Siemens SIMATIC FM 452 User Manual

Preface, Contents

User Information

SIMATIC

FM 452

Electronic Cam Controller

Installation and Parameter

Assignment

Manual

This manual is part of the documentation package

with the order number:

6ES7452-1AH00-8BG0

Product Overview

Basics of Cam Control

Installing and Removing the

FM 452

Wiring the FM 452 Electronic

Cam Controller

Installing the Software

Programming the FM 452

Putting the FM 452 into Operation

Reference Information

Machine Data and Cam Data

Settings

1

2

3

4

5

6

7

8

9

02/2000

C79000-G7076-C452

Edition 04

Encoders

Diagnostics

Samples

Appendices

Technical Specifications

Connection Diagrams

Data Blocks/Error Lists

Index

10

11

12

A

B

C

Notes on Safety

!

!

!

This manual contains notices which you should observe to ensure your own personal safety, as

well as to protect the product and connected equipment. These notices are highlighted in the manual by a warning triangle and are marked as follows according to the level of danger:

Danger

indicates that death, severe personal injury or substantial property damage will result if proper

precautions are not taken.

Warning

indicates that death, severe personal injury or substantial property damage can result if proper

precautions are not taken.

Caution

indicates that minor personal injury or property damage can result if proper precautions are not

taken.

Note

draws your attention to particularly important information on the product, handling the product,

or to a particular part of the documentation.

Qualified Personnel

Correct Usage

!

Trademarks

The reproduction, transmission or use of this document or its

contents is not permitted without express written authority.

Offenders will be liable for damages. All rights, including rights

created b y patent grant or registration of a utility model or design, are

reserved.

Siemens AG

Bereich Automatisierungs- und Antriebstechnik

Geschaeftsgebiet Industrie-Automatisierungssysteme

Postfach 4848, D-90327 Nuernberg

Only qualified personnel should be allowed to install and work on this equipment. Qualified

persons are defined as persons who are authorized to commission, to ground, and to tag circuits,

equipment, and systems in accordance with established safety practices and standards.

Note the following:

Warning

This device and its components may only be used for the applications described in the catalog or

the technical description, and only in connection with devices or components from other manufacturers which have been approved or recommended by Siemens.

This product can only function correctly and safely if it is transported, stored, set up, and installed correctly, and operated and maintained as recommended.

SIMATIC, SIMATIC NET and SIMATIC NET are registered trademarks of

SIEMENS AG.

Third parties using for their own purposes any other names in this document which refer to trademarks might infringe upon the rights of the trademark owners.

Disclaimer of LiabilityCopyright Siemens AG 1996 All rights reserved

We have checked the contents of this manual for agreement with the

hardware and software described. Since deviations cannot be

precluded entirely, we cannot guarantee full agreement. However,

the data in this manual are reviewed regularly and any necessary

corrections included in subsequent editions. Suggestions for

improvement are welcomed.

Siemens AG 1996

Subject to technical change.

Siemens Aktiengesellschaft C79000-G7076-C452

Preface

Numb

6ES7 452-1AH00-0AE0

Validity of the Manual

This manual contains the description of the FM 452 electronic cam controller valid

at the time the manual was printed. We reserve the right to describe modifications

in the functionality of the FM 452 in a product information leaflet.

The Manual with the

er in the Page Footer

....

EWA 4NEB 720 6012-02

EWA 4NEB 720 6012-02 a

C79000-G7076-C452 6ES7 452-1AH00-0AE0

MLFB (Order Number) Version

Contents of the Manual

This manual describes the hardware and software of the FM 452 electronic cam

controller.

It consists of the following:

• A section describing basic aspects (Chapters 1 to 7)

• A reference section (Chapters 8 to 12)

• An appendix (Chapters A, B and C)

... is Valid for the FM 452

1 =

2 =

5 =

2

43

3

54

6

87

or

2

43

• An index.

FM 452 Electronic Cam Controller

C79000-G7076-C452-04

iii

Preface

Further Support

If you have questions about using the products described in the manual and you

cannot find the answers here, please contact your local Siemens representative.

You will find the addresses, for example, in the appendix ”SIEMENS Worldwide” in

the installation manual

Installation

If you have any questions or comments on this manual, please fill out the remarks

form at the end of the manual and return it to the address shown on the form. We

would be grateful if you could take the time to answer the questions giving your

own personal opinion of the manual.

To help you to become familiar with working with SIMATIC S7 PLCs,

we offer a range of courses.

Please contact your regional training center or the central training center in

D-90027 Nuremberg, Tel. +49 911/895-3202 for more information.

CE Mark

S7-400/M7-400 Programmable Controllers, Hardware and

.

Our products meet the requirements of the EU directive 89/336/EEC

”Electromagnetic Compatibility” and the harmonized European standards (EN)

listed in the directive.

In compliance with the above mentioned EU directive, Article 10, the conformity

declarations are available for the relevant authorities at the following address:

Siemens Aktiengesellschaft

Bereich Automatisierungstechnik

A&D AS E48

Postfach 1963

92209 Amberg

Germany

iv

FM 452 Electronic Cam Controller

C79000-G7076-C452-04

Contents

1 Product Overview 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 What is the FM 452? 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Areas of Application of the FM 452 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Structure of an Electronic Cam Controller with an FM 452 1-4. . . . . . . . . . . .

2 Basics of Cam Control 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Cams 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Tracks 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.1 Tracks and Track Result 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.2 Special Tracks 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Hysteresis 2-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Dynamic Adjustment 2-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 Interfaces of the Cam Controller 2-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Installing and Removing the FM 452 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Wiring the FM 452 Electronic Cam Controller 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Pinout of the Front Connector 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Wiring the Front Connector 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Installing the Software 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Programming the FM 452 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Basics of Programming an FM 452 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 FC CAM_INIT (FC 0) 6-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 FC CAM_CTRL (FC 1) 6-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4 FC CAM_DIAG (FC 2) 6-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5 FC CAM_MSRM (FC 3) 6-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6 Data Blocks 6-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6.1 Templates for Data Blocks 6-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6.2 Channel DB 6-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6.3 Diagnostic DB 6-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6.4 Parameter DB 6-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.7 Interrupts 6-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.8 Technical Specifications 6-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.9 Fast Access to Module Data 6-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.10 Parameter Transfer Routes 6-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FM 452 Electronic Cam Controller

C79000-G7076-C452-04

v

Contents

7 Putting the FM 452 into Operation 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Machine Data and Cam Data 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 Writing and Reading the Machine and Cam Data 8-2. . . . . . . . . . . . . . . . . . . .

8.2 System of Units 8-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 Machine Data of the Axis 8-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4 Absolute Encoder Adjustment 8-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5 Machine Data of the Encoder 8-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6 Resolution 8-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.7 Number of Cams and Track Data 8-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.8 Interrupt Enable 8-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.9 Cam Data 8-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 Settings 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 Influence of Settings on the Switching Response of Time Cams 9-2. . . . . .

9.2 Set Actual Value / Set Actual Value on-the-fly / Cancel Set Actual Value 9-3

9.3 Zero Offset 9-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4 Set Reference Point 9-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5 Changing the Cam Edges 9-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6 Fast Cam Parameter Change 9-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.7 Length Measurement/Edge Acquisition 9-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.8 Retrigger Reference Point 9-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.9 Deactivating Software Limit Switches 9-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.10 Simulation 9-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.11 Counted Values of the Counter Cam Tracks 9-25. . . . . . . . . . . . . . . . . . . . . . . . .

