Siemens SIMATIC C7-626, SIMATIC C7-626 DP Installation, Assembly, Wiring

RGB ELEKTRONIKA AGACIAK CIACIEK

SPÓŁKA JAWNA

Jana Dlugosza 2-6 Street

51-162 Wrocław

Poland

biuro@rgbelektronika.pl

+48 71 325 15 05

www.rgbautomatyka.pl

www.rgbelektronika.pl

DATASHEET

www.rgbautomatyka.pl

www.rgbelektronika.pl

OTHER SYMBOLS:

KEYPAD 6ES7626-2AG00-0AE3

SIEMENS

YOUR

PARTNER IN

MAINTENANCE

At our premises in Wrocław, we have a fully equipped servicing facility. Here we perform all the repair

works and test each later sold unit. Our trained employees, equipped with a wide variety of tools and

having several testing stands at their disposal, are a guarantee of the highest quality service.

OUR SERVICES

ENCODERS

SERVO

DRIVERS

LINEAR

ENCODERS

SERVO AMPLIFIERS

CNC

MACHINES

MOTORS

POWER

SUPPLIERS

OPERATOR

PANELS

CNC

CONTROLS

INDUSTRIAL

COMPUTERS

PLC

SYSTEMS

Repair this product with RGB ELEKTRONIKA

ORDER A DIAGNOSIS

∠

Buy this product at RGB AUTOMATYKA

BUY

∠

Preface, Contents

User Information

Product Overview

1

Assembly

Installing and Preparing the C7

2

Configuring MPI Networks and

PROFIBUS-DP Networks

3

Connecting a Programming

Device to a C7

4

Inputs / Outputs

C7 Digital Input/Output

5

C7 Analog Input/Output

6

Universal Inputs

7

Maintenance

8

Appendices

General Technical Specifications

A

Guidelines for Handling

Electrostatically Sensitive

Devices (ESD)

B

Glossary, Index

C79000-G7076-C626-01

C7-626 / C7-626 DP

Control Systems

Volume 1

Installation, Assembly, Wiring

Manual

SIMATIC

C7-626 / C7-626 DP Control Systems

This manual contains notices which you should observe to ensure your own personal safety, as well as to

protect the product and connected equipment. These notices are highlighted in the manual by a warning

triangle and are marked as follows according to the level of danger:

!

Danger

indicates that death, severe personal injury or substantial property damage will result if proper precautions are

not taken.

!

Warning

indicates that death, severe personal injury or substantial property damage can result if proper precautions are

not taken.

!

Caution

indicates that minor personal injury or property damage can result if proper precautions are not taken.

Note

draws your attention to particularly important information on the product, handling the product, or to a particular

part of the documentation.

The device/system may only be set up and operated in conjunction with this manual.

Only qualified personnel should be allowed to install and work on this equipment. Qualified persons are

defined as persons who are authorized to commission, to ground, and to tag circuits, equipment, and sys-

tems in accordance with established safety practices and standards.

Note the following:

!

Warning

This device and its components may only be used for the applications described in the catalog or the technical

description, and only in connection with devices or components from other manufacturers which have been

approved or recommended by Siemens.

This product can only function correctly and safely if it is transported, stored, set up, and installed correctly, and

operated and maintained as recommended.

SIMATICR and SINECR are registered trademarks of SIEMENS AG.

Third parties using for their own purposes any other names in this document which refer to

trademarks might infringe upon the rights of the trademark owners.

We have checked the contents of this manual for agreement with the

hardware and software described. Since deviations cannot be precluded

entirely, we cannot guarantee full agreement. However, the data in this

manual are reviewed regularly and any necessary corrections included in

subsequent editions. Suggestions for improvement are welcomed.

E Siemens AG 1996

T echnical data subject to change.

Disclaimer of LiabilityCopyright E Siemens AG 1996 All rights reserved

The reproduction, transmission or use of this document or its contents is

not permitted without express written authority. Of fenders will be liable for

damages. All rights, including rights created by patent grant or registration

of a utility model or design, are reserved.

Siemens AG

Automation Group

Industrial Automation Systems

Postfach 4848, D-90327 Nürnberg

Siemens Aktiengesellschaft

Order No. C79000-G7076-C626

Safety Guidelines

Qualified Personnel

Correct Usage

Trademarks

iii

C7-626 / C7-626 DP Control Systems

C79000-G7076-C626-01

Preface

The information in this manual will enable you to do the following:

S Install and wire a C7-626 or C7-626 DP (Volume 1).

S Assign parameters to the CPU of the C7-626 or C7-626 DP, load a user

program into this CPU and run the program (Volume 2).

S Put the C7-626 and C7-626 DP into operation and use the operator

interface (O/I) functions (Volume 2).

The manual is divided to take into account two different types of reader:

S Volume 1:

Users who carry out the mechanical and electrical installation of the C7 at

the location of use and who bring the C7 to a state of readiness for

immediate use.

S Volume 2:

Users who create control programs and O/I configurations, load them into

the C7, and print out screen displays and messages.

This manual describes the hardware and software of the C7-626 and C7-626

DP. It consists of two volumes.

Volume 1 of the manual covers the following topics:

S Installation and preparation of the C7-626 or C7-626 DP

S Networking the C7-626 or C7-626 DP with programming devices (PGs)

and other devices

S Connecting the digital and analog I/Os

S Connecting the I/Os to the universal inputs

S Connecting the IM361 interface module

S Connecting a printer to the C7

Purpose

Audience

Contents of This

Manual

iv

C7-626 / C7-626 DP Control Systems

C79000-G7076-C626-01

Volume 2 of the manual covers the following topics:

S Starting up the C7

S Controlling with the C7 CPU

S Addressing and assigning parameters to the C7 I/O

S C7 diagnostics

S Using the O/I functions of the C7

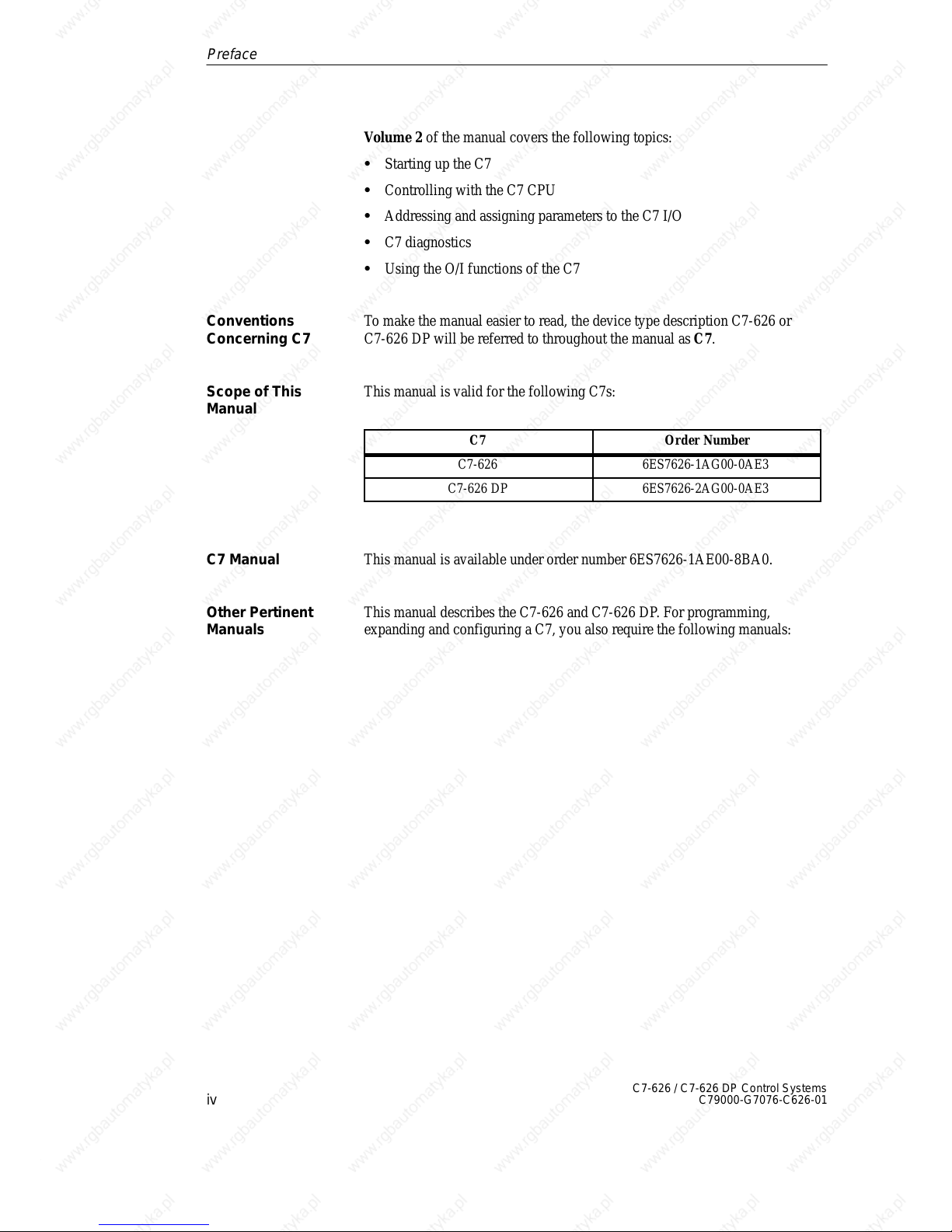

To make the manual easier to read, the device type description C7-626 or

C7-626 DP will be referred to throughout the manual as C7.

This manual is valid for the following C7s:

C7 Order Number

C7-626 6ES7626-1AG00-0AE3

C7-626 DP 6ES7626-2AG00-0AE3

This manual is available under order number 6ES7626-1AE00-8BA0.

This manual describes the C7-626 and C7-626 DP. For programming,

expanding and configuring a C7, you also require the following manuals:

Conventions

Concerning C7

Scope of This

Manual

C7 Manual

Other Pertinent

Manuals

Preface

v

C7-626 / C7-626 DP Control Systems

C79000-G7076-C626-01

C7

Programming

Assigning parameters

ConfiguringExpanding

ProTool

Hardware and Installation

If required

Statement List for

S7-300 and S7-400

Ladder Logic for

S7-300 and S7-400

System and Standard

Functions

STEP 7 User Manual

Program Design

Module Specifications

Preface

vi

C7-626 / C7-626 DP Control Systems

C79000-G7076-C626-01

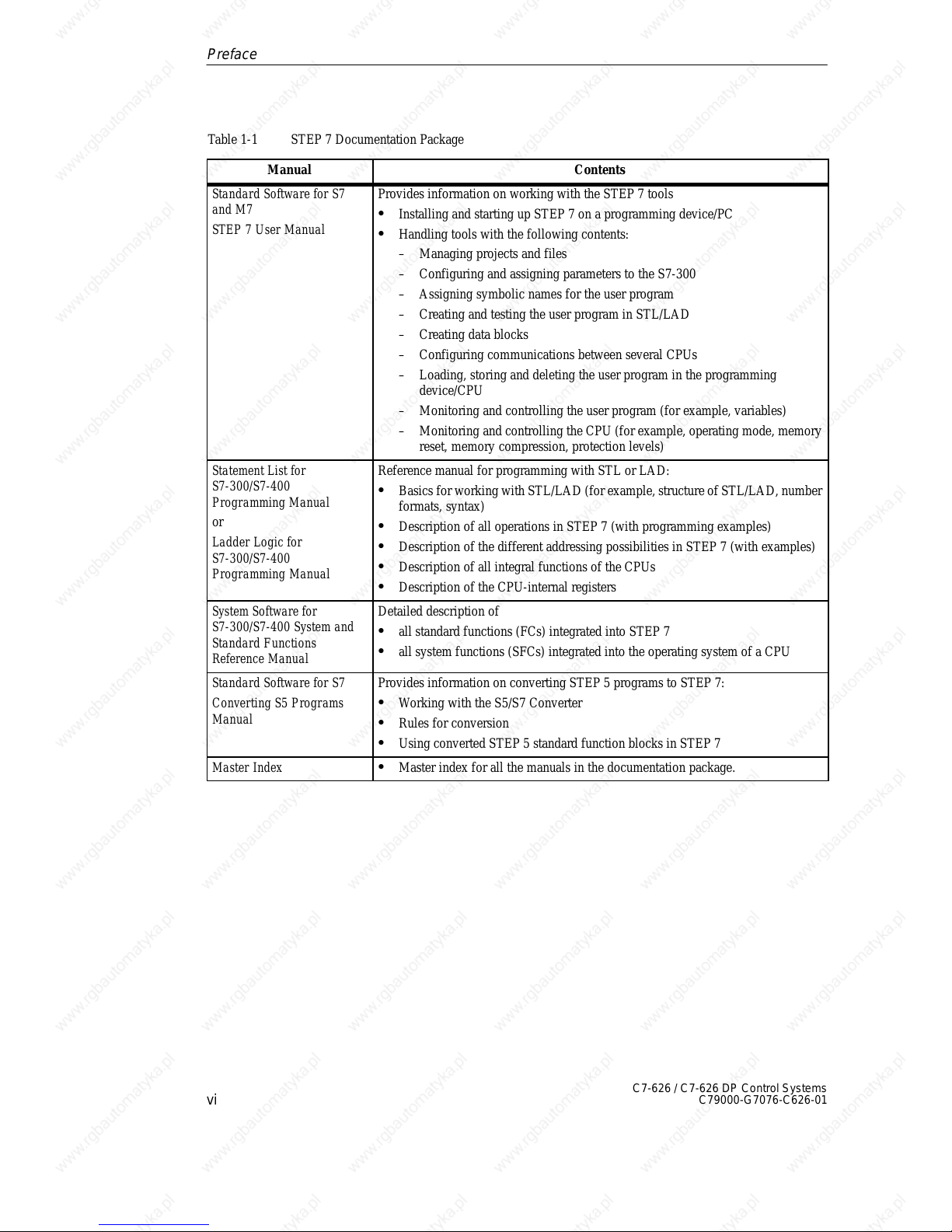

Table 1-1 STEP 7 Documentation Package

Manual Contents

Standard Software for S7

and M7

STEP 7 User Manual

Provides information on working with the STEP 7 tools

S Installing and starting up STEP 7 on a programming device/PC

S Handling tools with the following contents:

– Managing projects and files

– Configuring and assigning parameters to the S7-300

– Assigning symbolic names for the user program

– Creating and testing the user program in STL/LAD

– Creating data blocks

– Configuring communications between several CPUs

– Loading, storing and deleting the user program in the programming

device/CPU

– Monitoring and controlling the user program (for example, variables)

– Monitoring and controlling the CPU (for example, operating mode, memory

reset, memory compression, protection levels)

Statement List for

S7-300/S7-400

Programming Manual

or

Ladder Logic for

S7-300/S7-400

Programming Manual

Reference manual for programming with STL or LAD:

S Basics for working with STL/LAD (for example, structure of STL/LAD, number

formats, syntax)

S Description of all operations in STEP 7 (with programming examples)

S Description of the different addressing possibilities in STEP 7 (with examples)

S Description of all integral functions of the CPUs

S Description of the CPU-internal registers

System Software for

S7-300/S7-400 System and

Standard Functions

Reference Manual

Detailed description of

S all standard functions (FCs) integrated into STEP 7

S all system functions (SFCs) integrated into the operating system of a CPU

Standard Software for S7

Converting S5 Programs

Manual

Provides information on converting STEP 5 programs to STEP 7:

S Working with the S5/S7 Converter

S Rules for conversion

S Using converted STEP 5 standard function blocks in STEP 7

Master Index S Master index for all the manuals in the documentation package.

Preface

vii

C7-626 / C7-626 DP Control Systems

C79000-G7076-C626-01

You will find a list of further information sources on the subject of the

S7-300 and other programmable controllers in Appendix D of Volume 2 of

this manual.

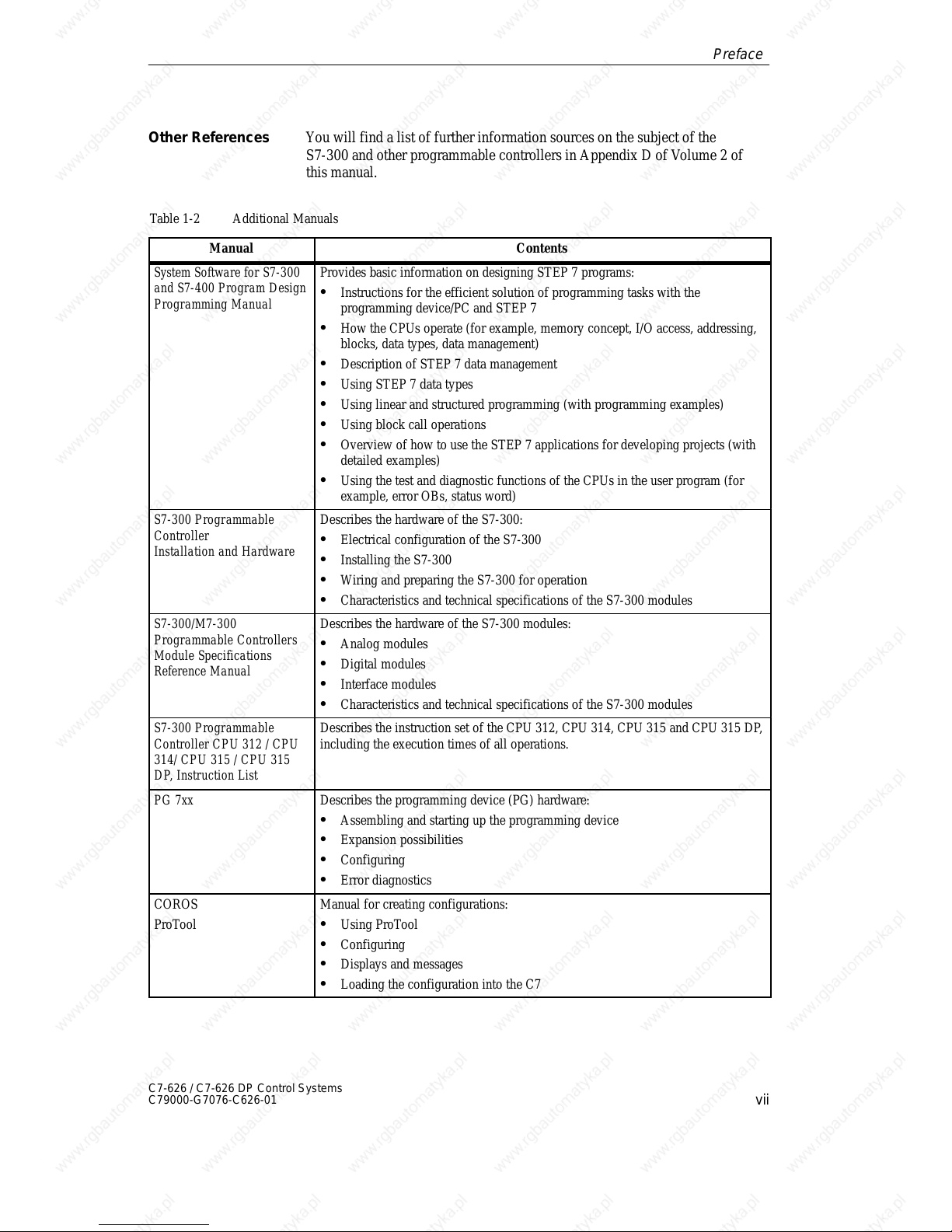

Table 1-2 Additional Manuals

Manual Contents

System Software for S7-300

and S7-400 Program Design

Programming Manual

Provides basic information on designing STEP 7 programs:

S Instructions for the efficient solution of programming tasks with the

programming device/PC and STEP 7

S How the CPUs operate (for example, memory concept, I/O access, addressing,

blocks, data types, data management)

S Description of STEP 7 data management

S Using STEP 7 data types

S Using linear and structured programming (with programming examples)

S Using block call operations

S Overview of how to use the STEP 7 applications for developing projects (with

detailed examples)

S Using the test and diagnostic functions of the CPUs in the user program (for

example, error OBs, status word)

S7-300 Programmable

Controller

Installation and Hardware

Describes the hardware of the S7-300:

S Electrical configuration of the S7-300

S Installing the S7-300

S Wiring and preparing the S7-300 for operation

S Characteristics and technical specifications of the S7-300 modules

S7-300/M7-300

Programmable Controllers

Module Specifications

Reference Manual

Describes the hardware of the S7-300 modules:

S Analog modules

S Digital modules

S Interface modules

S Characteristics and technical specifications of the S7-300 modules

S7-300 Programmable

Controller CPU 312 / CPU

314/ CPU 315 / CPU 315

DP, Instruction List

Describes the instruction set of the CPU 312, CPU 314, CPU 315 and CPU 315 DP,

including the execution times of all operations.

PG 7xx Describes the programming device (PG) hardware:

S Assembling and starting up the programming device

S Expansion possibilities

S Configuring

S Error diagnostics

COROS

ProTool

Manual for creating configurations:

S Using ProTool

S Configuring

S Displays and messages

S Loading the configuration into the C7

Other References

Preface

viii

C7-626 / C7-626 DP Control Systems

C79000-G7076-C626-01

This manual has the following aids to help you find specific information:

S At the beginning of the two volumes, you will find a complete directory

of contents.

S In each chapter, you will find information in the left-hand column of

every page giving you an overview of the contents of that section.

S After the Appendices, there is a Glossary containing important technical

terms used in the manual.

S At the end of the manual, there is a detailed index.

The C7 control system conforms to standards as described in Appendix A.1.

If you have any questions concerning the C7 control system, please contact

your local Siemens representative.

You will find a list of Siemens representatives worldwide in Volume 2 of the

manual, Appendix E.

If you have any questions or remarks concerning the manual, please fill in

and return the Suggestions/Corrections form at the back of Volume 2.

Structure of This

Manual

Standards

Queries

Preface

ix

C7-626 / C7-626 DP Control Systems

C79000-G7076-C626-01

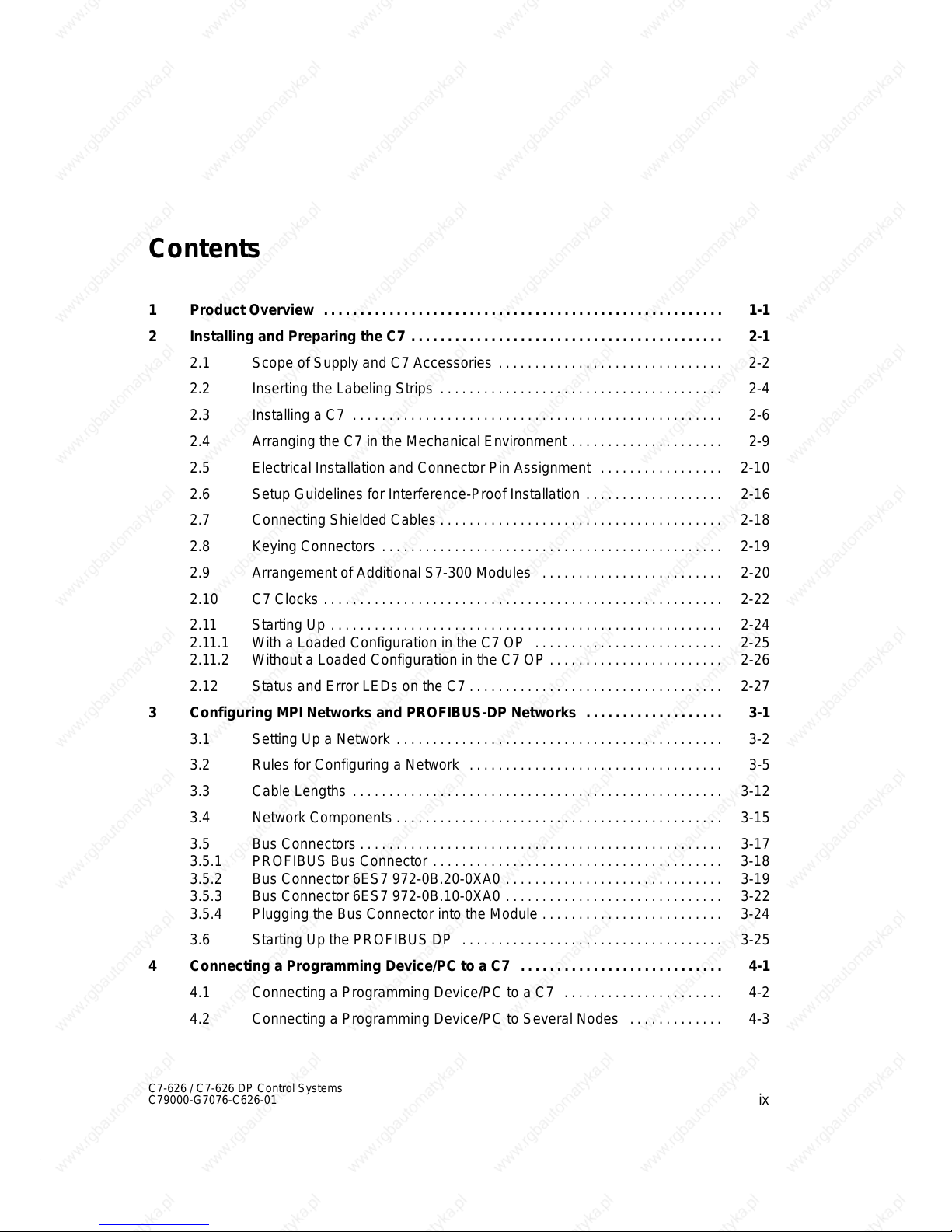

Contents

1 Product Overview 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Installing and Preparing the C7 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Scope of Supply and C7 Accessories 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Inserting the Labeling Strips 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Installing a C7 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Arranging the C7 in the Mechanical Environment 2-9. . . . . . . . . . . . . . . . . . . . .

