Siemens SIMATIC S7-1500R/H, SIMATIC S7-1500 Getting Started

___________________

___________________

___________________

___________________

___________________

SIMATIC

S7-1500

S7-1500R/H redundant system

Getting Started

10/2018

A5E44910930

Introduction to the example

1

Configuration

2

Programming

3

Commissioning

4

Additional information

5

-AA

Siemens AG

Division Digital Factory

Postfach 48 48

90026 NÜRNBERG

GERMANY

A5E44910930-AA

Ⓟ

Copyright © Siemens AG 2018.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

for the specific

09/2018 Subject to change

Table of contents

1 Introduction to the example ..................................................................................................................... 4

2 Configuration ........................................................................................................................................ 19

3 Programming ........................................................................................................................................ 34

4 Commissioning ..................................................................................................................................... 48

5 Additional information ............................................................................................................................ 51

1.1 Security information .................................................................................................................. 5

1.2 Structure and task of the example ............................................................................................ 6

1.3 Procedure ............................................................................................................................... 11

1.4 Requirements .......................................................................................................................... 12

1.5 Wiring diagram for a tunnel section ........................................................................................ 13

2.1 Configuring the assembly ....................................................................................................... 19

2.2 Configuring H CPUs ................................................................................................................ 22

2.3 Configuring ET 200SP ............................................................................................................ 25

2.4 Configuring HMI devices ......................................................................................................... 30

S7-1500R/H redundant system

Getting Started, 10/2018, A5E44910930-AA

3

1

S7-1500R/H redundant system

Basic knowledge required

WARNING

Personal injury and damage to property may occur.

Redundant automation systems are used in practice to achieve greater availability. In

redundantly operated systems, failure or malfunction of individual automation components

must not impede the operation of the plant.

For the S7-1500R/H redundant system, the CPUs are duplicated, in other words redundant.

The two CPUs process the same project data and the same user program in parallel. The

two CPUs are synchronized over redundancy connections. If one CPU fails, the other CPU

maintains control of the process.

The Getting Started guides you through the configuration and programming of an S7-1500H

redundant system using a concrete example. The following knowledge is required in order to

understand the Getting Started:

● General knowledge of automation technology

● Knowledge of requirements for high availability of automation systems

● Knowledge of the engineering system STEP 7 V15.1

The S7-1500 as a component of plants or systems is governed by specific standards and

regulations, based on the relevant field of application. Please observe the applicable safety

and accident prevention regulations such as IEC 60204-1 (general machine safety

requirements).

The example in this Getting Started serves as an introduction to the configuration and

programming of an S7-1500H redundant system. It cannot always and in every case be

transferred to effective live operations. Before you do this, you are urgently advised to

consult the current version of the system manual "SIMATIC S7-1500R/H redundant

system" and the device manuals of the modules used. The warnings and other information

there must be observed, even if they are not repeated in this Getting Started.

Failure to observe these regulations can result in serious injuries and damages to

machinery and facilities.

S7-1500R/H redundant system

4 Getting Started, 10/2018, A5E44910930-AA

Introduction to the example

1.1

Security information

1.1 Security information

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial

security concept. Siemens' products and solutions constitute one element of such a concept.

Customers are responsible for preventing unauthorized access to their plants, systems,

machines and networks. Such systems, machines and components should only be

connected to an enterprise network or the internet if and to the extent such a connection is

necessary and only when appropriate security measures (e.g. firewalls and/or network

segmentation) are in place.

For additional information on industrial security measures that may be implemented, please

visit (https://www.siemens.com/industrialsecurity).

Siemens' products and solutions undergo continuous development to make them more

secure. Siemens strongly recommends that product updates are applied as soon as they are

available and that the latest product versions are used. Use of product versions that are no

longer supported, and failure to apply the latest updates may increase customers' exposure

to cyber threats.

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS

Feed under (https://www.siemens.com/industrialsecurity).

