Siemens SIMATIC ST-1500, SIMATIC ET 200MP, SIMATIC ET 200SP Function Manual

___________________

___________________

___________

___________

___________

___________________

___________________

SIMATIC

S7-1500, ET 200MP, ET 200SP

Counting, measurement and

position detection

Function Manual

12/2017

A5E32009889

Preface

Documentation guide

1

The basics of counting,

measurement and position

detection

2

Using the

High_Speed_Counter

technology object

3

Using the

SSI_Absolute_Encoder

technology object

4

Using the module

5

Service & Support

A

-AG

Siemens AG

Division Digital Factory

Postfach 48 48

90026 NÜRNBERG

GERMANY

A5E32009889-AG

Ⓟ

Copyright © Siemens AG 2017.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

for the specific

01/2018 Subject to change

Preface

Purpose of the documentation

Basic knowledge required

Validity of the documentation

This documentation supports you in configuring and programming modules for counting and

measurement tasks of the S7-1500, ET 200MP and ET 200SP, as well as in position

feedback and position input.

The following knowledge is required in order to understand the documentation:

● General knowledge of automation technology

● Knowledge of the industrial automation system SIMATIC

● Knowledge about the use of Windows-based computers

● Proficiency with STEP 7

This documentation applies to the use of the following modules:

● S7-1500 modules

– TM Count 2x24V

– TM PosInput 2

– TM Timer DIDQ 16x24V

– CPU 1511C-1 PN

– CPU 1512C-1 PN

– DI 32x24VDC HF (as of firmware version V2.1.0)

– DI 16x24VDC HF (as of firmware version V2.1.0)

● ET 200SP modules

– TM Count 1x24V

– TM PosInput 1

– TM Timer DIDQ 10x24V

– DI 8x24VDC HS

TM Count, TM PosInput and compact CPU are suitable for complex counting and measuring

tasks and for position detection. TM Timer DIDQ and digital input modules are suitable for

simple counting tasks.

Counting, measurement and position detection

Function Manual, 12/2017, A5E32009889-AG

3

Preface

Conventions

Note

The notes contain important information on the product described in the documentation, on

the ha

should be paid.

Additional assistance

Please observe notes marked as follows:

ndling of the product or on part of the documentation to which particular attention

● You can find information about the technical support offerings in the appendix Service &

Support (Page 199).

● The range of technical documentation for the individual SIMATIC products and

automation systems is available on the Internet

(http://www.siemens.com/simatic-tech-doku-portal).

● The online catalog and the ordering system are available on the Internet

(https://mall.industry.siemens.com).

Counting, measurement and position detection

4 Function Manual, 12/2017, A5E32009889-AG

Table of contents

Preface ................................................................................................................................................... 3

1 Documentation guide .............................................................................................................................. 9

2 The basics of counting, measurement and position detection ................................................................ 14

2.1 Overview of modules and properties ...................................................................................... 14

2.2 Basics of counting, measuring and position input (TM Count, TM PosInput,

Compact CPU) ........................................................................................................................ 18

2.2.1 Convention .............................................................................................................................. 18

2.2.2 Overview of applications ......................................................................................................... 18

2.2.3 Recording of count signals ..................................................................................................... 22

2.2.3.1 Counting with incremental or pulse encoder .......................................................................... 22

2.2.3.2 Position input with SSI absolute encoder ............................................................................... 24

2.2.4 Behavior at the counting limits ................................................................................................ 25

2.2.5 Gate control with incremental or pulse encoder ..................................................................... 27

2.2.5.1 Software gate .......................................................................................................................... 27

2.2.5.2 Hardware gate ........................................................................................................................ 27

2.2.5.3 Internal gate ............................................................................................................................ 28

2.2.5.4 Counter behavior at gate start ................................................................................................ 29

2.2.6 Capture (Latch) ....................................................................................................................... 30

2.2.6.1 Capture with incremental or pulse encoder ............................................................................ 30

2.2.6.2 Capture with SSI absolute encoder ........................................................................................ 33

2.2.7 Synchronization ...................................................................................................................... 35

2.2.7.1 Synchronization by digital input .............................................................................................. 38

2.2.7.2 Synchronization at signal N .................................................................................................... 40

2.2.8 Comparison values ................................................................................................................. 43

2.2.8.1 Comparison values and outputs ............................................................................................. 43

2.2.8.2 Switching at comparison values with counter value as reference .......................................... 44

2.2.8.3 Switching at comparison values with position value (SSI absolute value) as reference ........ 48

2.2.8.4 Switching at comparison values with measured value as reference ...................................... 52

2.2.9 Measured value determination ............................................................................................... 54

2.2.9.1 Overview of measuring functions ............................................................................................ 54

2.2.9.2 Measured value determination with incremental or pulse encoder ........................................ 55

2.2.9.3 Measured value determination with SSI absolute encoder .................................................... 59

2.2.10 Hysteresis ............................................................................................................................... 62

2.2.10.1 Hysteresis with incremental or pulse encoder ........................................................................ 62

2.2.10.2 Hysteresis with SSI absolute encoder .................................................................................... 64

2.2.11 Interrupts ................................................................................................................................. 66

2.2.12 Position detection for Motion Control ...................................................................................... 66

2.2.13 Encoder signals ...................................................................................................................... 67

2.2.13.1 24 V and TTL count signals .................................................................................................... 67

2.2.13.2 RS422 count signals ............................................................................................................... 69

2.2.13.3 SSI signals .............................................................................................................................. 71

Counting, measurement and position detection

Function Manual, 12/2017, A5E32009889-AG

5

Table of contents

3 Using the High_Speed_Counter technology object ................................................................................ 92

2.2.14 Signal evaluation of incremental signals ................................................................................ 72

2.2.14.1 Overview ................................................................................................................................ 72

2.2.14.2 Single evaluation .................................................................................................................... 72

2.2.14.3 Double evaluation .................................................................................................................. 73

2.2.14.4 Quadruple evaluation ............................................................................................................. 74

2.2.15 Clock synchronization (TM Count and TM PosInput) ............................................................ 75

2.3 Basics of counting (TM Timer DIDQ) ..................................................................................... 76

2.3.1 Overview of applications ........................................................................................................ 76

2.3.2 Counting with incremental encoder........................................................................................ 77

2.3.3 Counting with pulse encoder .................................................................................................. 78

2.3.4 24 V count signals .................................................................................................................. 79

2.3.5 Isochronous mode ................................................................................................................. 80

2.4 Basics of counting (digital input modules) ............................................................................. 81

2.4.1 Overview of applications ........................................................................................................ 81

2.4.2 Counting with pulse encoders ................................................................................................ 82

2.4.3 Behavior at the counting limits ............................................................................................... 83

2.4.4 Gate control ............................................................................................................................ 85

2.4.4.1 Software gate ......................................................................................................................... 85

2.4.4.2 Hardware gate........................................................................................................................ 85

2.4.4.3 Internal gate ........................................................................................................................... 86

2.4.5 Comparison values ................................................................................................................ 87

2.4.6 Interrupts ................................................................................................................................ 90

2.4.7 24 V count signals .................................................................................................................. 90

2.4.8 Isochronous mode ................................................................................................................. 91

3.1 Convention ............................................................................................................................. 92

3.2 High_Speed_Counter technology object ................................................................................ 92

3.3 Overview of the configuration steps ....................................................................................... 93

3.4 Add technology object ............................................................................................................ 94

3.5 Configuring the High_Speed_Counter ................................................................................... 96

3.5.1 Working with the configuration dialog .................................................................................... 96

3.5.2 Basic parameters ................................................................................................................... 98

3.5.3 Counter inputs (High_Speed_Counter) .................................................................................. 99

3.5.4 Counter behavior.................................................................................................................. 104

3.5.4.1 Counting limits and start value ............................................................................................. 104

3.5.4.2 Counter behavior at limits and gate start ............................................................................. 105

3.5.5 Behavior of a DI (High_Speed_Counter) ............................................................................. 106

3.5.6 Behavior of a DQ (High_Speed_Counter) ............................................................................ 110

3.5.7 Specify measured value (High_Speed_Counter) ................................................................. 115

3.6 Programming the High_Speed_Counter .............................................................................. 117

3.6.1 High_Speed_Counter instruction ......................................................................................... 117

3.6.2 Call instruction in the user program ..................................................................................... 118

3.6.3 Description High_Speed_Counter ........................................................................................ 119

3.6.4 High_Speed_Counter input parameters ............................................................................... 125

3.6.5 High_Speed_Counter output parameters ............................................................................ 126

3.6.6 Error codes of parameter ErrorID ........................................................................................ 128

3.6.7 High_Speed_Counter static variables .................................................................................. 130

Counting, measurement and position detection

6 Function Manual, 12/2017, A5E32009889-AG

Table of contents

4 Using the SSI_Absolute_Encoder technology object ............................................................................ 136

5 Using the module ................................................................................................................................ 169

3.7 Commissioning the High_Speed_Counter ............................................................................ 132

3.7.1 Commissioning the technology object .................................................................................. 132

3.8 High_Speed_Counter diagnostics ......................................................................................... 134

3.8.1 Monitoring counter values, measured values, DIs and DQs ................................................ 134

4.1 Technology object SSI_Absolute_Encoder ........................................................................... 136

4.2 Overview of the configuration steps ...................................................................................... 137

4.3 Add technology object........................................................................................................... 138

4.4 Configuring SSI_Absolute_Encoder ...................................................................................... 140

4.4.1 Working with the configuration dialog ................................................................................... 140

4.4.2 Basic parameters .................................................................................................................. 141

4.4.3 SSI absolute encoder............................................................................................................ 142

4.4.4 Behavior of a DI (SSI_Absolute_Encoder) ............................................................................ 145

4.4.5 Behavior of a DQ (SSI_Absolute_Encoder) .......................................................................... 147

4.4.6 Specify measured value (SSI_Absolute_Encoder) ............................................................... 151

4.4.7 Examples of the frame format ............................................................................................... 153

4.5 Programming the SSI_Absolute_Encoder ............................................................................ 156

4.5.1 Instruction SSI_Absolute_Encoder ....................................................................................... 156

4.5.2 Call instruction in the user program ...................................................................................... 157

4.5.3 Description SSI_Absolute_Encoder ...................................................................................... 158

4.5.4 Input parameter SSI_Absolute_Encoder............................................................................... 161

4.5.5 Output parameter SSI_Absolute_Encoder ............................................................................ 162

