Siemens SIMATIC EM 300 User Manual

Important Information,

Contents

SIMATIC

EM 300 Motor Starters

Manual

Product Overview

Wiring

Commissioning

Hand-held Controller

Technical Specifications

SIGUARD Safety Integrated

Order Numbers

Dimension Drawings

1

2

3

4

5

6

A

B

GWA-4NEB 640070302-05

Edition 03/2010

Configuration Frame

Selection Help

Index

C

D

Safety guidelines

This manual contains notices which you should observe to ensure your own personal safety, as well as to protect the product and connected equipment. These notices are highlighted in the manual by a warning triangle

and are marked as follows according to the level of danger:

Danger

indicates that death, severe personal injury or substantial property damage will result if proper precautions

are not taken.

Warning

indicates that death, severe personal injury or substantial property damage can result if proper precautions are

not taken.

Caution

indicates that minor personal injury or property damage can result if proper precautions are not taken.

Caution

indicates that property damage can result if proper precautions are not taken.

Attention

draws your attention to particularly important information on the product, handling the product, or to a particular part of the documentation.

Qualified personnel

Only qualified personnel should be allowed to install and work on this equipment. Qualified persons are defined as persons who are authorized to commission, to ground, and to tag circuits, equipment, and systems in

accordance with established safety practices and standards.

Correct usage

Note the following:

Warning

This device and its components may only be used for the applications described in the catalogue or the technical descriptions, and only in connection with devices or components from other manufacturers which have

been approved or recommended by Siemens.

This product can only function correctly and safely if it is transported, stored, set up, and installed correctly,

and operated and maintained as recommended.

Brands

SIMATIC®, SIMATIC HMI® and SIMATIC NET® are brands of SIEMENS AG.

Some other designations used in these documents are also brands; the owner's rights may be violated if they

are used by third parties for their own purposes.

Copyright Siemens AG 2003 All rights reserved

The reproduction, transmission or use of this document or its contents is not permitted without express written authority. Offenders

will be liable for damages. All rights, including rights created by

patent grant or registration of a utility model or design, are reserved.

Disclaimer of liability

We have checked this manual to ensure that its contents are correct

and applicable in relation to the hardware and software it describes.

Despite all our endeavors, however, discrepancies cannot be wholly

excluded and so we cannot guarantee complete correctness and

applicability. However, the data in this manual are reviewed regularly

and any necessary corrections included in subsequent editions. Suggestions for improvement are welcomed.

Technical Assistance: Telephone: +49 (0) 911-895-5900 (8°° - 17°° CET) SIEMENS AG

Fax: +49 (0) 911-895-5907 Technical Assistance

Würzburger Str. 121

D-90766 Fürth

SIEMENS AG

Industry Sector

Postfach 4848

90026 Nürnberg

GERMANY

Siemens Aktiengesellschaft

E-mail: technical-assistance@siemens.com

Internet: www.siemens.com/industrial-controls/technical-assistance

Siemens AG 2003

Technical data subject to change without notice.

Important Information

Purpose of the Manual

This manual complements the ET 200X Distributed I/O Device manual. It describes all the functions of the EM 300 motor starters. The manual does not

deal with functions that have general applicability to the ET 200X. You will find

descriptions of these in the ET 200X Distributed I/O Device manual.

The information in this manual and in the ET 200X Distributed I/O Device

manual allows you to run the ET 200X with a EM 300 motor starter as a DPSlave on the PROFIBUS.

Target group

The manual describes the hardware of the EM 300 motor starters and is aimed

at configuration engineers, commissioning engineers and maintenance personnel, who use the ET 200X with PLC functionality.

It consists of chapters containing instructions and reference chapters.

Delivery package

This delivery package (order number 6ES7 198-8FA01-8BA0) consists of 4 manuals with the following contents:

BM 147/CPU

Basic Module

• Addressing

• ET 200X with

BM 147/CPU with

PROFIBUS DP

• Commissioning

and diagnostics

• Technical

specifications

• Order numbers

•List of STEP 7

operations

ET 200X

Distributed I/O Device

• Installing and wiring

• Commissioning

and diagnostics

• Technical

specifications of

digital and analog

modules

• Order numbers

for digital and

analog modules

EM 300

Motor Starters

• Wiring

• Commissioning

and diagnostics

• Technical

specifications

• Order numbers

• SIGUARD

Safety Integrated

EM 148-FC

Frequency Converter

• Wiring

• Commissioning

and diagnostics

• Functions and

technical

specifications

• Order numbers

SIMATIC - EM 300 Motor Starters

GWA-4NEB 640070302-05

i

Important Information

Applicability

This manual is valid for the EM 300 motor starters. It contains a description of

the components that were valid at the time the manual was published. We

reserve the right to enclose a Product Information bulletin containing up-to-date

information about new components and new versions of components.

Standards, Certificates and Approvals

The ET 200X distributed I/O device is based on EN 50170, Volume 2, PROFIBUS.

The ET 200X complies with the requirements and criteria of IEC 61131, Part 2 as

well as the requirements of the CE marking. CSA, UL and FM certifications

habe been obtained for the ET 200X. You will find detailed information on these

standards, certificates and approvals in the ET 200X Distributed I/O Device

manual.

Position in the Information Landscape

In addition to the ET 200X manuals, you will also need the manual for the DP

master used and the documentation for the configuration and programming

software used (see the list in Appendix A of the ET 200X Distributed I/O Device

manual).

Note

You will find a detailed list of the contents of the ET 200X manuals in Section 1.3

of this manual.

We recommend that you begin by reading this section so as to find out which

parts of which manuals are most relevant to you in helping you to do what you

want to do.

Aids to Finding Information

You can quickly access specific information in the manual by using the following

aids:

• At the beginning of the manual you will find a comprehensive table of contents.

• The sections of the chapters in the manual contain subheadings that allow

you to gain a quick overview of the content of the section.

• At the end of the manual you will find a detailed index that enables you to

find the information you require quickly and easily.

SIMATIC - EM 300 Motor Starters

ii GWA-4NEB 640070302-05

Contents

1 Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1 What are the Motor Starters EM 300 DS and EM 300 RS? . . . . . . . . . . . . 1-2

1.2 What are the Motor Starters EM 300 EDS and EM 300 ERS? . . . . . . . . . . 1-3

1.3 Guide to the ET 200X Manuals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

2 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1 Rules for Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2

2.2.1 Making up Connecting Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.2.2 Wiring the Power Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.2.3 Electrical Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.3

2.3.1 Making up Connecting Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.3.2 Wiring the Power Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.3.3 Electrical Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.4

2.4.1 Making up Connecting Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.4.2 Wiring the Power Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

2.4.3 Electrical Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Motor Starters EM 300 without a Braking Contact . . . . . . . . . . . . . . . . . . . . . 2-4

Motor Starters EM 300 with a 24 V DC Braking Contact . . . . . . . . . . . . . . . . 2-8

Motor Starters EM 300 with a 400 V AC resp. 500 V DC Braking Contact . . . . 2-12

3 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1 Motor Starters EM 300 DS and EM 300 RS . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.1.1 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.1.2 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.1.3 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.2

Motor Starters EM 300 EDS and EM 300 ERS . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.2.1 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.2.2 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.2.3 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

SIMATIC - EM 300 Motor Starters

GWA-4NEB 640070302-05

iii

Contents

4 Hand-held Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1 Functions and View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.2 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.3 LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.4 Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

5 Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1 General Technical Specifications of Motor Starters . . . . . . . . . . . . . . . . . . 5-2

5.2 Voltages and Currents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.3 Braking Current Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.4 Specifications of Motor Starters EM 300 DS/RS . . . . . . . . . . . . . . . . . . . . 5-5

5.5 Specifications of Motor Starters EM 300 EDS/ERS . . . . . . . . . . . . . . . . . . 5-6

5.6 Shipping and Storage Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

5.7 Mechanical and Climatic Environment Conditions . . . . . . . . . . . . . . . . . . . 5-8

6 SIGUARD Safety Integrated . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.1 Suggested Circuits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.1.1 Safety category 1 (EN 954-1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.1.2 Safety category 2 (EN 954-1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.1.3 Safety category 3 (EN 954-1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6.1.4 Safety category 4 (EN 954-1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

A Order Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

B Dimension Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

C Configuration Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

D Selection Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Index

SIMATIC - EM 300 Motor Starters

iv GWA-4NEB 640070302-05

Product Overview 1

Section Subject Page

1. 1

1. 2

1. 3

What are the Motor Starters EM 300 DS and

EM 300 RS?

What are the Motor Starters EM 300 DS and

EM 300 ERS?

