Siemens SIMATIC S7-1500, SIMATIC S7-1500 Motion Control V13 Function Manual

S7-1500 Motion Control V13 Update 3

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

SIMATIC

S7-1500

S7-1500 Motion Control V13

Update 3

Function Manual

07/2014

A5E03879256

Preface

Guide to documentation

S7-1500 / ET 200MP

1

Introduction

2

Basics

3

Guidelines

4

Using versions

5

Configuring

6

Programming

7

Downloading to CPU

8

Commissioning

9

Diagnostics

10

Instructions

11

Appendix

A

-AC

Siemens AG

Industry Sector

Postfach 48 48

90026 NÜRNBERG

GERMANY

A5E03879256-AC

Ⓟ

Copyright © Siemens AG 2013 - 2014.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

for the specific

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

07/2014 Subject to change

Preface

Purpose of the documentation

Required basic knowledge

Validity of the documentation

Conventions

Note

A note contains important information about the product described in the documentation,

about the handling of the product, and about sections in this documentation demanding your

particular

Further support

This documentation provides important information that you need to configure and

commission the integrated Motion Control functionality of the S7-1500 Automation systems.

In order to understand this documentation, the following knowledge is required:

● General knowledge in the field of automation

● General knowledge in the field of drive engineering and motion control

This documentation is valid for the S7-1500 product range.

● For the path settings in the project navigation it is presumed that the "Technology objects"

object is opened in the CPU subtree. The "Technology object" placeholder represents the

name of the technology object.

Example: "Technology object > Configuration > Basic parameters".

● The <TO> placeholder represents the name set in tags for the respective technology

object.

Example: <TO>.Actor.Type

● This documentation contains pictures of the devices described. The pictures may differ in

minor details from the devices supplied.

You should also observe the notes that are marked as follows:

attention.

● The range of technical documentation for the individual SIMATIC products and systems is

available on the Internet (http://www.siemens.com/simatic-tech-doku-portal).

● The online catalog and the online ordering system is available on the Internet

(http://mall.automation.siemens.com).

S7-1500 Motion Control V13 Update 3

Function Manual, 07/2014, A5E03879256-AC

3

Preface

Security information

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, solutions, machines, equipment and/or networks. They are

important components in a holistic industrial security concept. With this in mind, Siemens’

products and solutions undergo continuous development. Siemens recommends strongly

that you regularly check for product updates.

For the secure operation of Siemens products and solutions, it is necessary to take suitable

preventive action (e.g. cell protection concept) and integrate each component into a holistic,

state-of-the-art industrial security concept. Third-party products that may be in use should

also be considered. You can find more information about industrial security on the Internet

(http://www.siemens.com/industrialsecurity).

To stay informed about product updates as they occur, sign up for a product-specific

newsletter. You can find more information on the Internet

(http://support.automation.siemens.com).

S7-1500 Motion Control V13 Update 3

4 Function Manual, 07/2014, A5E03879256-AC

Table of contents

Preface ...................................................................................................................................................... 3

1 Guide to documentation S7-1500 / ET 200MP......................................................................................... 13

2 Introduction .............................................................................................................................................. 15

3 Basics ...................................................................................................................................................... 20

2.1 Integrated Motion Control Functionality of the CPU S7-1500 ................................................ 15

2.2 Principle of operation of S7-1500 Motion Control ................................................................... 16

3.1 Functions ................................................................................................................................ 20

3.2 Scale ....................................................................................................................................... 21

3.3 Speed-controlled axis technology object ................................................................................ 21

3.4 Positioning axis technology object .......................................................................................... 22

3.5 Synchronous axis technology object ...................................................................................... 23

3.6 External encoder technology object ........................................................................................ 25

3.7 Axis types ................................................................................................................................ 26

3.8 Modulo setting ......................................................................................................................... 26

3.9 Units of measure ..................................................................................................................... 27

3.10 Drive and encoder connection ................................................................................................ 28

3.10.1 Brief description ...................................................................................................................... 28

3.10.2 Frames .................................................................................................................................... 29

3.10.3 Setting reference values ......................................................................................................... 31

3.10.4 Tags ........................................................................................................................................ 32

3.11 Safety functions in the drive .................................................................................................... 33

3.11.1 Brief description ...................................................................................................................... 33

3.11.2 Safe Torque Off (STO) ........................................................................................................... 33

3.11.3 Safe Stop 1 (SS1) ................................................................................................................... 34

3.11.4 Safe Stop 2 (SS2) ................................................................................................................... 34

3.12 Actual values ........................................................................................................................... 35

3.12.1 Brief description ...................................................................................................................... 35

3.12.2 Incremental actual value ......................................................................................................... 35

3.12.3 Absolute actual value .............................................................................................................. 35

3.12.4 Tags ........................................................................................................................................ 36

3.13 Mechanics ............................................................................................................................... 37

3.13.1 Brief description ...................................................................................................................... 37

3.13.2 Tags ........................................................................................................................................ 38

3.14 Homing .................................................................................................................................... 39

3.14.1 Brief description ...................................................................................................................... 39

3.14.2 Terms ...................................................................................................................................... 40

3.14.3 Homing mode .......................................................................................................................... 41

S7-1500 Motion Control V13 Update 3

Function Manual, 07/2014, A5E03879256-AC

5

Table of contents

4 Guidelines ................................................................................................................................................ 85

5 Using versions ......................................................................................................................................... 86

3.14.4 Active homing with zero mark and proximity switch .............................................................. 43

3.14.5 Active homing with zero mark ................................................................................................ 46

3.14.6 Active homing with digital input .............................................................................................. 48

3.14.7 Passive homing with zero mark and proximity switch ............................................................ 50

3.14.8 Passive homing with zero mark ............................................................................................. 52

3.14.9 Passive homing with digital input ........................................................................................... 54

3.14.10 Direction reversal at the hardware limit switch (reversing cam) ............................................ 55

3.14.11 Direct homing ......................................................................................................................... 56

3.14.12 Absolute value adjustment ..................................................................................................... 56

3.14.13 Resetting the "Homed" status ................................................................................................ 57

3.14.14 Tags ....................................................................................................................................... 58

3.15 Control .................................................................................................................................... 59

3.15.1 Brief description ..................................................................................................................... 59

3.15.2 Control structure..................................................................................................................... 60

3.15.3 Tags ....................................................................................................................................... 61

3.16 Position-related monitoring .................................................................................................... 61

3.16.1 Brief description ..................................................................................................................... 61

3.16.2 Positioning monitoring ............................................................................................................ 62

3.16.3 Following error monitoring ..................................................................................................... 63

3.16.4 Tags ....................................................................................................................................... 64

3.17 Traversing range limitation ..................................................................................................... 65

3.17.1 Brief description ..................................................................................................................... 65

3.17.2 Hardware limit switches ......................................................................................................... 65

3.17.3 Software limit switch .............................................................................................................. 67

3.17.4 Tags ....................................................................................................................................... 68

3.18 Motion control and limits for dynamics ................................................................................... 69

3.18.1 Brief description ..................................................................................................................... 69

3.18.2 Velocity profile ........................................................................................................................ 70

3.18.3 Emergency stop deceleration ................................................................................................ 71

3.18.4 Tags ....................................................................................................................................... 72

3.19 Synchronous operation .......................................................................................................... 73

3.19.1 Brief description ..................................................................................................................... 73

3.19.2 Relative gearing ..................................................................................................................... 74

3.19.3 Master value coupling ............................................................................................................ 76

3.19.4 Tags ....................................................................................................................................... 77

3.20 O

perational sequence ............................................................................................................ 78

3.20.1 Organization Blocks for Motion Control ................................................................................. 78

3.20.2 Process image partition "OB Servo PIP" ............................................................................... 80

3.20.3 Operational Sequence and Timeouts .................................................................................... 80

3.20.4 Operating modes ................................................................................................................... 83

4.1 Guidelines on use of motion control....................................................................................... 85

5.1 Overview of versions .............................................................................................................. 86

5.2 Changing a technology version .............................................................................................. 89

S7-1500 Motion Control V13 Update 3

6 Function Manual, 07/2014, A5E03879256-AC

Table of contents

6 Configuring .............................................................................................................................................. 91

6.1 Adding and configuring drives in the device configuration ..................................................... 91

6.1.1 Add and configure PROFINET IO drives ................................................................................ 91

6.1.2 Add and configure PROFIBUS DP drives............................................................................... 94

6.1.3 Adding and configuring drives with analog connections ......................................................... 96

6.2 Add technology object ............................................................................................................ 99

6.3 Working with the configuration editor .................................................................................... 100

6.4 Compare values .................................................................................................................... 101

6.5 Configuring the Speed-Control Axis technology object ........................................................ 102

6.5.1 Configuration - Basic Parameters ......................................................................................... 102

6.5.2 Hardware interface ................................................................................................................ 102

6.5.2.1 Configuration - Drive ............................................................................................................. 102

6.5.2.2 Configuration - Data exchange ............................................................................................. 104

6.5.3 Extended Parameters ........................................................................................................... 105

6.5.3.1 Configuration - Mechanics .................................................................................................... 105

6.5.3.2 Configuration - Dynamic limits .............................................................................................. 105

6.5.3.3 Configuration - Dynamic Defaults ......................................................................................... 107

6.5.3.4 Configuration - Emergency stop ........................................................................................... 109

6.6 Configuring the positioning axis/synchronous axis technology object .................................. 110

6.6.1 Configuration - Basic Parameters ......................................................................................... 110

6.6.2 Hardware interface ................................................................................................................ 111

6.6.2.1 Configuration - Drive ............................................................................................................. 111

6.6.2.2 Configuration - Encoder ........................................................................................................ 113

6.6.2.3 Configuration - Data exchange ............................................................................................. 114

6.6.3 Configuration - master value interconnections (synchronous axis only) .............................. 124

6.6.4 Extended Parameters ........................................................................................................... 125

6.6.4.1 Configuration - Mechanics .................................................................................................... 125

6.6.4.2 Configuration - Position monitoring ....................................................................................... 129

6.6.4.3 Configuration - Dynamic limits .............................................................................................. 130

6.6.4.4 Configuration - Dynamic Defaults ......................................................................................... 132

6.6.4.5 Configuration - Emergency stop ........................................................................................... 134

6.6.4.6 Homing .................................................................................................................................. 135

6.6.4.7 Position monitoring ............................................................................................................... 144

6.6.4.8 Configuration - Control loop .................................................................................................. 146

6.7 Configuring the External Encoder technology object

.7.1 Configuration - Basic Parameters ......................................................................................... 147

6

............................................................ 147

6.7.2 Hardware interface ................................................................................................................ 148

6.7.2.1 Configuration - Encoder ........................................................................................................ 148

6.7.2.2 Configuration - Data exchange ............................................................................................. 149

6.7.3 Extended Parameters ........................................................................................................... 153

6.7.3.1 Configuration - Mechanics .................................................................................................... 153

6.7.3.2 Homing .................................................................................................................................. 155

6.8 Parameter view ..................................................................................................................... 159

6.8.1 Introduction to the parameter view ....................................................................................... 159

6.8.2 Structure of the parameter view ............................................................................................ 161

6.8.2.1 Toolbar .................................................................................................................................. 161

6.8.2.2 Navigation ............................................................................................................................. 161

6.8.2.3 Parameter table .................................................................................................................... 162

S7-1500 Motion Control V13 Update 3

Function Manual, 07/2014, A5E03879256-AC

7

Table of contents

7 Programming ......................................................................................................................................... 172

