Siemens SIMATIC CP 541 User Manual

Preface, Contents

User Information

SIMATIC

CP 541

Communications Processor

Manual

Overview

Communication Modes

Installing and Connecting the

CP 541

Assigning Parameters to the

CP 541

CP 541 with S5-95F/S5-115F

Diagnostics and Error Handling

Appendices

Technical Data

Optimizing SINEC L2

1

2

3

4

5

6

A

B

EWA 4NEB 812 6188-02

Edition 1

Parameters of DB1

DP Parameter Assignment

Message

DP Configuring Message

Definitions for the DP Master

Service Access Point (SAP) and

PROFIBUS Services

Program Examples

Glossary, Index

C

D

E

F

G

H

Safety

Guidelines

!

!

!

This manual contains notices which you should observe to ensure your own personal safety, as

well as to protect the product and connected equipment. These notices are highlighted in the

manual by a warning triangle and are marked as follows according to the level of danger:

Danger

indicates that death, severe personal injury or substantial property damage will result if proper

precautions are not taken.

Warning

indicates that death, severe personal injury or substantial property damage can result if proper

precautions are not taken.

Caution

indicates

Note

draws

to a particular part of the documentation.

that minor personal injury or property damage can result if proper precautions are not

your attention to particularly important information on the product, handling the product, or

taken.

Qualified Personnel

Correct Usage

!

Trademarks

Copyright

The

reproduction, transmission or use of this document or

not

permitted without

for damages. All rights, including rights created by patent grant or

registration of a utility model or design, are reserved.

Siemens AG

Automation Group

Industrial Automation Systems

P.O. Box 4848, D-90327 Nuremberg

Siemens

AG 1996 All rights reserved

express written authority

The device/system may only be set up and operated in conjunction with this manual.

Only qualified personnel should be allowed to install and work on this equipment. Qualified

persons are defined as persons who are authorized to commission, to ground, and to tag circuits,

equipment, and systems in accordance with established safety practices and standards.

Note the following:

Warning

This

device and its components may only be used for the applications described in the

technical

which have been approved or recommended by Siemens.

This

correctly, and operated and maintained as recommended.

SIMATIC and SINEC are registered trademarks of SIEMENS AG.

Third

marks might infringe upon the rights of the trademark owners.

description, and only in connection with devices or components from other manufacturers

product can only function correctly and safely if it is transported, stored, set up, and installed

parties using for their own purposes any other names in this document which refer to trade

. Of

its contents is

fenders will be liable

catalog or the

-

We have checked the contents of this manual for agreement with the

hardware and software described. Since deviations cannot be precluded

entirely, we cannot guarantee full agreement. However, the data in this

are reviewed regularly and any necessary

manual

subsequent editions. Suggestions for improvement are welcomed.

Siemens

Technical

AG 1996

data subject to change.

corrections included in

Siemens Aktiengesellschaft

Order No. 6ES5 998-1DL21

Preface

Purpose

The

information in this Manual allows you

to connect a programmable controller of the SIMA

CP 541;

to connect a programmable controller of the SIMA

CP 541 to SINEC L2;

to integrate a programmable controller of the SIMA

CP 541 as a DP slave in SINEC L2-DP;

to connect the CP 541 and start it.

TIC S5 family to the

TIC S5 family via the

TIC S5 family via the

Audience

Scope of this

Manual

This Manual is intended for readers wishing to integrate a programmable

controller of the SIMA

sumed that you already have experience in or knowledge of working with

programmable controllers of the SIMA

This Manual applies to:

Device

CP

541

Connecting cable 1 m

Connecting cable

2.5 m

This Manual contains a description of all functions of the CP 541 at the time

of publication of the Manual. We reserve the right to describe modifications

to the functions in a product information.

TIC S5 family via the CP 541 in SINEC L2. It is as

TIC S5 family and SINEC L2.

Order No.

6ES5 541-8AA1

6ES5 735-8BB00

6ES5 735-8BC50

1 01

Fr

om Revision Level

–

–

-

Communications

EW

A 4NEB 812 6188-02

Processor CP

541

iii

Preface

Other

Pertinent

Manuals

Structure of this

Manual

This CP 541

Manual describes the SINEC L2 interfacing of the CP 541.

The assigning of parameters to the programmable controller connected to the

CP 541 as a SINEC L1 slave can be found in the relevant manual.

The description of SINEC L2-DP and a DP master

, such as the IM 308-C

master interface module, are not part of this Manual. Further information on

this topic can be found in the manual:

ET 200 Distributed I/O System

.

Detailed information on SINEC L1 can be found in the manual: SINEC L1

Local Ar

T

ea Network

.

o facilitate rapid access to special information, the Manual contains the fol

lowing aids:

Given at the beginning of the Manual is a full, general table of contents, a

list of figures and a list of tables contained in the entire Manual.

In the chapters, the left column of each page provides a summary of the

contents of the section.

The appendices are followed by a glossary in which the important techni

cal terms used in the Manual are defined.

Given at the end of the Manual is a detailed index which allows rapid

access to the desired information.

-

-

Standards

Queries

The CP 541 is based on PROFIBUS Standard DIN 19245 and PROFIBUS DP

Standard DIN E 19245, Part 3.

In the event of queries on the CP 541, please consult:

Hotline SIMA

TIC

Nuremberg

T

el:

0911/895-7000

Fax: 0911/895-7001

In the event of queries or remarks relating to the Manual, please fill out the

correction sheet and return it to us. Y

ou will find it at the end of the Manual.

iv

Communications

Processor CP

EW

A 4NEB 812 6188-02

541

Contents

1 Overview 1-1

1.1 Performance

1.2 The

1.3 View

1.4 Suitable

2 Communication Modes 2-1.

2.1 PLC-PLC

2.2 DP

2.3 Broadcast

3 Installing and Connecting the CP 541 3-1.

3.1 Installing

3.2 Connecting

3.3 Starting

3.4 Operating

3.4.1 POWER

3.4.2 STOP

3.4.3 START 3-9

3.4.4 RUN

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Features of the CP 541

CP 541 in the SIMA

of the CP 541

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TIC Environment

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programmable Controllers for the CP 541

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

1-2.

1-4.

1-5.

1-7.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connection

Connection

via FDL Connection

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2.

2-3.

2-4.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

the CP

up the CP 541

ON

State

541

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

the CP

541

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

States of the CP 541

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2.

3-3.

3-5.

3-6.

3-7.

3-8.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

State

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-10.

4 Assigning

4.1 Configuring

4.2 Configuring

4.3 Configuring

5CP

541

with S5-95F/S5-1

5.1 Communication

5.1.1 Safety-Related

5.1.2 Safety-Related

5.2 Configuring

5.2.1 Configuring

5.2.2 Configuring

5.2.3 Configuring

5.3 Safety Times 5-9.

5.3.1 Local

5.3.2 Calculating

5.3.3 Condition

Communications

EW

A 4NEB 812 6188-02

Processor CP

Parameters to the CP

a PLC-PLC Connection

the Broadcast Mode

a DP Connection

15F 5-1.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Modes

PLC-PLC Connection

Broadcast via FDL

Connections

a Safety-Related PLC-PLC Connection

a Non-Safety-Related PLC-PLC Connection

the Safety-Related Broadcast Mode

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cycle T

ime for CP 541

the Local Cycle T

for the SINEC L1 Safety T

541

541 for the Connections 4-1.

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ime 5-11.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ime for Receiving

. . . . . . . . . . . . . . .

5-10.

5-14.

4-2.

4-3.

4-4.

5-2.

5-3.

5-4.

5-5.

5-6.

5-7.

5-8.

v

Contents

5.3.4 Setting

5.3.5 Example

5.3.6 Example

5.4 Redundant

6 Diagnostics

6.1 Local

6.2 Diagnostics

6.2.1 Structure

6.2.2 DB1

6.2.3 SINEC

6.2.4 SINEC

6.2.5 Internal

6.3 DP

IM 308-C with FB IM308C

6.3.1 Structure

6.3.2 Contents

6.3.3 Device-Related

6.3.4 Example

6.4 DP

A Technical

Data

B Optimizing

the Safety T

for Calculating the Local Cycle T

of V

SINEC L2 Configuration

and Error Handling

Diagnostics with LEDs

Block

of the Diagnostics Block

Errors

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

L2 Bus Errors

L1 Message Errors

Errors

imes 5-16.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

erification of Safety T

imes 5-18.

imes 5-22.

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Message Using the Example of an

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

of the Diagnosis

of the DP Standard Section

Diagnosis

of a Diagnostic Call with IM308-C and FB IM308C

Diagnosis in the Programmable Controller

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SINEC L2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-24.

6-1.

6-2.

6-4.

6-5.

6-6.

6-9.

6-10.

6-12.

6-13.

6-15.

6-16.

6-18.

6-19.

6-20.

A-1.

B-1.

C Parameters

C.1 Structure

C.2 Syntax

C.3 General

C.4 CP

C.5 DP

C.6 Default

C.7 Calculating

C.8 Example

DDP

Parameter Assignment Message

of DB1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

of DB1

of DB1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SINEC L2 Parameters - block Identifier SL2

541-Specific Parameters - Block ID COM

Parameters – Block ID ”DPS”

DB1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

the T

of Calculation of the T

E DP Configuring Message E-1.

F Definitions

G Service

H Program

H.1 PLC-PLC

H.2 DP

H.3 Safety-Related

for the DP Master

Access Point (SAP) and PROFIBUS Services

Examples

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connection

Connection

PLC-PLC Connection: S5-95F - S5-1

C-1.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C-2.

C-3.

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C-4.

C-8.

C-10.

C-12.

oken Rotation T

ime C-14.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

oken Rotation T

ime C-16.

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D-1.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

G-1.

H-1.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15F H-12.

. . . . . . . . . . . . .

H-2.

H-8.

F-1.

vi

Communications Processor CP

EW

A 4NEB 812 6188-02

541

Figures

Contents

Glossary

Index

1-1 CP

1-2 View

2-1 Address

2-2 Address

2-3 Address

541 in the SIMA

of the CP 541

TIC Environment

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Conversion for PLC-PLC Connection

Conversion for DP Connection

Conversion for Broadcast

3-1 Isolation of Terminals 3-4.

5-1 Address

5-2 Address

5-3 Graphic

5-4 Configuration

5-5 Schematic

6-1 Example

A-1 CP

C-1 Structure

C-2 Syntax

H-1 Configuration

H-2 Configuration

H-3 Configuration

Conversion for the Safety-Related PLC-PLC Connection

Conversion for Broadcast

Representation of Cycle T

Example for Calculating the Local Cycle T

Configuration of SINEC L2 in Redundant Configuration

of Configuration

541

Dimension Drawing

of DB1

of DB1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

for a PLC-PLC Connection

of a DP Connection

for a Safety-Related PLC-PLC Connection

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4.

1-5.

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2.

2-3.

2-4.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

imes 5-14.

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

imes 5-18.

. . . . . . . . .

. . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3.

5-4.

5-24.

6-19.

A-4.

C-2.

C-3.

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . .

H-2.

H-8.

H-12.

Communications Processor CP

EW

A 4NEB 812 6188-02

541

vii

Contents

Tables

1-1 LED

1-2 Mode

1-3 Connectors

1-4 Connectable

Indicators of the CP 541

Switch of the CP 541

and T

erminals of the CP 541

Programmable Controllers and Communication Modes;

both Stations Connected to SINEC L2 via CP 541

1-5 Connectable

Programmable Controllers and Communication Modes;

one Station Connected to SINEC L2 via CP 541

3-1 Cable

3-2 Components

5-1 Supported

6-1 Indications

6-2 Assignments

6-3 Significance

6-4 DB1

6-5 SINEC

6-6 SINEC

6-7 Structure

6-8 Structure

6-9 Structure

6-10 Structure

6-11 Structure

for Connecting the PLC and the CP 541

for SINEC L2

Failsafe Programmable Controllers

of the RUN LED

of the Data W

of DW0 in DB2

Error Codes

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

L2 Bus Errors

L1 Message Errors

of the Diagnostic Message

of Station Status 1 (Byte 0)

of Station Status 2 (Byte 1)

of Bytes 6 and 7 of the Diagnostic Message

of the Device-Related Diagnosis,

Byte 7 of the Diagnostic Message

C-1 SL2

C-2 Necessary

C-3 DP/FMS

C-4 PROFIBUS-DP

C-5 DP

C-6 User-Defined

C-7 COM

C-8 DPS

Parameters

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Basic Parameters According to Station Status (ST

Bus Profile (in Bit T

Bus Profile (in Bit T

Bus Profile for IM 308-B (in Bit T

Bus Profile (in Bit T

Parameters

Parameters

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C-9 Default Values in DB1

C-10 Basic

D-1 Structure

Load on SINEC L2 (in Bit T

of the DP Standard Section of the

Parameter Assignment Message

D-2 Structure

E-1 Structure

G-1 Meanings

G-2 PROFIBUS

of the Station Status in the Parameter Assignment Message

of Identifier Byte in Configuring Message

of Service Access Points (SAPs)

Services

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ords in DB2

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-6.

1-6.

1-6.

1-7.

1-8.

3-3.

3-3.

5-1.

6-2.

6-5.

6-5.

6-6.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-9.

6-10.

6-15.

6-16.

6-16.

6-18.

6-18.

C-4.

imes) C-6.

imes)

A)

. . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

imes)

imes)

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

C-5.

C-6.

C-6.

C-7.

C-8.

C-10.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

imes) C-15.

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C-13.

D-1.

D-2.

E-1.

G-1.

G-2.

viii

Communications Processor CP

EW

A 4NEB 812 6188-02

541

Overview

Introduction

1

The

CP 541 provides a link between programmable controllers of the

SIMA

TIC S5 family via SINEC L2 and other programmable controllers.

Given in this chapter is a summary covering the application of the CP 541

and its characteristics.

Definitions

Summary of this

Chapter

The following situation is covered by this Manual:

The programmable controller connected to the PG/PLC port is referred to

as a connected programmable controller

For working with the CP 541, it is not important to know which stations

are connected to SINEC L2. W

controllers on SINEC L2, but generally to SINEC L2.

Section Contents Page

1.1 Performance Features of the CP 541 1-2

1.2 The CP 541 in the SIMATIC Environment 1-4

1.3 View of the CP 541 1-5

1.4 Suitable Programmable Controllers for the CP 541 1-7

e therefore do not refer to programmable

.

Communications Processor CP

EW

A 4NEB 812 6188-02

541

1-1

Overview

1.1 Performance Features of the CP 541

The

Introduction

Fields of

Application

significant performance features of the CP 541 are described in the fol

lowing.

ou can use the CP 541 for the following fields of application:

Y

Subsequent networking of installed programmable controllers of the SI

MA

TIC S5 family

Substitute for SINEC L1

For connecting failsafe programmable controllers of the SIMA

family via SINEC L2

-

-

TIC S5

Communication

Modes

Y

ou can establish the following communication links via the CP 541:

PLC-PLC link

Broadcast

DP link for operating programmable controllers of the SIMA

ily as a DP slave with any DP master in SIMA

any DP master from another manufacturer

TIC S5 and S7/M7 or with

.

In contrast to other DP slaves, the CP 541 exhibits a minimum cycle time

of 10 ms. It supports PROFIBUS profiles DP/FMS and User Defined at

transmission rates of up to 1.5 Mbps and PROFIBUS-DP or DP for

IM 308-B at up to 187.5 Kbps.

Safety-related data traf

the SIMA

TIC S5 family

fic between failsafe programmable controllers of

The communication concept has been tested for freedom from reaction of

the safety-related SINEC L1 communications between failsafe program

mable controllers. The CP 541 is a non-safety-related module and can

therefore be operated without a special test. However

, the general condi

tions for special testing of the programmable controller must be observed.

TIC S5 fam

-

-

-

1-2

Communications

EW

A 4NEB 812 6188-02

Processor CP

541

Advantages for the

User

The

CP 541 of

It allows parallel operation of the various communication modes.

It supports the safety-related connection of failsafe programmable con

trollers of the SIMA

It can be used with most SIMA

It allows simple retrofitting on existing systems.

It is connected to the programmer interface of the programmable control

fers you various advantages.

TIC S5 family via SINEC L2.

TIC S5 systems.

ler with a simple plug-in cable; no bus terminal is needed.

Simple parameter assignment

Freedom from maintenance

It is secured directly on the standard rail; no slot in the connected pro

grammable controller is needed.

