Page 1

Important Information List of Safety Notes

Contents

SIMATIC

Programmable Controllers

S7 F/FH Systems

Manual

Product Overview

Getting Started

Safety Mechanisms

Configuration

Programming

Operation and Maintenance

Safety

Fail-Safe Function Blocks

Appendices

1

2

3

4

5

6

7

8

This manual is part of the documentation

package with the order number:

6ES7988-8FA10-8BA0

Edition 02/2003

A5E00085588-03

Check Lists

References

Glossary, Index

A

B

Page 2

Safety Guidelines

This manual contains notices intended to ensure personal safety, as well as to protect the products and

connected equipment against damage. These notices are highlighted by the symbols shown below and

graded according to severity by the following texts:

!

!

!

Safety Note

Contains important information on the acceptance and safety-related use of the product.

Warning

indicates that death, severe personal injury or substantial property damage can result if proper

precautions are not taken.

Caution

indicates that minor personal injury can result if proper precautions are not taken.

Note

draws your attention to particularly important information on the product, handl i ng the product , or to a

particular part of the documentation.

Qualified Personnel

Only qualified personnel should be allowed to install and work on this equipment. Qualified persons are

defined as persons who are authorized to commission, to ground and to tag circuits, equipment, and

systems in accordance with established safety practices and standards.

Correct Usage

Note the following:

!

Trademarks

Copyright © Siemens AG 2003 All rights reserved

The reproduction, transmission or use of this document or its

contents is not permitted without express written authority.

Offenders will be liable for damages. All rights, including rights

created by patent grant or registration of a utility model or design,

are reserved.

Siemens AG

Automation and Drives

Industrial Automation Systems

Postfach 4848, D- 90327 Nuern be rg

Siemens Aktiengesellschaft A5E00085588-03

This device and its components may only be used for the applications described in the catalog or the

technical description, and only in connection with devices or components f rom other manufacturers

which have been approved or recommended by Siemens.

This product can only function correctly and safely if it is transported, stored, s et up, and install ed

correctly, and operated and maintained as recommended.

SIMATIC®, SIMATIC HMI® and SIMATIC NET® are registered trademarks of SIEMENS AG.

Some of the other designations used in these documents are also registered trademarks; the owner’s rights

may be violated if they are used by third parties for their own purposes.

Disclaimer of Liability

We have checked t he contents of this manual for agreem ent with

the hardware and s oftware described. Since de viations cannot be

precluded entirel y, we cannot guarantee full a greement. However,

the data in this m anual are reviewed regul arly and any necessary

corrections included in subsequent editions. Suggestions for

improvement are welcom e d.

©Siemens AG 2003

Technical data subject to change.

Warning

Page 3

Important Information

Purpose of the Manual

The information contained in this manual enables you to configure and program S7

F/FH Systems using S7 F Systems V5.2.

Target Group

This manual is intended for system planners, configuration engineers and

programmers. Knowledge of STEP 7 and CFC is assumed in most areas.

Contents

This manual describes how to work with the S7 F/FH Systems using S7 F-Systems

V5.2 software. It consists of instructive chapters and reference chapters

(descriptions of the fail-safe function blocks and check lists for acceptance). The

manual covers the following topics:

• Safety Mechanisms

• Configuration

• Programming

• Maintenance

• Safety

• Fail-Safe Blocks

Scope of the Manual

The S7 F Systems V5.2

Options Package including

Authorization License V5.0

F-Copy License 6ES7 833 1CC00 6YX0 V5.0

Module Order Number As of Version

6ES7 833 1CC00 0YX0 V5.2

Fail-Safe Systems

A5E00085588-03 iii

Page 4

Important Information

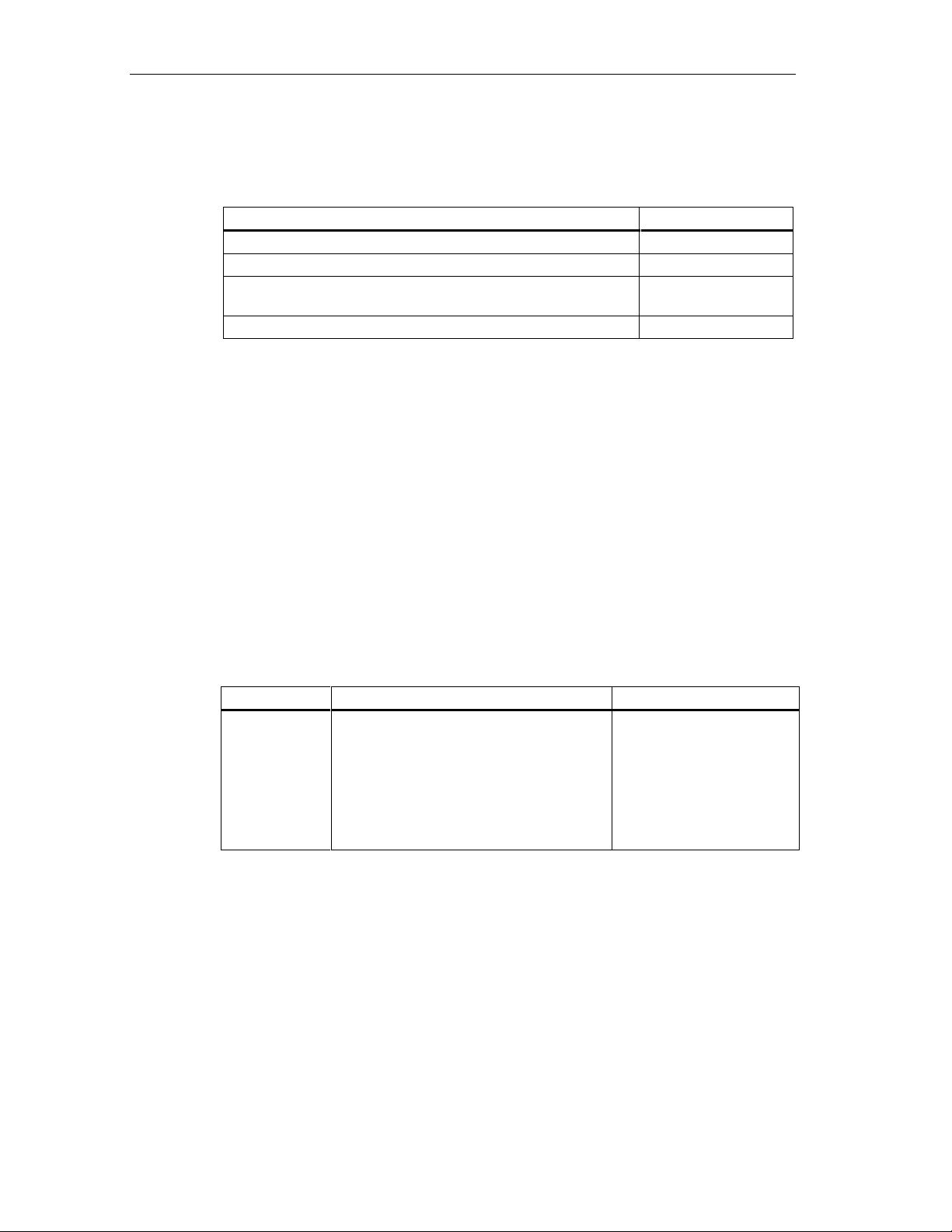

What’s New?

The following changes are new in the S7 F Systems V5.2:

Topic Chapter

New Fail-Safe Blocks Fail-Safe Blocks

Introduction to the F_Shutdown Logic Getting Started

Support of the new ET 200S failsafe modules to the S7 F/FH

Systems

Enhanced usability Programming

Standards, Certificates and Approvals

The S7 FH System and the fail-safe F-I/O’s are certified for use in safety mode up

to the following levels:

Throughout the

document

• Requirement classes AK1 to AK6

DIN V VDE 0801

• SIL1 to SIL3 (Safety Integrity Level) in accordance with IEC 61508

• Categories 1 to 4 in accordance with EN 954-1

Place in the Information Landscape

This manual is part of the documentation package for the S7 F/FH System.

System Documentation Package Order Number

S7 F Systems • Safety Engineering in SIMATIC S7

• Programmable Controllers,

S7 F/FH Systems

• ET200 S Distributed I/O System Fail-

Safe Modules

• Automation Systems S7-300 Fail-Safe

Signal Modules

CD-ROM

in accordance with DIN V 19250/

6ES7988-8FB10-8BA0

You can also obtain all the SIMATIC S7 documentation as a dedicated SIMATIC

S7 collection on CD-ROM.

iv A5E00085588-03

Fail-Safe Systems

Page 5

How to Use this Manual

To help you find specific information quickly, the manual contains the following

aids:

• There is a complete table of contents at the beginning of the manual.

• A heading indicating the contents of each section is provided in the left-hand

column on each page of each chapter.

• Following the appendices, you will find a glossary in which important technical

terms used in the manual are defined.

• At the end of the manual you will find a detailed index, which makes it easy for

you to find the information you are looking for.

Additional Support

For any unanswered questions about the use of products presented in this manual,

contact your local Siemens representative:

http://www.siemens.com/automation/partner

Important Information

Training Center

We offer courses to help you get started with the S7 automation system. Contact

your regional training center or the central training center in Nuremberg (90327),

Federal Republic of Germany.

Telephone: +49 (911) 895–3200

http://www.sitrain.com

H/F Competence Center

The H/F Competence Center in Nuremberg offers special workshops on SIMATIC

S7 fail-safe and fault-tolerant automation systems. The H/F Competence Center

can also provide assistance with onsite configuration, commissioning, and

troubleshooting.

Telephone: +49 (911) 895-4759

Fax: +49 (911) 895-5193

For questions about workshops, etc., contact: hf-cc@nbgm.siemens.de

For Safety Integrated questions (system, wiring, etc.), contact:

cocsi@nbgm.siemens.de

Fail-Safe Systems

A5E00085588-03 v

Page 6

Important Information

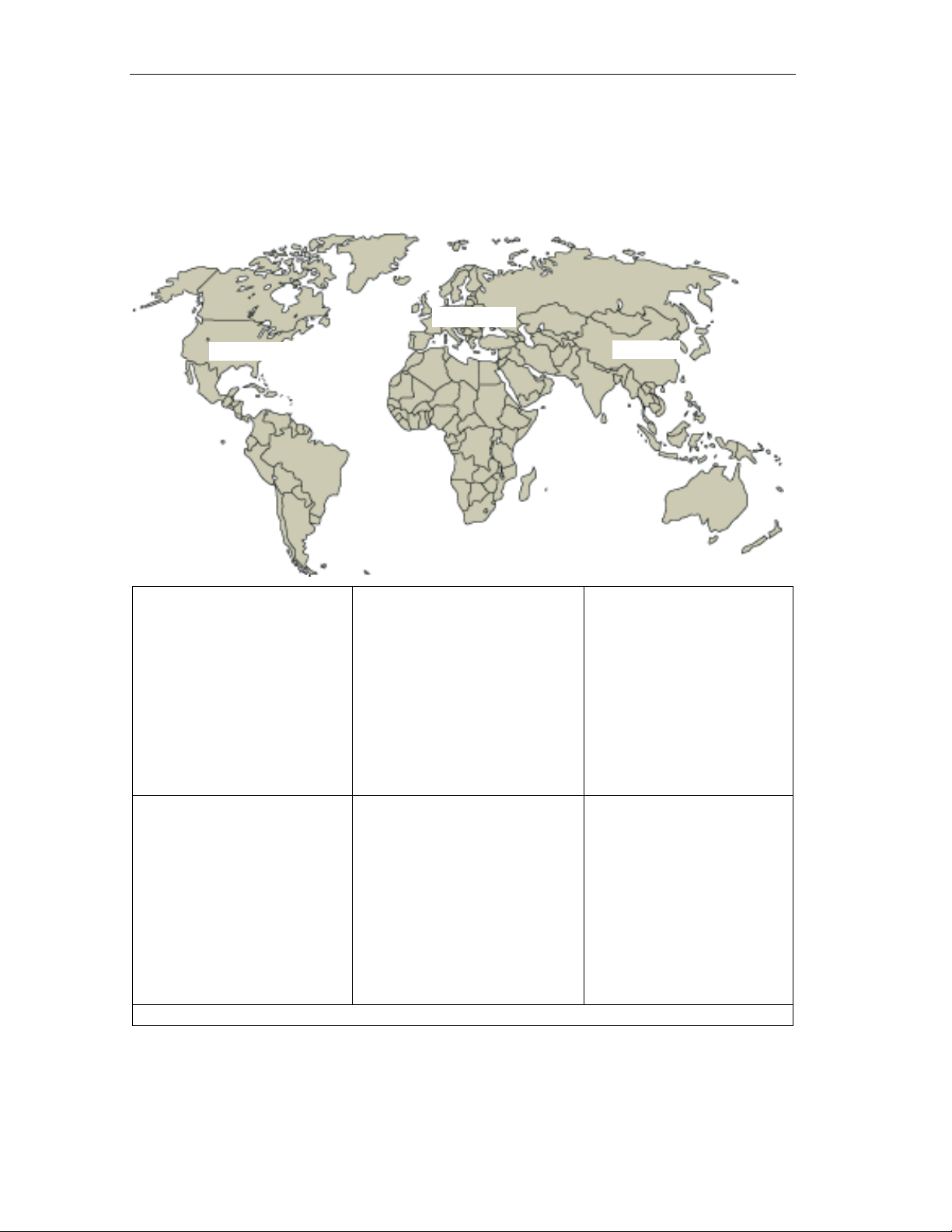

A&D Technical Support

Available worldwide, 24 hours a day:

Nuernberg

Johnson City

Worldwide (Nuremberg)

Technical Support

Local time: 24 hours per day/365 days

per year

Telephone: +49 (0) 180 5050–222

Fax: +49 (0) 180 5050-223

E-mail: adsupport@

siemens.com

GMT: +1:00

Europe/Africa (Nuremberg)

Authorization

Local time: M - F 8:00 a.m. to

5:00 p.m.

