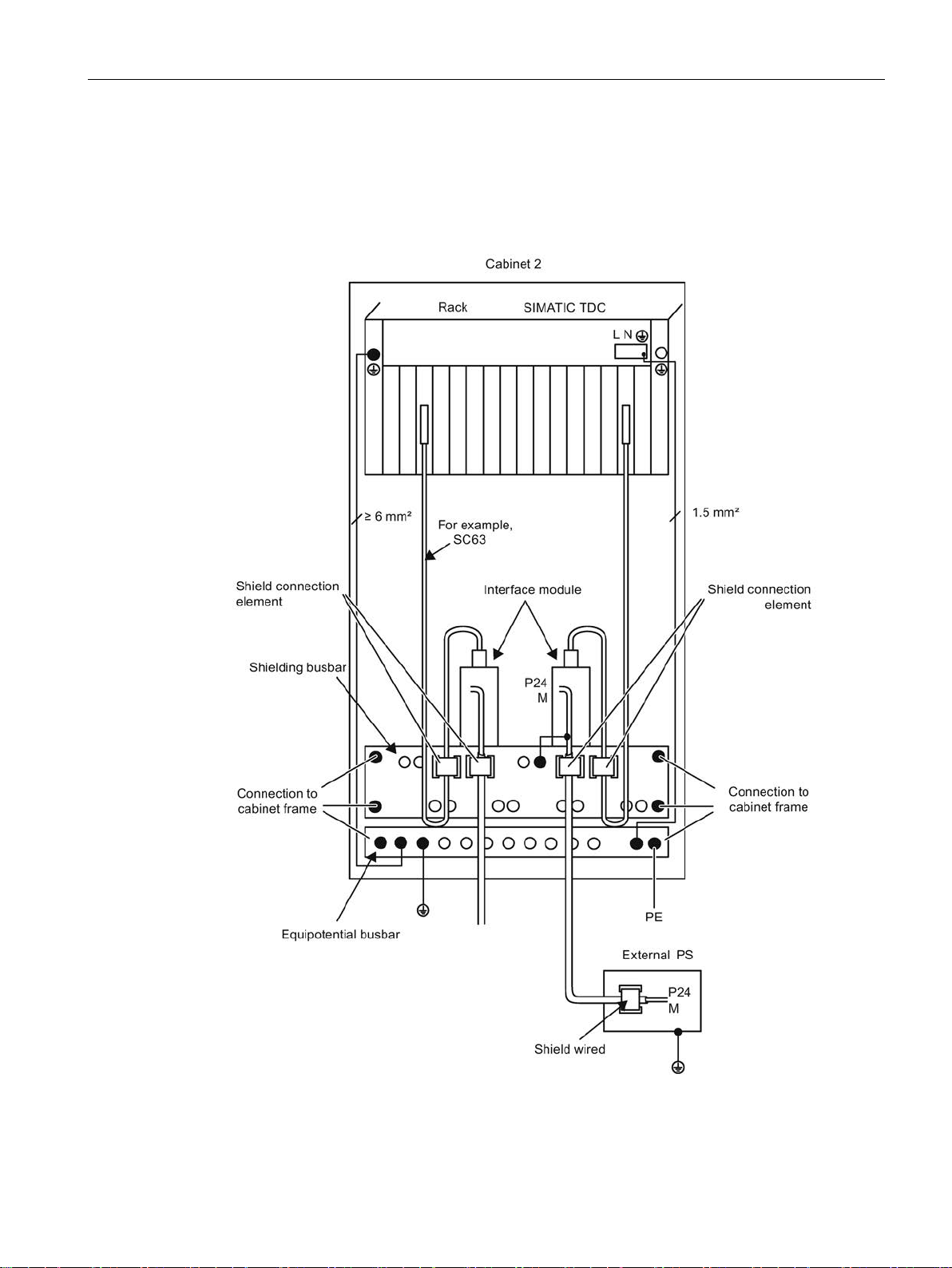

Termination of an external shielded cable with supply via interface module

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

1.11 Equipotential bonding

The shield must be connected to the shielding bus.

Ground of the external power supply must be wired to the shielding busbar, or to the

equipotential busbar.

