Page 1

SIMATIC

Industrial Ethernet - CloudConnect

SIMATIC CC712

Operating Instructions

05/2019

C79000

Preface

Application and functions

1

LEDs, Connectors, Buttons,

CLP

2

Installation, wiring,

commissioning

3

Configuration

4

Diagnostics and

maintenance

5

Technical specifications

6

Approvals

7

Dimension drawings

8

Accessories

A

SIMATIC CC712

-G8976-C503-01

Page 2

Siemens AG

Digital Industries

Postfach 48 48

90026 NÜRNBERG

GERMANY

C79000-G8976-C503-01

Ⓟ

Copyright © Siemens AG 2019.

All rights reserved

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

05/2019 Subject to change

Page 3

Preface

Validity of the document

Product name

Article number

Functions

SIMATIC CC712

Connection of 1 process station

This document contains information on the following product:

● SIMATIC CC712

Article number: 6GK1411-1AC00

Hardware product version 1

Firmware version V1.1

Gateway for connection of a SIMATIC S7 or Modbus s

server for SIMATIC S7 data

tation to a cloud system, OPC UA

Figure 1 SIMATIC CC712

The MAC address of the device is located below the socket for the power supply. You will

find the article number on the device front.

You will find the hardware product version on the right side of the device as placeholder "X".

"X 2 3 4", for example, indicates hardware product version 1.

The gateway is available in the following versions:

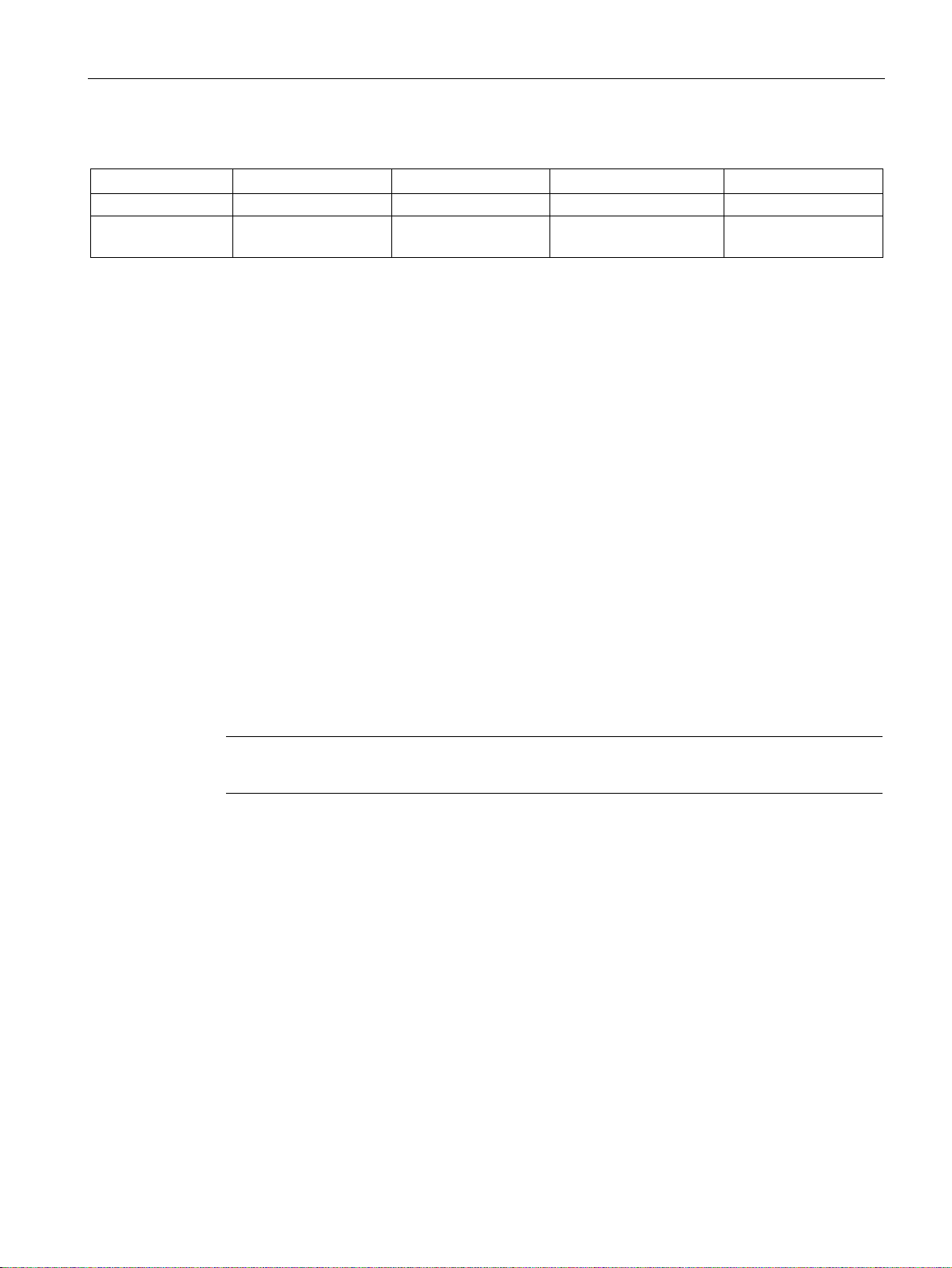

Table 1 Article numbers

Purpose of the manual

This manual describes the properties of the module and shows application examples. It

supports you when installing, connecting up and commissioning the module.

The required configuration steps are described. You will also find instructions for operation

and information about the diagnostics options.

SIMATIC CC712

Operating Instructions, 05/2019, C79000-G8976-C503-01

6GK1411-1AC00

3

Page 4

Preface

Required experience

To install, commission and operate the module, you require experience in the following

areas:

● Data transfer via Ethernet / Internet

● Cloud systems, MQTT

● OPC UA

● Automation engineering

Terminology: Names and abbreviations

The following terms and abbreviations are used in this document:

●

Device / Gateway / Module

Names for the product "SIMATIC CloudConnect 7"

●

Station

Process station (SIMATIC S7 / Modbus)

●

WBM

Web Based Management

Web pages of the device for configuration and diagnostics data

●

DB

Data block of a SIMATIC CPU

New in this release

First issue

Current manual release on the Internet

You can find the current version of this manual on the Internet pages of Siemens Industry

Online Support:

Link: (https://support.industry.siemens.com/cs/ww/en/ps/25621)

Cross references

In this document there are cross references to other sections.

To be able to return to the initial page after jumping to a cross reference, some PDF readers

support the command <Alt>+<left arrow>.

SIMATIC CC712

4 Operating Instructions, 05/2019, C79000-G8976-C503-01

Page 5

Preface

Note

Open source software

The product contains open source software. Read the license conditions for open source

software carefully before using the product.

License conditions

You will find license conditions in the following document on the supplied data medium:

● OSS_CloudConnect7_99.pdf

Security information

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial

security concept. Siemens’ products and solutions constitute one element of such a concept.

Firmware

Customers are responsible for preventing unauthorized access to their plants, systems,

machines and networks. Such systems, machines and components should only be

connected to an enterprise network or the internet if and to the extent such a connection is

necessary and only when appropriate security measures (e.g. firewalls and/or network

segmentation) are in place.

For additional information on industrial security measures that may be implemented, please

visit

Link: (http://www.siemens.com/industrialsecurity)

Siemens’ products and solutions undergo continuous development to make them more

secure. Siemens strongly recommends that product updates are applied as soon as they are

available and that the latest product versions are used. Use of product versions that are no

longer supported, and failure to apply the latest updates may increase customers’ exposure

to cyber threats.

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS

Feed under

Link: (http://www.siemens.com/industrialsecurity)

The firmware is signed and encrypted. This ensures that only firmware created by Siemens

can be downloaded to the device.

SIMATIC CC712

Operating Instructions, 05/2019, C79000-G8976-C503-01

5

Page 6

Preface

Recycling and disposal

The product is low in pollutants, can be recycled and meets the requirements of the WEEE

directive 2012/19/EU "Waste Electrical and Electronic Equipment".

Do not dispose of the product at public disposal sites. For environmentally friendly recycling

and the disposal of your old device contact a certified disposal company for electronic scrap

or your Siemens contact.

Keep to the local regulations.

You will find information on returning the product on the Internet pages of Siemens Industry

Online Support:

Link: (https://support.industry.siemens.com/cs/ww/en/view/109479891)

SIMATIC NET glossary

Explanations of many of the specialist terms used in this documentation can be found in the

SIMATIC NET glossary.

You will find the SIMATIC NET glossary on the Internet at the following address:

Link: (https://support.industry.siemens.com/cs/ww/en/view/50305045)

Training, Service & Support

You will find information on training, service and support in the multilanguage document

"DC_support_99.pdf" on the Internet pages of Siemens Industry Online Support:

Link: (https://support.industry.siemens.com/cs/ww/en/view/38652101)

SIMATIC CC712

6 Operating Instructions, 05/2019, C79000-G8976-C503-01

Page 7

Table of contents

Preface ................................................................................................................................................... 3

1 Application and functions ...................................................................................................................... 11

1.1 Application .............................................................................................................................. 11

1.2 Functions and communication services .................................................................................. 11

1.3 Configuration examples .......................................................................................................... 13

1.4 Other services and properties ................................................................................................. 15

1.5 Configuration limits - communication ...................................................................................... 15

1.6 Range of functions of the WBM .............................................................................................. 17

1.7 Scope of delivery and requirements ....................................................................................... 18

2 LEDs, Connectors, Buttons, CLP .......................................................................................................... 21

2.1 LEDs ....................................................................................................................................... 21

2.2 Connections ............................................................................................................................ 22

2.2.1 Ethernet interfaces (P1, P2) ................................................................................................... 22

2.2.2 External power supply............................................................................................................. 23

2.3 The button "SET" .................................................................................................................... 23

2.4 CLP Slot .................................................................................................................................. 24

3 Installation, wiring, commissioning ........................................................................................................ 25

3.1 Important notes on using the device ....................................................................................... 25

3.1.1 Notes on use in hazardous areas ........................................................................................... 25

3.1.2 Notes on use in hazardous areas according to ATEX / IECEx .............................................. 26

3.1.3 General notices on use in hazardous areas according to UL HazLoc / FM ........................... 27

3.2 Installation ............................................................................................................................... 28

3.3 Connecting .............................................................................................................................. 33

3.4 Commissioning ....................................................................................................................... 35

3.4.1 Commissioning ....................................................................................................................... 35

3.4.2 Using a CLP ............................................................................................................................ 35

4 Configuration ........................................................................................................................................ 37

4.1 Security recommendations ..................................................................................................... 37

4.2 Overview of the WBM pages .................................................................................................. 39

4.3 General functions of the WBM ................................................................................................ 41

4.4 Calling the WBM ..................................................................................................................... 42

4.4.1 Establishing a connection to the WBM ................................................................................... 42

4.4.2 Logging into the WBM............................................................................................................. 43

4.4.3 Log out .................................................................................................................................... 44

SIMATIC CC712

Operating Instructions, 05/2019, C79000-G8976-C503-01

7

Page 8

Table of contents

4.5 Start page ............................................................................................................................... 45

