Siemens SIMATIC PROFINET Function Manual

PROFINET with STEP 7 V14

___________________

___________________

___________________

___________________

___________________

___________________

SIMATIC

PROFINET

PROFINET with STEP 7 V14

Function Manual

09/2016

A5E03444486

Preface

Documentation guide

1

Description

2

Parameter

assignment/addressing

3

Diagnostics

4

Functions

5

-AG

Siemens AG

Division Digital Factory

Postfach 48 48

90026 NÜRNBERG

GERMANY

A5E03444486-AG

Ⓟ

Copyright © Siemens AG 2013 - 2016.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

for the specific

08/2016 Subject to change

Preface

Purpose of the documentation

Basic knowledge required

Scope

This function manual provides an overview of the PROFINET communication system with

SIMATIC STEP 7 V14.

STEP 7 V14 is integrated into the powerful graphical Totally Integrated Automation Portal

(TIA Portal), the new integration platform for all automation software tools.

This function manual supports you in planning a PROFINET system. The manual is

structured into the following subject areas:

● PROFINET basics

● PROFINET diagnostics

● PROFINET functions

The following knowledge is required in order to understand the manual:

● General knowledge of automation technology

● Knowledge of the industrial automation system SIMATIC

● Knowledge about the use of Windows-based computers

● Knowledge about how to use STEP 7 (TIA Portal)

This documentation is the basic documentation for all SIMATIC products from the

PROFINET environment. The product documentation is based on this documentation.

The examples are based on the functionality of the S7-1500 automation system.

PROFINET with STEP 7 V14

4 Function Manual, 09/2016, A5E03444486-AG

Preface

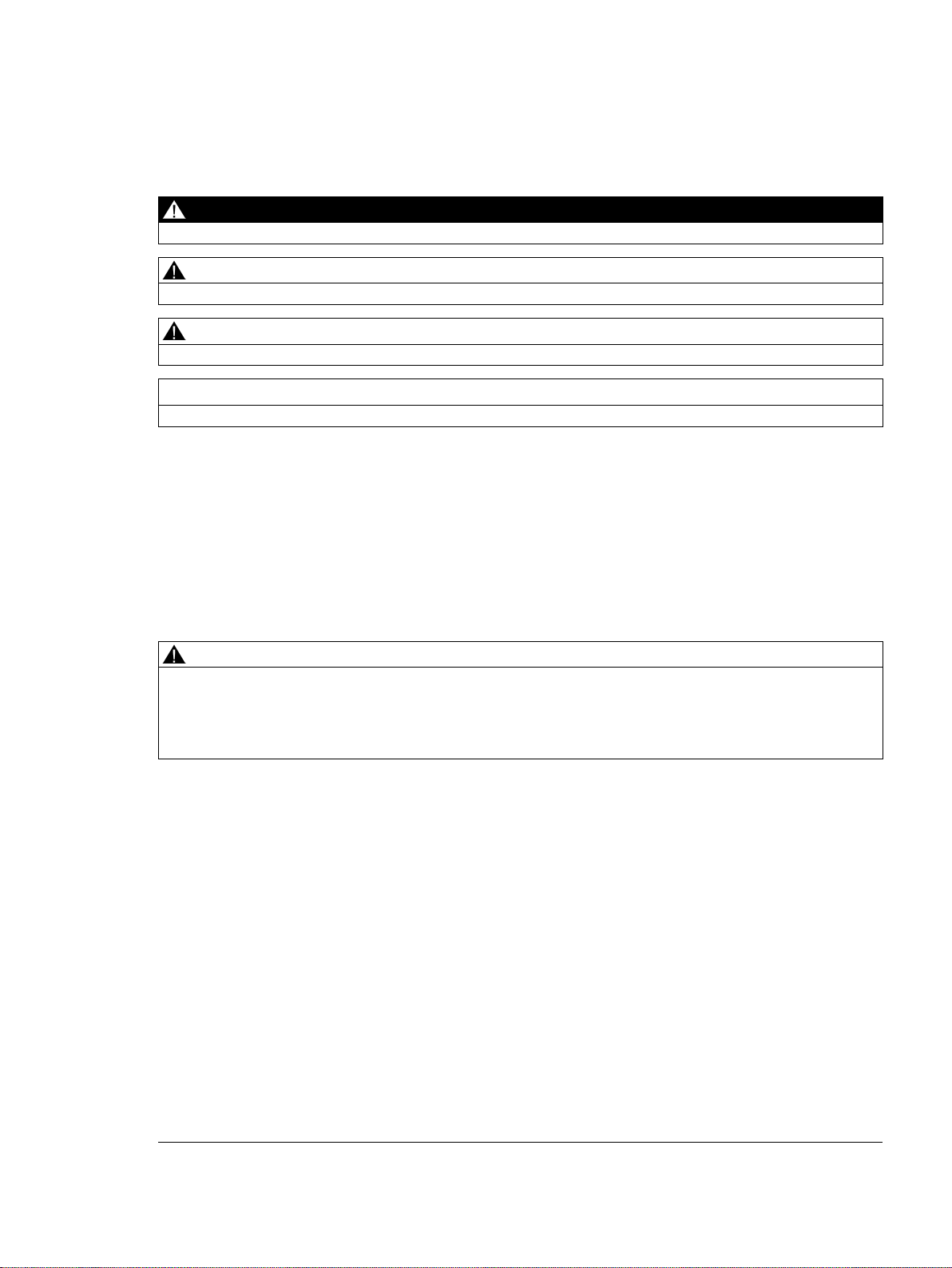

Changes compared to previous version

Function

Applications

User benefits

line.

processing.

By sending the cyclic IO data in both directions in

with MRP.

performance.

demand.

Conventions

STEP 7:

Note

A note contains important information on the product, on handling of the product and on the

section of the documentation to which you

See also

This manual encompasses the following new functions compared to the previous version

(version 12/2014):

PROFINET IO on the 2nd

PROFINET interface

IRT with very short data cycle

times down to 125 µs

MRPD: Media Redundancy

with Planned Duplication of

frames

PROFINET performance

upgrade

Limitation of the data infeed

into the network

You can operate another

PROFINET IO system on the CPU or

connect additional IO devices.

You realize high-end applications with

IO communication which place very

high performance demands on the IO

PROFINET IO IRT enables you to

realize applications that place particularly high demands on the reliability

and accuracy (isochronous mode).

You can implement applications with

high speed and send clock requirements. This is interesting for applications with high demands on

You limit the network load for standard

Ethernet communication to a maximum

value.

You use a fieldbus type in the plant.

The CPU can perform fast and deterministic data

exchange as an I-device with a higher-level controller (PROFINET/Ethernet) through the second

You make PROFINET IO communication and

standard communication possible via one cable

even with a send clock of 125 µs.

the ring, the communication to the IO devices is

maintained even when the ring is interrupted and

does not result in device failure even with fast

update times. You achieve higher reliability than

Better utilization of the bandwidth results in short

reaction times.

You flatten peaks in the data feed.

You share the remaining bandwidth based on

programming software "STEP 7 as of V12 (TIA Portal)" and subsequent versions.

This documentation contains pictures of the devices described. The figures may differ

slightly from the device supplied.

You should also pay particular attention to notes such as the one shown below:

We refer to "STEP 7" in this documentation as a synonym for the configuration and

should pay particular attention.

PRODIS (http://www.siemens.com/simatic-tech-doku-portal)

Catalog (http://mall.industry.siemens.com)

PROFINET with STEP 7 V14

Function Manual, 09/2016, A5E03444486-AG

5

Preface

Security information

Siemens Industry Online Support

Product support

Application examples

Services

Forums

mySupport

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial

security concept. Siemens’ products and solutions only form one element of such a concept.

Customer is responsible to prevent unauthorized access to its plants, systems, machines

and networks. Systems, machines and components should only be connected to the

enterprise network or the internet if and to the extent necessary and with appropriate security

measures (e.g. use of firewalls and network segmentation) in place.

Additionally, Siemens’ guidance on appropriate security measures should be taken into

account. For more information about industrial security, please visit

(http://www.siemens.com/industrialsecurity

Siemens’ products and solutions undergo continuous development to make them more

secure. Siemens strongly recommends to apply product updates as soon as available and to

always use the latest product versions. Use of product versions that are no longer supported,

and failure to apply latest updates may increase customer’s exposure to cyber threats.

).

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS

Feed under (http://www.siemens.com/industrialsecurity

You can find current information on the following topics quickly and easily here:

●

All the information and extensive know-how on your product, technical specifications,

FAQs, certificates, downloads, and manuals.

●

Tools and examples to solve your automation tasks – as well as function blocks,

performance information and videos.

●

Information about Industry Services, Field Services, Technical Support, spare parts and

training offers.

●

For answers and solutions concerning automation technology.

●

Your personal working area in Industry Online Support for messages, support queries,

and configurable documents.

).

This information is provided by the Siemens Industry Online Support in the Internet

(http://www.siemens.com/automation/service&support

PROFINET with STEP 7 V14

6 Function Manual, 09/2016, A5E03444486-AG

).

Preface

Industry Mall

The Industry Mall is the catalog and order system of Siemens AG for automation and drive

solutions on the basis of Totally Integrated Automation (TIA) and Totally Integrated Power

(TIP).

Catalogs for all the products in automation and drives are available on the Internet

(https://mall.industry.siemens.com

).