9.12 Position and Track Data 9-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.13 Encoder Data 9-27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.14 Cam and Track Data 9-28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.15 Control Signals for the Cam Controller 9-29. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.16 Return Signals for the Cam Controller 9-30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.17 Return Signals for Diagnostics 9-31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 Encoders 10-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1 Incremental Encoders 10-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2 Initiators 10-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.3 Absolute Encoders 10-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FM 452 Electronic Cam Controller

vi

C79000-G7076-C452-04

Contents

11 Diagnostics 11-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.1 Possibilities for Error Evaluation 11-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.2 Meaning of the Error LEDs 11-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.3 Diagnostic Interrupts 11-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12 Samples 12-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.1 Introduction 12-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.2 Requirements 12-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.3 Preparing the Samples 12-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.4 Code of the Samples 12-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.5 Testing a Sample 12-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.6 Adapting a Sample 12-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.7 Sample Program 1 “GettingStarted” 12-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.8 Sample Program 2 “Commission” 12-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.9 Sample Program 3 “OneModule” 12-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.10 Sample Program 4 “Interrupts” 12-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.11 Sample Program 5 “MultiModules” 12-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A Technical Specifications A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B Connection Diagrams B-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.1 Connection Diagram for Incremental Encoder Siemens 6FX 2001-2

(Up=5V; RS 422) B-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.2 Connection Diagram for Incremental Encoder Siemens 6FX 2001-2

(Up=24V; RS 422) B-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.3 Connection Diagram for Incremental Encoder Siemens 6FX 2001-4

(Up=24V; HTL) B-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.4 Connection Diagram for Absolute Encoder Siemens 6FX 2001-5

(Up=24V; SSI) B-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C Data Blocks/Error Lists C-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.1 Content of the Channel DB C-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.2 Content of the Parameter DB C-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.3 Data and Structure of the Diagnostic DB C-12. . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.4 Error Classes C-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index Index-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FM 452 Electronic Cam Controller

C79000-G7076-C452-04

vii

Contents

viii

FM 452 Electronic Cam Controller

C79000-G7076-C452-04

Product Overview

Chapter Overview

Section Contents Page

1.1 What is the FM 452? 1-2

1.2 Areas of Application of the FM 452 1-3

1.3 Structure of an Electronic Cam Controller with an FM 452 1-4

1

FM 452 Electronic Cam Controller

C79000-G7076-C452-04

1-1

Product Overview

1.1 What is the FM 452?

The FM 452 function module is a single-channel, electronic cam controller and is

used in the S7-400 programmable controller. It supports both rotary and linear

axes. When used for position sensing, you can connect initiators, incremental, or

absolute encoders (SSI). As a slave, the FM 452 can listen in on the SSI frame of

an absolute encoder.

You can use up to a maximum of 128 distance or time cams that you can assign to

32 cam tracks as required. The first 16 cam tracks are output via the digital outputs

on the module. For information about the functions and settings of the cam

controller, please refer to the following chapters.

You can operate several FM 452 modules at the same time. Combinations with

other FM/CP modules are also possible. One typical combination is to use the

module in conjunction with an FM 451 positioning module.