4.5.1 Info ......................................................................................................................................... 45

4.6 Interface configuration ........................................................................................................... 46

4.6.1 Ethernet .................................................................................................................................. 46

4.7 Process access ...................................................................................................................... 48

4.7.1 Station configuration .............................................................................................................. 48

4.8 OPC UA ................................................................................................................................. 52

4.8.1 OPC UA server ...................................................................................................................... 52

4.8.2 OPC UA Security ................................................................................................................... 54

4.8.3 Authentication ........................................................................................................................ 58

4.8.4 Properties of the OPC UA server ........................................................................................... 58

4.9 Cloud configuration ................................................................................................................ 59

4.9.1 Notes on structuring data ....................................................................................................... 59

4.9.2 Profile ..................................................................................................................................... 60

4.9.2.1 Profile ..................................................................................................................................... 60

4.9.2.2 MQTT configuration ............................................................................................................... 62

4.9.2.3 Certificates ............................................................................................................................. 64

4.9.2.4 Device parameters ................................................................................................................. 66

4.9.3 Topic editor ............................................................................................................................ 66

4.9.3.1 Topic settings ......................................................................................................................... 66

4.9.3.2 User data format .................................................................................................................... 71

4.9.3.3 Station assignment ................................................................................................................ 76

4.10 Data points ............................................................................................................................. 78

4.10.1 Notes on transfer time ............................................................................................................ 78

4.10.2 Data points ............................................................................................................................. 78

4.10.3 Import tags ............................................................................................................................. 84

4.11 Maintenance ........................................................................................................................... 87

4.11.1 System time ........................................................................................................................... 87

4.11.2 User ........................................................................................................................................ 89

4.11.3 Firmware ................................................................................................................................ 91

4.11.4 Saving .................................................................................................................................... 92

4.11.5 Communication / Restart ....................................................................................................... 93

4.11.6 Diagnostics ............................................................................................................................. 93

4.11.7 Logging ................................................................

.................................................................. 94

5 Diagnostics and maintenance ............................................................................................................... 95

5.1 Diagnostics options ................................................................................................................ 95

5.2 Loading new firmware ............................................................................................................ 95

5.3 Reset ...................................................................................................................................... 96

5.4 Device replacement in the event of a fault ............................................................................. 97

6 Technical specifications ........................................................................................................................ 99

6.1 Technical specifications - CloudConnect 712 ........................................................................ 99

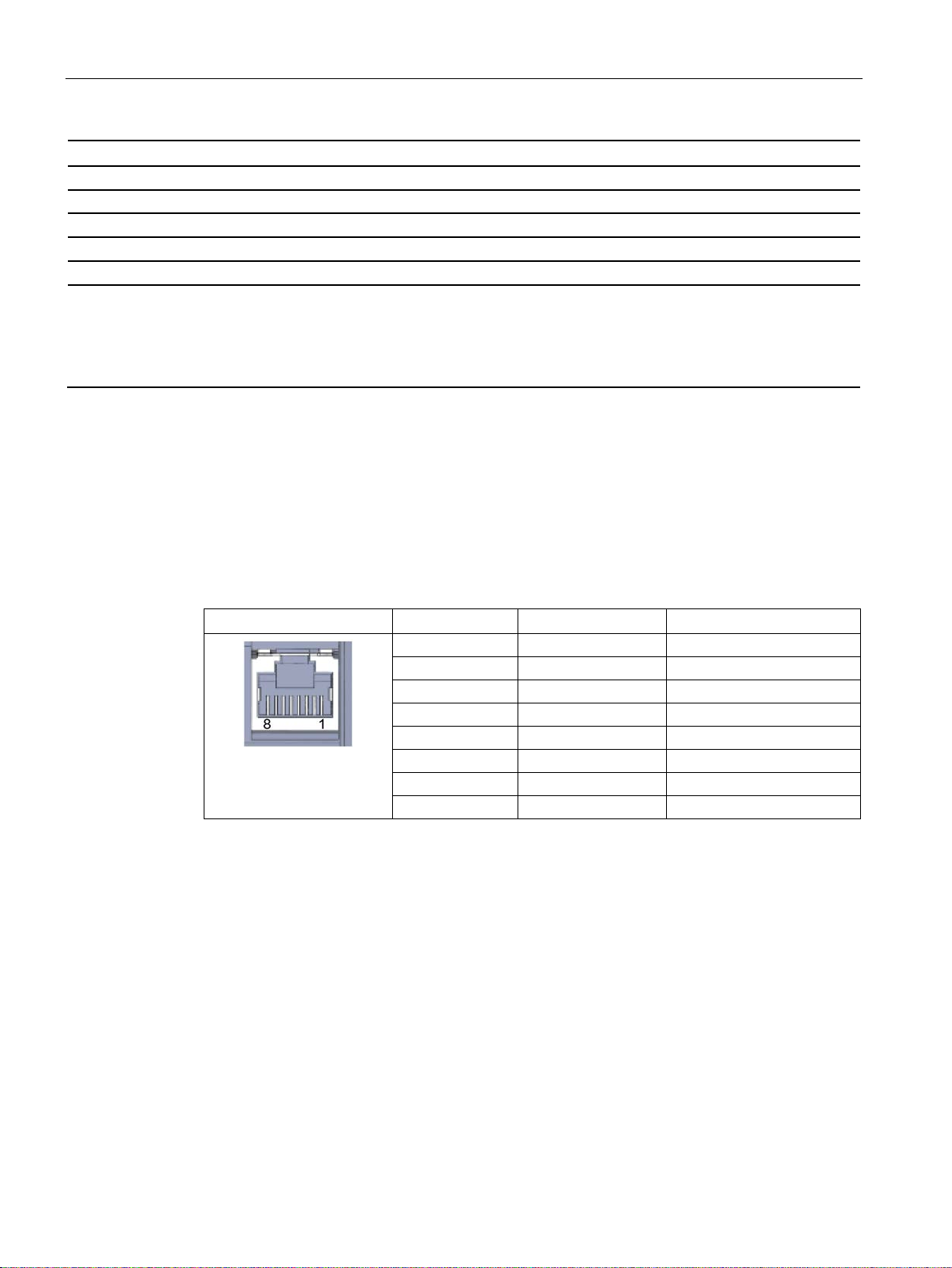

6.2 Pinout of the Ethernet interfaces.......................................................................................... 100

6.3 Permitted cable lengths - Ethernet....................................................................................... 101

6.4 Permitted cable lengths - Gigabit Ethernet .......................................................................... 101

SIMATIC CC712

8 Operating Instructions, 05/2019, C79000-G8976-C503-01

Page 9

Table of contents

7 Approvals ............................................................................................................................................ 103

8 Dimension drawings ............................................................................................................................ 107

A Accessories ........................................................................................................................................ 109

A.1 Power supply ........................................................................................................................ 109

A.2 CLPs ..................................................................................................................................... 109

Index................................................................................................................................................... 111

SIMATIC CC712

Operating Instructions, 05/2019, C79000-G8976-C503-01

9

Page 10

Table of contents

SIMATIC CC712

10 Operating Instructions, 05/2019, C79000-G8976-C503-01

Page 11

1

1.1 Application

Applications of the gateway

The gateway connects process stations to the following target systems:

● A cloud system via MQTT

Process stations: S7 / Modbus

● OPC UA clients

Process stations: S7

An S7 CPU data point can alternatively be configured for one of the two target systems.

1.2 Functions and communication services

Process stations

The gateway can communicate with the following process stations:

● SIMATIC S7-300/400/1200/1500

Communication via Ethernet (S7 communication)

● Modbus controllers

Communication via Ethernet (Modbus/TCP)

Protocols for the cloud connection

The gateway supports the following protocols for communication with a cloud broker or cloud

server:

● MQTT

According to OASIS standard version 3.1 / 3.1.1

The gateway is the publisher.

Supported cloud systems

The gateway supports the connection to cloud systems that support a broker functionality

with the above-mentioned requirements and the functions described below.

The configuration of cloud access ("Cloud profile") is adapted to communication with the

following cloud systems:

● MindSphere (Siemens)

Service: MindConnect IoT Extension

● AWS (Amazon)

Service: IoT Core

SIMATIC CC712

Operating Instructions, 05/2019, C79000-G8976-C503-01

11

Page 12

Application and functions

1.2 Functions and communication services

● Azure (Microsoft)

Service: IoT Hub

● IBM Cloud (IBM)

Service: Watson IoT Platform

● Other Cloud

Profile for another cloud system

OPC UA server for S7 data

For transfer of S7 process data, the gateway can be used as OPC UA server. The gateway

reads process data from the S7 CPU and, as OPC UA server, makes it available to one or

more OPC UA clients.

The server function can be enabled or disabled in the configuration.

The OPC UA server supports the following functions:

● Reading and writing tags

● Monitoring tags (MonitoredItems) using Subscriptions

● Hierarchical address browsing

The OPC UA server is implemented based on the "Micro Embedded Device 2017 Server

Profile" of the OPC Foundation. For details, see:

Link:

(https://apps.opcfoundation.org/ProfileReporting/ModifyProfile.aspx?ProfileID=19dfd3d2-

eb5a-40b0-b80b-b2b181d9fc51)

The OPC UA server supports the functions relevant for this profile from the following

specifications:

● IEC/TR 62541-1 (08-2012) OPC Unified Architecture - Part 1: Overview and Concepts

● IEC/TR 62541-2 (02-2009) OPC Unified Architecture - Part 2: Security Model

For the supported security profiles, refer to the section OPC UA Security (Page 54).

● IEC 62541-3 (08-2012) OPC Unified Architecture - Part 3: Address Space Model

For the supported data types, refer to the section Data points (Page 78).

● IEC 62541-4 (08-2012) OPC Unified Architecture - Part 4: Services

● IEC 62541-5 (08-2012) OPC Unified Architecture - Part 5: Information Model

● IEC 62541-6 (08-2012) OPC Unified Architecture - Part 6: Mappings

● IEC 62541-7 (09-2010) OPC Unified Architecture - Part 7: Profiles

Configuration using the WBM

You configure the gateway parameters in Web Based Management (WBM). The WBM

consists of Web pages stored in the gateway. From a configuration PC you connect to the

WBM of the gateway via HTTPS.