4.5.6 Error codes of parameter ErrorID ......................................................................................... 164

4.5.7 Static tags SSI_Absolute_Encoder ....................................................................................... 165

4.6 Commissioning SSI_Absolute_Encoder ............................................................................... 166

4.6.1 Commissioning the technology object .................................................................................. 166

4.7 SSI_Absolute_Encoder diagnostics ...................................................................................... 167

4.7.1 Monitoring counter values, measured values, DIs and DQs ................................................ 167

5.1 Using the technology module ............................................................................................... 169

5.1.1 Convention ............................................................................................................................ 169

5.1.2 Configuring a module ............................................................................................................ 169

5.1.2.1 Adding a technology module for hardware configuration (TM Count and TM PosInput) ..... 169

5.1.2.2 Adding a technology module to hardware configuration (Compact CPU) ............................ 170

5.1.2.3 Parameter assignment options ............................................................................................. 171

5.1.2.4 Basic parameters .................................................................................................................. 172

5.1.2.5 Additional parameters for Compact CPU .............................................................................. 180

5.1.3 Parameter assignment of module ......................................................................................... 183

5.1.3.1 Parameter setting (hardware configuration) Opening (TM Count and TM PosInput) ........... 183

5.1.3.2 Parameter setting (hardware configuration) Opening (Compact CPU) ................................ 183

5.1.4 Online & diagnostics module ................................................................................................ 183

5.1.4.1 Displaying and evaluating diagnostics .................................................................................. 183

5.1.5 Control and feedback interface (TM Count, TM PosInput) ................................................... 185

5.1.5.1 Assignment of the control interface ...................................................................................... 185

5.1.5.2 Assignment of the feedback interface ................................................................................... 188

Counting, measurement and position detection

Function Manual, 12/2017, A5E32009889-AG

7

Table of contents

A Service & Support ................................................................................................................................ 199

Index ................................................................................................................................................... 202

5.2 Using the digital input module .............................................................................................. 192

5.2.1 Configuring and assigning parameters to the module ......................................................... 192

5.2.1.1 Adding a module to the hardware configuration .................................................................. 192

5.2.1.2 Open hardware configuration ............................................................................................... 192

5.2.1.3 Counting operating mode ..................................................................................................... 193

5.2.2 Online & diagnostics module ............................................................................................... 198

5.2.2.1 Displaying and evaluating diagnostics ................................................................................. 198

Counting, measurement and position detection

8 Function Manual, 12/2017, A5E32009889-AG

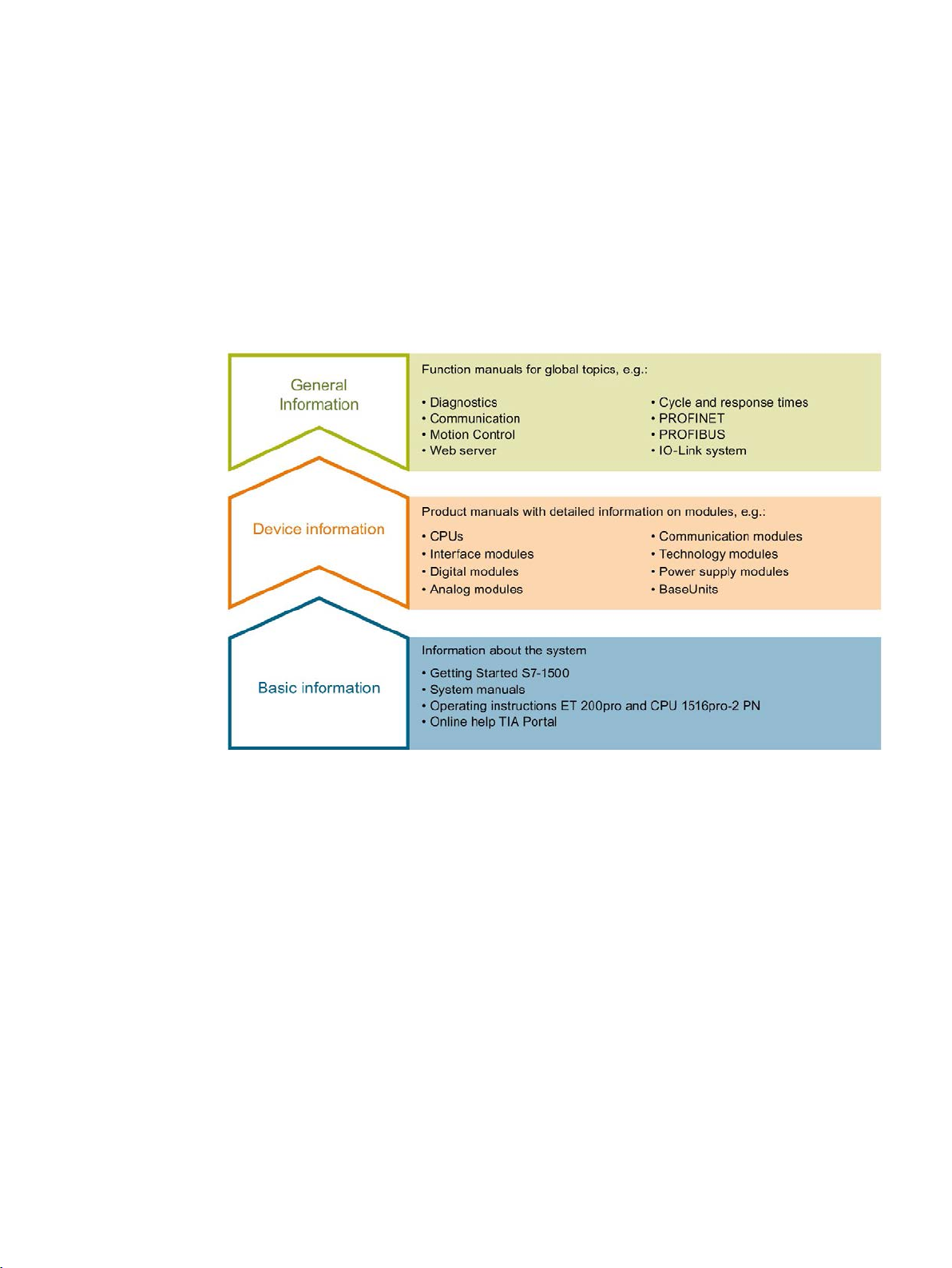

1

Basic information

Device information

The documentation for the SIMATIC S7-1500 automation system, for CPU 1516pro-2 PN

based on SIMATIC S7-1500, and for the distributed I/O systems SIMATIC ET 200MP,

ET 200SP and ET 200AL is divided into three areas.

This division allows you easier access to the specific information you require.

System manuals and Getting Started manuals describe in detail the configuration,

installation, wiring and commissioning of the SIMATIC S7-1500, ET 200MP, ET 200SP and

ET 200AL systems; use the corresponding operating instructions for CPU 1516pro-2 PN.

The STEP 7 online help supports you in configuration and programming.

Product manuals contain a compact description of the module-specific information, such as

properties, terminal diagrams, characteristics and technical specifications.

Counting, measurement and position detection

Function Manual, 12/2017, A5E32009889-AG

9

Documentation guide

General information

Manual Collections

"mySupport"

"mySupport" - Documentation

The function manuals contain detailed descriptions on general topics such as diagnostics,

communication, Motion Control, Web server, OPC UA.

You can download the documentation free of charge from the Internet

(http://w3.siemens.com/mcms/industrial-automation-systems-simatic/en/manual-

overview/Pages/Default.aspx).

Changes and additions to the manuals are documented in product information sheets.

You will find the product information on the Internet:

● S7-1500/ET 200MP (https://support.industry.siemens.com/cs/us/en/view/68052815)

● ET 200SP (https://support.industry.siemens.com/cs/us/en/view/73021864)

● ET 200AL (https://support.industry.siemens.com/cs/us/en/view/99494757)

The Manual Collections contain the complete documentation of the systems put together in

one file.

You will find the Manual Collections on the Internet:

● S7-1500/ET 200MP (https://support.industry.siemens.com/cs/ww/en/view/86140384)

● ET 200SP (https://support.industry.siemens.com/cs/ww/en/view/84133942)

● ET 200AL (https://support.industry.siemens.com/cs/ww/en/view/95242965)

With "mySupport", your personal workspace, you make the best out of your Industry Online

Support.

In "mySupport", you can save filters, favorites and tags, request CAx data and compile your

personal library in the Documentation area. In addition, your data is already filled out in

support requests and you can get an overview of your current requests at any time.

You must register once to use the full functionality of "mySupport".

You can find "mySupport" on the Internet (https://support.industry.siemens.com/My/ww/en).

In the Documentation area in "mySupport" you can combine entire manuals or only parts of

these to your own manual.

You can export the manual as PDF file or in a format that can be edited later.

You can find "mySupport" - Documentation on the Internet

(http://support.industry.siemens.com/My/ww/en/documentation).

Counting, measurement and position detection

10 Function Manual, 12/2017, A5E32009889-AG

Documentation guide

"mySupport" - CAx data

Application examples

TIA Selection Tool

In the CAx data area in "mySupport", you can access the current product data for your CAx

or CAe system.

You configure your own download package with a few clicks.

In doing so you can select:

● Product images, 2D dimension drawings, 3D models, internal circuit diagrams, EPLAN

macro files

● Manuals, characteristics, operating manuals, certificates

● Product master data

You can find "mySupport" - CAx data on the Internet

(http://support.industry.siemens.com/my/ww/en/CAxOnline).

The application examples support you with various tools and examples for solving your

automation tasks. Solutions are shown in interplay with multiple components in the system separated from the focus on individual products.

You will find the application examples on the Internet

(https://support.industry.siemens.com/sc/ww/en/sc/2054).

With the TIA Selection Tool, you can select, configure and order devices for Totally

Integrated Automation (TIA).

This tool is the successor of the SIMATIC Selection Tool and combines the known

configurators for automation technology into one tool.

With the TIA Selection Tool, you can generate a complete order list from your product

selection or product configuration.

You can find the TIA Selection Tool on the Internet

(http://w3.siemens.com/mcms/topics/en/simatic/tia-selection-tool).

Counting, measurement and position detection

Function Manual, 12/2017, A5E32009889-AG

11

Documentation guide

SIMATIC Automation Tool

PRONETA

You can use the SIMATIC Automation Tool to run commissioning and maintenance activities

simultaneously on different SIMATIC S7 stations as a bulk operation, independently of the

TIA Portal.