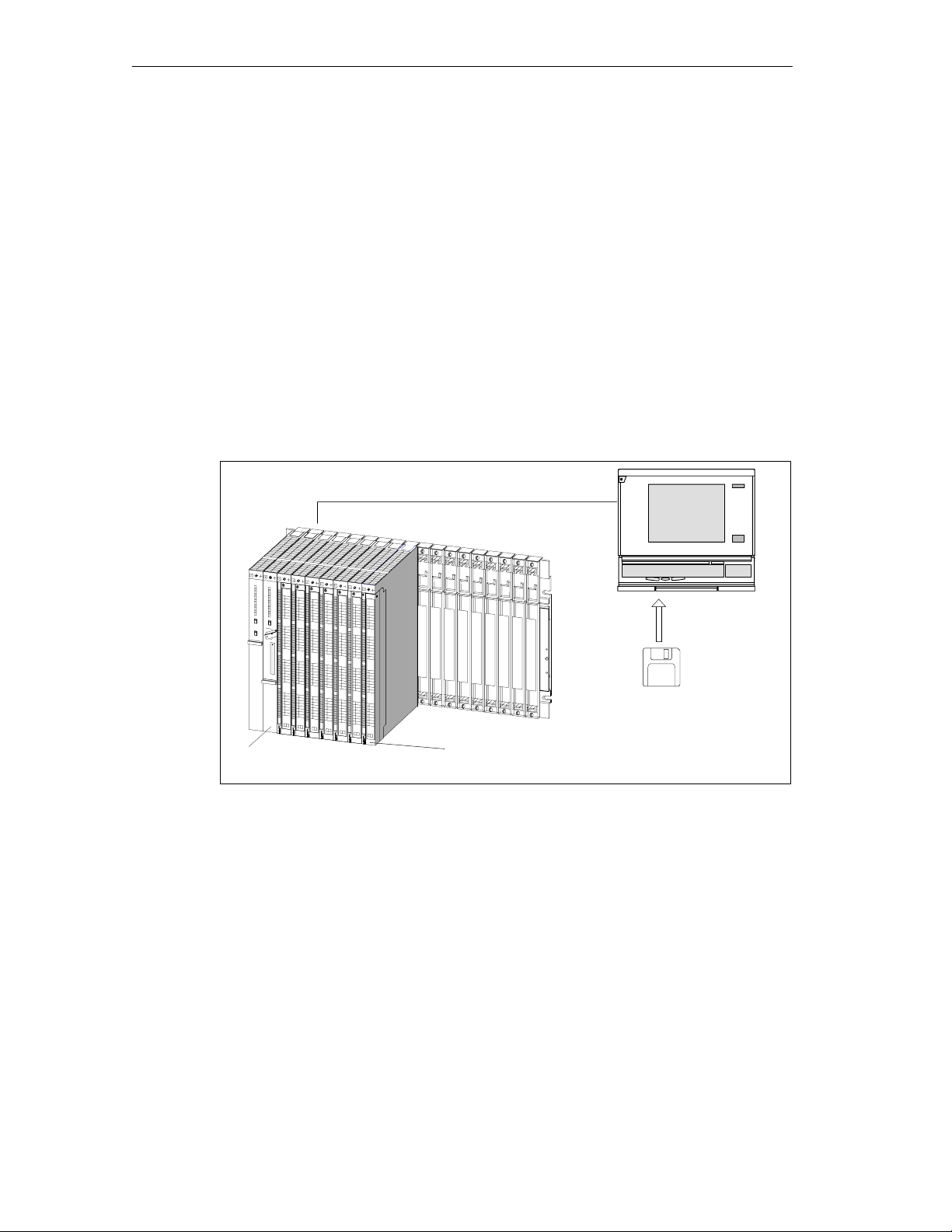

Programming device (PG) with STEP 7 and the

parameter assignment user interface for FM x52

1-2

Configuration package with

parameter assignment user

CPU

with user program and blocks of the FM 452

Figure 1-1 Structure of a SIMATIC S7-400 PLC with an FM 452

FM 452

interface, blocks and manual

FM 452 Electronic Cam Controller

C79000-G7076-C452-04

1.2 Areas of Application of the FM 452

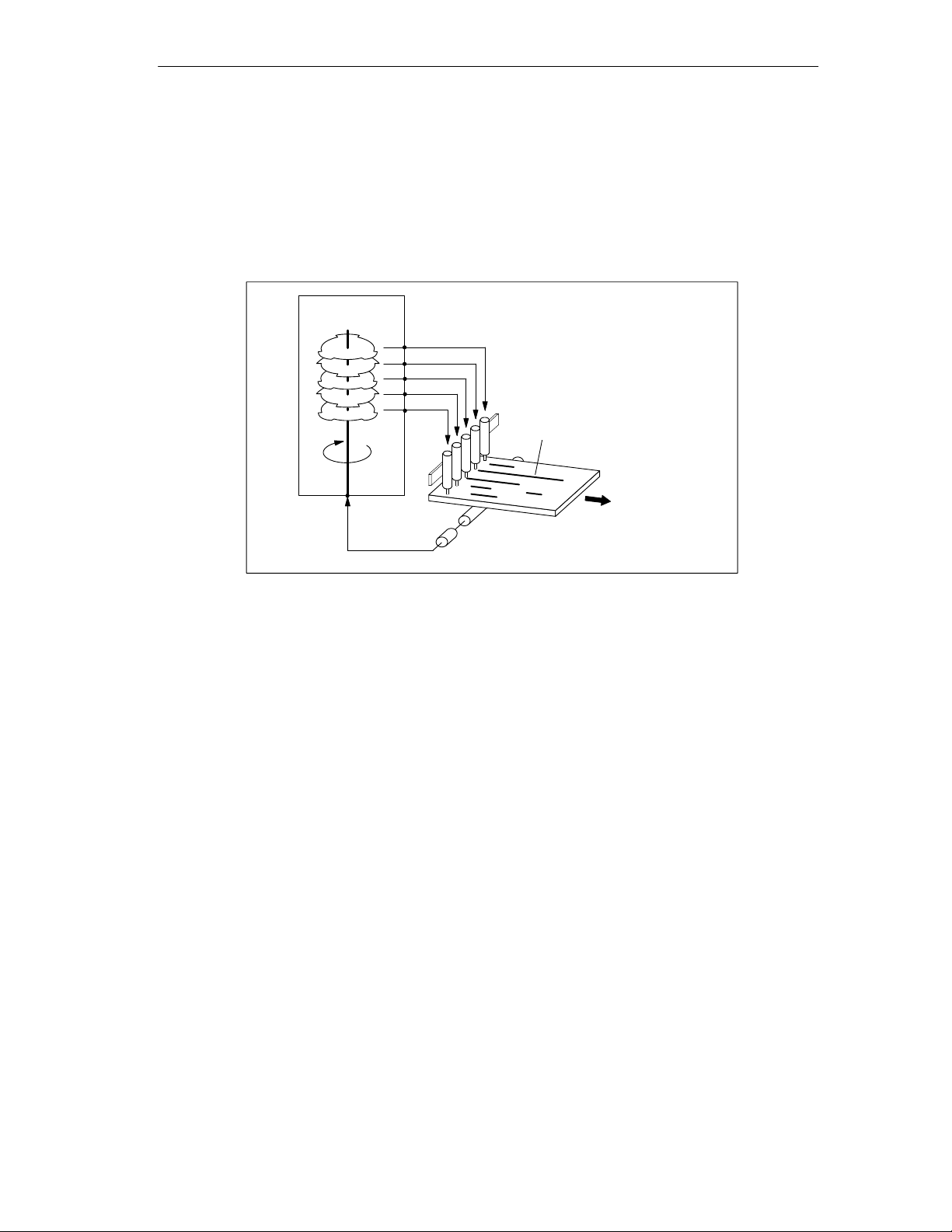

Example: Applying Glue Tracks

In the following example, glue tracks are applied to wooden boards. Each cam

track controls one glue gun via a digital output.

Product Overview

FM 452

Figure 1-2 Example of an Electronic Cam Control Application

Example: Controlling a Press

Another typical application is the automation of an eccentric press with a cam

controller.

This is a rotational process; in other words, after one revolution of the rotary axis,

the function starts again at the beginning.

Typical electronic cam controller tasks in this application include:

• Turning the lubricant supply on and off

• Triggering material feed and removal (for example controlling a gripper)

• Stopping the press at the “upper dead point”

Digital outputs trigger reactions

Q 0

Q 1

Q 2

Q 3

Q 4

Glue tracks

Wooden board

Direction of

transport

Encoder detects axis position

Example: Packaging System

Preserves are packed on a turntable. The electronic cam controller triggers actions

at specific angular positions:

