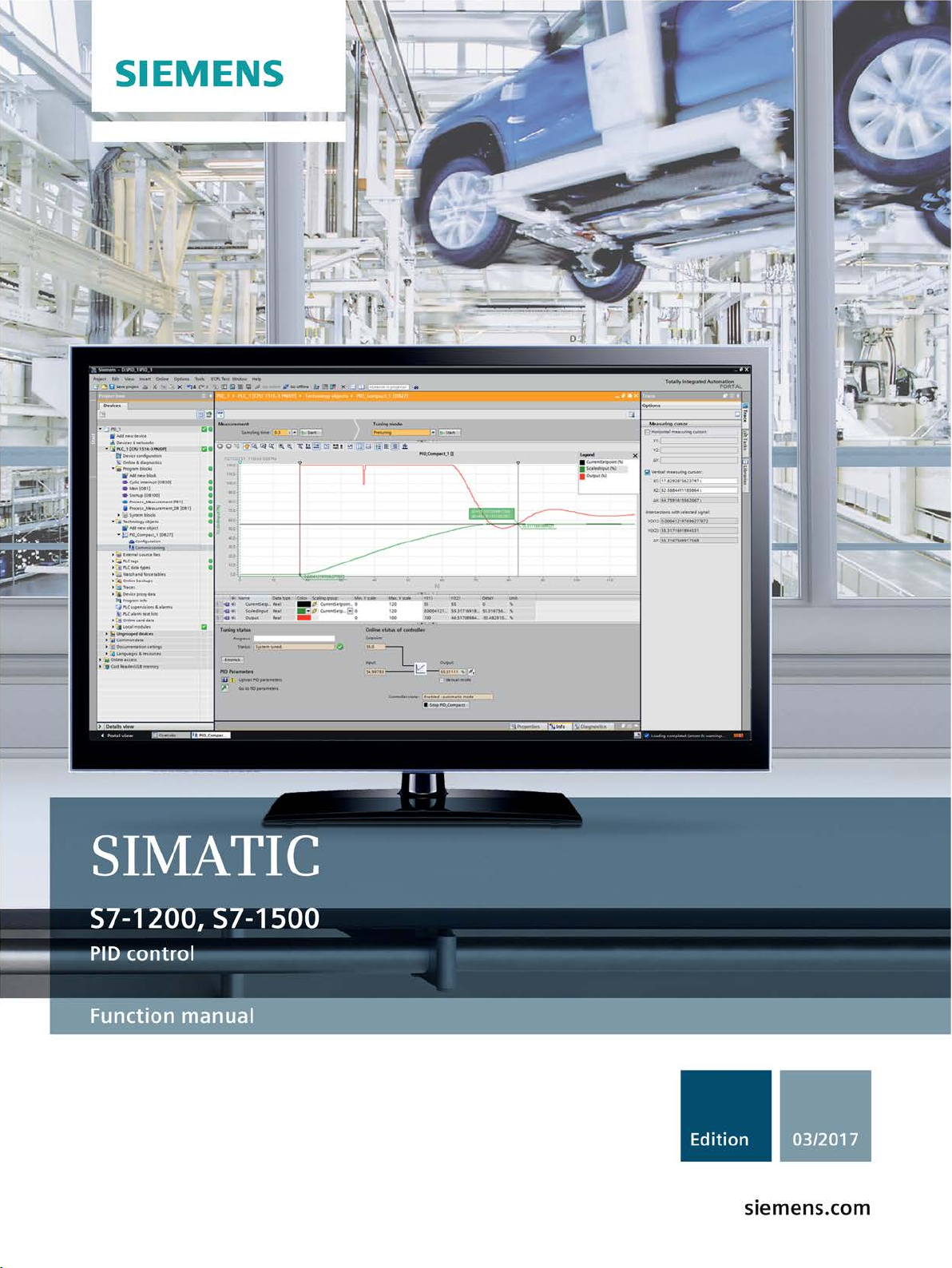

Siemens SIMATIC S7-1200, SIMATIC S7-1500 Function Manual

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

SIMATIC

S7-1200, S7-1500 PID control

Function Manual

03/2017

A5E35300227

Preface

Documentation guide

1

Principles for control

2

Configuring a software

controller

3

Using PID_Compact

4

Using PID_3Step

5

Using PID_Temp

6

Using PID basic functions

7

Auxiliary functions

8

Instructions

9

Service & Support

A

-AC

Siemens AG

Division Digital Factory

Postfach 48 48

90026 NÜRNBERG

GERMANY

A5E35300227-AC

Ⓟ

Copyright © Siemens AG 2017.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

for the specific

03/2017 Subject to change

Preface

Purpose of the documentation

Basic knowledge required

Validity of the documentation

Conventions

Note

The notes contain important information on the product described in the d

the handling of the product or on part of the documentation to which particular attention

should be paid.

Additional assistance

This documentation will support you in configuring and programming control tasks with the

S7-1200 and S7-1500 automation systems.

The following knowledge is required in order to understand the documentation:

● General knowledge of automation technology

● Knowledge of the industrial automation system SIMATIC

● Experience of working with STEP 7 (TIA Portal)

This documentation applies to the use of SW controllers on the CPUs of automation systems

S7-1200 and S7-1500 together with STEP 7 (TIA Portal). Additional SW controllers that are

not covered in this documentation are available for the use of S7-300 and S7-400 with

STEP 7 (TIA Portal). Section Overview of software controller (Page 38) gives a complete

overview of all SW controllers in STEP 7 (TIA Portal) and their possible applications.

Please observe notes marked as follows:

● Information on the offers of our Technical Support are available in the appendix Service &

Support (Page 523).

● The range of technical documentation for the individual SIMATIC products and

automation systems is available on the Internet

(http://www.siemens.com/simatic-tech-doku-portal).

ocumentation, on

● The online catalog and the ordering system are available on the Internet

(http://mall.automation.siemens.com).

PID control

4 Function Manual, 03/2017, A5E35300227-AC

Table of contents

Preface ................................................................................................................................................... 4

1 Documentation guide ............................................................................................................................ 12

2 Principles for control.............................................................................................................................. 16

3 Configuring a software controller ........................................................................................................... 38

2.1 Controlled system and actuators ............................................................................................ 16

2.2 Controlled systems ................................................................................................................. 18

2.3 Characteristic values of the control section ............................................................................ 20

2.4 Pulse controller ....................................................................................................................... 23

2.5 Response to setpoint changes and disturbances ................................................................... 27

2.6 Control Response at Different Feedback Structures .............................................................. 28

2.7 Selection of the controller structure for specified controlled systems ..................................... 36

2.8 PID parameter settings ........................................................................................................... 37

3.1 Overview of software controller .............................................................................................. 38

3.2 Steps for the configuration of a software controller ................................................................ 40

3.3 Add technology objects ........................................................................................................... 40

3.4 Configure technology objects ................................................................................................. 42

3.5 Call instruction in the user program ........................................................................................ 43

3.6 Downloading technology objects to device ............................................................................. 44

3.7 Commissioning software controller ......................................................................................... 45

3.8 Save optimized PID parameter in the project ......................................................................... 45

3.9 Comparing values ................................................................................................................... 46

3.9.1 Comparison display and boundary conditions ........................................................................ 46

3.9.2 Comparing values ................................................................................................................... 47

3.10 Parameter view ....................................................................................................................... 49

3.10.1 Introduction to the parameter view ......................................................................................... 49

3.10.2 Structure of the parameter view .............................................................................................. 51

3.10.2.1 Toolbar .................................................................................................................................... 51

3.10.2.2 Navigation ............................................................................................................................... 52

3.10.2.3 Parameter table ...................................................................................................................... 52

3.10.3 Opening the parameter view ................................................................................................... 54

3.10.4 Default setting of the parameter view ..................................................................................... 55

3.10.5 Working with the parameter view ............................................................................................ 57

3.10.5.1 Overview ................................................................................................................................. 57

3.10.5.2 Filtering the parameter table ................................................................................................... 58

3.10.5.3 Sorting the parameter table .................................................................................................... 59

3.10.5.4 Transferring parameter data to other editors .......................................................................... 59

PID control

Function Manual, 03/2017, A5E35300227-AC

5

Table of contents

4 Using PID_Compact .............................................................................................................................. 72

5 Using PID_3Step ................................................................................................................................. 115

3.10.5.5 Indicating errors ..................................................................................................................... 60

3.10.5.6 Editing start values in the project ........................................................................................... 60

3.10.5.7 Status of configuration (offline) .............................................................................................. 62

3.10.5.8 Monitoring values online in the parameter view ..................................................................... 63

3.10.5.9 Change display format of value ............................................................................................. 64

3.10.5.10 Create snapshot of monitor values ........................................................................................ 65

3.10.5.11 Modifying values .................................................................................................................... 65

3.10.5.12 Comparing values .................................................................................................................. 67

3.10.5.13 Applying values from the online program as start values ...................................................... 68

3.10.5.14 Initializing setpoints in the online program ............................................................................. 70

3.11 Display instance DB of a technology object. .......................................................................... 71

4.1 Technology object PID_Compact........................................................................................... 72

4.2 PID_Compact V2.................................................................................................................... 73

4.2.1 Configuring PID_Compact V2 ................................................................................................ 73

4.2.1.1 Basic settings V2.................................................................................................................... 73

4.2.1.2 Process value settings V2 ...................................................................................................... 77

4.2.1.3 Advanced settings V2 ............................................................................................................ 78

4.2.2 Commissioning PID_Compact V2 .......................................................................................... 86

4.2.2.1 Pretuning V2 .......................................................................................................................... 86

4.2.2.2 Fine tuning V2 ........................................................................................................................ 88

4.2.2.3 "Manual" mode V1 ................................................................................................................. 90

4.2.3 Override control with PID_Compact V2 ................................................................................. 91

4.2.4 Simulating PID_Compact V2 with PLCSIM ............................................................................ 95

4.3 PID_Compact V1.................................................................................................................... 96

4.3.1 Configuring PID_Compact V1 ................................................................................................ 96

4.3.1.1 Basic settings V1.................................................................................................................... 96

4.3.1.2 Process value settings V1 .................................................................................................... 100

4.3.1.3 Advanced settings V1 .......................................................................................................... 101

4.3.2 Commissioning PID_Compact V1 ........................................................................................ 108

4.3.2.1 Commissioning V1 ............................................................................................................... 108

4.3.2.2 Pretuning V1 ........................................................................................................................ 109

4.3.2.3 Fine tuning V1 ...................................................................................................................... 111

4.3.2.4 "Manual" mode V1 ............................................................................................................... 113