SIMATIC CC712

12 Operating Instructions, 05/2019, C79000-G8976-C503-01

Page 13

Application and functions

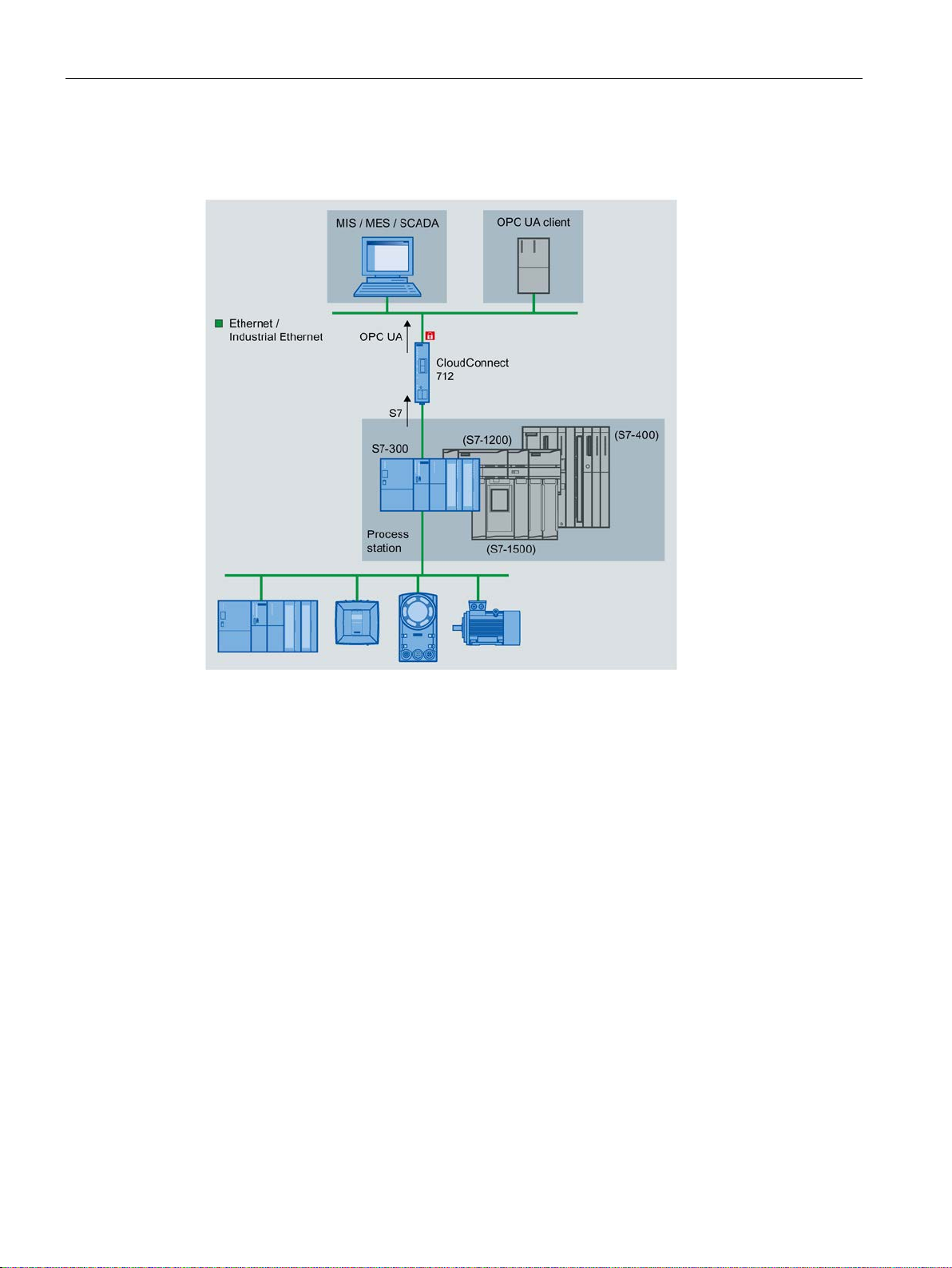

1.3 Configuration examples

1.3 Configuration examples

Below you will find examples of possible configurations with the "CloudConnect 7" gateway:

Connection of a process station to a cloud broker

In the configuration shown, the gateway reads process data from a process station and

transfer the data to a cloud broker using MQTT.

The process station is a SIMATIC S7-300 in this example. It can also be any other station

from the S7 product family.

A Modbus station, such as the programmable controller of a third-party supplier, can also be

connected.

● When it is connected to a SIMATIC S7, the gateway communicates using an S7

connection.

● When it is connected to a Modbus station, the gateway communicates using

Modbus/TCP.

Figure 1-1 CloudConnect 712 for connecting a station to the cloud

Connection of a process station to OPC UA clients

In the configuration shown, the gateway transfers process data over OPC UA to a central

control room or one or more OPC UA clients.

SIMATIC CC712

Operating Instructions, 05/2019, C79000-G8976-C503-01

13

Page 14

Application and functions

1.3 Configuration examples

The gateway reads process data from a S7 station and, as OPC UA server, makes it

available to one or more OPC UA clients.

Figure 1-2 CloudConnect 712 for connecting a station to OPC UA clients

SIMATIC CC712

14 Operating Instructions, 05/2019, C79000-G8976-C503-01

Page 15

Application and functions

1.4 Other services and properties

1.4 Other services and properties

Other services and properties

● IP configuration

– The gateway supports IP addresses according to IPv4 and IPv6.

– Address assignment:

The IP address, the subnet mask and the address of the default router can be set in

the configuration.

– DHCP: As an alternative, the IP address can be obtained from a DHCP server.

– Optionally, the host name can be ungrouped from a DNS server.

●

Time-of-day synchronization over Industrial Ethernet

Time-of-day synchronization of the gateway can be configured according to the following

NTP method (Network Time Protocol):

– NTP

– NTP (secure)

For more information, refer to the section System time (Page 87).

●

CLP (Exchangeable storage medium)

The gateway can save the configuration data on a CLP. The CLP is an external storage

medium and does not ship with the product.

For information on the CLP slot, see section CLP Slot (Page 24).

For information on the functions of the CLP, see section Using a CLP (Page 35).

For ordering data of the available CLPs, see appendix CLPs (Page 109).

●

Diagnostics

With the following means and methods, you can obtain the diagnostics data of the

gateway:

– LEDs

– Web diagnostics

You will find more information on diagnostics in the section Diagnostics (Page 93).

1.5 Configuration limits - communication

The gateway supports the following maximum quantity structure.

SIMATIC CC712

Operating Instructions, 05/2019, C79000-G8976-C503-01

15

Page 16

Application and functions

1.5 Configuration limits - communication

Connection resources over the process interface

● Number of connections to S7 stations

Max. 1 S7 connection to one S7 connection

●

Number of connections to Modbus stations

Max. 10 connections to Modbus stations

●

Number of connections to the configuration PC

Max. 1 HTTPS connection

Number of process data

● Tags in the data area of S7 CPUs

– Max. 500 tags

●

Tags per S7 CPU

– Max. 500 tags

●

Tags in the data area of Modbus stations

– Max. 100 tags per Modbus station

Connections over the Cloud interface

● Number of sessions with the broker

Max. 1 session

●

Number of connections to OPC UA clients

Max. 10 simultaneous sessions with OPC UA clients

OPC UA server

As OPC UA server, the gateway supports the following quantity structure.

●

Number of tags in the CPU data area

– Max. 500 symbols: / PLC tags

●

Number of supported subscriptions

– Max. 5 subscriptions per session

– In total maximum of 50 subscriptions at the same time

●

Number of items per subscription

– Max. 500 tags per subscription

– Max. 2500 tags over all subscriptions

SIMATIC CC712

16 Operating Instructions, 05/2019, C79000-G8976-C503-01

Page 17

Application and functions

1.6 Range of functions of the WBM

1.6 Range of functions of the WBM

Web Based Management (WBM)

You configure the gateway using its Web Based Management (WBM). The WBM consists of

Web pages that can be called up in the Web browser of a connected PC. From your PC you

connect to the WBM via HTTPS.

For information on the Web browsers that can be used on the PC, see section Scope of

delivery and requirements (Page 18).

Access to the WBM

To call the WBM, you need to establish a connection between the PC and the gateway via

LAN, see section Establishing a connection to the WBM (Page 42).

Overview of the functions of the WBM

The WBM provides the following functions:

●

User management

In the open WBM, you specify the user name and the password for the "Administrator"

role. You can only access the WBM with this administrator information.

●

Configuration

Using the WBM, configure the following function areas:

– Basic functions such as the time of day or IP address

– Connection of the process station

– Connection to the higher-level network (cloud, OPC clients)

– Communication functions

●

Maintenance and diagnostic functions

– Diagnostics

– Loading and storing the configuration data

– Downloading new firmware versions

Reusing the configuration file

The configuration data you create in the WBM is saved in the gateway.

If you want to back up the data as well, you can also save the configuration data in the WBM

area "Maintenance" on a CLP inserted in the gateway.

If you are using multiple gateways with partially identical configuration data, you can export

the configuration file of a gateway, copy it, and download it to additional gateways where you

can adapt it as needed.

SIMATIC CC712

Operating Instructions, 05/2019, C79000-G8976-C503-01

17

Page 18

Application and functions

1.7 Scope of delivery and requirements

1.7 Scope of delivery and requirements

Scope of delivery

The following positions ship with the gateway:

● Gateway "CloudConnect 7"

● Terminal block for power supply of the gateway

● Data storage medium with documentation

Required accessories

The following accessories (which do not ship with the product) are required for gateway

operation:

● Power supply

You need a 24 V DC external voltage source.

● PC

To configure the gateway, you need a configuration PC with suitable Web browser (see

below).

● LAN cable

For the connection of the configuration PC to the X2 LAN interface of the gateway, you

need a Cat 5 ITP cable.

Communication partner

● Process access

For process access you need a station in productive operation, alternatively:

– S7 station

– Modbus station

●

Cloud access / OPC clients

– For cloud access, you need the access set up to a cloud broker.

– You need at least one set up OPC UA client for connection via OPC.

Requirements in the S7 stations

The following requirements need to be met in your STEP 7 project or in the connected S7

stations.

● Tags / symbols

For access to the process data, tags or symbols must be created in the relevant CPU.

STEP 7 Professional: The "Optimized block access" option must be disabled in DBs. For

further details, see section Data points (Page 78).

SIMATIC CC712

18 Operating Instructions, 05/2019, C79000-G8976-C503-01

Page 19

Application and functions

1.7 Scope of delivery and requirements

● CPU 1200/1500

– Read protection cannot be configured under "Protection & Security" in the CPU.

– Access via PUT/GET must be configured under "Protection & Security" in the CPU.

● CPU 300/400

Read protection cannot be configured under "Protection" in the CPU.

● CP 300/400

The following requirements must be met on the CP for access to the station via a CP:

– "Module access protection" is configured as "Not locked".

– When "IP access protection" is configured, the IP address of the gateway must be

configured with the right "A".

● CP 1200

For access to the station via a telecontrol CP, S7 communication must be enabled on the

CP under "Communication types".

Web browser for the configuration PC

For access to the WBM of the gateway, the configuration PC needs one of the following Web

browsers.

● Apple Safari

● Firefox Quantum

● Google Chrome

● Microsoft Edge

● Microsoft Internet Explorer

The Web browser must accept cookies. The application uses a cookie.

JavaScript must be enabled in your Web browser.

Recommendation: Use the latest available version of the Web browser.