2.5 Electrical Installation and Connector Pin Assignment 2-10. . . . . . . . . . . . . . . . .

2.6 Setup Guidelines for Interference-Proof Installation 2-16. . . . . . . . . . . . . . . . . . .

2.7 Connecting Shielded Cables 2-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8 Keying Connectors 2-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.9 Arrangement of Additional S7-300 Modules 2-20. . . . . . . . . . . . . . . . . . . . . . . . .

2.10 C7 Clocks 2-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.11 Starting Up 2-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.11.1 With a Loaded Configuration in the C7 OP 2-25. . . . . . . . . . . . . . . . . . . . . . . . . .

2.11.2 Without a Loaded Configuration in the C7 OP 2-26. . . . . . . . . . . . . . . . . . . . . . . .

2.12 Status and Error LEDs on the C7 2-27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Configuring MPI Networks and PROFIBUS-DP Networks 3-1. . . . . . . . . . . . . . . . . . .

3.1 Setting Up a Network 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Rules for Configuring a Network 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Cable Lengths 3-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Network Components 3-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 Bus Connectors 3-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.1 PROFIBUS Bus Connector 3-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.2 Bus Connector 6ES7 972-0B.20-0XA0 3-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.3 Bus Connector 6ES7 972-0B.10-0XA0 3-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.4 Plugging the Bus Connector into the Module 3-24. . . . . . . . . . . . . . . . . . . . . . . . .

3.6 Starting Up the PROFIBUS DP 3-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Connecting a Programming Device/PC to a C7 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Connecting a Programming Device/PC to a C7 4-2. . . . . . . . . . . . . . . . . . . . . .

4.2 Connecting a Programming Device/PC to Several Nodes 4-3. . . . . . . . . . . . .

x

C7-626 / C7-626 DP Control Systems

C79000-G7076-C626-01

5 C7 Digital Input/Output 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Digital Input Function 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Digital Output Function 5-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Status Bits of the DI/DO 5-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 C7 Analog Input/Output 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Connecting Transducers to Analog Inputs 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.1 Connecting Voltage and Current Transducers 6-5. . . . . . . . . . . . . . . . . . . . . . . .

6.2 Connecting Loads/Actuators to the Analog Output 6-6. . . . . . . . . . . . . . . . . . . .

6.3 Analog Input Function 6-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.1 Characteristics and Technical Specifications of the Analog Input Module 6-10

6.4 Analog Output Function 6-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Universal Inputs 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Maintenance 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 Changing and Disposing of the Back-Up Battery 8-2. . . . . . . . . . . . . . . . . . . . .

8.2 Replacing the C7 8-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A General Technical Specifications A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.1 Technical Specifications A-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.2 Notes on the CE Marking A-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.3 Notes for the Machine Manufacturer A-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.4 Transport and Storage Conditions for Back-Up Batteries A-7. . . . . . . . . . . . . .

B Guidelines for Handling Electrostatically Sensitive Devices (ESD) B-1. . . . . . . . . .

B.1 What is ESD? B-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.2 Electrostatic Charging of Objects and Persons B-3. . . . . . . . . . . . . . . . . . . . . . .

B.3 General Protective Measures Against Electrostatic Discharge Damage B-4.

B.4 Taking Measurements and Working on ESD Modules B-6. . . . . . . . . . . . . . . . .

B.5 Packing Electrostatically Sensitive Devices B-6. . . . . . . . . . . . . . . . . . . . . . . . . .

Glossary Glossary-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index Index-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

1-1

C7-626 / C7-626 DP Control Systems

C79000-G7076-C626-01

Product Overview

This chapter contains general information concerning the C7-626 and

C7-626 DP. A brief overview of the performance range provides you with a

first impression of the two units.

This chapter also tells you which additional components you can connect to a

C7 device.

To operate the C7, you require the following accessories:

S Programming device (PG) or PC with a multipoint interface and

programming device cable.

S You must load the following on to the programming device or PC

– the STEP 7 applications

– ProTool.

Overview

Accessories for

Operating the C7

1

1

1-2

C7-626 / C7-626 DP Control Systems

C79000-G7076-C626-01

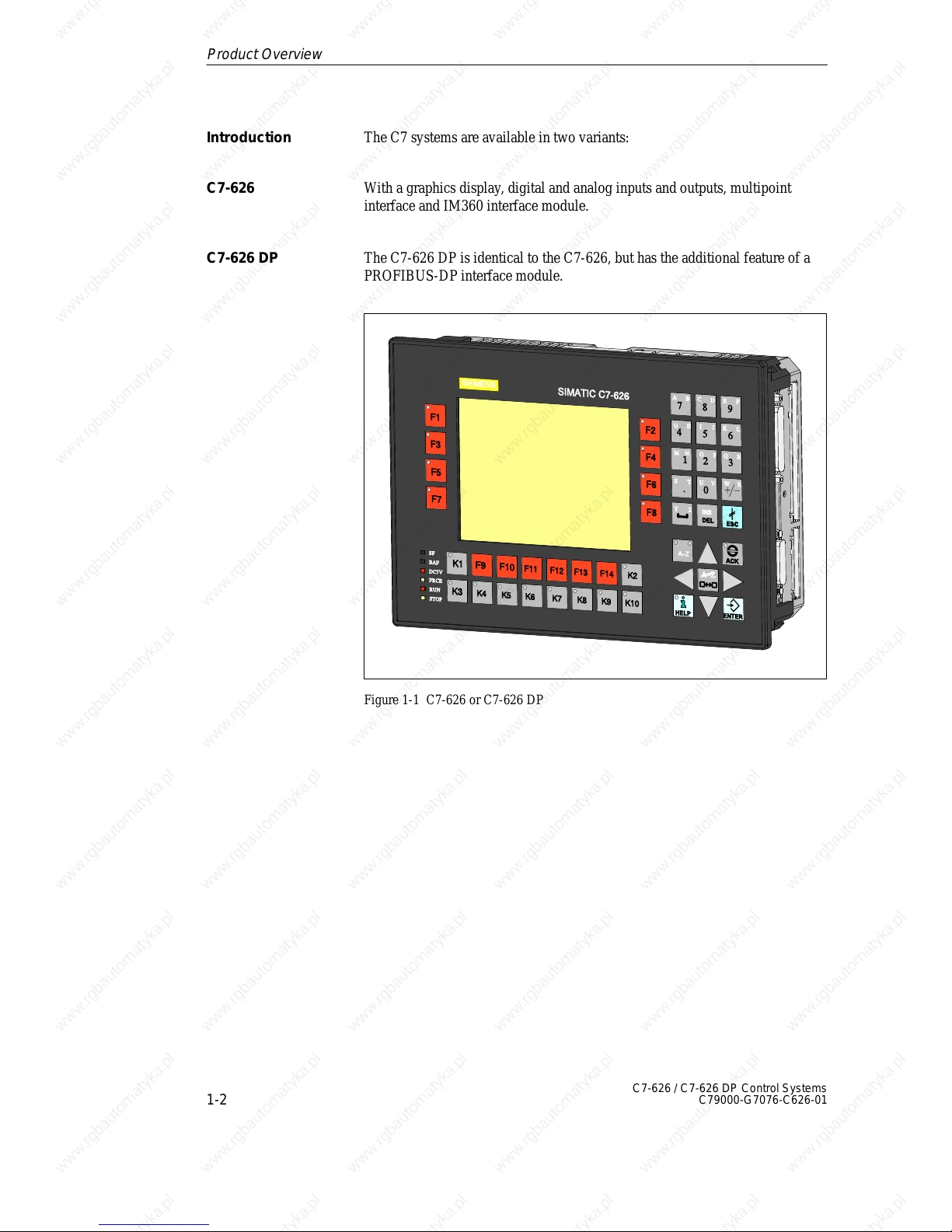

The C7 systems are available in two variants:

With a graphics display, digital and analog inputs and outputs, multipoint

interface and IM360 interface module.

The C7-626 DP is identical to the C7-626, but has the additional feature of a

PROFIBUS-DP interface module.

Figure 1-1 C7-626 or C7-626 DP

Introduction

C7-626

C7-626 DP

Product Overview

1

1-3

C7-626 / C7-626 DP Control Systems

C79000-G7076-C626-01

With the C7 devices you can:

S Load and run user programs on the C7 CPU.

S Connect the C7-626 DP to the PROFIBUS DP via an integrated DP

interface.

S Process digital and analog signals using the integrated I/Os of the C7.

S Use interrupt inputs and counters (for frequency measurement, period

duration measurement, etc.).

S Load and use O/I applications that you have created using the “ProTool”

configuring tool.

S Use these configurations to monitor and intervene in the process you are

controlling with the user program.

S Output data to a printer.

The C7 has two units that work independently of each other and can

communicate with each other via the internally-looped C7 multipoint

interface (MPI).

S C7 CPU

S C7 OP

These components will be referred to explicitly in the manuals as required.

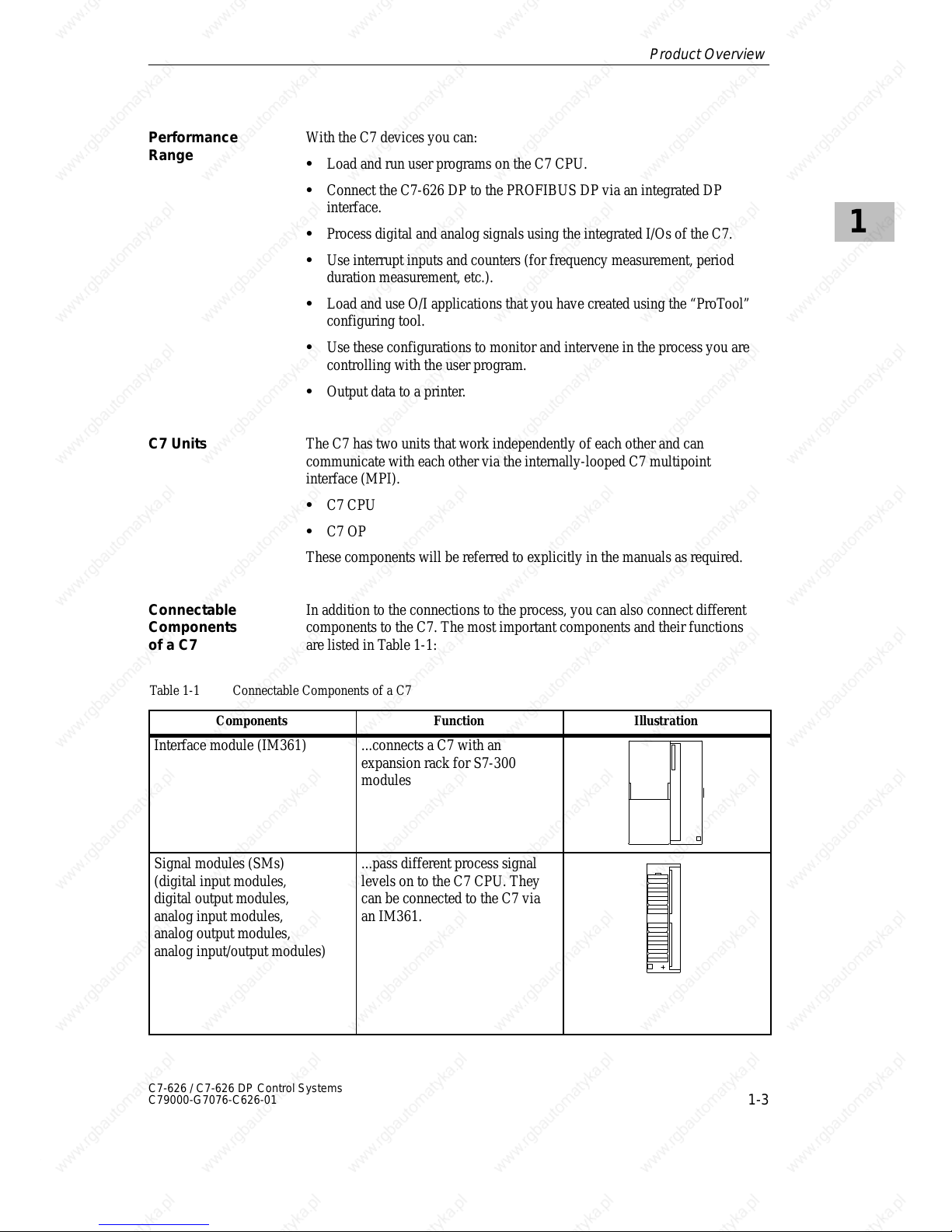

In addition to the connections to the process, you can also connect different

components to the C7. The most important components and their functions

are listed in Table 1-1:

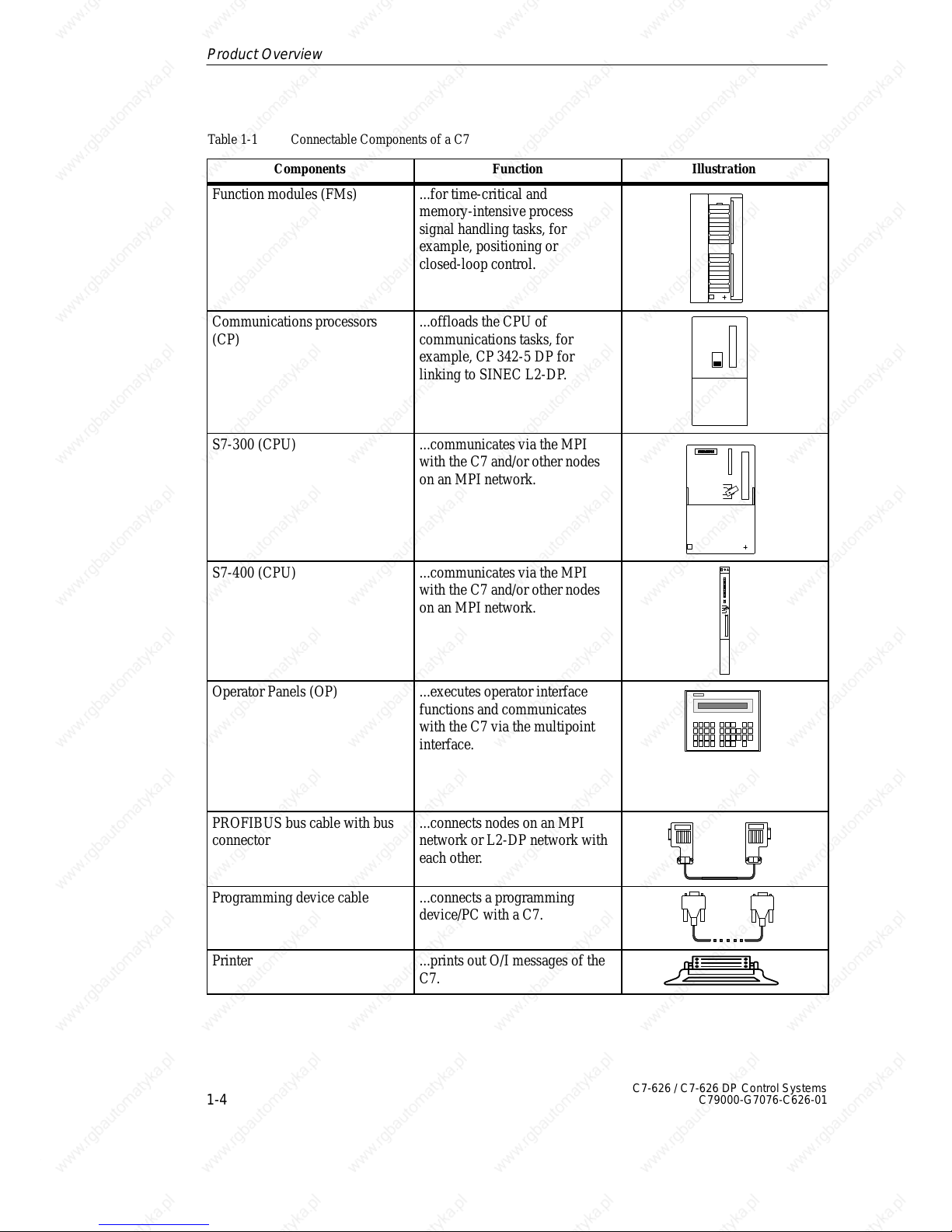

Table 1-1 Connectable Components of a C7

Components

Function Illustration

Interface module (IM361) ...connects a C7 with an

expansion rack for S7-300

modules

Signal modules (SMs)

(digital input modules,

digital output modules,

analog input modules,

analog output modules,

analog input/output modules)

...pass different process signal

levels on to the C7 CPU. They

can be connected to the C7 via

an IM361.

Performance

Range

C7 Units

Connectable

Components

of a C7

Product Overview

1

1-4

C7-626 / C7-626 DP Control Systems

C79000-G7076-C626-01

Table 1-1 Connectable Components of a C7

Components IllustrationFunction

Function modules (FMs) ...for time-critical and

memory-intensive process

signal handling tasks, for

example, positioning or

closed-loop control.

Communications processors

(CP)

...offloads the CPU of

communications tasks, for

example, CP 342-5 DP for

linking to SINEC L2-DP.

S7-300 (CPU) ...communicates via the MPI

with the C7 and/or other nodes

on an MPI network.

S7-400 (CPU) ...communicates via the MPI

with the C7 and/or other nodes

on an MPI network.

Operator Panels (OP) ...executes operator interface

functions and communicates

with the C7 via the multipoint

interface.

PROFIBUS bus cable with bus

connector

...connects nodes on an MPI

network or L2-DP network with

each other.

Programming device cable ...connects a programming

device/PC with a C7.

Printer ...prints out O/I messages of the

C7.

Product Overview

1

1-5

C7-626 / C7-626 DP Control Systems

C79000-G7076-C626-01

Table 1-1 Connectable Components of a C7

Components IllustrationFunction

Programming device (PG) or PC

with the STEP 7 and ProTool

software packages

...configures, assigns

parameters, programs and tests

the C7

RS 485 repeater ...for amplifying the signals in

an MPI network or L2-DP

network, and for linking

segments of an MPI or L2-DP

network.

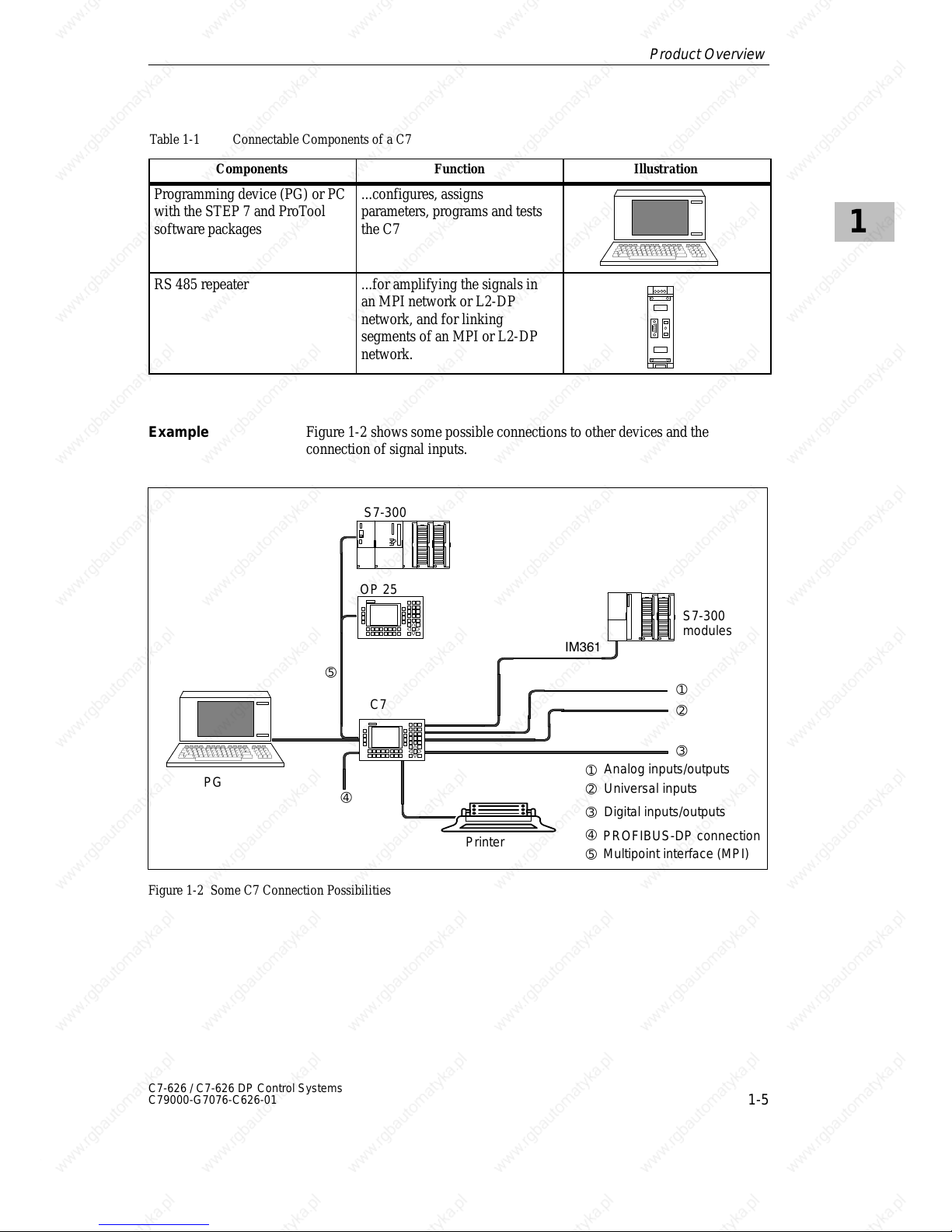

Figure 1-2 shows some possible connections to other devices and the

connection of signal inputs.

IM361

C7

S7-300

modules

S7-300

PG

Printer

Digital inputs/outputs

Universal inputs

Analog inputs/outputs

OP 25

➀

➂

➁

➃

➄

➀

➁

➂

➃

➄

PROFIBUS-DP connection

Multipoint interface (MPI)