4.3.3 Simulating PID_Compact V1 with PLCSIM .......................................................................... 114

5.1 Technology object PID_3Step .............................................................................................. 115

5.2 PID_3Step V2 ....................................................................................................................... 116

5.2.1 Configuring PID_3Step V2 ................................................................................................... 116

5.2.1.1 Basic settings V2.................................................................................................................. 116

5.2.1.2 Process value settings V2 .................................................................................................... 121

5.2.1.3 Final controlling element settings V2 ................................................................................... 122

5.2.1.4 Advanced settings V2 .......................................................................................................... 125

5.2.2 Commissioning PID_3Step V2 ............................................................................................. 129

5.2.2.1 Pretuning V2 ........................................................................................................................ 129

5.2.2.2 Fine tuning V2 ...................................................................................................................... 131

5.2.2.3 Commissioning with manual PID parameters V2 ................................................................ 133

5.2.2.4 Measuring the motor transition time V2 ............................................................................... 134

PID control

6 Function Manual, 03/2017, A5E35300227-AC

Table of contents

6 Using PID_Temp ................................................................................................................................. 157

5.2.3 Simulating PID_3Step V2 with PLCSIM ................................................................................ 137

5.3 PID_3Step V1 ....................................................................................................................... 138

5.3.1 Configuring PID_3Step V1 .................................................................................................... 138

5.3.1.1 Basic settings V1 .................................................................................................................. 138

5.3.1.2 Process value settings V1 .................................................................................................... 143

5.3.1.3 V1 final controlling element setting ....................................................................................... 144

5.3.1.4 Advanced settings V1 ........................................................................................................... 147

5.3.2 Commissioning PID_3Step V1 .............................................................................................. 150

5.3.2.1 Commissioning V1 ................................................................................................................ 150

5.3.2.2 Pretuning V1 ......................................................................................................................... 151

5.3.2.3 Fine tuning V1 ....................................................................................................................... 152

5.3.2.4 Commissioning with manual PID parameters V1 ................................................................. 153

5.3.2.5 Measuring the motor transition time V1 ................................................................................ 154

5.3.3 Simulating PID_3Step V1 with PLCSIM ................................................................................ 156

6.1 Technology object PID_Temp ............................................................................................... 157

6.2 Configuring PID_Temp.......................................................................................................... 158

6.2.1 Basic settings ........................................................................................................................ 158

6.2.1.1 Introduction ........................................................................................................................... 158

6.2.1.2 Controller type ....................................................................................................................... 159

6.2.1.3 Setpoint ................................................................................................................................. 159

6.2.1.4 Process value ....................................................................................................................... 160

6.2.1.5 Heating and cooling output value ......................................................................................... 160

6.2.1.6 Cascade ................................................................................................................................ 162

6.2.2 Process value settings .......................................................................................................... 163

6.2.2.1 Process value limits .............................................................................................................. 163

6.2.2.2 Process value scaling ........................................................................................................... 163

6.2.3 Output settings ...................................................................................................................... 164

6.2.3.1 Basic settings of output ......................................................................................................... 164

6.2.3.2 Output value limits and scaling ............................................................................................. 167

6.2.4 Advanced settings ................................................................................................................. 170

6.2.4.1 Process value monitoring ..................................................................................................... 170

6.2.4.2 PWM limits ............................................................................................................................ 171

6.2.4.3 PID parameters ..................................................................................................................... 174

6.3 Commissioning PID_Temp ................................................................................................... 181

6.3.1 Commissioning ..................................................................................................................... 181

6.3.2 Pretuning ............................................................................................................................... 182

6.3.3 Fine tuning ............................................................................................................................ 185

6.3.4 "Manual" mode ...................................................................................................................... 189

6.3.5 Substitute setpoint ................................................................................................................ 190

6.3.6 Cascade commissioning ....................................................................................................... 190

6.4 Cascade control with PID_Temp .......................................................................................... 191

6.4.1 Introduction ........................................................................................................................... 191

6.4.2 Program creation .................................................................................................................. 193

6.4.3 Configuration ......................................................................................................................... 195

6.4.4 Commissioning ..................................................................................................................... 197

6.4.5 Substitute setpoint ................................................................................................................ 198

6.4.6 Operating modes and fault response .................................................................................... 198

PID control

Function Manual, 03/2017, A5E35300227-AC

7

Table of contents

7 Using PID basic functions .................................................................................................................... 207

6.5 Multi-zone controlling with PID_Temp ................................................................................. 199

6.6 Override control with PID_Temp .......................................................................................... 202

6.7 Simulating PID_Temp with PLCSIM .................................................................................... 206

7.1 CONT_C ............................................................................................................................... 207

7.1.1 Technology object CONT_C ................................................................................................ 207

7.1.2 Configure controller difference CONT_C ............................................................................. 208

7.1.3 Configure the controller algorithm CONT_C ........................................................................ 209

7.1.4 Configure the output value CONT_C ................................................................................... 210

7.1.5 Programming a pulse controller ........................................................................................... 211

7.1.6 Commissioning CONT_C ..................................................................................................... 212

7.2 CONT_S ............................................................................................................................... 213

7.2.1 Technology object CONT_S ................................................................................................ 213

7.2.2 Configure controller difference CONT_S ............................................................................. 214

7.2.3 Configuring control algorithm CONT_S ............................................................................... 214

7.2.4 Configure manipulated value CONT_S ................................................................................ 215

7.2.5 Commissioning CONT_S ..................................................................................................... 215

7.3 TCONT_CP .......................................................................................................................... 216

7.3.1 Technology object TCONT_CP ............................................................................................ 216

7.3.2 Configure TCONT_CP ......................................................................................................... 217

7.3.2.1 Controller difference ............................................................................................................. 217

7.3.2.2 Controlling algorithm ............................................................................................................ 218

7.3.2.3 Manipulated value continual controller ................................................................................ 219

7.3.2.4 Manipulated value pulse controller ...................................................................................... 220

7.3.3 Commissioning TCONT_CP ................................................................................................ 222

7.3.3.1 Optimization of TCONT_CP ................................................................................................. 222

7.3.3.2 Requirements for an optimization ........................................................................................ 224

7.3.3.3 Possibilities for optimization ................................................................................................. 226

7.3.3.4 Tuning result ........................................................................................................................ 229

7.3.3.5 Parallel tuning of controller channels ................................................................................... 230

7.3.3.6 Fault descriptions and corrective measures ........................................................................ 231

7.3.3.7 Performing pretuning ........................................................................................................... 234

7.3.3.8 Performing fine tuning .......................................................................................................... 234

7.3.3.9 Cancelling pretuning or fine tuning ...................................................................................... 235

7.3.3.10 Manual fine-tuning in control mode ...................................................................................... 235

7.3.3.11 Performing fine tuning manually .......................................................................................... 236

7.4 TCONT_S ............................................................................................................................. 237

7.4.1 Technology object TCONT_S .............................................................................................. 237

7.4.2 Configure controller difference TCONT_S ........................................................................... 237

7.4.3 Configure controller algorithm TCONT_S ............................................................................ 238

7.4.4 Configure manipulated value TCONT_S ............................................................................. 239

7.4.5 Commissioning TCONT_S ................................................................................................... 239

PID control

8 Function Manual, 03/2017, A5E35300227-AC

Table of contents

8 Auxiliary functions ............................................................................................................................... 240

9 Instructions ......................................................................................................................................... 241

8.1 Polyline ................................................................................................................................. 240

9.1 PID_Compact ........................................................................................................................ 241

9.1.1 New features of PID_Compact ............................................................................................. 241

9.1.2 Compatibility with CPU and FW ............................................................................................ 244

9.1.3 CPU processing time and memory requirement PID_Compact V2.x ................................... 245

9.1.4 PID_Compact V2 .................................................................................................................. 246

9.1.4.1 Description of PID_Compact V2 ........................................................................................... 246

9.1.4.2 Mode of operation of PID_Compact V2 ................................................................................ 249

9.1.4.3 Input parameters of PID_Compact V2 .................................................................................. 251

9.1.4.4 Output parameters of PID_Compact V2 ............................................................................... 253

9.1.4.5 In/out parameters of PID_Compact V2 ................................................................................. 254

9.1.4.6 Static tags of PID_Compact V2 ............................................................................................ 255

9.1.4.7 Changing the PID_Compact V2 interface ............................................................................. 263

9.1.4.8 Parameters State and Mode V2 ........................................................................................... 265

9.1.4.9 Parameter ErrorBits V2 ......................................................................................................... 269

9.1.4.10 Tag ActivateRecoverMode V2 .............................................................................................. 271

9.1.4.11 Tag Warning V2 .................................................................................................................... 273

9.1.4.12 IntegralResetMode V2 tag .................................................................................................... 274

9.1.4.13 Sample program for PID_Compact ....................................................................................... 276

9.1.5 PID_Compact V1 .................................................................................................................. 283

9.1.5.1 Description of PID_Compact V1 ........................................................................................... 283

9.1.5.2 Input parameters of PID_Compact V1 .................................................................................. 286

9.1.5.3 Output parameters of PID_Compact V1 ............................................................................... 287

9.1.5.4 Static tags of PID_Compact V1 ............................................................................................ 288

9.1.5.5 Parameters State and sRet.i_Mode V1 ................................................................................ 293

9.1.5.6 Parameter Error V1 ............................................................................................................... 297

9.1.5.7 Parameter Reset V1 ............................................................................................................. 298

9.1.5.8 Tag sd_warning V1 ............................................................................................................... 300

9.1.5.9 Tag i_Event_SUT V1 ............................................................................................................. 300

9.1.5.10 Tag i_Event_TIR V1 .............................................................................................................. 301

9.2 PID_3Step ............................................................................................................................. 302

9.2.1 New features of PID_3Step .................................................................................................. 302

9.2.2 Compatibility with CPU and FW ............................................................................................ 304

9.2.3 CPU processing time and memory requirement PID_3Step V2.x ........................................ 305

9.2.4 PID_3Step V2 ....................................................................................................................... 306

9.2.4.1 Description of PID_3Step V2 ................................................................................................ 306

9.2.4.2 Mode of operation of PID_3Step V2 ..................................................................................... 312

9.2.4.3 Changing the PID_3Step V2 interface .................................................................................. 315

9.2.4.4 Input parameters of PID_3Step V2 ....................................................................................... 316

9.2.4.5 Output parameters of PID_3Step V2

....................................................................................