PROFINET with STEP 7 V14

Function Manual, 09/2016, A5E03444486-AG

7

Table of contents

Preface ................................................................................................................................................... 4

1 Documentation guide ............................................................................................................................ 11

2 Description ............................................................................................................................................ 15

3 Parameter assignment/addressing ........................................................................................................ 41

4 Diagnostics ........................................................................................................................................... 69

2.1 Introduction to PROFINET ..................................................................................................... 15

2.1.1 PROFINET terms ................................................................................................................... 17

2.1.2 Basic terminology of communication ..................................................................................... 20

2.1.3 PROFINET interface .............................................................................................................. 23

2.1.4 Implementation of the PROFINET device model in SIMATIC ............................................... 26

2.2 Setting up PROFINET ............................................................................................................ 27

2.2.1 Active Network Components .................................................................................................. 28

2.2.2 Cabling technology ................................................................................................................ 30

2.2.3 Wireless design ...................................................................................................................... 33

2.2.3.1 Basics ..................................................................................................................................... 33

2.2.3.2 Tips on assembly ................................................................................................................... 35

2.2.4 Network security..................................................................................................................... 36

2.2.4.1 Basics ..................................................................................................................................... 36

2.2.4.2 Network components and software........................................................................................ 38

2.2.4.3 Application example ............................................................................................................... 39

3.1 Assigning an IO device to an IO controller ............................................................................ 42

3.2 Device name and IP address ................................................................................................. 44

3.2.1 Device name .......................................................................................................................... 45

3.2.2 IP address .............................................................................................................................. 46

3.2.3 Assigning a device name and IP address .............................................................................. 49

3.2.4 Assign device name via communication table ....................................................................... 54

3.2.5 Permitting changes to the device name and IP address directly on the device .................... 57

3.3 Configuring topology .............................................................................................................. 59

3.3.1 Topology view in STEP 7 ....................................................................................................... 61

3.3.2 Interconnecting ports in the topology view ............................................................................. 64

3.3.3 Interconnecting ports - Inspector window .............................................................................. 65

3.3.4 Automatic assignment of devices by offline/online comparison ............................................ 66

3.3.5 Apply the port interconnections identified online manually to the project .............................. 67

3.3.6 Include the devices identified online manually in the project ................................................. 68

3.3.7 Automatic assignment of devices by advanced offline/online comparison ............................ 68

4.1 Diagnostics mechanisms of PROFINET IO ........................................................................... 69

4.1.1 Diagnostics levels in PROFINET IO ...................................................................................... 71

4.1.2 I&M data (identification and maintenance) ............................................................................ 73

4.1.3 Loading I&M data to PROFINET IO devices and your modules ............................................ 73

4.2 Diagnostics using status LEDs .............................................................................................. 75

PROFINET with STEP 7 V14

8 Function Manual, 09/2016, A5E03444486-AG

Table of contents

5 Functions .............................................................................................................................................. 93

4.3 Diagnostics via the display of the S7-1500 CPUs .................................................................. 76

4.4 Diagnostics via Web server .................................................................................................... 80

4.5 Diagnostics in STEP 7 ............................................................................................................ 83

4.6 Extended maintenance concept ............................................................................................. 86

4.7 Diagnostics of the network topology ....................................................................................... 88

4.8 Diagnostics in the user program ............................................................................................. 89

4.8.1 Diagnostics and configuration data records ........................................................................... 89

4.8.2 Evaluate diagnostics in the user program .............................................................................. 91

5.1 Connecting other bus systems ............................................................................................... 94

5.1.1 Connecting other bus systems ............................................................................................... 94

5.1.2 Linking PROFINET and PROFIBUS ....................................................................................... 95

5.1.3 Connect the DP slave via the IE/PB Link to a PROFINET IO system .................................... 96

5.2 Intelligent IO devices (I-devices) ............................................................................................. 98

5.2.1 I-device functionality ............................................................................................................... 98

5.2.2 Properties and Advantages of the I-Device ............................................................................ 99

5.2.3 Characteristics of an I-Device ............................................................................................... 100

5.2.4 Data Exchange between higher- and lower-level IO system ................................................ 104

5.2.5 Configuring the I-device ........................................................................................................ 106

5.2.6 Program examples ................................................................................................................ 109

5.2.7 Diagnostics and interrupt characteristics .............................................................................. 112

5.2.8 Rules for the Topology of a PROFINET IO System with I-Device ........................................ 114

5.2.9 Boundary conditions when using I-devices .......................................................................... 118

5.2.10 Configuring PROFIenergy with I-devices.............................................................................. 118

5.3 Shared device ....................................................................................................................... 121

5.3.1 Useful information on shared devices ................................................................................... 121

5.3.2 Configuring shared device .................................................................................................... 124

5.3.3 Configuring an I-device as a shared device.......................................................................... 128

5.3.4 Module-internal shared input/shared output (MSI/MSO) ...................................................... 137

5.4 Media redundancy (ring topologies) ..................................................................................... 144

5.4.1 Media Redundancy Protocol (MRP) ..................................................................................... 145

5.4.2 Configuring media redundancy ............................................................................................. 148

5.4.3 Media Redundancy with Planned Duplication of frames (MRPD) ........................................

5.

4.4 Multiple rings ......................................................................................................................... 152

150

5.5 Real-time communication ..................................................................................................... 157

5.5.1 Introduction ........................................................................................................................... 157

5.5.2 RT ......................................................................................................................................... 158

5.5.3 IRT ........................................................................................................................................ 159

5.5.4 Comparison of RT and IRT ................................................................................................... 162

5.5.5 Configuring PROFINET IO with IRT ..................................................................................... 162

5.5.6 Setting the bandwidth usage for the send clock ................................................................... 166

5.5.7 Setup recommendations for optimizing PROFINET ............................................................. 167

5.5.8 Limitation of the data infeed into the network ....................................................................... 171

PROFINET with STEP 7 V14

Function Manual, 09/2016, A5E03444486-AG

9

Table of contents

Glossary .............................................................................................................................................. 242

Index ................................................................................................................................................... 255

5.6 PROFINET with performance upgrade ................................................................................ 172

5.6.1 Dynamic frame packing ....................................................................................................... 173

5.6.2 Fragmentation ...................................................................................................................... 175

5.6.3 Fast forwarding .................................................................................................................... 176

5.6.4 Configuration of IRT with high performance ........................................................................ 177

5.6.5 Sample configuration for IRT with high performance........................................................... 181

5.7 Isochronous mode ............................................................................................................... 182

5.7.1 What is isochronous mode? ................................................................................................. 182

5.7.2 Use of isochronous mode .................................................................................................... 183

5.7.3 Isochronous applications ..................................................................................................... 183

5.7.4 Time sequence of synchronization ...................................................................................... 185

5.7.5 Basics of Programming ........................................................................................................ 186

5.7.6 Program processing according to the IPO model with application cycle = 1 ....................... 187

5.7.7 Program execution according to the IPO model with application cycle > 1 ......................... 188

5.7.8 Configuring isochronous mode ............................................................................................ 189

5.7.9 Setting the application cycle and delay time ........................................................................ 192

5.8 Device replacement without exchangeable medium ........................................................... 193

5.8.1 Device replacement without exchangeable medium/PG function ....................................... 194

5.8.2 Replacing an IO device without exchangeable medium ...................................................... 196

5.8.3 Permit overwriting of PROFINET device name ................................................................... 197

5.9 Standard machine projects .................................................................................................. 199

5.9.1 Multiple use IO systems ....................................................................................................... 200

5.9.1.1 What you should know about multiple use IO systems ....................................................... 200

5.9.1.2 Configuring multiple use IO systems ................................................................................... 204

5

.9.1.3 Adapt multiple use IO systems locally ................................................................................. 207

5.9.2 Configuration control for IO systems ................................................................................... 209

5.9.2.1 Information about configuration control of IO systems ........................................................ 209

5.9.2.2 Configuring IO devices as optional ...................................................................................... 212

5.9.2.3 Enabling optional IO devices in the program ....................................................................... 213

5.9.2.4 Configuring flexible order of IO devices ............................................................................... 219

5.9.2.5 Customizing arrangement of IO devices in the program ..................................................... 222

5.9.2.6 System behavior and rules .................................................................................................. 225

5.10 Saving energy with PROFIenergy........................................................................................ 227

5.11 Docking systems .................................................................................................................. 229

5.11.1 Configuring docking systems ............................................................................................... 232

5.12 Accelerating startup ............................................................................................................. 234

5.12.1 Options for accelerating the startup of IO devices ............................................................... 234

5.12.2 Prioritized startup ................................................................................................................. 236

5.12.3 Configuring prioritized startup .............................................................................................. 237

5.12.4 Optimize the port settings .................................................................................................... 239

5.12.5 Optimize the cabling of the ports ......................................................................................... 240

5.12.6 Measures in the user program ............................................................................................. 241