Optional

● CLP

Exchangeable storage medium for storing configuration data

● NTP server - can be reached over interface P1 / P2

● DHCP server - can be reached over interface P1

● DNS server - can be reached over interface P1

SIMATIC CC712

Operating Instructions, 05/2019, C79000-G8976-C503-01

19

Page 20

Application and functions

1.7 Scope of delivery and requirements

SIMATIC CC712

20 Operating Instructions, 05/2019, C79000-G8976-C503-01

Page 21

2

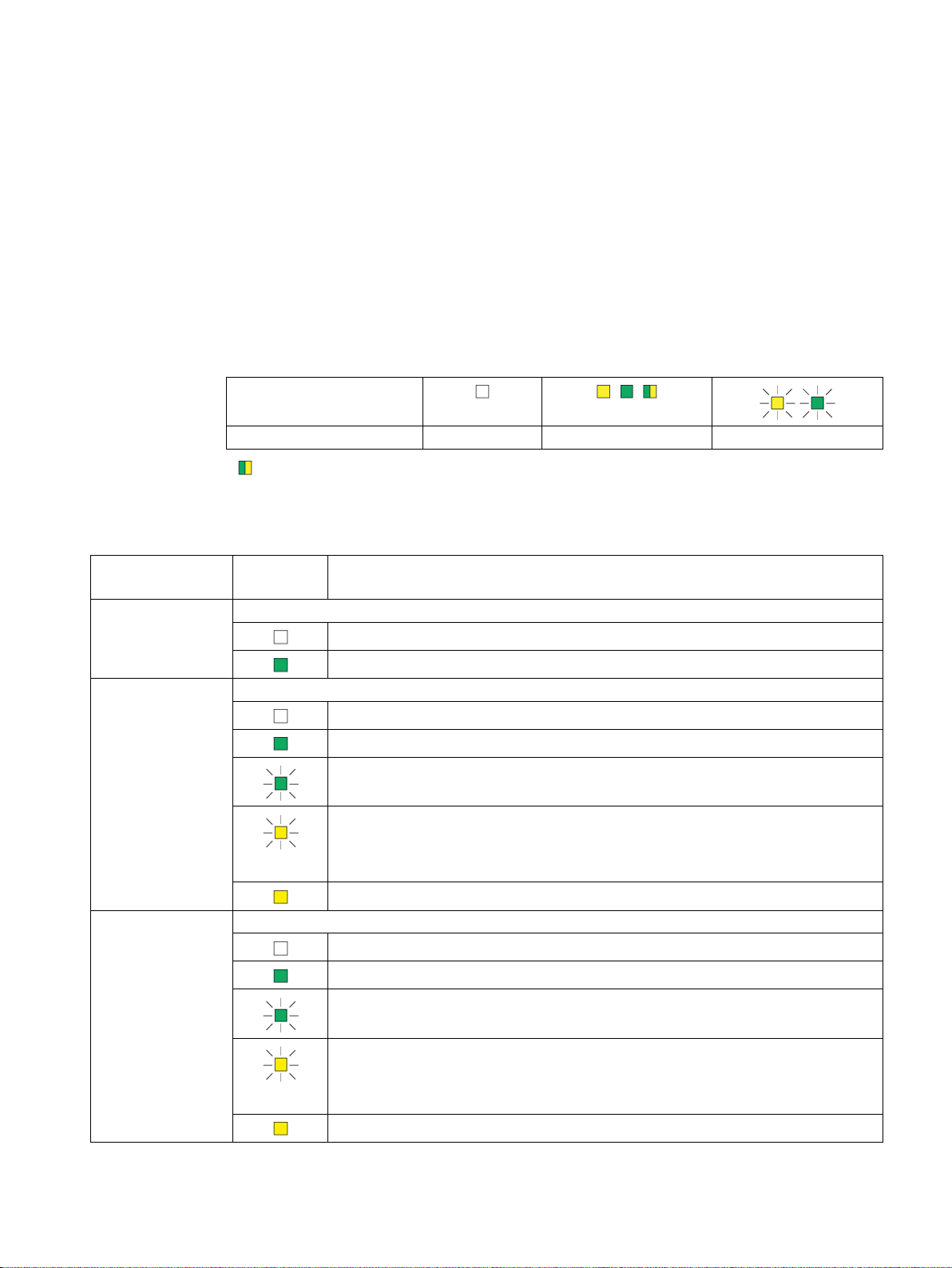

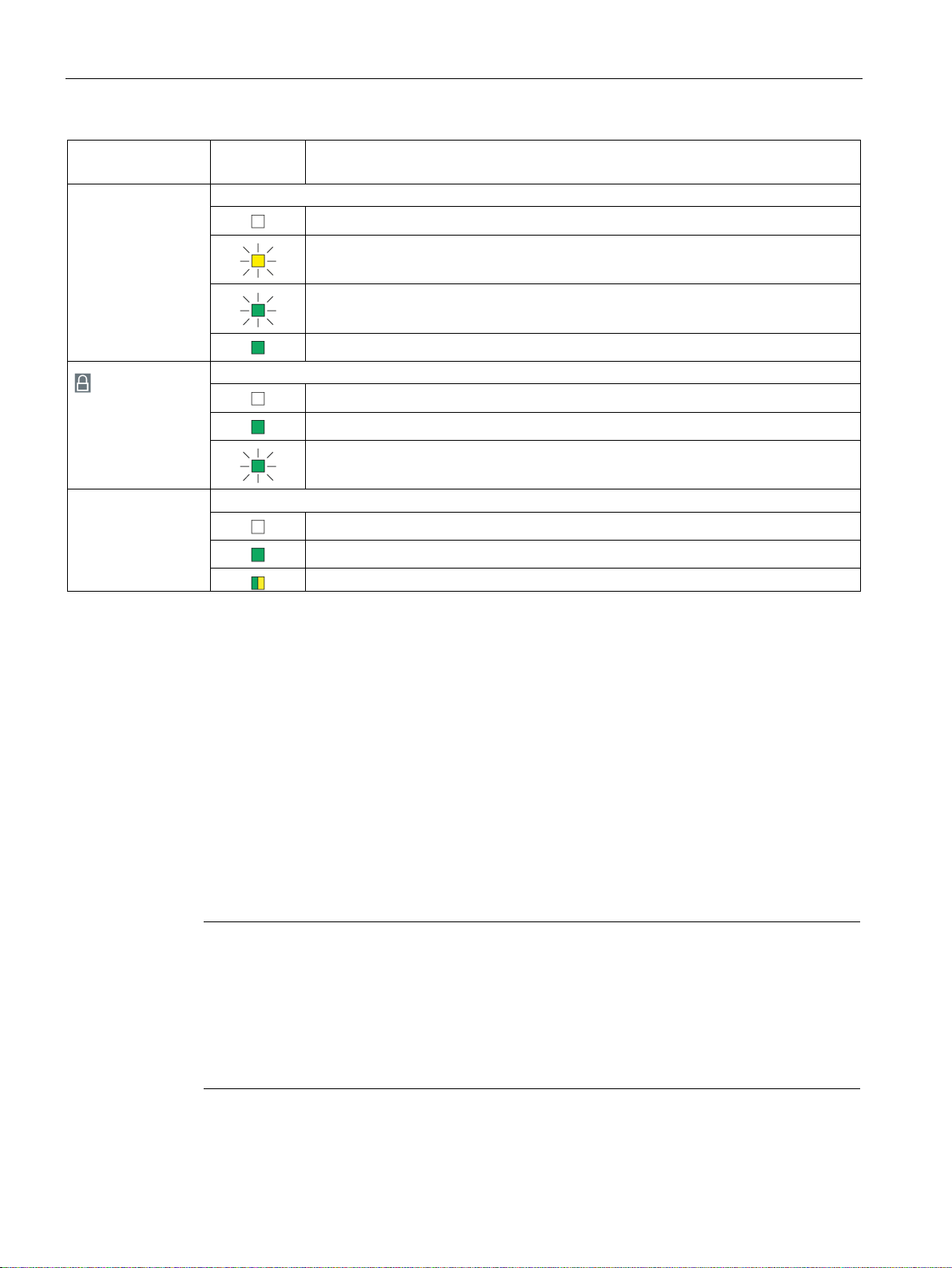

LED symbol

LED status

OFF

ON (steady light) *

Flashing

LED name

(colors)

LED pattern

Meaning / Module status

Power

Power supply

Device Connection

Connection to process stations

Cloud Connection

Connection to Cloud

2.1 LEDs

LEDs

The LEDs on the front show the states of the module.

The LED symbols in the table below correspond to the following states of the LEDs:

* : Part flashes yellow and part lit green

Meaning of the LED displays

(green)

(green / yellow)

(green / yellow)

Power OFF

Power ON

No connection to configured process stations

Existing connection to all configured process stations

No connection to at least one of the configured process stations

No communication with process stations Possible causes:

• Stop of communication over WBM ("Maintenance" tab)

• Incorrect configuration

No process station configured

No connection to cloud server

Existing connection to cloud server

Connection establishment to cloud server

No communication with process server Possible causes:

• Interruption of the communication

• Incorrect configuration

No cloud server configured

SIMATIC CC712

Operating Instructions, 05/2019, C79000-G8976-C503-01

21

Page 22

LEDs, Connectors, Buttons, CLP

LED name

(colors)

LED pattern

Meaning / Module status

Diagnosis

Diagnostics

Security

P1 / P2

Connection to Ethernet at interface P1 or P2

Existing connection with data traffic

Note

Connection to subnets

The two Ethernet interfaces are not designed as a switch,

different networks.

If the connection to the cloud is in the same subnet as the process connection, enable the

"Cloud interface in the same s

configuration.

2.2 Connections

(green / yellow)

No error

Error, diagnostic message available. (See WBM "Maintenance > Diagnostics messages")

Reset is initiated (button pressed during startup).

Reset is executed (button can be released).

(green)

(green / yellow)

No secure connection to cloud server / OPC UA clients configured

All connections to cloud server / OPC UA clients configured as secure

At least one unsecure connection to cloud server / OPC UA clients configured

No Ethernet connection

Existing Ethernet connection

2.2 Connections

2.2.1 Ethernet interfaces (P1, P2)

Ethernet interfaces

The gateway has two Ethernet interfaces according to Gigabit standard IEEE 802.3ab,

designed as RJ45 socket. They support autocrossing, autonegotiation and autosensing.

● P1

Cloud interface for connection of a cloud broker and OPC clients

● P2

Process interface for connecting the stations of the automation plant

but are intended for connection to

ubnet" option in the "Interface configuration" in the

SIMATIC CC712

22 Operating Instructions, 05/2019, C79000-G8976-C503-01

The pin assignment of the Ethernet interfaces and other data can be found in the section

Technical specifications (Page 99).