Figure 1-2 Some C7 Connection Possibilities

Example

Product Overview

1

1-6

C7-626 / C7-626 DP Control Systems

C79000-G7076-C626-01

Product Overview

2-1

C7-626 / C7-626 DP Control Systems

C79000-G7076-C626-01

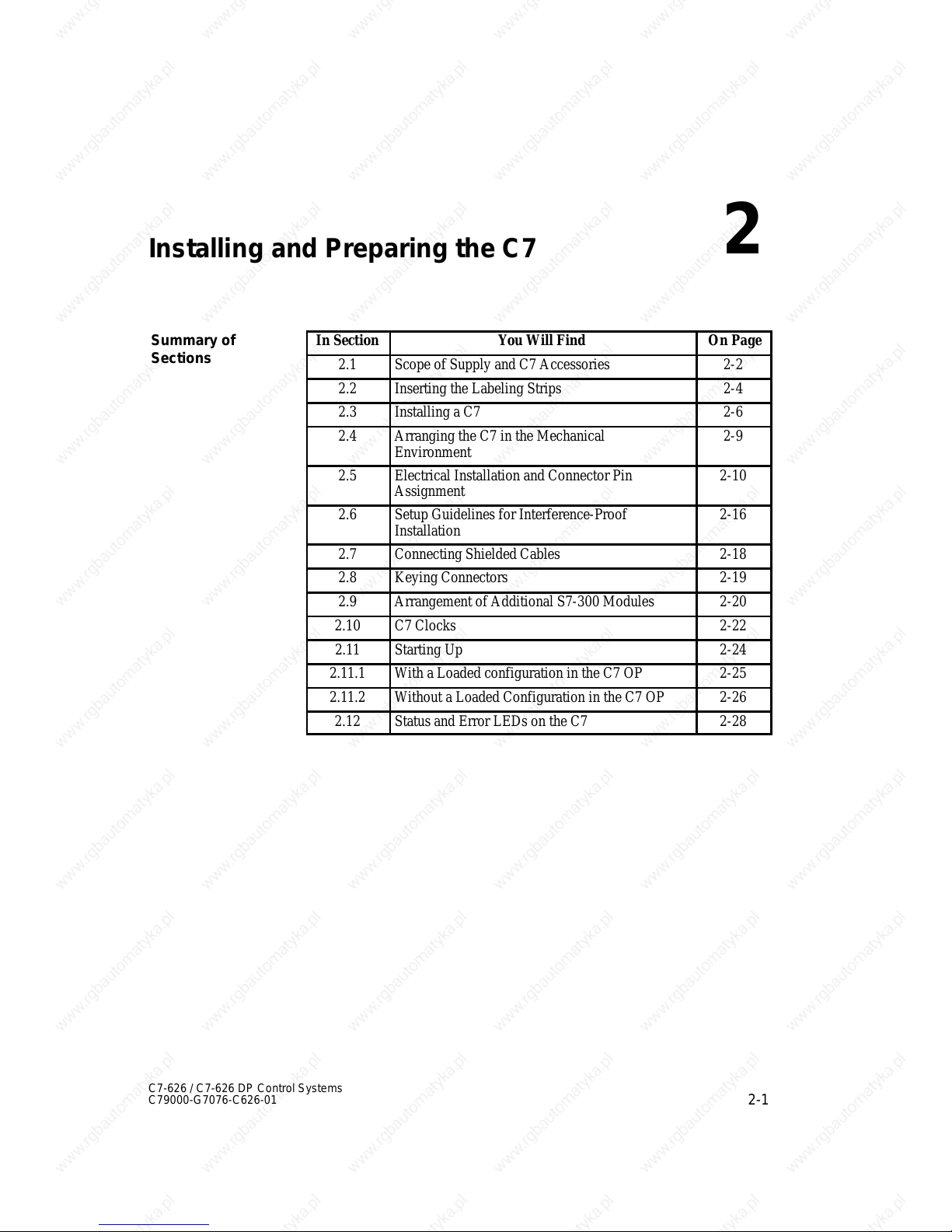

Installing and Preparing the C7

In Section You Will Find On Page

2.1 Scope of Supply and C7 Accessories 2-2

2.2 Inserting the Labeling Strips 2-4

2.3 Installing a C7 2-6

2.4 Arranging the C7 in the Mechanical

Environment

2-9

2.5 Electrical Installation and Connector Pin

Assignment

2-10

2.6 Setup Guidelines for Interference-Proof

Installation

2-16

2.7 Connecting Shielded Cables 2-18

2.8 Keying Connectors 2-19

2.9 Arrangement of Additional S7-300 Modules 2-20

2.10 C7 Clocks 2-22

2.11 Starting Up 2-24

2.11.1 With a Loaded configuration in the C7 OP 2-25

2.11.2 Without a Loaded Configuration in the C7 OP 2-26

2.12 Status and Error LEDs on the C7 2-28

Summary of

Sections

2

2

2-2

C7-626 / C7-626 DP Control Systems

C79000-G7076-C626-01

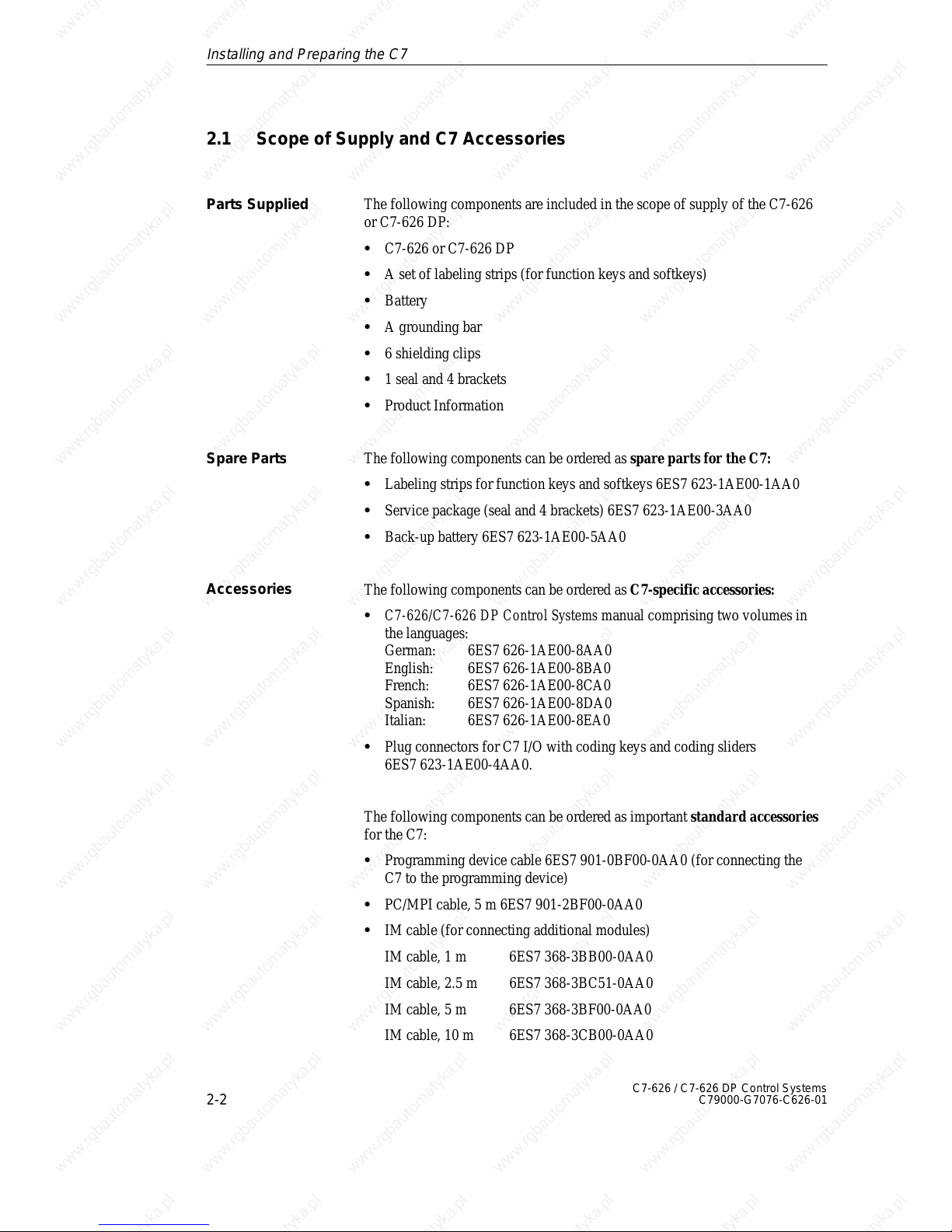

2.1 Scope of Supply and C7 Accessories

The following components are included in the scope of supply of the C7-626

or C7-626 DP:

S C7-626 or C7-626 DP

S A set of labeling strips (for function keys and softkeys)

S Battery

S A grounding bar

S 6 shielding clips

S 1 seal and 4 brackets

S Product Information

The following components can be ordered as spare parts for the C7:

S Labeling strips for function keys and softkeys 6ES7 623-1AE00-1AA0

S Service package (seal and 4 brackets) 6ES7 623-1AE00-3AA0

S Back-up battery 6ES7 623-1AE00-5AA0

The following components can be ordered as C7-specific accessories:

S C7-626/C7-626 DP Control Systems manual comprising two volumes in

the languages:

German: 6ES7 626-1AE00-8AA0

English: 6ES7 626-1AE00-8BA0

French: 6ES7 626-1AE00-8CA0

Spanish: 6ES7 626-1AE00-8DA0

Italian: 6ES7 626-1AE00-8EA0

S Plug connectors for C7 I/O with coding keys and coding sliders

6ES7 623-1AE00-4AA0.

The following components can be ordered as important standard accessories

for the C7:

S Programming device cable 6ES7 901-0BF00-0AA0 (for connecting the

C7 to the programming device)

S PC/MPI cable, 5 m 6ES7 901-2BF00-0AA0

S IM cable (for connecting additional modules)

IM cable, 1 m 6ES7 368-3BB00-0AA0

IM cable, 2.5 m 6ES7 368-3BC51-0AA0

IM cable, 5 m 6ES7 368-3BF00-0AA0

IM cable, 10 m 6ES7 368-3CB00-0AA0

Parts Supplied

Spare Parts

Accessories

Installing and Preparing the C7

2

2-3

C7-626 / C7-626 DP Control Systems

C79000-G7076-C626-01

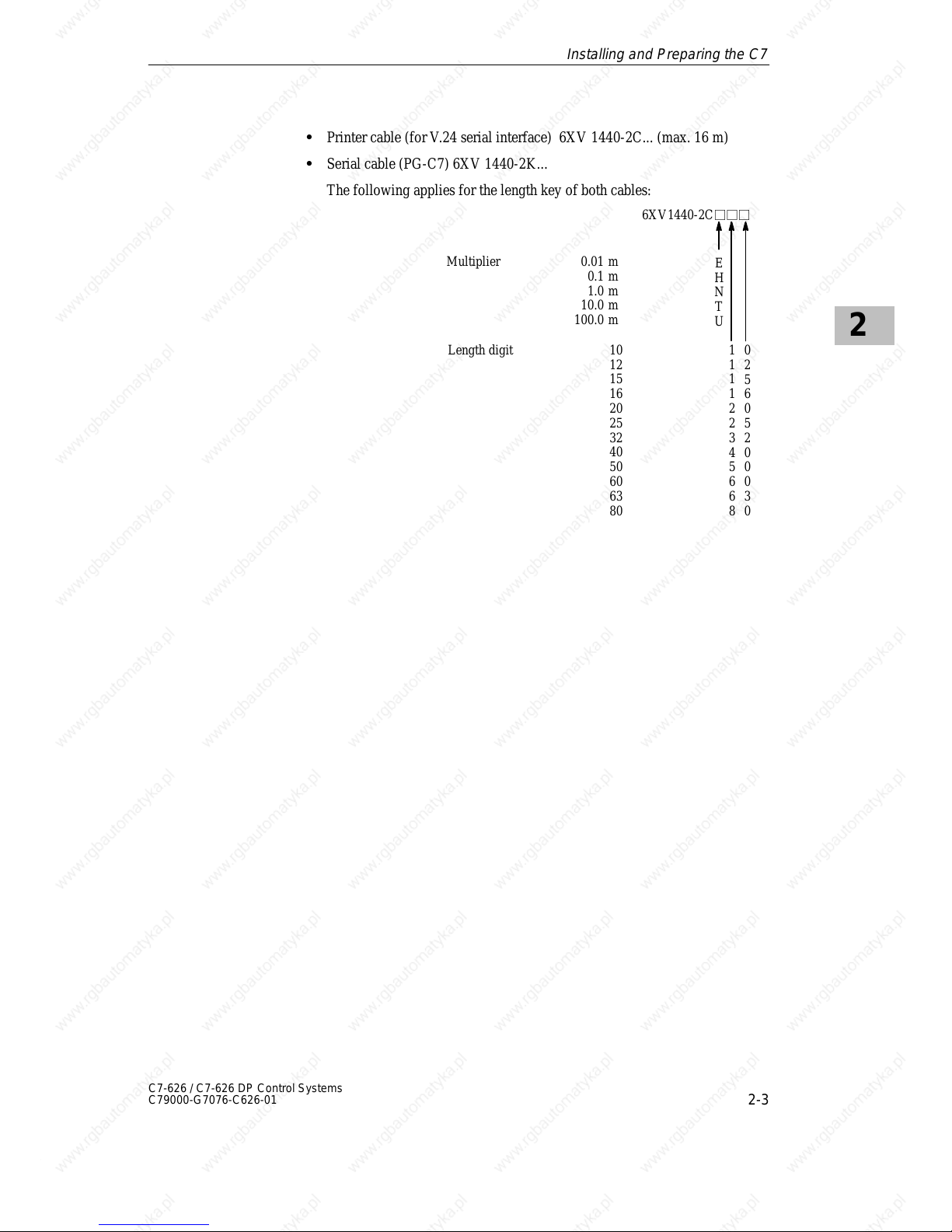

S Printer cable (for V.24 serial interface) 6XV 1440-2C... (max. 16 m)

S Serial cable (PG-C7) 6XV 1440-2K...