PROFINET with STEP 7 V14

10 Function Manual, 09/2016, A5E03444486-AG

1

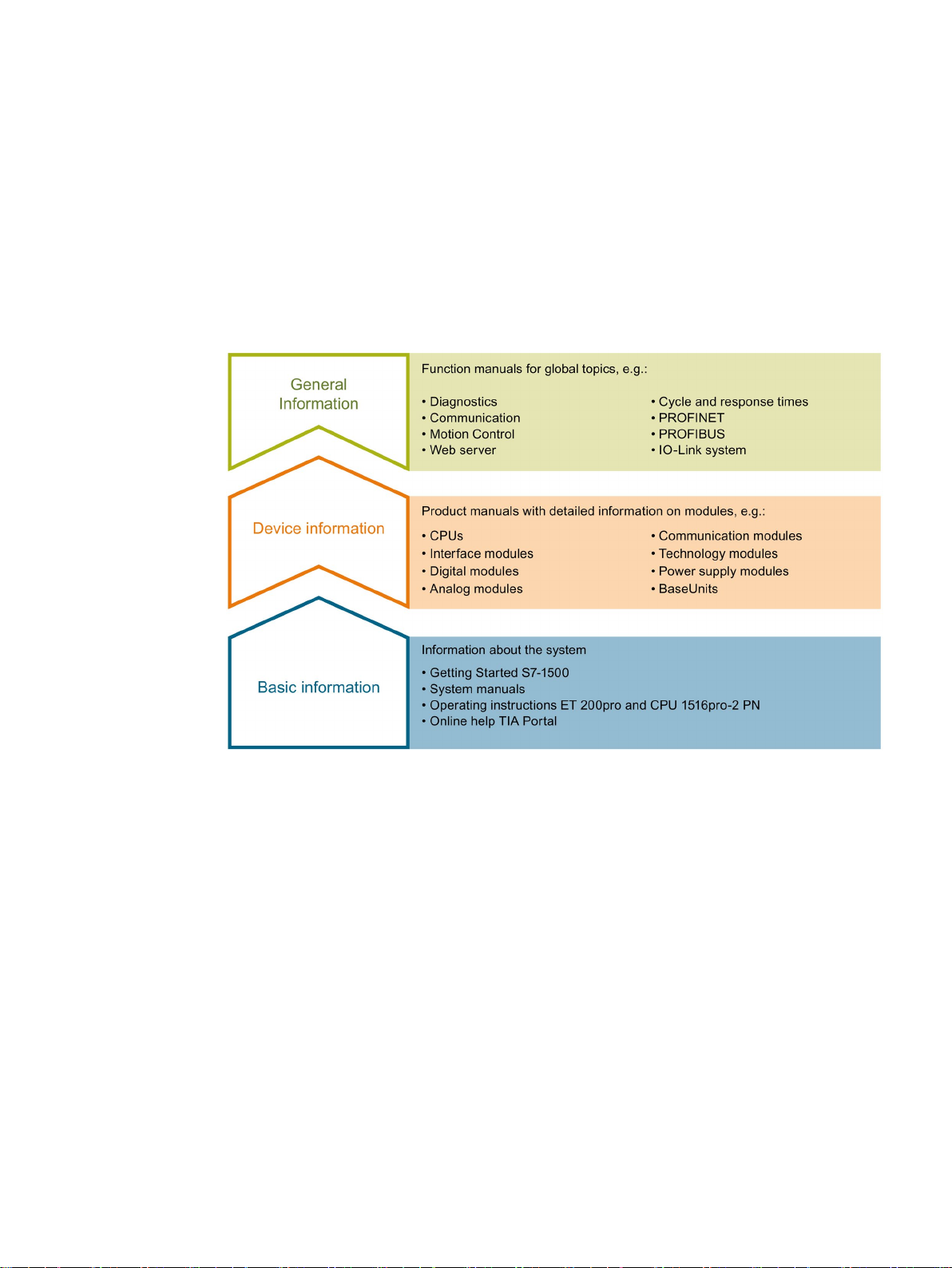

Basic information

Device information

The documentation for the SIMATIC S7-1500 automation system, for CPU 1516pro-2 PN

based on SIMATIC S7-1500, and for the distributed I/O systems SIMATIC ET 200MP,

ET 200SP and ET 200AL is divided into three areas.

This division allows you easier access to the specific information you require.

System manuals and Getting Started manuals describe in detail the configuration,

installation, wiring and commissioning of the SIMATIC S7-1500, ET 200MP, ET 200SP and

ET 200AL systems; use the corresponding operating instructions for CPU 1516pro-2 PN.

The STEP 7 online help supports you in configuration and programming.

Product manuals contain a compact description of the module-specific information, such as

properties, terminal diagrams, characteristics and technical specifications.

PROFINET with STEP 7 V14

Function Manual, 09/2016, A5E03444486-AG

11

Documentation guide

General information

Manual Collections

"mySupport"

"mySupport" - Documentation

The function manuals contain detailed descriptions on general topics such as diagnostics,

communication, Motion Control, Web server, OPC UA.

You can download the documentation free of charge from the Internet

http://w3.siemens.com/mcms/industrial-automation-systems-simatic/en/manual-

(

overview/Pages/Default.aspx).

Changes and additions to the manuals are documented in product information sheets.

You will find the product information on the Internet:

● S7-1500/ET 200MP (https://support.industry.siemens.com/cs/us/en/view/68052815

● ET 200SP (https://support.industry.siemens.com/cs/us/en/view/73021864)

● ET 200AL (https://support.industry.siemens.com/cs/us/en/view/99494757)

The Manual Collections contain the complete documentation of the systems put together in

one file.

You will find the Manual Collections on the Internet:

● S7-1500/ET 200MP (https://support.industry.siemens.com/cs/ww/en/view/86140384

● ET 200SP (https://support.industry.siemens.com/cs/ww/en/view/84133942)

● ET 200AL (https://support.industry.siemens.com/cs/ww/en/view/95242965)

With "mySupport", your personal workspace, you make the best out of your Industry Online

Support.

In "mySupport", you can save filters, favorites and tags, request CAx data and compile your

personal library in the Documentation area. In addition, your data is already filled out in

support requests and you can get an overview of your current requests at any time.

)

)

You must register once to use the full functionality of "mySupport".

You can find "mySupport" on the Internet (https://support.industry.siemens.com/My/ww/en

).

In the Documentation area in "mySupport" you can combine entire manuals or only parts of

these to your own manual.

You can export the manual as PDF file or in a format that can be edited later.

You can find "mySupport" - Documentation on the Internet

(http://support.industry.siemens.com/My/ww/en/documentation

PROFINET with STEP 7 V14

12 Function Manual, 09/2016, A5E03444486-AG

).

Documentation guide

"mySupport" - CAx data

Application examples

TIA Selection Tool

In the CAx data area in "mySupport", you can access the current product data for your CAx

or CAe system.

You configure your own download package with a few clicks.

In doing so you can select:

● Product images, 2D dimension drawings, 3D models, internal circuit diagrams, EPLAN

macro files

● Manuals, characteristics, operating manuals, certificates

● Product master data

You can find "mySupport" - CAx data on the Internet

(http://support.industry.siemens.com/my/ww/en/CAxOnline

).

The application examples support you with various tools and examples for solving your

automation tasks. Solutions are shown in interplay with multiple components in the system separated from the focus on individual products.

You will find the application examples on the Internet

(https://support.industry.siemens.com/sc/ww/en/sc/2054

With the TIA Selection Tool, you can select, configure and order devices for Totally

Integrated Automation (TIA).

This tool is the successor of the SIMATIC Selection Tool and combines the known

configurators for automation technology into one tool.

With the TIA Selection Tool, you can generate a complete order list from your product

selection or product configuration.

You can find the TIA Selection Tool on the Internet

(http://w3.siemens.com/mcms/topics/en/simatic/tia-selection-tool

).

).

PROFINET with STEP 7 V14

Function Manual, 09/2016, A5E03444486-AG

13

Documentation guide

SIMATIC Automation Tool

PRONETA

You can use the SIMATIC Automation Tool to run commissioning and maintenance activities

simultaneously on different SIMATIC S7 stations as a bulk operation, independently of the

TIA Portal.

The SIMATIC automation tool provides a variety of functions:

● Scanning of a PROFINET/Ethernet plant network and identification of all connected CPUs

● Address assignment (IP, subnet, gateway) and station name (PROFINET device) to a

CPU

● Transfer of the date and programming device/PC time converted to UTC time to the

module

● Program download to CPU

● Operating mode switchover RUN/STOP

● CPU localization by means of LED flashing

● Reading out CPU error information

● Reading of CPU diagnostic buffer

● Reset to factory settings

● Updating the firmware of the CPU and connected modules

You can find the SIMATIC Automation Tool on the Internet

(https://support.industry.siemens.com/cs/ww/en/view/98161300

With SIEMENS PRONETA (PROFINET network analysis), you analyze the plant network

during commissioning. PRONETA features two core functions:

● The topology overview independently scans PROFINET and all connected components.

● The IO check is a fast test of the wiring and the module configuration of a plant.

You can find SIEMENS PRONETA on the Internet

(https://support.industry.siemens.com/cs/ww/en/view/67460624

).

).

PROFINET with STEP 7 V14

14 Function Manual, 09/2016, A5E03444486-AG

2

2.1

Introduction to PROFINET

What is PROFINET IO?

Objectives of PROFINET

Within the framework of Totally Integrated Automation (TIA), PROFINET IO is the logical

further development of:

● PROFIBUS DP, the established fieldbus and

● Industrial Ethernet

PROFINET IO is based on 20 years of experience with the successful PROFIBUS DP and

combines the normal user operations with the simultaneous use of innovative concepts of

Ethernet technology. This ensures the integration of PROFIBUS DP into the PROFINET

world.

PROFINET IO as the Ethernet-based automation standard of PROFIBUS/PROFINET

International defines a cross-vendor communication, automation, and engineering model.

The objectives of PROFINET:

● Industrial networking, based on Industrial Ethernet (open Ethernet standard)

● Compatibility of Industrial Ethernet and standard Ethernet components

● High robustness due to Industrial Ethernet devices. Industrial Ethernet devices are suited

to the industrial environment (temperature, noise immunity, etc.).

● Use of IT standards such as TCP/IP, http.