Telephone: +49 (0) 180 5050–-222

Fax: +49 (0) 180 5050-223

E-mail: adsupport@

siemens.com

GMT: +1:00

In general, English and German are spoken by Technical Support and Authorization staff.

United States (Johnson City)

Technical Support and

Authorization

Local time: M - F 8:00 a.m. to 5:00 p.m.

Telephone: +1 (0) 770 740–3505

Fax: +1 (0) 770 740–3699

E-mail: isd-callcenter@

sea.siemens.com

GMT: -5:00

Asia/Australia (Beijing)

Technical Support and

Authorization

Local time: M - F 8:00 a.m. to

5:00 p.m.

Telephone: +86 10 64 75 75 75

Fax: +86 10 64 74 74 74

E-mail: adsupport.asia@

GMT: +8:00

Beijing

siemens.com

vi A5E00085588-03

Fail-Safe Systems

Page 7

Service & Support on the Internet

In addition to our paper documentation, we also provide all of our technical

information on the Internet at:

http://www.siemens.com/automation/service&support

Here, you will find the following information:

• Newsletter providing the latest information on your products

• Exact documents for your requirements, which you can access by performing

an online search in Service & Support

• Forum in which users and experts worldwide exchange ideas

• Your local Automation & Drives contact, who can be accessed in our Contacts

database

• Information about local service, repair, and replacement parts. Much more

information can be found under "Services“.

Important Information

Fail-Safe Systems

A5E00085588-03 vii

Page 8

Important Information

viii A5E00085588-03

Fail-Safe Systems

Page 9

Safety Notes

Keep Safety and Standard Functions Se parat e............................................................. 1- 19

Public Network Safety F-CPU Communication Not Allowed..........................................3-12

Safety Rules for Safety Operation....................................................................................4-2

CPU containing safety program must have a password ..................................................4-3

I/O Group Diagnosis.........................................................................................................4-5

Modify Variables can cause Shutdown ............................................................................4-7

Limiting Access through ES..............................................................................................4-8

Password Protection.........................................................................................................4-8

Safety Program and CPU Passwords should be different ...............................................4-9

Authorized use of Password...........................................................................................4-10

Compiler Generated Values off-limits...............................................................................5-5

Comparison Changes Signature ......................................................................................5-6

Symbol Table Entries for F-Blocks cannot be changed .................................................5-10

Do not change automatically inserted F-Control Blocks. ...............................................5-11

Incorrect changes to fail-safe blocks input parameters may result in the

Safety Program and its outputs being disabled. .............................................5-12

During simulation of Input Channels the Simulation value is always available

on the block’s output. ......................................................................................5-22

Automatic Reintegration may not always be possible....................................................5-25

Startup Protection to handle short power failures in the F-I/O. ......................................5-26

Automatic Reintegration through F_QUITES.................................................................5-27

Default MAX_CYC..........................................................................................................5-30

Safety Program must be re-compiled if S7 connections used for CPU-CPU

Communication have changed........................................................................5-32

Use F_LIM_R for plausibility check of standard to F-data conversion...........................5-37

When Deactivating Safety Mode....................................................................................5-40

F-Blocks outputs’ always use the preset initial values. ..................................................5-44

Safety Program on Memory Card...................................................................................5-48

Downloading...................................................................................................................5-49

OB Cycle Times Changes Restricted.............................................................................5-50

Password Protection Level............................................................................................. 5- 54

Download Operation Aborted.........................................................................................5-55

Safety Program disable if change to failsafe outputs.....................................................5-56

ES changes can change signature.................................................................................5-56

Simulation Warning (V5.0 and below) ............................................................................5-59

Simulation Warning (V5.1 and above)............................................................................5-61

Allowable F Control Block comparison changes............................................................5-75

Checking online comparison output ...............................................................................5-76

Simulation of PROFIsafe devices not permitted...............................................................6-1

Duplicate Masters must be avoided .................................................................................6-2

Safety measures must be followed...................................................................................6-2

Pulse Detection.................................................................................................................7-9

Archive STEP 7 Projects ................................................................................................7-14

Do Not Change PAR_ID and COMPLEM parameters .....................................................8-2

Do not change automatically supplied FB inputs .............................................................8-4

Fail-safe FB numbers .......................................................................................................8-7

Fail-Safe Systems

A5E00085588-03

ix

Page 10

Safety Notes

Safety Program can be installed in OB 3x ONLY.............................................................8-8

Do NOT change CRC_IMP input....................................................................................8-26

Use F_LIM_R for plausibility check of standards to F-data conversion.........................8-35

Reintegration through User Acknowledgement with F_QUITES....................................8-45

PD_FLAG not to be interconnected................................................................................8-56

F_SHUTDN in slowest configured OB............................................................................8-74

Fail-Safe Systems

x A5E00085588-03

Page 11

Contents

1 Product Overview 1-1

1.1 Overview ...........................................................................................................1-1

1.2 Basic Configuration Variants.............................................................................1-4

1.3 Components of an S7 F System.......................................................................1-7

1.4 Hardware Components .....................................................................................1-8

1.5 Software Components.....................................................................................1-10

1.6 Installing the S7 F Systems Optional Package...............................................1-11

1.6.1 Getting Started Information Applicable to All Use-Case-Scenarios................1-11

1.6.2 Use-case-scenarios ........................................................................................1-12

1.7 Working with F-Systems .................................................................................1-19

2 Getting Started 2-1

2.1 Introduction........................................................................................................2-1

2.2 S7 F System - Getting Started..........................................................................2-4

2.2.1 S7 F System, Setting up the Hardware.............................................................2-4

2.2.2 Configuring the S7 F System ............................................................................2-6

2.2.3 S7 F System, Creating a Fail-Safe User Program............................................2-8

2.2.4 Starting Up the S7 F System ..........................................................................2-11

2.2.5 S7 F System, Monitoring Errors......................................................................2-12

2.3 Fault-Tolerant S7 FH System - Getting Started..............................................2-13

2.3.1 Fault-Tolerant S7 FH System, Setting Up the Hardware................................2-13

2.3.2 Configuring the Fault-Tolerant S7 FH System................................................2-15

2.3.3 Fault-Tolerant S7 FH System, Creating a Fail-Safe User Program................2-16

2.3.4 Starting Up a Fault-Tolerant S7 FH System ...................................................2-16

2.3.5 Fault-Tolerant S7 FH System, Monitoring Errors............................................2-17

3 Safety Mechanisms 3-1

3.1 Introduction to the Safety Mechanisms.............................................................3-1

3.2 Safety Mode...................................................................................................... 3-2

3.3 Fault Reactions .................................................................................................3- 3

3.4 Startup of an F-System .....................................................................................3-4

3.5 Self-Tests and Command Tests .......................................................................3-5

3.6 Logical and Timed-Based Progr am Execution Monitoring................................3-5

3.7 Fail-Safe User Times ........................................................................................3-7

3.8 Password Protection for F-Systems..................................................................3-8

3.9 Safety-Related Comm unication ........................................................................3-9

3.9.1 Communication Between the Safety Program and the

Standard User Program .................................................................................. 3-10

3.9.2 Communication Between F-Run-Time Groups...............................................3-11

3.9.3 Communication Between the F-CPU and F-I/Os............................................3-11

3.9.4 Safety-Related Communication Between F-CPUs .........................................3-12

Fail-Safe Systems

A5E00085588-03

xi

Page 12

Contents

4 Configuration 4-1

4.1 Overview ...........................................................................................................4-1

4.2 Hardware Configuration and Par ameter Assignment .......................................4-1

4.3 CPU Parameter Assignment.............................................................................4- 3

4.4 Parameter Assignment of F-I/Os.......................................................................4-4

4.5 Configuring Redundant F-I/Os ..........................................................................4-6

4.6 Configuring the Network s and Connections......................................................4-6

4.7 Programming Device Functions in STEP 7......................................................4-7

4.8 Setting up, Modifying and Cancelling Access Rights........................................4-8

4.8.1 Setting up Access Rights for the CPU ..............................................................4-8

4.8.2 Entering/Changing the Password for the Safety Program................................4-9

4.8.3 Cancelling Access Rights for the Safety Program..........................................4-10

4.9 Configuration in Run .......................................................................................4-11

5 Programming 5-1

5.1 Overview ...........................................................................................................5-1

5.1.1 Structure of the Safety Program .......................................................................5-1

5.1.2 Blocks of the Safety Program............................................................................5-2

5.2 Creating Safety Programs.................................................................................5-4

5.2.1 Creating a Safety Program - Basic Procedure.................................................5-4

5.2.2 Safety Notes for Programming..........................................................................5-5

5.2.3 Defining the Program Structure.........................................................................5-7

5.2.4 Inserting CFC Charts ........................................................................................5-8

5.2.5 Inserting Run-Time Groups...............................................................................5-9

5.3 Inserting and Interconnecting Fail-Safe Blocks...............................................5-10

5.3.1 Inserting Fail-Safe Blocks ...............................................................................5-10

5.3.2 Automatically Inserted F-Blocks......................................................................5-11

5.3.3 Interconnecting and Assigning Parameters to F-Blocks.................................5-12

5.3.4 Defining the Run Sequence............................................................................5-14

5.3.5 Interconnecting F-Driver Blocks......................................................................5-16

5.3.6 Passivation and Reintegration of the Input and Output Channels..................5-24

5.3.7 Programming Startup Protection.....................................................................5-28

5.3.8 Example: Reintegration after Startup of the Safety Program..........................5-29

5.3.9 Assigning Parameters to the F Cycle Time Monitoring...................................5-30

5.3.10 Interconnecting F Communication Blocks.......................................................5-31

5.4 Processing of the Safety Program .................................................................. 5-39

5.4.1 Managing Safety Program s............................................................................. 5- 39

5.4.2 Deactivating Safety Mode ...............................................................................5-40

5.4.3 Activating Safety Mode ...................................................................................5-42

5.4.4 Compiling a Safety Program ........................................................................... 5- 43

5.4.5 Creating Fail-Safe Block Types.......................................................................5-44

5.4.6 Downloading a Safety Program ......................................................................5-47

5.4.7 Downloading the Entire Safety Program.........................................................5-48

5.4.8 Changes to the Safety Program in RUN Mode..............................................5-49

5.4.9 Downloading Changes....................................................................................5-54

5.4.10 Testing the Safety Program ............................................................................5-56

5.4.11 Testing a Safety Program Offline with S7-P LC Sim.........................................5-57

5.4.12 Changing Fail-Safe Constants in CFC Test Mode..........................................5-62

5.4.13 Displaying Information.....................................................................................5-65

5.4.14 Saving reference data.....................................................................................5-66

5.4.15 Comparing Safety Programs...........................................................................5-67

5.4.16 Logging the Safety Program ...........................................................................5-76

5.4.17 Printing the Safety Program............................................................................5-77

Fail-Safe Systems

xii A5E00085588-03

Page 13

Contents

6 Operation and Maintenance 6-1

6.1 Operation and Maintenance of the F-Systems .................................................6-1

6.2 Rules for Operation...........................................................................................6-1

6.3 Working with the Safety Program .....................................................................6-2

6.4 Changing the Safety Program...........................................................................6-3

6.5 Replacing Software and Hardware Components..............................................6-4

6.6 Uninstalling the S7 F/FH System......................................................................6-5

7 Safety 7-1

7.1 Standards, Certificates and Ap prov als..............................................................7-1

7.2 Safety Requirements .........................................................................................7- 4

7.3 System Configuration........................................................................................7-7

7.4 Monitoring Times...............................................................................................7-8

7.4.1 Configuring the Monitoring Times for F/FH Systems........................................7-8

7.4.2 Calculation of the Minimum Monitoring Times................................................7-10

7.5 Acceptance of an F-System............................................................................7-14

7.5.1 Initial Acceptance of a Safety Program...........................................................7-15

7.5.2 Acceptance of Changes to the Safety Program..............................................7-20

7.5.3 Acceptance of F-Block Types .........................................................................7-22

7.5.4 Responsibilities and Qual if icati ons .................................................................7-22

8 Fail-Safe Blocks 8-1

8.1 Overview ...........................................................................................................8-1