SIMATIC TDC hardware

System Manual, 08/2017, A5E01114865-AL

25

Installation and EMC guidelines

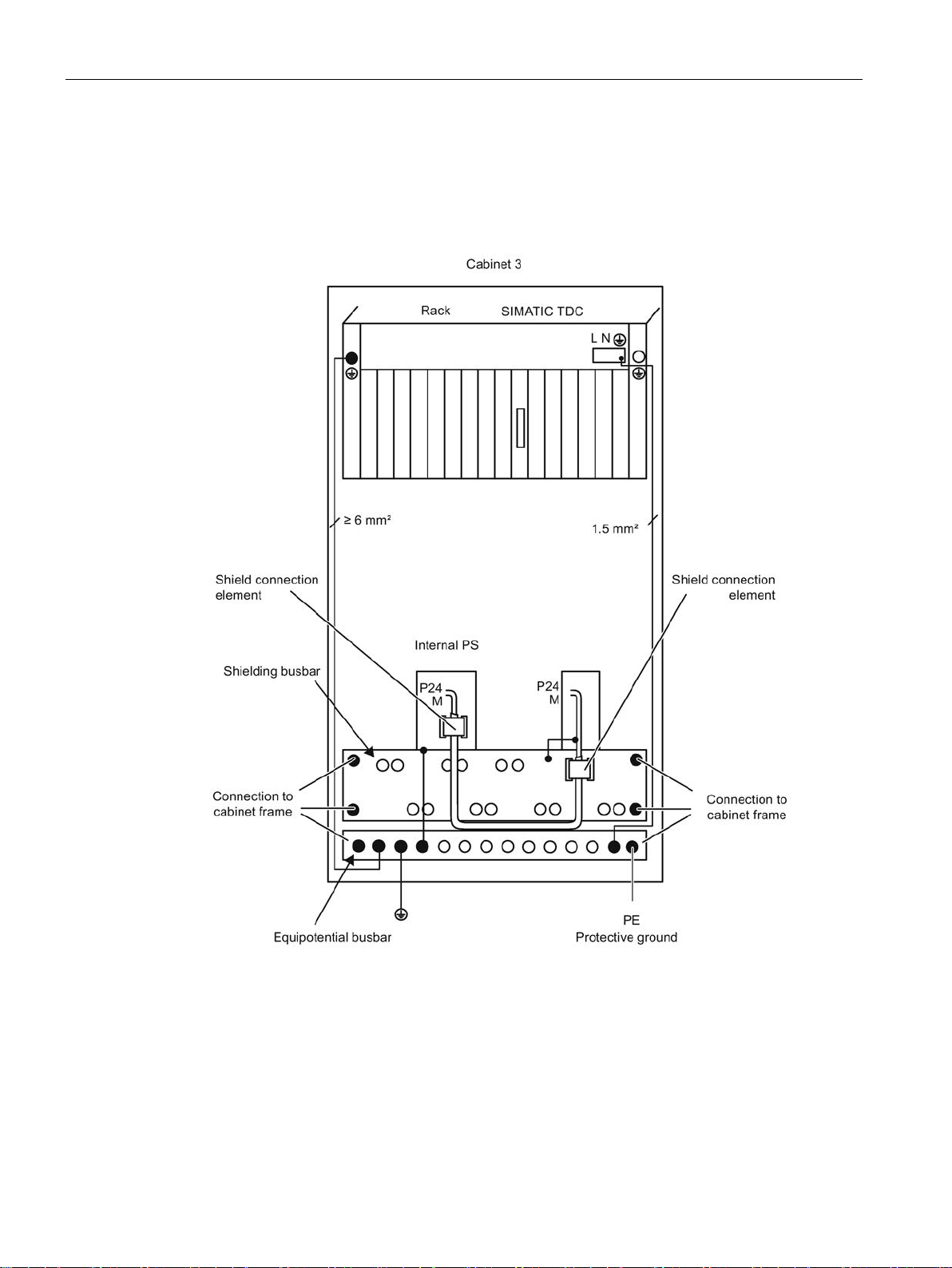

Termination of an internal power supply via interface module

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

1.11 Equipotential bonding

The shield must be connected to the shielding bus.

Ground of the internal power supply must be connected to the shielding busbar, or to the

equipotential busbar.