Overview

-

-

-

Communications

EW

A 4NEB 812 6188-02

Processor CP

541

1-3

Overview

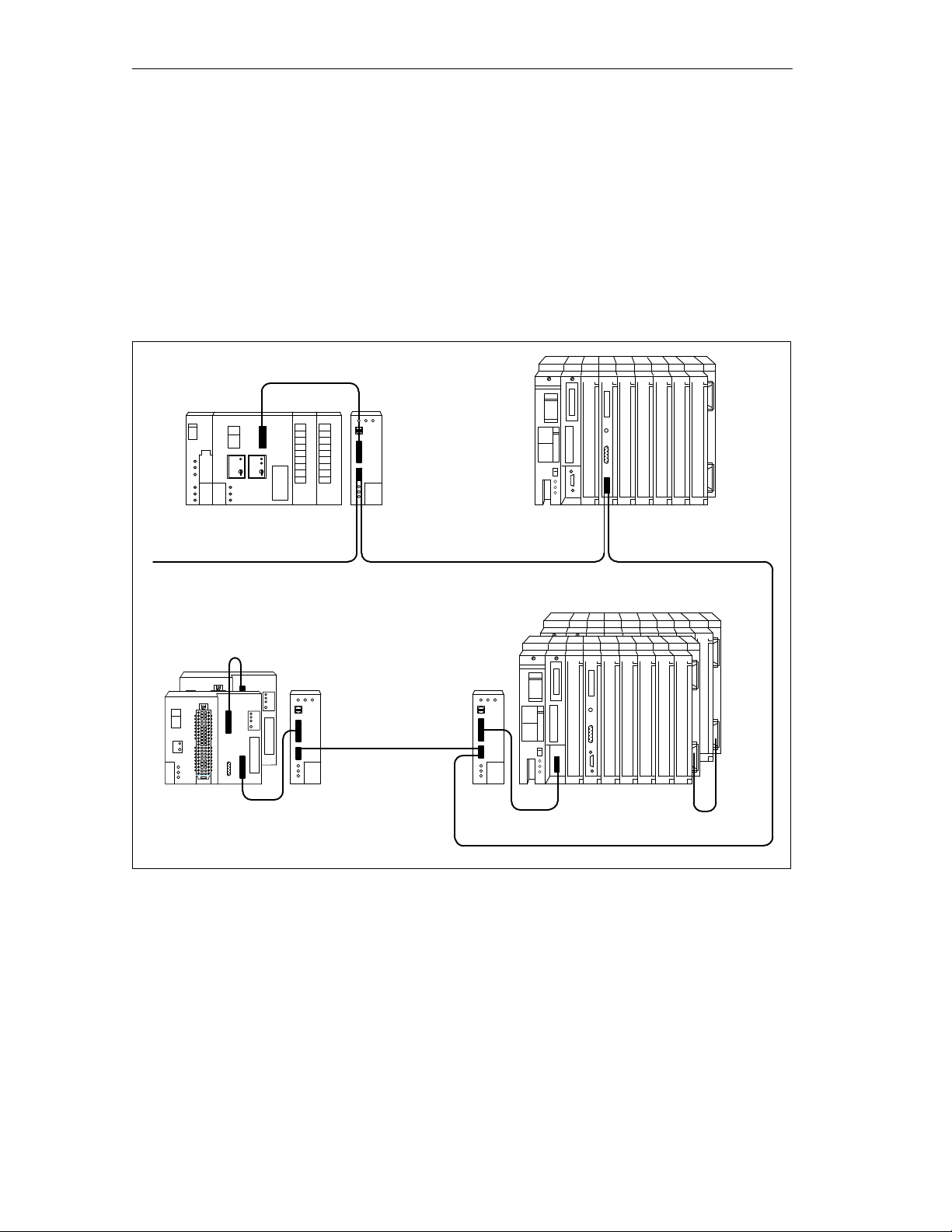

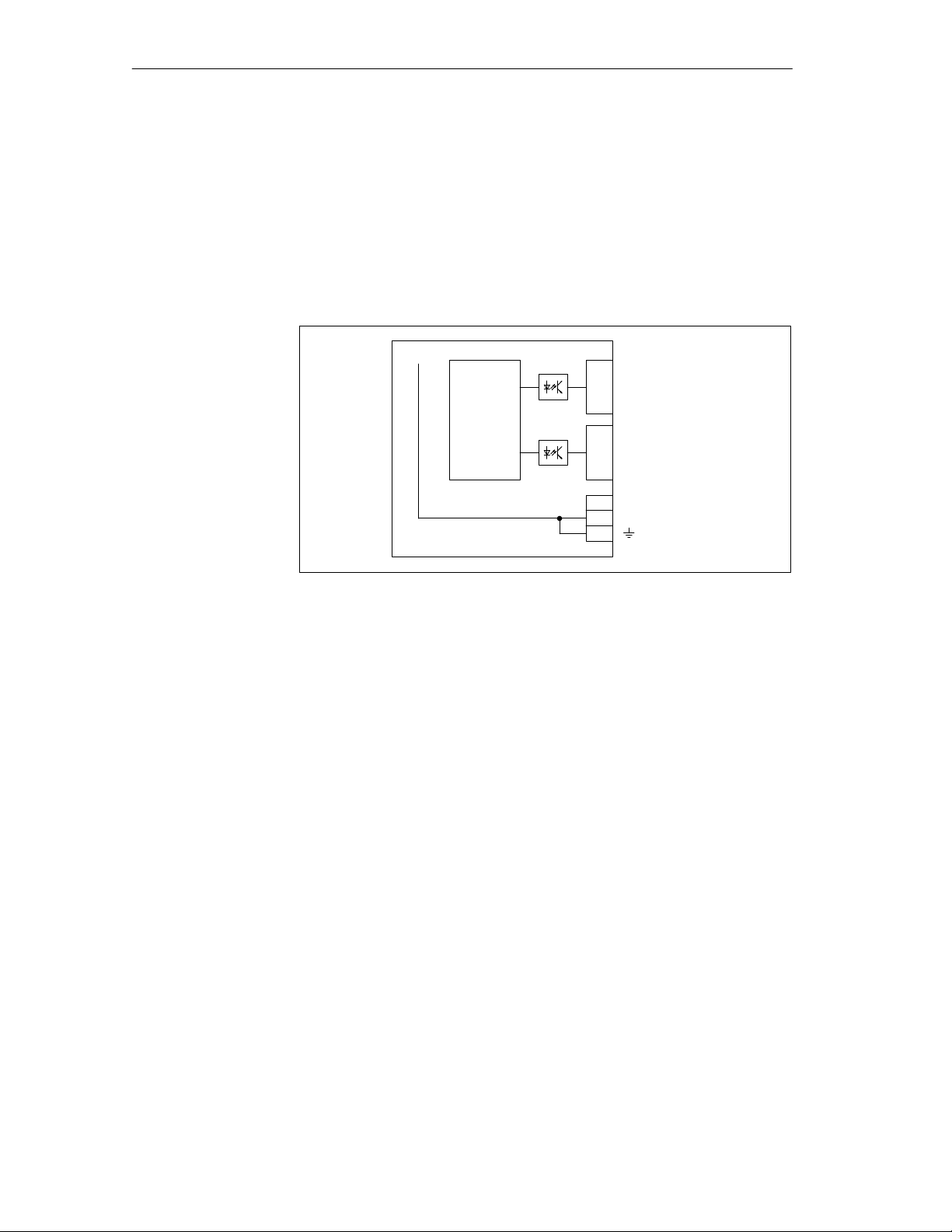

1.2 The CP 541 in the SIMATIC Environment

Incorporation in

SIMATIC

S5-100U

SINEC L2

Figure 1-1

shows the incorporation of the CP 541 in the SIMA

TIC environ

-

ment.

On account of the various communication modes, possible combinations of

communication modes and number of connectable programmable controllers,

Figure 1-1 is merely an example.

CP

541

S5-115U CP

5430

541

Figure 1-1 CP 541 in the SIMATIC Environment

For

CP 541 Emulates

SINEC L1

the connected programmable controller

figured SINEC L1 bus. The connected programmable controller is an

L1 slave.