8.1.1 Fail-Safe Blocks ................................................................................................8-1

8.1.2 F-Data Types.....................................................................................................8-2

8.1.3 Block I/Os..........................................................................................................8-4

8.1.4 Block Numbers..................................................................................................8-6

8.1.5 Installation in Cyclic Interrupt OBs....................................................................8-8

8.2 Driver Blocks for F-I/Os.....................................................................................8-9

8.2.1 F_CH_DI .........................................................................................................8-10

8.2.2 F_CH_DO........................................................................................................8-13

8.2.3 F_CH_AI..........................................................................................................8-16

8.2.4 Common Features of the Driver Blocks..........................................................8-22

8.3 Blocks for F Communication Between CPUs..................................................8-25

8.3.1 F_SENDBO.....................................................................................................8-27

8.3.2 F_RCVBO .......................................................................................................8-29

8.3.3 F_SENDR........................................................................................................8-31

8.3.4 F_RCVR..........................................................................................................8-33

8.4 Blocks for Converting Data .............................................................................8-35

8.4.1 F_BO_FBO......................................................................................................8-36

8.4.2 F_I_FI..............................................................................................................8-37

8.4.3 F_R_FR...........................................................................................................8-38

8.4.4 F_TI_FTI..........................................................................................................8-39

8.4.5 F_FBO_BO......................................................................................................8-40

8.4.6 F_FI_I..............................................................................................................8-41

8.4.7 F_FR_R...........................................................................................................8-42

8.4.8 F_FR_FI..........................................................................................................8-43

8.4.9 F_FTI_TI..........................................................................................................8-44

8.4.10 F_QUITES.......................................................................................................8-45

8.5 F-System Blocks .............................................................................................8-47

8.5.1 F_S_BO...........................................................................................................8-48

8.5.2 F_R_BO ..........................................................................................................8-49

8.5.3 F_S_R.............................................................................................................8-51

8.5.4 F_R_R.............................................................................................................8-52

Fail-Safe Systems

A5E00085588-03

xiii

Page 14

Contents

8.5.5 F_START ........................................................................................................8-54

8.6 F Control Blocks..............................................................................................8-55

8.6.1 F_CYC_CO.....................................................................................................8-56

8.6.2 F_M_DI8..........................................................................................................8-58

8.6.3 F_M_DI24........................................................................................................8-61

8.6.4 F_M_DO8........................................................................................................8-64

8.6.5 F_M_DO10......................................................................................................8-66

8.6.6 F_M_AI6..........................................................................................................8-68

8.6.7 F_PLK .............................................................................................................8-70

8.6.8 F_PLK_O.........................................................................................................8-71

8.6.9 F_SHUTDN.....................................................................................................8-72

8.6.10 F_TEST...........................................................................................................8-77

8.6.11 F_TESTC ........................................................................................................8-78

8.6.12 F_TESTM........................................................................................................8-79

8.6.13 DB_RES..........................................................................................................8-80

8.6.14 DB_INIT...........................................................................................................8-81

8.6.15 FAIL_MSG.......................................................................................................8-82

8.6.16 RTG_LOGIC....................................................................................................8-83

8.6.17 SFC F_CTRL...................................................................................................8-84

8.7 Logic Blocks with the BOOL Data Type..........................................................8-85

8.7.1 F_AND4...........................................................................................................8-85

8.7.2 F_OR4.............................................................................................................8-87

8.7.3 F_XOR2 ..........................................................................................................8-88

8.7.4 F_NOT.............................................................................................................8-89

8.7.5 F_2OUT3.........................................................................................................8-89

8.7.6 F_XOUTY........................................................................................................8-91

8.8 Comparison Blocks for Two Input Values of the Same Type .........................8-92

8.8.1 F_LIM_HL........................................................................................................8-92

8.8.2 F_LIM_LL........................................................................................................8-94

8.8.3 F_2oo3_R........................................................................................................8-96

8.8.4 F_1oo2_R........................................................................................................8-98

8.9 Flip-Flop Blocks.............................................................................................8-100

8.9.1 F_RS_FF.......................................................................................................8-100

8.9.2 F_SR_FF.......................................................................................................8-102

8.10 IEC Pulse and Counter Blocks......................................................................8-103

8.10.1 F_CTUD........................................................................................................8-103

8.10.2 F_TP..............................................................................................................8-105

8.10.3 F_TON...........................................................................................................8-107

8.10.4 F_TOF...........................................................................................................8-109

8.11 Pulse Blocks..................................................................................................8-111

8.11.1 F_F_TRIG .....................................................................................................8-111

8.11.2 F_R_TRIG.....................................................................................................8-112

8.11.3 F_LIM_TI.......................................................................................................8-113

8.12 Arithmetic Blocks with the INT Data Type.....................................................8-114

8.12.1 F_LIM_I.........................................................................................................8-114

8.13 Arithmetic Blocks with the REAL Data Type.................................................8-115

8.13.1 F_ADD_R......................................................................................................8-115

8.13.2 F_SUB_R......................................................................................................8-116

8.13.3 F_MUL_R......................................................................................................8-117

8.13.4 F_DIV_R........................................................................................................8-118

8.13.5 F_ABS_R ......................................................................................................8-119

8.13.6 F_MAX3_R....................................................................................................8-120

8.13.7 F_MID3_R.....................................................................................................8-121

8.13.8 F_MIN3_R.....................................................................................................8-122

Fail-Safe Systems

xiv A5E00085588-03

Page 15

Contents

8.13.9 F_LIM_R........................................................................................................8-123

8.13.10 F_SQRT........................................................................................................8-124

8.13.11 F_AVEX_R....................................................................................................8-125

8.13.12 F_SMP_AV....................................................................................................8-127

8.14 Multiplex Blocks ............................................................................................8-128

8.14.1 F_MUX2_R....................................................................................................8-128

8.15 Error Handling...............................................................................................8-129

8.15.1 Error Handling of Driver Blocks.....................................................................8-130

8.15.2 Error Information at the Outputs of the Driver Blocks...................................8-132

8.15.3 Errror Information in the Diagnostic Buffer....................................................8-134

8.15.4 Error Information at the Output RETVAL ......................................................8-140

8.16 Run Times.....................................................................................................8-141

8.16.1 Run Times of the Fail-Safe Blocks................................................................8-141

A Check Lists A-1

A.1 Life Cycle of the Fail-Safe Programmable Controllers..................................... A-1

A.2 Check List of the Certified Modules ................................................................. A-5

A.3 Check List of the Certified F-Blocks.................................................................A-7

A.4 Check List of the Safety Parameters of the F-Drivers ................................... A-10

B References B-1

Glossary Glossary-1

Index Index-1

Fail-Safe Systems

A5E00085588-03

xv

Page 16

Contents

Fail-Safe Systems

xvi A5E00085588-03

Page 17

1 Product Overview

1.1 Overview

SIMATIC S7 F/FH Systems

The S7 F/FH Programmable Controllers (F-Systems) are used in systems with

increased safety requirements. The aim of the S7 F/FH System is to control

processes that can immediately be returned to a safe state. In other words, when

these processes are suddenly shut down, it represents no danger to either man or

the environment.

Safety Requirements

The S7 F/FH System fulfills the following safety requirements:

• Requirement classes AK1 to AK6 in accordance with DIN V 19250/DIN V VDE

0801

• SIL1 to SIL3 (Safety Integrity Level)

• Categories 1 to 4 in accordance with EN 954-1

Principle Behind the Safety Functions

Fail-safe behavior is achieved by means of safety functions primarily in the

software. Safety functions are executed by the S7 F/FH programmable controller in

order to return the system to a safe state, or keep it in a safe state when a

hazardous event occurs.

The safety function for the process can be executed by means of a user safety

function or a fault reaction function. If the F-System can no longer execute its

actual user safety function in the event of a fault, it executes the fault reaction

function. For example, the associated outputs are switched off and the Safety

Program or parts of the Safety Program are disabled, if necessary.

For example: The F-System has to open a valve when there is excess pressure

(user safety function). In the event of a dangerous fault occurring in the CPU, all

the outputs are switched off (fault reaction function), thus opening the valve and

returning the other actuators to a safe state

valve would be opened.

in accordance with IEC 61508

. If the F-System were intact, only the

Fail-Safe Systems

A5E00085588-03

1-1

Page 18

Product Overview

The safety functions are primarily incorporated in the following components:

• In the safety-related user program on the central processing unit

• In the fail-safe input/output modules

Safety and Availability

To increase the availability of the automation system and consequently avoid

process downtimes as a result of failures in the F-System, fail-safe systems can be

optionally configured for high availability (fault tolerance). This increased

availability can be achieved by means of redundant components (power supply,

central processing unit and communication and I/O systems).

The fail-safe and fault-tolerant S7 F/FH Systems allow production to continue

without causing any harm to people or the environment.