• Placing and folding of cartons on the turntable

• Placing the preserves in the cartons

• Closing the cartons

• Placing the cartons on a conveyor belt

FM 452 Electronic Cam Controller

C79000-G7076-C452-04

1-3

Product Overview

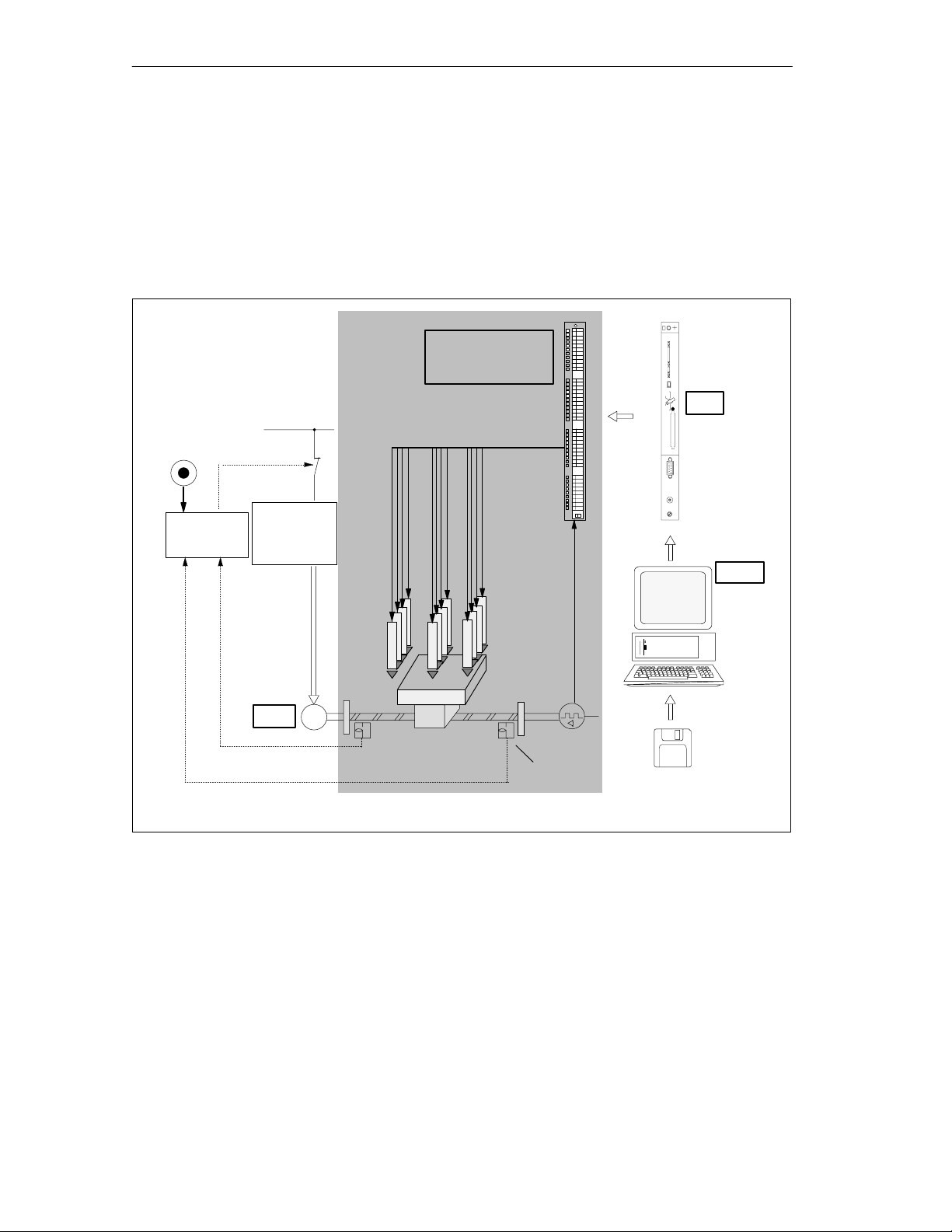

1.3 Structure of an Electronic Cam Controller with an FM 452

Electronic Cam Controller

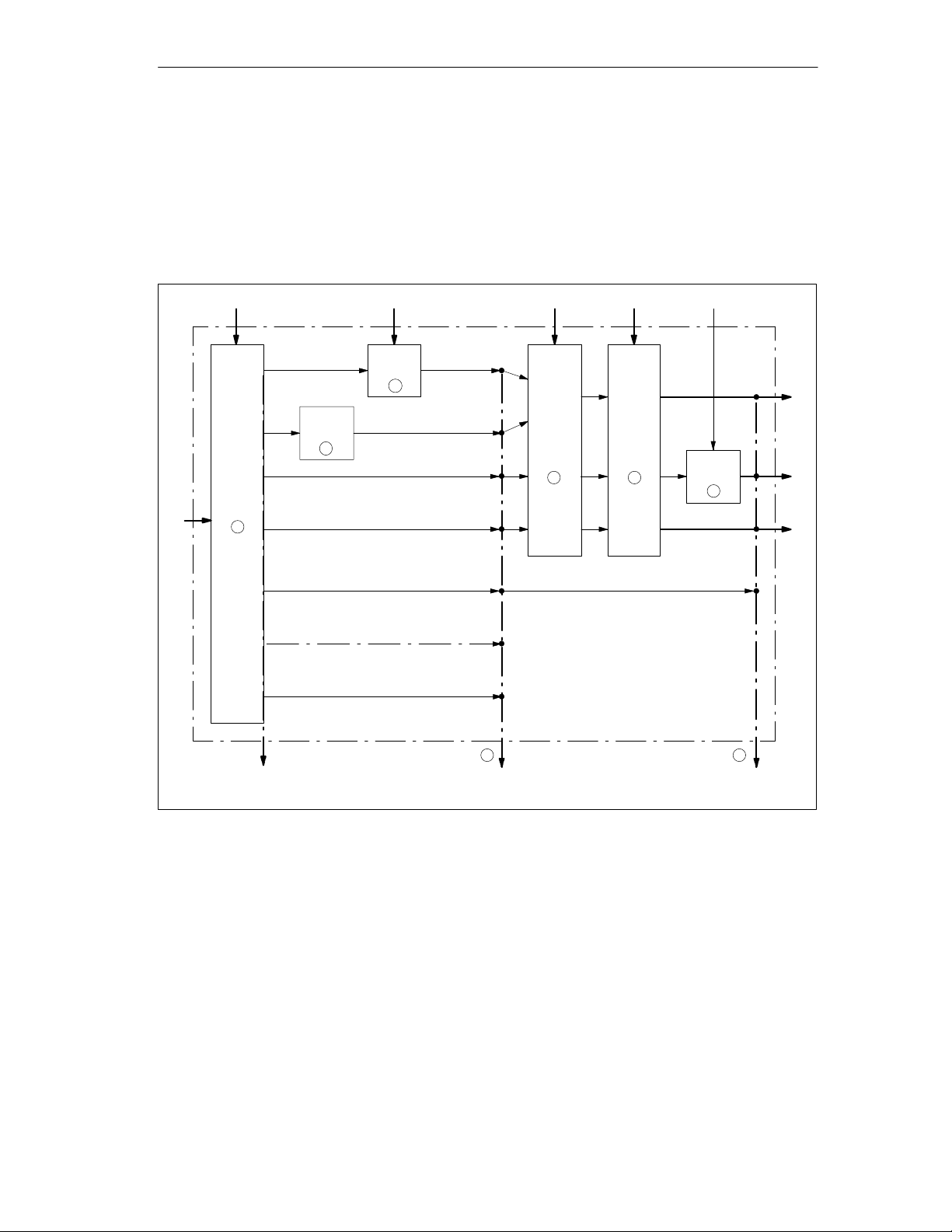

Figure 1-3 shows the components of an electronic cam controller. The schematic is

explained briefly below.

EMER

STOP

Safety

system

Power

supply

Power

controller

Motor

FM 452 Electronic

Cam Controller

Digital outputs Q 0 to 15

Processing

stations

Workpiece

M

Mechanical

transmission

elements

Encoder

Limit switch

11

CPU

PG/PC

Figure 1-3 Electronic Cam Controller

Power Controller and Safety System

The motor is controlled by the power controller. The power controller can consist of

a contactor circuit, for example, controlled by an FM 451 positioning module.

If the safety system responds (EMER STOP or limit switch), the power controller

turns off the motor.

1-4

FM 452 Electronic Cam Controller

C79000-G7076-C452-04

Motor

The motor is controlled by the power controller and drives the spindle.

FM 452 Electronic Cam Controller

The electronic cam controller detects the current position of the axis using the

information from an encoder. The encoder signals are evaluated (for example

pulses counted) that are proportional to the distances traveled. Depending on the

actual position, the digital outputs are activated or deactivated (“cams”). The

processing stations are controlled via the digital outputs.

Encoder

The encoder supplies information both about position and direction.

CPU

Product Overview

PG/PC

The CPU executes the user program. Data and signals are exchanged between

the user program and the module using function calls.

You assign the required parameters and program the electronic cam controller on a

programming device or PC.

• Parameter assignment: You set parameters for the FM 452 either using the

parameter assignment user interface or using the parameter DB.

• Programming: You program the FM 452 with function blocks that you

incorporate directly in your user program.

• Testing and putting into operation: You test the FM 452 using the

assignment user interface

operation.

with which you also finally put the system into

parameter

FM 452 Electronic Cam Controller

C79000-G7076-C452-04

1-5

Product Overview

1-6

FM 452 Electronic Cam Controller

C79000-G7076-C452-04

Basics of Cam Control

Chapter Overview

Section Contents Page

2.1 Cams 2-2

2.2 Tracks 2-4

2.3 Hysteresis 2-8

2.4 Dynamic Adjustment 2-10

2.5 Interfaces of the Cam Controller 2-11

2

FM 452 Electronic Cam Controller

C79000-G7076-C452-04

2-1

Basics of Cam Control

2.1 Cams

Types of Cam

With the appropriate parameter settings, each cam can be either a distance cam or

time cam.

Table 2-1 compares the characteristics of both types of cam.

Direction Detection

The direction of movement of the axis is determined as follows:

• With each pulse of an incremental encoder.

• With each error-free frame of an SSI encoder.

2-2

FM 452 Electronic Cam Controller

C79000-G7076-C452-04

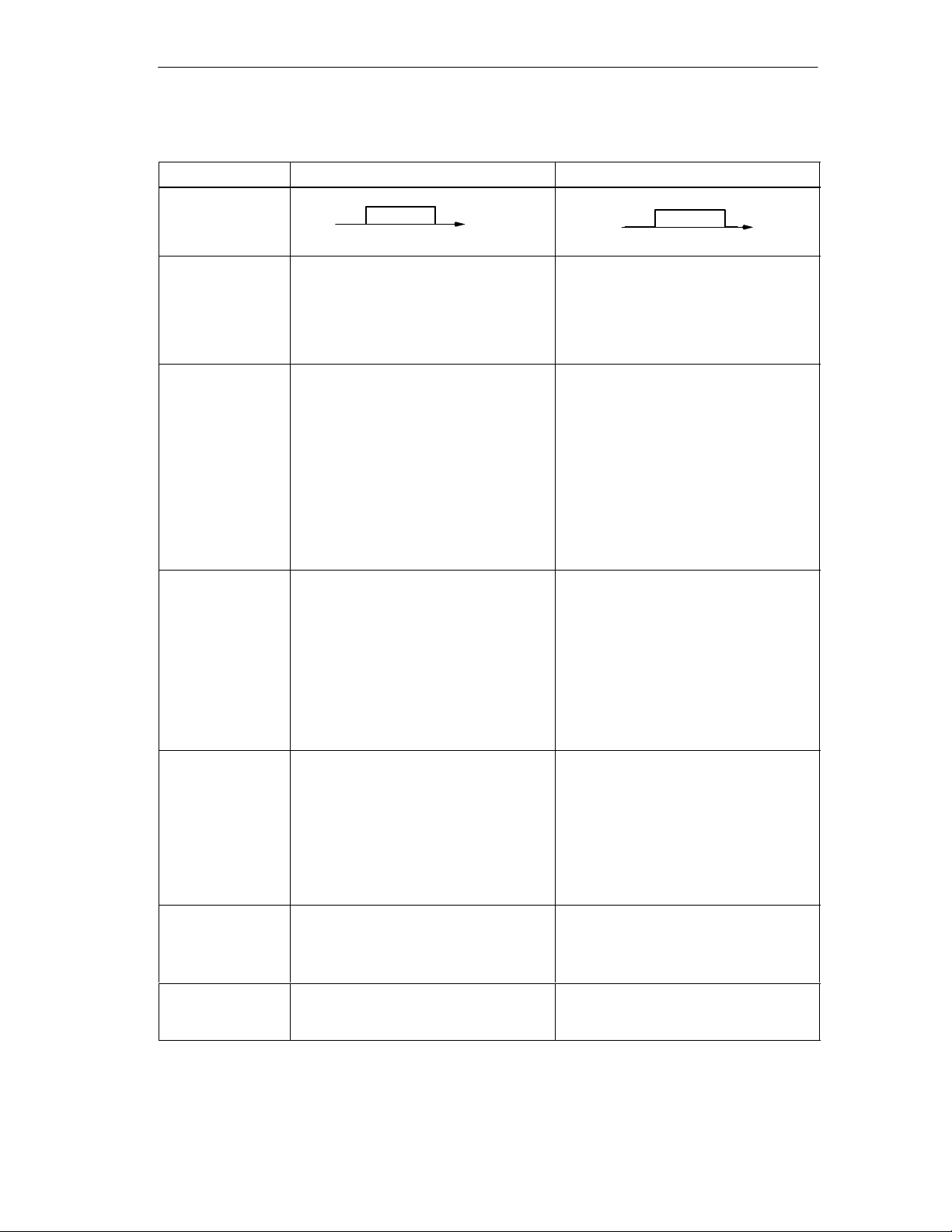

Table 2-1 Definition and Switching of the Two Cam Types

Distance Cam Time Cam

Representation

Parameter

Settings

The following parameters are required:

• Cam start

Cam length

s

Cam endCam start

• Cam end

• Activation direction

• Lead time

Activation

Direction

Two activation directions are possible:

• Positive: The cam is activated at the

cam start when the axis is moving in

the direction of increasing actual

values.