1-4

CP

541

S5-115FS5-95F CP

, the CP 541 emulates a fully con

Communications

Processor CP

EW

A 4NEB 812 6188-02

-

541

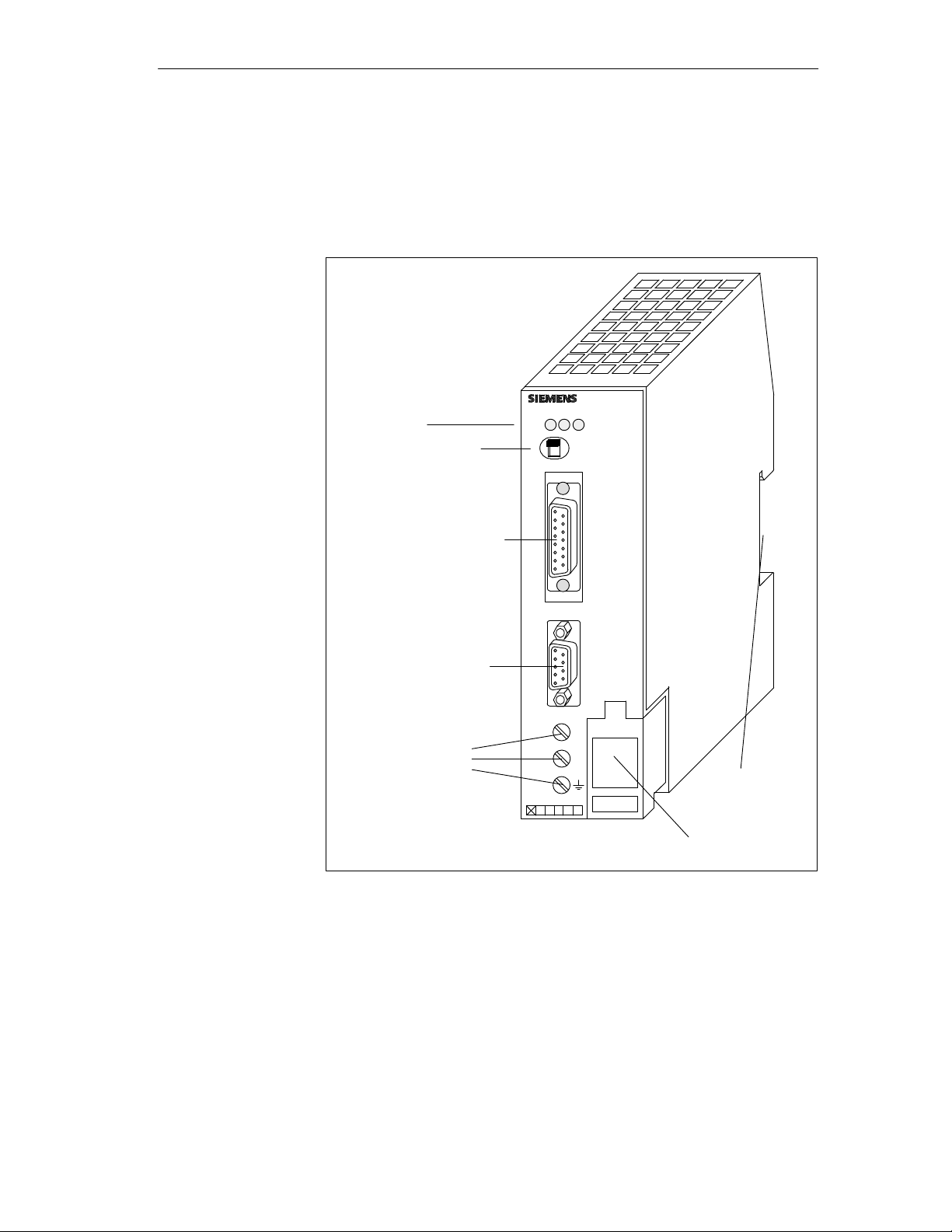

1.3 View of the CP 541

Overview

View

Figure 1-2

is a view of the CP 541

LED indicator

Mode switch

Connector for PG/PLC

Connector for SINEC L2

SIMATIC S5

ERR

RUN BF L2

RUN

STOP

0

PG/AG

SINEC L2

–

AG/AG

– DP

CP 541

Communications

EW

A 4NEB 812 6188-02

Processor CP

T

erminals for

24 V DC

power supply

Figure 1-2 View of the CP 541

541

24 V DC

6ES5 541-8AA1

12345 6

L+

M

Mount for

1

standard rail

Cover for

cable inlet

1-5

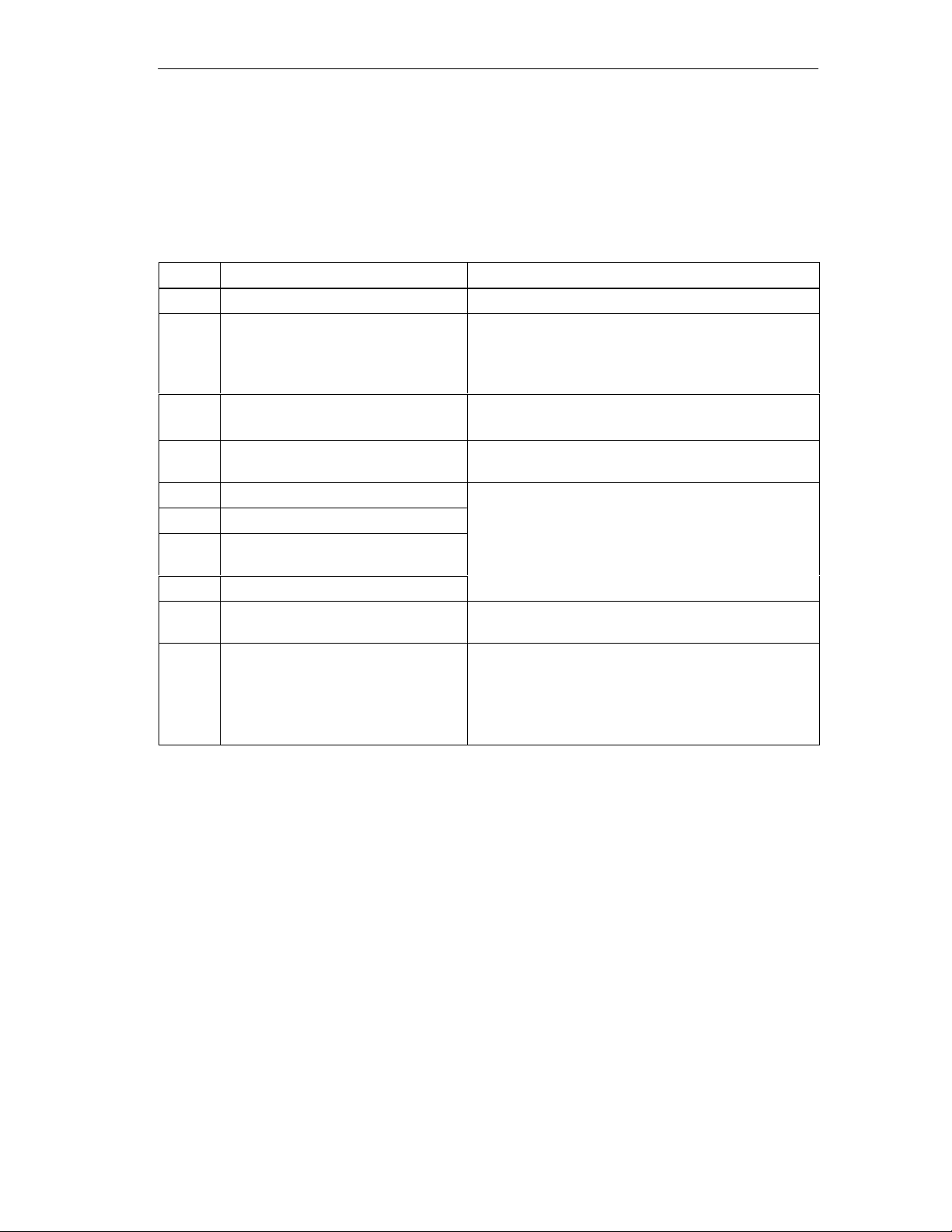

Overview

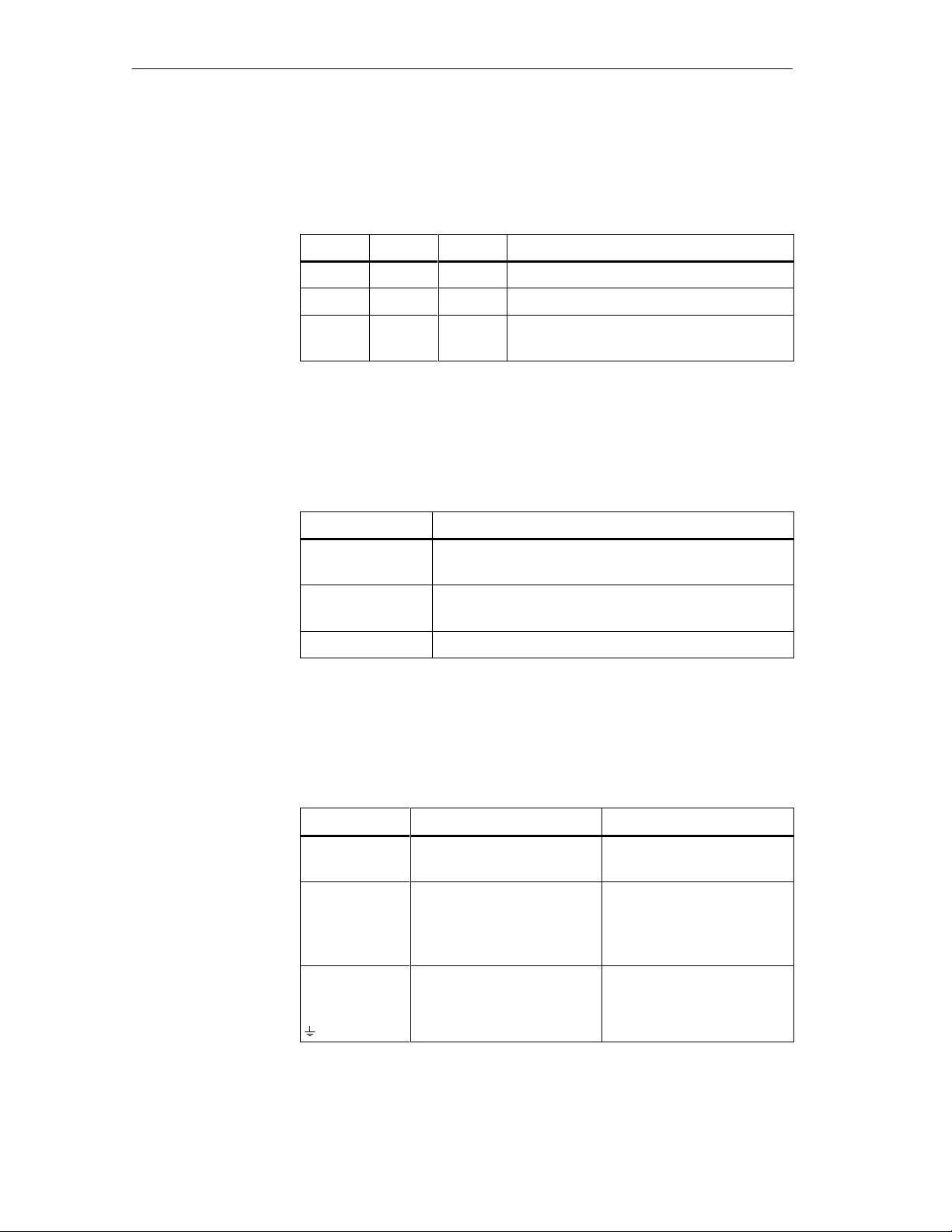

LED Indicators

The

CP 541 has three LEDs to indicate the operational state of the CP 541

and any errors.

Table 1-1 LED Indicators of the CP 541

LED Color Position Meaning

Mode Switch

Connectors and

Terminals

RUN Green Left Operational

ERR Red Middle

BF L2

Red Right

Error in CP 541 or at PG/PLC connection

Error at L2 connection or SINEC L2 not

state

yet activated

The CP 541 has a mode switch with three settings. The meanings of the dif

ferent settings are given in T

Table 1-2 Mode Switch of the CP 541

Switch

Setting

RUN

able 1-2.

Meaning

The CP 541 is in normal operation. Data will be ex

-

changed between the PLC and SINEC L2.

STOP Y

ou can assign parameters to the CP 541 with a PG

and read out the diagnostics block.

0

The CP 541 is switched of

f.

The CP 541 has various connectors and terminals; these are listed in

T

able 1-3.

-

1-6

Table 1-3 Connectors and Terminals of the CP 541

Designation Type Meaning

PG/PLC 15-pin

SINEC L2

- PLC-PLC

sub. D female with

slide latch

9-pin sub. D female with

screw-type connection

For PG cable or connecting

cable to PLC

For L2 bus connector

- DP

L+

Screw terminals

24

V DC power supply

M

Communications

Processor CP

EW

A 4NEB 812 6188-02

541

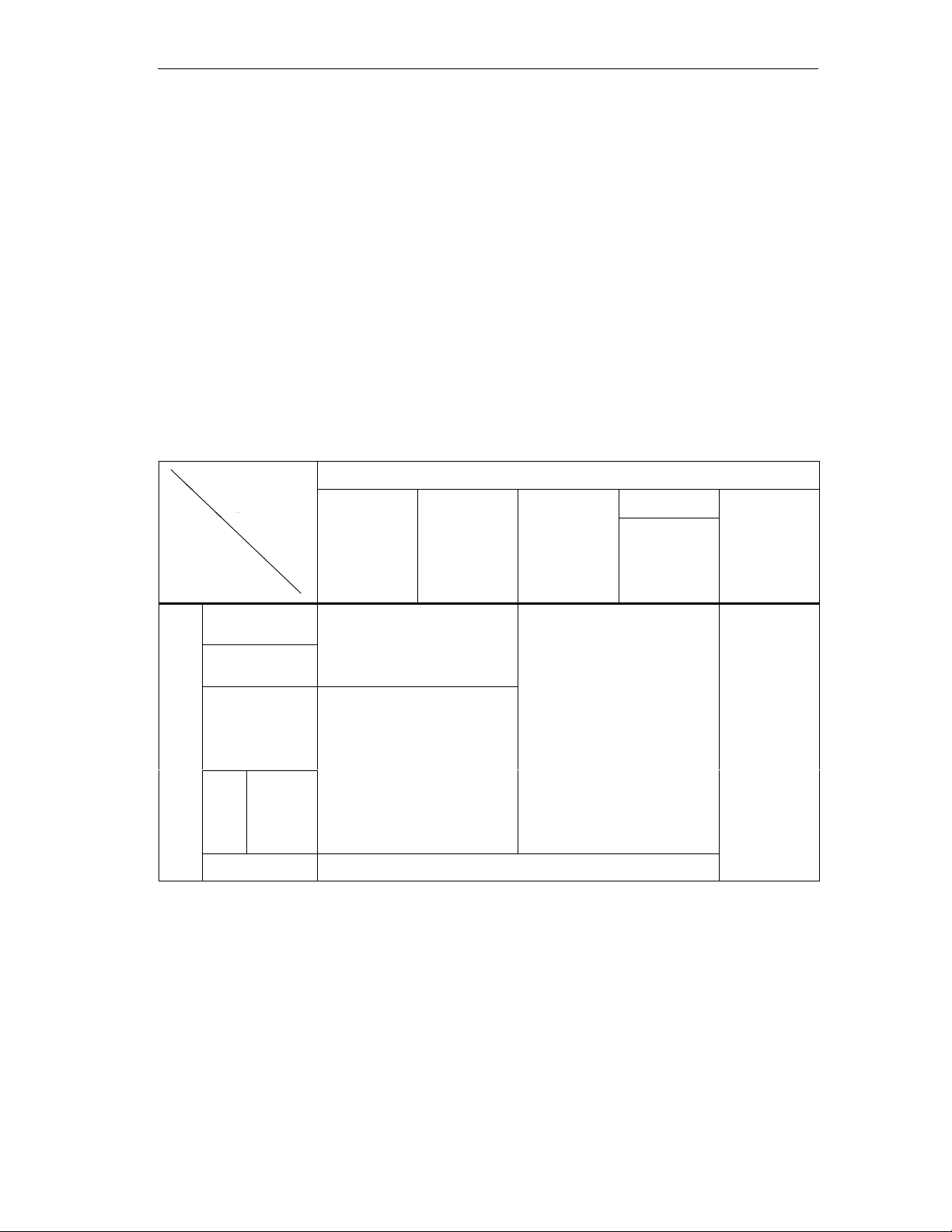

1.4 Suitable Programmable Controllers for the CP 541

SINEC L2

p

PLC-PLC

541

PLC-PLC

The

Introduction

summaries in T

of the SIMA

TIC S5 family which you can connect to the CP 541.

Also given are the communication modes you can install by means of CP 541

via SINEC L2 and the appropriate programmable controllers.

