Page 1

Preface, Contents

SIMATIC

ET 200C

Distributed I/O Station

Manual

Configuration

ET 200C Configuration Options

ET 200C Components

Mechanical and Electrical

Installation

Address Assignment and Param-

eterization with COM ET 200

Startup and Test with

COM ET 200

Fault Diagnostics with the

IM 308-B

Fault Diagnostics with the

IM 308-C

Connection of the

ET 200 Handheld

1

2

3

4

5

6

7

8

9

Edition 03

General Technical Specifications

Digital Modules

Analog Modules

Other ET 200C Components

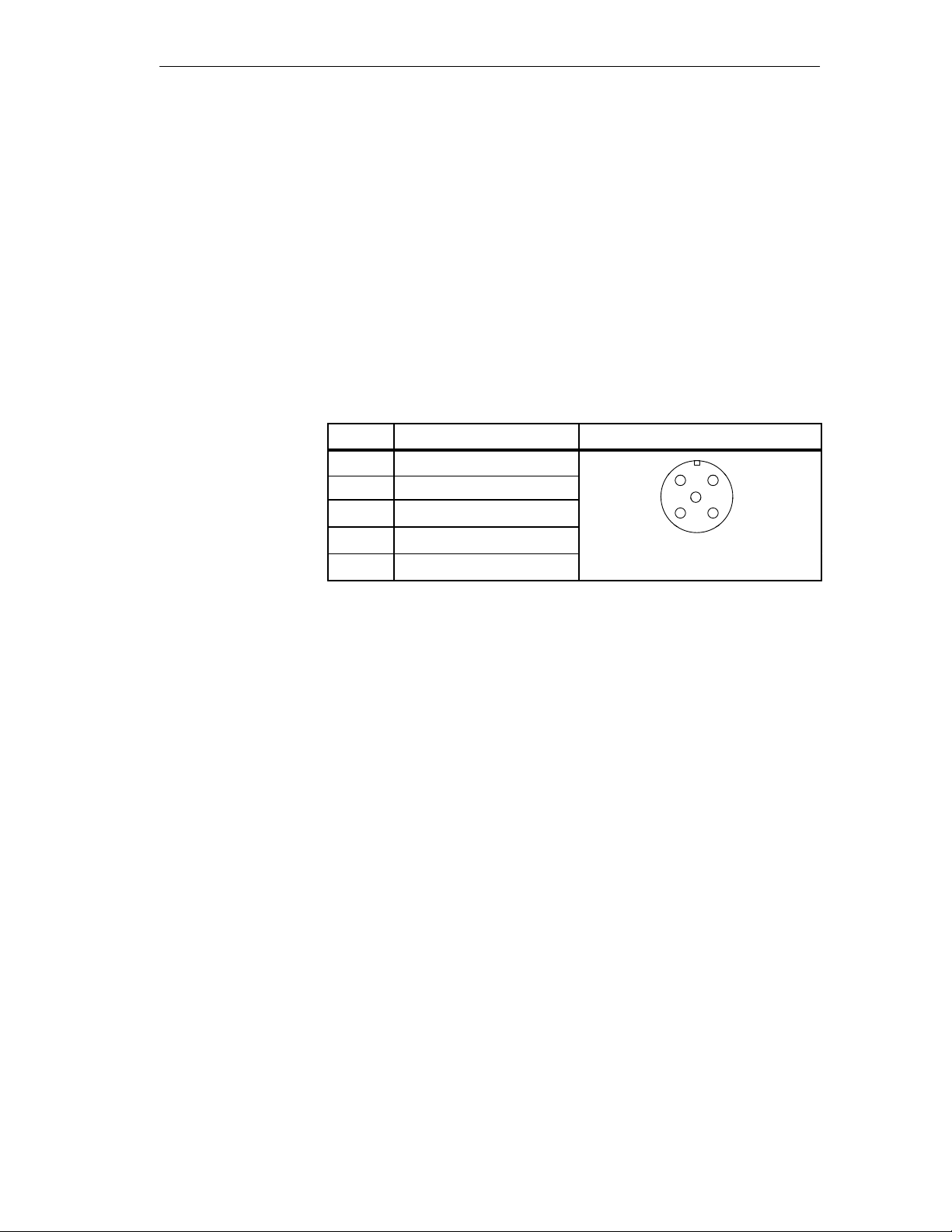

Pin Assignments of the ET 200C

Modules

Type files

Safety-Related Guidelines

Glossary, Index

10

11

12

13

A

B

C

EWA 4NEB 812 6119-02b

Page 2

Safety Guidelines

!

!

!

This manual contains notices which you should observe to ensure your own personal safety,

as well as to protect the product and connected equipment. These notices are highlighted in

the manual by a warning triangle and are marked as follows according to the level of danger:

Danger

indicates that death, severe personal injury or substantial property damage will result if

proper precautions are not taken.

Warning

indicates that death, severe personal injury or substantial property damage can result if

proper precautions are not taken.

Caution

indicates that minor personal injury or property damage can result if proper precautions are

not taken.

Note

draws your attention to particularly important information on the product, handling the

product, or to a particular part of the documentation.

Qualified Personnel

Correct Usage

!

Only qualified personnel should be allowed to install and work on this equipment. Quali-

fied persons are defined as persons who are authorized to commission, to ground, and to tag

circuits, equipment, and systems in accordance with established safety practices and standards.

The device/system may only be set up and operated in conjunction with this manual.

Note the following:

Warning

This device and its components may only be used for the applications described in the catalog or the technical description, and only in connection with devices or components from

other manufacturers which have been approved or recommended by Siemens.

This product can only function correctly and safely if it is transported, stored, set up, and

installed correctly, and operated and maintained as recommended.

SIMATIC and SINEC are registered trademarks of SIEMENS AG.

Copyright

Copyright Siemens AG 1994 All Rights Reserved

The reproduction, transmission or use of this document or its contents

is not permitted without express written authority. Offenders will be

liable for damages. All rights, including rights created by patent grant

or registration of a utility model or design, are reserved.

Exclusion of Liability

We have checked the contents of this manual for agreement with the

hardware and software described. Since deviations cannot be precluded entirely, we cannot guarantee full agreement. However, the data

in this manual is reviewed regularly and any necessary corrections

included in subsequent editions. Suggestions for improvement are

welcomed.

Technical data subject to change.

Page 3

Preface

Purpose

of the Manual

Contents

of the Manual

The information in this manual will enable you to:

install, connect and operate the ET 200C distributed I/O station,

look up the module characteristics and technical data.

This section shows you how the manual is structured.

What is ET 200C?

What configuration options do I

have with ET 200C?

What are the components of ET 200C?

What is involved in mechanical and

electrical installation?

How do I set the address and parameters

with COM ET 200?

How do I perform startup and testing

with COM ET 200?

Errors?

Chap. 1

Chap. 2

Chap. 3

Chap. 4

Chap. 5

Chap. 6

Chap. 7, 8

Scope

of the Manual

ET 200C Distributed I/O Station

EWA 4NEB 812 6119-02b

How do I connect the ET 200 handheld?

T echnical data?

Pin assignment, type files?

This manual covers all the ET 200C modules that can be addressed with the

DP standard bus protocol. Each of these ET 200C modules has an order

number beginning with 6ES7 (See Chapter 10.1).

This manual is applicable to operation of ET 200C in conjunction with

Chap. 9

Chap. 10, 11, 12, 13

Appendix A, B

IM 308-B master interface and COM ET 200

IM 308-C master interface and COM ET 200 Windows.

Operation with the IM 308-B master interface and COM ET 200 is described

in detail in this manual.

iii

Page 4

Preface

Scope

of the Manual

(Continued)

Other Important

Manuals

Quick Access

As regards operation of ET 200C with the IM 308-C master interface and

COM ET 200 Windows, this manual describes only parameterization with

COM ET 200 Windows. See the manual entitled ET 200 Distributed

I/O System (order number 6ES5 998-3ES12) for detailed information on how

to use COM ET 200 Windows and on working with the FB IM 308C standard

function block.

COM ET 200 Windows has an online Help system that provides valuable

assistance for starting up and operating the ET 200C modules.

This manual follows on from the manual entitled ET 200 Distributed

I/O System, which is the master description for the series.

You must read and understand the manual ET 200 Distributed I/O System in

order to use this manual.

A number of features in this manual will help you to obtain quick access to

the information you require:

At the start of the manual you will find a general table of contents, plus a

list of all the illustrations and a list of all the tables in the manual.

On each page throughout the manual, the bold-face headings on the left

summarize the contents of the individual passages.

Standards

Questions

Suggestions

The Appendices are followed by a Glossary containing definitions of the

important terms used in this manual.

The manual closes with a detailed index that you can use to find

information on the topic of your choice.

The ET 200C modules function as DP standard slaves in accordance with the

definitions of DIN E 19245, Parts 1 and 3.

Please address all questions about the ET 200C distributed I/O station to:

Hotline SIMATIC

Erlangen

Phone (+ 49 for Germany) 9131/7-43344

You will find suggestion sheets at the end of the manual. Please note any

suggestions or proposals you may have on these sheets and return them to

use. Your suggestions will help us improve the next edition of the manual.

ET 200C Distributed I/O Station

iv

EWA 4NEB 812 6119-02b

Page 5

Contents

1 Configuration 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 What is the ET 200? 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 What is the ET 200C? 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 ET 200C Configuration Options 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Overview of the ET 200C Configuration Options 2-2. . . . . . . . . . . . . . . . . .

2.1.1 Configuration with Power Supply Connector without T Connector 2-4. . . .

2.1.2 Configuration with Power Supply Connector and with T Connectors 2-7.

2.1.3 Configuration using Several Power Supply Connectors 2-10. . . . . . . . . . . .

2.1.4 Configuration without Power Supply Connector 2-12. . . . . . . . . . . . . . . . . . .

2.1.5 Configuration with Programmer Connector 2-16. . . . . . . . . . . . . . . . . . . . . . .

3 ET 200C Components 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Digital Input Module ET 200C; DI 8 DC 24V

(6ES7 141-0BF00-0XB0) 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Digital Output Module ET 200C; DO 8 DC 24V/0.5A

(6ES7 142-0BF00-0XB0) 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Digital Output Module ET 200C; DO 8 DC 24V/2A

(6ES7 142-0BF10-0XB0) 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Digital Input/Output Module ET 200C; DI 16/DO 16 DC 24V

(6ES 143-0BL00-0XB0 and 6ES7 143-0BL10-0XB0) 3-8. . . . . . . . . . . . . .

3.5 Analog Input Module ET 200C; AI 4/8 12 Bit

(6ES7 144-0KH00-0XB0) 3-1 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6 Analog Input Module ET 200C; AI 4 12 Bit

(6ES7 144-0HF00-0XB0) 3-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.7 Analog Output Module ET 200C; AO 4 12 Bit

(6ES7 145-0HF00-0XB0) 3-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.8 T Connector (6ES5 762-2CT11) 3-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.9 Power Supply Connector (6ES5 762-2CS11) 3-18. . . . . . . . . . . . . . . . . . . . .

3.10 Programmer Connector (6ES5 762-2CA12) 3-19. . . . . . . . . . . . . . . . . . . . . .

3.1 1 Cables 3-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.12 Terminating Resistor (6ES5 755-2CA11) 3-22. . . . . . . . . . . . . . . . . . . . . . . . .

3.13 Adapter Cable (6ES5 755-8CA11) 3-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ET 200C Distributed I/O Station

EWA 4NEB 812 6119-02b

v

Page 6

Contents

4 Mechanical and Electrical Installation 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Installation of ET 200C 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Electrical Wiring of the ET 200C Distributed I/O Station 4-3. . . . . . . . . . . .

4.2.1 Grounded Configuration 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.2 Ungrounded Configuration 4-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Wiring of the ET 200C 4-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.1 Wiring of the Bus Connection 4-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.2 Wiring of ET 200C; DI 8 DC 24V (6ES7 141-0BF00-0XB0) 4-13. . . . . . .

4.3.3 Wiring of ET 200C; DO 8 DC 24V/0.5A (6ES7 142-0BF00-0XB0)

and ET 200C; DO 8 DC 24V/2A (6ES7 142-0BF10-0XB0) 4-15. . . . . . .

4.3.4 Wiring of ET 200C; DI 16/DO 16 DC 24V/2A

(6ES7 143-0BL00-0XB0) 4-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.5 Wiring of ET 200C; DI 16/DO 16 DC 24V/2A

(6ES7 143-0BL10-0XB0) 4-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.6 Wiring of ET 200C; AI 4/8 12 Bit (6ES7 144-0KH00-0KB0) 4-21. . . . . . .

4.3.7 Wiring of ET 200C; AI 4 12 Bit (6ES7 144-0HF00-0KB0) 4-30. . . . . . . . .

4.3.8 Wiring of ET 200C; AO 4 12 Bit (6ES7 145-0HF00-0KB0) 4-35. . . . . . . .

4.3.9 Wiring of the Load Voltage Supply 4-41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.10 Wiring of the External Power Supply to the PS Connector 4-42. . . . . . . . . .