● Real-time capability

● Seamless integration of other fieldbus systems

PROFINET with STEP 7 V14

Function Manual, 09/2016, A5E03444486-AG

15

Description

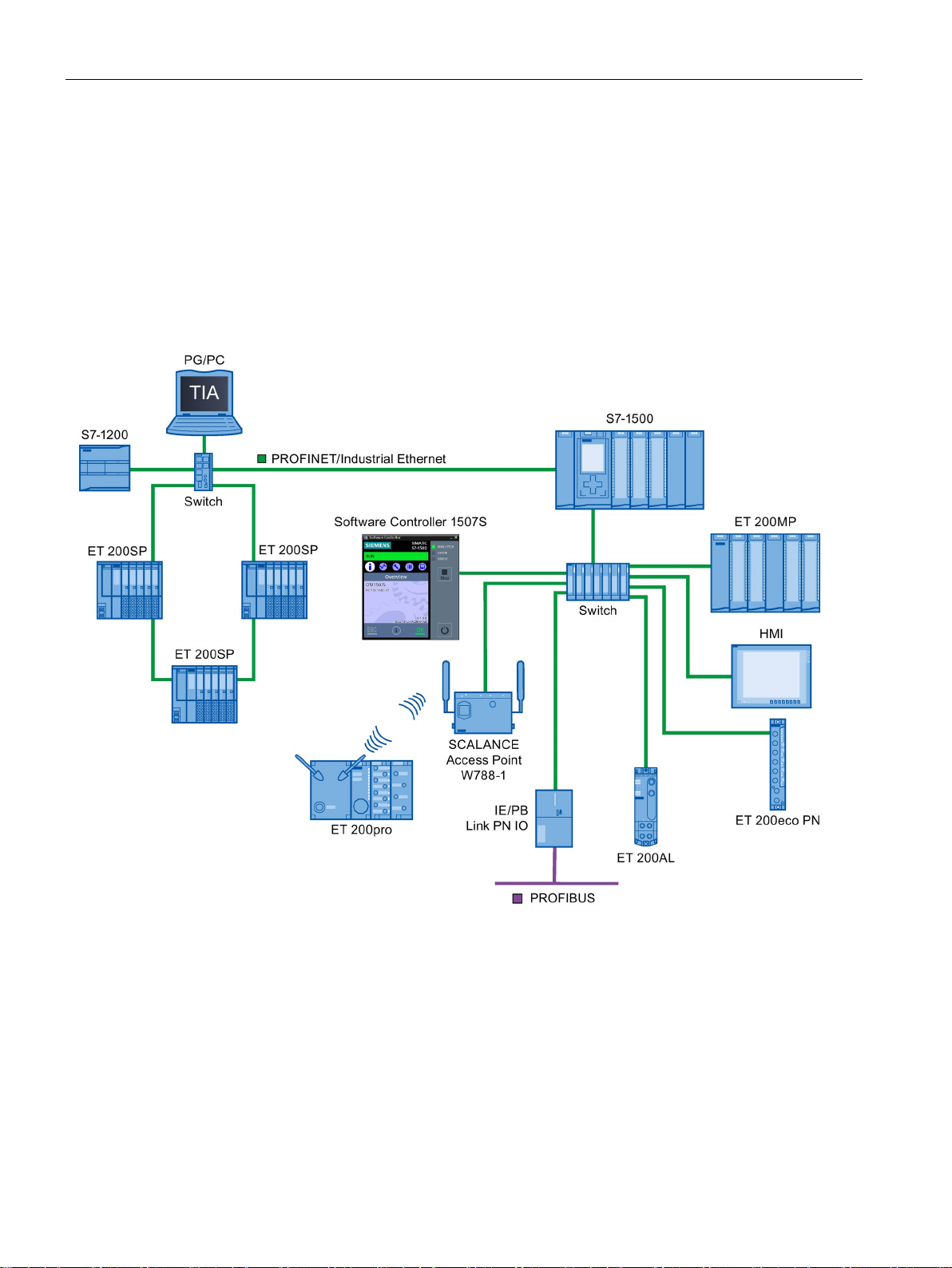

Implementation of PROFINET in SIMATIC

PROFINET IO

STEP 7

2.1 Introduction to PROFINET

PROFINET is implemented in SIMATIC as follows:

● We have implemented communication between field devices in SIMATIC with

● Installation technology and network components are available as SIMATIC NET products.

● Ethernet standard protocol and procedures (e.g., SNMP = Simple Network Management

Protocol for network parameter assignment and diagnostics) are used for remote

maintenance and network diagnostics.

.

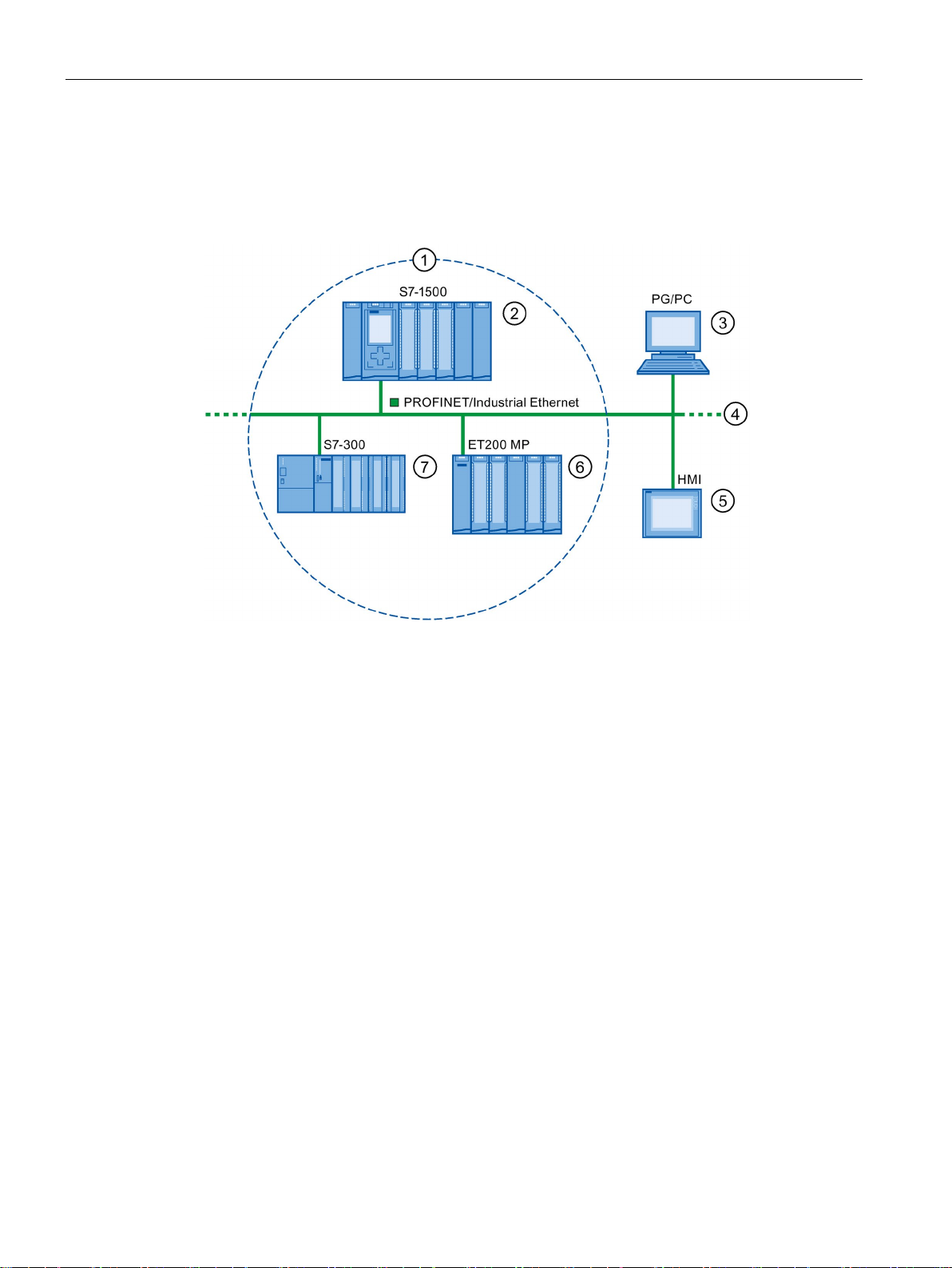

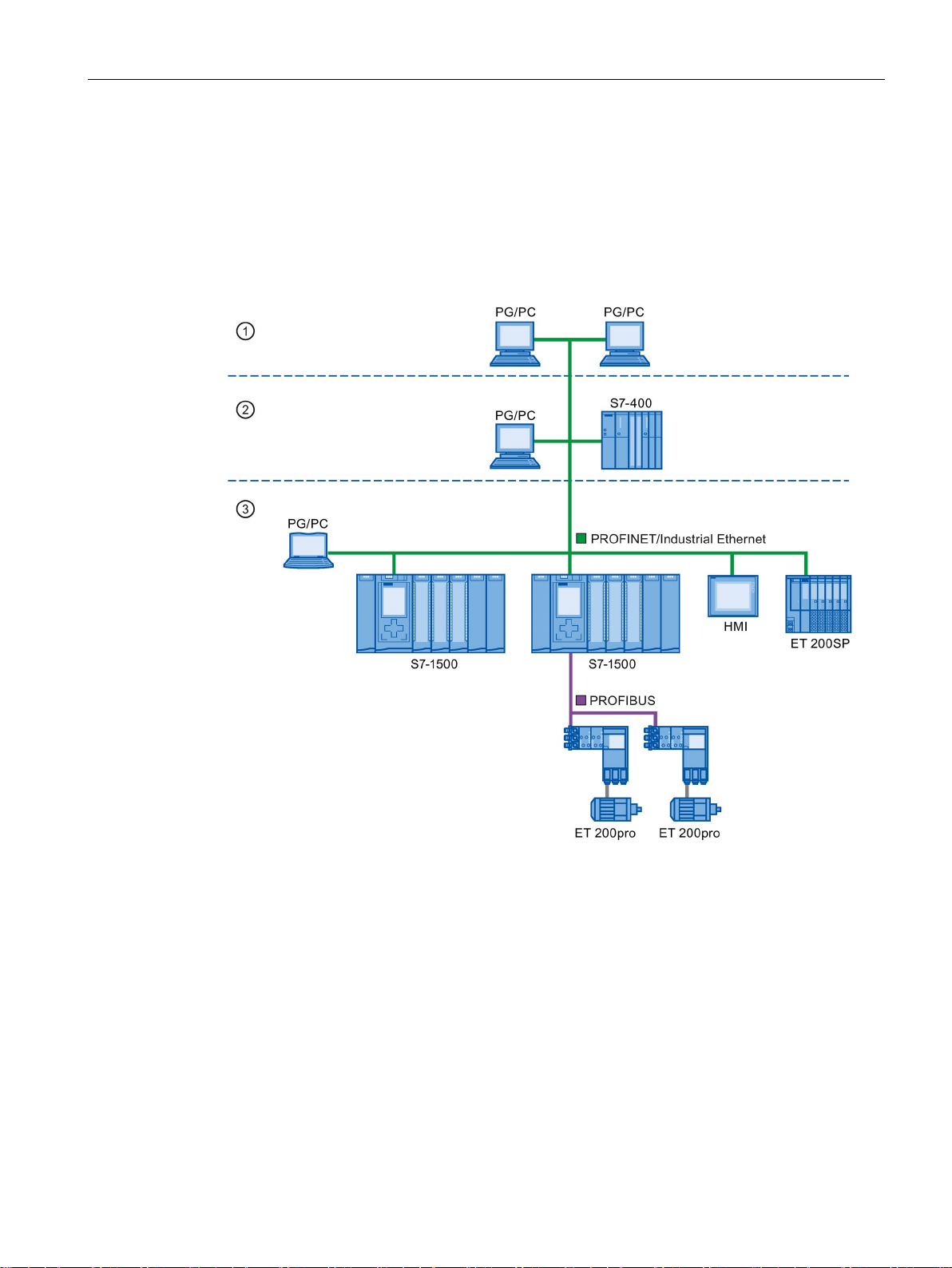

Figure 2-1 PROFINET overview configuration

The STEP 7 engineering tool supports you in setting up and configuring an automation

solution. STEP 7 provides a uniform application view over all bus systems.

