Siemens SIMATIC ET 200eco User Manual

SIMATIC

Preface, Contents

1

Product Overview

2

Installation

ET 200eco

Distributed I/O Station

Manual

Wiring

Commissioning and diagnostics

General Technical Data

Technical Data

Appendices

Order Numbers

Dimensional Drawings

I/O Address Area

3

4

5

6

A

B

C

This manual has the order number

6ES7198-8GA00-8BA0

Edition 02/2003

A5E00158716-02

Glossary, Index

Safety Guidelines

This manual contains notices intended to ensure personal safety, as well as to protect the products and

connected equipment against damage. These notices are highlighted by the symbols shown below and

graded according to severity by the following texts:

Danger

!

indicates that death, severe personal injury or substantial property damage will result if proper precautions

are not taken.

Warning

!

indicates that death, severe personal injury or substantial property damage can result if proper

precautions are not taken.

Caution

!

indicates that minor personal injury can result if proper precautions are not taken.

Caution

indicates that property damage can result if proper precautions are not taken.

Notice

draws your attention to particularly important information on the product, handling the product, or to a

particular part of the documentation.

Qualified Personnel

Only qualified personnel should be allowed to install and work on this equipment. Qualified persons are

defined as persons who are authorized to commission, to ground and to tag circuits, equipment, and

systems in accordance with established safety practices and standards.

Correct Usage

Note the following:

Warning

!

Trademarks

The reproduction, transmission or use of this document or its

contents is not permitted without express written authority.

Offenders will be liable for damages. All rights, including rights

created by patent grant or registration of a utility model or

design, are reserved.

Siemens AG

Bereich Automation and Drives

Geschaeftsgebiet Industrial Automation Systems

Postfach 4848, D- 90327 Nuernberg

Siemens Aktiengesellschaft A5E00158716-02

This device and its components may only be used for the applications described in the catalog or the

technical description, and only in connection with devices or components from other manufacturers which

have been approved or recommended by Siemens.

This product can only function correctly and safely if it is transported, stored, set up, and installed

correctly, and operated and maintained as recommended.

SIMATIC, SIMATIC HMI and SIMA TIC NET are registered trademarks of SIEMENS AG.

Third parties using for their own purposes any other names in this document which refer to trademarks

might infringe upon the rights of the trademark owners.

Disclaim of LiabilityCopyright W Siemens AG 2002-2003 All rights reserved

We have checked the contents of this manual for agreement

with the hardware and software described. Since deviations

cannot be precluded entirely, we cannot guarantee full

agreement. However, the data in this manual are reviewed

regularly and any necessary corrections included in

subsequent editions. Suggestions for improvement are

welcomed.

Siemens AG 2003

Technical data subject to change.

Preface

Purpose of this manual

The information in this manual helps you to operate the ET 200eco distributed

I/O station as DP slave on PROFIBUS DP.

Basic knowledge required

To understand the manual, you require general experience in the field of

automation engineering.

This manual edition contains a description of the components valid at the time of

its release. We reserve the right to append a Product Information that contains

up–to–date information on new components or components of a new version.

Range of validity of this manual

This manual is valid for the ET 200eco distributed I/O station.

Changes as compared to the previous version

This manual contains the following changes and additions as compared to the

previous manual:

• I/O module 16 DO 0.5 A (6ES7 142-3BH00-0XA0)

• I/O module 8 DI / 8 DO 1.3 A (6ES7 143-3BH00-0XA0)

Note: You tell the previous version of the ET 200eco manual by the number

indicated in the footer: A5E00158716-01.

The number of this manual is: A5E00158716-02.

CE label

The product series SIMATIC S7- ET 200eco distributed I/O station is compliant

with requirements and protective aims of following EU guidelines.

• EU guideline 73/23/EEC “Low–voltage guidelines”

• EU guideline 89/336/EEC “EMC compatibility”

C-Tick-Mark

The product series SIMATIC S7- ET 200eco distributed I/O station is compliant

with the standard AS/NZS 2064 (Australia and New Zealand).

ET 200eco Distributed I/O Station

A5E00158716-02

iii

Preface

Standards

The product series SIMATIC S7 ET 200eco distributed I/O station is compliant with

requirements and criteria of IEC 61131–2.

The ET 200eco distributed I/O station is based on the IEC 61784-1:2002 Ed1

CP 3/1 standard.

Its place in information technology

In addition to this documentation, you require the corresponding manual for your

DP master.

Manual

This manual describes the hardware of your ET 200eco distributed I/O station. It

consists of introductory chapters and reference chapters (technical specifications).

The manual deals with the following topics:

• Installation and wiring of the ET 200eco distributed I/O station

• Commissioning and diagnostics of the ET 200eco distributed I/O station

• Components of the ET 200eco distributed I/O station

• Order Numbers

• The glossary contains explanations of important terms.

• The index helps you to quickly find textual information on important keywords.

Recycling and disposal

ET 200eco equipment can be recycled due to the low content of harmful

substances in its components.

Please contact a company certified for disposal of electronic waste material for

environment friendly recycling and disposal of your old equipment.

iv

ET 200eco Distributed I/O Station

A5E00158716-02

Further support

Please contact your local SIEMENS partner if you have any further queries on the

products described in this manual.

http://www.ad.siemens.de/partner

Training Centers

We offer a range of courses to help you get started with the ET 200eco distributed

I/O station and the SIMATIC S7 PLCs. Please contact your local training center or

the central training center in

D 90327 Nuremberg.

Phone: +49 (911) 895-3200.

Internet: http://www.sitrain.com

Preface

ET 200eco Distributed I/O Station

A5E00158716-02

v

Preface

A&D Technical Support

Open round the clock, worldwide:

Johnson City

Nuremberg

Beijing

T echnical Support

Worldwide (Nuremberg)

T echnical Support

Local time:0:00 to 24:00 / 365 days

Phone: +49 (0) 180 5050-222

Phone: +49 (0) 180 5050-223

E-Mail: adsupport@

GMT: +1:00

Europe/Africa (Nuremberg)

Authorization

siemens.com

United States (Johnson City)

Technical Support and

Authorization

Local time: 8:00 to 17:00

Phone: +49 (0) 180 5050-222

Phone: +49 (0) 180 5050-223

E-Mail: adsupport@

siemens.com

GMT: +1:00

German and English spoken at the Technical Support and Authorization hotlines.

Local time: 8:00 to 17:00

Phone: +1 (0) 423 262 2522

Fax: +1 (0) 423 262 2289

E-Mail: simatic.hotline@

sea.siemens.com

GMT: –5:00

Asia/Australia (Beijing)

Technical Support and

Authorization

Local time: 8:00 to 17:00

Phone: +86 10 64 75 75 75

Fax: +86 10 64 74 74 74

E-mail: adsupport.asia@

siemens.com

GMT: +8:00

vi

ET 200eco Distributed I/O Station

A5E00158716-02

Service & Support on the Internet

In addition to our documentation services, we also offer you our knowledge base

on the Internet.

http://www.ad.siemens.de/support

Here, you will find:

• our Newsletter, a source that offers updated information on your products

• your appropriate documentation via our Service & Support search engine

• a forum for the exchange of information between users and specialists

worldwide

• your local Automation & Drives partner via our partner database.

• information on repairs, replacement parts and on–site service. Please refer to

our ”Service” pages for further topics.

Preface

ET 200eco Distributed I/O Station

A5E00158716-02

vii

Preface

viii

ET 200eco Distributed I/O Station

A5E00158716-02

Contents

1 Product overview 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 What are distributed I/O stations? 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 What is the ET 200eco distributed I/O station? 1-4. . . . . . . . . . . . . . . . . . . . . .

2 Installation 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Mounting position/dimensions 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 I/O module installation 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Installation of the terminal block 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Label replacement 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 Removing ET 200eco 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6 PROFIBUS address assignment 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Wiring 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 General rules and regulations for the operation of ET 200eco 3-1. . . . . . . . .

3.2 ET 200eco operation on a grounded power supply 3-2. . . . . . . . . . . . . . . . . . .

3.3 Electrical structure of the ET 200eco system 3-4. . . . . . . . . . . . . . . . . . . . . . . .

3.4 Wiring ET 200eco 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.1 How to connect ET 200eco to protective earth (PE) 3-8. . . . . . . . . . . . . . . . . .

3.4.2 How to wire I/O modules 3-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.3 How to wire the ECOFAST terminal block 3-19. . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.4 Wiring the M12, 7/8” terminal block 3-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.5 How to loop the PROFIBUS DP and the supply voltage 3-27. . . . . . . . . . . . . . .