ables 1-4 and 1-5 indicate the programmable controllers

Overview

Stations via

Both

CP 541

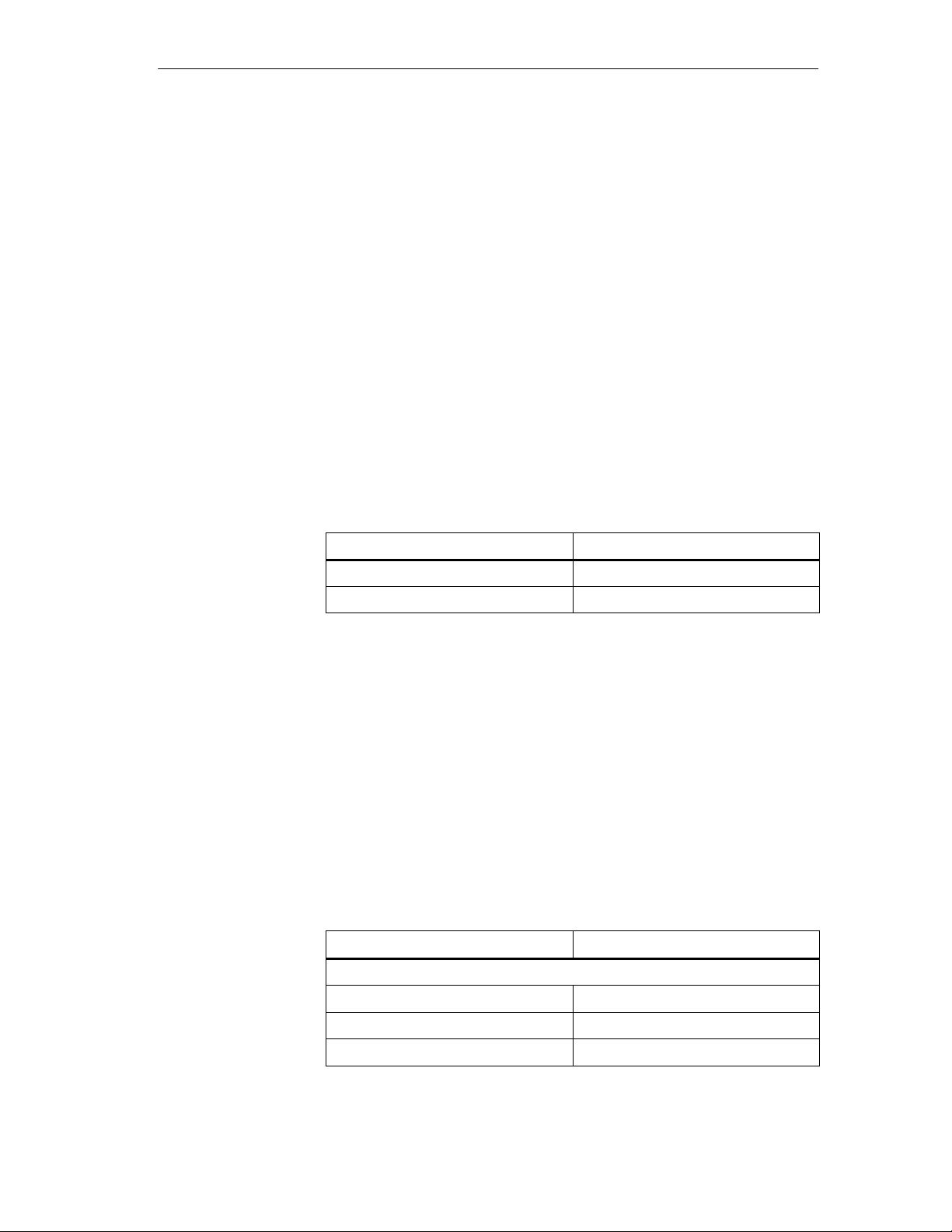

Table 1-4 Connectable Programmable Controllers and Communication Modes; both Stations Connected to SI-

NEC L2 via CP 541

SINEC

L2

partner

When both SINEC L2 stations are connected via CP 541, T

the possible communication modes in relation to the appropriate program

mable controllers of the SIMA

TIC S5 family

CP

541 with

.

CP

able 1-4 shows

-

530 in

S5-90U

S5-115H

S5-135U

S5-155U

S5-155H

S5-115H

Connected

PLC

S5-95F

S5-95F S5-115F

PLC-PLC and safety-related

S5-95U

S5-100U

S5-115U

PLC-PLC

S5-115F

Broadcast and safety-related

broadcast

S5-90U

To

CP

541

S5-95U

S5-100U

S5-115U

CP

530

in

S5-115H

S5-135U

S5-155U

S5-155H

PLC-PLC

Broadcast

PLC-PLC

Broadcast

PLC-PLC

S5-115H PLC-PLC

Communications

EW

A 4NEB 812 6188-02

Processor CP

541

1-7

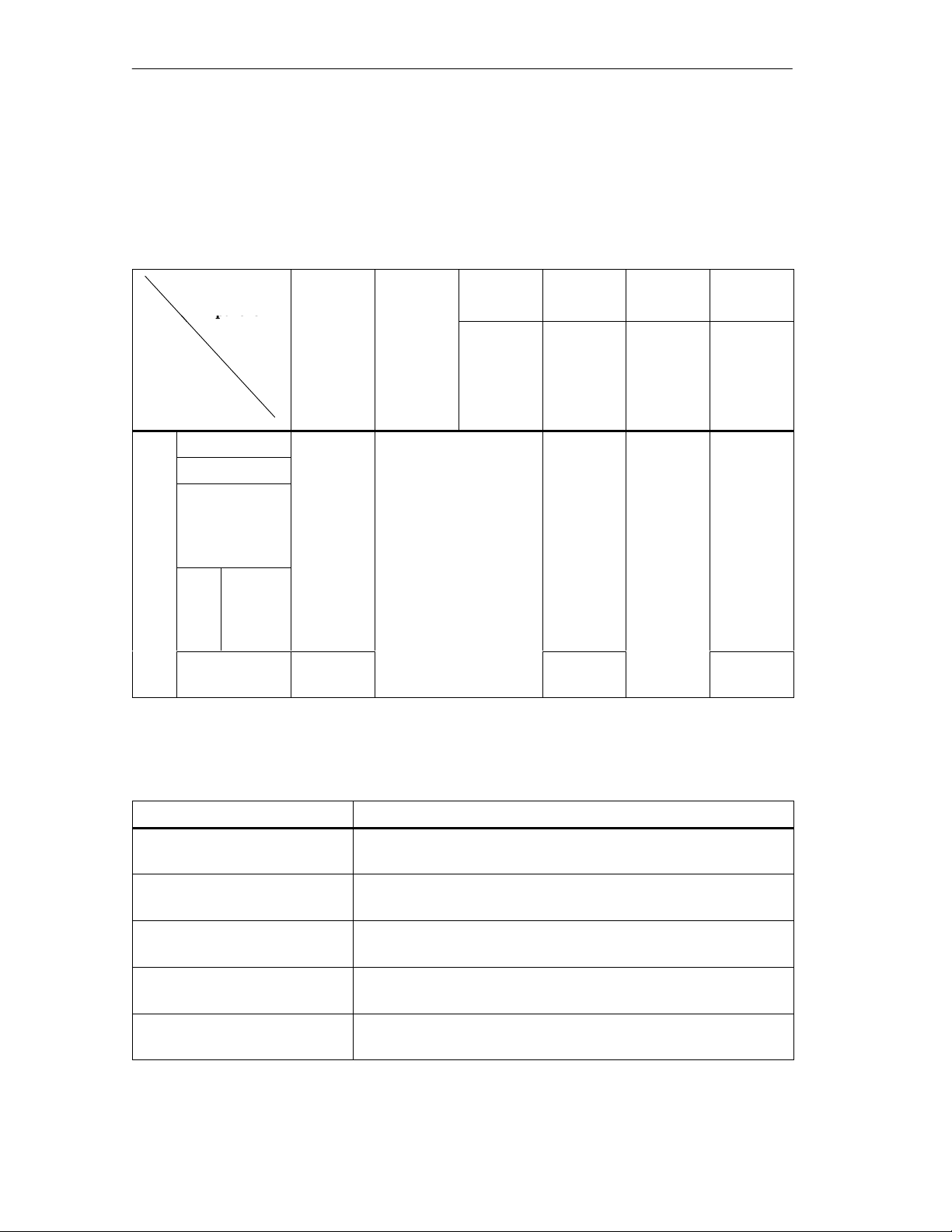

partner

S5-95U

CP

DP

Broadcast

DP

Overview

When

One Station via

CP 541

Table 1-5 Connectable Programmable Controllers and Communication Modes; one Station Connected to

SINEC L2 via CP 541

one SINEC L2 station is connected via CP 541, T

possible communication modes in relation to the appropriate programmable

controllers of the SIMA

TIC S5 family

.

able 1-5 shows the

Connected

PLC

To

541

CP

530

in

SINEC

L2

partner

S5-95U

and

SINEC L2

connec-

tion

S5-95F

S5-115F

S5-90U

S5-95U

S5-100U

S5-115U

PLC-PLC

Broadcast

S5-115H

S5-135U

S5-155U

S5-155H

S5-115H PLC-PLC

S5-95U as

DP master

IM 308B

IM308C

S5-115U

S5-115H

S5-135U

S5-155U

S5-155H

CP

5430

CP

5431

S5-115U

S5-115H

S5-135U

S5-155U

S5-155H

PLC-PLC

DP

Broadcast

PLC-PLC

DP

CP

342-5DPCP

S7-300 PG

Broadcast

5412

A2

DP

DP

Meanings of

Designations

Designation Meaning

PLC-PLC (see Section 2.1)

DP (see Section 2.2)

Broadcast (see Section 2.3)

Safety-related PLC-PLC (see

Section 5.1.1)

Safety-related broadcast (see

Section 5.1.2)

1-8

The abbreviations in T

The PLC-PLC connection serves to transmit messages between two

programmable controllers.

The DP connection serves to exchange messages with a higher

level DP master

Y

ou use a broadcast to transmit messages to all stations connected

to SINEC L2.

The safety-related PLC-PLC connection serves to transmit safety-

related messages between two failsafe programmable controllers.

Y

ou use safety-related broadcast to transmit safety-related mes

sages to all stations connected to SINEC L2.

ables 1-4 and 1-5 have the following meanings:

.

Communications

Processor CP

EW

A 4NEB 812 6188-02

-

-

541

Communication Modes

This

Introduction

chapter provides an overview of the communication modes you can use

via the CP 541.

2

Declarations

Acknowledgment

Summary of this

Chapter

The following two declarations apply to the entire Manual. Y

declarations to facilitate understanding of the various communication modes.

Node address

The node address is the address with which the programmable controller

connected to the CP 541 is accessed by it.

Station number

The station number is the number which distinguishes the various stations

on the SINEC L2. Each station number is uniquely assigned to a station.

The CP 541 always provides a positive acknowledgment to all messages it

receives from the programmable controller

Section Contents Page

2.1 PLC-PLC Connection 2-2

2.2 DP Connection 2-3

2.3 Broadcast via FDL Connection 2-4

.

ou require these

Communications

EW

A 4NEB 812 6188-02

Processor CP

541

2-1

Communication Modes

2.1 PLC-PLC Connection

The

Introduction

PLC-PLC connection serves for message-oriented communication be

tween two programmable controllers, without a detour via an additional sta

tion.

-

-

Message Length

Parameter

Assignment

Address

Conversion

Each message of the non-safety-related PLC-PLC connection can contain up

to 64 bytes of data.

If you install a PLC-PLC connection, you must parameterize the CP 541 as

an active station.