The SIMATIC automation tool provides a variety of functions:

● Scanning of a PROFINET/Ethernet plant network and identification of all connected

CPUs

● Address assignment (IP, subnet, gateway) and station name (PROFINET device) to a

CPU

● Transfer of the date and programming device/PC time converted to UTC time to the

module

● Program download to CPU

● Operating mode switchover RUN/STOP

● CPU localization by means of LED flashing

● Reading out CPU error information

● Reading of CPU diagnostic buffer

● Reset to factory settings

● Updating the firmware of the CPU and connected modules

You can find the SIMATIC Automation Tool on the Internet

(https://support.industry.siemens.com/cs/ww/en/view/98161300).

With SIEMENS PRONETA (PROFINET network analysis), you analyze the plant network

during commissioning. PRONETA features two core functions:

● The topology overview independently scans PROFINET and all connected components.

● The IO check is a fast test of the wiring and the module configuration of a plant.

You can find SIEMENS PRONETA on the Internet

(https://support.industry.siemens.com/cs/ww/en/view/67460624).

Counting, measurement and position detection

12 Function Manual, 12/2017, A5E32009889-AG

Documentation guide

SINETPLAN

SINETPLAN, the Siemens Network Planner, supports you in planning automation systems

and networks based on PROFINET. The tool facilitates professional and predictive

dimensioning of your PROFINET installation as early as in the planning stage. In addition,

SINETPLAN supports you during network optimization and helps you to exploit network

resources optimally and to plan reserves. This helps to prevent problems in commissioning

or failures during productive operation even in advance of a planned operation. This

increases the availability of the production plant and helps improve operational safety.

The advantages at a glance

● Network optimization thanks to port-specific calculation of the network load

● Increased production availability thanks to online scan and verification of existing systems

● Transparency before commissioning through importing and simulation of existing STEP 7

projects

● Efficiency through securing existing investments in the long term and optimal exploitation

of resources

You can find SINETPLAN on the Internet (https://www.siemens.com/sinetplan).

Counting, measurement and position detection

Function Manual, 12/2017, A5E32009889-AG

13

detection

2

2.1

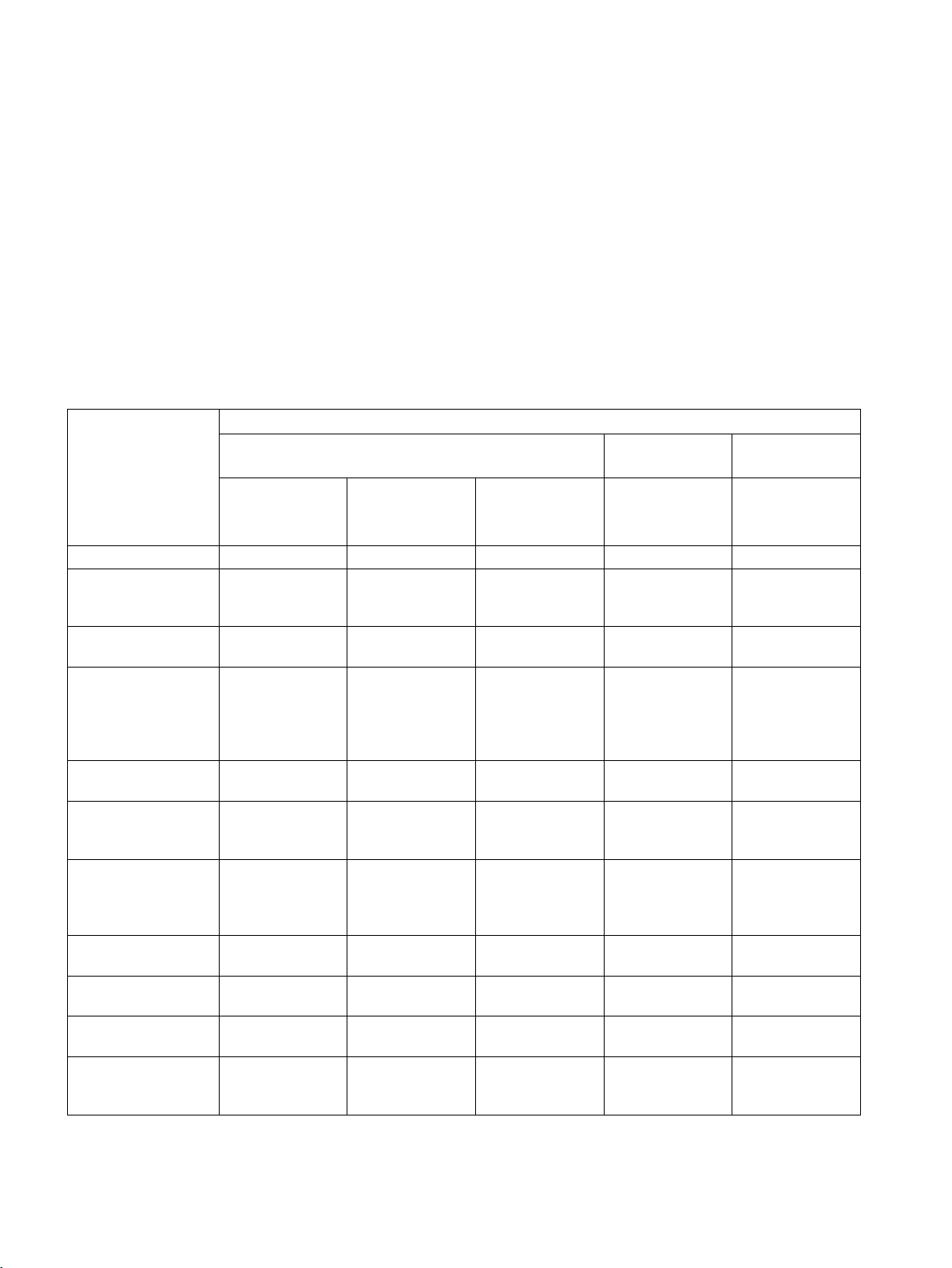

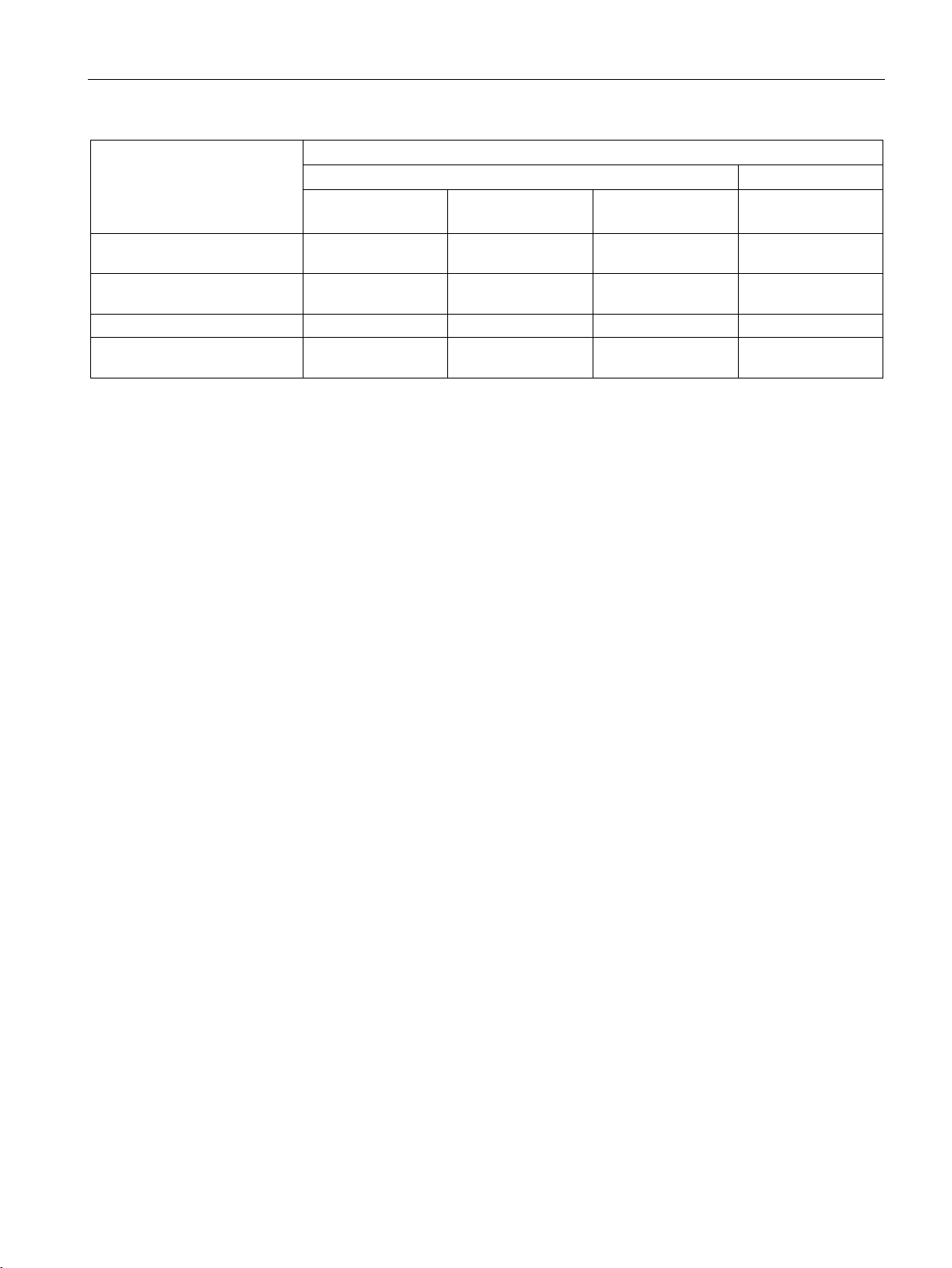

Overview of modules and properties

Modules for the S7-1500 and ET 200MP systems

Property

S7-1500 / ET 200MP

Technology module

Digital input mod-

ule

Compact CPU

TM Count 2x24V

TM PosInput 2

TM Timer DIDQ

16x24V

DI 32x24VDC HF,

DI 16x24VDC HF

CPU 1511C-1

PN,

CPU 1512C-1 PN

ed/deactivated

frequency

(Page 72)

range

(Page 24)

connection

connection

(Page 71) connection

(Page 66)

The table below summarizes the performance features of the modules for counting,

measuring and position input for the S7-1500 and ET 200MP systems.