4.4 Setting DIL Switches on Analog Modules of ET 200C 4-43. . . . . . . . . . . . . .

4.4.1 Setting the Station Number of Analog Modules by Means of

DIL Switch Block S1 4-44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.2 Setting the Measurement Type for Analog Module ET 200C;

AI 4/8 12 Bit 4-46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.3 Setting Measurement Type for Analog Module ET 200C;

AI 4 12 Bit 4-50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.4 Setting Connection Mode for Analog Module ET 200C;

AO 4 12 Bit 4-52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Address Assignment and Parameterization with COM ET 200 5-1. . . . . . . . . . . .

5.1 Address Assignment with COM ET 200 V4.x 5-2. . . . . . . . . . . . . . . . . . . . . .

5.1.1 Enter Station Number 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.2 Enter Address Area and Station Type 5-5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.3 Enter Station Name, Addresses and Address Identifier 5-7. . . . . . . . . . . . .

5.1.4 Enter Parameterization Frame with COM ET 200 V4.x 5-12. . . . . . . . . . . . .

6 Startup and Test with COM ET 200 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Connecting the Programmer 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Starting Up and Testing the ET 200C Distributed I/O Station 6-4. . . . . . . .

6.3 Testing the ET 200C Distributed I/O Station 6-6. . . . . . . . . . . . . . . . . . . . . .

7 Fault Diagnostics with the IM 308-B 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Using LEDs to Diagnose Problems 7-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Using COM ET 200 V4.x to Diagnose Problems 7-5. . . . . . . . . . . . . . . . . . .

7.3 Using STEP 5 to Diagnose Problems (Station Diagnosis) 7-7. . . . . . . . . .

7.3.1 “Overview” Diagnostics 7-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.2 ”Parameter Assignment and Addressability” Diagnostics 7-12. . . . . . . . . . .

7.3.3 Station Status Diagnostics 7-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ET 200C Distributed I/O Station

vi

EWA 4NEB 812 6119-02b

Page 7

7.3.4 Manufacturer Identification Diagnostics 7-17. . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.5 Device-related Diagnostics – Digital ET 200C 7-18. . . . . . . . . . . . . . . . . . . . .

8 Fault Diagnostics with the IM 308-C 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 Using LEDs to Diagnose Problems 8-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Using STEP 5 to Diagnose Problems (Station Diagnostics) 8-6. . . . . . . . .

8.2.1 Diagnosing the station status 8-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.2 Diagnosing the Manufacturer Identification 8-17. . . . . . . . . . . . . . . . . . . . . . .

8.2.3 Device-related Diagnostics – Digital ET 200C 8-18. . . . . . . . . . . . . . . . . . . . .

8.2.4 Identification- and Device-related Diagnostics – Analog ET 200C 8-21. . . .

9 Connection of the ET 200 Handheld 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 Connection of the ET 200 Handheld 9-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 General Technical Specifications 10-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1 Overview of Digital and Analog Modules for the ET 200C 10-2. . . . . . . . . . .

10.2 General Technical Specifications 10-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11 Digital Modules 11-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

11.1 Digital Input Module ET 200C; DI 8 DC 24V

(6ES7 141-0BF00-0BX0) 11-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.2 Digital Output Module ET 200C; DO 8 DC 24V/0.5A

(6ES7 142-0BF00-0XB0) 11-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.3 Digital Output Module ET 200C; DO 8 DC 24V/2A

(6ES7 142-0BF10-0XB0) 1 1-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4 Digital Input/Output Module ET 200C; DI 16/DO 16 DC 24V/2A

(6ES7 143-0BL00-0XB0 and 6ES7 143-0BL10-0XB0) 11-16. . . . . . . . . . . . .

12 Analog Modules 12-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.1 Analog Input Module ET 200C; AI 4/8 12 Bit

(6ES7 144-0KH00-0XB0) 12-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.2 ET 200C Analog Input Module; AI 4 12 Bit

(6ES7 144-0HF00-0XB0) 12-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.3 ET 200C Analog Output Module; AO 4 12 Bit

(6ES7 145-0HF00-0XB0) 12-33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13 Other ET 200C Components 13-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1 T Connector (6ES5 762-2CT11) 13-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2 Power Supply Connector (6ES5 762-2CS11) 13-3. . . . . . . . . . . . . . . . . . . . .

13.3 Programmer Connector (6ES5 762-2CA12) 13-5. . . . . . . . . . . . . . . . . . . . . .

13.4 Cables 13-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.5 Terminating Resistor (6ES5 755-2CA11) 13-8. . . . . . . . . . . . . . . . . . . . . . . . .

13.6 Adapter Cable (6ES5 755-8CA11) 13-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ET 200C Distributed I/O Station

EWA 4NEB 812 6119-02b

vii

Page 8

Contents

A Pin Assignments of the ET 200C Modules A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.1 Pin Assignments of ET 200C Digital Modules A-2. . . . . . . . . . . . . . . . . . . . .

A.2 Pin Assignments of ET 200C Analog Modules A-5. . . . . . . . . . . . . . . . . . . .

B Type Files B-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.1 Type Files, ET 200C Digital Modules for COM ET 200 V4.x B-2. . . . . . . . .

B.1.1 Type File SN8010TD.200: COM ET 200 V4.x - C-8DI DP B-3. . . . . . . . . . .

B.1.2 Type File SN8011TD.200: COM ET 200 V4.x - C-8DO DP B-4. . . . . . . . . .

B.1.3 Type File SN8012TD.200: COM ET 200 V4.x - C-8DO/2A DP B-5. . . . . . .

B.1.4 Type File SN8013TD.200: COM ET 200 V4.x - C-16DI/16DO/2A DP B-6.

B.2 Type Files of ET 200C Analog Modules for COM ET 200 Windows B-7. .

B.2.1 Type File SI800FAD.200: COM ET 200 Windows - C-4/8AI DP B-8. . . . . .

B.2.2 Type File SI800EAD.200: COM ET 200 Windows - C-4AI DP B-13. . . . . . .

B.2.3 Type File SI800DAD.200: COM ET 200 Windows - C-4AO DP B-16. . . . . .

C Safety-Related Guidelines C-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.1 Active and Passive Faults in Automation Equipment C-2. . . . . . . . . . . . . . .

C.2 Suggestions for Configuring and Installing a Distributed I/O Station C-3. .

viii

ET 200C Distributed I/O Station

EWA 4NEB 812 6119-02b

Page 9

Figures

1-1 ET 200 Bus Users Described in this Manual 1-2. . . . . . . . . . . . . . . . . . . . . .

1-2 ET 200C Digital and Analog Modules 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 Other ET 200C Components 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1 Legend 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 SINEC L2-DP Field Bus and Power Supply Looped Through

at ET 200C Slave Station 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3 SINEC L2-DP Field Bus and Power Supply Looped Through

with T Connectors 2-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-4 Rule for Use of a T Connector 2-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5 Configuration using Several Power Supply Connectors 2-11. . . . . . . . . . . .

2-6 SINEC L2-DP Field Bus Looped Through with T Connectors –

Individual External Power Supply to Each Slave Station 2-13. . . . . . . . . . . .

2-7 Rules for Use of a T Connector 2-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-8 Rules for Current Connection 2-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-9 Configuration with Programmer Connector 2-16. . . . . . . . . . . . . . . . . . . . . . .

3-1 Digital Input Module ET 200C; DI 8 DC 24V

(6ES7 141-0BF00-0XB0) 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2 Digital Output Module ET 200C; DO 8 DC 24V/0.5A

(6ES7 142-0BF00-0XB0) 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3 Digital Output Module ET 200C; DO 8 DC 24V/2A

(6ES7 142-0BF10-0XB0) 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4 Digital Input/Output Module ET 200C; DI 16/DO 16 DC 24V

with Circular Connector

(6ES7 143-0BL00-0XB0) 3-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5 Digital I/O Module ET 200C; DI 16/DO 16 DC 24 V with

Conduit Thread Glands (6ES7 143-0BL10-0XB0) 3-10. . . . . . . . . . . . . . . . .

3-6 Analog Input Module ET 200C; AI 4/8 12 Bit

(6ES7 144-0KH00-0XB0) 3-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-7 Analog Input Module ET 200C; AI 4 12 Bit

(6ES7 144-0HF00-0XB0) 3-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-8 Analog Output Module ET 200C; AO 4 12 Bit

(6ES7 145-0HF00-0XB0) 3-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-9 T Connector 3-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-10 Power Supply Connector 3-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-11 Programmer Connector 3-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-12 Terminating Resistor 3-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-13 Adapter Cable 3-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1 Grounded Configuration for ET 200C with 24 V DC

Current/Load Voltage Supply 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2 Ungrounded Configuration for ET 200C 4-7. . . . . . . . . . . . . . . . . . . . . . . . . .

4-3 Bus Connections of the ET 200C Modules 4-10. . . . . . . . . . . . . . . . . . . . . . .

4-4 Sensor Supply Returned to Input without Load 4-14. . . . . . . . . . . . . . . . . . . .

4-5 Sensor Supply Returned to Input with Load 4-14. . . . . . . . . . . . . . . . . . . . . . .

4-6 Output Returned to Input without Load 4-16. . . . . . . . . . . . . . . . . . . . . . . . . . .

4-7 Output Returned to Input with Load 4-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-8 Output Returned to Input without Load 4-18. . . . . . . . . . . . . . . . . . . . . . . . . . .

4-9 Output Returned to Input with Load 4-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-10 Arrangement of Screw Terminals of ET 200C;

DI 16/DO 16 DC 24V/2A (6ES7 143-0BL10-0XB0) 4-20. . . . . . . . . . . . . .

4-11 Components of the Cable Gland for the Grounding Cable 4-21. . . . . . . . . .

Contents

ET 200C Distributed I/O Station

EWA 4NEB 812 6119-02b

ix

Page 10

Contents

4-12 Arrangement of Screw Terminals and DIL Switches in ET 200C;

AI 4/8 12 Bit 4-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-13 Connection to ET 200C; AI 4/8 12 Bit of Thermocouples

for Floating Measurement and External Floating Compensation 4-24. . . . .

4-14 Connection to ET 200C; AI 4/8 12 Bit of Thermocouples for

Non-Floating Measurement and External Non-Floating Compensation 4-25

4-15 Connection to ET 200C; AI 4/8 12 Bit of Thermocouples for

Non-Floating Measurement and Internal Compensation 4-26. . . . . . . . . . . .

4-16 Connection to ET 200C; AI 4/8 12 Bit of Resistance Thermometers

(Pt 100) in 2-Wire Circuit for Floating Measurement 4-27. . . . . . . . . . . . . . .

4-17 Connection to ET 200C; AI 4/8 12 Bit of Resistance Thermometers

(Pt 100) in 4-Wire Circuit for Floating Measurement 4-28. . . . . . . . . . . . . . .

4-18 Connection to ET 200C; AI 4/8 12 Bit of Voltage Sensors

in 2-Wire Circuit for Non-Floating Measurement 4-29. . . . . . . . . . . . . . . . . . .

4-19 Components of the Cable Gland for the Grounding Cable 4-30. . . . . . . . . .

4-20 Arrangement of Screw Terminals and DIL Switches in ET 200C;

AI 4 12 Bit 4-32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-21 Connection to ET 200C; AI 4 12 Bit of Voltage Sensors

in 2-Wire Circuit for Floating Measurement 4-33. . . . . . . . . . . . . . . . . . . . . . .

4-22 Connection to ET 200C; AI 4 12 Bit of Current Sensors

in 2-Wire Circuit for Floating Measurement 4-34. . . . . . . . . . . . . . . . . . . . . . .

4-23 Components of the Cable Gland for the Grounding Cable 4-35. . . . . . . . . .

4-24 Arrangement of Screw Terminals and DIL Switches in ET 200C;

AO 4 12 Bit 4-37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-25 Connection of Loads to ET 200C; AO 4 12 Bit, 4-Wire Circuit

for Voltage Output 4-38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-26 Connection of Loads to ET 200C; AO 4 12 Bit, 2-Wire Circuit

for Voltage Output 4-39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-27 Connection of Loads to ET 200C; AO 4 12 Bit, 2-Wire Circuit

for Current Output 4-40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-28 DIL Switch Block in Default Position (As Delivered) 4-44. . . . . . . . . . . . . . . .

4-29 Example of How to Set a Station Number at DIL Switch

Block S1 4-45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-30 Block Diagram of DIL Switches in DIL Switch Block S2 4-47. . . . . . . . . . . . .

4-31 Block Diagram of DIL Switches in DIL Switch Block S4 4-49. . . . . . . . . . . . .

4-32 Block Diagram of DIL Switches in DIL Switch Block S5 4-51. . . . . . . . . . . . .

5-1 “CONFIGURING” Screen (1) 5-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2 “CONFIGURING” Screen (2) 5-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3 ”CONFIGURING” Screen (3) 5-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-4 Structure of the Parameterization Frame for ET 200C: Byte 0 5-13. . . . . . .

5-5 Structure of the Parameterization Frame for ET 200C: Byte 1 5-13. . . . . . .

6-1 Connecting the Programmer to the ET 200C 6-2. . . . . . . . . . . . . . . . . . . . . .