8 Downloading to CPU ............................................................................................................................. 198

9 Commissioning ...................................................................................................................................... 199

6.8.3 Opening the parameter view ................................................................................................ 163

6.8.4 Working with the parameter view ......................................................................................... 164

6.8.4.1 Overview .............................................................................................................................. 164

6.8.4.2 Filtering the parameter table ................................................................................................ 164

6.8.4.3 Sorting the parameter table ................................................................................................. 165

6.8.4.4 Transferring parameter data to other editors ....................................................................... 165

6.8.4.5 Indicating errors ................................................................................................................... 166

6.8.4.6 Editing start values in the project ......................................................................................... 166

6.8.4.7 Monitoring values online in the parameter view ................................................................... 168

6.8.4.8 Modifying values .................................................................................................................. 169

6.8.4.9 Comparing values ................................................................................................................ 170

7.1 Introduction .......................................................................................................................... 172

7.2 Technology data block ......................................................................................................... 172

7.2.1 Introduction .......................................................................................................................... 172

7.2.2 Evaluating the technology data block .................................................................................. 173

7.2.3 Evaluate StatusWord, ErrorWord and WarningWord .......................................................... 175

7.2.4 Change restart-relevant data ............................................................................................... 177

7.3 Motion Control instructions .................................................................................................. 178

7.3.1 Motion Control instruction parameters ................................................................................. 178

7.3.2 Add Motion Control instructions ........................................................................................... 181

7.4 Starting Motion Control jobs ................................................................................................. 183

7.5 Tracking active jobs ............................................................................................................. 184

7.5.1 Introduction .......................................................................................................................... 184

7.5.2 Motion Control instructions with "Done" parameter ............................................................. 185

7.5.3 Motion Control instructions without "Done" parameter ........................................................ 189

7.5.4 Motion Control instruction "MC_MoveJog" .......................................................................... 193

7.6 Ending Motion Control jobs .................................................................................................. 196

7.7 Restart of technology objects ............................................................................................... 197

9.1 Introduction .......................................................................................................................... 199

9.2 Commissioning guidelines ................................................................................................... 199

9.3 Axis control panel ................................................................................................................. 202

9.3.1 Function and structure of the axis control panel .................................................................. 202

9.3.2 Using the axis control panel ................................................................................................. 206

9.4 Optimization ......................................................................................................................... 207

9.4.1 Function and structure of the optimization ........................................................................... 207

9.4.2 Optimize position controller .................................................................................................. 210

9.5 Simulation mode .................................................................................................................. 213

S7-1500 Motion Control V13 Update 3

8 Function Manual, 07/2014, A5E03879256-AC

Table of contents

10 Diagnostics ............................................................................................................................................ 214

11 Instructions ............................................................................................................................................ 234

10.1 Introduction ........................................................................................................................... 214

10.2 Diagnostic concept ................................................................................................................ 214

10.3 Technology alarms ................................................................................................................ 215

10.4 Errors in Motion Control instructions ..................................................................................... 219

10.5 Speed-controlled axis technology object .............................................................................. 220

10.5.1 Status and error bits .............................................................................................................. 220

10.5.2 Motion status ......................................................................................................................... 223

10.5.3 PROFIdrive frame ................................................................................................................. 224

10.6 Positioning axis/synchronous axis technology object ........................................................... 225

10.6.1 Status and error bits .............................................................................................................. 225

10.6.2 Motion status ......................................................................................................................... 229

10.6.3 PROFIdrive frame ................................................................................................................. 230

10.7 External encoder technology object ...................................................................................... 231

10.7.1 Status and error bits .............................................................................................................. 231

10.7.2 Motion status ......................................................................................................................... 232

10.7.3 PROFIdrive frame ................................................................................................................. 233

11.1 S7-1500 Motion Control V2 .................................................................................................. 234

11.1.1 MC_Power ............................................................................................................................ 234

11.1.1.1 MC_Power: Enable, disable technology objects V2 ............................................................. 234

11.1.1.2 MC_Power: Function chart V2 .............................................................................................. 238

11.1.2 MC_Home ............................................................................................................................. 239

11.1.2.1 MC_Home: Home technology objects, set home position V2 .............................................. 239

11.1.3 MC_MoveJog ........................................................................................................................ 244

11.1.3.1 MC_MoveJog: Move axes in jog mode V2 ........................................................................... 244

11.1.3.2 MC_MoveJog: Function chart V2 .......................................................................................... 248

11.1.4 MC_MoveVelocity ................................................................................................................. 249

11.1.4.1 MC_MoveVelocity: Move axes at predefined velocity V2 ..................................................... 249

11.1.4.2 MC_MoveVelocity: Function chart V2 ................................................................................... 254

11.1.5 MC_MoveRelative ................................................................................................................. 255

11.1.5.1 MC_MoveRelative: Relative positioning of axes V2 ............................................................. 255

11.1.5.2 MC_MoveRelative: Function chart V2 .................................................................................. 259

11.1.6 MC_MoveAbsolute ................................................................................................................ 260

11.1.6.1 MC_MoveAbsolute: Absolute positioning of axes V2 ........................................................... 260

11.1.6.2 MC_MoveAbsolute: Function chart V2 ................................................................................. 264

11.1.7 MC_MoveSuperimposed ...................................................................................................... 265

11.1.7.1 MC_MoveSuperimposed: Superimposed positioning of axes V2 ......................................... 265

11.1.7.2 MC_MoveSuperimposed: Function chart V2 ........................................................................ 269

11.1.8 MC_GearIn ............................................................................................................................ 270

11.1.8.1 MC_GearIn: Start gearing V2 ............................................................................................... 270

11.1.8.2 MC_GearIn: Function chart V2 ............................................................................................. 274

11.1.9 MC_Halt ................................................................................................................................ 275

11.1.9.1 MC_Halt: Stop axes V2 ......................................................................................................... 275

11.1.9.2 MC_Halt: Function chart V2 .................................................................................................. 278

11.1.10 MC_Reset ............................................................................................................................. 279

11.1.10.1 MC_Reset: Acknowledge alarms, restart technology objects V2 ......................................... 279

S7-1500 Motion Control V13 Update 3

Function Manual, 07/2014, A5E03879256-AC

9

Table of contents

A Appendix ................................................................................................................................................ 321

11.2 S7-1500 Motion Control V1 .................................................................................................. 282

11.2.1 MC_Power ............................................................................................................................ 282

11.2.1.1 MC_Power: Enable, disable technology objects V1 ............................................................ 282

11.2.1.2 MC_Power: Function chart V1 ............................................................................................. 286

11.2.2 MC_Home ............................................................................................................................ 287

11.2.2.1 MC_Home: Home technology objects, set home position V1 .............................................. 287

11.2.3 MC_MoveJog ....................................................................................................................... 292

11.2.3.1 MC_MoveJog: Move axes in jog mode V1 .......................................................................... 292

11.2.3.2 MC_MoveJog: Function chart V1 ......................................................................................... 296

11.2.4 MC_MoveVelocity ................................................................................................................ 297

11.2.4.1 MC_MoveVelocity: Move axes at predefined specified velocity V1 ..................................... 297

11.2.4.2 MC_MoveVelocity: Function chart V1 .................................................................................. 302

11.2.5 MC_MoveRelative ................................................................................................................ 303

11.2.5.1 MC_MoveRelative: Relative positioning of axes V1 ............................................................ 303

11.2.5.2 MC_MoveRelative: Function chart V1 ................................................................................. 307

11.2.6 MC_MoveAbsolute ............................................................................................................... 308

11.2.6.1 MC_MoveAbsolute: Absolute positioning of axes V1 .......................................................... 308

11.2.6.2 MC_MoveAbsolute: Function chart V1 ................................................................................ 312

11.2.7 MC_Halt ............................................................................................................................... 313

11.2.7.1 MC_Halt: Stop axes V1 ........................................................................................................ 313

11.2.7.2 MC_Halt: Function chart V1 ................................................................................................. 317

11.2.8 MC_Reset ............................................................................................................................ 318

11.2.8.1 MC_Reset: Acknowledge alarms, restart technology objects V1 ........................................ 318

A.1 Tags of the technology object SpeedAxis ............................................................................ 321

A.1.1 Legend ................................................................................................................................. 321

A.1.2 Actual values and setpoints (speed axis) ............................................................................ 321

A.1.3 Variable simulation (speed axis) .......................................................................................... 322

A.1.4 Actor tags (speed axis) ........................................................................................................ 322

A.1.5 LoadGear tags (speed axis) ................................................................................................. 323

A.1.6 DynamicLimits tags (speed axis) ......................................................................................... 324

A.1.7 DynamicDefaults tags (speed axis) ..................................................................................... 324

A.1.8 Override tags (speed axis) ................................................................................................... 325

A.1.9 StatusDrive tags (speed axis) .............................................................................................. 325

A.1.10 StatusWord tag (speed axis) ................................................................................................ 326

A.1.11 ErrorWord tag (speed axis) .................................................................................................. 328

A.1.12 ErrorDetail tags (speed axis) ............................................................................................... 329

A.1.13 WarningWord tag (speed axis) ............................................................................................ 330

A.1.14 ControlPanel tags (speed axis) ............................................................................................ 331

A.1.15 InternalToTrace tags (speed axis) ....................................................................................... 332

A.2 Tags of the positioning axis/synchronous axis technology object ....................................... 332

A.2.1 Legend ................................................................................................................................. 332

A.2.2 Actual values and setpoints (positioning axis/synchronous axis) ........................................ 333

A.2.3 Simulation tag (positioning axis / synchronous axis) ........................................................... 333

A.2.4 Actor tags (positioning axis/synchronous axis) .................................................................... 334

A.2.5 Sensor[n] tags (positioning axis/synchronous axis) ............................................................. 336

A.2.6 LoadGear tags (positioning axis/synchronous axis) ............................................................ 338

A.2.7 Mechanics tags (positioning axis/synchronous axis) ........................................................... 338

A.2.8 Properties tags (positioning axis/synchronous axis) ............................................................ 338

A.2.9 Modulo tags (positioning axis/synchronous axis) ................................................................ 339

A.2.10 DynamicLimits tags (positioning axis/synchronous axis) ..................................................... 339

S7-1500 Motion Control V13 Update 3

10 Function Manual, 07/2014, A5E03879256-AC

Table of contents

A.2.11 DynamicDefaults tags (positioning axis/synchronous axis) .................................................. 340

A.2.12 PositionLimits_SW tags (positioning axis/synchronous axis) ............................................... 340

A.2.13 PositionLimits_HW tags (positioning axis/synchronous axis) ............................................... 341

A.2.14 Homing tags (positioning axis/synchronous axis) ................................................................. 342

A.2.15 Override tags (positioning axis/synchronous axis) ............................................................... 343

A.2.16 PositionControl tags (positioning axis/synchronous axis) ..................................................... 344

A.2.17 FollowingError tags (positioning axis/synchronous axis) ...................................................... 345

A.2.18 PositionMonitoring tags (positioning axis/synchronous axis) ............................................... 346

A.2.19 StandstillSignal tags (positioning axis/synchronous axis) .................................................... 347

A.2.20 StatusPositioning tags (positioning axis/synchronous axis) ................................................. 347

A.2.21 StatusDrive tags (positioning axis/synchronous axis) .......................................................... 348

A.2.22 StatusSensor[n] tags (positioning axis/synchronous axis) ................................................... 349