4 Commissioning and diagnostics 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 ET 200eco configuration 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 ET 200eco commissioning and startup 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Diagnostics with LED display 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 ET 200eco diagnostics 4-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.1 Reading diagnostic data 4-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.2 Structure of ET 200eco slave diagnostics 4-11. . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.3 Station status 1 to 3 4-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.4 Master PROFIBUS address 4-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.5 Manufacturer ID 4-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.6 Device–specific diagnostic data 4-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ET 200eco Distributed I/O Station

A5E00158716-02

ix

Contents

5 General technical data 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Standards and approvals 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 EMC compatibility, shipping and storage conditions 5-3. . . . . . . . . . . . . . . . . .

5.3 Mechanical and climatic ambient conditions 5-5. . . . . . . . . . . . . . . . . . . . . . . . .

5.4 Specification of isolation tests, protection class,

type of protection and rated voltage for ET 200eco 5-7. . . . . . . . . . . . . . . . . . .

6 Technical data 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 ECOFAST terminal block (6ES7 194-3AA00-0AA0) 6-2. . . . . . . . . . . . . . . . . .

6.2 Terminal block M12, 7/8” (6ES7 194-3AA00-0BA0) 6-4. . . . . . . . . . . . . . . . . . .

6.3 I/O module 8 DI (6ES7 141-3BF00-0XA0) 6-7. . . . . . . . . . . . . . . . . . . . . . . . . .

6.4 I/O module 16 DI (6ES7 141-3BH00-0XA0) 6-10. . . . . . . . . . . . . . . . . . . . . . . . .

6.5 I/O module 8 DO 2A (6ES7 142-3BF00-0XA0) 6-13. . . . . . . . . . . . . . . . . . . . . .

6.6 I/O module 16 DO 0.5 A (6ES7 142-3BH00-0XA0) 6-16. . . . . . . . . . . . . . . . . . .

6.7 I/O module 8 DI / 8 DO 2 A (6ES7 143-3BH00-0XA0) 6-19. . . . . . . . . . . . . . . .

6.8 I/O module 8 DI / 8 DO 1.3 A

(6ES7 143-3BH00-0XA0) 6-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A Order numbers A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B Dimensional drawings B-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C I/O address area C-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Glossary Glossary-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index Index-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

x

ET 200eco Distributed I/O Station

A5E00158716-02

Figures

1-1 Typical structure of a PROFIBUS-DP network 1-3. . . . . . . . . . . . . . . . . . . . . . .

1-2 View of the ET 200eco distributed I/O station 1-4. . . . . . . . . . . . . . . . . . . . . . . .

2-1 Mounting the I/O module onto the base 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 Inserting and screw–tightening the terminal block at the I/O module 2-4. . . .

2-3 Removing labels 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-4 How to set the PROFIBUS-DP address at terminal block M12, 7/8” 2-7. . . .

2-5 How to unscrew the configuration module 2-8. . . . . . . . . . . . . . . . . . . . . . . . . . .

2-6 How to set the PROFIBUS address at the configuration module 2-8. . . . . . .

3-1 ET 200eco operation with reference potential bonded to

equipotential earth 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2 Potentials in an ET 200eco installation with M12, 7/8” terminal block 3-5. . .

3-3 Potentials in an ET 200eco installation with ECOFAST terminal block 3-6. .

3-4 Connecting the I/O module to protective earth 3-9. . . . . . . . . . . . . . . . . . . . . . .

3-5 How to connect the M12 plug 3-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-6 Y connector 3-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-7 Connecting the ECOFAST connector 3-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-8 Connecting the ECOFAST connector 3-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-9 How to wire the M12, 7/8” plug 3-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-10 How to connect the M12 terminating resistor 3-26. . . . . . . . . . . . . . . . . . . . . . . .

3-11 Loop–through of the PROFIBUS DP and power bus 3-27. . . . . . . . . . . . . . . . .

4-1 ET 200eco startup 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2 LED display on the ET 200eco 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3 Structure of ET 200eco slave diagnostics data 4-11. . . . . . . . . . . . . . . . . . . . . .

4-4 Structure of ET 200eco device–specific diagnostics data 4-15. . . . . . . . . . . . . .

6-1 Block diagram of the ECOFAST terminal block 6-3. . . . . . . . . . . . . . . . . . . . . .

6-2 Block diagram of the M12, 7/8” terminal module 6-6. . . . . . . . . . . . . . . . . . . . .

6-3 Block diagram of I/O module 8 DI 6-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-4 Block diagram of I/O module 16 DI 6-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-5 Block diagram of I/O module 8 DO 2A 6-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-6 Block diagram of I/O module 16 DO 0.5 A 6-17. . . . . . . . . . . . . . . . . . . . . . . . . .

6-7 Block diagram of I/O module 8 DI / 8 DO 2A 6-20. . . . . . . . . . . . . . . . . . . . . . . .

6-8 Block diagram of I/O module 8 DI / 8 DO 1.3 A 6-24. . . . . . . . . . . . . . . . . . . . . .

B-1 Dimensional drawing of an I/O module with installed M12, 7/8”

terminal block B-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B-2 Dimensional drawing of an I/O module with installed ECOFAST

terminal block B-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C-1 Address area of I/O module 8 DI C-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C-2 Address space of I/O module 16 DI C-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C-3 Address area of I/O module 8 DO 2 A C-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C-4 Address area of I/O module 16 DO 0.5 A C-3. . . . . . . . . . . . . . . . . . . . . . . . . . .

C-5 Address area of I/O module 8 DI / 8 DO 2 A C-4. . . . . . . . . . . . . . . . . . . . . . . .

C-6 Address area of I/O module 8 DI / 8 DO 1.3 A C-5. . . . . . . . . . . . . . . . . . . . . . .

Contents

ET 200eco Distributed I/O Station

A5E00158716-02

xi

Contents

Tables

1-1 ET 200eco components 1-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1 Mounting dimensions 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1 Pin assignment of the M12 coupler plug for the I/O module 8 DI 3-10. . . . . . .

3-2 Pin assignment of the M12 coupler plug for the I/O module 16 DI 3-10. . . . . .

3-3 Pin Assignment for M12 Coupler Plug for I/O Module 8 DO 2 A 3-11. . . . . . . .

3-4 Pin assignment of M12 coupler plug for I/O module 16 DO 0.5 A 3-11. . . . . .

3-5 Pin assignment of M12 coupler plug for I/O module

8 DI / 8 DO 2 A 3-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-6 Pin assignment of M12 coupler plug for I/O module

8 DI / 8 DO 1.3 A 3-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-7 The Y connector and I/O module 16 DI 3-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-8 Y connector for I/O module 16 DO 0.5 A 3-16. . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-9 Y connector plug for I/O module 8 DI / 8 DO 2 A 3-17. . . . . . . . . . . . . . . . . . . . .

3-10 Y connector plug for I/O module 8 DI / 8 DO 1.3 A 3-18. . . . . . . . . . . . . . . . . . .

3-11 Pin assignment of the ECOFAST connector 3-20. . . . . . . . . . . . . . . . . . . . . . . . .

3-12 Pin assignment of the M12 plug (PROFIBUS DP) 3-24. . . . . . . . . . . . . . . . . . . .

3-13 Pin assignment of the 7/8” plug (Power bus) 3-24. . . . . . . . . . . . . . . . . . . . . . . .

4-1 GSD file Implementation in the configuration software 4-2. . . . . . . . . . . . . . .

4-2 Software required for commissioning 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3 Prerequisite for commissioning the ET 200eco 4-3. . . . . . . . . . . . . . . . . . . . . .

4-4 Steps for commissioning the DP slave 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-5 Status and error display with LEDs 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-6 Reading diagnostics data of ET 200eco under STEP 7 and STEP 5 4-8. . .

4-7 Structure of the station status 1(byte 0) ET 200eco 4-12. . . . . . . . . . . . . . . . . .

4-8 Structure of station status 2 (byte 1) ET 200eco 4-13. . . . . . . . . . . . . . . . . . . . .

4-9 Structure of station status 3 (byte 2) ET 200eco 4-13. . . . . . . . . . . . . . . . . . . . .

4-10 Structure of the ET 200eco manufacturer ID (bytes 4 and 5) 4-14. . . . . . . . . .

6-1 Pin-out of the sockets X01 and X02 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2 Pin-out of the plugs DP1 and DP2 (M12) 6-5. . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3 Pin-out of the connectors X01 and X02 (7/8”) 6-5. . . . . . . . . . . . . . . . . . . . . . .

6-4 Pin-out of the digital input sockets X1 to X8 6-7. . . . . . . . . . . . . . . . . . . . . . . . .

6-5 Pin-out of the digital input sockets X1 to X8 6-10. . . . . . . . . . . . . . . . . . . . . . . . .