S7-1500R/H redundant system

Getting Started, 10/2018, A5E44910930-AA

5

Introduction to the example

1.2

Structure and task of the example

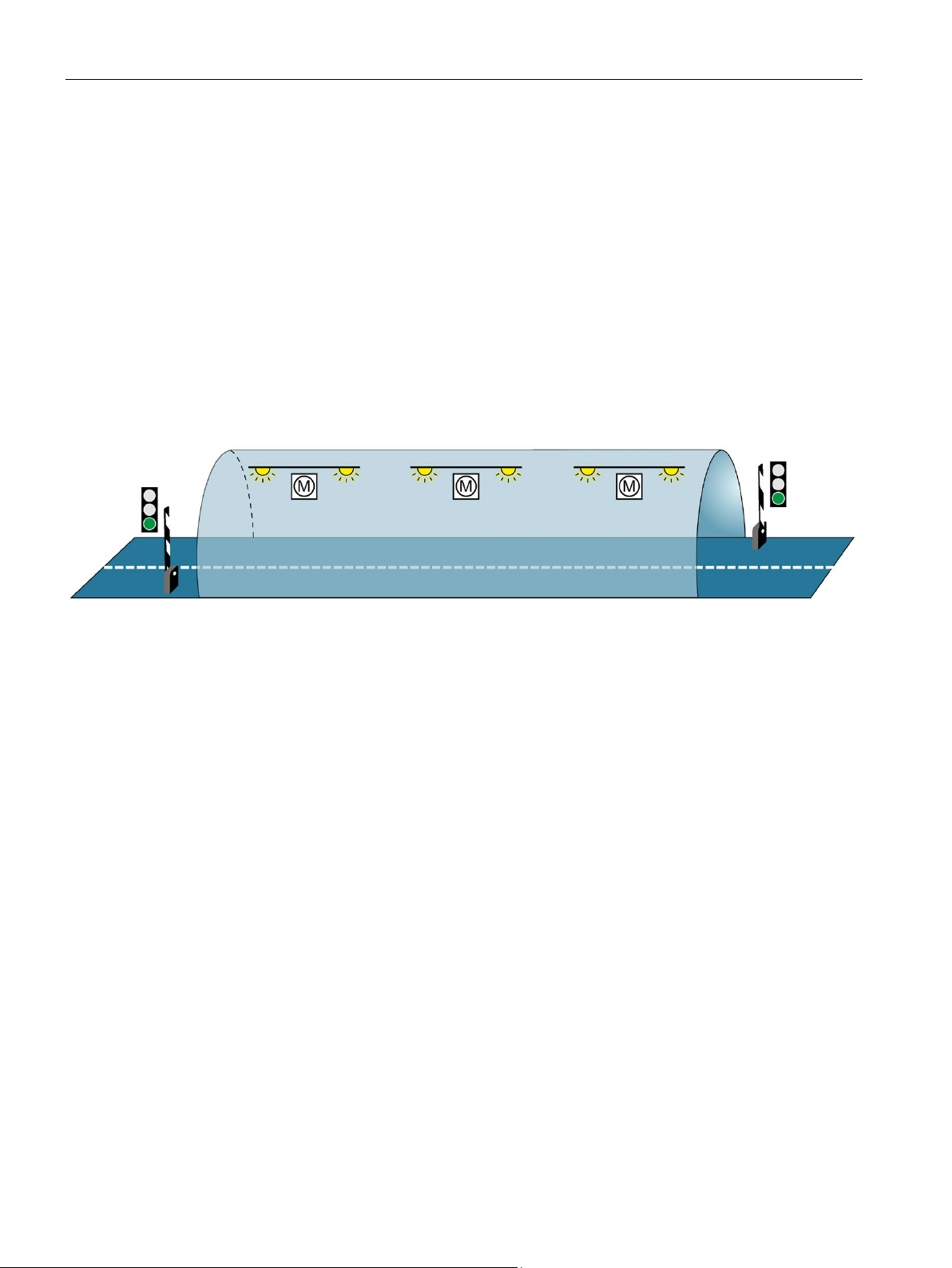

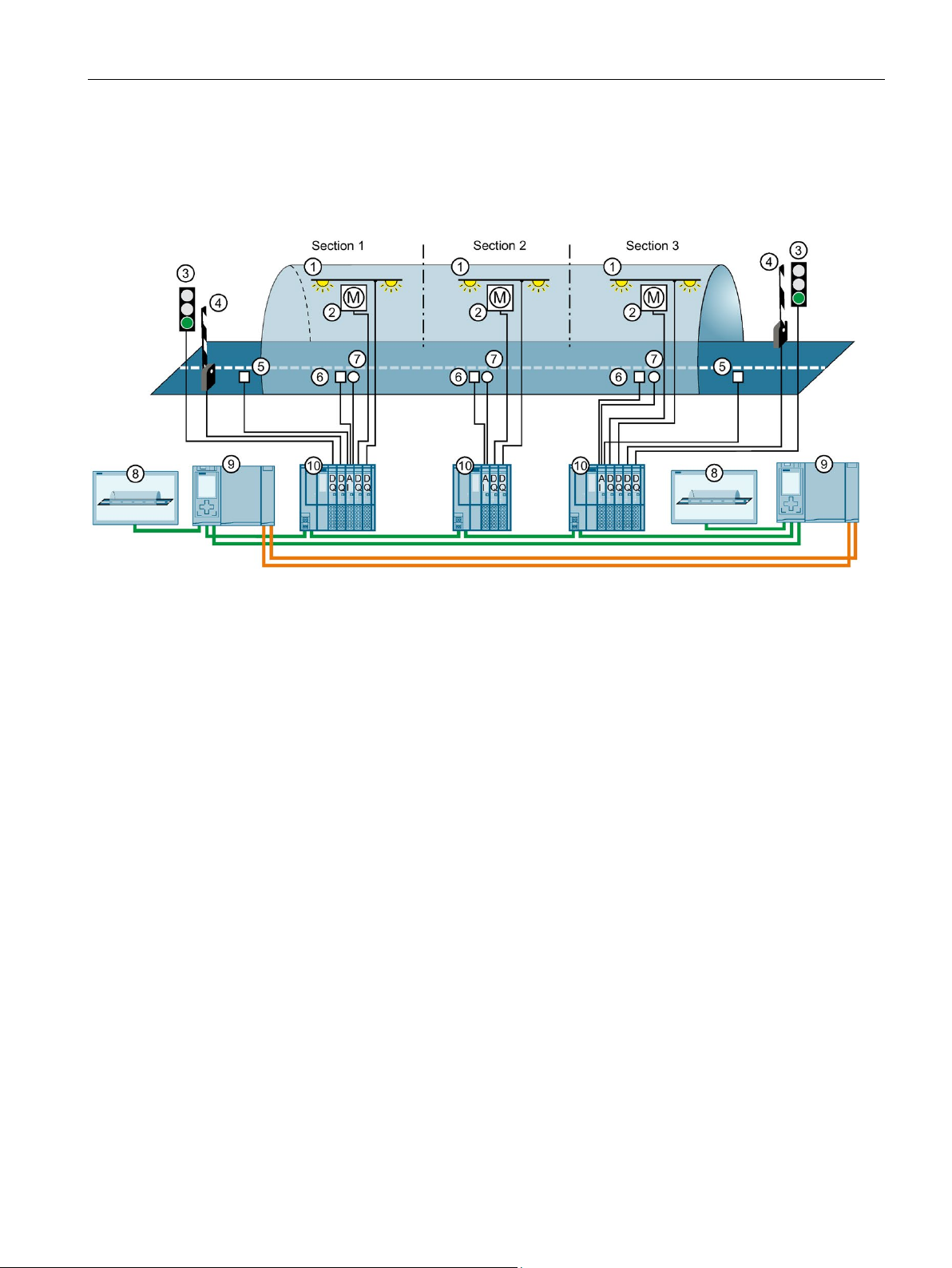

Automation task light and fan control in a tunnel

Control of the safety ventilation as a function of the air pollution level in the tunnel

Control of the traffic lights and the barriers as a function of the air pollution level in the tunnel

Control of the lighting in the tunnel as a function of the illuminance of the outdoor light

1.2 Structure and task of the example

The continuing increase in traffic volumes coupled with growing safety requirements demand

state-of-the-art tunnel systems. At the same time, equipment requirements for these

constructions are rising, especially when it comes to maximum safety and availability.

The example below comprises three subtasks:

● Control of the safety ventilation as a function of the air pollution level in the tunnel

● Control of the traffic lights and the barriers as a function of the air pollution level in the

tunnel

● Control of the lighting in the tunnel as a function of the illuminance of the outdoor light

Figure 1-1 Example Light and fan control tunnel

Fans are used in the tunnel to extract harmful exhaust gases and supply fresh air.