The following applies for the length key of both cables:

6XV1440-2Cjjj

Multiplier 0.01 m

0.1 m

1.0 m

10.0 m

100.0 m

E

H

N

T

U

1

1

1

1

2

2

3

4

5

6

6

8

Length digit 10

12

15

16

20

25

32

40

50

60

63

80

0

2

5

6

0

5

2

0

0

0

3

0

Installing and Preparing the C7

2

2-4

C7-626 / C7-626 DP Control Systems

C79000-G7076-C626-01

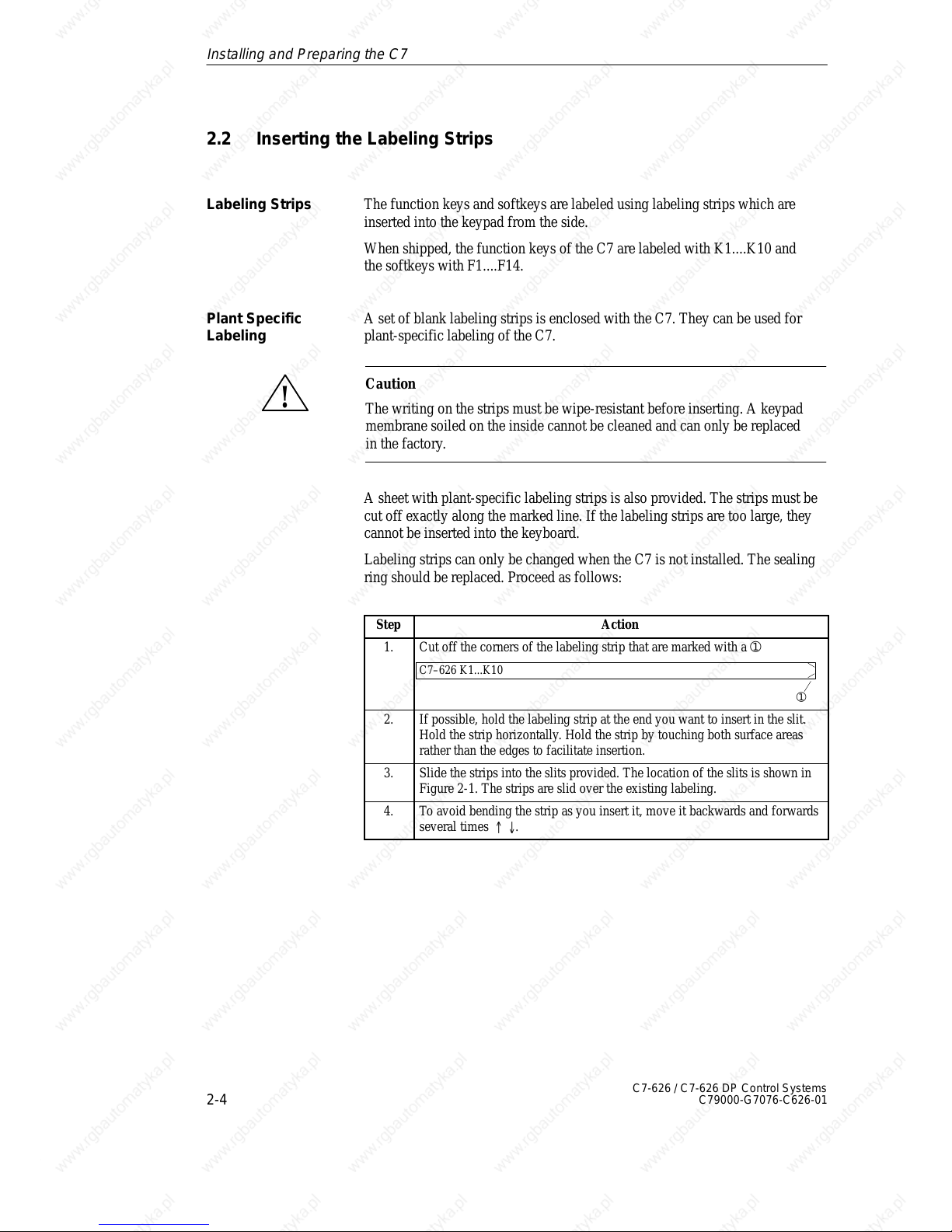

2.2 Inserting the Labeling Strips

The function keys and softkeys are labeled using labeling strips which are

inserted into the keypad from the side.

When shipped, the function keys of the C7 are labeled with K1....K10 and

the softkeys with F1....F14.

A set of blank labeling strips is enclosed with the C7. They can be used for

plant-specific labeling of the C7.

!

Caution

The writing on the strips must be wipe-resistant before inserting. A keypad

membrane soiled on the inside cannot be cleaned and can only be replaced

in the factory.

A sheet with plant-specific labeling strips is also provided. The strips must be

cut off exactly along the marked line. If the labeling strips are too large, they

cannot be inserted into the keyboard.

Labeling strips can only be changed when the C7 is not installed. The sealing

ring should be replaced. Proceed as follows:

Step Action

1. Cut off the corners of the labeling strip that are marked with a ➀

C7–626 K1...K10

➀

2. If possible, hold the labeling strip at the end you want to insert in the slit.

Hold the strip horizontally. Hold the strip by touching both surface areas

rather than the edges to facilitate insertion.

3. Slide the strips into the slits provided. The location of the slits is shown in

Figure 2-1. The strips are slid over the existing labeling.

4. To avoid bending the strip as you insert it, move it backwards and forwards

several times .

Labeling Strips

Plant Specific

Labeling

Installing and Preparing the C7

2

2-5

C7-626 / C7-626 DP Control Systems

C79000-G7076-C626-01

Labeling Strips

Labeling Strips

Figure 2-1 Inserting Labeling Strips

Installing and Preparing the C7

2

2-6

C7-626 / C7-626 DP Control Systems

C79000-G7076-C626-01

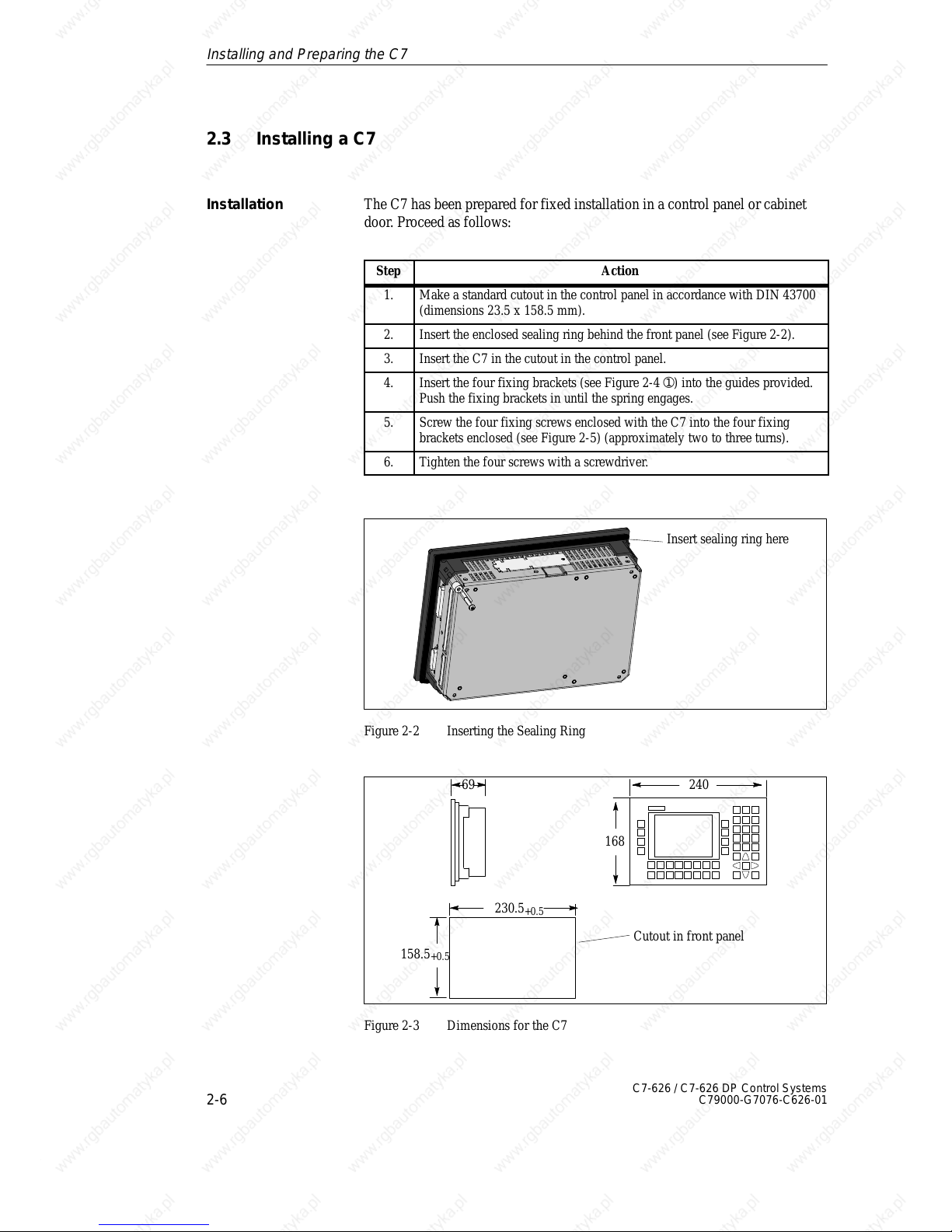

2.3 Installing a C7

The C7 has been prepared for fixed installation in a control panel or cabinet

door. Proceed as follows:

Step Action

1. Make a standard cutout in the control panel in accordance with DIN 43700

(dimensions 23.5 x 158.5 mm).

2. Insert the enclosed sealing ring behind the front panel (see Figure 2-2).

3. Insert the C7 in the cutout in the control panel.

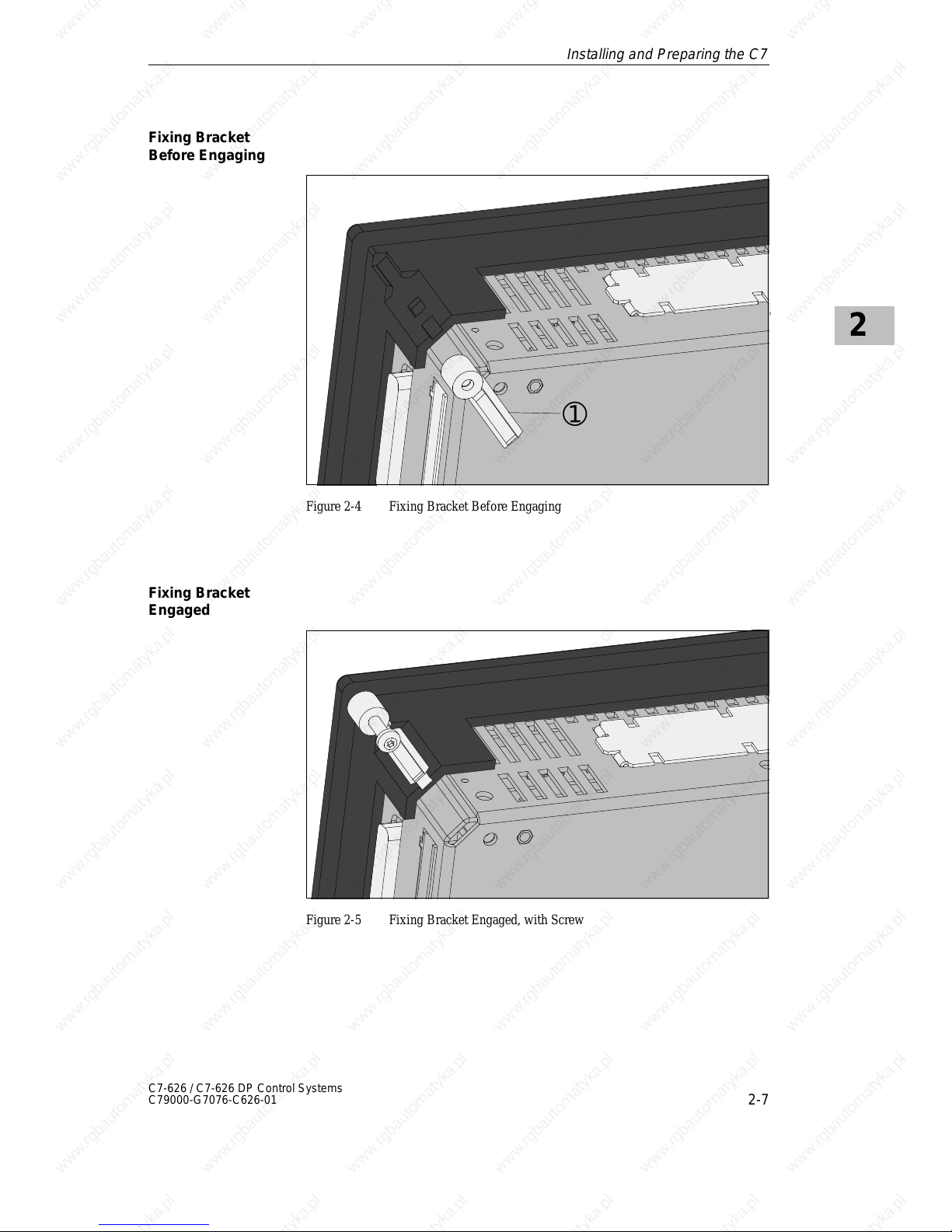

4. Insert the four fixing brackets (see Figure 2-4 ➀) into the guides provided.

Push the fixing brackets in until the spring engages.