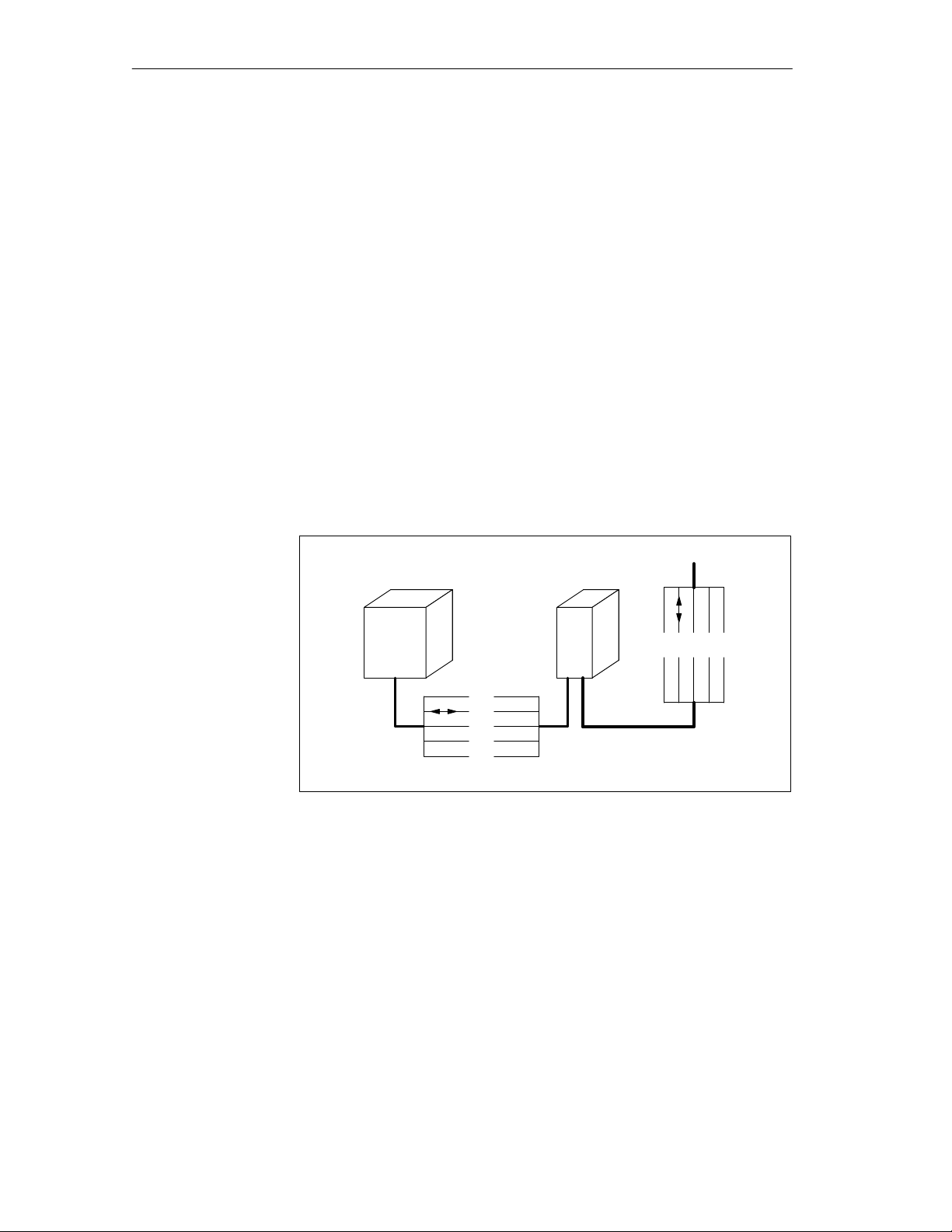

The node address specified in the programmable controller is converted by

the CP 541 to the station number and vice versa. Node address 1 is converted

to station number 1, node address 2 to station number 2, etc.

SINEC L2

PLC

1

2

3

30

CP

541

1 3032

Address Range

2-2

Figure 2-1 Address Conversion for PLC-PLC Connection

Node

addresses 1 to 30 are available in the connected programmable control

ler for the PLC-PLC connection.

Communications

Processor CP

EW

A 4NEB 812 6188-02

-

541

2.2 DP Connection

Introduction

The

tween a DP master and a DP slave.

Communication Modes

DP connection is data-oriented non-safety-related communication be

-

Message Length

Parameter

Assignment

Address

Conversion

Monitoring of the

Connected PLC

The DP connection can contain up to 16 words of data in each direction.

Y

ou install the DP connection in the connected programmable controller as a

connection with node address 0 (see Section 4.3).

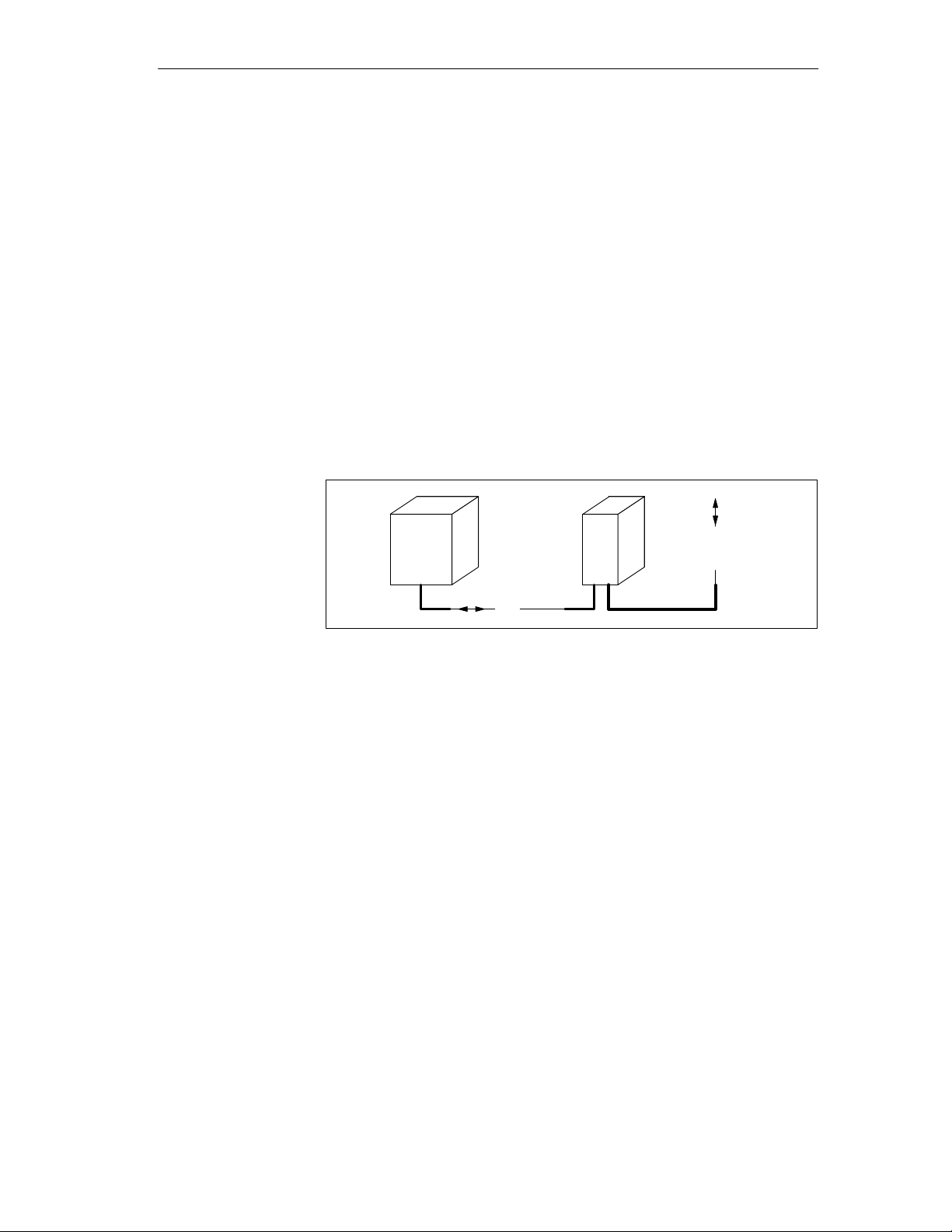

Node address 0 sent by the connected programmable controller is converted

to the DP master station number by the CP 541.

SINEC L2

PLC

0

Figure 2-2 Address Conversion for DP Connection

The

CP 541 monitors the DP connection to the programmable controller

CP

541

DP

master

.

Monitoring is active as soon as the CP 541 is accepted in the DP cycle and

the programmable controller has sent the first DP message.

DP Master

Monitoring

Note Relating to

the S5-1

Communications

EW

15F

A 4NEB 812 6188-02

Processor CP

When writing the user program in the programmable controller

, ensure that

cyclic DP data are presented within the response monitoring time (DPWD,

see Appendix C.5).

When the CP 541 no longer receives DP messages from the programmable

controller

, it emits a diagnosis to the DP master

.

As soon as the CP 541 is accepted in the DP cycle and the DP watchdog is

activated, the CP 541 monitors the connection to the DP master

.

If the DP connection to the DP master fails, the CP 541 informs the program

mable controller (see Section 6.4).

W

ith the S5-1

15F

, you can install either the DP connection or a non-safetyrelated PLC-PLC connection. Both connections are not simultaneously pos

sible because they both use node address 0.

541

-

-

2-3

Communication Modes

2.3 Broadcast via FDL Connection

The

Introduction

broadcast serves to transmit messages to all L2 stations which monitor

the SINEC L2 via FDL and the set SAP (service access point), and use the

SDN service.

Message Length

Implementation

Address

Conversion

Each broadcast message can contain up to 64 bytes of data.

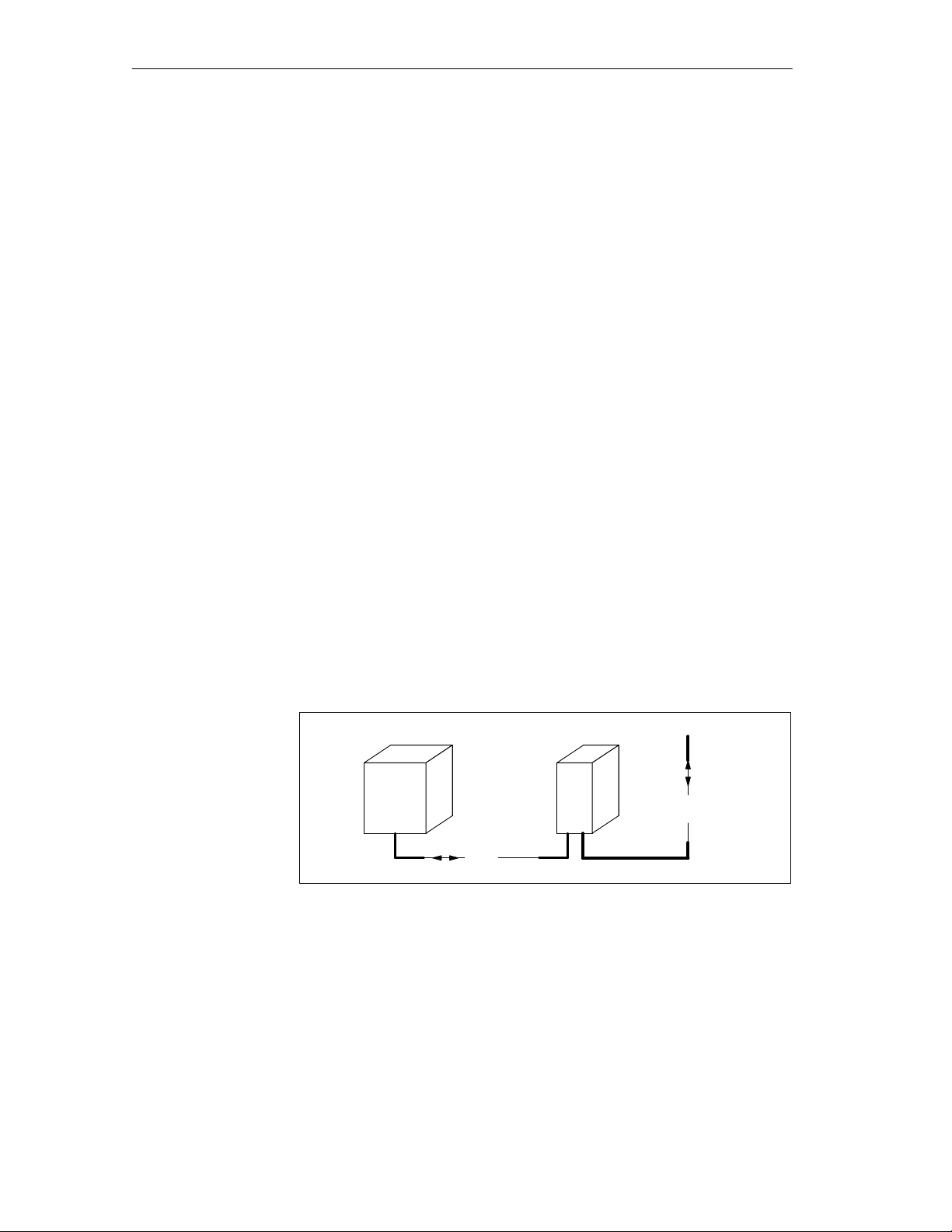

The CP 541 converts a broadcast message from the connected programmable

controller to a multicast message on SINEC L2. A service access point (SAP)

is used for this conversion.