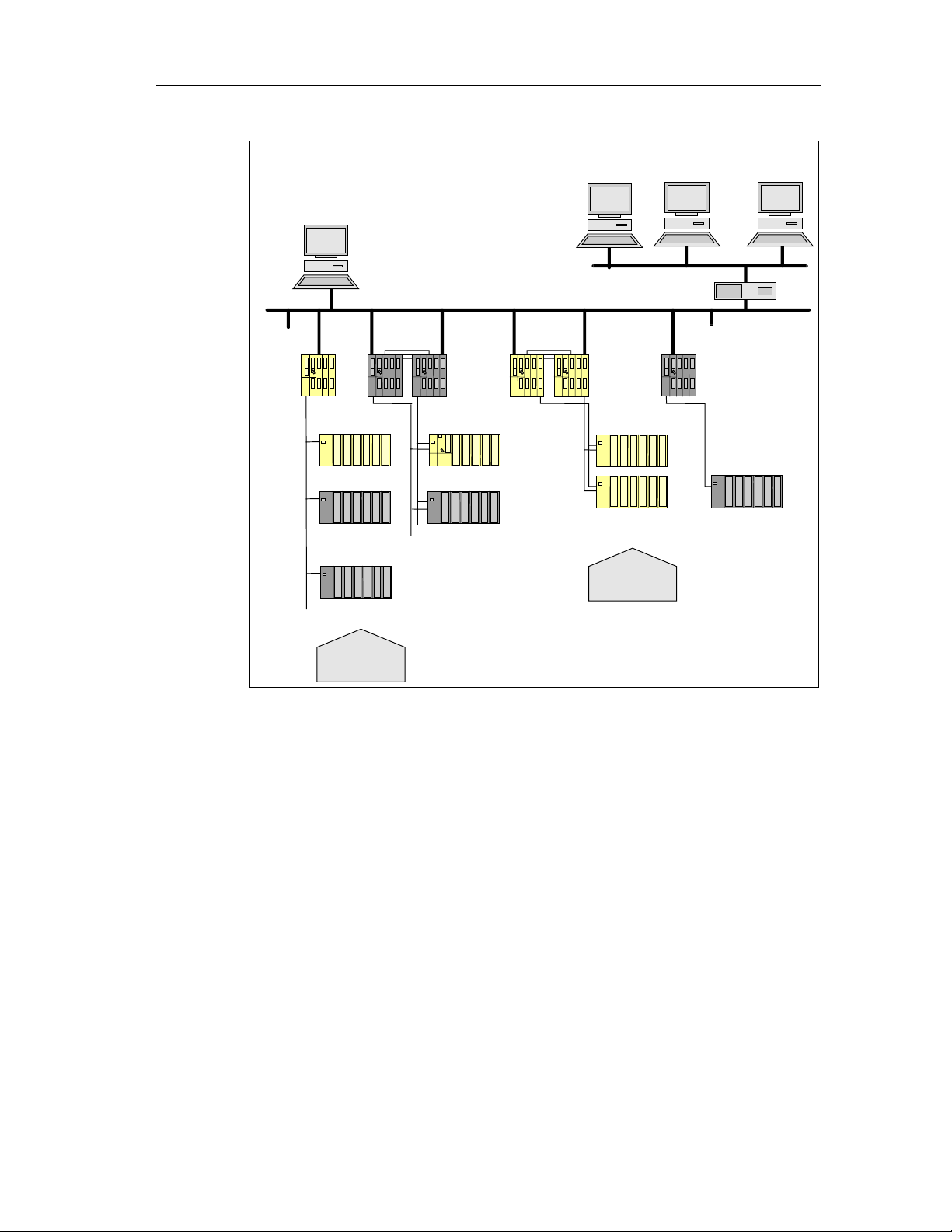

Use in Process Engineering

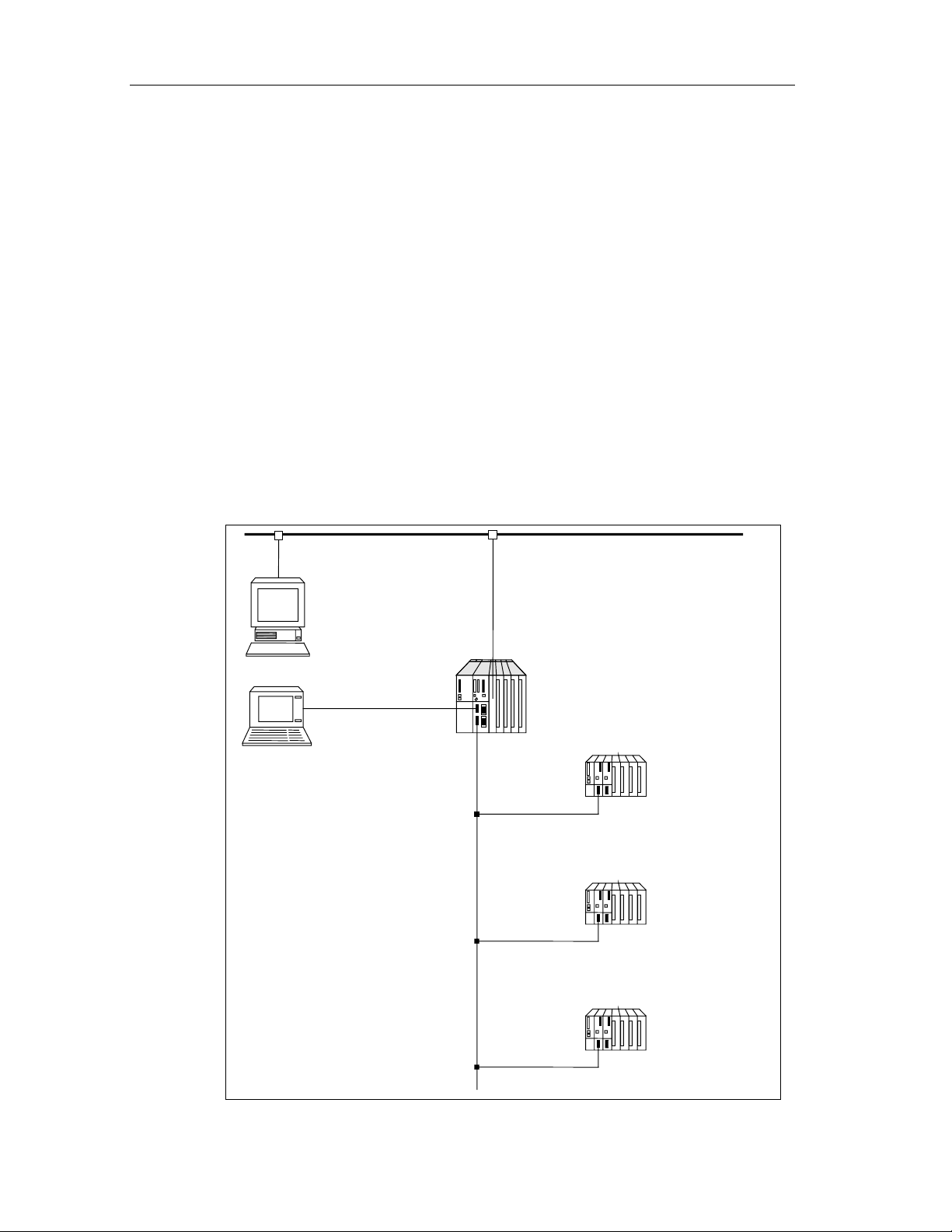

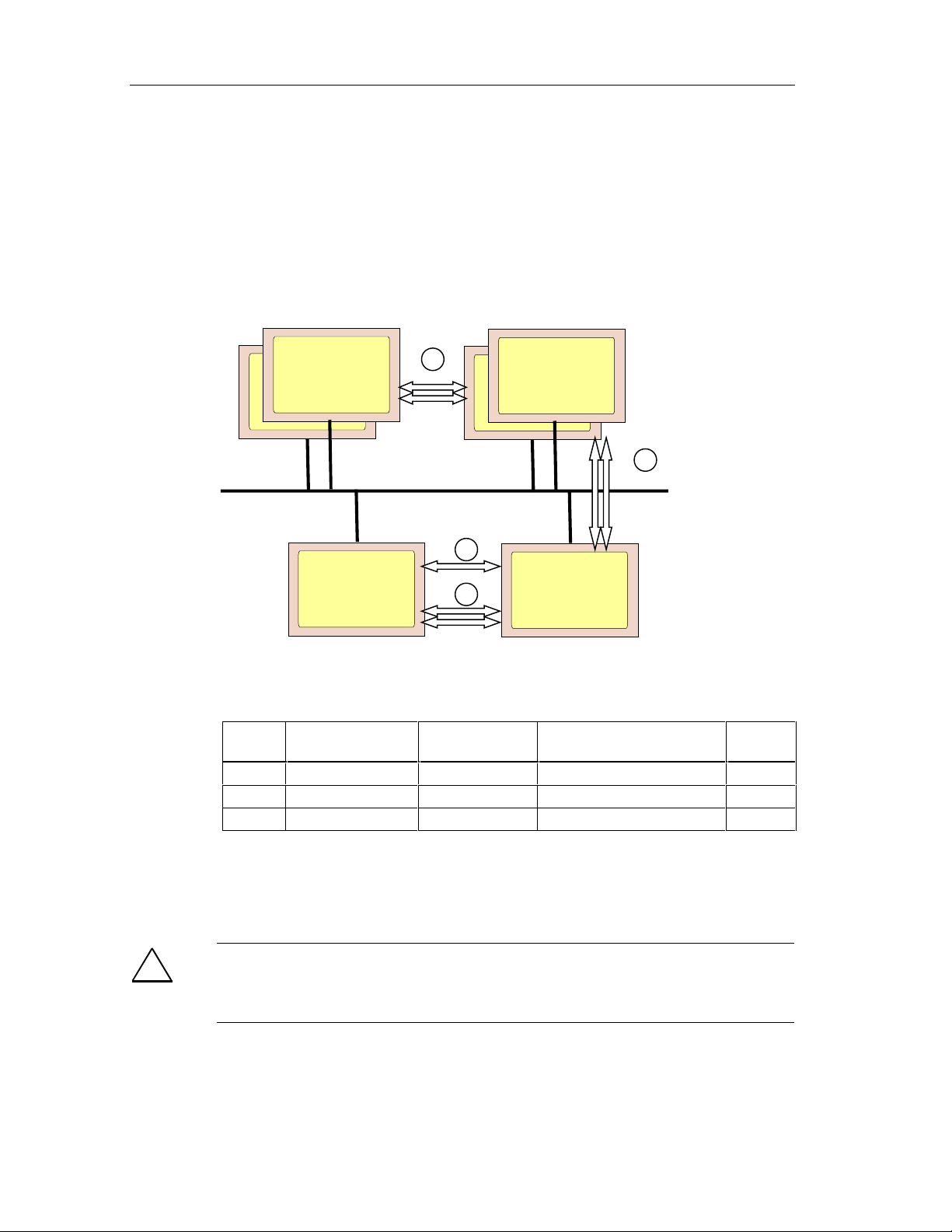

The figure below shows integration options for the S7 F/FH Systems in process

automation systems with PCS 7.

Fail-Safe Systems

1-2 A5E00085588-03

Page 19

Product Overview

Operator Stations (OS)

Central engineering system (ES)

PC

S7 F Sys

F-SMs

Standard SMs

ET 200M ET 200M

Standard SMs

ET 200S

Standard SMs

PC

PC

...

Standard Ethernet

Industrial Ethernet or PROFIBUS

S7-400H S7 FH Sys S7-400 Standard

F-SMs

F-SMs

ET 200M ET 200M

Boiler prot.

Emerg. stop

PC

Burner,

coal mill

Fail-Safe Systems

A5E00085588-03

1-3

Page 20

Product Overview

7 F System

safe signal modules

1.2 Basic Configuration Variants

This section describes the two basic configuration variants of F-Systems:

• Fail-safe S7 F System

• Fail-safe, fault-tolerant S7 FH System

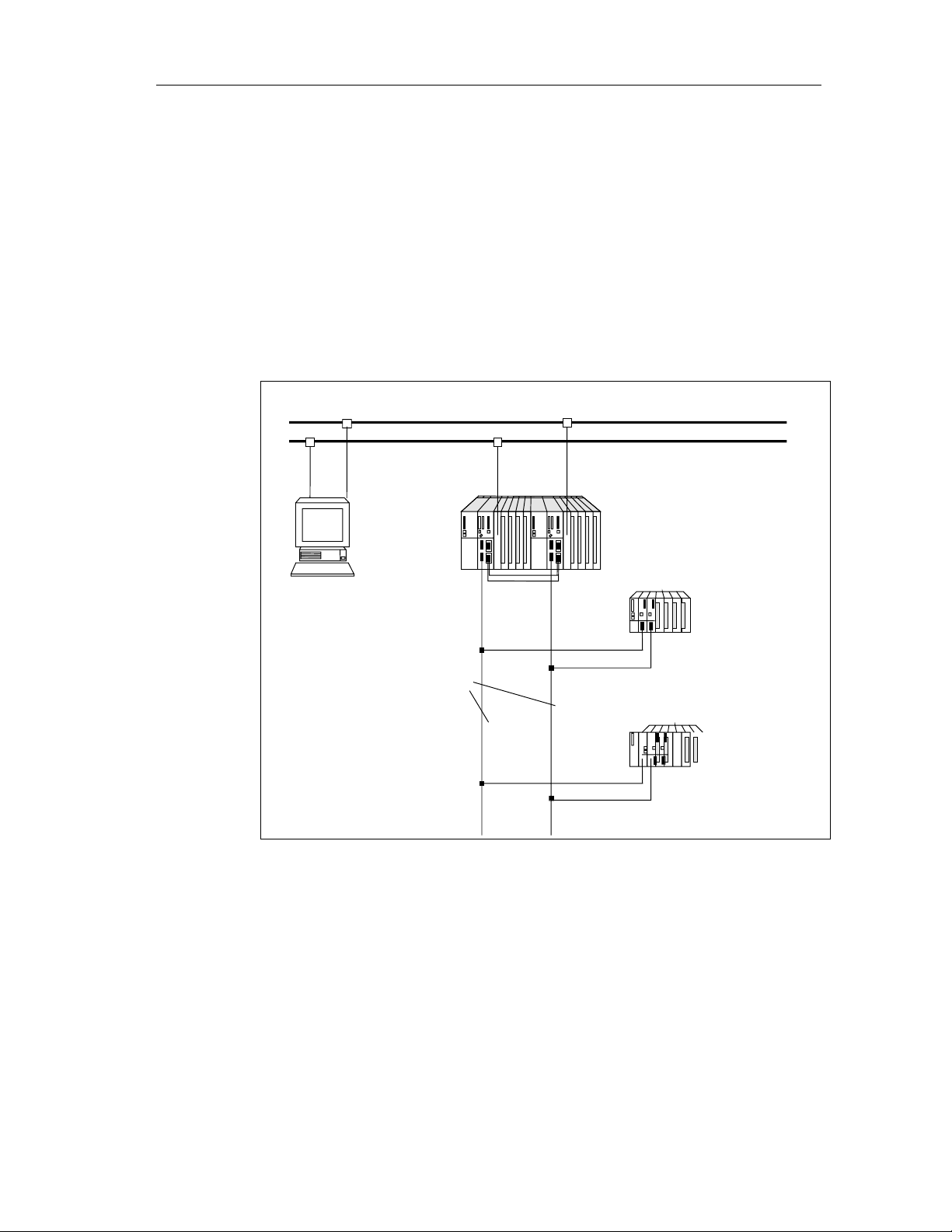

S7 F System

The S7 F System is a fail-safe automation system consisting of at least the

following components:

• An F-capable CPU module such as CPU 417-4 H that can run a fail-safe (F)

user program

• One or more fail-safe inputs/outputs (F-I/Os) in a distributed I/O device

(redundancy optional)

The following figure shows the hardware and software components of an F

System.

modules.