6-2 Connecting the Programmer to the SINEC L2-DP Field Bus 6-3. . . . . . . .

6-3 “SYSTEM START-UP/TEST: STATION SELECTED” Screen 6-5. . . . . . . .

6-4 ”SYSTEM START-UP/TEST: STATUS/CONTROL” Screen 6-7. . . . . . . . . .

7-1 ”INDIVIDUAL DIAGNOSTICS” Screen 7-6. . . . . . . . . . . . . . . . . . . . . . . . . . .

7-2 Structure of the Diagnostics Word after Requesting the

Diagnostics ”Overview” 7-1 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-3 Structure of the Diagnostics Word after Requesting the

Diagnostics for ”Parameter Assignment and Addressability” 7-13. . . . . . . .

7-4 Structure of the Diagnostics Word after Requesting the Station

Status (Station Status 1 and Station Status 2) 7-15. . . . . . . . . . . . . . . . . . . .

ET 200C Distributed I/O Station

x

EWA 4NEB 812 6119-02b

Page 11

7-5 Structure of the Diagnostics Word after Requesting the

Station Status (Station Status 3 and Master Address) 7-16. . . . . . . . . . . . . .

7-6 Structure of the Diagnostics Word after Request for Manufacturer

Identification 7-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-7 Structure of the Diagnostics Word after Requesting the Header

and the Device-related Diagnostics of ET 200C;

DI 16/DO 16 DC 24V/2A 7-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-8 Structure of the Diagnostics Word after Requesting the

Device-related Diagnostics of ET 200C; DI 8 DC 24V, ET 200C;

DO 8 DC 24V/0.5A and ET 200C; DO 8 DC 24V/2A 7-20. . . . . . . . . .

8-1 Diagram Illustrating How Station Diagnostics is Requested

with FB IM308C 8-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-2 Structure of the Diagnostics Word (Station Status 1 and

Station Status 2) 8-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-3 Structure of the Diagnostics Word ”Station Status 3 and

Master Station Number” 8-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-4 Structure of the ”Manufacturer Identification” Diagnostics Word 8-17. . . . .

8-5 Structure of the Diagnostics Word ”Header and Device-related

Diagnostics” of ET 200C; DI 16/DO 16 DC 24V 8-19. . . . . . . . . . . . . . . . .

8-6 Structure of the Diagnostics Word for ”Device-related Diagnostics”

for ET 200C; DI 8 DC 24V; ET 200C; DO 8 DC 24V/0.5A and

ET 200C; DO 8 DC 24V/2A 8-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-7 Structure of Diagnostics Word for Identification-related Diagnostics

(DW n + 3) for Analog ET 200C Modules 8-24. . . . . . . . . . . . . . . . . . . . . . . . .

8-8 Structure of Diagnostics Word ”Header – Device-related Diagnostics”

(DW n + 4) for Analog ET 200C Modules 8-25. . . . . . . . . . . . . . . . . . . . . . . . .

8-9 Structure of Diagnostics Word ”Device-related Diagnostics –

Diagnostics Alarm” (DW n + 5) for Analog ET 200C Modules 8-25. . . . . . .

8-10 Structure of Diagnostics Word ”Device-related Diagnostics –

Diagnostics Alarm” (DW n + 6) for Analog ET 200C Modules 8-26. . . . . . .

8-11 Structure of Diagnostics Word ”Device-related Diagnostics –

Diagnostics Alarm” (DW n + 7) for Analog ET 200C Modules 8-26. . . . . . .

8-12 Structure of Diagnostics Word ”Device-related Diagnostics –

Diagnostics Alarm” (DW n + 8) for Analog ET 200C Modules 8-27. . . . . . .

8-13 Structure of Diagnostics Word ”Device-related Diagnostics –

Diagnostics Alarm” (DW n + 9) for Analog ET 200C Modules 8-27. . . . . . .

8-14 Structure of Diagnostics Word ”Header and Device-related

Diagnostics – Diagnostics Alarm” (DW n + 10)

for Analog ET 200C Modules 8-28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-15 Structure of Diagnostics Word ”Header and Device-related

Diagnostics – Diagnostics Alarm” (DW n + 12)

for Analog ET 200C Modules 8-29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-16 Structure of Diagnostics Word ”Device-related Diagnostics –

Limit Value Alarm” (DW n + 6) for Analog ET 200C Modules 8-30. . . . . . . .

9-1 Connection of ET 200 Handheld for Configuration with Power Supply

Connector and without T Connector 9-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-2 Connection of ET 200 Handheld for Configuration with External

Power Supply 9-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-3 Connection of the Handheld to the Unassigned Bus Connection

of the ET 200C Station for Configuration with

Power Supply Connector and T Connector 9-4. . . . . . . . . . . . . . . . . . . . . . .

Contents

ET 200C Distributed I/O Station

EWA 4NEB 812 6119-02b

xi

Page 12

Contents

9-4 Connection of the Handheld to the T Connector for Configuration

with Power Supply Connector and T Connector 9-4. . . . . . . . . . . . . . . . . . .

11-1 Digital Input Module ET 200C; DI 8 DC 24V: Block Diagram 11-3. . . . . .

11-2 Digital Input Module ET 200C; DI 8 DC 24 V;

Dimension Drawing 1 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-3 Digital Input Module ET 200C; DI 8 DC 24 V; Dimension Drawing

with T Connector and Plug Connectors (with Pin/Socket Inserts) 11-5. . . .

11-4 Digital Output Module ET 200C; DO 8 DC 24V/0.5A:

Block Diagram 11-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-5 Digital Output Module ET 200C; DO 8 DC 24 V/0.5A;

Dimension Drawing 1 1-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-6 Digital Output Module ET 200C; DO 8 DC 24 V/0.5A;

Dimension Drawing with T Connector and Plug Connectors

(with Pin/Socket Inserts) 11-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-7 Digital Output Module ET 200C; DO 8 DC 24V/2A:

Block Diagram 11-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-8 Digital Output Module ET 200C; DO 8 DC 24 V/2A;

Dimension Drawing 1 1-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-9 Digital Output Module ET 200C; DO 8 DC 24 V/2A;

Dimension Drawing with T Connector and Plug Connectors

(with Pin/Socket Inserts) 11-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-10 Digital Input/Output Module ET 200C; DI 16/DO 16 DC 24V/2A:

Block Diagram 11-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-11 Digital Input/Output Module ET 200C; DI 16/DO 16 DC 24 V/2A

(6ES7 143-0BL00-0XB0); Dimension Drawing 11-20. . . . . . . . . . . . . . . . . . . .

11-12 Digital Input/Output Module ET 200C; DI 16/DO 16 DC 24 V/2A

(6ES7 143-0BL10-0XB0); Dimension Drawing 11-21. . . . . . . . . . . . . . . . . . . .

11-13 Digital Input/Output Module ET 200C; DI 16/DO 16 DC 24 V/2A

(6ES7 143-0BL00-0XB0); Dimension Drawing with T Connector

and Plug Connectors (with Pin/Socket Inserts) 11-22. . . . . . . . . . . . . . . . . . . .

11-14 Digital Input/Output Module ET 200C; DI16/DO 16 DC 24 V/2A

(6ES7 143-0BL10-0XB0); Dimension Drawing with T Connector

and Plug Connectors (with Pin/Socket Inserts) 11-23. . . . . . . . . . . . . . . . . . . .

12-1 ET200C Analog Input Module; AI 4/8 12 Bit: Block Diagram 12-4. . . . . .

12-2 Screw Terminals and Their Assignments in the ET 200C;

AI 4/8 12 Bit 12-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12-3 ET 200C Analog Input Module; AI 4/8 12 Bit:

Dimensional Drawing 12-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12-4 ET 200C Analog Input Module; AI 4/8 12 Bit:

Dimensional Drawing with T-connector 12-19. . . . . . . . . . . . . . . . . . . . . . . . . . .

12-5 ET200C Analog Input Module; AI 4 12 Bit: Block Diagram 12-21. . . . . . .

12-6 Screw Terminals with Assignments in the ET 200C; AI 4 12 Bit 12-21. . .

12-7 ET 200C Analog Input Module; AI 4 12 Bit:

Dimensional Drawing 12-31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12-8 ET 200C Analog Input Module; AI 4 12 Bit:

Dimensional Drawing with T-connector 12-32. . . . . . . . . . . . . . . . . . . . . . . . . . .

12-9 ET 200C Analog Output Module; AO 4 12 Bit: Block Diagram 12-34. . . .

12-10 Screw Terminals with Assignments in the ET 200C;

AO 4 12 Bit 12-34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

xii

ET 200C Distributed I/O Station

EWA 4NEB 812 6119-02b

Page 13

12-11 ET 200C Analog Output Module; AO 4 12 Bit:

Dimensional Drawing 12-42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12-12 ET 200C Analog Output Module; AO 4 12 Bit:

Dimensional Drawing with T-connector 12-43. . . . . . . . . . . . . . . . . . . . . . . . . . .

13-1 Power Supply Connector: Dimension Drawing with Plug Connectors

(with Pin/Socket Insert) 13-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13-2 Power Supply Connector: Dimension Drawing 13-4. . . . . . . . . . . . . . . . . . . .

13-3 Programmer Connector: Dimension Drawing with Plug Connectors

(with Pin/Socket Insert) 13-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13-4 Programmer Connector: Dimension Drawing 13-6. . . . . . . . . . . . . . . . . . . . .

Contents

ET 200C Distributed I/O Station

EWA 4NEB 812 6119-02b

xiii

Page 14

Contents

T ables

1-1 Maximum baud rates with components of ET 200C 1-6. . . . . . . . . . . . . . . .

1-2 Length of the SINEC L2 Bus Cable in Accordance

with the Baud Rate on the SINEC L2-DP Bus 1-7. . . . . . . . . . . . . . . . . . . . .

2-1 ET 200C Configuration Options 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 Permissible Current Load for Load Voltage Supply 2-6. . . . . . . . . . . . . . . .

2-3 Permissible Current Load for Load Voltage Supply 2-9. . . . . . . . . . . . . . . .

2-4 Length of the Bus Cable, if SINEC L2-DP Field Bus

and Power Supply are Combined in One Cable 2-10. . . . . . . . . . . . . . . . . . .

2-5 Current Consumption of the Digital Modules of ET 200C 2-10. . . . . . . . . . .

2-6 Permissible Current Load for Load Voltage Supply 2-14. . . . . . . . . . . . . . . .

2-7 Length of the Spur Line of the Programmer Connection

in Accordance with the Baud Rate on the SINEC L2-DP Bus 2-17. . . . . . . .

3-1 ET 200C Cables 3-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2 Order Numbers for Standard Cable Lengths (Core Cross-Sectional

Area 0.75 mm

2

/Max. Current Load 4 A) 3-21. . . . . . . . . . . . . . . . . . . . . . . . . .

3-3 Order Numbers for Standard Cable Lengths (Core Cross-Sectional

Area 0.75 mm

2

/Max. Current Load 4 A) 3-21. . . . . . . . . . . . . . . . . . . . . . . . . .

4-1 Distances between ET 200C Modules and Cable Ducts 4-2. . . . . . . . . . . .

4-2 Order Numbers for Circular Connectors 4-8. . . . . . . . . . . . . . . . . . . . . . . . . .

4-3 Pin Assignment of the Bus Connection where only the SINEC L2-DP

is Connected 4-1 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-4 Pin Assignment of the Bus Connection where only the Power Supply

is Connected 4-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-5 Pin Assignment of the Bus Connection if SINEC L2-DP and

Power Supply are Connected 4-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-6 Pin Assignment of the Inputs of ET 200C; DI 8 DC 24V

(6ES7 141-0BF00-0XB0) 4-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-7 Pin Assignments of the Outputs of ET 200C; DO 8 DC 24V/0.5A

(6ES7 142-0BF00-0XB0) and ET 200C; DO 8 DC 24V/2A

(6ES7 142-0BF10-0XB0) 4-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-8 Pin Assignments of the Inputs of ET 200C;

DI 16/DO 16 DC 24V/2A (6ES7 143-0BL00-0XB0) 4-17. . . . . . . . . . . . . .

4-9 Pin Assignments of the Outputs of ET 200C;

DI 16/DO 16 DC 24V/2A (6ES7 143-0BL00-0XB0) 4-17. . . . . . . . . . . . . .

4-10 Connection Assignments of ET 200C; DI 16/DO 16 DC 24V/2A

(6ES7 143-0BL10-0XB0) 4-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-11 Connection Assignment of the Inputs of ET 200C; AI 4/8 12 Bit

(6ES7 144-0KH00-0KB0) 4-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-12 DIL-Switch blocks in the ET 200C; AI 4/8 12 Bit 4-23. . . . . . . . . . . . . . . .

4-13 Connection Assignment of the Inputs of ET 200C; AI 4 12 Bit

(6ES7 144-0HF00-0KB0) 4-31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-14 DIL Switch Blocks in ET 200C; AI 4 12 Bit 4-32. . . . . . . . . . . . . . . . . . . . .