Uninterrupted operation of the ventilation system is required to keep the concentration of

pollutants below a set level. Constant availability must be ensured for the event that

individual automation components fail, for example because of a fire in the tunnel. The S71500H redundant system with two redundant H-CPUs is used to ensure fan availability.

Three fans ventilate the tunnel.

The tunnel entries are controlled via two traffic lights. The traffic light control also requires

higher availability for safety reasons.

If the pollutant concentration exceeds a maximum limit for more than 2 minutes in a tunnel

section, then the tunnel is blocked.

The abrupt transition between light and dark at the entry to the tunnel is compensated for by

tunnel lighting in the various tunnel sections. Two light sensors measure the light intensity

outside the tunnel. The light intensity of the entry lights in the tunnel is controlled accordingly.

The interior lights in the tunnel are controlled by the prevailing daytime / nighttime.

S7-1500R/H redundant system

6 Getting Started, 10/2018, A5E44910930-AA

Introduction to the example

Technology diagram

①

Tunnel lighting

②

Fan ③ Traffic lights

④

Barriers

⑤

Outdoor light sensors

⑥

Turbidity sensors

⑦

Air-quality sensors

⑧

HMI devices

⑨

H-CPUs

⑩

IO devices for tunnel sections 1 to 3

1.2 Structure and task of the example

The technology diagram below shows the structure of the automation solution.

Figure 1-2 Technology diagram

S7-1500R/H redundant system

Getting Started, 10/2018, A5E44910930-AA

7

Introduction to the example

Automation components of the example

2 S7-1500 H-CPUs

3 ET 200SP as IO devices in the PROFINET ring

2 Comfort Panels

1.2 Structure and task of the example

The configuration consists of:

● When a CPU fails in redundant operation, the other CPU maintains control over the

tunnel operation.

An ET 200SP (IO device) distributed I/O system is found in every tunnel section (1 to 3).

Sensors and actuators are connected to each IO device for the following tasks:

● Measurement of the pollutant concentration and as a function thereof:

– Control of the fan speed and air flow

– Control of the traffic lights and barriers

● Measurement of the light outside the tunnel:

– Control of the entry lights

● Control of the interior lights in the tunnel, depending on the day / night time.

The Comfort Panels are used by operators as a control center for monitoring tunnel

operation.

S7-1500R/H redundant system

8 Getting Started, 10/2018, A5E44910930-AA

Introduction to the example

Principle of operation

Controlling the speed of the fans and controlling the traffic lights and barriers

Controlling the lighting in the tunnel

The user program

The Comfort Panels

1.2 Structure and task of the example

Every fan:

● has two speeds (stages), which are switched on or off depending on the measured

pollutant concentration.

● has 2 directions of rotation. Depending on whether pollution is measured, the fan must

blow or suck.

The H-CPU measures the pollutant concentrations in the tunnel via analog input modules

and air-quality sensors.

If the pollutant concentration exceeds the maximum limit, the H-CPU responds in ET 200SP

via digital output modules as follows:

● It increases the speed of the fan motors

● It switches the traffic light system to red after two minutes

● It closes the barriers after two minutes

If the pollutant concentration falls below an average limit, the H-CPU responds in ET 200SP

via digital output modules as follows:

● It switches the ventilation motors to stop

● It switches the traffic lights to green

● It opens the barriers

The H-CPU measures the light intensity outside and inside the tunnel using analog input

modules. Depending on the outdoor light, digital output modules adjust the brightness of the

entry lights in the tunnel to the optimum vision conditions. The digital output modules also

control the interior lights in the tunnel, depending on the day / night time.

in the CPU specifies limits and controls the input and output modules of

the ET 200SP.

visualize the S7-1500H redundant system in an HMI screen. If required,

the operator can switch to manual operation via the HMI screen and change limit values.

S7-1500R/H redundant system

Getting Started, 10/2018, A5E44910930-AA

9

Introduction to the example

S7-1500H versus S7-1500R

Advantages and benefits of the solution

1.2 Structure and task of the example

As an alternative to S7-1500H, you can use an S7-1500R redundant system for the solution

to the automation task. In this example, the S7-1500H redundant system is used as it offers

the following advantages for tunnel automation:

● much higher performance than S7-1500R with:

– separate redundancy connections over fiber-optic cable

– high computing power

– a higher number of PROFINET devices can be used

● distance between the two H CPUs up to 10 km

● High availability of the system: If an H-CPU fails or is being maintained, the lighting and

fan control continues to function. The tunnel does not need to be blocked.