Number of counters 2 2 41 2 6

Use of counters can

be activat-

Maximum signal

Maximum count frequency for incremental encoders with

quadruple evaluation

Maximum counting

Maximum position

value range

RS422/TTL incremental and pulse

encoder (Page 69)

24 V incremental

encoder connection

24 V pulse encoder

— — X X X

200 kHz 1 MHz 50 kHz 1 kHz 100 kHz

800 kHz 4 MHz 200 kHz — 400 kHz

32 bits (Page 22) 32 bits (Page 22) 32 bits (Page 77) 32 bits (Page 82) 32 bits (Page 22)

— 31 bits — — —

— X — — —

X (Page 67) — X (Page 79) — X (Page 67)

X (Page 67) — X (Page 79) X (Page 90) X (Page 67)

SSI absolute encoder

Position input for

Motion Control

Counting, measurement and position detection

14 Function Manual, 12/2017, A5E32009889-AG

— X — — —

X X — — X

The basics of counting, measurement and position detection

Property

S7-1500 / ET 200MP

Technology module

Digital input mod-

ule

Compact CPU

TM Count 2x24V

TM PosInput 2

TM Timer DIDQ

16x24V

DI 32x24VDC HF,

DI 16x24VDC HF

CPU 1511C-1

PN,

CPU 1512C-1 PN

5 V encoder supply

— X — — —

24 V encoder supply

X X X — X

counter

counter

counter

Hysteresis (Page 62)

X X — — X

Software gate

X (Page 27)

X (Page 27)

—

X (Page 85)

X (Page 27)

Hardware gate

X (Page 27)

X (Page 27)

—

—

X (Page 27)

(Latch) (Page 30)

(Page 35)

Comparison functions

X (Page 43)

X (Page 43)

—

X (Page 87)

X (Page 43)

(Page 54)

PROFINET

signals

support

digital inputs

1

ter. Other channel configurations do not allow any counter use.

2.1 Overview of modules and properties

Number of additional

digital inputs per

Number of physical

digital outputs per

Number of logical

digital outputs per

Capture function

Synchronization

Frequency, velocity

and period duration

measurement

Support for isochronous mode on

3 2 — — 2

2 2 — — 1

2 2 — 1 2

X X — — X

X X — — X

X X — — X

X (Page 75) X (Page 75) X (Page 80) X (Page 91) —

Support for diagnostic

X (Page 66) X (Page 66) — — X (Page 66)

interrupts for sensor

Hardware interrupt

Configurable filter for

X (Page 66) X (Page 66) — X (Page 90) X (Page 66)

X X — X X

count signals and

The number of available counters is dependent on the channel configuration. In order to use four counters, you must

choose the use of eight inputs in the channel configuration. If you choose the use of three inputs, you can use one coun-

Counting, measurement and position detection

Function Manual, 12/2017, A5E32009889-AG

15

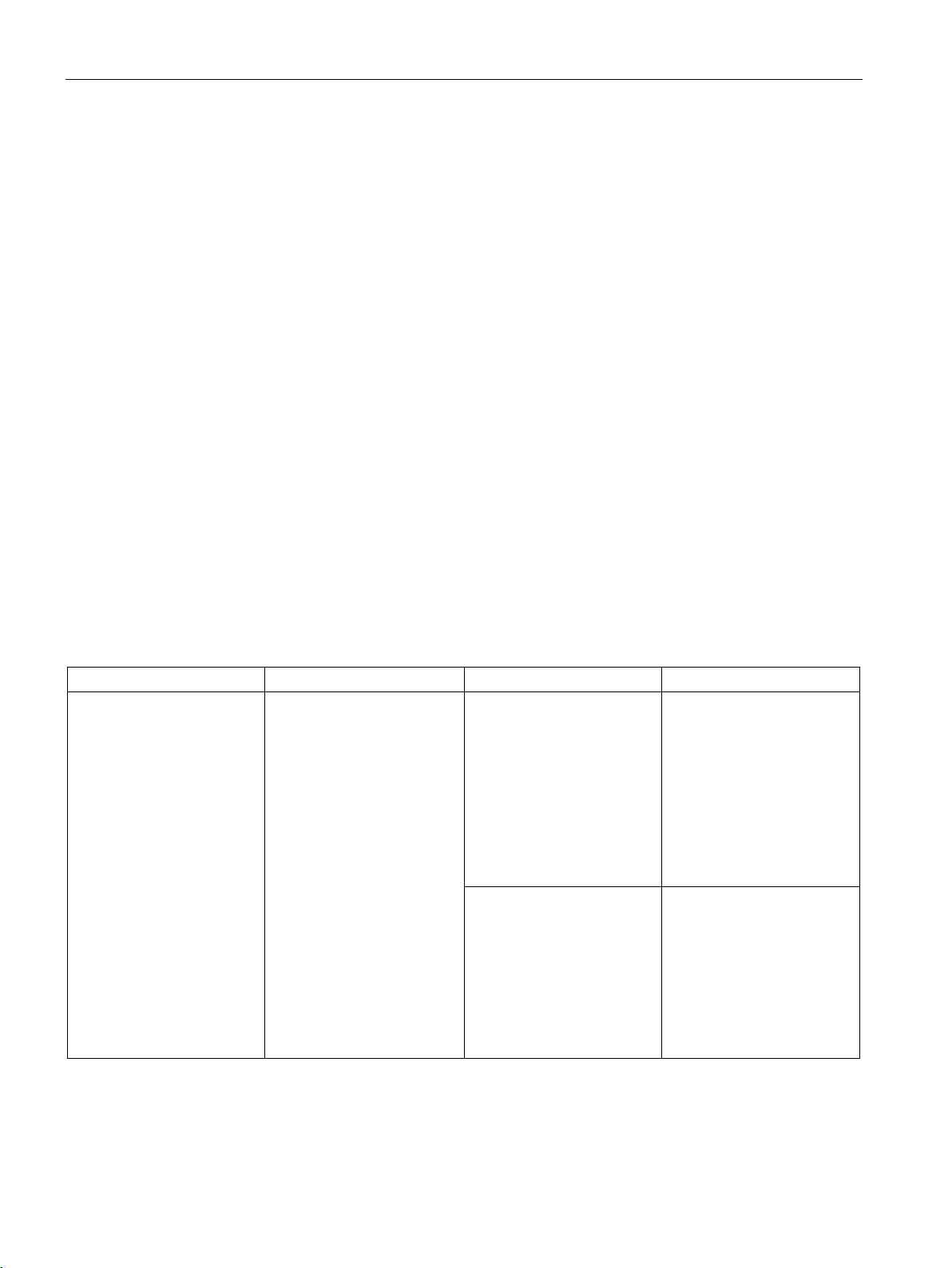

The basics of counting, measurement and position detection

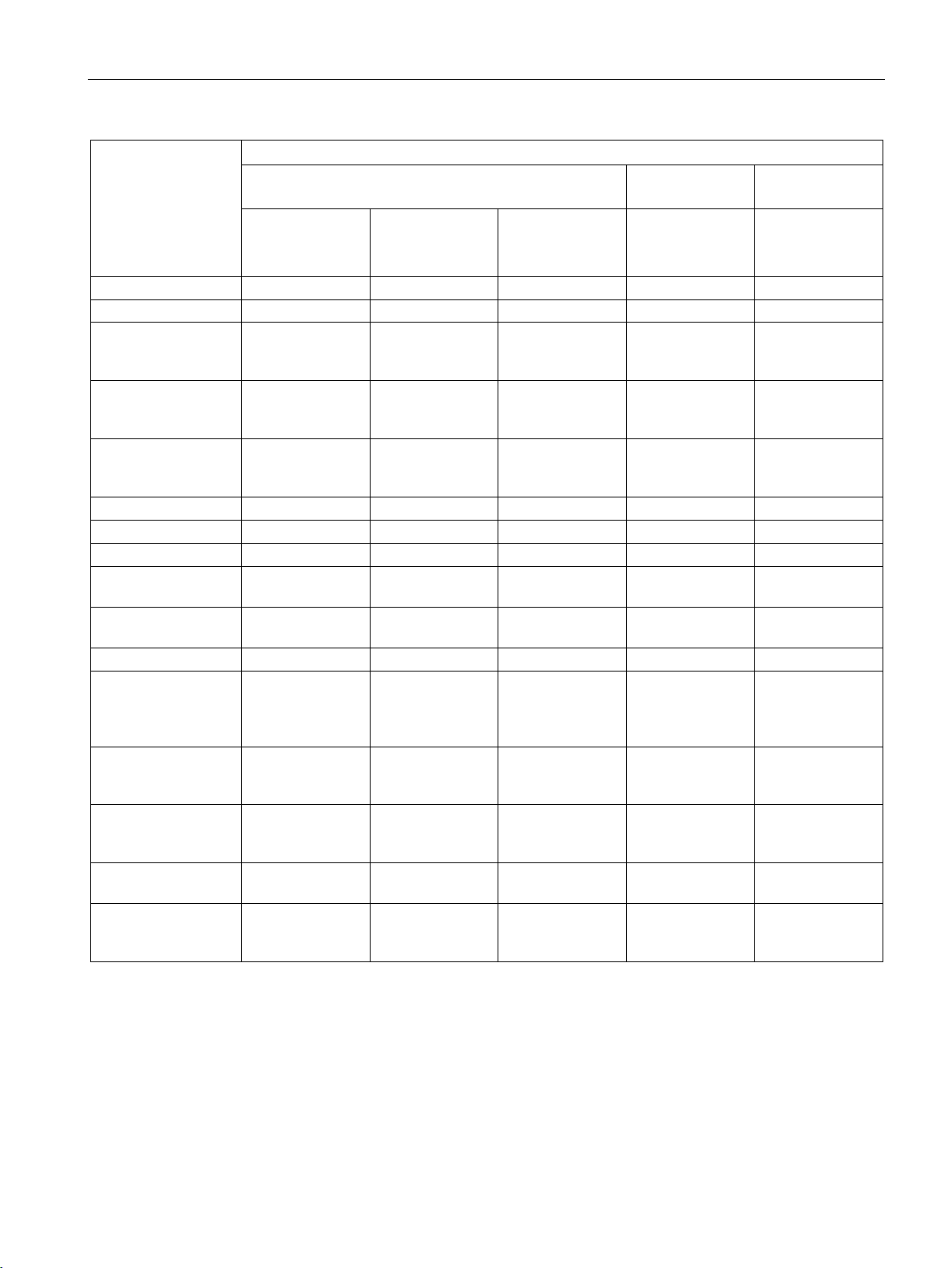

Modules for the ET 200SP system

Property

ET 200SP

Technology module

Digital input module

TM Count 1x24V

TM PosInput 1

TM Timer DIDQ

10x24V

DI 8x24VDC HS

Number of counters

1 1 31

4

Maximum signal frequency

200 kHz

1 MHz

50 kHz

10 kHz

quadruple evaluation (Page 72)

Maximum counting range

32 bits (Page 22)

32 bits (Page 22)

32 bits (Page 77)

32 bits (Page 82)

(Page 24)

nection

connection

24 V pulse encoder connection

X (Page 67)

—

X (Page 79)

X (Page 90)

(Page 71) connection

trol (Page 66)

5 V encoder supply

— — —

—

24 V encoder supply

X X X

X

inputs per counter

puts per counter

Hysteresis X X — —

Software gate

X (Page 27)

X (Page 27)

—

X (Page 85)

Hardware gate

X (Page 27)

X (Page 27)

—

X (Page 85)

(Page 30)

Synchronization (Page 35)

X X —

—

Comparison functions

X (Page 43)

X (Page 43)

—

X (Page 87)

(Page 54)

2.1 Overview of modules and properties

The following table provides an overview of the performance features of the modules for

counting, measuring and position input for the ET 200SP system.