A.2.23 StatusSynchronizedMotion tags (synchronous axis) ............................................................ 350

A.2.24 StatusWord tag (positioning axis/synchronous axis) ............................................................ 351

A.2.25 ErrorWord tag (positioning axis/synchronous axis) .............................................................. 353

A.2.26 ErrorDetail tags (positioning axis/synchronous axis) ............................................................ 355

A.2.27 WarningWord tag (positioning axis/synchronous axis) ......................................................... 356

A.2.28 ControlPanel tags (positioning axis/synchronous axis) ........................................................ 357

A.2.29 InternalToTrace tags (positioning axis/synchronous axis) .................................................... 358

A.3 Tags of the technology object external encoder ................................................................... 358

A.3.1 Legend .................................................................................................................................. 358

A.3.2 Actual values and setpoints (external encoder) .................................................................... 359

A.3.3 Sensor tags (external encoder) ............................................................................................ 359

A.3.4 Mechanics tags (external encoder) ....................................................................................... 361

A.3.5 LoadGear tags (external encoder) ........................................................................................ 361

A.3.6 Properties tags (external encoder) ....................................................................................... 361

A.3.7 Modulo tags (external encoder) ............................................................................................ 362

A.3.8 Homing tags (external encoder) ........................................................................................... 362

A.3.9 StatusSensor tags (external encoder) .................................................................................. 363

A.3.10 StatusWord tag (external encoder) ....................................................................................... 364

A.3.11 ErrorWord tag (external encoder) ......................................................................................... 365

A.3.12 ErrorDetail tags (external encoder) ....................................................................................... 366

A.3.13 WarningWord tag (external encoder) .................................................................................... 367

A.3.14 InternalToTrace tags (external encoder) .............................................................................. 367

A.4 Technology alarms ................................................................................................................ 368

A.4.1 Overview ............................................................................................................................... 368

A.4.2 Technology alarms 101-110 ................................................................................................. 371

A.4.3 Technology alarms 201-204 ................................................................................................. 375

A.4.4 Technology alarms 304-

342 .................................................................................................

A.4.5 Technology alarms 401-431 ................................................................................................. 379

A.4.6 Technology alarms 501-550 ................................................................................................. 381

A.4.7 Technology alarm 601 .......................................................................................................... 385

A.5 Error ID ................................................................................................................................. 386

A.6 MC_Power function chart ...................................................................................................... 388

A.6.1 Drive connection via PROFIdrive .......................................................................................... 388

A.6.1.1 StopMode 0 ........................................................................................................................... 388

A.6.1.2 StopMode 1 ........................................................................................................................... 389

A.6.1.3 Alarm response "Stop with maximum dynamic values" ........................................................ 390

A.6.1.4 Alarm response "Remove enable" ........................................................................................ 391

S7-1500 Motion Control V13 Update 3

Function Manual, 07/2014, A5E03879256-AC

376

11

Table of contents

Glossary ................................................................................................................................................ 397

Index ...................................................................................................................................................... 400

A.6.2 Analog drive connection ....................................................................................................... 392

A.6.2.1 StopMode 0 .......................................................................................................................... 392

A.6.2.2 StopMode 1 .......................................................................................................................... 393

A.6.2.3 Alarm response "Stop with maximum dynamic values" ....................................................... 394

A.6.2.4 Alarm response "Remove enable" ....................................................................................... 395

A.7 SINAMICS drives ................................................................................................................. 396

A.7.1 Homing SINAMICS drives with external zero marks ........................................................... 396

S7-1500 Motion Control V13 Update 3

12 Function Manual, 07/2014, A5E03879256-AC

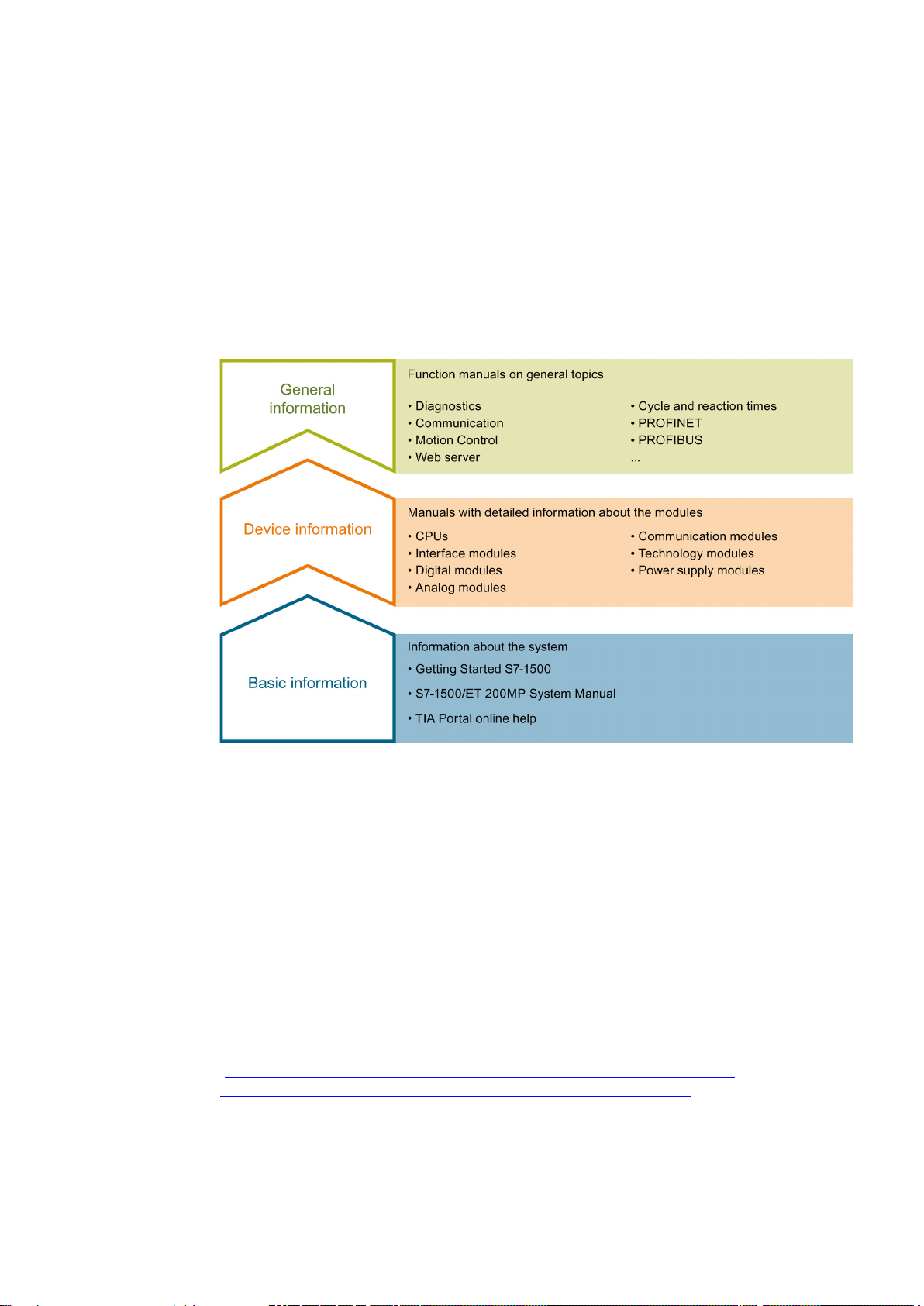

1

Basic information

Device information

General information

The documentation for the SIMATIC S7-1500 automation system and the SIMATIC

ET 200MP distributed I/O system is arranged into three areas.

This arrangement enables you to access the specific content you require.

System Manual and Getting Started describe in detail the configuration, installation, wiring

and commissioning of the SIMATIC S7-1500 and ET 200MP systems. The STEP 7 online

help supports you in the configuration and programming.

Manuals contain a compact description of the module-specific information, such as

properties, terminal diagrams, characteristics, technical specifications.

The function manuals contain detailed descriptions on general topics regarding the SIMATIC

S7-1500 and ET 200MP systems, e.g. diagnostics, communication, Motion Control, Web

server.

You can download the documentation free of charge from the Internet

(http://www.automation.siemens.com/mcms/industrial-automation-systems-

simatic/en/manual-overview/tech-doc-controllers/Pages/Default.aspx).

Changes and supplements to the manuals are documented in a Product Information.

S7-1500 Motion Control V13 Update 3

Function Manual, 07/2014, A5E03879256-AC

13

Guide to documentation S7-1500 / ET 200MP

Manual Collection S7-1500 / ET 200MP

My Documentation Manager

Applications & Tools

CAx Download Manager

The Manual Collection contains the complete documentation on the SIMATIC S7-1500

automation system and the ET 200MP distributed I/O system gathered together in one file.

You can find the Manual Collection on the Internet

(http://support.automation.siemens.com/WW/view/en/86140384).

The My Documentation Manager is used to combine entire manuals or only parts of these to

your own manual.

You can export the manual as PDF file or in a format that can be edited later.

You can find the My Documentation Manager on the Internet

(http://support.automation.siemens.com/WW/view/en/38715968).

Applications & Tools supports you with various tools and examples for solving your

automation tasks. Solutions are shown in interplay with multiple components in the system separated from the focus in individual products.

You can find Applications & Tools on the Internet

(http://support.automation.siemens.com/WW/view/en/20208582).

The CAx Download Manager is used to access the current product data for your CAx or CAe

systems.

You configure your own download package with a few clicks.

In doing so you can select:

● Product images, 2D dimension drawings, 3D models, internal circuit diagrams, EPLAN

macro files

● Manuals, characteristics, operating manuals, certificates

● Product master data

You can find the CAx Download Manager on the Internet

(http://support.automation.siemens.com/WW/view/en/42455541).

S7-1500 Motion Control V13 Update 3

14 Function Manual, 07/2014, A5E03879256-AC

2

2.1

Integrated Motion Control Functionality of the CPU S7-1500

S7-1500 Motion Control supports controlled positioning and moving of axes and is an

integral part of every CPU S7-1500 as well as every CPU S7-1500SP. The Motion Control

functionality supports the technology objects rotation axis, positioning axis, synchronous axis

and external encoders.

Drives with PROFIdrive capability and drives with analog setpoint interface are controlled by

means of standardized Motion Control instructions according to PLCopen.

The axis control panel and comprehensive online and diagnostic functions support easy

commissioning and optimization of drives.

S7-1500 Motion Control is constantly integrated into the CPU S7-1500 system diagnostics.