6-6 Pin-out of the digital output sockets X1 to X8 6-13. . . . . . . . . . . . . . . . . . . . . . . .

6-7 Pin-out of the digital output sockets X1 to X8 6-16. . . . . . . . . . . . . . . . . . . . . . . .

6-8 Pin-out of the digital input and output sockets X1 to X8 6-19. . . . . . . . . . . . . . .

6-9 Pin-out of the digital input and output sockets X1 to X8 6-23. . . . . . . . . . . . . . .

A-1 ET 200eco components – Order numbers A-1. . . . . . . . . . . . . . . . . . . . . . . . . .

A-2 ET 200eco accessories – Order numbers A-1. . . . . . . . . . . . . . . . . . . . . . . . . .

A-3 I/O module accessories – Order numbers A-2. . . . . . . . . . . . . . . . . . . . . . . . . .

A-4 Accessories for the ECOFAST terminal block – Order numbers A-2. . . . . . .

A-5 M12, 7/8” terminal block accessories – Order numbers A-3. . . . . . . . . . . . . .

A-6 STEP 7 and SIMATIC S7 Manual A-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A-7 PROFIBUS DP and SIMATIC S7 Manual A-4. . . . . . . . . . . . . . . . . . . . . . . . . . .

xii

ET 200eco Distributed I/O Station

A5E00158716-02

Product overview

In this chapter

This product information shows you

• the place of the ET 200eco distributed I/O station in the ET 200 distributed I/O

station and

• the components comprising the ET 200eco distributed I/O station.

Chapter overview

Chapter Topic Page

1.1 What are distributed I/O stations? 1-2

1.2 What is the ET 200eco distributed I/O system? 1-4

1

ET 200eco Distributed I/O Station

A5E00158716-02

1-1

Product overview

1.1 What are distributed I/O stations?

Distributed I/O systems – Field of application

Many systems are configured with a centralized process I/O system in the local

PLC.

Greater distances between remote I/O and the PLC can result in badly arranged

and extensive wiring. Also, electromagnetic interference may reduce reliabilty.

Plants of this type are suitable for operation with distributed I/O systems:

• local controlling CPU

• distributed I/O systems (inputs and outputs) operate at remote locations

• the high–performance PROFIBUS-DP provides high data transmission rates for

trouble–free communication between the controlling CPU and the I/O systems.

What is PROFIBUS–DP?

PROFIBUS-DP is an open bus system according to the IEC 61784-1:2002 Ed1CP

3/1 standard with a “DP” transfer protocol (DP stands for distributed periphery, or

distributed I/O).

PROFIBUS-DP is physically an electrical network that is based on shielded twisted

pair cables or optical waveguide networking.

The ”DP” protocol allows fast, cyclic data exchange between the controlling CPU

and distributed I/O systems.

What are DP masters and DP slaves?

The DP master forms the interface between the controlling CPU and the

distributed I/O system. The DP master exchanges data with distributed I/O

systems via PROFIBUS-DP and monitors the PROFIBUS DP.

Distributed I/O systems (= DP slaves) prepare sensors and actuator data locally

for their transfer to the PLC via PROFIBUS DP.

Which devices can I connect to PROFIBUS-DP?

A wide range of devices can be connected on the PROFIBUS-DP as DP masters

or DP slaves, provided that they operate in accordance with IEC 61784-1:2002

Ed1 CP 3/1. Among others, devices from the following product families can be

used:

1-2

• SIMATIC S5

• SIMATIC S7/M7/C7

• SIMATIC programming devices/PCs

• SIMATIC HMI (operator control and monitoring stations OP, OS, TD)