4-15 Pin Assignment, Outputs of ET 200C; AO 4 12 Bit

(6ES7 145-0HF00-0XB0) 4-36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-16 DIL Switch Blocks in ET 200C; AO 4 12 Bit 4-37. . . . . . . . . . . . . . . . . . . .

4-17 Pin Assignment of the Load Voltage Supply 4-41. . . . . . . . . . . . . . . . . . . . . .

4-18 Pin Assignment of the External Power Supply 4-42. . . . . . . . . . . . . . . . . . . . .

4-19 Module-Specific DIL Switch Blocks in ET 200C; AI 4/8 12 Bit 4-46. . . . .

4-20 DIL Switches in DIL Switch Block S2 4-47. . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-21 DIL Switches in DIL Switch Block S3 4-48. . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-22 DIL Switches in DIL Switch Block S4 4-49. . . . . . . . . . . . . . . . . . . . . . . . . . . .

xiv

ET 200C Distributed I/O Station

EWA 4NEB 812 6119-02b

Page 15

4-23 Module-Specific DIL Switch Block in ET 200C; AI 4 12 Bit 4-50. . . . . . . .

4-24 DIL Switches in DIL Switch Block S5 4-51. . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-25 Module-specific DIL-switch block in ET 200C; AO 4 12 Bit 4-52. . . . . . .

4-26 DIL Switches in DIL Switch Block S2 4-53. . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1 Type File Designations for ET 200C 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2 Address Identifiers for ET 200C (DP Standard) 5-8. . . . . . . . . . . . . . . . . . .

7-1 Fault Messages through LEDs on the ET 200C; DI 8 DC 24V 7-2. . . .

7-2 Fault Messages through LEDs of the ET 200C;

DO 8 DC 24V/0.5A and ET 200C; DO 8 DC 24V/2A 7-3. . . . . . . . . .

7-3 Fault Messages through LEDs of the ET 200C;

DI 16/DO 16 DC 24V/2A 7-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-4 STEP 5 Diagnostics Facilities 7-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-5 Structure of the Station Diagnostics for ET 200C 7-8. . . . . . . . . . . . .

7-6 Combination of the Diagnostics ”Overview” and Diagnostics

for ”Parameter Assignment and Addressability” 7-13. . . . . . . . . . . . . . . . . . .

8-1 Fault Messages through LEDs on the ET 200C; DI 8 DC 24V 8-2. . . .

8-2 Fault Messages through LEDs of the ET 200C;

DO 8 DC 24V/0.5A and ET 200C; DO 8 DC 24V/2A 8-3. . . . . . . . . .

8-3 Fault Messages through LEDs of the ET 200C;

DI 16/DO 16 DC 24V/2A 8-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-4 Fault Messages through LEDs of the ET 200C; AI 4/8 12 Bit,

AI 4 12 Bit and AO 4 12 Bit 8-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-5 STEP 5 Diagnostics Facilities, Operation with IM 308-C 8-6. . . . . . . . . . . .

8-6 Structure of Station Diagnostics for Digital ET 200C Modules 8-7. . . . . . .

8-7 Structure of Station Diagnostics for ET 200C; AI 4/8 12 Bit 8-8. . . . . . .

8-8 Structure of Station Diagnostics for ET 200C; AI 4 12 Bit 8-9. . . . . . . .

8-9 Structure of Station Diagnostics for ET 200C; AO 4 12 Bit 8-10. . . . . . .

8-10 Position of the Diagnostics Data in the Data Block 8-14. . . . . . . . . . . . . . . . .

8-11 Position of Diagnostics Data in Data Block for ET 200C

(digital ET 200C) 8-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-12 Position of Diagnostics Data in Data Block for ET 200C;

AI 4/8 12 Bit 8-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-13 Position of the Diagnostics Data in the Data Block for ET 200C;

AI 4 12 Bit 8-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-14 Position of the Diagnostics Data in the Data Block for ET 200C;

AO 4 12 Bit 8-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-1 Parameters for Digital Input Module ET 200C; DI 8 DC 24 V 11-3. . . . .

11-2 Parameters for Digital Output Module ET 200C;

DO 8 DC 24 V/0.5A 11-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-3 Parameters for Digital Output Module ET 200C;

DO 8 DC 24 V/2A 11-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-4 Parameters for Digital Input/Output Module ET 200C;

DI 16/DO 16 DC 24 V/2A 11-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12-1 Parameters for ET 200C Analog Input Module; AI 4/8 12 Bit 12-5. . . . . .

12-2 Parameters for ET 200C Analog Input Module; AI 4/8 12 Bit:

Range of Values, Bytes 25 to 28 12-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12-3 Presentation of an Analog Input Value as Bit Pattern for SIMATIC S5

with ET 200C; AI 4/8 12 Bit 12-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12-4 Description of Bit for ET 200C; AI 4/8 12 Bit 12-8. . . . . . . . . . . . . . . . . . . .

12-5 Digitized Measured Values for ET 200C; AI 4/8 12 Bit

(Measuring Ranges:

" 80 mV, " 250 mV, " 500 mV and

" 1000 mV) 12-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

ET 200C Distributed I/O Station

EWA 4NEB 812 6119-02b

xv

Page 16

Contents

12-6 Digitized Measured Values for ET 200C; AI 4/8 12 Bit with

Resistance Sensors 12-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12-7 Digitized Measured Values for ET 200C; AI 4/8 12 Bit with

Linearization; Type K Thermocouple (Nickel-Chromium/

Nickel-Aluminum, to IEC 584) 12-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12-8 Digitized Measured Values for ET 200C; AI 4/8 12 Bit with

Linearization; Type J Thermocouple (Iron/Copper-Nickel

(Constantan), to IEC 584) 12-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12-9 Digitized Measured Values for ET 200C; AI 4/8 12 Bit

with Linearization; Type L Thermocouple (Iron/Copper-Nickel

(Constantan), to DIN 43710) 12-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12-10 Presentation of an Analog Input Value as Bit Pattern for SIMATIC S7

with ET 200C; AI 4/8 12 Bit 12-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12-11 Digitized Measured Values for ET 200C; AI 4/8 12 Bit

(Measuring Ranges: " 80 mV, " 250 mV, " 500 mV and

" 1000 mV) 12-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12-12 Digitized Measured Values for ET 200C; AI 4/8 12 Bit for Pt 100

Resistance Sensors 12-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12-13 Digitized Measured Values for ET 200C; AI 4/8 12 Bit for Type K

Thermocouple 12-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12-14 Digitized Measured Values for ET 200C; AI 4/8 12 Bit for Type N

Thermocouple 12-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12-15 Digitized Measured Values for ET 200C; AI 4/8 12 Bit for Type J

Thermocouple 12-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12-16 Digitized Measured Values for ET 200C; AI 4/8 12 Bit for Type E

Thermocouple 12-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12-17 Parameters for ET 200C Analog Input Module; AI 4 12 Bit 12-22. . . . . . .

12-18 Presentation of an Analog Input Value as Bit Pattern for ET 200C;

AI 4 12 Bit 12-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12-19 Description of bits for ET 200C; AI 4 12 Bit 12-24. . . . . . . . . . . . . . . . . . . . .

12-20 Digitized Measured Values for ET 200C; AI 4 12 Bit

(Measuring Ranges: " 1.25 V, " 2.5 V, " 5 V, " 10 V) 12-25. . . . . . . . . . .

12-21 Digitized Measured Values for ET 200C; AI 4 12 Bit

(Measuring Range: " 20 mA) 12-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12-22 Digitized Measured Values for ET 200C; AI 4 12 Bit

(Measuring Range: 0 ... 20 mA) 12-27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12-23 Digitized Measured Values for ET 200C; AI 4 12 Bit

(Measuring Range: 4 ... 20 mA) 12-27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12-24 Presentation of an Analog Input Value as Bit Pattern for SIMATIC S7

with ET 200C; AI 4 12 Bit 12-28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12-25 Digitized Measured Values for ET 200C; AI 4 12 Bit

(Measuring Ranges: " 1.25 V, " 2.5 V, " 5 V and " 10 V) 12-28. . . . . . .

12-26 Digitized Measured Values for ET 200C;

AI 4 12 Bit (Measuring Range: " 20 mA) 12-29. . . . . . . . . . . . . . . . . . . . . .

12-27 Digitized Measured Values for ET 200C; AI 4 12 Bit

(Measuring Ranges: 0 to 20 mA and 4 to 20 mA) 12-30. . . . . . . . . . . . . . . . . .

12-28 Parameters for ET 200C Analog Output Module; AO 4 12 Bit 12-35. . . . .

12-29 Substitute Value Output of ET 200C; AO 4 12 Bit on Interruption

in Communication 12-36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12-30 Presentation of an Analog Input Value as Bit Pattern for ET 200C;

AO 4 12 Bit 12-37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12-31 Description of bits for ET 200C; AO 4 12 Bit 12-37. . . . . . . . . . . . . . . . . . . .

xvi

ET 200C Distributed I/O Station

EWA 4NEB 812 6119-02b

Page 17

12-32 Analog Output Signals of ET 200C; AO 4 12 Bit

(Ranges of Values: " 10 V, 0 ... 10 V, " 20 mA, 0 ... 20 mA,

4 ... 20 mA) 12-38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12-33 Presentation of an Analog Input Value as Bit Pattern for SIMATIC S7

with ET 200C; AO 4 12 Bit 12-39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12-34 Digitized Measured Values for ET 200C; AO 4 12 Bit

(Output Ranges: " 20 mA, 0 to 20 mA and 4 to 20 mA) 12-40. . . . . . . . . . . .

12-35 Digitized Measured Values for ET 200C; AO 4 12 Bit

(Output Ranges: 0 to 10 V and " 10 V) 12-41. . . . . . . . . . . . . . . . . . . . . . . . . .

A-1 Pin Assignment of Bus Connector for ET 200 C Digital Modules,

only SINEC L2-DP Connected A-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A-2 Pin Assignment of Bus Connector for ET 200C Digital Modules,

only Separate Power Supply Connected A-2. . . . . . . . . . . . . . . . . . . . . . . . .

A-3 Pin Assignment of Bus Connector for ET 200C Digital Modules,

SINEC L2-DP and Power Supply Combined in a Common Cable A-2. . . .

A-4 Pin Assignment, Inputs of ET 200C; DI 8 DC 24V and ET 200C;

DI 16/DO 16 DC 24V/2A (6ES7 143-0BL00-0BX0) A-3. . . . . . . . . . . . . .

A-5 Pin Assignment, Outputs of ET 200C; DO 8 DC 24V/0.5A,

ET 200C; DO 8 DC 24V/2A and ET 200C;

DI16/DO16 DC 24V/2A (6ES7 143- 0BL00-0XB0) A-3. . . . . . . . . . . . . .

A-6 Pin Assignment, Inputs and Outputs of ET 200C;

DI 16/DO 16 DC 24V/2A (6ES7 143-0BL10-0XB0) A-3. . . . . . . . . . . . . .

A-7 Pin Assignment for Load Voltage Supply, ET 200C Modules

with Outputs A-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A-8 Pin Assignment, External Power Supply at PSU Feed A-4. . . . . . . . . . . . . .

A-9 Pin Assignment of Bus Connector for ET 200C Analog Modules,

only SINEC L2-DP Connected A-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A-10 Pin Assignment of Bus Connector for ET 200C Analog Modules,

only Separate Power Supply Connected A-5. . . . . . . . . . . . . . . . . . . . . . . . .

A-11 Pin Assignment of Bus Connector for ET 200C Analog Modules,

SINEC L2-DP and Power Supply Combined in a Common Cable A-5. . . .

A-12 Pin Assignment, Inputs of ET 200C; AI 4/8 12 Bit

(6ES7 144-0KH00-0XB0) A-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A-13 Pin Assignment, Inputs of ET 200C; AI 4 12 Bit

(6ES7 144-0HF00-0XB0) A-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A-14 Pin Assignment, Outputs of ET 200C; AO 4 12 Bit

(6ES7 145-0HF00-0XB0) A-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B-1 Designations of Type Files for ET 200C Digital Modules B-2. . . . . . . . . . . .

B-2 Designations of Type Files for ET 200C Analog Modules B-7. . . . . . . . . . .

Contents

ET 200C Distributed I/O Station

EWA 4NEB 812 6119-02b

xvii

Page 18

Contents

xviii

ET 200C Distributed I/O Station

EWA 4NEB 812 6119-02b

Page 19

Configuration

1

In this Chapter

This chapter ”Configuration” provides you with information on

the position of the ET 200C distributed I/O station in the distributed I/O

system and

the components of the ET 200C.

ET 200C Distributed I/O Station

EWA 4NEB 812 6119-02b

1-1

Page 20

Configuration

1.1 What is the ET 200?

Definition

Stations Described

in this Manual

The distributed I/O system ET 200 is based on the PROFIBUS standard

(DIN 19245, Part 1) and the PROFIBUS-DP draft standard (DIN 19245,

Part 3).

At SIEMENS, the PROFIBUS is called SINEC L2.

The field bus on which the ET 200 distributed I/O system is based, is a variant

of SINEC L2 called SINEC L2-DP. This version is designed for communication

with the distributed I/O at extremely short response times.