You can expand the configuration with standard S7-400 and S7-300

Operator Station

(system visualization)

Programming device

Programmable controller

S

ET 200M distributed I/O device

Fail-

(optionally redundant)

ET 200M distributed I/O device

Standard modules

(optionally redundant)

ET 200S distributed I/O device

Standard modules

Fail-Safe Systems

1-4 A5E00085588-03

Page 21

Product Overview

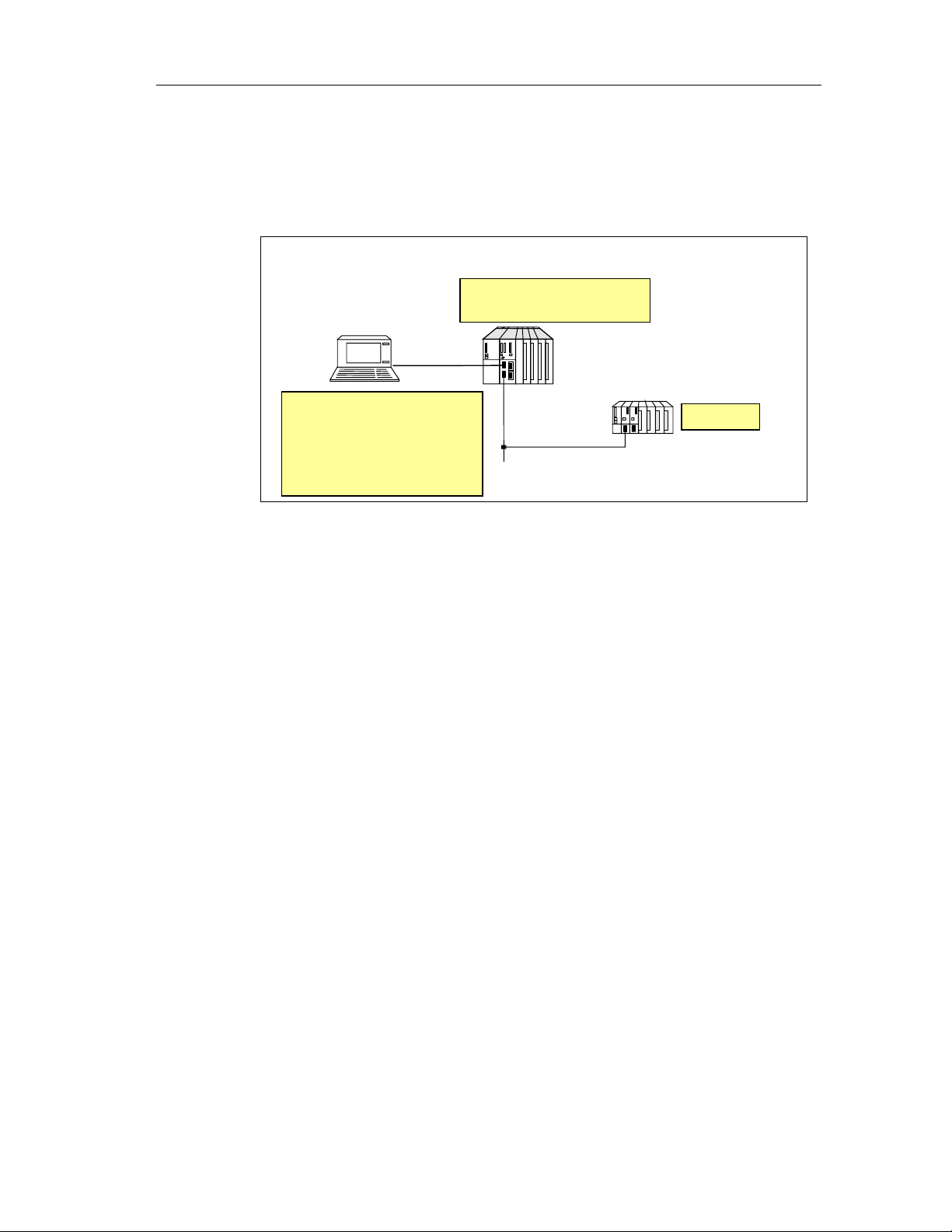

S7 FH System

The S7 FH System is a fail-safe, fault-tolerant automation system consisting of at

least the following components:

• A fault-tolerant S7 400H system (master and standby) running a fail-safe (F)

• One or more fail-safe inputs/outputs (F-I/Os) in a distributed I/O device

The following figure shows an example of an S7 FH configuration with a redundant

CPU, shared, switched distributed I/O modules connected via a redundant system

bus.

user program

(redundancy optional)

Redundant system bus (PROFIBUS or Ethernet)

Operator station

(System visualization)

Redundant

PROFIBUS - DP

Programmable controller

S7 FH System

ET 200M distributed I/O device

Fail - safe signal modules

(optionally redundant)

ET 200M distributed I/O device

Standard modules

(optionally redun dant)

Fail-Safe Systems

A5E00085588-03

1-5

Page 22

Product Overview

Combination of Standard, Fault-Tolerant and Fail-Safe Components

Standard, fault-tolerant (H) and fail-safe (F) components and systems can be used

together as follows:

• Standard systems, H systems, F Systems and FH Systems can be used

together in a single system.

• Standard modules and F-I/Os can be used together in a single automation

system.

• A safety-related F user program can be run together with a non-safety-related

standard user program in a fail-safe (F) or fail-safe, fault-tolerant (FH) system.

The fact that fail-safe (F), fault-tolerant (H) and standard components can be

combined has the following advantages:

• You can set up a fully integrated automation system in which you can make

use of the innovation of the standard CPUs and, at the same time, use fail-safe

components independently of standard components such as FMs or CPs. You

can configure and program the whole system using standard tools such as

HWCONFIG and CFC.

• The fact that you can combine standard and fail-safe program parts in a single

CPU reduces acceptance costs because only fail-safe program parts are

subject to acceptance procedures. Maintenance costs can also be reduced by

locating as many functions as possible in the standard section, which can be

modified during operation.

Fail-Safe Systems

1-6 A5E00085588-03

Page 23

Product Overview

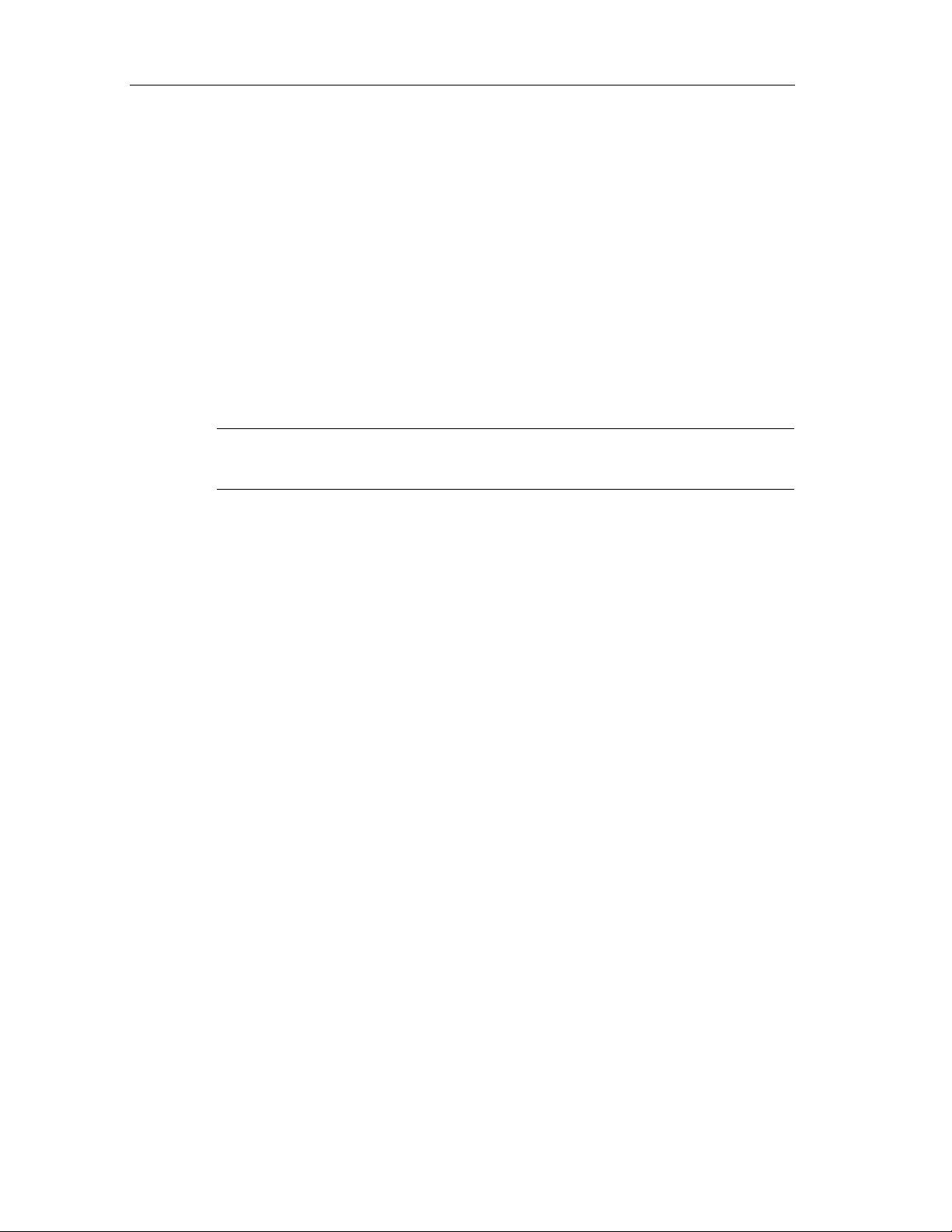

1.3 Components of an S7 F System

The figure below shows the hardware and software components required for the

configuration and operation of the S7 F.

S7 F programmable controller

F user program

Programming device

Optional package

S7 F Systems with

•

Configuration tool

•

F library

•

Safety program

editing

F run - time license

distributed I/O device

(optionally redundant)

F - I /Os

Interaction of the Components

The S7 F System consists of hardware and software components that have to be

combined with one another in order to configure an S7 F System.

Wiring the F-I/Os

The F-I/Os must be wired with the sensors and actuators in such a way as to

ensure that the desired safety level can be achieved.

Configuring the Hardware

The configuration set using HWCONFIG must correspond to the hardware

configuration; in other words, the circuit diagram of the I/O system must be

reflected in the parameter settings. The F-capable CPU must be configured.

Creating the F User Program

You create the fail-safe user program in CFC using fail-safe blocks from the

"Failsafe Blocks" library. For the connection to the F-I/Os you use F Channel and

Module driver blocks, to which you have to assign parameters. Some of the

parameters are assigned automatically as a result of the hardware configuration of

the F-I/Os.

When the executable F user program is generated, safety tests are carried out

automatically and additional fault detection functions incorporated.

Fail-Safe Systems

A5E00085588-03

1-7

Page 24

Product Overview

Compatibility of standard and fail-safe components in a programmable logic

controller

If you use a safety protector in the ET 200M, then you can operate fail-safe signal

modules with the S7-300 standard signal modules in an ET 200M even in safety

mode in SIL 3.

The safety protector protects the fail-safe signal modules from possible overvoltage

in the event of a fault. To do this, the fail-safe signal modules must be inserted in

the ET 200M configuration to the right of the safety protector, and all the standard

signal modules must be inserted to the left of the safety protector.

1.4 Hardware Components

An F System consists of hardware components that fulfill certain safety

requirements, such as:

• A CPU such as the CPU 417-4H with an F-Copy License

• F-I/Os

You can also expand the F System with standard components.

F-Capable CPUs

For S7 F/FH Systems, the CPU (e.g. the CPU 417-4 H as of V2.0) with an F-Copy

License is used either individually or as a fault-tolerant master/standby system.

The F-Copy License permits you to use the CPU as an F-CPU (i.e. to run a failsafe user program on it).

An F-capable CPU is a CPU that is approved for use in the S7 F/FH. It only

becomes an F-CPU if there is an F user program running on it. Otherwise, a

standard S7 program runs on the CPU. A combination of standard and F user

programs is possible because the safety-related data of the F user program is

protected from the influence of non-safety-related data. The CPU must be

configured as an F-CPU in this case as well.