• Devices from other vendors

ET 200eco Distributed I/O Station

A5E00158716-02

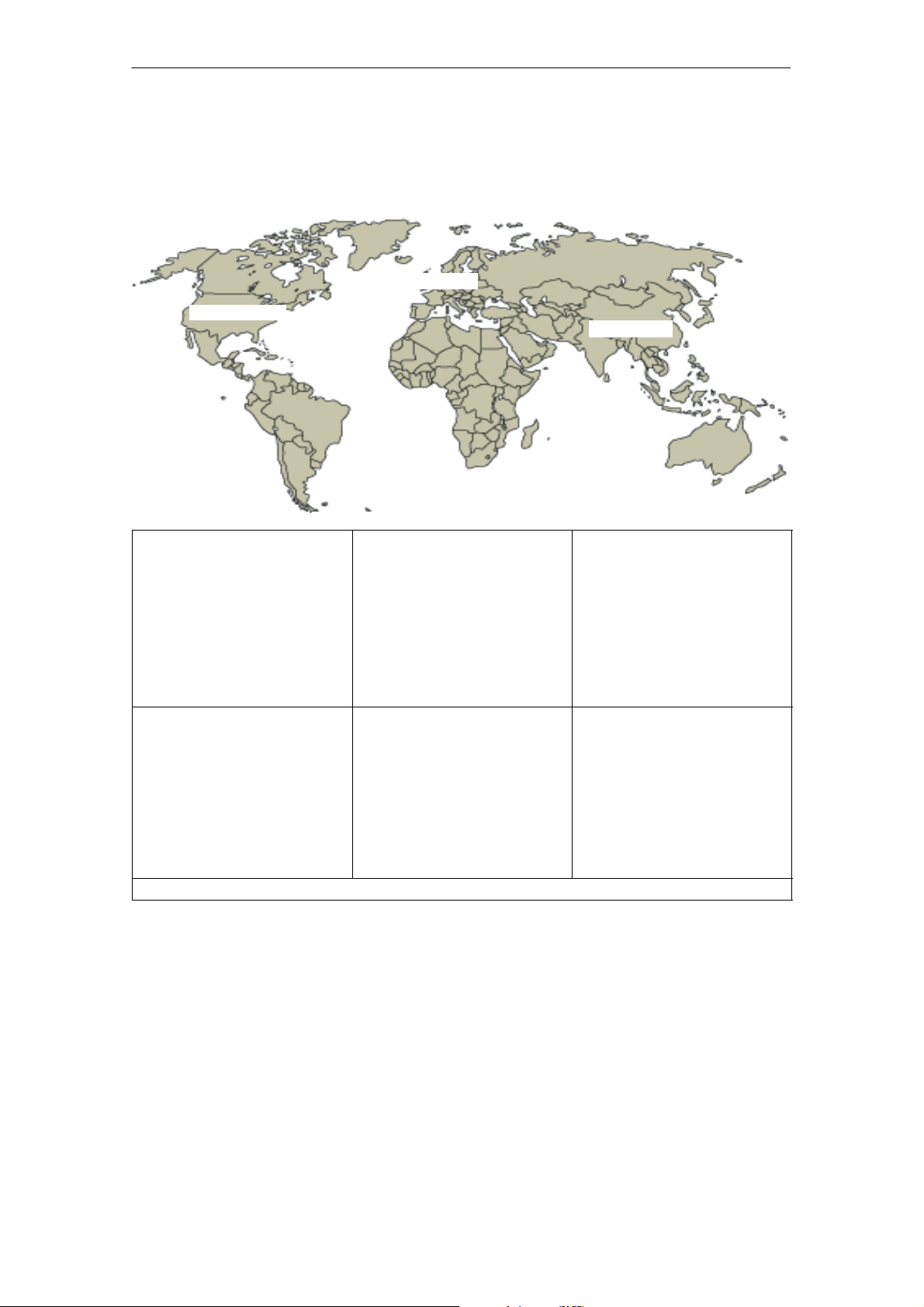

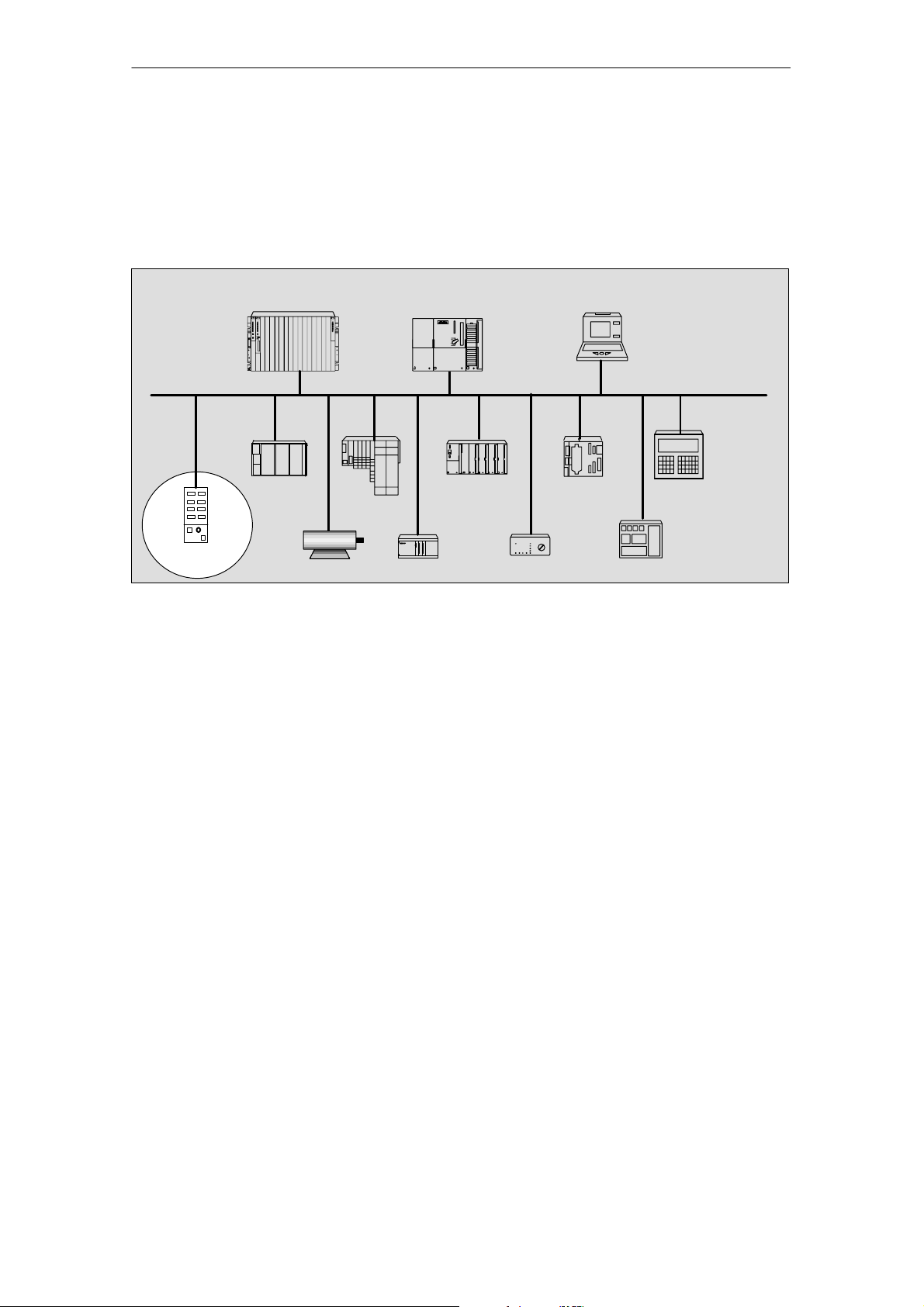

Structure of a PROFIBUS-DP network

The figure below shows you a typical PROFIBUS DP network structure. The DP

masters are integrated in the corresponding unit, e.g. the S7-400 or S7-300 is

equipped with a PROFIBUS-DP interface. The DP slaves, namely the distributed

I/O, are interconnected to the DP masters via PROFIBUS DP.

Product overview

S7-400

ET 200X

ET 200S

ET200eco

drive

Figure 1-1 Typical structure of a PROFIBUS-DP network

S7-300

ET 200M S5-95U-DP

S7-200

DP/AS–I Link

PG/PC

DP master

PROFIBUS-DP

DP slaves

OP/OS

further field devices

ET 200eco Distributed I/O Station

A5E00158716-02

1-3

Product overview

1.2 What is the ET 200eco distributed I/O station?

Definition

The ET 200eco distributed I/O station is a compact DP slave (degree of protection

IP 65, IP 66 or IP 67).

Field of application

• Due to its rugged design and degree of protection IP 65, IP 66 or IP 67, the

ET 200eco distributed I/O station is primarily suitable for operation under harsh

industrial conditions.

• The compact design of ET 200eco allows its use in confined areas and

• its easy handling features ensure efficient commissioning and maintenance.

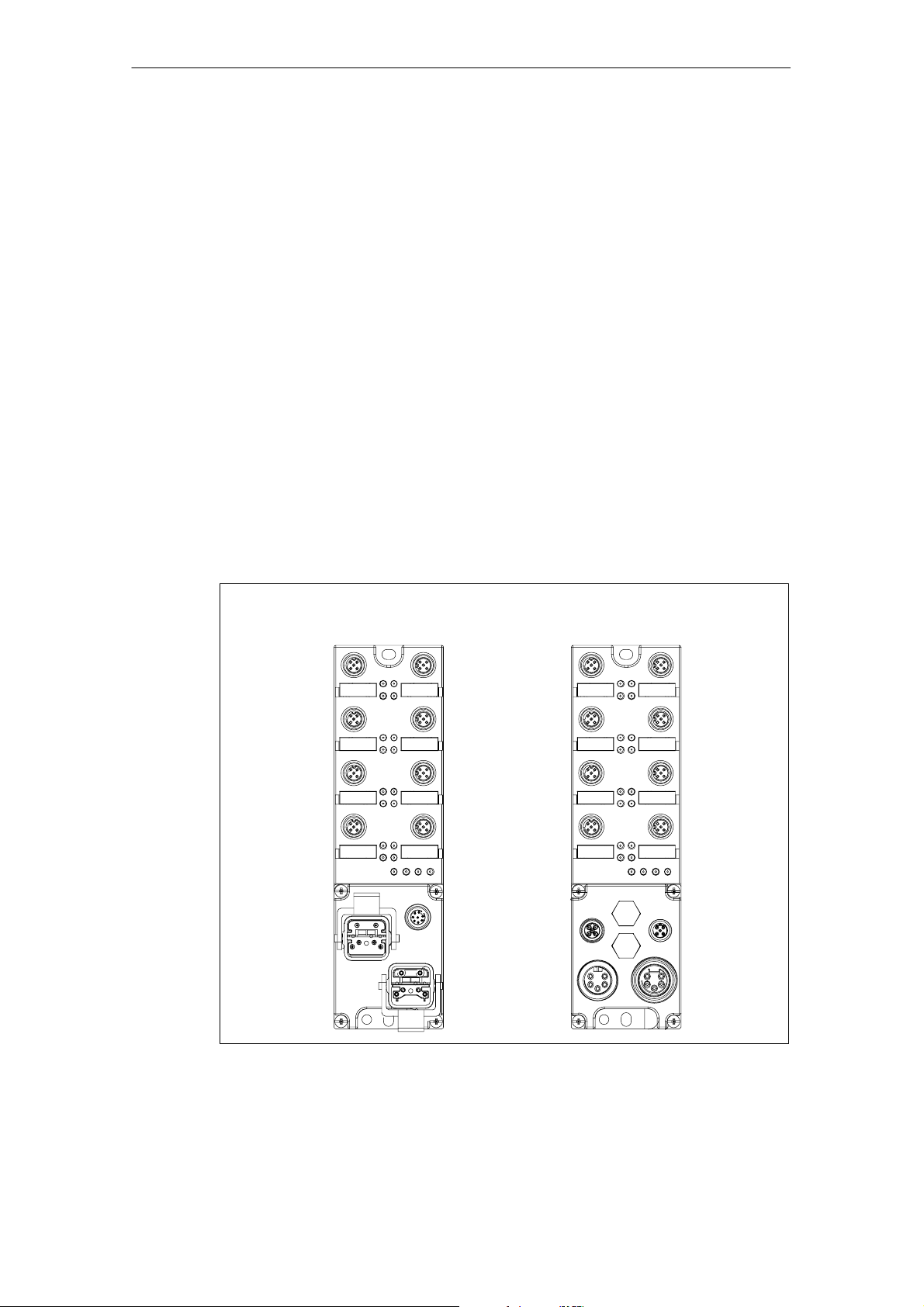

View

The ET 200eco consists of an I/O module and a terminal block. These components

are available in different versions.