Page 23

LEDs, Connectors, Buttons, CLP

WARNING

EXPLOSION HAZARD

Note

Configuration data is deleted

By resetting to factory settings, the gateway is reset to the status as it was delivered from

the factory

2.3 The button "SET"

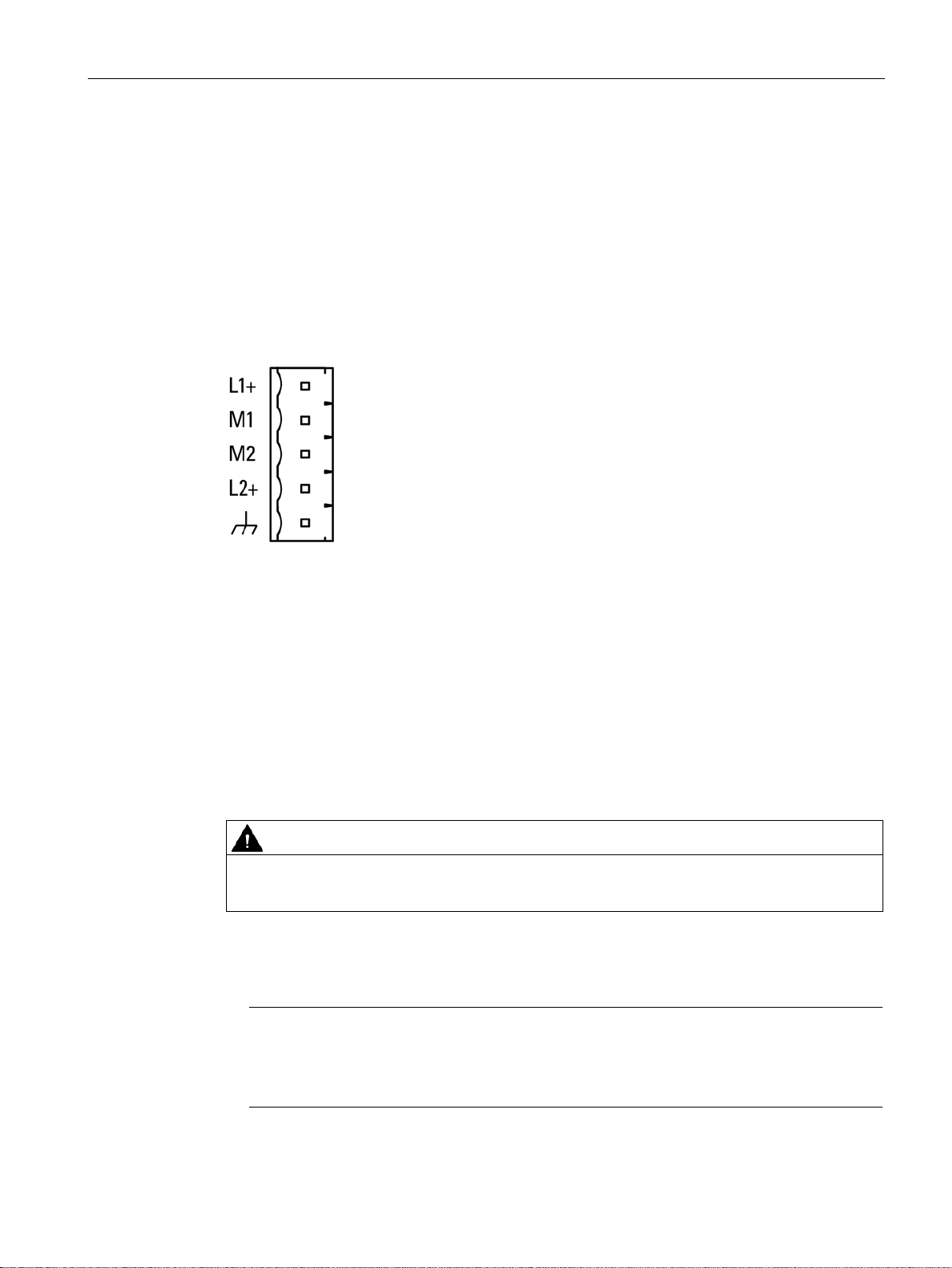

2.2.2 External power supply

External power supply

The connector (socket) for the external 24 V DC power supply is located on the front of the

gateway. The external power supply is redundant (optional use).

The power supply is connected to the gateway with the supplied 5-pin plug-in terminal block.

The connection has a mechanical reverse polarity protection. The terminal block is designed

so that it can only be inserted in one position into the socket of the gateway.

Figure 2-1 Socket of the external power supply

For information on allocation of the socket and for the connection, see section Connecting

(Page 33).

You will find further data on the power supply in section Technical specifications (Page 99).

2.3 The button "SET"

Functions of the button

Do not press the button if there is a potentially explosive atmosphere.

The "SET" button has the following functions:

●

Resetting to factory settings

. This deletes all the configured settings.

For the precise effects of resetting, refer to the section Reset (Page 96).

SIMATIC CC712

Operating Instructions, 05/2019, C79000-G8976-C503-01

23

Page 24

LEDs, Connectors, Buttons, CLP

Duration of pressing

the button (seonds)

Function and operation

Resetting to factory settings

address set at the factory.

2.4 CLP Slot

Pressing the button

≥ 5 s

1. Turn off the power supply.

2. Switch the power supply on again while pressing the button.

Hold down the button for at least 5 seconds during startup.

Reset is prepared while the "Diagnosis" LED flashes.

3. Release the button when the LED stops flashing.

While the LED lights up with a green steady light, the gateway performs the reset.

Once reset is complete, the gateway performs a restart and can be reached using the default IP

2.4 CLP Slot

The slot for an optional CLP is located on the back of the module.

For information on inserting and removing the CLP, see section Using a CLP (Page 35).

SIMATIC CC712

24 Operating Instructions, 05/2019, C79000-G8976-C503-01

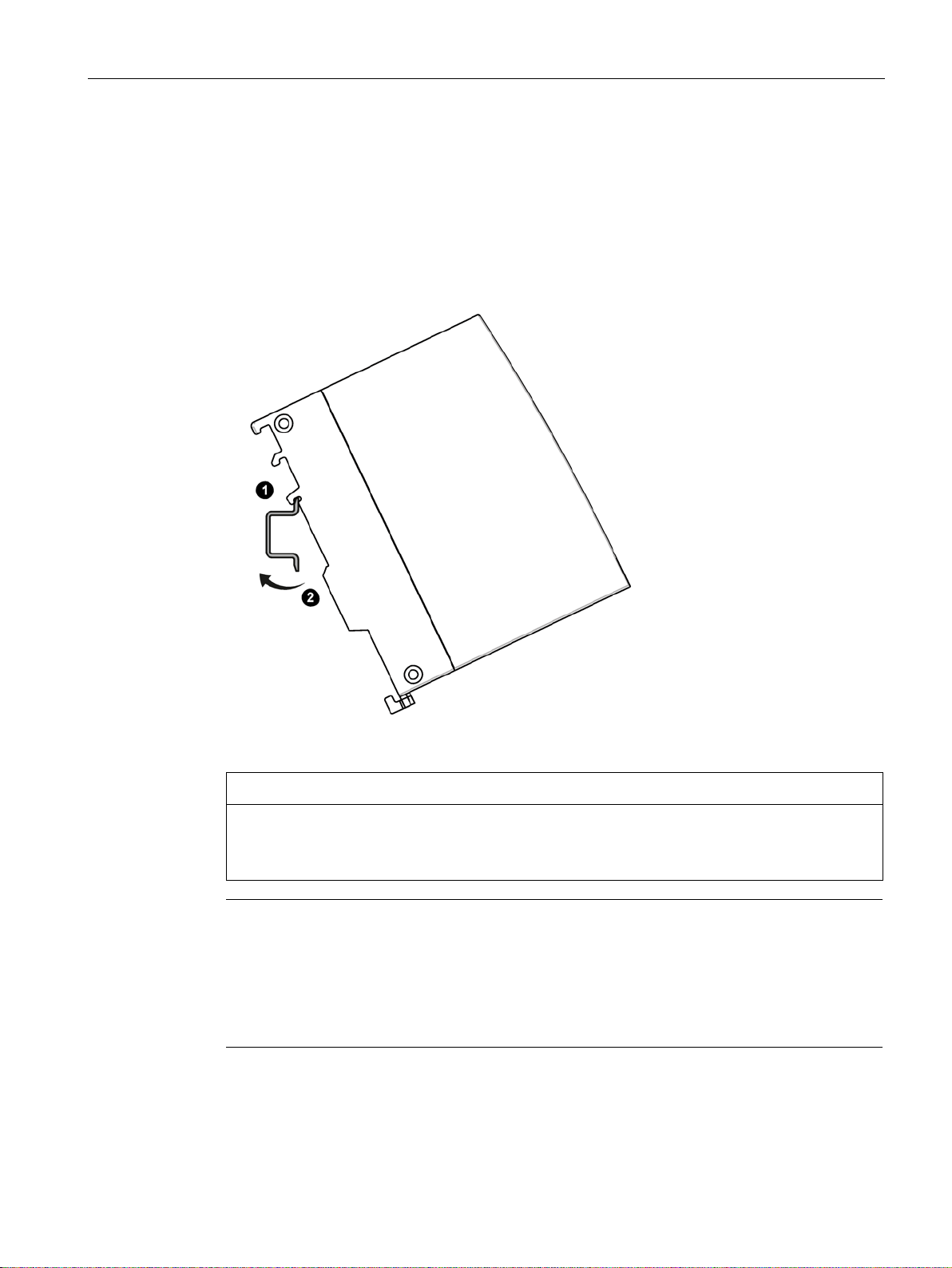

Figure 2-2 Slot for optional CLP on the back of the device

Page 25

3

WARNING

WARNING

EXPLOSION HAZARD

WARNING

WARNING

WARNING

EXPLOSION HAZARD

3.1 Important notes on using the device

Safety notices on the use of the device

Note the following safety notices when setting up and operating the device and during all

associated work such as installation, connecting up or replacing the device.

If the device is installed in a cabinet, the inner temperature of the cabinet corresponds to

the ambient temperature of the device.

3.1.1 Notes on use in hazardous areas

Replacing components may impair suitability for Class 1, Division 2 or Zone 2.

The device may only be operated in an environment with pollution degree 1 or 2 as

described in IEC 60991-1.

The device may only be operated in an environment with pollution degree 1 or 2 (see

IEC 60664-1).

SIMATIC CC712

Operating Instructions, 05/2019, C79000-G8976-C503-01

Do not connect or disconnect cables to or from the device when a flammable or

combustible atmosphere is present.

25

Page 26

Installation, wiring, commissioning

WARNING

WARNING

WARNING

DIN rail

WARNING

Requirements for the cabinet/enclosure

WARNING

Cable

WARNING

3.1 Important notes on using the device

When used in hazardous environments corresponding to Class I, Division 2 or Class I,

Zone 2, the device must be installed in a cabinet or a suitable enclosure.

If a device is operated in an ambient temperature of more than 60 to 70 °C, the

temperature of the device housing may be higher than 70 °C. The device must therefore be

installed so that it is only accessible to service personnel or users that are aware of the

reason for restricted access and the required safety measures at an ambient temperature

higher than 60 °C.

3.1.2 Notes on use in hazardous areas according to ATEX / IECEx

In the ATEX and IECEx area of application only the Siemens DIN rail 6ES5 710-8MA11

may be used to mount the modules.

To comply with EC Directive 2014/34 EU (ATEX 114) or the conditions of IECEx, this

enclosure or cabinet must meet the requirements of at least IP54 (in compliance with

EN 60529) according to EN 60079-7.

If the cable or conduit entry point exceeds 70 °C or the branching point of conductors

exceeds 80 °C, special precautions must be taken. If the equipment is operated in an air

ambient in excess of 50 °C, only use cables with admitted maximum operating temperature

of at least 80 °C.

Take measures to prevent transient voltage surges of more than 40% of the rated voltage.

This is the case if you only operate devices with SELV (safety extra-low voltage).