9.2.4.6 In/out parameters of PID-3Step V2 ....................................................................................... 320

9.2.4.7 Static tags of PID_3Step V2 ................................................................................................. 321

9.2.4.8 Parameters State and Mode V2 ........................................................................................... 330

9.2.4.9 Parameter ErrorBits V2 ......................................................................................................... 335

9.2.4.10 Tag ActivateRecoverMode V2 .............................................................................................. 338

9.2.4.11 Tag Warning V2 .................................................................................................................... 340

PID control

Function Manual, 03/2017, A5E35300227-AC

318

9

Table of contents

9.2.5 PID_3Step V1 ....................................................................................................................... 341

9.2.5.1 Description PID_3Step V1 ................................................................................................... 341

9.2.5.2 Operating principle PID_3Step V1 ....................................................................................... 347

9.2.5.3 PID_3Step V1 input parameters .......................................................................................... 350

9.2.5.4 PID_3Step V1 output parameters ........................................................................................ 352

9.2.5.5 PID_3Step V1 static tags ..................................................................................................... 354

9.2.5.6 Parameter State and Retain.Mode V1 ................................................................................. 361

9.2.5.7 Parameter ErrorBits V1 ........................................................................................................ 369

9.2.5.8 Parameter Reset V1 ............................................................................................................ 371

9.2.5.9 Tag ActivateRecoverMode V1 ............................................................................................. 372

9.2.5.10 Tag Warning V1 ................................................................................................................... 374

9.2.5.11 Tag SUT.State V1 ................................................................................................................ 375

9.2.5.12 Tag TIR.State V1 ................................................................................................................. 375

9.3 PID_Temp ............................................................................................................................ 376

9.3.1 New features of PID_Temp .................................................................................................. 376

9.3.2 Compatibility with CPU and FW ........................................................................................... 376

9.3.3 CPU processing time and memory requirement PID_Temp V1 .......................................... 377

9.3.4 PID_Temp ............................................................................................................................ 378

9.3.4.1 Description of PID_Temp ..................................................................................................... 378

9.3.4.2 Mode of operation of PID_Temp .......................................................................................... 383

9.3.4.3 Input parameters of PID_Temp ............................................................................................ 389

9.3.4.4 Output parameters of PID_Temp ......................................................................................... 391

9.3.4.5 In/out parameters of PID_Temp V2 ..................................................................................... 393

9.3.4.6 PID_Temp static tags ........................................................................................................... 395

9.3.4.7 PID_Temp state and mode parameters ............................................................................... 430

9.3.4.8 PID_Temp ErrorBits parameter ............................................................................................ 439

9.3.4.9 PID_Temp ActivateRecoverMode tag .................................................................................. 442

9.3.4.10 PID_Temp Warning tag ........................................................................................................ 444

9.3.4.11 PwmPeriode tag ................................................................................................................... 445

9.3.4.12 IntegralResetMode tag ......................................................................................................... 447

9.4 PID basic functions .............................................................................................................. 449

9.4.1 CONT_C ............................................................................................................................... 449

9.4.1.1 Description CONT_C ........................................................................................................... 449

9.4.1.2 How CONT_C works ............................................................................................................ 450

9.4.1.3 CONT_C block diagram ....................................................................................................... 452

9.4.1.4 Input parameter CONT_C .................................................................................................... 453

9.4.1.5 Out

put parameters CONT_C ............................................................................................... 454

9.4.2 CONT_S ............................................................................................................................... 455

9.4.2.1 Description CONT_S ............................................................................................................ 455

9.4.2.2 Mode of operation CONT_S ................................................................................................. 456

9.4.2.3 Block diagram CONT_S ....................................................................................................... 457

9.4.2.4 Input parameters CONT_S .................................................................................................. 458

9.4.2.5 Output parameters CONT_S ................................................................................................ 459

9.4.3 PULSEGEN .......................................................................................................................... 460

9.4.3.1 Description PULSEGEN ...................................................................................................... 460

9.4.3.2 Mode of operation PULSEGEN ........................................................................................... 461

9.4.3.3 Mode of operation PULSEGEN ........................................................................................... 464

9.4.3.4 Three-step control ................................................................................................................ 465

9.4.3.5 Two-step control................................................................................................................... 468

9.4.3.6 Input parameters PULSEGEN ............................................................................................. 469

9.4.3.7 Output parameter PULSEGEN ............................................................................................ 470

PID control

10 Function Manual, 03/2017, A5E35300227-AC

Table of contents

A Service & Support ............................................................................................................................... 523

Index................................................................................................................................................... 526

9.4.4 TCONT_CP ........................................................................................................................... 471

9.4.4.1 Description TCONT_CP ........................................................................................................ 471

9.4.4.2 Mode of operation TCONT_CP ............................................................................................. 472

9.4.4.3 Operating principle of the pulse generator ........................................................................... 481

9.4.4.4 Block diagram TCONT_CP ................................................................................................... 484

9.4.4.5 Input parameters TCONT_CP .............................................................................................. 486

9.4.4.6 Output parameters TCONT_CP ............................................................................................ 487

9.4.4.7 In/out parameters TCONT_CP ............................................................................................. 488

9.4.4.8 Static variables TCONT_CP ................................................................................................. 489

9.4.4.9 Parameter STATUS_H.......................................................................................................... 494

9.4.4.10 Parameters STATUS_D ........................................................................................................ 495

9.4.5 TCONT_S ............................................................................................................................. 496

9.4.5.1 Description TCONT_S .......................................................................................................... 496

9.4.5.2 Mode of operation TCONT_S ............................................................................................... 497

9.4.5.3 Block diagram TCONT_S...................................................................................................... 501

9.4.5.4 Input paramters TCONT_S ................................................................................................... 503

9.4.5.5 Output parameters TCONT_S .............................................................................................. 504

9.4.5.6 In/out parameters TCONT_S ................................................................................................ 504

9.4.5.7 Static variables TCONT_S .................................................................................................... 505

9.4.6 Integrated system functions .................................................................................................. 506

9.4.6.1 CONT_C_SF ......................................................................................................................... 506

9.4.6.2 CONT_S_SF ......................................................................................................................... 506

9.4.6.3 PULSEGEN_SF .................................................................................................................... 507

9.5 Polyline ................................................................................................................................. 508

9.5.1 Compatibility with CPU and FW ............................................................................................ 508

9.5.2 Description Polyline .............................................................................................................. 508

9.5.3 Operating principle Polyline .................................................................................................. 512

9.5.4 Input parameters of Polyline ................................................................................................. 516

9.5.5 Output parameters of Polyline .............................................................................................. 516

9.5.6 Static tags of Polyline............................................................................................................ 517

9.5.7 ErrorBits parameter ............................................................................................................... 518

PID control

Function Manual, 03/2017, A5E35300227-AC

11

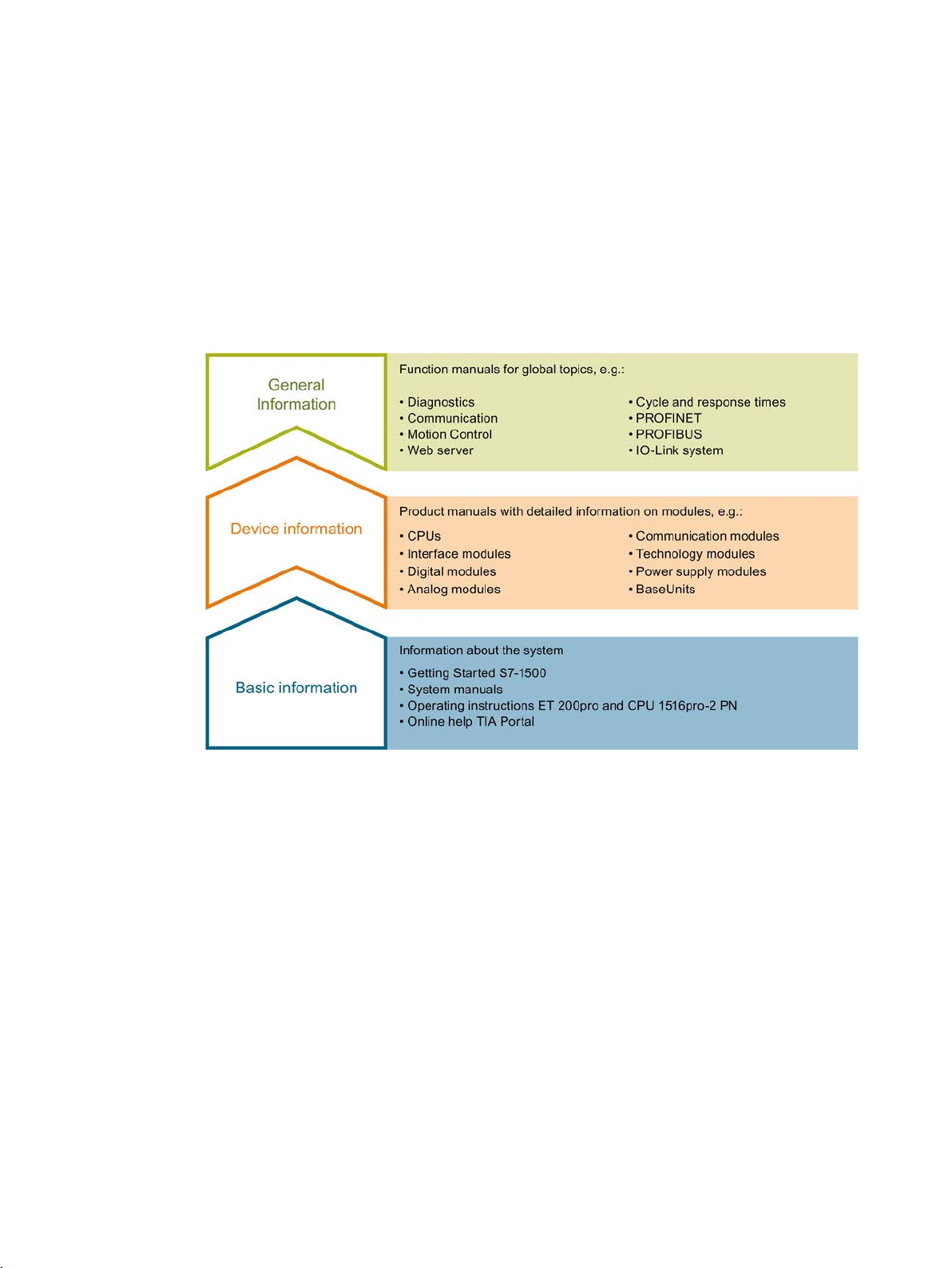

1

Basic information

Device information

The documentation for the SIMATIC S7-1500 automation system, for CPU 1516pro-2 PN

based on SIMATIC S7-1500, and for the distributed I/O systems SIMATIC ET 200MP,

ET 200SP and ET 200AL is divided into three areas.

This division allows you easier access to the specific information you require.