Guide to the ET 200X Manuals

1-2

1-3

1-4

SIMATIC - EM 300 Motor Starters

GWA-4NEB 640070302-05

1-1

Product Overview

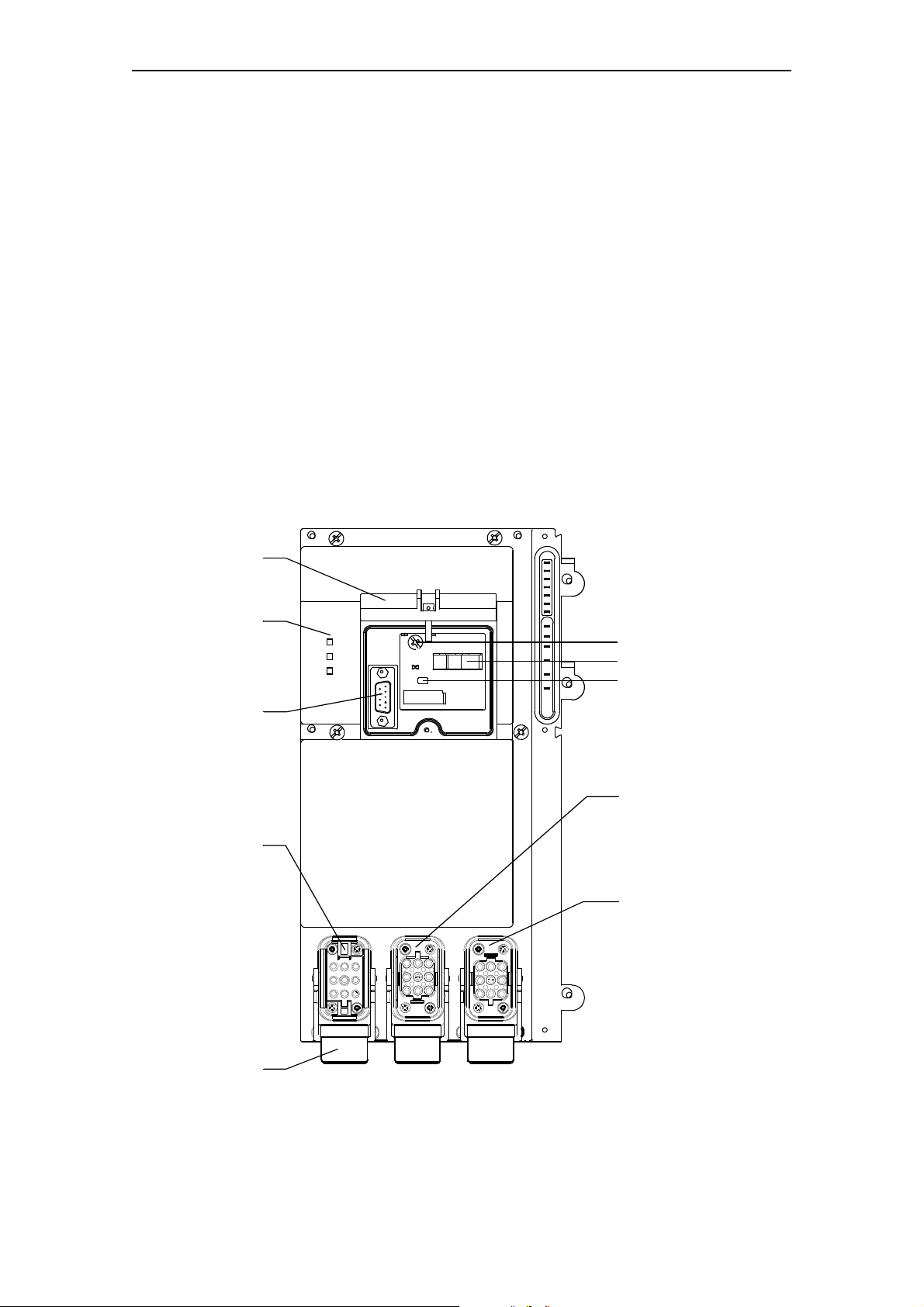

Interlock

DC24V

STATE

Power connector

for feeding

– load supply voltage

– braking voltage (on

versions with a 24 V

DC braking contact)

Circuit-breaker

– Scale for current setting

– Toggle switch

– Test opening

LEDs

– Auxiliary power

–State

Power socket

for connecting

– load

–brake

Power socket

for looping through

– load supply voltage

– braking voltage (on

versions with a 24 V

DC braking contact)

Transparent cover,

open

SUB-D

(for hand-held

controller only!)

1.1 What are the Motor Starters EM 300 DS and EM 300 RS?

Motor starters EM 300 DS/RS

Motor starters EM 300 DS and EM 300 RS are electromechanical motor starters, that can be used on the ET 200X distributed I/O device as expansion

module. Up to six motor starters EM 300 can be added to the basic module.

Characteristics

The motor starters EM 300 DS/RS:

• Are suitable for switching and protecting any three-phase loads up to 5.5 kW

with 400 V AC.

• Are available as either direct starters (EM 300 EDS) or reversing starters

(EM 300 ERS) with adjustment ranges from 0.14 to 0.2 A and 9 to 12 A

respectively.

• Can be equipped with a 24 V DC, max. 3 A, or 500 V DC, max. 0,2 A, braking

contact as an option.

View

The diagram below shows the components of a motor starter EM 300 DS/RS.

SIMATIC - EM 300 Motor Starters

1-2 GWA-4NEB 640070302-05

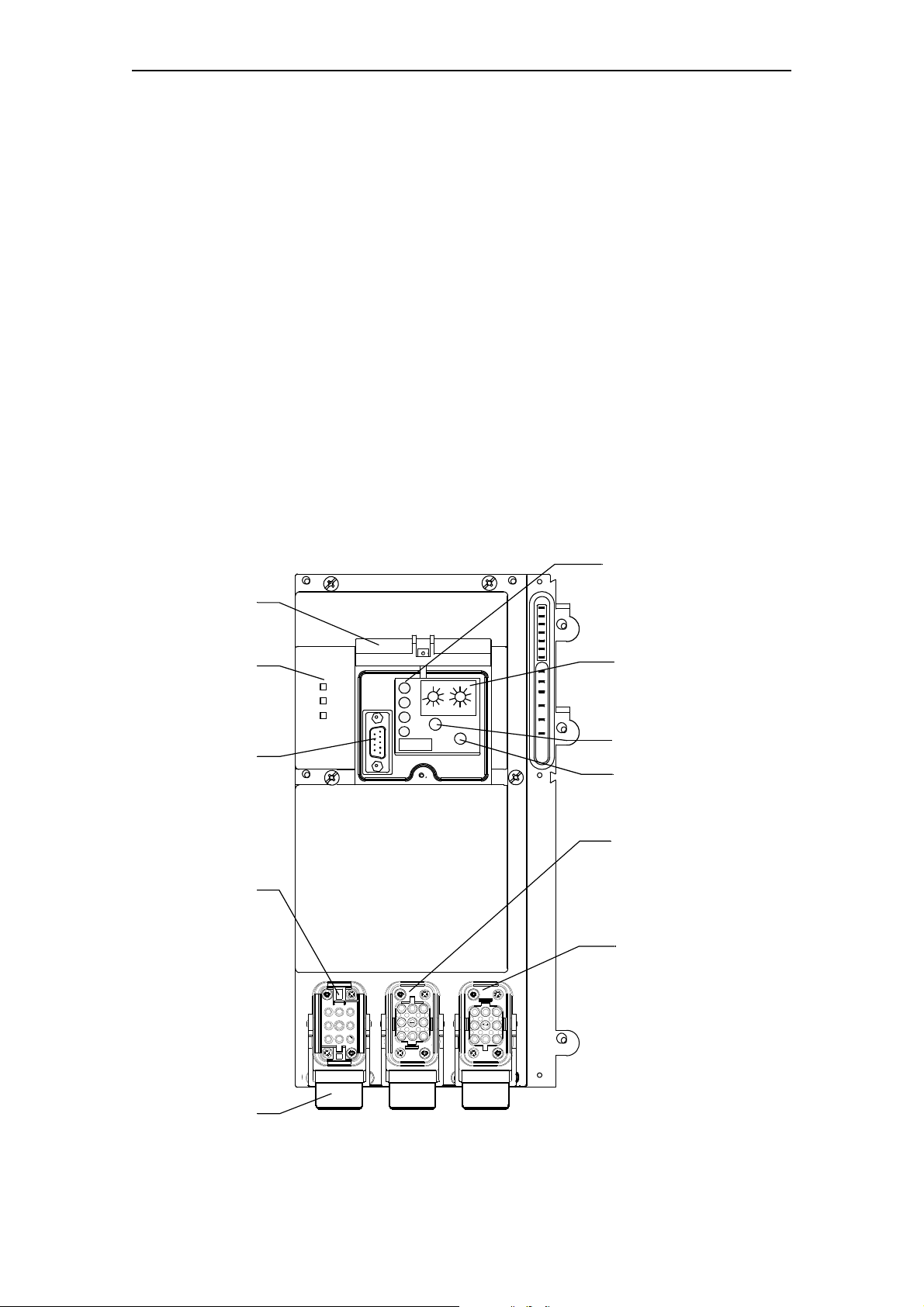

Product Overview

Interlock

TEST/RESET button

DC24V

STATE

LEDs

– Auxiliary power

–State

(from Version 2)

Transparent cover,

open

SUB-D

(for hand-held

controller only!)

Power connector

for feeding

– load supply voltage

– braking voltage (on

versions with a 24 V

DC braking contact)

Power socket

for looping through

– load supply voltage

– braking voltage (on

versions with a 24 V

DC braking contact)

Power socket

for connecting

– load

–brake

LEDs

–READY

–RUN

–FAULT

–OVERLOAD

Rotary encoder switches

1 and 2 for setting the

current

Rotary encoder switch

Tripping REMOTE/LOCAL

Power connector

for feeding

– load supply voltage

– braking voltage (on

versions with a 24 V

DC braking contact)

SUB-D

(for hand-held

controller only!)

1.2 What are the Motor Starters EM 300 EDS and EM 300 ERS?

Motor starters EM 300 EDS/ERS

Motor starters EM 300 EDS and EM 300 ERS are electronic motor starters,

which can be used on the ET 200X distributed I/O device as expansion module.

Up to six motor starters EM 300 can be added to the basic module.

Characteristics

The motor starters EM 300 EDS/ERS:

• Are suitable for switching and protecting any three-phase loads up to 2.2 kW

with 400 V AC.

• Are available as either direct starters (EM 300 EDS) or reversing starters

(EM 300 ERS) with adjustment ranges from 0.6 to 2.18 A and 2.0 to 5.95 A

respectively.

• Can be equipped with a 24 V DC, max. 3 A, or 400 V AC, max. 0.5 A, or

500 V DC, max. 0.2 A braking contact as an option.

View

The diagram below shows the components of a motor starter EM 300 EDS/ERS.