Use of counters can be activated/deactivated

Maximum count frequency for

incremental encoders with

Maximum position value range

RS422/TTL incremental and

pulse encoder (Page 69) con-

24 V incremental encoder

SSI absolute encoder

Position input for Motion Con-

Number of additional digital

— — X X

800 kHz 4 MHz 200 kHz —

— 31 bits — —

— X — —

X (Page 67) — X (Page 79) —

— X — —

X X — —

3 2 — 1

Number of physical digital

outputs per counter

Number of logical digital out-

Capture function (Latch)

Frequency, velocity and period

duration measurement

Counting, measurement and position detection

16 Function Manual, 12/2017, A5E32009889-AG

2 2 — —

2 2 — 1

X X — —

X X — —

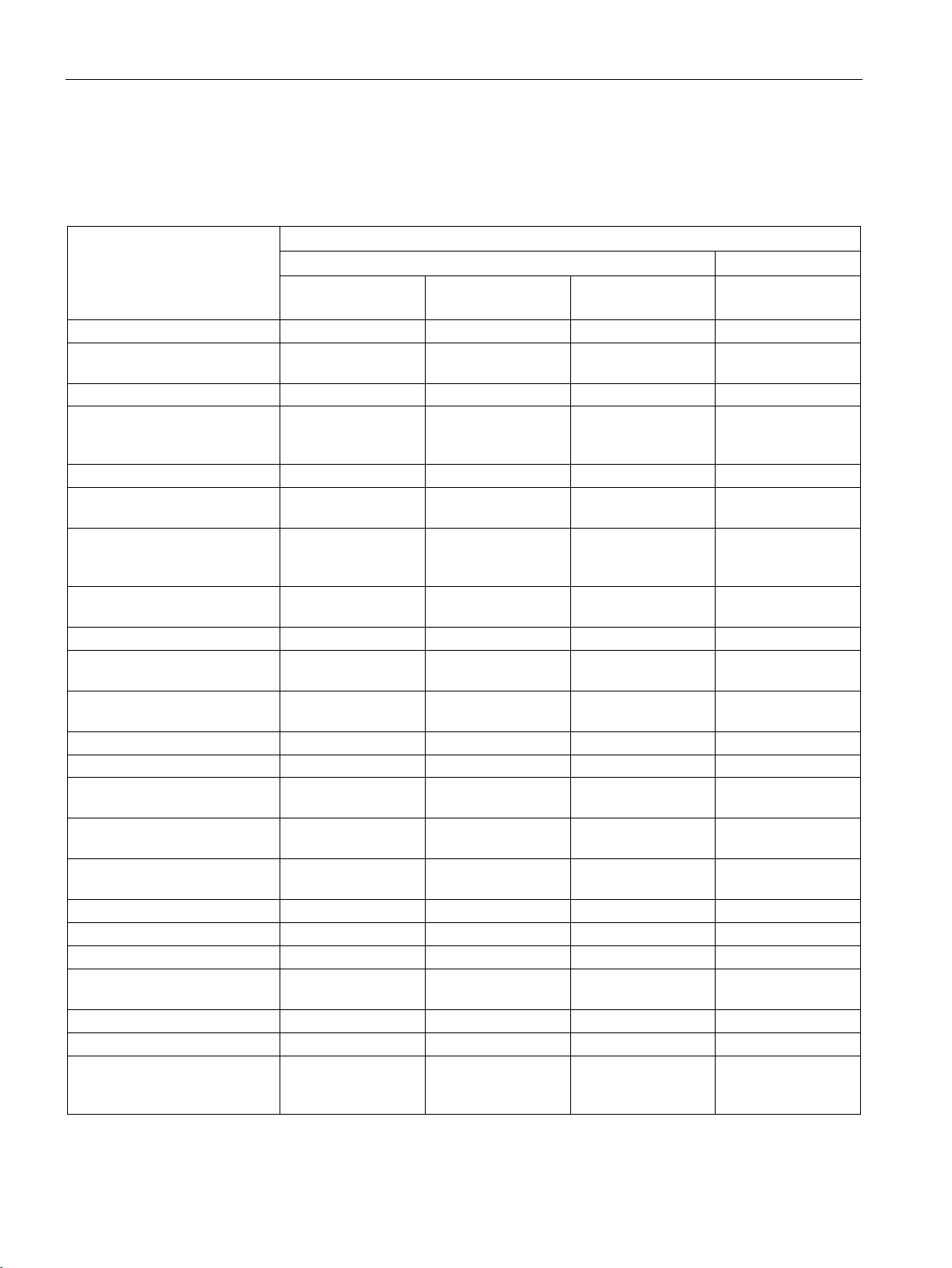

The basics of counting, measurement and position detection

Property

ET 200SP

Technology module

Digital input module

TM Count 1x24V

TM PosInput 1

TM Timer DIDQ

10x24V

DI 8x24VDC HS

on PROFINET

Hardware interrupt support

X (Page 66)

X (Page 66)

—

—

signals and digital inputs

1

One counter for incremental encoder (A, B phase-shifted) and two counters for pulse encoder

2.1 Overview of modules and properties

Support for isochronous mode

Support for diagnostic interrupts for sensor signals

Configurable filter for count

X (Page 75) X (Page 75) X (Page 80) X (Page 91)

X (Page 66) X (Page 66) — —

X X — X

Counting, measurement and position detection

Function Manual, 12/2017, A5E32009889-AG

17

The basics of counting, measurement and position detection

2.2

Basics of counting, measuring and position input (TM Count,

TM PosInput, Compact CPU)

2.2.1

Convention

Technology module

2.2.2

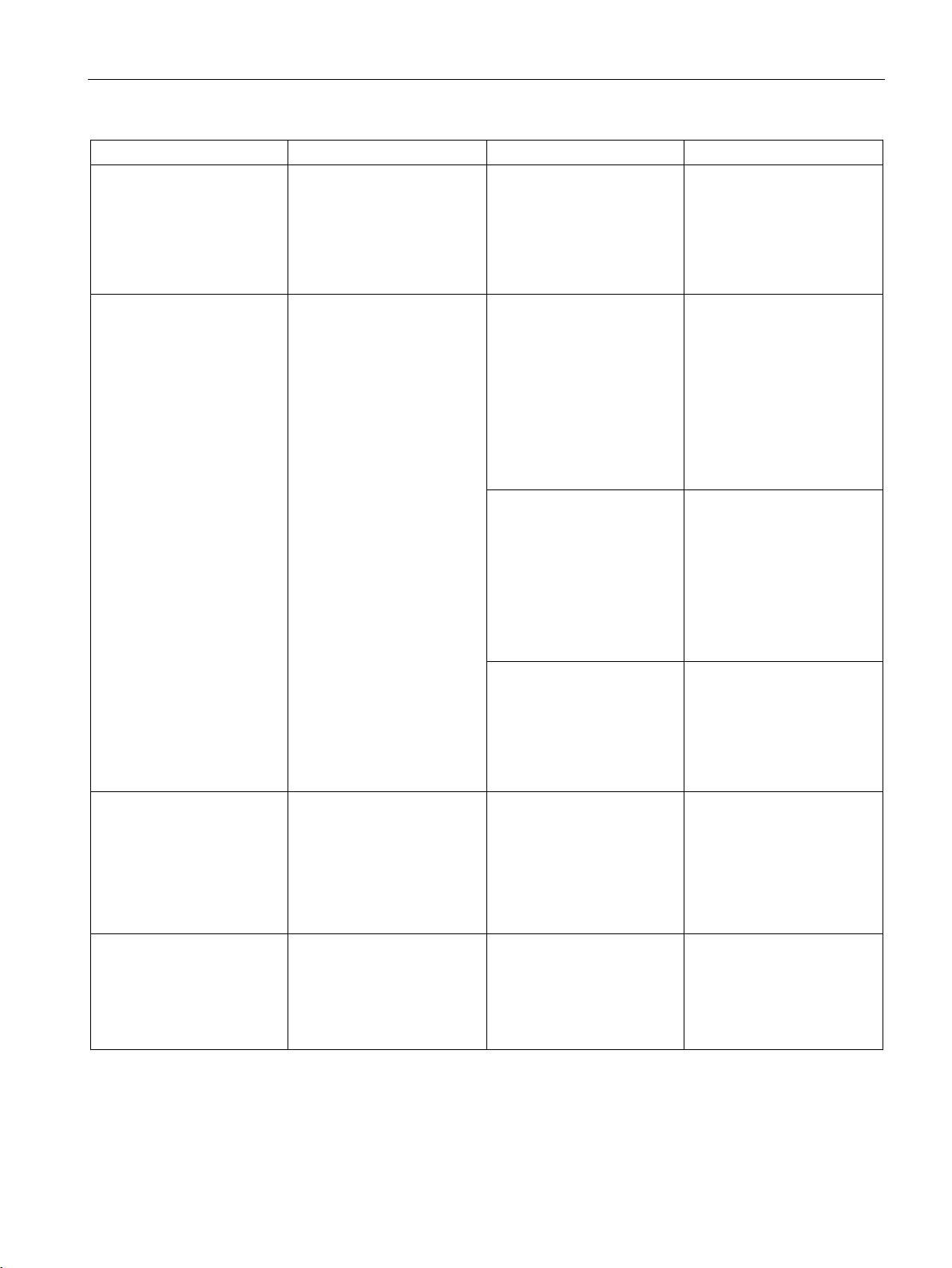

Overview of applications

Introduction

System environment for TM Count and TM PosInput

Application scenarios

Components required

Configuration software

In the user program

object

2.2 Basics of counting, measuring and position input (TM Count, TM PosInput, Compact CPU)

: We use the term "technology module" in this documentation both for the

technology modules TM Count and TM PosInput and the technology component of the

compact CPUs.