ET 200eco with ECO-

FAST terminal block

ET 200eco with M12,

7/8”terminal block

1-4

Figure 1-2 View of the ET 200eco distributed I/O station

ET 200eco Distributed I/O Station

A5E00158716-02

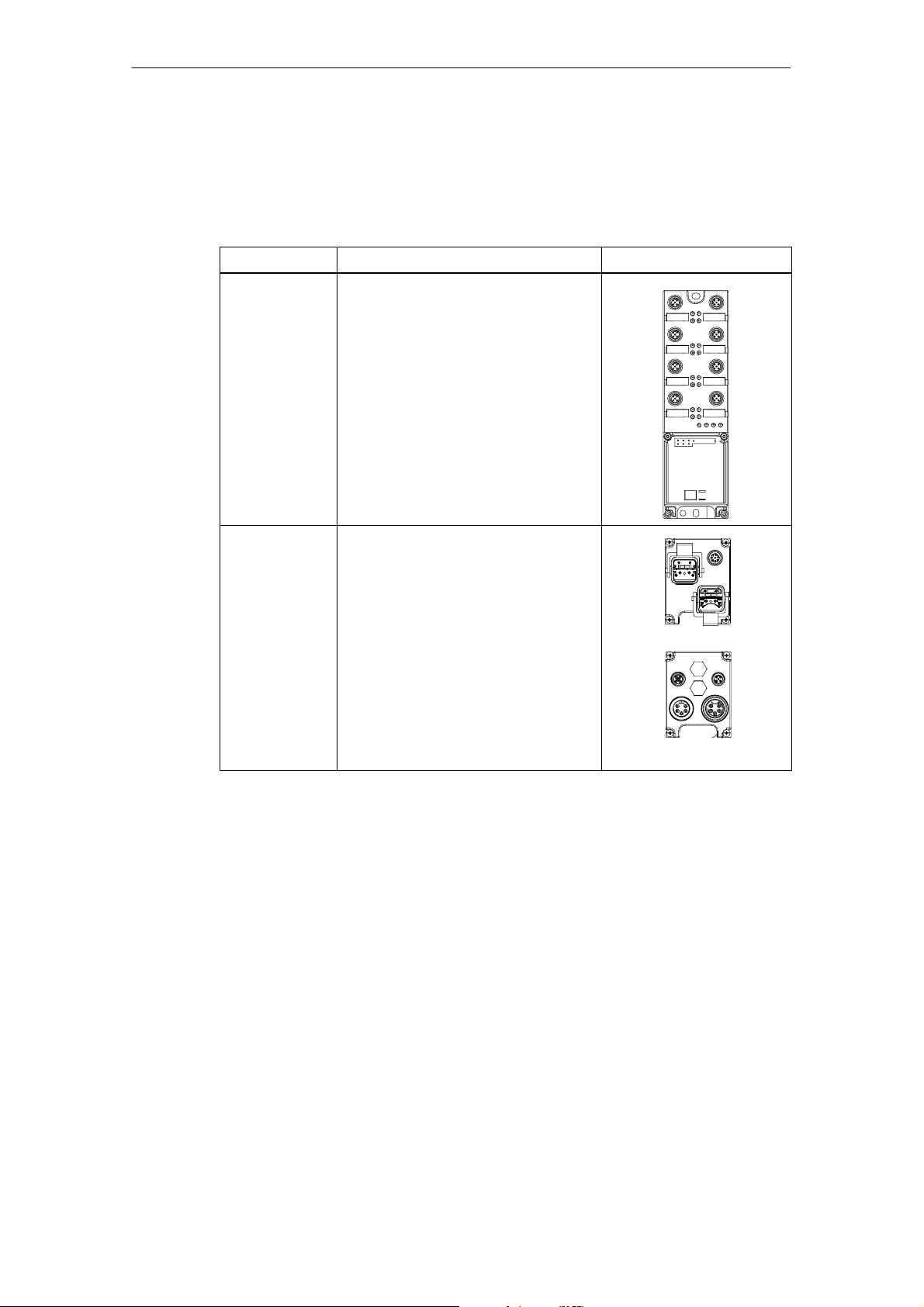

ET200eco components

The table provides an overview of the major components of ET 200eco:

Table 1-1 ET 200eco components

Product overview

Component

I/O module You connect sensors and actuators to

the I/O module. The I/O module is

available in the following versions:

Function Figure

• 8 DI

• 16 DI

• 8 DO 2A

• 16 DO 0.5 A

• 8 DI / 8 DO 2A

• 8 DI / 8 DO 1.3 A

Terminal block You connect the ET 200eco power

supply and the PROFIBUS-DP cable to

the terminal block. The terminal block is

available in the following versions:

• ECOFAST

• M12, 7/8”

DP master

The ET 200eco station can communicate with all DP masters that operate

according to IEC 61784-1:2002 Ed1 CP 3/1.

ET 200eco Distributed I/O Station

A5E00158716-02

1-5

Product overview

1-6

ET 200eco Distributed I/O Station

A5E00158716-02

Installation

Easy installation

The design of the ET 200eco distributed I/O station allows easy installation.

Chapter overview

Chapter Topic Page

2.1 Mounting position/dimensions 2-1

2.2 I/O module installation 2-2

2.3 Installation of the terminal block 2-3

2.4 Label replacement 2-4

2.5 Removing ET 200eco 2-5

2.6 Setting the PROFIBUS address 2-6

2

2.1 Mounting position/dimensions

Mounting position

The ET 200eco can be mounted in any position

Mounting and spacing dimensions

Table 2-1 Mounting dimensions

Dimensions

Mounting width 60 mm

Mounting height 210 mm

Mounting depth • with terminal block ECOFAST: 60 mm (without plug)

• with terminal block M12, 7/8”: 54 mm (without plug)

ET 200eco Distributed I/O Station

A5E00158716-02

2-1

Installation

2.2 I/O module installation

Properties

• The I/O module must be mounted onto a solid base.

• The I/O module (without terminal block) can be prewired.

Requirements

Screws:

Screw type Explanation

M5 cylindrical head screw to ISO

1207/ISO 1580 (DIN 84/DIN 85)

Cylindrical head screw with M5

hexagonal socket to DIN 912

Tools required

Medium size Pillipps screwdriver or 8 mm socket wrench

Minimum screw length: 20 mm.

Additionally required: DIN 125 washers.

Additionally required: DIN 125 washers.

2-2

ET 200eco Distributed I/O Station

A5E00158716-02

Procedure

Installation

Using the screws, tighten the I/O module onto a level base. The I/O module must

be screwed onto the base at both fastening points (at the front panel top and

bottom). Tightening torque: 3 N/m.

5.5 x 7

30

5

210

200

60

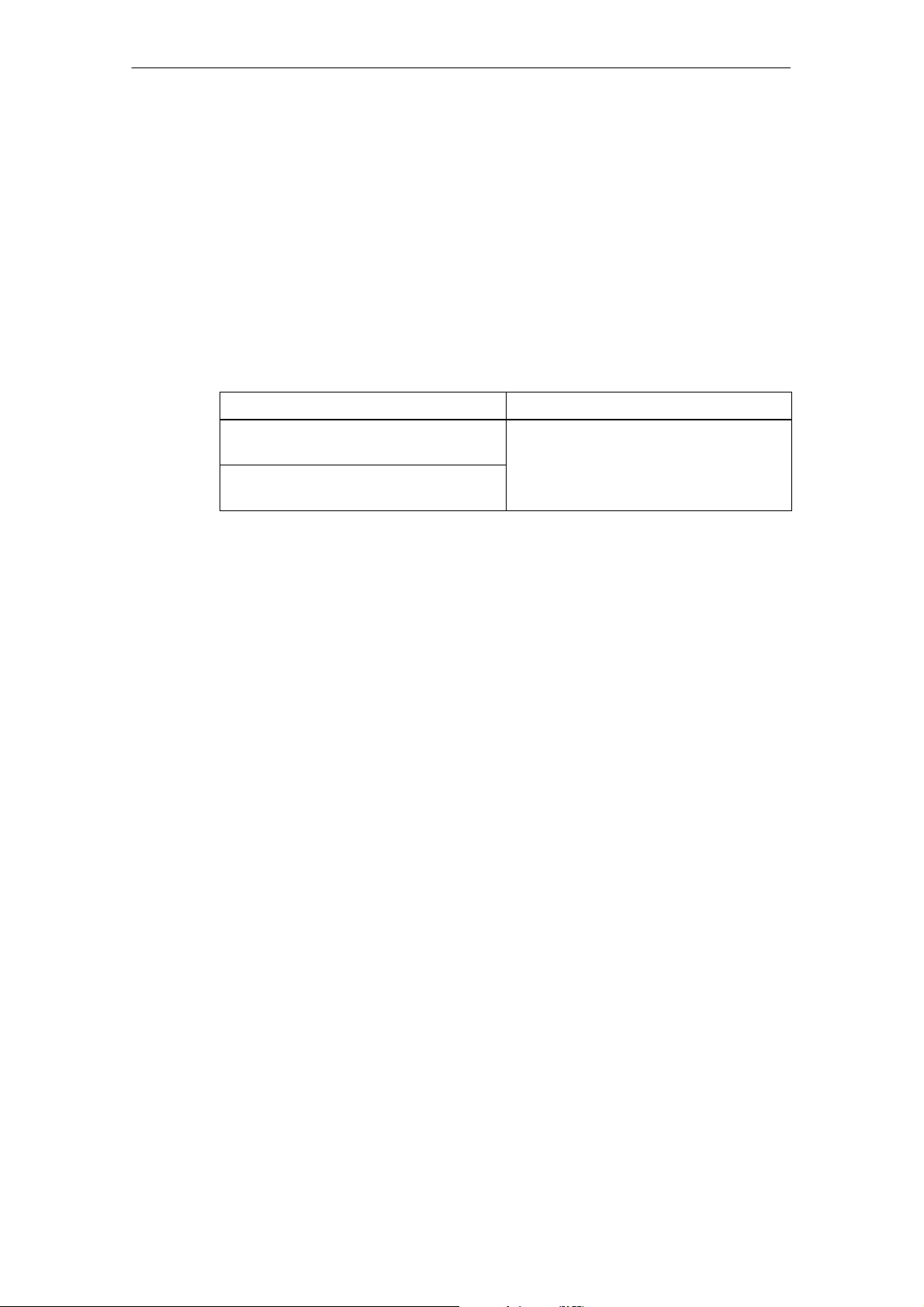

Figure 2-1 Mounting the I/O module onto the base

2.3 Installation of the terminal block

Properties

The terminal block connects the ET 200eco to the power supply and to the

PROFIBUS DP network.