SAP

The CP 541 uses the default SAP 52 for broadcast. Y

SAP with parameter BSAP in frame COM of DB1.

The SAP number must be identical for all participating stations.

ou can change the

SDN

SDN (send data with no acknowledge) of the PROFIBUS protocol is used

for the broadcast.

Y

ou send the broadcast from the connected programmable controller to node

address 31. This node address is converted to station number 127 by the CP

541.

SINEC L2

FDL Connection

2-4

PLC

31

Figure 2-3 Address Conversion for Broadcast

You

can establish a point-to-point connection to any PROFIBUS station

which can exchange data via FDL (free layer 2). Y

CP

541

127

ou do this with a broadcast

and use the SAP to specify only one other station in SINEC L2 which can

receive the message.

If only the CP 541 and another station in SINEC L2 use this SAP

, you can

utilize this special form of broadcast to establish a connection to any other

non-Siemens device.

Communications

Processor CP

EW

A 4NEB 812 6188-02

541

Installing and Connecting the CP 541

When

Introduction

you have studied this chapter

start up the CP 541.

, you will be able to install, connect and

3

Installation of

Equipment

Working on

Cabinets

Summary of this

Chapter

Programmable controllers of the SIMA

series must be installed in electrical apparatus rooms or in enclosed housings,

such as metal or plastic cabinets.

Programmable controllers of the SIMA

S5-155U/H series must be installed in grounded, enclosed metal housings

such as cabinets.

T

o protect the modules from the dischar

sonnel must dischar

and control boxes.

Section Contents Page

3.1 Installing the CP 541 3-2

3.2 Connecting the CP 541 3-3

3.3 Starting up the CP 541 3-5

3.4 Operating States of the CP 541 3-6

ge themselves electrostatically before opening cabinets

TIC S5-90U, S5-95U/F and S5-100U

TIC S5-1

ge of static electricity

15U/H/F

, S5-135U and

, operating per

-

Communications

EW

A 4NEB 812 6188-02

Processor CP

541

3-1

Installing

and Connecting the CP 541

3.1 Installing the CP

The

Introduction

Mounting

Removal

CP 541 is mounted like a programmable controller of the SIMA

family

, for example the S5-95U or S5-100U, on a standard rail to

EN 50022-35

Mount the CP 541 on a standard rail. Y

Mount the CP 541 in the following order:

1.

Hook the CP 541 onto the rail.

2.

Swing the CP 541 down until the slide is heard to engage.

Remove the CP 541 in the following order:

1.

Switch of

2.

Remove the connecting cables.

3.

Use a screwdriver to push the slide down.

4.

Swing the CP 541 out of the rail.

541

15.

f the 24

TIC S5

ou need a free space of 46 mm.

VDC supply for the CP 541.

3-2

Communications

EW

A 4NEB 812 6188-02

Processor CP

541

Installing and Connecting the CP 541

3.2 Connecting the CP

Introduction

Supply

of Power

Connecting the

PLC to the CP 541

Connect

W

SIT

meeting the requirements given in Appendix A.

Connect the supply of power (24

CP 541. Ensure correct polarity

Connect the CP 541 and the programmable controller with the preassembled

connecting cable (see T

Observe correct connector assignments.

Table 3-1 Cable for Connecting the PLC and the CP 541

the CP 541 as follows.

e recommend the use of a SIT

OP power supply unit, you must use a safety-separated power supply

541

OP power supply unit. If you do not use a

VDC) to the three screw terminals on the

.

able 3-1).

Length Order

1 m

6ES5 735-8BB00

2.5 m 6ES5 735-8BC50

No.

Connecting the

Programmer

Connecting

SINEC L2

Components for

SINEC L2

Y

ou connect a programmer (PG) for parameter assignment or to evaluate the

diagnostics block, instead of the programmable controller

, to the PG/PLC

connector of the CP 541.

Connect SINEC L2 to the 9-pin subminiature D female connector of the CP

541. Use standard components of SINEC L2 (see the manual:

L2/L2FO Network Components

The components for SINEC L2 are given in T

Table 3-2 Components for SINEC L2

, 6GK1 970-5CA00-0AA).

able 3-2.

Name Order

SINEC

No.

Bus cable

Indoor

For burying in ground

Bus connector IP20

6XV1 830-0AH10

6XV1 830-3AH10

6ES5 762-2AA12

Communications

EW

A 4NEB 812 6188-02

Processor CP

541

3-3

Installing and Connecting the CP 541

Connecting the

Bus Cable

Electrical Separa

tion (Isolation)

Connect

with the bus connector

The PG/PLC interface and the SINEC L2 interface are safety-separated (iso

-

the bus cable to the bus connector, as explained in the instructions

.

lated) via optocouplers.

The reference potential and protective conductor terminal are internally con

nected.

PG/PLC

Logic

SINEC L2

24 V

M

Figure 3-1 Isolation of Terminals

-

-

Grounded

Configuration

Ungrounded

Configuration

Shielding

EMC Guidelines

As

a rule, you should use a grounded arrangement. This of

jection of interference. Any interference currents are dischar

to the protective conductor

Y

ou configure the CP 541 with a grounded reference potential by connecting

.

fers very high re

ged from the rail

the protective conductor terminal of the CP 541 to the protective conductor

Use a copper conductor with a cross-section of 2.5 mm.

T

o use the CP 541 in an ungrounded arrangement, you must fit the rail on

which the CP 541 is mounted, in an insulated arrangement. In the installed

state, the reference potential of the CP 541 is electrically connected to the

rail.

T

o dischar

protective conductor

V

alues for the network:

Parallel connection of R=100 kΩ und C=1

ge interference, you must connect the rail via an RC network to the

.

µF.

Connect the cable shields of the SINEC L2, and of the connecting cable be

tween CP 541 and the programmable controller

, to a shield bar at each end.

Further instructions for EMC-oriented configuration can be found in the

manual for the connected programmable controller

.

-

.

-

3-4

Communications

EW

A 4NEB 812 6188-02

Processor CP

541

3.3 Starting up the CP 541

Installing

and Connecting the CP 541

Startup

Step Action Meaning

1 Mount the CP 541 on the rail. See Section 3.1.

2 Make connections for a programmer, the

SINEC L2 and the power supply.

3 Switch the CP 541 to the STOP state. The CP 541 will be initialized (See Section 3.4.1).

4 Read DB1 into the programmer. DB1 is always present in the CP 541. After a reset, there is a

5 Make the necessary changes to DB1. You

6 T

7 Remove the programmer from the CP

8 Assign parameters to the connected PLC.

9 Connect the CP 541 to the PLC with the

10 Set the mode switch of the CP 541 to

ransfer the modified DB1 to the CP 541.

541.

connecting cable.

RUN.

Switch the connected PLC to RUN.

Proceed

in the following order for the first startup.

See Section 3.2

If you are restarting the CP 541 after an interval, connect the

PLC via the connecting cable instead of the programmer.

Skip Steps 4 to 7.

Programmer operation is only possible in the STOP state.

default DB1 in the CP 541.

have defined the parameters to be changed in Chapter 4.

For

normal operation, you must

PLC.

DB1 will be stored after a STOP-RUN transition.

The exchange of data between the connected PLC and SINEC L2 will begin.

a successful start and initialization of the interfaces, the

After

green RUN LED lights up. The CP 541 is in the RUN state.

provide the connection to the

Operation

Communications

EW

A 4NEB 812 6188-02

Processor CP

After

startup, the CP 541 executes the exchanging of data.

Detailed information on the operating states of the CP 541 can be found in

Section 3.4.

541

3-5

Installing and Connecting the CP 541

3.4 Operating

Introduction

Operating

States

States of the CP 541

You

can subdivide the operational behavior of the CP 541 into individual

operating states and their transitions, as explained in following.

W

e subdivide the operational behavior into the following operating states and

state transitions:

POWER ON

POWER ON is understood to mean the behavior when the CP 541 has

been switched on (from 0 to ST

restored.

ST

OP state

In the ST

OP state, you can use your PG to access both DBs in the CP 541.

START

The START serves to evaluate and store DB1 and activate the SINEC L2

interface.

RUN state

In the RUN state, the CP 541 executes the exchanging of data between

the connected programmable controller and SINEC L2.

OP), or when operating voltage has been

Summary of this

Section

Section Contents Page

3.4.1 POWER ON 3-7

3.4.2 STOP State 3-8

3.4.3 START 3-9

3.4.4 RUN State 3-10

3-6

Communications

EW

A 4NEB 812 6188-02

Processor CP

541

DB1 i

Y

EEPROM ok?