Safety-relevant sections of the user program must be password-protected on the

CPU and in the ES/programming device against unauthorized access. In addition,

comprehensive self-tests run on the CPU. These ensure a high rate of fault

detection.

F-I/Os

The following F-I/Os are available:

For ET 200M:

• SM 326; DI 24 x 24 V DC; with Diagnostic Interrupt

• SM 326; DI 8 x NAMUR; with Diagnostic Interrupt

• SM 326; DO 10 x 24 V DC/2A, with Diagnostic Interrupt

• SM 336; AI 6 x 13Bit, with Diagnostic Interrupt

Fail-Safe Systems

1-8 A5E00085588-03

Page 25

Product Overview

ET 200M F-I/Os can be used in a single-channel or redundant configuration:

Please refer to the manual: Automation System S7-300 Fail-Safe Signal Modules’

For ET 200S:

• PM-E F 24 VDC PROFIsafe Power Module

• 4/8 F-DI 24 VDC PROFIsafe Digital Electronic Mod ul e

• 4 F-DO 24 VDC/2 A PROFIsafe Digital Electronic Module

• PM-D F PROFIsafe Power Module

Please refer to the manual: ET 200S Distributed I/O System, Fail-Safe Modules

Standard Components

The restrictions for fault-tolerant systems apply to the use of standard components.

You will find the restrictions for standard components in safety mode of fail-safe

signal modules in the safety information in Chapter 3 of the "S7-300 Programmable

Controller, Fail-Safe Signal Modules".

Additional Information

You can find detailed descriptions of the hardware components for the S7 F/FH

Systems in the following manuals:

• S7-400, M7-400 Programmab le Con tr ol lers , Insta llati on and Modu le Data

• S7-400H Programmable Controller, Fault-Tolerant Systems

• S7-300 Programmable Controller, Fail-Safe Signal Modules

• ET 200S Distributed I/O System, Fail-Safe Modules

Fail-Safe Systems

A5E00085588-03

1-9

Page 26

Product Overview

1.5 Software Components

The S7 F Systems have the following software components:

• S7 F Systems (Programming)

• S7 F Configuration Pack (Configuration of the F-I/O’s)

• The fail-safe user program (F user program) on the CPU

The S7 F Systems Optional Package

The S7 F Systems optional package is available for the configuration and

programming of the S7 F System. This gives you:

• Support for the configuration of the F-I/Os with HWCONFIG.

• The "Failsafe Blocks" library for the programming of fail-safe user programs.

• Support for the processing of the F user program and for the integration of fault

detection functions in the F user program.

Fail-Safe User Program

A fail-safe user program is referred to below simply as a Safety Program.

You create Safety Programs with CFC using the fail-safe blocks contained in a

library shipped with the S7 F Systems optional package. The fail-safe blocks

contain fault detection and fault reaction functions, as well as functions for

programming safety functions. In other words, they ensure that failures and faults

are detected and that an appropriate reaction is initiated that will keep the Fsystem in a safe state or return it to a safe state.

The user program on the CPU can be made up of safety-related sections (Safety

Program) and not safety-related sections (Standard Program). The Safety Program

is written in separate CFC charts. A combination of F and standard blocks in one

chart is not permissible and is detected during compilation. Data transfers between

the standard and the Safety Program are carried out via conversion blocks.

During compilation, certain fault detection and fault reaction functions are

automatically added to the Safety Program. The S7 F Systems optional package

also provides functions for comparing Safety Programs and supporting the

acceptance of Safety Program s .

Additional Information

You can find detailed information in the following sections.

• Configuration

• Programming

• Fail-Safe Blocks

and in the context-sensitive help information.

Fail-Safe Systems

1-10 A5E00085588-03

Page 27

Product Overview

1.6 Installing the S7 F Systems Optional Package

Before using an existing project with S7 F Systems V5.2, please read this entire

section which provides you with:

• getting started information applicable to the three use-case-scenarios

described below.

• the three use-case-scenarios are as follows, please select the one that best

suits your needs:

1. Compiling/editing current projects based on Failsafe Blocks (V1_1)

a. Upgrading a PC/Programming Device/Workstation containing S7 F

Systems V5.1 Optional Package

b. Installing S7 F Systems V5.2 Optional Package on a new

PC/Programming Device/Workstation

2. Upgrading current projects based on Failsafe Blocks (V1_1) to Failsafe Blocks

(V1_2)

3. Modifying or creating projects based on Failsafe Blocks (V1_2)

1.6.1 Getting Started Information Applicable to All Use-Case-Scenarios

Installing the Optional Package

1. Start the PC/Programming Device/Workstation that has the STEP 7 basic

software package installed. Make sure that there are no open STEP 7

applications.

2. Insert the optional package product CD.

3. Run the SETUP.EXE program on the CD.

4. Follow the setup program instructions.

Reading the Readme File

The readme file (S7 F Systems – Readme) contains important, up-to-date

information about the software. You can display this file on completion of the setup

program, or open it later using the Start > Simatic > Product Notes > English

menu command. It is located in the S7ftl directory of STEP 7.

Starting the Optional Package

The optional package does not contain any applications that have to be started

explicitly. Support for configuration and programming of the F-Systems is

integrated in SIMATIC Manager, HWCONFIG and CFC.

Fail-Safe Systems

A5E00085588-03

1-11

Page 28

Product Overview

Displaying the Integrated Help System

Context-sensitive help information is available for the optional package dialog

boxes. Help can be displayed at any time during configuration or programming by

pressing F1, or clicking the Help button. You can obtain more help information by

choosing the Help > Contents > Calling Help on Optional Packages > S7-

400F/FH – Working with F Systems.

Authorization

Authorization is required for the S7 F Systems optional package. Authorization can

be installed in the same way as STEP 7 and the optional packages. You can find

information on how to install and work with the authorization component in the

readme file and in STEP 7’s main help system.

Note

SIMATIC S7 F Systems V5.0 lic en se al so su pports V5.2

F-Copy License

An F-Copy License permits you to use the CPU as an F-CPU (e.g. to run a Safety

Program on it).

1.6.2 Use-case-scenarios

Scenario 1: Compiling/Editing Current Projects based on Failsafe Blocks (V1_1)

1. a. Upgrading From S7 F-Systems V5.1 to S7 F-Systems V5.2 to Support

Failsafe Blocks (V1_1) Projects

Use this scenario if you have:

An existing PC/Programming Device/Workstation with S7 F Systems V5.1 Optional

Package installed, and you wish to use existing projects based on Failsafe Blocks

(V1_1).

Fail-Safe Systems

1-12 A5E00085588-03

Page 29

Product Overview

Software Requirements

The following software packages must be installed on the PC/programming device

in order to use, modify, or create projects based on Failsafe Blocks (V1_1) library

with S7 F Systems V5.2:

• S7 F Systems V5.2

• STEP 7 V5.1.3 or higher

• CFC V5.2.4

• S7 H Systems Optional Package V5.1or higher (required for S7 FH Systems)

Procedure

If S7 F Systems V5.1 is already installed, the projects based on Failsafe Blocks

(V1_1) library are supported without an y addit ional pr oc ed ures .

1.b. Installing S7 F Systems V5.2 on a New PC to Support Failsafe Blocks (V1_1)

Projects

Use this scenario if you have:

Purchased a new PC/Programming Device/Workstation, and you wish to use

projects based on Failsafe Blocks (V1_1) library.

Software Requirements

The following software packages must be installed on the PC/programming device

in order to use, modify, or create projects based on Failsafe Blocks (V1_1) library

with S7 F Systems V5.2:

• S7 F Systems V5.2

• STEP 7 V5.1.3 or higher

• CFC V5.2.4

• S7 H Systems Optional Package V5.1or higher (required for S7 FH Systems)

Procedure

1. If S7 F Systems V5.2 is installed, uninstall it.

2. Install S7 F Systems V5.1

3. Install S7 F Systems V5.2

4. If you had PCS7 Driver Blocks or PCS7 Library installed, you must also install

Fail-Safe Systems

A5E00085588-03

these.

1-13

Page 30

Product Overview

Scenario 2: Upgrading Failsafe Blocks (V1_1) Projects to Failsafe Blocks (V1_2)

Use this scenario if you wish to:

Upgrade current projects based on Failsafe Blocks (V1_1) to the new Failsafe

Blocks (V1_2) library contained in S7 F Systems V5.2. You must have the

minimum software requirements to allow this.

Software/Firmware Requirements

The following software packages must be installed on the PC/Programming

Device/Workstation in order to upgrade projects based on Failsafe Blocks (V1_1)

library to Failsafe Blocks (V1_2):

• S7 F Systems V5.2

• STEP7 V5.2 or higher

• S7 H Systems Optional Package V5.1 or higher (required for S7 FH Systems)

• CFC V5.2.4

• CPU S7-417F/FH V3.1 or higher

ET 200S fail-safe module drivers are available, but this requires CFC V6.0.

Fail-Safe Systems

1-14 A5E00085588-03

Page 31

Product Overview

Procedure: Updating Failsafe Blocks (V1_1) Project to Failsafe Blocks (V1_2)

1. Ensure the above software requirements are met.

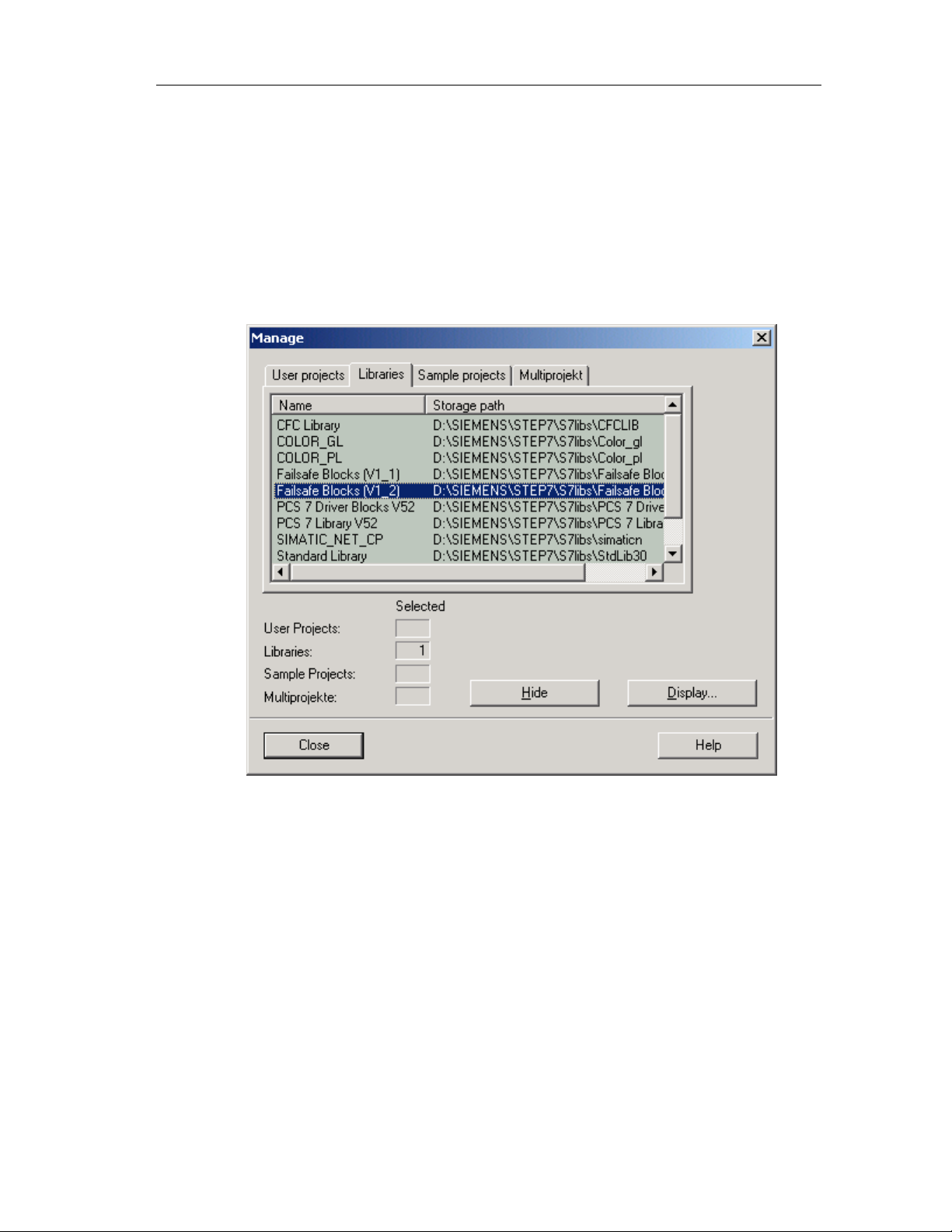

2. Ensure Failsafe Blocks (V1_2) is available within the Manage dialog box in

SIMATIC Manager.

a. Within SIMATIC Manager open the Manage dialog box by choosing File

>Manage…

b. Verify Failsafe Blocks (V1_2) is in the list. If it is, then go to step 3.