Requirements

The I/O module is installed.

Tools required

Medium size Phillips screwdriver

ET 200eco Distributed I/O Station

A5E00158716-02

2-3

Installation

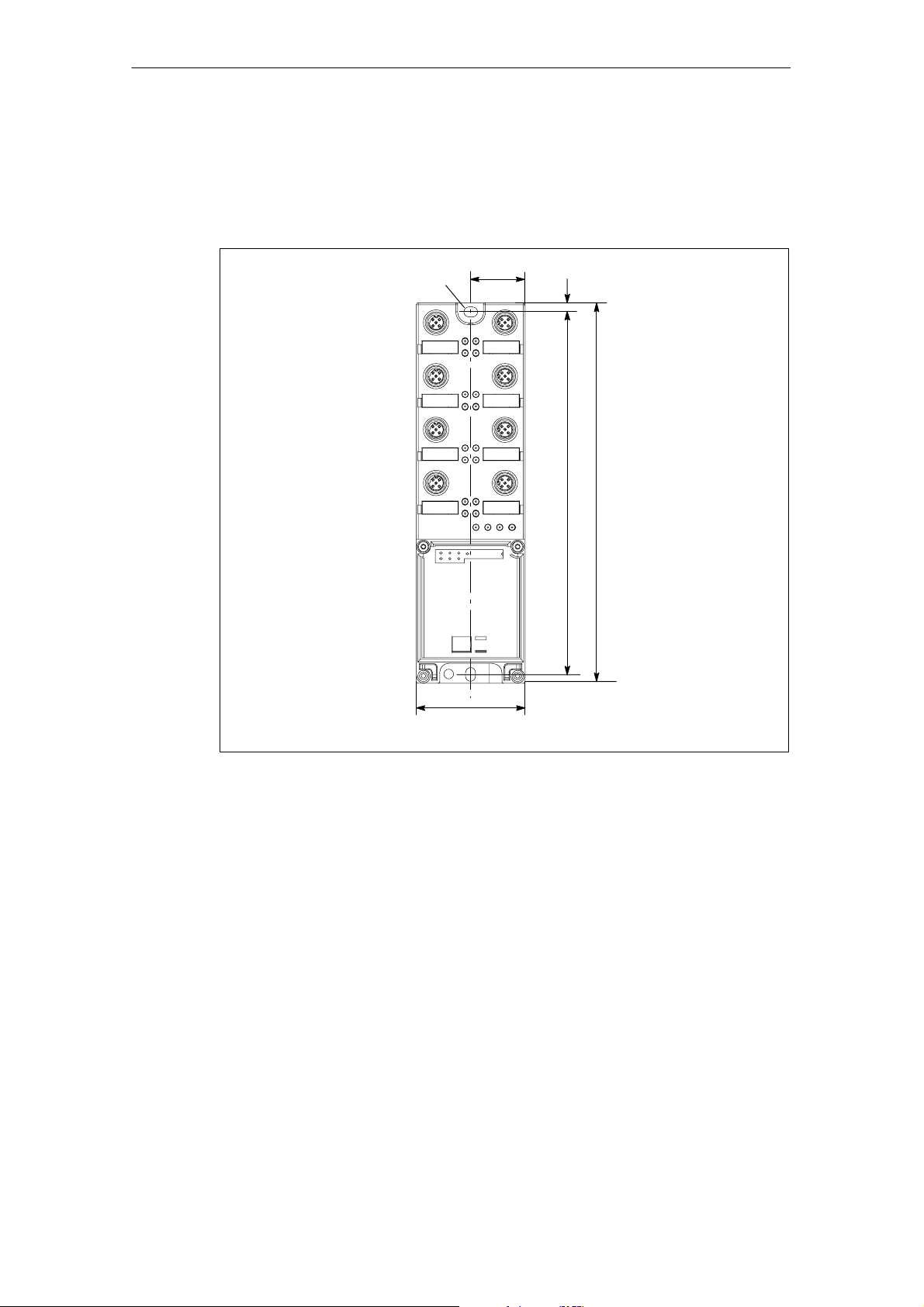

Installation of the terminal block

1. Insert the terminal block into the I/O module.

2. Bolt the terminal block to the I/O module (with a torque of 1 to 1.3 nm). Tighten

the screws evenly in diagonally opposite sequence.

The terminal block is equipped with four captive screws (see Figure 2-2).

2

2

2

1

Figure 2-2 Inserting and screw–tightening the terminal block at the I/O module

Note

The protection type IP 65, IP 66 or IP 67 is only ensured after the terminal block is

screwed tight onto the I/O module!

2

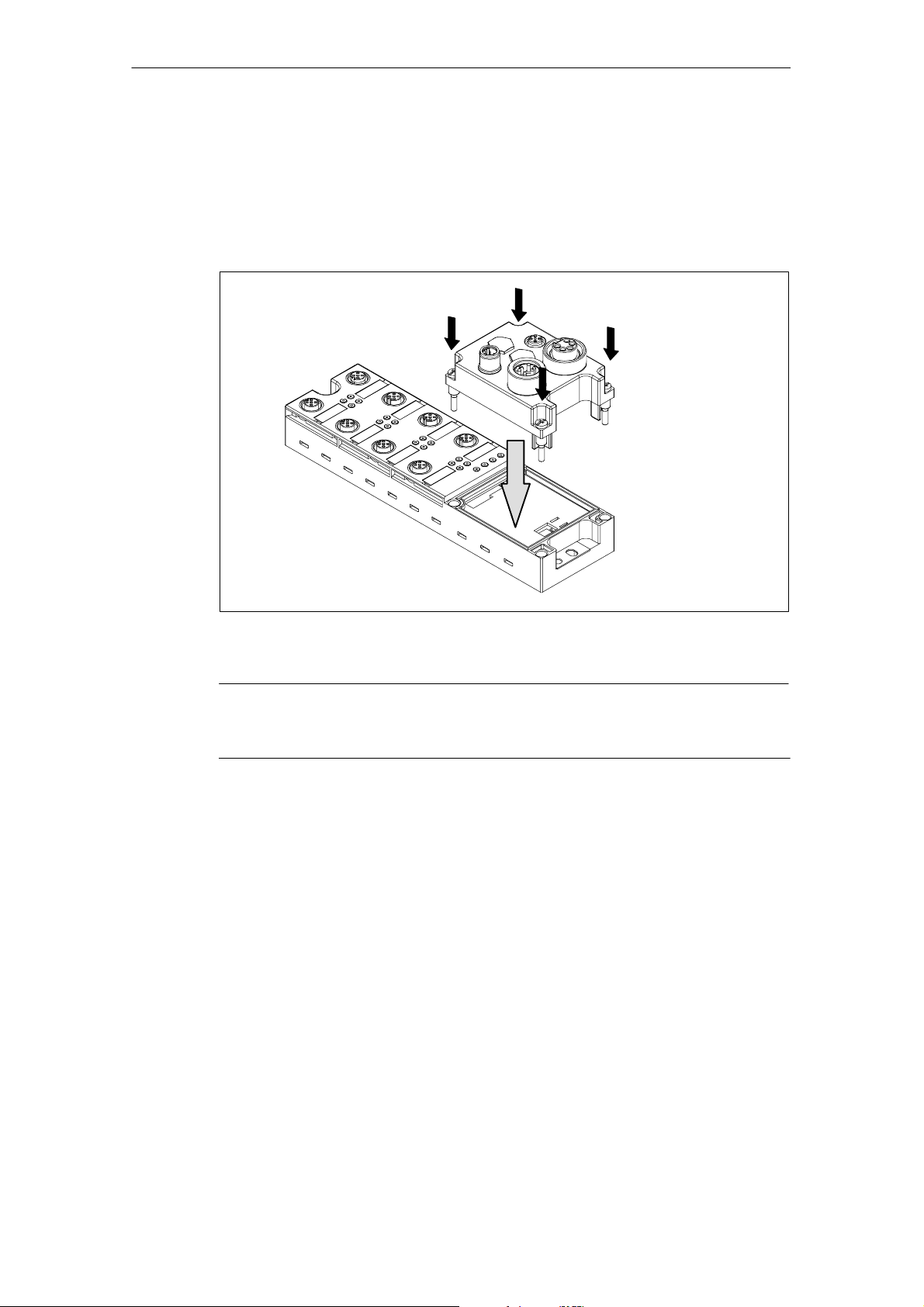

2.4 Label replacement

Properties

You can use these labels to identify each of the I/O module’s channels and the

terminal block. The system is supplied with snap–on labels:

• 8 labels on the I/O module

• 1 label on the terminal block

Requirements

Replacement labels are available on order. For order numbers please refer to

Appendix A.