• Negative: The cam is activated at the

cam end when the axis is moving in

the direction of decreasing actual

values.

You can set both activation directions at

the same time.

Activation The cam is activated:

• At the cam start when the axis is

moving in a positive direction and the

positive activation direction is set.

• At the cam end when the axis is

moving in a negative direction and

the negative activation direction is

set.

• The actual value is within the range

of the cam.

Deactivation The cam is deactivated when:

• The selected distance has been

traveled,

• The activation direction is opposite to

the direction of movement of the axis

and no hysteresis is set,

• The actual value is no longer within

the range of the cam.

Active length The active length of the cam is defined

by the cam start and cam end.

Cam start and cam end belong to the

active section of the cam.

On Time The on time of the cam depends on the

speed at which the axis travels the

active length of the cam.

Basics of Cam Control

Activation

time

Cam start Cam end

The following parameters are required:

s

• Cam start

• Activation time

• Activation direction

• Lead time

Two activation directions are possible:

• Positive: The cam is activated at the

cam start when the axis is moving in

the direction of increasing actual

values.

• Negative: The cam is activated at the

cam start when the axis is moving in

the direction of decreasing actual

values.

You can set both activation directions at

the same time.

The cam is activated:

• At the cam start when the direction of

movement of the axis matches the

activation direction.

After it has been activated, the full cam

activation time elapses even if the

direction of movement of the axis

changes after the cam is activated. If the

cam start is passed again during this

time, the cam is not retriggered.

The cam is deactivated when the

selected time has expired.

The active length of the cam depends on

the speed at which the axis travels while

the cam is active.

The on time of the cam is selected with

the activation time.

FM 452 Electronic Cam Controller

C79000-G7076-C452-04

2-3

Basics of Cam Control

2.2 Tracks

2.2.1 Tracks and Track Result

Tracks

With the 32 tracks, you can control a maximum of 32 different switching actions.

You can evaluate the tracks with the return signals.

Each of the first 16 tracks (track 0 to 15) has a digital output (Q0 to Q15) of the

FM 452 assigned to it that can, for example, control a connected contactor directly.

Track Result

You have a maximum of 128 cams available that can be assigned to any track.

Several cams can be assigned to each track. The track result is obtained by the

logical ORing of all cam values of this track (see Figure 2-4, page 2-11).

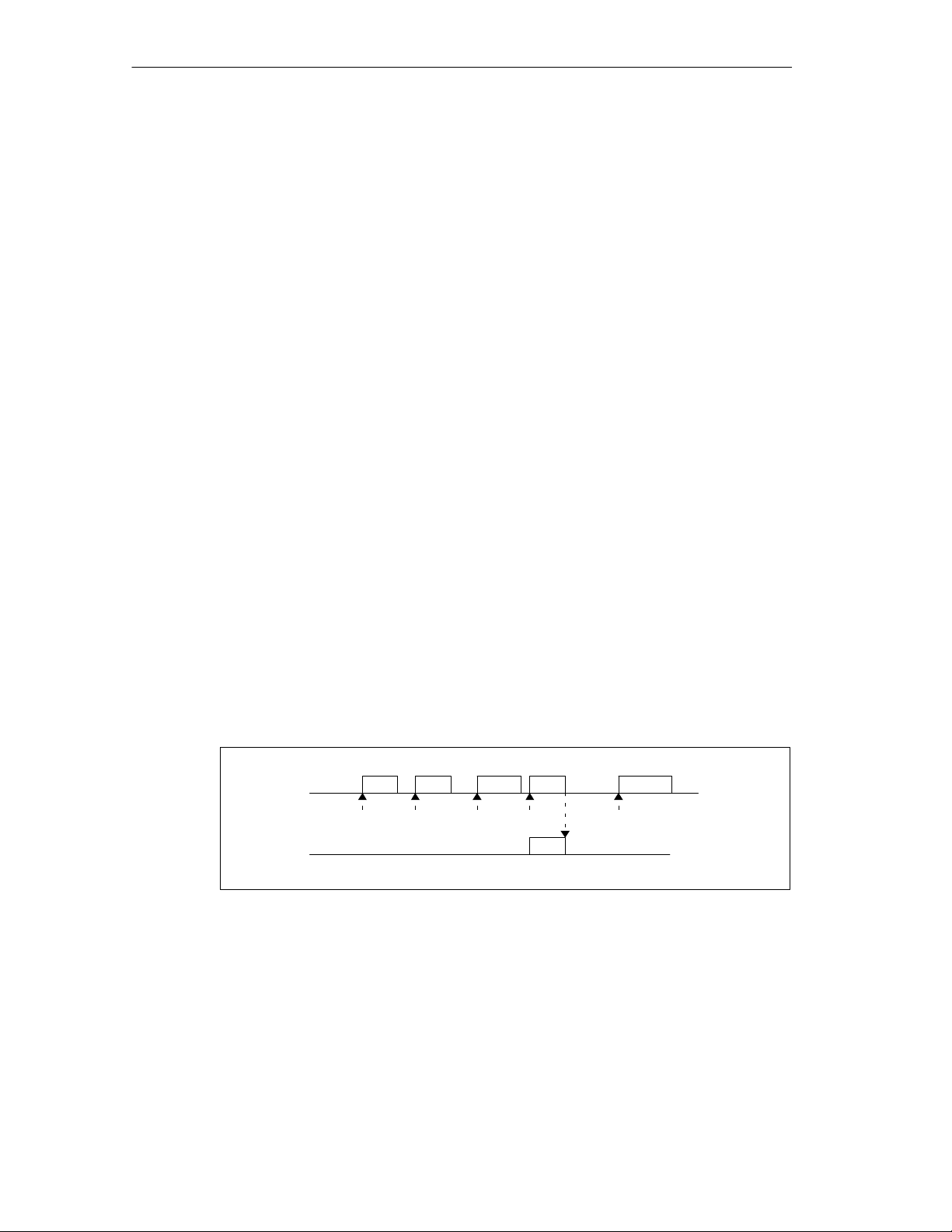

Example of a Track Result

During parameter assignment, you specify the following cams for track 3:

Cam Cam start Cam end

1 101 m 106 m

2 100 m 104 m

This results in the following track result:

Cam 1

Cam 2

Track result

Track 3

Figure 2-1 Calculating the Track Result

105 m100 m 110 m

s

Track Enable

To allow the track results of tracks 0 to 15 to be applied as track signals to the

digital outputs Q0 to Q15 of the FM 452, the cam tracks you are using must be

enabled.

2-4

FM 452 Electronic Cam Controller

C79000-G7076-C452-04

External Enable of Tracks 3 to 10

You can set an external enable for tracks 3 to 10 in the machine data. The track

signals 3 to 10 are then ANDed with digital inputs I3 to I10 before they can switch

the respective digital outputs Q3 to Q10 of the FM 452.

A digital output (Q3 to Q10) is switched when the following conditions are met:

• The relevant track is enabled

• At least one cam on this track is active (track result = 1).

• The corresponding digital input I3 to I10 was set by an external event.

Setting the Track Signals

The track signals 0 to 15 (corresponding to digital outputs Q0 to Q15) can be set

via the cam controller or the CPU.