The technology module is configured and assigned parameters using the configuration

software.

The technology module functions are controlled and monitored via the user program.

The technology modules can be used in the following system environments:

Central operation with a

S7-1500 CPU or ET 200SP

CPU

• S7-1500 Automation

System or ET 200SP Distributed I/O System

• Technology module

STEP 7 (TIA Portal):

Operating with "Counting

and measurement" technology object

• Device configuration with

hardware configuration

• Parameter setting with

technology object

Counting and measurement

functions:

High_Speed_Counter instruction for the technology

object

Position input with SSI absolute encoder:

SSI_Absolute_Encoder instruction for the technology

Counting, measurement and position detection

18 Function Manual, 12/2017, A5E32009889-AG

STEP 7 (TIA Portal):

Position input for "Mo-

tion Control" technology

object

• Device configuration with

hardware configuration

• Parameter setting with

axis technology object

Instructions for "Motion Control" technology object

The basics of counting, measurement and position detection

Application scenarios

Components required

Configuration software

In the user program

object

parameter settings with HSP

2.2 Basics of counting, measuring and position input (TM Count, TM PosInput, Compact CPU)

Central operation with a

S7-1500 CPU or ET 200SP

CPU

Distributed operation with a

S7-1500 CPU

Distributed operation with a

CPU S7-300/400 or S7-1200

• S7-1500 automation

system

• ET 200 distributed I/O

system

• Technology module

• S7-300/400 automation

system

• ET 200 distributed I/O

system

• Technology module

STEP 7 (TIA Portal):

Manual operation (without

technology object)

• Device configuration and

parameter setting with

hardware configuration

STEP 7 (TIA Portal):

Operating with "Counting

and measurement" technology object

• Device configuration with

hardware configuration

• Parameter setting with

technology object

STEP 7 (TIA Portal):

Position input for "Mo-

tion Control" technology

object

• Device configuration with

hardware configuration

• Parameter setting with

axis technology object

STEP 7 (TIA Portal):

Manual operation (without

technology object)

• Device configuration and

parameter setting with

hardware configuration

STEP 7 (TIA Portal):

Device configuration and

parameter setting with hardware configuration

STEP 7:

Device configuration and

Direct access to control and

feedback interface of the

technology module in the I/O

data

Counting and measuring

functions:

High_Speed_Counter instruction for the technology

object

Position input with SSI absolute encoder:

SSI_Absolute_Encoder instruction for the technology

Instructions for "Motion Control" technology object

Direct access to technology

module control and feedback

interface in the I/O data

Direct access to technology

module control and feedback

interface in the I/O data

Distributed operation in a

third-party system

Counting, measurement and position detection

Function Manual, 12/2017, A5E32009889-AG

• Third-party automation

system

• ET 200 distributed I/O

system

• Technology module

Third-party configuration

software:

Device configuration and

parameter settings with GSD

file

Direct access to technology

module control and feedback

interface in the I/O data

19

The basics of counting, measurement and position detection

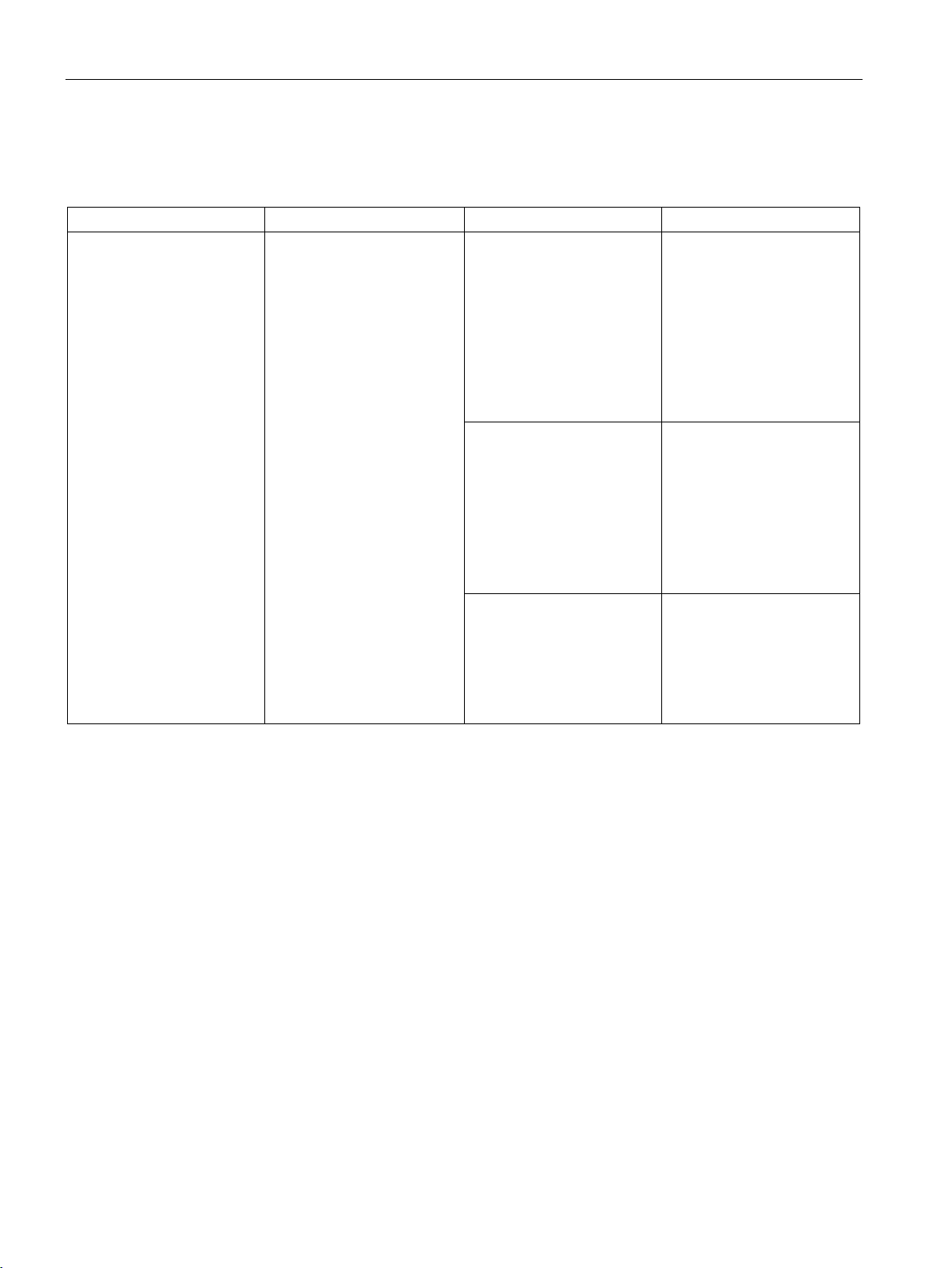

System environment for a Compact CPU

Application scenarios

Components required

Configuration software

In the user program

Parameter assignment options

2.2 Basics of counting, measuring and position input (TM Count, TM PosInput, Compact CPU)

The Compact CPUs can be used in the following system environments:

Central operation with a

S7-1500 Compact CPU

• S7-1500 automation

system

• Compact CPU

STEP 7 (TIA Portal):

Operating with "Counting

and measurement" technology object

• Device configuration with

hardware configuration

• Parameter settings with

High_Speed_Counter

technology object

STEP 7 (TIA Portal):

Position input for "Mo-

tion Control" technology

object

• Device configuration with

hardware configuration

• Parameter setting with

axis technology object

STEP 7 (TIA Portal):

Manual operation (without

technology object)

• Device configuration and

parameter setting with

hardware configuration

Counting and measuring

functions:

High_Speed_Counter instruction for the technology

object

Instructions for "Motion Control" technology object

Direct access to control and

feedback interface of the

technology module in the I/O

data

In an S7-1500 system, you have two options for parameter assignment and control of

technology module functions:

● Configuration using the technology object and control using the associated instruction

Access to the control and feedback interface of the technology module takes place

through the technology object.

● Parameter setting via hardware configuration

The control and feedback interface of the technology module is accessed using direct

access to the I/O data.

Counting, measurement and position detection

20 Function Manual, 12/2017, A5E32009889-AG

2.2 Basics of counting, measuring and position input (TM Count, TM PosInput, Compact CPU)

Configuration via technology object

Parameter setting via hardware configuration

For central and distributed use, we recommend the convenient, graphics-assisted

configuration using a technology object. A detailed description of this configuration can be

found starting from section High_Speed_Counter technology object (Page 92).

You specify the "Operation with technology object "Counting and measuring"" in the device

configuration of the technology module: see section Operating mode (Page 174).

You can assign the technology module and counting channel in the basic parameters of the

technology object: see section Basic parameters (Page 98).

You specify the "Manual operation (without technology object)" in the device configuration of

the technology module: see section Operating mode (Page 174).

Additional support for parameter setting via hardware configuration is available in the

context-sensitive help for the parameters in STEP 7 (TIA Portal). A description of the control

and feedback interface is available in the following sections:

The basics of counting, measurement and position detection

Assignment of the control interface (Page 185)

Assignment of the feedback interface (Page 188)

Counting, measurement and position detection

Function Manual, 12/2017, A5E32009889-AG

21

The basics of counting, measurement and position detection

2.2.3

Recording of count signals

2.2.3.1

Counting with incremental or pulse encoder

Counter limits

Start value

Gate control

2.2 Basics of counting, measuring and position input (TM Count, TM PosInput, Compact CPU)

Counting refers to the recording and adding up of events. The counters of the technology

modules capture and evaluate pulse and incremental signals. The count direction can be

specified using encoder or pulse signals or through the user program.

You can control counting processes using the digital inputs of the technology module. You

can switch the digital outputs exactly at defined counter values, regardless of the user

program.

You can configure the response of the counters using the functionalities described below.