The distributed I/O system comprises active and passive stations, the

SINEC L2-DP field bus and the SINEC L2 network components. The

distributed I/O station is a slave station.

+

IM 308-B

IM 308-C

ET 200CET 200B

ET 200U

SINEC L2-DP Field Bus

(2-wire or Fiber-Optic Cable)

Figure 1-1 ET 200 Bus Users Described in this Manual

Other field

devices

1-2

ET 200C Distributed I/O Station

EWA 4NEB 812 6119-02b

Page 21

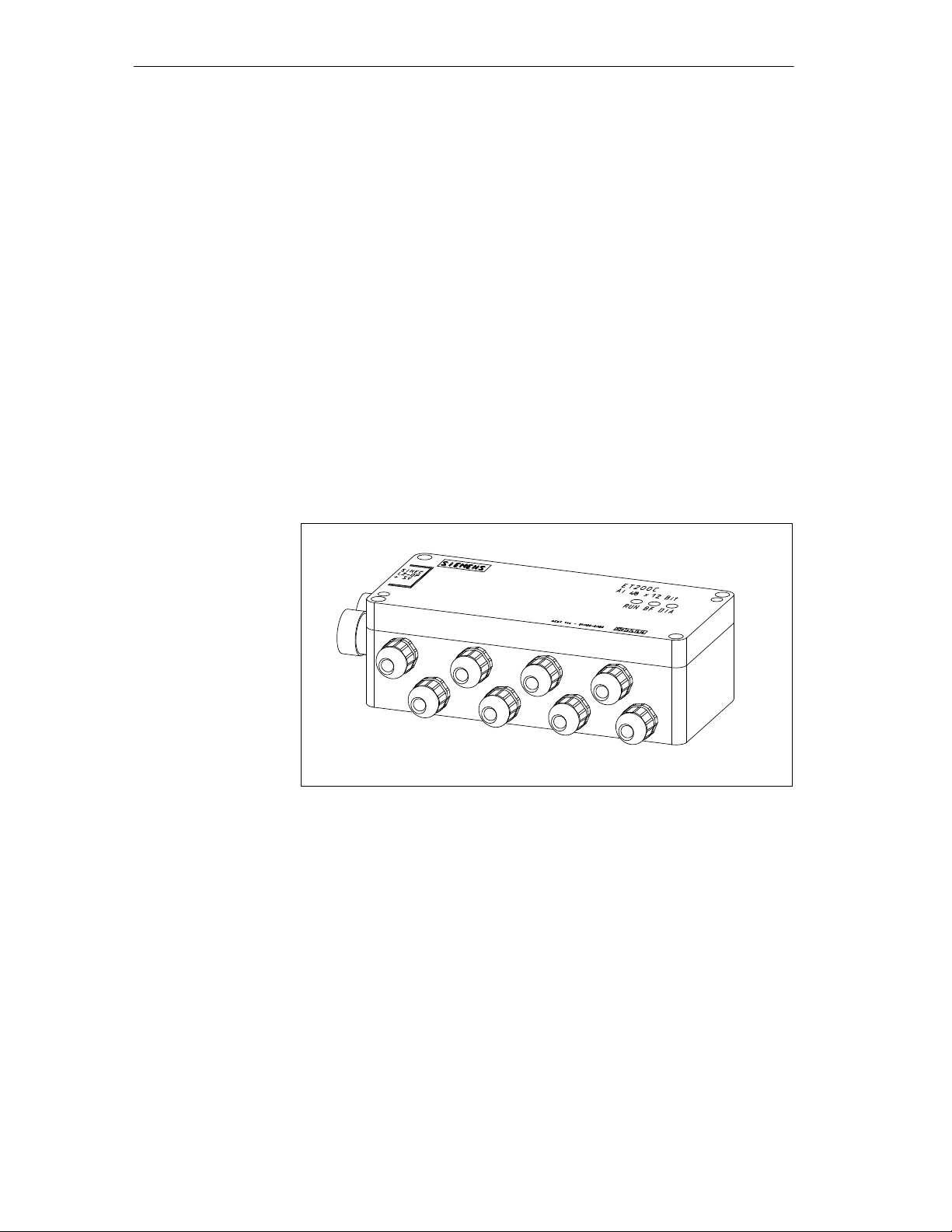

1.2 What is the ET 200C?

Configuration

Range of Modules

The ET 200C Distributed I/O Station is part of the ET 200 Distributed I/O

System.

The ET 200C digital and analog modules each form a slave station.

Digital Input Module

DI 8 DC 24V

Digital Output Module

DO 8 DC 24V/0,5A

Digital Output Module

DO 8 DC 24V/2A

8DI

8DO

8DO/2A

Digital Input/Output Module

DI 16/DO 16 DC 24V/2A

Analog Input Module

AI 4/8 12 Bit

Analog Input Module

AI 4 12 Bit

16DI/16DO

4/8AI

4AI

ET 200C Distributed I/O Station

EWA 4NEB 812 6119-02b

Analog Output Module

AO 4 12 Bit

Figure 1-2 ET 200C Digital and Analog Modules

4AO

1-3

Page 22

Configuration

What is the ET 200C?, Continued

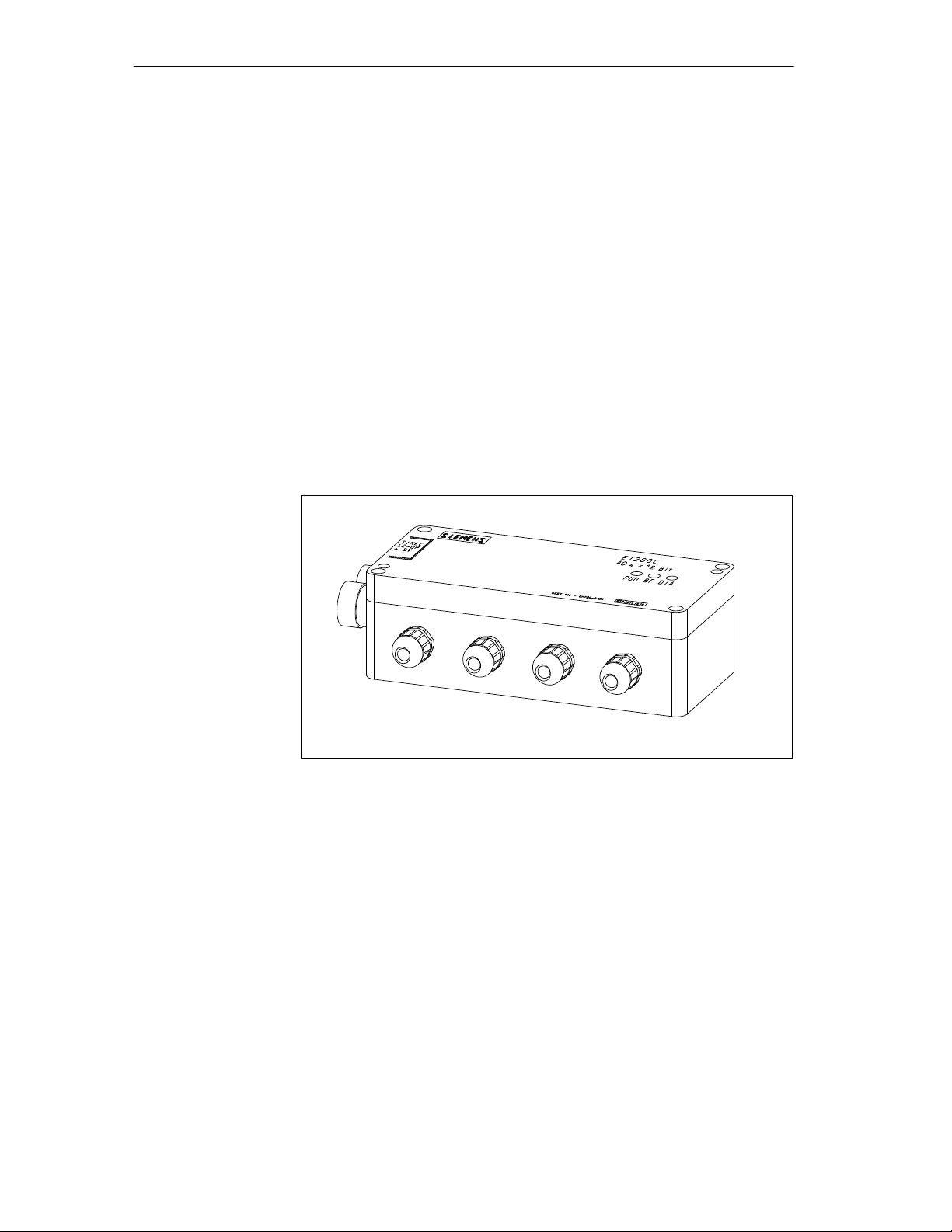

Other Components

Operating ET 200C

ET 200C also includes other components. Not all components may be necessary for operation:

T-Connector

Power Supply Connector

(PS Conn.)

Programmer Connector

Bus Cable

Power Supply Cable

Combined Bus/

Power-Supply Cable

SV-

SV

Einsp.

PG

2-core

3-core

5-core

Terminating Resistor

Adapter Cable

Figure 1-3 Other ET 200C Components

All ET 200C components can be addressed under the DP standard bus protocol.

Note

ET 200C can be operated with the following master interface modules and

versions of COM ET 200:

IM 308-B (revision level 5 or higher) and COM ET 200 (V4.0 or later,

see Chapters 5 and 6), only in conjunction with ET 200C digital modules

IM 308-C (revision level 1 or higher) and COM ET 200 Windows

1-4

ET 200C Distributed I/O Station

EWA 4NEB 812 6119-02b

Page 23

Configuration

Characteristics of

the ET 200C

The ET 200C Distributed I/O Station has the following characteristics:

Degree of protection IP 66/IP 67

All components of the ET 200C (excluding adapter cables) are designed

with degree of protection IP 66 and 67. However, IP 66 and IP 67 are only

ensured if the installation rules in Section 4.1 are observed.

Compact design

ET 200C is ideal for applications where space is at a premium. A digital

input module with T connector, for example, measures only

289 129 57 mm. An analog module with T connector measures a

mere 289 101 57 mm.

Connections

– Digital inputs and/or digital outputs, analog inputs or analog outputs

– Protective conductor connection for each input/output (digital modules

only)

– 2-wire and 3-wire proximity switches can be connected

Electrical isolation between the SINEC L2-DP field bus and the process

side of the ET 200C modules.

Direct connection of programmer or ET 200 handheld possible (with

adapter cable and programmer with programmer interface module

CP5410-S5DOS/ST)

– For setting the station number (digital modules require ET 200

handheld; analog modules by means of internal DIL switches or the

ET 200 handheld)

– For testing and startup

– Diagnostics

Diagnostics of the inputs/outputs for the following types of fault (can be

switched off with COM ET 200)

– Short-circuit/overload of the sensor supply or outputs

– Wire break in sensor supply (except in DI 16/DO 16 DC 24V/2A)

or at the outputs

– Load voltage of the outputs (digital modules only)

A diagnostic report on defective inputs/outputs can also be output via the

IM 308-B master interface module.

ET 200C Distributed I/O Station

EWA 4NEB 812 6119-02b

1-5

Page 24

Configuration

Characteristics of

the ET 200C

(Continued)

The digital modules have the following LEDs

– RUN

– BF (bus fault)

– DIA (diagnostics of the inputs/outputs or undervoltage of the outputs)

–U

in DO 8 DC 24V/0.5A and DO 8 DC 24V/2A or UL1, UL2 in

L

DI 16/DO 16 DC 24V/2A (load voltage supply of the outputs)

– Status of the inputs/outputs or individual diagnostics

The analog modules have the following LEDs

– RUN

– BF (bus fault)

– DIA (diagnostics of the inputs/outputs)

High data throughput:

The bus accommodates, for example, the IM 308-C master interface and

ten ET 200C; DI 16/DO 16 DC 24V/2A distributed I/O stations each

with 2-byte inputs/outputs. The baud rate is 12 Mbaud. The reaction time

for a complete data cycle is thus 0.45 ms.

The reaction time t

A, B, T

= master-dependent constants

byte

for a data cycle is calculated as follows:

DP

t

= A

DP

+ (B + (number of I/O bytes T

+ (B + (number of I/O bytes T

+ ...