● Reliable monitoring and control of the tunnel facilities over large distances, up to 10 km

between the two H-CPUs

● Monitoring of the system and targeted information of the operating engineers in real time

● Signals are recorded and output directly in the ET 200SP distributed I/O systems in the

tunnel. There are no long cable runs.

S7-1500R/H redundant system

10 Getting Started, 10/2018, A5E44910930-AA

Introduction to the example

1.3

Procedure

Tasks

Step

Procedure

Further information

I/O modules and 2 Comfort Panels.

tion (Page 13)

1.3 Procedure

Perform the following tasks for implementation of the example:

Table 1- 1 Procedure for tunnel automation

1 Configure hardware in STEP 7:

Configure the assembly with 2 H-CPUs, 3 ET 200SP stations with their

2 Creating a user program in STEP 7:

• Program the user program in an organization block.

• You create an HMI screen.

3 Installing modules and wiring the assembly:

• Install all modules.

• Wire the load current supply, the modules in the PROFINET ring,

the redundancy connections and the Comfort Panels.

4 Commissioning the example:

• Insert the SIMATIC memory cards in the H-CPUs.

• Switch on the load current supply and the CPUs.

• Assign redundancy IDs to the CPUs in the configuration on com-

missioning.

• Load the project data (hardware configuration and user program) to

the CPUs.

• Check the LEDs and evaluate the information on the CPU displays.

• Test how the example works.

Section Configuring (Page 19)

Section Programming (Page 34)

Redundant System S7-1500R/H

(https://support.industry.siemens.com/cs/

ww/en/view/109754833) system manual

ET 200SP Distributed I/O System

(https://support.industry.siemens.com/cs/

ww/en/view/58649293) system manual

Chapter Wiring diagram for a tunnel sec-

Chapter Commissioning (Page 48)

S7-1500R/H redundant system

Getting Started, 10/2018, A5E44910930-AA

11

Introduction to the example

1.4

Requirements

Requirements for the Example

Hardware/software

Modules//Versions

2 ET 200SP for tunnel sections 1 and 3 each consisting of:

1 ET 200SP for tunnel section 2 consisting of:

2 HMI devices

TP1900 Comfort

S7-1500R/H

ET 200SP

Accessories

1 mounting rail, 2 fiber-optic cables, PROFINET cables

the PG/PC

1.4 Requirements

The following hardware and software is available for processing the example:

Table 1- 2 Hardware/software requirements

2 H-CPUs with synchronization modules and SIMATIC

Memory Cards

3 ET 200SP distributed I/O

systems

• 2 identical 1517H-3 PN CPUs with identical article numbers, function versions and firm-

ware version

• 4 synchronization modules for cables up to 10 km in length (6ES7960-1FB00-0AA5)

• 2 SIMATIC Memory Cards e.g. with 256 Mbyte capacity (6ES7954-8LL02-0AA0)

• 1 interface module IM 155-6 PN HF (6ES7155-6AU01-0CN0), FW version V4.2 or later

(with system redundancy S2)

• 4 digital output modules:

– 2 DQ 4x24VDC/2A ST each with a light-colored BaseUnit, BU type A0: BU15-

P16+A0+2D

– 1 DQ 4x24VDC/2A ST with a dark-colored BaseUnit, BU type A0: BU15-P16+A0+2B

– 1 DQ 4x24..230VAC/2A HF with a light-colored BaseUnit, BU type U0: BU20-

P16+A0+2D

• 1 analog input module:

– AI 4xU/I 2-wire ST with a dark-colored BaseUnit, BU type A0: BU15-P16+A0+2B

• 1 server module

• 1 interface module IM 155-6 PN HF (6ES7155-6AU01-0CN0), FW version V4.2 or later

(with system redundancy S2)

• 2 digital output modules:

– 1 DQ 4x24VDC/2A ST with a light-colored BaseUnit, BU type A0: BU15-P16+A0+2D

– 1 DQ 4x24..230VAC/2A HF with a light-colored BaseUnit, BU type U0: BU20-

P16+A0+2D

• 1 analog input module:

– AI 4xU/I 2-wire ST with a dark-colored BaseUnit, BU type A0: BU15-P16+A0+2B

• 1 server module

2 load current supplies for

3 load current supplies for

PC/PG with EngineeringSystem

Switch for the connection of

S7-1500R/H redundant system

PM 190 W 120/230 V AC

Load current supplies with 24 V DC output voltage (with safe electrical isolation)

PG/PC with Ethernet interface and the following correctly installed software package:

• SIMATIC STEP 7 Professional, V15.1 or later

SCALANCE X-204IRT

12 Getting Started, 10/2018, A5E44910930-AA

Introduction to the example

Additional requirement

Installing modules and wiring the assembly

Conventions

1.5

Wiring diagram for a tunnel section

Introduction

1.5 Wiring diagram for a tunnel section

The PG/PC is connected to a switch via the PROFINET interface. The switch is a device in

the PROFINET ring during commissioning.

You can set up and wire the hardware before or after configuration and programming of the

user program.

You can find additional information on installation and wiring of an ET 200SP in the

ET 200SP distributed I/O system

(https://support.industry.siemens.com/cs/ww/en/view/58649293) system manual .

The wiring diagram for an ET 200SP for a tunnel section can be found in the section Wiring

diagram for a tunnel section (Page 13).

The procedure for installation and wiring of an S7-1500R/H redundant system is available in

the S7-1500R/H redundant system

(https://support.industry.siemens.com/cs/ww/en/view/109754833) system manual.

Steps and settings which are specific for configuration and programming of an S7-1500H

redundant system will be dealt with in detail in the following sections. Procedures which you

are already familiar with from configuring and programming a SIMATIC S7-1500 will only be

briefly outlined.