PROFINET with STEP 7 V14

16 Function Manual, 09/2016, A5E03444486-AG

Description

Documentation from PROFIBUS & PROFINET International on the Internet

Overview of the most important documents and links

2.1.1

PROFINET terms

Definition: Devices in the PROFINET environment

2.1 Introduction to PROFINET

You will find numerous documents on the topic of PROFINET at the Internet address

(http://www.profibus.com

organization, which is also responsible for PROFINET.

Additional information can be found on the Internet (http://www.siemens.com/profinet).

) of the "PROFIBUS & PROFINET International" PROFIBUS user

A compilation of the most important PROFINET application examples, FAQs and other

contributions in the Industry Online Support is available in this FAQ

).

(https://support.industry.siemens.com/cs/ww/en/view/108165711

In the PROFINET environment, "device" is the generic term for:

● Automation systems (PLC, PC, for example)

● Distributed I/O systems

● Field devices (for example, hydraulic devices, pneumatic devices)

● Active network components (for example, switches, routers)

● Gateways to PROFIBUS, AS interface or other fieldbus systems

PROFINET with STEP 7 V14

Function Manual, 09/2016, A5E03444486-AG

17

Description

PROFINET IO devices

Number

PROFINET

Explanation

①

PROFINET IO System

②

and output signals with field devices.

③

(PROFINET IO supervisor)

diagnostics

④

PROFINET/Industrial Ethernet

Network infrastructure

⑤

HMI (Human Machine Interface)

Device for operating and monitoring functions.

⑥

ed PROFINET IO functionality)

⑦

I-device

Intelligent IO device

2.1 Introduction to PROFINET

The following graphic shows the general names used for the most important devices in

PROFINET. In the table below the graphic you can find the names of the individual

components in the PROFINET IO context.

IO controller Device used to address the connected IO devices.

This means that: The IO controller exchanges input

Programming device / PC

IO device A distributed field device that is assigned to one of

Figure 2-2 PROFINET devices

PG/PC/HMI device used for commissioning and for

the IO controllers (e.g., Distributed IO, valve terminals, frequency converters, switches with integrat-

PROFINET with STEP 7 V14

18 Function Manual, 09/2016, A5E03444486-AG

Description

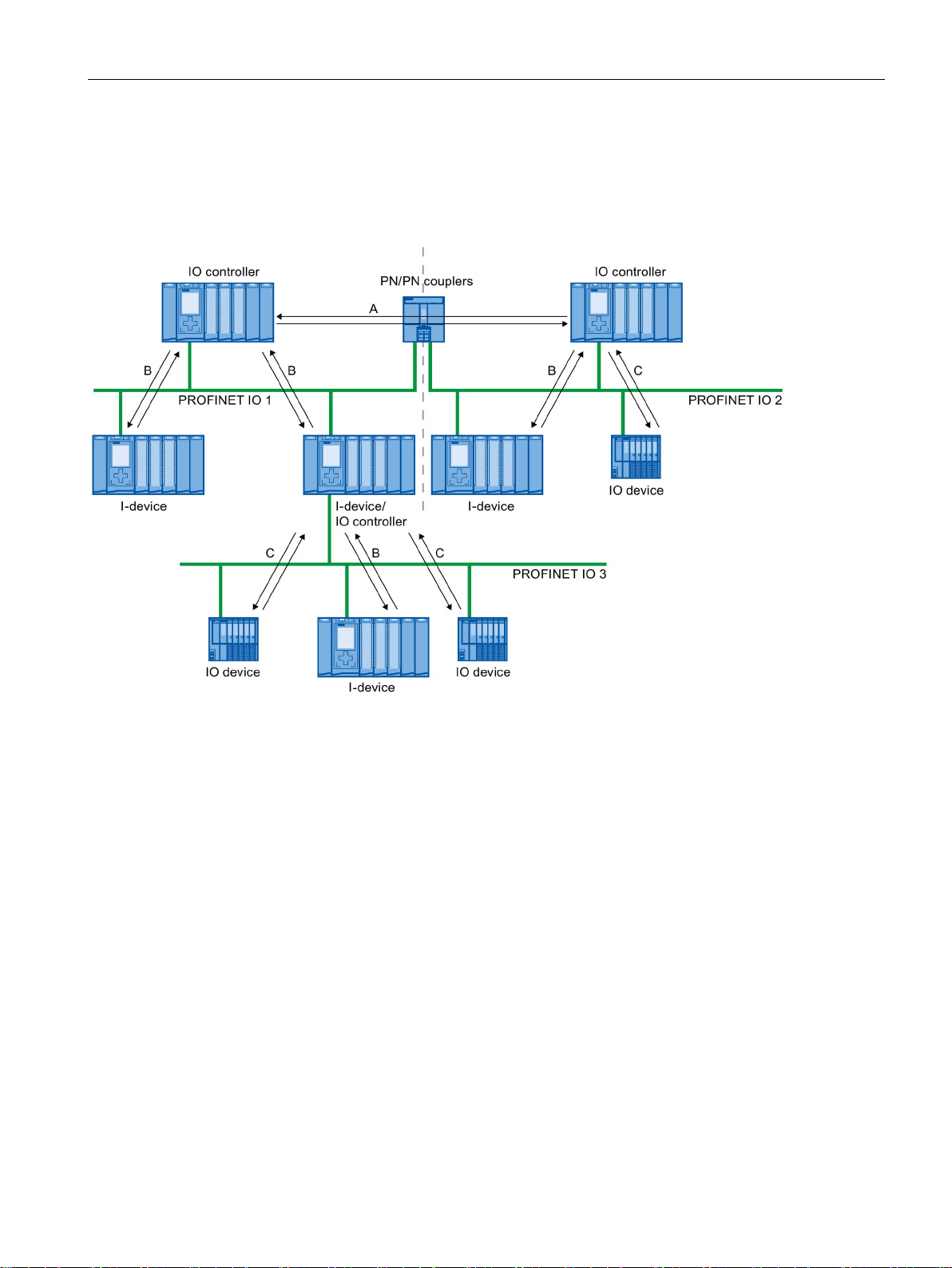

IO communication via PROFINET IO

A

IO controller - IO controller communication via PN/PN coupler

B

IO controller - I-device communication

C

IO controller - IO-device communication

2.1 Introduction to PROFINET

The inputs and outputs of distributed I/O devices are read and written by means of

PROFINET IO using what is referred to as IO communication. The following figure provides

an overview of IO communication by means of PROFINET IO.

Figure 2-3 IO communication via PROFINET IO

PROFINET with STEP 7 V14

Function Manual, 09/2016, A5E03444486-AG

19

Description

IO communication via PROFINET IO

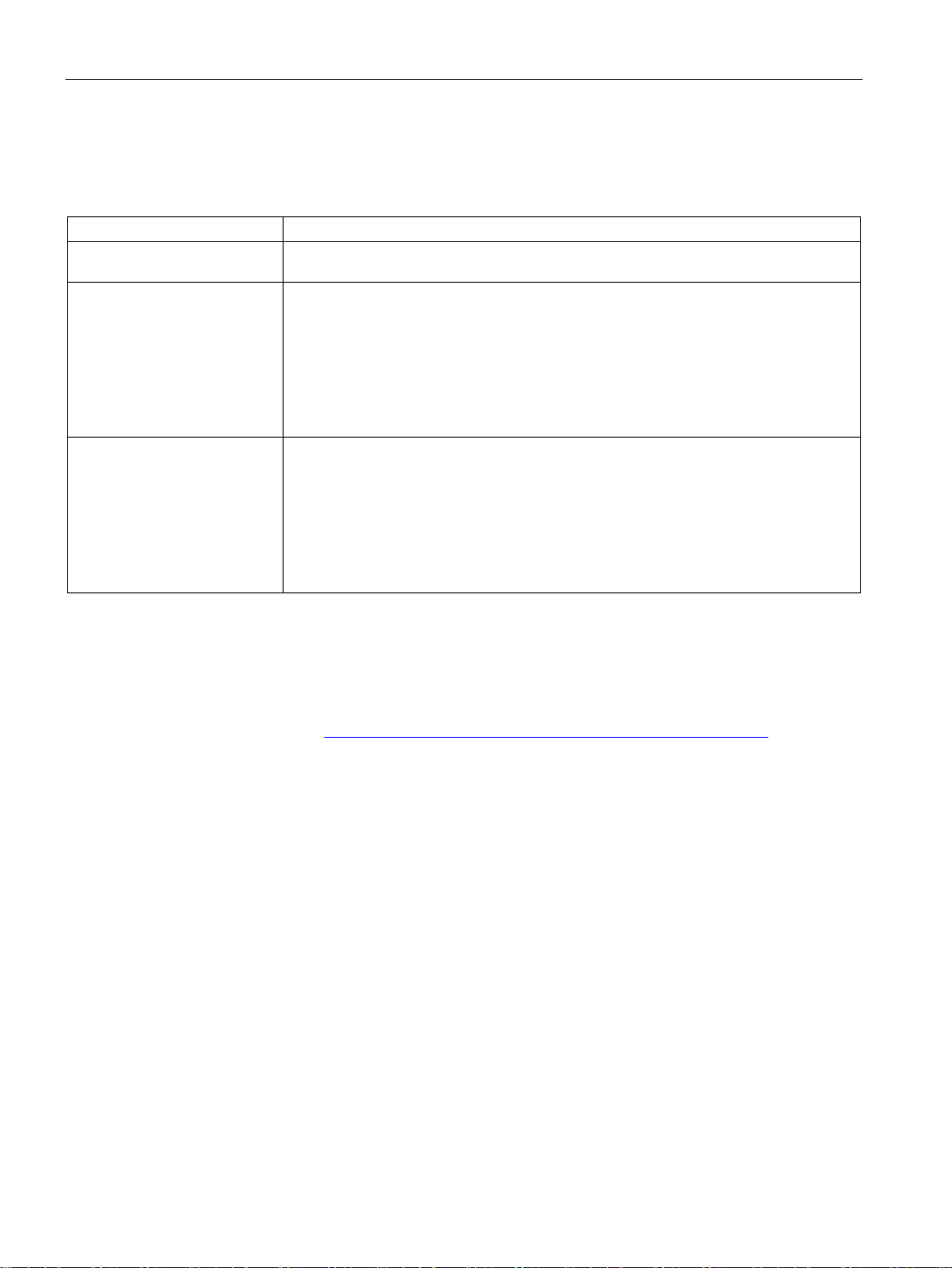

Communication between ...