2-4

ET 200eco Distributed I/O Station

A5E00158716-02

Tools required

Screwdriver, 2.5 mm to 4 mm blade

Label replacement

1. Insert the screwdriver into the small opening on the label and lever it out.

Installation

1

Figure 2-3 Removing labels

2. Snap the new label tag into the holder on the module.

2.5 Removing ET 200eco

Procedure

The ET 200eco is wired and in operation.

1. Switch off the ET 200eco power supply.

2. Disconnect the terminal block wiring.

3. Unscrew the terminal block and remove it from the I/O module.

4. Disconnect the wiring on the I/O module.

5. Unscrew the I/O module.

Note

Please note Chapter 3.4.5 before you replace the I/O module.

ET 200eco Distributed I/O Station

A5E00158716-02

2-5

Installation

2.6 PROFIBUS address assignment

Properties

Specify the PROFIBUS address under which the ET 200eco I/O station is

accessed on PROFIBUS DP.

Requirements

• The PROFIBUS-DP address for ET 200eco is set at the terminal block.

• All PROFIBUS-DP addresses must be unique.

• The set PROFIBUS address must match the PROFIBUS address specified in

your configuration software (for this ET 200eco).

• A change of PROFIBUS–DP address is only valid after the ET 200eco has

been powered up (power ON).

Tools required

• 14 mm socket wrench

• Screwdriver with 2.5 mm blade

2-6

ET 200eco Distributed I/O Station

A5E00158716-02

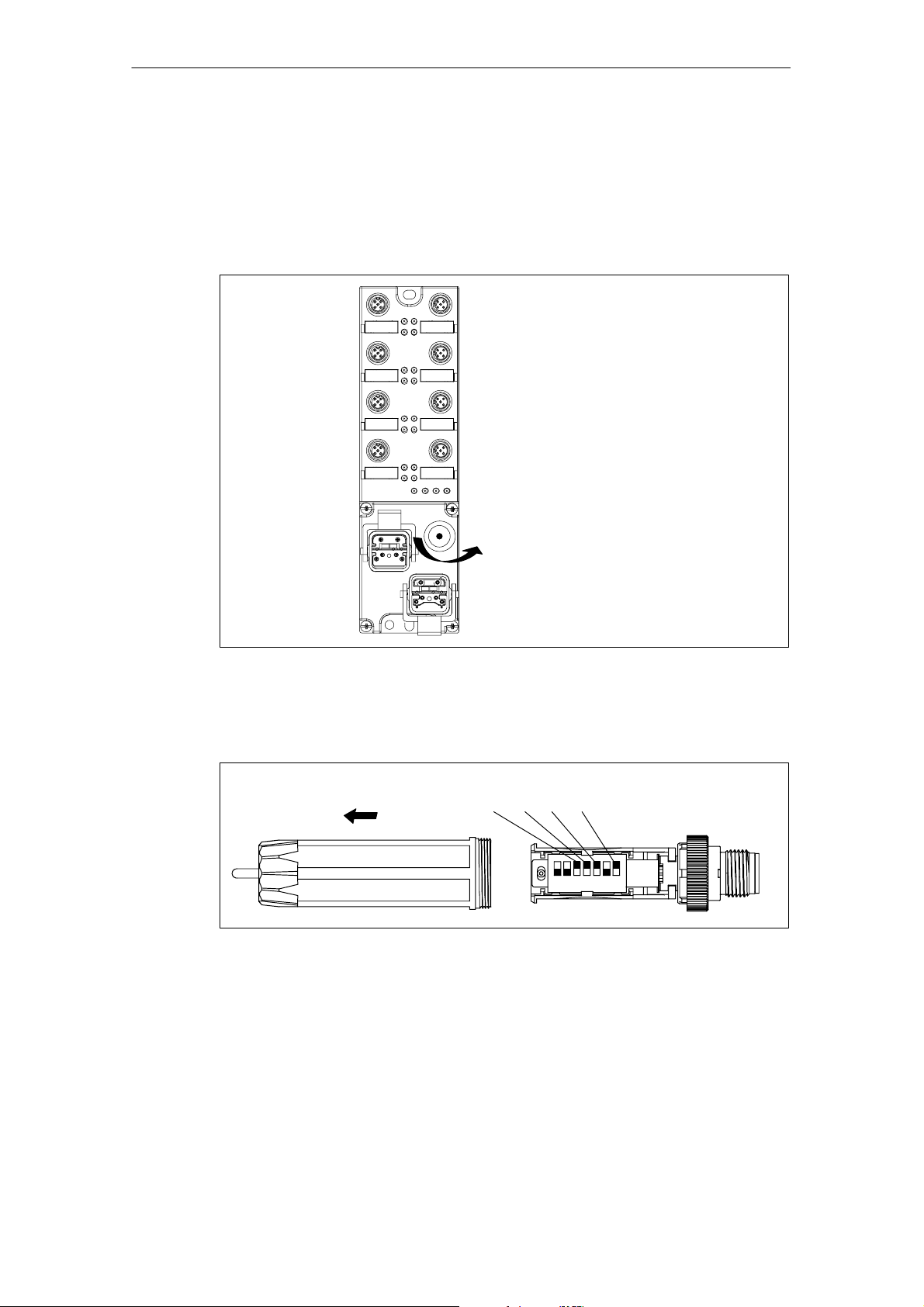

How to set the PROFIBUS-DP address at the terminal block M12, 7/8”

The permitted PROFIBUS-DP address range is 1 to 99.

1. Remove both lock caps on the rotary selector switches (use the 14–mm socket

wrench if need be).

2. Using the screwdriver, set the required PROFIBUS address on the selector

switches.

– Lower selector switch: one’s place

– Upper selector switch: ten’s place

3. Screw the two caps onto the selector switches again (Torque : 0.5 to 0.8 N/m).

Example PROFIBUS address 92:

x10

Position 9

Installation

x1

Position 2

x10

Rotary selector

x1

switch for setting

the PROFIBUS

address

Figure 2-4 How to set the PROFIBUS-DP address at terminal block M12, 7/8”

ET 200eco Distributed I/O Station

A5E00158716-02

2-7

Installation

How to set the PROFIBUS-DP address at the ECOFAST terminal block

Valid range of the PROFIBUS DP addresses: 1 to 99. If you select a higher

address, the I/O module will return an error signal via the red bus error LED.

1. Unscrew and remove the configuration module from the ECOFAST terminal

block.

1

Figure 2-5 How to unscrew the configuration module

2. Unscrew and remove the cap of the configuration module.

3. Set the PROFIBUS address on the DIL switches.

Example: PROFIBUS address 92

22 + 23 + 24 + 26 = 4 + 8 + 16 + 64 = 92

2

ON ON

1723456

Figure 2-6 How to set the PROFIBUS address at the configuration module

4. Screw on the cap again. Reinsert the configuration module and fasten it on the

terminal block with the screws.

2-8

ET 200eco Distributed I/O Station

A5E00158716-02

Wiring

Introduction

Special rules and regulations apply to the integration of ET 200eco distributed I/O

stations in plants and systems.

This chapter provides an overview of the essential rules for the integration of

ET 200eco distributed I/O stations in plants or systems.

Chapter overview

Chapter Topic Page

3.1 General rules and regulations for the operation of ET 200eco 3-1

3.2 ET 200eco must be operated on a grounded power supply 3-2

3.3 Electrical installation of ET 200eco 3-4

3.4 Wiring ET 200eco 3-7

3

3.1 General rules and regulations for the operation of ET 200eco

EMERGENCY–OFF devices

All EMERGENCY–OFF devices according to IEC 204 (corresponds to

DIN VDE 113) must be enabled for all plant or system operating states.