Installing and Connecting the CP 541

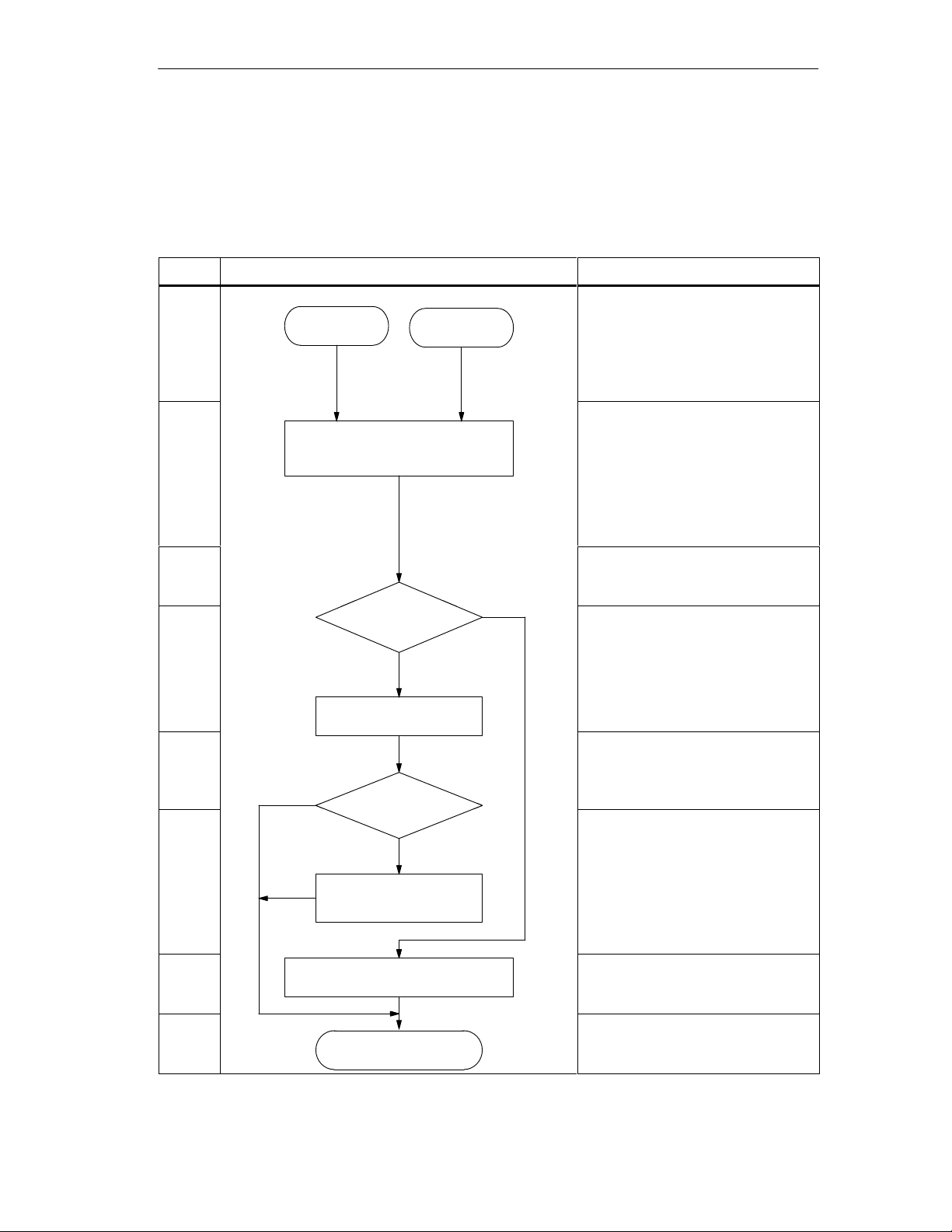

3.4.1 POWER ON

In

Power

On

Step Flowchart Explanation

POWER ON, the CP 541 reacts as shown in the following flowchart.

1

Switch on

Power

restored

Whether or not you set the mode

switch from 0 to STOP, or whether

power is restored after a power fail

ure, the CP 541 reacts in the same

way.

2

CP

541 being initialized;

it executes an internal test.

In the initialization phase, all inter

nally stored interface data are reset

to reach a defined initial state.

-

An internal test is simultaneously

executed. During the test, the green

RUN LED flashes at 8 Hz.

3

The CP 541 checks whether a DB1

is present.

DB1 in

n

4

EEPROM?

es

If no DB1 is stored in the EE

-

PROM, it is subjected to a test of

No

approx. 6 s.

During the test, the green RUN

CP 541 tests EEPROM

5

LED flashes at 8 Hz.

W

ith the EEPROM test, the CP 541

tests the EEPROM for proper func

-

tioning.

No

6

Yes

If the EEPROM is OK, the CP 541

loads the default DB1 from the op

erating system.

-

7

8

Communications

EW

A 4NEB 812 6188-02

CP

Processor CP

CP

541 reads in

the default DB1

541 copies DB1 into RAM

STOP state

541

If an error occurs, DB2 can be read

out but the CP 541 cannot be

switched to the RUN state.

The CP 541 copies DB1 from the

EEPROM into the main memory

The CP 541 is in the ST

OP state.

.

The RUN LED flashes at 2 Hz.

3-7

Installing and Connecting the CP 541

3.4.2 STOP State

In

the ST

Meaning

nected programmable controller is not activated.

OP state, the CP 541 is initialized and the interface for the con

-

LED

RUN

Programmer

Operation

DB1

DB2

In the ST

In the ST

OP state, the RUN LED flashes at 2 Hz.

OP state, you can connect a programmer to the CP 541. The pro

-

grammer allows you to access the two data blocks DB1 and DB2.

The PG interface is activated in the ST

DB1 is the initialization block. Y

W

ith the entries in DB1, you af

OP state.

ou store the parameters for the CP 541 there.

fect the operational behavior and interchange

of data between the connected programmable controller and SINEC L2.

A full description of DB1 can be found in Appendix C.

DB2 is the diagnostics block. The CP 541 stores the determined diagnostic

data there. Y

ou can only read out DB2.

By means of the diagnostic data, you can establish whether there are errors in

the CP 541 or in the two communication interfaces.

A full description of DB2 can be found in Section 6.2.

3-8

Communications

EW

A 4NEB 812 6188-02

Processor CP

541

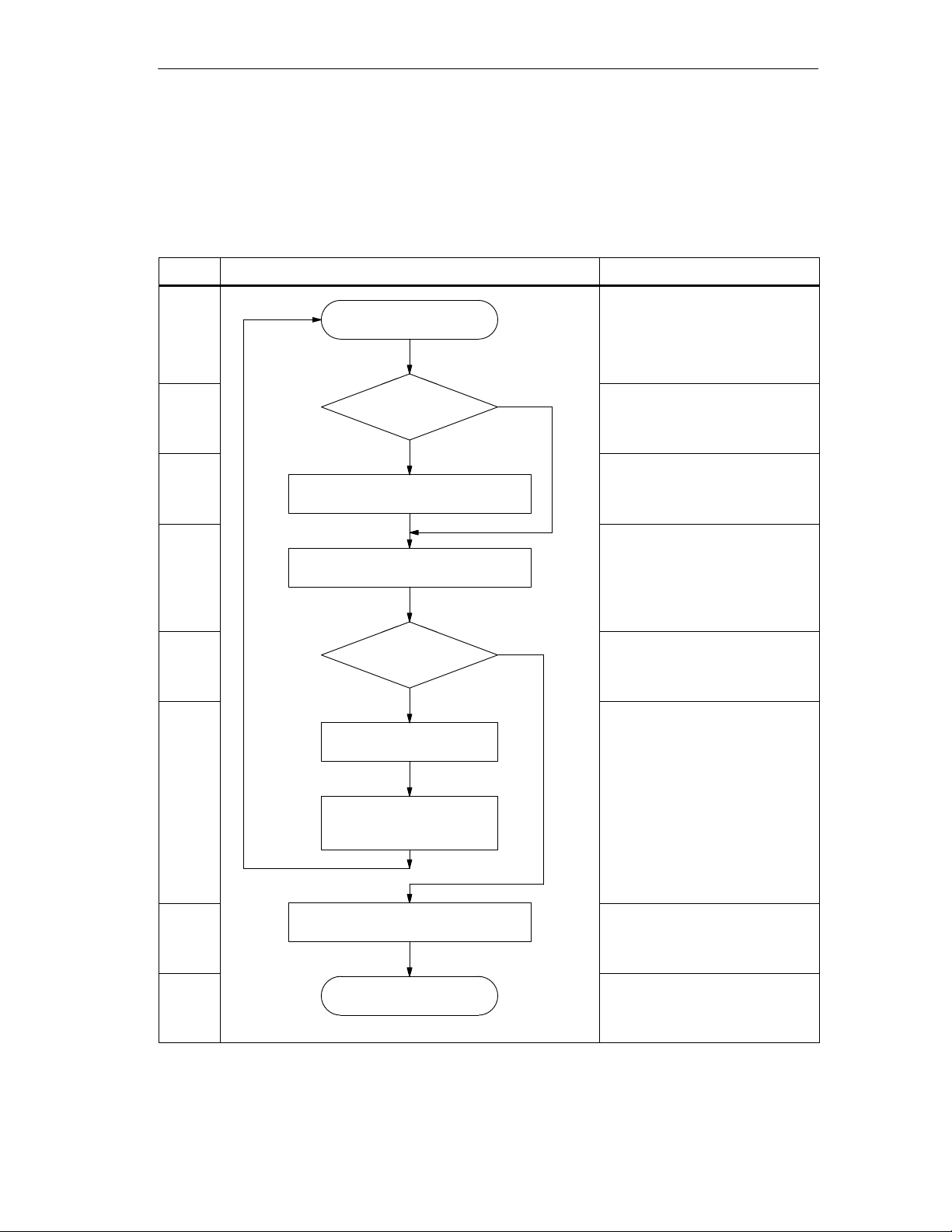

3.4.3 START

STOP

No

Installing

and Connecting the CP 541

START

The STAR

T is explained in the following flowchart.

Step Flowchart Explanation

1

STOP state

The CP 541 is in the ST

state.

RUN LED flashes at 2 Hz.

2

3

Mode switch set to RUN

4

CP

Setting

of mode

switch?

STOP

541 evaluates DB1

RUN

The CP 541 evaluates the set

ting of the mode switch.

Set the mode switch from ST

to RUN.

The CP 541 evaluates the pa

rameters in DB1 and checks

them for completeness and plau

sibility.

5

DB1 ok?

Yes

Is DB1 complete and are all pa

rameters in order?

OP

-

OP

-

-

-

No

6

CP

541 evaluates error

If an error is detected, the CP

541 evaluates the error and gen

erates an appropriate diagnostics

-

message in DB2.

CP 541 switches

error LED on

7

CP

541 copies DB1 into EEPROM

ally activated.

In the event of an error

541 remains in the ST

, the CP

OP state.

The CP 541 writes DB1 into the

The ERR error LED is addition

-

EEPROM.

8

RUN state

The CP 541 is in the RUN state.

The RUN LED lights up.

Communications

EW

A 4NEB 812 6188-02

Processor CP

541

3-9

Installing and Connecting the CP 541

3.4.4 RUN State

In

Meaning

the RUN state, both the PLC interface and the SINEC L2 interface are

ready to exchange data.

Operator inputs via the programmer are not possible in the RUN state.

Exchange of Data

Communication

The CP 541 transfers the data from the connected programmable controller to

SINEC L2 and vice versa.

A description of communication modes supported by the CP 541 can be

found in Chapter 2 and Section 5.1.

3-10

Communications

EW

A 4NEB 812 6188-02

Processor CP

541

Loading...

Loading...