Basics of Cam Control

FM 452 Electronic Cam Controller

C79000-G7076-C452-04

2-5

Basics of Cam Control

2.2.2 Special Tracks

Definition

By setting the relevant parameters, you can set tracks 0 to 2 as special tracks, as

follows:

• Track 0 or 1: Counter cam track

• Track 2: Brake cam track

Requirements

The following requirements must be met to allow the use of the special tracks:

• Cams are assigned to the track

• Cam processing is active

• The relevant track is enabled

• The track is selected as a special track

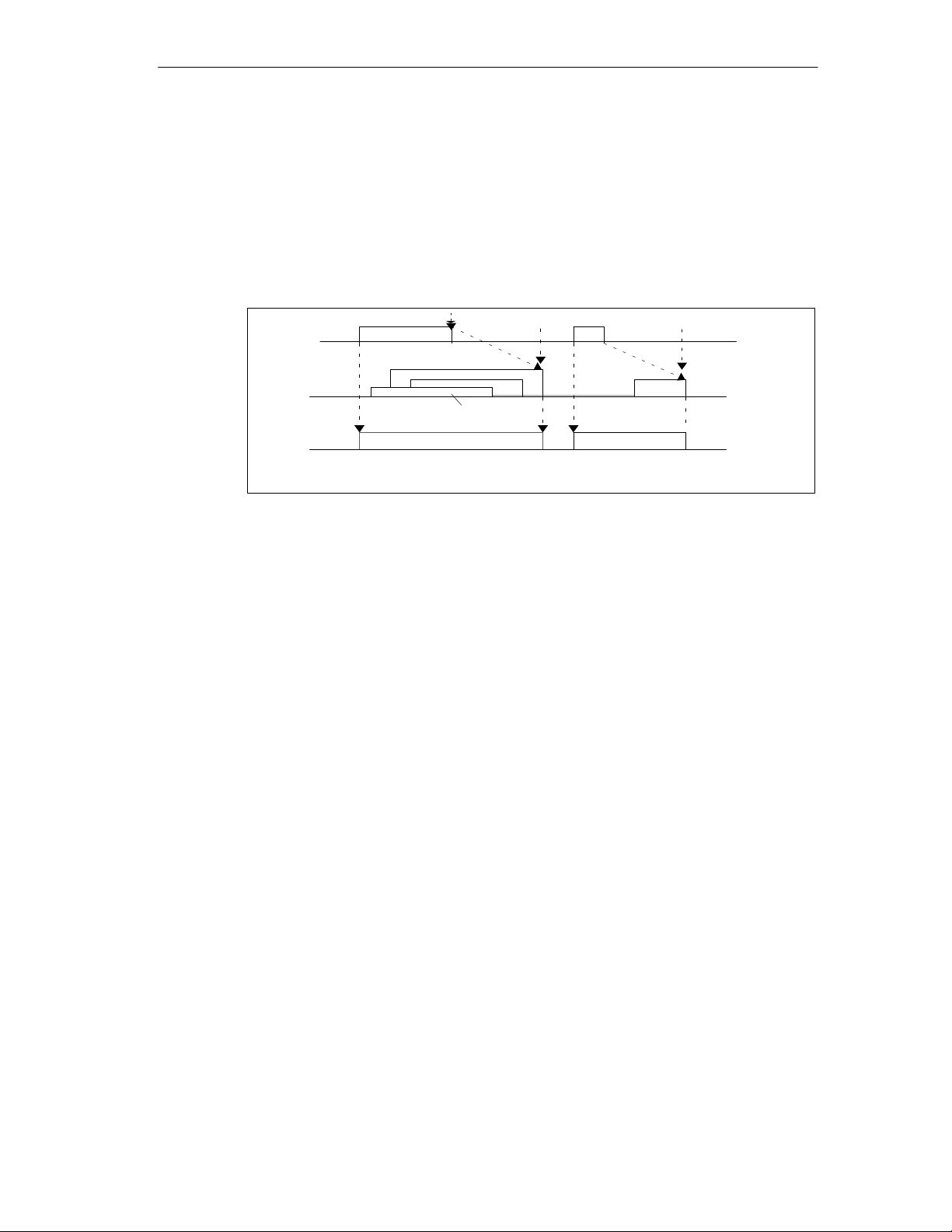

Counter Cam Track

A counter cam track counts the status changes of the track results on this track.

You must specify a value for the counter and start the counter function.

Each rising edge of the track result decrements the counter value of the relevant

track by 1.

As long as the counter value for the counter cam track is higher than 0, the track

flag bit remains 0.

Once the counter value reaches the value 0, the track flag bit is set and, if selected

in the parameter settings, the track signal is set (see Figure 2-4, page 2-11).

At the next falling edge of the track result (all cams on this track are off), the track

flag bit is cleared again and the counter is reset to the specified value.

Cam

Track 0

4

32 10 3Counter reading

Track flag bit

The maximum counter value set in the machine data is 4

Figure 2-2 Switching a Counter Cam Track

4

2-6

FM 452 Electronic Cam Controller

C79000-G7076-C452-04

Brake Cam Track

To use track 2 as a brake cam track, digital input I0 must be connected.

A rising signal edge at I0 sets the track flag bit.

The track flag bit is reset again when:

• There is no longer a “1” signal at I0 and afterwards

• the falling edge of the track result of track 2 is detected.

Basics of Cam Control

Brake enable

I0

Cam

Track 2

Track flag bit

1 to 4 indicate 4 cams which influence the brake cam track

Figure 2-3 Response of a Brake Cam Track

1

Braking point

3

2

4

In the example (Figure 2-3), the track flag bit is deactivated by the falling edges of

cams 3 and 4.

FM 452 Electronic Cam Controller

C79000-G7076-C452-04

2-7

Basics of Cam Control

2.3 Hysteresis

Definition

Mechanical disturbances on the axis can cause changes in the actual position

value. If the actual position value fluctuates around the edge of a cam or within an

active cam with only one activation direction, this cam would be continuously

activated and deactivated. Hysteresis prevents this switching.

A hysteresis is dependent on the actual value and applies to all cams. It becomes

active as soon as a change of direction is detected. Hysteresis also takes effect

even if no cam is set at the current axis position.

Rules for the Hysteresis Range

The following rules apply to the hysteresis range:

• Hysteresis is always activated when there is a change in direction.

• Within the hysteresis, the indication of the actual value remains constant.

• The direction is not changed within the hysteresis.

• Within the hysteresis, a distance cam is neither activated nor deactivated.

• Within the hysteresis, a time cam is not activated; an active time cam is

deactivated when the set activation time elapses (even within the hysteresis

range).

• After leaving the hysteresis range, the FM 452 determines the following:

– the actual position value,

– The current direction of motion of the axis

– the current states of all cams

• The hysteresis range applies to all cams.