SIMATIC - EM 300 Motor Starters

GWA-4NEB 640070302-05

1-3

Product Overview

The ET 200X consists of the

following components:

You need the information contained in the following manuals:

ET 200X-DESINA/ECOFAST

ET 200X

ET 200X

Distributed I/O Device

EM 300 Motor Starters

BM 147/CPU Basic module

ET 200X

Distributed I/O Device

EM 300 Motor Starters

ET 200X

Distributed I/O Device

ET 200X

Distributed I/O Device

Distributed I/O Device

+

+

+

EM 300 Motor Starters

+

Frequency Converter

Distributed I/O Device

+

+

BM 147/CPU Basic module

EM

DI

EMDOEM

AI

EM

AO

MS

MS

BM

DI/DO

EM

DI

EMDOEM

AI

EM

AO

BM

DI/DO

EM

143

EM

DI

EMDOEM

AI

EM

AO

BM

147

DI/DO

EM

143

DI/DO

EM

143

DI/DO

EM

143

DI/DO

EM

DI

EMDOEM

AI

MS

BM

147

EM

AO

MS

EM

DI

EM

AI

EM

AO

MS MS

BM

DI/DO

EM-FC

1.3 Guide to the ET 200X Manuals

You are Using the following Components ...

The components of the ET 200X are described in various manuals in the

ET 200X package. The figure below shows possible ET 200X configurations

and the manuals required for them.

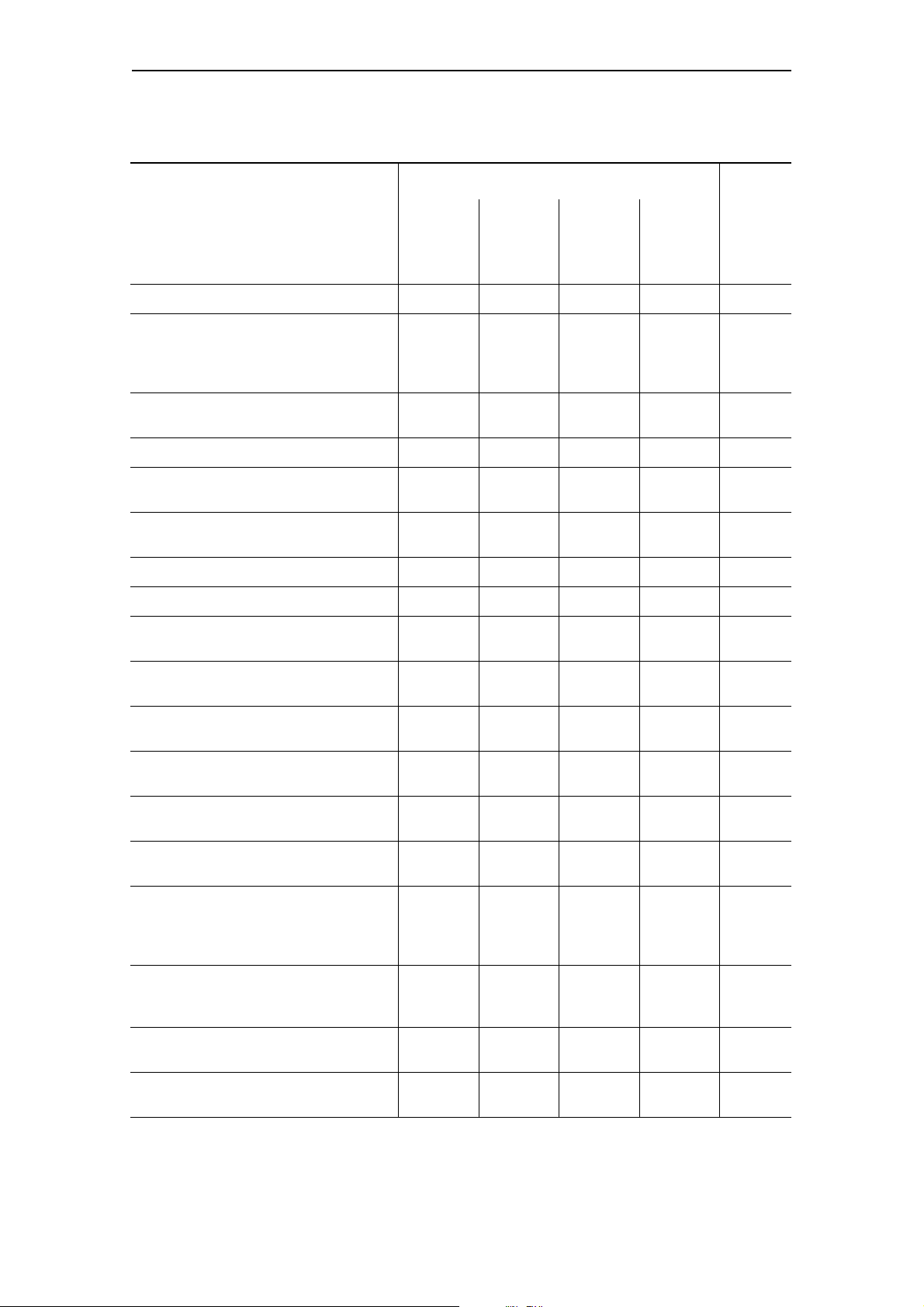

Where Do You Find What Information?

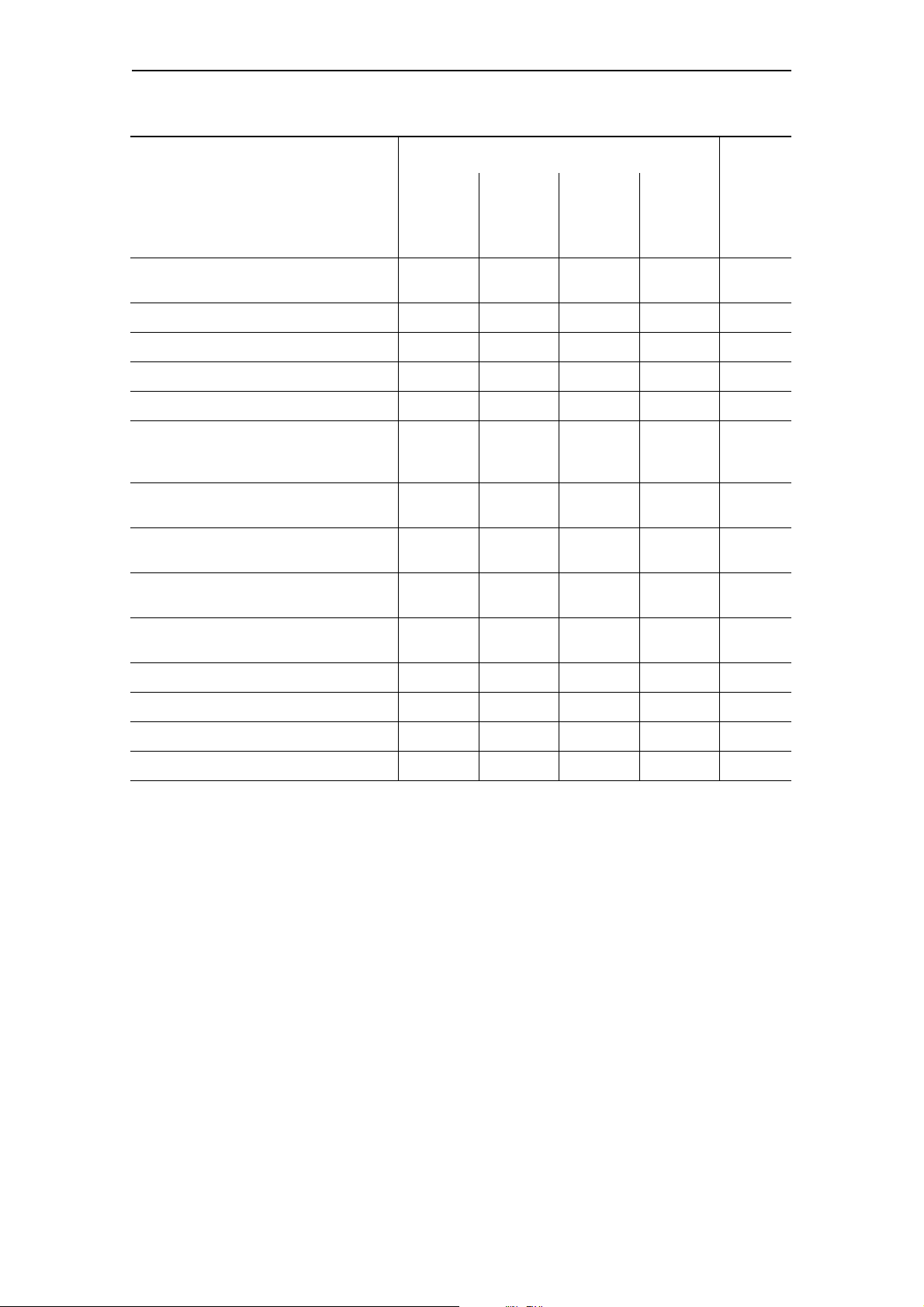

The table below will help you get your bearings and find the information you

need quickly. It tells you which manual you need to refer to and which chapter

deals with the topic you are interested in.