System manuals and Getting Started manuals describe in detail the configuration,

installation, wiring and commissioning of the SIMATIC S7-1500, ET 200MP, ET 200SP and

ET 200AL systems; use the corresponding operating instructions for CPU 1516pro-2 PN.

The STEP 7 online help supports you in configuration and programming.

Product manuals contain a compact description of the module-specific information, such as

properties, terminal diagrams, characteristics and technical specifications.

PID control

12 Function Manual, 03/2017, A5E35300227-AC

Documentation guide

General information

Manual Collections

"mySupport"

"mySupport" - Documentation

The function manuals contain detailed descriptions on general topics such as diagnostics,

communication, Motion Control, Web server, OPC UA.

You can download the documentation free of charge from the Internet

(http://w3.siemens.com/mcms/industrial-automation-systems-simatic/en/manual-

overview/Pages/Default.aspx).

Changes and additions to the manuals are documented in product information sheets.

You will find the product information on the Internet:

● S7-1500/ET 200MP (https://support.industry.siemens.com/cs/us/en/view/68052815)

● ET 200SP (https://support.industry.siemens.com/cs/us/en/view/73021864)

● ET 200AL (https://support.industry.siemens.com/cs/us/en/view/99494757)

The Manual Collections contain the complete documentation of the systems put together in

one file.

You will find the Manual Collections on the Internet:

● S7-1500/ET 200MP (https://support.industry.siemens.com/cs/ww/en/view/86140384)

● ET 200SP (https://support.industry.siemens.com/cs/ww/en/view/84133942)

● ET 200AL (https://support.industry.siemens.com/cs/ww/en/view/95242965)

With "mySupport", your personal workspace, you make the best out of your Industry Online

Support.

In "mySupport", you can save filters, favorites and tags, request CAx data and compile your

personal library in the Documentation area. In addition, your data is already filled out in

support requests and you can get an overview of your current requests at any time.

You must register once to use the full functionality of "mySupport".

You can find "mySupport" on the Internet (https://support.industry.siemens.com/My/ww/en).

In the Documentation area in "mySupport" you can combine entire manuals or only parts of

these to your own manual.

You can export the manual as PDF file or in a format that can be edited later.

You can find "mySupport" - Documentation on the Internet

(http://support.industry.siemens.com/My/ww/en/documentation).

PID control

Function Manual, 03/2017, A5E35300227-AC

13

Documentation guide

"mySupport" - CAx data

Application examples

TIA Selection Tool

SIMATIC Automation Tool

In the CAx data area in "mySupport", you can access the current product data for your CAx

or CAe system.

You configure your own download package with a few clicks.

In doing so you can select:

● Product images, 2D dimension drawings, 3D models, internal circuit diagrams, EPLAN

macro files

● Manuals, characteristics, operating manuals, certificates

● Product master data

You can find "mySupport" - CAx data on the Internet

(http://support.industry.siemens.com/my/ww/en/CAxOnline).

The application examples support you with various tools and examples for solving your

automation tasks. Solutions are shown in interplay with multiple components in the system separated from the focus on individual products.

You will find the application examples on the Internet

(https://support.industry.siemens.com/sc/ww/en/sc/2054).

With the TIA Selection Tool, you can select, configure and order devices for Totally

Integrated Automation (TIA).

This tool is the successor of the SIMATIC Selection Tool and combines the known

configurators for automation technology into one tool.

With the TIA Selection Tool, you can generate a complete order list from your product

selection or product configuration.

You can find the TIA Selection Tool on the Internet

(http://w3.siemens.com/mcms/topics/en/simatic/tia-selection-tool).

You can use the SIMATIC Automation Tool to run commissioning and maintenance activities

simultaneously on different SIMATIC S7 stations as a bulk operation, independently of the

TIA Portal.

The SIMATIC automation tool provides a variety of functions:

● Scanning of a PROFINET/Ethernet plant network and identification of all connected CPUs

● Address assignment (IP, subnet, gateway) and station name (PROFINET device) to a

CPU

● Transfer of the date and programming device/PC time converted to UTC time to the

module

● Program download to CPU

PID control

14 Function Manual, 03/2017, A5E35300227-AC

Documentation guide

PRONETA

● Operating mode switchover RUN/STOP

● CPU localization by means of LED flashing

● Reading out CPU error information

● Reading of CPU diagnostic buffer

● Reset to factory settings

● Updating the firmware of the CPU and connected modules

You can find the SIMATIC Automation Tool on the Internet

(https://support.industry.siemens.com/cs/ww/en/view/98161300).

With SIEMENS PRONETA (PROFINET network analysis), you analyze the plant network

during commissioning. PRONETA features two core functions:

● The topology overview independently scans PROFINET and all connected components.

● The IO check is a fast test of the wiring and the module configuration of a plant.

You can find SIEMENS PRONETA on the Internet

(https://support.industry.siemens.com/cs/ww/en/view/67460624).

PID control

Function Manual, 03/2017, A5E35300227-AC

15

2

2.1

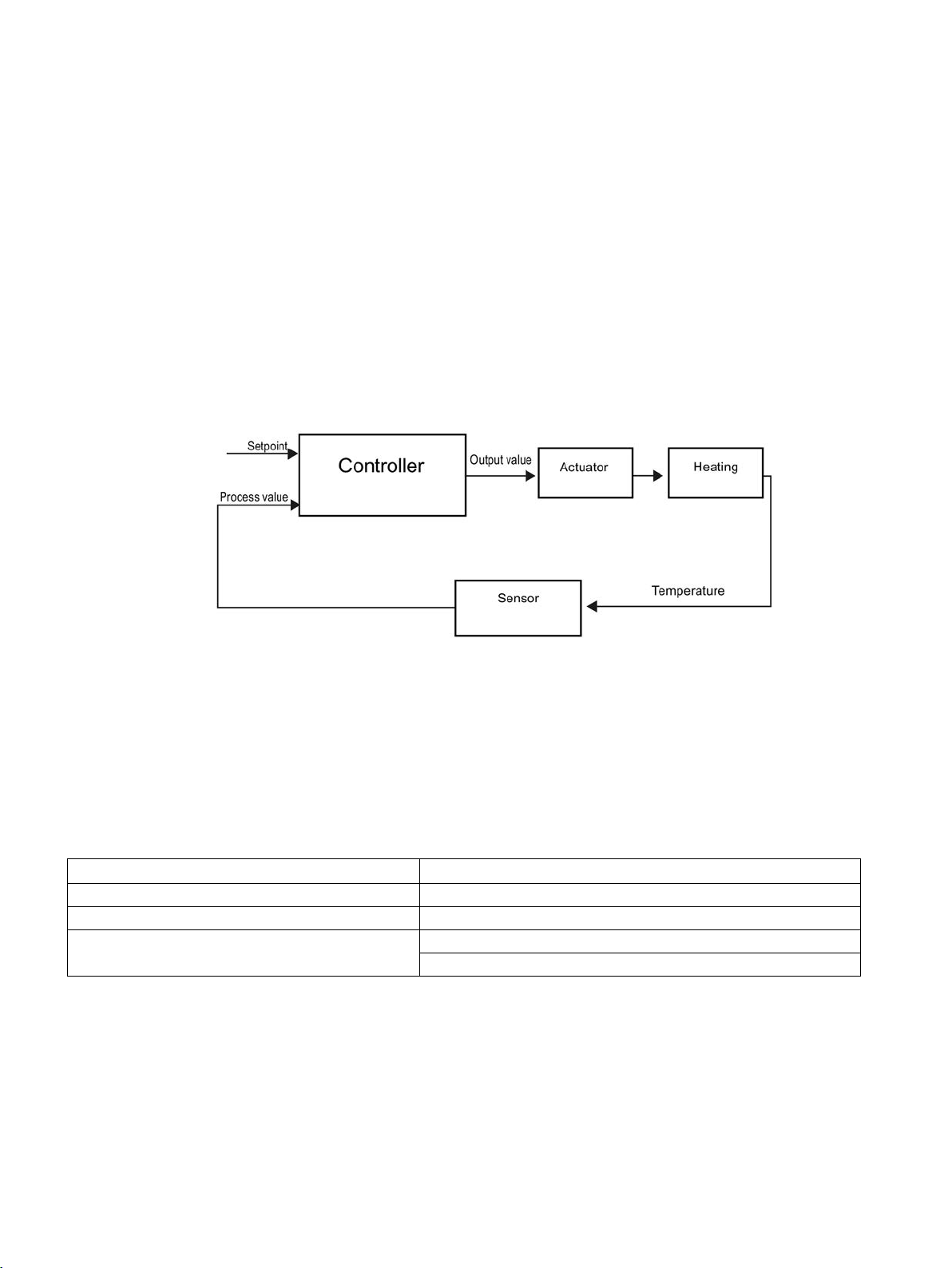

Controlled system and actuators

Controlled system

Actuators

Application

Actuator

Liquid and gaseous mass flow

Valve, shutter, gate valve

Solid mass flow, e.g., bulk material

Articulated baffle, conveyor, vibrator channel

Switching contact, contactor, relay, thyristor

Variable resistor, variable transformer, transistor

Room temperature control by means of a heating system is a simple example of a controlled

system. A sensor measures the room temperature and transfers the value to a controller.

The controller compares the current room temperature with a setpoint and calculates an

output value (manipulated variable) for heating control.

A properly set PID controller reaches this setpoint as quickly as possible and then holds it a

constant value. After a change in the output value, the process value often changes only with

a time delay. The controller has to compensate for this response.

The actuator is an element of the controlled system and is influenced by the controller. Its

function modifies mass and energy flows.

The table below provides an overview of actuator applications.

Flow of electrical power

PID control

16 Function Manual, 03/2017, A5E35300227-AC

Principles for control

2.1 Controlled system and actuators

Actuators are distinguished as follows:

● Proportional actuators with constant actuating signal

These elements set degrees of opening, angular positions or positions in proportion to

the output value. The output value has an analog effect on the process within the control

range.

Actuators in this group include spring-loaded pneumatic drives, as well as motorized

drives with position feedback for which a position control system is formed.

An continuous controller, such as PID_Compact, generates the output value.

● Proportional actuators with pulse-width modulated signal

These actuators are used to generate the output of pulses with a length proportional to

the output value within the sampling time intervals. The actuator - e.g. a heating resistor

or cooling apparatus - is switched on in isochronous mode for durations that differ

depending on the output value.

The actuating signal can assume unipolar "On" or "Off" states, or represent bipolar states

such as "open/close", "forward/backward", "accelerate/brake".

The output value is generated by a two-step controller such as PID_Compact with pulsewidth modulation.