S7-1500 Motion Control V13 Update 3

Function Manual, 07/2014, A5E03879256-AC

15

Introduction

2.2

Principle of operation of S7-1500 Motion Control

Overview

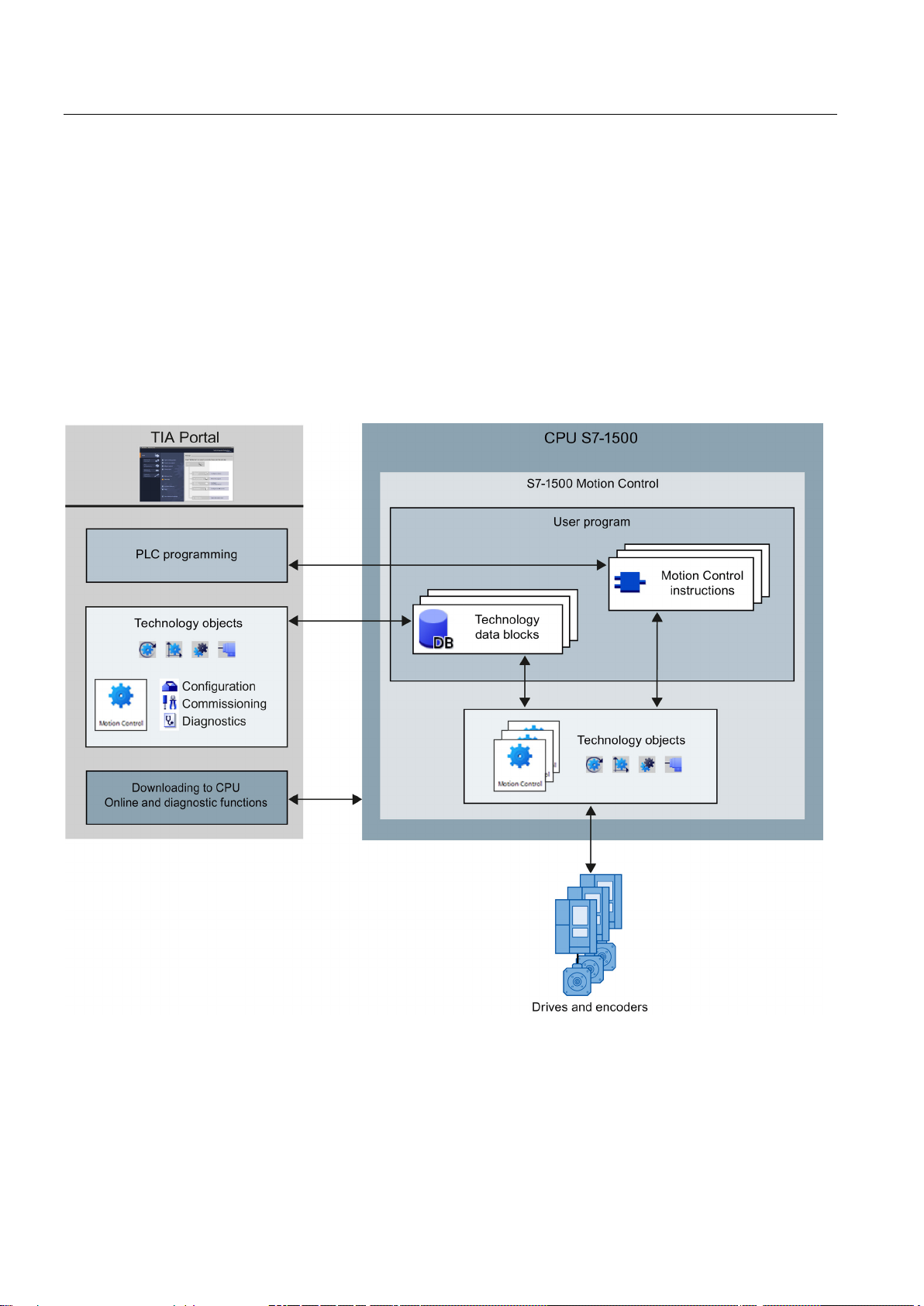

2.2 Principle of operation of S7-1500 Motion Control

You create a project, configure technology objects, and load the configuration into the CPU

using the TIA Portal. The Motion Control functionality is processed in the CPU.

You control the technology objects with the Motion Control instructions in your user program.

The TIA Portal provides additional functions for commissioning, optimization (Page 199) and

diagnostics (Page 214).

The following figure shows schematically the user interfaces and the integration of Motion

Control into the CPU S7-1500. The concepts are then briefly explained:

S7-1500 Motion Control V13 Update 3

16 Function Manual, 07/2014, A5E03879256-AC

Introduction

TIA Portal

Technology objects

Speed axis technology object

Positioning axis technology object

2.2 Principle of operation of S7-1500 Motion Control

The TIA Portal supports you in the planning and commissioning of Motion Control

functionality:

● Integrating and configuring hardware

● Creating and configuring technology objects

● Creating the user program

● Downloading to CPU

● Commissioning of axes

● Optimization of drives

● Diagnostics

You use the TIA Portal to configure the hardware, the technology objects as well as your

user program. You download the program you created to the CPU. You test your user

program and diagnose the hardware with the online and diagnostic functions of the

TIA Portal.

Technology objects represent real objects (e.g., a drive) in the controller. You can call the

functions of the technology objects by means of Motion Control instructions in your user

program. The technology objects provide open- and closed-loop control of the movement of

the real objects, and report status information (e.g. the current position).

The configuration of the technology objects represents the properties of the real object. The

configuration data are stored in a technology data block.

The following technology objects are available for Motion Control:

●

●

The speed axis technology object ("TO_SpeedAxis") permits the specification of the

speed for a drive. You program the movement of the axis with Motion Control

instructions.

The positioning axis technology object ("TO_PositioningAxis") permits the positioncontrolled positioning of a drive. You assign positioning jobs to the axis with Motion

Control instructions in your user program.

S7-1500 Motion Control V13 Update 3

Function Manual, 07/2014, A5E03879256-AC

17

Introduction

Synchronous axis technology object

External encoder technology object

Technology data block

Motion Control instructions

User program

2.2 Principle of operation of S7-1500 Motion Control

●

The synchronous axis technology object ("TO_SynchronousAxis") includes all functions of

the positioning axis technology object. You can also interconnect the axis with a master

value so that the axis follows the position change of a leading axis in synchronous

operation.

●

The external encoder technology object ("TO_ExternalEncoder") detects a position, and

makes it available to the controller. The detected position can be evaluated in the user

program.

The properties of real objects are configured by means of the technology objects and saved

in a technology data block. The technology data block contains all configuration data,

setpoint and actual values, and status information of the technology object. The TIA Portal

automatically creates the technology data block when the technology object is created. You

access the data of the technology data block with your user program.

With the Motion Control instructions you perform the desired functionality in the technology

objects. The Motion Control instructions are available in the TIA Portal under "Instructions >

Technology > Motion Control > S7-1500 Motion Control".

The Motion Control instructions conform to PLCopen (version 2.0).

The Motion Control instructions and the technology data block represent the programming

interfaces for the technology objects. Use the Motion Control instructions to start Motion

Control jobs at technology objects in your user program. You track the status of running jobs

with the output parameters of the Motion Control instructions. You access status information

of the technology object with the technology data block and change specific configuration

parameters during runtime.

S7-1500 Motion Control V13 Update 3

18 Function Manual, 07/2014, A5E03879256-AC

Introduction

Drives and encoders

2.2 Principle of operation of S7-1500 Motion Control

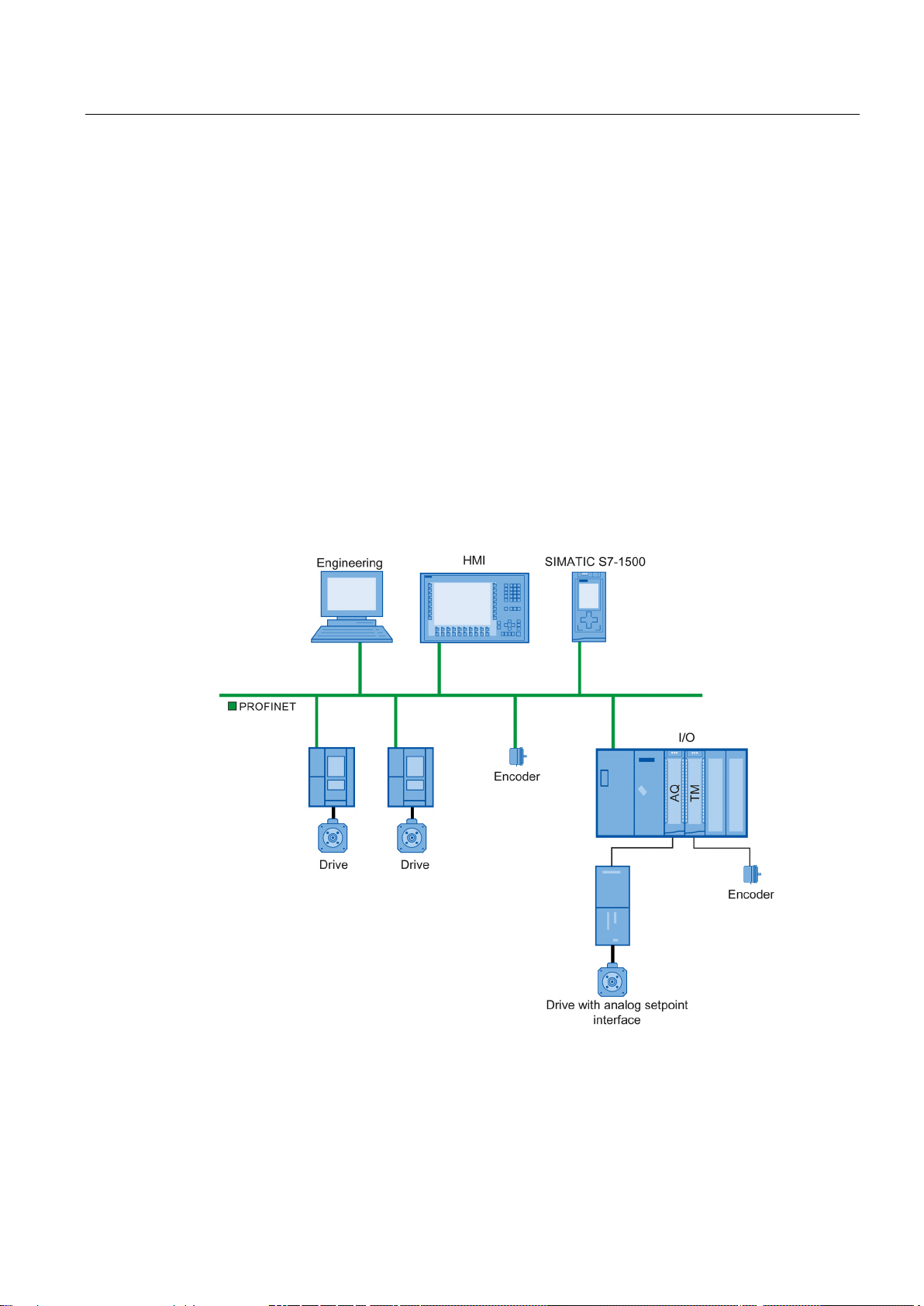

Drives permit the movement of the axis. They are integrated into the hardware configuration.

When you perform a Motion Control job in your user program, the technology object takes

over the control of the drive and the reading in of values from position encoders.

Drives and encoders with PROFIdrive capability are connected by means of PROFIdrive

frames. The following connections are possible:

● PROFINET IO

● PROFIBUS DP

● Technology module (TM)

Drives with analog setpoint interfaces are connected using an analog output (AQ) and an

optional enable signal. Analog inputs and outputs are made available by means of

corresponding IO modules.

A drive is also called an actuator, and an encoder is also called a sensor.

The figure below shows an example configuration in which all components are connected to

the CPU by means of PROFINET IO:

S7-1500 Motion Control V13 Update 3

Function Manual, 07/2014, A5E03879256-AC

19

3

3.1

Functions

Function

Speed axis

Positioning axis

Synchronous axis

External encoder

Motion Control instructions (user program)

Enable, disable technology objects

home position

Moving axes in jog mode

Moving axes with the specified speed

Position axis relatively

Position axis absolutely

Start gearing

technology objects

TIA Portal

TIA Portal

("Kv" factor)

You can perform the Motion Control function by means of Motion Control instructions in your

user program or the TIA Portal (under Commissioning).