1-4 GWA-4NEB 640070302-05

SIMATIC - EM 300 Motor Starters

Manual

Product Overview

Subject

ET 200X configuration options

Installing the ET 200X, motor starters

and frequency converters;

setting the PROFIBUS address;

connecting a terminating resistor

Installing the ET 200X-DESINA/ECOFAST;

setting the PROFIBUS address

BM 147/CPU addressing

Electrical configuration and wiring

of the ET 200X

Electrical configuration and wiring

of the ET 200X-DESINA/ECOFAST

Wiring of motor starters

Wiring of frequency converters

The ET 200X with the BM 147/CPU

with PROFIBUS DP

ET 200X

Distributed

I/O Device

x

x

x

x

x

BM 147/

CPU

Basic

Module

x

x

EM 300

Motor

Starters

x

EM 148-FC

Frequency

Converter

x

Chapter/

Appendix

2

3

3

2

4

4

2

2

3

Commissioning and diagnostics

of the ET 200X

Commissioning and diagnostics

of the ET 200X-DESINA/ECOFAST

Commissioning and diagnostics

of the ET 200X with BM 147/CPU

Commissioning and diagnostics

of the ET 200X with motor starters

Commissioning and diagnostics of the

ET 200X with frequency converters

General technical specifications of

the ET 200X (standards, cerificates

and approvals, EMC, environmental

conditions etc.)

Technical specifications of the basic

and expansion modules with DI, DO,

AI and AO

Technical specifications of the

BM 147/CPU

Technical specifications of the motor

starters

x

x

x

x

x

x

x

x

x

5

5

4

3

3

6

7

5

5

SIMATIC - EM 300 Motor Starters

GWA-4NEB 640070302-05

1-5

Product Overview

Manual

Subject

Functions and technical specifications

of frequency converters

BM 147/CPU cycle and response times

Order numbers of the components

Order numbers of the motor starters

Order numbers of frequency converters

Dimensioned drawings of the basic

modules and digital and analog

expansion modules

Dimensioned drawings of the motor

starters

Dimensioned drawings of frequency

converters

Configuration and parameter assignment frames

Configuration and parameter assignment frames for the BM 147/CPU

ET 200X

Distributed

I/O Device

x

x

x

BM 147/

CPU

Basic

Module

x

x

EM 300

Motor

Starters

x

x

EM 148-FC

Frequency

Converter

x

x

x

Chapter/

Appendix

4

6

A

A

A

C

B

B

C

A

Configuration frame for motor starters

List of STEP 7 operations

Execution times of SFCs

Glossary

x

x

xx

x

C

B

C

Glossary

SIMATIC - EM 300 Motor Starters

1-6 GWA-4NEB 640070302-05

Wiring 2

Section Subject Page

2.1 Rules for Wiring 2-2

2.2 Motor Starters EM 300 without a Braking Contact 2-4

2.2.1 Making up Connecting Cables 2-4

2.2.2 Wiring the Power Connectors 2-5

2.2.3 Electrical Design 2-7

2.3 Motor Starters EM 300 with a 24 V DC Braking Contact 2-8

2.3.1 Making up Connecting Cables 2-8

2.3.2 Wiring the Power Connectors 2-9

2.3.3 Electrical Design 2-11

2.4 Motor Starters EM 300 with a 400 V AC resp.

500 V DC Braking Contact

2.4.1 Making up Connecting Cables 2-12

2.4.2 Wiring the Power Connectors 2-13

2.4.3 Electrical Design 2-15

2-12

SIMATIC - EM 300 Motor Starters

GWA-4NEB 640070302-05

2-1

Wiring

2.1 Rules for Wiring

Warning

Dangerous high voltage! Take care to avoid electric shock and injuries from

burns. Always deenergize the system and the device before carrying out any

work.

Selecting the motor connecting cables

The core cross section of the motor connecting cables must match the given

environmental conditions. The cross section is governed by:

• the nominal current set on the unit,

• the method of cable laying,

• the ambient temperature,

• the insulation material of the motor connecting cable (PVC, rubber).

For PVC motor connecting cables laid in cable ducts, the following maximum

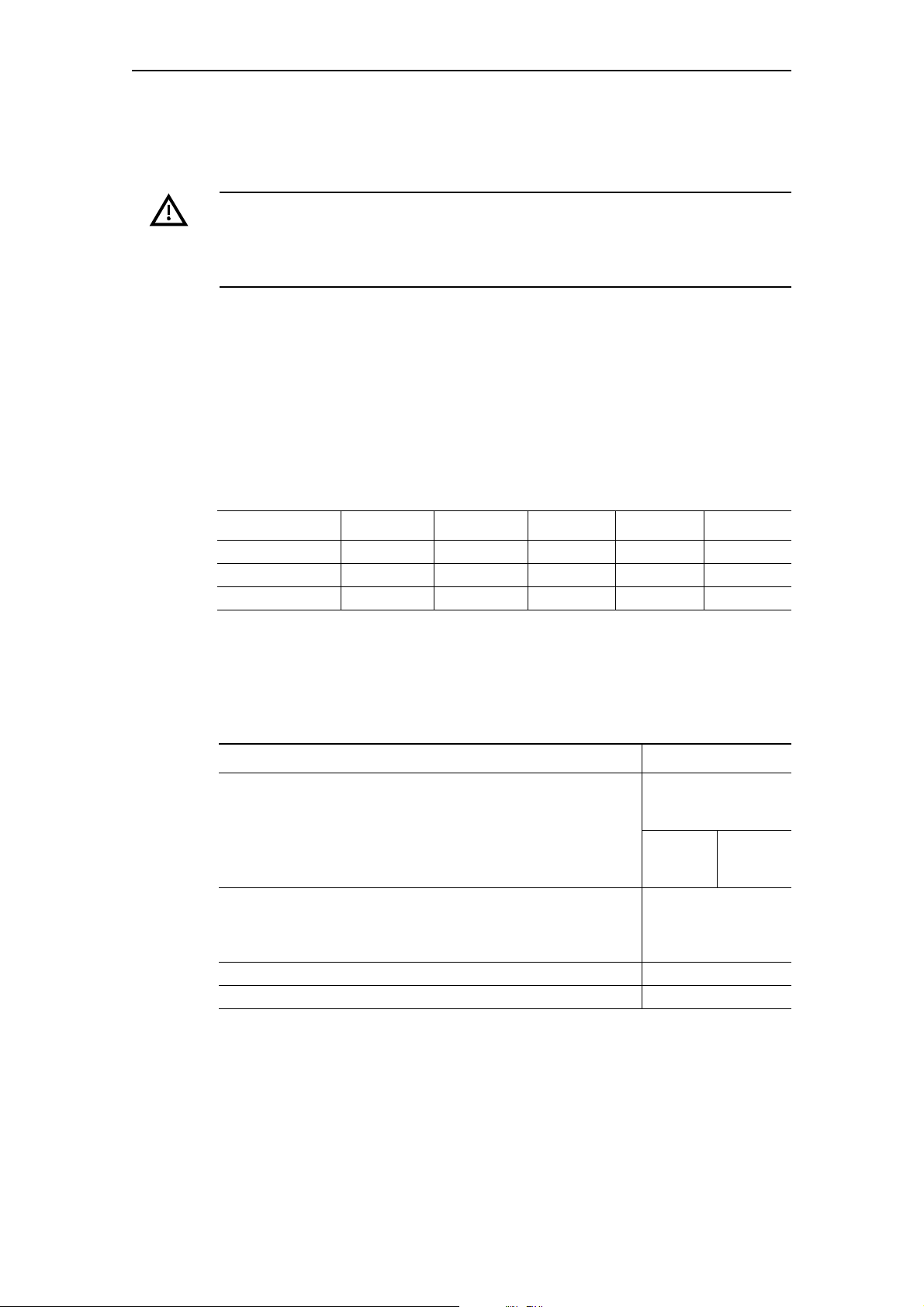

current carrying capacities apply according to environment temperature:

T

= 30 °C 40 °C 45 °C 50 °C 55 °C

env

4 x 1.5 mm

4 x 2.5 mm

4 x 4.0 mm

2

2

2

Wiring power connectors

The rules and procedure for wiring the power connectors apply both to the

electromechanical (

EDS/ERS). Observe the following rules when wiring the power plug:

Current carrying capacity of the connection depending on the

connected core cross-section and the environment temperature

1. 5 m m

Permissible outside diameter of cable

Sealing insert green

Bared length of cores 8 mm

Bared length of cable sheath 20 mm

14 A 12.2 A 11.1 A 9.9 A 8.5 A

19 A 16.5 A 15.0 A 13.5 A 11.6 A

26 A 22.6 A 20.5 A 18.5 A 15.9 A

EM 300 DS/RS) and the electronic motor starter (EM 300

Rules for flexible conductors Data

at T

env

55 °C 40 °C

2.5 mm

4.0 mm

red

white

2

2

2

12 A

20 A

30 A

7.0 ... 10.5 mm

9.0 ... 13.0 mm

11.5 ... 15.5 mm

15 A

25 A

35 A

SIMATIC - EM 300 Motor Starters

2-2 GWA-4NEB 640070302-05

Motor starter EM 300 with braking contact

The 400 V power supply for the motor and the 24 V DC power supply for the

brake are fed to the load through a common cable and connector. There is a danger of voltage overspill if the cable is flattened. Do not therefore connect loads

with degree of protection "extra-low voltage" to the braking circuit.

In order to avoid voltage overspill in case of fault the supply voltage for the

brake must be drawn from a power supply unit with safe electrical isolation

(PELV).

Motor starter EM 300 without braking contact

The braking supply voltage of motor starters without a 24 V braking contact is

internally not looped through. The 24 V DC braking voltage must then be drawn

from the power supply unit again.

Unused connections

Seal unused connections with caps, only then is degree of protection IP 65

guaranteed (order number 3 RK1 902-0CK00 (1 piece) or 3 RK1 902-0CJ00

(10 pieces).

Wiring

SIMATIC - EM 300 Motor Starters

GWA-4NEB 640070302-05

2-3

Wiring

X2

X1

X3

2.2 Motor Starters EM 300 without a Braking Contact

2.2.1 Making up Connecting Cables

Accessories

If you want to make up your own connecting cable for motor starters EM 300

without braking contact, you will need one crimping tool for contact pins/jacks

(alternatively, they can be soldered) and the following components.