● Actuators with integral action and three-step actuating signal

Actuators are frequently operated by motors with an on period that is proportional to the

actuator travel of the choke element. This includes elements such as valves, shutters,

and gate valves. In spite of their different design, all of these actuators follow the effect of

an integral action at the input of the controlled system.

A step controller, such as PID_3Step. generates the output value.

PID control

Function Manual, 03/2017, A5E35300227-AC

17

Principles for control

2.2

Controlled systems

Controlled system types

Self-regulating controlled systems

Proportional-action controlled systems

PT1 controlled systems

2.2 Controlled systems

The properties of a controlled system can hardly be influenced as these are determined by

the technical requirements of the process and machinery. Acceptable control results can

only be achieved by selecting a suitable controller type for the specific controlled system and

adapting the controller to the time response of the controlled system. Therefore, it is is

indispensable for the configuration of the proportional, integral and derivative actions of the

controller to have precise knowledge of the type and parameters of the controlled system.

Controlled systems are classified based on their time response to step changes of the output

value.

We distinguish between the following controlled systems:

● Self-regulating controlled systems

– Proportional-action controlled systems

– PT1 controlled systems

– PT2 controlled systems

● Non-self-regulating controlled systems

● Controlled systems with and without dead time

In proportional-action controlled systems, the process value follows the output value almost

immediately. The ratio between the process value and output value is defined by the

proportional Gain of the controlled system.

Examples:

● Gate valve in a piping system

● Voltage dividers

● Step-down function in hydraulic systems

In a PT1 controlled system, the process value initially changes in proportion to the change of

the output value. The rate of change of the process value is reduced as a function of the time

until the end value is reached, i.e., it is delayed.

Examples:

● Spring damping system

● Charge of RC elements

● Water container that is heated with steam.

The time constants are often identical for heating and cooling processes, or for charging and

discharge characteristics. With different time constants, controlling is clearly more complex.

PID control

18 Function Manual, 03/2017, A5E35300227-AC

Principles for control

PT2 controlled systems

Non-self-regulating controlled systems

Controlled systems with dead time

2.2 Controlled systems

In a PT2 controlled system, the process value does not immediately follow a step change of

the output value, i.e., it increases in proportion to the positive rate of rise and then

approaches the setpoint at a decreasing rate of rise. The controlled system shows a

proportional response characteristic with second order delay element.

Examples:

● Pressure control

● Flow rate control

● Temperature control

Non-self-regulating controlled systems have an integral response. The process value

approaches an infinite maximum value.

Example:

● Liquid flow into a container

A dead time always represents the runtime or transport time that has to expire before a

change to the system input can be measured at the system output.

In controlled systems with dead time, the process value change is delayed by the amount of

the dead time.

Example:

Conveyor

PID control

Function Manual, 03/2017, A5E35300227-AC

19

Principles for control

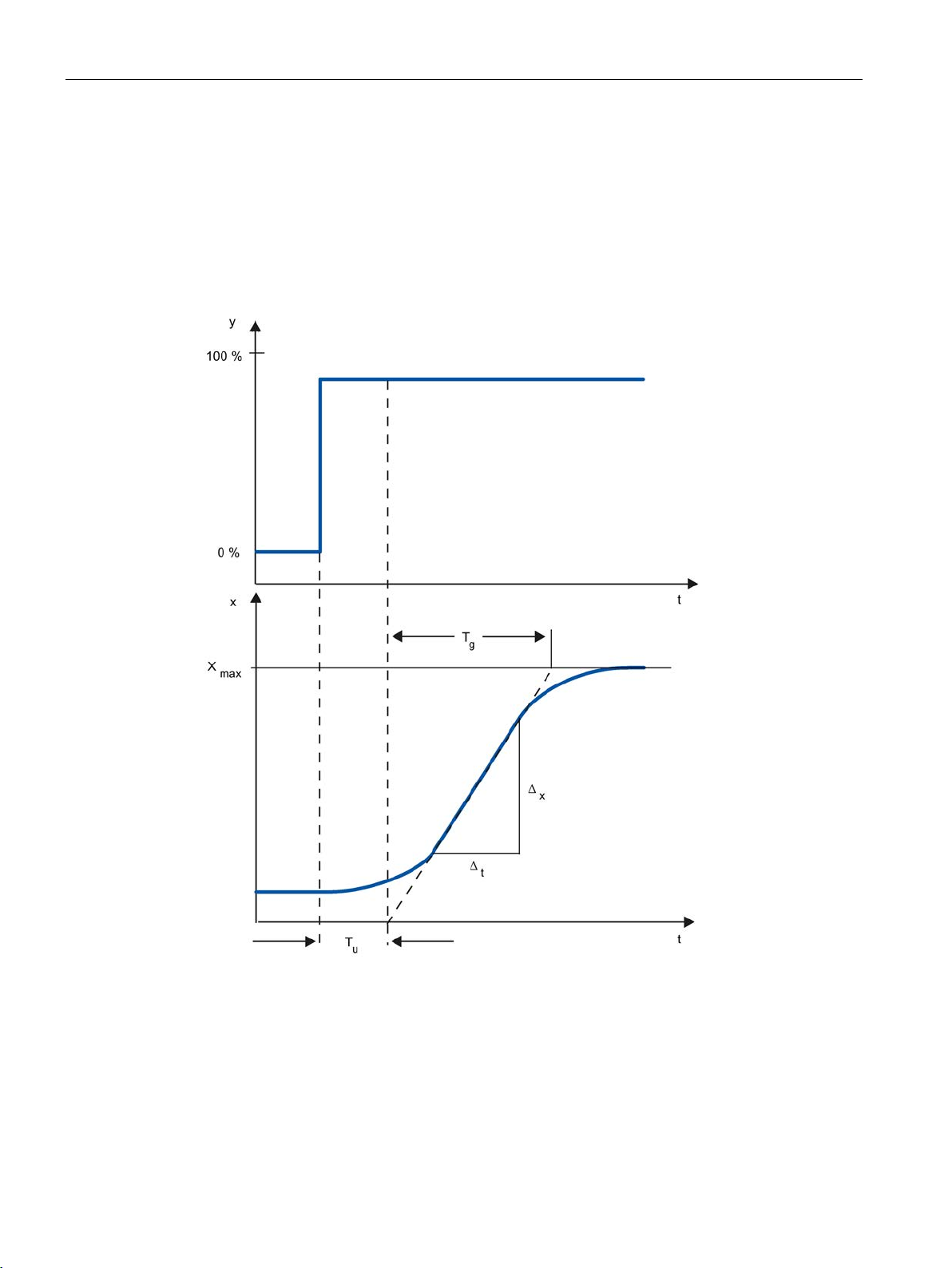

2.3

Characteristic values of the control section

Determining the time response from the step response

2.3 Characteristic values of the control section

Time response of the controlled system can be determined based on the time characteristic

of process value x following a step change of output value y. Most controlled systems are

self-regulating controlled systems.

The time response can be determined by approximation using the variables Delay time Tu,

Recovery time T

and Maximum value X

g

. The variables are determined by applying

max

tangents to the maximum value and the inflection point of the step response. In many

situations, it is not possible to record the response characteristic up to the maximum value

because the process value cannot exceed specific values. In this case, the rate of rise v

used to identify the controlled system (v

PID control

= Δx/Δt).

max

max

is

20 Function Manual, 03/2017, A5E35300227-AC

Principles for control

Process type

Tu / Tg

Suitability of the controlled system for controlling

I

< 0,1

can be controlled well

III

> 0,3

difficult to control

Influence of the dead time on the controllability of a controlled system

Tt

Dead time

Tu

Delay time

Tg

Recovery time

y

Output value

x

Process value

2.3 Characteristic values of the control section

The controllability of the controlled system can be estimated based on the ratio Tu/Tg, or Tu ×

v

max/Xmax

II 0.1 to 0.3 can still be controlled

. Rule:

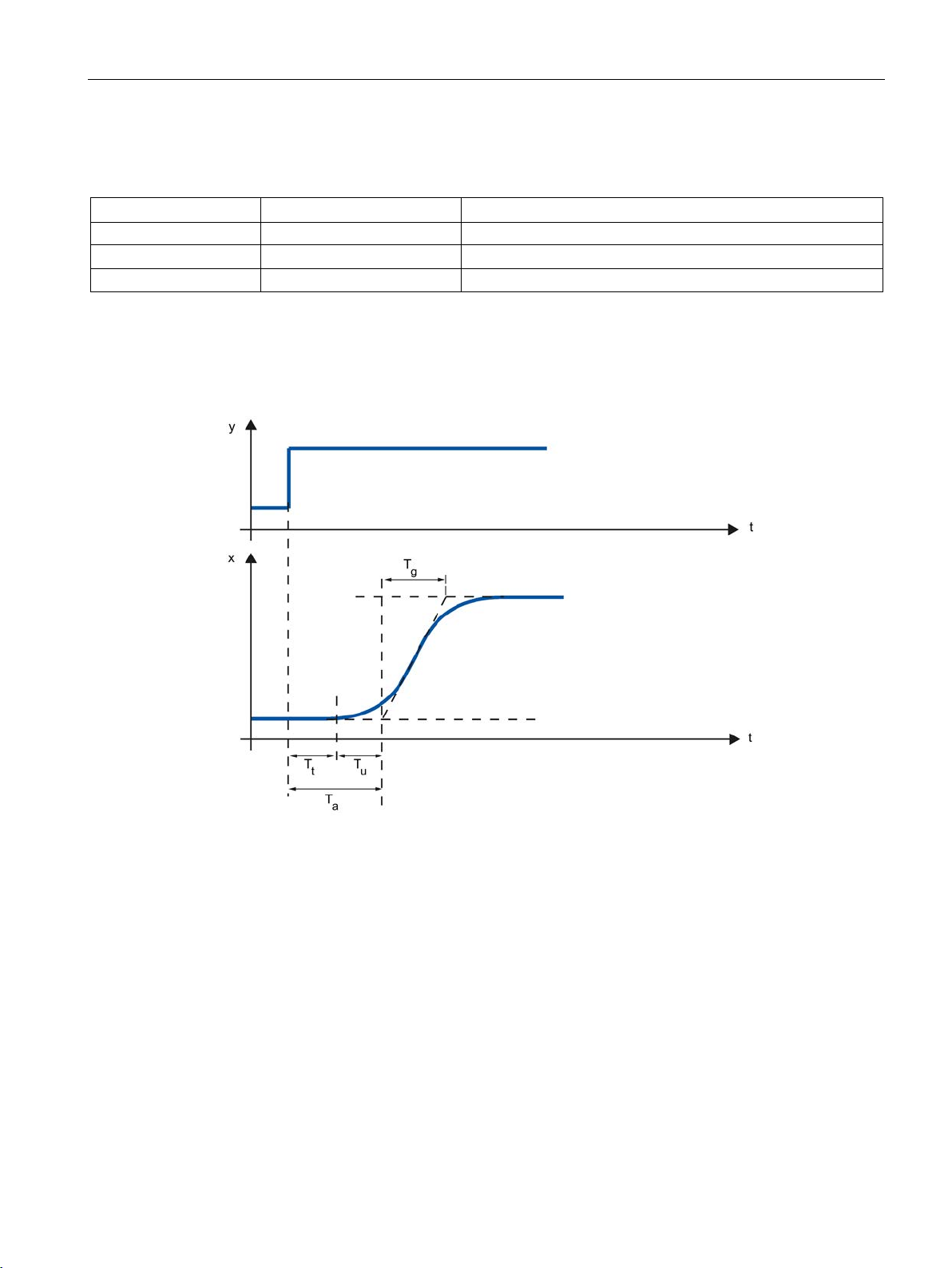

A controlled system with dead time and recovery reacts as follows to a jump of the output

value.