The following table shows the functions that are supported by technology objects:

"MC_Power (Page 234)"

"MC_Home (Page 239)"

Homing technology objects, setting

"MC_MoveJog (Page 244)"

"MC_MoveVelocity (Page 249)"

"MC_MoveRelative (Page 255)"

"MC_MoveAbsolute (Page 260)"

"MC_MoveSuperimposed

(Page 265)"

Superimposed positioning of axes

"MC_GearIn (Page 270)"

"MC_Halt (Page 275)"

Stop axis

"MC_Reset (Page 279)"

Acknowledging alarms, restarting

X X X X

- X X X

X X X -

X X X -

- X X -

- X X -

- X X -

- - X -

X X X -

X X X X

"Axis control panel (Page 202)"

Moving and homing axes using the

"Optimization (Page 207)"

Optimization of position control

S7-1500 Motion Control V13 Update 3

20 Function Manual, 07/2014, A5E03879256-AC

X X X -

- X X -

Basics

3.2

Scale

3.3

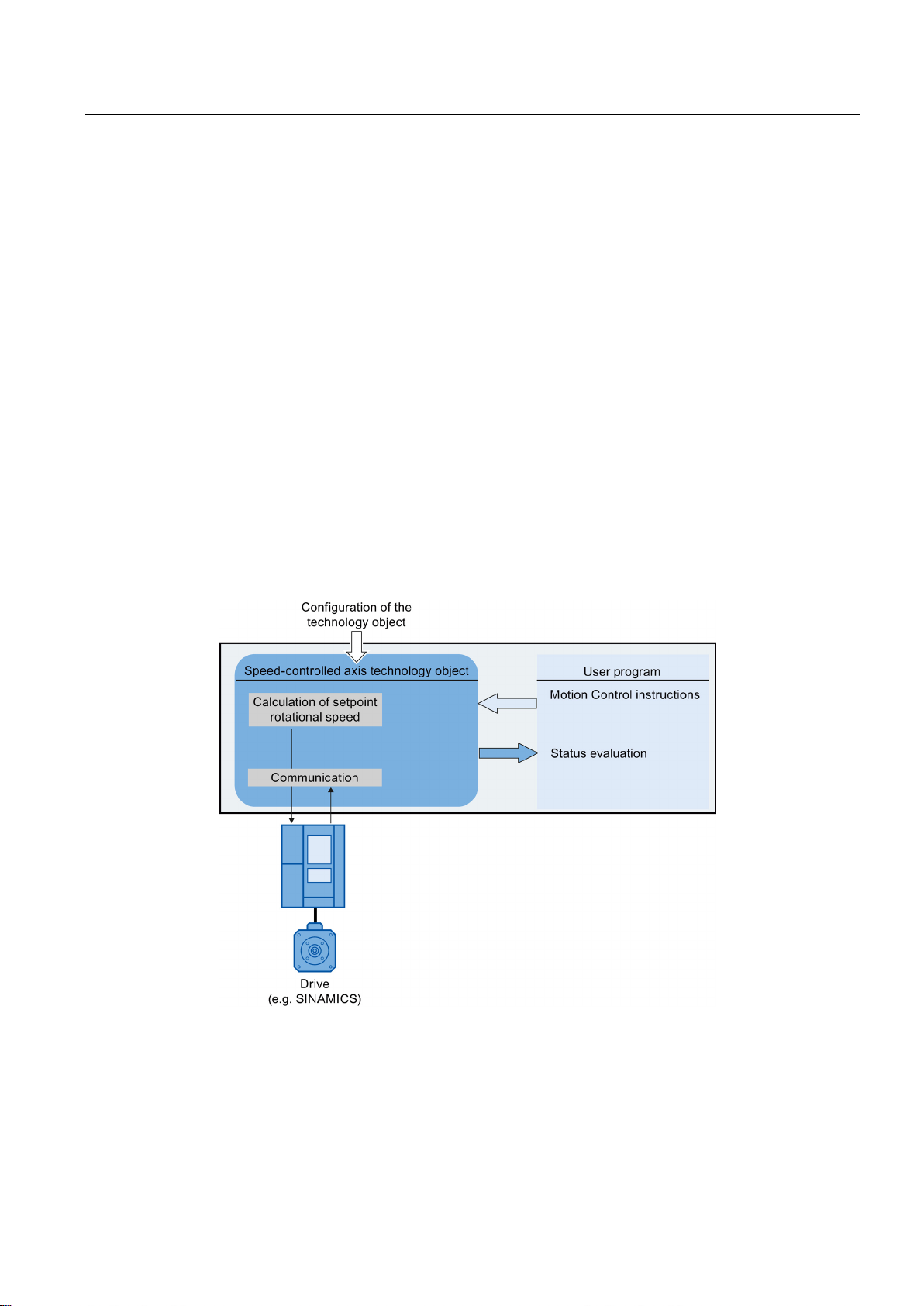

Speed-controlled axis technology object

3.2 Scale

For information on the number of technology objects that may be used, refer to the technical

specifications of the utilized CPU.

A synchronous axis requires twice as many resources as a speed-controlled axis or

positioning axis. You can configure two fewer speed or positioning axes for every

synchronous axis you use.

The speed axis technology object calculates speed setpoints, taking account of the specified

dynamics, and outputs them to the drive. All movements of the speed axis occur under

speed control. The system takes account of an existing load gear.

A drive is assigned to each speed axis by means of a PROFIdrive frame, or by means of an

analog setpoint interface.

The speed is specified in revolutions per unit of time.

The following figure shows the basic principle of operation of the speed axis technology

object:

S7-1500 Motion Control V13 Update 3

Function Manual, 07/2014, A5E03879256-AC

21

Basics

3.4

Positioning axis technology object

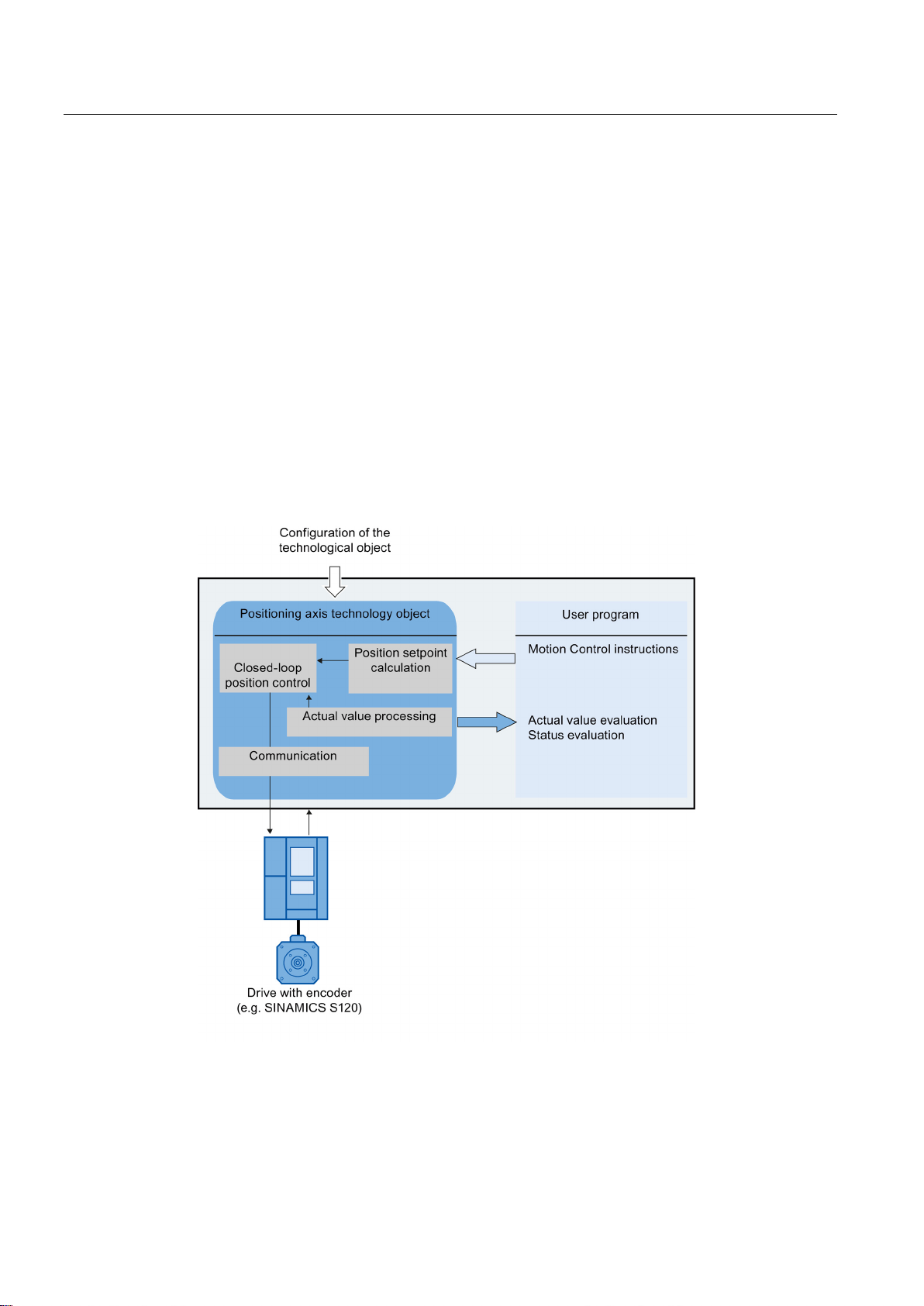

3.4 Positioning axis technology object

The positioning axis technology object calculates position setpoints, taking account of the

specified dynamics, and outputs corresponding speed control setpoints to the drive. All

movements of the positioning axis occur under position control. For absolute positioning, the

physical position must be known to the positioning axis technology object.

Each positioning axis is assigned a drive by means of a PROFIdrive frame or by means of

an analog setpoint interface, and an encoder by means of a PROFIdrive frame.

The relationship between the encoder values and a defined position is created by assigning

parameters to the mechanical properties and the encoder settings, as well as to a homing

process. The technology object can also perform movements without a position relationship,

and relative position movements, even without being in a homed status.

Depending on the execution of the mechanics, a positioning axis is implemented as linear

axis or rotary axis (Page 26).