+ (B + (number of I/O bytes T

)) [slave 1]

byte

)) [slave 2]

byte

)) [slave n]

byte

1-6

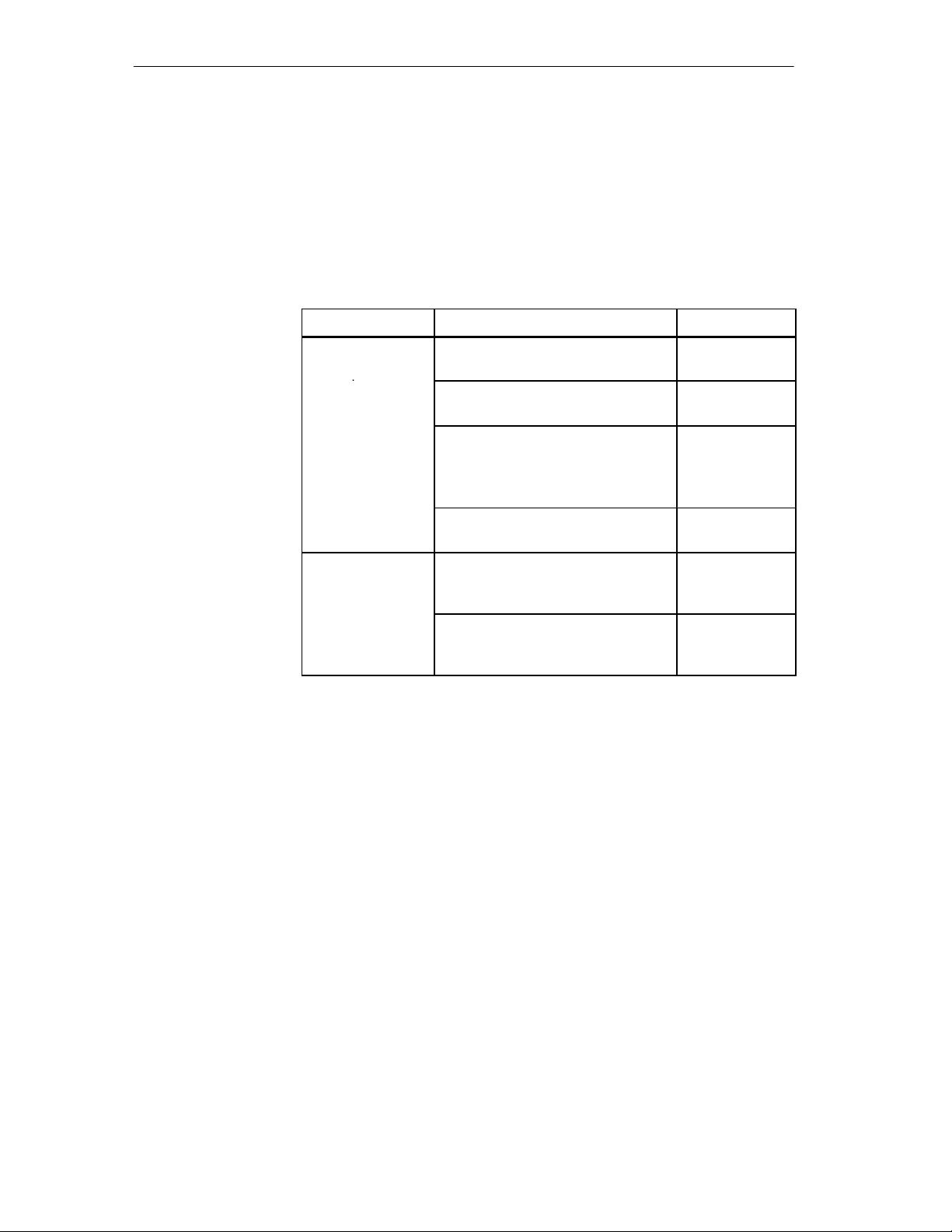

Table 1-1 Maximum baud rates with components of ET 200C

With master interface ET 200C components Maximum baud rate

IM 308-B All digital modules 1.500 kbaud

IM 308-C All digital modules 12.000 kbaud

IM 308-C All digital modules 1.500 kbaud

ET 200C Distributed I/O Station

EWA 4NEB 812 6119-02b

Page 25

Configuration

Length of the SINEC L2 bus cable

The following values apply for the SINEC L2 bus cable in accordance

with the baud rate on the bus when configuring the ET 200C.

Table 1-2 Length of the SINEC L2 Bus Cable in Accordance with the Baud Rate on

the SINEC L2-DP Bus

Baud rate Max. length of bus cable

< 500 kbaud 500 m/segment

500 kbaud 400 m/segment

1500 kbaud 200 m/segment

> 1500 kbaud 100 m/segment

ET 200C Distributed I/O Station

EWA 4NEB 812 6119-02b

1-7

Page 26

Configuration

1-8

ET 200C Distributed I/O Station

EWA 4NEB 812 6119-02b

Page 27

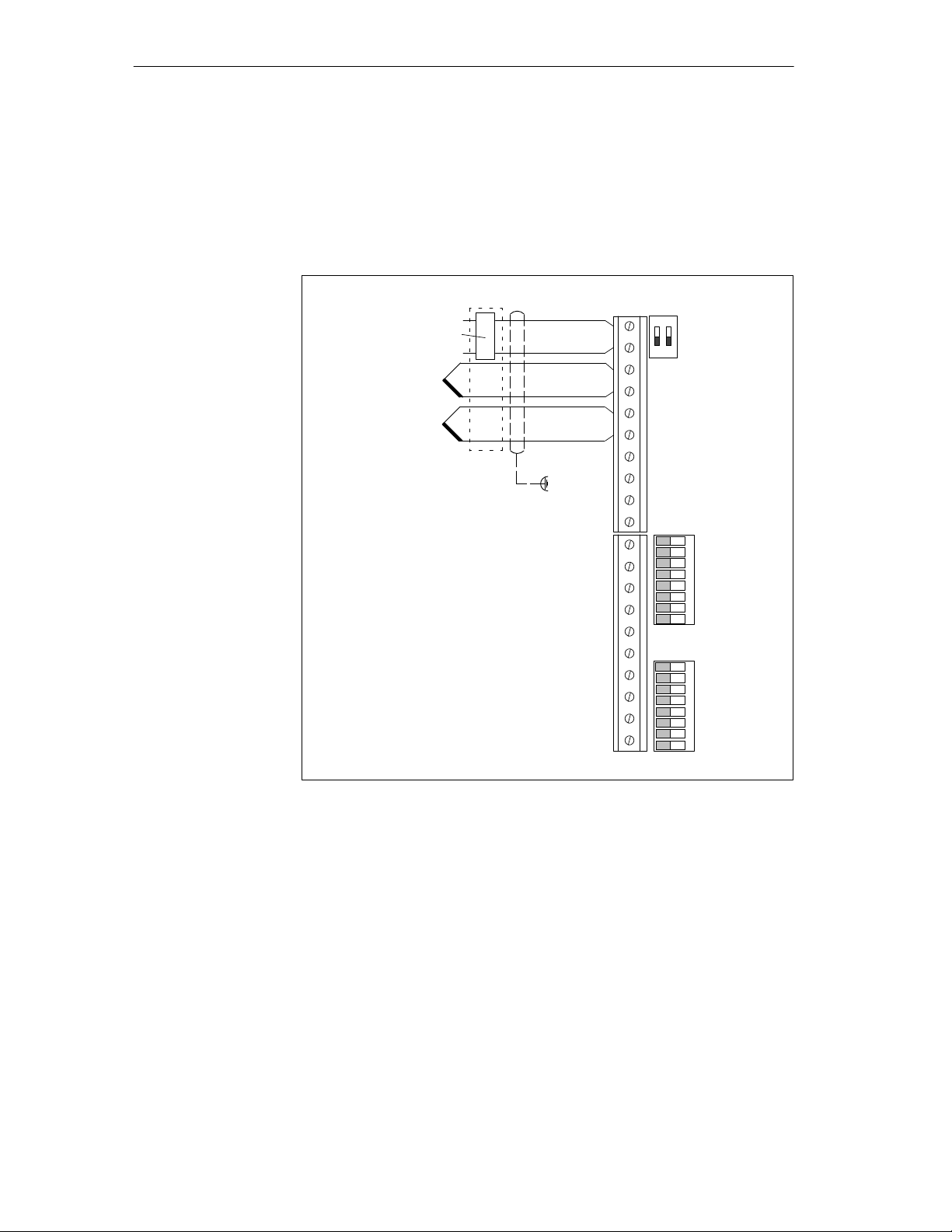

ET 200C Configuration Options

This chapter describes the configuration options offered to you by ET 200C.In this Chapter

2

ET 200C Distributed I/O Station

EWA 4NEB 812 6119-02b

2-1

Page 28

pp y

ET 200C Configuration Options

2.1 Overview of the ET 200C Configuration Options

Configuration

Options

The table below contains the various configuration options made available by

ET 200C.

Table 2-1 ET 200C Configuration Options

PS connector Configuration Described in

Configuration

with power supply

connector

Configuration with power supply

connector and without T connector

Configuration with power supply

Section 2.1.1

Section 2.1.2

connector and with T connector

Configuration with several power

Section 2.1.3

supply connectors (the level of

expansion with one power supply

connector is limited)

Configuration with programmer

Section 2.1.5

connector

Configuration

without power

Configuration without power

supply connector

Section 2.1.4

supply connector

(each module has

a separate power

Configuration with programmer

connector

Section 2.1.5

supply)