SIMATIC CC712

26 Operating Instructions, 05/2019, C79000-G8976-C503-01

Page 27

Installation, wiring, commissioning

WARNING

LAN connection (Local Area Network)

WARNING

EXPLOSION HAZARD

WARNING

EXPLOSION HAZARD

WARNING

WARNING

Explosion hazard

3.1 Important notes on using the device

A LAN or LAN segment with all the interconnected devices should be contained completely

in a single low voltage power distribution system in a building. The LAN is designed either

for “Environment A” according to IEEE802.3 or "Environment 0" according to IEC TR

62102.

Do not connect any electrical connectors directly to the telephone network (Telephone

Network Voltage) or a WAN (Wide Area Network).

Do not press the SET button if there is a potentially explosive atmosphere.

3.1.3 General notices on use in hazardous areas according to UL HazLoc / FM

This equipment is suitable for use in Class I, Division 2, Groups A, B, C and D or nonhazardous locations only.

This equipment is suitable for use in Class I, Zone 2, Group IIC or non-hazardous locations

only.

You may only connect or disconnect cables carrying electricity when the power supply is

switched off or when the device is in an area without inflammable gas concentrations.

Do not remove or replace while circuit is live when a flammable or combustible atmosphere

is present.

Do not disconnect equipment when a flammable or combustible atmosphere is present.

SIMATIC CC712

Operating Instructions, 05/2019, C79000-G8976-C503-01

27

Page 28

Installation, wiring, commissioning

WARNING

EXPLOSION HAZARD

WARNING

WARNING

WARNING

Open equipment

WARNING

Cable temperatures

3.2 Installation

The equipment is intended to be installed within an ultimate enclosure. The inner service

temperature of the enclosure corresponds to the ambient temperature of the module. Use

installation wiring connections with admitted maximum operating temperature of at least

30 ºC higher than maximum ambient temperature.

Wall mounting is only permitted if the requirements for the housing, the installation

regulations, the clearance and separating regulations for the control cabinets or housings

are adhered to. The control cabinet cover or housing must be secured so that it can only be

opened with a tool. An appropriate strain-relief assembly for the cable must be used.

Substitution of components may impair suitability for Division 2.

3.2 Installation

The device is "open equipment" acc. to the standard UL 61010-2-201. To fulfill

requirements for safe operation with regard to mechanical stability, flame retardation,

stability, and protection against contact, the following alternative types of installation are

specified:

• Installation in a suitable cabinet.

• Installation in a suitable enclosure.

• Installation in a suitably equipped, enclosed control room.

If the cable or housing socket exceeds 70 °C or the branching point of the cables exceeds

60 °C, special precautions must be taken. If the equipment is operated in an ambient

environment in excess of 40 °C, only use cables with permitted maximum operating

temperature of at least 80 °C.

SIMATIC CC712

28 Operating Instructions, 05/2019, C79000-G8976-C503-01

Page 29

Installation, wiring, commissioning

NOTICE

Install and remove the device only when the power is off.

NOTICE

Installation location - Dependency of the temperature range

Minimum clearances

3.2 Installation

Switch off the power supply of the device before you install or remove the device. Installing

and removing devices with the power supply on can lead to damage to the devices and to

loss of data.

Installation options

You have the following options to install the gateway:

● Wall mounting

● Mounting on the following rail types (rack):

– DIN rail

– S7-1500 standard rail

– S7-300 standard rail

You can find suitable standard rails in the Siemens accessories program for automation

technology, for example:

35 mm standard mounting rail for 19" cabinets, article numbers 6ES5710-8MA11

● Mounting on pedestal

You can use the SCALANCE M pedestal "6GK5898-8MD00" for table mounting (does not

ship with the product).

Installation location

Note the dependency of the permitted temperature range of the installation location.

• Horizontal installation of the rack (DIN rail) means a vertical position of the modules.

• Vertical installation of the rack (DIN rail) means a horizontal position of the modules.

You will find the permitted temperature ranges in the section Technical specifications

(Page 99).

Mount the device so that its upper and lower ventilation slits are not covered, allowing

adequate ventilation as protection from overheating.

Keep to the following minimum clearances for the circulation of air when the rack is

installed horizontally:

• Above the device: At least 33 mm

SIMATIC CC712

Operating Instructions, 05/2019, C79000-G8976-C503-01

• Below the device: At least 25 mm

29

Page 30

Installation, wiring, commissioning

Installation of the rack

Installation position of the modules

3.2 Installation

Horizontal installation of the rack

Vertical installation of the rack

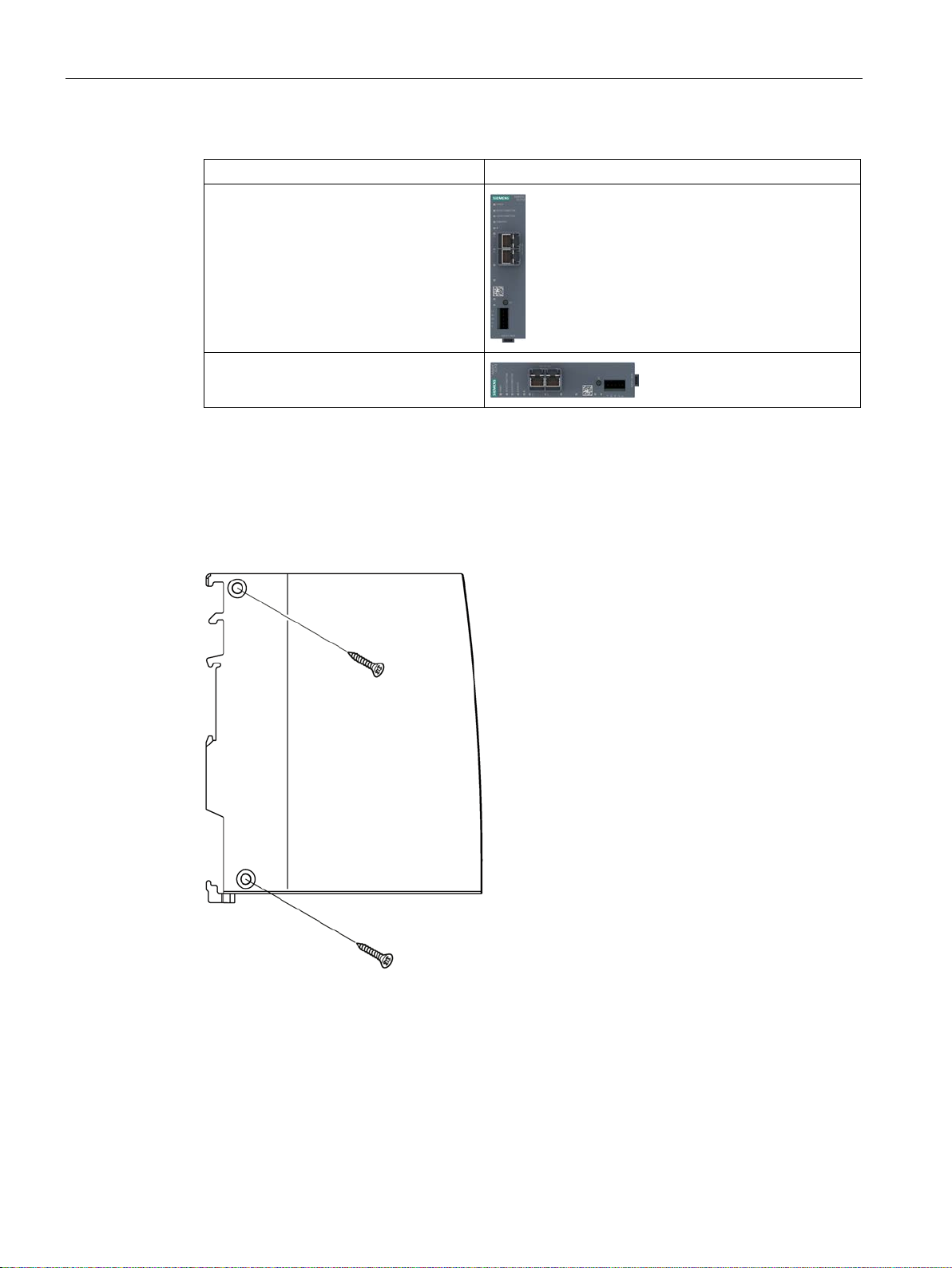

Wall mounting

1. Prepare the drill holes for wall mounting. For the dimensions, refer to the section

"Dimension drawings (Page 107)".

2. Secure the device to the wall with two screws (4 mm).

SIMATIC CC712

30 Operating Instructions, 05/2019, C79000-G8976-C503-01

Page 31

Installation, wiring, commissioning

NOTICE

Grounding

Note

Protecting the modules from slipping on the DIN rail

If you install the modules in an area with mechanical load, use suitable clamping devices at

both ends of the device group to secure the modules on the DIN rail, e.g. Siemens and

retainer 8WA1808.

The end retainers prevent the modules separa

3.2 Installation

Installation on a DIN rail

1. Insert the device with the respective guide ① into the standard rail:

– Top guide for S7-1500 standard rail

– Center guide for S7-300 standard rail

– Bottom guide for DIN rail

2. Tilt the device to the back until the mounting rail release audibly locks in place

3. Ground the mounting rail.

②.

For reasons of electrical safety, the DIN rail must be connected to the protective conductor

system (PE) of the electrical system.

ting under mechanical load.

SIMATIC CC712

Operating Instructions, 05/2019, C79000-G8976-C503-01

31

Page 32

Installation, wiring, commissioning

3.2 Installation

Mounting on pedestal

1. Insert the device with the bottom housing guide on the top edge of the pedestal ①.

2. Press the device against the pedestal until the mounting rail release audibly locks in place

②.

Uninstalling

Follow the steps below to remove the device from the rail:

1. Turn off the supply voltage of the device.

2. Pull the power supply plug and the cables of the communication networks.

3. Pull down the mounting rail release on the rear of the device.

4. Tilt the device out of the standard rail.

SIMATIC CC712

32 Operating Instructions, 05/2019, C79000-G8976-C503-01

Page 33

Installation, wiring, commissioning

NOTICE

Suitable fusing for the power supply cable

Note

Protective ground

A PELV circuit contains a connection to protective ground. Without a connection to protective

ground, or in case there is a fault in the connection to the protective ground, the voltage for

the circuit is not stabilized.

WARNING

Power supply

3.3 Connecting

3.3 Connecting

The current at the connecting terminals must not exceed 4 A. Use a fuse for the power

supply that protects against currents > 4 A.

The fuse has to be designed for protection of DC power supply circuits as well as for the

following requirements.

• In areas used according to NEC or CEC:

– Suitable for DC (min. 60 V / max. 4 A)

– Cut-off voltage min. 10 kA

– UL/CSA listet (UL 248-1 / CSA 22.2 No. 248.1)

– Classes R, J, L, T or CC

• In other areas:

– Suitable for DC (min. 60 V / max. 4 A)

– Cut-off voltage min. 10 kA

– Approved for power supply circuits (branch circuits) according to local regulations

(e.g. IEC 60127-1, EN 60947-1)

– Breaking characteristics: B or C circuit breakers and fuses

You do not need a fuse for the power supply cable if you use a voltage source according

NEC Class 2 or a power supply from the range of accessories, see attachment Power

supply (Page 109).