The figure below shows the basic principle of operation of the positioning axis technology

object:

S7-1500 Motion Control V13 Update 3

22 Function Manual, 07/2014, A5E03879256-AC

Basics

3.5

Synchronous axis technology object

Relative position relationship

Synchronization

Travel synchronous

3.5 Synchronous axis technology object

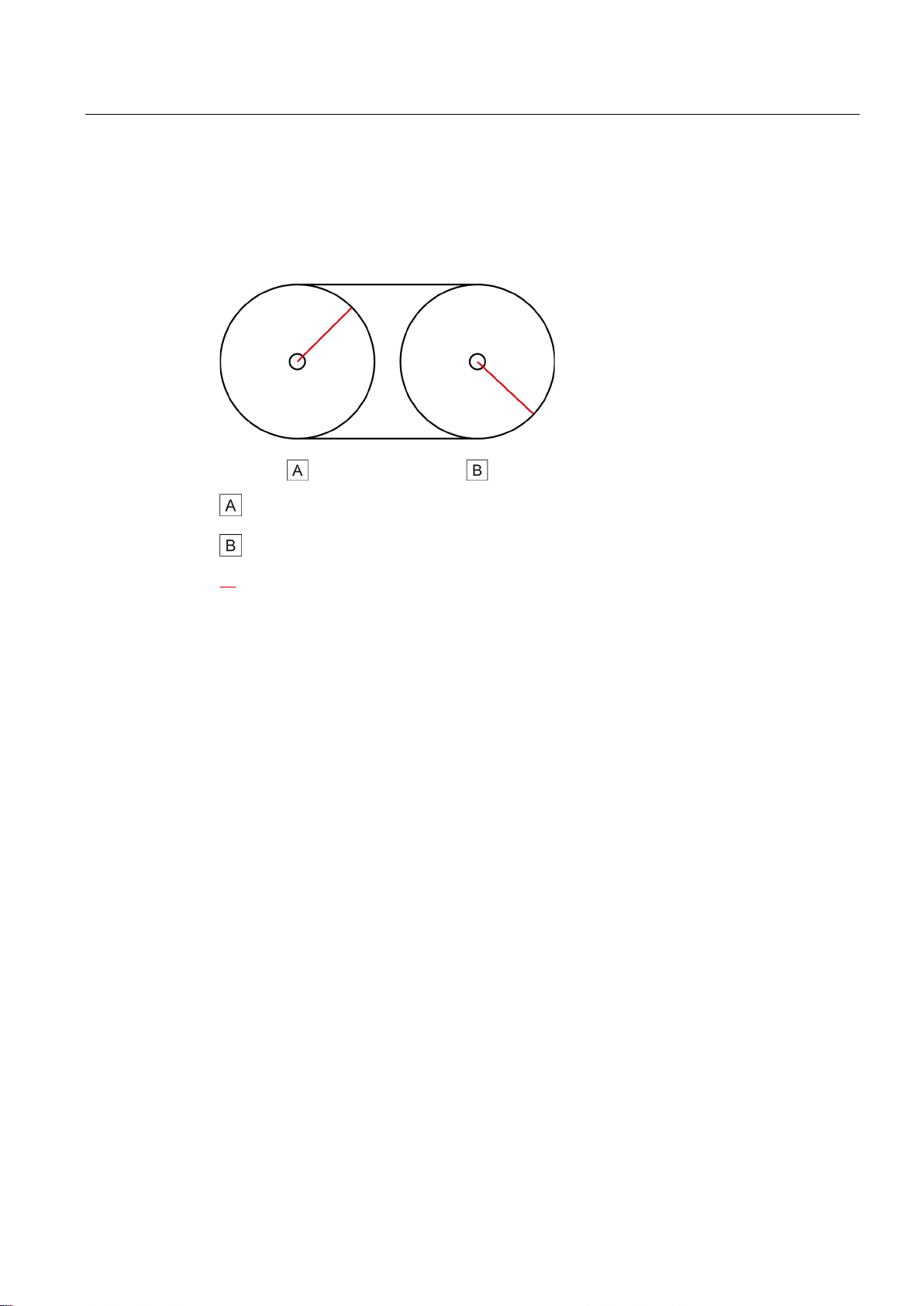

The synchronous axis technology object follows the position change of a leading axis in

relative synchronous operation. A relative gearing exists, for example, when two

mechanically coupled rollers are driven by the same motor:

Leading axis (driven axis)

Following axis

The change of the leading axis position setpoint is multiplied by a specified gear ratio and

passed on to the following axis as setpoint. The synchronous axis technology object outputs

this setpoint as speed setpoint to the drive limited to the maximum speed of the drive

(<TO>.Actor.DriveParameter.MaxSpeed).

The synchronous axis technology object includes all functions of the positioning axis

technology object. All movements of the synchronous axis occur under position control.

If the synchronous axis is operated without synchronous operation, the dynamic limits

configured at the technology object apply.

If the synchronous axis is operated as following axis in synchronous operation, the following

dynamic limits apply depending on the status of the synchronous operation.

●

During synchronization, dynamic limits configured at the technology object apply to the

lead axis and the following axis respectively.

●

If the synchronous axis is operated as following axis, the dynamic limits of the leading

axis are multiplied by the gear ratio apply. The configured dynamic limits of the following

axis are ignored. The dynamic of the following axis is limited to the maximum speed of

the drive.

The following hardware components are assigned to each synchronous axis:

● A drive by means of a PROFIdrive frame or by means of an analog setpoint interface

("MC_GearIn.InGear" = TRUE)

S7-1500 Motion Control V13 Update 3

Function Manual, 07/2014, A5E03879256-AC

● An encoder by means of a PROFIdrive frame

Depending on the execution of the mechanics, a synchronous axis is implemented as linear

axis or rotary axis (Page 26).

23

Basics

3.5 Synchronous axis technology object

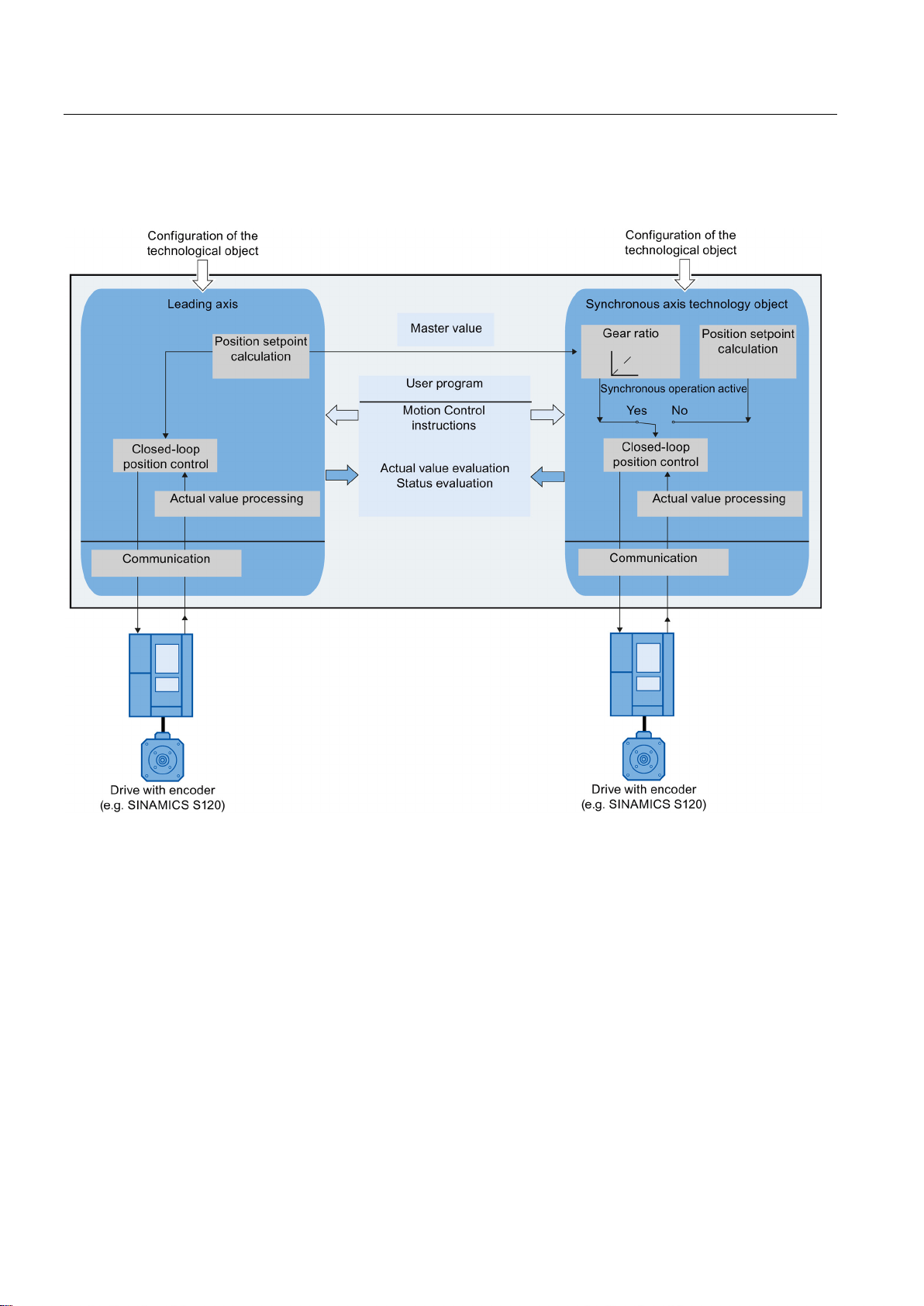

The figure below shows the basic principle of operation of the synchronous axis technology

object:

S7-1500 Motion Control V13 Update 3

24 Function Manual, 07/2014, A5E03879256-AC

Basics

3.6

External encoder technology object

Linear system of units

Rotary system of units

Note

The positioning axis/synchronous axis technology objects and external encoder are

independent of each other, and cannot be coupled to each other. The actual position of an

external encoder cannot be used for position control of a

axis.

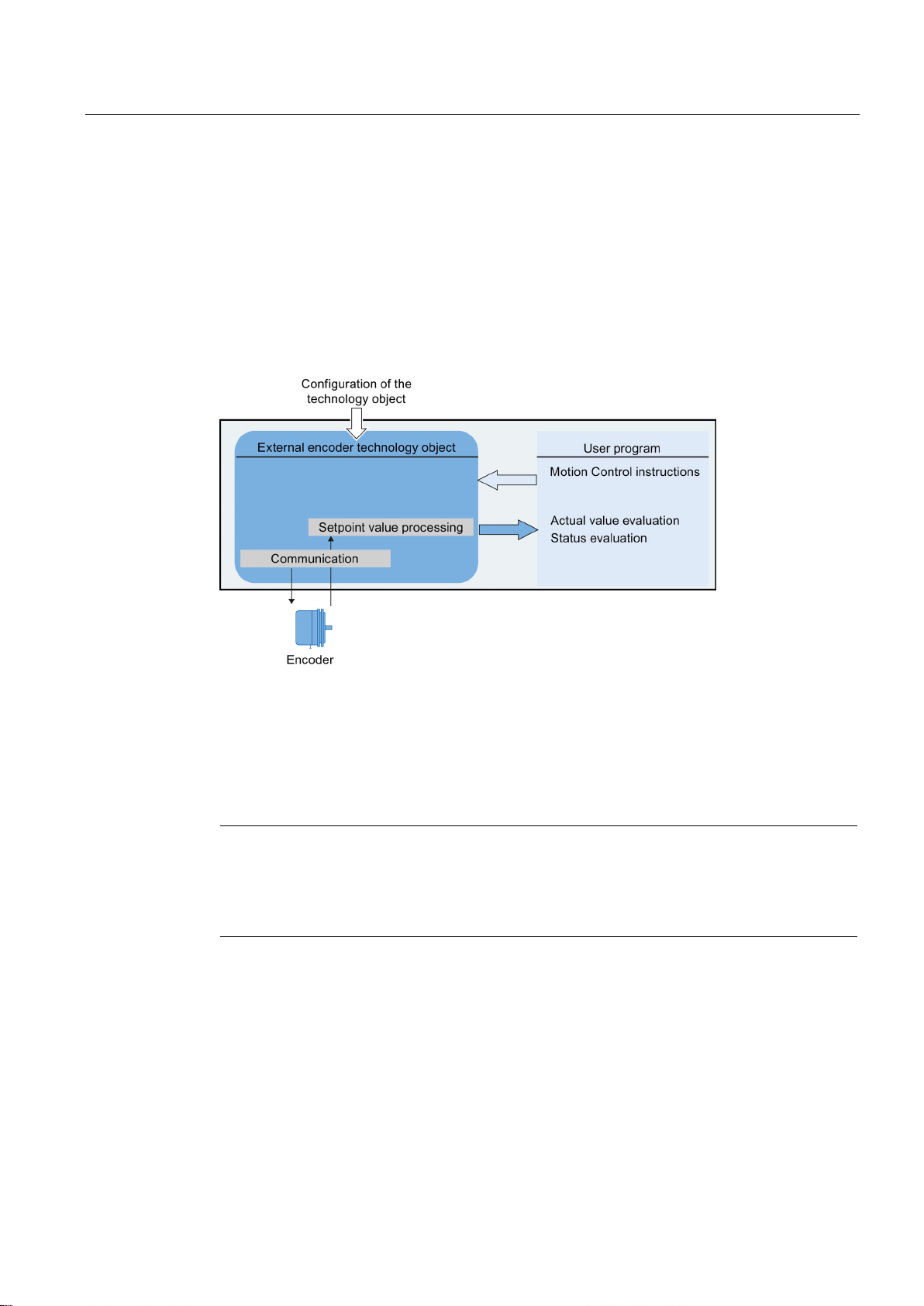

3.6 External encoder technology object

The external encoder technology object detects a position, and makes it available to the

controller.