Yo u n e ed . . .

For connecting load

supply voltage

One flexible 4-core copper

cable 2.5 mm

(3 conductors + PE)

One set of connectors

• 2.5 mm

• 4.0 mm2:3RK1902-0CB00

—resp.

2

/ 4.0 mm

2

:3RK1902-0CA00

2

For connecting load For looping through

load supply voltage

One flexible 4-core copper

cable 1.5 mm

(3 conductors + PE)

One set of connectors

• 1.5 mm2: 3RK1902-0CE00

• 2.5 mm2: 3RK1902-0CC00

one motor connecting cable

with plug, 4 x 1.5 mm

• 3 m: 3 RK1 902-0CM00

• 5 m: 3 RK1 902-0CP00

• 10 m: 3 RK1 902-0CQ00

2

/ 2.5 mm

2

2

One flexible 4-core copper

cable 2.5 mm

(3 conductors + PE)

One set of connectors

• 2.5 mm2: 3RK1902-0CC00

• 4.0 mm2: 3RK1902-0CD00

resp.

one power connecting cable

with plug and socket

• 6 x 2.5 mm2, 0.12 m:

• 4 x 4.0 mm2, 0.15 m:

2

/ 4.0 mm

3 RK1 902-0CH00

3 RK1 902-0CG00

2

SIMATIC - EM 300 Motor Starters

2-4 GWA-4NEB 640070302-05

2.2.2 Wiring the Power Connectors

1

2

3

4

5

6

7

8

12

3

45

6

7

8

1

23

4

5

6

7

8

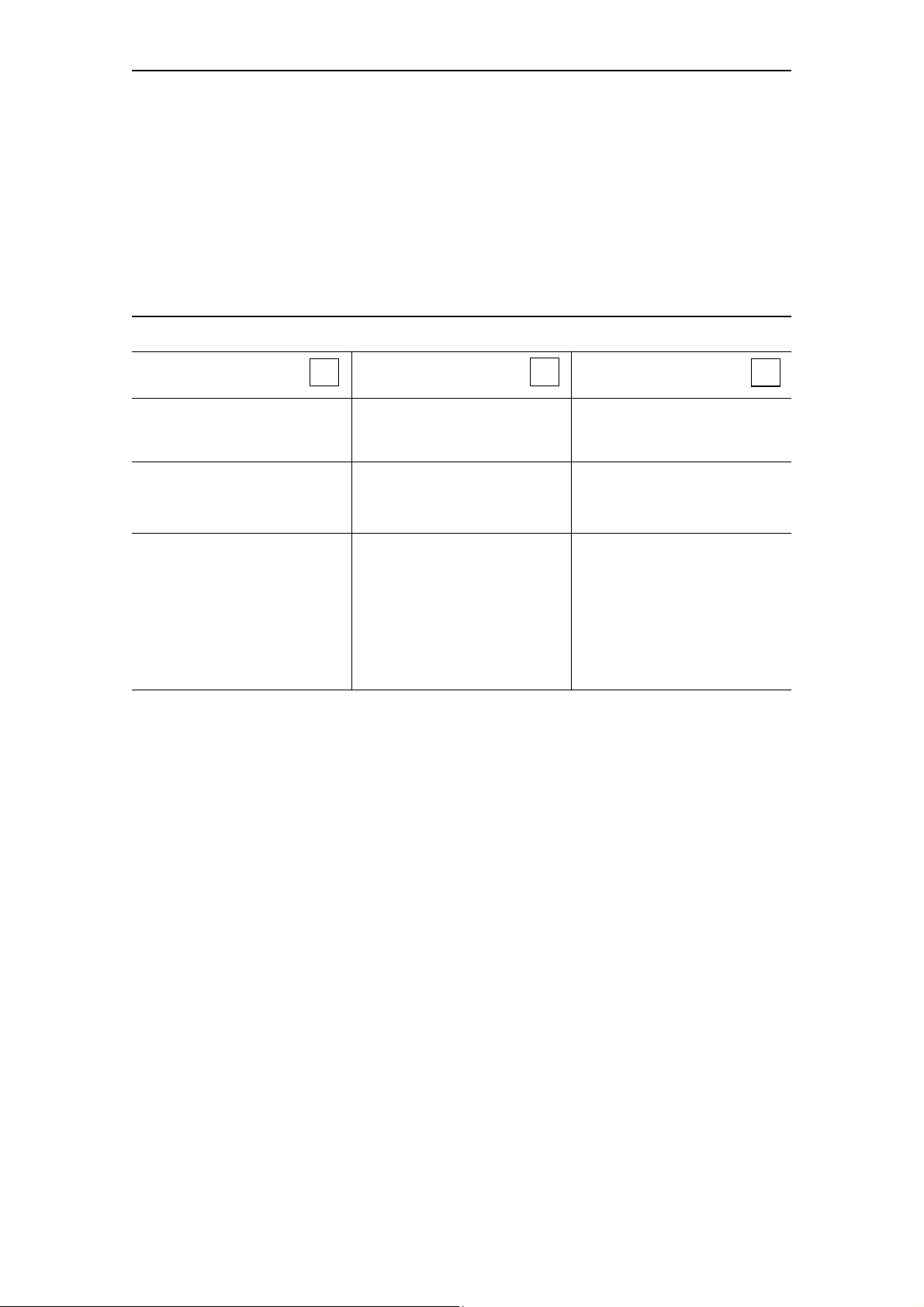

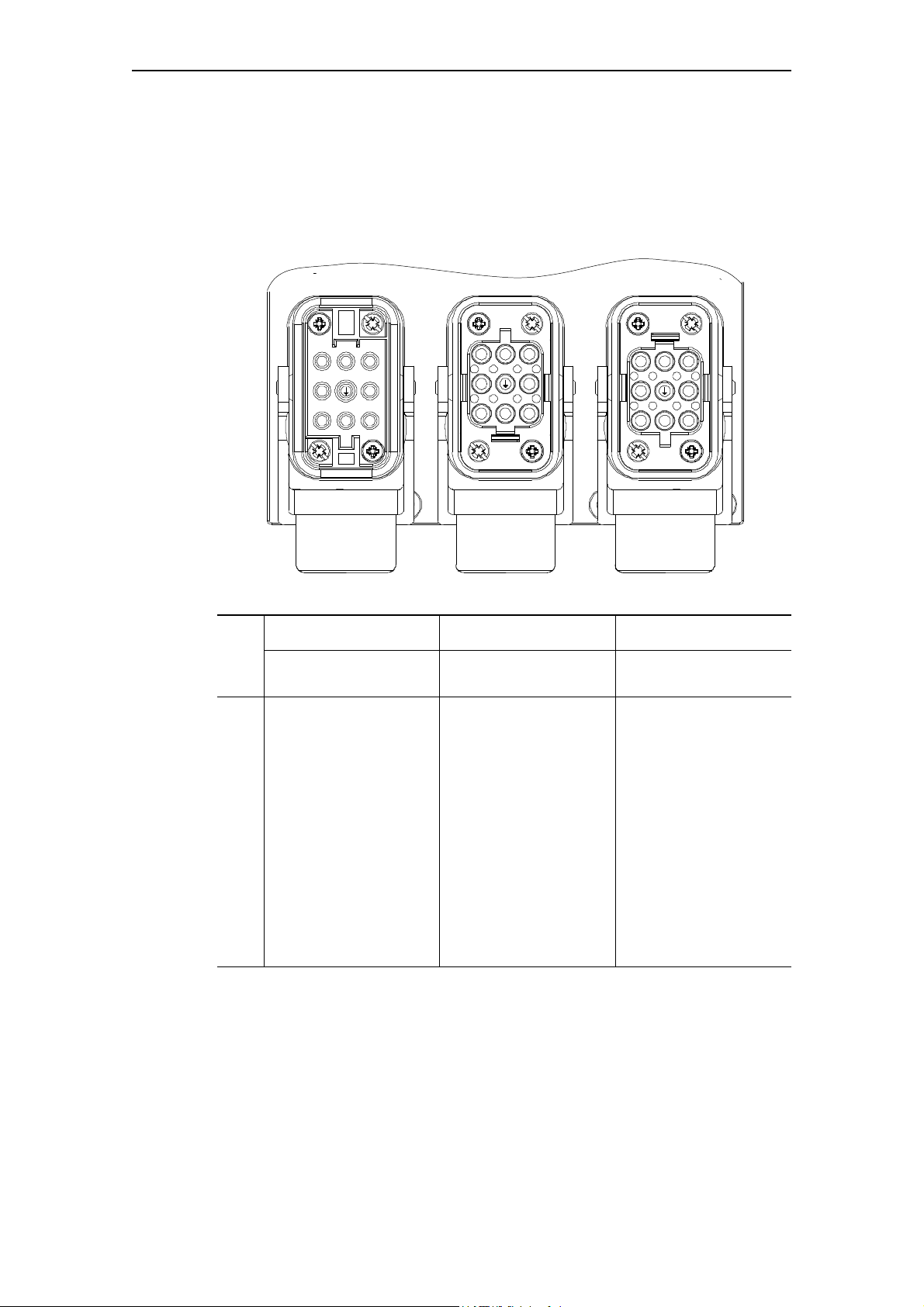

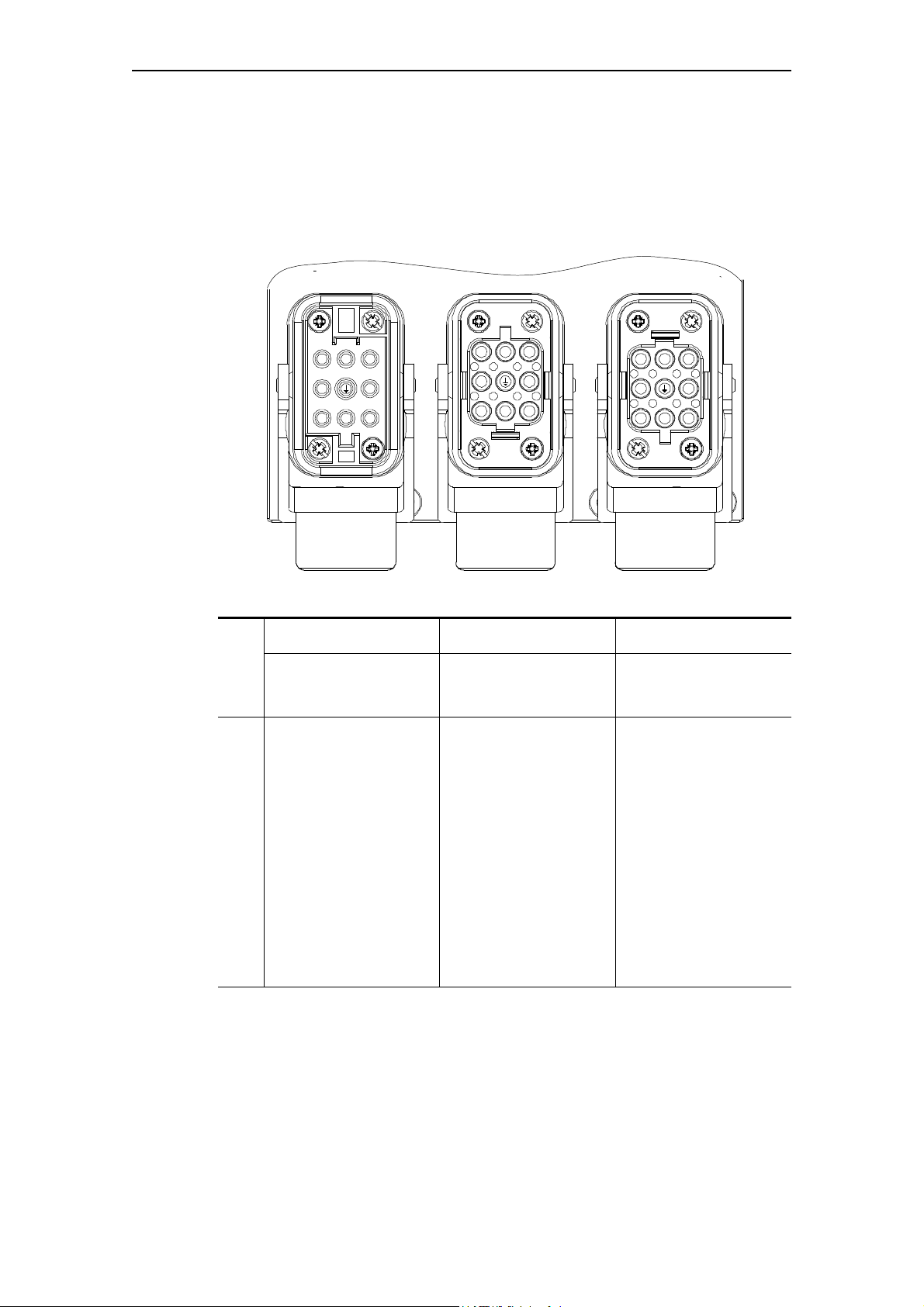

Pinout

The diagram and the table below indicate the pinout of the power connector and

the two power sockets on the motor starter without a braking contact.

Wiring

Coding

Pin-

Plug X1 Socket X2 Socket X3

out

Connecting load

supply voltage

Connecting load Looping through

load supply voltage

1 — Phase 1 —

2 Phase 2 — Phase 2

3 — Phase 3 —

4———

5———

6 Phase 1 — Phase 3

7 — Phase 2 —

8 Phase 3 — Phase 1

PE PE PE

e

To avoid confusion of compact starter power sockets X2 and X3, the mounting

position of X2 is rotated by 180° relative to the mounting position of X3.