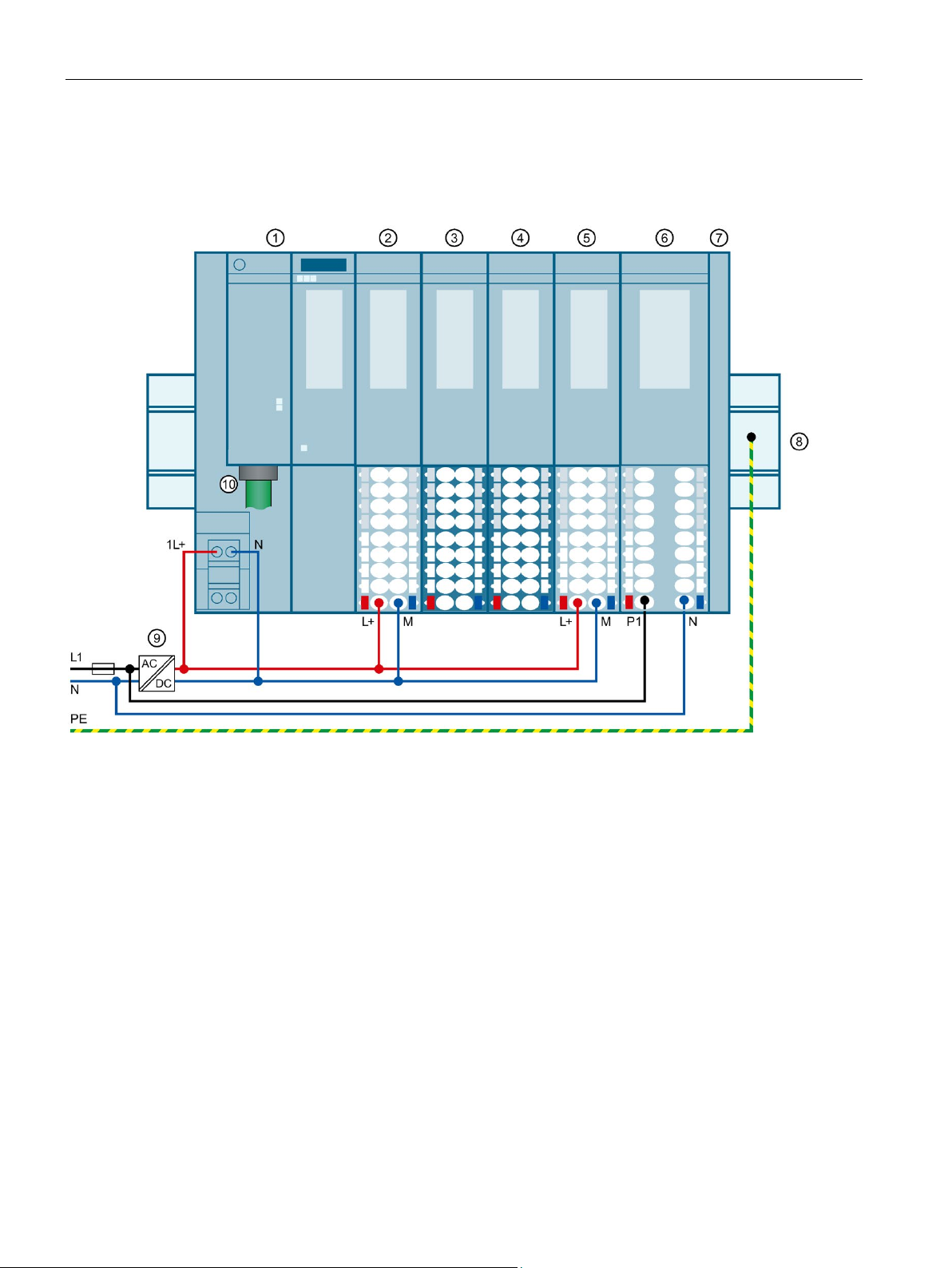

The figures below show the wiring of the I/O modules of an ET 200SP distributed I/O system

for tunnel section 1 or 3.

When wiring the tunnel section 2, there is no wiring of the digital output modules for the

traffic lights control and barrier control nor of the outdoor light sensor on the analog input

module.

S7-1500R/H redundant system

Getting Started, 10/2018, A5E44910930-AA

13

Introduction to the example

Connecting the supply voltage, PROFINET cables and grounding

①

Interface module IM 155-6 PN HF (6ES7155-6AU01-0CN0 firmware version V4.2 and later)

②

type A0)

③

type A0)

④

seUnit BU15-P16+A0+2B (BU type A0)

⑤

(BU type A0)

⑥

P16+A0+2D (BU type U0)

⑦

Server module

⑧

Mounting rail grounded at PE

⑨

Load current supply with 24 V DC output voltage (with safe electrical isolation)

⑩

PROFINET cables for the PROFINET ring

1.5 Wiring diagram for a tunnel section

The following figure shows the wiring of the supply voltage, the PROFINET cables and the

grounding on the ET 200SP.

Traffic light control: DQ 4x24VDC/2A ST digital output module with a light-colored BaseUnit BU15-P16+A0+2D (BU

Barrier control: DQ 4x24VDC/2A ST digital output module with a dark-colored BaseUnit BU15-P16+A0+2B (BU

Measuring the light intensity and air pollution level: 4xU/I 2-wire ST analog input module with a dark-colored Ba-

Fan control system: DQ 4x24VDC/2A ST digital output module with a light-colored BaseUnit BU15-P16+A0+2D

Light control system: DQ 4x24..230VAC/2A HF digital output module with a light-colored BaseUnit BU20-

Figure 1-3 Wiring diagram

S7-1500R/H redundant system

14 Getting Started, 10/2018, A5E44910930-AA

Introduction to the example

Connecting traffic light control

Connecting barrier control

1.5 Wiring diagram for a tunnel section

The following figure shows the wiring of the traffic lights on the DQ 4x24VDC/2A ST digital

output module

Figure 1-4 Wiring of the traffic lights

②.

The following figure shows the wiring of the barrier control on the DQ 4x24VDC/2A ST digital

output module

The barrier is opened and closed via a three-phase motor. The direction of rotation of the

three-phase motor is controlled via a reversing contactor:

● Open barrier → Contactor K1 actuated

● Close barrier → Contactor K2 actuated

If the barriers have reached their respective end position, they automatically switch off via

limit switches.

③.

Figure 1-5 Wiring of the barrier control

S7-1500R/H redundant system

Getting Started, 10/2018, A5E44910930-AA

15

Loading...

Loading...