Explanation

receives data from these devices.

A fixed quantity of data is transferred cyclically between the user programs in CPUs of IO

via direct access.

A fixed quantity of data is cyclically transferred between the user programs in CPUs of IO

via direct access.

See also

2.1.2

Basic terminology of communication

PROFINET communication

2.1 Introduction to PROFINET

Table 2- 1 IO communication via PROFINET IO

IO controllers and IO devices The IO controller sends data cyclically to the IO devices of its PROFINET IO system and

IO controller and I-device

controllers and I-devices.

The IO controller does not access the I/O module of the I-device, but instead accesses

configured address ranges, i.e. transfer ranges, which may be located inside our outside

the process image of the CPU of the I-device. If parts of the process image are used as

transfer ranges, it is not permitted to use these for real I/O modules.

Data transfer takes place using load- and transfer operations via the process image or

IO controller and IO controller

controllers. A PN/PN coupler is required as additional hardware.

The IO controllers mutually access configured address ranges, i.e. transfer ranges,

which may be located inside or outside the process image of the CPU. If parts of the

process image are used as transfer ranges, it is not permitted to use these for real I/O

modules.

Data transfer takes place using load- and transfer operations via the process image or

Network security (Page 36)

Functions (Page 93)

Communication (http://support.automation.siemens.com/WW/view/en/59192925

PROFINET communication takes place via Industrial Ethernet. The following transmission

types are supported:

● Acyclic transmission of engineering and diagnostics data and interrupts

● Cyclic transmission of user data

The PROFINET-IO communication takes place in real-time.

For additional information on the real-time communication, refer to chapter Real-time

communication (Page 157).

)

PROFINET with STEP 7 V14

20 Function Manual, 09/2016, A5E03444486-AG

Description

Transparent data access

①

Management level

②

Control level

③

Production level

2.1 Introduction to PROFINET

Access to process data from different levels of the factory is supported by PROFINET

communication. By using Industrial Ethernet, standard mechanisms of communication and

information technology such as OPC/XML can now be used along with standard protocols

such as UDP/TCP/IP and HTTP in automation engineering. This allows transparent access

from company management level directly to the data from the automation systems at the

control level and production level.

PROFINET with STEP 7 V14

Function Manual, 09/2016, A5E03444486-AG

Figure 2-4 Access to process data

21

Description

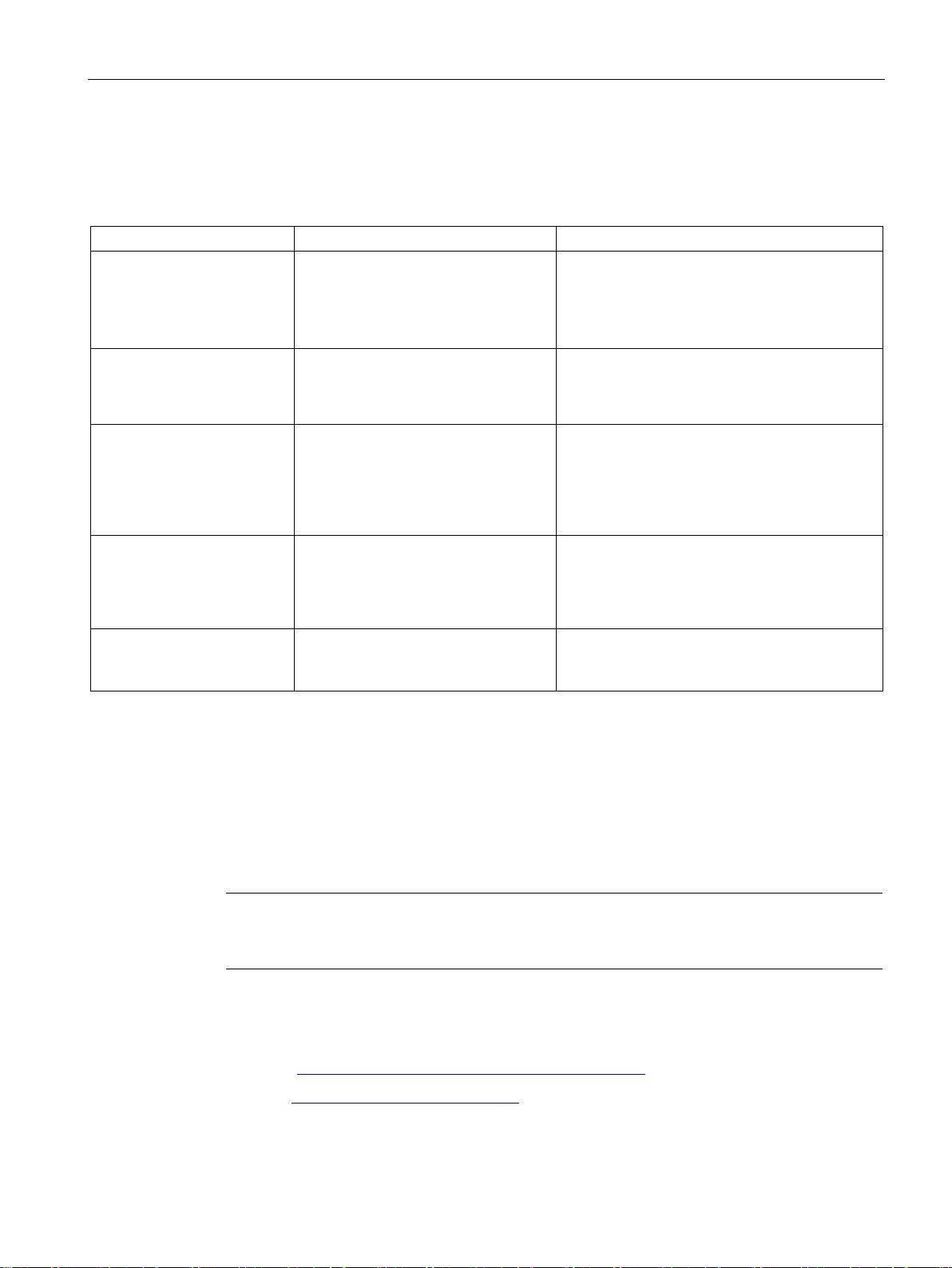

Update time

Watchdog time

Send clock

Relationship between the update time and send clock

Send clock

Update time

Reduction ratios

250 μs

250 μs to 128 ms

1,2, ..., 512

1 ms

1 ms to 512 ms

1,2, ..., 512

2 ms

2 ms to 512 ms

1,2, ..., 256

4 ms

4 ms to 512 ms

1,2, ..., 128

Additional information

2.1 Introduction to PROFINET

The update time is a time interval. IO controller and IO device/I-device exchange IO data

cyclically in the IO system within this time interval. The update time can be configured

separately for each IO device and determines the interval at which output data is sent from

the IO controller to the IO device (output module/submodule) as well as input data from the

IO device to the IO controller (input module/submodule).

STEP 7 calculates the update time automatically in the default setting for each IO device of

the PROFINET IO system, taking into account the volume of data to be exchanged as well

as the set send clock.

For additional information on the update time, refer to section Real-time communication

(Page 157).

The watchdog time is the time interval that an IO controller or IO device permits, without

receiving IO data. If the IO device is not supplied by the IO controller with data within the

watchdog time, the device detects the missing frames and outputs substitute values. This is

reported in the IO controller as a station failure.

In STEP 7, the watchdog time is made up from an integral multiple of the update time and

can be set by the user.

The period of time between two consecutive communication cycles. The send clock is the

shortest possible interval in data exchange.

The calculated update times are reduction ratios (1, 2, 4, 8, ..., 512) of the send clock. The

minimum possible update time thus depends on the minimum send clock of the IO controller

that can be set and the efficiency of the IO controller and IO device. Depending on the send

clock, it can be that only some of the reduction ratios are available (STEP 7 guarantees this

through a pre-selection).

The following tables illustrate the dependency of the update time that can be set on the send

clock, using an example of the CPU 1516-3 PN/DP. The update times satisfy the

requirements of the PROFINET standard IEC 61158.