SIMATIC - EM 300 Motor Starters

GWA-4NEB 640070302-05

2-5

Wiring

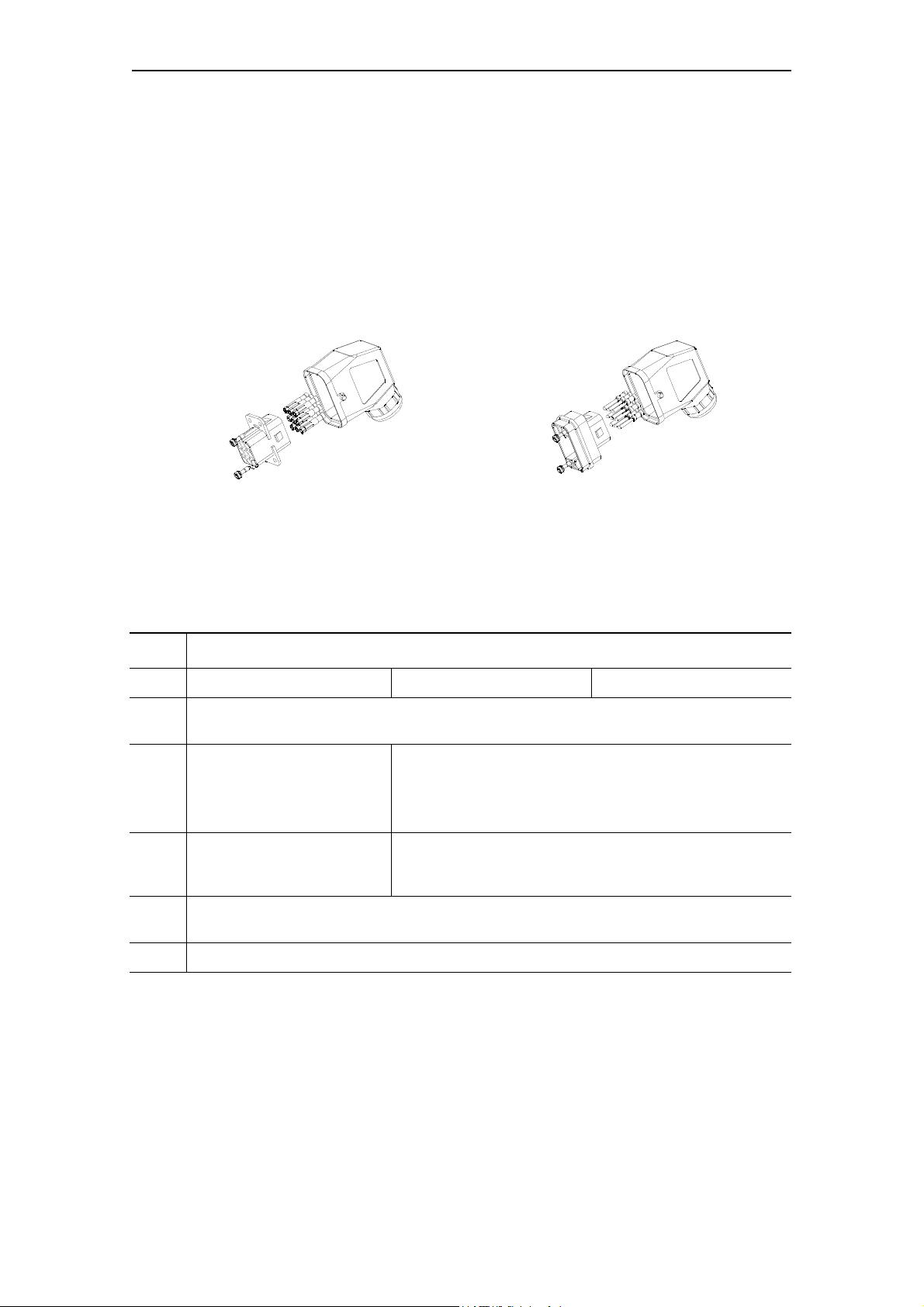

connector shell connector shell

socket insert

jacks contact pins

pin insert

Power socket

• for connecting load supply voltage

Power connector

• for connecting the load

• for looping through the load supply

voltage

Power connectors

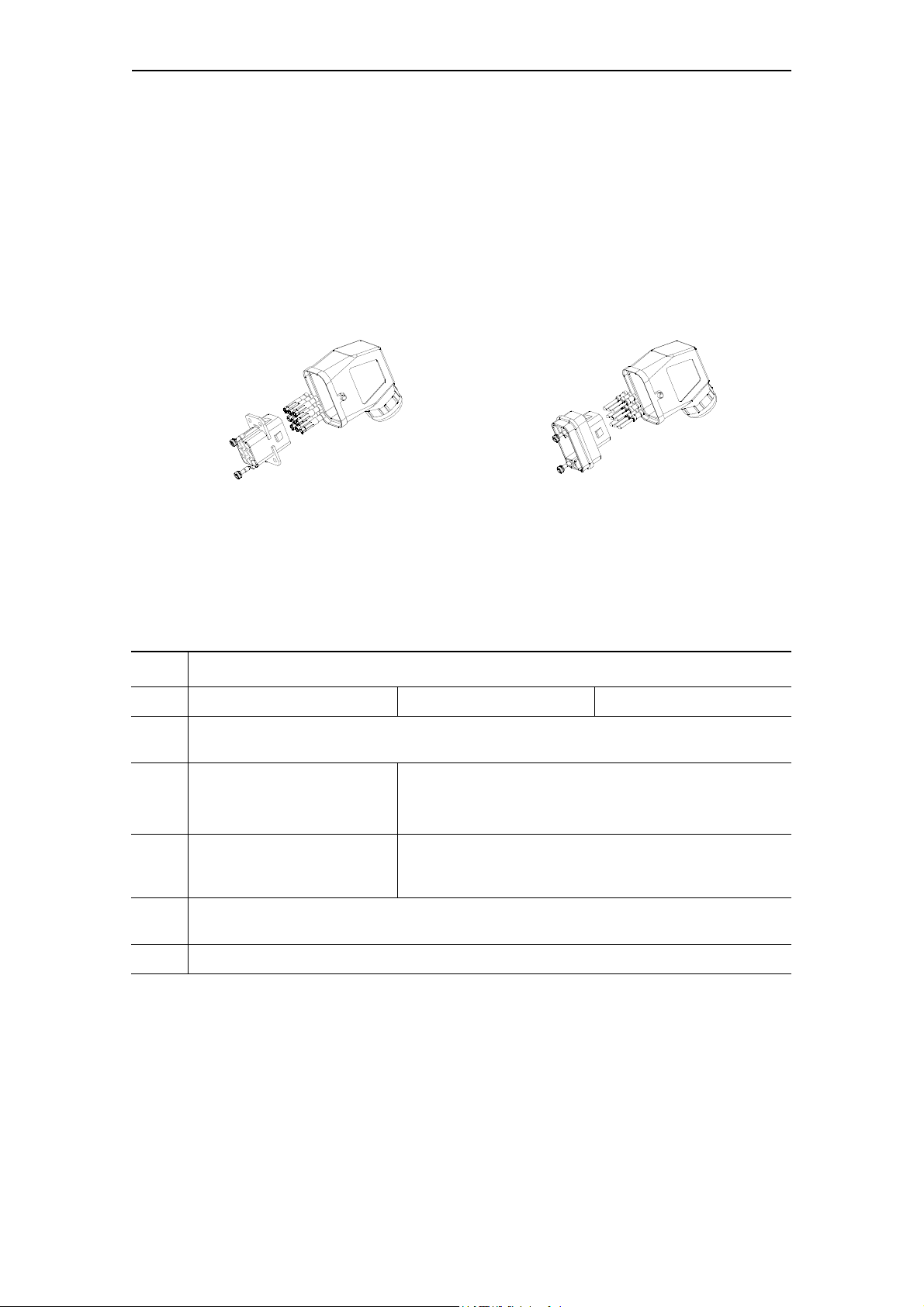

The power connectors of a motor starter without a braking contact consist of

the following components:

Installing and wiring power connectors

Install the power connectors of a motor starter without a braking contact as follows. Please note the wiring rules described in Chapter 2.1.

Step Procedure

Socket for X1 Connector for X2 Connector for X3

1 Feed the cable through the gland, the appropriately-sized sealing ring supplied and the

connector shell.

2 Fasten the jacks to the cores

• for phases 1 to 3

•for PE

3 Press the jacks into the

socket insert until they snap

into place.

4 Withdraw the cable sufficiently to be able to screw the socket or pin insert tightly inside

the connector shell with the enclosed screws.

5 Screw the gland tight.

Fasten the contact pins to the cores

• for phases 1 to 3

•for PE

Press the contact pins into the pin insert until they snap

into place.

SIMATIC - EM 300 Motor Starters

2-6 GWA-4NEB 640070302-05

2.2.3 Electrical Design

AC

DC

AC

DC

M

3~

L1

L2

L3

N

PE

1L+

X2 X3X1

1M

2L+

2M

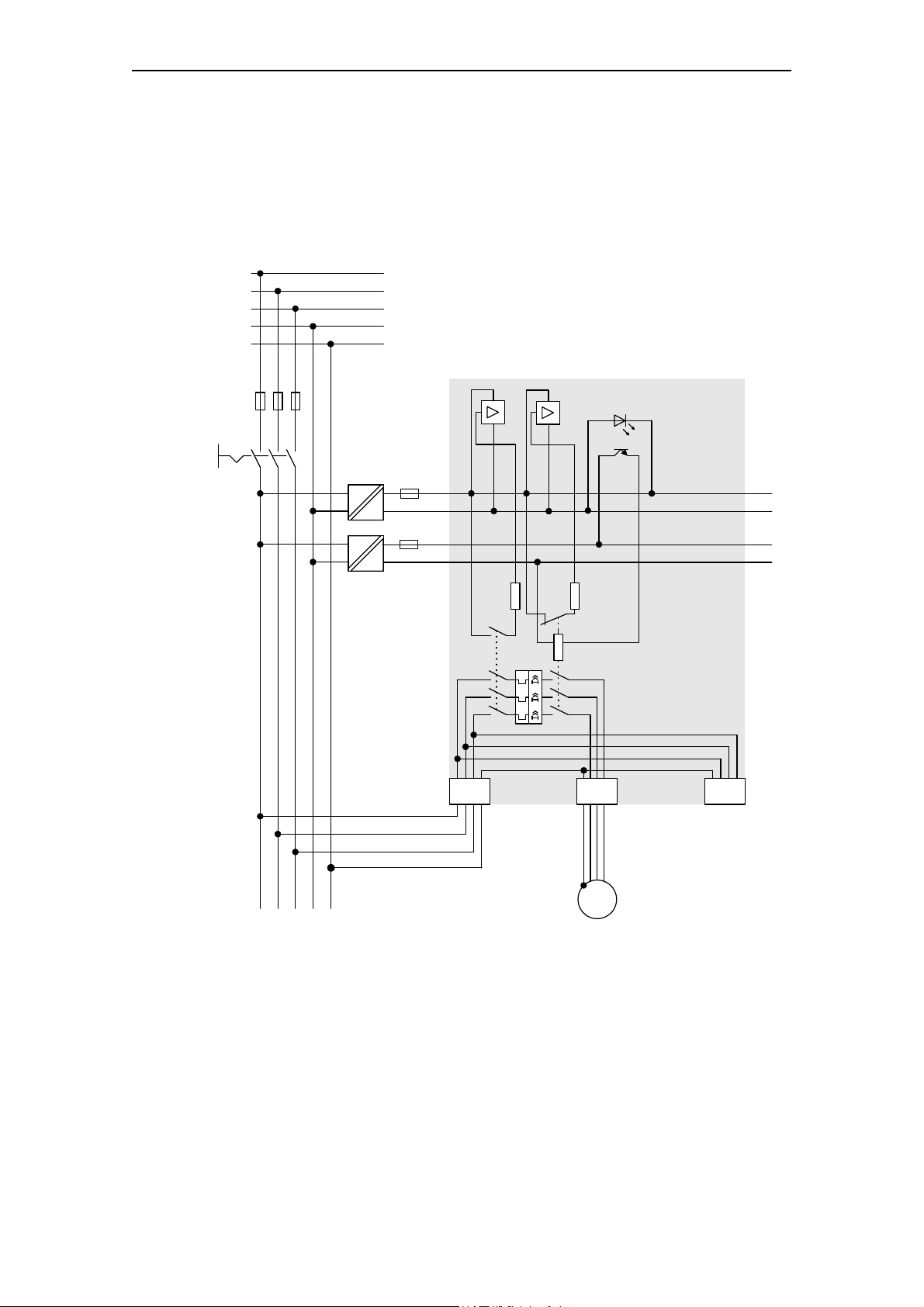

Configuration

The following diagram shows the electrical design of a motor starter EM 300

DS/RS without a braking contact.

Wiring