The device is designed for operation with a directly connectable safety extra-low voltage

(SELV) and protective extra-low voltage (PELV) according to IEC 60364-4-41.

Recommendation: Use the power supply of a process station if this is in the vicinity of the

gateway.

SIMATIC CC712

Operating Instructions, 05/2019, C79000-G8976-C503-01

33

Page 34

Installation, wiring, commissioning

NOTICE

Connection only with power off

Note

The power supply unit of the device is not electrically isolated.

Terminal

Assignment

L1+

24 VDC

M1

Reference ground

L2+

24 V DC for redundant connection (optional)

3.3 Connecting

Order of the work

Only connect the device with the power switched off.

The device can be disconnected from the power supply with the terminal block.

Requirement: The device is mounted.

1. Connect the external power supply to the terminal block of the device.

2. Connect the cables of the two Ethernet networks to the interfaces of the device.

See the note in section Ethernet interfaces (P1, P2) (Page 22).

Turn the power supply on only after the device has been completely wired and connected.

The further procedure is described in the section Commissioning (Page 35).

Power supply

Use only copper cables for the power supply.

● Wire: 0.5 ...3 mm

● Stranded wire: 0.5 ...2.5 mm

2

(AWG 20 ...18)

2

● Tightening torque for screw terminals: 0.6 to 0.8 Nm

The 5-pin plug-in terminal block for the socket has a mechanical reverse polarity protection.

Table 3- 1 Pin assignment of the socket for the power supply

M2 Ground reference for redundant connection

Ground

You will find information about the connectable cable cross sections, power consumption

and further technical details in section Technical specifications (Page 99).

SIMATIC CC712

34 Operating Instructions, 05/2019, C79000-G8976-C503-01

Page 35

Installation, wiring, commissioning

3.4 Commissioning

3.4 Commissioning

3.4.1 Commissioning

Commissioning

1. Turn on the power supply after connecting it to the gateway.

2. Connect the configuration PC to the gateway for configuration, refer to the section

Establishing a connection to the WBM (Page 42).

If you want to use a CLP, turn off the power supply before you start configuring, insert the

CLP and turn on the power supply again.

Requirements for operation

At least the following requirements apply to operating the gateway:

● Configuration of the device

● At least one running process station

● A setup cloud service or OPC UA client

● Connecting the gateway to the networks of the communication partners

Applying the configuration data during commissioning

The "Apply" button

All saved configuration data that you create in the WBM is loaded into the gateway by

clicking the "Apply" button and used immediately. In this way, you can commission the

gateway step-by-step.

For information on the buttons of the WBM, see section General functions of the WBM

(Page 41).

3.4.2 Using a CLP

Exchangeable storage medium CLP

The gateway can be operated with an exchangeable CLP. The configuration data can be

stored on this exchangeable medium and this is retained if there is a power failure.

This exchangeable medium makes it easier to replace a damaged component or for any

other application of the gateway. By simply exchanging the plug, all data can be transferred

without having to be configured again.

The CLP is supplied with power by the gateway. The CLP retains all data permanently when

the power is turned off.

SIMATIC CC712

Operating Instructions, 05/2019, C79000-G8976-C503-01

35

Page 36

Installation, wiring, commissioning

Note

Use new CLPs

Only use a brand

eway. The gateway formats

a brand

CLPs that have already been used in other device types cannot be used for the gateway.

Note

Insert and remove only when power is off

The CLP may be inserted or removed only when the power is off!

3.4 Commissioning

-new CLP or a CLP that was formatted by a gat

-new CLP when it starts up with it.

Startup of the gateway with configuration file on CLP

When a configuration file is saved on the CLP and you insert the CLP into a gateway, the

gateway always starts up with the configuration data of the CLP.

By inserting a CLP into a brand-new gateway or a gateway that was reset to factory settings,

you can cause the gateway to always start up with the configuration file saved on the CLP.

Function

An unwritten CLP (factory state) is automatically formatted for the gateway on startup of the

device.

Inserting the CLP

The configuration of the gateway which you configure and apply is automatically backed up

on the CLP.

A device with an inserted CLP automatically uses the configuration data of the inserted CLP

when it starts up. This is, however, only possible when the data was written by a compatible

device type.

This allows fast and simple replacement of the basic device. If a device is replaced, the CLP

is taken from the failed device and inserted in the replacement. As soon as it starts up, the

replacement automatically applies the same device configuration as the failed device.

The slot for the CLP is located on the back of the device, see section CLP Slot (Page 24).

1. Turn off the power to the device.

2. Insert the CLP in the slot.

The CLP can only be inserted in one position.

Removing the CLP

1. Turn off the power to the device.

2. Insert a screwdriver between the front edge of the CLP and the slot and remove the CLP.

Diagnostics

General malfunctions of the CLP are signaled by the respective diagnostic message.

SIMATIC CC712

36 Operating Instructions, 05/2019, C79000-G8976-C503-01

Page 37

4

4.1 Security recommendations

Keep to the following security recommendations to prevent unauthorized access to the

system.

General

● You should make regular checks to make sure that the device meets the following

recommendations and other internal security guidelines if applicable.

● Evaluate your plant as a whole in terms of security. Use a cell protection concept with

suitable products.

● Check regularly for security updates of the products and use them.

● Check regularly for new features on the Siemens Internet pages.

– Here you will find information on industrial security:

Link: (http://www.siemens.com/industrialsecurity)

– Here you will find information on security in industrial communication:

Link: (http://w3.siemens.com/mcms/industrial-communication/en/ie/industrial-ethernet-

security/Seiten/industrial-security.aspx)

– You will find a publication on the topic of network security (6ZB5530-1AP0x-0BAx)

here:

Link:

(http://w3app.siemens.com/mcms/infocenter/content/en/Pages/order_form.aspx?node

Key=key_518693&infotype=brochures)

Enter the following filter: 6ZB5530

● Keep the software up to date. Always use the latest software version of the device.

– Information regarding product news and new software versions is available at the

following address:

Link: (https://support.industry.siemens.com/cs/ww/en/ps/15248/dl)

Physical access

Restrict physical access to the devices to qualified personnel.

Security functions of the product

Think about the services with which you want to enable access to the process stations via

public networks.

Use the options for security settings in the configuration of the product:

● Activate the security functions of the product and the devices involved.

● Use secure protocol variants (see below).

SIMATIC CC712

Operating Instructions, 05/2019, C79000-G8976-C503-01

37

Page 38

Configuration

4.1 Security recommendations

Passwords

● Define rules for the use of devices and assignment of passwords.

● Regularly update the passwords to increase security.

● Make sure that all passwords are protected and inaccessible to unauthorized personnel.

● Do not use one password for different users and systems.

Protocols

Secure and non-secure protocols

● Only activate protocols that you require to use the system.

● Use secure protocols when access to the device is not prevented by physical protection

measures.

– The NTP protocol provides a secure alternative with NTP (secure).

– Access to the Web server is only possible with HTTPS.

Server ports

The following table provides you with an overview of the open ports on this device.

●

Protocol / function

Protocols that the device supports.

●

Port number (protocol)

Port number assigned to the protocol.

●

Default of the port

– Open

The port is open at the start of the configuration.

– Closed

The port is closed at the start of the configuration.

●

Port status

– Open

The port is always open and cannot be closed.

– Open after configuration

The port is open if it has been configured.

●

Authentication

Specifies whether or not the protocol authenticates the communications partner during

access.

SIMATIC CC712

38 Operating Instructions, 05/2019, C79000-G8976-C503-01

Page 39

Configuration

Protocol / function

Port number (protocol)

Default of the port

Port status

Authentication

HTTPS

443 (TCP)

Open

Open

Yes

OPC UA server port

Note

Ensure that the PC and gateway are located in a protected network.

4.2 Overview of the WBM pages

Table 4- 1 Server ports

4840 (or individually

configured) (TCP)

Open when the server

is enabled.

Client ports

Make sure that you open port 443 in your configuration PC (HTTPS) as well as the required

client ports of the services used in the respective firewall in the subnet of the cloud in

intermediary routers/gateways.

This can be:

● Broker port

– MQTT unsecured: 1883 (TCP)

– MQTT via TLS: 8883 (TCP)

The port number can be set in WBM.

● NTP / 123 (UDP)

● DNS / 53 (UDP)

● DHCP / 67, 68 (UDP)

HTTPS connection over the process interface

For security reasons, you can only establish a connection to the WBM via the process

interface of the gateway from your PC.

Open after configuration

(server)

Yes, when security is

enabled.

The cloud interface is blocked for access to the WBM.

4.2 Overview of the WBM pages

Opening the WBM pages

All page titles that you need for navigation through the WBM are located at the top of each

WBM page.

Open a WBM page by clicking the page title.

SIMATIC CC712

Operating Instructions, 05/2019, C79000-G8976-C503-01

39

Page 40

Configuration

4.2 Overview of the WBM pages

The WBM tabs

The following list provides an overview of the WBM pages and their functions.

● Start page (Page 45)

– Info

The page provides an overview of important status and configuration data of the

gateway.

● Interface configuration (Page 46)

– Configuring the gateway interfaces

● Process access (Page 48)

– Configuration of the process access (SIMATIC S7 / Modbus/TCP)

● OPC UA (Page 52)

– Configuring the OPC UA server

● Cloud configuration (Page 59)

– Configuring the cloud access

– Configuring the MQTT settings

– Certificate management

– Configuring the topics/groups and the user data format

● Data points (Page 78)

– Configuring the data points of the process stations

● Maintenance (Page 87)