Fail-Safe Systems

A5E00085588-03

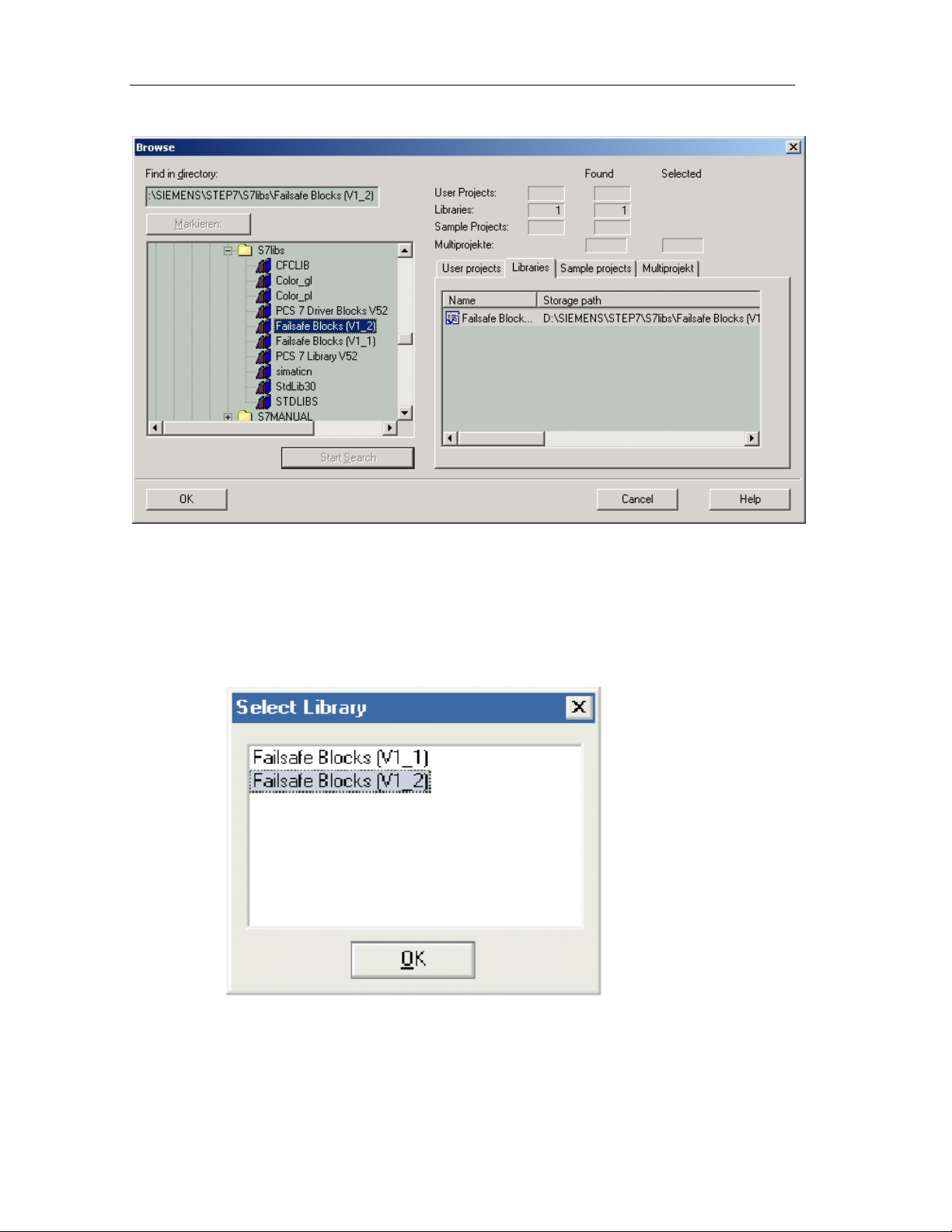

c. Open the library within SIMATIC Manager by choosing File > Open… and

press the Browse button.

d. Open the folder \SIEMENS\STEP7\S7LIBS and select Failsafe Blocks

(V1_2) and press OK. This will open the Failsafe Blocks (V1_2) library.

1-15

Page 32

Product Overview

e. Close the library.

f. Go back to step 2.a.

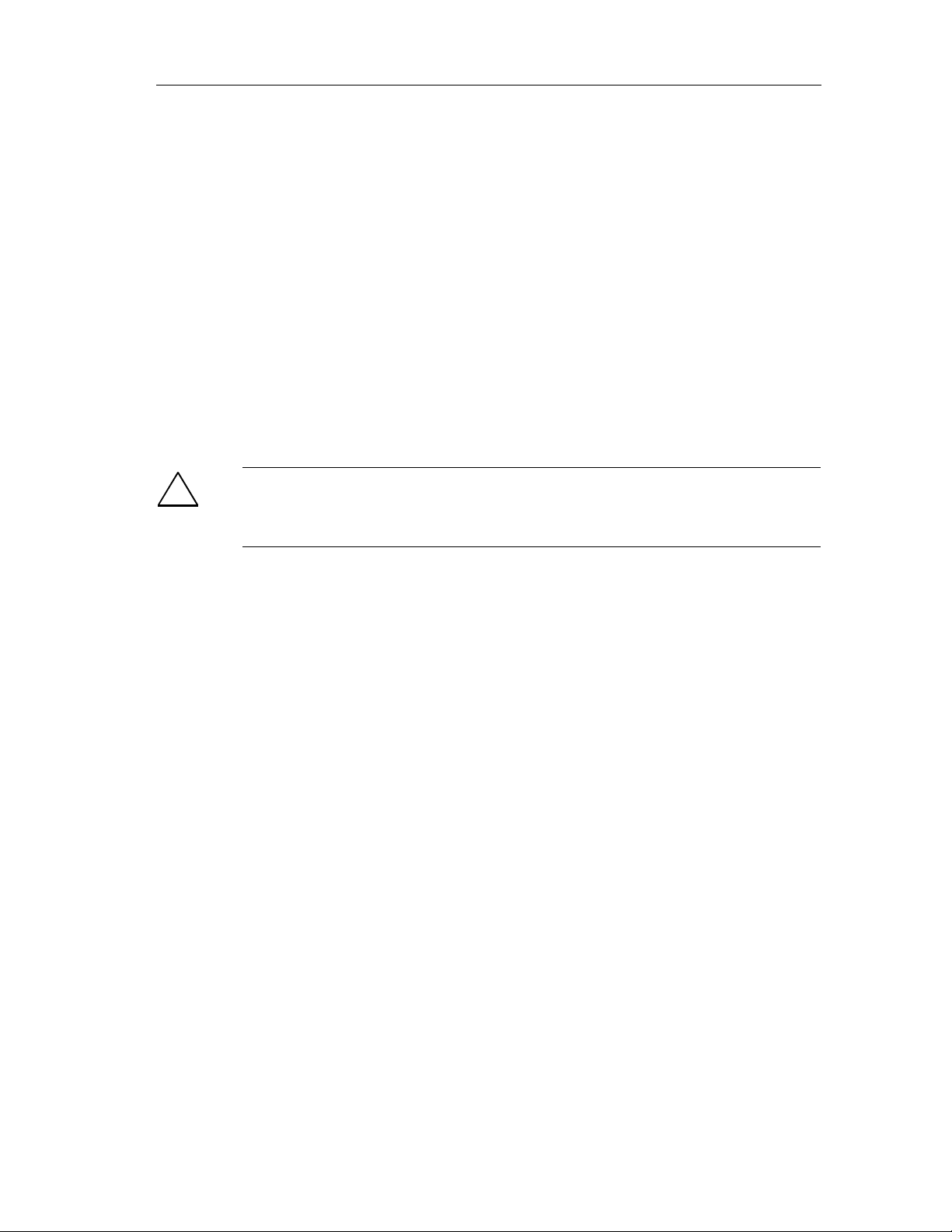

3. Choose the Options > Edit Safety Program menu command.

4. Press the Library Version... Button.

5. Select the Library to which you wish to upgrade to, and press the OK button.

6. Open a CFC Chart from the Program.

7. Choose the Options > Block Types menu command.

8. Select all blocks in the Charts Folder pane.

Fail-Safe Systems

1-16 A5E00085588-03

Page 33

Product Overview

9. Press the New Versio n... But ton to import.

10. Recompile the program.

Important Note

You must Import the new Block Type after upgrading the library to insure all blocks

are up to date. Failure to Import new block types may result in a failed compile.

Important Note

Unplaced F-Blocks from the block container are automatically deleted when the

safety program is compiled.

Important Note

Run-time groups containing F-Blocks in task OB1 must be moved to OB3x

because OB1 is no longer supported.

Fail-Safe Systems

A5E00085588-03

1-17

Page 34

Product Overview

Scenario 3: Modifying or Creating Projects Based on Failsafe Blocks (V1_2)

Use this scenario if you wish to:

Modify or create projects based on Failsafe Blocks (V1_2) library contained in S7 F

Systems V5.2. You must have the minimum software requirements to allow this.

Software/Firmware Requirements

The following software packages must be installed on the PC/Programming

Device/Workstation in order to modify or create projects based on Failsafe Blocks

(V1_2) library:

• S7 F Systems V5.2

• STEP7 V5.2 or higher

• S7 H Systems Optional Package V5.1 or higher (required for S7 FH Systems)

• CFC V5.2.4

• CPU S7-417F/FH V3.1 or higher

ET 200S fail-safe module drivers are available, but this requires CFC V6.0.

Procedure

There are no additional procedures beyond this.

Fail-Safe Systems

1-18 A5E00085588-03

Page 35

Product Overview

1.7 Working with F-Systems

This section describes the basic procedure for working with fail-safe systems. Only

those steps that are relevant to F-Systems and differ from the standard procedure

are included.

Planning the System

Process-dependent planning tasks such as defining a piping and instrumentation

diagram, creating a flowchart, creating a measuring point list, defining a structure,

etc. are not described here. When you plan the system, specify the required safety

functions with the corresponding Safety Integrity Levels (SILs). From these, derive

the demands on the components in order to implement the safety functions (PLCs,

sensors, actuators). These decisions affect other tasks such as hardware

installation, configuration, and programming.

!

Safety Note – Keep Safety and Standard Functions Separate

It is important to separate standard (e.g. not safety-related) and safety (e.g. safetyrelated) functions rigorously during planning.

Fail-Safe Systems

A5E00085588-03

1-19

Page 36

Product Overview

Basic Procedure

Configure S7 F/FH hardware

Set addresses on the F-I/Os via DIP switches

Wire modules according to required circuit program

Configure system

Parameterize CPU for safety program

Parameterize F-I/Os according to safety class and circuit diagram

Create Safety Program

Place, interconnect, and parameterize F function blocks

Generate executable code and load to the CPU of the S7 F/FH

Commission the system

Have safety-related sections accepted by expert before safety mode

is operational

Maintain system

Replace hardware components

Change Safety Program

Update operating system

Fail-Safe Systems

1-20 A5E00085588-03

Page 37

Product Overview

Compiling as a Program

To compile the Safety Program, proceed as follows:

1. Carry out a consistency check by choosing the Chart > Check Consistency

>Charts as Program menu command. (This step is optional.)

2. Choose the Chart > Compile > Charts as Program menu command.

3. Select one of the following options in the "Compile Charts as Program" dialog

box:

• Entire Program, if the whole program is to be compiled.

• Changes, if only the changes are to be compiled.

4. If the F module drivers are not yet placed, select the "Generate Module

Drivers" check box in the "Compile Charts as Program" dialog box. This

automatically inserts and interconnects the required F module drivers in

separate charts @Fx.

Result: The Safety Program is compiled and can be downloaded to the CPU.

Safety functions are added to the charts of the Safety Program automatically. The

automatically added elements, such as additional blocks and interconnections, are

partially visible in the CFC charts, but must on no account be changed or deleted.

Graphical moving of blocks within the same chart is permissible

Fail-Safe Systems

A5E00085588-03

1-21

Page 38

Product Overview

Fail-Safe Systems

1-22 A5E00085588-03

Page 39

2 Getting Started

2.1 Introduction

This introduction uses concrete examples to walk you through the steps required to

create a working application, which will enable you to discover how a fail-safe

automation system works, and how it behaves in the event of a fault/error.