The controllability of a self-regulating controlled system with dead time is determined by the

ratio of T

T

t/Tg

PID control

Function Manual, 03/2017, A5E35300227-AC

to Tg. Tt must be small compared to Tg. Rule:

t

≤ 1

21

Principles for control

Response rate of controlled systems

Parameters of certain controlled systems

Physical

quantity

Controlled system

Delay time Tu

Recovery time Tg

Rate of rise v

max

Small electrically heated furnace

0.5 to 1 min

5 to 15 min

Up to 60 K/min.

Large gas-heated annealing furnace

0.2 to 5 min

3 to 60 min

1 to 30 K/min

Autoclaves (2.5 m3)

0.5 to 0.7 min

10 to 20 min

Not specified

High-pressure autoclaves

12 to 15 min

200 to 300 min

Not specified

Steam superheater

30 s to 2.5 min

1 to 4 min

2°C/s

Injection molding machines

0.5 to 3 min

3 to 30 min

5 to 20 K/min

Extruders

1 to 6 min

5 to 60 min

Packaging machines

0.5 to 4 min

3 to 40 min

2 to 35 K/min

Room heating

1 to 5 min

10 to 60 min

1° C/min

Pipeline with gas

0 to 5 s

0.2 to 10 s

Pipeline with liquid

None

None

Gas pipeline

None

0.1 s

Not relevant

Drum boiler with gas or oil firing

None

150 s

Not relevant

Drum boiler with impact grinding mills

1 to 2 min

2 to 5 min

Not relevant

Vessel level

Drum boiler

0.6 to 1 min

Not specified

0.1 to 0.3 cm/s

Small electric drive

None

0.2 to 10 s

Not relevant

Large electric drive

None

5 to 40 s

Not relevant

Steam turbine

None

Not specified

50 min–1

Small generators

None

1 to 5 s

Not relevant

Large generators

None

5 to 10 s

Not relevant

2.3 Characteristic values of the control section

Controlled systems can be judged on the basis of the following values:

T

< 0.5 min, Tg < 5 min = fast controlled system

u

T

> 0.5 min, Tg > 5 min = slow controlled system

u

Temperature

Large electrically heated annealing furnace

Distillation tower 1 to 7 min 40 to 60 min 0.1 to 0.5° C/s

1 to 5 min 10 to 20 min Up to 20 K/min.

Flow rate

Pressure

Speed

Voltage

Not relevant

PID control

22 Function Manual, 03/2017, A5E35300227-AC

Principles for control

2.4

Pulse controller

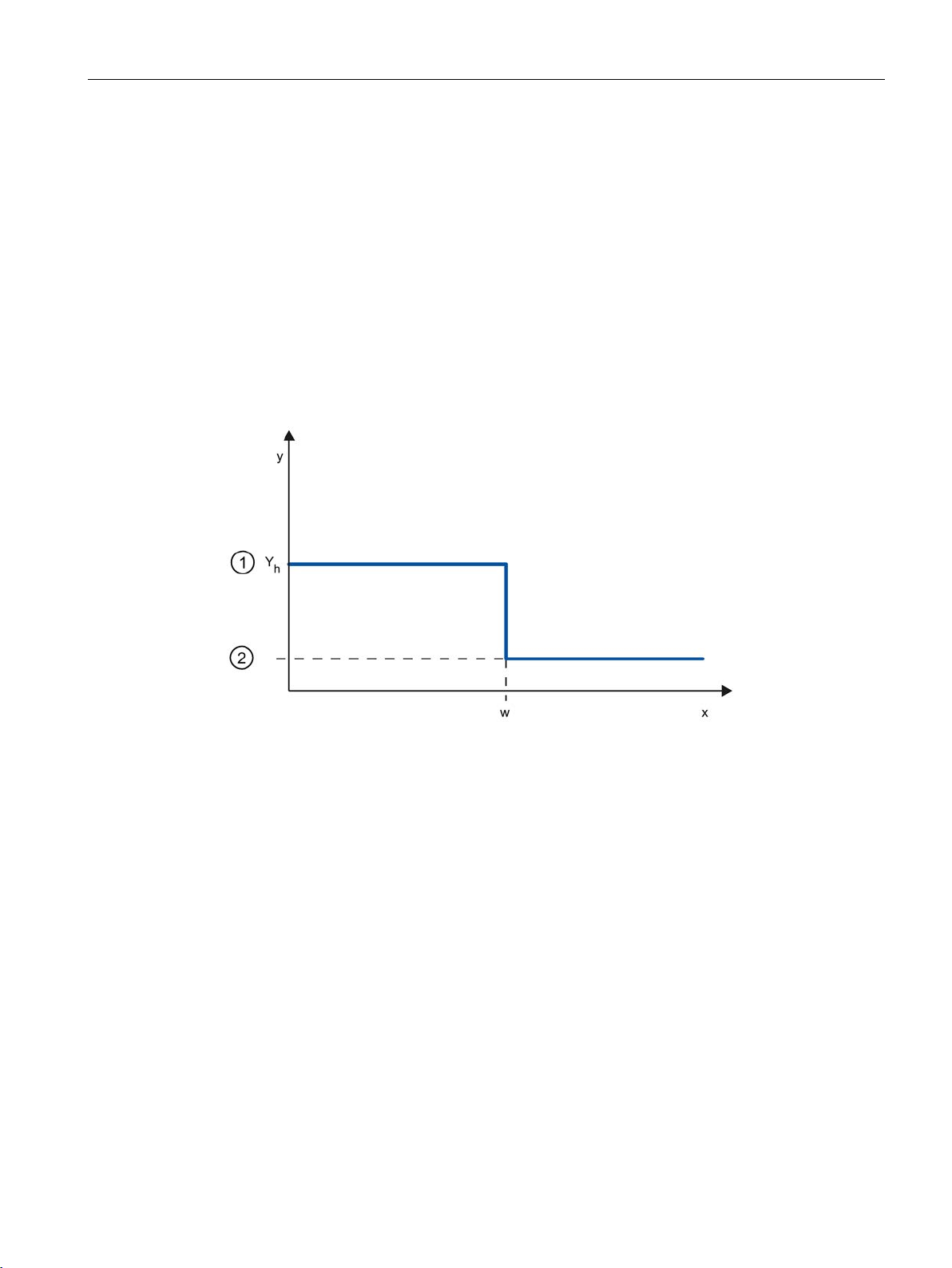

Two-step controllers without feedback

①

ON

②

OFF

Yh

Control range

w

Setpoint

2.4 Pulse controller

Two-step controllers have the state "ON" and "OFF" as the switching function. This

corresponds to 100% or 0% output. This behavior generates a sustained oscillation of

process value x around setpoint w.

The amplitude and duration of the oscillation increase in proportion to the ratio between the

delay time T

mainly for simple temperature control systems (such as electrically directly heated furnaces)

or as limit-value signaling units.