5. Screw the four fixing screws enclosed with the C7 into the four fixing

brackets enclosed (see Figure 2-5) (approximately two to three turns).

6. Tighten the four screws with a screwdriver.

Insert sealing ring here

Figure 2-2 Inserting the Sealing Ring

168

24069

230.5

+0.5

158.5

+0.5

Cutout in front panel

Figure 2-3 Dimensions for the C7

Installation

Installing and Preparing the C7

2

2-7

C7-626 / C7-626 DP Control Systems

C79000-G7076-C626-01

➀

Figure 2-4 Fixing Bracket Before Engaging

Figure 2-5 Fixing Bracket Engaged, with Screw

Fixing Bracket

Before Engaging

Fixing Bracket

Engaged

Installing and Preparing the C7

2

2-8

C7-626 / C7-626 DP Control Systems

C79000-G7076-C626-01

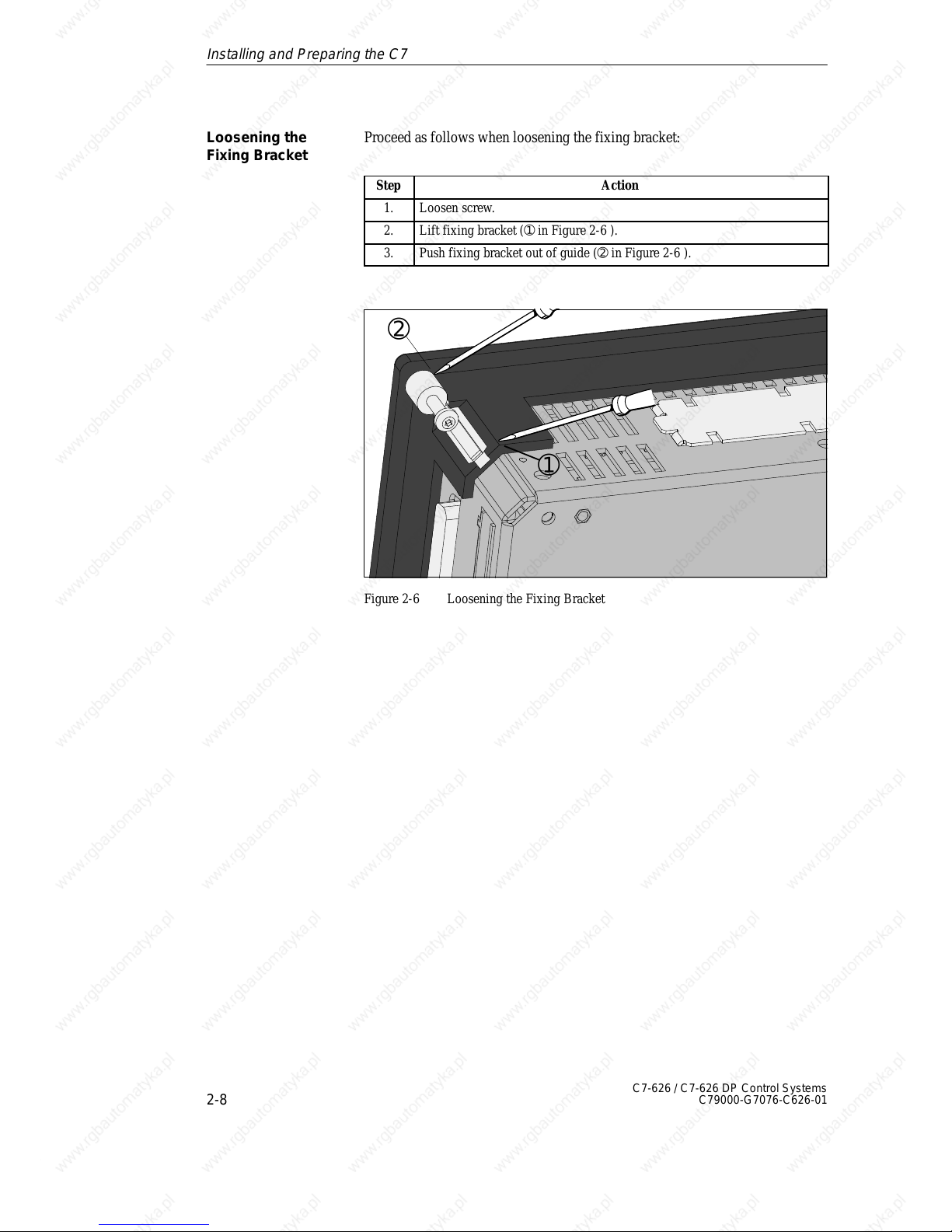

Proceed as follows when loosening the fixing bracket:

Step Action

1. Loosen screw.

2. Lift fixing bracket (➀ in Figure 2-6 ).

3. Push fixing bracket out of guide (➁ in Figure 2-6 ).

➁

➀

Figure 2-6 Loosening the Fixing Bracket

Loosening the

Fixing Bracket

Installing and Preparing the C7

2

2-9

C7-626 / C7-626 DP Control Systems

C79000-G7076-C626-01

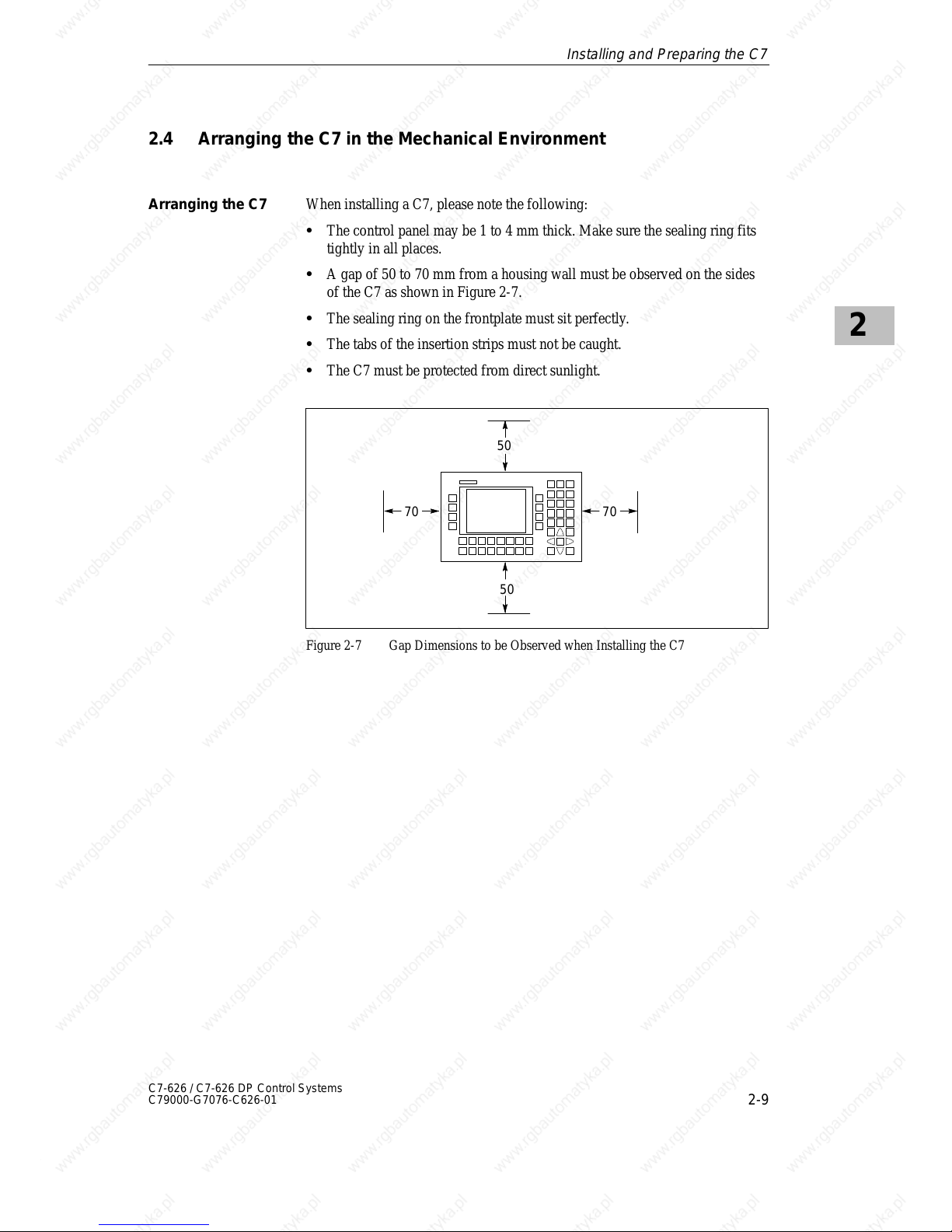

2.4 Arranging the C7 in the Mechanical Environment

When installing a C7, please note the following:

S The control panel may be 1 to 4 mm thick. Make sure the sealing ring fits

tightly in all places.

S A gap of 50 to 70 mm from a housing wall must be observed on the sides

of the C7 as shown in Figure 2-7.

S The sealing ring on the frontplate must sit perfectly.

S The tabs of the insertion strips must not be caught.

S The C7 must be protected from direct sunlight.

50

50

70 70

Figure 2-7 Gap Dimensions to be Observed when Installing the C7

Arranging the C7

Installing and Preparing the C7

2

2-10

C7-626 / C7-626 DP Control Systems

C79000-G7076-C626-01

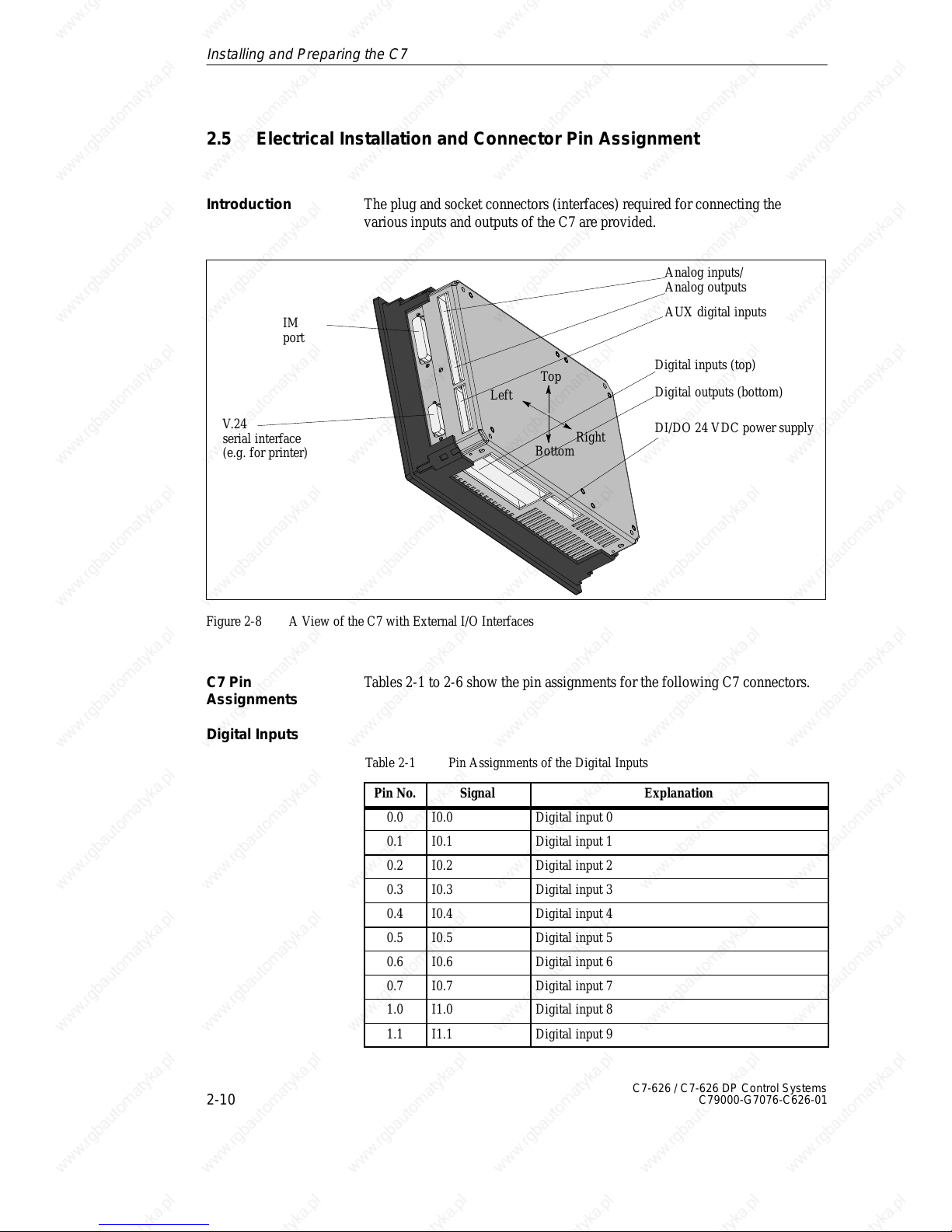

2.5 Electrical Installation and Connector Pin Assignment

The plug and socket connectors (interfaces) required for connecting the

various inputs and outputs of the C7 are provided.