SIMATIC TDC hardware

26 System Manual, 08/2017, A5E01114865-AL

Installation and EMC guidelines

Example of grounding and potential equalization

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

1.12 Protective ground

SIMATIC TDC hardware

System Manual, 08/2017, A5E01114865-AL

27

Installation and EMC guidelines

1.12

Protective ground

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

1.12 Protective ground

Protective ground is bonded to the cabinets or components via PE conductor. It is required in

SIMATIC TDC for safe operation and as interference suppression measure.

The protective conductor must be routed and dimensioned in accordance with IEC 61131-2

(11.9).

SIMATIC TDC hardware

28 System Manual, 08/2017, A5E01114865-AL

Installation and EMC guidelines

1.13

Power losses in the control cabinet

Built-in versions

1)

2)

3)

4)

Frame / panel

Control cabinet (open) with

open

Air vents > 600 cm²

Cabinet (closed) with

intrinsic convection and

forced convection

Closed cabinet with

heat e

SHUTDOWN MODE

Shutdown mode

ONE / ON

Shutdown is initiated upon the failure of one fan

Note

In the SHUTDOWN MODE, the internal output voltages of the rack are switched off. External

voltages connected to the module input must be switched off simultaneously (refer to section

Machinery directive

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

1.13 Power losses in the control cabinet

The dissipation capability of a cabinet and therefore the air intake temperature of the rack

depends on the type of cabinet, on the ambient temperatures and on the internal

arrangement of the devices.

For installation variants 1) and 2), it is presumed that there is a clearance of at least 1 meter

between the top of the control cabinet and the building's ceiling.

Using the SHUTDOWN MODE switch the user can select whether to shut down the rack

immediately on failure of the first fan, or not until an additional fan failure.

TWO / OFF Shutdown is initiated upon the failure of one or more fans

For additional rack-specific information see:

UR6021 (6DD1682-0CH3) Control and display elements (Page 41)

UR5213 (6DD1682-0CH2)

UR5213 (6DD1682-0CH0)

-circuit ventilation

Control and display elements (Page 55)

Control and display elements (Page 67)

xchanger

(Page 17)).

SIMATIC TDC hardware

System Manual, 08/2017, A5E01114865-AL

29

Installation and EMC guidelines

Air intake temperature

Shutdown mode

Maximum air intake temperature up to 2000 m above

sea level

Shutdown on fan failure

1.14

Power supply

Measures against disturbance voltages

Interference suppression on mains

24 V power supply

NOTICE

Network devices

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

1.14 Power supply

The maximum air intake temperature on the SIMATIC TDC may not be exceeded. The

following limits are valid, depending on the "shutdown mode" switch setting.

ONE / ON

TWO / OFF

Shutdown on failure of two fans

The following notes related to the EMI/EMC measures to take for systems/plants should be

observed in order to avoid disturbance peaks on the supply cables in the cabinet:

The power supply of the rack already has a line filter with sufficient attenuation (refer to

"Manufacturers declaration").

For more demanding applications, you can install an additional line filter (e.g. 250 V AC /

10 A) or overvoltage arrester in the mains line, as close as possible to the cable entry on the

cabinet. Ground of the line filter/arrester must be wired to the equipotential busbar of the

cabinet using the shortest possible conductor length.

60° Centigrade

35° Centigrade

To attenuate external interference, a line filter must be provided for the 24 V power supply of

the digital I/O (e.g. SIFI-B line filter, Order No. B84112-B-.... from Epcos/NF 1-1 line filter of

Phoenix Contact). This filter should be installed as close as possible to the terminal block.

The shield connections of the line filter must be bonded to ground across the shortest

possible distance.

The 24 V power supply must also be equipped with lightning/overvoltage protection.

For more information, refer to the installation manual "SIMATIC Automation Systems

S7-400, Hardware and Installation

(http://support.automation.siemens.com/WW/view/de/1117849/0/en)".

Safe electrical isolation to IEC 61131-2 IEC 61131-2 (11.1.2.1.3) must be ensured for all

power supply units operated on SIMATIC TDC devices and modules.

SIMATIC TDC hardware

30 System Manual, 08/2017, A5E01114865-AL

Loading...

Loading...