The following two systems will be used as examples to lead you through the initial

commissioning phase to an actual work ing appl ication.

• A fail-safe, S7 F system, and

• A fail-s afe, fault-tolerant S7 FH system

Terminology

The following table describes terminology used in the example projects.

F_SHUTDN A standard function block used to manage the shutdown and

restart of the Safety Program. Please se e cha pter 8 for more

information on the F_SHUTDN function block.

F-run-time

group

Safety

Program

Force Full

Shutdown

Full

Shutdown

Partial

Shutdown

This is a run-time group that has F-Blocks within it. The Step 7

definition of run-time groups: (Run-time groups are used to

structure tasks. The blocks are installed sequentially in the runtime groups. Run-time groups can be activated and deactivated

separately. If a run-time group is deactivated, the blocks it

contains will no longer be activated.)

This is the collection of all F-run-time groups within the project.

The user may force the manual shutdown of the entire Safety

Program through the RQ_FULL input of the F_SHUTDN function

block.

The Shutdown logic responds to an internal diagnostic that has

detected a failure by disabling the entire Safety Program (Please

note that CPU will remaining running). This is configured on the

F_SHUTDN SHUTDOWN input.

The Shutdown logic responds to an internal diagnostic that has

detected a failure by disabling only that F-run-time group that

encountered the failure (Please note that CPU will remain

running). This is configured on the F_SHUTDN SHUTDOWN

input.

Fail-Safe Systems

A5E00085588-03

2-1

Page 40

Getting Started

Restart The shutdown logic’s F_SHUTDN RE START in put al low s you to

restart the Safety Program that has been shutdown.

Reintegration of I/O may be necessary after this action.

Shutdown The Shutdown logic responds to an internal diagnostic that has

detected a failure by disabling either the entire Safety Program

(Full Shutdown) or the isolated F-run-time group (Partial

Shutdown). The shutdown logic response depends on how you

configured the shutdown logic, either Partial Shutdown or Full

Shutdown.

S7 F Systems V5.2 Shutdown Logic

S7 F Systems V5.2 is packaged with an enhancement that allows you to manage

shutdown and restart of the Safety Program. When an F-run-time group is created

by the user, and the project is compiled, the shutdown logic is automatically placed

by the CFC Editor. The CFC Editor creates charts to contain this logic:

@F_ShutDn and @F_DbInit1. Please note that the @ is used by the CFC editor to

denote automatically created and is a reserved name. There are other charts that

are automatically placed that are used to provide information to the shutdown logic

and these include: @F_Init1, @F_CycCo-OB35, and @F_TestMode.

At the center of the shutdown logic is the F_SHUTDN function block in the

@F_ShutDn chart. The F_SHUTDN block provides you with the following action:

• You can force a manual shutdown of the entire Safety Program or you can

restart the shutdown Safety Program.

• You can use the SHUTDOWN input to set either Full Shutdown or Partial

Shutdown.

• You can use the FAILURE input of the F_SHUTDN function block to identify

that a failure occurs and observe the FULL_SD output if a failure is detected

while SHUTDOWN = Full Shutdown.

The F_SHUTDN block also has an input F_PRG_SI to provide you with the overall

Safety Program Signatur e, and an output SAF E_ M to provid e you with the current

safety mode status of the Safety Program.

The F_SHUTDN function block also reports error events to the Diagnostic Buffer.

The events reported are Restart, Full Shutdown, and Partial Shutdown. Similarly,

alarm messages are also reported to WinCC under these three conditions.

Basic Procedure

Carry out the following tasks step by step:

• Set up the hardware (F-I/O and CPU).

• Configure the F-system.

• Create a fail-safe program using CFC charts.

• Commission the F-system, and check if the fail-safe program is operational.

Fail-Safe Systems

2-2 A5E00085588-03

Page 41

Getting Started

You will then be able to configure a fault-tolerant F-system.

Sample Projects Provided

Note

The sample projects require Step 7 V5.2 and the S7 H Systems Optional Package

Version 5.1.

You can find two sample projects in step7\Examples:

• ZEN32 01_FSystem_Fproj – For an F System

• ZEN32 02_FHSystem_FHProj – For a fault-tolerant FH System

You can use the examples to check the results of similar project sessions

described below.

Passwords

The passwords for the projects provided are:

• CPU password: anna

• Safety Program password: otto

Fail-Safe Systems

A5E00085588-03

2-3

Page 42

Getting Started

ET 200M Distributed I/O

Safety Protector

2.2 S7 F System - Getting Started

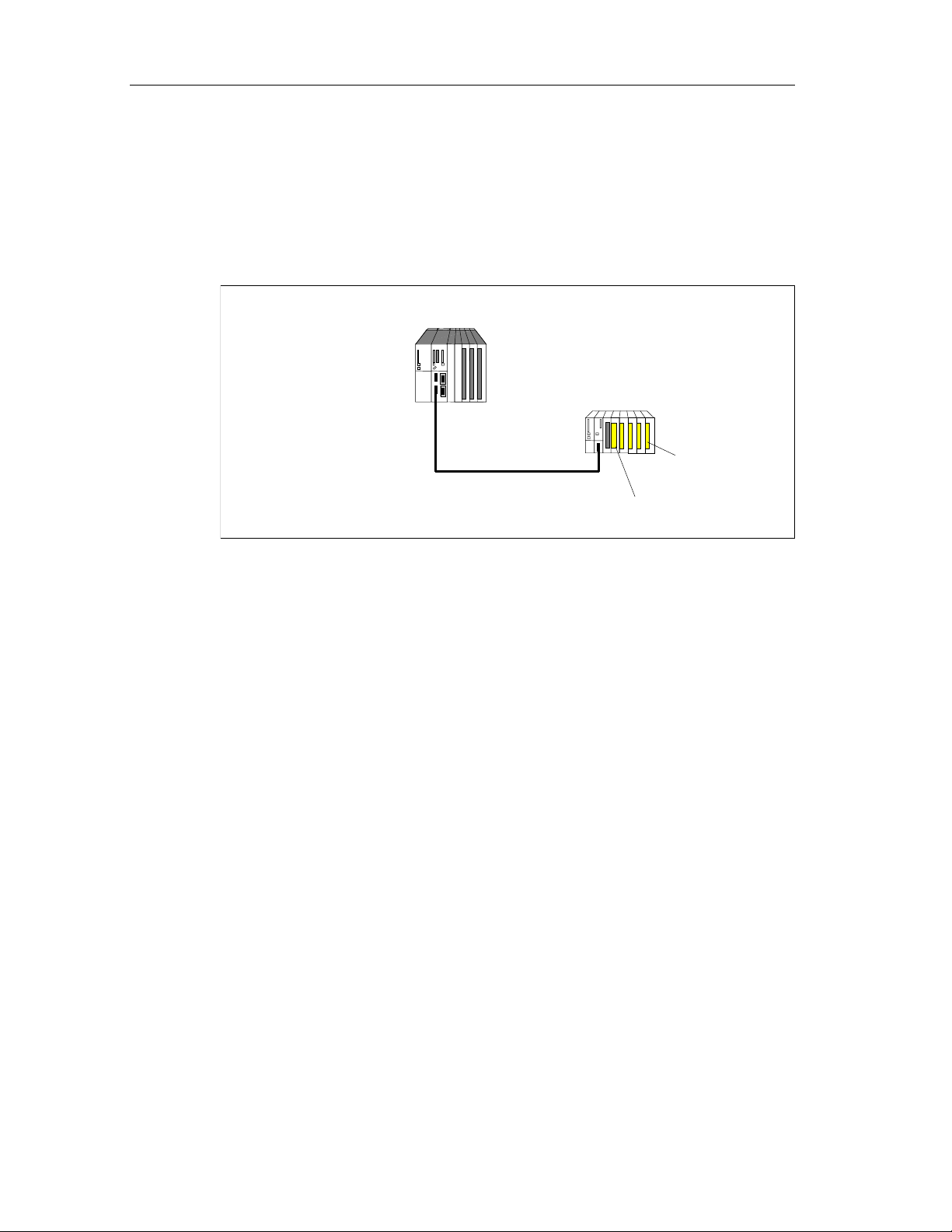

2.2.1 S7 F System, Setting up the Hardware

The following figure shows you an example of a hardware configuration.

S7 F programmable

controller

Profibus DP Cable

Single-channel, one-sided

Fail-safe

signal modules

Module

For this example, you need the following hardware components:

• A programmable logic controller consisting of:

- 1 mounting rack (UR2-H)

- 1 power supply (PS 407 10A)

- 1 CPU 417-4H

• An ET 200M distributed I/O device with an active backplane bus consisting of:

- 1 power supply (PS307 5A)

- 1 IM 153-2 Bus Interface Module

- 1 Safety Protector Module

- 1 fail-safe digital input module (SM 326F DI 24xDC24V)

- 1 fail-safe digital output module (SM 326F DO10xDC24V/2A)

• Other accessories

- PROFIBUS cables and connectors

Set the DIL switches for the individual components as follows:

• IM153-2 PROFIBUS address 3

• SM 326F DI 24 Module address 8

(Only found on the reverse side; only in steps of 8)

2-4 A5E00085588-03

• SM 326F DO10 Module address 24

(Only found on the reverse side; only in steps of 8)

Fail-Safe Systems

Page 43

Getting Started

Connect actuators, or alternatively terminating resistors, to the output module (e.g.

between 12 Ω and 3.4 kΩ with 1 watt), or disable group diagnosis for unused

channels in the hardware configuration.

Interface restrictions between S7-400 CPU and ET 200M I/O

The ET 200M components which can be used in safety mode depend on the safety

class and the use of a safety protector in the ET 200M configuration:

• If you comply with the requirements of safety class SIL 2 or use a safety

protector in SIL 3 in ET 200M, you can use all the available IM 153-2 interface

modules and you can set up the PROFIBUS-DP with the copper cable (as in

standard mode).

• If you don’t use a safety protector in SIL 3 in ET 200M, you must connect the

PROFIBUS-DP lines - the S7 F System and the S7 400H programmable

controllers with fiber optic cables as described in the S7 F/FH Programmable

Controllers.

Additional Information

You can find detailed descriptions of the hardware components in the following

manuals:

•

S7-400, M7-400 Programmab le Controllers, Installation and Module

Specifications

•

S7-400H Programmable Controller, Fault-Tolerant Systems

•

S7-300 Programmable Controller, Fail-Safe Signal Modules

•

ET 200S Distributed I/O System, Fail-Safe Modules

Fail-Safe Systems

A5E00085588-03

2-5

Page 44

Getting Started

2.2.2 Configuring the S7 F System

The following steps show you how to create a new project and configure the

hardware setup described above.

Procedure

1. Open SIMATIC Manager, and create a new project called "FProject" using the

File > New menu command.

2. Insert a new S7-400 station: Ins ert > Statio n > SIMATIC 400 Station.

3. Open the hardware configuration (HWCONFIG) of the SIMATIC 400(1) station

created (you can change the name) by double-clicking the hardware object (or

right-click the Open Object pop-up menu command).

4. Insert the individual hardware components of the SIMATIC 400 from the

"Hardware Catalog" window (you can open the catalog with View > Catalog)

by dragging and dropping them to the station window.

5. First place the UR2 mounting rack from the RACK 400 catalog.

6. Insert the standard power supply (PS 407 10 A) in slot 1 of the mounting rack.

7. Place the CPU 417-4H V3.1 in slot 3: Create a subnet (which will subsequently

be connected to the ET 200M) in the "Properties - PROFIBUS Interface DP

Master" dialog box by clicking New.

Fail-Safe Systems

2-6 A5E00085588-03

Page 45

Getting Started

8. Select the CPU, and choose the Edit > Object Properties menu command (or

9. From the PROFIBUS-DP catalog, insert the IM 153-2 directly in the

10. Insert the input module SM 326F DI24xDC24V from the DI-300 catalog of the

11. Select the module. Right-click to choose Edit Symbols from the pop-up menu

12. Double-click to open the properties dialog box, and select "Enable Diagnostic

13. Insert the output module SM 326F DO10xDC24V/2A from the DO-300 catalog

double-click the CPU): The "Properties - CPU 417-4H" dialog box appears:

Enter a password for the CPU on the "Protection" tab, and select the

"CPU Contains Safety Program" check box.

"PROFIBUS(1): DP Master System (1)" in the station window: Enter the

address 3 on the "Parameters" tab in the "Properties - Profibus Interface ET

200M IM153-2" dialog box.

IM 153-2 in slot 4 of the ET 200M (you can see a detailed view in the lower

part of the station window).