AUX digital inputs

IM

port

V.24

serial interface

(e.g. for printer)

Analog inputs/

Analog outputs

Digital inputs (top)

DI/DO 24 VDC power supply

Digital outputs (bottom)

Top

Bottom

Left

Right

Figure 2-8 A View of the C7 with External I/O Interfaces

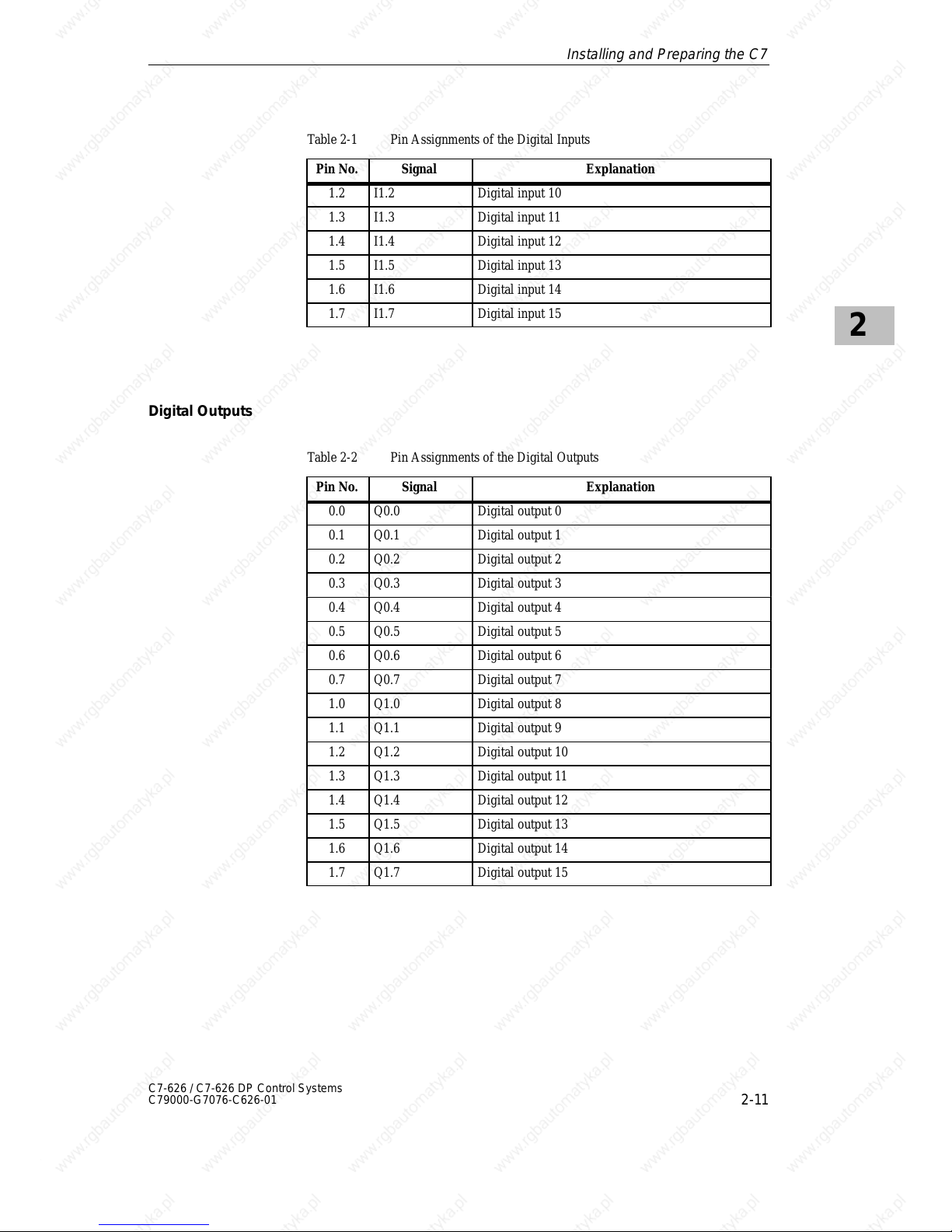

Tables 2-1 to 2-6 show the pin assignments for the following C7 connectors.

Table 2-1 Pin Assignments of the Digital Inputs

Pin No. Signal Explanation

0.0 I0.0 Digital input 0

0.1 I0.1 Digital input 1

0.2 I0.2 Digital input 2

0.3 I0.3 Digital input 3

0.4 I0.4 Digital input 4

0.5 I0.5 Digital input 5

0.6 I0.6 Digital input 6

0.7 I0.7 Digital input 7

1.0 I1.0 Digital input 8

1.1 I1.1 Digital input 9

Introduction

C7 Pin

Assignments

Digital Inputs

Installing and Preparing the C7

2

2-11

C7-626 / C7-626 DP Control Systems

C79000-G7076-C626-01

Table 2-1 Pin Assignments of the Digital Inputs

Pin No. ExplanationSignal

1.2 I1.2 Digital input 10

1.3 I1.3 Digital input 11

1.4 I1.4 Digital input 12

1.5 I1.5 Digital input 13

1.6 I1.6 Digital input 14

1.7 I1.7 Digital input 15

Table 2-2 Pin Assignments of the Digital Outputs

Pin No.

Signal Explanation

0.0 Q0.0 Digital output 0

0.1 Q0.1 Digital output 1

0.2 Q0.2 Digital output 2

0.3 Q0.3 Digital output 3

0.4 Q0.4 Digital output 4

0.5 Q0.5 Digital output 5

0.6 Q0.6 Digital output 6

0.7 Q0.7 Digital output 7

1.0 Q1.0 Digital output 8

1.1 Q1.1 Digital output 9

1.2 Q1.2 Digital output 10

1.3 Q1.3 Digital output 11

1.4 Q1.4 Digital output 12

1.5 Q1.5 Digital output 13

1.6 Q1.6 Digital output 14

1.7 Q1.7 Digital output 15

Digital Outputs

Installing and Preparing the C7

2

2-12

C7-626 / C7-626 DP Control Systems

C79000-G7076-C626-01

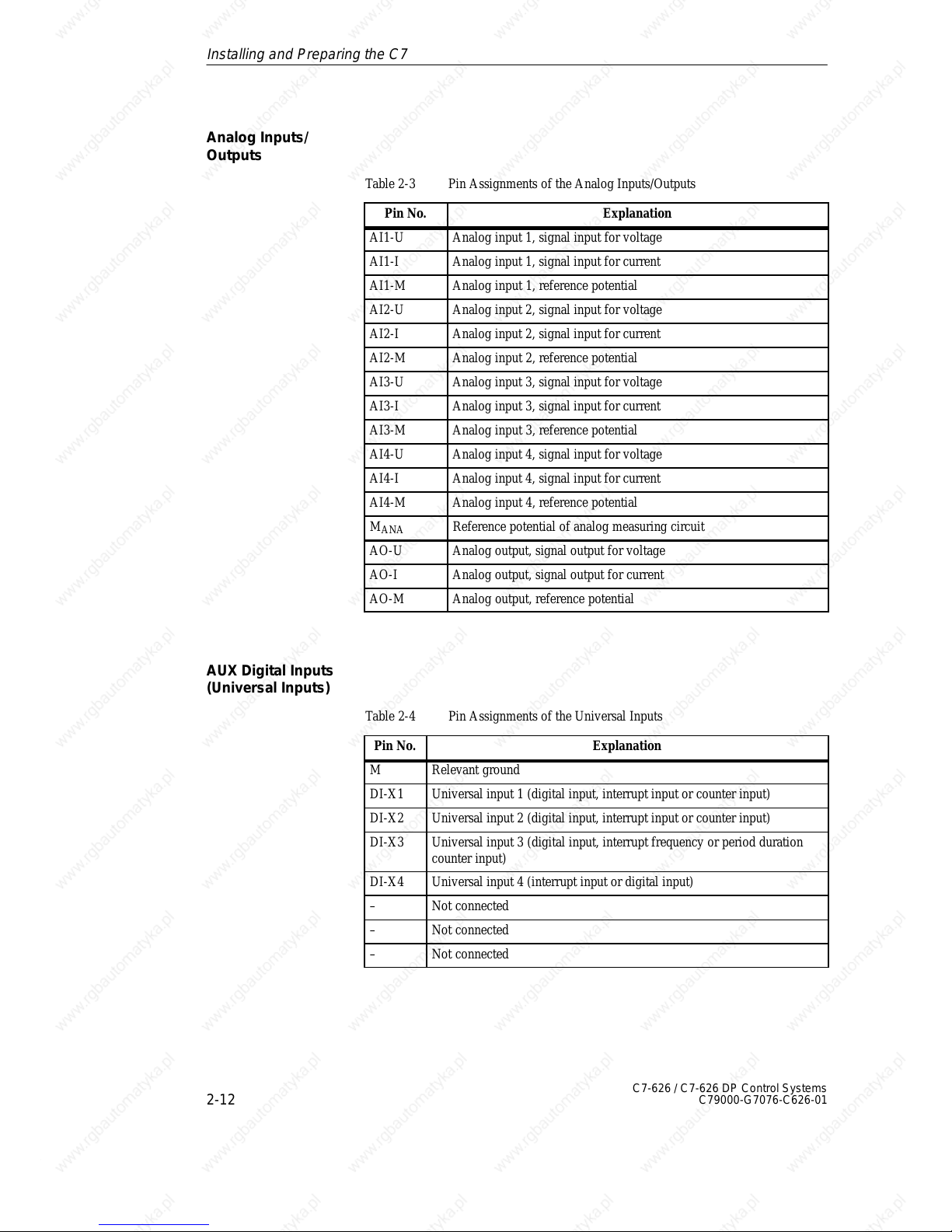

Table 2-3 Pin Assignments of the Analog Inputs/Outputs

Pin No. Explanation

AI1-U Analog input 1, signal input for voltage

AI1-I Analog input 1, signal input for current

AI1-M Analog input 1, reference potential

AI2-U Analog input 2, signal input for voltage

AI2-I Analog input 2, signal input for current

AI2-M Analog input 2, reference potential

AI3-U Analog input 3, signal input for voltage

AI3-I Analog input 3, signal input for current

AI3-M Analog input 3, reference potential

AI4-U Analog input 4, signal input for voltage

AI4-I Analog input 4, signal input for current

AI4-M Analog input 4, reference potential

M

ANA

Reference potential of analog measuring circuit

AO-U Analog output, signal output for voltage

AO-I Analog output, signal output for current

AO-M Analog output, reference potential

Table 2-4 Pin Assignments of the Universal Inputs

Pin No.

Explanation

M Relevant ground

DI-X1 Universal input 1 (digital input, interrupt input or counter input)

DI-X2 Universal input 2 (digital input, interrupt input or counter input)

DI-X3 Universal input 3 (digital input, interrupt frequency or period duration

counter input)

DI-X4 Universal input 4 (interrupt input or digital input)

– Not connected

– Not connected

– Not connected

Analog Inputs/

Outputs

AUX Digital Inputs

(Universal Inputs)

Installing and Preparing the C7

Loading...

Loading...