The counter limits define the counter value range used. The counter limits are configurable

and can be modified during runtime using the user program.

The highest counter limit that can be set is 2147483647 (2

can be set is –2147483648 (–2

You can configure the response of the counter at the counter limits:

● Continue or stop counting upon violation of a counter limit (automatic gate stop)

● Set counter value to start value or to opposite counter limit upon violation of a counter

limit

31

).

31

–1). The lowest counter limit that

You can configure a start value within the counter limits. The start value can be modified

during runtime by the user program.

The technology module can, as configured, set the current counter value to the start value

upon synchronization, upon Capture function activation, upon violation of a counter limit or

when the gate is opened.

Opening and closing the hardware gate and software gate defines the period of time during

which the counting signals are captured.

The hardware gate is controlled externally via a digital input of the technology module. The

software gate is controlled via the user program. The hardware gate can be enabled through

parameter assignment. The software gate (bit in the control interface of the cyclic I/O data)

cannot be disabled.

Counting, measurement and position detection

22 Function Manual, 12/2017, A5E32009889-AG

The basics of counting, measurement and position detection

Capture (Latch)

Synchronization

Hysteresis

2.2 Basics of counting, measuring and position input (TM Count, TM PosInput, Compact CPU)

You can configure an external reference signal edge that triggers the saving of the current

counter value or position value as a Capture value. The following external signals can trigger

the Capture function:

● Rising or falling edge of a digital input

● Both edges of a digital input

● Rising edge of the N signal at the encoder input

When using a digital input, you can specify whether counting is to continue from the current

counter value or from the start value after the Capture function.

You can configure an external reference signal edge to load the counter with the specified

start value. The following external signals can load the counter with the start value:

● Rising or falling edge of a digital input

● Rising edge of signal N at the encoder input

● Rising edge of signal N at the encoder input depending on the level of the assigned

digital input

You can specify hysteresis for the comparison values, within which a digital output is

prevented from switching again. An encoder can come to a standstill at a specific position,

and slight movements may make the counter value fluctuate around this position. If a

comparison value or a counting limit lies within this fluctuation range, the corresponding

digital output will be switched on and off with corresponding frequency if hysteresis is not

used. The hysteresis prevents these unwanted switching operations.

Counting, measurement and position detection

Function Manual, 12/2017, A5E32009889-AG

23

The basics of counting, measurement and position detection

2.2.3.2

Position input with SSI absolute encoder

Description

Gray-dual conversion

Capture (Latch)

Hysteresis

Range for position value

Complete SSI frame

2.2 Basics of counting, measuring and position input (TM Count, TM PosInput, Compact CPU)

You can use the TM PosInput technology modules with an SSI absolute encoder for position

detection. The technology module reads the position value via a synchronous serial interface

from the SSI absolute encoder and makes it available to the controller.

You can switch the digital outputs of the technology module exactly at defined position

values, regardless of the user program. Position input with an SSI absolute encoder does not

involve gate control. Due to system constraints, synchronization is not possible with an SSI

absolute encoder.

Gray-code and dual-code SSI absolute encoders are supported.

You can configure one or both edges of a digital input that triggers a saving of the current

position value as Capture value.

You can specify hysteresis for the comparison values, within which a digital output is

prevented from switching again. An encoder can come to a standstill at a specific position,

and slight movements may make the position value fluctuate around this position. If a

comparison value or a limit lies within this fluctuation range, the corresponding digital output

is switched on and off with corresponding frequency if hysteresis is not used. The hysteresis

prevents these unwanted switching operations.

You can specify a frame length of 10 bits to 40 bits for the SSI absolute encoder. The

configurable bit numbers of the LSB and the MSB of the position value in the frame define

the value range. The technology module can read a position value with a maximum length

of31 bits and communicate it to the controller. The position value is treated as unsigned

positive value and can assume values between 0" and "2

Instead of having a measured variable returned, you can choose to have the least significant

32 bits of the current unprocessed SSI frame returned. This provides you with encoderspecific additional bits, such as error bits, in addition to the position value. If the SSI frame is

shorter than 32 bits, the complete SSI frame is returned right-aligned and the top unused bits

are returned with "0" in the feedback interface.

(MSB-LSB+1)-1

".

Counting, measurement and position detection

24 Function Manual, 12/2017, A5E32009889-AG

The basics of counting, measurement and position detection

2.2.4

Behavior at the counting limits

Violation of a counting limit

Counting limit violated

Status bit

High counting limit

EVENT_OFLW is set

Note

The high counting limit and the start value define the value range of the counter:

Value range of the counter = (high limit

Examples

2.2 Basics of counting, measuring and position input (TM Count, TM PosInput, Compact CPU)

The high counting limit is violated when the current counter value is equal to the high

counting limit and another upward count pulse is received. The counter low limit is violated

when the current counter value is equal to the counter low limit and another downward count

pulse is received.

The appropriate status bit is set in the feedback interface in the event of limit violation:

Low counting limit EVENT_UFLW is set

You can reset the status bits with RES_EVENT .

You can configure whether or not and from which counter value counting is to continue

following counting limit violation.

– start value) + 1

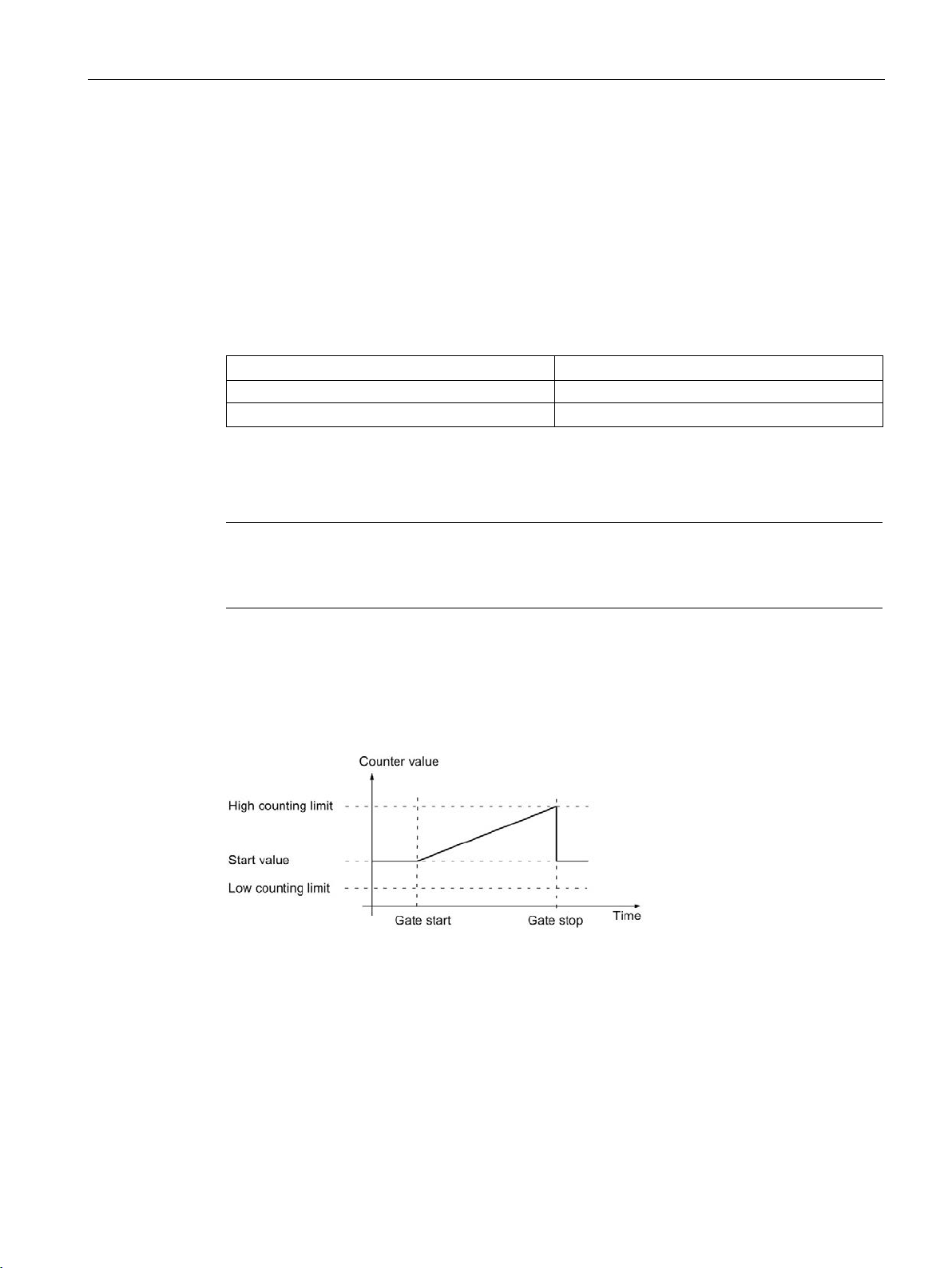

The figure below shows an example for terminating the counting process (automatic gate

stop) after an overflow and setting the counter to the start value:

Counting, measurement and position detection

Function Manual, 12/2017, A5E32009889-AG

25

The basics of counting, measurement and position detection

2.2 Basics of counting, measuring and position input (TM Count, TM PosInput, Compact CPU)

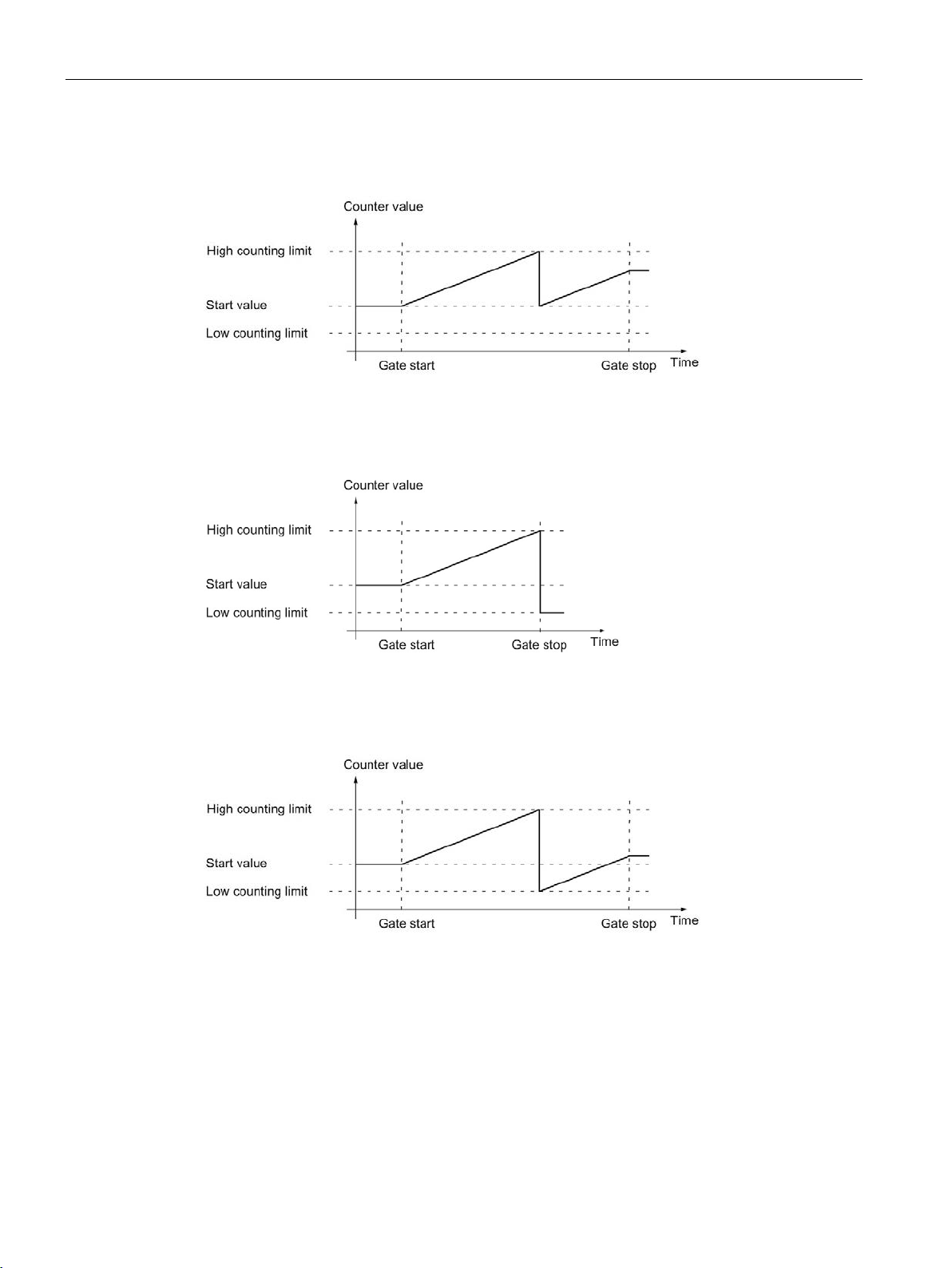

The figure below shows an example for continuing the counting process after an overflow

and setting the counter to the start value:

The figure below shows an example for terminating counting after an overflow and setting

the counter to the opposite counting limit:

The figure below shows an example for continuing the counting process after an overflow

and setting the counter to the opposite counting limit:

Counting, measurement and position detection

26 Function Manual, 12/2017, A5E32009889-AG

The basics of counting, measurement and position detection

2.2.5

Gate control with incremental or pulse encoder

2.2.5.1

Software gate

2.2.5.2

Hardware gate

Note

The configured input filters delay the

Level-triggered opening and closing of the hardware gate with a digital input

2.2 Basics of counting, measuring and position input (TM Count, TM PosInput, Compact CPU)

Many applications require counting processes to be started or stopped in accordance with

other events. In such cases, counting is started and stopped using the gate function.

The technology modules have two gates for each channel. These define the resulting

internal gate:

● Software gate

● Hardware gate

The software gate of the channel is opened and closed with the control bit (Page 185)

SW_GATE. The status of the software gate is indicated by the feedback bit (Page 188)

STS_SW_GATE .

The hardware gate is optional. You open and close the hardware gate by means of signals

at the configured digital inputs of the channel.

control signal of the digital input.

The status of a DIm digital input is indicated by the respective feedback bit (Page 188)

STS_DIm .

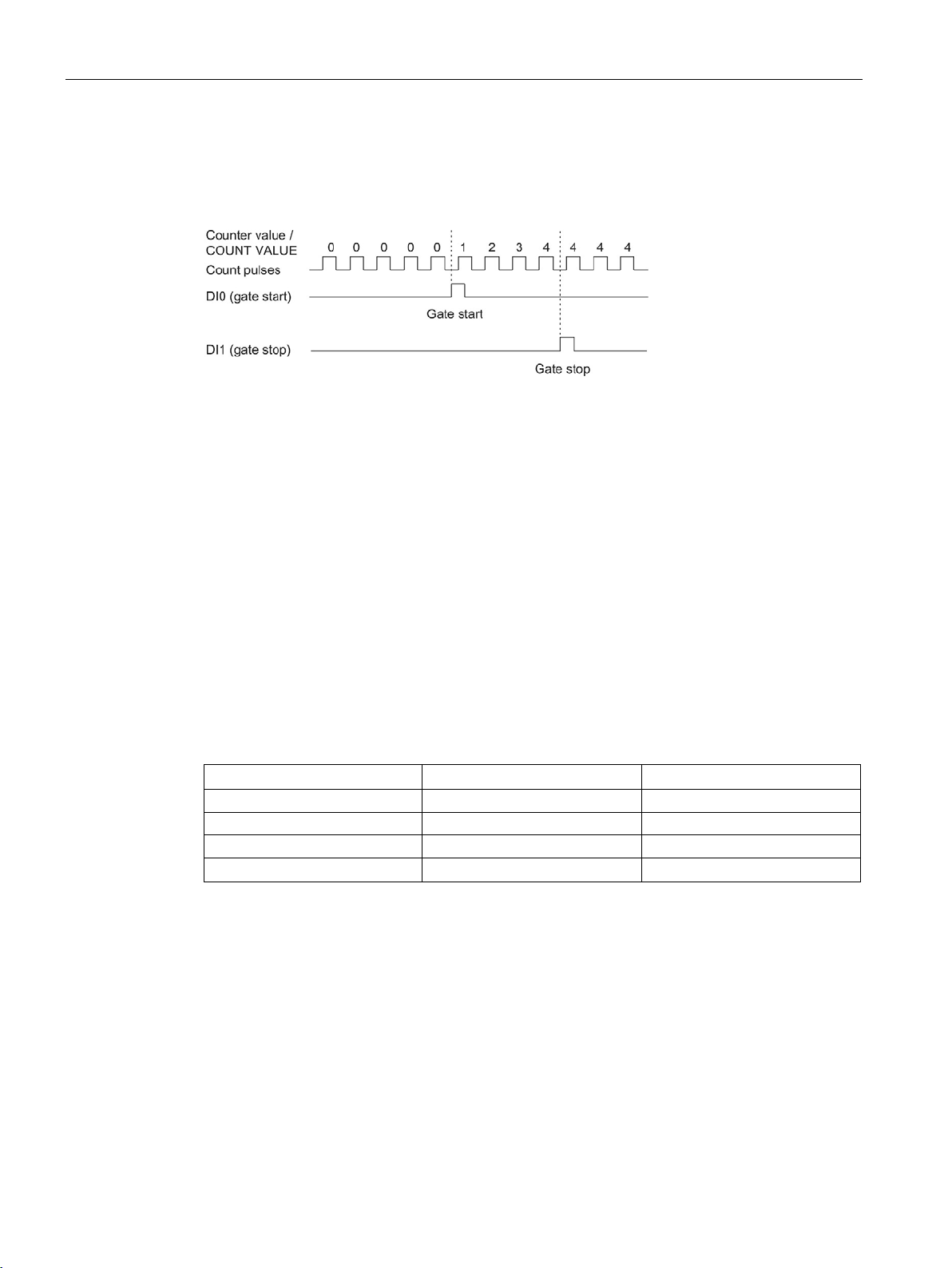

The figure below shows an example of level-triggered opening and closing with a digital

input. The digital input is configured to be active with high level:

As long as the digital input is active, the hardware gate is open and the count pulses are

counted. The hardware gate is closed when the digital input becomes inactive. The counter

value stays constant and ignores any further count pulses.

Counting, measurement and position detection

Function Manual, 12/2017, A5E32009889-AG

27

The basics of counting, measurement and position detection

Edge-triggered opening and closing of the hardware gate with two digital inputs

2.2.5.3

Internal gate

Internal gate

Hardware gate

Software gate

Internal gate

Open/not configured

open

open

Open/not configured

closed

closed

closed

open

closed

2.2 Basics of counting, measuring and position input (TM Count, TM PosInput, Compact CPU)

The figure below shows an example of opening and closing with two digital inputs. The two

digital inputs are configured so that the rising edge of the hardware gate opens:

The hardware gate is opened with the configured edge at the digital input that is configured

for opening. The hardware gate is closed with the configured edge at the digital input that is

configured for closing.

The internal gate is open if the software gate is open and the hardware gate is open or has

not been configured. The status of the internal gate is indicated by the feedback bit

(Page 188) STS_GATE.

If the internal gate is open, counting is started. If the internal gate is closed, all other count

pulses are ignored and counting is stopped.

If you want to control a counting process with the hardware gate only, the software gate must

be open. If you do not configure a hardware gate, the hardware gate is considered to be

always open. In this case, you open and close the internal gate with the software gate only.

closed closed closed

When you configure the counter behavior, you can specify whether the counting process is

to start from the start value or from the current counter value when the internal gate is

opened.

Counting, measurement and position detection

28 Function Manual, 12/2017, A5E32009889-AG

The internal gate can also be automatically closed upon violation of a counting limit. The

software or hardware gate must then be closed and reopened to continue counting.

The basics of counting, measurement and position detection

2.2.5.4

Counter behavior at gate start

Setting counter to start value

Continuing with the current counter value

2.2 Basics of counting, measuring and position input (TM Count, TM PosInput, Compact CPU)

You have the following configuration options for counter behavior upon gate start:

● Setting counter to start value

● Continuing with the current counter value

Counter behavior is as follows for this configuration:

Each counting process starts with the start value when the internal gate is opened.

The figure below shows an example for continuing the counting process after counter is set

to the start value:

Counter behavior is as follows for this configuration:

Each counting process starts from the current counter value after the internal gate is

reopened.

The figure below shows an example for continuing the counting process with the current

counter value:

Counting, measurement and position detection

Function Manual, 12/2017, A5E32009889-AG

29

Loading...

Loading...