2-8

FM 452 Electronic Cam Controller

C79000-G7076-C452-04

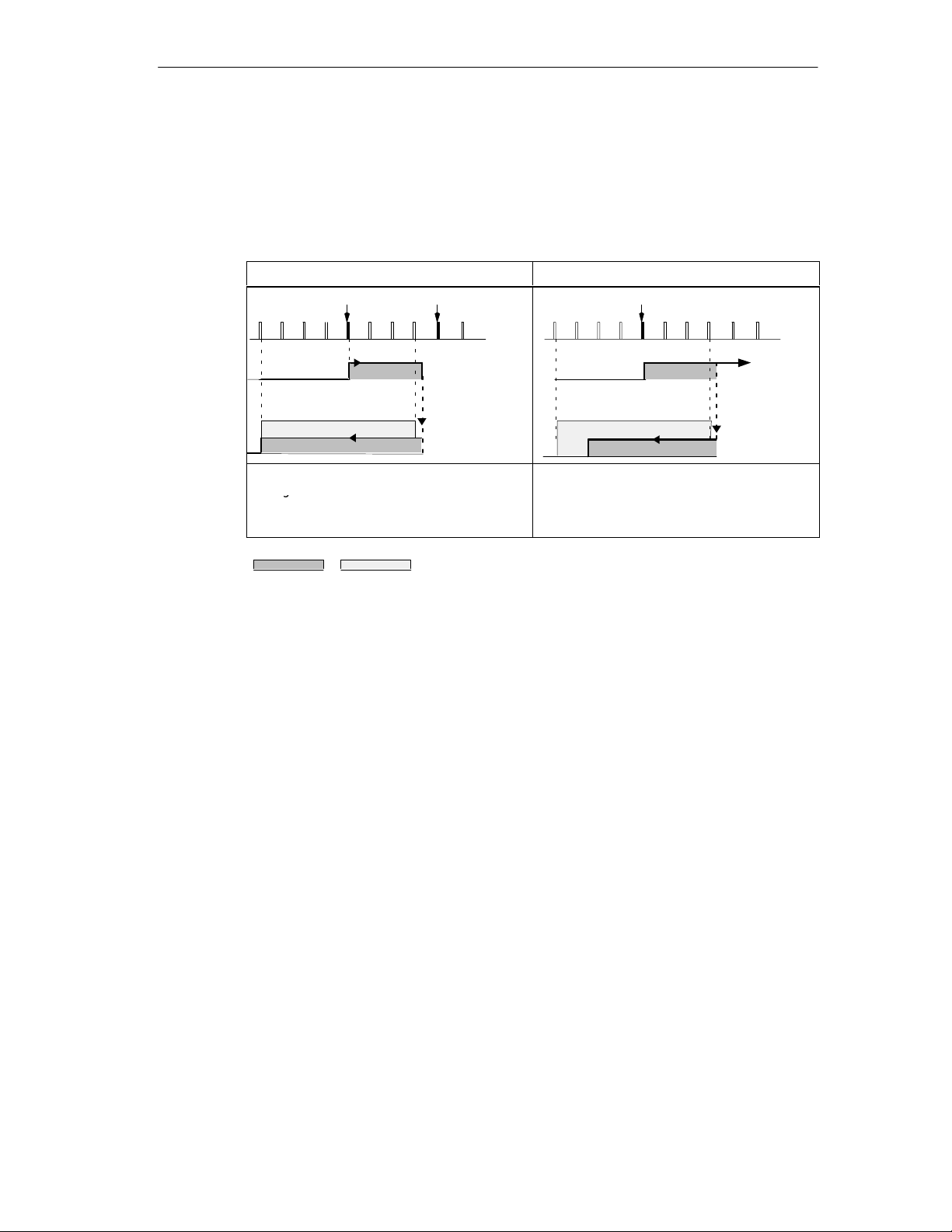

Effects of a Change of Direction on a Cam with Hysteresis

g

The following table illustrates the response of a cam when there is a change of

direction. A distinction must be made between the behavior of a distance cam and

a time cam. The activation direction of the cam is positive.

Table 2-2 Effects of a Change of Direction on a Cam

Basics of Cam Control

Distance cam

CS

23 4567 8

Hysteresis

The hysteresis becomes active after

change of direction is detected.

The cam is deactivated once the

hysteresis range is exited.

Cam Hysteresis

CE

9

1

0

Distance cam

Change

of

direction

Distance cam

Time cam

CS

2345 678

Hysteresis

The cam always remains active for the

selected activation time.

9

1

Time cam

0

Change

of

direction

Time cam

FM 452 Electronic Cam Controller

C79000-G7076-C452-04

2-9

Basics of Cam Control

2.4 Dynamic Adjustment

Purpose

The dynamic adjustment is used to compensate delays resulting from the

connected switching elements.

Lead Time

This delay can be specified as a lead time that you specify separately for each

cam. Per cam, you can specify one lead time. The lead time applies to the cam

start and cam end.

Lead Distance

The lead distance of a cam is calculated continuously depending on the current

feedrate and the lead time. The entire cam is displaced by this distance in the

direction of the actual value. The range selected is known as the “static range”, the

range calculated as a result of the lead time is known as the “dynamic range”.

Lead distance lead time · current feedrate of the axis

Calculation of the lead distances of all cams is carried out within ¼ of the longest

selected lead time in the FM 452.

If you set a very large lead time for a cam, you reduce the dynamics of the cam

processing.

2-10

FM 452 Electronic Cam Controller

C79000-G7076-C452-04

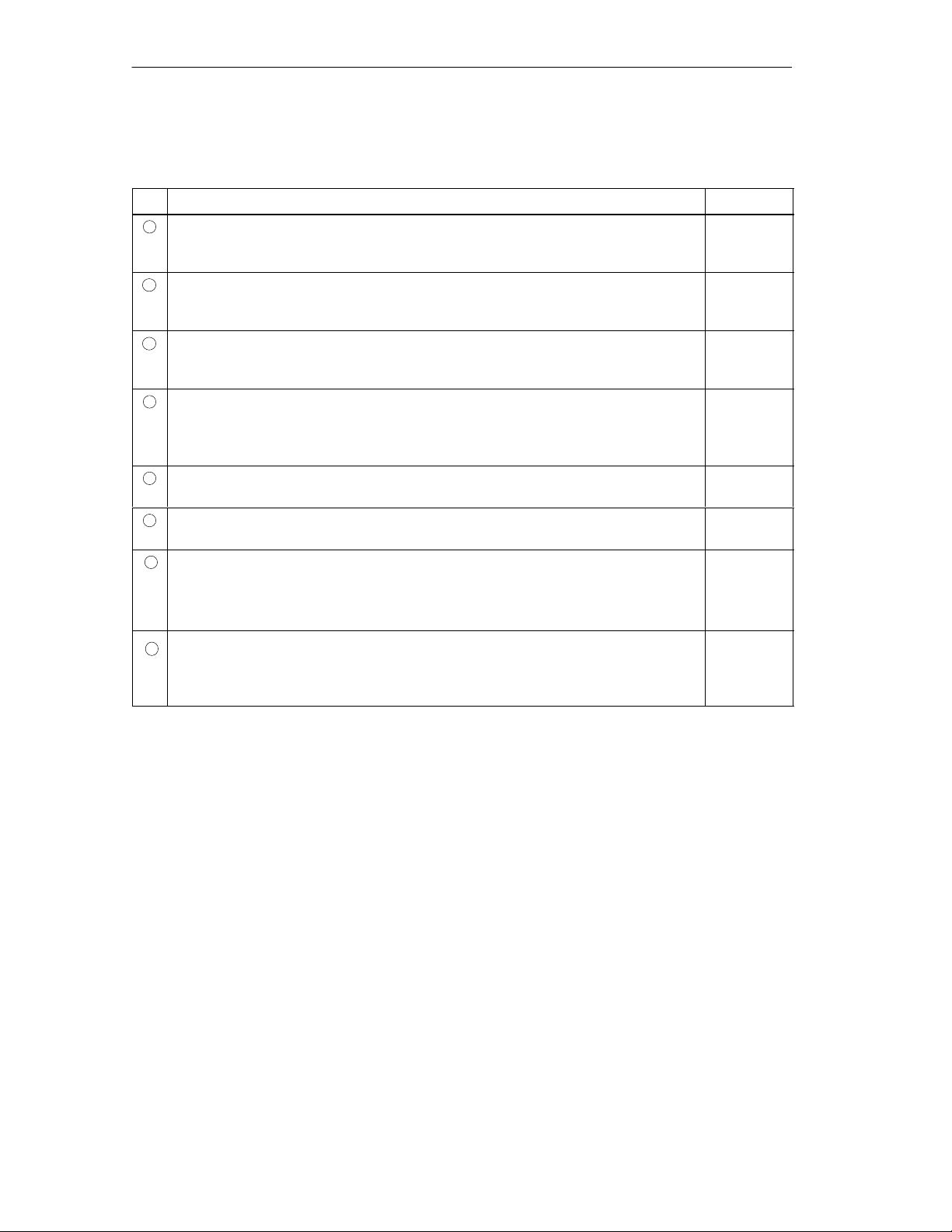

2.5 Interfaces of the Cam Controller

Overview

The schematic below shows the most important interfaces to illustrate the

relationship between data, inputs and outputs.

Basics of Cam Control

Encoder signals

1

Cam Data

I0

Track 2

3

Track

0 to 1

2

Track 3 ... 10

Track 1 1 to 1 5

Track 16 to 31

Actual value, feedrate, direction

Cam flag bits of cam 0 to 127

Machine data Channel DB I3 to I10

Track 3

4 5

Track 10

6

FM 452

Q0 to Q2Q3 to Q10Q11 to Q15

Digital outputs:

Track result

Figure 2-4 Interfaces of the FM 452

FM 452 Electronic Cam Controller

C79000-G7076-C452-04

7 8

Track flag bits, cam flag bits

and data

Track signals

2-11

Basics of Cam Control

The schematic is explained in the table below.

No. Description Section

1

When the FM 452 processes the cams, the cam flag bits are calculated from the

switching conditions and the current actual value. The track results based on the

assignment of the cams to the tracks are also calculated.

2

If you have set track 0 or track 1 as a counter cam track, the track result of the cam

controller (point 1) is logically combined with the counter result to produce the track

flag bit. Otherwise, the track flag bit is the same as the track result.

3

If you have set track 2 as a brake cam track, the track result of the cam controller

(point 1) is logically combined with input I0 to produce the track flag bit. Otherwise,

the track flag bit is the same as the track result.

4

Using machine data, you can control whether the previously detected track flag bits

of tracks 0 to 15 of the cam controller are passed on or whether they are set directly

by the track enable (TRACK_EN).

5

You enable the track signals of tracks 0 to 15 with TRACK_EN and the count function

with CNTC0_EN / CNTC1_EN.

6

The track signals of tracks 3 to 10 can be ANDed with digital inputs I3 to I10 if you

have enabled this option in the machine data (EN_IN_I3 to EN_IN_I10).