ET 200eco Distributed I/O Station

A5E00158716-02

3-1

Wiring

Plant startup after specific events

The table below shows what you need to observe for a restart of the plant after

specific events.

If... then...

Startup after voltage drop or loss

Startup of ET 200eco after an

interrupt of bus communication

Startup after release of the

”EMERGENCY–OFF” device

24 VDC power supply

The table below shows what you have to observe when operating the 24 VDC

power supply.

hazardous states must not develop. If necessary,

force EMERGENCY–OFF!

controlled and defined startup must be ensured at

all times.

For... always provide...

buildings an external lightning

protection

24 VDC supply lines,

signal lines

24 VDC supply safe (electrical) isolation of the extra–low voltage

Power supply routing Power loss in the through–loop (see Chapter 3.4.5).

internal lightning protection

Protection against external electrical interference

The table below shows what you have to observe in order to protect your system

from electrical interference and faults.

For... ensure that...

all plants or systems

equipped with an ET 200eco,

power supply/signal/bus

cables

signal and bus cables a cable/wire break can not cause indefinite plant or

the plant or system is connected to a grounding conductor

in order to discharge electromagnetic interference.

correct installation and cable routing.

system states.

lightning protection measures

(e.g. lightning protection

(e.g. lightning protection

elements)

3.2 ET 200eco operation on a grounded power supply

Below you can find information on the overall structure of an ET 200eco distributed

I/O station that is operated on a grounded power supply (TN-S network). The

topics treated here are: shutdown devices, short–circuit/overload protection to

DIN VDE 0100 and DIN EN 60204-1.

ET 200eco Distributed I/O Station

3-2

A5E00158716-02

Definition: Grounded powersupply

The neutral conductor of grounded power supplies is connected to ground. Any

ground fault at a live conductor or grounded part of the system will trigger a

response of the protection devices.

Components and protective measures

Vario1us components and protective devices are mandatory for plant/system

installation. The type of components and the binding character of the regulations

for protective measures depends on the DIN VDE regulation that applies to your

plant installation. The table below refers to Figure 3-1.

Wiring

Compare... Refe-

Shutdown device for the

controller, signal transducers and actuators

Short–circuit and overload protection

rence to

Figure 3-1

...Part 460:

...Part 725:

DIN VDE 0100 DIN EN 60204

Main switch

Single–pole fusing of circuits

Safety electrical isolation

Safety electrical isolation is required for :

• Modules that require a 60 VDC or 25 VAC power supply

• 24 VDC load current circuit

ET 200eco installation with grounded reference potential

In ET 200eco installations with grounded reference potential all electrical

interference is discharged to protective earth. These connections must be

interconnected externally or in the connector (see Figure 3-1: Interconnecting 1M

and PE).

...Part 1:

Isolating switches

...Part 1:

grounded secondary circuit:

single–pole fusing

ET 200eco installation with floating reference potential

In ET 200eco installations with floating reference potential any electrical

interference is discharged to protective earth via an internal RC network (see

Figure 3-1: No interconnection 1M to PE).

Isolation monitoring

The following situations always require isolation monitoring:

• ungrounded ET 200eco installations

• if hazardous plant states can develop due to successive faults

ET 200eco Distributed I/O Station

A5E00158716-02

3-3

Wiring

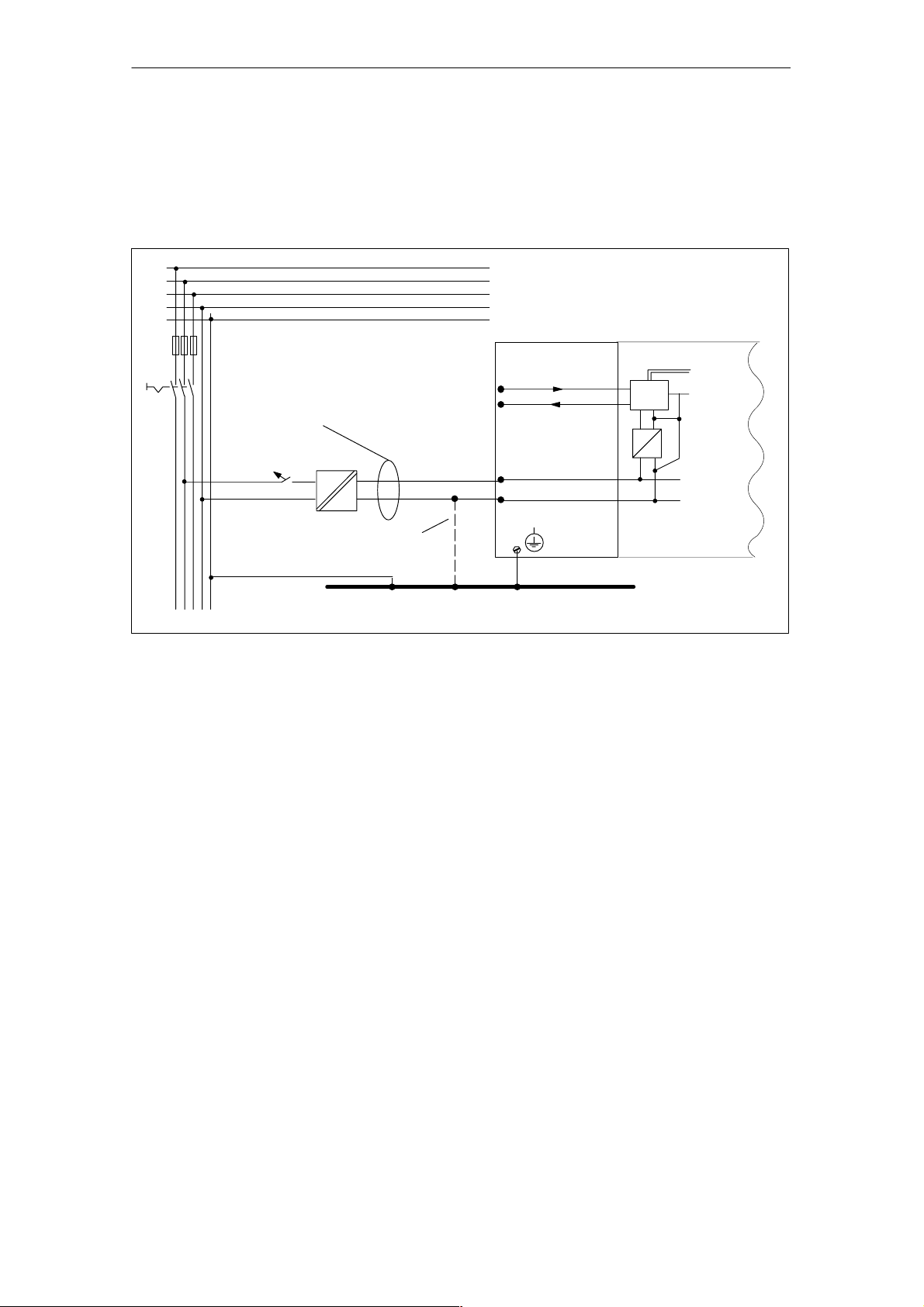

Overall structure of ET 200eco

Figure 3-1 shows the overall structure of an ET 200eco distributed I/O station

((Load supply voltages and grounding concept) with power supply from a TN-S

network.

L1

L2

L3

n

PE

for ET 200eco

with ECOFAST terminal block:

24 VDC NS

AC

DC

PROFIBUS-DP

24 VDC

Low–voltage distribution,

e.g. in a TN-S system (3 400 V)

ET 200eco

Terminal block I/O module

A

B

1 L+

1

M

mP

1M is not connected to PE in installations without grounding.

Grounding bus

Figure 3-1 ET 200eco operation with reference potential bonded to equipotential earth

Data

M

internal

3.3 Electrical structure of the ET 200eco system

Isolated potential

The electrical circuit of an ET 200eco is galvanically separated between:

• 1L+ (electronic circuit/sensor supply):

Potential isolation to PROFIBUS-DP and 2L+ (load voltage supply),except I/O

module 8 DI/8 DO 2 A.

• 2L+ (load voltage supply):

Potential isolation to all other circuit elements execpt I/O module 8 DI/8 DO 2 A.

For I/O module 8 DI/8 DO 2 A, 1M and 2M are interconnected internally.

• PROFIBUS-DP interface:

Potential isolation to other circuit components.

3-4

ET 200eco Distributed I/O Station

A5E00158716-02

Loading...

Loading...