– Time-of-day synchronization / setting the time

– User management

– Firmware update

– Configuration backup

– Process communication, restart

– Diagnostic messages

– Exporting logging data

SIMATIC CC712

40 Operating Instructions, 05/2019, C79000-G8976-C503-01

Page 41

Configuration

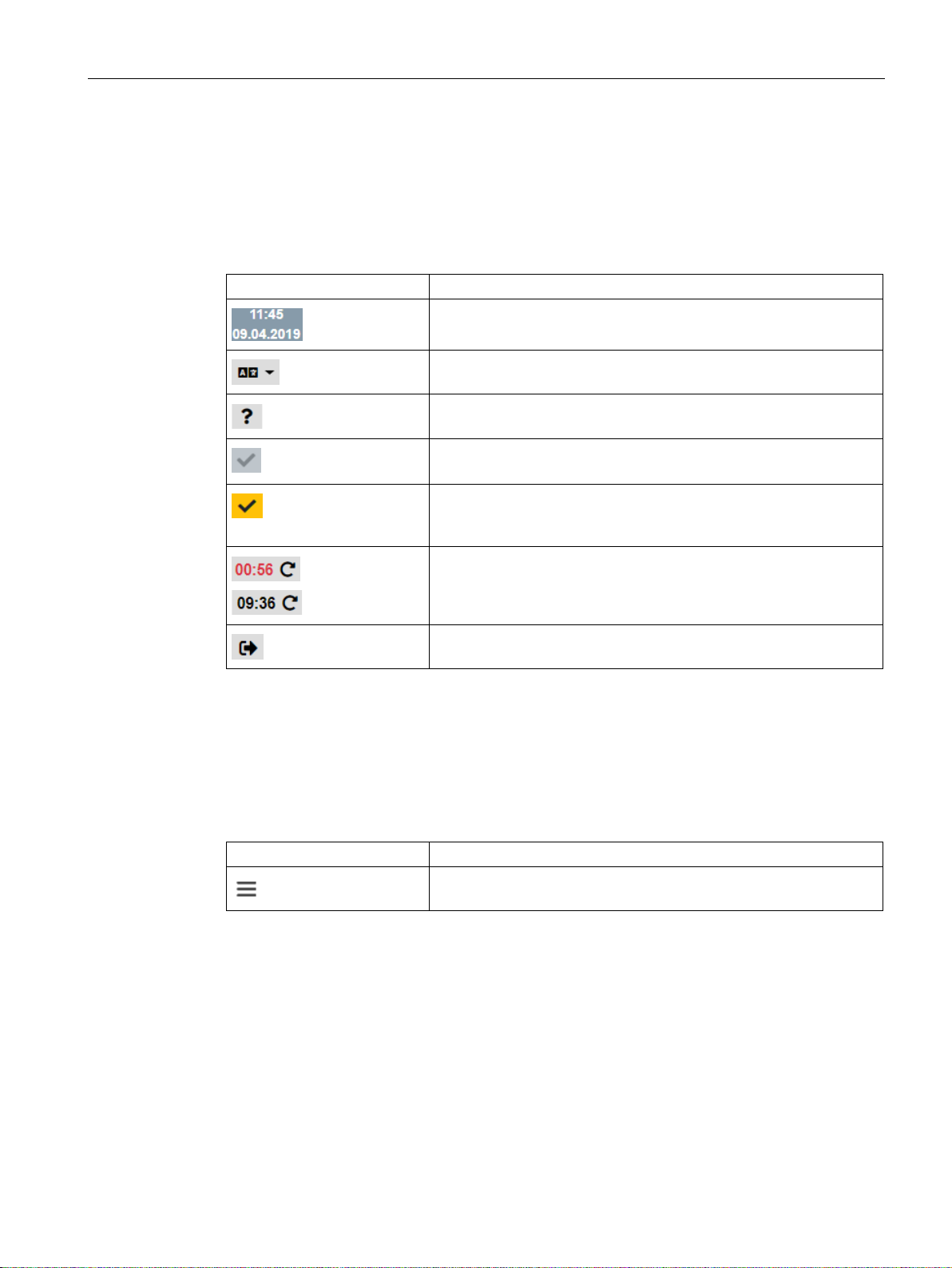

Symbol

Function

Runtime system is restarted with the applied settings.

Symbol

Function

4.3 General functions of the WBM

4.3 General functions of the WBM

Symbols in the toolbar

You can reach the following functions using the displays and symbols in the toolbar:

Time and date of the runtime system

Switching the WBM language

Opens the online help of the WBM.

Apply

All saved data is applied to the Runtime system.

Apply

Applies saved configuration data to the Runtime system. The

Menu bar

Save

Counter which displays the remaining time of the current session.

By clicking the time display, the counter of the session duration is

reset.

Log off: Ends the connection to the WBM

The menu bar shows the tabs of the WBM over which you reach the different pages of the

WBM.

When you minimize your browser window, the display of the tabs disappears and the

following symbol is displayed:

Shows the tab titles as navigation with a minimized browser window.

Confirm all your entries by clicking the "Save" button. Your settings are thus saved to the

buffer.

The saved configuration data is not applied by the device yet by saving. This prevents

inconsistent changes from being loaded to the Runtime system when the WBM page is

changed.

SIMATIC CC712

Operating Instructions, 05/2019, C79000-G8976-C503-01

41

Page 42

Configuration

Note

IP address of the CP

By default, the DHCP client of the gateway is disabled. Make sure that the PC has a fixed IP

address during the first connection setup and that it is located in the same subnet as the

connected interfac

When using a DHCP server you do not need to specify the addressing on the PC to be

connected. When it is connected to the network, the PC is assigned an address.

4.4 Calling the WBM

Application to the runtime system

All saved configuration data is applied to the Runtime system by clicking on the "Apply"

symbol.

Incorrect entries in the configuration

The input boxes of the WBM are checked during input for faulty content and consistency.

Notes are output for boxes with detected errors during saving. The settings can only be

saved after the error has been corrected.

Grayed out fields cannot be edited.

4.4 Calling the WBM

4.4.1 Establishing a connection to the WBM

Requirements

You can establish a connection between a PC and the gateway via HTTPS:

You can establish a connection over the P2 interface of the gateway.

The condition for access to the gateway is that the PC is located in the same subnet and that

the gateway can be reached.

First connection setup with preset IPv4 address

Use the following preset IPv4 address of the gateway during the first connection setup:

● P2 interface address: 192.168.0.55

e of the gateway.

SIMATIC CC712

42 Operating Instructions, 05/2019, C79000-G8976-C503-01

Page 43

Configuration

Note

Changing standard user data

For security reasons,

must be changed when you log i

User data

Default values set in the factory

User name

admin

Password

admin

4.4 Calling the WBM

Connection to the Web server of the gateway

Follow the steps below to connect the PC to the Web server of the gateway:

1. Open the Web browser.

2. Enter the IP address of the gateway in the address line of the Web browser:

– https://<Address>

With HTTPS connections when you log in, a warning can appear that the Web page is

not secure or that the certificate is not trustworthy. If you are sure that you have entered

the correct address, ignore the message. If necessary add the connection to the

exceptions (depending on the Web browser).

When the connection setup is successful, the logon window of the WBM opens.

4.4.2 Logging into the WBM

HTTPS connection

Only HTTPS connections are supported.

You can establish a connection between a PC and the WBM of the device.

Changing standard user data

Standard user data for the first login to the WBM is preassigned by the system:

An administrator can be set up with all available rights for operation of the WBM.

the factory set user data (user name, password) of the standard user

n the first time, see section User (Page 89).

SIMATIC CC712

Operating Instructions, 05/2019, C79000-G8976-C503-01

43

Page 44

Configuration

Note

Entering the wrong user name or password

After entering an incorrect user name or incorrect password three times a lockout time of a

few minutes begin

4.4 Calling the WBM

Logging in

After establishing a connection between the PC and the device, the WBM opens with the

logon page.

s. Only after the lockout time has expired can you try to log in again.

● User name

Enter the user name here.

●

Password

Enter the password here.

●

Logging in

Click the button to set up the connection to the WBM.

When you log in for the first time, you are prompted to change the default user data. You can

find the rules for password assignment in the section User (Page 89).

Open Source Software and links to additional information

You can find the following links at the bottom of the login page:

●

Help

Opens the online help of the WBM.

●

Open Source Software

Opens the license terms document for the Open Source Software.

If necessary, you can save the document on your PC.

●

Siemens

Opens the Siemens AG homepage.

4.4.3 Log out

Manual logout using the button

You log out from the WBM by clicking on this button in the toolbar.

The connection to the device is terminated. All changes to the configuration data not saved

previously are lost.

SIMATIC CC712

44 Operating Instructions, 05/2019, C79000-G8976-C503-01

Page 45

Configuration

4.5 Start page

Automatic logout after timeout

After 600 seconds without saving or changing the WBM page, you are logged out and

disconnected from the WBM. In this case, you must log in again.

In the WBM toolbar you can see the counter in the upper right-hand corner which displays

the remaining time of the current session. By clicking the time display, the counter of the

session duration is reset and the time of the session duration starts all over again.

4.5 Start page

4.5.1 Info

The page provides an overview of important status and configuration data of the device.

Status

Process interface

● Operating state

Operating state of the device

●

System runtime (dd-hh-mm-ss)

Time since the last startup (dd-hh-mm-ss)

●

Hardware product version

Hardware product version of the device

●

U-Boot version

Current U-Boot version for the firmware bootloader

●

Software version

Current firmware version of the device

●

Serial number

Serial number of the device

The parameter group displays the current address data of the P2 interface.

●

MAC address

●

IPv4

Address parameters, Default router

SIMATIC CC712

Operating Instructions, 05/2019, C79000-G8976-C503-01

45

Page 46

Configuration

Address data preset in the factory

Process interface (P2)

Cloud interface (P1)

IPv4 address

192.168.0.55

192.168.121.55

IPv6 address

-

-

Subnet mask

255.255.255.0

255.255.255.0

4.6 Interface configuration

Cloud interface

The parameter group displays the current address data of the P1 interface.

●

MAC address

●

IPv4 / IPv6

Address parameters, Default router

DNS server

The parameter group shows the IPv4 addresses of up to two configured DNS servers.

4.6 Interface configuration

4.6.1 Ethernet

In this tab, you configure the address data of the Ethernet interfaces of the device.

Interface and factory default addresses

You configure the following interfaces on the web pages:

● Process interface (P2)

The interface (P2) is used for connecting to the subnet of the process stations.

● Cloud interface (P1)

The interface (P1) is used for connecting to the Internet or to a router over which the

broker or the network with OPC UA clients can be reached.

The device supports IPv4 addresses, and for cloud access also IPv6 addresses.

The following address data is preset in the factory:

Table 4- 2 Preset address data

Host name CloudConnect7 CloudConnect7

SIMATIC CC712

46 Operating Instructions, 05/2019, C79000-G8976-C503-01

Page 47

Configuration

Note

No address check

The address bands are not checked automatically.

Make sure that the subnets of the two interfaces are not the same.

Note

No reachability when IP address data of the process interface is applied

The IP parameters of the process interface must match the settings of the IP address

data of your PC.

Note

DHCP server

The devi

function, a DHCP server must be located in the subnet.

The factory preset host name of the device is transferred to the DHCP server, see table

"Preset address data" above.

4.6 Interface configuration

Process interface / Cloud interface

You configure both interfaces separately.

●

Cloud interface in the same subnet

You can find this option under the parameter group of the Cloud interface.

Only enable the option if the connection to the cloud is in the same subnet as the process

connection.

When the option is enabled, the Cloud interface is disabled and the corresponding input

fields are locked.

The following parameters apply to both interfaces.

●

MAC address

MAC address of the interface

●

IPv4 / IPv6

Enable the respective IP address.

Alternatively, the Cloud interface supports IPv6 addresses.

● IP address

Shows the preset, last configured or the last IP address to be obtained from the DHCP

server.

During the initial configuration: Assign the IP address of the respective interface or

activate addressing by a DHCP server.

●

IP address via DHCP

Enable the option if you want to obtain the address data of the Cloud interface from a

DHCP server.

When the option is enabled, the address data boxes are grayed out, and the values

obtained from the DHCP server are displayed.

ce supports the DHCP client function at the cloud Cloud interface. To use the

SIMATIC CC712

Operating Instructions, 05/2019, C79000-G8976-C503-01

47

Page 48

Configuration

4.7 Process access

● Subnet mask

Shows the preset, last configured or the last subnet mask to be obtained from the DHCP

server.

During the initial configuration: Assign the subnet mask of the respective interface.

●

Default router

Shows the configured IP address of the router being used or the one last obtained with

DHCP.

During the initial configuration: Assign the IP address of the router.

DNS server

● DNS server