The following diagram shows the characteristic of a two-step controller

and recovery time Tg of the controlled system. These controllers are used

u

PID control

Function Manual, 03/2017, A5E35300227-AC

23

Principles for control

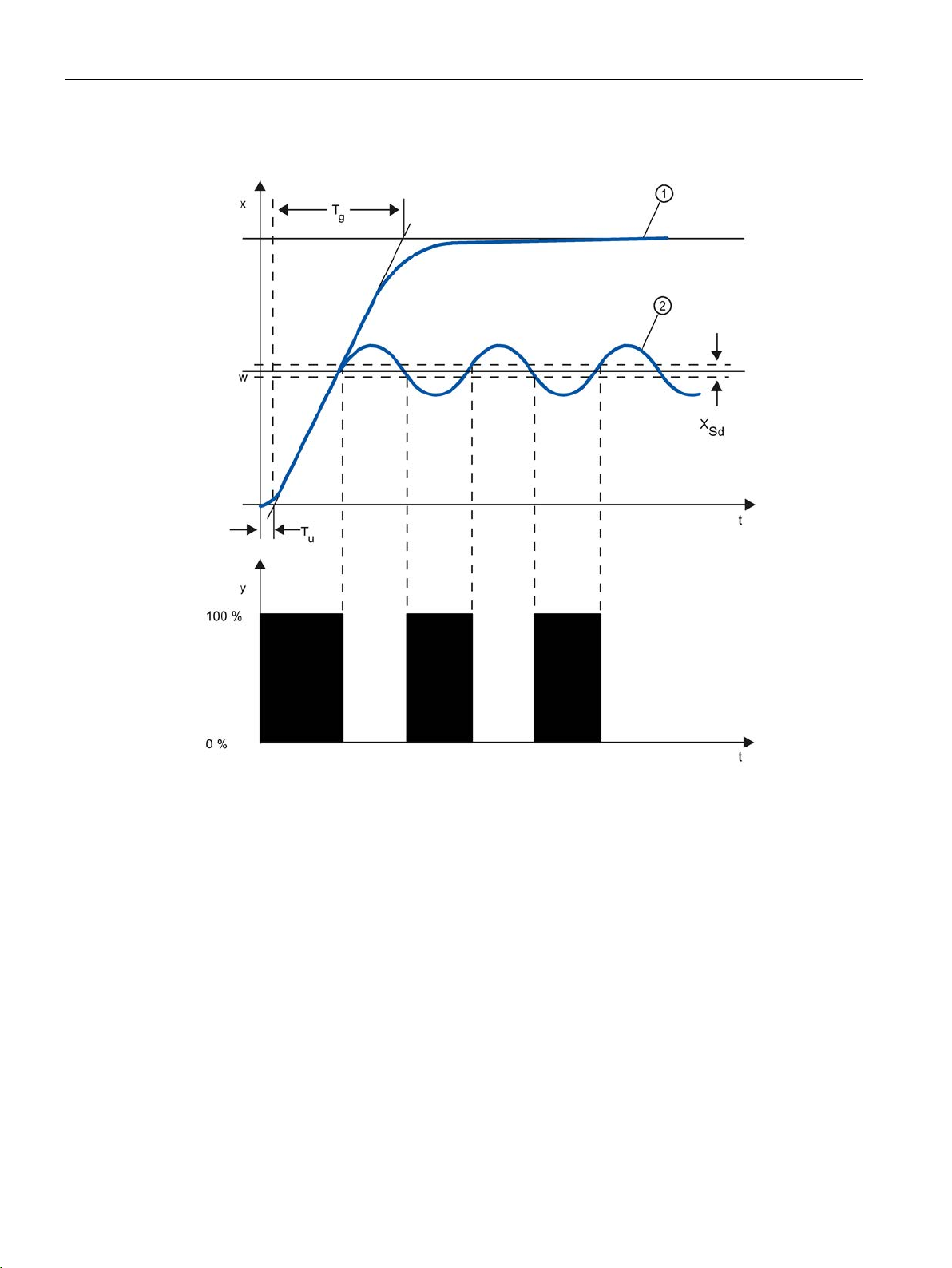

①

Response characteristic without controller

②

Response characteristic with two-step controller

Tu

Delay time

Tg

Recovery time

XSd

Switching difference

2.4 Pulse controller

The following diagram shows the control function of a two-step controller

PID control

24 Function Manual, 03/2017, A5E35300227-AC

Principles for control

Two-step controllers with feedback

2.4 Pulse controller

The behavior of two-step controllers in the case of controlled systems with larger delay

times, such as furnaces where the functional space is separated from the heating, can be

improved by the use of electronic feedback.

The feedback is used to increase the switching frequency of the controller, which reduces

the amplitude of the process value. In addition, the control-action results can be improved

substantially in dynamic operation. The limit for the switching frequency is set by the output

level. It should not exceed 1 to 5 switches per minute at mechanical actuators, such as

relays and contactors. In the case of voltage and current outputs with downstream thyristor

or Triac controllers high switching frequencies can be selected that exceed the limit

frequency of the controlled system by far.

Since the switching pulses can no longer be determined at the output of the controlled

system, results comparable with those of continuous controllers are obtained.

The output value is generated by pulse-width modulation of the output value of a continuous

controller.

Two-step controllers with feedback are used for temperature control in furnaces, at

processing machines in the plastics, textile, paper, rubber and foodstuff industries as well as

for heating and cooling devices.

PID control

Function Manual, 03/2017, A5E35300227-AC

25

Principles for control

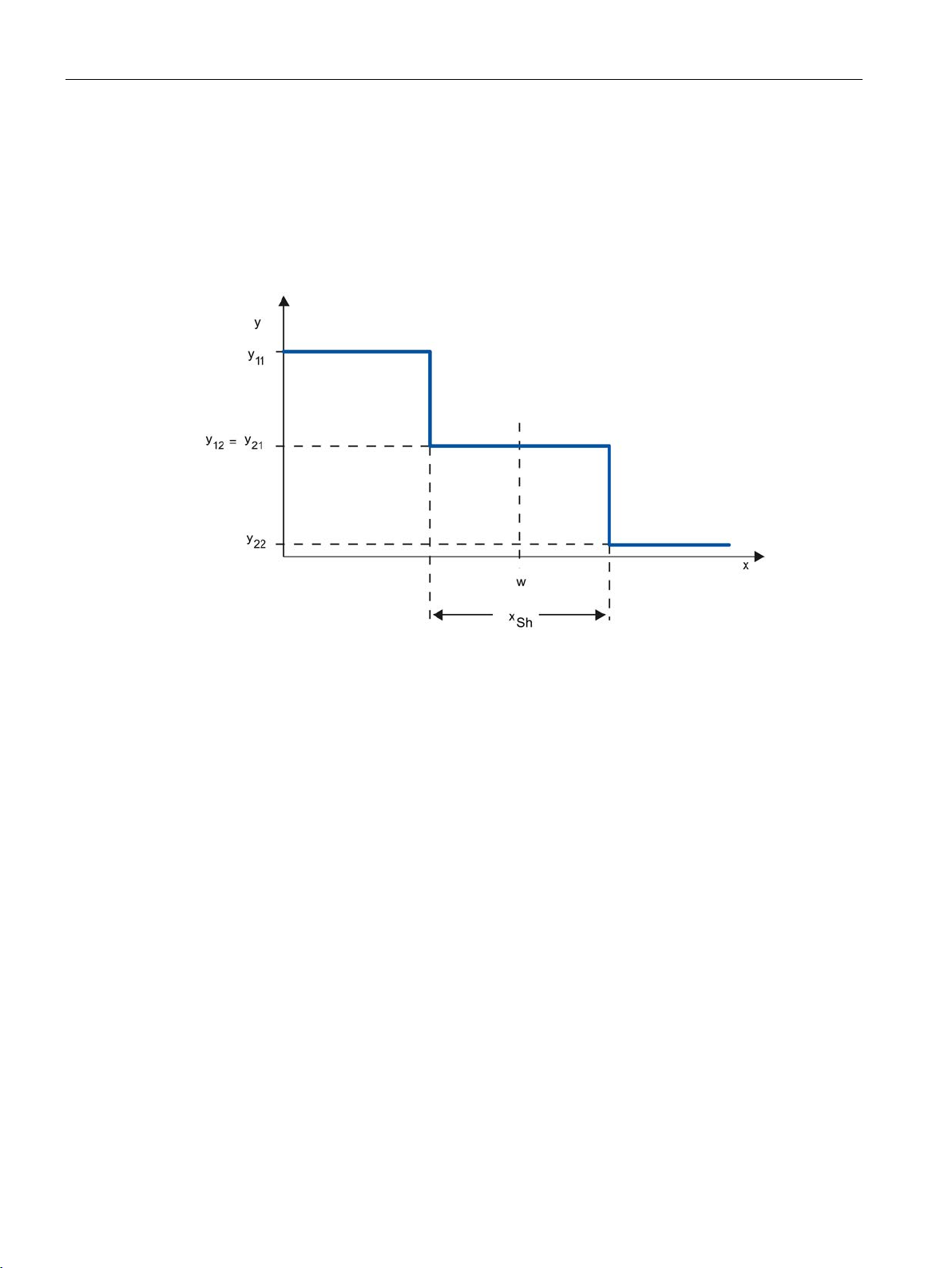

Three-step controllers

y22 = 100% cooling

x

Physical quantity of the process value, e.g., temperature in° C

w

Setpoint

xSh

Distance between Switching Point 1 and Switching Point 2

2.4 Pulse controller

Three-step controllers are used for heating / cooling. These controllers have two switching

points as their output. The control-action results are optimized through electronic feedback

structures. Fields of applications for such controllers are heating, low-temperature, climatic

chambers and tool heating units for plastic-processing machines.

The following diagram shows the characteristic of a three-step controller

y Output value, e.g.

y11 = 100% heating

y12 = 0% heating

y21 = 0% cooling

PID control

26 Function Manual, 03/2017, A5E35300227-AC

Principles for control

2.5

Response to setpoint changes and disturbances

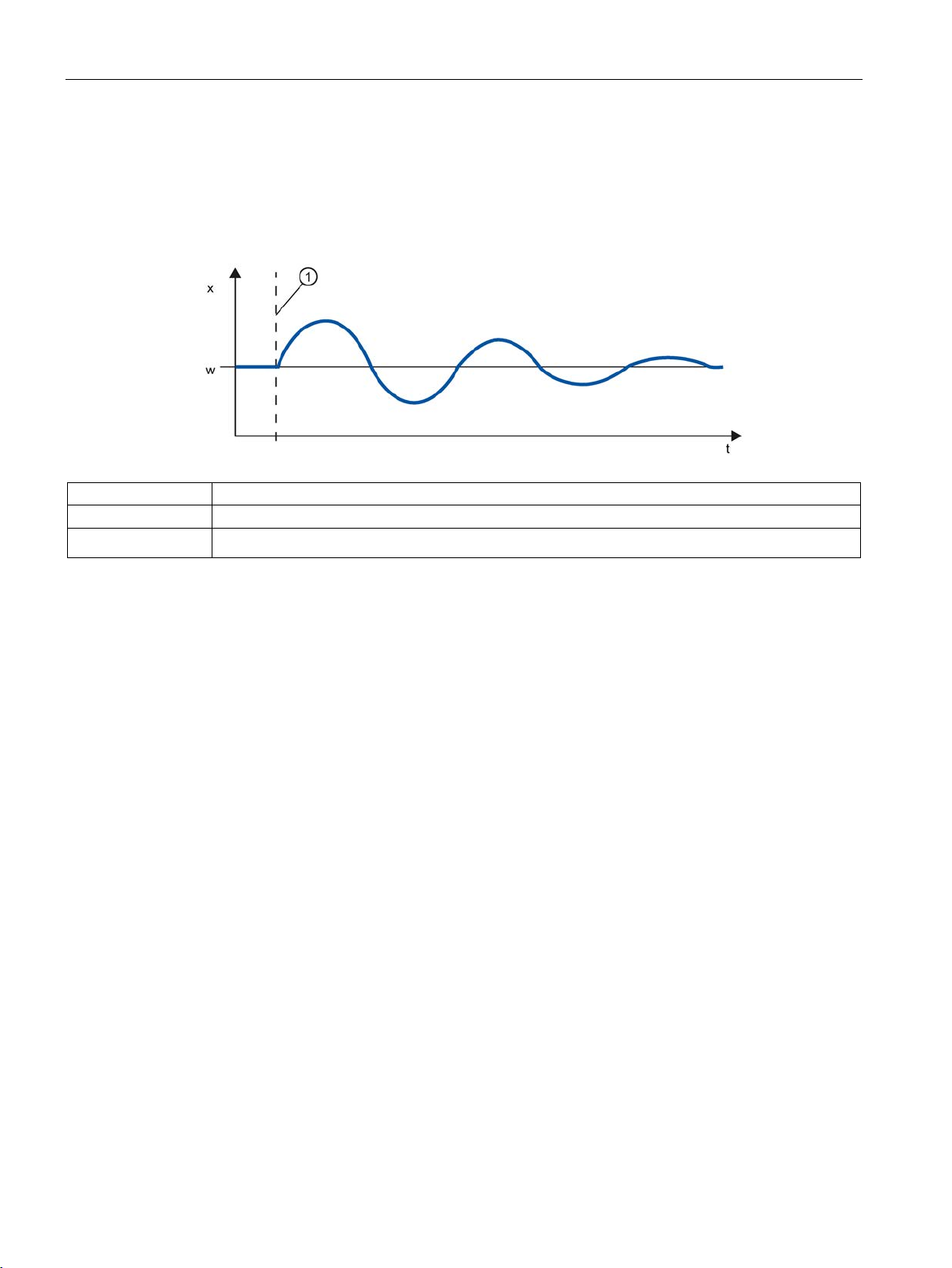

Response to setpoint changes

x

Process value

w

Setpoint

2.5 Response to setpoint changes and disturbances

The process value should follow a setpoint change as quickly as possible. The response to

setpoint changes is improved by minimizing fluctuation of the process value and the time

required to reach the new setpoint.