2-2

ET 200C Distributed I/O Station

EWA 4NEB 812 6119-02b

Page 29

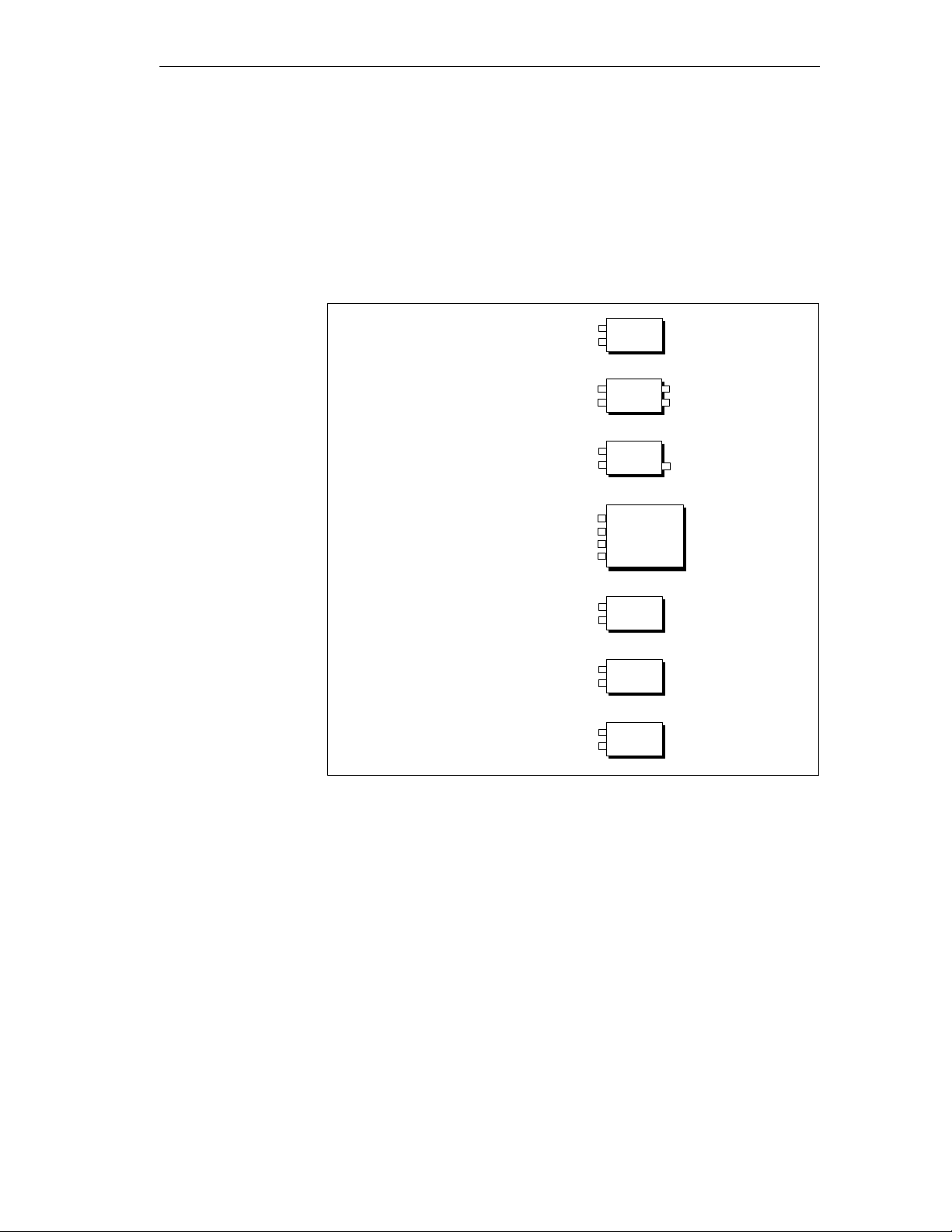

ET 200C Configuration Options

Legend for the

Following

Sections

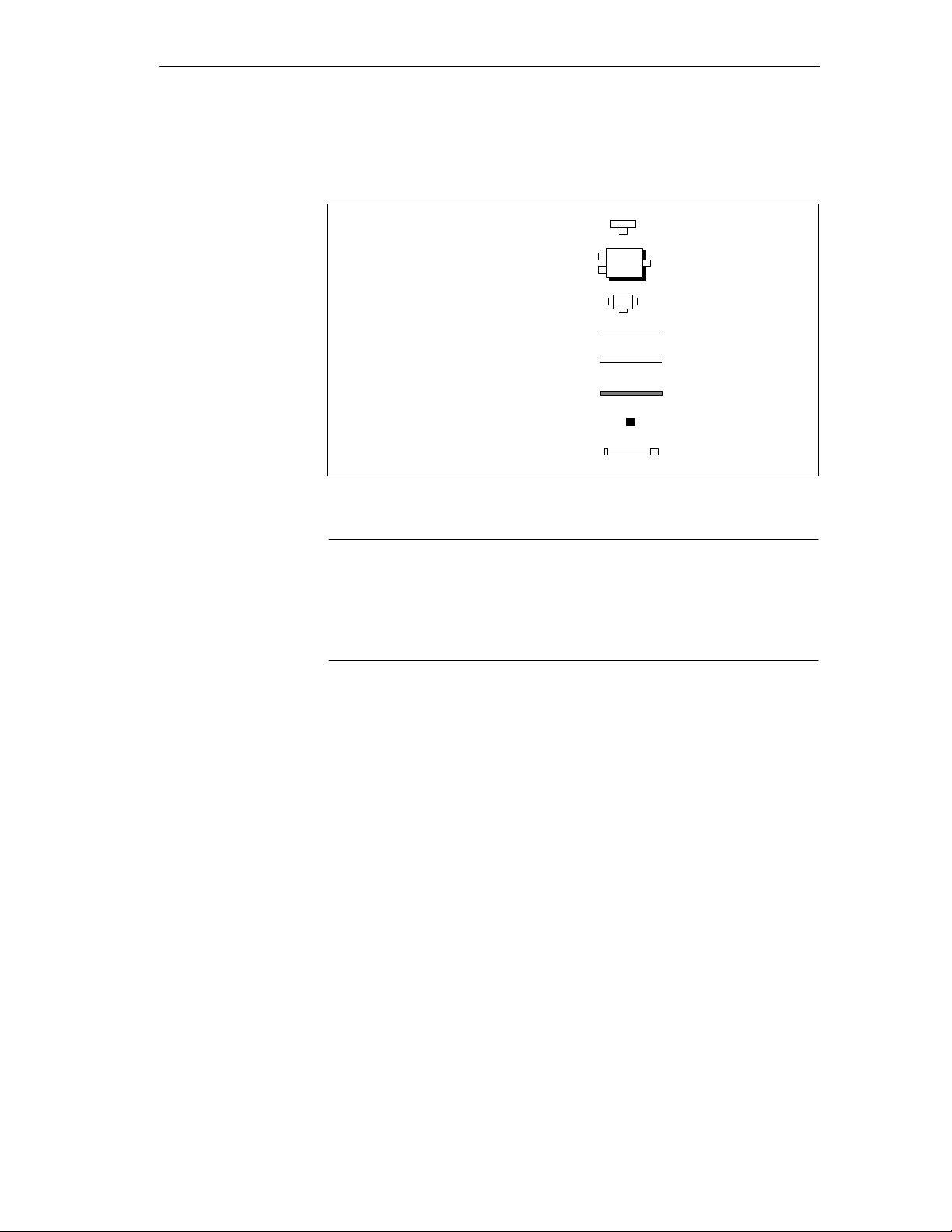

The ET 200C configuration options are described in the following sections

by means of diagrams which are based on the following legend:

T Connector

PS

Power Supply Connector

Programmer Connector

Bus Cable incl. PS Cable

Bus Cable

PS Cable

SV

conn.

PG

2-core

3-core (see note)

5-core

Terminating Resistor

Adapter Cable

Figure 2-1 Legend

Note

You will require a 3-core cable for the load voltage supply and the separate

power supply connectors of the digital modules. You can, however, also use

the prefabricated, 5-core cable from Siemens for the load voltage. T wo of

the conductors will then not be used in this case (see Section 3.11).

ET 200C Distributed I/O Station

EWA 4NEB 812 6119-02b

2-3

Page 30

ET 200C Configuration Options

2.1.1 Configuration with Power Supply Connector without T Connector

Definition

Advantage

Constraint

Cables

In a configuration with looped field bus and power supply, the individual

modules are connected directly to the field bus.

The power supply is combined with the field bus in a single cable via the

power supply connector.

You do not need a T connector.

The power supply is run over the bus cable, i.e. no external power supply is

required for the slave station.

If a slave station is disconnected from the bus, the “Bus traffic” is interrupted

for slave stations located further down the line.

Since there is then no terminating resistor available, bus traffic might be disturbed for slave stations still connected to the bus.

The level of expansion using one power supply connector is limited

(see Section 2.1.3).

Different types of cable can be used for the various configurations:

Read Section 3.11 if you wish to use prefabricated cables from Siemens.

Read Section 4.3 if you wish to prepare the cables yourself.

2-4

ET 200C Distributed I/O Station

EWA 4NEB 812 6119-02b

Page 31

ET 200C Configuration Options

Configuration

A possible configuration with power supply connector and without

T connector can be seen in Fig. 2-2:

External Power

Supply

SINEC L2-DP

1)

No separate load voltage

supply is necessary for

analog output modules

PS

SV

conn.

4/8AI

1)

4AO

8DO

Load Voltage

Supply Looped On

8DO

External Load

V oltage Supply

16DI/16DO

Load V oltage

Supply for

Channel Group Q0

Load V oltage Supply for Channel

Group Q1

ET 200C Distributed I/O Station

EWA 4NEB 812 6119-02b

Figure 2-2 SINEC L2-DP Field Bus and Power Supply Looped Through at

ET 200C Slave Station

2-5

Page 32

ET 200C Configuration Options

Configuration with Power Supply Connector without T Connector,

Continued

Rules for the

External Load

Voltage Supply

The maximum permissible current for the external load voltage supply is

limited:

Table 2-2 Permissible Current Load for Load Voltage Supply

Digital module T otal permissible curr ent load

ET 200C;

max. 4 A

DO 8 DC 24V/0.5A

ET 200C;

DO 8 DC 24V/2A

Ambient temperature:

–25 ... +25 C max. 10 A

+26 ... +40 C max. 8 A

+41 ... +60 C max. 4 A

ET 200C;

DI 16/DO 16 DC 24V/2A

(outputs in groups of 4)

Ambient temperature:

–25 ... +25 C max. 3.5 A per group of 4

+26 ... +40 C max. 2.5 A per group of 4

+41 ... +60 C max. 1.5 A per group of 4

Note

An external load voltage supply can only be looped via the digital output

module DO 8 DC 24V/0.5A until the maximum current of 4 A is reached.

The maximum current load of 4 A is not protected by means of a fuse in the

module.

2-6

ET 200C Distributed I/O Station

EWA 4NEB 812 6119-02b

Page 33

ET 200C Configuration Options

2.1.2 Configuration with Power Supply Connector and with T Connectors

Definition

Advantage

Constraint

Cables

In a configuration with power supply connector and T connectors, the individual modules are connected to the field bus by T connectors.

The power supply is combined with the field bus in a single cable via the

power supply connector.

A slave station can be disconnected at any time from the bus without interrupting the “Bus traffic” for the remaining slave stations.

The power supply is fed over the bus cable, i.e. no external power supply is

required for the slave stations.

The level of expansion with one power supply connector is limited

(see Section 2.1.3).

Different types of cable can be used for the various configurations:

Read Section 3.11 if you wish to use prefabricated cables from Siemens.

Read Section 4.3 if you wish to prepare the cables yourself.

ET 200C Distributed I/O Station

EWA 4NEB 812 6119-02b

2-7

Page 34

ET 200C Configuration Options

Configuration with Power Supply Connector and with T Connectors,

Continued

Configuration

A possible configuration with power supply connector and with T connector

can be seen in Fig. 2-3:

External Power

Supply

PS

SV

conn.

SINEC L2-DP

1)

No separate load voltage

supply is necessary for

analog output modules

4AI

1)

4AO

8DO

8DO

16DI/16DO

Load V oltage Supply for

Channel Group Q1

Load Voltage Supply

Looped On

External Load

V oltage Supply

Load V oltage

Supply for Channel Group Q0

2-8

Figure 2-3 SINEC L2-DP Field Bus and Power Supply Looped Through with

T Connectors

ET 200C Distributed I/O Station

EWA 4NEB 812 6119-02b

Page 35

ET 200C Configuration Options

Rules for the

External Load

Voltage Supply

The maximum permissible current for the external load voltage supply is

limited:

Table 2-3 Permissible Current Load for Load Voltage Supply

Digital module Total permissible current load

ET 200C;

max. 4 A

DO 8 DC 24V/0.5A

ET 200C;

DO 8 DC 24V/2A

Ambient temperature:

–25 ... +25 C max. 10 A

+26 ... +40 C max. 8 A

+41 ... +60 C max. 4 A

ET 200C;

DI 16/DO 16 DC 24V/2A

(outputs in groups of 4)

Ambient temperature:

–25 ... +25 C max. 3.5 A per group of 4

+26 ... +40 C max. 2.5 A per group of 4

+41 ... +60 C max. 1.5 A per group of 4

Note

An external load voltage supply can only be looped via the digital output

module DO 8 DC 24V/0.5A until the maximum current of 4 A is reached.

The maximum current load of 4 A is not protected by means of a fuse in the

module.

Rules for the

T Connector

Spur lines are not permitted on the ET 200C except for the programmer or

the ET 200 handheld. This means that the 12-pin plug of the T connector is

always secured directly to the bus connection of a module.

8DI 8DI

Without Spur Line With Spur Line

Figure 2-4 Rule for Use of a T Connector

ET 200C Distributed I/O Station

EWA 4NEB 812 6119-02b

2-9

Page 36

ET 200C Configuration Options

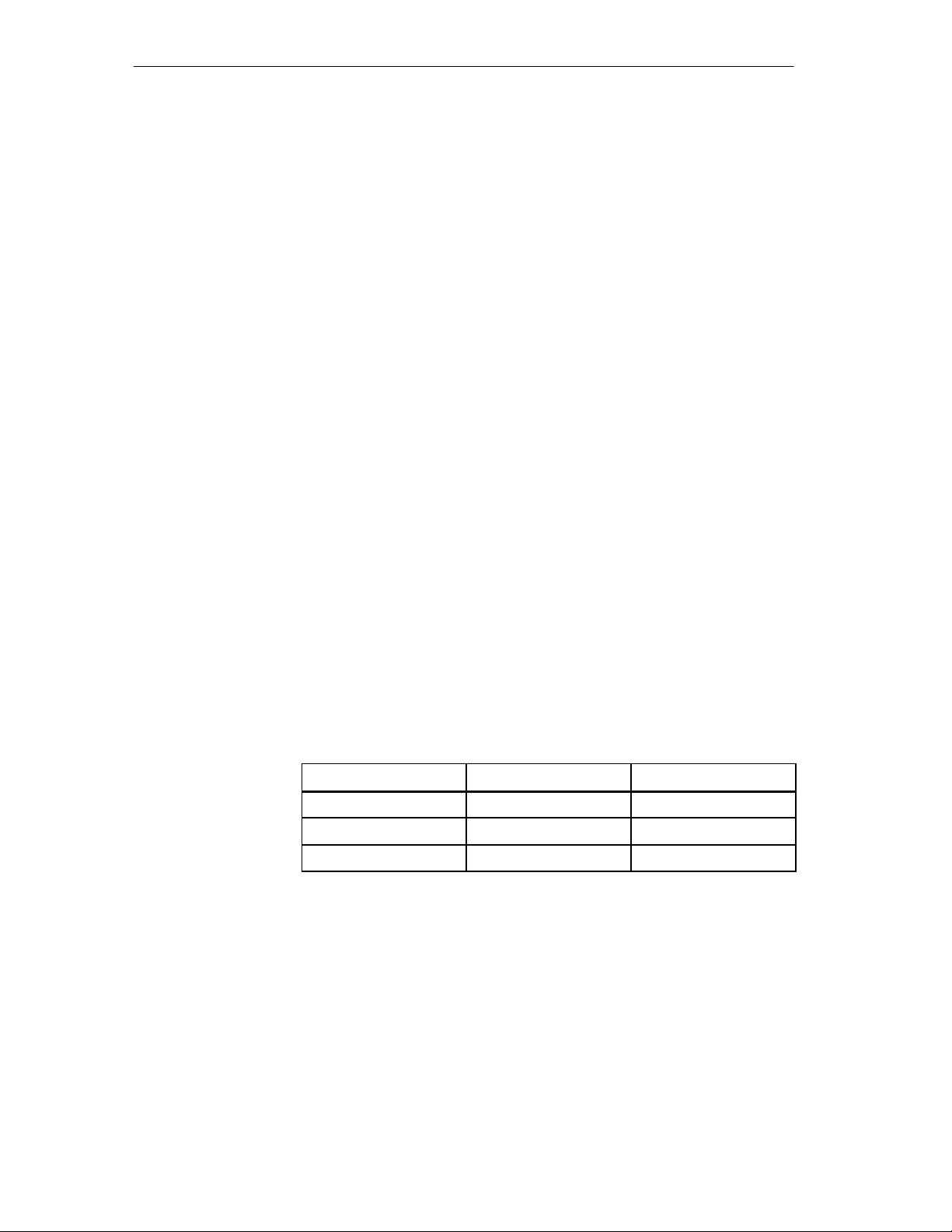

2.1.3 Configuration using Several Power Supply Connectors

Constraint when

Using One Power

Supply Connector

In the configurations using a power supply connector (see Sections 2.1.2 and

2.1.1), the power supply is fed over the bus cable.