SIMATIC - EM 300 Motor Starters

GWA-4NEB 640070302-05

2-7

Wiring

X2

X1

X3

2.3 Motor Starters EM 300 with a 24 V DC Braking Contact

2.3.1 Making up Connecting Cables

Accessories

If you want to make up your own connecting cable for motor starters EM 300

with a 24 V DC braking contact, you will need one crimping tool for contact

pins/jacks (alternatively, they can be soldered) and the following components.

Yo u n e ed . . .

For connecting load

supply voltage

One flexible 6-core copper

cable 2.5 mm

2

/ (4.0 mm2)

(3 conductors + PE + 24 V + M)

One set of connectors

• 2.5 mm

• 4.0 mm

2

:3RK1902-0CA00

2

:3RK1902-0CB00

For connecting load

with a brake 24 V DC

One flexible 6-core copper

cable 1.5 mm2 / 2.5 mm

(3 conductors + PE + 24 V + M)

One set of connectors

• 1.5 mm

• 2.5 mm

— resp.

one motor connecting cable

with plug, 6 x 1.5 mm

• 3 m:3 RK1 902-0CN00

• 5 m:3 RK1 902-0CR00

• 10 m:3 RK1 902-0CS00

2

2

: 3RK1902-0CE00

2

: 3RK1902-0CC00

2

For looping through

load supply voltage

and brake voltage

One flexible 6-core copper

cable 2.5 mm2 / (4.0 mm2)

(3 conductors + PE + 24 V + M)

One set of connectors

• 2.5 mm

• 4.0 mm

2

: 3RK1902-0CC00

2

: 3RK1902-0CD00

resp.

one power connecting cable

with plug and socket,

6 x 2.5 mm

2

• 0.12 m: 3 RK1 902-0CH00

SIMATIC - EM 300 Motor Starters

2-8 GWA-4NEB 640070302-05

2.3.2 Wiring the Power Connectors

1

2

3

4

5

6

7

8

12

3

45

6

7

8

1

23

4

5

6

7

8

Pinout

The diagram and the table below indicate the pinout of the power connector and

the two power sockets on a motor starter with a 24 V DC braking contact.