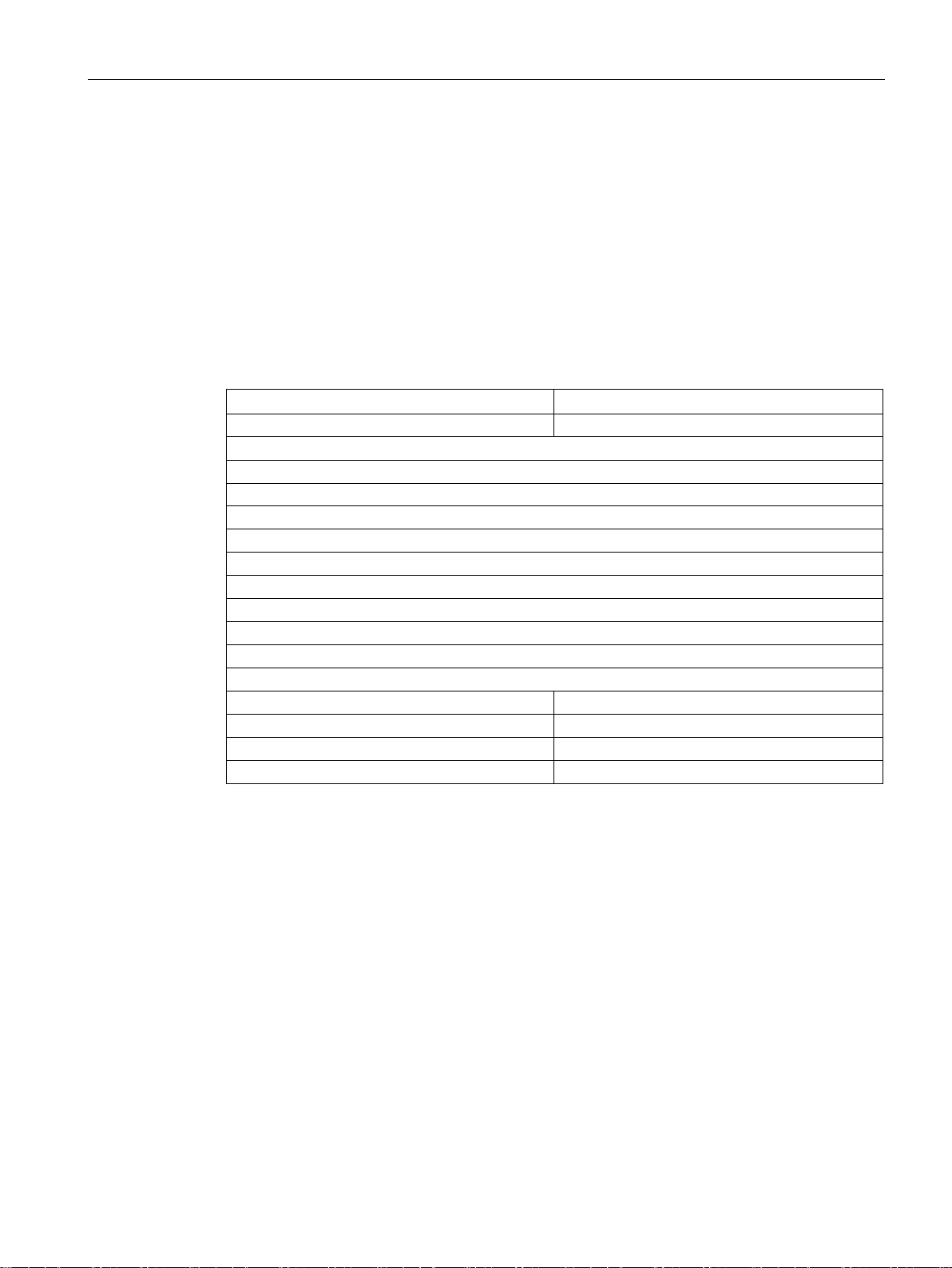

Table 2- 2 With real-time communication the following applies:

500 μs 500 μs to 256 ms 1,2, ..., 512

PROFINET with STEP 7 V14

22 Function Manual, 09/2016, A5E03444486-AG

For information on real-time communication, refer to the section Real-Time Communication

(RT) (Page 158).

Description

2.1.3

PROFINET interface

Overview

Properties

Identification and numbering of the interfaces and ports

Element

Symbol

Interface number

Interface

X

In ascending order starting from number 1

(for each interface)

Ring port

R

Examples of identification

Sample labeling

Interface number

Port number

X2 P1

2

1

X1 P2

1

2

X1 P1 R

1

1 (ring port)

2.1 Introduction to PROFINET

PROFINET devices of the SIMATIC product family have one or more PROFINET interfaces

(Ethernet controller/interface). The PROFINET interfaces have one or more ports (physical

connection options).

In the case of PROFINET interfaces with multiple ports, the devices have an integrated

switch.

PROFINET devices with two ports on one interface allow you to configure the system in a

line or ring topology. PROFINET devices with three or more ports on one interface are also

ideal for setting up tree topologies.

Properties and rules for naming the PROFINET interface and its representation in STEP 7

are explained in the following.

Every PROFINET device on the network is uniquely identified via its PROFINET interface.

For this purpose, each PROFINET interface has:

● A MAC address (factory default)

● An IP address

● A PROFINET device name

Interfaces and ports for all modules and devices in the PROFINET system are identified with

the following characters:

Table 2- 3 Identification for interfaces and ports of PROFINET devices

Port P In ascending order starting from number 1

Three examples illustrate the rules for identifying PROFINET interfaces:

Table 2- 4 Examples for identifying PROFINET interfaces

PROFINET with STEP 7 V14

Function Manual, 09/2016, A5E03444486-AG

23

Description

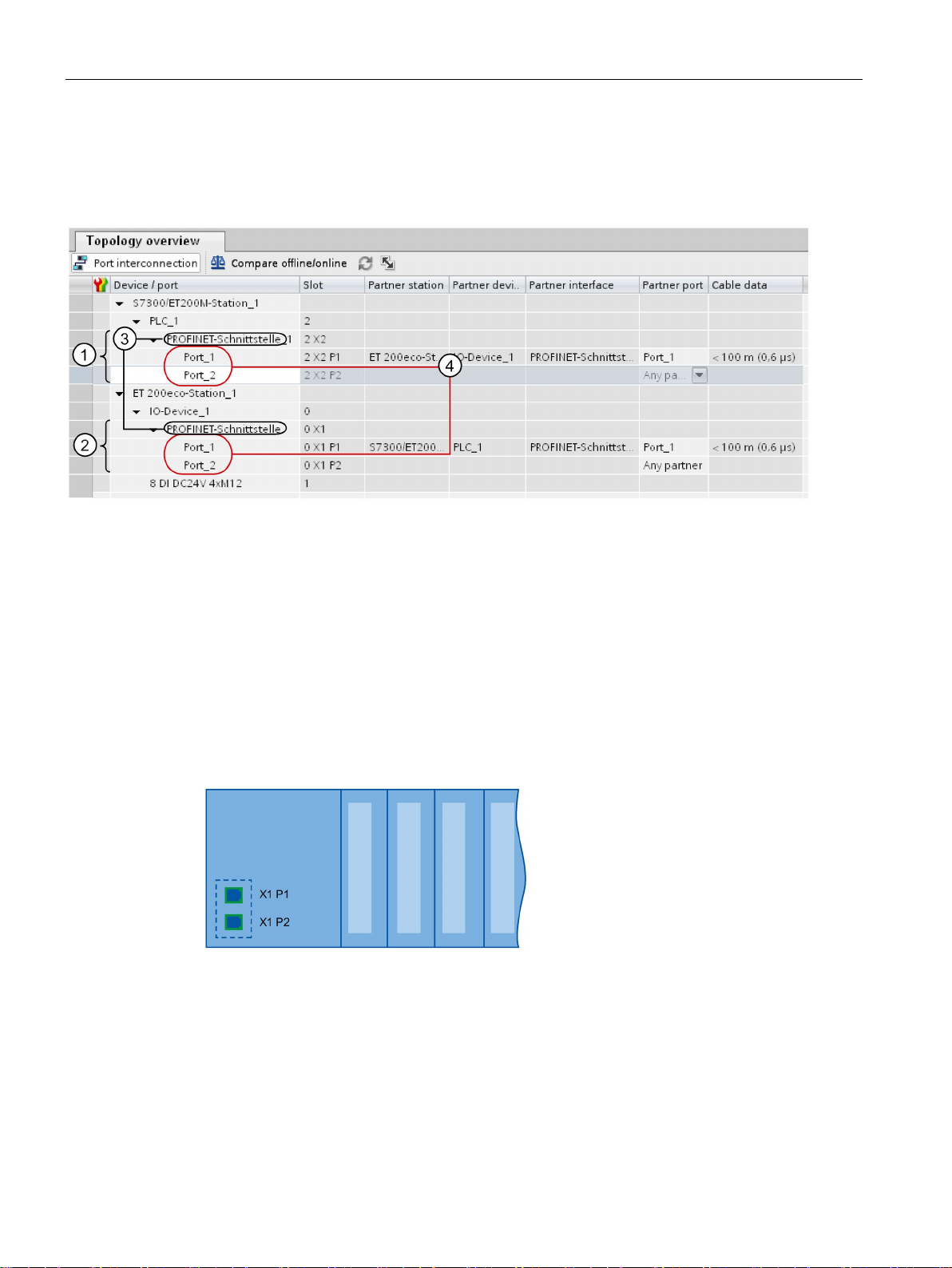

Representation of PROFINET Interfaces in the Topology Overview in STEP 7

Number

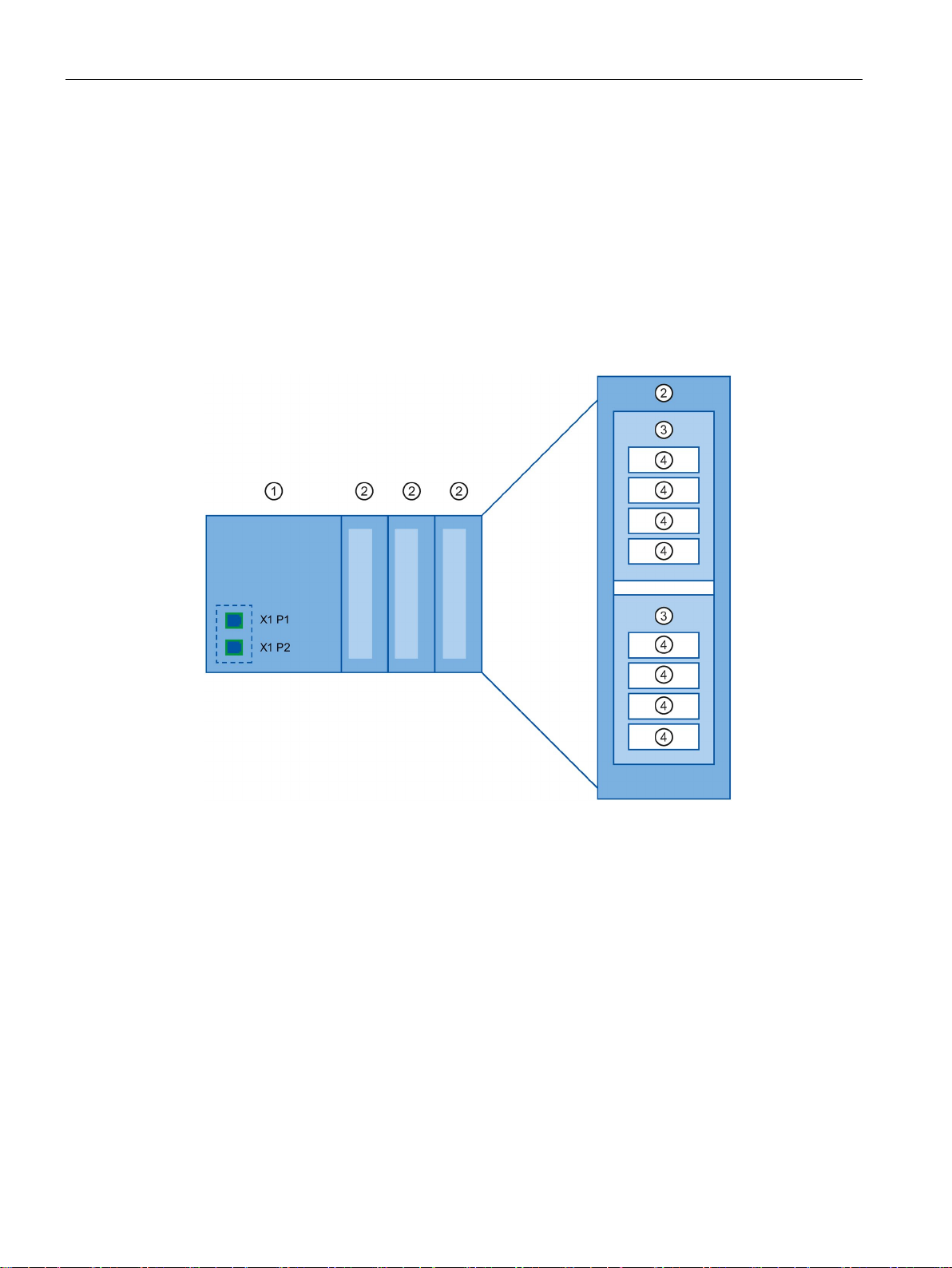

Description

①

PROFINET interface of an IO controller in STEP 7

②

PROFINET interface of an IO device in STEP 7

③

These lines represent the PROFINET interface.

④

These lines represent the "ports" of a PROFINET interface.

Schematic Representation of a PROFINET Interface with Integrated Switch

2.1 Introduction to PROFINET

You can find the PROFINET interface in the topology overview in STEP 7. The PROFINET

interface for an IO controller and an IO device is represented as follows in STEP 7:

Figure 2-5 Representation of the PROFINET interfaces in STEP 7

The following schematic diagram shows the PROFINET interface with integrated switch and

its ports for all PROFINETdevices.

Figure 2-6 PROFINET interface with integrated switch

PROFINET with STEP 7 V14

24 Function Manual, 09/2016, A5E03444486-AG

Description

Functional differences of the PROFINET interfaces

PROFINET interface (X1)

PROFINET interface (X2)

2 ports with PROFINET IO functionality:

1 port with PROFINET IO functionality:

PG communication

HMI communication

S7 communication

Time-of-day synchronization

Web server

Open communication

OPC UA server

IO controller

I-device

RT

IRT

-

Isochronous mode

-

Media redundancy

-

Prioritized startup

-

Additional Information on the Functionality of PROFINET interfaces

2.1 Introduction to PROFINET

PROFINET interfaces can provide different functions. PROFINET interface functions include

identification, configuration, diagnostics and communication services (e.g., open

communication). PROFINET interfaces that provide PROFINET IO functions and network

security functions are also available.

The following table illustrates the differences using the example of the CPU 1516-3 PN/DP

(as of firmware version V2.0), which features two PROFINET interfaces with different

functionality.

Table 2- 5 Differences between the PROFINET interfaces of the CPU 1516-3 PN/DP (as of firm-

ware version V2.0)

Identification, configuration and diagnostics

You can find information on the number and functionality of the interfaces of a PROFINET

device in the documentation for the specificPROFINET device.

PROFINET communication services are described in the Communication function manual.

In the Network security section you can find components that are used to protect networks

against hazards.

The Functions section describes the PROFINET IO functions.

PROFINET with STEP 7 V14

Function Manual, 09/2016, A5E03444486-AG

25

Description

2.1.4

Implementation of the PROFINET device model in SIMATIC

Slots and modules

Number

Description

①

Slot with bus interface

②

Slot with module

③

Subslot with submodule

④

Channel

2.1 Introduction to PROFINET

A PROFINET device can have a modular and compact structure. A modular PROFINET

device consists of slots into which the modules are inserted. The modules have channels

which are used to read and output process signals. A compact device has the same design

and can include modules, however, it cannot be physically expanded, which means that no

modules can be inserted.

This is illustrated by the following graphic.

PROFINET with STEP 7 V14

26 Function Manual, 09/2016, A5E03444486-AG

Figure 2-7 Configuration of a PROFINET device

A module can contain multiple submodules.

Description

Representation of PROFINET Device Model in the Device View of STEP 7

2.2

Setting up PROFINET

Contents of this chapter

Physical connections of industrial networks

2.2 Setting up PROFINET

The following figure shows the representation of the PROFINET device model in the device

view of STEP 7, based on the example of a distributed I/O system ET 200MP:

Figure 2-8 PROFINET device model in the device view of STEP 7

The following chapter provides background information on building your communication

network.

● Overview of the most important passive network components: These are network

components that forward a signal without the possibility of actively influencing it, for

example, cables, connectors, etc.

● Overview of the most important active network components: These are network

components that actively affect a signal, for example switches, routers, etc.

● Overview of the most common network structures (topologies).

PROFINET devices can be networked in industrial systems in two different physical ways:

● Connected line

– By means of electrical pulses via copper cables

– By means of optical pulses via fiber-optic cables

● Wireless via wireless network using electromagnetic waves

PROFINET with STEP 7 V14

Function Manual, 09/2016, A5E03444486-AG

27

Description

Fast Ethernet

Industrial Ethernet

2.2.1

Active Network Components

Introduction

Switched Ethernet

Switches

2.2 Setting up PROFINET

PROFINET devices and cabling technology in SIMATIC are suited for industrial use, as they

are based on Fast Ethernet and Industrial Ethernet.

●

You can use Fast Ethernet to transfer data at a speed of 100 Mbps. This transmission

technology uses the 100 Base-T standard for this.

●

Structure of Ethernet in industrial environment.

The biggest difference from standard Ethernet is the mechanical current carrying capacity

and noise immunity of the individual components.

The following active network components are available for PROFINET:

● Switch

● Router

PROFINET IO is based on switched Ethernet with full-duplex operation and a bandwidth of

100 Mbps. In this way, the network can be used much more efficiently through the

simultaneous data transfer of several devices. The PROFINET IO frames are processed with

high priority.

Switches are network components used to connect several terminal devices or network

segments in a local network (LAN).

For the communication of a device with several other devices on PROFINET, the device is

connected to the port of a switch. Other communication devices (including switches) can

then be connected to the other ports of the switch. The connection between a

communication device and the switch is a point-to-point connection.

A switch has the task of receiving and distributing frames. The switch "learns" the Ethernet

address(es) of a connected PROFINET device or additional switches and only forwards

those frames that are intended for the connected PROFINET device or the connected

switch.

PROFINET with STEP 7 V14

28 Function Manual, 09/2016, A5E03444486-AG

Description

Switch variants

Selection Guide for Switches

Switches of the SCALANCE product family

2.2 Setting up PROFINET

Switches are available in two models:

● Integrated into a PROFINET device

For PROFINET devices with multiple ports (two or more), we are dealing with devices

with an integrated switch (for example, CPU 1516-3 PN/DP).

● As autonomous device (for example, switches of the SCALANCE product family)

To use PROFINET with the RT class "RT", you can use any switch of "PROFINET

Conformance Class A" or higher. All switches of the SCALANCE product family meet these

requirements.

If you want to use PROFINET functions that provide an additional value, such as topology

recognition, diagnostics, device exchange without exchangeable medium/programming

device, you have to use a switch of the "PROFINET Conformance Class B" or higher.

To use PROFINET with the RT class "IRT", you must use a switch of "PROFINET

Conformance Class C". With switches of the SCALANCE product family, watch out for the

catalog feature "IRT PROFINET IO switch".

To select appropriate switches, we recommend the SIMATIC NET Selection Tool on the

Internet (http://support.automation.siemens.com/WW/view/en/39134641

Use the switches of the SCALANCE product family if you want to use the full scope of

PROFINET. They are optimized for use in PROFINET IO.

In the SCALANCE X device family, you will find switches with electrical and optical ports and

with a combination of both variants. SCALANCE X202-2IRT, for example, has two electrical

ports and two optical ports and supports IRT communication.

Beginning with the SCALANCE X200, you can configure, diagnose and address switches of

the SCALANCE X device series as PROFINET IO devices using STEP 7.

).

PROFINET with STEP 7 V14

Function Manual, 09/2016, A5E03444486-AG

29

Description

Router

Note

If devices need to communicate beyond the limits of a network, you must configure

router so that it allows this communication to take place.

2.2.2

Cabling technology

Cables for PROFINET

Simple method for the prefabrication of twisted pair cables

Note

A maximum of four plug

2.2 Setting up PROFINET

A router connects separated network segments with each other (e.g. management level and

control level). The volume of data volume must be coordinated with the services of the

respective network segment. A router also separates two networks and acts as a mediator

between both networks. It thus reduces the network load. Routing functionality is provided in

the SCALANCE X device family, with SCALANCE X300 or higher.

Communication devices on different sides of a router can only communicate with one

another if you have explicitly enabled communication between them via the router.

If you want to access manufacturing data directly from SAP, for example, use a router to

connect your Industrial Ethernet in the factory with the Ethernet in your office.

the

Information on routing with STEP 7 is available in the function manual Communication

(http://support.automation.siemens.com/WW/view/en/59192925

).

Electrical and optical cables are available for PROFINET. The type of cable depends on the

data transfer requirements and on the ambient conditions.

When you set up your PROFINET system, you can cut the twisted-pair cable to the required

length on site, strip it with the

Ethernet Fast Connect RJ45 plugs

stripping tool

using the cut-and-clamp method. For more information on

installation, refer to the installation instructions in the "SIMATIC NET Industrial Ethernet

Network Manual" (http://support.automation.siemens.com/WW/view/en/8763736

-in pairs are allowed between two switches per Ethernet path.

(for Industrial Ethernet), and fit the

Industrial

).

PROFINET with STEP 7 V14

30 Function Manual, 09/2016, A5E03444486-AG

Loading...

Loading...