This design is limited by the following factors:

If the power supply and the SINEC L2-DP field bus are combined in one

cable, the following values apply for the length of the bus cable between

the power supply connector and the last slave station connected:

Table 2-4 Length of the Bus Cable, if SINEC L2-DP Field Bus and Power Supply

are Combined in One Cable

Current load Max. cable length

< 1 A 80 m

< 2 A 40 m

< 4 A 20 m

A maximum of 4 A can be looped via the power supply connector. The

current consumption of the digital modules limits the number of digital

modules that can be connected.

Table 2-5 Current Consumption of the Digital Modules of ET 200C

Digital module Current consumption comprises Current

consumption

ET 200C; DI 8 DC 24V Power supply for internal logic

typ. 135 mA

and

Sensor supply

application-specific

(see Section 4.3.2)

ET 200C; DO 8 DC 24V/0.5A Power supply for internal logic typ. 90 mA

ET 200C; DO 8 DC 24V/2A Power supply for internal logic typ. 90 mA

ET 200C; DI16/DO16 DC 24V/2A Power supply for internal logic

typ. 90 mA

and

Sensor supply

application-specific

(see Section 4.3.2)

ET 200C; AI 4/8 12 Bit Power supply for internal logic typ. 80 mA

ET 200C; AI 4 12 Bit Power supply for internal logic typ. 130 mA/ 24 V

ET 200C; AI 4 12 Bit Power supply for internal logic typ. 120 mA

2-10

ET 200C Distributed I/O Station

EWA 4NEB 812 6119-02b

Page 37

ET 200C Configuration Options

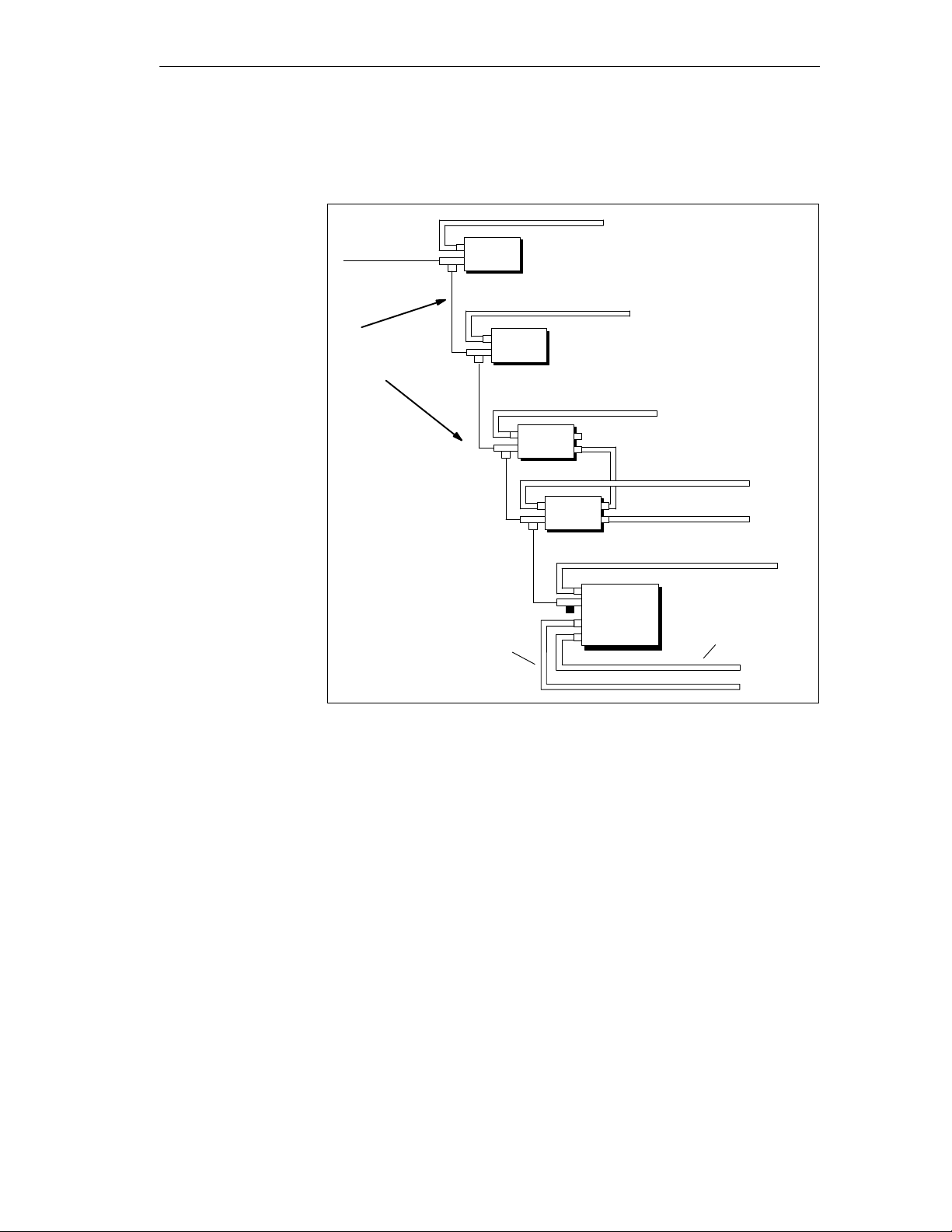

Remedy

You are planning several power supply connectors per segment. A possible

configuration with several power supply connectors can be seen in Fig. 2-5.

External

Power Supply

SINEC L2-DP

External

Power Supply

1

In this case, you can use a 2 or 5-core cable. The 2 “left” connections for

“External power supply” and “SINEC L2-DP” are not jumpered!

PS

SV

conn.

SINEC L2-DP

PS

SV

conn.

8DI

1

8DI

8DO

External Load

8DO

V oltage Supply

Figure 2-5 Configuration using Several Power Supply Connectors

ET 200C Distributed I/O Station

EWA 4NEB 812 6119-02b

2-11

Page 38

ET 200C Configuration Options

2.1.4 Configuration without Power Supply Connector

Definition

Advantage

Cables

In a configuration with a separate power supply each slave station is supplied

individually with current. This current supply may not be fed over the bus

cable.

The T connector for connecting SINEC L2-DP is essential for being able to

loop the SINEC L2-DP field bus.

The power supply is not run over the bus (2-core instead of 5-core cable).

A slave station can be disconnected at any time from the bus without the

“Bus traffic” being interrupted for slave stations further down the line, since

the field bus is looped via the T connectors.

Different types of cable can be used for the various configurations:

Read Section 3.11 if you wish to use prefabricated cables from Siemens.

Read Section 4.3 if you wish to prepare the cables yourself.

Note

You must prepare the cables yourself for the load voltage supply of

ET 200C; DO 8 DC 24V/2A or ET 200C; DI 16/DO 16 DC 24V/2A

and for separate power supplies (see Section 4.3).

2-12

ET 200C Distributed I/O Station

EWA 4NEB 812 6119-02b

Page 39

ET 200C Configuration Options

Configuration

A possible configuration without power supply connector can be seen in

Fig. 2-6.

External Power Supply

4AI

SINEC L2-DP

External Power Supply

1)

Two-wire

Cable (!!)

1)

4AO

External Power Supply

8DO

8DO

No separate load voltage

supply is necessary for

analog output modules

External Power Supply

External Load V oltage Supply

External Power Supply

16DI/16DO

Load V oltage Supply for

V oltage Supply for

Channel Group Q0

Channel Group Q1

Figure 2-6 SINEC L2-DP Field Bus Looped Through with T Connectors –

Individual External Power Supply to Each Slave Station

External Load

ET 200C Distributed I/O Station

EWA 4NEB 812 6119-02b

2-13

Page 40

ET 200C Configuration Options

Configuration without Power Supply Connector, Continued

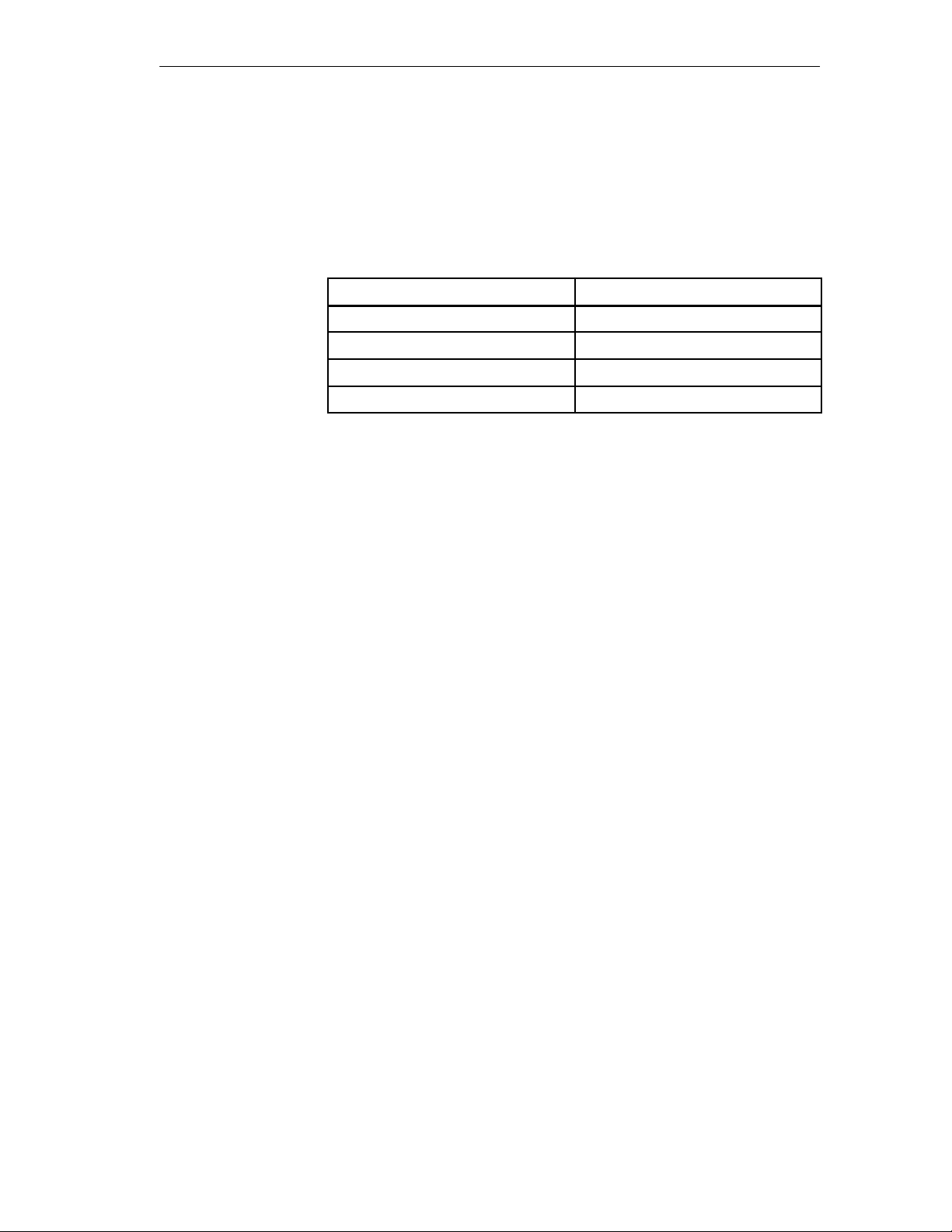

Rules for the

External Load

Voltage Supply

The maximum permissible current for the external load voltage supply is

limited:

Table 2-6 Permissible Current Load for Load Voltage Supply

Digital module Total permissible current load

ET 200C;

Max. 4 A

DO 8 DC 24V/0.5A

ET 200C;

DO 8 DC 24V/2A

Ambient temperature:

–25 ... +25 C max. 10 A

+26 ... +40 C max. 8 A

+41 ... +60 C max. 4 A

ET 200C;

DI 16/DO 16 DC 24V/2A

(outputs in groups of 4)

Ambient temperature:

–25 ... +25 C max. 3.5 A per group of 4

+26 ... +40 C max. 2.5 A per group of 4

+41 ... +60 C max. 1.5 A per group of 4

Note

An external load voltage supply can only be looped via the digital output

module DO 8 DC 24V/0.5A until the maximum current of 4 A is reached.

The maximum current load of 4 A is not protected by means of a fuse in the

module.

Rules for the

T Connector

2-14

Spur lines are not permitted on the ET 200C except for the programmer or

the ET 200 handheld. This means that the 12-pin plug of the T connector is

always secured directly to the bus connection of a module.

8DI 8DI

Without Spur Line With Spur Line

Figure 2-7 Rules for Use of a T Connector

ET 200C Distributed I/O Station

EWA 4NEB 812 6119-02b

Page 41

ET 200C Configuration Options

Rules for Current

Connection

!