The relationship between the encoder values and a defined position is created by assigning

parameters to the mechanical properties and the encoder settings, as well as to a homing

process.

The following figure shows the basic principle of operation of the external encoder

technology object:

Specification of the position occurs according to the selected system of units:

●

The position is specified as a linear measure, e.g. millimeters (mm).

●

The position is specified as an angular measure, e.g. degrees (°).

positioning axis or synchronous

S7-1500 Motion Control V13 Update 3

Function Manual, 07/2014, A5E03879256-AC

25

Basics

3.7

Axis types

Linear axis

Rotary axis

3.8

Modulo setting

3.7 Axis types

Axes can be configured with different axis types:

● Positioning and synchronous axes can be configured as rotary or linear axis.

● Speed axes are always rotary axes.

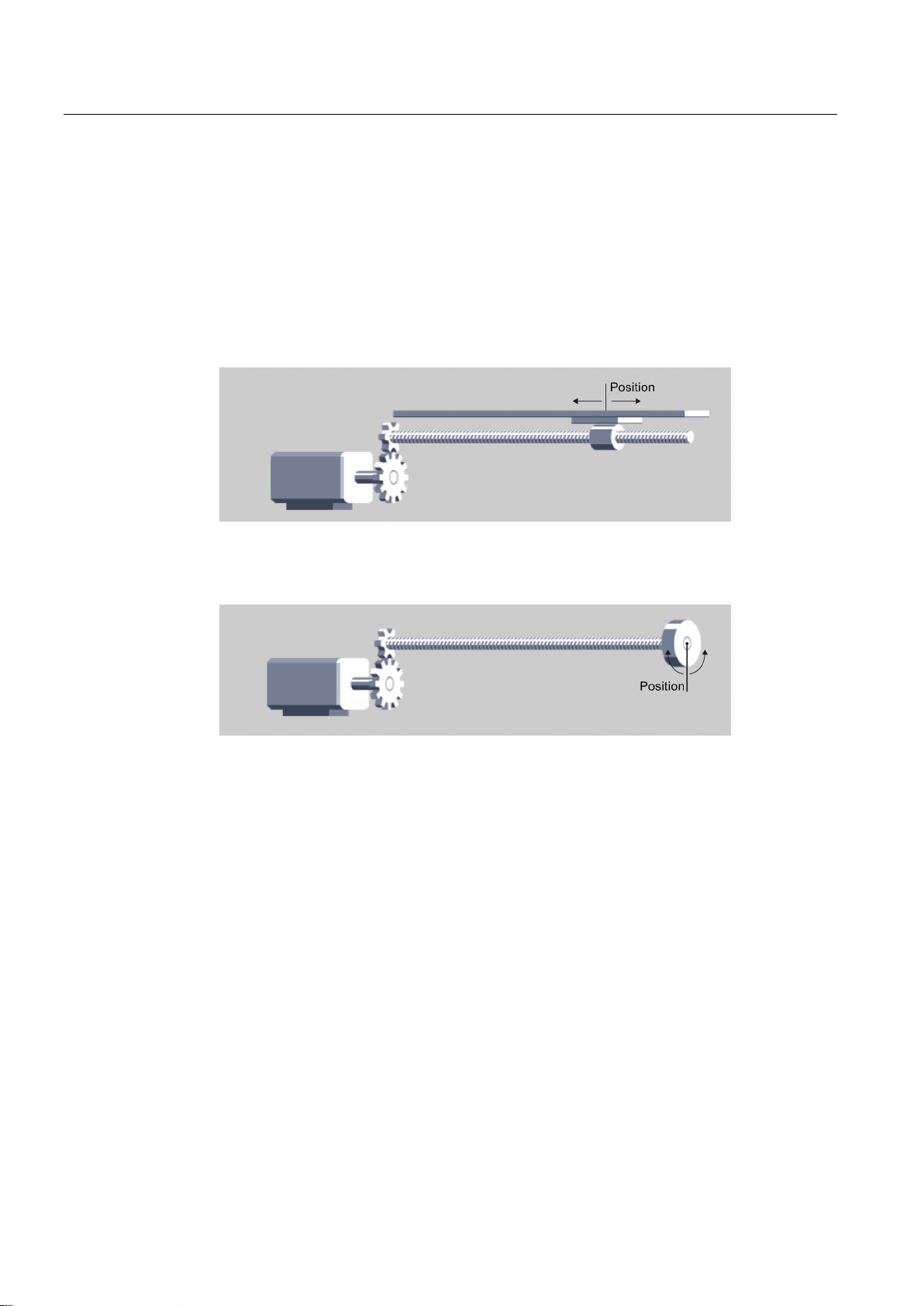

Depending on the execution of the mechanics, an axis is implemented as a linear axis or

rotary axis:

●

For linear axes, the position of the axis is specified as a linear measure,

e.g. millimeters (mm).

●

For rotary axes, the position of the axis is specified as an angular measure,

e.g. degrees (°).

The positioning axis, synchronous axis and external encoder technology objects can be

enabled with the "Modulo" setting.

If an axis is moved in only one direction, the position value continually increases. To limit the

position value to a recurring reference system, you can enable the "Modulo" setting.

When "modulo" is enabled, the position value of the technology object is represented by

means of a recurring modulo range. The modulo range is defined by the start value and the

length.

For example, to limit the position value of a rotary axis to a full rotation, the modulo range

can be defined with start value = 0° and length = 360°. With an encoder resolution of

0.1°/encoder step, the position value is represented in the modulo range 0° to 359.9°.

S7-1500 Motion Control V13 Update 3

26 Function Manual, 07/2014, A5E03879256-AC

Basics

3.9

Units of measure

Position

Velocity

nm, μm, mm, m, km

mm/s, mm/min, mm/h, m/s, m/min, m/h, km/min, km/h

in, ft, mi

in/s, in/min, ft/s, ft/min, mi/h

°, rad

°/s, °/min, rad/s, rad/min

Note

When setting or changing the units of measurement, note the effect on the depiction and the

user program:

•

•

•

•

All information and displays are output in the selected unit of measure.

3.9 Units of measure

The table below shows the supported units of measure for position and velocity:

The acceleration is configured accordingly as unit of measure of the position/s².

The jerk is configured accordingly as unit of measure of the position/s³.

The speed is configured as revolutions per unit of time: 1/s, 1/min, 1/h

Depiction in the technology data block

Supply to the parameters in the user program

Input and display of the position and speed in the TIA Portal

Setpoint settings by leading axes in synchronous operation

S7-1500 Motion Control V13 Update 3

Function Manual, 07/2014, A5E03879256-AC

27

Basics

3.10

Drive and encoder connection

3.10.1

Brief description

PROFIdrive

3.10 Drive and encoder connection

A speed axis is assigned a drive.

A positioning axis/synchronous axis is assigned a drive and an encoder.

An external encoder is assigned an encoder.

The setpoint value at the drive is specified either with PROFIdrive message frames, or with

an analog output.

The following connection options are available for an encoder:

● Encoder to drive

● Encoder on technology module

● PROFIdrive encoder directly to PROFIBUS DP / PROFINET IO

The encoder value is transmitted exclusively via PROFIdrive message frames.

PROFIdrive is the standardized standard profile for drive technology in the connection of

drives and encoders via PROFIBUS DP and PROFINET IO.

Drives that support the PROFIdrive profile are connected according to the PROFIdrive

standard.

Communication between controller and drive/encoder is by means of various PROFIdrive

message frames. Each of the message frames has a standardized structure. Depending on

the application, you can select the applicable message frame. Control words and status

words as well as setpoints and actual values are transmitted in the PROFIdrive message

frames.

The PROFIdrive profile likewise supports the "Dynamic Servo Control" (DSC) control

concept. DSC uses rapid position control in the drive. This can be used to solve highly

dynamic positioning jobs.

S7-1500 Motion Control V13 Update 3

28 Function Manual, 07/2014, A5E03879256-AC

Basics

3.10.2

Frames

3.10 Drive and encoder connection

The transmission of the encoder value occurs either in a frame together with the setpoint

(frame 3 or frame 5), or in a separate encoder frame (frame 81 or frame 83).