7

Y ou can read out all the track and cam flag bits at this point (in other words before

they are logically combined with machine and channel data) using the job

ACTPOS_EN or CAMOUT_EN.

For tracks 3 to 31, the track flag bit is the same as the track result (point 1).

After being logically combined with the machine and channel data, the track signals

8

of tracks 0 to 15 are available in the return signals. The track signals of tracks 16 to

31 are identical to the track flag bits of point 7. The track signals of tracks 0 to 15 are

available at digital outputs Q0 to Q15.

2.1

(page 2-2)

2.2.2

(page 2-6)

2.2.2

(page 2-7)

8.7

(page 8-23),

9.15

(page 9-29)

9.11

(page 9-25)

8.7

(Page 8-23)

9.12

(page 9-26)

9.14

(page 9-28)

2-12

FM 452 Electronic Cam Controller

C79000-G7076-C452-04

Installing and Removing the FM 452

Important Safety Rules

When integrating an S7-400 with an FM 452 in a plant or system, there are

important rules and regulations that are described in the installation manual

S7-400/M7-400 Programmable Controllers, Hardware and Installation

Selecting Slots

The electronic cam controller FM 452 can be installed in a central or expansion

rack just like a signal module.

Configuring the Mechanical Layout

The options available for the mechanical layout of your system and how to

configure the system are described in the installation manual

S7-400/M7-400 Programmable Controllers, Hardware and Installation

Tools Required for Installation and Removal

3

.

.

To install or remove the FM 452, you require a 4.5 mm screwdriver.

Installing the FM 452 Electronic Cam Controller

1. Hook the FM 452 on at the top and swing it down.

2. Secure the FM 452 with screws (torque approximately 0.8 to 1.1 Nm).

3. Label the FM 452 with its slot number using the number wheel of the rack.

The numbering scheme and numbering of slots is described in the installation

manual

Removing the FM 452 Electronic Cam Controller

1. Switch off the power controller.

2. Release the front connector and remove it.

3. Undo the securing screws on the module.

4. Swing the module upwards and remove it.

S7-400/M7-400 Programmable Controllers, Hardware and Installation

.

FM 452 Electronic Cam Controller

C79000-G7076-C452-04

3-1

Installing and Removing the FM 452

3-2

FM 452 Electronic Cam Controller

C79000-G7076-C452-04

Wiring the FM 452 Electronic Cam Controller

Chapter Overview

Section Contents Page

4-1 Pinout of the Front Connector 4-2

4.2 Wiring of the Front Connector 4-5

Important Safety Rule

It is essential for the safety of the system to install the elements listed below and to

adapt them to your system.

• EMERGENCY STOP switch with which you can turn off the entire system.

• EMERGENCY STOP limit switches connected directly to the power units of all

drives.

• Motor circuit-breaker.

4

FM 452 Electronic Cam Controller

C79000-G7076-C452-04

4-1

Wiring the FM 452 Electronic Cam Controller

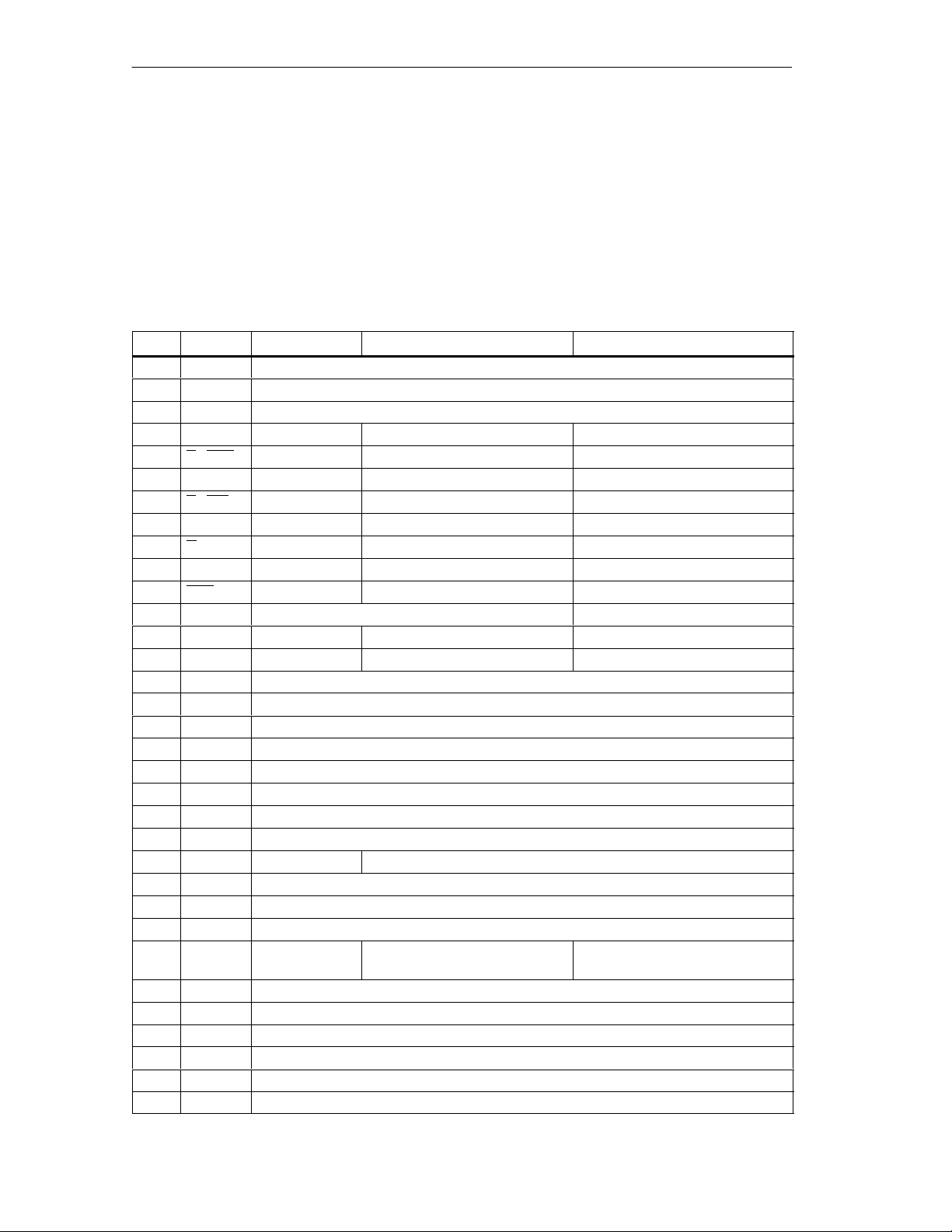

4.1 Pinout of the Front Connector

Front Connector

Connect the encoder, the digital inputs and outputs and the auxiliary power

supplies via the 48-pin front connector.

Pinout of the Front Connector

Pin Name Initiator Incremental Encoder Absolute Encoder

1 --2 --3 1L+ Auxiliary supply 24 V DC

4 A / DA T --- Encoder signal A (5 V) SSI data

5 A / DA T --- Encoder signal A inverse (5 V) SSI data inverse

6 B / CLI 1--- Encoder signal B (5 V) SSI shift clock input

7 B / CLI 1--- Encoder signal B inverse (5 V) SSI shift clock input inverse

8 N --- Zero mark signal (5 V) --9 N --- Zero mark signal inverse (5 V) --10 CLS

11 CLS

12 A* Encoder signal A (24 V) --13 B* --- Encoder signal B (24 V) --14 N* --- Zero mark signal (24 V) --15 Q0 Digital output 0

16 Q1 Digital output 1

17 Q2 Digital output 2

18 Q3 Digital output 3

19 Q4 Digital output 4

20 Q5 Digital output 5

21 Q6 Digital output 6

22 Q7 Digital output 7

23 5.2 V DC --- Encoder supply (5.2 V)

24 24 V DC Encoder supply (24 V)

25 M

26 2L+ Auxiliary supply 24 V DC

27 RE --- Sourcing/sinking (see

28 Q8 Digital output 8

29 Q9 Digital output 9

30 Q10 Digital output 10

31 Q11 Digital output 11

32 Q12 Digital output 12

33 Q13 Digital output 13

2

--- --- SSI shift clock output

2

--- --- SSI shift clock output inverse

3

Encoder ground

---

Appendix B3)

1

1

4-2

FM 452 Electronic Cam Controller

C79000-G7076-C452-04

Loading...

Loading...