Wiring

Pin-

Plug X1 Socket X2 Socket X3

out

Connecting load

supply voltage

Connecting load

with brake

Looping through load

supply voltage and

brake voltage

1 — Phase 1 —

2 Phase 2 — Phase 2

3 — Phase 3 —

4 GND GND + 24 V DC

5 + 24 V DC + GND

6 Phase 1 — Phase 3

7 — Phase 2 —

8 Phase 3 — Phase 1

PE PE PE

e

SIMATIC - EM 300 Motor Starters

GWA-4NEB 640070302-05

2-9

Wiring

connector shell connector shell

socket insert

jacks contact pins

pin insert

Power socket

• for connecting load supply voltage

Power connector

• for connecting the load with a brake

• for looping through the load supply

voltage and the braking voltage

Power connectors

The power connectors of a motor starter EM 300 with a 24 V DC braking contact consist of the following components:

Installing and wiring power connectors

Install the power connectors of a motor starter with a 24 V DC braking contact

as follows. Please note the wiring rules described in Chapter 2.1

Step Procedure

Socket for X2 Connector for X2 Connector for X3

1 Feed the cable through the gland, the appropriately-sized sealing ring supplied and the

connector shell.

2 Fasten the jacks to the cores

• for phases 1 to 3

• for the brake

•for PE

3 Press the jacks into the

socket insert until they snap

into place.

4 Withdraw the cable sufficiently to be able to screw the socket or pin insert tightly inside the

connector shell with the enclosed screws.

5 Screw the gland tight.

Fasten the contact pins to the cores

• for phases 1 to 3

• for the brake

•for PE

Press the contact pins into the pin insert until they snap

into place.

SIMATIC - EM 300 Motor Starters

2-10 GWA-4NEB 640070302-05

2.3.3 Electrical Design

Motor with 24 V DC brake

6

2

8

X1

X3

8

2

6

1

7

3

X2

4

5

1 W

1 V

1 U

P E

5

4

54

M

3

+24 V DC

M

L1

L2

L3

K1

A1 A2

Galvanic

isolation

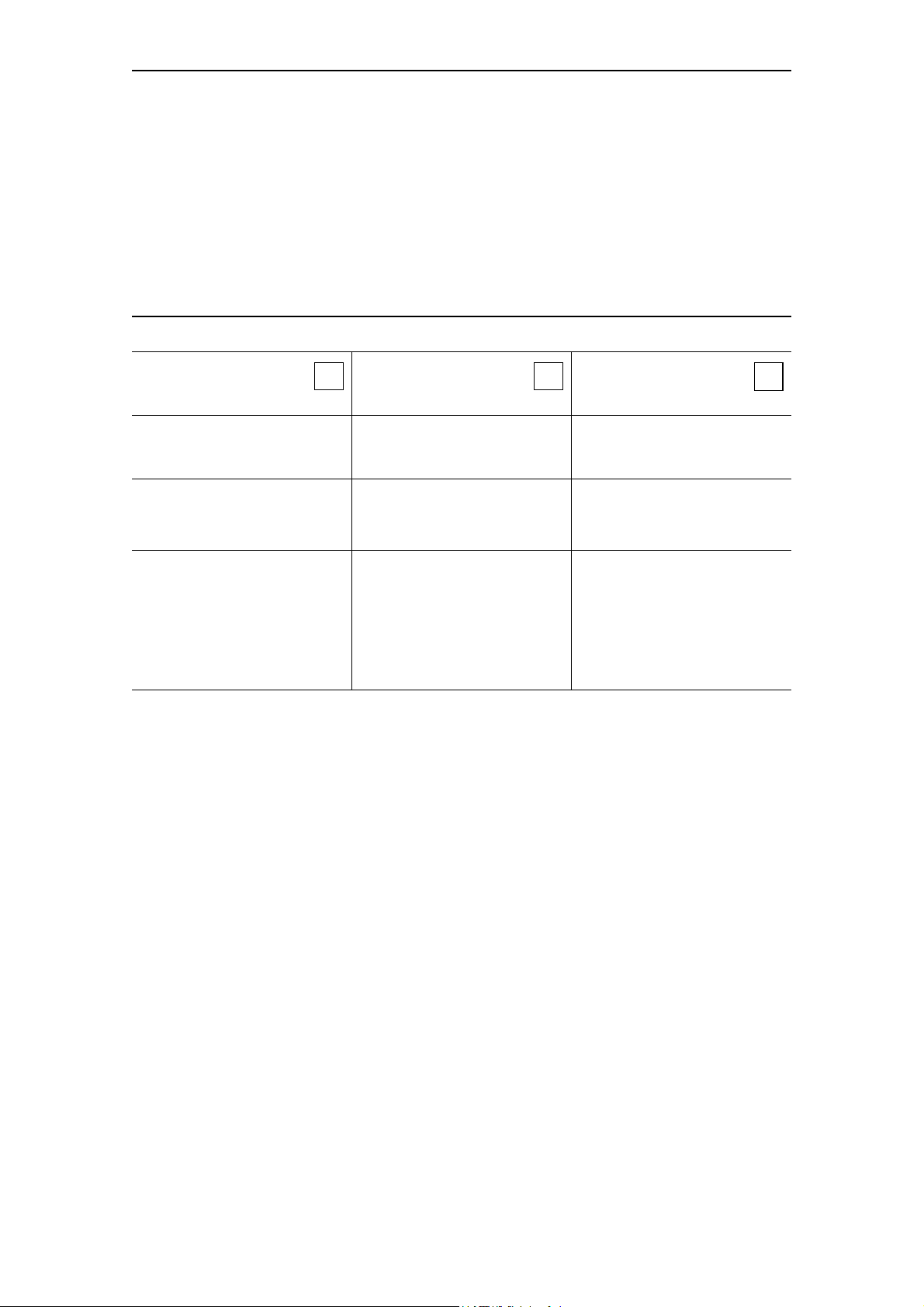

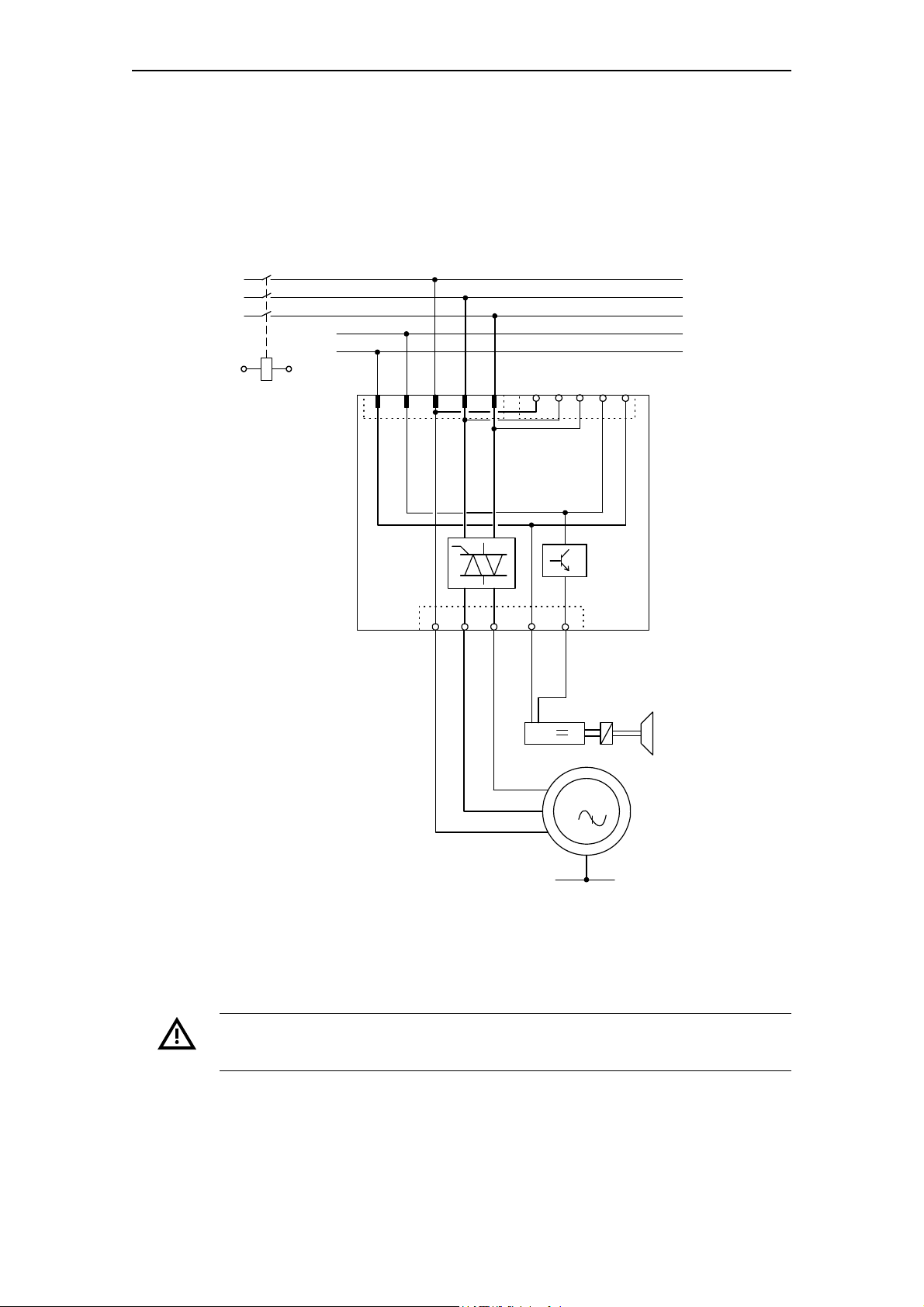

Suggested circuit

The following diagram suggests one way of controlling the motor with a

24 V DC brake via an electronic compact starter EM 300 EDS/ERS.

Wiring

Galvanic isolation

An external isolating contactor must be fitted to ensure galvanic isolation from

the power supply system!

SIMATIC - EM 300 Motor Starters

GWA-4NEB 640070302-05

2-11

Loading...

Loading...