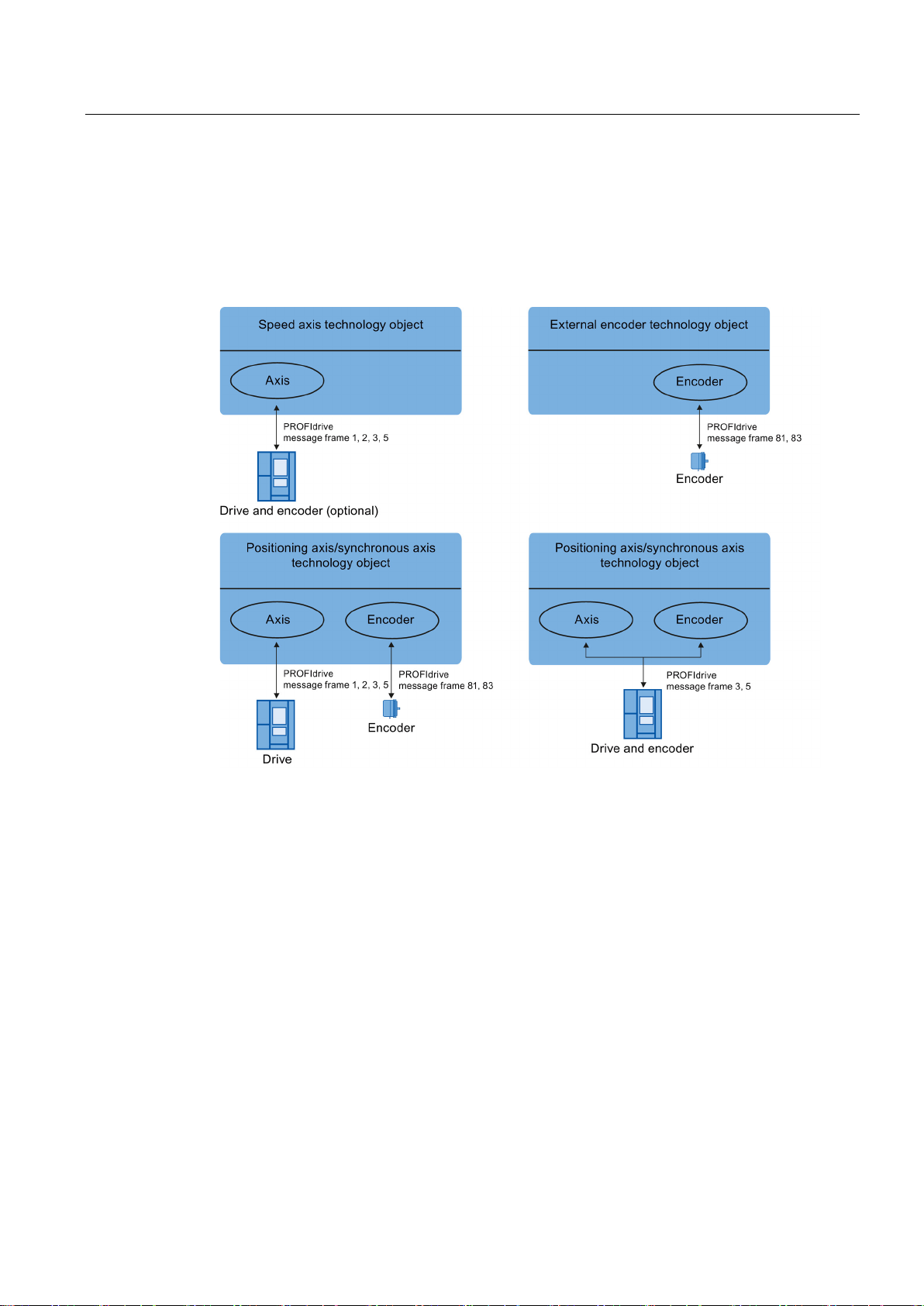

The following figure represents the relationship between the technology objects and the

drives / encoders:

Explanation of the figure:

● The setpoint of a speed axis is transmitted to a drive via PROFIdrive frame 1, 2, 3 or 5.

● The encoder value of an external encoder is transmitted via PROFIdrive frame 81 or 83.

● The setpoint of a positioning axis/synchronous axis is transmitted to a drive via

PROFIdrive frame 1, 2, 3 or 5

● Encoder value of the positioning axis/synchronous axis

The encoder value can be transmitted in the following PROFIdrive frames:

– Transmission in the same PROFIdrive frame, in which the setpoint is also transmitted.

For example, with PROFIdrive frame 3 or 5

– Transmission in PROFIdrive frame 81 or 83.

S7-1500 Motion Control V13 Update 3

Function Manual, 07/2014, A5E03879256-AC

29

Basics

Frame types

Frame

Brief description

Standard frames

Standard frames encoder

3.10 Drive and encoder connection

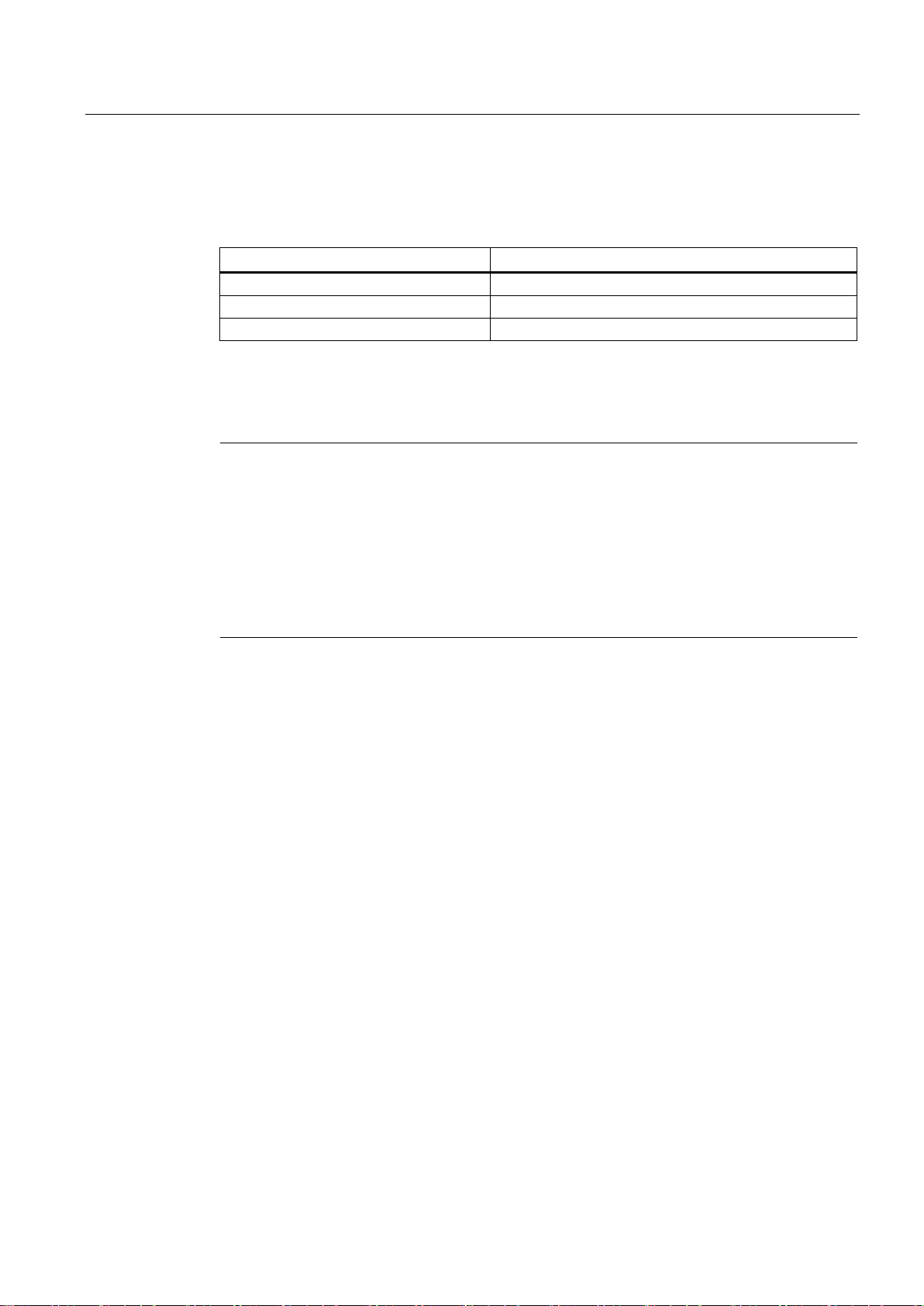

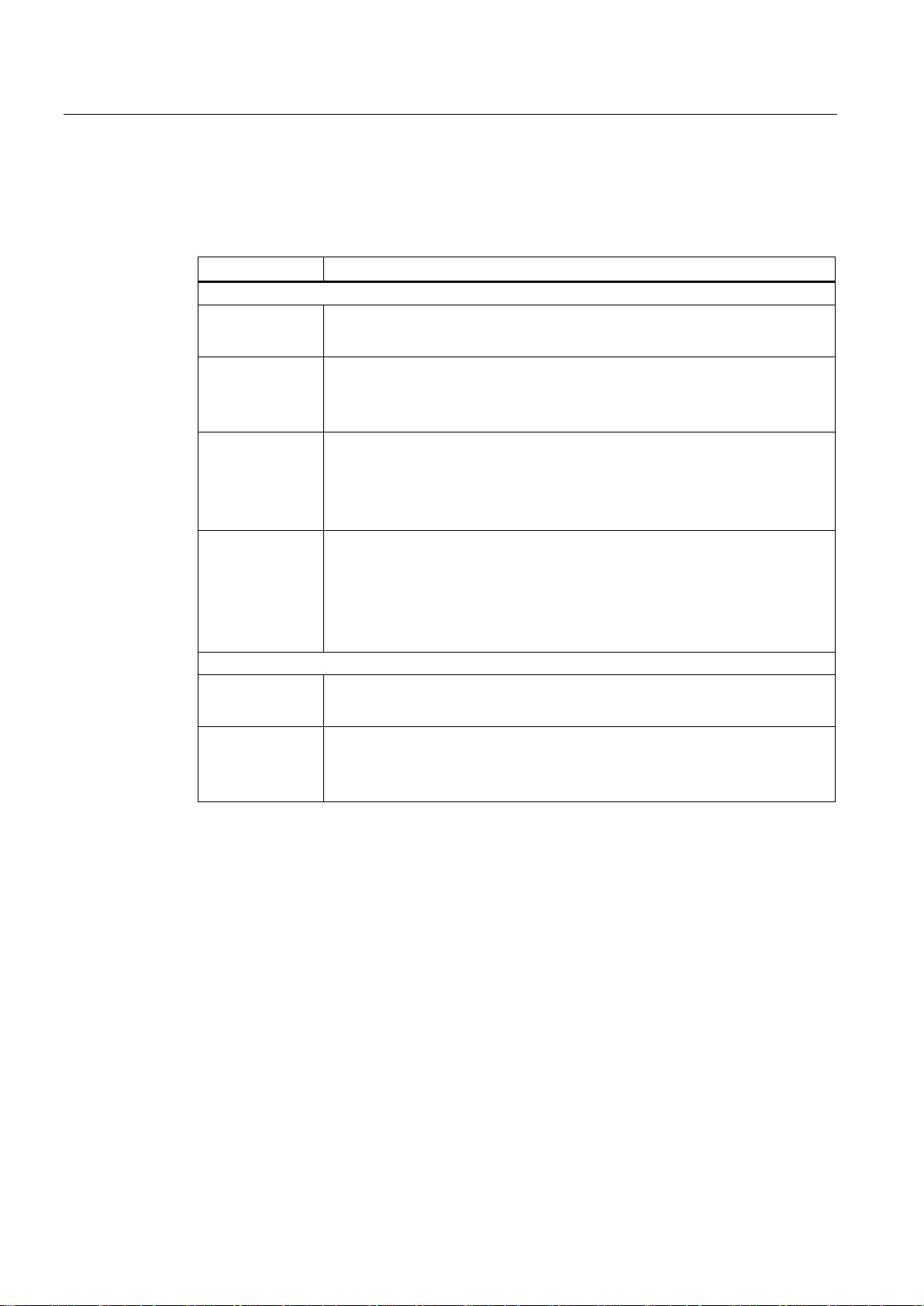

The following table shows the supported PROFIdrive frame types for the assignment of

drives and encoders:

1

2

3

5

81

83

• 16 bit speed setpoint (NSET)

• 16 bit actual speed value (NACT),

• 32 bit speed setpoint (NSET)

• 32 bit actual speed (NACT)

• Signs of life

• 32 bit speed setpoint (NSET)

• 32 bit actual speed (NACT)

• Encoder actual value

• Signs of life

• 32 bit speed setpoint (NSET)

• 32 bit actual speed (NACT)

• Dynamic Servo Control (DSC)

• Encoder actual value

• Signs of life

• Encoder actual value

• Signs of life

• 32 bit actual speed (NACT)

• Encoder actual value

• Signs of life

When connecting by means of a PROFIdrive frame, the drives and encoders are handled

and switched on in accordance with the PROFIdrive profile.

S7-1500 Motion Control V13 Update 3

30 Function Manual, 07/2014, A5E03879256-AC

Loading...

Loading...