PID control

Function Manual, 03/2017, A5E35300227-AC

27

Principles for control

Response to disturbances

x

Process value

①

2.6

Control Response at Different Feedback Structures

Control behavior of controllers

2.6 Control Response at Different Feedback Structures

The setpoint is influenced by disturbance variables. The controller has to eliminate the

resulting control deviations in the shortest time possible. The response to disturbances is

improved by minimizing fluctuation of the process value and the time required to reach the

new setpoint.

w Setpoint

Influencing a disturbance variable

Disturbance variables are corrected by a controller with integral action. A persistent

disturbance variable does not reduce control quality because the control deviation is

relatively constant. Dynamic disturbance variables have a more significant impact on control

quality because of control deviation fluctuation. The control deviation is eliminated again only

by means of the slow acting integral action.

A measurable disturbance variable can be included in the controlled system. This inclusion

would significantly accelerated the response of the controller.

A precise adaptation of the controller to the time response of the controlled system is

decisive for the controller's precise settling to the setpoint and optimum response to

disturbance variables.

The feedback circuit can have a proportional action (P), proportional-derivative action (PD),

proportional-integral action (PI), or proportional-integral-derivative action (PID).

If step functions are to be triggered by control deviations, the step responses of the

controllers differ depending on their type.

PID control

28 Function Manual, 03/2017, A5E35300227-AC

Principles for control

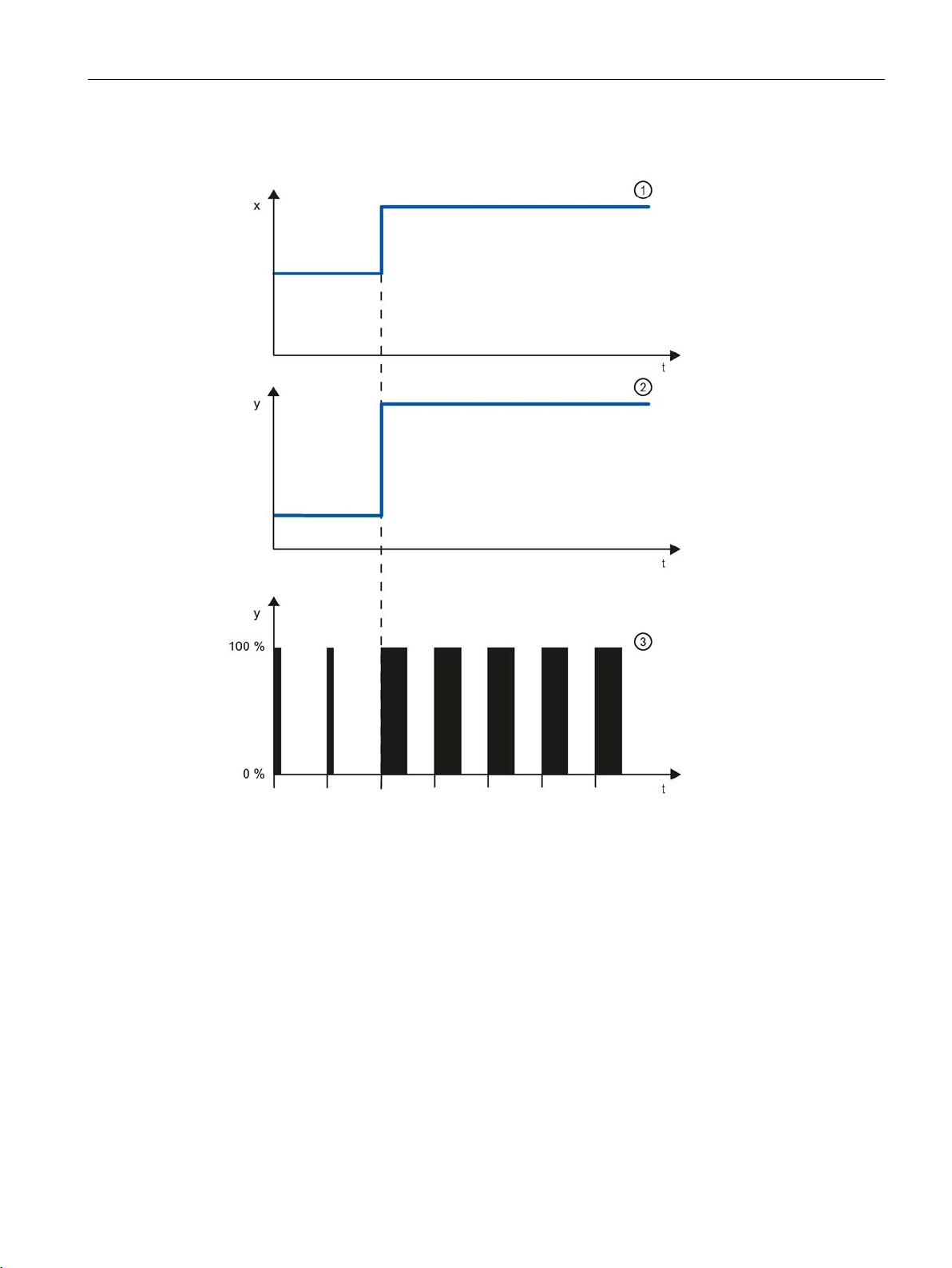

Step response of a proportional action controller

①

Control deviation

②

Output value of a continuous controller

③

Output value of a pulse controller

Equation for proportional action controller

2.6 Control Response at Different Feedback Structures

Output value and control deviation are directly proportional, meaning:

Output value = proportional gain × control deviation

y = GAIN × x

PID control

Function Manual, 03/2017, A5E35300227-AC

29

Principles for control

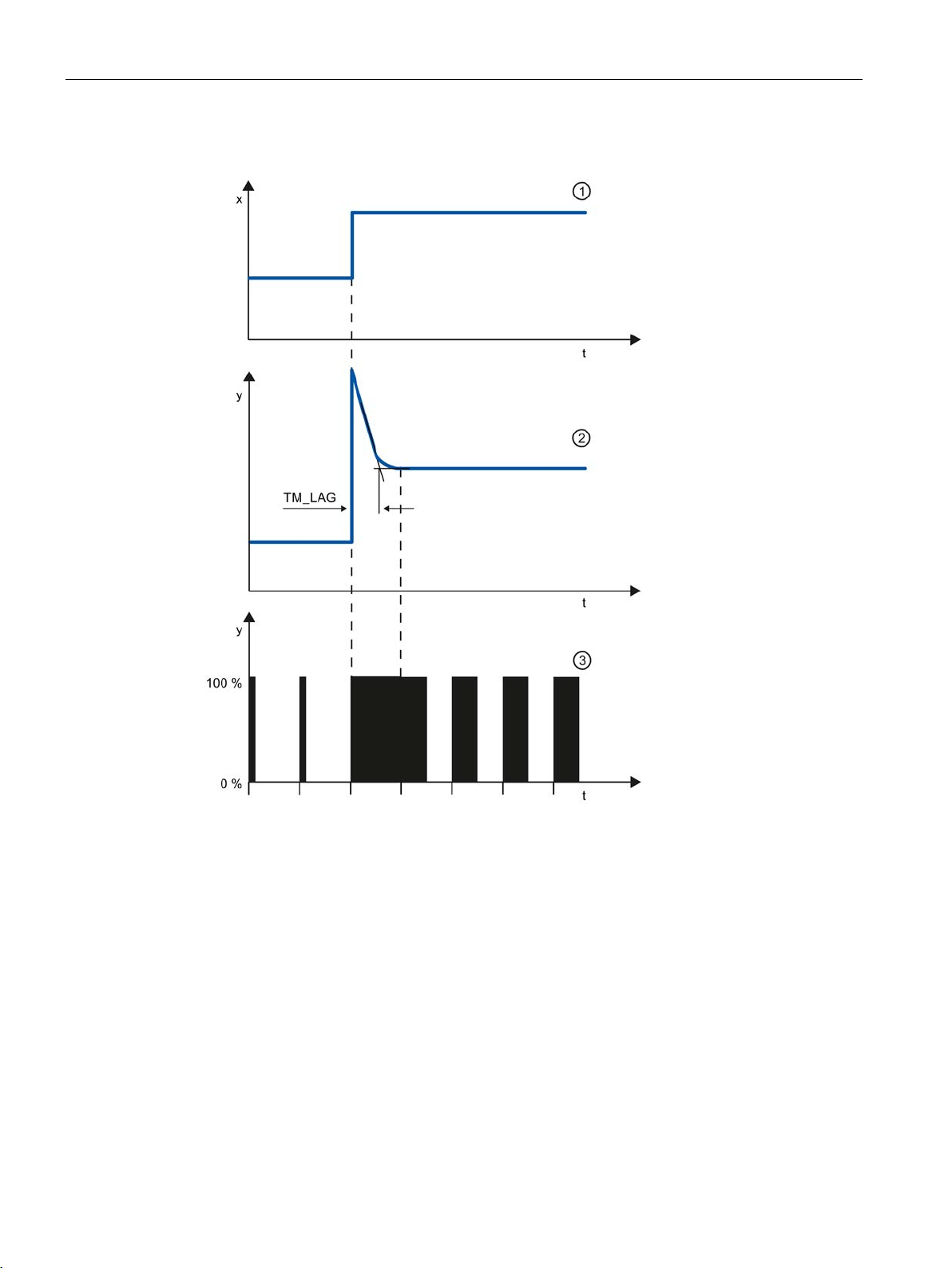

Step response of a PD-action controller

①

Control deviation

②

Output value of a continuous controller

③

Output value of a pulse controller

TM_LAG

Delay of the Derivative action

2.6 Control Response at Different Feedback Structures

PID control

30 Function Manual, 03/2017, A5E35300227-AC

Loading...

Loading...